Organic-inorganic hybrid membrane for pervaporation separation of methanol/methyl acetate azeotropic system and preparation method thereof

A technology of methyl acetate and pervaporation, applied in the preparation of organic compounds, carboxylate esters, organic chemistry, etc., to achieve the effects of low density, good toughness, good mechanical properties and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

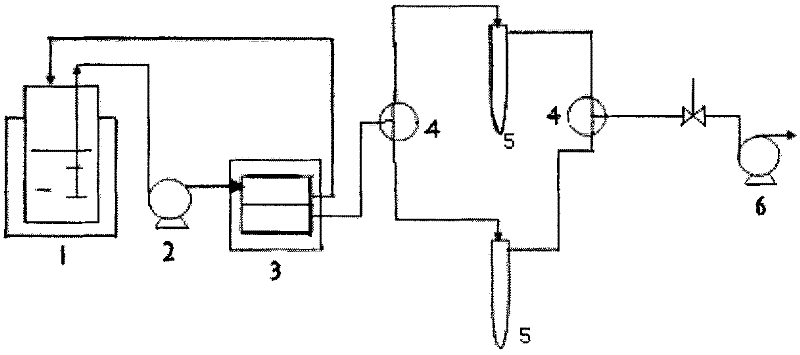

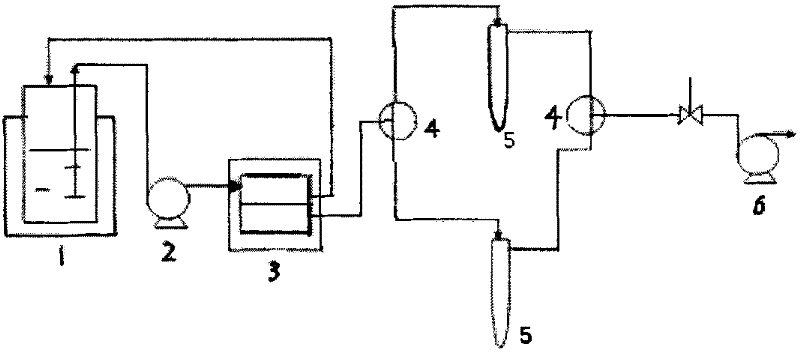

Method used

Image

Examples

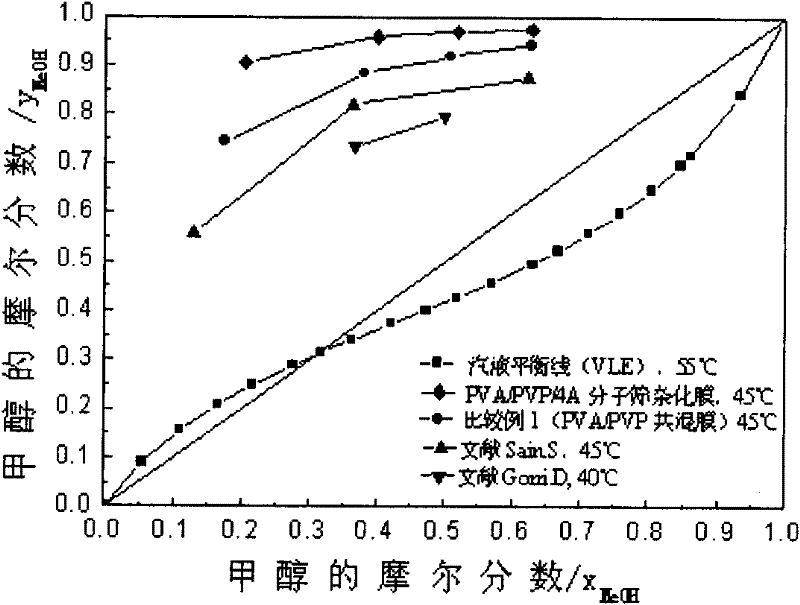

Embodiment 1

[0035] Add 3.5g of PVA (polymerization degree 1750, the same below), 1.5g of PVP (K90), 0.1282g of 4A molecular sieve and 44.8718g of dimethyl sulfoxide (the total weight of the solution is 50g) into the flask. Heat and stir in a constant temperature water bath at 95° C. for 4 hours to completely dissolve PVA and PVP and uniformly disperse 4A molecular sieves to obtain a PVA / PVP / 4A molecular sieve blend. 4A molecular sieve accounts for 2.5wt% of the total amount of PVA / PVP / 4A molecular sieve. Weigh 0.5g DAS and dissolve it in 49.5g dimethyl sulfoxide under dark conditions and stir to dissolve it, then add an equal amount of PVA / PVP / 4A molecular sieve blend to this solution, and stir evenly in the dark to obtain cast Membrane fluid. Filter the casting solution, let it sit for defoaming, scrape the film on clean glass, and dry it at a constant temperature of 80°C under dark conditions. Place the dried film under a straight-tube high-pressure mercury lamp (short-wave UVC, cente...

Embodiment 2

[0038] Change the content of 4A molecular sieve so that 4A molecular sieve accounts for 1.5wt% of the total amount of PVA / PVP / 4A molecular sieve. All the other conditions are with embodiment 1. Use this membrane to separate the methanol / methyl acetate azeotrope by pervaporation. The raw material side is kept at normal pressure, the permeate side is vacuumed, the temperature of the feed liquid is 45°C, and the retentate is returned to the feed liquid tank. The test is carried out after 3 hours of permeation reaches stability. , the permeate flux of the membrane is 24g / (m 2 h), the separation coefficient is 28.5.

Embodiment 3

[0040] Change the content of 4A molecular sieve so that 4A molecular sieve accounts for 3.5wt% of the total amount of PVA / PVP / 4A molecular sieve. All the other conditions are with embodiment 1. Use this membrane to separate the methanol / methyl acetate azeotrope by pervaporation. The raw material side is kept at normal pressure, the permeate side is vacuumed, the temperature of the feed liquid is 45°C, and the retentate is returned to the feed liquid tank. The test is carried out after 3 hours of permeation reaches stability. , the permeate flux of the membrane is 45.1g / (m 2 · h), the separation coefficient is 15.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com