Patents

Literature

5799 results about "PVA - Polyvinyl alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyvinyl alcohol (PVA), a colourless, water-soluble synthetic resin employed principally in the treating of textiles and paper.

Water-soluble copolymer film packet

Owner:MONOSOL LLC +1

PVP and PVA as in vivo biocompatible acoustic coupling medium

An vivo biocompatible and bio-excretable lubricant and ultrasound coupling fluid or gel comprising polyvinylpyrrolidone (PVP) and / or polyvinyl alcohol (PVA). The inventive couplant fluid or gel comprises polyvinylpyrrolidone and / or polyvinyl alcohol solutions in water to which humectants such as alkylene glycols and / or polyalkylene glycols are added to achieve desired tactile and drying characteristics. Additionally, such fluids and gels may be prepared by addition of organic and inorganic cross-linkers.

Owner:ILLINOIS TOOL WORKS INC

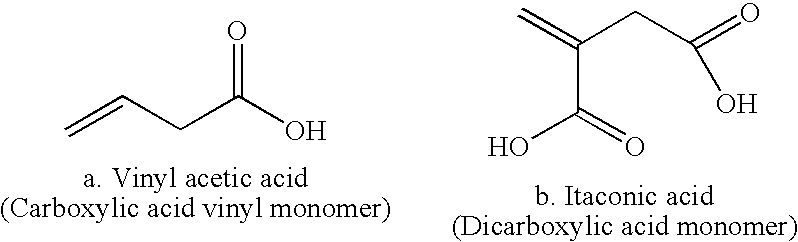

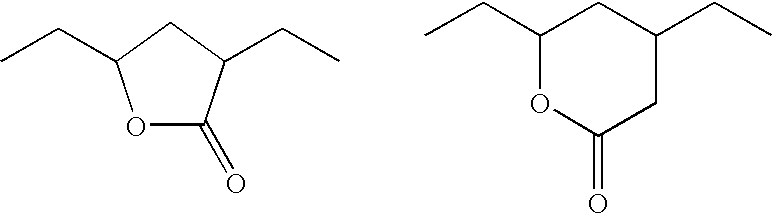

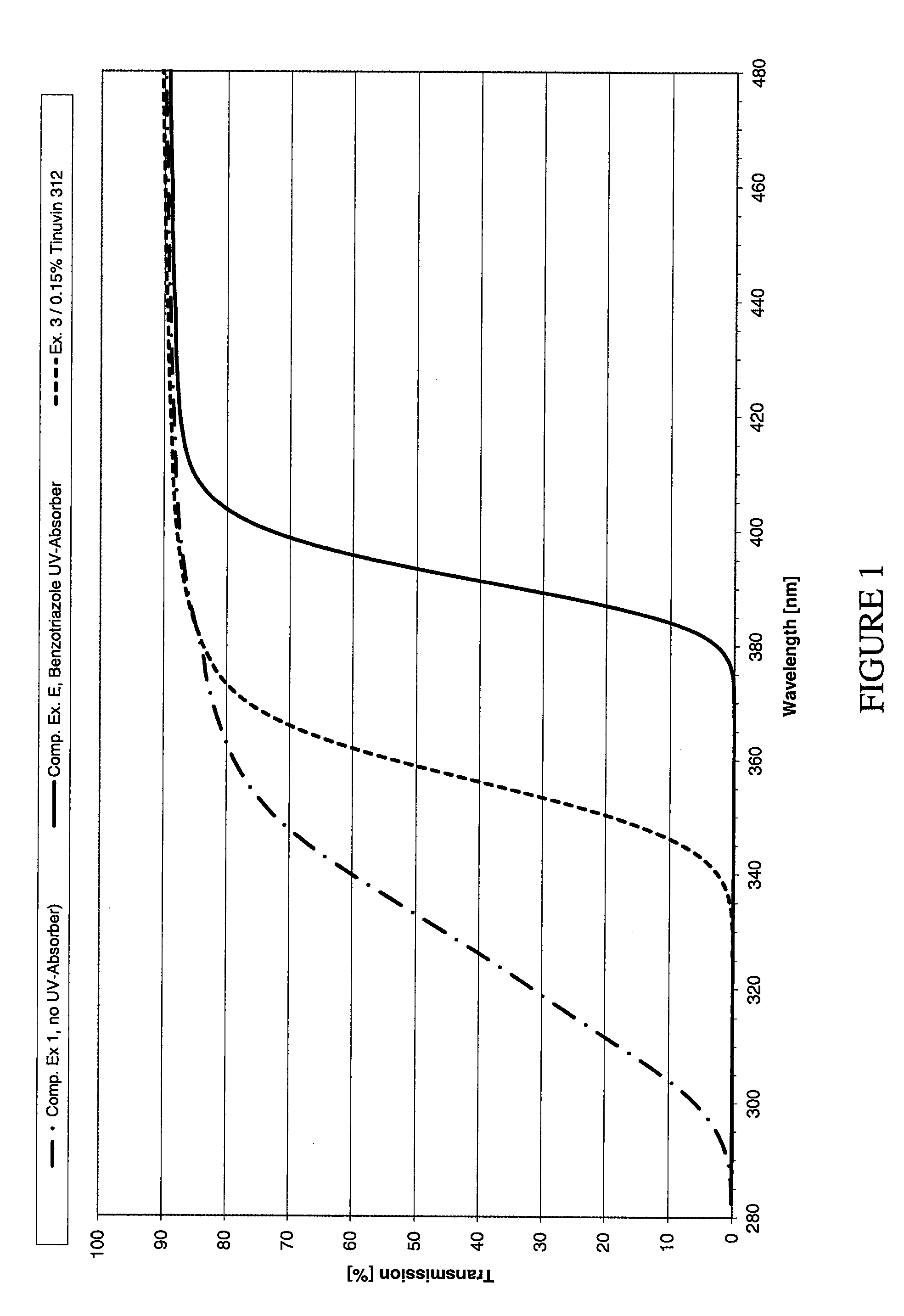

Plasticizer-Containing Films Based On Polyvinyl Acetal Having Selective Permeability For UV Radiation

InactiveUS20120052310A1Climate change adaptationSynthetic resin layered productsPlasticizerUltraviolet

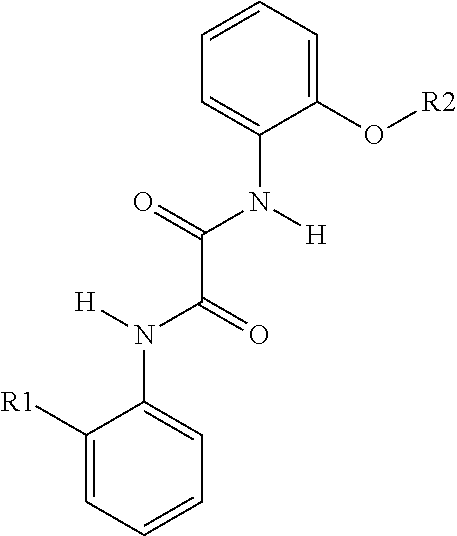

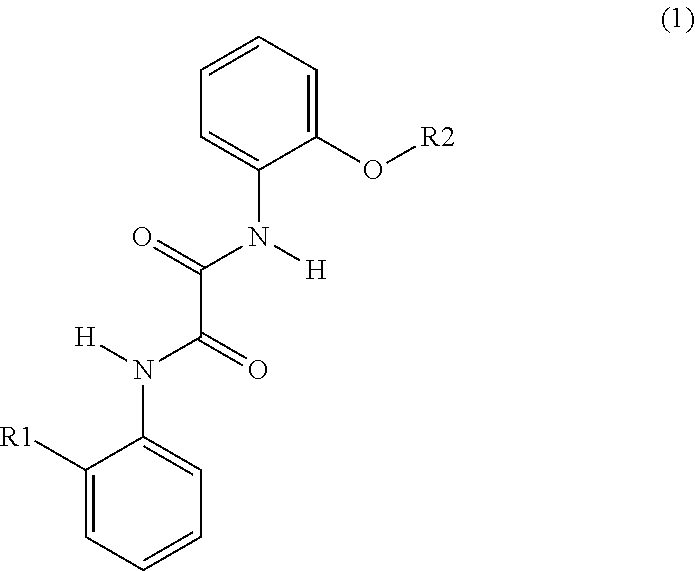

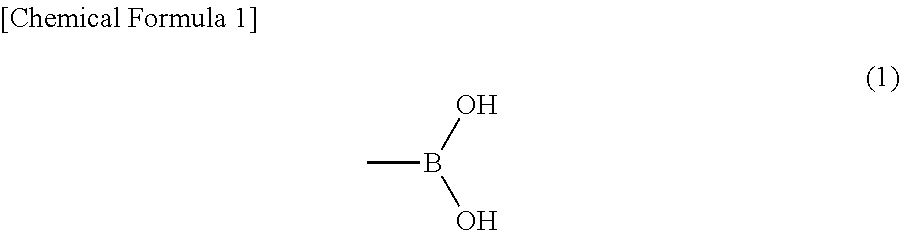

Plasticizer-containing films based on polyvinyl acetal containing a UV absorbers of the oxanilide type of formula (1)exhibit high UVA transmission while also exhibiting low UVB transmission, with reduced tendency to yellow.

Owner:KURARAY EURO GMBH

Poly alcohol-based binder composition

InactiveUS6884849B2Improve curing effectEmission reductionNon-fibrous pulp additionSynthetic resin layered productsAlcoholCarboxylic acid

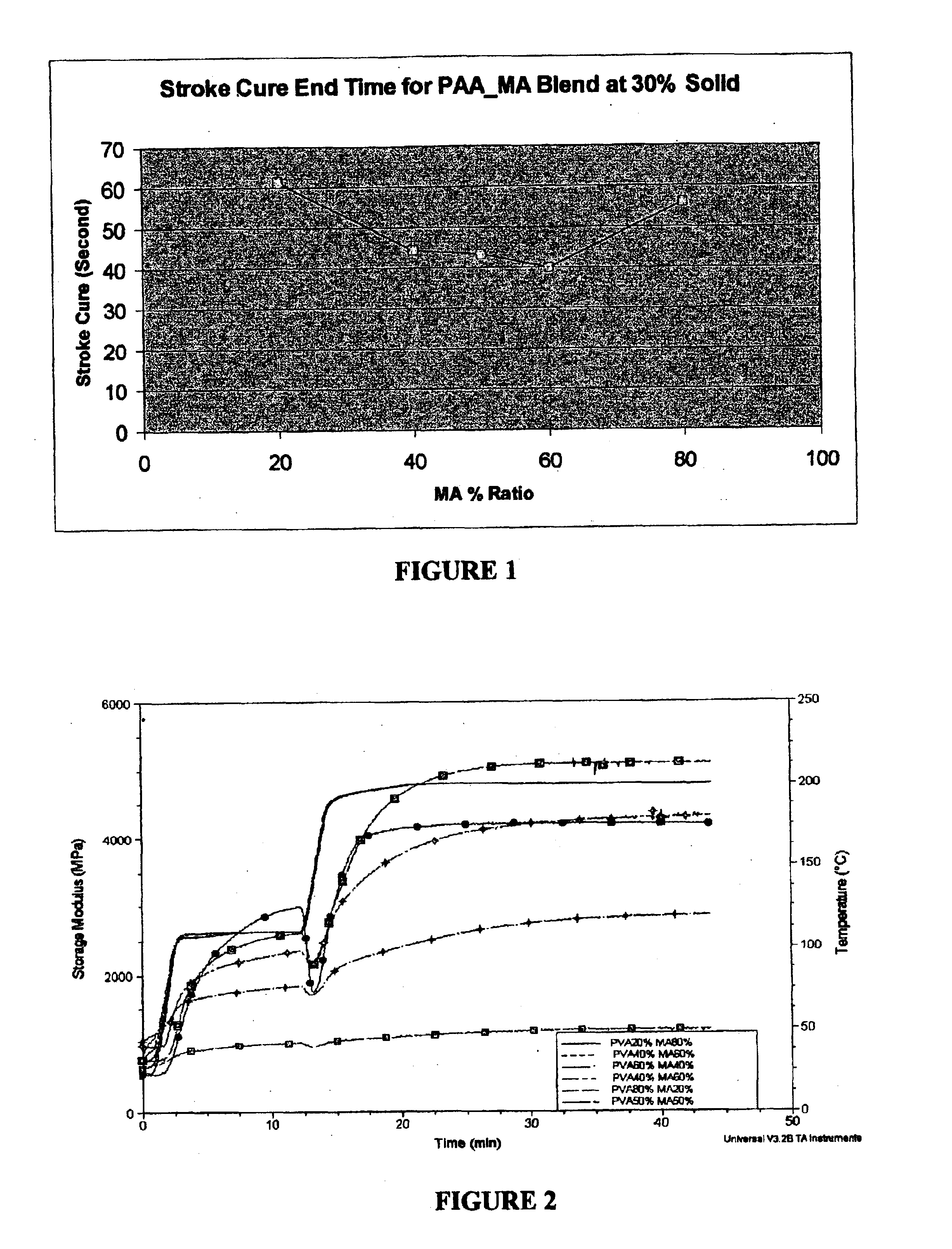

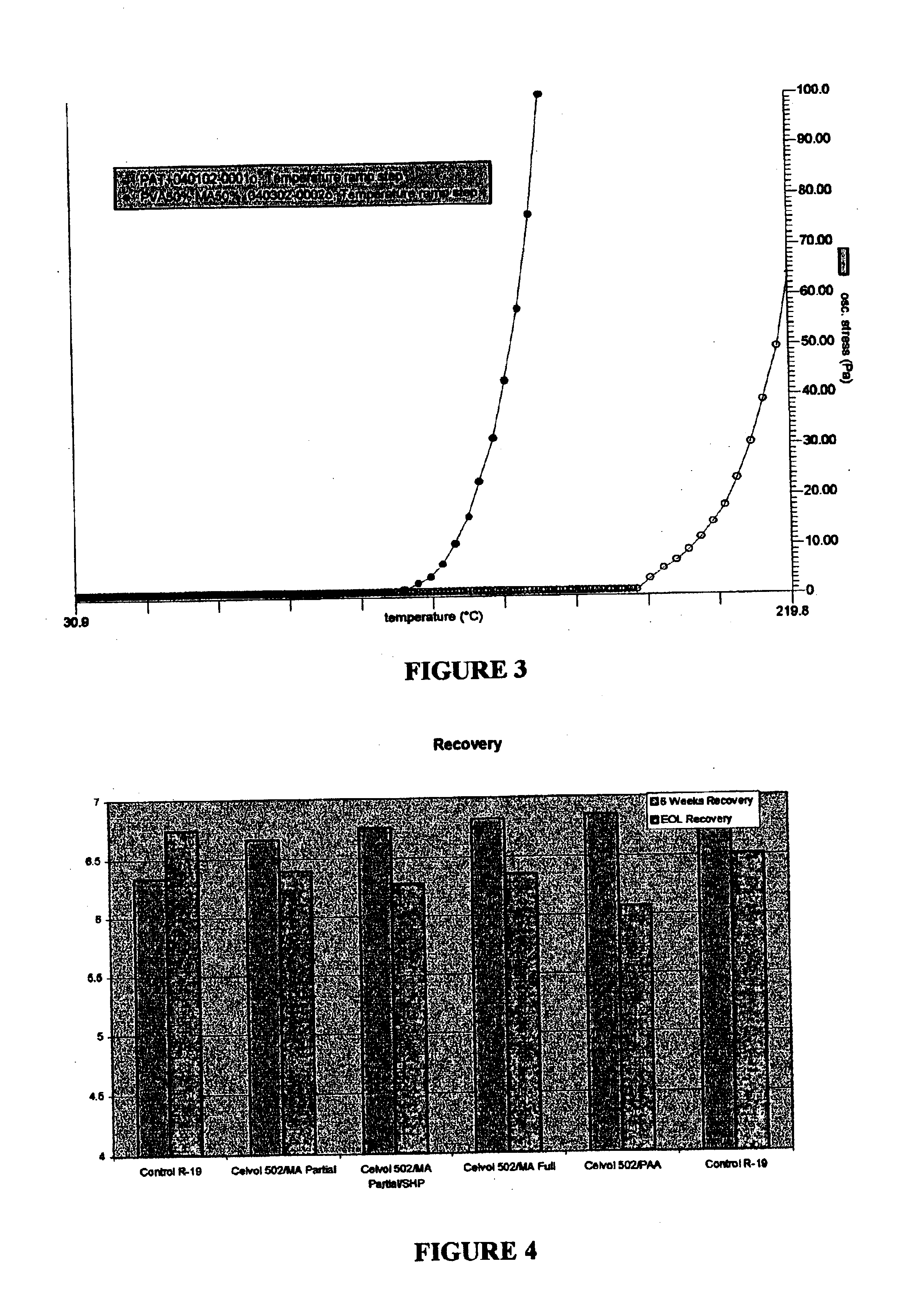

The present invention provides a binder composition comprising a low molecular weight polycarboxylic acid, such as maleic anhydride, and a low molecular weight poly alcohol, such as polyvinyl alcohol, that exhibits improved cure performance with reduced emissions without sacrificing the performance of the final product or complication the manufacturing process. The binder composition may also incorporate a cure catalyst or accelerant such as sodium hypophosphite.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

High-Strength Film Laminates Having Layers Of Plasticizer-Containing Polyvinyl (N)Acetal and Plasticizer-Containing Polyvinyl (Iso)Acetal

ActiveUS20130022824A1Improve mechanical propertiesHigh plasticizer compatibilitySynthetic resin layered productsGlass/slag layered productsArchitectural glassGlass composites

The invention relates to film laminates, formed from at least three layers A, B and C, each layer containing at least one plasticizer and at least one polyvinyl acetal, wherein, at least one of the layers A, B or C contains at least one polyvinyl (iso)acetal having a mean degree of polymerisation of less than 3000, 10 to 25% by weight of polyvinyl alcohol groups and a proportion 50 to 80% by weight of polyvinyl (iso)acetal groups, and wherein layer B has a plasticizer content of less than 32% by weight. The film laminates can be used for the production of glass / film laminate / glass composites for motor vehicles, aircraft, ships, architectural glazings, façade components, or for the production of photovoltaic modules.

Owner:KURARAY EURO GMBH

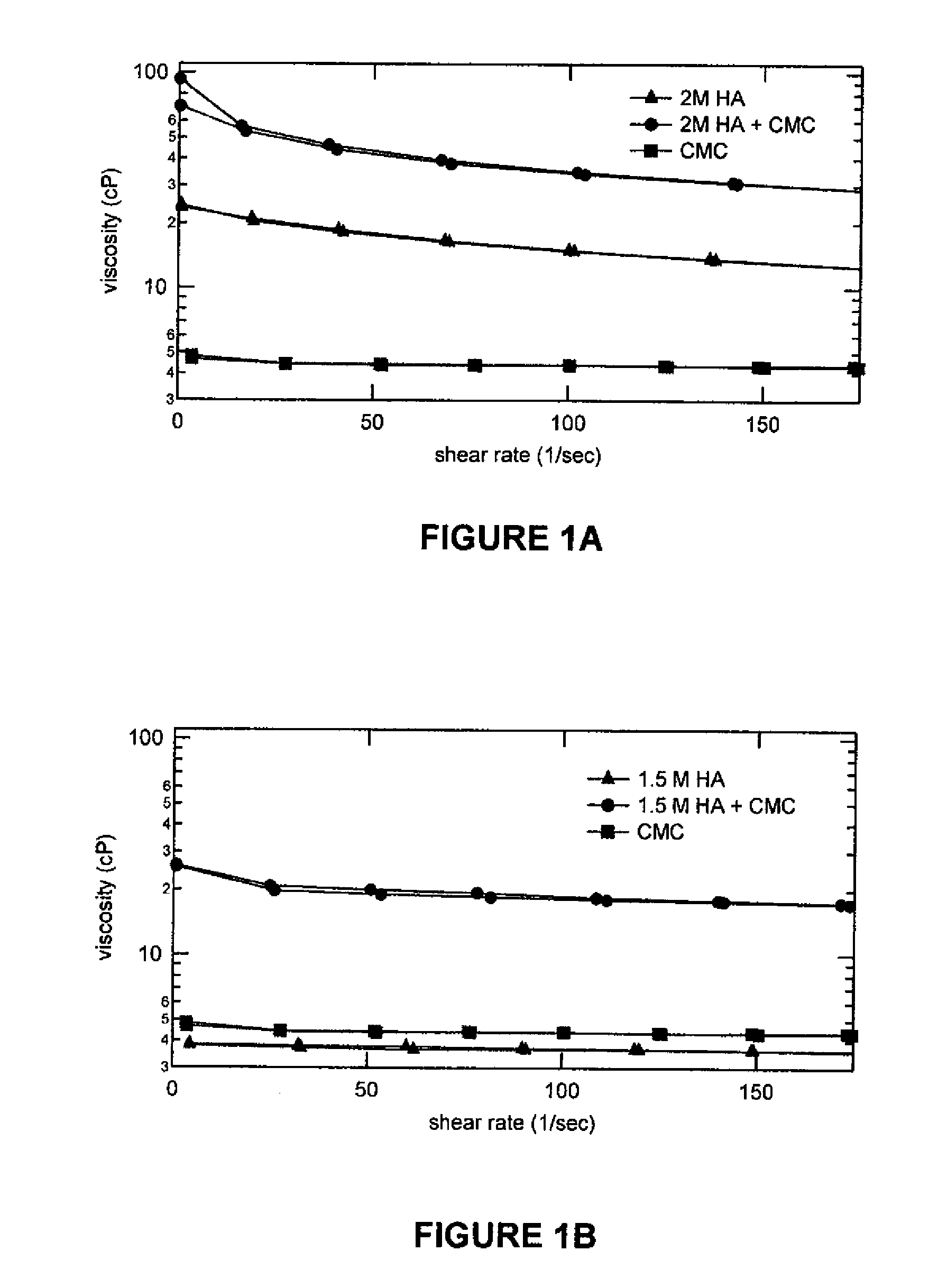

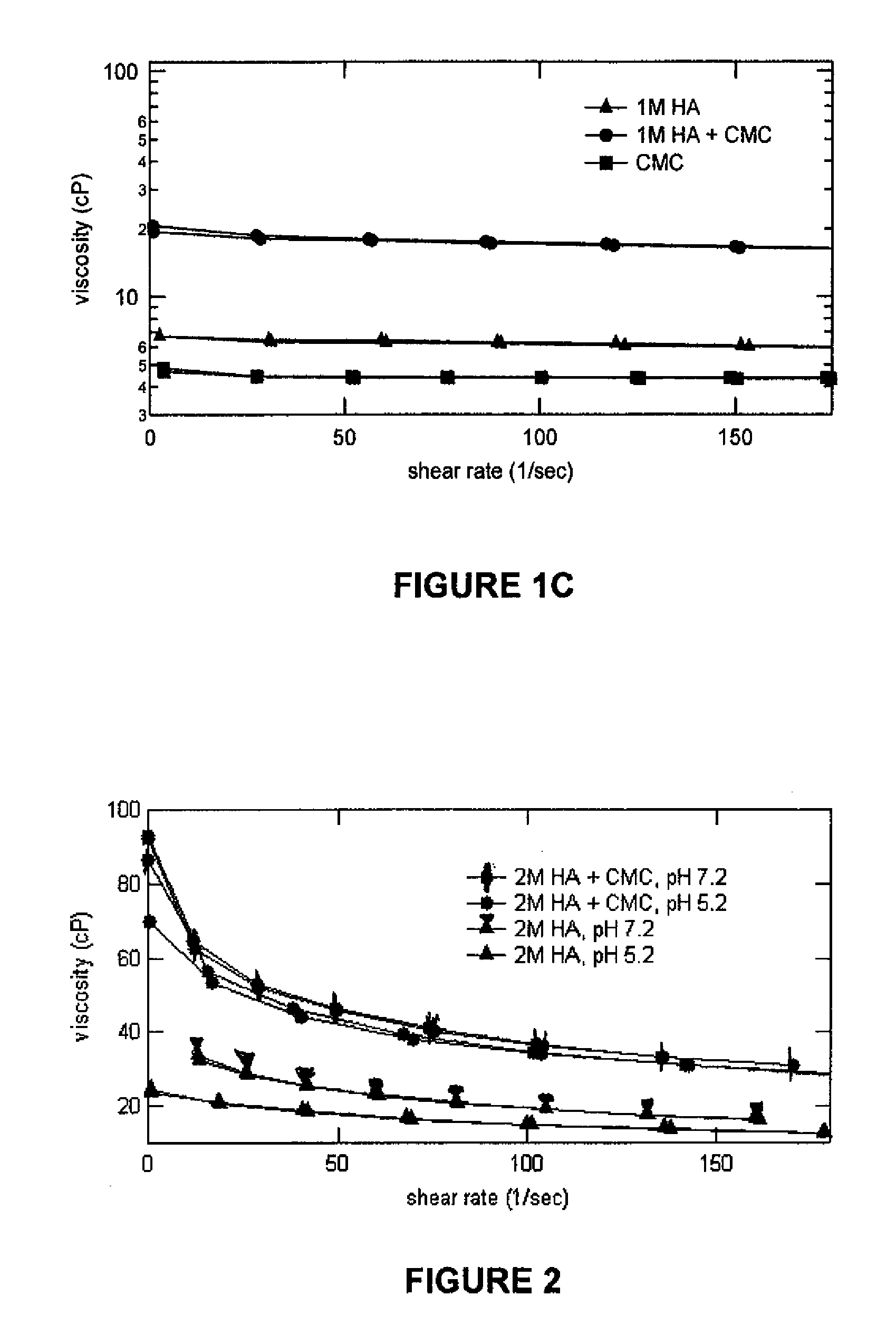

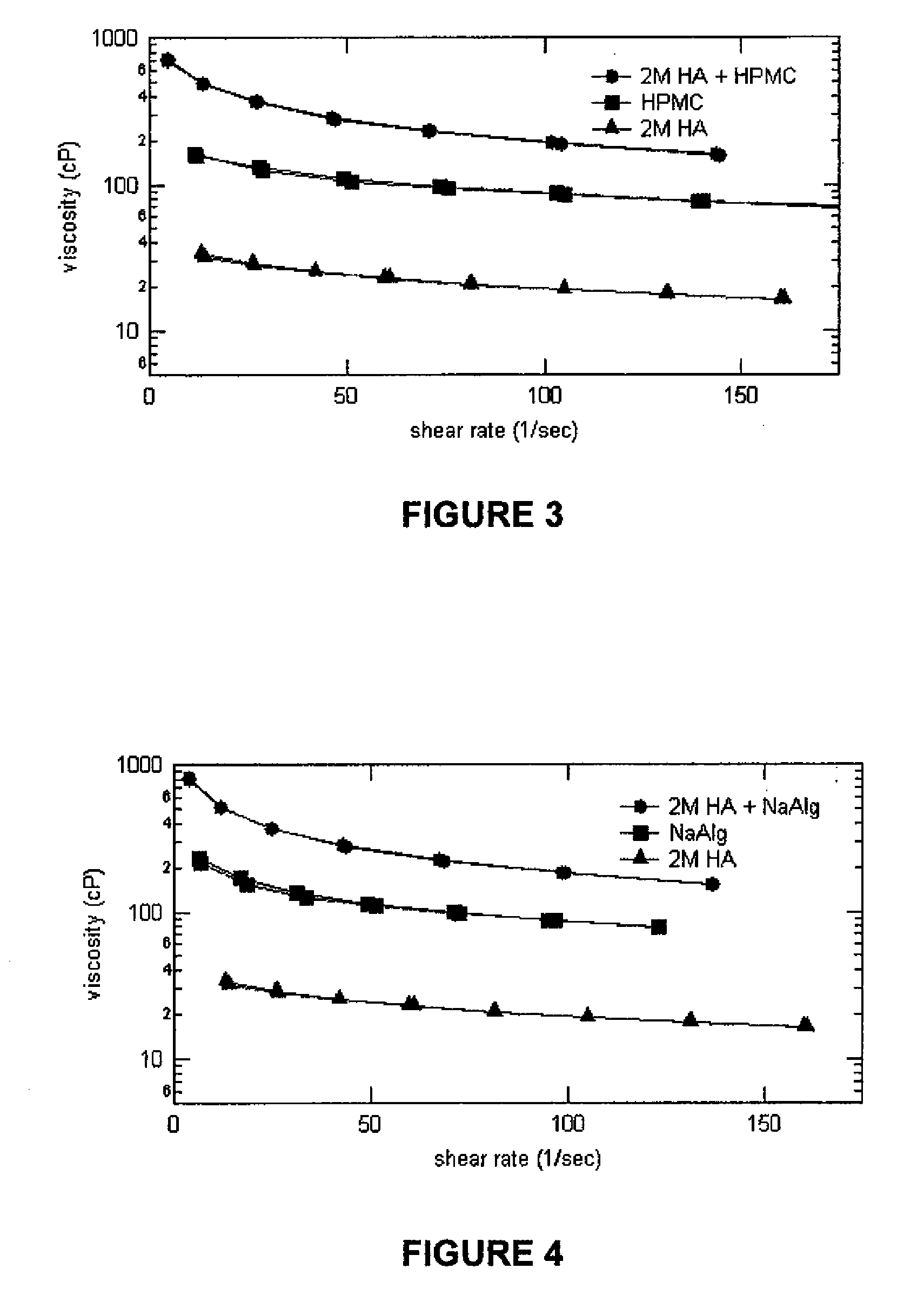

Stabilized Glycosaminoglycan Preparations and Related Methods

Compositions comprising a glycosaminoglycan (e.g., a hyaluronan, hyaluronic acid, hyaluronate, sodium hyaluronate, dermatan sulfate, karatan sulfate, chondroitin 6-sulfate, heparin, etc.) in combination with at least one component selected from; i) polyglycols (e.g., polyethylene glycol), ii) long chain hydroxy polyanionic polysaccharides (e.g., dextran, sodium alginate, alginic acid, propylene glycol alginate, carboxymethyl cellulose and carboxyethyl cellulose, hydroxyl ethyl starch, hydroxyl propyl methyl cellulose, hydroxy propyl ethyl cellulose, hydroxy propyl cellulose, methyl cellulose, polylysine, polyhistidine, polyhydroxy proline, poly ornithine, polyvinyl pyrolidone, polyvinyl alcohol, chitosan, etc.) and iii) long chain Nitrogen containing polymers (e.g., Polylysine, Polyvinylpyrrolidone, and polyvinyl alcohol). The invention also includes methods for using such compositions (e.g., as substance delivery materials, tissue fillers or bulking agents, as moistening or hydrating agents, etc.)

Owner:S K PHARMA INC

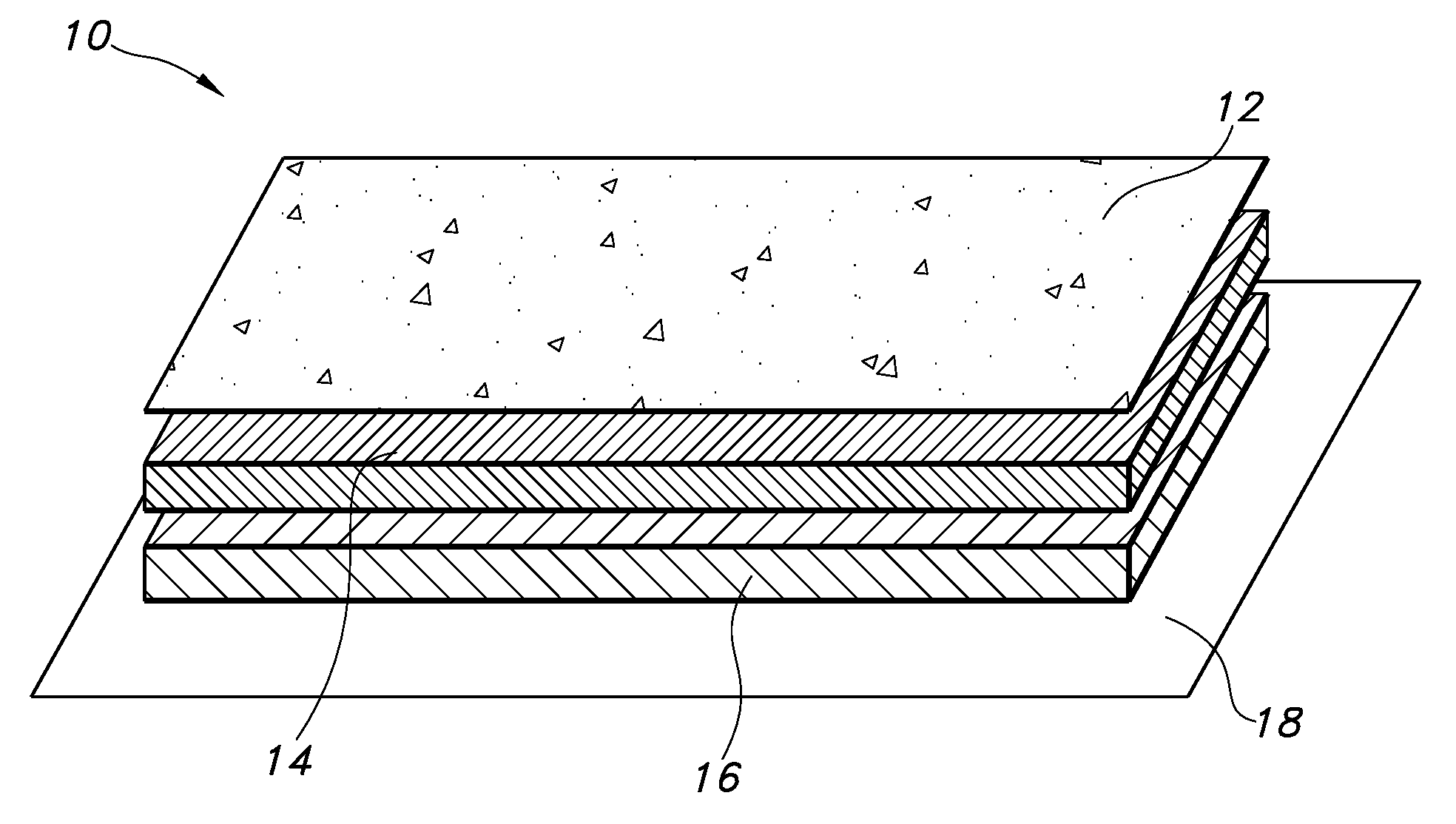

Enhanced personal care absorbent articles

The present invention relates to a personal care absorbent article comprising at least two substrates each having an internal and external surface, wherein at least one substrate is a fluid permeable bodyside substrate selected from spunbond, meltblown, coform, airlaid, bonded-carded web, spunlace materials and combinations thereof; at least one substrate is an impermeable backsheet; and an absorbent core disposed in between said substrates; wherein at least the external surface of at least one substrate has applied to it a benefit agent selected from an additive composition wherein said additive composition is a polymer dispersion selected from polyolefin dispersions, polyisoprene dispersions, polybutadiene-styrene block copolymer dispersions, latex dispersions, polyvinyl pyrrolidone-styrene copolymer dispersions, polyvinyl alcohol-ethylene copolymer dispersions, and combinations thereof; an enhancement component selected from microparticles, expandable microspheres, fibers, additional polymer dispersions, scents, anti-bacterials, moisturizers, medicaments, soothers and combinations thereof; and combinations thereof.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Fusion preparation method of polyvinyl alcohol film

InactiveCN101864132ALower melt processing temperatureSolving Melt Processing ProblemsFlat articlesPlasticizerPVA - Polyvinyl alcohol

The invention discloses a fusion preparation method of a polyvinyl alcohol film, which comprises the steps of mixing 100 parts by weight of polyvinyl alcohol, 10-45 parts by weight of small molecular plasticizer, 3-15 parts by weight of polymeric plasticizer, 1-5 parts by weight of processing agent, and 0.01-5 parts by weight of inorganic nanofiller, putting the components into a double-screw extruder, and fusing and plasticizing at the temperature of 140-250 DEG C and the screw rotate speed of 50-200rpm to directly extrude to form films or extrude to form films via fusing and plasticizing after pelleting. By choosing reasonable small molecular and polymeric compound plasticizers and inorganic nanofillers, the invention effectively reduces the fusing processing temperature of PVA, and solves the fusing processing problem of polyvinyl alcohol which has high molecular weight and high alcoholysis degree and is difficult to dissolve in water at normal temperature, and the obtained film has high transparency and good mechanical properties, is environmental-friendly, is non-toxic, and can be used for packaging a variety of products.

Owner:SICHUAN UNIV

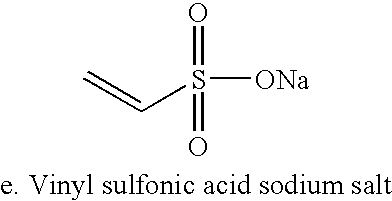

Non-phosphorus compound scale and corrosion inhibitor for treatment of circulating cooling water

ActiveCN1621362AEasy to useIncrease the concentration factorScale removal and water softeningPhosphateTungstate

The composite phosphate-free scale inhibiting corrosion inhibitor for treating circular cooling water consists of scale inhibitor and corrosion inhibitor. The scale inhibitor consists of one or several of PASP, PVA, oxidized starch, polyacrylic acid, acrylic acid / acrylate copolymer and acrylic acid / acrylate copolymer with sulfo radical. The corrosion inhibitor consists of one or several of sodium salt / potassium salt / ammonium salt of organic salt, sodium / potassium / ammonium borate, nitrous organic matter, soluble molybdenate, soluble tungstate, soluble nitrate, soluble nitrite and soluble zinc salt. The composite scale inhibiting corrosion inhibitor has excellent scale inhibiting and corrosion inhibiting performance, is environment friendly, and is especially the treatment of hard circulation water with high calcium and high alkali content.

Owner:BEIJING YANHUA XINGYE TECH DEV +1

Cementitious Veneer and Laminate Material Incorporating Reinforcing Fibers

A cementitious veneer and laminate composition is provided. The cementitious laminate composition includes a substrate, a primer layer applied to the substrate, the primer layer comprising a mixture of polyvinyl alcohol catalyst, Portland cement, and sand; and a cementitious veneer layer applied to the primer layer, the cementitious veneer layer comprising a mixture of magnesium sulfate, filler, magnesium oxide, gypsum cement or bassanite, cellulose ethers, and polyvinyl alcohol catalyst. The polyvinyl alcohol catalyst comprises a mixture of polyvinyl alcohol fibers dissolved in water and mixed with butylene carbonate. The veneer layer is applied to the substrate and primer layer by means including spraying and manual spreading, and can be ornamentally manipulated either before or after curing of the veneer layer. The veneer composition can be formed into laminated tiles or panels for use in building applications.

Owner:ECOMELD CORP

Method for finishing bacterium fixation by utilizing polyvinyl alcohol-borate secondary crosslinking

The invention relates to a method for finishing bacterium fixation by utilizing polyvinyl alcohol-borate secondary crosslinking, belonging to the field of water treatment. The method comprises the steps of: after mixing polyvinyl alcohol and bacteria in proportion, putting the mixture into saturated borate solution and carrying out first crosslinking fixation, after the fixation, taking out supernate and regulating pH of the supernate, carrying out second crosslinking fixation on the polyvinyl alcohol by utilizing the supernate in which the pH is regulated, and cleaning the polyvinyl alcohol after the fixation, so as to finish the whole fixation process. The method has the advantages that the damage to the bacteria in the fixation process is greatly reduced, and the phenomena of adhesion, water solubility and expansion are effectively reduced as well, thus providing conditions for large-scale industrial application of biologic active fillers and biologic active filter materials based on the polyvinyl alcohol.

Owner:BEIJING UNIV OF TECH

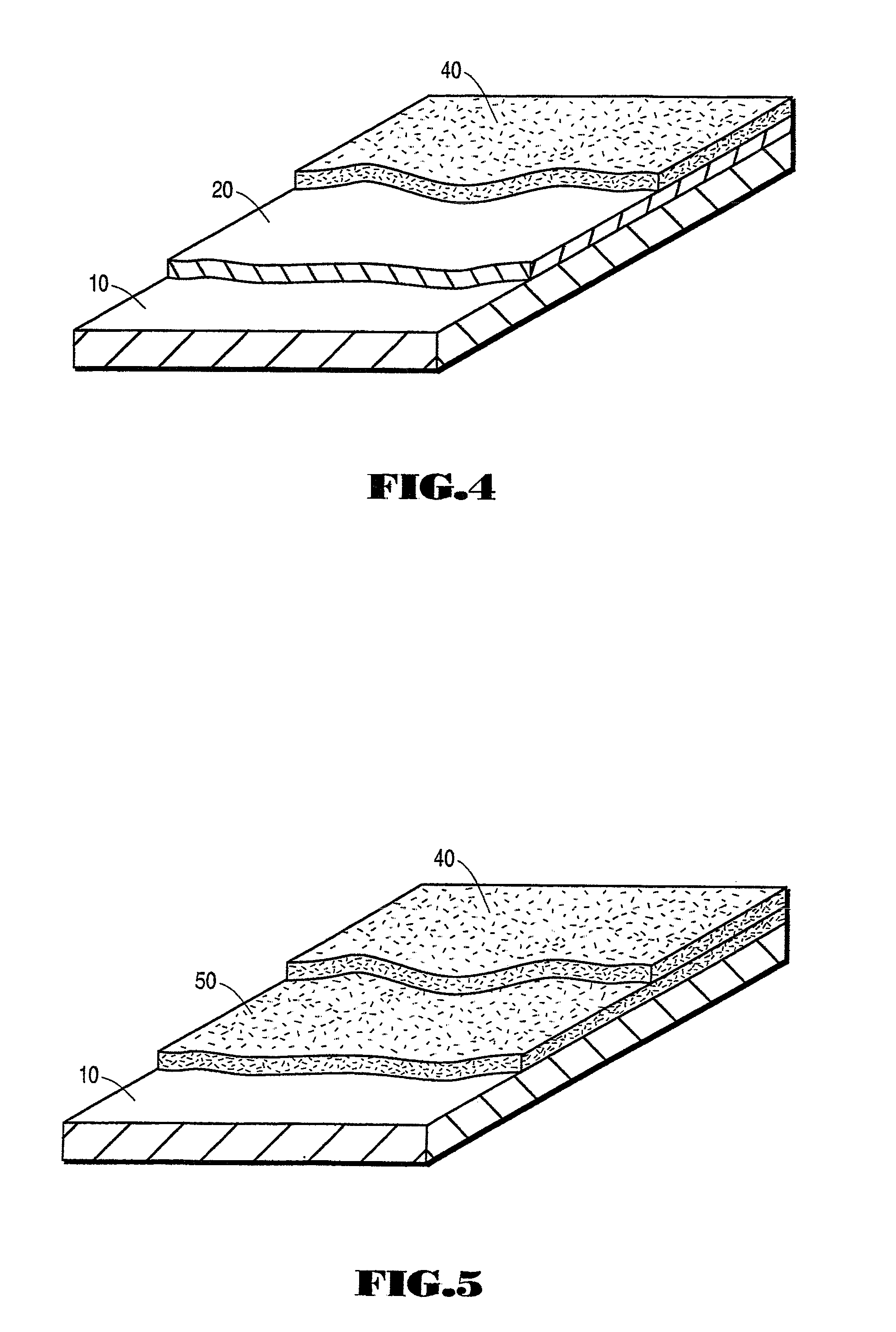

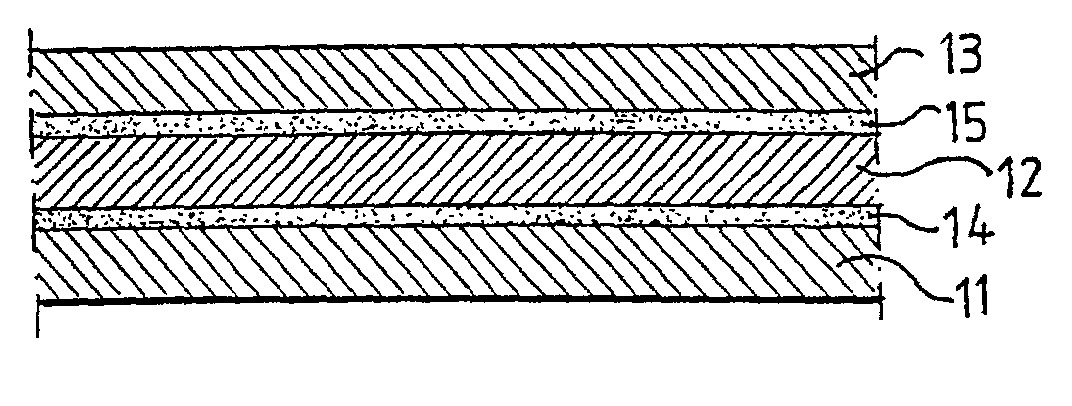

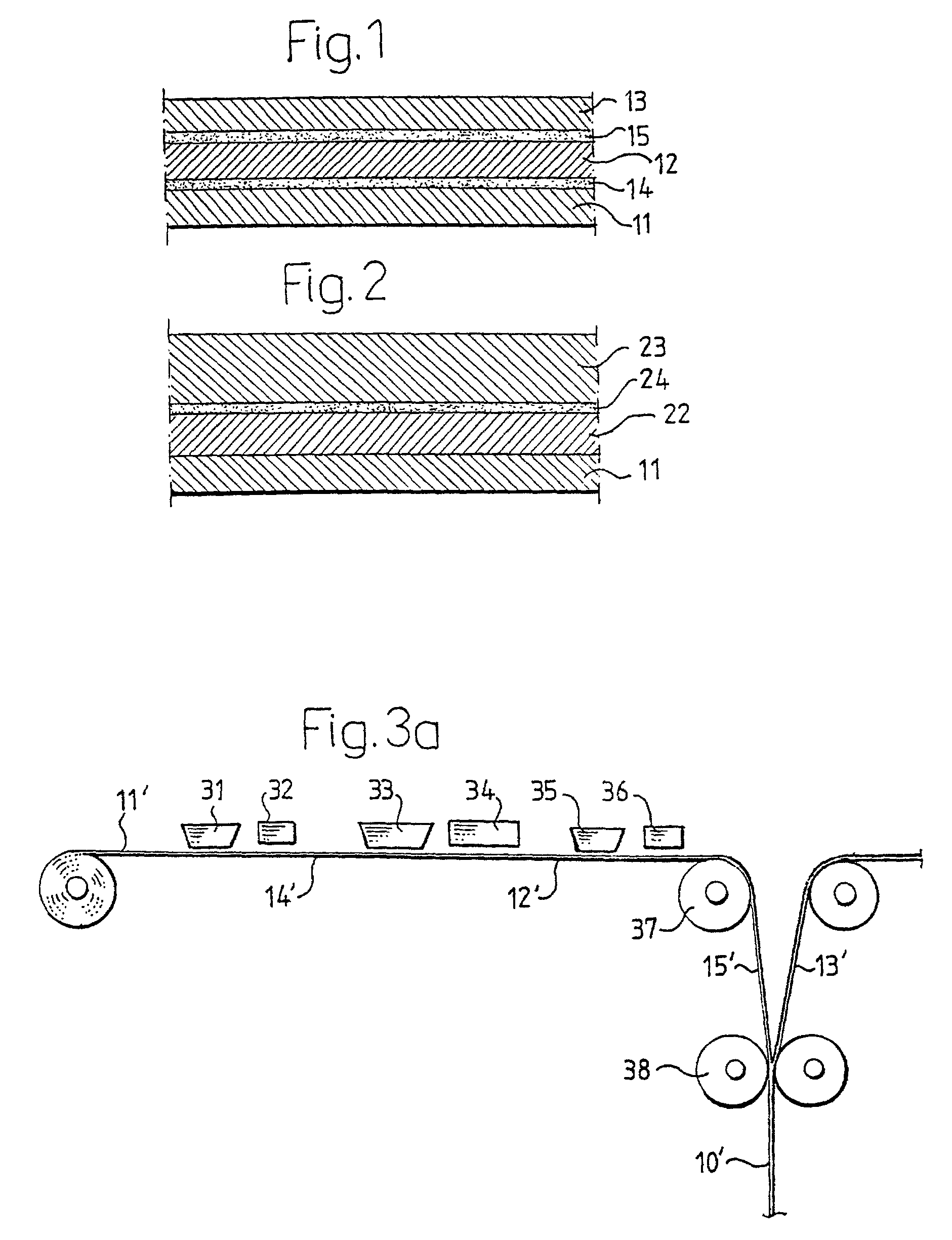

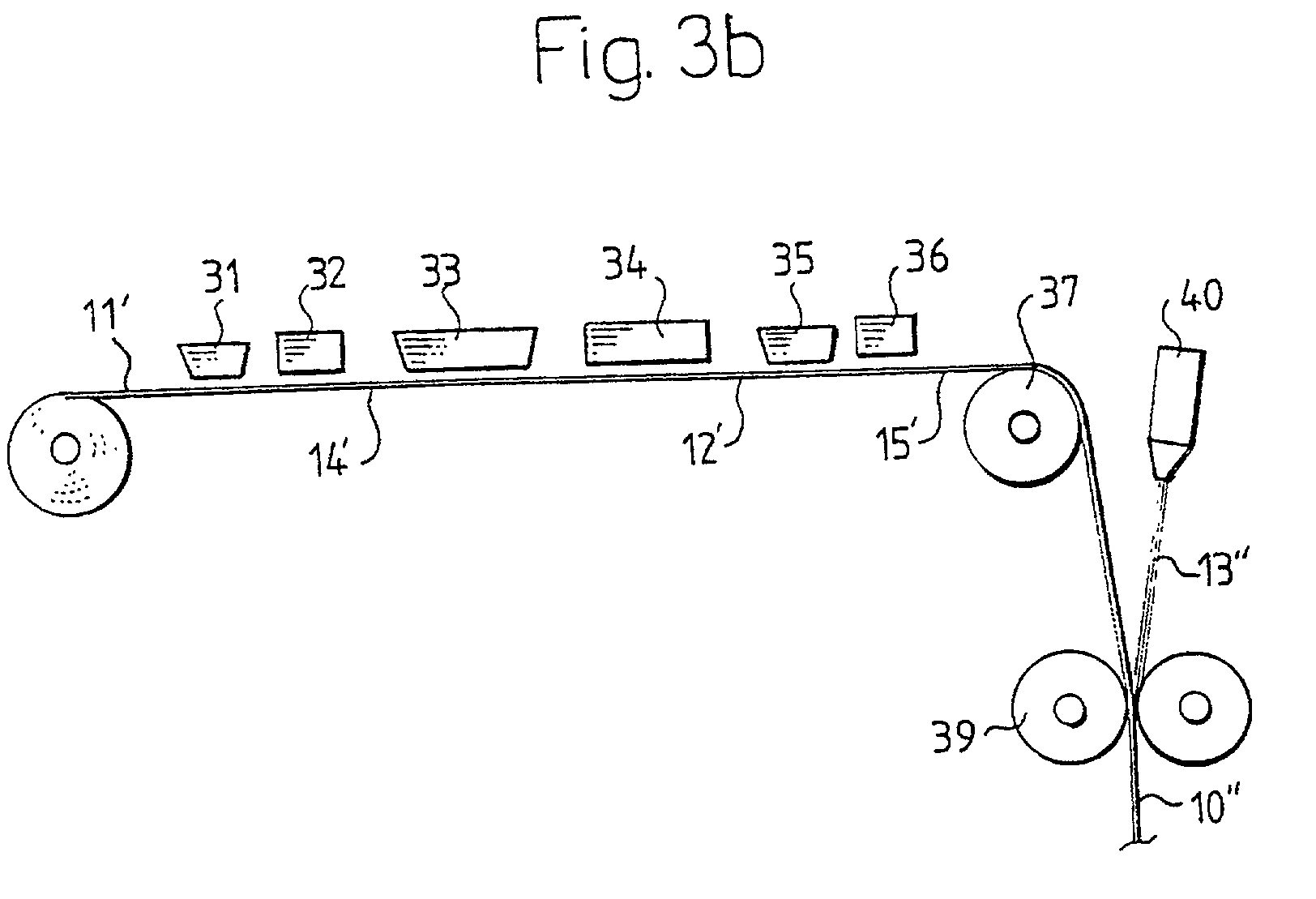

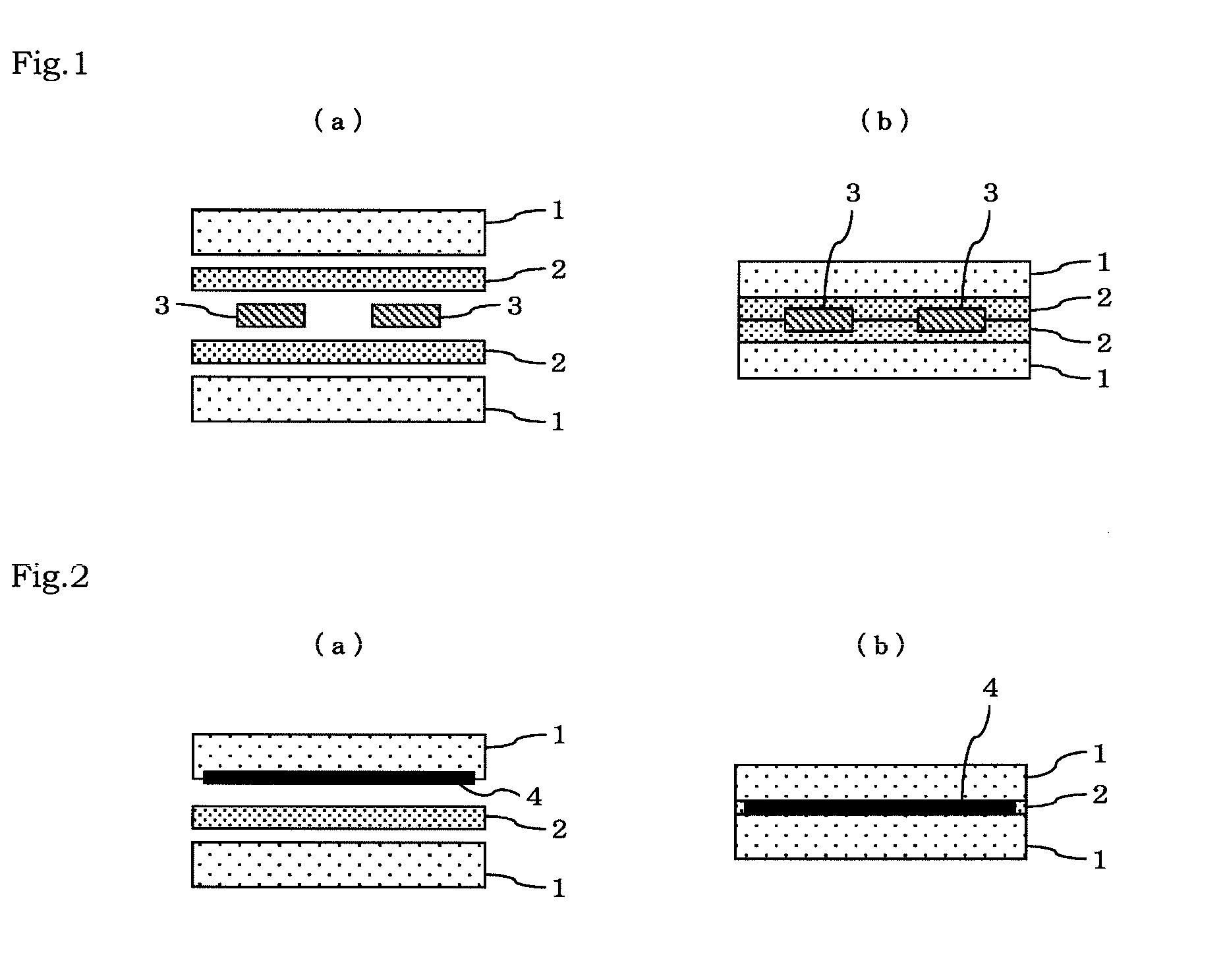

Biodegradable packaging laminate, a method of producing the packaging laminate, and packaging containers produced from the packaging laminate

InactiveUS20020127358A1Improve adhesionExcellent gas barrier performanceAdhesive processesLiquid surface applicatorsLactideBiopolymer

Packaging laminate for packages for liquid foods having excellent liquid and oxygen gas barrier properties in which all included layers are biodegradable. The packaging laminate includes at least one liquidtight layer (11, 13) of homo or copolymers of monomers selected from a group consisting of lactic acid, glycol acid, lactide, glycolide, hydroxy butyric acid, hydroxy valeric acid, hydroxy caproic acid, valerolactone, butyrolactone and caprolactone, as well as an oxygen gas barrier layer (12) of ethylene vinyl alcohol, polyvinyl alcohol, starch or starch derivatives. The oxygen gas barrier layer is preferably applied by a dispersion coating process. The layers may be laminated directly to one another or indirectly by means of interjacent adhesive layers. The packaging laminate may also include a core layer of, for example, paper or paperboard, or a biopolymer. The invention also realises a method of producing the biodegradable packaging laminate according to the invention.

Owner:TETRA LAVAL HLDG & FINANCE SA

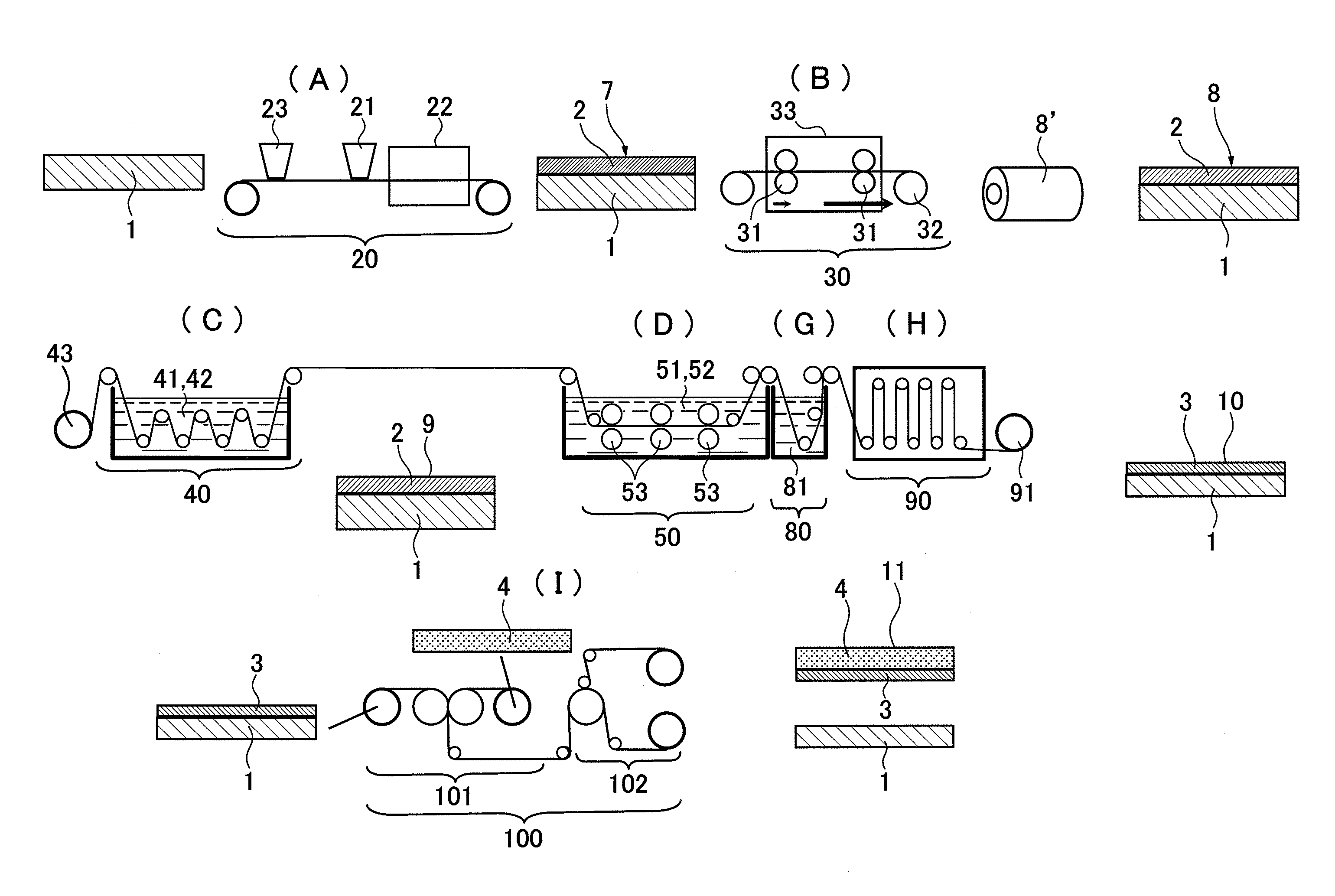

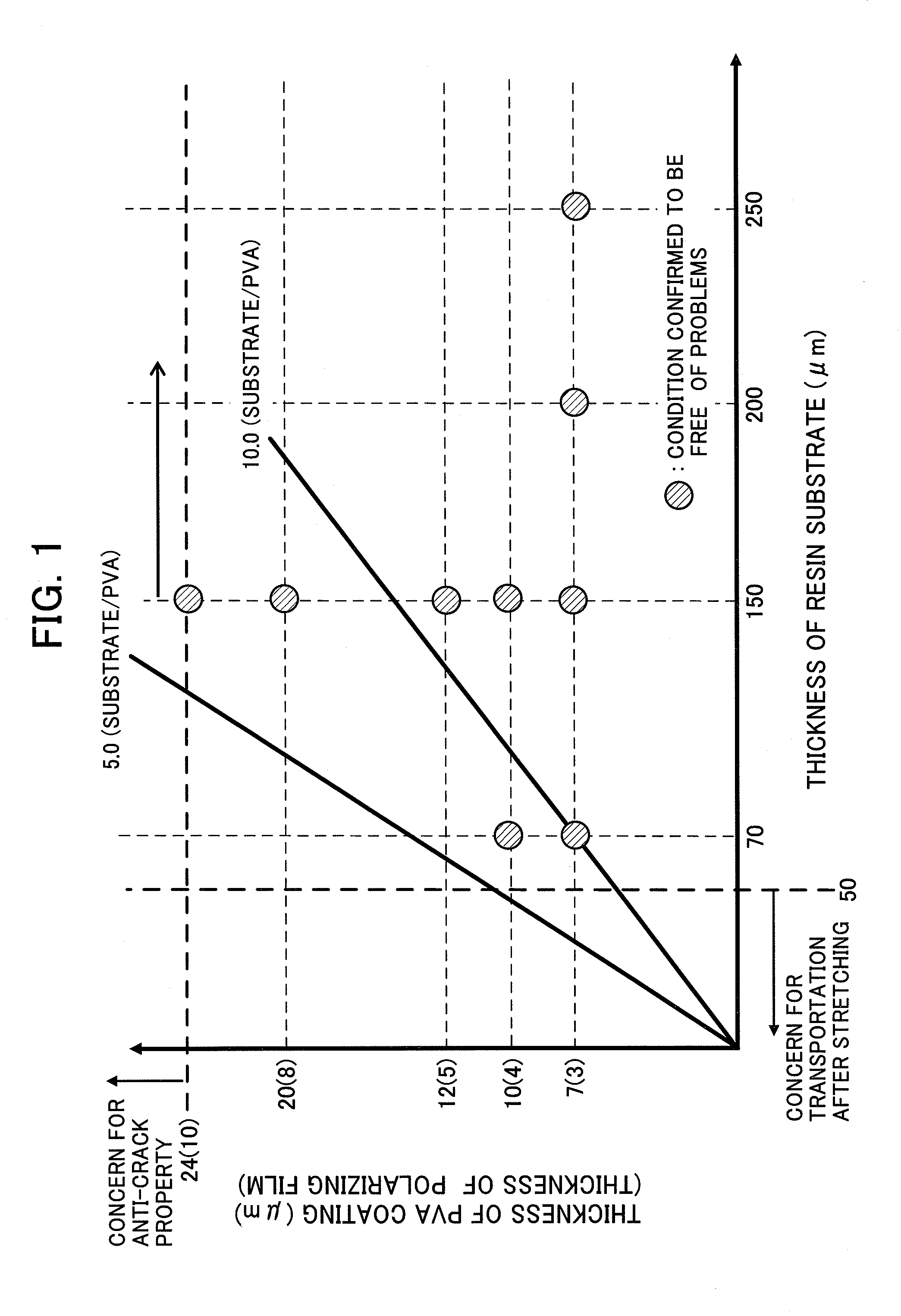

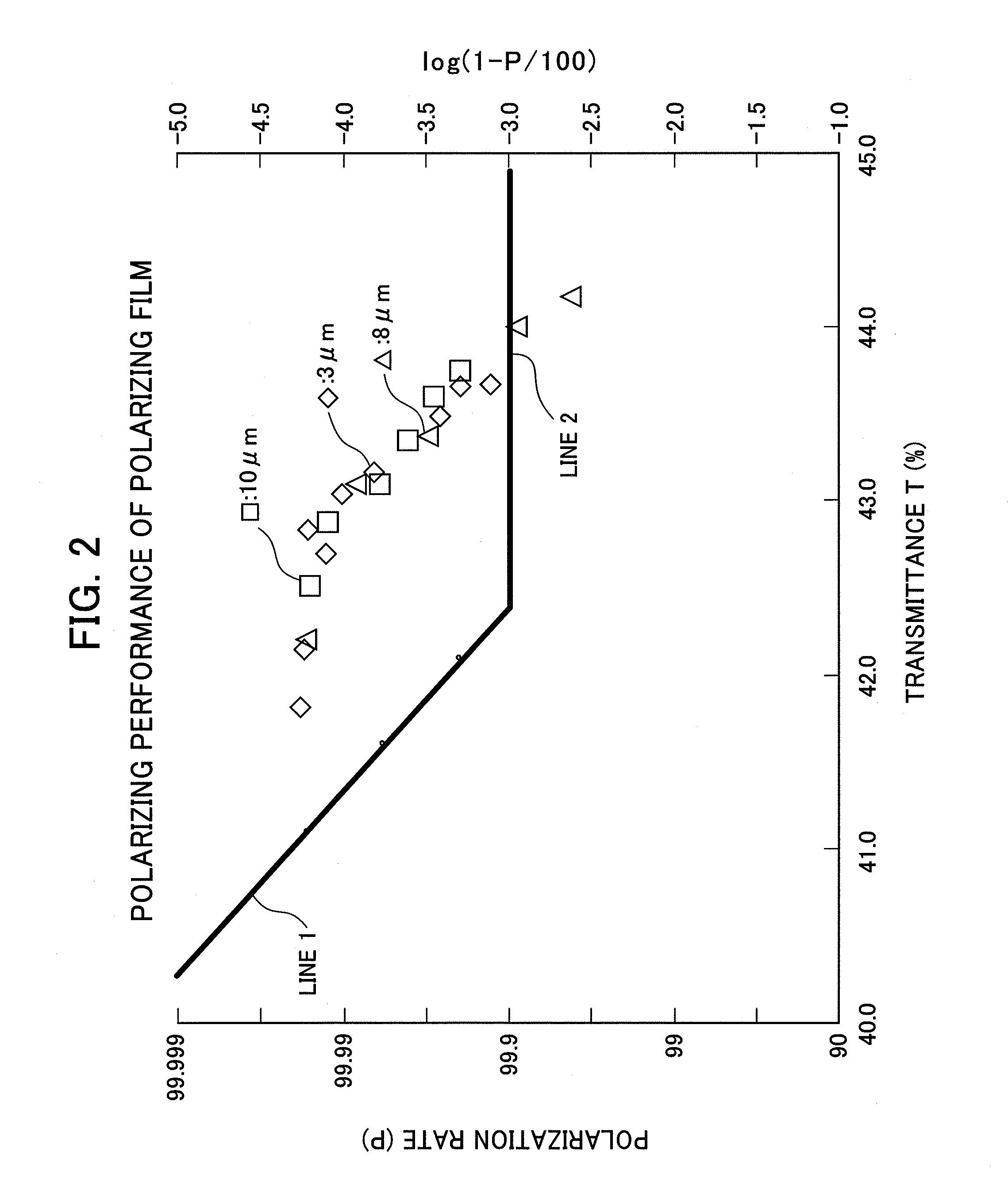

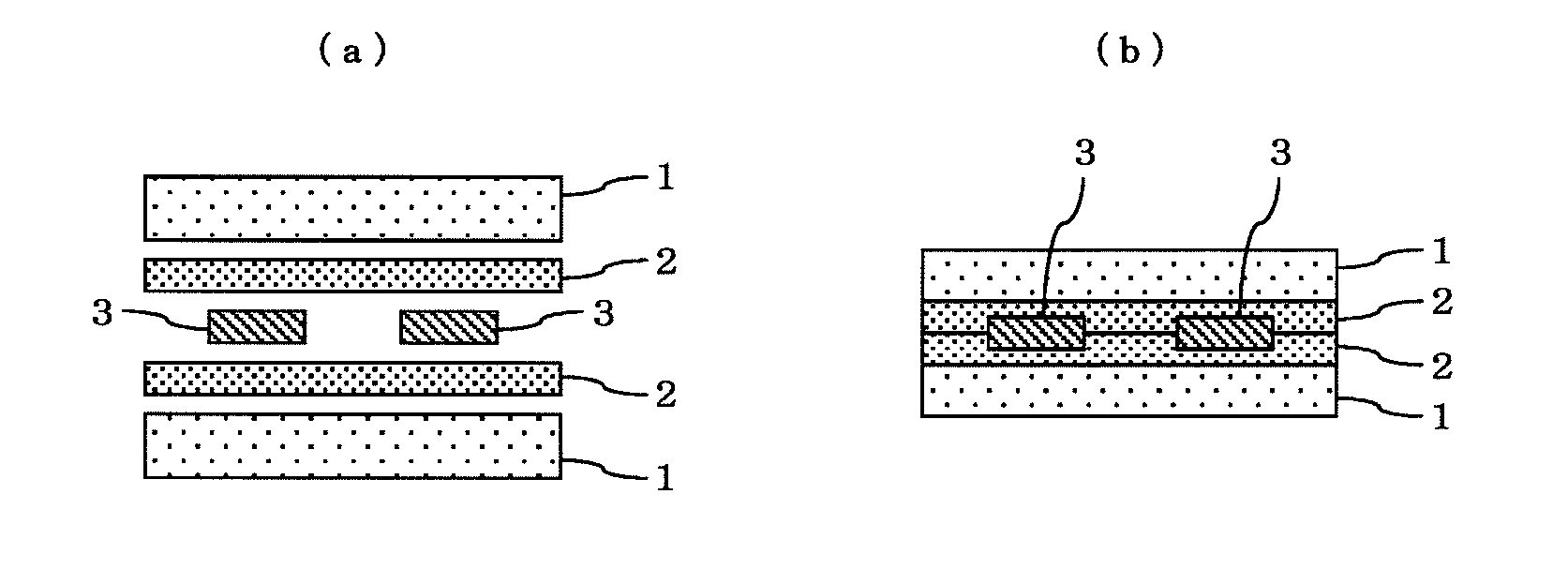

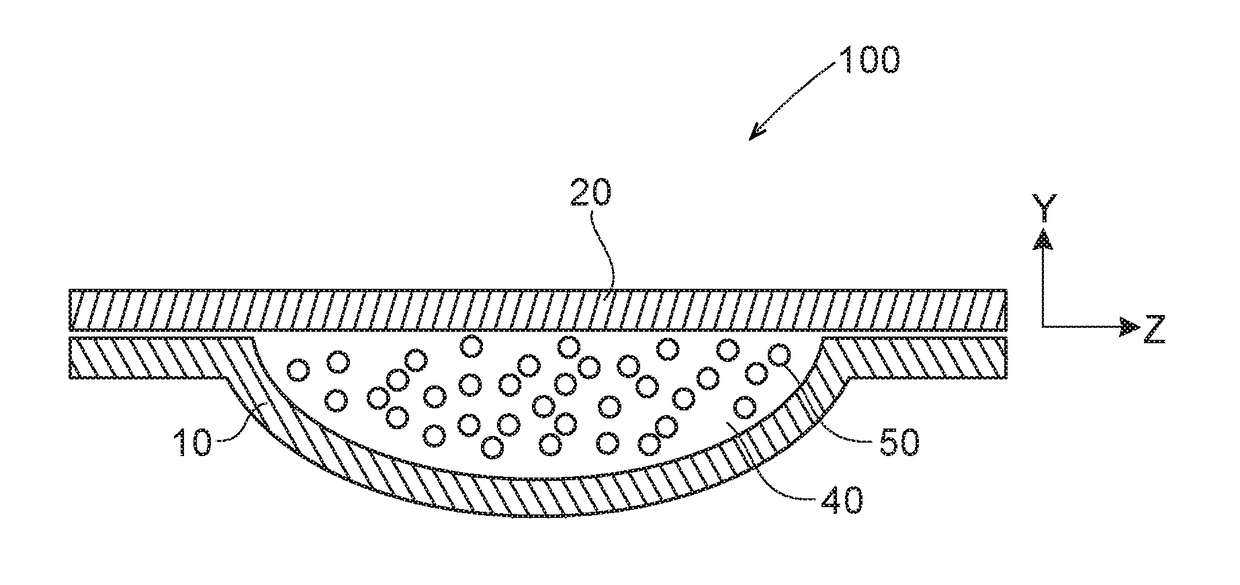

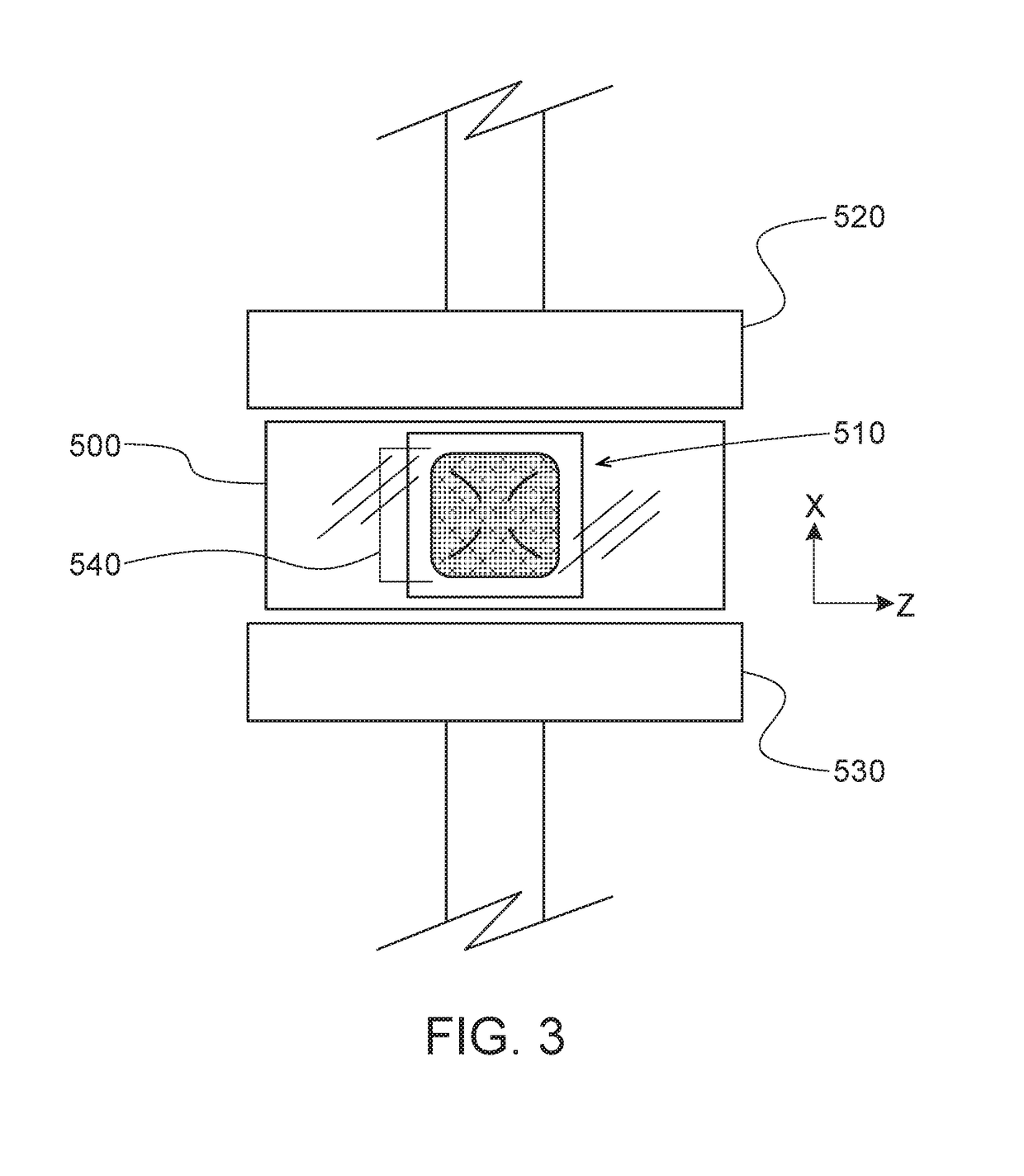

Polarizing film, optical film laminate comprising polarizing film, and stretched laminate for manufacturing the same

ActiveUS20120057232A1Improving molecular orientationImprove completenessElectroluminescent light sourcesSolid-state devicesOptical propertyTransmittance

A polarizing film includes a polyvinyl alcohol (PVA) type resin having a dichroic material impregnated therein. The polarizing film is formed by stretching the PVA type resin, such that the thickness of the polarizing film is decreased to 10 μm or less, and. The polarizing film has optical properties which satisfy conditions represented by formulae:P>−(100.929T-42.4−1)×100 (where T<42.3); andP≧99.9 (where T≧42.3)where T represents a single layer transmittance and P a polarization rate. The polarizing film can be made by providing a laminate comprising a PVA type resin layer formed on a non-crystallizable ester type thermoplastic resin substrate.

Owner:NITTO DENKO CORP

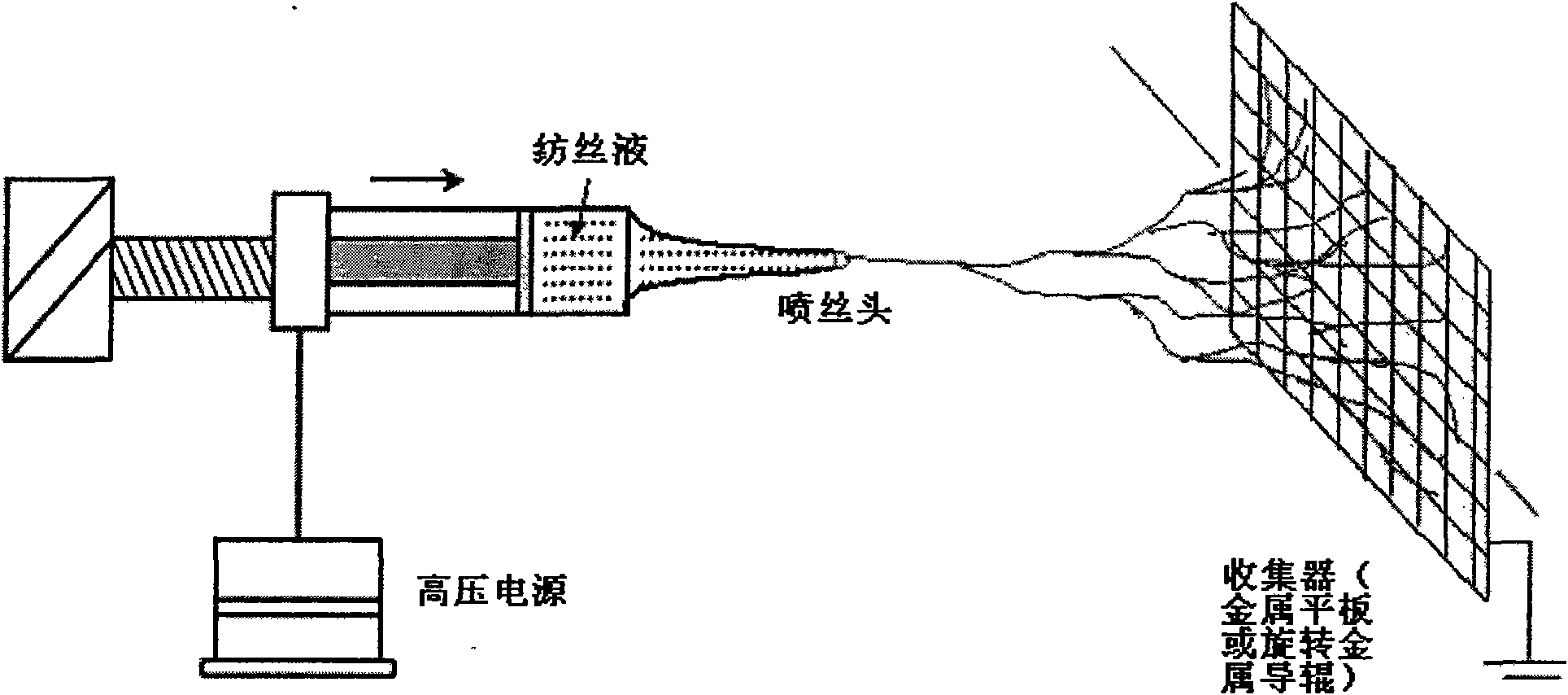

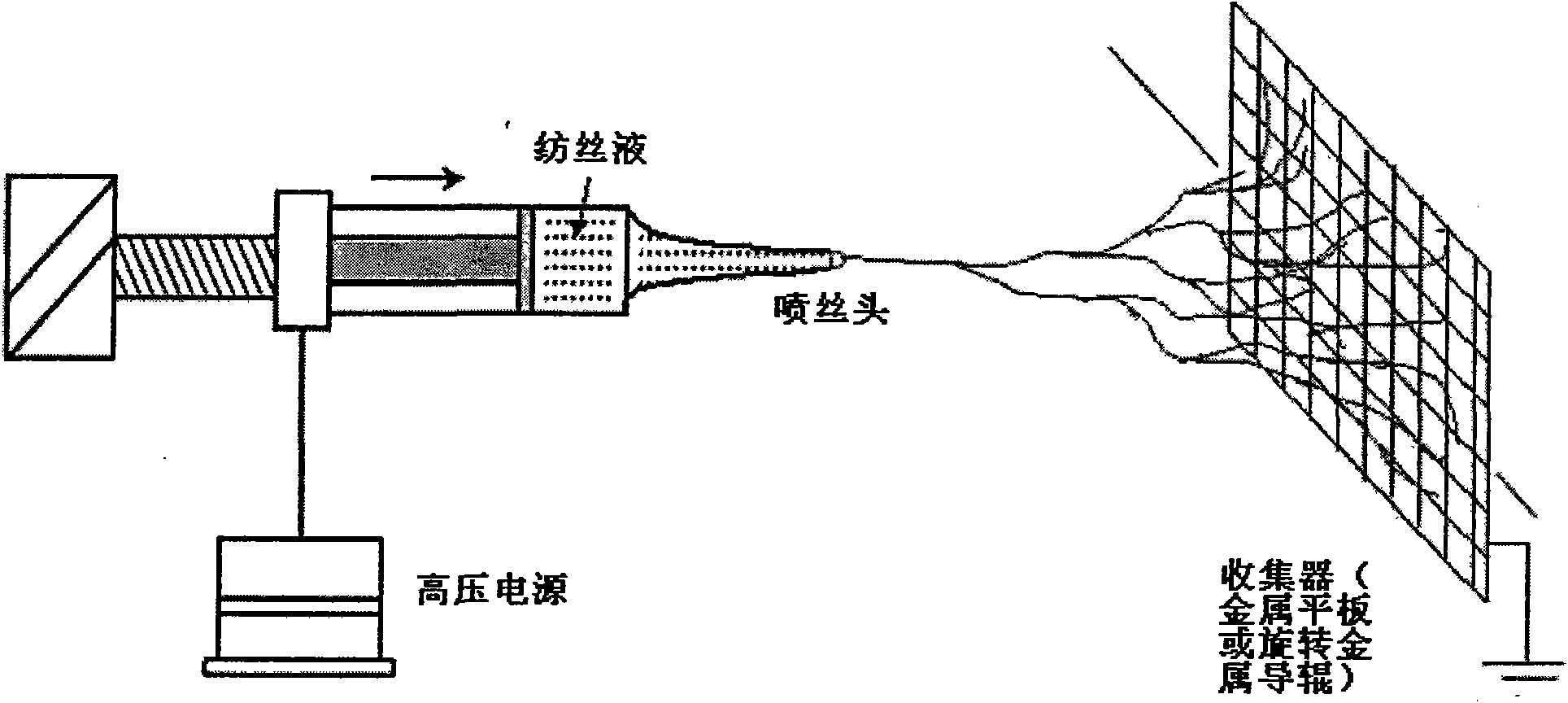

Method for preparing polytetrafluoroethylene superfine fiber

InactiveCN101994161AEasy to prepareArtificial filament washing/dryingFilament/thread formingFiberElectrospinning

The invention discloses a method for preparing a polytetrafluoroethylene superfine fiber, comprising the following steps of: firstly dissolving polyvinyl alcohol into water to prepare a polyvinyl alcohol solution, then evenly mixing the polyvinyl alcohol solution with polytetrafluoroethylene concentrated dispersion to prepare a spinning solution; then making the spinning solution into a polytetrafluoroethylene / polyvinyl alcohol superfine fiber by adopting an electrostatic spinning method; and finally, carrying out polyvinyl alcohol removal aftertreatment on the prepared polytetrafluoroethylene / polyvinyl alcohol superfine fiber to obtain the polytetrafluoroethylene superfine fiber. The prepared polytetrafluoroethylene superfine fiber is white or dark brown, and the diameter of the fiber is 30-2000nm.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

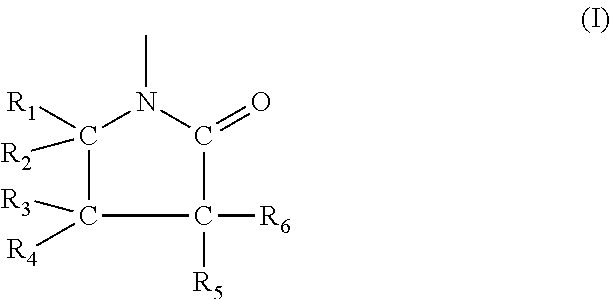

Pvp copolymer for harsh chemical packaging

A water soluble film useful in unit-dose chemical packaging is disclosed. The film may include: a water soluble saccharide and a polyvinyl alcohol copolymer consisting essentially of: (a) from 80 to 99 mole percent of vinyl alcohol and vinyl ester monomer; and (b) from 1 to 20 mole percent of a pyrrolidone comonomer. Such compositions may be used to provide a water-soluble film simultaneously satisfying requirements in regard to water solubility, biodegradability, and physical properties, even when used for packaging of harsh, oxidizing chemicals.

Owner:SEKISUI SPECIALTY CHEM AMERICA

Moisture barrier film coating composition, method and coated form

A dry moisture barrier film coating composition for forming a moisture barrier film coating for pharmaceutical tablets and the like comprises polyvinyl alcohol, soya lecithin, and optionally a flow aid, a colorant, and / or a suspending agent. A liquid coating solution or dispersion for forming a moisture barrier film coating for pharmaceutical tablets and the like comprises polyvinyl alcohol, soya lecithin, water, and optionally a flow aid, a colorant, and / or a suspending agent. A method of coating pharmaceutical tablets and the like with a moisture barrier film coating comprises forming a liquid coating solution or dispersion for forming a moisture barrier film coating for pharmaceutical tablets and the like comprising polyvinyl alcohol, soya lecithin, water, and optionally a flow aid, a colorant, and / or a suspending agent, applying the coating solution or dispersion onto the tablets to form a film coating on the tablets, and drying the film coating on the tablets.

Owner:BPSI HLDG LLC

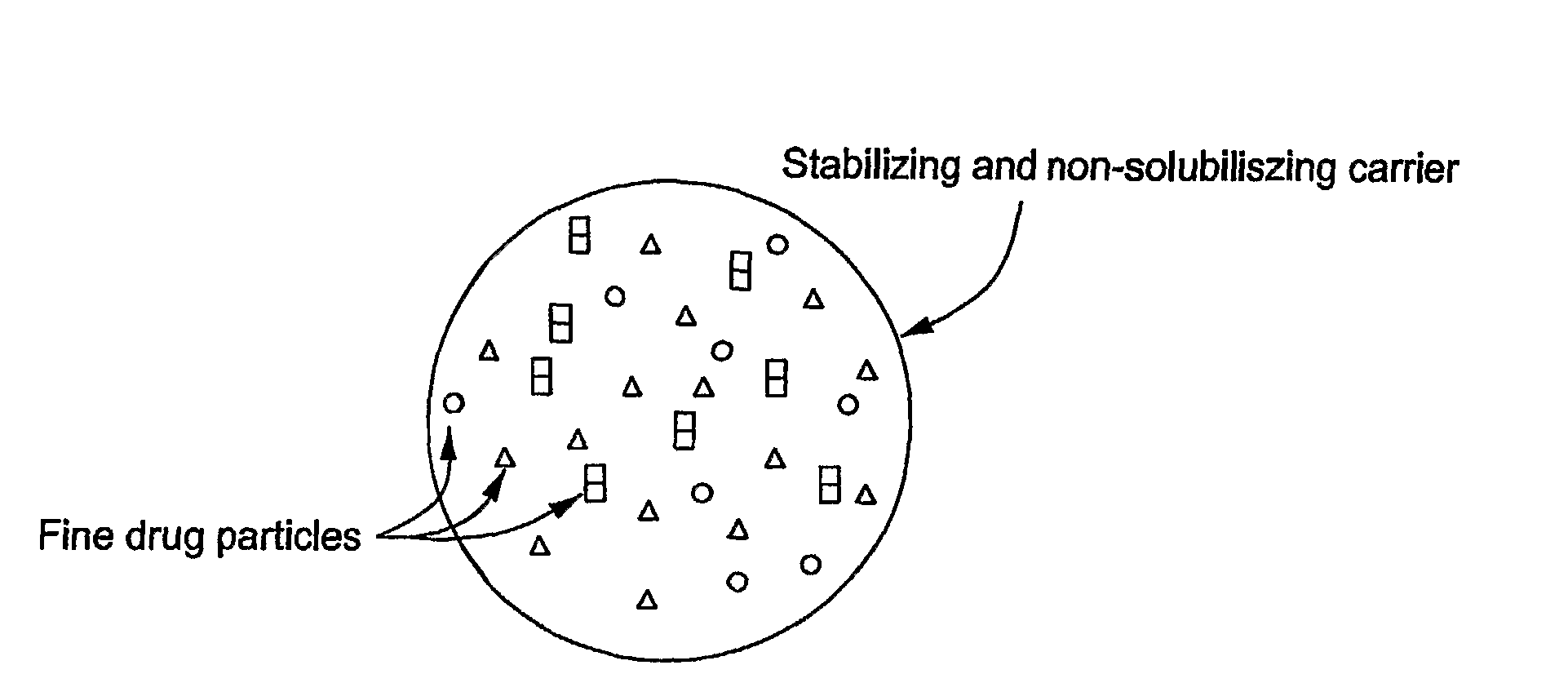

Stabilized Hme Composition With Small Drug Particles

ActiveUS20080274194A1Facilitated releaseReduce releasePowder deliveryCyclic peptide ingredientsAntioxidantCarrier system

A hot-melt extruded composition having finely divided drug-containing particles dispersed within a polymeric and / or lipophyllic carrier matrix is provided. The carrier softens or melts during hot-melt extrusion but it does not dissolve the drug-containing particles during extrusion. As a result, a majority or at least 90% wt. of the drug-containing particles in the extrudate are deaggregated during extrusion into essentially primary crystalline and / or amorphous particles. PEO is a suitable carrier material for drugs insoluble in the solid state in this carrier. Various functional excipients can be included in the carrier system to stabilize the particle size and physical state of the drug substance in either a crystalline and / or amorphous state. The carrier system is comprised of at least one thermal binder, and may also contain various functional excipients, such as: super-disintegrants, antioxidants, surfactants, wetting agents, stabilizing agents, retardants, or similar functional excipients. A hydrophilic polymer, such as hydroxypropyl methylcellulose (HPMC E15), polyvinyl alcohol (PVA), or poloxamer, and / or a surfactant, such as sodium lauryl sulfate (SLS), can be included in the composition. A process for preparing the extrudate is conducted at a temperature approximating or above the softening or melting temperature of the matrix and below the point of solubilization of drug-containing particles in the carrier system, and below the recrystallization point in the case of amorphous fine drug particles.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Polymeric films

ActiveUS20090312462A1Excellent oxygen barrier propertiesSuitable for usePaper coatingDomestic articlesMolten statePolymer science

A polymer composition and its use for thin film packaging applications including on a dry basis: a) from 45 to 90% by weight of starch; b) from 0.1 to 15% by weight of a water soluble polymer selected from polyvinyl alcohol, polyvinylacetate, and copolymers of ethylene and vinyl alcohol which have a melting point compatible with the molten state of the starch component; and c) from 5 to 45% by weight of one or more plasticizers having a molecular weight in the range of 50-6000, more preferably 50-2500 and more preferably still 100-400 and desirably selected from the group consisting of sorbitol, glycerol, maltitol, xylitol, mannitol, erythritol, glycerol trioleate, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate, polyethylene oxide, ethylene glycol, diethylene glycol or polyethylene glycol.

Owner:PLANTIC TECH

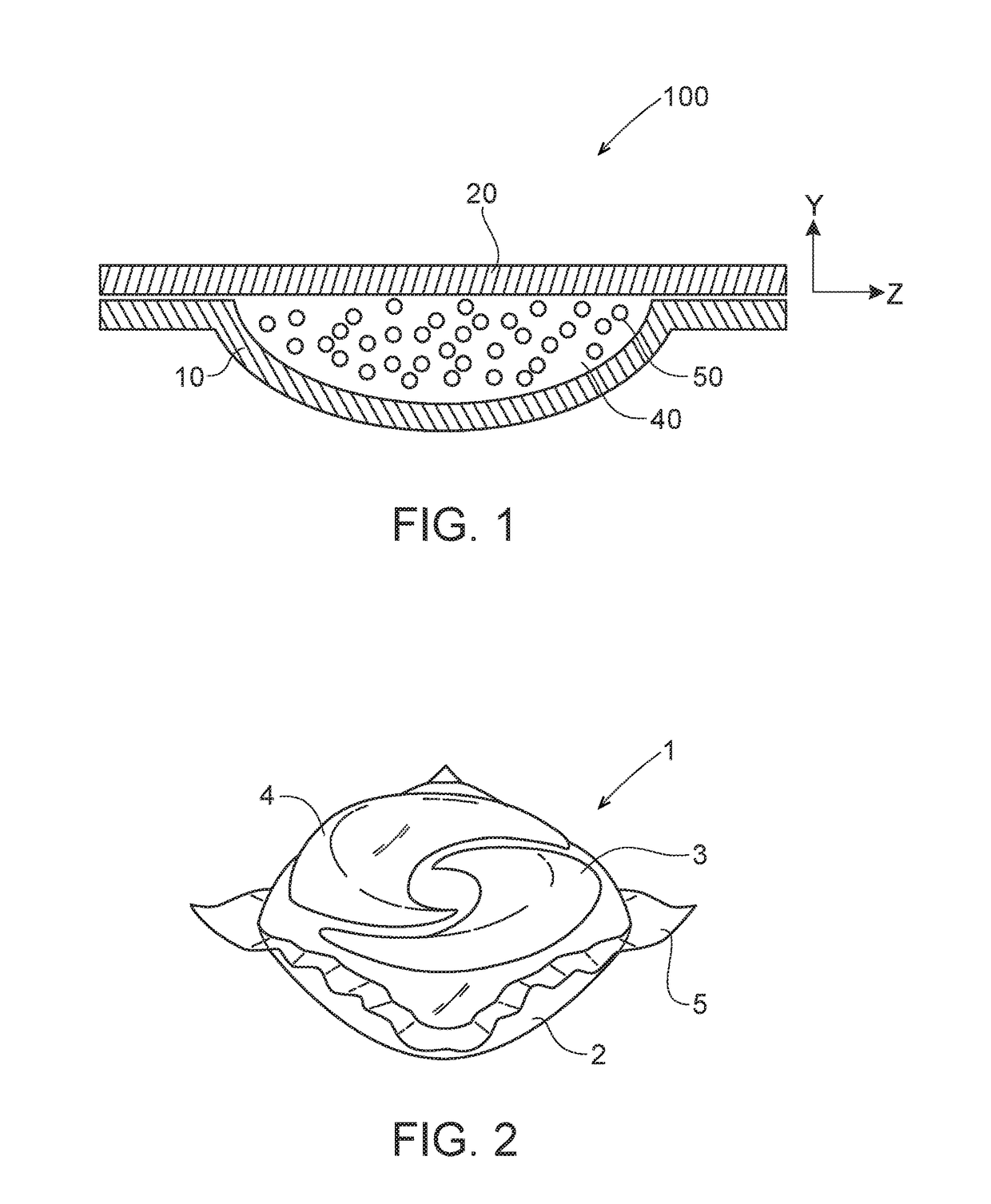

Polyvinyl alcohol microspheres, and methods for making and therapeutic uses of the same

The present invention relates to microspheres useful for embolization which comprises polyvinylalcohol. The present invention also relates to an injectable suspension suitable for embolization which comprises the polyvinylalcohol microspheres and a suitable liquid carrier. The present invention further relates to a method for prophylactic or therapeutic embolization which comprises administering to a mammal an injectable suspension containing the polyvinylalcohol microspheres and a suitable liquid carrier. Finally, the present invention relates to a process for producing the polyvinylalcohol microspheres.

Owner:BIOSPHERE MEDICAL SA (FR)

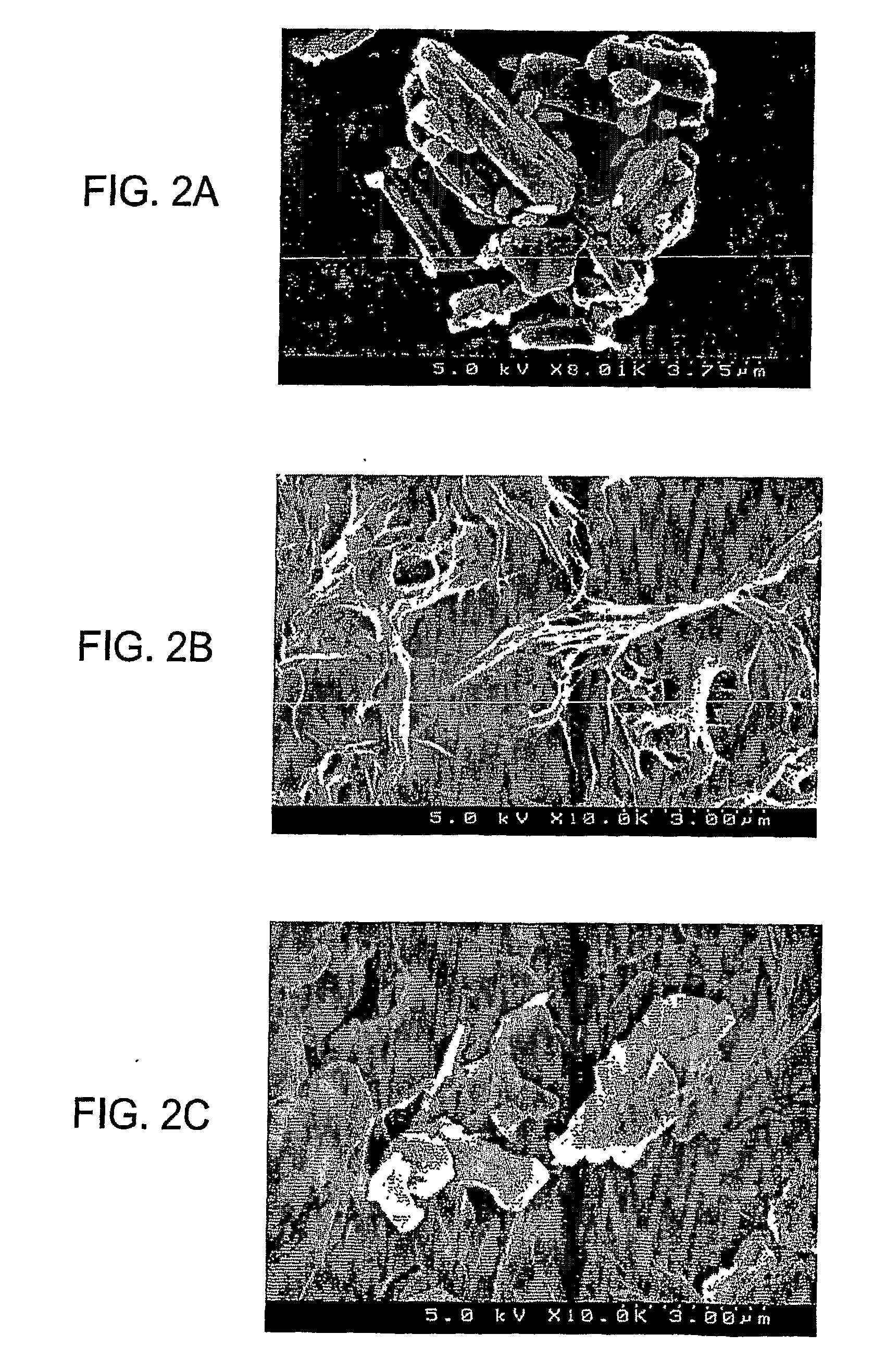

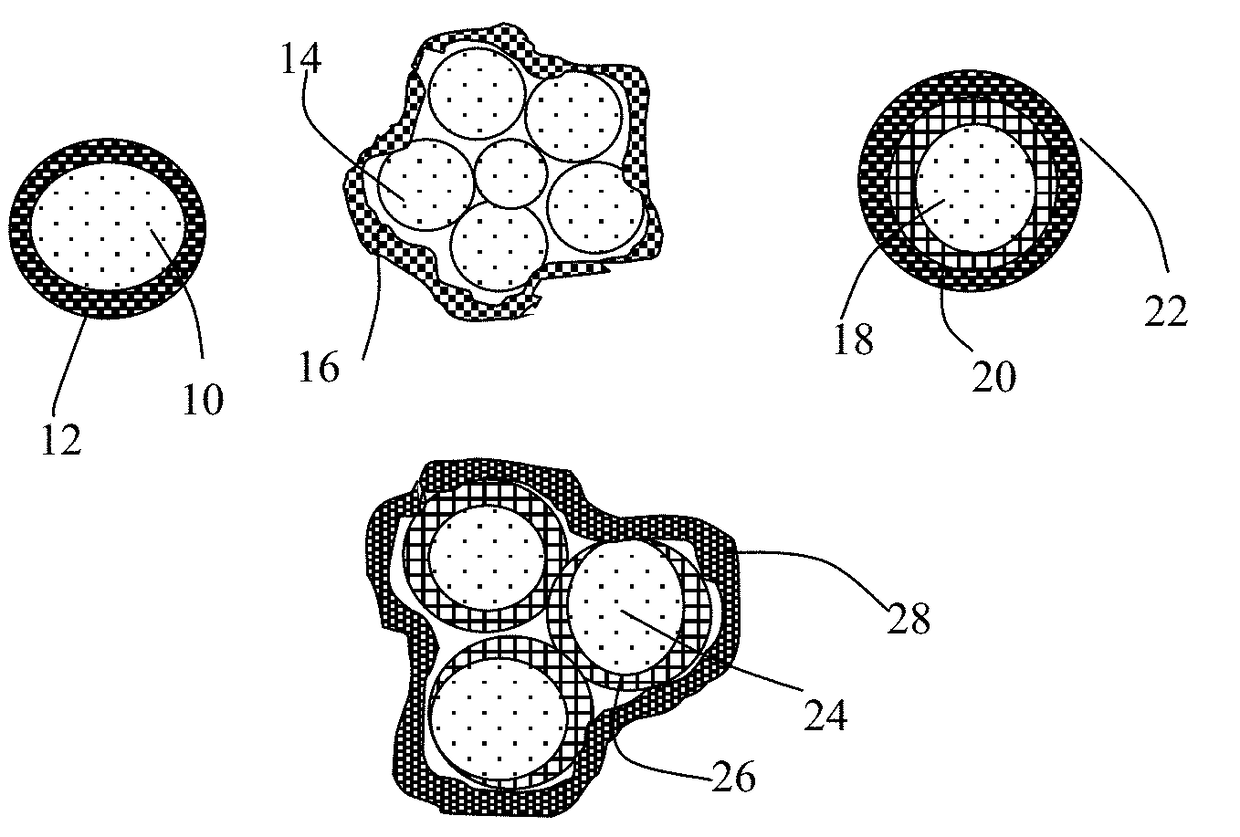

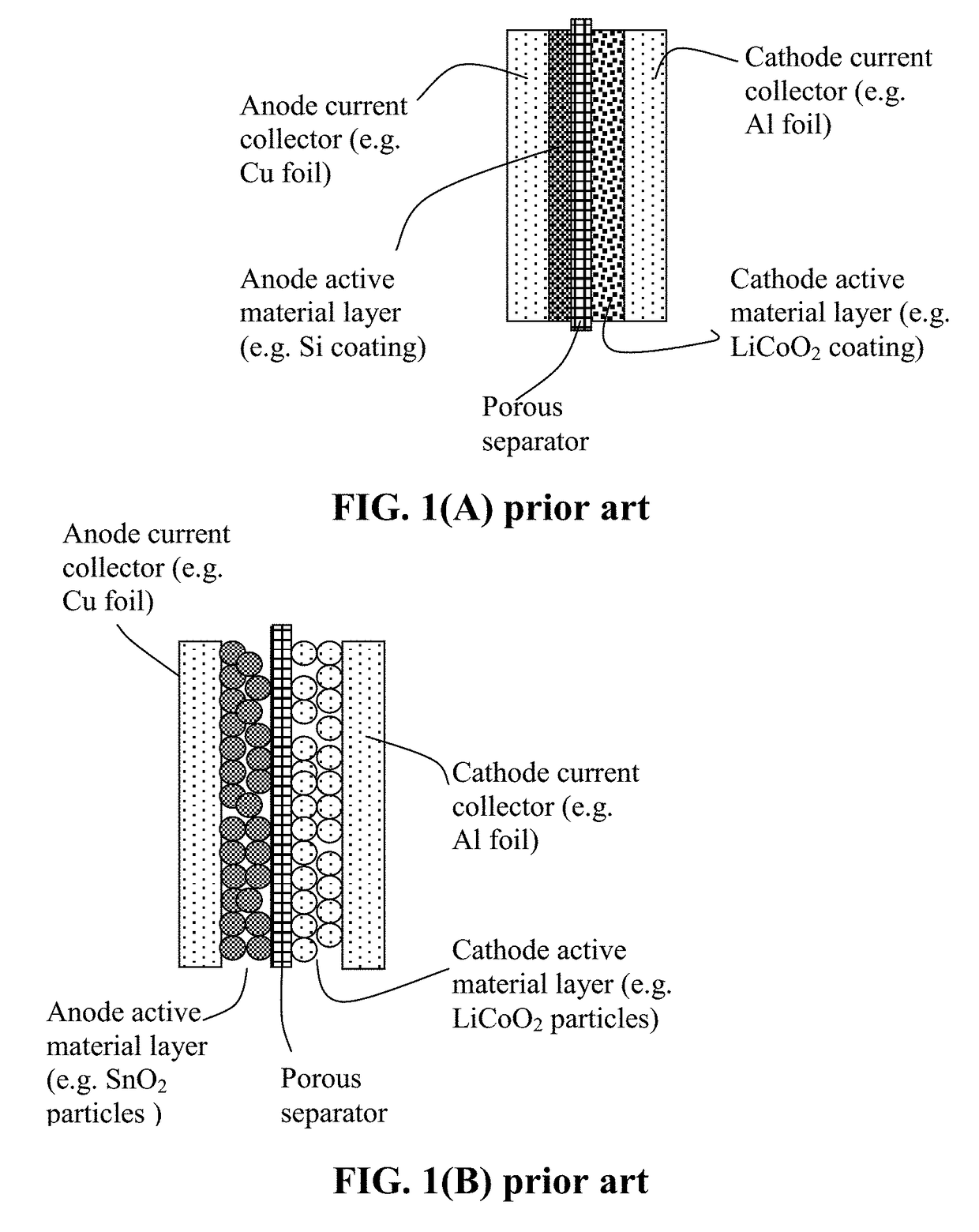

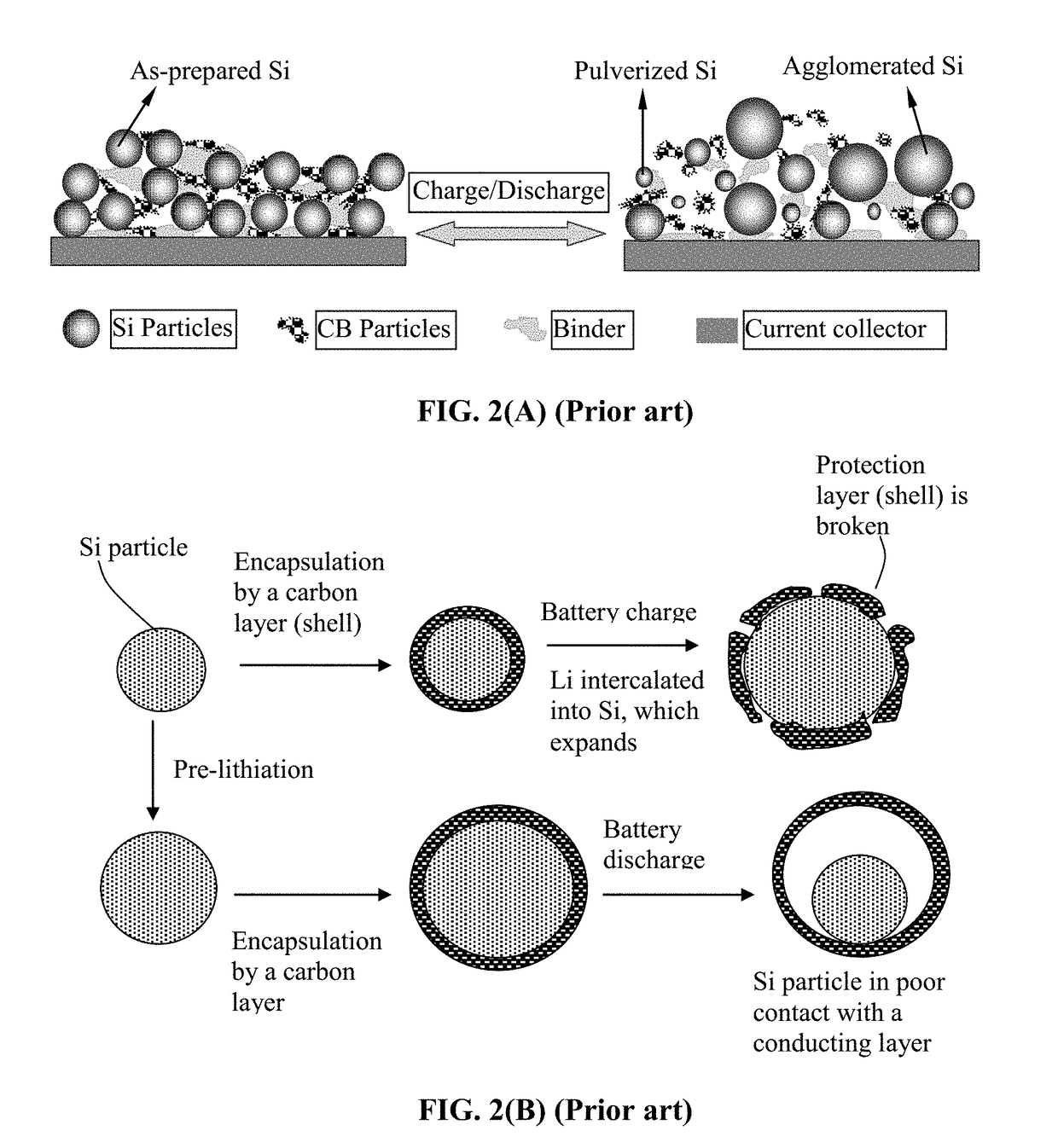

Encapsulated Anode Active Material Particles, Lithium Secondary Batteries Containing Same, and Method of Manufacturing

ActiveUS20180287142A1Improve lithium ion conductivitySolid electrolytesNegative electrodesParticulatesPolyethylene oxide

Provided is particulate of an anode active material for a lithium battery, comprising one or a plurality of anode active material particles being embraced or encapsulated by a thin layer of a high-elasticity polymer having a recoverable tensile strain no less than 5%, a lithium ion conductivity no less than 10−6 S / cm at room temperature, and a thickness from 0.5 nm to 10 μm, wherein the polymer contains an ultrahigh molecular weight (UHMW) polymer having a molecular weight from 0.5×106 to 9×106 grams / mole. The UHMW polymer is preferably selected from polyacrylonitrile, polyethylene oxide, polypropylene oxide, polyethylene glycol, polyvinyl alcohol, polyacrylamide, poly(methyl methacrylate), poly(methyl ether acrylate), a copolymer thereof, a sulfonated derivative thereof, a chemical derivative thereof, or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

Polyvinyl acetal laminate and use thereof

InactiveUS20120204940A1Improve interlayer adhesionSimilar polaritySynthetic resin layered productsGlass/slag layered productsPolymer sciencePolyolefin

It is an object of the present invention to provide a laminate of a layer that contains a polyvinyl acetal and a layer that contains a polyolefin (hydrocarbon polymer), which exhibits excellent adhesion between the layers. The present invention relates to a laminate obtained by laminating a layer A that includes a composition A containing a polyvinyl acetal and a layer B that includes a composition B containing a polyolefin and / or an adhesive functional group-containing olefinic polymer, wherein a mass ratio of (the polyolefin) / (the adhesive functional group-containing olefinic polymer) is 0 / 100 to 99.95 / 0.05.

Owner:KURARAY CO LTD

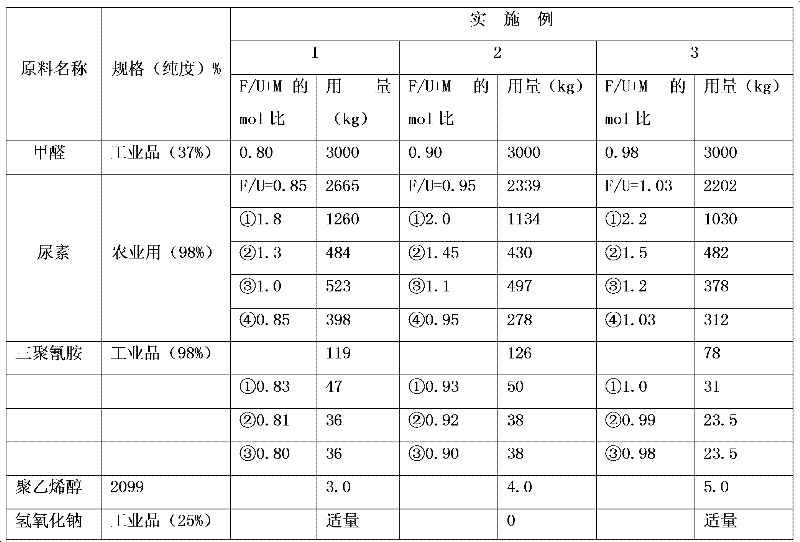

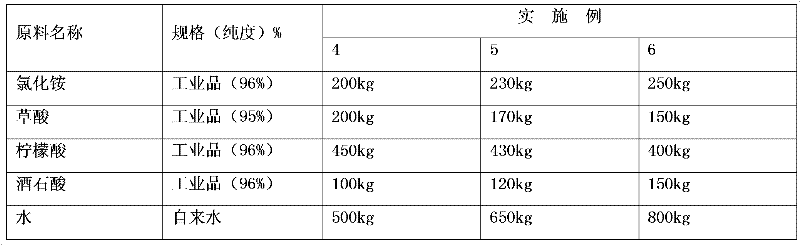

E0-grade melamine modified urea-formaldehyde resin adhesive, and preparation method and application thereof

InactiveCN102604573AImprove stabilityLow costAldehyde/ketone condensation polymer adhesivesMelamineResin adhesive

The invention relates to an E0-grade melamine modified urea-formaldehyde resin adhesive, and a preparation method and application thereof. The E0-grade melamine modified urea-formaldehyde resin adhesive is characterized by comprising an E0-grade melamine modified urea-formaldehyde resin, a composite curing agent and a composite filler, wherein the E0-grade melamine modified urea-formaldehyde resin is prepared from the following raw materials in parts by mass: 100 parts of formaldehyde, 0.1-0.5 part of polyvinyl alcohol, 100-200ml of basic catalyst and 200-400ml of acidic catalyst; the mol ratio of the formaldehyde to the urea+melamine (F / (U+M)) is equal to 0.80-0.98; the composite curing agent is prepared from the following raw materials in parts by mass: 200-250 parts of ammonium chloride, 150-200 parts of oxalic acid, 400-450 parts of citric acid, 100-150 parts of tartaric acid and 500-800 parts of water; and the composite filler is prepared from the following raw materials in parts by mass: 60 parts of industrial flour, 20 parts of 800-mesh light calcium carbonate and 20 parts of 800-mesh wood meal. The E0-grade melamine modified urea-formaldehyde resin adhesive is used for gluing plates. The E0-grade melamine modified urea-formaldehyde resin adhesive has the advantages of low free formaldehyde content, low cost, favorable precompression performance, good gluing performance and the like.

Owner:BEIHUA UNIV

High-strength film laminates having layers of plasticizer-containing polyvinyl (N)acetal and plasticizer-containing polyvinyl (ISO)acetal

ActiveUS8597792B2Improve mechanical propertiesGood compatibilitySynthetic resin layered productsGlass/slag layered productsArchitectural glassGlass composites

The invention relates to film laminates, formed from at least three layers A, B and C, each layer containing at least one plasticizer and at least one polyvinyl acetal, wherein, at least one of the layers A, B or C contains at least one polyvinyl (iso)acetal having a mean degree of polymerization of less than 3000, 10 to 25% by weight of polyvinyl alcohol groups and a proportion 50 to 80% by weight of polyvinyl (iso)acetal groups, and wherein layer B has a plasticizer content of less than 32% by weight. The film laminates can be used for the production of glass / film laminate / glass composites for motor vehicles, aircraft, ships, architectural glazings, façade components, or for the production of photovoltaic modules.

Owner:KURARAY EURO GMBH

Pouches having water-soluble films made from polyvinyl alcohol polymer blends, and related methods

ActiveUS20170298216A1Flexible coversOrganic detergent compounding agentsWater solublePVA - Polyvinyl alcohol

Pouches that include a water-soluble film and a composition at least partially enclosed by the water-soluble film in at least one compartment, where the water-soluble film includes a polyvinyl alcohol (PVOH) resin blend. Methods of making and using such pouches and films.

Owner:THE PROCTER & GAMBLE COMPANY

Mesoporous-macroporous carbon production method

The invention belongs to the field of chemical engineering and industry, and particularly relates to a mesoporous-macroporous carbon production method. The production method comprises: completely mixing a phenol formaldehyde resin, an epoxy resin and the like or a mixture thereof, and a curing agent according to a certain weight ratio, carrying out heating curing, adding polyvinyl alcohol and the like as pore forming agents and adding graphite powder and the like as support agents after the cured material is crushed, completely mixing, pressing to form a preform, and carrying out high temperature carbonization under the protection of gas to obtain the mesoporous-macroporous carbon. The mesoporous-macroporous carbon prepared by using the production method has advantages of simple preparation method, easy pore size control and the like, wherein the pore size of the mesoporous-macroporous carbon can be adjusted within 50 nm-10 mum, has a specific surface area of 100-1000 m<2> / g, and can be used in electrode materials of supercapacitors, electrode materials of lithium ion batteries, electrode materials of capacitance method desalination devices, blood purification, catalyst carriers, water treatments, gas purification, solvent recovery and the like.

Owner:NO 63971 TROOPS PLA

Biological degradation liquid film and preparation method

InactiveCN101161718AHigh strengthImprove water resistanceOrganic fertilisersSoil conditioning compositionsCarboxymethyl cellulosePlasticizer

The invention belongs to a biodegradation liquid mulching film and the preparation method thereof. The invention prepares polyvinyl alcohol into an aqueous solution with mass fraction of 5-10 percent; carboxymethyl cellulose is also prepared into an aqueous solution with mass fraction of 5-10 percent; starch with mass fraction of 5-10 percent is added into a reactor having an agitator, a condenser and a thermometer and is gelatinized for 30 minutes under 75-85 DEG C and then becomes transparent and slabby starch paste, the prepared polyvinyl alcohol solution and carboxymethyl cellulose solution are then added into the reactor, and surfactant and plasticizer are also added into the solution. The PH value is set as 2-4, cross-linking agent is then added, and the biodegradation liquid mulching film is obtained after 1-2-hour reaction under 85-90 DEG C. The film can be sprayed to the land surface through spray method after being thinned up.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

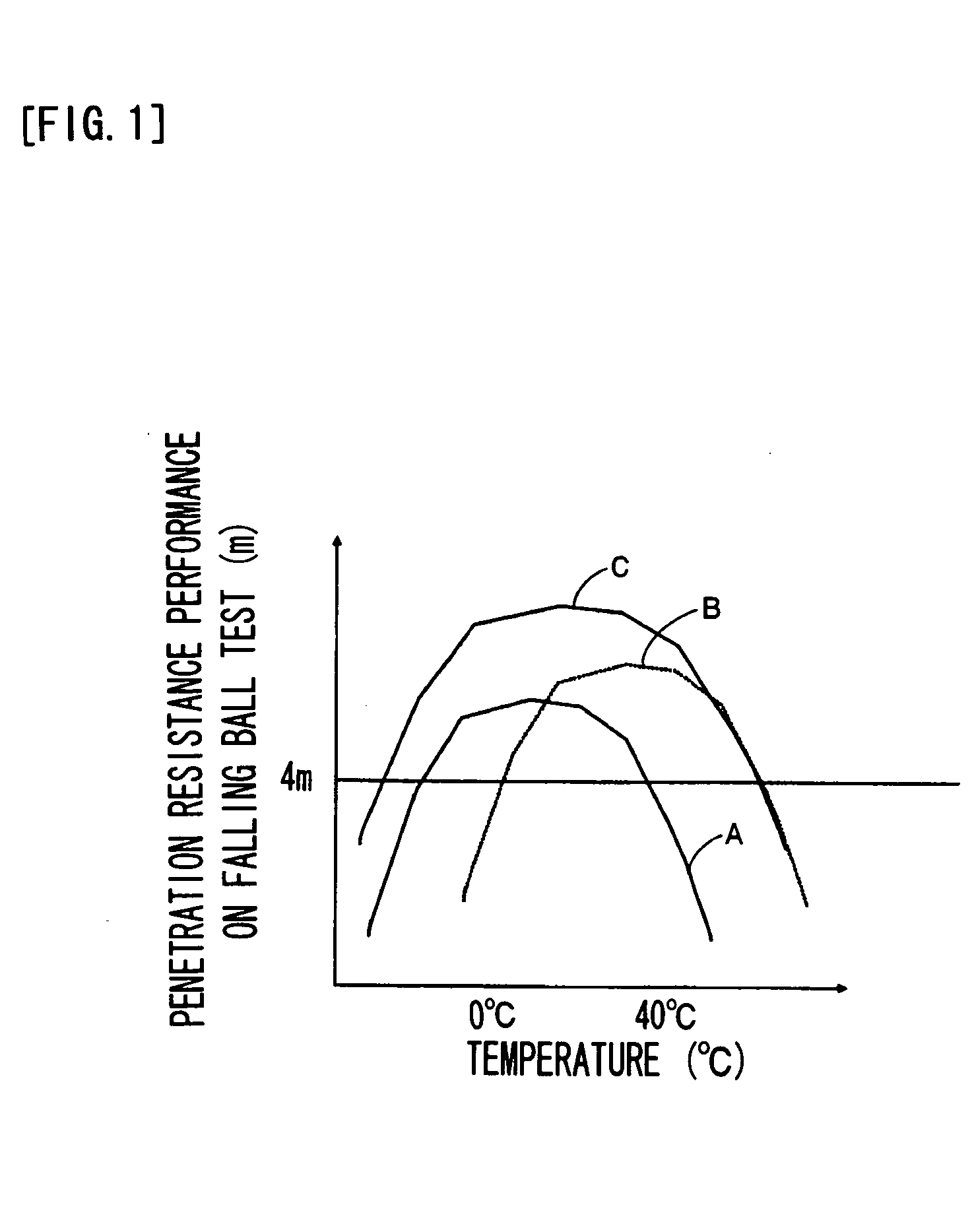

Thermoplastic resin sheet and laminate

ActiveUS20070014976A1Improve impact resistanceReduced in surface densitySynthetic resin layered productsVehicle componentsAcetic acidPVA - Polyvinyl alcohol

A thermoplastic resin sheet is provided which has good penetration resistance over a range from low to high temperature region and can be used as an intermediate film of a laminated glass. The thermoplastic resin sheet has such a layered structure that a first polyvinyl acetal resin layer (A) is provided on each side of a second polyvinyl acetal resin layer (B). The first polyvinyl acetal resin layer (A) is comprised mainly of an acetalized product of polyvinyl alcohol with aldehyde (a) having 4-6 carbon atoms. The second polyvinyl acetal resin layer (B) is comprised mainly of a coacetalized product of polyvinyl alcohol with aldehyde (a) having 4-6 carbon atoms and aldehyde (b) having 1-3 carbon atoms. A polymer unit (X) derived from the aldehyde (a) and a polymer unit (Y) derived from the aldehyde (b), in total, account for at least 55% by mole while the first polymer unit (X) alone accounts for 0.5-80% by mole of the total of the coacetalized product.

Owner:SEKISUI CHEM CO LTD

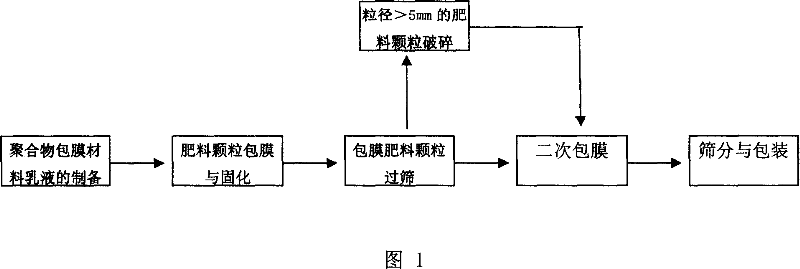

Biological biodegradable self-control slow-releasing fertilizer and preparation method thereof

ActiveCN101037368AImprove controllabilityGuaranteed degradabilityAgriculture gas emission reductionUrea compound fertilisersEpoxyPolymer science

The invention discloses a biodegradable self-controlling slow-release fertilizer which is produced by uniformly coating a layer of controlled-release layer of water soluble macromolecule polymer at the surface of the urea or complex fertilizer grain. The weight ratio of the complex fertilizer grain to macromolecule polymer is 0.3-0.4:9.7-9.6. The macromolecule polymer is produced in proportion of fibrin, oxidized starch, polyvinyl alcohol, polyurethane prepolyme, epoxide resin, epoxide resin solidified agent, cross linker, emolsifier, ignition primer, deionized water. The invention adopts glue and latex crosslinking with a biodegradable material to improve the controlled-release capability of the fertilizer and conquer the ''white pollution'', increase the usage ratio of nitrogen of 20-35%, and satisfy the crop need in a whole growth period.

Owner:格瑞昊尔斯生物科技(山东)有限公司

Polyvinyl alcohol-polypeptide-polyethylene glycol graft copolymer and preparation method thereof

InactiveCN102181060AEasy to manufacturePrecise control of relative contentDibutyl tin dilauratePolyethylene glycol

The invention relates to a polyvinyl alcohol-polypeptide-polyethylene glycol graft copolymer and a preparation method thereof. The molecular weight of polyvinyl alcohol is 20,000-80,000; the molecular weight of a polypeptide chain segment is 4,000-8,000; and the molecular weight of a polyethylene glycol chain segment is 350-750. The preparation method comprises the following steps of: (1) synthesizing a polypeptide homopolymer which contains an end-NCO radical: adding the polypeptide homopolymer, diisocyanate, dibutyltin dilaurate serving as a catalyst and dimethyl sulfoxide serving as a solvent into a reactor for reacting to obtain a target product; (2) synthesizing a polyvinyl alcohol-polypeptide graft copolymer: adding the polypeptide homopolymer which contains the end-NCO radical, the solvent and the catalyst into the reactor, adding polyvinyl alcohol and reacting to obtain a target product; and (3) synthesizing a polyvinyl alcohol-polypeptide-polyethylene glycol graft copolymer: adding the polyvinyl alcohol-polypeptide graft copolymer, the solvent and the catalyst into a drying reactor, adding polyethylene glycol monomethyl ether and reacting to obtain a target product.

Owner:SHANDONG UNIV OF TECH

High solid content vinyl acetate-ethylene copolymer emulsion and method for synthesizing the same

ActiveCN101200518AReduce consumptionIncrease the conversion rate of the polymerization reactionMonocarboxylic acid ester polymer adhesivesSodium bicarbonatePhenol

The present invention relates to high solid content vinyl acetate-ethylene copolymer latex for binder and the synthetic method, including 55 to 75 portion of vinyl acetate, 24 to 45 portion of ethylene, 3 to 5 portion of N-methylol acrylamide, 2 to 4 portion of PVA1788 and PVA0588, 0.4 to 1.0 portion of the compound of nonionic emulsifying agent nonyl phenol polyoxyethylene alkyl ether and anion emulsifying agent alkyl sulphate with 2:1 mixture ratio, 0.2 to 1.0 portion of 35 percents oxydol with 1:1 mixture ratio, 0.05 to 0.4 portion of formol zinc sulphate, 0.1 to 0.5 portion of ferrous sulphate, 0.5 to 1.0 portion of regular dodeca-carbon thiol-alcohol, 0.05 to 0.35 portion of potassium phosphate, 0.1 to 0.5 portion of sodium bicarbonate and 45 to 55 portion of de-ionized water. With the adoption of latex polymerization, low-residual monomer VAE latex with solid content more than 65 percents is synthesized, which is used as binder to be applied in timber processing industry and packaging industry.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com