Insulated concrete form panel reinforcement

a technology of insulated concrete and form panels, which is applied in the direction of shaping building parts, building components, walls, etc., can solve the problems of inability to meet the requirements of a high-vulcanity location, the support of t-walls or columns is less well known in the past, and the location of high vulnerability of traditional spacers used in other locations in the icf system is not particularly suitabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

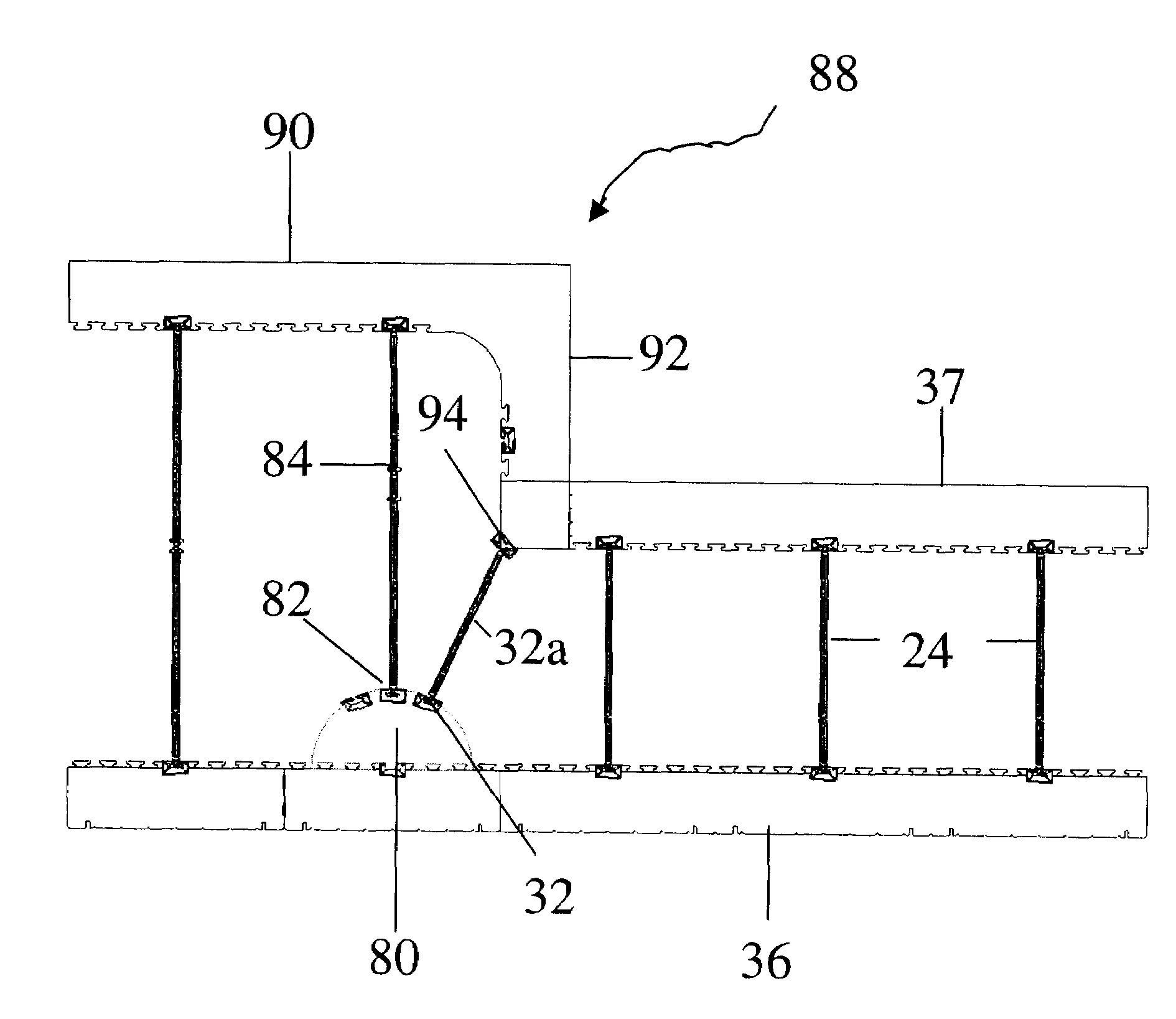

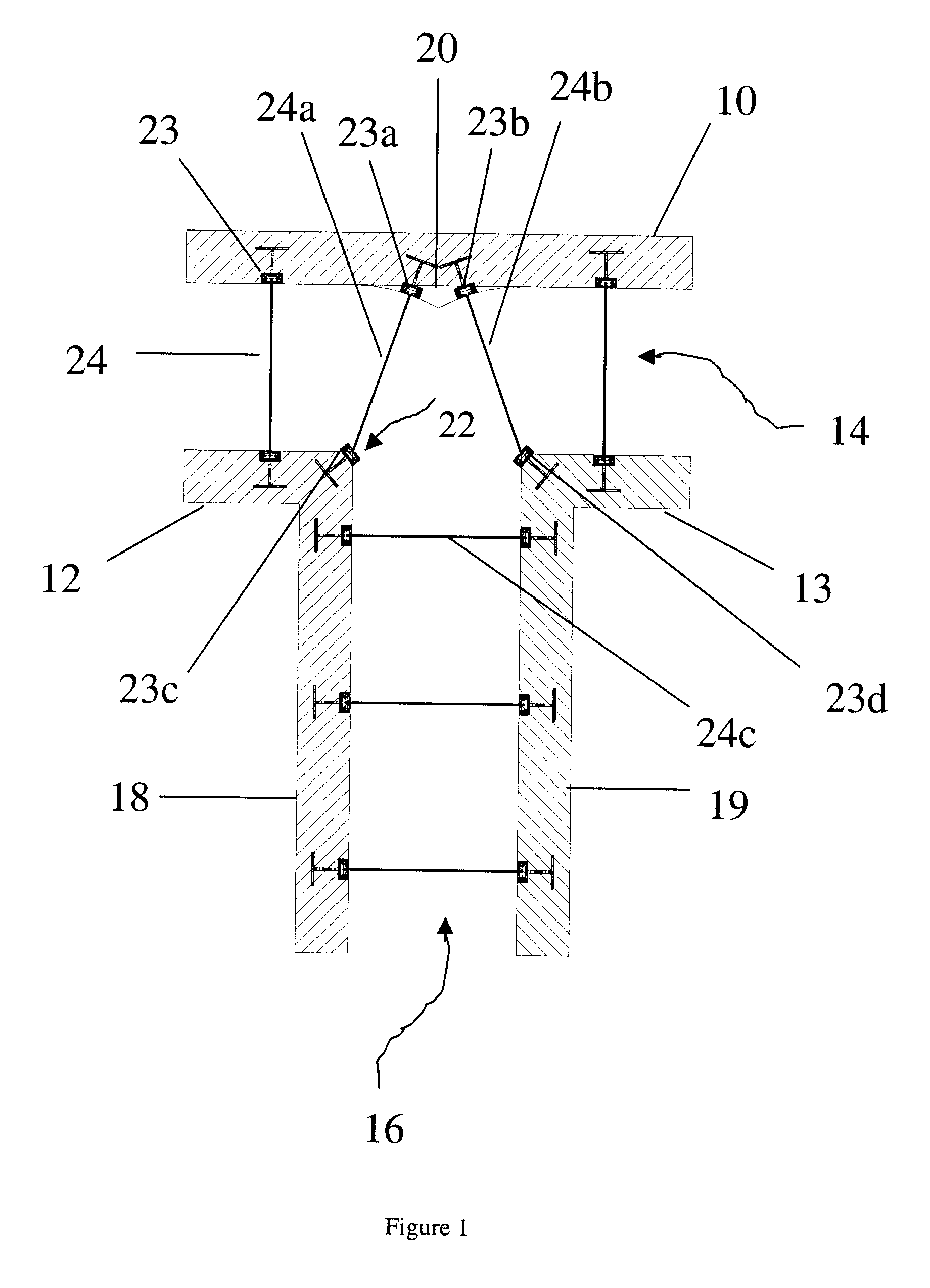

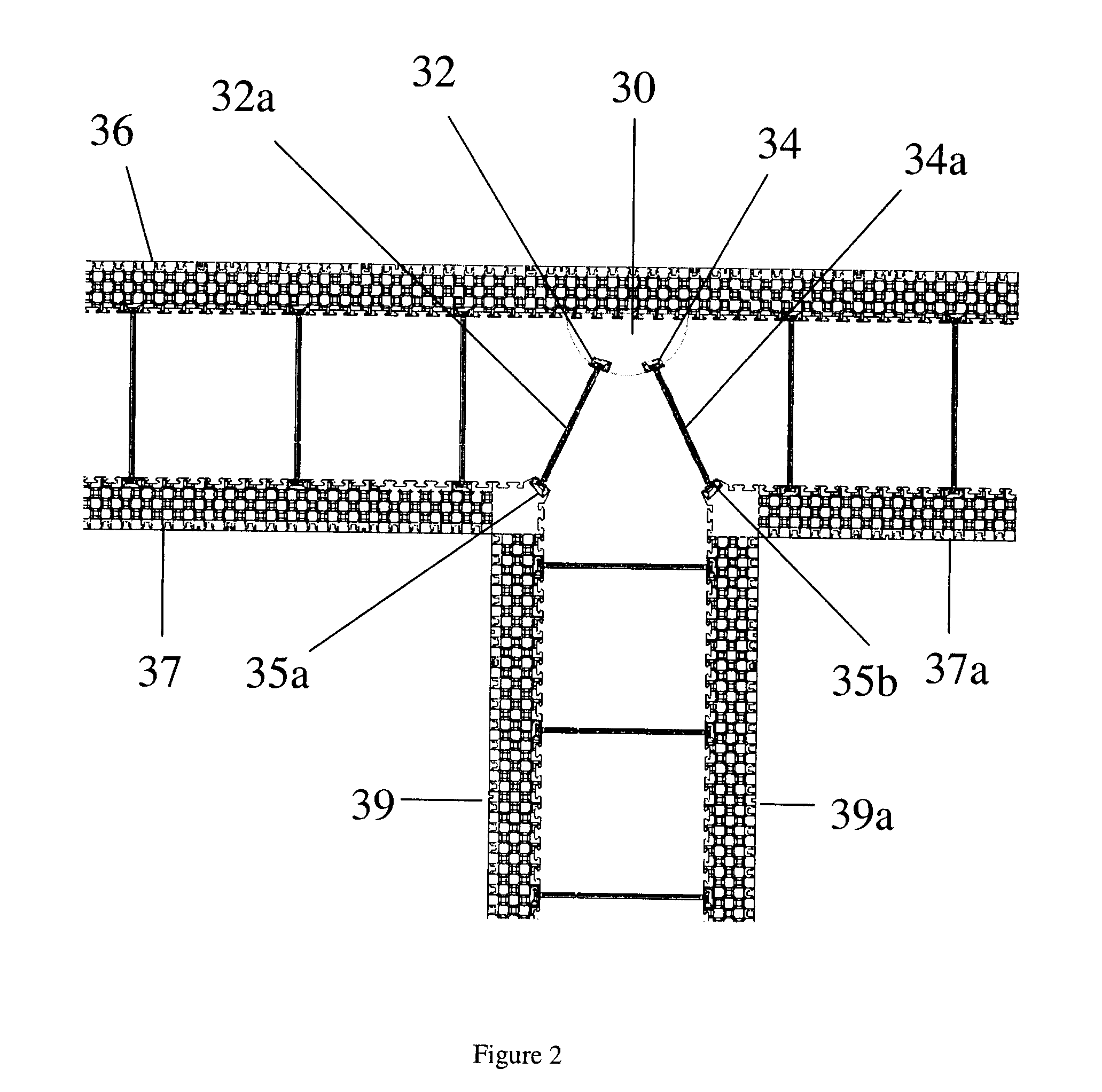

[0039]Generally, the present invention provides an ICF system having a reinforcement at a T-wall intersection. More particularly, the present invention provides an insulated concrete form comprising a main panel, a first opposing panel opposite the main panel, a spacer having first and second ends for maintaining a fixed spacing between the main panel and the first opposing panel, a reinforcement on the main panel for stiffening the main panel, a spacer retention element integrated in the reinforcement for securing the first end of the spacer to the main panel, and a first opposing spacer retention element in the first opposing panel for securing the second end of the spacer to the first opposing panel.

[0040]A panel having a reinforcement connected thereto in an ICF according to the present invention is referred to herein as a reinforced panel. The reinforced panel can be used at any location along an ICF system. The reinforced panel is particularly suitable at locations vulnerable ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com