Easy open woven polypropylene bag

a polypropylene bag and woven technology, applied in the field of bags, can solve the problems of large opening force, difficult to open packages or bags, and difficult to meet the needs of retail or consumer applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

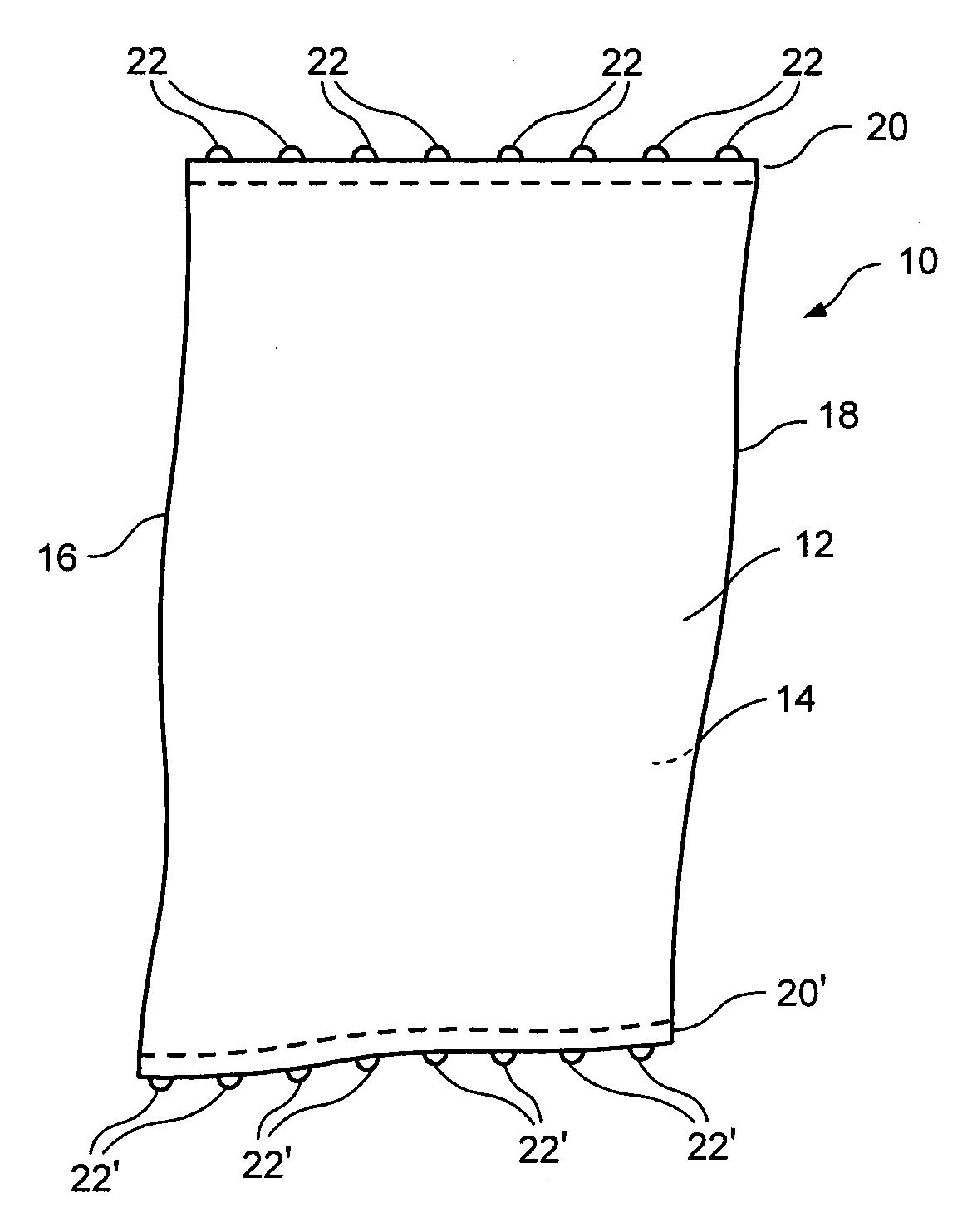

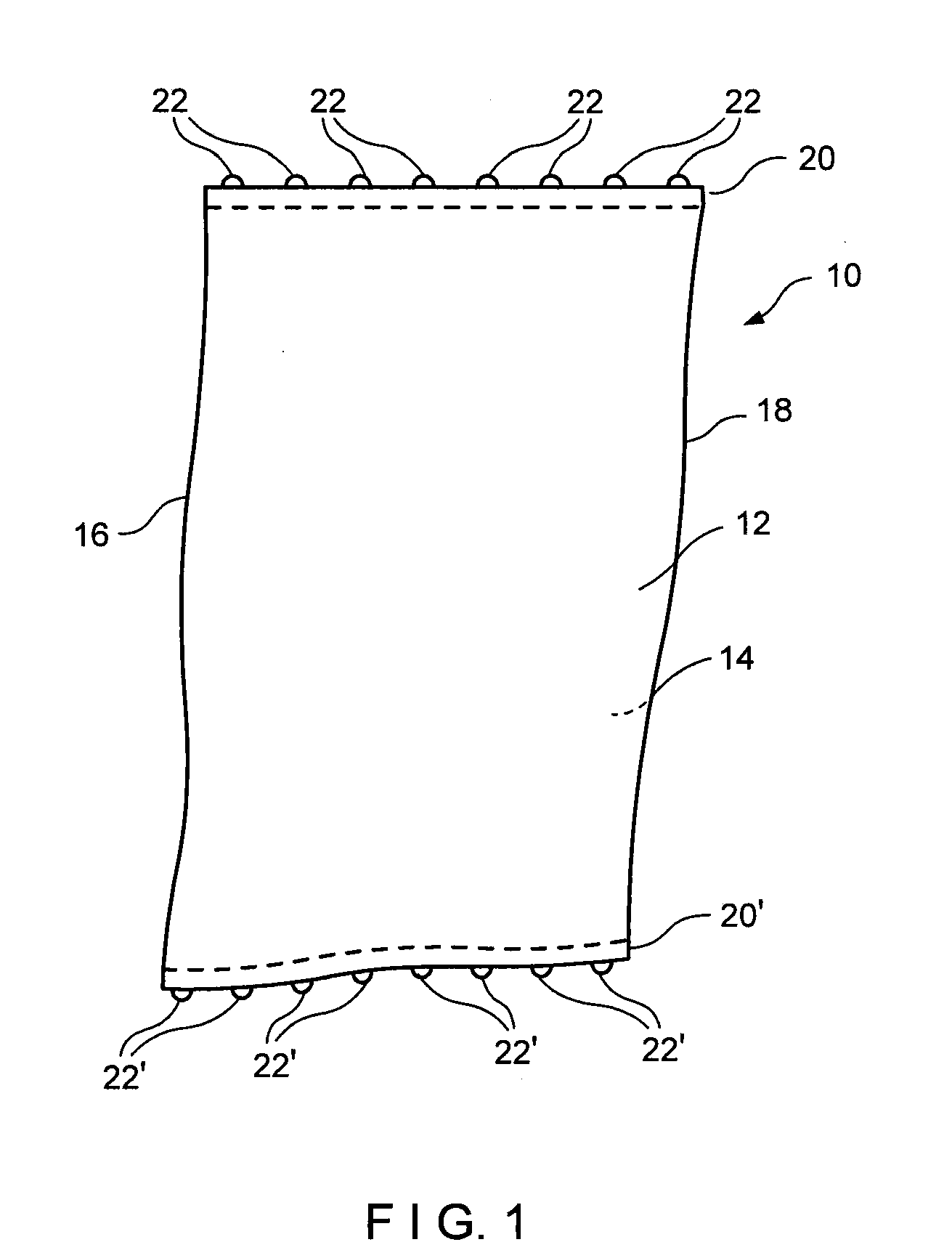

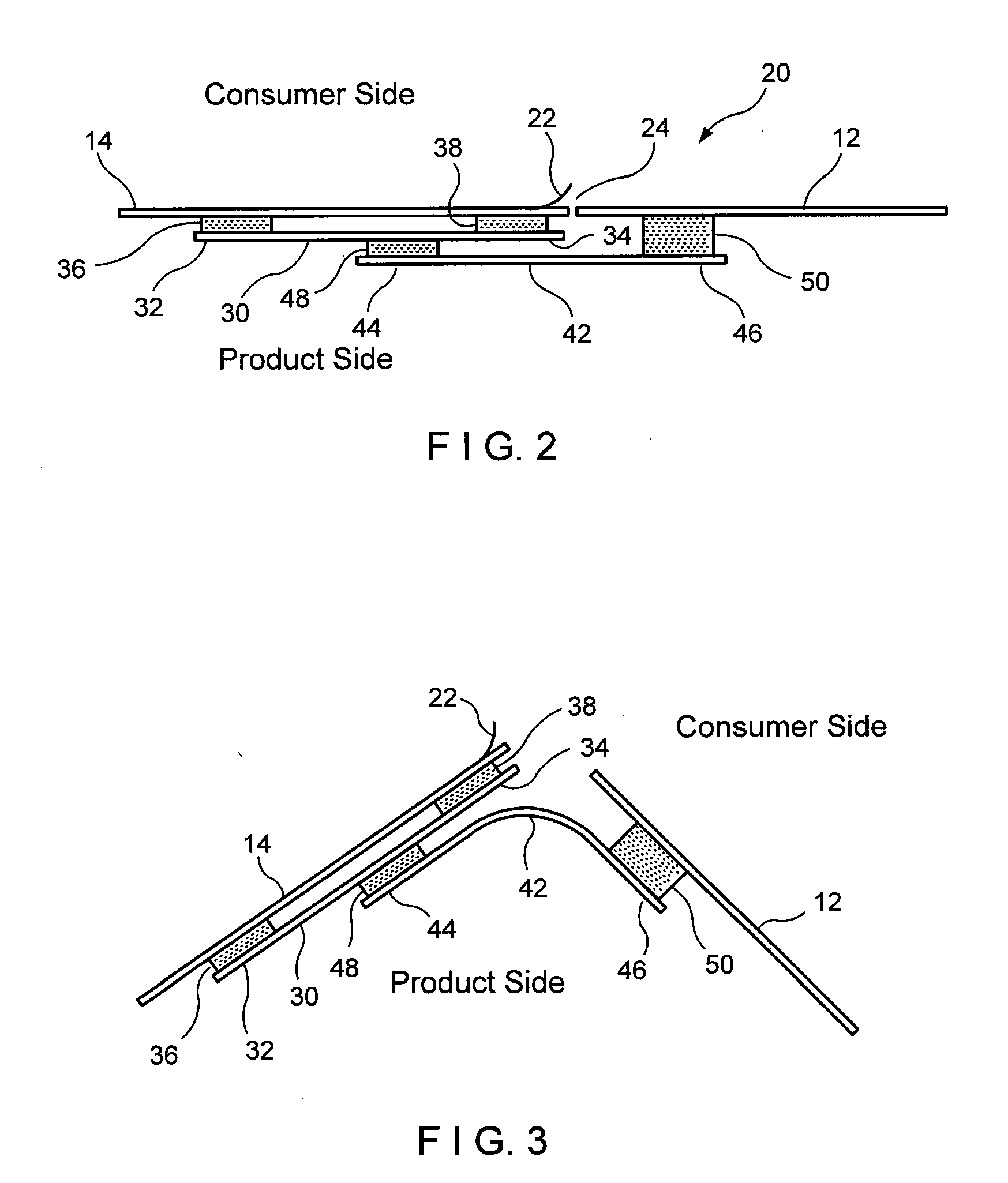

[0014]Referring now to the drawings in detail wherein like numerals indicate like elements, one sees that FIG. 1 is a simple drawing of a large package or bag 10. Package or bag 10 includes front and rear walls 12, 14, respectively, which are typically made from woven polypropylene, and sealed together along first and second side seals 16, 18 However, those skilled in the art may see a range of equivalent materials after review of the present disclosure, such as but not limited to, multilayer laminates incorporating scrim, netting, gauze or woven materials, made from claf (heat-sealable, cross-laminated non-woven open-mesh fabric), or strong resin materials such as nylon, polypropylene, high density polyethylene, polystyrene or other similar substrates. The package or bag 10 is typically considered to be “large” within the common usage of the industry in that is designed to be filled with 14-50 pounds of product, although different capacities may be used. The product may include, bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com