Patents

Literature

422 results about "Burst pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Burst pressure is sometimes defined as the point at which something such as a valve or hose will fail as a result of pressure, and it may also be defined as the point right before failure will occur. In either case, this pressure could be considered an expression of the maximum pressure which something can endure before it will break.

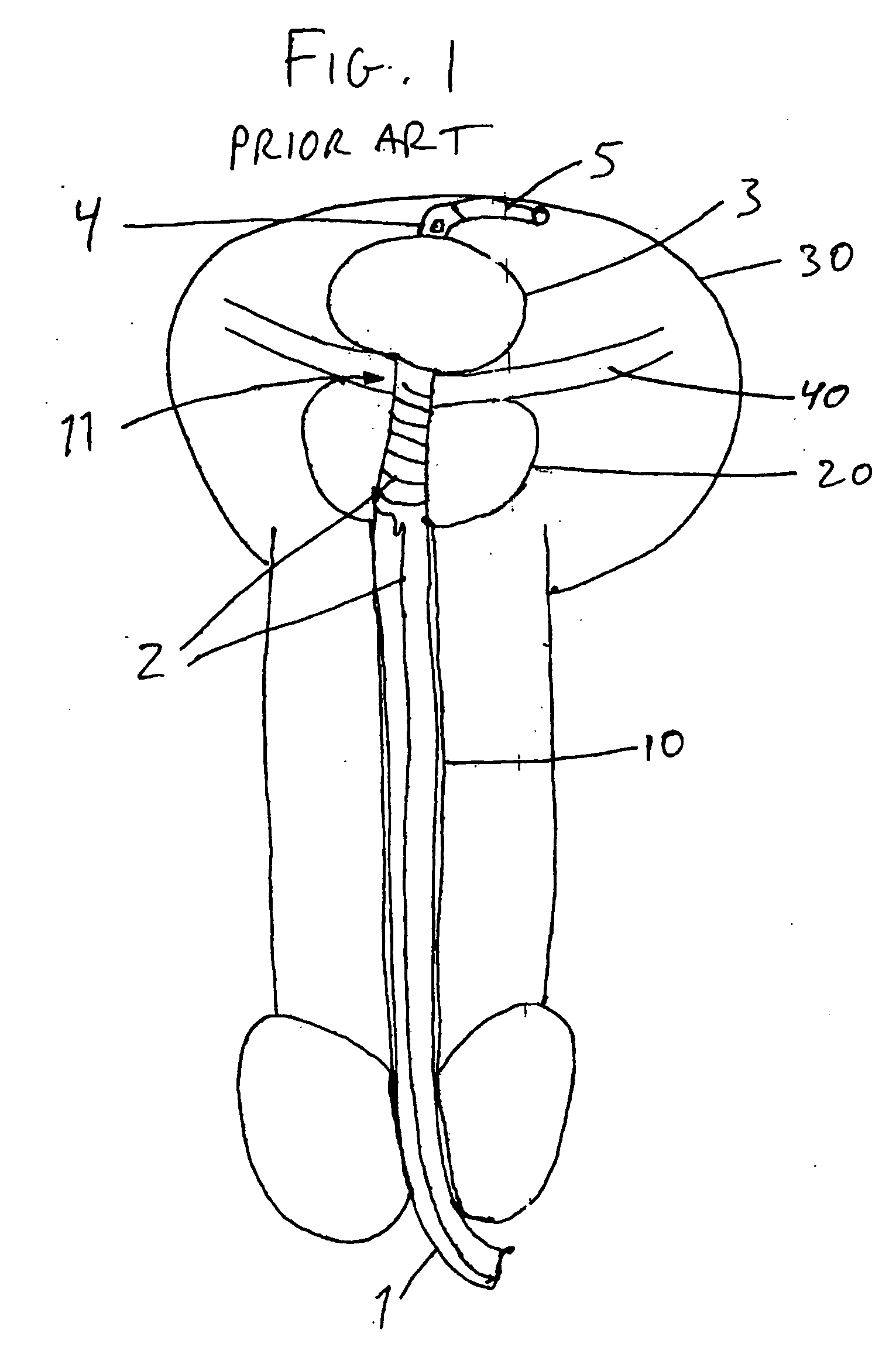

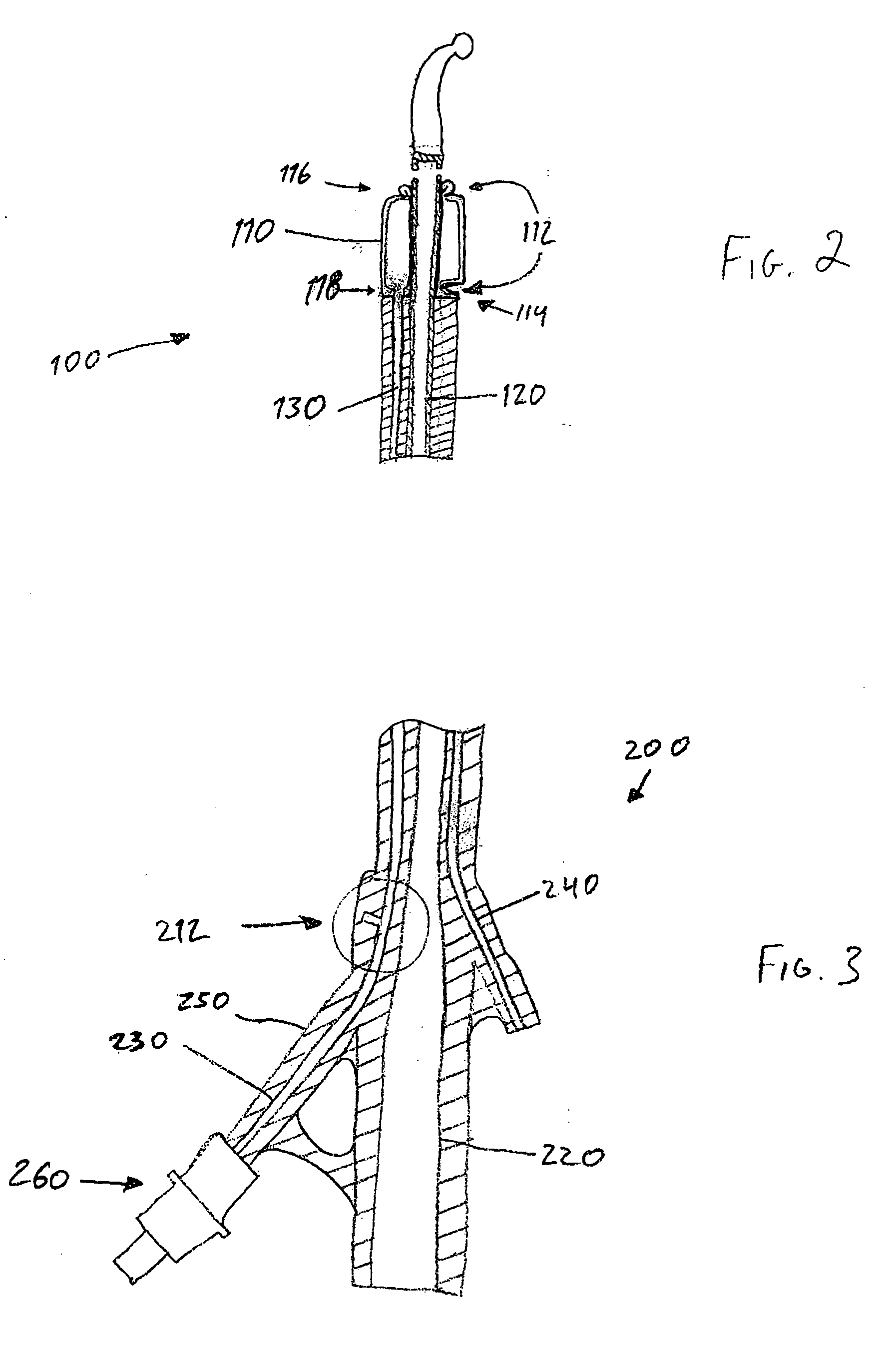

Balloons for medical devices and fabrication thereof

InactiveUS6500148B1Error minimizationIncrease the diameterBalloon catheterSurgeryPolyamideMedical device

Dilation balloons and catheters including same are provided. The balloons are fabricated of a material such as a nylon or a polyamide material, and they have an inflated, non-distended working profile as well as a stretched inflated profile which is achieved by applying pressure through a dilatation catheter or the like that is in excess of that needed to achieve the inflated, non-distended profile and which is adequate to effect dilatation or the like up to a maximum pre-bursting pressure application. The maximum pre-bursting size of the balloon can be tailored depending upon the needs of the particular balloon within a wide range of possible maximum pre-bursting sizes.

Owner:CORDIS CORP

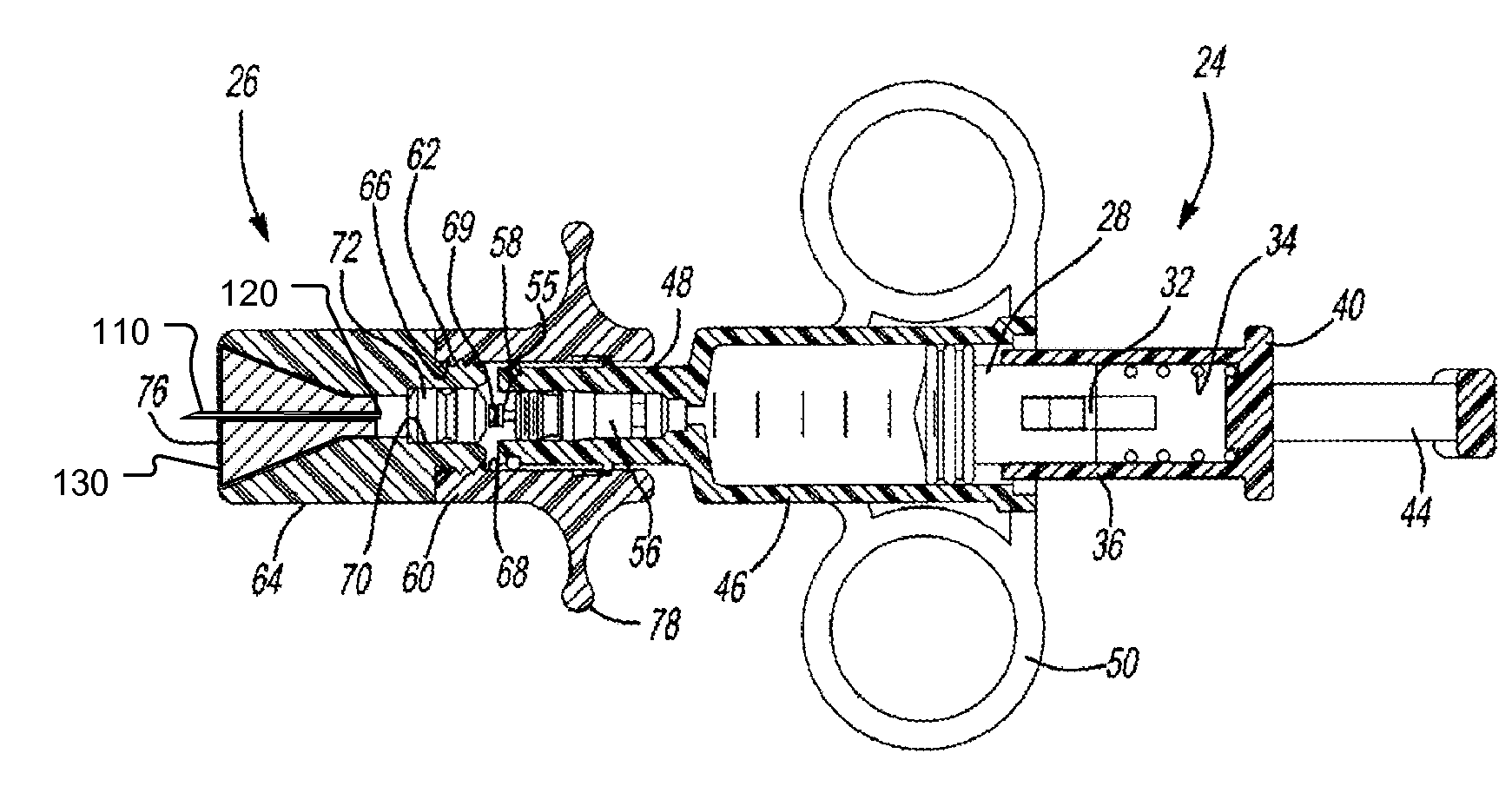

Valved Delivery Device and Method

InactiveUS20060276755A1Easy to takeImprove delivery rateInfusion syringesMedical devicesBiomedical engineeringMembrane configuration

A valved medicament delivery device including a housing having a chamber including coaxially aligned inlet and outlet, a medicament cartridge located within the chamber having a passage therethrough and membranes sealing the passage having a burst pressure of less than 10 atmospheres, a manually actuatable fluid delivery device having an outlet in fluid communication with the chamber and a manually actuated valve located between the outlet of the fluid delivery device and the chamber inlet for delivery of fluid under pressure to the valve. The medicament delivery device of this invention may be utilized to deliver a controlled unit dose of an medicament on demand by first pressurizing a pressure chamber in the pressure delivery device upstream of the valve, then opening the valve to open the membranes and express the medicament through the chamber outlet.

Owner:BECTON DICKINSON & CO

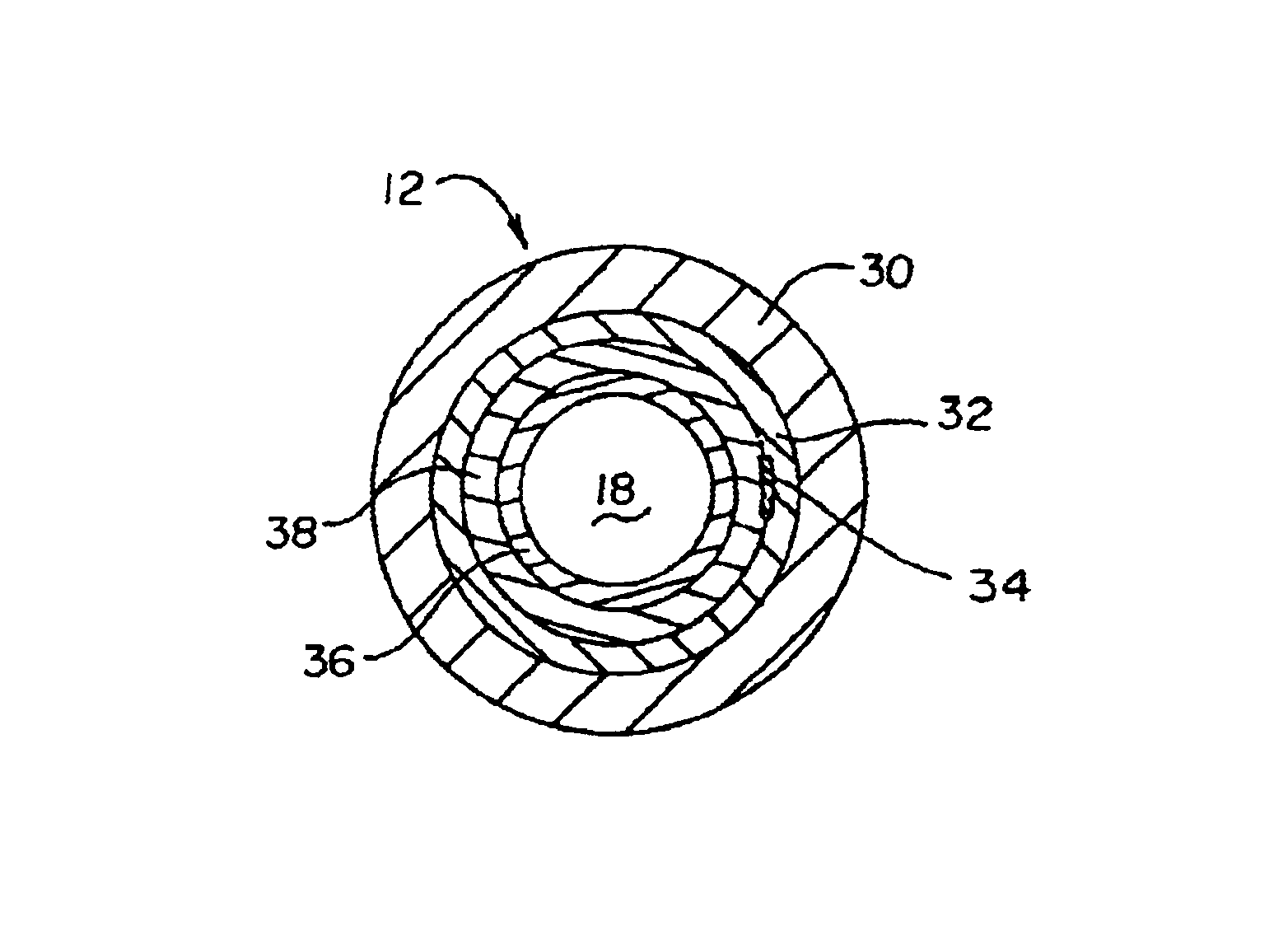

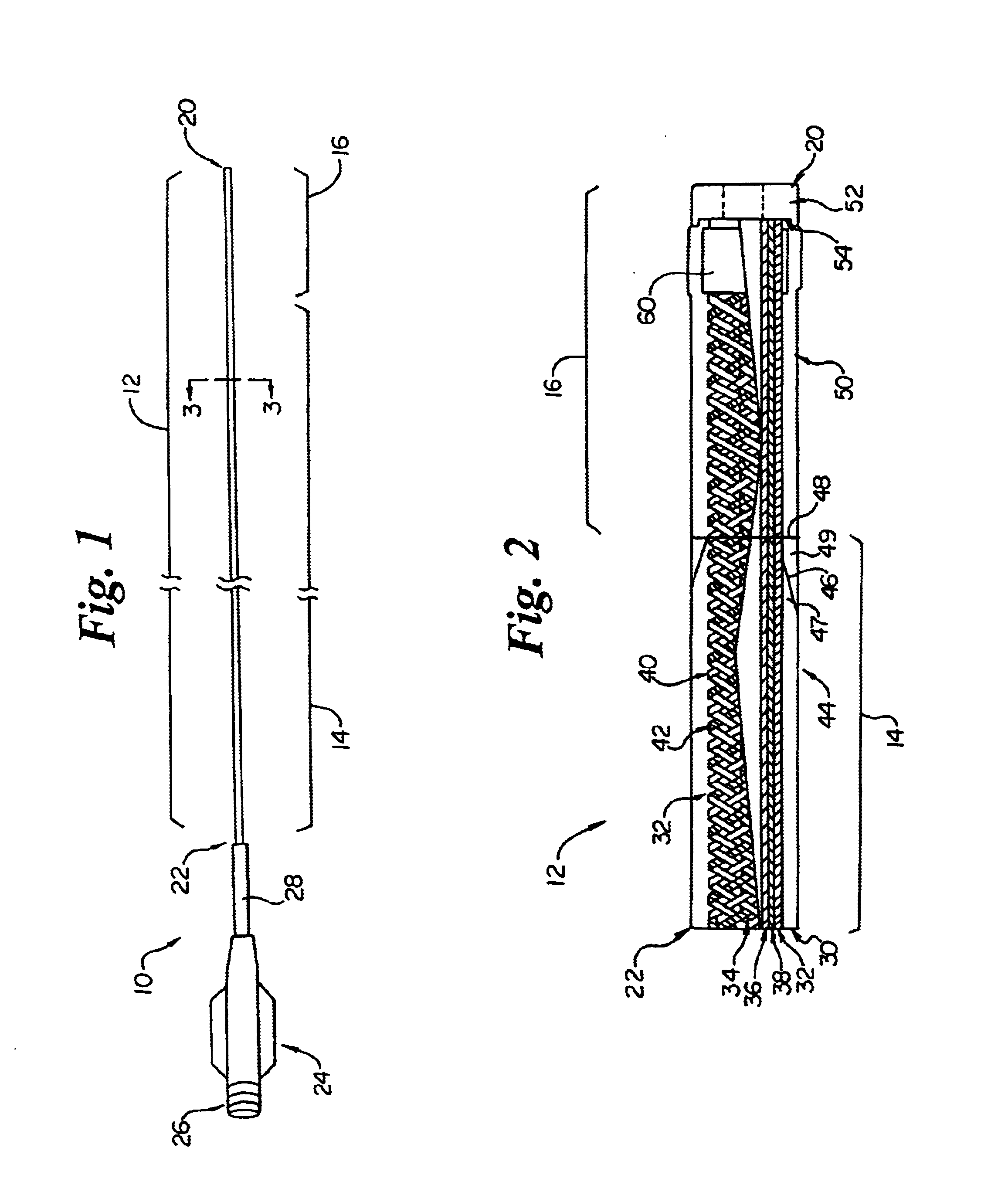

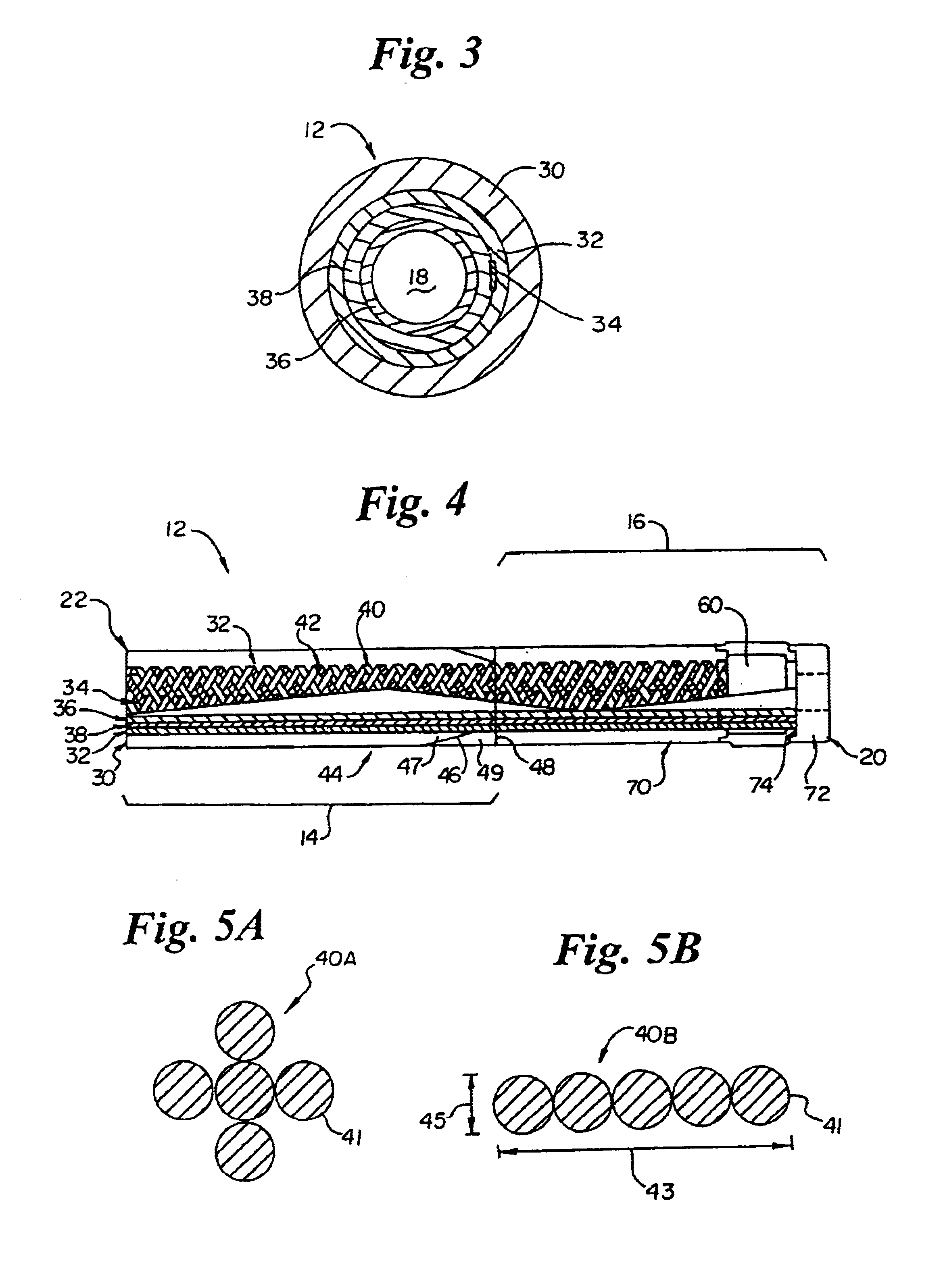

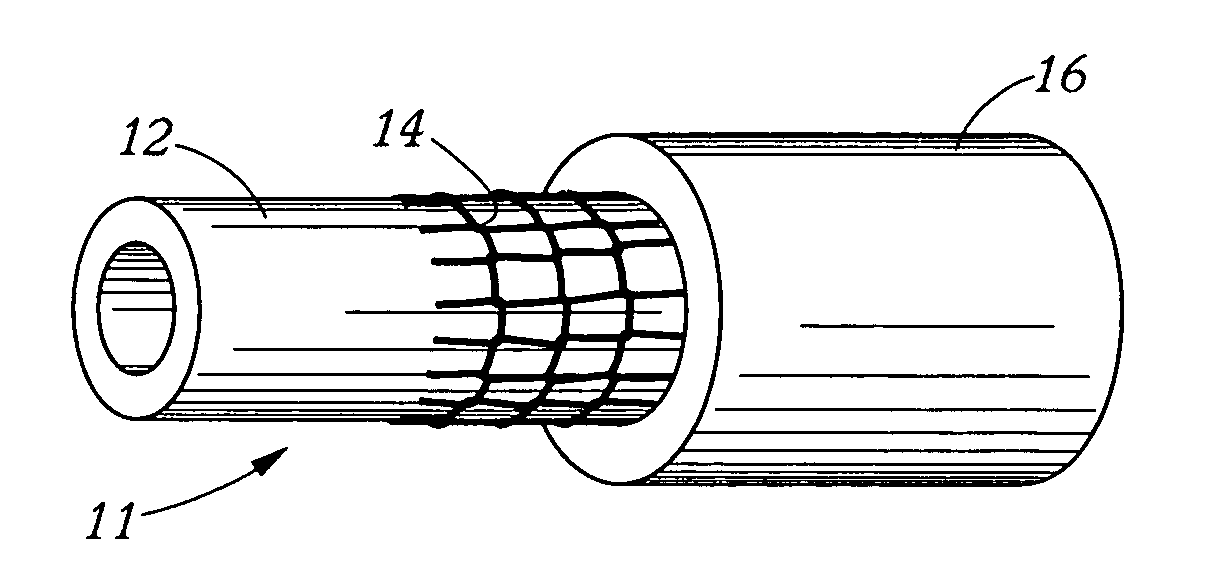

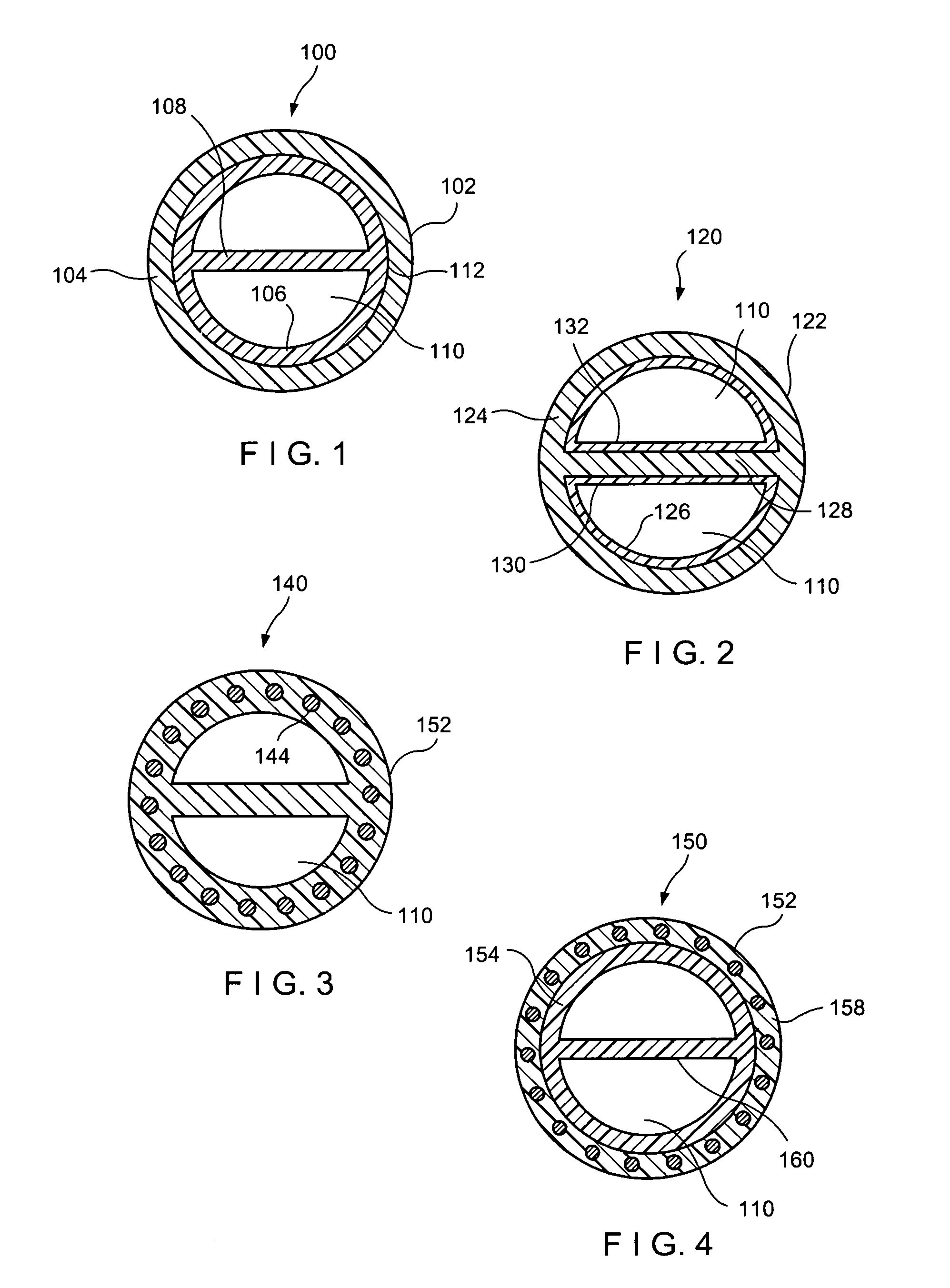

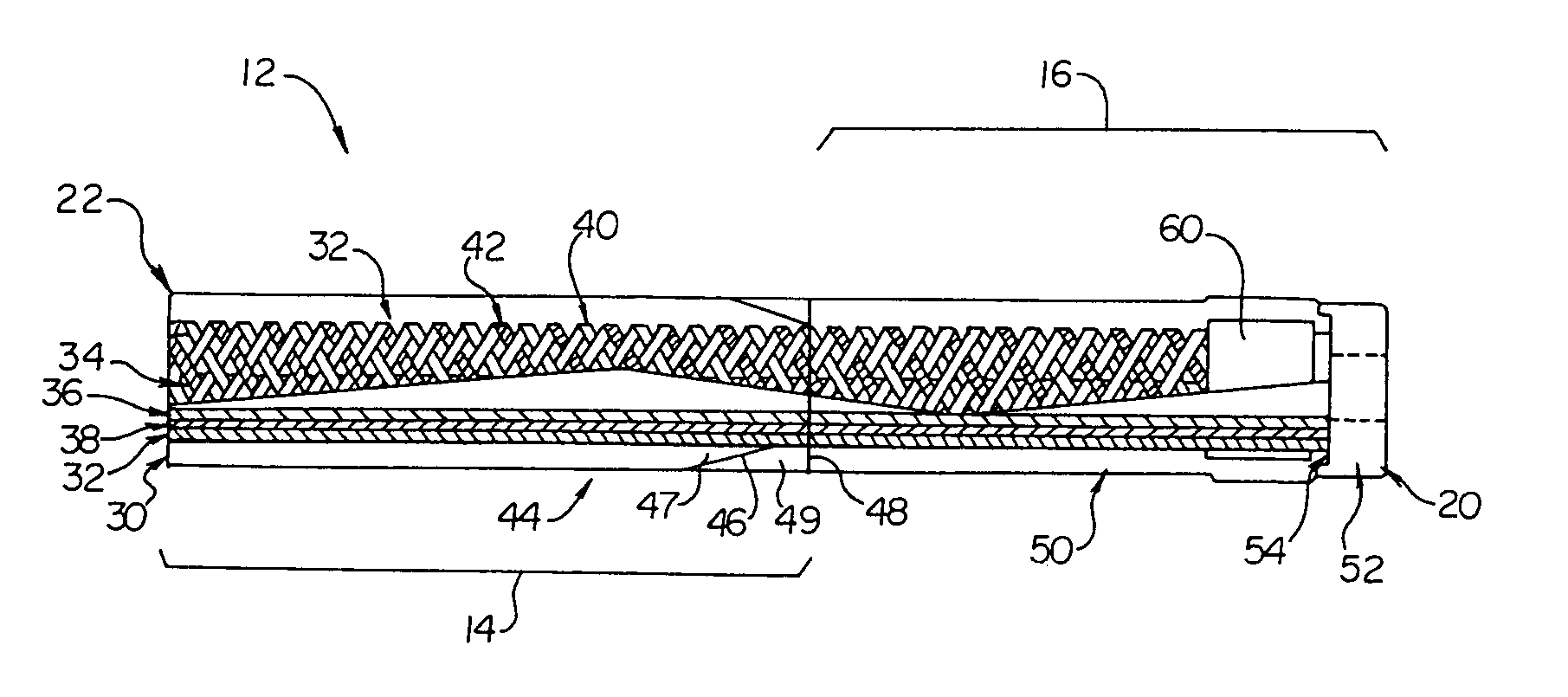

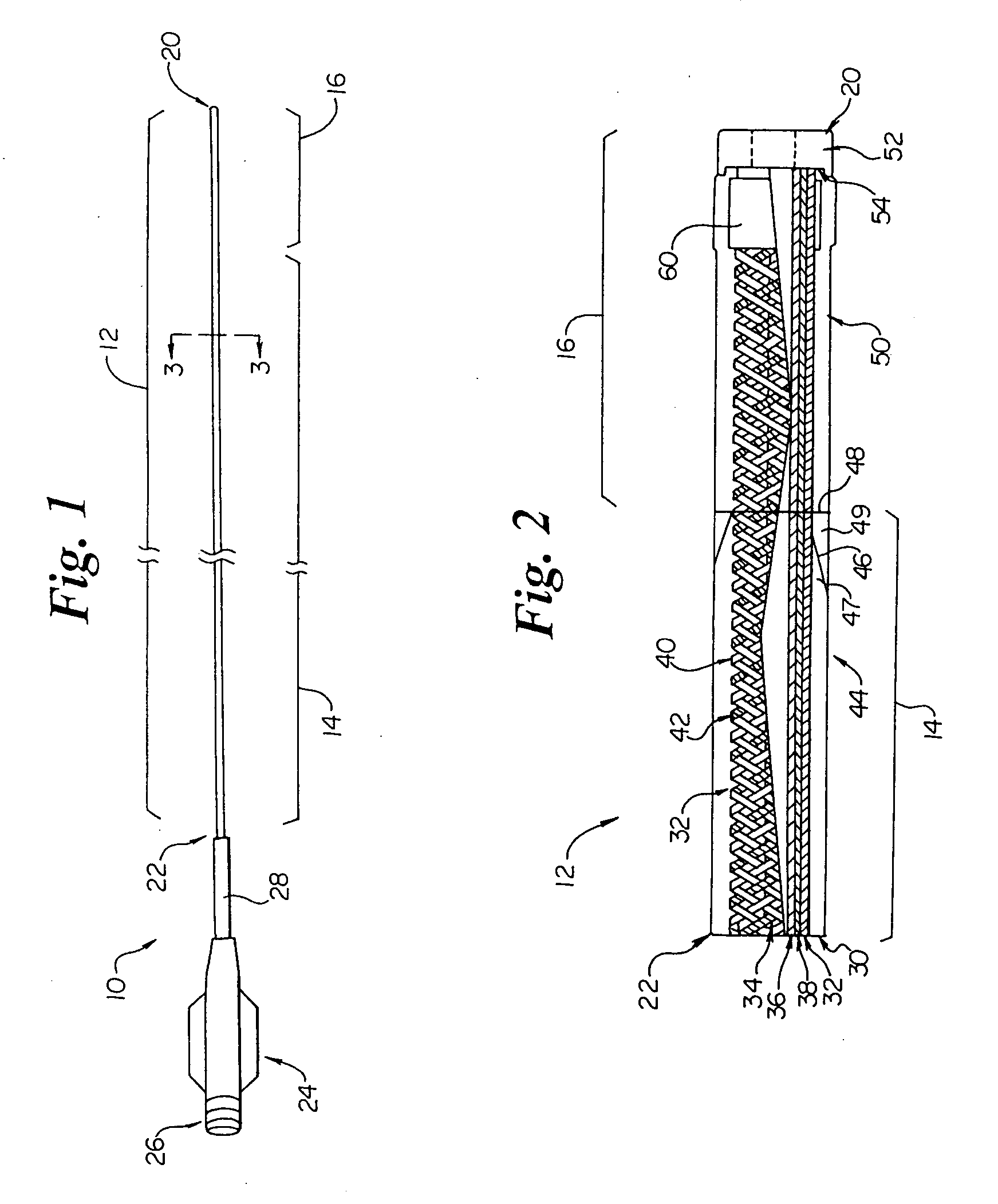

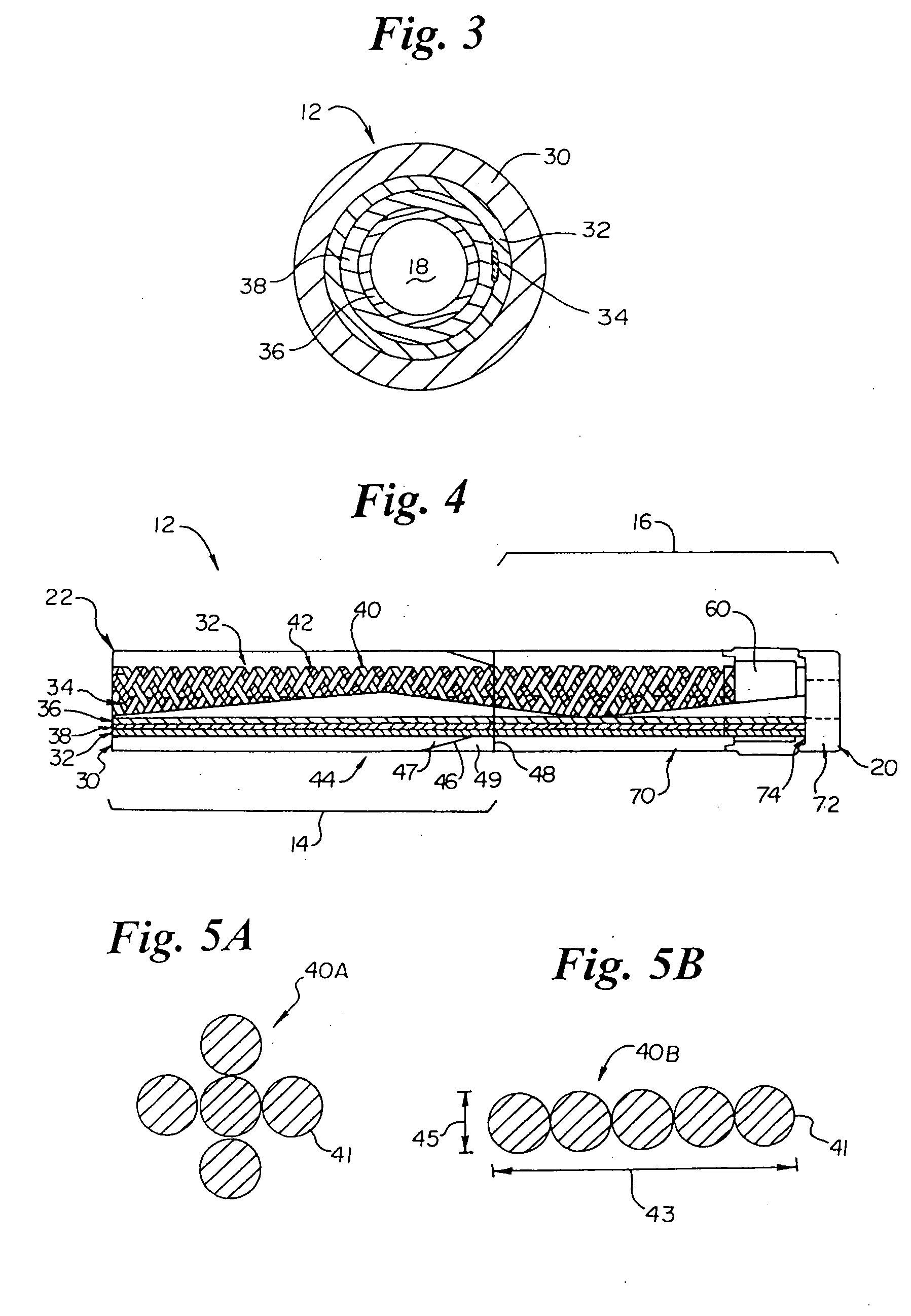

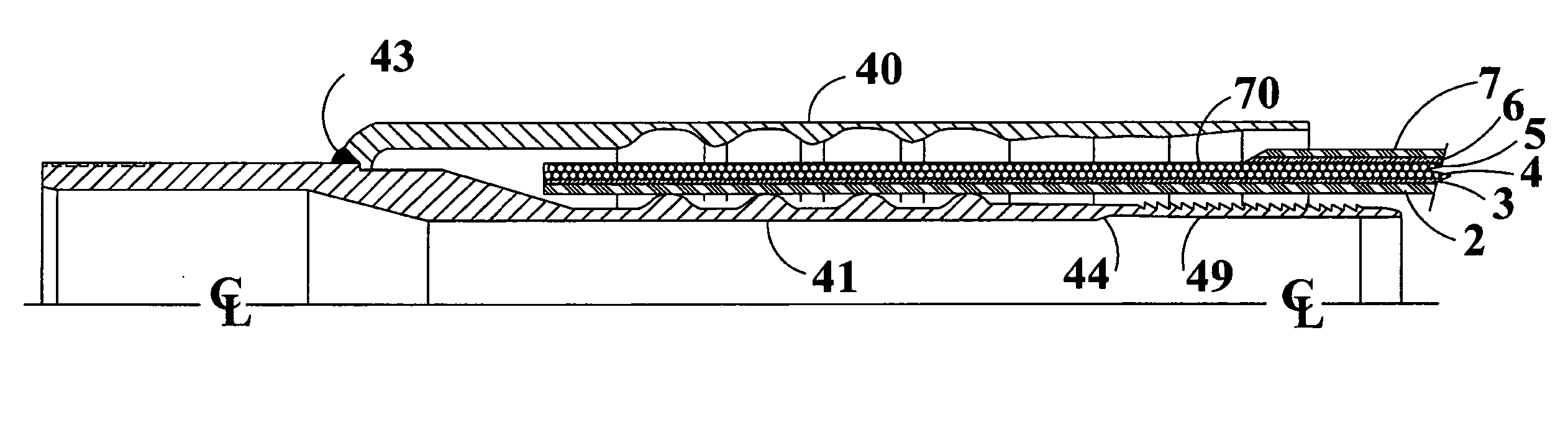

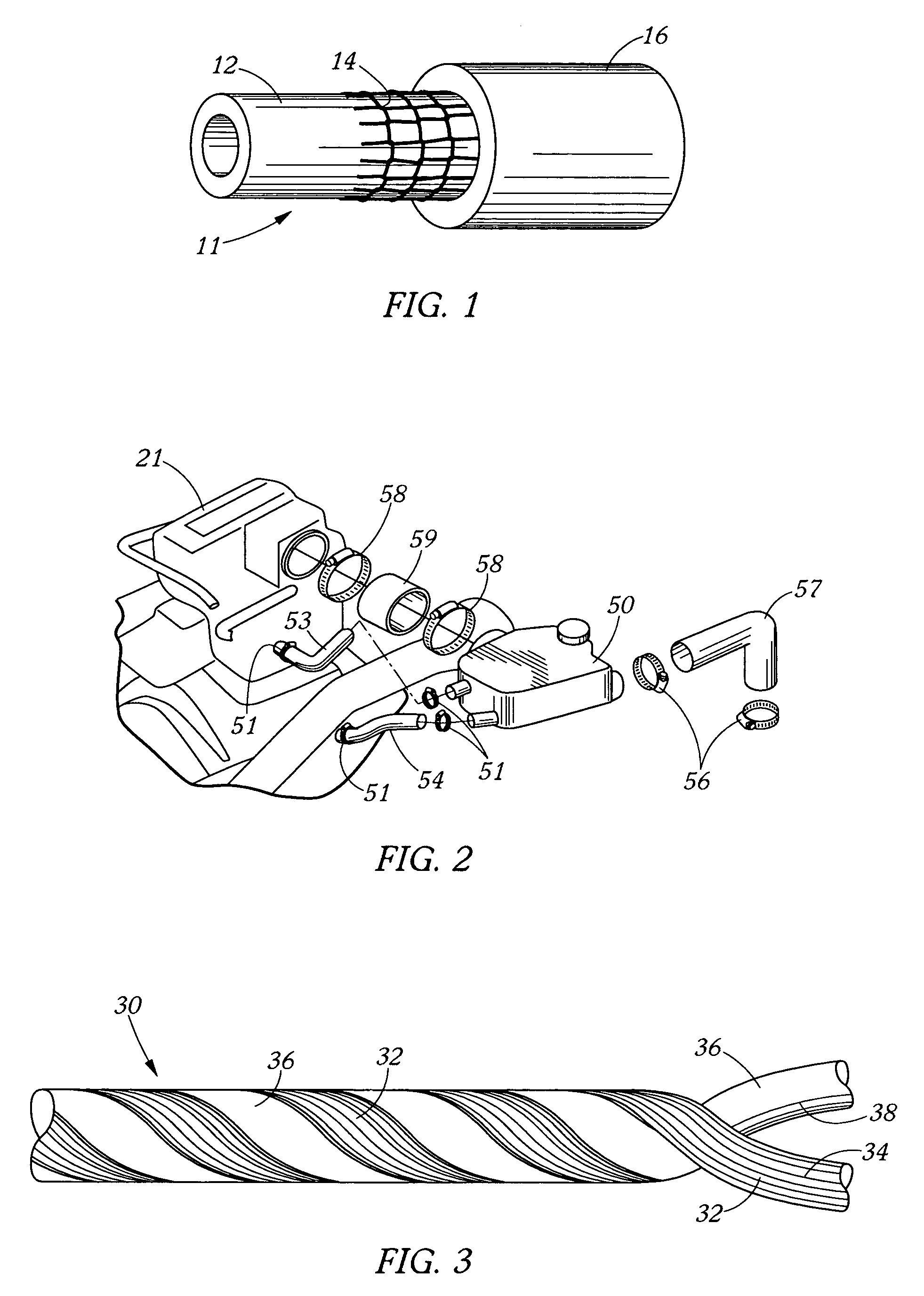

Intravascular catheter with composite reinforcement

InactiveUS6866660B2Increase flexibilityGood flexibilityCatheterDiagnostic recording/measuringIntravascular catheterGuide tube

An intravascular catheter that exhibits the combined features of superior flexibility, softness, radiopacity and oval / kink resistance. The catheter includes an elongate shaft having a proximal region, a distal region and a lumen extending therethrough. The proximal region of the shaft includes an inner lubricious polymer layer, a reinforcement layer and an outer layer. The reinforcement layer comprises a braid having one or more metallic members and a plurality of polymer members wherein each polymer member comprises a plurality of monofilaments, preferably formed of LCP. The polymer members of the braid provide improved flexibility and softness in addition to high burst pressure. The metallic member(s) of the braid provide improved radiopacity and oval / kink resistance. The catheter may also include a longitudinal member extending along the reinforcement layer.

Owner:SCI MED LIFE SYST

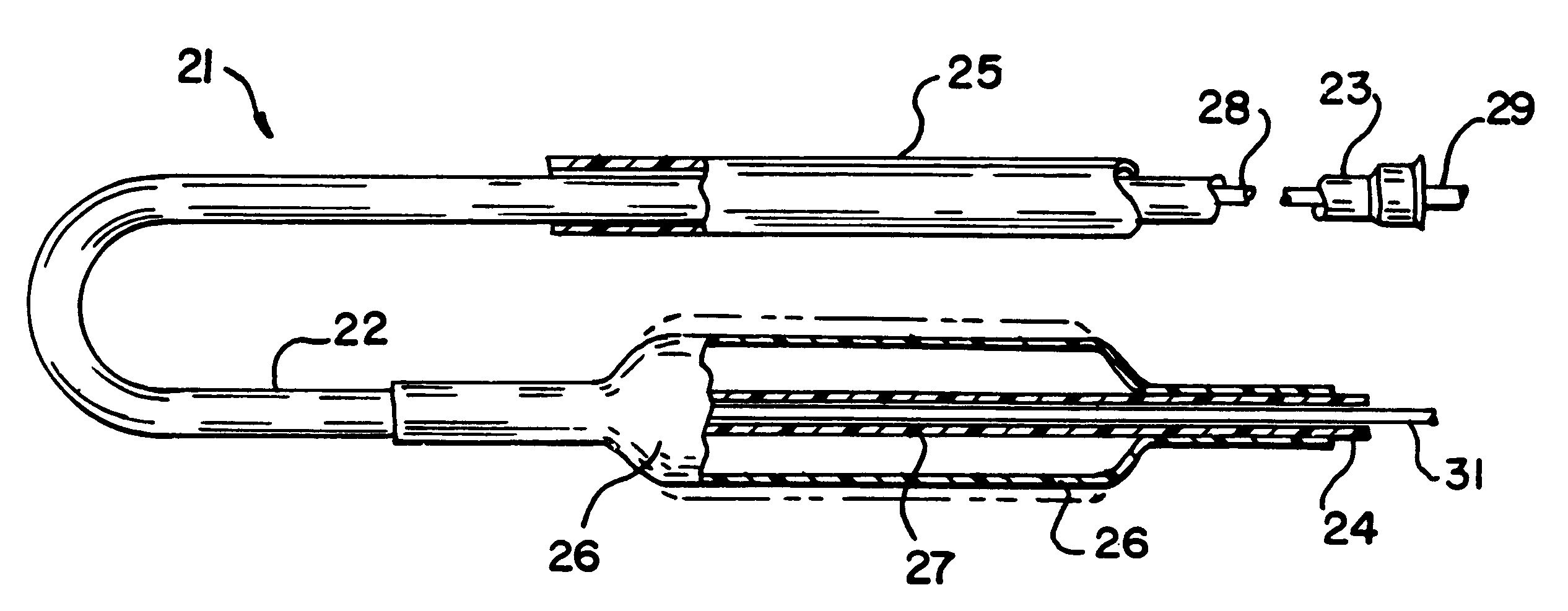

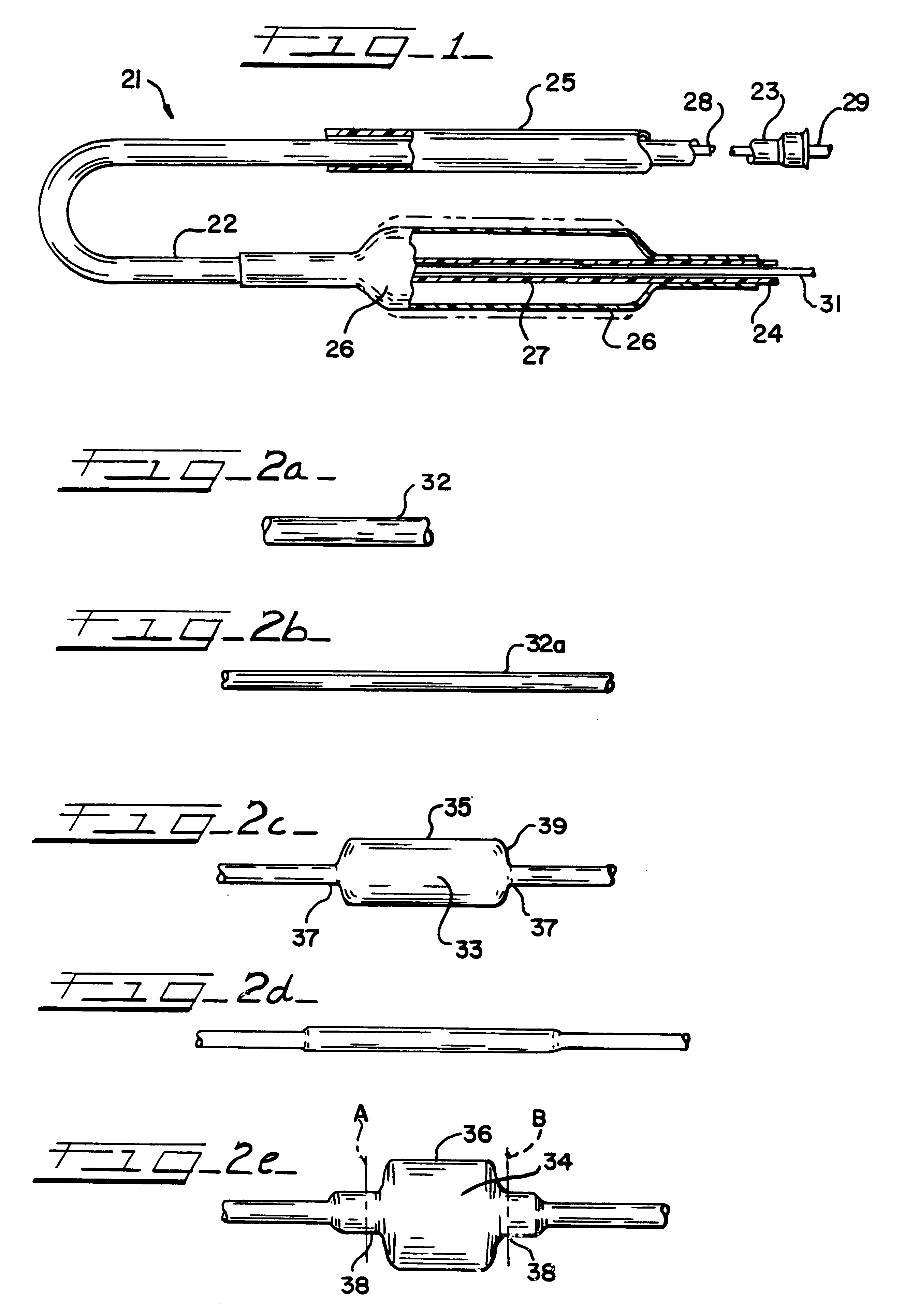

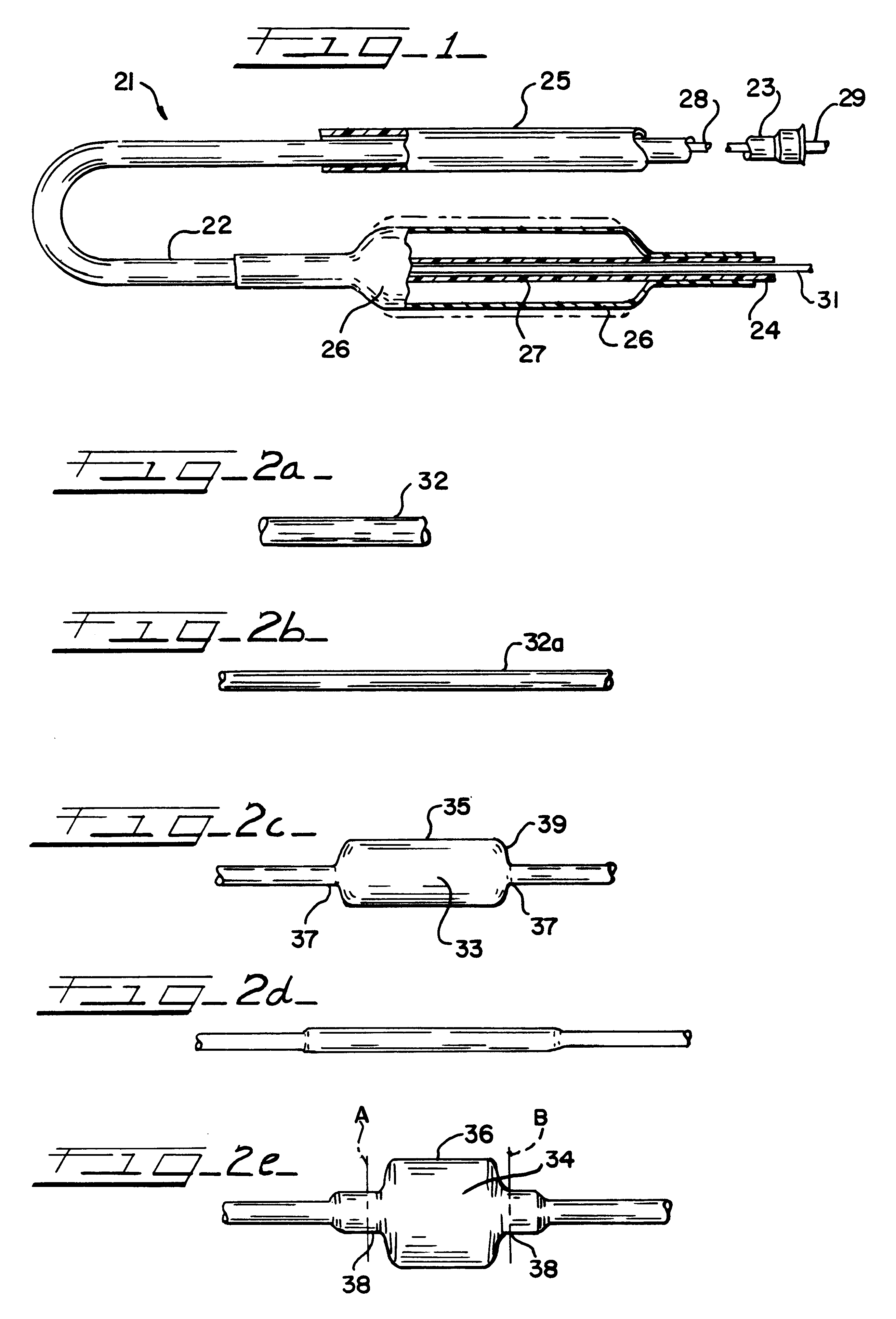

Balloons for medical devices and fabrication thereof

InactiveUS6110142AConvenient coatingHigh strengthBalloon catheterSurgeryMedical deviceBiomedical engineering

Dilatation balloons and catheters including same are provided. The balloons are fabricated of a biaxially orientable material such as a nylon or a polyamide material, and they have an inflated, non-distended working profile as well as a stretched inflated profile which is achieved by applying pressure through a dilatation catheter or the like that is in excess of that needed to achieve the inflated, non-distended profile and which is adequate to effect dilatation or the like up to a maximum pre-bursting pressure application. The maximum pre-bursting size of the balloon can be tailored depending upon the needs of the particular balloon within a wide range of possible maximum pre-bursting sizes.

Owner:CORDIS CORP

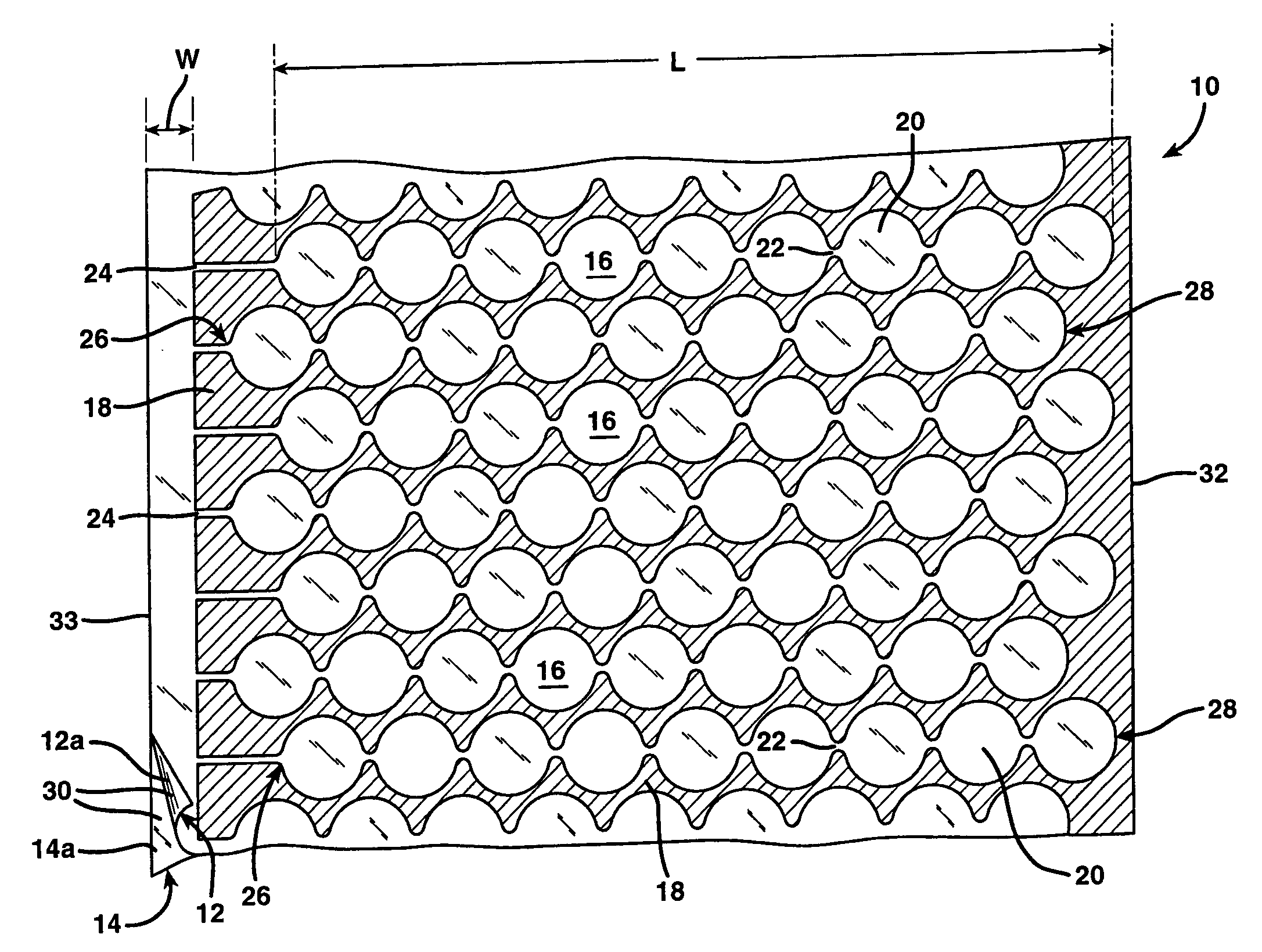

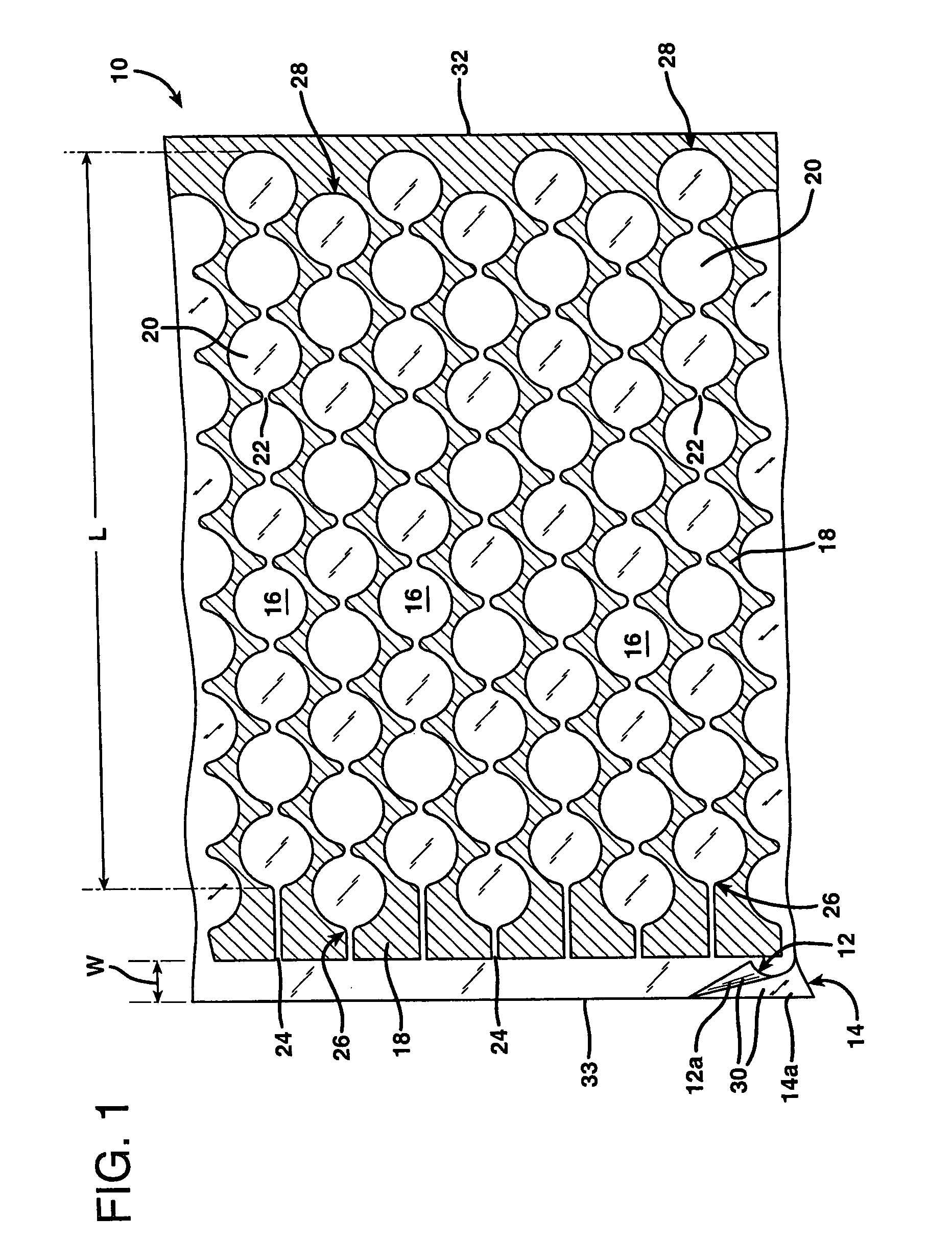

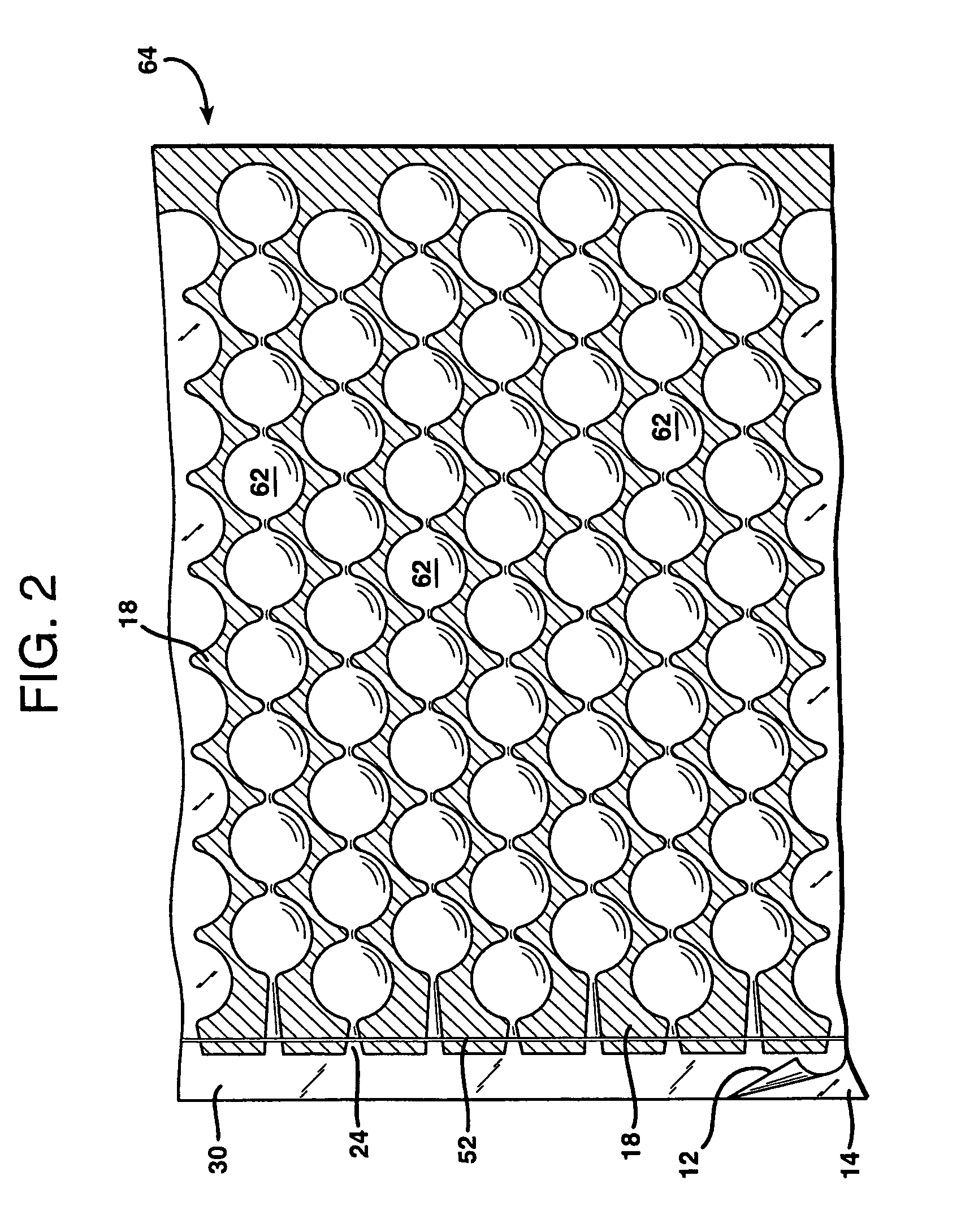

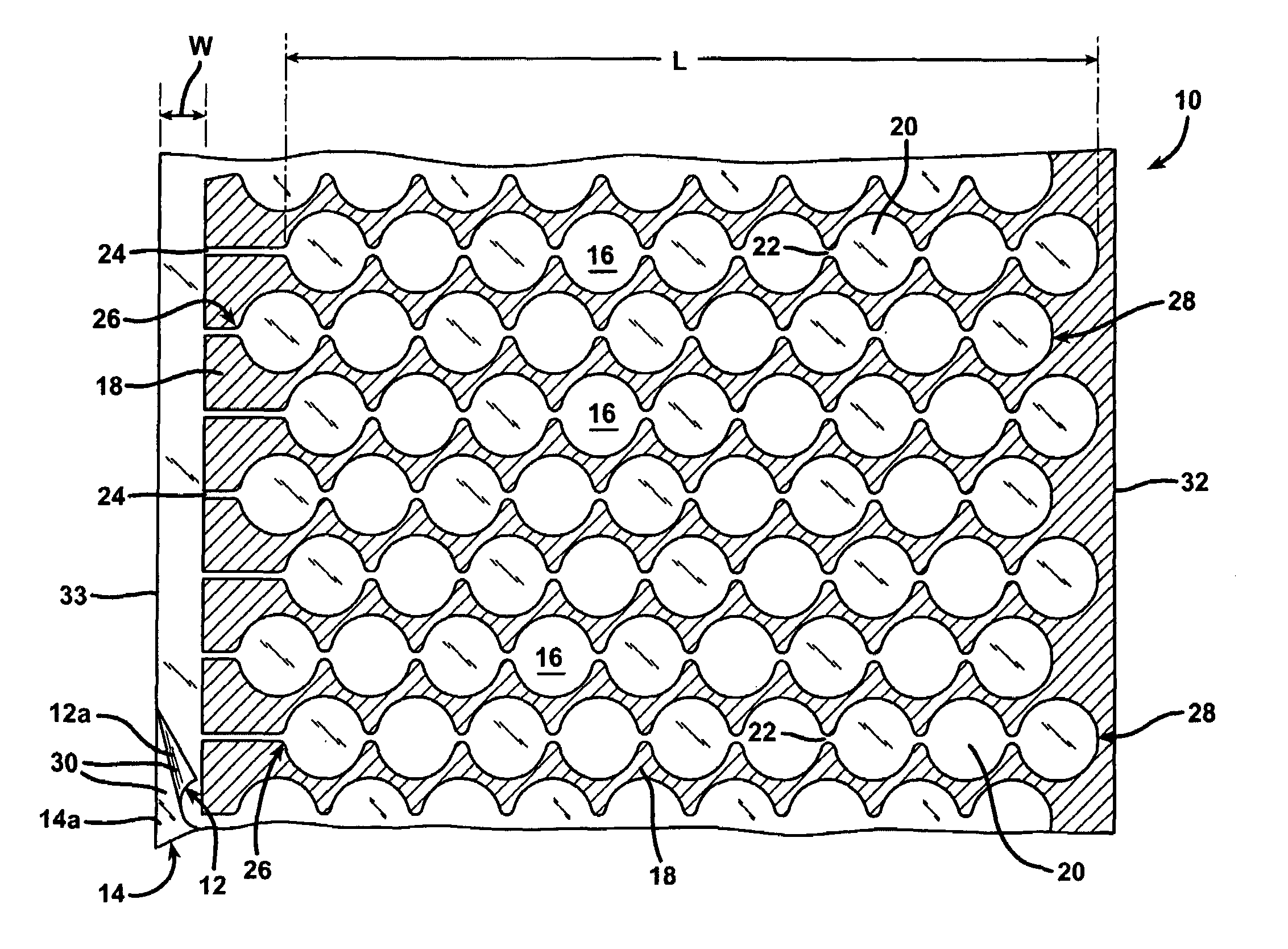

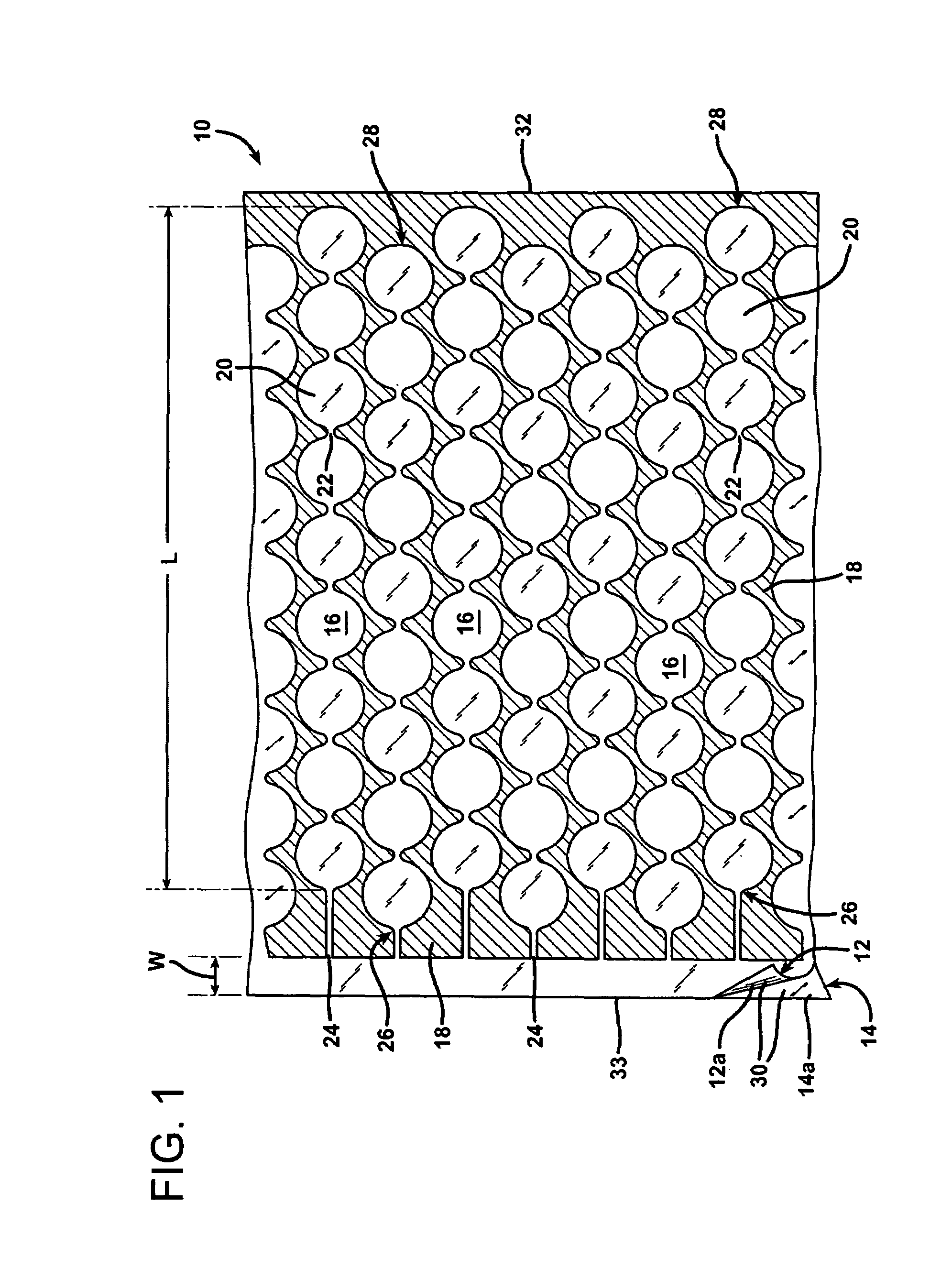

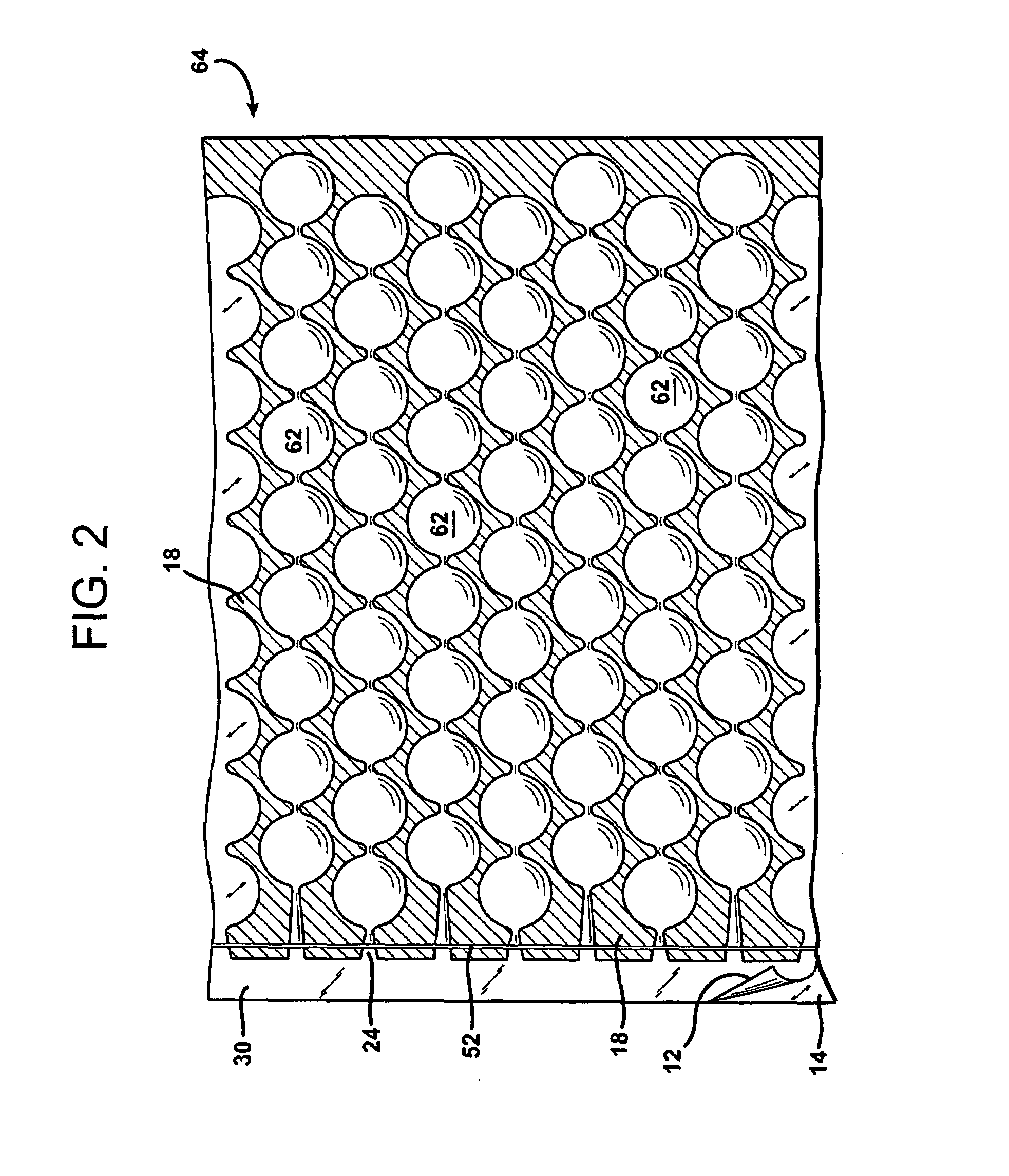

High strength high gas barrier cellular cushioning product

InactiveUS6982113B2Small sizeReduce environmental stressPaper/cardboard articlesSynthetic resin layered productsCushioningPolyolefin

An inflatable cushioning article is made from a multilayer film having a seal layer, a gas barrier layer, and a tie layer adhering the seal layer to the gas barrier layer. The cushioning article has a plurality of inflatable chambers, with each of the chambers having a plurality of cells connected in series to one another via inflation channels. Although the inflatable article can be made from relatively thin films, the article exhibits a relatively high burst pressure and can be inflated to, for example 3 psi, and withstand conditions such as 140° F. and high altitude, without film delamination, seal failure, or film rupture. Preferably, the tie layer comprises an anhydride modified polyolefin having an anhydride content of at least 150 ppm.

Owner:SEALED AIR U S

High strength high gas barrier cellular cushioning product

InactiveUS7223461B2Small sizeReduce environmental stressPaper/cardboard articlesSynthetic resin layered productsCushioningPolyolefin

An inflatable cushioning article is made from a multilayer film having a seal layer, a gas barrier layer, and a tie layer adhering the seal layer to the gas barrier layer. The cushioning article has a plurality of inflatable chambers, with each of the chambers having a plurality of cells connected in series to one another via inflation channels. Although the inflatable article can be made from relatively thin films, the article exhibits a relatively high burst pressure and can be inflated to, for example 3 psi, and withstand conditions such as 140° F. and high altitude, without film delamination, seal failure, or film rupture. Preferably, the tie layer comprises an anhydride modified polyolefin having an anhydride content of at least 150 ppm.

Owner:SEALED AIR U S

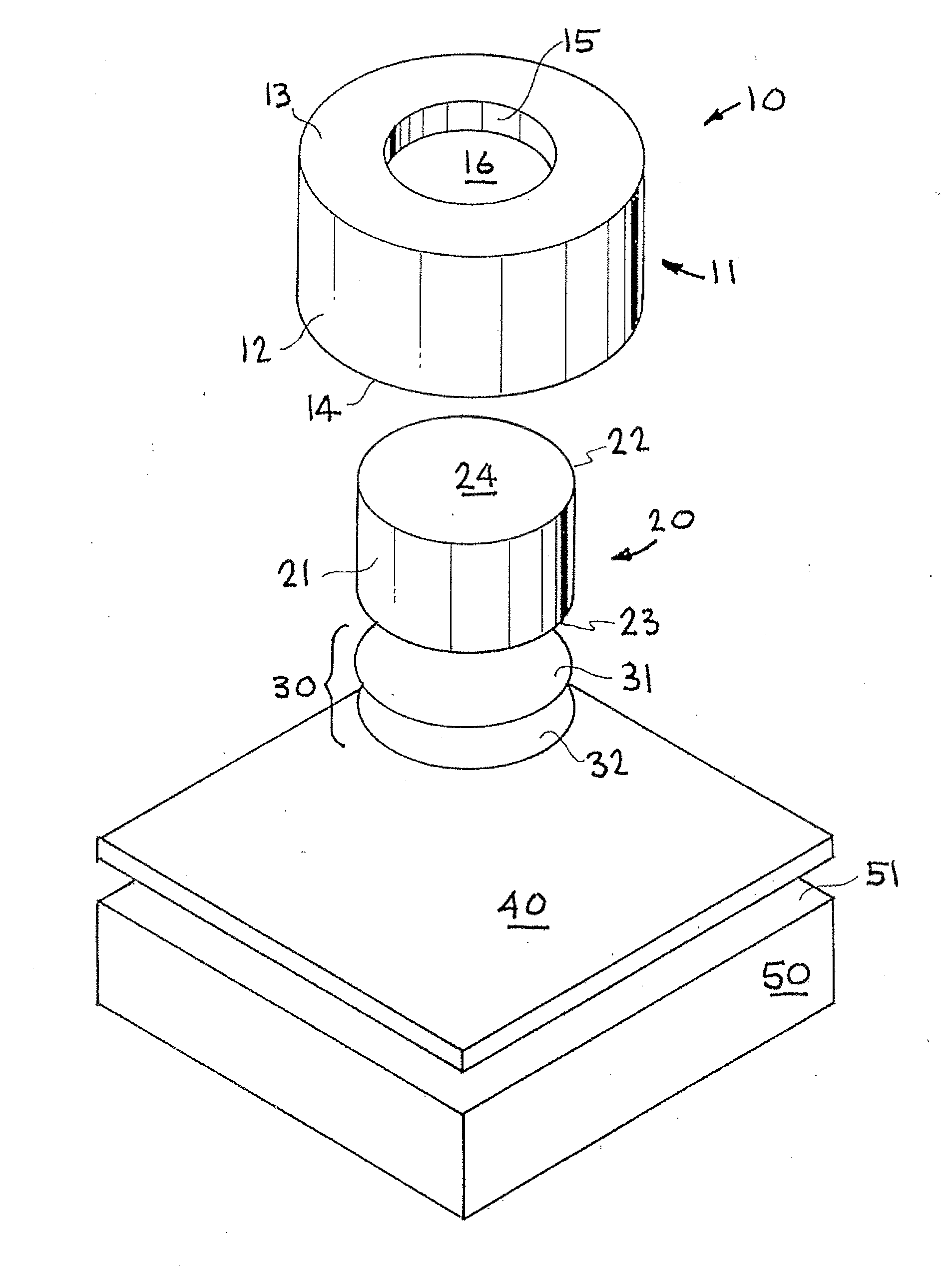

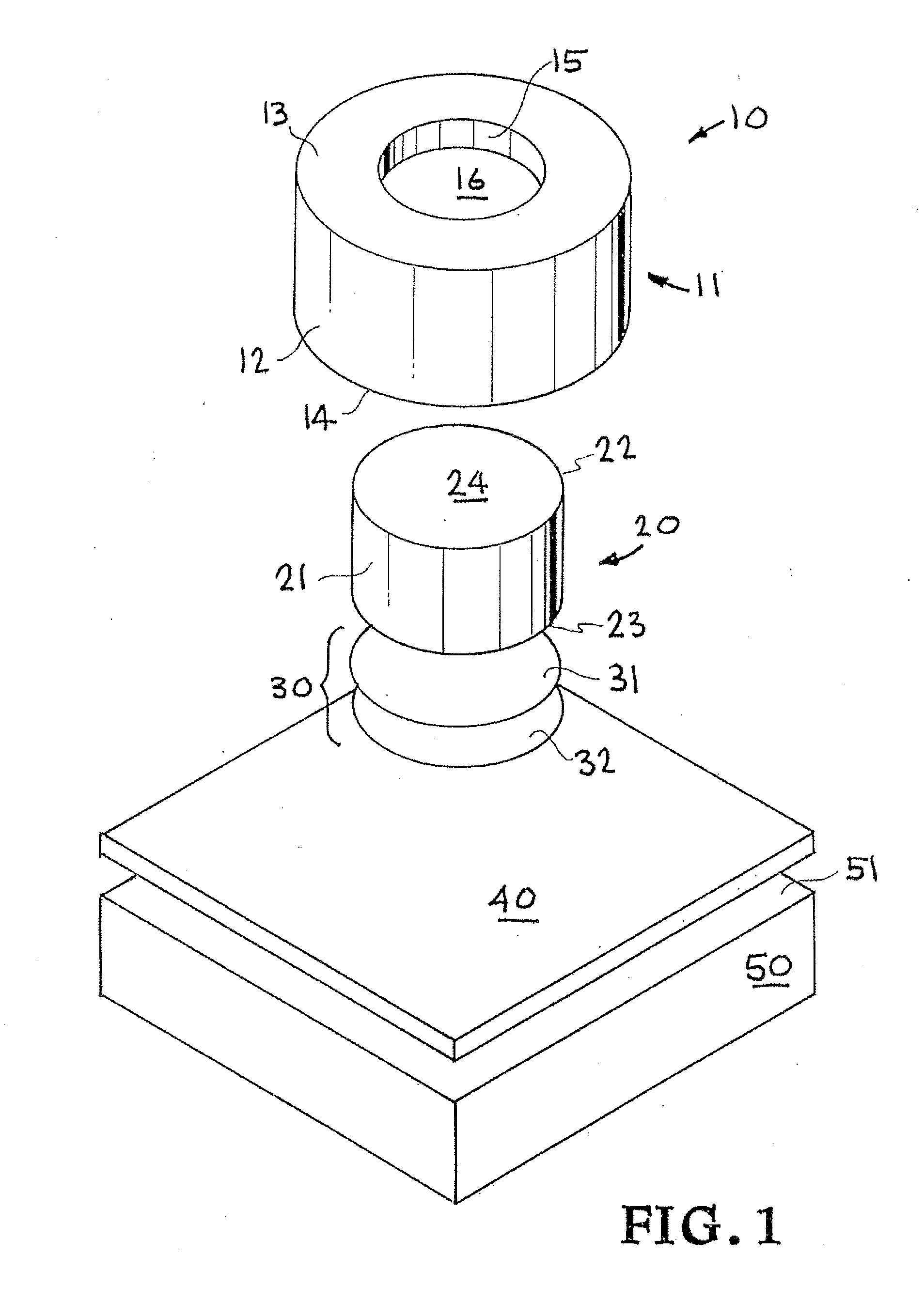

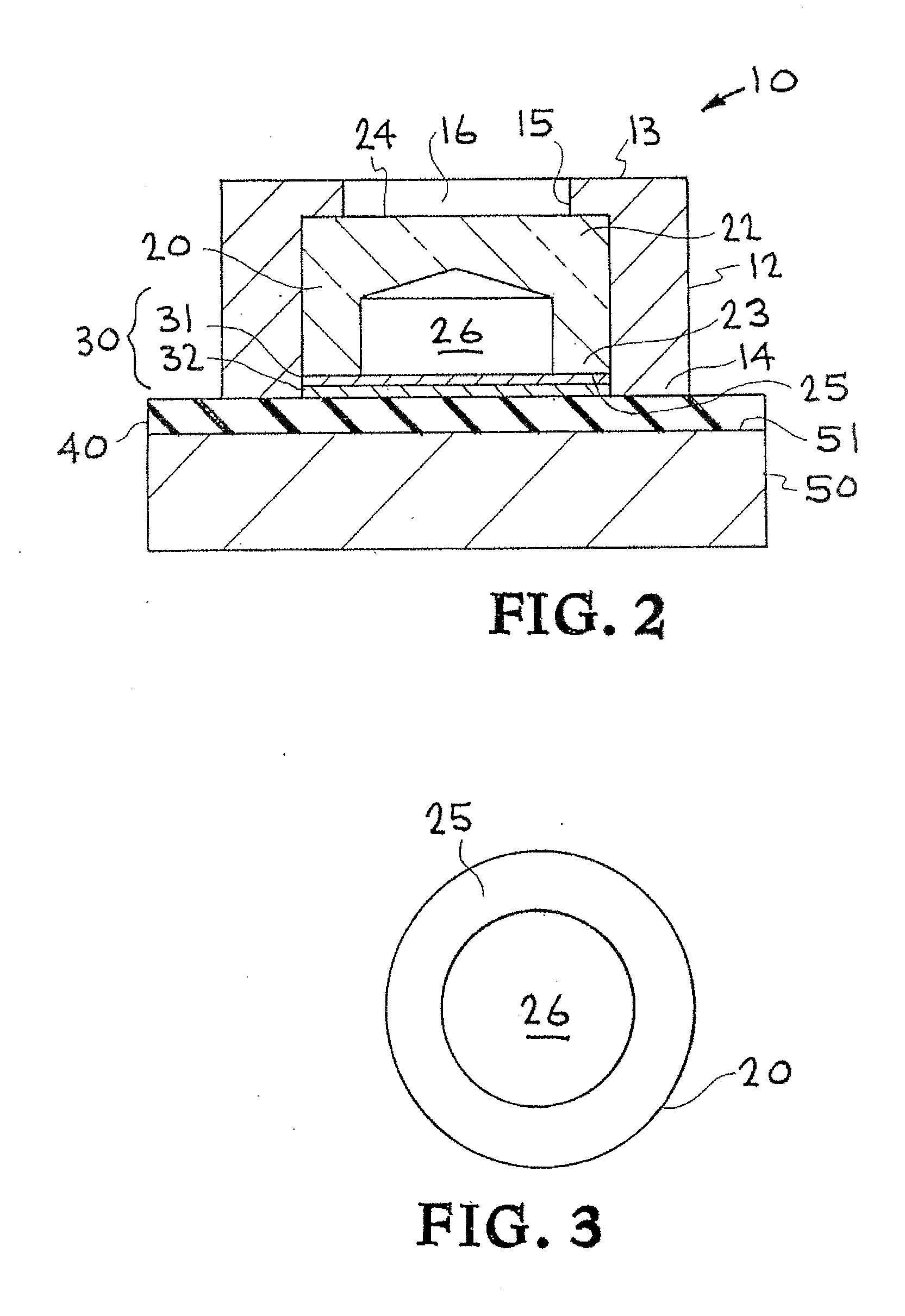

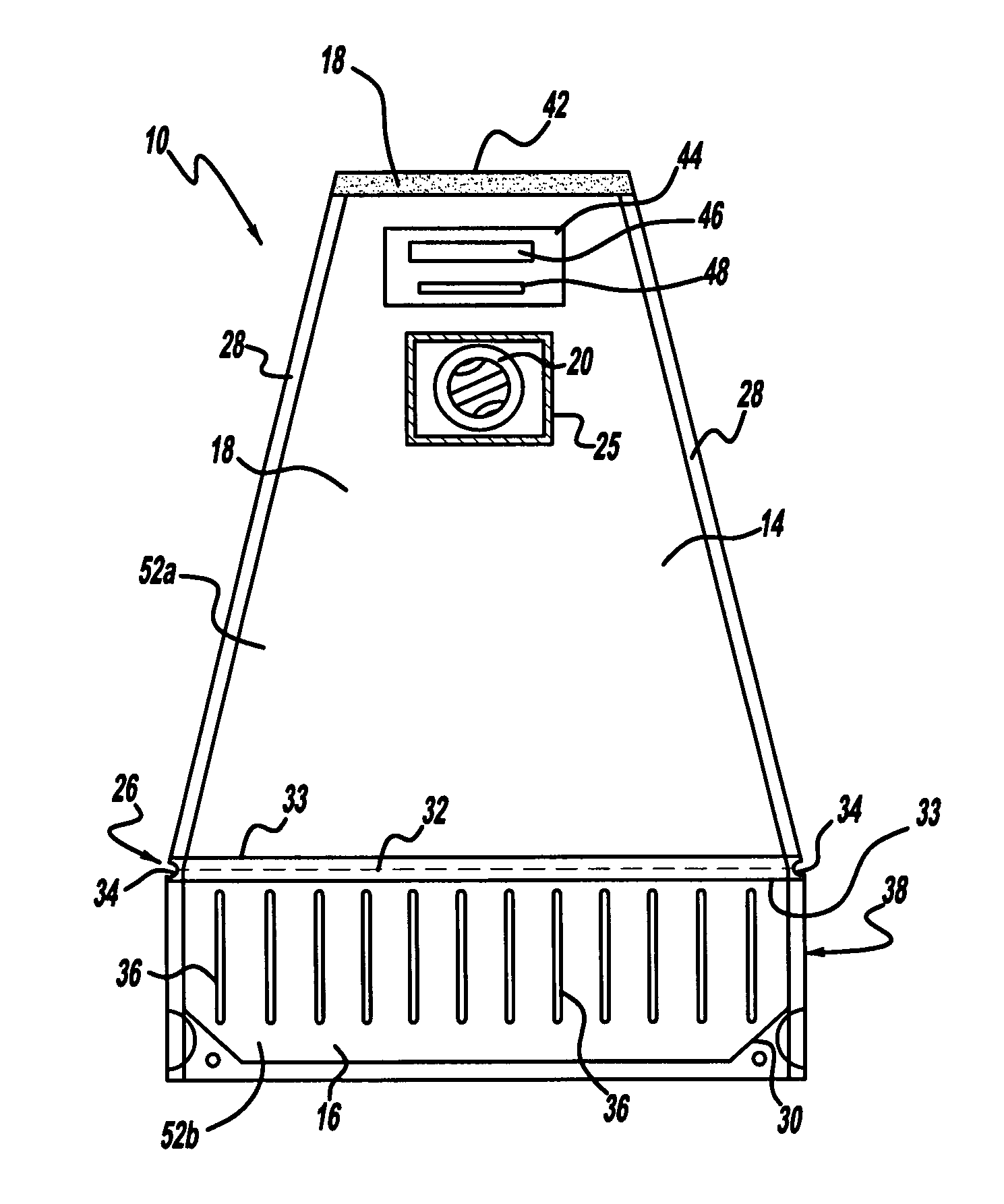

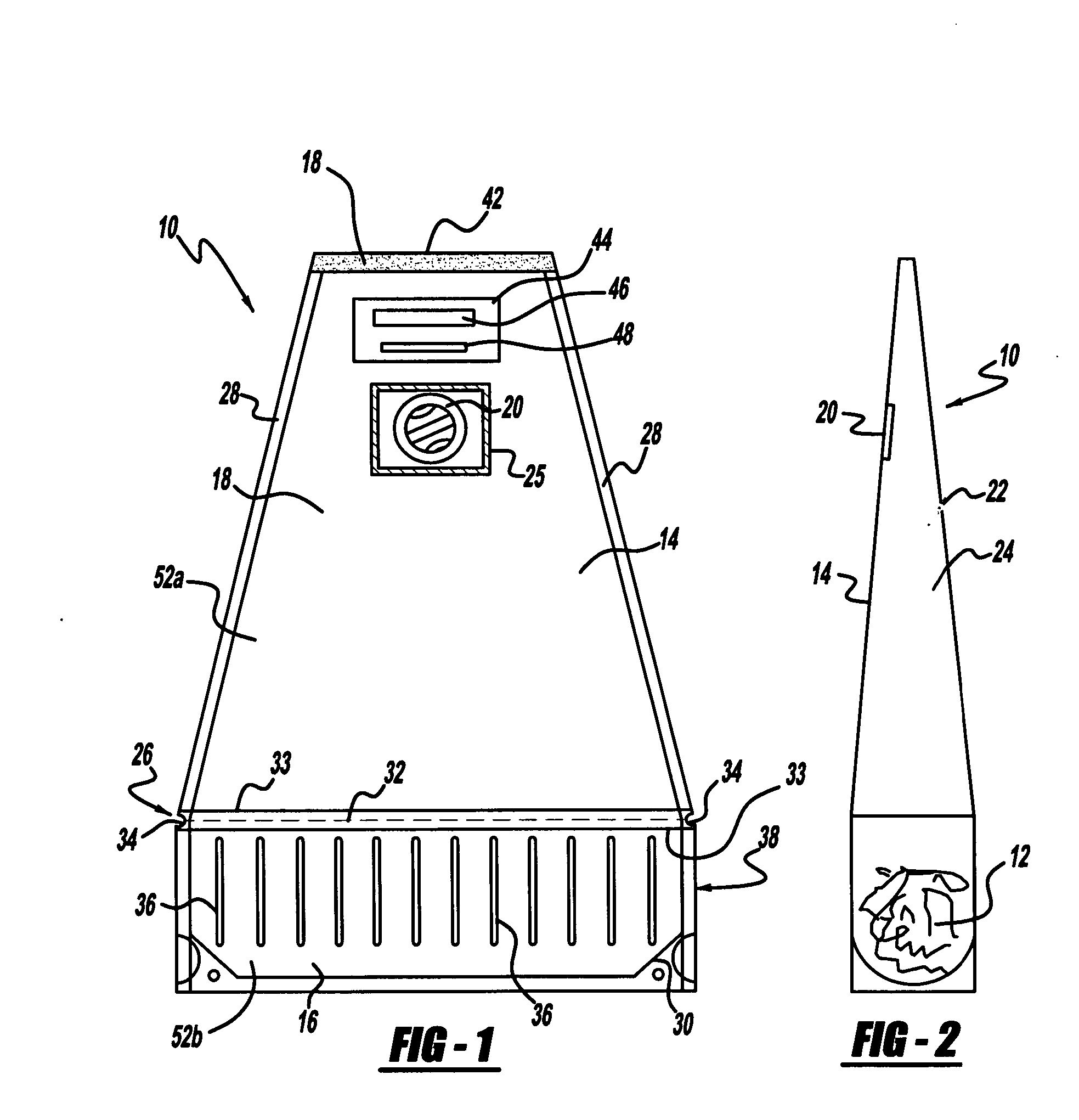

Passive blast pressure sensor

ActiveUS20100275676A1Easy and quick to readChange colorFuel testingAcceleration measurementChange colorEngineering

A passive blast pressure sensor for detecting blast overpressures of at least a predetermined minimum threshold pressure. The blast pressure sensor includes a piston-cylinder arrangement with one end of the piston having a detection surface exposed to a blast event monitored medium through one end of the cylinder and the other end of the piston having a striker surface positioned to impact a contact stress sensitive film that is positioned against a strike surface of a rigid body, such as a backing plate. The contact stress sensitive film is of a type which changes color in response to at least a predetermined minimum contact stress which is defined as a product of the predetermined minimum threshold pressure and an amplification factor of the piston. In this manner, a color change in the film arising from impact of the piston accelerated by a blast event provides visual indication that a blast overpressure encountered from the blast event was not less than the predetermined minimum threshold pressure.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

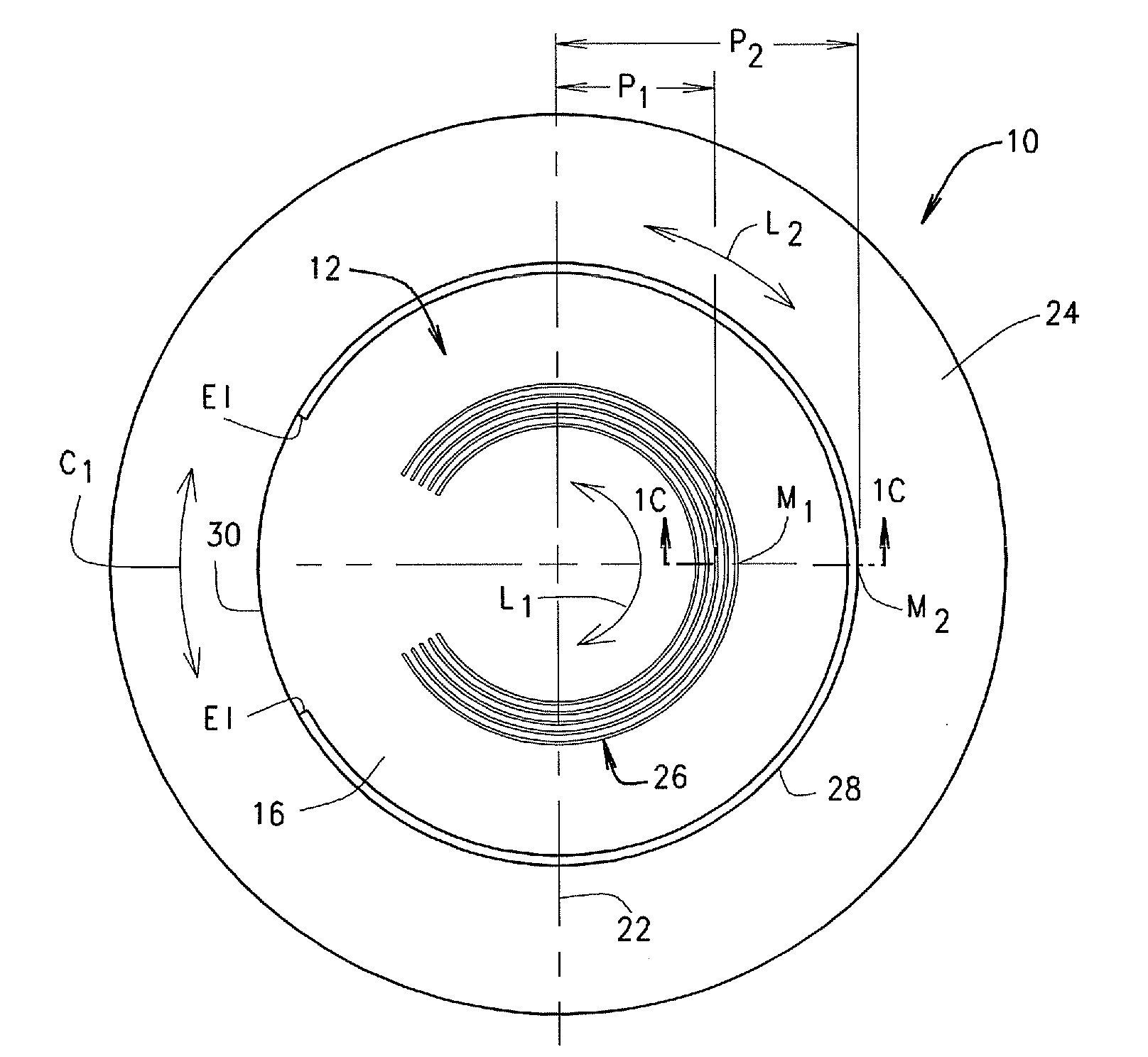

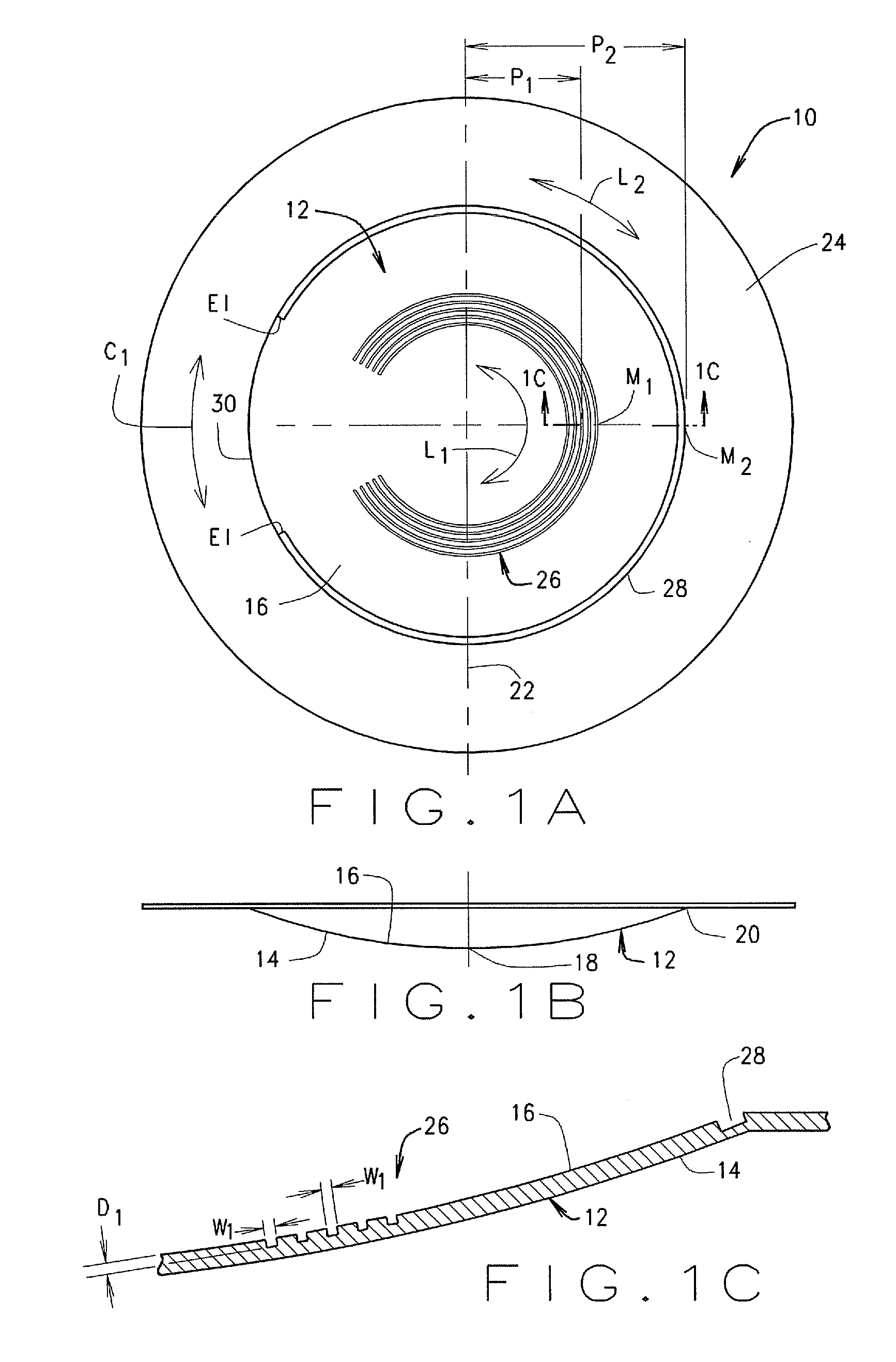

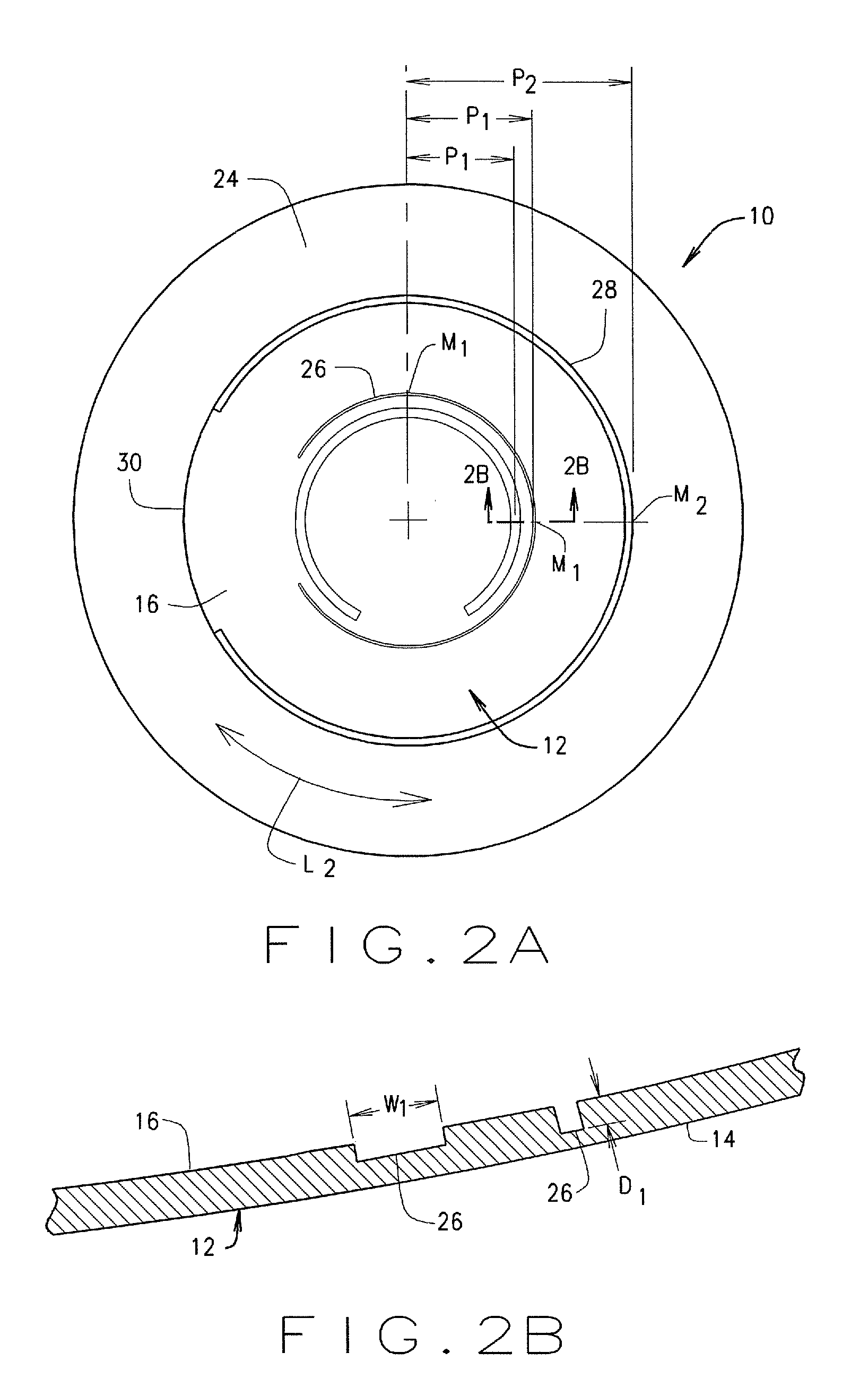

Balloons for medical devices and fabrication thereof

Dilatation balloons and catheters including same are provided. The balloons are fabricated of a material such as a nylon or a polyamide material, and they have an inflated, non-distended working profile as well as a stretched inflated profile which is achieved by applying pressure through a dilatation catheter or the like that is in excess of that needed to achieve the inflated, non-distended profile and which is adequate to effect dilatation or the like up to a maximum pre-bursting pressure application. The maximum pre-bursting size of the balloon can be tailored depending upon the needs of the particular balloon within a wide range of possible maximum pre-bursting sizes.

Owner:CORDIS CORP

Controlling the rated burst pressure of a rupture disc through the use of control scores on the disc dome

ActiveUS20100140264A1Reducing reversalReducing buckling pressureLarge containersEqualizing valvesCircular discRadial position

A rupture disc for use in a pressure relief system includes a dome having a concave and a convex side and a circumferential flange associated therewith. At least one control score is formed or otherwise produced in the dome at a radial position between an apex of the dome and an outer circumference of the dome. At least one of a depth, a width, a length and the radial portion of the at least one control score is selectively controlled so that the depth, width, length, and / or radial position of the at least one control score controls the pressure at which the dome will start to collapse.

Owner:CONTINENTAL DISC CORP

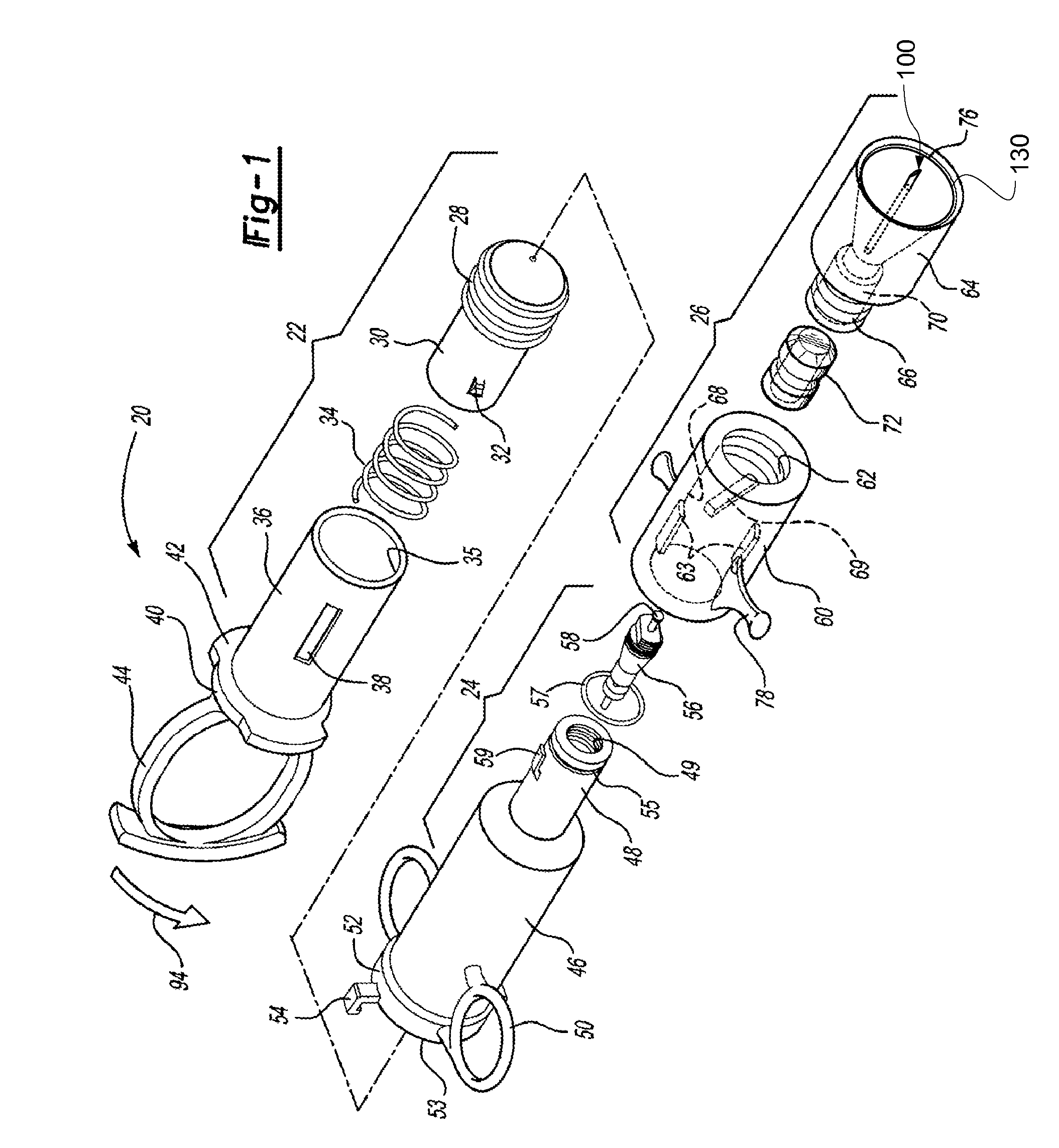

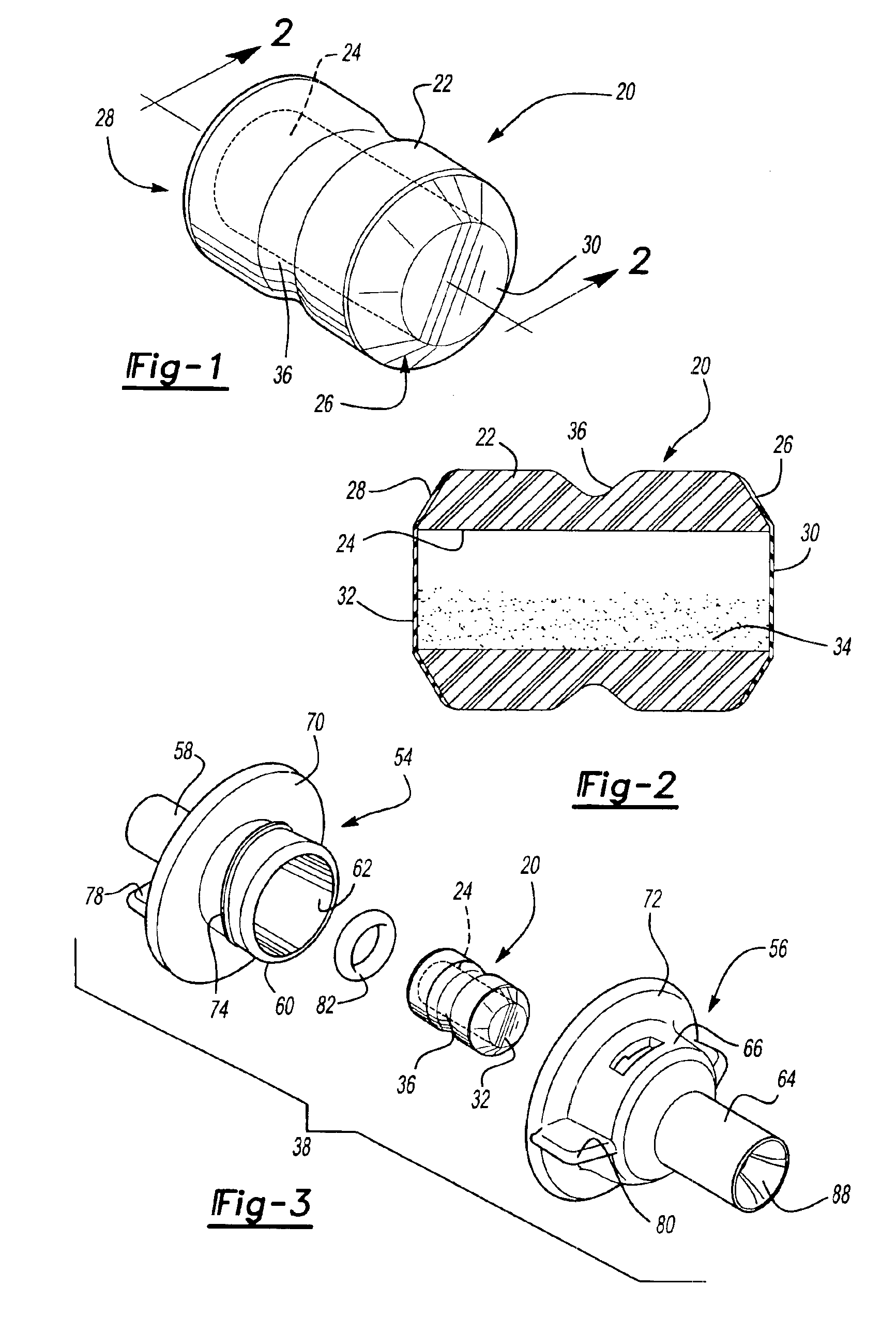

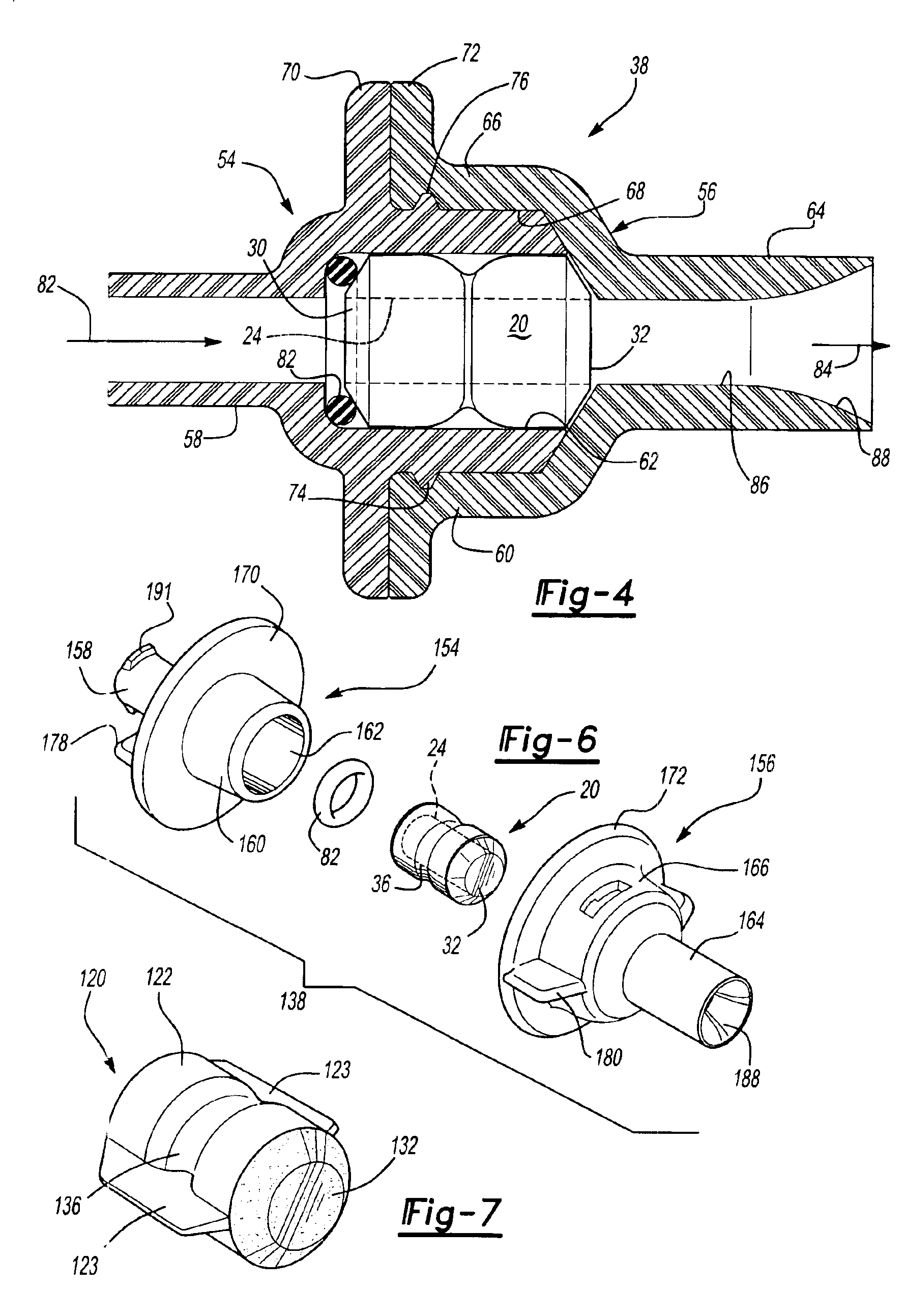

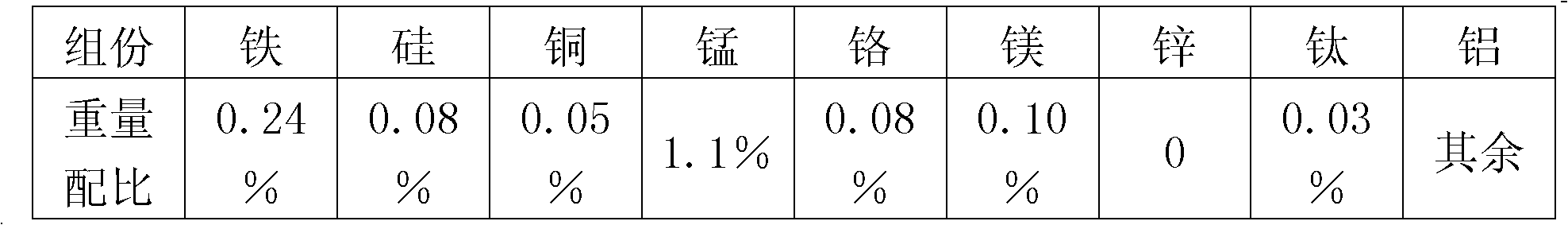

High pressure reinforced rubber hose swage or crimped coupling and method of attachment

InactiveUS7338090B2High possible lockExtended diameter rangeJoints with sealing surfacesHose connectionsTO-18Coupling

Swage end-connector for high pressure reinforced flexible hose particularly suitable in the petrochemical and drilling industries for hoses. Two connectors are disclosed one for intermediate hose pressure burst ratings up to 12,500 psi and internal diameters up to 3½ inches and higher hose pressure burst ratings up to 18,750 psi and internal diameters up to 4 inches. Both embodiment connectors will withstand the rated burst pressure of the hose to which they are connected and will withstand a pump-off force that exceeds the burst pressure of the hose. That is, the hose will fail before the connector pops off the hose.

Owner:BALDWIN & LOKE

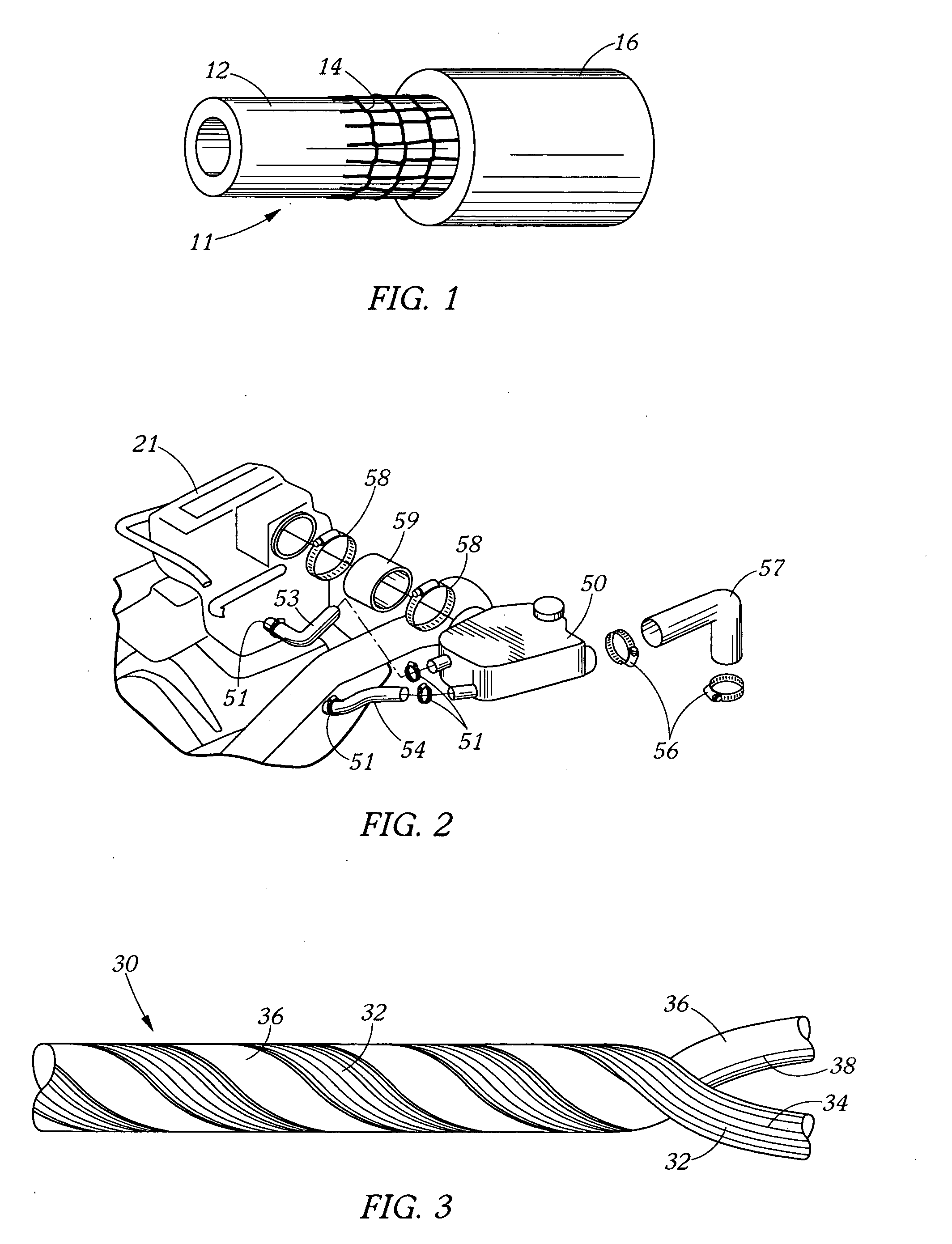

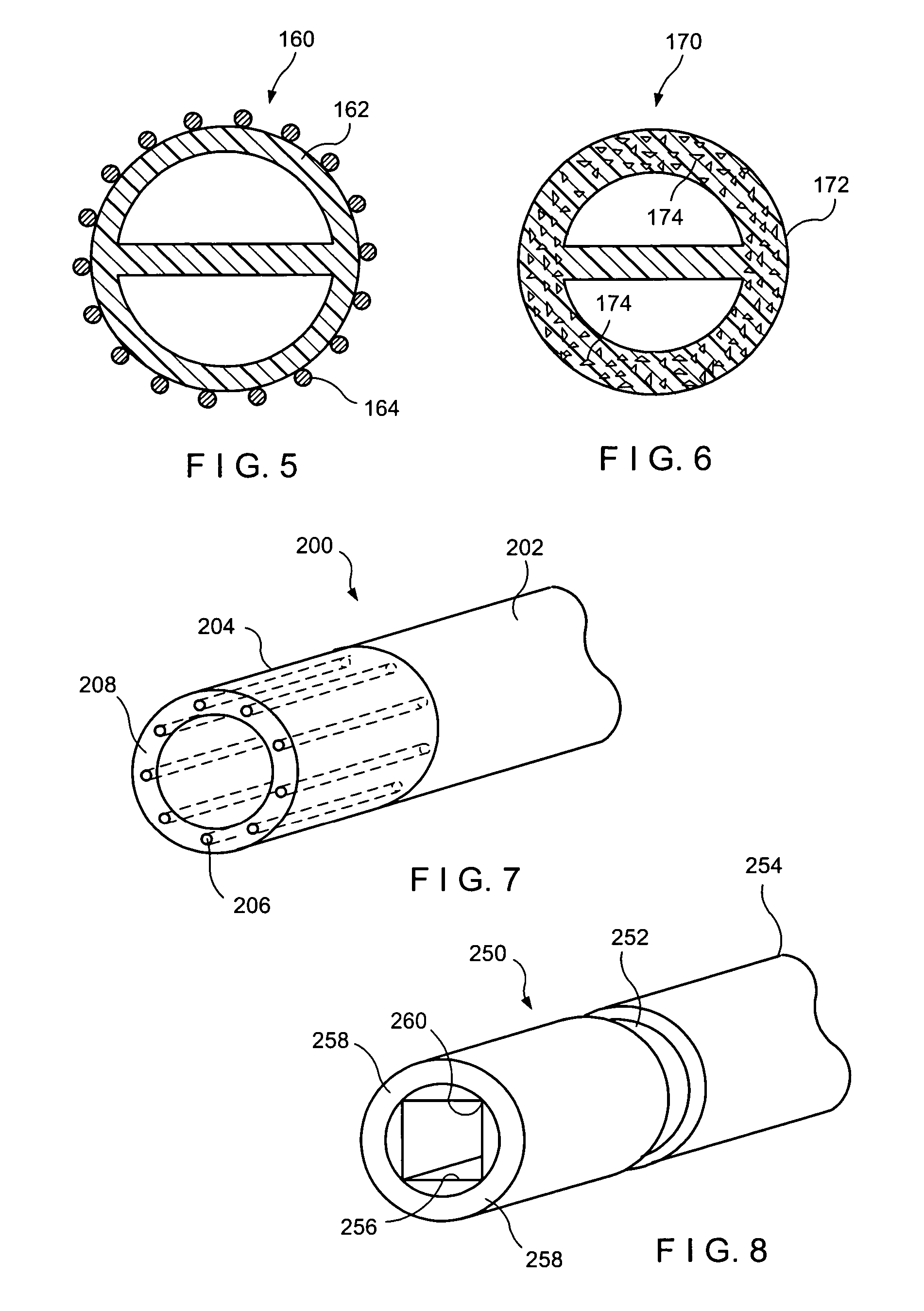

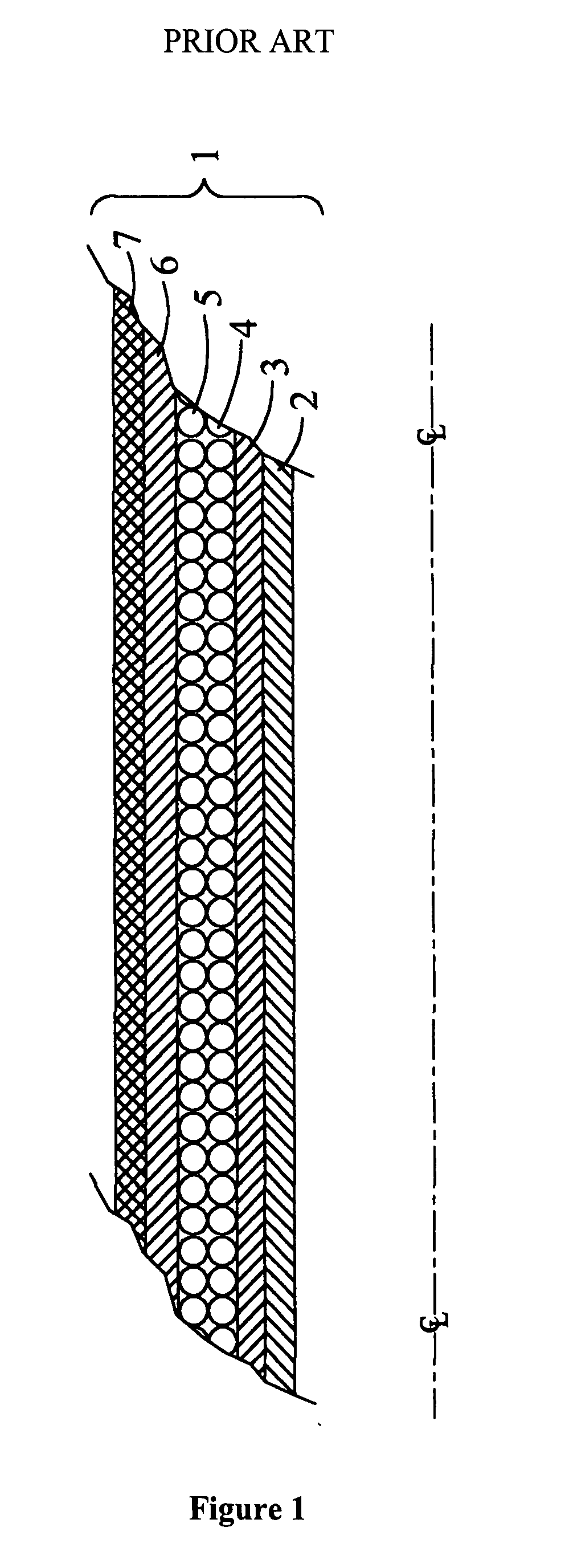

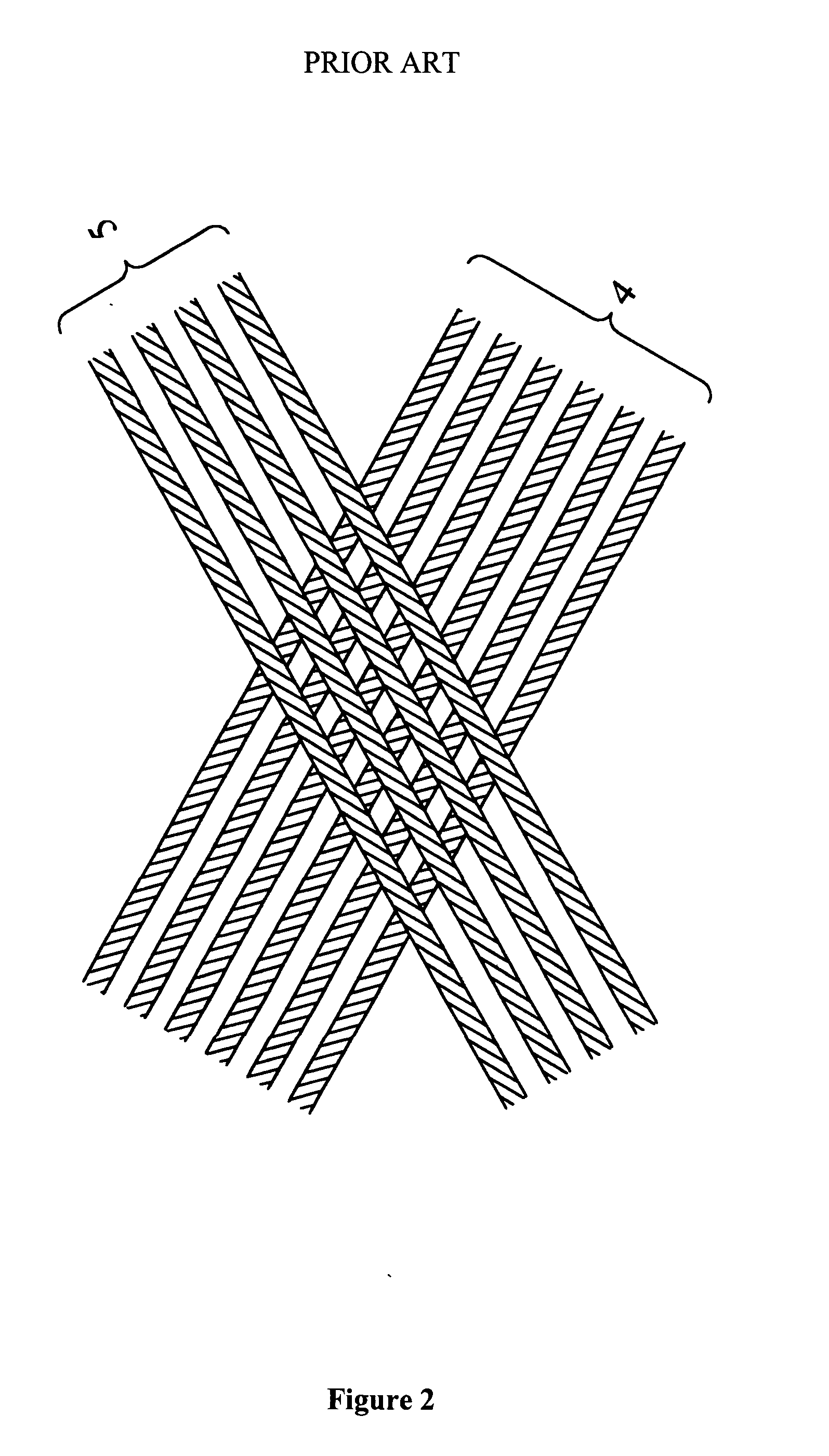

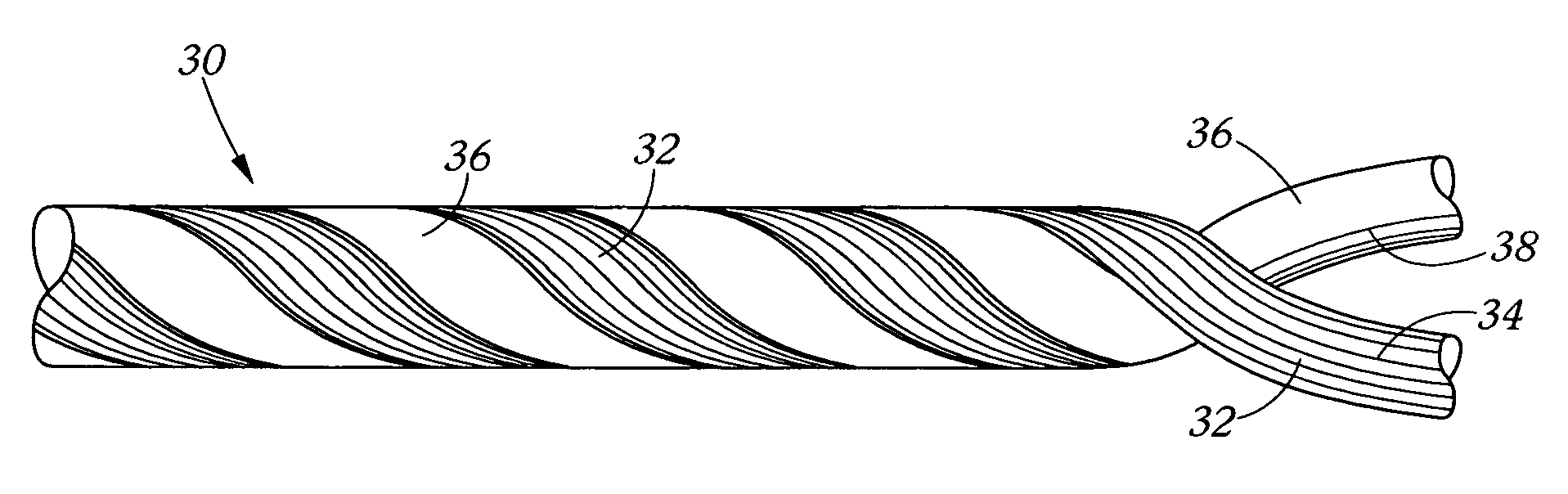

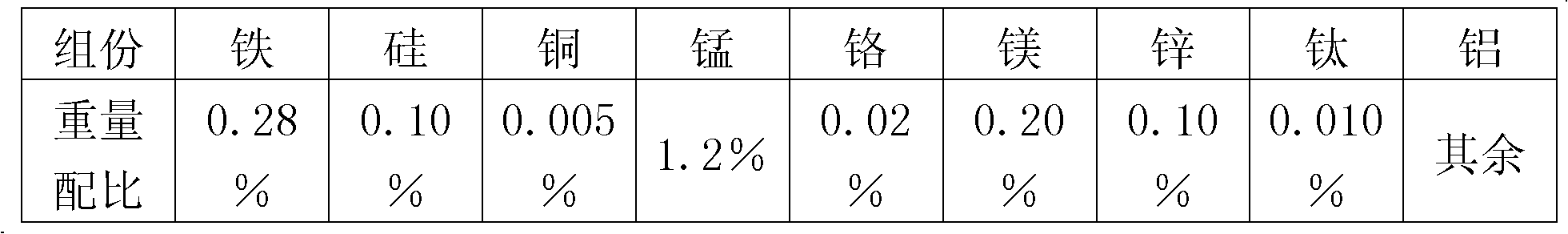

Fluid transfer hose reinforced with hybrid yarn

ActiveUS20080072984A1Improve adhesionDramatic performance improvementEngine sealsInternal combustion piston enginesYarnAramides

A flexible hose comprising a tube, a knit fabric, and a cover. The knit fabric comprises a hybrid yarn which comprises a first yarn of co-para-aramid fibers and a second yarn of meta-aramid fibers. The hose exhibits significantly improved burst pressure and / or improved impulse fatigue resistance.

Owner:THE GATES CORP

Reinforced venous access catheter

A catheter for medical procedures comprises a shaft portion having a distal end insertable into a body lumen, the shaft portion having a wall defining a working lumen extending therewithin and a first strengthening element coupled to the wall to increase a burst pressure of the shaft portion, wherein the first strengthening element cooperates with a base material of the wall to define a flexible region of the shaft portion allowing the shaft portion to be atraumatically inserted into the body lumen.

Owner:ANGIODYNAMICS INC

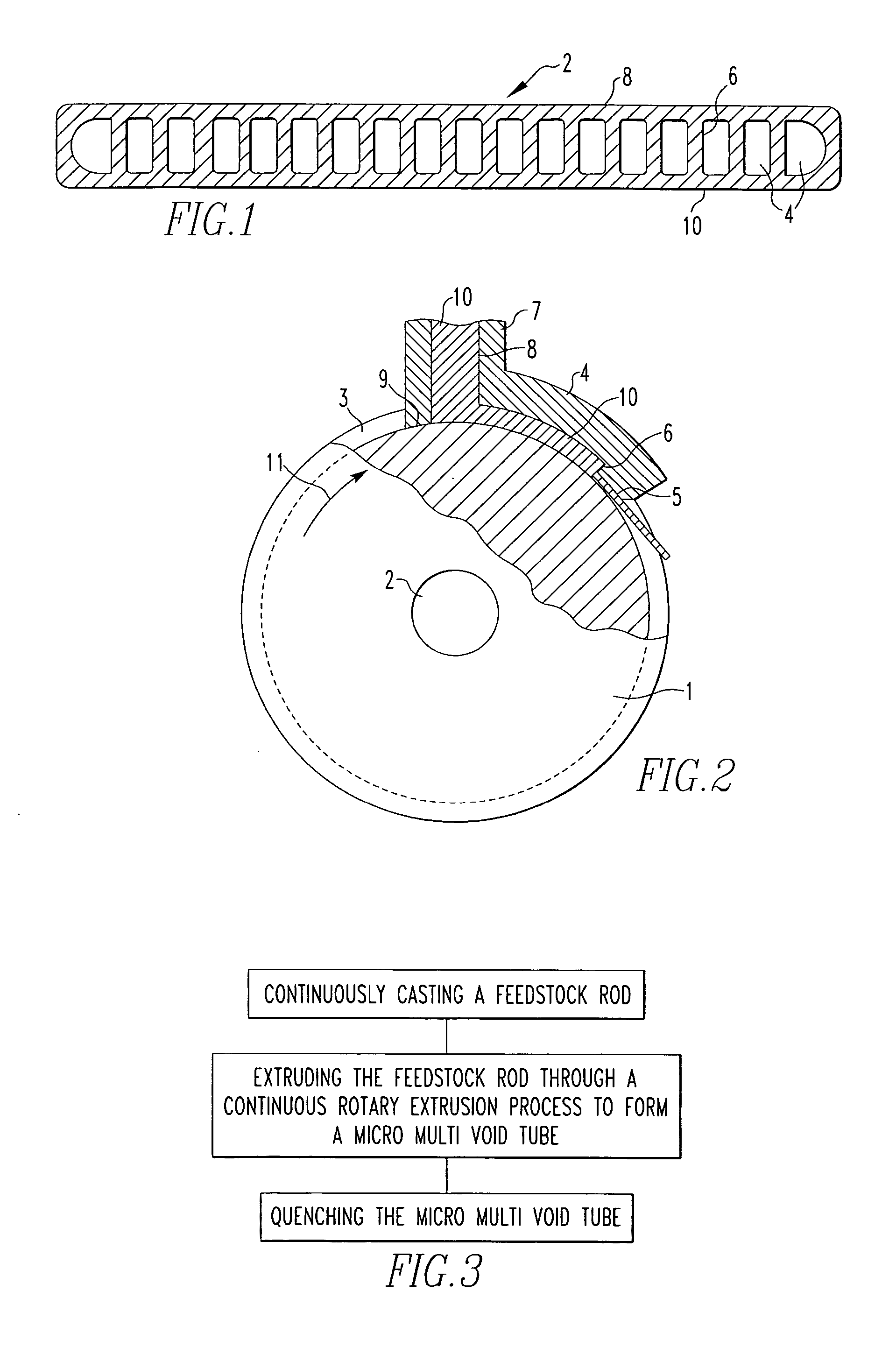

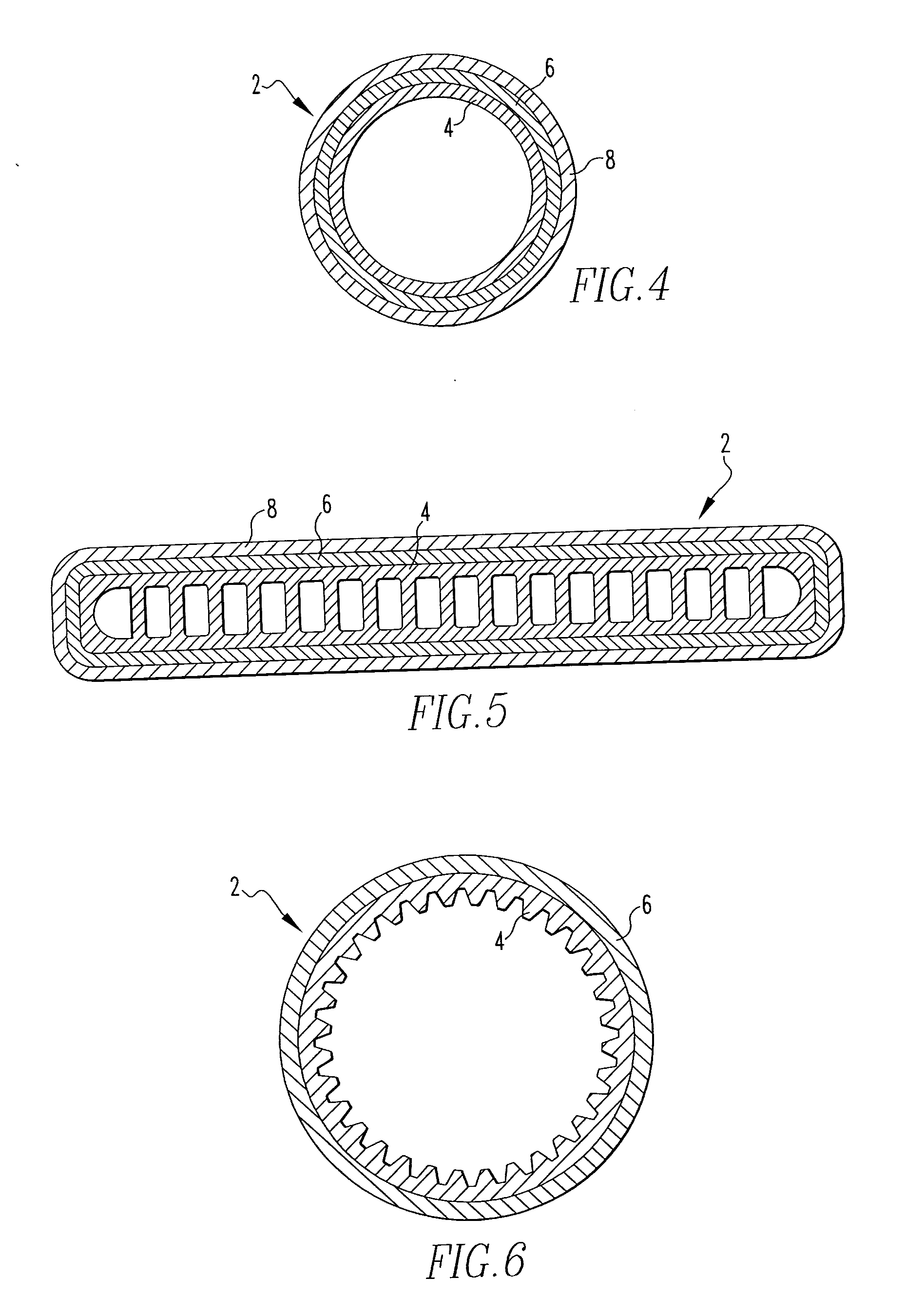

Heat exchanger tubing by continuous extrusion

InactiveUS20060118282A1Low costHigh strengthCorrosion preventionCoatingsPlate heat exchangerManganese

Owner:ARCONIC INC

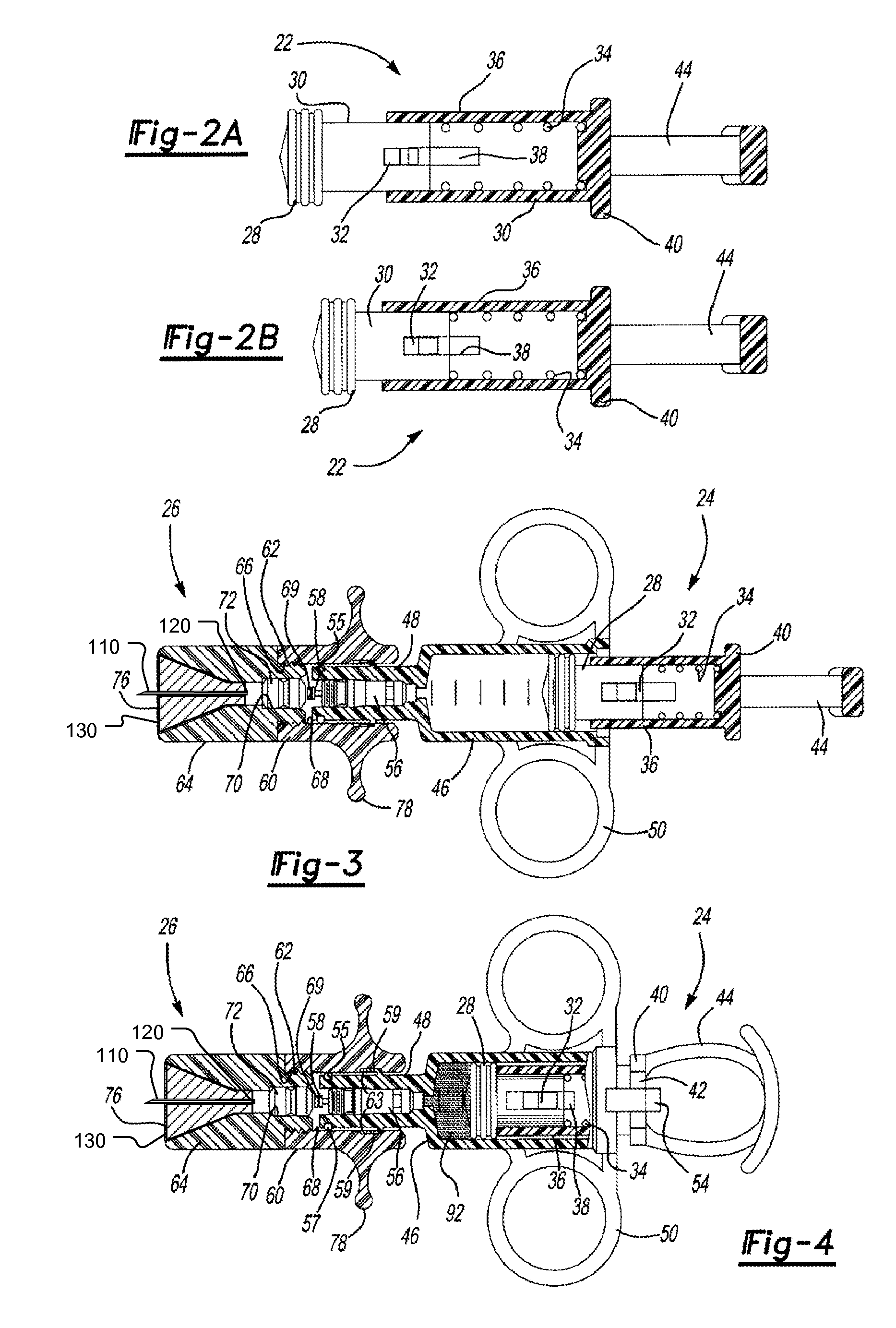

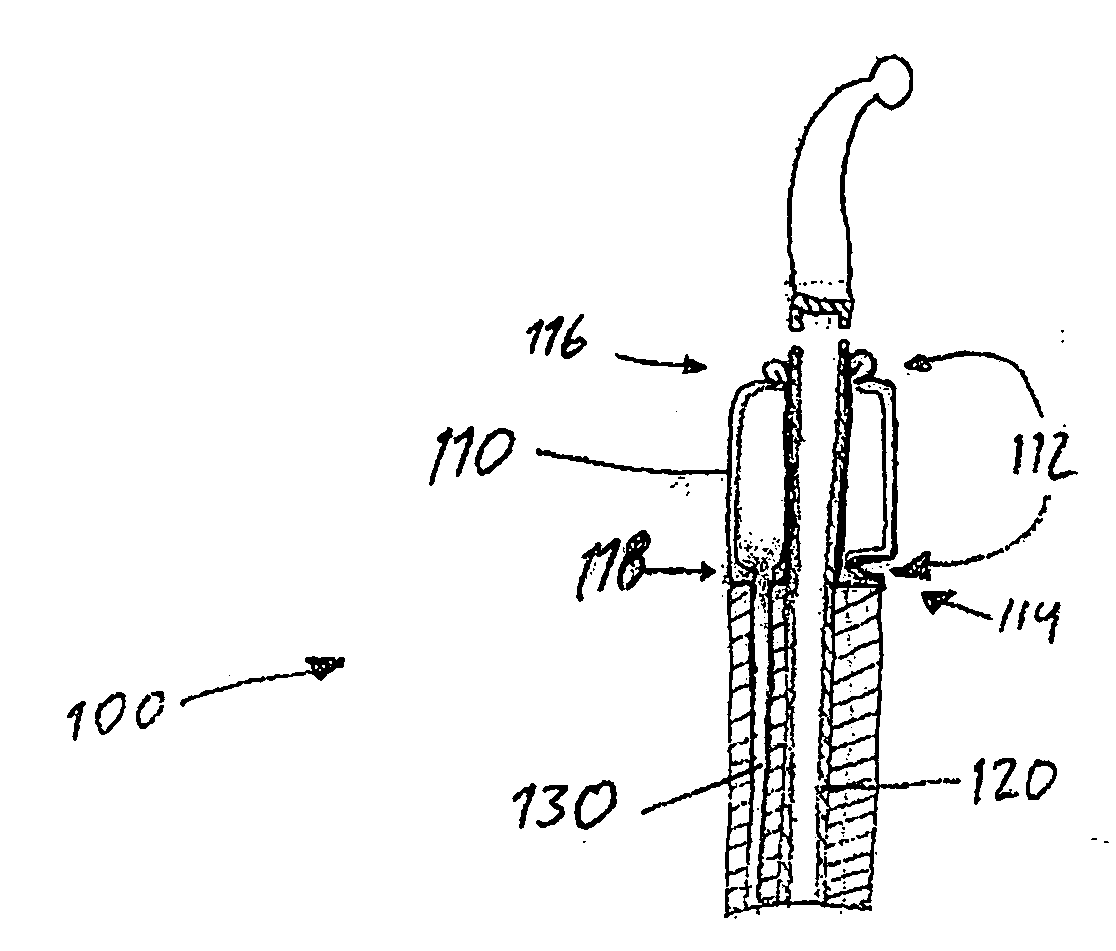

Pressure-limiting balloon catheter and method for using the catheter

InactiveUS20060167438A1Quick deflationAvoid injuryBalloon catheterSurgeryBalloon catheterSafety valve

A pressure-limiting or breakaway catheter includes a multi-lumen shaft having a distal end and a hollow balloon portion disposed at the distal end of the shaft. The balloon portion has a distal end and an interior. The shaft and / or the balloon portion has a balloon safety valve formed to open to the environment outside the shaft and / or the balloon portion when greater than a given bursting pressure exists within the shaft and / or the interior of the balloon portion. The safety valve can be formed to burst at a first breaking force less than a second breaking force required to burst the balloon portion and / or the shaft. Also provided is a breakaway catheter kit including a set of the breakaway catheters, each having the balloon safety valve with different safety valve breaking constants.

Owner:KALSER GARY +1

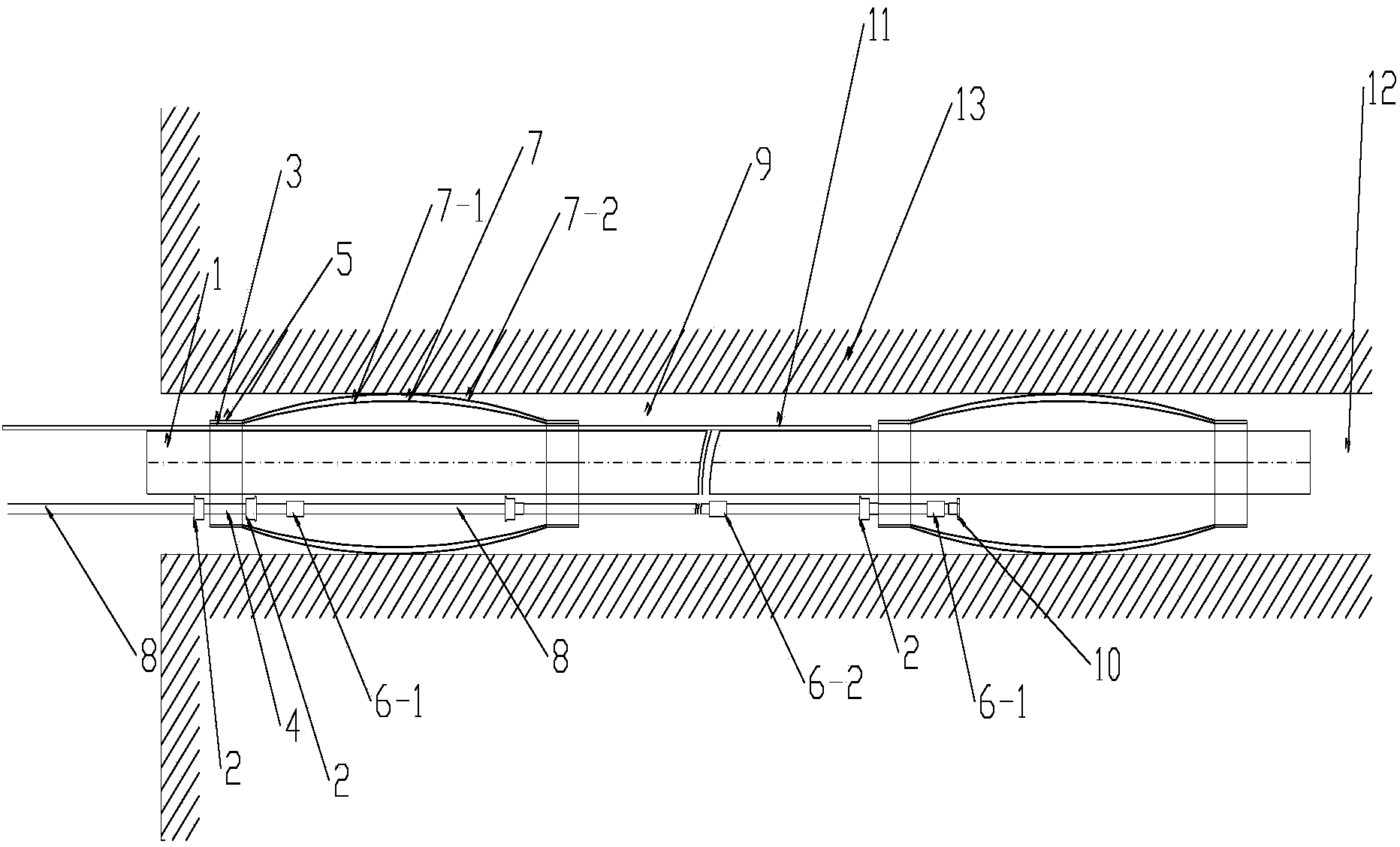

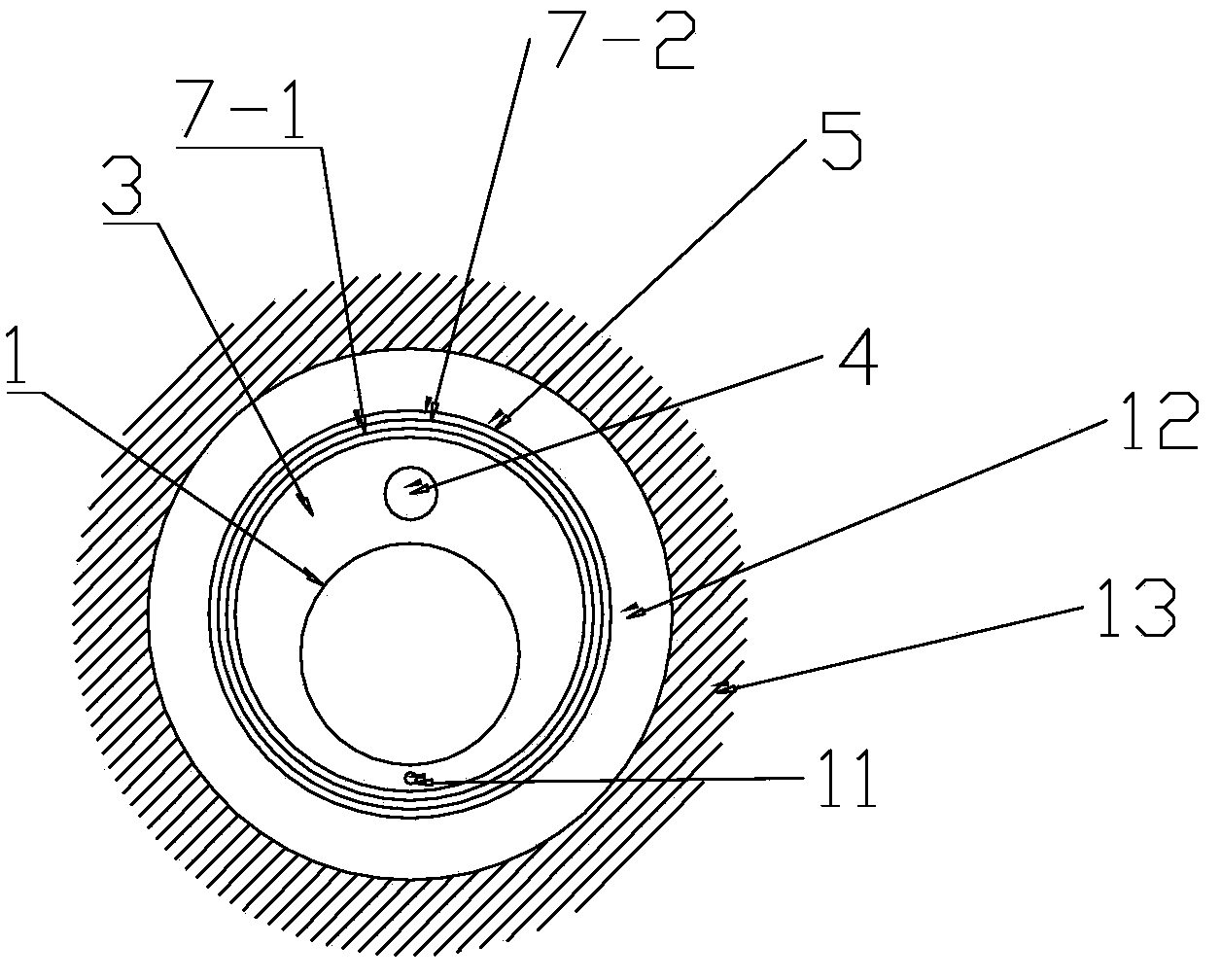

Gas extraction drilling hole injection expanding type bag hole sealing device

InactiveCN104343415ASealing effect is reliableEasy to operateGas removalSealing/packingSlurryEngineering

The invention discloses a gas extraction drilling hole injection expanding type bag hole sealing device, and belongs to the technical field of gas extraction drilling hole grouting hole sealing. The gas extraction drilling hole injection expanding type bag hole sealing device at least comprises two hole sealing bags for sealing drilling holes in a coal bed as well as a gas extraction pipe, a grouting pipe and a slurry return pipe which penetrate through the inner cavities of the two hole sealing bags, wherein the hole sealing bags are arranged at the two ends of the grouting pipe at an interval; a closed space is at least formed in the drilling holes in the coal bed; one-way bursting valves A are respectively arranged on the passages of the grouting pipe in the hole sealing bags; a one-way bursting valve B is respectively arranged on the passage inside the closed space; the bursting pressures of the one-way bursting valves A are smaller than that of the one-way bursting valve B. By setting the hole sealing bags and the bursting valves, hole sealing slurry is injected in the hole sealing bags and the closed space between the hole sealing bags successively, the hole sealing bags are quickly expanded, and finally the bags and hole walls as well as the slurry in the closed space and the hole walls are tightly combined, so that the drilling holes in the coal bed are tightly blocked, the hole sealing effect is reliable, and the operation is simple.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Heatable package with frangible seal and method of manufacture

InactiveUS20060127549A1Prevent leakageCost-effective manufacturingContainer decorationsLevel indicationsEngineeringGas release

A flexible pouch having an integral valve for both packaging a product and serving the product and a method of making the same is provided. The flexible pouch includes a panel having an upper edge, an opposed lower edge, and a side edge extending therebetween the upper and lower edges. The flexible pouch further includes a valve disposed in the panel, wherein the valve is a one-way valve for releasing a gas from the pouch at a predetermined gas release pressure. A frangible seal encloses the valve to isolate the valve from the product contained in the flexible pouch, such that the frangible seal is intact when the pressure within the flexible pouch is less than a predetermined frangible seal pressure, and the frangible seal is broken when the pressure within the flexible pouch is greater than the predetermined frangible seal bursting pressure. The method includes the steps of forming the pouch, and inserting a valve in the panel. The method also includes the steps of enclosing the valve with a frangible seal and sealing the edges of the pouch, leaving an upper edge open. The method still also includes the steps of opening, filling and sealing the filled pouch. The method further includes the steps of increasing the pressure in the pouch until the pressure exceeds the predetermined frangible seal bursting pressure and the frangible seal breaks, to release the gas from the pouch.

Owner:POUCH PAC INNOVATIONS

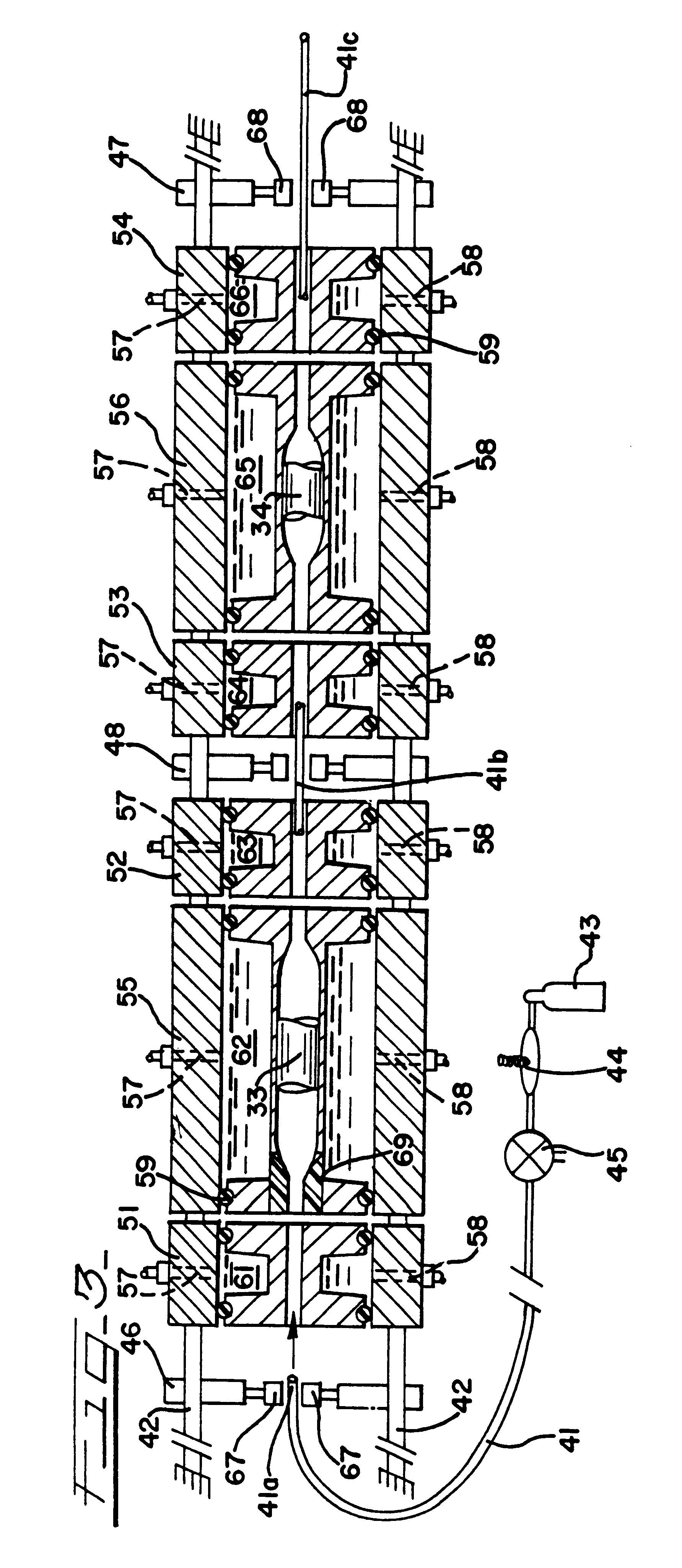

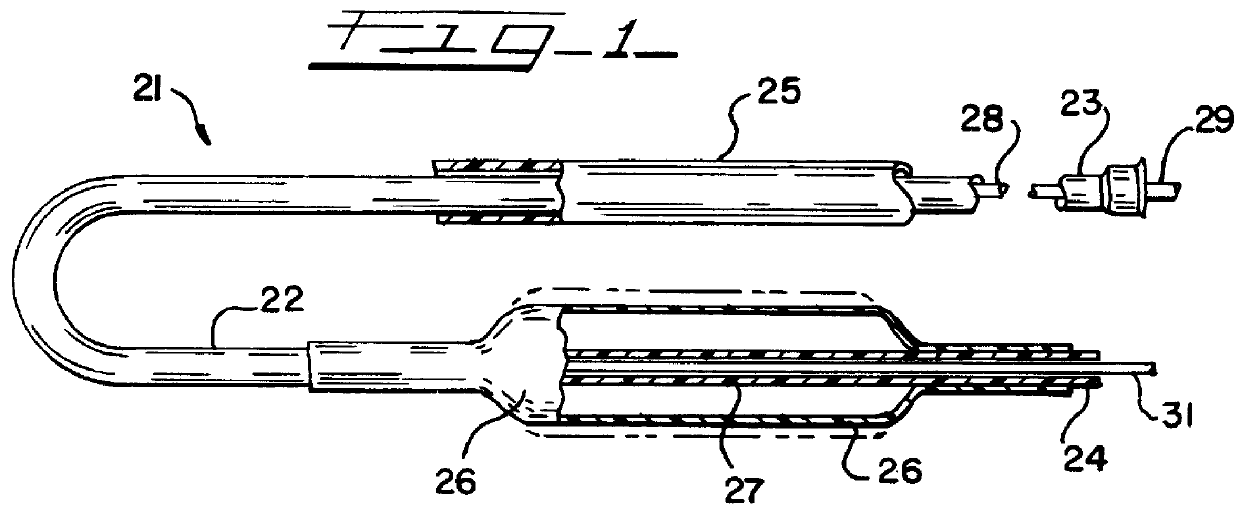

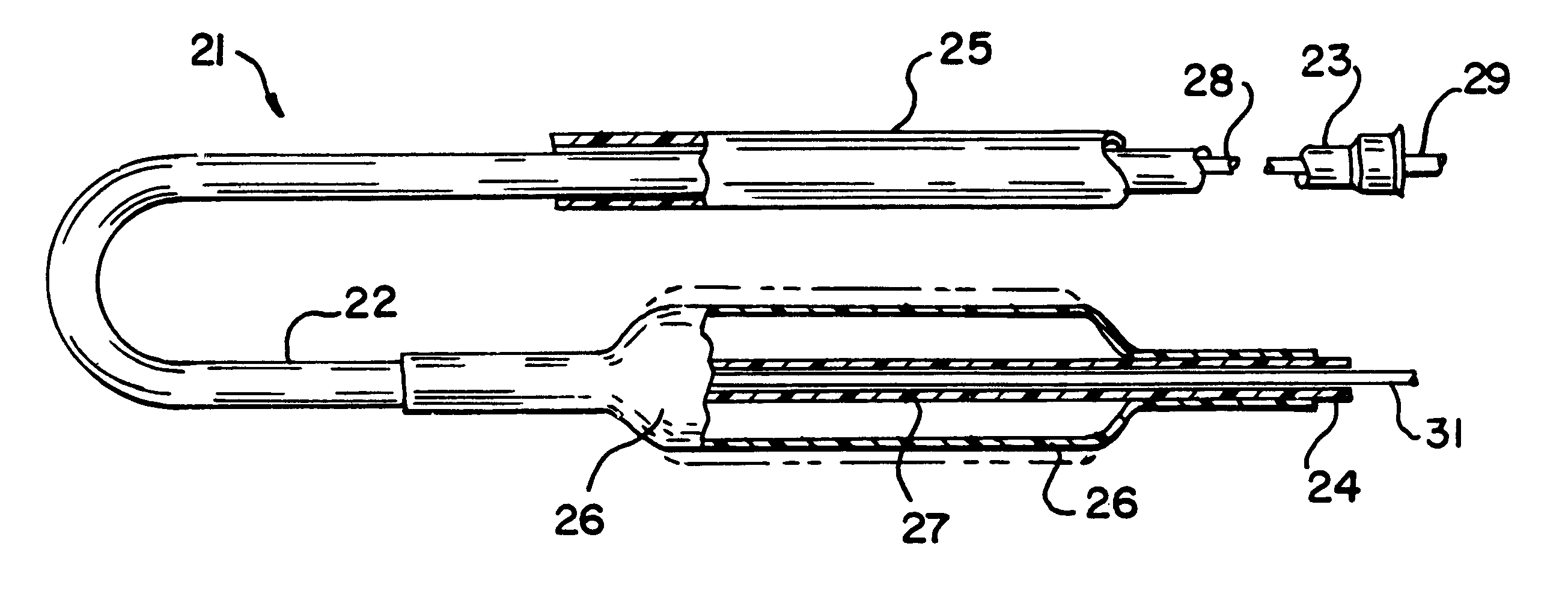

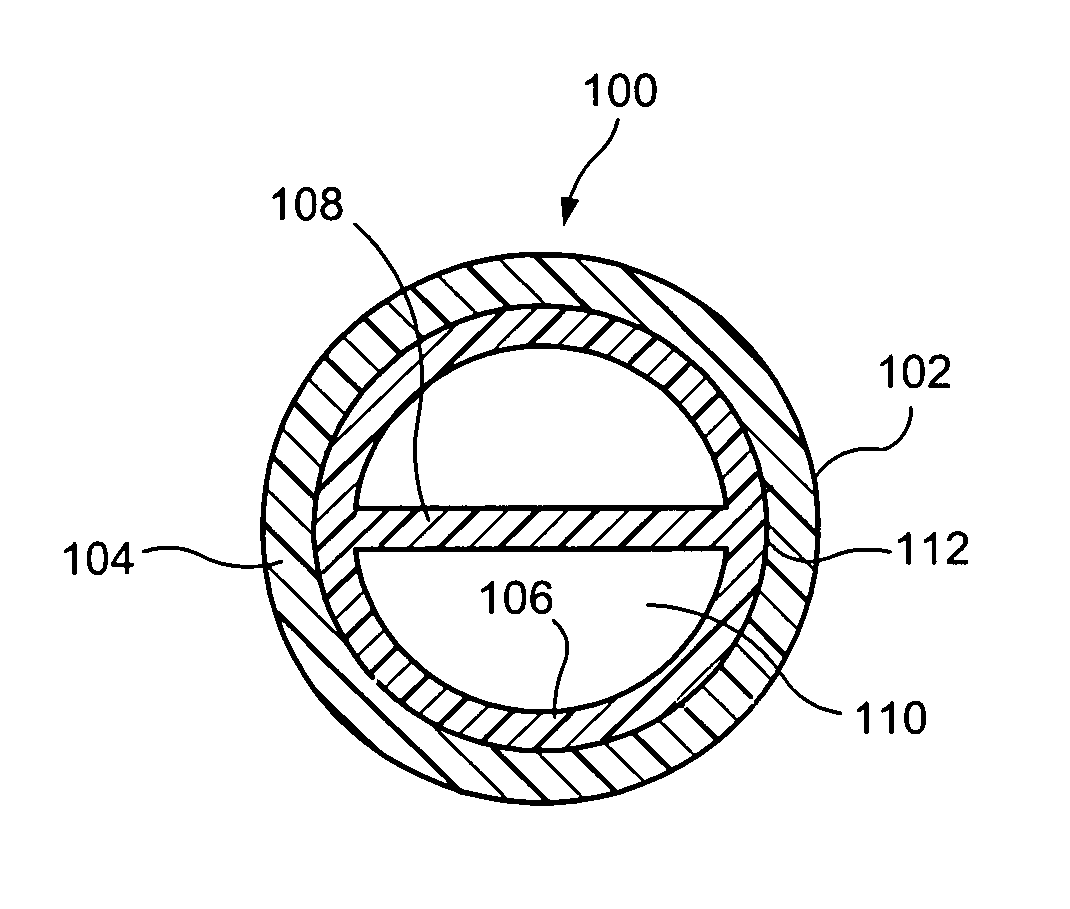

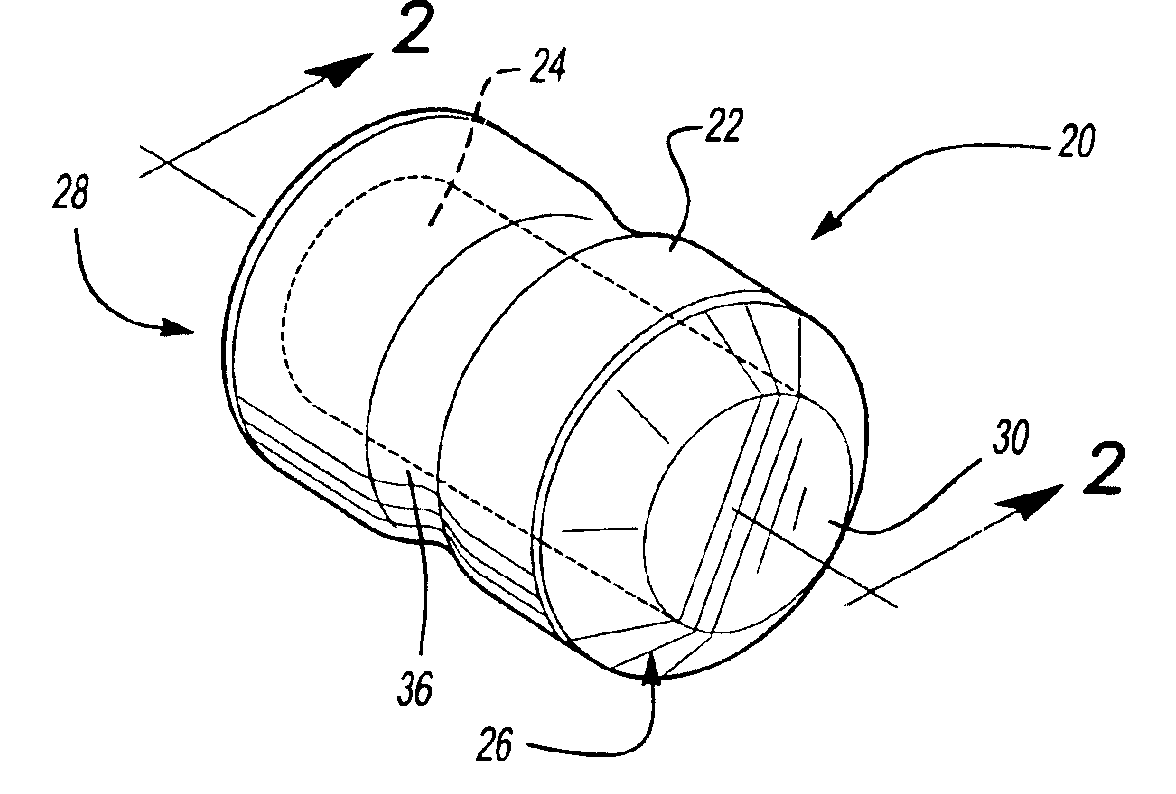

Medicament respiratory delivery device, cartridge and method of making same

InactiveUS6929005B2Reduce deliveryEasy doseRespiratorsLiquid surface applicatorsPolyolefinBiomedical engineering

A medicament respiratory delivery device including a housing having a chamber, an inlet and an outlet generally coaxially aligned with the chamber, wherein the chamber includes a medicament cartridge having a body including a generally cylindrical passage extending through the opposed ends of the cartridge generally coaxially aligned with the inlet and outlet of the housing having thin burstable polyolefin membranes having a burst pressure of between 1.2 and 10 atmospheres stretched taut over the ends of the cartridge, such that fluid delivered to the inlet ruptures the membranes, entraining medicament contained within the cartridge passage which is delivered to the patient's respiratory system through the outlet. The method of forming the cartridge includes stretching out and bending a membrane to one end of the cartridge, preferably by heat bonding, filling the cartridge with a medicament and sealing the opposed end preferably with a second burstable membrane by stretching out a membrane over a convex surface and heat bonding.

Owner:BECTON DICKINSON & CO

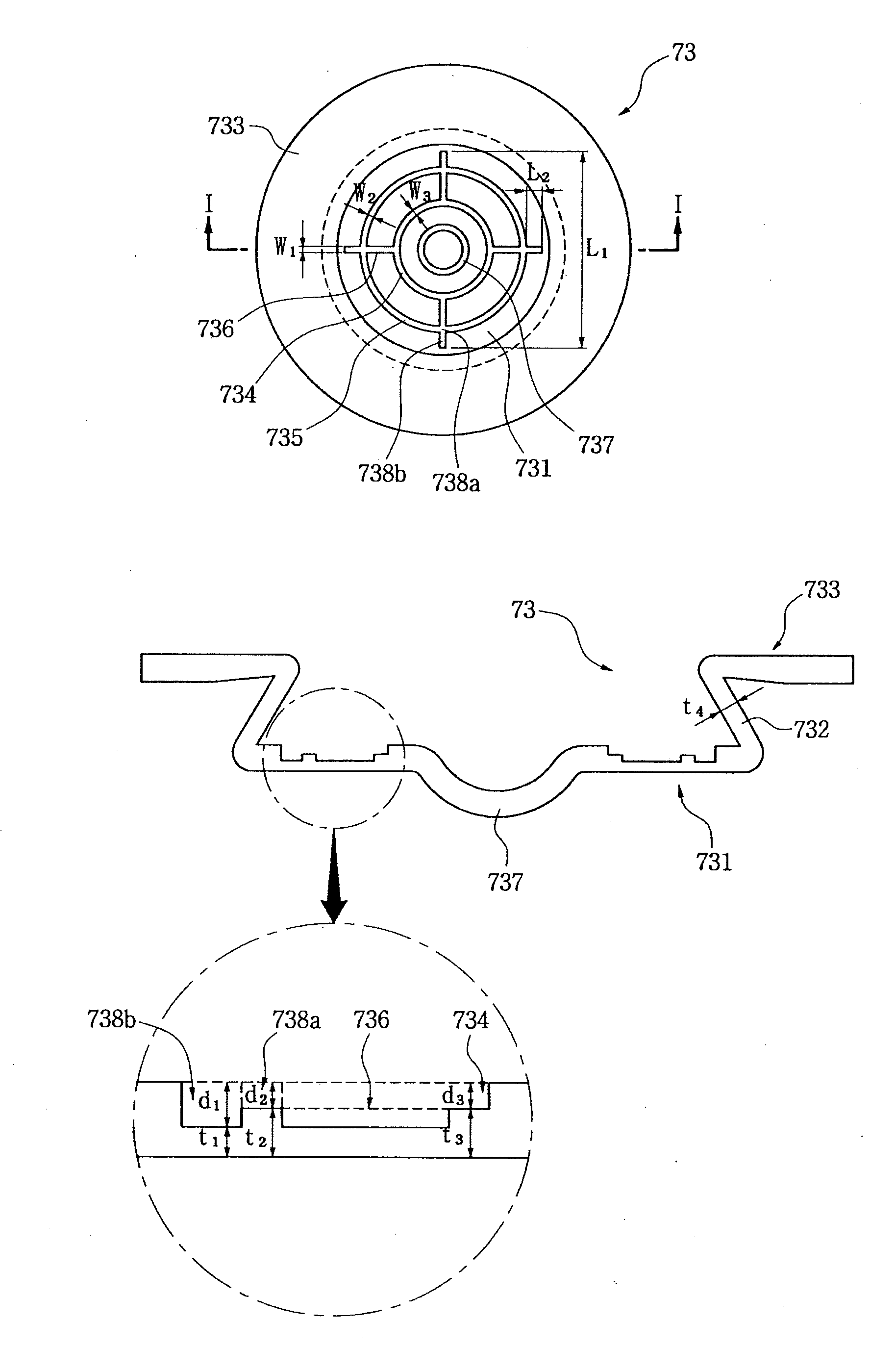

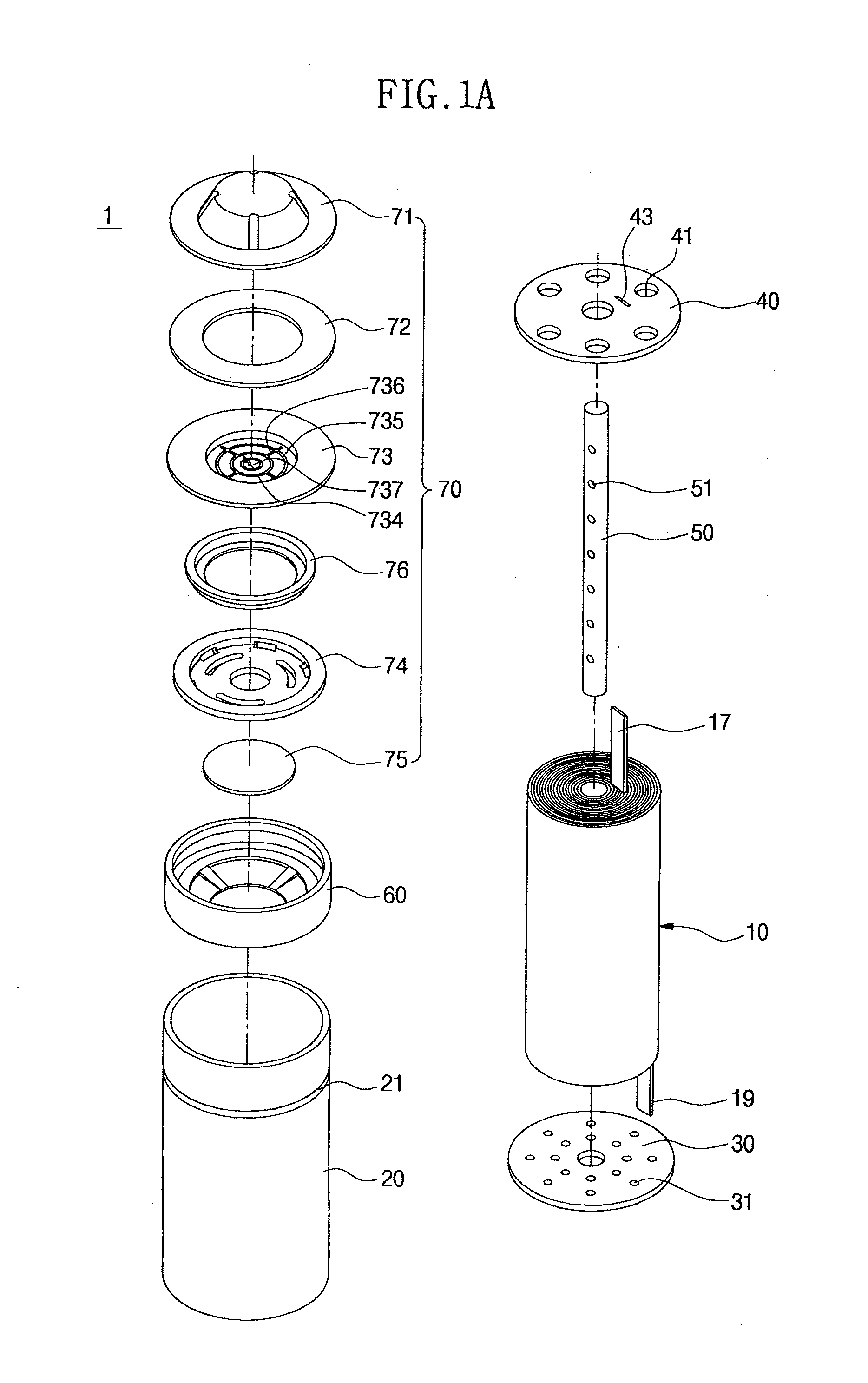

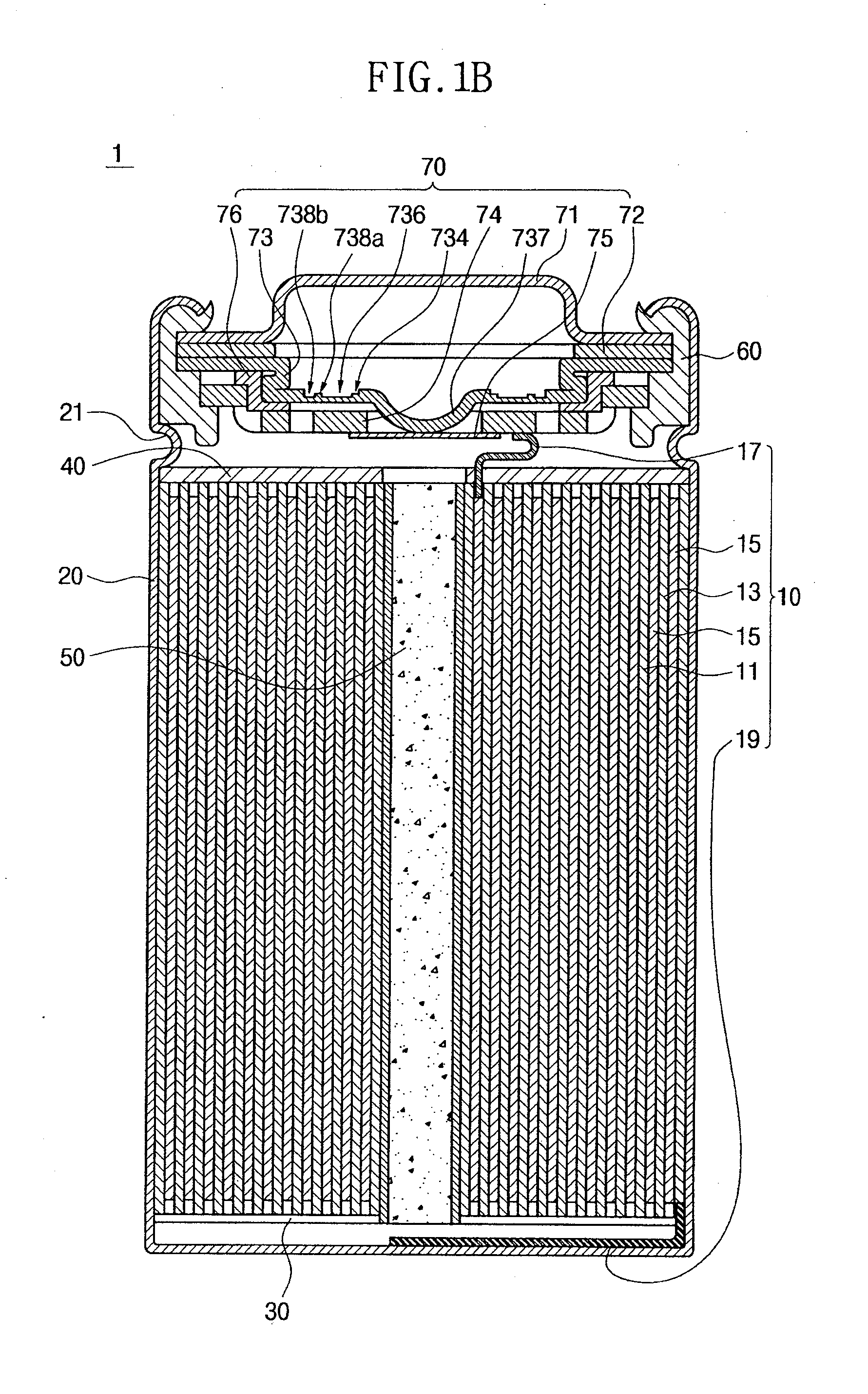

Cap assembly and secondary battery using the same

ActiveUS20100136388A1Improve battery safetyCurrent conducting connectionsEngineeringMechanical engineering

A cap assembly for a battery and a battery incorporating the cap assembly. The cap assembly includes a plate that connects the electrodes of the bare cell of the battery. The cap assembly includes a vent member that includes a protrusion that is physically connected to the plate. Excess pressure within the bare cell results in the protrusion disconnecting from the plate thereby interrupting current. The vent further includes two circular notches, an inner notch and an outer notch. The vent further includes a cross notch that extends radially outward so as to intersect and extend beyond both the first and second notches. The notches are configured to release when the pressure within the bare cell exceeds a burst pressure.

Owner:SAMSUNG SDI CO LTD

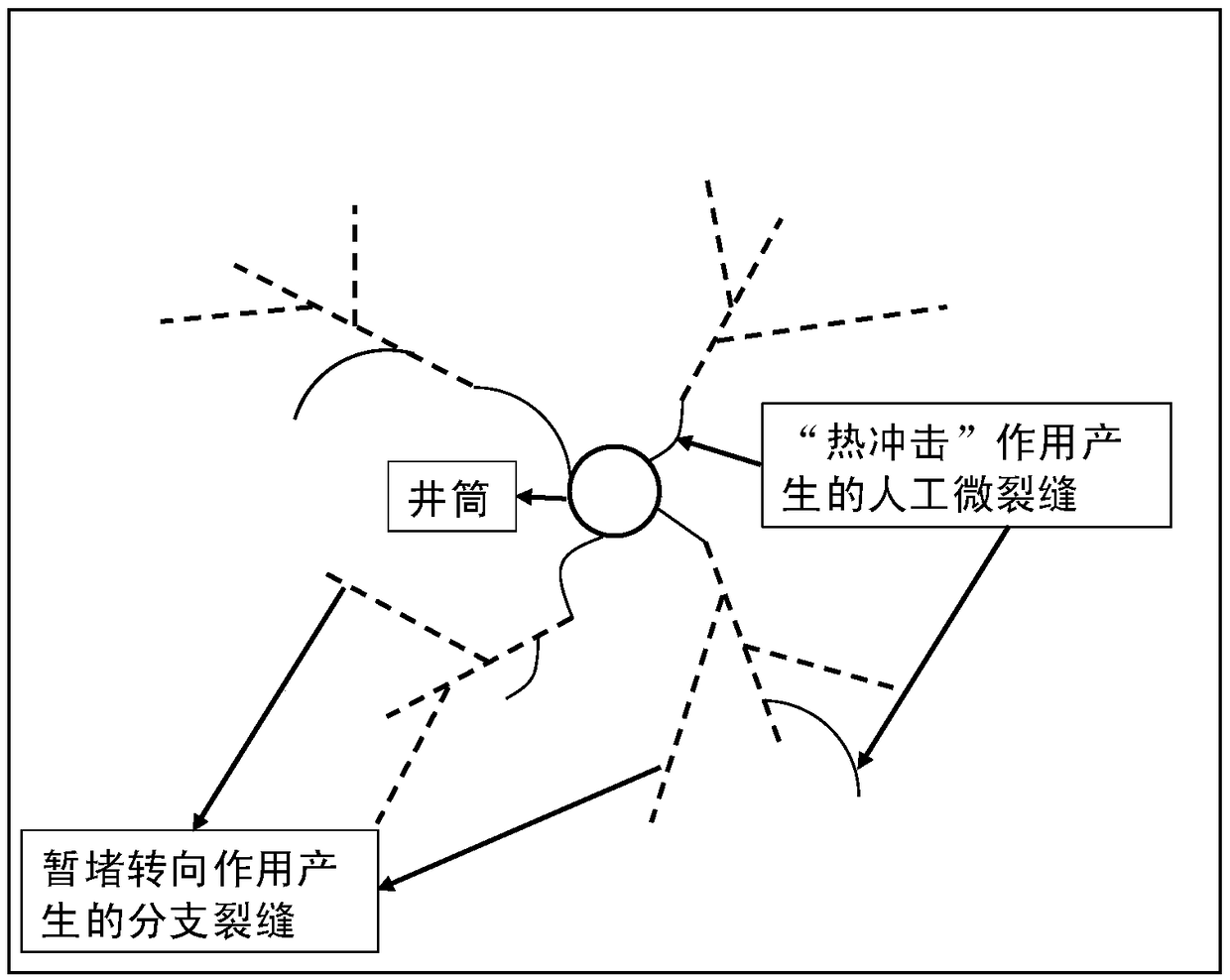

Fracturing method for increasing complexity of high-temperature stratum artificial crack net

ActiveCN108661617AReduce construction pressureIncrease the complexity of artificial fracturesFluid removalHorizontal wellsFracturing fluid

The invention discloses a fracturing method for increasing the complexity of a high-temperature stratum artificial crack net and belongs to the technical field of petroleum and natural gas engineeringexploitation. The method comprises the following steps that low-temperature work liquid is injected into a high-temperature stratum, a strong cold-hot stress impacting effect is generated through thehigh-temperature difference between the low-temperature work liquid and the high-temperature stratum, rock around a well is induced to generate micro cracks, then fracturing liquid is injected to enable the micro cracks to continue to expand forwards, finally temporary plugging steering liquid is injected to conduct bridge plugging on the artificial cracks to force the cracks to steer to form multi-branch cracks, and the steps are executed at least once. Through the fracturing method, the multiple artificial cracks can be formed, the seepage area is enlarged, the single-well yield and economic benefits are increased, the bursting pressure can be lowered, the fracturing construction risk caused by high temporary plugging steering pressure in the high-temperature stratum is avoided, and safe construction is ensured. The fracturing method is suitable for the high-temperature strata such as hot dry rock, deep-layer shale gas and deep-layer compact oil gas, can be used for vertical well fracturing construction and can also be applied to fracturing construction of horizontal wells, oblique wells and the like.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

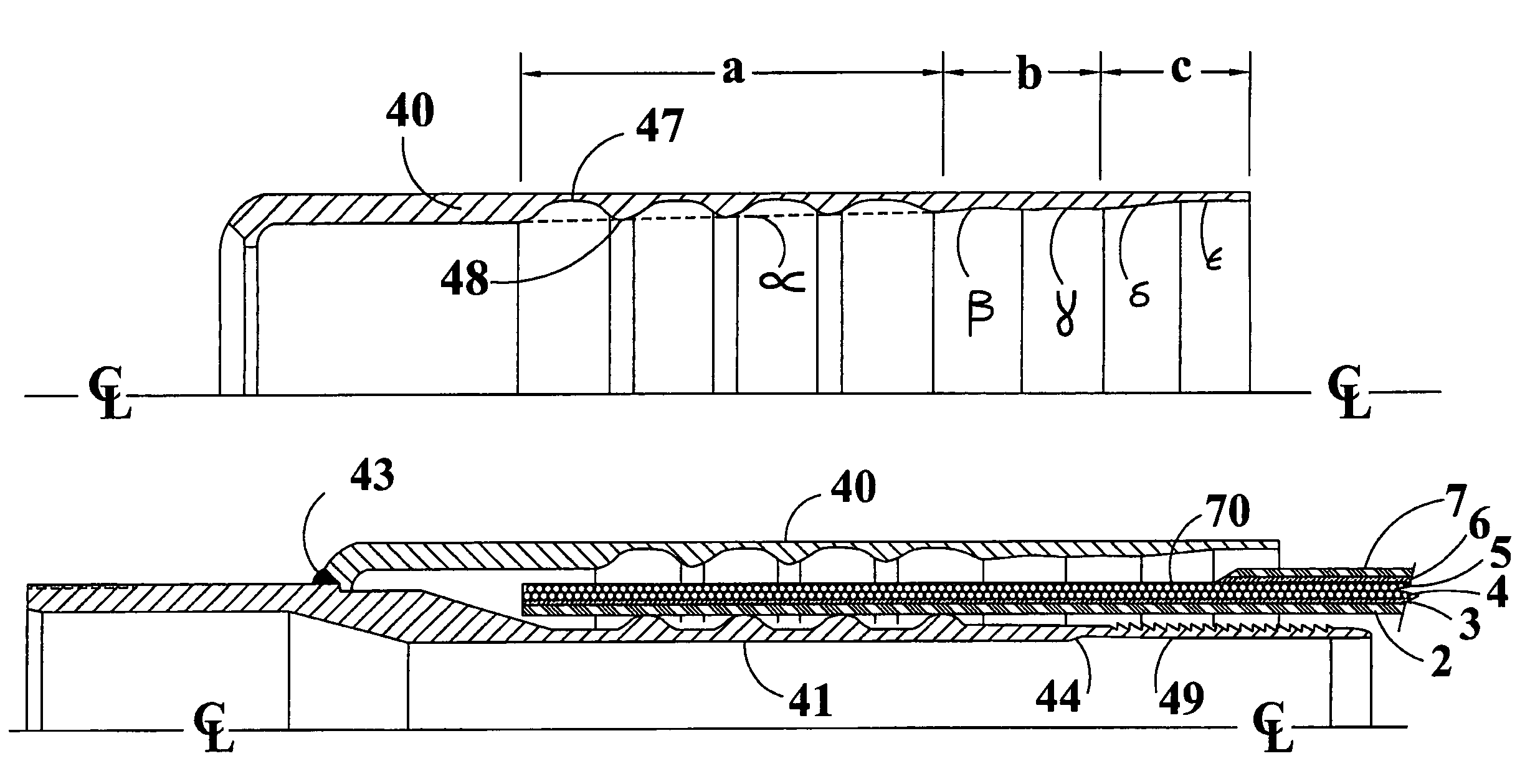

Intravascular catheter with composite reinforcement

InactiveUS20050182388A1Superior flexibility and softness and radiopacity and durabilityHigh burst resistanceCatheterTube connectorsIntravascular catheterGuide tube

An intravascular catheter that exhibits the combined features of superior flexibility, softness, radiopacity and oval / kink resistance. The catheter includes an elongate shaft having a proximal region, a distal region and a lumen extending therethrough. The proximal region of the shaft includes an inner lubricious polymer layer, a reinforcement layer and an outer layer. The reinforcement layer comprises a braid having one or more metallic members and a plurality of polymer members wherein each polymer member comprises a plurality of monofilaments, preferably formed of LCP. The polymer members of the braid provide improved flexibility and softness in addition to high burst pressure. The metallic member(s) of the braid provide improved radiopacity and oval / kink resistance. The catheter may also include a longitudinal member extending along the reinforcement layer.

Owner:BOSTON SCI SCIMED INC

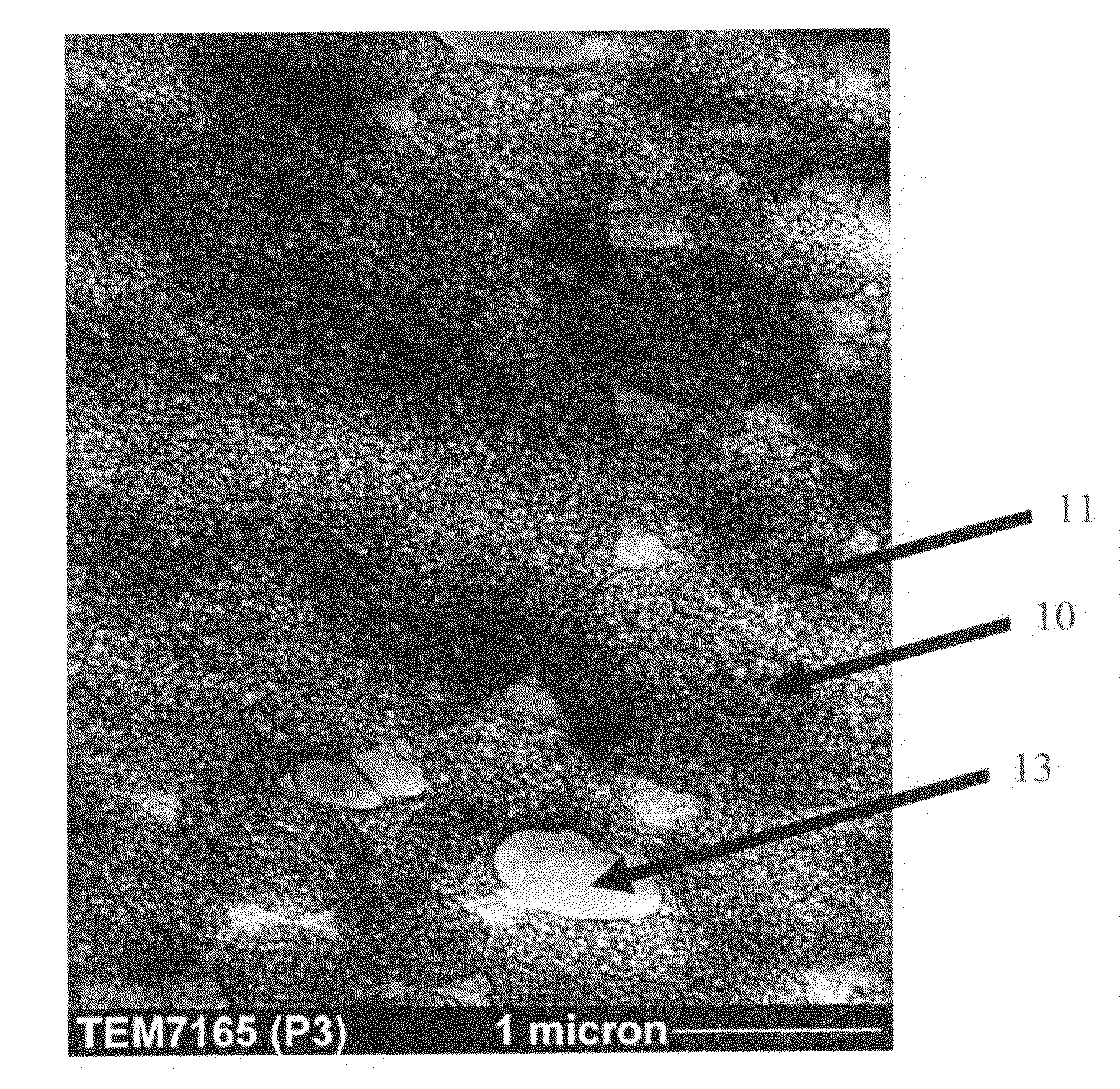

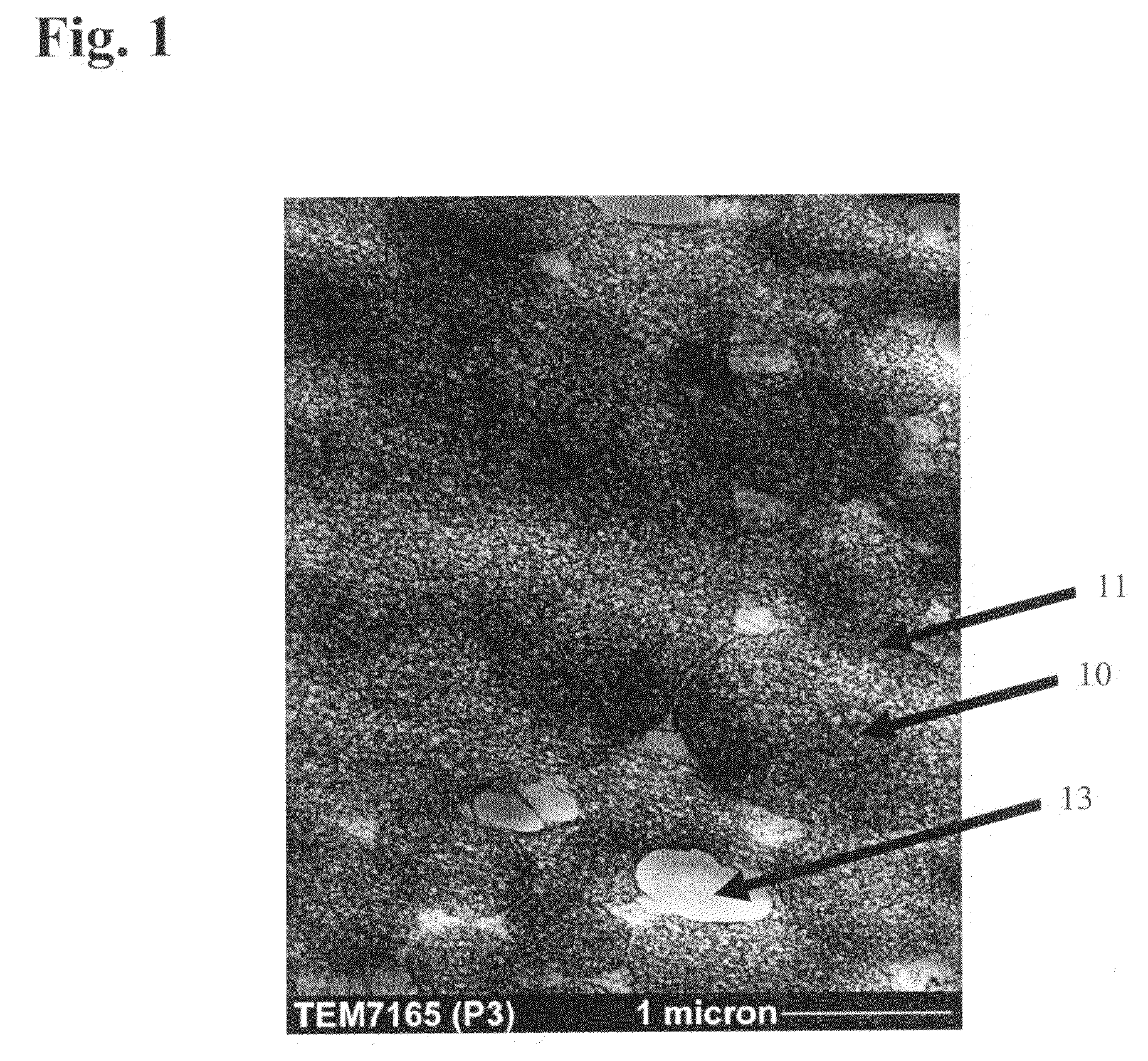

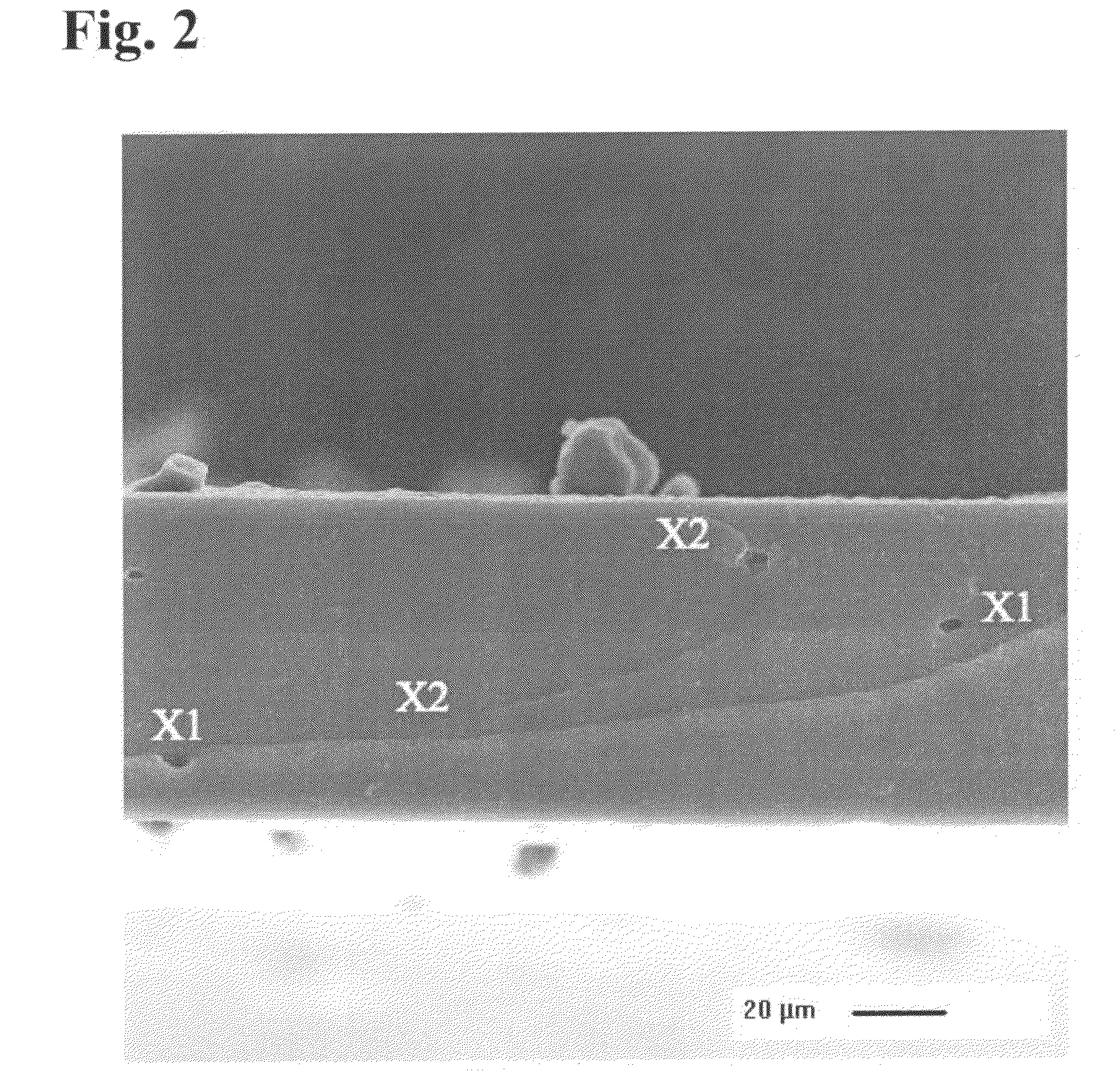

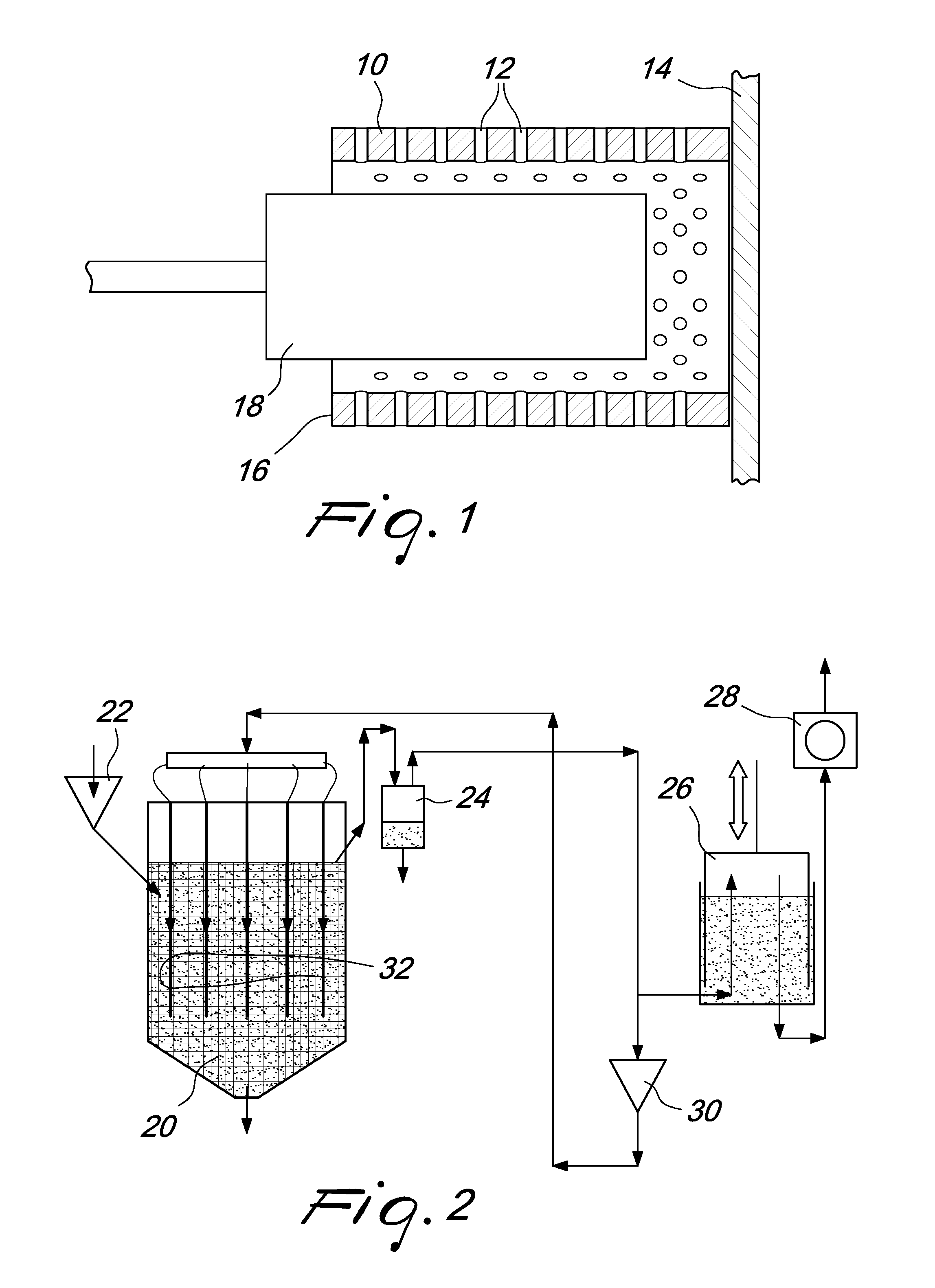

Dip-formed synthetic polyisoprene latex articles with improved intraparticle and interparticle crosslinks

ActiveUS8087412B2Uniform curingMale contraceptivesSynthetic resin layered productsCross-linkVulcanization

A synthetic polyisoprene latex emulsion has pre-vulcanization composition and post vulcanization composition. The pre-vulcanization composition comprises soluble sulfur with high S8 ring structure that is catalytically broken by a zinc dithiocarbamate. Surfactants present in the pre-vulcanization composition wets synthetic polyisoprene particles and permeates small sized sulfur and accelerator molecules into the interior of these particles thereby pre-vulcanizing the particles. The degree of pre-vulcanization is verified by isopropanol index test. The latex emulsion has post-vulcanization composition with accelerators that crosslink inter-particle region during post vulcanization cure cycle. The dipped synthetic polyisoprene article is substantially uniformly cured both in the inter-particle and intra-particle regions and reliably exhibits high cross link density, uniform distribution of double bonds in TEM and zinc segregation at the boundaries or original particles by electron microprobe analysis. The films exhibit high tensile strength, tensile modulus, tear strength, burst pressure and burst volume.

Owner:LIFESTYLES HEALTHCARE PTE LTD

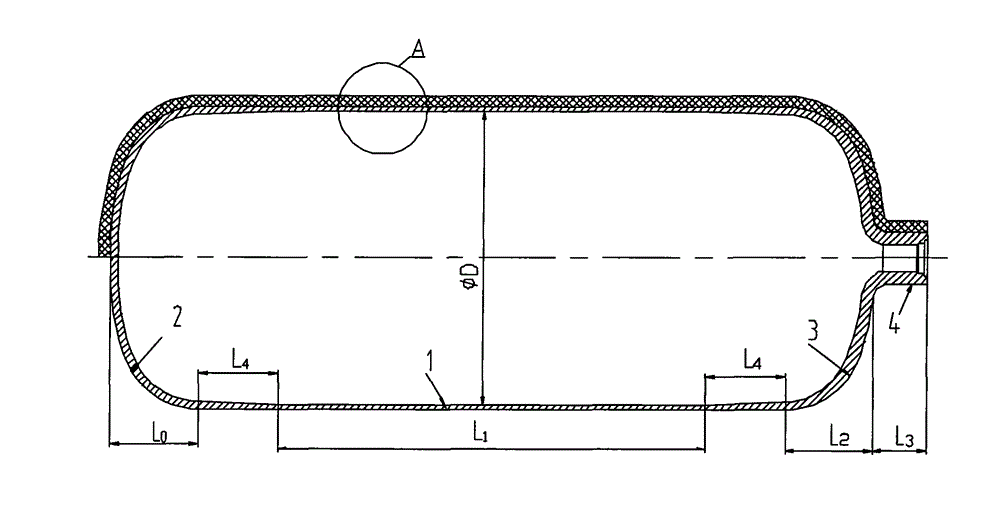

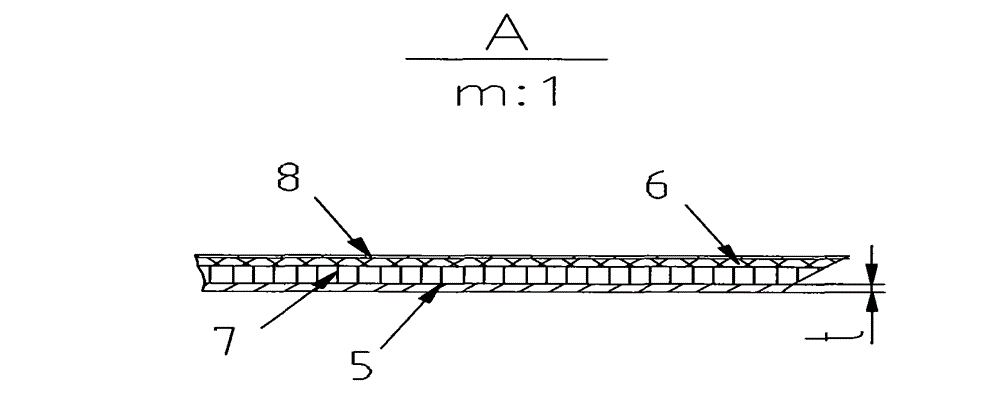

Method for producing carbon fiber-completely winded composite gas cylinder with aluminum inner container

InactiveCN102748584AIncrease burst pressureImprove air tightnessPressure vesselsGlass fiberCarbon fibers

The invention relates to a method for producing a carbon fiber-completely winded composite gas cylinder with an aluminum inner container. The carbon fiber-completely winded composite gas cylinder with the aluminum inner container has main bearing structures of the aluminum inner container and a carbon fiber completely-winding layer. The carbon fiber completely-winding layer on a cylinder body is prepared by alternately winding longitudinally spirally winding fiber layers and circumferentially winding fiber layers in a laying order designed optimally. Glass fiber layers are winded on the surface of the carbon fiber completely-winding layer and are used as impact resistant protective layers of the carbon fiber-completely winded composite gas cylinder with the aluminum inner container. The carbon fiber-completely winded composite gas cylinder with the aluminum inner container has main technical indexes of a safety factor great than or equal to 3.4 and fatigue cycle number N great than or equal to 10000. The method provided by the invention satisfies reasonable stress field distribution, and guarantees that the carbon fiber-completely winded composite gas cylinder with the aluminum inner container can bear maximum burst pressure under the condition of a minimum fiber use amount, produces cracks located at a cylinder body and does not produce fragments. The method guarantees that the aluminum inner container of the carbon fiber-completely winded composite gas cylinder with the aluminum inner container is always in an elastic deformation state under preset work pressure, and guarantees that the carbon fiber-completely winded composite gas cylinder with the aluminum inner container has lasting and good gas tightness and optimal safety.

Owner:BEIJING TIANHAI IND

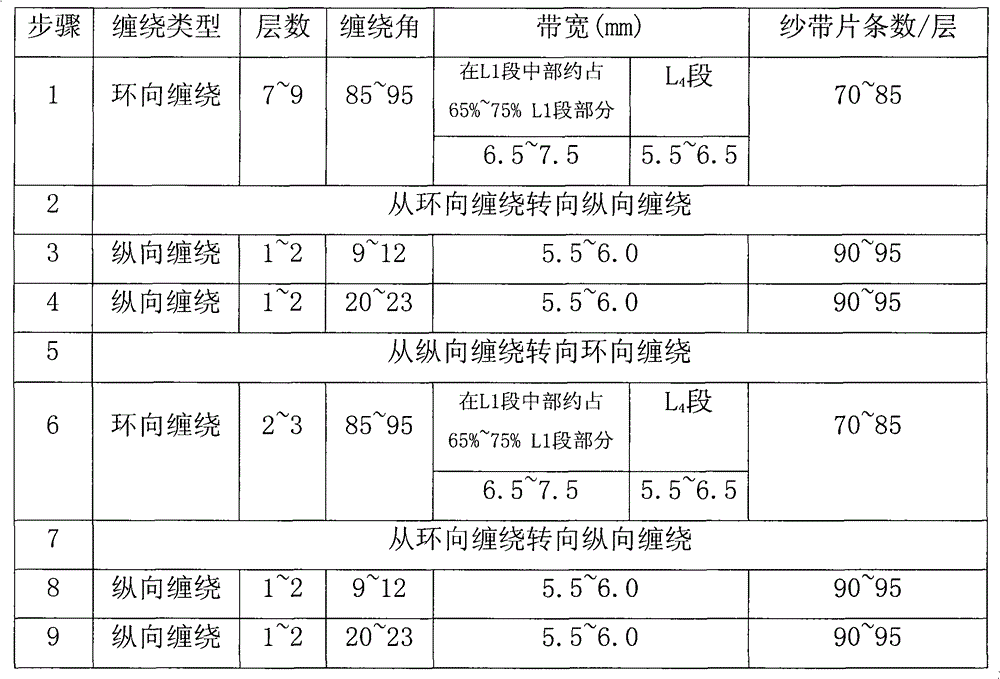

Process for the production of fuel gas from municipal solid waste

InactiveUS20130316428A1Increase productionImprove efficiencyBiological substance pretreatmentsSpecific water treatment objectivesOrganic fractionBiological cell

After separating from solid urban waste an organic fraction containing biological cells, the latter is extruded through a grid having small-bore holes, under a pressure higher than the bursting pressure of the cell membranes, so that most of these are disrupted and a gel of a doughy consistency is produced. The gel is then loaded into a biodigester, where it is readily attacked by bacteria.

Owner:DB TECH BV

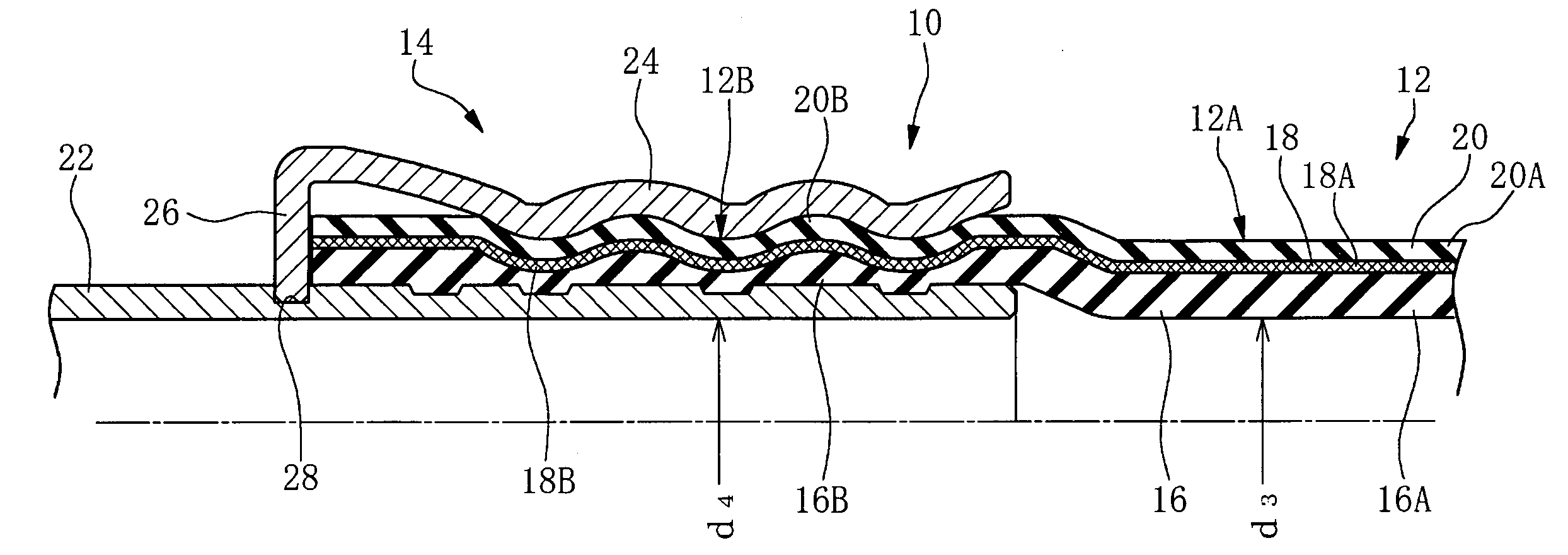

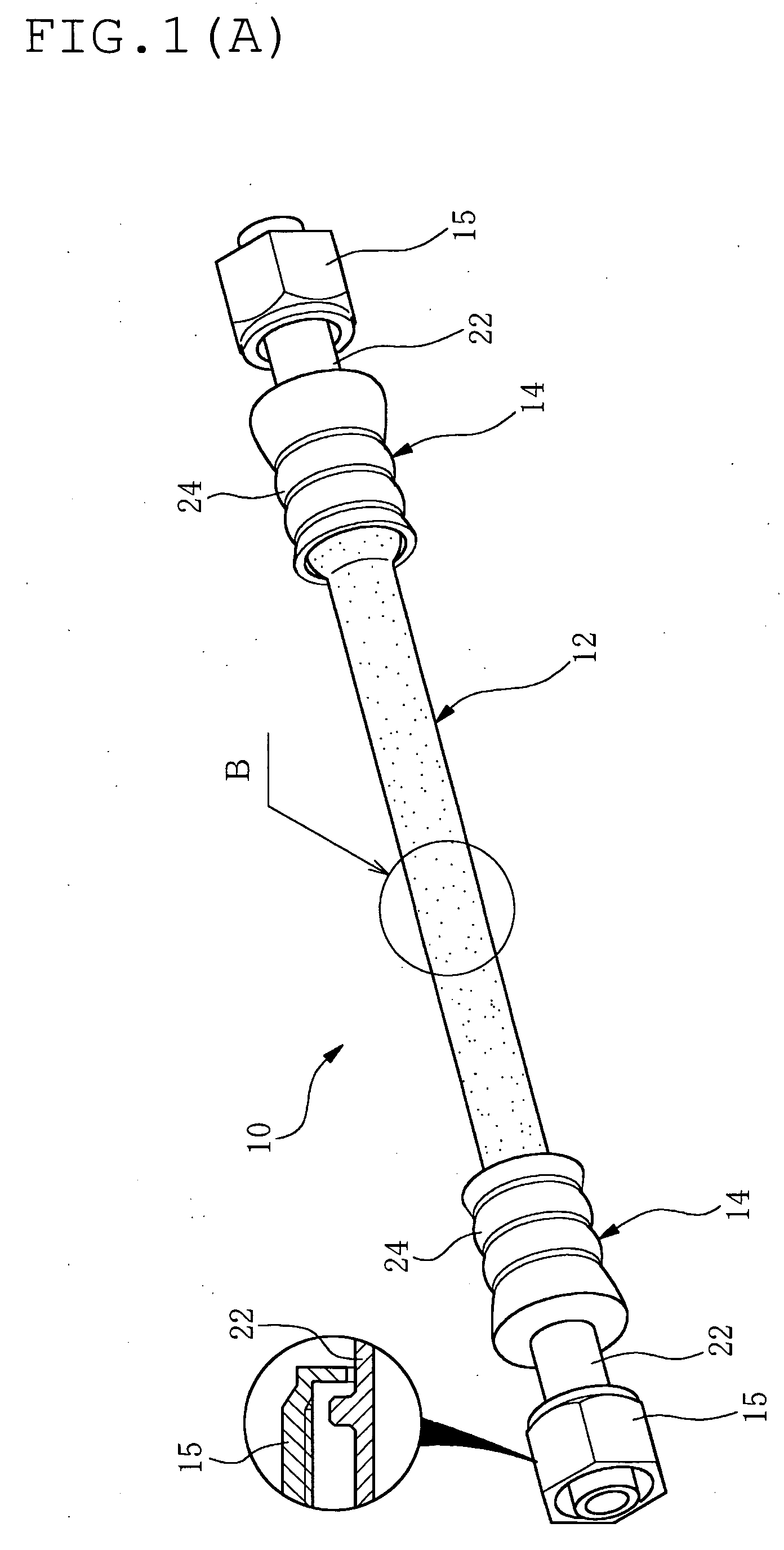

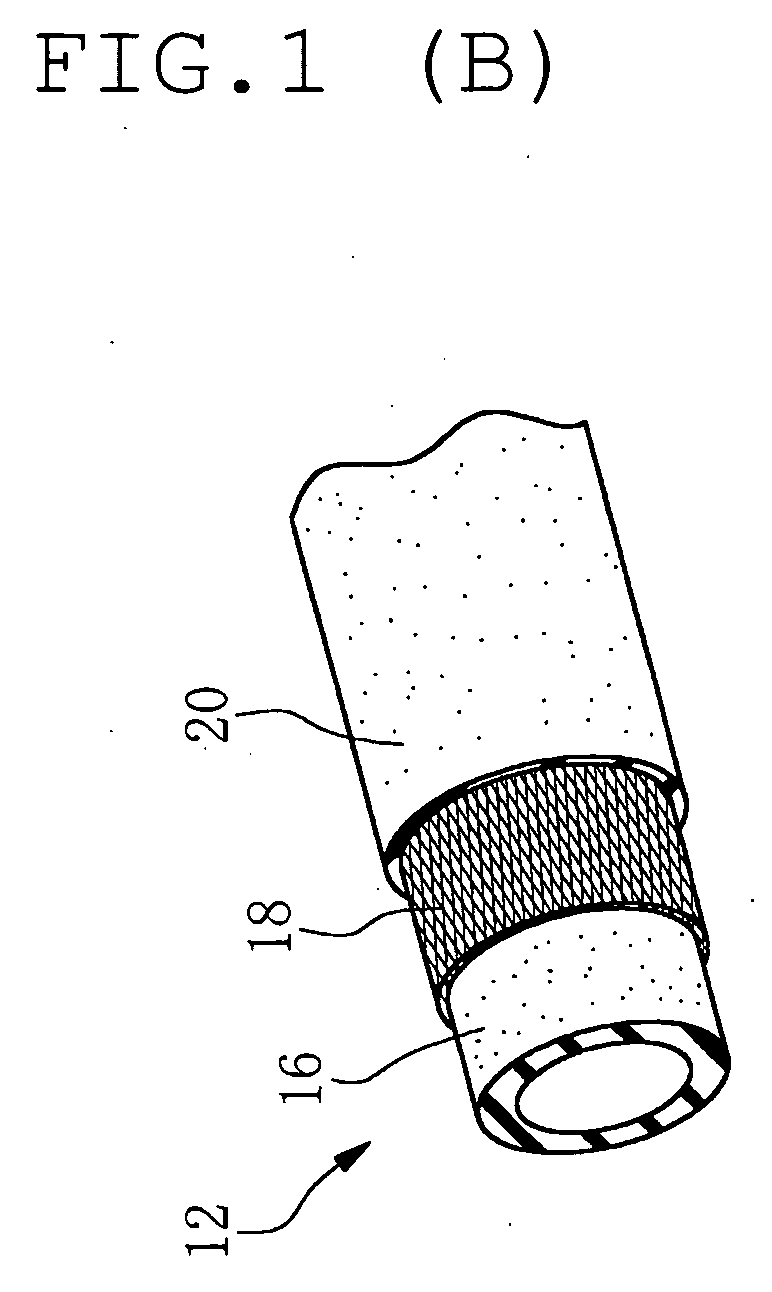

High pressure resistant vibration absorbing hose and method of producing the same

InactiveUS20060011249A1Reduce pressureReduced durabilityFlexible pipesHose connectionsVolumetric Mass DensityEngineering

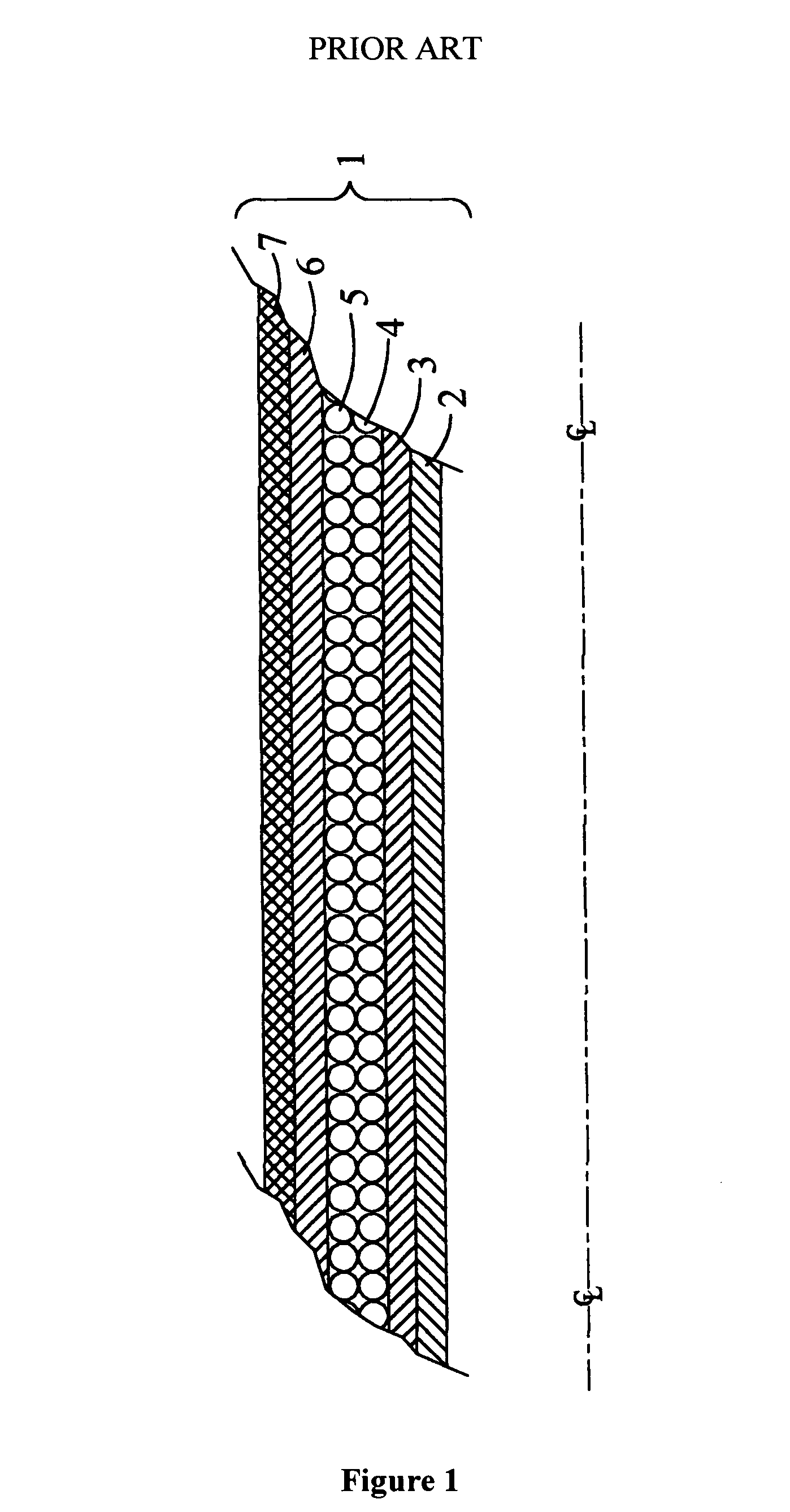

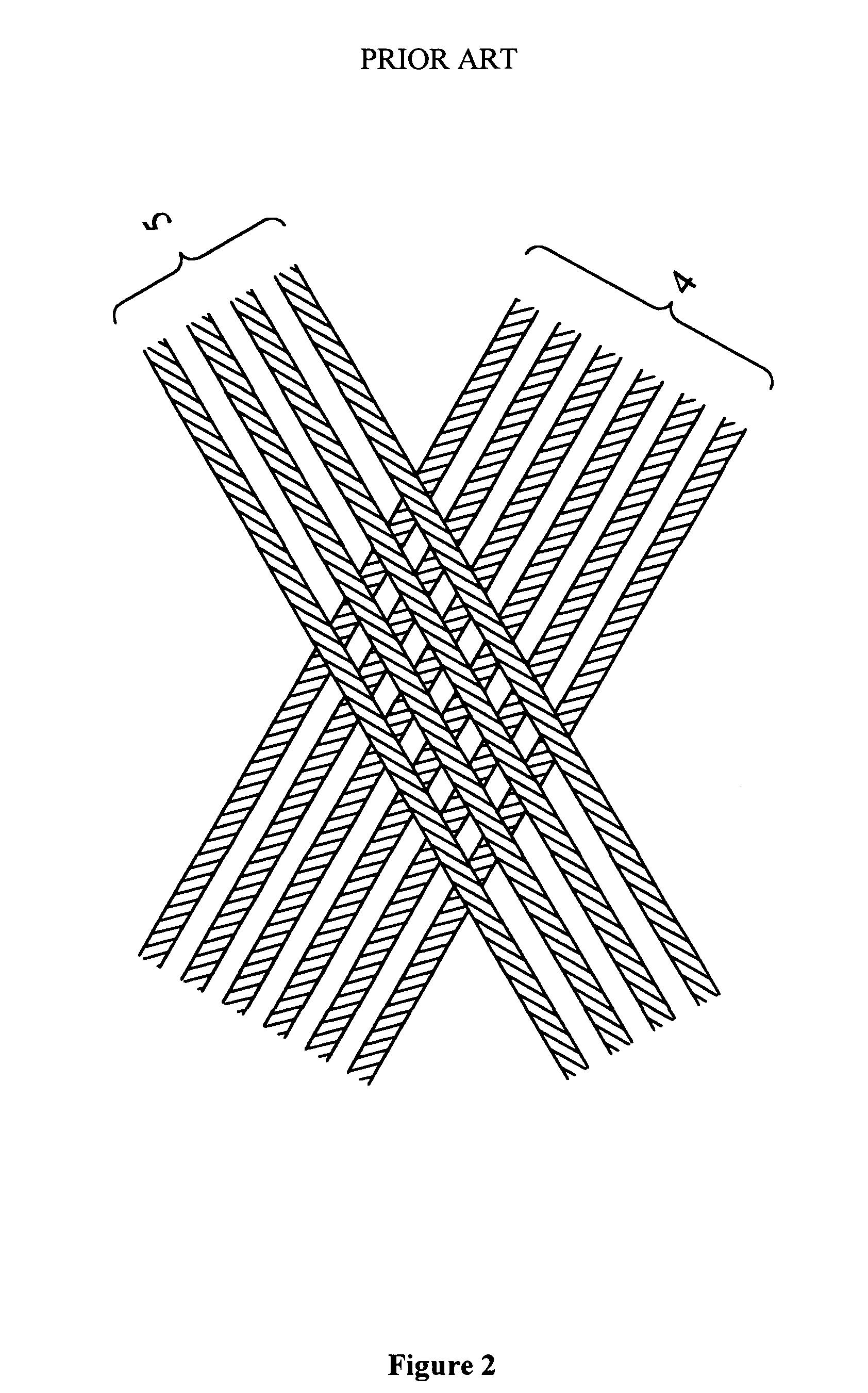

A high pressure resistant vibration absorbing hose with a bursting pressure of 5 MPa or higher has a hose body and a joint fitting. The joint fitting is to be attached to a swaged portion of the hose body. The hose body has an inner surface rubber layer, a reinforcing layer of high braid or winding density of 50% or more, and an outer surface rubber layer. The swaged portion is designed to have a larger diameter than the main portion of the hose body and the inner surface rubber layer has a wall thickness equal to or larger than 1.0 mm at a swaged portion in a state before the joint fitting is securely swaged thereto. The reinforcing layer has a braid or winding angle θ of a reinforcing wire member equal to or lower than a neutral angle 54.7° and higher than 48°.

Owner:SUMITOMO RIKO CO LTD

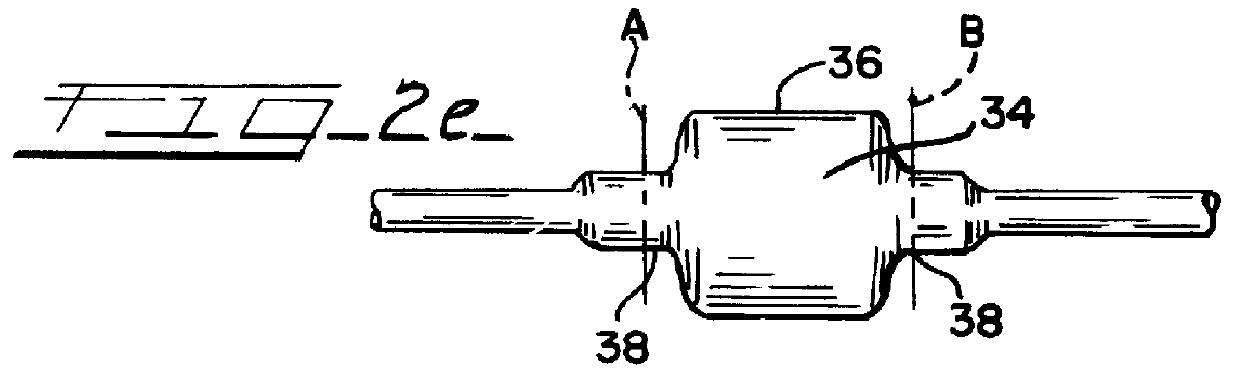

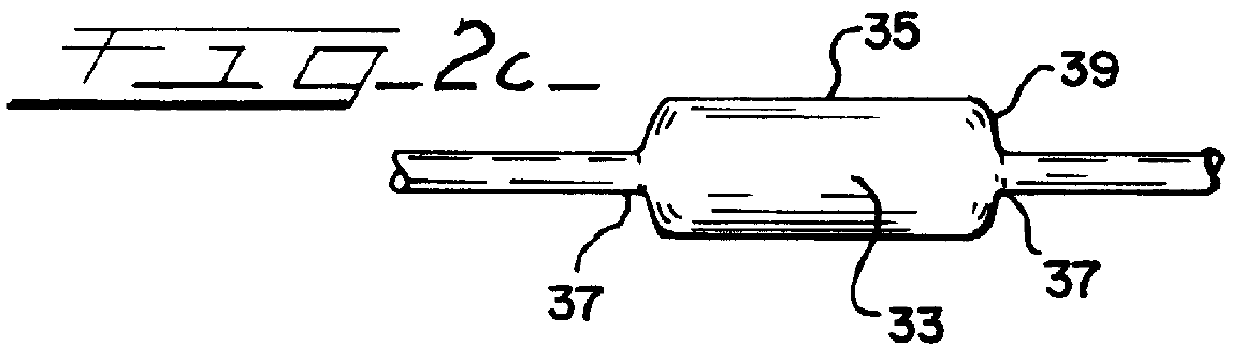

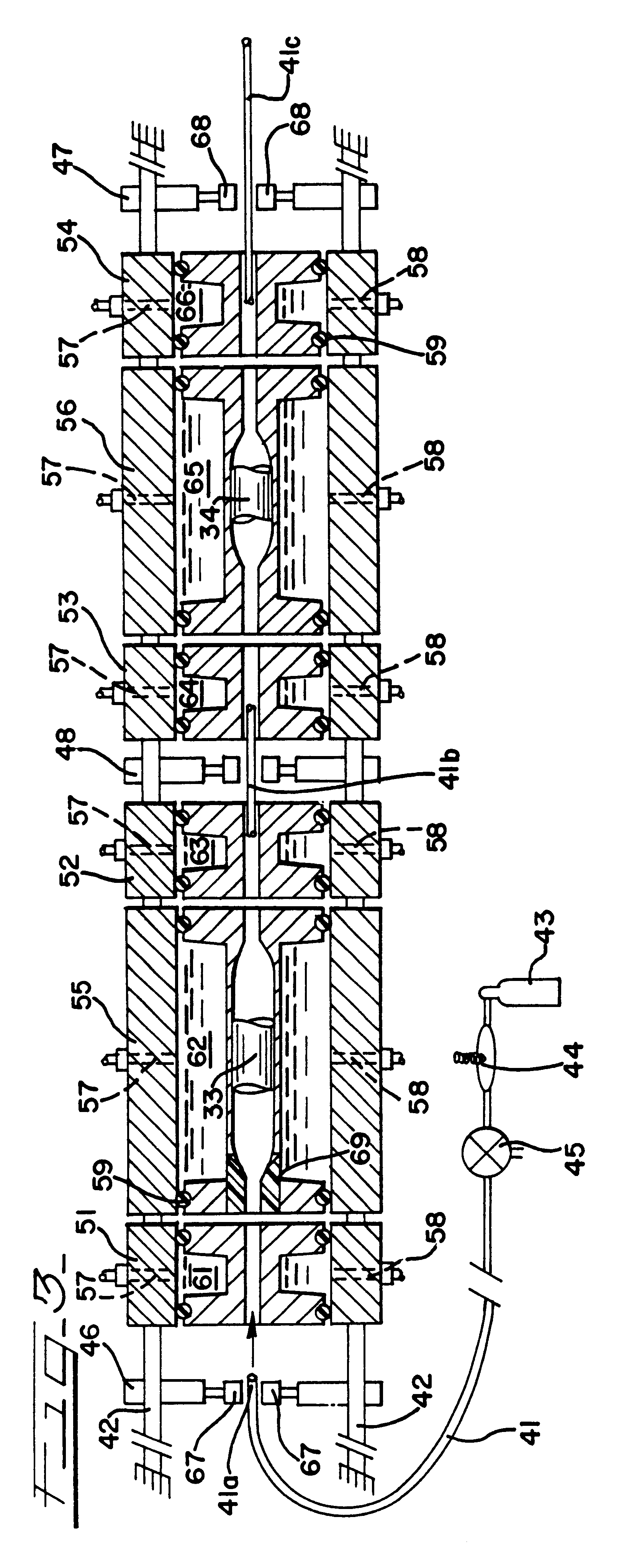

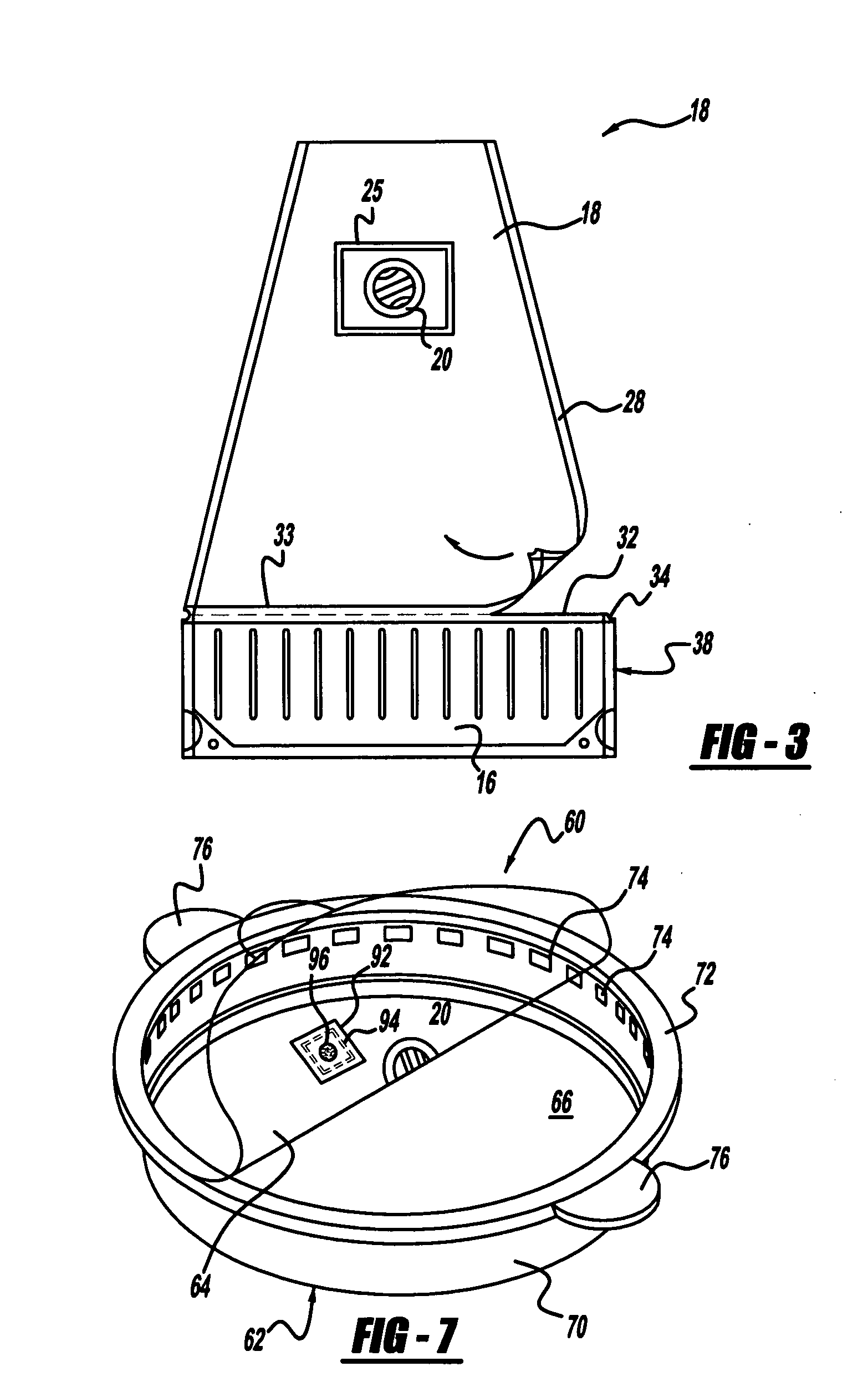

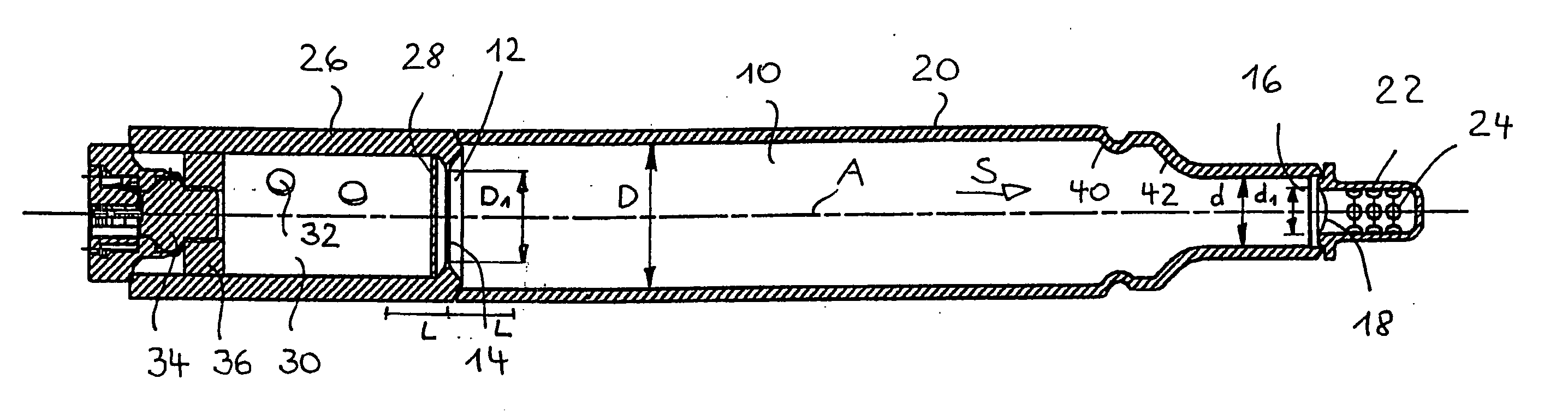

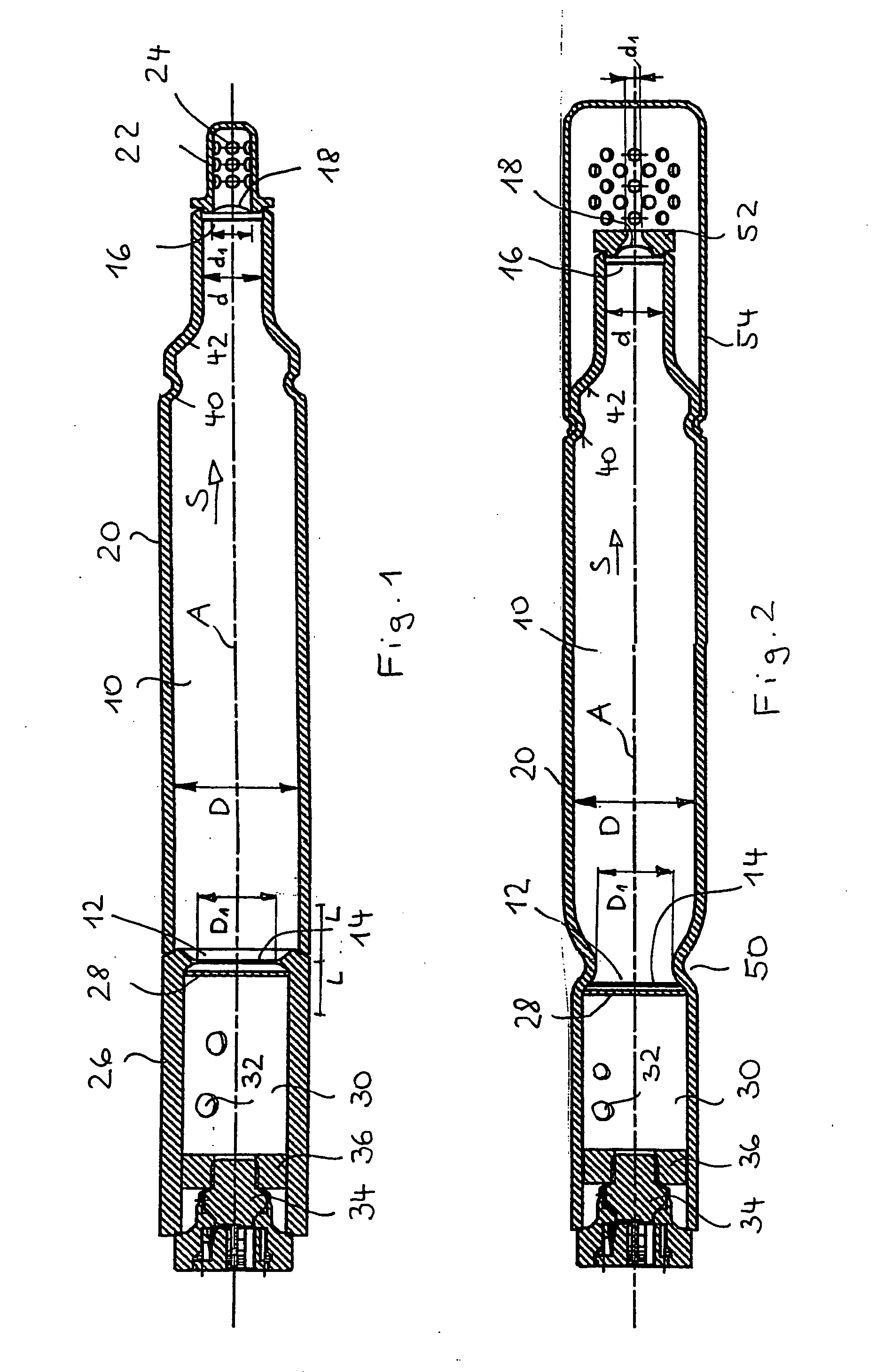

Gas generator

InactiveUS20050146123A1Convenient ArrangementPedestrian/occupant safety arrangementBiomedical engineeringMembrane configuration

A gas generator, in particular for vehicle occupant restraint systems, is provided with a pressure chamber (10) filled with compressed gas, a pyrotechnic igniter (34) arranged outside the pressure chamber (10), a first membrane (14) provided close to the igniter (34) and closing a first opening (12) of the pressure chamber (10), and a second membrane (18) provided further away from the igniter (34) and closing a second opening (16) of the pressure chamber. The first membrane (14) is configured such that it tears at a higher bursting pressure than the second membrane (18).

Owner:TRW AIRBAG SYST

Method of attachment for a high pressure reinforced rubber hose coupling

InactiveUS20070157443A1High possible lockExtended diameter rangePipe-jointsHose connectionsTO-18Engineering

A method of attachment for swage end-connector for high pressure reinforced flexible hose particularly suitable in the petrochemical and drilling industries for hoses is disclosed. Two connectors are discussed one for intermediate hose pressure burst ratings up to 12,500 psi and internal diameters up to 3½ inches and higher hose pressure burst ratings up to 18,750 psi and internal diameters up to 4 inches. Both embodiment connectors will withstand the rated burst pressure of the hose to which they are connected and will withstand a pump-off force that exceeds the burst pressure of the hose. That is, the hose will fail before the connector pops off the hose.

Owner:BALDWIN & LOKE

Highly Water Permeable Hollow Fiber Membrane Type Blood Purifier and Process for Manufacturing the Same

InactiveUS20080000830A1Improve securityExcellent in module-assembling easeMembranesSemi-permeable membranesHollow fibreHydrophobic polymer

The present invention relates to a highly water-permeable hollow fiber membrane type blood purifier which comprises hydrophobic polymer hollow fiber membranes each containing a hydrophilic polymer, wherein the hollow fiber membrane has a hydrophilic polymer content of 25 to 50 mass % and a ratio of hole areas of 8 to 25% at its outer surface, and has a thickness non-uniformity degree of 0.6 or more, a thickness of 10 to 60 μm and a burst pressure of 0.5 to 2 MPa, and which is characterized in that the blood purifier has a water permeability of 150 to 2,000 ml / m2 / hr / mmHg, and in that said blood purifier is exposed to radioactive rays on conditions that the oxygen concentration of an ambient atmosphere around the hollow fiber membranes is from 0.001% inclusive to 0.1% inclusive, and that the moisture content of the hollow fiber membrane to its weight is from 0.2 mass % inclusive to 7 mass % inclusive. The present invention also relates to a process for manufacturing the same-blood purifier.

Owner:NIPRO CORP

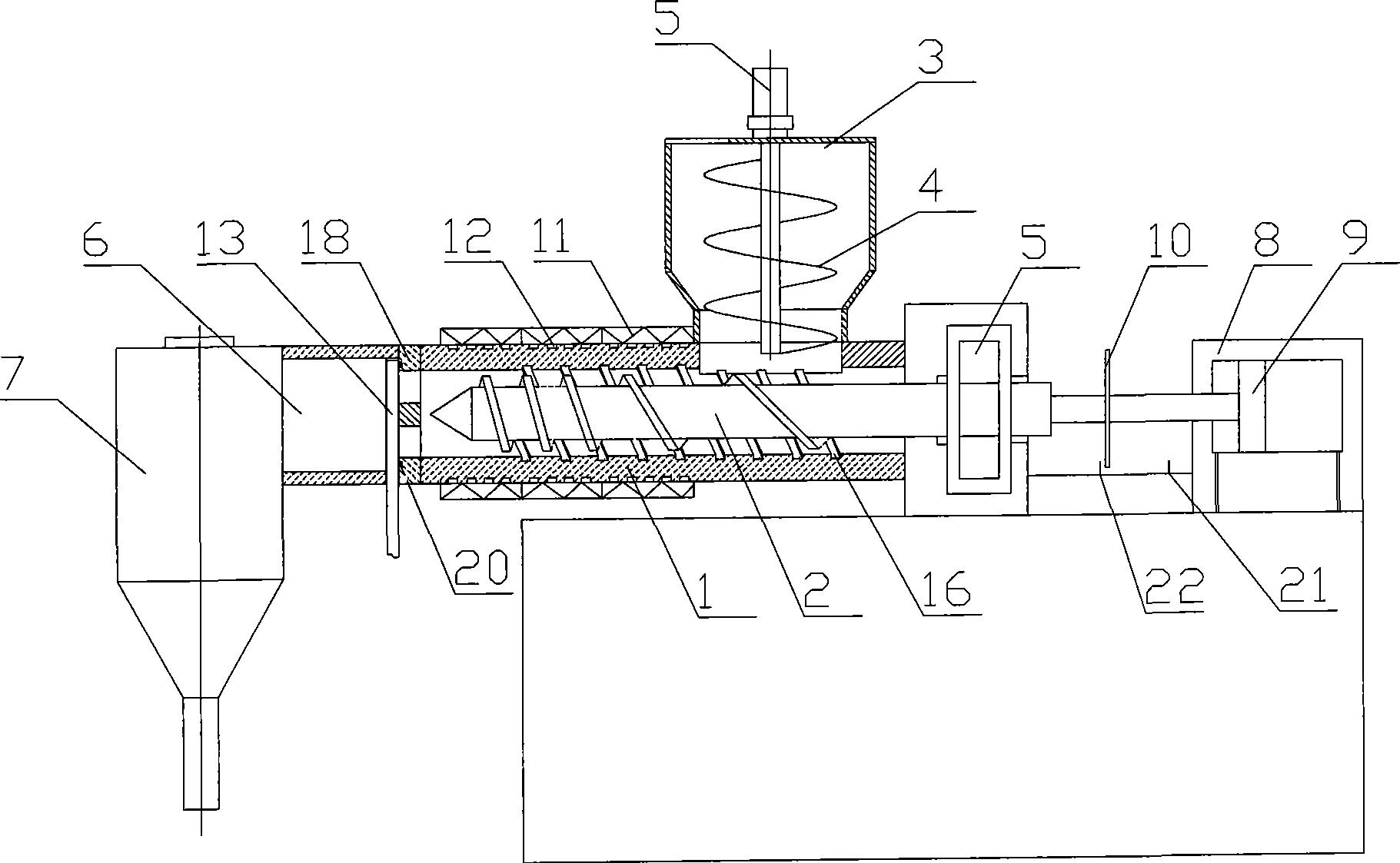

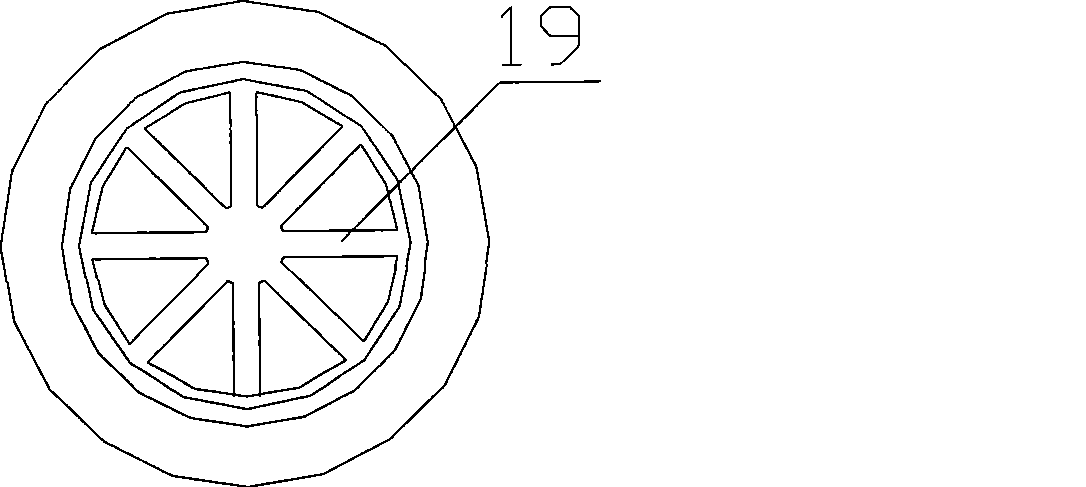

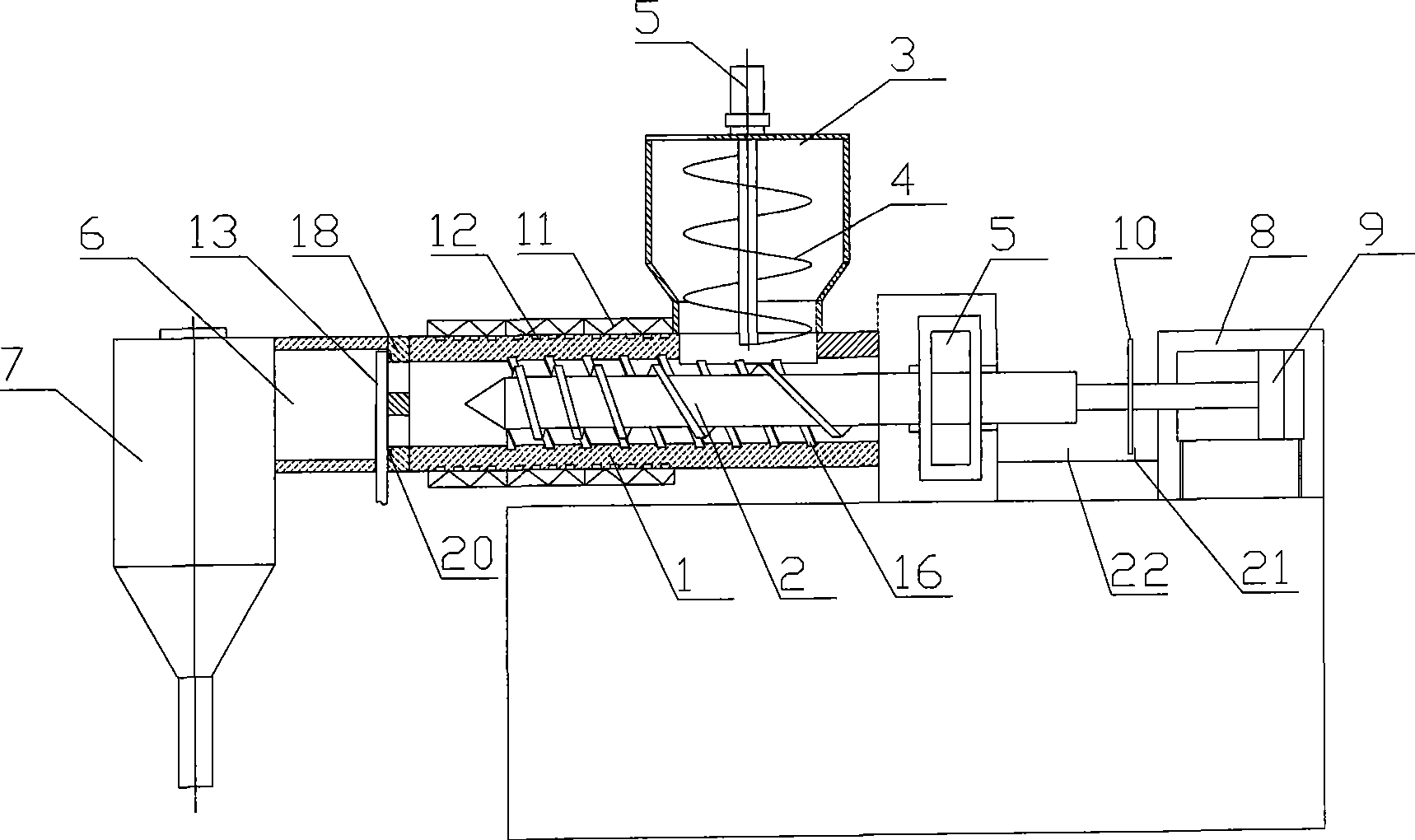

Screw rod injection type plant fibre steam blasting device and method

ActiveCN101463570AEnables semi-continuous operationIndependent control of blasting temperatureRaw material divisionTemperature controlRetention time

The invention discloses a screw injection type device for vegetation fiber steam-explosion and a method thereof. The device comprises a charging barrel which is internally provided with a squeezing screw rod matching the charging barrel; a feed inlet and a feed outlet are arranged on the charging barrel; a quick opening valve is arranged at the feed outlet; the squeezing screw rod is driven by a driving mechanism; an advancing mechanism is arranged at the rear end of the squeezing screw rod and a temperature controller is arranged on the charging barrel. The invention can respectively control the explosion pressure, the temperature and the retention time and has better suitability; therefore, while fiber cell separation is realized by vegetation fiber steam-explosion, modifying agent can be added in to realize in-situ modification of vegetation fiber, thus satisfying diverse application requirements of vegetation fiber.

Owner:GUANGZHOU HUAXINKE ENTERPRISE +1

Fluid transfer hose reinforced with hybrid yarn

ActiveUS7572745B2Retained tensile strengthIncrease burst pressureEngine sealsInternal combustion piston enginesYarnAramides

A flexible hose comprising a tube, a knit fabric, and a cover. The knit fabric comprises a hybrid yarn which comprises a first yarn of co-para-aramid fibers and a second yarn of meta-aramid fibers. The hose exhibits significantly improved burst pressure and / or improved impulse fatigue resistance.

Owner:THE GATES CORP

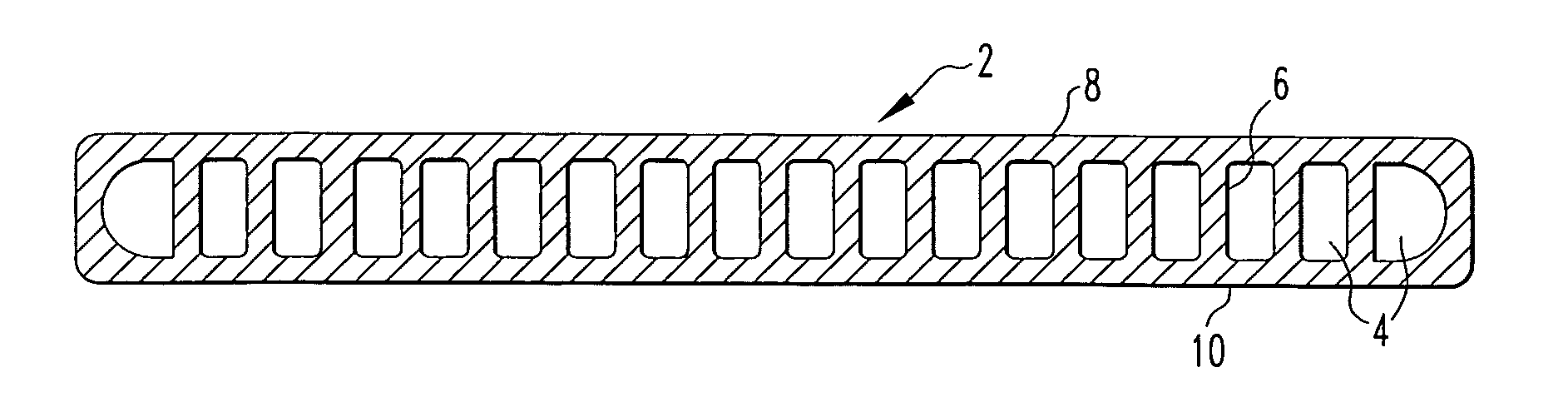

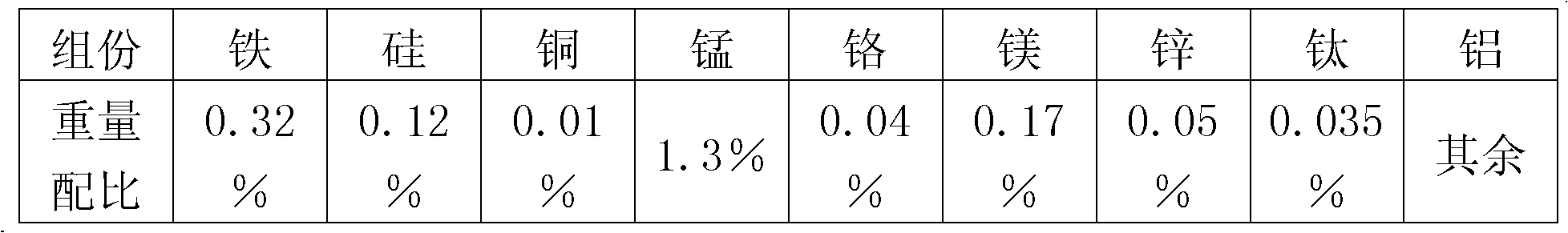

Parallel flow tubes used for heat exchanger and manufacturing method thereof

The invention discloses parallel flow tubes used for a heat exchanger and a manufacturing method thereof. A material of the parallel flow tubes comprises the following components in percentage by weight: 0.24 to 0.35 percent of ferrum, 0.05 to 0.12 percent of silicon, 0.005 to 0.05 percent of copper, 1.1 to 1.4 percent of manganese, 0.02 to 0.08 percent of chromium, 0.10 to 0.20 percent of magnesium, 0 to 0.10 percent of zinc, 0.010 to 0.035 percent of titanium and the balance of aluminum. The parallel flow tubes used for the heat exchanger have the characteristics of light weight, and high pressure resistance, durability and system safety. The method related to the invention solves the problems of crack inner rib, poor welding, low bursting pressure of thin wall and the like of the parallel flow tubes for the heat exchanger.

Owner:江苏格林威尔金属材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com