Patents

Literature

154 results about "Dialdehyde starch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dialdehyde starch is a polysaccharide derived by chemical modification from natural starch from wheat or corn. It is prepared by periodate oxidation of starch. There are many uses including the paper industry, where in it has been shown to improve the wet strength of consumer products. These products include toilet paper and paper towels.

Air-filtration paper for automobile engine filter and preparation method of air-filtration paper

ActiveCN102912677AImprove adsorption capacityImprove filtering effectNon-macromolecular organic additionPaper/cardboardBursting strengthFiber

The invention discloses air-filtration paper for an automobile engine filter and a preparation method of the air-filtration paper. The air-filtration paper for the automobile engine filter is prepared from the following materials in parts by weight: 60-70 parts of hardwood pulp, 30-40 parts of cotton pulp, 10-15 parts of modified polyester fiber, 2-5 parts of nanocarbon, 1-3 parts of kaolin, 1-2 parts of lime milk, 2-4 parts of modified zealite sieve, 0.5-0.8 parts of water talcum powder, 3-4 parts of polyacrylic emulsion, 2-5 parts of polyvinyl acetate emulsion, 0.5-1 part of sodium laurylsulfate, 0.5-1 part of silane coupling agent DL171, 0.4-0.8 parts of sodium laurylsulfate and 4-6 parts of dialdehyde starch. The filtration paper prepared by the method has the advantages of good water permeability, large filter area, small maximum aperture, high filter precision, high water tolerance, strong bursting strength, thermostability and the like, has a stable performance index at a normal temperature under a high-temperature work condition, and has better effects of temperature resistance and filtering, and filtering efficiency can be up to 99.98%.

Owner:ANHUI PHOENIX INT CO LTD

Recyclable high-strength biological packaging material

The invention belongs to the technical field of polymer materials and relates to a recyclable high-strength biological packaging material which is used as a basic material for making various packaging products. The recyclable high-strength biological packaging material comprises the following components in part by mass: 50 to 70 parts of starch, 10 to 30 parts of polyethylene, 5 to 15 parts of plant fibers, and 1 to 5 parts of additive. The starch comprises natural starch or chemical-modified starch, such as dialdehyde starch which is oxidized starch obtained by oxidizing the starch by using periodic acid and salt; the plant fibers are made from rice husk, rice straw, wheat straw, corn stalks, cotton stalks, wood dust and bamboo dust and other crop straw or plant stems; and the additive is one or more of a foaming agent, a plasticizing agent, a stabilizer, a filler, a coupling agent and a moisture proof agent. The technical process of the method is simple, the principle of the method is safe and reliable, the raw materials are readily available, and the practical value of the method is high; and the prepared material has high strength, and can be recycled and degraded.

Owner:QINGDAO UNIV OF SCI & TECH

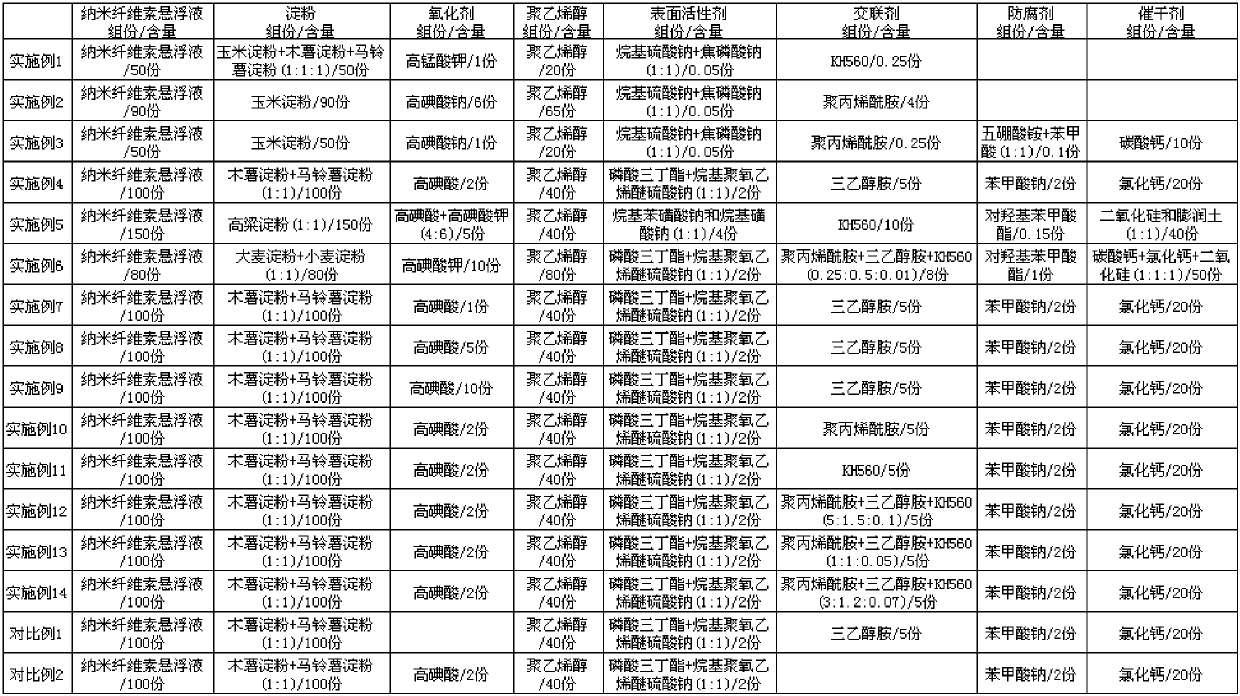

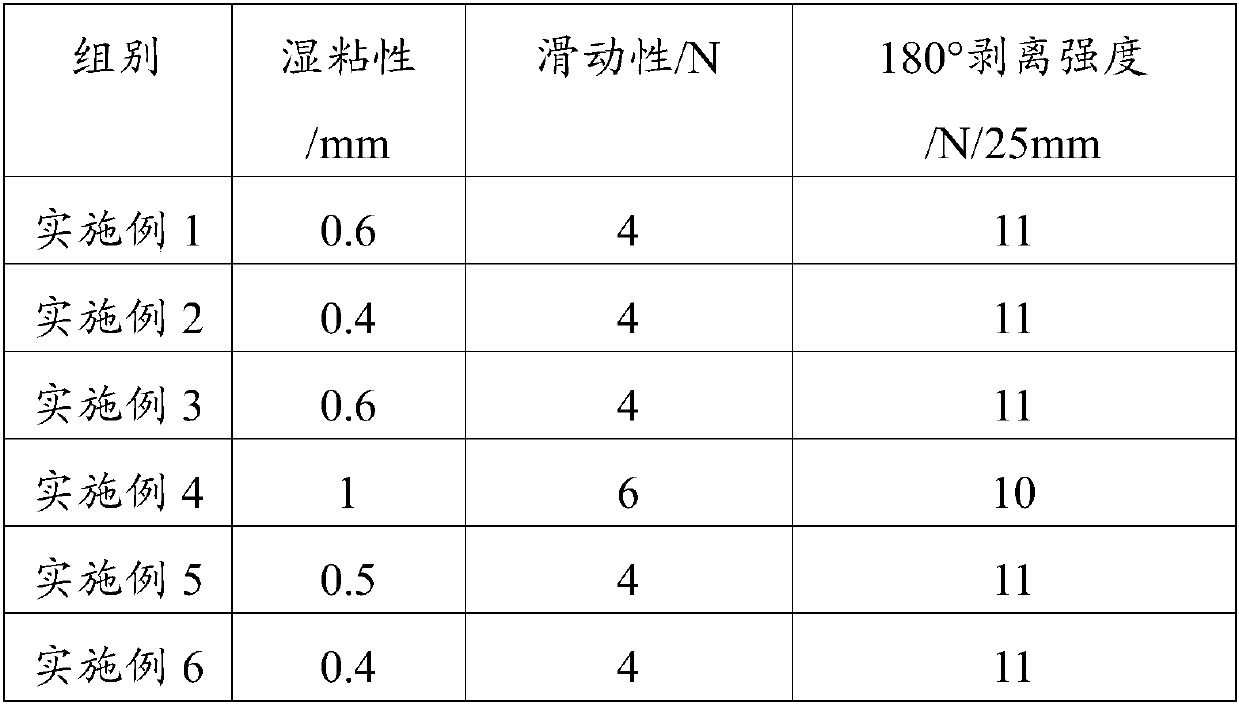

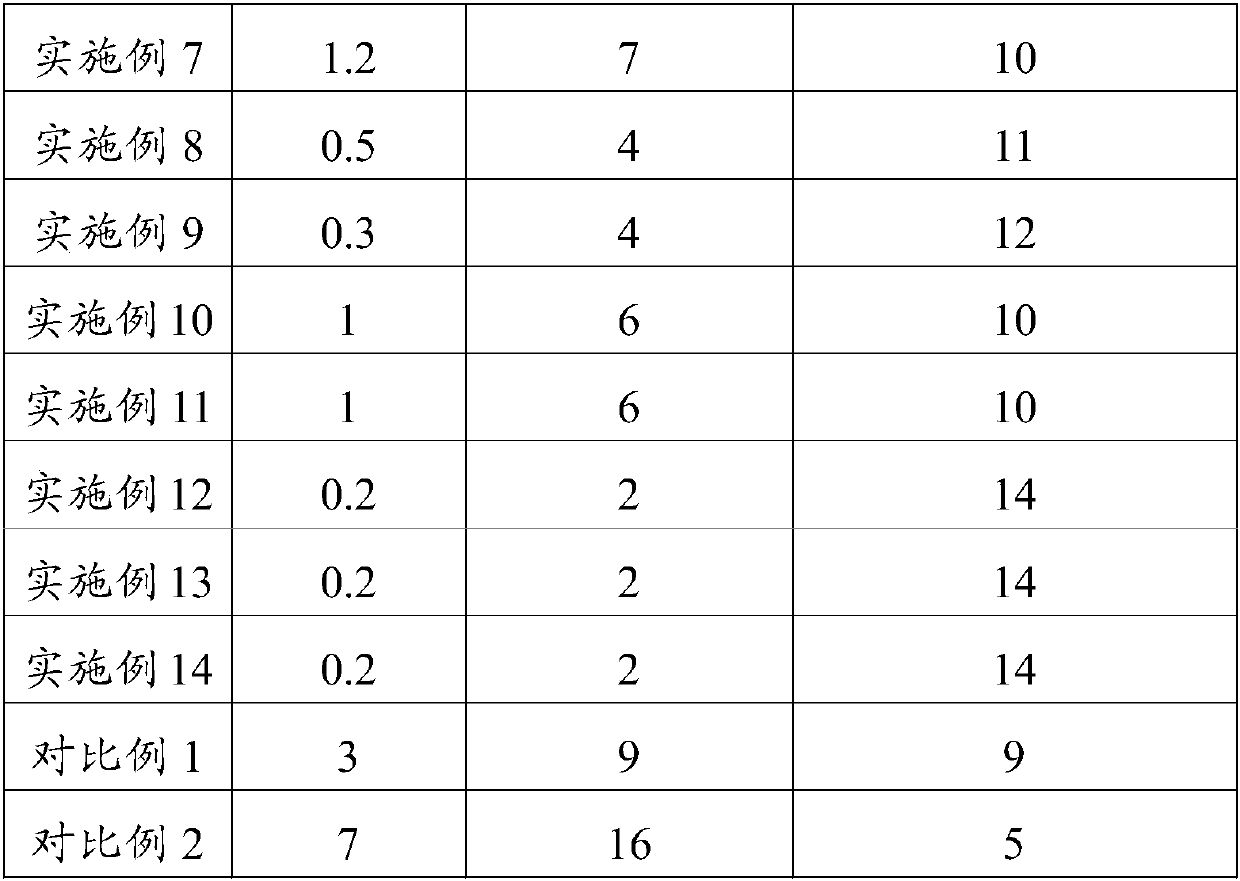

Starch adhesive and preparation method thereof

ActiveCN107779122AImprove water resistanceGood storage stabilityNon-macromolecular adhesive additivesStarch derivtive adhesivesAdhesiveSolvent

The application provides a starch adhesive. The starch adhesive is prepared from the following components in parts by weight: 50 to 150 parts of nanocellulose suspension, 50 to 150 parts of starch, 1to 10 parts of an oxidant, 20 to 80 parts of polyvinyl alcohol, 0.01 to 5 parts of a surfactant and 0.25 to 10 parts of a crosslinking agent. The starch adhesive has good properties including good waterproof performance, good storage stability, excellent initial adhesion, great adhesion, good flowability and good coagulation resistance. The application further provides a preparation method of thestarch adhesive. The preparation method comprises the following steps: (1) preparing the nanocellulose suspension, preparing a polyvinyl alcohol solution and preparing a dialdehyde starch solution; and (2) mixing the dialdehyde starch solution, the nanocellulose suspension, the polyvinyl alcohol solution and the crosslinking agent and stirring and reacting with certain pH value and temperature toprepare the starch adhesive. According to the method provided by the invention, starch and waste paper products are used as raw materials, aldehyde substances are not added in a reaction process and water is used as a solvent; and a production technology and a product have an environment-friendly property and all the raw materials can react sufficiently.

Owner:GUANGDONG YULAN GRP

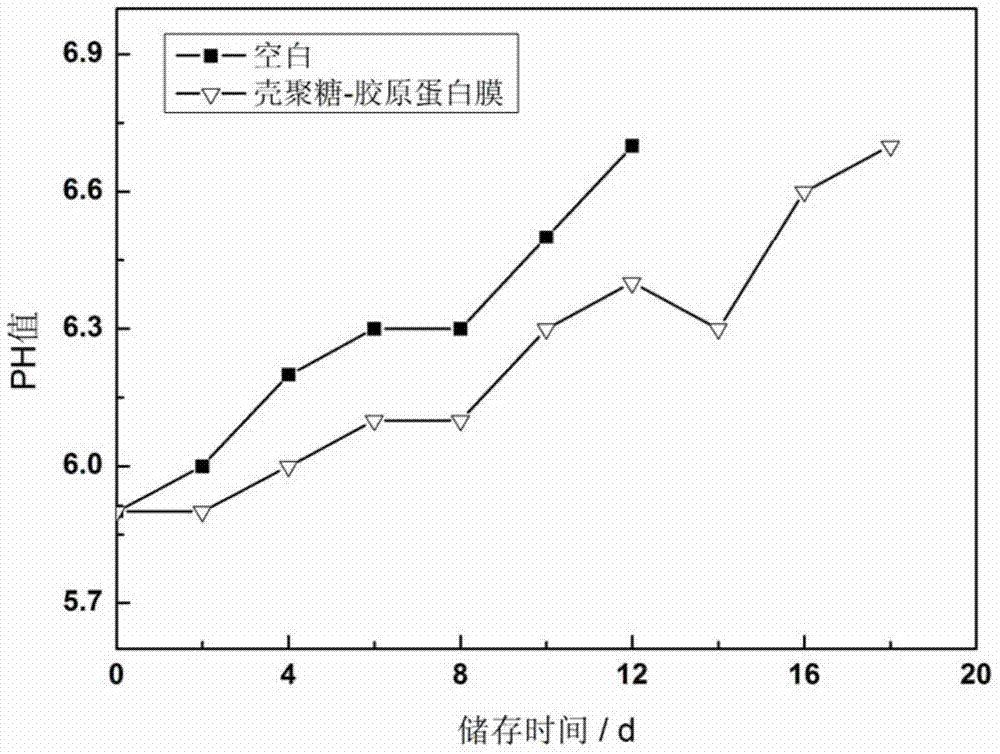

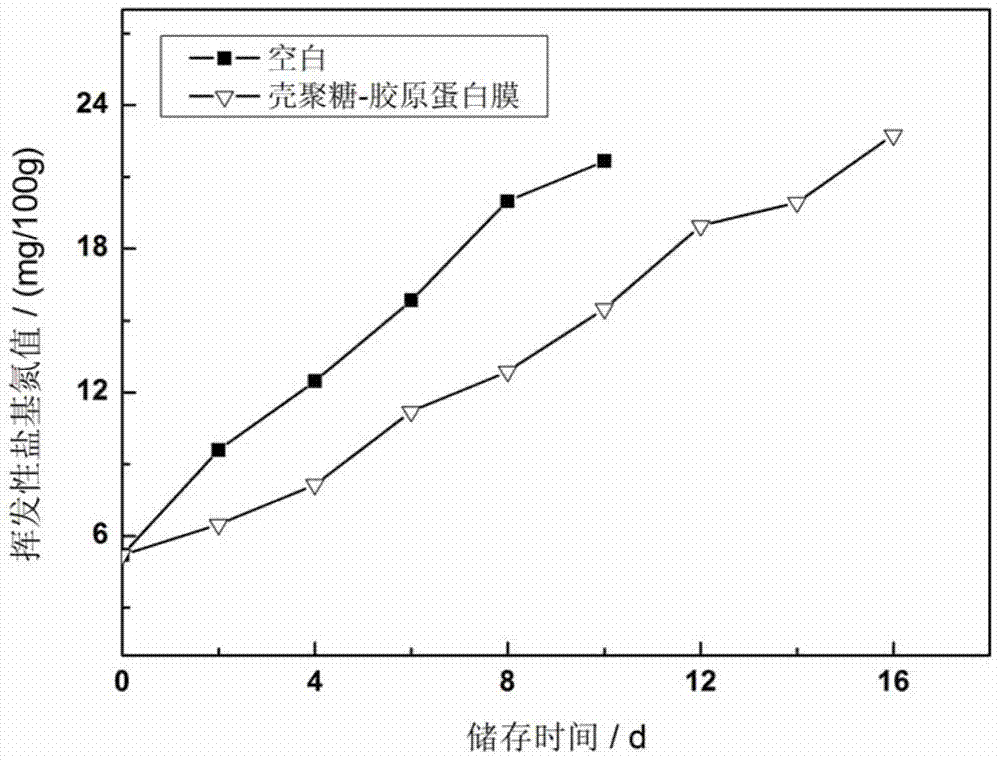

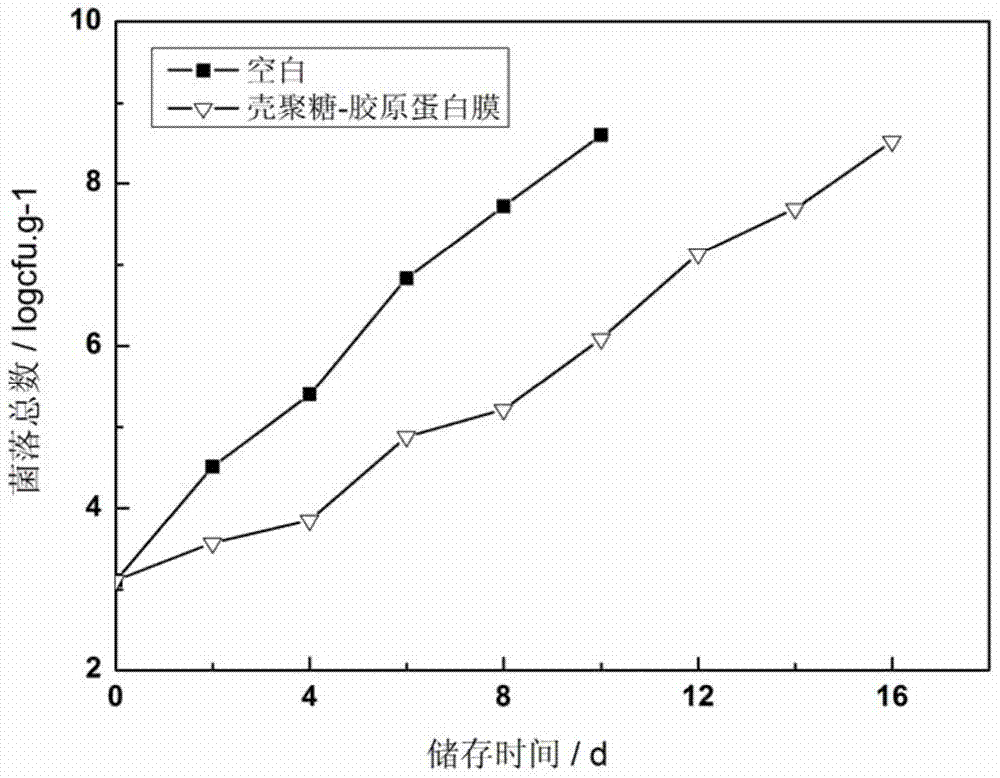

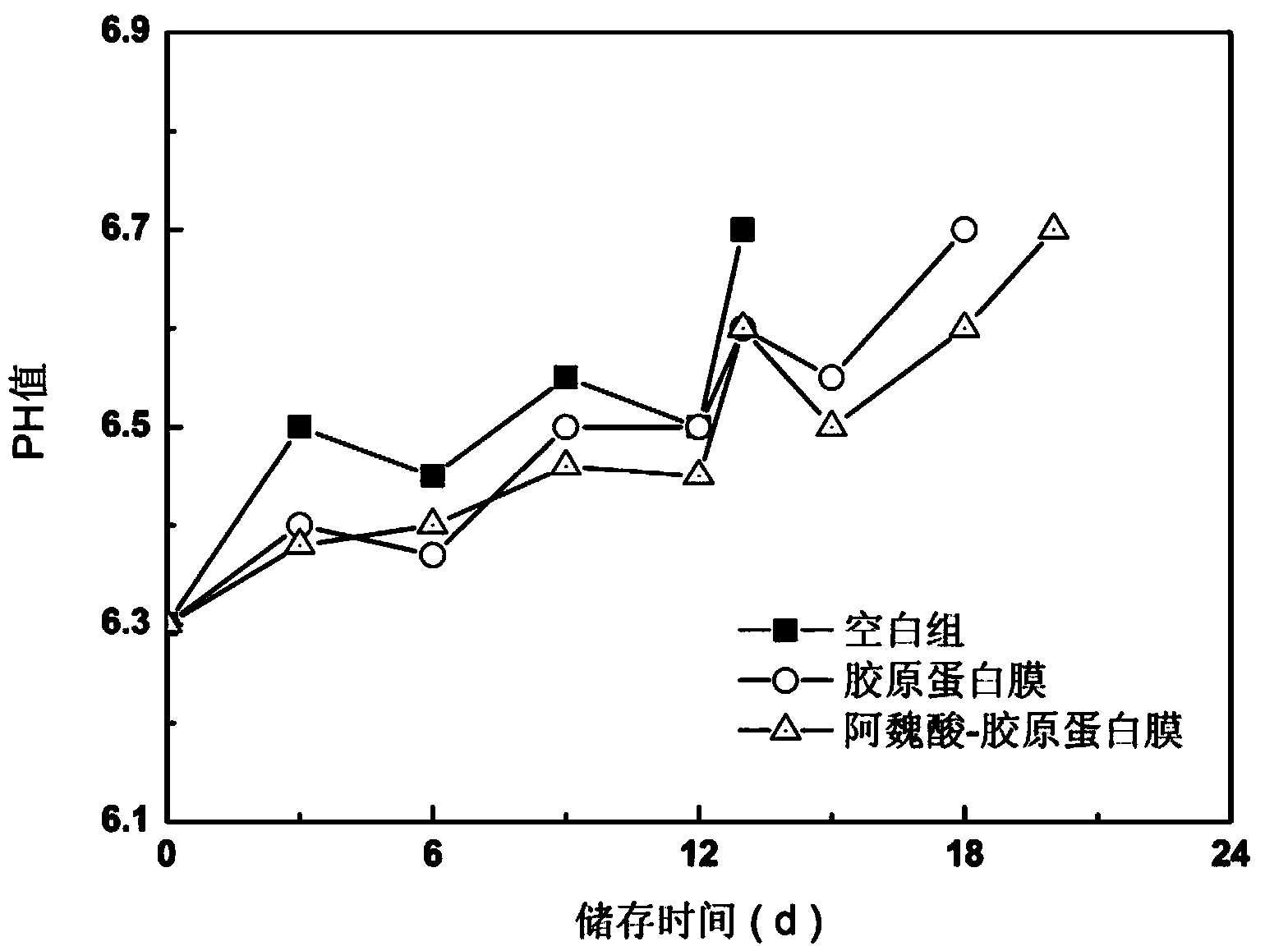

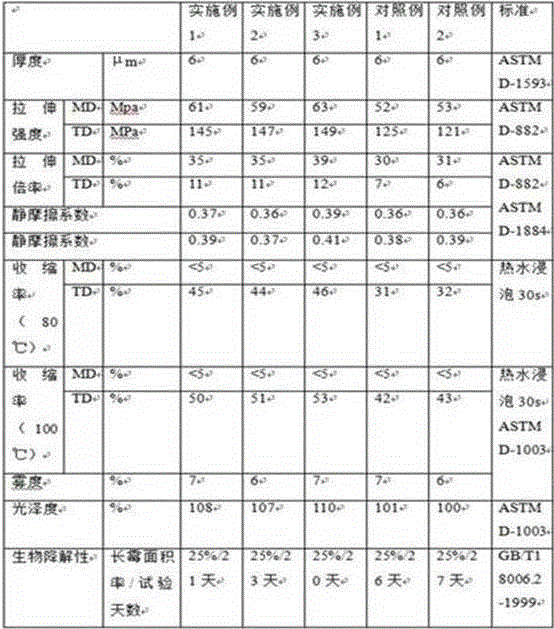

Edible chitosan-collagen antibacterial film and preparation method thereof

ActiveCN103570958ALow tensile strengthEasily brokenFlexible coversWrappersOrganic glassThermal treatment

The invention discloses an edible chitosan-collagen antibacterial film and a preparation method thereof. The preparation method comprises the following steps: adding collagen to water, stirring and dissolving at the thermal treatment temperature of 60 DEG C-70 DEG C, sequentially adding glycerin, dialdehyde starch and chitosan, and controlling the pH value of the solution to 5-6; carrying out thermal treatment for 10-20 minutes at the temperature of 60 DEG C-70 DEG C, placing in a stirring defoaming machine so as to remove air bubbles, then carrying out curtain coating on an organic glass plate, cooling film formation liquid, drying, cooling at a normal temperature, and stripping a film, thus obtaining the edible chitosan-collagen antibacterial film. The edible chitosan-collagen antibacterial film has particularly excellent mechanical property; when the thickness of the edible chitosan-collagen antibacterial film is 0.21mm, the tensile strength of the film reaches 2-4.11Mpa, and the elongation at break of the film reaches 130.12-172.48%; meanwhile, the edible chitosan-collagen antibacterial film has relatively good antibacterial property and is capable of prolonging the shelf life of chilled meat by 6 days.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Modified starch and manufacturing method and application of modified starch

ActiveCN102634049AReduce crystallinityImprove chemical reactivityOrganic solventOCTENYLSUCCINIC ACID

The invention discloses modified starch and a manufacturing method and application of the modified starch. The manufacturing method of the modified starch provided by the invention comprises the following steps: dispersing starch by an organic solvent, adding water and uniformly mixing to prepare a starch suspension, and performing the microwave or the ultrasonic treatment to obtain the modified starch. According to the invention, crystalline regions in modified starch granules are greatly reduced, and the crystallinity of the modified starch granules is decreased from 15-45% to 8-30%. After the crystallinity is decreased, cassava starch is used for manufacturing dialdehyde starch, hydroxypropyl starch and octenyl succinic anhydride starch ester and has obviously improved reactivity.

Owner:GUANGXI UNIV FOR NATITIES

Dialdehyde starch crosslinked chitosan magnetic microsphere and preparation thereof

InactiveCN101343369ANo side effectsImprove bindingPharmaceutical non-active ingredientsAntineoplastic agentsCrosslinked chitosanCross-link

The invention relates to diadehyde starch cross-linking chitosan magnetic microsphere and the preparation method, and the diadehyde starch cross-linking chitosan magnetic microsphere belongs to the functional macromolecule material. The preparation method comprises the following steps: firstly, the diadehyde starch is prepared; secondly, the diadehyde starch cross-linking magnetic microsphere is prepared; and thirdly, the diadehyde starch cross-linking chitosan magnetic microsphere is prepared. The diadehyde starch cross-linking chitosan magnetic microsphere uses the magnetic microsphere prepared through the cross-linking reaction of the chitosan and the diadehyde starch, the magnetic microsphere has no toxic side effect to the human body. The diadehyde starch cross-linking chitosan magnetic microsphere prepared through the invention is used for the targeting drug carrier, and the diadehyde starch cross-linking chitosan magnetic microsphere contains a large quantity of aldehyde groups, which is convenient for the combination of the amino groups in the drug, thereby enhancing the drug carrying amount, and simultaneously after the drug arrives at the lesion location, which can be easily combined with the proteases in the human body, to fully exert the drug effect.. The diadehyde starch cross-linking chitosan magnetic microsphere and the preparation methodare particularly suitable for the treatment to the tumour.

Owner:HEZHOU UNIV

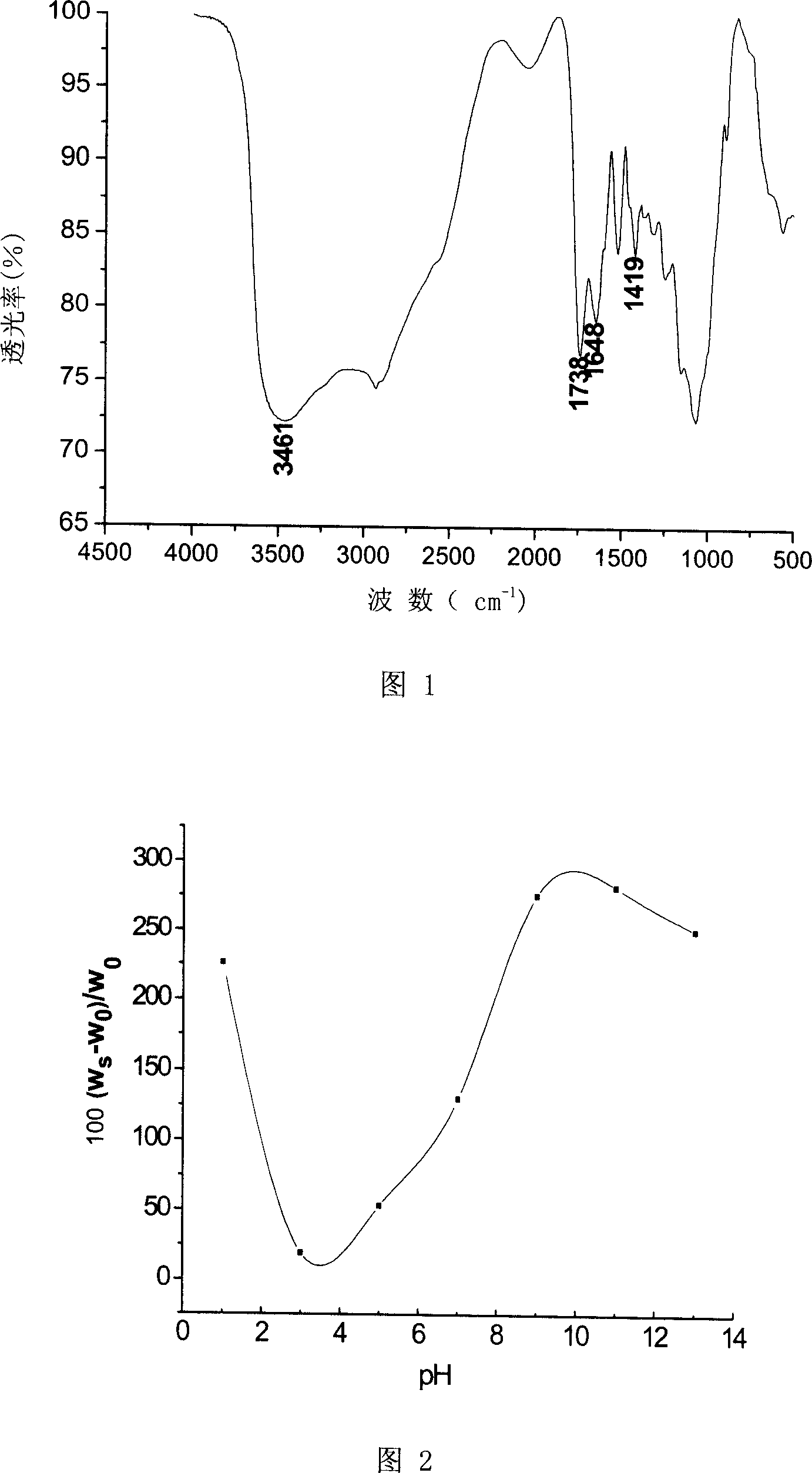

Preparation method of pH sensitive carboxymethyl chitosan hydrogel

The invention discloses a preparing method of pH value sensitive dialdehyde starch crosslinking carboxymethyl chitosan aquagel, which comprises the following steps: blending carboxymethyl chitosan solution with density at 1-4% and dialdehyde starch solution with density at 1-6% according to the weight rate at 1:0.5-5.0; stirring evenly under 30-60 Deg C; defoaming in the vacuum; stewing at indoor temperature for 6-36h to form gel; washing through deionized water; drying in the vacuum to obtain constant weight material as the product.

Owner:WUHAN UNIV OF TECH

Wheat protein/methyl cellulose composite edible film and preparation method thereof

The invention discloses a wheat protein / methyl cellulose composite edible film and a preparation method thereof. The wheat protein / methyl cellulose composite edible film comprises the following components by weight portions: 100 portions of wheat protein, 25 to 900 portions of methyl cellulose, 30 to 700 portions of glycerine plasticizer and 1 to 17 portions of dialdehyde starch. The film is prepared by adopting a solution casting method and carrying out high temperature and heat treatment; and the film preparation method and the process flow are simple and easy to promote and implement. The composite edible film prepared on the basis of the invention has excellent mechanical performance, can adjust the mechanical performance and moisture permeability of the film according to the ratio of the methyl cellulose and protein, does not contain additives which are harmful to the body and can be used for edible package films of foods, candy products and the like.

Owner:ZHEJIANG UNIV

Soyabean protein/dialdehyde starch/nano silver composite membrane, preparation method and application thereof

InactiveCN101445615AImprove antibacterial propertiesImprove mechanical propertiesFlexible coversWrappersCross-linkSilver ion

The invention discloses a soyabean protein / dialdehyde starch / nano silver composite membrane with an anti-bacterial function and a preparation method thereof. The soyabean protein / the dialdehyde starch / the nano silver composite membrane is prepared by the solution casting method, soybean protein and a plasticizer glycerin are dispersed in water, then the soybean protein aqueous solution and dialdehyde starch as well as silver nitrate solution are evenly mixed, cast and baked to form the membrane; a cross-linking reaction occurs between aldehyde groups on the dialdehyde starch and amino groups on the soybean protein during the membrane forming, and the aldehyde groups further reduce silver ions into nano silver ions at the same time. The invention further discloses application of the composite membrane to being used as a food packaging material and a medical material. The soybean protein / the dialdehyde starch / the nano silver composite membrane has excellent mechanical property and anti-bacterial property and can be quickly degraded in the natural environment.

Owner:SUN YAT SEN UNIV

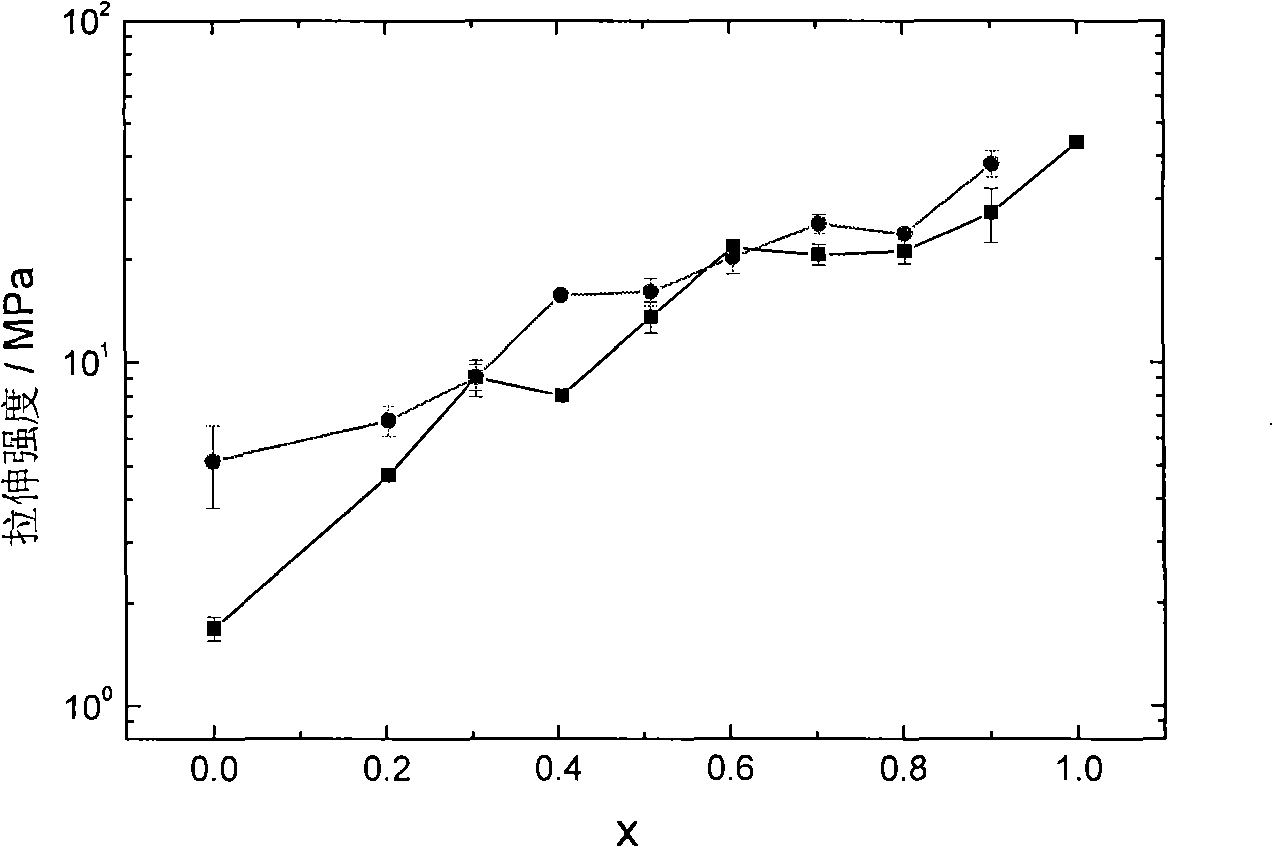

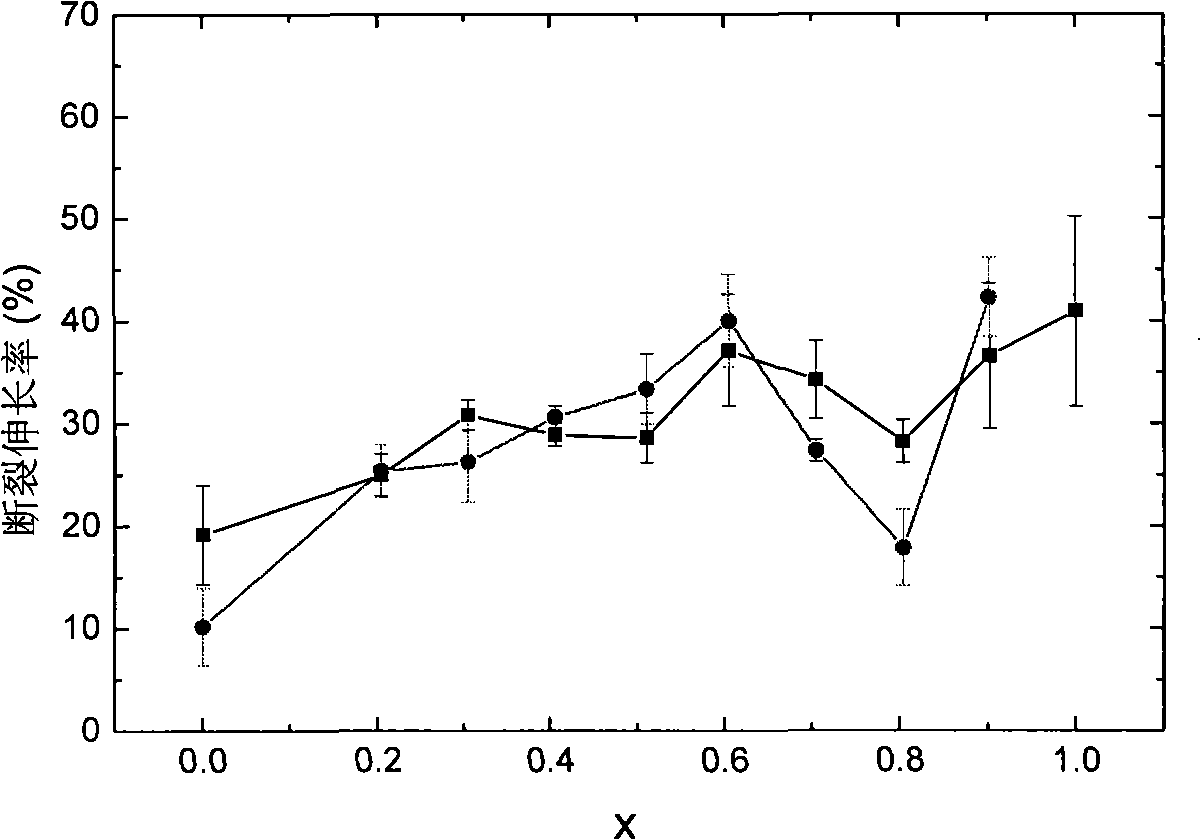

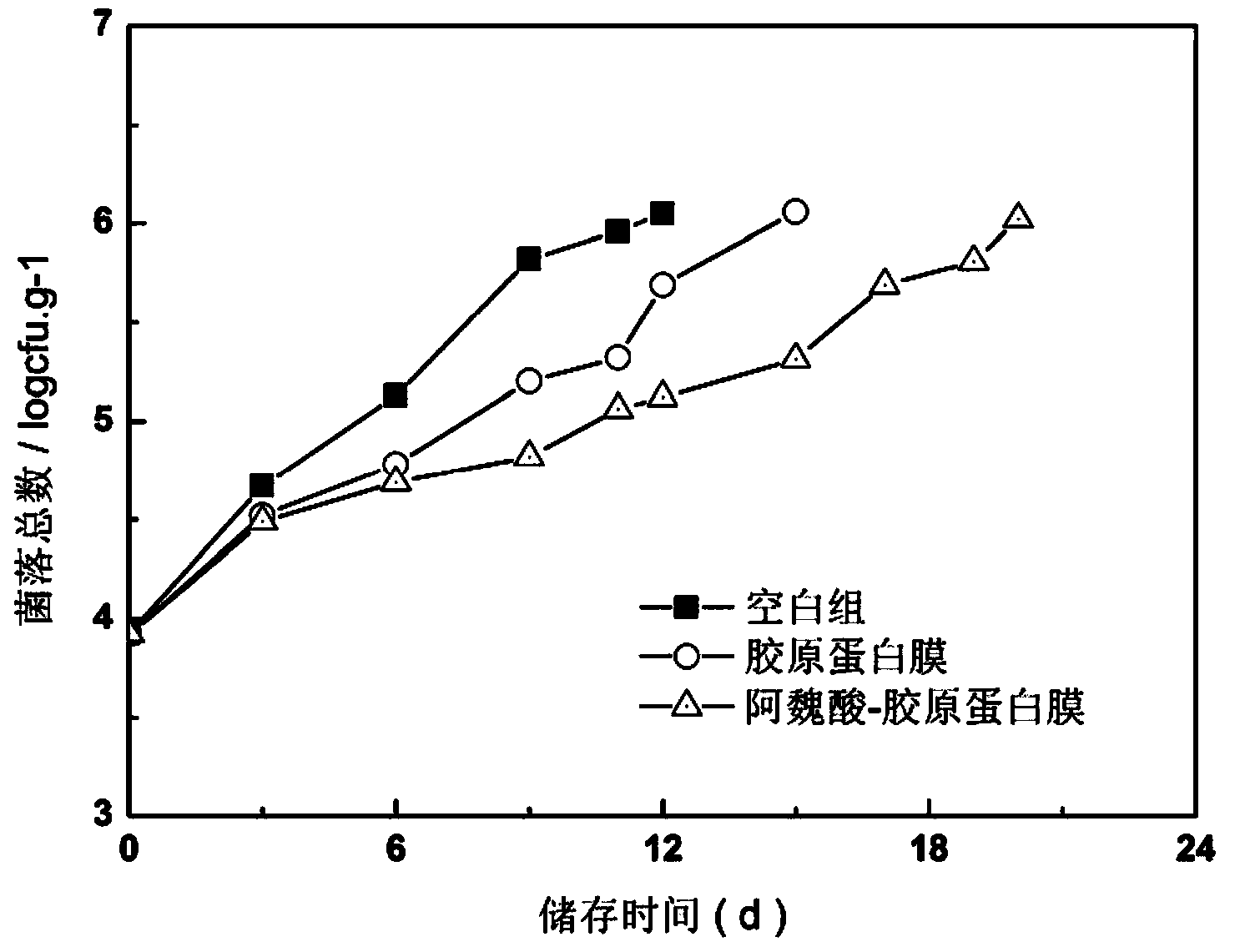

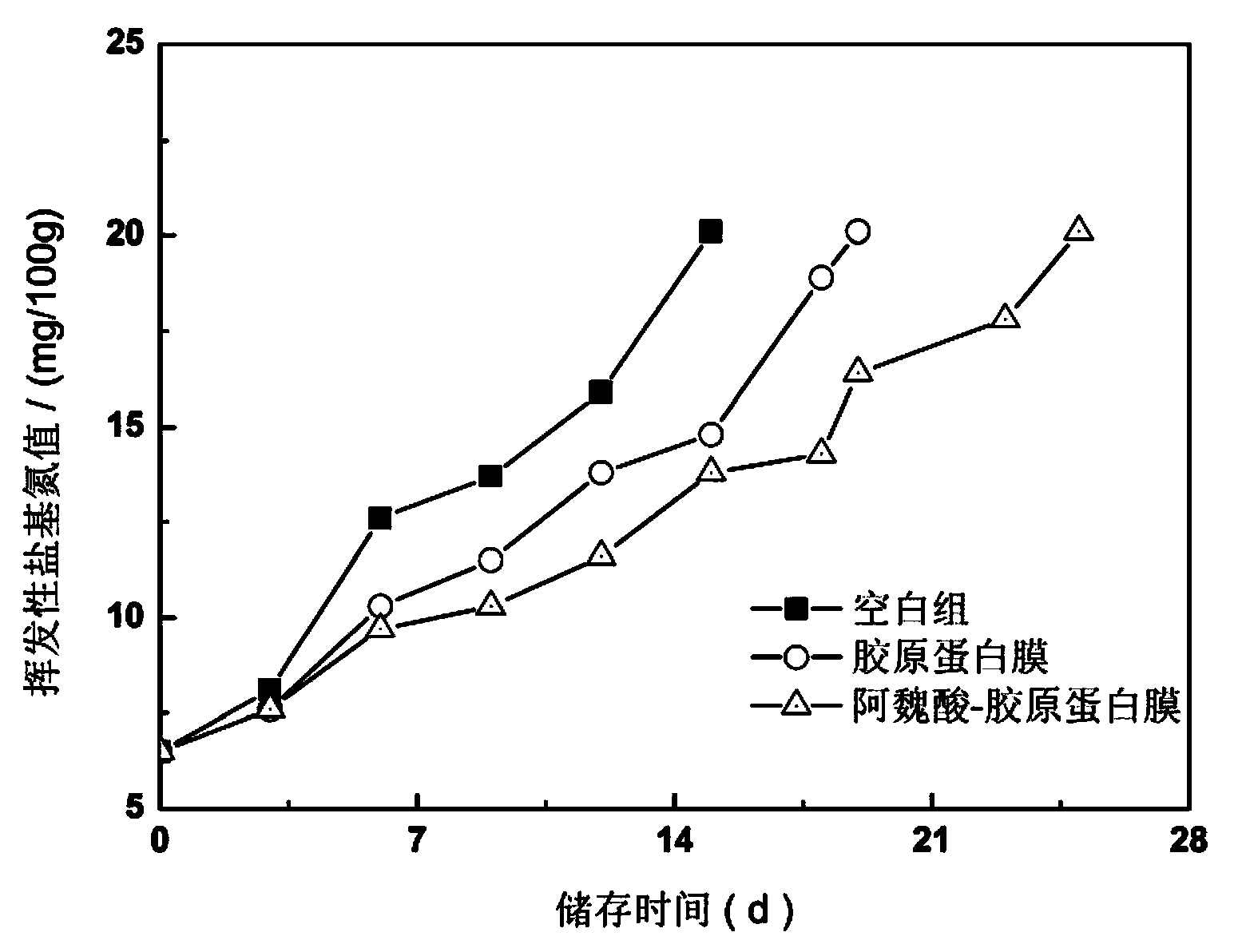

Ferulic acid-collagen antimicrobial film, and preparation method and application thereof

ActiveCN103554532APlay the role of cross-linkingImprove mechanical propertiesMeat/fish preservation by coatingInhibition zoneGlycerol

The invention discloses a ferulic acid-collagen antimicrobial film, and a preparation method and application thereof. The preparation method comprises the following steps: adding collagen in water, dissolving by stirring at the heat treatment temperature of 60-70 DEG C, sequentially adding glycerol, dialdehyde starch, sodium alginate and ferulic acid, carrying out heat treatment at 60-70 DEG C for 20-30 minutes, removing bubbles in a stirring debubbling machine, running on an organic glass plate, drying after the film forming solution is cooled, cooling at normal temperature, and peeling off the film to obtain the ferulic acid-collagen antimicrobial film. The edible food packaging film has the advantages of high transparency, high barrier property, higher mechanical strength and mold resistance; and the oxford cup method detects that the diameters of inhibition zones of the obtained film for Gram-negative bacteria and Gram-positive bacteria are 17-22mm, and the film has strong antibacterial capacity. The prepared film is used for sausage preservation, and can prolong the shelf life of sausage by 8.5 days.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Total-starch type biodegradable plastic

A total-starch type biodegradable plastic by using dialdehyde starch whose oxidization degree is no less than 40% as the fundamental and principal raw material, through blended refining with long chain non-saturated carboxylic acid or acid anhydrides grafted and modified compositions, degradable aliphatic polyester or hydroxy acid blending component, organic peroxides initiating agent, polyhydric alcohol esters plasticizing agent, polyhydric alcohols and / or their esters compound stabilizing agent, higher hydrocarbons, aliphatic acids and their esters or polyamides compound lubricating agent.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Production process of PVA (polyvinyl alcohol)-based composite packaging material

InactiveCN103540068ANo pollution in the processNo dopingFlexible coversWrappersPolyvinyl alcoholBiological materials

The invention discloses a production process of a PVA (polyvinyl alcohol)-based composite packaging material, relating to the field of film packaging materials. The production process comprises the following three technical processes: preparation of dialdehyde starch, preparation of jute fibers and preparation of a PVA-based composite film. According to the process method, in the preparation process of the dialdehyde starch, corn starch is used as a raw material, no pollution is caused, the cost is low, the raw material is sufficient, a far-infrared quick constant-temperature drying box is used as drying equipment, the dialdehyde starch is dried sufficiently, and no impurity is doped; in the preparation process of the jute fibers, the temperature control is reasonable, a right amount of reagent is added, the jute fibers are pulverized through a YSC-701 type ultrafine pulverizer, and the pulverized fibers are small in particle size and favorable in pulverization effect; and in the preparation process of the PVA-based composite film, parameters such as addition of each component, temperature, time and the like are strictly controlled, thereby ensuring that the prepared PVA-based composite film has favorable mechanical property and water resistance and can meet the requirements for practical production. By using the biological material as the raw material for production, the PVA-based composite film produced by the process is low in cost and degradable, thus greatly reducing environmental pollution.

Owner:TONGCHENG FURUN PACKAGING MATERIAL

Process for working bionic reinforced plate

The present invention relates to a technological process of producing non-timber fiber board with crop stalk as main material. During the semi-drying process, different material is adopted based on different use, and the produce process includes spraying adhesive, spreading, pressing, and other steps. The spread layers include middle reinforcing rib layer, coarse material layers and fine material layers on two sides. The adhesive is polymer adhesive of dialdehyde starch, protein complex or water soluble polymer resin. The present invention has the advantages of short production period, high strength, low cost and no environmental pollution.

Owner:刘海通

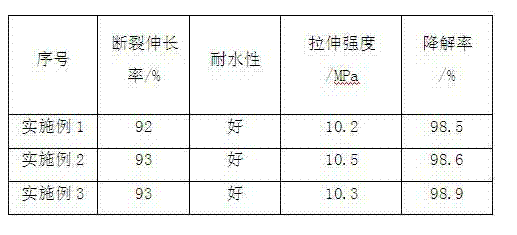

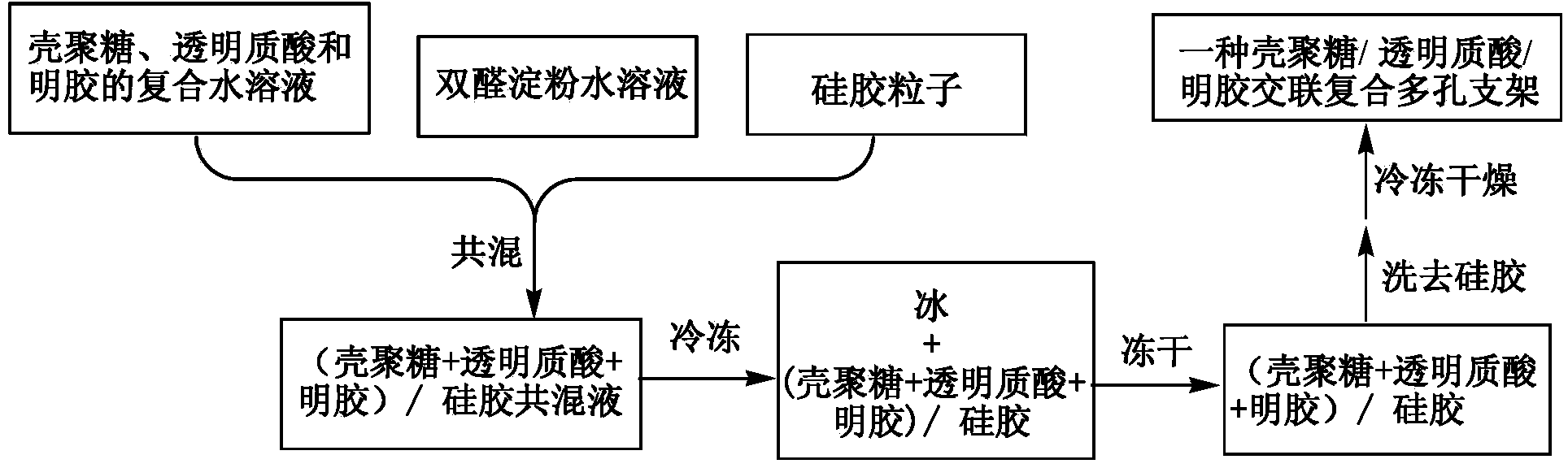

Method for preparing chitosan/hyaluronic acid/gelatin crosslinked composite porous stent

InactiveCN103705982AImprove mechanical propertiesImprove adhesionProsthesisPolymer scienceCrosslinking reagent

The invention relates to the technical field of novel materials, and in particular relates to a method for preparing a chitosan / hyaluronic acid / gelatin crosslinked composite porous stent. The method uses chitosan, hyaluronic acid, gelatin and other natural biological materials as raw materials and dialdehyde starch as a crosslinking agent, and combines a lyophilisation method and a particulate leaching method to prepare the chitosan / hyaluronic acid / gelatin crosslinked composite porous stent, which is excellent in mechanical performance and made of a pure natural biological material. The chitosan / hyaluronic acid / gelatin crosslinked composite porous stent prepared by the method has the characteristics of high porosity, high pore strength, large pore diameter and the like, the pore diameter is 100-300 mu m, and the porosity is more than 90 percent. The stent is of an opening pore structure with small pores in large pores, and is suitable for cell implanting on the surface of the composite stent. Compared with a chitosan stent, the crosslinked composite porous stent has a better mechanical performance, proliferation and differentiation of cells on the surface of the composite stent can be more favored, and the compatibility of the composite stent to biological cells is excellent.

Owner:江苏创基新材料有限公司

Preparation method of self-repairing medical catheter coating

InactiveCN108578786ASimple methodSimple and fast operationCatheterCoatingsBiological propertyDistilled water

The invention discloses a preparation method of a self-repairing medical catheter coating. A chitosan (CS) solution with positive charge is first applied to a medical catheter material by dripping, and then the medical catheter material is soaked into a dialdehyde starch (DS) solution with negative charge for a period of time, then a medical catheter is removed and rinsed with distilled water repeatedly, and chitosan and dialdehyde starch are assembled on the medical catheter repeatedly. As the reversible schiff base connection can be formed between an amino group of the chitosan and an aldehyde group of the dialdehyde starch, and the schiff base substance formed has good biological properties, the medical catheter coating prepared in a layer-by-layer self-assembly method has self-repairing properties and antibacterial effects. The preparation method is simple, effective and easy to operate and requires less time.

Owner:SOUTHEAST UNIV

Collagen covalent cross-linking hydrogel and preparation method thereof

InactiveCN103131029AImprove performanceImprove mechanical propertiesProsthesisAbsorption (skin)Biology

The invention particularly relates to a collagen covalent cross-linking hydrogel and a preparation method thereof. An injectable hydrogel causes the problems of red and swollen, warty bumps and too fast absorption and the like after being used, and can not be used or can not fully meet requirements of beauty and wrinkle reduction. According to the preparation method, the Schiffbase reaction principle and the Acetalization reaction principle are utilized. By mass, 2.0%-5.0% of Dialdehyde starch solution, 2.0%-4.0% of collagen solution and 1.0%-5.0% of chitosan solution are stirred in a mixed mode with the size ratio of (1-4): (1-3): (1-3) to obtain the covalent cross-linking hydrogel. The prepared collagen covalent cross-linking hydrogel can form stable gel within a temperature range of 4-40 DEG C, and the gel takes 2-3 minutes in forming time, and is good in mechanical performance, and poor in immune rejection reaction. Degradation time of the gel is obviously prolonged and can reach about 12 months, and the gel is safer and more effective when applied to treat skin dimpling, wound trauma and wrinkles ( crows-feet and forehead wrinkles and frown lines and the like).

Owner:NORTHWEST UNIV(CN)

Production method for dialdehyde starch adhesive

InactiveCN102617819AFast bondingGood initial adhesionStarch derivtive adhesivesAldehyde/ketone condensation polymer adhesivesAdhesivePhenol

The invention discloses a production method for a dialdehyde starch adhesive. The method comprises the following steps of: (1) dispersing alkali lignin: uniformly stirring 100 kilograms of dialdehyde starch and 800 kilograms of water, adding into a reaction kettle, adjusting the pH value to 9-9.5 by using alkaline water, adding 50 kilograms of alkali lignin and 5 kilograms of urea for the first time while stirring, heating to 40 DEG C, and reacting for 20 minutes; (2) forming hydroxymethyl and undergoing a condensation polymerization reaction: continually heating to 60 DEG C after the step (1), adding 50 kilograms of phenol and 5 kilograms of urea for the second time, heating to 90 DEG C, preserving heat, and reacting for 30 minutes; and (3) undergoing a starch complexing reaction: cooling and reacting simultaneously, cooling to 75 DEG C, adding 1.5 kilograms of sodium borate, cooling and reacting simultaneously while stirring, cooling to 45 DEG C, and discharging. The adhesive is mainly used for bonding bamboo and wood materials, and has the advantages of no free formaldehyde, high bonding speed, high initial viscosity, high water tolerance and high corrosion resistance.

Owner:湖州南浔长三角家居集成设计研发服务中心有限公司

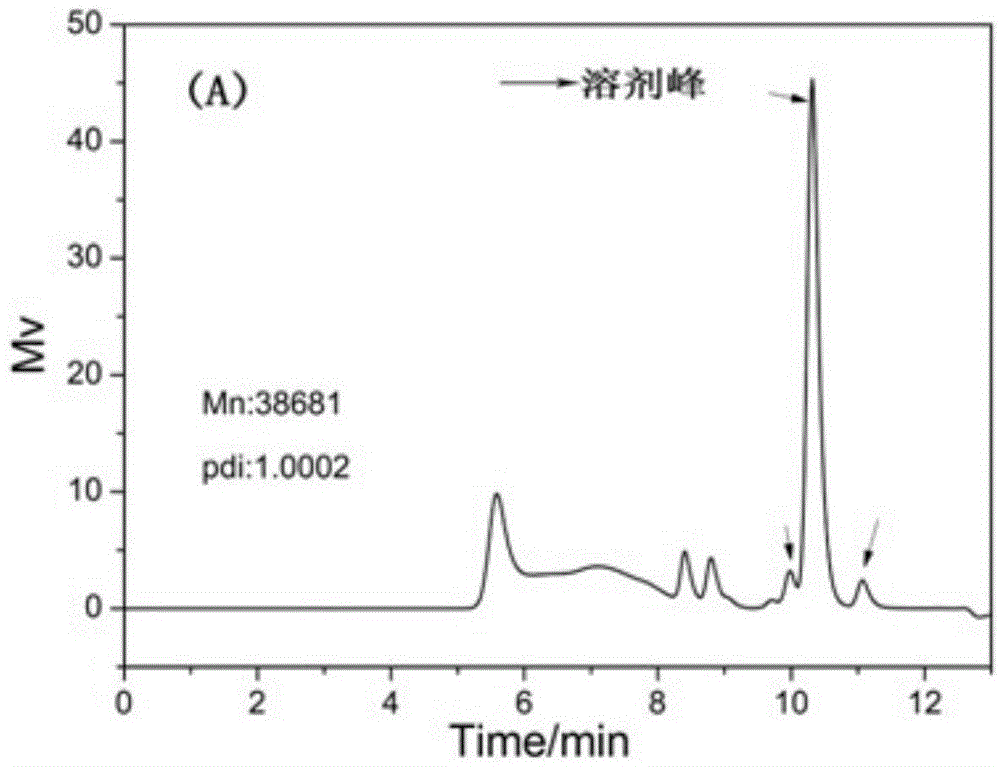

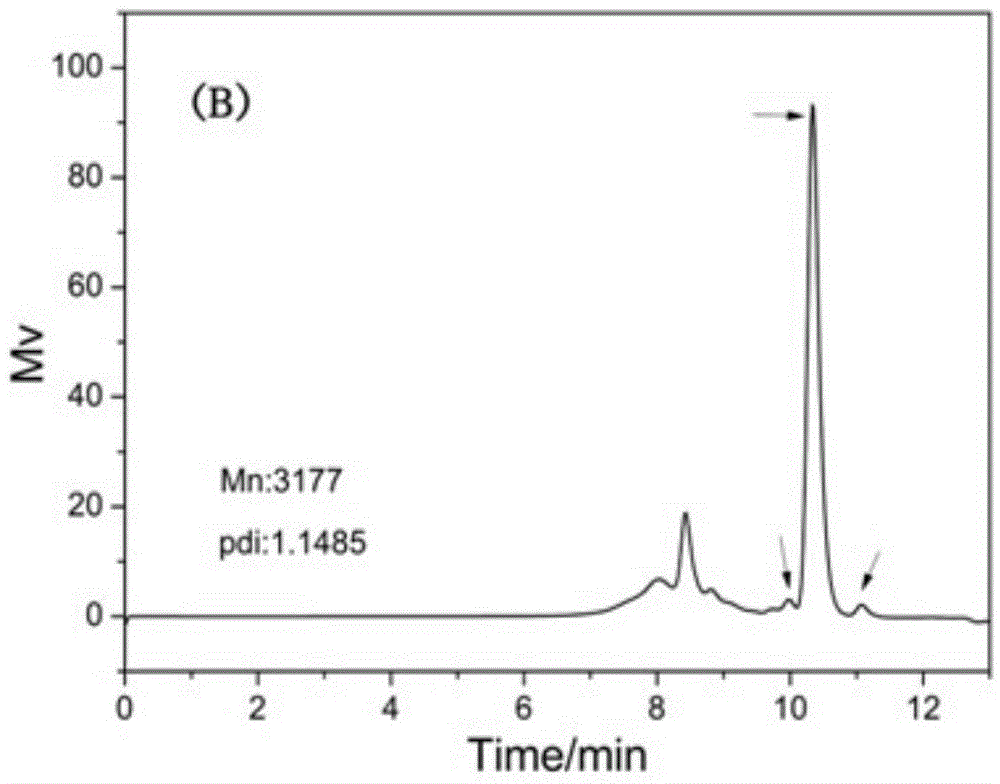

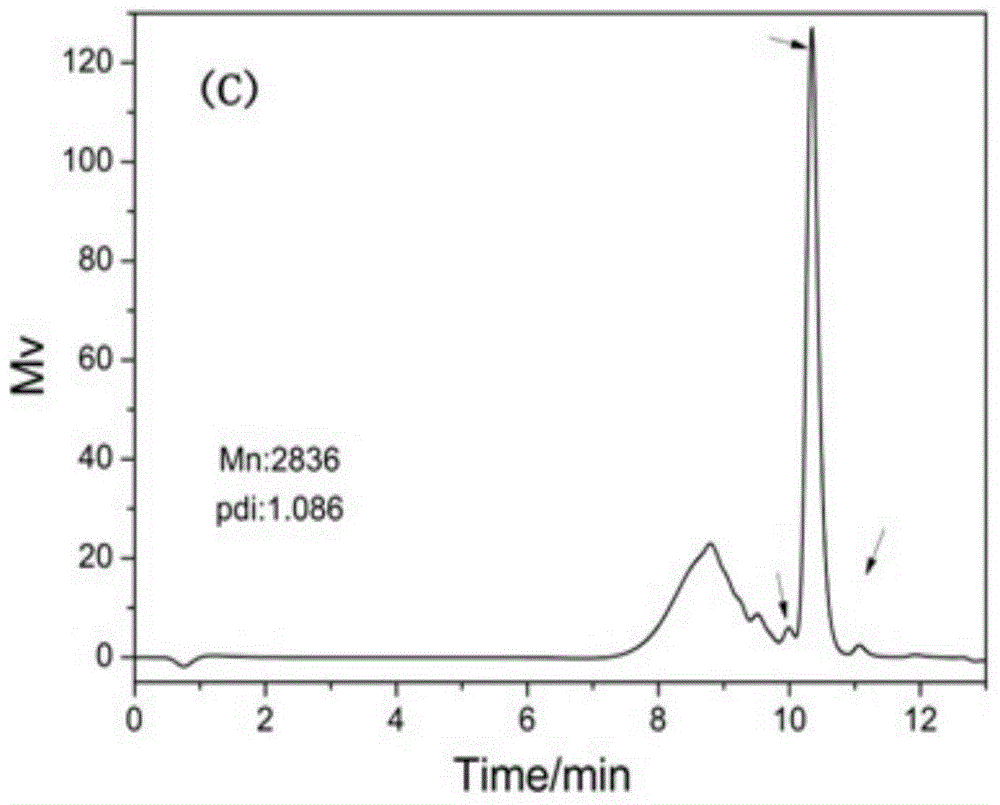

Modified rice dialdehyde starch retanning filler for leather and preparation method of filler

InactiveCN104087688AHarm reductionGood retanning filling effectTanning treatmentAqueous solutionUltimate tensile strength

The invention discloses a modified rice dialdehyde starch retanning filler for leather and a preparation method of the filler. The preparation method comprises the following steps: performing dihydroformylation modification and degradation on rice starch, wherein a used dihydroformylation agent is periodic acid or sodium periodate, a used degradation agent is a water solution of enzyme or acid, the relative average molecular weight of the obtained modified rice dialdehyde starch retanning filler is 2000-40000Da, and the aldehyde content is 30%-98%. The modified rice dialdehyde starch retanning filler prepared by adopting the method has good retanning filling capability on the leather; when the filler is applied to the leather, the leather strength can be improved, the leather location difference can be effectively reduced, the leather yield can be increased, the hand feel of the leather is full and soft, and the absorption of grease and dye in a subsequent process cannot be influenced.

Owner:SHANGYU LANBO NEW MATERIAL SCI & TECH

Method for preparing magnetic macromolecular microsphere of crosslinking dialdehyde starch

InactiveCN1961960AIncrease loading capacityImprove bindingInorganic non-active ingredientsMicrosphereHuman proteins

The invention relates to a method for preparing magnetic natural macromolecule micro ball as target drug carrier, wherein the invention modifies the amidon magnetic micro ball, prepares crosslink bi-aldehydes amidon magnetic micro ball, to convert more hydroxyl into aldehydes, to combine the -NH2 of drug; when the micro ball is used to target drug preparation, it can improve the carry amount, to combine the human protein enzyme at the ill part.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Starch-based biodegradable bionic bait added with modified nano calcium carbonate

The invention discloses starch-based biodegradable bionic bait added with modified nano calcium carbonate. A preparation method of the starch-based biodegradable bionic bait includes: evenly dispersing high hydrophobic modified dialdehyde starch in distilled water, heating for gelatinization, adding polylactic acid, polyvinyl alcohol and plasticizer glycerin, sufficiently mechanically evenly stirring and mixing, adding preprocessed jute fibers, high-speed stirring modified nano calcium carbonate, stirring, and adding into a single-screw extruder to prepare master batch; evenly pacing the master batch into a mould of the bionic bait, prepressing the mould in a plate vulcanizing machine, and performing hot-press molding. The high hydrophobic modified dialdehyde starch, the polylactic acid and the polyvinyl alcohol are used as the raw materials, the modified nano calcium carbonate and the preprocessed jute fibers are added, and the starch-based biodegradable bionic bait is prepared through the compounding of the materials above; by adding the jute fibers which has a lot of hydroxyl on the surface, the blending compatibility of the dialdehyde starch and polyvinyl alcohol can be increased, and mechanical performance is increased while the water resistance of the bait is increased.

Owner:界首市汇珠渔具有限公司

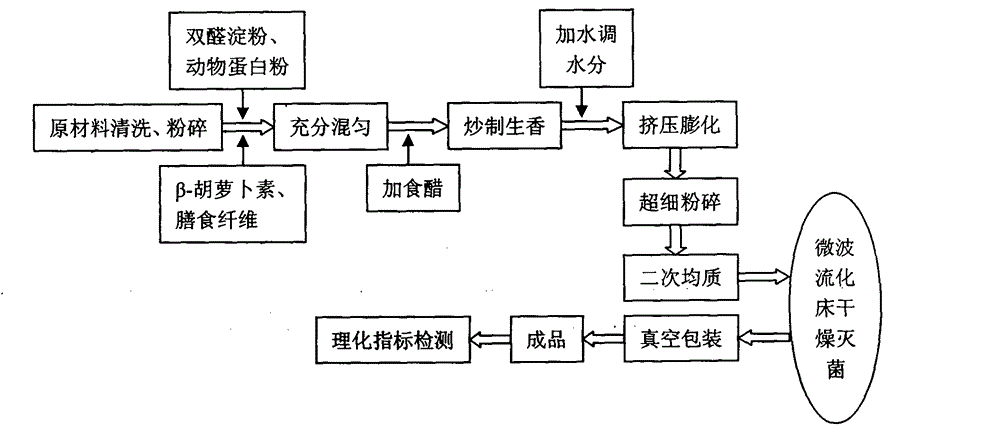

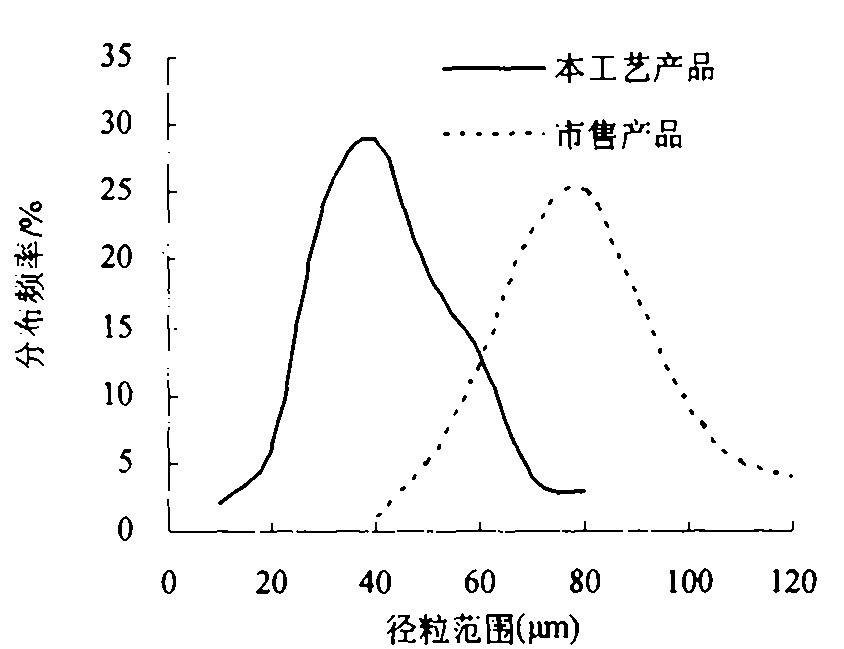

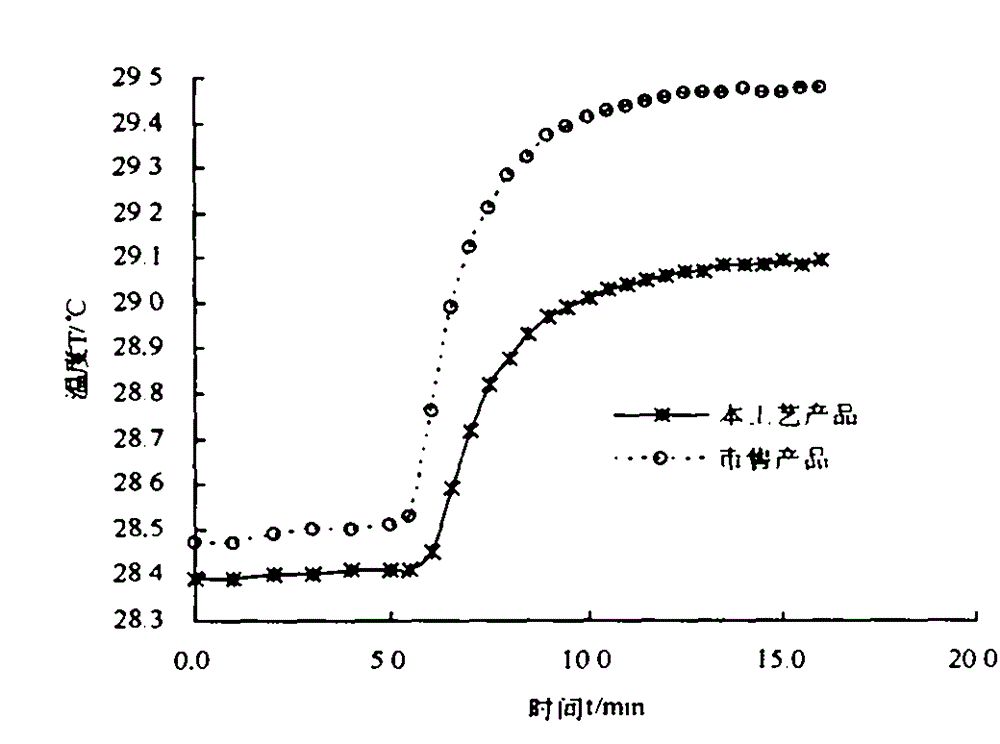

Preparation method of low heat nutritious instant rice paste

InactiveCN104872502AHigh retention rateSuitable for absorptionFood preparationBiotechnologyNutrition

The invention relates to a method for preparing low heat nutritious instant rice paste by taking cereals as raw materials. The method comprises the steps of: washing rice, low fat peanut kernels and the like; drying at a low temperature, after smashing, mixing the smashed rice and low fat peanut kernels and the like uniformly with dialdehyde starch, resistant starch, dietary fiber, beta-carotene and animal albumen powder according to a ratio, frying the mixture until the mixture emits sweet smell, adjusting moisture, extruding the mixture at the low temperature, performing ultrafine grinding and secondary homogenizing, and performing vacuum packing to obtain finished products after microwave fluid bed drying and sterilizing. Compared with the available similar products, the rice paste has the advantages that the crude protein is higher by 2.79%-10.45%, the crude protein in vitro digestibility coefficient is higher by 5.9%-10.3%, the amino acid is higher by 2.65%-8.63%, the crude fat is lower by 2.48%-3.96%, the dietary fiber is higher by 2.42%-3.79%, a food energy value and a bioenergy value are respectively lower by 8%-15% and 14%-26%, the VA is higher by 0.59%-0.87%. The low heat nutritious instant rice paste has the beneficial effects of unique flavor and high nutrition, easy absorption, strong satiety, good water absorption property and reconstituability without clustering, and convenient eating, and especially suits the middle aged and elderly people, diabetes and obese patients, and has wide market prospect.

Owner:NANJING UNIV OF FINANCE & ECONOMICS +1

High-strength high-temperature resistant oil filter paper and preparation method thereof

InactiveCN102912678AImprove high temperature resistanceHigh strengthNon-macromolecular organic additionPaper/cardboardFiberBursting strength

The invention discloses high-strength high-temperature resistant oil filter paper and a preparation method of the high-strength high-temperature resistant oil filter paper. The high-strength high-temperature resistant oil filter paper is prepared from the following materials in parts by weight: 50-60 parts of softwood pulp, 20-30 parts of polybenzimidazole fibre, 20-30 parts of high silica glass fibre, 2-5 parts of modified sepiolite, 1-3 parts of lithopone, 2-4 parts of activated clay, 1-2 parts of nanometer titania, 0.5-0.8 parts of decabromodiphenyl ether, 2-3 parts of cationic polyacrylate latex, 0.5-1 part of glycerol triglyceride acid, 0.4-0.8 parts of diethanol amide, 0.5-1 part of vinyltriethoxysilane, 0.4-0.8 parts of sodium laurylsulfate and 2-5 parts of dialdehyde starch. The filter paper prepared by the method has the advantages of good water permeability, large filter area, small maximum aperture, high filter precision, strong bursting strength, thermostability and the like, has a stable performance index at a normal temperature under a high-temperature work condition, and has better effects of temperature resistance and filtering, and filtering efficiency can be up to 99.98%.

Owner:ANHUI PHOENIX INT CO LTD

Preparation method of biomass-modified paper wet-strength agent

ActiveCN106087565AImprove dry strengthSimple preparation stepsReinforcing agents additionPaper/cardboardPapermakingWet strength

The invention relates to a preparation method of a biomass-modified paper wet-strength agent and belongs to the technical field of papermaking. According to the method, biomass corn starch and chitosan are used as raw materials and chemically modified, dialdehyde starch with the good crosslinking property and modified chitosan rich in carboxyl are prepared and are mixed and crosslinked with a wet-strength agent intermediate and epichlorohydrin, and the biomass-modified paper wet-strength agent is prepared finally. The prepared biomass-modified paper wet-strength agent can enhance the dry strength of paper as well as the wet strength of the paper, the dry-strength tensile strength is in a range of 39.54-45.65 N.m / g, the wet-strength tensile strength is in a range of 28.9-30.2 N.m / g, the preparation steps are simple, the required cost is low, and the method can be widely applied to paper enhancement and has relatively high use value.

Owner:安徽清荷纸业有限公司

Biodegradable heat shrinking film

The invention relates to a biodegradable heat shrinking film, and belongs to the technical field of high polymer materials. The heat shrinking film is prepared through the steps that dialdehyde starch, polyvinyl alcohol, chitosan and sodium carboxymethylcellulose are added into a reaction kettle and subjected to a reaction on the sealed condition to obtain modified dialdehyde starch; a stirring mixer is adopted for stirring polylactic acid, high density polyethylene, polybutylene adipate, the modified dialdehyde starch, polypropylene glycol, a plasticizer, a cross-linking agent, a bulking agent, a surface active agent, a photo-decomposing agent, an inorganic filler, a nucleating agent and a coupling agent to be uniform; the mixed raw materials are placed into a double-screw extruder for extrusion granulation. The heat shrinking film has the good biodegradability and the good physical performance.

Owner:李杰

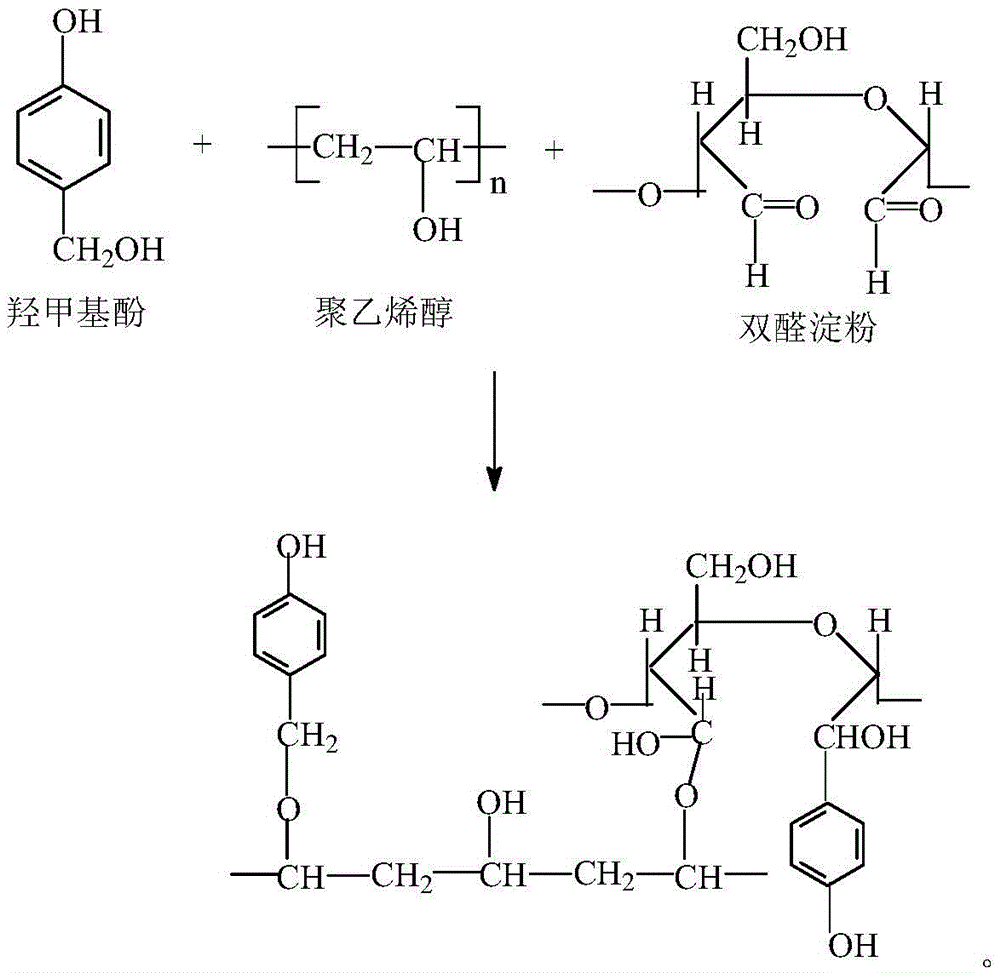

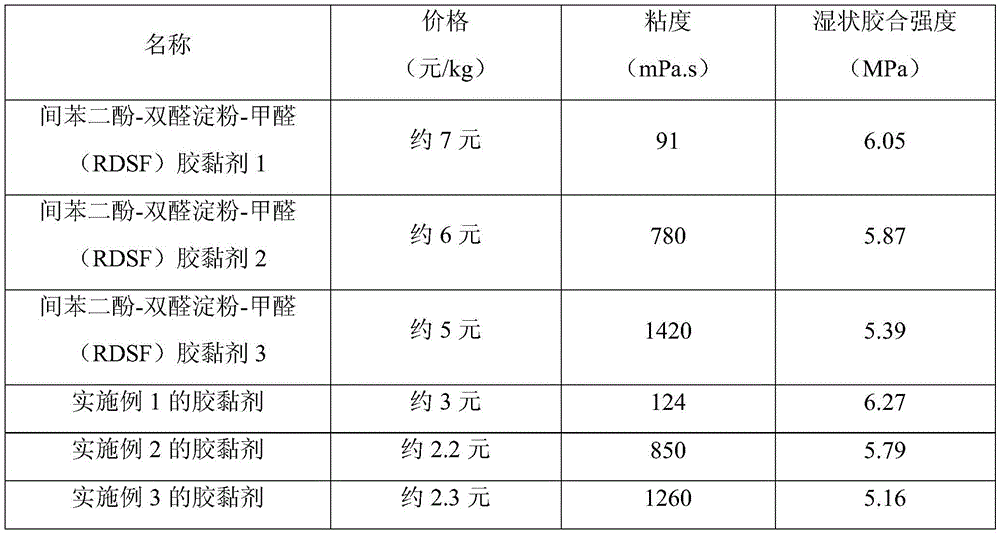

Phenol-dialdehyde starch-formaldehyde resin adhesive and preparation method thereof

ActiveCN105647449AReduce dependenceReduce manufacturing costAldehyde/ketone condensation polymer adhesivesPVA - Polyvinyl alcoholResin adhesive

The invention discloses a phenol-dialdehyde starch-formaldehyde resin adhesive. The adhesive comprises, by weight, 94.11 parts of phenol, 81.2-146.1 parts of formaldehyde solution, 8-100 parts of dialdehyde starch, 12-566.7 parts of water and 5-20 parts of polyvinyl alcohol. The dialdehyde starch which is a renewable degradable biomass resource is adopted to replace part of formaldehyde, and dependence, on petroleum resources, of a phenolic resin adhesive can be lowered; compared with an existing resorcinol-dialdehyde starch-formaldehyde resin adhesive, production cost is lowered remarkably; the phenol-dialdehyde starch-formaldehyde resin adhesive is high in adhesiveness, excellent in waterproofness, capable of meeting binding requirements of wood and bamboo and equivalent to the resorcinol-dialdehyde starch-formaldehyde resin adhesive in binding performance, so that performance-cost ratio is increased obviously, and the phenol-dialdehyde starch-formaldehyde resin adhesive can replace conventional phenolic resin adhesive and the existing resorcinol-dialdehyde starch-formaldehyde resin adhesive for use.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Collagen plastic and preparation method thereof

The invention relates to a collagen plastic and a preparation method thereof. The method comprises the following steps: preparing white leather powder from leather-making leftover materials at first; then blending the white leather powder with dialdehyde starch according to a mass ratio of 10: 1-10; adding a plasticizer accounting for 10 to 30% of the dry weight of the white leather powder and carrying out stirring at room temperature for 1 to 3 h; and carrying out processing via a double-screw extruder at 50 to 180 DEG C at a speed of 100 to 300 rpm so as to prepare the collagen plastic. The collagen plastic prepared in the invention has high mechanical strength and heat stability, good biocompatibility and environmental degradability, and wide application prospects in fields like biological materials, food and medicine packaging.

Owner:SICHUAN UNIV

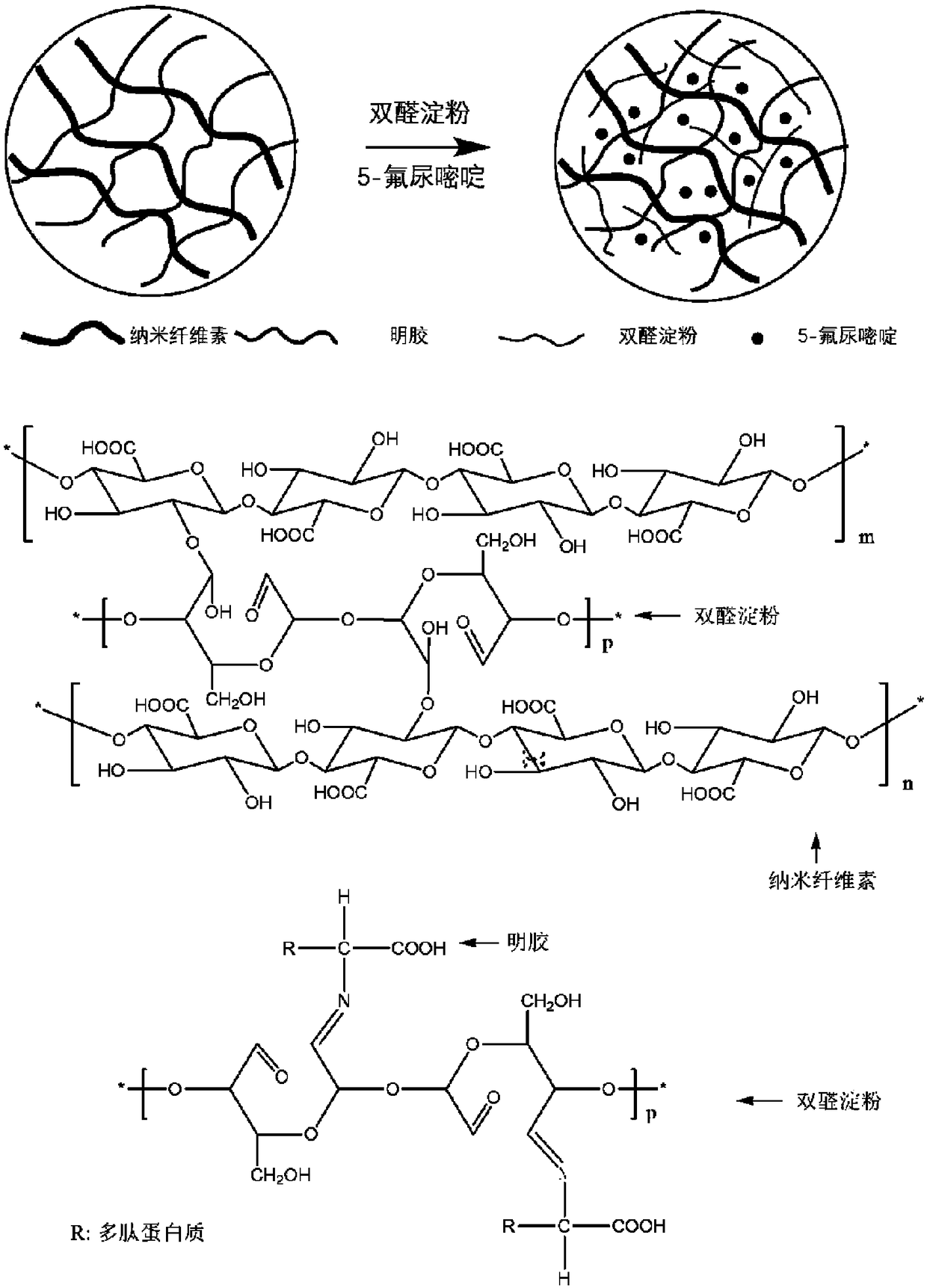

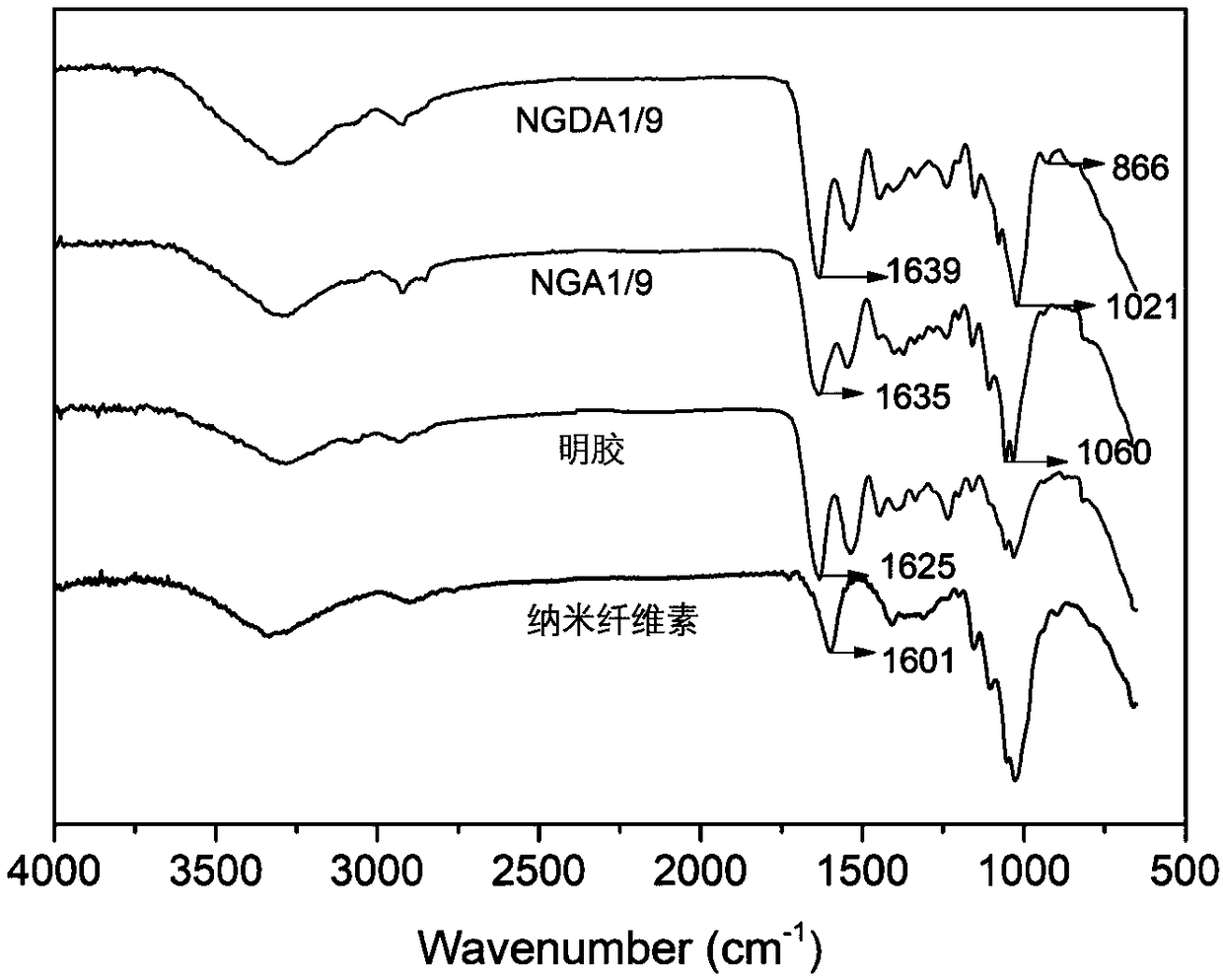

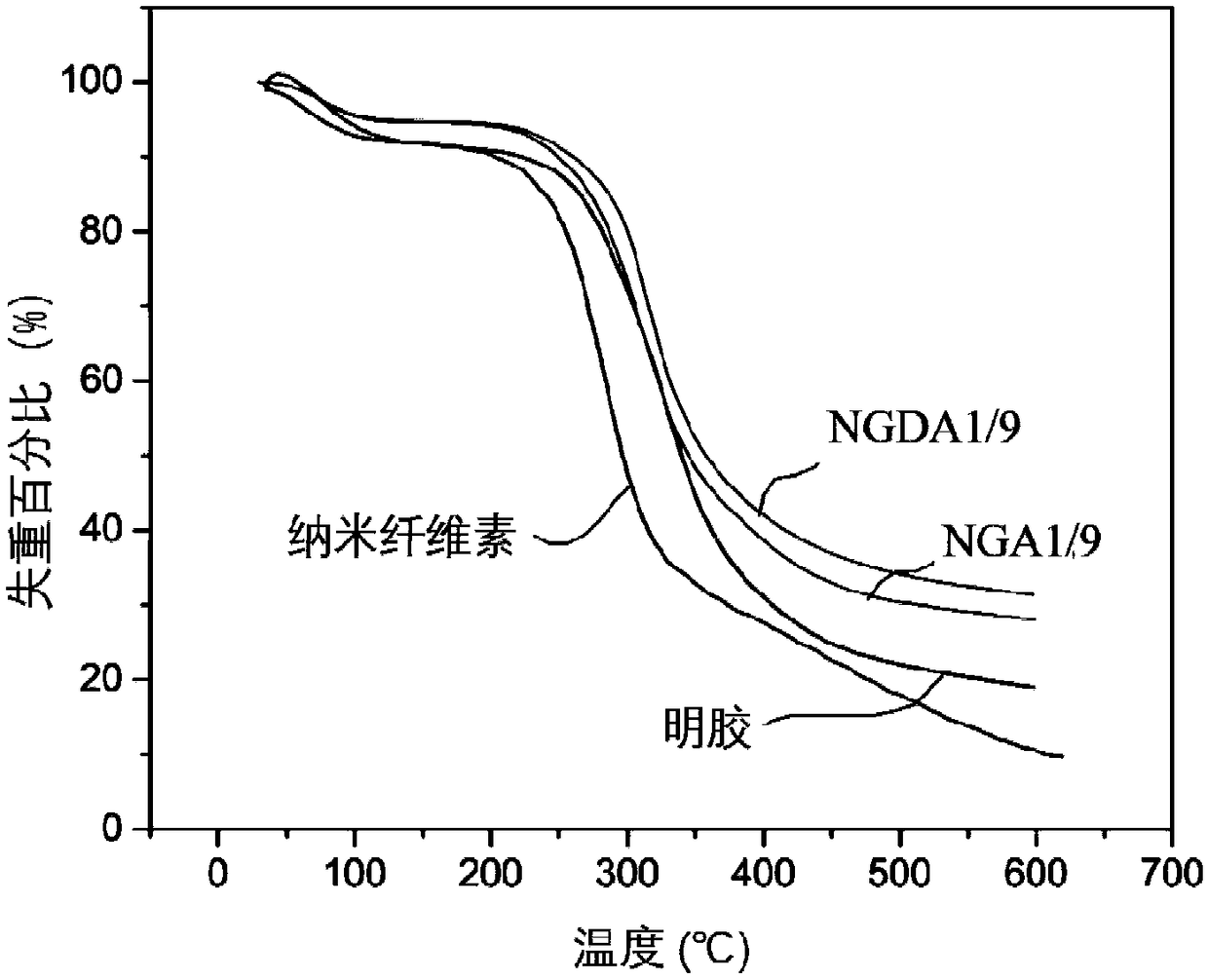

Nano-crystalline cellulose/gelatin composite aerogel and application thereof

ActiveCN109225077AGood biocompatibilityPromote degradationPowder deliveryOrganic active ingredientsTemperature controlPolymer science

The invention discloses nano-crystalline cellulose / gelatin composite aerogel and an application thereof. The composite aerogel is prepared by steps as follows: 1), preparing a nano-crystalline cellulose dispersion liquid; 2), weighing gelatin particles, adding the gelatin particles to the nano-crystalline cellulose dispersion liquid for dissolving and blending, and performing stirring and uniformdispersing; 3), adding gelatinized dialdehyde starch to the nano-crystalline cellulose / gelatin mixed solution which is mixed uniformly, and performing temperature-control reaction to obtain a uniformand transparent solution; 4), precooling the solution obtained in step 3) to form hydrogel, quickly freezing the hydrogel by adopting liquid nitrogen, and performing freeze drying in a freeze dryer toobtain a nano-crystalline cellulose / gelatin aerogel sample; 5), curing the obtained aerogel in a drying oven to obtain the aerogel. The nano-crystalline cellulose / gelatin composite aerogel material is prepared by hydrogen-bond interaction and dialdehyde starch chemical crosslinking, has better biocompatibility and biodegradability, can be used as a drug sustained-release material and has good practicability.

Owner:NANJING FORESTRY UNIV

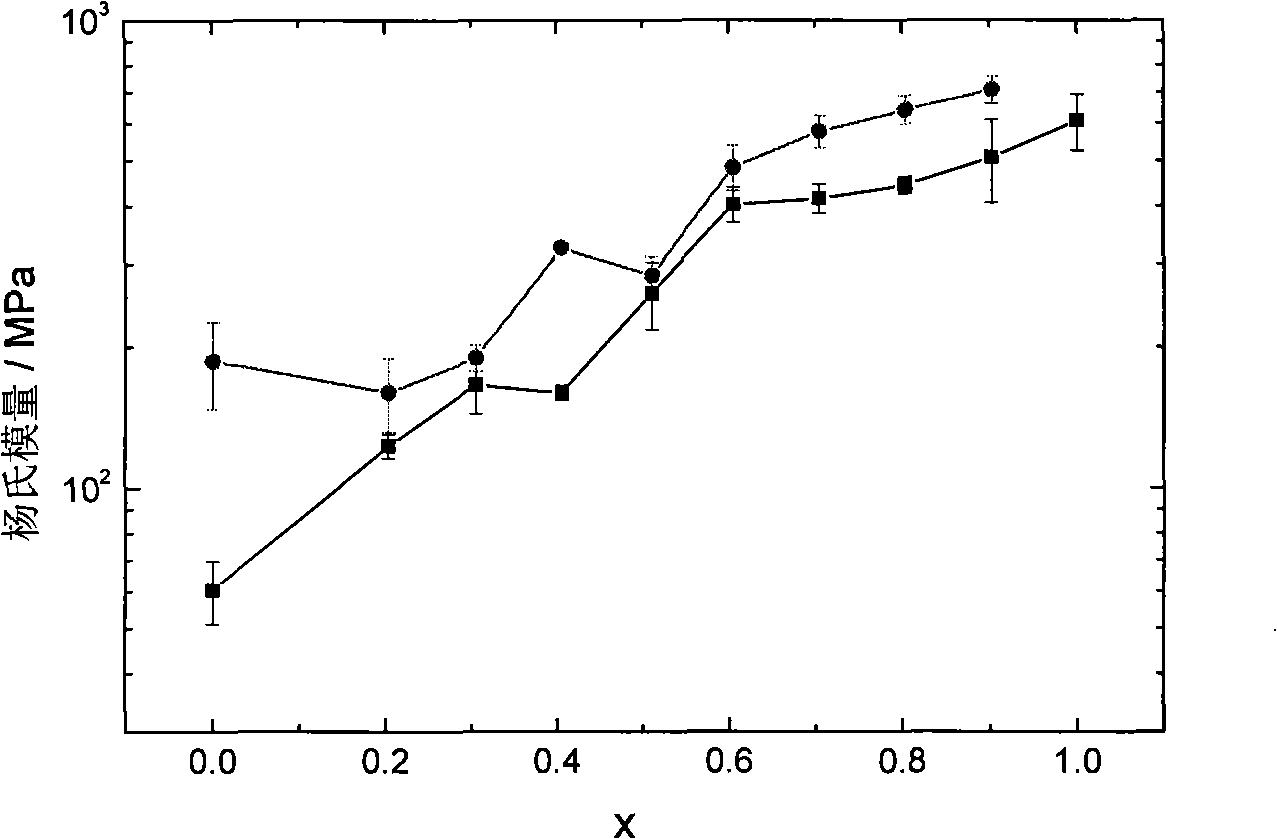

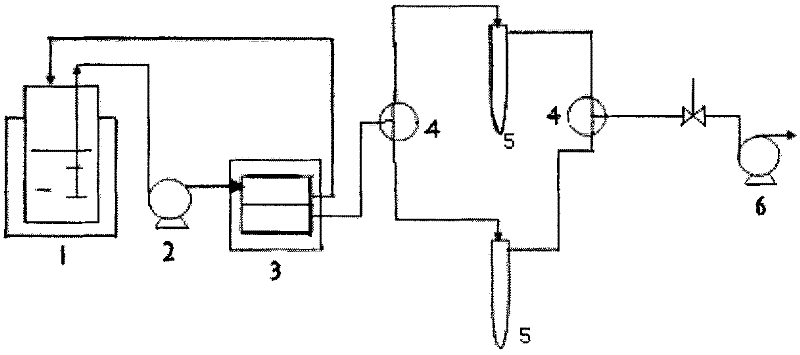

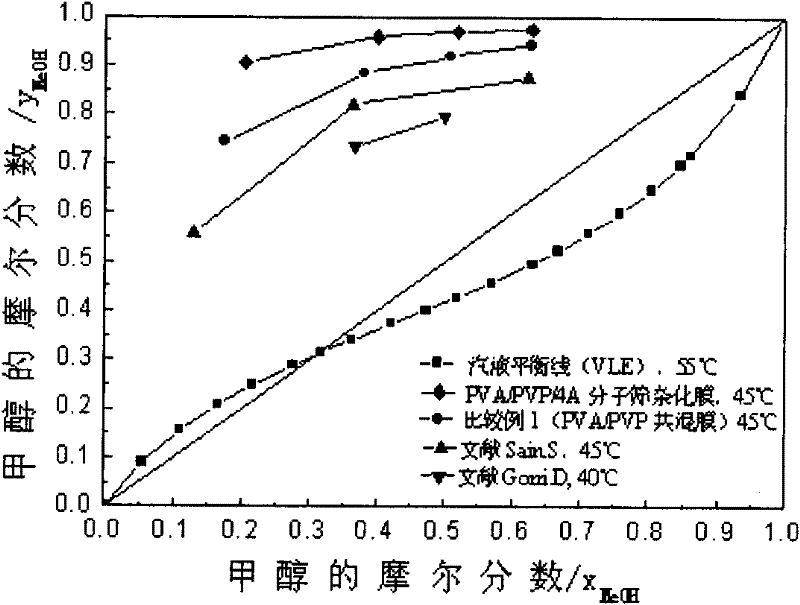

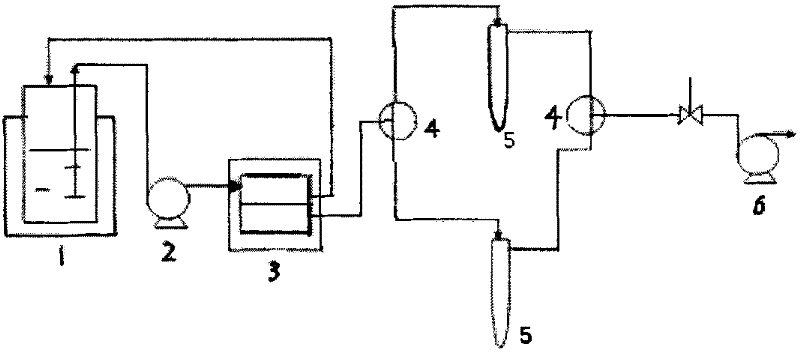

Organic-inorganic hybrid membrane for pervaporation separation of methanol/methyl acetate azeotropic system and preparation method thereof

InactiveCN102266729ANo separation performanceImprove toughnessSemi-permeable membranesOrganic compound preparationWater bathsSeparation coefficient

The invention discloses an organic-inorganic hydrid film used for pervaporation separation of a methanol / methyl acetate azeotropic system and a preparation method thereof. The preparation method comprises the following processes of: (1) heating and stirring polyvinyl alcohol (PVA), polyvinylpyrrolidone (PVP), a 4A molecular sieve and a solvent of dimethyl sulfoxide according to proportions in a constant-temperature water bath to obtain a PVA / PVP / 4A molecular sieve mixing solution; and (2) weighing DAS (Dialdehyde Starch) according to a proportion, dissolving into the dimethyl sulfoxide, stirring in a dark place and dissolving, then adding the equivalent PVA / PVP / 4A molecular sieve mixing solution obtained in the step (1) to the solution, and uniformly stirring to obtain a casting film solution. The casting film solution is filtered and defoamed, and then the film is scraped from glass and dried. The dried film is placed below a high-pressure mercury lamp and irradiated for 30-60 min toensure that coupling reaction is completed so as to obtain a 4A molecular sieve-filled DAS-crosslinking polyvinyl alcohol / polyvinylpyrrolidone organic-inorganic hydrid film. The organic-inorganic hydrid film has favorable mechanical strength and chemical stability and a higher pervaporation separation coefficient and can effectively break azeotropic components and has better separation degree than the traditional method.

Owner:NINGBO UNIV

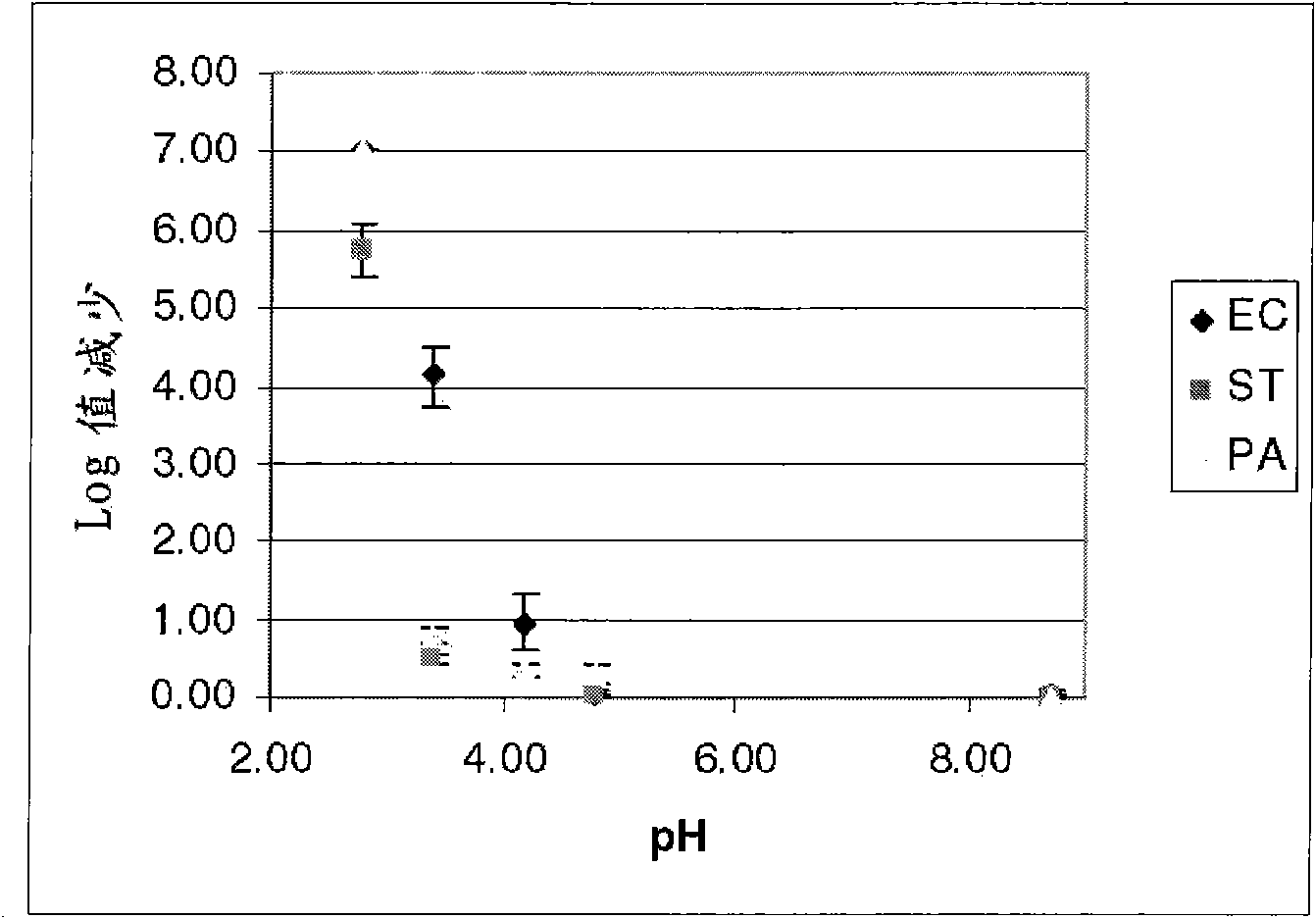

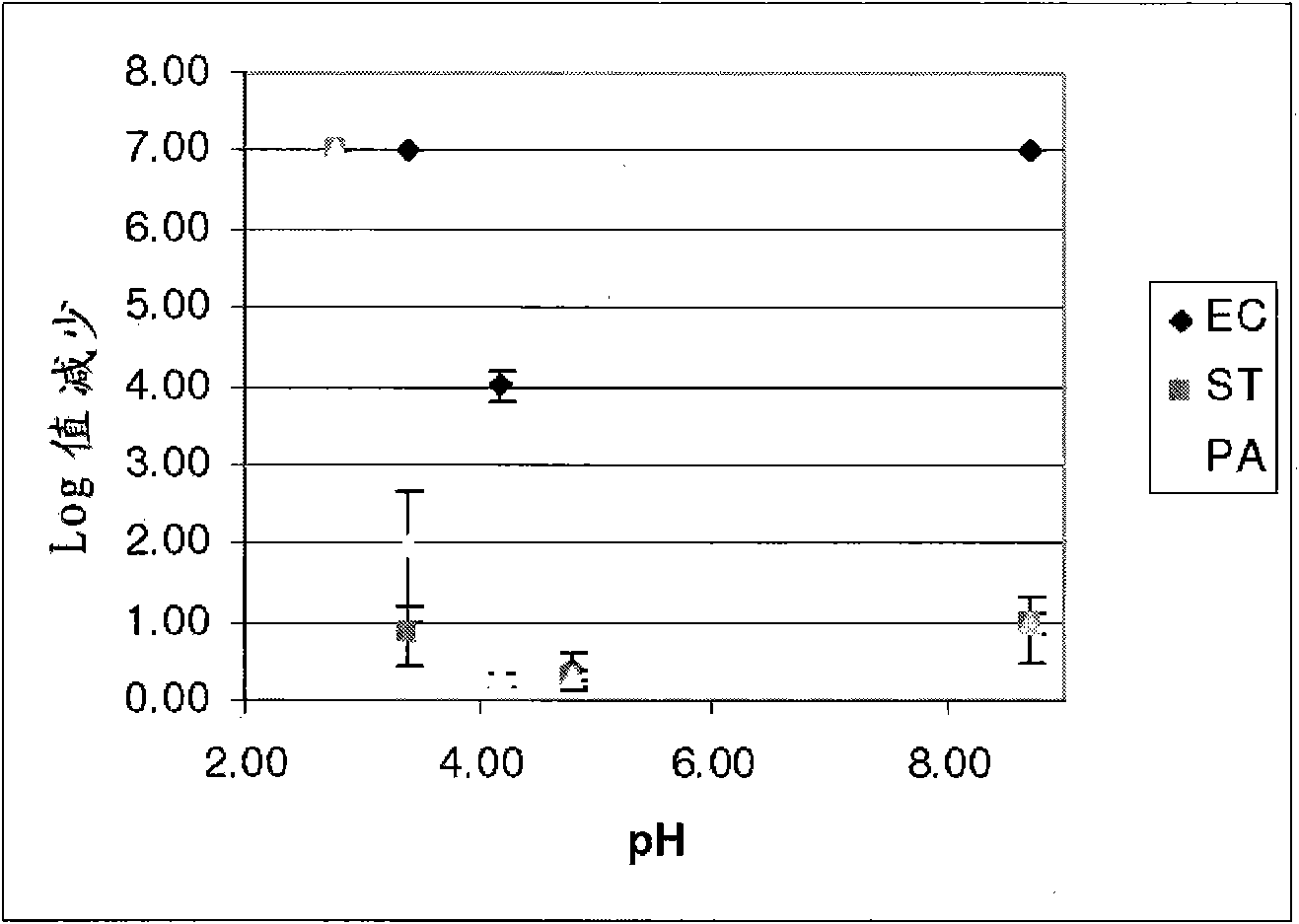

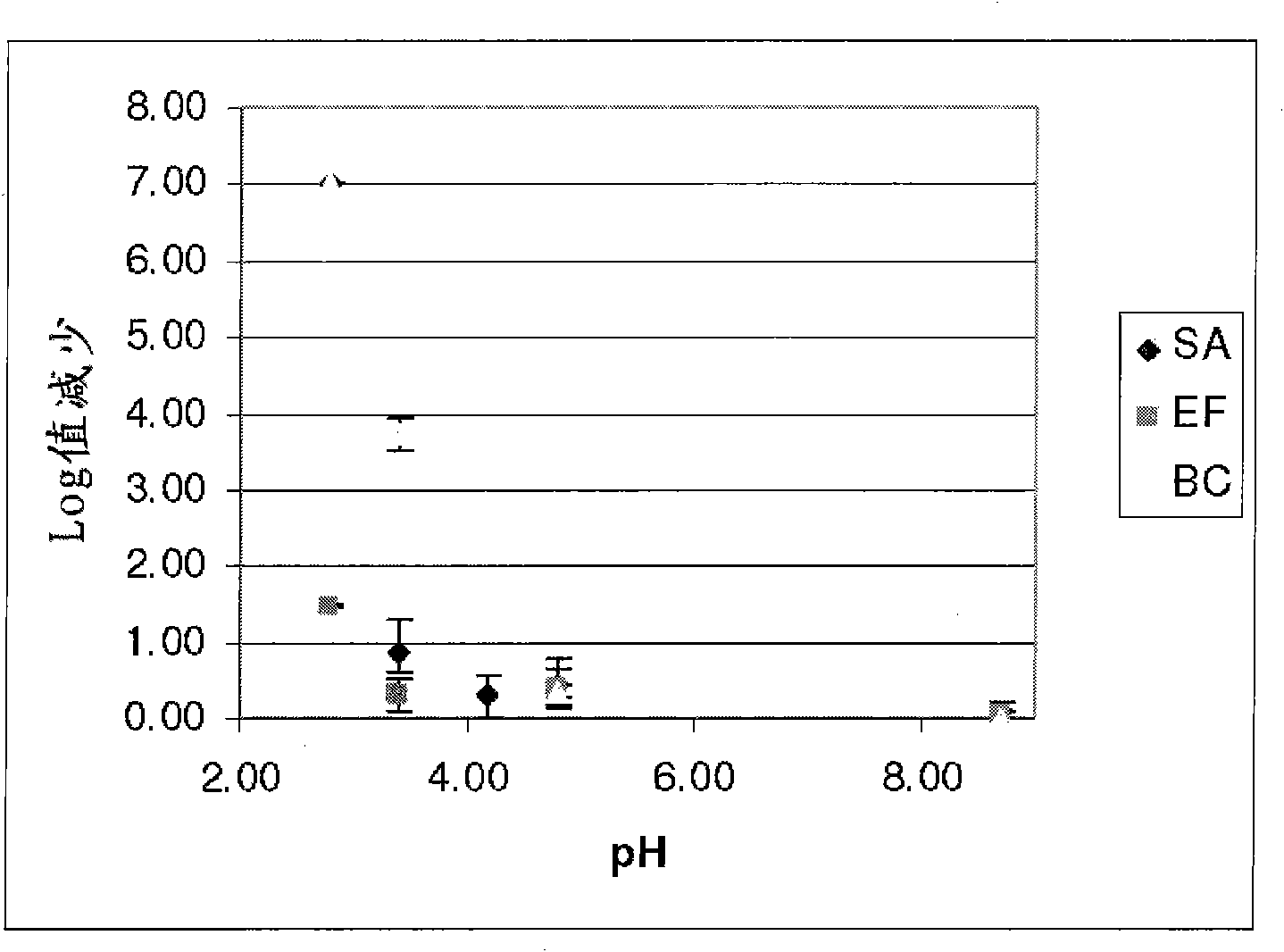

Antimicrobial agent, method of preparing an antimicrobial agent and articles comprising the same

The present disclosure is directed to method of preparing an antimicrobial agent comprising heating a dialdehyde polysaccharide. The method comprises subjecting a dialdehyde polysaccharide, such as a dialdehyde starch or a dialdehyde cellulose, to heating and / or sonication for a period of time. Also provided herein is an antimicrobial composition comprising the prepared dialdehyde polysaccharide. The antimicrobial composition is effective at killing microbial agents such as viruses and bacteria within a short period of time.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

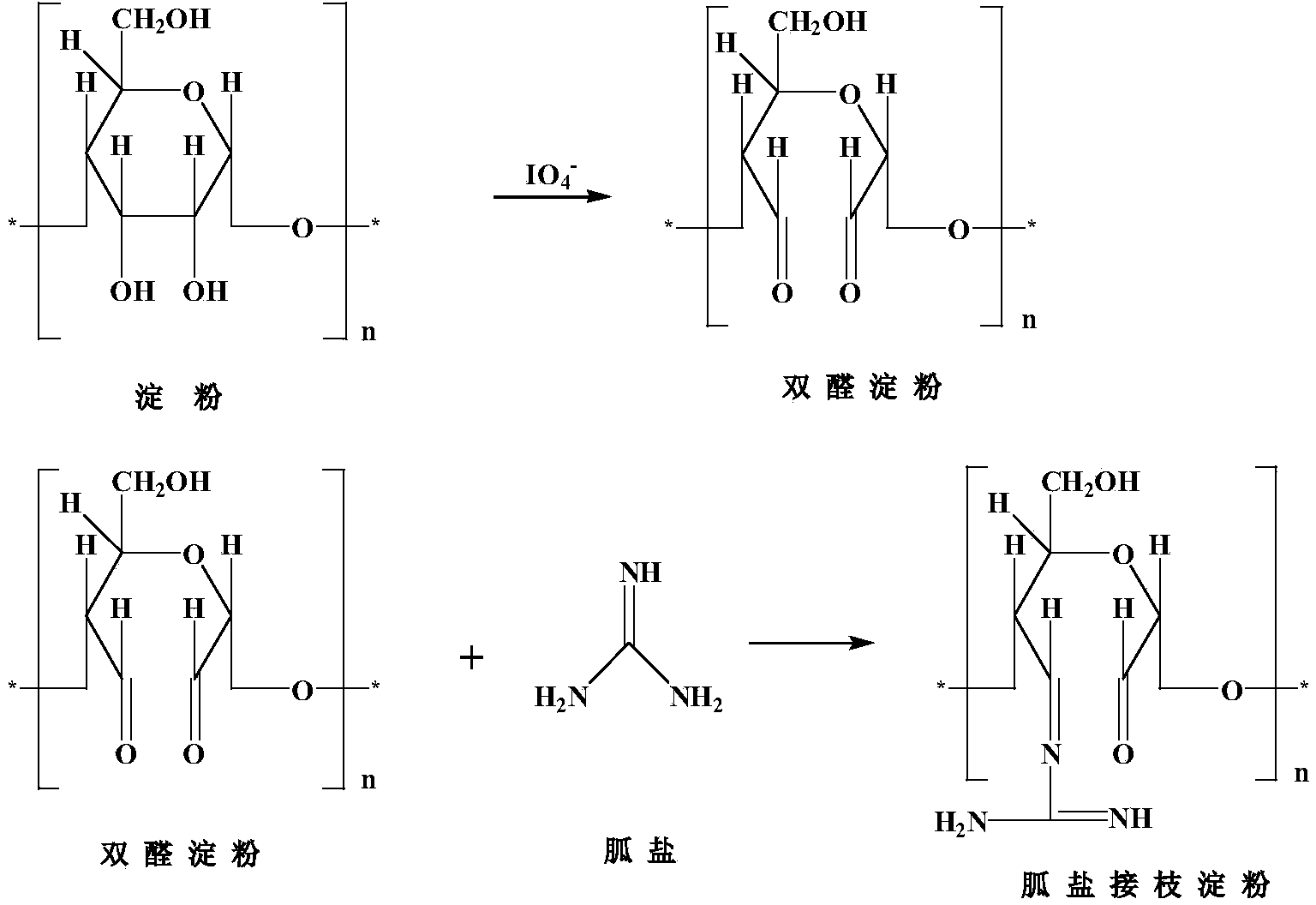

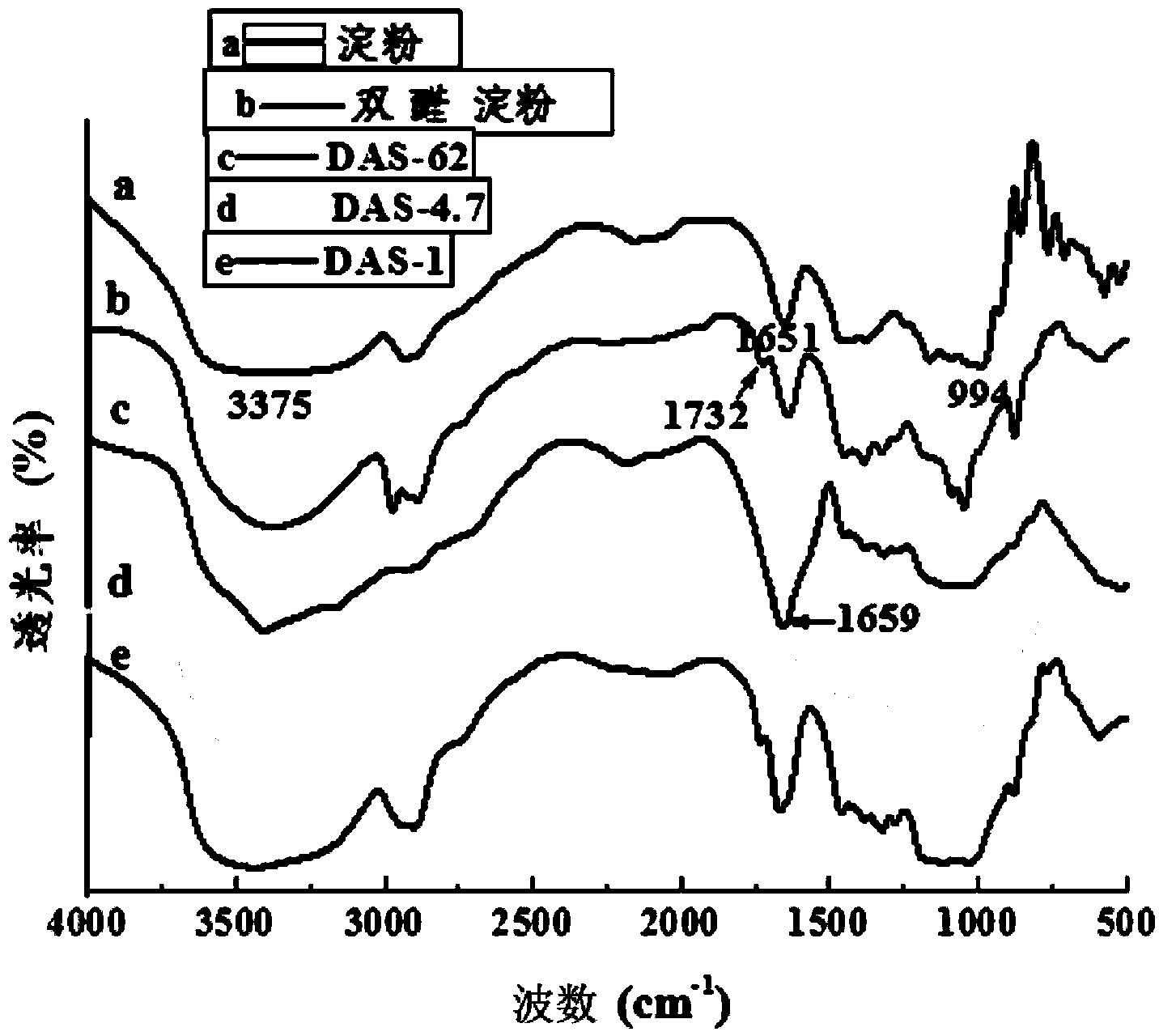

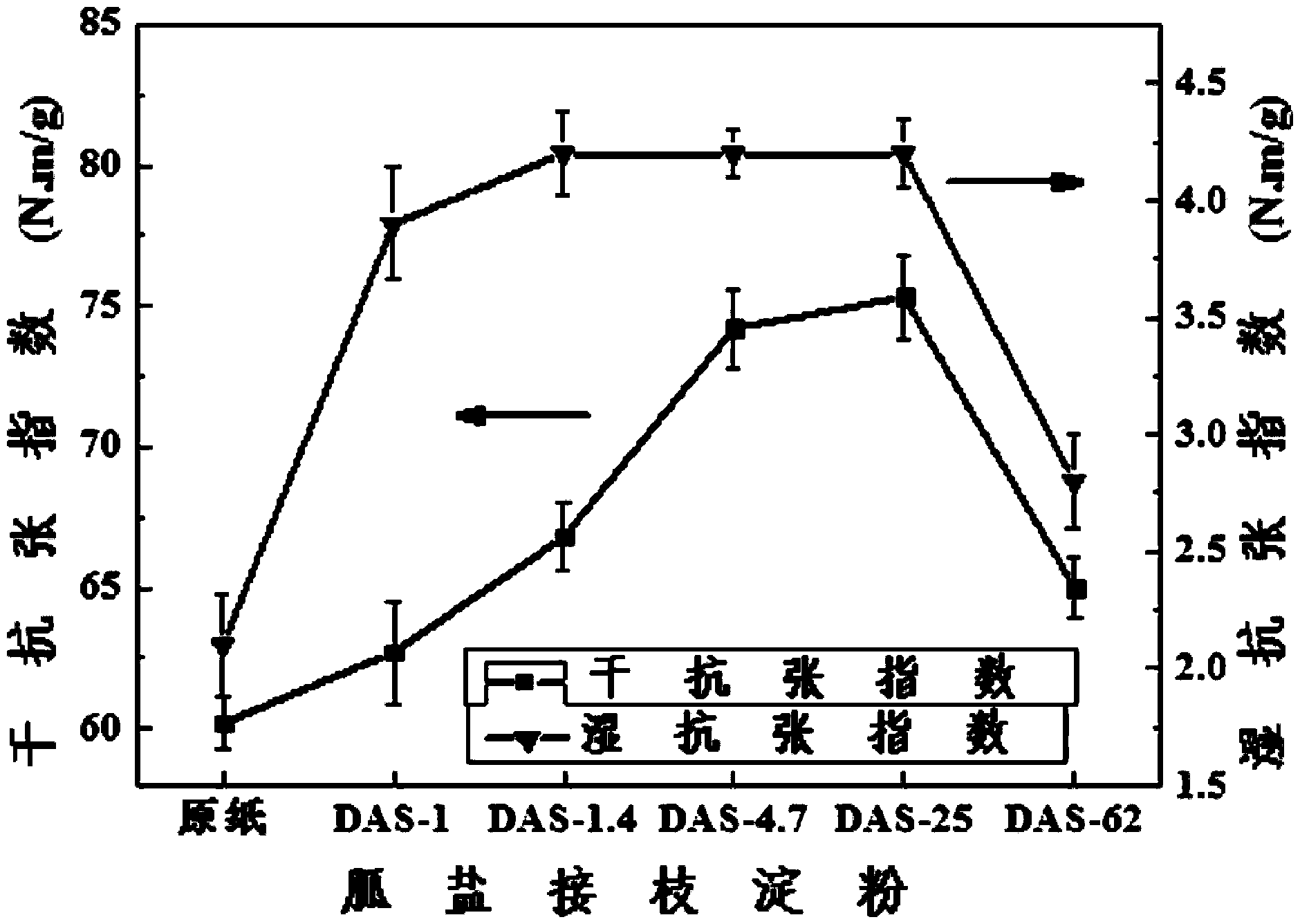

Guanidine salt grafted starch multifunctional papermaking additive and preparation method thereof

InactiveCN103724441AHigh tensile strengthImprove product qualityReinforcing agents additionPaper/cardboardPapermakingDistilled water

The invention discloses a guanidine salt grafted starch multifunctional papermaking additive and a preparation method thereof. The method comprises the following steps: adding starch into a sodium periodate solution, heating and reacting for 4 hours, filtering the product, washing and drying to obtain dialdehyde starch; dispersing the dialdehyde starch in distilled water, adding a guanidine salt and reacting at a certain temperature for 2 hours, filtering the product, washing, drying, and obtaining guanidine salt grafted starch; and finally, coating the guanidine salt grafted starch on the paper surface, and preparing high-strength high-antibacterial property functional paper. The guanidine salt grafted starch multifunctional papermaking additive is coated on the paper surface, so that the paper simultaneously has high strength and high antibacterial property, and the two defects of low strength and low antibacterial property of the paper are improved. Therefore, the multifunctional papermaking additive has high application value.

Owner:FUJIAN AGRI & FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com