Patents

Literature

365results about How to "Prevent arching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

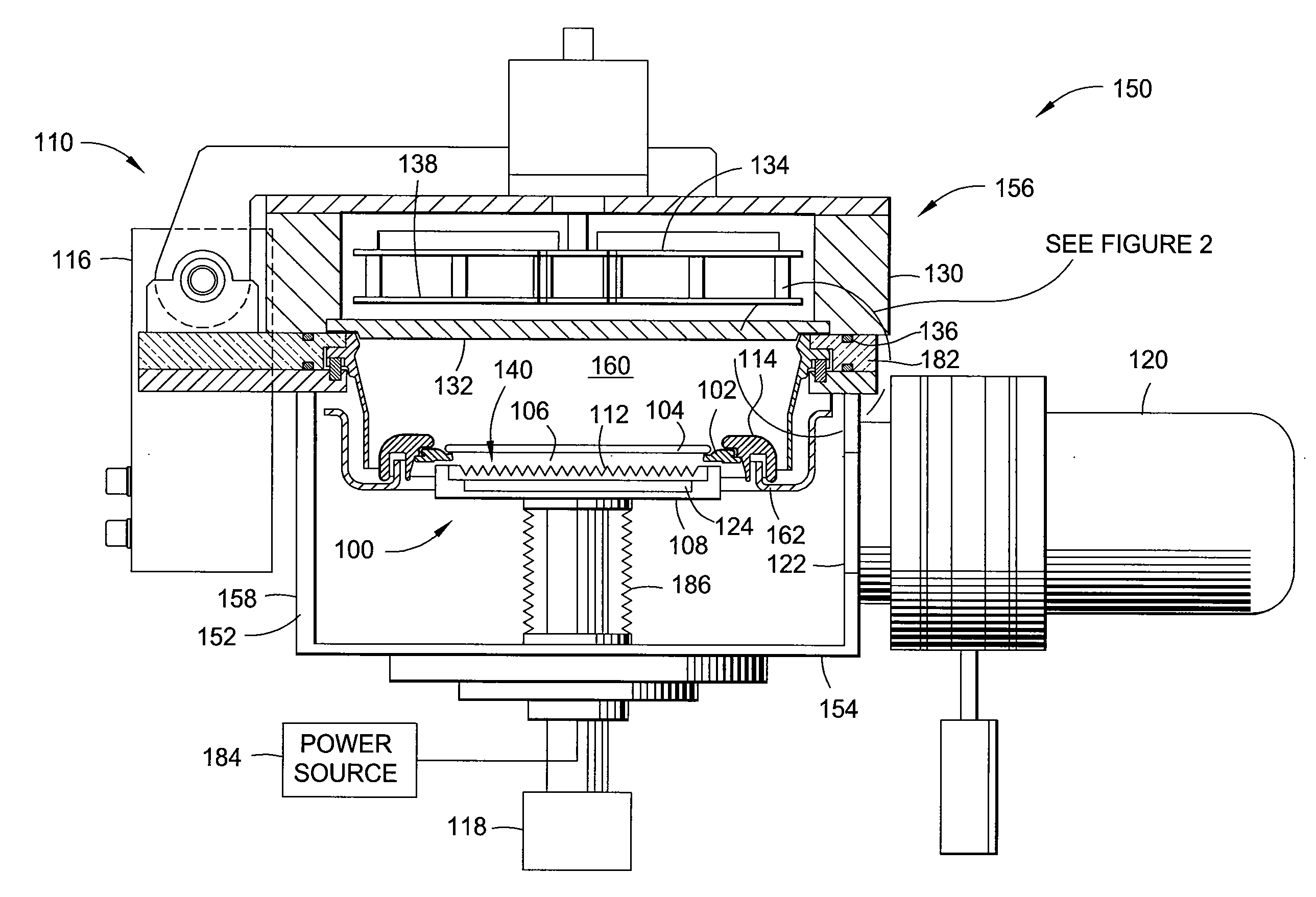

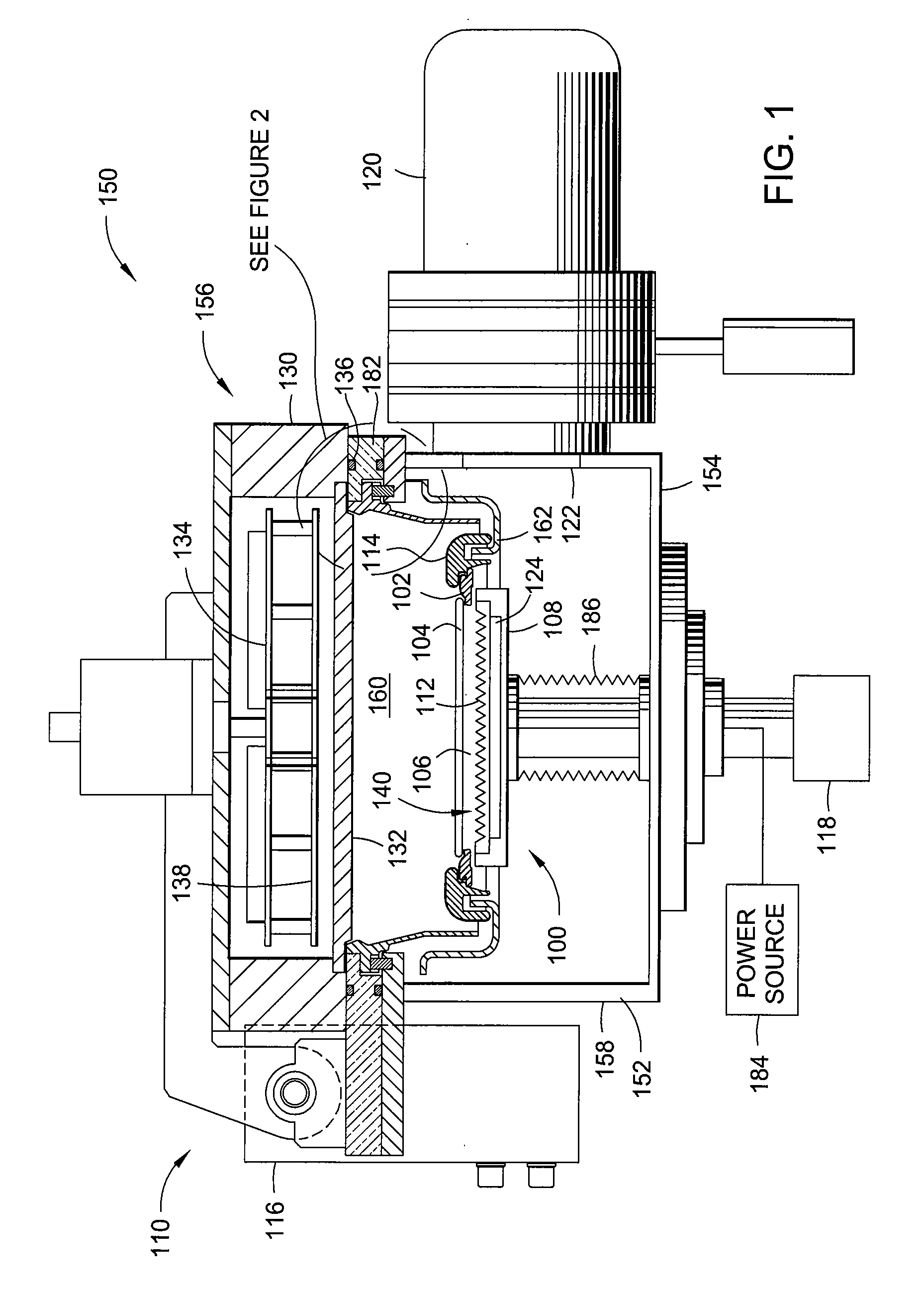

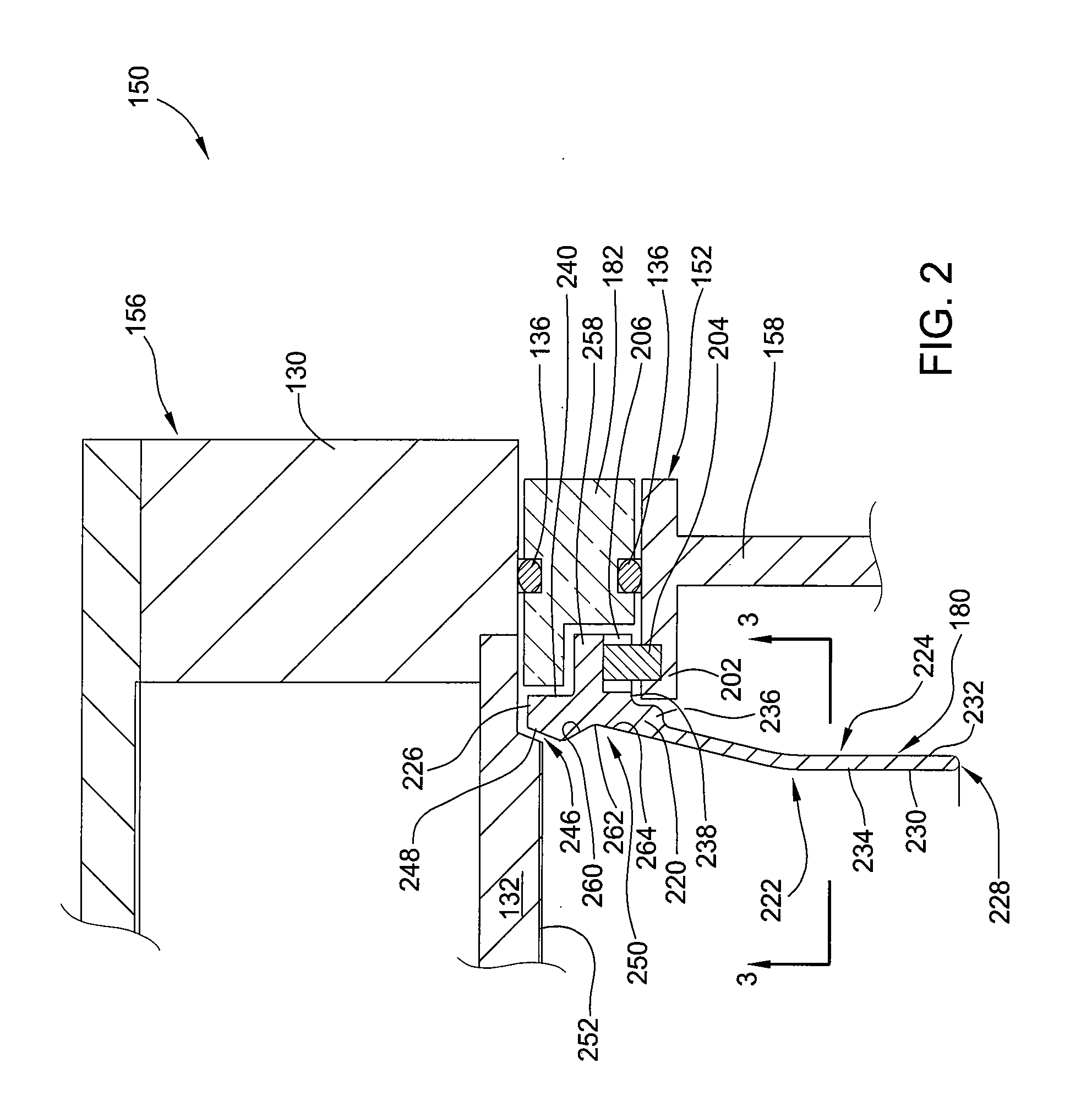

Ground shield with reentrant feature

ActiveUS20070295602A1Good repeatabilityImprove uniformityCellsElectric discharge tubesEngineeringPhysical vapor deposition

The invention generally provides a ground shield for use in a physical vapor deposition (PVD) chamber. In one embodiment, a ground shield includes a generally cylindrical body comprising an outer wall, an inner upper wall, an inner lower wall having a diameter less than a diameter of the inner upper wall and a reentrant feature coupling the upper and inner lower walls. The reentrant feature advantageously prevents arching between the shield and target, which promotes greater process uniformity and repeatability along with longer chamber component service life.

Owner:APPLIED MATERIALS INC

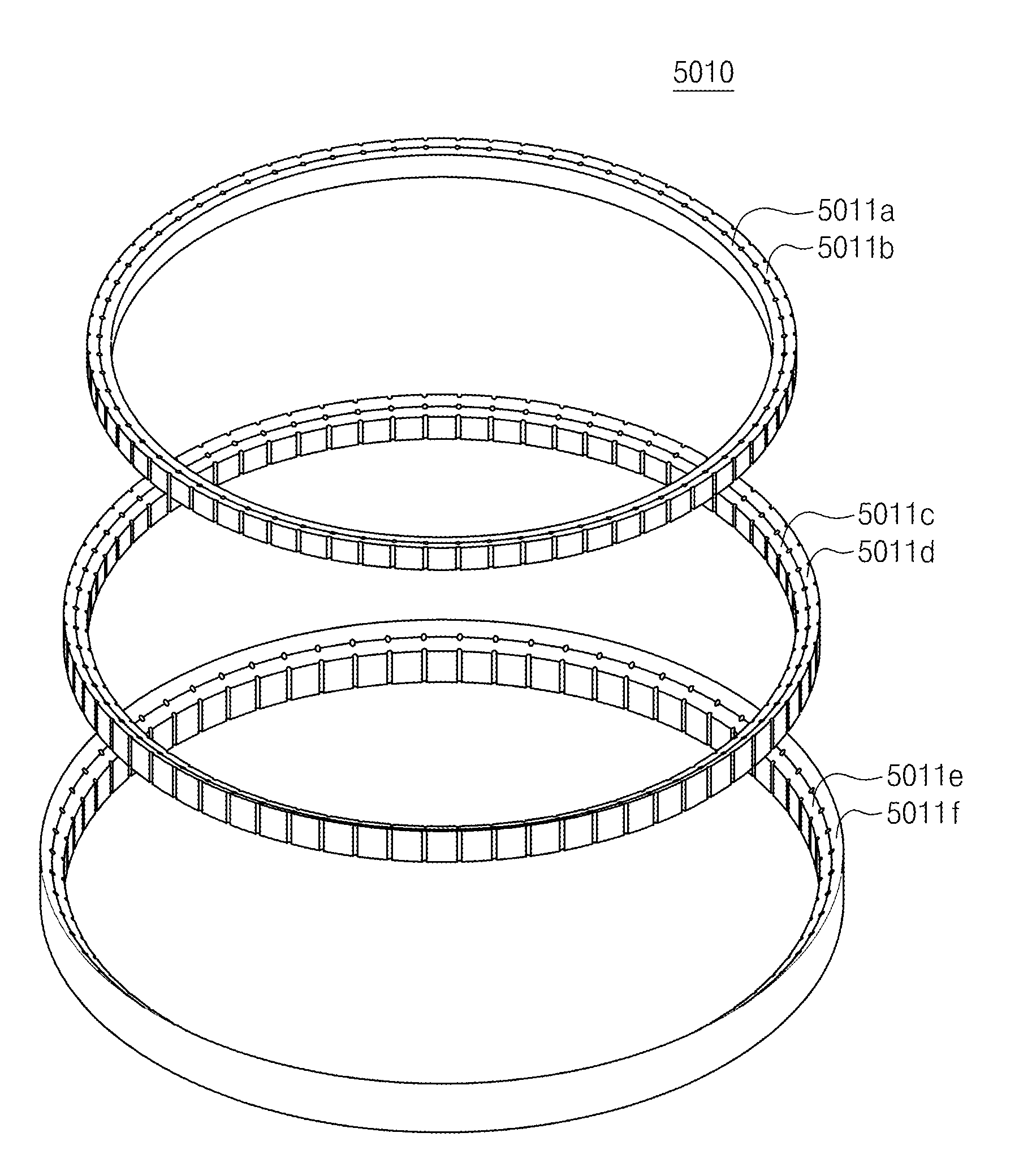

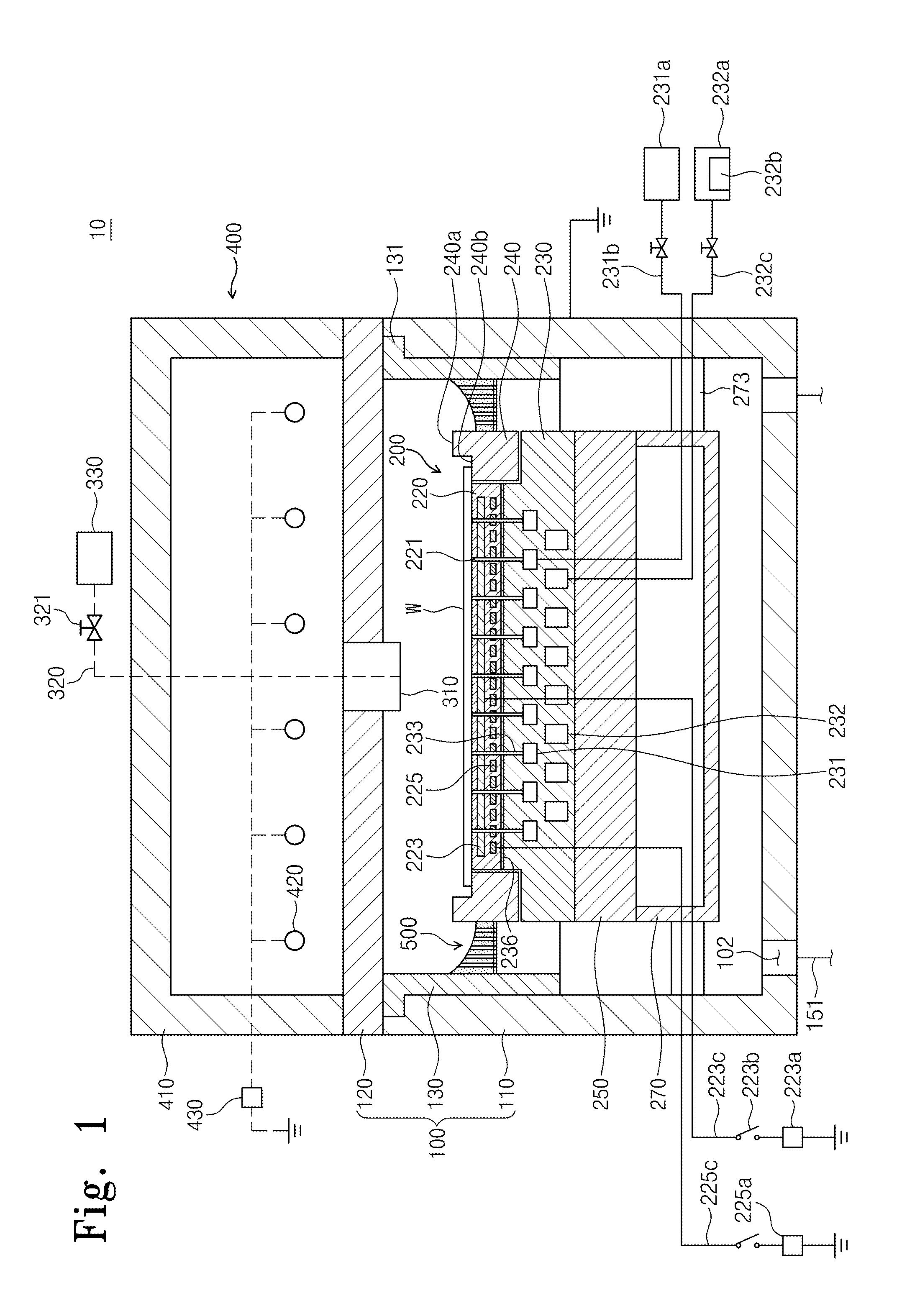

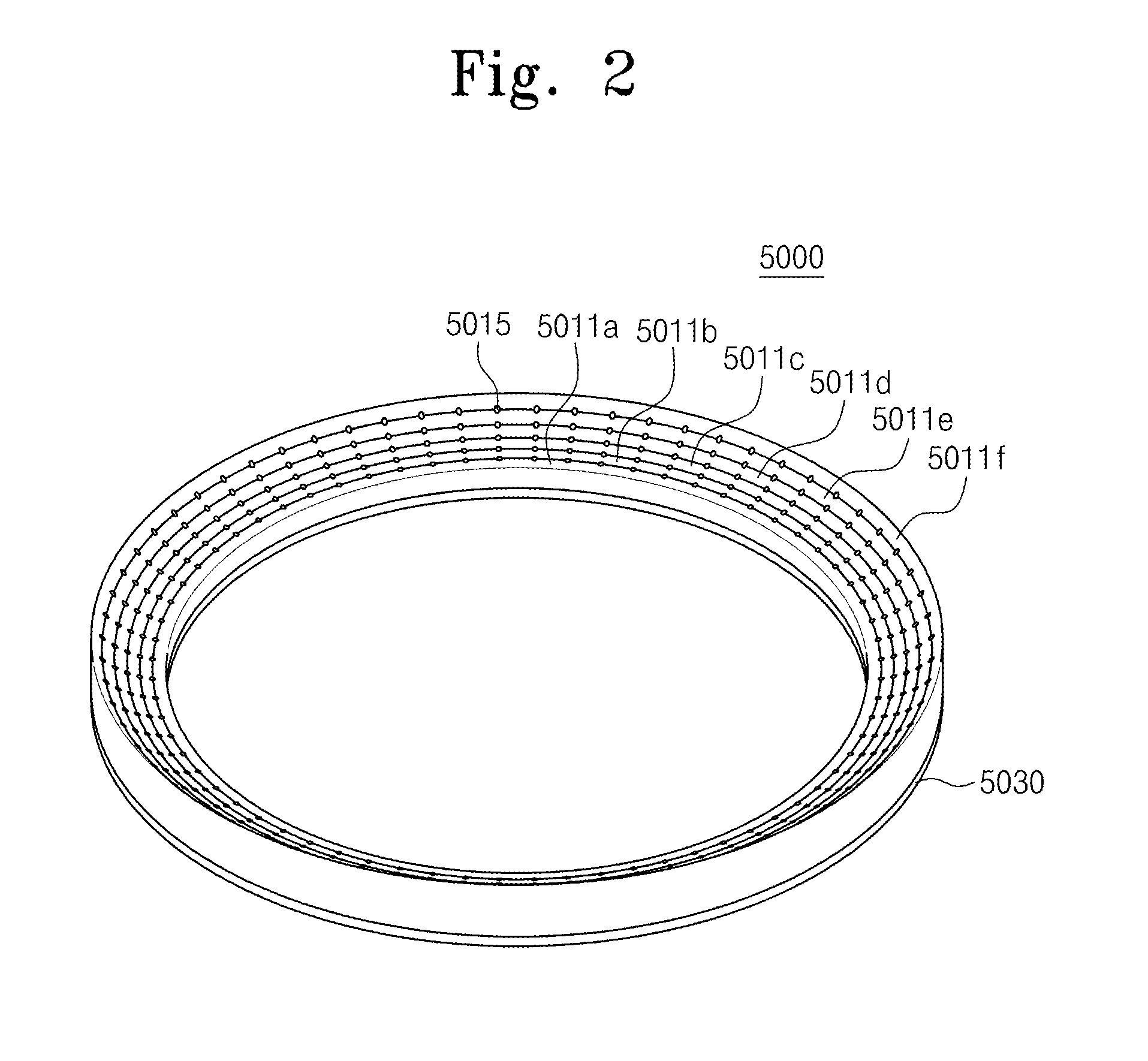

Apparatus for treating substrate

ActiveUS20140034240A1Prevent archingElectric discharge tubesSemiconductor/solid-state device manufacturingInterior spaceMetallic materials

Provided is a substrate treatment apparatus using plasma. The substrate treatment apparatus includes a housing having an inner space in which a substrate is treated, a support member disposed within the housing to support the substrate, a gas supply unit supplying a gas into the housing, a plasma source generating plasma from the gas supplied into the housing, and a baffle unit disposed to surround the support member within the housing, the baffle unit including a baffle in which through holes for exhausting the gas into the inner space of the housing are defined. The baffle is divided into a plurality of areas when viewed from an upper side, and each of portions of the plurality of areas is formed of a metallic material, and each of the other portions of the plurality of areas is formed of a nonmetallic material.

Owner:SEMES CO LTD

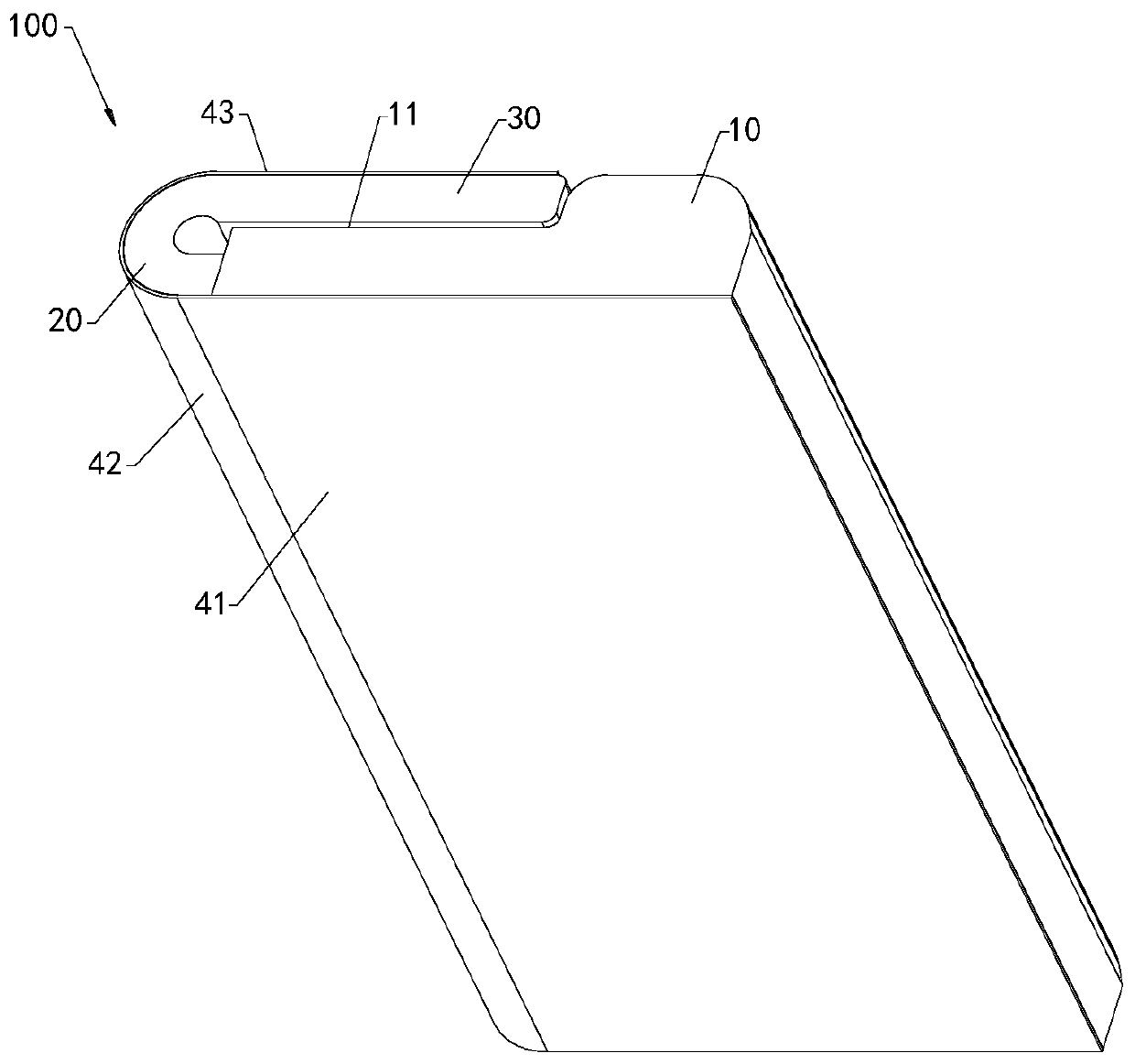

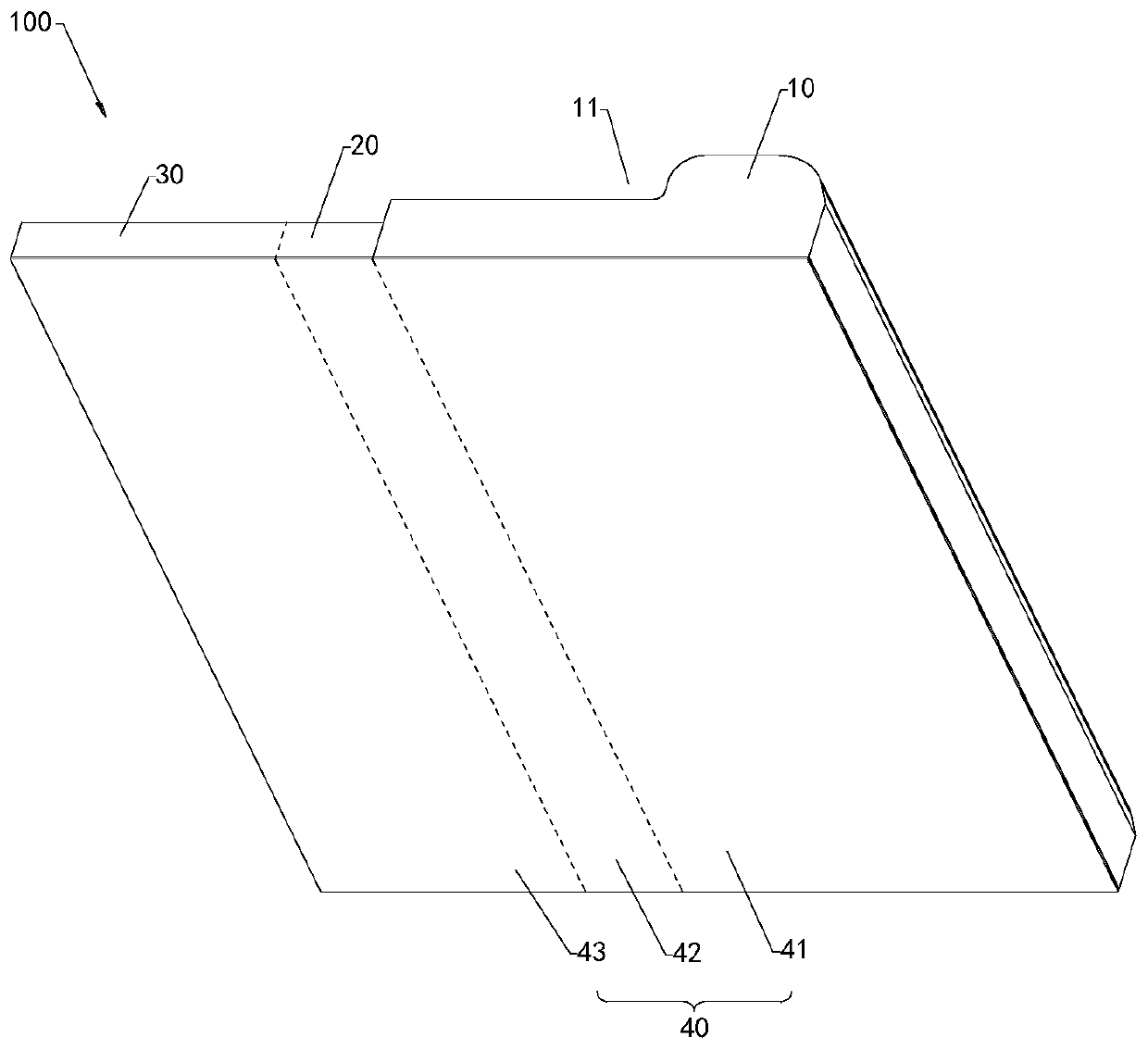

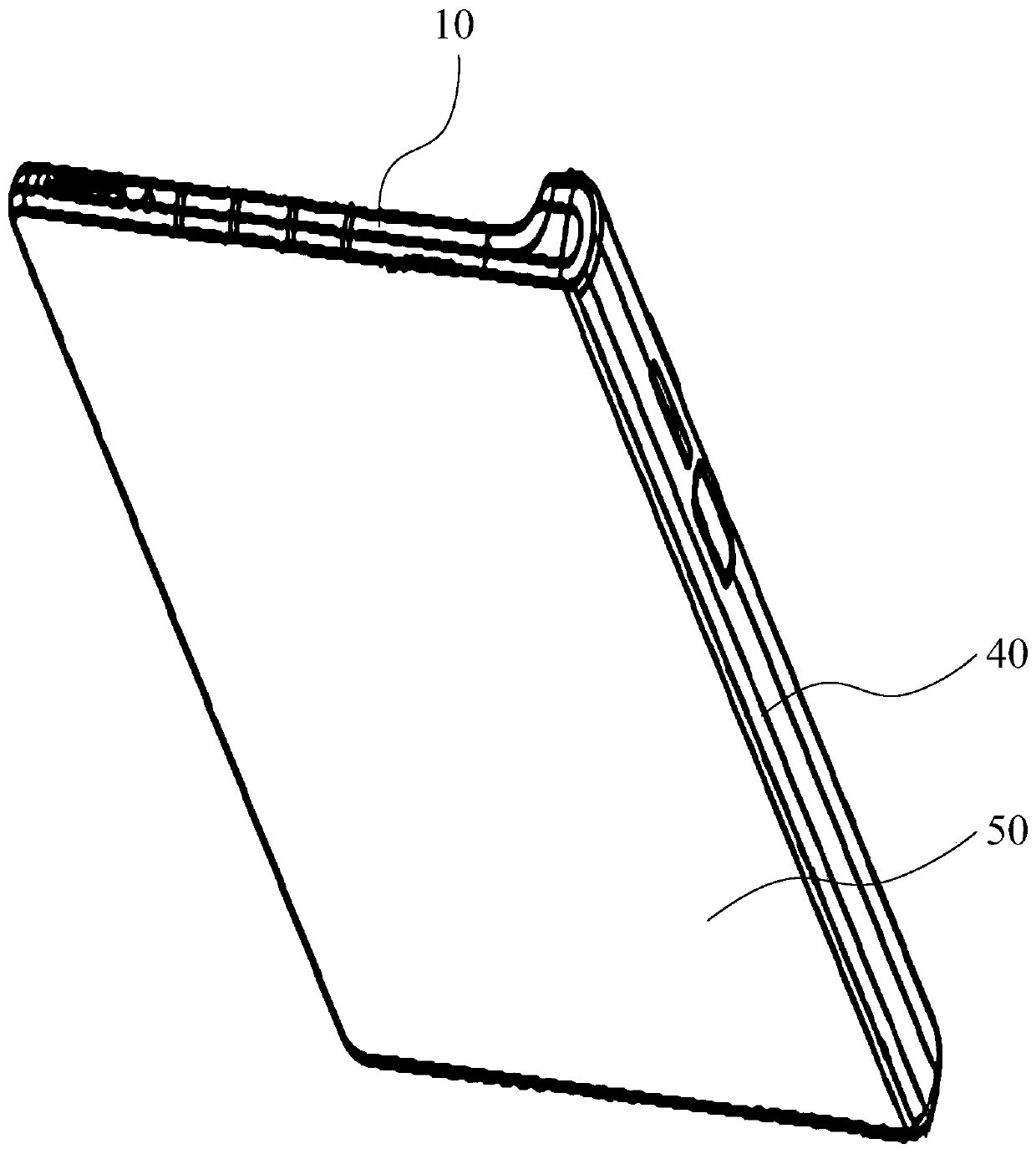

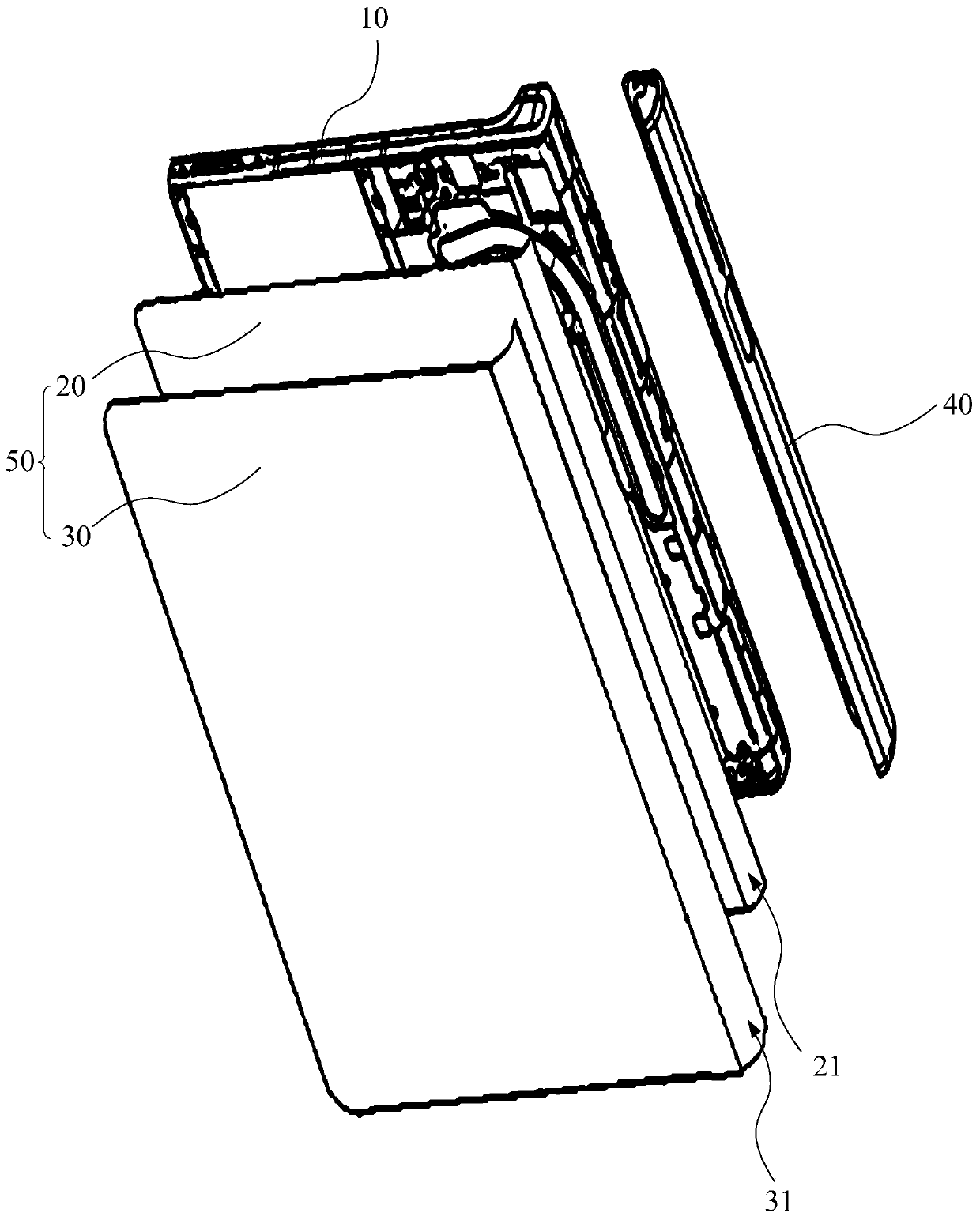

Flexible screen and electronic device

ActiveCN109658826AImprove foldabilityIncrease stressInput/output processes for data processingIdentification meansMechanical engineeringEngineering

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

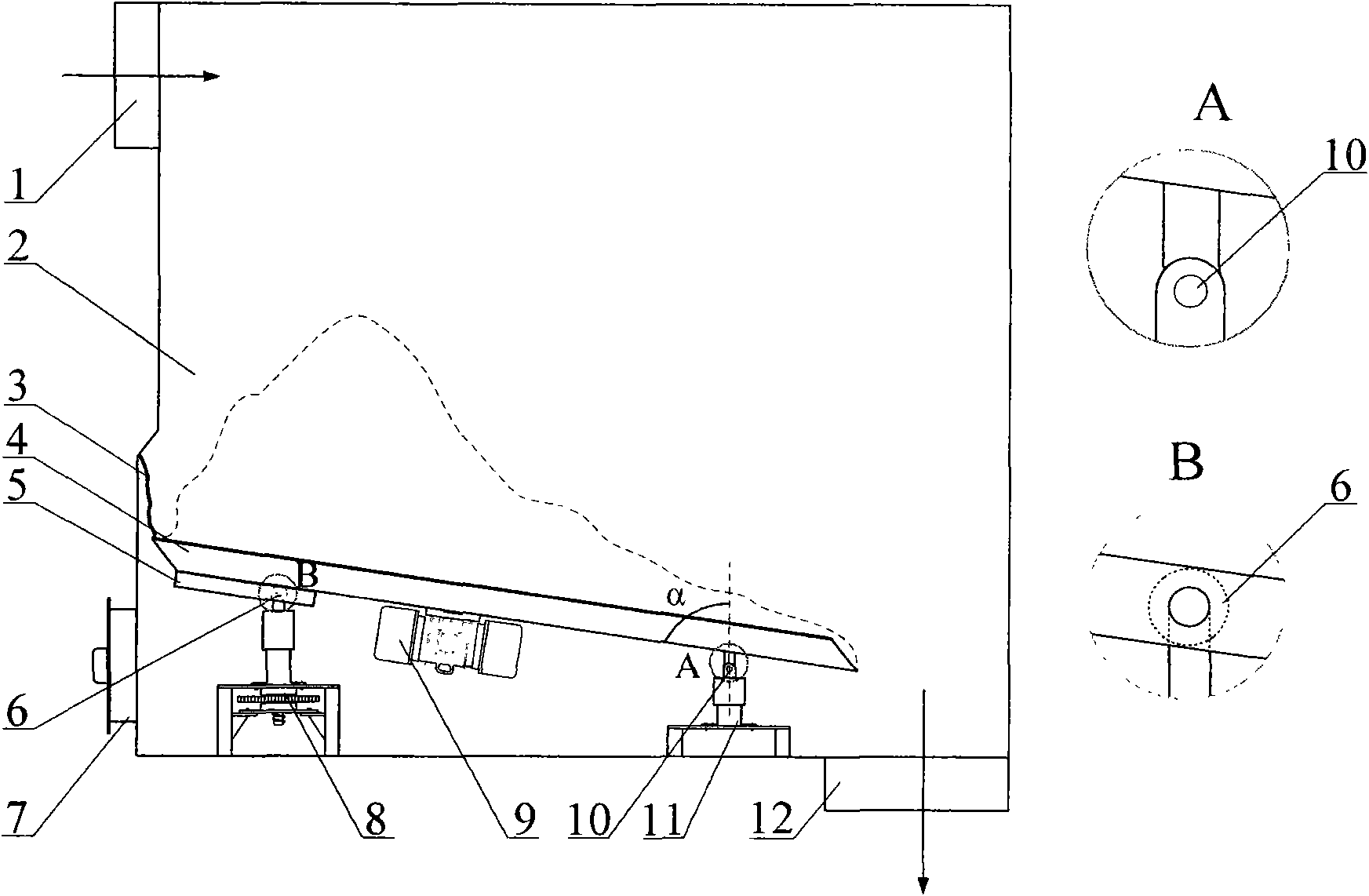

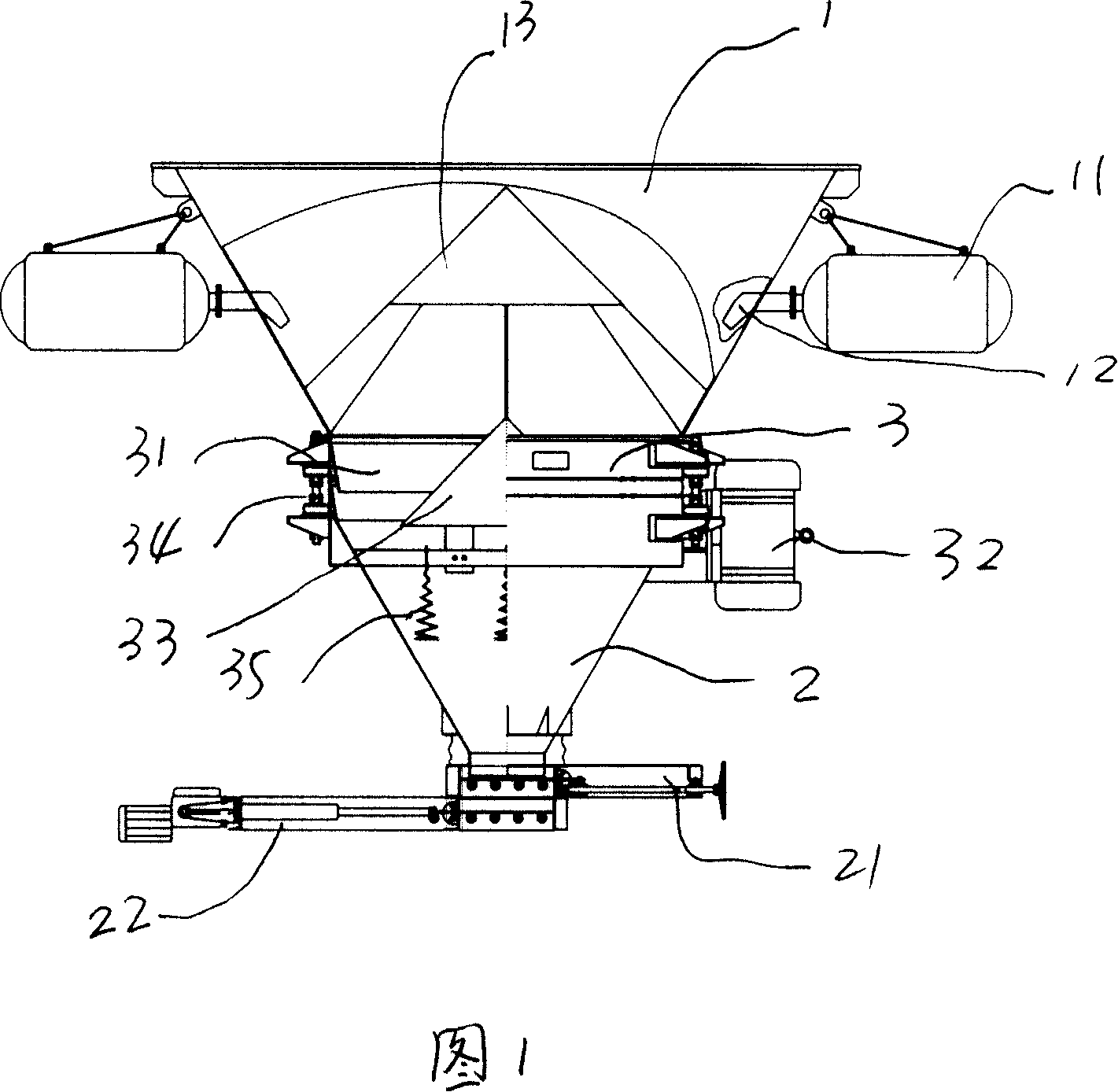

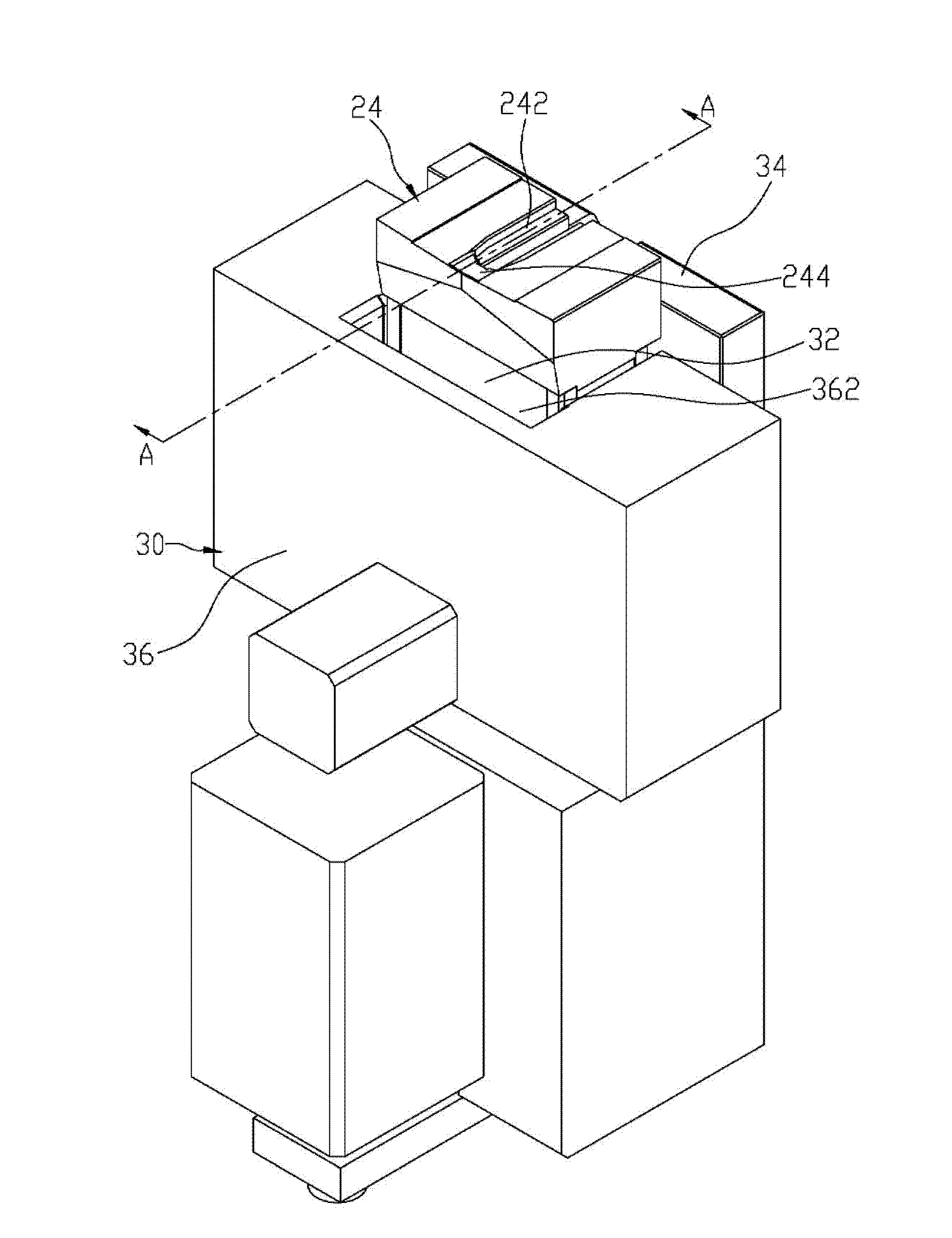

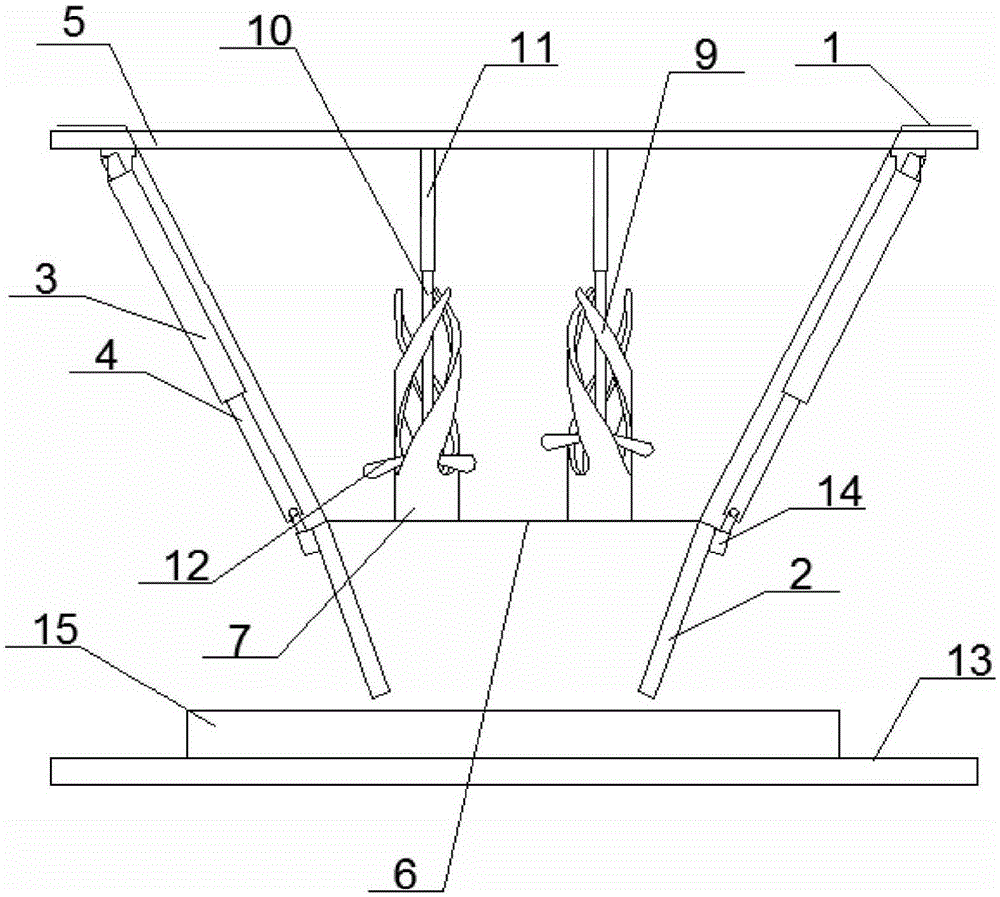

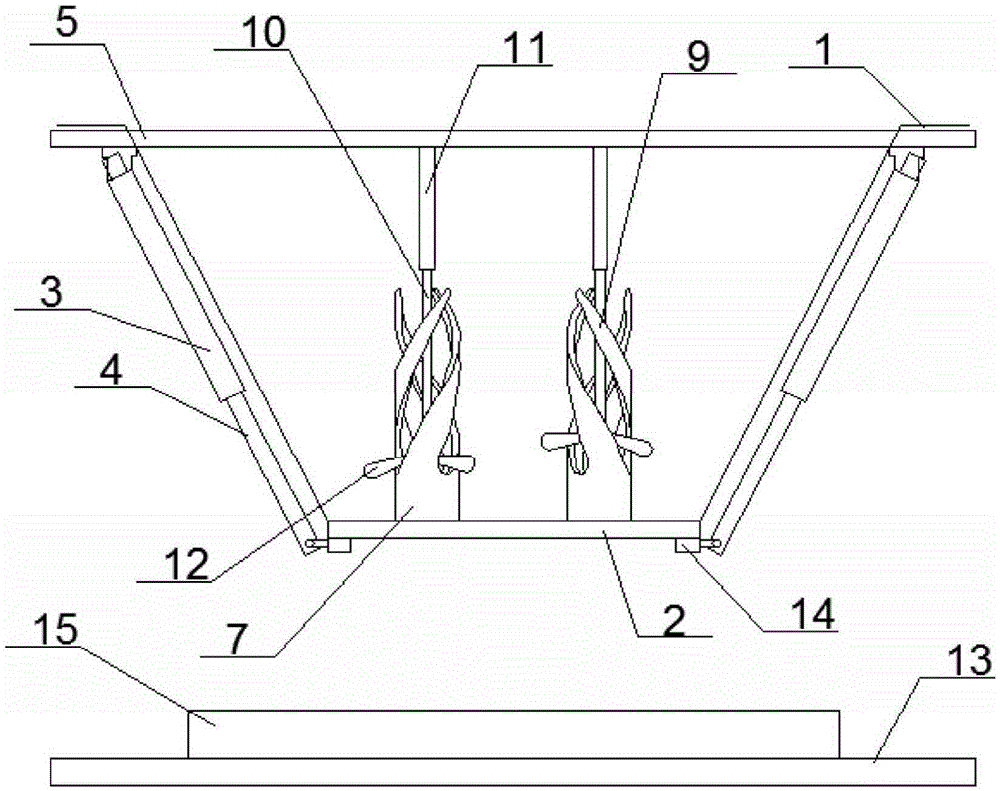

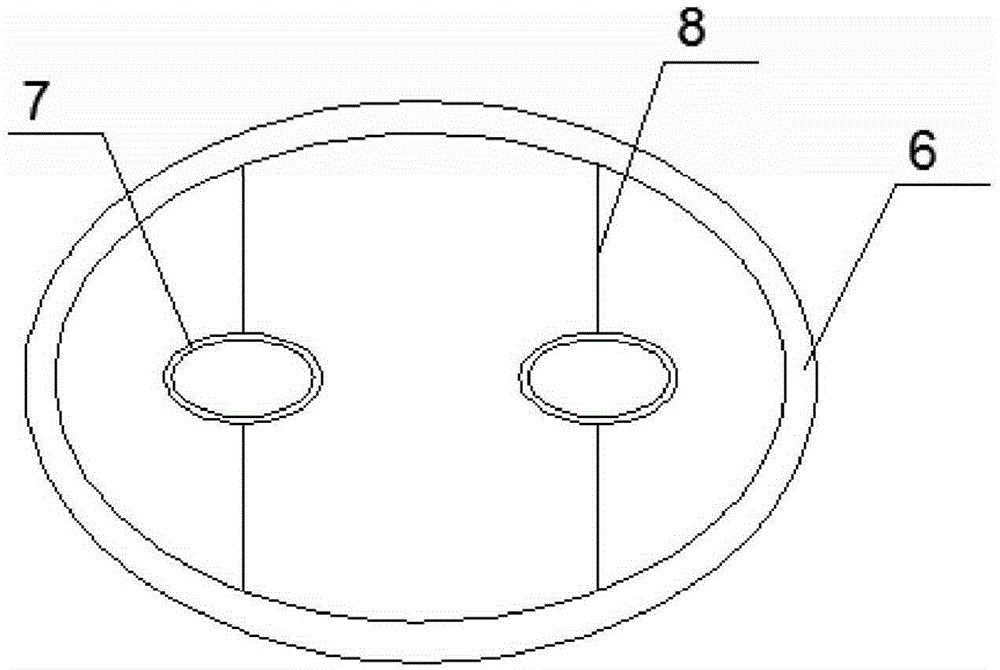

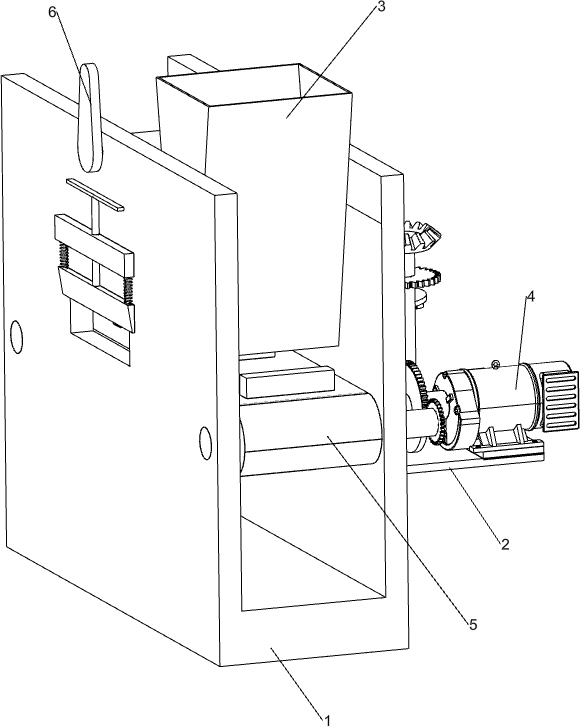

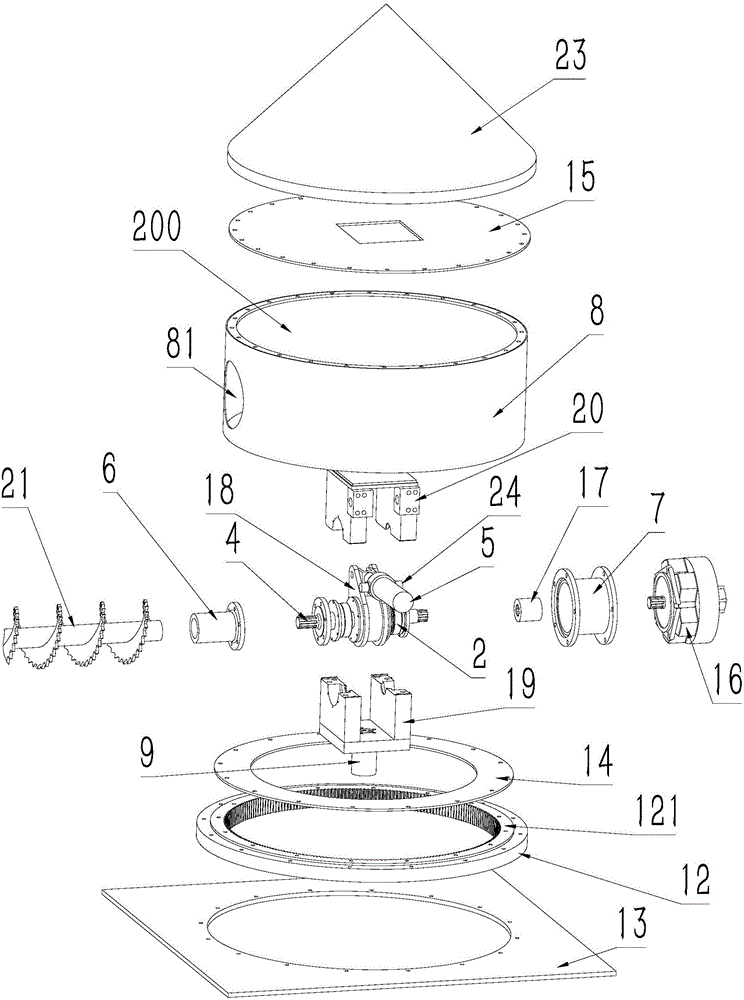

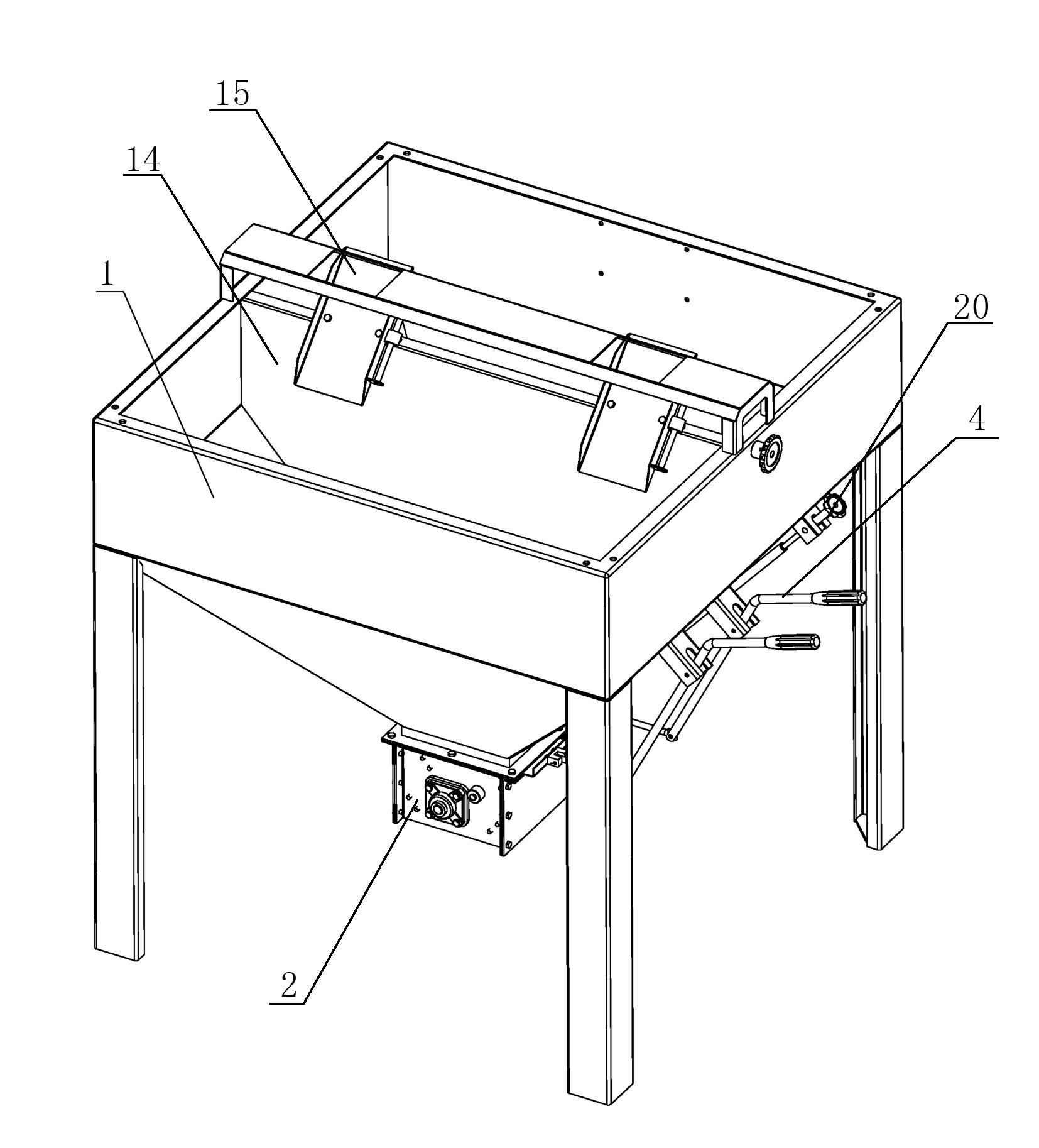

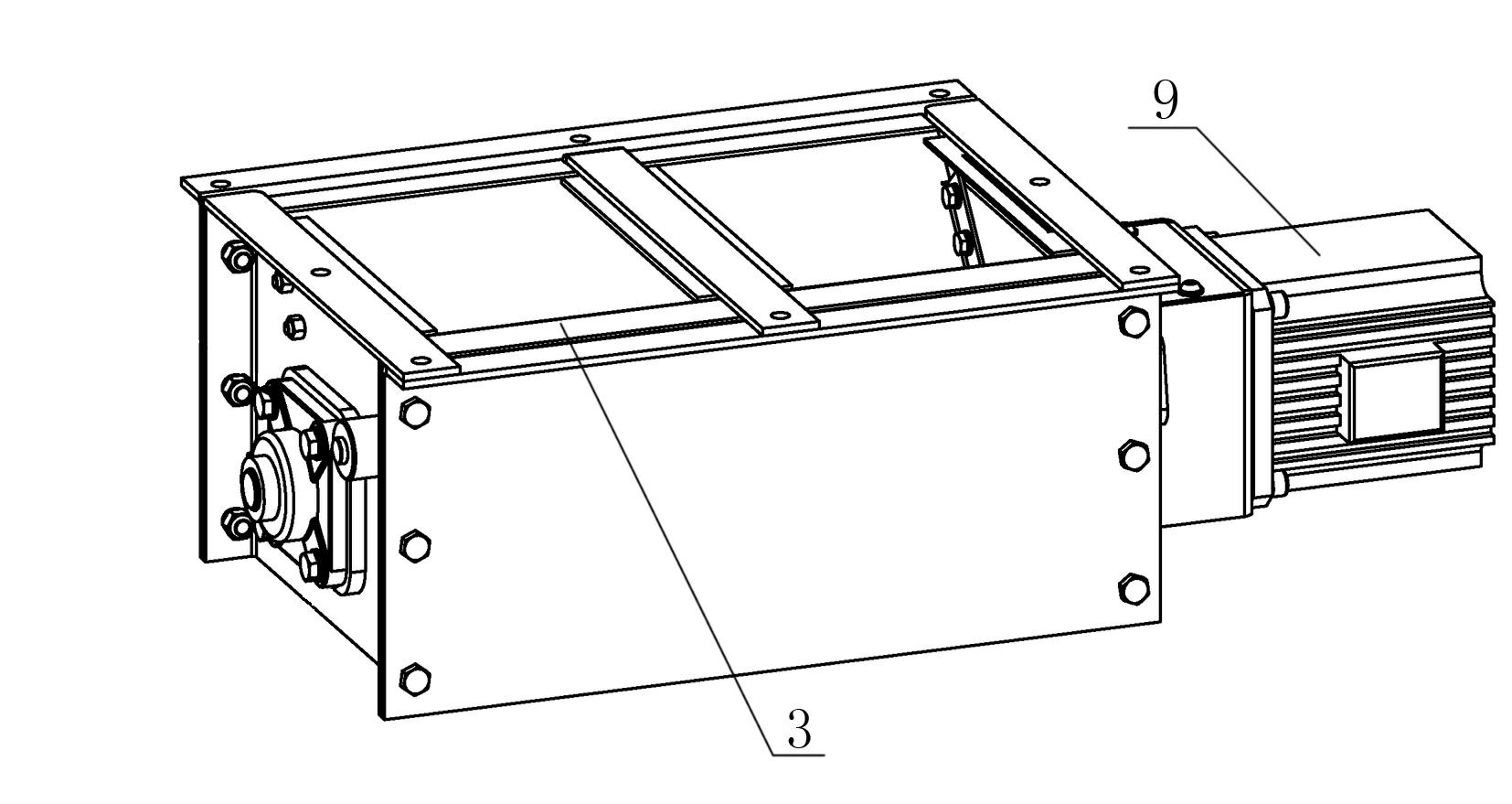

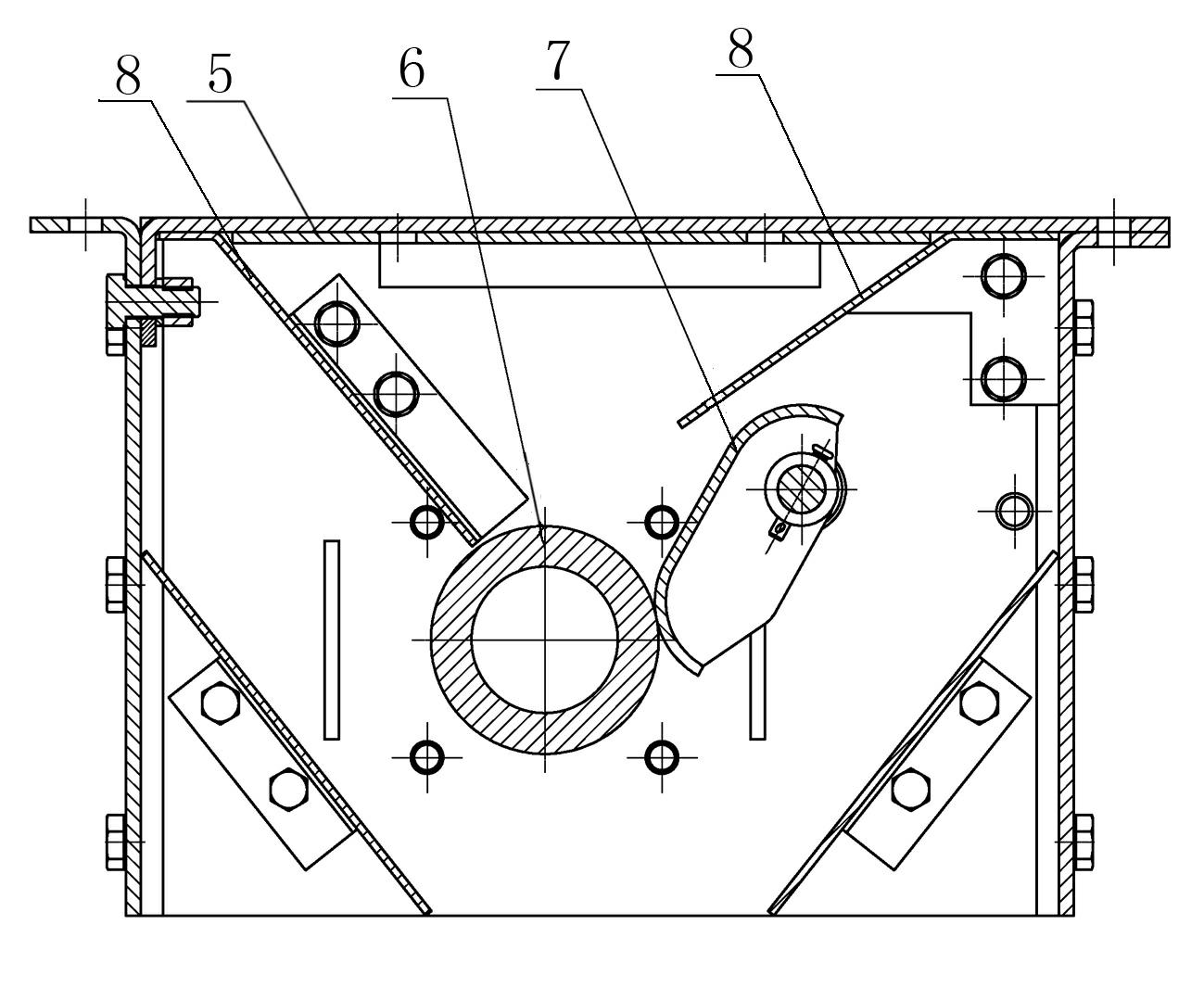

Biomass feed divider with changeable trough obliquity and vibration frequency and amplitude

ActiveCN101613039AContinuous, stable and even distribution of materialsAchieve free rotationLarge containersLoading/unloadingMultiple formsMaterial distribution

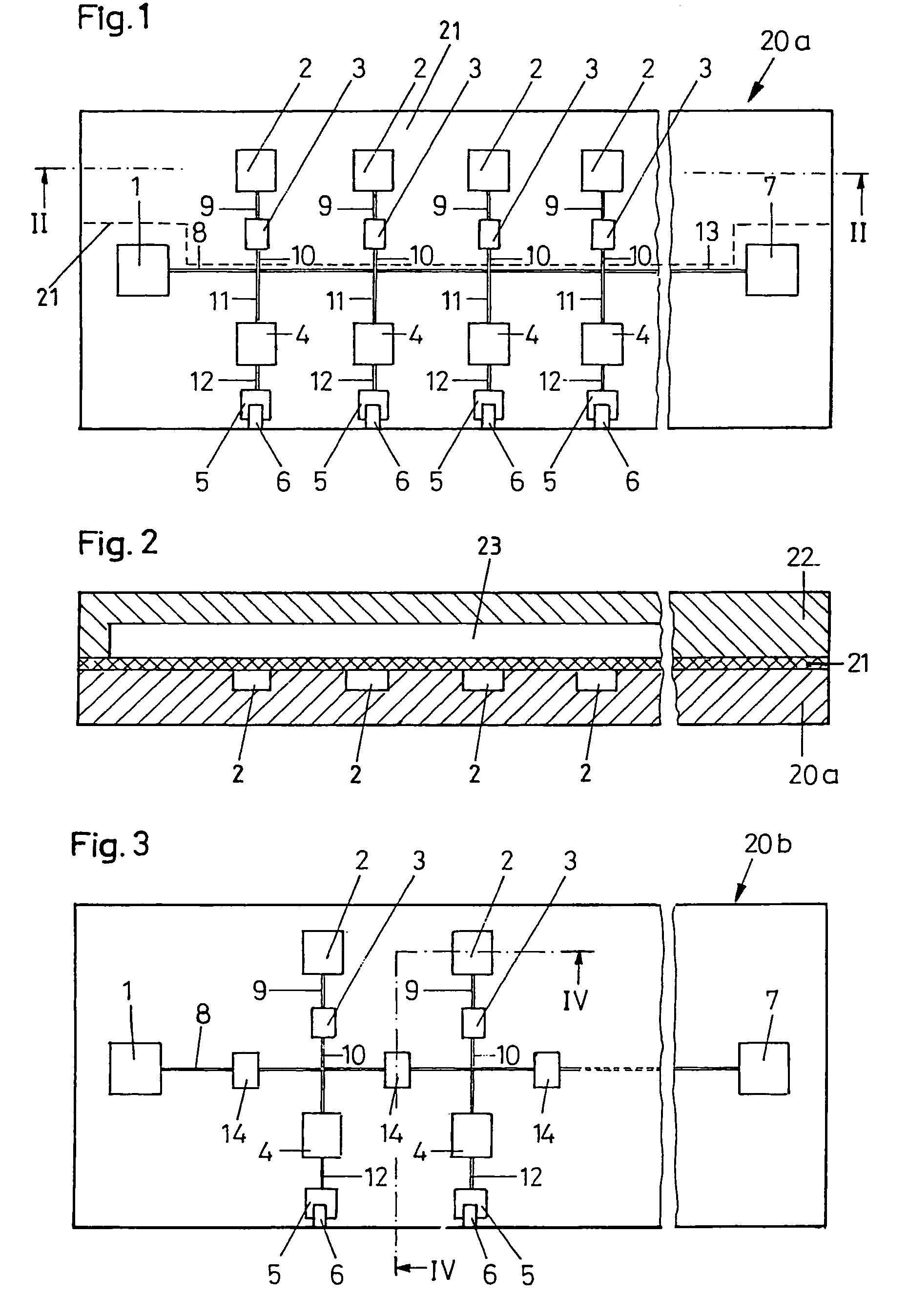

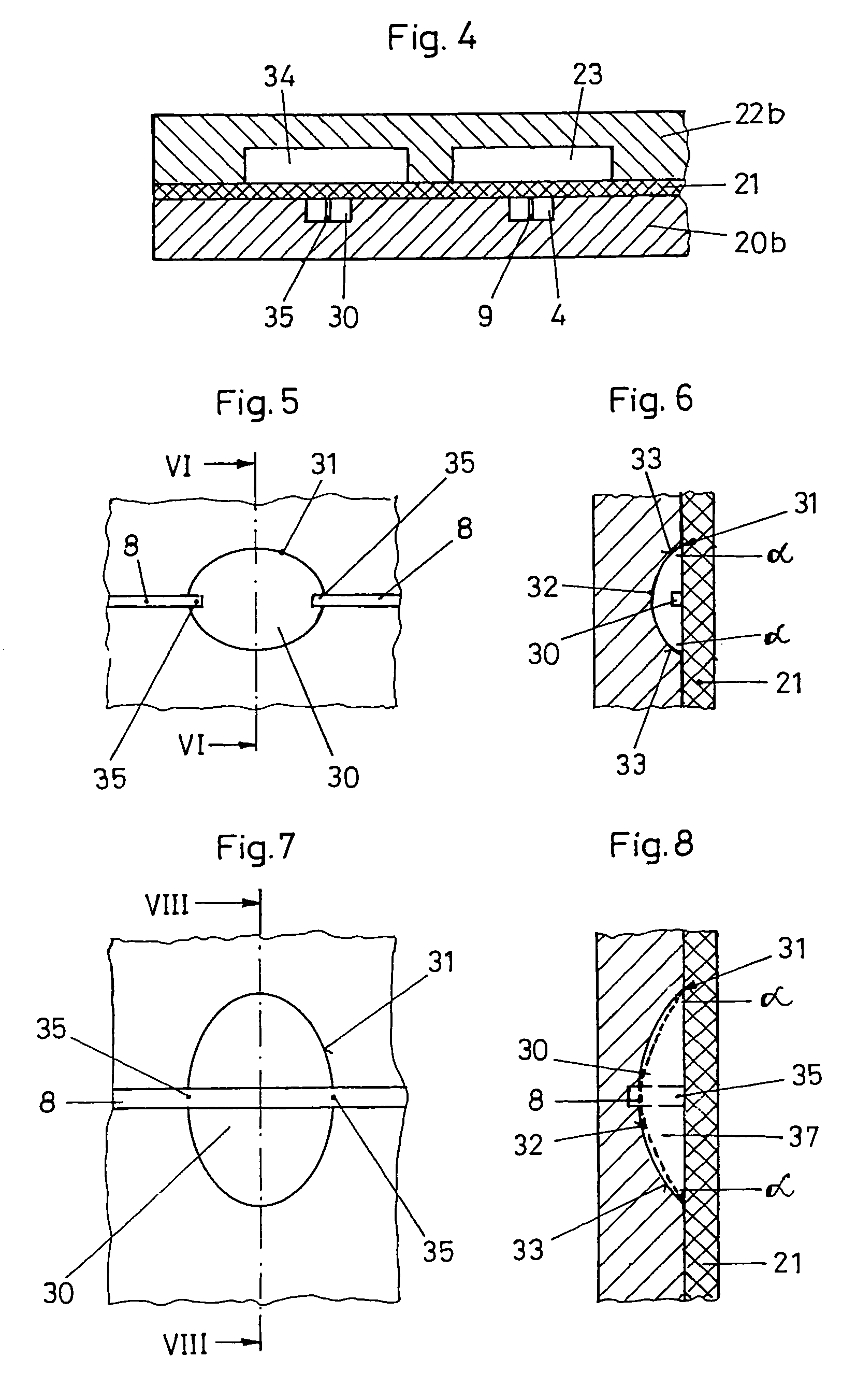

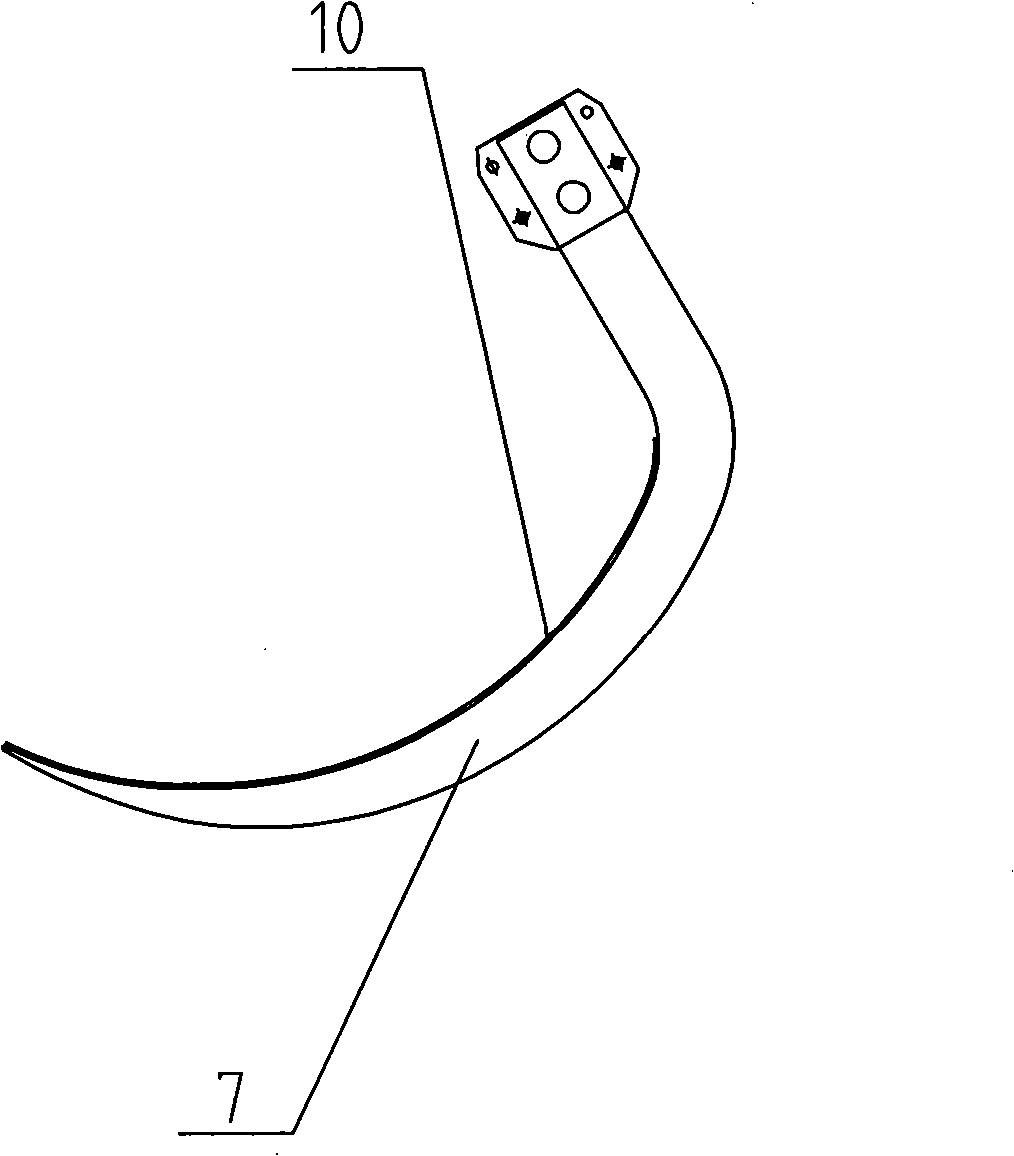

The invention relates to a biomass feed divider with changeable trough obliquity and vibration frequency and amplitude, which realizes continuous, stable and safe feed division by adopting two regulating measures of changing obliquity of a trough and changing vibration frequency and amplitude and by exciting force generated by a vibrating motor (9). The device is formed by arranging one or a plurality of independent distributors in parallel, wherein each distributor mainly comprises a trough body (4), a vibrating motor (9), an elevating (8), a spring supporting mechanism (11) and an auxiliary mechanism; the trough body (4) is supported by the spring supporting mechanism (11) at the front part and the elevating (8) at the rear part, the vibrating motor (9) is arranged in the middle of the bottom of the trough body (4), and the rear part of the trough body (4) is connected with bulkhead by canvas (3). The device integrates material storage and material distribution, is not only suitable for hard biomass but also is suitable for soft biomass, and has lateral expansibility, thereby being convenient to be used together with material equipment of various types.

Owner:SOUTHEAST UNIV

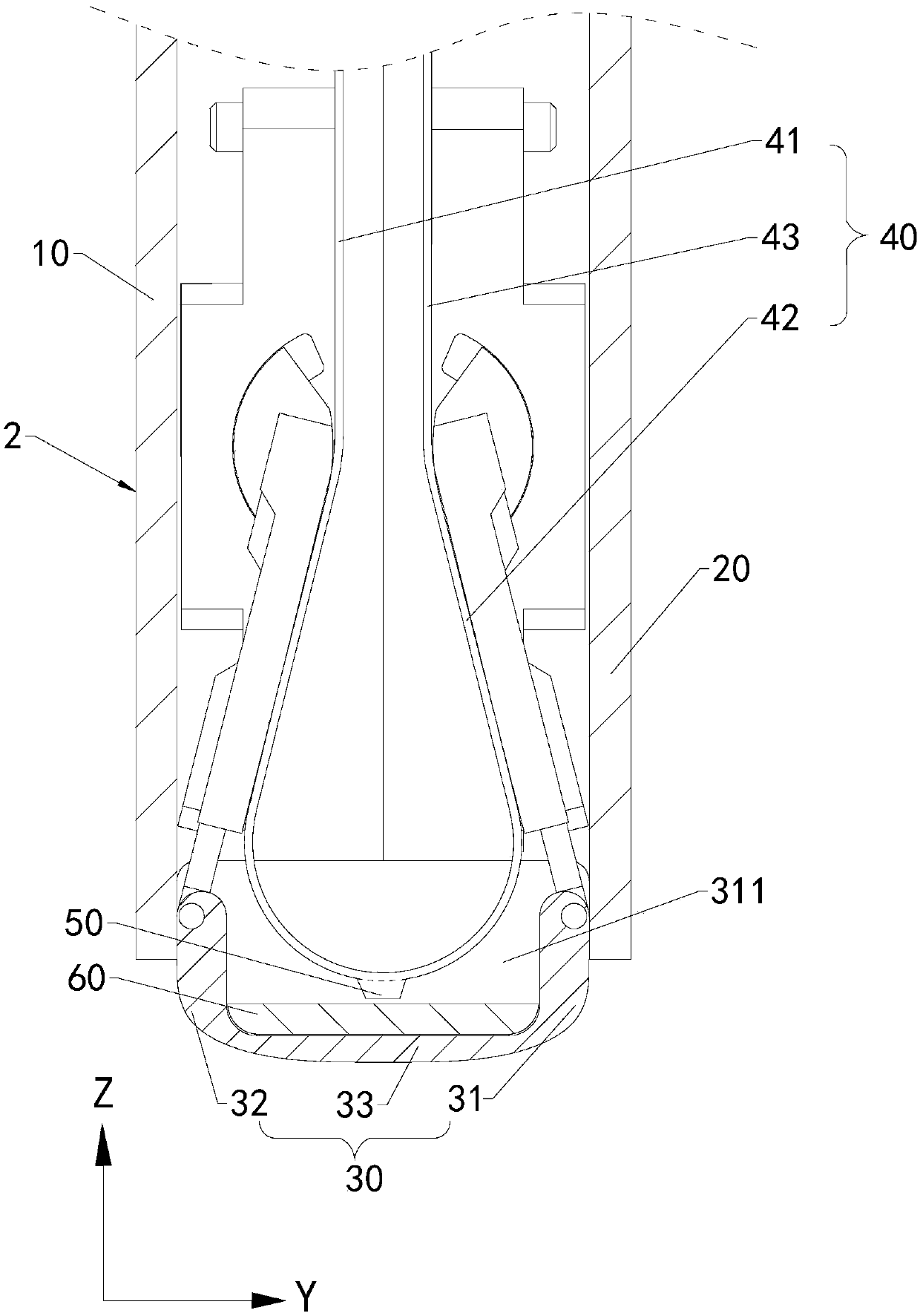

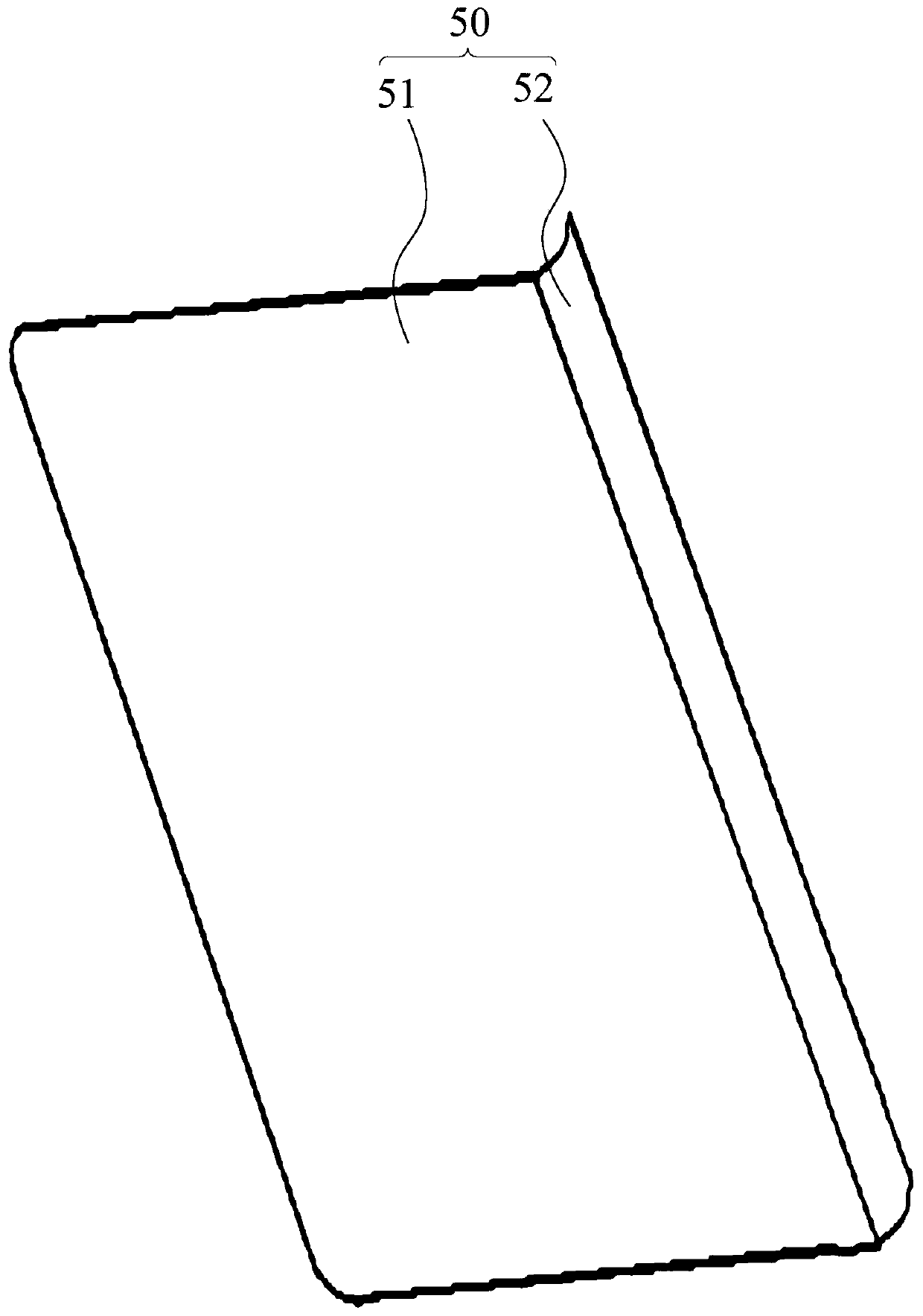

Flexible display screen and terminal comprising same

InactiveCN110277022AStrong rigidityImprove visual experienceTelephone set constructionsIdentification meansEngineeringFlexible display

The invention provides a flexible display screen and a terminal comprising the same. The flexible display screen comprises a display layer and a supporting layer, wherein the supporting layer is located on the back face of the display layer so as to improve the rigidity of the display screen; the supporting layer comprises one or more bent areas and one or more non-bent areas; and the bent areas can be bent or curved relative to the non-bent areas so as to enable the supporting layer to be bent or curved. The flexible display screen has the high rigidity, when the display screen is folded or curled, bending can be conducted at the certain radian, folds or arches or creases caused by folding or curling are avoided, and the visual experience of a user is improved.

Owner:HUAWEI TECH CO LTD

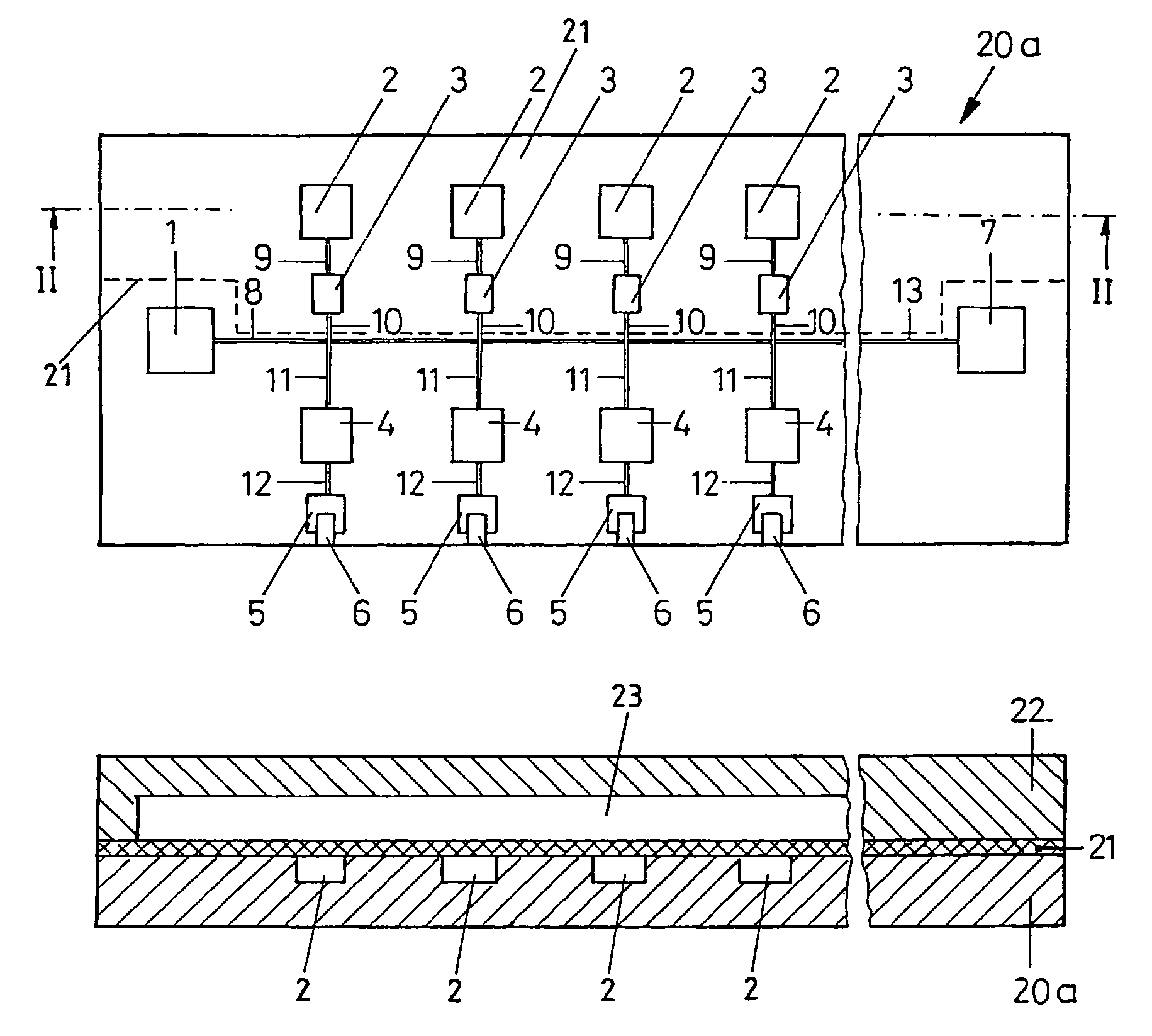

Device for parallel metering of liquids

ActiveUS7036917B2Avoid connectionPrevents venting of the deviceLiquid surface applicatorsBurettes/pipettesMain channelElectrical and Electronics engineering

A device for parallel metering of a liquid with the following features:the device has a first body;the first body has a main channel, secondary channels, one inlet and outlets;the main channel is connected to the inlet;the secondary channels are connected to one outlet at a time;the secondary channels are connected to the main channel;the device has at least one first chamber with a first pressure medium;the first body has means for transferring transfer means pressure surges of the pressure medium from a first chamber to the secondary channels;each transfer means is connected to a secondary channel; andat least one means for preventing a fluidic connection between the secondary channels and the chamber is assigned to the transfer means.

Owner:BOEHRINGER INGELHEIM MICROPARTS

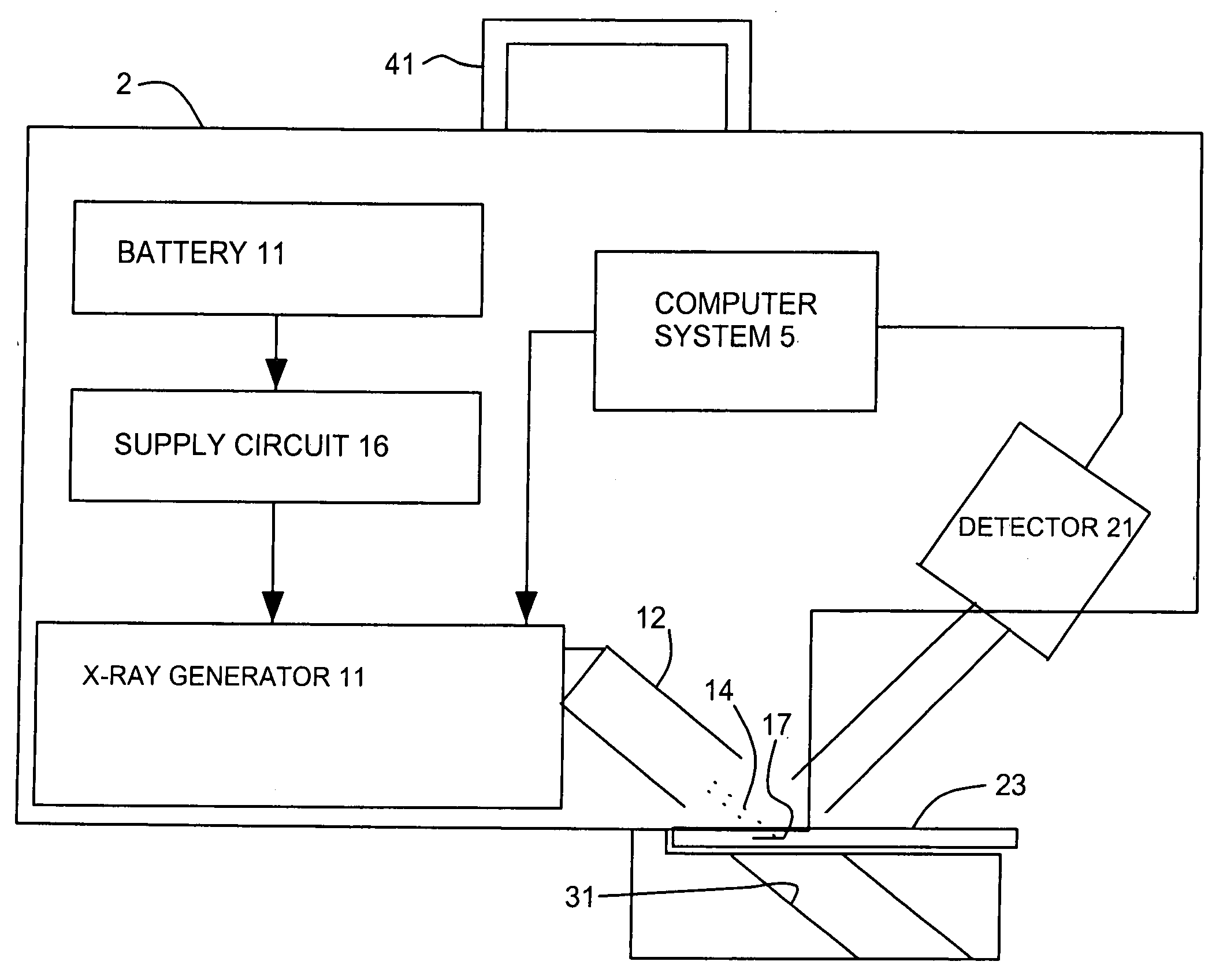

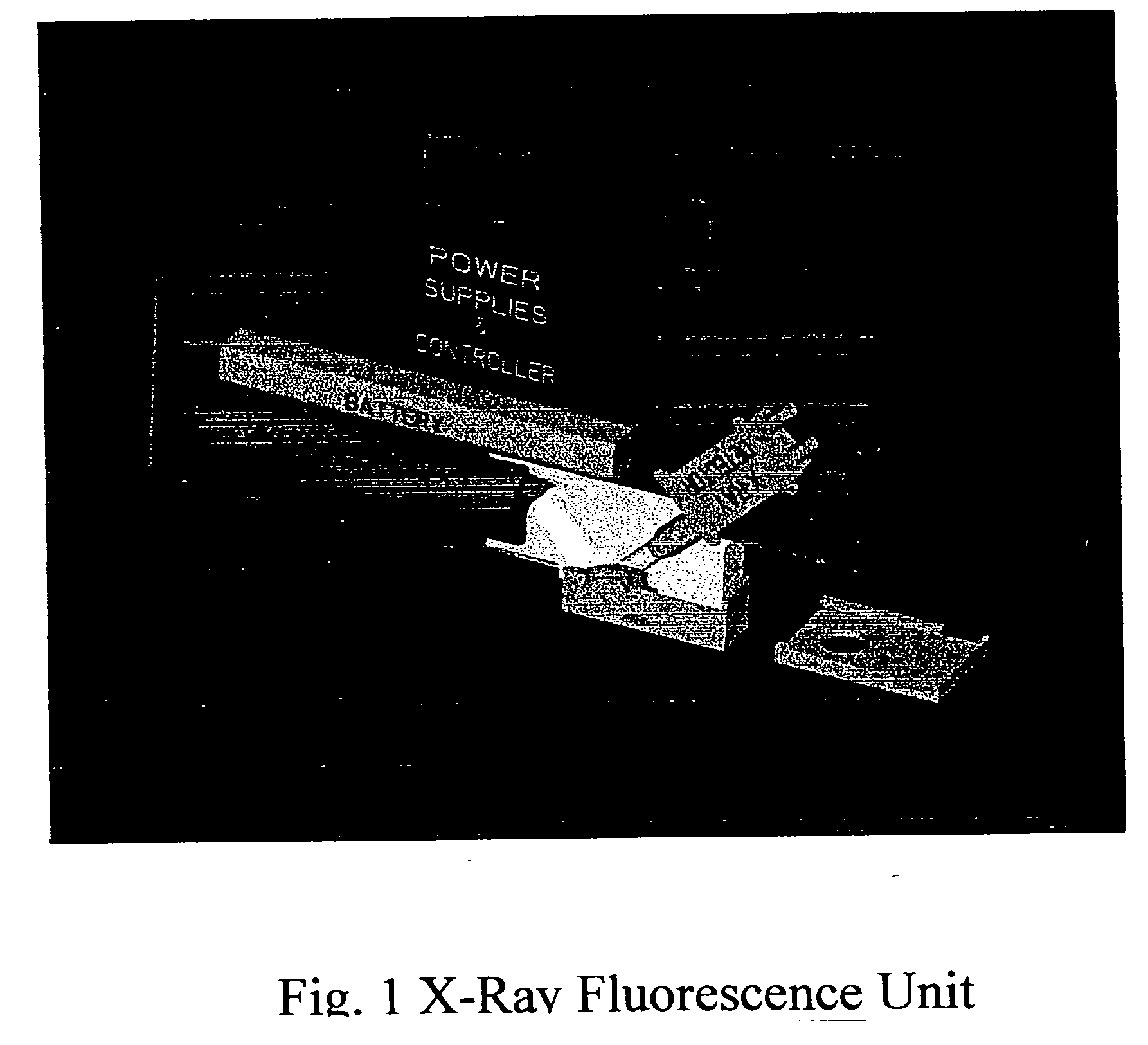

Portable x-ray fluorescence using machine source

InactiveUS20050226373A1Prevent archingX-ray spectral distribution measurementMaterial analysis using radiation diffractionFluorescencePhysics

Owner:TROMBKA JACOB I +5

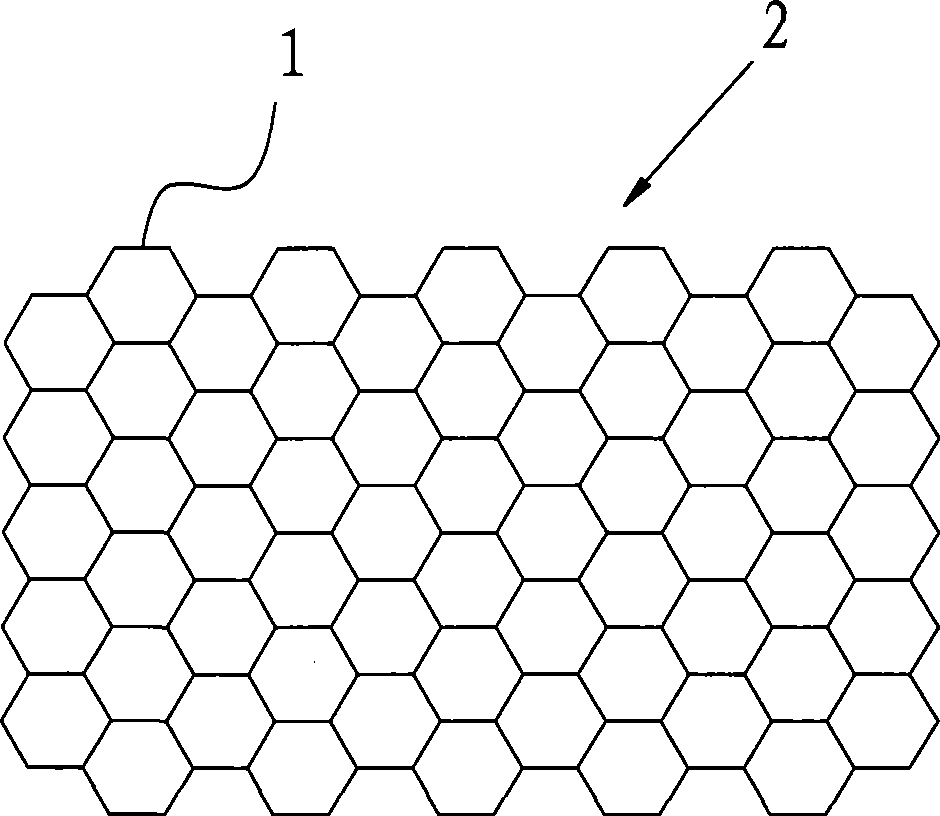

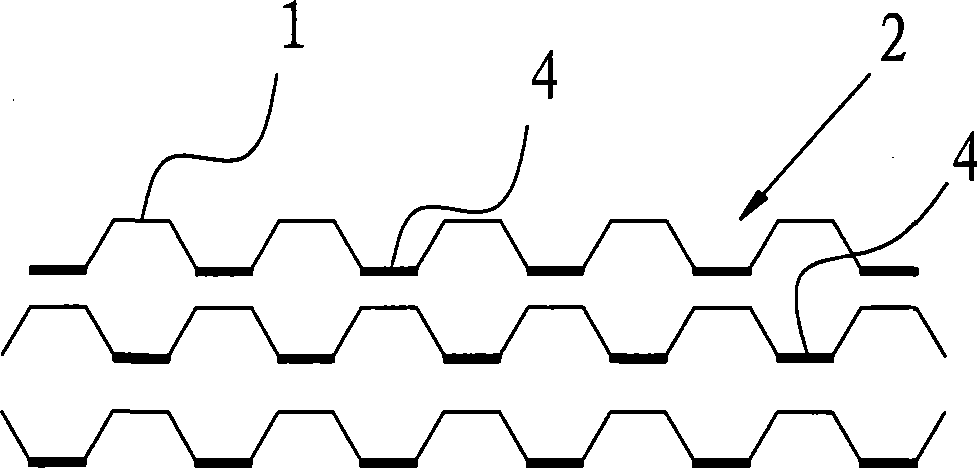

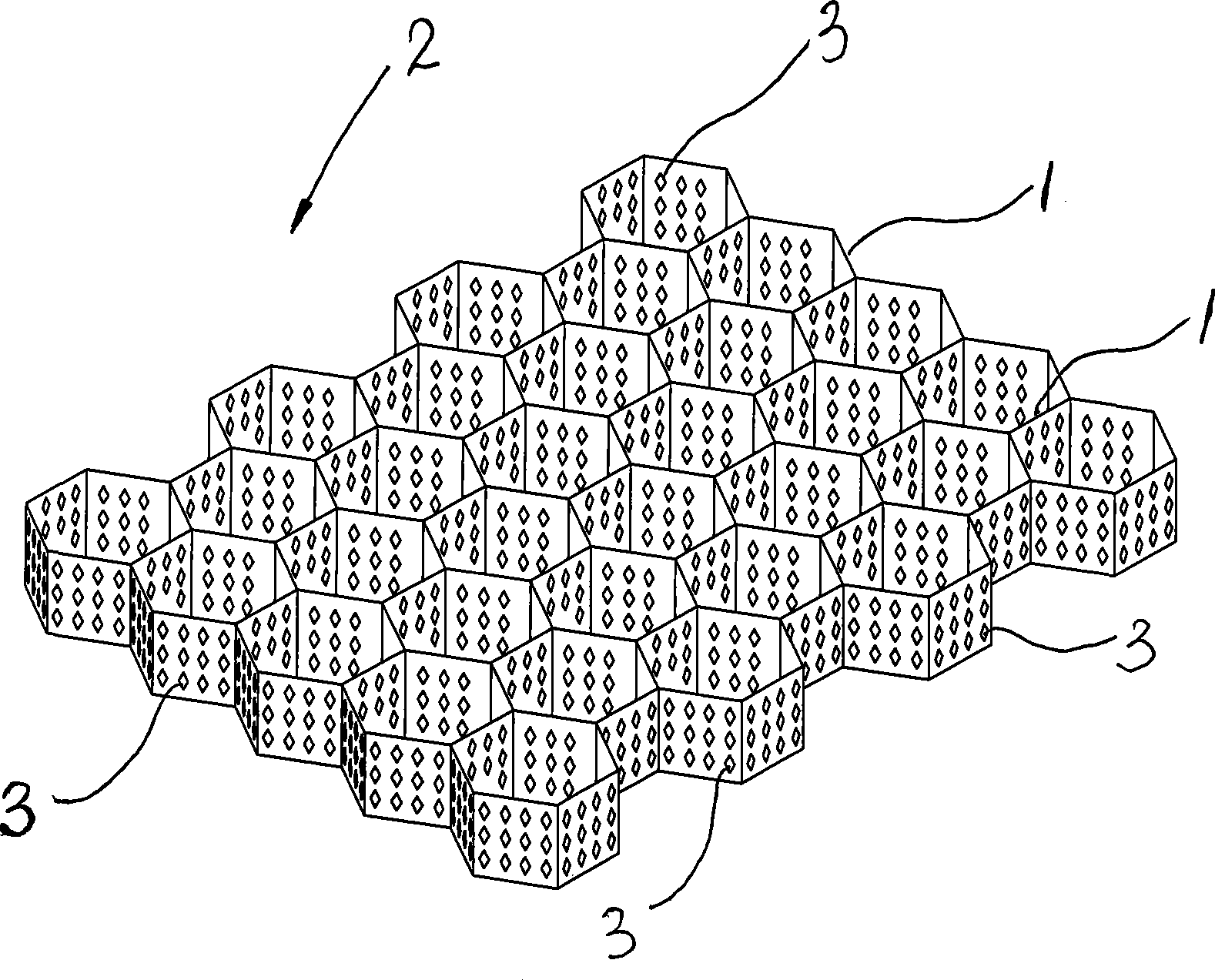

High intensity lightweight honeycomb core and production method thereof

InactiveCN101380832AReduce pressurePrevent archingLamination ancillary operationsLaminationHoneycombAluminium

The invention relates to a honeycomb core with high strength and light weight, which comprises a honeycomb core body which is formed by assembling a plurality of boards. The boards are provided with a plurality of eyelets to ensure that the whole honeycomb core is in a single-track ventilation passage with the outside world and the high-temperature gas in the honeycomb core can be discharged from the eyelets, thus reducing the pressure bored by the honeycomb core and preventing the appearing of arch bar and being not easily affected with damp. Different from the existing technology in the manufacturing method of the honeycomb core with high strength and light weight, after gluing, the steps of drying and pricking are added, and alloy aluminium plate is pressed for 2 hours under the temperature of 183 DEG C to 187 DEG C; the strength of the alloy aluminium tape is 31.8 N / cm, which meets the tensile strength when using in aviation, high-speed trains and wind-power blades and has major surplus.

Owner:苏州航通蜂窝科技有限公司

Clay vibrating bunker

InactiveCN101148215AGuarantee unimpededPrevent bridgingLarge containersLoading/unloadingBunkerEngineering

The clay vibrating bin includes one upper cone, one lower cone, one vibrating unit set in between the upper cone and the lower cone. The upper cone has one air gun with nozzle in the inner wall, and the lower cone has one hand valve and one electric valve in the lower part. The clay vibrating bin has fluent and homogeneous material feeding and easy cleaning.

Owner:JIANGSU WANLI MACHINERY

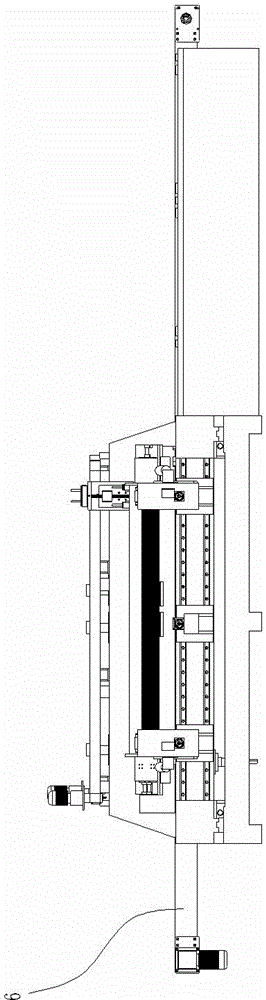

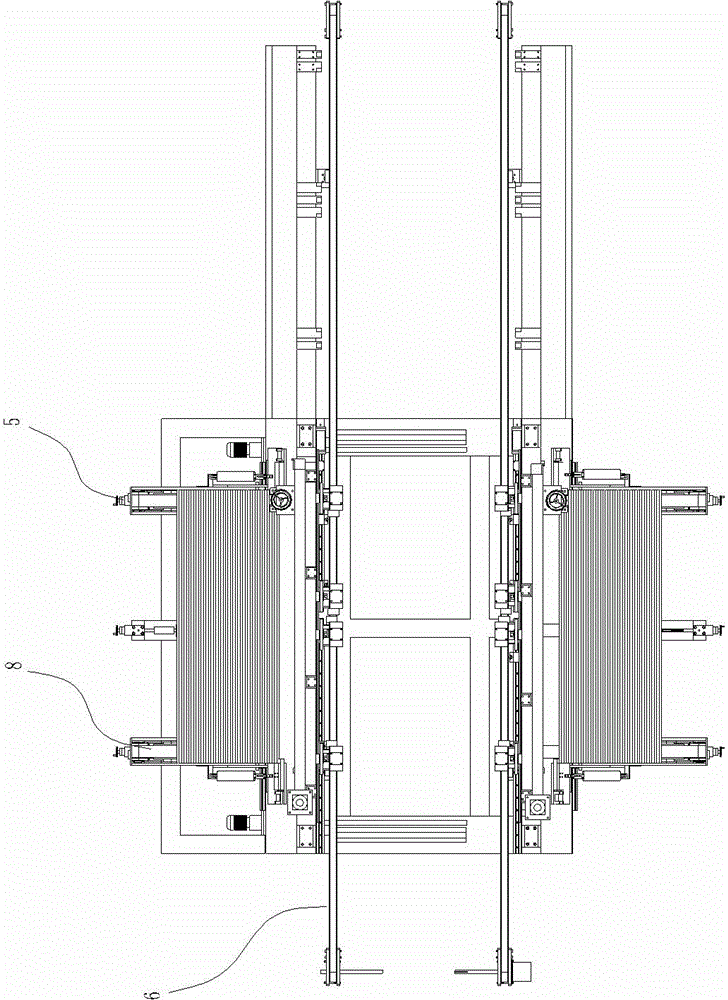

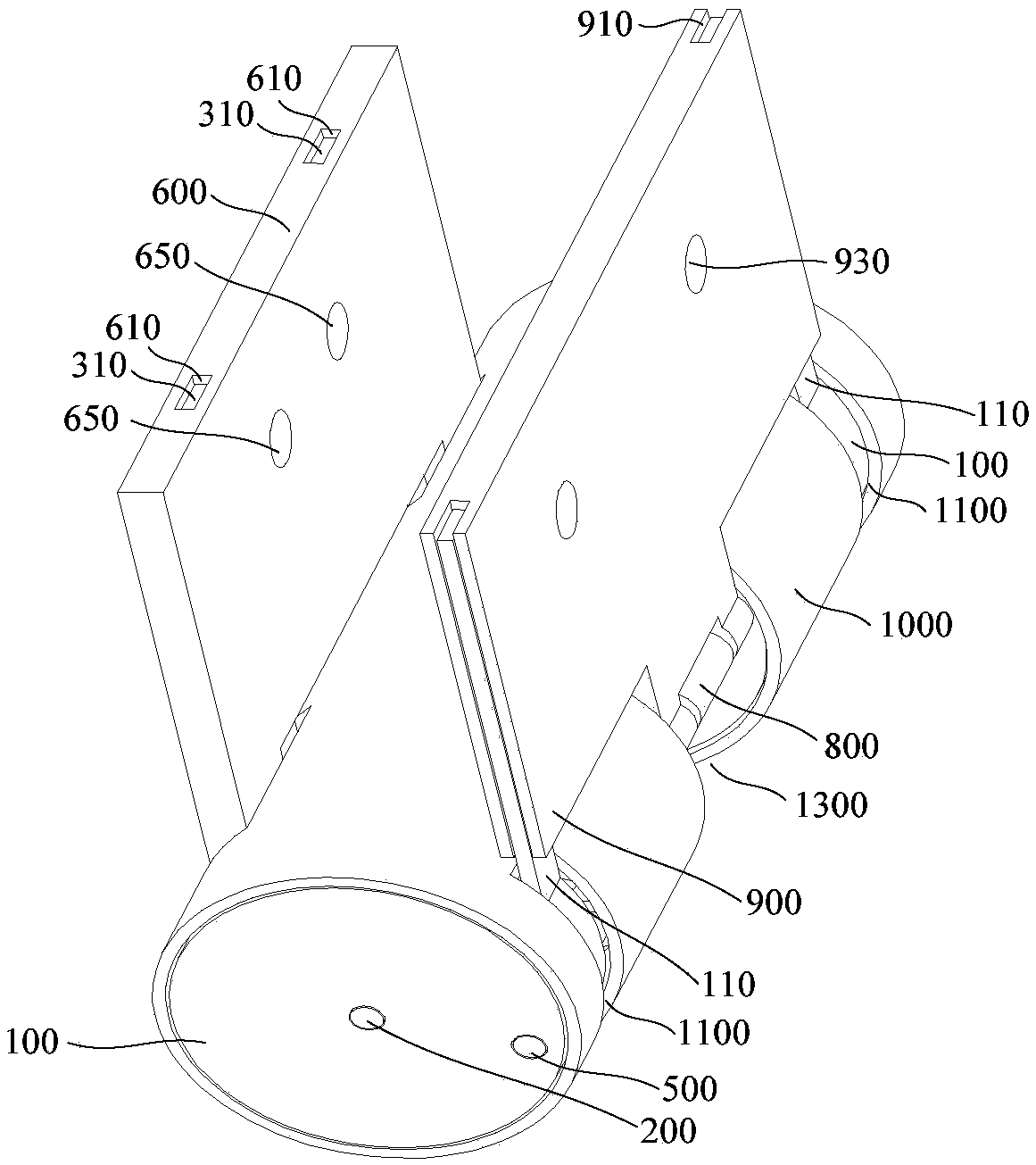

Automatic wooden door assembly machine

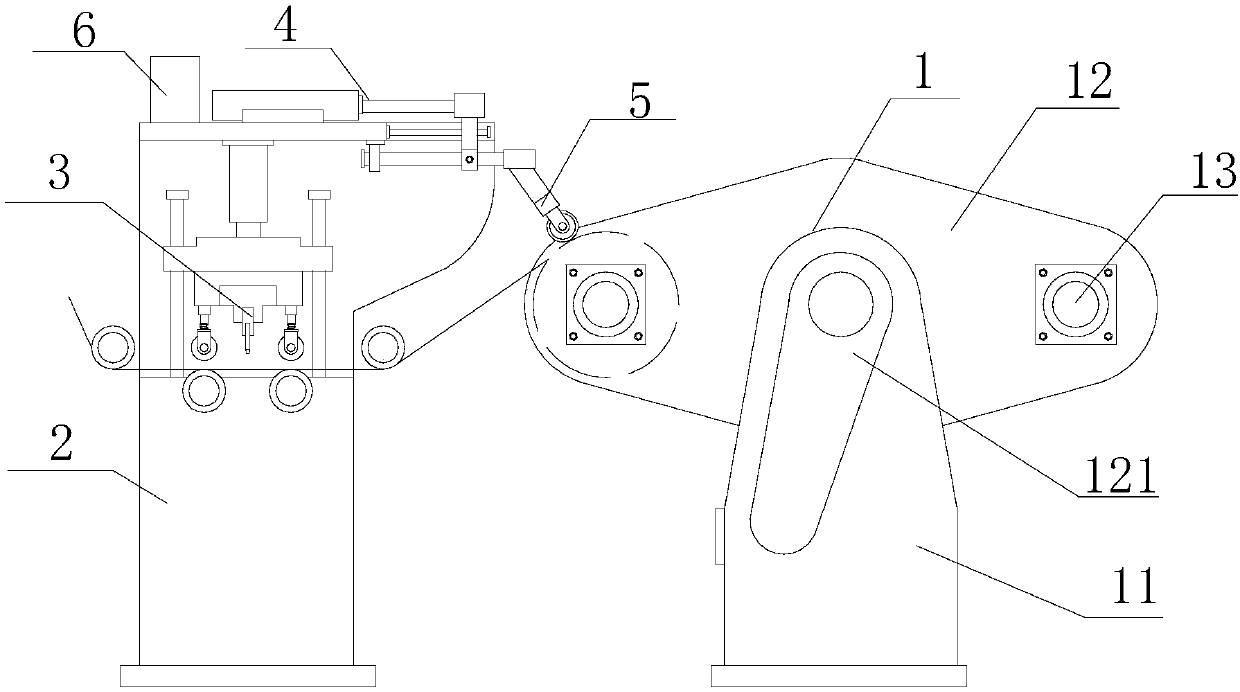

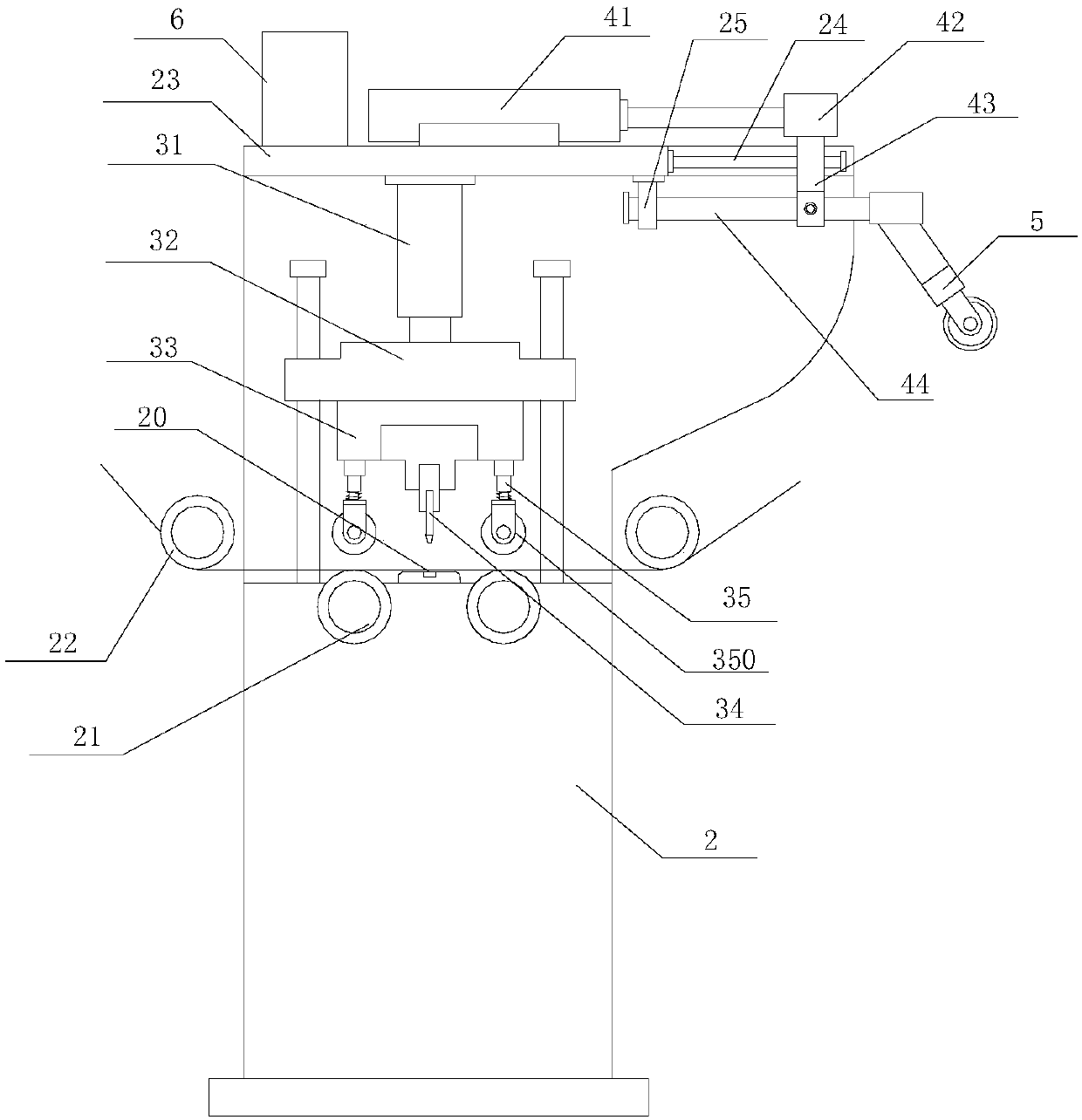

InactiveCN105690502AReduce labor intensityImprove work efficiencyWood veneer joiningArticle feedersPistonEngineering

The invention provides an automatic wooden door assembly machine. The automatic wooden door assembly machine can realize automatic feeding, assembly, glue applying and the like, thereby reducing the labor intensity of workers, increasing the working efficiency and reducing the labor cost. The automatic wooden door assembly machine comprises a base, wherein the base comprises a rack as well as a first bracket and a second bracket which are parallel and arearranged on the rack; detachable door sheet clamps and cross beam clamps are symmetrically arranged in the front of the upper sides of the first bracket and the second bracket; longitudinal beam conveying devices are arranged on the outer sides of the first bracket and the second bracket; overturningdevices are arranged on support frames of the longitudinal beam conveying devices; upper ends of the first bracket and the second bracket are fixedly connected with support seats respectively; a glue dispensing device and a horizontal pressing device are arranged on a support beam at the upper part of each support seat; inner side surfaces of the first bracket and the second bracket are connected with horizontal conveying mechanisms through piston rods of lifting cylinders.

Owner:WUXI FORMEN TECHN

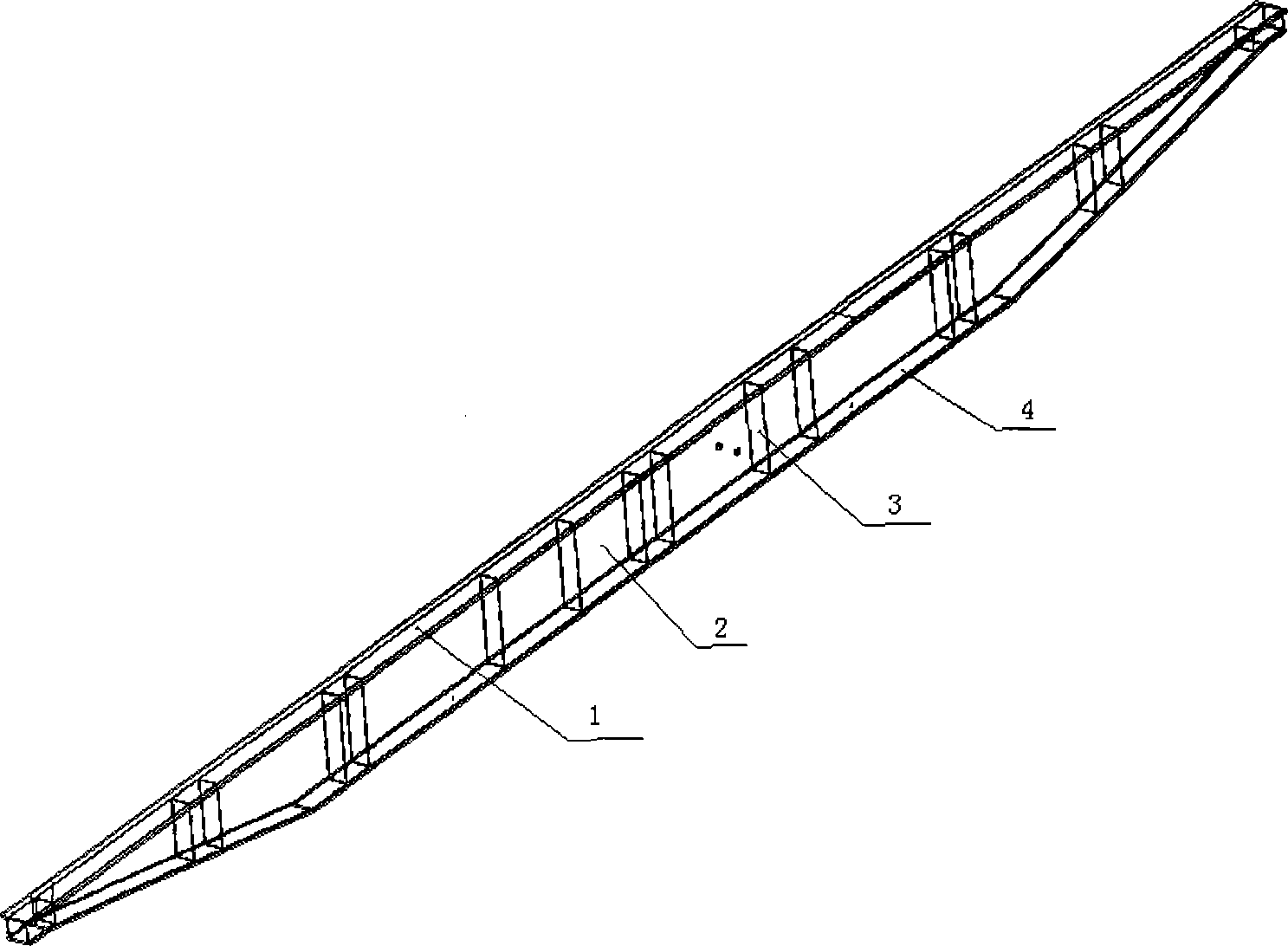

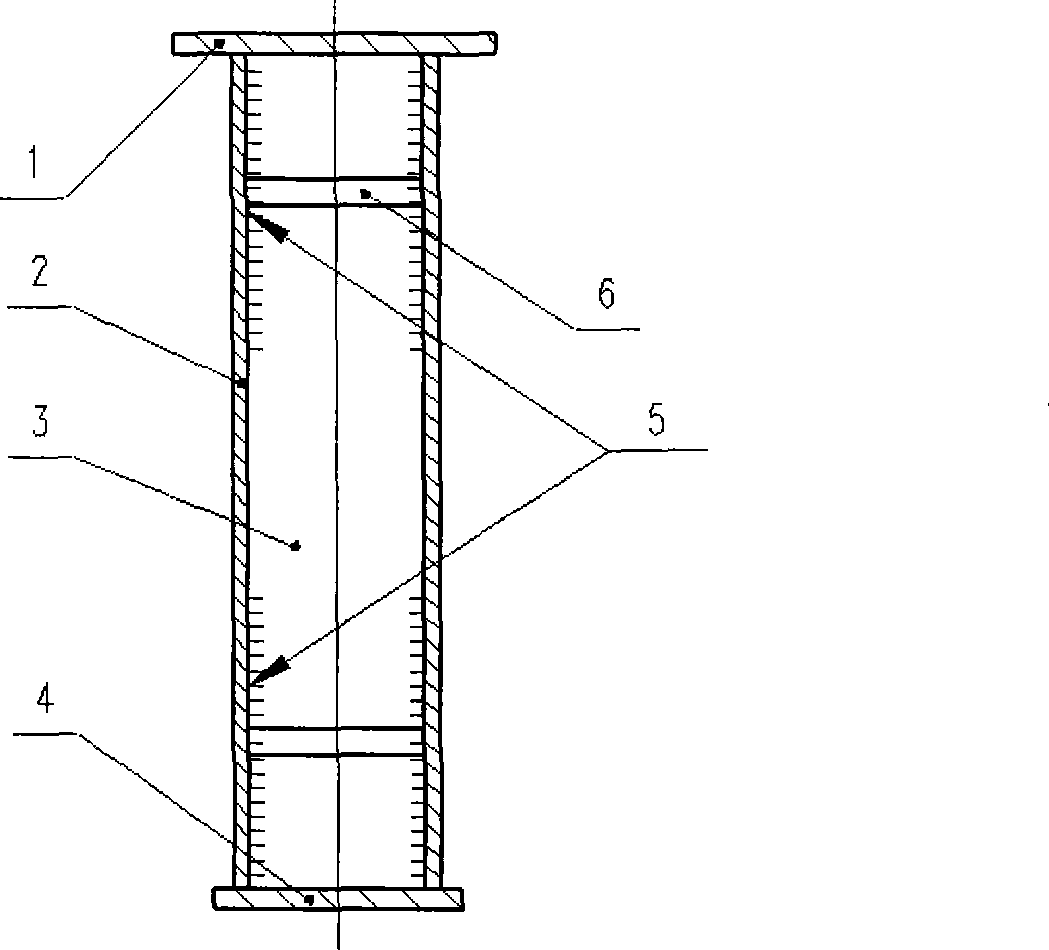

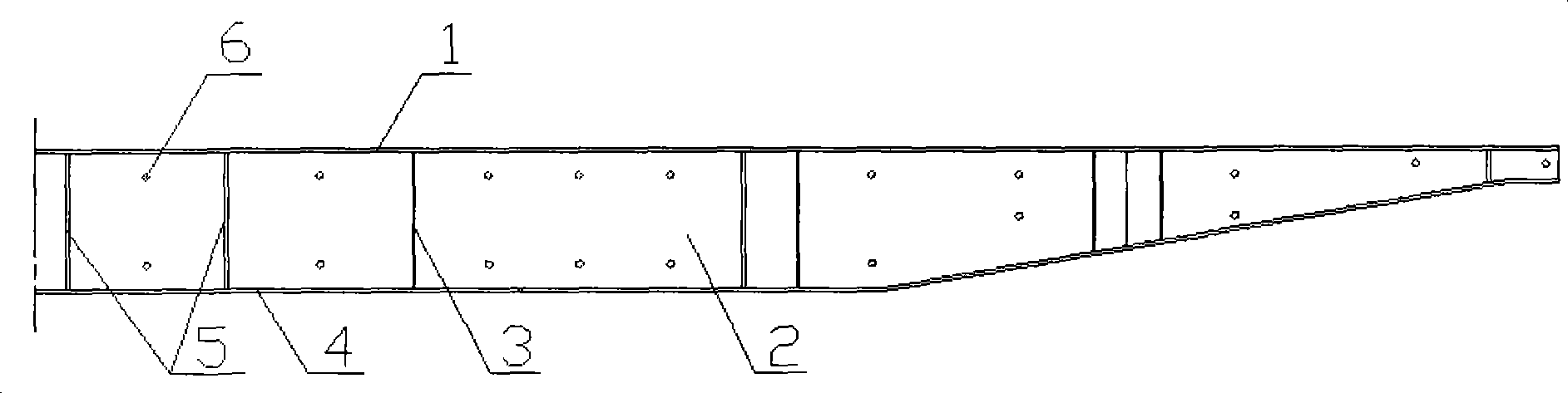

Method for assembling vertical rectangle box type structure girder

ActiveCN101434243AGuaranteed lumen sizeIncreased stiffness in all directionsWagons/vansWelding/soldering/cutting articlesProcess supportWeld seam

The invention provides a narrow-high long-big box style structural beam, comprising upper cover plates (1), web plates (2), inner-cavity clapboards of the structural beam (3) and lower cover plates (4). A plurality of process support rods (6) are arranged inside the inner cavity of the structural beam and connected with the web plates through spot welding. The assembling method of the structural beam is as follows: the clapboards and the web plates are fixed by spot welding as well as the web plates and the process support rods; the gaps caused by the spot welding between the clapboards and web plates are filled through welding; the symmetric welding is carried out from the middle part to two ends of the structural beam on the vertical direction and the multi-layer and multi-strip welding is adopted according to the size of welding angles; then the upper cover plates and lower cover plates are respectively fixed on the upper and lower ends of the web plates and clapboards through spot welding; and then welding seams are filled and the multi-layer and multi-strip welding is adopted according to the size of welding angles. The structural beam can avoid the falling or rising of the web plates so as to guarantee the inner cavity size of the structural beam, the parallelism of the web plates and the rigid on each direction and the assembling method is simple.

Owner:CRRC YANGTZE CO LTD

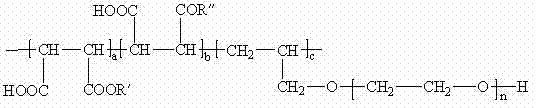

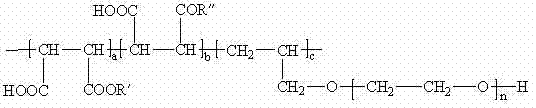

Polycarboxylate cement grinding aid and preparation method thereof

The invention provides polycarboxylate cement grinding aid and a preparation method thereof. The preparation method comprises the following steps of: carrying out an acylation reaction on maleic anhydride and alkylol amine to synthesize a small monomer; and then copolymerizing the small monomer with allyl polyethylene glycol as a large monomer and maleic anhydride as a small monomer under an aqueous solution condition. The polycarboxylate cement grinding aid can increase the flowability of cement, so that the cement with the polycarboxylate cement grinding aid is beneficial to being transported, can be avoided from being arched and has good adaptability, strong stability, small effective dosage and wide adaptability. After the polycarboxylate cement grinding aid is added, 3 to 8 kilowatt-hours can be averagely reduced while producing per ton of cement. The preparation method disclosed by the invention has the advantages of simple formula design, convenience for production operation and no exhaust of three wastes and can realize the clean production of the cement grinding aid.

Owner:SHANXI UNIV +1

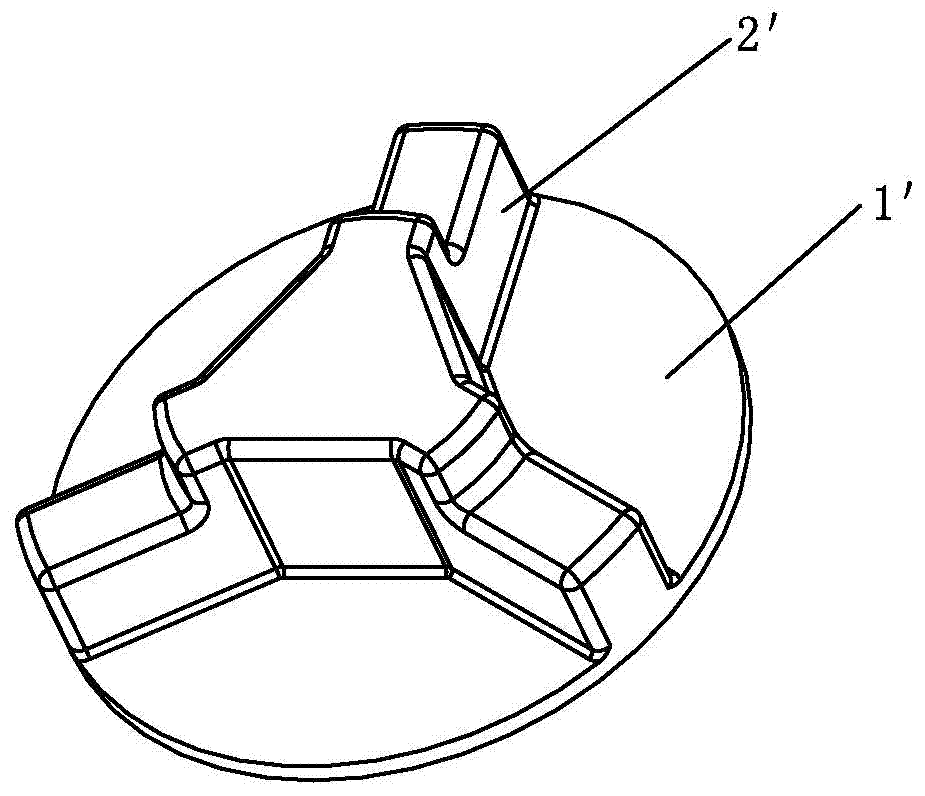

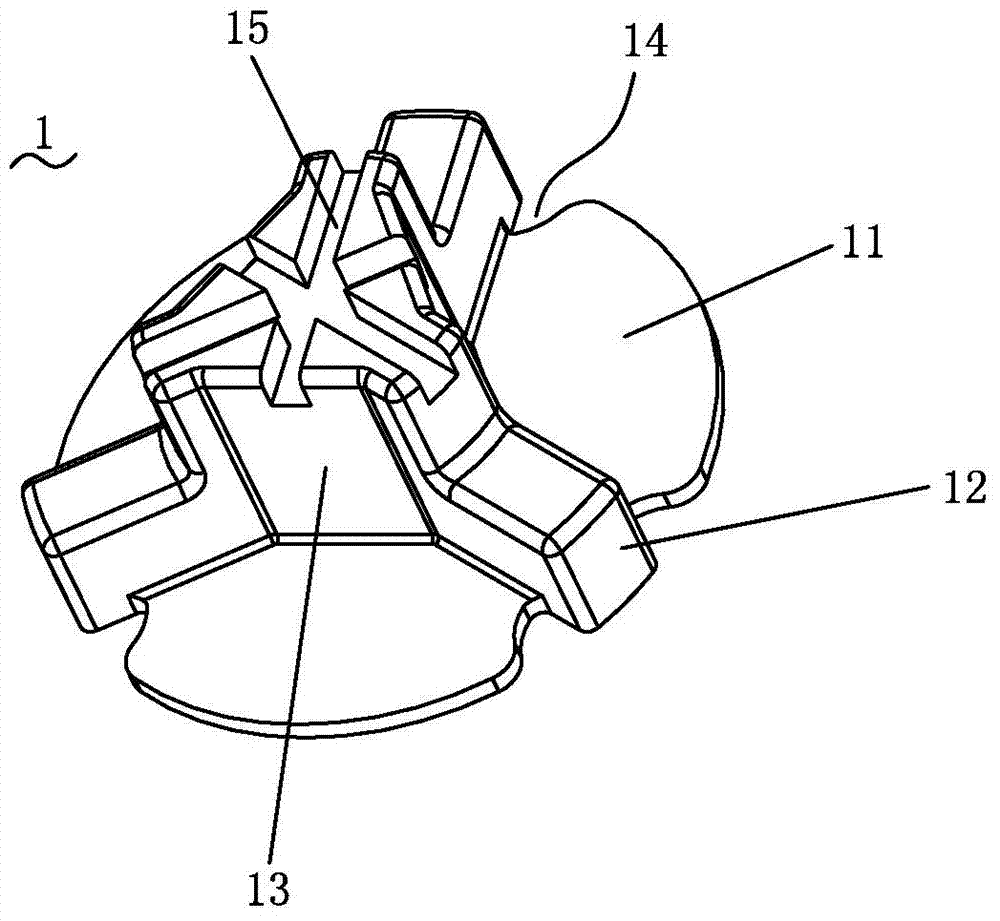

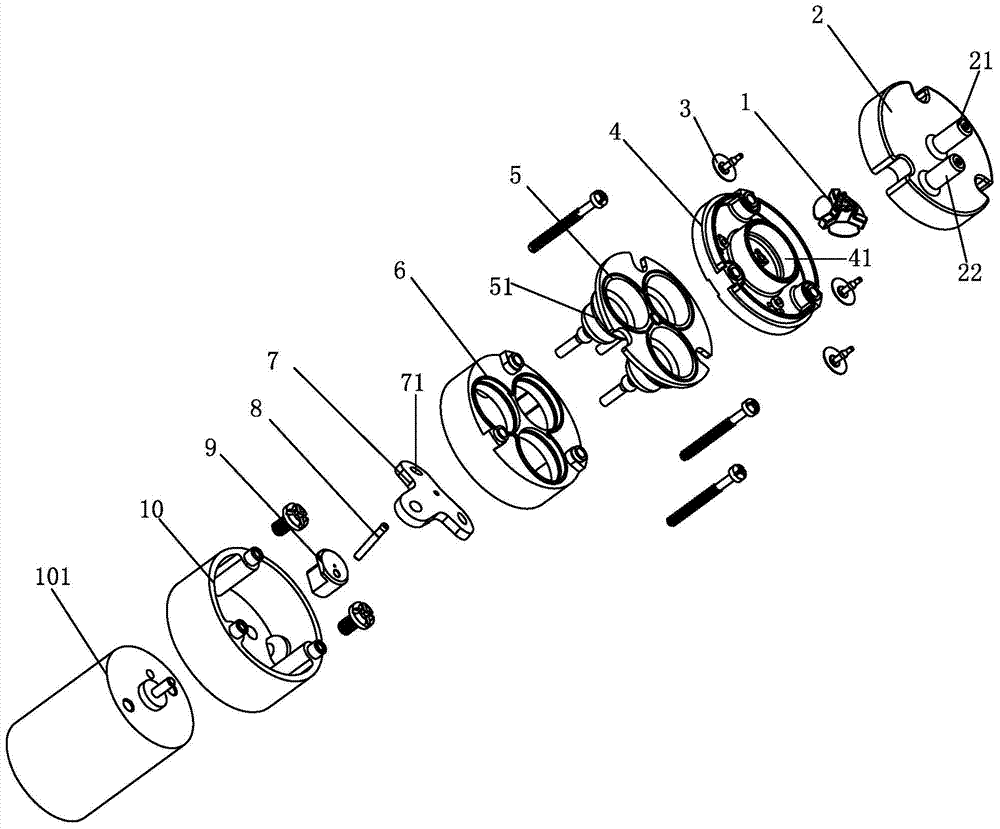

Valve block with improved air tightness and air pump

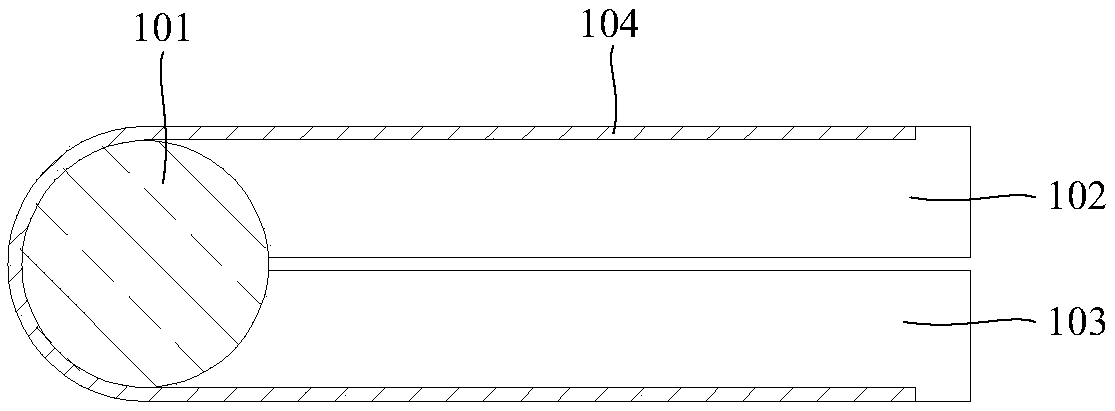

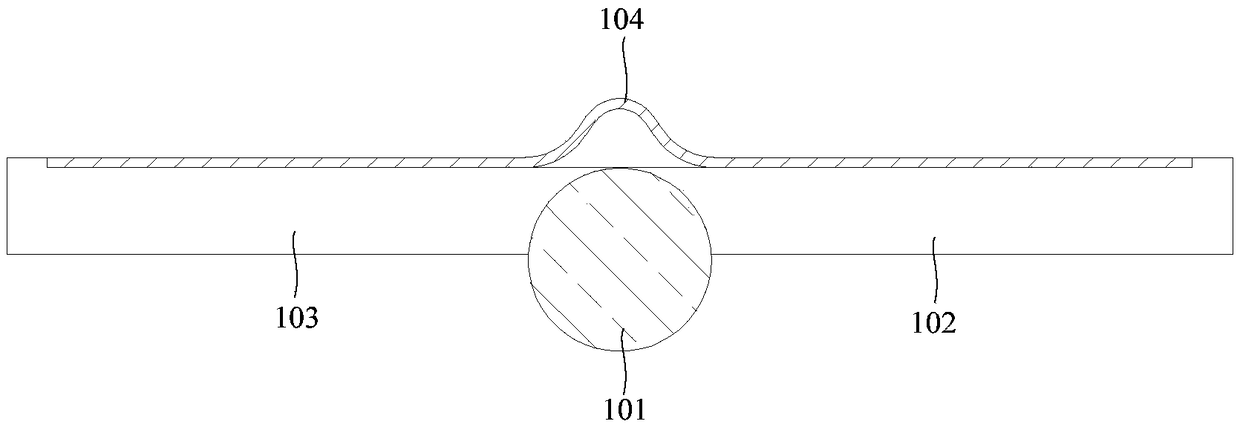

ActiveCN103573613APrevent archingGuaranteed air tightnessPositive displacement pump componentsLiquid fuel engine componentsAir pumpEngineering

The invention discloses a valve block with improved air tightness and an air pump, wherein the valve block is provided with at least two elastically swinging blades, the blades are separated by radially arranged ribs, and a buffering structure is arranged at the end part, used for connecting the rib, of each blade to provide a deformation buffering space for the assembly and extrusion of each blade. The air pump is provided with the valve block with improved air tightness, and each blade of the valve block, as a one-way air outlet valve block of the air pump, is matched in the air pump. The structure of the valve block is improved to effectively prevent each blade in the valve block from deforming or bulging during the assembly, so that the air tightness of the air pump is greatly improved.

Owner:XIAMEN KOGE MICRO TECH

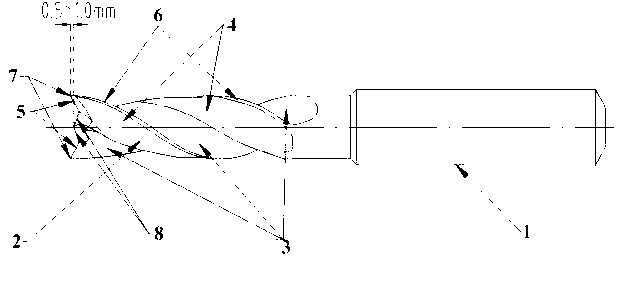

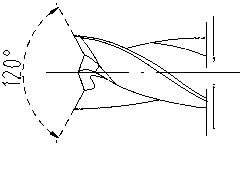

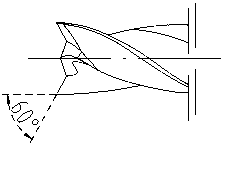

Drill bit with low chisel edge

The invention relates to a drill bit with a low chisel edge. The drill bit comprises a handle portion and a head portion, wherein the handle portion is a cylinder, the head portion is a coaxial cylinder which shares the same axis with the handle portion, two chip discharge grooves are formed in the head portion, a solid portion forming the chip discharge grooves is a knife back, intersecting lines of the two chip discharge grooves and the knife back in the axis direction respectively form two main cutting edges, intersecting lines of the two chip discharge grooves and the knife back in the radial direction form seamed edges, the seamed edges and the main cutting edges intersect to form a knife point, the chisel edge with 140-degree convexity is arranged between the two main cutting edges, and a sharp point of the chisel edge is 0.5-1mm lower than the knife point in the axis direction. Due to the chisel edge with the 140-degree convexity, knife strength is guaranteed, and meanwhile prominent centring capacity is guaranteed; the powerful centring capacity can inhibit bouncing and thereby guarantees long service life of a knife; and the drill bit is suitable for drilling machining for carbon fiber composite materials used for aviation.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

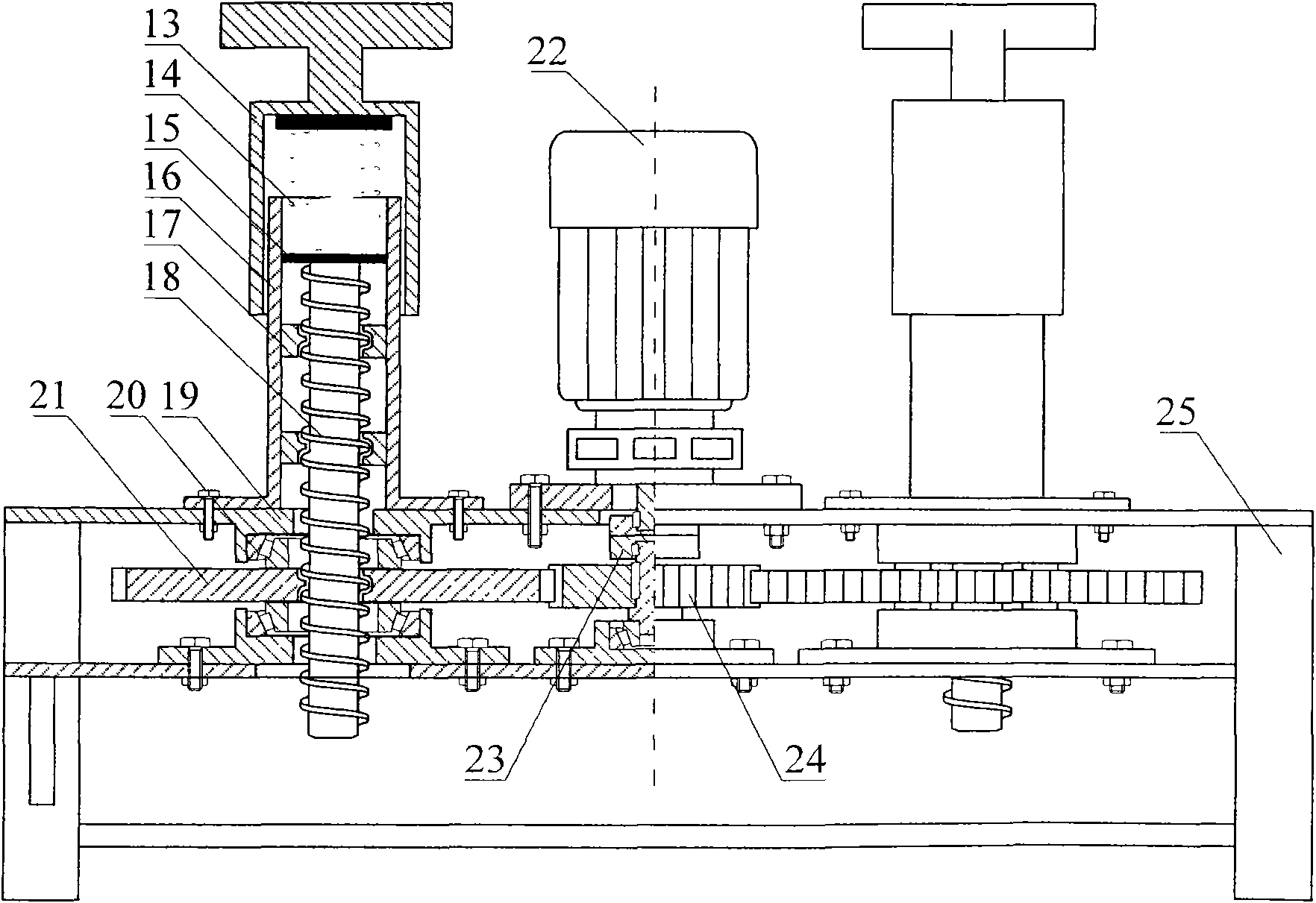

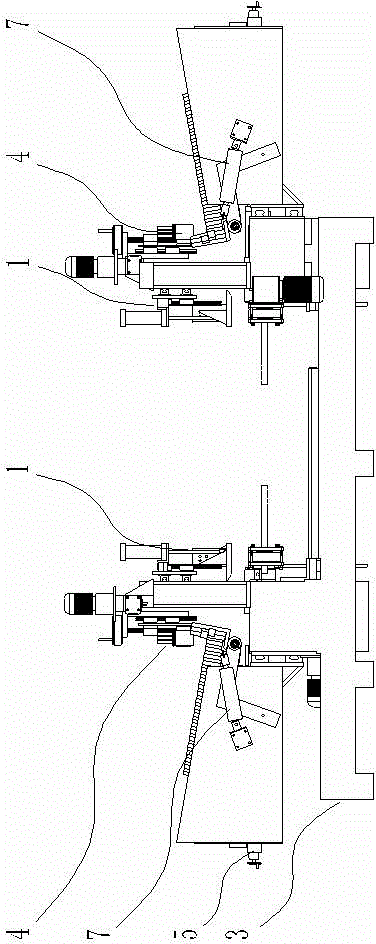

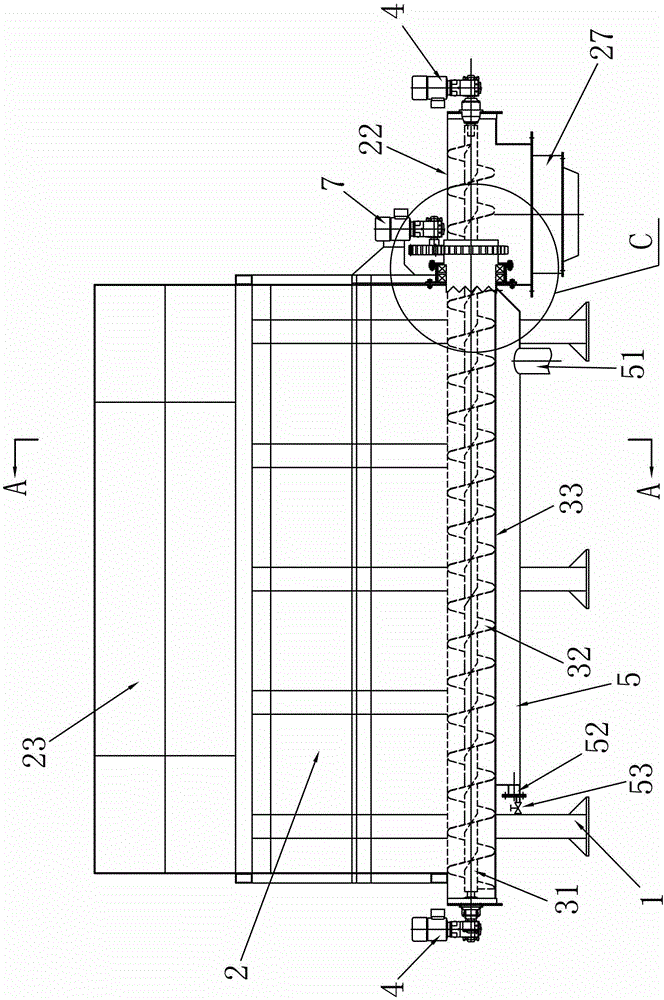

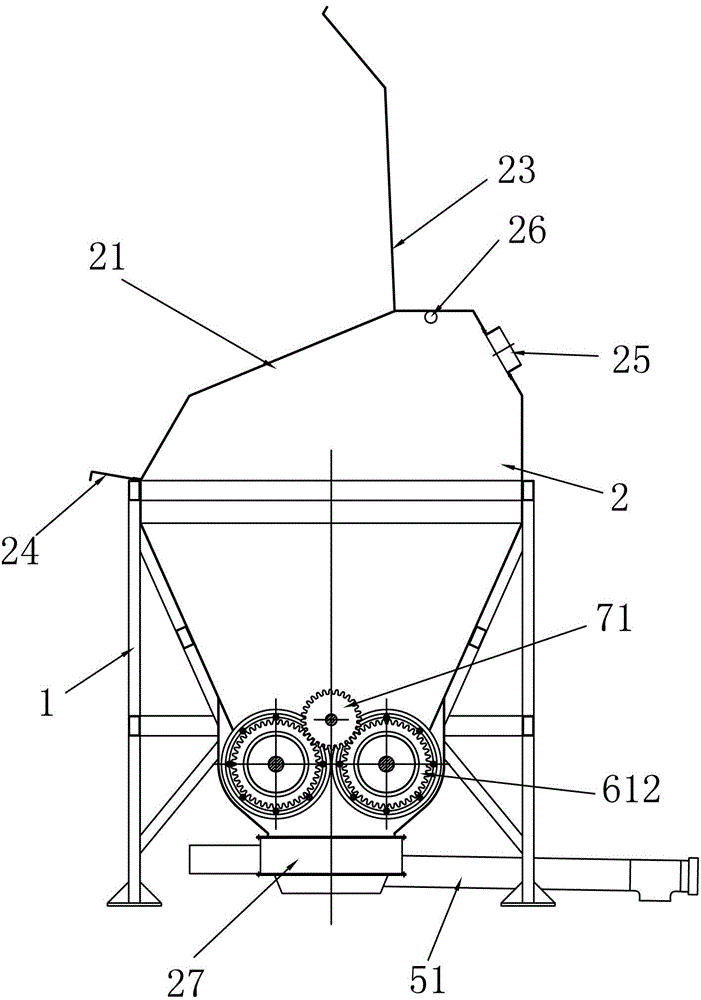

Food waste raw material receiving comprehensive treatment apparatus

InactiveCN102941208ASmooth dischargeReduce the numberSolid waste disposalPackagingFailure rateHelical blade

The present invention provides a food waste raw material receiving comprehensive treatment apparatus, and relates to a solid waste treatment apparatus, particularly to a waste treatment apparatus for food waste solid-liquid separation. A purpose of the present invention is to provide a food waste raw material receiving comprehensive treatment apparatus having functions of bag breaking, clogging resistance and failure rate reduction. The apparatus mainly comprises a rack 1, a receiving bin body 2 and at least a screw conveying separation mechanism, wherein the apparatus is characterized in that an arc pocket groove 33 in the screw conveying separation mechanism is provided with a plurality of liquid draining holes 331, a liquid draining guide sleeve 5 is arranged below the liquid draining holes, and is communicated with a liquid guide pipeline 51, at least an anti-winding steel belt 34 is fixed on the inner wall of the arc pocket groove and between a gap of the inner wall of the arc pocket groove and a helical blades 32, a bearing 6 is fixed on the receiving bin body, a bearing 6 is fixed on the receiving bin body, a bag breaking bush 61 is inserted and arranged inside the bearing, the bag breaking bush is sleeved outside the helical blades, one end of the bag breaking bush extends into the receiving bin body 2, the extending end is provided with saw-shaped cutter teeth, and the bag breaking bush is driven by a bag breaking driving motor 7.

Owner:北京弗瑞格林环境科技有限公司

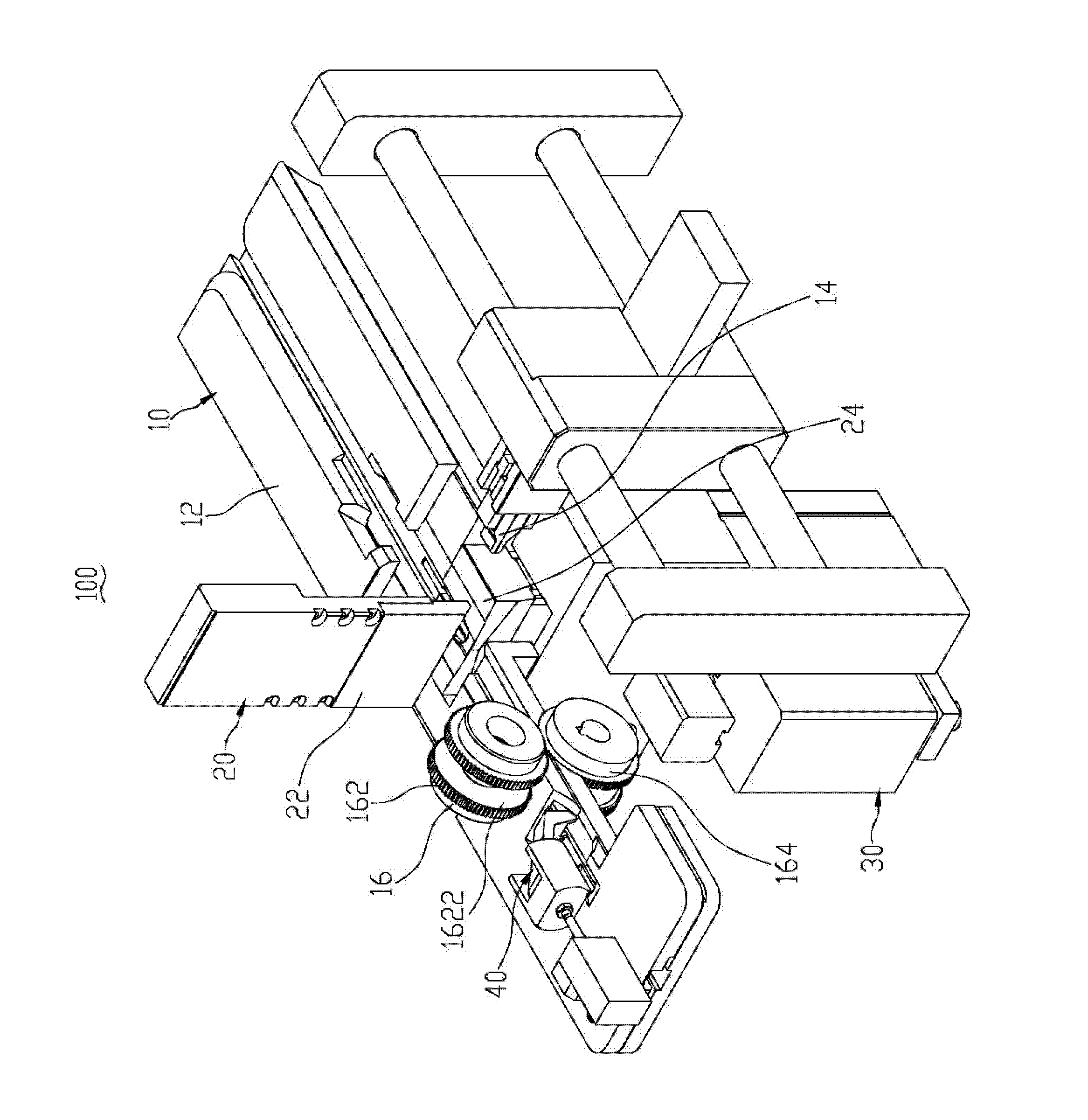

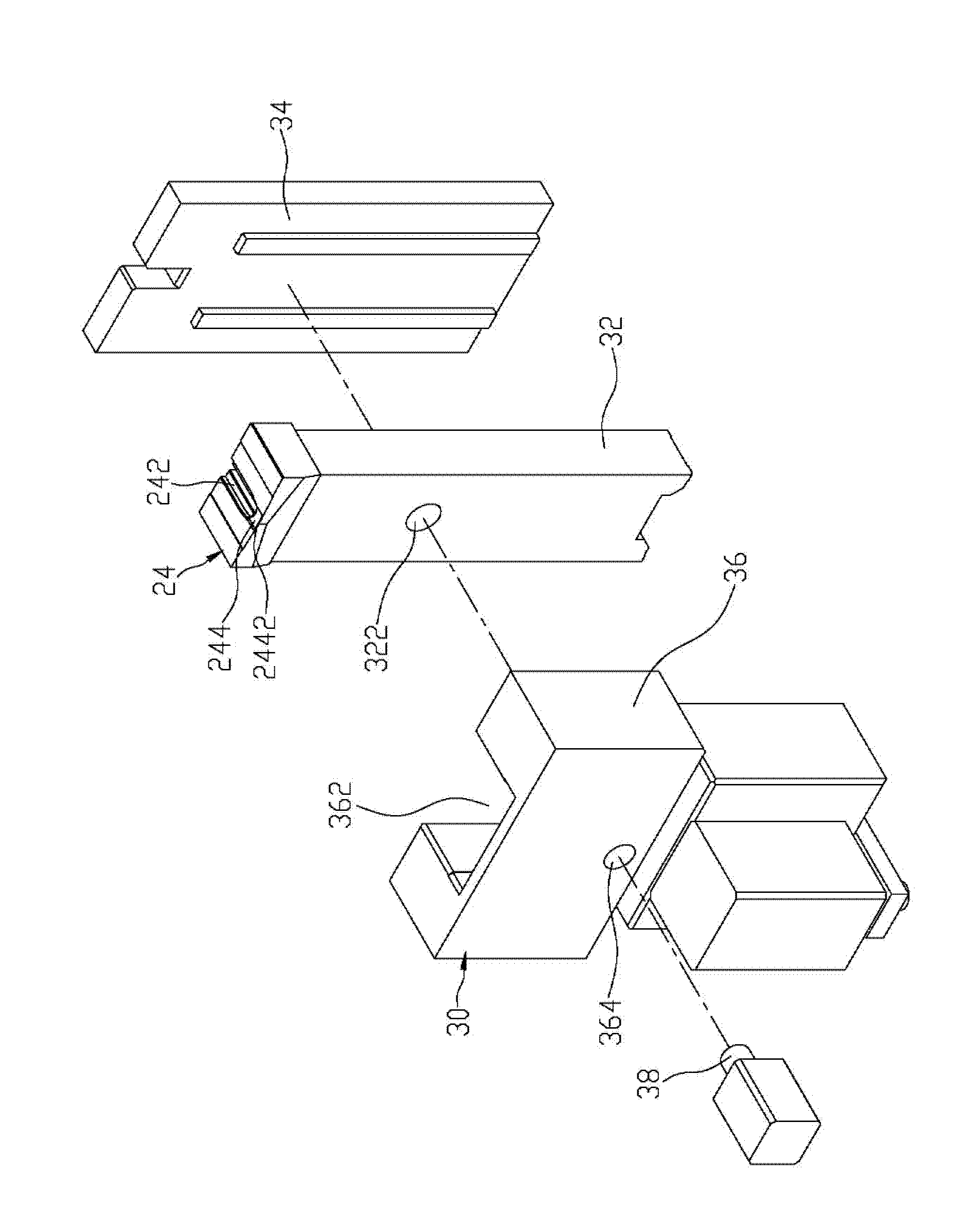

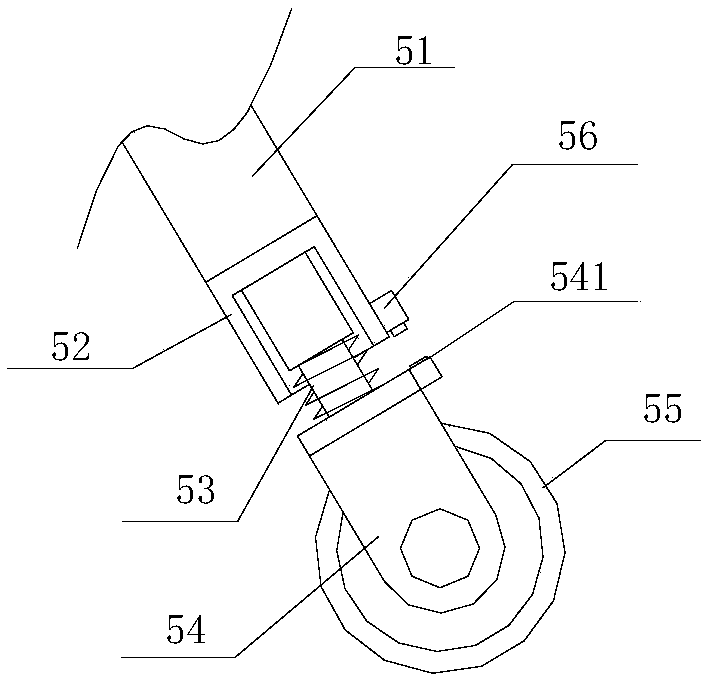

Zipper long chain cutting device

The invention relates to a zipper long chain cutting device which is used for cutting a zipper long chain into strips of zippers. The zipper long chain cutting device comprises a conveying mechanism and a cutting mechanism, wherein the cutting mechanism comprises an upper cutter and a lower cutter, the conveying mechanism comprises a fabric strap clamp and an output wheel set, the fabric strap clam and the output wheel set are arranged on two sides of the cutting mechanism, and the fabric strap clamp is used for clamping and conveying the zipper long chain to the output wheel set. The zipper long chain cutting device further comprises a jacking blocking mechanism, wherein the jacking mechanism comprises a sliding block which can move up and down in a reciprocation mode and a positioning bar which can horizontally and transversely move in a reciprocation mode, a positioning hole is formed in the sliding block, the lower cutter is fixed on the sliding block, and the positioning bar is at least partially taken in the positioning hole and is connected with the side wall of the positioning hole in an abutting mode when the cutting mechanism works. The cutting mechanism can cut the zipper long chain according to a predetermined position, and thus zippers obtained through cutting have the advantage of being neat in cuts.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

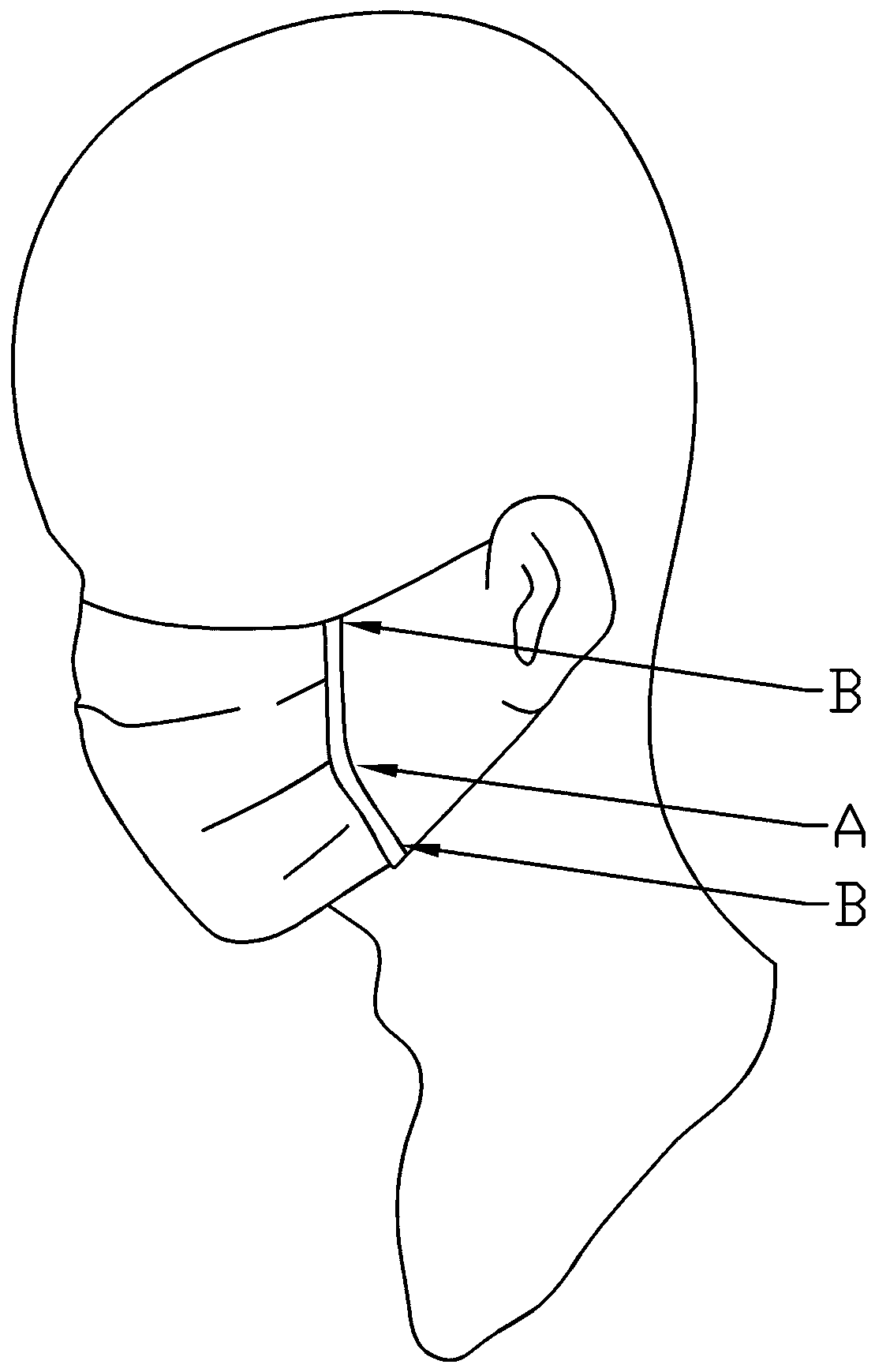

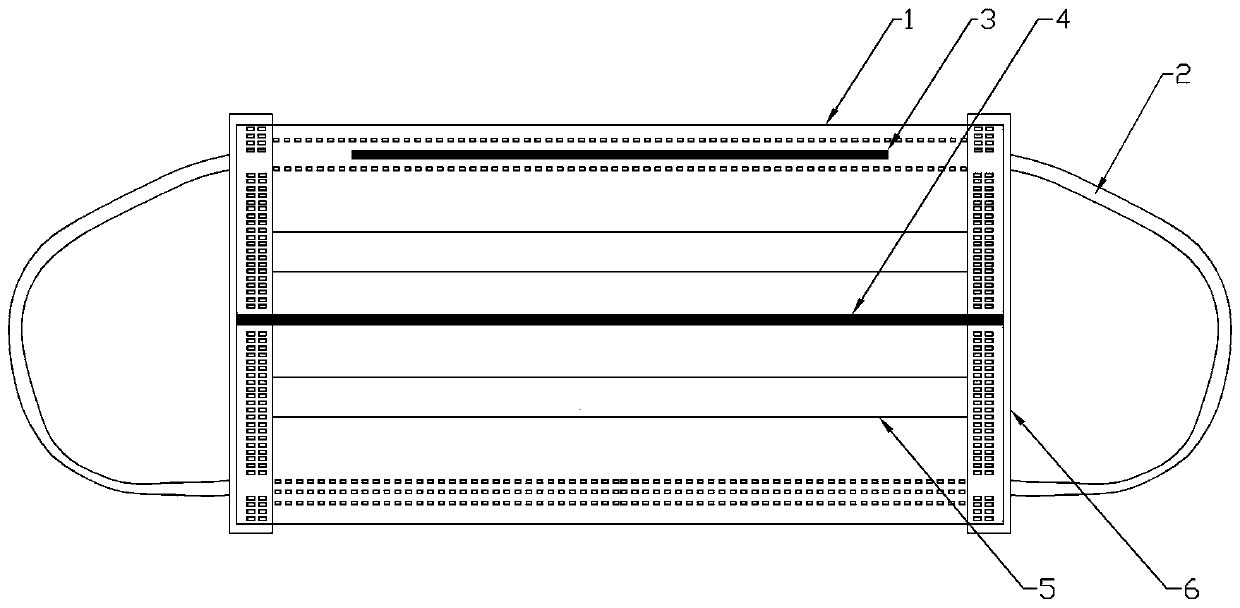

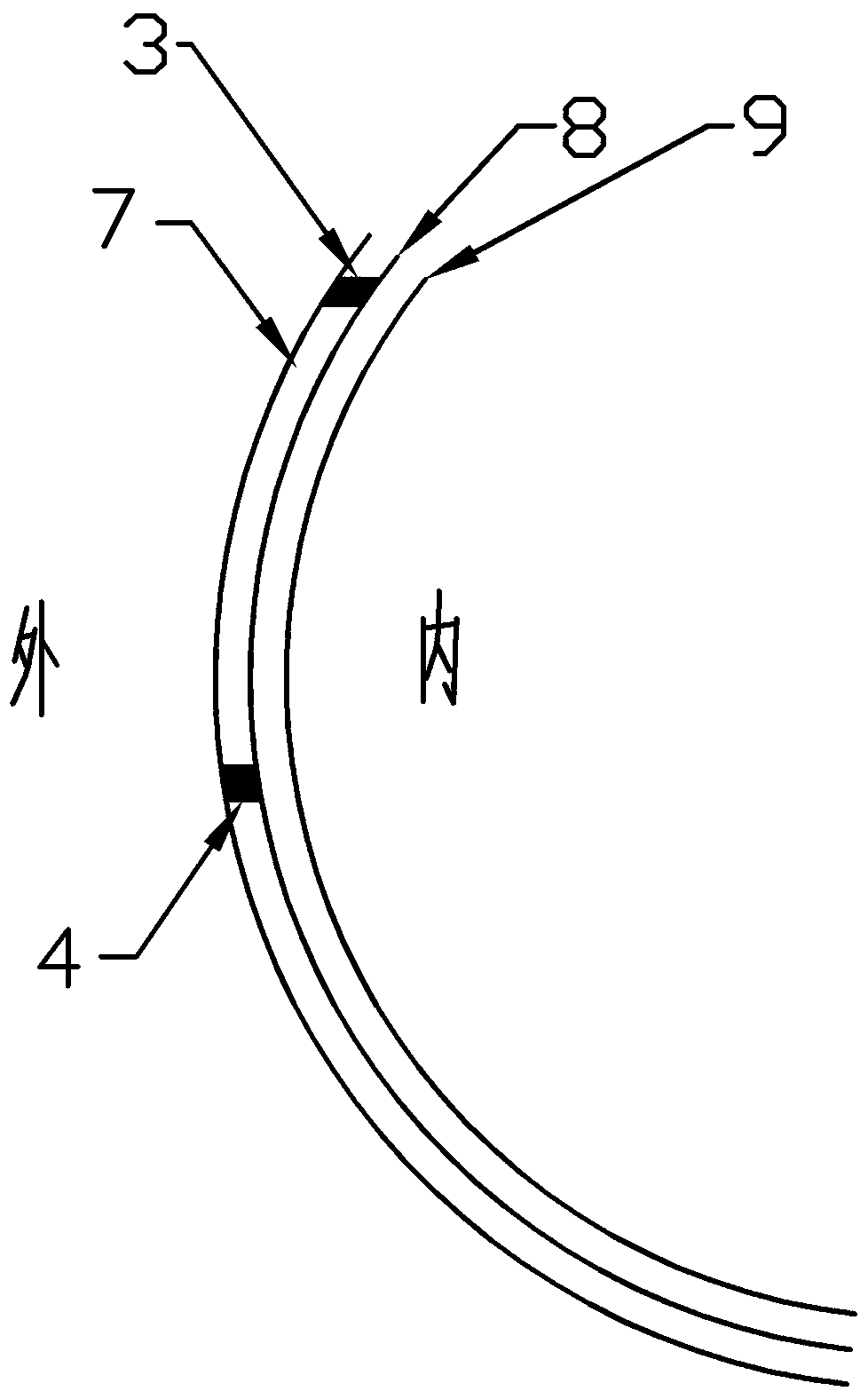

Mask

PendingCN111053311APrevent archingNot easy to get wetProtective garmentSpecial outerwear garmentsNasal bridgeStructural engineering

The invention discloses a mask, and aims to provide a mask which is simple in structure, good in fitness, high in comfort and excellent in using effect. The mask comprises a mask face body, tensioningstraps are arranged on the left side and the right side of the mask face body, a nose bridge shaping strip is arranged at the upper end of the mask face body, at least one supporting shaping strip isfurther arranged on the mask face body, and two ends of the supporting shaping strip are fixed to the middles on the left side and the right side of the mask face body respectively. The mask providedby the invention is applied to the technical field of health protection articles.

Owner:ZHUHAI YIDA MACHINERY EQUIP

Anti-blocking switch gear of discharge bin

ActiveCN105346876AAvoid blocking problems such as archingIncrease the output speedLarge containersEngineeringMechanical engineering

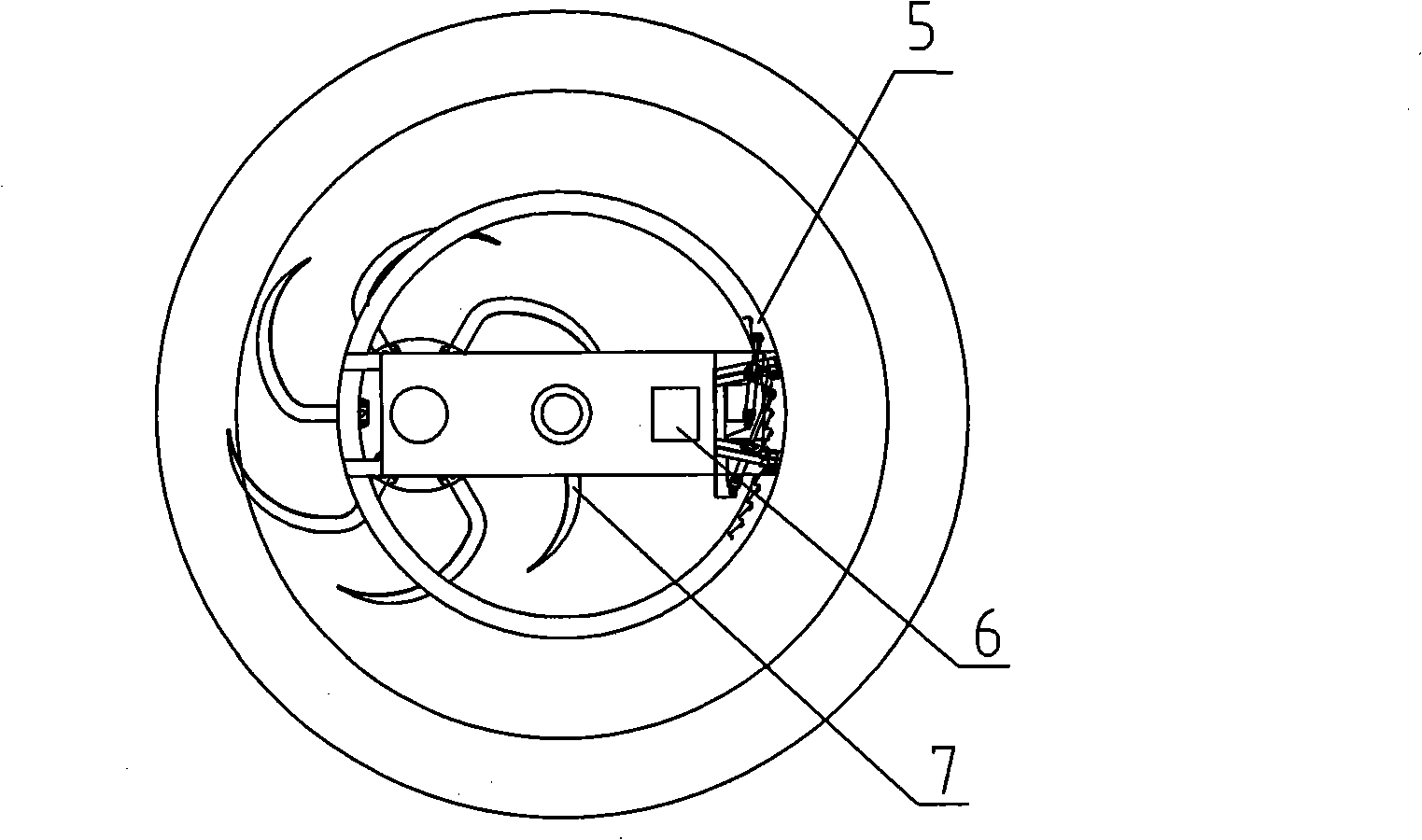

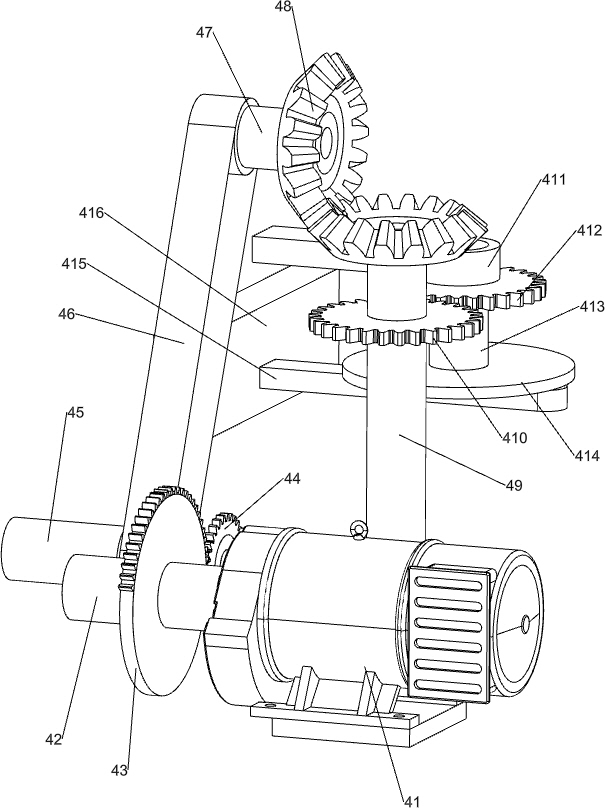

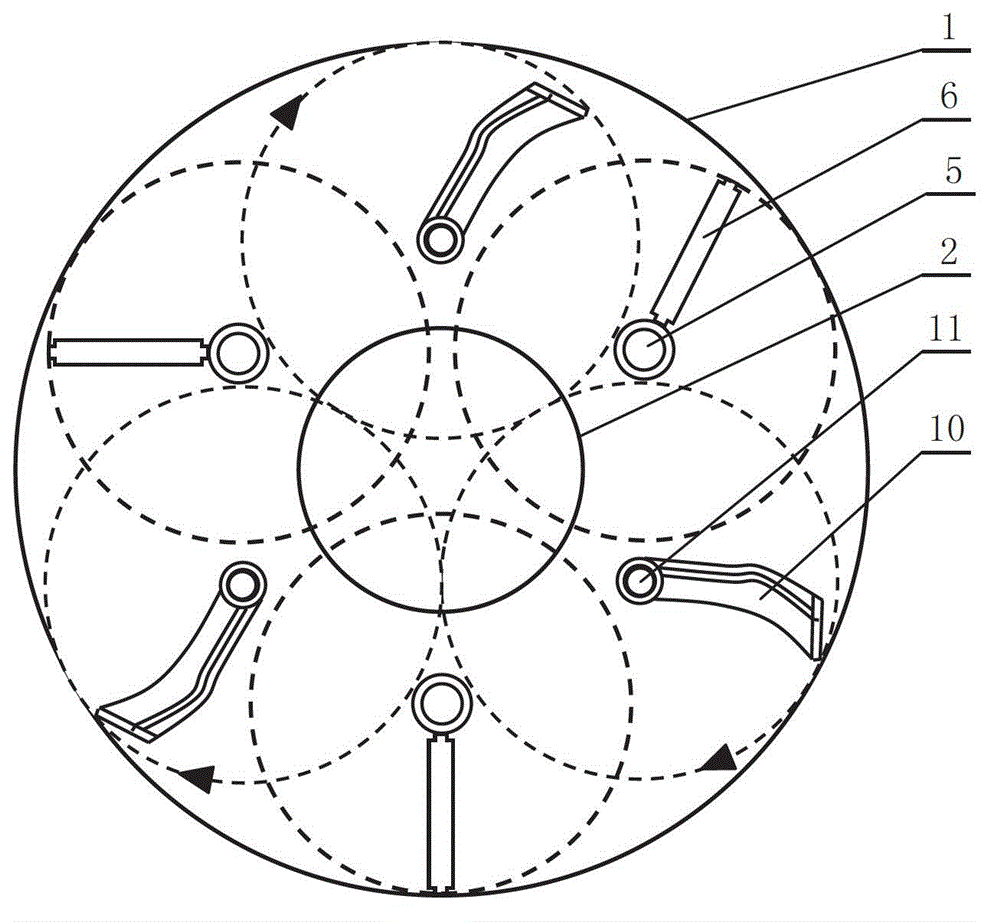

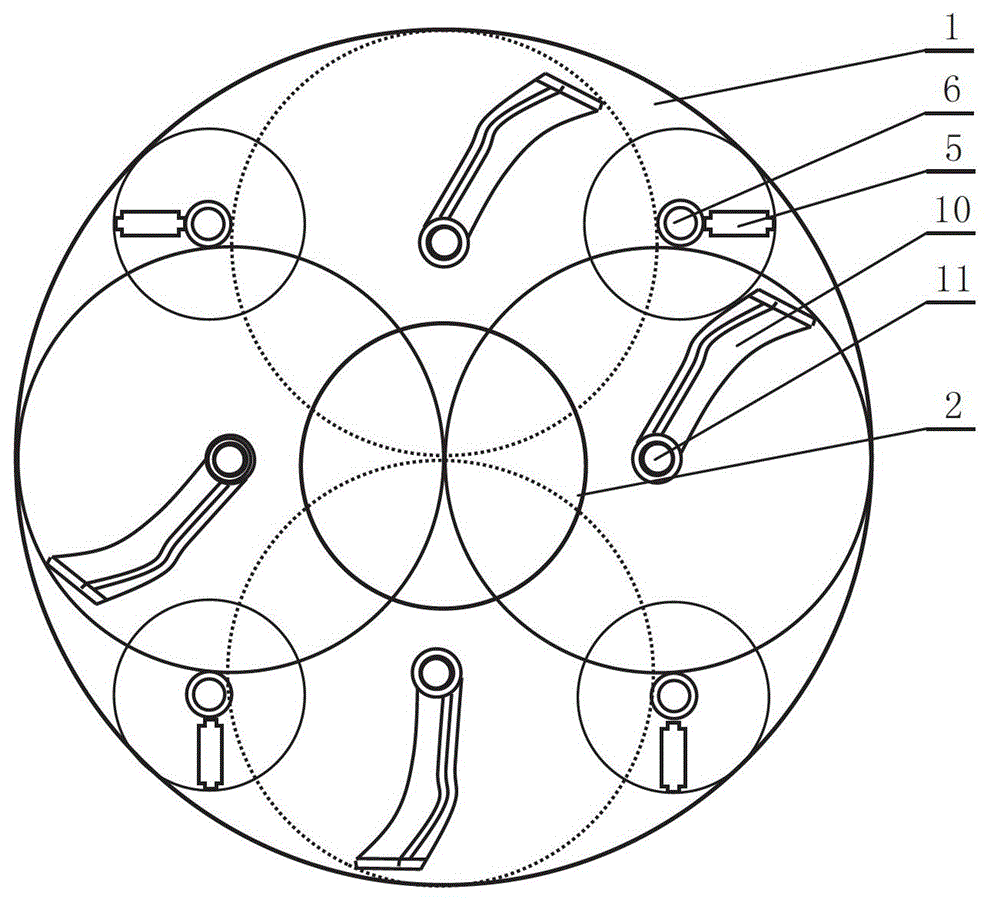

The invention discloses an anti-blocking switch gear of a discharge bin, the anti-blocking switch gear is arranged above a discharge hole in the bottom of the discharge bin, and the cross section of the discharge hole is circular. The anti-blocking switch gear comprises a discharge mechanism, an arch breaking mechanism and a rotary mechanism, wherein the discharge mechanism comprises a baffle plate, an air cylinder and a circular ring; the circular ring is connected with a motor, so that the motor drives the circular ring to rotate for driving the air cylinder and the baffle plate to rotate; the arch breaking mechanism comprises a circular-ring-shaped base and a cylindrical supporting base; the base is hinged with the baffle plate to realize linkage; the side edge of the upper surface of the supporting base is provided with a plurality of spiral pawls which are in upward right-handed rotation, so that a plurality of spiral openings are formed; the rotary mechanism comprises an outer rod, an inner rod extending into a space formed by the pawls, and a plurality of blades, wherein one blade is blocked into one opening, so that the corresponding blade is driven to rotate in a rotary process of the supporting base. The anti-blocking switch gear has the advantages of being capable of effectively preventing the discharge hole from arching, uniform in discharge of the discharge bin, simple in structure, high in working efficiency and the like.

Owner:GUANGXI SHENTA MACHINERY EQUIP CO LTD

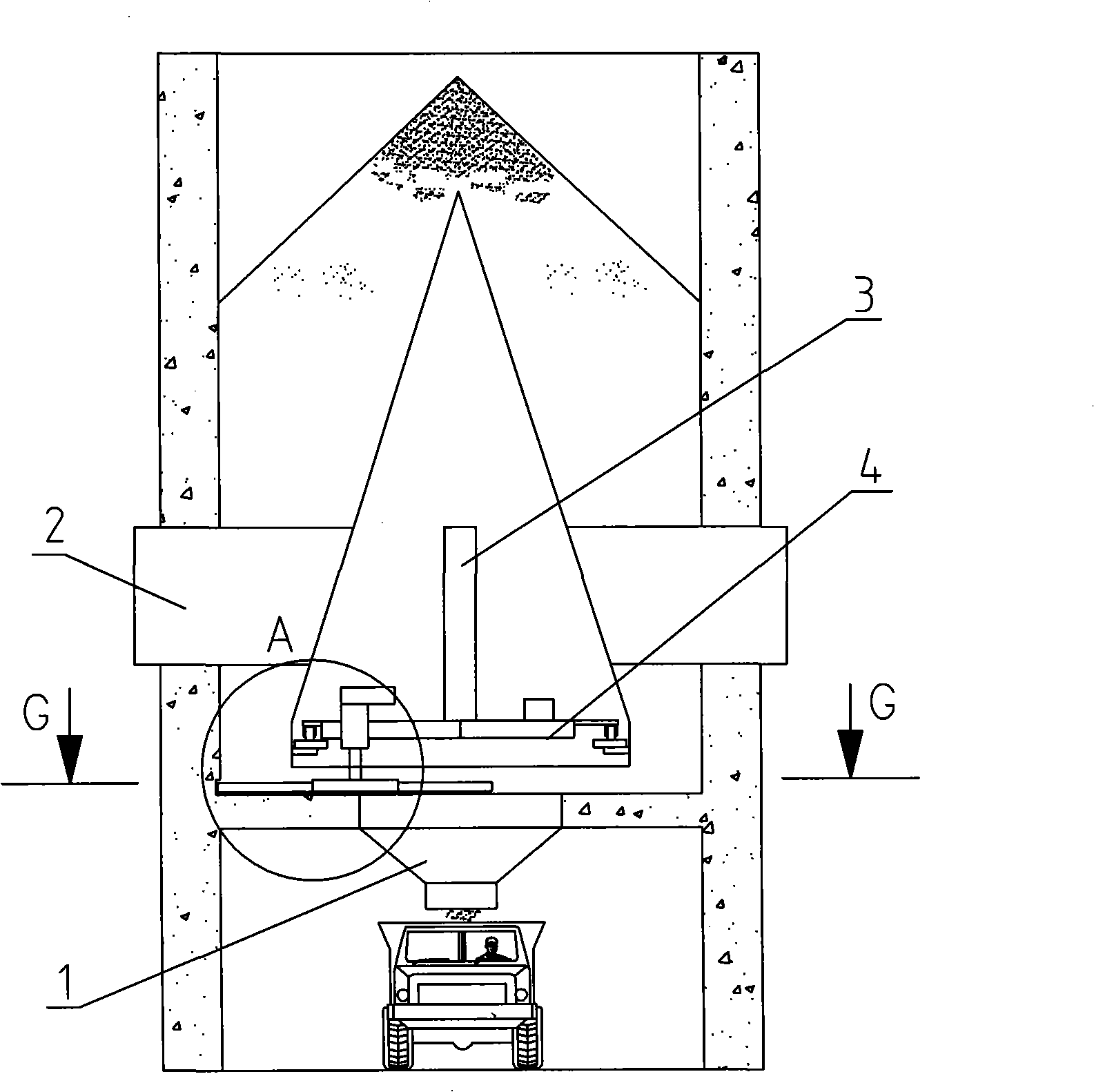

Bulk material silo cutter tooth unloader

The invention relates to a cutter teeth discharging machine of a bulk material silo, which is characterized in that: a slewer is arranged right above a discharging hopper on the bottom of the silo; the slewer is a slewing tray frame slewing around a central shaft; one side of the edge of the slewing disk is provided with a set of hydraulic driving system while the other side thereof is provided with a rotary cutterhead with a speed reduction motor; the cutterhead is provided with one to six cutter teeth and the working surface of the cutter teeth is provided with scrapers; an decompression cone which is used for preventing the material from arching and is supported on the wall of the silo is arranged in the silo right above the slewer. By adopting the discharging machine, whether single-cutter discharging or multi-cutter discharging is adopted can be determined according to storage amount of the bulk material and the size of the silo. The discharging machine has the advantages of flexible layout position of the silo, small labor load for maintenance and environmental protection.

Owner:SINOFINN NEW ENERGY INVESTMENT

Moving terminal and hinge mechanism

Owner:VIVO MOBILE COMM CO LTD

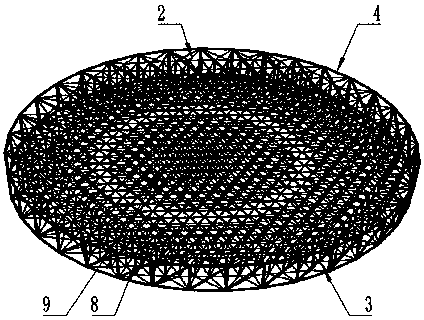

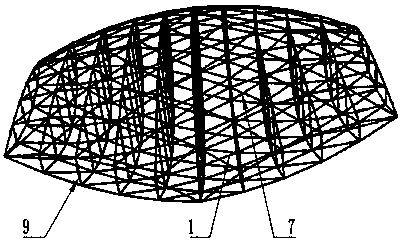

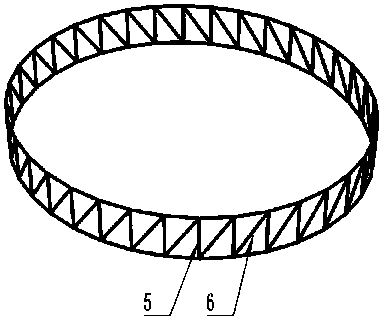

Circular cross cable antenna

ActiveCN108306100AAvoid collapsing dimensionsLight in massAntenna supports/mountingsRadiating elements structural formsCable netEngineering

The present invention provides a circular cross cable antenna which comprises an annular truss and a front cable net and a back cable net which are interlaced by cables. The annular truss comprises aplurality of vertical rods and inclined rods with the equal number. Nodes on the circumference of the front cable net are correspondingly connected to connection parts of the vertical rods and the inclined rods at the top of the annular truss, the front cable net and the back cable net are paraboloids and are in symmetrical arrangement, nodes corresponding to non-intersecting parts of the front cable net and the back cable net are connected by flexible ropes, and nodes corresponding to intersecting parts of the front cable net and the back cable net are connected by support rods. According tothe circular cross cable antenna, a ring-shaped expandable structure is adopted, so the weight is small, the profile precision is good, the storage ratio is high, the excessive arch height is avoided,the overlarge antenna folding size is avoided, the weight of the antenna is reduced, symmetrical cable net structures are used by front and back cable net surfaces, and the good structural stabilityis provided.

Owner:XIDIAN UNIV

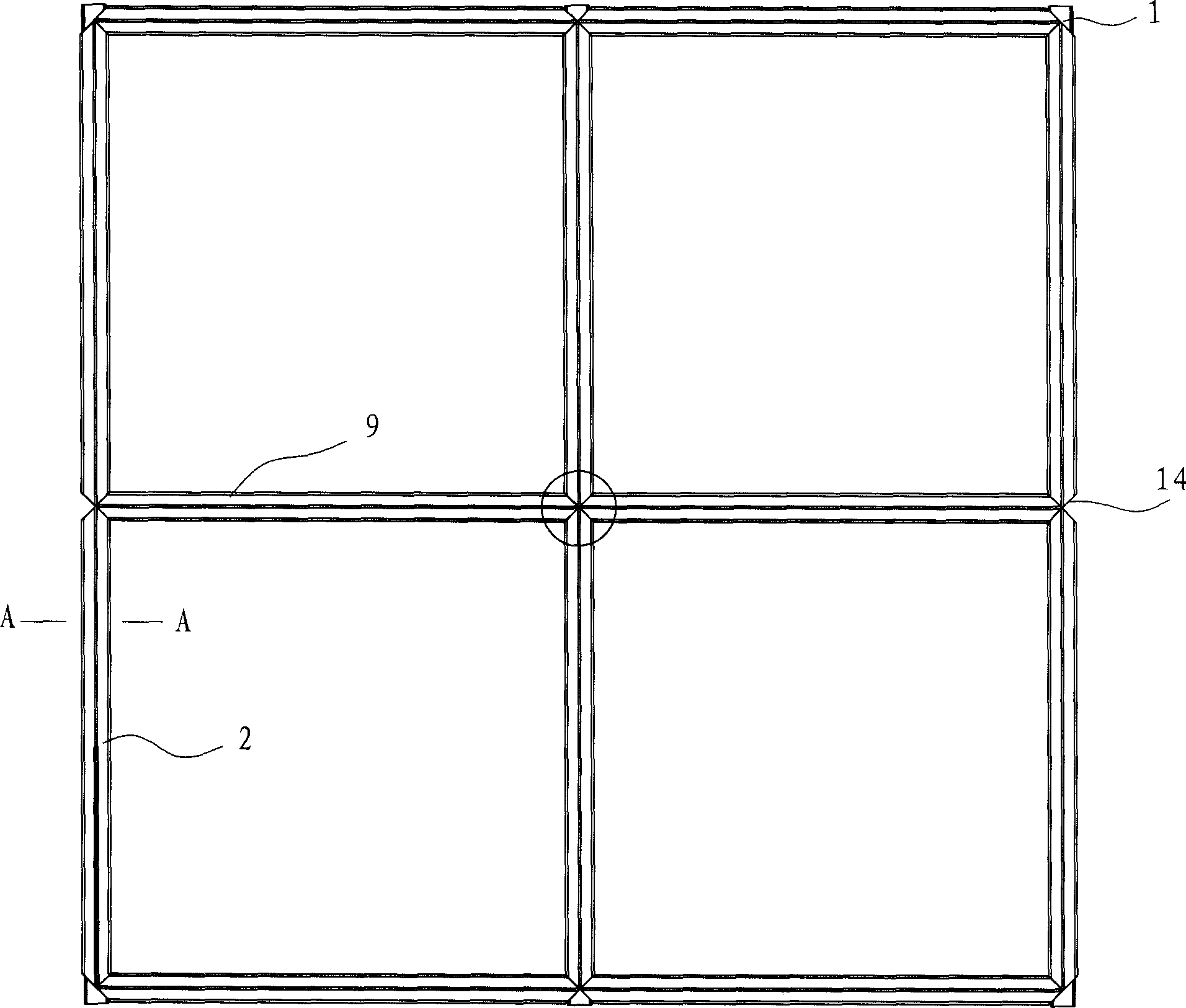

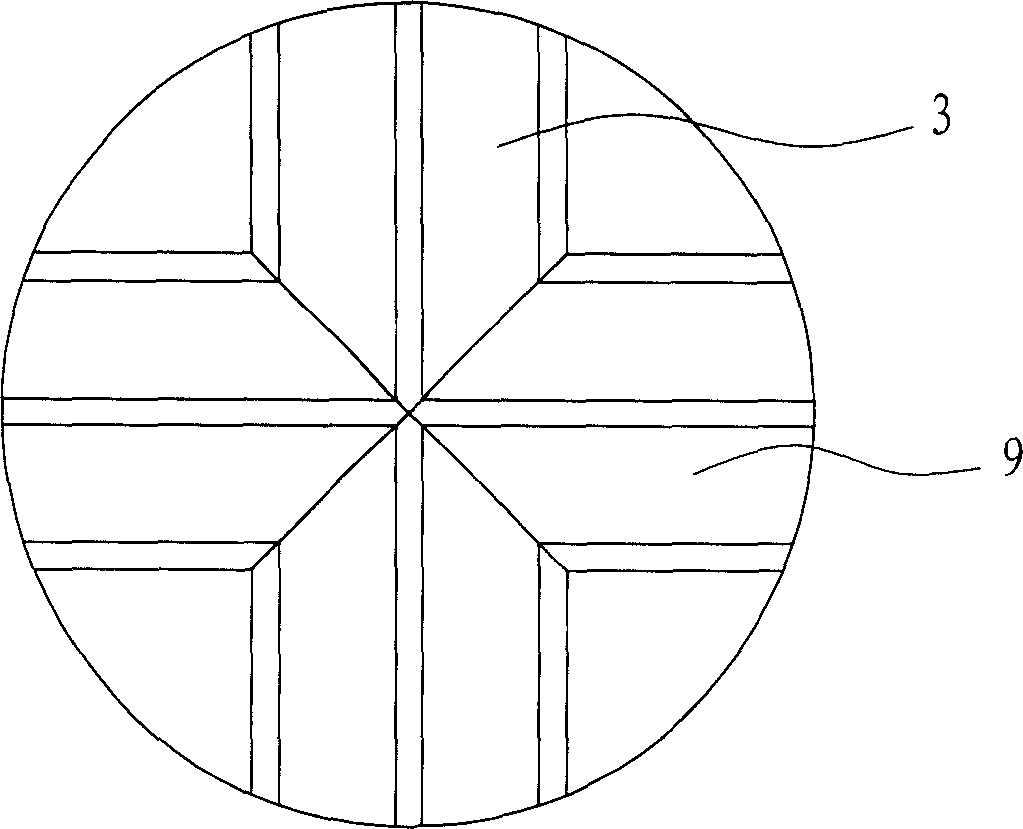

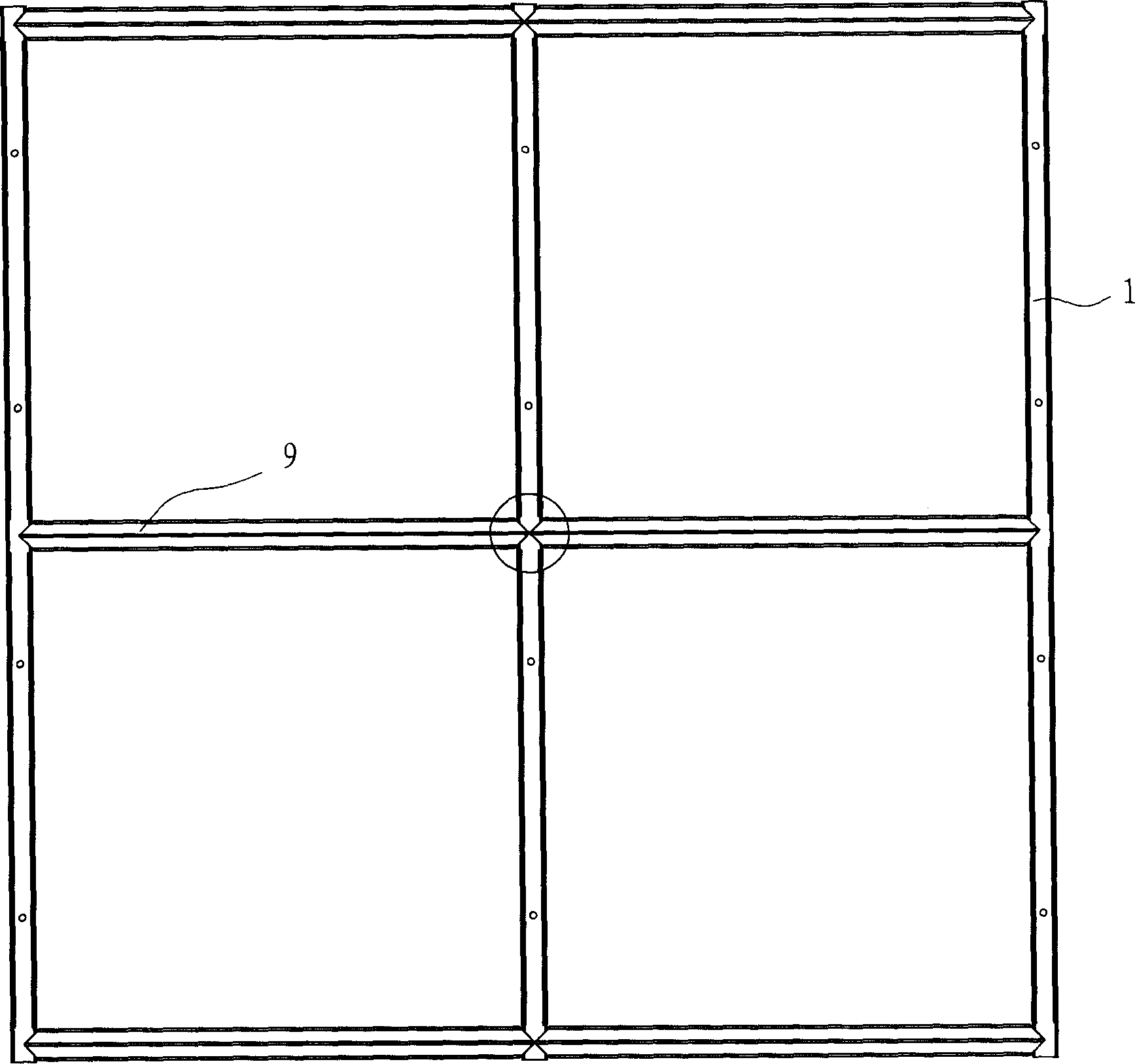

Keel frame for paving floor tiles

A keel frame used for laying ground brick is prepared as forming frame structure by longitudinal keel and horizontal keel, forming longitudinal keel by master keel and sub keel checked on master keel as well as a numbers of foot components firm-joint on bottom of master keel, applying structural section with notch upwards as master keel and forming foot component by base and horizontal regulation mechanism. It can be used to raise quality and speed of ground brick-laying effectively.

Owner:陈杰

Asparagus cutting device for vegetable processing

ActiveCN111702854AAvoid cutsImprove work efficiencyMetal working apparatusVegetable processingAsparagus adscendens

The invention relates to an asparagus cutting device, and particularly relates to the asparagus cutting device for vegetable processing. The technical problem to be solved by the invention is how to provide the asparagus cutting device for vegetable processing that does not need to manually lay asparagus flat and does not need to manually cut off the roots of the asparagus by using a cutter. The asparagus cutting device for the vegetable processing is used for solving the technical problems, the asparagus cutting device for the vegetable processing comprises a base, a material falling box, a flattening mechanism and a conveying mechanism; one side of the base is connected with a supporting plate; the inner wall of the base is connected with the material falling box; the flattening mechanism is mounted between the base and the supporting plate; and the conveying mechanism is mounted on the base and is in transmission connection with the flattening mechanism. According to the asparagus cutting device for the vegetable processing, the conveying mechanism can intermittently convey asparagus backwards, the flattening mechanism can flatten the asparagus, so that the roots of the asparagus with different lengths move to the left side of the base through the opening in the left side, and a cutting mechanism can cut off the roots of the asparagus with different lengths.

Owner:巴中市惠丰农业开发有限公司 +2

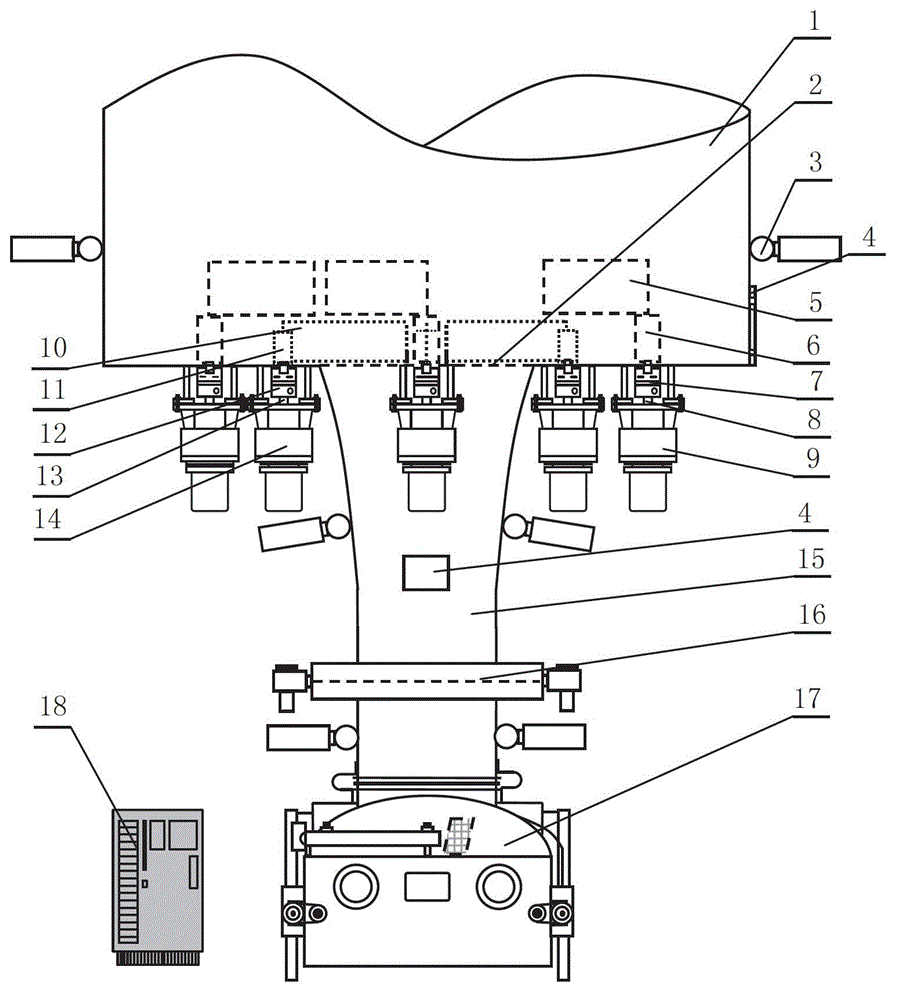

Bin sweeping machine and bin

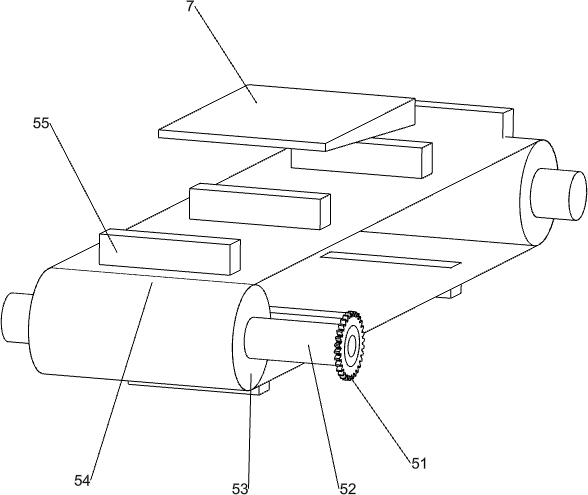

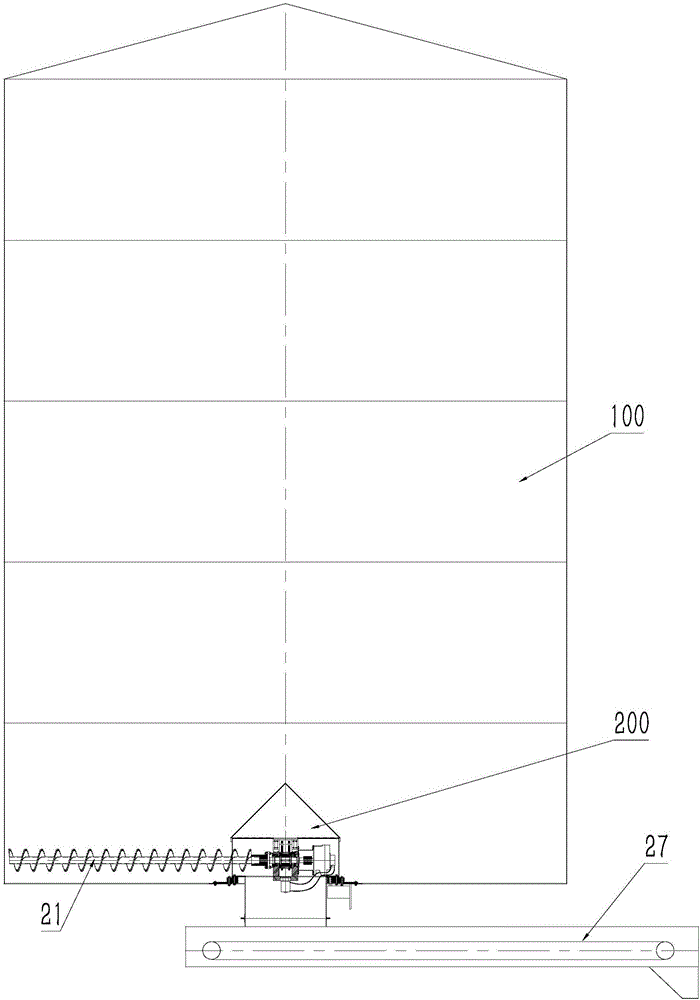

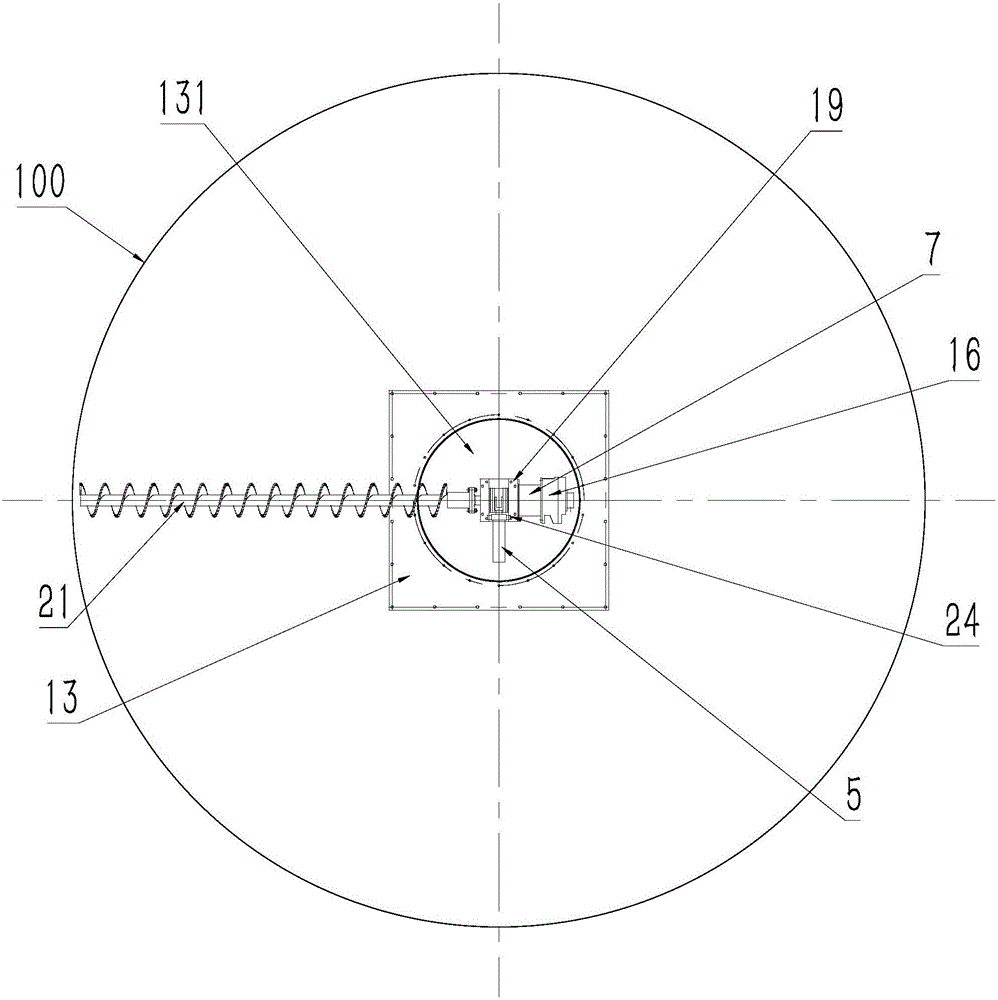

ActiveCN106742844ARealization of revolutionAchieve rotationLarge containersHydraulic motorRotational axis

The invention provides a bin sweeping machine which can solve the phenomena of bridging and arching of materials in a bin, outputs all the materials in the bin, is small in size and good in effect, and is particularly applicable to output of highly wet materials in the flat-bottom bin. The bin sweeping machine is characterized in that the lower end of a barrel body which has a top and does not have a bottom is rotatably arranged on a bottom plate; a revolution driving device used for driving the barrel body to rotate relative to the bottom plate is arranged on the bottom plate; a bracket is fixed in the barrel body; a screw conveyer penetrates through a material inlet in the side wall of the barrel body and stretches to the outer part of the barrel body in the radial direction of the barrel body; a material outlet which communicates with the bottom of the barrel body is formed in the bottom plate; the screw conveyer is rotatably arranged on the bracket; an autorotation hydraulic motor used for driving the screw conveyer to rotate around the axis relative to the bracket is further arranged on the bracket; the output end of the autorotation hydraulic motor is connected with the screw conveyer; external hydraulic oil is supplied to the autorotation hydraulic motor through a rotation connector; the rotation connector is arranged on the bracket; and a rotating shaft of the rotation connector and the axis of the barrel body are coaxial.

Owner:溧阳市金诺机械有限公司

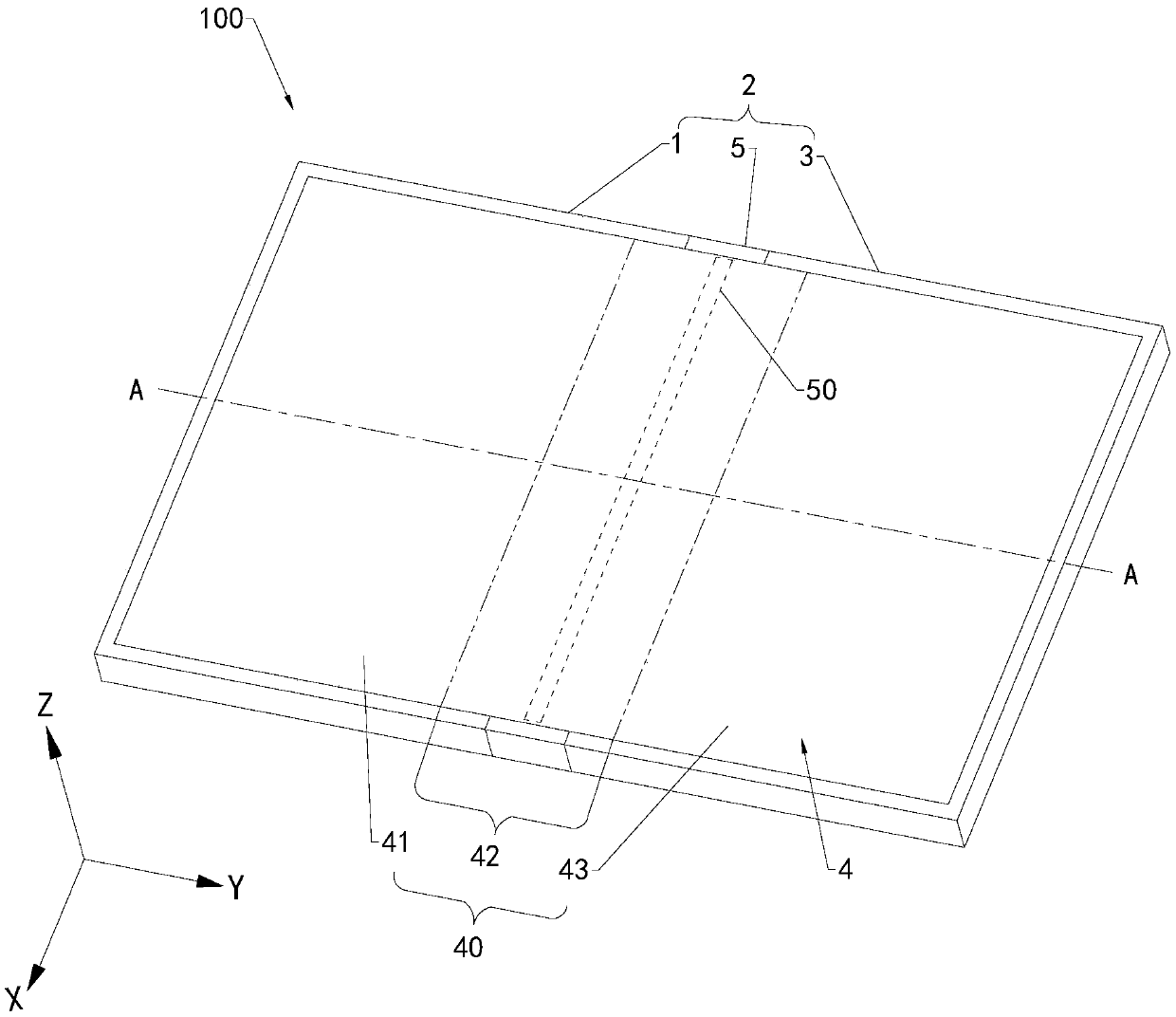

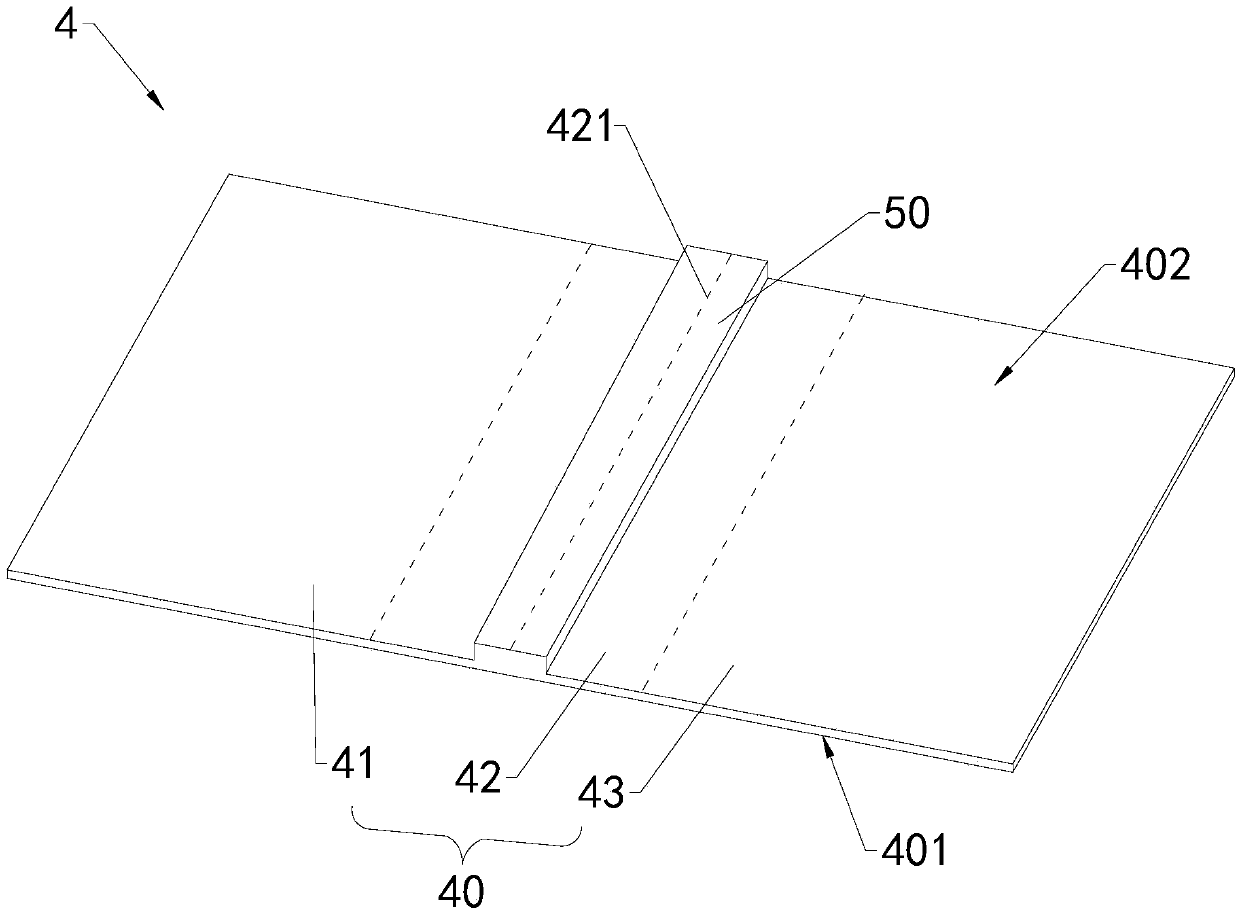

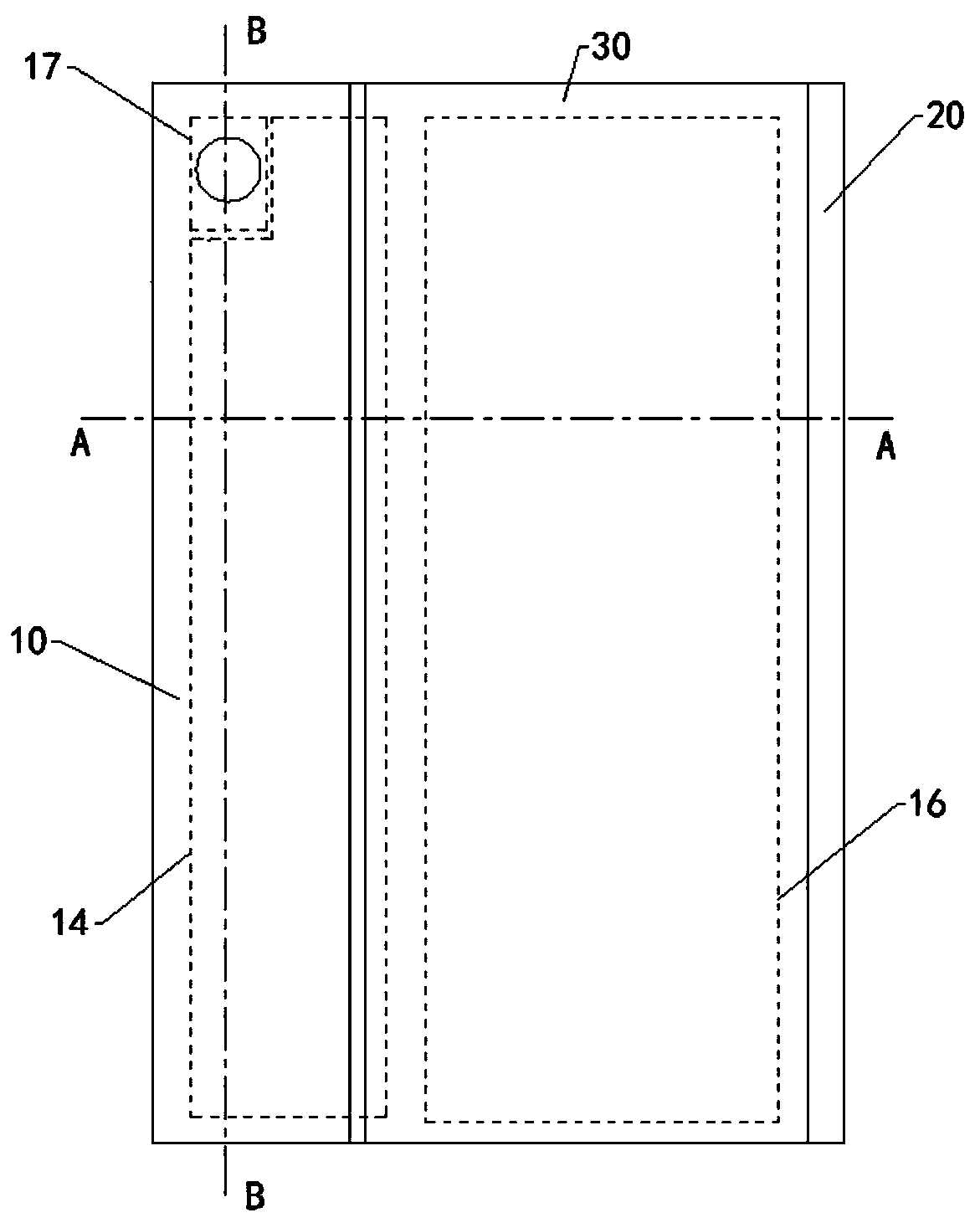

Display component and electronic equipment

PendingCN110444119APrevent archingIncrease the proportionSubstation equipmentDetails for portable computersEngineeringElectronic equipment

The embodiment of the invention provides a display component and electronic equipment. The display component comprises a screen component, a rigid cover plate and a supporting piece, wherein the screen component comprises a flexible screen and a flexible cover plate, and the flexible cover plate covers the flexible screen; the supporting piece is used for supporting the flexible screen; the edge of the flexible screen is provided with a first extension part, and the outer surface of the first extension part is an arc surface; the edge of the flexible cover plate is provided with a second extension part, and the inner surface of the second extension part is an arc surface; the arc surface of the outer surface of the first extension part is matched with at least one part of the arc surface of the inner surface of the second extension part, and the second extension part covers the first extension part; the edge of the supporting piece is provided with a first side surface in an arc surface, the arc surface of the first side surface is matched with the arc surface of the inner surface of the first extension part, and the first extension part covers the first side surface; and the rigidcover plate covers at least one part of the second extension part and at least one part of the supporting piece. Through the display component and the electronic equipment, arc surface fixation between the flexible cover plate and the flexible screen is realized, and the screen-to-body ratio is increased.

Owner:HUAWEI TECH CO LTD

Material dividing and feeding large hopper

InactiveCN102320434APrevent archingGuaranteed continuityLarge containersLoading/unloadingEngineeringMaterial storage

The invention relates to a material dividing and feeding large hopper, which consists of a hopper casing and a feeding material dividing device arranged in the hopper casing, wherein the feeding material dividing device consists of a feeding box and a pull plate type material door, the feeding box is provided with more than two cabin storage passages, the pull plate type material door is used for controlling the opening and closing of the cabin storage passages, and the upper end of the feeding box is provided with a referral plate for separating the cabin storage passages. The feeding box part of the material dividing and feeding large hopper adopts a feeding roller for feeding, and a circular arc groove is milled on the feeding roller, so the flow speed of the materials is stable and uniform, and in addition, the material blockage and the material arching can be prevented. The closing and the opening of different material storage spaces are controlled through the pull plate type material door, and the material flow speed is precisely controlled through combining a material pressing cutter and a fine adjusting device of the material pressing cutter. Therefore, the material discharge flow rate can be precisely controlled, and the material dividing and feeding large hopper can preferably adapt to the requirements of subsequent equipment.

Owner:HEBEI PINGLE FLOUR MACHINERY GROUP

Rotary-cut type integrated central feeding machine

ActiveCN102874608AIncrease effective storage capacityKeep flowingLarge containersLoading/unloadingProcess engineeringMechanical engineering

The invention discloses a rotary-cut type integrated central feeding machine, and solves the problem of poor dredging effect in the prior art. The rotary-cut type integrated central feeding machine comprises an improved raw coal bin, a scraping device, a material pushing device, a hyperbolical or dried shrimp-shaped central feed hopper, an insert plate door, an intelligent electric cabinet and the like, wherein the hyperbolical or dried shrimp-shaped central feed hopper is connected with the feed opening of the raw coal bin; and the scraping device, the material pushing device and the insert plate door are controlled by the intelligent electric cabinet. The central feeding machine is designed reasonably, simple in structure, and convenient to mount, occupies no effective space of the improved raw coal bin, can be controlled intelligently, is high in practicability, mainly used for solving the problem of coal blockage of the improved raw coal bin of a coal burning power plant, is suitable for conveying raw coal of various qualities and types, and coal slime, and is also suitable for material conveying stock bins in other industries.

Owner:ANHUI KANGDI ELECTRIC POWER SCI & TECH

Aluminizing film winding device

InactiveCN109573692APrevent archingGuaranteed smooth windingWebs handlingControl systemPressure sense

The invention discloses an aluminizing film winding device. The device comprises a winding device, a machine frame, a cutting device, an adjusting driving mechanism, a winding and pressing roller mechanism and a control system, wherein the winding device is provided with a transposition rotating arm, and winding roller assemblies are symmetrically arranged on the transposition rotating arm, the cutting device is arranged on the machine frame, and a cutting knife is arranged below the cutting device, a second driving air cylinder is arranged on the adjusting driving mechanism, and a second elastic telescopic support, a second roller mounting seat, a second compression roller assembly and a pressure sensing unit are arranged on the winding and pressing roller mechanism, the pressure sensingunit is connected with the control system, and the control system controls the winding and pressing roller mechanism to move by adjusting driving mechanism; the winding and pressing roller mechanism is adopted for pressing the thin film, and the phenomenon that an arch is generated in the winding process is avoided; and the adjusting driving mechanism is adopted for adjusting the pressure betweena winding pressing roller and a winding roller in real time, so that the flattening of winding is ensured.

Owner:海盐嘉豪镀铝材料有限公司

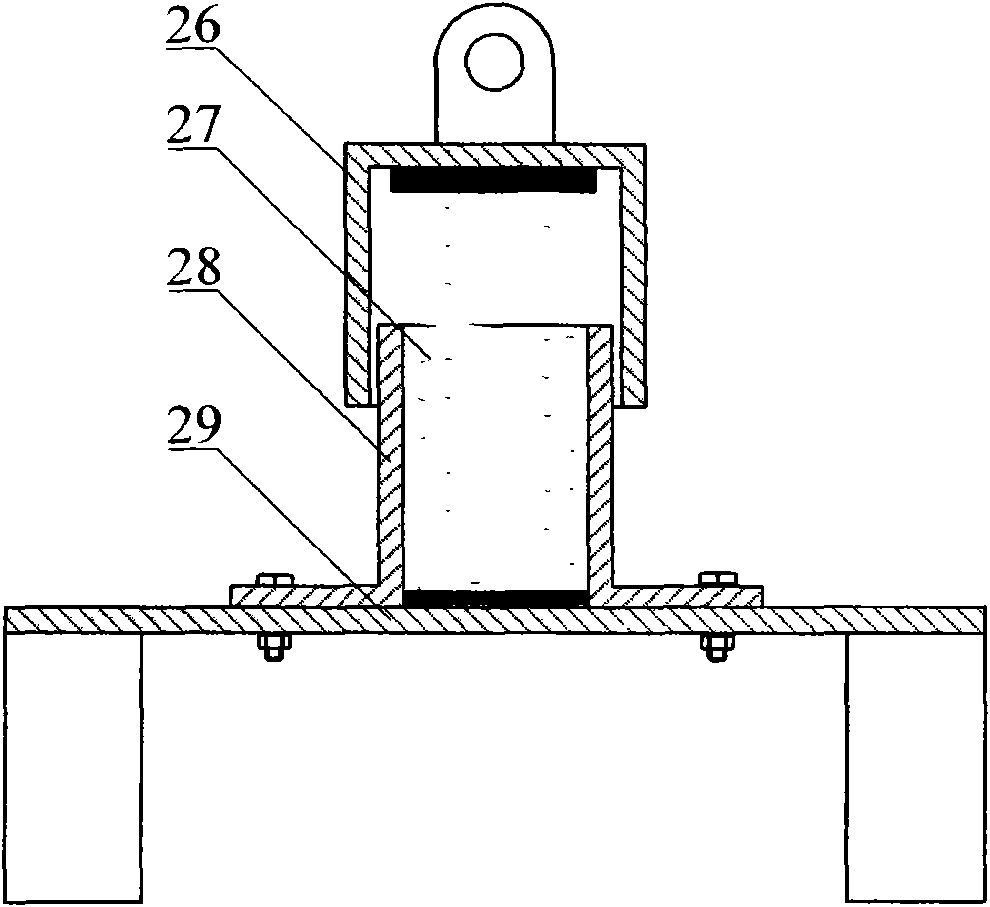

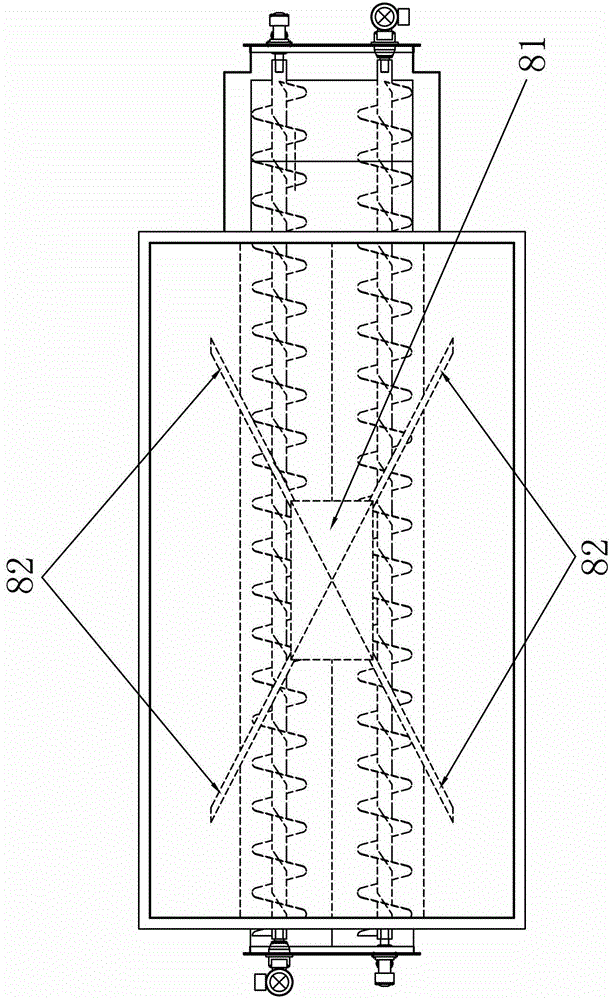

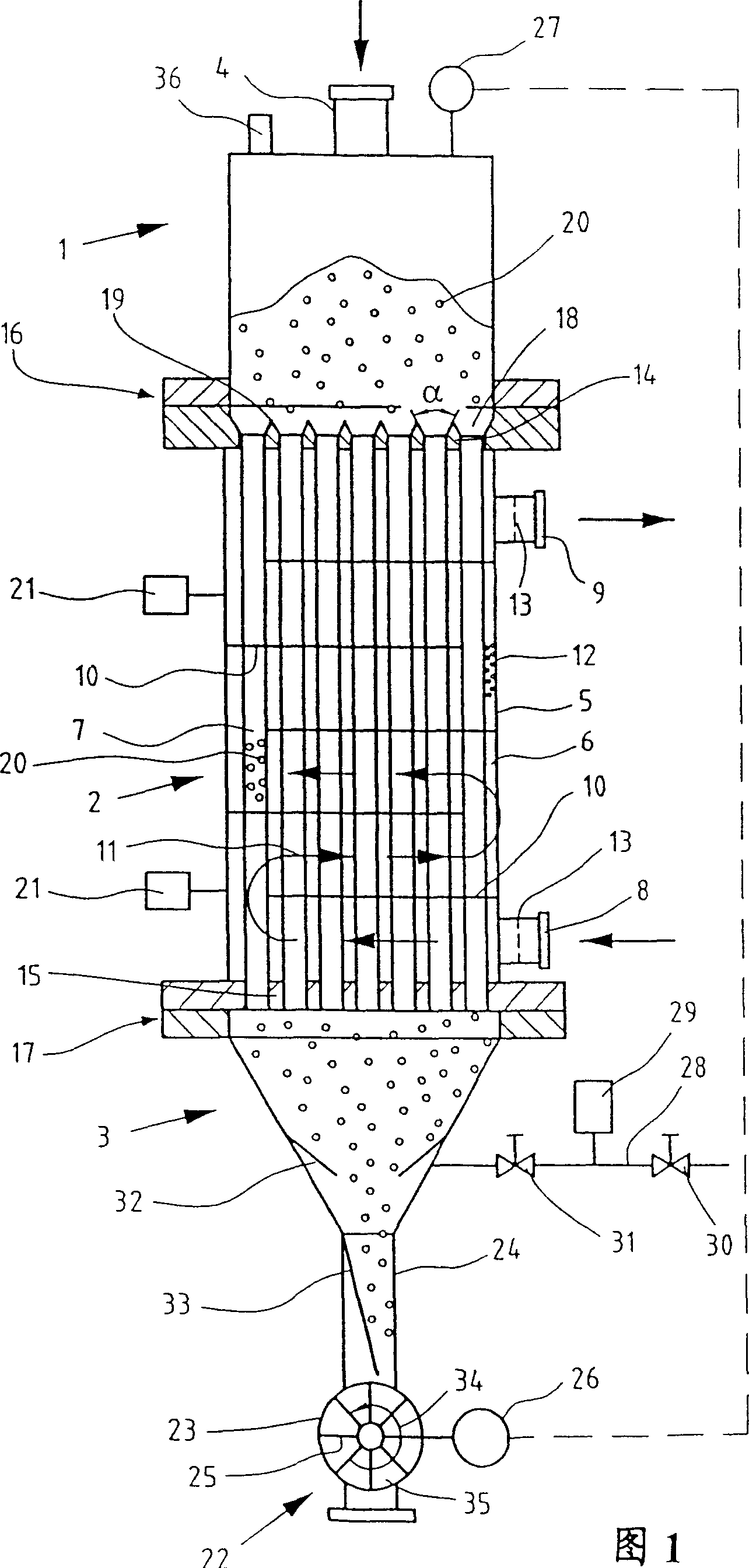

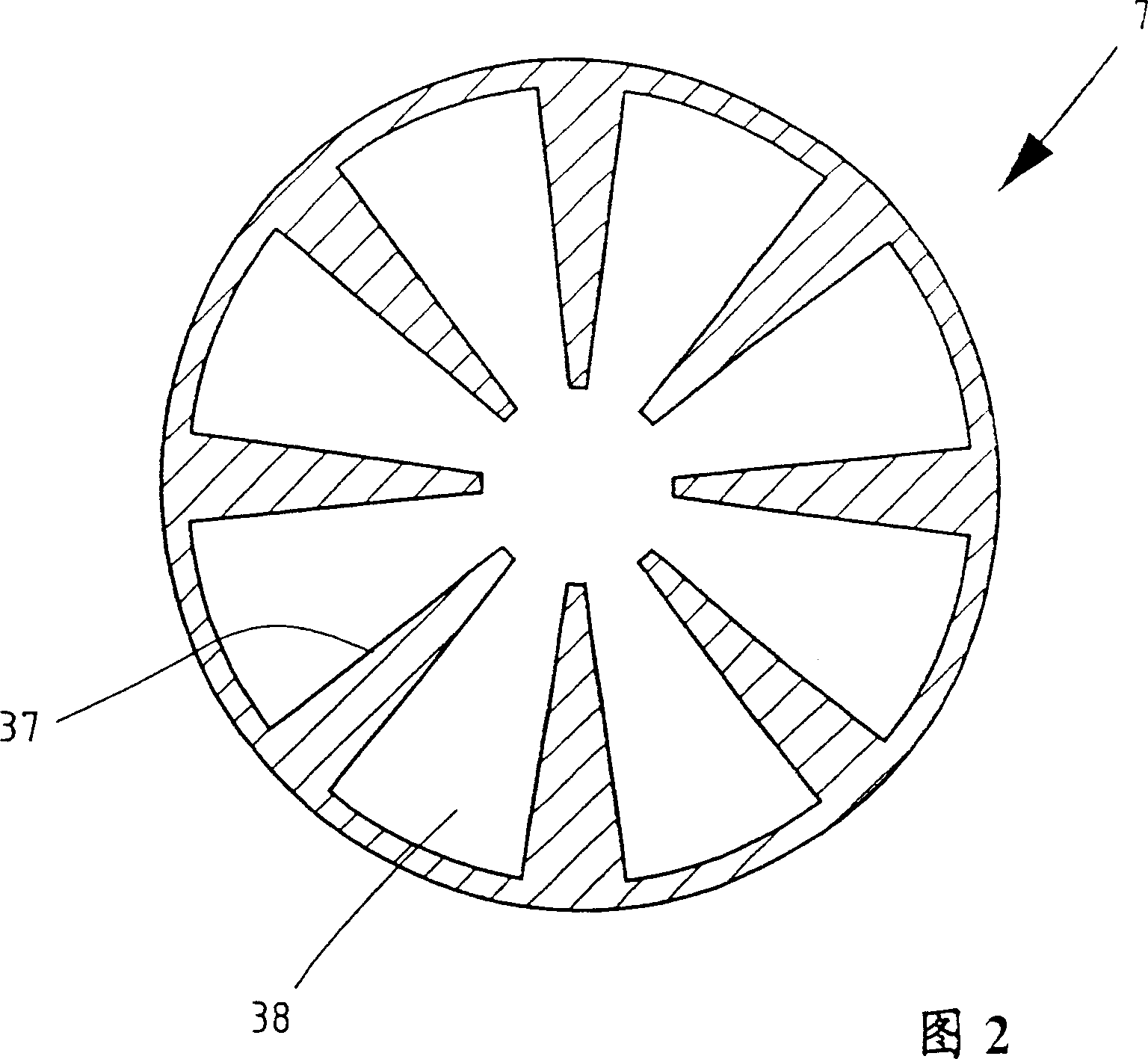

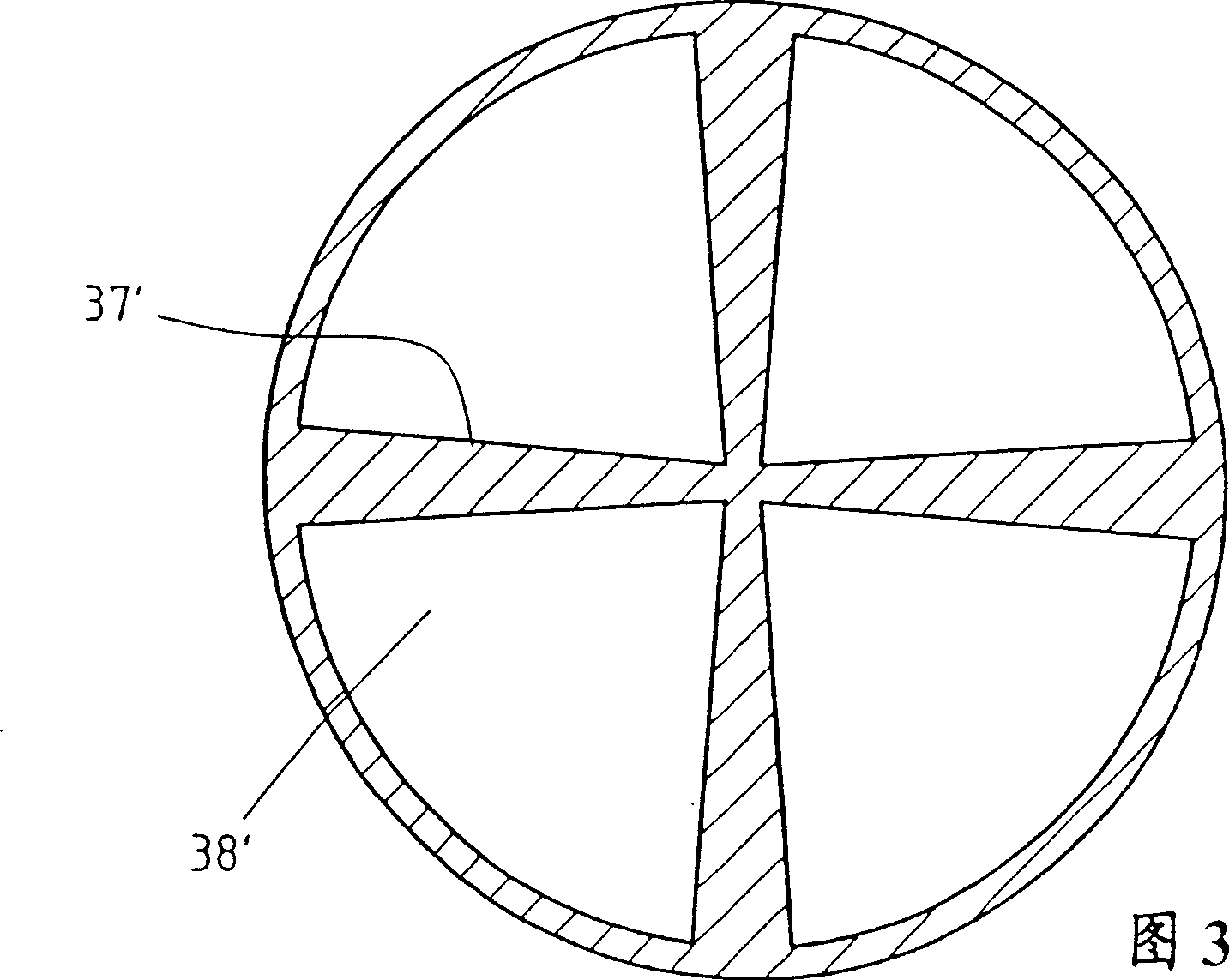

Device for maintaining temperature of bulk material

InactiveCN1683898APrevent archingIncrease flow rateHeat exchanger casingsDirect contact heat exchangersEngineeringGravitation

The invention relates to a device for adjusting the temperature of a loose material (20), comprising a heat exchange section (2). A buffer section (1) for the loose material (20) is located at front of the heat exchange section, while a material discharge section (3) is located behind the heat exchange section. A heat exchanger tube (7) is arranged on the heat exchange section (2) along the gravity direction. Besides, a feeding device (8) and a discharging device (9) for carrying a heat fluid are communicated with the exchange section (2).

Owner:COPERION WAESCHLE

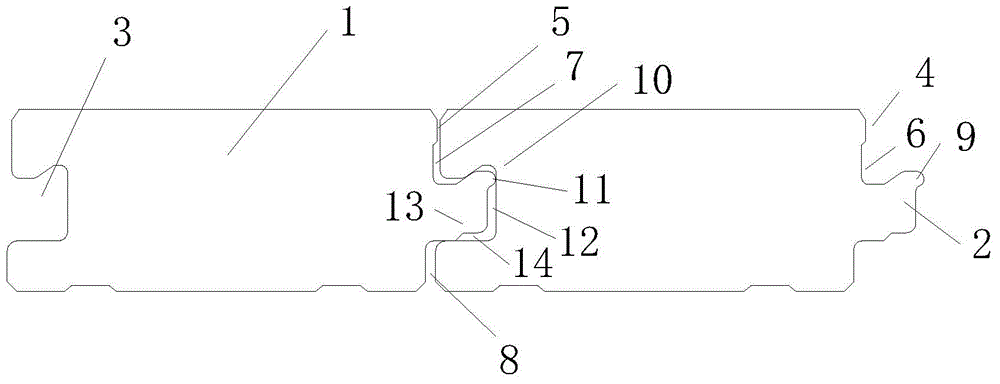

Steplike lock catch wood floor

ActiveCN104481114AEasy and stable installationPrevent archingFlooringEngineeringStructural engineering

Owner:JIUSHENG WOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com