Patents

Literature

338results about How to "Expand the affected volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

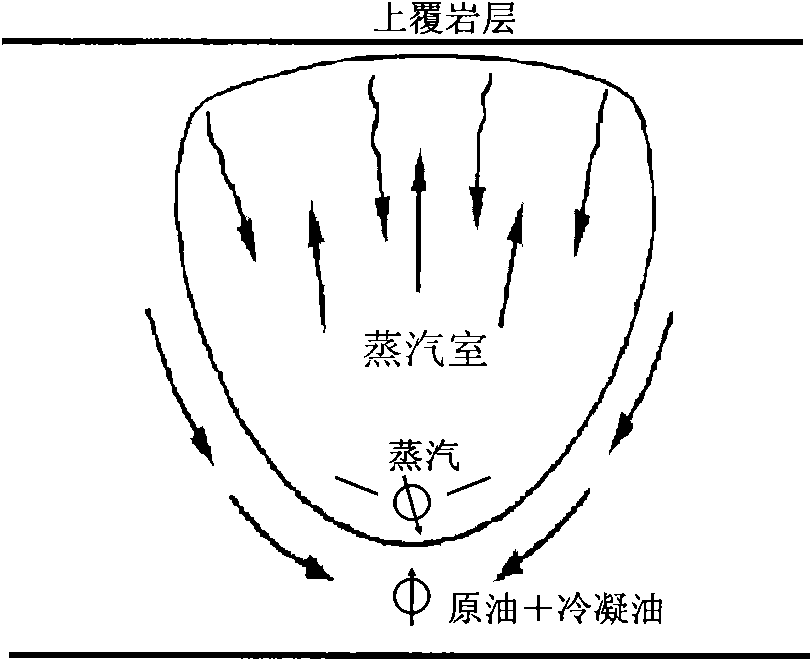

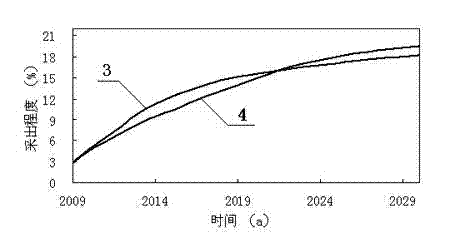

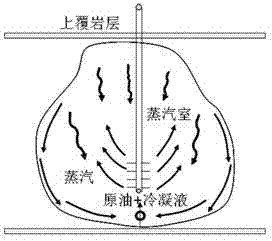

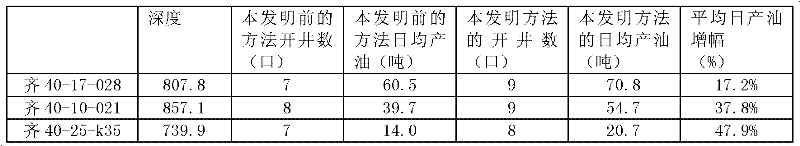

Gas-assisted SAGD method for exploiting super heavy oil

The invention relates to a gas-assisted SAGD method for exploiting super heavy oil; the selecting layer thickness is 530m, remaining oil saturation is more than 0.50, oil layer thickness is more than 10.0m, horizontal permeability is more than 250md, the ratio of the vertical permeability to the horizontal permeability is more than 0.1, the oil layer porosity is more than 0.20, continuous distributed impermeable clay and intercalated shale oil pools do not exist in the oil layer; a horizontal well is drilled between soaking vertical wells, the well spacing is 35m or a pair of horizontal wells are drilled at the bottom of the oil layer, the vertical distance is 6m; swallowing is carried out for 3 stages, when the hot communication is formed between the wells, the vertical wells is used to inject steam continuously, the production of horizontal wells is 3 years, then the vertical wells is used to inject nitrogen and steam until the underground volume ratio is 0.5 and the total injection rate of nitrogen is 0.10PV, then the steam is injected continuously, the steam injection rate is 1.4m / d.ha.m, the dryness of steam at the bottom of wells is 70%, the production-injection ratio is maintained at 1.2; the recovery percent is increased by 6.0-9.0% and the oil-steam ratio is improved by 0.02-0.05.

Owner:PETROCHINA CO LTD

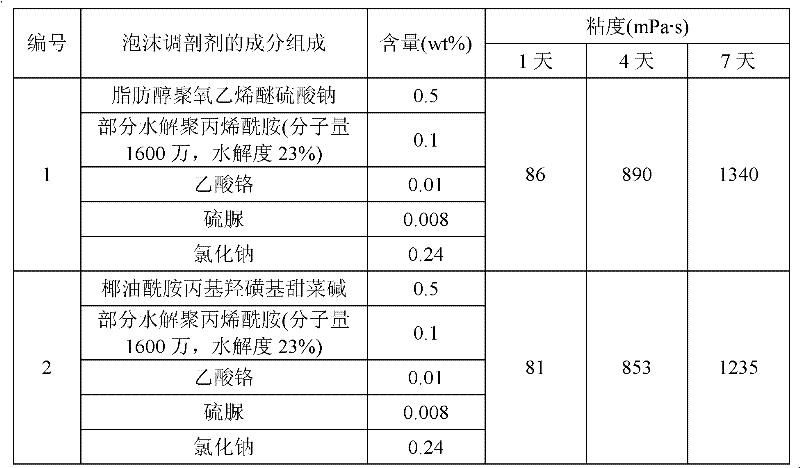

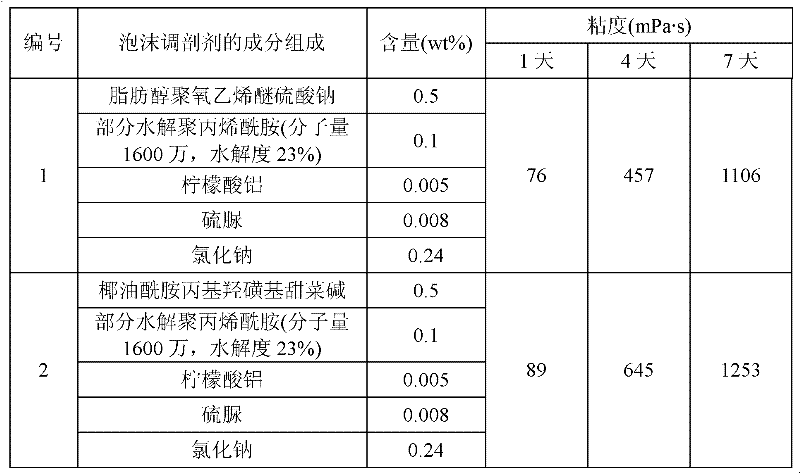

Foam profile control agent applicable to oil field in-depth profile control

The invention provides a foam profile control agent applicable to oil field in-depth profile control. The foam profile control agent provided in the invention comprises a polymer cross-linking solution and gas; under formation pressure, a volume ratio of the gas to the polymer cross-linking solution is 0.2: 1 to 1: 1; and the polymer cross-linking solution of the foam profile control agent comprises, by weight, 0.3 to 1.2 wt% of a surfactant, 0.01 to 0.8 wt% of a polymer, 0.001 to 0.2 wt% of a cross-linking agent, 0.001 to 0.1 wt% of a stabilizing agent and 0.05 to 1.5 wt% of inorganic salt, with the balance being water. The foam profile control agent has an effect on delaying cross-linking, can effectively plug a high-permeability zone, can reduce oil-water interfacial tension and has the effects of enlarging swept volume and improving oil displacement efficiency.

Owner:PETROCHINA CO LTD +1

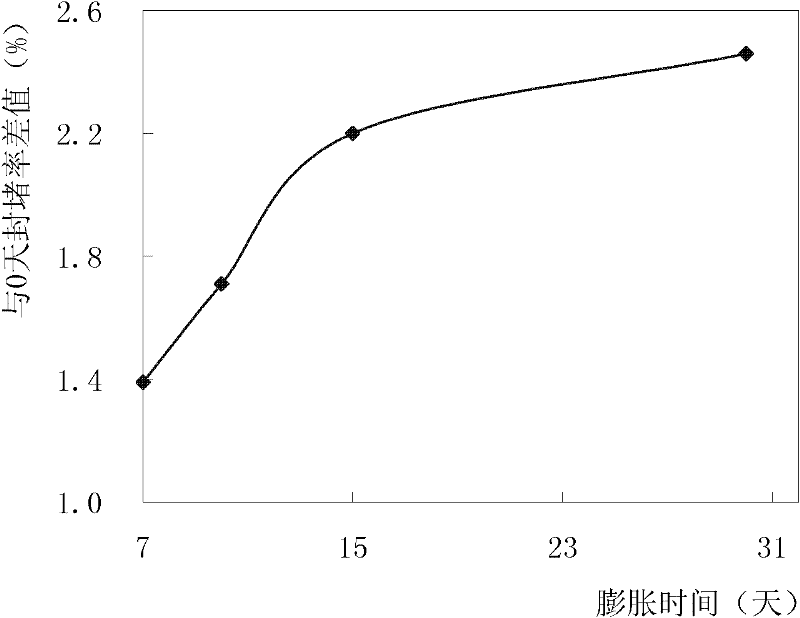

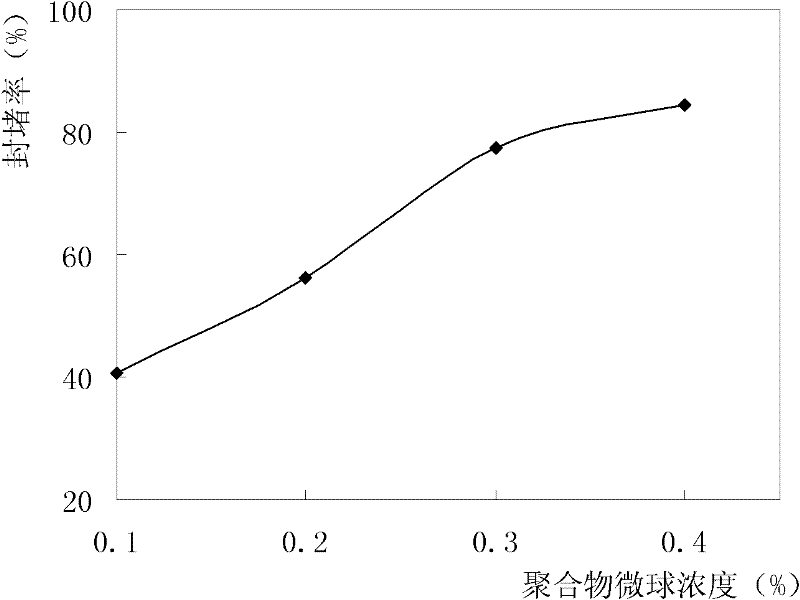

Polymer microspheres for water flooding reservoir deep oil displacement and profile control and preparation method thereof

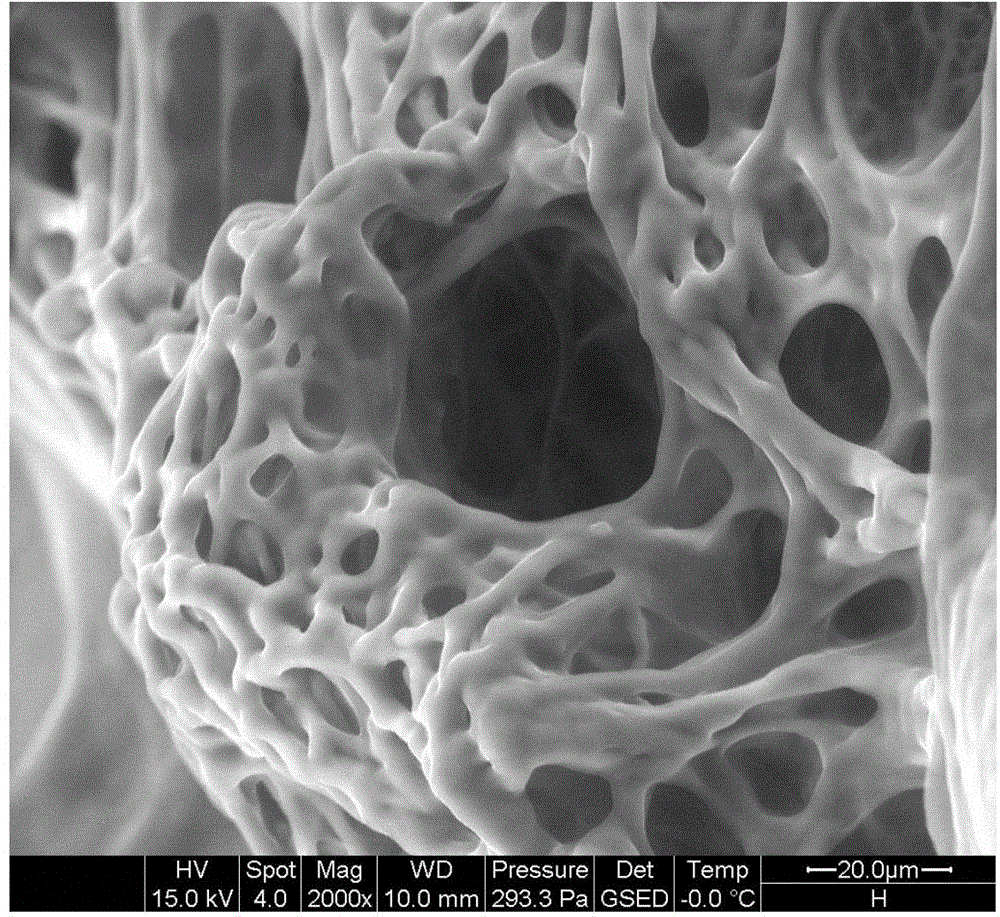

InactiveCN101619118AExpand the affected volumeEffective blockingDrilling compositionMicrosphereActive agent

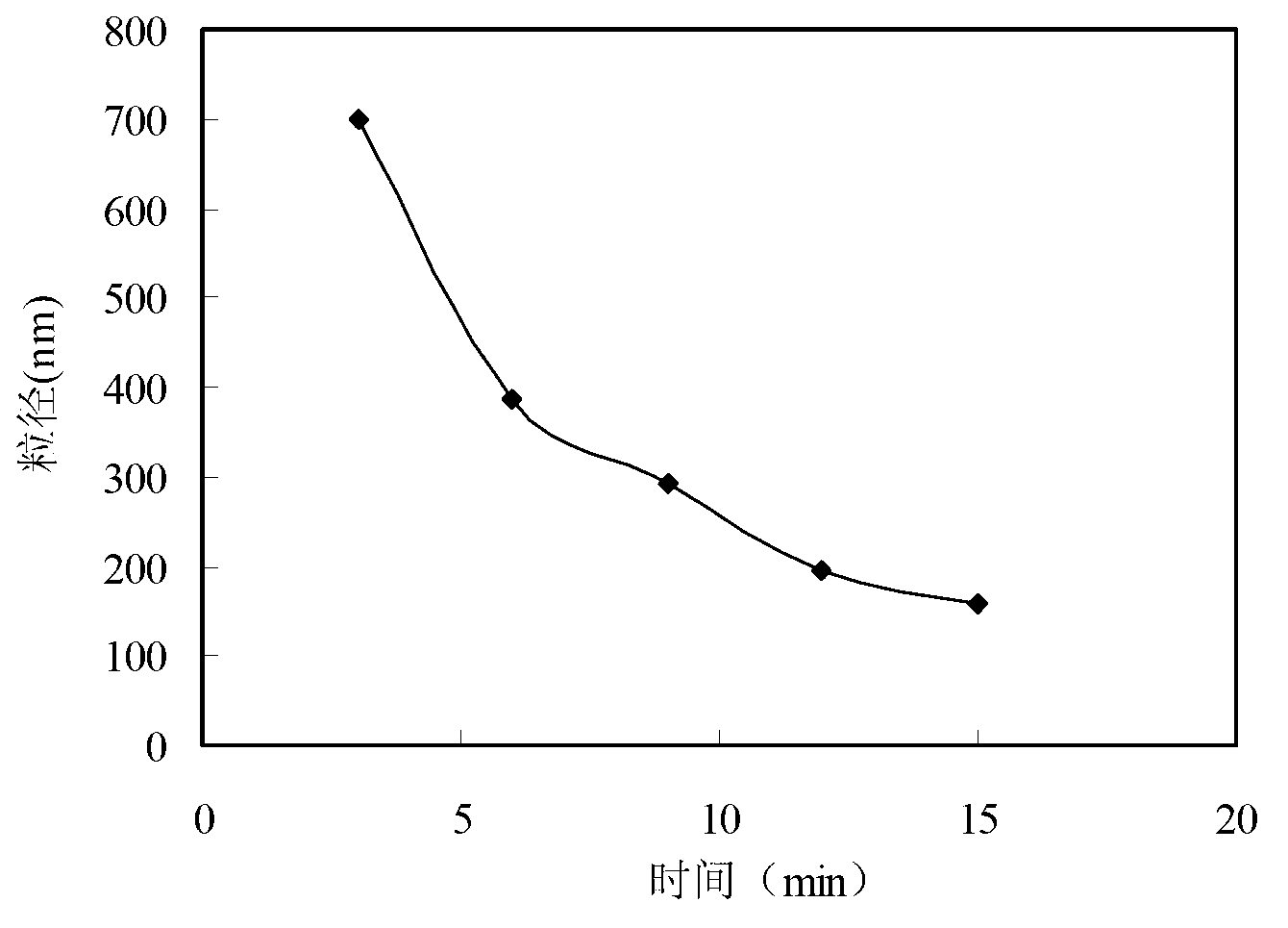

The invention relates to polymer microspheres for in-depth reservoir oil displacement and profile control and a preparation method thereof. In the method, based on the method that photopolymerization is used to prepare the polymer, water-soluble anionic monomer is used and acrylamide monomer water solution, dispersant and crosslinking agent are added to form oil-water mixed emulsion in the mixed medium of surfactant and solvent, then initiator is decomposed by ultraviolet through photopolymerization under controllable temperature so as to initiate emulsion polymerization and 50-500nm of microspheres are formed. The polymer microspheres material prepared by the invention can be used in various environmental conditions and is characterized of safe and stable reaction system, simple and convenient operation, flexible and controllable reaction process and time, high production efficiency, low energy consumption, non-pollution and the like. The invention utilizes the ability of microspheres that microspheres can be dispersed in arbitrary concentration and injected in the water and can gradually swell after entering in depth of the formation to plug the pore throat so as to effectively plug the high permeable strip of the formation, expand the water swept volume and significantly increase crude oil recovery of water flooding reservoir.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +4

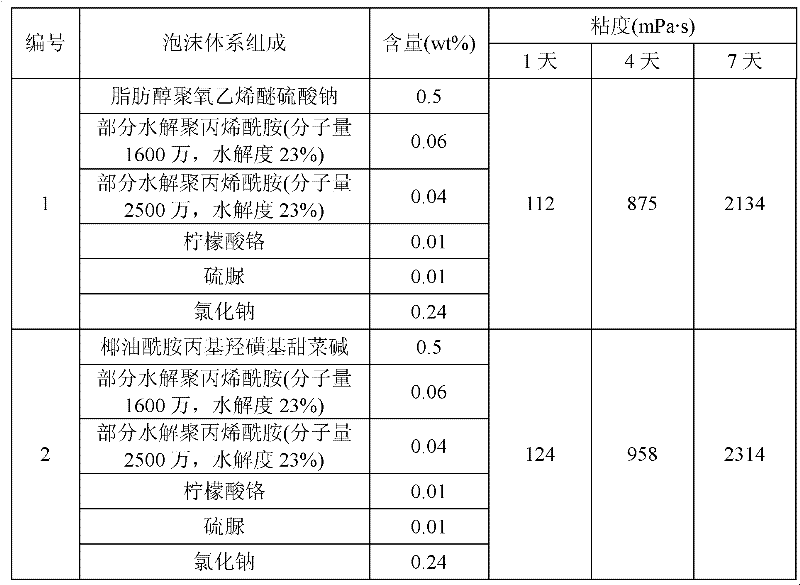

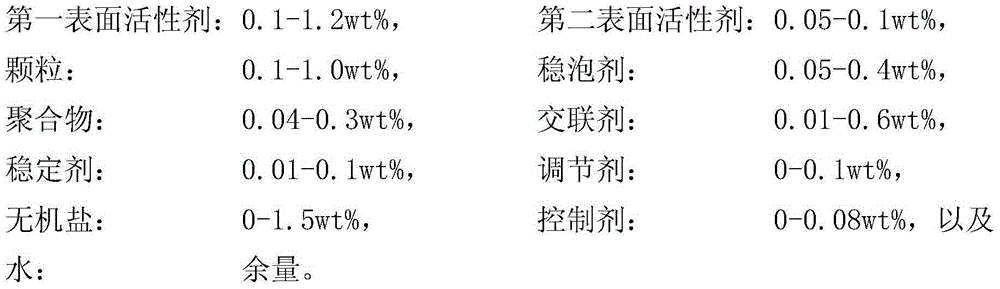

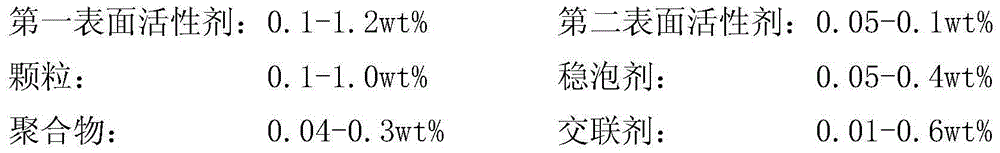

Foam profile control system suitable for advanced profile control of oilfield and preparation method of foam profile control system

ActiveCN104152126AStrong salt toleranceStrong deep sealing abilityFluid removalDrilling compositionSalt resistanceInorganic salts

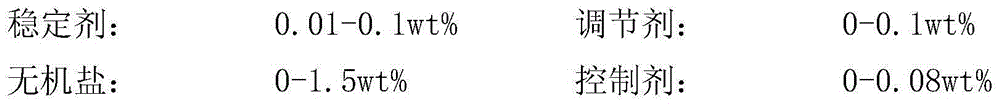

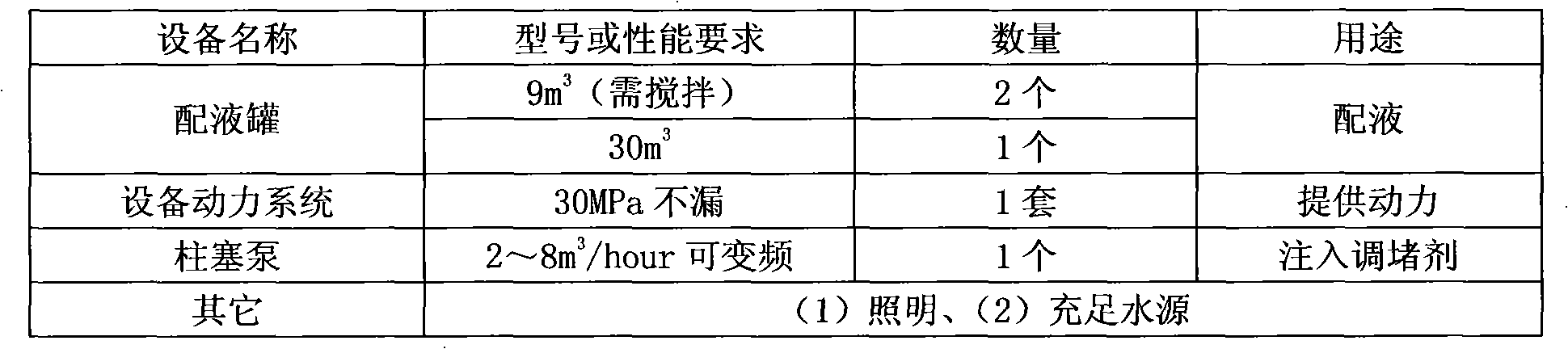

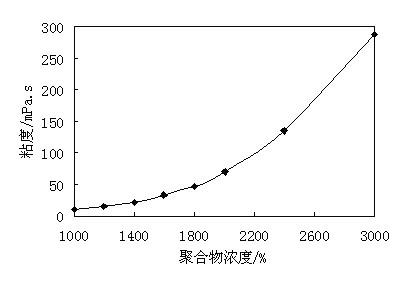

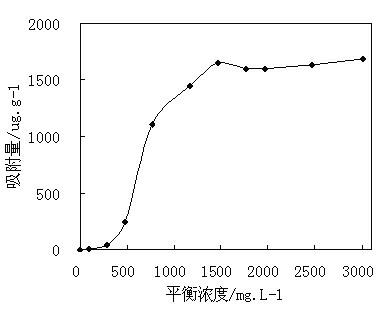

The invention discloses a foam profile control system suitable for advanced profile control of an oilfield. A liquid of the system is prepared from a first surfactant, a second surfactant, granules, a foam stabilizer, a polymer, a crosslinking agent, a stabilizer, an adjustor, inorganic salt, a control agent and water. The foam profile control system has three characteristics of foam, gels and granules at the same time, and has a strong deep sealing capacity to a high-permeability oil layer, namely, has an effect on expanding the swept volume. The system further can reduce the oil-water interface tension, and mainly exerts a gel performance at a low-permeability layer and a foam property at a high-permeability layer, that is, the system has the effects on improving the oil dispelling efficiency and selectively plugging water. When the system is used, as gases exist, the use level of the foam profile control system is reduced, and the foam profile control system has the characteristics of temperature resistance and salt resistance at the same time.

Owner:PETROCHINA CO LTD +1

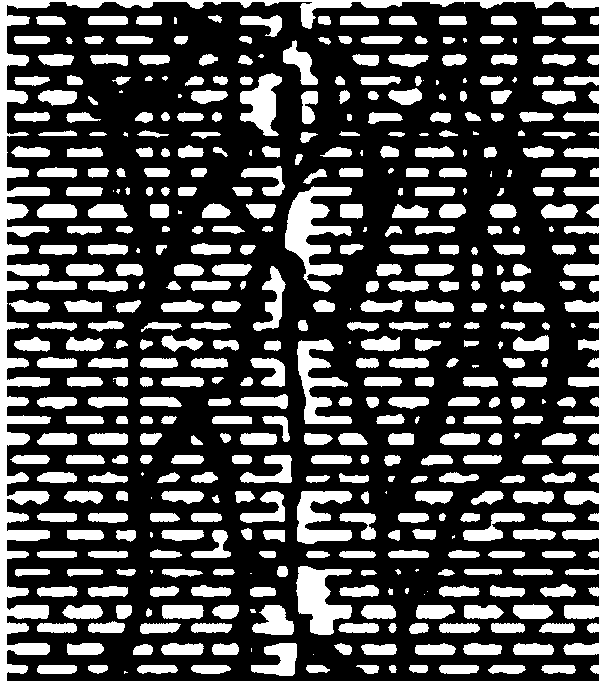

Deep profile control method for fractured oil reservoir

The invention relates to a deep profile control method for a fractured oil reservoir. By the method, the recovery ratio of crude oil can be increased. Four sections of plugs are provided for plugging different types of fluid-channeling channels, wherein in the first section of plug, a high-strength solidification system is used for plugging fracture; in the second section of plug, inorganic gel is used for plugging microfracture or large pores; in the third section of plug, a water drive flow direction changing agent and weak gel are used for further filling the fracture and the pores so as to displace residual oil in the pores; and in the fourth section of plug: a strong gel YQY plugging agent is used for plugging the fracture near the wellbore. By the method, the problem that the oil well is flooded by water caused by the fracture of the fractured oil reservoir water injection well can be effectively solved; the water absorption condition of a storage layer is changed; the utilization ratio of the injected water is increased; the swept volume is enlarged; and the oil displacement efficiency is improved finally.

Owner:PETROCHINA CO LTD

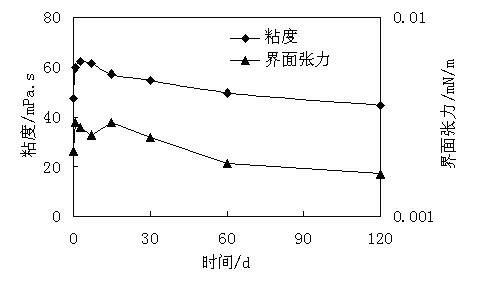

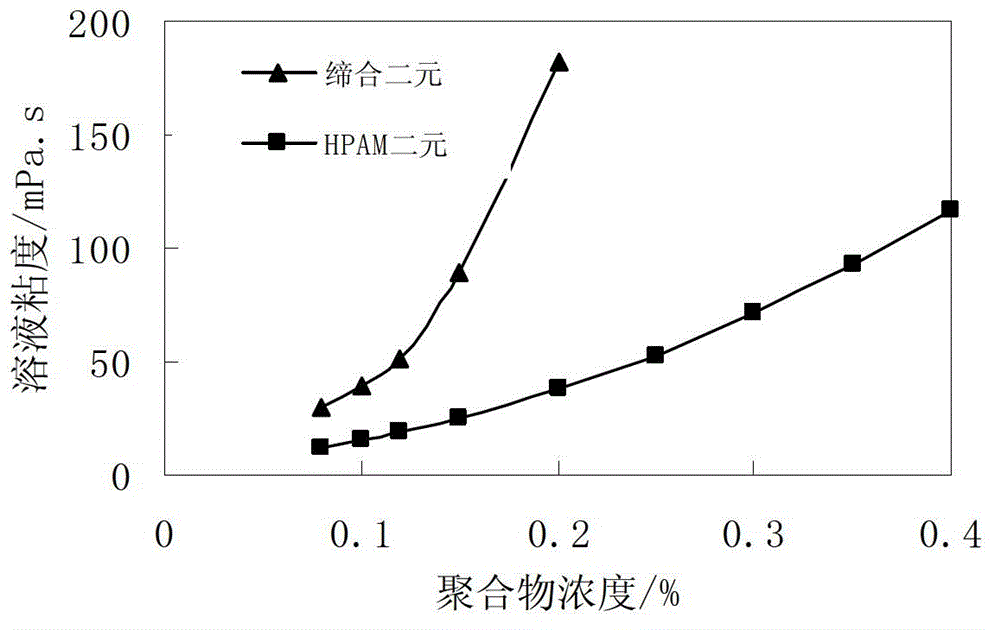

Hydrophobically associating polymer and mixed surfactant binary compound oil displacement system

InactiveCN102504794ATemperature resistanceImprove salt toleranceDrilling compositionSalt resistancePolymer science

The invention relates to a hydrophobically associating polymer and mixed surfactant binary compound oil displacement system for use in tertiary oil extraction. The system mainly comprises the following components in percentage by weight: 0.1 to 0.3 percent of hydrophobically associating polymer, 0.1 to 0.6 percent of surfactant and 99.2 to 99.8 percent of water. The hydrophobically associating polymer in the system has high temperature resistance, high salt resistance and viscosity increasing capacity and can largely reduce dosage of polymer; and with high solubilizing capacity, the polymer can increase the dissolution of the surfactant in sewage, thereby increasing the use concentration of the surfactant. The oil displacement system which is dissolved by sewage from extraction can save lots of fresh water; with high viscosity increasing capacity, the system can effectively control flow rate, increase swept volume, increase oil water interface tension to 10<-3>mN / m and increase the oil extraction rate; and because of high stability and injection property, the system can be injected in large dose. According to an indoor oil displacement experiment, the binary compound oil displacement system can improve the extraction rate by over 20 percent compared with that of water displacement. The system without alkali avoids serious damage to the oil layer and corrosion and damage to oilpipes and has a great application prospect.

Owner:SOUTHWEST PETROLEUM UNIV

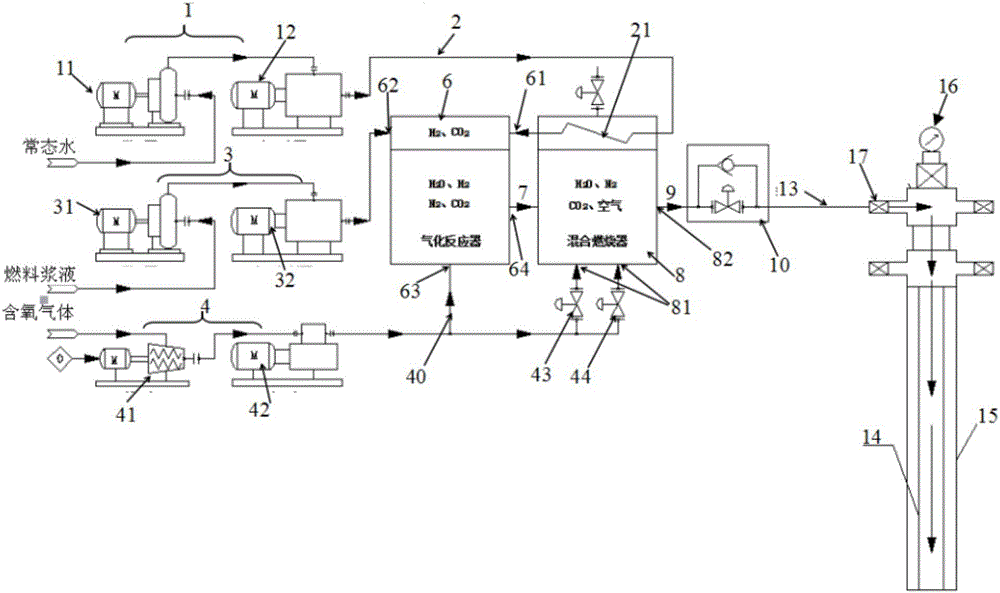

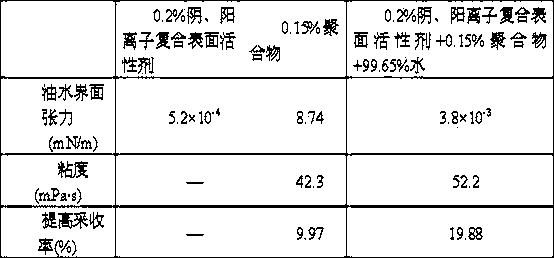

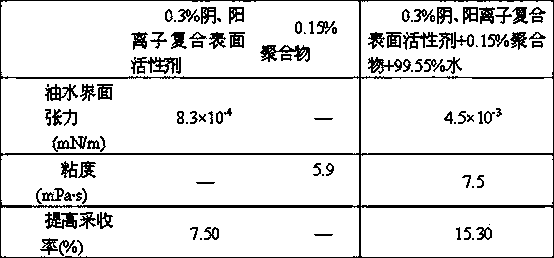

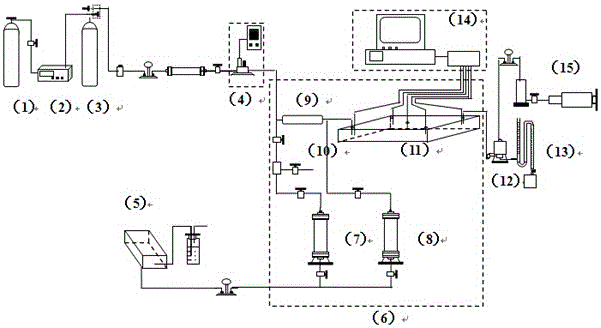

Supercritical multisource multielement thermal fluid injection-production system and injection-production method

InactiveCN106640008AImprove insulation effectLow thermal conductivityLiquid fuel feeder/distributionFluid removalCombustionProduct gas

The invention discloses a supercritical multisource multielement thermal fluid injection-production system and injection-production method. The system comprises a supercritical multisource multielement thermal fluid generating system and an oil tube. The oil tube is arranged in an exploiting shaft; the supercritical multisource multielement thermal fluid generating system comprises a supercritical gasification reactor and a supercritical mixed combustion reactor; in the presence of supercritical water, a gasification reaction is performed on fuel slurry in the supercritical gasification reactor, and the gasification product of the reaction and oxygen-containing gas dissolved in the supercritical water combust in the supercritical mixed combustion reactor to form a supercritical multisource multielement thermal fluid containing supercritical water and carbon dioxide; the supercritical mixed combustion reactor is connected to the oil tube. The supercritical multisource multielement thermal fluid injection-production system provided by the invention has the effects that thermal efficiency is high, the viscosity of thickened oil is reduced, the flowability of the thickened oil is improved and the recovery efficiency is increased.

Owner:CHINA NAT OFFSHORE OIL CORP +1

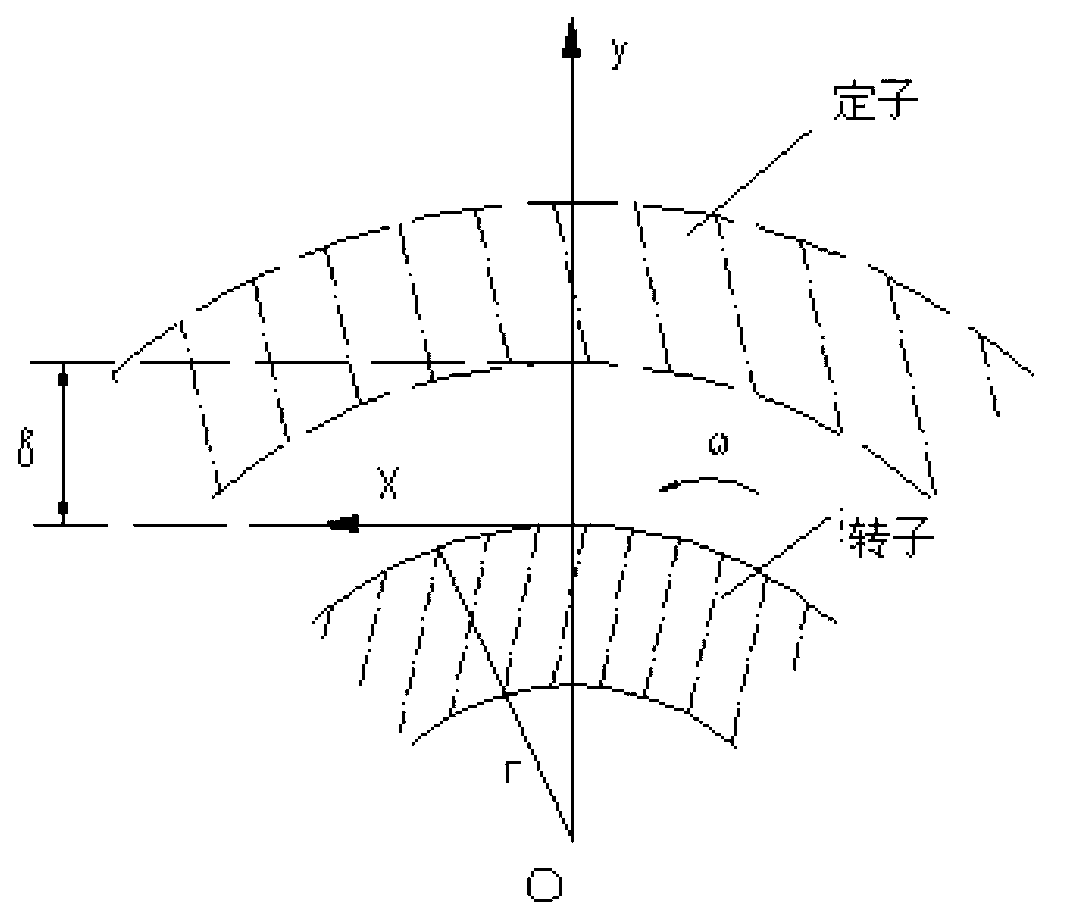

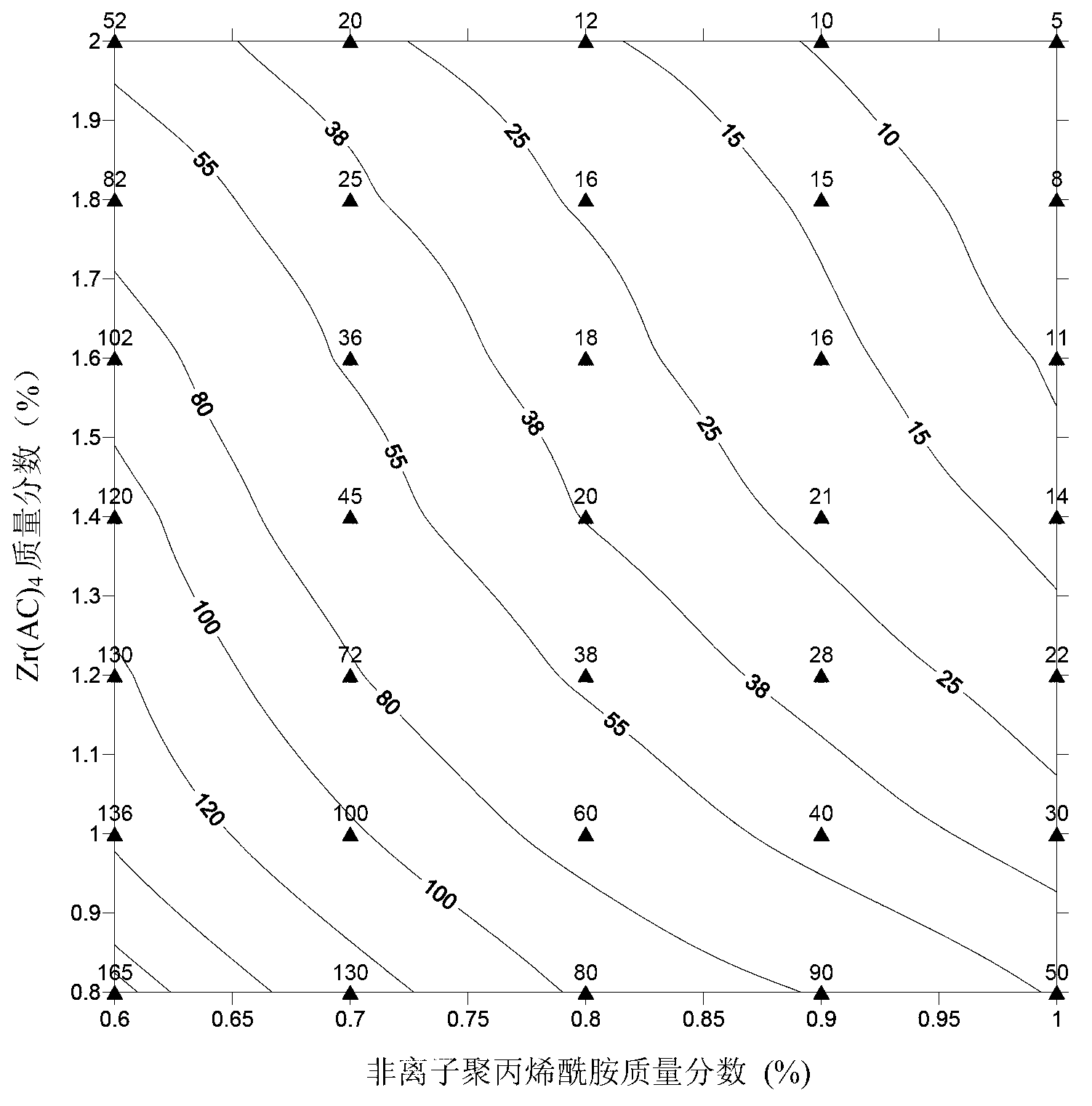

Preparation method of environment-friendly multi-scale zirconium gel dispersion plugging agent

ActiveCN102936490AExpand the affected volumeEnhanced overall recoveryDrilling compositionMicron scaleMass ratio

The invention relates to a preparation method of an environment-friendly multi-scale zirconium gel dispersion plugging agent. The method includes processing a formed gel system through a mechanical shearing method to enable the gel to form a nano-scale, micron-scale or millimeter-scale gel dispersion, wherein the mass fraction of nonionic polyacrylamide in gelling fluid is 0.6-1%, the mass fraction of a zirconium acetate cross-linking agent is 1-2%, and the gelling is performed at a temperature of 30 DEG C; and taking a colloid mill as a shearing device, adjusting the revolving speed and the shearing spacing of the colloid mill, adding the gel and water into the colloid mill according to a mass ratio of (1-6):1, performing circulating shearing until the gel is evenly dispersed to obtain a multi-scale zirconium gel dispersion solution. The plugging agent can enter the deep positions of stratums through the grain size, adjust water injection profiles effectively, and play a deep fluid diversion role, so that follow-up water is driven to low and medium permeable layers, the water swept volume is enlarged, and the oil recovery is further enhanced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Polymer microspheres for high temperature hypersalinity reservoir deep profile control and preparation method thereof

InactiveCN101619119AExpand the affected volumeEnhanced overall recoveryDrilling compositionPolymer scienceMicrosphere

The invention provides polymer microspheres for high temperature hypersalinity reservoir deep profile control and a preparation method thereof. In the method, based on the method that photopolymerization is used to prepare the polymer microspheres, heat and salt resistance polymer materials such as sodium 3-acryloylamino-3-methyl butyrate, 2-acryloylamino-2-methylpropane sulfonic acid, acrylamide monomer and the like and water-soluble anionic monomer are adopted and dispersant and cross-linking agent are added as so to form oil-water mixed emulsion in the mixed medium of surfactant and solvent; then initiator is decomposed by ultraviolet through photopolymerization under controllable temperature so as to initiate emulsion polymerization and 50-500nm of microspheres are formed. The invention utilizes the ability of microspheres that microspheres can be dispersed in arbitrary concentration and injected in the water and can gradually swell after entering in depth of the formation to plug the pore throat so as to effectively plug the high permeable strip of the formation, expand the water swept volume, significantly increase crude oil recovery of water flooding reservoir and is applicable to high temperature hypersalinity reservoir deep profile control.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +4

Method for activating indigenous microorganisms of oil reservoir for oil displacement after polymer flooding

ActiveCN104234675AIncrease the number ofExpand the affected volumeFluid removalInjection wellPolymer flooding

The invention discloses a method for activating indigenous microorganisms of an oil reservoir for oil displacement after polymer flooding. The method is characterized in that an oil displacement slug capable of activating indigenous microorganisms of the oil reservoir is injected into a target oil reservoir of the oil displacement through an injection well; the oil displacement slug comprises an activating agent slug and an activating agent protection slug; during an injection process, the activating agent slug and the activating agent protection slug are alternately injected for at least more than 2 times; the total volume of the activating agent slug is two times or more bigger than that of the activating agent protection slug (the most suitable range is controlled to be 2-5 times). According to the method disclosed by the invention, the number of the functional microorganisms of the oil reservoir is increased by injecting an exogenous activating agent; the recovery efficiency can be improved by 3-5 percent after the polymer flooding, and the applicability is good.

Owner:PETROCHINA CO LTD +1

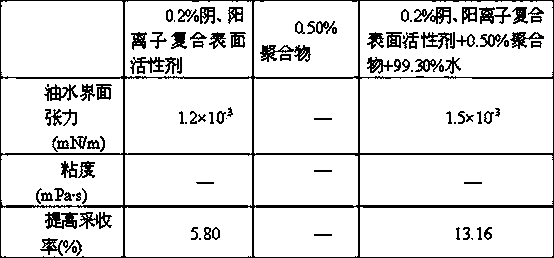

Method of displacing oil by anionic-cationic composite surfactant

ActiveCN103422840ALarge adsorption capacityLow critical micelle concentrationFluid removalDrilling compositionSURFACTANT BLENDOil well

The invention relates to a method of displacing oil by anionic-cationic composite surfactant and mainly solves the problems that the prior method of displacing oil by surfactant is low in oil displacement efficiency in tertiary oil recovery and an oil displacement system containing inorganic base is harmful to stratums and oil wells, corrosive to equipment and pipelines and difficult for demulsification. According to the technical scheme, crude oil is allowed to contact with oil-displacing agent, and the oil-displacing agent comprises, by weight percent, 0.01-5.0% of anionic-cationic composite surfactant, 0.01-3.0% of polymer, and 92.0-99.98% of injected water. The problems are solved well. The method is applicable to tertiary oil recovery for oil fields.

Owner:CHINA PETROLEUM & CHEM CORP +1

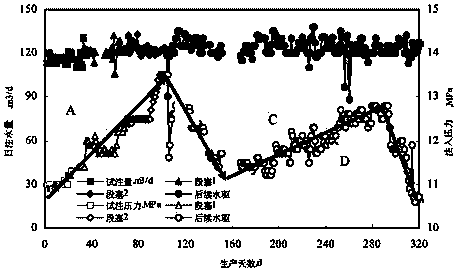

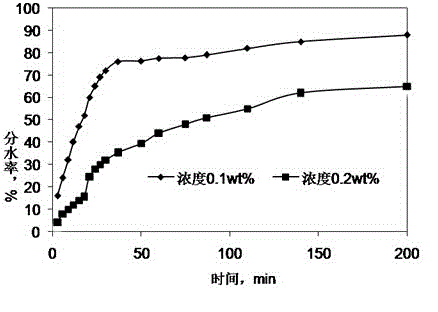

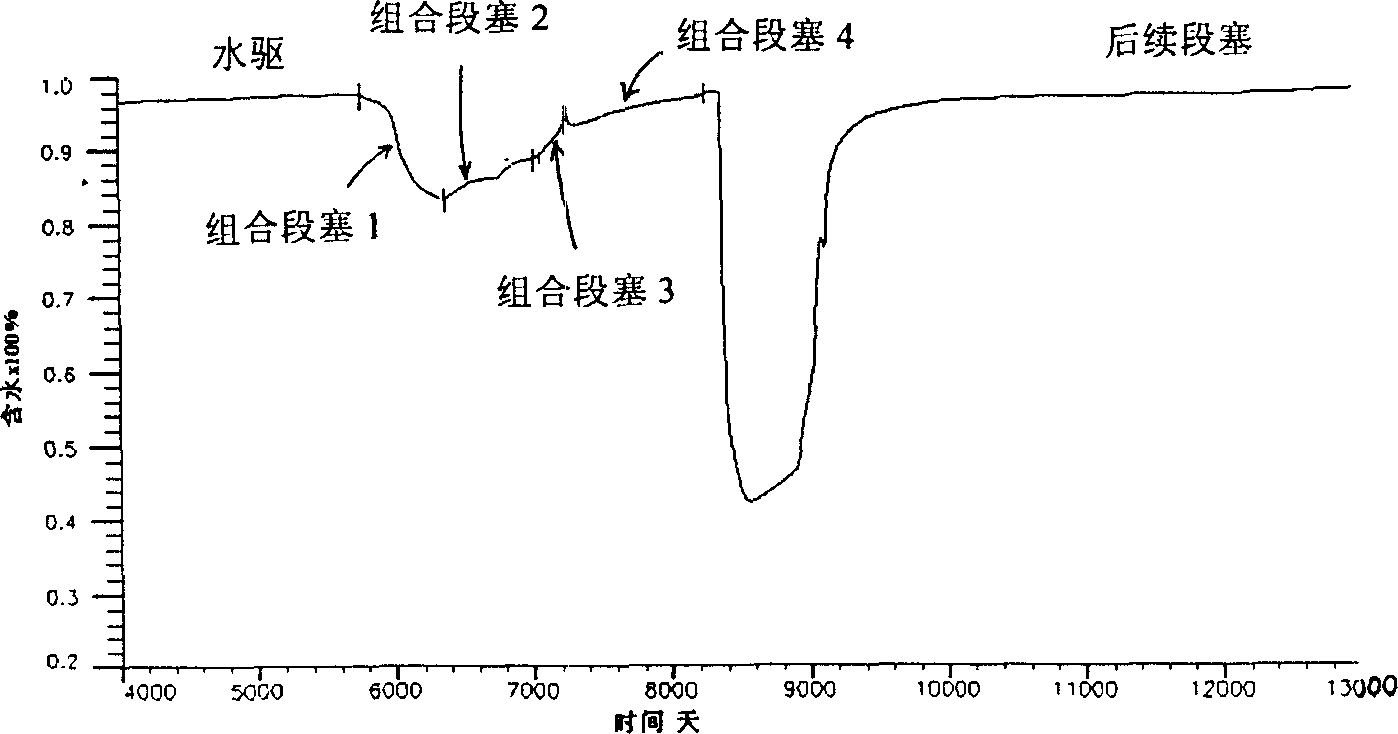

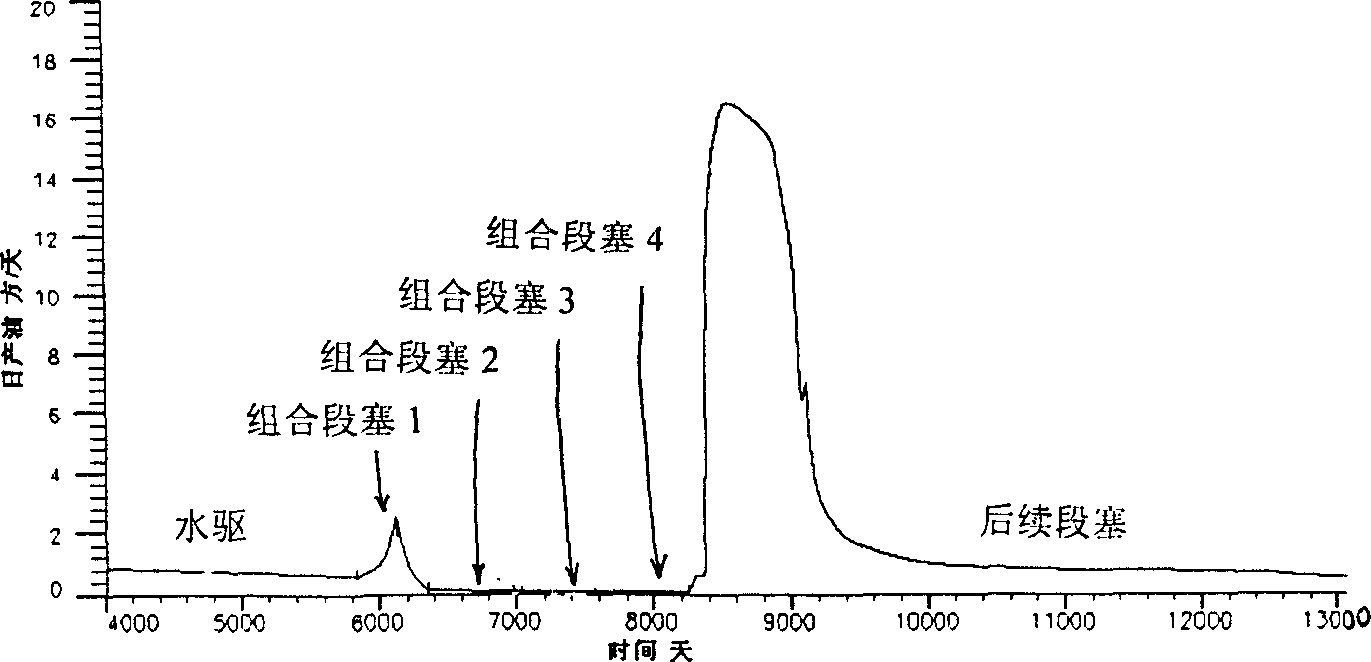

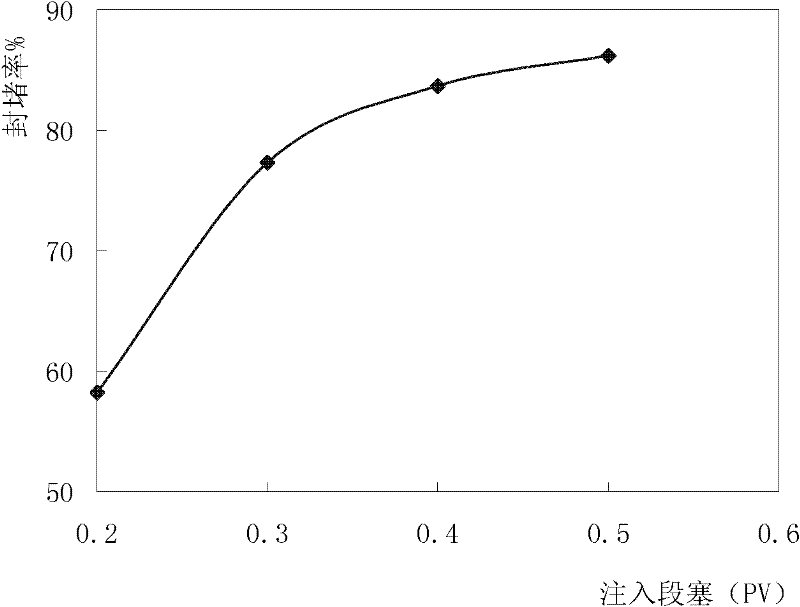

Thermal production well filling vapor and nitrogen foam profile control technique

InactiveCN101016835AExpand the affected volumeIncrease crude oil productionFluid removalChemistryNitrogen gas

The invention relates to a thermal developing well pouring steam nitrogen foam adjusting method comprising steam, nitrogen and foaming agent pouring method and nitrogen generating pouring method, wherein the steam is poured via an oil tube, the nitrogen and the foaming agent are poured in via a muffle, while the mass ratio between the foaming agent, steam is 1:250-500, the mass ratio between the nitrogen and the stem is 50-80:1, the pouring speed is steam at 10-13t / h, foaming agent at 0.1-0.5t / h, and nitrogen at 900-1000Nm3 / h. And the invention uses four-section plug pouring process, while the first section plug pours nitrogen via the muffle for 12h at 900-1000Nm3 / h, the second section plug pours the steam via the oil tube for 24h at 10-13t / h, and the third section plug pours steam via the oil tube and pours nitrogen and foaming agent via the muffle at 10-13t / h, 900-1000Nm3 / h, and 0.1-0.5t / h for 2h, the fourth section plug stops pouring foaming agent and holds the pouring speed of the nitrogen and the steam for 12h, repeats the steps of four section plugs until preset demand, closes the well, then opens well to produce.

Owner:SINOPEC SHENGLI OILFIELD

Method of raising oil deposil erude petroleum recovery ratio

A method for increasing the recovering rate of crude oil includes preparing the mixed solution from polyacrylamide, foaming agent and water, and proportionally filling said mixed solution and gas or N2 in the water injecting well alternatively by the alternative period of 20 days.

Owner:中国石化胜利油田有限公司地质科学研究院

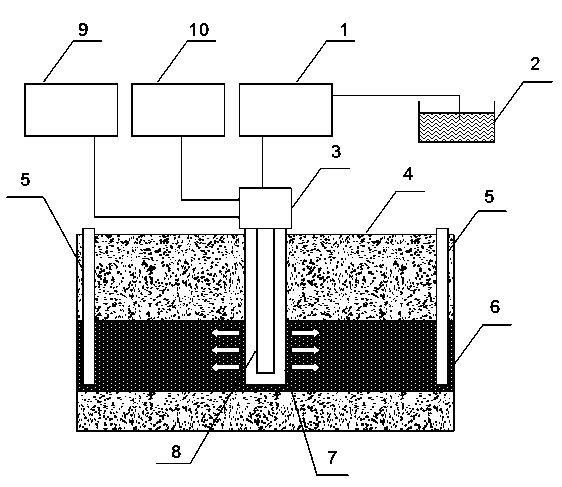

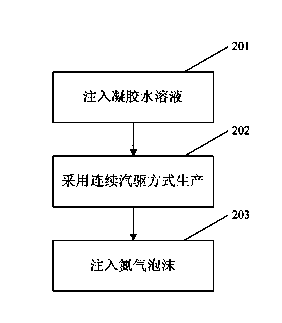

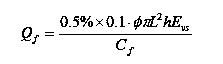

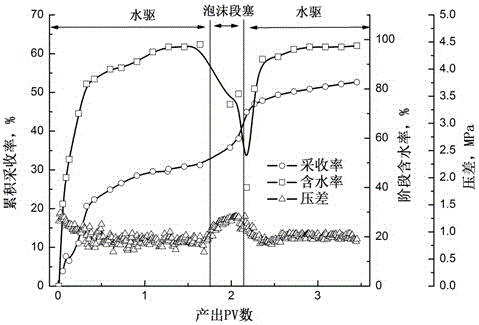

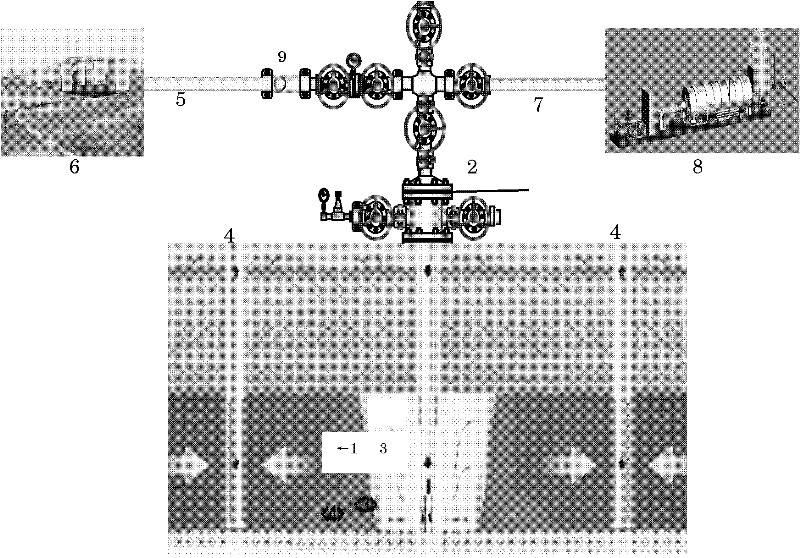

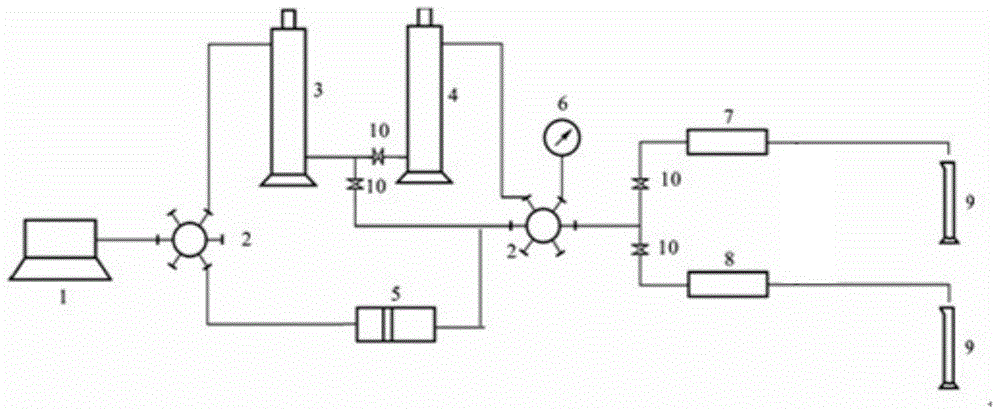

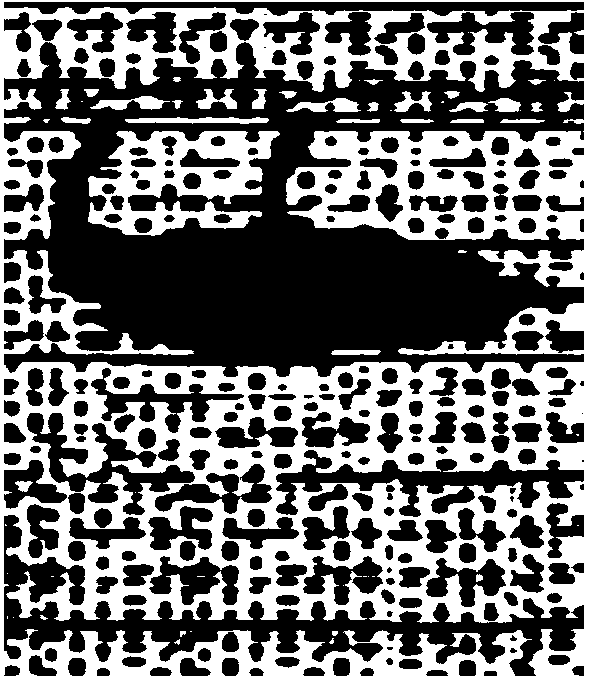

High-temperature blocking and adjusting device and method for super-heavy oil reservoir steam flooding

ActiveCN103541705AExpand the affected volumeReduce water contentFluid removalFoaming agentGas oil ratio

The invention provides a high-temperature blocking and adjusting device and method for super-heavy oil reservoir steam flooding. The high-temperature blocking and adjusting device for super-heavy oil reservoir steam flooding comprises an injection device, a thermal-recovery steam injection well mouth, a nitrogen injection device and a steam injection device. The injection device is connected with the thermal-recovery steam injection well mouth for injecting gel solutions or foaming agent solutions, the nitrogen injection device is connected with the thermal-recovery steam injection well mouth and used for generating and injecting high-purity nitrogen, and the steam injection device is connected with the thermal-recovery steam injection well mouth and used for generating and injecting high-dryness steam. According to the high-temperature blocking and adjusting device and method for super-heavy oil reservoir steam flooding, gel and nitrogen foams are combined, comprehensive water content of a steam flooding well group can be obviously lowered, the gas oil ratio can be obviously improved, the high-temperature blocking and adjusting effect of a super-heavy oil reservoir can be greatly improved, and blocking and adjusting cost is saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

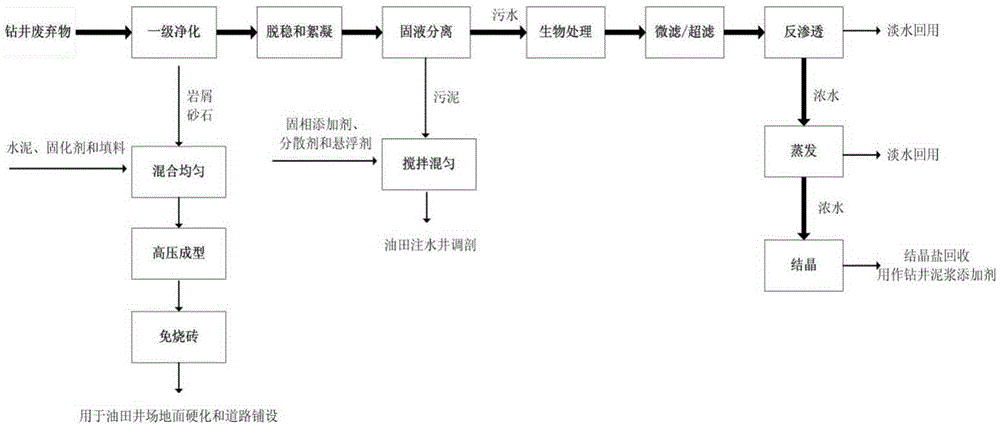

Drilling wastes recycling method

ActiveCN105347609AAdapt to dispersionAdapt to mobilityWaste water treatment from quariesWater treatment compoundsSludgeEvaporation

The invention belongs to the technical field of sewage processing, and concretely relates to a drilling wastes recycling method. The method comprises the following steps: performing primary purifying, removing rock debris and sandstones; performing destabilizing and flocculating treatment, conglomerating the suspending granules into a flocculent body; performing solid-liquid separating, using a separated sludge for profile control of a water injection well in an oil field; performing biological treatment on the separated sewage to reduce COD, carrying out microfiltration and ultrafiltration processing for removing a suspension and a colloid as well as reducing SDI, performing reverse osmosis to obtain fresh water for reuse, evaporating concentrated water obtained by reverse osmosis and crystallization, reusing the fresh water obtained by evaporation, and reusing the common salt and potassium chloride obtained by crystallization as an additive of a drilling fluid. The method realizes harmlessness and recycling of the drilling wastes, eliminates pollution on surrounding environment, and is in favor of protection of resources such as soil, air and underground water at periphery of a well field. The method can be widely used in a recycling treatment process of the drilling wastes in the oil field.

Owner:CHINA PETROLEUM & CHEM CORP +1

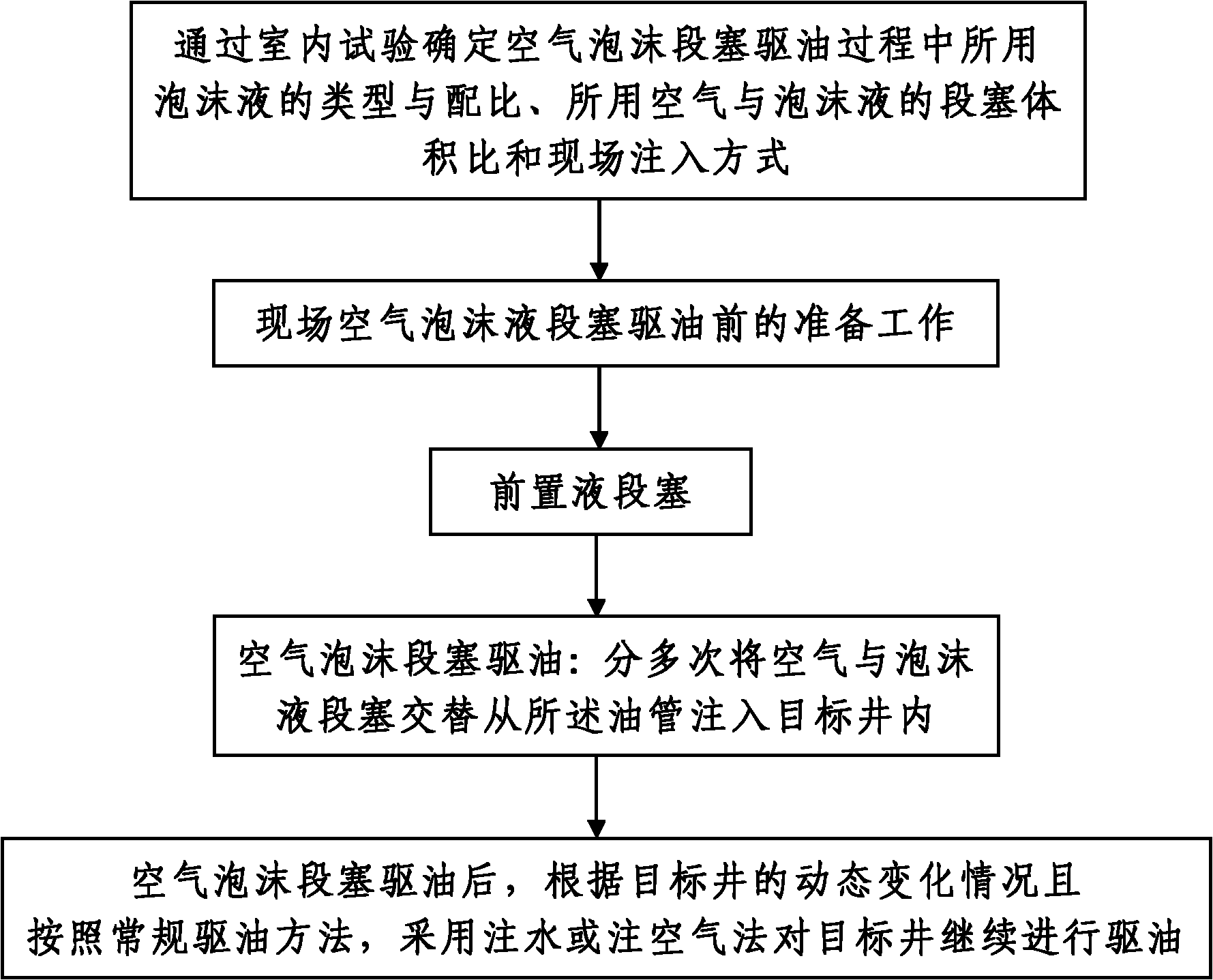

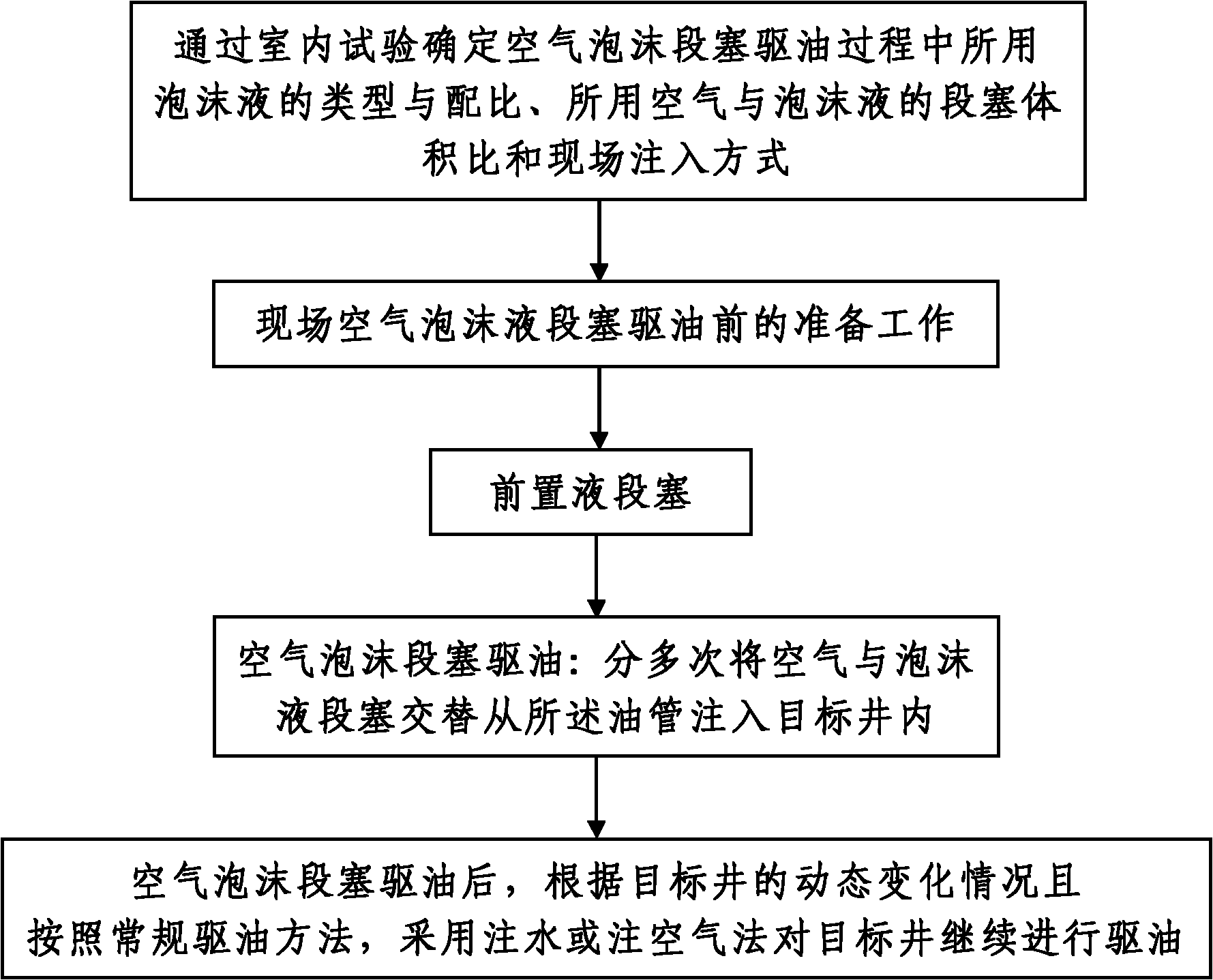

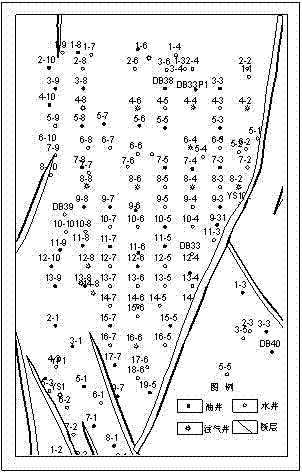

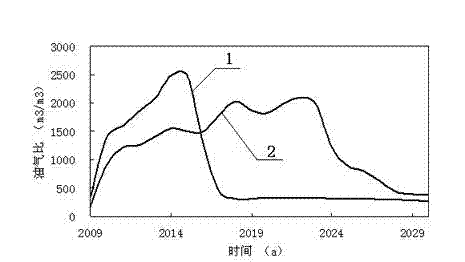

Air foam slug flow driving process for oil recovery of oil field

InactiveCN102061906ASimplify construction stepsEasy constructionFluid removalInjection airOil displacement

The invention discloses an air foam slug flow driving process for the oil recovery of an oil field, comprising the following steps of: 1 determining type and proportion of the used foam liquid, slug volume ratio and on-site injection manner of the used air and the foam liquid during the air foam slug flow driving by an indoor test; and 2 carrying out the air foam liquid slug flow driving on site,wherein the oil flow driving process comprises the following steps of: preparation before the oil flow driving; slugging a pad fluid; slugging the air foam; alternatively injecting the air and foam liquid slug from a specially manufactured device to a target well for many times; and continuously carrying out the oil flow driving on the target well by a water or air injection method according to the dynamic change condition of the target well and a conventional oil displacement method after the injection of the air foam slug is finished. The invention has the advantages of reasonable design, simple and convenient construction steps, good use effect and convenience of realizing, can effectively solve various practical problems of poor water injection effect, difficult improvement on the water injection capability, poor oil flow driving efficiency and the like during the ultralow reservoir waterflooding.

Owner:YANCHANG OIL FIELD

CO2 drive oil-gas-water separate well injecting oil reservoir mixing drive development method

ActiveCN102777157AExpand the affected volumeAir channeling controlFluid removalSweep efficiencyProduct gas

The invention provides a CO2 drive oil-gas-water separate well injecting oil reservoir mixing drive development method, and belongs to the field for improving recovery ratio of an oil reservoir. The method comprises the following steps of: firstly, determining a development well pattern, well spacing and a development layer system of the oil reservoir; then, utilizing an overall process numerical simulation technique to determine advantage seepage direction and sweep efficiency of injection gas, designing an injection well in the advantage seepage direction of the injection gas as a water injection well, designing other injection wells as a gas injection well, forming water-gas mixed drive of partial water injected to well and partial gas injected into well; and finally determining the injection parameter of an injection production well and the development index forecast of a whole region. The method can form a water barrier in a gas channeling direction, thereby effectively controlling gas channeling, enlarging swept volume of the injected gas, and improving recovery efficiency; and the method provided by the invention has excellent guiding function on the gas injection drive oil well pattern, well type and injection and production parameter of a developed block and an undeveloped block, and the application prospect is wide.

Owner:CHINA PETROLEUM & CHEM CORP +1

Clay foam stabilizing complex additive for foam flooding as well as preparation method and application of clay foam stabilizing complex additive

ActiveCN103694983AIncrease foam volumeExtended half-lifeFluid removalDrilling compositionHalf-lifeSolid particle

The invention relates to a clay foam stabilizing complex additive for foam flooding as well as a preparation method and an application of the clay foam stabilizing complex additive. The clay foam stabilizing complex additive comprises the following raw materials in parts by weight: 0.2-0.9 part of sodium dodecyl benzene sulfonate, 1-10 parts of clay particles and 100 parts of water, wherein the particle sizes of the clay particles range from 25mu m to 100mu m. The hydrophobic clay particles are added into the clay foam stabilizing complex additive for foam flooding, provided by the invention to ensure that the solid particles are attached on the surface of a liquid film and in a liquid film layer to form a rigid compact shell, so that the strength of the foam liquid film is enhanced, the liquid drainage of the liquid film is inhibited, the liquid film is prevented from thinning, and furthermore, the bubbling volume of the foam is increased, and the half-life period of the foam is prolonged.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Foam oil displacement system with ultralow interfacial tension and use method of foam oil displacement system

ActiveCN105154055AReduce interfacial tensionImprove oil washing efficiencyFluid removalDrilling compositionCelluloseCocamidopropyl dimethylamine

The invention provides a foam oil displacement system with ultralow interfacial tension and a use method of the foam oil displacement system. The oil displacement system is formed by mixing raw materials in percentage by weight as follows: 0.1%-0.3% of a foaming agent, 0.05%-0.15% of an inorganic reagent, 0.01%-0.10% of a foam stabilizer and the balance of water, wherein the foaming agent is dodecyl dimethyl betaine, dodecyl hydroxysulfobetaine, dodecyl hydroxypropyl sulphobetaine, lauramide propyl hydroxysulfobetaine, lauramide propyl betaine, cocamidopropyl dimethylamine oxide, gemini oxidized tertamine, polyoxyethylene dodecanol ether sulfate or sodium dodecyl sulfate; the inorganic reagent is sodium hydroxide, anhydrous sodium carbonate or sodium metaborate; the foam stabilizer is partially HPAM (hydrolyzed polyacrylamide), acrylamide copolymer, PACHV (high-viscosity polyanionic cellulose) or HPMC (hydroxypropyl methyl cellulose).

Owner:CHINA PETROLEUM & CHEM CORP +1

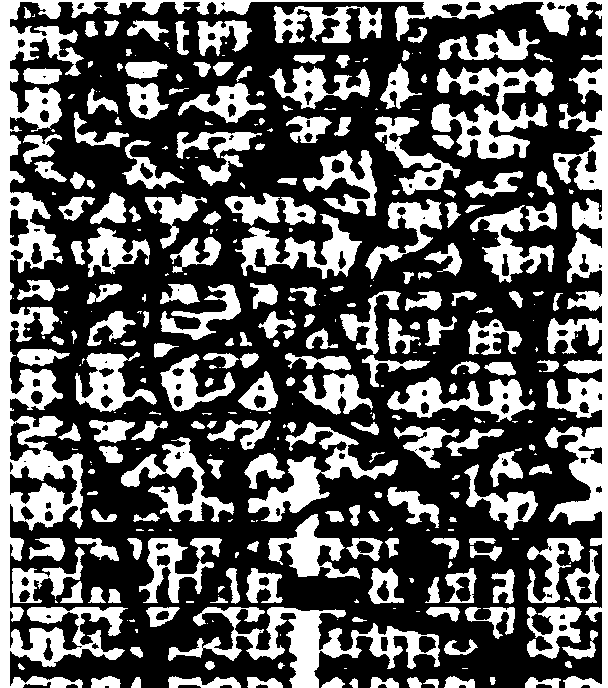

Method for carrying out profile control on fracture-type oil reservoir

The invention relates to a method for carrying out profile control on a fracture-type oil reservoir, which comprises the following steps of injecting 0.1 to 0.3 percent of zwitterionic polymer solution into an oil layer; suspending and carrying expansion-retarding 0.2 to 1.0 percent of salt-resistance high-intensity water-absorbent resin particles by a zwitterionic gel profile control agent and injecting the obtained product into a fracture of the oil layer; injecting 30 to 50m<3> of acrylamide gel; suspending 0.2 to 0.5 percent of water insoluble solid particles by the zwitterionic gel profile control agent and injecting the obtained product into the fracture; and alternately injecting 1,000m<3> of partially hydrolyzed polyacrylamide solution with a molecular weight of 15 million, degree of hydrolysis of 10 to 20 percent and 1,000m<3> of petroleum sulfonate surfactant solution, wherein the concentration of the hydrolyzed polyacrylamide solution is 0.05 to 0.15 percent and the concentration of the petroleum sulfonate surfactant solution is 0.2 to 0.5. According to the method, profile control and flooding effects of the fracture-type oil reservoir can be improved; water content of a fracture main direction oil well is reduced; and yield of crude oil of a fracture side direction oil well is increased.

Owner:PETROCHINA CO LTD

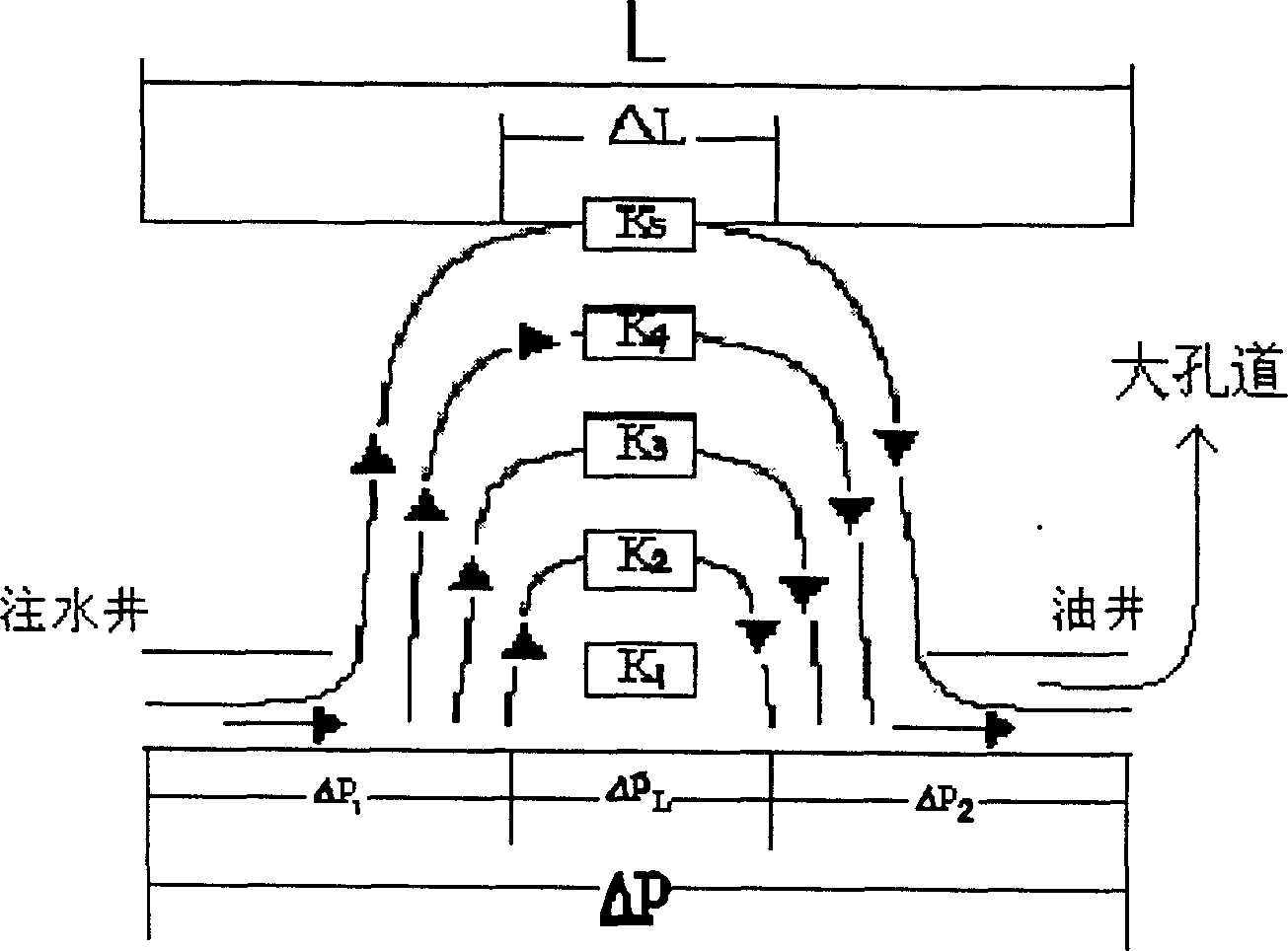

Multi-block equal-fluidity energy-gathering parallel synchronous oil displacement method for heterogeneous oil reservoir

ActiveCN1828010AReduce driving resistanceReduce circulationFluid removalFluid viscosityPressure difference

The invention discloses a method for multi-section equal-fluidity energy-assembled parallel synchronous oil driving in non-uniform oil layer. First, according to the water adsorption ability, dividing the non-uniform oil layer into several sections; then selecting the fluidity of oil driving agent and keep the fluidity of each section same; uses the formula that the fluidity=oil layer filter rate / fluid viscidity to calculate the fluid viscidity of needed oil driving agent; and selecting polymers to attain the fluid in said viscidity; the sub sections in different viscidities are connected to the integrated one; at last, from high to low viscidity, filling sub sections into oil layer. The invention changes the integrated oil driving into separated oil driving, with less driving resistance; the energy-assembled section has high part pressure, and high driving pressure difference. And it can reduce ineffective water cycle, improve efficiency and reduce the consumption of driving agent.

Owner:DAQING OILFIELD CO LTD +1

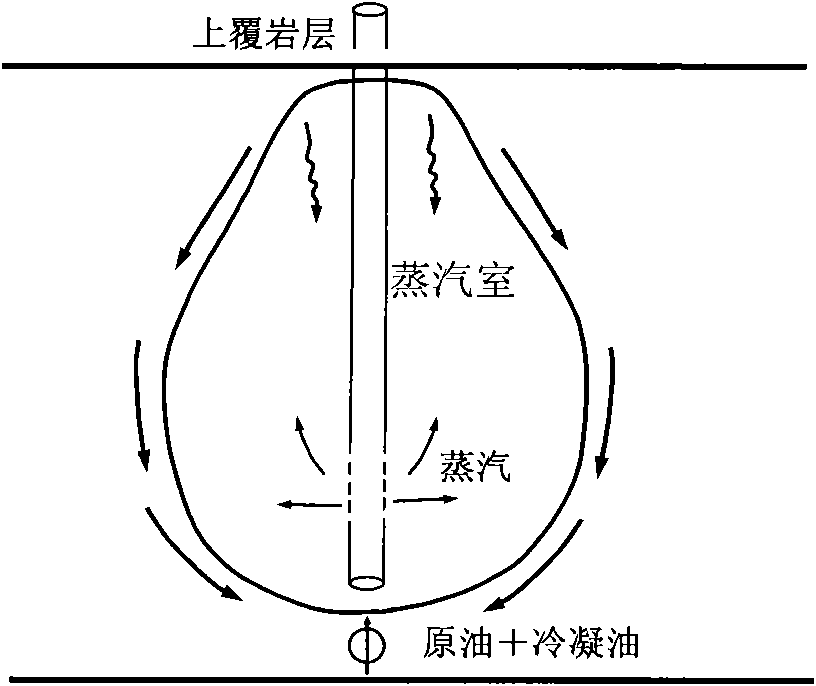

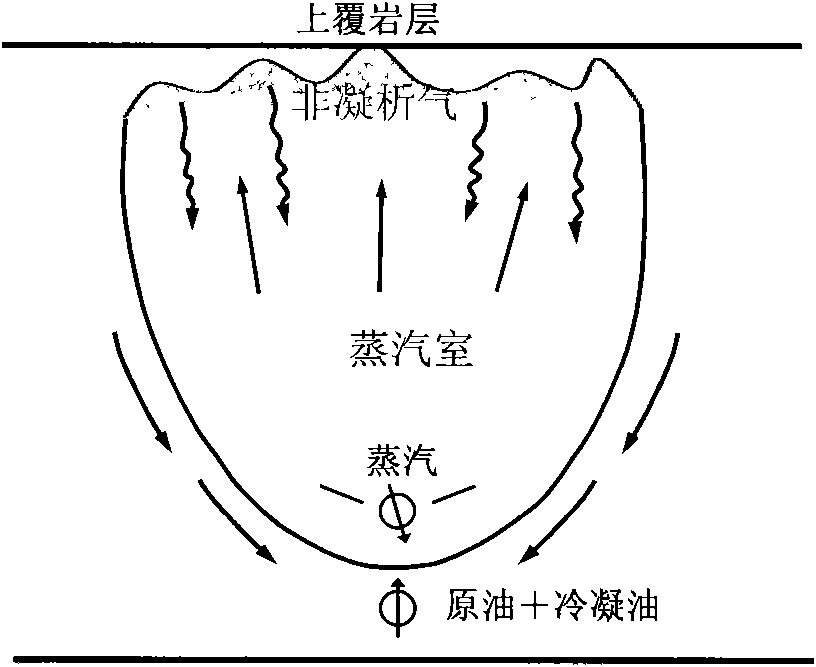

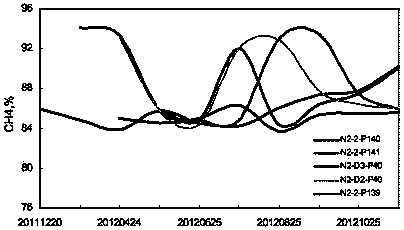

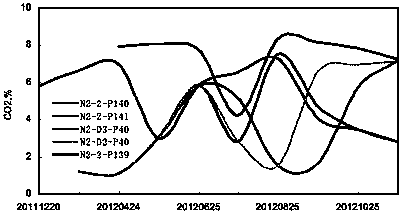

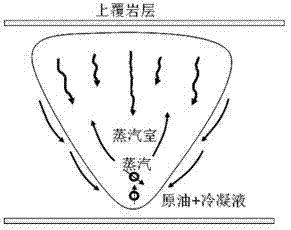

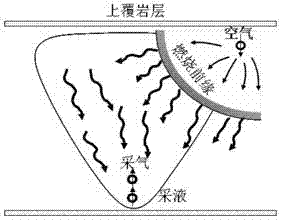

Later-period air injection exploitation method for super heavy oil reservoir using steam assisted gravity drainage (SAGD) exploitation

The invention relates to a later-period air injection exploitation method for super heavy oil reservoir using steam assisted gravity drainage (SAGD) exploitation. The method comprises the following steps of: newly drilling a straight well as an air injection well at a position where a steam cavity of the super heavy oil reservoir develops poorly; perforating on the upper part of the air injection well to complement a perforation section with the length of 2-3m; continuously injecting air by the air injection well at the speed of 20,000-80,000m<3> / day and firing to exploit; and stopping injecting the air when the volume percentage of the oxygen in the produced gas reaches 3 percent or the volume ratio of the volume of the injected air and the volume of the produced crude oil reaches over 3,000m<3> / m<3>. With the adoption of the method, the later-period heat loss is reduced by using the SAGD technology, and the stable production of the whole system is maintained by utilizing heat energy released by reacting substances in the oil reservoir.

Owner:PETROCHINA CO LTD

Method for developing heavy oil reservoir of horizontal well by combining staged volume fracturing and fracturing filling

ActiveCN105422068AReduce heat lossImprove seepage propertiesFluid removalSealing/packingPorosityGeomorphology

The invention provides a method for developing a heavy oil reservoir of a horizontal well by combining staged volume fracturing and fracturing filling. According to the method, firstly, a steam injection well is deployed at the bottom of the oil reservoir; a production well is deployed at the middle upper part of the oil reservoir; then, the volume fracturing or fracturing filling operation is performed according to the porosity degree and seepage rate distribution condition of the two horizontal wells; then, the two wells form heat communication in a steam throughput mode; next, the two wells transfer to continuous steam injection production; and the production is stopped when the oil-steam ratio is lowered to 0.1. According to the invention, a fracture net system is formed in a compact region by the volume fracturing, so that the seepage capability of the oil reservoir is improved; the fracturing filling process is used in a high-porosity and high-permeability region for performing compaction so as to reduce a formation sand production phenomenon; the seepage mode of a low-permeability region oil reservoir is converted from the single seepage to the sewage and fracture laminar flow; meanwhile, a high-permeability region is filled with small-grain-size sand for filling loose reservoir sandstone particle pores, so that the permeability near the production well is reduced,the oil reservoir anisotropy is reduced and the whole oil reservoir can be uniformly used and developed.

Owner:PETROCHINA CO LTD

Steam drive exploitation method for heavy oil reservoir

The invention belongs to the field of oil exploitation, and relates to a steam drive exploitation method for a heavy oil reservoir, in particular to a steam drive exploitation method of intermediate-deep layer heavy oil aided by injecting air. The method comprises the following steps of synchronously and continuously injecting steam and air in a steam injection well according to a certain mass ratio in the process of intermediate-deep layer heavy oil steam drive production, and performing a low-temperature oxidation reaction between crude oil and oxygen. According to the method disclosed by the invention, heat utilization and recovery ratio of intermediate-deep layer heavy oil steam drive can be improved; a problem of steam channeling among injection and exploitation wells can be eased, and development effect of steam drive can be improved.

Owner:PETROCHINA CO LTD

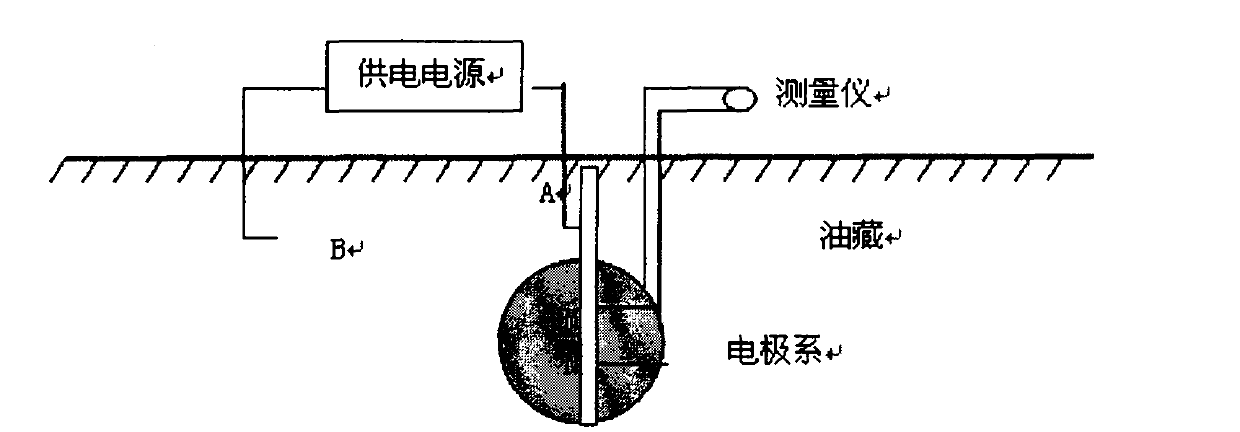

Resistivity data collecting and processing method based on oil-water front

InactiveCN101769151AImprove comprehensive benefitsExpand the affected volumeBorehole/well accessoriesGeotechnical engineeringOil water

The invention provides a resistivity data collecting and processing method based on an oil-water front, which belongs to a method for measuring the change of the resistivity of a geological stratum with a core containing oil and water in the physical simulation of geophysical exploration and development. The method comprises the steps of simulating an actual stratum (manufacturing an artificial cement rock core model), arranging a simulation well, arranging a front monitoring system and measuring the change of the resistivity in the artificial cement rock core model. The method not only can well simulate and measure the underground geological condition but also can further learn the position of the residual oil of a reservoir and the change rule of the oil-water front.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

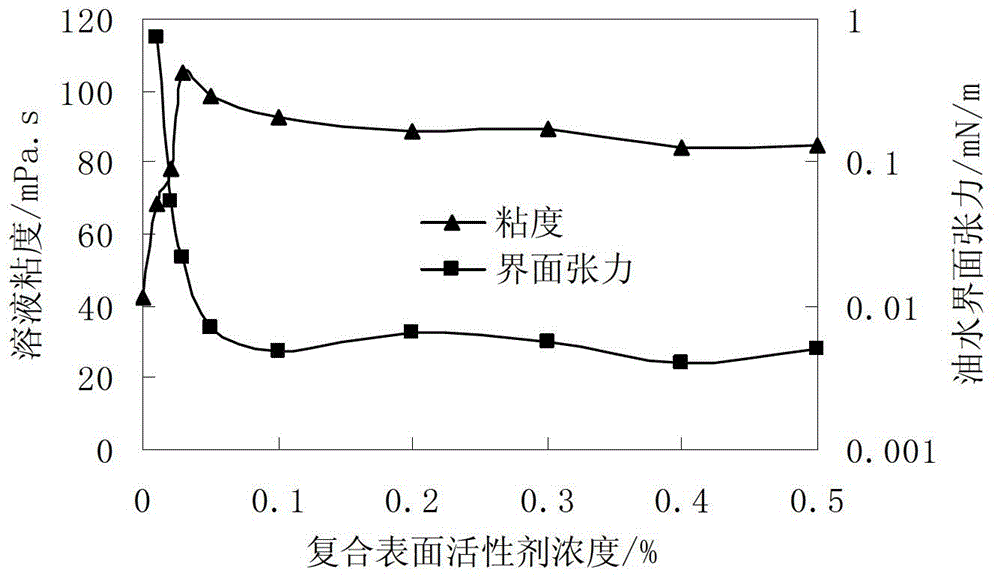

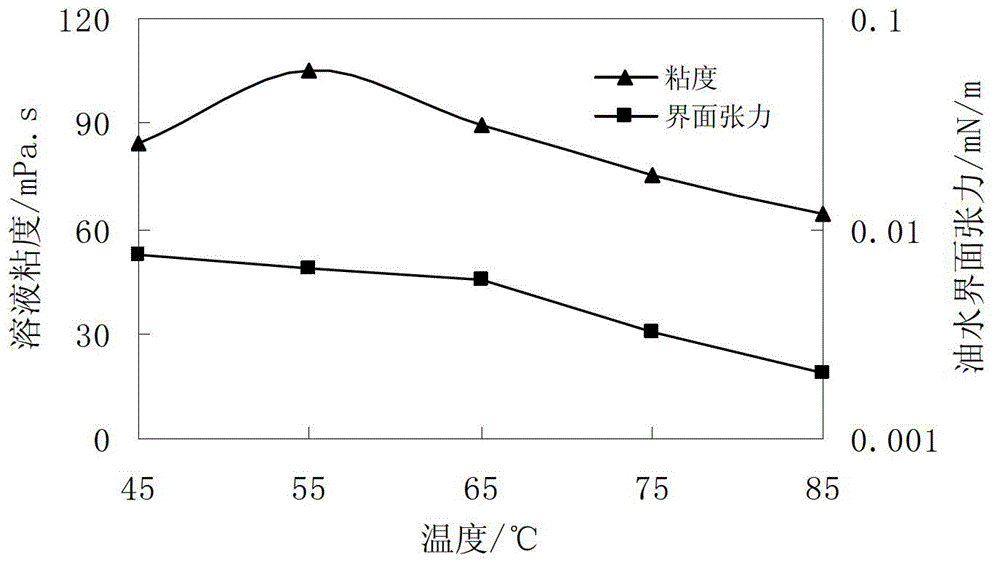

Hydrophobically associated polymer-composite surfactant binary combination flooding system and method

The invention discloses a hydrophobically associated polymer-composite surfactant binary combination flooding system and method. The hydrophobically associated polymer-composite surfactant binary combination flooding system mainly comprises the following components in percentage by weight: 0.08-0.3 wt% of hydrophobically associated polymer, 0.05-0.5 wt% of composite surfactant and 99.2-99.87 wt% of water. The composite surfactant is composed of the following components in percentage by weight: 50-70 wt% of fatty acid diester disulfonate and 30-50 wt% of oleic acid diglycollic amide. The hydrophobically associated polymer-composite surfactant binary combination flooding system has favorable tackifying property, and enables the oil-water interfacial tension to reach 10<-3>nM / m under low surfactant concentration (0.05%), thereby enhancing the displacement efficiency; and the hydrophobically associated polymer-composite surfactant binary combination flooding system can enhance the recovery rate by more than 30% on the basis of water flooding, lowers the polymer consumption by more than 50% as compared with the 250-million ultrahigh-molecular-weight polyacrylamide binary combination flooding system with close properties, and enhances the recovery rate by 6%, thereby greatly lowering the oil displacement cost on the premise of increasing the yield.

Owner:SICHUAN GUANGYA POLYMER CHEM

Environmental-friendly gel plugging agent applicable to low-temperature oil pool and applications of gel plugging agent

ActiveCN103980872AExpand the affected volumeEnhanced overall recoveryFluid removalDrilling compositionCross-linkHigh intensity

The invention relates to an environmental-friendly gel plugging agent applicable to a low-temperature oil pool and applications of the gel plugging agent. The gel plugging agent is prepared from 0.2%-0.6% of ampholytic polyacryamide, 0.5%-2.0% of an organic zirconium cross-linking agent solution, and the balance of water. The gel plugging agent is used for deep water shut-off and profile control constructions in the low-temperature oil pool of 25-35 DEG C and by virtue of the plugging agent, the recovery rate of crude oil can be raised. The gel plugging agent can form a non-flowing high-strength gel system at low temperature and has low viscosity and good injectivity; without toxic chemical materials such as chromium type cross-linking agents, the gel plugging agent is conductive to environmental friendliness.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

A kind of natural carboxylate-polymer microsphere binary compound flood control system and its preparation and application

InactiveCN102295918AReduce dosageRaw materials are easy to getDrilling compositionMicrosphereControl system

The invention relates to a natural carboxylate-polymer microballoon binary composite control system, and a preparation and application thereof. The binary composite control system comprises raw materials of: 0.1-0.5% of polymer microballoon, 0.05-0.5% of natural mixed carboxylate, 0.05% of suspending agent polyacrylamide and the balance of water. The binary composite control system of the invention has effects of profile control and plugging, strong oil scrubbing ability, and can effectively solve a problem of crude oil recovery ratio increase after polymer flooding and avoid damages to stratum and oil extraction equipment caused by alkali.

Owner:SHANDONG UNIV

Variable intensity water injection exploitation method for carbonate fracture-cavity oil reservoir

ActiveCN103670350AExpand the affected volumeAnti-channeling channelFluid removalCarbonate rockFluid field

The invention provides a variable intensity water injection exploitation method for a carbonate fracture-cavity oil reservoir. The variable intensity water injection exploitation method includes the following steps that a injection-exploitation well group is selected in a fracture-cavity unit and subjected to water injection, water injection intensity is adjusted in the water injection process, and water injection is stopped until earnings of oil exploitation are smaller than cost of water injection. According to the water injection exploitation method, a flow field is changed through variable intensity water injection, the swept volume can be enlarged, and then oil recovery is improved.

Owner:CHINA PETROLEUM & CHEM EXPLORATION & PRODION RES INST +1

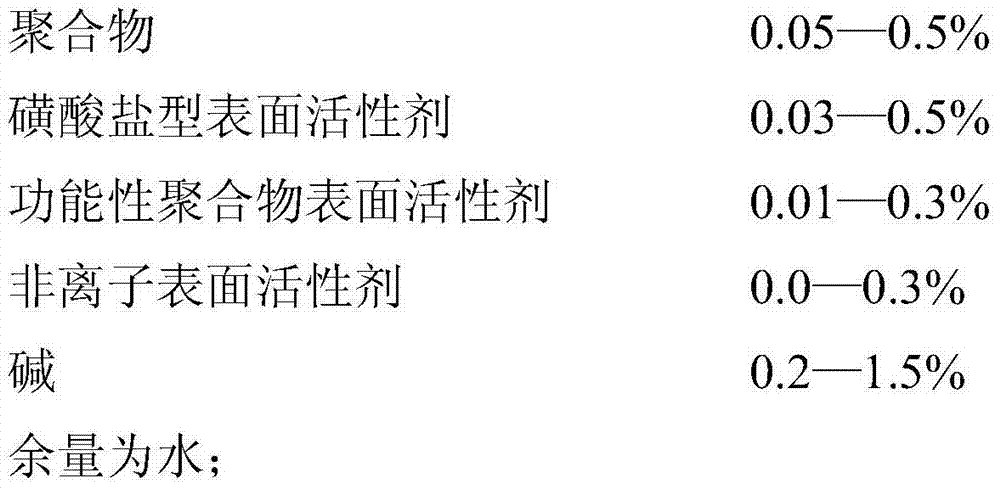

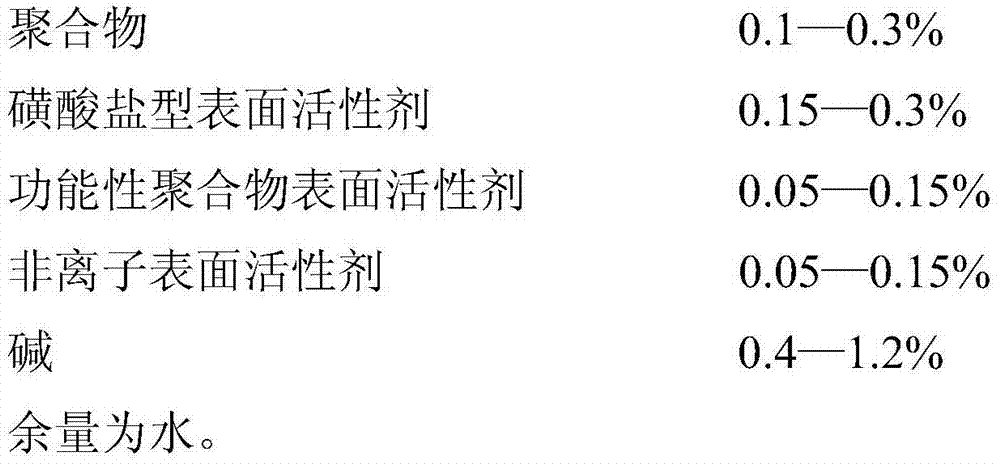

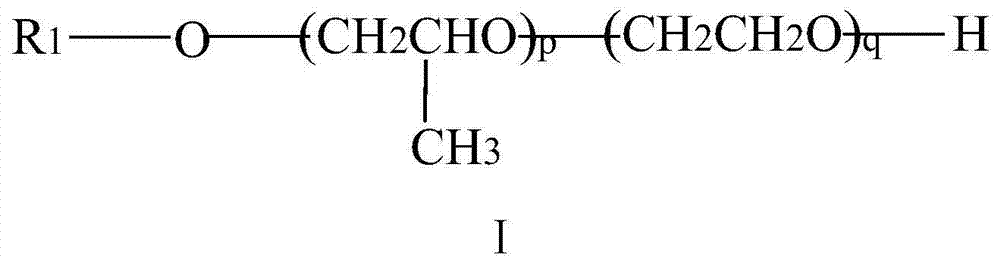

Functional polymeric surfactant reinforced combination flooding composition and application thereof

InactiveCN104327820AEnhanced overall recoveryGood emulsifying effectDrilling compositionHydrophilic monomerPolymeric surface

A functional polymeric surfactant reinforced combination flooding composition contains the following ingredients, by weight, 0.05-0.5% of polymer, 0.03-0.5% of a sulfonate surfactant, 0.01-0.3% of a functional polymeric surfactant, 0.0-0.3% of a nonionic surfactant, 0.2-1.5% of alkali and the balance water. The functional polymeric surfactant is a copolymer of an acrylamide monomer and / or a hydrophilic monomer and / or a functional monomer. According to the reinforced combination flooding composition, multiple oil-displacement mechanisms are combined. In a low-concentration system, the purpose that a three-compounds combination flooding has higher crude oil recovery can be achieved. After polymer flooding, oil reservoir also has a certain effect of raising crude oil recovery.

Owner:大连东方创新科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com