Drill bit with low chisel edge

A chisel edge and drill bit technology, used in the field of high-efficiency high-speed precision tools and low chisel edge drill bits, can solve problems such as delamination and exit burrs, and achieve the effects of reducing material delamination, suppressing runout, and improving heat dissipation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

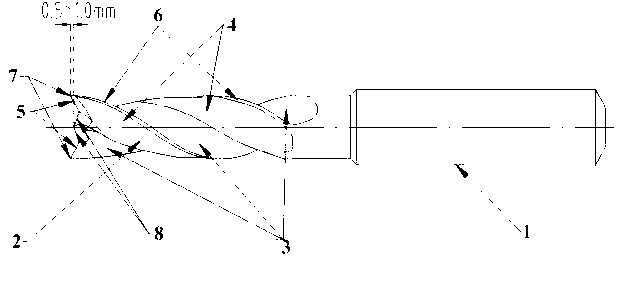

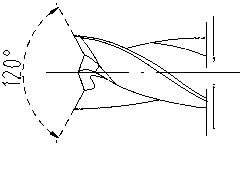

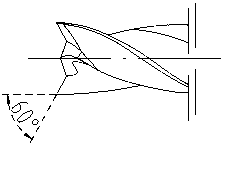

[0023] The design concept of the low-chisel drill bit of the present invention is to improve the sharpness of the drill bit, change the traditional processing method in which the chisel edge of the drill bit touches the workpiece first, and change the traditionally designed convex angle into a 120° inner concave angle to avoid radial force when drilling. A protective sipe with a negative rake angle is used at the rear end of the drill to improve the stability of the guide and reduce the secondary cutting of the workpiece by the edge of the drill, thereby inhibiting the tendency of the workpiece to produce arches and burrs.

[0024] Such as figure 1 As shown, the low chisel drill bit includes a shank 1 and a head 2, the shank 1 is a cylinder, the head 2 is a coaxial cylinder coaxial with the shank, and there are two rows on the head The chip flute 3, the solid part forming the chip flute is the tool back 4, the intersection line of the two chip flutes 3 and the tool back 4 in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com