Thermoplasticity winding pressure pipeline and manufacturing method thereof

A pressure pipe and thermoplastic technology, applied in the direction of rigid pipes, pipes, mechanical equipment, etc., can solve the problems of poor wettability of reinforced layer resin and low performance of pipes, and achieve convenient transportation and construction, good impact resistance, high strength and rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

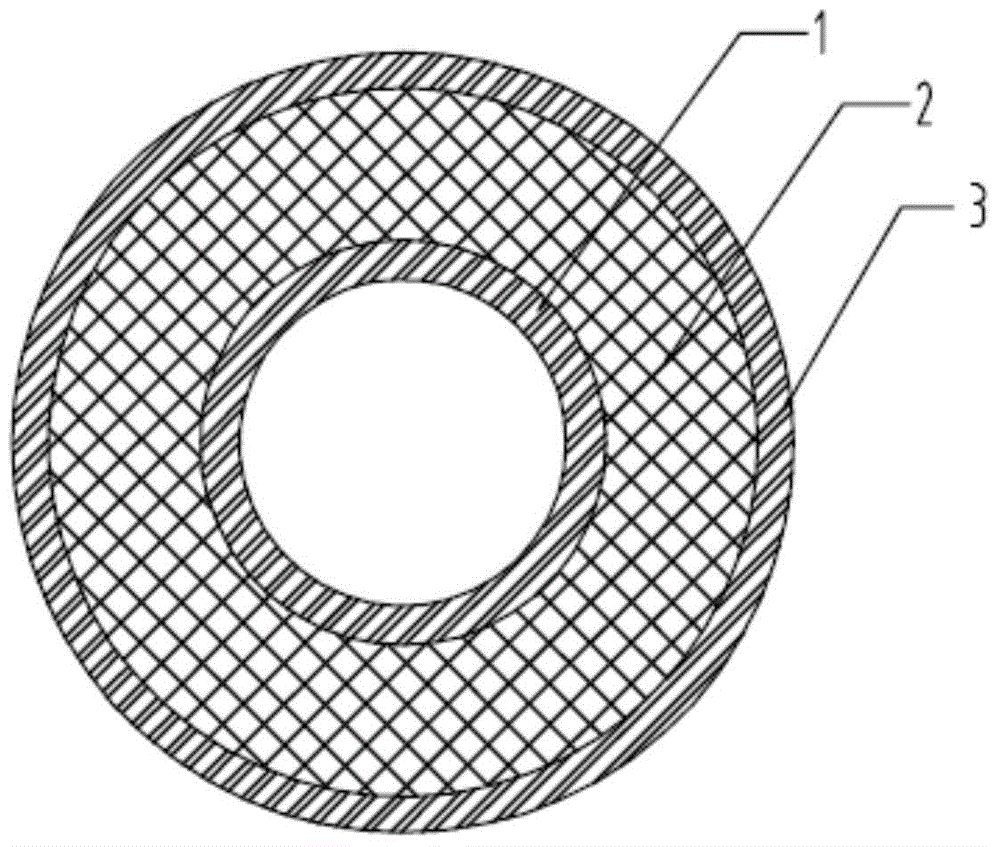

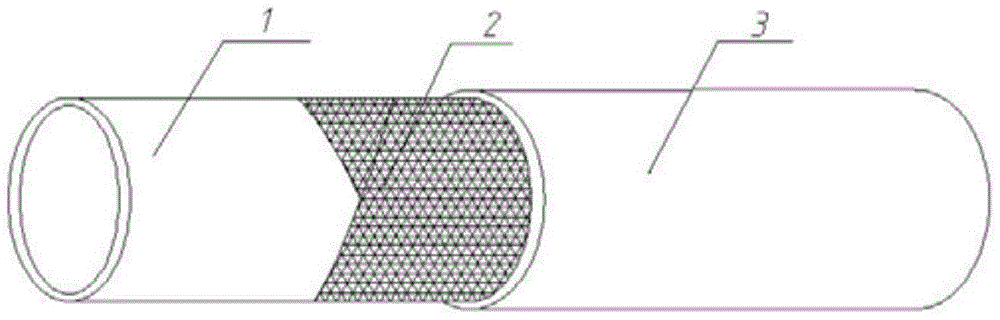

[0041] Such as Figure 1 ~ Figure 3 As shown, a thermoplastic winding pressure pipe has an inner diameter of 150mm and is composed of an inner lining layer 1, a structural layer 2 and an outer protective layer 3 from the inside to the outside (see Table 1 for the structural composition data).

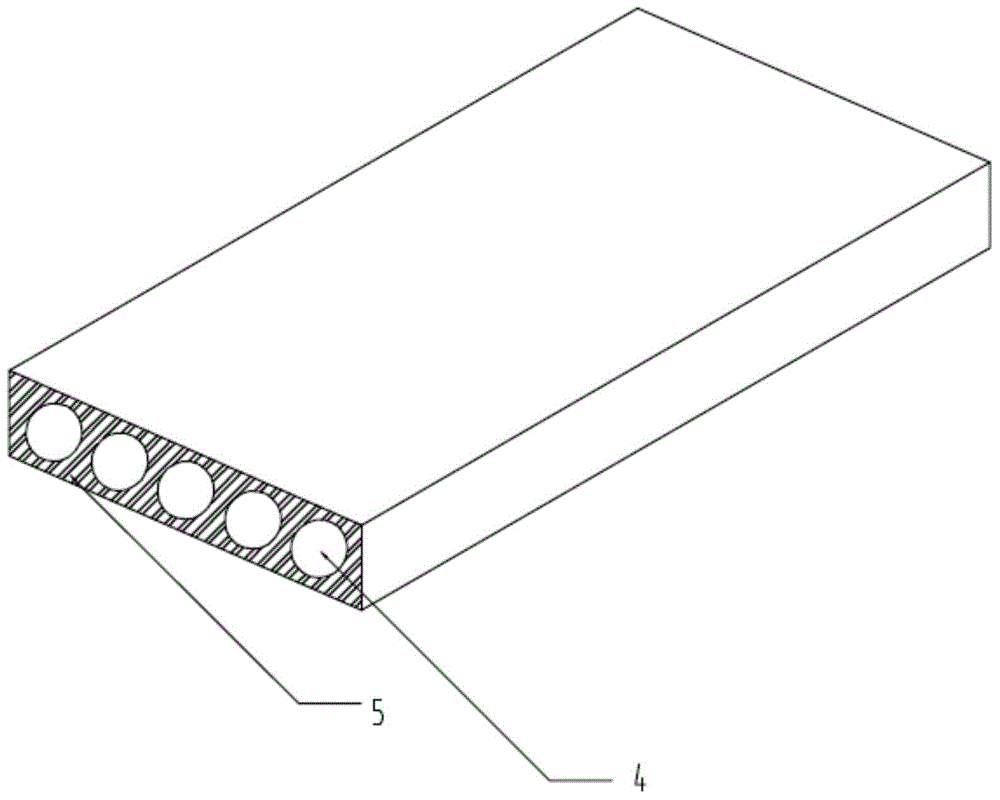

[0042] image 3 Among them, the structural layer 2 is composed of continuous fiber 4 reinforced thermoplastic 5 prepreg tape, and the prepreg tape is wound on the inner lining layer 1 through cross and hoop winding processes, and the thickness of the structural layer is 3 mm; the outer protective layer 3 is made of thermoplastic Sheet construction, 1 mm thick, by winding a thermoplastic sheet on the structural layer 2 .

[0043] Table 1

[0044] pipe

thickness

material

winding angle

Lining

2mm

PP pipe

hoop winding

preheating, surface melting

structural layer

3mm

40%PP+60%glass

65°cross winding / loop...

Embodiment 2

[0052] Such as Figure 1 ~ Figure 3 As shown, a thermoplastic winding pressure pipe has an inner diameter of 500mm and is composed of an inner lining layer 1, a structural layer 2 and an outer protective layer 3 from the inside to the outside (see Table 2 for the structural composition data).

[0053] image 3 Among them, the structural layer 2 is composed of continuous fiber 4 reinforced thermoplastic 5 prepreg tape, and the prepreg tape is wound on the inner liner 1 through cross and hoop winding processes, with a thickness of 10mm; the outer protective layer 3 is made of thermoplastic sheet Constructed, with a thickness of 1 mm, by winding a thermoplastic sheet on the structural layer 2 .

[0054] Table 2

[0055]

[0056] The preparation method is as follows:

[0057] (1) Wrap a polypropylene sheet with a thickness of 1mm on the mandrel to form an inner lining.

[0058] (2) After the continuous fiber-reinforced thermoplastic prepreg tape is preheated by an infrared ...

Embodiment 3

[0062] Such as Figure 1 ~ Figure 2 As shown, a thermoplastic winding pressure pipe, the pipe includes an inner lining layer 1, a structural layer 2 and an outer protective layer 3 from the inside to the outside, and the inner diameter of the pipe is 80 mm (see Table 3 for its structural composition data).

[0063] image 3 Among them, the structural layer 2 is a continuous glass fiber 4 reinforced polypropylene 5 prepreg tape, which is heated and wound in a cross-hoop direction on the surface of the inner lining layer to form a winding layer with a cross-hoop structure; the outer protective layer is a polypropylene sheet heated The winding layer formed on the surface of the structural layer after winding.

[0064] table 3

[0065]

[0066] The preparation method is as follows:

[0067] (1) Put the PP pipe with an inner diameter of 80mm and a wall thickness of 1mm directly on the expansion and contraction shaft, and then expand and tighten the expansion and contraction s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com