Patents

Literature

173 results about "Separation coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

SEPARATION coefficient is the ratio of the PERSON (or ITEM) TRUE S.D., the "true" standard deviation, to RMSE, the error standard deviation. It provides a ratio measure of separation in RMSE units, which is easier to interpret than the reliability correlation. This is analogous to the Fisher Discriminant Ratio.

Sodium alginate-graphite phase carbon nitride nano-sheet hybridized composite membrane as well as preparation and application of composite membrane

InactiveCN104772043AThe preparation process is simple and controllableRaw materials are easy to getDistillationCross-linkSeparation coefficient

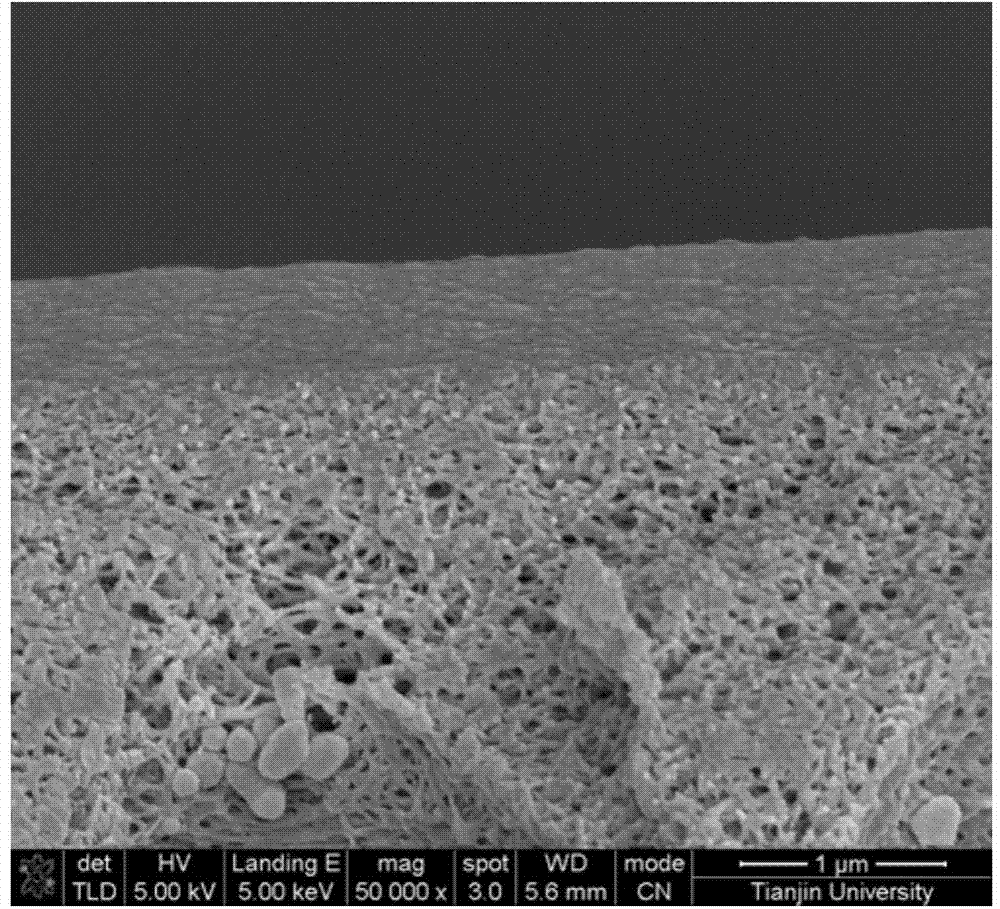

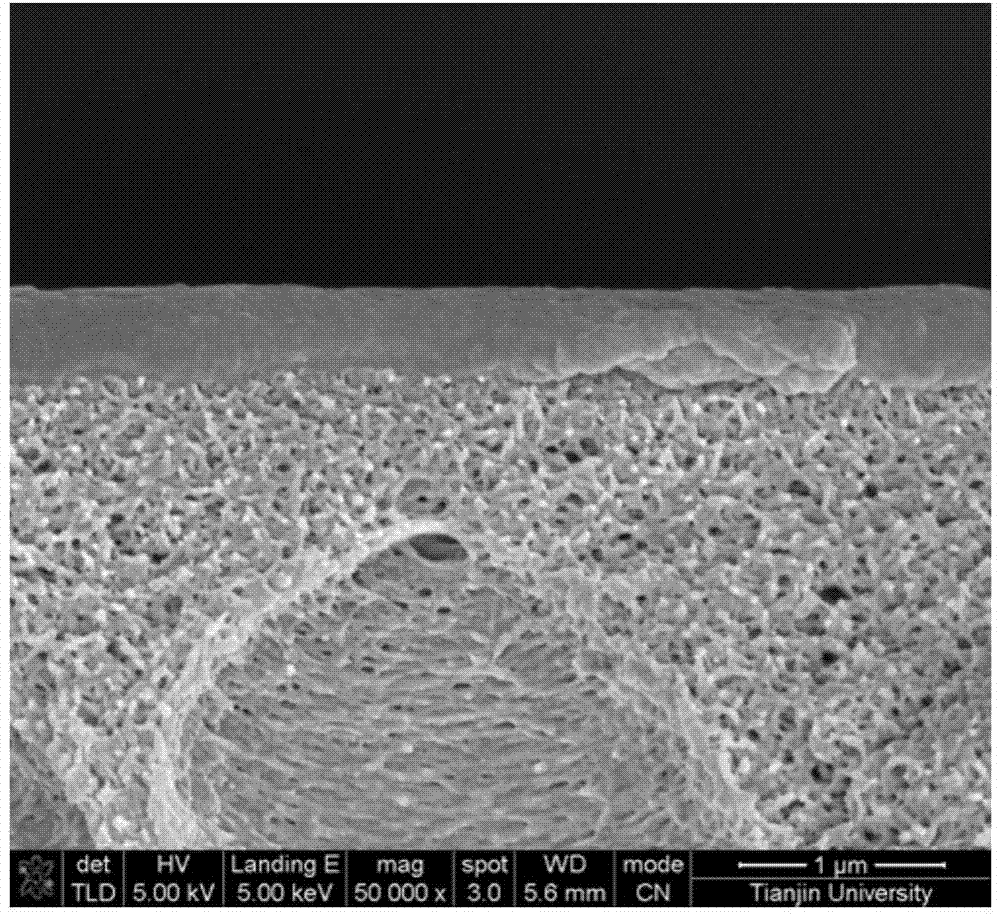

The invention relates to a sodium alginate-graphite phase carbon nitride nano-sheet hybridized composite membrane. The composite membrane is prepared by the steps of firstly, with melamine as the raw material, preparing ultrathin and porous graphite phase carbon nitride nano-sheet by using a hot separation and liquid-phase separation combined method; blending the nano-sheet and sodium alginate to obtain a casting membrane liquid; defoaming, then preparing the membrane by using a spin-coating method; performing cross-linking with a calcium chloride solution; and finally drying to obtain the sodium alginate-graphite phase carbon nitride nano-sheet hybridized composite membrane. According to the hybridized composite membrane, by virtue of the structure characteristic that the graphite phase carbon nitride nano-sheet is planar, ultrathin and porous, the thicknesses of separation layers are reduced; an orderly transmission channel is built; the transmission resistance of water molecule is lowered; the ethyl alcohol molecule is prevented from transmitting; therefore the osmosis and the selectivity of the membrane are improved simultaneously. According to the hybridized composite membrane, the preparation process is simple, raw materials are easily available and the structure is controllable, and the composite membrane is used for ethyl alcohol / water mixture separation, and has relative high osmosis flux and separation coefficient.

Owner:TIANJIN UNIV

Preparation method of high purity hydrogen

InactiveCN101648698AProcess energy savingProcess environmental protectionProductsReagentsSeparation coefficientSorbent

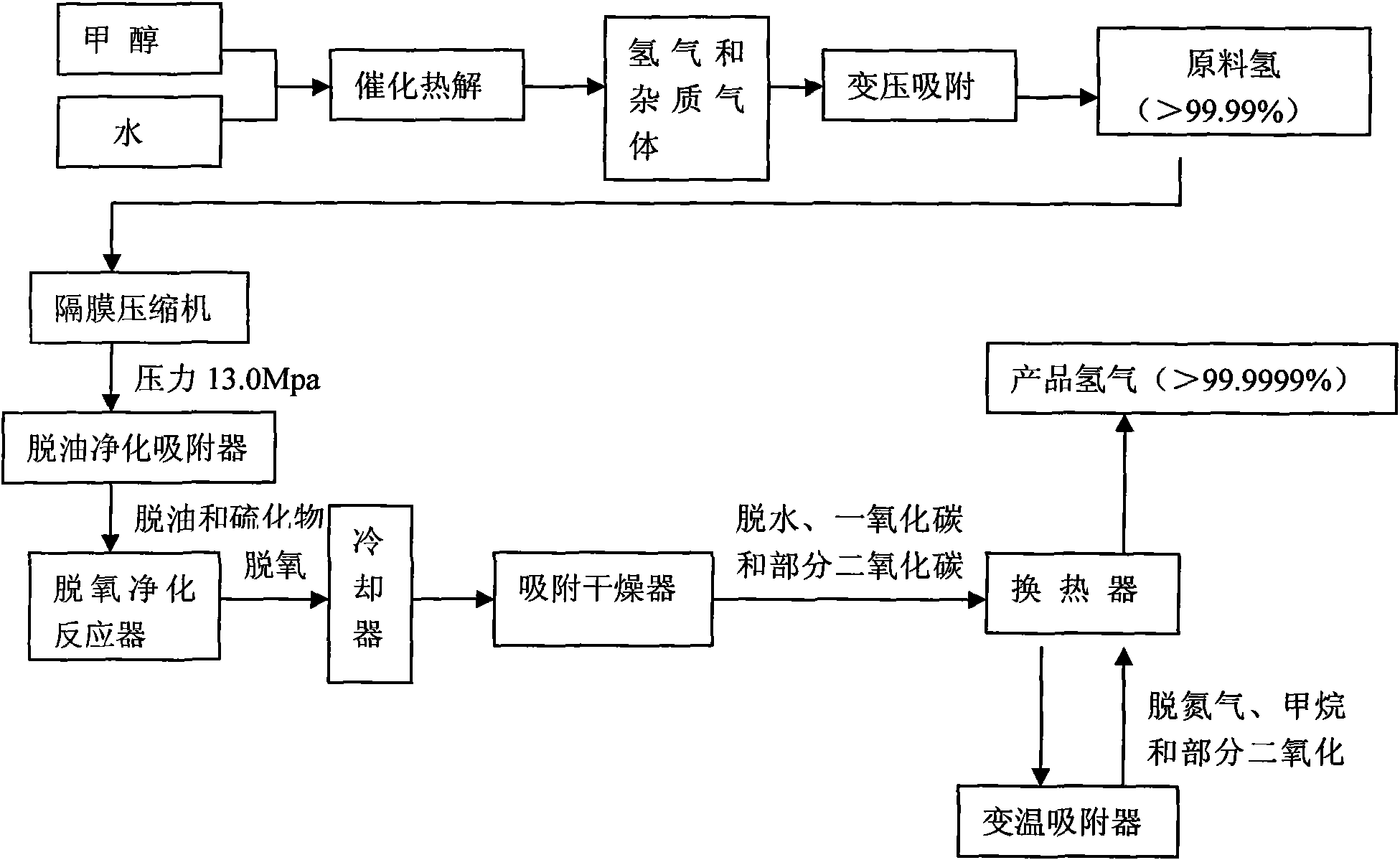

The invention discloses a preparation method of hydrogen. The invention uses the hydrogen with the purity of 99.99% as raw material, adopts pressure and temperature pressure swing adsorption technology and utilizes the principle that the hydrogen separation coefficient of residual impurities in hydrogen such as N2, CH4 and the like is larger than that of the surface of adsorbents such as activatedcarbon, fine-pored silica gel and the like, to prepare hydrogen with the purity of more than 99.9999%. The process of the invention is characterized by energy-saving, environmental protection, safety, capability of large-scale production and convenient operation. The use of pressure and temperature pressure swing adsorption technology avoids the defect of the traditional technology that inert gassuch as nitrogen and the like in hydrogen are hard to remove, no discharge of three wastes is appeared, the coexist of oxygen and hydrogen is precluded and the method is safer and more reliable.

Owner:JINAN DEYANG SPECIAL GAS

Method for extracting and separating vanadium and chromium from alkaline aqueous solution

InactiveCN104694749AHigh extraction recoveryLarge single-stage separation factorProcess efficiency improvementSingle stageSeparation coefficient

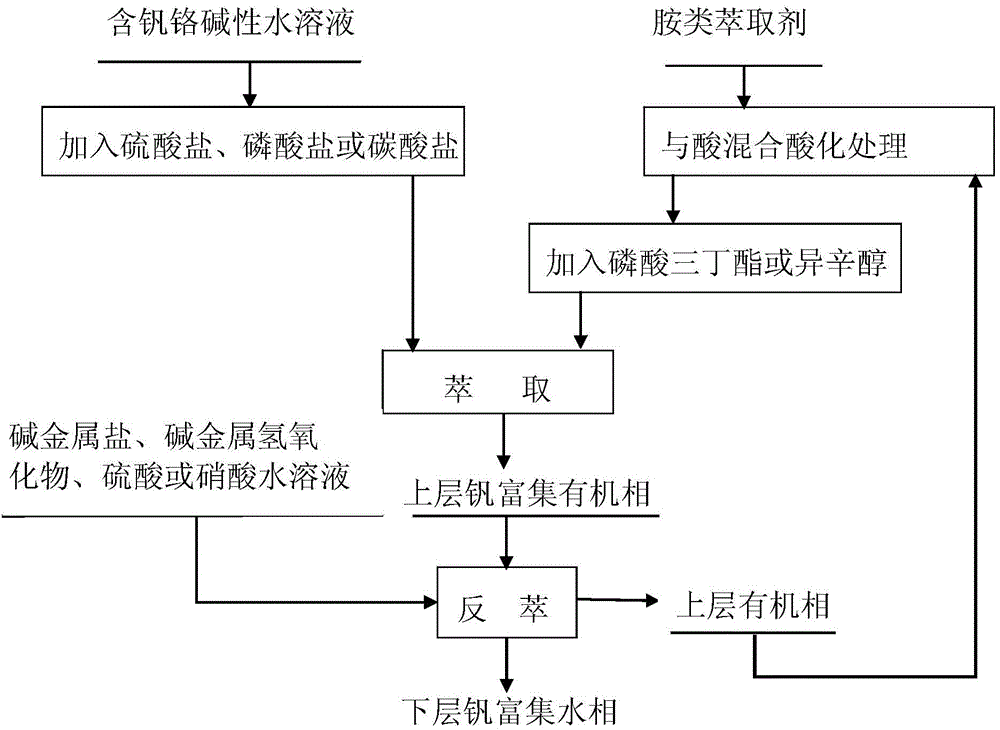

The invention discloses a method for extracting and separating vanadium and chromium from an alkaline aqueous solution. The method comprises the following steps: adding sulfate, carbonate and / or phosphate into the alkaline aqueous solution containing vanadium and chromium; adding an acidized amine extraction agent obtained by mixing with an acid solution in advance, mixing with the alkaline aqueous solution containing vanadium and chromium, and extracting vanadium, wherein chromium is not extracted and remains in the alkaline aqueous solution; after extraction, an organic phase loaded with vanadium can be subjected to reverse extraction by using an alkali metal salt, alkali metal hydroxides, sulfuric acid or aqueous nitric acid solution and can be acidized again to be recycled. According to the method disclosed by the invention, the vanadium and chromium can be extracted and separated from the concentrated alkaline aqueous solution with the pH value of more than 11, the single stage separation coefficient of the vanadium and chromium is large, the process flow is simple, and the extraction agent can be recycled.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

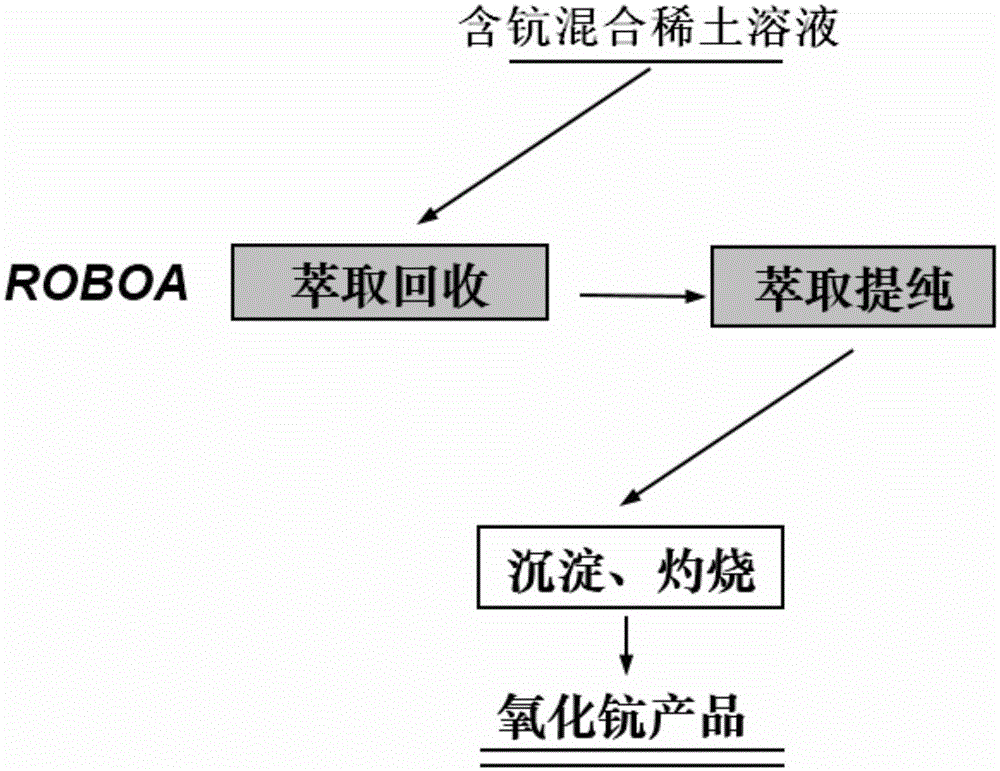

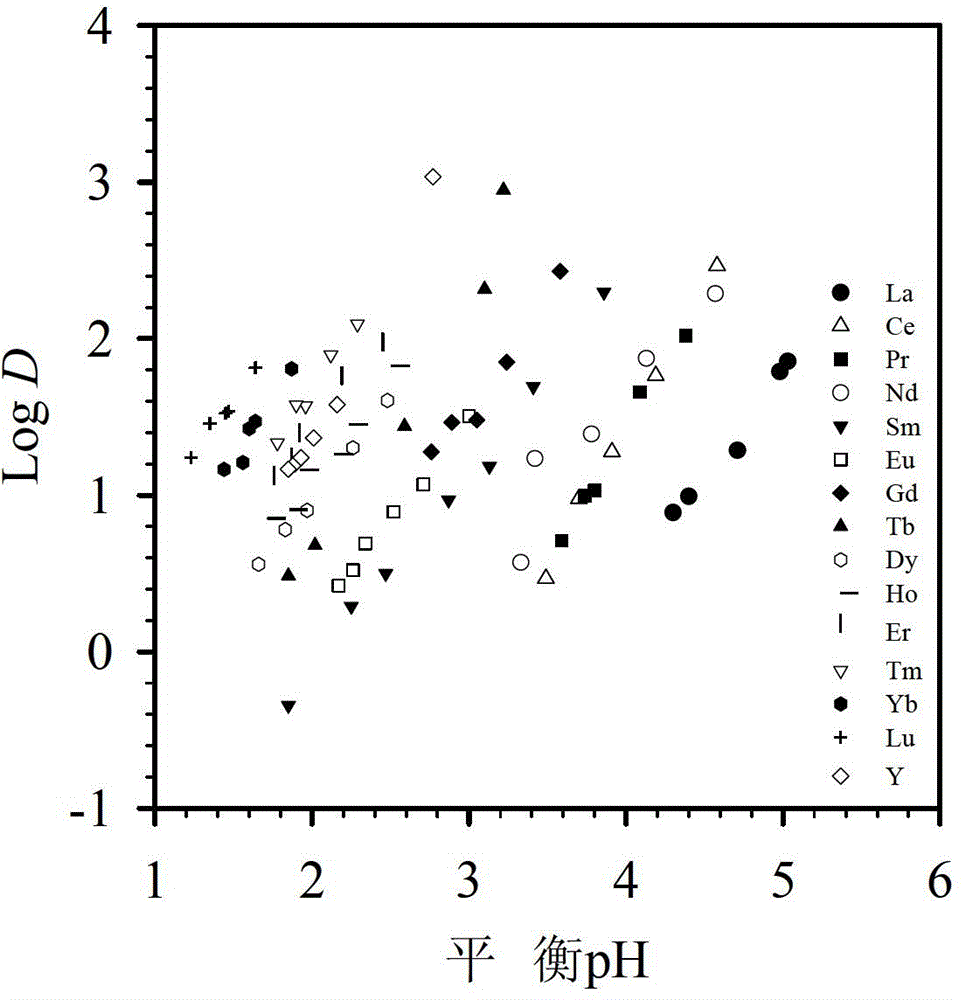

Scandium element extraction method

ActiveCN106702180AReduce concentrationHigh separation selectivityProcess efficiency improvementRare-earth elementEmulsion

Theinvention provides a scandium element extraction method. The scandium element extraction method comprises the following steps of: (A) mixing alkoxy phenoxy carboxylic acid, tributyl phosphate and a diluting agent to obtain an organic phase; and (B) extracting a scandium-containing mischmetal solution by using the organic phase to obtain a scandium ion-containing solution. The scandium element extraction method has the beneficial effects that the separation selectivity between the scandium element and other rare earth elements can be effectively improved by adopting the alkoxy phenoxy carboxylic acid as the extraction agent on the basis of ensuring the purity of a scandium product and relatively high yield; the concentration of the organic phase is effectively prevented from decreasing after extraction by adopting the tributyl phosphate as an additive, so that the organic phase can be recycled; meanwhile, an emulsion phenomenon in an extraction process can be avoided; and experimental results show that the separation coefficients of the scandium element and a lanthanide element are 526 due to adoption of the scandium element extraction method.

Owner:王艳良

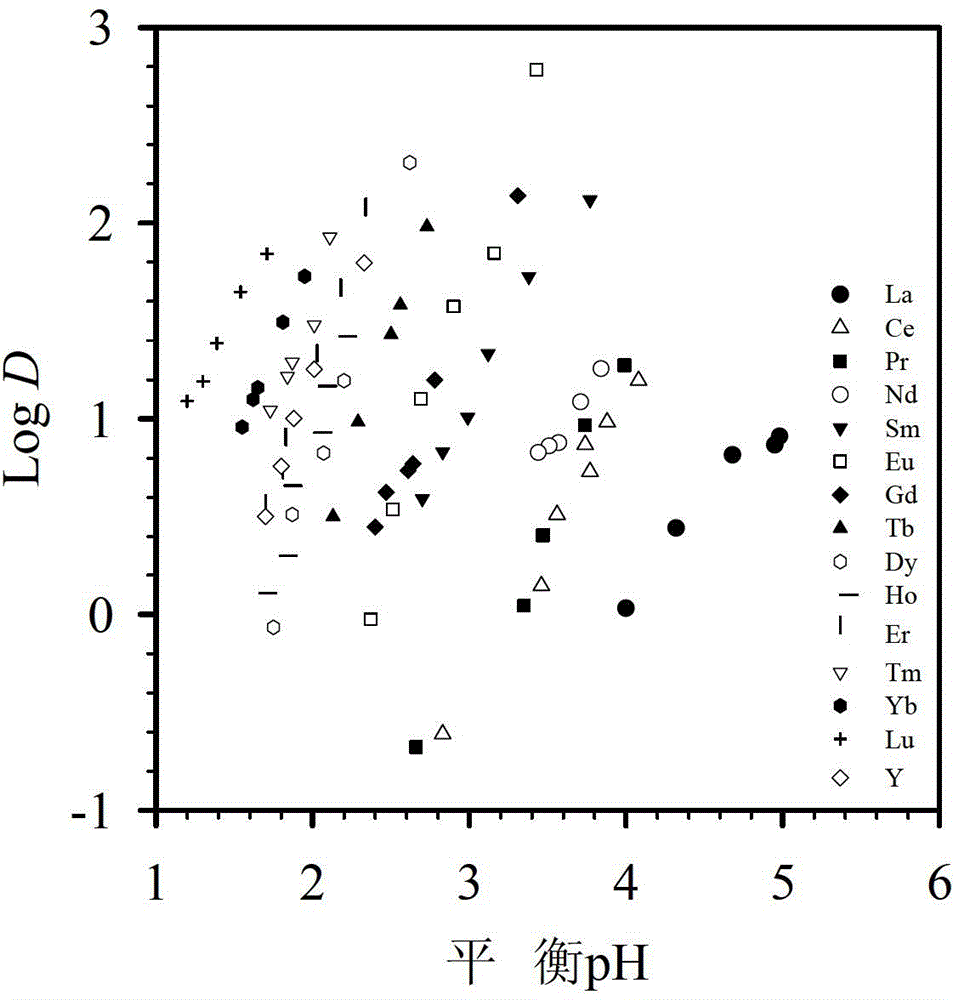

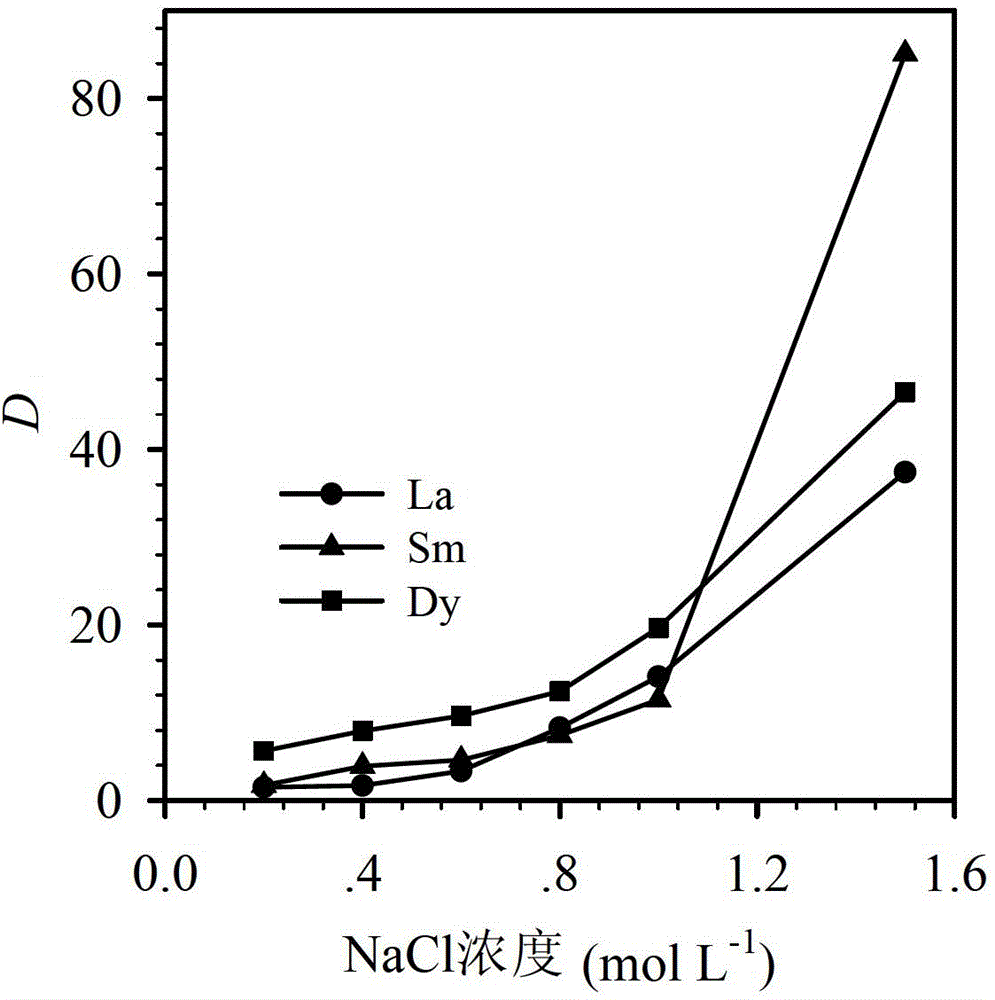

Method for extracting and separating rare earth elements in hydrochloric acid system

InactiveCN102876894AHigh separation factorLow extraction acidityProcess efficiency improvementRare-earth elementSeparation coefficient

The invention provides a method for extracting and separating rare earth elements in a hydrochloric acid system. The method includes the steps: taking mono (2-ethylhexyl) phosphonate 2-ethylhexyl methoxy cinnamate trialkyl methyl ammonium or phosphonate (2-ethylhexyl) diester trialkyl methyl ammonium as an extracting agent; taking normal heptane as diluent; and extracting the rare earth elements in rare earth chloride water solution into the normal heptane. The extracting agent used in the method does not need to be saponified, extraction and reverse extraction acidity is low, and separation coefficient for the rare earth elements is high.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

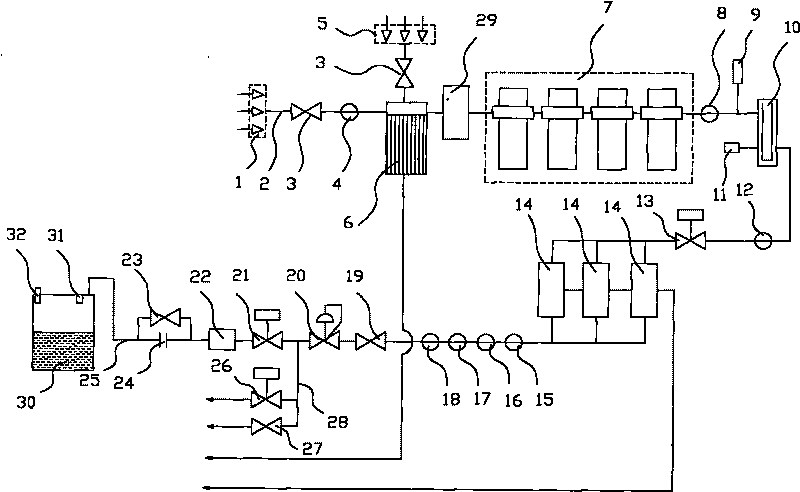

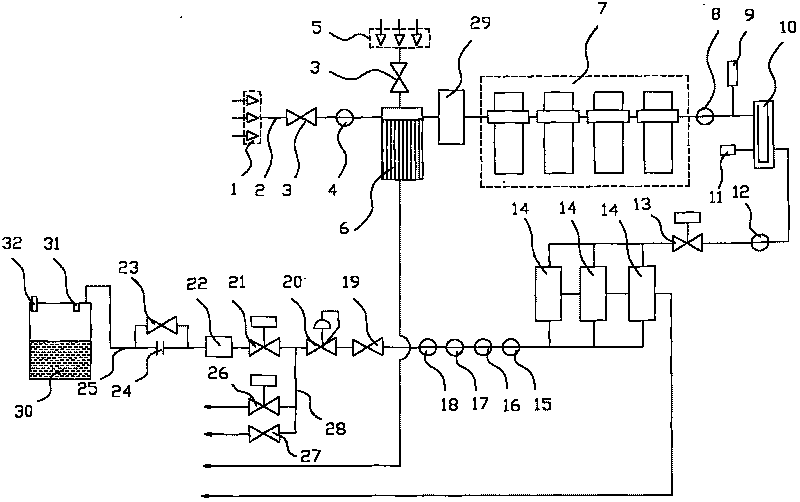

Inert system for civil airplane

InactiveCN101708776ASuppress fire explosionSmall sizeFuel tank safety measuresFire rescueAviationAutomatic control

The invention discloses an inert system for a civil airplane, relates to a composite-film separated nitrogen making system, and belongs to the field of aviation industry machining building. The inert system for the civil airplane comprises an air pre-treating system, a gas film separating system and an automatic control system, wherein compressed air is output from the air pre-treating system and the gas film separating system under the control of the automatic control system; high-temperature compressed gas produced by an engine compressor of the airplane passes through a supply pipeline and the air pre-treating system to supply compressed air to the gas film separating system; cold air produced by an external duct of the airplane engine passes through a fan supply pipeline to supply cold air for refrigeration to the air pre-treating system; and the gas film separating system consists of a plurality of composite-film pipe components with the same or different separation coefficients and the optimum working temperatures which are connected through manifolds, and outputs and distributes nitrogen gas to each fuel tank of the airplane through parallelly connected pneumatic or electric variable-flow valves and a low-flow hole.

Owner:张星

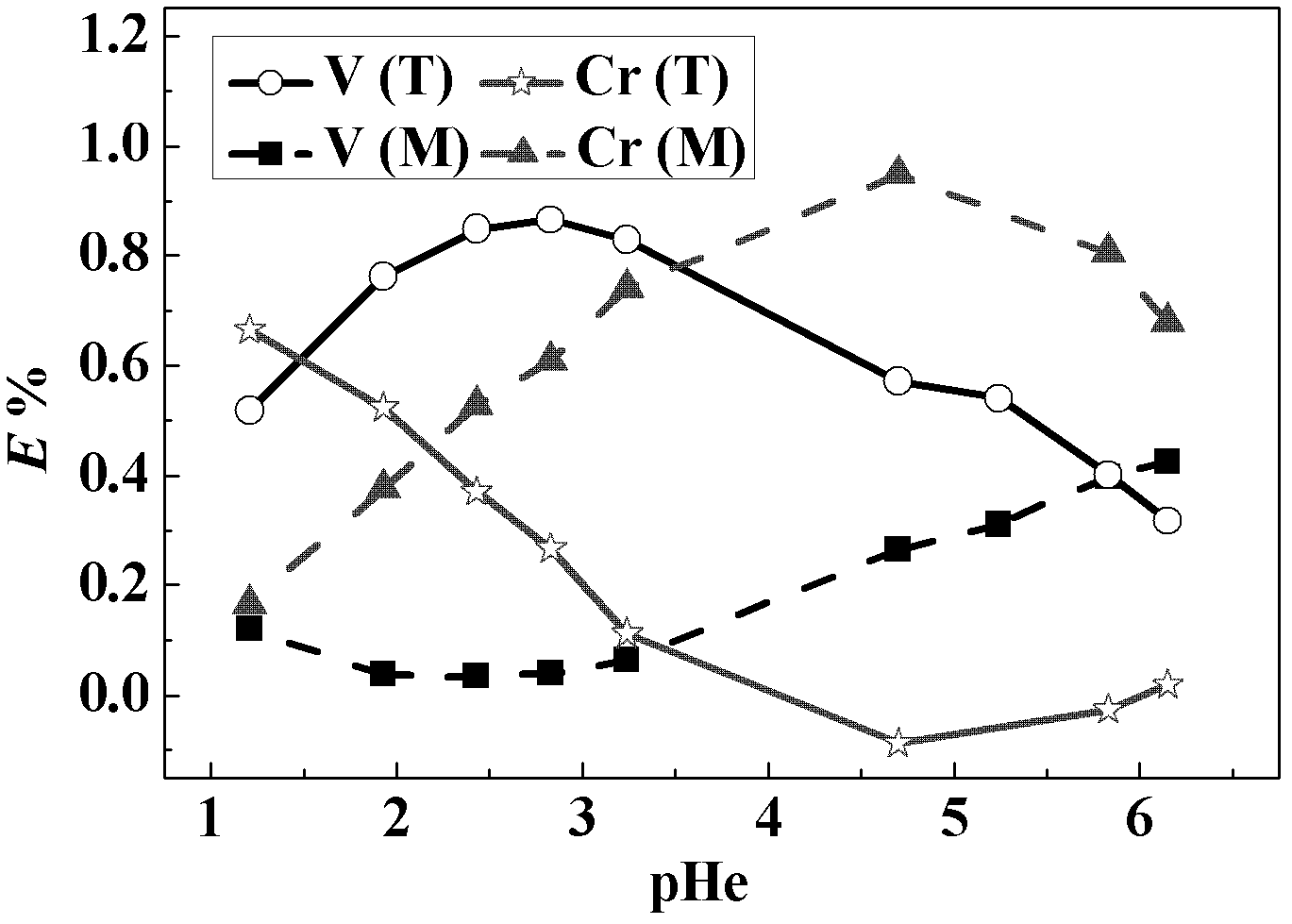

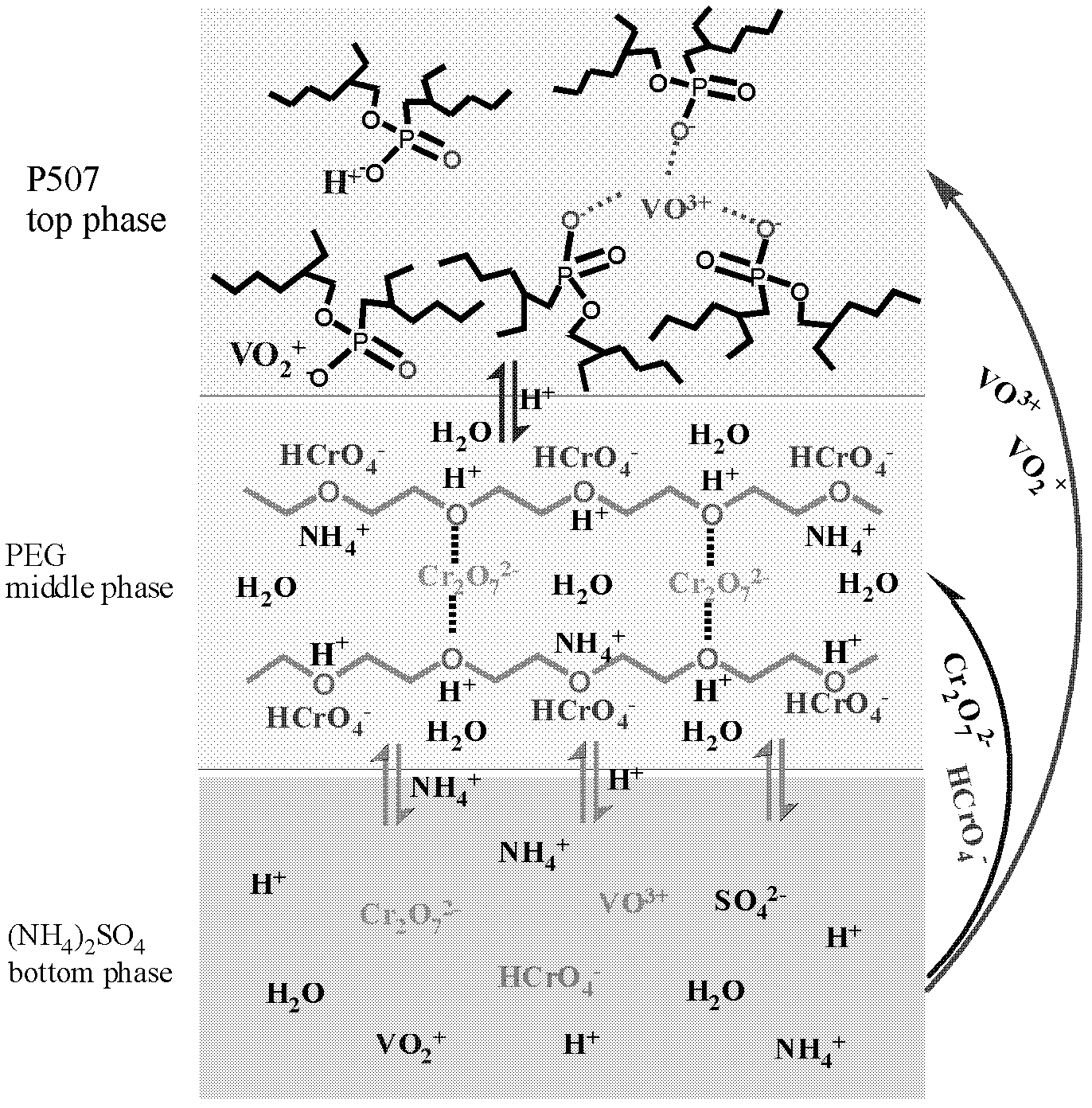

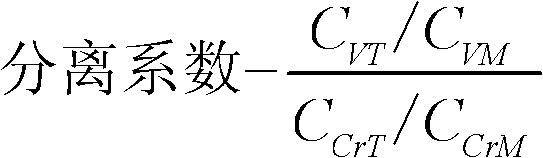

Method for extracting and separating vanadium from chromium by using three-phase system

InactiveCN102534266AHigh separation factorEfficient separationProcess efficiency improvementPolymer dissolutionSeparation coefficient

The invention relates to a method for extracting and separating vanadium from chromium by using liquid-liquid-liquid three-phase system, which comprises the following steps of: adding phase forming salt and a polymer in vanadium and chromium solution and forming an aqueous two-phase system after the phase forming salt and the polymer are dissolved; and then adding an organic phase in the formed aqueous two-phase system, vibrating and carrying out phase separation to obtain the three-phase system. Compared with the prior art, the method has the advantages that: (1) the separation coefficient of vanadium from chromium is large, so that the effective separation of vanadium from chromium can be realized in one step; (2) the utilization rate of vanadium and chromium is high, so that the resource waste is effectively reduced; (3) the method is good in physical phenomenon, short in process flow, simple and convenient in operation, low in cost, less in energy consumption and good in control, and as long as the effective separation of vanadium from the chromium can be realized, the production process for further recovering vanadium and chromium is mature.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

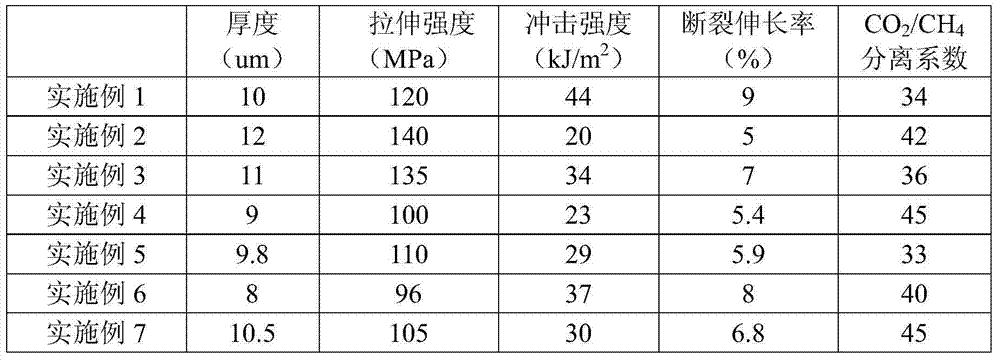

Aramid fiber III/polyvinyl alcohol blended gas separation film and preparation method thereof

ActiveCN103537205AGood flexibilityImprove performanceSemi-permeable membranesDispersed particle separationOrganic solventSeparation coefficient

The invention belongs to the technical field of aramid fiber III blended materials, and discloses an ultrathin high-strength aramid fiber III / polyvinyl alcohol blended gas separation film, and a preparation method and application thereof. The preparation method comprises the following steps: dissolving aramid fiber III in an organic solvent, adding assistant and strong alkali, stirring uniformly while heating, adding polyvinyl alcohol, and stirring to form a film casting solution; and scratching the film casting solution to form a film, evaporating out the solvent, putting in a gel bath to obtain a gel film, and carrying out heat treatment to obtain the ultrathin high-strength aramid fiber III / polyvinyl alcohol blended gas separation film. The polyvinyl alcohol with favorable toughness is introduced into the rigid heterocyclic ring aramid fiber, thereby keeping the favorable properties of the aramid fiber III and enhancing the flexibility; and the impact strength of the obtained aramid fiber III / polyvinyl alcohol blended gas separation film is 23-44 kJ / m<2>, the elongation at break is 5-9%, the film thickness is 8-12 um, and the CO2 / CH4 separation coefficient is 32-45.

Owner:中科检测技术服务(广州)股份有限公司

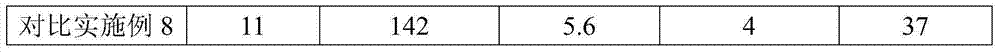

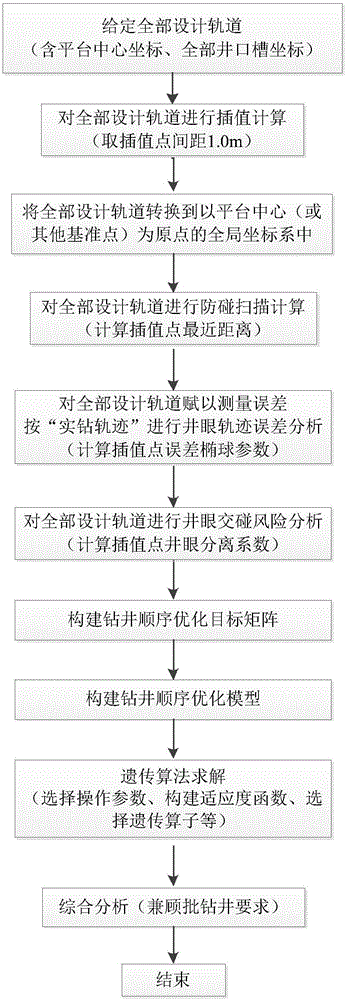

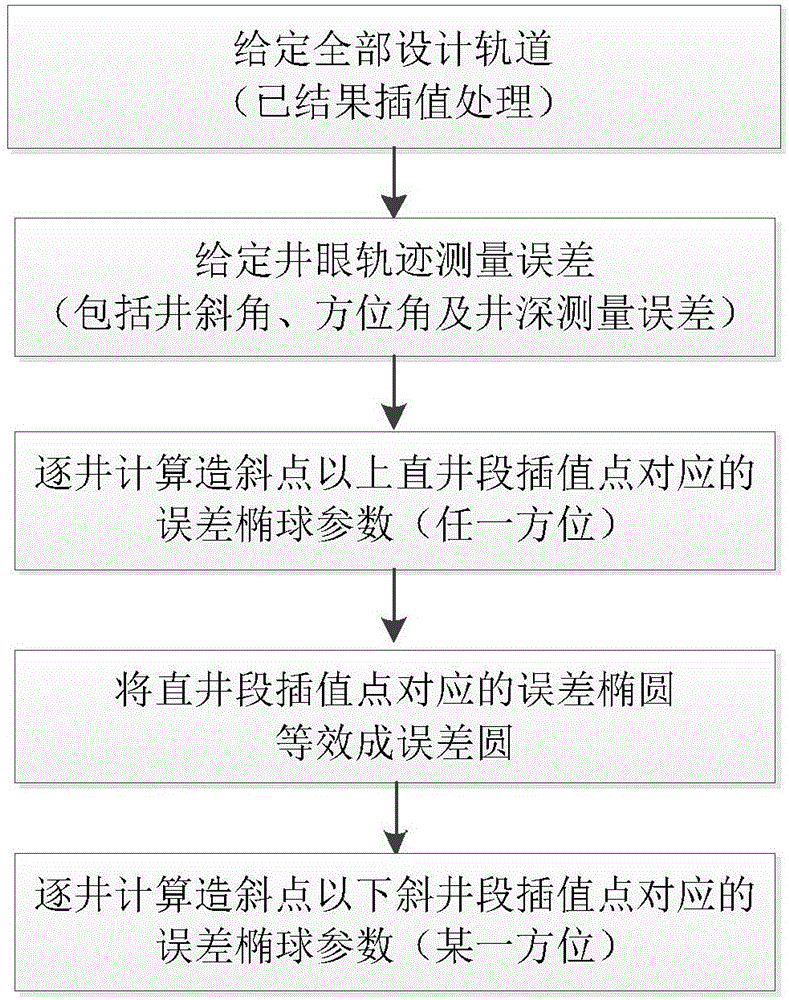

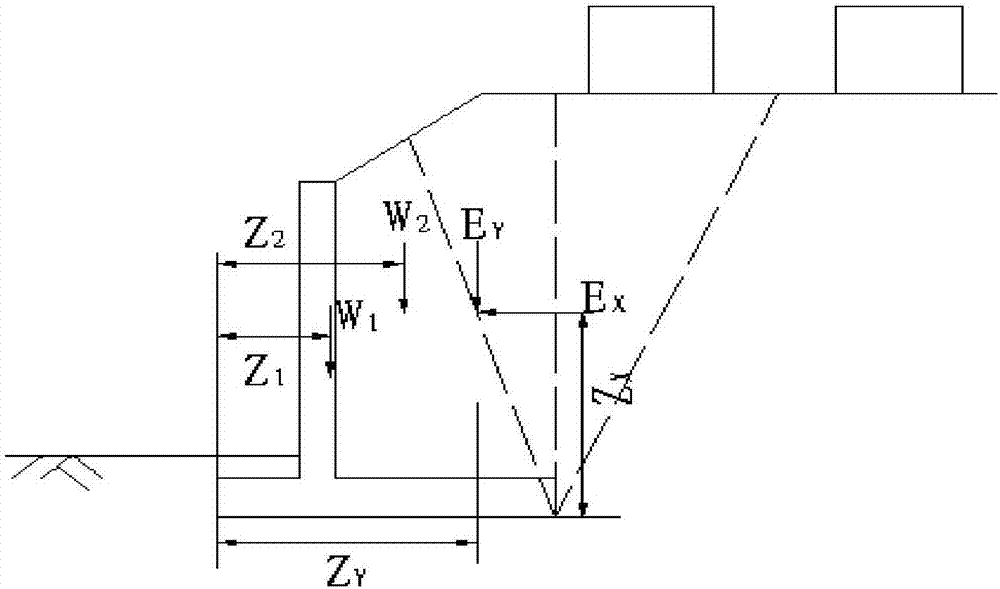

Method for optimizing well drilling sequence of offshore cluster well group

The present invention discloses a method for optimizing a well drilling sequence of an offshore cluster well group. The method includes a well drilling sequence optimizing index, an optimizing model and a genetic algorithm solution, specially includes the steps as follows: presetting a well trajectory design scheme (containing wellhead groove parameters) of the whole well group; performing interpolation calculation (separation distance 1m), coordinate transformation, and minimum range sweep analysis for all designing trajectories; giving a measure error to all designing trajectories so as to calculate error ellipsoid parameters corresponding to all interpolating points; performing a well colliding risk analysis for the whole well group (calculating a well separation coefficient); building a well drilling sequence optimal object matrix and a mathematical programming model; solving the model by utilizing a genetic algorithm; and analyzing data by synthesis (giving consideration to a batch drilling requirement). The optimized well drilling sequence facilitates reducing the well colliding risk and an anti-colliding workload, facilitates saving a well drilling time and a well drilling cost by utilizing the batch well drilling method, and satisfies the requirement for optimizing the drilling sequence of the offshore large-scale cluster well group.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

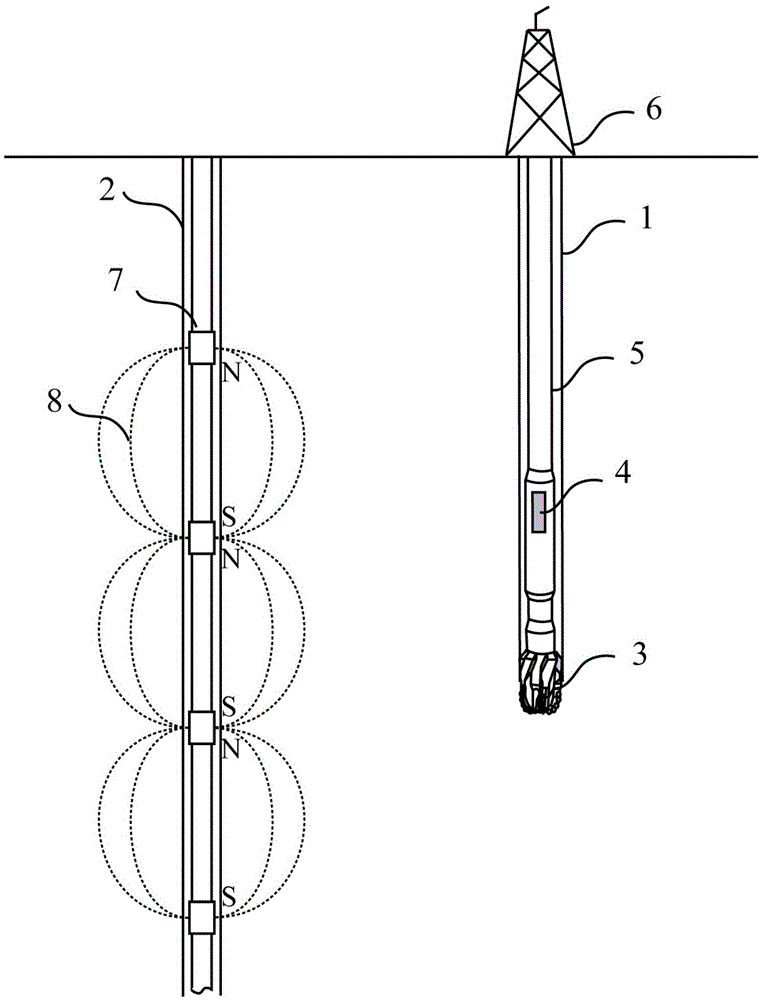

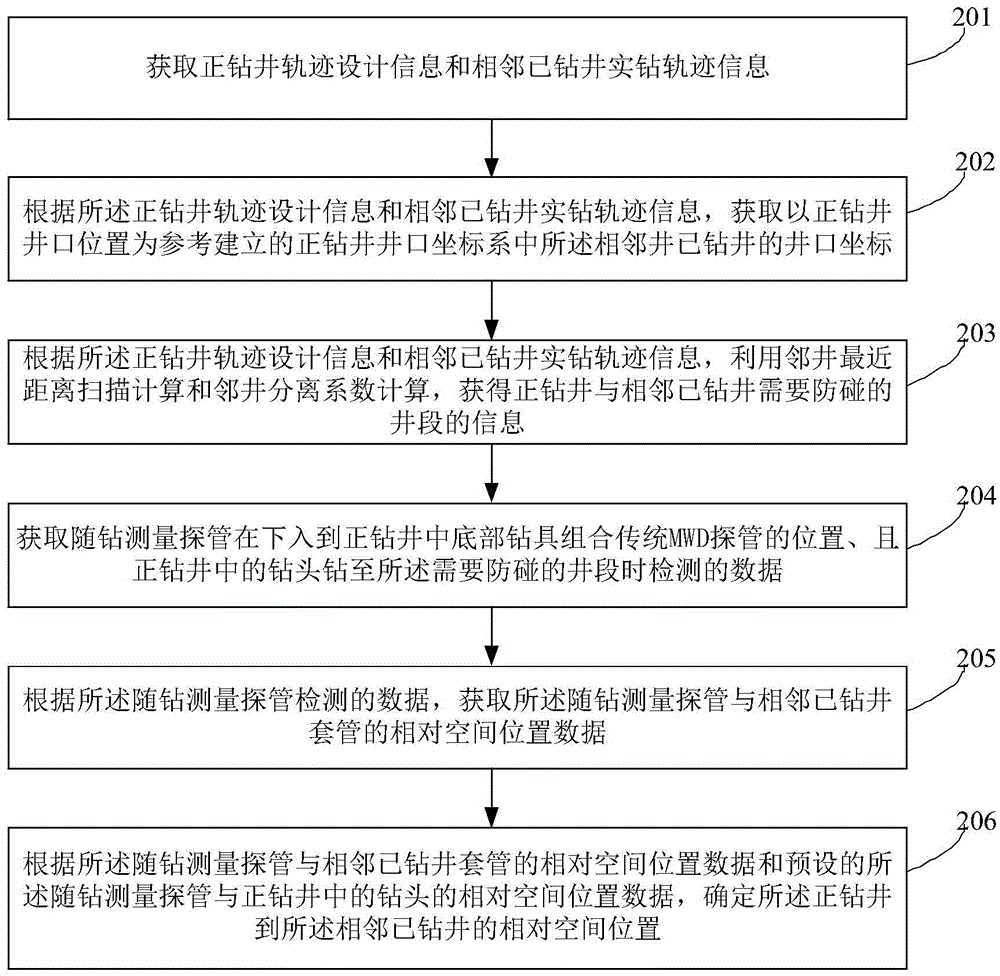

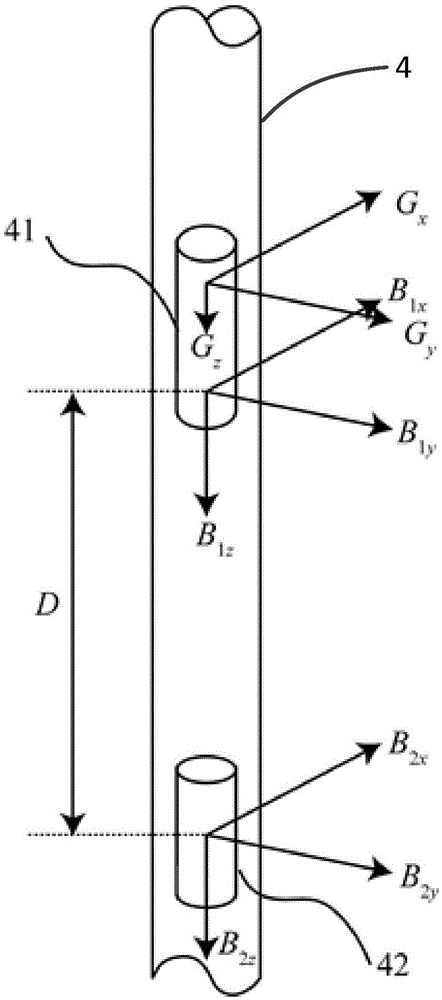

Drilling well and adjacent drilled well active anti-collision method

ActiveCN105545289AAvoid collisionAvoid Cumulative ErrorsConstructionsSeparation coefficientWell drilling

The invention provides a drilling well and adjacent drilled well active anti-collision method. The method comprises: obtaining drilling well trajectory design information and adjacent drilled well actual drilling trajectory information; according to the information, obtaining wellhead coordinates of adjacent drilled wells in a drilling well wellhead coordinate system which is established using a drilling well wellhead position as reference; according to the above information, using adjacent well nearest distance scanning and adjacent well separation coefficient calculation, to obtain well section information of the drilling well and the adjacent drilled well, the well section needing anti-collision; obtaining data detected when a measurement exploring tube while drilling is lowered to the traditional MWD exploring tube position of a bottom hole assembly on the bottom of a drilling well, and a drill drills to the well section needing anti-collision, according to the data, obtaining relative spatial position data of the measurement exploring tube while drilling and an adjacent drilled well casing; according to the data and preset relative spatial position data of the measurement exploring tube while drilling and the drill in a drilling well, determining the relative spatial position of the drilling well to the adjacent drilled well. The method can determine relative spatial position of the drilling well to the adjacent wells, and prevents a problem of collision of two wells in a well drilling or well adjusting process.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

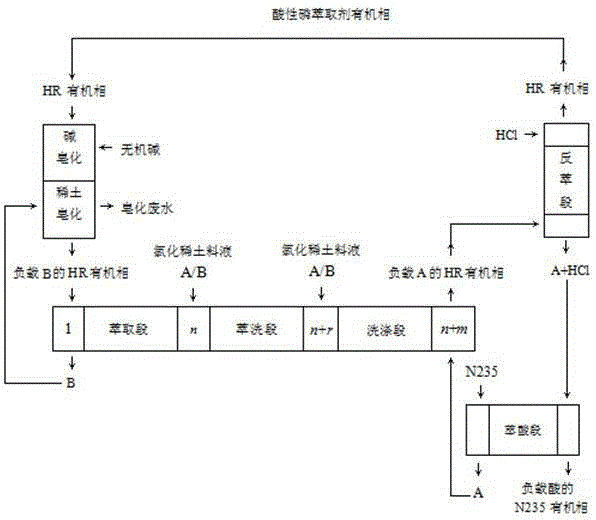

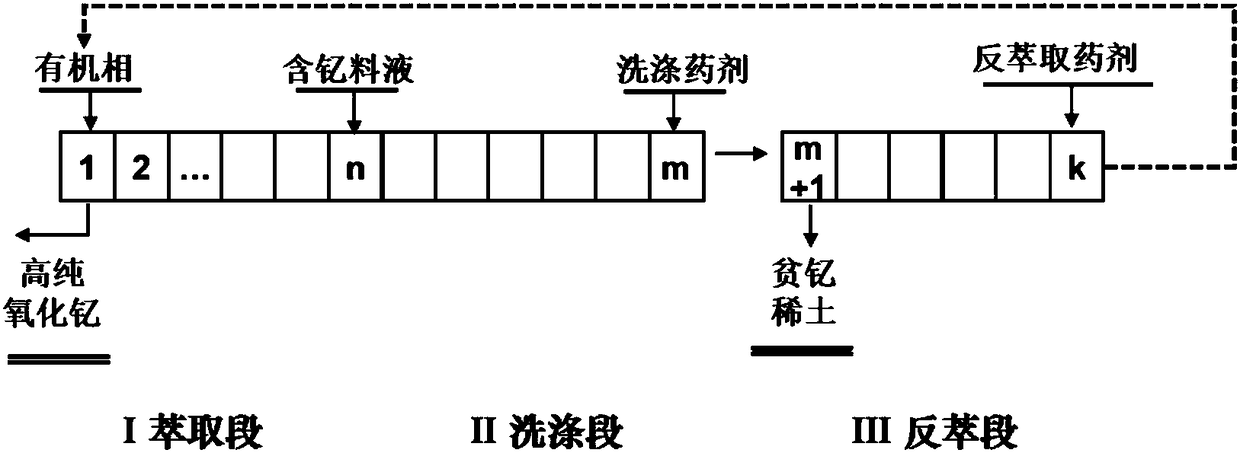

Two-feeding-opening fully-loaded rare earth fractional extraction separation process method

InactiveCN104561546AReduce acid and alkali consumptionHigh degree of greeningProcess efficiency improvementSide effectTotal investment

The invention discloses a two-feeding-opening fully-loaded rare earth fractional extraction separation process method. According to the method, P507 serves as a rare earth extracting agent; in a two-feeding-opening fractional extraction separation process, an acid extraction section which takes N235 as an acid extracting agent and takes trioctyl phosphate as an N235 organic phase demulsifying agent is arranged, and the side effect of hydrogen ions can be eliminated through the acid extracting effect of the N235, so that not only is the rare earth separation coefficient not reduced, but also the extracting amount of rare earth in a two-feeding-opening fractional extraction system is not lower than the saponification amount of the rare earth. Compared with the existing two-feeding-opening fractional extraction process, the consumption of acid and alkali in a rare earth separation process can be greatly reduced, wherein the consumption amount of an alkaline reagent is reduced by 39 to 51 percent, and the consumption amount of hydrochloric acid can be reduced by 17 to 26 percent; the waste water discharging amount in the rare earth extraction separation process is greatly reduced; the green degree of rare earth separation is greatly improved; the stage number of extracting tanks can be reduced by 32 to 38 percent; the total investment of the rare earth extraction separation process is reduced. Therefore, the separation cost is remarkably reduced.

Owner:NANCHANG HANGKONG UNIVERSITY

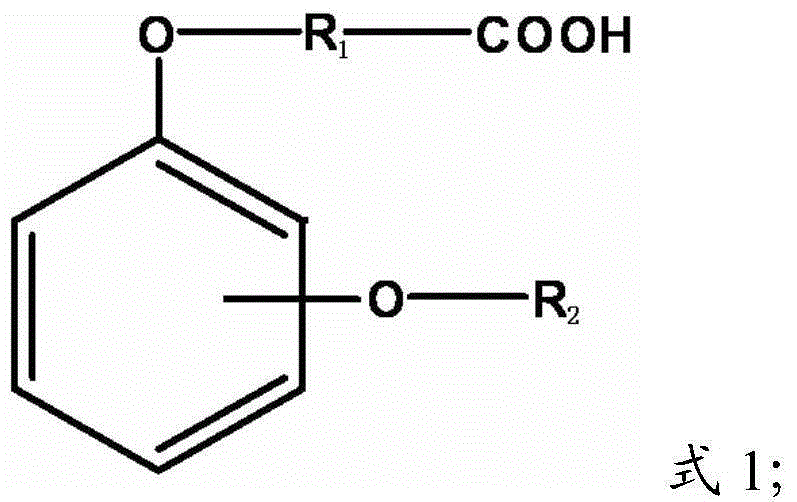

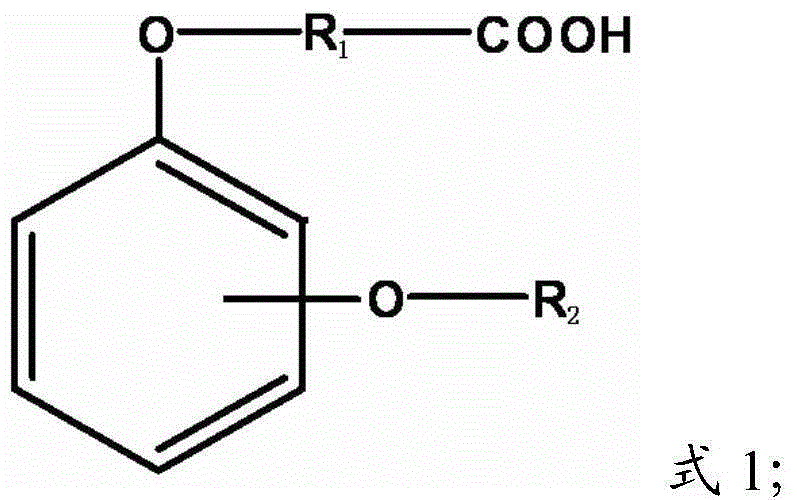

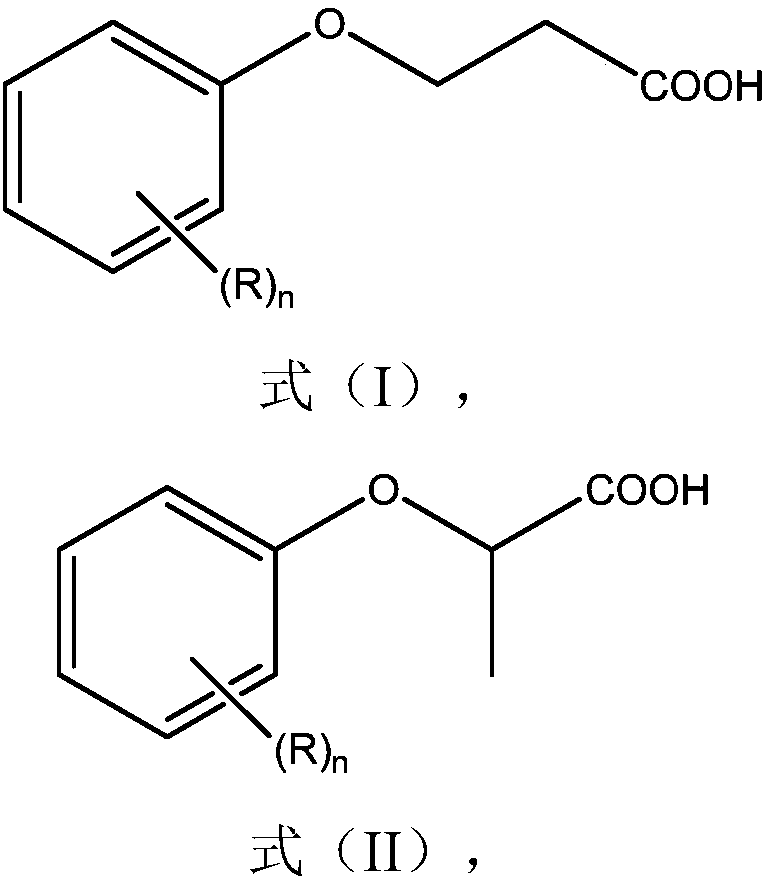

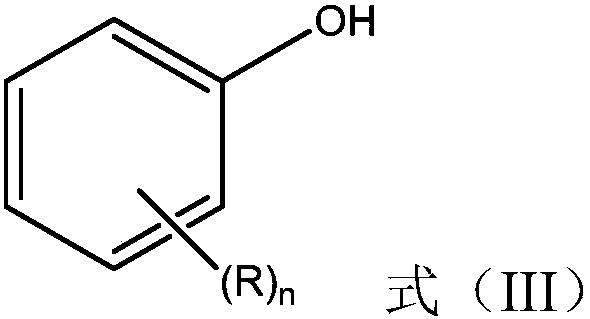

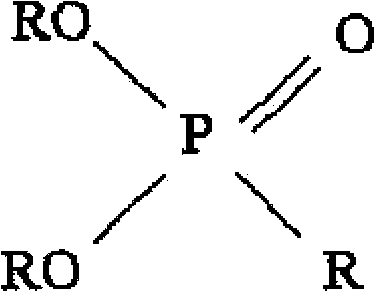

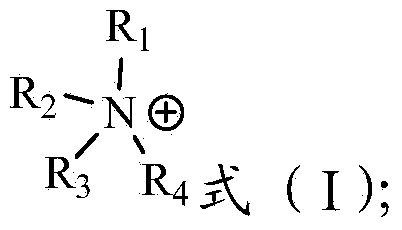

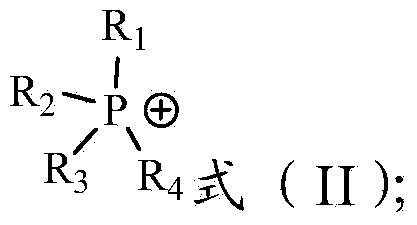

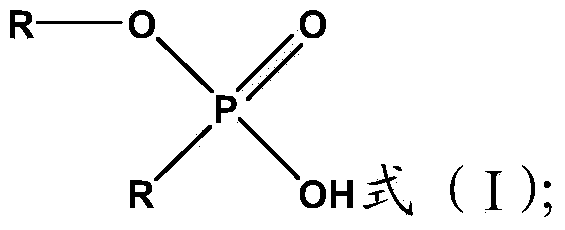

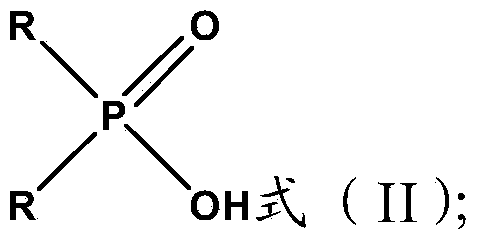

Extracting agent for rare earth extraction separation, preparing method thereof and extraction separation method using same

ActiveCN108456792AEfficient synthesisEasy to synthesizeProcess efficiency improvementSeparation coefficientDiluent

The invention discloses an extracting agent for rare earth extraction separation, a preparing method thereof and an extraction separation method using the extracting agent. The extraction separation method comprises the following steps of (1), mixing one or a plurality of diluents in an extracting agent which is represented by a formula (I) and / or a formula (II), and obtaining an organic phase; (2), mixing the organic phase obtained in the step (1) with yttrium-containing rare earth material solution, performing selective extraction for keeping the yttrium in a water phase and making poor-yttrium rare earth enter an organic phase, namely realizing extraction of rare earth yttrium. The extracting agent and the extraction separation method are advantageous in that 1, high selectivity of theextracting agent in rare earth extraction separation is realized, not only is a separation coefficient between light rare earth and yttrium kept, but also a separation range between heavy rare earth and the yttrium is improved; 2, the organic phase of the process can be cycled by more than one year without remarkable concentration reduction; 3, high extraction phenomenon and no emulsification arerealized; and 4, simple synthesis and low cost of the extracting agent are realized.

Owner:XIAMEN INST OF RARE EARTH MATERIALS

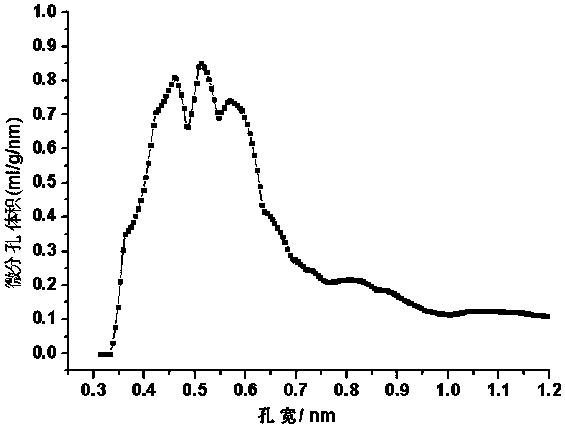

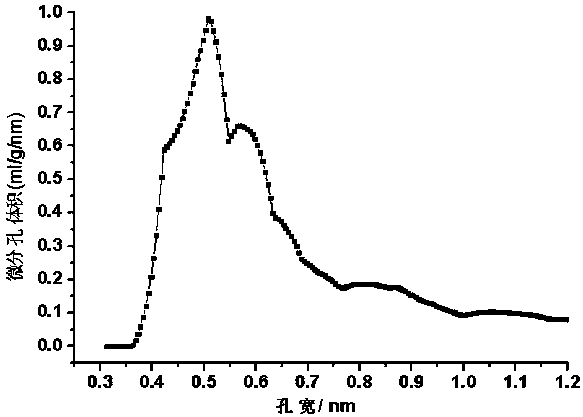

Preparation method of coal-based carbon molecular sieve

InactiveCN109179415ALarge adsorption capacitySimple process conditionsCarbon compoundsMolecular sieveActivated carbon

The invention discloses a preparation method of a coal-based carbon molecular sieve, wherein the preparation method mainly includes the following steps: (1) screening coal-based activated carbon withsuitable pore size; (2) depositing with a methane deposition agent with different concentrations, and adjusting the pore size of coal-based activated carbon to prepare carbon molecular sieve samples;and (3) preparing a carbon molecular sieve sample with large nitrogen adsorption capacity and small methane adsorption capacity, wherein the carbon molecular sieve sample is advantageous to separationin kinetics. The coal-based activated carbon has the advantages of wide pore size range, wide source and low price. The deposited gas is mixed gas of inert gas and methane. The deposited gas has no pollution to the environment. The nitrogen adsorption capacity of the prepared product is large and the equilibrium separation coefficient is small, and dynamic separation of nitrogen and methane is facilitated.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

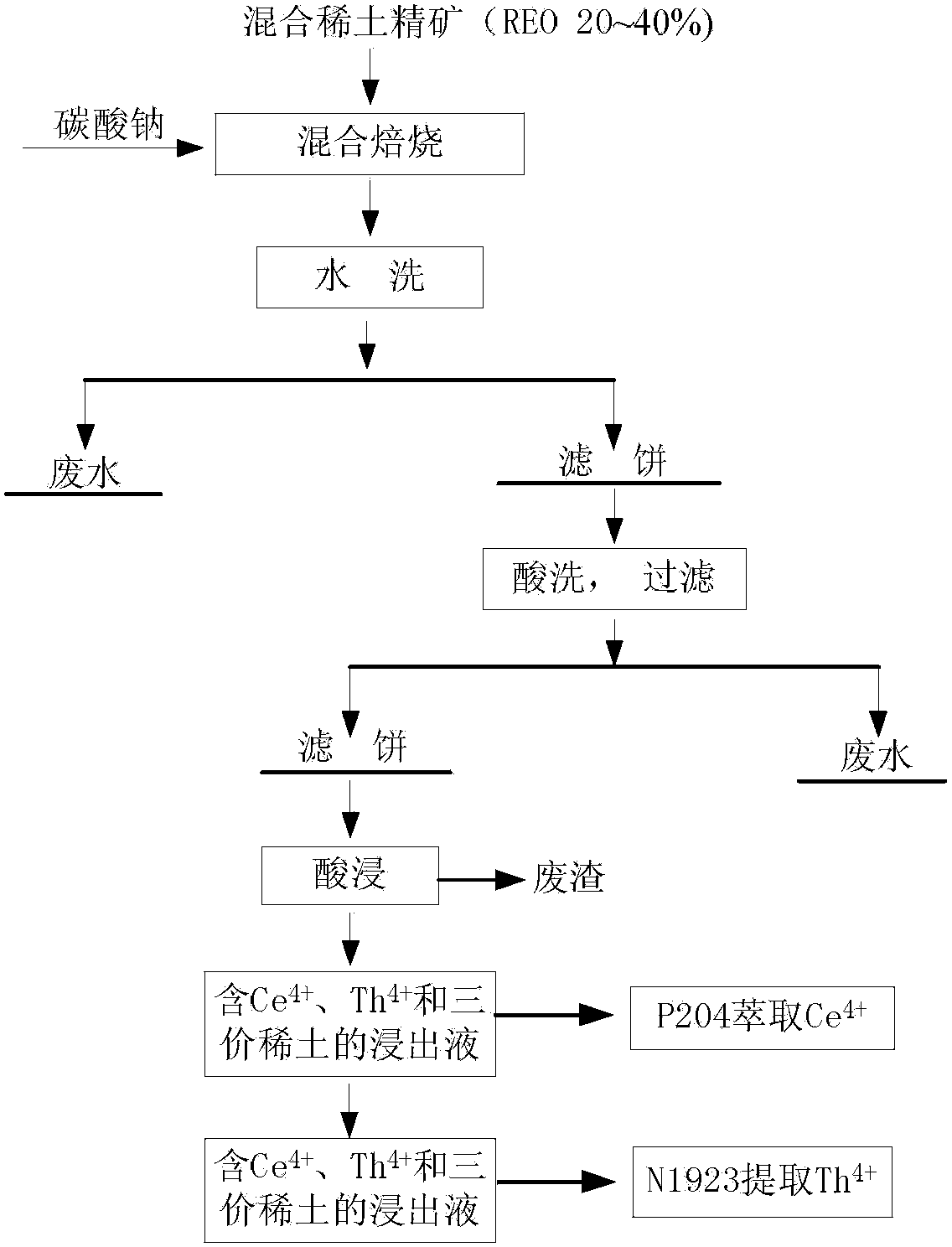

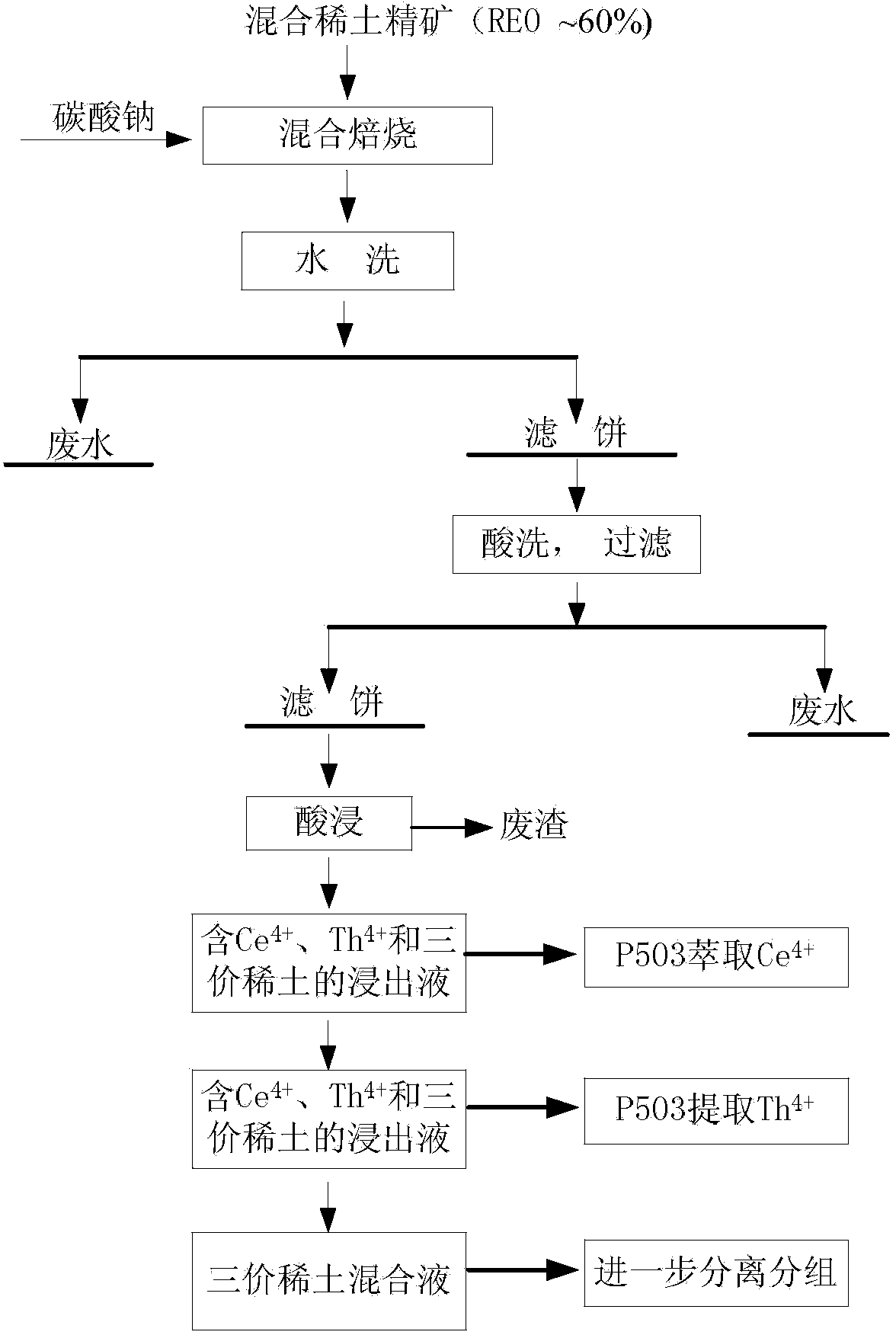

Clean separating method of Baotou rare-earth ore concentrate

InactiveCN103540740AReduce pollutionReduce contentProcess efficiency improvementRare-earth elementSeparation coefficient

The invention relates to a clean separating method of Baotou rare-earth ore concentrate. The method comprises the following steps: roasting the rare-earth ore concentrate by using sodium carbonate; carrying out acid leaching by adopting a nitric acid after washing and pickling by a dilute acid, so as to obtain a leach liquor containing Ce4<+>, Th4<+> and trivalent rare-earth elements; respectively extracting the Ce4<+> and Th4<+> by adopting a P503 extracting agent, and then carrying out separation of light rare earth. By adopting the same extracting agent, selective separation of cerium, thorium and other trivalent rare earth can be achieved; the clean separating method is economical to a factory, small in equipment pressure, and easy to operate; only separation of lanthanum, praseodymium and neodymium exists in separation of the trivalent rare earth; the extraction technology is mature. Interference of an adjacent element trivalent cerium is not generated, so that the separation coefficient of lanthanum, praseodymium and neodymium is large; corresponding extraction and separation flows are greatly simplified and shortened.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

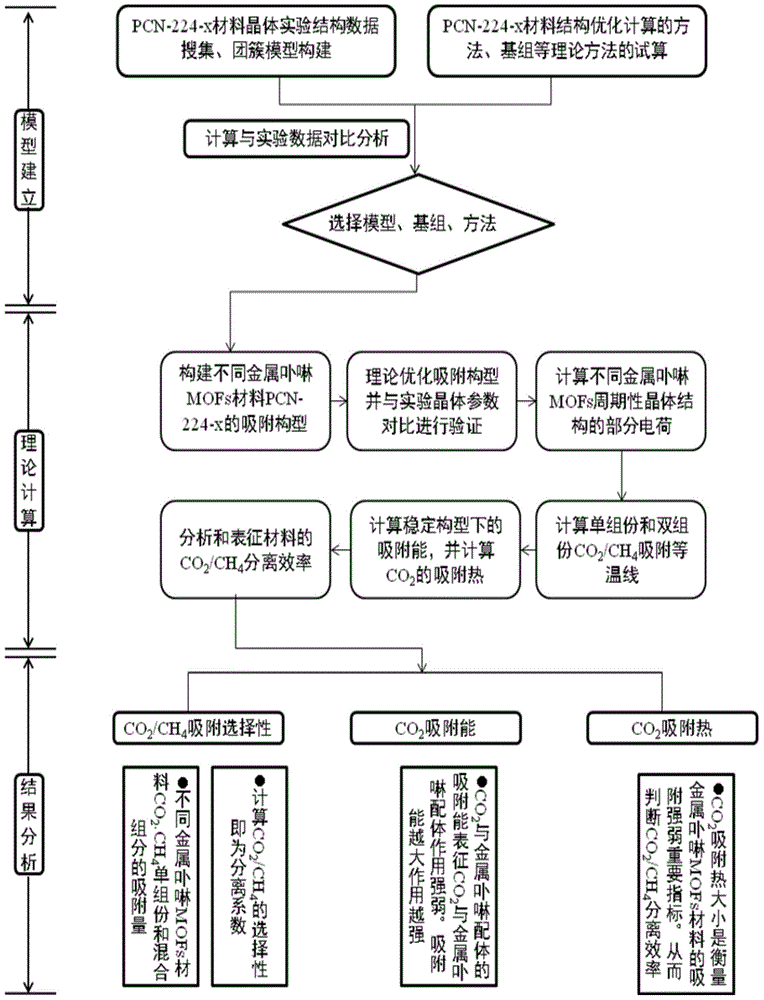

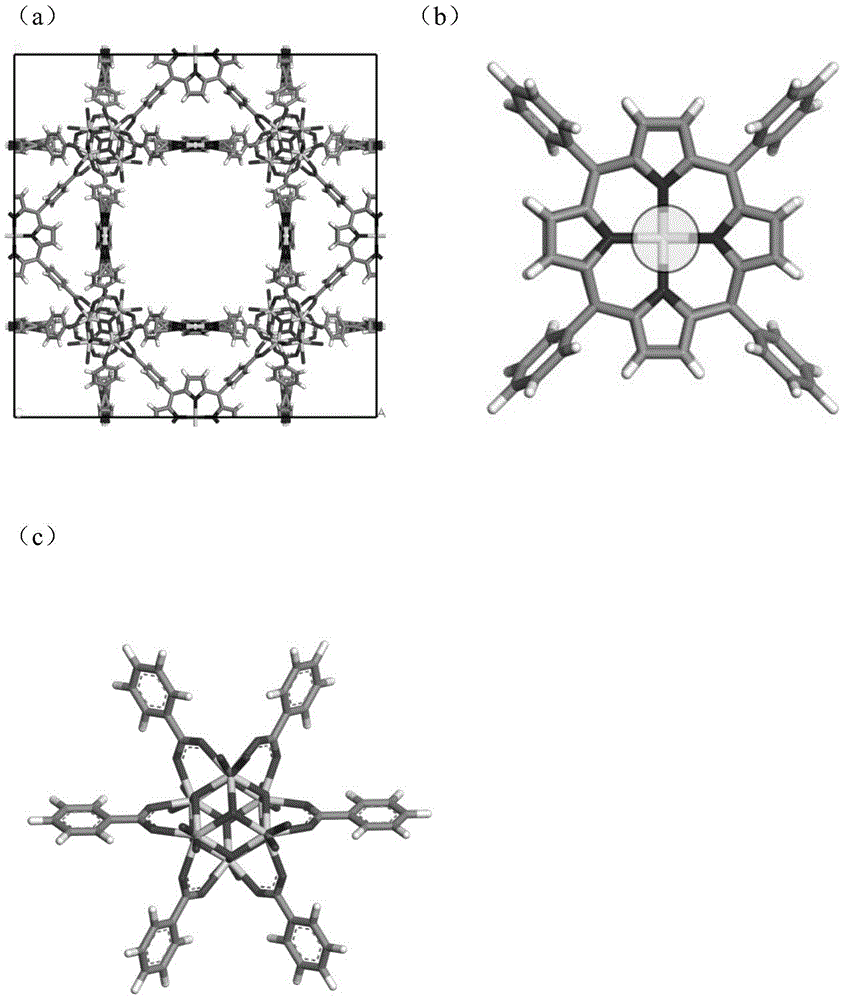

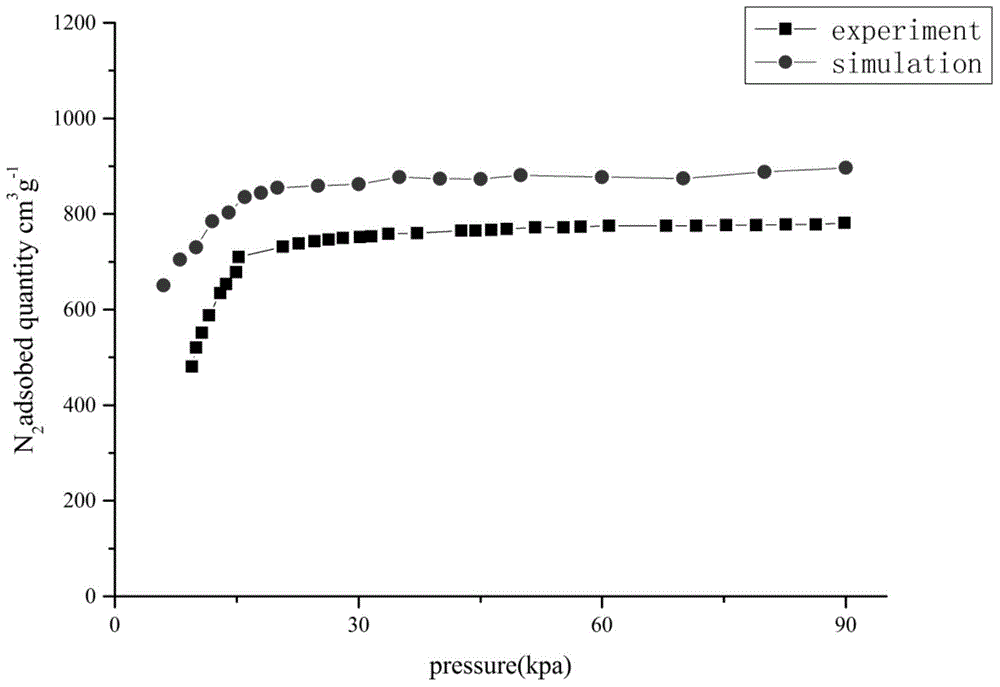

Method for quantitatively analyzing efficiency of metalloporphyrin MOFs materials in separating CO2/CH4

InactiveCN104899356AAvoid complexityOvercome stabilityAdsorption purification/separationSpecial data processing applicationsMolecular sievePartial charge

The invention discloses a method for quantitatively analyzing efficiency of metalloporphyrin MOFs materials in separating CO2 / CH4. According to the method of the invention, the efficiency of the metalloporphyrin MOFs materials in separating CO2 / CH4 is quantitatively analyzed based on density functional theory calculation of auantum chemistry and Monte Carlo molecular simulation. By determining interaction energy between probe molecules and different metalloporphyrin ligands and adsorption heat, interaction between CO2 and metalloporphyrin MOFs materials is quantitatively analyzed, and finally calculation of selectivity in adsorption of CO2 / CH4 is used to characterize efficiency and features of different metalloporphyrin MOFs materials in separating CO2 / CH4. The method comprises steps of: construction of a cluster model; structural optimization of a stable structure and calculation of partial charges; calculation of a CO2 / CH4 separation coefficient; calculation of adsorption energy and adsorption heat; and analysis and characterization of efficiency in separating CO2 / CH4. According to the method of the invention, efficiency of metalloporphyrin MOFs materials in separating CO2 / CH4 can be quantitatively characterized without any actual experiment. The method of the invention can be further extended for analysis of efficiency of other porous molecular sieves of known crystal structures and MOFs materials in separating CO2 / CH4.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

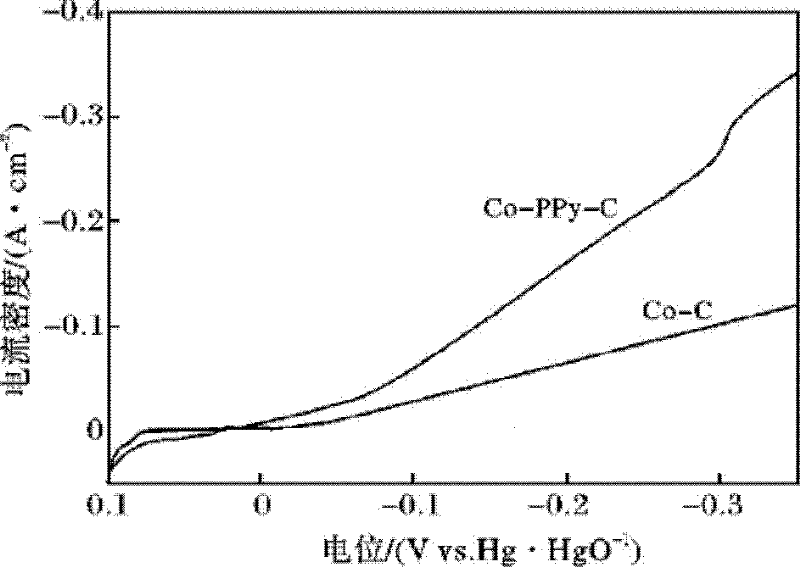

Gas diffusion electrode of zinc-air battery and preparation method for gas diffusion electrode

InactiveCN102544520APrevent leakageLimiting current reductionFuel and primary cellsCell electrodesWater vaporSeparation coefficient

The invention relates to a gas diffusion electrode of a zinc-air battery and a preparation method for the gas diffusion electrode of the zinc-air battery. The electrode comprises a middle current collector, a waterproof ventilating layer and a catalytic layer, wherein the waterproof ventilating layer is pressed and coated at the both sides of the current collector. The catalyst adopted by the catalytic layer is Co-PPy-C composite. One side of the waterproof ventilating layer, which is close to air, is coated with a polymer layer. According to the gas diffusion electrode of the zinc-air battery, the limiting current and the water absorbing speed are reduced, and the separation coefficient of oxygen and vapor is increased. For an AA type zinc-air battery assembled by the gas diffusion electrode of the zinc-air battery, the discharge capacity of the battery is greatly improved in dry and humid environments, and the utilization rate of the zinc electrode is obviously improved.

Owner:SHANGHAI YAOYU INDAL

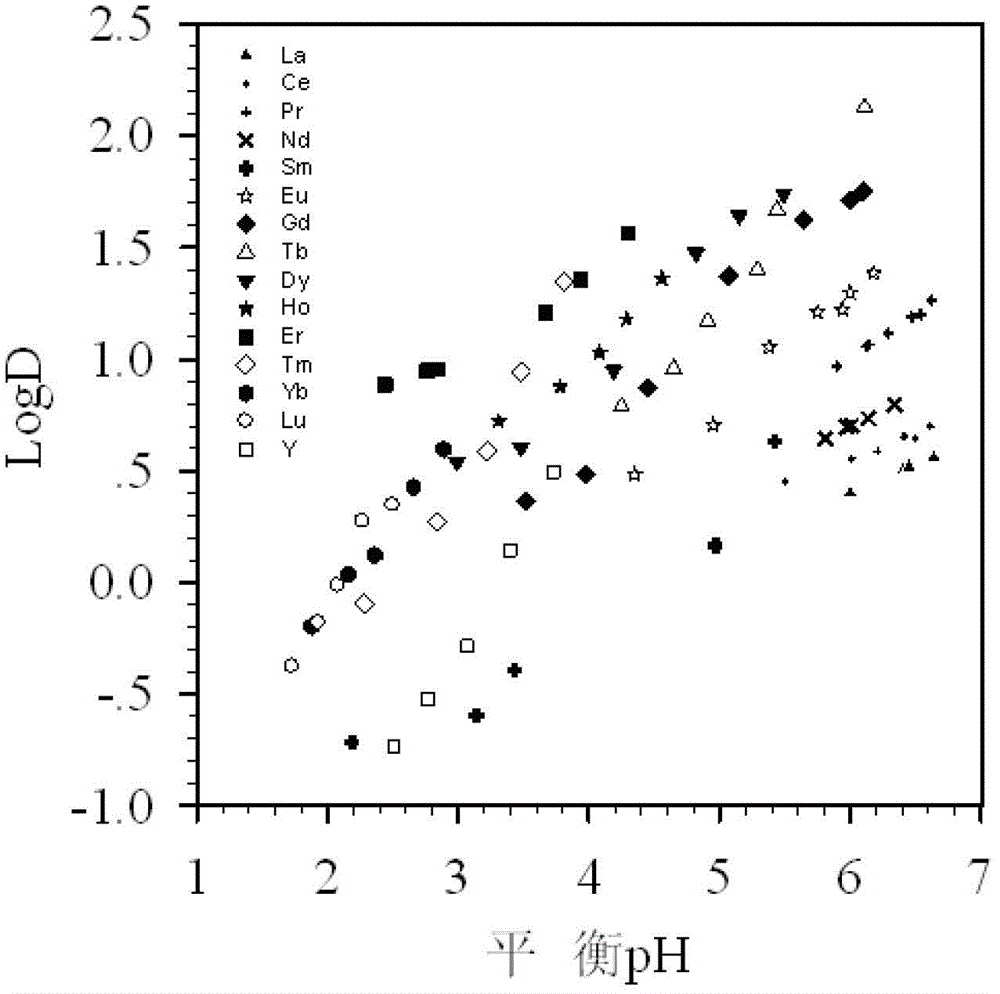

Extraction separation method for heavy rare earth elements

InactiveCN104195336AImprove the extraction separation factorHigh selectivityProcess efficiency improvementRare-earth elementPhosphonium

The invention provides an extraction separation method for heavy rare earth elements. The extraction separation method comprises the following steps: mixing rare earth concentrates with inorganic acid to obtain a raw material liquid; using an organic phase comprising an extraction agent and a thinning agent to extract rare earth elements in the raw material liquid, wherein the extraction agent is a difunctional ionic liquid extraction agent, and the difunctional ionic liquid extraction agent comprises one deprotonated acid phosphine negative ion of quaternary ammonium positive ions and quaternary phosphonium positive ions. According to the method provided by the invention, in the extraction process, due to the fact that the quaternary ammonium positive ions or the quaternary phosphonium positive ions in the difunctional ionic liquid extraction agent are distributed in an organic phase and a water phase, the competitive effect of ionic liquid positive ions and rare earth ions is strengthened, and the extraction separation coefficient of heavy rare earth is improved. Moreover, in the subsequent extraction process, due to specific phase transfer effect of ions, a stripping agent is easier to enter the organic phase, and the reextraction rate is greatly improved.

Owner:XIAMEN INST OF RARE EARTH MATERIALS

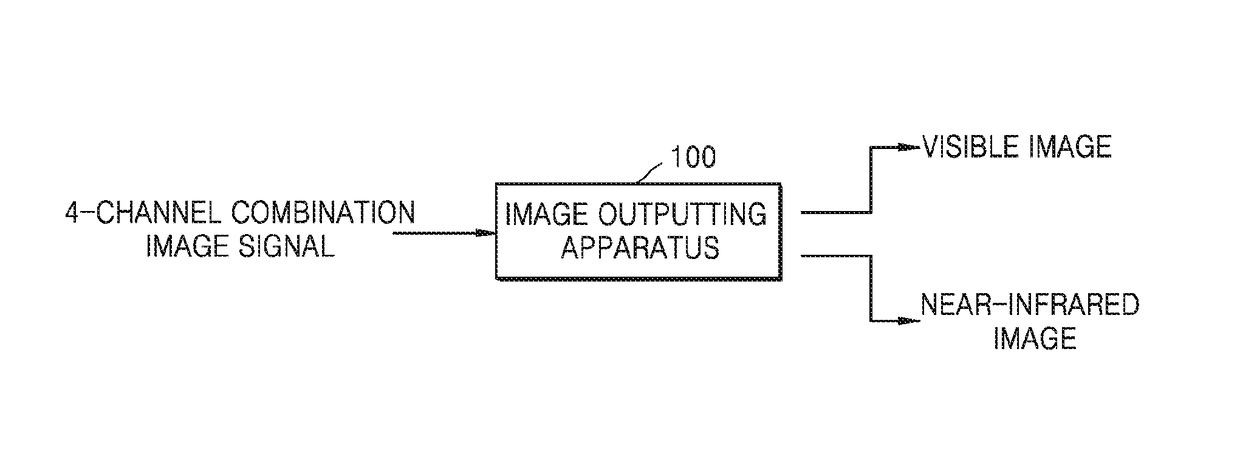

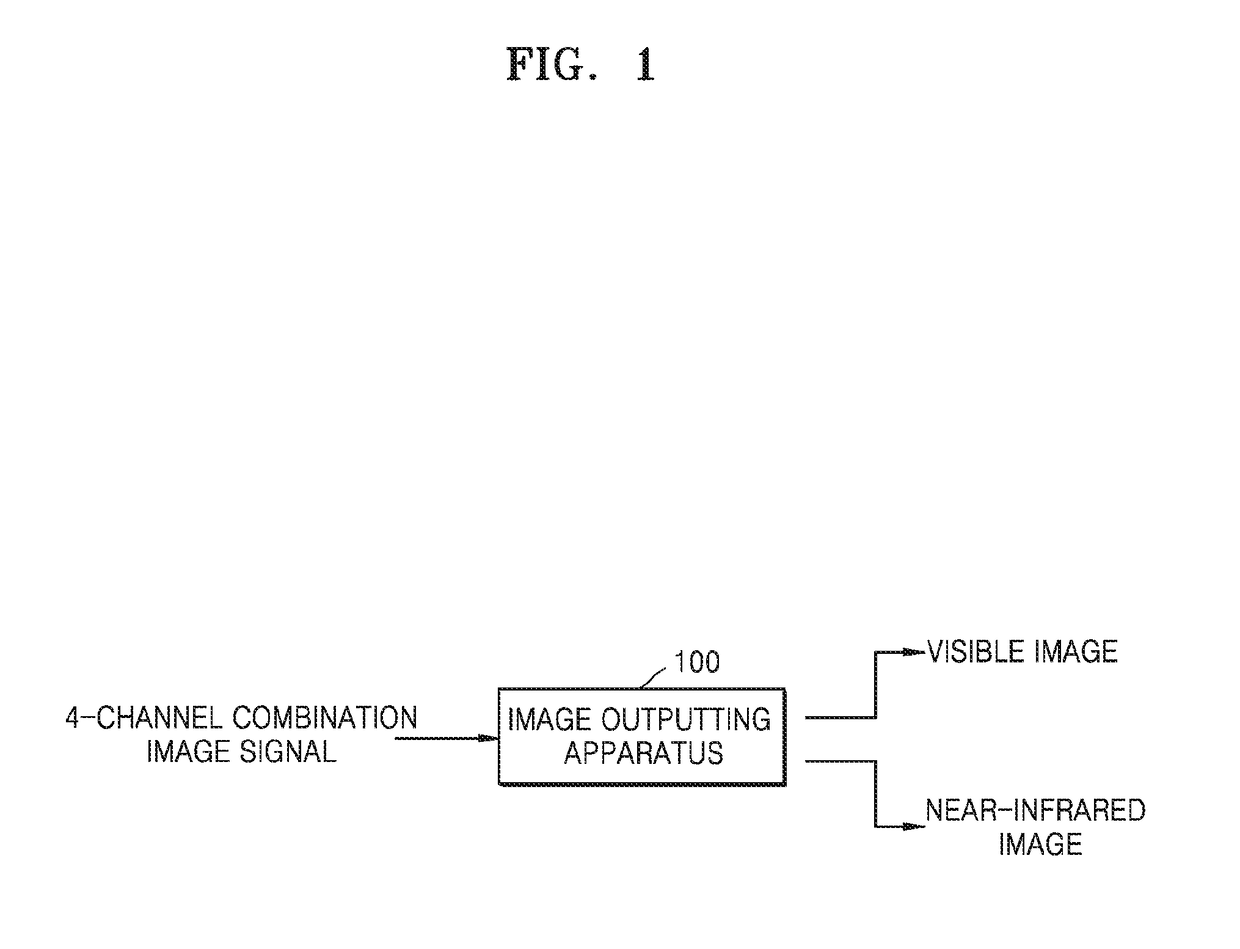

Method and apparatus for outputting images

ActiveUS20170180683A1Television system detailsColor signal processing circuitsPattern recognitionSeparation coefficient

A method and an apparatus for outputting an image by using a color filter array (CFA) sensor are provided. The method includes receiving a 4-channel combination image signal through the CFA sensor, and separating the 4-channel combination image signal into a visible image signal and a near-infrared image signal, based on a signal separation coefficient including a color coefficient that is determined to convert 4-channel color data into 3-channel color data and a weight coefficient that is determined based on a 4-channel signal configured of near-infrared image signals. The method further includes outputting the visible image signal and the near-infrared image signal.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Method for extracting and separating rare earth elements in sulfuric acid system

InactiveCN102876893AHigh separation factorLow extraction acidityProcess efficiency improvementRare-earth elementSeparation coefficient

The invention provides a method for extracting and separating rare earth elements in a sulfuric acid system. The method includes the steps: taking mono (2-ethylhexyl) phosphonate 2-ethylhexyl methoxy cinnamate trialkyl methyl ammonium as an extracting agent; taking normal heptane as diluent; and extracting the rare earth elements in rare earth sulfate water solution into the normal heptane. The extracting agent used in the method does not need to be saponified, extraction and reverse extraction acidity is low, and separation coefficient for the rare earth elements is high.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

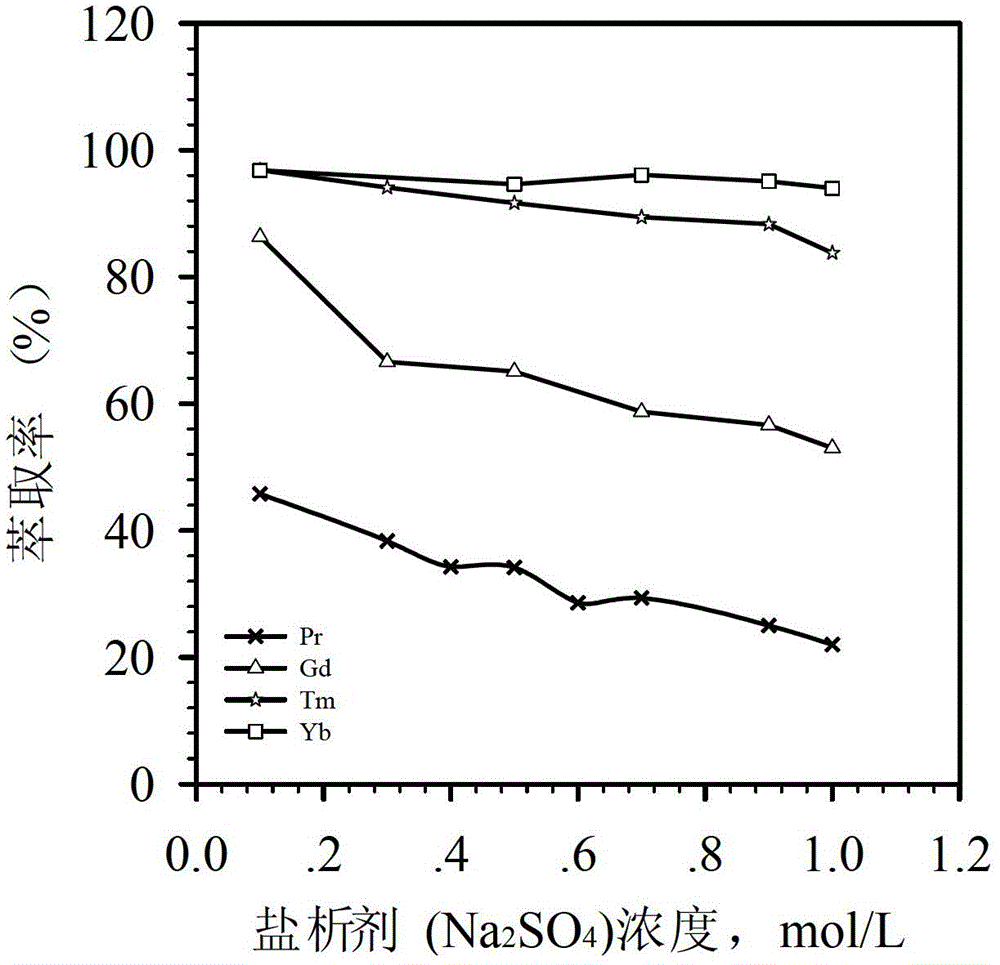

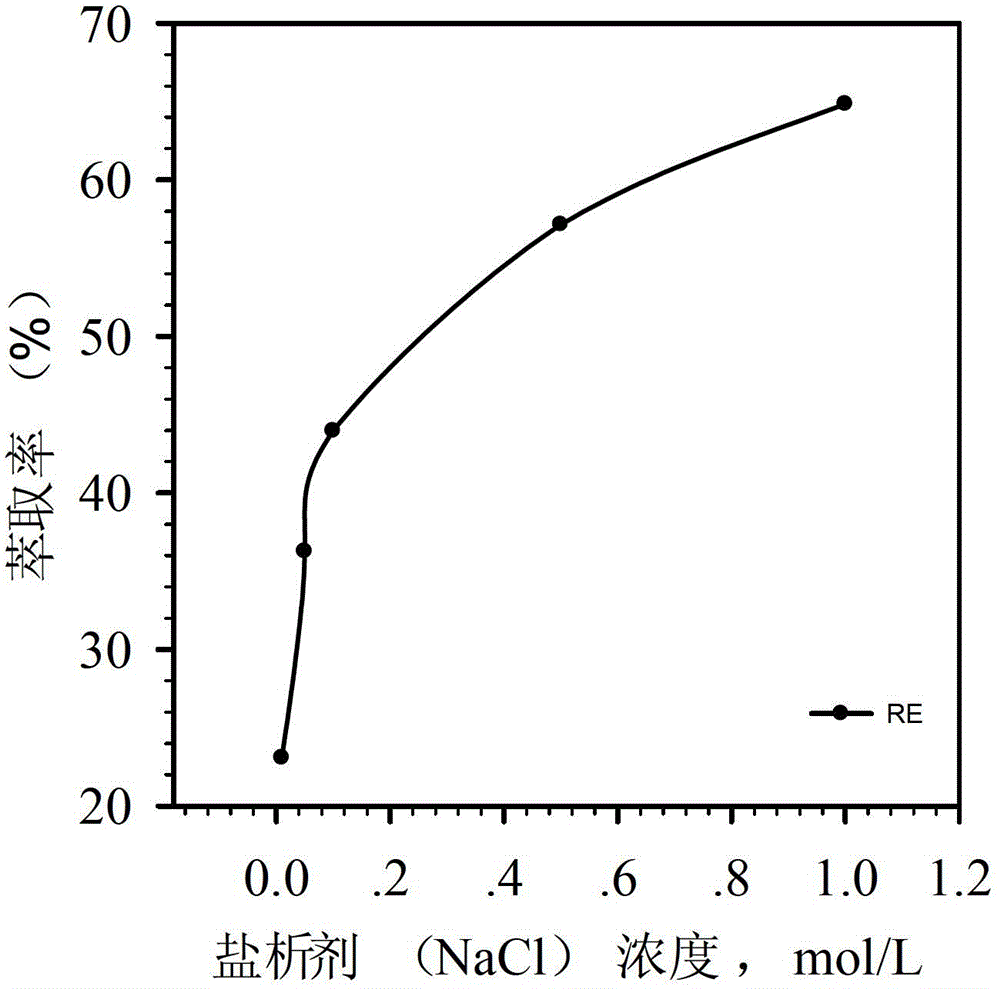

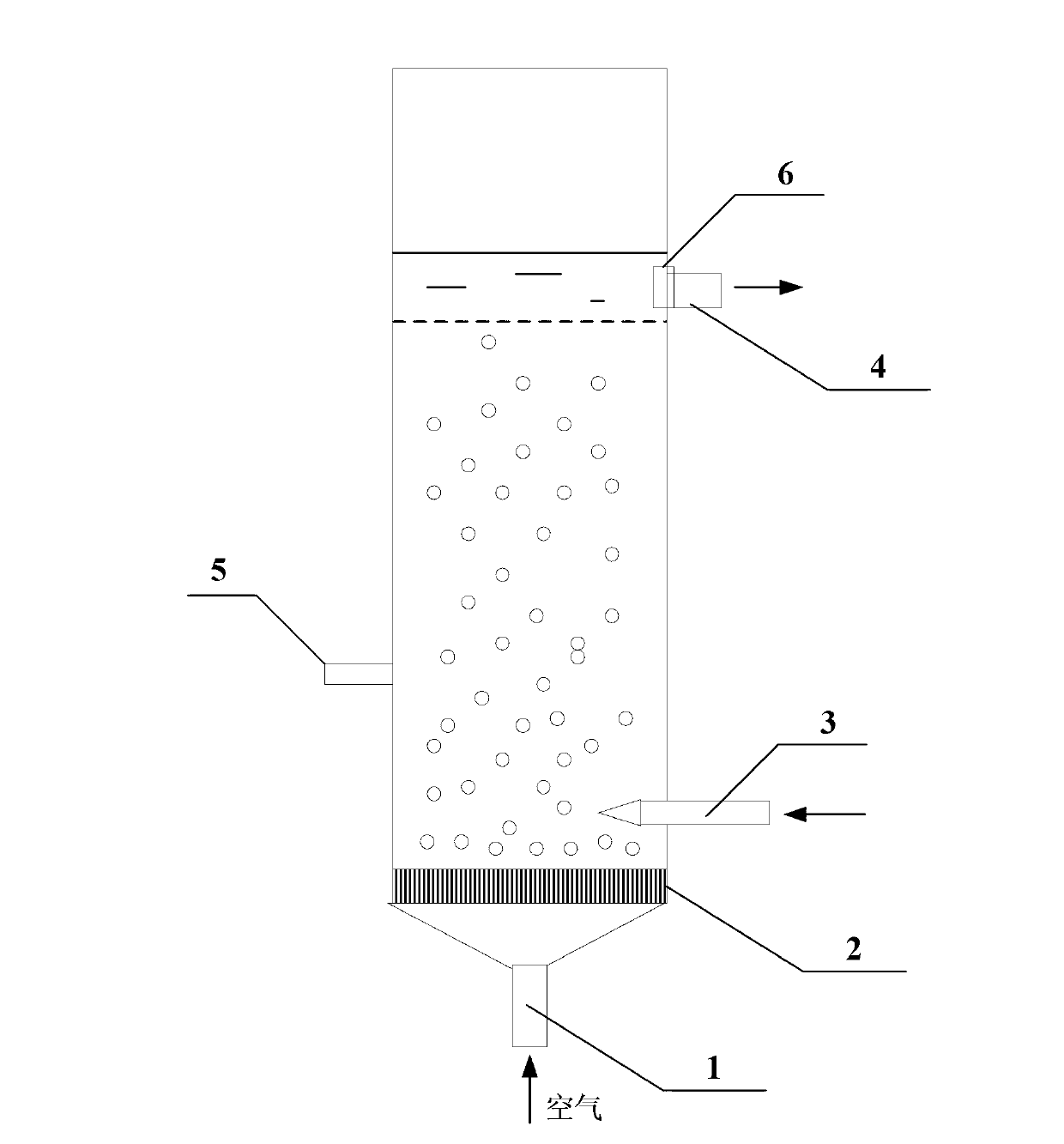

Method and device for extracting and separating praseodymium and neodymium

InactiveCN103122408AAchieve separationFast separationRecovering materialsSingle stageSeparation coefficient

The invention relates to a method and device for dynamically extracting and separating praseodymium and neodymium in a nonequilibrium state. The method comprises the following steps of: adding a water-soluble complexing agent to a water solution containing praseodymium and neodymium ions at room temperature; regulating the pH value of the solution; slowly adding an organic extractant in an aeration state, or adding inorganic electrolyte salt and then adding a water-soluble high-molecular polymer with an organic extractant functional group modified; and then collecting organic phases or polymer phases which are positioned on the top of a container, and carrying out reverse extraction and recovery on the praseodymium or the neodymium which is contained in the organic phases or the polymer phases. The method and device disclosed by the invention can be used for realizing the dynamic separation of the praseodymium and the neodymium and have the advantages of fast praseodymium and neodymium separation, high separation coefficient and high single-stage extraction stage efficiency.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Low-temperature palladium replacement separation method

The invention discloses a method for separating hydrogen isotope in the manner of palladium replacement. The method comprises the following steps: 1) cooling, namely soaking a raw material column and a palladium replacement separating column into liquid nitrogen and cooling to liquid nitrogen temperature, wherein the raw material column and the palladium replacement separating column are arranged as stainless steel pipes which are connected with each other and are communicated with each other and thus hydrogen is conveniently introduced into the columns and can flow and separate therein; 2) adsorbing hydrogen, namely introducing hydrogen into the raw material column, and adsorbing hydrogen till completing adsorption at low temperature; 3) separating at low temperature, namely separating the raw material column and the palladium replacement separating column from liquid hydrogen, thereby avoiding the corresponding low-temperature treatment; 4) transferring to the separating column, namely heating the raw material column for naturally separating hydrogen therein and guiding the separated hydrogen into the palladium replacement separating column; 5) replacing, separating and collecting, namely heating the palladium replacement separating column in the same manner, collecting gas flowing out from the separating column in segments, and analyzing gas composition for confirming a separation coefficient.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

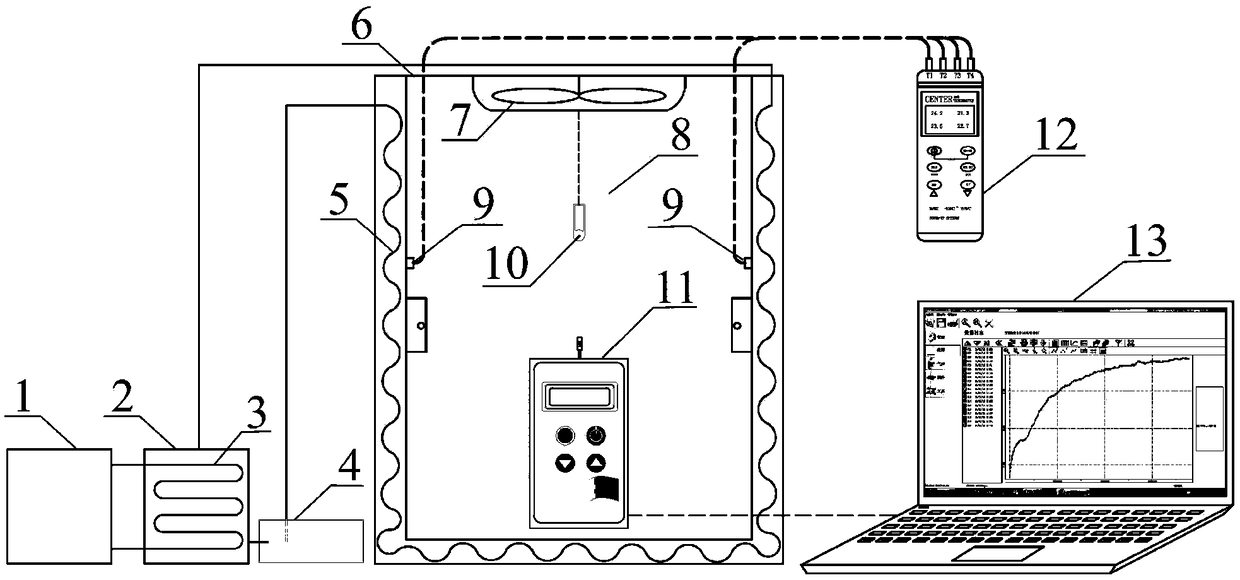

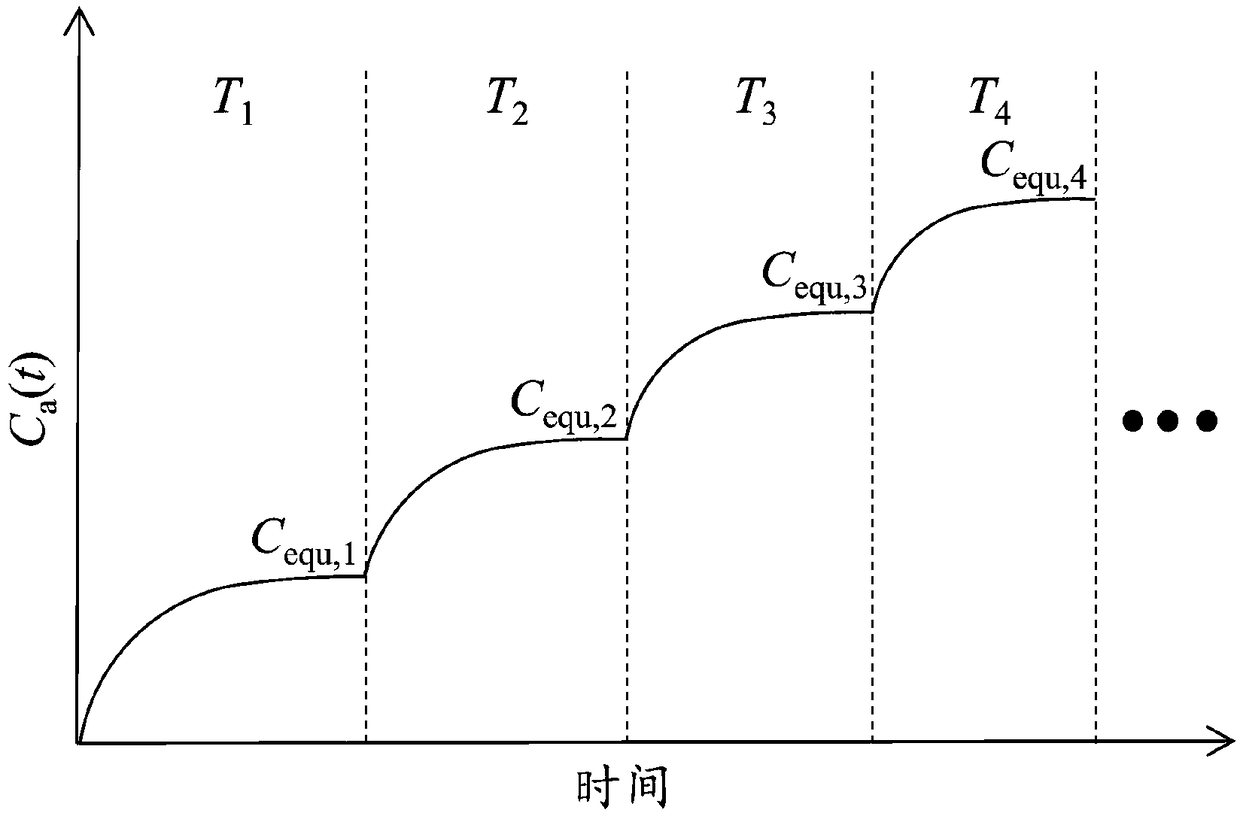

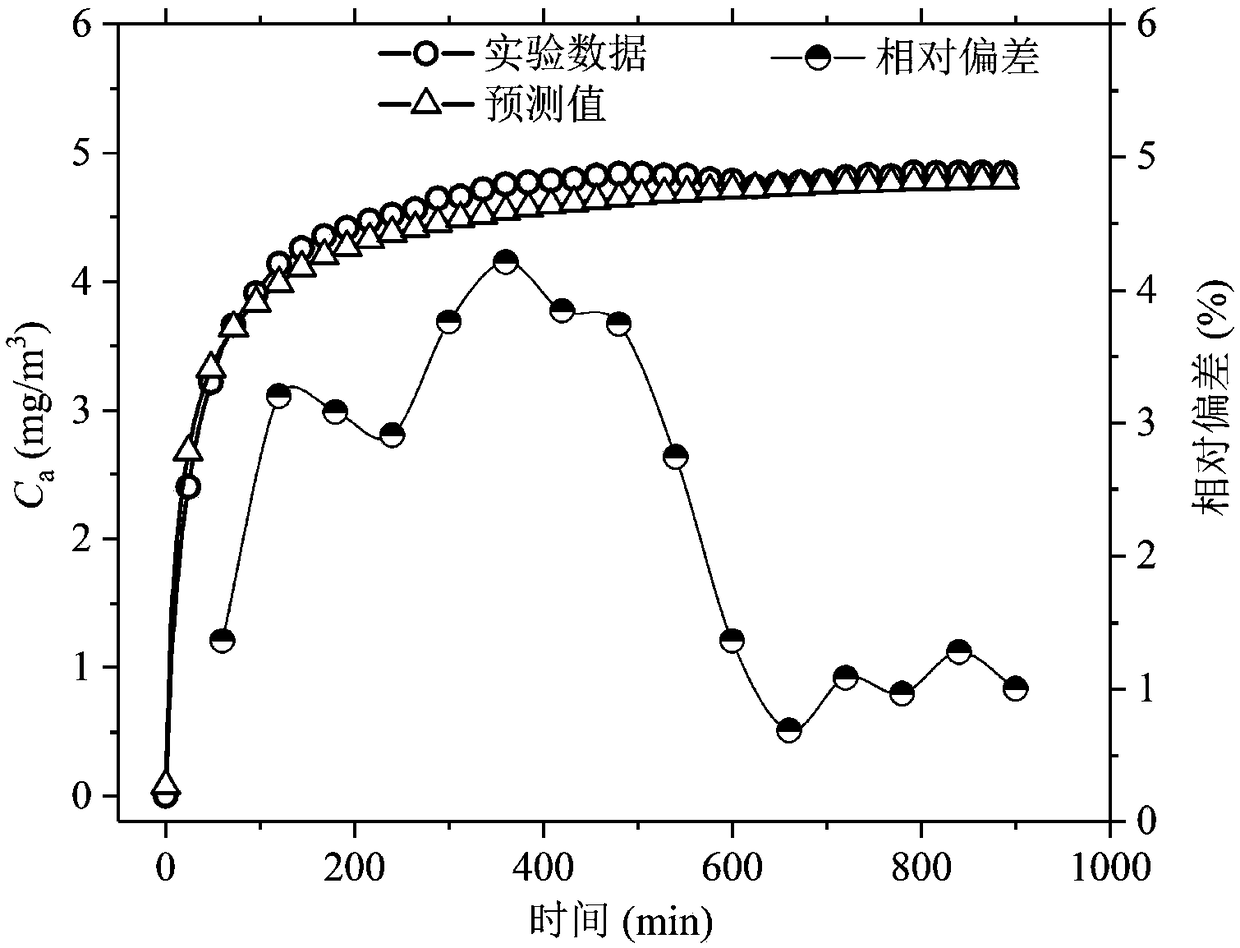

Step-temperature closed emission method for simultaneous determination of formaldehyde emission characteristic parameters of building materials at multiple temperatures

ActiveCN108918575AImprove measurement efficiencySave time and costMaterial thermal analysisSeparation coefficientEngineering

The invention relates to a step-temperature closed emission method for simultaneous determination of formaldehyde emission characteristic parameters of building materials at multiple temperatures. Based on a adsorption potential theory and a Henry's law, a functional relationship between a separation coefficient K and an initial dissipative concentration C0 is established, and an analytical formula of the equilibrium concentration Cequ of formaldehyde in the closed environment is derived. A sealed environment cabin is used to maintain a constant temperature and a humidity space, and the building material samples are subjected to formaldehyde emission test, and the formaldehyde hourly concentration and equilibrium concentration at the initial temperature are measured. The temperature is then raised and the corresponding new equilibrium concentration is measured. The above operations can be repeated in sequence to obtain a formaldehyde equilibrium concentration value at multiple temperatures. The nonlinear fitting is carried out on the formaldehyde hourly concentration at the initial temperature, the K at the temperature can be determined. When the Cequ of the building material at other temperatures is known, the K at the corresponding temperature can be quickly obtained by the ratio of the equilibrium concentrations, and the corresponding C0 can be calculated. The method greatlyimproves the measurement efficiency of formaldehyde emission characteristics.

Owner:XI AN JIAOTONG UNIV

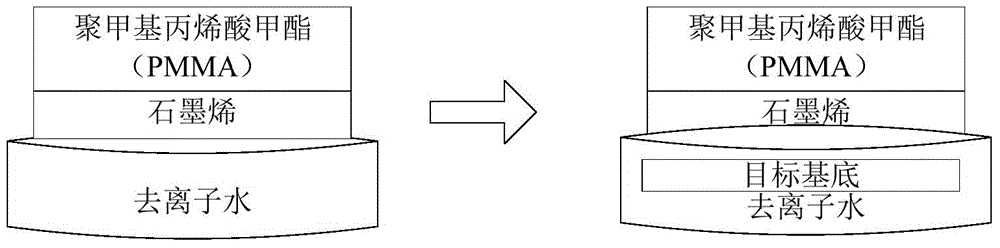

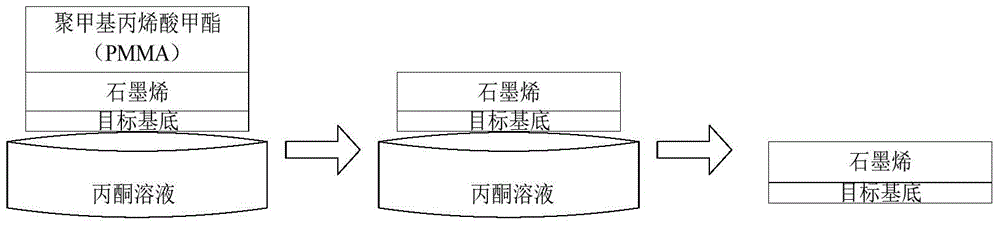

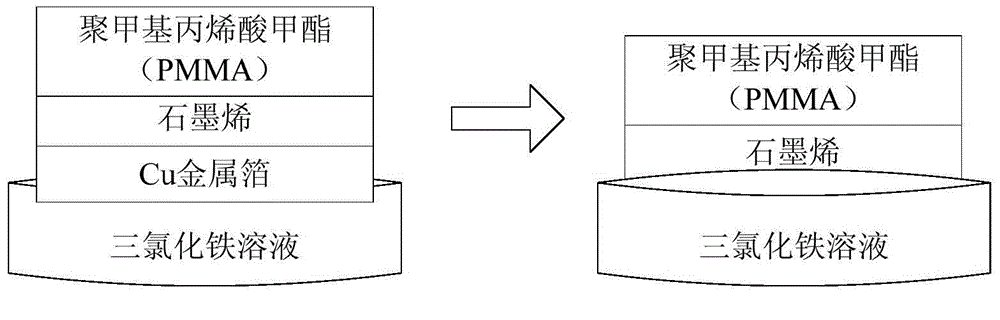

Multi-aperture graphene film manufacturing method and gas separation element

InactiveCN104649257AHigh selectivitySimple preparation processDispersed particle separationSeparation coefficientCvd graphene

The invention discloses a multi-aperture graphene film manufacturing method. In the method, an energy beam is used for radiating the graphene film with lattice imperfection, as a result, the carbon bonding with lattice imperfection in graphene carbon ring hexagonal structure is broken, aperture is generated, and the multi-aperture graphene film is generated; moreover, size of the aperture is controlled by regulation on concentration of the lattice imperfection and / or radiation intensity of the energy beam. The invention further discloses a gas separation element using the multi-aperture graphene film manufactured by the method. By the method, the graphene film with gas permeation aperture is prepared actually for the first time, and application of the graphene film in the aspect of gas separation is realized successfully; in the method, size of aperture can be controlled as needed, moreover, the preparation technology is simple, the implementation cost is low, so that the method is suitable for large-scale industrial application; the gas separation element provided by the invention has very strong selectivity and high permeability to gas molecules, and by experimental verification, separation coefficient of the gas separation element to H2 / N2 at normal temperature is up to 260.

Owner:NANJING UNIV OF TECH +1

Tributyl phosphate extraction resin for zirconium-hafnium separation and preparation method thereof

ActiveCN101643847AEfficient separationEliminate emulsificationProcess efficiency improvementAlcoholSeparation coefficient

The invention relates to tributyl phosphate extraction resin for zirconium-hafnium separation and a preparation method thereof. The preparation method is characterized by comprising the following steps: adding a solvent into a reaction kettle, wherein the solvent is a mixture of water and alcohols and the mixed weight ratio of the water and the alcohols is 100:2-100; after the solvent is stirred evenly, adding resin into the solvent, wherein the weight ratio of the solvent to the resin is 100:5-100; after the mixture is stirred evenly, adding tributyl phosphate into the mixture, wherein the weight ratio of the tributyl phosphate to the resin is 15-400:100; and stirring the mixture for 0.5 to 20 hours at the temperature of between 10 and 100 DEG C, and filtering the mixture to obtain the TBP extraction resin. The TBP-resin prepared by the method serving as the extraction resin for filling an extraction chromatographic column can effectively separate zirconium and hafnium, fully exerts the advantages of a liquid-liquid extraction process such as large TBP extracted zirconium capacity and large zirconium-hafnium separation coefficient, and eliminates the problem of emulsification produced by liquid-liquid extraction so as to successfully implement a zirconium-hafnium TBP extraction separation process.

Owner:有研资源环境技术研究院(北京)有限公司

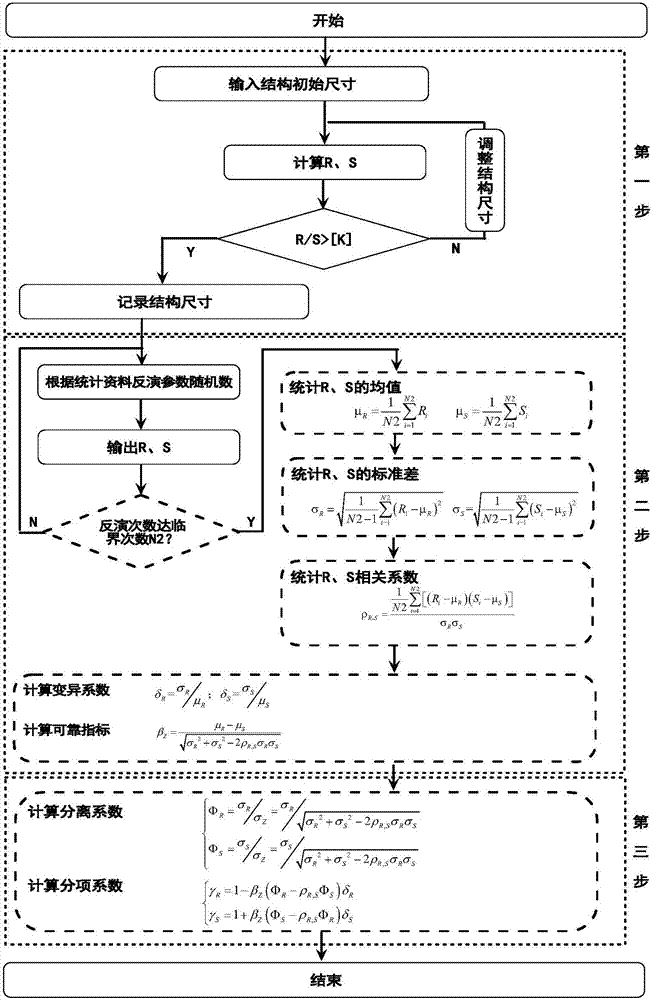

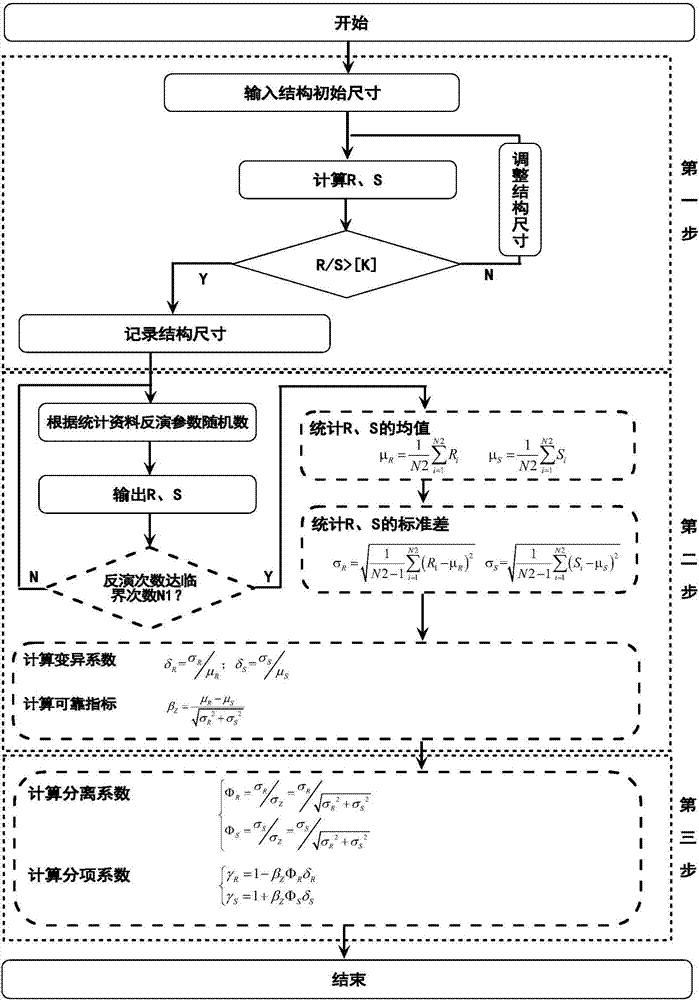

Method for determining roadbed retaining wall structure partial coefficient

InactiveCN107403029AGuaranteed reasonablenessGuaranteed validityGeometric CADSpecial data processing applicationsSeparation coefficientEngineering

The invention relates to a method for determining a roadbed retaining wall structure partial coefficient. The method includes the steps of firstly, performing retaining wall design according to a target safety coefficient regulated by an original specification, and determining the size of a retaining wall under an original specification system; secondly, using a Monte Carlo method to calculate the reliable indexes of the structure according to the structural design size obtained in the first step; thirdly, according to statistical features and the reliable indexes, comprehensively considering the average, standard deviation and related coefficient of resistance and load items in a limit state equation, calculating the function item average, standard deviation and separation coefficient on the basis of a general separation method, and exporting the retaining wall partial coefficient on the basis. The method has the advantages that the partial coefficient in a new specification can inherit the reliability level of an original safety coefficient design method to the maximum extent, logical self-consistency of the safety coefficient, reliability index, partial coefficient and failure probability is guaranteed at the same time, corresponding matching relationships of specific numerical indexes are achieved, and design result consistency is achieved.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

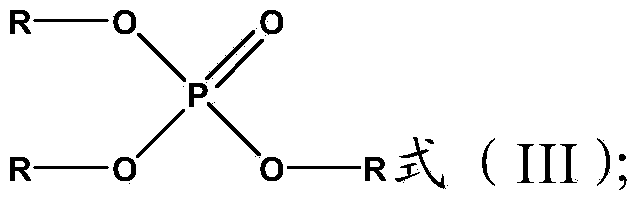

Extraction separation method for heavy rare earth elements

ActiveCN104195335AImprove the extraction separation factorHigh selectivityProcess efficiency improvementRare-earth elementSeparation coefficient

The invention provides an extraction separation method for heavy rare earth elements. The extraction separation method comprises the following steps: mixing rare earth concentrates with inorganic acid to obtain a raw material liquid; mixing an extraction agent with a thinning agent to obtain an organic phase; using the organic phase to extract rare earth elements in the raw material liquid, wherein the extraction agent is the mixture of alkyl phosphonic monoalkyl ester and dialkyl hypophosphorous acid. By taking the mixture of alkyl phosphonic monoalkyl ester and dialkyl hypophosphorous acid as the extraction agent, the selectivity for rare earth elements is high, and the extraction agent is combined with the inorganic acid and the thinning agent, so that the separation coefficient for the rare earth elements, particularly adjacent rear earth elements, are improved, and reverse extraction is easy.

Owner:XIAMEN INST OF RARE EARTH MATERIALS

Method and device for reducing, extracting and separating rear earth through fused salt and liquid metal

The invention provides a method and a device for reducing, extracting and separating rear earth through fused salt and liquid metal. Liquid aluminum serves as a cathode, a graphite rod serves as an anode, KCl-LiCl is added into an electrolytic cell to be heated and smelted to serve as electrolyte, and lithium obtained from electrolysis at the cathode is dissolved in the liquid aluminum to obtain a liquid aluminum-lithium alloy by means of electrolysis; praseodymium chloride and samarium chloride are added into the electrolytic cell to serve as a fused salt phase, and a constant speed stirring extraction reaction is carried out in an argon atmosphere with the liquid aluminum-lithium alloy as an extraction agent; the fused salt phase is separated from a liquid metal phase, samarium is extracted into the liquid metal phase to form an aluminum-lithium-samarium alloy, and praseodymium is left in the fused salt phase so as to separate the samarium from the praseodymium. The method and the device provided by the invention are suitable for extreme conditions such as high temperature, and strong radiation; the reducing agent can be recycled to save resources; the distribution coefficient of the samarium in the alloy and the fused salt is 68.1-142.4, the distribution coefficient of the praseodymium in the alloy and the fused salt is 2.9-23.2, and the samarium-praseodymium separation coefficient is 5.0-23.3.

Owner:HARBIN ENG UNIV

Preparation method of amino modified biochar

PendingCN109529783AImprove adsorption capacityHigh adsorption selectivityOther chemical processesWater contaminantsFiltrationSeparation coefficient

The invention provides a preparation method of amino modified biochar. The method comprises the following steps of selecting biomass raw materials; drying the crushed biomass raw materials into a granular shape; charging the granular biomass raw materials into a muffle furnace fully filled with nitrogen gas; after thermal cracking reaction, generating the biochar; adding 100mL of deionized water into 1g to 5g of biochar for mixing; after the full stirring is performed for 30min to 60min; adding triethylene diamine; after heating is performed to 40 to 80 DEG C, maintaining the state for 12h to18h; performing cooling; generating an amino modified biochar water solution; sequentially performing suction filtration, washing, drying and cooling on the amino modified biochar water solution; preparing the amino modified biochar. Through the technical scheme, the prepared amino modified biochar has great adsorption capacity on heavy metal cadmium and lead; the separation coefficient is high; the preparation materials can be easily obtained; the preparation process is simple; the production cost is low.

Owner:BINZHOU UNIV

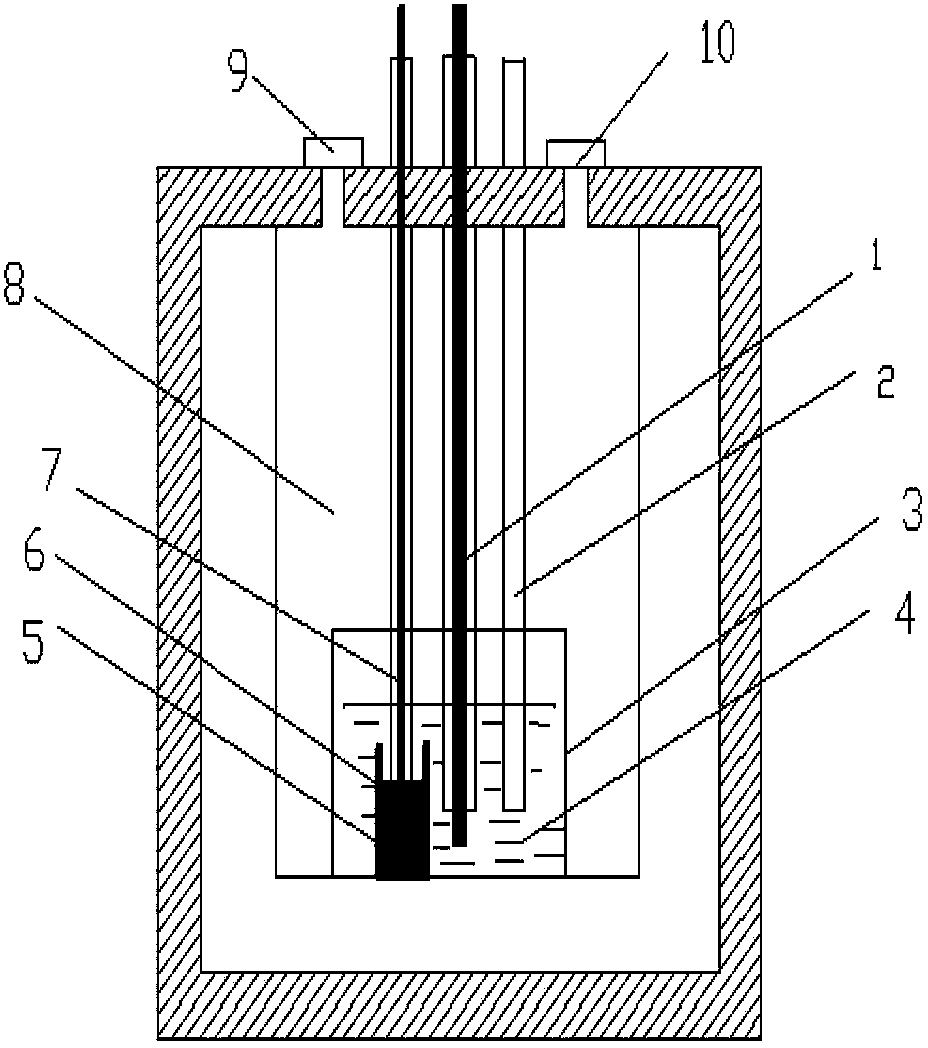

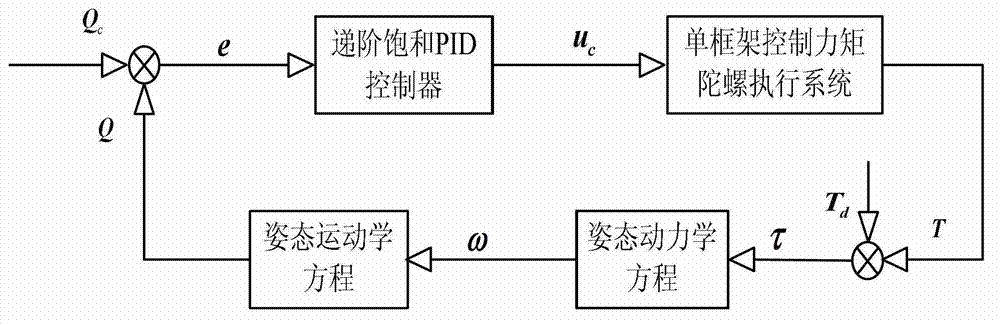

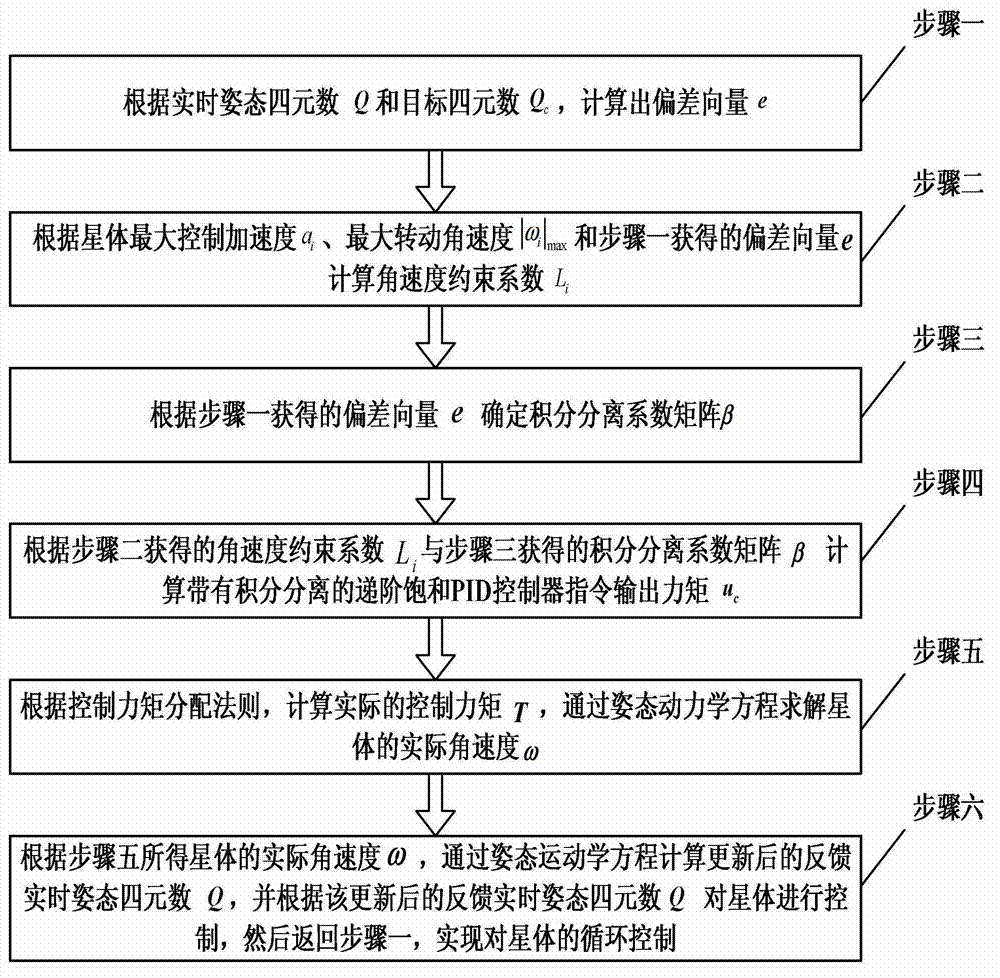

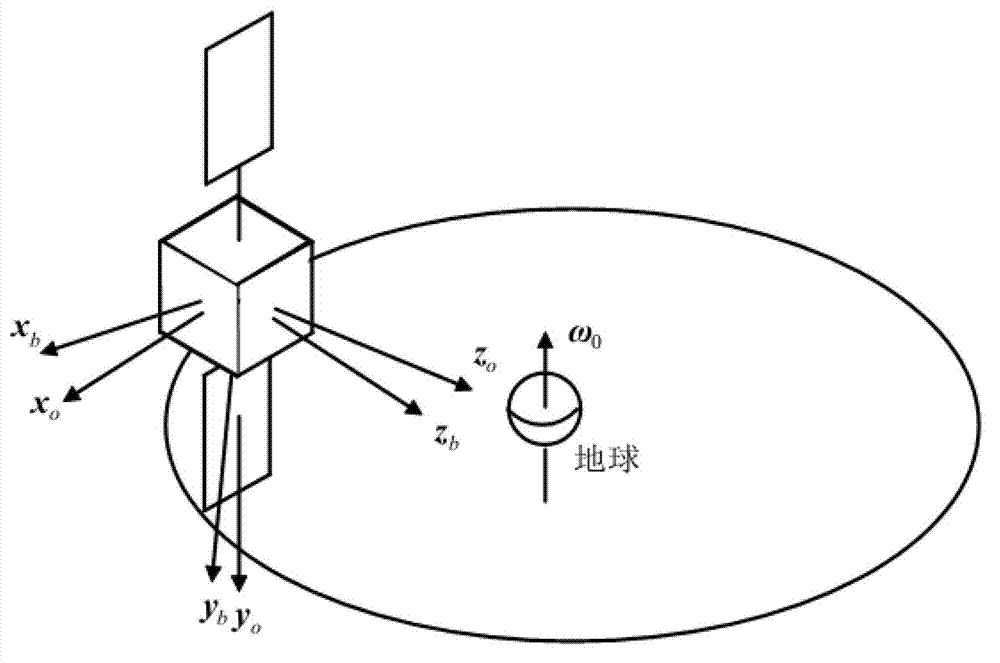

Control method for hierarchical saturation PID (Proportion Integration Differentiation) controller based on integral separation

ActiveCN103034121AGive full play to the advantagesReduce adverse effectsControllers with particular characteristicsDeviation vectorKinematics equations

A control method for a hierarchical saturation PID (Proportion Integration Differentiation) controller based on integral separation relates to a control method for a hierarchical saturation PID controller, and solves the problem of larger system overshoot and even system oscillation caused by calculated control quantity far more than limit control quantity which corresponds to the maximal output capacity of an execution mechanism due to the integral accumulation of PID operation, wherein the integral accumulation of the PID operation is caused by the hierarchical saturation PID controller added in an integral item. The method comprises the following steps: a deviation vector e is calculated according to a real-time online quaternion Q and a target quaternion Qc; an angular velocity restraint coefficient Li is calculated according to the maximal star control acceleration ai, the maximal rotating angular velocity |Omega i|max and the deviation vector e obtained in the step 1, and an integral separation coefficient matrix Beta is determined according to the deviation vector e; output moment uc is calculated by combining the angular velocity restraint coefficient Li with the integral separation coefficient matrix Beta; and actual star angular velocity speed omega and a updated feedback real-time posture quaternion Q are solved respectively through a posture kinetic equation and a posture kinematic equation. The method can be widely applied in control systems for spacecrafts.

Owner:哈尔滨工大卫星技术有限公司

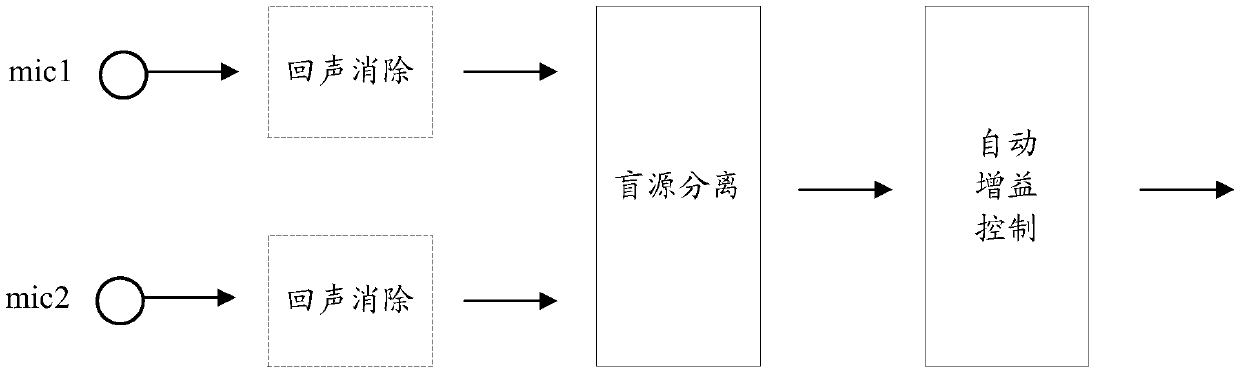

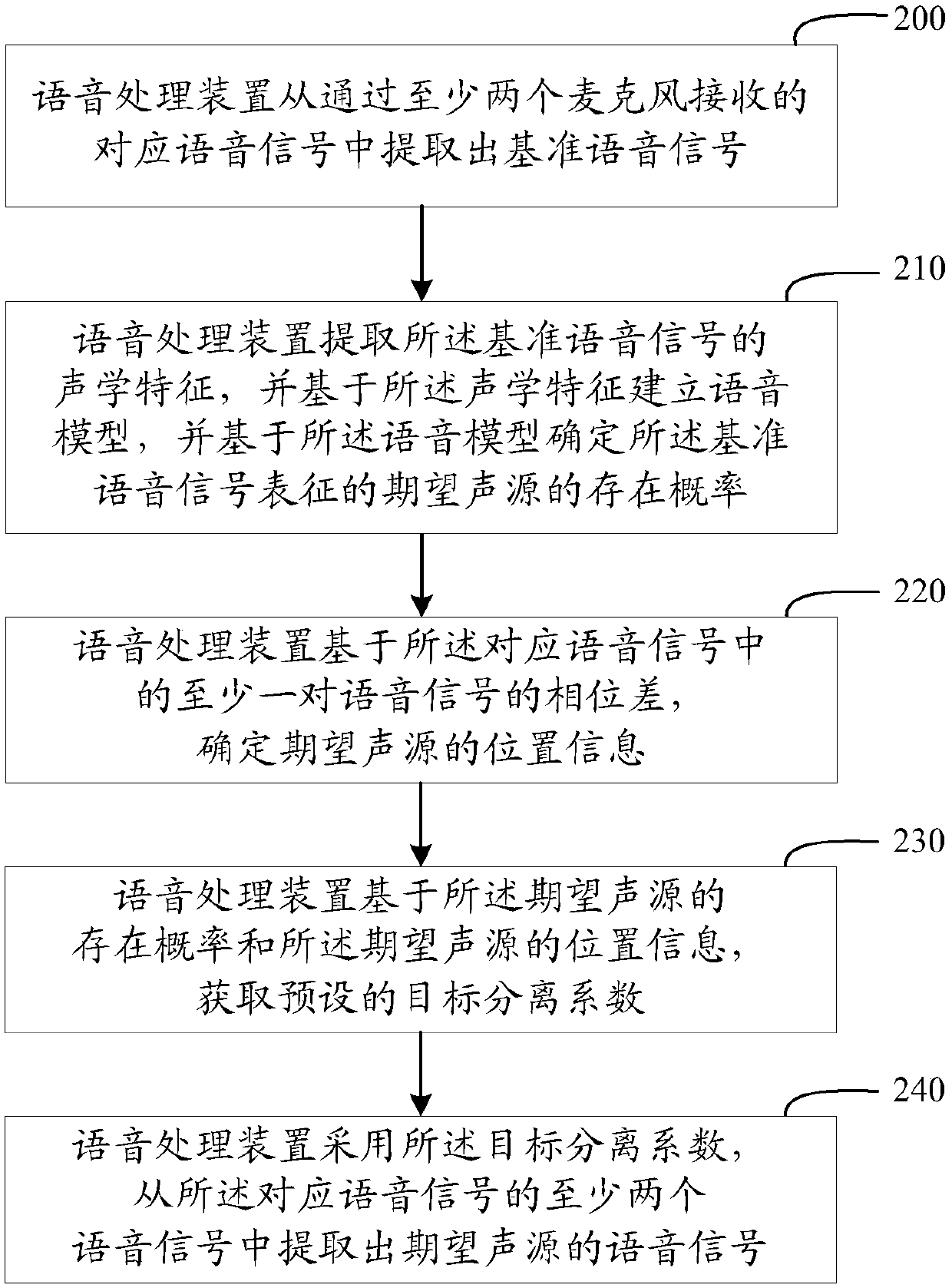

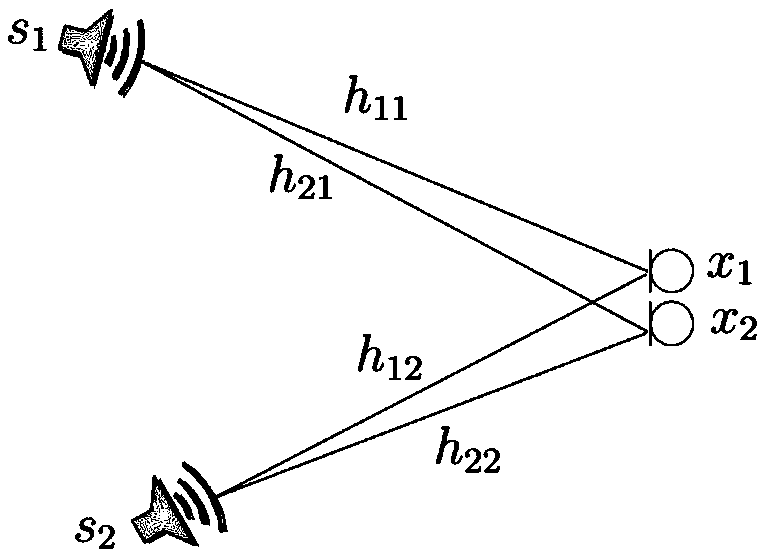

Method and device for extracting voice signal of desired sound source

ActiveCN110610718AStable separationAccurate extractionSpeech analysisSound sourcesSeparation coefficient

The invention relates to the audio processing technology, in particular to a method and device for extracting a voice signal of a desired sound source. The method and device for extracting the voice signal of the desired sound source is used for ensuring the voice recognition rate without increasing hardware costs. The method for extracting the voice signal of the desired sound source comprises the following steps: obtaining the existence probability of the desired sound source and position information of the desired sound source based on relevant characteristics of corresponding voice signalsreceived through at least two microphones; then obtaining a preset target separation coefficient; and extracting the voice signal of the desired sound source from at least two voice signals of the corresponding the voice signals by using the target separation coefficient. Thus, since a stable corresponding relationship is preset between the position information and a target separation system, a stable direction can be formed based on the position information; therefore, the corresponding target separation coefficient is obtained quickly, and the voice signal of the desired sound source is extracted quickly and accurately from the reverberation environment; and therefore, the voice recognition rate in interference environments is greatly improved without increasing the hardware costs.

Owner:ACTIONS ZHUHAI TECH CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com