Wall Opening Form

a wall opening and form technology, applied in the field of forming openings, can solve the problems of dimensioned lumber buck construction that requires a significant amount of work, dimensioned lumber may be prone to rotting and water damage, and the opening is not as secure, so as to reduce the amount of bracing. , the effect of easy seclusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

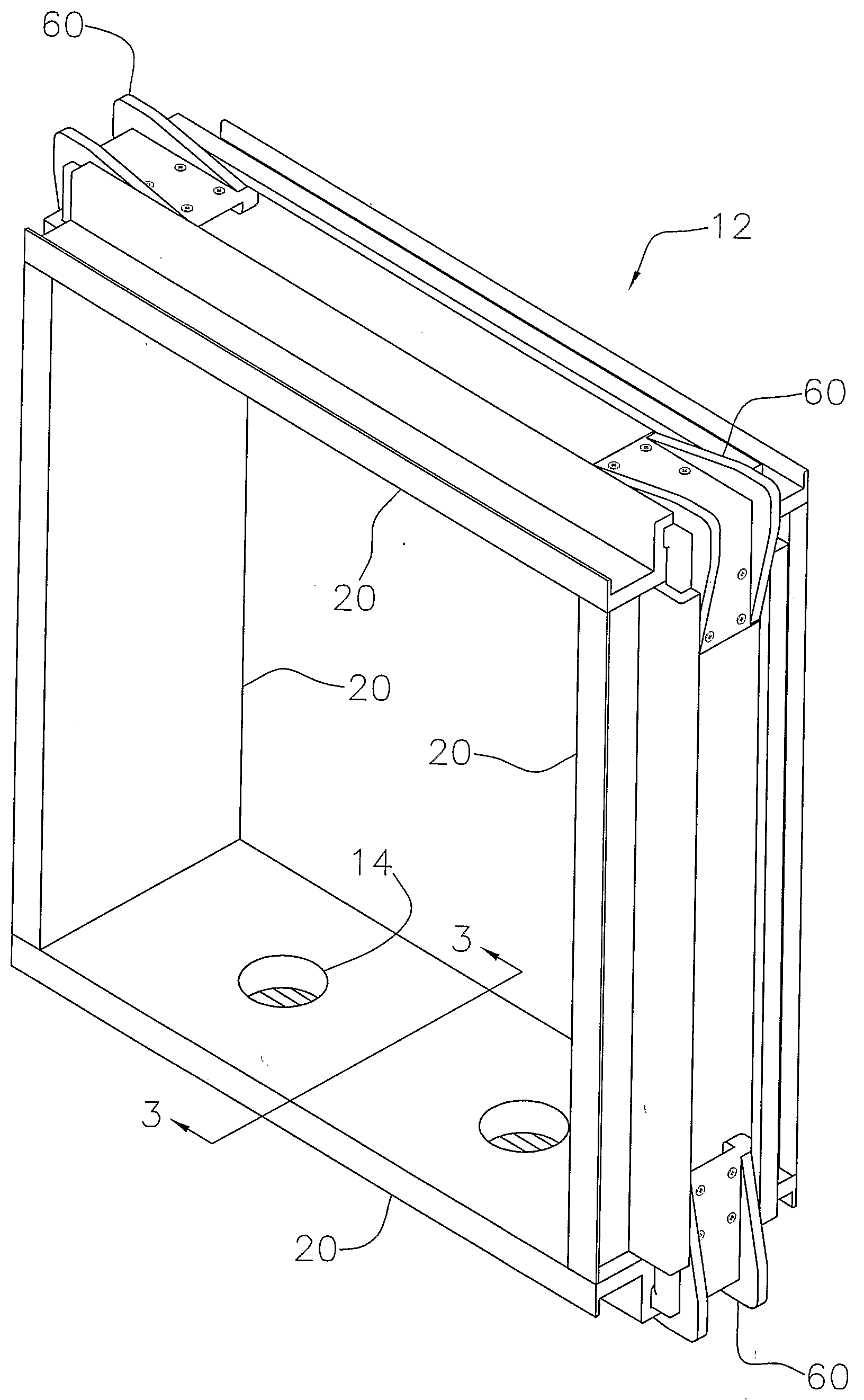

[0024]Referring to FIG. 1, an insulating concrete form wall is shown generally at 2. The insulating concrete wall comprises a pair of opposed first and second wall forms 4 and 6, respectively constructed of forming panels 7 and ties 9 forming a wall cavity 8 therebetween. The insulating concrete wall may include an opening 10 bounded by a wall-opening frame 12 according to a first embodiment of the invention. A window or a door may then be located within the opening 10 and secured to the wall-opening frame 12.

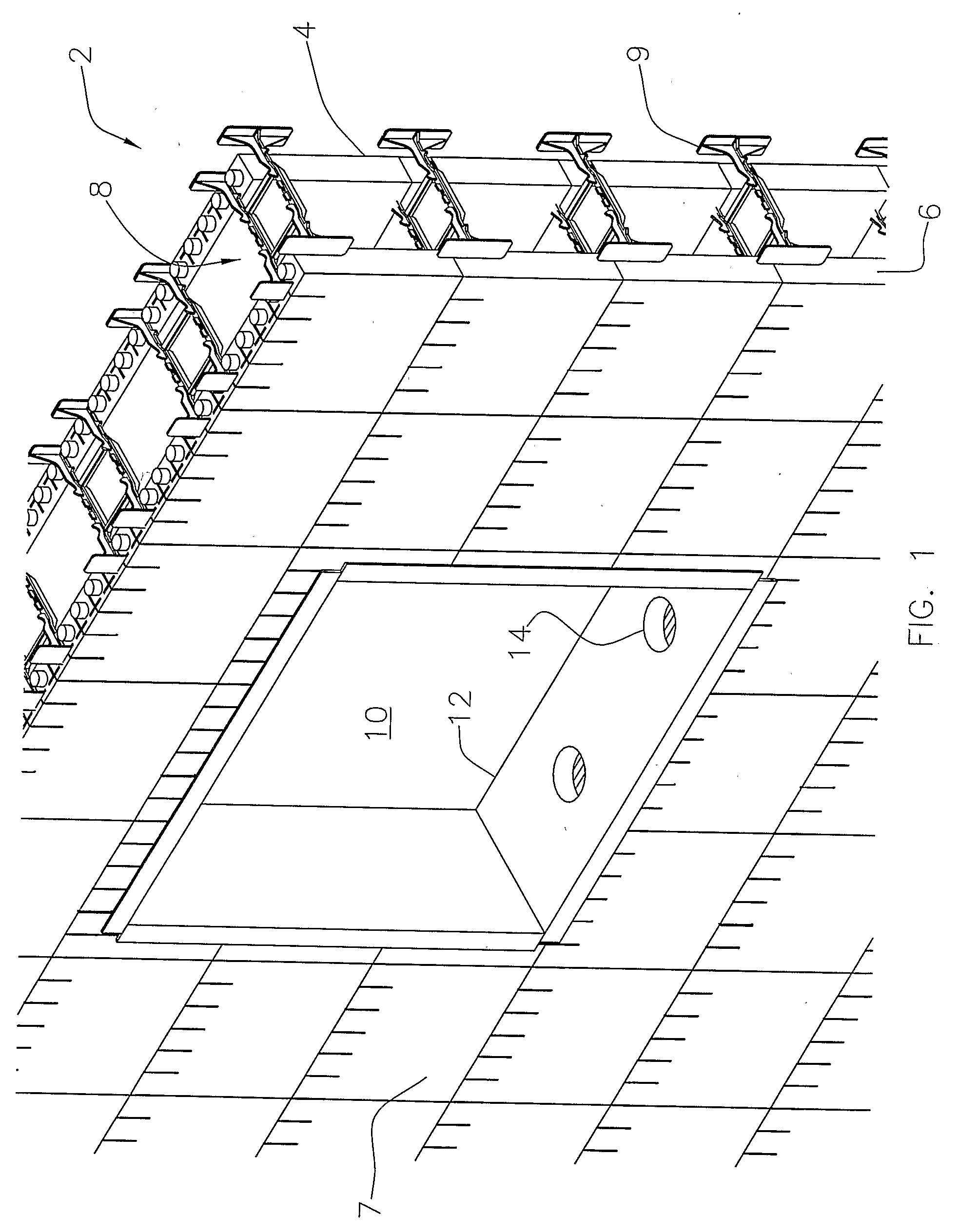

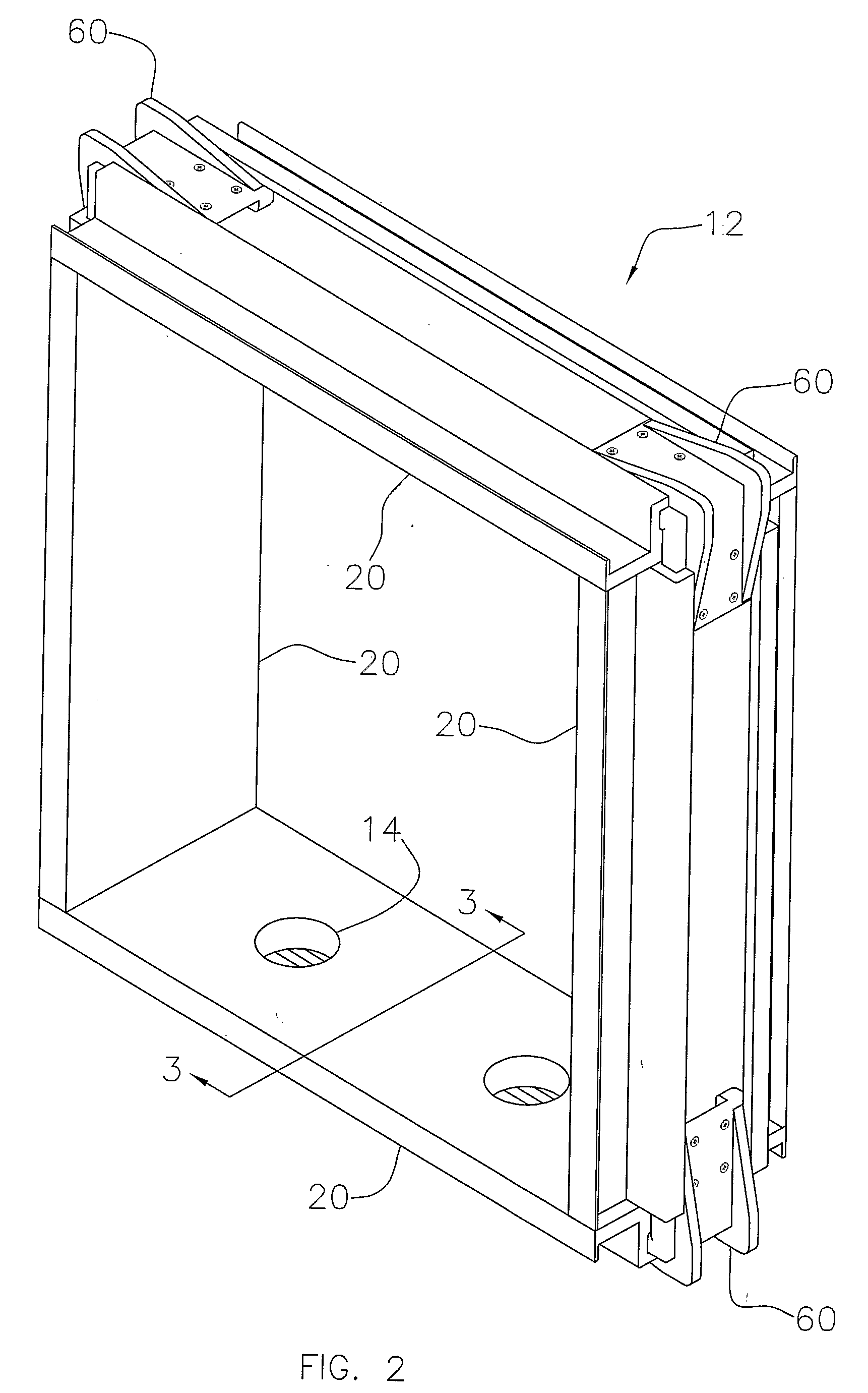

[0025]As shown in FIG. 2, the wall-opening frame 12 comprises a plurality of frame members 20 connected at adjacent ends to form a completed frame. The frame members 20 may be arranged in a rectangle as shown in FIG. 2 or in an inverted U-shape to form an opening for a door (not shown).

[0026]Now referring to FIG. 3, a cross sectional view of a frame member 20 of FIG. 2 is shown taken along the line 3-3. Each frame member 20 comprises a substantially elongate member as shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com