Steplike lock catch wood floor

A wooden floor and stepped technology, which is applied in the field of stepped lock wooden floors, can solve the problems of unsatisfactory firmness of wooden floors, affecting the quality of use of users, and floor warping, so as to achieve superior firmness and improve living quality , The effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

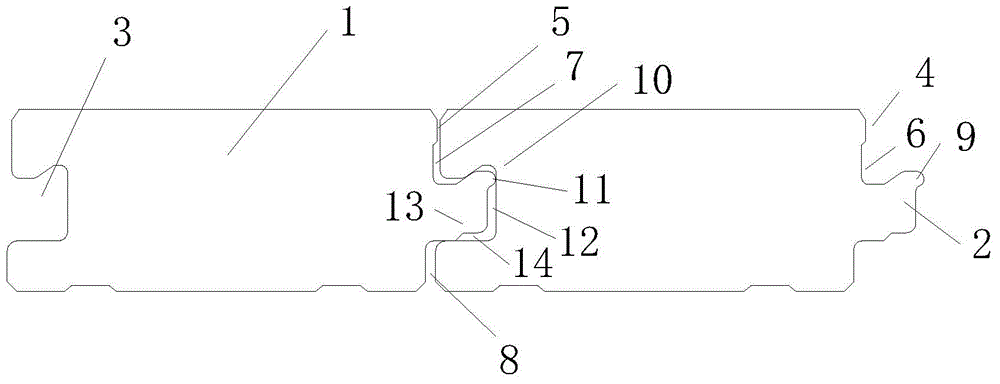

[0016] Embodiment: a kind of stepped locking wooden floor, as attached figure 1 As shown, including the substrate 1, the two sides of the substrate 1 are provided with tenons 2 and grooves 3 that cooperate with each other, the upper side of the tenon 2 is provided with a protrusion 4, and a first gap 5 is formed between the protrusion 4 and the upper side of the groove 3, The lower part of the protrusion 4 is provided with an upper groove 6, a second gap 7 is formed between the upper groove 6 and the upper side of the groove 3, and a third gap 8 is formed between the lower side of the tenon 2 and the lower side of the groove 3; The upper part of the tenon 2 is provided with an oblique protrusion 9, the upper part of the groove 3 is provided with an oblique groove 10 corresponding to the oblique protrusion 9, and the side of the tenon 2 is provided with a side protrusion 11, and the side protrusion 11 and the groove 3 The sides of the tenon 2 are in contact with each other, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com