Patents

Literature

93 results about "Insulating concrete form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Insulating concrete forms are manufactured from any of the following materials...

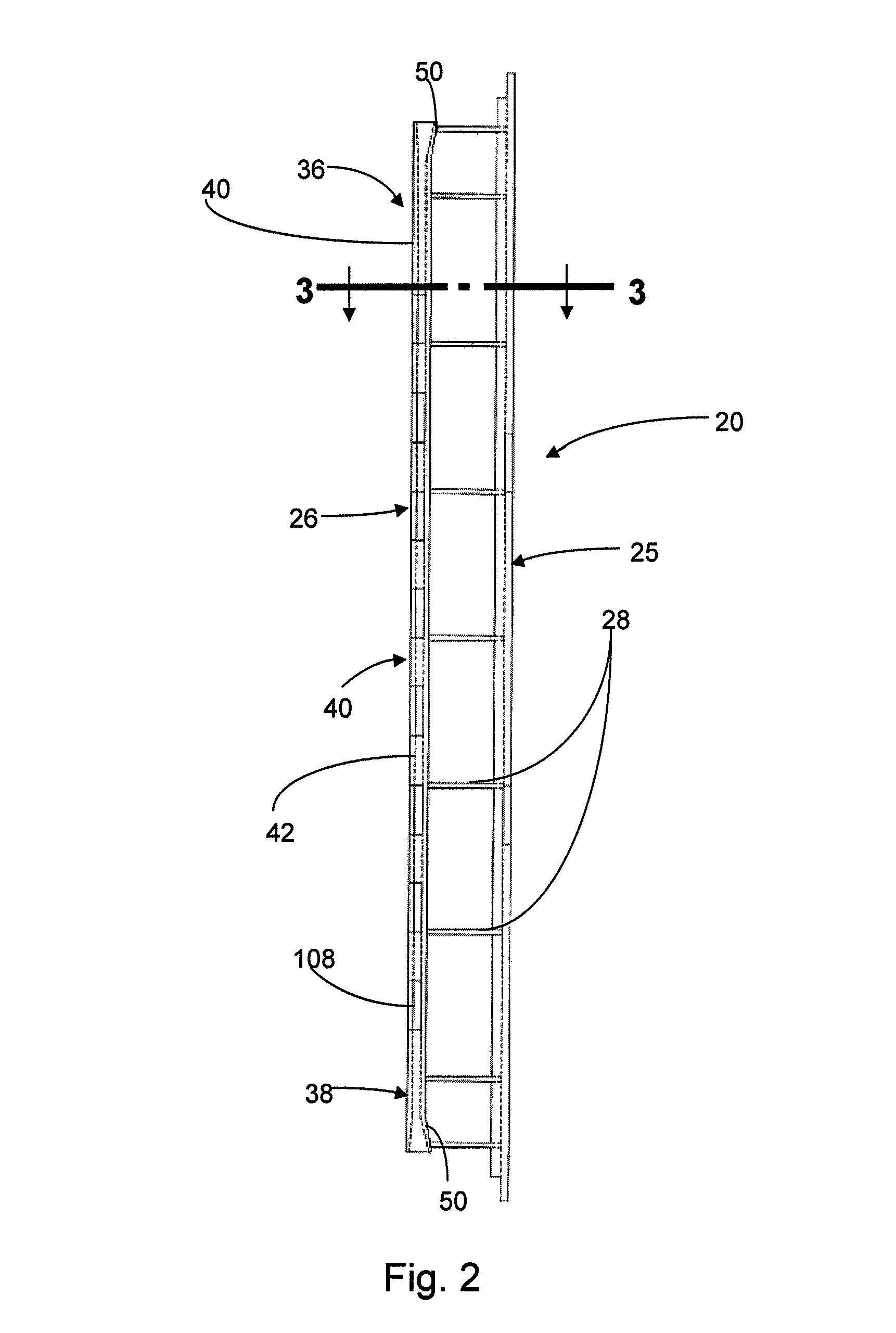

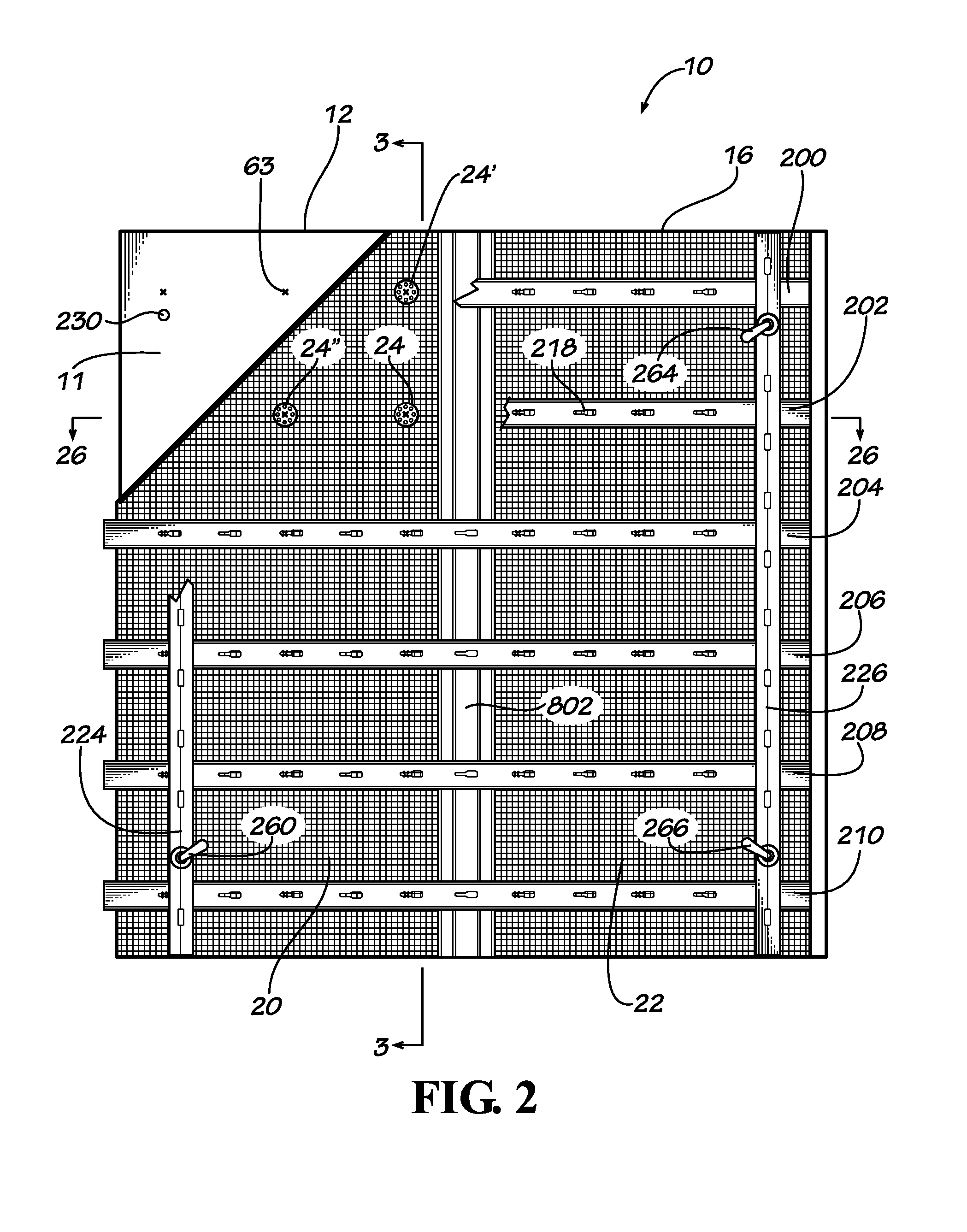

Insulated concrete form and method of using same

InactiveUS20130074432A1Retain heatEasy and inexpensive attachmentCeilingsConstruction materialInsulating concrete formFlange

Owner:CIUPERCA ROMEO ILARIAN

Lightweight compositions and articles containing such

A lightweight cementitious composition containing from 22 to 90 volume percent of a cement composition and from 10 to 78 volume percent of particles having an average particle diameter of from 0.2 mm to 8 mm, a bulk density of from 0.03 g / cc to 0.64 g / cc, an aspect ratio of from 1 to 3, where after the lightweight cementitious composition is set it has a compressive strength of at least 1700 psi as tested according to ASTM C39. The cementitious composition can be used to make concrete masonry units, construction panels, road beds and other articles and can be included as a layer on wall panels and floor panels and can be used in insulated concrete forms. Aspects of the lightweight cementitious composition can be used to make lightweight structural units.

Owner:SYNTHEON

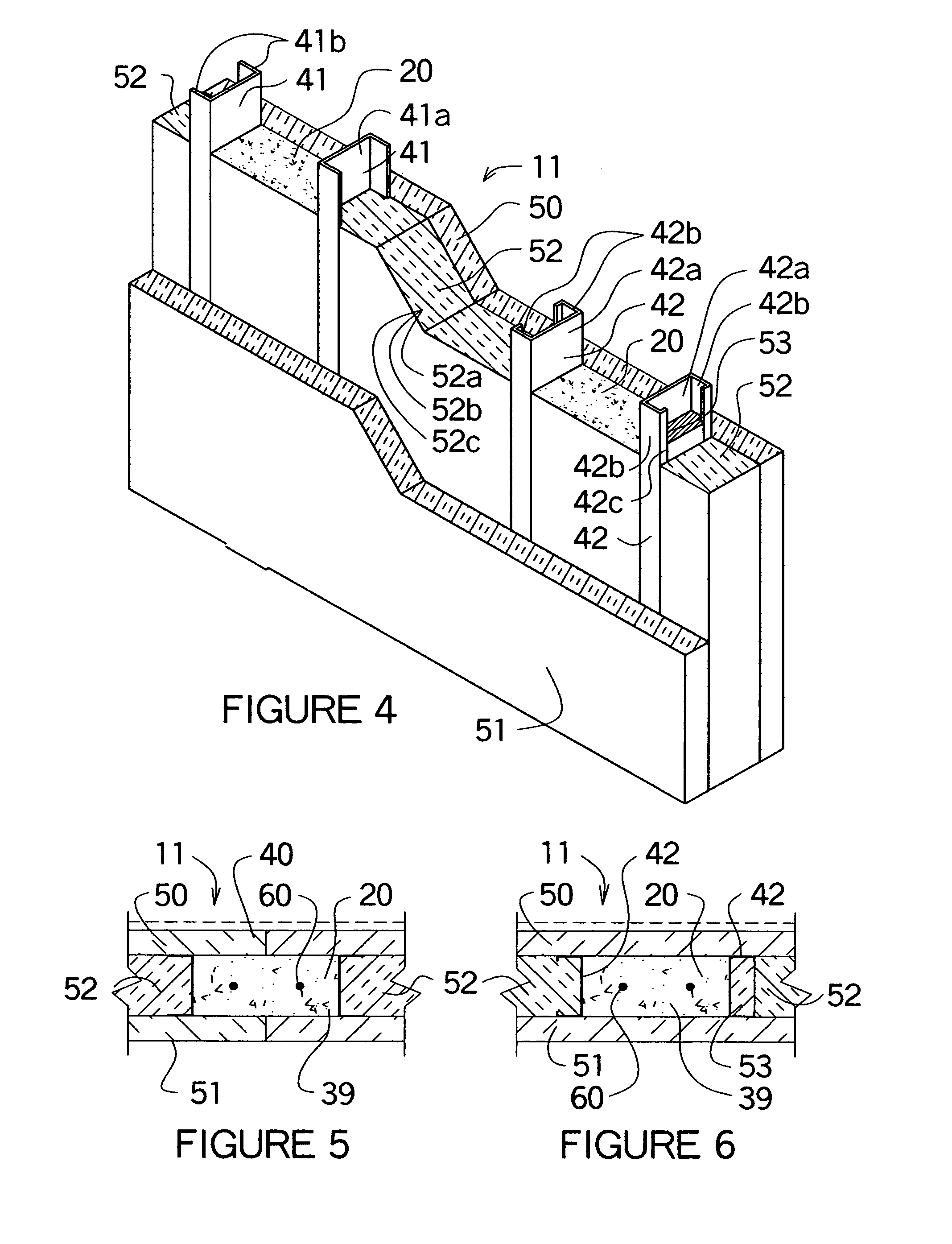

Insulating concrete form having locking mechanism engaging tie with anchor

Owner:AIRLITE PLASTICS

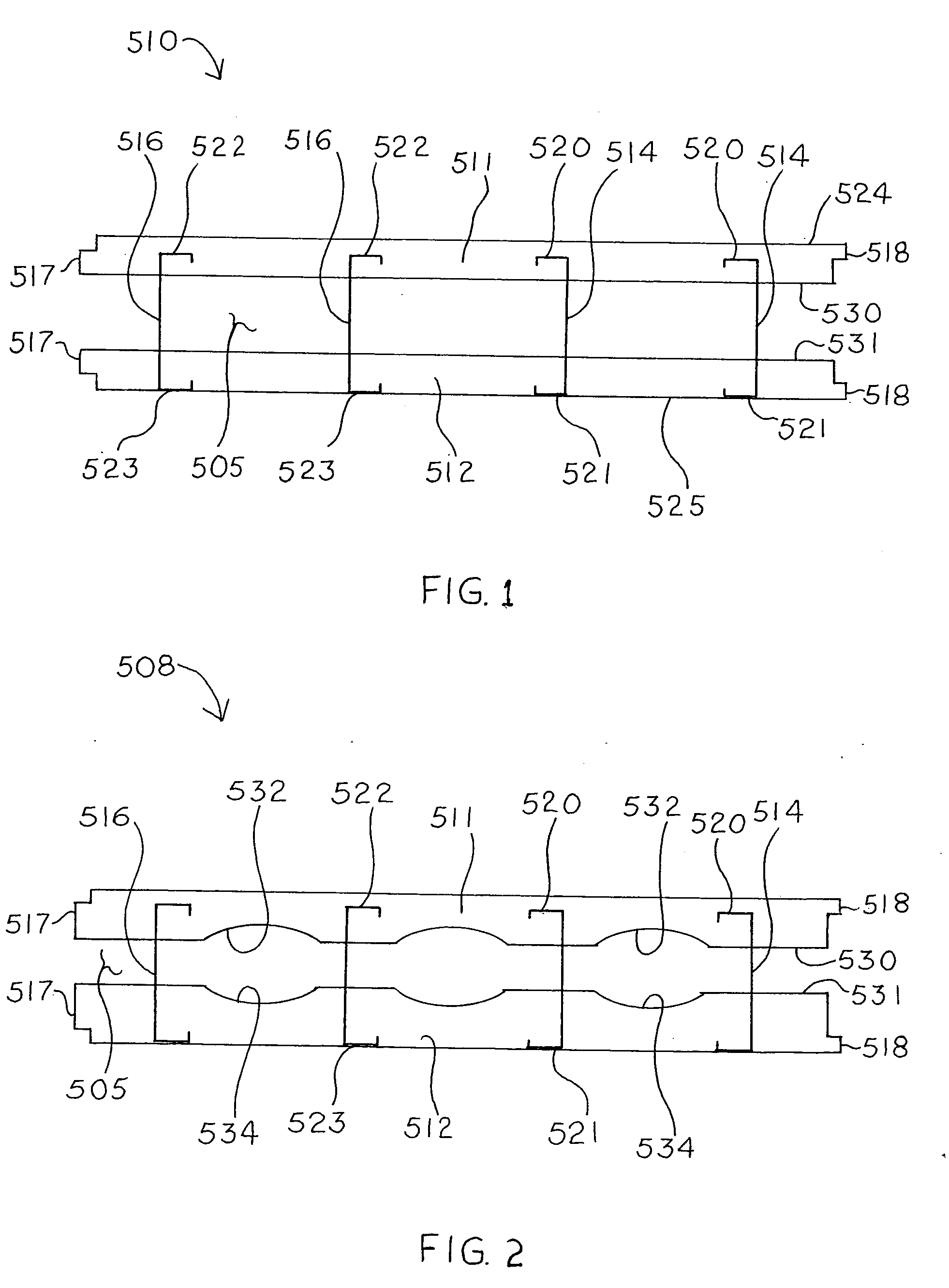

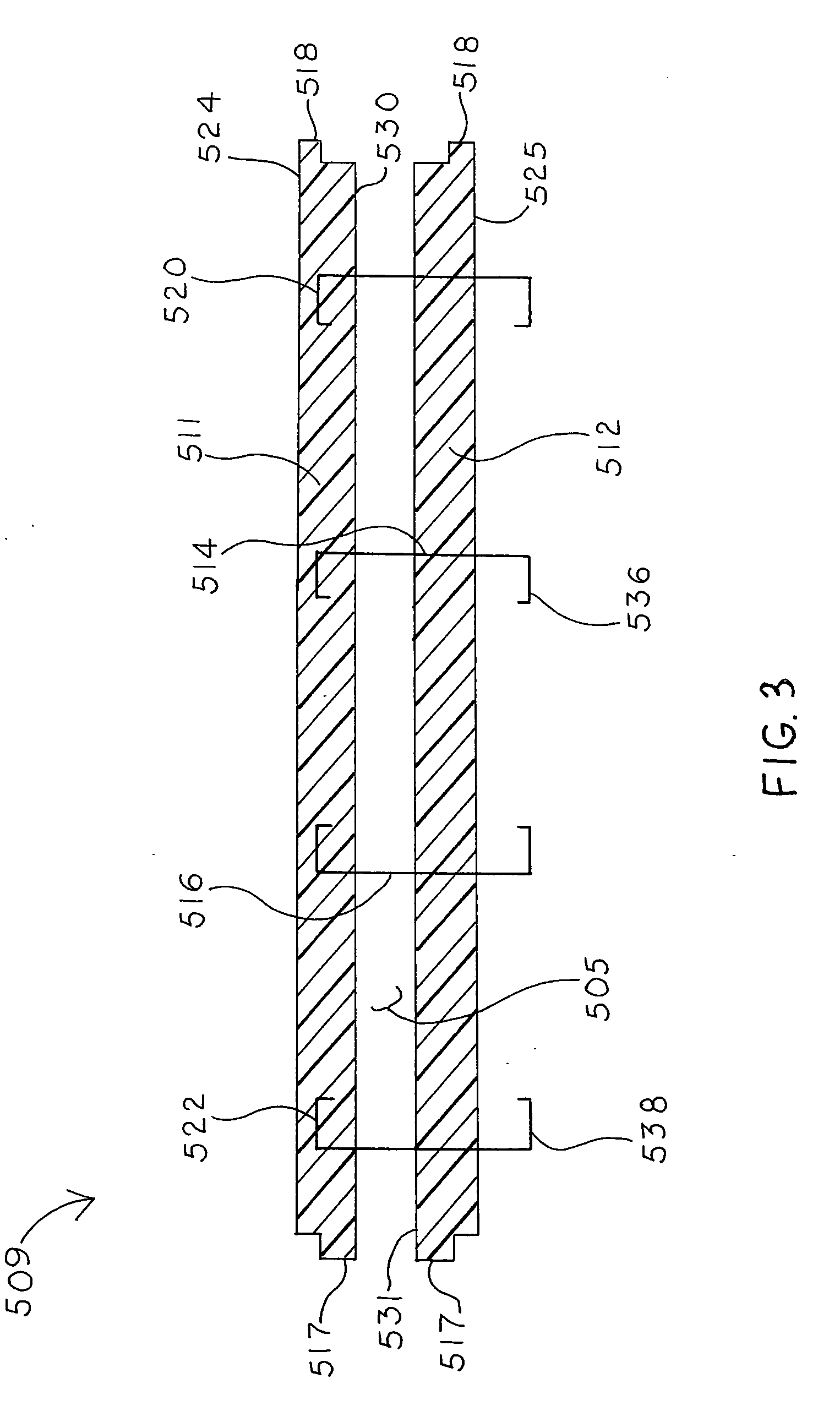

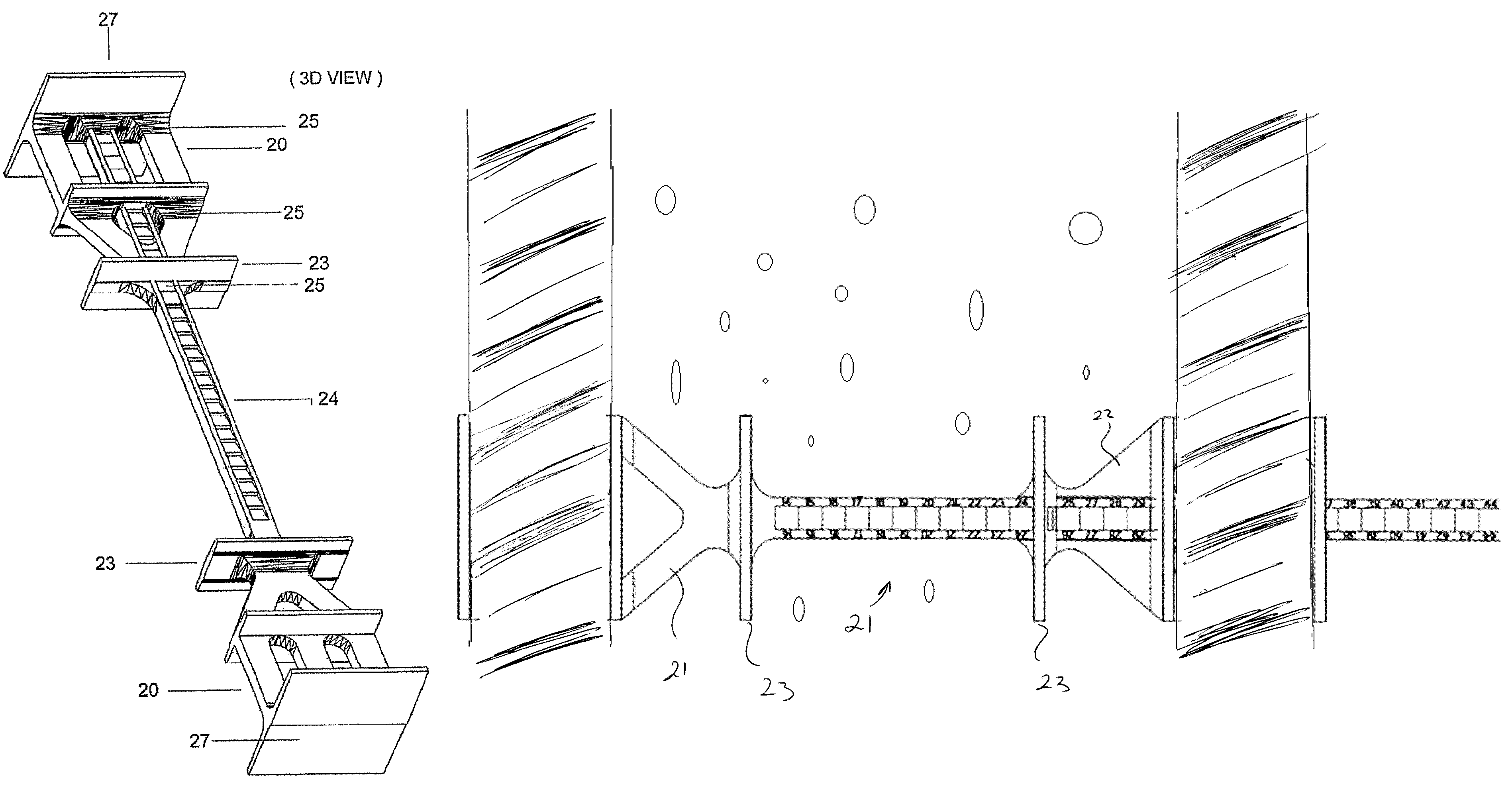

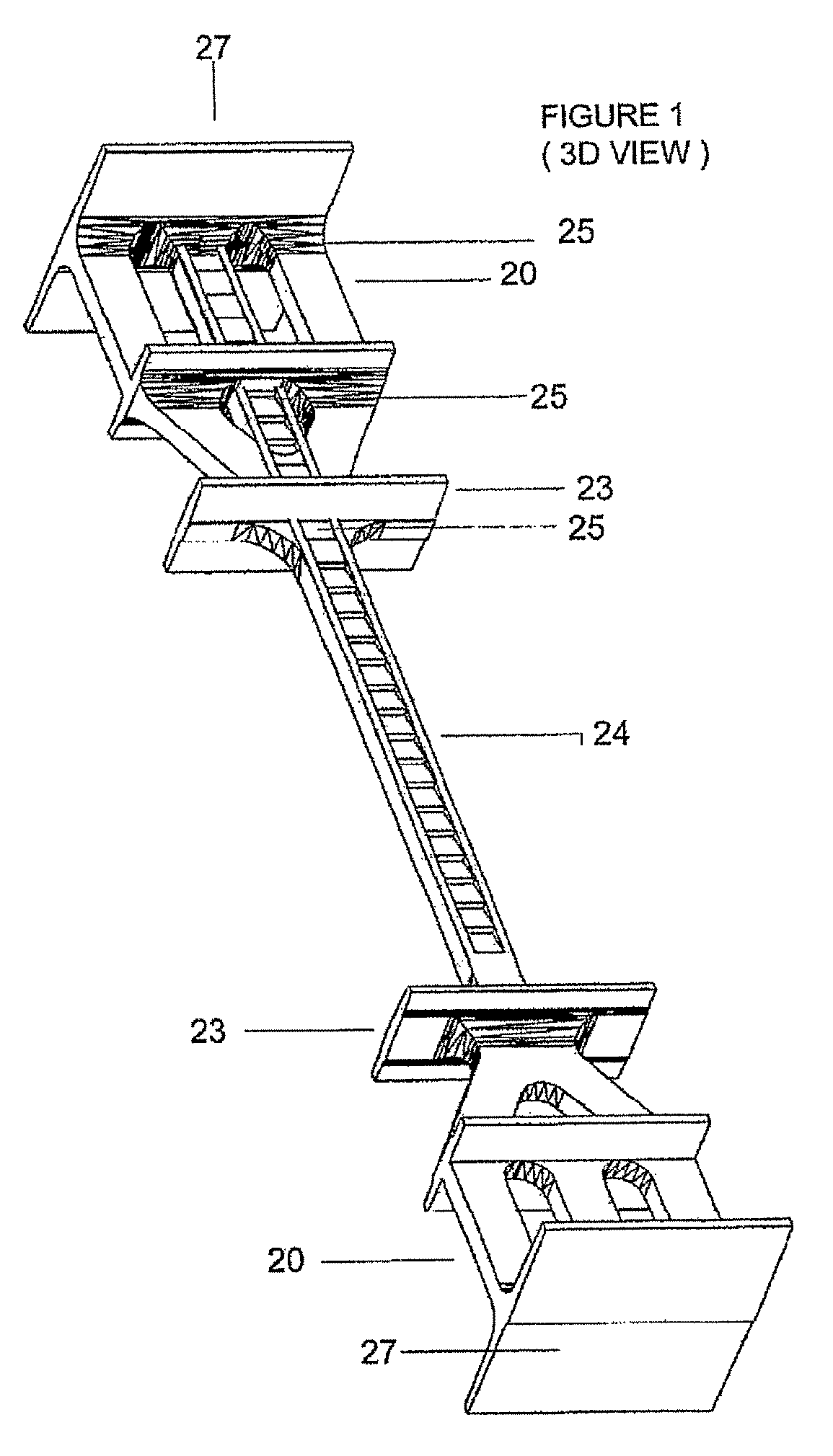

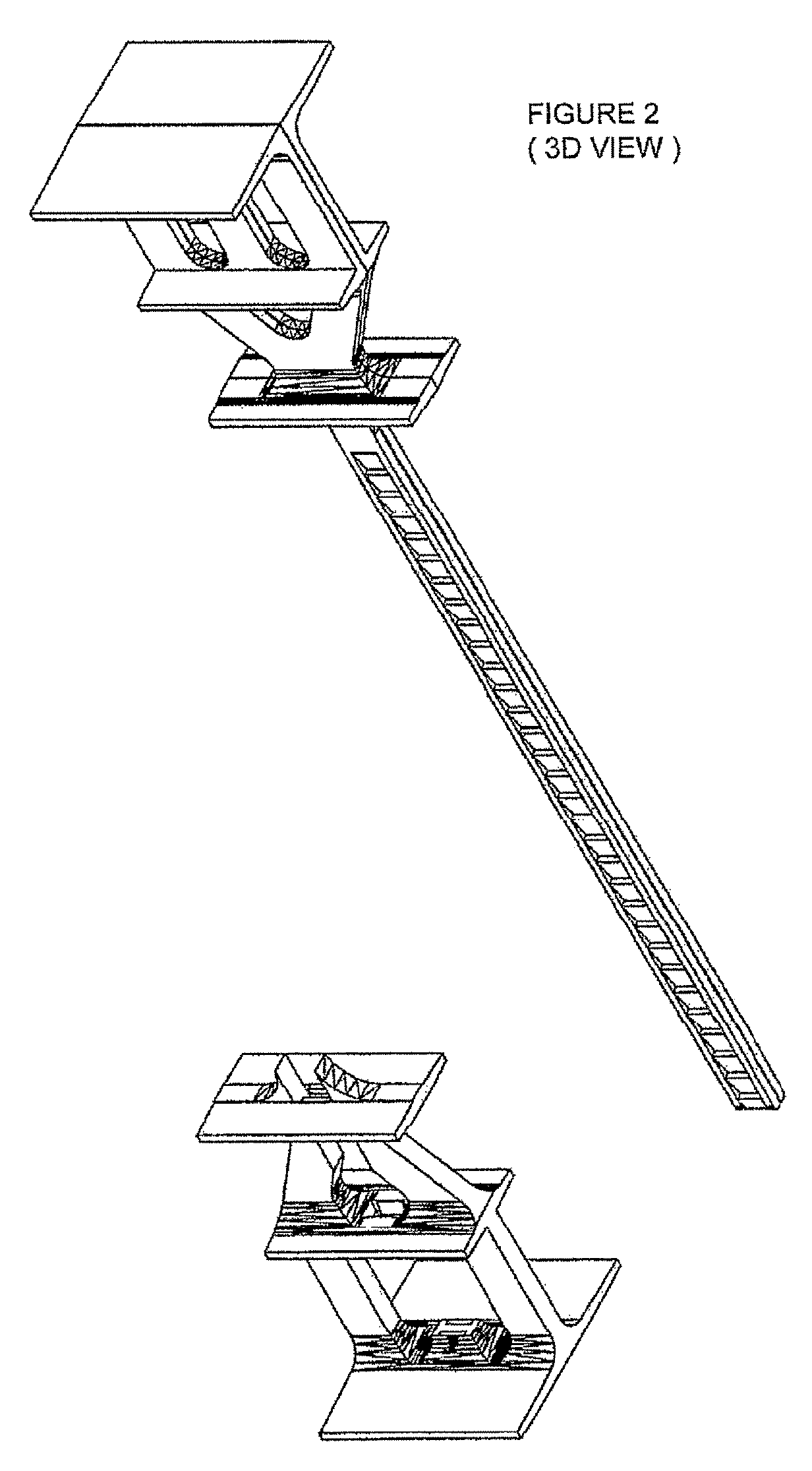

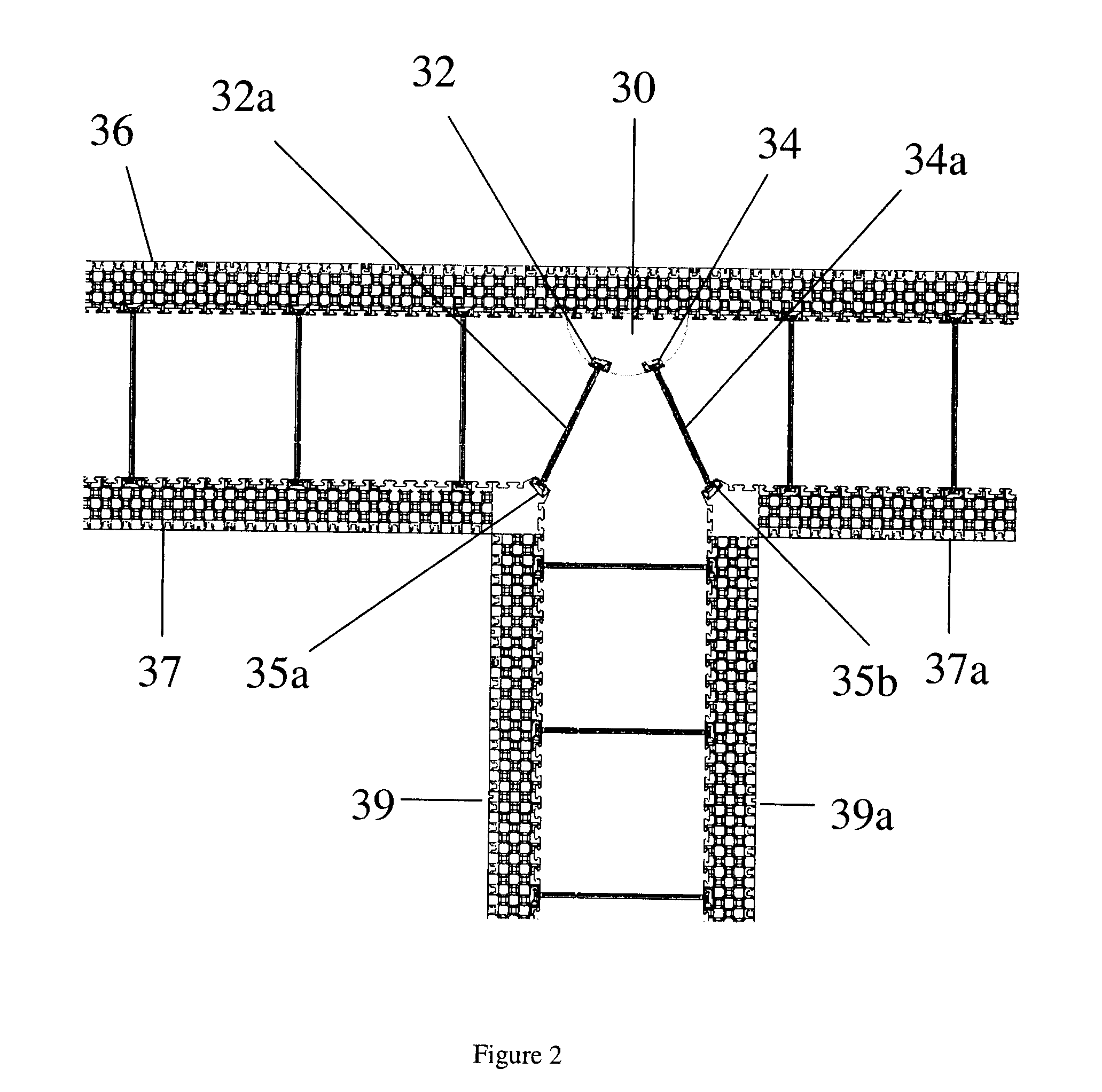

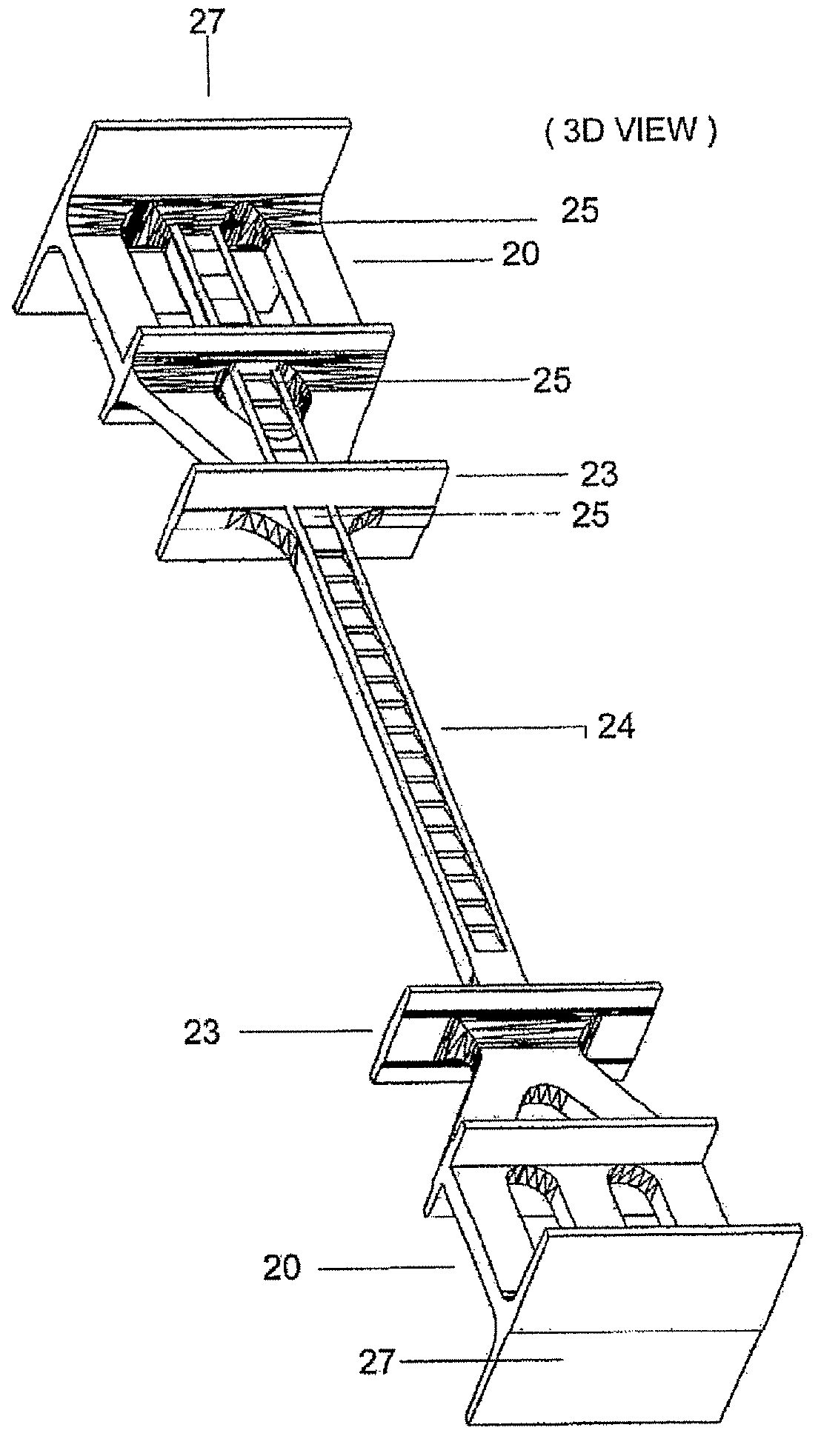

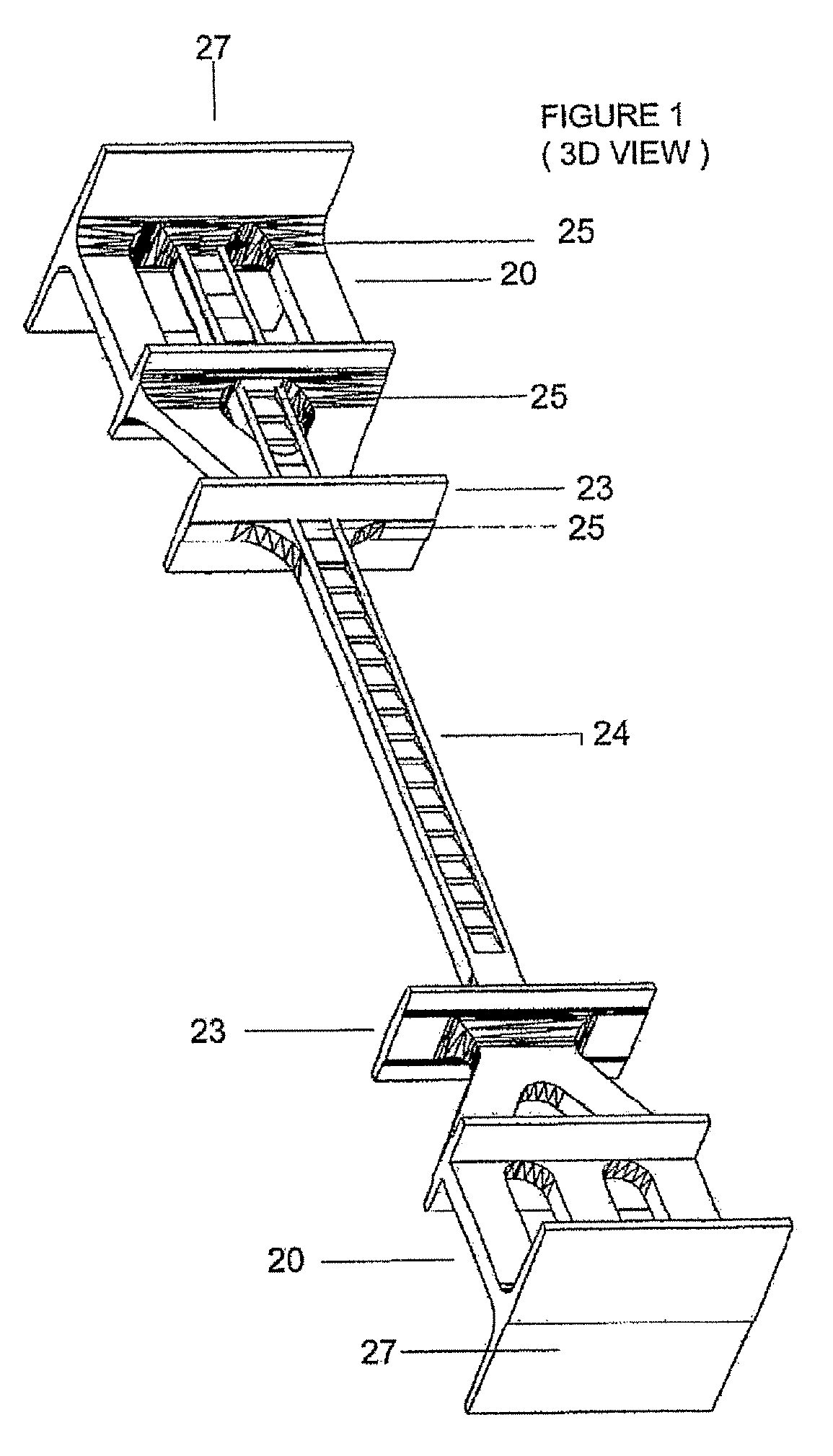

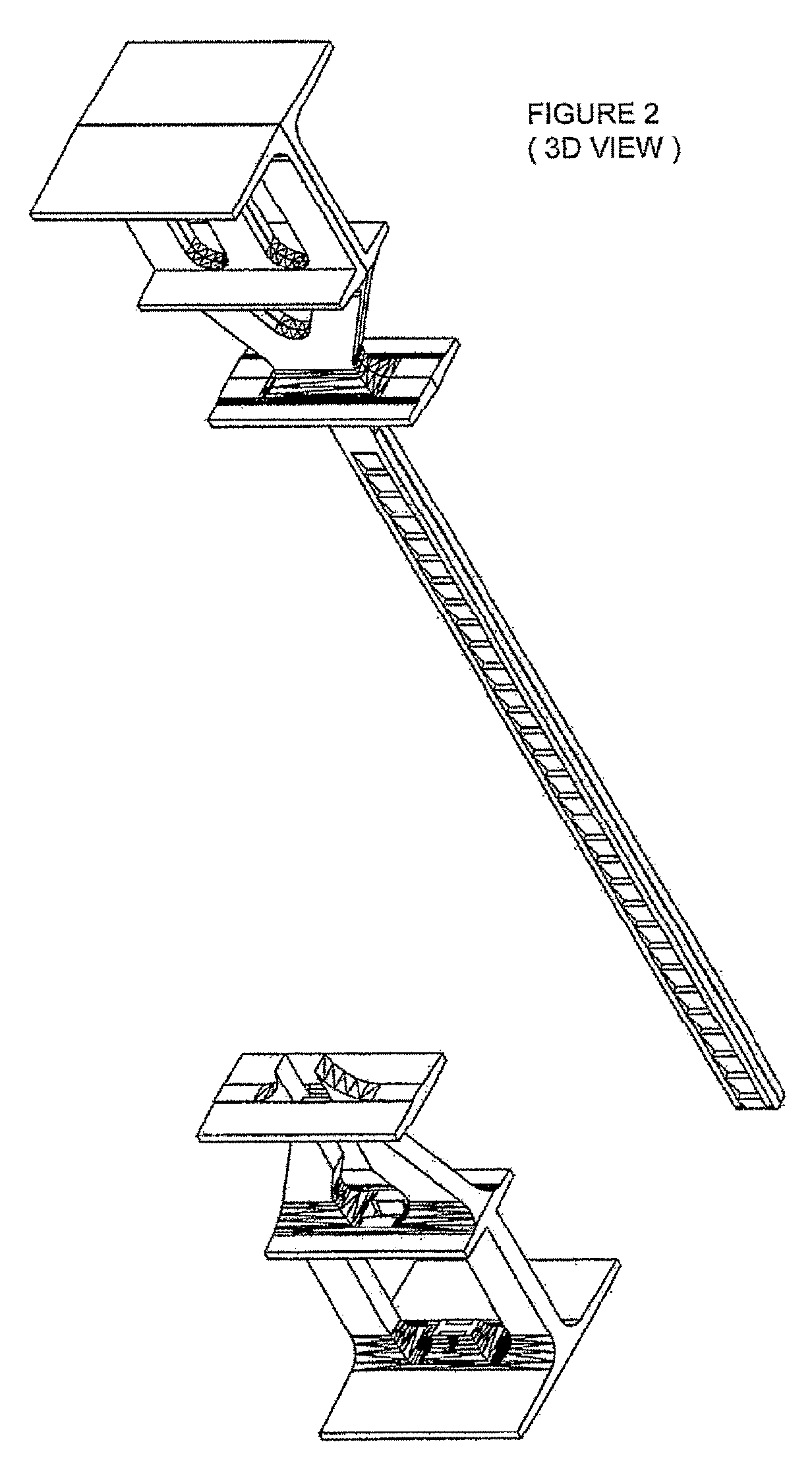

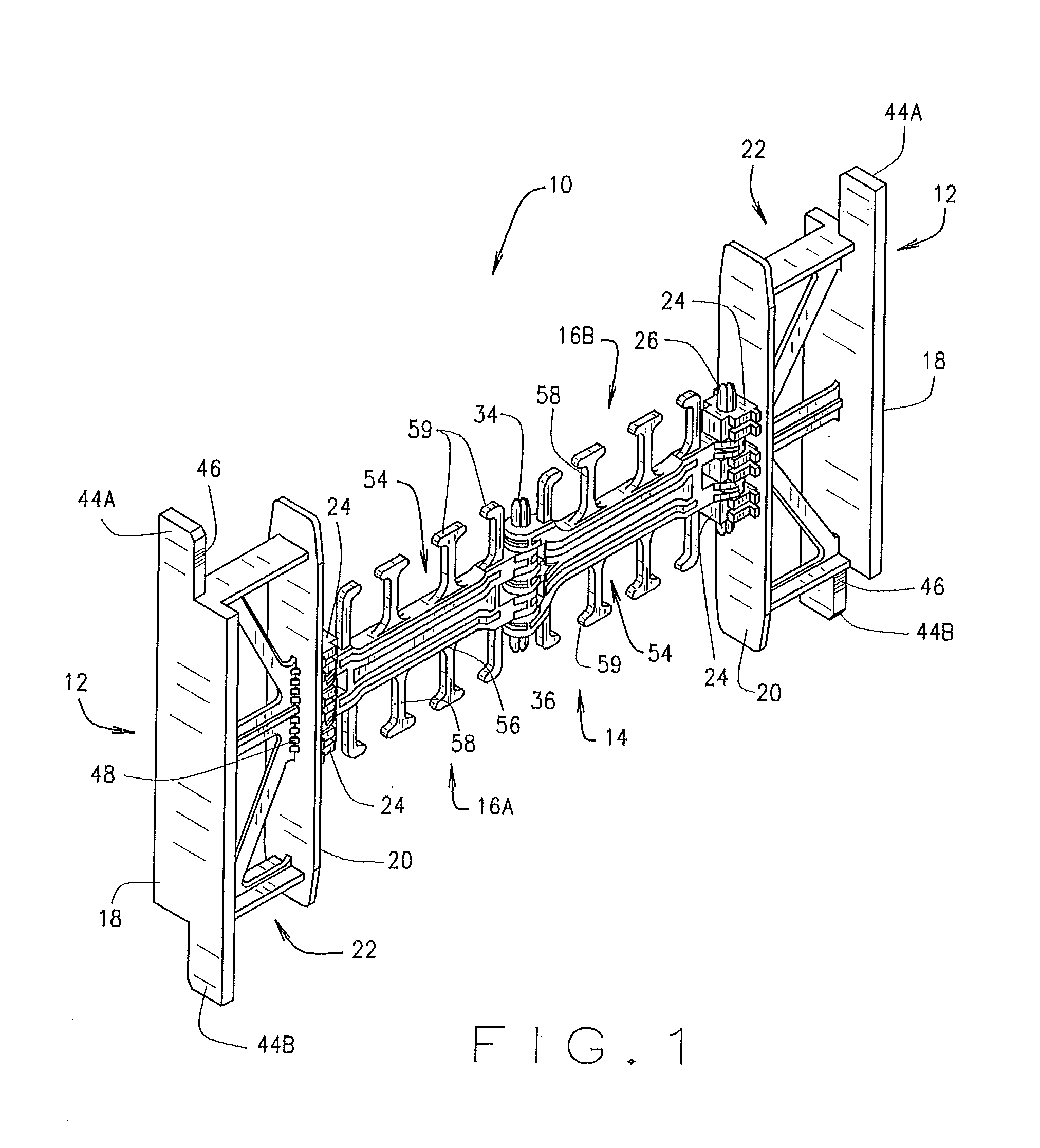

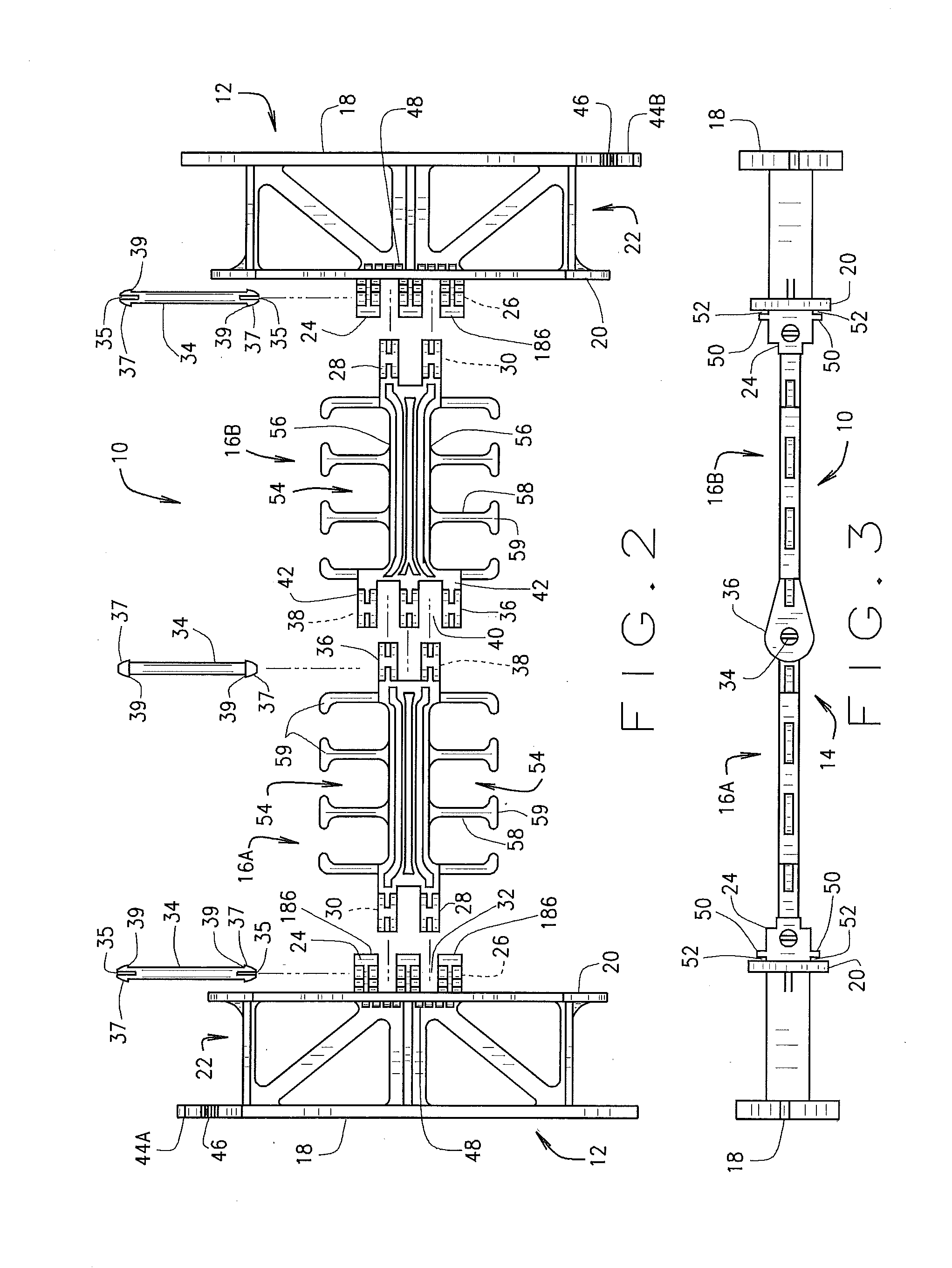

Insulated concrete form system with variable length wall ties

InactiveUS7818935B2Accelerate buildingFaster and cheap and better buildingWallsAuxillary members of forms/shuttering/falseworksEngineeringPolypropylene

Variable length polypropylene ties are used to form an insulated concrete wall by holding sheet materials in a fixed distance part so concrete can be cast between the two sheet materials.

Owner:VELICKOVIC PJER MISE

Insulated concrete form and method of using same

InactiveUS8756890B2Improve sound insulationImproved curing environmentCeilingsConstruction materialEngineeringInsulating concrete form

Owner:CIUPERCA ROMEO ILARIAN

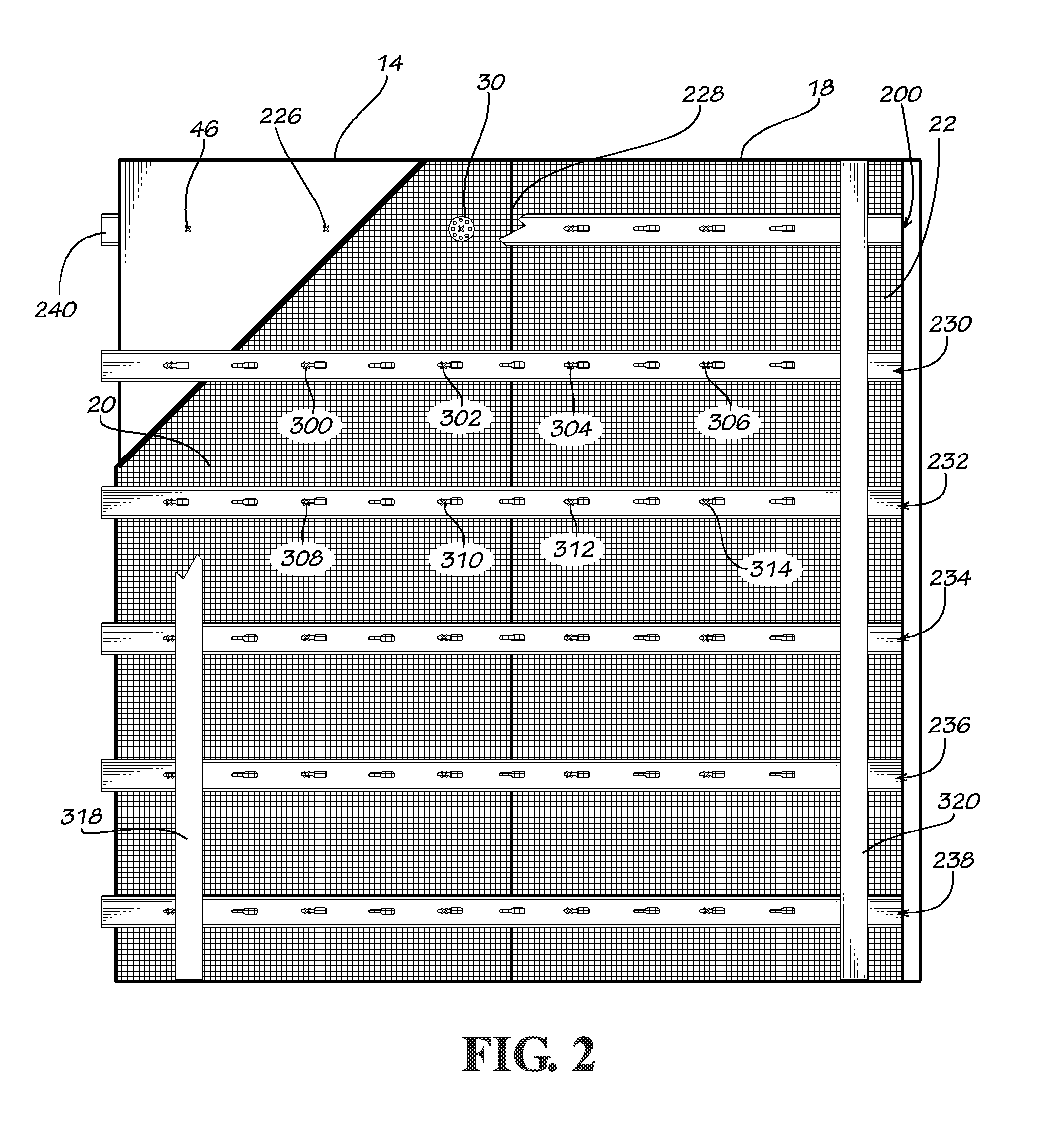

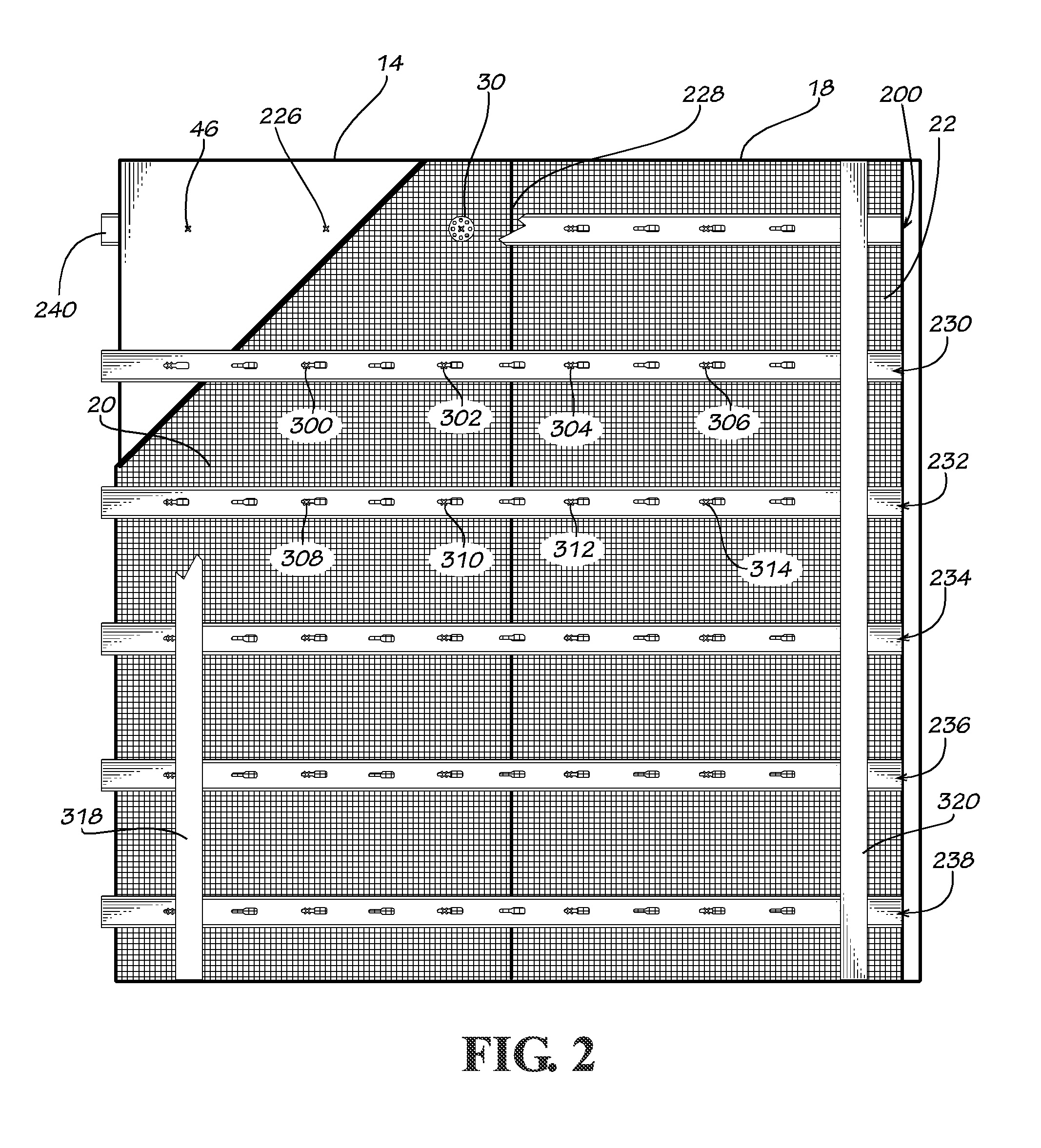

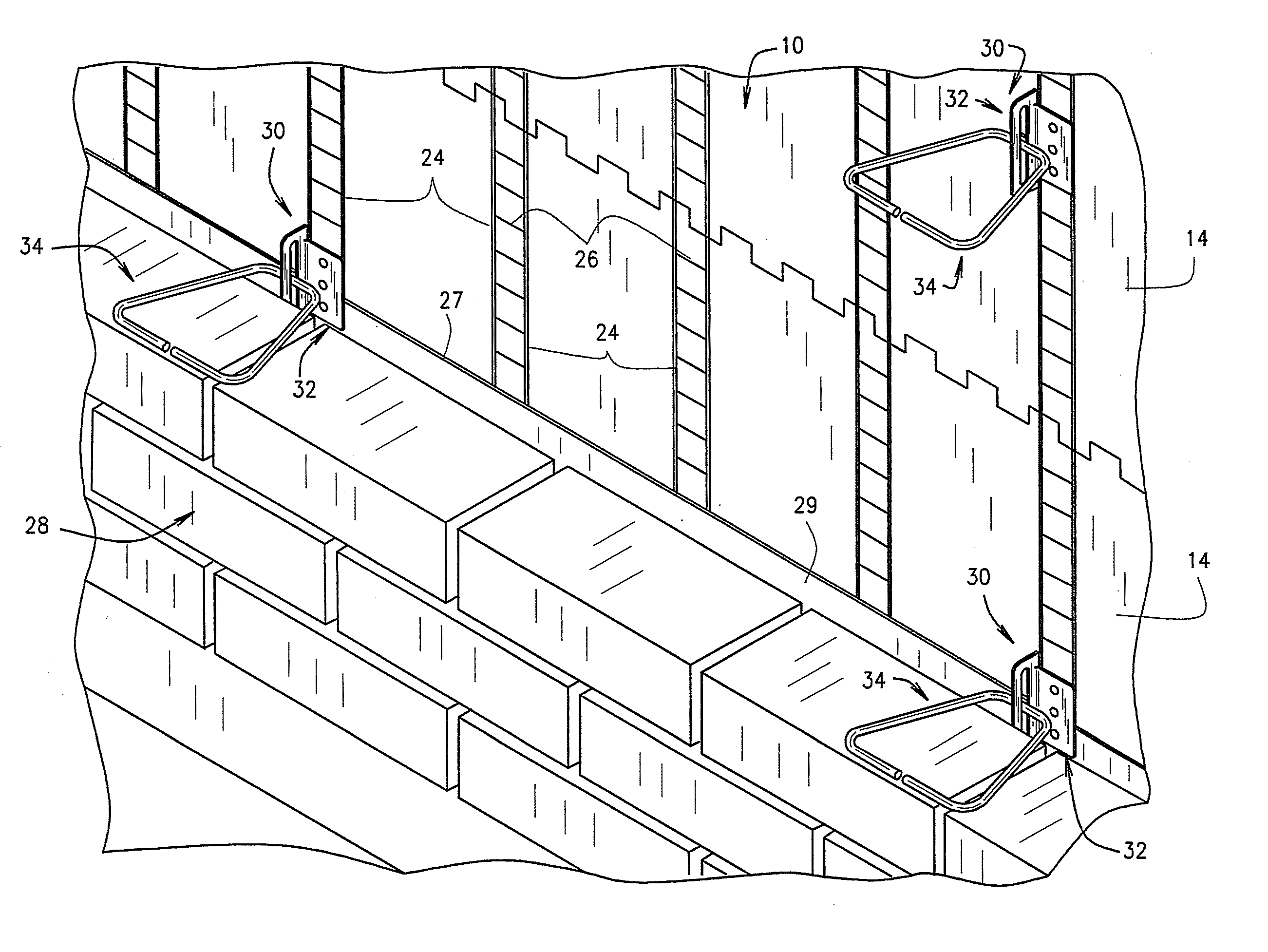

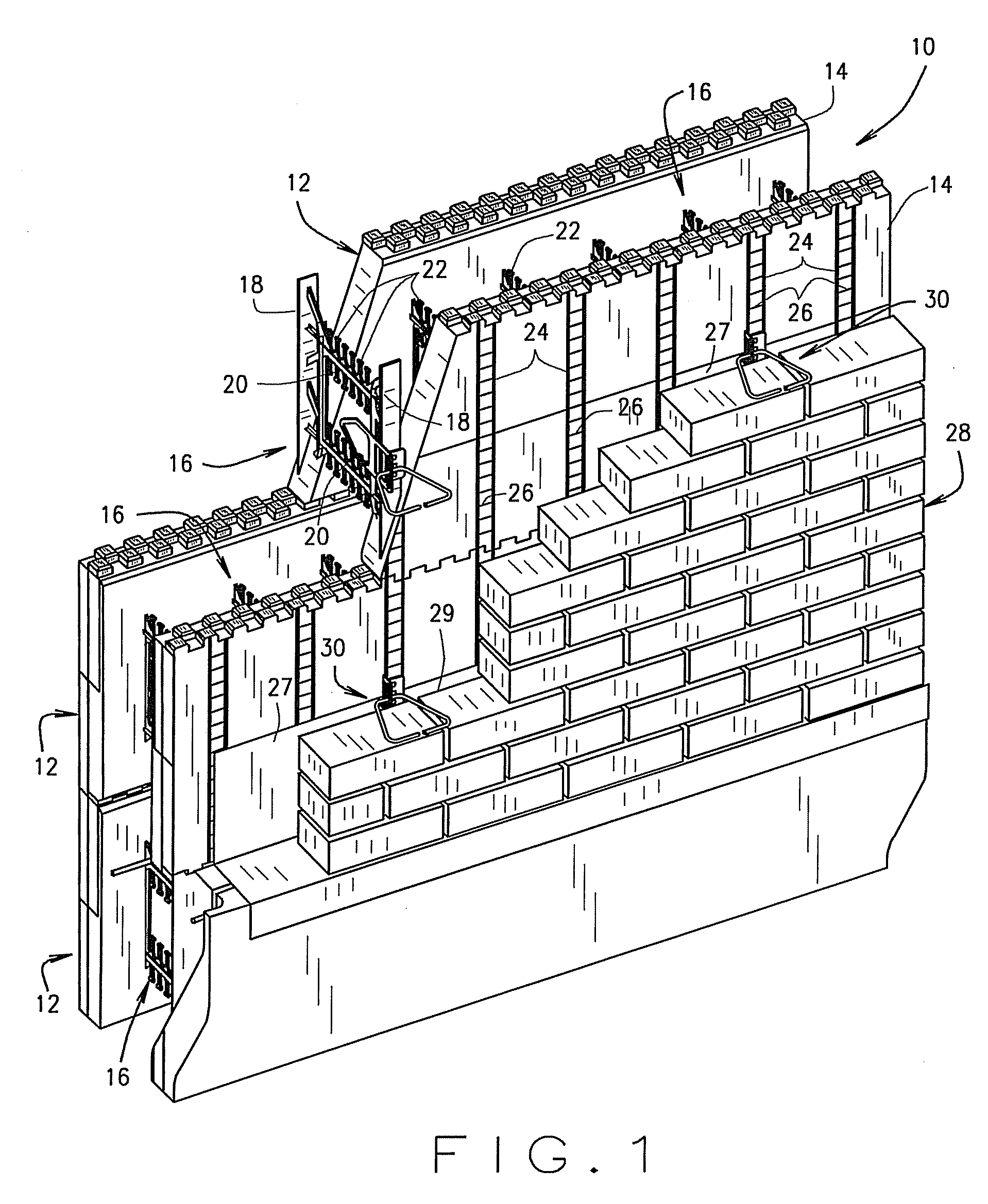

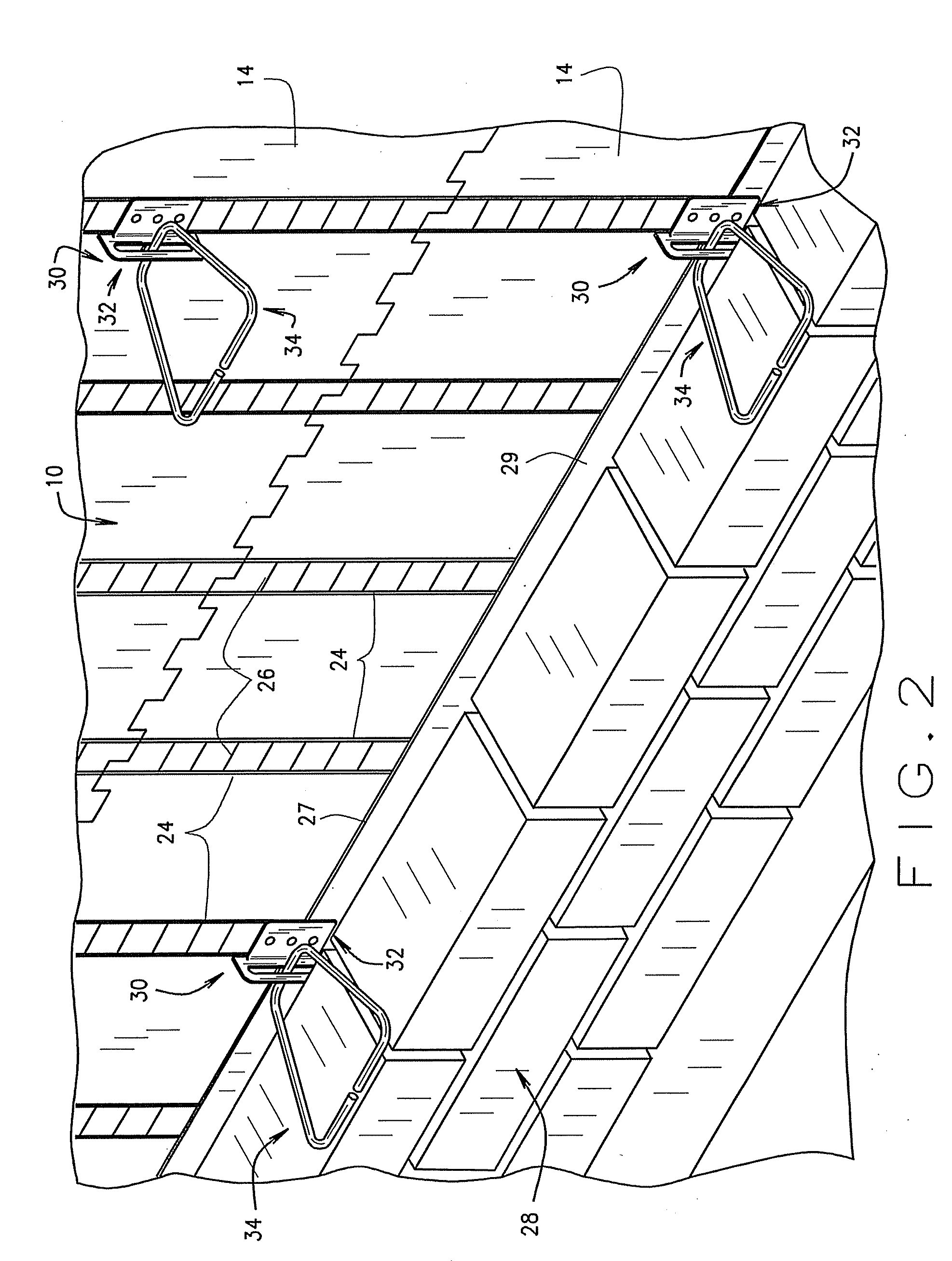

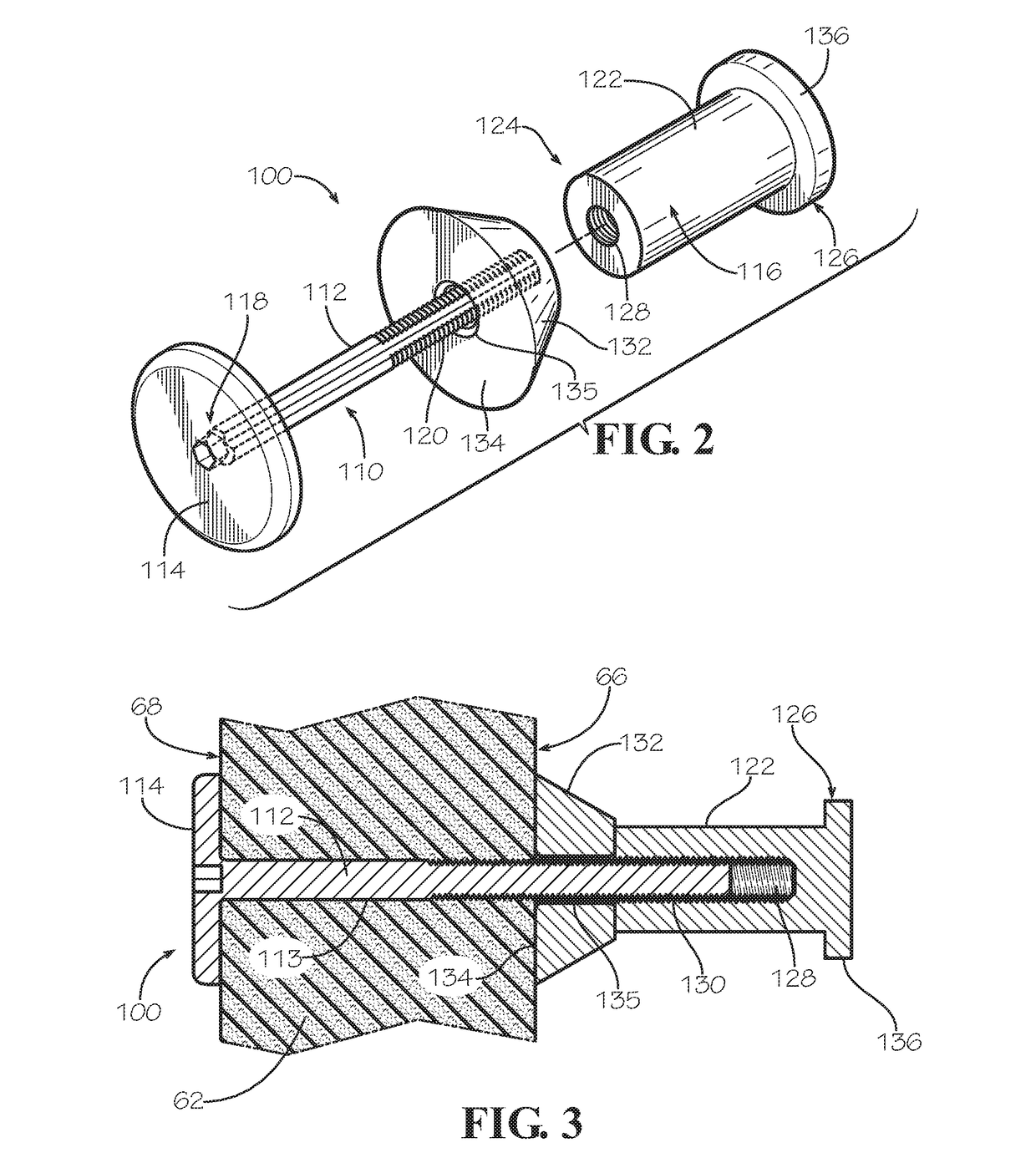

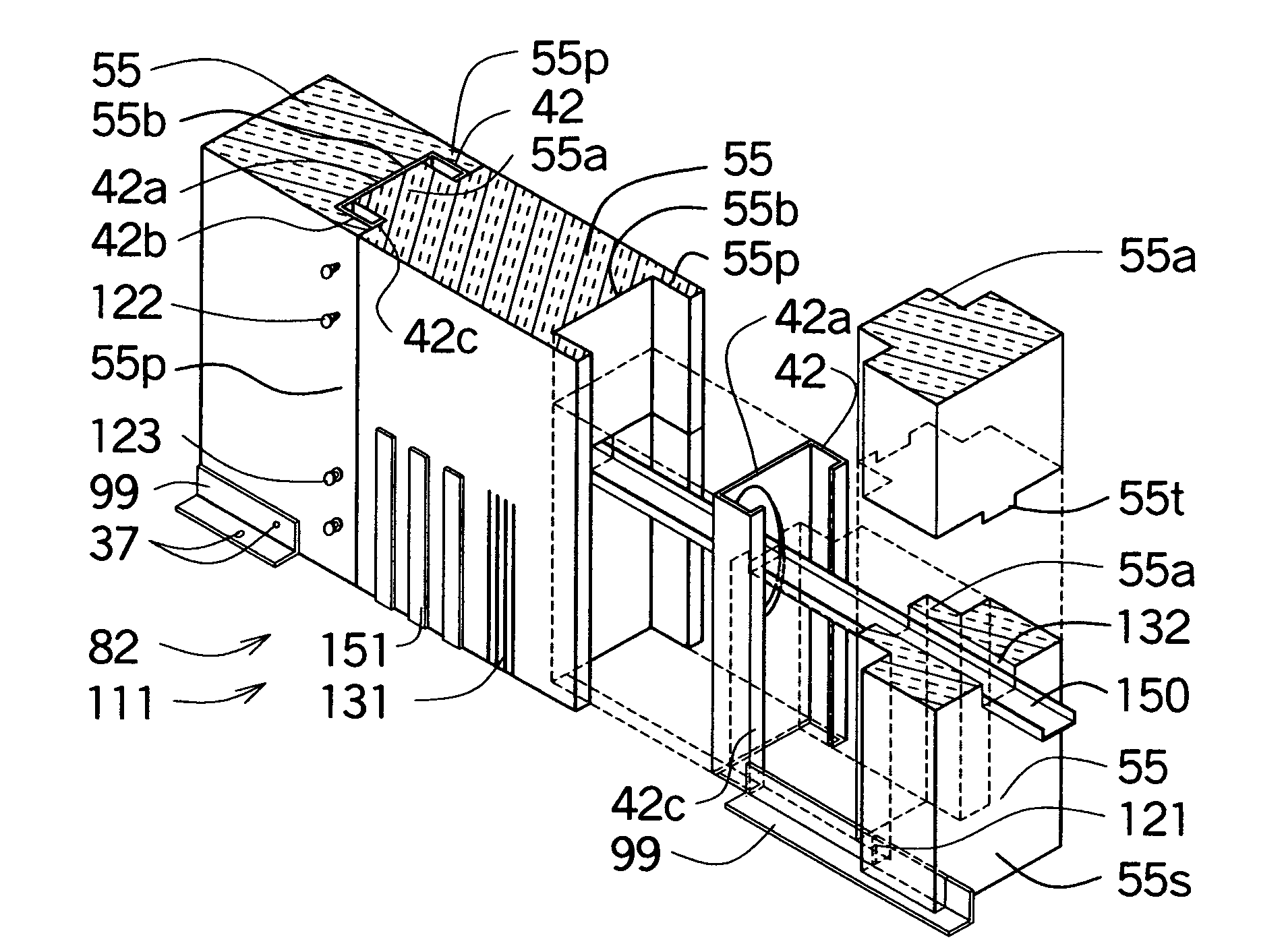

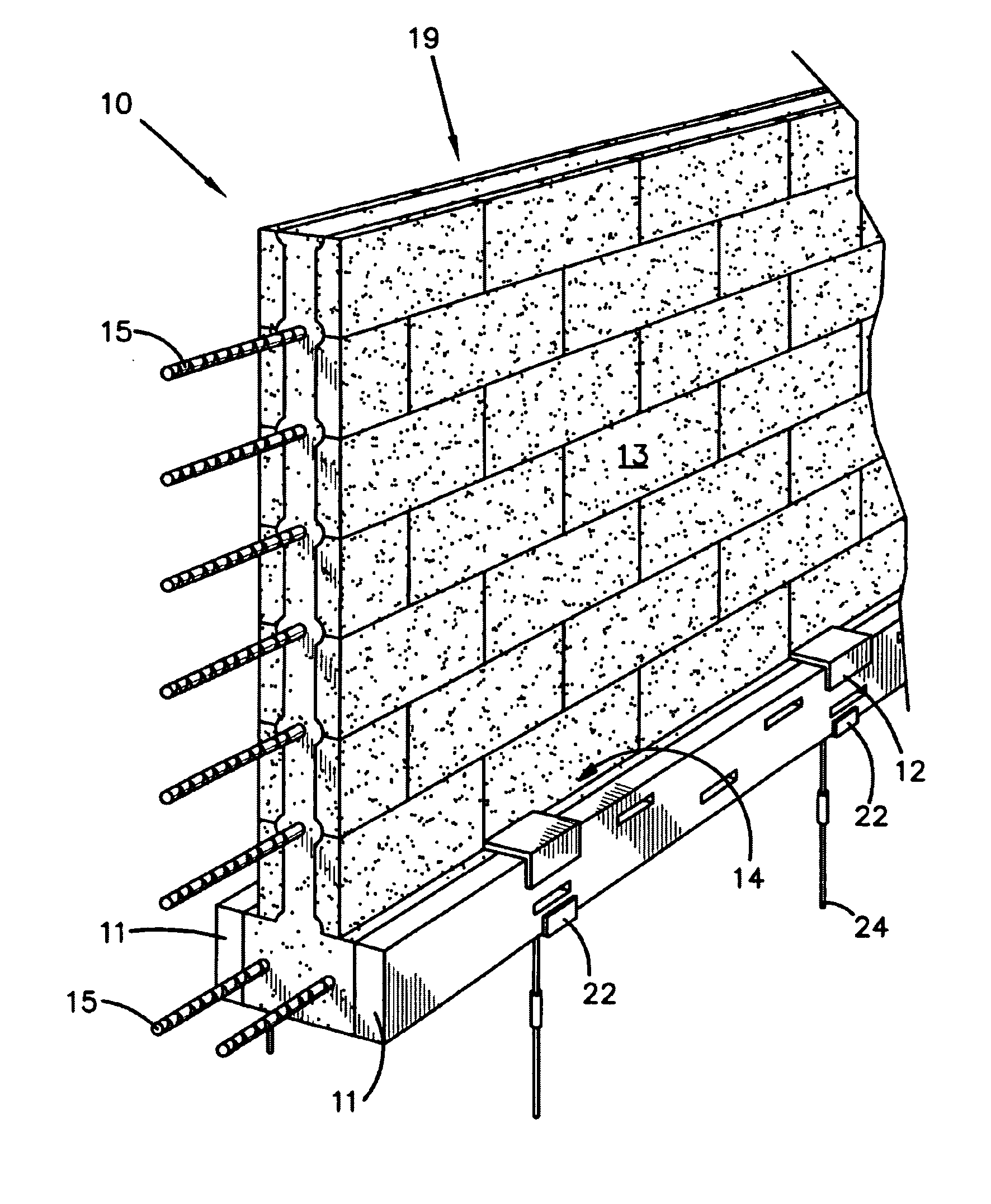

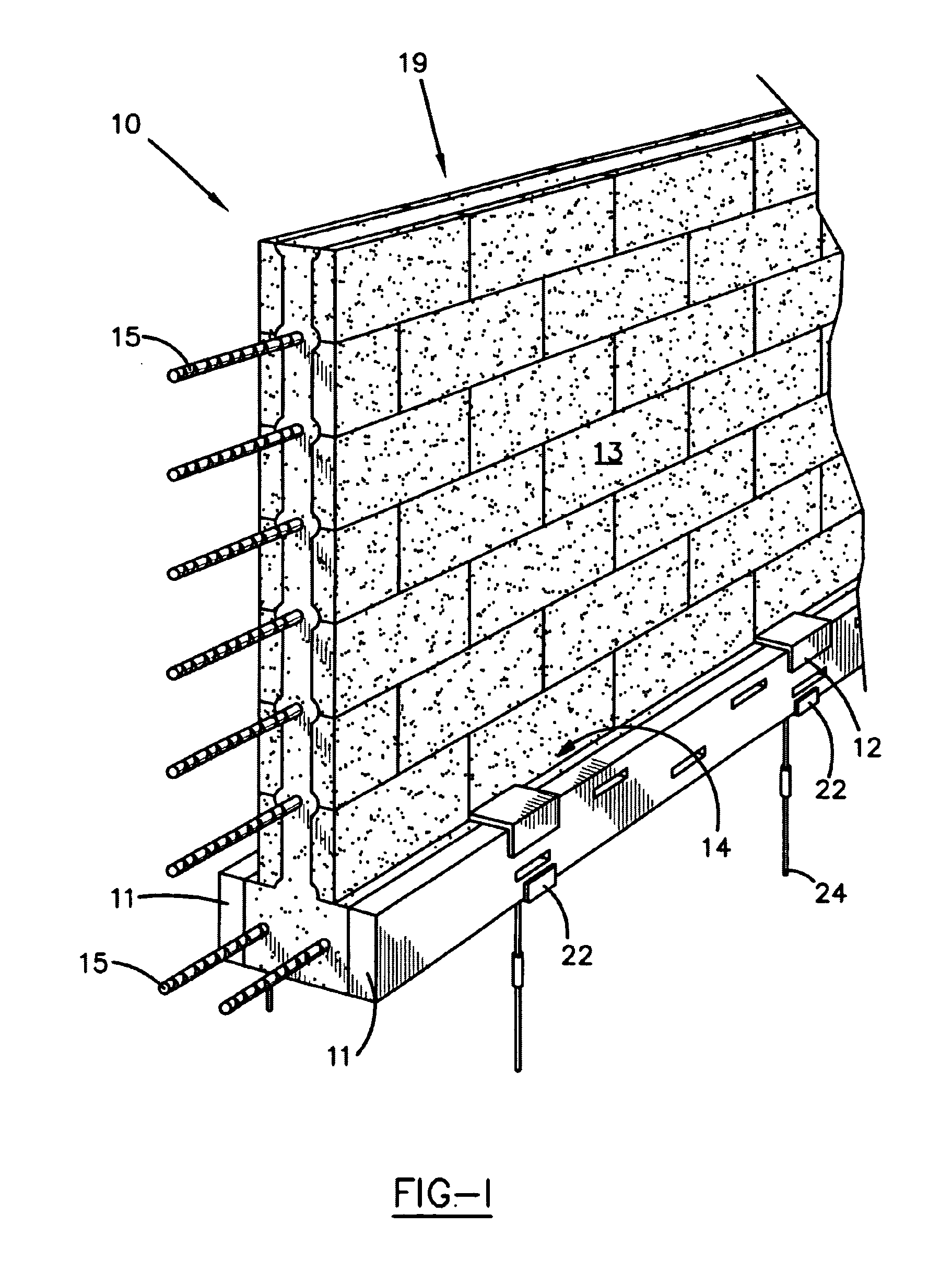

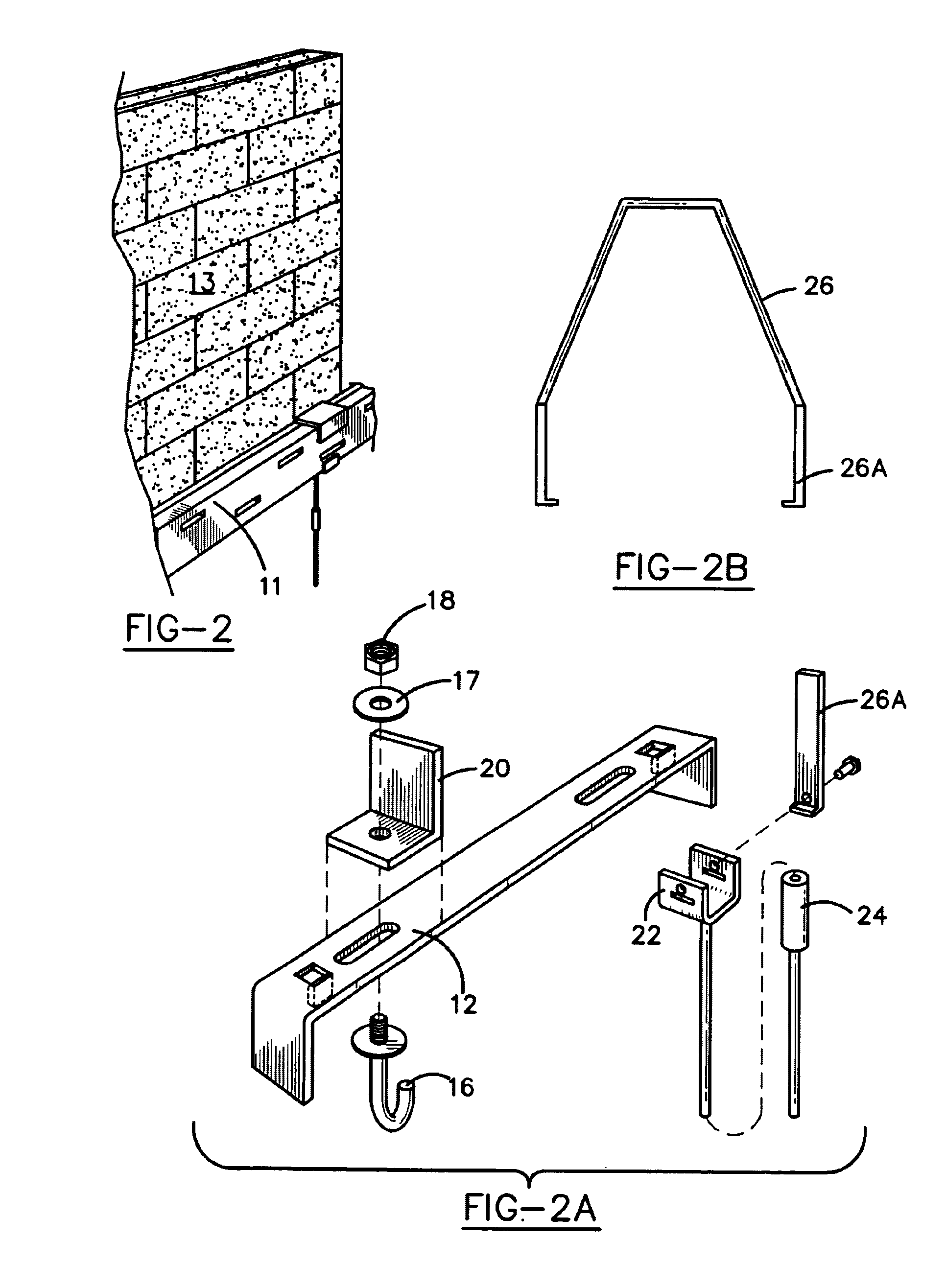

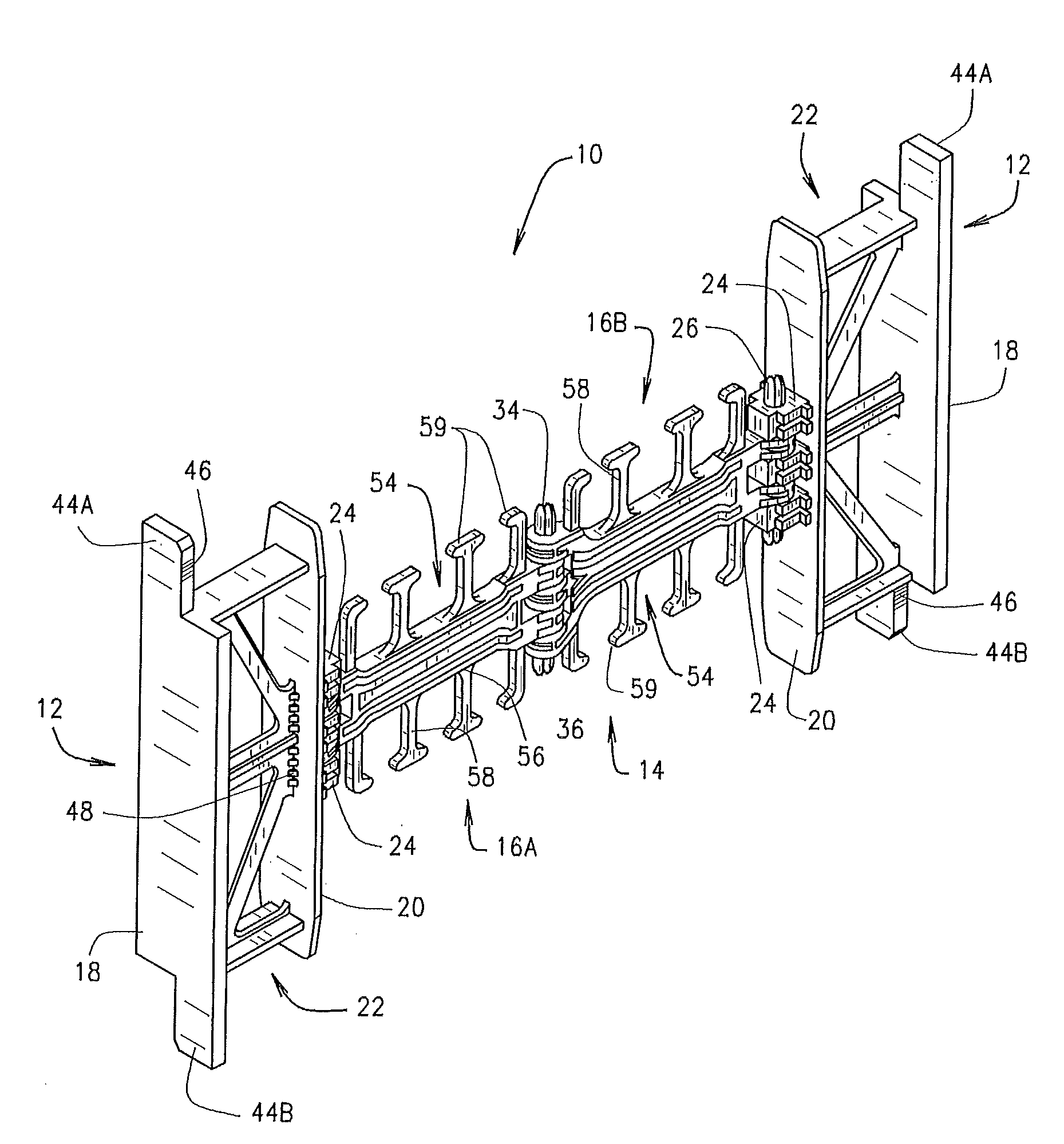

Adjustable masonry anchor assembly for use with insulating concrete form systems

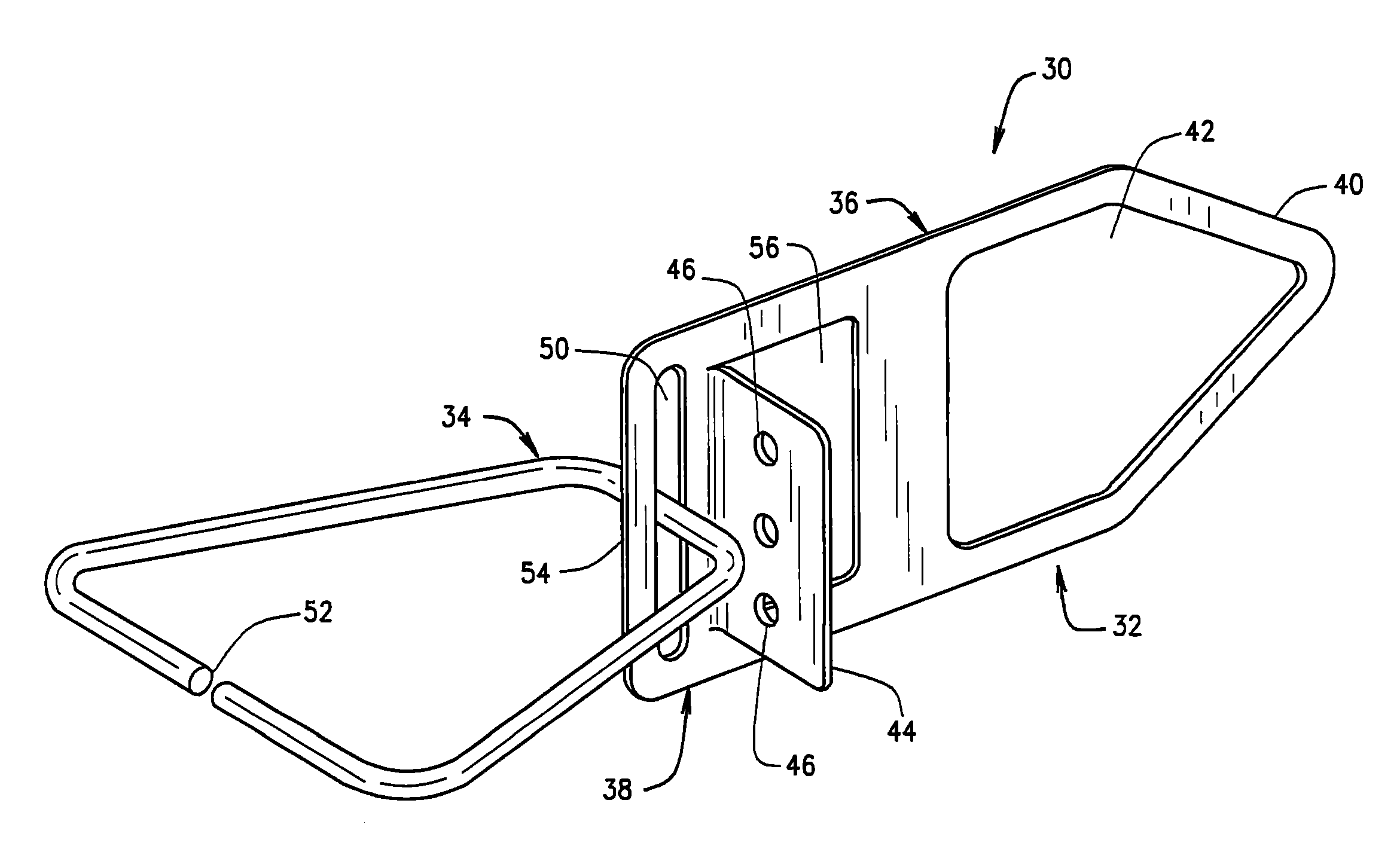

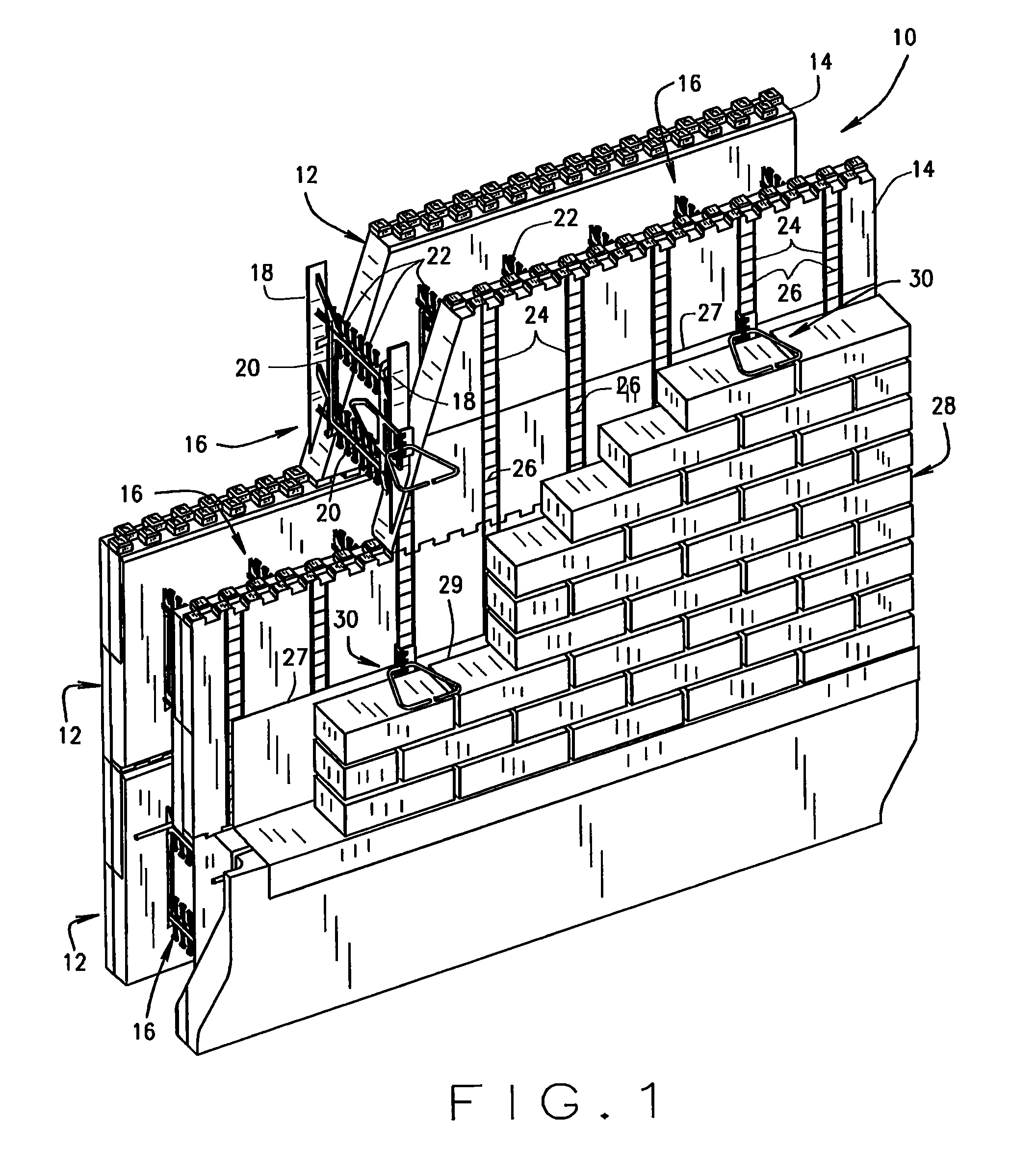

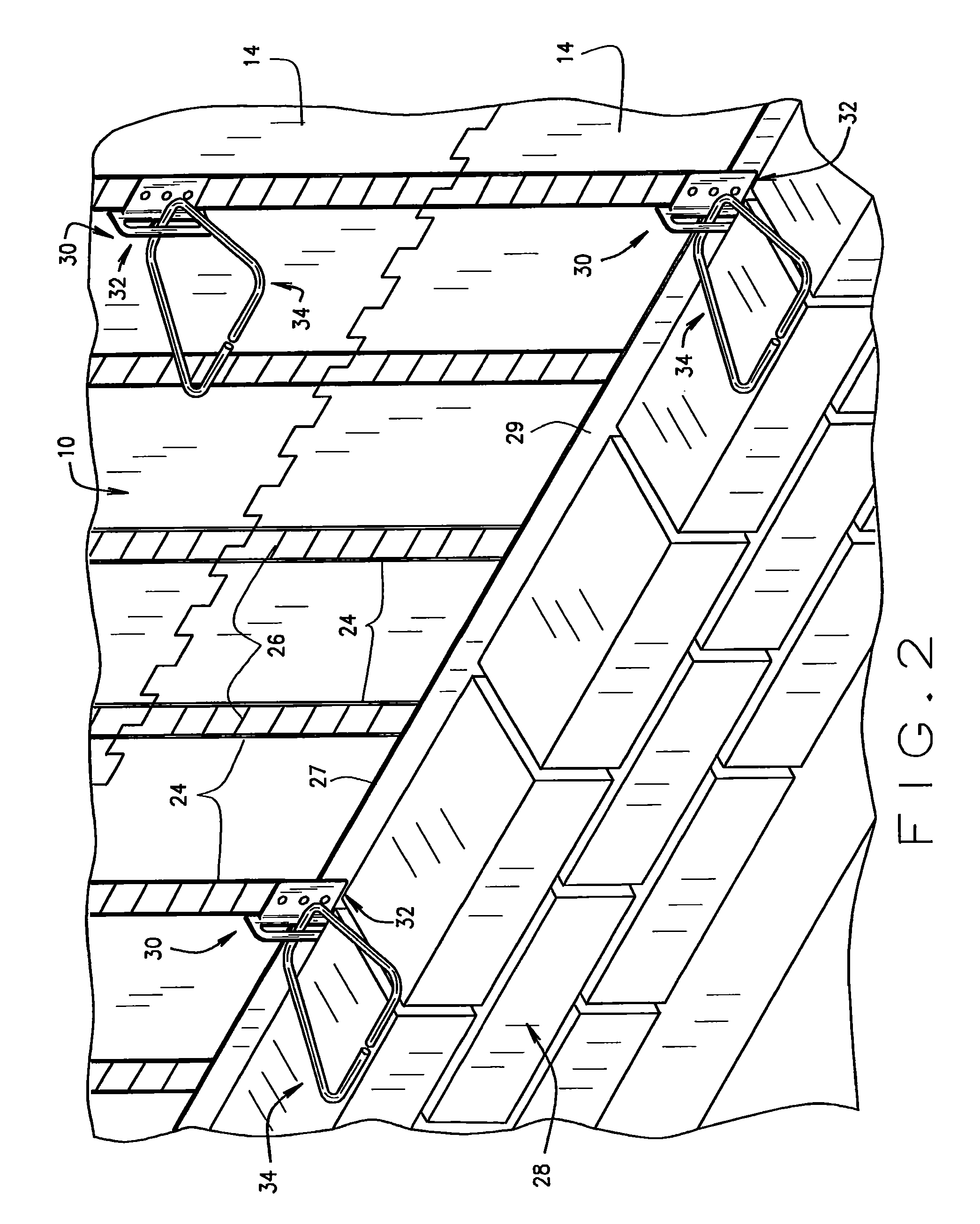

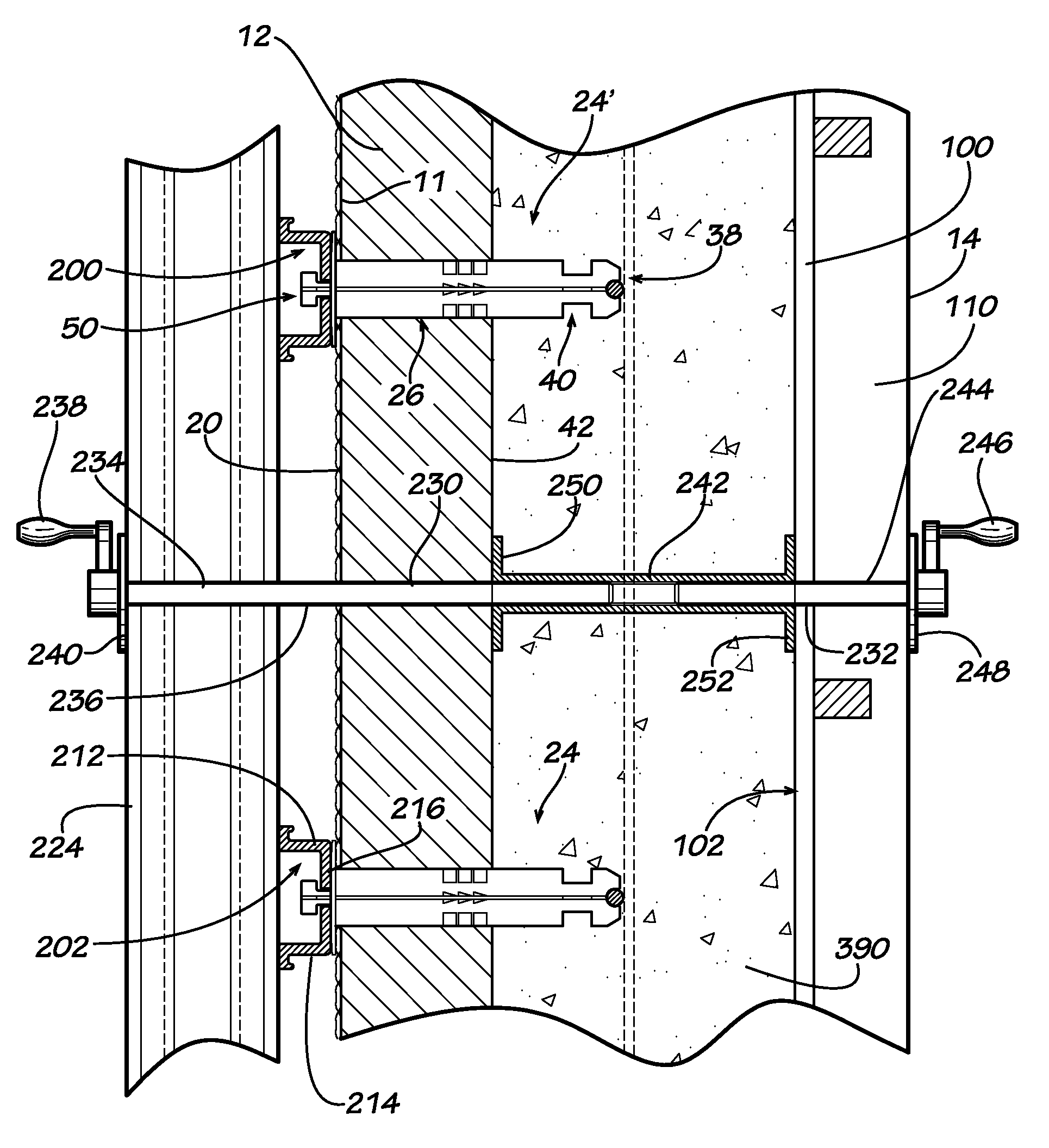

An anchor assembly for use in joining together a masonry wall structure and a supporting back wall structure wherein the back wall structure is preferably formed using insulated concrete form (ICF) blocks each having a pair of opposed ICF panels associated therewith, the anchor assembly including an anchor member and a tie member. The anchor member includes an anchor portion adapted to penetrate one of the ICF panels and having at least one opening associated therewith so as to lie between the opposed ICF panels when attached thereto for allowing poured concrete to flow therethrough, and an attachment portion having a tab member positioned and located to overlay an ICF panel flange member when the anchor member is inserted within the ICF panel, the tab member being attachable to the ICF panel flange member. The attachment portion further includes an elongated slot for receiving the tie member, the tie member being adjustably movable along the length of the slot so as to be positionable between the courses of brick or other masonry material associated with the masonry wall structure as the masonry wall structure is being erected.

Owner:AIRLITE PLASTICS

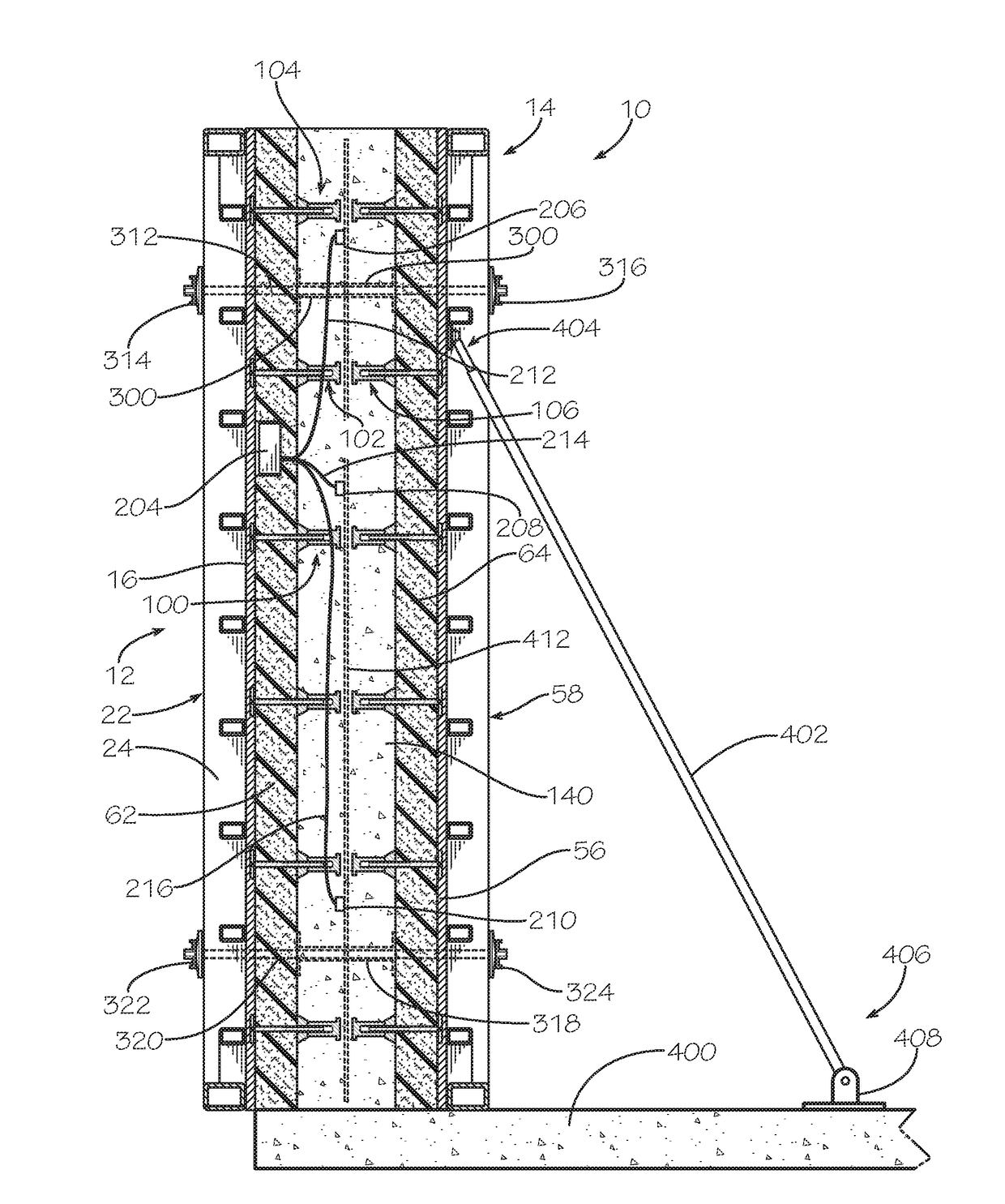

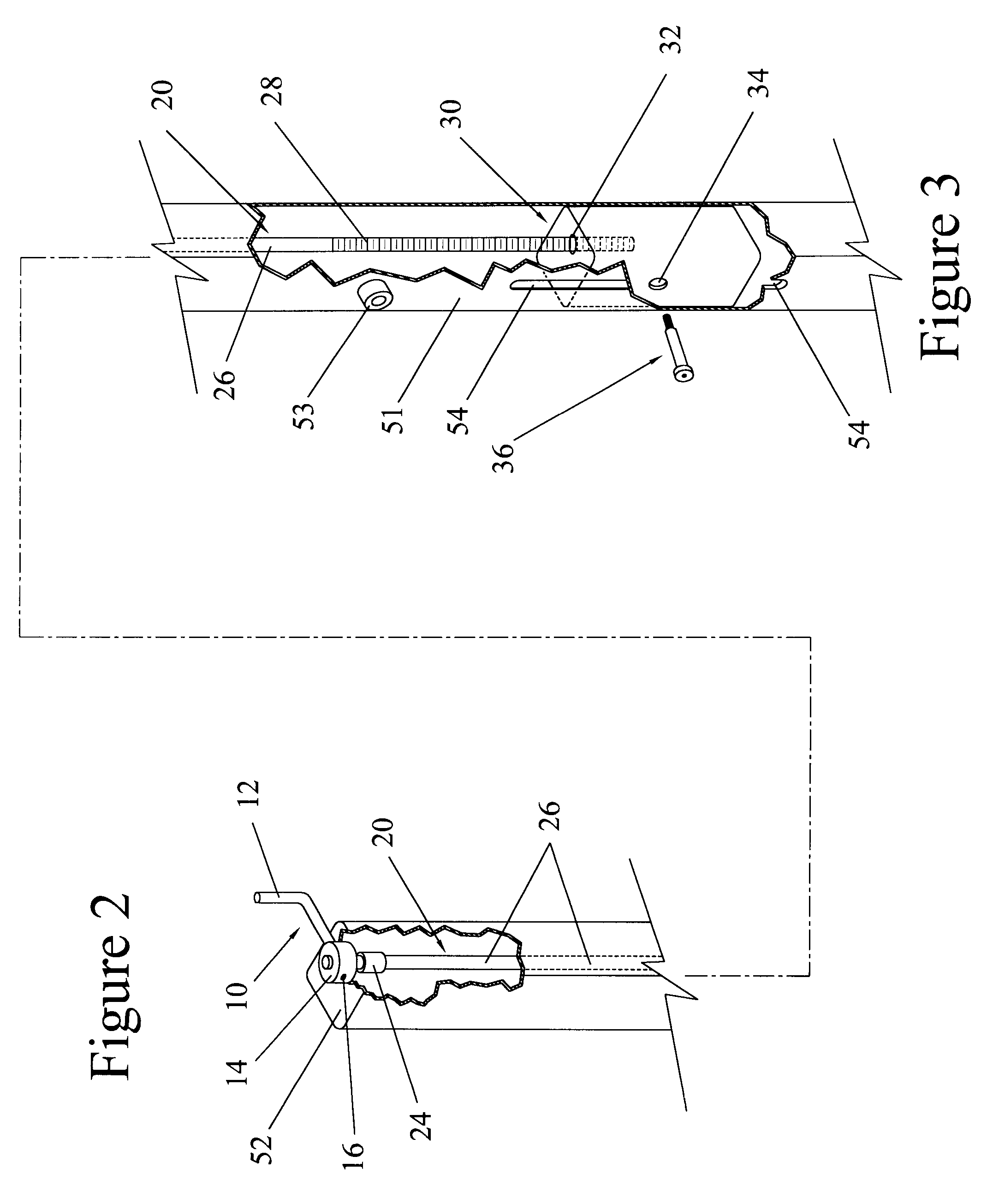

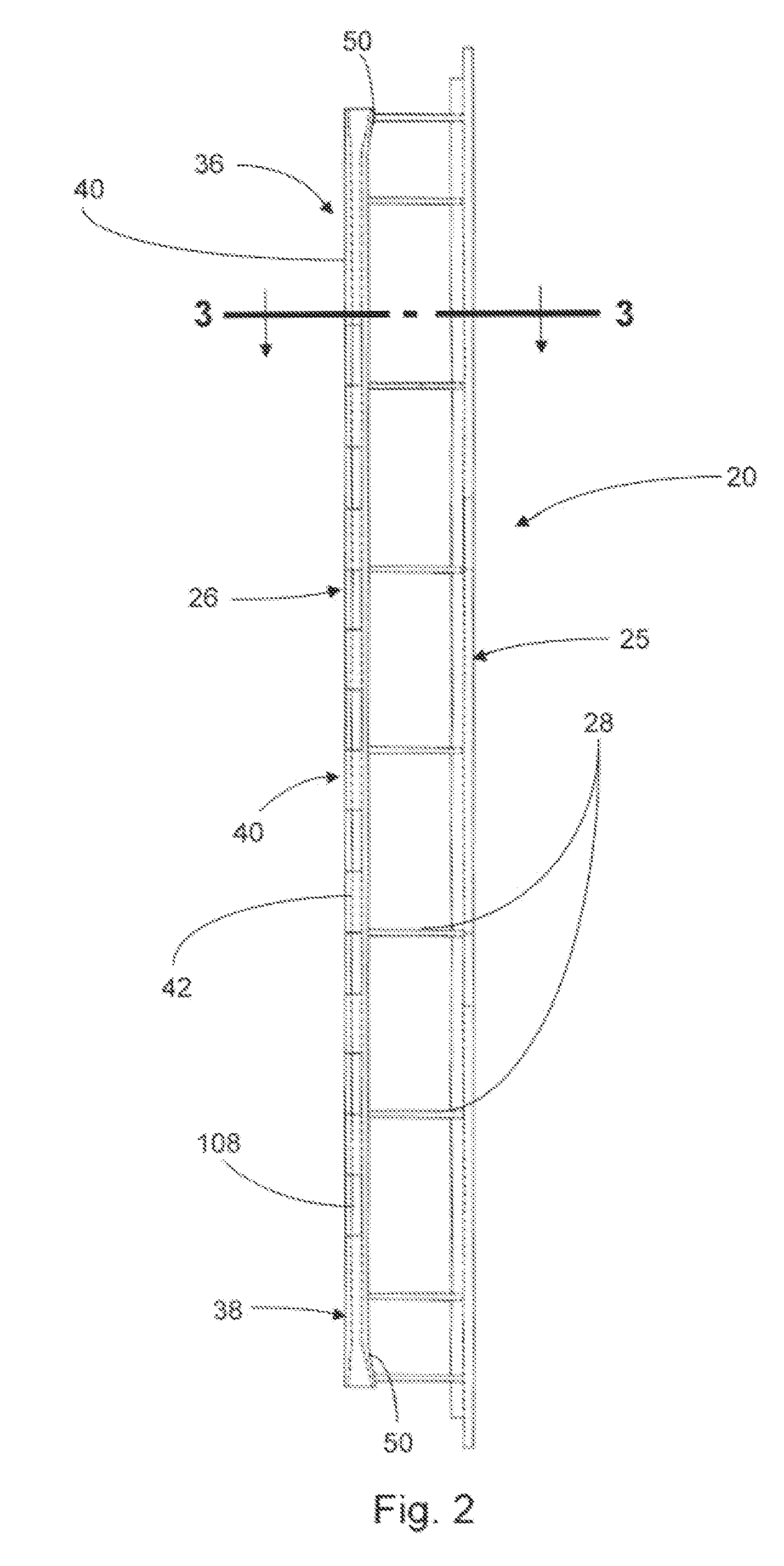

Self-annealing concrete, self-annealing concrete forms, temperature monitoring system for self-annealing concrete forms and method of making and using same

ActiveUS20170218614A1Improved curing environmentAvoid insufficient heatingConstruction materialWallsForming faceTemperature monitoring

The invention comprises a product. The product comprises a first removable concrete form having a concrete forming face and a first insulating panel insert having a first primary surface and an opposite second primary surface, wherein the second primary surface of the first insulating panel insert contacts the concrete forming face of the first removable concrete form. The product also comprises an elongate anchor member having an enlarged portion and an elongate portion, the elongate portion having a first end and an opposite second end, wherein the enlarged portion is disposed adjacent the first end and contacts the second primary surface of the first insulating panel insert and wherein the elongate portion extends through the first insulating panel insert and extends outwardly from the first primary surface of the first insulating panel insert. A method of using a removable insulated concrete form system is also disclosed.

Owner:CIUPERCA ROMEO ILARIAN

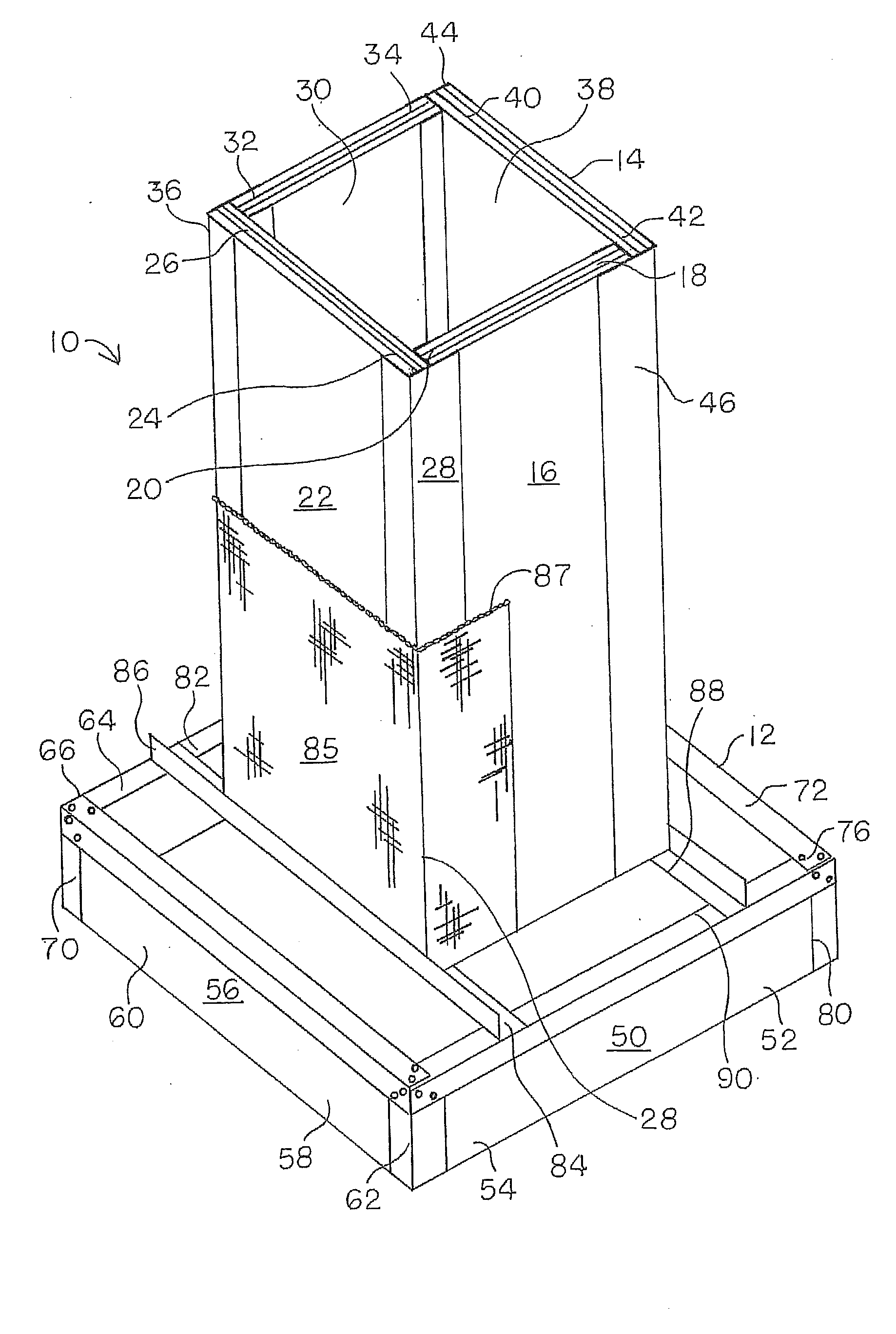

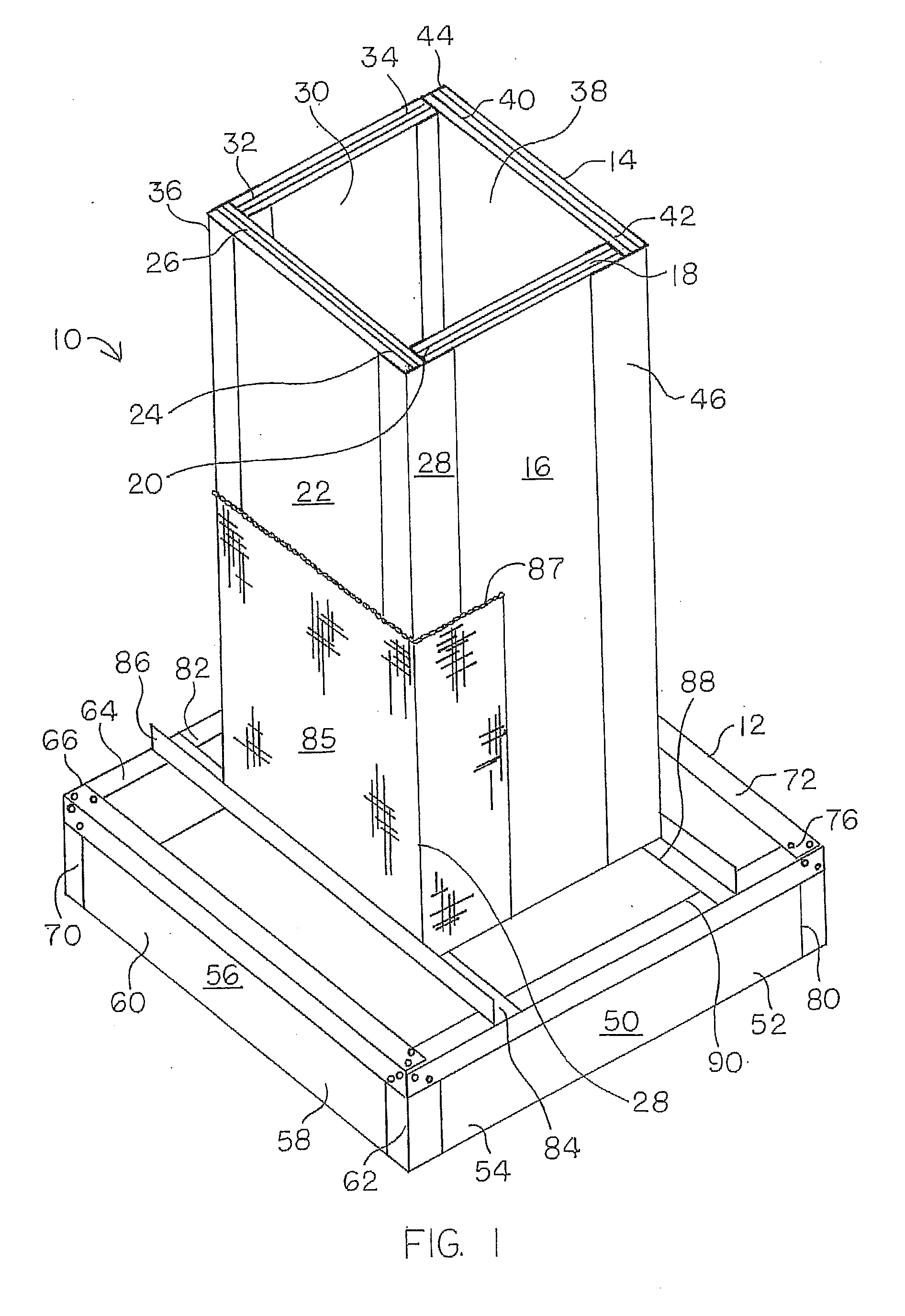

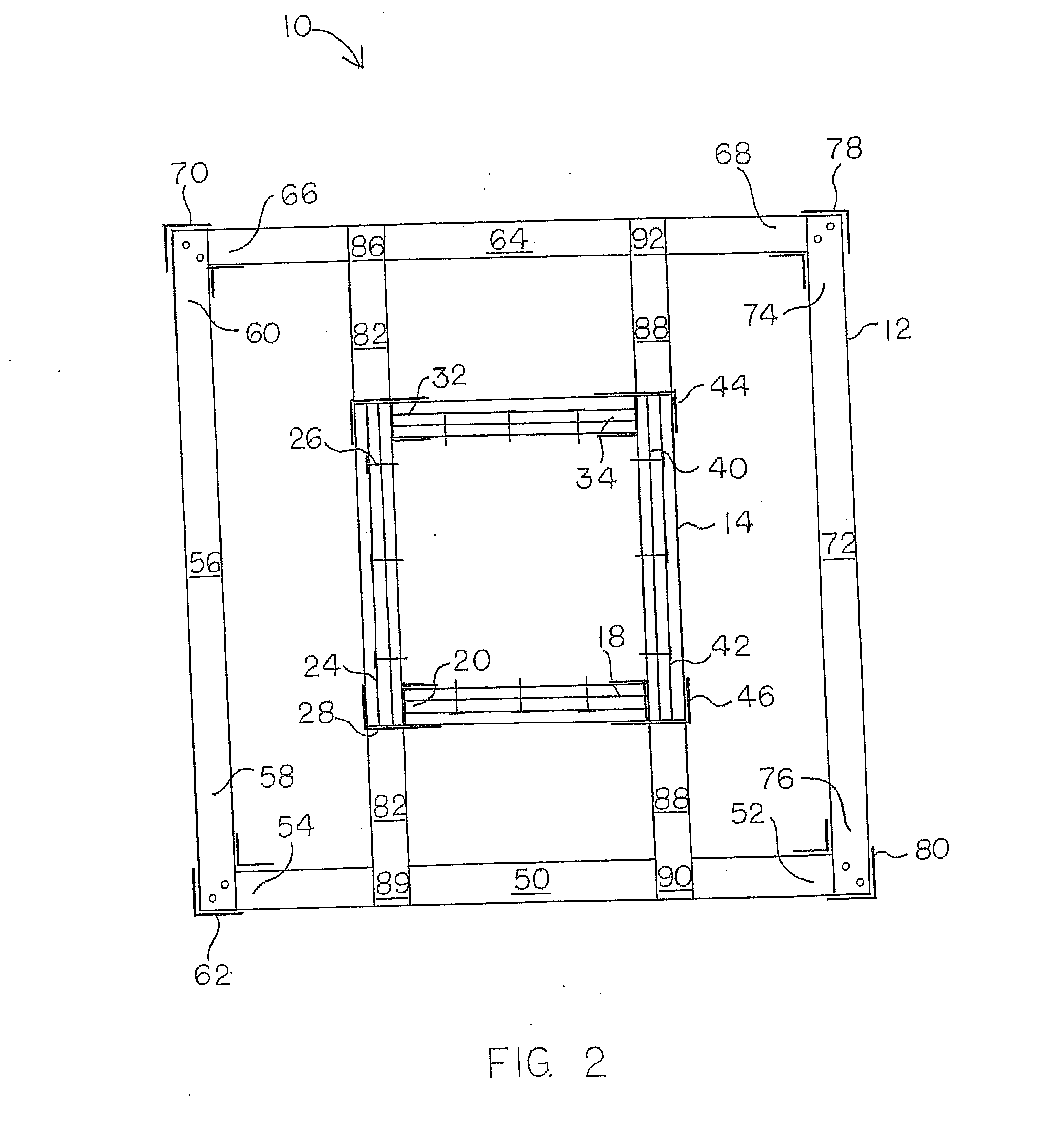

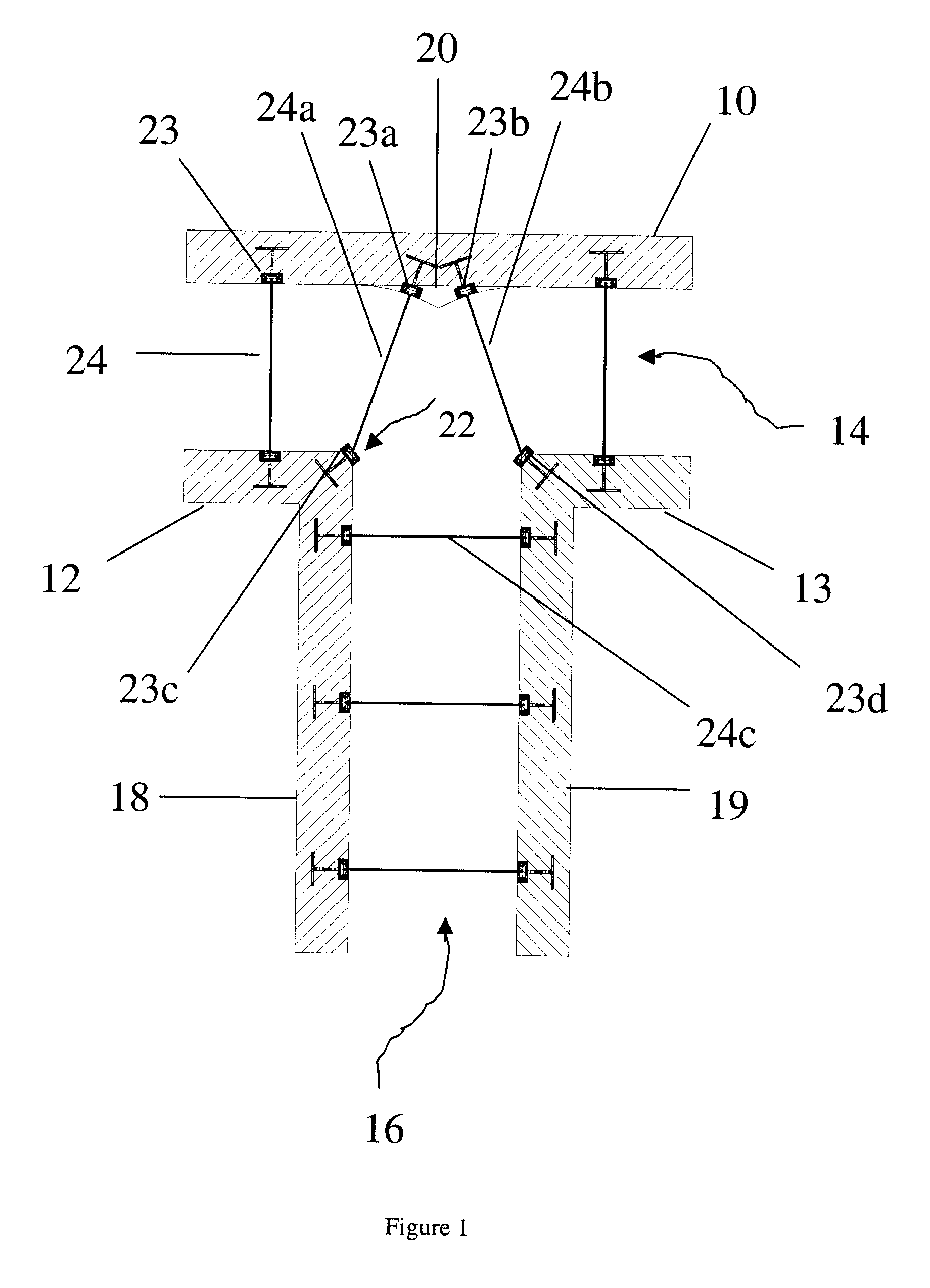

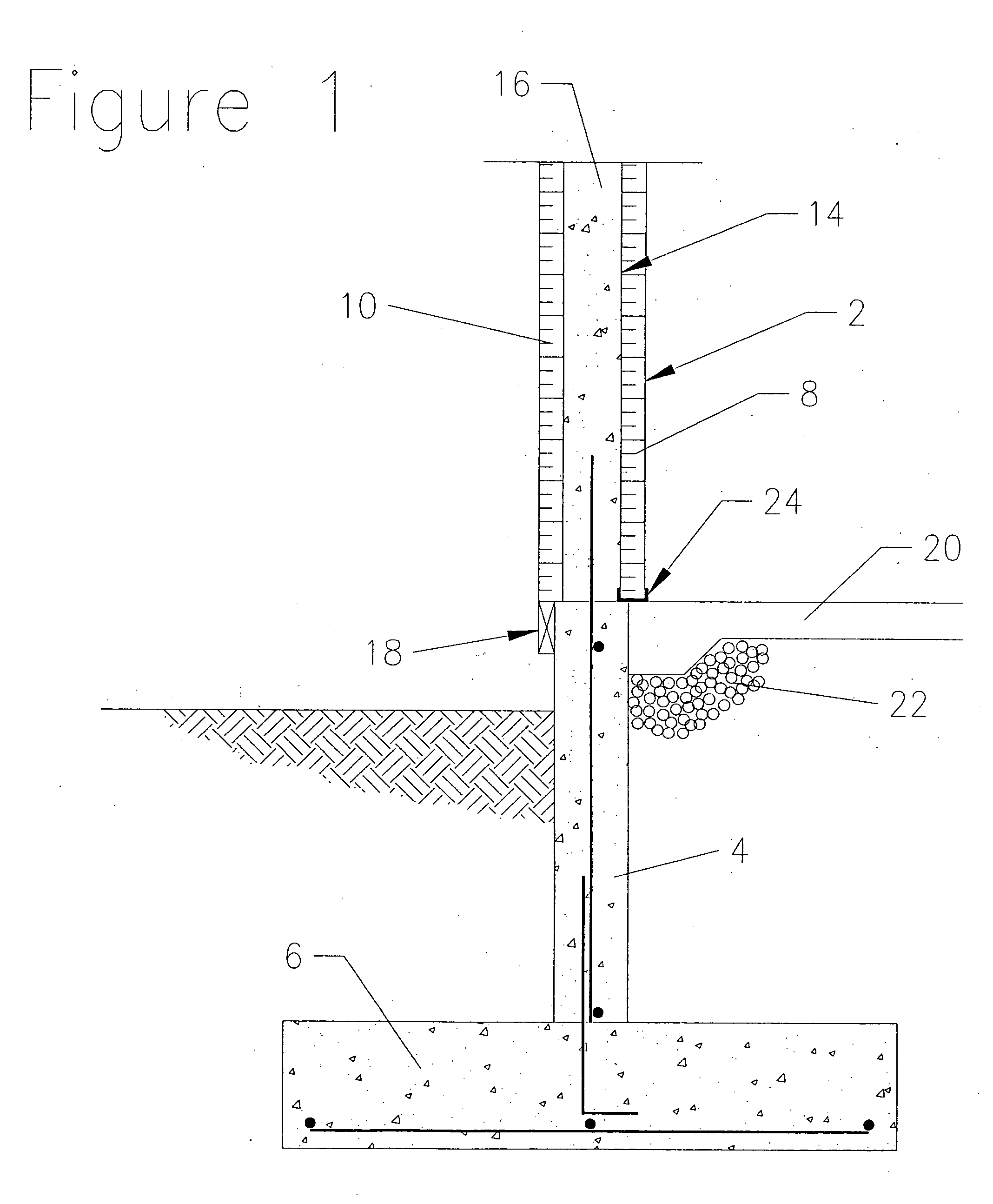

Method of constructing an insulated shallow pier foundation building

A method of constructing a shallow pier foundation building that includes a) placing a plurality of insulating pier forms along a perimeter of the building; b) placing a plurality of insulating concrete forms between the insulating piers to form a continuous insulating surface to the surrounding soil and a continuous forming surface to provide a slab form; c) placing a concrete composition in the insulating piers and insulating concrete forms and allowing the concrete composition to cure and harden; and d) placing a concrete slab composition in the slab form and allowing the concrete composition to cure and harden.

Owner:NOVA CHEM INC

Adjustable masonry anchor assembly for use with insulating concrete form systems

An anchor assembly for use in joining together a masonry wall structure and a supporting back wall structure wherein the back wall structure is preferably formed using insulated concrete form (ICF) blocks each having a pair of opposed ICF panels associated therewith, the anchor assembly including an anchor member and a tie member. The anchor member includes an anchor portion adapted to penetrate one of the ICF panels and having at least one opening associated therewith so as to lie between the opposed ICF panels when attached thereto for allowing poured concrete to flow therethrough, and an attachment portion having a tab member positioned and located to overlay an ICF panel flange member when the anchor member is inserted within the ICF panel, the tab member being attachable to the ICF panel flange member. The attachment portion further includes an elongated slot for receiving the tie member, the tie member being adjustably movable along the length of the slot so as to be positionable between the courses of brick or other masonry material associated with the masonry wall structure as the masonry wall structure is being erected.

Owner:AIRLITE PLASTICS

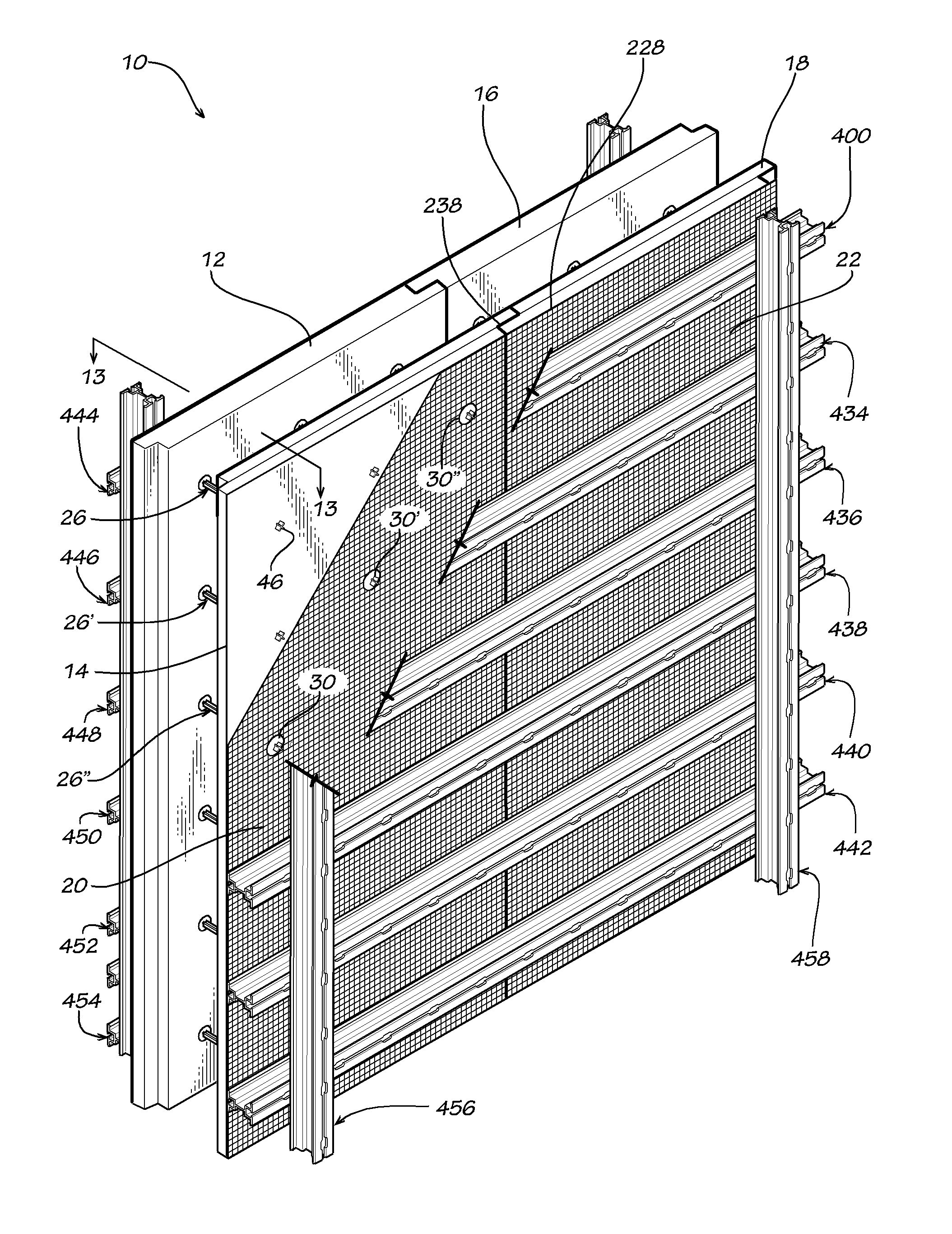

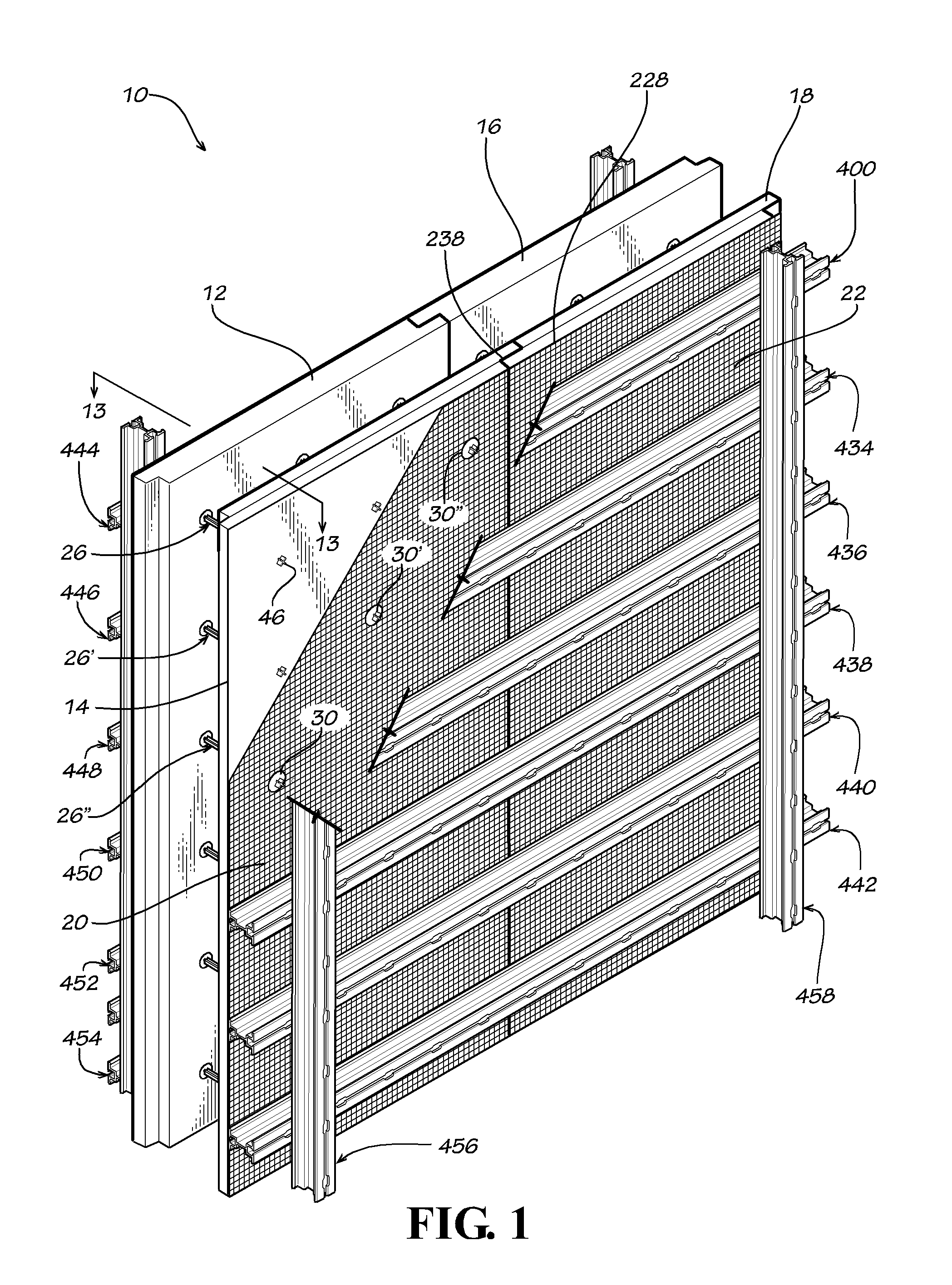

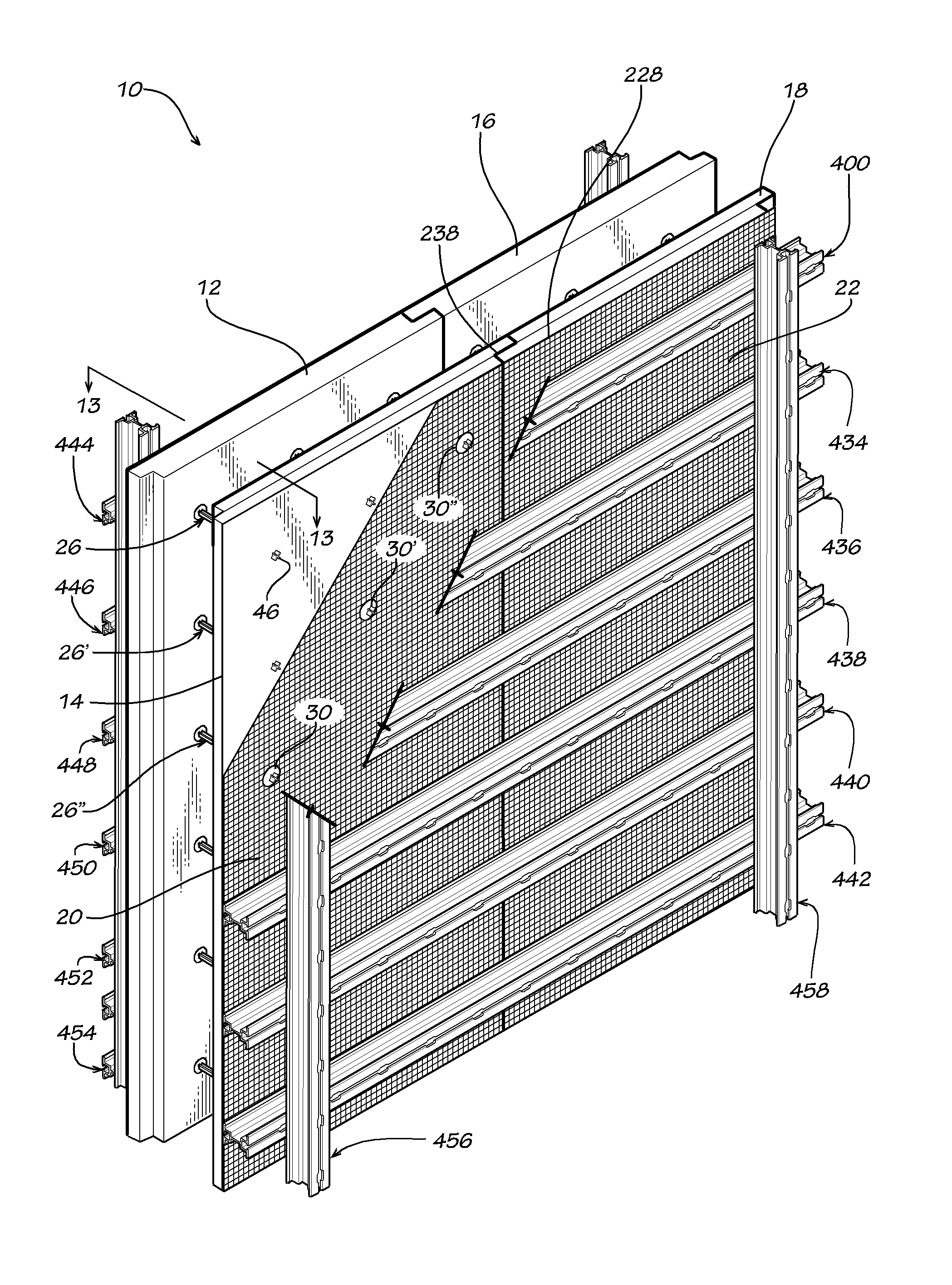

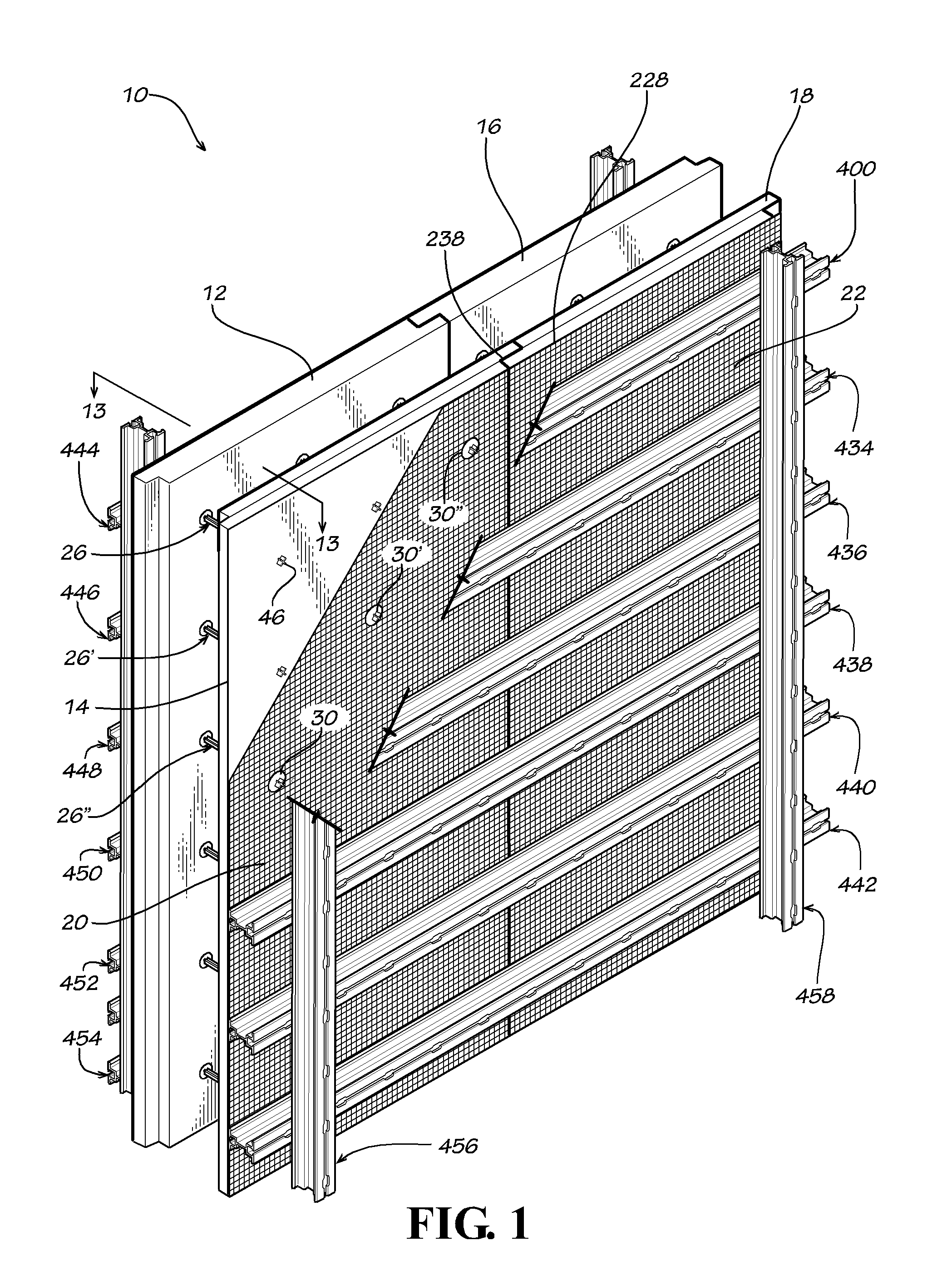

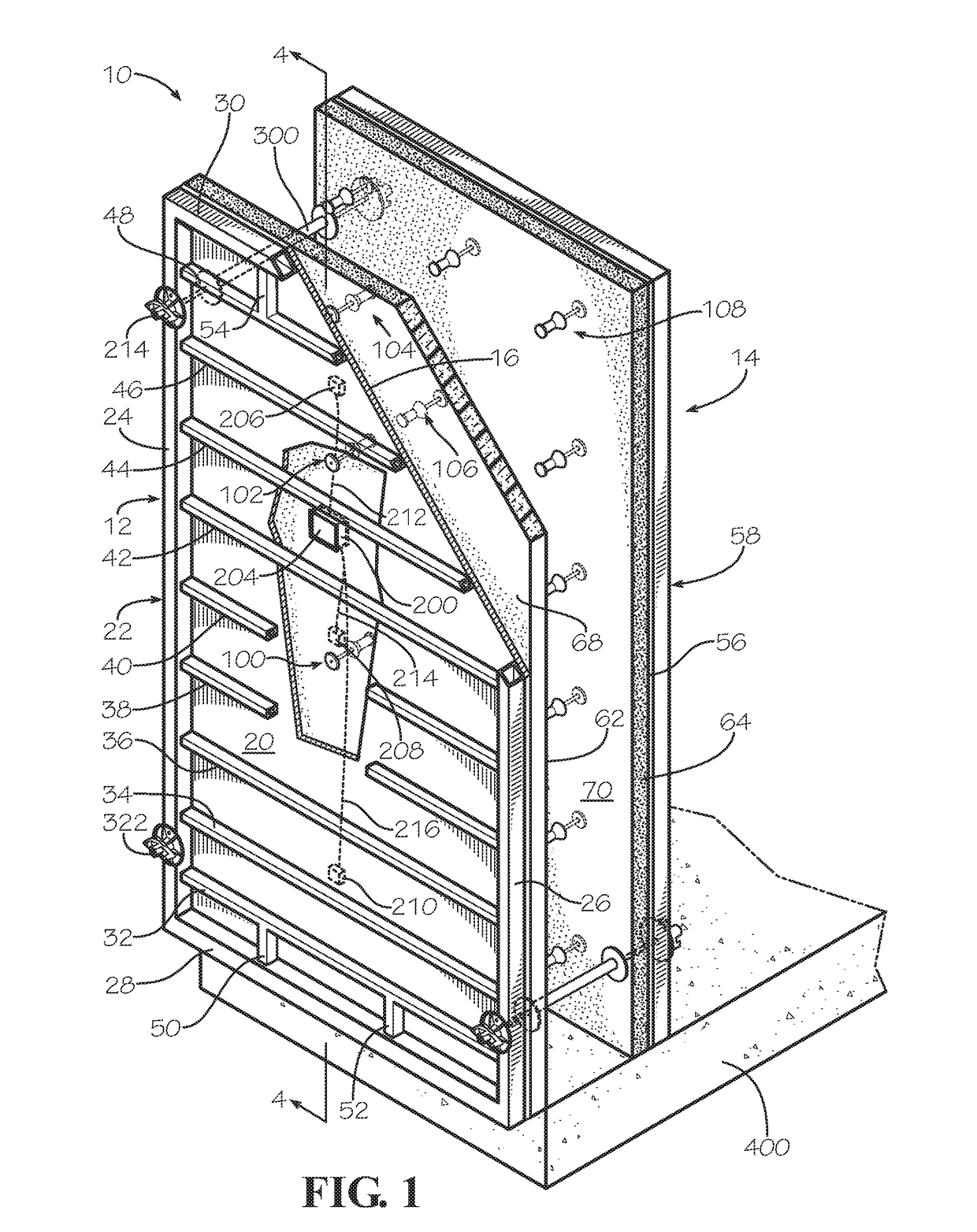

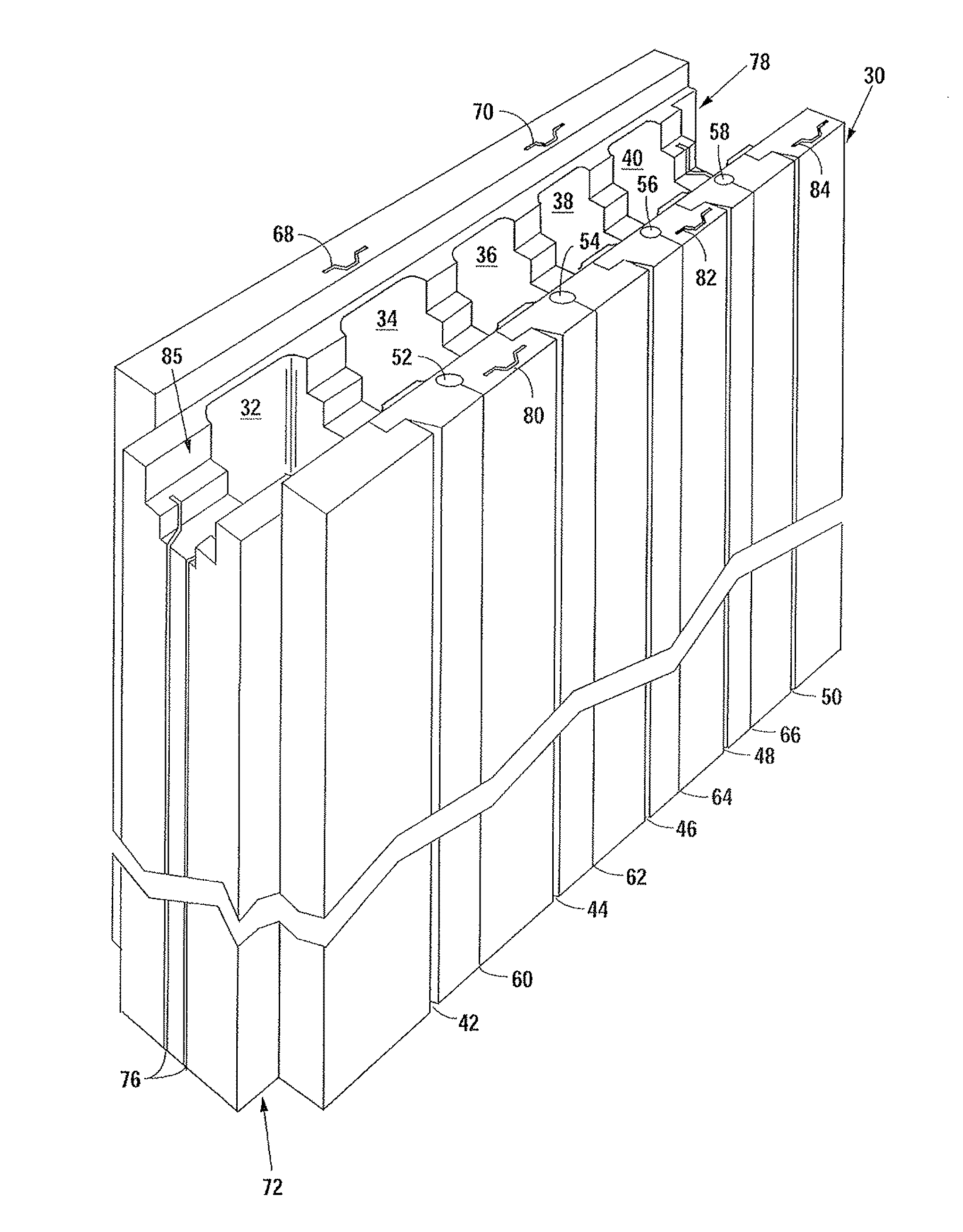

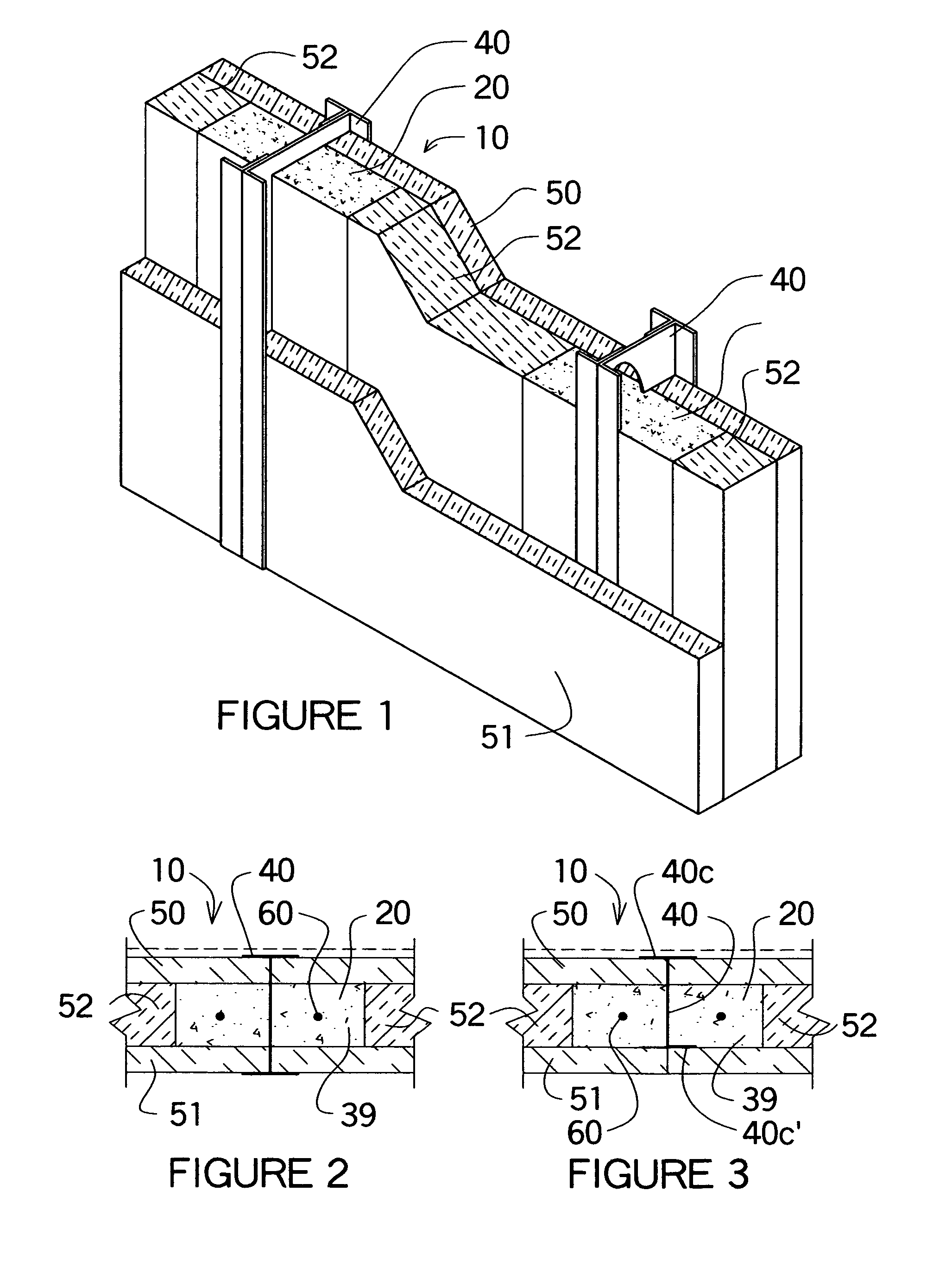

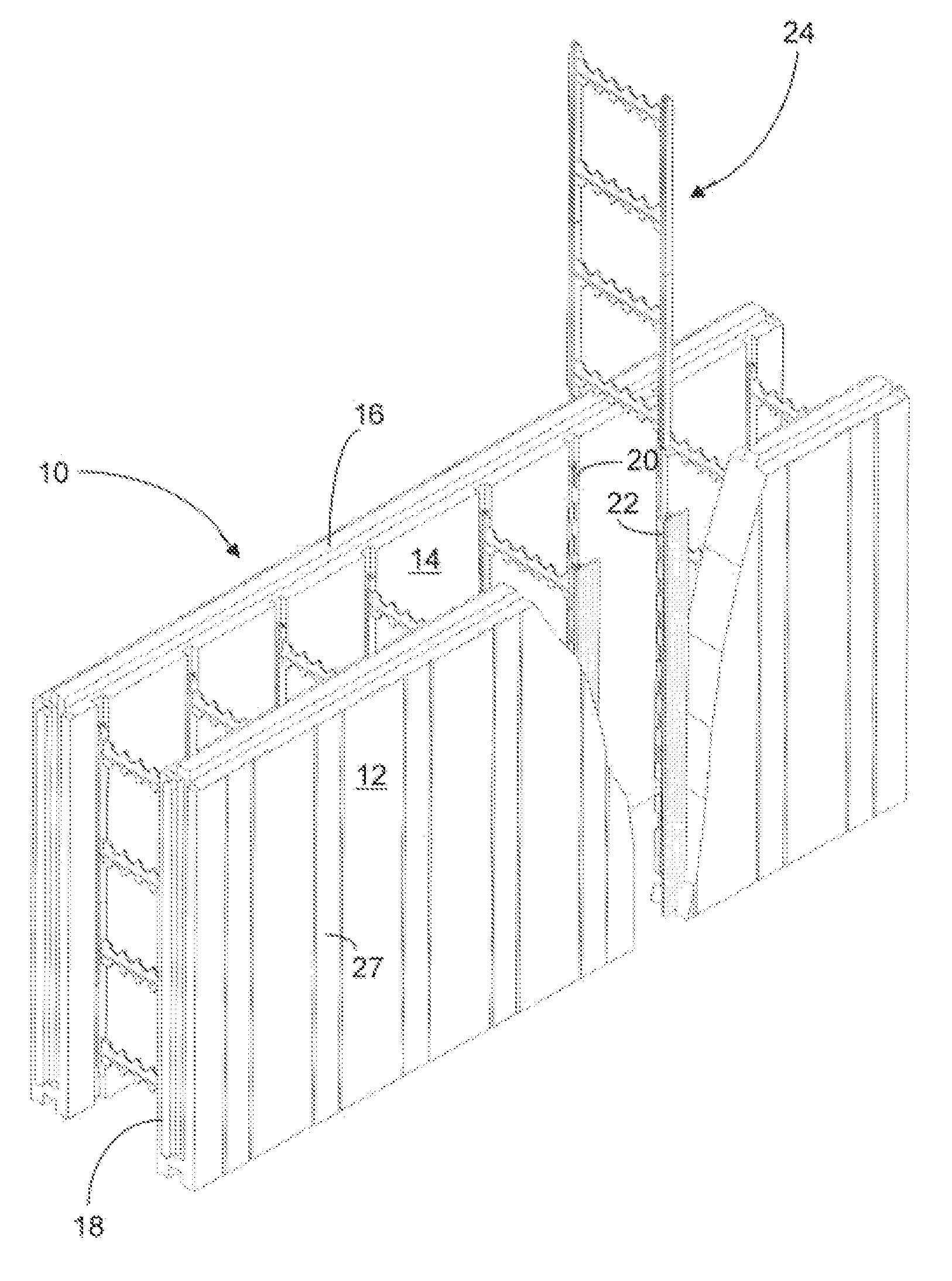

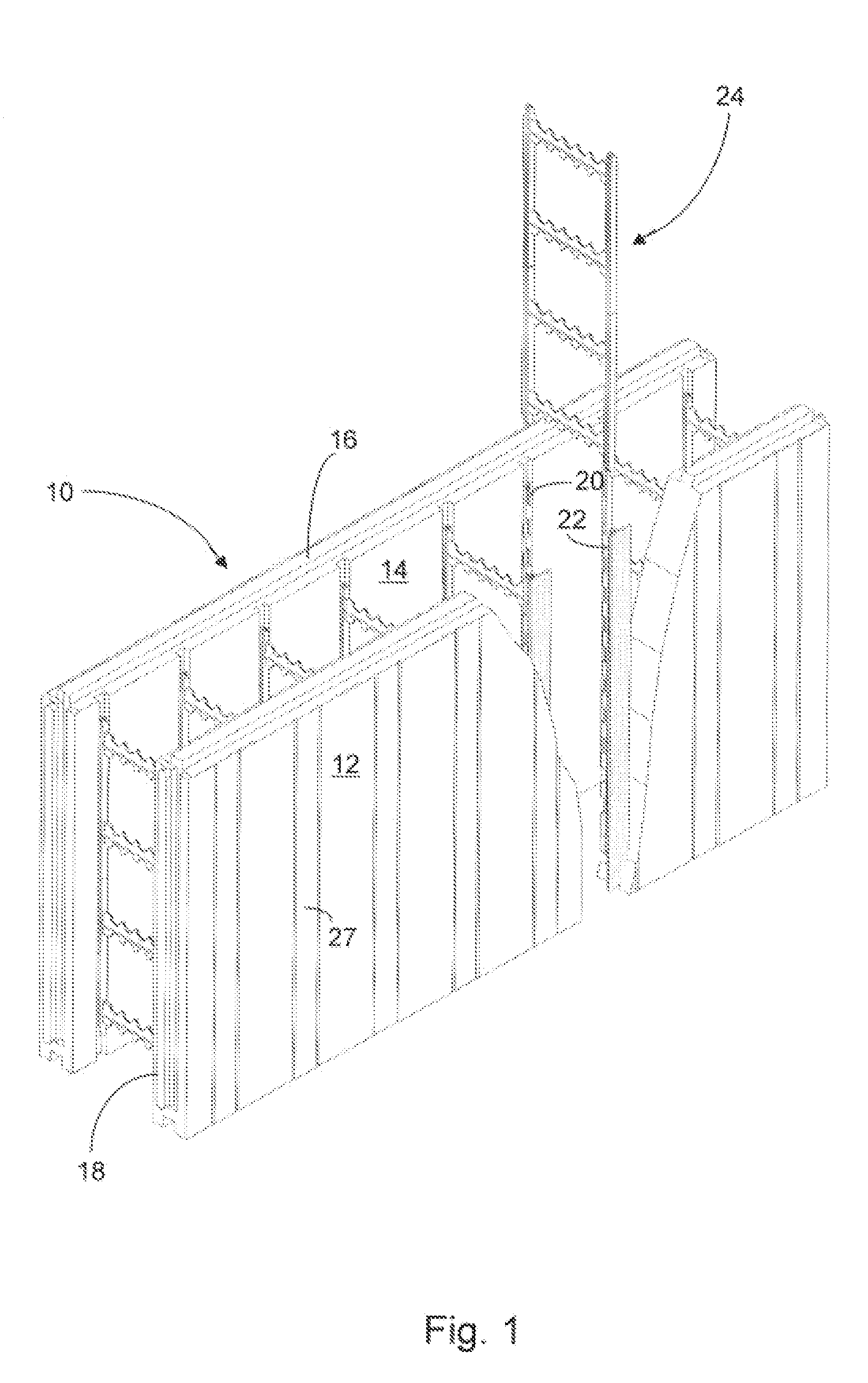

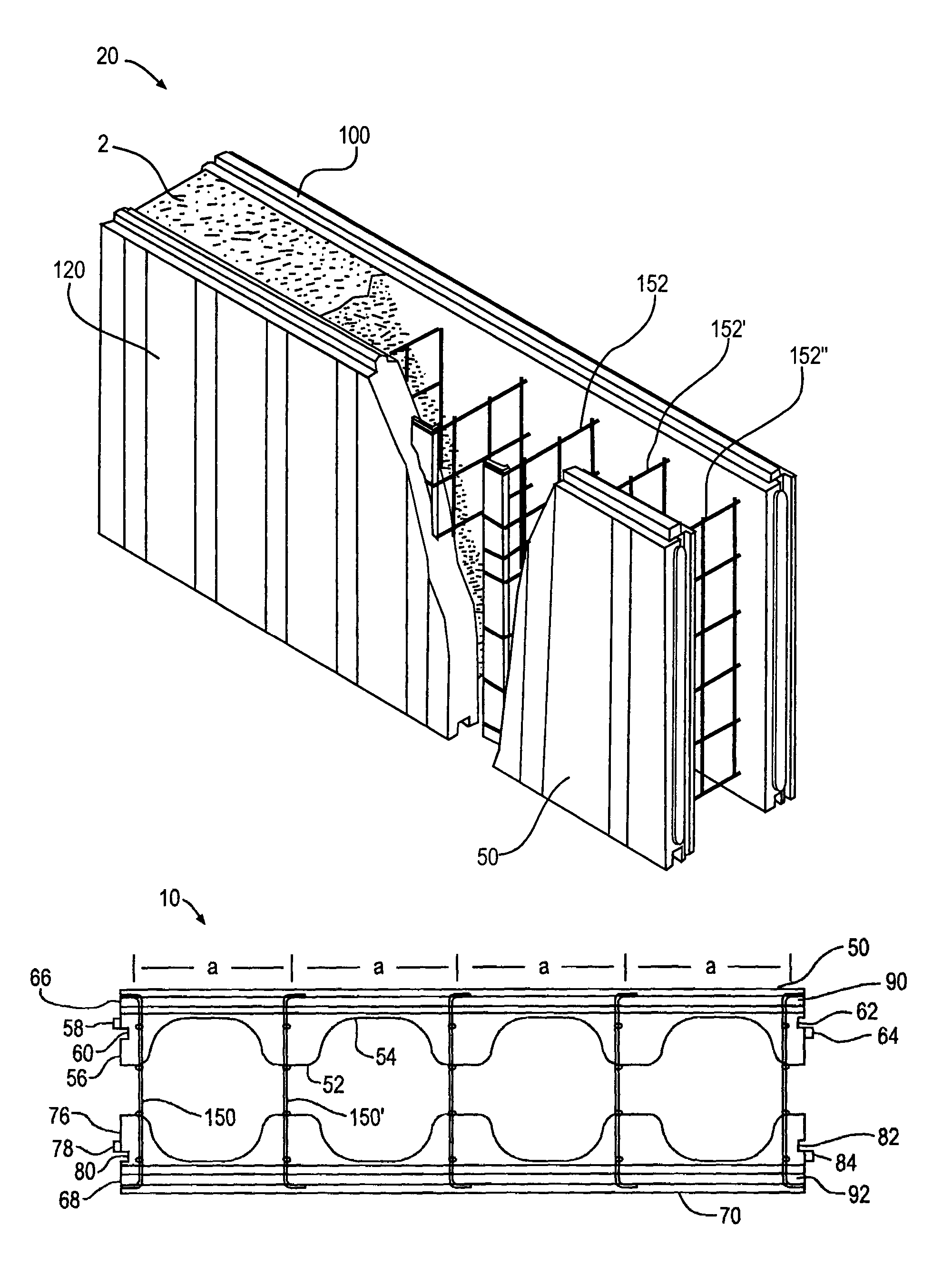

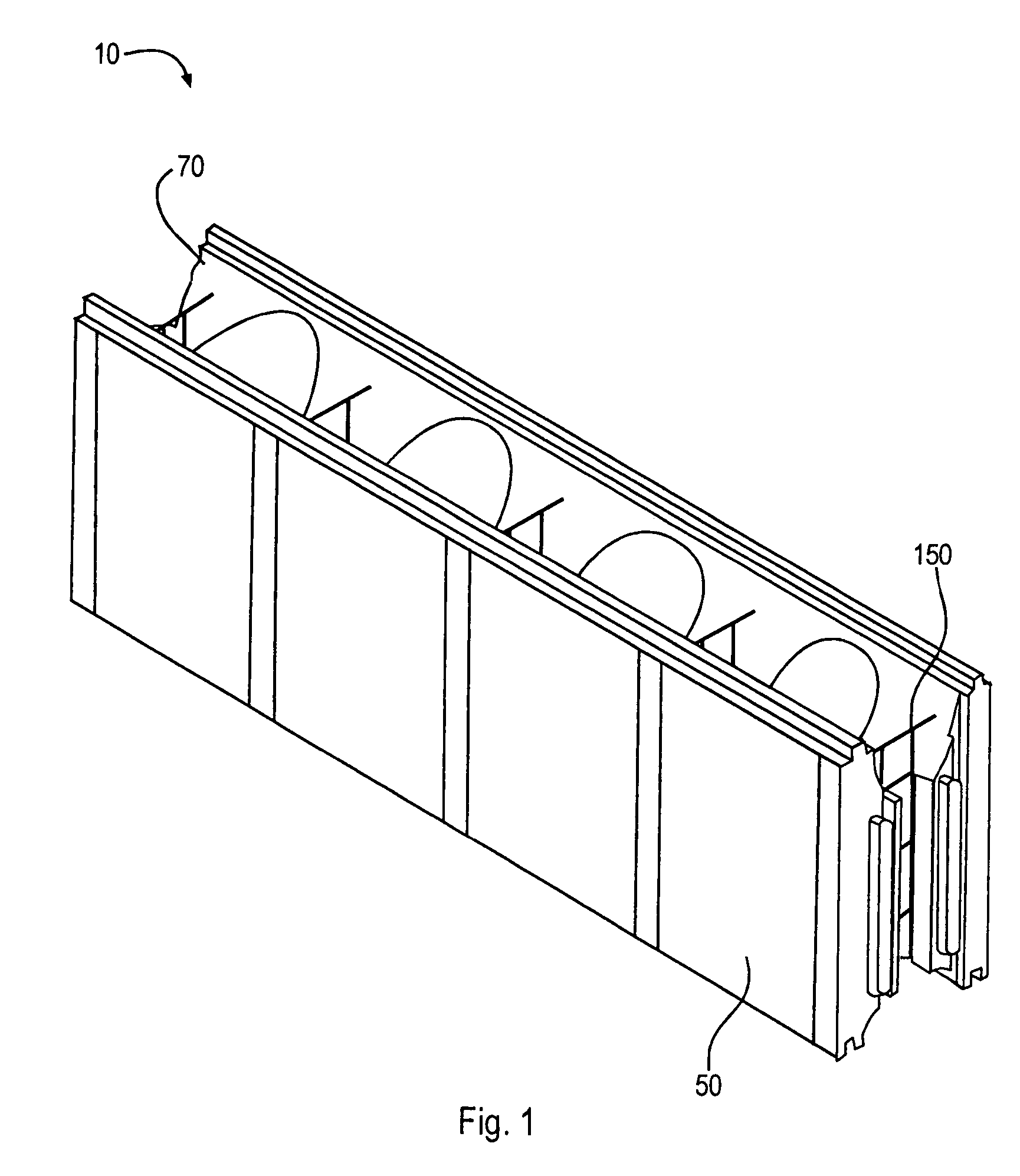

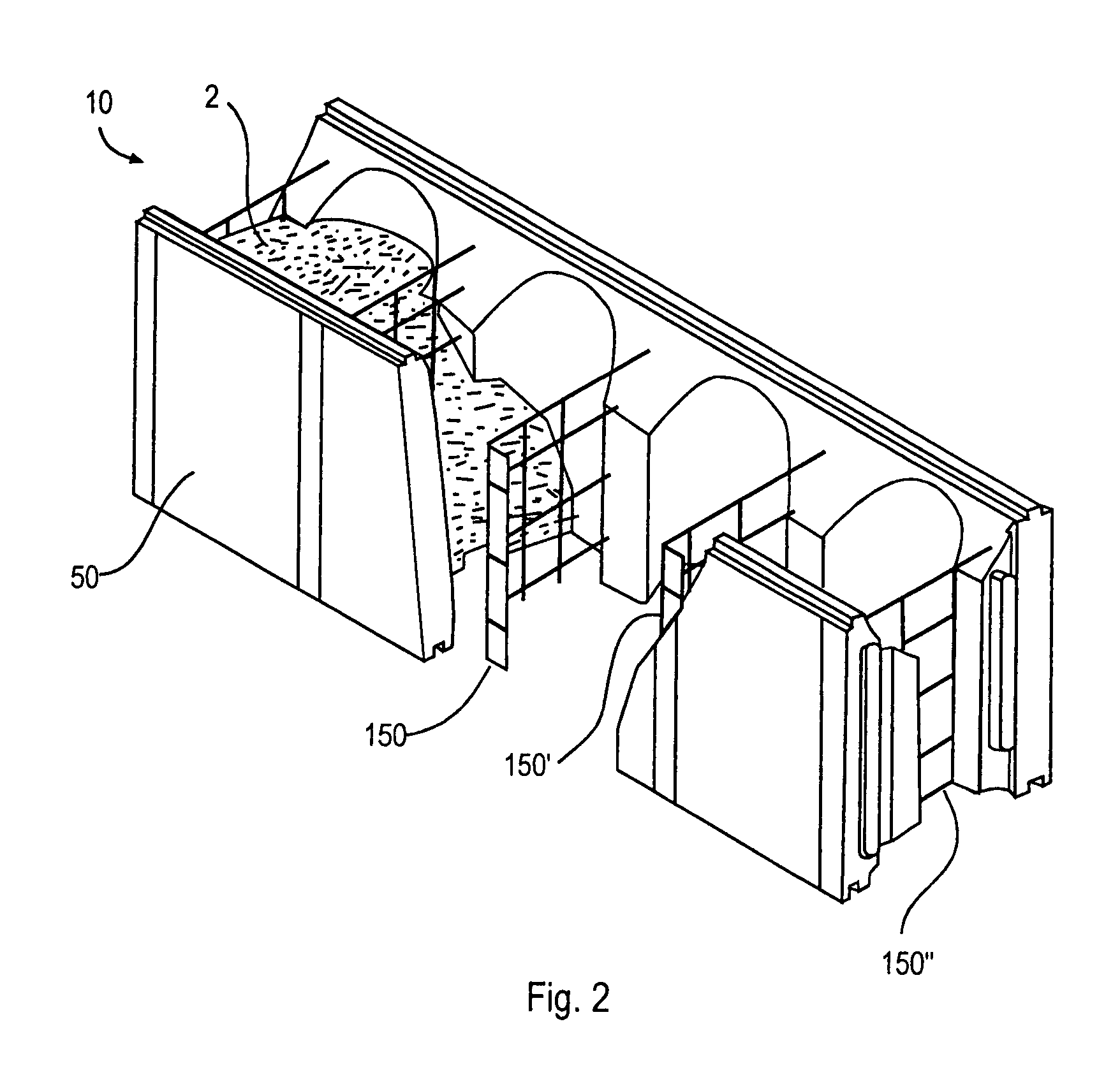

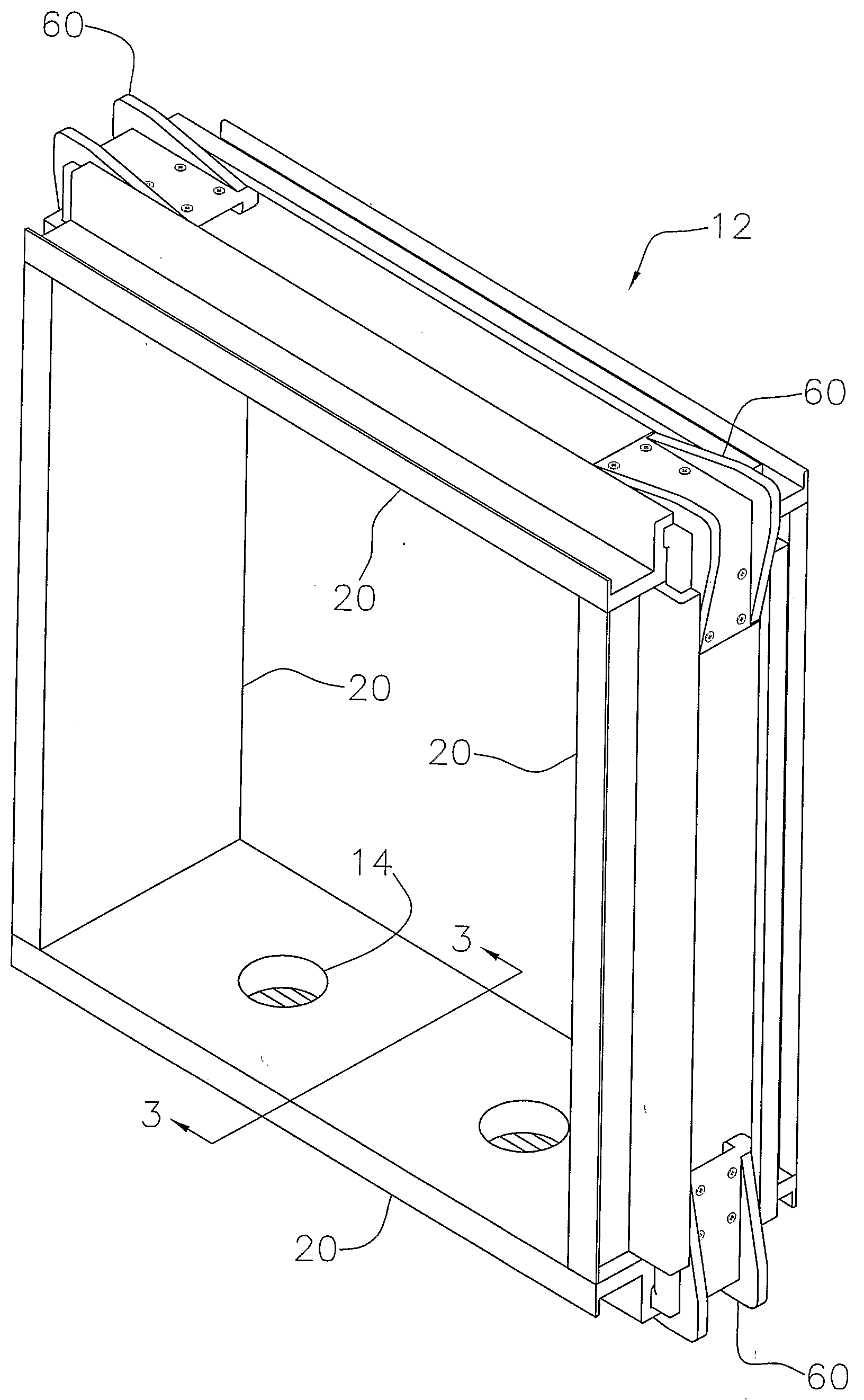

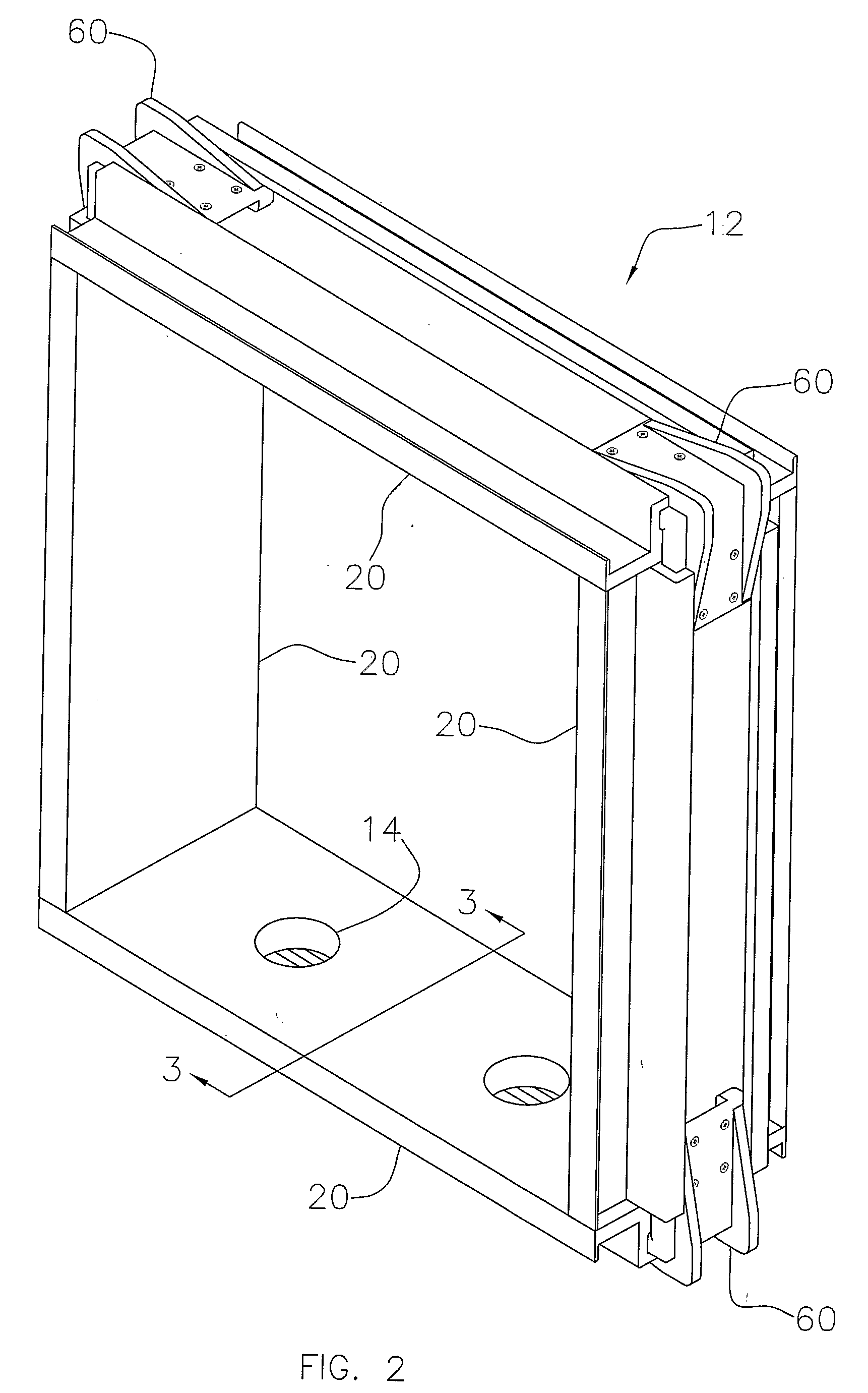

Hybrid insulated concrete form and method of making and using same

The invention comprises a product. The product comprises a foam insulating panel having a first primary surface and an opposite second primary surface. A removable concrete form is spaced from the foam insulating panel and a concrete receiving space is defined between the second primary surface of the foam insulating panel and the removable concrete form. A method of using a hybrid insulated concrete form is also disclosed.

Owner:CIUPERCA ROMEO ILARIAN

Hybrid insulated concrete form and method of making and using same

ActiveUS20140263942A1Retain heatEasy and inexpensive attachmentMoulding surfacesWallsInsulating concrete form

The invention comprises a product. The product comprises a foam insulating panel having a first primary surface and an opposite second primary surface. A removable concrete form is spaced from the foam insulating panel and a concrete receiving space is defined between the second primary surface of the foam insulating panel and the removable concrete form. A method of using a hybrid insulated concrete form is also disclosed.

Owner:CIUPERCA ROMEO ILARIAN

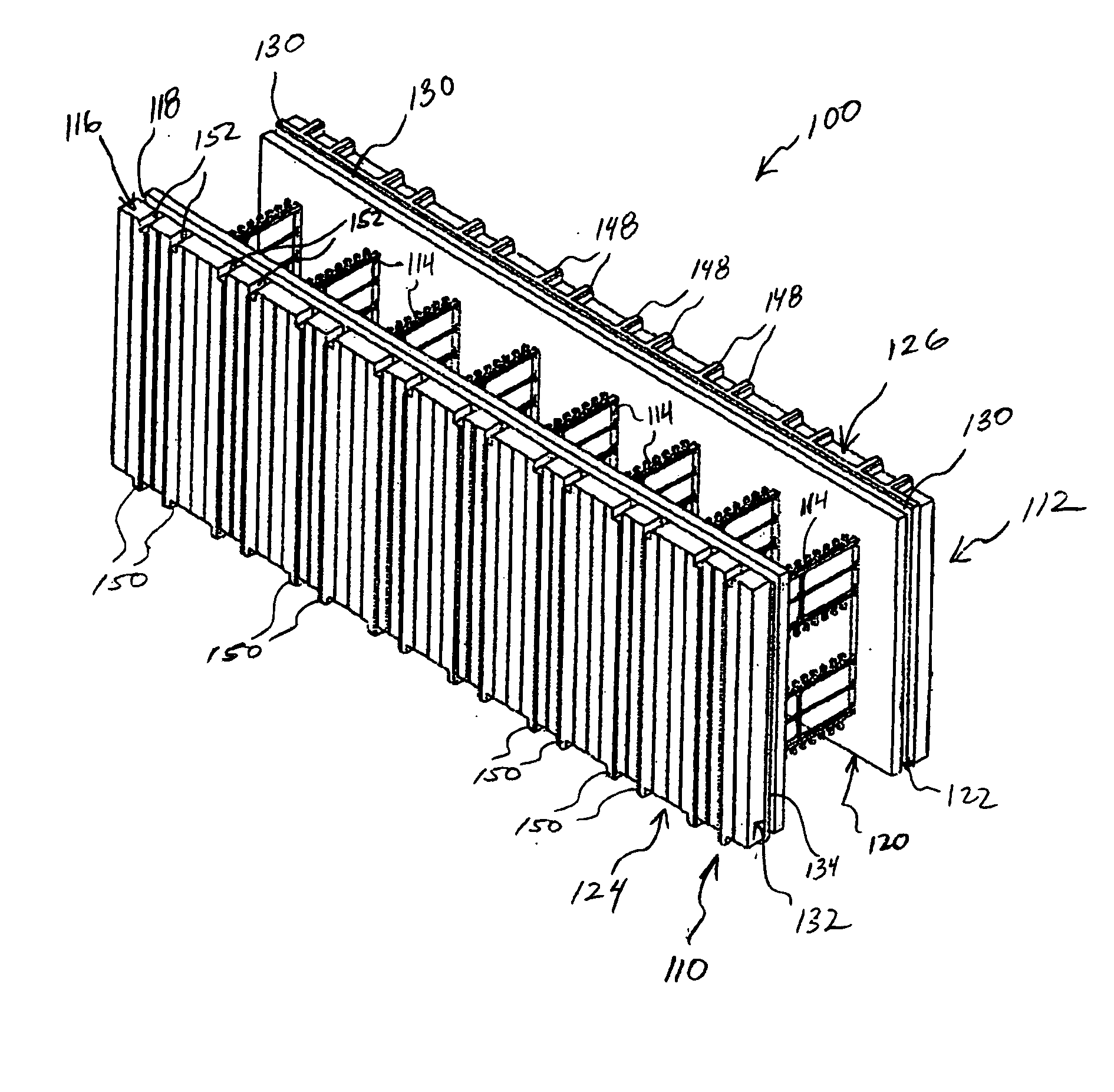

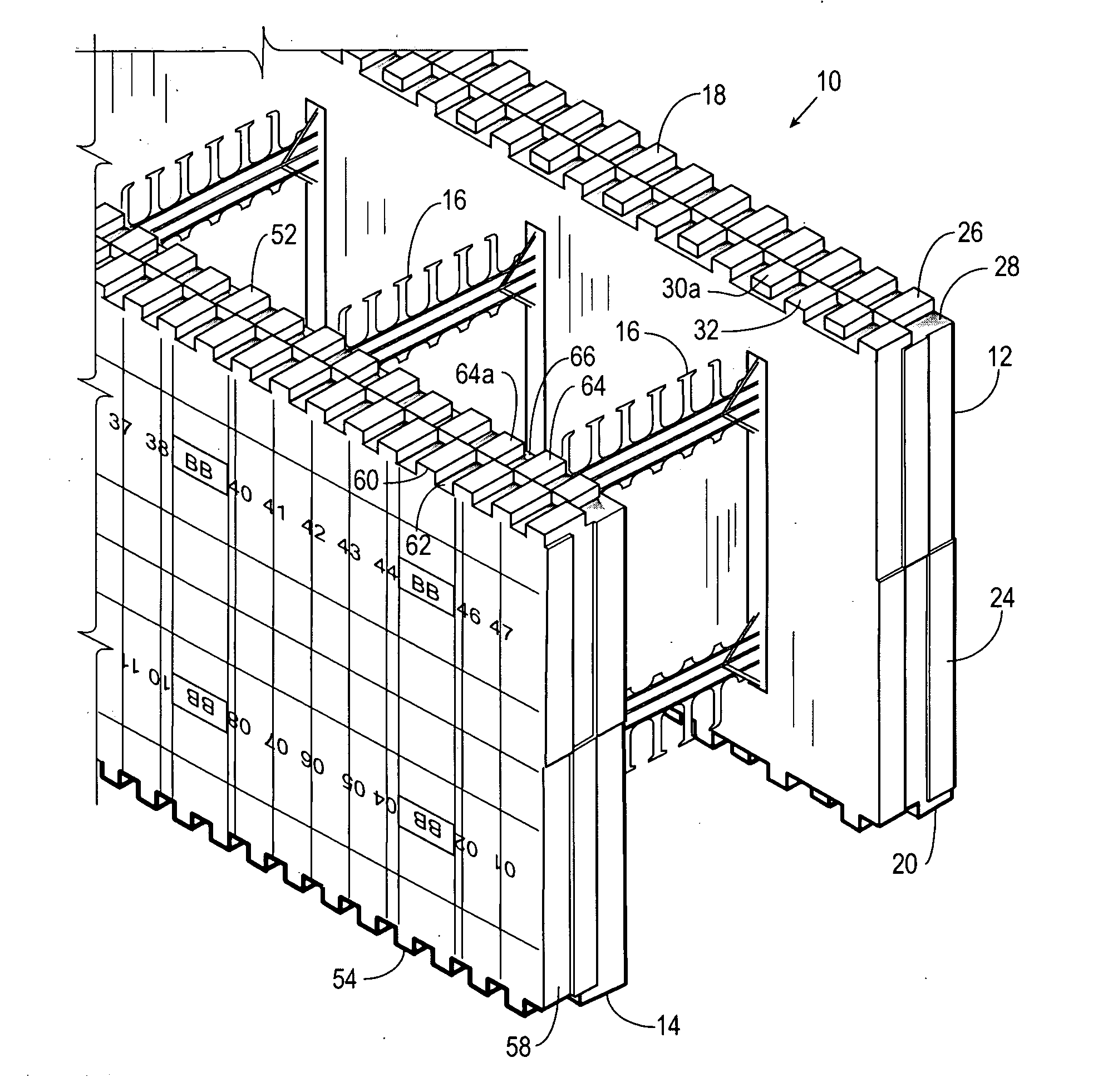

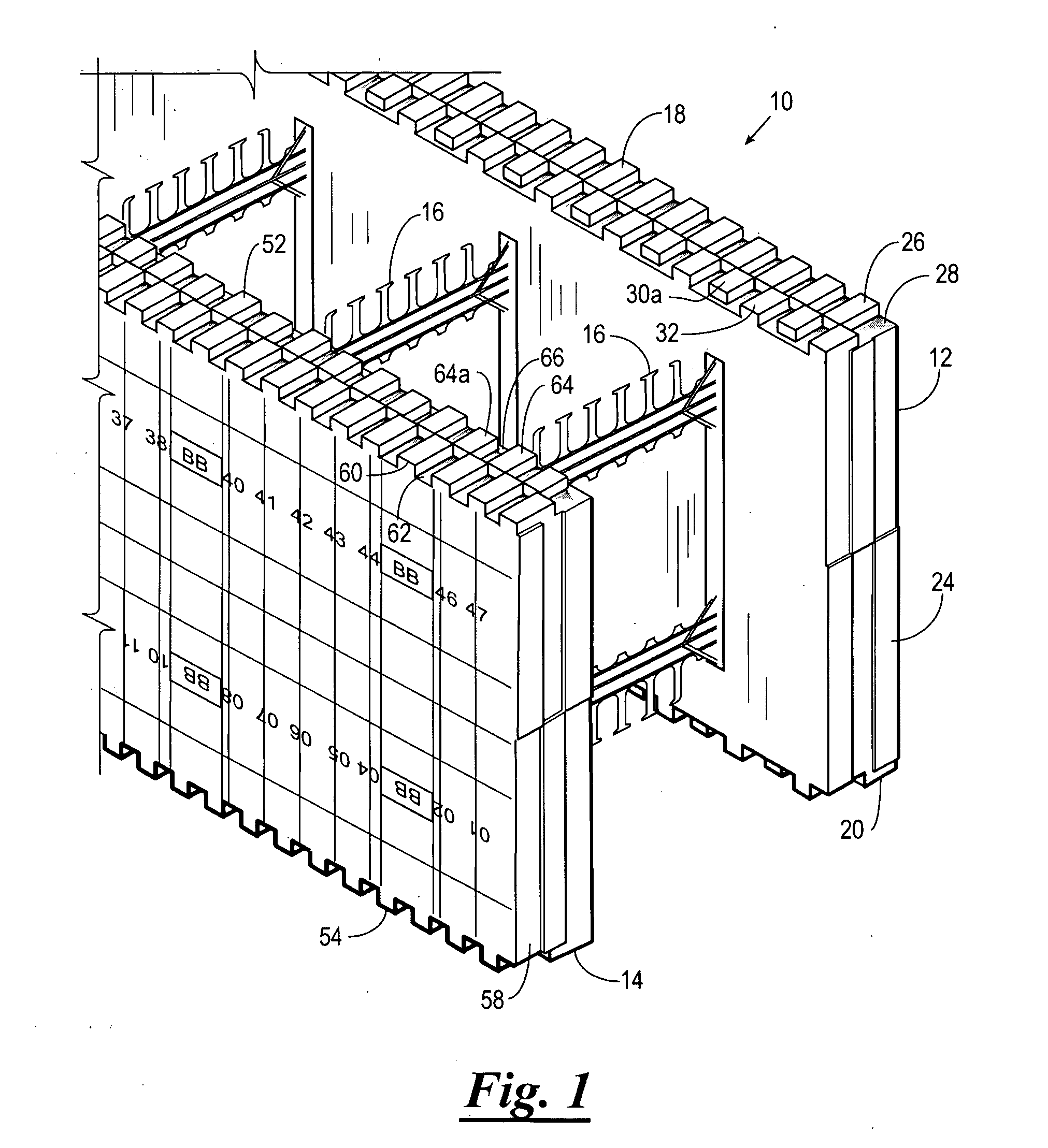

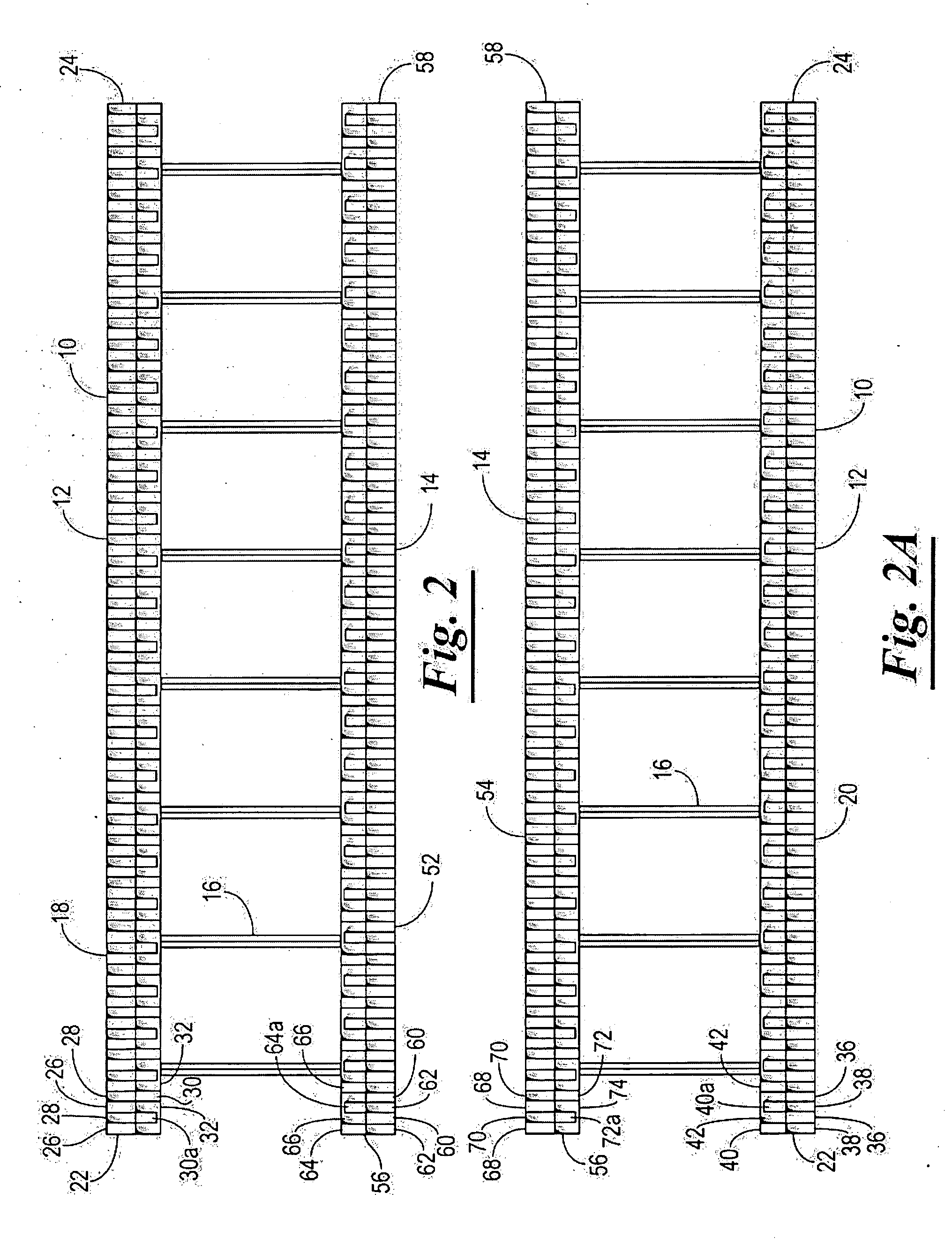

Stackable block for insulating concrete form system

A concrete form system comprising a reversibly stackable insulating form blocks each block having a pair of panels separated by two or more ties. Each of the top, bottom and side edges of the panels includes either a tongue or groove so as to engage a corresponding tongue or groove of a panel of another block stacked vertically or horizontally adjacent thereto. The panels of each block are arranged in opposite orientation to each other so as to enable the block to be stackable in either an upside-down or right-side-up orientation.

Owner:PLASTI FAB

Composite pre-formed construction articles

InactiveUS20060251851A1FloorsSynthetic resin layered productsInsulating concrete formPolymeric matrix

A composite building panel that includes a central body, substantially parallelepipedic in shape, containing an expanded polymer matrix, having opposite faces, a top surface, and a bottom surface; at least one embedded framing stud longitudinally extending across the central body between the opposite faces, having a first end embedded in the expanded polymer matrix, a second end extending away from the bottom surface of the central body, and one or more expansion holes in the embedded studs between the first end of the embedded stud and bottom surface through which the polymer matrix expands. A concrete layer can optionally cover a portion of the top surface and / or bottom surface. The building panel can be positioned perpendicular to a structural wall and / or foundation to provide a floor panel. The second end of the framing studs can be embedded in a second central body to provide an insulated concrete form.

Owner:SYNTHEON HLDG SPA

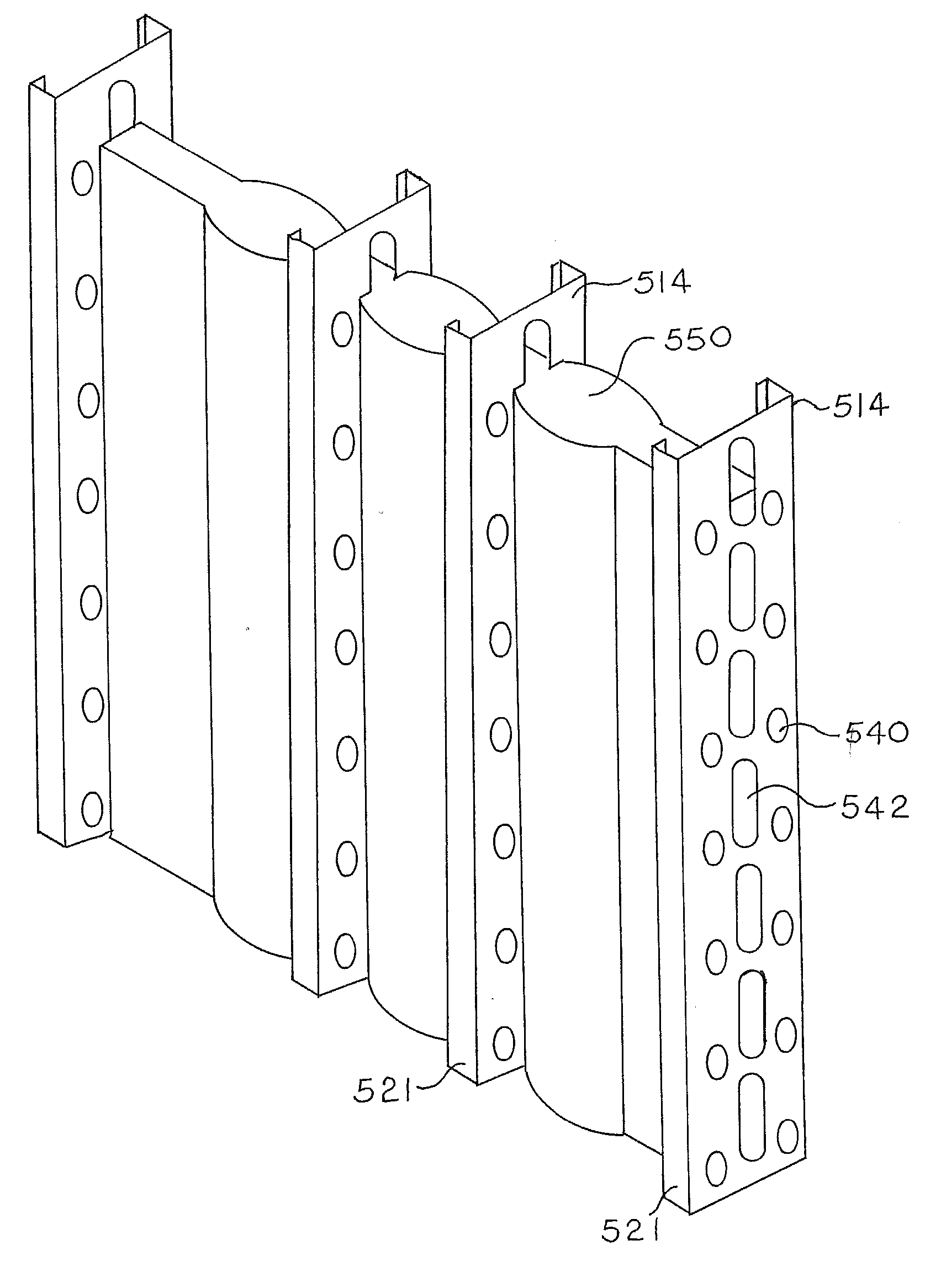

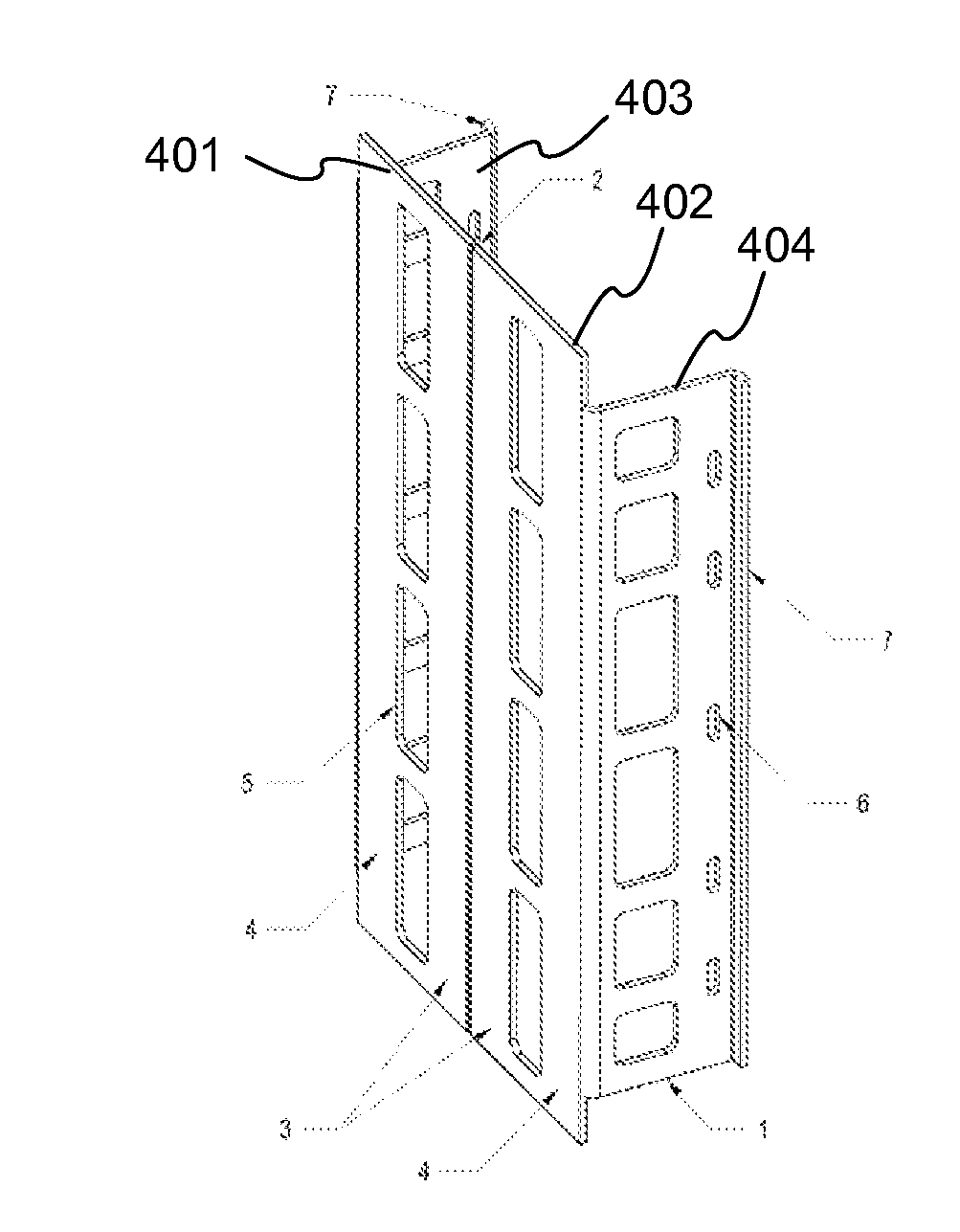

Insulated concrete form panel reinforcement

An insulated concrete form (ICF) panel reinforcement is disclosed. The ICF comprises a main panel, a reinforcement on the main panel for stiffening the main panel, a spacer retention element integrated in the reinforcement for securing a spacer to the panel, and a first opposing panel opposite the main panel and having a first opposing spacer retention element integrated therein for securing the spacer to the first opposing panel. The ICF panel reinforcement is particularly useful at high stress locations in ICF systems, such as at T-wall intersections.

Owner:PHIL INSUL CORP

Polystyrene wall, system, and method for use in an insulated foam building

Owner:SOLID GREEN SYST +1

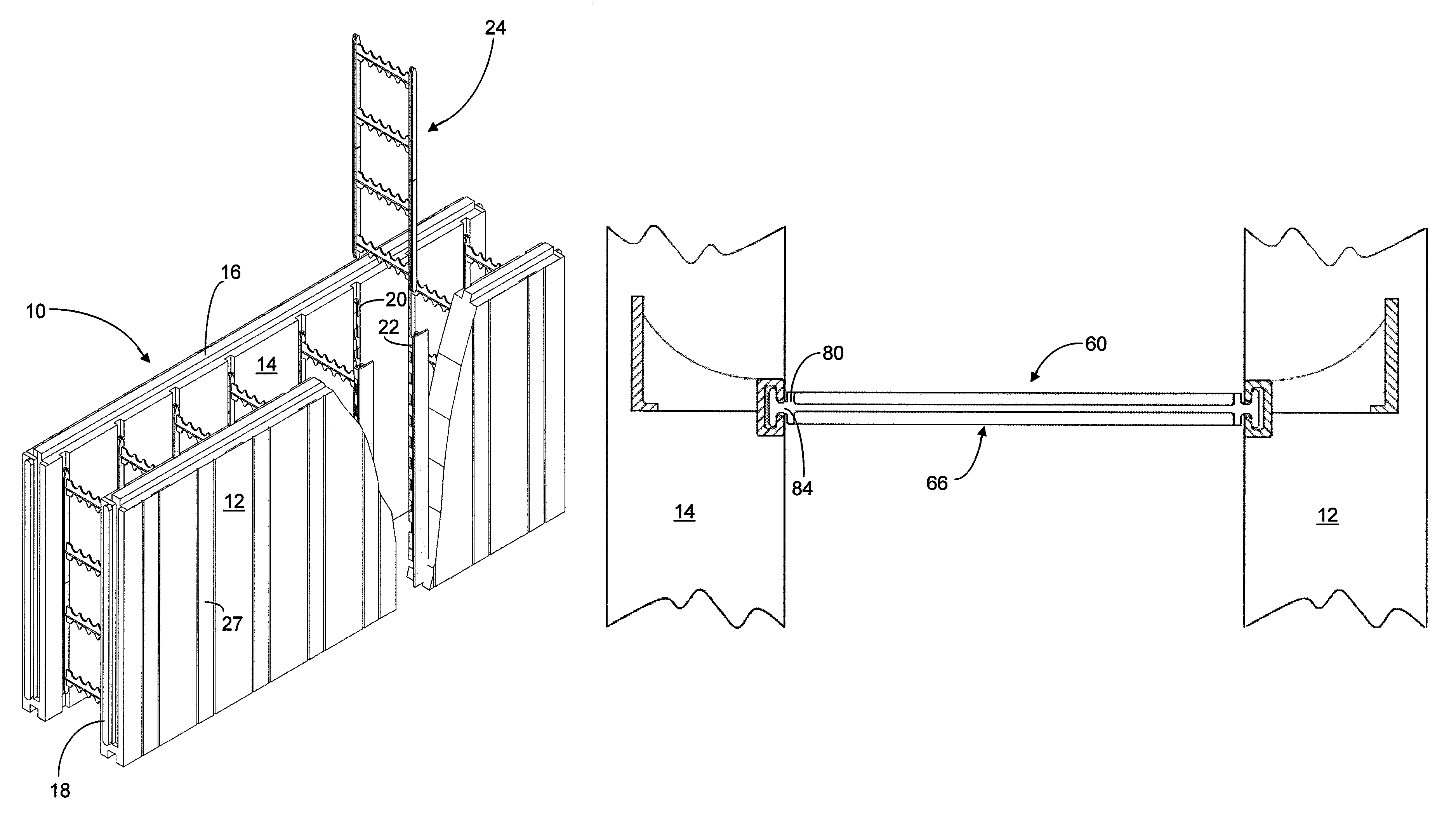

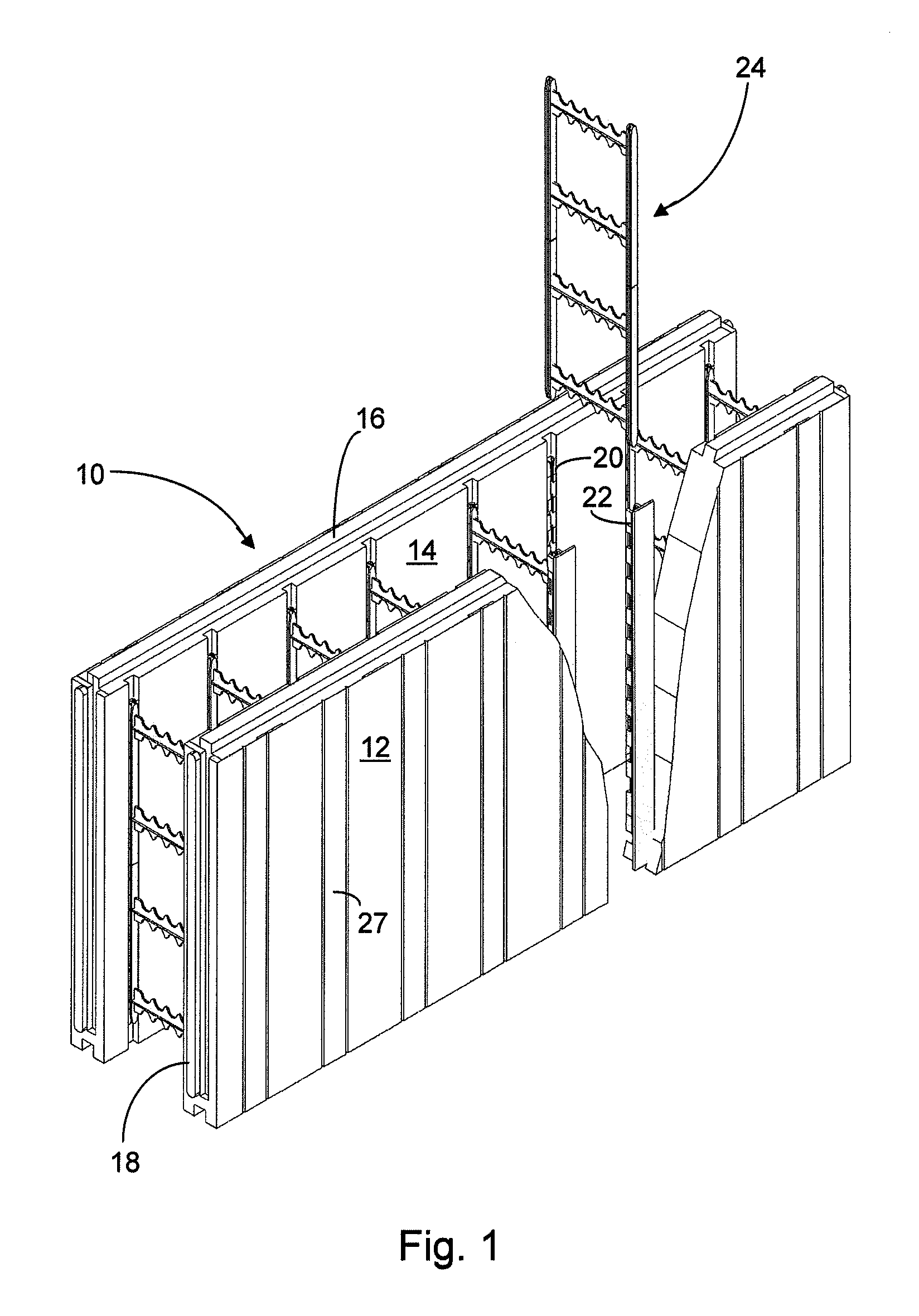

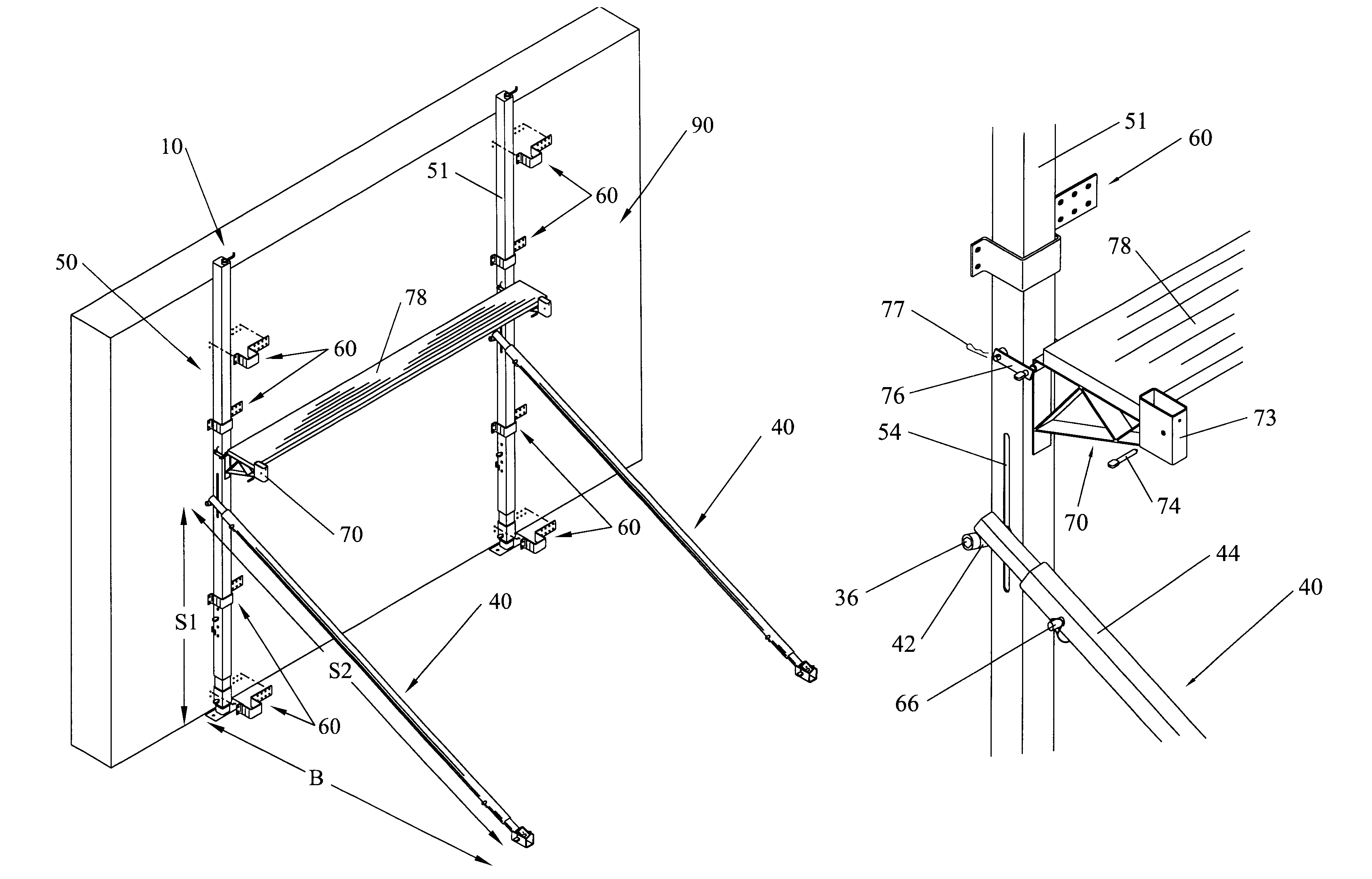

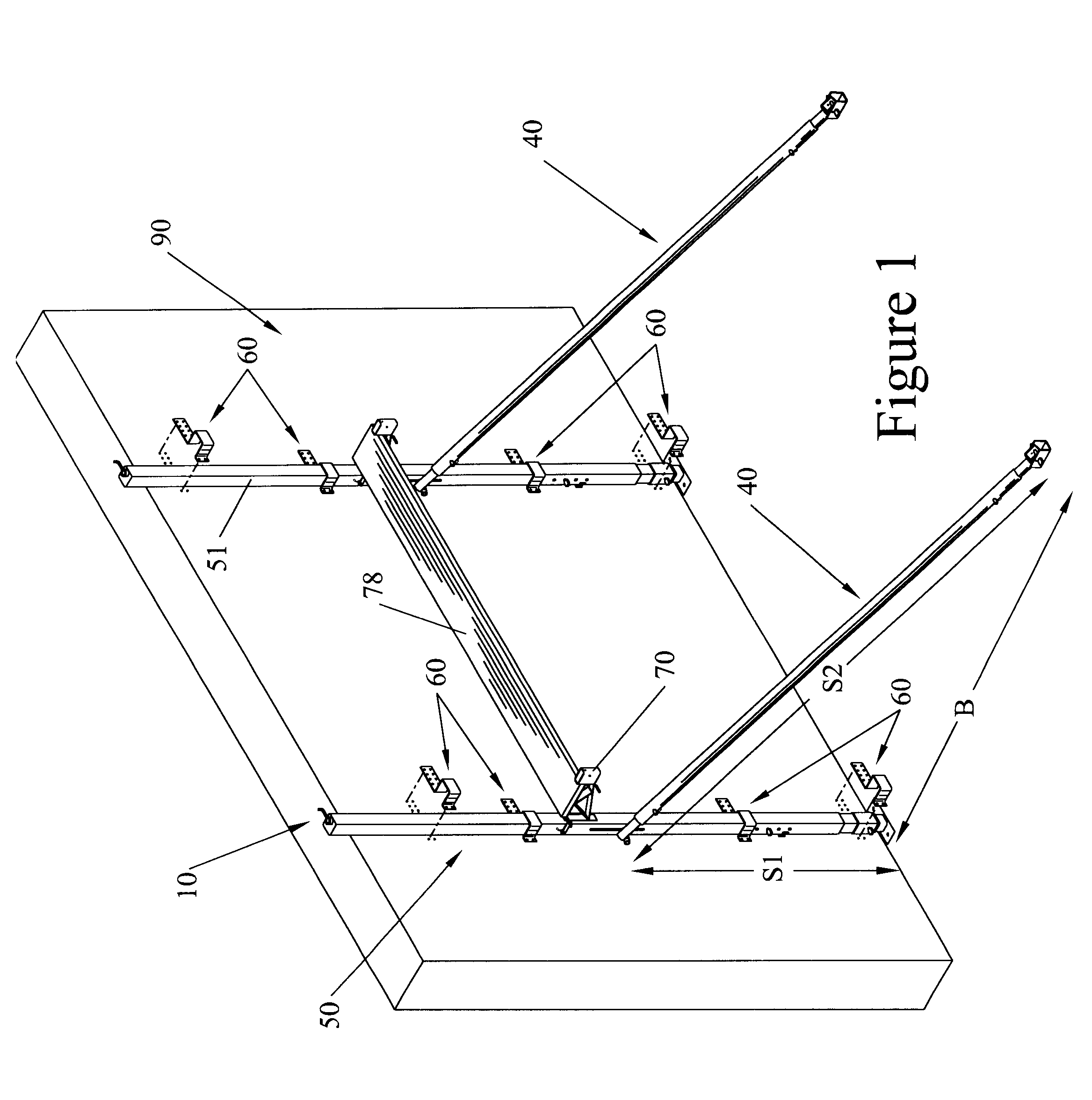

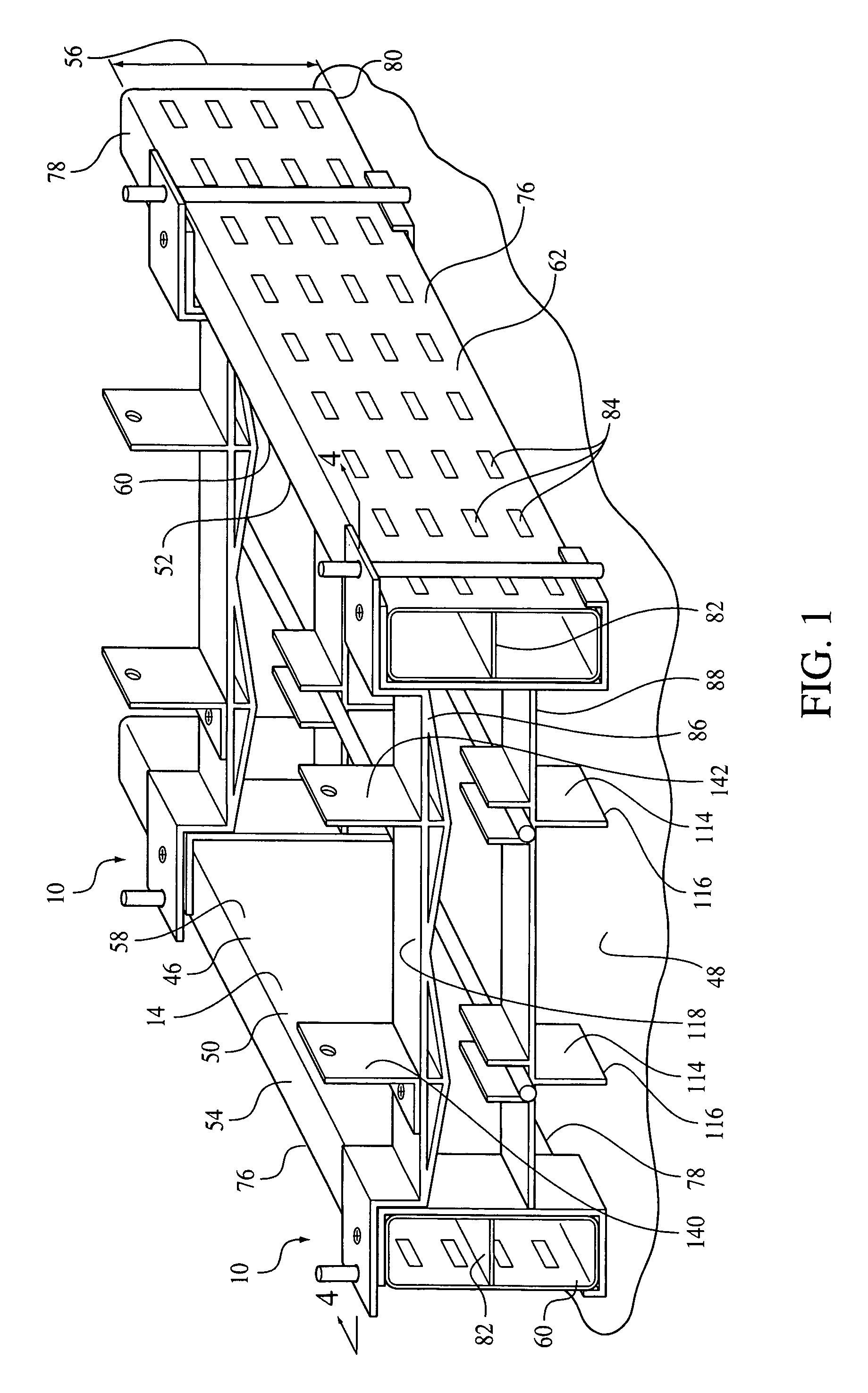

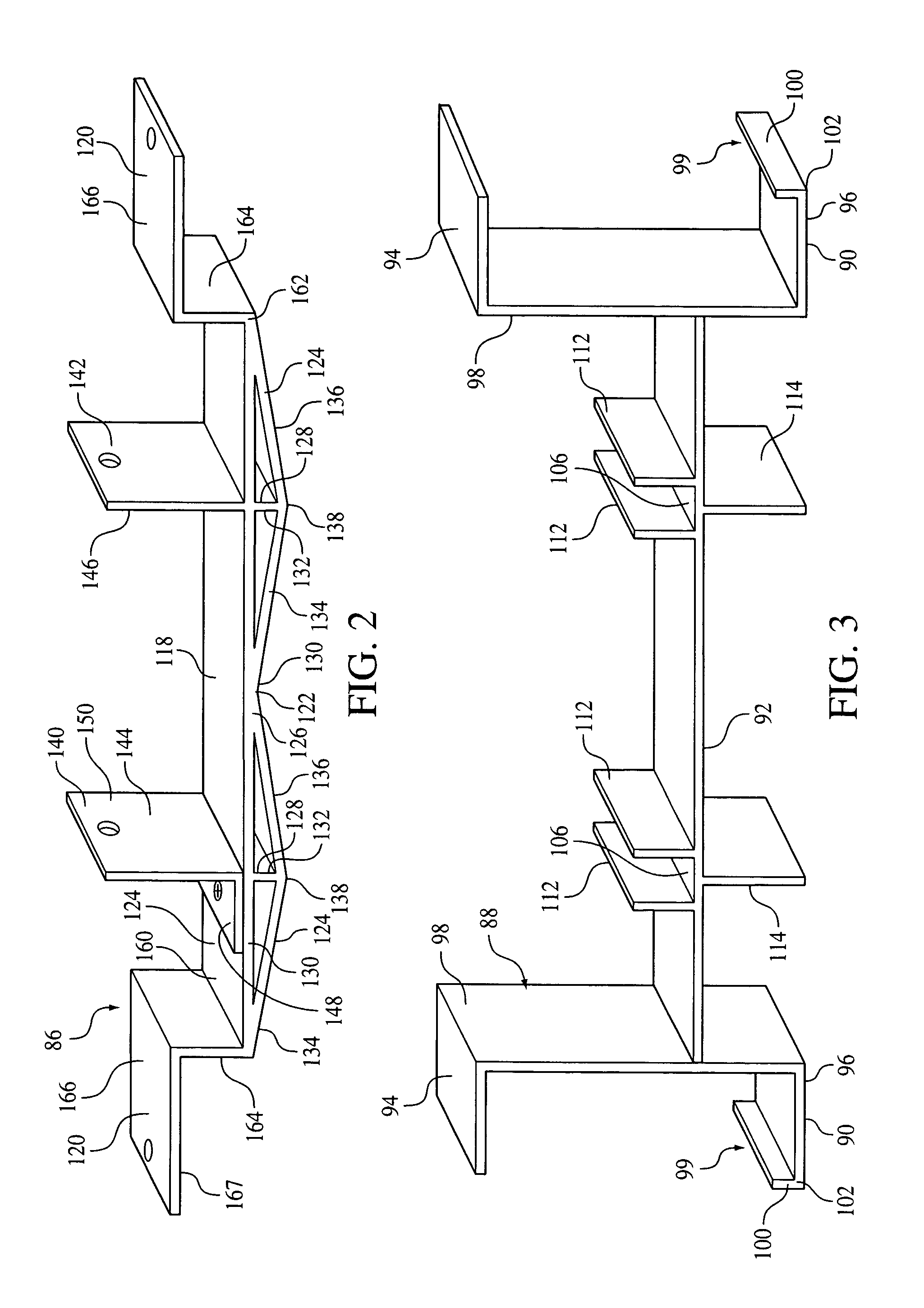

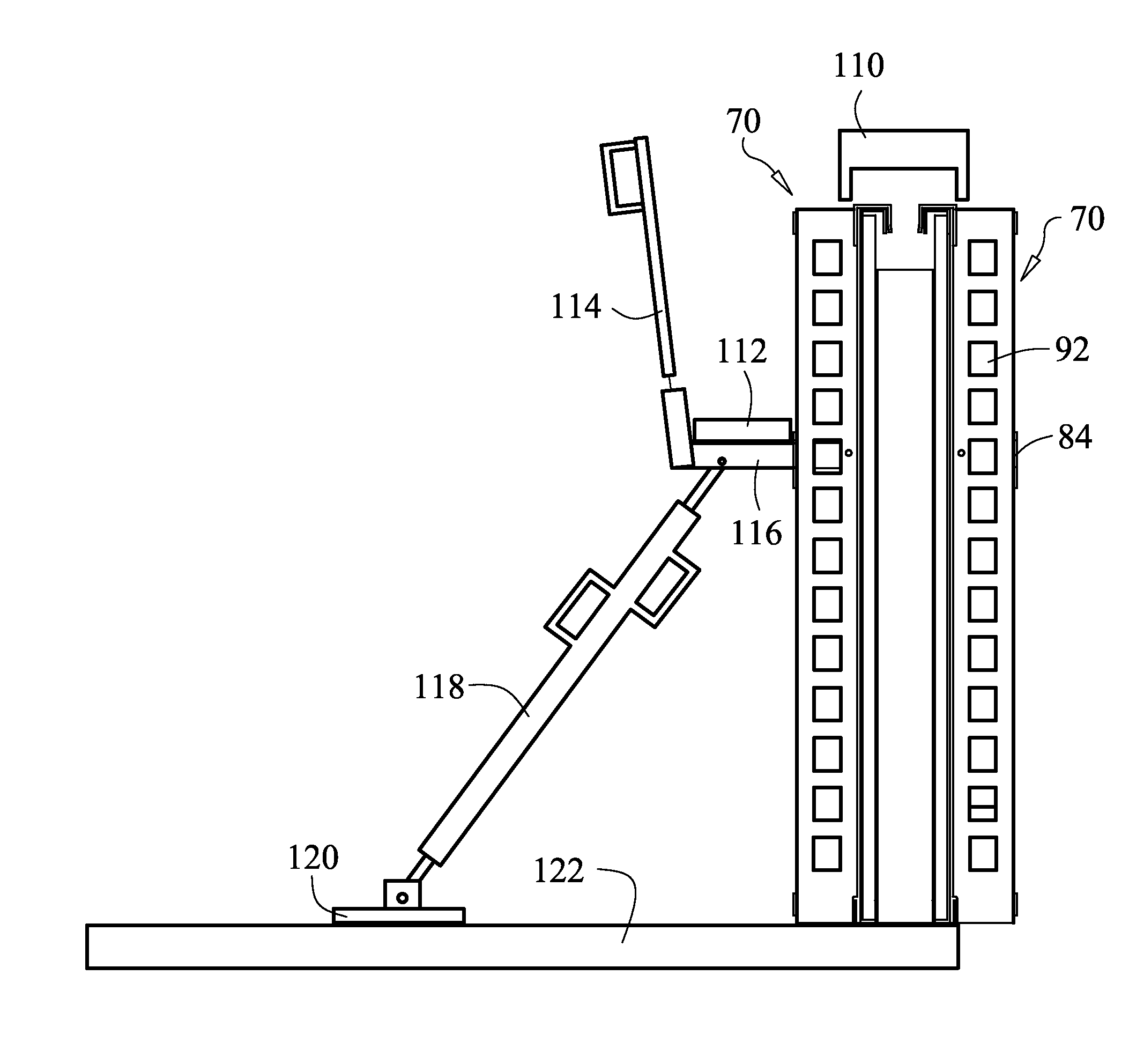

Adjustable scaffold used with concrete-receiving forms

InactiveUS6550188B2Rigid enoughEasy to moveStands/trestlesTowersSquare cross sectionExpanded polystyrene

Walls of expanded polystyrene, concrete-receiving forms (referred to as insulated or insulating concrete forms or ICFs) need to be vertical while they are being filled with concrete and while the concrete is curing. An apparatus with a vertical member and a brace member is such that one person can erect it and use it to adjust walls of ICFs so as to be vertical or plumb. The apparatus is capable of being readily used with the forms of any manufacturer by being provided with asymmetrical brackets for detachably attaching the vertical member to a wall firmly, but not rigidly. The apparatus provides a support for a platform, or scaffold, for a person to stand on while guiding the concrete pouring and while plumbing the wall. The vertical member extends upward from the ground and is held firmly against the wall with asymmetrical brackets. The brace member extends from the vertical member at a pivot with the other end of the brace member attached to the ground or floor. A lead screw in the vertical member is used to change the height of the pivot and thus slightly, and adjustably, tilt the vertical member into or out of the wall so as to cause the wall to be vertical. The vertical member and the brace member are preferably adjustable in length, however neither member changes length a noticeable amount while being used to cause the wall to be vertical. The members are preferably made of sections of square cross section, steel tubing that may be nested together.

Owner:BOLINGER DAVID N +1

Lightweight compositions and articles containing such

A lightweight cementitious composition containing from 22 to 90 volume percent of a cement composition and from 10 to 78 volume percent of particles having an average particle diameter of from 0.2 mm to 8 mm, a bulk density of from 0.03 g / cc to 0.64 g / cc, an aspect ratio of from 1 to 3, where after the lightweight cementitious composition is set it has a compressive strength of at least 1700 psi as tested according to ASTM C39. The cementitious composition can be used to make concrete masonry units, construction panels, road beds and other articles and can be included as a layer on wall panels and floor panels and can be used in insulated concrete forms. Aspects of the lightweight cementitious composition can be used to make lightweight structural units.

Owner:SYNTHEON HLDG SPA

Insulated concrete form system with variable length wall ties

InactiveUS20070094974A1Improve carrying capacityImprove energy savingWallsAuxillary members of forms/shuttering/falseworksPolypropyleneInsulating concrete form

Variable length polypropylene ties are used to form an insulated concrete wall by holding sheet materials in a fixed distance part so concrete can be cast between the two sheet materials.

Owner:VELICKOVIC PJER MISE

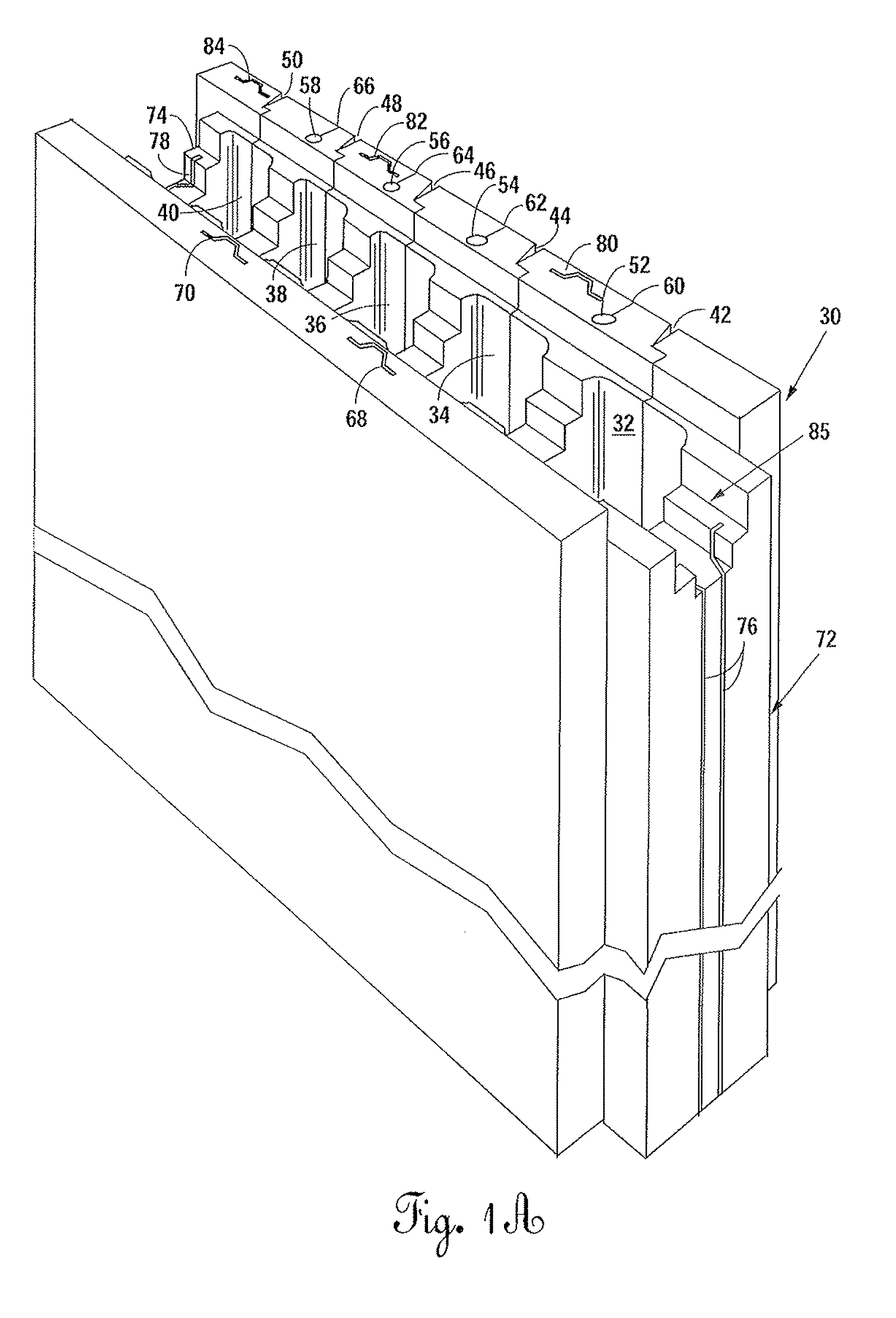

Building construction using structural insulating core

The present invention relates to a structural insulating foam core wall that is versatile to be used as an independent framed wall, combination of an independent wall and Insulated Concrete Form (ICF) wall, in conjunction as part of a precast wall or as part of forming system to form a concrete beams and column structure, and modular units with concrete beams and columns. The structural insulating core wall, can also be used as individual foam spacer blocks, with or without brackets and horizontal bracing channels. Various types of flanges extensions are added to form different support channel flanges. The interlocking foam spacers and support channels which can be glued or screwed together to form structural insulating panels (SIPS), independent walls or as part of a precast wall with columns and beams integrated within the wall panels.

Owner:LEBLANG DENNIS WILLIAM

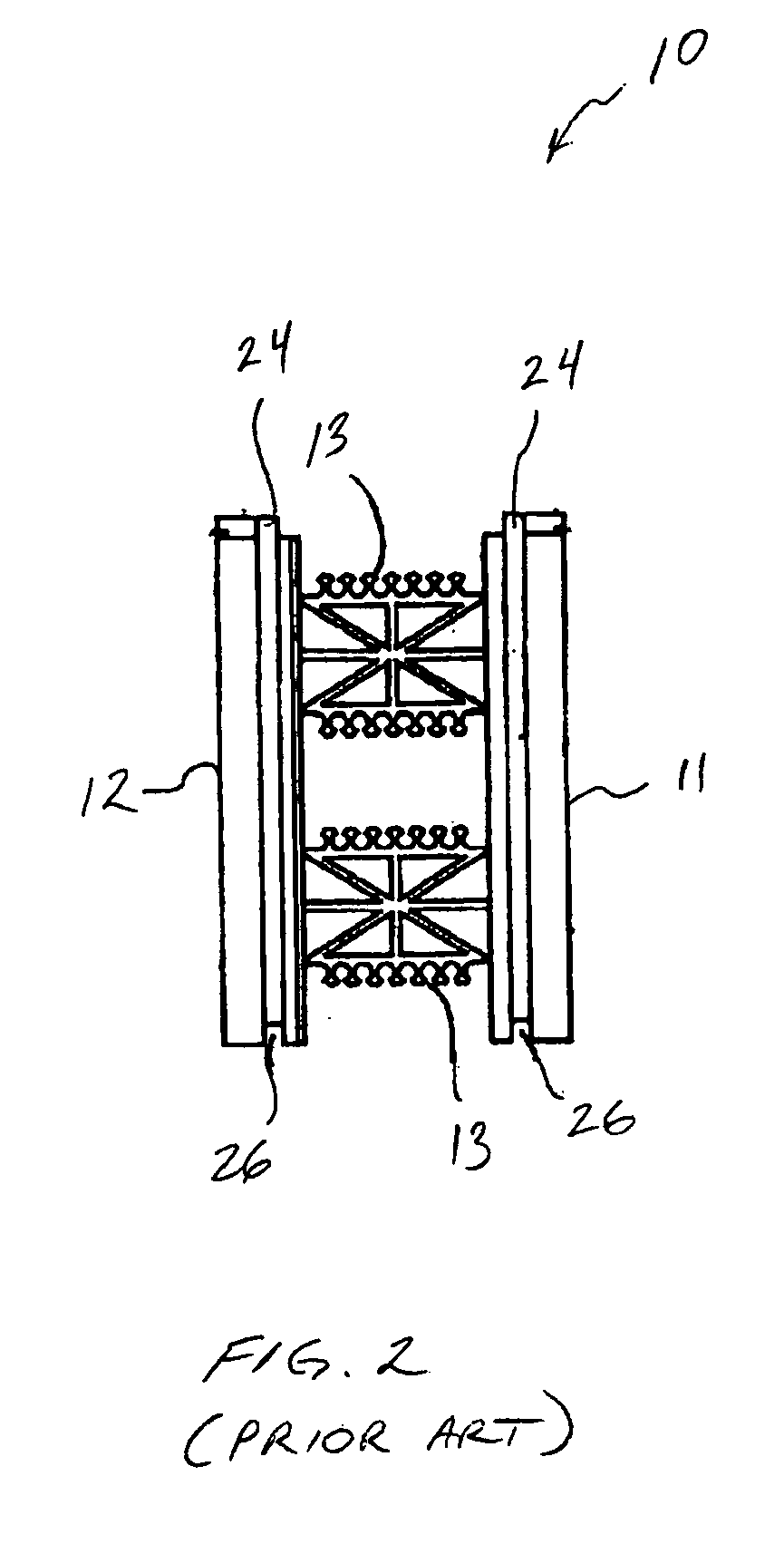

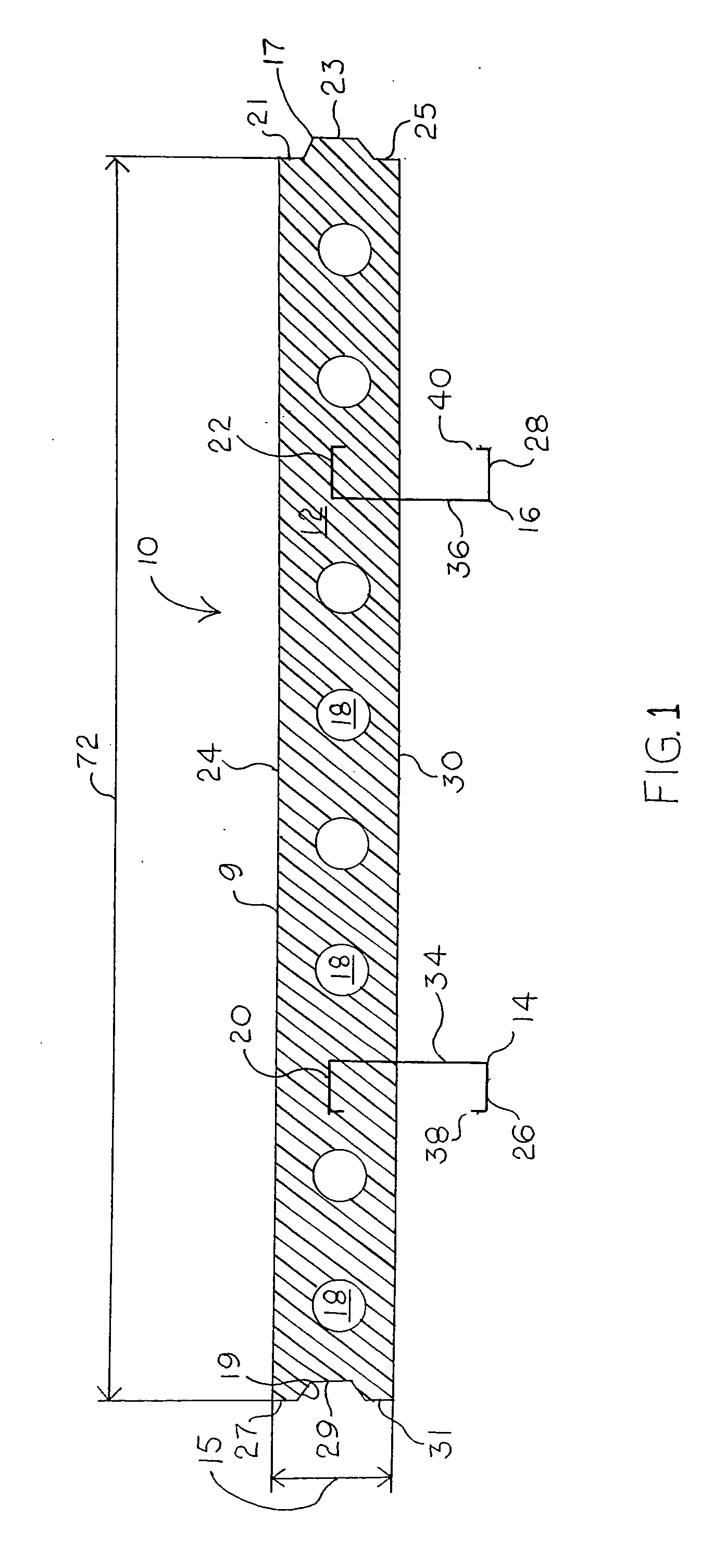

Insulating concrete form

A knocked-down insulating concrete form including two spaced apart lightweight panels maintained in position by a tie assembly.

Owner:AIRLITE PLASTICS

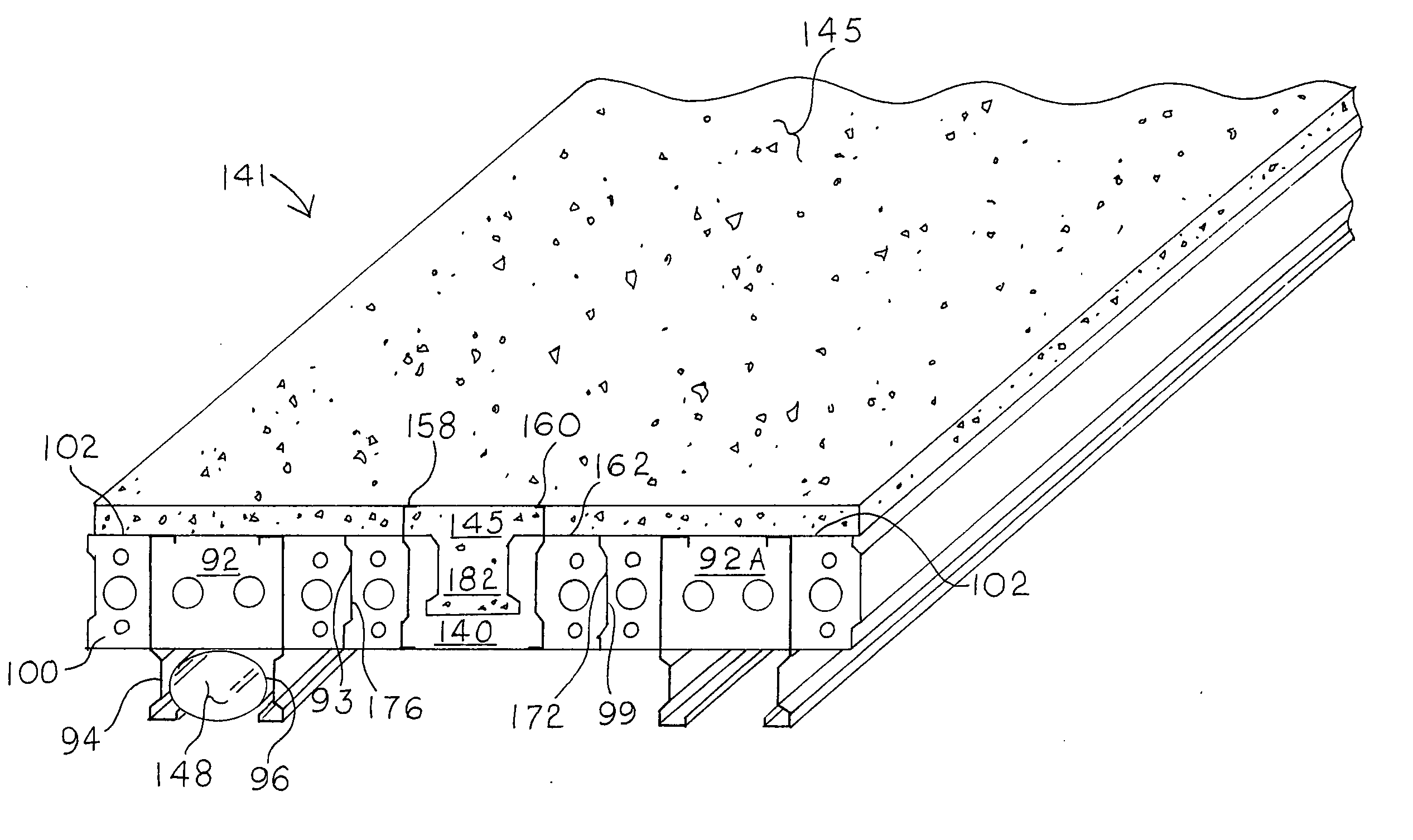

System support assembly

A system support assembly comprises a pair of substantially parallel footer forms, insulated concrete forms, footer form base saddles, a poly form saddle assembly and first and second vertical stabilizers. The footer form base saddle may be generally u-shaped and is driven into the ground forming two substantially parallel areas. Each footer form is placed within the row formed by the footer form base saddles such that a cavity is defined therebetween which will ultimately form the footer of the foundation. The poly form saddle assemble comprises a poly form saddle and fasteners. The poly form saddle may also be generally u-shaped and is placed over both footer forms, thus straddling the same. The poly form saddle may then be secured with corresponding fasteners. The insulated concrete forms are placed side by side and are stacked upward, such that a wall is formed. A first poly form vertical stabilizer is placed over the wall and operatively connected to the footer form base saddle. More insulated concrete forms are stacked to complete the wall. The second poly form vertical stabilizer may then be placed, preferably laterally spaced from the first poly from vertical stabilizer. The second poly form vertical stabilizer is also operatively connected to the footer form base saddle. Then, the concrete is poured into the insulated concrete forms such that the foundation wall and footers are poured and cured at one time.

Owner:INGRID C GREEN

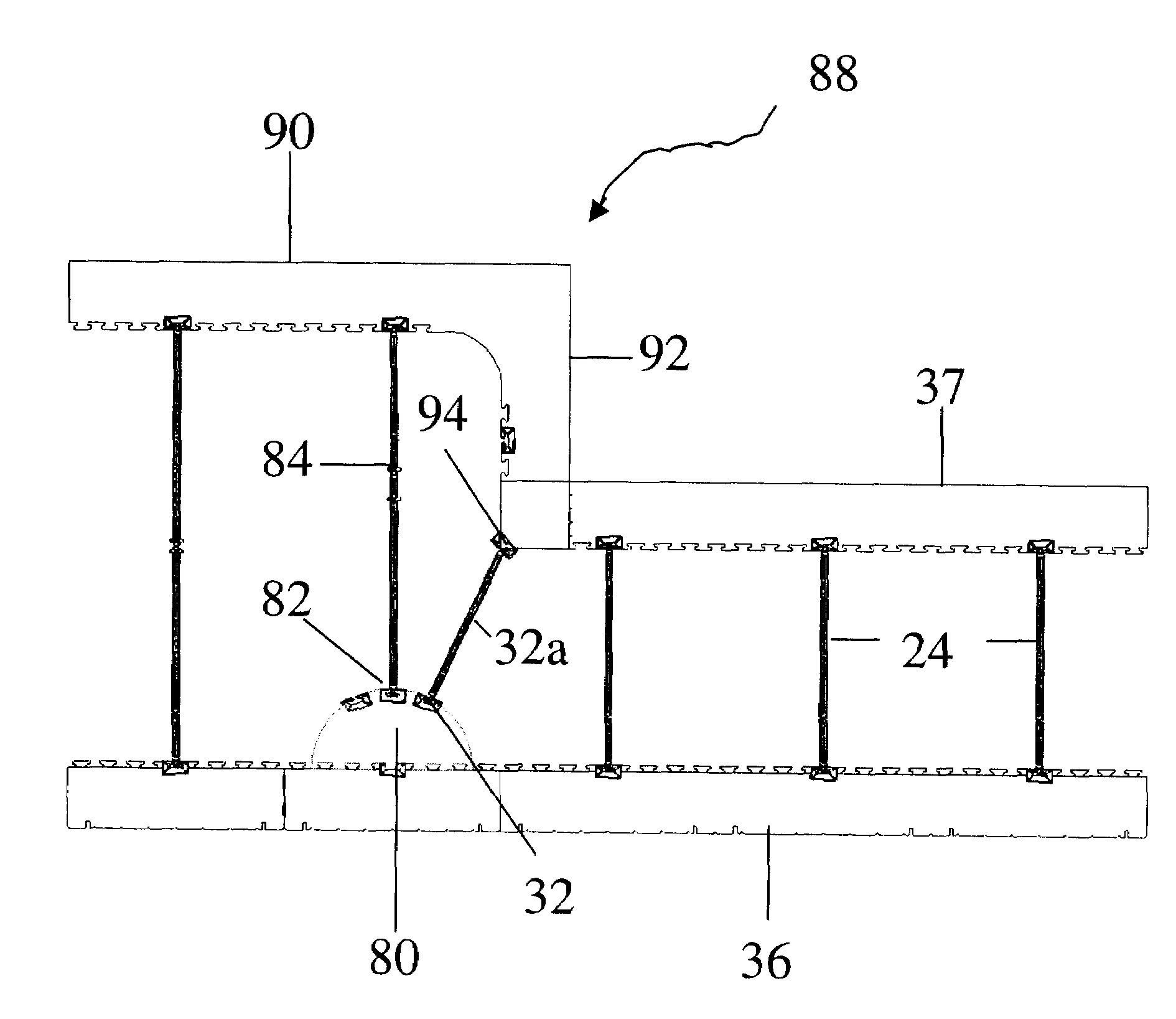

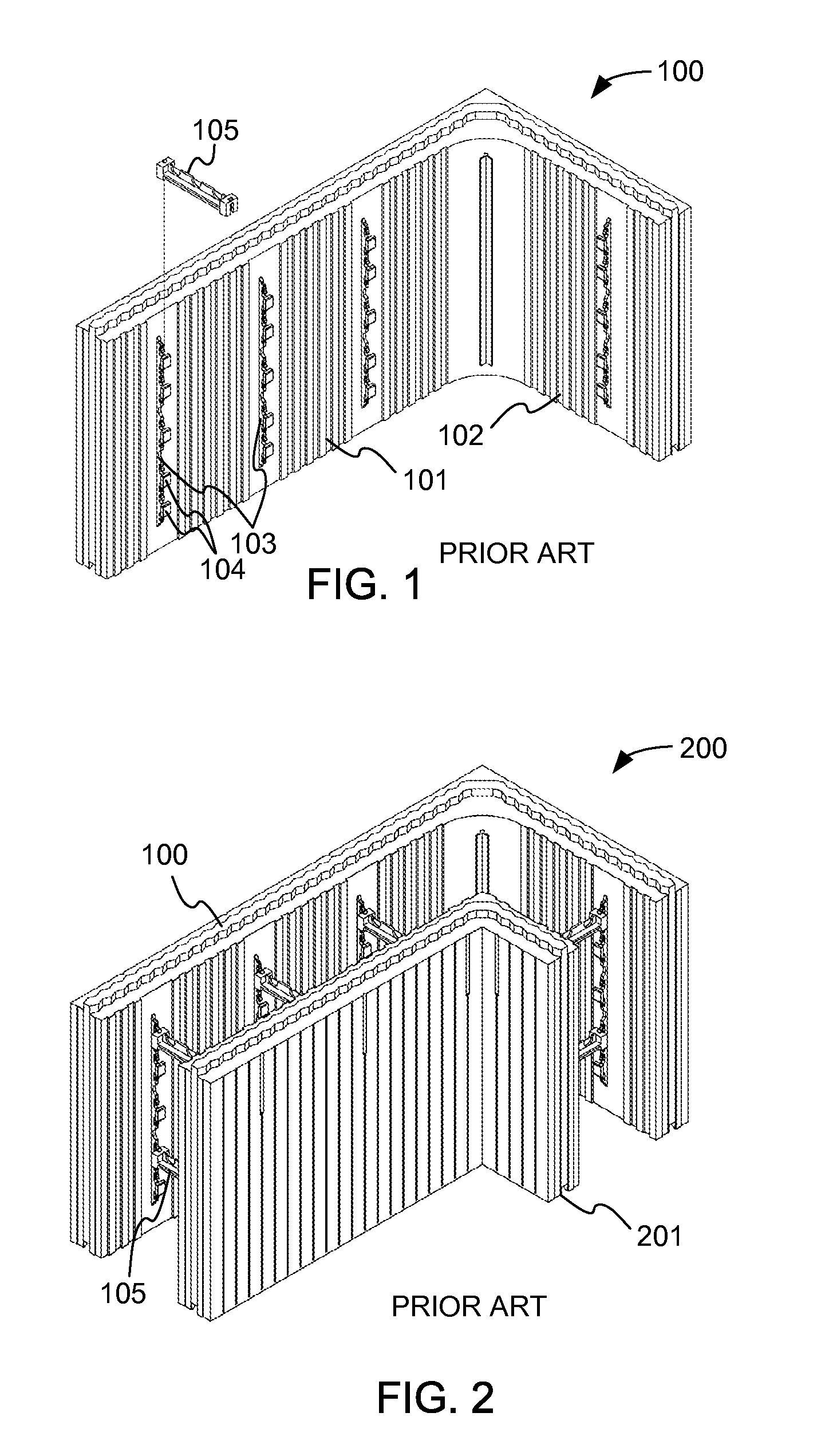

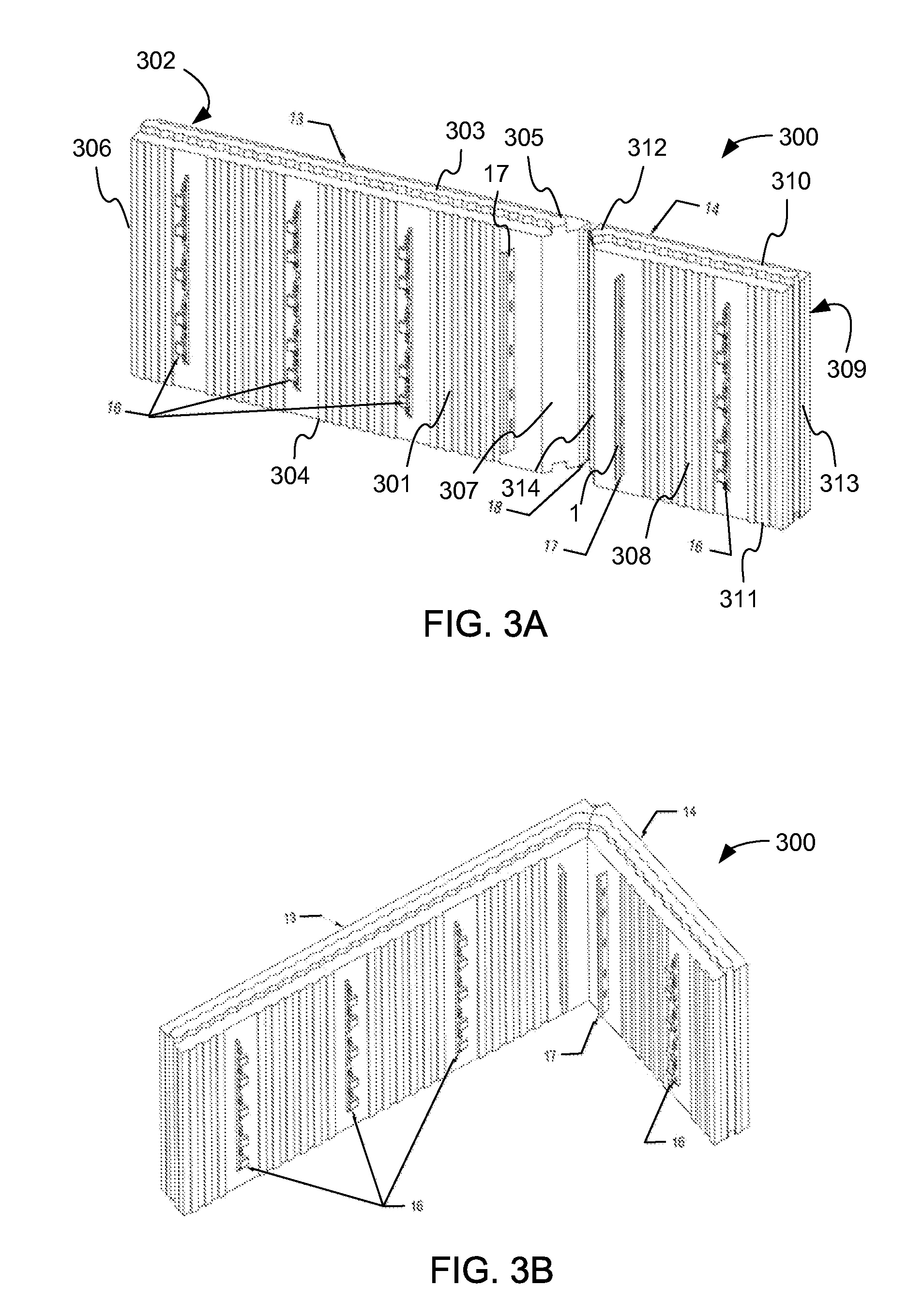

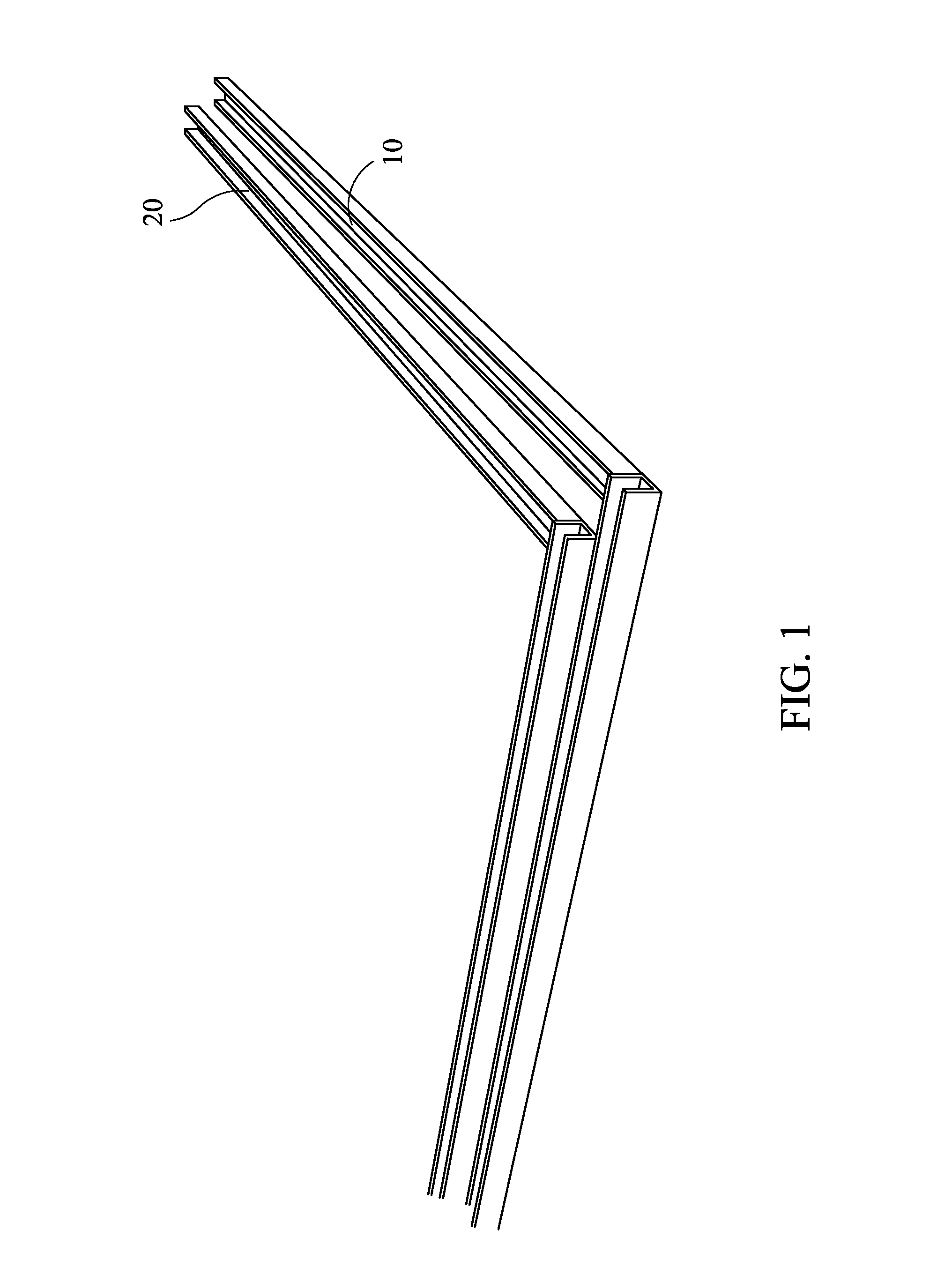

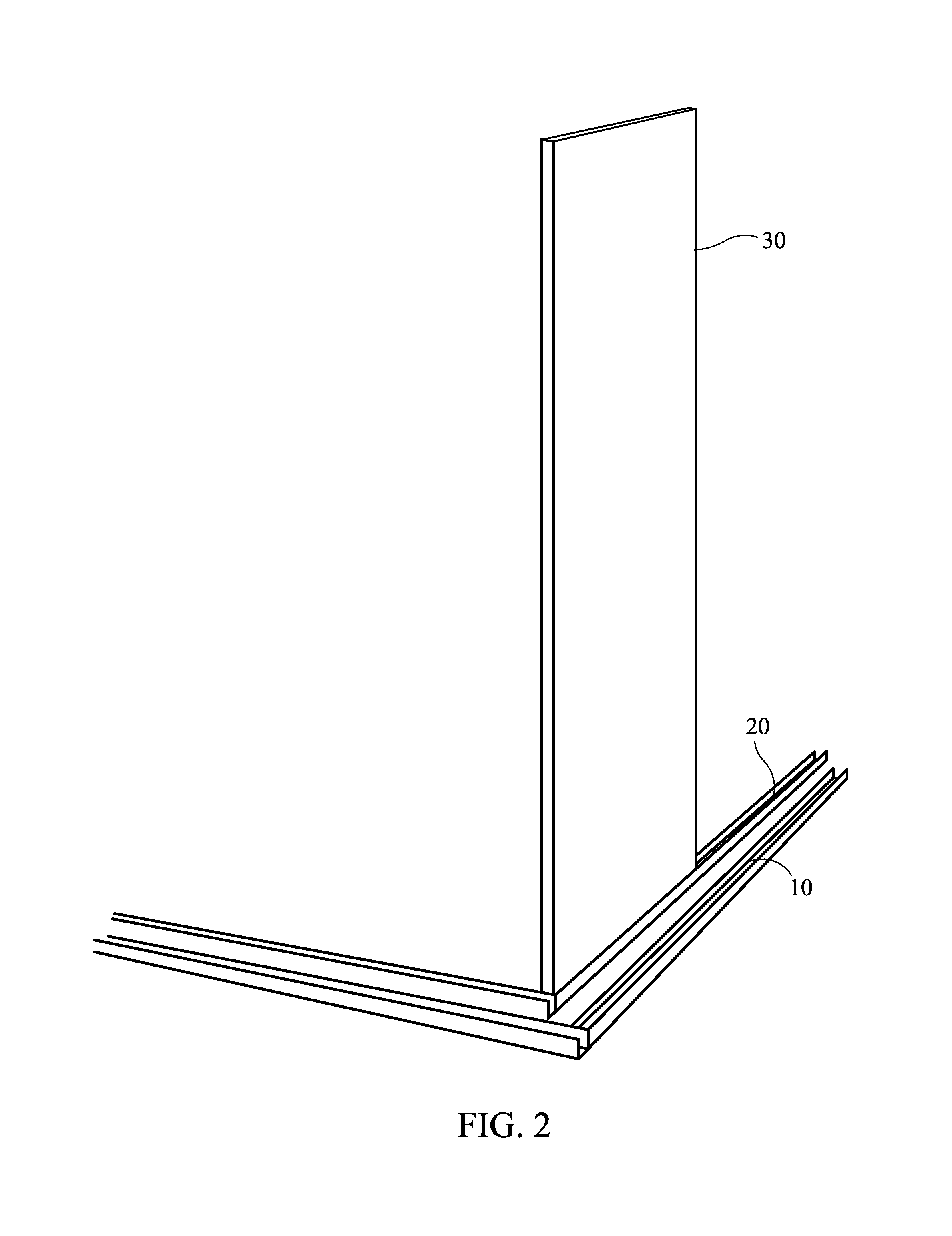

Hinged corner form for an insulating concrete form system

A corner form panel used in an insulating concrete form system includes a hinged corner web member at least partially embedded in each of two segments of the form panel. The hinged corner web member enables the two segments to rotate with respect to each other, so that the form panel can be opened to a flat configuration for shipping, and folded into a corner configuration at the jobsite. Both inside and outside corner panels may be provided, and may use different hinged corner web members. The corner web member may include features for connecting the inside and outside corner panels, to reinforce the resulting form unit.

Owner:AIRLITE PLASTICS

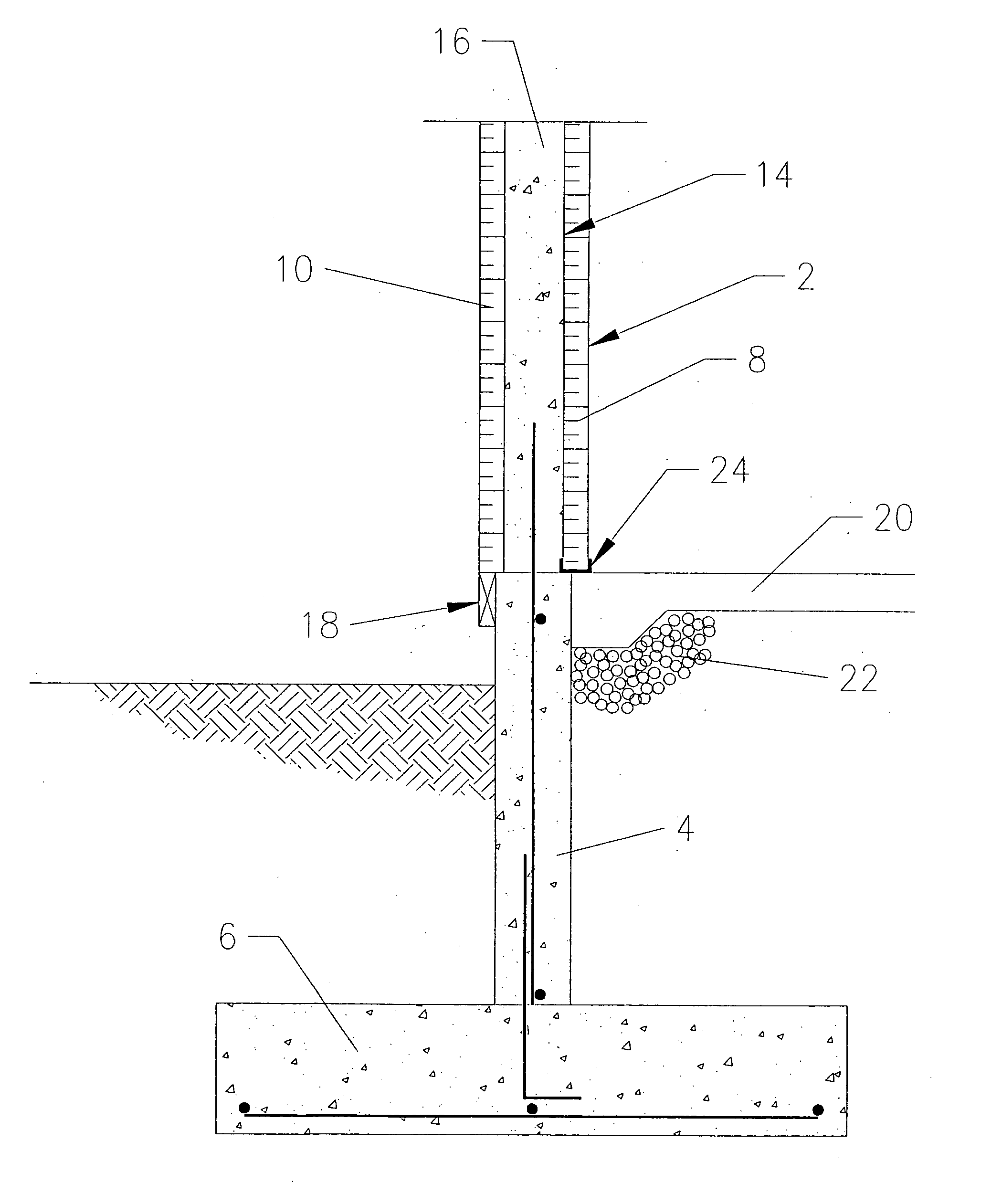

Insulated concrete form holder

ActiveUS7444789B1Shorten the timeSimple construction processWallsBuilding repairsInsulating concrete formSupport surface

An insulated concrete form holder is provided for holding insulated concrete forms that form the first course of a wall so that the first course of insulated concrete forms are formed integrally with the foundation of a building. The form holder has a support surface for supporting the form holder in a foundation form and a form support surface for contacting the bottom of the insulated concrete form and supporting the insulated concrete form thereon. The form support surface is positionable between the top and the bottom of the foundation form, said form support surface is spaced from the top of the foundation form a distance less than the height of the insulated concrete form so that the top of the insulated concrete form is positionable above the top of the foundation form. The form holder includes form support upright portions extending upwardly from the form support surface for contacting the sides of the insulated concrete form and restraining lateral movement of the insulated concrete form.

Owner:MOORE DANIEL W

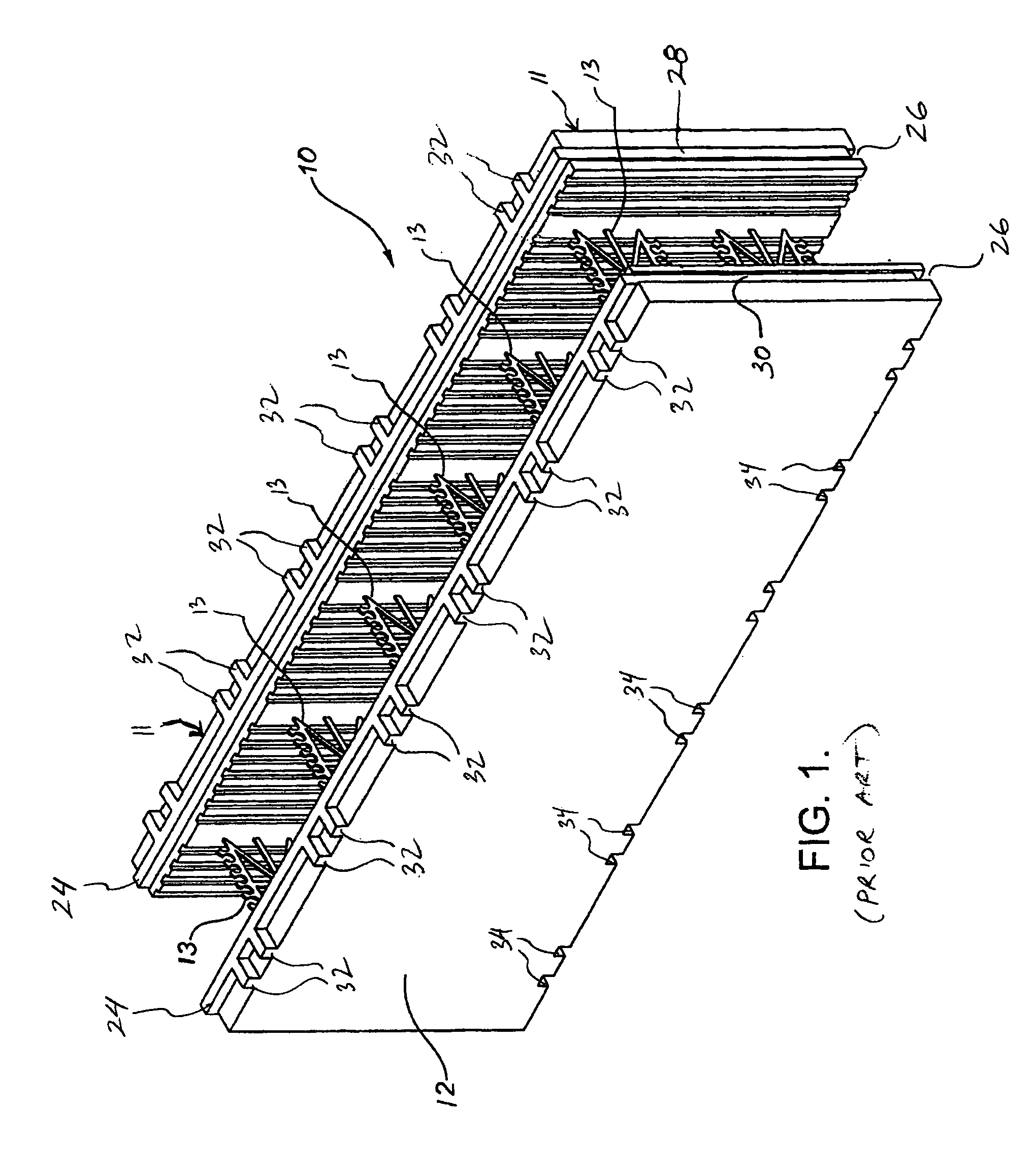

Isulated concrete form having welded wire form tie

InactiveUS7415804B2Improve structural strengthEasy constructionWallsMouldsEngineeringTongue and groove

An insulating concrete form with two opposing panels, each panel having on each end thereof both a tongue and a groove for interconnecting with a similar form, the tongues and grooves positioned such that a similar form may be reversibly positioned and still interconnected, the opposing panels on each form joined by a plurality of metal wire ties with both horizontal and vertical members, preferably welded one to another, with each horizontal wire bent to form a right angle on each end with a metal attachment strip disposed within such right angle.

Owner:AIRLITE PLASTICS

Wall Opening Form

InactiveUS20090193729A1Easy to getReduce supportWallsWindow/door framesNatural fiberMechanical engineering

Disclosed is a frame member for forming an opening through an insulating concrete form wall having opposed first and second forms. The frame member comprises an elongate member dimensioned to extend between the opposed forms. The elongate member is composed of a natural fiber plastic composite material having an opening forming surface and a wall forming surface and a pair of longitudinal retention fins extending from the wall forming surface. Each of the retention fins has a distal lip portion wherein the lip portions cooperate to form a hollow between the lip portions and the wall forming surface. Also disclosed is a frame for forming an opening through an insulating concrete form wall comprising at least three frame members and at least two corner connectors for connecting said frame members. The corner connectors comprise a bracket insertable into the hollows.

Owner:QUAD LOCK BUILDING SYST

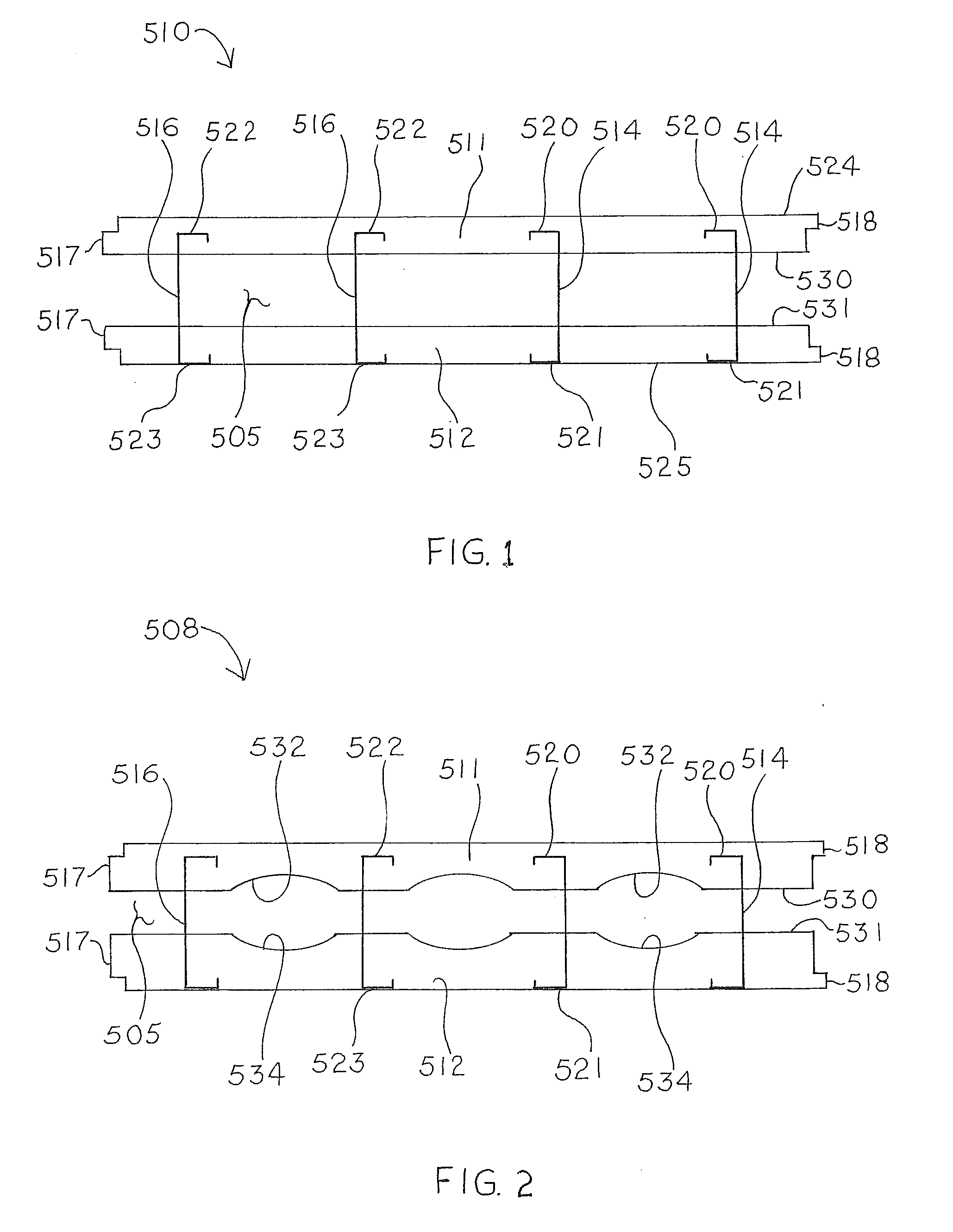

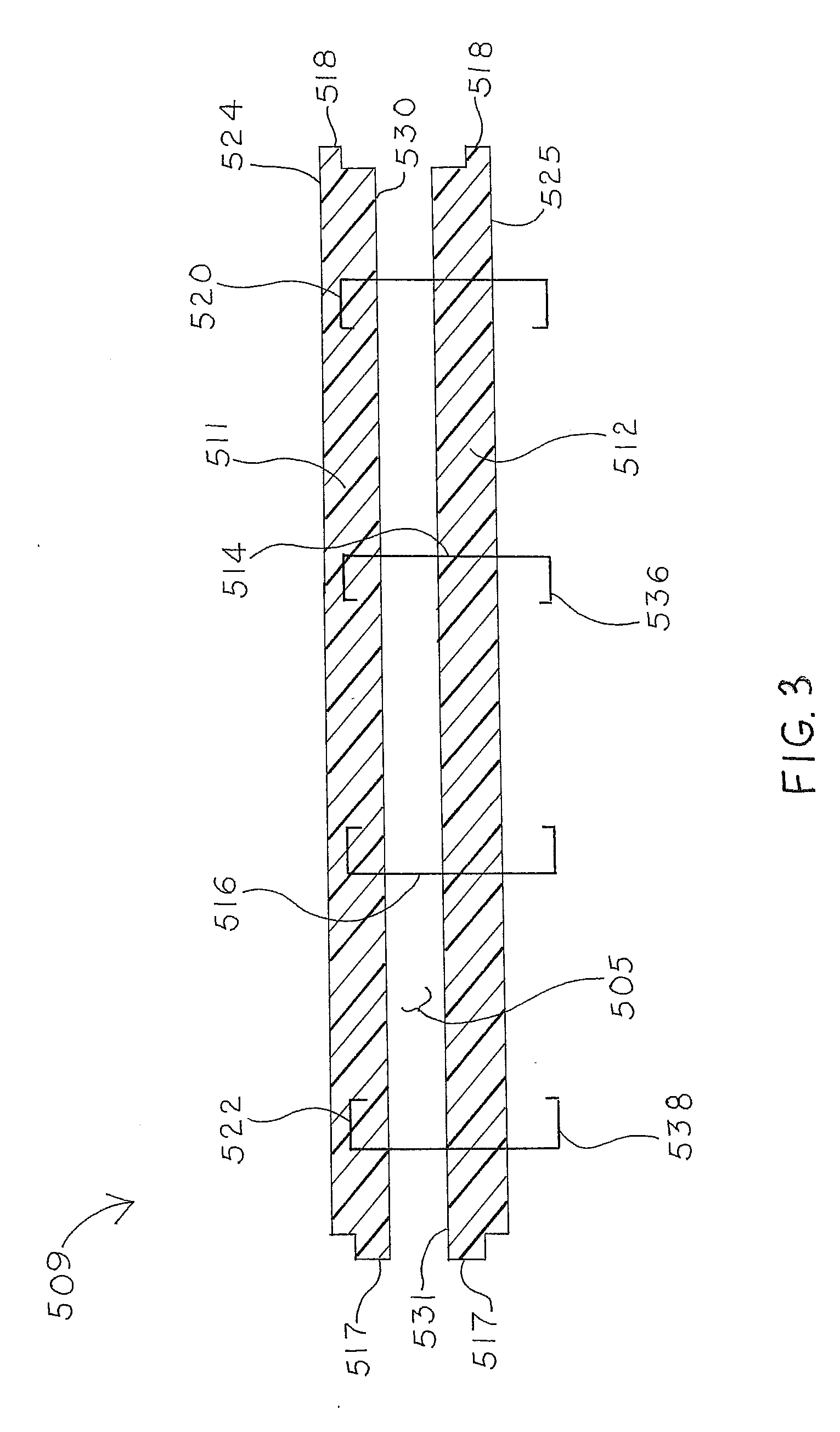

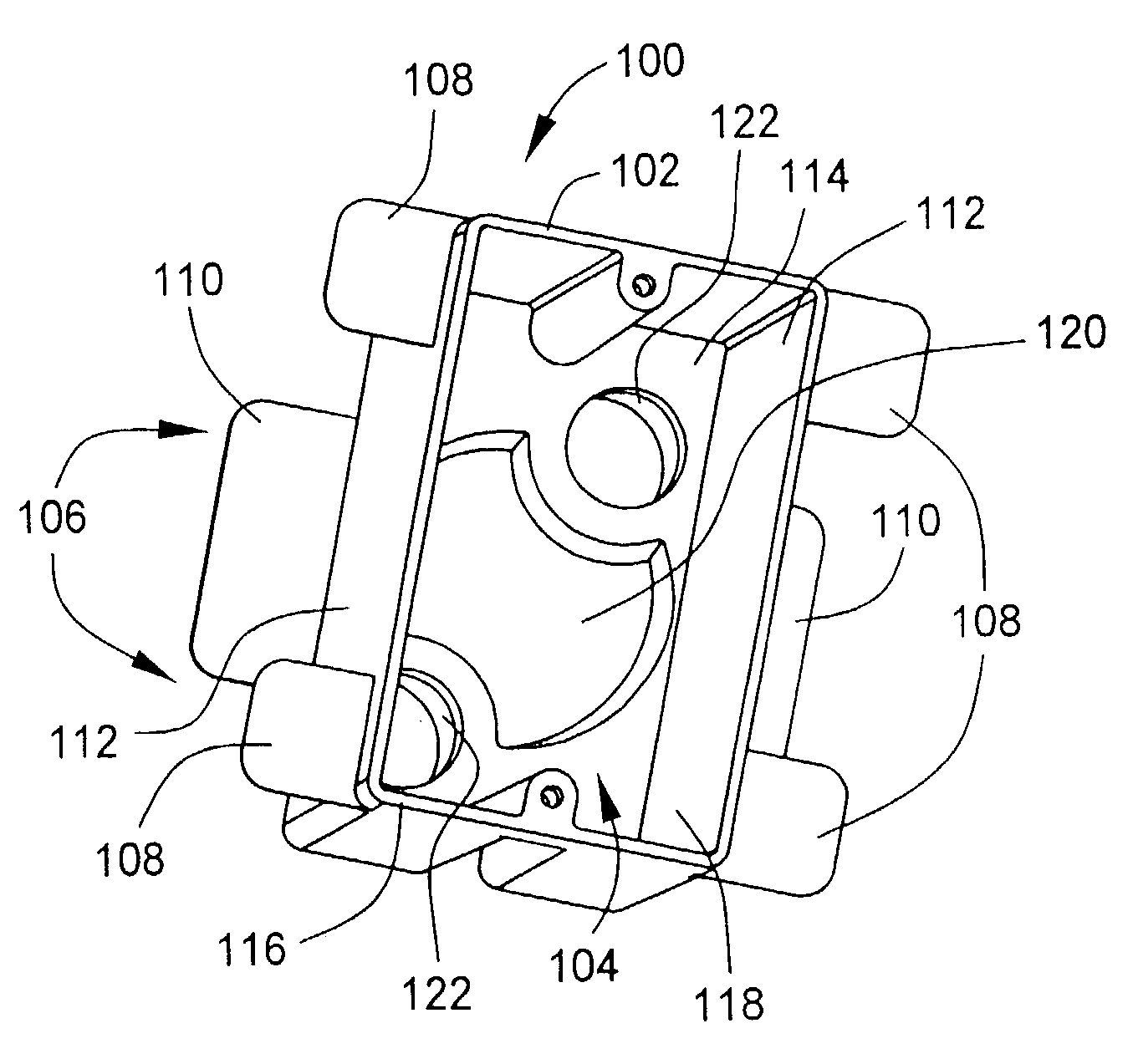

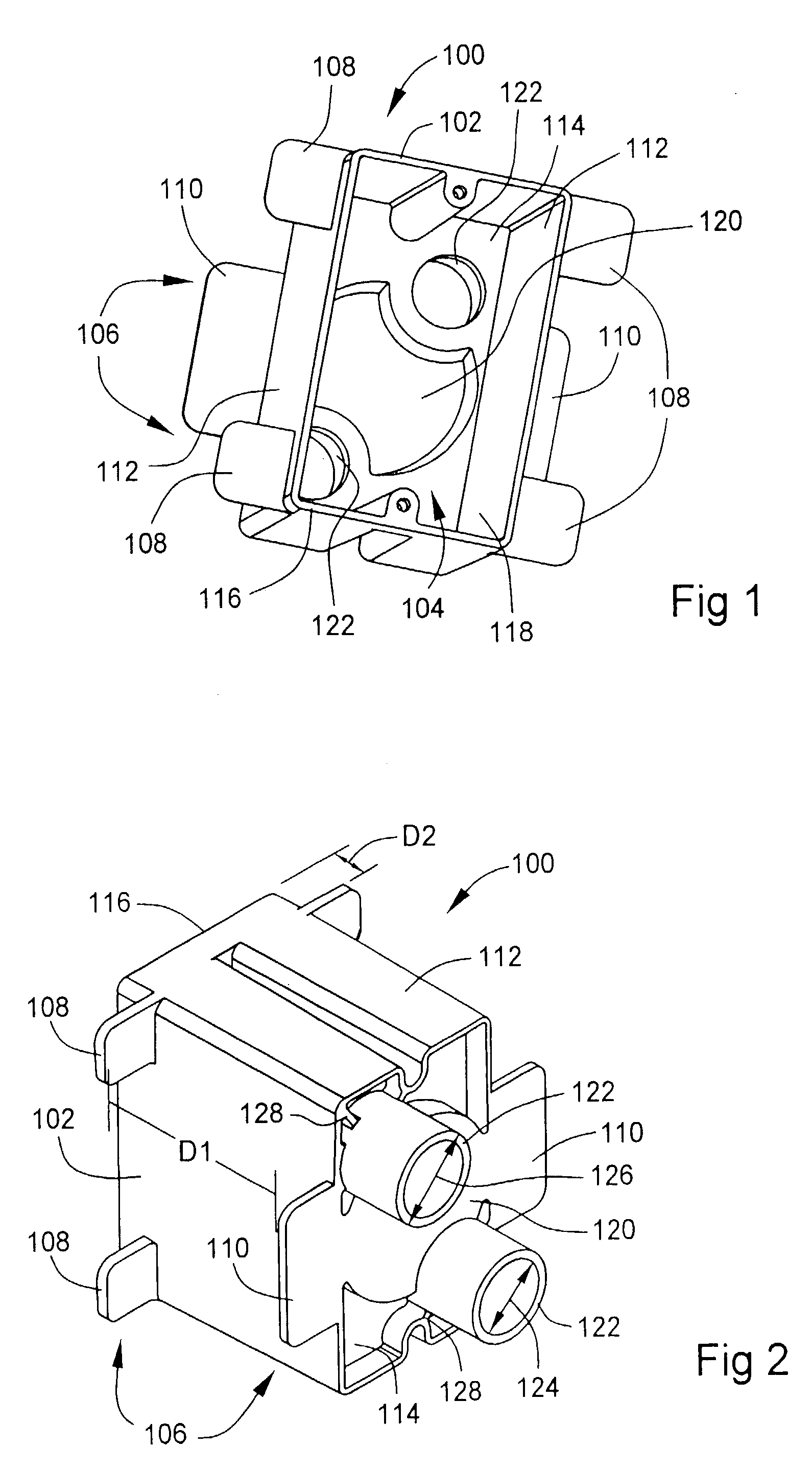

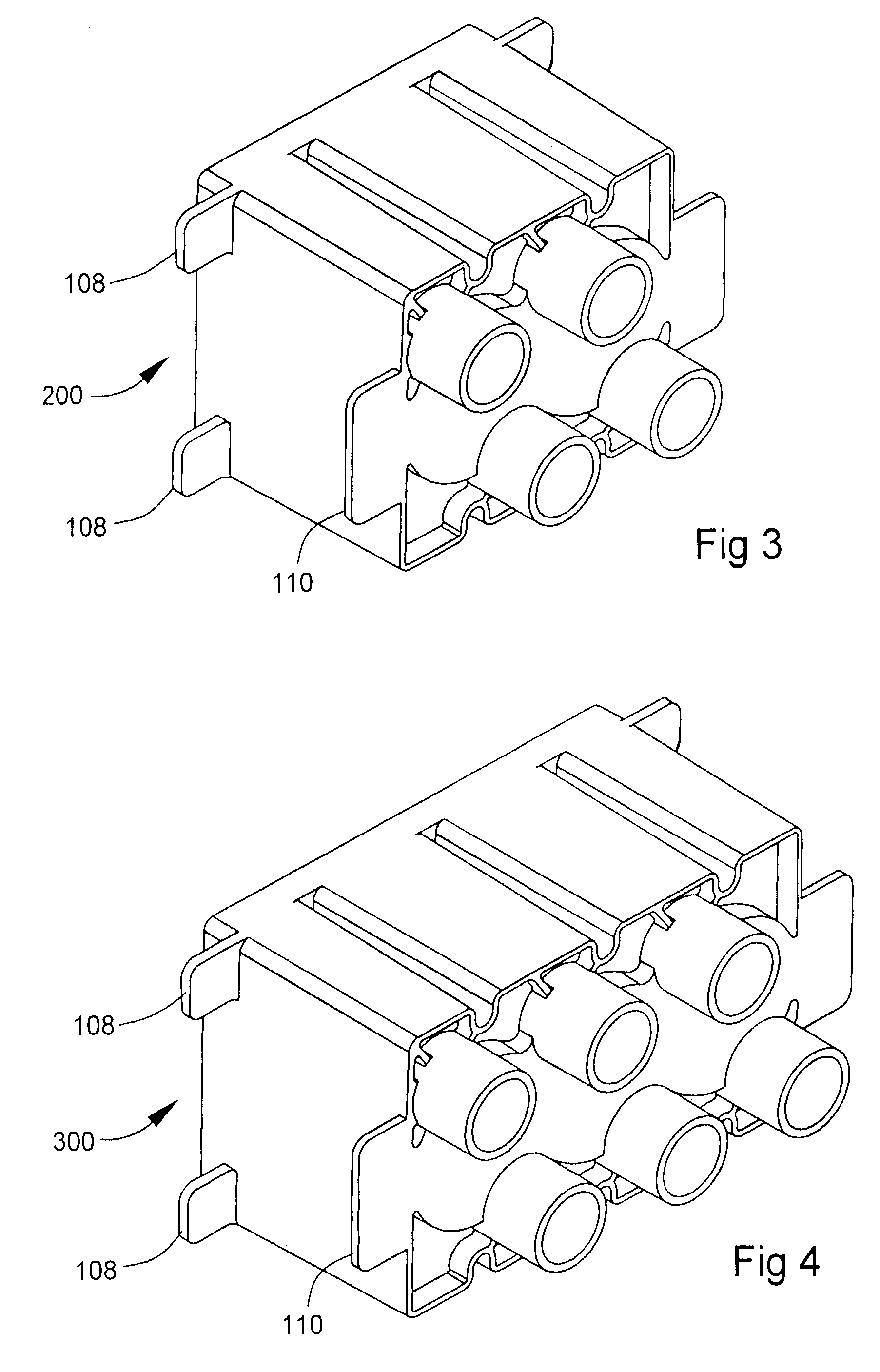

Insulating concrete form (ICF) system with tie member modularity

ActiveUS20140260055A1Improve efficiencyIncrease flexibilityWallsForms/shuttering/falseworksModularityEngineering

A modular tie member which promotes flexibility in manufacturing ICF blocks of varying widths and heights, one embodiment including a pair of side wall bracket members each encapsulated within a respective panel member forming an ICF block and a web member pivotally attached to and extending between the side wall bracket members. Each bracket member may include an extension portion and / or another interlocking mechanism associated with each opposite end thereof positioned for overlapping and engaging similar members associated with similarly constructed tie members when one tie member is stackably arranged one on top of another tie member. The extension portions and / or the other interlocking mechanism extend into respective teeth associated with the horizontally opposed edges of the panel members for mating with the extension portions and / or the other interlocking mechanism of another tie member associated with a similarly constructed ICF block positioned in vertical arrangement thereto. In still another embodiment, the web member is a one-piece member which is slidably engageable with the pair of bracket members thereby allowing the ICF blocks to be field assembled at the construction site.

Owner:ICF MFORM

Insulating concrete block

An insulating concrete block adapted to be interlocked with other insulating concrete blocks to form an insulating concrete form for casting concrete. The insulating concrete block including a first foam panel and a second foam panel supported in a spaced apart, parallel relationship to form a concrete receiving cavity. Each of the first panel and the second panel having a top end, a bottom end, a first end, and a second end. The top end and the bottom end of each of the first and second panels having an outside row of a plurality of projections and an inside row of a plurality of projections. The projections of the outside row being spaced apart to define a plurality of recesses and the projections of the inside row being spaced apart to define a plurality of recesses with the projections of the outside row being adjacent to the recesses of the inside row and the recesses of the outside row being adjacent projections of the inside row. At least some of the projections of the inner row are set back from an inner edge of the panel such that when one panel is interconnected with a like panel a plurality of spaced apart recesses are formed along an inner face defined by the interconnected panels.

Owner:BUILDBLOCK BUILDING SYST

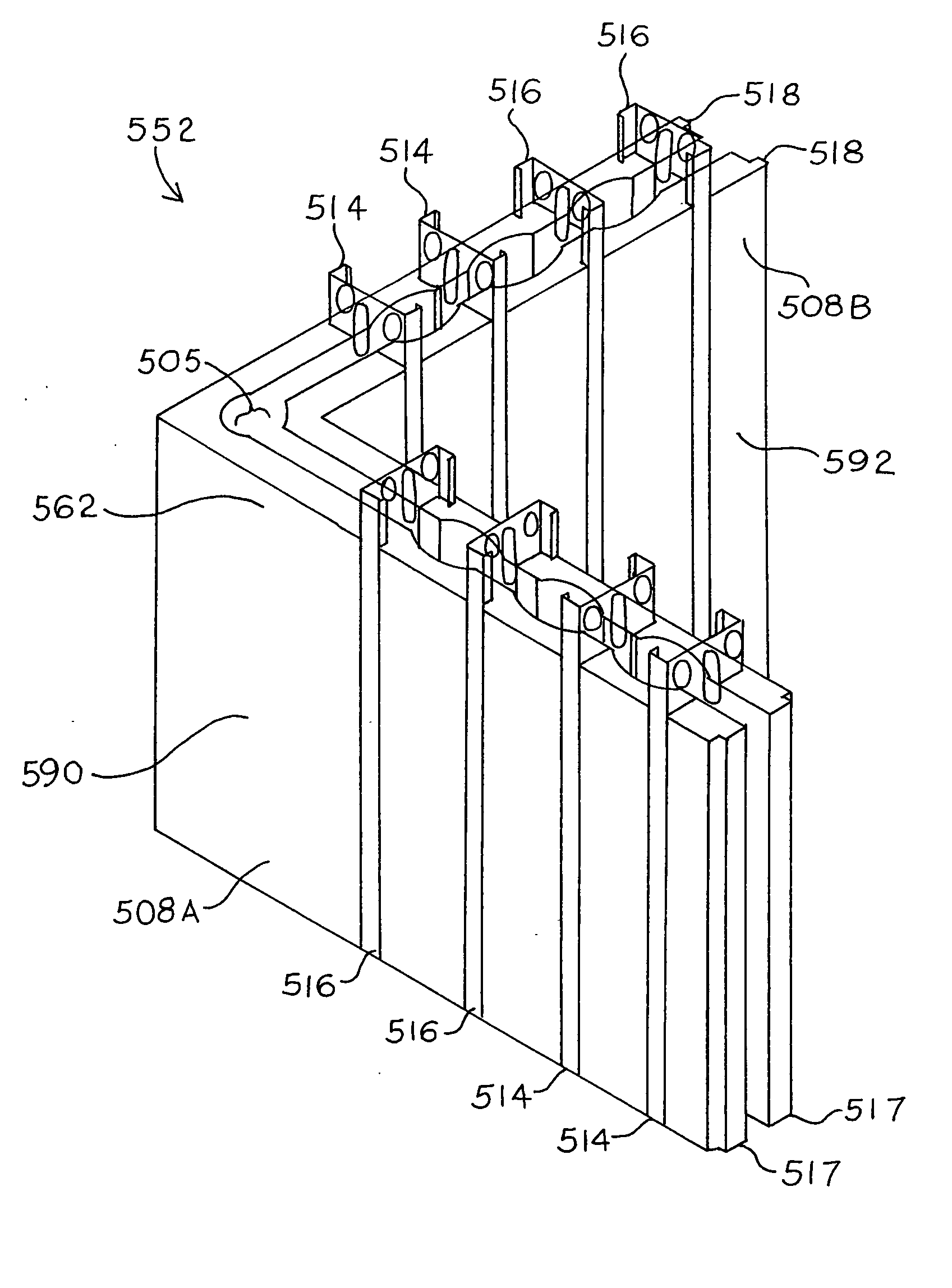

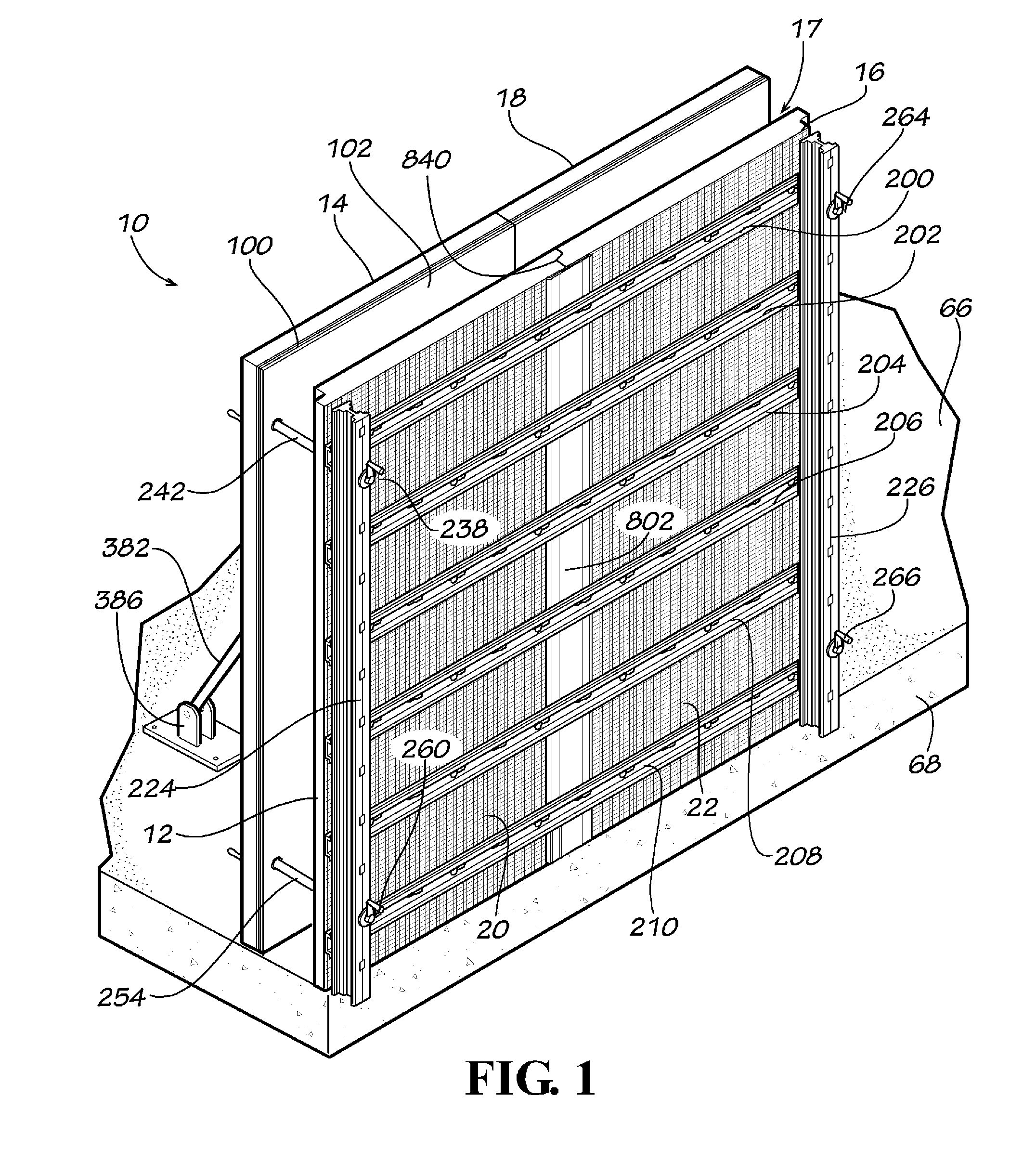

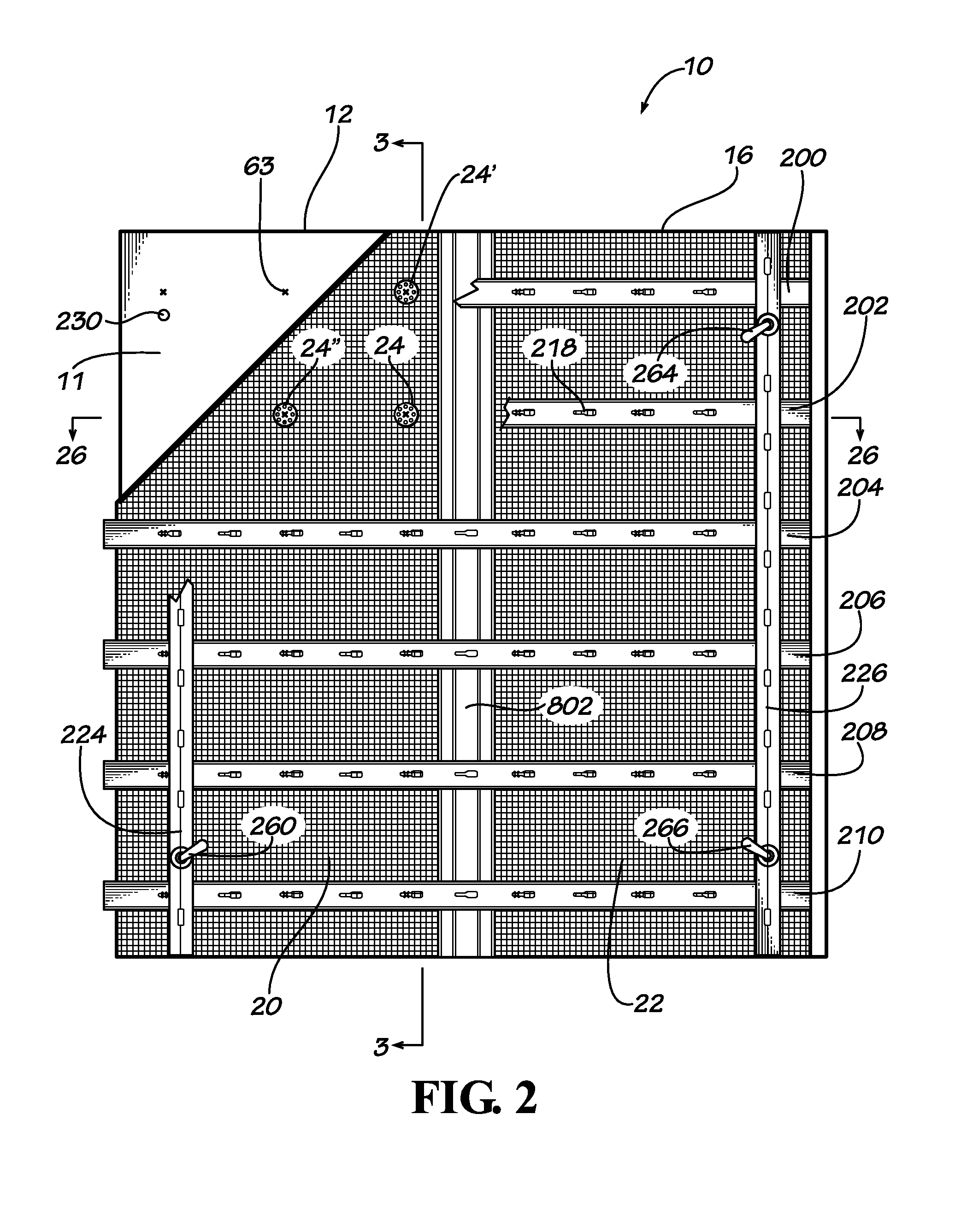

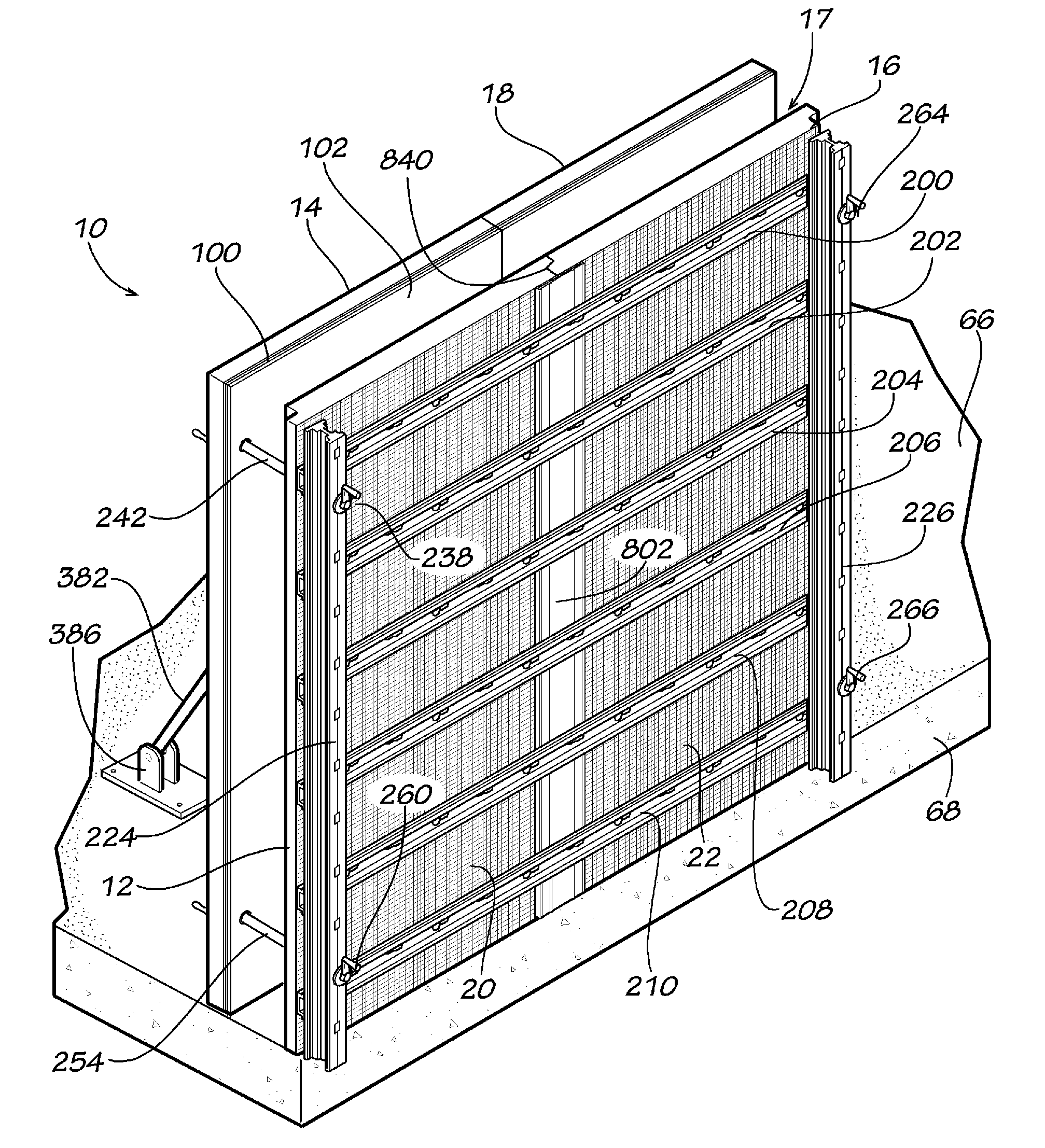

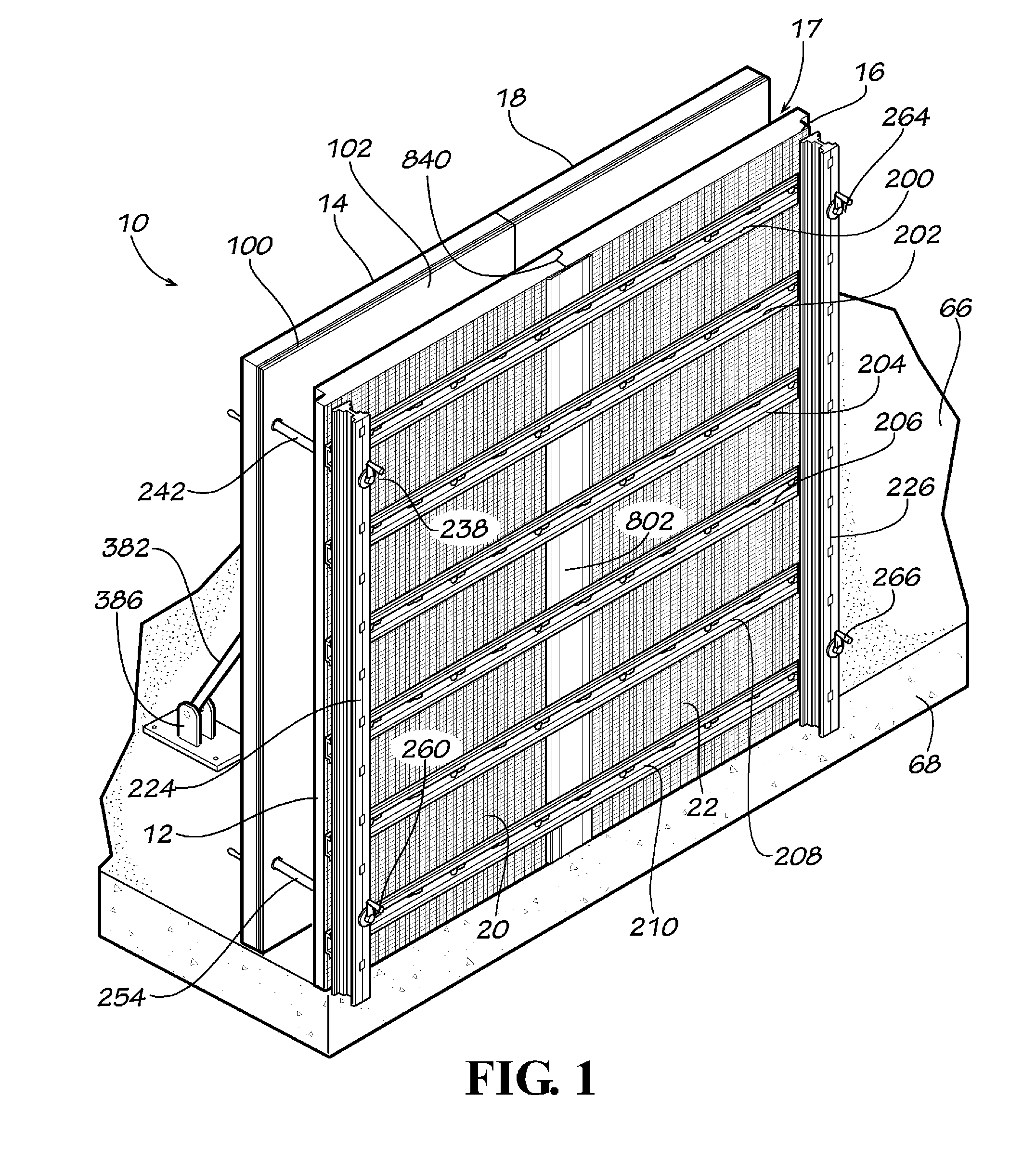

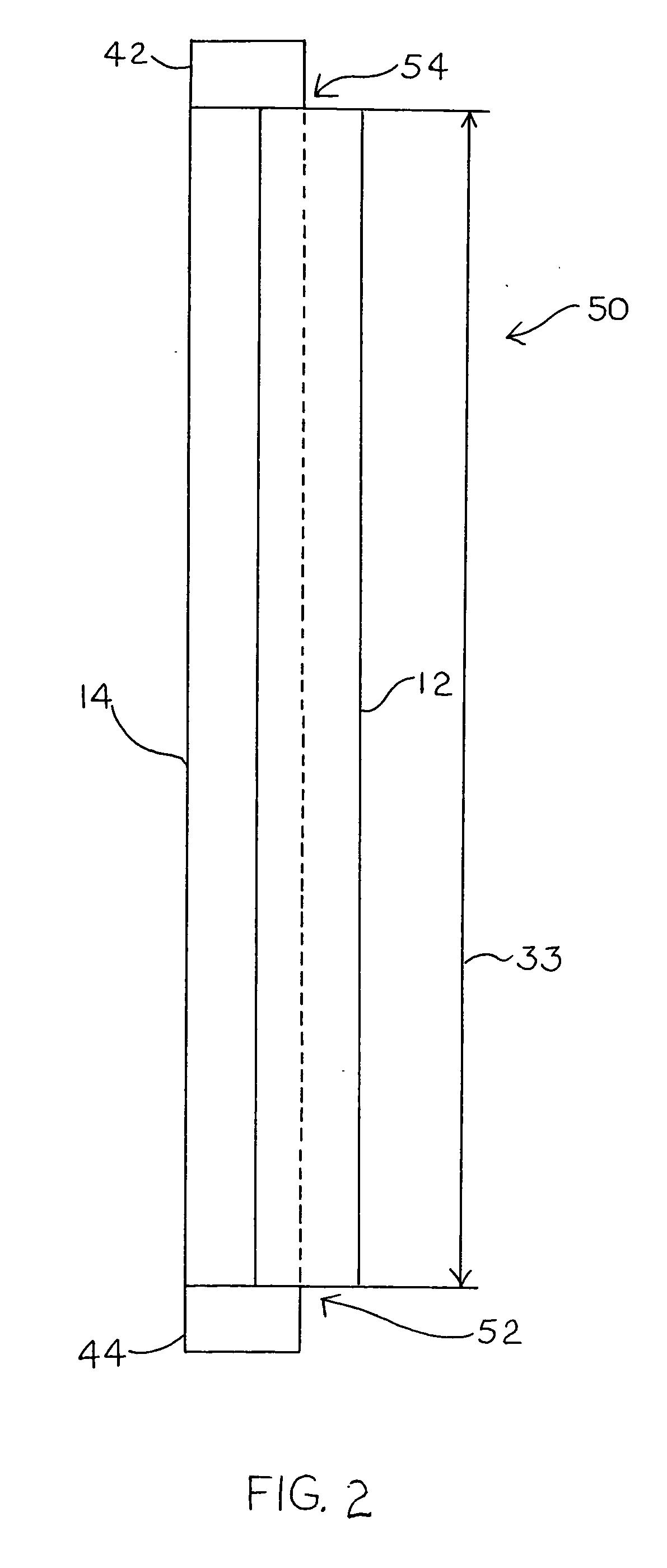

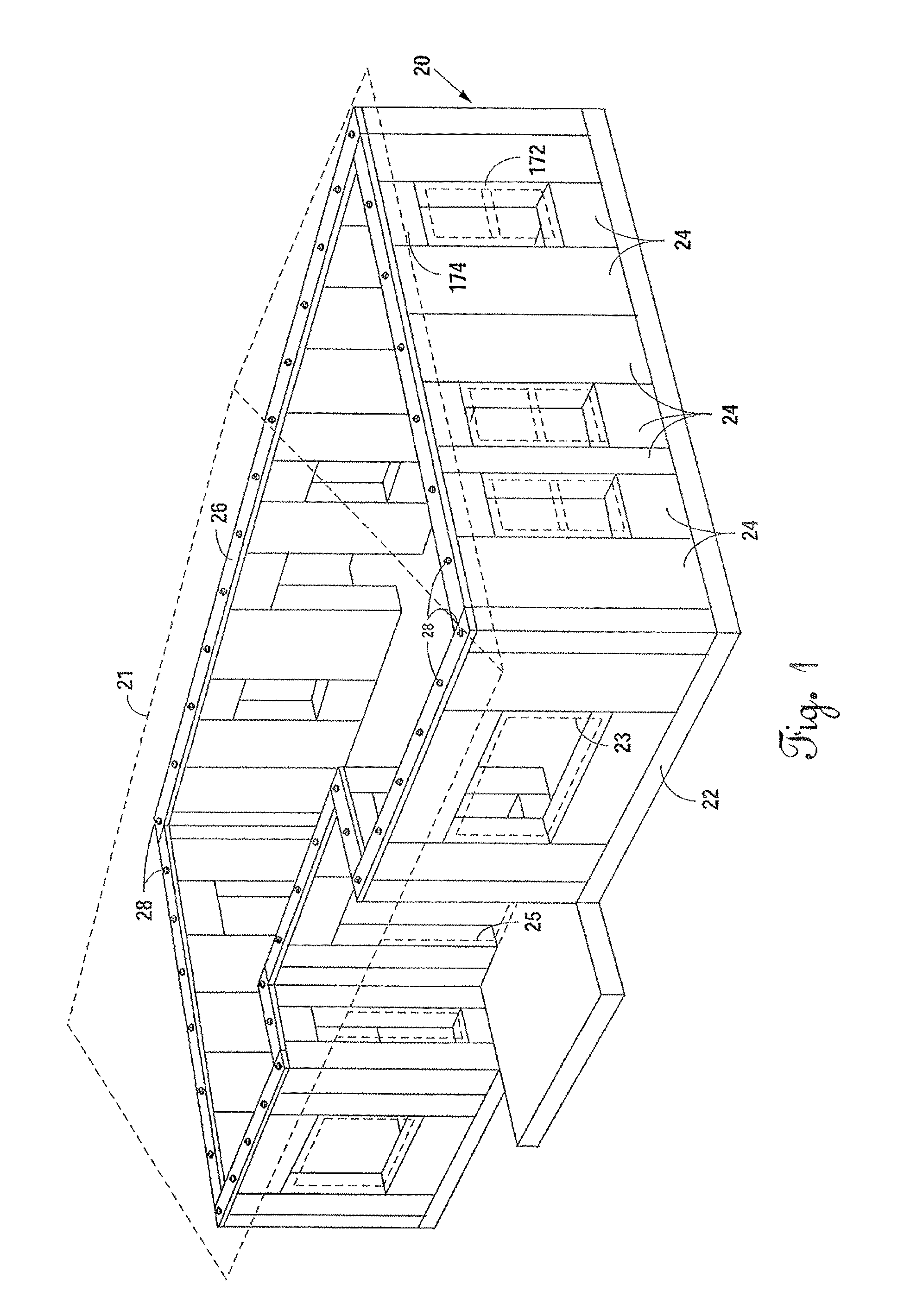

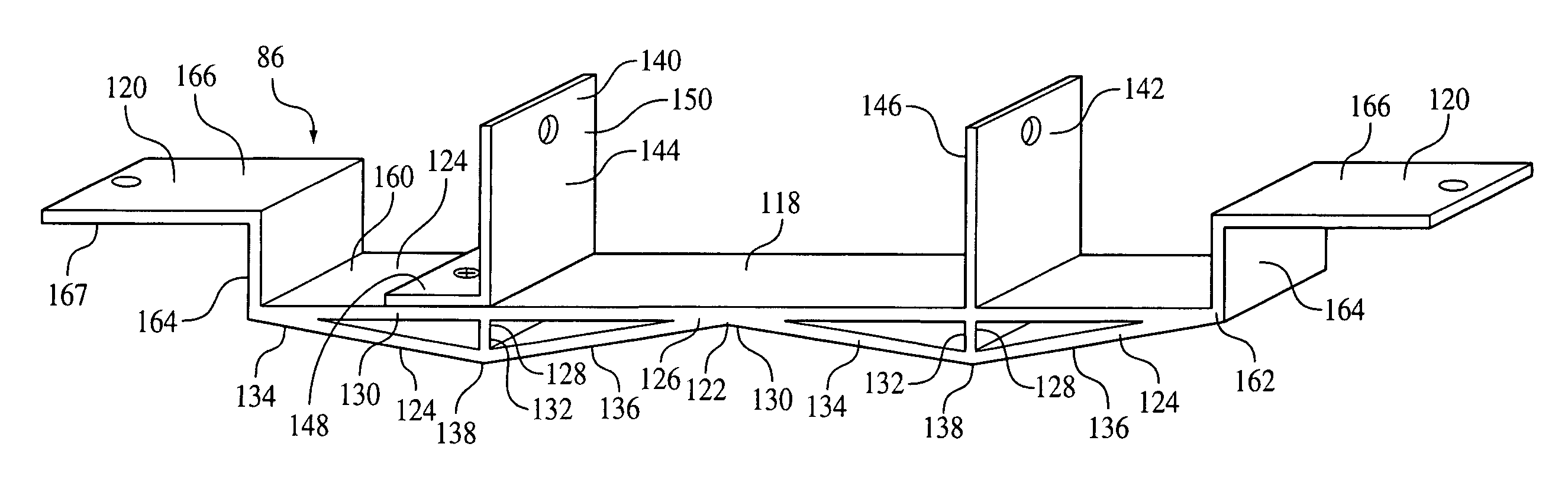

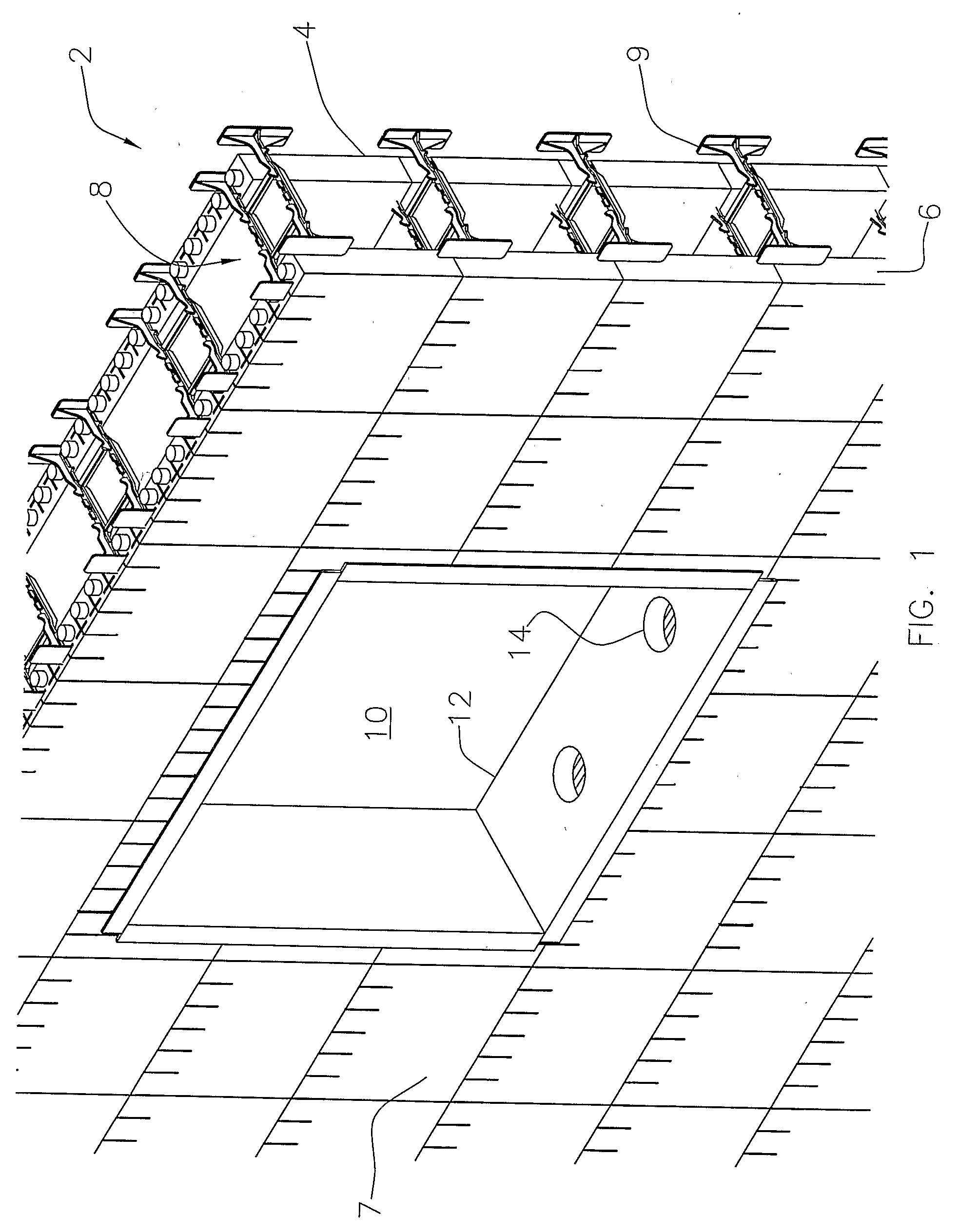

Insulated concrete form method and system

An insulated concrete form system having a pair of bottom U-shaped channels secured to a concrete slab that serve as a footprint for a concrete wall. Exterior and interior foam sheets are aligned within the bottom U-shaped channels that define the wall. Top U-shaped channels are slipped over a top edge of the foam sheets. A plurality of strongbacks are used to provide structural support for the foam sheets during a concrete pour of the wall. The strongbacks each have a pair of hangers adapted to be secured over the top U-shaped channels to secure the strongbacks to the foam sheets. A top wall spacer is used to join a strongback on one side of the wall cavity to a strongback on a second side of the cavity to resist pressure exerted outward on the foam sheets during a concrete pour to form the wall.

Owner:BRADLEY SABINA

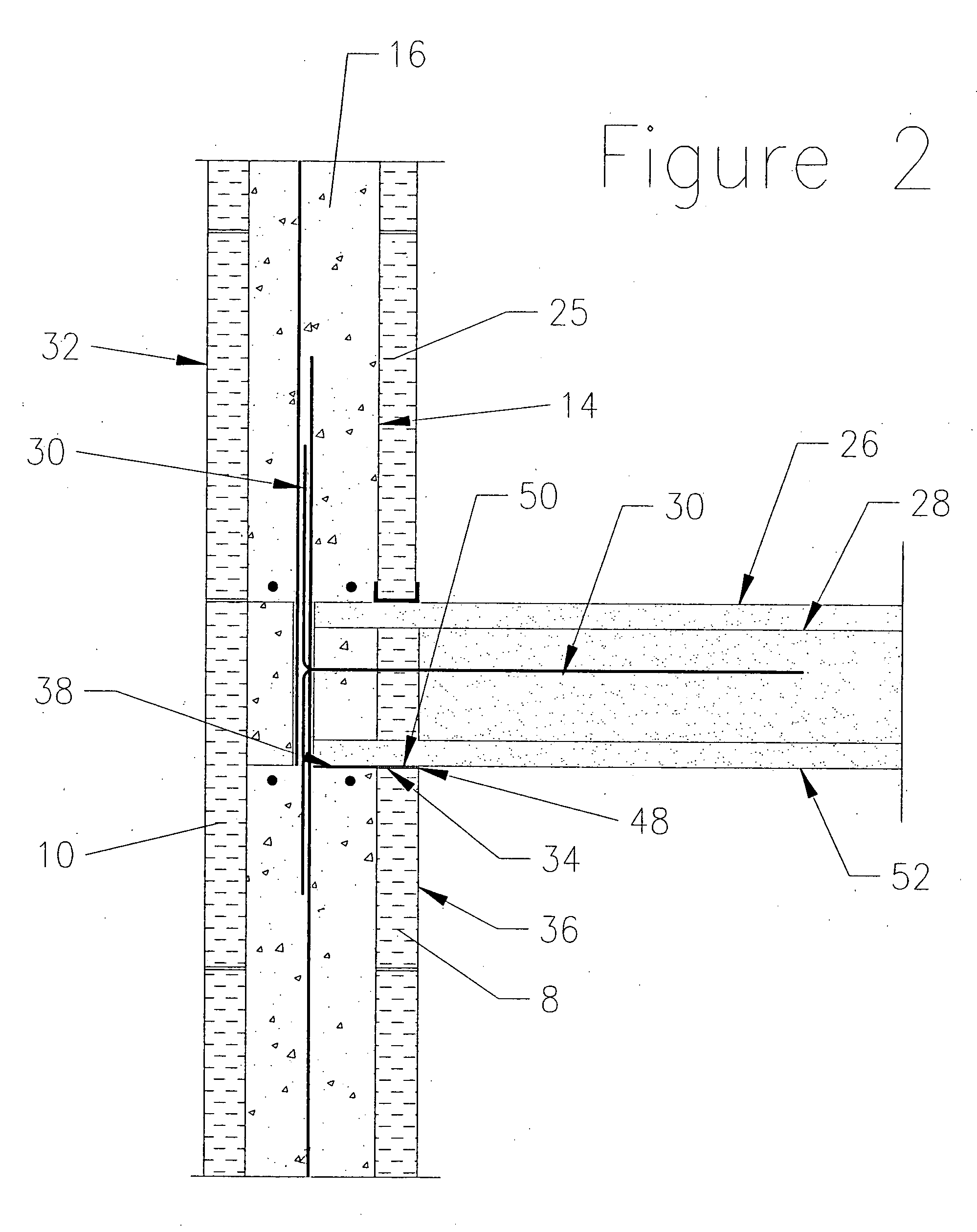

Multi-storey insulated foam building

Multi-storey ICF building having concrete walls poured into insulated concrete forms with adjustments mounted between floors and an outside foam layer and guides for an inside for layer. ICF buildings can be constructed with greater than three stories and masonry or stucco exteriors without the use of supplementary forms.

Owner:WAY ALVEN J

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com