Shell powder interior wall paint and preparation method and device thereof

A preparation device and a technology for shell powder, applied in the field of coatings, can solve the problems of reduced formaldehyde or moisture fixation capacity, reduced adsorption capacity, and high preparation cost, and achieve the effects of ensuring the adsorption and degradation of formaldehyde, the improvement of adsorption capacity, and the improvement of curing strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A shell powder interior wall paint, comprising the following components by weight: 200 parts of coarse shell powder, 100 parts of fine shell powder, 1.5 parts of dispersant, 2 parts of emulsifier, 1 part of defoamer, 1 part of ethanol, and 2 parts of sodium carbonate , 8 parts of vegetable gum; the particle size of the coarse shell powder is 20-50 mesh, the content of CaO in the coarse shell powder is not higher than 10%, the particle surface of the coarse shell powder is covered with a layer of aluminum oxide cladding layer, aluminum oxide The cladding layer is embedded with chopped fibers, and the aluminum oxide cladding layer is mixed with a copper-manganese catalyst; the particle size of the fine shell powder is 500-800 mesh, and the CaO content in the fine shell powder is not less than 50%. Wherein dispersant, emulsifier, defoamer can adopt the conventional selection in the field of wall paint, have no obvious influence on technical effect of the present invention. ...

Embodiment 2

[0023] A preparation method of shell powder interior wall paint, comprising the following steps:

[0024] 1) Powder the raw shells, and sieve to obtain a coarse powder with a particle size of 20-50 mesh and a fine powder with a particle size of 500-800 mesh;

[0025] 2) Alumina sol is prepared, and copper-manganese catalyst (CuO-MnO) is mixed into the alumina sol; wherein the loading of copper-manganese catalyst is 30wt%, n(Cu):n(Mn)=1:4.

[0026] 3) The coarse powder obtained in step 1) is first soaked with hydrogen peroxide to remove the fishy smell, then mixed with the alumina sol obtained in step 2), and mixed with chopped fibers. dried, crushed and sieved again, and calcined at low temperature to obtain coarse shell powder;

[0027] 4) The fine powder is calcined above 800°C to obtain fine shell powder;

[0028] 5) Mix the coarse shell powder of step 3) with the fine shell powder of step 4), and add powdery dispersant, emulsifier, defoamer, ethanol, sodium carbonate, ve...

Embodiment 3

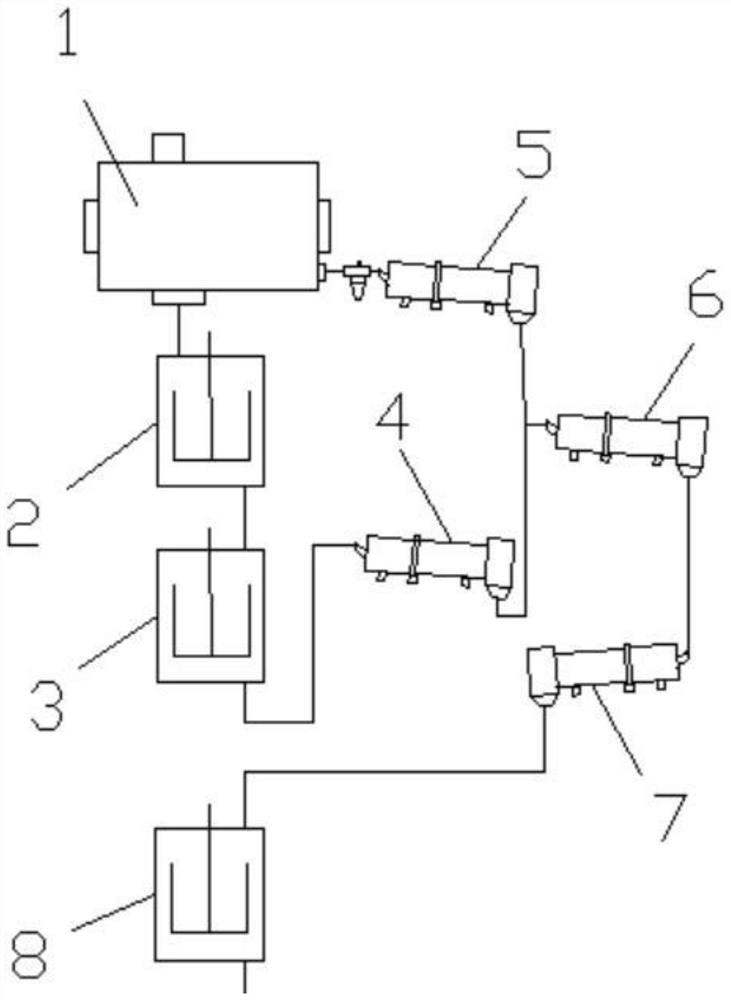

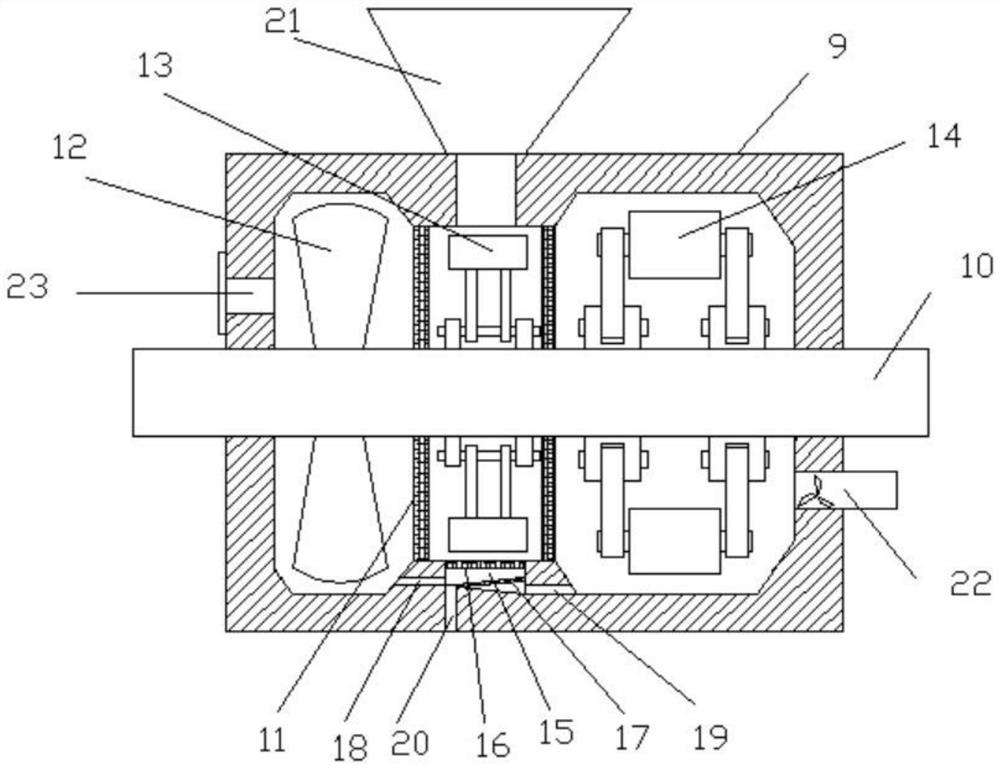

[0030] Such as figure 1 and 2 , a preparation device for shell powder interior wall paint, comprising a shell pulverizer 1, a dipping tank 2, a coarse powder mixing tank 3, a drying cylinder 4, a calcining kiln 5, a primary cooling kiln 6, a secondary cooling kiln 7 and a finished product mixing tank 8. The shell crusher is provided with a coarse powder outlet and a fine powder outlet, the coarse powder outlet is connected to the dipping tank, the dipping tank is connected to the coarse powder mixing tank, the coarse powder mixing tank is connected to the drying cylinder, and the fine powder outlet is connected to the calcining kiln , the calcining kiln and drying cylinder are connected to the primary cooling kiln, the primary cooling kiln is connected to the secondary cooling kiln, and the secondary cooling kiln is connected to the finished product mixing tank. Among them, the calcining kiln, primary cooling kiln and secondary cooling kiln all adopt rotary kiln structure, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com