Constant-flow feeding device

A feeding device and steady flow technology, applied in the field of wet material feeding equipment, can solve the problems of unguaranteed batching accuracy, sticking on the material wall, and harsh working environment, etc., to achieve enhanced wear resistance, smooth material flow, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention are described below in conjunction with the drawings.

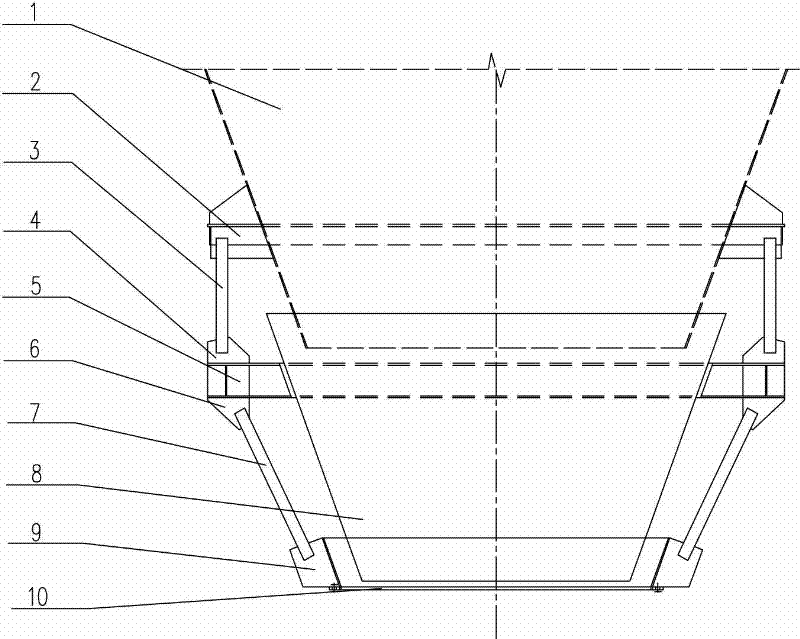

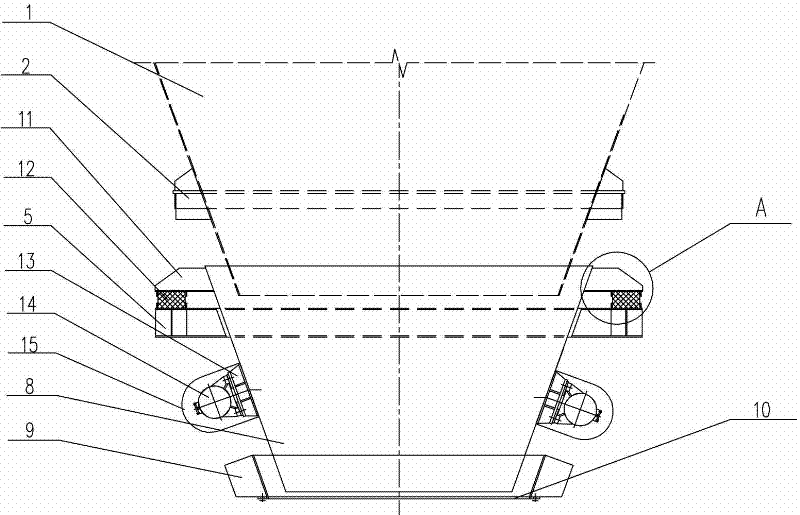

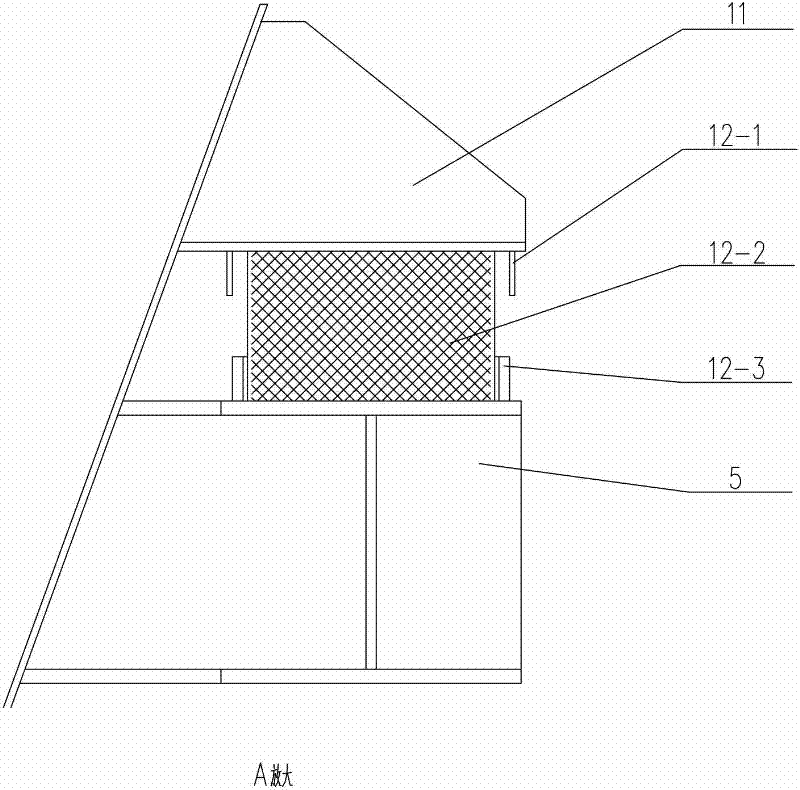

[0024] Such as figure 1 , figure 2 , image 3 As shown, the steady flow feeding device of the present invention is characterized in that it includes a consolidation ring 2 fixedly connected to the silo metal ore trough 1, and the consolidation ring carries the load of the entire device. The hopper body 8 is set under the silo metal ore tank 1. The bottom of the silo metal ore tank 1 is inserted into the hopper body 8. The dihedral angle between the generatrix of the hopper body 8 and the plane where the lower mouth is located is greater than or equal to 70 degrees, This angle is conducive to the downward movement of materials. The inner surface of the funnel body 8 is provided with a rare earth oil-containing nylon liner to enhance its wear resistance and prolong its service life. A set of ear seats 11 evenly arranged on the outer surface of the upper part of the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com