Aramid fiber III/polyvinyl alcohol blended gas separation film and preparation method thereof

A technology of gas separation membrane and polyvinyl alcohol, applied in separation methods, semi-permeable membrane separation, dispersed particle separation, etc., can solve the problems of membrane damage, poor pressure resistance, etc., and achieve easy control, improved flexibility, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

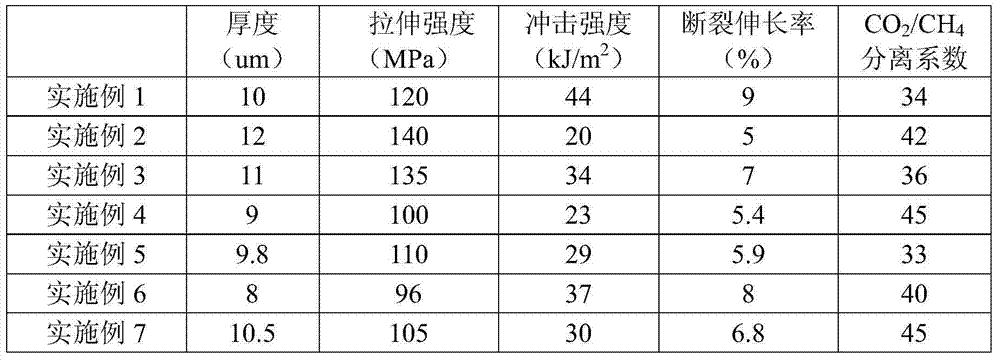

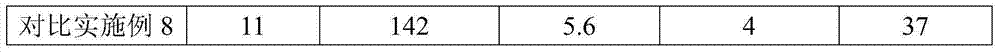

Examples

Embodiment 1

[0037] Example 1: Preparation of ultra-thin, high-strength aramid fiber III / polyvinyl alcohol blend gas separation membrane

[0038] (1) Dissolve 5 parts by weight of aramid fiber III (provided by Guangdong Caiyan Co., Ltd.) in 140 parts by weight of dimethyl sulfoxide (DMSO), add 7 parts of potassium hydroxide, and stir for 10 days at a temperature of 20°C to form homogeneous solution. Add 5 parts by weight of PVA-2499 into the above solution, stir evenly to form a casting solution for later use

[0039] (2) Use a scraper to scrape out a film with a thickness of 400um on smooth glass from the casting solution obtained in (1).

[0040] (3) Evaporate the solvent from the film scraped in (2) at 50°C for 10 minutes, and then pour it into distilled water to obtain a gel film.

[0041] (4) Dry the gel membrane obtained in (3) at 120°C to obtain an aramid III / polyvinyl alcohol blended gas separation membrane.

Embodiment 2

[0042] Example 2: Preparation of ultra-thin, high-strength aramid fiber III / polyvinyl alcohol blended gas separation membrane

[0043] (1) Dissolve 10 parts by weight of aramid fiber III in 150 parts by weight of N,N-dimethylformamide (DMAC), add 15 parts by weight of potassium tert-butoxide, and 7 parts by weight of lithium chloride. Stir for 2 days to form a homogeneous solution. Add 2 parts by weight of PVA-1799 into the above solution, stir evenly to form a casting solution for use.

[0044] (2) Use a scraper to scrape out a film with a thickness of 300um on a smooth glass from the casting solution obtained in (1).

[0045] (3) Evaporate the solvent from the film scraped in (2) at 100°C for 5 minutes, and then pour it into distilled water to obtain a gel film.

[0046] (4) Dry the gel membrane obtained in (3) at 100°C to obtain an aramid III / polyvinyl alcohol blended gas separation membrane.

Embodiment 3

[0047] Example 3: Preparation of ultra-thin, high-strength aramid fiber III / polyvinyl alcohol blended gas separation membrane

[0048](1) Dissolve 8 parts by weight of aramid fiber III in 100 parts by weight of N,N-dimethylacetamide (DMAC), add 5 parts by weight of sodium hydride (NaH), 10 parts by weight of calcium chloride, and heat at 30°C A homogeneous solution was formed under stirring for 7 days. Add 0.4 parts by weight of PVA-1788 into the above solution, stir evenly to form a casting solution for use.

[0049] (2) Use a scraper to scrape out a film with a thickness of 100um on a smooth glass from the casting solution obtained in (1).

[0050] (3) Evaporate the solvent from the film scraped in (2) at 120°C for 5 minutes, and then pour it into distilled water to obtain a gel film.

[0051] (4) Dry the gel membrane obtained in (3) at 180°C to obtain an aramid III / polyvinyl alcohol blended gas separation membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com