Stackable block for insulating concrete form system

a technology of concrete form and stackable foam, which is applied in the direction of walls, building components, construction materials, etc., can solve the problems of product wastage, block only being used in one orientation, and particularly faced with wastag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

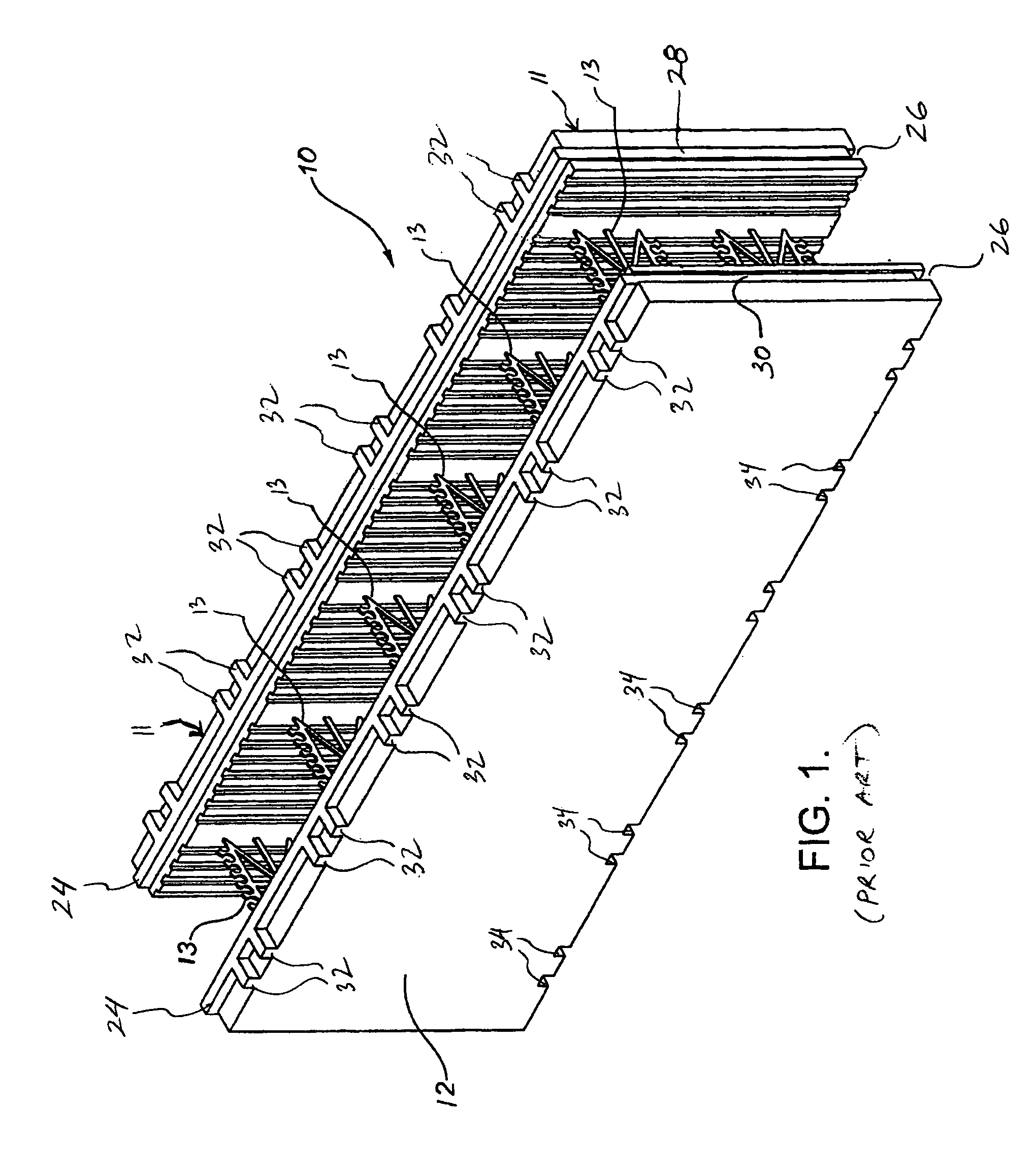

[0027]FIG. 1 illustrates a prior art form block as described, for example, in U.S. Pat. No. 5,896,714. As shown, the block 10 comprises opposing panels 11 and 12 made of an insulating foam material as will be known to persons skilled in the art. The panels 11 and 12 are joined together by means of a plurality of ties 13 extending there-between. The panels 11, 12 are maintained in an aligned and parallel manner, with the ties 13 extending perpendicularly between the panels. As shown in FIG. 1 and as known in the art, the facing surfaces of each panel 11 and 12 are preferably provided with a plurality of grooves so as to form a stronger bond with the concrete.

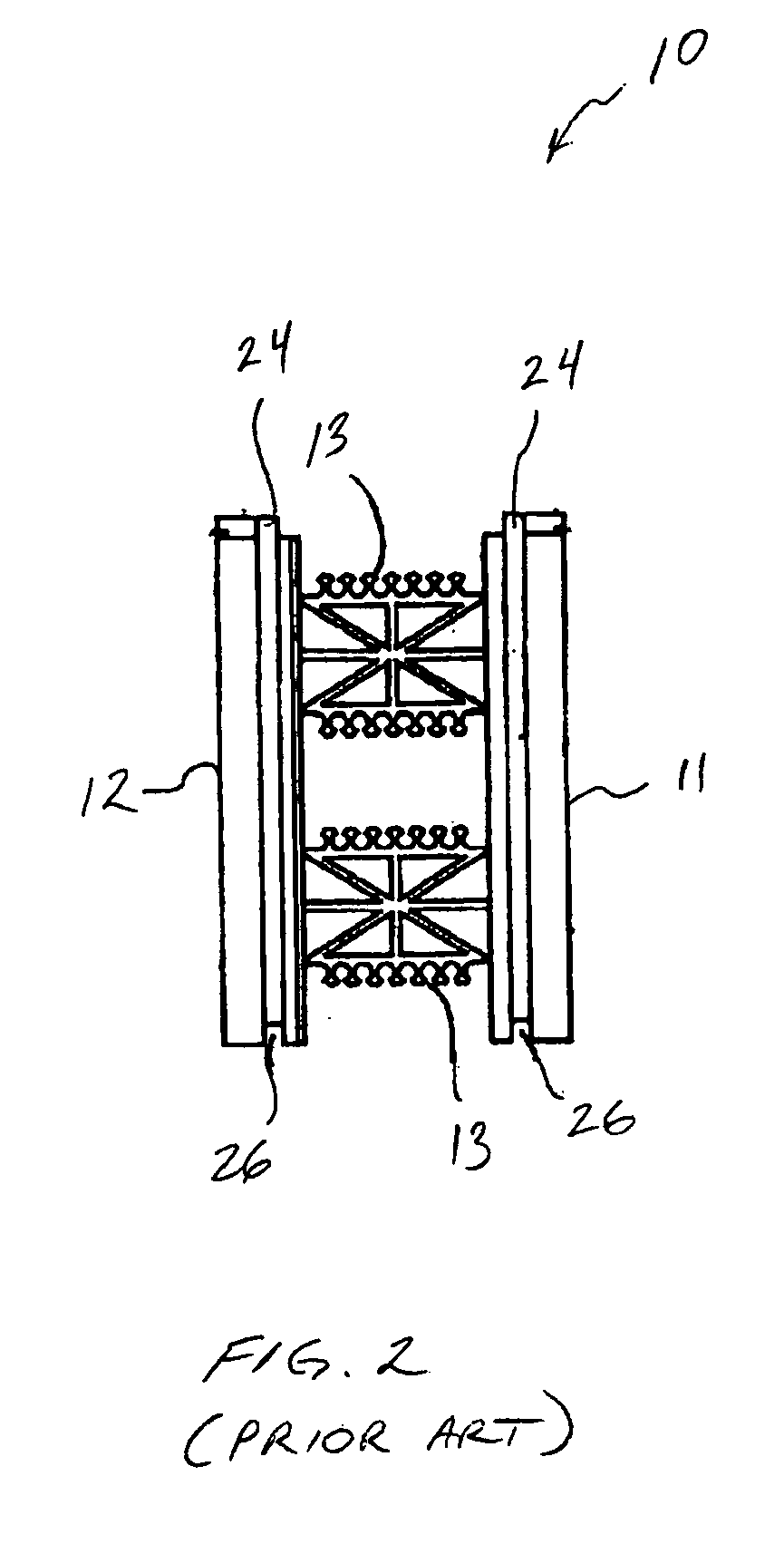

[0028]FIG. 2 illustrates an end view of the block of FIG. 1 and more clearly illustrates the tongues 24 and grooves 26 of the prior art form block. FIG. 2 also illustrates the ties 13 as known in the art. The ties comprise a central, planar web portion and two flanges on opposite ends of the web portion. The flanges are embedded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com