Patents

Literature

131results about How to "Guaranteed degradability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing amylaceous fully degradable plastic

A starch-type fuel-degradable plastics is prepared from superfine starch, plasticizer, compatibilizer, cooxidanta nd synthetic degradating material. Its advantages are synergistic effect of the combination of optical degradation, thermal oxidizing degradation and biologic degradation and short degradation period (one year).

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

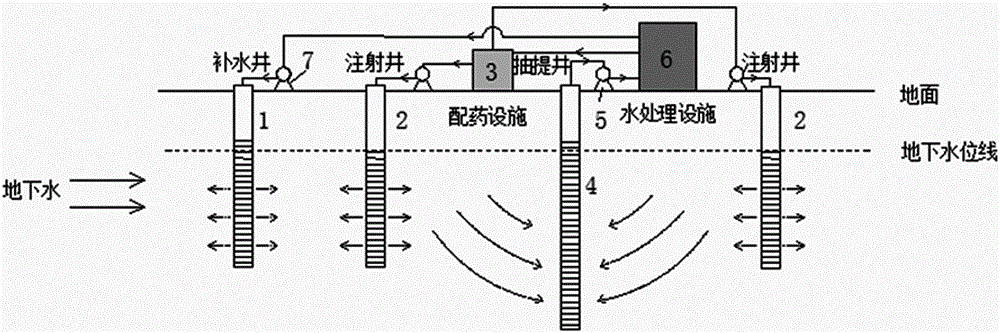

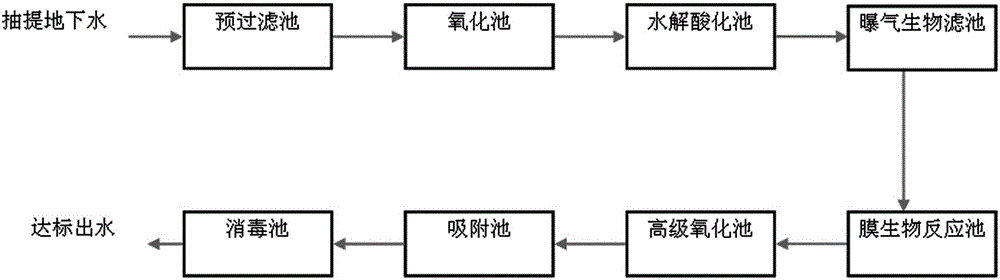

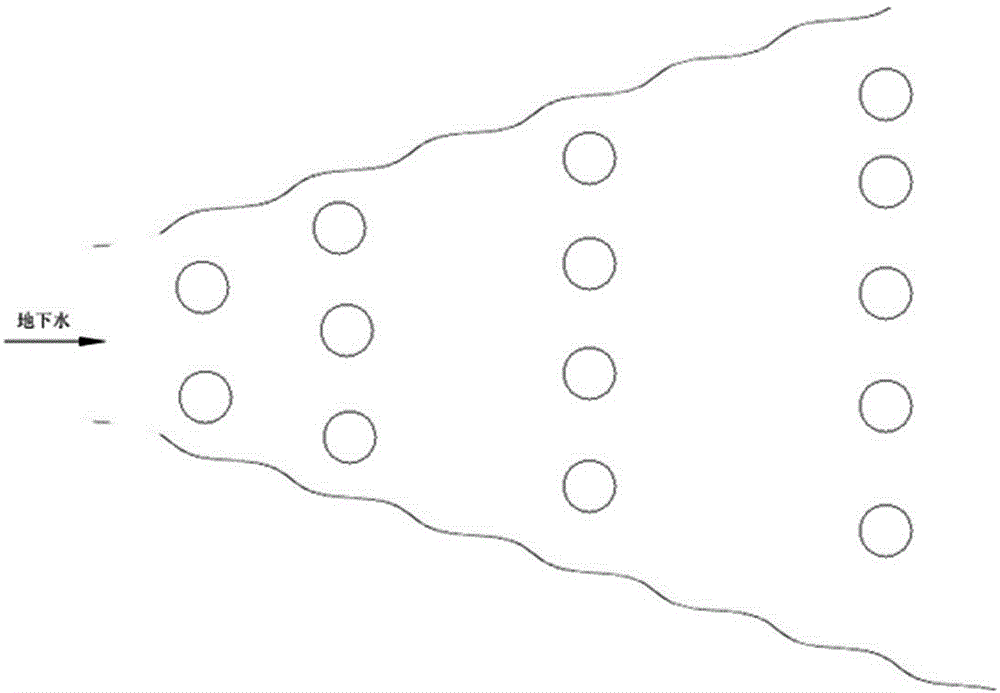

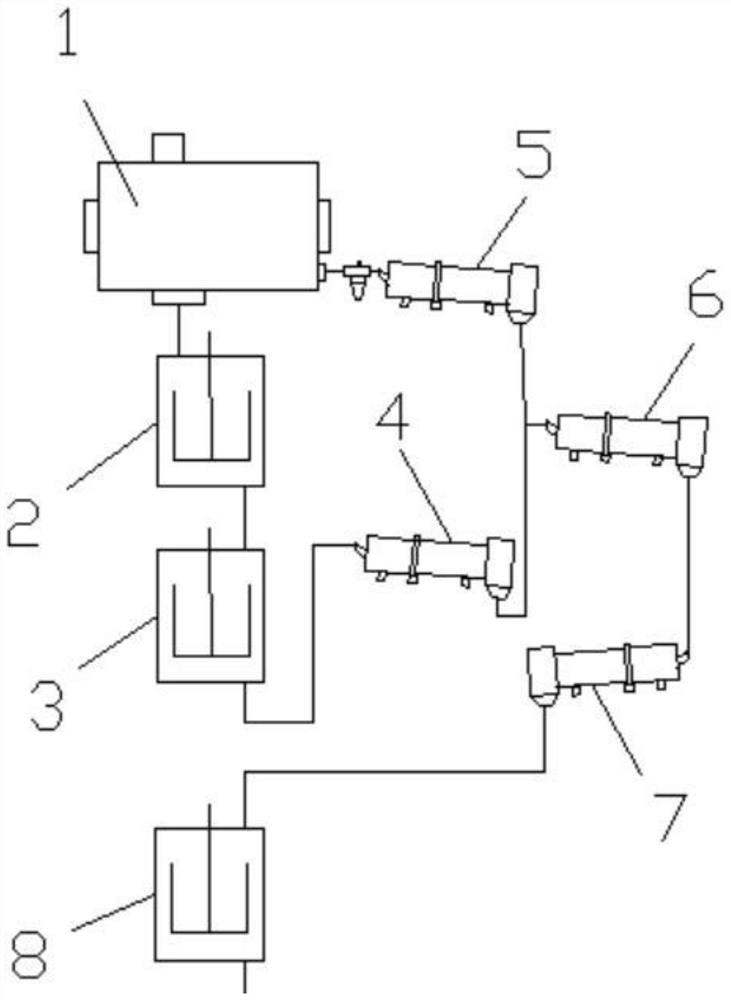

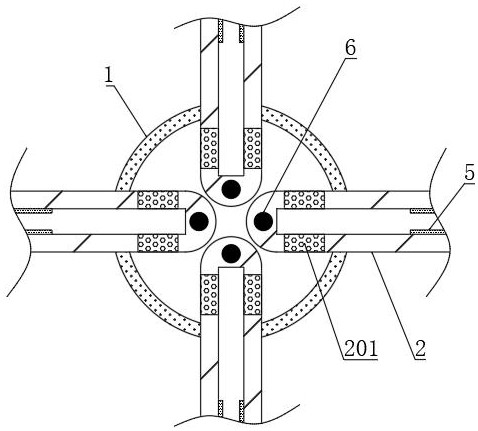

In-situ injection-extraction-water replenishing circulatory disposal system for organic contaminated soil and groundwater and combined remediation method

ActiveCN105032916ASpeed up the flowIncrease the speed of diffusionContaminated soil reclamationMultistage water/sewage treatmentInjection wellWater treatment

The invention discloses an in-situ injection-extraction-water replenishing circulatory disposal system for organic contaminated soil and groundwater and a combined remediation method. The system is consist of an injection well, an extraction well, a water replenishing well, a water treatment facility, a dispensing facility. The method comprises the following steps: extracting a pollution source or groundwater in a seriously polluted area to the ground for processing, then using the processed groundwater as a preparation drug or as replenished water to be directly injected to the underground, and injecting the drug into the underground pollution plume area through the injection well. The system and the method are used for processing the organic contaminated soil and groundwater in situ and have the advantages of being small in disturbance, environmental-friendly, short in remediation cycle and wide in range of application and has no secondary pollution.

Owner:中节能大地(杭州)环境修复有限公司

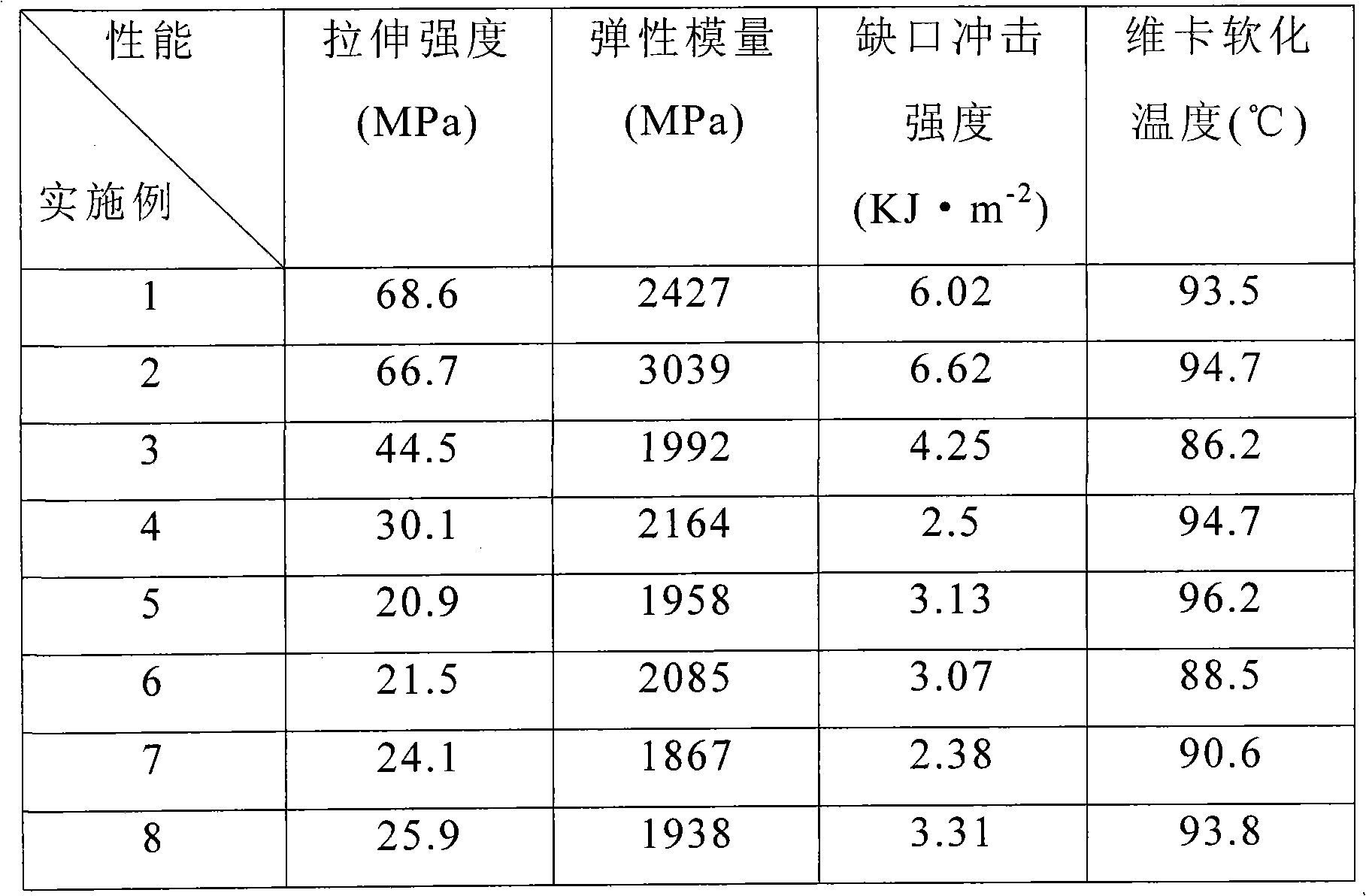

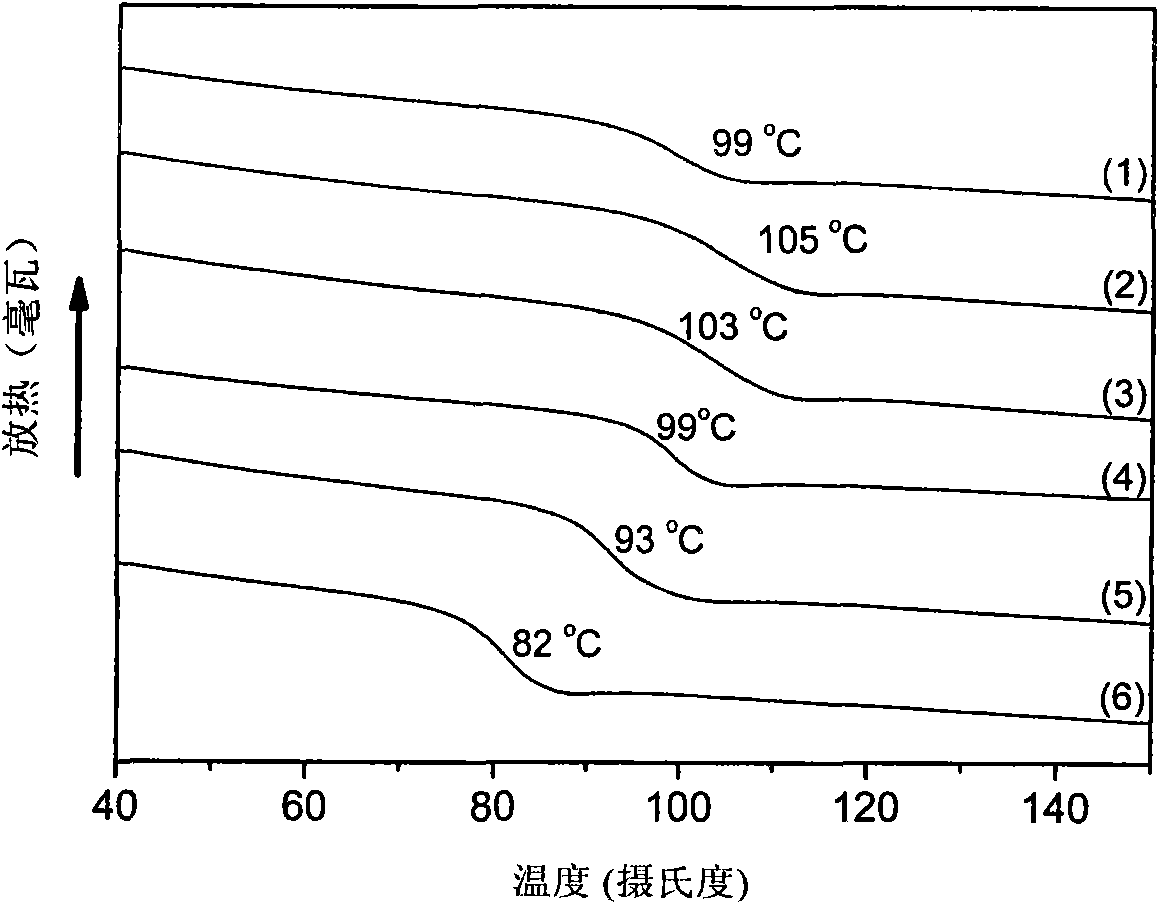

Heat-resistant polylactic acid composite material and preparation method thereof

The invention provides a heat-resistant polylactic acid composite material and a preparation method thereof, which belong to the technical field of polymer materials. The preparation method solves the technical problems of low product biodegradability, high cost, poor mechanical performance and the like of the prior method for preparing polylactic acid crosslinking materials and polymer crosslinking materials. The heat-resistant polylactic acid composite material comprises the following components in portion by weight: 50 to 99 portions of polylactic acid resin with an oligomerization-D lactic acid content, 0.1 to 15 portions of nucleating agent and 1 to 50 portions of starch or modified starch, wherein the content of a poly-D lactic acid in the poly-lactic acid resin with the oligomerization-D lactic acid content is less than 5 weight percent. The preparation method for the composite material comprises the following steps: a, mixing and pelleting; b, injection molding; and c, heat treatment. The composite material has the advantages of high mechanical and heat-resistant performance. The preparation method for the composite material is simple in technical process, high in processability and low in cost and can realize large-scale industrial production.

Owner:ZHEJIANG HISUN BIOMATERIALS

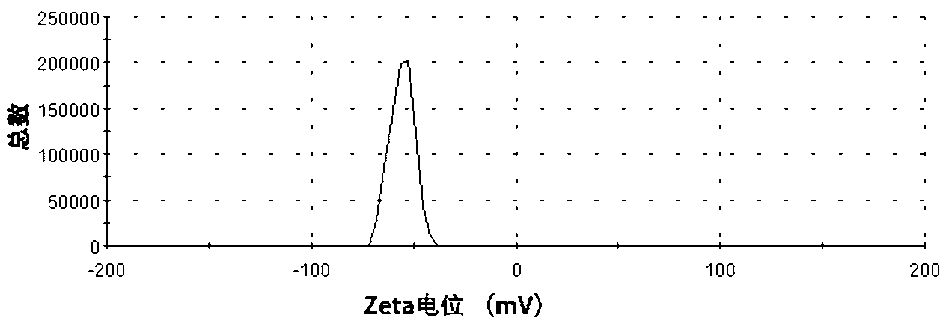

Preparation method based on amphoteric cellulose composite material

InactiveCN103480344AImprove adsorption capacityReasonable useOther chemical processesCellulosePolymer science

The invention discloses a preparation method based on an amphoteric cellulose composite material. Cellulose is used as a raw material to obtain amphoteric quaternary ammonium-sulfated cellulose, then the amphoteric quaternary ammonium-sulfated cellulose is used as a carrier of oxidized grapheme and chitosan, the amphoteric quaternary ammonium-sulfated cellulose, the oxidized grapheme and the chitosan can be powerfully combined under the actions of the covalent bond, the electrostatic attraction, the hydrogen bond and the like, and then is subjected to freeze-drying to obtain the amphoteric quaternary ammonium-sulfated cellulose, the oxidized grapheme and the chitosan ternary composited material. The composite material has the renewability, the degradability, green and environment-friendly effect and high-efficiency adsorbability, the condition is mild and easy to realize in the preparation process, and the cellulose can be reasonably and effectively utilized, therefore, the preparation method has good economic and social benefits.

Owner:SUZHOU UNIV

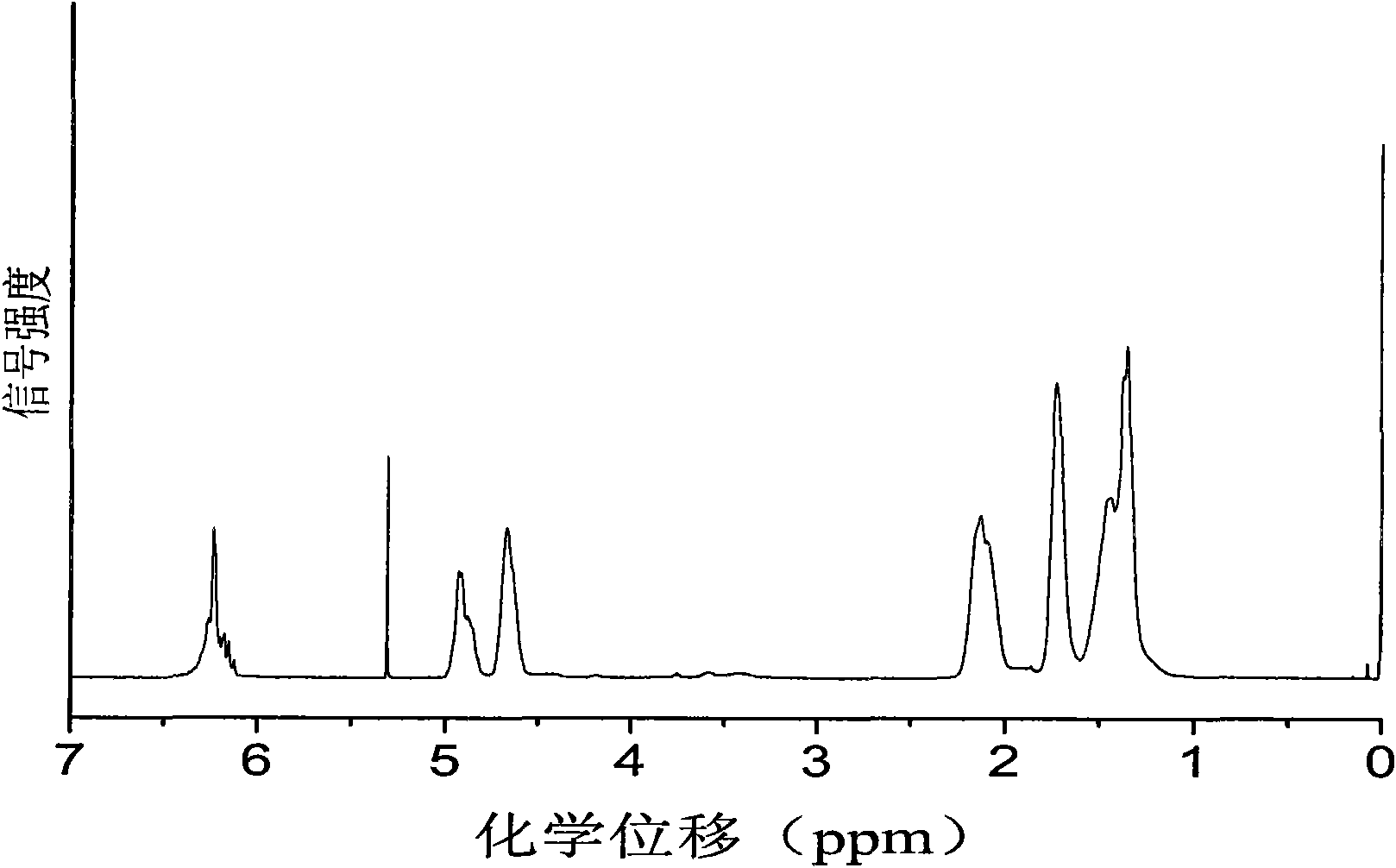

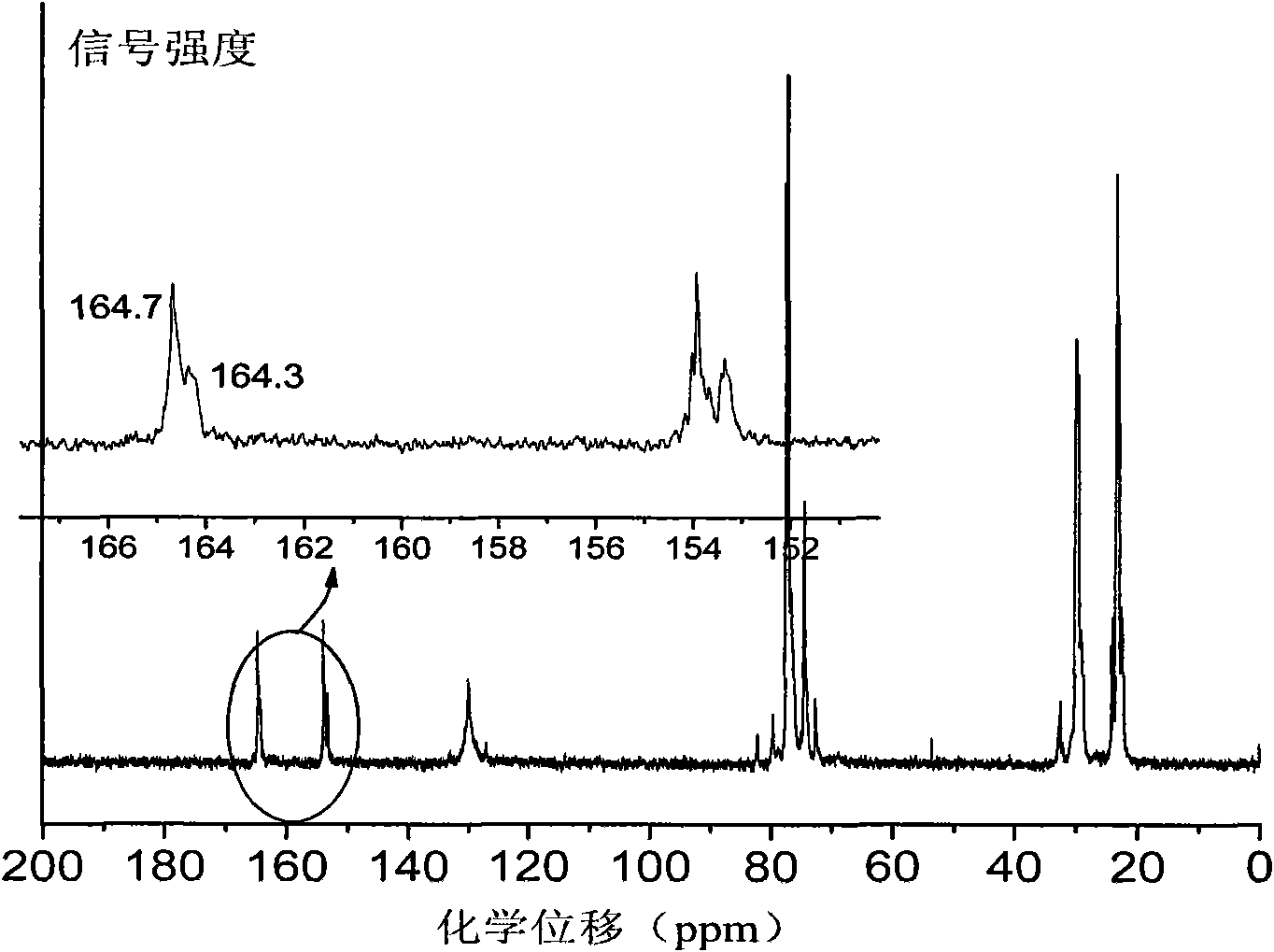

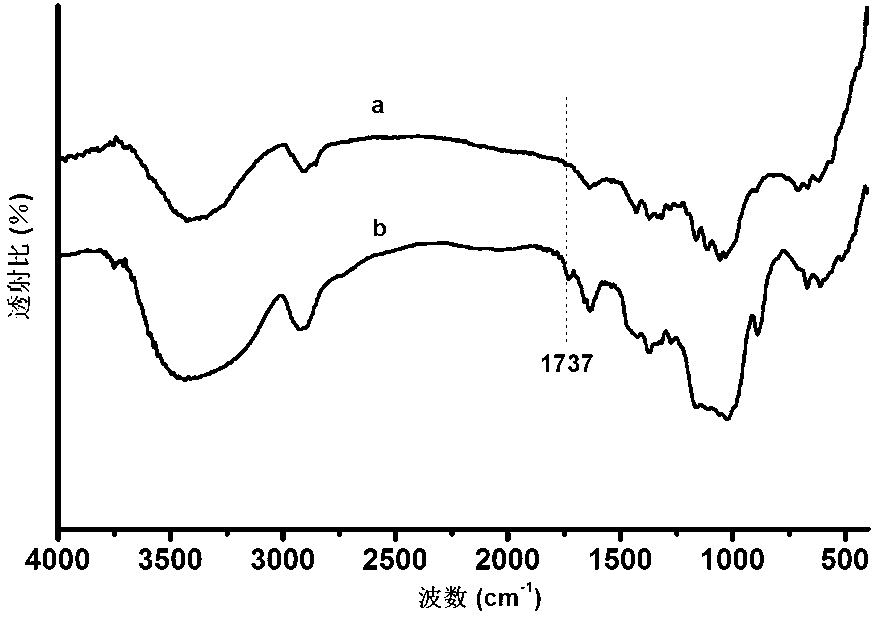

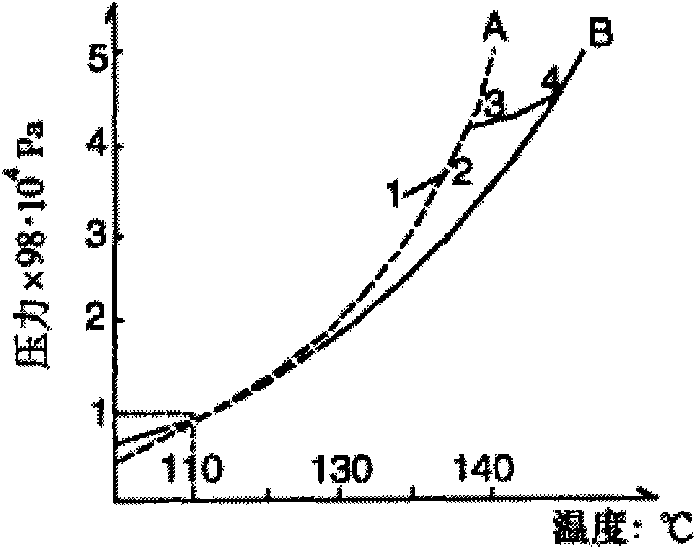

Terpolymer containing polyester chain links and polycarbonate chain links and synthetic method thereof

The invention discloses a terpolymer containing polyester chain links and polycarbonate chain links and a synthetic method thereof. The synthetic method comprises the following steps: mixing zinc-cobalt double metal cyanide complex catalyst, cyclohexene oxide and dicarboxylic anhydride in a solvent, introducing CO2 under the temperature of 30 to 150 DEG C till the pressure of CO2 is 0.5 to 10.0MPa, carrying out copolyreaction for 0.5 to 48 hours so as to obtain a crude product, and preparing the terpolymer which contains polyester chain links and polycarbonate chain links and has excellent thermal property and easy decomposition after purification. The molar percentage content of the polyester chain links, the polycarbonate chain links and polyether chain links of the terpolymer containing polyester chain links and polycarbonate chain links in the main chain are respectively 5 to 70 percent, 23 to 90 percent and 0.5 to 7 percent.

Owner:ZHEJIANG UNIV

Preparation method of colloidal solution of nano-ZnO

InactiveCN103318945AImprove water solubilityLow viscosityMaterial nanotechnologyZinc oxides/hydroxidesHydroxypropylmethyl celluloseChemistry

The invention discloses a preparation method of a colloidal solution of nano-ZnO. The method comprises the following steps: mixing an aqueous modified cellulose solution having a concentration of 0.001-100g / L with a zinc salt solution having a concentration of 0.01-100g / L according to a volume ration of 1:10-100:1, wherein the modified cellulose is dialdehyde hydehydroxypropyl methyl cellulose obtained through the selective oxidation of the secondary hydroxyl groups in the C2 and C3 positions of hydroxypropyl methyl cellulose; and slowly adding an alkaline solution for adjusting the pH value to 8.5-11.5, and stirring at 20-90DEG C for 1-600min until reaction completion in order to obtain the colloidal solution of nano-ZnO having an average particle size of 1-100nm. The prepared nano-ZnO has the advantages of ultrahigh stability, antibiosis and ultraviolet resistance, good biocompatibility and good biodegradability, and can be applied to the coat field, the textile field, the medical health field and the like.

Owner:SUZHOU UNIV

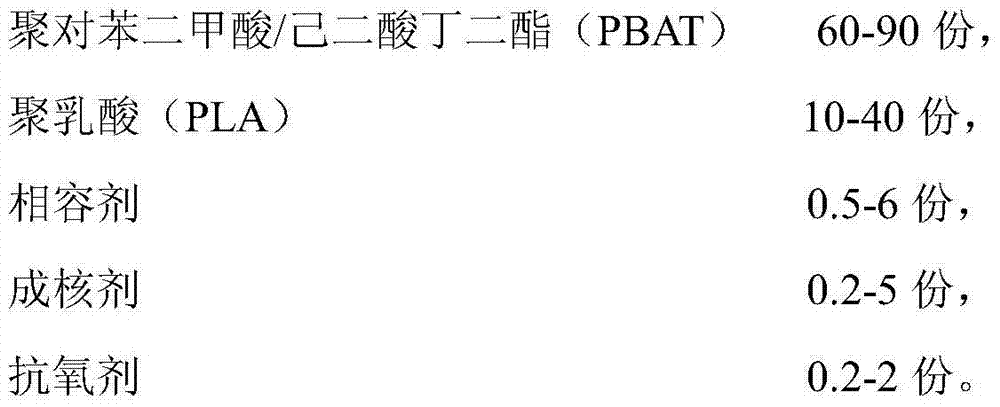

Degradable fiber and preparation method thereof

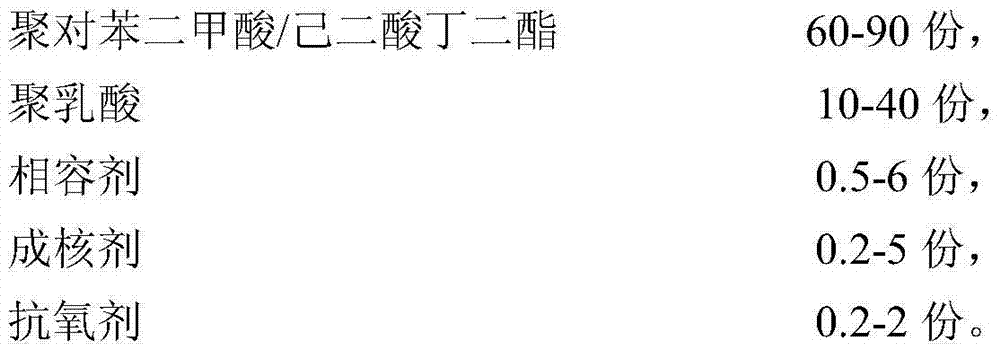

ActiveCN104514041AHigh mechanical strengthGood melt spinnabilityConjugated synthetic polymer artificial filamentsArtifical filament manufactureFiberPolymer science

Belonging to the technical field of high polymer materials, the invention relates to a degradable fiber and a preparation method thereof. The degradable fiber material is prepared from the following components by weight: 60-90 parts of poly(butylene adipate / terephthalate), 10-40 part of polylactic acid, 0.5-6 parts of a compatibilizer, 0.2-5 parts of a nucleating agent, and 0.2-2 parts of an antioxidant. Compared with the prior art, the degradable fiber provided by the invention has good melting spinnability under a low spinning temperature of 170-240DEG C and a high spinning speed of 500-2000m / min, and can crystallize in later spinning and treatment processes, so that the fiber can have high mechanical strength and lasting and steady soft handfeel, and can satisfy the use requirements so as to expand application fields.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

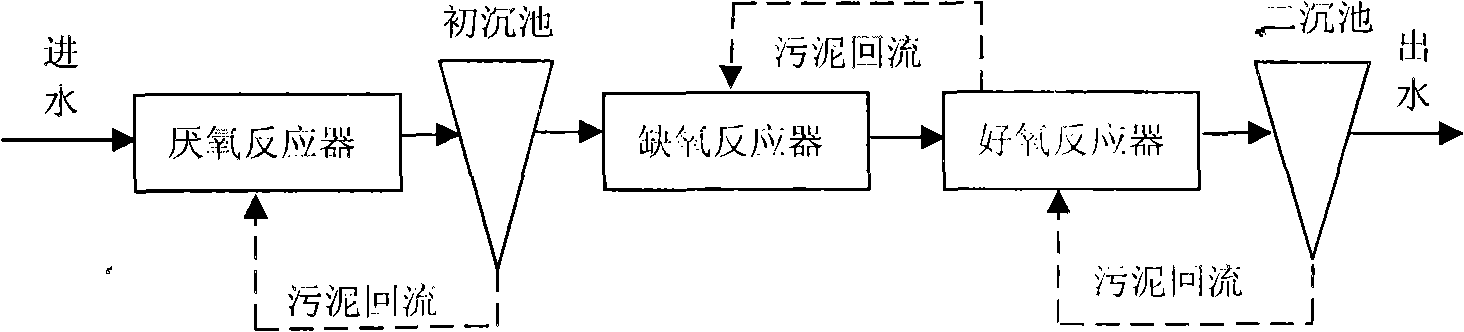

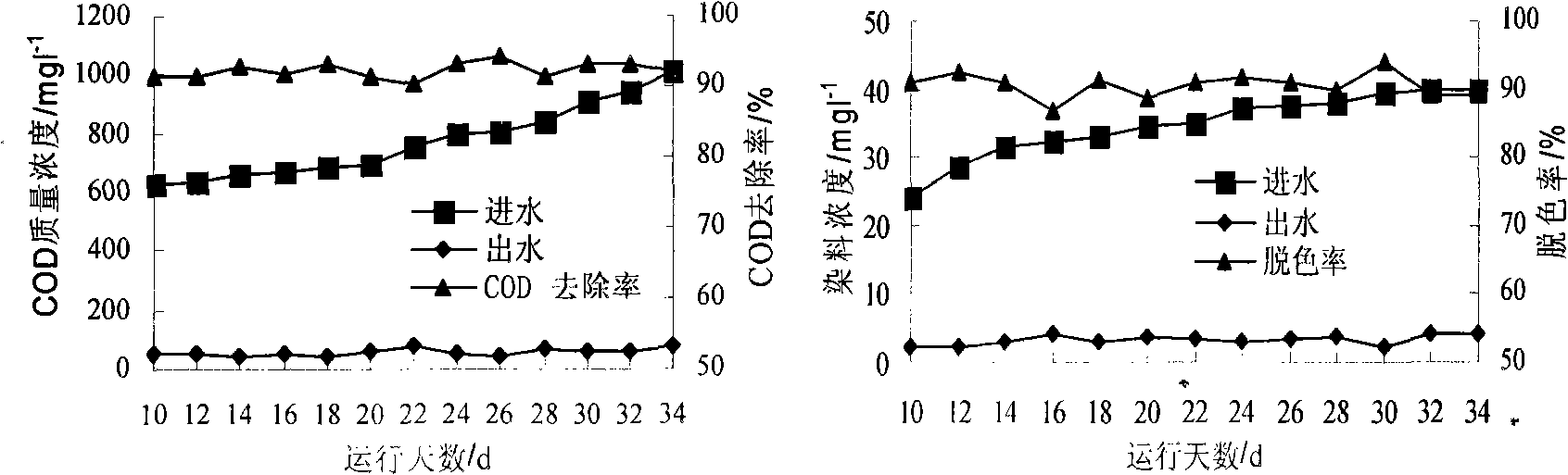

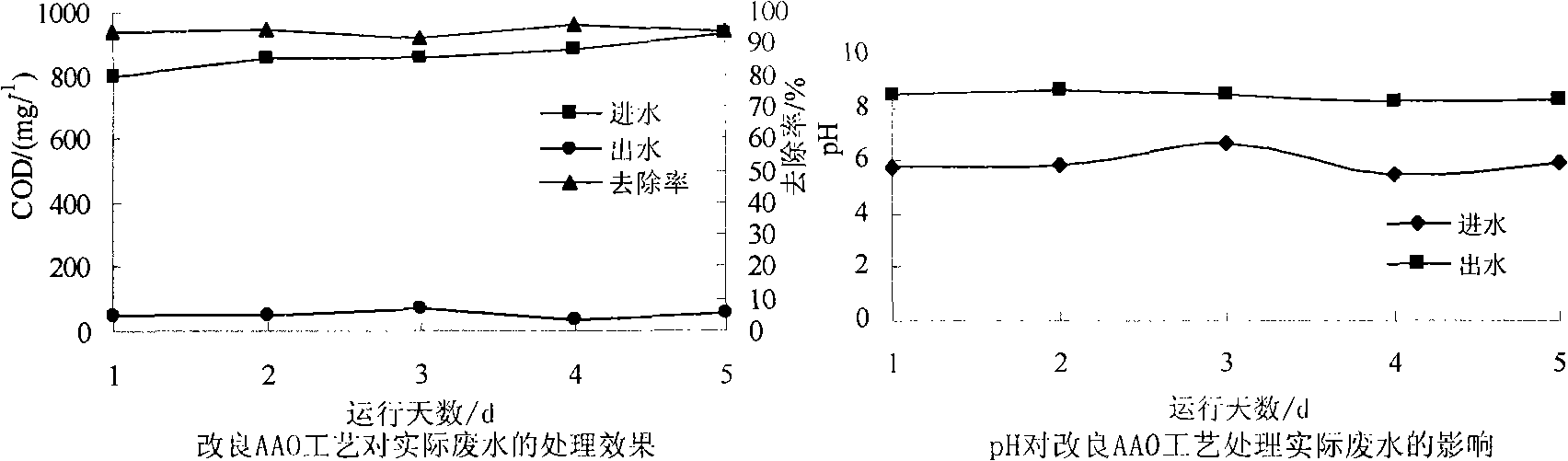

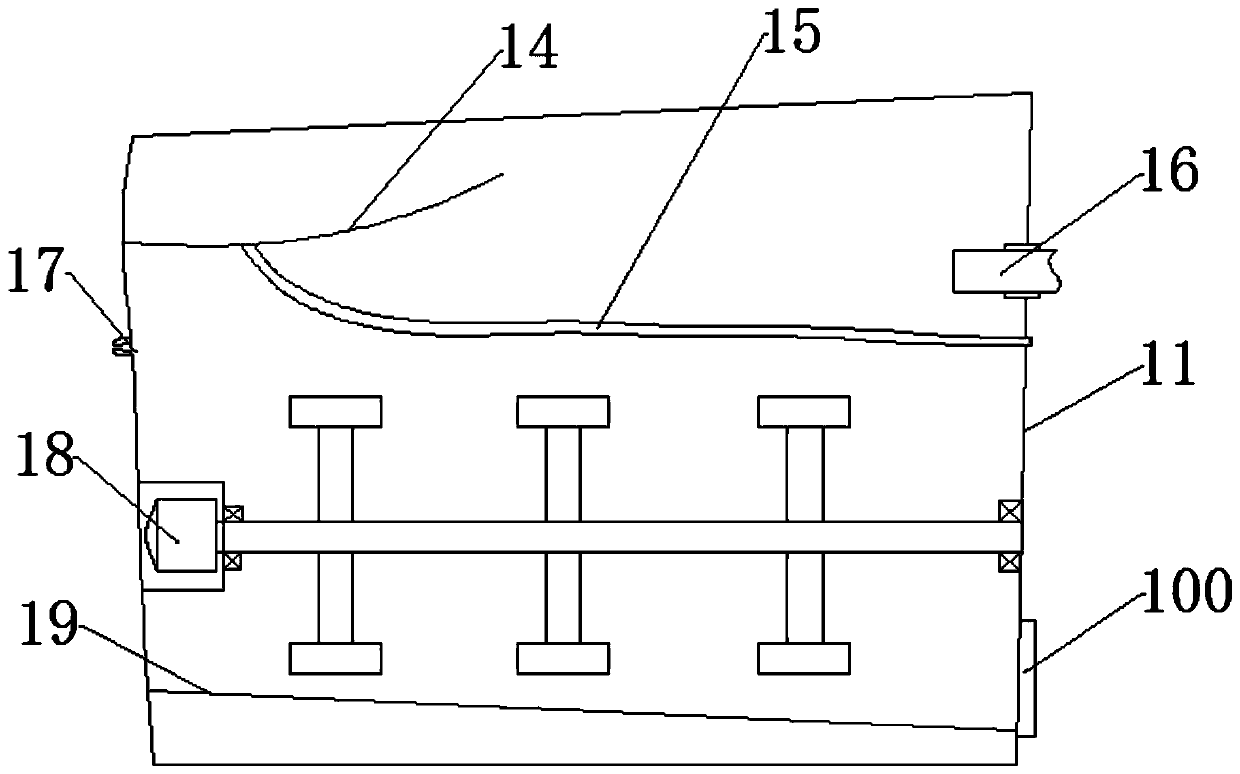

Device for improving AAO treated dyeing wastewater and method thereof

InactiveCN101774690AGuaranteed degradabilityFew influencing factorsTreatment with aerobic and anaerobic processesWaste water treatment from textile industryAerobic organismAnaerobic reactor

The invention relates to a method for improving AAO treated dyeing wastewater and a device thereof. The device comprises an anaerobic reactor, a primary settling tank, an anoxic reactor, an aerobic reactor and a secondary settling tank, wherein the anaerobic reactor is communicated with the primary settling tank, the anoxic reactor, the aerobic reactor and the secondary settling tank through pipelines in sequence; the primary settling tank is communicated with the anaerobic reactor through a sludge pump by a return pipe; the aerobic reactor is communicated with the anoxic reactor through the sludge pump by the return pipe; and the secondary settling tank is communicated with the aerobic reactor through the sludge pump by the return pipe. The method comprises the following steps: controlling the reflux ratio of sludge to be maintained at 100 percent and the reflux ratio of mixed solution to be 100 percent without sludge discharge at environmental temperature of between 20 and 30 DEG C, wherein preferably, retention period of an anaerobic unit is 6.5 hours, retention period of an anoxic unit is 6.5 hours, and the retention period of an anoxic unit is 16 hours; and then discharging water. The method and the device are organically combined with anaerobic, anoxic and aerobic biological treatment methods to achieve advantage complementation with one another.

Owner:DONGHUA UNIV

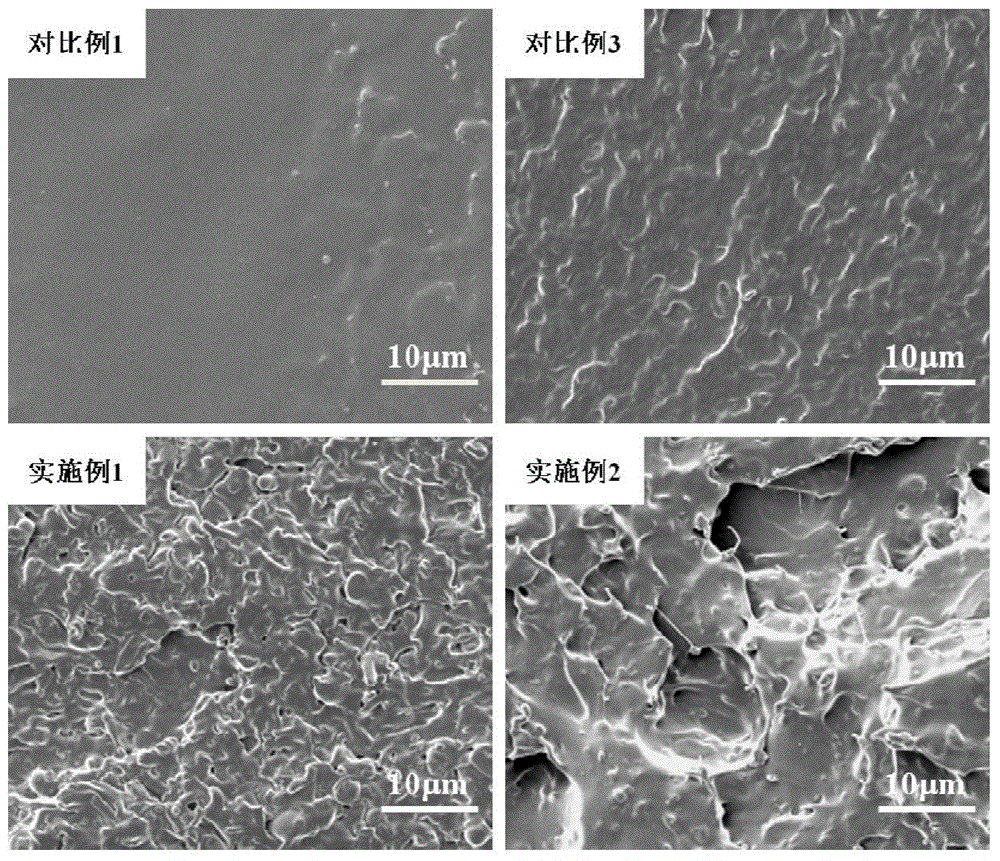

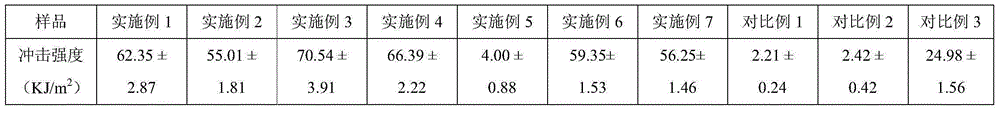

Reactive blending and toughening modified polylactic acid based composite material and preparation method thereof

The invention provides a reactive blending and toughening modified polylactic acid based composite material and a preparation method thereof. The composite material comprises raw materials including 70-90 parts by weight of polylactic acid, 10-30 parts by weight of a toughening agent soft segment, a cross-linking agent and a toughening agent hard segment, wherein the dosage of the cross-linking agent accounts for 1%-15% of the weight of the toughening agent soft segment; the dosage of the toughening agent hard segment is determined according to an amount ratio of contained isocyanic acid functional groups to total hydroxyl substances contained in the toughening agent soft segment and the cross-linking agent being (1.0-1.05):1. The high-toughness polylactic acid based composite material can still keep the degradable feature of polylactic acid, further, the preparation method is simple and easy, and the property of polylactic acid can be regulated and controlled by changing the molecular weight, the content and the degree of crosslinking of the toughening agent soft segment.

Owner:ZHEJIANG UNIV OF TECH

Leaf vegetable release-controlling fertilizer

InactiveCN101215202APromote growthIncrease plant heightSuperphosphatesAlkali orthophosphate fertiliserSocial benefitsLeafy vegetables

The invention discloses a controlled release fertilizer of leafy vegetable, which is composed of the following components with the following weight proportion, (NH4)2HPO4 taking 14-16, (NH4)2SO4 taking 3-5, NH4Cl taking 13-20, K2SO4 taking 35-40, calcium superphosphate taking 8-15, diatomite taking 7-12 and high molecular polymer taking 20-25. The controlled release fertilizer of leafy vegetable effectively holds the rule of the fertilizer efficiency releasing and the fertilizer requirement of the leafy vegetable and achieves the anastomosis of the releasing peak of the azophoska fertilizer and the peak of leafy vegetable absorbing azophoska, thereby being more beneficial to the absorbability and the utilization of the fertilizer, decreasing fertilizing frequency, saving time and fertilizing amount, having perfect economic benefit and social benefit.

Owner:SHANDONG UNIV

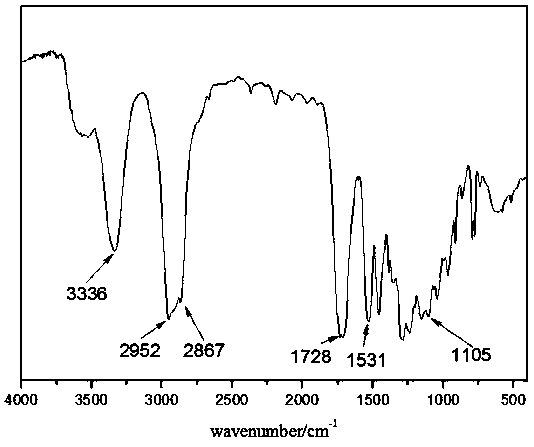

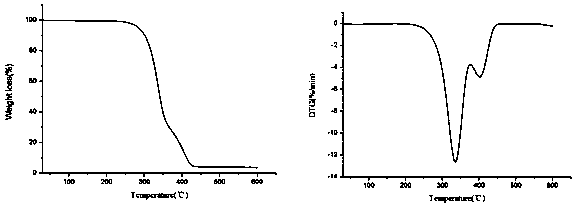

Degradable polyurethane biological material and preparation method thereof

The invention discloses a degradable polyurethane biological material and a preparation method thereof. The degradable polyurethane biological material is prepared from the following components in parts by weight: 7.8 to 19 percent of poly epsilon-caprolactone (PCL), 3 to 15.6 percent of polyethylene glycol (PEG), 12.8 to 13.8 percent of isocyanate, 3.1 to 4.1 percent of a chain extender, 0.09 to0.11 percent of a catalyst and 57.6 to 63 percent of a green solvent, wherein isophorone diisocyanate (IPDI), hexamethylene diisocyanate (HDI), dicyclohexyl methane diisocyanate (HMDI) or mixed isocyanate of more than two of the above materials is adopted as the isocyanate. The preparation method comprises the following steps: blending according to the proportion of the raw materials, adding the vacuum-dried PCL and PEG into the isocyanate dropwise, reacting at 70 to 85 DEG C for 2 to 3 hours, adding the solvent and the catalyst, adjusting the temperature to be 55 to 65 DEG C, adding the chainextender, performing chain-extending reaction for 4 to 5 hours, casting the obtained polyurethane solution on a polytetrafluoroethylene mold, and naturally volatilizing the solvent in a ventilation kitchen to prepare a polyurethane film.

Owner:ZHENGZHOU UNIV

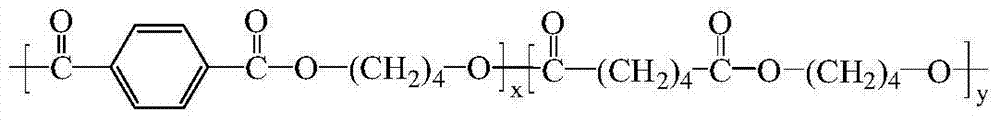

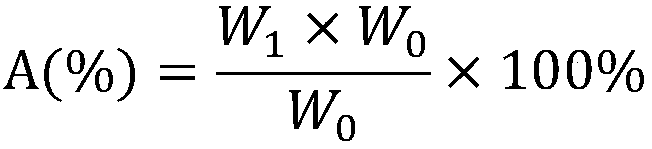

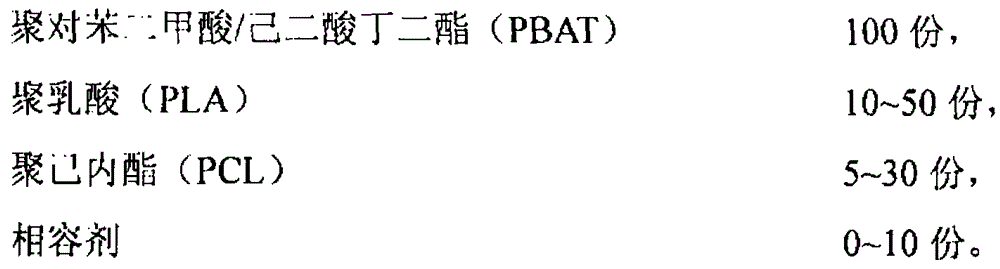

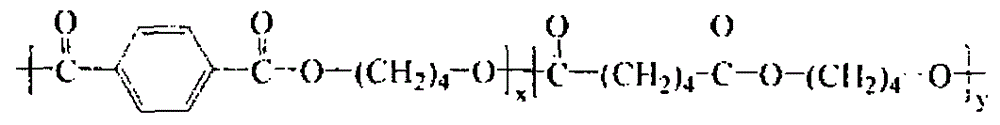

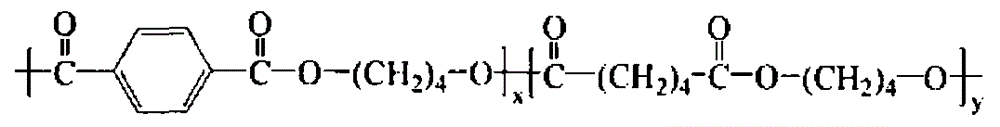

PBAT melt-blowing degradable non-woven fabric and manufacturing method thereof

InactiveCN105586712ALarge specific surface areaHigh porosityHeating/cooling textile fabricsMelt spinning methodsPorosityEngineering

The invention relates to a PBAT melt-blowing degradable non-woven fabric and a manufacturing method thereof. The manufacturing method comprises: blending 100 parts of dried PBAT, 10-50 parts of dried polylactic acid, 5-30 parts of dried polycaprolactone, and 0-10 parts of compatilizer for 3-10 min, through a screw extruder, heating, melting, and extruding the above to form a melt, when the melt is extruded from the spinneret orifice of a die head, the melt being blown by high-pressure hot airflow on two sides of the spinneret orifice, and being stretched to superfine fibers and coagulating on a drum-type receiver which is a certain distance away from the nozzle, the superfine fibers bonding to form a non-woven fabric, after being cooled, taking the non-woven fabric down from the drum and putting the non-woven fabric in a drying oven to dry and shape, to obtain the PBAT melt-blowing degradable non-woven fabric. Compared with the prior art, the method is simple in device, short in process flow, and low in energy consumption. Using the melt-blowing method to manufacture the non-woven fabric, fibers of the non-woven fabric are thin in diameter, and the non-woven fabric is characterized by large specific surface area, high porosity, and excellent filter efficiency.

Owner:六安载丰新材料有限公司

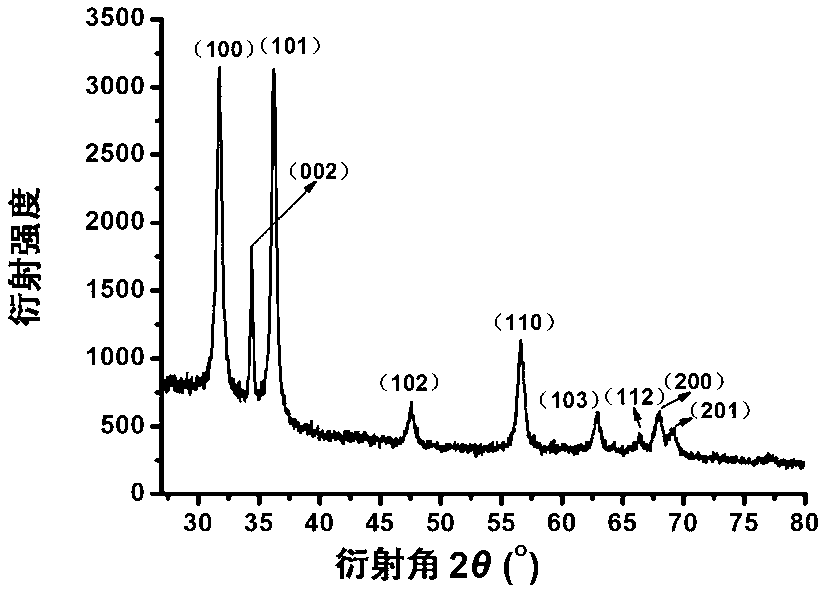

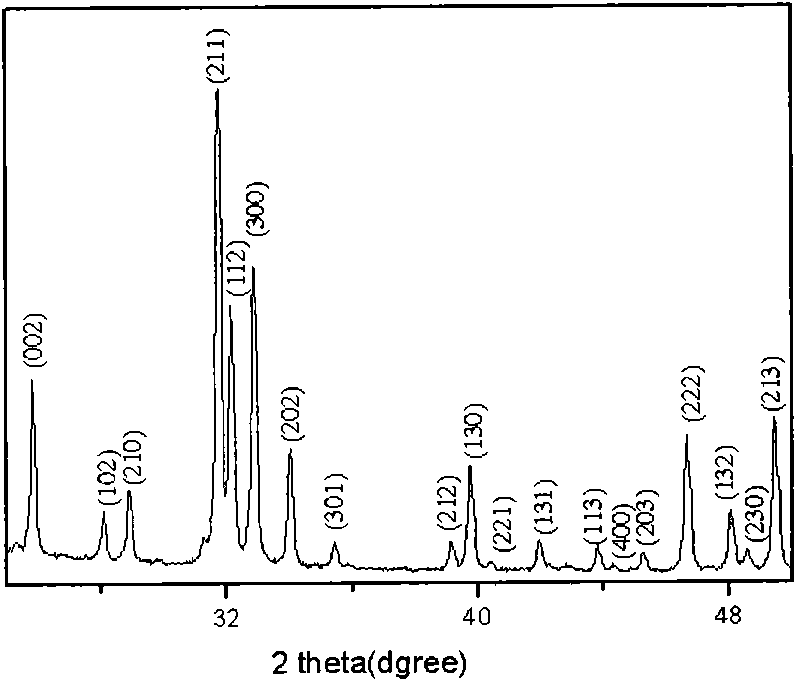

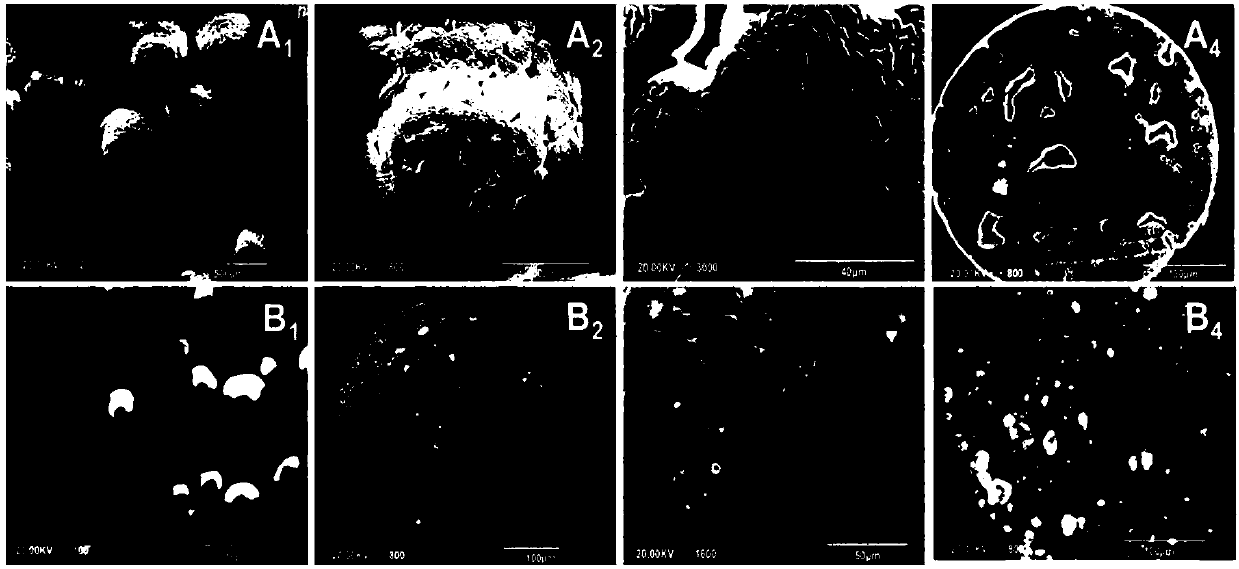

Alpha-calcium sulfate hemihydrates/beta-tertiary calcium phosphate porous granular-type composite artificial bones and preparation method thereof

The invention discloses a method for preparing alpha-calcium sulfate hemihydrates (alpha-CSH) / beta-tertiary calcium phosphate (beta-TCP) porous granular-type composite artificial bones, which is characterized in that the alpha-CSH is directly synthesized on the surface and / or in the pores of the beta-TCP granules synchronously by the hydrothermal synthesis process and finally the alpha-CSH / beta-TCP porous granular-type artificial bones is prepared. The invention has the advantages that the preparation process is simpler, the preparation period can be effectively reduced, and the preparation efficiency is improved; the proportion between alpha-CSH and beta-TCP phases of the granular-type composite artificial bones can be effectively controlled, thereby controlling the pore structure of the artificial bone granules; meanwhile, the invention guarantees the in-situ solidifying performance and degrading performance of the composite artificial bones, controls the evenness of the product and the porosity and pore diameter of the beta-TCP granules, improves the bone-formation performance and degrading performance of the composite artificial bones and further improves the quality of the product, thereby finally obtaining the composite artificial bones having self-solidifying performance and controllable degradation and having a certain biomechanical strength. The invention has good application and market prospect.

Owner:BEIJING ZHONGNUO HENGKANG BIOTECH

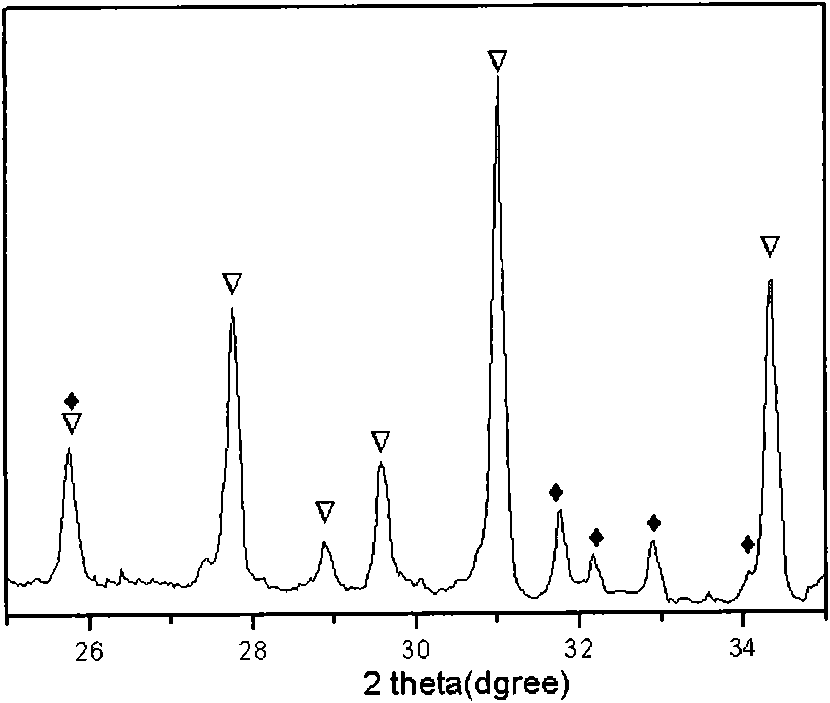

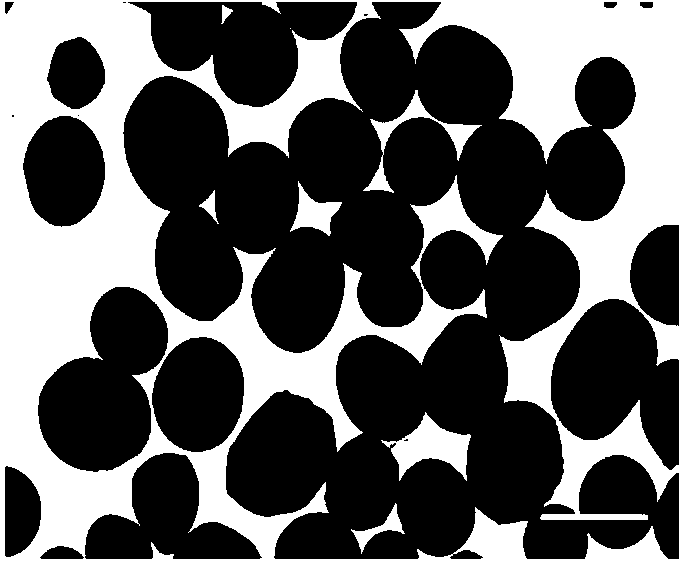

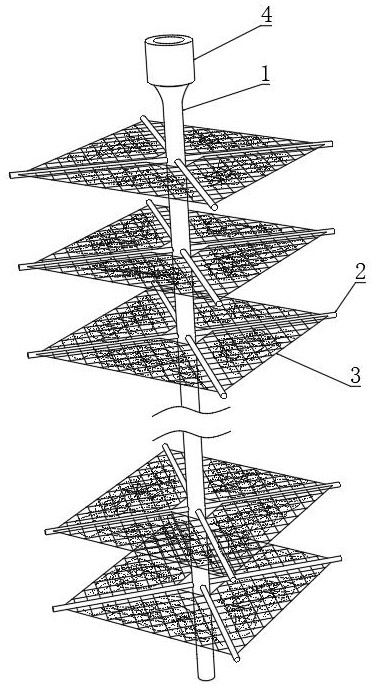

Preparation method of microcarrier used for cell three dimensional multiplication culture

InactiveCN107670113AGood biological propertiesHealthy growthPharmaceutical delivery mechanismTissue regenerationMicrosphereOsteoblast

The invention discloses a preparation method of a microcarrier used for cell three dimensional multiplication culture, and belongs to the field of tissue engineering material. According to the preparation method, Poly-L-lactic acid (PLLA) is taken as a matrix, gelatin is taken as a dispersant, and composite microspheres are prepared; the particle size of the composite microspheres is adjusted viacontrolling the concentration of a PLLA dichloromethane solution, the mass ratio of nano-hydroxyapatite (nHAp) to PLLA, and the using amount of gelatin; the PLLA is taken as the matrix to ensure the mechanical strength and biological degradability of a support; composite nHAp is capable of improving the osteo inductivity and the conductivity of the support, and at the same time, assisting PLLA toimprove cell osteogenic capability, and avoiding damage of cells under an overly acidic environment; the existing of nHAp is capable of forming a large amount of small pores on the surfaces of the PLLA microspheres, the existing of the small pores is capable of improving the mass transfer capability of the support, and providing cells with more abundant attachment sites. The microcarrier possessesexcellent biological performance on osteoblasts, and is suitable to be used in the field of bone tissue engineering.

Owner:DALIAN UNIV OF TECH

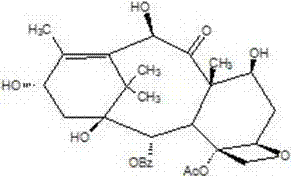

Method for extracting 10-deacetylbaccatin III from taxus chinensis

ActiveCN107880001AGuaranteed degradabilityGuaranteed damageOrganic chemistry10-DeacetylbaccatinAqueous solution

The invention discloses a method for extracting 10-deacetylbaccatin III from taxus chinensis. The method comprises the following steps: soaking and extracting 10-deacetylbaccatin III in taxus chinensis by adopting an aqueous solution containing a stability maintainer; and extracting, performing discoloring and flocculating treatment, recrystallizing and the like, thereby obtaining the high-purity10-deacetylbaccatin III. The method disclosed by the invention is clean, low in cost, non-harsh in extraction conditions, less in by-products, less in pigments and high in extraction rate, and is applicable to industrialized production and market popularization and application.

Owner:上海卓鼎生物技术有限公司

High-strength shape-memory 3D (three dimensional) printing bioplastics and preparation method

InactiveCN106928671AImprove mechanical propertiesHigh tensile modulusAdditive manufacturing apparatusCross-linkBiocompatibility Testing

The invention discloses high-strength shape-memory 3D (three dimensional) printing bioplastics. The high-strength shape-memory 3D printing bioplastics are prepared by compounding PLLA (Poly-L-lactic acid), PCL and CaCO3, wherein the PLLA accounts for 25 to 80 percent of the total mass of the material. The PCL accounts for 17 to 72 percent of the total mass of the material, the CaCO3 accounts for 3 percent of the total mass of the material, the high-strength shape-memory 3D printing bioplastics are prepared by virtue of fused deposition molding; the PLLA and the PCL are blended, so that the mechanical strength of the PCL is improved, good biocompatibility is ensured; by virtue of machining or radiation cross-linking treatment, the PLLA has the shape memory characteristics; after the PLLA is blended and extruded with the PCL, the shape memory property of the material can also be maintained; by adding little CaCO3, not only can a capacity increasing effect be achieved and the performance degradation caused by the mixing be avoided, the mechanical strength of the material can be further improved; and moreover, the invention also discloses a preparation method of the high-strength shape-memory 3D printing bioplastics. The method is easy in operation, low in technological conditions and low in requirement on production equipment, capable of being widely popularized, and wide in application prospect.

Owner:GUANGZHOU SUN SHING BIOTECH CO LTD

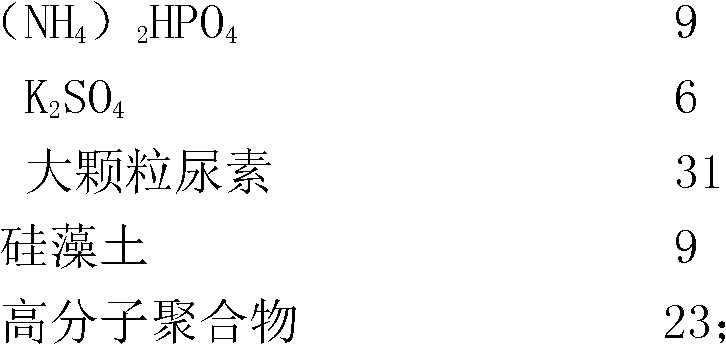

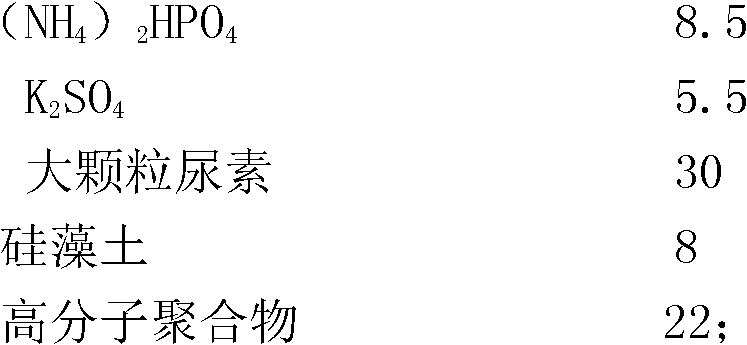

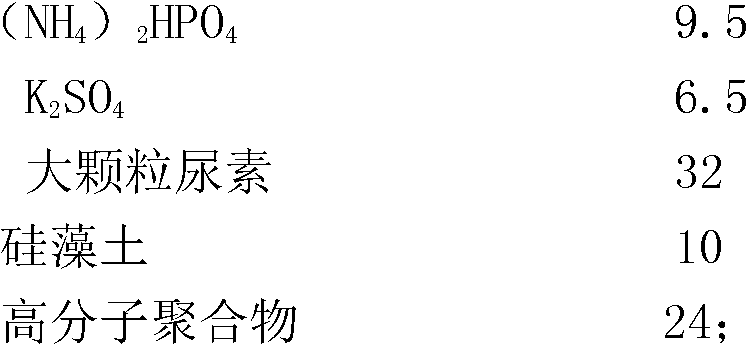

Corn slow-release fertilizer

InactiveCN102424641AGuaranteed degradabilityReduce dosageFertilizer mixturesWater solubleLarge particle

The invention discloses a corn slow-release fertilizer. The corn slow-release fertilizer is prepared by uniformly spraying a layer of water-soluble high molecular polymer on the surface of fertilizer particles, and comprises the following ingredients: 8.5-9.5 weight portions of (NH4)2HPO4, 5.5-6.5 weight portions of K2SO4, 30-32 weight portions of large particle urea, 8-10 weight portions of diatomite, and 22-24 weight portions of high molecular polymer. The corn slow-release fertilizer effectively overcomes nitrogen loss caused in fertilizing, increases the utilization rate of nitrogenous fertilizers, benefits the absorption and continuous utilization of crops, fully makes full use of the effects of fertilizers, and simultaneously increases the yield of corn. The corn slow-release fertilizer conforms to the policy guidance of developing energy saving, environment friendly, and continuously efficient agriculture.

Owner:SHANDONG UNIV

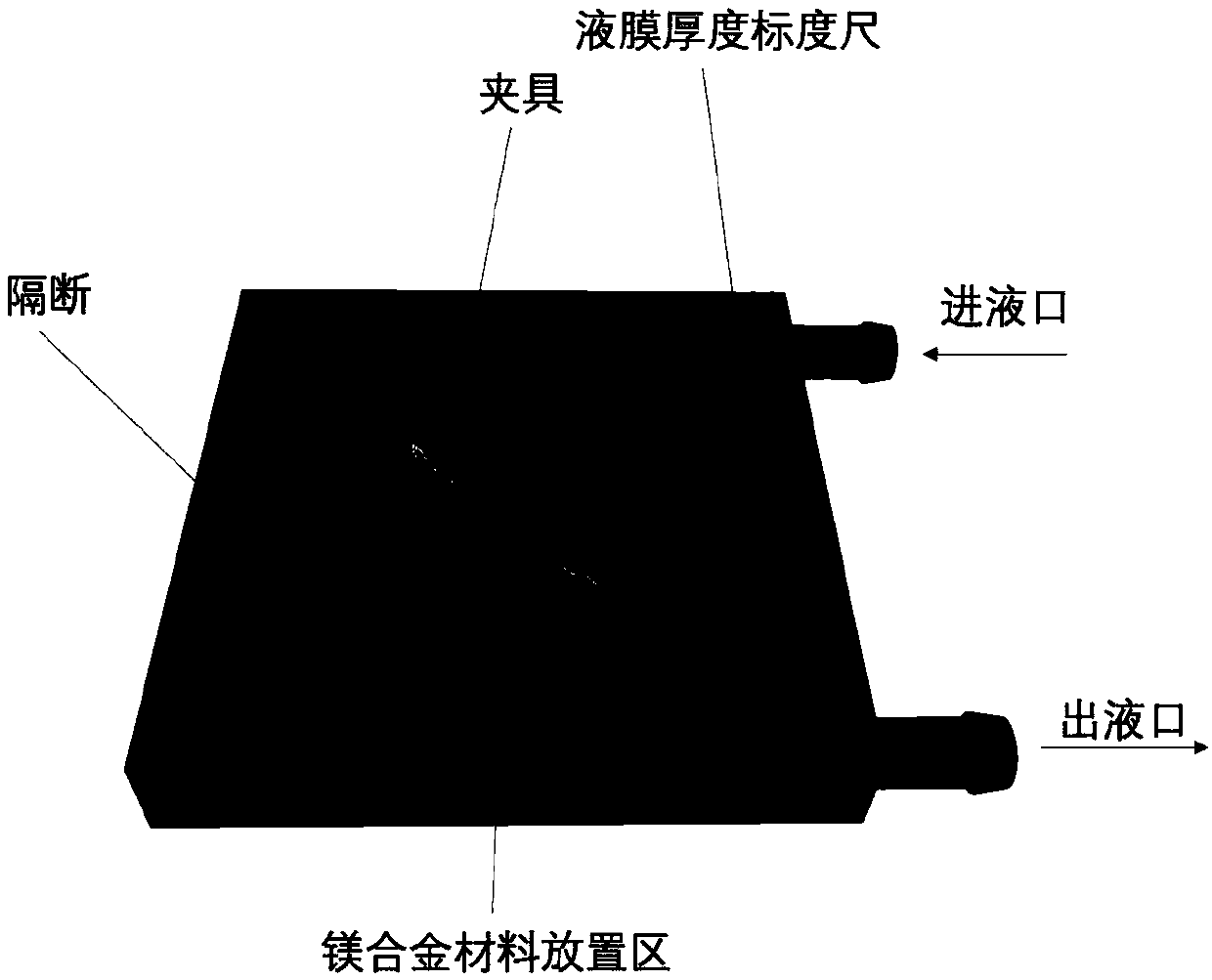

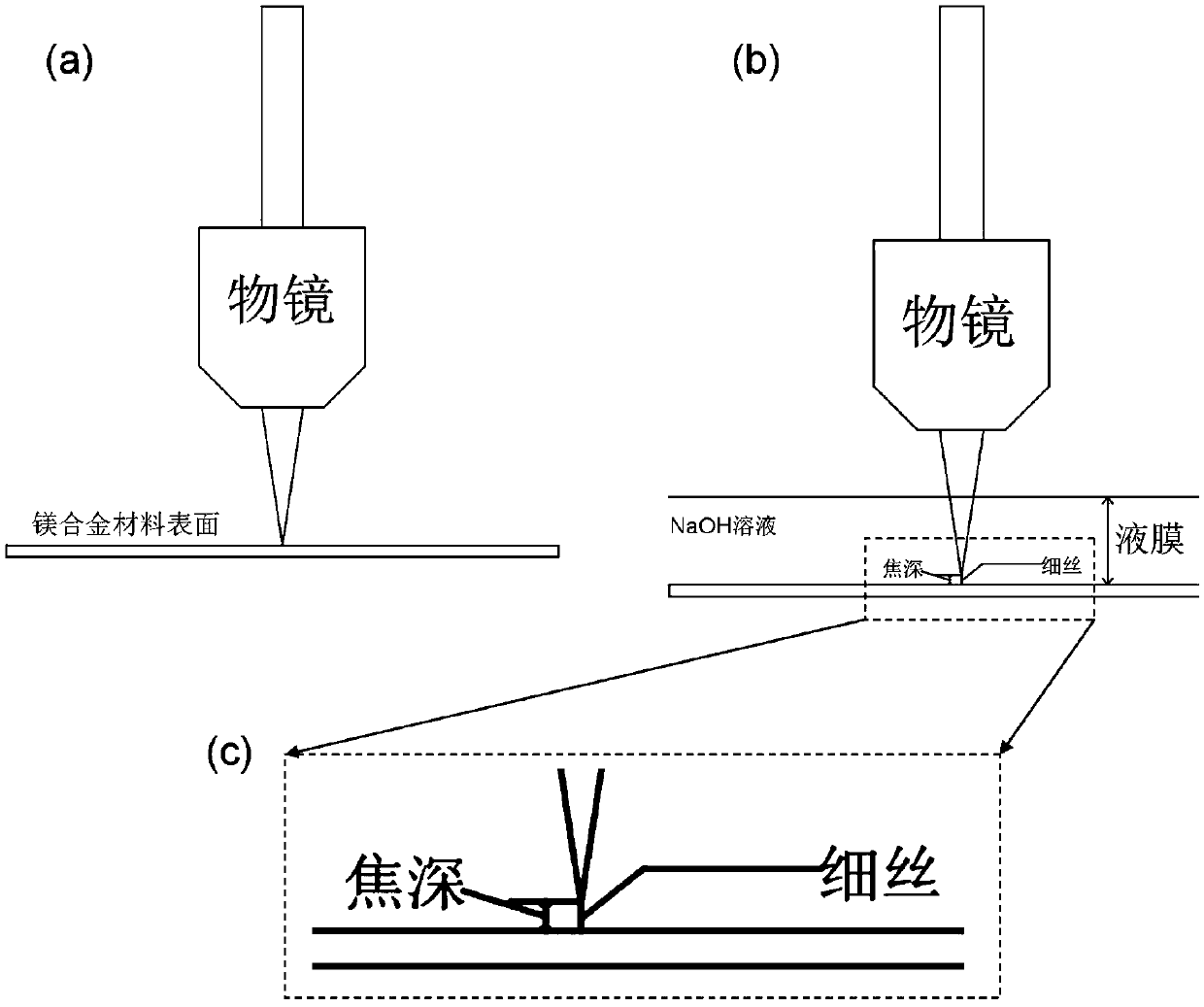

Degradable metal guided tissue regeneration barrier membrane and preparation method thereof

ActiveCN109620429ASignificant progressAvoid rapid degradationTeeth fillingTeeth cappingMicro nanoLiquid medium

The invention discloses a degradable metal guided tissue regeneration barrier membrane and a preparation method thereof. A transparent liquid medium which does not react with metal is used as a protective solution, and especially when a sodium hydroxide solution is adopted, it is achieved that pure magnesium and magnesium alloy materials are processed in water. By using a flowing liquid membrane,the heat diffusion situation on the periphery of a processing site can be obviously improved, and self cleaning in the processing process is achieved. On the basis that the processing quality of the micro-nano structure of the metal surface is ensured, the processing precision is obviously improved, the processing precision reaches about 10 micrometers, and it is of great significance for loadingof a specific drug, such as a drug of a specified size. The content of oxides in the processing product can be remarkably reduced, the adverse effects of excessive oxides on drug loading are avoided,and the degradability and the mechanical property of the metal guided tissue regeneration membrane are ensured. Through the multi-level mesh hole structure of micro-nano patterns, level-by-level release of the drug is achieved; compared with the prior art that deep holes are directly dug in the surface of magnesium alloy to load the drug, the medical treatment effects of treating inflammation andguiding tissue regeneration are greatly improved.

Owner:浙江沣沅生物科技有限公司

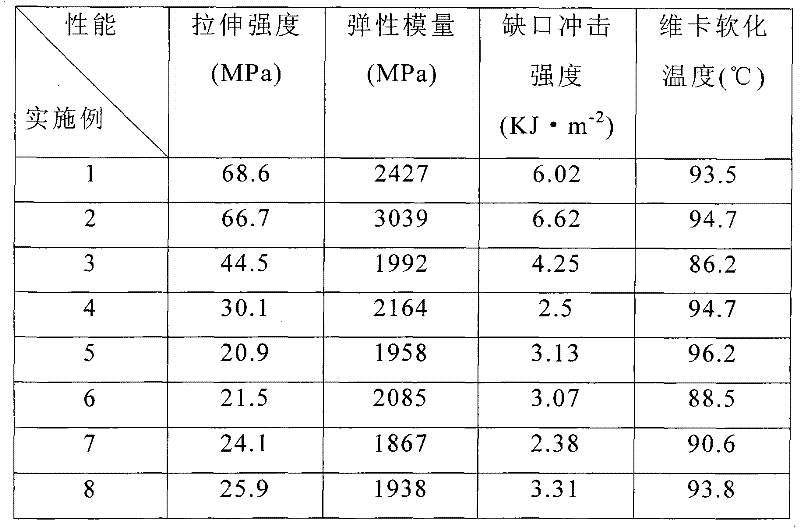

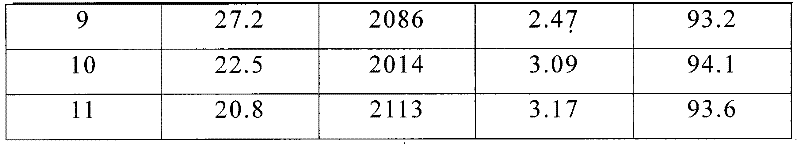

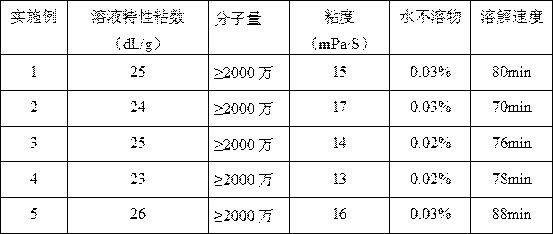

Novel heat-resistant salt-resistant polyacrylamide and synthesis method thereof

The invention provides novel heat-resistant salt-resistant polyacrylamide and a synthesis method thereof. Polyacrylamide structurally includes sulfonic acid radicals and pyrrolidone radicals, the salt-resistant performance of heat-resistant salt-resistant polyacrylamide reaches 20,000 degrees of mineralization, the total number of calcium and magnesium ions reaches 504 mg / L, and the temperature reaches 85 DEG C. The synthesis method includes the following steps of firstly, in a redox and azo compounding trigger system, refined acrylamide monomers (AM), functional monomers AMPS and vinylpyrrolidone react under the trigger temperature of -2-0 DEG C to obtain glue; secondly, pelleting, hydrolysis, drying, smashing and sieving are carried out. Under the ultralow temperature, the redox and azocompounding trigger system is adopted for polymerization, sulfonic acid radical strong water groups and pyrrolidone radicals are introduced into polyacrylamide, a self-made mixed stabilizer is added during hydrolysis, and not only is the salt-resistant capability of polyacrylamide improved, but also ultra-high molecular weight shear degradation and heat-resistant performance are ensured.

Owner:TIANJIN BO HONG CHEM +1

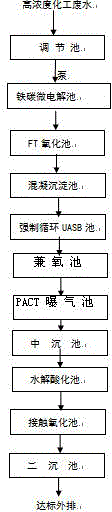

Method for treating high-concentration chemical wastewater

InactiveCN104829045AFacilitated releaseImprove convenienceMultistage water/sewage treatmentActivated sludgeHigh concentration

The invention discloses a method for treating high-concentration chemical wastewater. The method comprises a pre-treatment step, an up-flow type anaerobic sludge bed treatment step and a contact oxidation treatment step in sequence. The method has the innovation point that the pre-treatment step comprises an iron-carbon micro-electrolysis step and a coal / natural indirect liquidation oxidization step; the contact oxidation treatment step comprises an anaerobic treatment step and a two-stage aerobic treatment step; the first-stage aerobic treatment step in the two-stage aerobic treatment step comprises an anoxic and biochar-process activated sludge combined treatment step. According to the method for treating high-concentration chemical wastewater, the operation feasibility is improved, the labor intensity is reduced, the filler is enabled to be in a suspension state without being blocked and plugged by controlling the grain size of the filler and operation parameters of an aeration system and an inner circulating system, the iron powder and the carbon powder are released to the sewage in a facilitated mode, the gas phase, the liquid phase and the solid phase are completely contacted, and the treatment efficiency is improved.

Owner:NANTONG DAHENG ENVIRONMENTAL ENG CO LTD

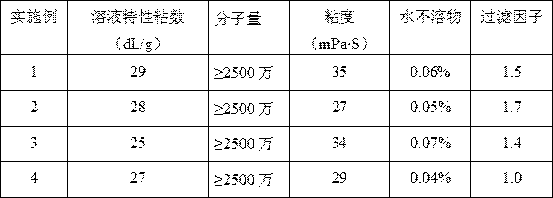

A kind of heat-resistant polylactic acid composite material and preparation method thereof

The invention provides a heat-resistant polylactic acid composite material and a preparation method thereof, belonging to the technical field of polymer materials. It solves the technical problems such as poor biodegradability, high cost and poor mechanical properties of existing methods for preparing polylactic acid cross-linked materials and products in polymer cross-linked materials. The heat-resistant polylactic acid composite material includes the following components by weight: 50-99 parts of polylactic acid resin with oligo-D lactic acid content; 0.1-15 parts of nucleating agent; 1-50 parts of starch or modified starch; The poly-D lactic acid content in the polylactic acid resin with the oligo-D lactic acid content is lower than 5wt%. The preparation method of the composite material comprises the following steps: a. mixing and granulating; b. injection molding; c. heat treatment. The composite material has excellent mechanical properties and good heat resistance. The preparation method of the composite material has the advantages of simple technological process, strong processability and low cost, and can realize large-scale industrialized production.

Owner:ZHEJIANG HISUN BIOMATERIALS

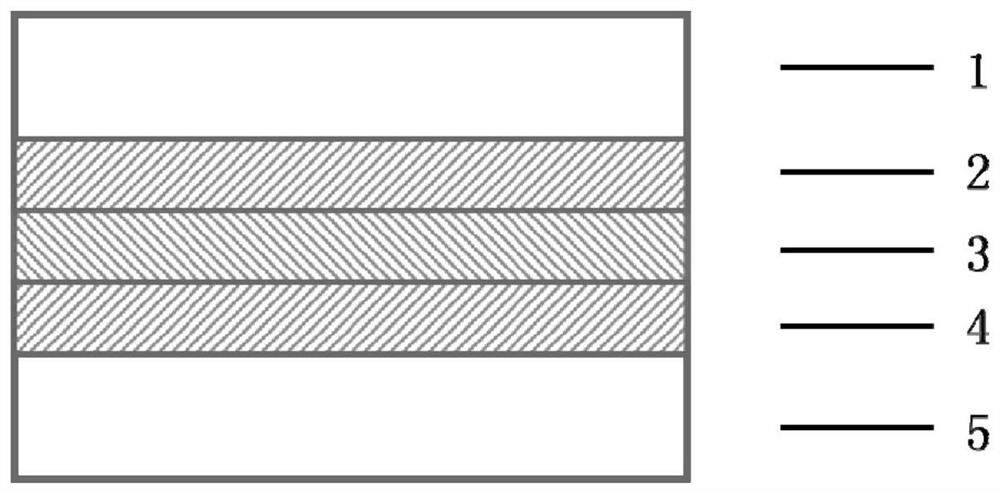

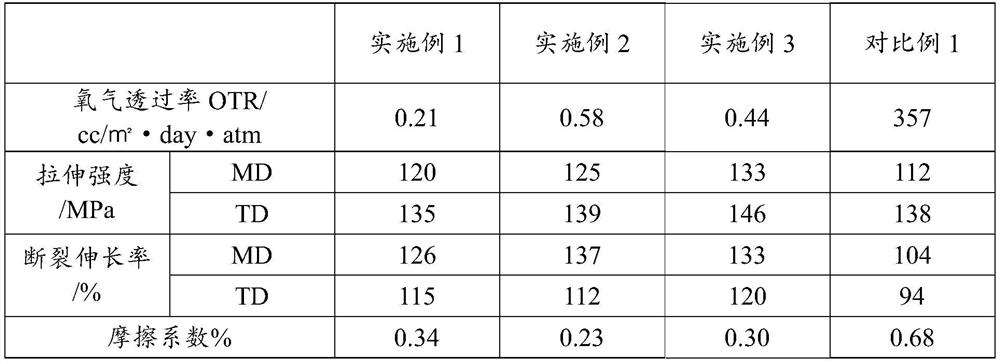

High-barrier polylactic acid film and preparation method thereof

ActiveCN112622380AGuaranteed degradabilityImprove mechanical propertiesSynthetic resin layered productsUnsaturated alcohol polymer adhesivesPolymer sciencePolyvinyl alcohol

Owner:厦门长塑实业有限公司

Instant polyacrylamide for offshore oil displacing and synthesis method thereof

InactiveCN109134752AHigh molecular weightImprove salt resistanceDrilling compositionFunctional monomerSynthesis methods

The invention provides instant polyacrylamide for offshore oil displacing, which comprises a sulfonic acid group, the salt resistance of the instant polyacrylamide for offshore oil displacing reaches326.3 million mineralization degrees, the total amount of calcium and magnesium ions reaches 885 mg / L, and temperature is 85 DEG C. The method comprises the following steps: 1, in a redox and azo compound initiation system, a refined acrylamide monomer AM and a functional monomer AMPS react at an initiation temperature of 2 DEG C to obtain colloid; 2, granulating, hydrolyzing, drying, crushing andsieving are carried out. According to the invention, the redox and azo compound initiation system are used for polymerization under the ultra-low temperature, a sulfonic acid group strong water groupis introduced into the polyacrylamide, and self-made mixed stabilizer is added at the same time of hydrolysis, so that the salt resistance of the polyacrylamide is improved, the ultrahigh molecular weight shear degradation and temperature resistance are ensured, the dissolving speed is improved, and the dissolving performance is improved.

Owner:TIANJIN BO HONG CHEM +1

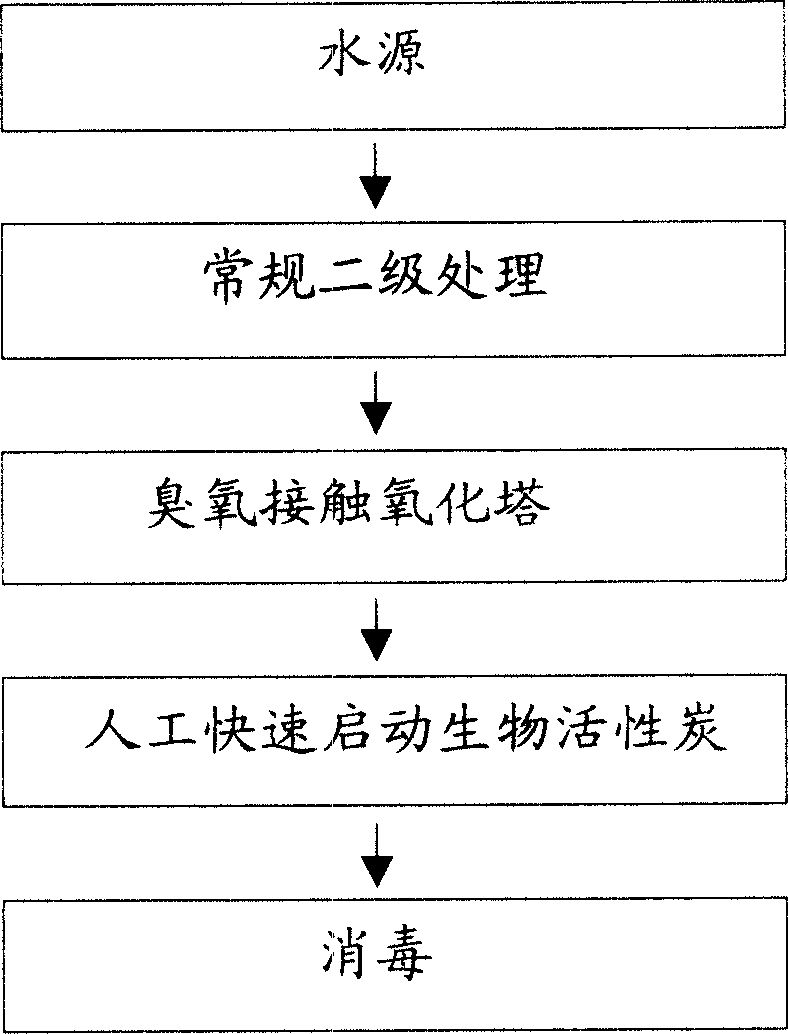

Rapid-start bioactive carbon reinforcing technique

InactiveCN1709809AEfficient removalLow running costMultistage water/sewage treatmentEnhancement TechnologiesChemistry

The invention discloses one kind of fast starting biology activated charcoal enhancement technology. First treat the water with conventional tap water processing; After that, the conventional processing water is introduced to ozone contact oxidation column; The ozone contact oxidation column's water leakage is send in again by manual screening, domesticates in universities biology fungus and be fixed in fast start biology activated charcoal storage tank; The coal pot water leakage enters the disinfection contact pond again, extinguishes the microorganism in the running water. This invention domesticates the microorganism technology through manual screening, the immobilized cell technology and the water treatment craft technology, the economy removes the tap water convention processing under-water micro organic matter highly effectively, specially ' three leads ' matter, which enables the water leakage in the entire system to achieve the new tap water quality standard request, thus the realization depth processing technology universities and the efficient request, guarantees people's potable water safety and enhances the tap water deeply processing efficiency with the method of biology activated charcoal enhancement technology.

Owner:HARBIN INST OF TECH

Plastics biodegrading method with coleoptera larvae and intestinal microflorae of coleoptera larvae

PendingCN110150231AImprove degradation efficiencyStable growthFood processingAnimal feeding stuffIntestinal microorganismsOrganism

The invention discloses a plastics biodegrading method with coleoptera larvae and the intestinal microflorae of the coleoptera larvae and belongs to plastics degrading methods. The method specificallycomprises the following steps of, firstly, uniformly mixing plastics and feeds, and filling the mixture into a container containing yellow melworms; secondly, culturing the yellow melworms in an incubator; thirdly, during the culturing process, replenishing feeds. The plastics biodegrading method with the coleoptera larvae and the intestinal microflorae of the coleoptera larvae can not only improve the survival rate of the larvae, but also improve the plastics degrading rate by more than 150%.

Owner:HARBIN INST OF TECH

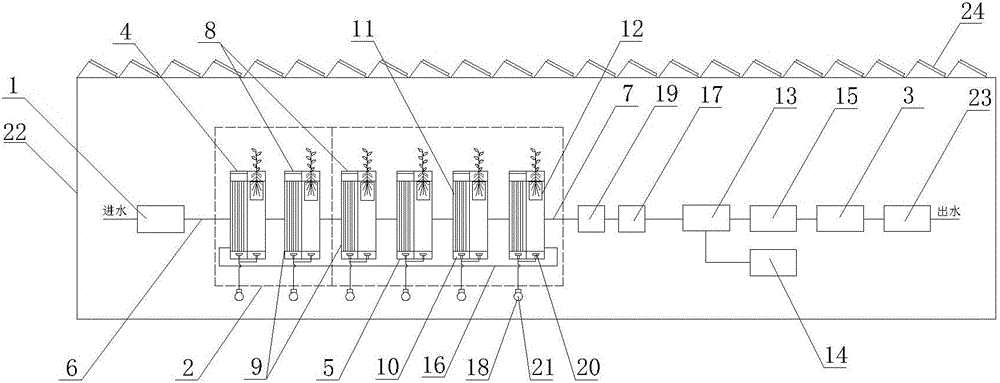

Sewage treatment method and system

PendingCN106396297ASmall footprintReduce energy consumptionSpecific water treatment objectivesWater contaminantsPrecipitationSewage

The invention discloses a sewage treatment method. The sewage treatment method comprises the following steps: S01, pre-treating sewage: enabling the sewage to pass through a first-grade pre-treatment system to remove floating matters and suspension matters; S02, introducing the sewage treated by the step S01 into a second-grade reaction system, and enabling the sewage to pass an anaerobic section and an aerobic section in sequence; degrading organic matters in the sewage and removing main pollutants in the sewage through utilizing microorganisms attached on surfaces of emergent aquatic plants and artificial fillers; S03, introducing the sewage treated by the step S02 into a third-grade advanced treatment system, and carrying out flocculation, precipitation, filtration and disinfection deep treatment on the sewage to reach emission or recycling standards. The invention further discloses a sewage treatment system. By adopting the method and the system, provided by the invention, the occupied area of a sewage treatment device can be reduced, the odorous pollution of a sewage treatment plant is reduced; the yield of sludge can also be reduced and the sludge treatment and disposal difficulty is reduced; particularly, the method and the system can meet the conditions in low-temprature regions.

Owner:华电水务工程有限公司

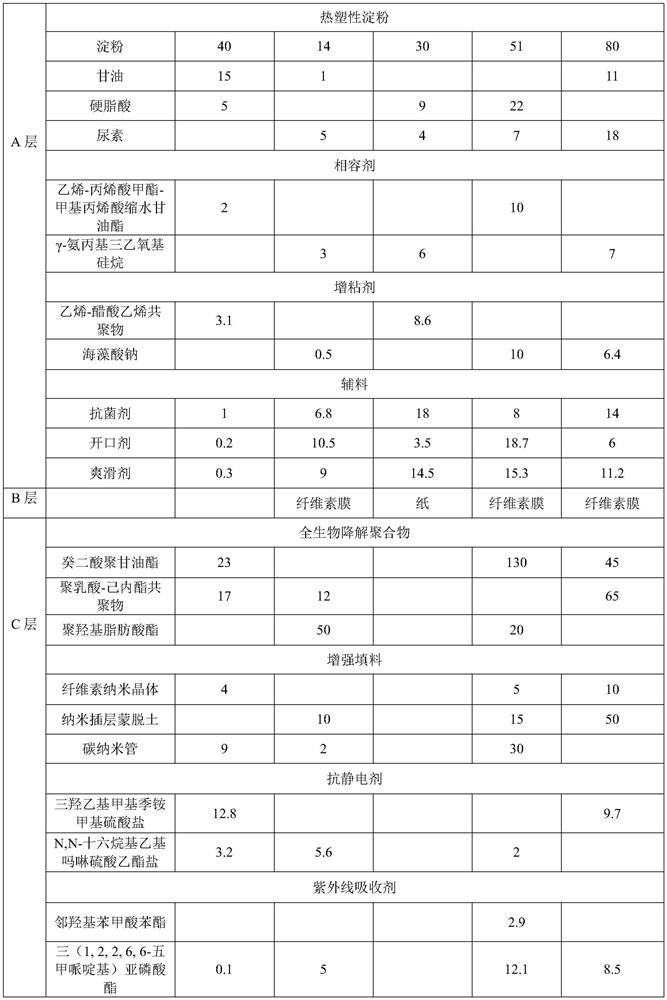

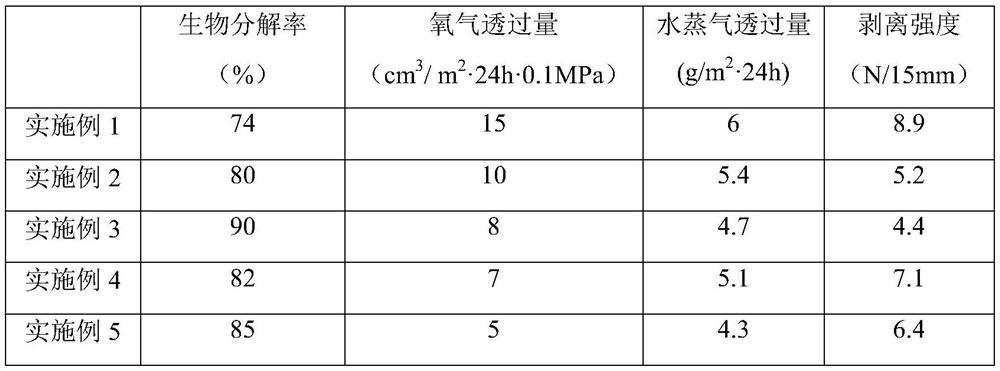

Degradable high-barrier composite film and preparation method thereof

PendingCN114211841AReduce manufacturing costHigh barrierSynthetic resin layered productsPaper/cardboard layered productsCellulosePolymer science

The invention discloses a degradable high-barrier composite membrane and a preparation method thereof.The composite membrane is of a layer structure of one of A / B, A / C, A / B / C and A / B / A / C. The layer A is a modified poly (butylene terephthalate)-adipate copolymer and comprises, by mass, 50-103 parts of poly (butylene terephthalate)-adipate copolymer, 20-109 parts of thermoplastic starch and 2-10 parts of compatilizer; 0.5 to 10 parts of a tackifier and 1.5 to 42 parts of an auxiliary material; the layer B is paper or a cellulose membrane; and the layer C is a composite material and comprises the following components in parts by mass: 40-150 parts of a full-biodegradable polymer, 12-60 parts of a reinforcing filler, 2-16 parts of an antistatic agent and 0.1-15 parts of an ultraviolet light absorber. The composite film disclosed by the invention has good barrier property and relatively high interlayer peel strength, and can be applied to the field of packaging of liquid and fresh foods.

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

Shell powder interior wall paint and preparation method and device thereof

ActiveCN111748228AHigh curing strengthGuaranteed degradabilityCoatingsGrain treatmentsFiberPtru catalyst

The invention relates to shell powder interior wall paint and a preparation method and device thereof. The shell powder interior wall paint is prepared from the following components: coarse shell powder, fine shell powder, a dispersing agent, an emulsifying agent, a defoaming agent, ethanol, sodium carbonate and vegetable gum, wherein the particle size of the coarse shell powder is 20-50 meshes, the content of CaO in the coarse shell powder is not higher than 10%, the particle surface of the coarse shell powder is covered with an aluminum oxide coating layer, chopped fibers are embedded in thealuminum oxide coating layer, and a copper-manganese catalyst is doped in the aluminum oxide coating layer; the particle size of the fine shell powder is 500-800 meshes, and the content of CaO in thefine shell powder is not lower than 50%. In the composition of the scheme, the coarse shell powder is used for replacing most of the fine shell powder, the use amount of vegetable gum is greatly reduced, the adsorption capacity is greatly improved, and the capacity of adsorbing and degrading formaldehyde and adjusting the humidity of the shell powder interior wall paint is effectively guaranteed.

Owner:焦作市流金伟业科技有限公司

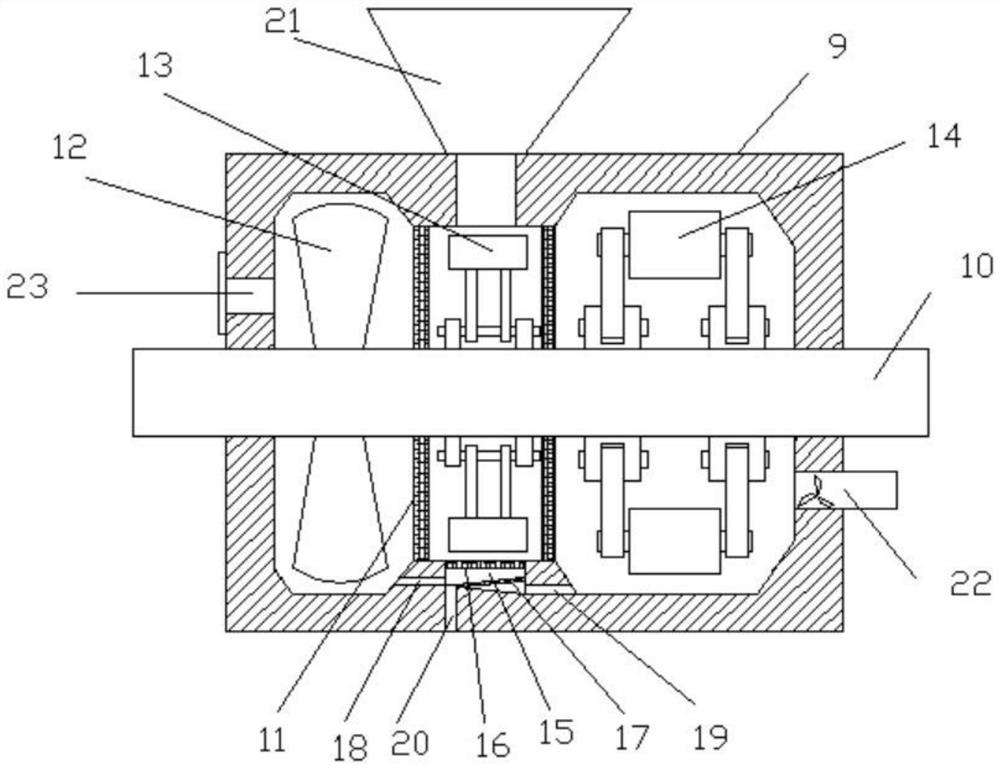

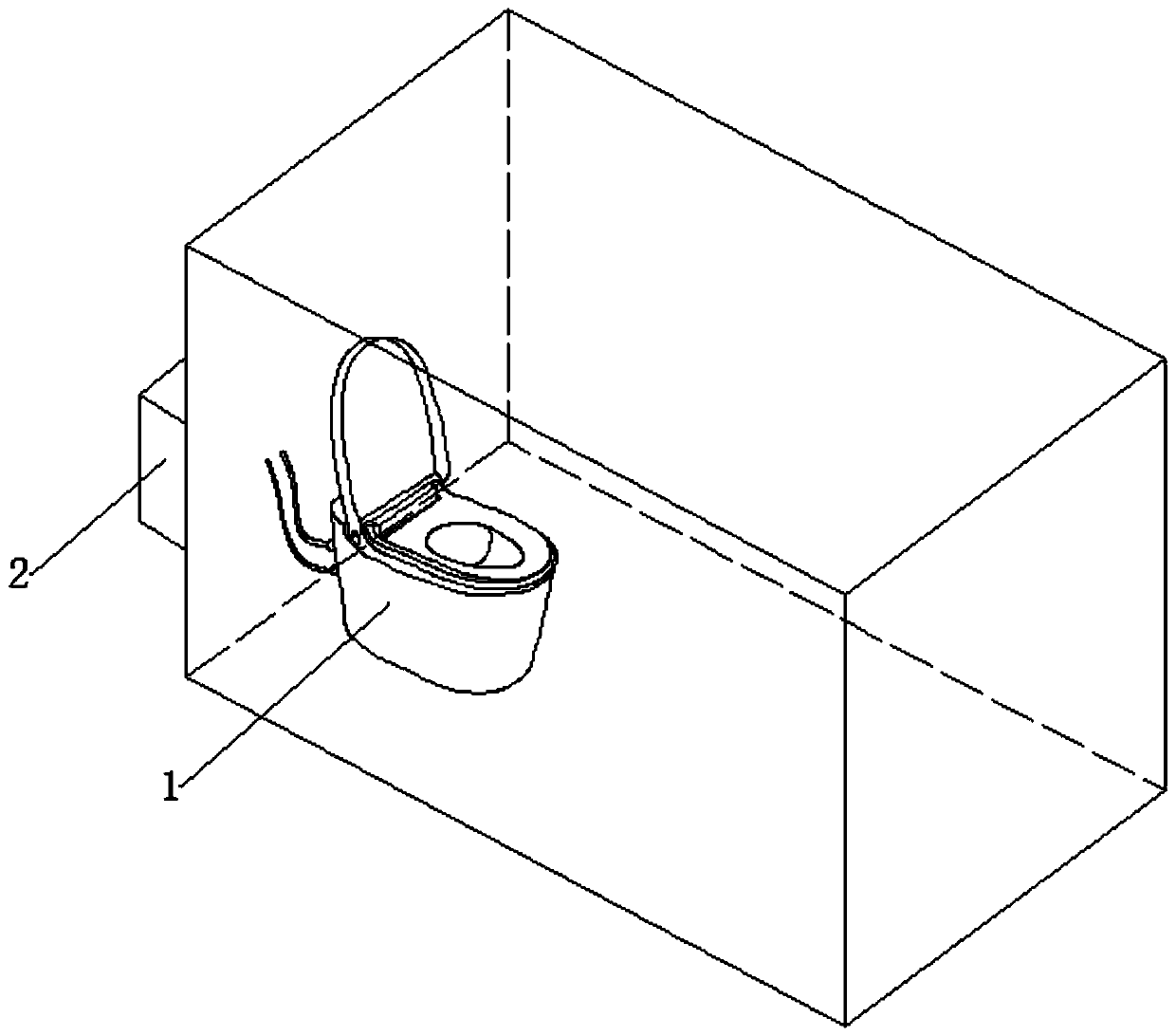

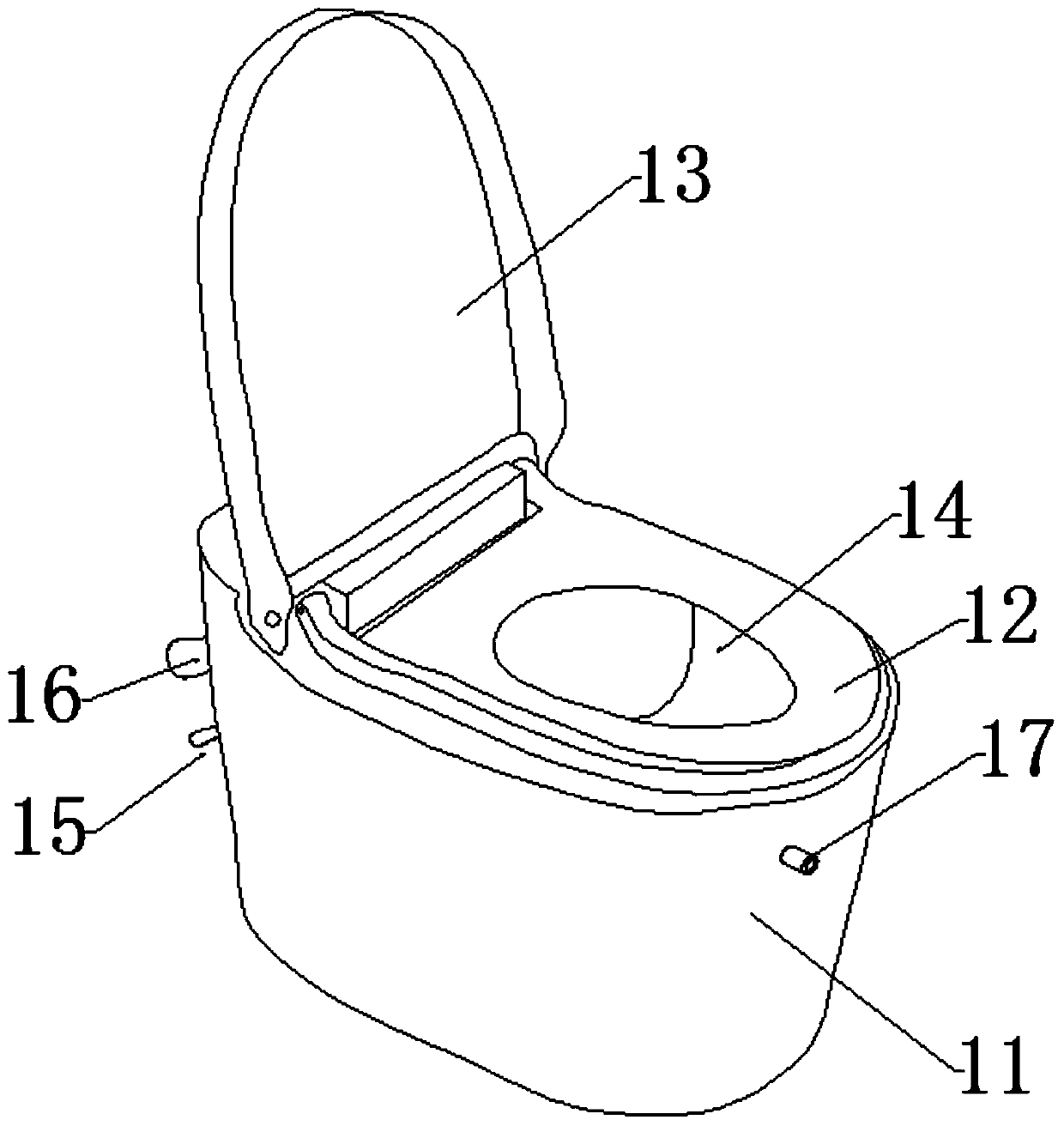

Microbial degradation toilet

PendingCN111248807AAvoid the problem of low fermentation efficiencyWon't hurtBathroom accessoriesBiological sludge treatmentBiotechnologyMicroorganism

The invention belongs to the technical field of microbial degradation, and discloses a microbial degradation toilet. The problems that in the prior art, urine is difficult to separate and collect through a microorganism closestool, and the overall excrement degradation effect is poor are solved. The biodegradable toilet comprises a closestool and a sewage discharging device which are arranged on the inner side and the outer side of a toilet respectively, the closestool comprises a closestool body, a microbial degradation pool is arranged at the bottom in the closestool body, a urinal is arranged on one side in the closestool body, the periphery of the urinal is sunken towards the middle, a urine conveying pipe is connected to the bottom of the sunken position of the urinal, and the other end of the urine conveying pipe penetrates out of the closestool body and is connected with a liquid conveying pipe; and the sewage discharging device comprises a pump body capable of pumping water, and a liquid inlet pipe of the pump body is connected with the liquid conveying pipe. Urine is independently collected through the urinal, the urine conveying pipe and the pump body, so that a better environment is prevented from being provided for degradation of microorganisms, and the overall degradation effect is improved.

Owner:四川卫利清环保科技有限公司

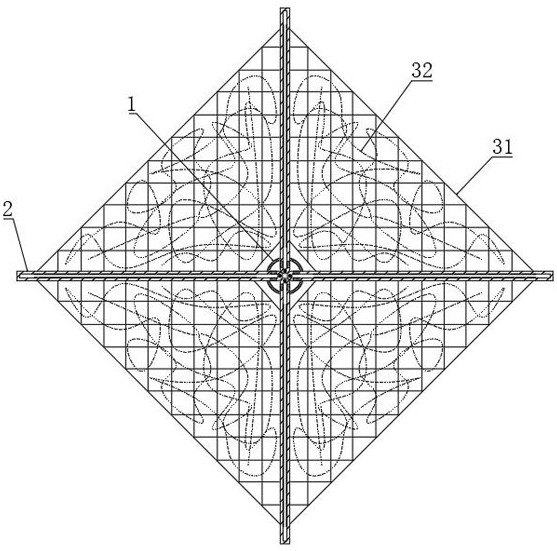

Pneumatic de-molding type sewage treatment combined filler and matched device thereof

PendingCN112320927AFall off quicklyHigh strengthSpecific water treatment objectivesSustainable biological treatmentPolymer scienceAir filter

The invention discloses a pneumatic de-molding type sewage treatment combined filler and a matched device thereof, belongs to the field of combined fillers, and has the advantages that in the use process, oxygen-containing gas is introduced into a hollow elastic bag rope, so that on one hand, the hollow elastic bag rope can be expanded to drive a film attaching disc silk screen to outwards extendand expand; a biofilm loose due to the pulling action, which accelerates the shedding of the aged biofilm initially, on the other hand, oxygen-containing gas is dispersed into the sewage through the gas filtering shaping pipe to form gas flow impact on the film attaching disc silk screen, so that the falling of the biological film is further promoted, the oxygen content of the sewage is increased,and the degradation efficiency of the biological film is improved; the oxygen-containing gas drives a collision ball to continuously float up and down and collide with an air filtering shaping pipe,so that the film attaching disc silk screen generates certain vibration and depth to promote falling of the biofilm, the blockage condition of the biofilm is greatly reduced through the three auxiliary demolding processes, and the continuous and efficient degradation performance of the combined filler is guaranteed.

Owner:何娜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com