Patents

Literature

107results about How to "Construction and transportation are convenient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

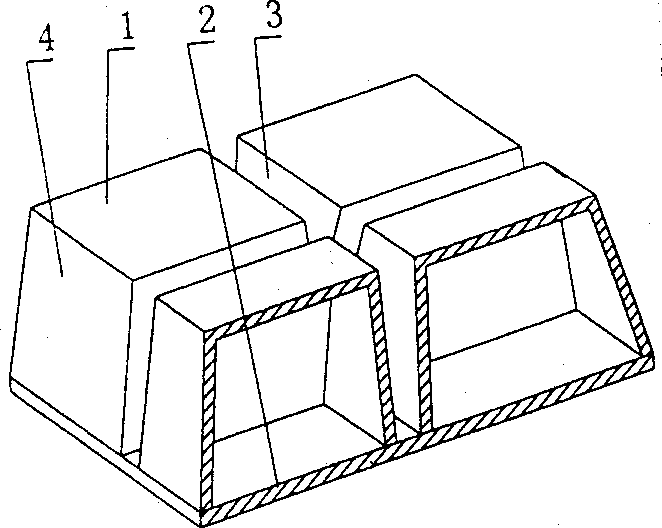

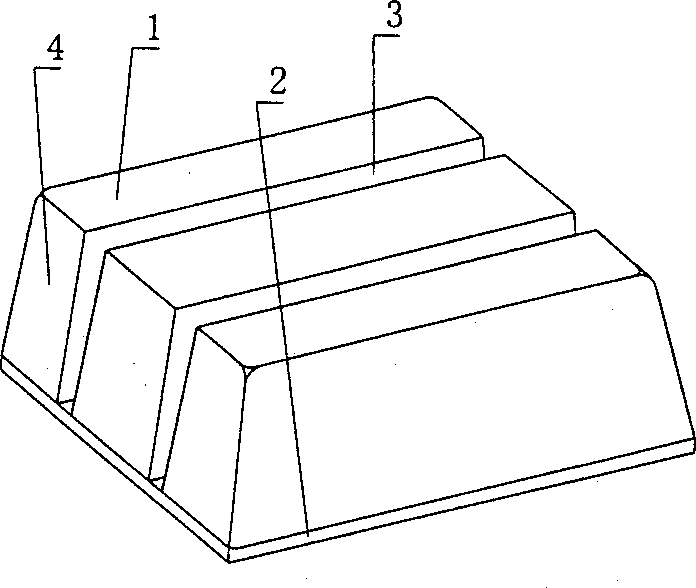

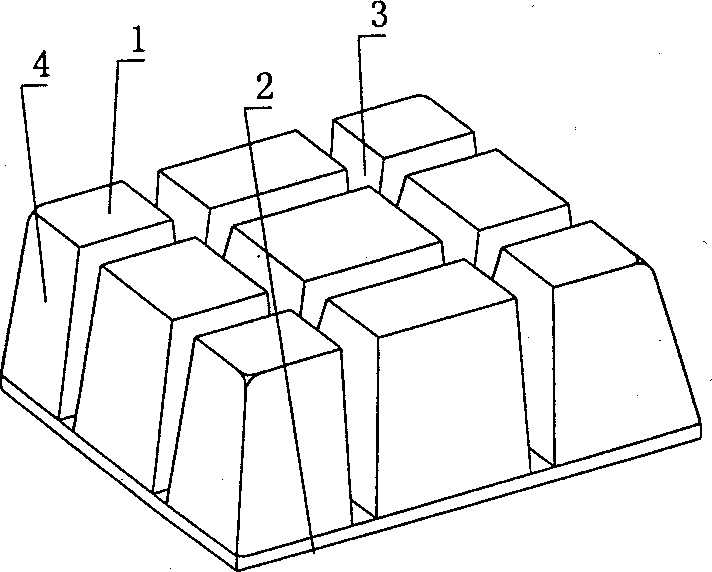

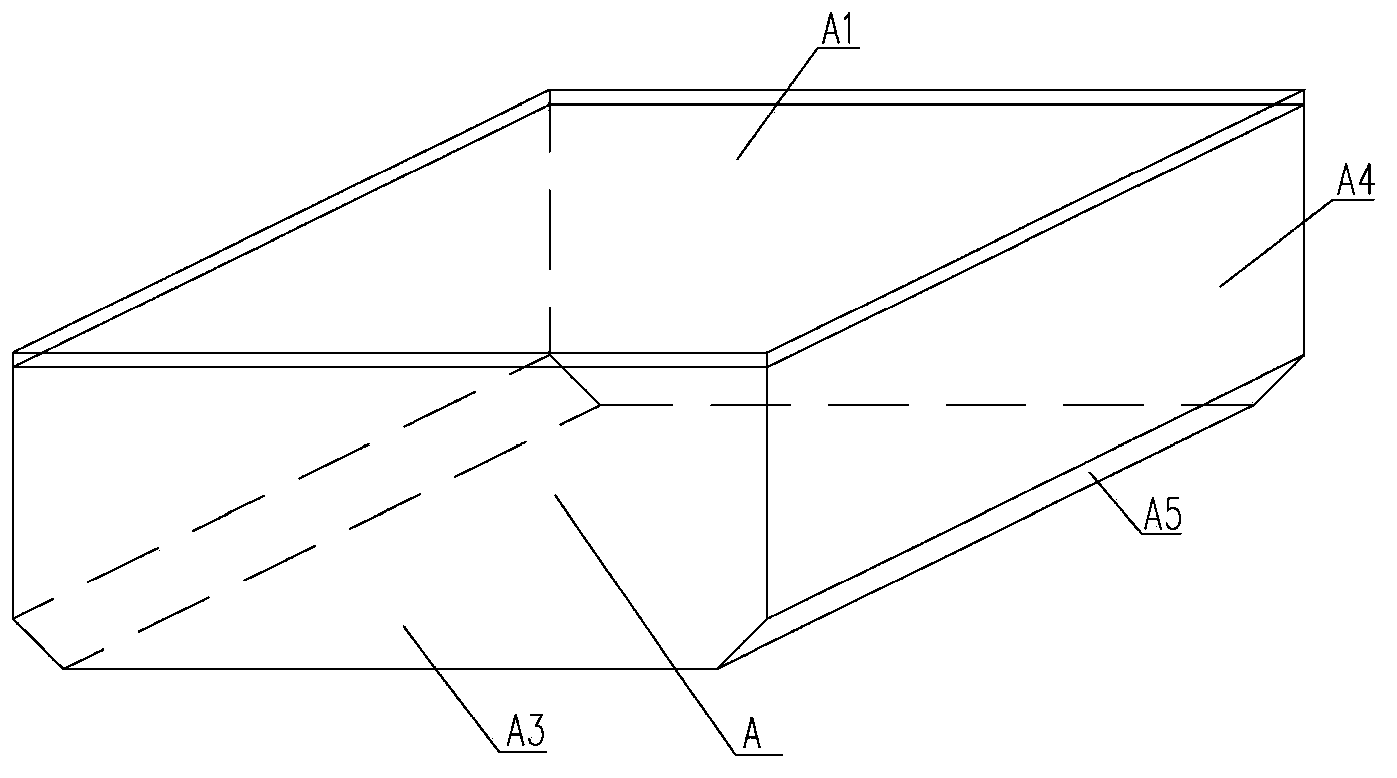

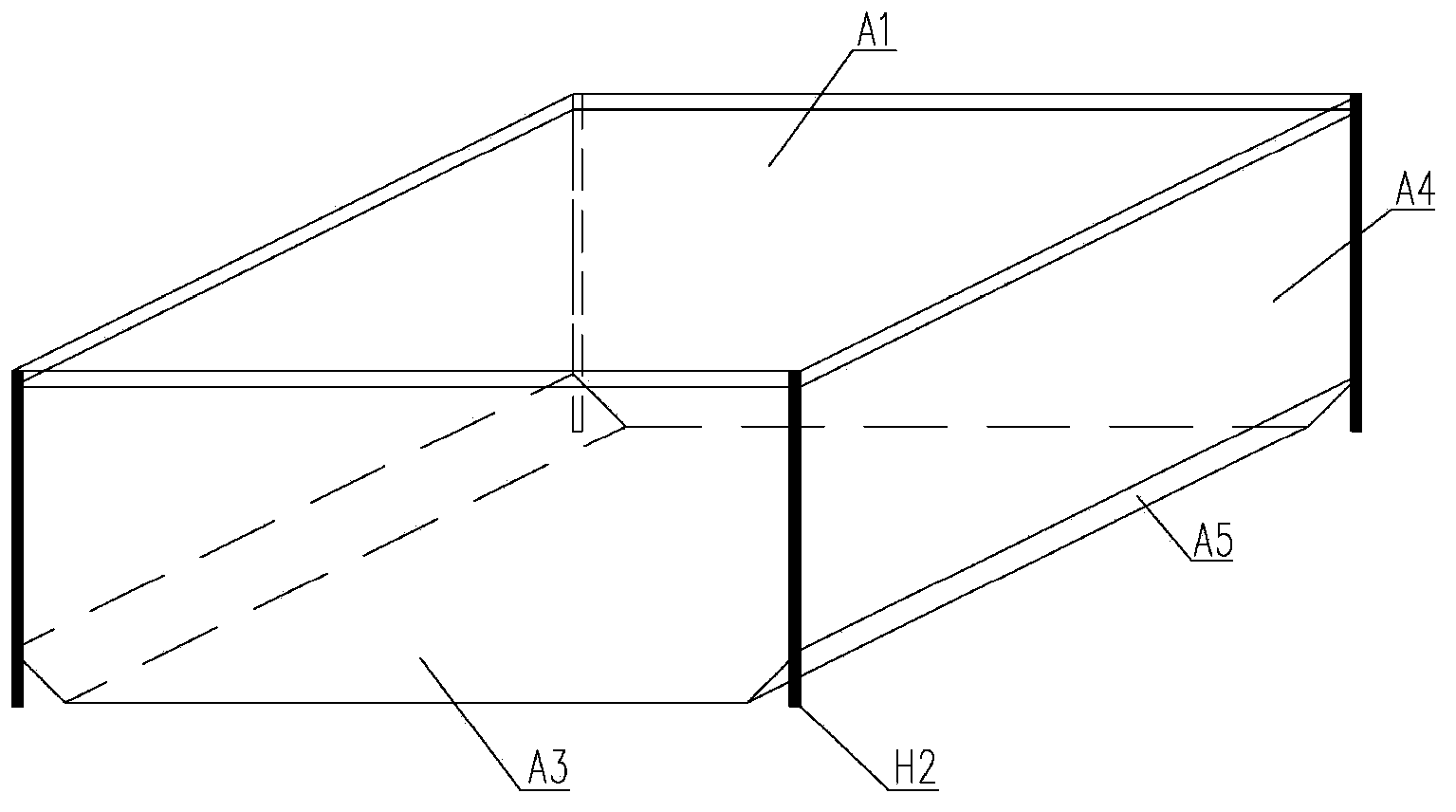

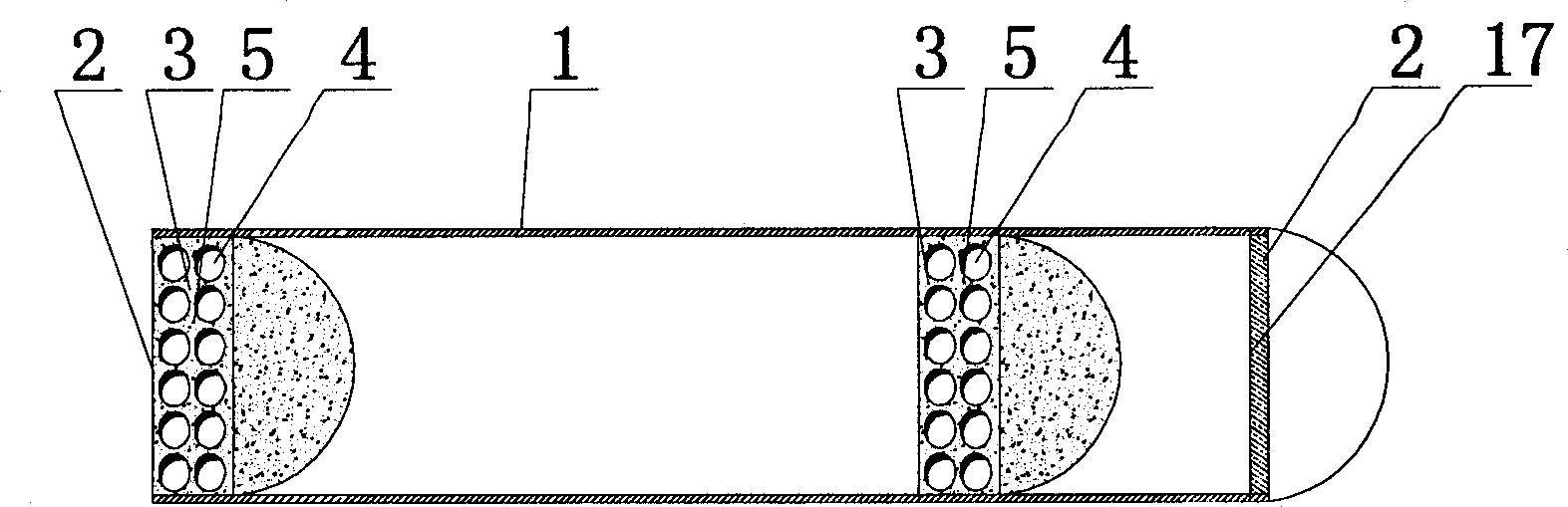

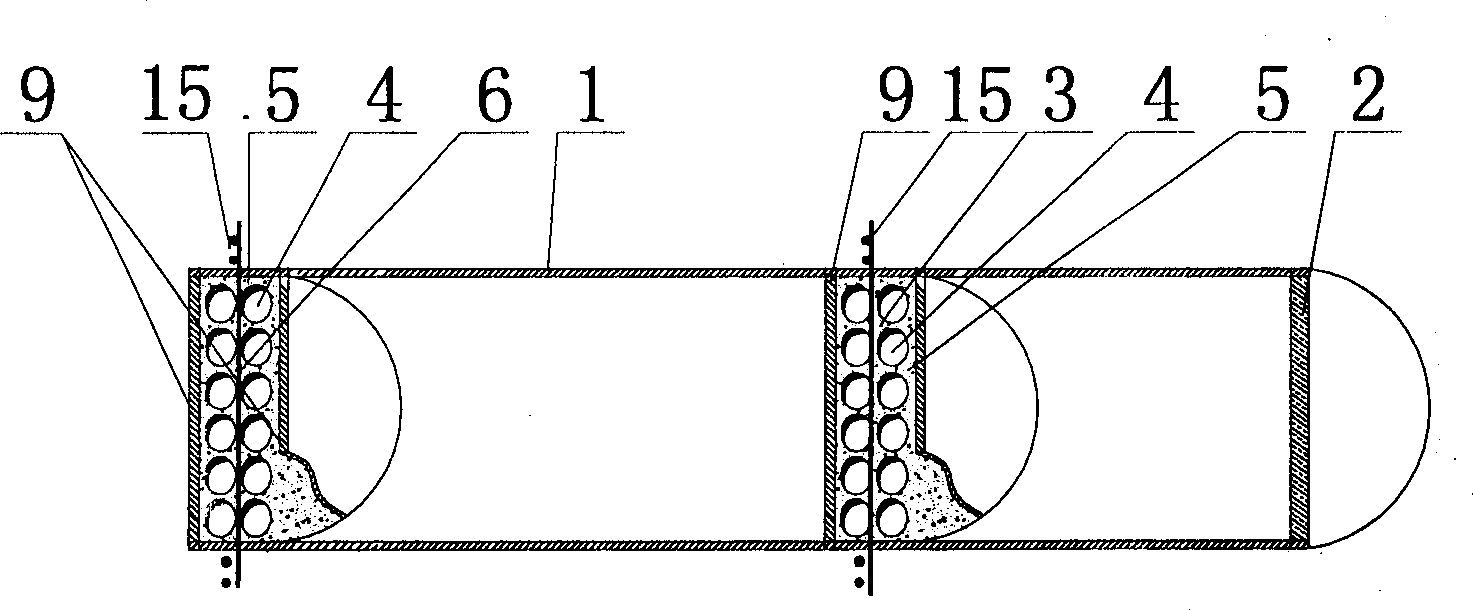

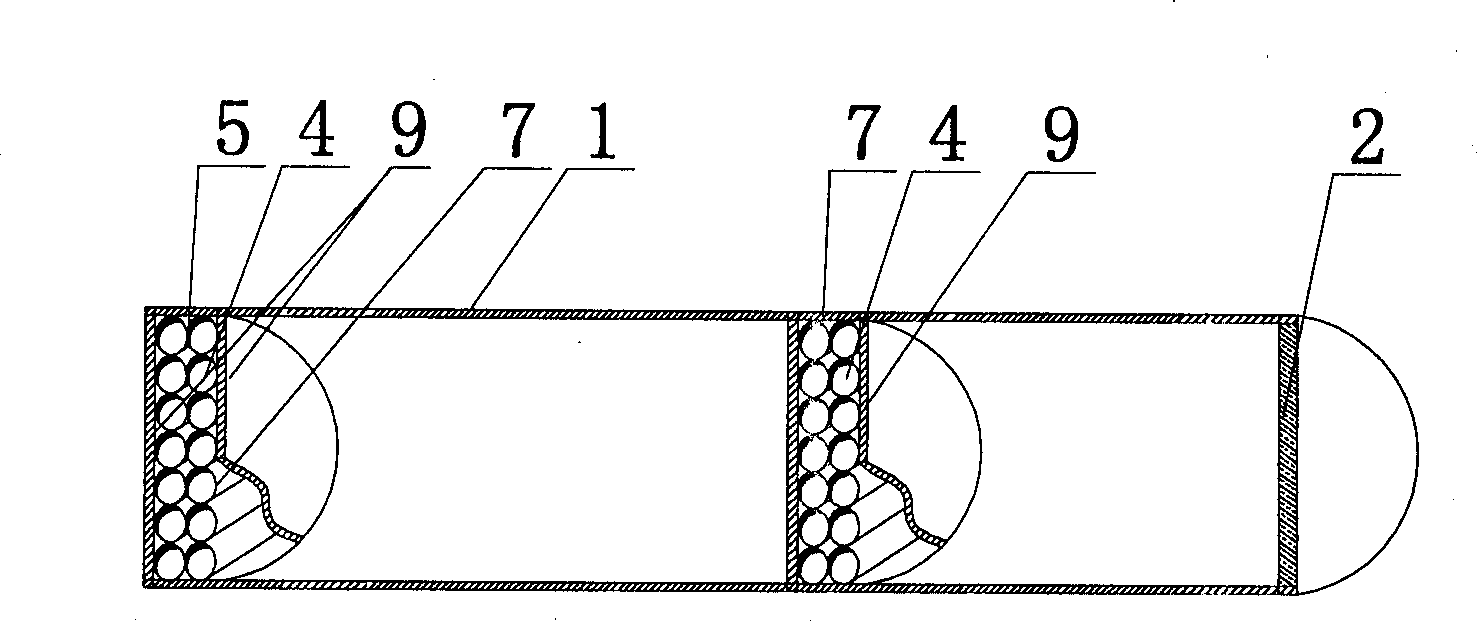

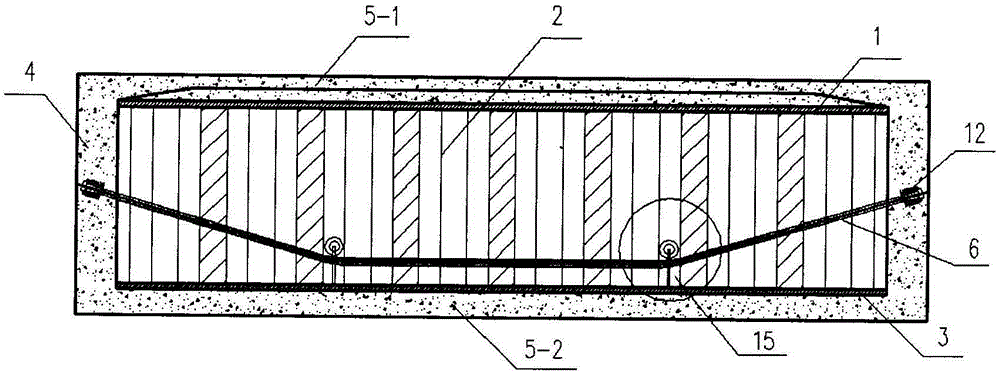

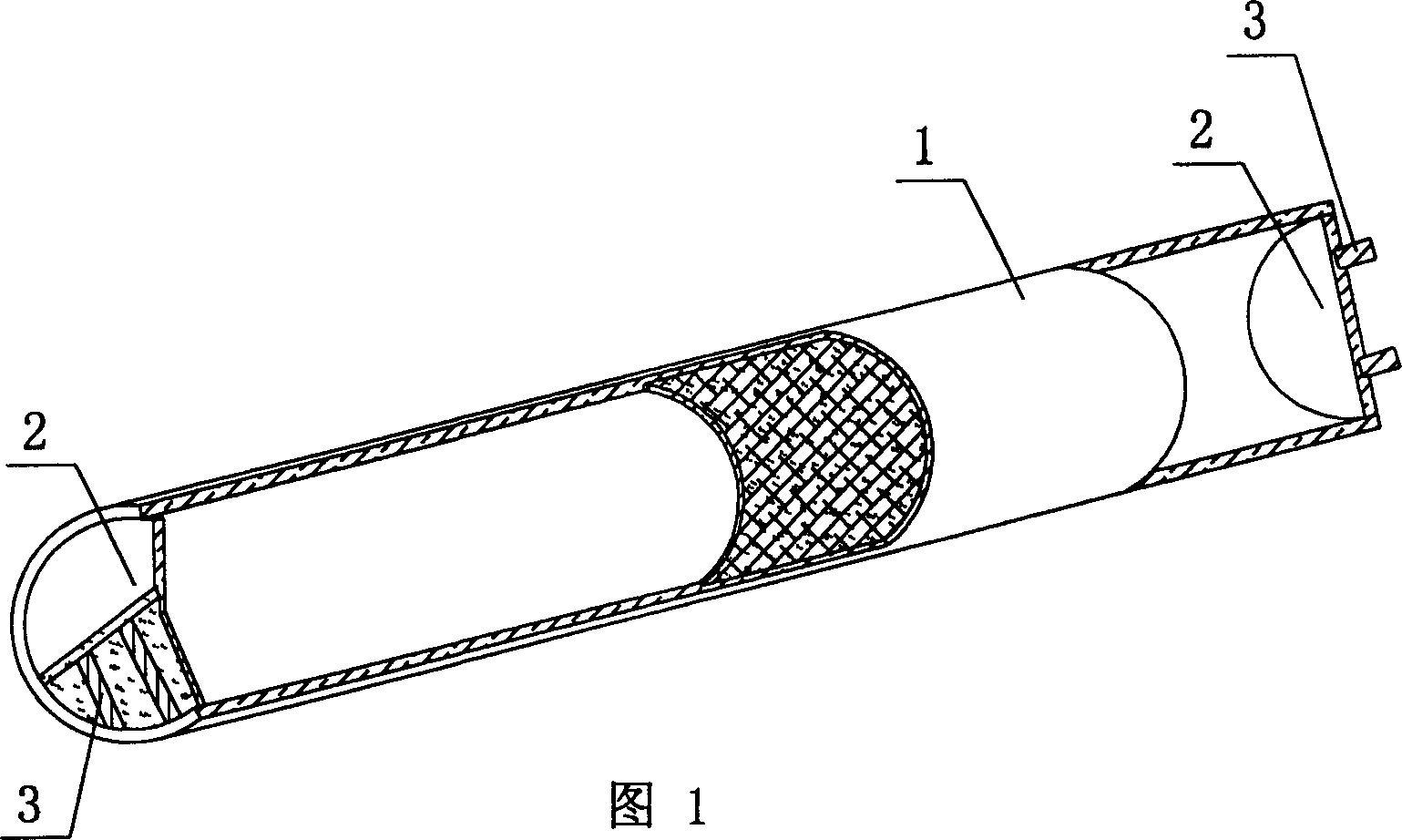

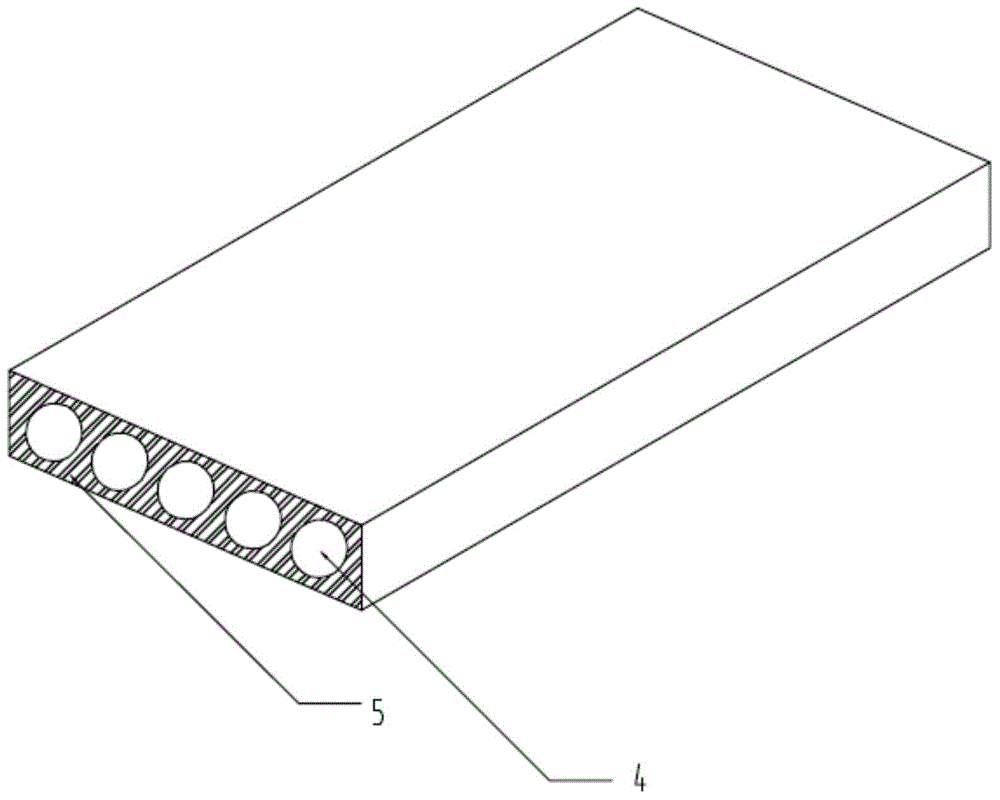

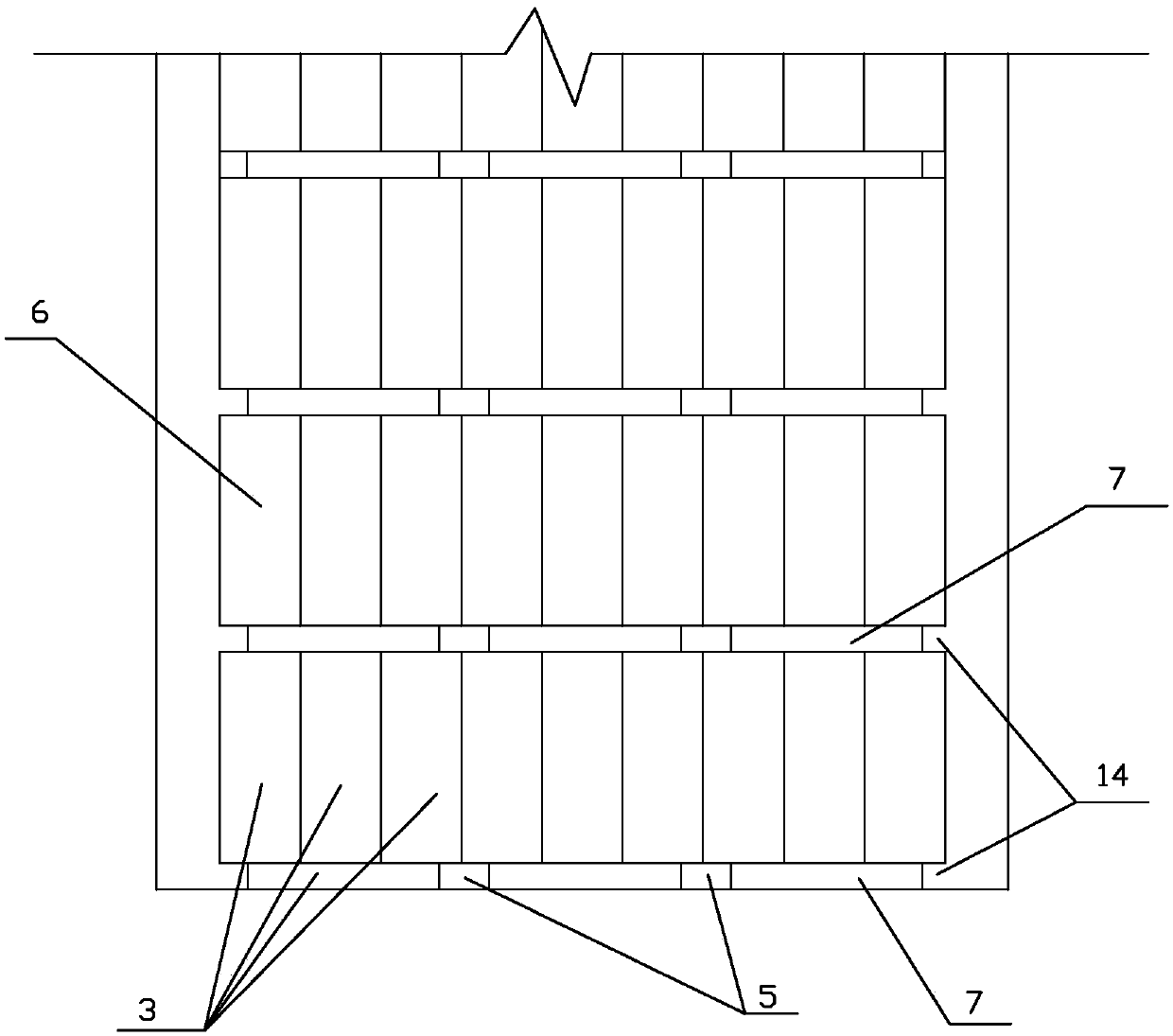

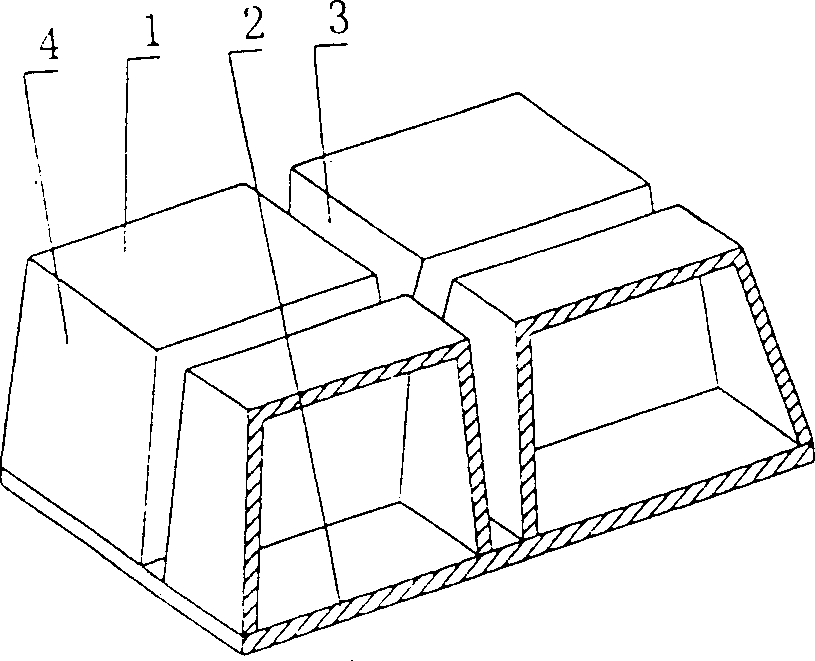

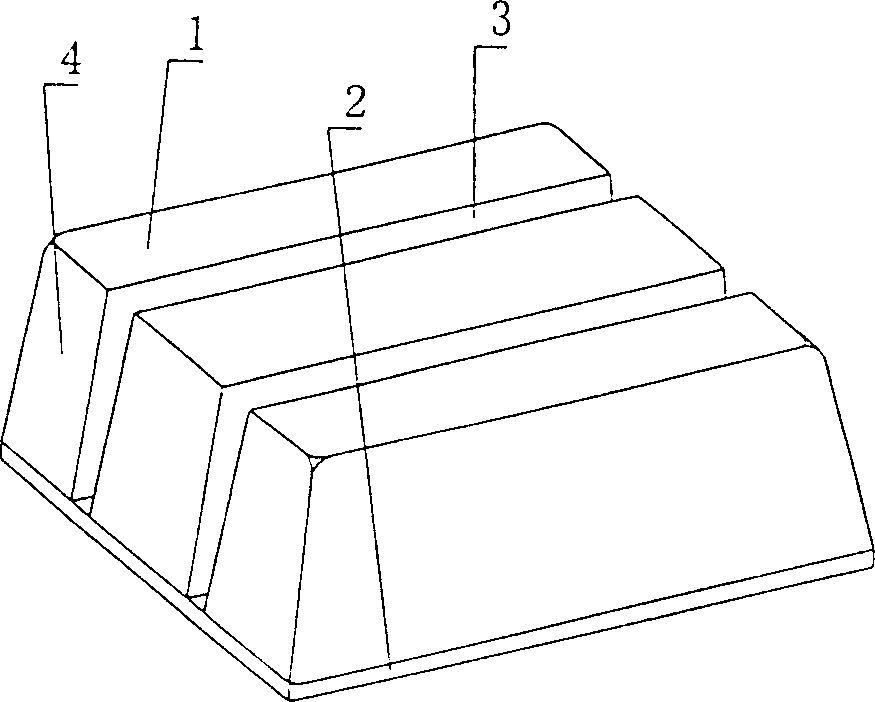

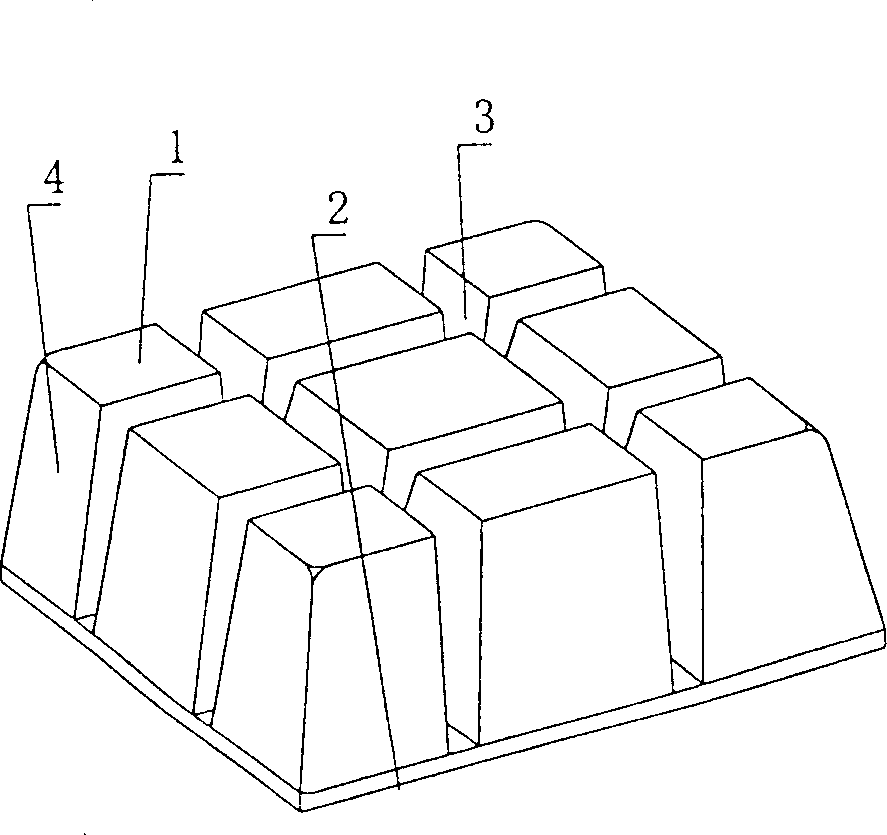

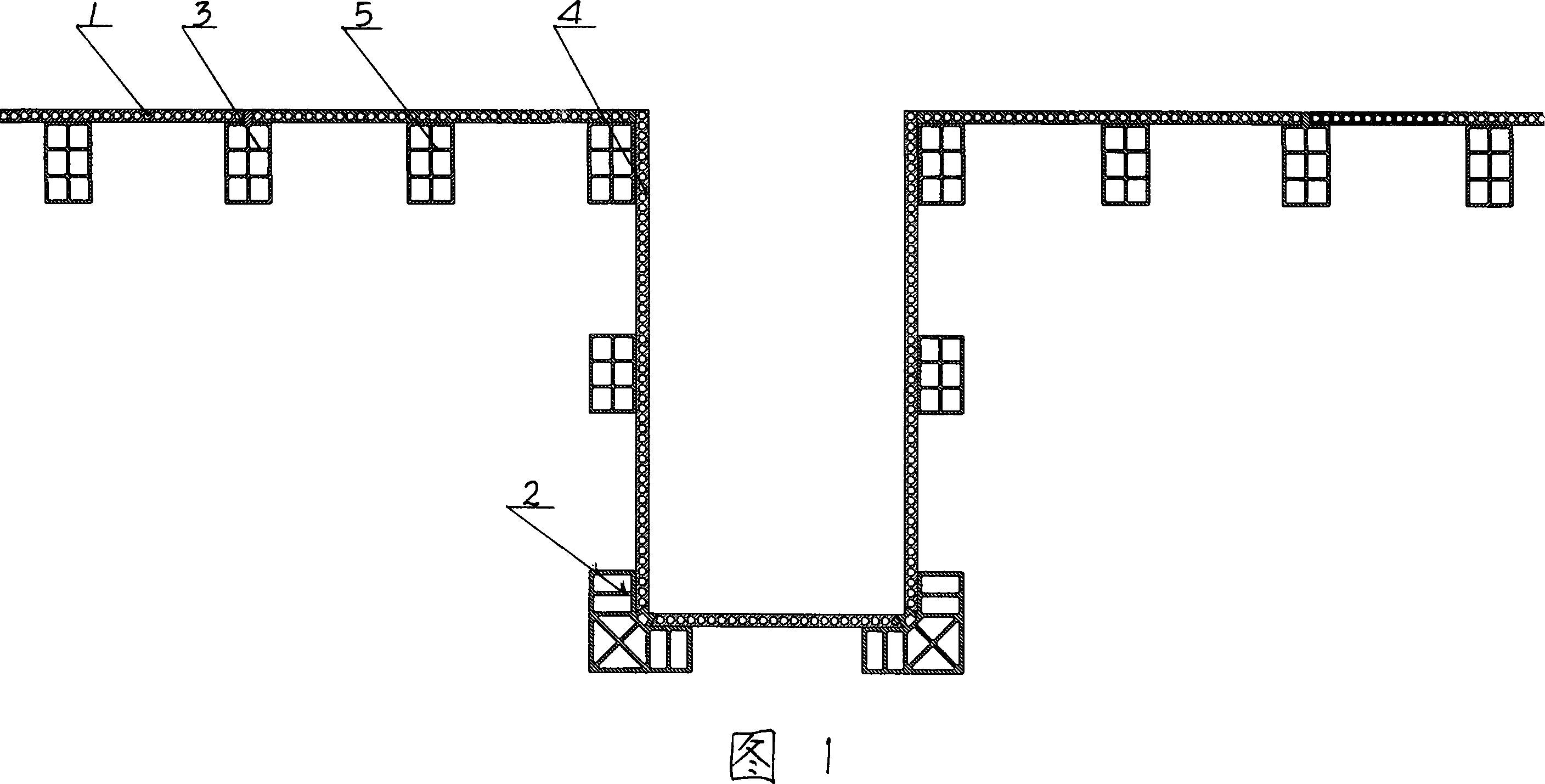

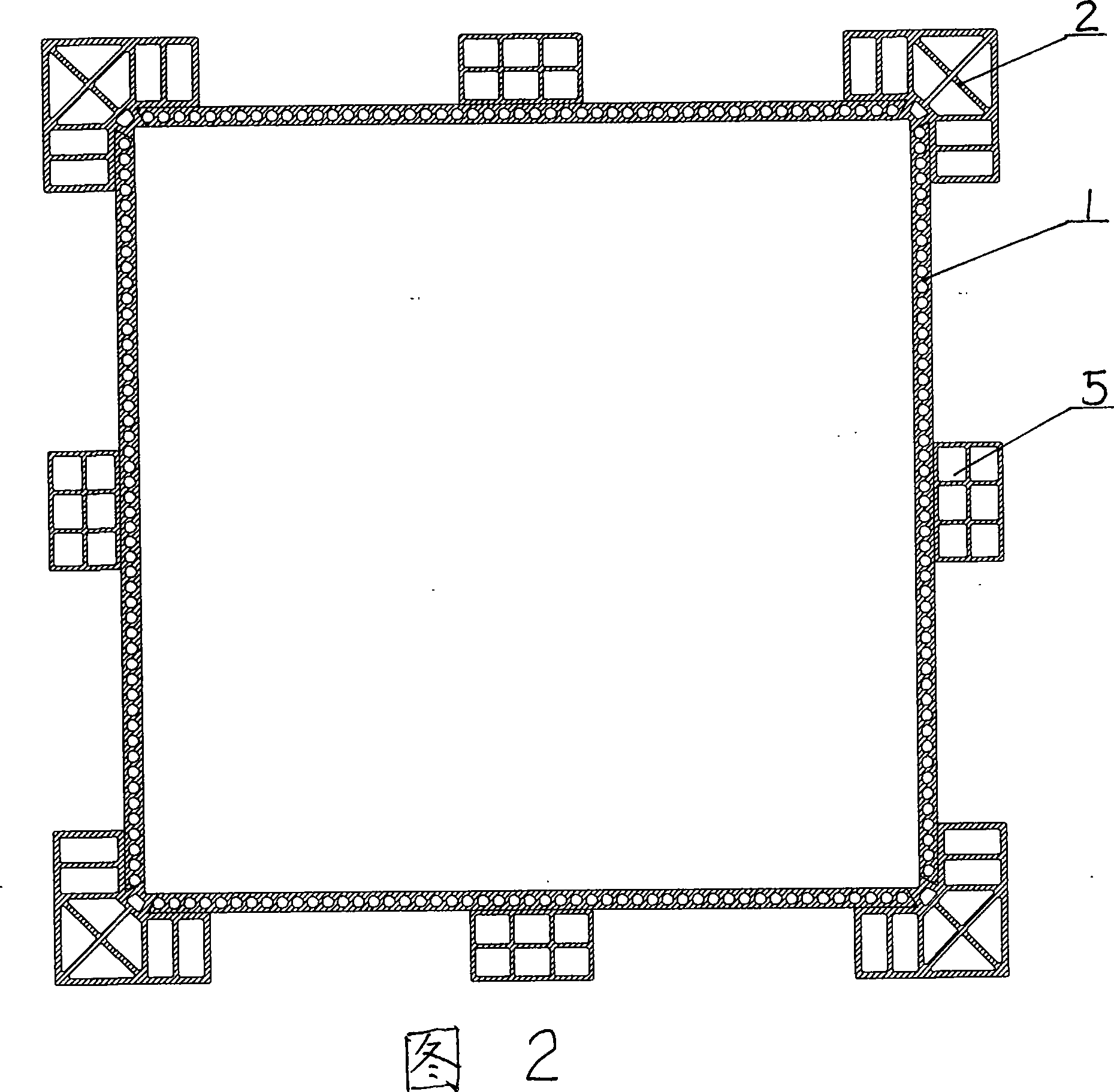

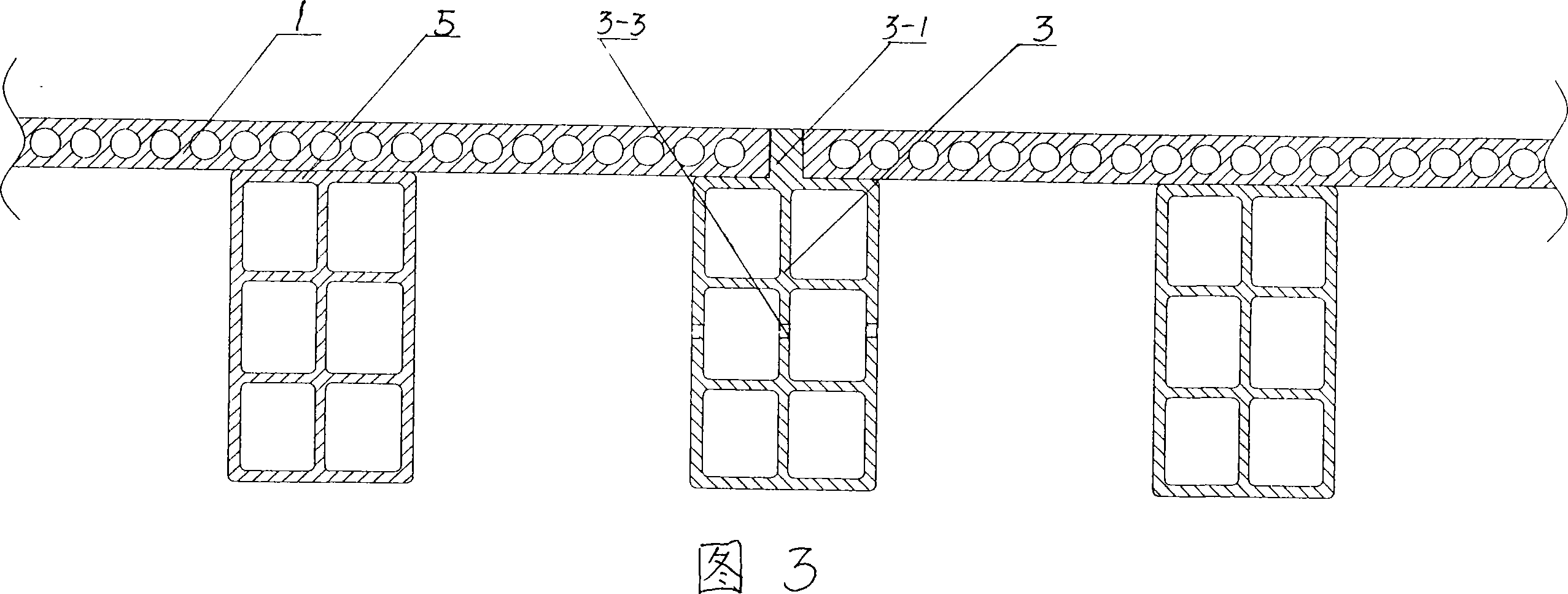

Comobined ribbed cavity member for spatial structure roof

A combined-rib cavity member for space-structure flooring includes cavity form and structure bottom plate, which are connected into one integral whole. It is characterized by that there are at least two cavity forms arranged alternate with each other on the structure bottom plate, its side forms with the structure bottle plate at least one subrit form cavity of casti-in-situ structure, and other other sides of the cavity form forms the side fromboard of main rib or beam or wall for cast-in-situ structure. By this, the subrib of cast-in-situ structure can be formed in the sub-rib form cavity on the structure battom plate, the sub-rib participates in load bearing of structural bottom slat, cast-in-situ main rib, cast-in-sita upper slab so to a load-bearing space structure, improved mechanical property, raise integrity and anti-shock property, decrease structural wt. lower cost and make construction be convenient.

Owner:湖南邱则有专利战略策划有限公司

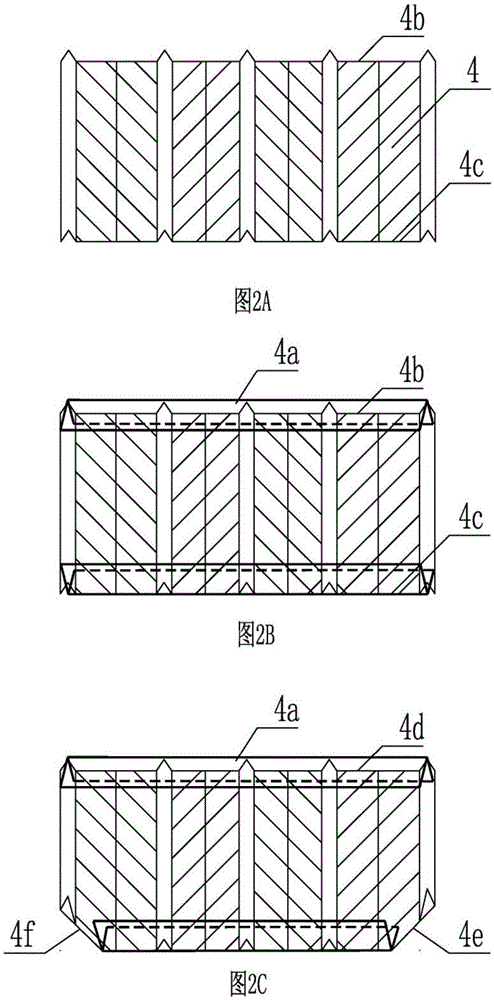

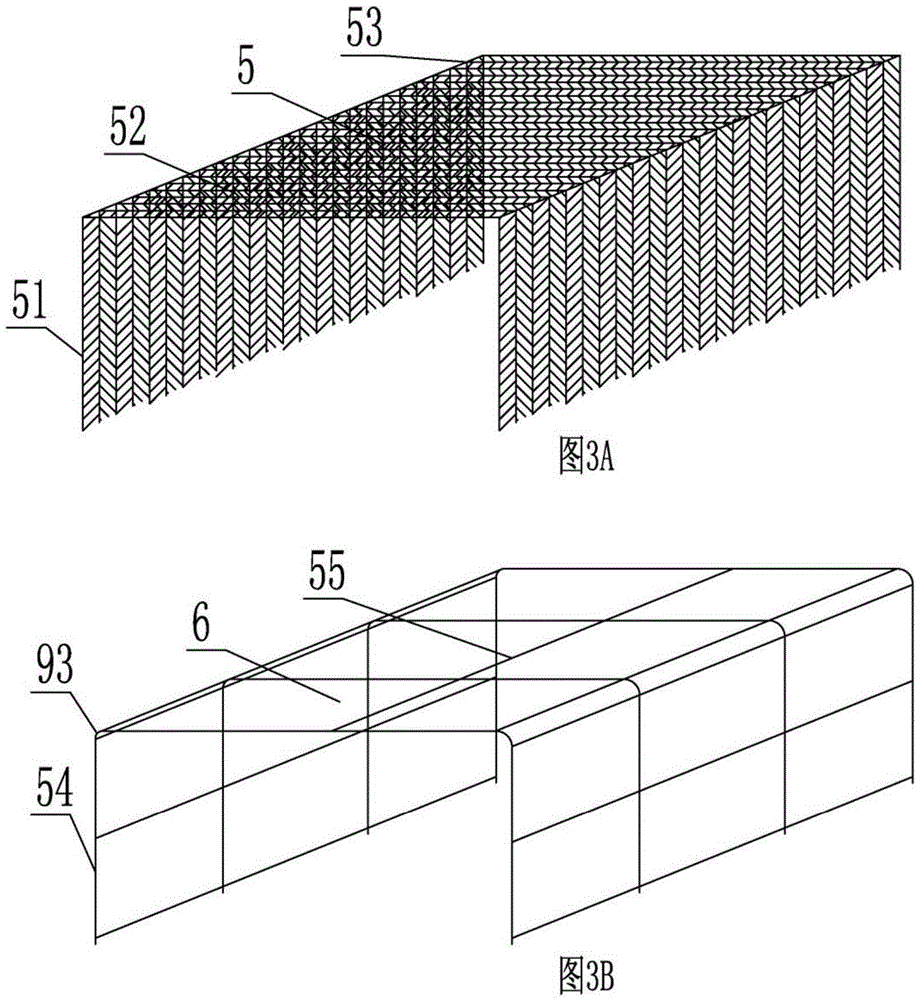

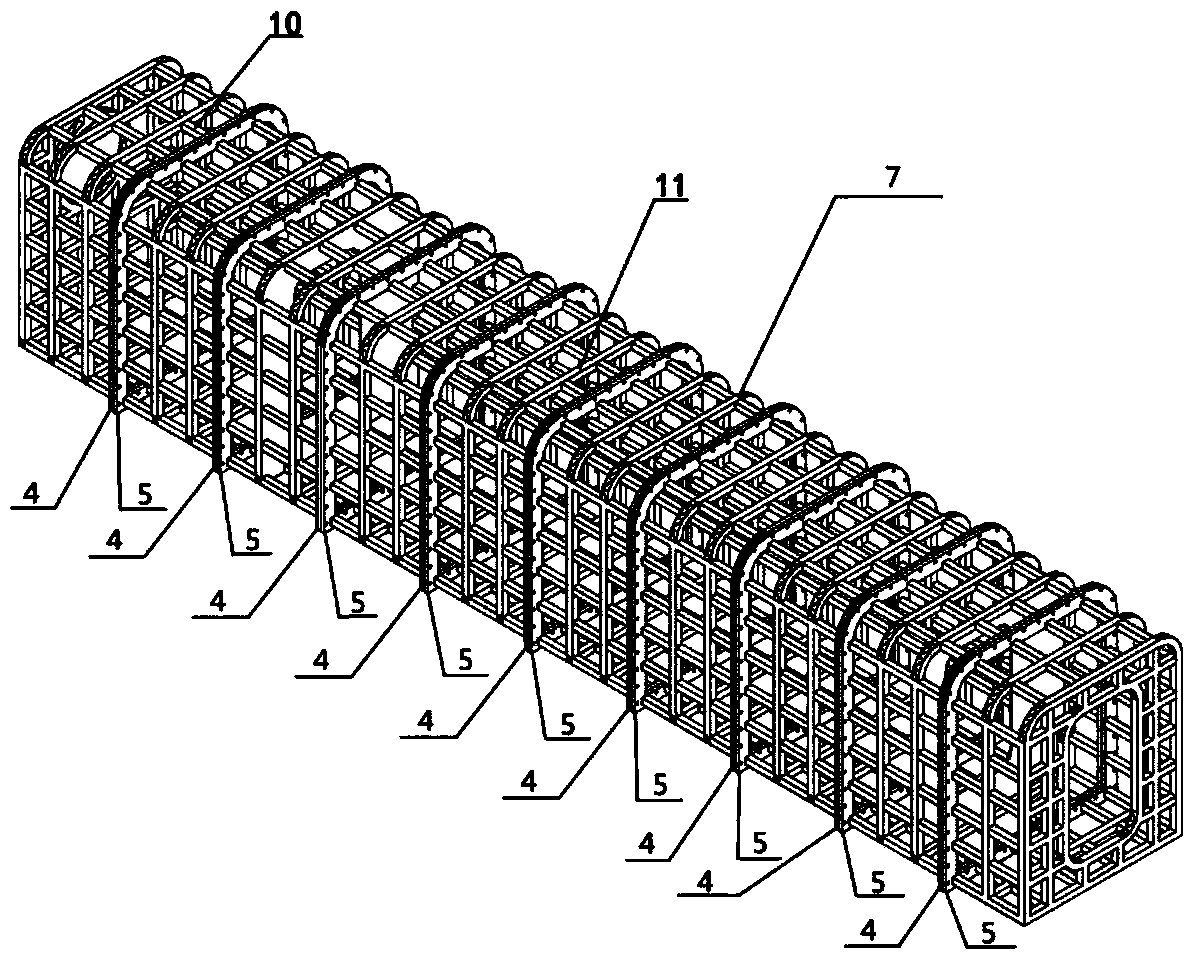

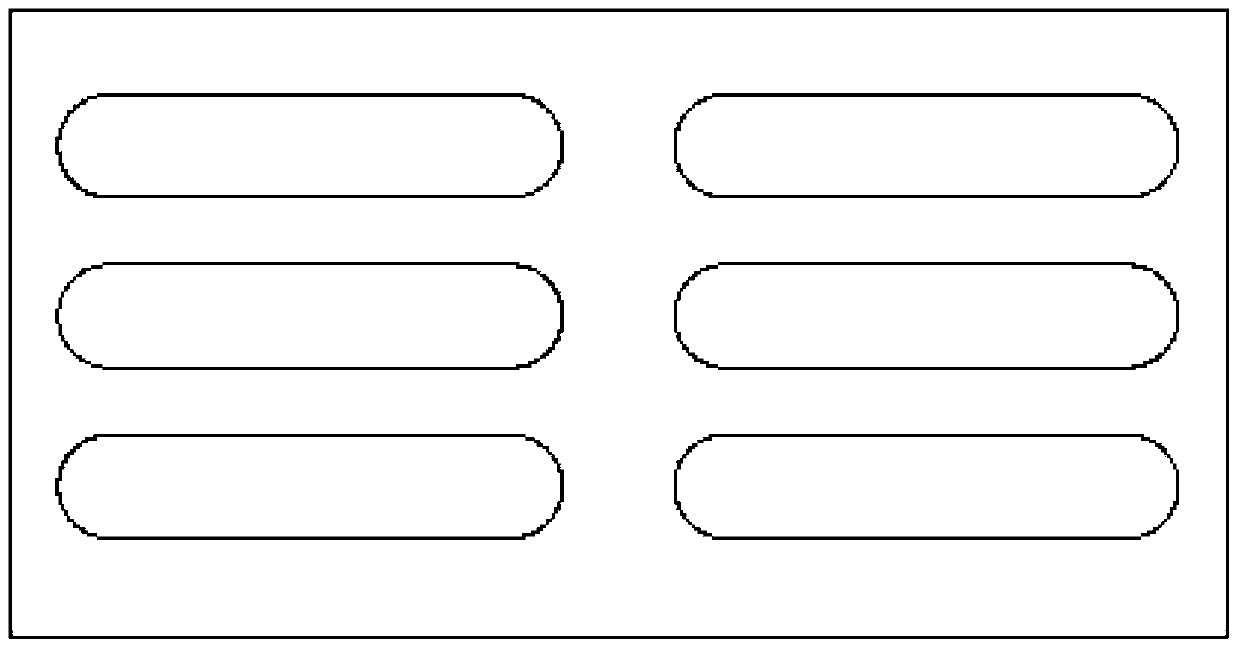

Netlike box-shaped component for forming holes in cast-in-situ hollow floor

The invention provides a netlike box-shaped component for forming holes in a cast-in-situ hollow floor. The netlike box-shaped component is formed by combining a box roof, a box body (side wall) and a box bottom; the box roof is compounded with cement mortar or styrofoam or a board; the box body and the box bottom are manufactured by netlike bodies; each netlike body comprises a netlike board, reinforcing ribs and connecting nets; the netlike board, the reinforcing ribs and the connecting nets form an interacting integral structure; the area of a grid in the netlike board is smaller than 120 mm<2>; the reinforcing ribs are V-shaped; the reinforcing ribs are higher than 3mm; the space between the reinforcing ribs in each netlike body is larger than 30mm; the netlike box-shaped component is formed by combining at least two netlike bodies; at least two structural inclined planes are arranged at corners of the box bottom and the box body of the netlike box-shaped component; the netlike bodies of the netlike box-shaped component are made of steel or plastic. The unsealed netlike box-shaped component replaces a fully-sealed hollow filling body and a solid filling body as a hole forming technology of the conventional cast-in-situ hollow floor, so that technical defects of the existing hollow floor are effectively solved.

Owner:王本淼 +1

Construction method for mounting outdoor embedded high-density polyethylene double-wall corrugated drain pipe

InactiveCN101565964AReduce weightConstruction and transportation are convenientSewerage structuresSewer pipelinesLow speedDouble wall

The invention relates to a construction method for mounting an outdoor embedded high-density polyethylene double-wall corrugated drain pipe (CPP).The method is characterized by comprising the following processes of foundation trench digging, pipe mounting and backfilling, wherein the foundation trench digging technical process comprises measuring and setting out, mechanical grooving, levelling and tamping of a groove bottom, grit gravel cushioning and foundation sanding; the pipe mounting technical process comprises pipe mounting, well chamber building and rendering; and the backfilling technical process comprises soil filling for a chest, a water tight test, soil backfilling and tamping. The method solves the problems of discharge of rainwater and sewage of current municipal engineering, industrial wastewater discharge, subdistrict drain engineering, low speed for cement and metal pipe construction in the engineering of pipelines preburying and the like, heavy pipe weight, inconvenience for conveying and carrying, large labor intensity, high mounting cost and the like, and is applicable to the discharge of the rainwater and the sewage of the current municipal engineering, the industrial wastewater discharge, the subdistrict drain engineering, and the construction for mounting engineering drain pipes such as the pipelines preburying and the like.

Owner:QINGDAO HENGSHENGYUAN GROUP CONSTR

Ribbed steel engraved mesh for cast-in-place cavity floor

InactiveCN105421663AInhibitionFast productionFloorsBuilding reinforcementsSheet steelMetallic materials

The invention provides a ribbed steel engraved mesh for a cast-in-place cavity floor. The ribbed steel engraved mesh is composed of an engraved mesh, a supporting mesh and an engraved end mesh; the engraved mesh, the supporting mesh and the engraved end mesh all are made of a pure metal material; the engraved mesh forms a periphery of the ribbed steel engraved mesh; the engraved end mesh closes the ribbed steel engraved mesh and the supporting engraved mesh to form an engraved end section shape of the ribbed steel engraved mesh; the supporting mesh controls a height of an internal space of the ribbed steel engraved mesh; the engraved mesh and the engraved end mesh are fabricated from steel mesh bodies, and each steel mesh body comprises steel sheet dilated mesh holes, a V-shaped rib and a steering connecting piece; the dilated mesh holes on two sides of the steering connecting pieces are not in the same direction; the V-shaped rib is greater than 6mm high; at least four measuring fixed marks are formed by pressing on the V-shaped rib of the steel mesh body of the engraved mesh in a vertical direction; and the supporting mesh is a steel mesh body or a reinforcing mesh body; the ribbed steel engraved mesh is used for casting the cavity floor, and the ribbed steel engraved mesh is directly buried in concrete cast in place at edges of a cavity to achieve a suppression effect on temperature cracks of the floor.

Owner:王本淼 +2

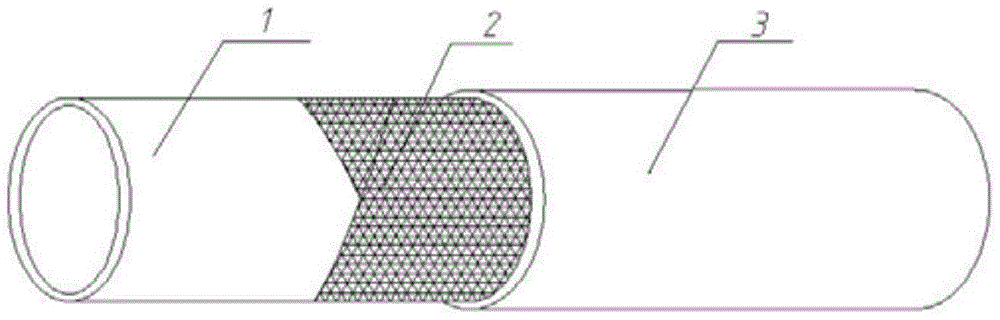

Hollow pipe member for in-situ deposited steel bar reinforced concrete combined structure

The hollow pipe member consists of hollow pipe, blockages at two ends of the pipe and transverse reinforcing ribs inside the pipe. All the hollow pipe, blockages and transverse reinforcing ribs have the same cross section shape, circular, square, trapezoidal or other. The member is featured by that its porous transverse reinforcing ribs is used, resulting in light weight and low cost as well as high strength, great deformation resistance, high antiseismic performance and other advantages of the member.

Owner:湖南邱则有专利战略策划有限公司

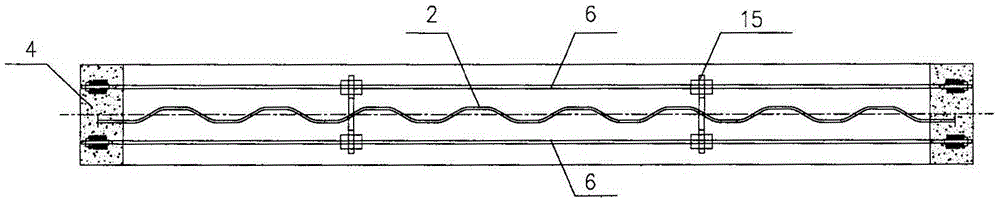

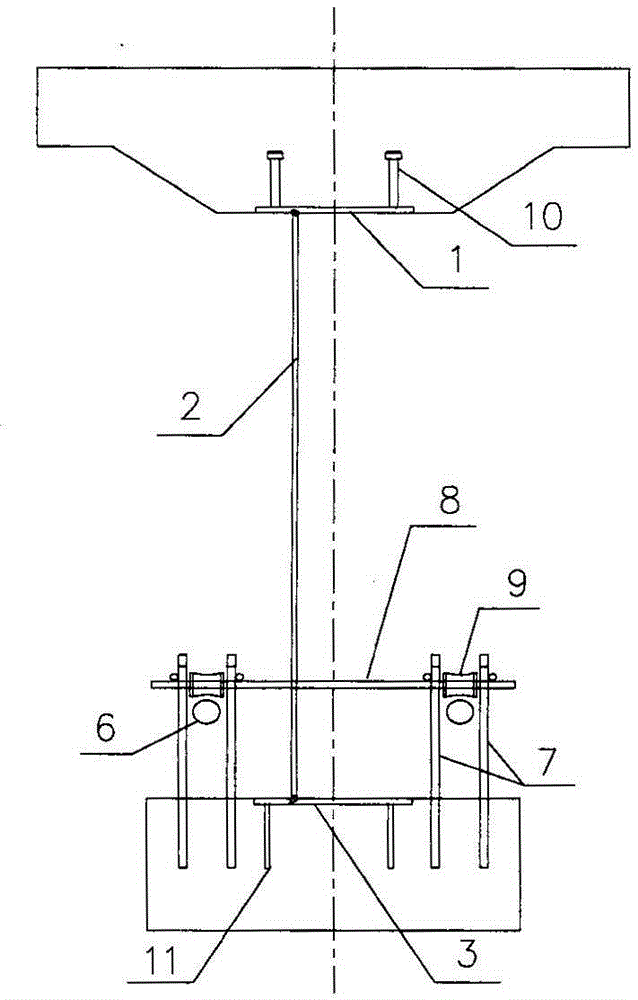

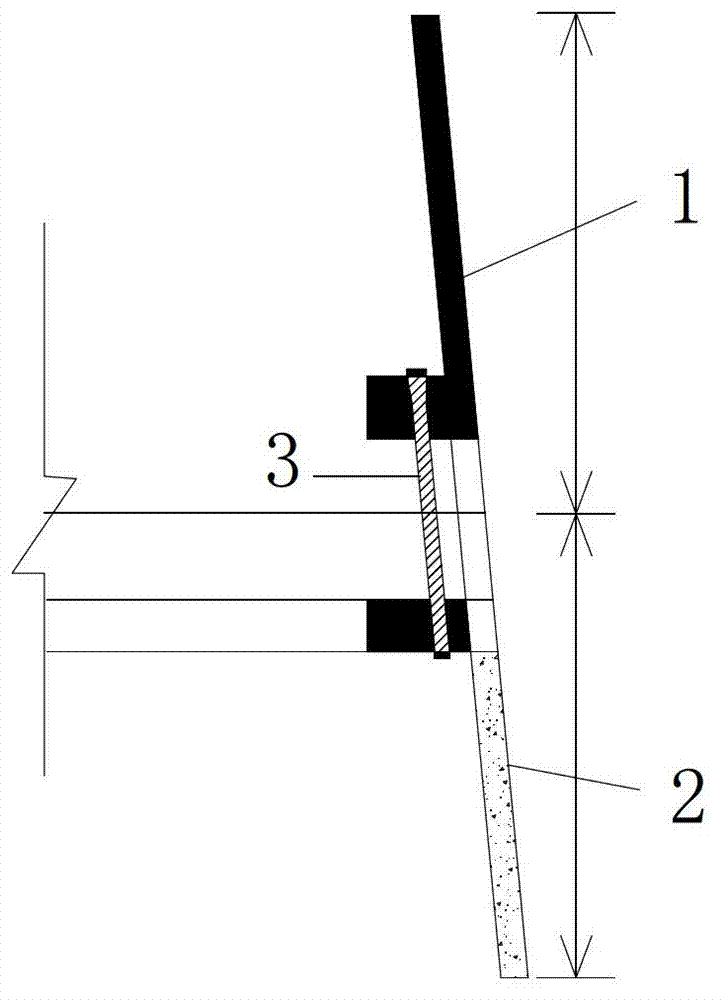

External prestressing corrugated steel web T-shaped beam and construction method

InactiveCN105369729AReduce usageLight weightBridge structural detailsBridge erection/assemblyShaped beamPre stress

The invention discloses an external prestressing corrugated steel web T-shaped beam and a construction method. The T-shaped beam comprises a concrete top plate, a concrete bottom plate, end cross beams, a corrugated steel web, shear connectors and external prestressing cables. The concrete top plate and the concrete bottom plate are connected with the corrugated steel web through the shear connectors to form a T-shaped beam section. The end cross beams are arranged at the two ends of the T-shaped beam and connected with the concrete top plate, the concrete bottom plate and the corrugated steel web. The external prestressing cables are steered at the break angle through steering devices and anchored to the end cross beams. The external prestressing corrugated steel web T-shaped beam has the advantages of stress performance, the material utilization rate and durability of a common corrugated steel web T-shaped beam, structural stress is optimized, the member structure is simplified, the amount of adopted prestressed reinforcement is reduced, and manufacturing cost is reduced; the problems that during internal prestressing construction, stretch-draw porous channels are blocked, and grouting is not compact after stretching and drawing are carried out are solved, the construction quality is ensured, and the bridge structure can be maintained and reinforced easily during the later stage.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

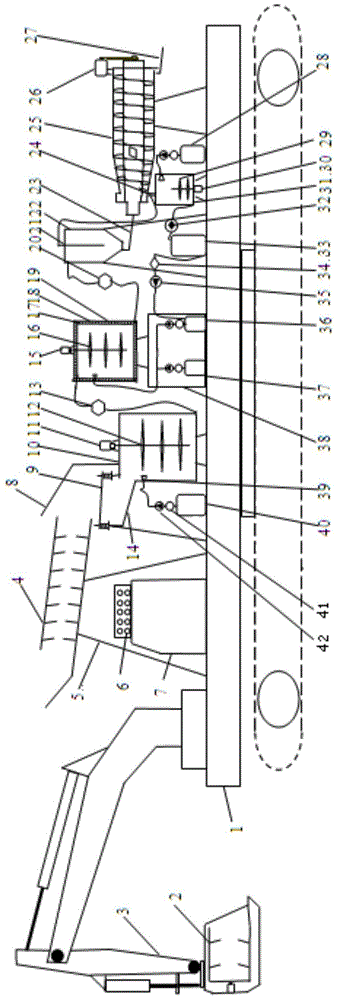

Contaminated soil treatment equipment through leaching

ActiveCN105107835AEasy to operateReasonable structureContaminated soil reclamationAutomatic controlContaminated soils

The invention relates to contaminated soil treatment equipment through leaching. The contaminated soil treatment equipment comprises a crawler-type road roller, a screening and crushing system, a pulping system, a soil treating system and a medicament feed system; the screening and crushing system is used for breaking hard soil blocks in contaminated soil and screening impurities such as rocks and plastic in the contaminated soil; the pulping system is used for further removing large-particle substances in the contaminated soil, so that the treatment amount of the contaminated soil is reduced, and the treatment cost is reduced; through the adoption of the soil treating system, quick remediation of the contaminated soil through leaching is realized; through the adoption of the medicament feed system, the feed of medicaments and reutilization of a leacheate is realized. All materials and devices are mounted on the crawler-type road roller, so that the transportation and the construction are convenient. The contaminated soil treatment equipment integrates functions of soil excavation, soil screening, medicament adding, soil leaching, leacheate reutilization and automatic control, is compact in structure, convenient to operate and high in suitability and efficiency, is suitable for application of large-scale engineering, and can realize efficient and quick remediation of various contaminated sites.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI +1

Thin-wall tube for hollowing out concrete

InactiveCN1401865ASolve the anti-deformationImprove tensile propertiesFloorsUltimate tensile strengthHollow core

A thin-wall hollow pipe for in-situ pouring bar reinforced non-beam concrete floor is composed of pipe wall and two end plugs, and is characterized by that each end plug has at least one thin strip for improving its tension, tension and compression resistance. Its advantages are simple structure, high strength, high crack, deformation and vibration resistance and low cost.

Owner:湖南邱则有专利战略策划有限公司

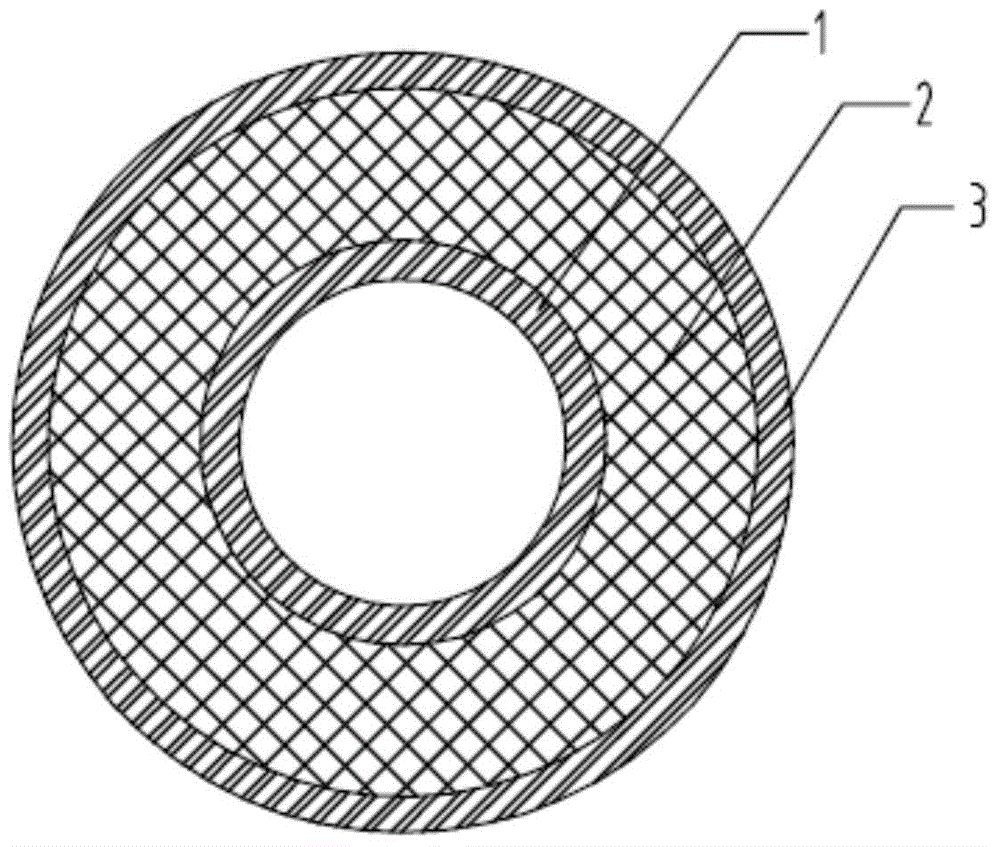

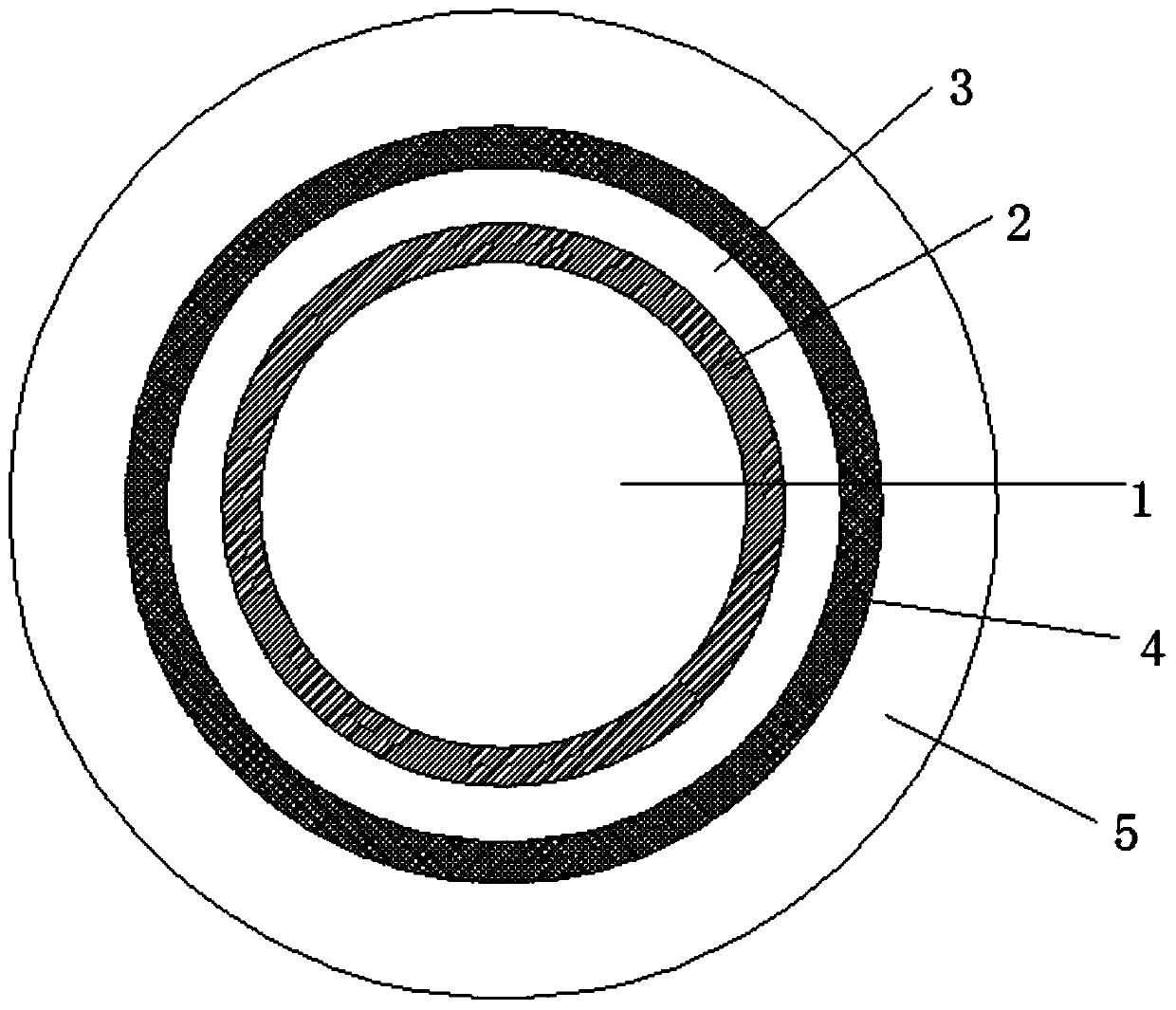

Thermoplasticity winding pressure pipeline and manufacturing method thereof

The invention belongs to the technical field of pipeline materials and relates to a thermoplasticity winding pressure pipeline and a manufacturing method of the thermoplasticity winding pressure pipeline. The thermoplasticity winding pressure pipeline sequentially comprises a lining layer, a structural layer and an outer protecting layer from interior to exterior, the inner walls of the lining layer and the structural layer are connected, the outer wall of the structural layer and the outer protecting layer are connected, and the structural layer is a constant fiber reinforcing thermoplasticity material presoaking belt winding layer. The manufactured thermoplasticity winding pressure pipeline has a higher strength and rigidity and can manufacture a large-caliber pipeline, and the thermoplasticity winding pressure pipeline is excellent in lightness, good in anti-impact performance, environment-friendly and convenient to transport and construct.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

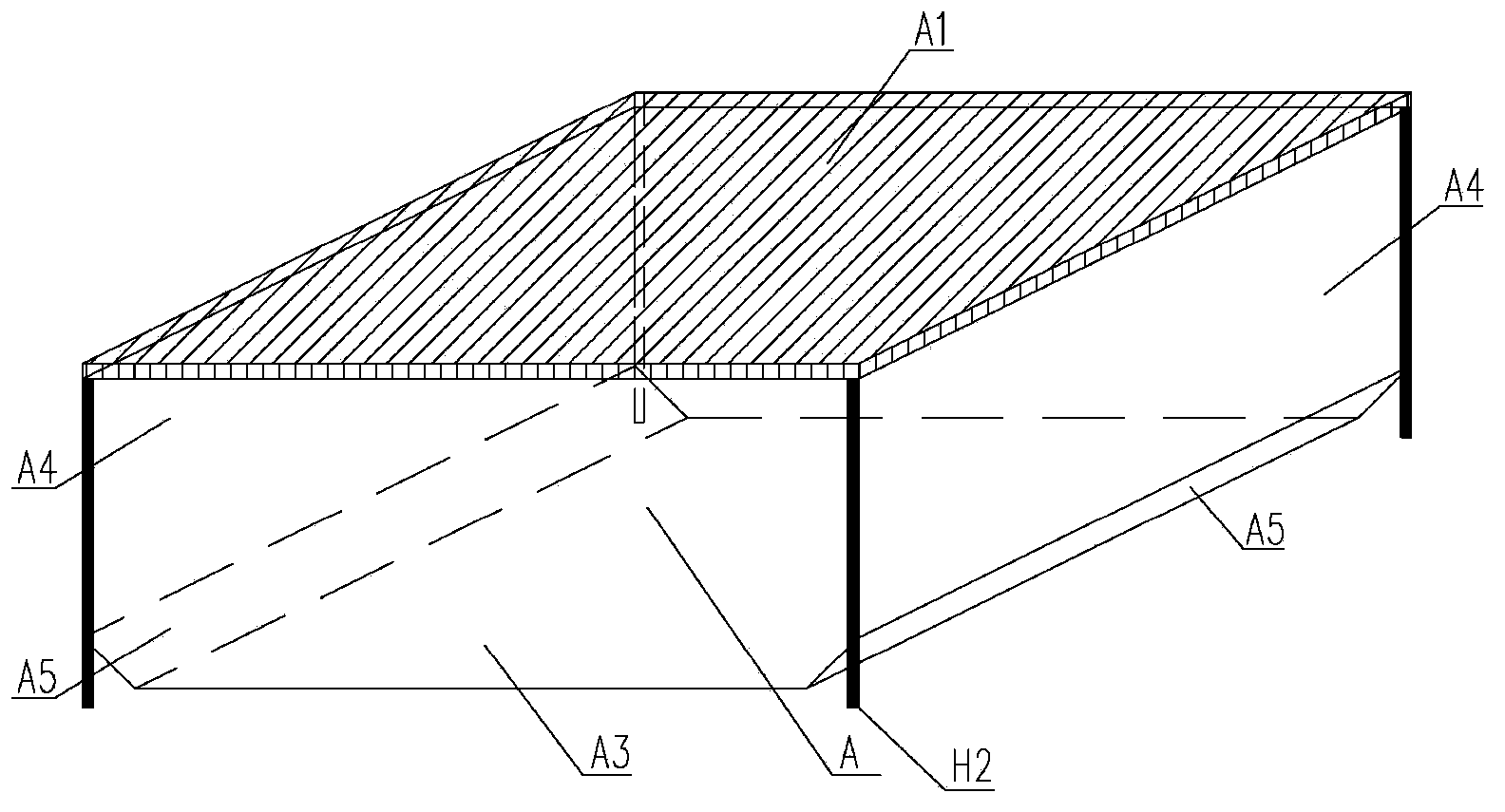

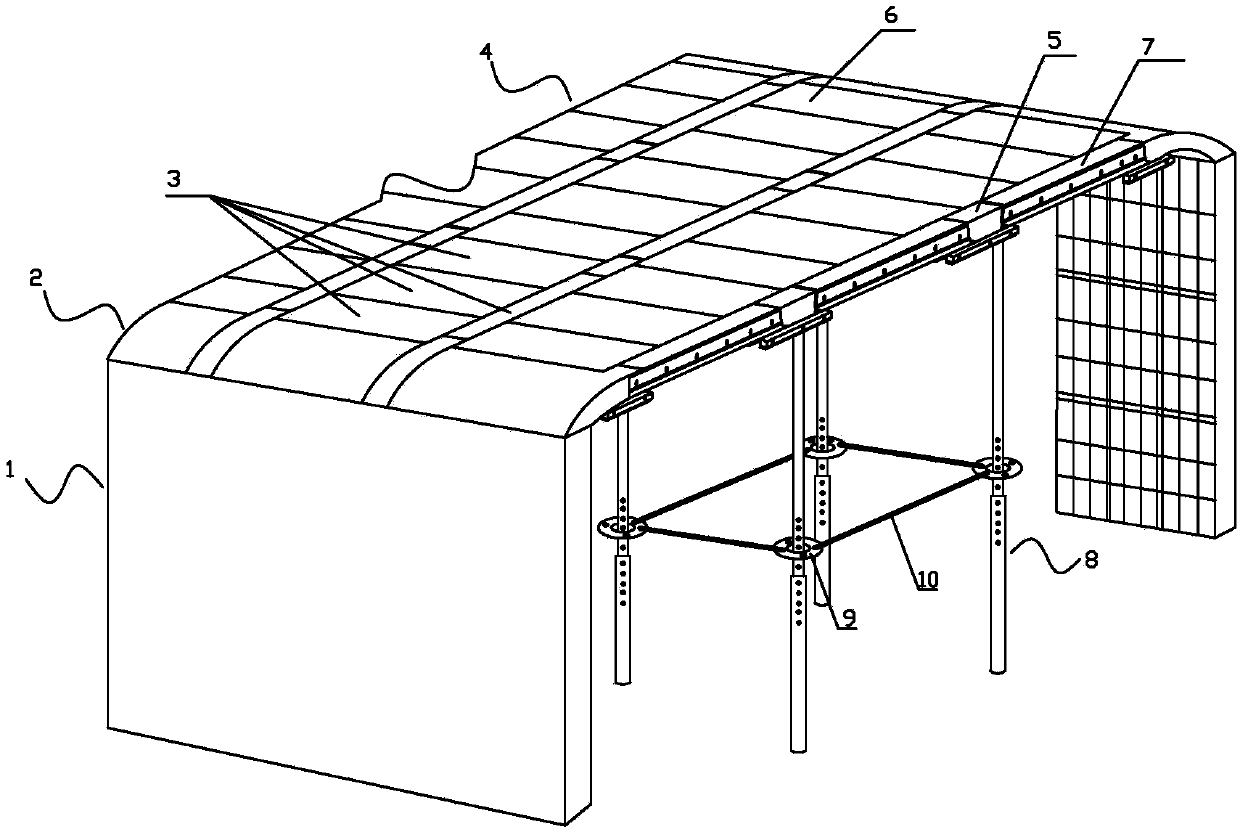

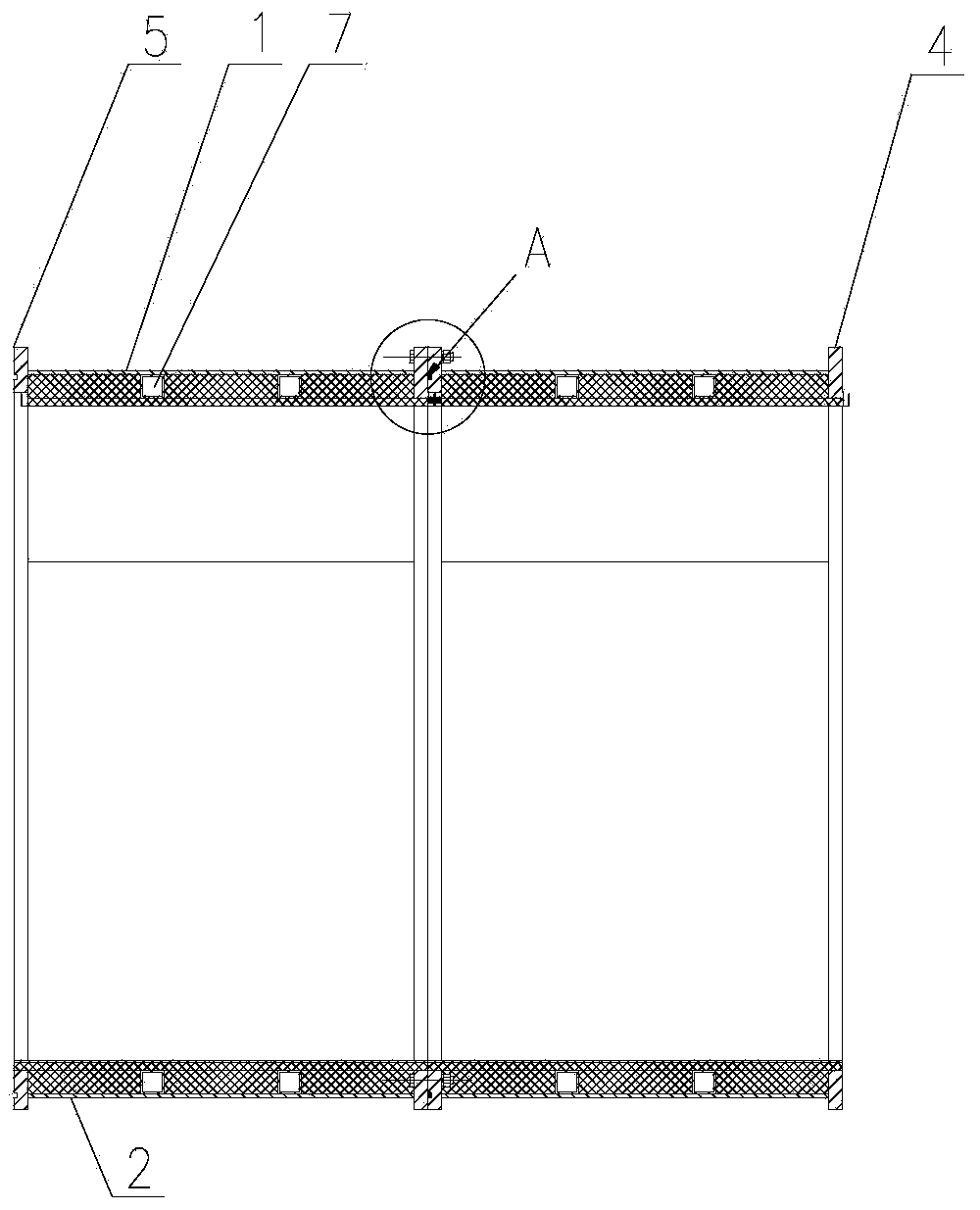

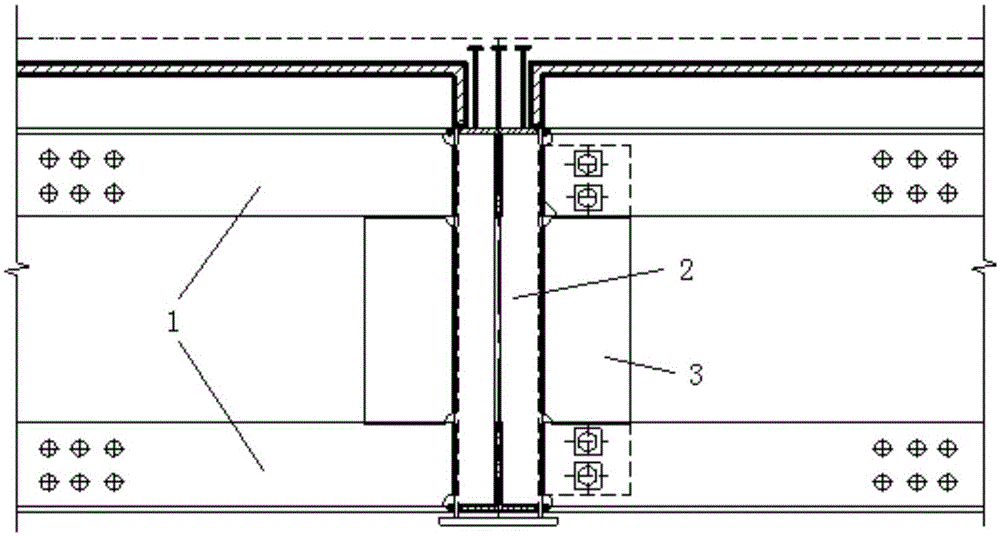

Underground pipe gallery formwork

PendingCN107558495AConstruction and transportation are convenientFast constructionArtificial islandsUnderwater structuresReinforced concreteArchitectural engineering

The invention discloses an underground pipe gallery formwork. The underground pipe gallery formwork comprises side wall formworks, a top wall formwork and corner formworks used for connecting the sidewall formworks and the top wall formwork. The top wall formwork is composed of a plurality of aluminum alloy formwork units. Each aluminum alloy formwork unit comprises a plurality of parallel aluminum alloy flat plates with the side edges being detachably connected, and a transverse top formwork keel which is detachably connected with the ends of the multiple aluminum alloy flat plates. Supporting heads with the top faces supporting a pipe gallery reinforced concrete top plate are formed in gaps of every two adjacent aluminum alloy formwork units. The supporting heads and the two adjacent top formwork keels are detachably connected, and the top formwork keels and the corner formworks are also detachably connected. The supporting heads are fixedly connected with stand columns supported onto the ground. The other end, far away from the corresponding top formwork keel, of each aluminum alloy formwork unit is detachably connected with the top formwork keel of another adjacent aluminum alloy formwork unit. The underground pipe gallery formwork can be conveyed and transported conveniently, and the turnover frequency of the formwork is high.

Owner:杭州伟业建设集团有限公司

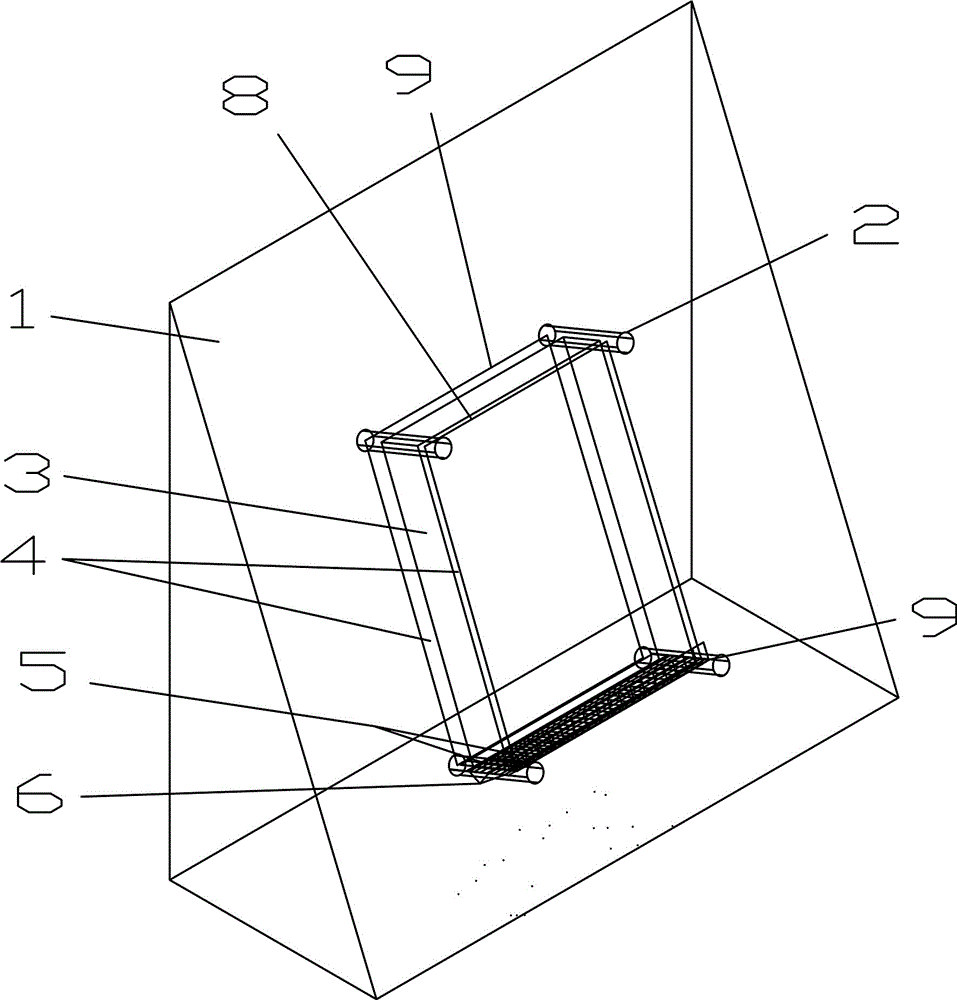

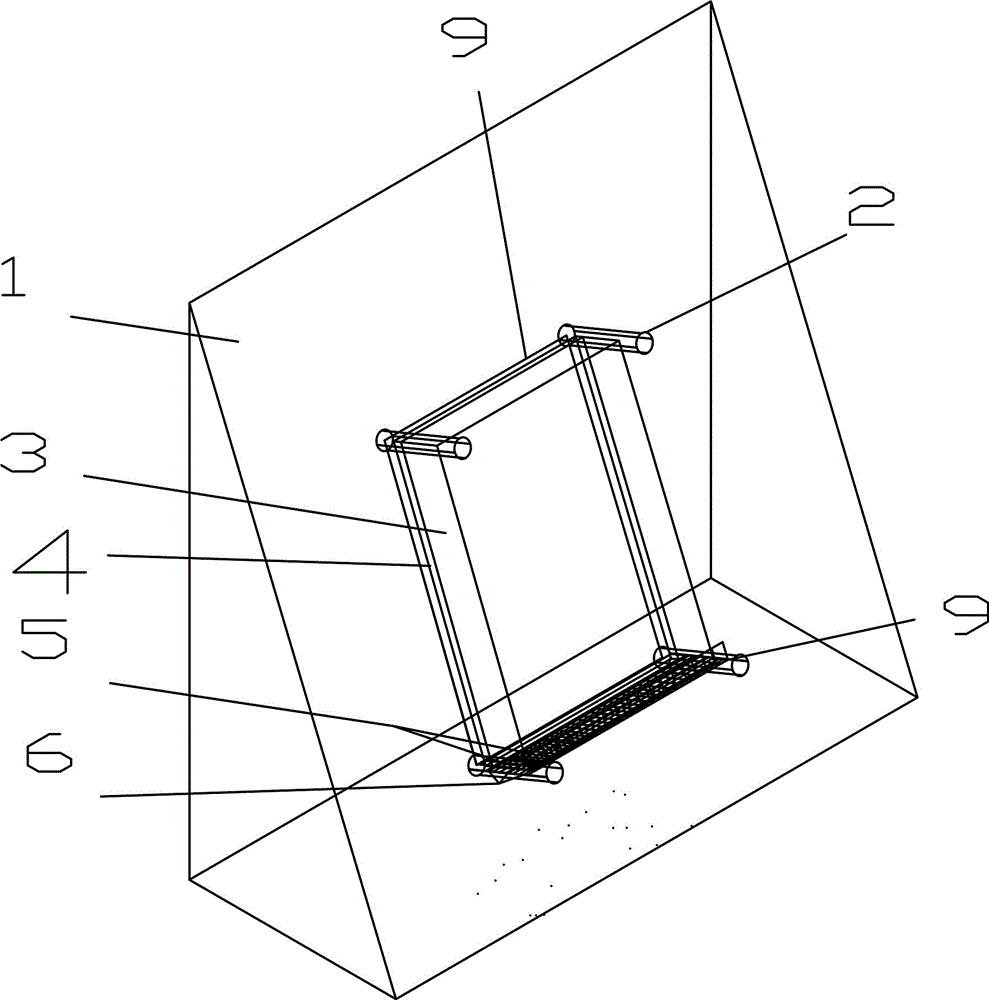

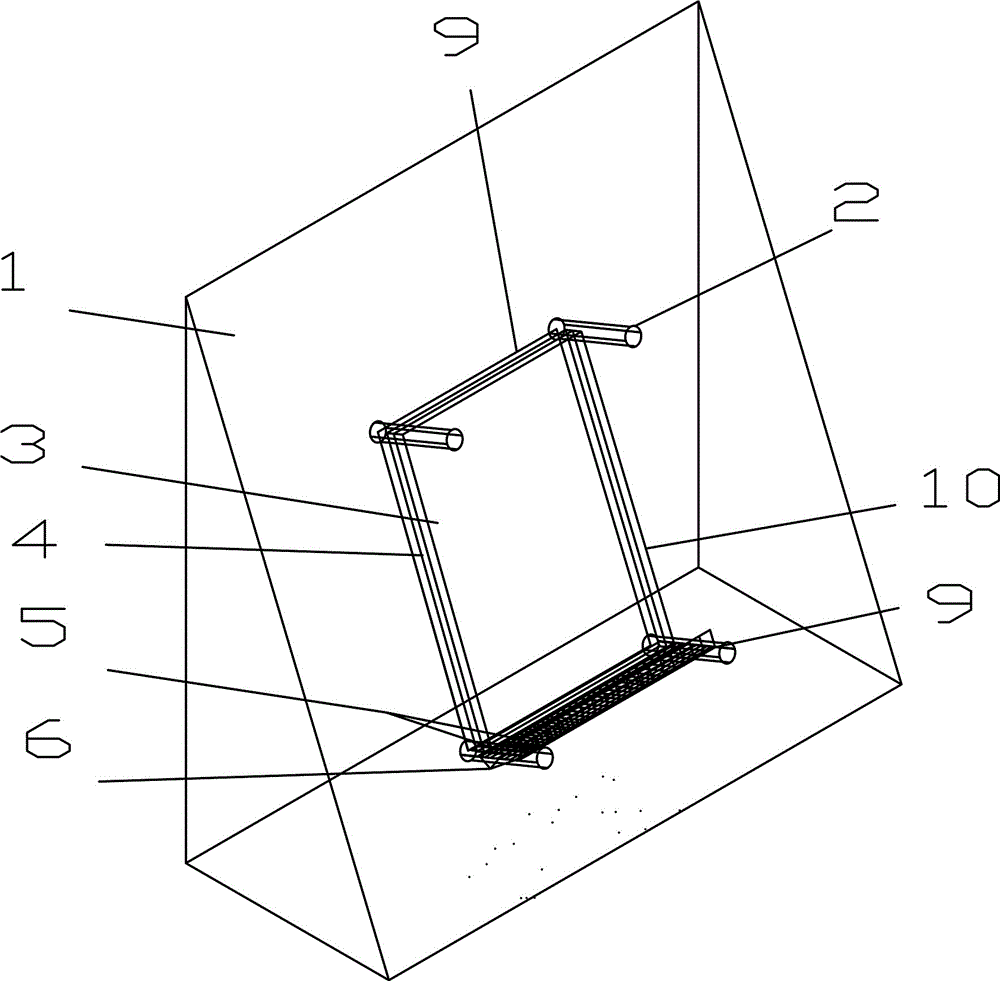

Ecological greening device for side slope with flexible ceramsite plates, and greening method thereof

ActiveCN106638630AImprove survival rateReduce direct washoutExcavationsReceptacle cultivationVegetationGreening

The invention discloses an ecological greening device for a side slope with flexible ceramsite plates. The ecological greening device comprises a plurality of anchor rods embedded in the slope surface of the side slope, wherein each four anchor rods form a square body; the two anchor rods at the lower end of the square body are connected through a plurality of steel wires; iron wire blocks are laid on the plurality of steel wires; a geotextile layer is laid on the slope surface of the side slope among the plurality of anchor rods of the square body and on the iron wire blocks at the lower end of the square body; a nutritive vegetation soil layer is laid on each geotextile layer in the square body; the corresponding flexible ceramsite plate is embedded in each nutritive vegetation soil layer; and planting grass is further laid on each nutritive vegetation soil layer. The ecological greening device for the side slope with the flexible ceramsite plates, and the greening method thereof, which are provided by the invention, are capable of solving the problem that side slope greening cannot be realized or soil is easy to scour of an existing method; and the stability between nutritive vegetation soil and a rock wall can be improved through reducing the direct scouring of rainwater for the nutritive vegetation soil and providing a pressure coating force, thus the survival rate of plants is increased, and a role of large-area greening protection is played.

Owner:CHINA THREE GORGES UNIV

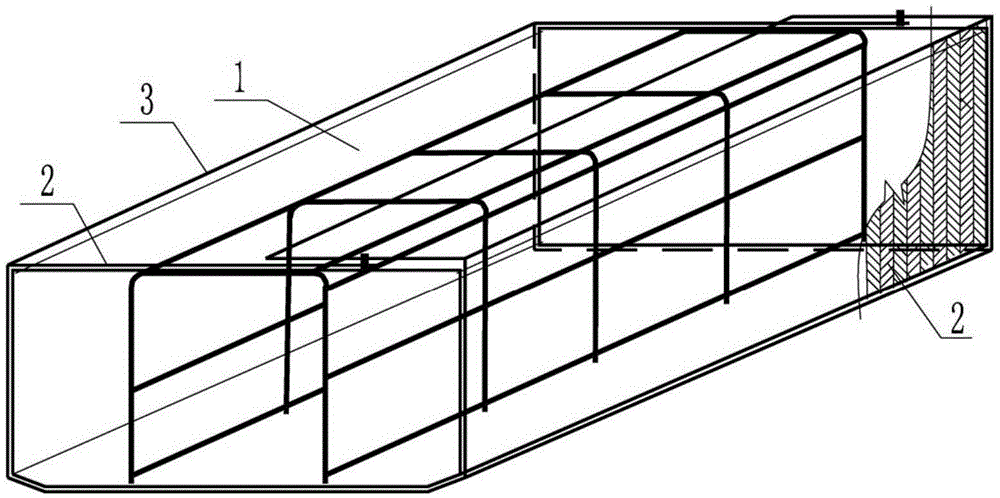

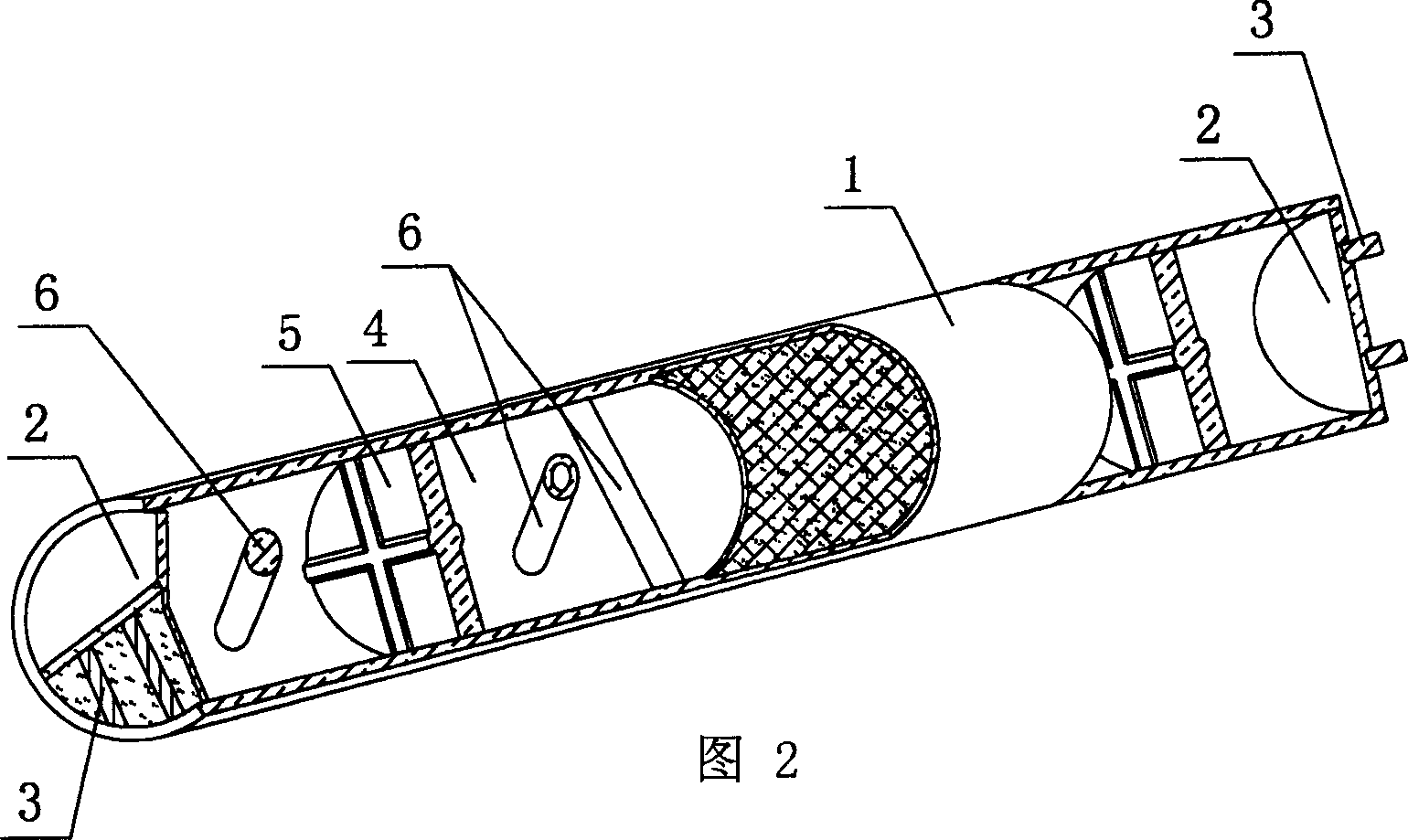

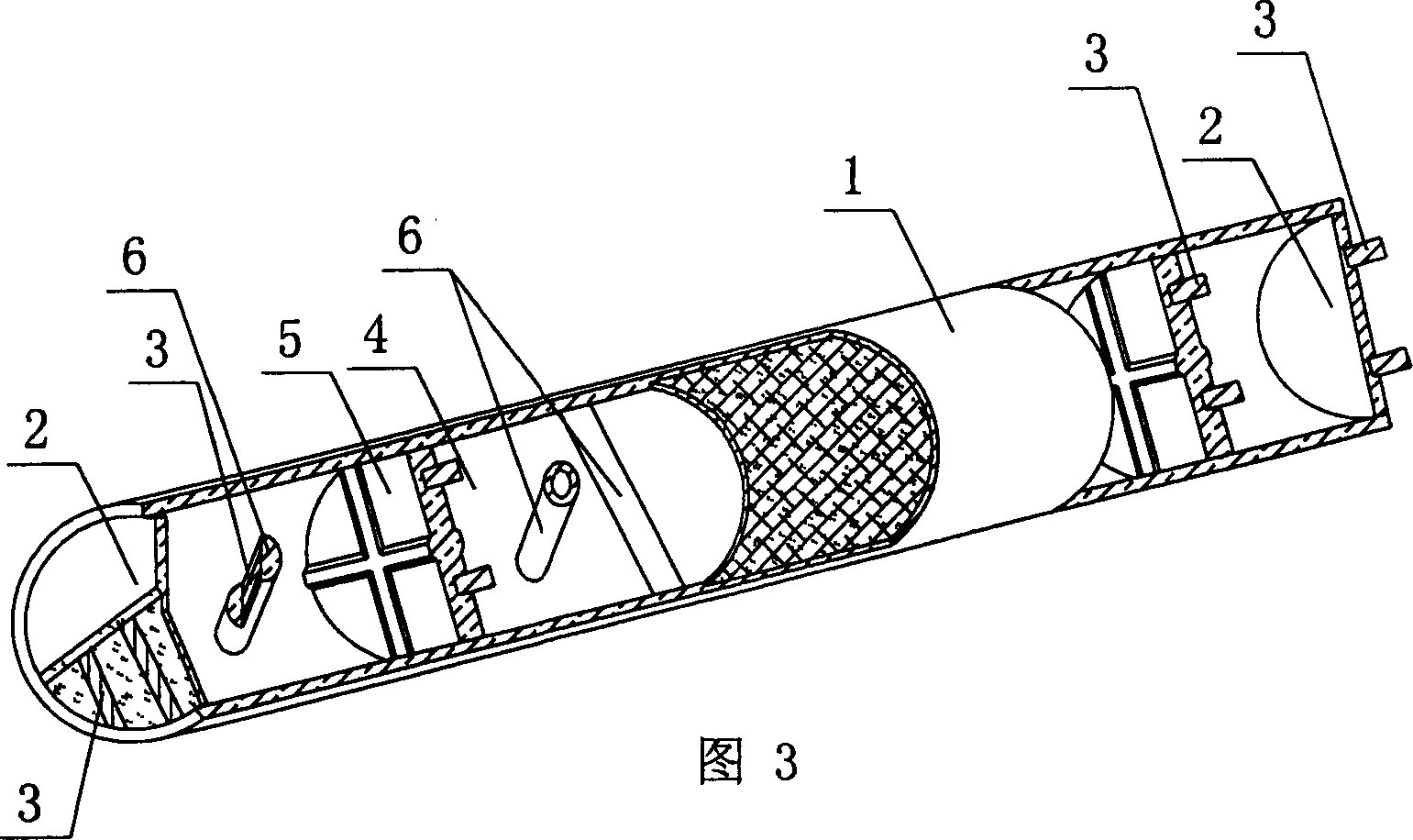

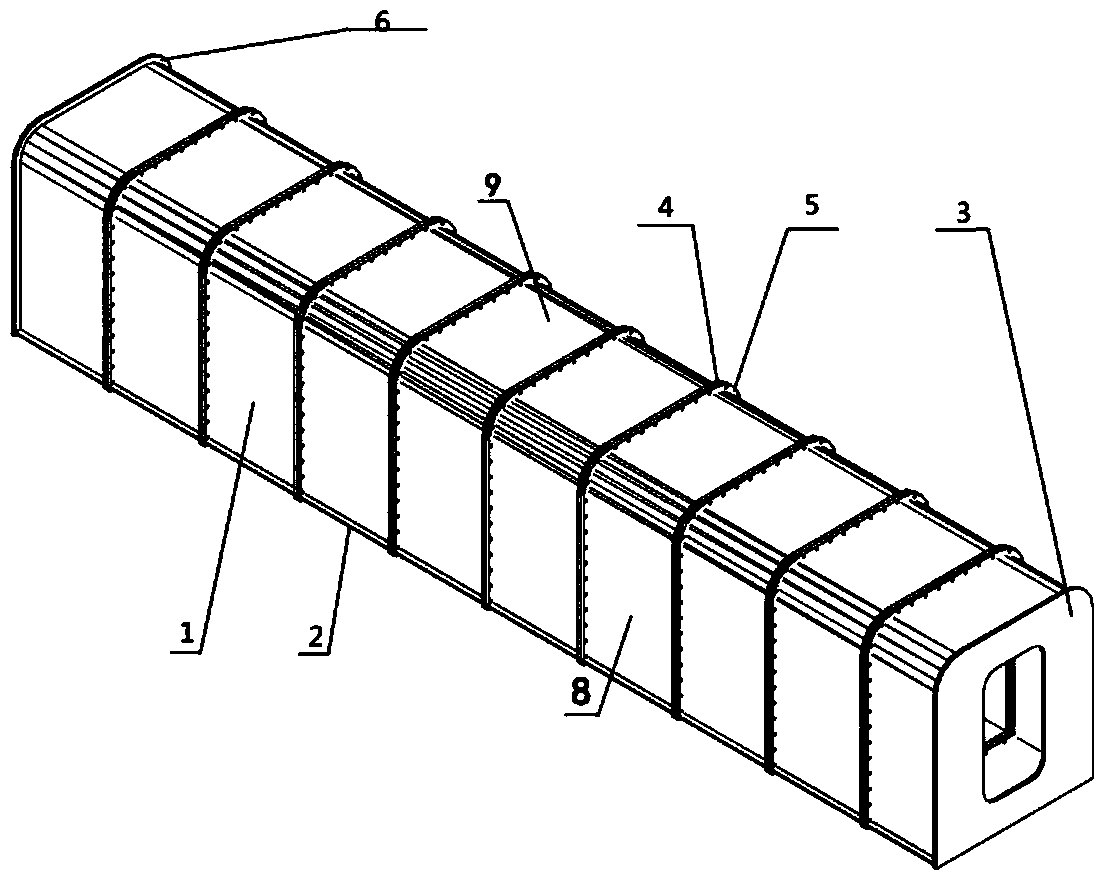

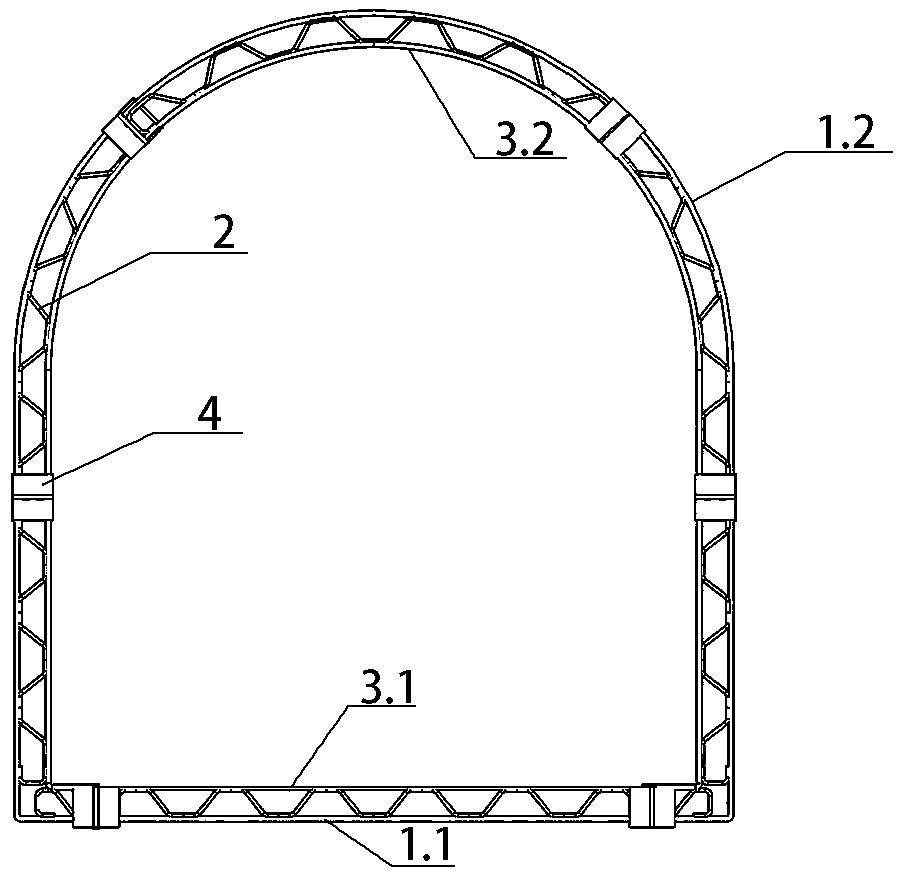

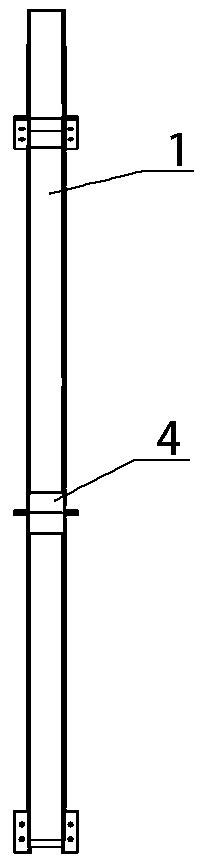

Closed-loop type mine-used lifesaving cabin body

InactiveCN103758563AReduce weightEasy to move and interchangeEngine sealsSafety equipmentsVertical planeClosed loop

The invention discloses a closed-loop type mine-used lifesaving cabin body. The closed-loop type mine-used lifesaving cabin body is composed of a plurality of cabin body units in a combined mode end to end, wherein each cabin body unit comprises an inverted-U-shaped cabin body shell and a cabin body bottom shell which is used in cooperation with the cabin body shell, the two ends of each cabin body unit are provided with a cabin body connecting flange I and a cabin body connecting flange II respectively, the cabin body units are fixedly connected through cooperation between the cabin body connecting flanges I and the cabin body connecting flanges II, a plurality of horizontal plane closed-loop type reinforcing ribs are arranged on the two sides and the end faces of the interior of the lifesaving cabin body and are arranged in the cabin body direction, a plurality of vertical plane closed-loop type reinforcing ribs in the cabin body direction and a plurality of annular reinforcing ribs parallel to the cabin body connecting flanges I are arranged on the top surface, the bottom surface and the end faces of the lifesaving cabin body, and the reinforcing ribs in the three directions are staggered to form a closed-loop type reinforcing rib grid structure. According to the closed-loop type mine-used lifesaving cabin body, due to the fact that the reinforcing ribs are of a closed-loop and grid structure, stress is effectively dispersed, and antiknock performance is improved; due to the fact that the structure with the split units is adopted, movement and exchange of the closed-loop type mine-used lifesaving cabin body are convenient, and construction and transport are convenient.

Owner:浙江杭钻机械制造股份有限公司

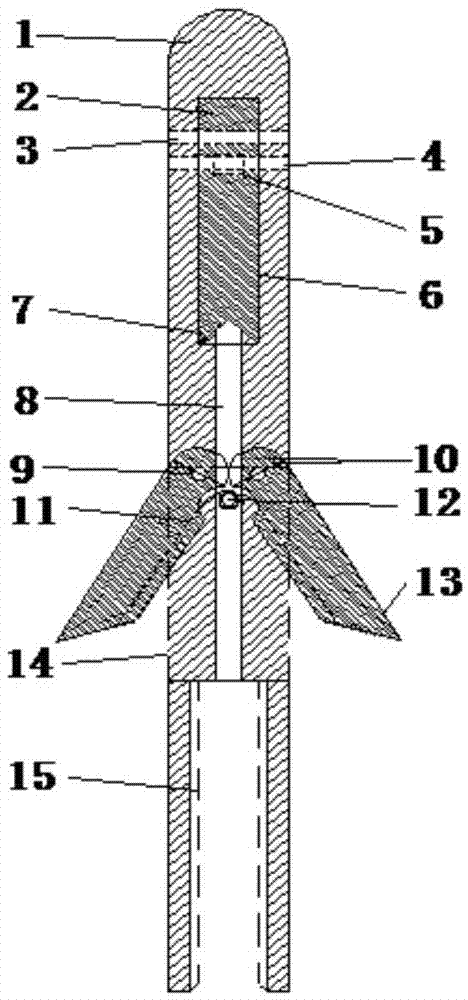

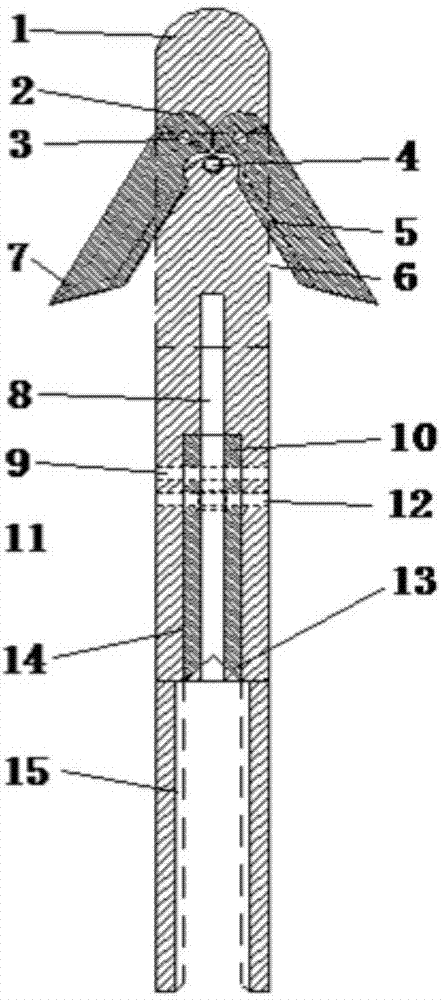

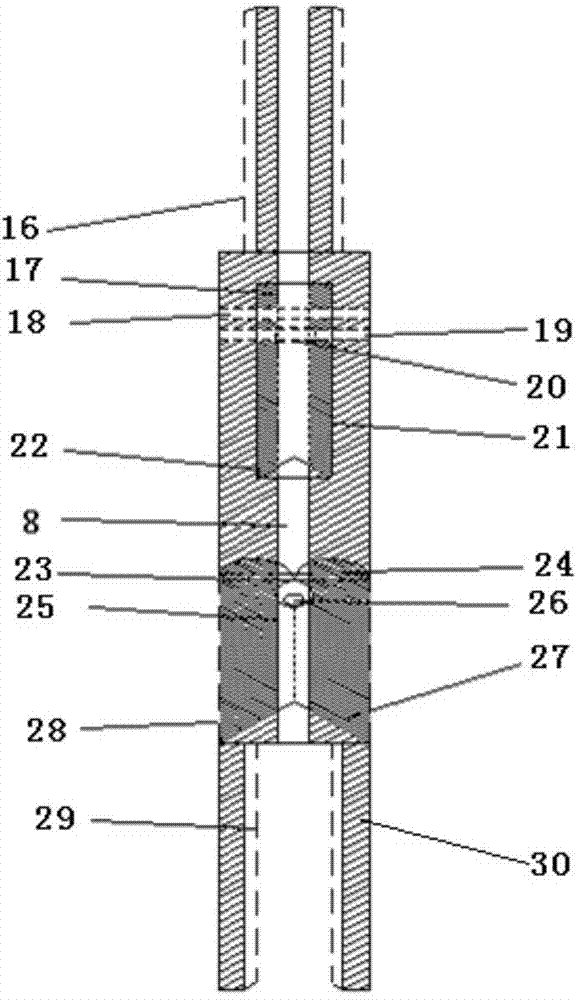

Multi-joint self-expansion anchor rod

InactiveCN103939120AEasy to installControl deformationAnchoring boltsUltimate tensile strengthSelf expansion

The invention relates to a multi-joint self-expansion anchor rod for tunnel engineering construction. The multi-joint self-expansion anchor rod comprises an anchoring head and one or more anchor rod bodies, strip-shaped square holes orthogonal in space position are respectively formed in the head portions and the middle portions of the anchoring head and the anchor rod bodies, a group of elastic self-expansion wedge blocks are respectively installed in the strip-shaped square holes through pins and comprises an inverted V-shaped spring and two wedge blocks symmetrically attached to the outer edge of a spring reed. In the actual construction, the wedge blocks attached to the outer edge of the spring reed are always open and tightly in contact with a surrounding rock in the anchor rod feeding process, and after the anchor rods are fed to the bottom, the anchor rods are embedded into a pore wall rock to play an anchoring effect of the anchor rods. After anchoring is finished, reinforcement can be achieved through grouting holes or the designed anchoring effect can be achieved without the anchor rod grouting construction process. The multi-joint self-expansion anchor rod for tunnel engineering construction is reasonable in structure, convenient to construct, quick, high in efficiency, good in anchoring strength and supporting effect and capable of keeping the integrity and stability of the surrounding rock to the most extent.

Owner:罗宗帆

Graphite composite resistance-reduction cloth production process

InactiveCN104376921AAvoiding the disadvantages of corroding metal grounding bodiesExtended service lifeCable/conductor manufactureConnection contact member materialElectricityYarn

The invention belongs to the technical field of lightning protection and grounding for electric power, railways, telecommunications, factories and mines, high-rise buildings and the like, and particularly relates to a graphite composite resistance-reduction cloth production process. The graphite composite resistance-reduction cloth production process comprises the following steps that expansible graphite with the carbon content being 99.5 percent or more is selected and high-temperature expansion is conducted at 1000 DEG C, so that graphite worms are obtained; the surface of special fiber is evenly immersed with an adhesive; the special fiber is evenly laid between an upper layer of electricity-conducting low-resistance graphite coiled material and a lower layer of electricity-conducting low-resistance graphite coiled material; the composite electricity-conducting low-resistance graphite coiled materials are cut into electricity-conducting low-resistance graphite belts; the electricity-conducting low-resistance graphite belts are made into electricity-conducting low-resistance graphite yarn through a twisting machine in a unidirectional twisting mode; the graphite composite resistance-reduction cloth is woven by a braiding machine through the electricity-conducting low-resistance graphite yarn formed in a twisted mode. The graphite composite resistance-reduction cloth production process is simple, controllable in production cost and capable of bringing convenience to large-scale production, application and popularization.

Owner:河南盛煌电力设备有限公司

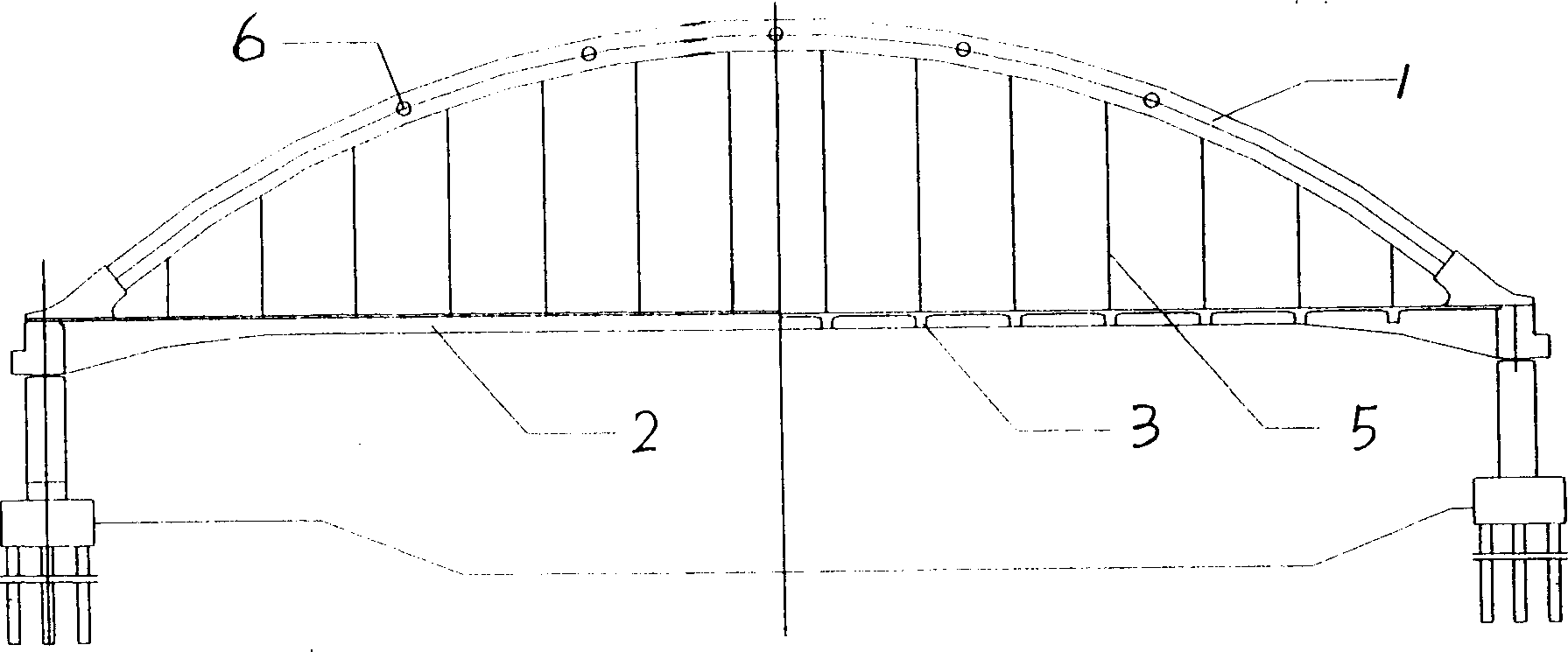

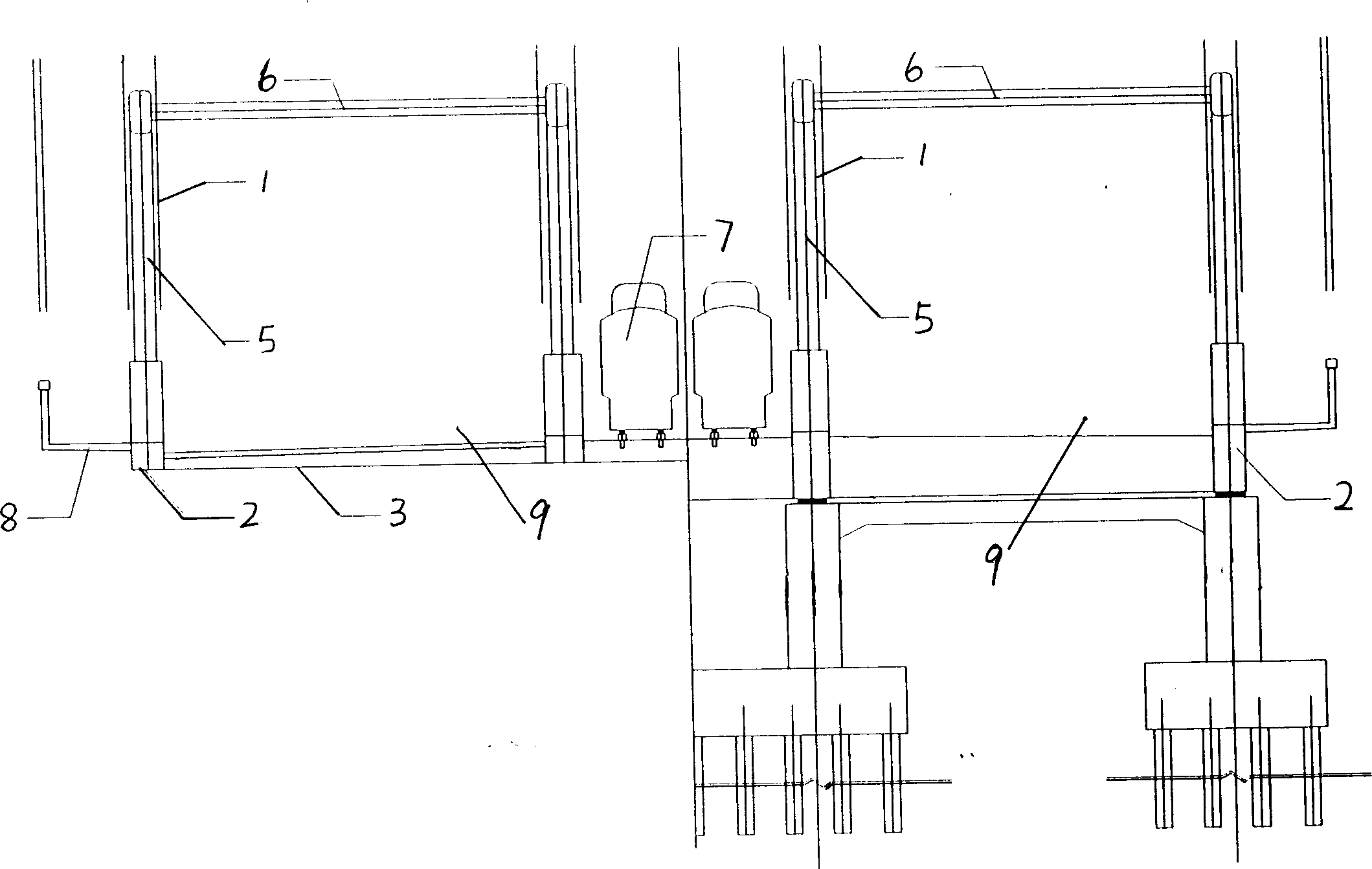

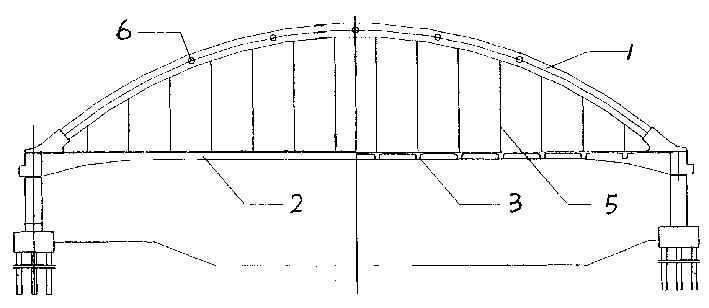

Track traffic and urban road integrated tie arch bridge

InactiveCN1483895AStringer lightThe structural form is clearly stressedRoadwaysArch-type bridgeRail transitSteel tube

The present invention relates to a track transportation and urban road integrated tied-arch bridge, and it is characterized by that the described track transportation and urban road system adopts four sheets of arch rib, the track transportation is positioned in the centre, the up-and-down traffic lanes are set at two sides, and the walkway is set at most outside. Said invention can combine track transportation bridge and urban road bridge together, can adopt steel tube concrete structure and its cost is low.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

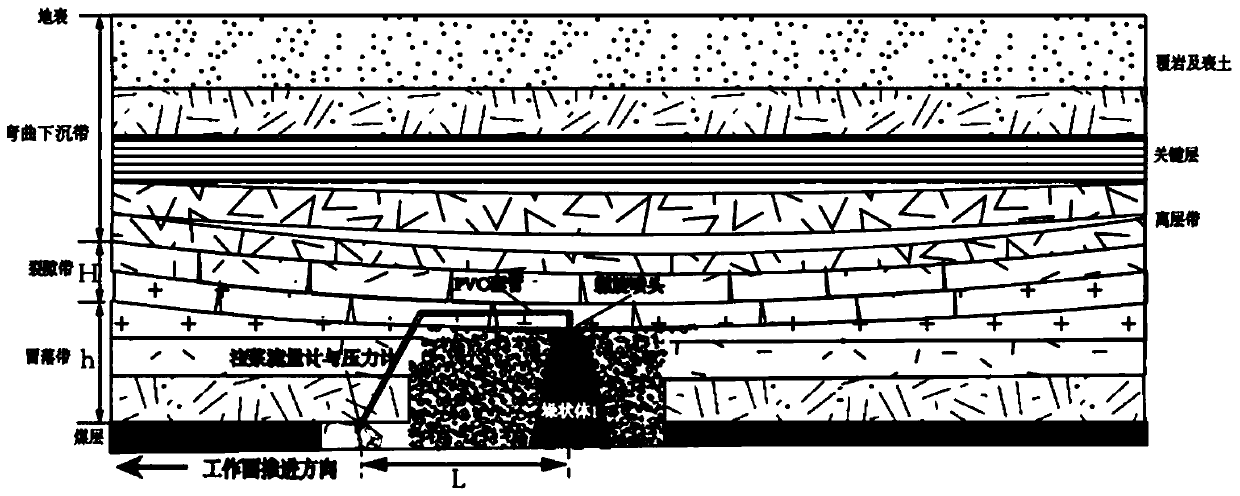

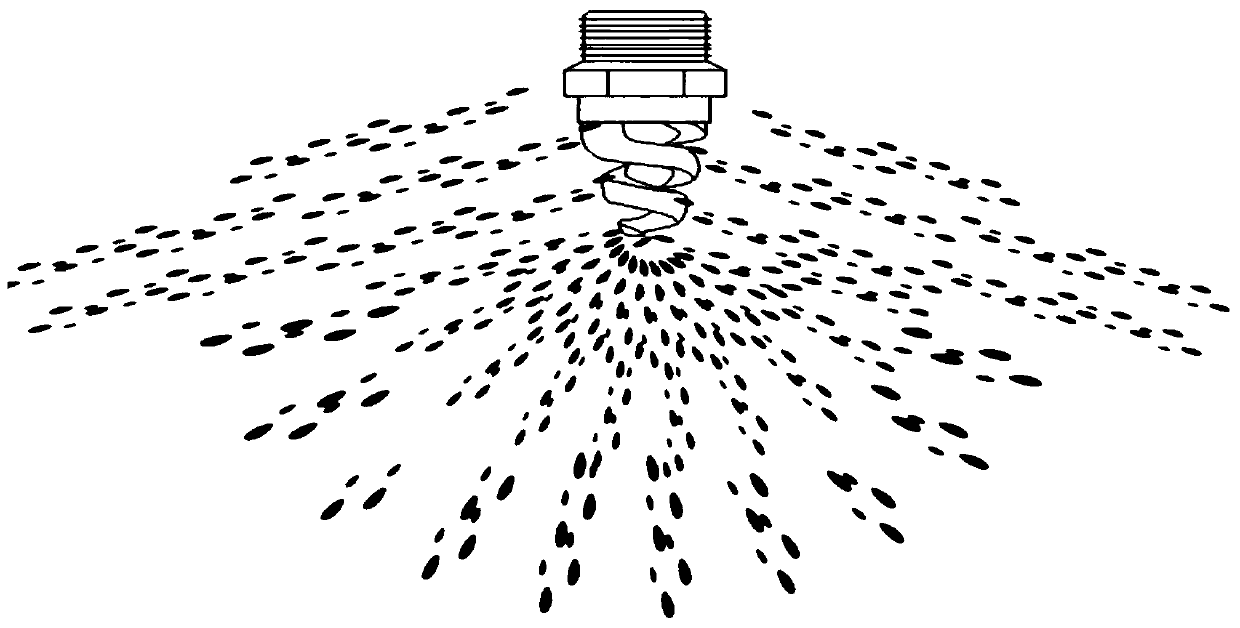

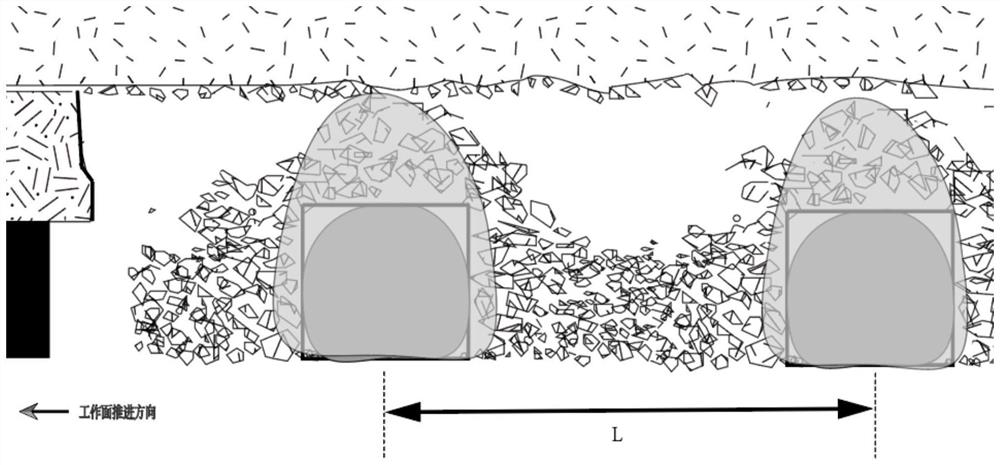

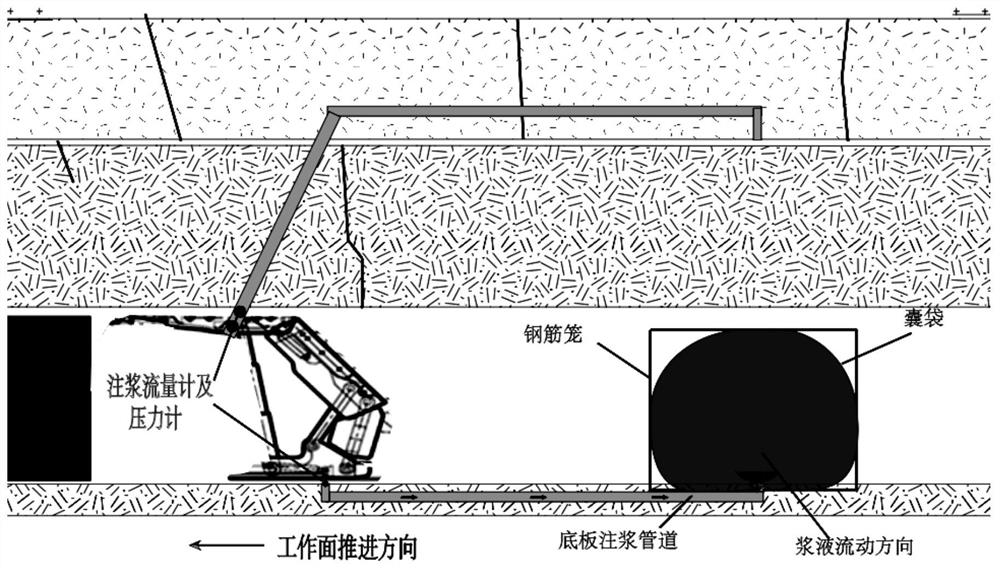

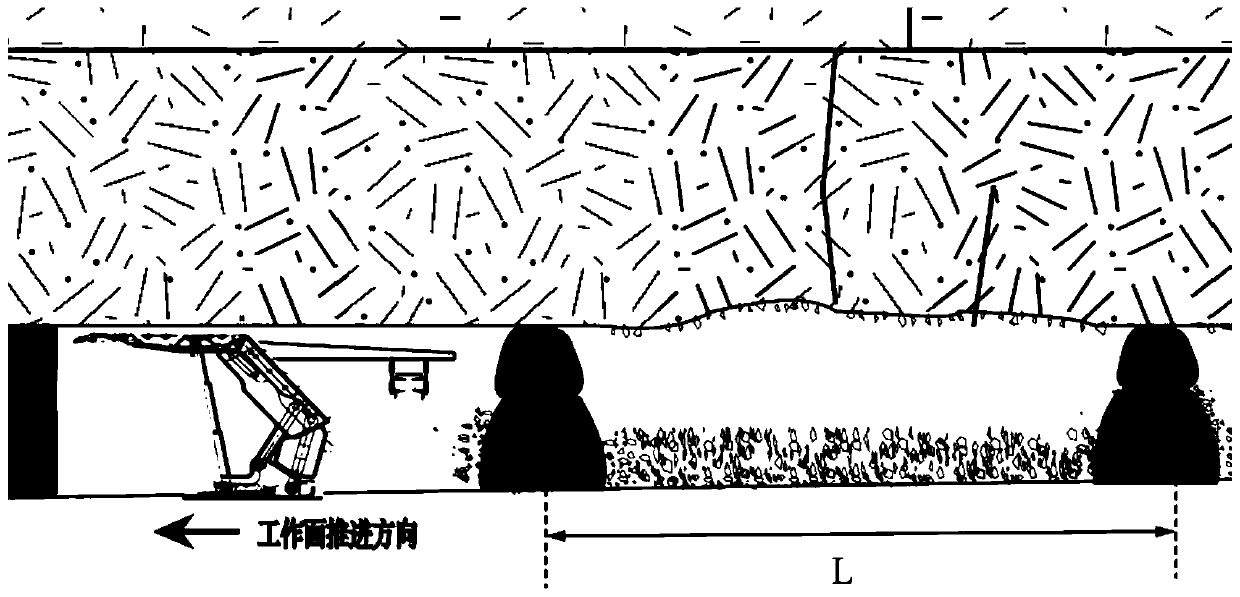

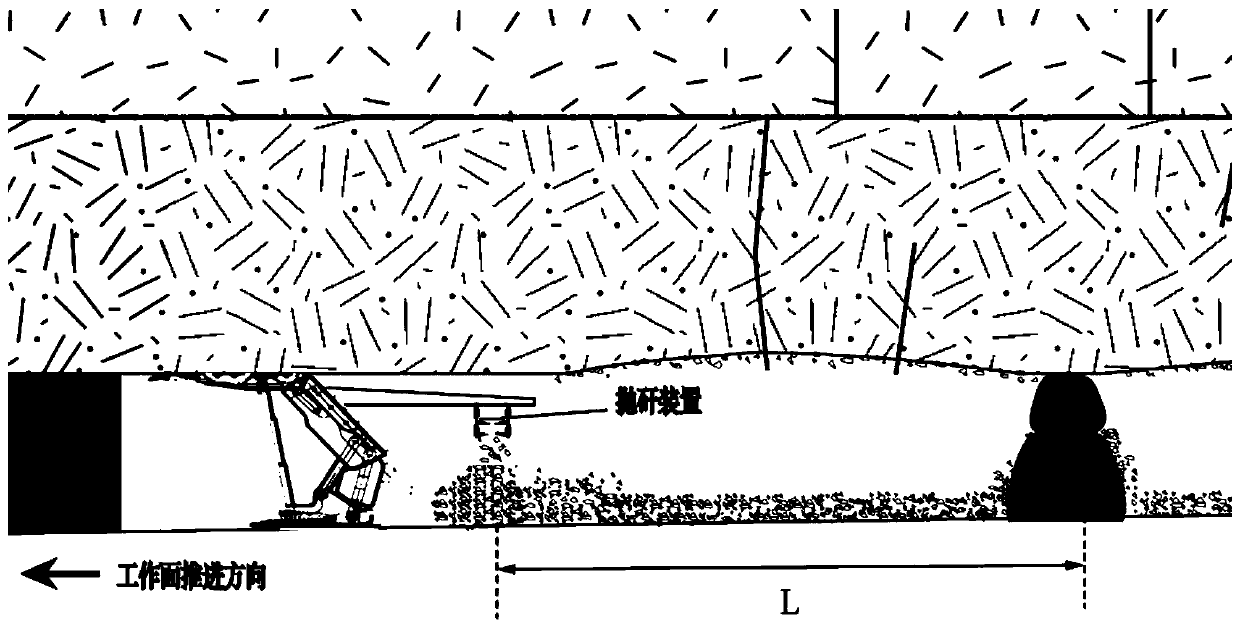

Point source type spaced grouting damage reducing method by roof caving crack expansion filling and directional drilling

ActiveCN111335943AConvenient transportation and constructionEasy to get materialsMaterial fill-upPolyvinyl chlorideSpray nozzle

The invention discloses a point source type spaced grouting damage reducing method by roof caving crack expansion filling and directional drilling. The method comprises the following steps of: after coal mining operation is carried out, a roof naturally caves to form a state of full filling or near-complete filling; firstly, spaced underground directional drilling is adopted to the upper part of acaving broken body, and a PVC (polyvinyl chloride) casing pipe and a grouting pipe are synchronously laid to realize fixed-point grouting, wherein the performance of a grouting material is selected by referring to a relevant national standard and is subjected to targeted mix proportion design, and a proper accelerator is selected to accurately control the initial setting time of grout; and then,a grouting flow meter and a grouting pressure meter are laid on a grouting pipeline to realize the accurate and real-time monitoring of a grouting quantity, and meanwhile, a spiral spray nozzle is selected to carry out surface-shaped injection grouting. Through grouting pipeline pressure control and flow monitoring, the grouting quantity and a grouting speed are determined, and finally, a point source type spaced grouting stack pile body layout scheme is formed.

Owner:XIAN UNIV OF SCI & TECH

Comobined ribbed cavity member for spatial structure roof

Owner:湖南邱则有专利战略策划有限公司

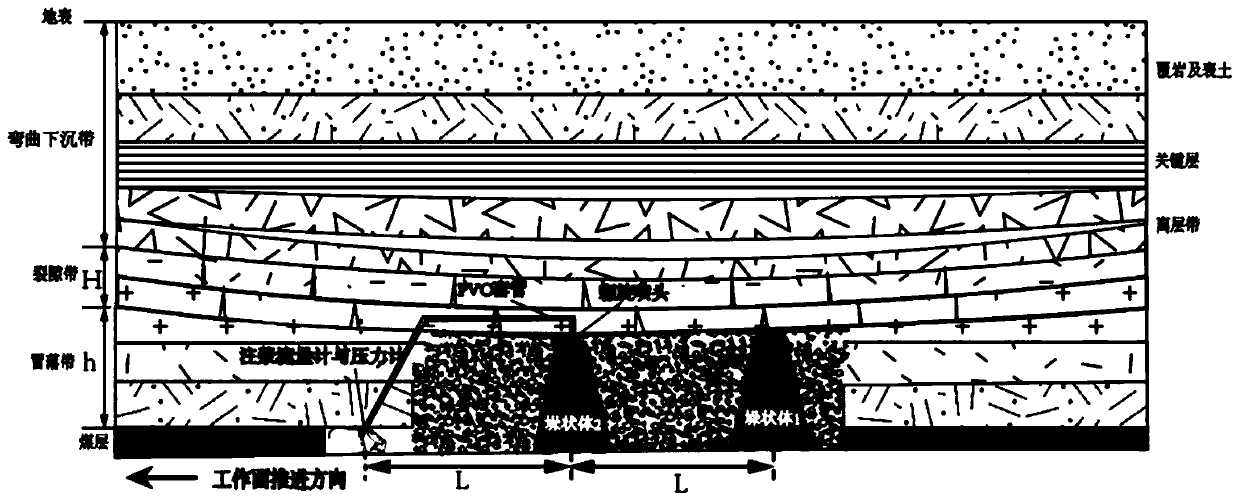

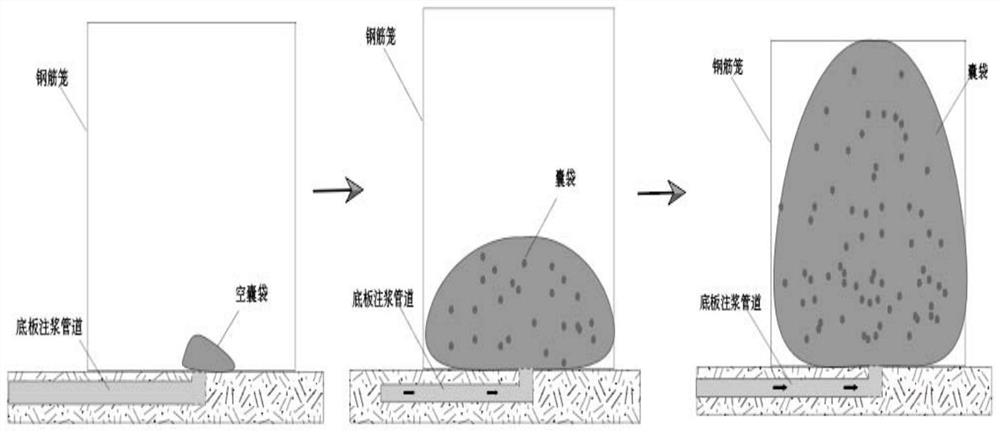

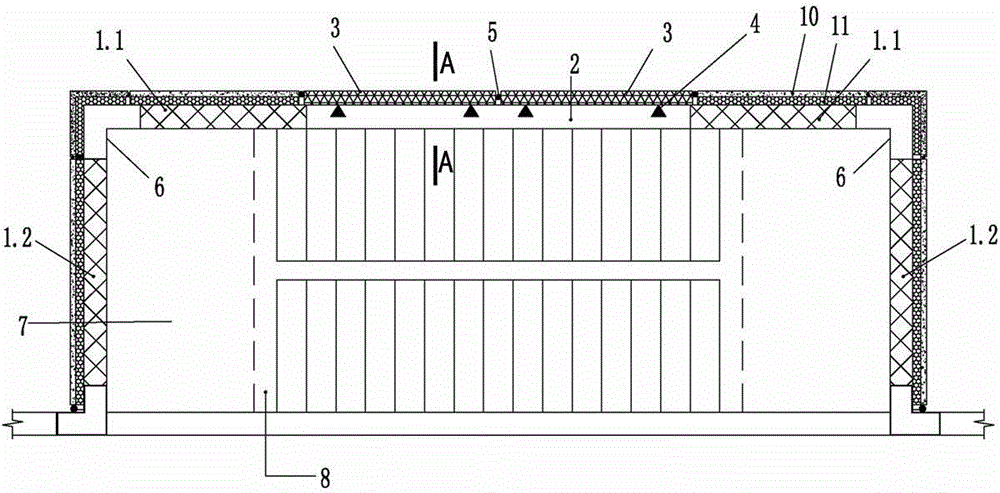

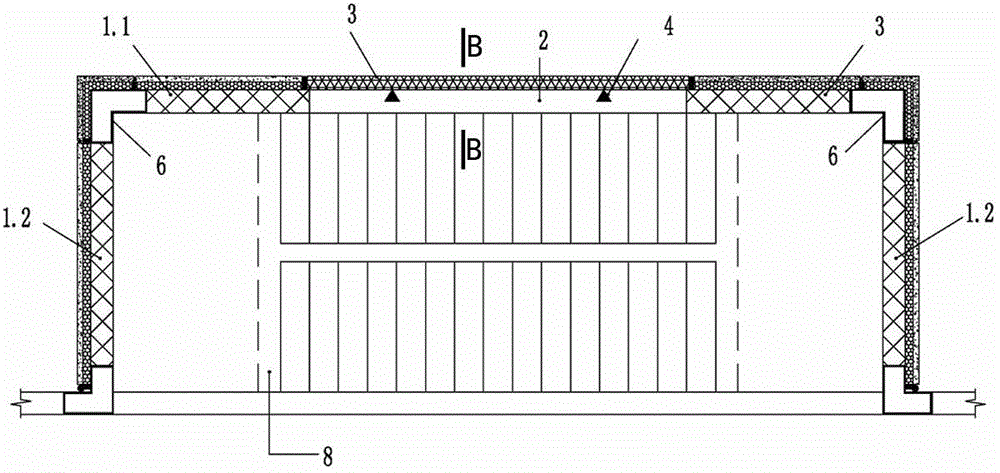

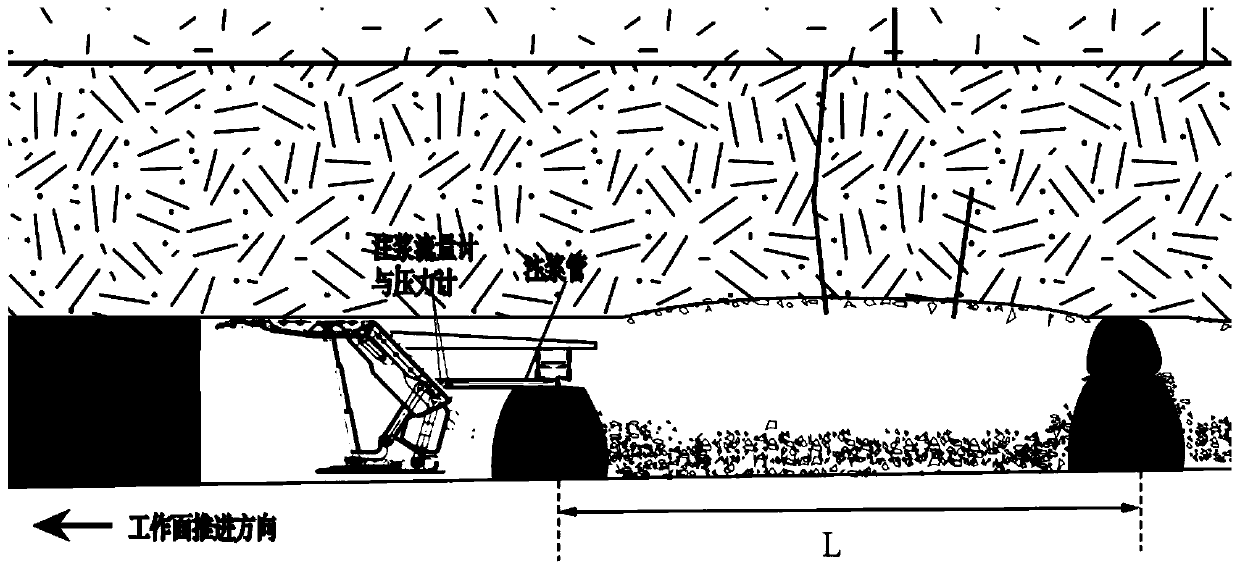

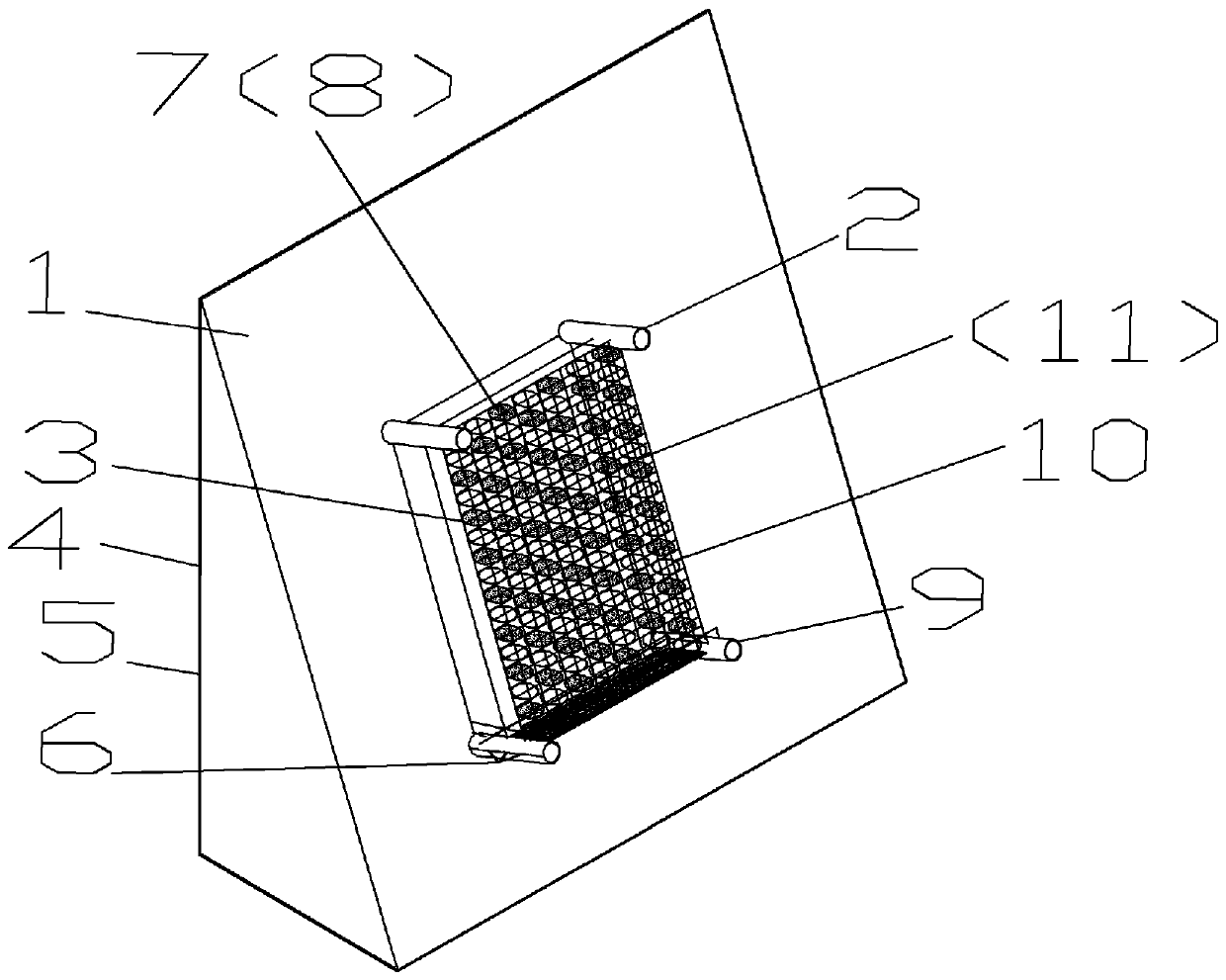

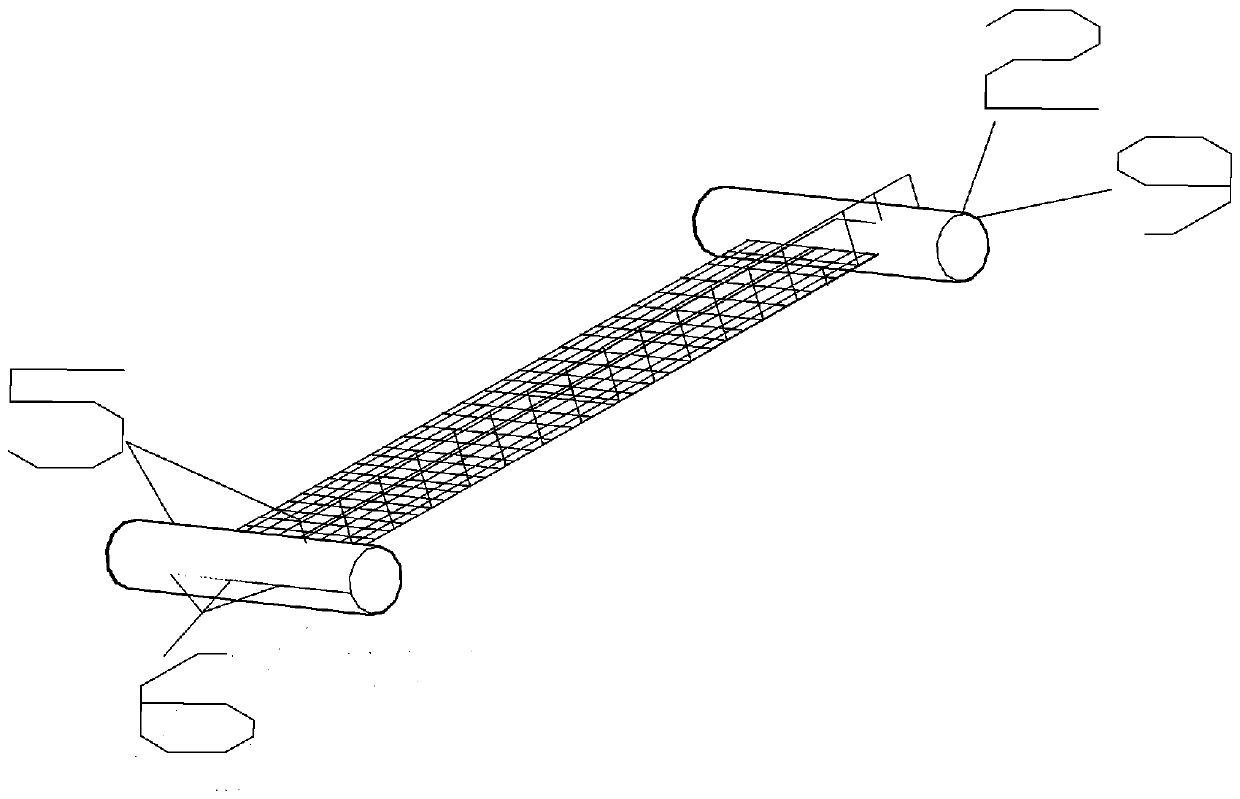

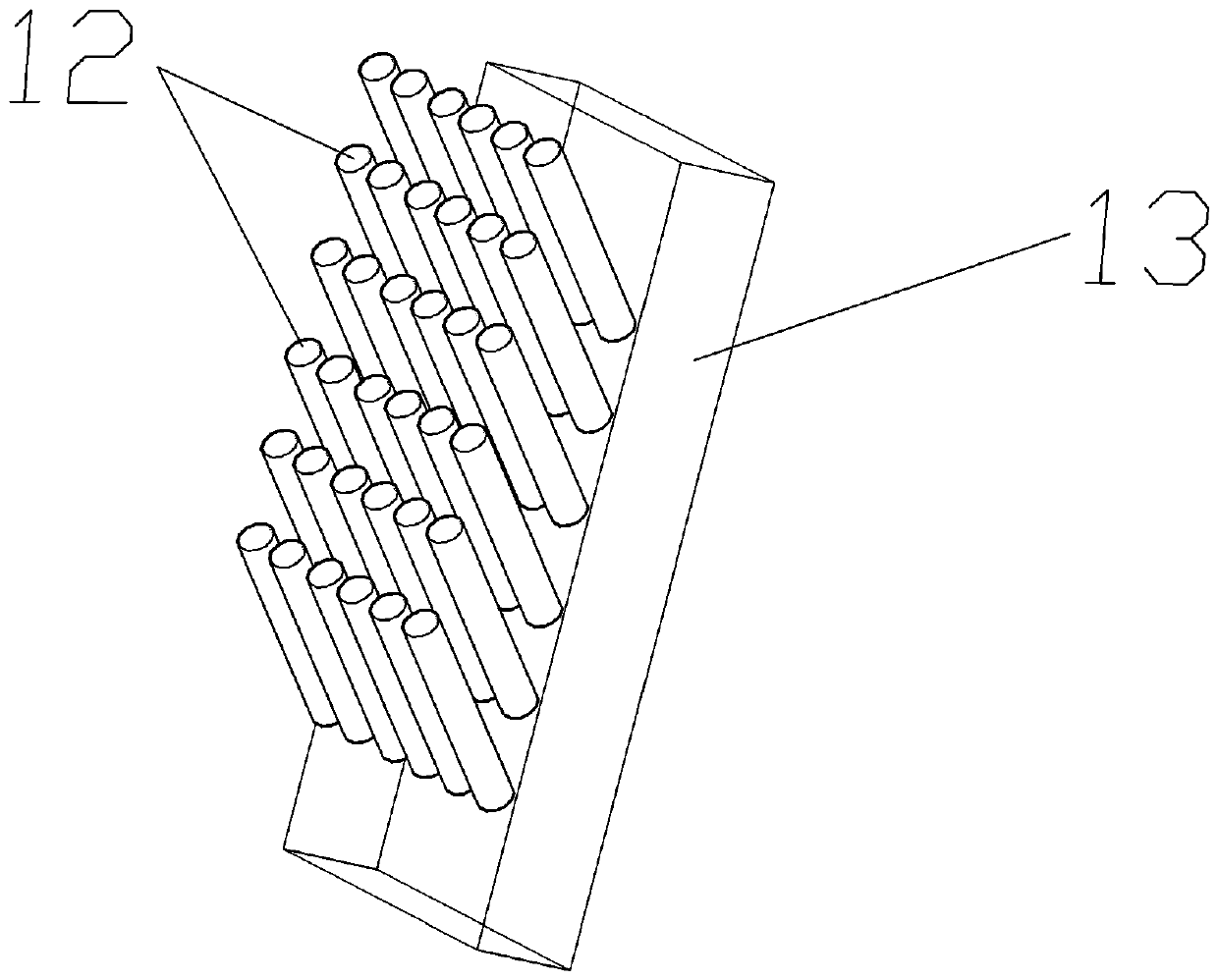

Spaced overlying strata broken expansion filling reinforcement cage bag grouting loss reduction method

The invention discloses a spaced overlying strata broken expansion filling reinforcement cage bag grouting loss reduction method, and aims to solve the problem that a goaf is not completely filled with broken bodies formed by natural caving of a top plate. During the coal mining operation, the effect of temporarily supporting a top plate by using a hydraulic bracket is utilized, and at the moment,spaced reinforcement cage bag supports are arranged before the goaf top plate is collapsed, and grouting is carried out; controlling the grouting process by utilizing the initial setting time of theslurry and combining a grouting pressure gauge and a flowmeter which are arranged on a grouting pipeline; and after the goaf collapses, the directional drilling technology is used for conducting jet grouting on broken overlying strata collapsed on the upper portion of the reinforcement cage grouting bag, a composite supporting structure is formed to stably support the roof overlying strata, and collapse and subsidence of an upper rock stratum are effectively prevented.

Owner:XIAN UNIV OF SCI & TECH

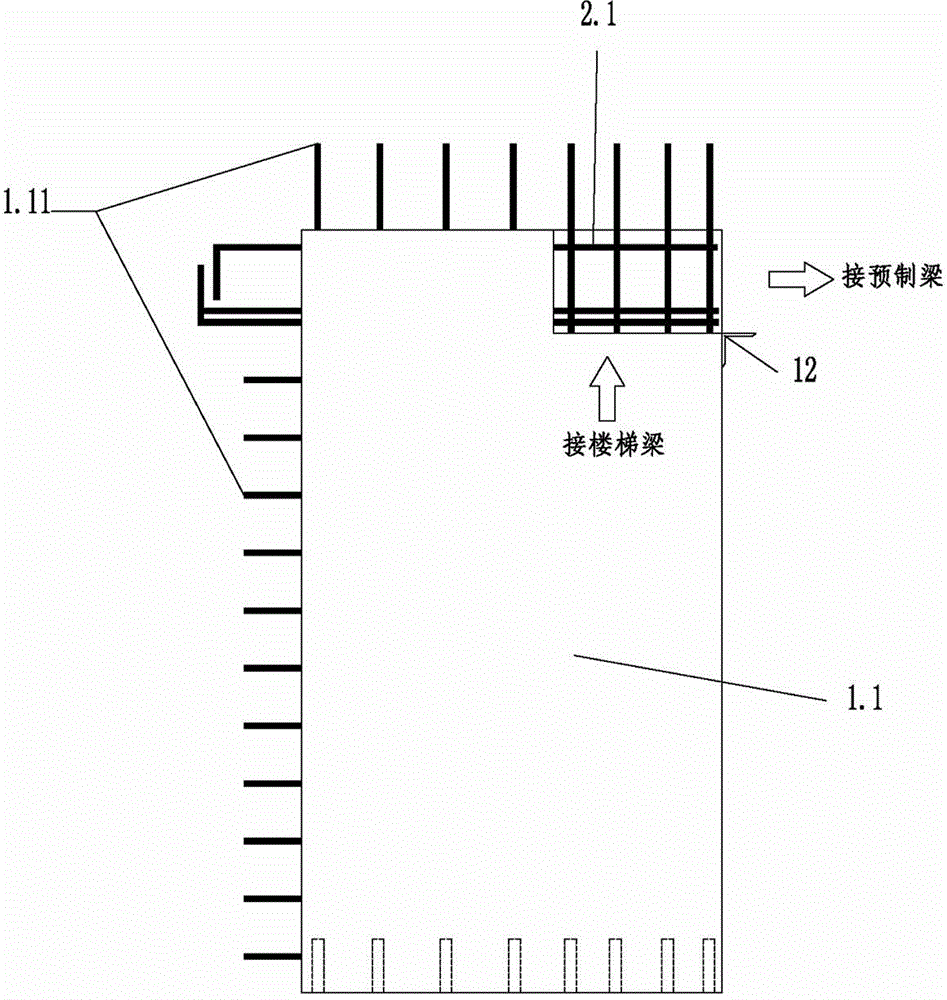

Assembly type concrete stairwell external wall structure and construction method thereof

The invention relates to an assembly type concrete stairwell external wall structure and a construction method thereof. The structure comprises prefabricated bearing longitudinal shear wallboards, prefabricated bearing transverse shear wallboards, a prefabricated beam, a non-bearing out-hung wallboard and hanging board connection pieces. The prefabricated bearing longitudinal shear wallboards and the prefabricated bearing transverse shear wallboards are adopted for the outer side part of a rest platform, and the prefabricated beam and the non-bearing out-hung wallboard are adopted for the outer side portion of a step plate. One side of each prefabricated bearing longitudinal shear wallboard is connected with a stairwell cast-in-situ edge component through a lateral connection rebar, and the other side of each prefabricated bearing longitudinal shear wallboard is connected with the prefabricated beam through a reserved rebar overlapping region, and the prefabricated bearing longitudinal shear wallboards are connected with stair beams and rest platform floors in the vertical direction of the prefabricated bearing longitudinal shear wallboards. The left sides and the right sides of the prefabricated bearing transverse shear wallboards are connected with the stairwell cast-in-situ edge components through lateral connection rebars. The assembly type concrete stairwell external wall structure is light in weight, good in wall limb stability, good in structural antitorque effect, easy and convenient to construct and low in cost.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

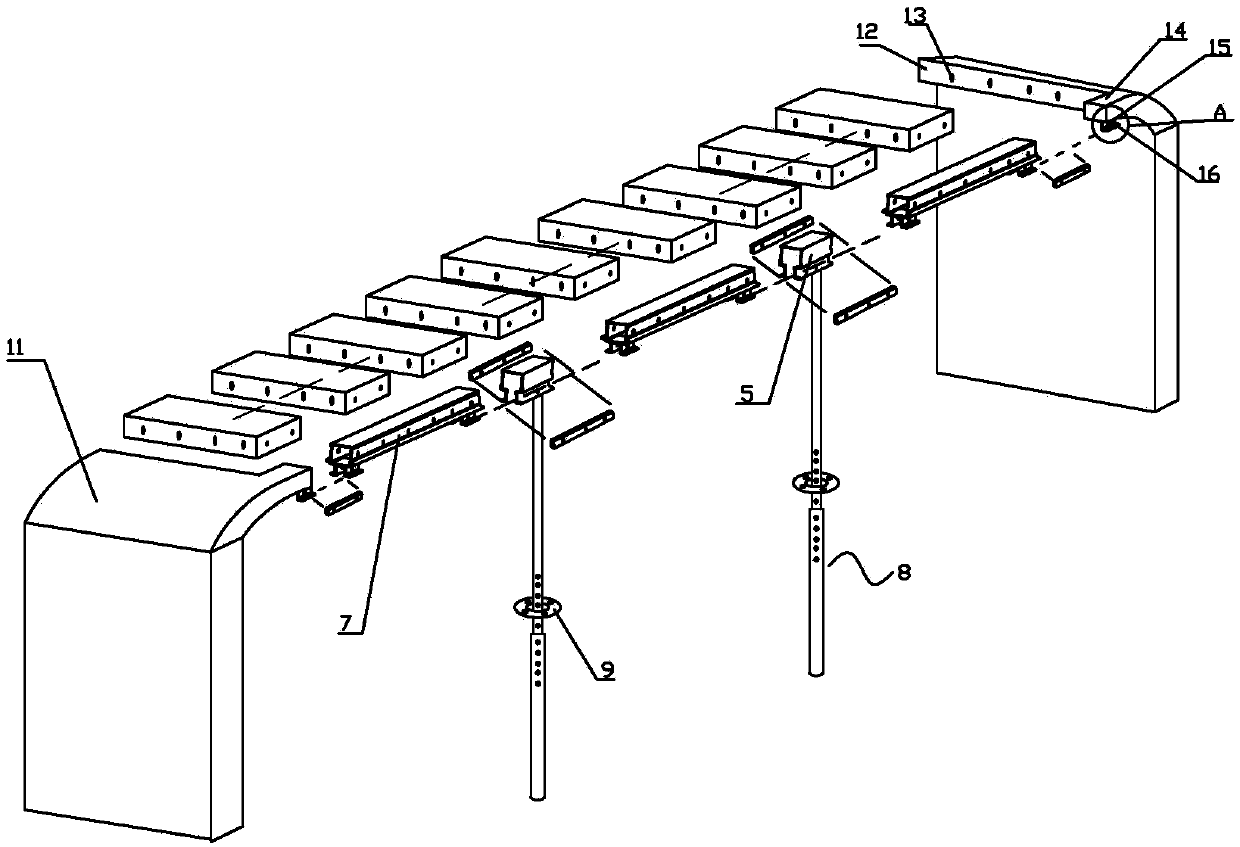

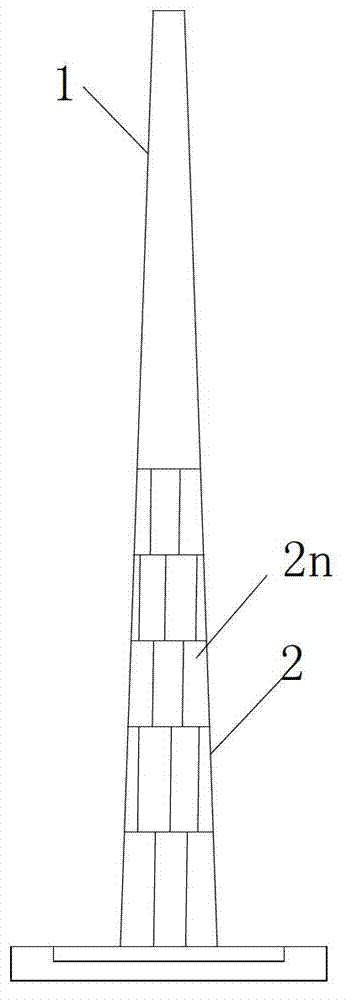

Fan tower

InactiveCN102734088ANovel structureConstruction and transportation are convenientFinal product manufactureWind motor supports/mountsEconomic benefitsEngineering

The invention discloses a fan tower. The tower body of the fan tower comprises a steel tower section at the upper part and a precast concrete tower section at the lower part connected with the steel tower section, wherein the precast concrete tower section is formed by splicing multiple precast concrete units. The steel-precast concrete combined fan tower disclosed by the invention overcomes the restriction in terms of manufacturing, transportation and the like of the traditional steel tower, has high economic benefits, breaks through the limitation that the height of the steel tower cannot exceed 100m, and can meet the requirement on the tower height of the current fan development.

Owner:GUODIAN UNITED POWER TECH

Assemblied polyvinyl chloride building engineering shuttering

InactiveCN101089329AConstruction and transportation are convenientAccelerated corrosionForming/stuttering elementsBuilding designUltimate tensile strength

The present invention relates to a kind of combined polyvinyl chloride building engineering form. It includes hollow perforated board, special-shaped outside corner, special-shaped square pien, square wood, beam side and form closing cover basic structure unit made of polyvinyl chloride material. The above-mentioned basic structure unit can be formed into the engineering form meeting the external form of said designed building component.

Owner:天津市富士特实业有限公司

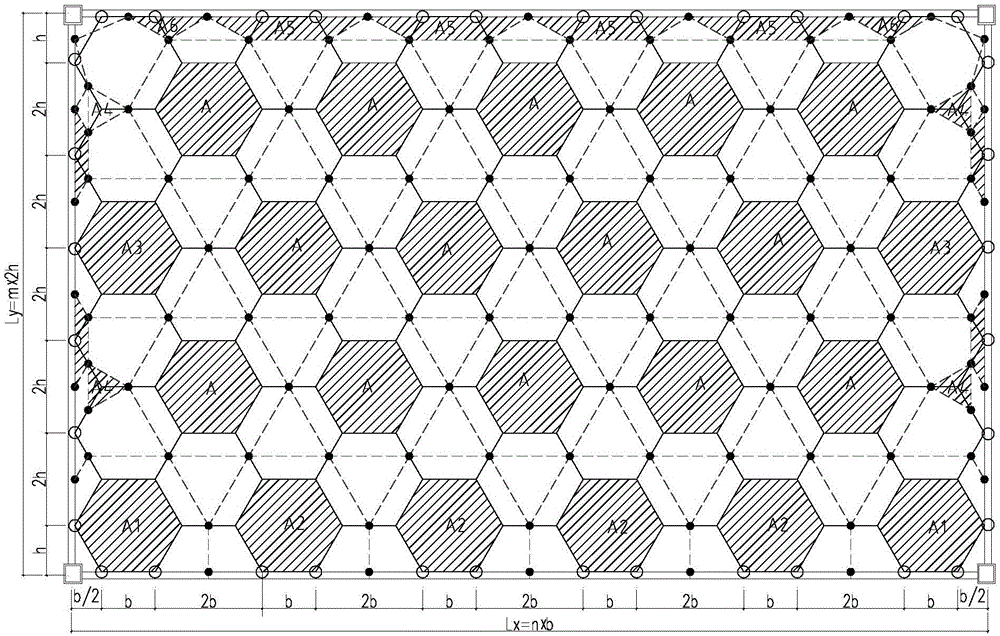

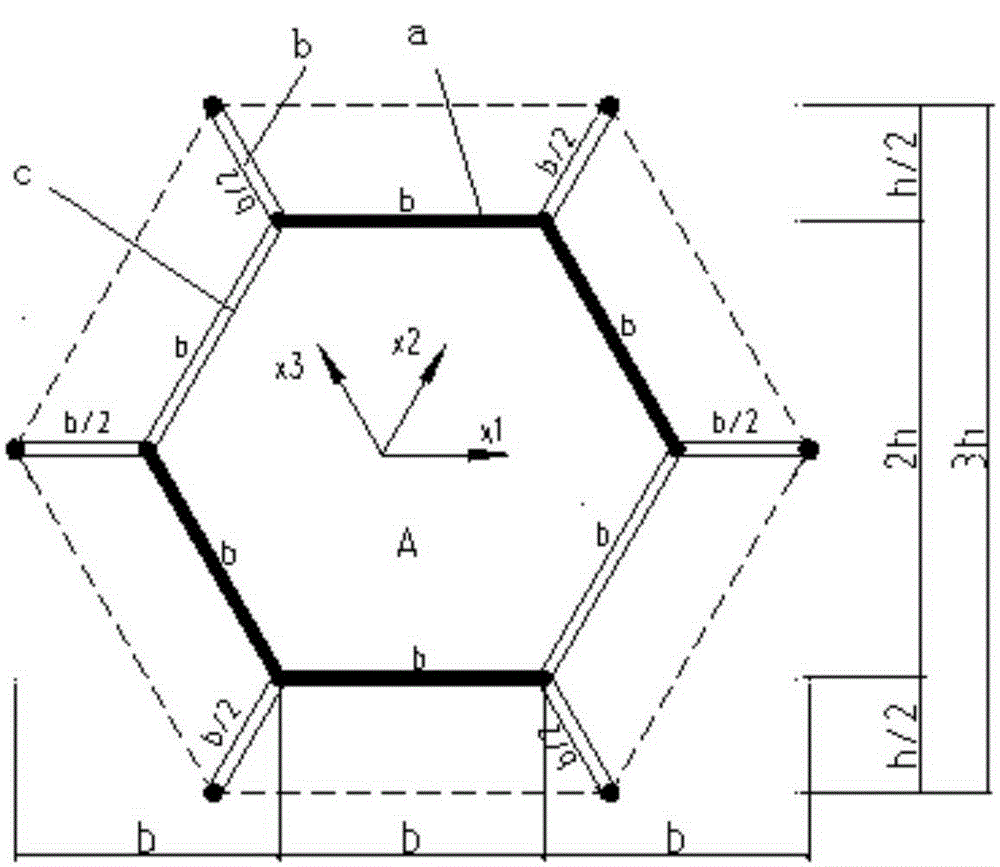

Manufacturing method for regular hexagonal honeycomb latticed steel hollow floor frame box type structure

InactiveCN105133767AConstruction and transportation are convenientFloorsReinforced concreteHoneycomb

The invention relates to a manufacturing method for regular hexagonal honeycomb latticed steel hollow floor frame box type structure. The manufacturing method is characterized by comprising the following steps of blanking, welding and processing a component (a), a component (b) and a component (c) in a factory workshop, transporting the component (a), the component (b) and the component (c) to a construction site, assembling the component (a), the component (b) and the component (c) into a floor frame unit (A), a floor frame unit (B) and a floor frame unit (C), connecting the floor frame unit (A) and the floor frame unit (B) and the floor frame unit (C) via high-strength bolts to form a regular hexagonal honeycomb steel plane grid and placing the grid on a floor height marked position via a supporting wall rack. A reinforced bar concrete three-dimensional grid regular hexagonal prefabricating plate is installed on the supported regular hexagonal honeycomb steel plane grid; pin holes are formed in the regular hexagonal honeycomb steel plane grid; reinforcing bars are tied thereon; concrete is cast on a template formed by the regular hexagonal prefabricating plate; the template is maintained. The manufacturing method for the regular hexagonal honeycomb latticed steel hollow floor frame box type structure, steel components are can all blanked and manufactured in the factory and transportation and construction can be facilitated.

Owner:TIANJIN JINWANFANG STEEL STRUCTURE +3

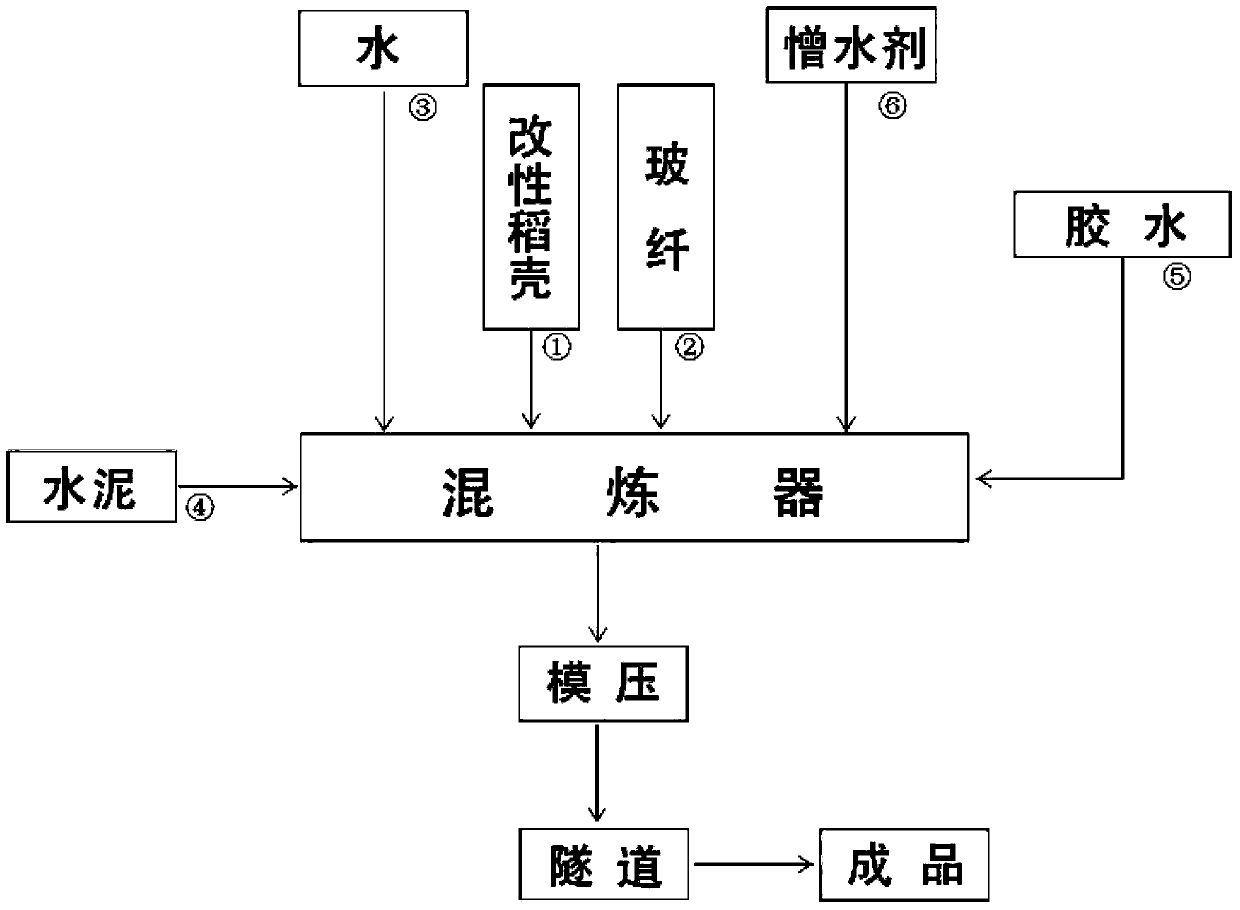

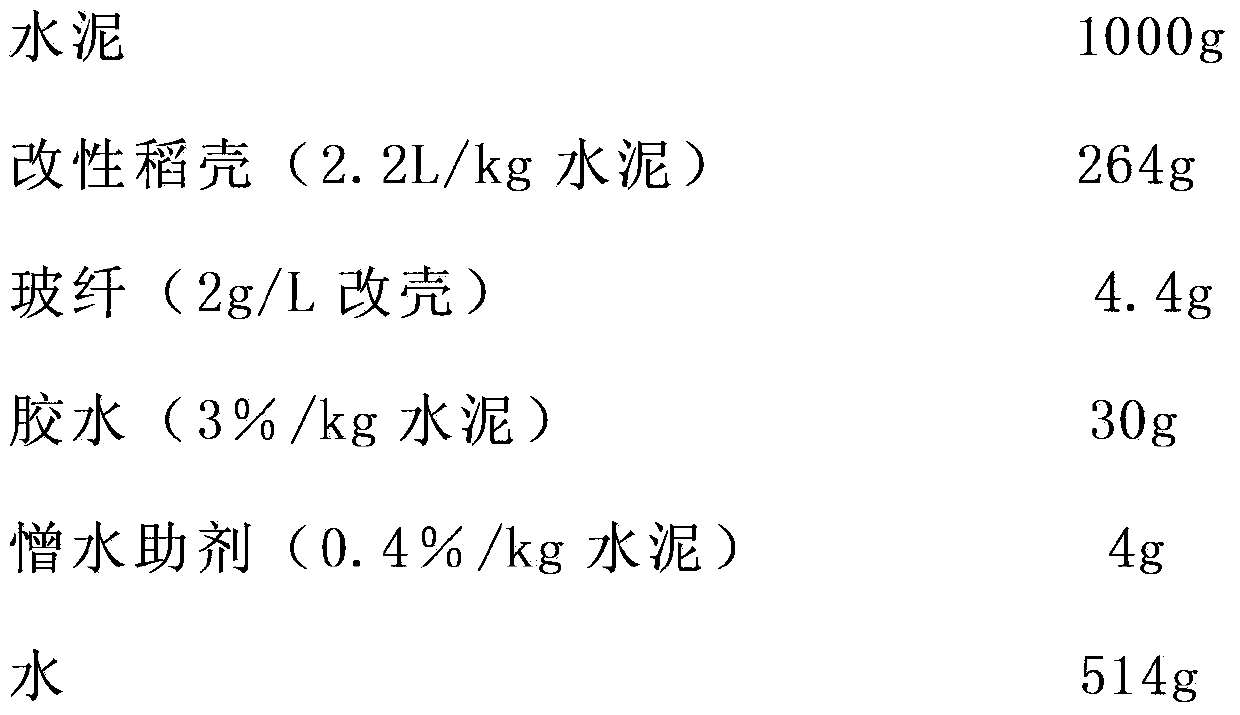

Rice husk heat-insulating porous building block and preparation method thereof

The invention discloses a preparation method of a rice husk heat-insulating porous building block. The preparation method comprises the following steps: a, preparing the following raw materials in parts by weight: 1,000 parts of cement, 264 parts of modified rice husks, 4.4 parts of staple glass fiber, 30 parts of glue, 4 parts of hydrophobic aid and 514 parts of water; b, diluting the glue with water for later use, wherein the mass ratio of the glue to the water is 1:1; c, diluting the hydrophobic aid with water for later use, wherein the mass ratio of the hydrophobic aid to the water is 1:10; d, adding the residual water, the modified rice husks and the staple glass fiber into mixing equipment, and stirring and mixing; e, adding the cement into the mixing equipment and stirring; f, adding the glue which is diluted with water in the step b into the mixing equipment and stirring; g, adding the hydrophobic aid which is diluted with water in the step c into the mixing equipment and stirring; h, adding the mixture into a mold and forming; and i, after mold stripping, performing hydration reaction under the steam environment. The rice husk heat-insulating porous building block provided by the invention is light in weight and small in heat conductivity coefficient and the invention also provides the preparation method of the rice husk heat-insulating porous building block.

Owner:江苏协和装饰工程有限公司

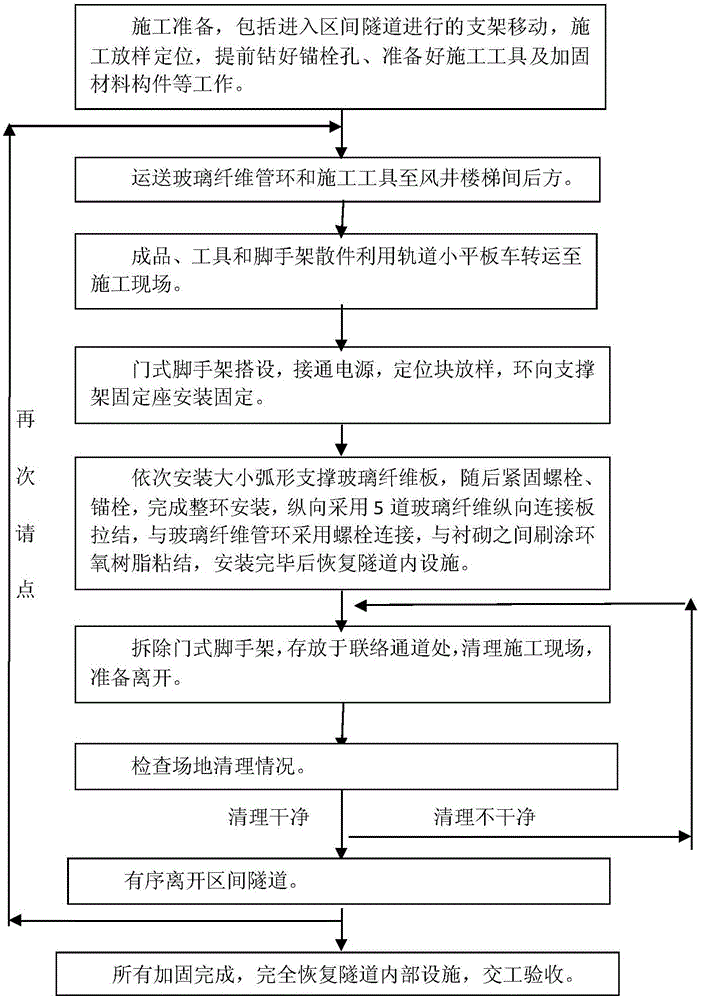

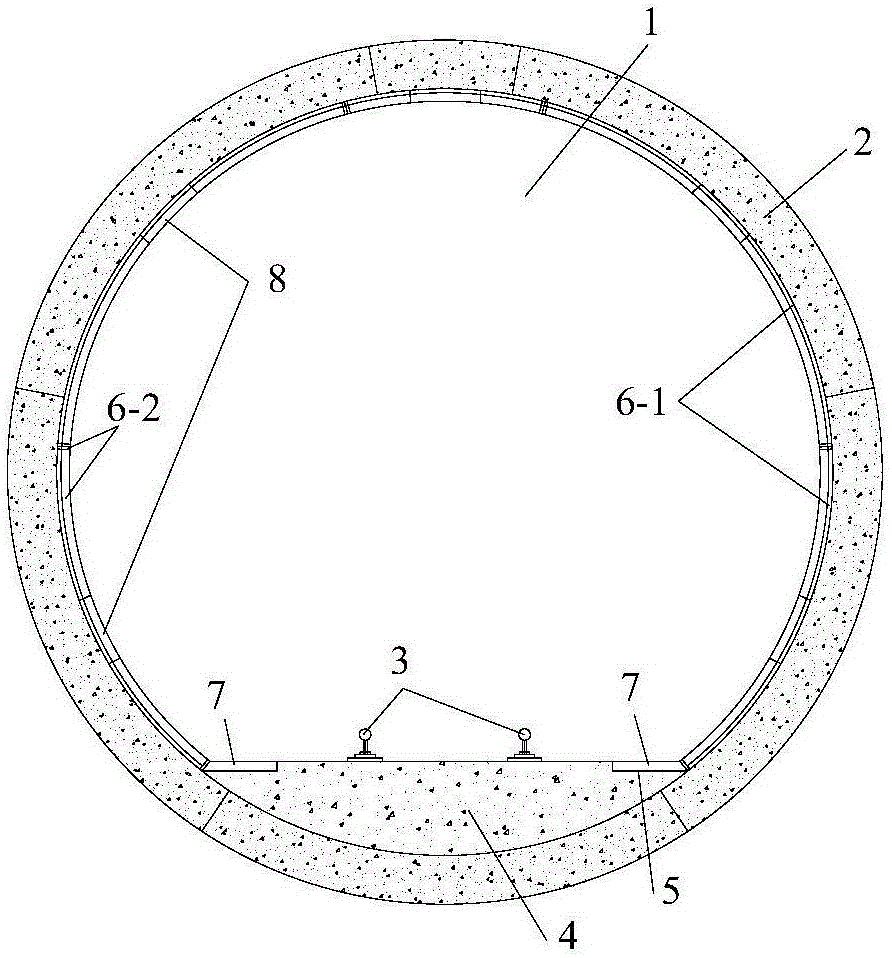

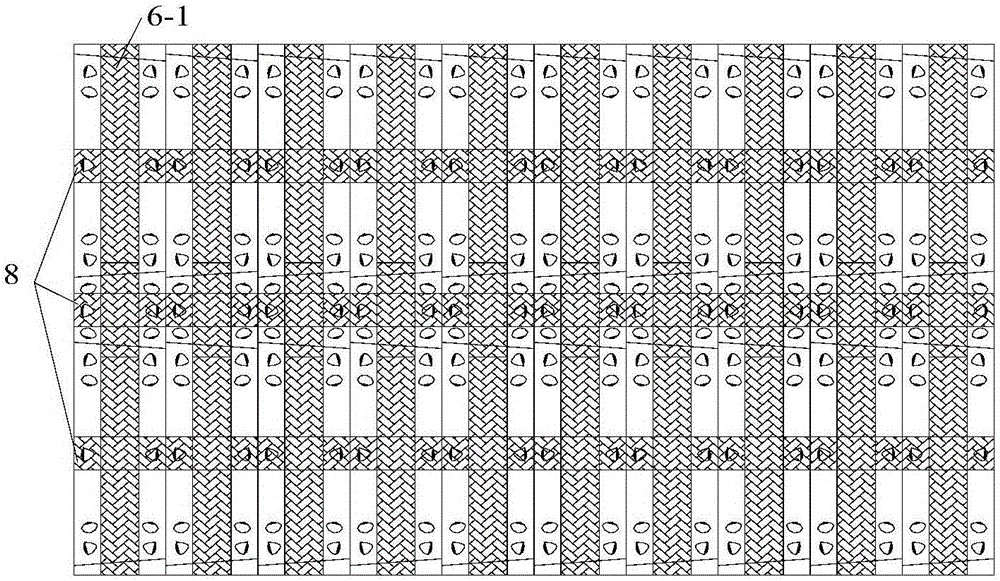

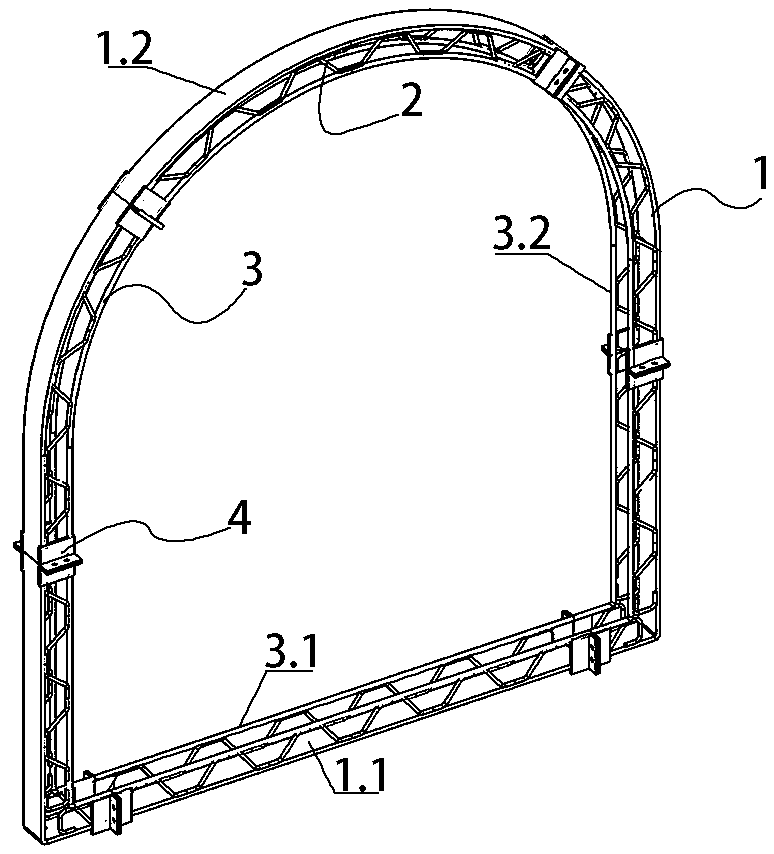

Tunnel reinforcing device based on fiberglass pipe segments and construction method thereof

ActiveCN106640123AReduce accidentsGuaranteed service lifeUnderground chambersNon-woven fabricsGlass fiberDisease

The invention belongs to the technical field of tunnel reinforcing protection and discloses a tunnel reinforcing device based on fiberglass pipe segments and a construction method thereof, and the tunnel reinforcing device is suitable for an existing operating subway tunnel. The tunnel reinforcing device comprises fiberglass pipe rings and a longitudinal connecting plate, wherein the fiberglass pipe rings are used for reinforcing the tunnel in the ring direction, and the longitudinal connecting plate is used for longitudinal fixing; each fiberglass pipe ring comprises a supporting frame and two supporting frame fixing seats, wherein the supporting frame is formed by assembling a plurality of arc-shaped supporting fiberglass plates in the circumferential direction, and the bottoms of the left side and the right side of the supporting frame are supported by the supporting frame fixing seats correspondingly; the multiple arc-shaped supporting fiberglass plates and the two supporting frame fixing seats are evenly distributed on the same cross section of the tunnel, so that the reinforcing fiberglass pipe rings are connected into a whole; and according to the construction method of the tunnel reinforcing device based on the fiberglass pipe segments, through the fiberglass pipe rings, the existing operating subway tunnel pipe segments are reinforced in the ring direction, and the fiberglass pipe rings are combined into a whole through the longitudinal connecting plate to longitudinally reinforce the tunnel pipe segments. According to the tunnel reinforcing device based on the fiberglass pipe segments and the construction method thereof, the anti-deformation capacity of the tunnel is improved, occurrence of lining diseases in the tunnel is reduced, and driving safety and the service life of the tunnel are guaranteed.

Owner:ZHEJIANG UNIV CITY COLLEGE

Soil resistance reducing agent

InactiveCN107622813AImprove the defect that it is easy to lose with rainwaterExtended service lifeNon-conductive material with dispersed conductive materialCable/conductor manufactureCalcium bicarbonateSodium Bentonite

The invention relates to the technical field of resistance reducing agents and particularly relates to a soil resistance reducing agent. The soil resistance reducing agent is particle-shaped and comprises, by weight, 30 to 50 parts of expanded graphite, 50 to 70 parts of bentonite, 5 to 12 parts of calcium bicarbonate, 10 to 15 parts of polyaniline, 20 to 40 parts of sodium carboxymethylcellulose,8 to 12 parts of barium sulfate and 12 to 15 parts of sodium polyacrylate. By adopting a specific formula process, the resistance reducing agent is made to be particle-shaped, dust rising can be avoided, construction, transportation and storage are facilitated, the resistivity is low, and the persistence is strong.

Owner:JIAXING JIAHE ELECTRIC POWER EQUIP

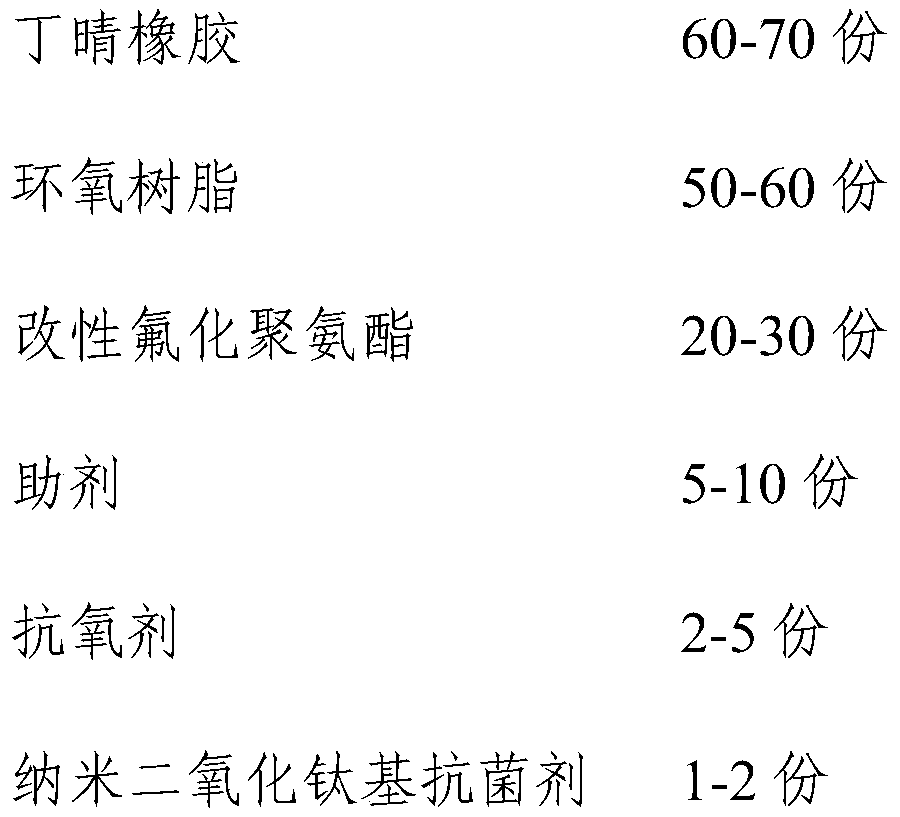

Anti-rat and anti-bird pecking optical cable

ActiveCN107722401BImprove tensile propertiesImprove stress resistanceSynthetic resin layered productsFibre mechanical structuresEpoxyGlass fiber

The invention discloses a ratproof and bird-damage-prevention optical cable. An inner sheath is made of a material prepared from the following ingredients of 60 to 70 parts of nitrile rubber buna, 50to 60 parts of epoxy resin, 20 to 30 parts of modified fluorinated polyurethane, 5 to 10 parts of auxiliary agents, 2 to 5 parts of antioxidants and 1 to 2 parts of nanometer titania-based antibacterial agents; an outer sheath is made of a material prepared from the following ingredients of 50 to 70 parts of crosslinked polyethylene, 10 to 20 parts of ethylene propylene rubber, 5 to 15 parts of glass fiber, 5 to 10 parts of polyether sulfone, 15 to 25 parts of modified nanometer aluminum hydroxide composite flame retardants, 2 to 5 parts of antioxidants, 2 to 5 parts of anti-ultraviolet agentsand 5 to 10 parts of auxiliary agents. The ratproof and bird-damage-prevention optical cable has the advantages that the inner sheath structure is used; good waterproof, dampproof and mildewproof characteristics are realized; the service life of the optical fiber is prolonged.

Owner:JIANGSU ETERN +1

Spaced arrangement gangue filling and bag grouting combined support loss reduction method

InactiveCN111550283AReduce impact on coal mining operationsIncrease production capacityMaterial fill-upCantilevered beamMining engineering

The invention discloses a spaced arrangement gangue filling and bag grouting combined support loss reduction method. The method is suitable for thin and medium-thickness coal seams with hard top plates in mining areas with more gangues in middle and west. The method is characterized in that gangue is piled by adopting a hydraulic support rear gangue throwing device, interval type cemented gangue and bag combined support is arranged in the coal mining operation, the top plates are in a cantilever beam state, before the top plates are broken and collapsed, the broken gangue is thrown and accumulated to a reserved supporting point through a gangue throwing machine by means of a working gap of temporary supporting of a hydraulic support, and after the broken gangue is grouted and glued to a certain strength, grouting bags are arranged for grouting supporting; and meanwhile, the grouting process is controlled through the initial setting time and the grouting pressure of the cement paste, the construction quality is guaranteed, and therefore, the supporting means can meet the environmental protection requirement and the technical requirement of green mining.

Owner:XIAN UNIV OF SCI & TECH

Method for conducting slope support and greening through specific hole-planted shrubs

ActiveCN107604930AAvoid affecting growthImprove survival rateExcavationsCultivating equipmentsSoil textureBiology

The invention discloses a method for conducting slope support and greening through specific hole-planted shrubs. The method comprises the following steps that (1), a material is selected; (2), a slopesurface is selected to be finished and measured; (3), shrub seeds are soaked or shrub seedlings cultivated into seedlings are prepared to manufacture nutritive vegetation soil; (4), a mold is adoptedto manufacture a vegetation concrete module containing the shrub seeds; (5), anchor rods are supported, iron wire bracing and iron wire net erecting are conducted among the anchor rods, and a layer of geotechnical cloth is laid; (6), the thick nutritive vegetation soil is laid, and seeds are planted in the soil; and (7), management after seeding and later-period regular watering and fertilizing protection are conducted. The method for conducting slope support and greening through the specific hole-planted shrubs is suitable for slope surfaces of various rock textures and soil textures and particularly suitable for rock and soil side slope surfaces which are high steep and unsmooth, are provided with multiple small rock gaps and are under bad weather conditions.

Owner:CHINA THREE GORGES UNIV

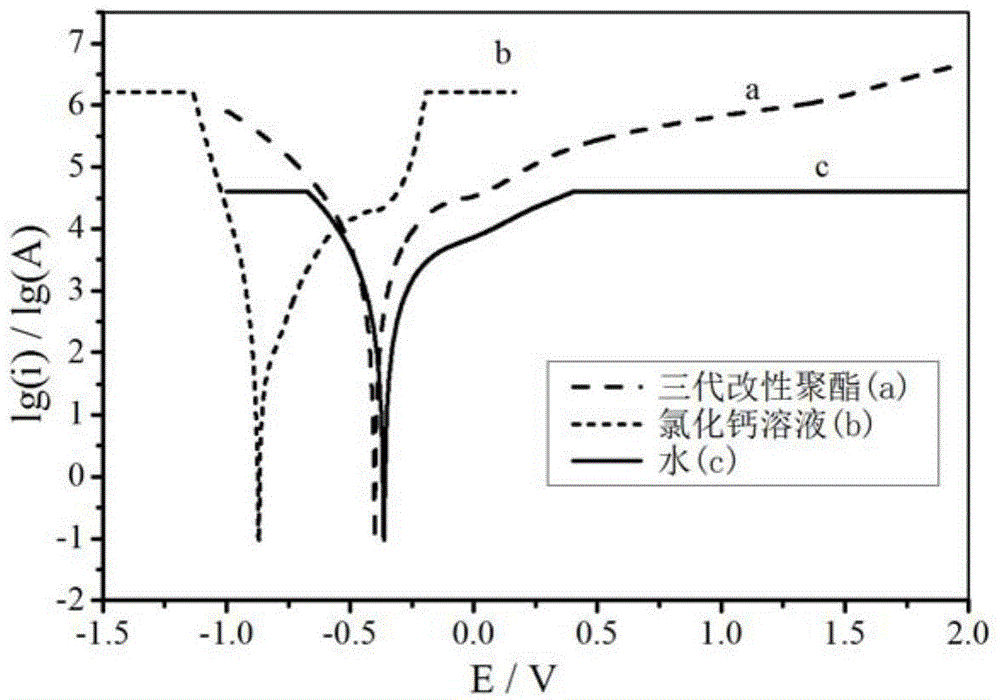

Preparation method of modified hyperbranched polyester for environment-friendly dust suppressant

InactiveCN104945608AThe synthesis process time is shortenedImprove efficiencyOther chemical processesEthyl phosphateChemistry

The invention discloses a preparation method of modified hyperbranched polyester. The preparation method comprises the following steps: adopting N,N-2-hydroxyethyl-3-alanine methyl ester as a monomer, pentaerythrotol as the nucleus and p-toluenesulfonic acid as a catalyst to prepare second-generation hyperbranched polyester through mass polymerization; then adopting stearic acid as a modifier, p-toluenesulfonic acid as a catalyst and N,N-2-hydroxyethyl-3-alanine methyl ester as a monomer to prepare a modified monomer; adopting p-toluenesulfonic acid as a catalyst to enable the monomer, the modified monomer and the second-generation hyperbranched polyester to react so as to obtain the modified hyperbranched polyester. The preparation method simplifies the synthesis process, greatly reduces time consumption, meanwhile, reduces the probability of autopolymerization side reaction of the monomer in the growing process of the hyperbranched polyester and improves the efficiency.

Owner:SHANDONG UNIV OF SCI & TECH

3D printed steel fiber reinforced concrete tunnel preliminary support grating arch frame and construction method thereof

PendingCN110159299AReduce processing stepsAvoid precisionAdditive manufacturing apparatusUnderground chambersSteel frame3d printer

The invention provides a 3D printed steel fiber reinforced concrete tunnel preliminary support grating arch frame and a construction method thereof. The arch frame is divided into a plurality of unitjoints in the extending direction of the arch frame. Each unit joint is formed in an integral printed manner through 3D printing equipment. Each unit joint comprises a 3D printed outer support plate,a 3D printed reinforcing support, a 3D printed inner side support and 3D printed bolt connecting plates. The 3D printed bolt connecting plates are arranged at the head end and the tail end of each unit joint. Transverse plates of two L-shaped plates on the same side of two adjacent unit joints are mutually connected to form the overall arch frame. According to the arch frame, the steel fiber reinforced concrete outer support plates are large in stress area, can bear surrounding rock pressure more effectively than grating steel frame main reinforcement, and can effectively ensure stress performance of preliminary support components. The arch frame is integrally manufactured by adopting the printing form of a 3D printer, the weight of the arch frame is low compared with grating steel arch frame preliminary support components, hoisting and installing are facilitated, and the hoisting cost can be reduced effectively. Meanwhile, the situation that traditionally, grating steel frame is welded and machined manually on preliminary support site is avoided, the labor cost is reduced, and the construction period is shortened.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com