Bulk material silo cutter tooth unloader

A technology of unloader and bulk material, which is applied to the unloading of desulfurization gypsum silos in thermal power plants, and the field of silo knife-tooth unloader, which can solve the problem of high viscosity of desulfurization gypsum, high forklift operation rate, and reduction of storage capacity, etc. problems, to achieve the effect of keeping the environment clean and hygienic, less maintenance work, and flexible layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

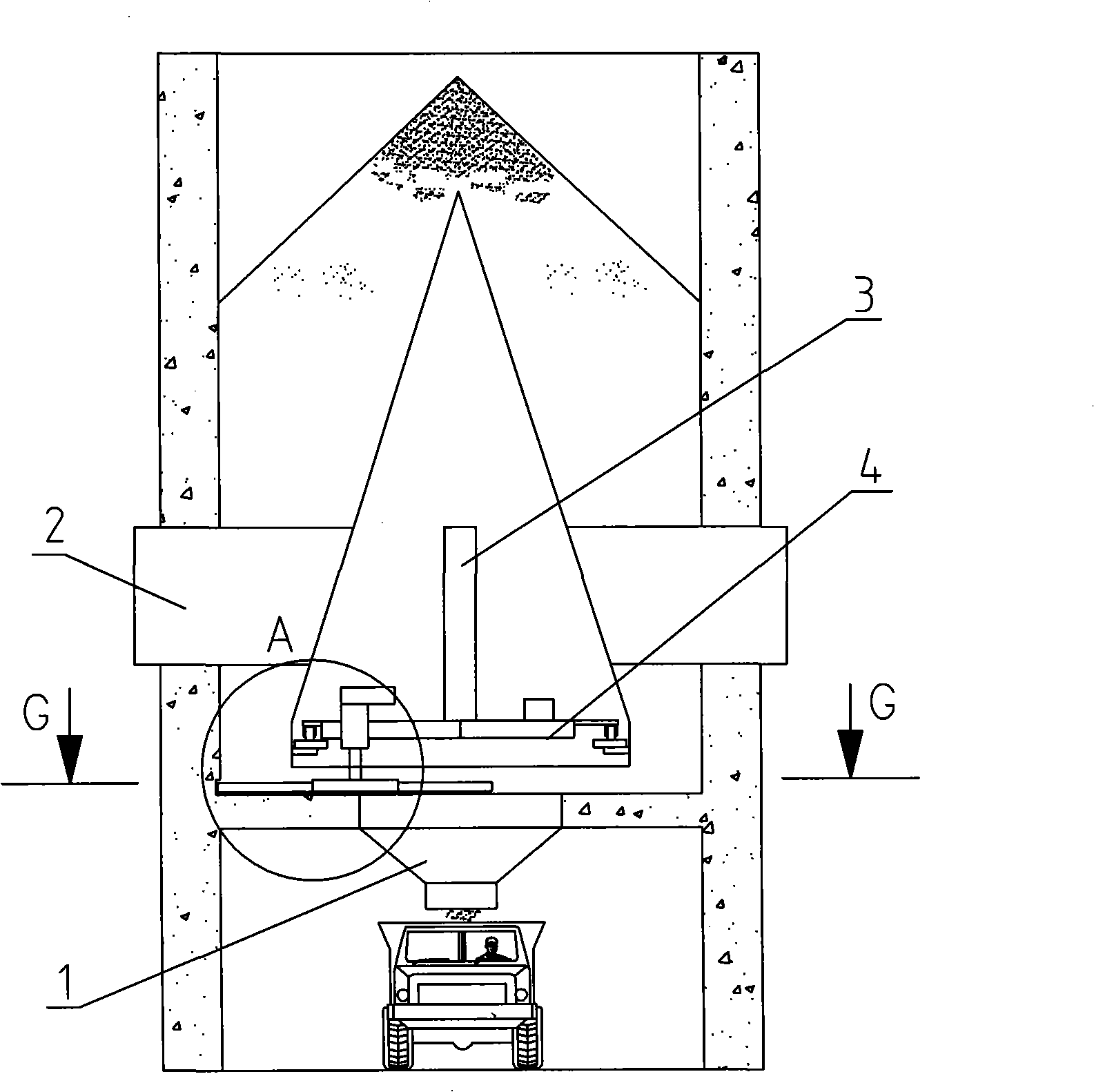

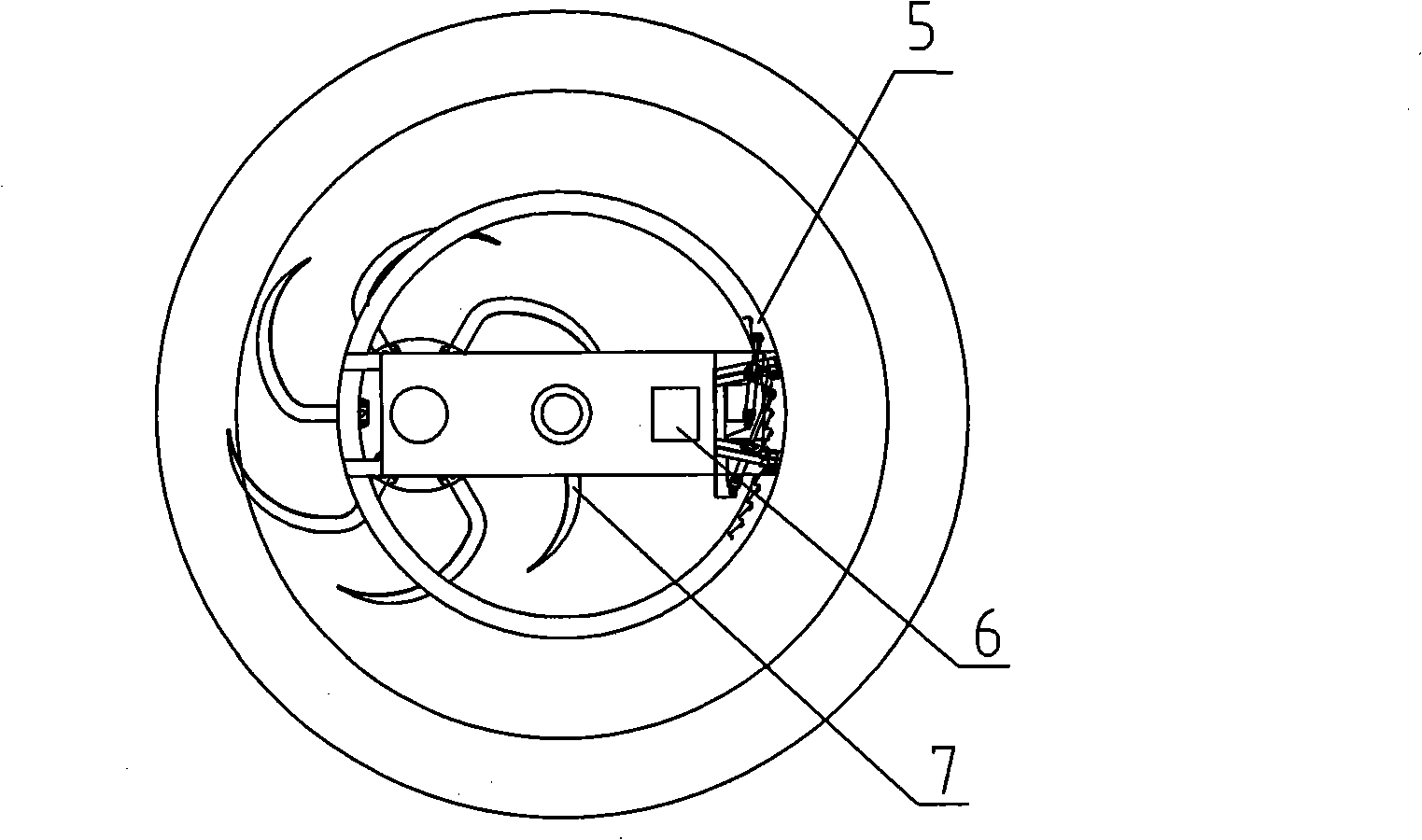

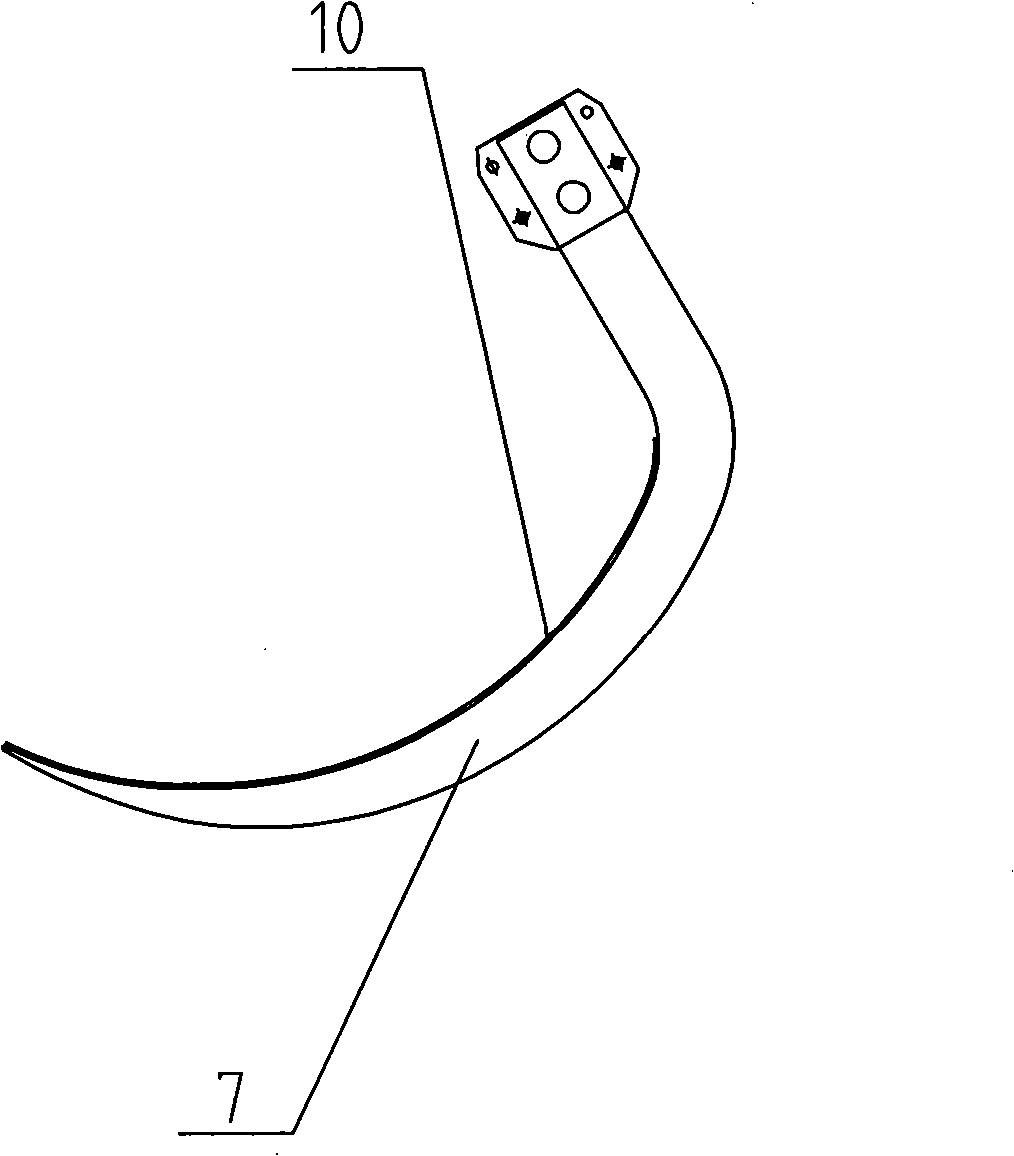

[0014] According to attached figure 1 , 2 , 3 and 4, the present invention consists of the bottom plate of the warehouse and the lower hopper 1, the decompression cone 2, the central shaft frame 3, the rotary frame 4, the ratchet 5, the hydraulic drive system 6, the cutter teeth 7, the planetary gear motor 8, and the cutter head 9 , scraper plate 10 and other parts and ultra-high molecular polyethylene, coordinated operation, quantitative control device for unloading bulk materials from the silo. Two power sources of the present invention are placed on the rotary disc frame 4, and the four corners of the rotary disc frame are provided with rollers, supporting the rotary disc frame to rotate and walk on the ratchet wheel 5 at the bottom inner ring of the decompression cone 2. One is revolution drive——executed by two oil cylinders of the hydraulic drive system 6, by alternately pushing the ratchet wheel 5 installed at the bottom of the decompression cone 2, so that the rotary f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com