Patents

Literature

49results about How to "Ensure stable production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

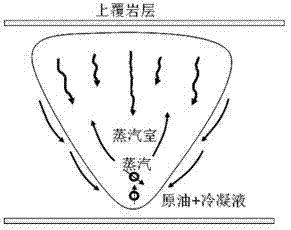

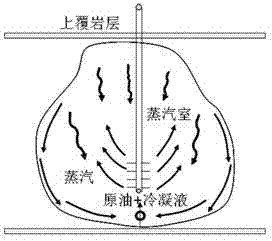

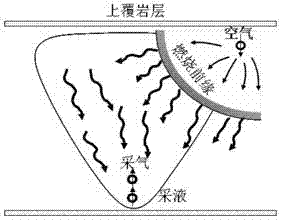

Later-period air injection exploitation method for super heavy oil reservoir using steam assisted gravity drainage (SAGD) exploitation

The invention relates to a later-period air injection exploitation method for super heavy oil reservoir using steam assisted gravity drainage (SAGD) exploitation. The method comprises the following steps of: newly drilling a straight well as an air injection well at a position where a steam cavity of the super heavy oil reservoir develops poorly; perforating on the upper part of the air injection well to complement a perforation section with the length of 2-3m; continuously injecting air by the air injection well at the speed of 20,000-80,000m<3> / day and firing to exploit; and stopping injecting the air when the volume percentage of the oxygen in the produced gas reaches 3 percent or the volume ratio of the volume of the injected air and the volume of the produced crude oil reaches over 3,000m<3> / m<3>. With the adoption of the method, the later-period heat loss is reduced by using the SAGD technology, and the stable production of the whole system is maintained by utilizing heat energy released by reacting substances in the oil reservoir.

Owner:PETROCHINA CO LTD

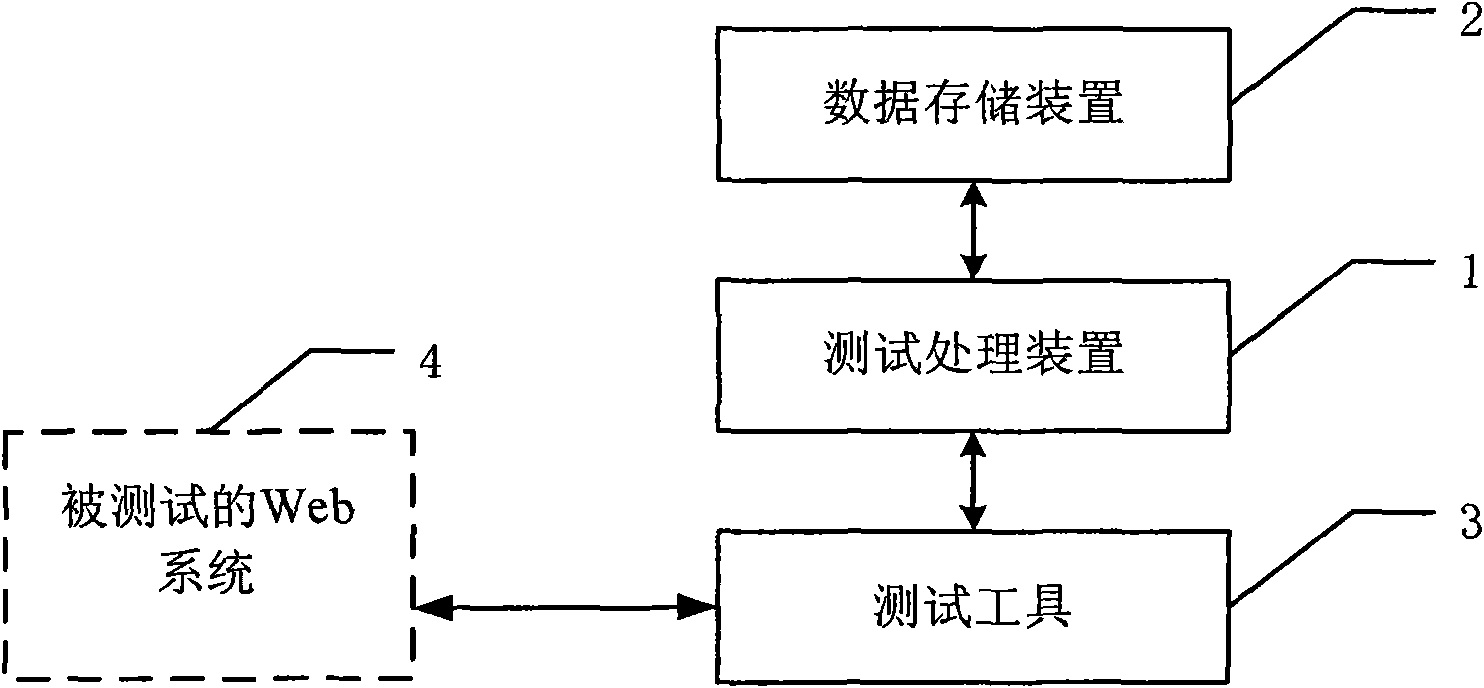

Device and method for automatically testing web page

ActiveCN102012857AImprove automated testing efficiencyQuality improvementSoftware testing/debuggingSpecial data processing applicationsTest efficiencyWeb page

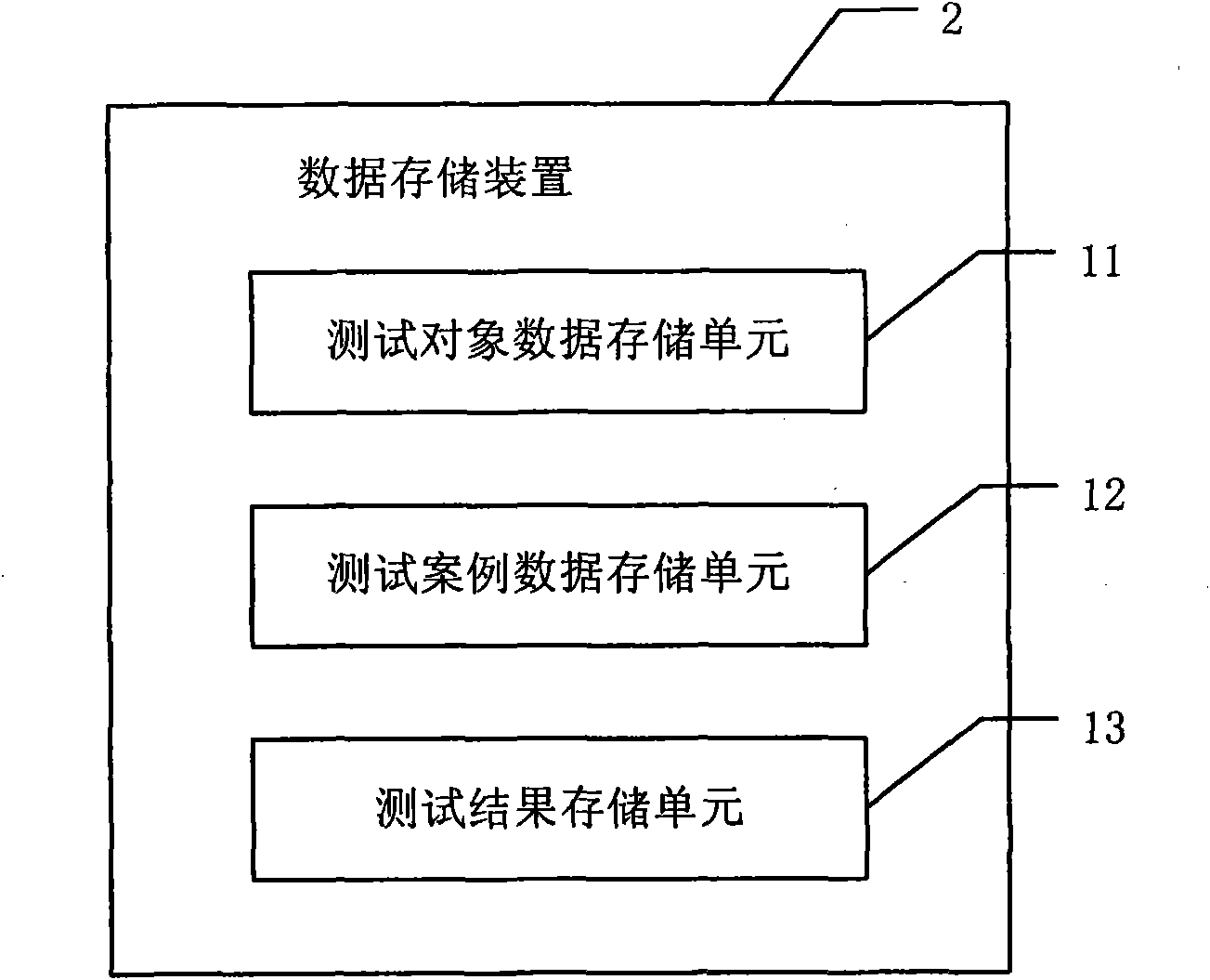

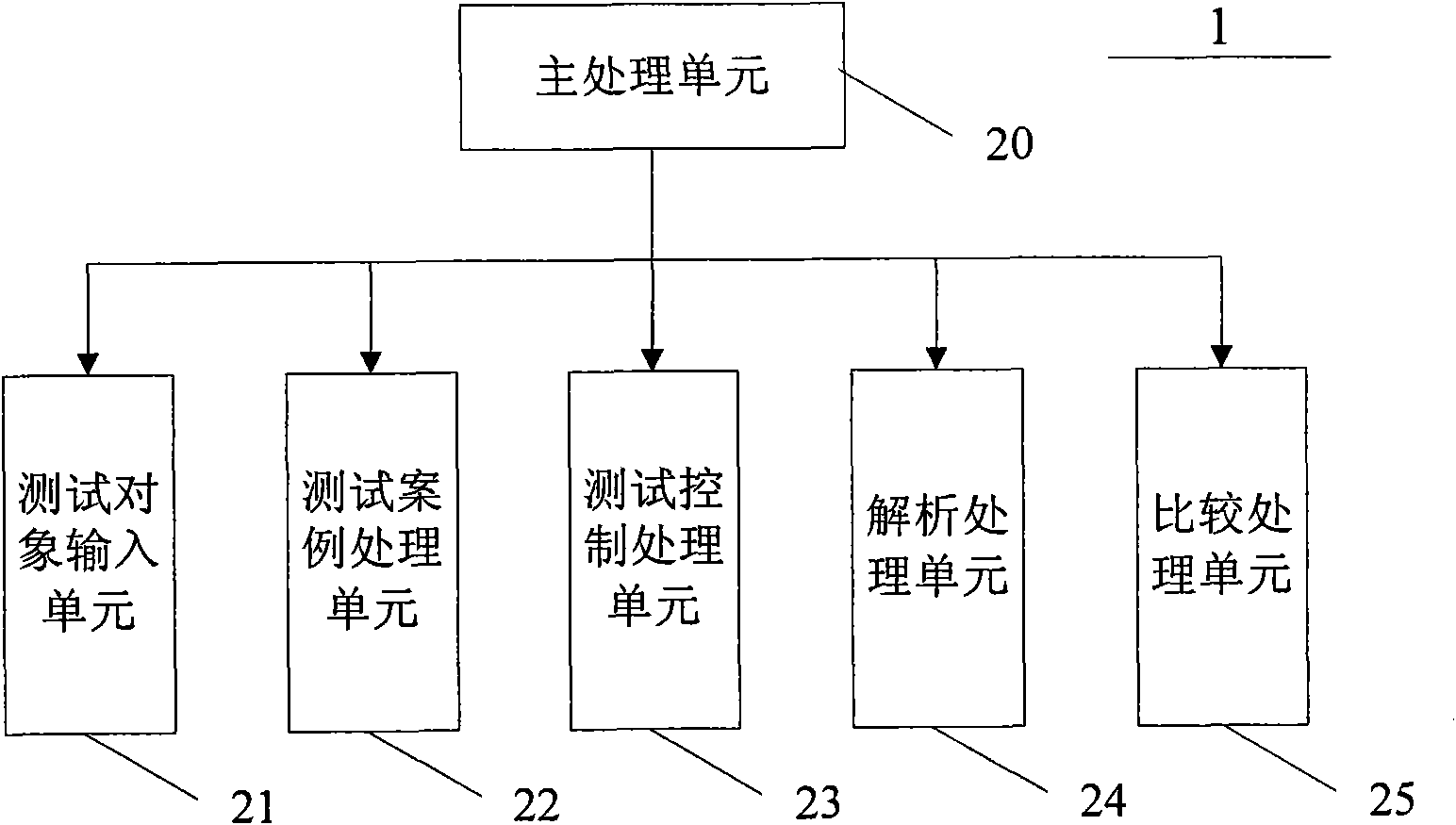

The present invention discloses a device for automatically testing a web page, including the following components: a testing and processing apparatus to test and process a web page; a data storage apparatus used to store information of tested web pages, tested cases and data of test results; a testing tool to browse web pages, parse contents, control execution processes and to obtain error information; wherein the data storage apparatus and the testing tool are both connected with the testing and processing apparatus, and the testing tool is connected with the detected web system. The invention also discloses a method for automatically testing a web page. With the invention, the testing efficiency of web pages is greatly enhanced through parsing input domain objects of web pages and employing a testing method based on objects of web pages, and the invention will effectively improve software quality, guarantee stability and security of enterprise production.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

Beneficiation treatment method for electrolytic aluminium carbon residues

The invention relates to a beneficiation treatment method for electrolytic aluminium carbon residues. The method comprises the following steps: taking carbon residues out of the electrolytic cell for electrolytic aluminium, crushing and grinding the carbon residues into 20-60-mesh powder; adding water, a collecting agent and a foaming agent into the ground carbon residue particles to obtain ore pulp; and sequentially feeding the ore pulp into a roughing flotation machine and two scavenging flotation machines for flotation, wherein a foam product scraped by the roughing flotation machine is carbon powder and material obtained after the second scavenging flotation machine scavenges and scrapes off the foam product is filtered, dried and calcined to obtain a cryolite product. The beneficiation treatment method for electrolytic aluminium carbon residues can be used for enriching and efficiently recycling carbon and cryolite in electrolytic aluminium carbon residues.

Owner:平顶山市华兴浮选工程技术服务有限公司

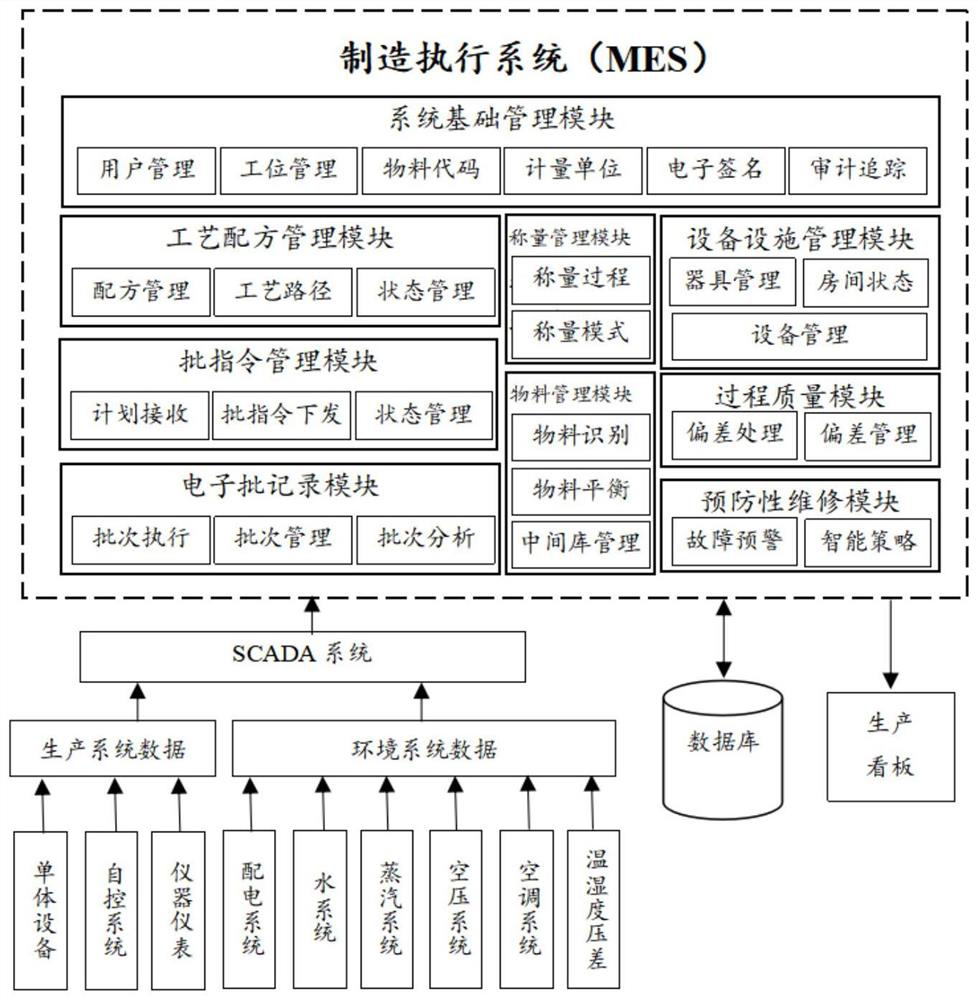

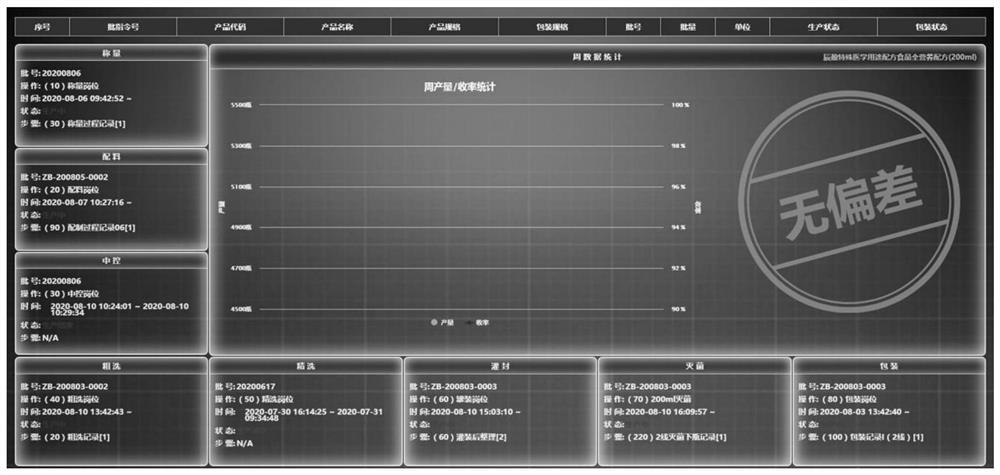

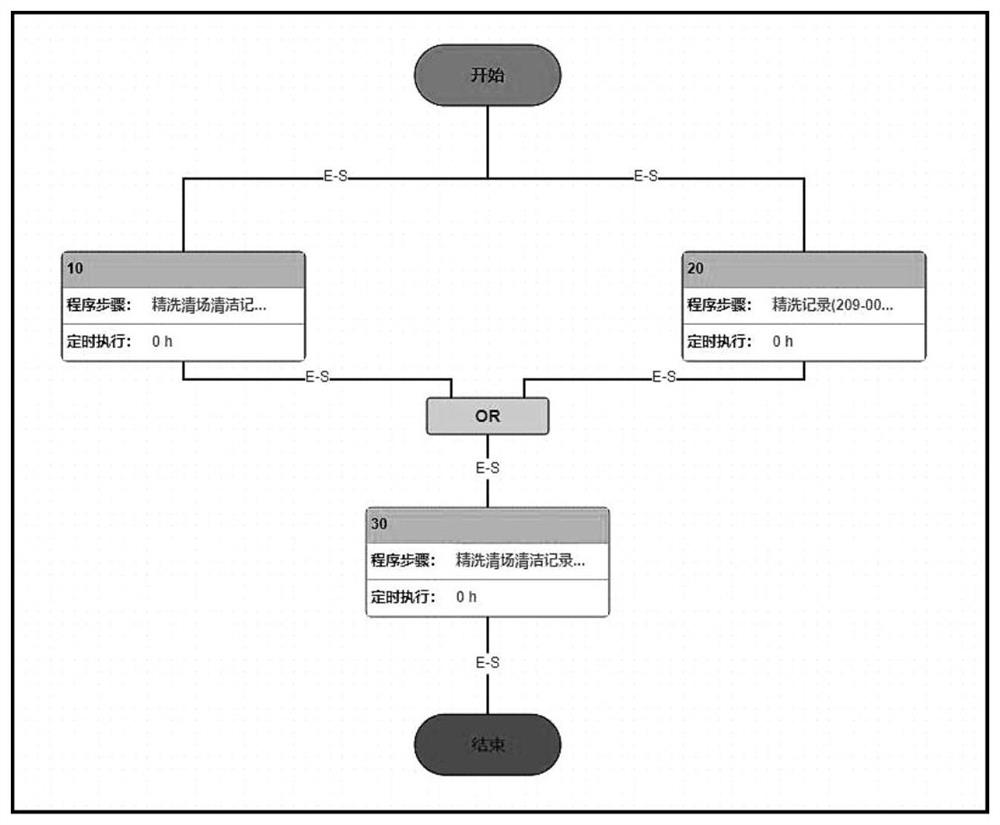

Method for producing formula food for special medical purposes by using manufacturing execution system

ActiveCN112258053AEasy to traceGuaranteed validityResourcesNeural architecturesManufacture execution systemFormulary

The invention discloses a method for producing formula food for special medical purposes by using a manufacturing execution system. The method comprises the following steps: generating a sales order in an ERP system; making a production scheduling plan according to the sales order; transmitting a production scheduling plan in the ERP to the MES system by using an enterprise connector; wherein theenterprise connector is an API interface, a message bus or an intermediate table; and acquiring data; centralized acquisition and control of production system data and environment system data are realized through an SCADA system platform, real-time acquisition and storage of massive process data are realized, and data support is provided for an MES system; the production efficiency is improved, and the production value energy consumption is reduced; through customized production process flow control and information management, material and energy loss caused by misoperation of personnel and unreasonable production is reduced, and the product productivity is maximized.

Owner:CISEN PHARMA

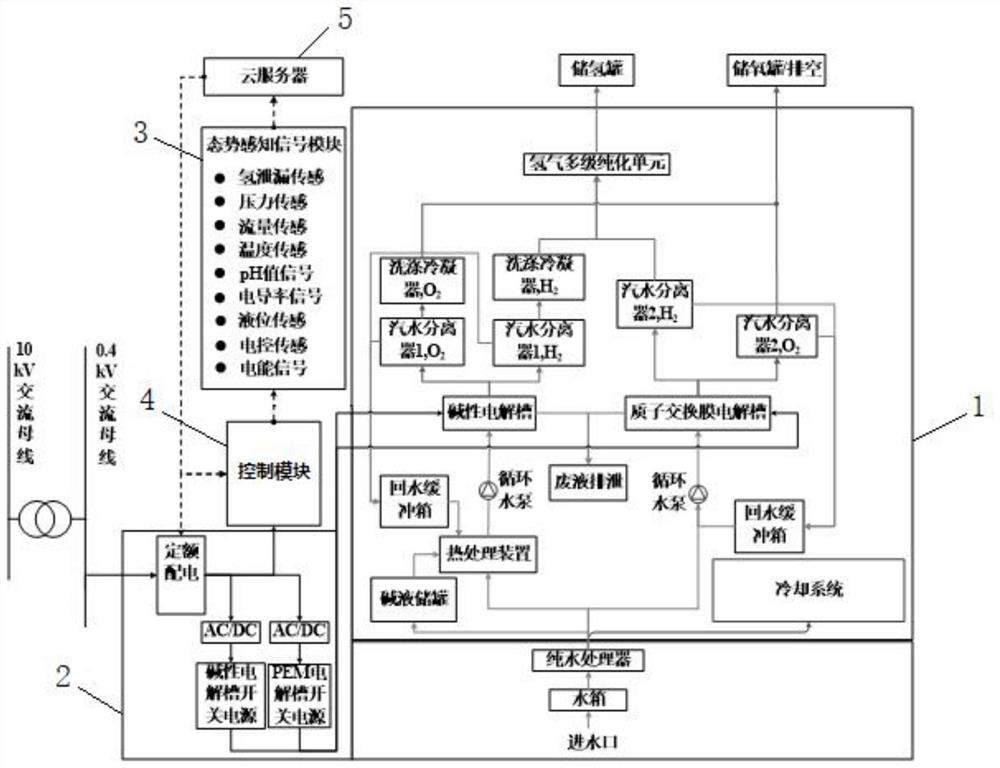

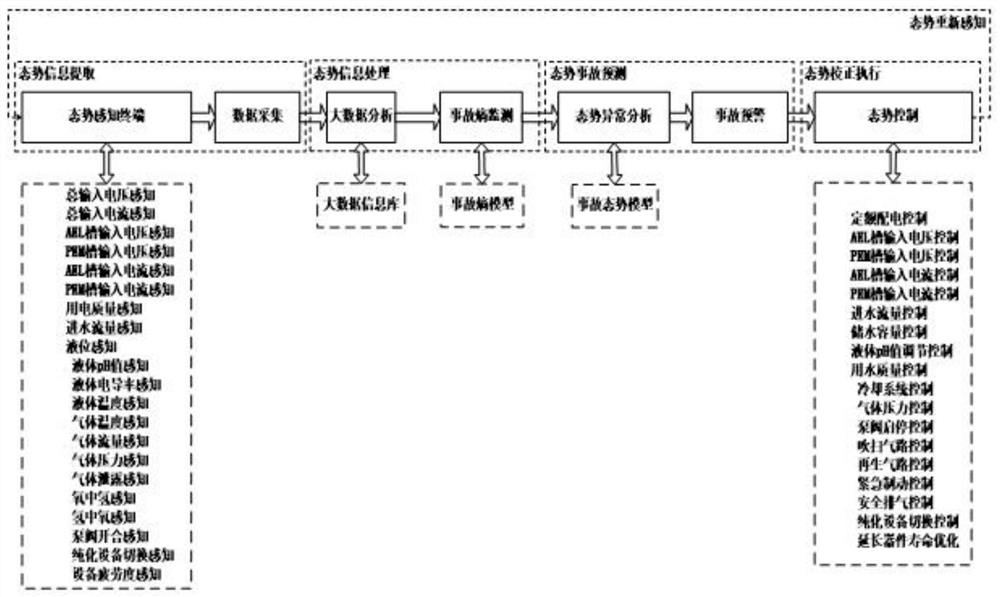

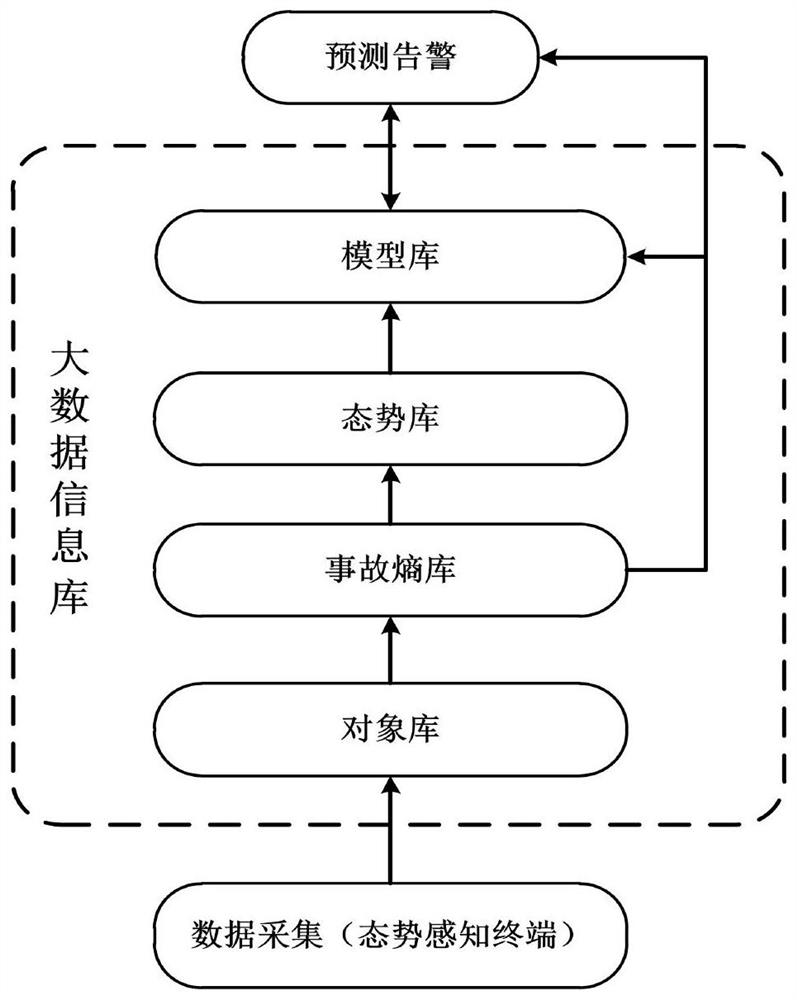

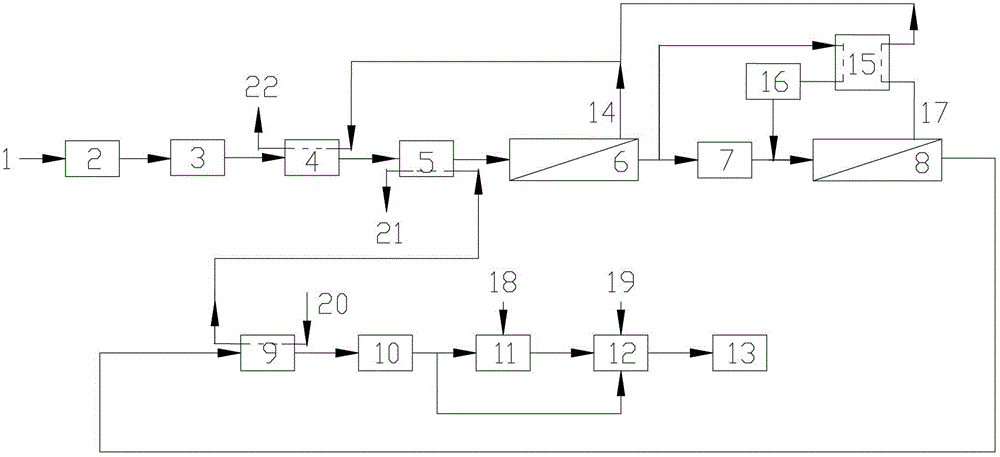

Hydrogen production system based on AEL and PEM water electrolysis and situation control method

ActiveCN113388856AGuaranteed uptimeRealize unattendedCellsEnergy inputElectrolysed waterControl system

The invention discloses a hydrogen production system based on AEL and PEM water electrolysis and a situation control method. According to the hydrogen production system, an AEL water electrolysis tank and a PEM water electrolysis tank are matched with each other and highly integrated in a water electrolysis hydrogen production system, and anaccident early warning monitoring method based on situation awareness is provided in consideration of a related complex management and control system, and is different from the lacking of situation awareness early warning function for detection information in an existing water electrolysis hydrogen production system. According to the invention, an optimal working mode of a hydrogen production system is evaluated based on accident entropy, the situation awareness object category is predicted after the situation awareness information is acquired, and then the increment change of the working mode of the situation awareness object to the accident entropy of the system is evaluated so as to provide the increment direction of the accident situation for accident early warning, so that the system can autonomously obtain a control decision through situation awareness information analysis, adjustment is carried out through different pieces of situation awareness information, and optimal working situation optimization of the system is achieved.

Owner:宝武清洁能源有限公司 +1

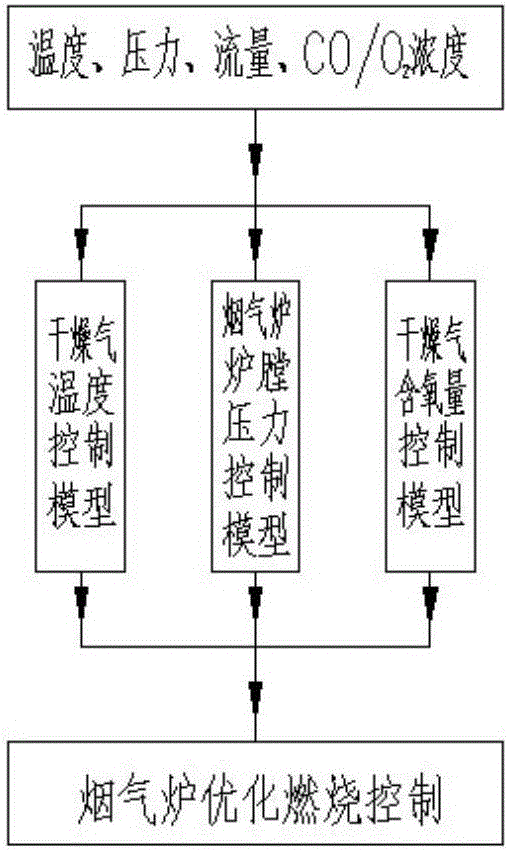

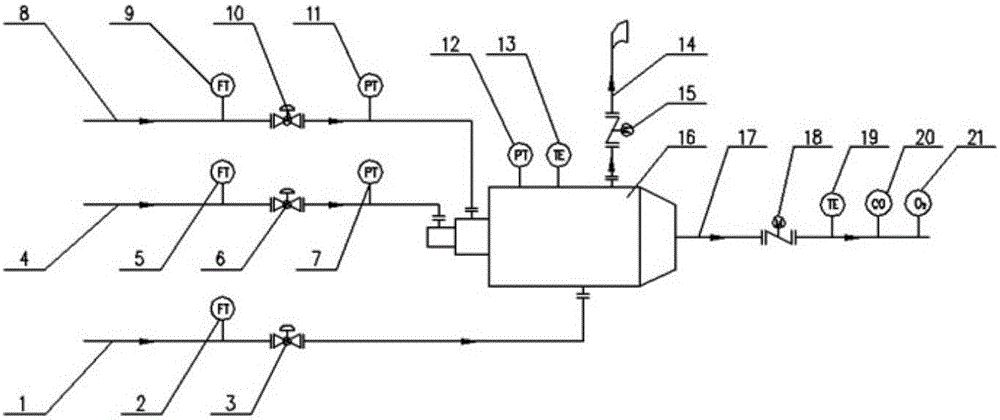

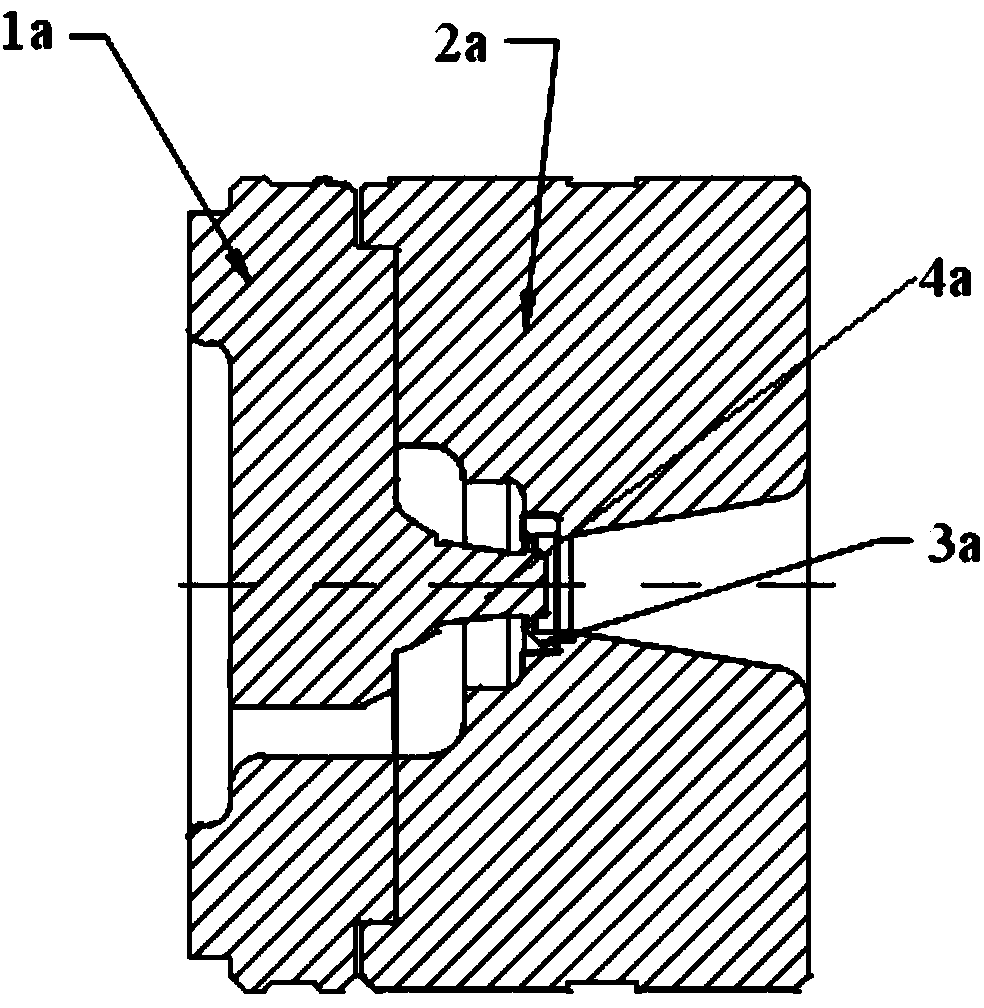

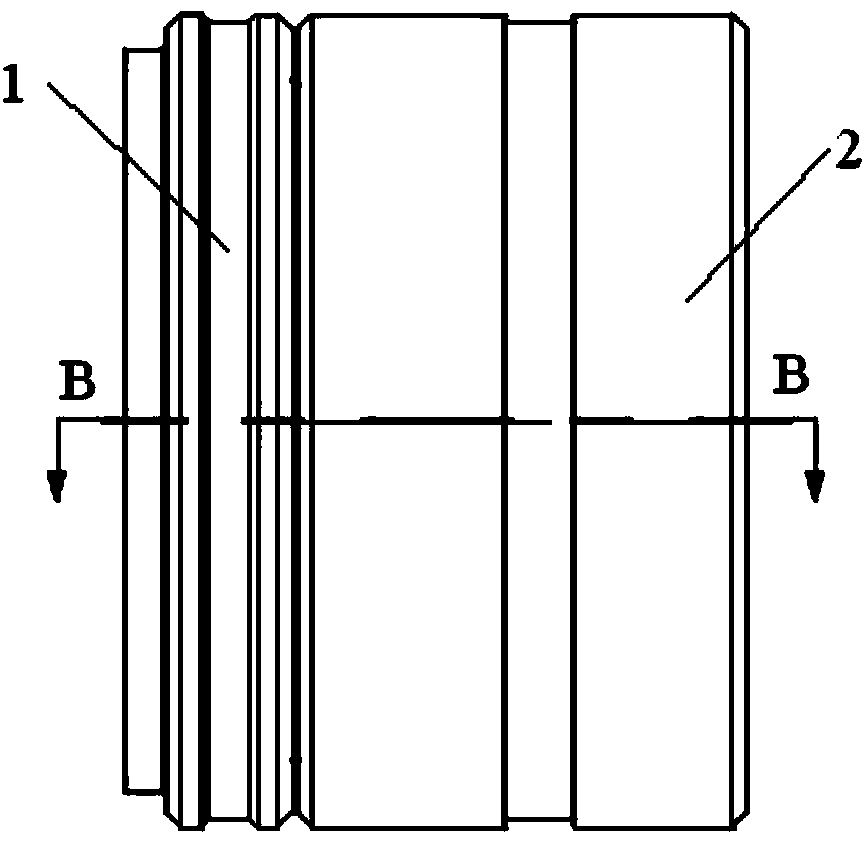

Method for controlling full-automatic optimization burning furnace of blast furnace coal injection system flue gas furnace

ActiveCN106839746AIndicators fluctuate greatlyReduce labor intensityDrying gas arrangementsBlast furnace detailsAutomatic controlAir temperature

The invention relates to a method for controlling a full-automatic optimization burning furnace of a blast furnace coal injection system flue gas furnace. The method comprises a step S1 of establishing a model: respectively establishing a dry air temperature control model, a flue gas furnace hearth pressure control model and a dry air oxygen content control model; a step S2 of performing parameter adjustment: adjusting medium temperature, pressure, flow, CO concentration and O2 concentration through the three models in the step S1, and respectively controlling dry air temperature, flue gas furnace hearth pressure and dry air oxygen content. The method has the advantages that the flue gas furnace runs under an optimum working condition through full-automatic burning furnace optimization and precise control over the flue gas furnace, index fluctuation in the flue gas furnace burning and control system is high, it is guaranteed that a system performs production stably, and a negative impact caused by manual operation is eliminated; in addition, the method not only can improve automatic control level, but also can greatly reduce operators' labor intensity and improve production efficiency.

Owner:CISDI ENG CO LTD

Preparation method of water used for oilfield flooding, water flooding and water gathering

InactiveCN102942282AGuaranteed uptimeSmall footprintMultistage water/sewage treatmentWater useElectrolysis

The invention belongs to the technical field of oil field development and relates to a preparation method of water used for oilfield flooding, water flooding and water gathering. Firstly seawater is subjected to sterilization and algae killing and then filtered by virtue of an electrolysis chlorine producing device and then is subjected to heat exchange by virtue of a primary preheater and a secondary preheater, then the seawater is conveyed into an ultrafiltration device to be filtered, so as to obtain ultrafiltration producing water; one part of the ultrafiltration producing water is conveyed into a nanofiltration device by virtue of a high pressure pump, the rest of the ultrafiltration producing water enters into an energy recycling device, is subjected to energy exchange together with concentrated water of the nanofiltration device and then is conveyed into the nanofiltration device; then nanofiltration producing water is subjected to heat exchange together with produced water by virtue of a heat exchanger; and the nanofiltration producing water is deoxidized and then is directly taken as injected water to enter into a water injection system or a matching and gathering device, polyacrylamide is added to prepare a polymer mother solution, and finally the polymer mother solution is diluted and injected underground to displace oil. The preparation method provided by the invention is easy to operate, low in cost, low in energy consumption, low in oxygen corrosion rate and beneficial to popularization of waterflooding and polymer flooding techniques.

Owner:OCEAN UNIV OF CHINA

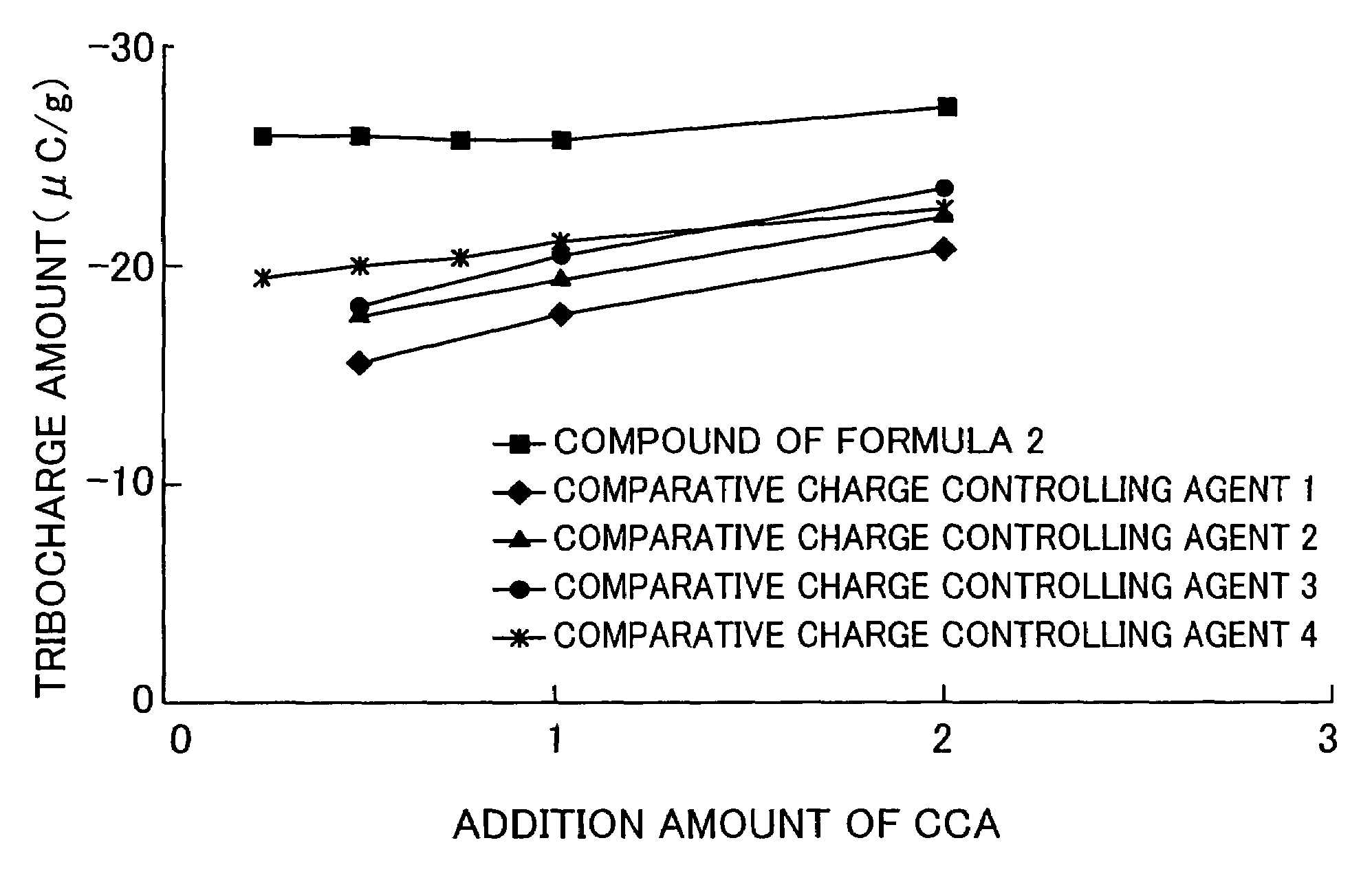

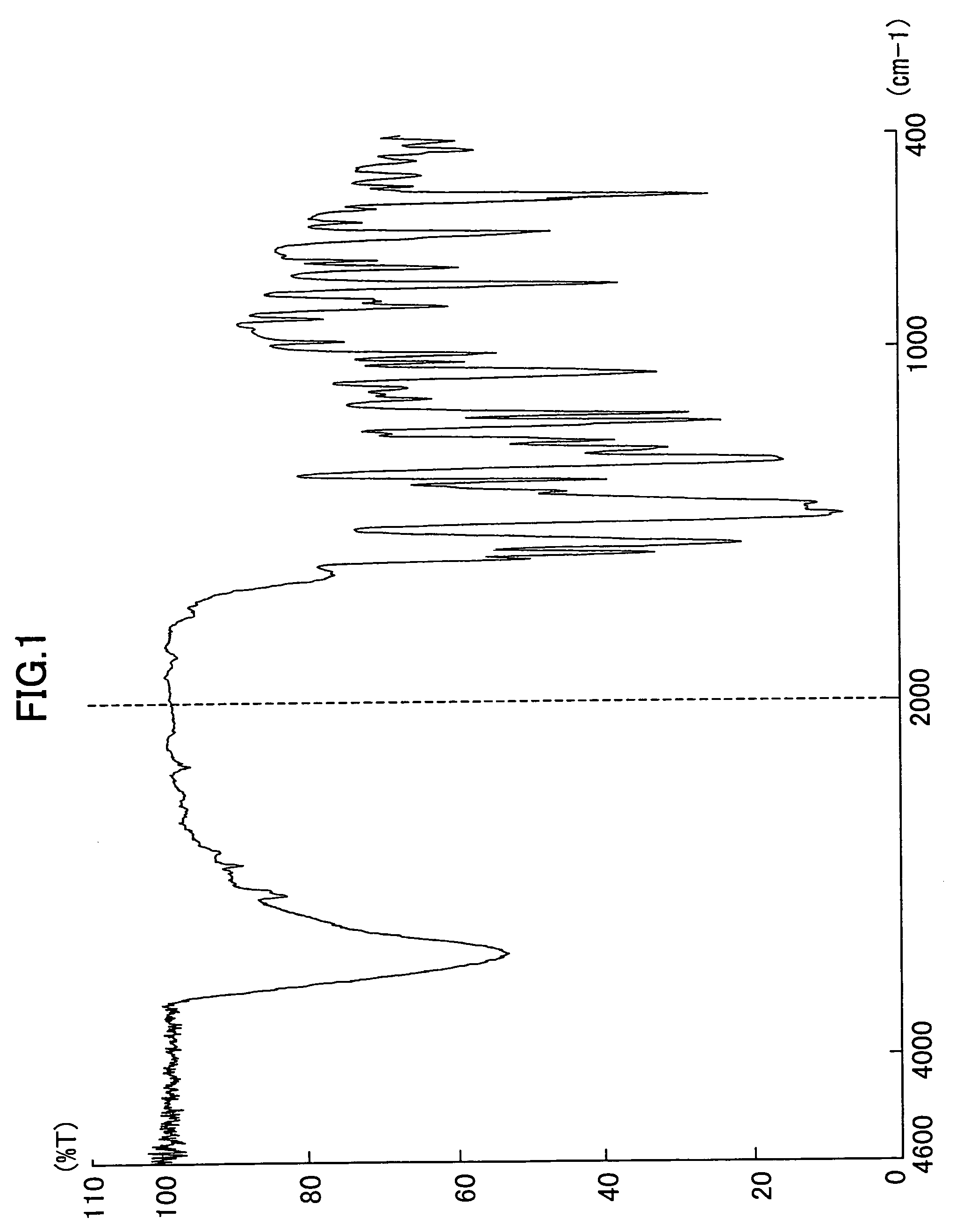

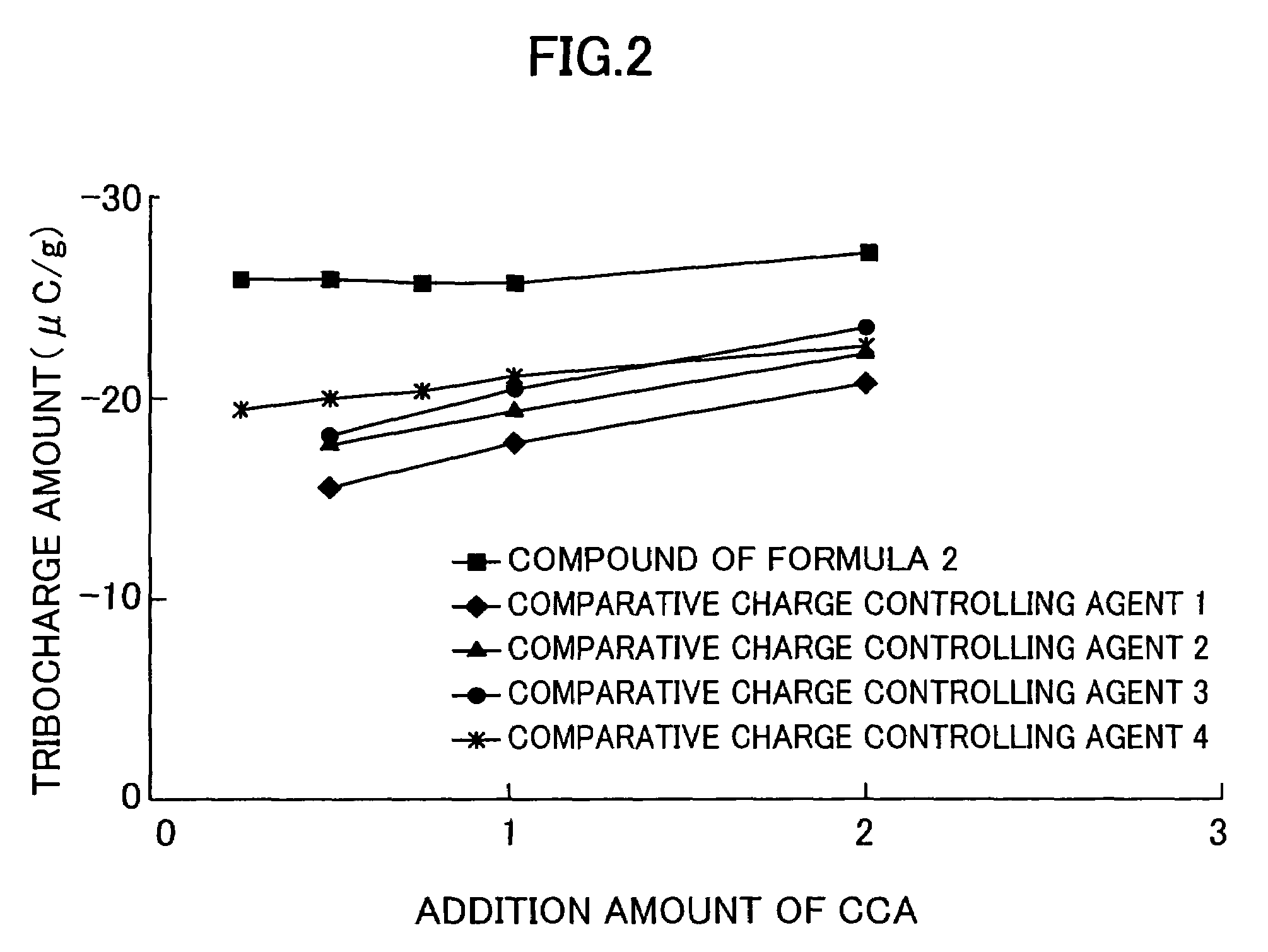

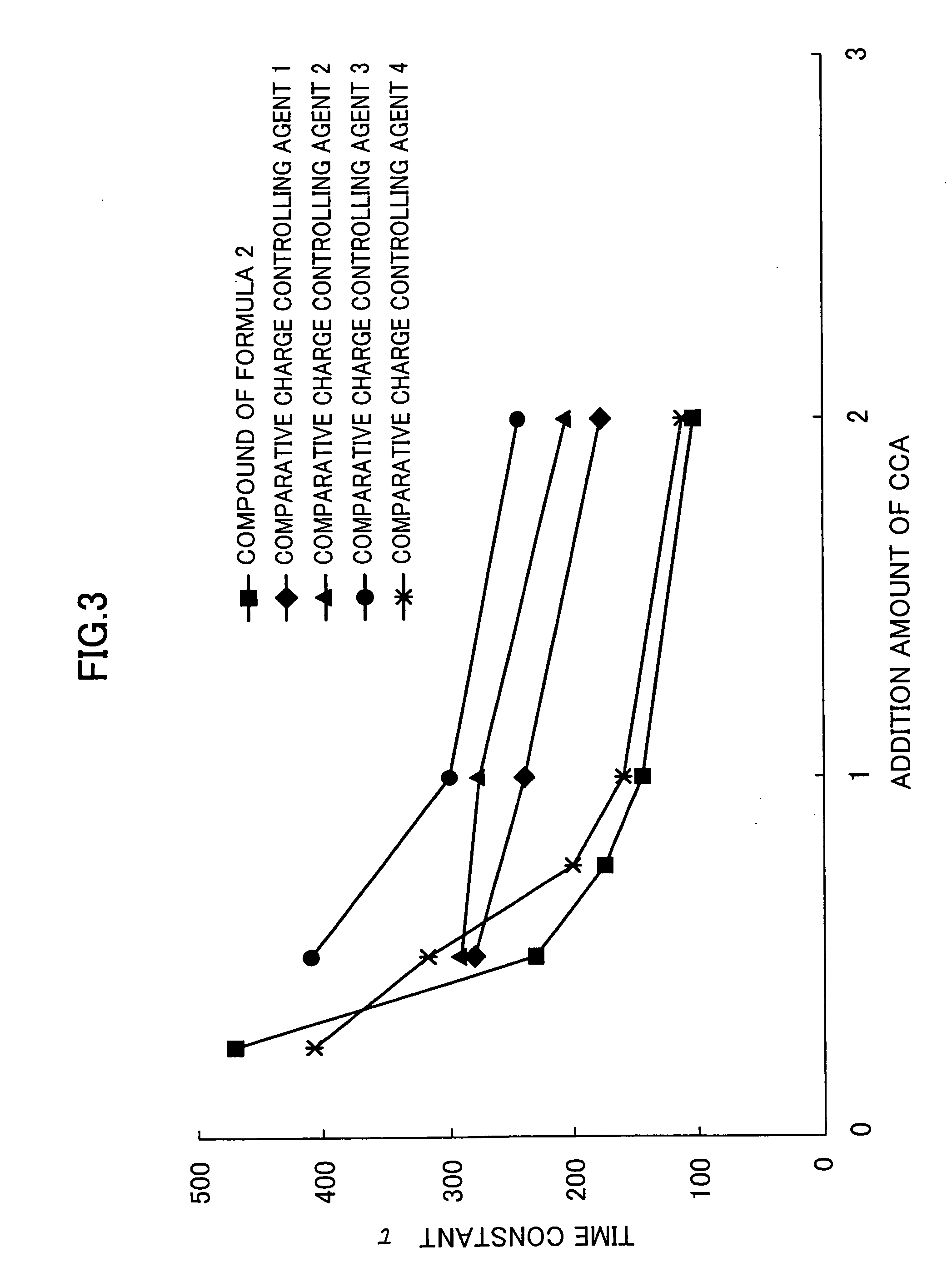

Mono azo iron complex compound, and charge controlling agent and toner using the same

ActiveUS7402369B2Easy to chargeReduce consumptionOrganic chemistryCoupling reaction in azo dyesCharge controlAlkali metal

The present invention is to provide a charge controlling agent and negatively chargeable toner that do not contain any toxic metal, are essentially free from the risk of evoking ignition or explosion, and can exhibit a high charge amount and rapid initial increase in charging.The charge controlling agent is a mono azo iron complex compound represented by Formula (1):wherein J represents H, alkali metal, ammonium, or alkyl ammonium, or two or more of those elements in combination.

Owner:HODOGOYA CHEMICAL CO LTD

Mono azo iron complex compound, and charge controlling agent and toner using the same

ActiveUS20070020547A1Easy to chargeReduce consumptionCoupling reaction in azo dyesOnium based azo dyesCharge controlAlkali metal

The present invention is to provide a charge controlling agent and negatively chargeable toner that do not contain any toxic metal, are essentially free from the risk of evoking ignition or explosion, and can exhibit a high charge amount and rapid initial increase in charging. The charge controlling agent is a mono azo iron complex compound represented by Formula (1): wherein J represents H, alkali metal, ammonium, or alkyl ammonium, or two or more of those elements in combination.

Owner:HODOGOYA CHEMICAL CO LTD

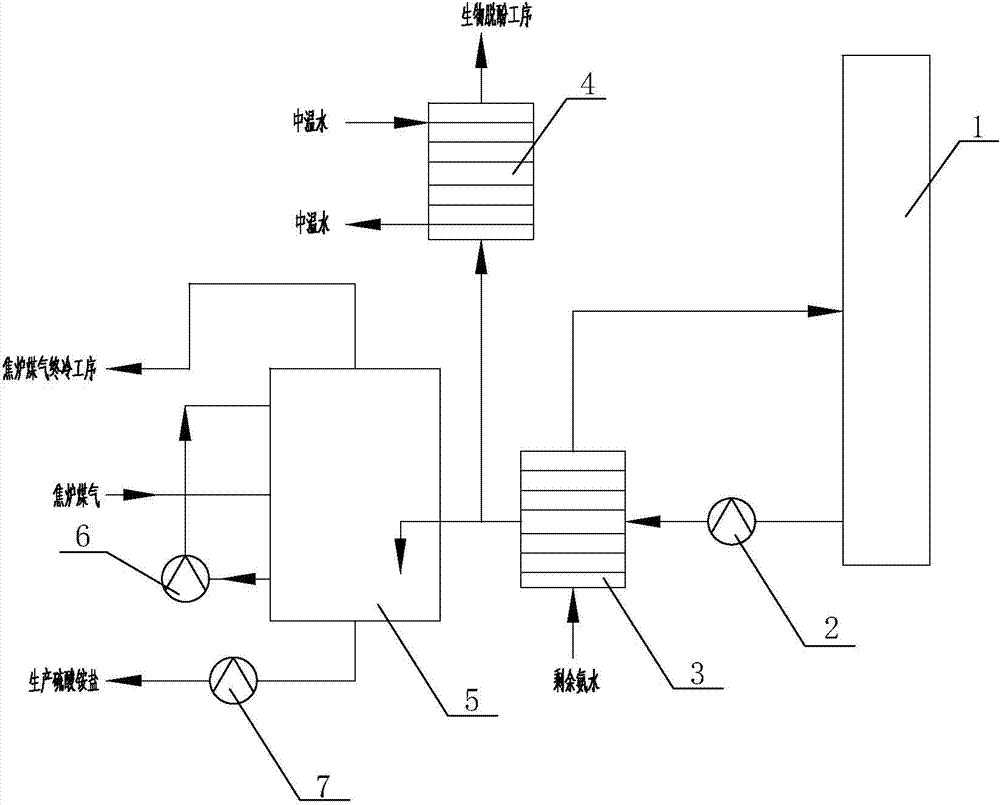

Method for ammonia removal of coke oven gas

InactiveCN104726141AStable productionAchieve reuseMultistage water/sewage treatmentCombustible gas purificationDistillationWastewater

The invention discloses a method for ammonia removal of a coke oven gas. According to the method, on the basis of the existing production process method, residual ammonia water is used for cooling ammonia distillation wastewater, which is generated by an ammonia still, to 55-65 DEG C in a first heat exchanger, and then the cooled ammonia distillation wastewater is used as new water delivered into a saturator to prepare a mother solution. Because the temperature of the added ammonia distillation wastewater is close to that of the mother solution in the saturator, the temperature of the mother solution cannot be greatly influenced after the ammonia distillation wastewater is added into the mother solution, and the temperature of the mother solution always fluctuates up and down in a reasonable range of set values, thereby ensuring the normal and stable production of an ammonia removal process of the coke oven gas; and the ammonia distillation wastewater is used for replacing middle-temperature water or low-temperature water and the like to serve as the new water supplemented into the mother solution, so that the new water consumption of the ammonia removal process is reduced, and the repeated utilization of the ammonia distillation wastewater is realized at the same time.

Owner:SHANDONG IRON & STEEL CO LTD

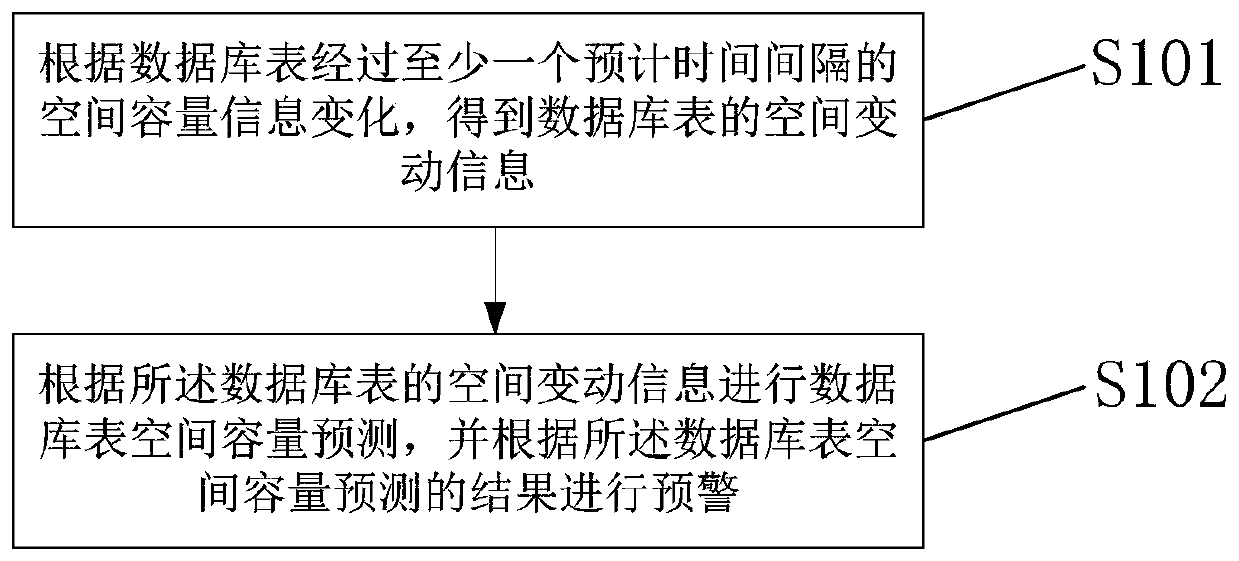

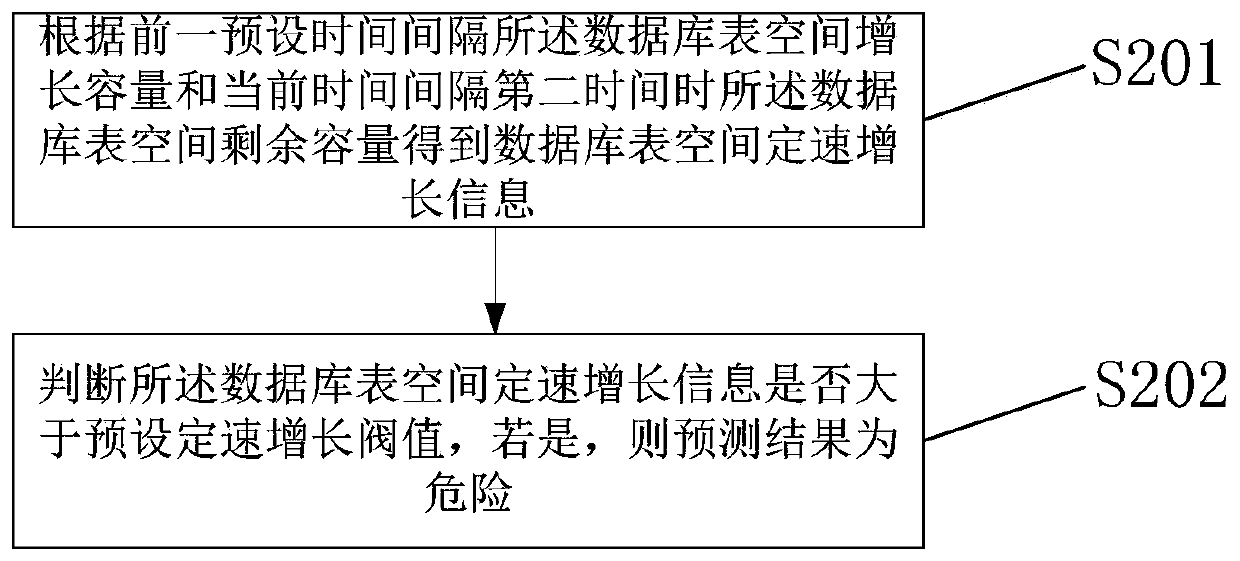

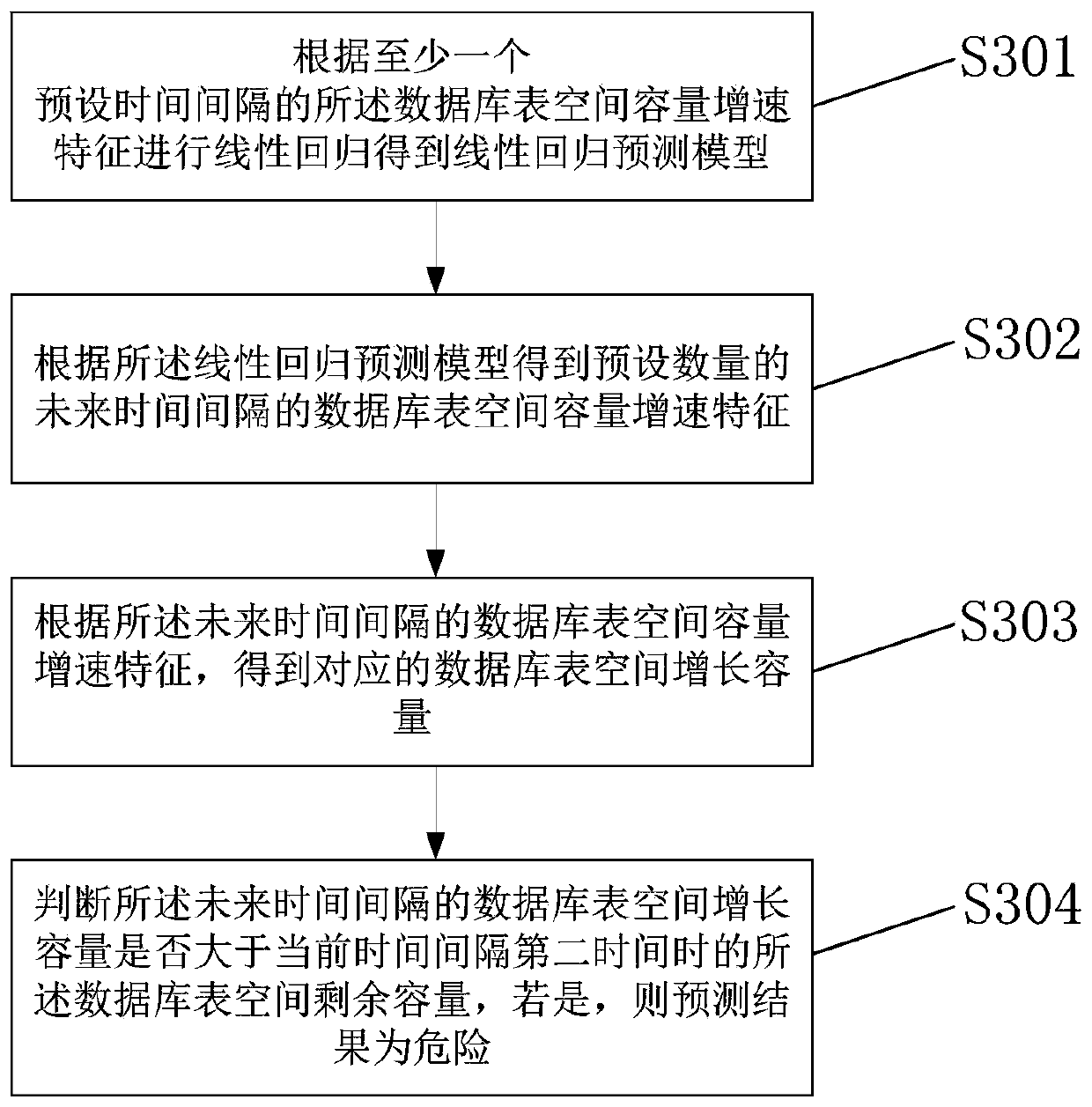

Database table space capacity monitoring method and device

PendingCN110287082AGuarantee production safetyEnsure stable productionHardware monitoringSpecial data processing applicationsSpatial capacityDependability

The embodiment of the invention provides a database table space capacity monitoring method and device, and the method comprises the steps: obtaining the space change information of a database table according to the spatial capacity information change of the database table after at least one expected time interval; performing database table space capacity prediction according to the space change information of the database table, and performing early warning according to a database table space capacity prediction result. The spatial capacity of the database table can be effectively and automatically monitored, the spatial capacity of the database table is accurately predicted by combining the spatial change information of the database table, the accuracy and reliability of monitoring the spatial capacity of the database table are improved, and the production safety and stability of a user are guaranteed.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

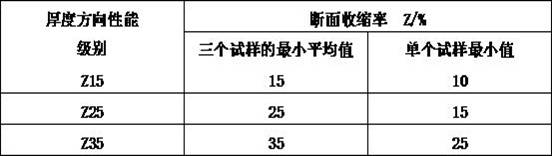

Method for improving Z-direction performance of Q390E thick plate with thickness of 50-80mm

ActiveCN113215495AReduce manufacturing costEnsure stable productionProcess efficiency improvementAlkalinityThick plate

The invention discloses a method for improving Z-direction performance of a Q390E thick plate with the thickness of 50-80mm. The plate comprises the following chemical components, by weight, 0.07-0.10% of C, 1.4-1.50 % of Mn, 0.15-0.25% of Si, less than or equal to 0.005% of S, less than or equal to 0.015% of P, 0.020-0.04% of Als, 0.025-0.035% of Nb, 0.035-0.045% of Ti, less than or equal to 20PPM of T[O], less than or equal to 50PPM of N and less than or equal to 1.5PPM of H. The thickness of the plate ranges from 50-80mm. The whole process flow comprises the steps of molten iron pre-desulfurization treatment, converter treatment, LF and RH refining, 250mm thick plate blank treatment, heating, controlled rolling and controlled cooling and stack cooling. A converter tapping slag washing process is adopted, high-alkalinity synthetic slag is used, and the synthetic slag comprises the components, more than or equal to 60% and less than or equal to 70% of CaO, 15-20% of BaO, more than 0 and less than or equal to 3.0% of SiO2, more than 0 and less than or equal to 4.5% of Al2O3, more than 2.0% and less than or equal to 4.1% of Na2O, less than or equal to 7.5% of CaF2 and less than or equal to 4% of MgO. Casting powder used in the continuous casting process comprises the specific chemical components, by weight, 4.1-6.5% of C, 25-30% of CaO, 27-32% of SiO2, 5-10% of Na2O, 7-10% of TiC, 3-6% of TiO2, 5-8% of F, 7-15% of B2O3, less than or equal to 3% of Al2O3, 1-1.5% of MgO; less than or equal to 3% of MnO, less than 3% of Fe2O3; and less than 0.5% of H2O.

Owner:XINJIANG BAYI IRON & STEEL

Production method for selenium-enriched rice

InactiveCN108834792ANovel ideaSimple processSeed and root treatmentExcrement fertilisersAnimal fecesChitin formation

The invention relates to a production method for selenium-enriched rice. The production method comprises the following steps: preparing a selenium-enriched organic liquid fertilizer; improving a ricefield when the rice field overwinters; applying the selenium-enriched organic liquid fertilizer to rice from breeding, raising rice seedling and planting processes for management. In the embodiment process, the rice field is improved by means of a biofertilizer formed by combining crop straws, animal feces and chitin and the selenium-enriched organic liquid fertilizer composed of organic selenium,organic matters and chitin when the rice field overwinters. The soil of a used land is conditioned to be neutral with biological bacterial manure, the improving effect of the soil is obvious, and then the selenium-enriched organic liquid fertilizer is sprayed to the land, so that a selenium-free plot is changed to selenium-enriched soil within a short time, and therefore, the phenomenon that a natural high-selenium soil resource at present is extremely scanty is overcome effectively, and selenium-enriched agricultural products are developed quickly. Meanwhile, the prepared selenium-enriched organic liquid fertilizer is low in cost, high in selenium and organic matters and obvious in using effect.

Owner:田东县合乐源农作物农民专业合作社

Composite red mud depositing separating washing method and tank

ActiveCN1623902AReduce the filter sectionEnsure stable productionAluminates/aluminium-oxide/aluminium-hydroxide purificationSedimentation settling tanksRed mudSodium aluminate

An integrated red mud settling, separating and washing method includes such steps as settling the diluted slurry, separating the solution of sodium aluminate from red mud, washing with hot water for removing alkali, and stacking the red mud. The flat-bottom settling bath is used for settling and separation. The efficient settling bathes are used for hot-water washing. Its advantage is very low cost.

Owner:GUIYANG AL-MG DESIGN & RES INST

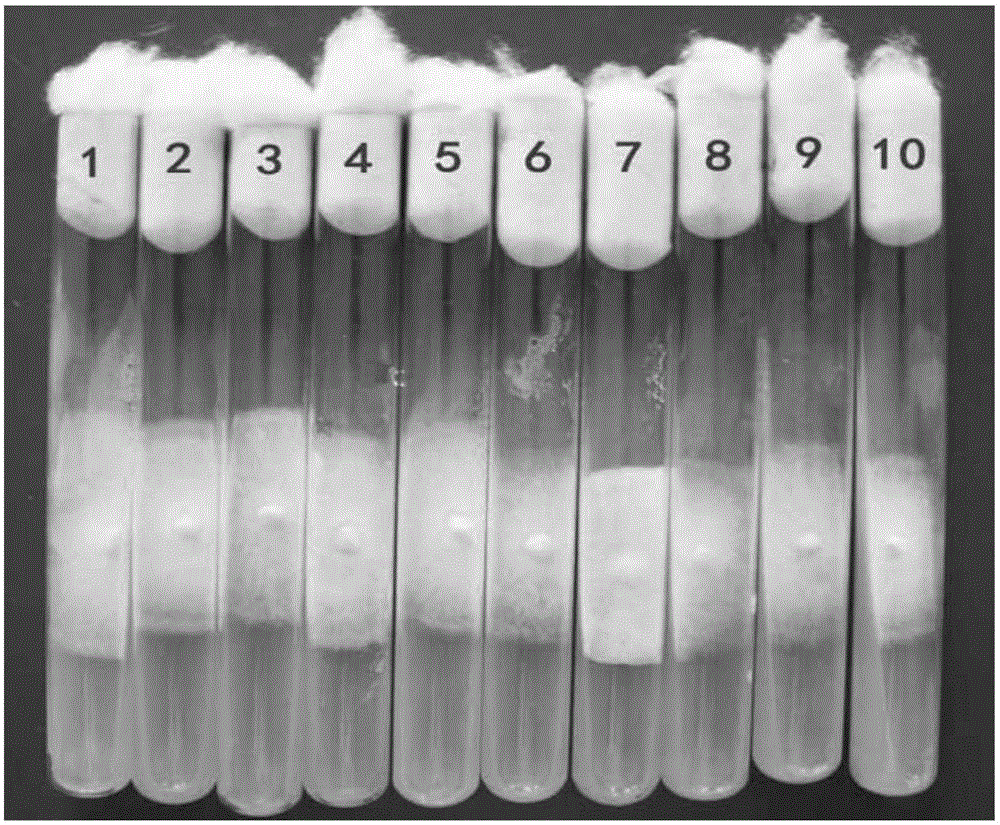

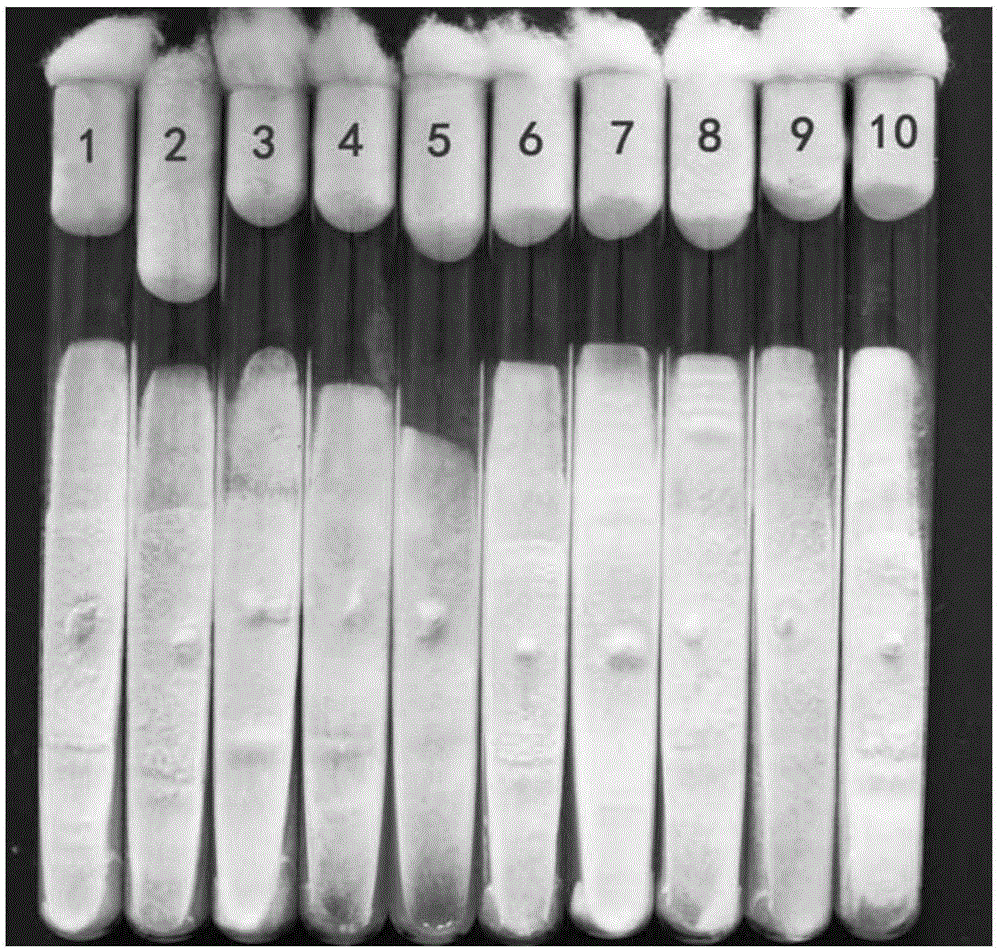

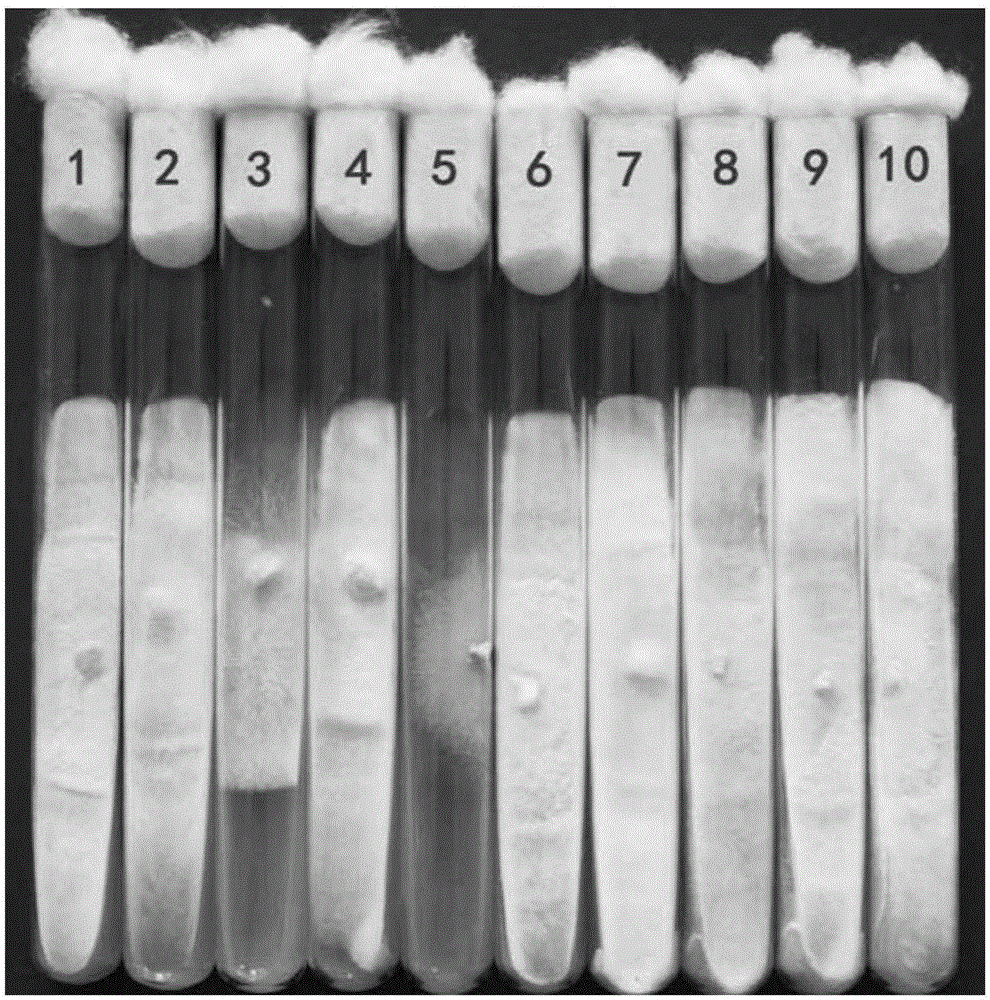

Method evaluating black fungus mycelium high temperature resistance feature

InactiveCN105145114ASimple and fast identificationSimple and quick identificationHorticultureHeat shockMycelium

The invention discloses a method evaluating a black fungus mycelium high temperature resistance feature and relates to an evaluating method for a black fungus high temperature resistance feature. The method is to provide a method with high feasibility and capable of simply and quickly identifying and affirming black fungus types whether to have a high-temperature resistant feature. The evaluating method comprises the following steps of (1) manufacturing a panel or an inclined surface via cPDA culture medium, (2) introducing black fungus into the cPDA inclined surface or the cPDA panel and culturing the black fungus for 96 hours at the temperature of 25 DEG C, (3) placing the black fungus at the temperature of 60 DEG C and conducting heat shock to the black fungus for 2 hours, and (4) placing the black fungus at the temperature of 25 DEG C. The mycelium continues to grow or restore growth and then the black fungus mycelium high temperature resistance feature is affirmed. The method is applied to evaluation of the black fungus high temperature resistance feature.

Owner:INST OF MICROBIOLOGY HEILONGJIANG ACADEMY OF SCI

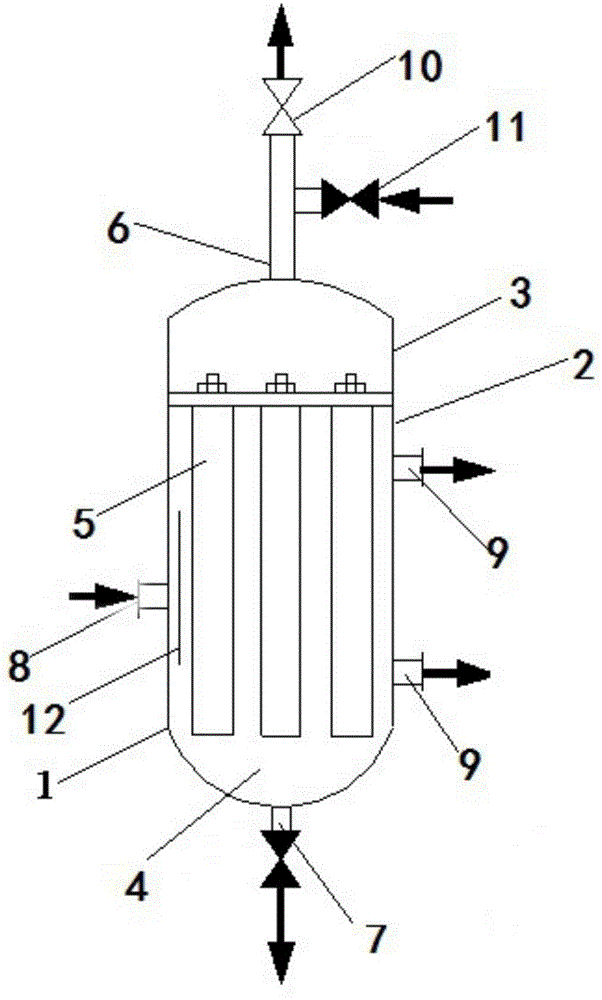

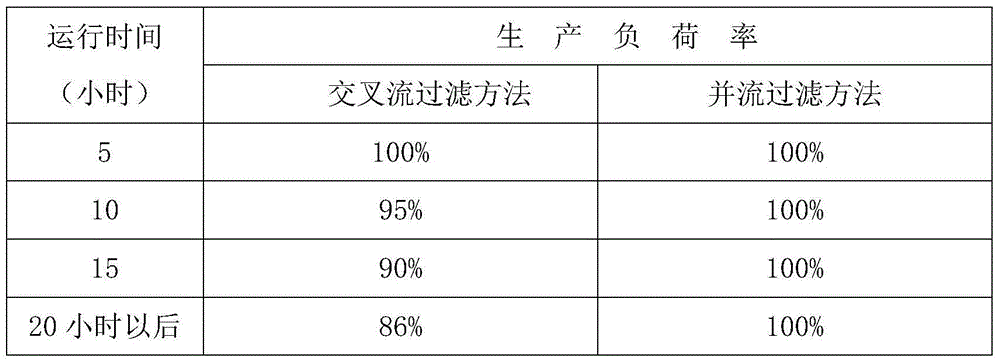

Filter

InactiveCN104083928AAvoid accumulationAvoid flow dead endsStationary filtering element filtersEngineeringHigh load

The invention discloses a filter which comprises an internally hollow cylinder, an upper head and a lower head, wherein the cylinder is internally provided with a filter element; a circular ring pipe is arranged on the outer wall of the cylinder; the upper head is arranged at the upper part of the cylinder; a filter fluid discharging hole / back flushing fluid inlet is arranged at the top of the upper head; the lower head is arranged at the bottom of the cylinder; a discharging hole is formed in the lower head; a reaction circulating fluid inlet and one or more reaction circulating fluid outlets are formed in the side wall of the cylinder; the filter fluid discharging hole / back flushing fluid inlet is respectively connected with an adjusting valve and a back flushing valve; the included angle alpha between the reaction circulating fluid outlet and the reaction circulating fluid inlet is greater than 0 degree and less than 360 degrees; the reaction circulating fluid outlet is connected with the circular ring pipe; a main outlet is formed in the circular ring pipe. According to the filter, a concurrent flow filter method is used, so that catalyst particles are prevented from accumulating in the filter and then a reaction system keeps high-load stable continuous running.

Owner:NANJING COLLEGE OF CHEM TECH

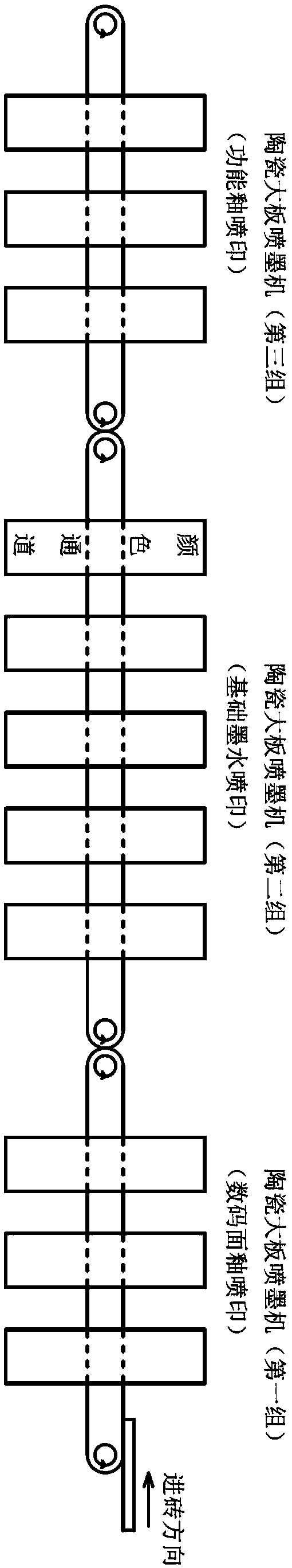

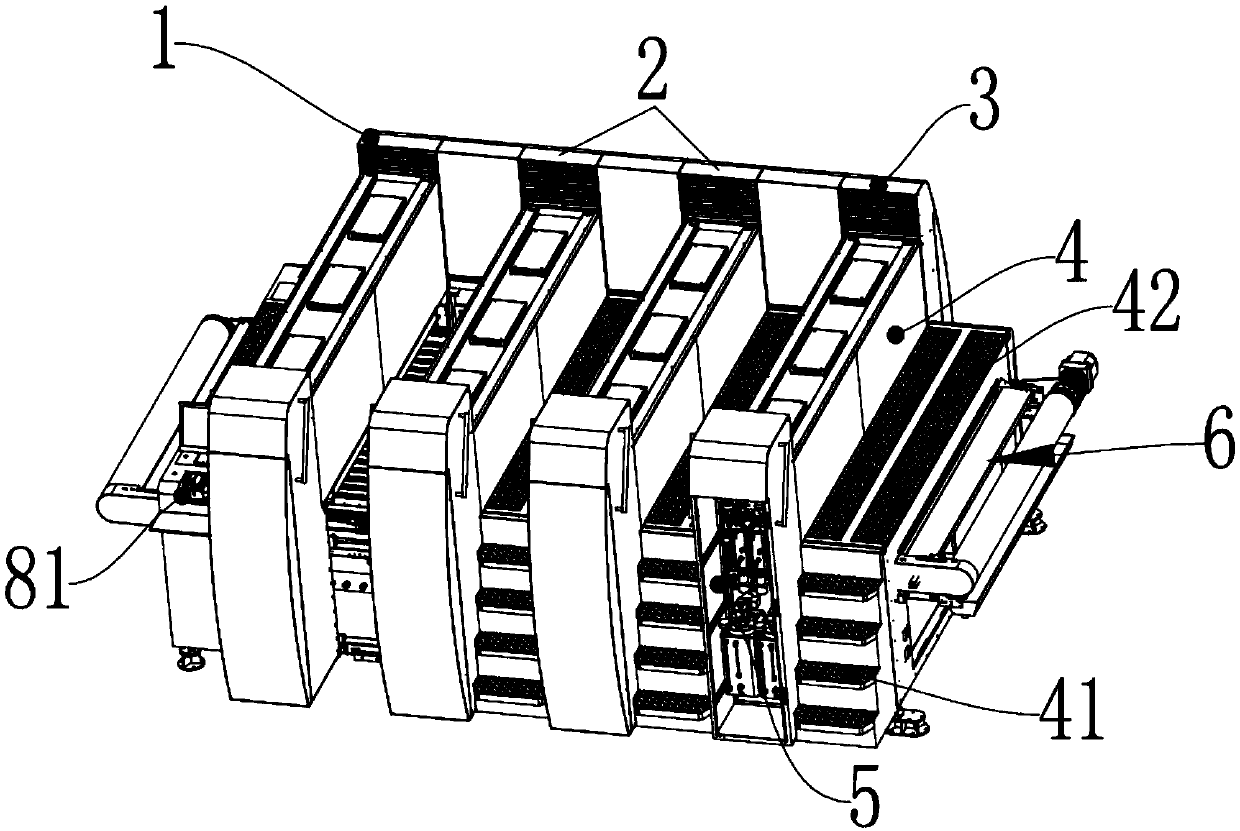

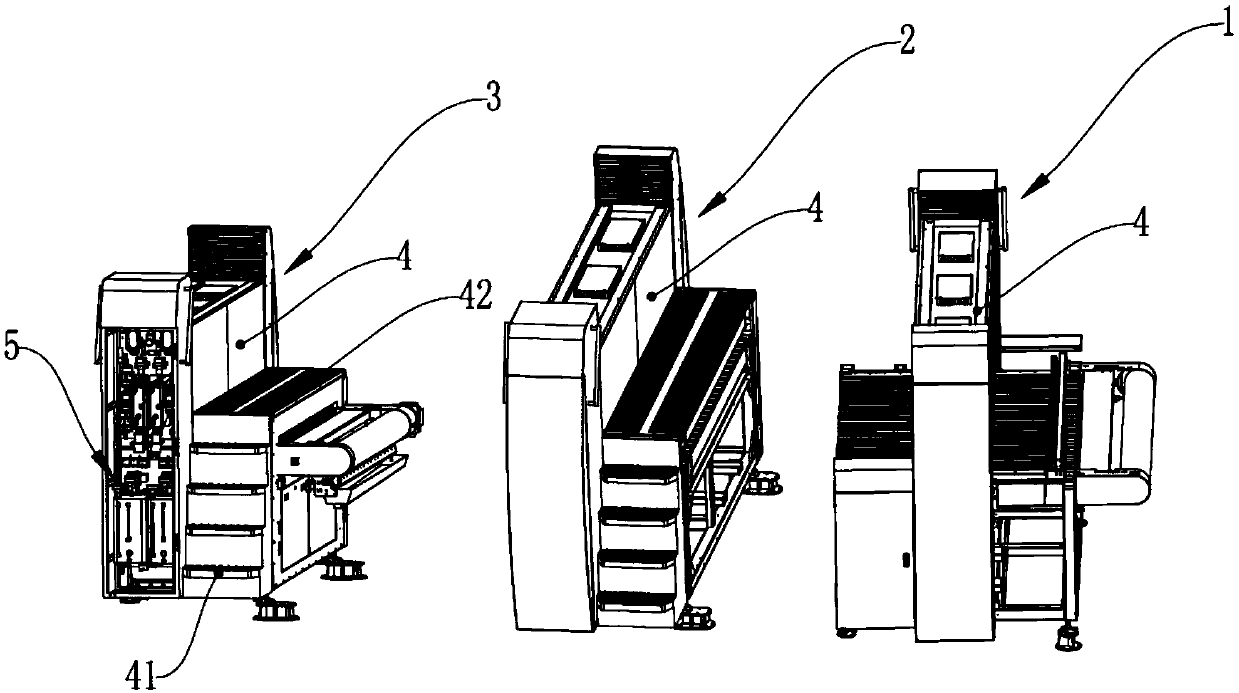

Full-digital anhydrous glazing line

ActiveCN109605556AAvoid wastingAchieving special surface effectsCeramic shaping apparatusMetallurgyDigitization

The invention discloses a full-digital anhydrous glazing line. The full-digital anhydrous glazing line comprises three sets of ceramic large plate ink-jet machines which are connected in series. The first set of ceramic large plate ink-jet machine is used for digital overglaze jet-printing. The second set of ceramic large plate ink-jet machine is used for basic ink jet-printing. The third set of ceramic large plate ink-jet machine is used for functional glaze jet-printing. According to the full-digital anhydrous glazed line and the ceramic large plate ink-jet machines, the digital glaze is jet-printed as needed in a digitization mode, accurate positioning of the functional ink or the glaze is achieved, unnecessary material waste is avoided, an anhydrous workshop is achieved, the occupied area is saved, and environment protection is achieved.

Owner:HOPE CERAMICS MACHINERY

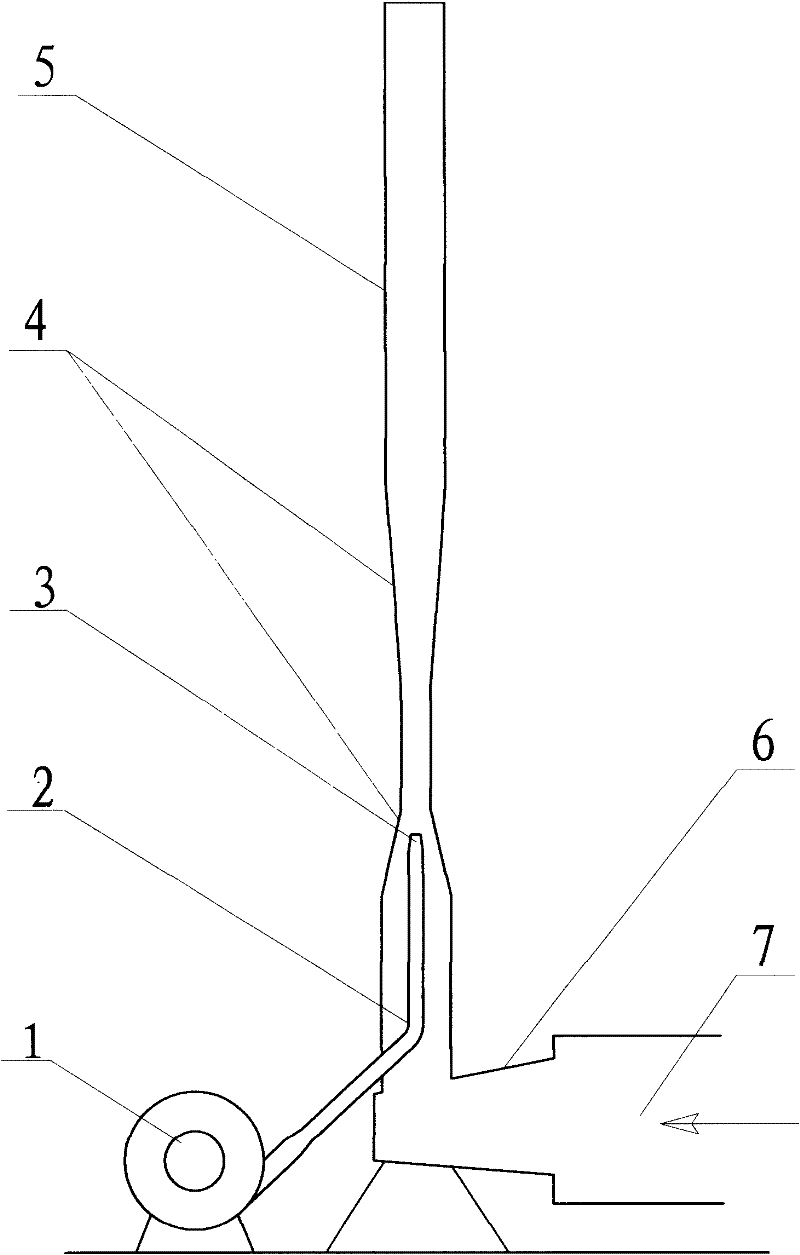

Jet fan induced draft smoke exhaust device

InactiveCN102261851AImprove the operating environmentAvoid direct contactWaste heat treatmentImpellerFlue gas

The invention relates to a jet fan induced wind and smoke exhaust device, which is mainly composed of a fan, an air outlet pipe, an injection port, a jet flue, a flue, a kiln tail gas inlet, and a kiln, and is especially capable of jetting induced air through a high-pressure fan. The non-contact active exhaust of the flue gas from the kiln is carried out, and the exhaust gas of the kiln is discharged from the chimney quickly and efficiently, so as to effectively solve the symptoms of dynamic balance failure of the fan impeller due to the corrosion of residual adhesives and the rust of the bearing bush of the fan. Serious Problem.

Owner:重庆正川医药包装材料股份有限公司

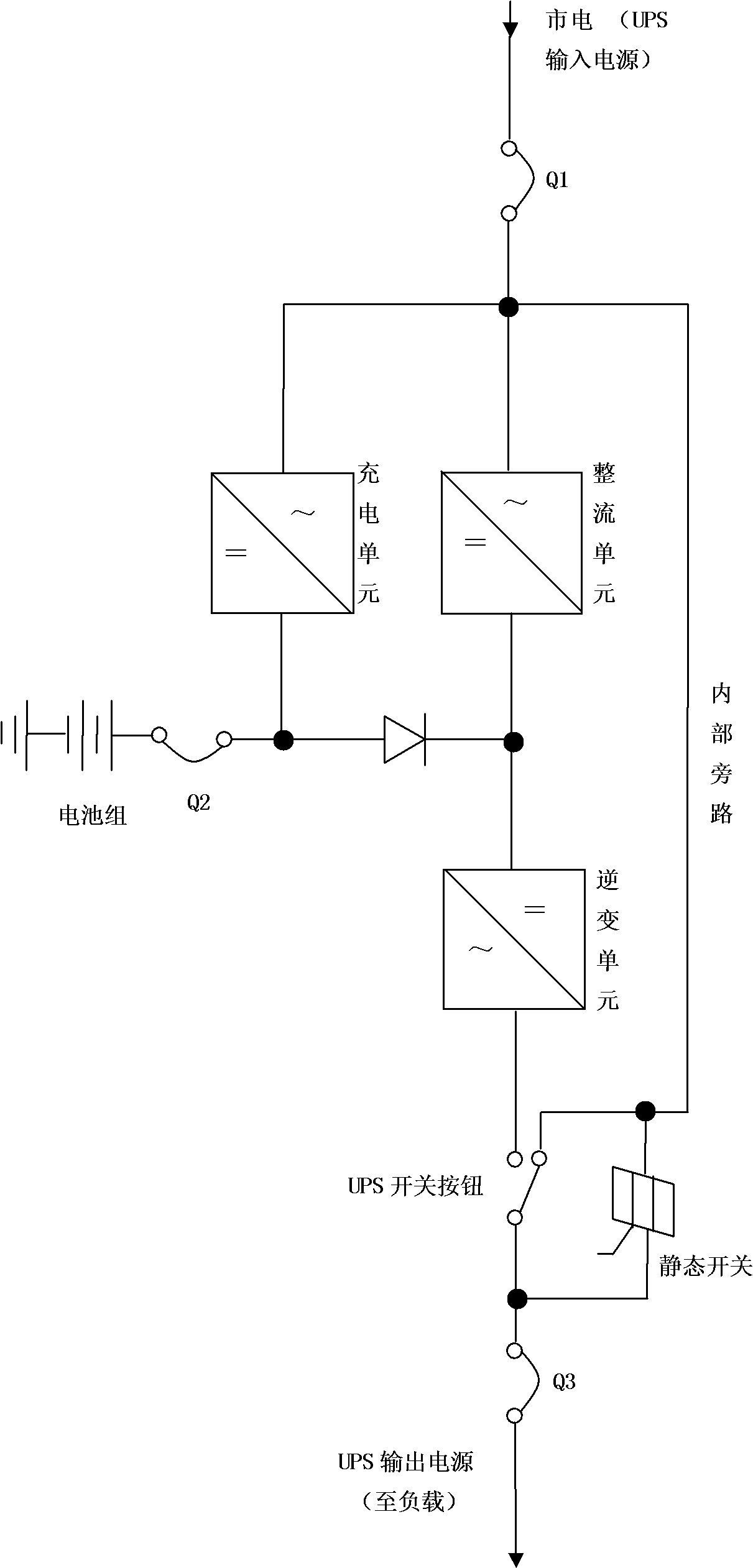

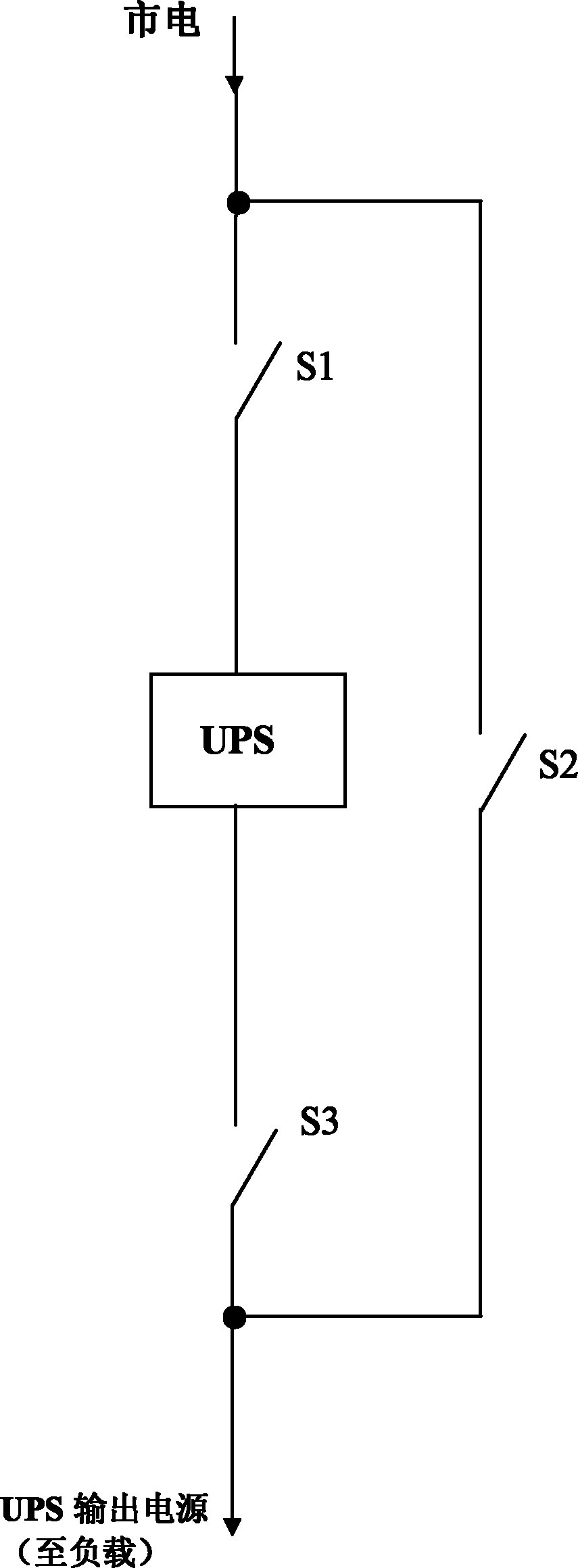

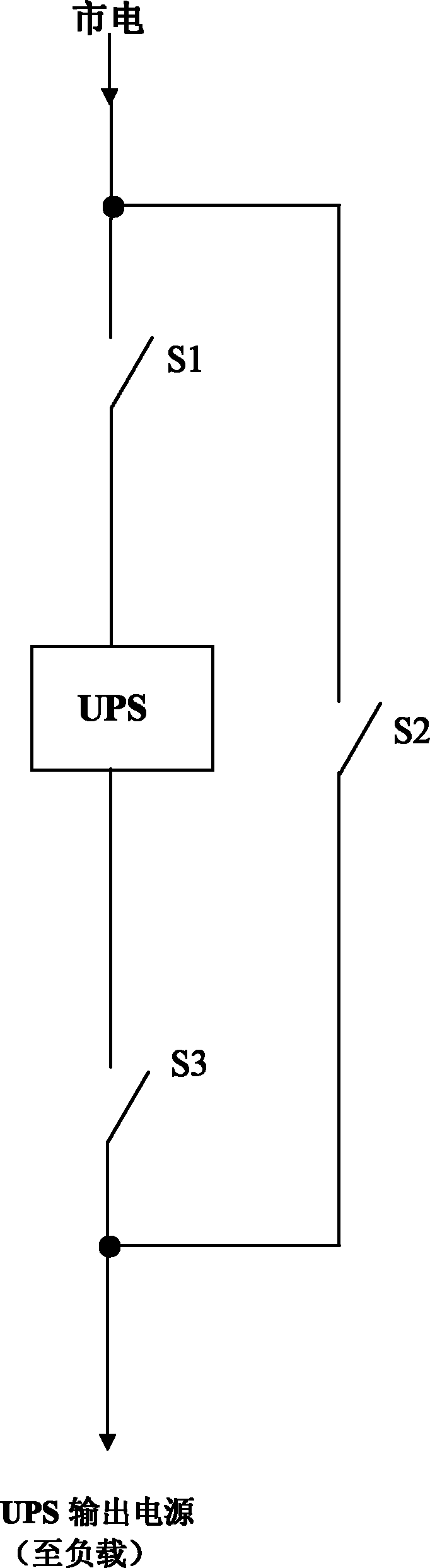

Test method for external bypass of uninterrupted power supply (UPS)

InactiveCN102142712AAvoid the disadvantages of replacement only when the whole line is stoppedEnsure stable productionEmergency power supply arrangementsEngineeringSafe operation

The invention discloses a test method for an external bypass of an uninterrupted power supply (UPS) and belongs to the technical field of test. The external bypass is added on the basis of an own line of the UPS, wherein the external bypass consists of a UPS external bypass input breaker S1, a UPS external bypass main breaker S2 and a UPS external bypass output breaker S3. When the UPS operates normally, the external bypass is opened; when the UPS fails, the external bypass is closed, an external network power supply, namely a mains supply, supplies power to production equipment through the external bypass of the UPS, and an operator changes the damaged UPS into a good UPS within a short period; and after the good UPS comes into operation, the external bypass is opened, and the mains supply supplies the power to the production equipment through the UPS so as to guarantee the stable and safe operation of the production equipment. The method has the advantages that: the problem of abnormal operation of the production equipment due to self-damage of the UPS and instable power output is solved.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

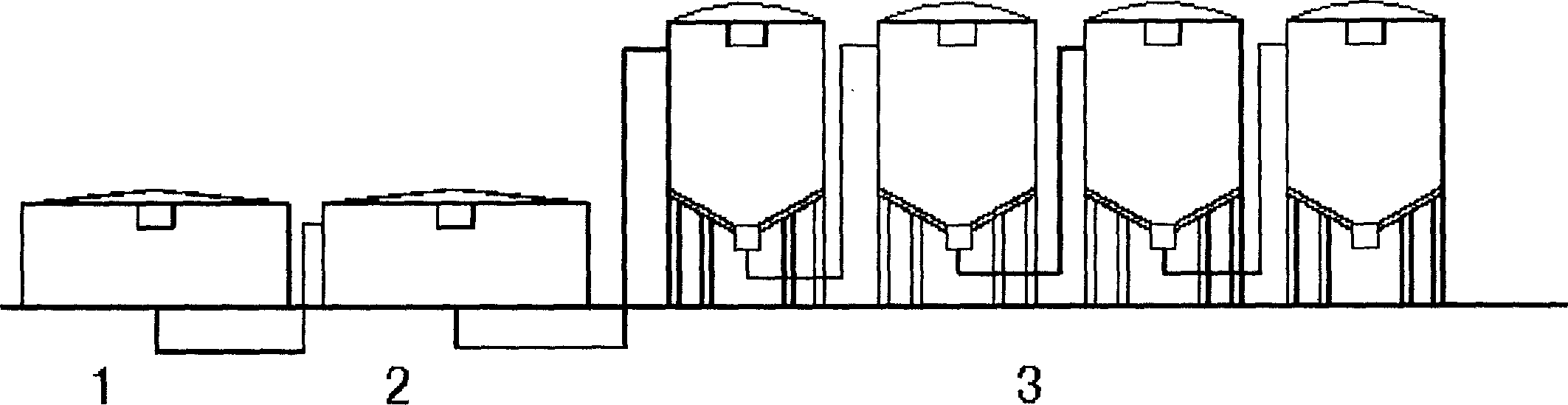

Production method of carbon

InactiveCN103342350AEnsure stable productionGuarantee product qualityCarbon preparation/purificationCarbon productMethods of production

The invention discloses a production method of carbon, and relates to the improvement of a technique for a carbon material production process. The production method comprises the following steps of: calcinating, crushing and screening, material batching and blending in a raw material storage bay, material conveying implemented by using an integrated screw conveyor, kneading, molding and roasting. The production method is characterized in that (1) a heating device is added on the outer wall of the raw material storage bay for material batching and blending, and used for carrying out heating and heat preservation on material batching and blending; (2) a heating device is arranged on the outer wall of the integrated screw conveyor for material conveying, and used for carrying out heating and heat preservation on material batching and blending. According to the production method of carbon disclosed by the invention, aiming at the problem that in the existing production of carbon products, the preheating temperature of dry materials is too low, and the kneading effect is not ideal, the heating device is added on the outside of the raw material storage bay or the integrated screw conveyor so as to raise the temperature of dry materials in the raw material storage bay or the integrated screw conveyor, in such a way, the temperature of dry materials meets technological requirements, the occurrence of a phenomenon that a paste material is kneaded non-uniformly is eliminated, and a situation that the production of carbon products is stable and the quality of carbon products reaches the standard is ensured.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

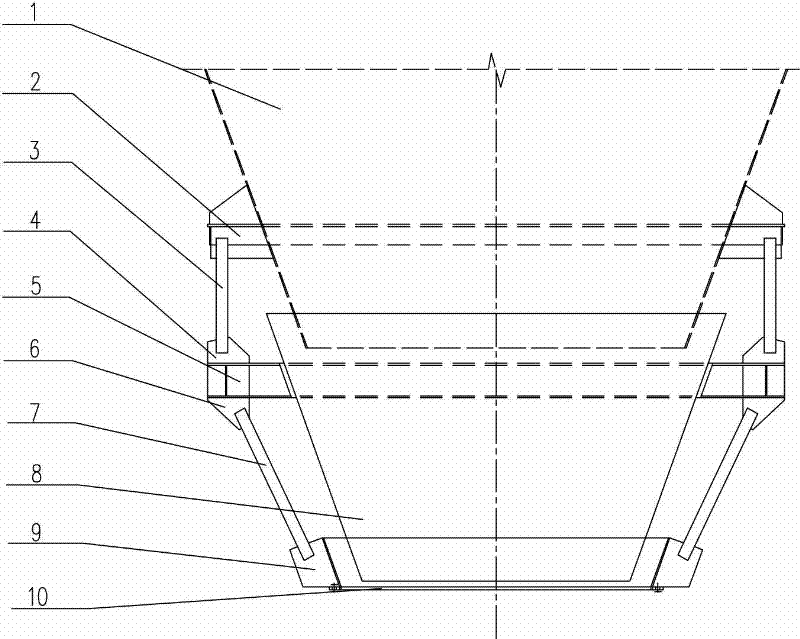

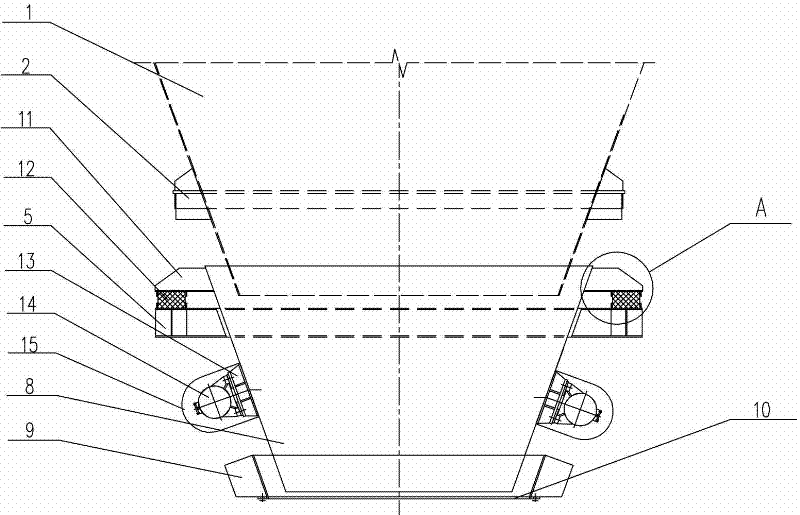

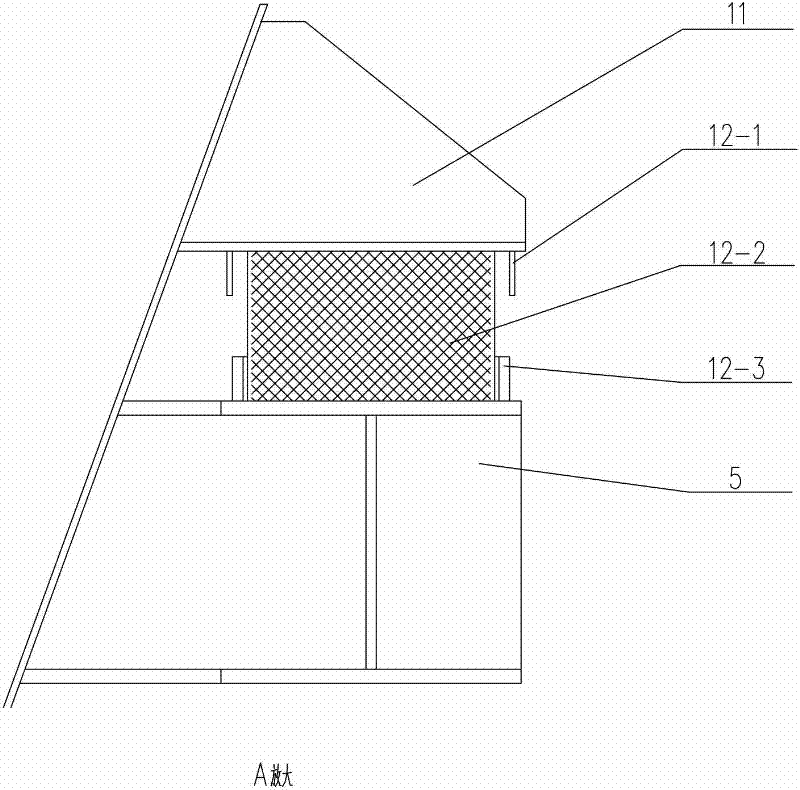

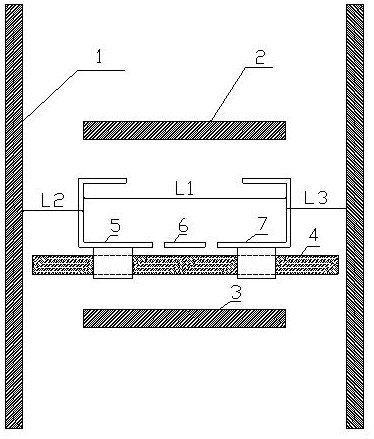

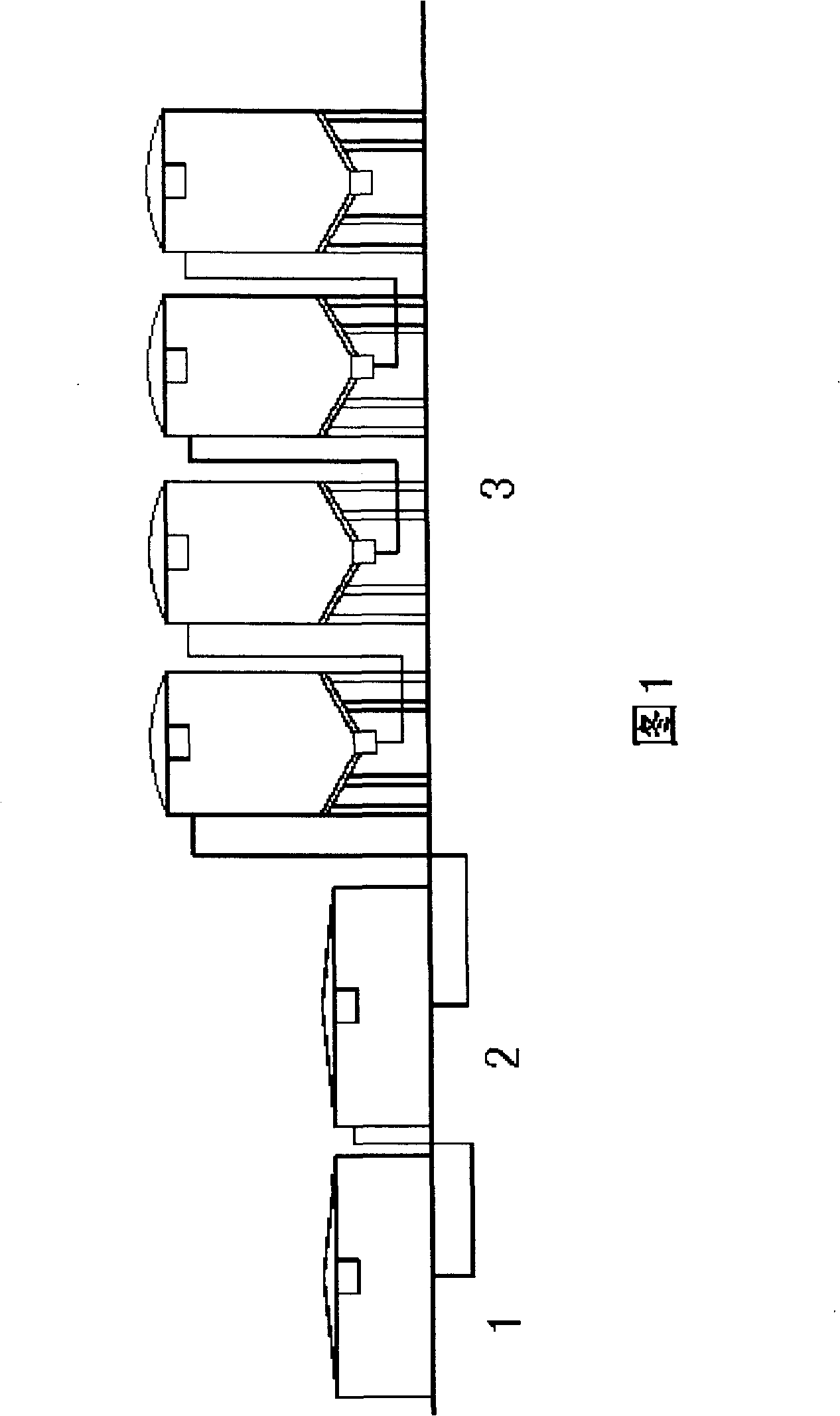

Constant-flow feeding device

The invention relates to a constant-flow feeding device which is characterized by comprising a concreted ring fixedly connected with a bunker metallic ore chute, a hopper body arranged below the bunker metallic ore chute, a group of lugs uniformly arranged on the outer surface of the upper part of the hopper body, a backing ring arranged below the group of lugs, buffering mechanisms respectively arranged between the upper surface of the backing ring and the lugs, a group of upper connecting plates which are uniformly arranged on the upper surface of the backing ring and crossly arranged together with the buffering mechanisms, a group of upper connecting rods respectively connected with the upper connecting plates and the concreted ring, a group of lower connecting plates uniformly arranged on the lower surface of the backing ring, an annular flange arranged below the hopper body, a circumferential protective plate arranged on the upper surface of the annular flange, a lower connecting rod for connecting the circumferential protective plate with the lower connecting plates, and a group of vibration mechanisms respectively arranged at outer surfaces at two sides in the middle of the hopper body, wherein the bottom of the bunker metallic ore chute is inserted into the hopper body; and the annular flange is connected with a feeding apparatus through a bolt. The constant-flow feeding device has the advantages that the discharge is smooth, the material flow is stable and uniform, and the overhauling is convenient.

Owner:NORTHERN ENG & TECH CORP MCC

Calibration method of side guide plate of finishing mill

InactiveCN111715704AEnsure stable productionSimple methodGuiding/positioning/aligning arrangementsMeasuring devicesForeign matterManufacturing line

The invention belongs to the technical field of steelmaking, and relates to a calibration method of a side guide plate of a finishing mill. The calibration method relates to a rack memorial archway, an inlet upper guide and guard, an inlet lower guide and guard, a side guide plate A on the operation side and a side guide plate B on the transmission side; and the calibration method comprises the following steps of 1), mounting the side guide plate A and the side guide plate B on slideways, and arranging a cross beam in the middle; 2), checking whether foreign matters exist on slideways of the side guide plate A and the side guide plate B or not before calibration; 3), simultaneously opening the two sides of the side guide plate A and the side guide plate B for a certain opening degree, andmanually closing and opening to test whether the side guide plate A and the side guide plate B are flexible or not; and 4), detecting whether mechanical jamming exists on the slideways or not. The calibration method has the characteristics of being simple, easy to operate, capable of avoiding production accidents, capable of ensuring stable production of a production line and the like.

Owner:XINJIANG BAYI IRON & STEEL

Composite red mud depositing separating washing method and tank

ActiveCN100439251CReduce the filter sectionGuaranteed construction investmentAluminates/aluminium-oxide/aluminium-hydroxide purificationSedimentation settling tanksRed mudSodium aluminate

An integrated red mud settling, separating and washing method includes such steps as settling the diluted slurry, separating the solution of sodium aluminate from red mud, washing with hot water for removing alkali, and stacking the red mud. The flat-bottom settling bath is used for settling and separation. The efficient settling bathes are used for hot-water washing. Its advantage is very low cost.

Owner:GUIYANG AL-MG DESIGN & RES INST

Process for purifying (meth)acrylic acid and process for producing (meth)acrylic esters

ActiveUS7148373B2Component can be removedSpeed up the processOrganic compound preparationOrganic chemistry methodsMeth-Manganese

There is provided a process for purifying (meth)acrylic acid by efficiently removing transition metal components from crude (meth)acrylic acid containing the transition metal components as impurities. When the crude (meth)acrylic acid containing the transition metal components as impurities is contacted with the cation exchange resin to remove the transition metal components therefrom, water is previously added to the crude (meth)acrylic acid prior to contacting the crude (meth)acrylic acid with the cation exchange resin. In the preferred embodiment of the present invention, the transition metal component is manganese.

Owner:MITSUBISHI CHEM CORP

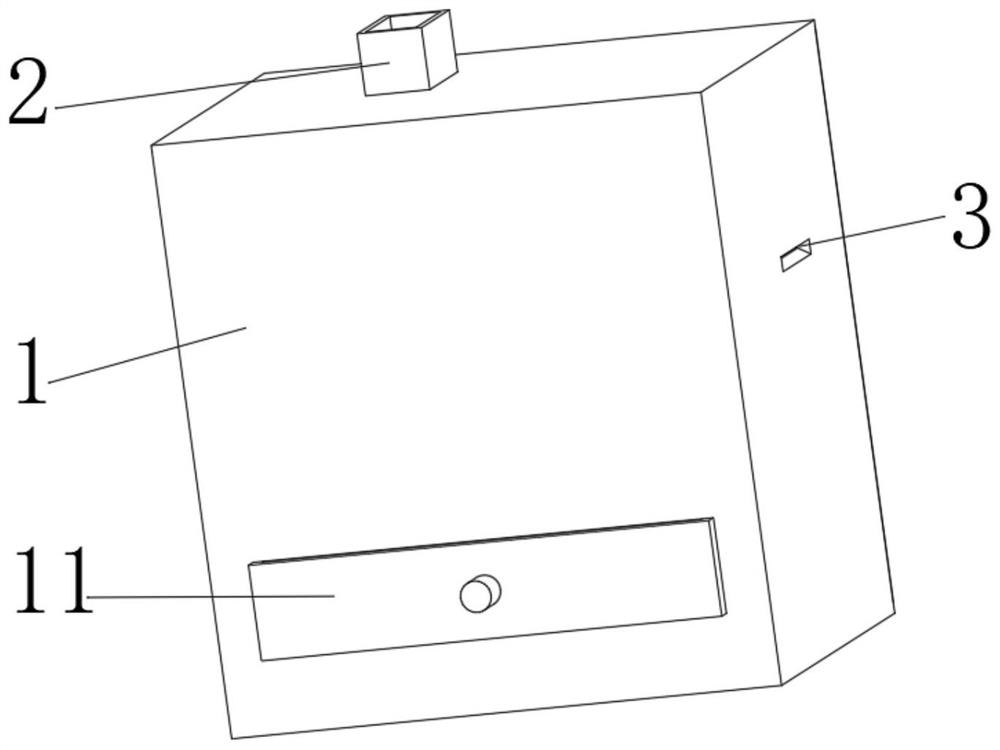

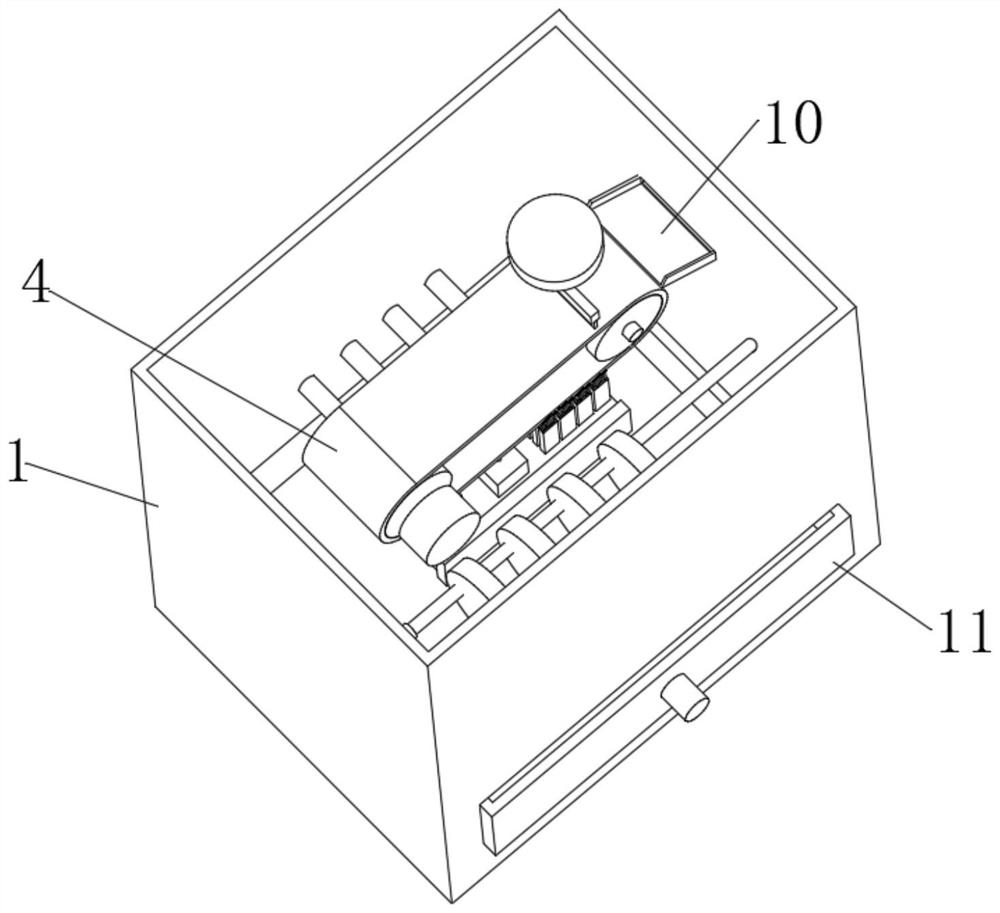

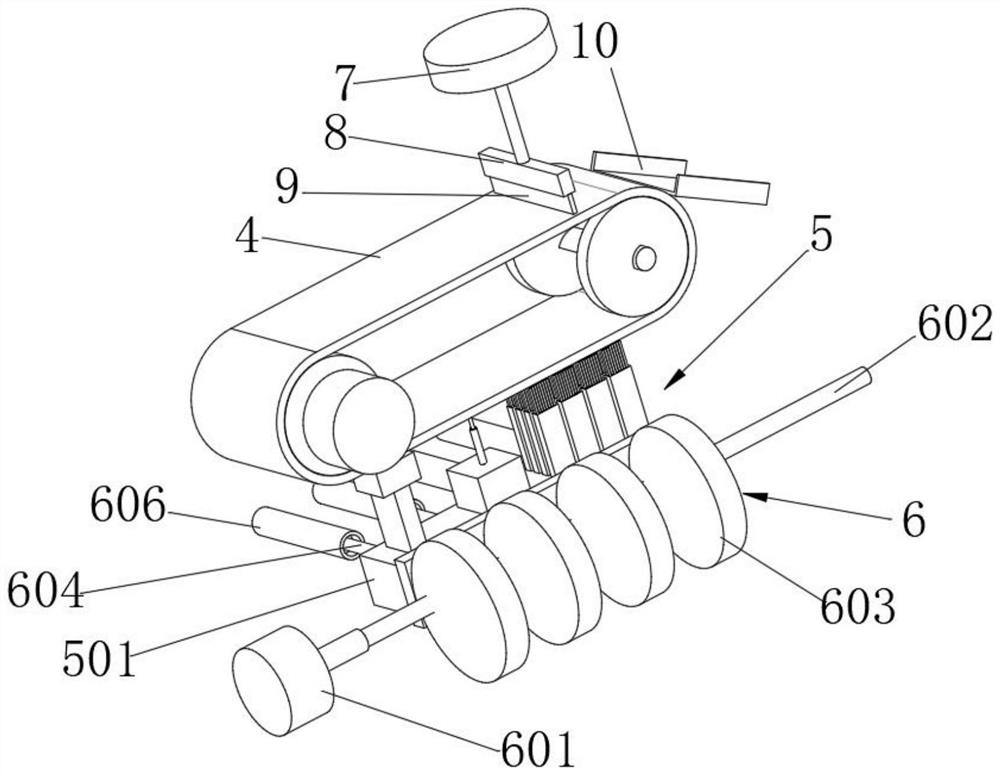

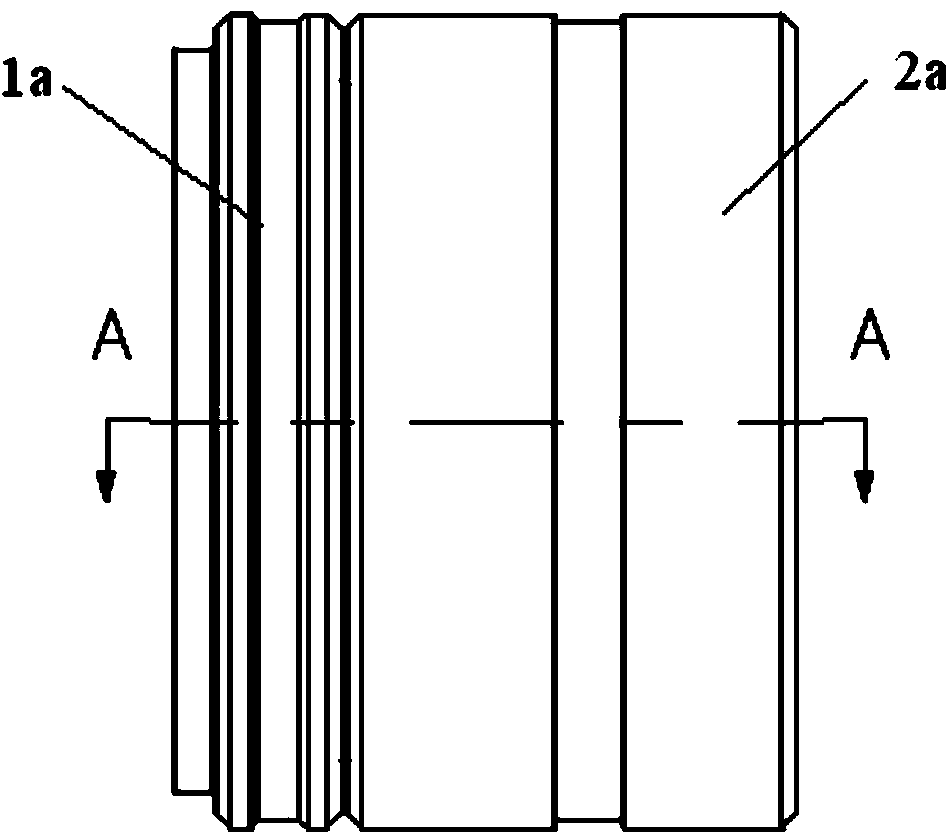

Online cleaning device for copper bar chain of tobacco cutter

PendingCN114212486ASimple structureEasy to useTobacco treatmentCleaningReciprocating motionStructural engineering

The invention discloses a tobacco cutter copper bar chain online cleaning device which is characterized in that a copper bar chain body is located in a tobacco cutter body, the tobacco cutter body is provided with a feeding port and a discharging port, the tobacco cutter body is a box body, and the bottom of the tobacco cutter body is provided with a cleaning assembly and a driving assembly which are located below the copper bar chain body; the cleaning assembly is opposite to the lower conveying face of the copper bar chain body and comprises a first containing plate and three sets of cleaning ends located on the plane of the first containing plate which are arranged along the lower conveying face, and the three sets of cleaning ends conduct three-level cleaning on the lower conveying face of the copper bar chain body. The driving assembly comprises an eccentric wheel located on the front side face of the first containing plate and a first telescopic rod located on the rear side face of the first containing plate, and the first containing plate reciprocates perpendicular to the lower conveying face under clamping of the driving assembly. By means of the device, sequential three-level sweeping and transverse reciprocating motion are achieved, the copper bar chain body is thoroughly swept, blocking is prevented, and production operation is guaranteed.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Hot extrusion mold for small-sized aluminum alloy round tube

InactiveCN103831315ASolve abnormal problems such as poor stabilityEnsure stable productionExtrusion diesExtrusion mandrelsMaterials scienceAluminium alloy

The invention relates to a hot extrusion mold for a small-sized aluminum alloy round tube. The hot extrusion mold comprises an upper mold and a lower mold, wherein a lower mold core is arranged in an inner cavity of the lower mold. The hot extrusion mold is characterized in that a through hole is formed in the center of the upper mold, an upper mold core is inlaid in the through hole, a pressure relief ball is arranged at one end of the upper mold core, and a core head working tape is arranged at the other end of the upper mold core and is located in the inner cavity of the lower mold core; the outer end face of the pressure relief ball is a spherical surface, the inner end face of the pressure relief ball is a plane matched with the end face of the upper mold. According to the hot extrusion mold, the stable production aiming at the small-sized and high-precision round tube can be guaranteed, and particularly the abnormal problems that the core head working tape of the upper mold core is easy to wear, the utilization stability of the mold is poor due to pressure fluctuation, and the like are solved.

Owner:JIANGSU ASIA PACIFIC LIGHT ALLOY TECH CO LTD

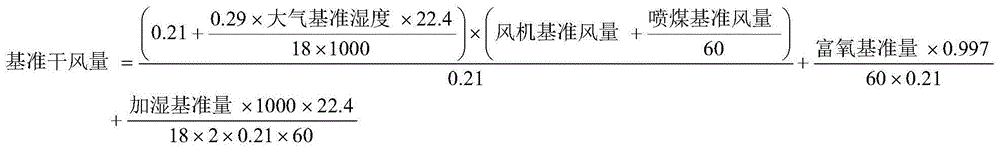

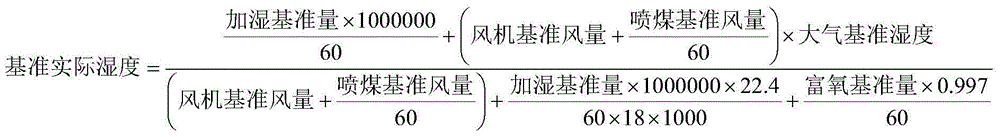

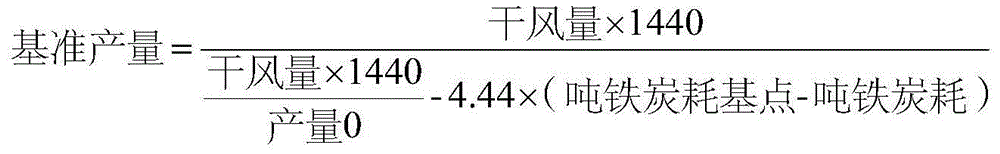

Method for precisely determining coal injection rate during blowing-down and blowing-in periods of blast furnace

The invention discloses a method for precisely determining the coal injection rate during blowing-down and blowing-in periods of a blast furnace; mutual influence of the various parameters, such as a coal ratio, a fuel ratio, the air volume, oxygen enrichment, humidification, crude fuel components, the yield and the like, is counted; furthermore, the mutual influence is digitized; furthermore, existing molten iron temperature measurement and the silicon content of molten iron are also considered; after the influence factors are quantified, wind consumption per ton of iron and a carbon consumption base point as references are calculated; and the coal loss amount is automatically calculated after a real-time data accumulated value during blowing-down, blowing-in and dead back periods is compared and calculated with the references according to a control object.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

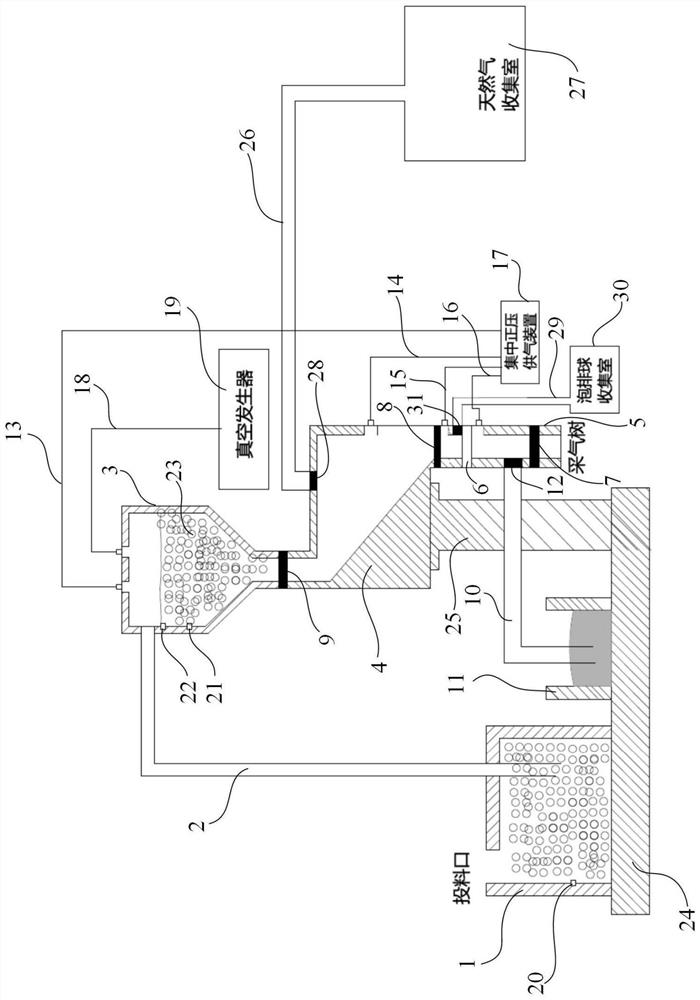

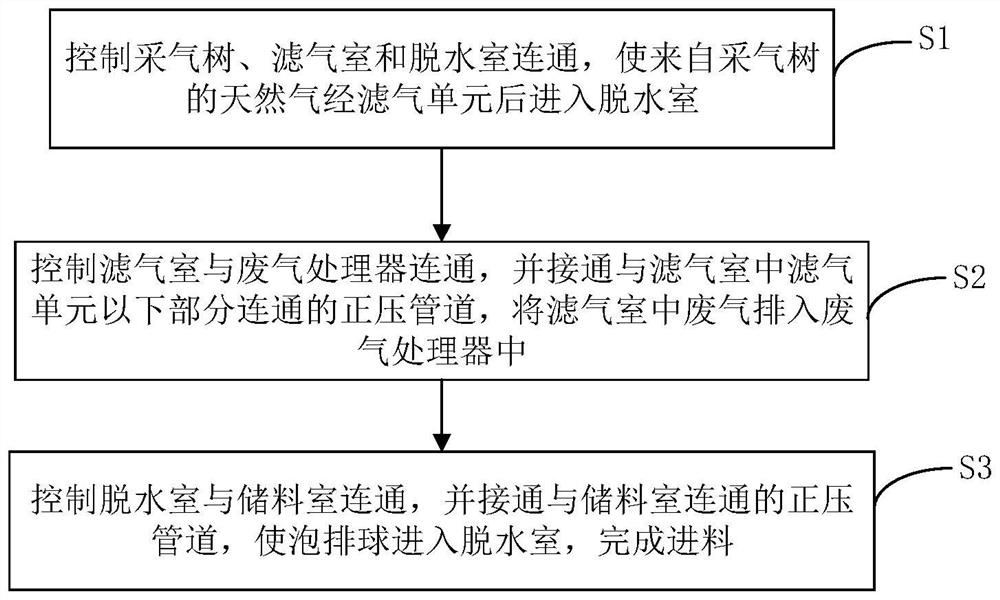

Automatic foam discharging ball filling device and method

ActiveCN114704233AAchieve separationAchieving processing powerFluid removalWell/borehole valve arrangementsAir filterProcess engineering

The invention discloses an automatic foam scrubbing ball filling device which comprises a storage mechanism, a conveying mechanism and a waste gas treatment device. The storage mechanism comprises a stock bin and a storage chamber which are communicated through a feeding pipeline, and the storage chamber is located above the stock bin. The conveying mechanism comprises a dewatering chamber communicated with the storage chamber and an air filtering chamber communicated with the dewatering chamber; the input end of the gas filtering chamber is communicated with the gas production tree; the gas filtering chamber is divided into two parts through a filtering unit arranged in the gas filtering chamber, the part below the gas filtering unit is communicated with a waste gas treater for absorbing waste gas in natural gas through a first exhaust pipeline, and the part above the gas filtering unit is communicated with a foam discharging ball collecting chamber through a discharging pipeline; the material storage chamber, the dehydration chamber and the air filtering chamber are respectively communicated with a centralized positive pressure air supply device through positive pressure pipelines; and the storage chamber is communicated with a vacuum generator through a vacuum pipeline. According to the device, automatic feeding and discharging of foam discharging balls are conducted through the air pressure difference, waste gas can be separated and treated at the same time, and the natural gas extraction efficiency and the extraction work stability can be improved.

Owner:SICHUAN UNIV

Process for purifying (meth)acrylic acid and process for producing (meth)acrylic esters

ActiveUS20050171382A1Component can be removedSpeed up the processOrganic compound preparationOrganic chemistry methodsMeth-Cationic exchange

There is provided a process for purifying (meth)acrylic acid by efficiently removing transition metal components from crude (meth)acrylic acid containing the transition metal components as impurities. When the crude (meth)acrylic acid containing the transition metal components as impurities is contacted with the cation exchange resin to remove the transition metal components therefrom, water is previously added to the crude (meth)acrylic acid prior to contacting the crude (meth)acrylic acid with the cation exchange resin. In the preferred embodiment of the present invention, the transition metal component is manganese.

Owner:MITSUBISHI CHEM CORP

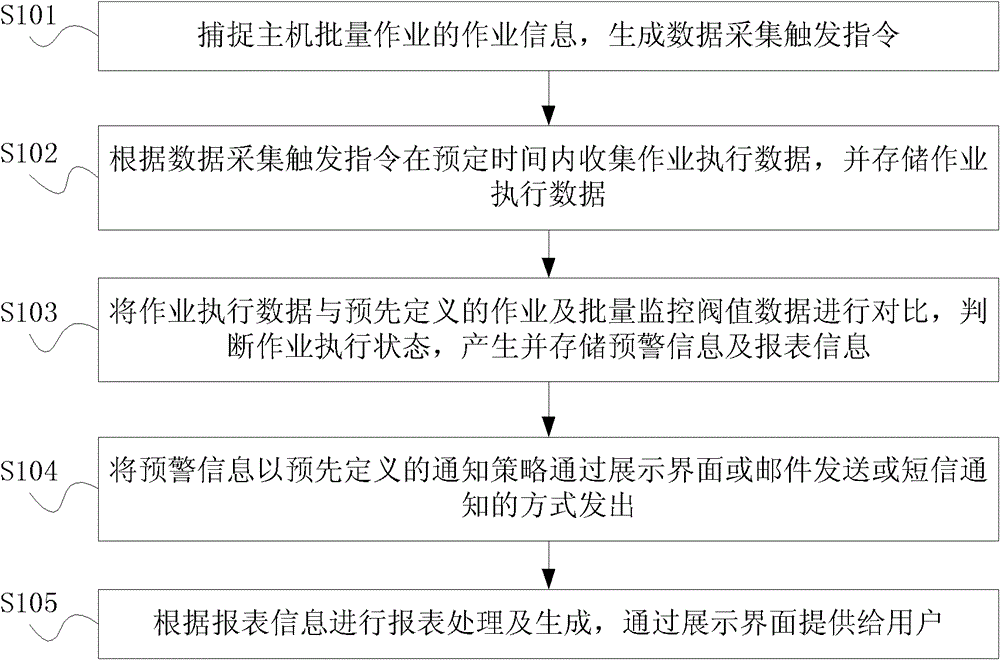

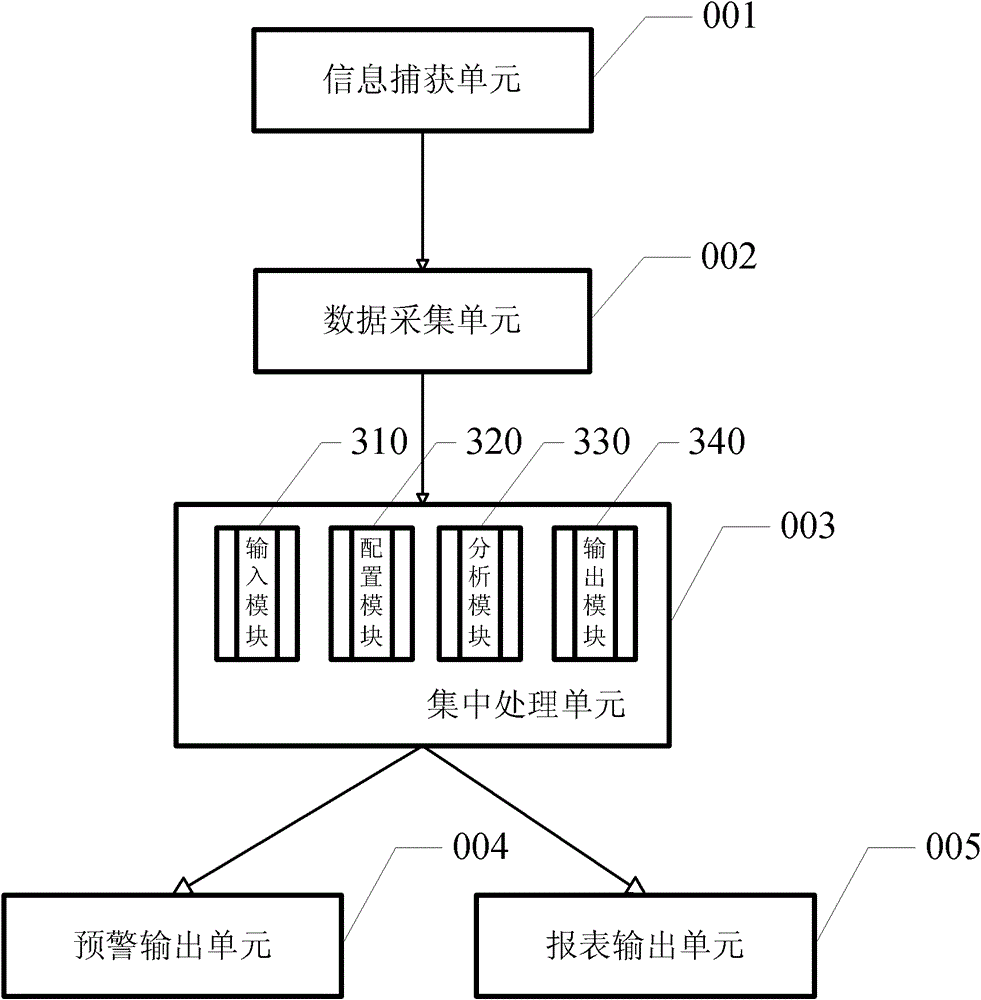

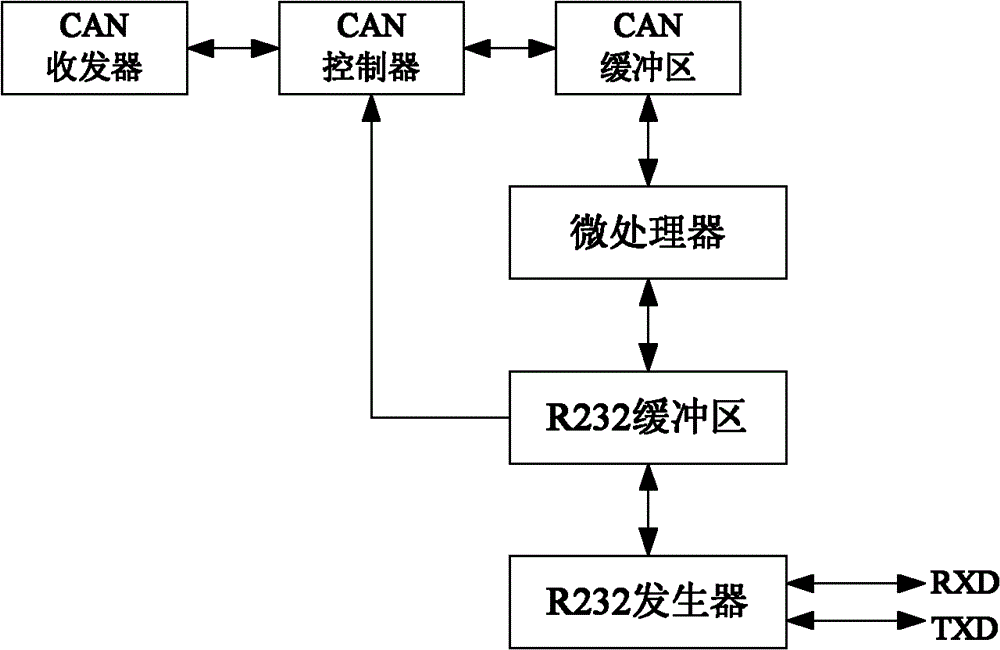

Monitoring method and device for host batch job data

ActiveCN102226890BOvercoming the lack of effective monitoring meansEnsure stable productionHardware monitoringMultiprogramming arrangementsData acquisitionData treatment

The invention provides a monitoring method and device for host batch job data. The method comprises the following steps of: capturing job information of host batch job to generate a data acquisition trigger instruction; collecting job execution data within predetermined time according to the data acquisition trigger instruction, and storing the job execution data; comparing the job execution datawith the predefined job and batch monitoring threshold data to judge a job execution state, and generating and storing early warning information and report information; sending out the early warning information through a predefined strategy of notice by means of a presentation interface or email sending or short message notification; and performing report processing and generation according to the report information, and providing a report for users through the presentation interface. With the method and the device, automatic monitoring on batch data processing of a computer host is implemented.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com