Patents

Literature

385results about How to "High burst resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

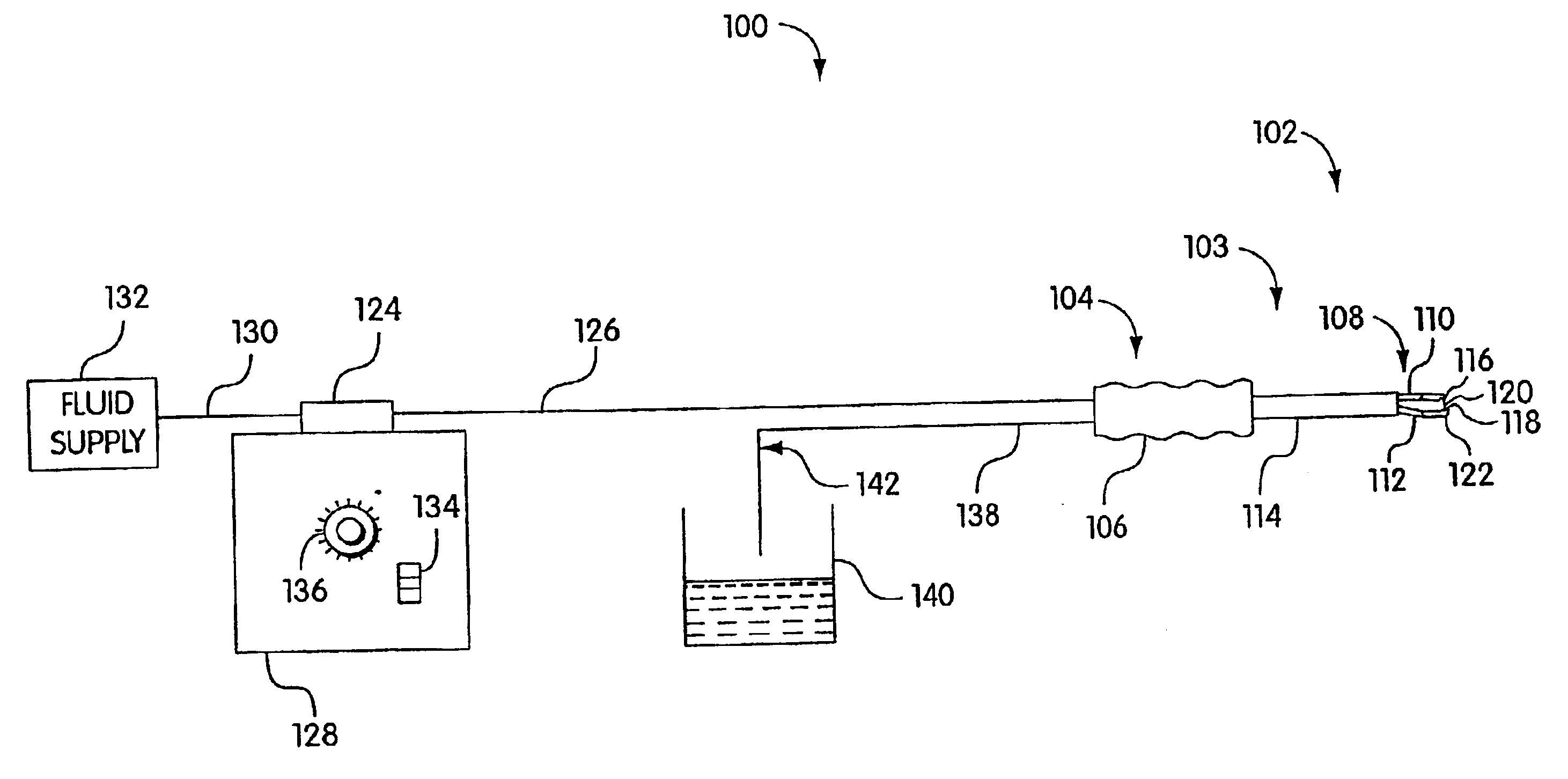

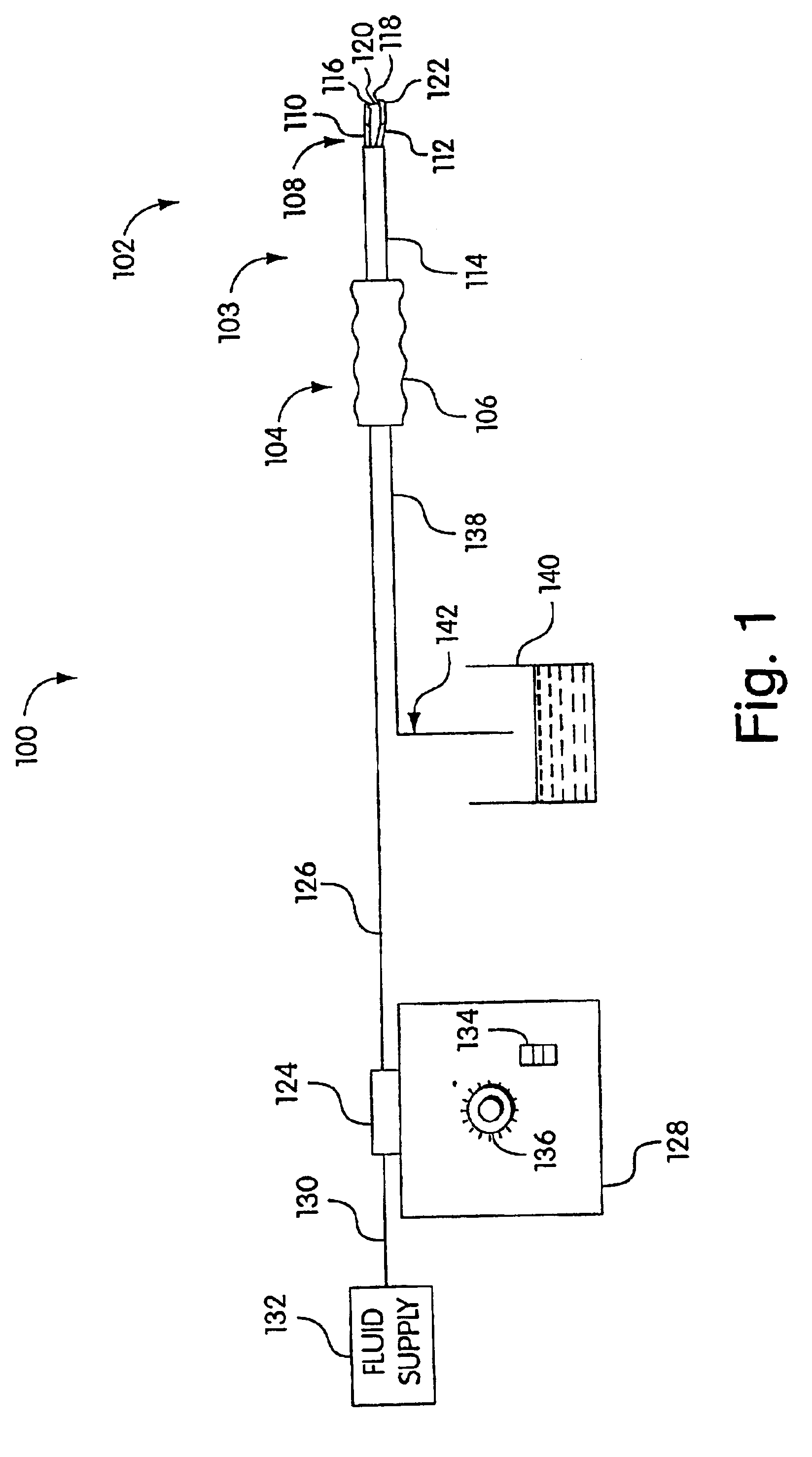

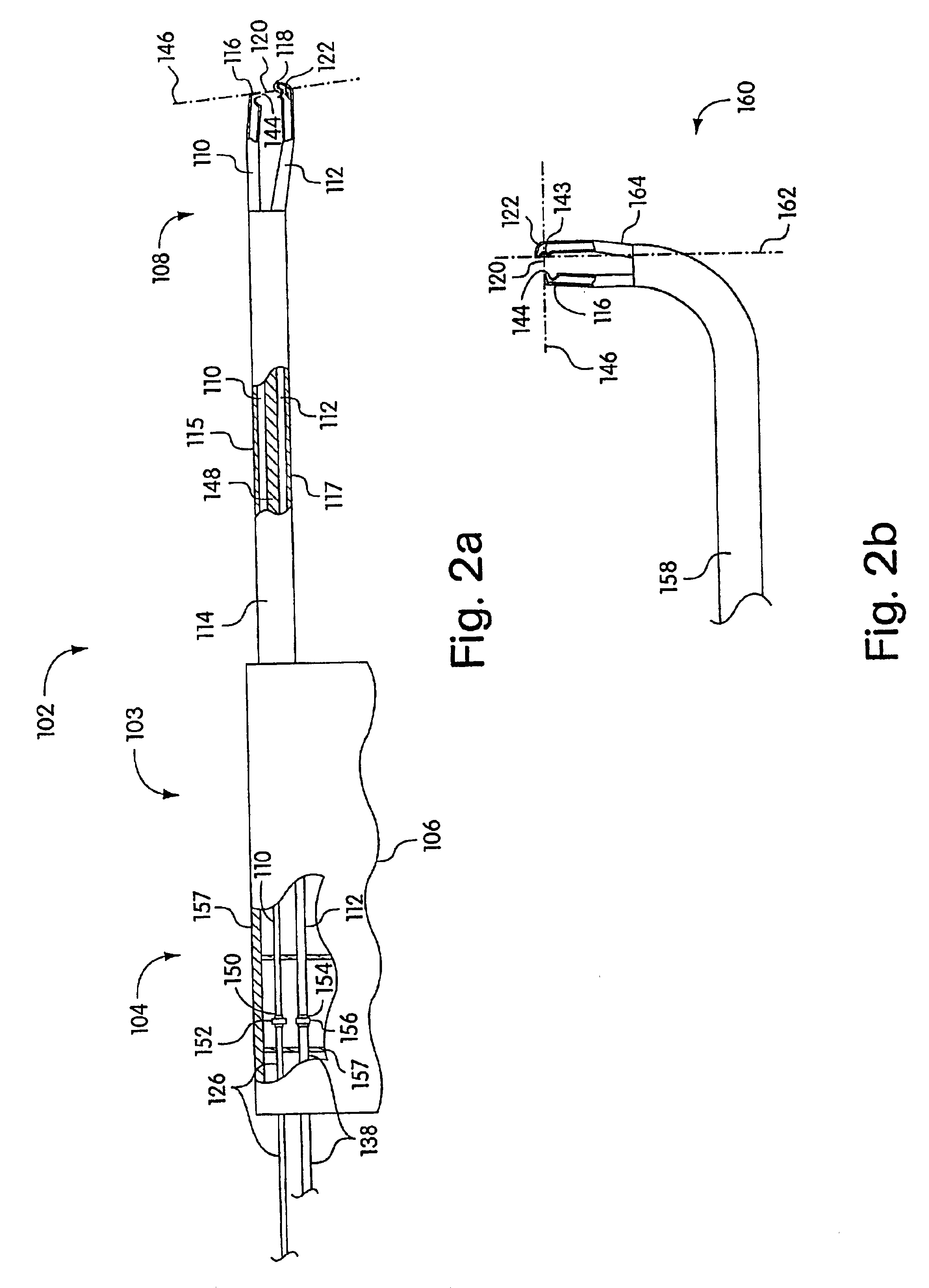

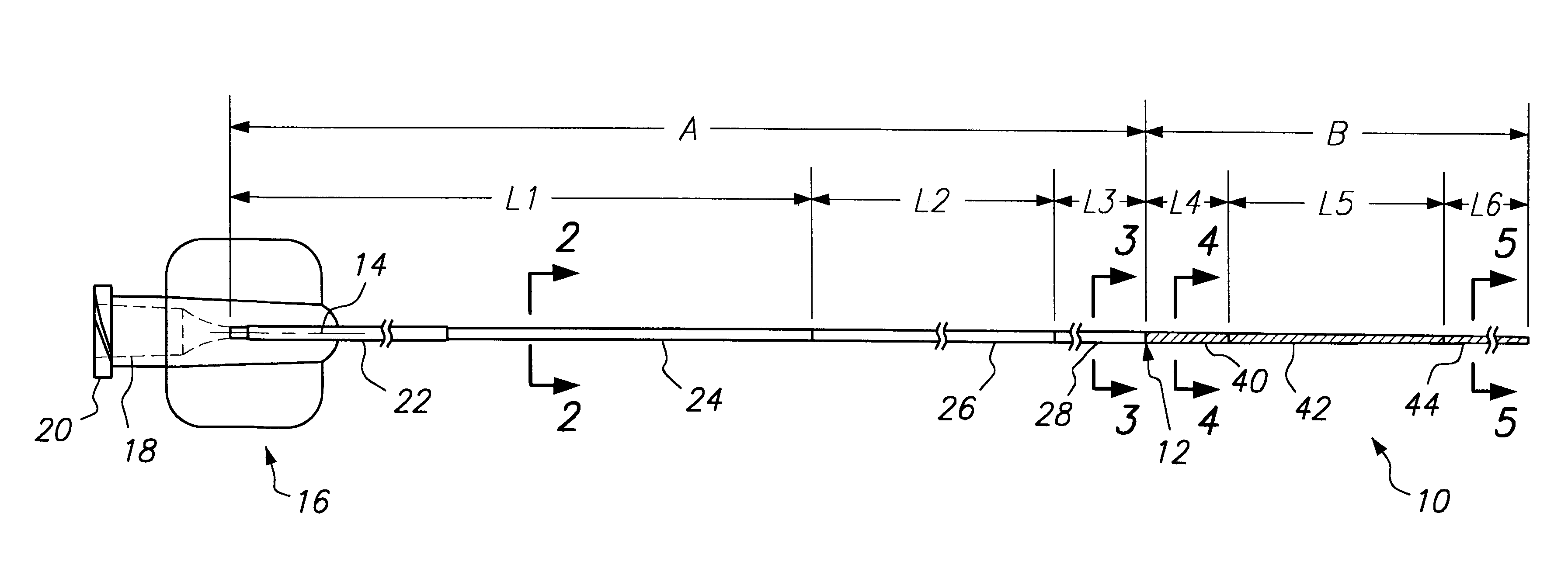

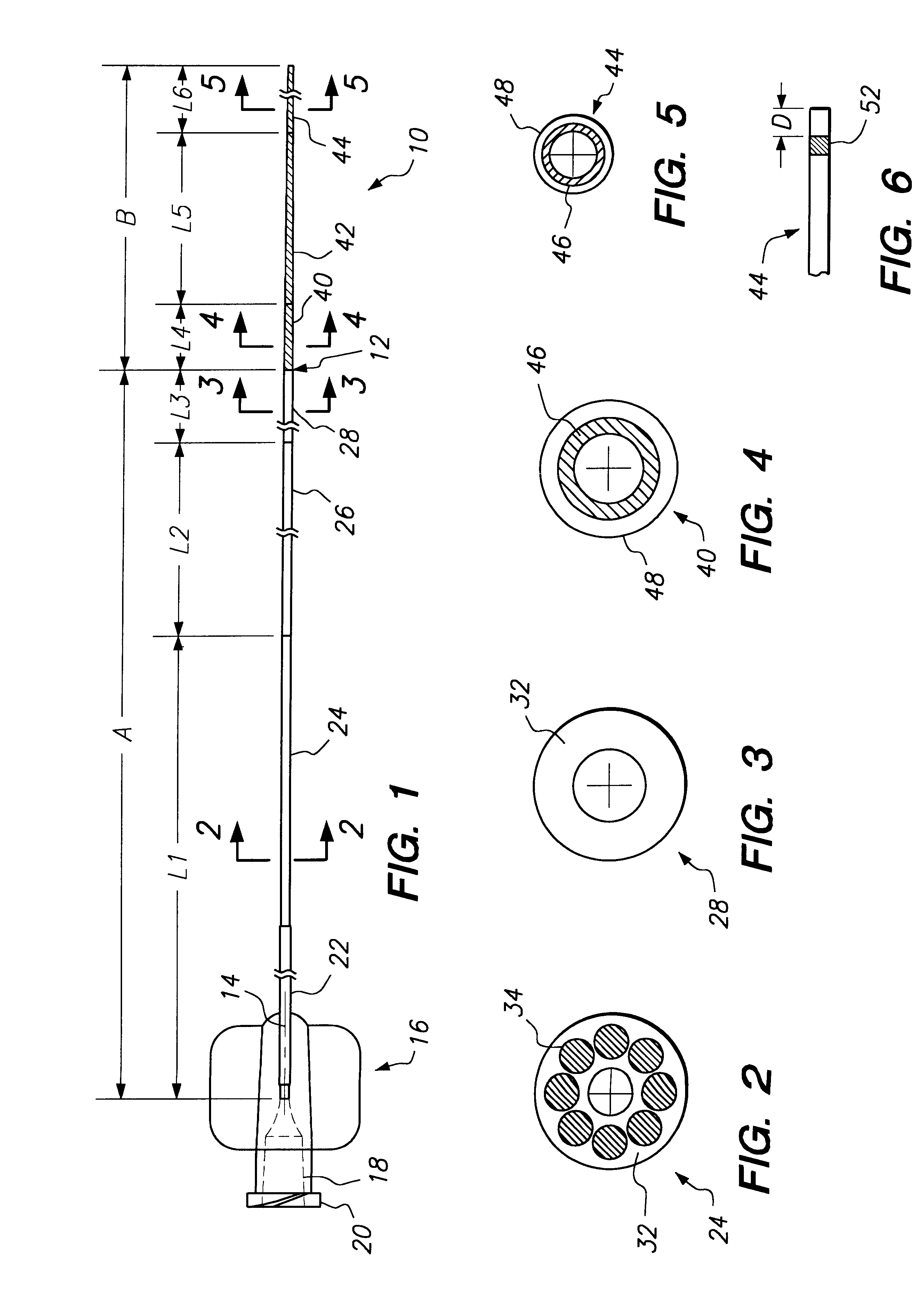

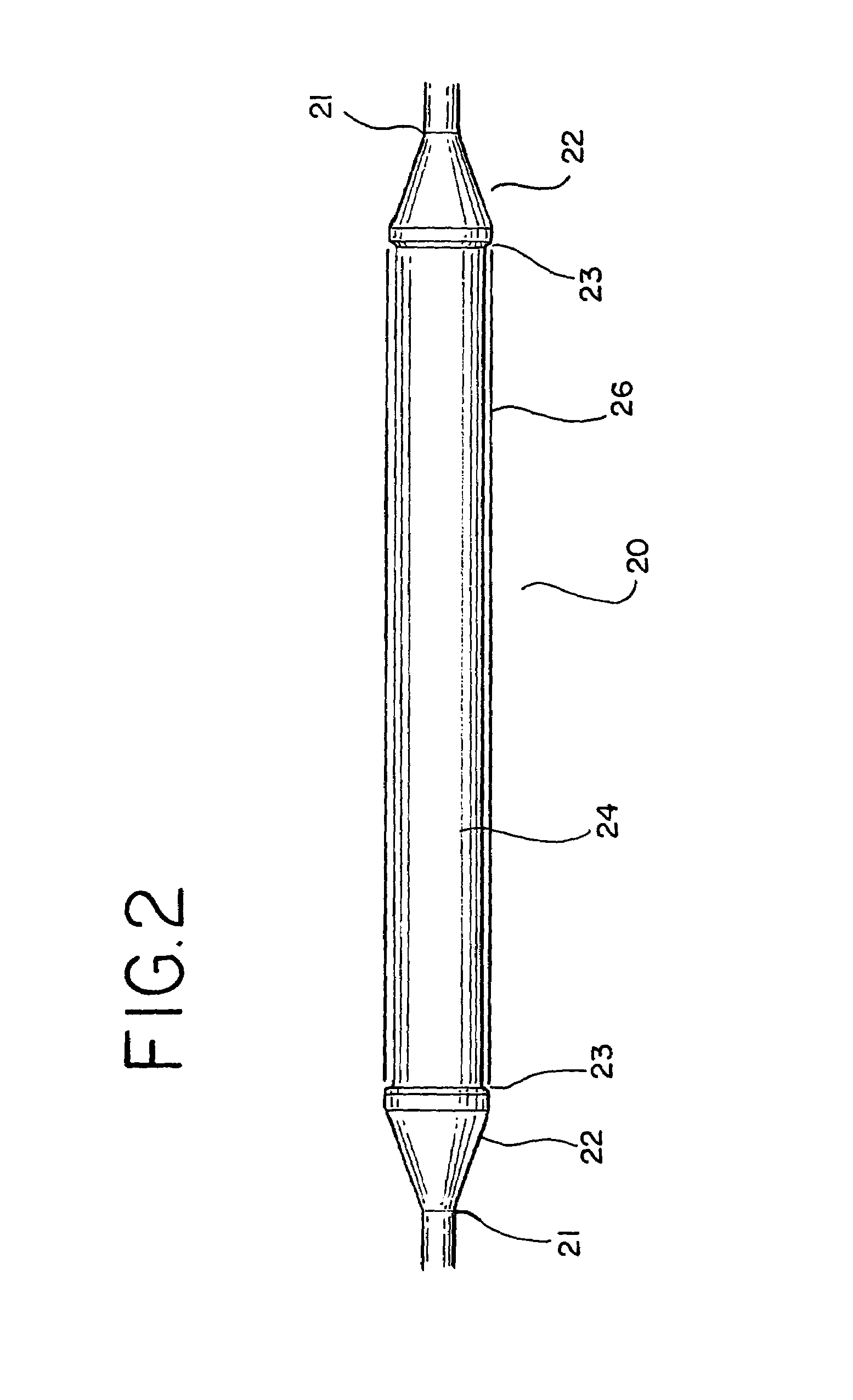

Fluid jet surgical instruments

The invention provides a variety of surgical instruments for forming a liquid jet, which are useful for performing a wide variety of surgical procedures. In some embodiments, the invention provides surgical liquid jet instruments having a pressure lumen and an evacuation lumen, where the pressure lumen includes at least one nozzle for forming a liquid jet and where the evacuation lumen includes a jet-receiving opening for receiving the liquid jet when the instrument is in operation. In some embodiments, the pressure lumen and the evacuation lumen of the surgical liquid jet instruments are constructed and positionable relative to each other so that the liquid comprising the liquid jet, and any tissue or material entrained by the liquid jet can be evacuated through the evacuation lumen without the need for an external source of suction. The invention also provides a variety of surgical liquid jet instruments that are constructed and configured specifically for use in a surrounding liquid environment or a surrounding gaseous environment. The invention also provides a variety of surgical liquid jet instruments that are rotatably deployable from an undeployed position, for insertion into the body of a patient, to a deployed position, in which there is a separation distance between the liquid jet nozzle and the jet-receiving opening that defines a liquid jet path length. The invention also provides surgical methods utilizing the inventive surgical liquid jet instruments, and methods for forming components of the surgical liquid jet instruments.

Owner:HYDROCISION

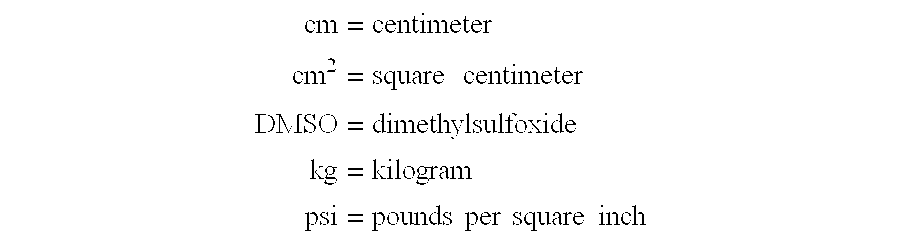

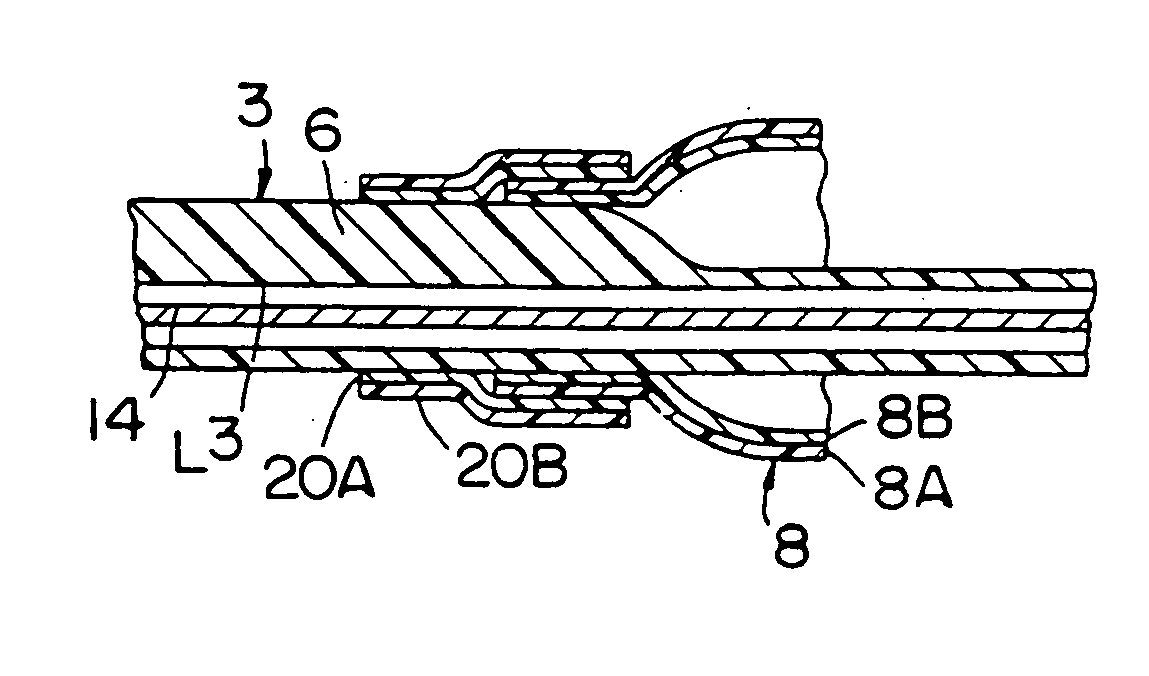

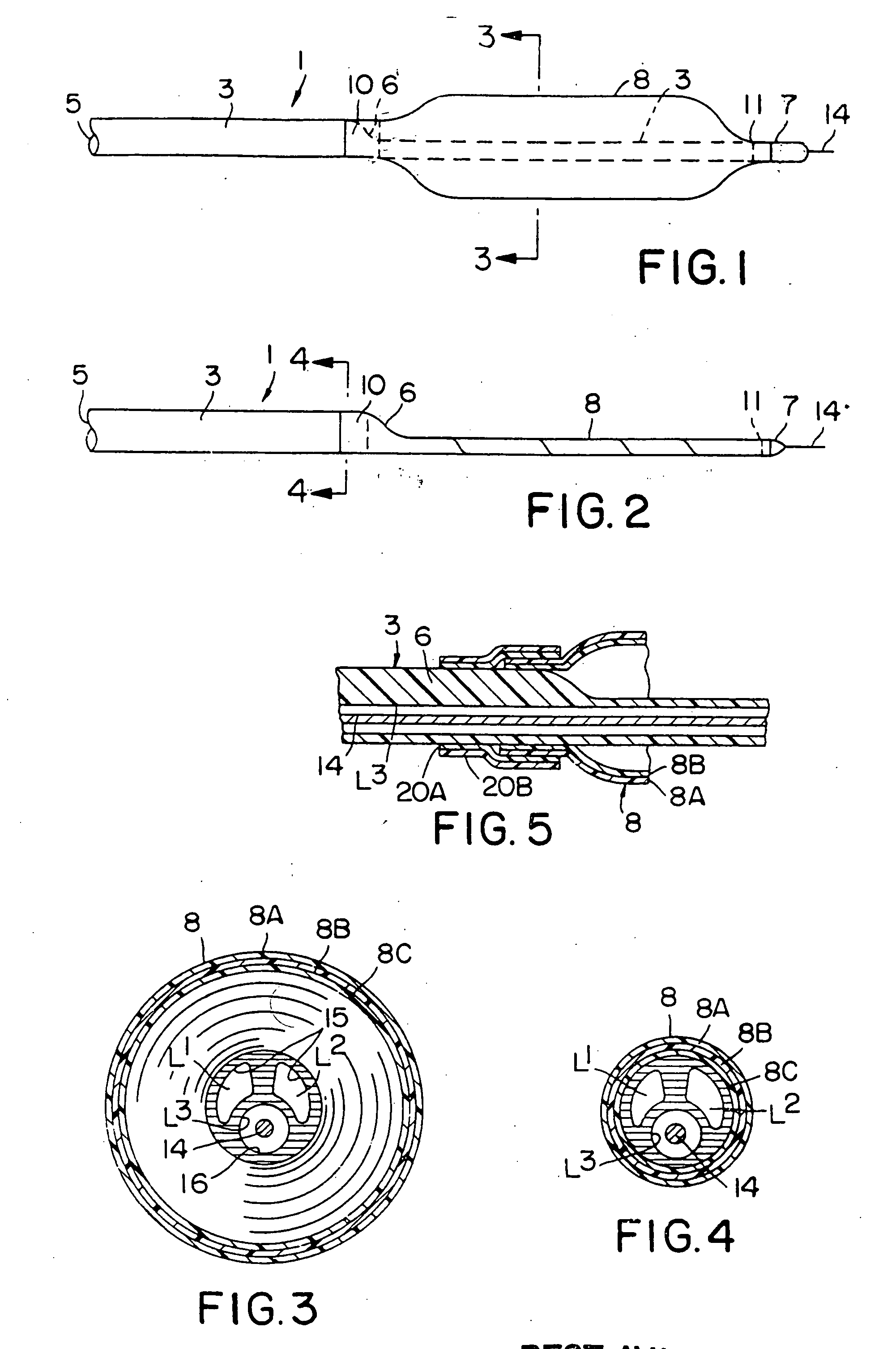

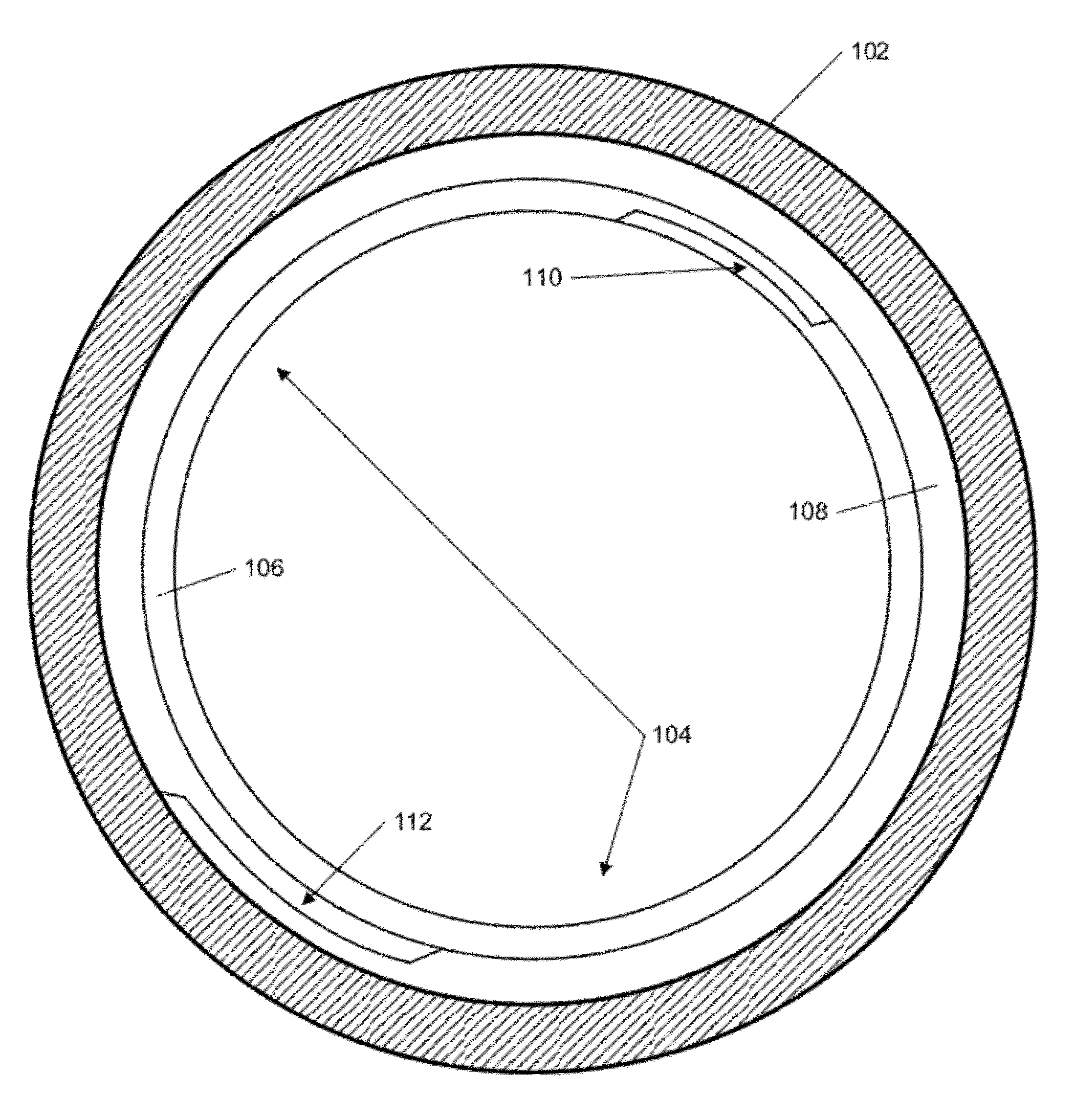

Flow directed catheter

A flow directed microcatheter is formed having a gradually changing flexibility and diameter between a proximal end and a distal end of the microcatheter. The changing properties of the microcatheter according to the present invention provide the flexibility of the distal tip needed to allow the microcatheter to be directed by the flow of blood within the vasculature, and the columnar strength and torquability at the proximal end and along the length of the microcatheter needed to advance and direct the distal tip to the target site. A proximal segment of the microcatheter includes a plurality of strands which vary in diameter to change the flexibility of the microcatheter. A distal segment of the microcatheter includes an inner layer which is compatible with solvents, such as DMSO, and an outer layer which provides strength and flexibility. The proximal segment and the distal segment of the microcatheter are joined by a kink resistant fuse joint.

Owner:TYCO HEALTHCARE GRP LP

Drug delivery balloon catheter

The present invention is directed to an apparatus and method for delivering a drug to a selected site in the vascular system of a patient. More specifically, the apparatus is a balloon catheter comprising an expandable balloon with a pouch around at least a portion of the balloon. When the balloon is not expanded, an agent can be located in the area between the pouch and the balloon. The agent is released through the pouch when the balloon is expanded.

Owner:NOVOSTE CORP

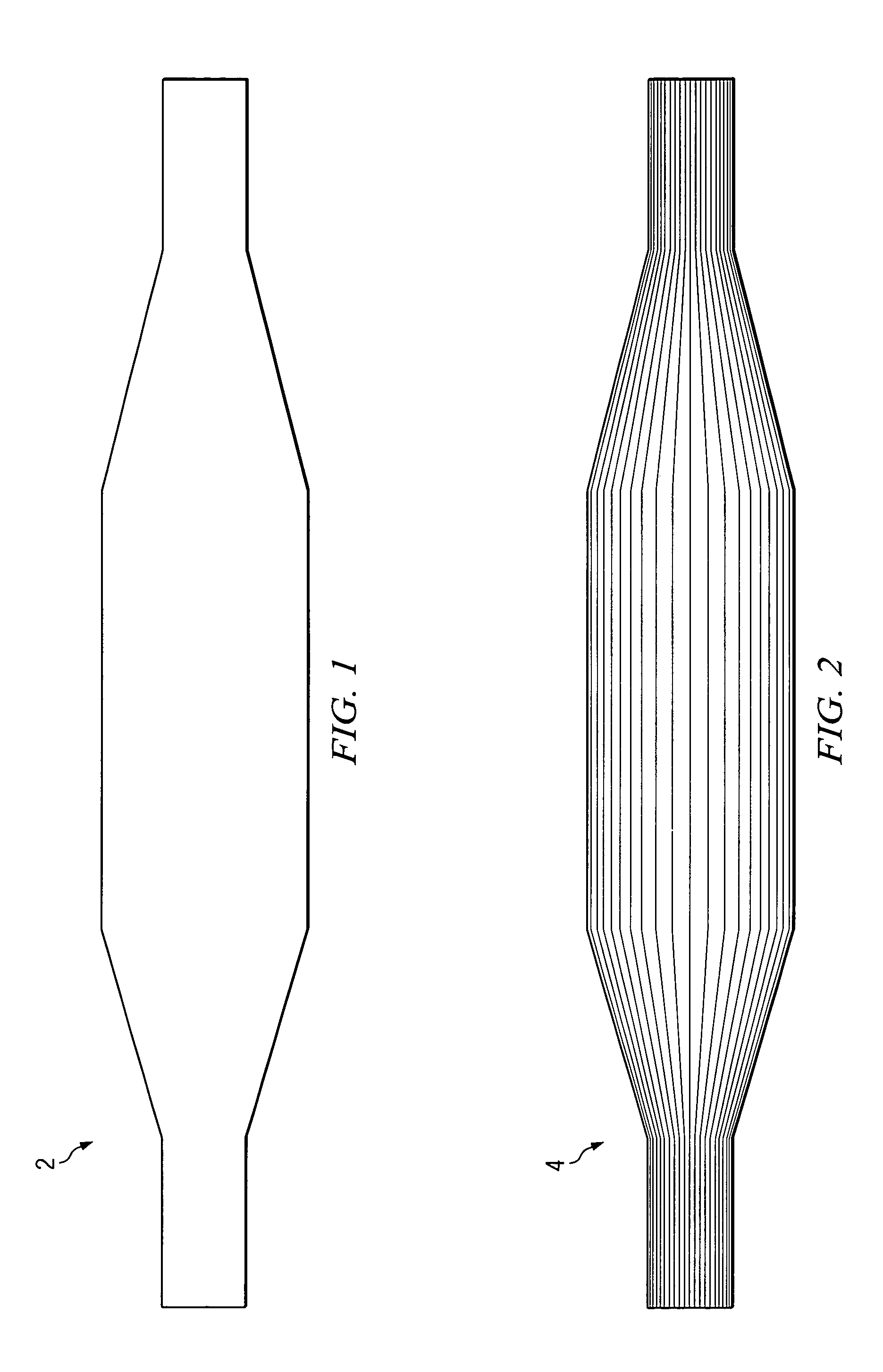

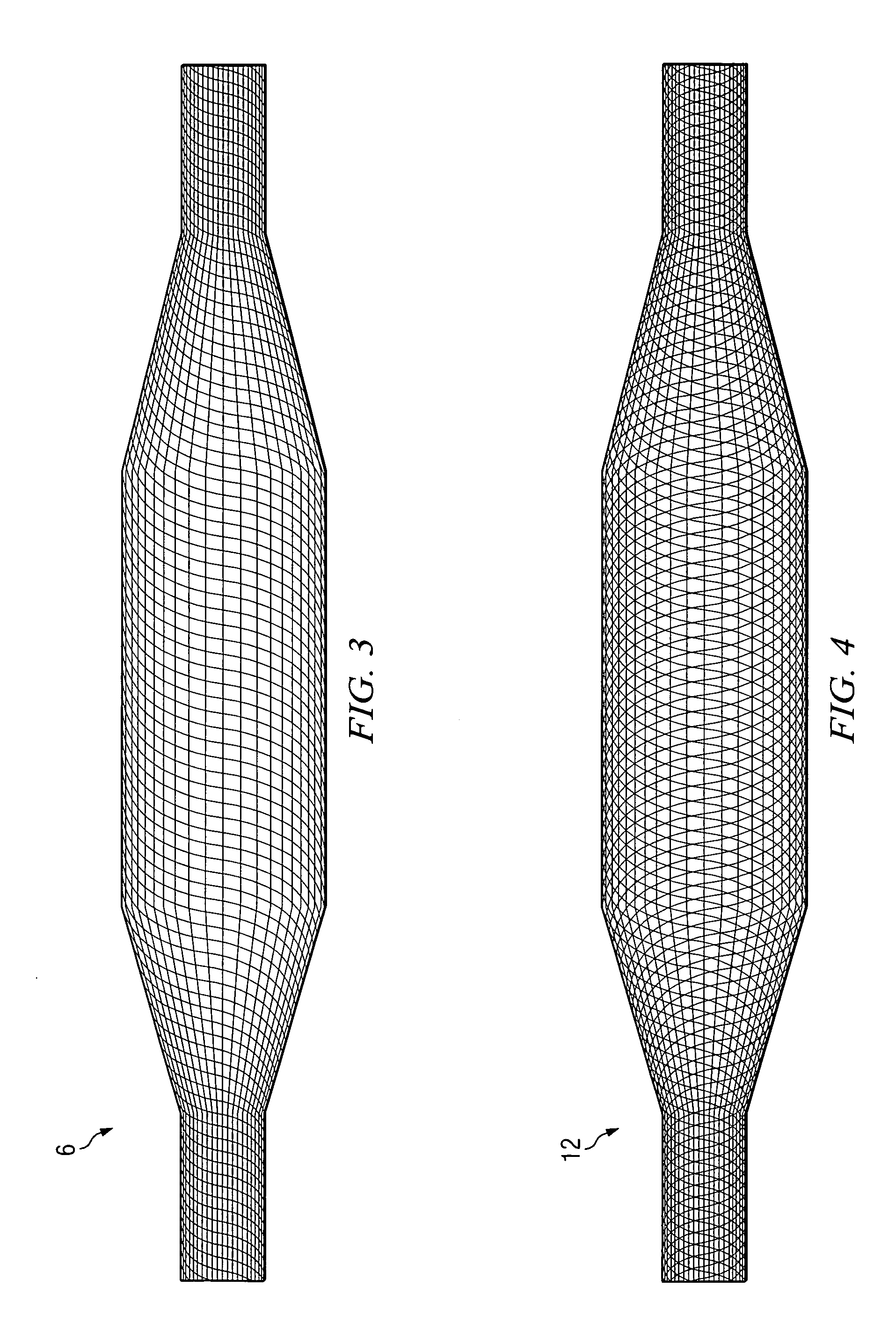

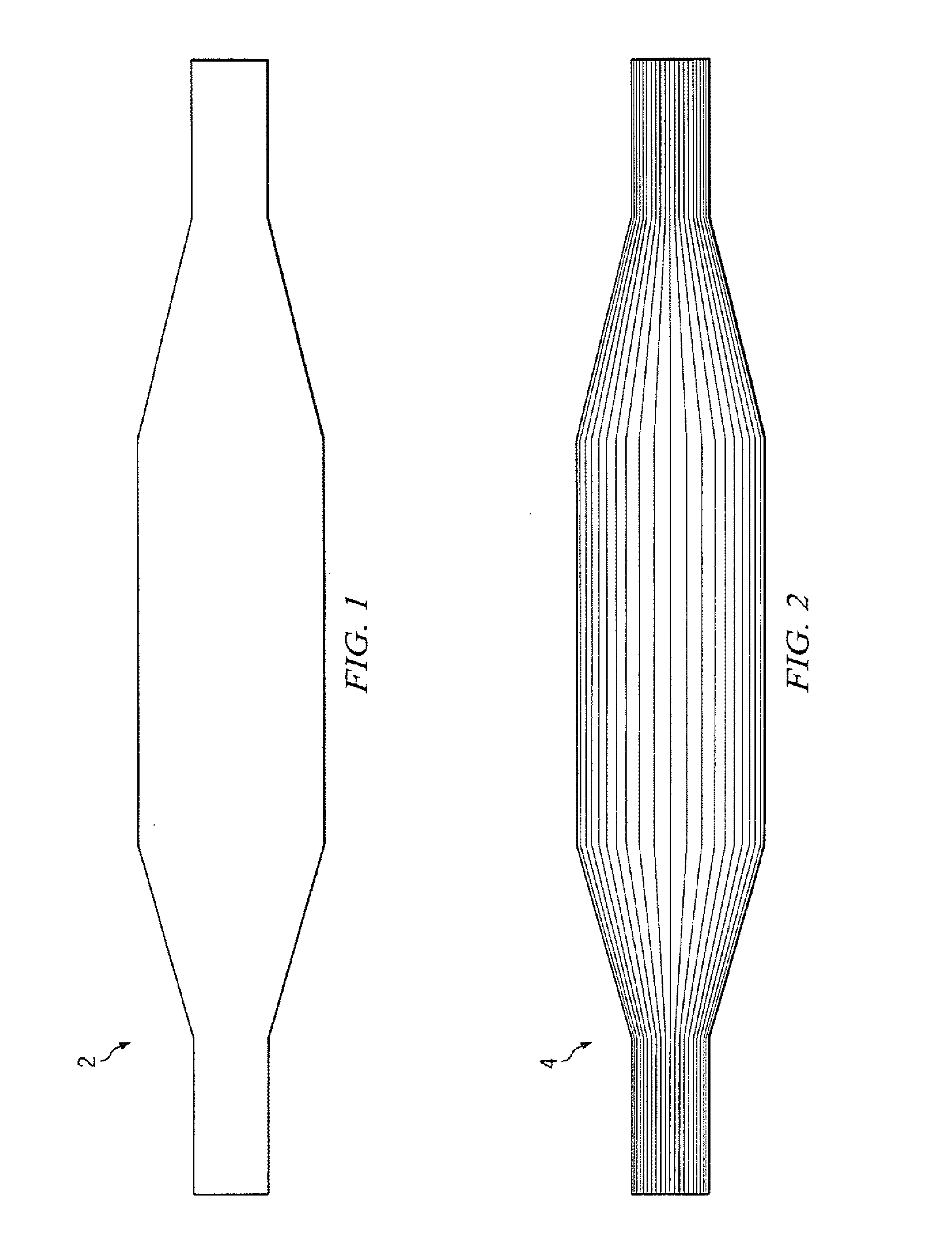

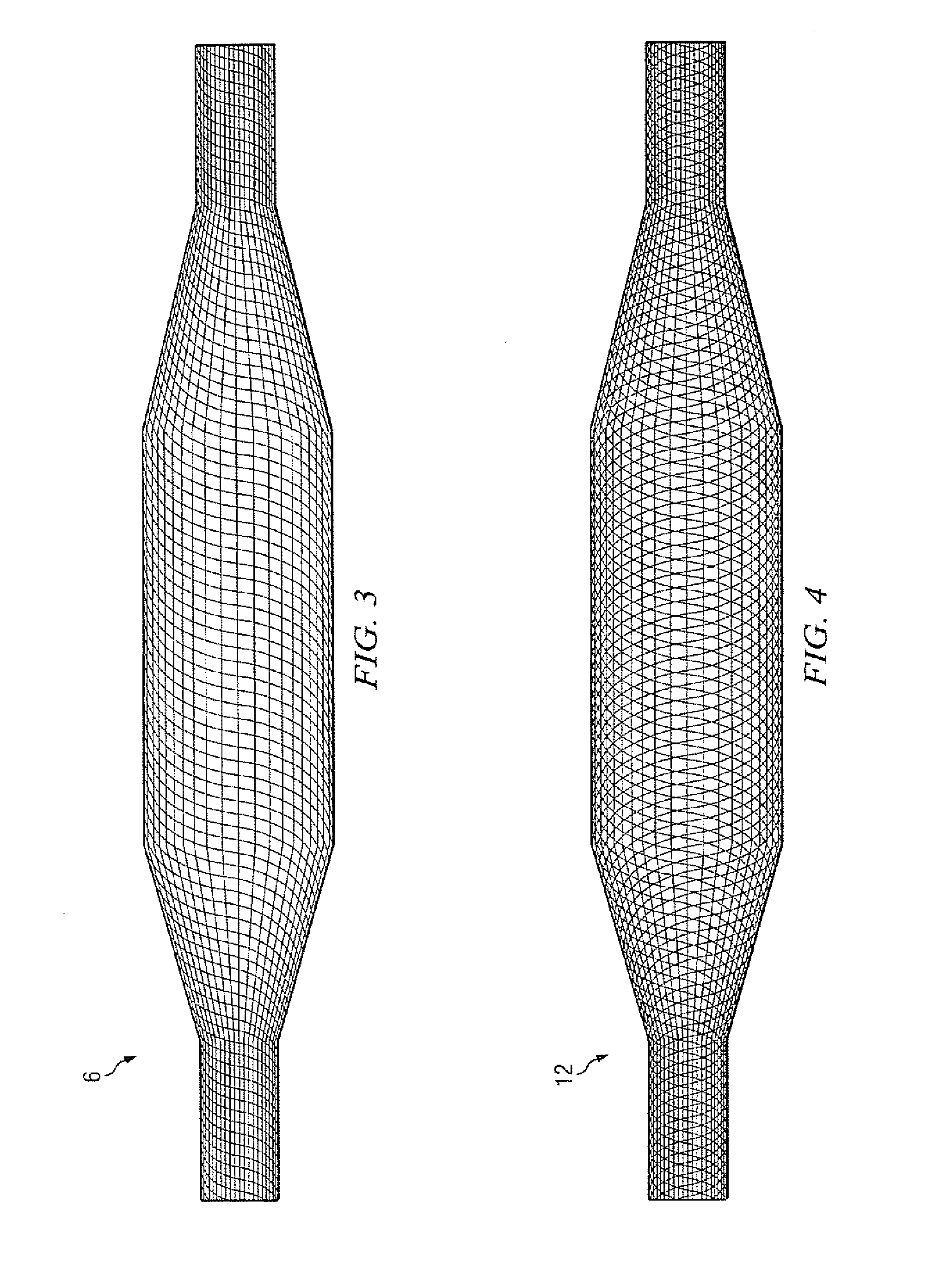

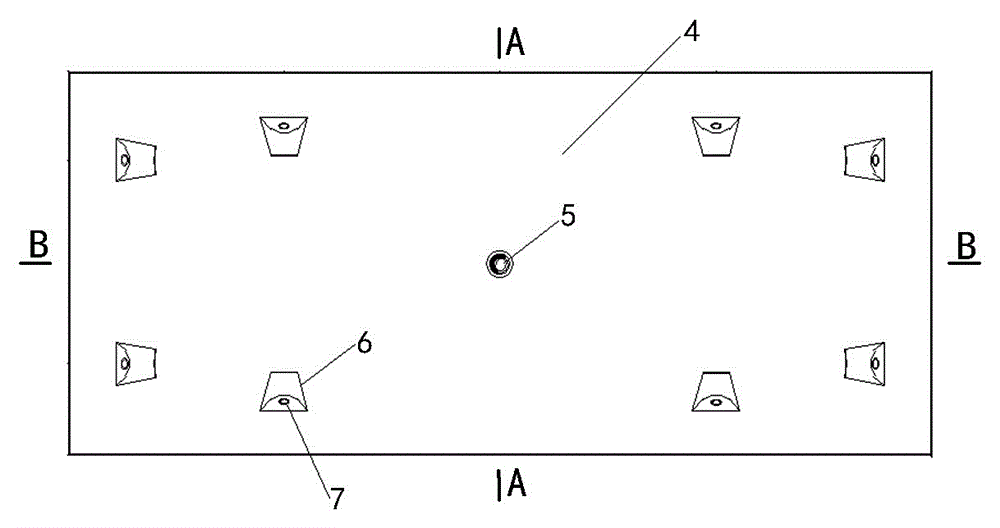

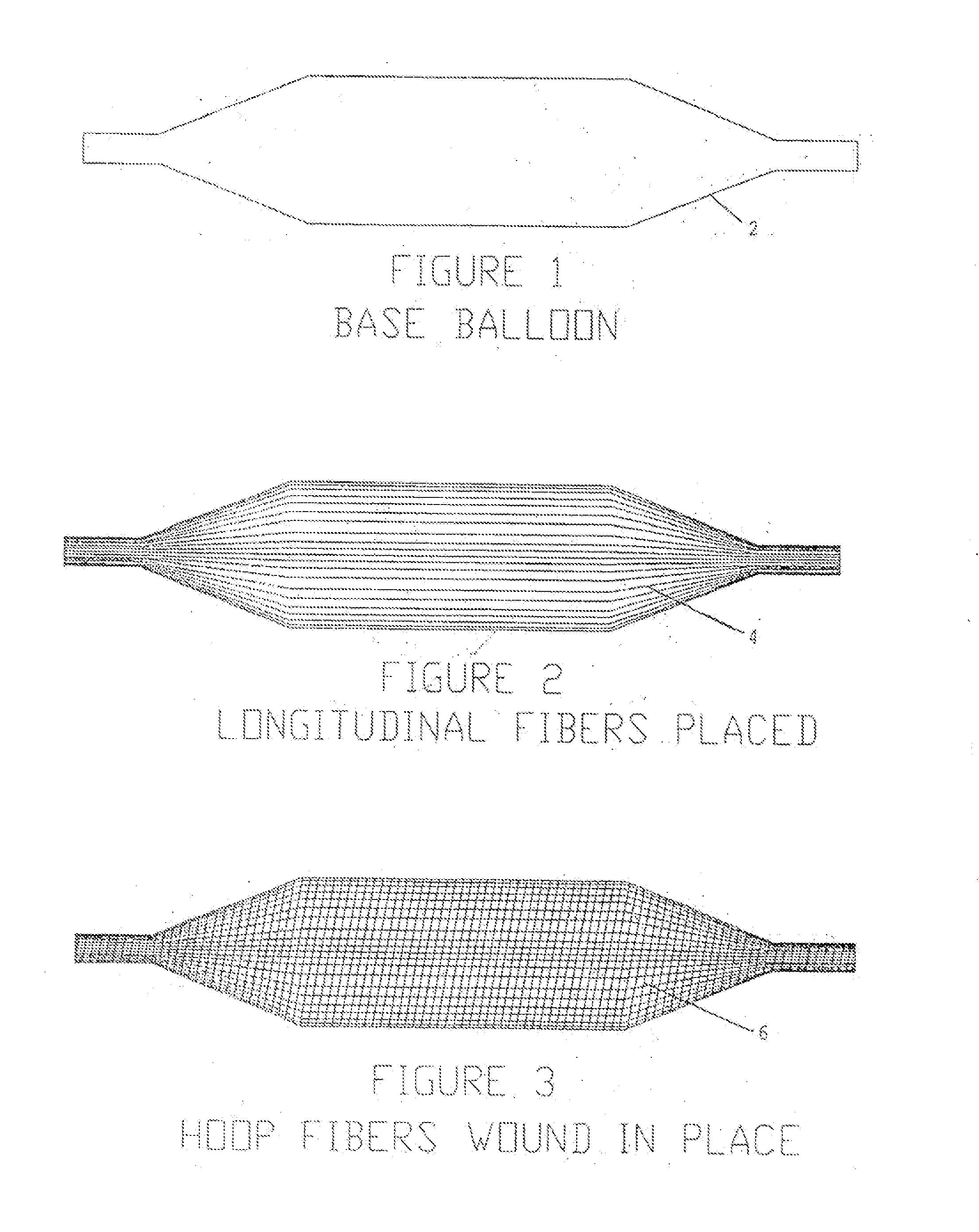

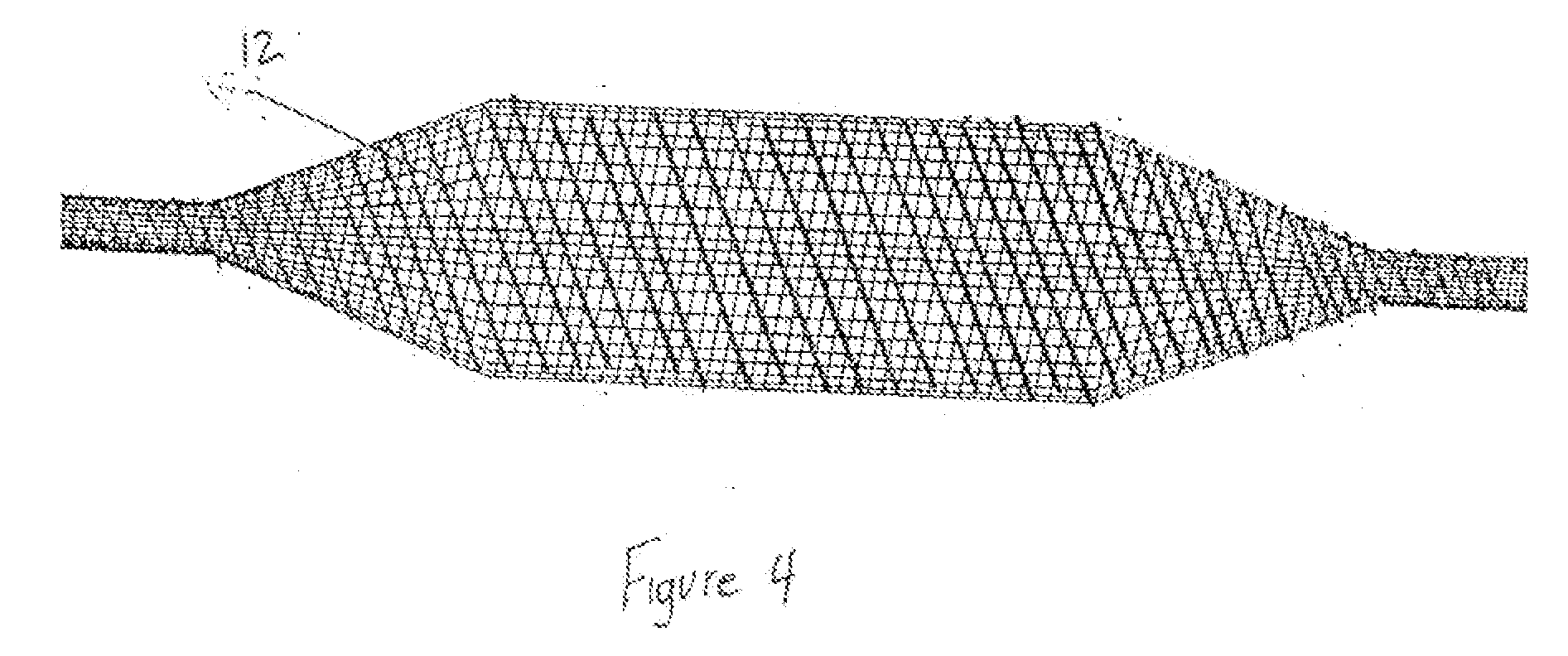

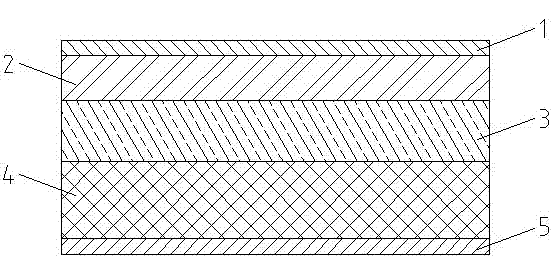

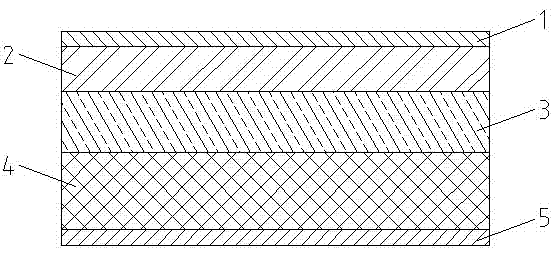

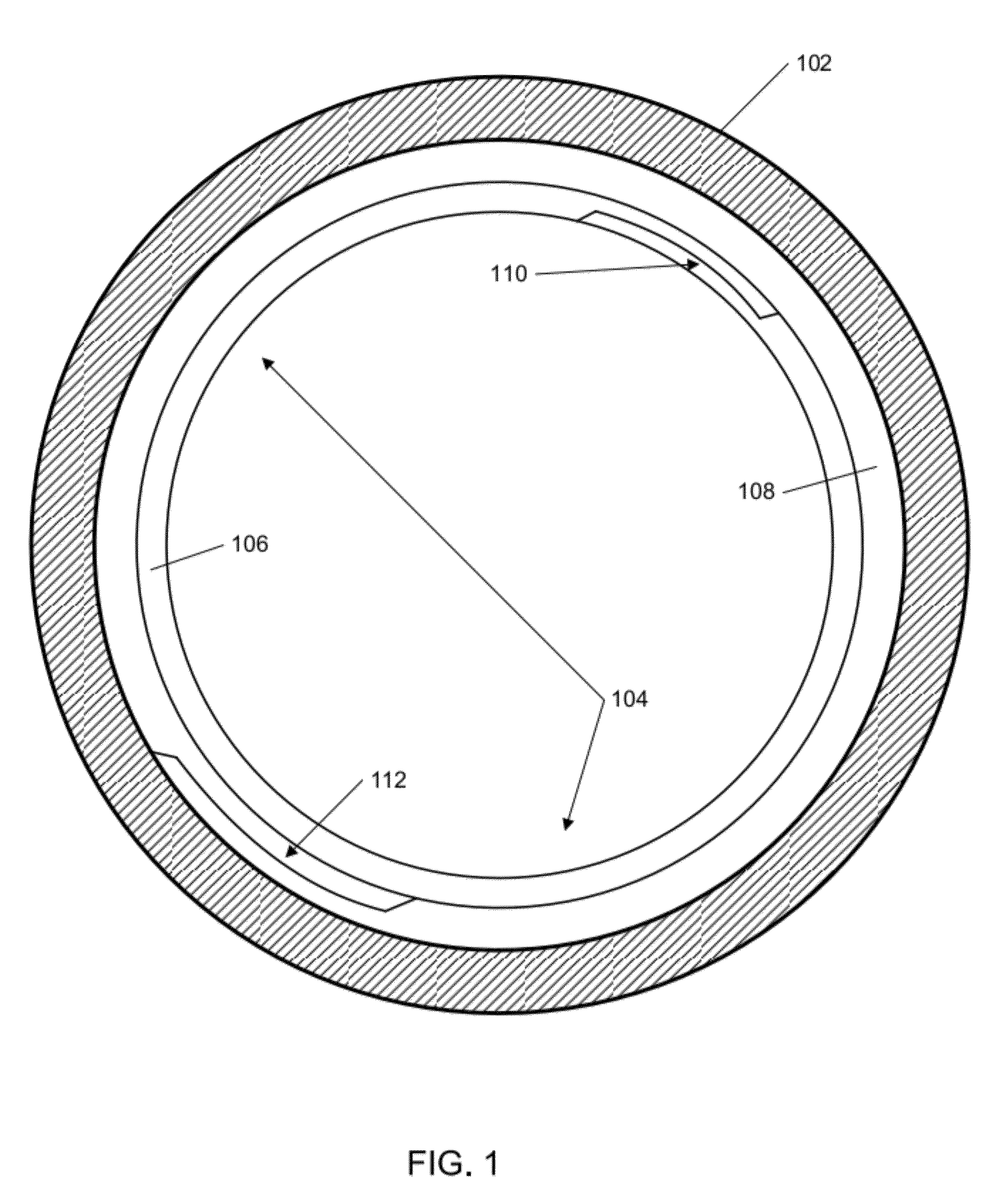

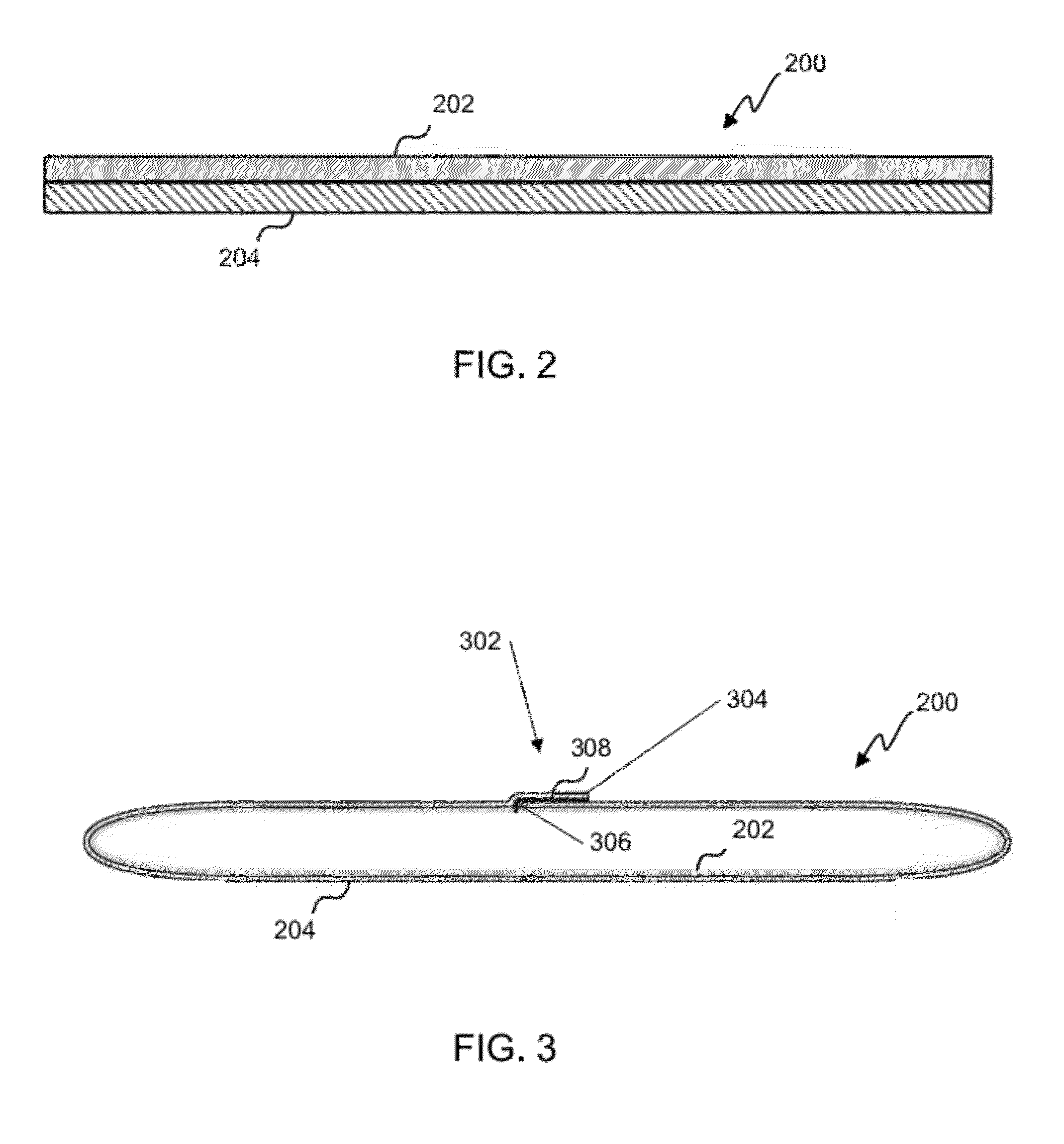

Non-compliant medical balloon having a longitudinal fiber layer

InactiveUS20050123702A1High tensile strengthSuperior burst strengthBalloon catheterLayered productsFiber layerMedicine

Owner:CR BARD INC

Co-extruded medical balloon

InactiveUS20050238833A1Excessive abrasionSoft touchBalloon catheterSurgeryCopolymerBiomedical engineering

A medical balloon for attachment to a catheter tube, and method of making the balloon. The balloon comprises a plurality of co-extruded and coextensive layers of different polymeric materials (20A, 20B) at least one of which is a base structural layer (20B) and the other of which (20A) is formed of polyethylene and copolymers thereof or of Selar. The base structural layer is thicker than the other layer.

Owner:BOSTON SCI SCIMED INC

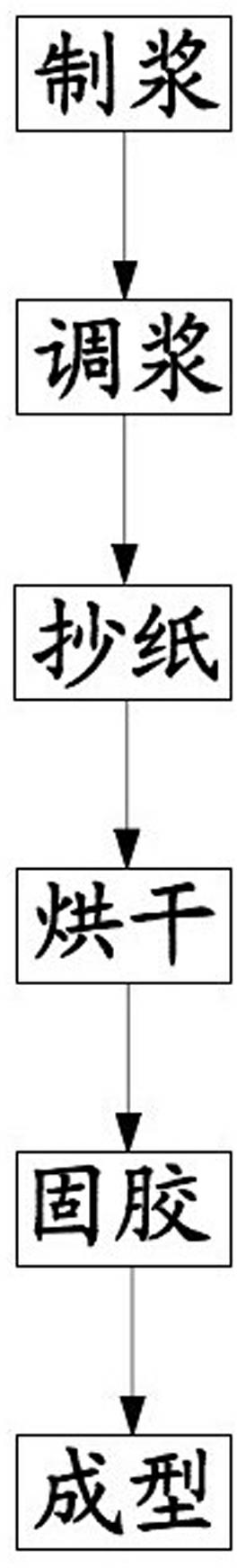

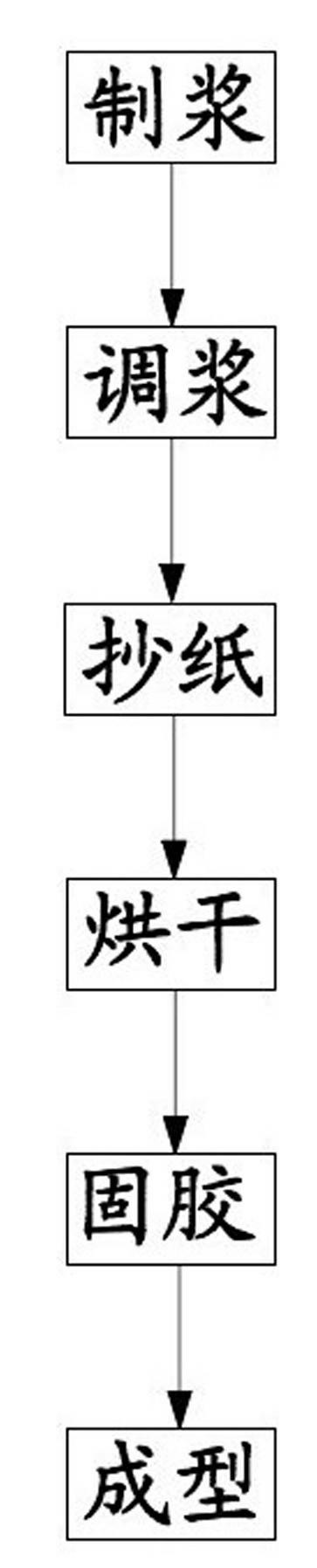

Filter paper for cooling system in wire electrical discharge machining (WEDM) and production method of filter paper

InactiveCN102444054AReduce the maximum apertureReduce the average pore sizeNon-fibrous pulp additionPaper/cardboardPolyesterGlass fiber

The invention relates to filter paper for a cooling system in wire electrical discharge machining (WEDM), which comprises the following components in percent by weight: 18-25 percent of phenolic resin, 0.5-5 percent of glass fiber, 0.5-5 percent of polyester fiber and 65-82 percent of wood pulp fiber. A production method of the filter paper comprises the steps of pulping, pulp mixing, paper making, drying, glue setting and forming. The filter paper adopts the wood pulp fiber as the main material which is matched with a proportion of glass fiber and polyester fiber, so that the bore diameter of the filter paper can be reduced, and the filtering accuracy can be improved; and in addition, since the polyester is chemically-synthesized fiber and has high strength, the bursting strength of the filter paper is improved, and the service life of the filter paper is prolonged. In the production process of the filter paper, thermosetting phenolic resin is introduced by dipping setting glue, and the size stability, the high temperature resistance and the water resistance of the filter paper are further improved. When being applied to a cooling liquid circulating system in WEDM, the filter paper is not deformed or expanded and has good strength in water, and the phenomena of water jetting and black water generating due to bursting are avoided.

Owner:SUZHOU XINYE PAPER - MAKING

Non-transparent quartz crucible for polysilicon crystallization and manufacturing method thereof

InactiveCN101348324AHighlight substantive featuresSignificant progressGlass shaping apparatusSilicon compoundsCrack resistanceSlurry

The invention provides an opaque quartz crucible used in multicrystal silicon crystallization and a method for manufacturing the same. The crucible is of a regular square structure, and the compositions in mass ratio of the crucible are more than 99.7 Wt percent of silicon dioxide, less than 600ppm of aluminum oxide and less than 30ppm of ferric oxide. The method comprises the following steps: firstly, a raw material, i.e. high purity quartz is put into granulation equipment for wet method granulation, the grain size is controlled between 70 and 100mu m; then, slurry is fully stirred and then is fed into a gypsum mould under a pressure of between 2 and 3bar after being deposited for 24 to 48 hours; moreover, early grouting is assisted by slight vibration; the slurry is further settled for 5 to 8 hours, and is demoulded after fully dewatered; the slurry is dried inside a drier; and finally, a blank is put in a kiln for sintering so as to obtain the opaque quartz crucible. The proposal adopts grouting forming by a high-purity quartz material, and the sintered crucible has uniform inner structure; moreover, the crucible has excellent thermal shock stability and cracking resistance, and can meet the technological requirements for manufacturing multicrystal silicon cast ingots.

Owner:常熟华融太阳能新型材料有限公司

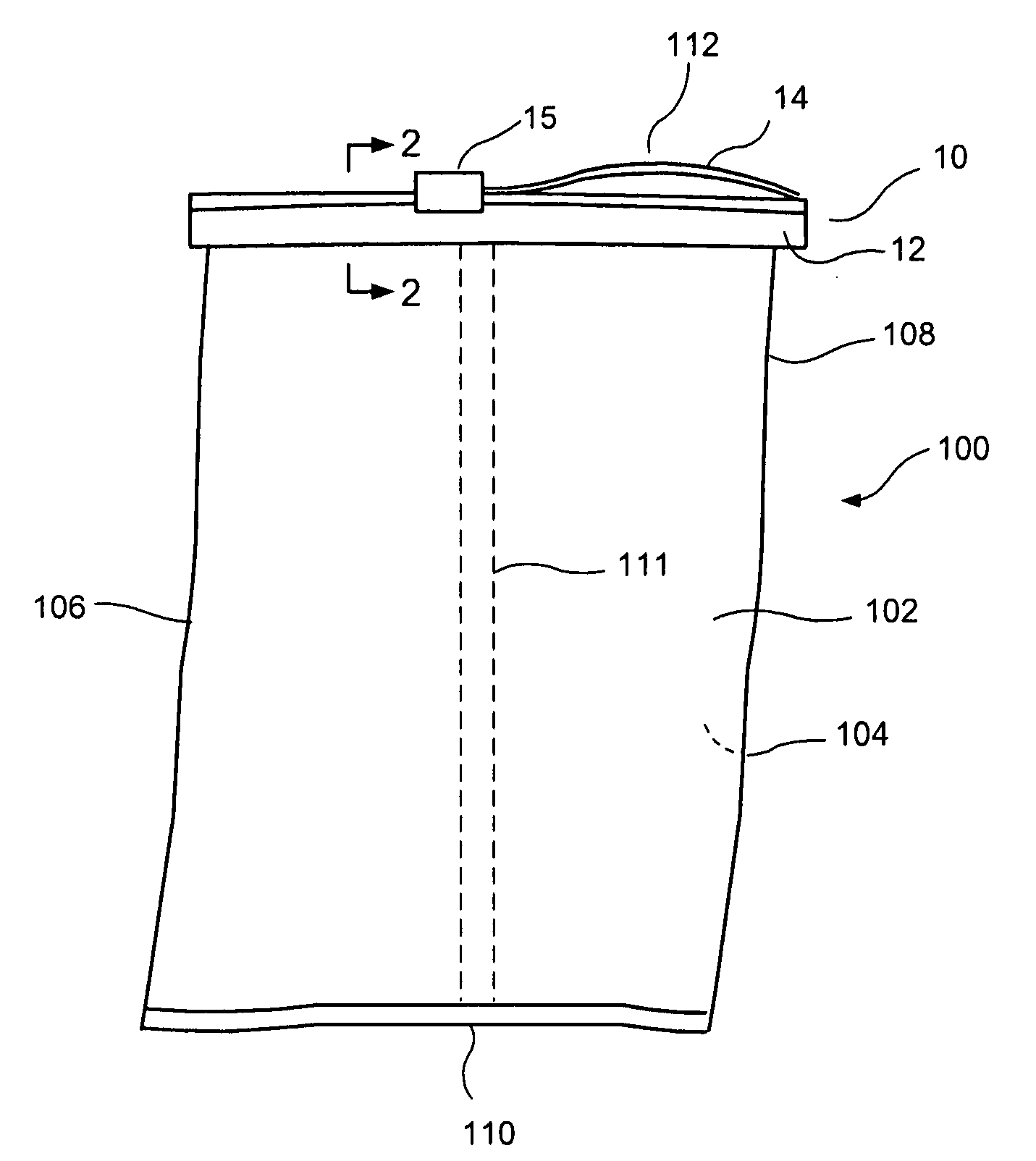

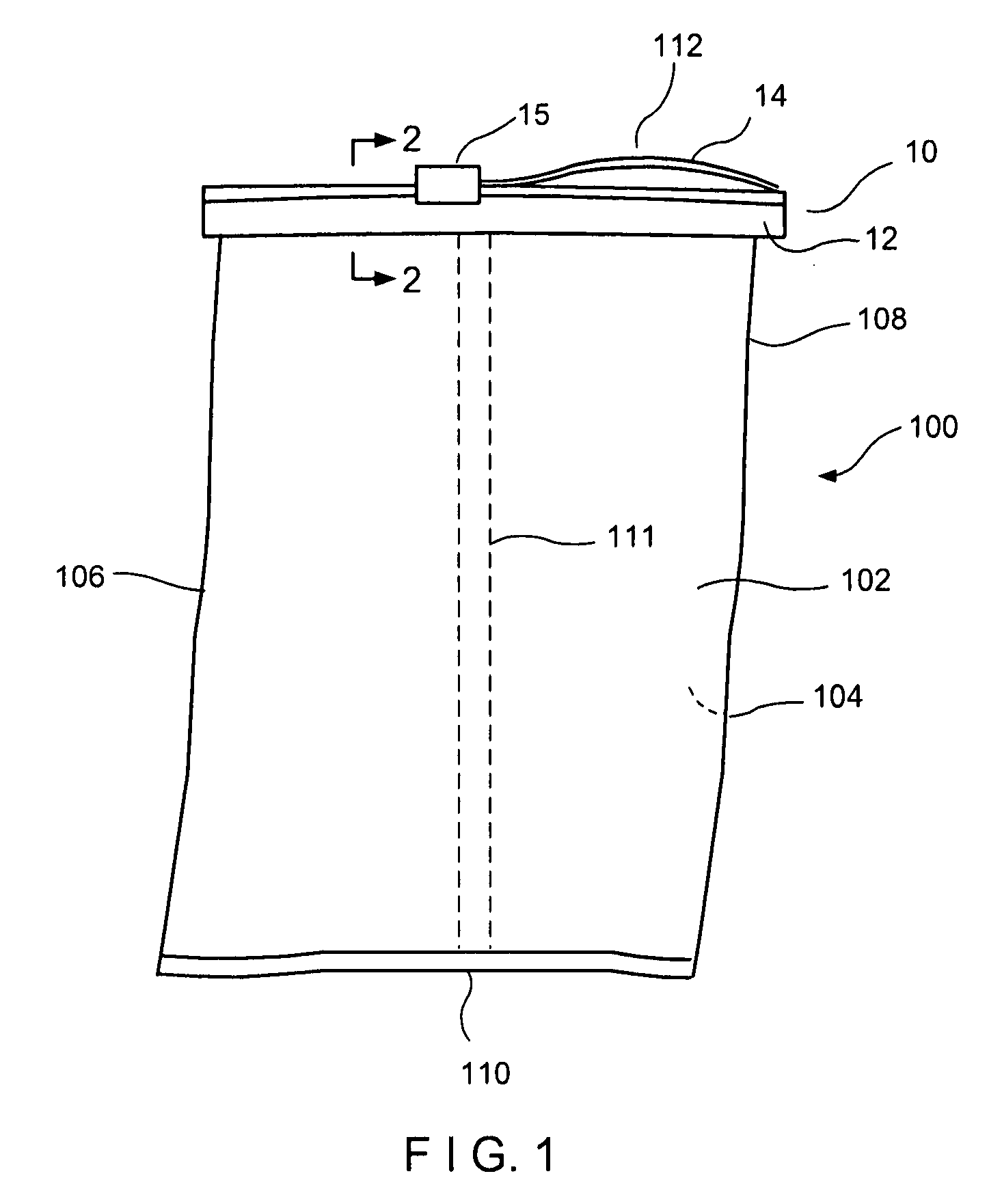

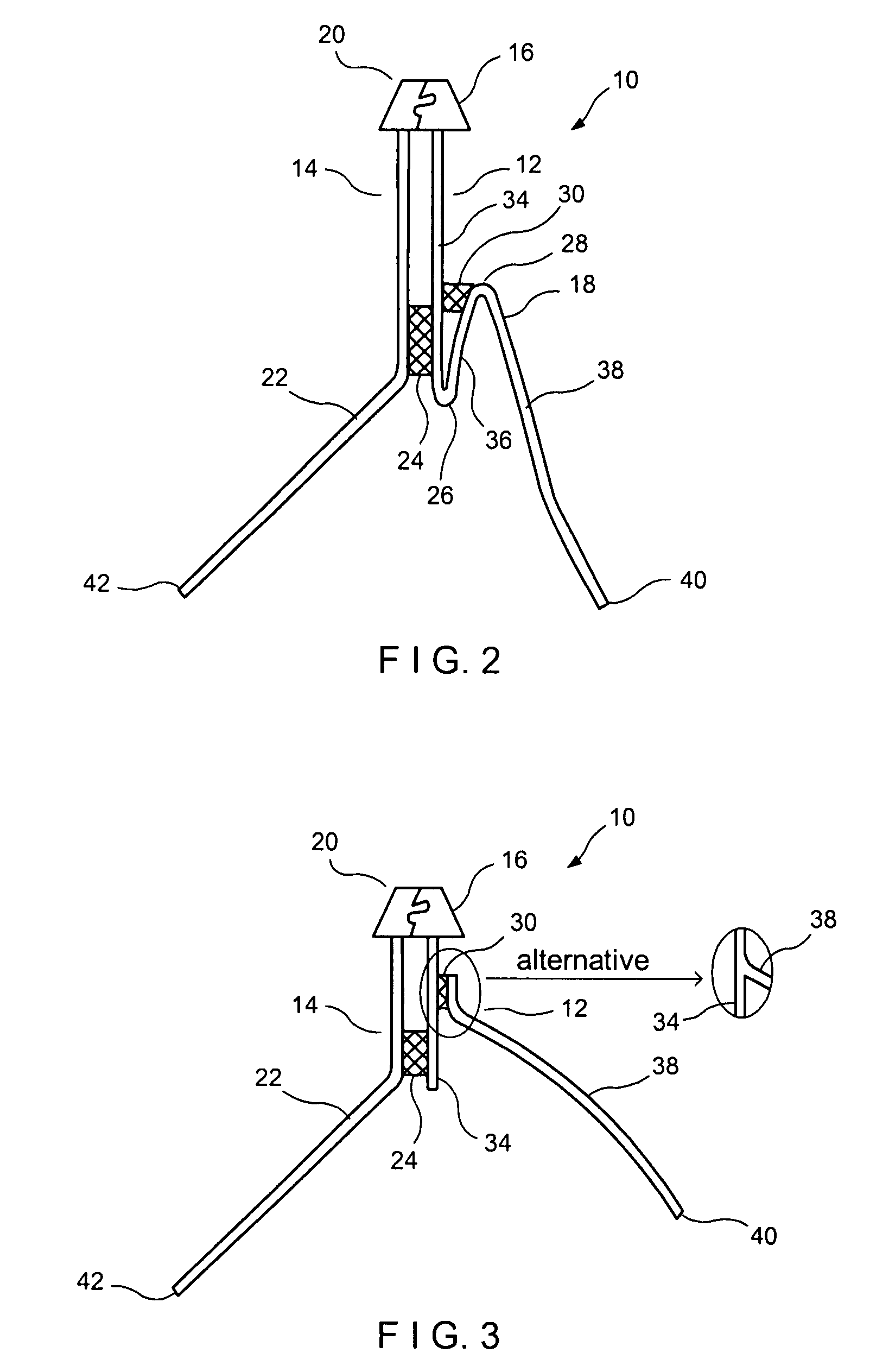

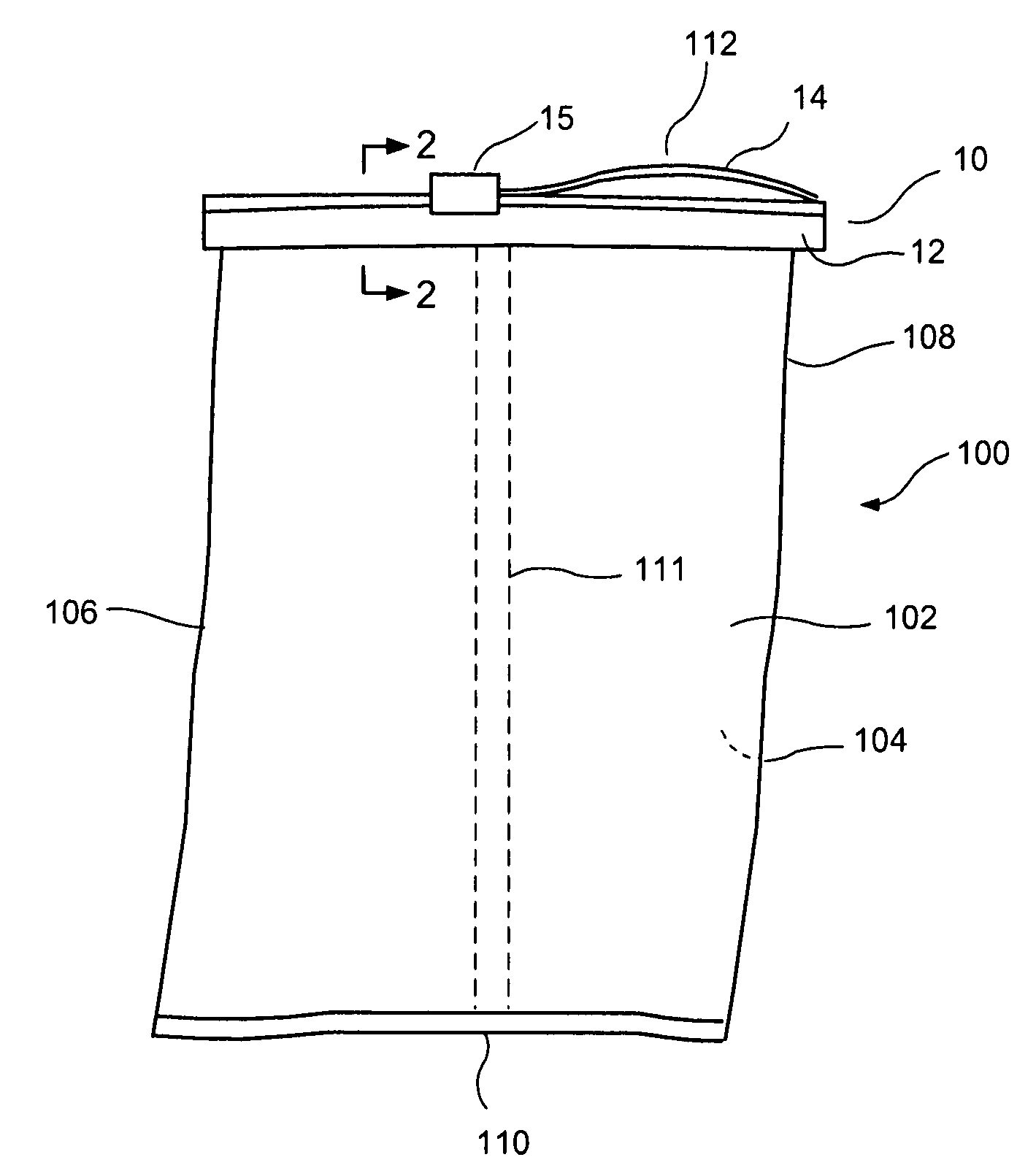

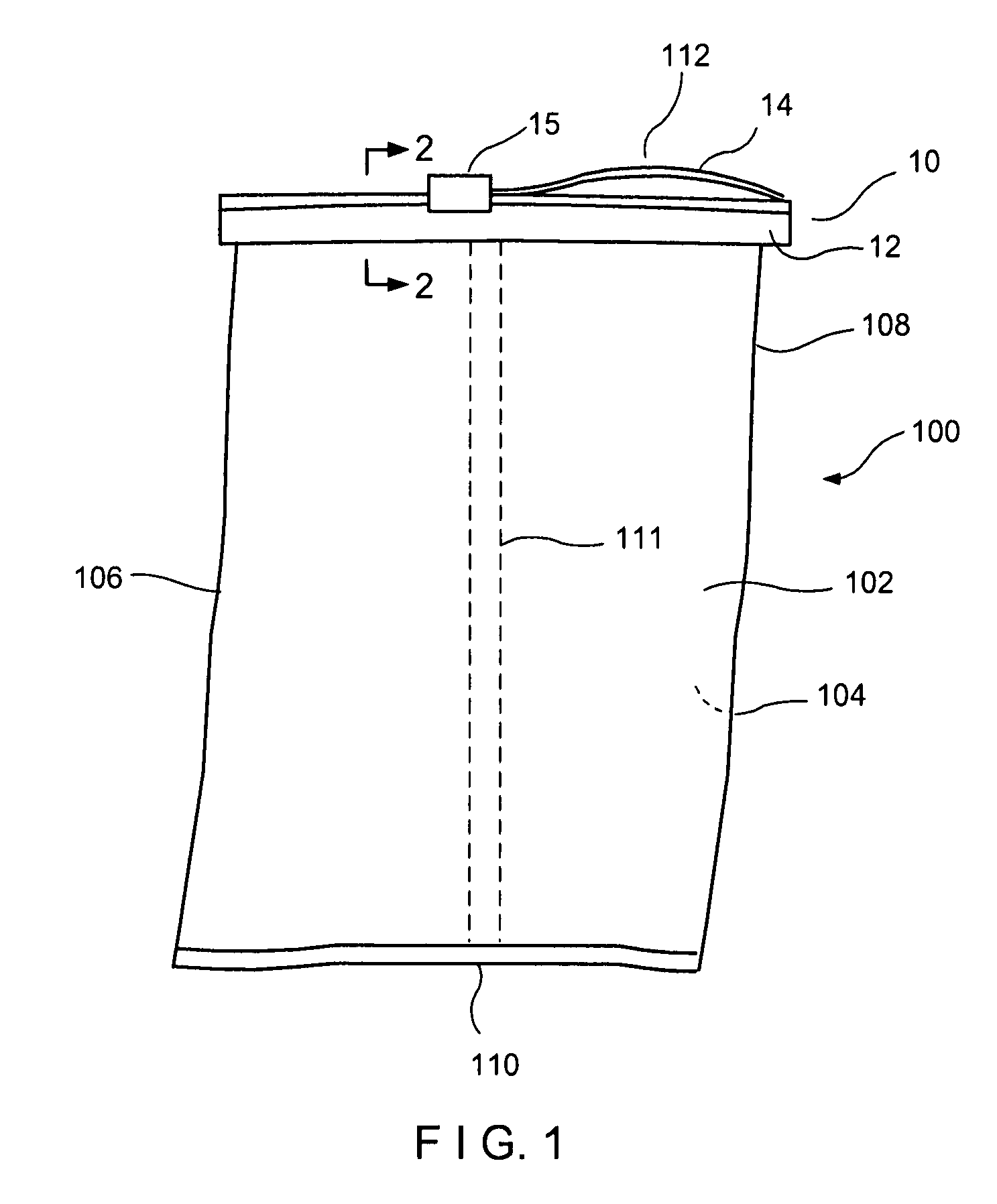

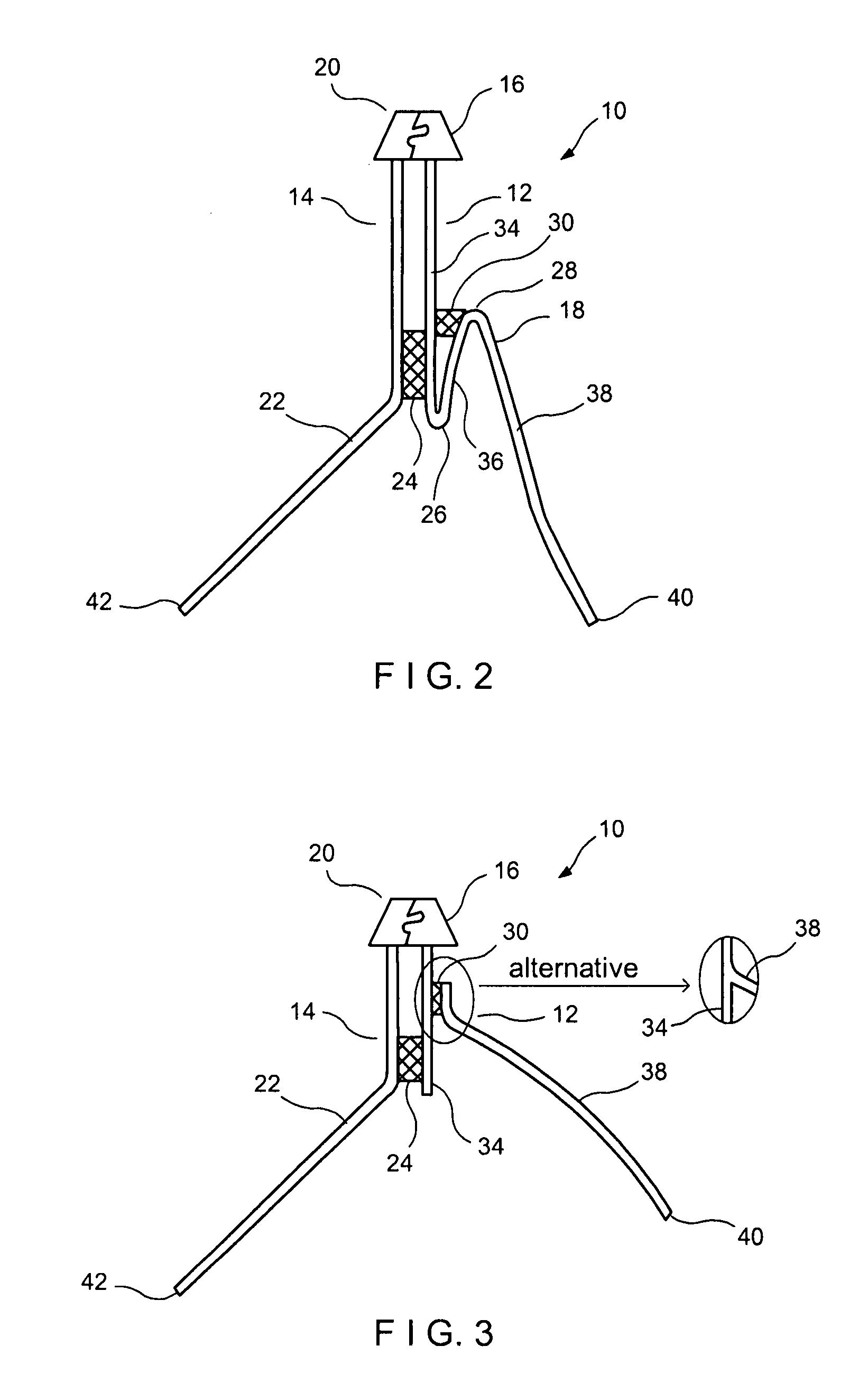

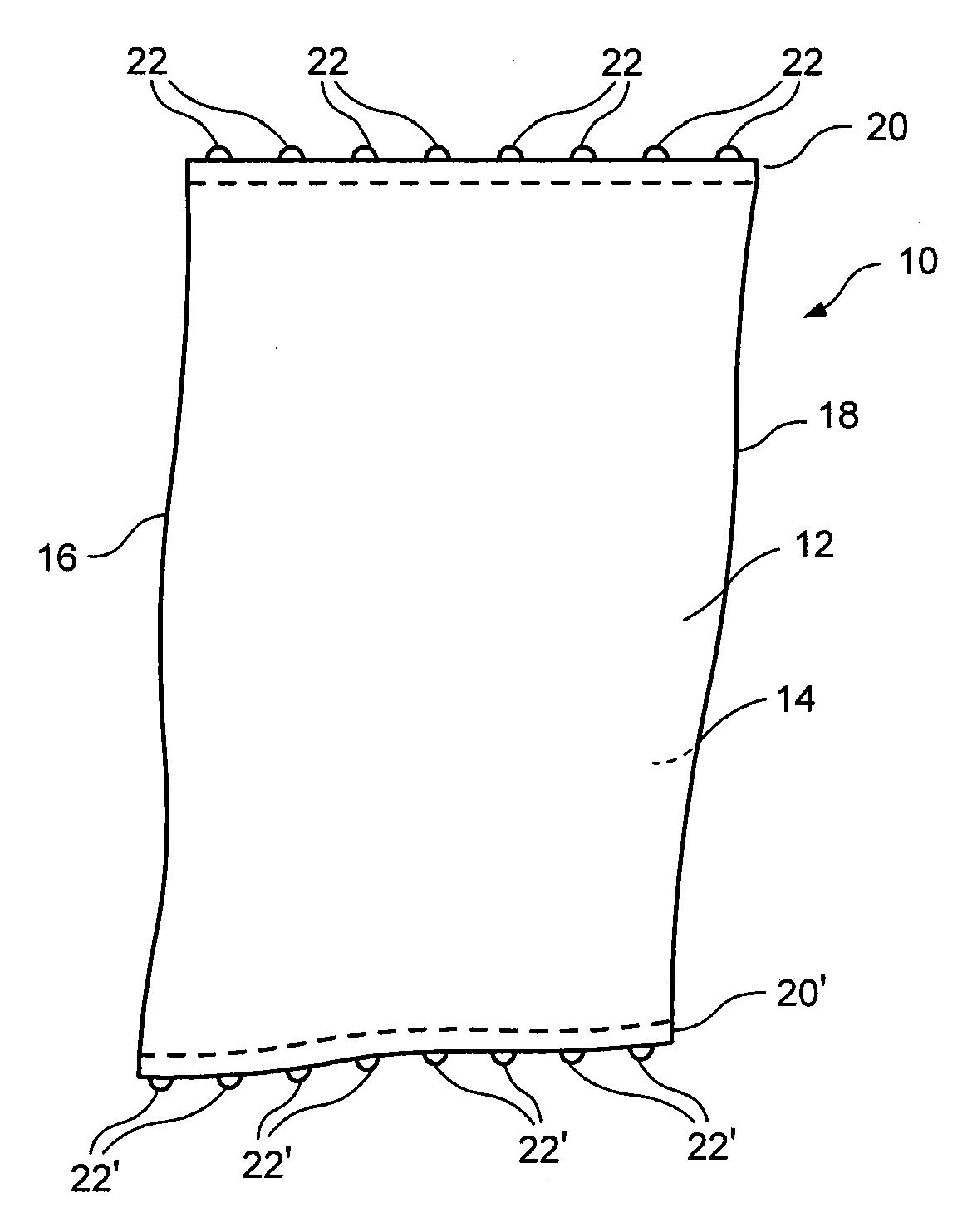

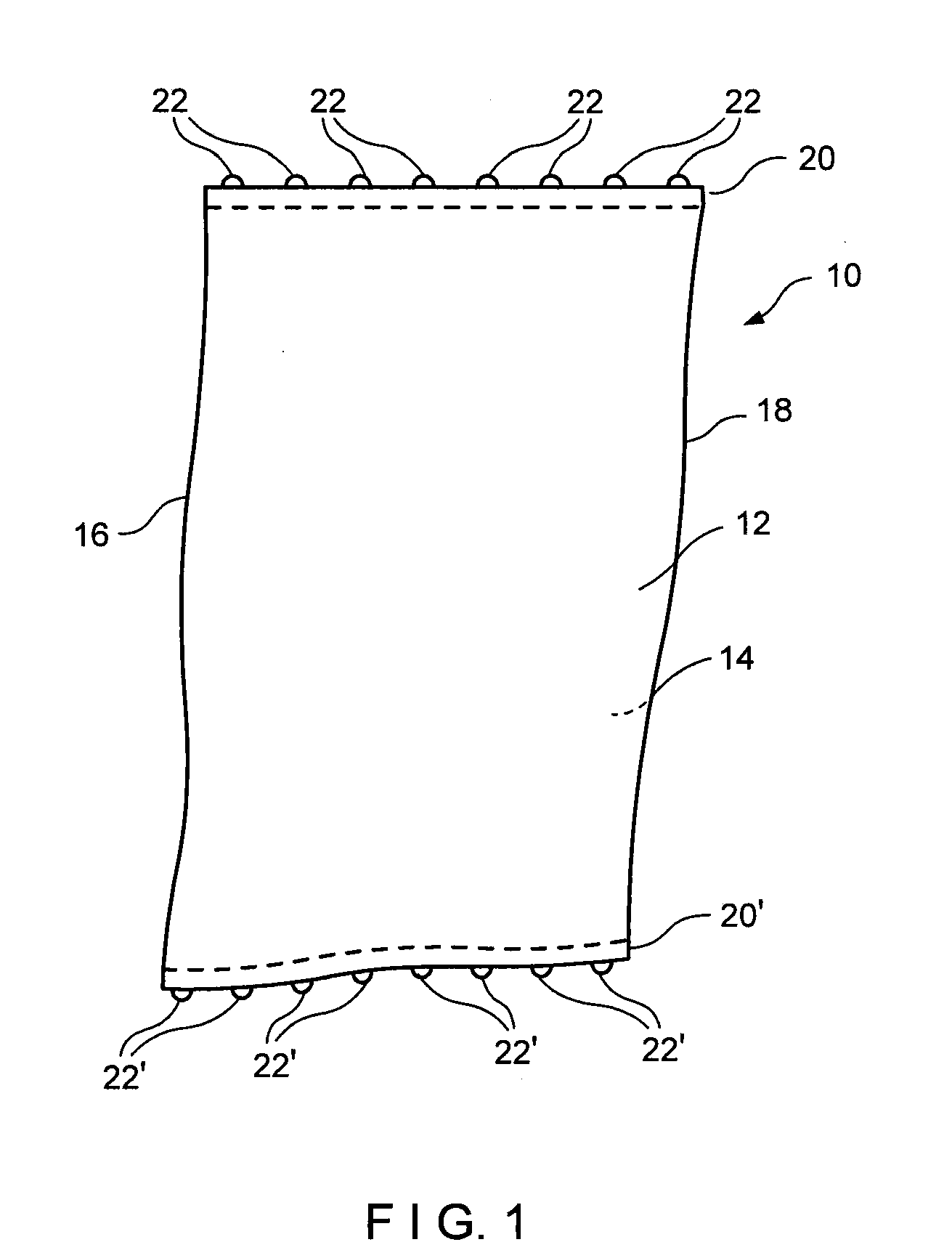

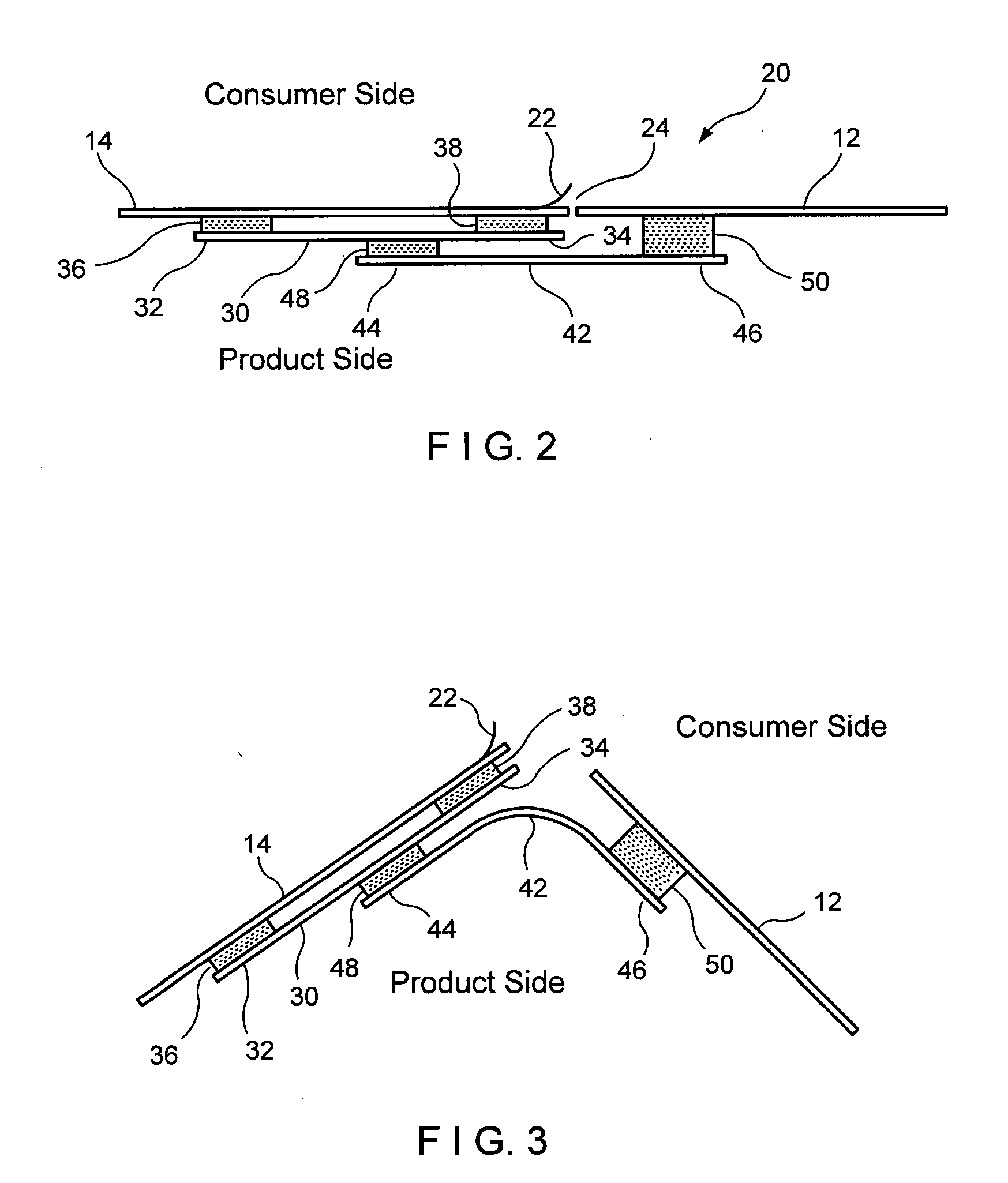

High burst zipper assembly for large reclosable packages

InactiveUS20080050052A1High burst resistanceIncrease in manufacturing and related costSnap fastenersEnvelopes/bags making machineryFlangeShear force

The present disclosure relates to a high burst slider zipper which allows for bottom filling of reclosable packages, such as large bags, and further provides increased resistance to damage from the dropping or shock loading of the filled package. This is achieved by providing a peel seal or other frangible or separable connection between the zipper profiles, and by sealing a portion of one of the flanges to itself by a hard seal above the peel seal. This causes the external forces on a bag from bottom filling or shock loading to be directed toward the hard seal and further directed so as to cause a shear force against the peel seal, thereby increasing the resistance of the package to external forces.

Owner:ILLINOIS TOOL WORKS INC

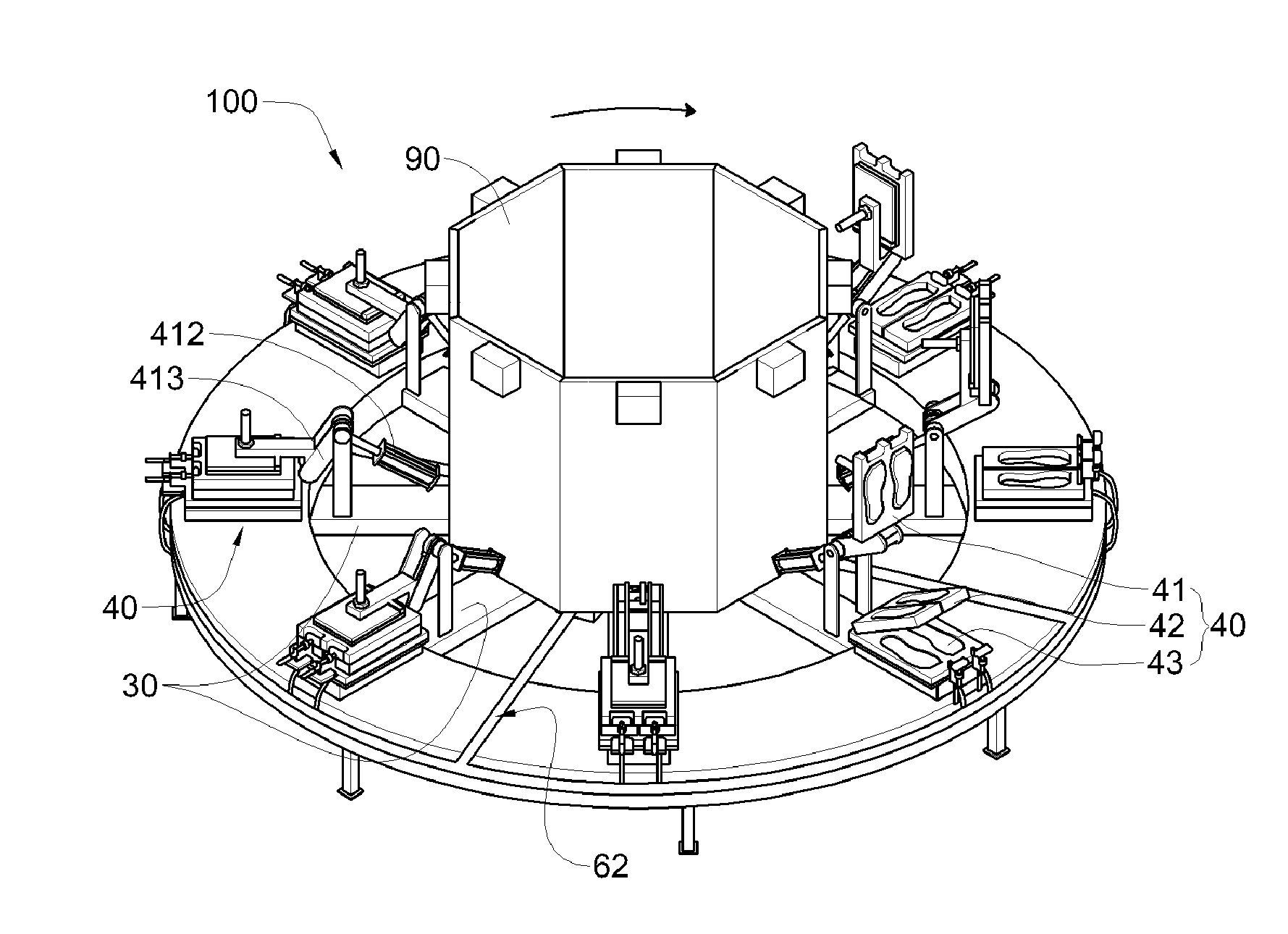

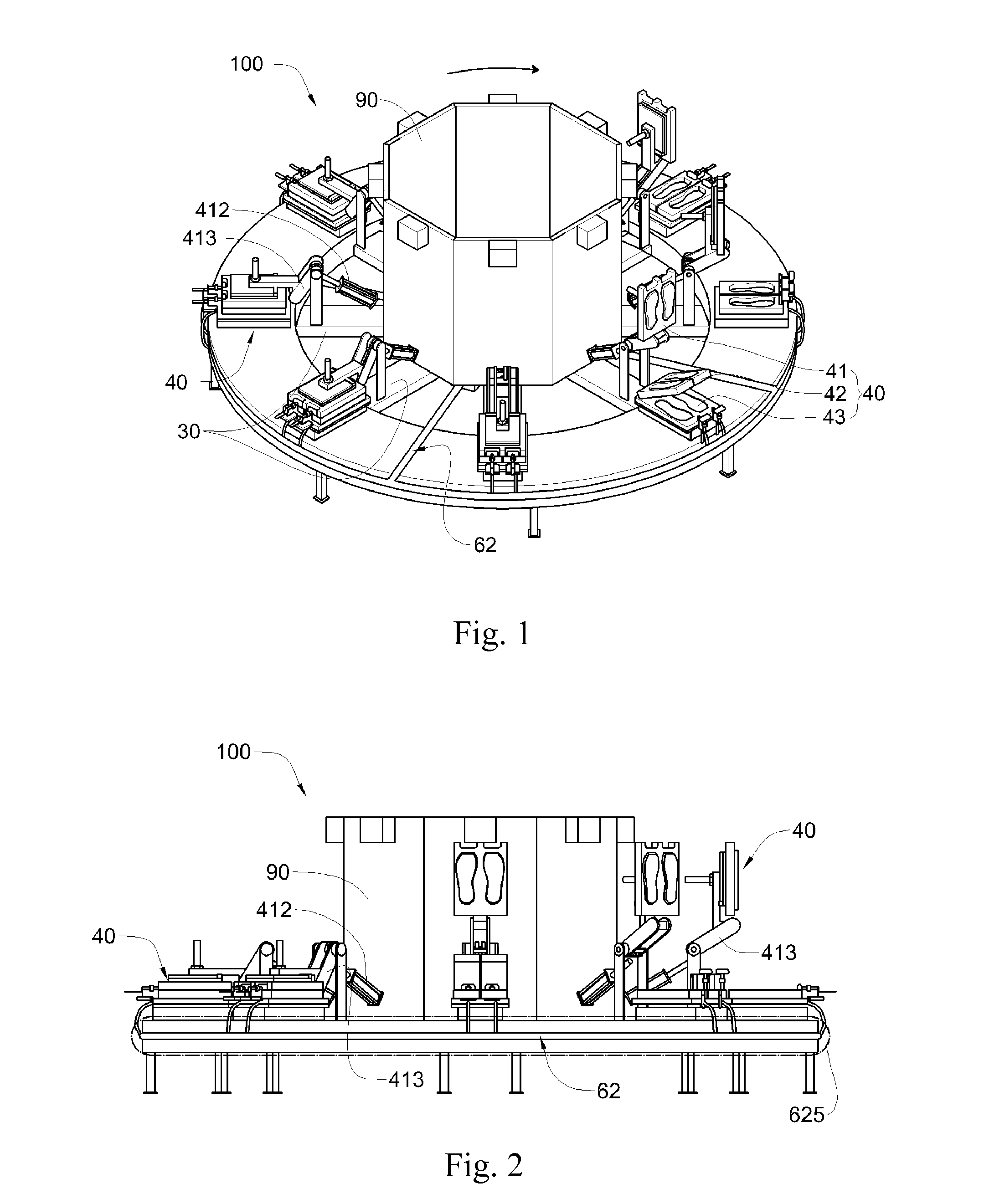

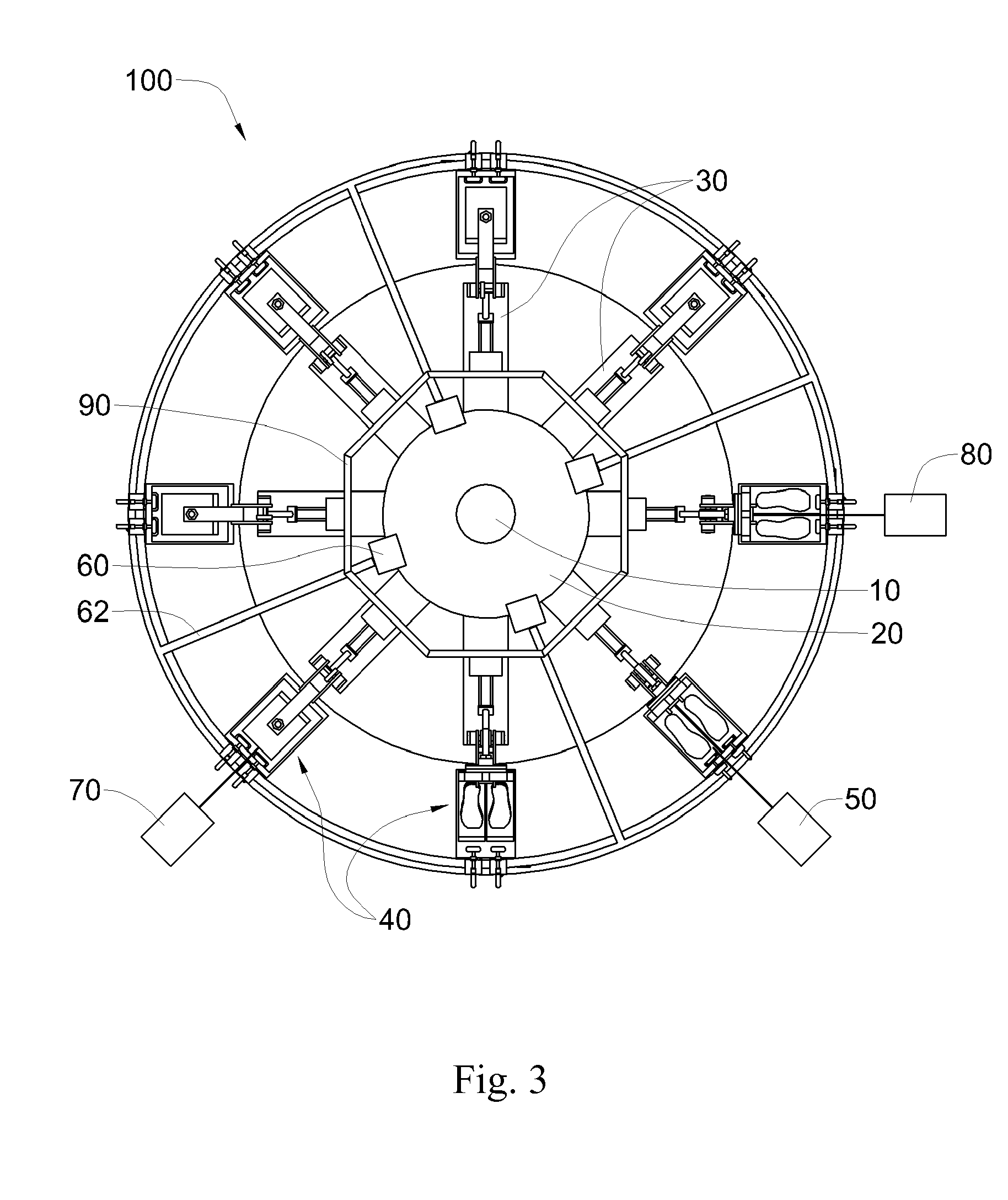

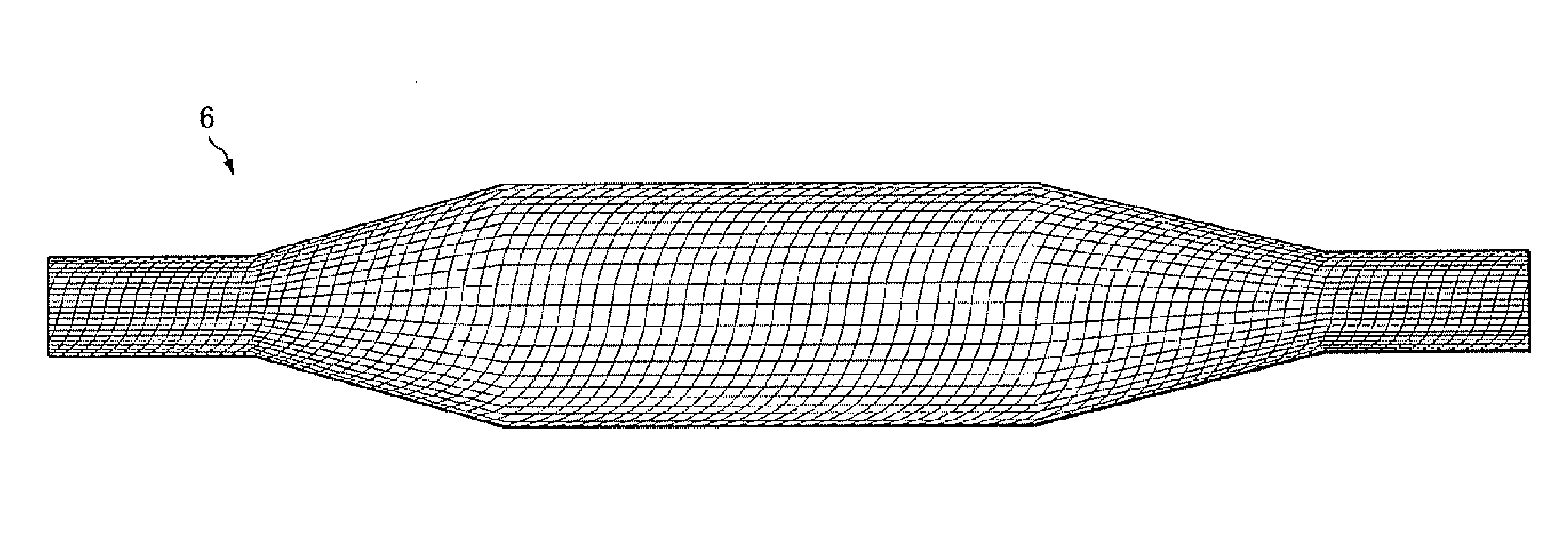

Polyurethane-coated spandex fabric-fused midsole and apparatus and method for manufacturing the same

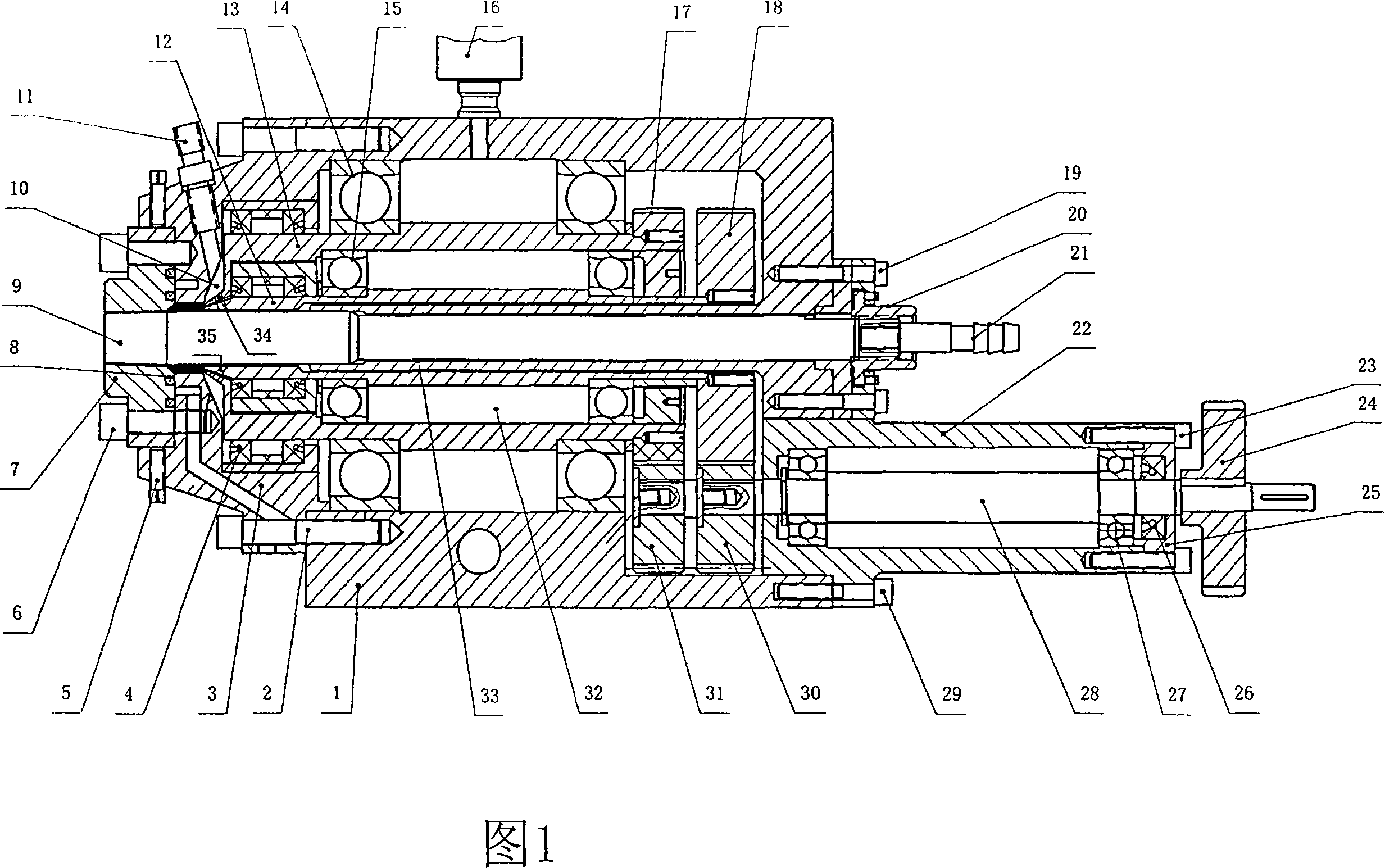

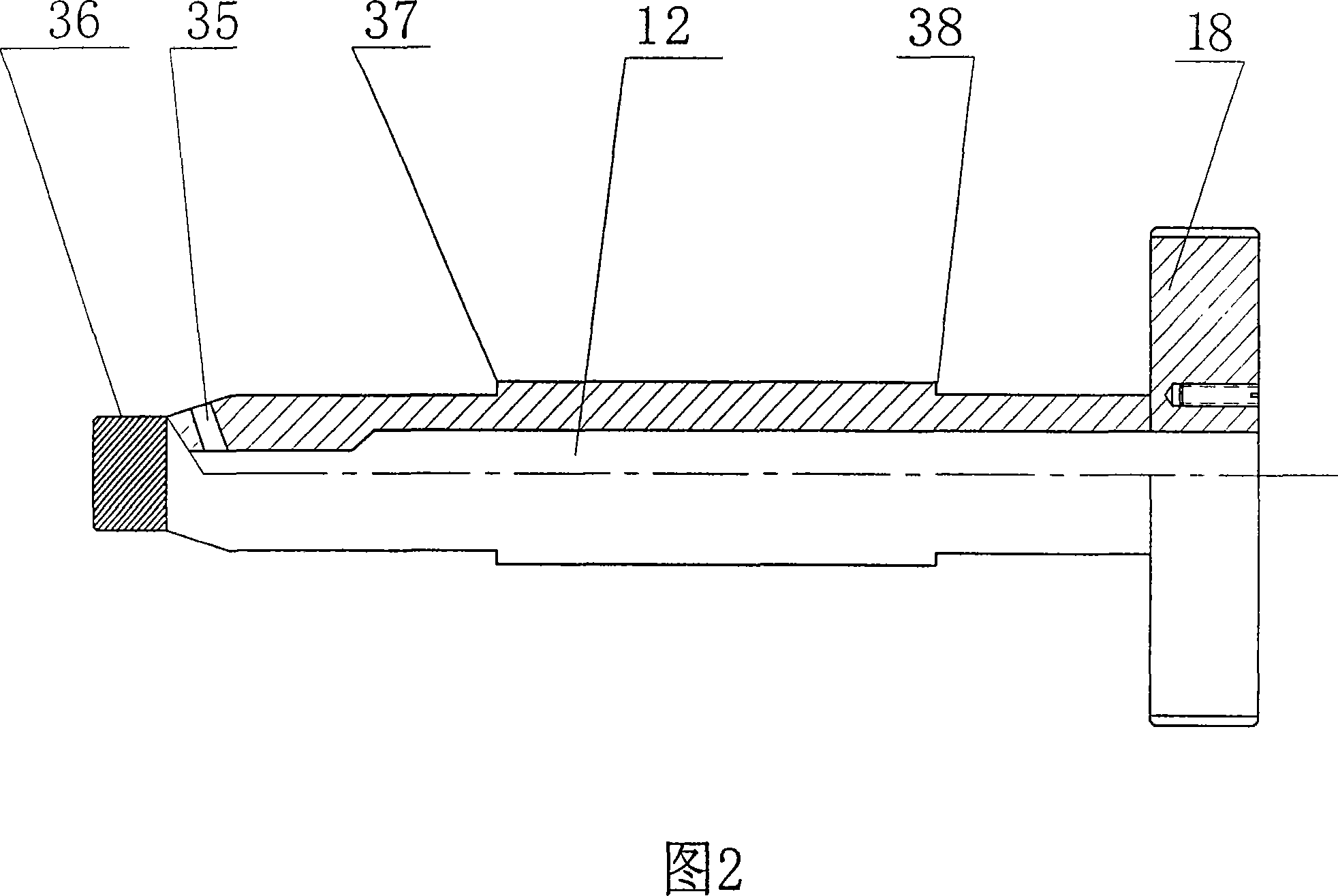

ActiveUS20120056345A1Easily and conveniently manufacturedReduce laborTailstocks/centresConfectioneryEngineeringMechanical engineering

The present invention relates to a polyurethane-coated (PU-coated) spandex fabric-fused midsole, and an apparatus and method for manufacturing the same, which allow a shoe midsole to be easily and conveniently manufactured through a single automatic process, and allows a PU-coated spandex fabric to be easily fused to a surface of the midsole in the process of manufacturing the midsole. For this purpose, there is provided a polyurethane-coated (PU-coated) spandex fabric-fused midsole manufacturing apparatus including: a central axis rotated by a driving force of a motor; a rotary disc fitted on the central axis to be rotated together with the central axis; a plurality of midsole forming mold units, which are mounted on the outer ends of support members radially extending from the outer circumference of the rotary disc, respectively; a PU-coated spandex fabric supply apparatus installed above the trace of rotation of the midsole forming mold units to provide a PU-coated spandex fabric to each of the midsole forming mold units; vacuum means installed between the rotary disc and the midsole forming mold units to vacuum the inside of a midsole forming mold unit supplied with a PU-coated spandex fabric to such an extent that the PU-coated spandex fabric comes into close contact with the inner surface of the midsole forming mold unit; a resin introducing apparatus installed outside of the trace of rotation of the midsole forming mold units to introduce polyurethane (PU) resin into the midsole forming mold unit having the PU-coated spandex fabric film in contact with inner surface thereof; and a foam-molded product removal apparatus installed outside of the trace of rotation of the midsole forming mold units to remove a foam-molded product formed by foaming the polyurethane resin introduced into the midsole forming unit by leaving the polyurethane resin in the midsole forming mold unit at a predetermined temperature for a predetermined length of time.

Owner:LEE DONG GUN

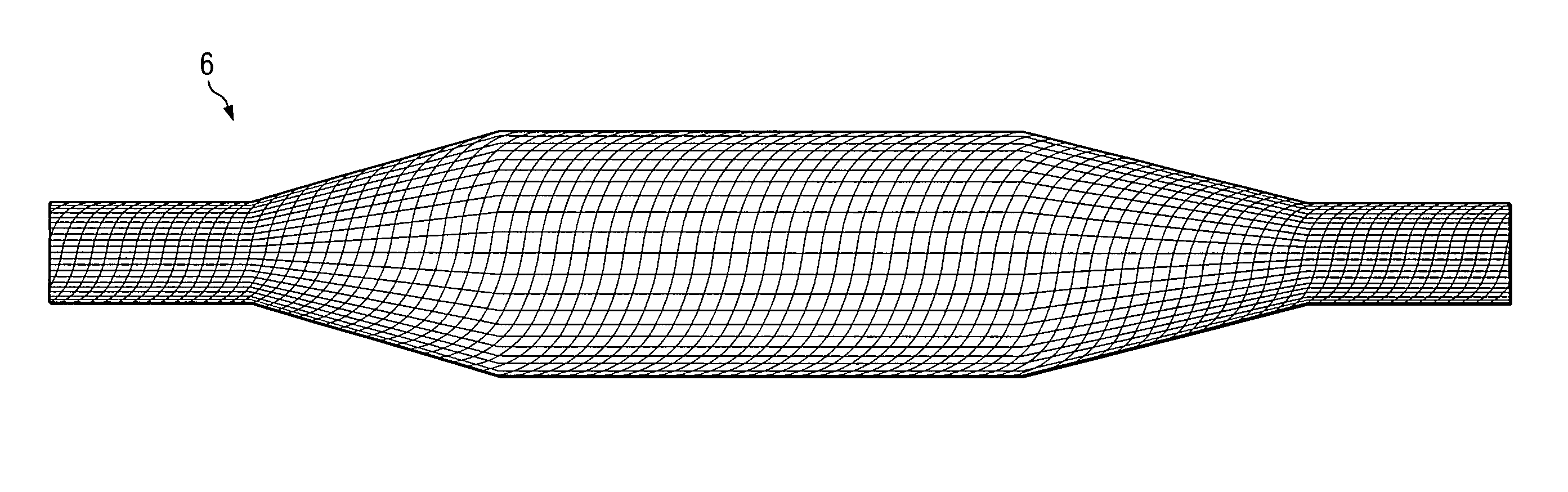

Non-Compliant Medical Balloon Having a Longitudinal Fiber Layer

InactiveUS20100179581A1High tensile strengthHigh burst resistanceBalloon catheterLamination ancillary operationsMedicineFiber layer

Owner:CR BARD INC

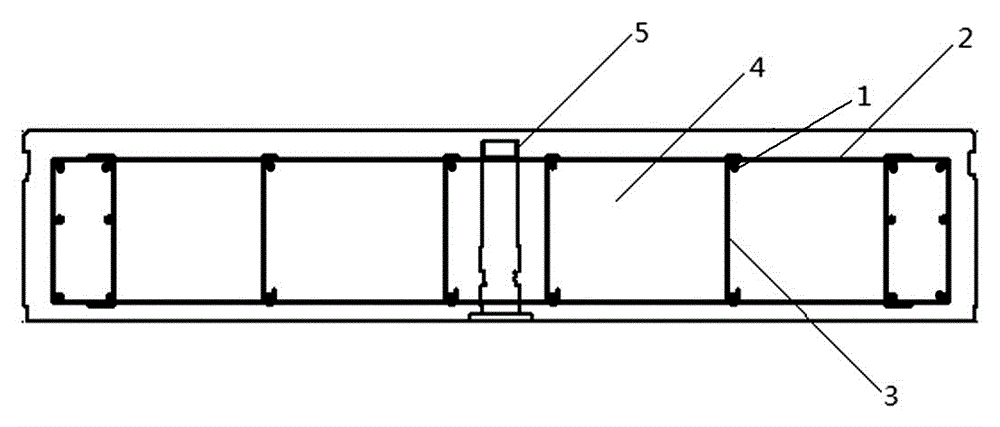

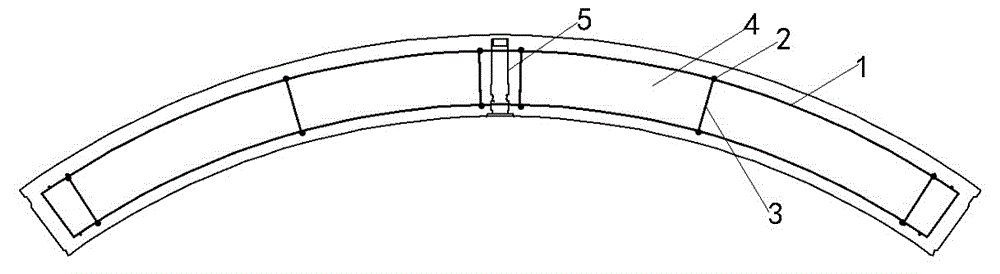

Ultra-high performance hybrid fiber concrete shield segment and preparation method thereof

InactiveCN105041336AReduce dosageReduce consumptionUnderground chambersTunnel liningCrack resistanceReinforced concrete

The invention discloses an ultra-high performance hybrid fiber concrete shield segment and a preparation method thereof. The ultra-high performance hybrid fiber concrete shield segment is of a reinforced concrete structure which consists of a steel skeleton and concrete, wherein the reinforcement ratio of used main reinforcements is 0.5%-1.0%, the distances of the main reinforcements are 150-300mm, the grades of steel reinforcements are not less than three, the smallest steel reinforcement distance of distributed reinforcements is 400mm, the biggest steel reinforcement distance of used distributed reinforcements is 2000mm, and the grades of the steel reinforcements are not less than two. The ultra-high performance hybrid fiber concrete shield segment is made from ultra-high performance hybrid fiber concrete, and comprises cementitious materials, sands, crushed stones, steel fibers, synthetic fibers, water reducer, defoamer and water. The ultra-high performance hybrid fiber concrete shield segment is less in dosage of the steel reinforcements and concrete and high in early strength, can prevent steam preservation, reduces energy consumption, and is green, energy-saving and environmentally friendly. The ultra-high performance hybrid fiber concrete shield segment is strong in anti-burst performance when having a fire, excellent in toughness and crack resistance and excellent in durability, enables edge joints not to easily break, and overcomes the defects of traditional segments.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +2

Method of producing high burst zipper assemblies for large reclosable packages

ActiveUS20080050056A1High burst resistanceIncrease in manufacturing and related costEnvelopes/bags making machineryFlexible coversEngineeringFlange

The present disclosure relates to a method for producing a high burst slider zipper which allows for bottom filling of reclosable packages, such as large bags, and further provides increased resistance to damage from the dropping or shock loading of the filled package. This is achieved by providing a peel seal or other frangible or separable connection between the zipper profiles, and by sealing a portion of one of the flanges to itself by a hard seal above the peel seal. This causes the external forces on a bag from bottom filling or shock loading to be directed toward the hard seal and further directed so as to cause a shear force against the peel seal, thereby increasing the resistance of the package to external forces.

Owner:ILLINOIS TOOL WORKS INC

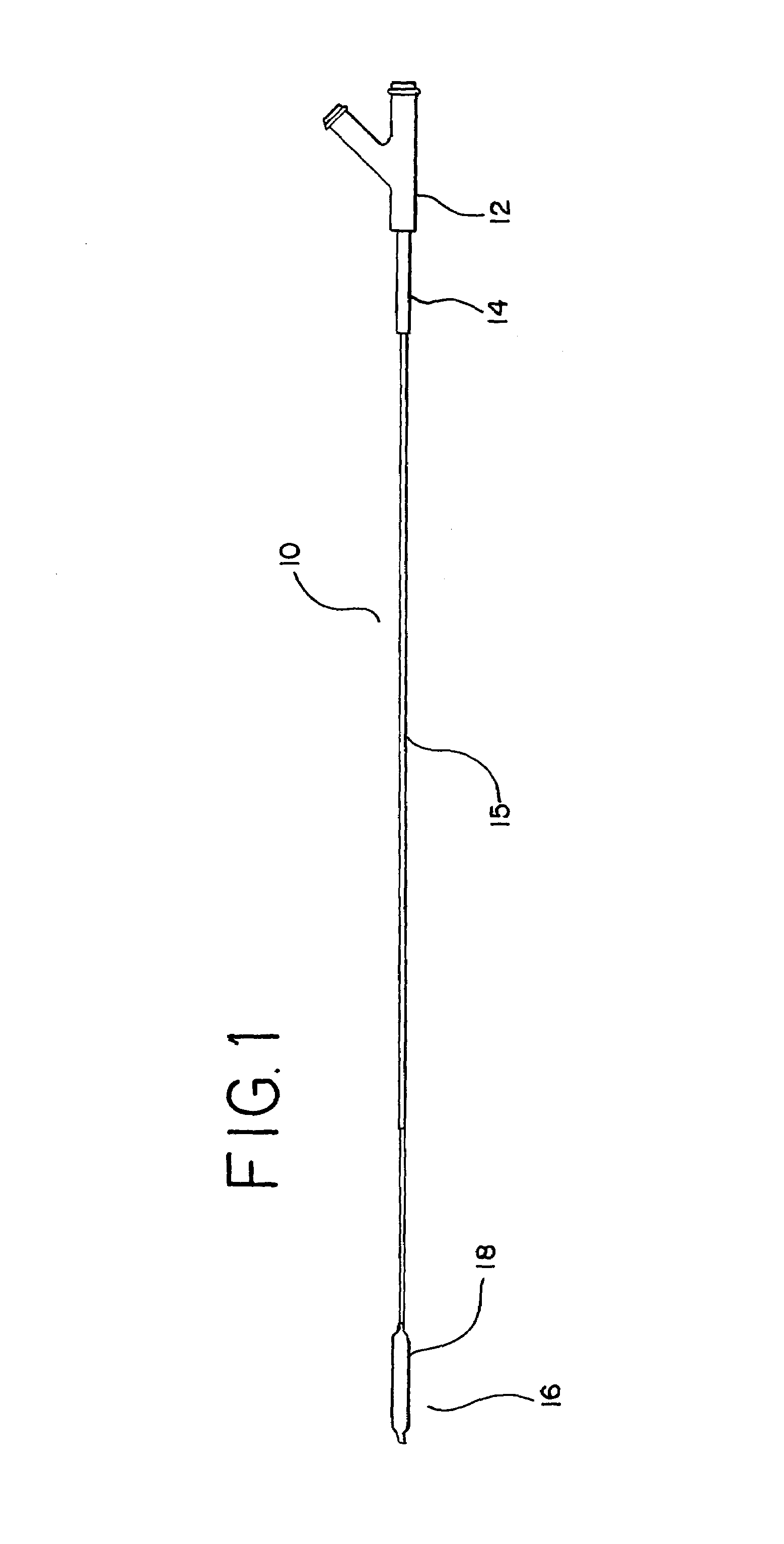

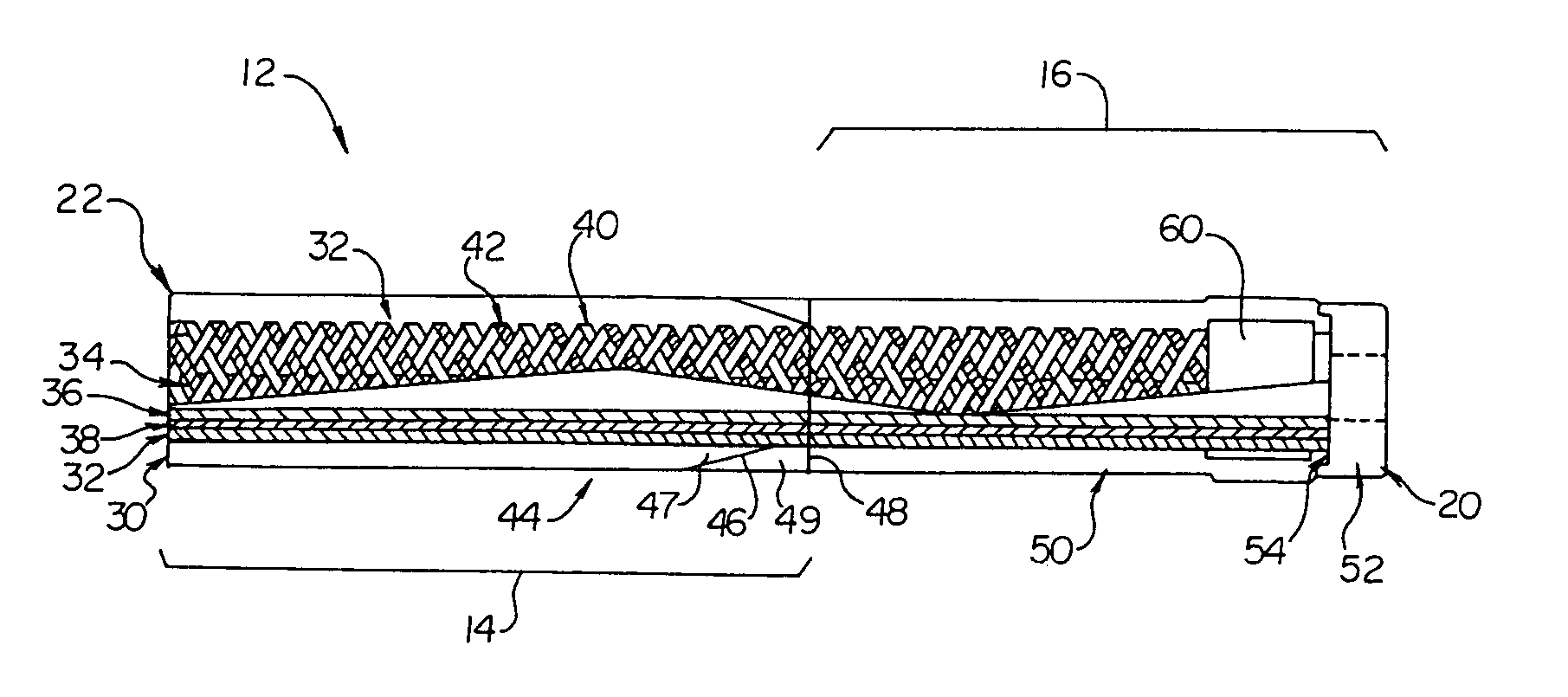

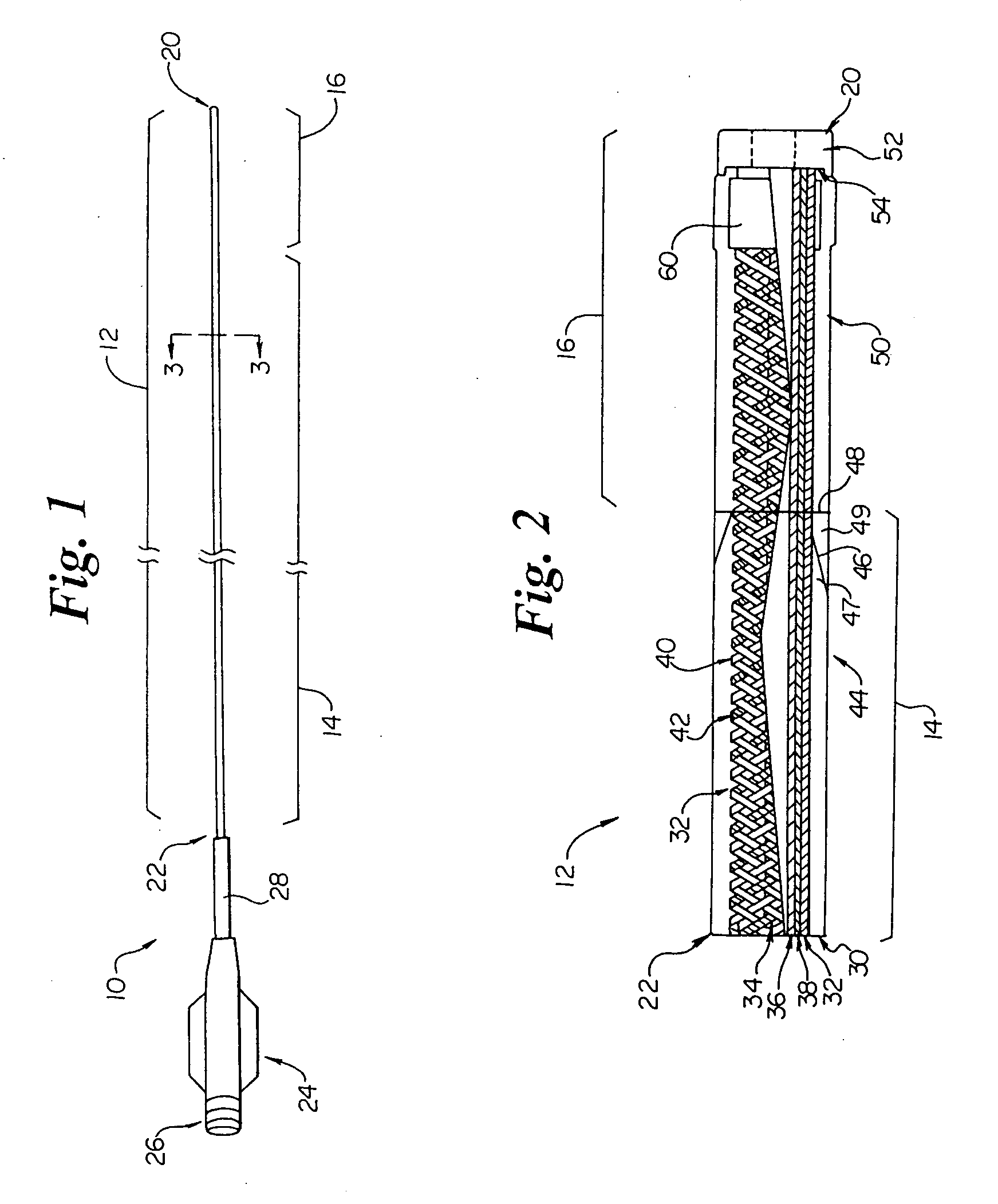

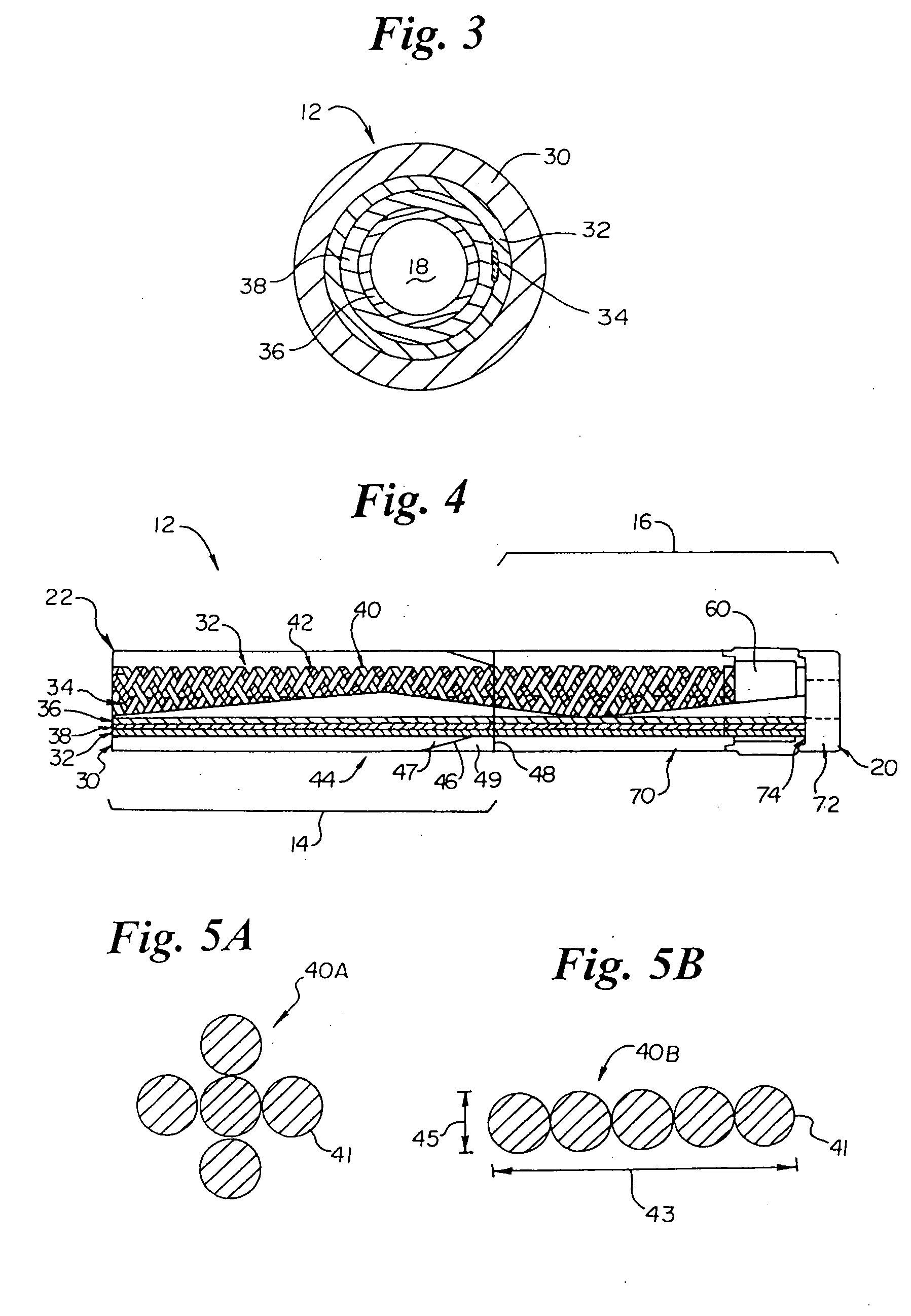

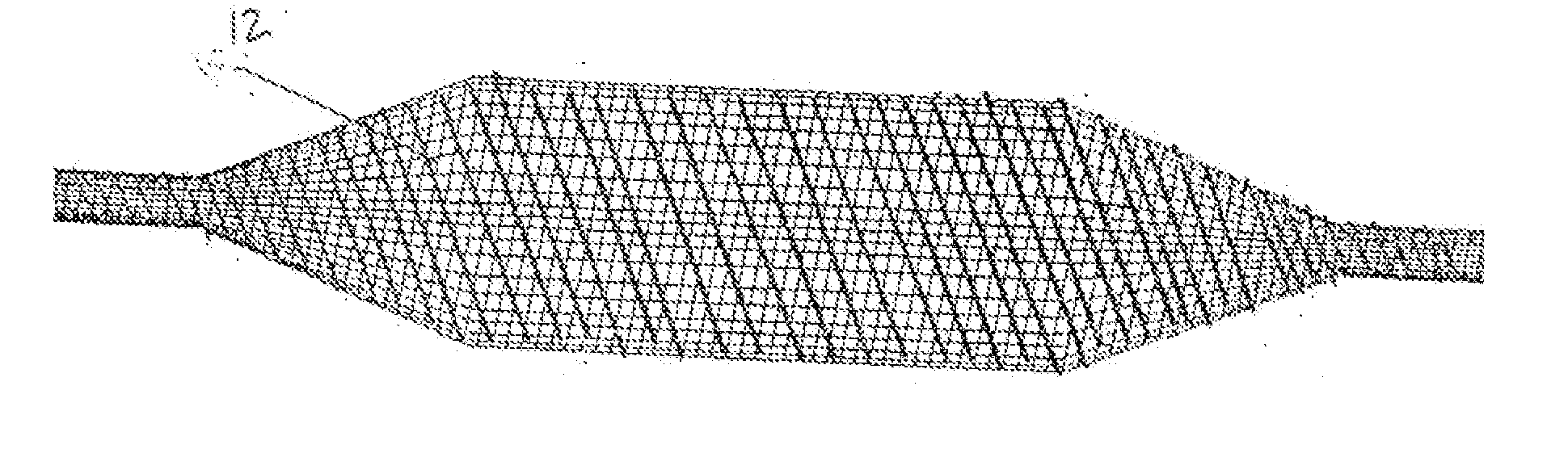

Intravascular catheter with composite reinforcement

InactiveUS20050182388A1Superior flexibility and softness and radiopacity and durabilityHigh burst resistanceCatheterTube connectorsIntravascular catheterGuide tube

An intravascular catheter that exhibits the combined features of superior flexibility, softness, radiopacity and oval / kink resistance. The catheter includes an elongate shaft having a proximal region, a distal region and a lumen extending therethrough. The proximal region of the shaft includes an inner lubricious polymer layer, a reinforcement layer and an outer layer. The reinforcement layer comprises a braid having one or more metallic members and a plurality of polymer members wherein each polymer member comprises a plurality of monofilaments, preferably formed of LCP. The polymer members of the braid provide improved flexibility and softness in addition to high burst pressure. The metallic member(s) of the braid provide improved radiopacity and oval / kink resistance. The catheter may also include a longitudinal member extending along the reinforcement layer.

Owner:BOSTON SCI SCIMED INC

Method for preparing polyurethane surface sizing agent

InactiveCN101768243AImprove adhesionGood film formingWater-repelling agents additionPaper/cardboardEmulsionOrganic solvent

The invention discloses a method for preparing a novel polyurethane surface sizing agent. Diisocyanate and polyglycol are first uniformly blended and then added with a moderate amount of catalyst to react, so that polyurethane prepolymer is obtained; hydrophilic chain extender is then added to react with the polyurethane prepolymer; the temperature is reduced, organic base is added to regulate to the pH value, deionized water is added under high-speed shearing, and after emulsification, polyurethane emulsion is obtained; and the temperature is increased, vinyl monomer is added in the polyurethane emulsion, and initiator is used to initiate polymerization, so that the modified aqueous polyurethane emulsion surface sizing agent is prepared. The invention can completely eliminate the adverse affection of small-molecular emulsifier and organic solvent on the application performance of sizing agent product and environment protection, and replaces internal sizing.

Owner:SHAANXI UNIV OF SCI & TECH

Medical balloon

InactiveUS20070059466A1High burst resistanceHigh tensile strengthSurgeryMedical devicesOptoelectronicsMaterials science

A non-compliant medical balloon, where the non-compliant medical balloon may be changed from a deflated state to an inflated state by increasing pressure within the balloon, is made with a first fiber layer, a second fiber layer over said first fiber layer such that the fibers of the first fiber layer and the fibers of the second fiber layer form an angle and a binding layer coating the first fiber layer and said second fiber layer. The interior surface area of the non-compliant medical balloon remains unchanged when the balloon changes from a deflated state to an inflated state.

Owner:CR BARD INC

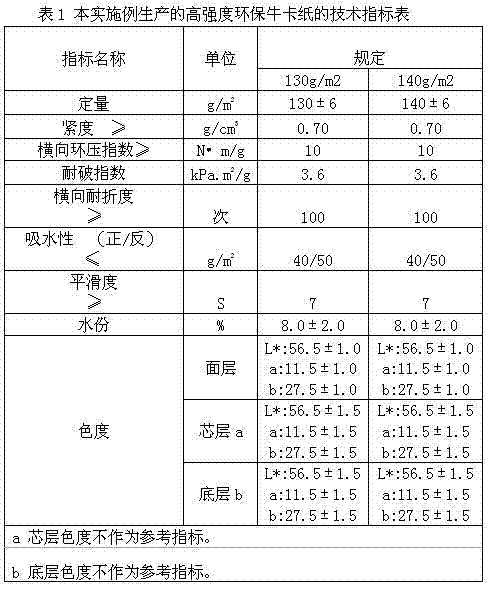

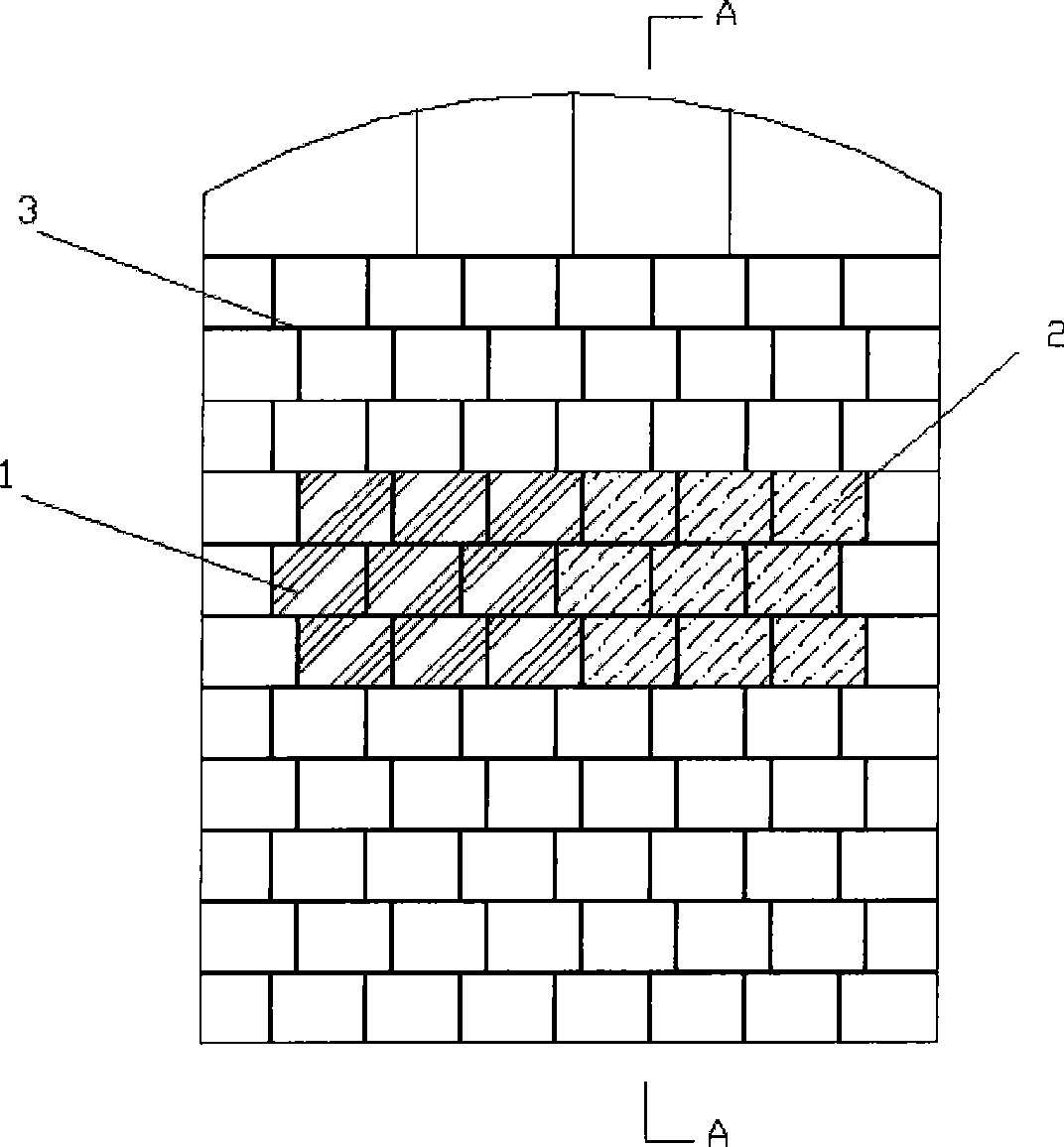

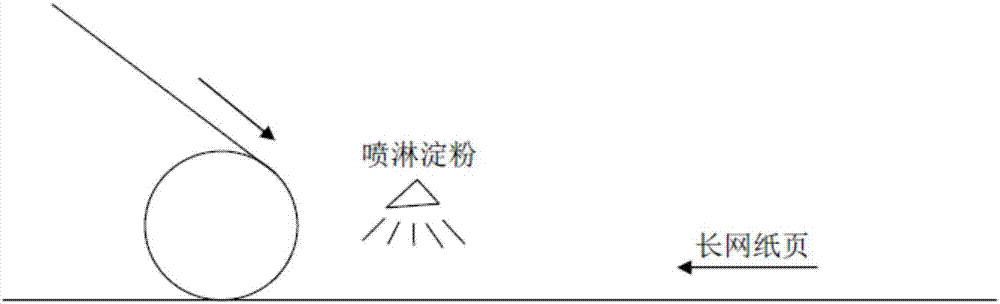

High-intensity environment-friendly craft paper and manufacturing method thereof

The invention relates to a high-intensity environment-friendly craft paper and a manufacturing method. Currently, the craft paper which is low in quantitation and low in wood pulp proportion, has high intensity, and is mainly made of secondary fiber is unavailable yet. The craft paper is characterized by consisting of a face layer, a core layer, a bottom layer, a front-side glue applying layer and a back-side glue applying layer; the sizing agent of the face layer is nature-color wood pulp; the sizing agent of the core layer is mid fiber and long fiber which are graded from the old corrugatedcontainer (OCC) secondary fiber; and the sizing agent of the bottom layer is short fiber which is graded from the OCC secondary fiber. The method for manufacturing the high-intensity environment-friendly craft paper comprises the steps of pulping, making glue and making paper, wherein the pulping comprises the steps of making the sizing agent of the face layer, making the sizing agent of the corelayer and making the sizing agent of the bottom layer. The craft paper is reasonable in structural design, low in quantitation, low in wood pulp proportion and high in intensity, and is mainly made of the secondary fiber. Moreover, the process is simple, the production cost is low, and the manufactured high-intensity environment-friendly craft paper has good quality.

Owner:JIAN GRP

Refractory castable for kilneye and kiln head cover of rotary kiln

The invention discloses a refractory castable for a kilneye and a kiln head cover of a rotary kiln, comprising 50-60 parts of refractory aggregate, 28-39 parts of refractory micro powder, 5-8 parts of oxide micro powder, 4-6 parts of bonding agent and 1.56-2.8 parts of additive, wherein the granularity of the refractory aggregate is 1-8mm, the granularity of the refractory micro powder is less than 1.0mm, the granularity of the oxide micro powder is less than 5mum, and the granularity of the bonding agent is less than 0.088mm. The refractory castable adopts the complex phase technology, has good balance in notably improving mechanical strength, wearing resistance and thermal shock resistance of the material, enables the castable to obtain excellent comprehensive performance, and effectively solves the problems that the prior refractory castable for the kilneye and the kiln head cover of the rotary kiln is easy to wear, has bad thermal shock resistance or lower strength and short service life.

Owner:LUOYANG INST OF SCI & TECH +1

Air-filtration paper for automobile engine filter and preparation method of air-filtration paper

ActiveCN102912677AImprove adsorption capacityImprove filtering effectNon-macromolecular organic additionPaper/cardboardBursting strengthFiber

The invention discloses air-filtration paper for an automobile engine filter and a preparation method of the air-filtration paper. The air-filtration paper for the automobile engine filter is prepared from the following materials in parts by weight: 60-70 parts of hardwood pulp, 30-40 parts of cotton pulp, 10-15 parts of modified polyester fiber, 2-5 parts of nanocarbon, 1-3 parts of kaolin, 1-2 parts of lime milk, 2-4 parts of modified zealite sieve, 0.5-0.8 parts of water talcum powder, 3-4 parts of polyacrylic emulsion, 2-5 parts of polyvinyl acetate emulsion, 0.5-1 part of sodium laurylsulfate, 0.5-1 part of silane coupling agent DL171, 0.4-0.8 parts of sodium laurylsulfate and 4-6 parts of dialdehyde starch. The filtration paper prepared by the method has the advantages of good water permeability, large filter area, small maximum aperture, high filter precision, high water tolerance, strong bursting strength, thermostability and the like, has a stable performance index at a normal temperature under a high-temperature work condition, and has better effects of temperature resistance and filtering, and filtering efficiency can be up to 99.98%.

Owner:ANHUI PHOENIX INT CO LTD

Abrasion resistant steel fiber reinforcement pouring precast block for coke dry quenching oven

The invention relates to a dry quenching furnace, in particular to an abrasion-resistant reinforced precast block for the dry quenching furnace. The abrasion-resistant steel fiber reinforced precast block is formed by roasting the raw materials comprising the following compositions: 4 to 10 percent of cement, 3 to 10 percent of silica fume, 3 to 10 percent of alpha-Al2O3, 5 to 10 percent of SiC, and the balance being refractory aggregates. The precast block has good strength and low wear rate and reduces the maintenance work and the cost.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Rare earth alloy iron pan and production method thereof

InactiveCN103239139AImprove mechanical propertiesHigh burst resistanceCooking-vessel materialsSocial benefitsVegetable oil

A rare earth alloy iron pan production method includes: (1) smelting cast iron by an intermediate frequency furnace, and heating the iron molten iron till the temperature is higher than 1400 DEG C; (2) smashing rare earth ferrosilicon alloy till the size ranges from 2mm to 6mm, and preheating till the temperature reaches 60 DEG C; (3) placing the rare earth ferrosilicon alloy block with a quantity of weight ratio ranging from 0.3% to 1.8% in a ladle and then pouring the molten iron, and mixing and drossing; (4) casting after the molten iron is cleared, preheating a casting mold and injecting the molten iron to the mold, and pressing an upper pan mold down to form an iron pan; (5) taking out the iron pan after the iron pan is chilled in the mold, and clearing in a mechanical fine grinding and buffing manner; (6) feeding the iron pan into an electric furnace, heating till temperature ranges from 270 DEG C to 330 DEG C, painting edible vegetable oil on the pan body to form an oil film, and allowing oil molecules to penetrate in the pan body; and (7) taking out the iron pan and detecting. The rare earth alloy iron pan production method has good social benefit and economic benefit, and is adaptable to the field of iron pans.

Owner:SANSUI HONGLI KITCHEN UTENSILS CO LTD

Novel main iron runner casting material

The invention discloses a novel main iron runner casting material which is prepared from alumina, corundum, SiC, SiO2 micropowder, alpha-Al2O3 micropowder, modified nano carbon powder, explosion-proof fiber, metallic silicon powder, calcium aluminate cement and sodium tripolyphosphate. According to the invention, since the modified nano carbon powder, of which the activity is much higher than that of asphalt carbon residues, is substituted for the asphalt, so the oxidation resistance effect is better. In addition, the modified nano carbon powder used as a substitute for asphalt can improve the bursting resistance of the product in the baking process.

Owner:长兴云峰炉料有限公司

Easy open woven polypropylene bag

InactiveUS20100209026A1Easy to openHigh burst resistanceFlexible coversWrappersBursting strengthEngineering

The disclosure relates to a large package, typically with woven polypropylene walls, including an easy-open strip with a pre-activated peel seal. The easy-open strip achieves a high burst strength by configuring the pre-activated peel seal in shear mode in response to internal (product side) forces while achieving a low consumer opening force by configuring the peel seal in response to external (consumer side) forces.

Owner:ILLINOIS TOOL WORKS INC

Refractory castable for rotary kiln mouth and kiln head hood

The invention provides a refractory castable for a rotary kiln mouth and a kiln head hood. The refractory castable comprises the following components in parts by weight: 40-50 parts of aggregate, 25-40 parts of fine powder, 6-15 parts of oxide micro powder, 1-3 parts of binding agent and 2-2.5 parts of additives, wherein the aggregate is composed of 30 parts of special-grade alumina, 10 parts of corundum, 30 parts of mullite, 15 parts of andalusite and 15 parts of spinel; the fine powder is composed of 60 parts of zirconite powder and 40 parts of silicon carbide powder; the oxide micro powder comprises aluminum oxide micro powder; the binding agent is calcium aluminate cement in which the content of aluminum oxide is 80%; and the additives are composed of 30 parts of metal aluminum powder, 30 parts of organic anti-explosion fibers, 30 parts of sodium hexametaphosphate and 10 parts of heat-resistant steel fibers.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

Methods of orienting multifilament yarn and monofilaments of poly-4-hydroxybutyrate and copolymers thereof

ActiveUS9555155B2Improve toughnessGood drapeSuture equipmentsMedical devicesPolymer scienceSoft tissue repair

Resorbable multifilament yarns and monofilament fibers including poly-4-hydroxybutyrate and copolymers thereof with high tenacity or high tensile strength have been developed. The yarns and fibers are produced by cold drawing the multifilament yarns and monofilament fibers before hot drawing the yarns and fibers under tension at temperatures above the melt temperature of the polymer or copolymer. These yarns and fibers have prolonged strength retention in vivo making them suitable for soft tissue repairs where high strength and strength retention is required. The multifilament yarns have tenacities higher than 8.1 grams per denier, and in vivo, retain at least 65% of their initial strength at 2 weeks. The monofilament fibers retain at least 50% of their initial strength at 4 weeks in vivo. The monofilament fibers have tensile strengths higher than 500 MPa. These yarns and fibers may be used to make various medical devices for various applications.

Owner:TEPHA INC

Collagen fabric casing for sausage knitting and former device

InactiveCN101099500AEvenly distributedHigh mechanical strengthSausage casingsFiberAgricultural engineering

The present invention discloses a collagen protein fibre casing weaving-forming machine. It includes the following several portions: machine frame with internal cavity, forming spindle, weaving sleeve, storage flange and ring-shaped nozzle component. Said invention also provides the concrete structure of every above-mentioned portion and connection mode of all the above-mentioned portions, and also provides the working principle of said casing weaving-forming machine and its concrete operation method.

Owner:柳州市宏升胶原蛋白肠衣有限公司

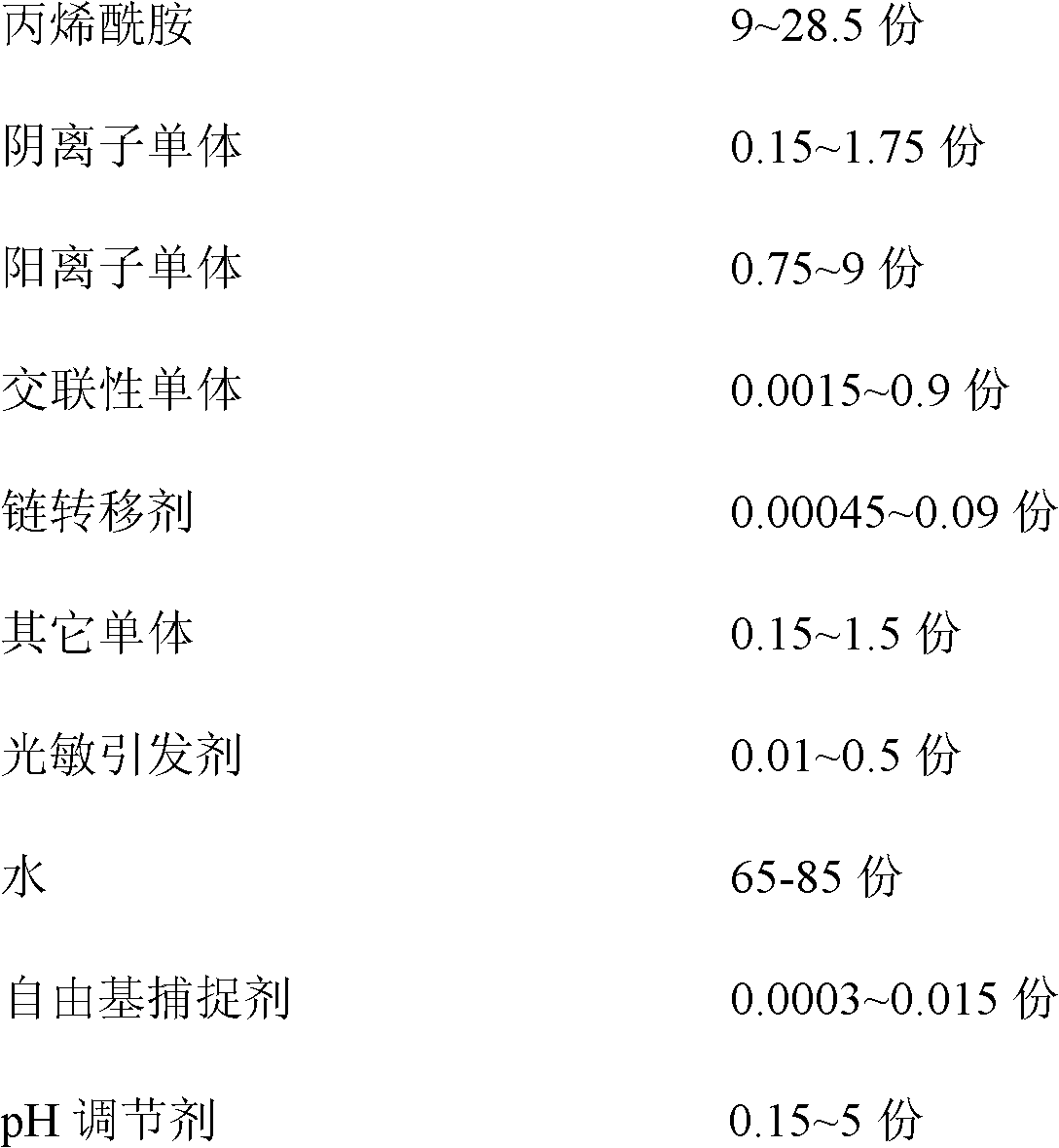

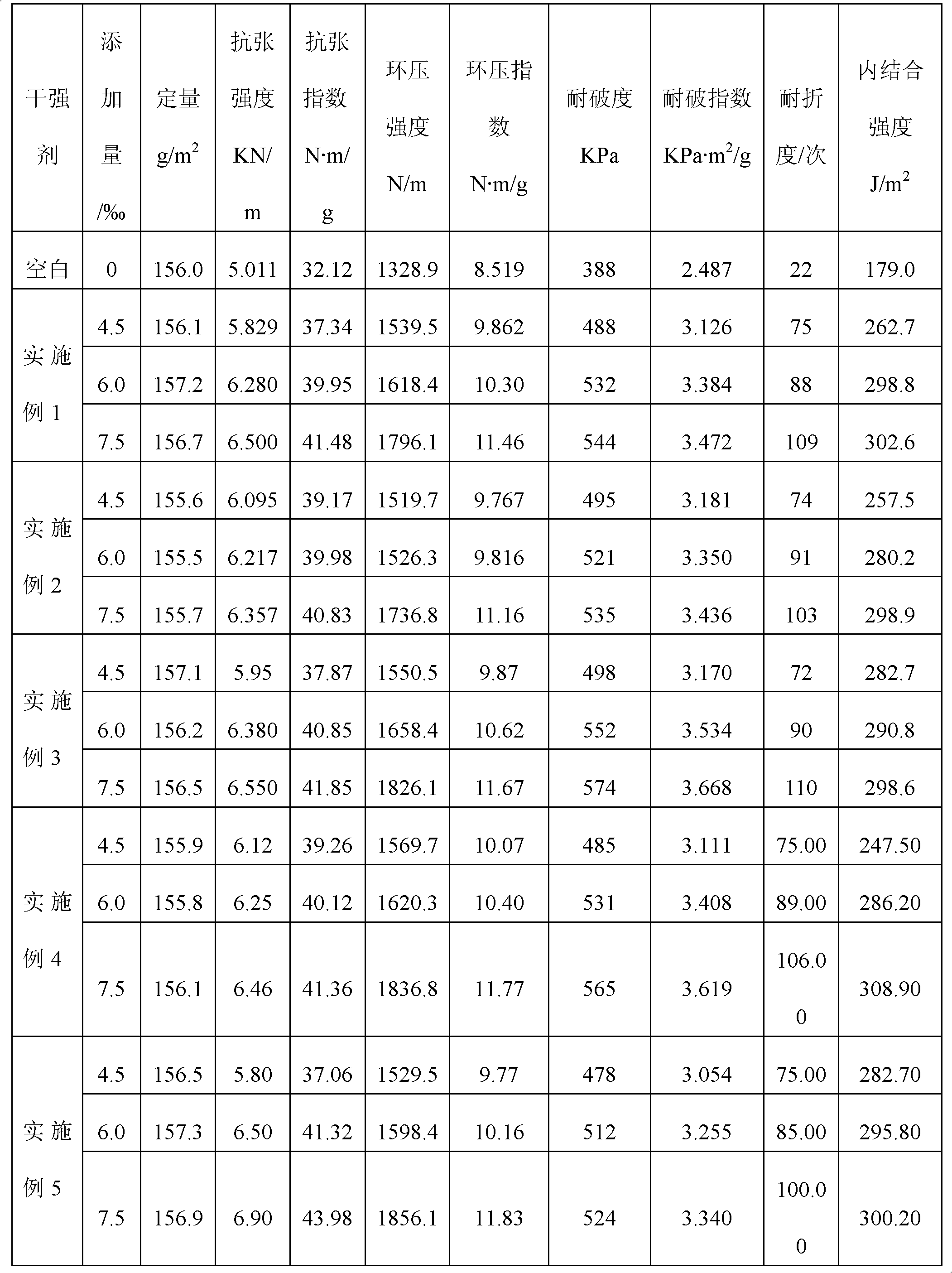

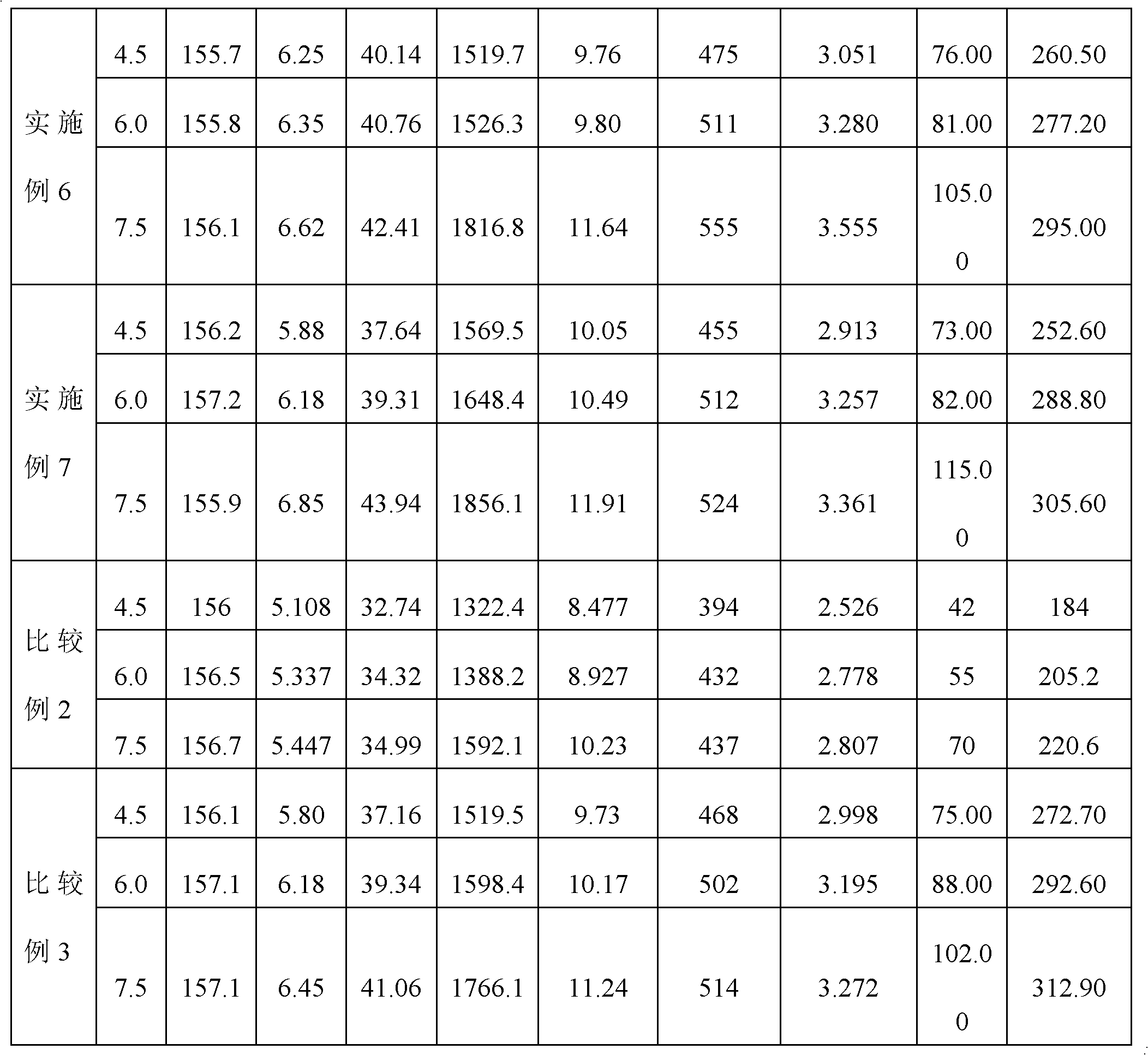

Paper dry intensifier and preparation method thereof

ActiveCN102627724AModerate molecular weightModerate degree of branchingReinforcing agents additionPaper/cardboardCross-linkFunctional monomer

The invention provides a paper dry intensifier and a preparation method thereof. The preparation method comprises the following steps: in nitrogen atmosphere, reacting water, acrylamide, an anionic monomer, a cationic monomer, a cross-linked monomer, a chain transfer agent, other functional monomers and a photoinitiator under ultraviolet irradiation; adding a pH regulator for regulating the pH value to be 4-6; and adding a radical catcher, and mixing to obtain the paper dry intensifier. The intensifier synthesized by the method has the characteristics of low usage amount and good effect. The intensifier can be used in production of various paper such as case board paper, corrugating base paper, coated paper, cop tube paper, specialty paper and the like, and has the effect of improving the paper dry intensity, which is more remarkable when the recovered waste paper is used as papermaking raw materials. The intensifier can have an excellent paper dry enhancement effect without being added with aluminum sulfate.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Disposable rain-proof antibacterial shoe covers and preparation method thereof

InactiveCN102863850AGood film formingImprove water resistanceDextran coatingsFootwearPlastic materialsAnti bacterial

The invention relates to a disposable rain-proof antibacterial shoe cover and a preparation method thereof. The preparation method of the disposable rain-proof antibacterial shoe cover comprises the following steps: preparing impregnation liquid, degassing, soaking with a binder, drying, imprinting anti-skidding bottom lines and demoulding. The disposable rain-proof antibacterial shoe cover uses konjac glucomannan as the carrier, also uses other additives, has good film-forming property, water resistance and antibacterial property and also has high tensile strength and good flexibility; compared with the plastic material, konjac glucomannan used as the main material of the disposable environmentally friendly shoe cover has high tensile strength, good wearing effect and good antibacterial effect, thus the cleanness and hygiene of the shoes can be kept when people walk in rain; the shoe cover can be completely biodegraded, the shoe cover is environmentally friendly and low-carbon; the raw materials are common and low in cost; and the production process is simple and the additional pigment can be kept to some extent.

Owner:FUJIAN AGRI & FORESTRY UNIV

Curable pressure pipe liner

InactiveUS20120145271A1High internal pressureImprove pressure resistancePipe elementsInternal pressureEngineering

A curable liner tube, once inserted into a pipe and cured, can withstand relatively high internal pressures as well as relatively high external pressures, and can also resist destructive effects from liquids and gases with which the pipe and liner tube come in contact. The liner tube is sufficiently pliable in an uncured condition to lie substantially flat and to be substantially circular in cross section in an expanded state, and comprises an outer strengthening system that is configured for placement in a pipe interior and that changes from a pliable condition to a hardened condition upon curing, and a membrane system disposed inwardly relative to the outer strengthening system when placed in the pipe interior, comprising an impermeable sealing film having a facing surface that faces the interior of the pipe.

Owner:MCKELLER CHRISTOPHER +1

Polylactic acid forming paper and preparation method

ActiveCN102877355AGood compatibilityNon-irritatingPaper/cardboardRetention agents additionPolyesterFiber

The invention provides polylactic acid forming paper adopting polylatic acid fibers as a raw material and a preparation method thereof so as to solve the vices of hair slip and powder drop of the conventional forming paper and reduce excessive consumption of production of the conventional forming paper on resources to a certain extent. The invention adopts the following technical means: the polylactic acid forming paper comprises the following components in parts by weight: 15-65 parts of polylactic acid fibers, 15-20 parts of hardwood fibers with whiteness of 80-85% and 10-15 parts of polyester fibers, wherein the polylactic fibers are 4-6 mm long, and the fineness is 1-5 D; the polyester fibers are 4-10 mm long and the fineness is 0.5-1.4 D; the ratio of the forming paper is 10-50 g and the air permeability is 500-50000 um / pa.s.

Owner:HONGTA TOBACCO GRP +1

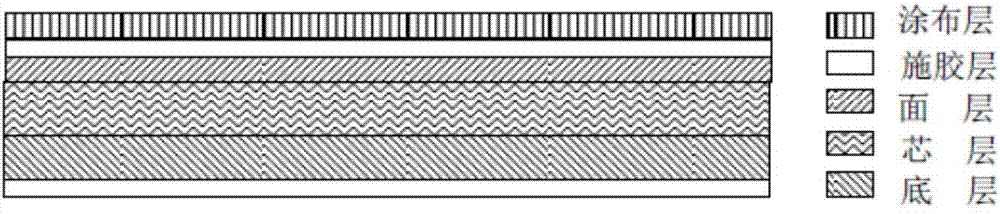

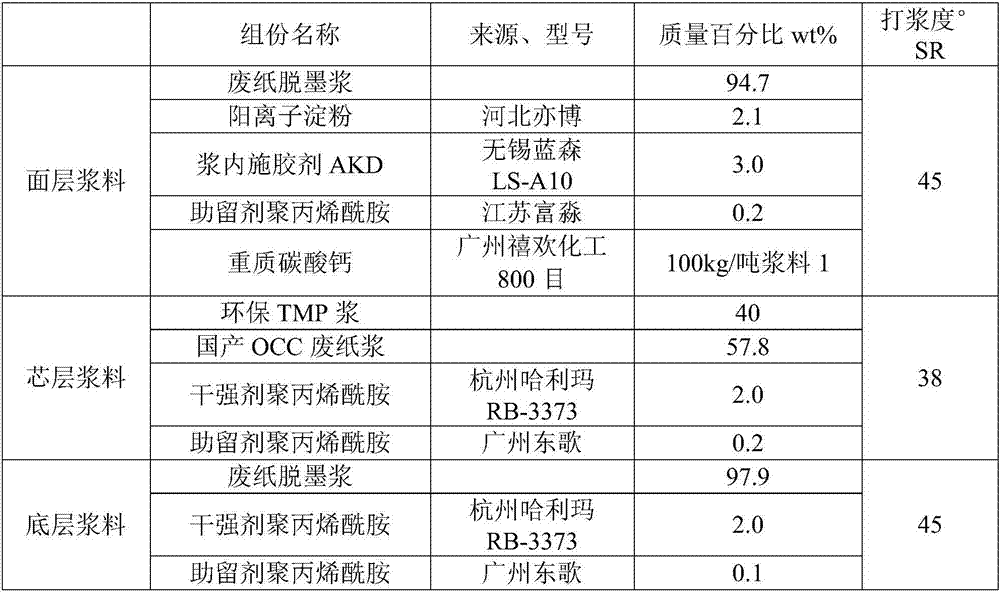

Environment-friendly low-basis-weight coated duplex board with grey back and preparation method thereof

The invention belongs to the technical field of papermaking and particularly relates to an environment-friendly low-basis-weight coated duplex board with grey back and a preparation method thereof. The environment-friendly low-basis-weight coated duplex board with grey back includes a coating layer, a front glue applied layer, a surface layer, a core layer, a bottom layer, and a back glue applied layer, all the layers being laminated by spraying a starch solution. In the invention, a mechanical thermal pulp TMP for producing medium-density polymeric plates is employed, wherein the mechanical thermal pulp is environment-friendly and low-cost, and has wide sources. In addition, the invention mainly provides a production technology of the low-basis-weight coated duplex board with grey back by applying the novel environment-friendly TMP pulp. The technology mainly includes three-layer mesh lamination shaping, spraying starch solution as interlayer adhesive and the like processes, so that the coated duplex board with grey back has excellent performance, is environment-friendly and energy-saving, and is low in cost.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com