Patents

Literature

62 results about "Increased stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

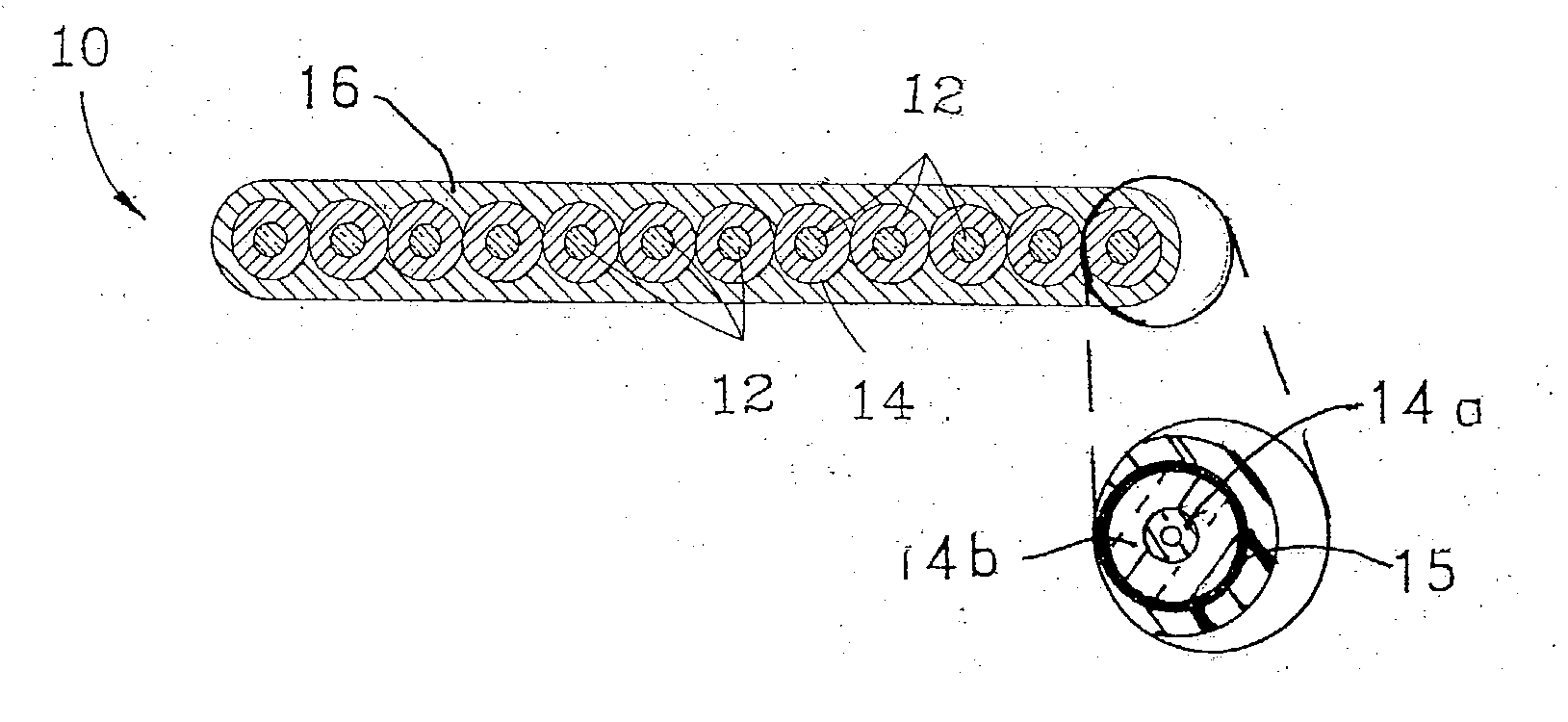

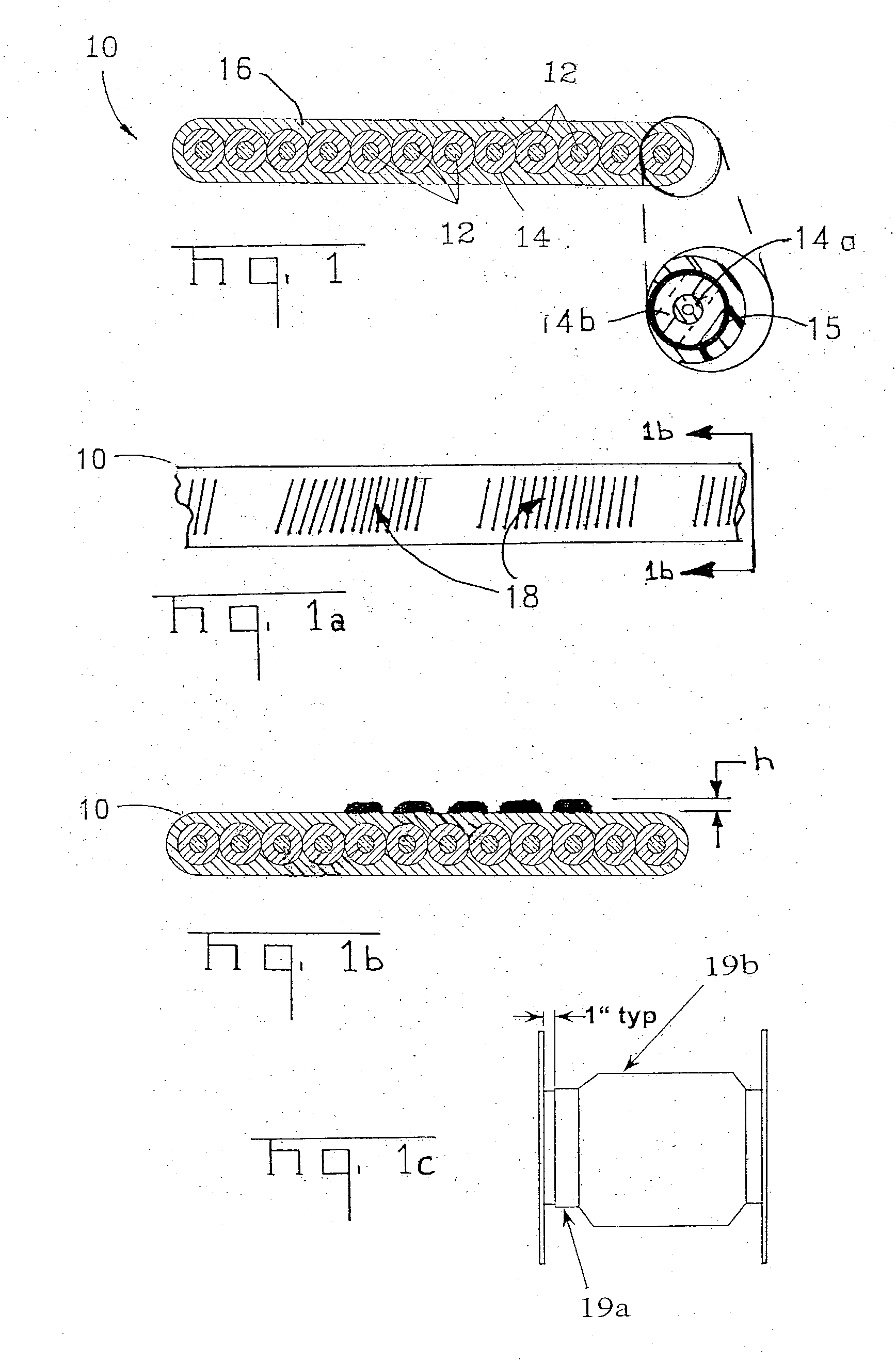

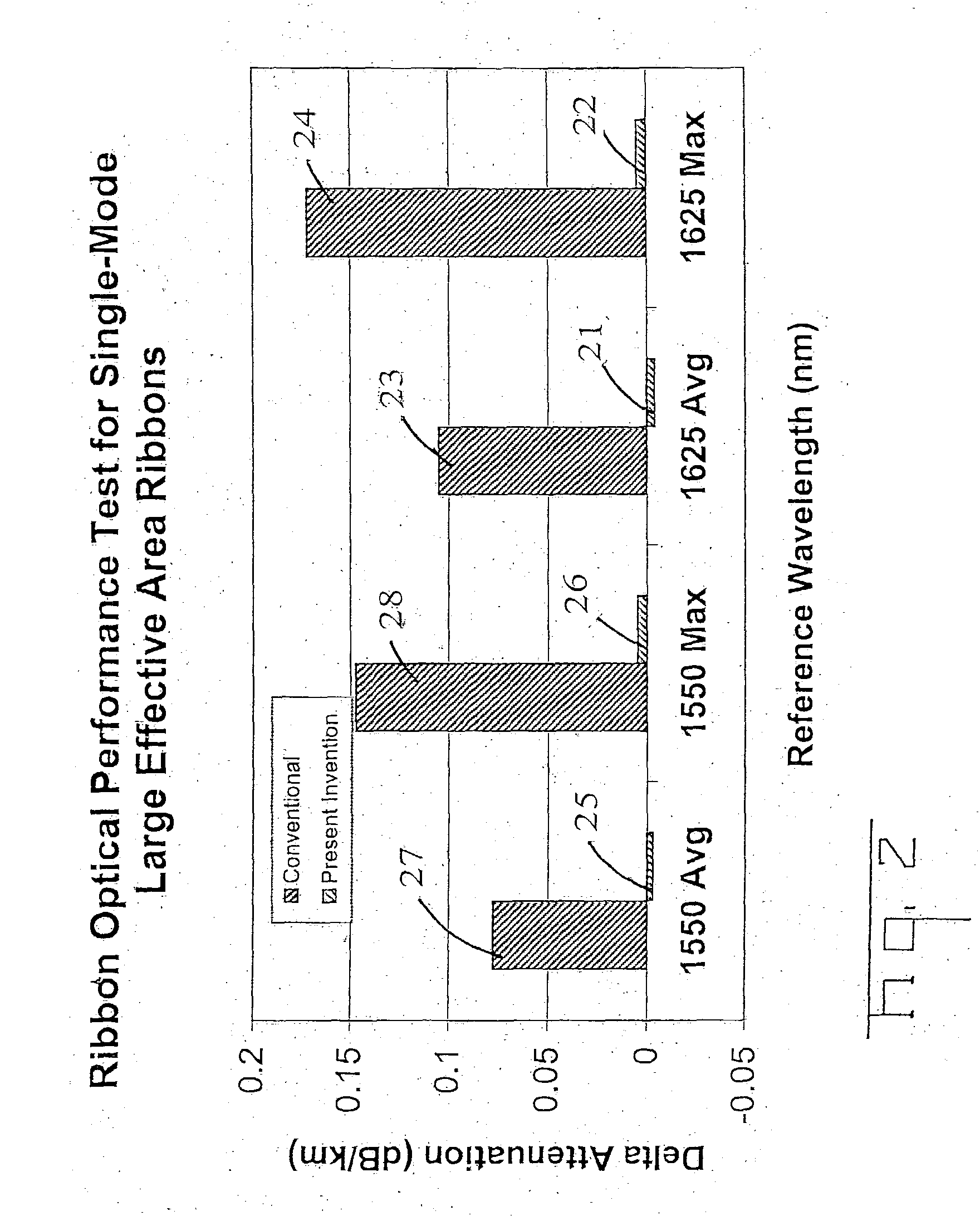

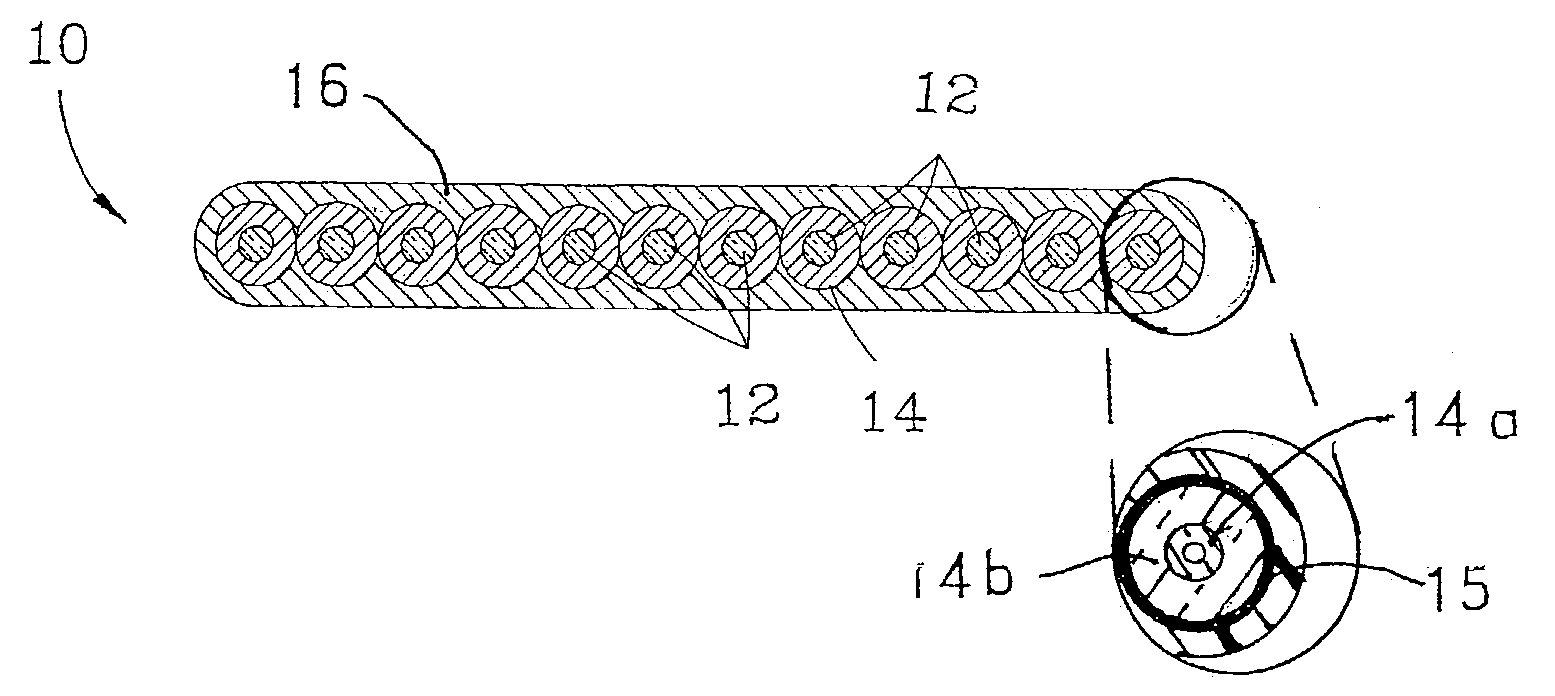

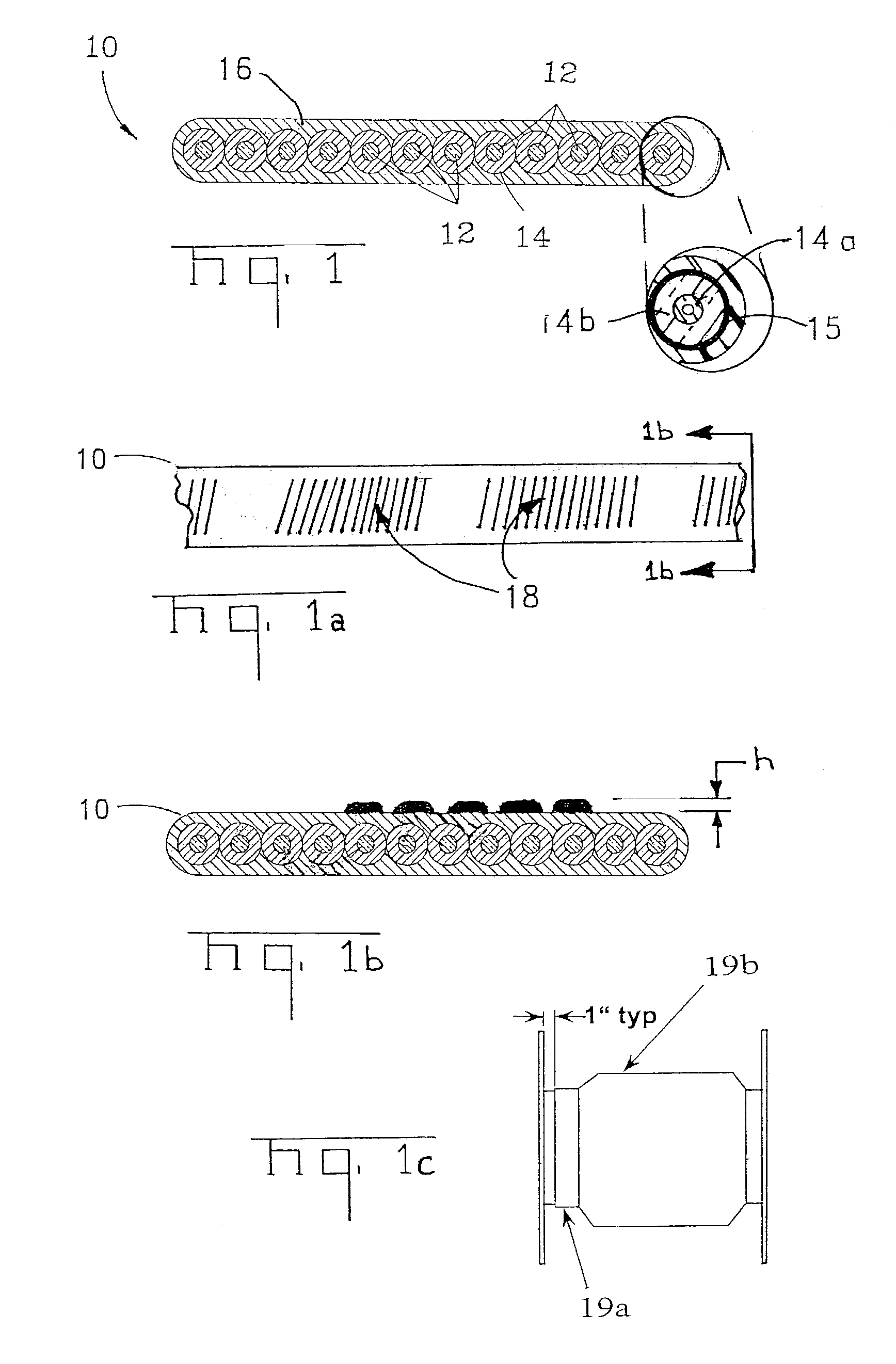

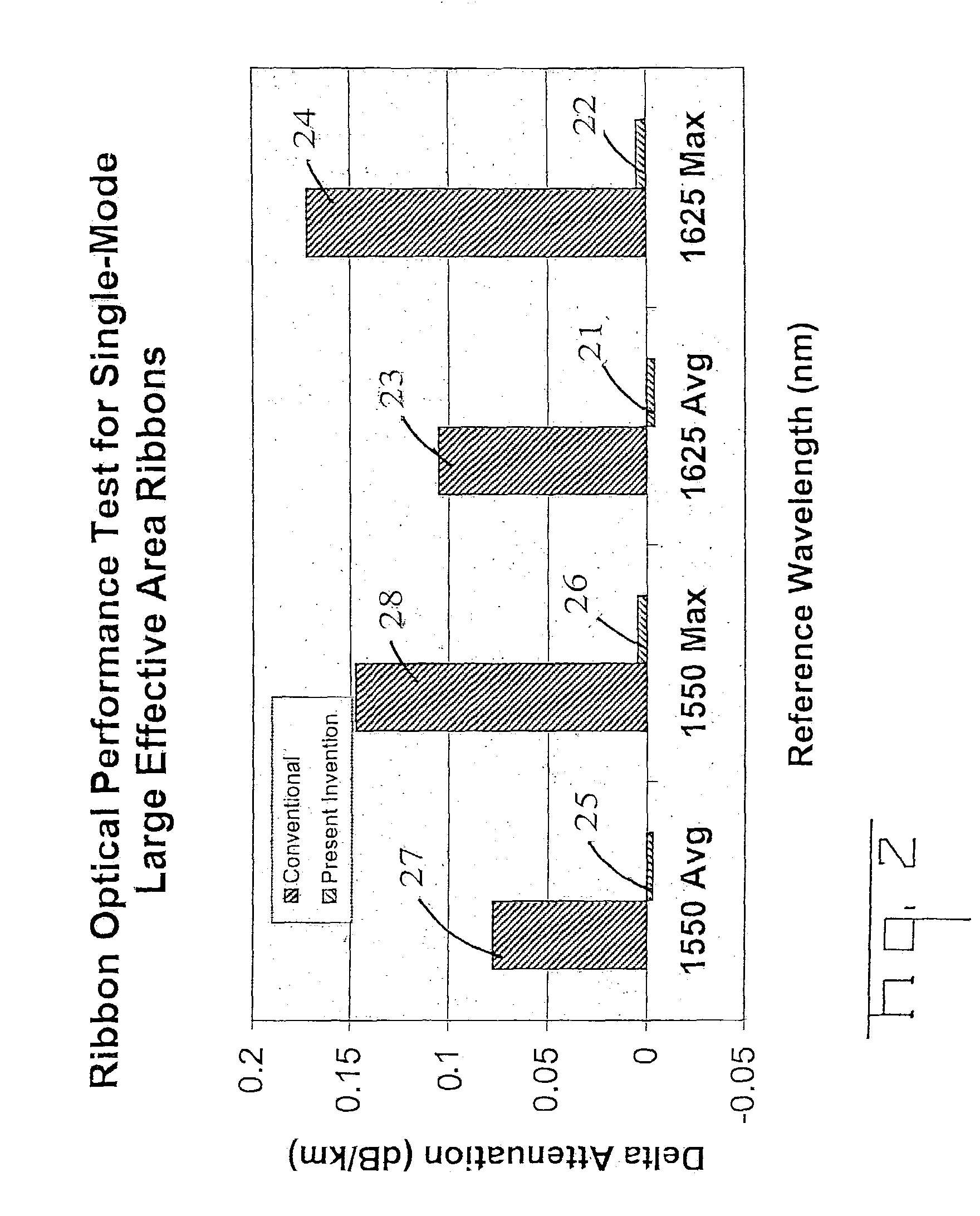

Fiber optic articles, assemblies, and cables having optical waveguides

ActiveUS20050013573A1Optical fibre with multilayer core/claddingFibre mechanical structuresFiberUltrasound attenuation

Fiber optic articles, assemblies, and cables preserve optical performance by using optical waveguides having a core, a cladding, and a coating system according to the present invention. Moreover, the optical articles, assemblies, and cables of the present invention may achieve performance levels that were previously unattainable, for instance, the present invention contemplates acceptable optical performance for wavelengths such as 1625 nm and higher. Additionally, articles, assemblies, and / or cables of the present invention advantageously preserve optical performance, i.e., have relatively low delta attenuation, when subjected to manufacturing processes and / or environmental conditions such as temperature cycling. In other words, the articles, assemblies, and cables can withstand increased stress / strain before having significant attenuation.

Owner:CORNING OPTICAL COMM LLC

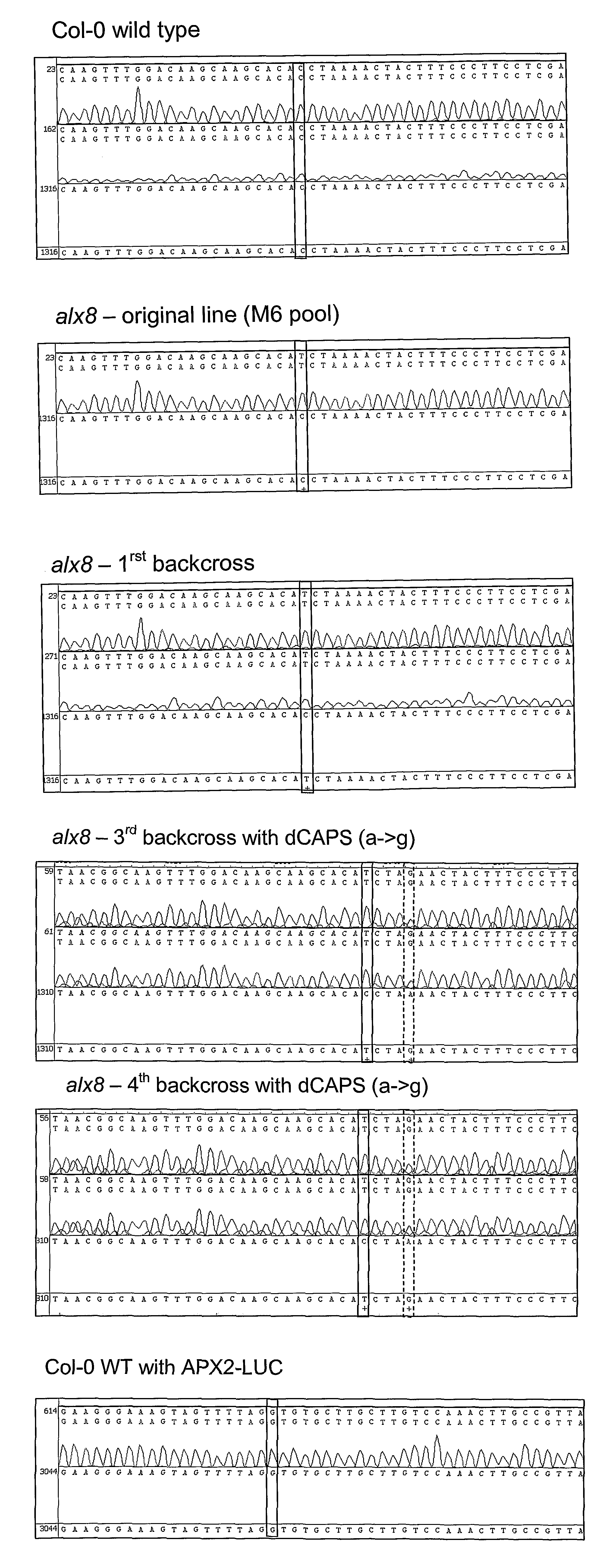

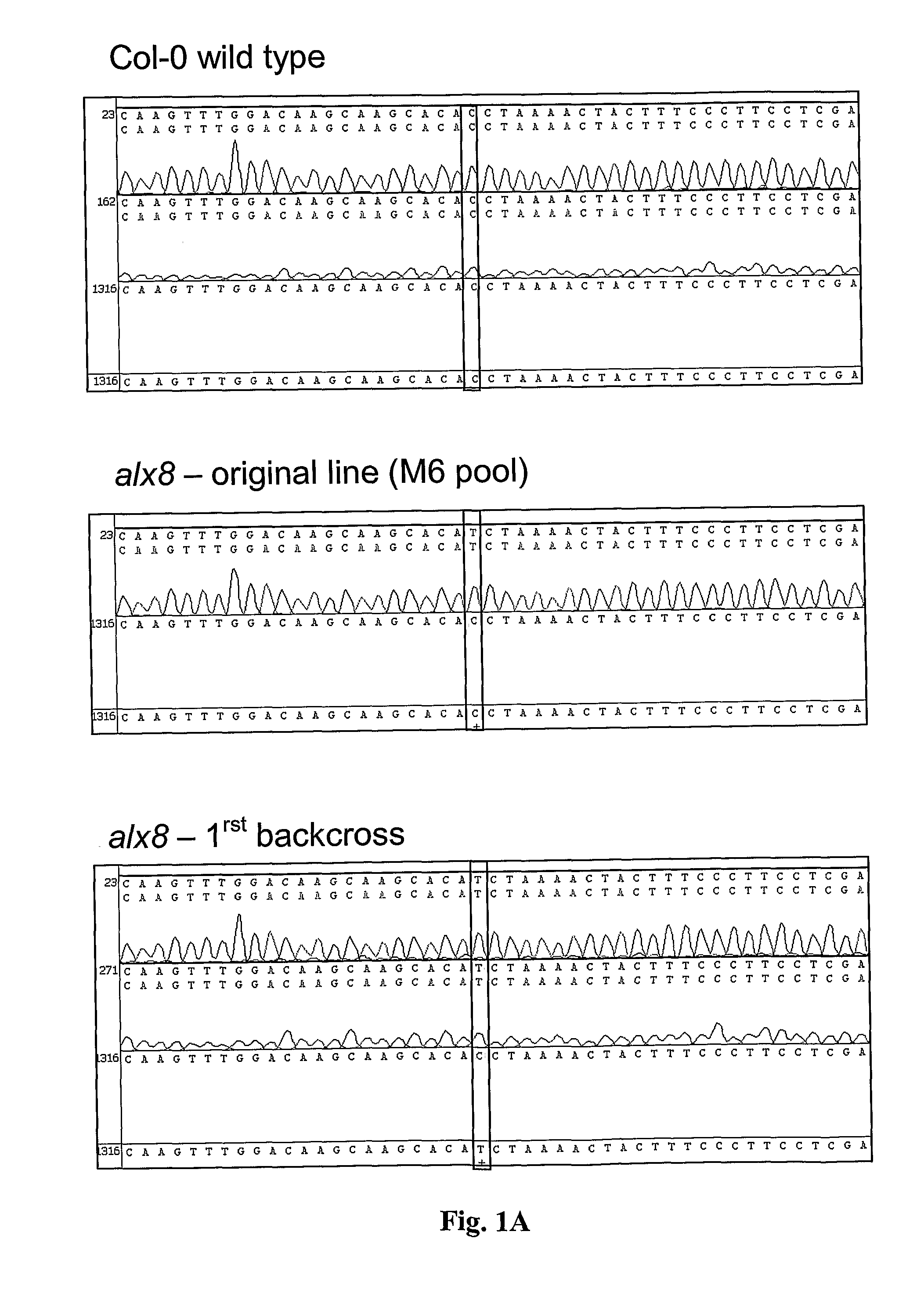

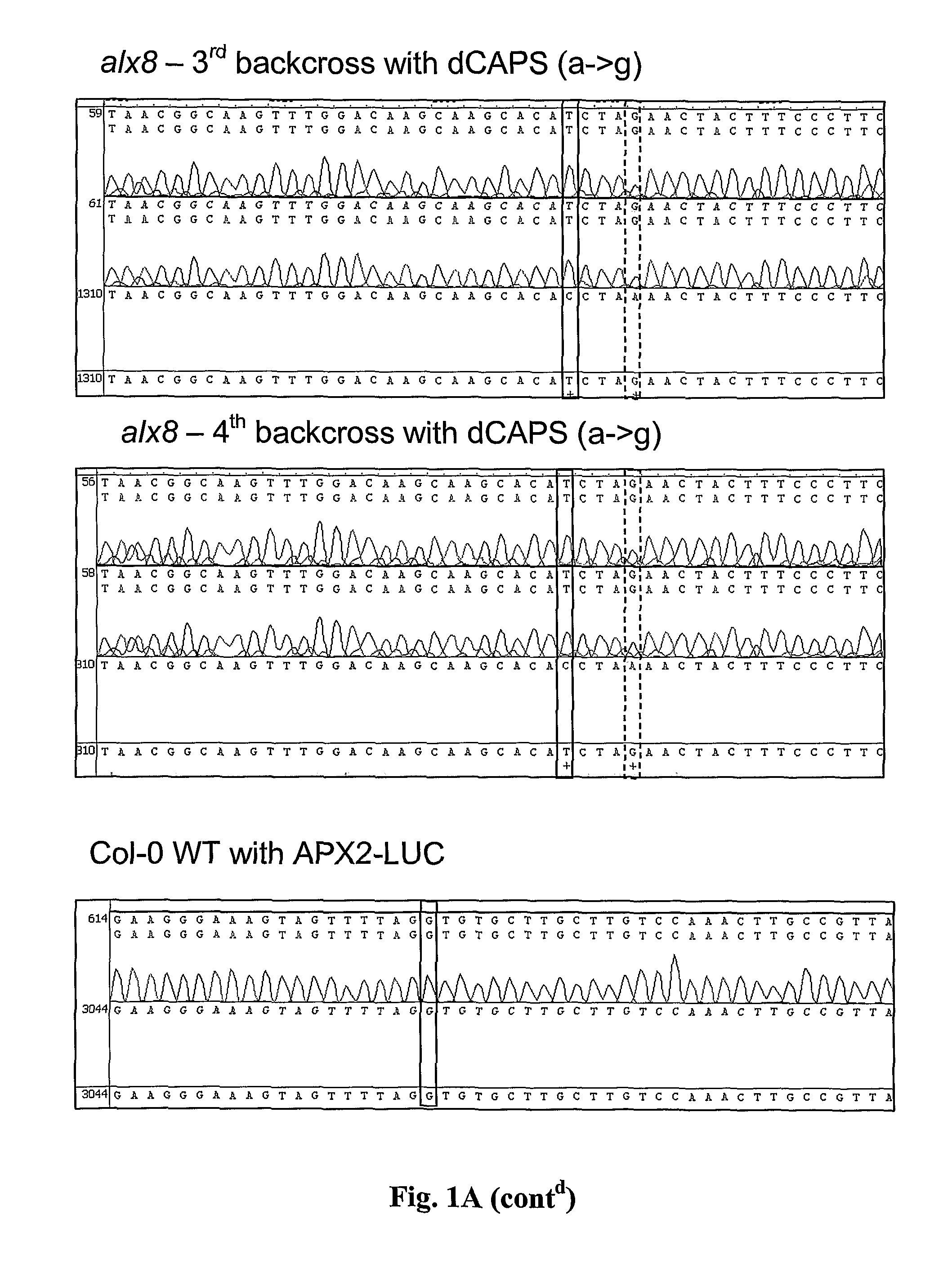

Method for improving stress resistance in plants and materials therefor

ActiveUS20100257633A1Improve stress resistanceReduced activityBryophytesOther foreign material introduction processesPlant cellGenome

The present invention provides a method for obtaining a plant with increased stress resistance relative to a wild-type plant, comprising: (a) introducing at least one mutation or exogenous nucleic acid into the genome of one or more plant cells which results in reduced activity associated with SAL1 or a homologue thereof in said one or more plant cells; (b) regenerating one or more plants from said one or more plant cells; and (c) selecting one or more plants that have increased stress resistance relative to a wild-type plant.

Owner:AUSTRALIEN NAT UNIV

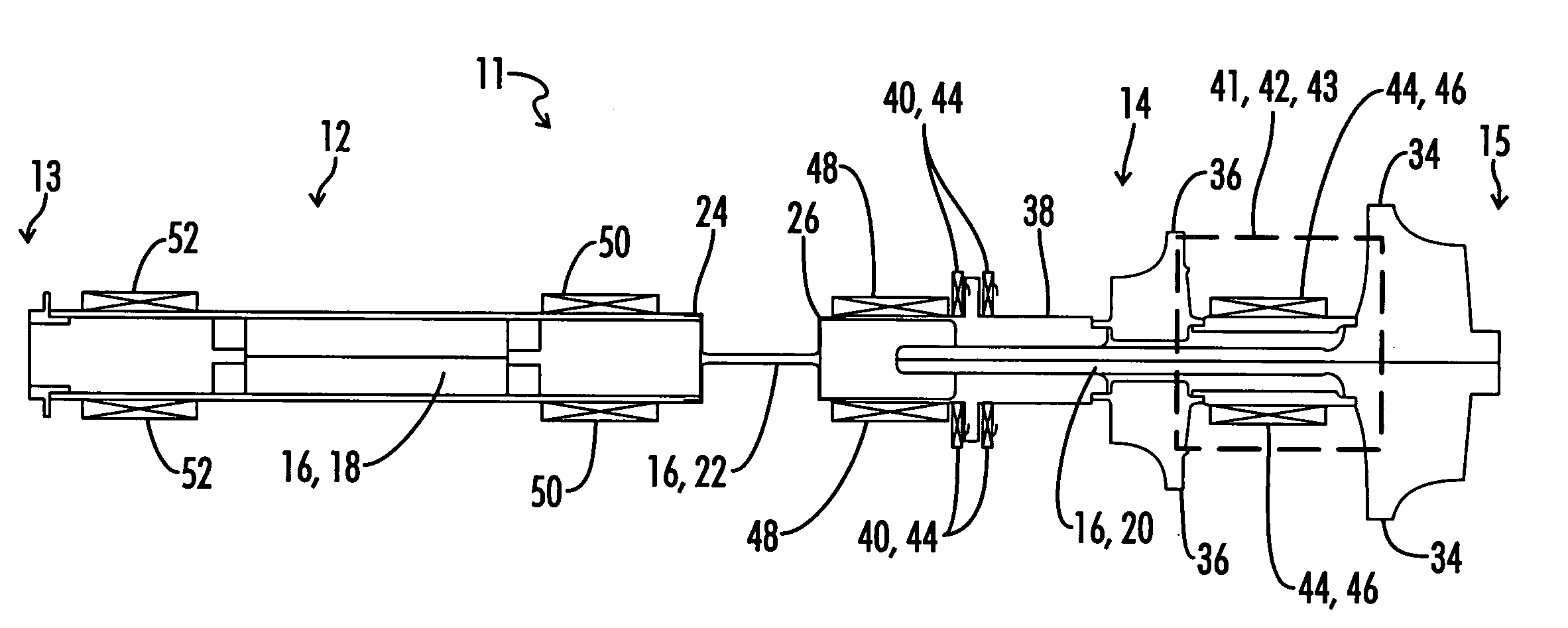

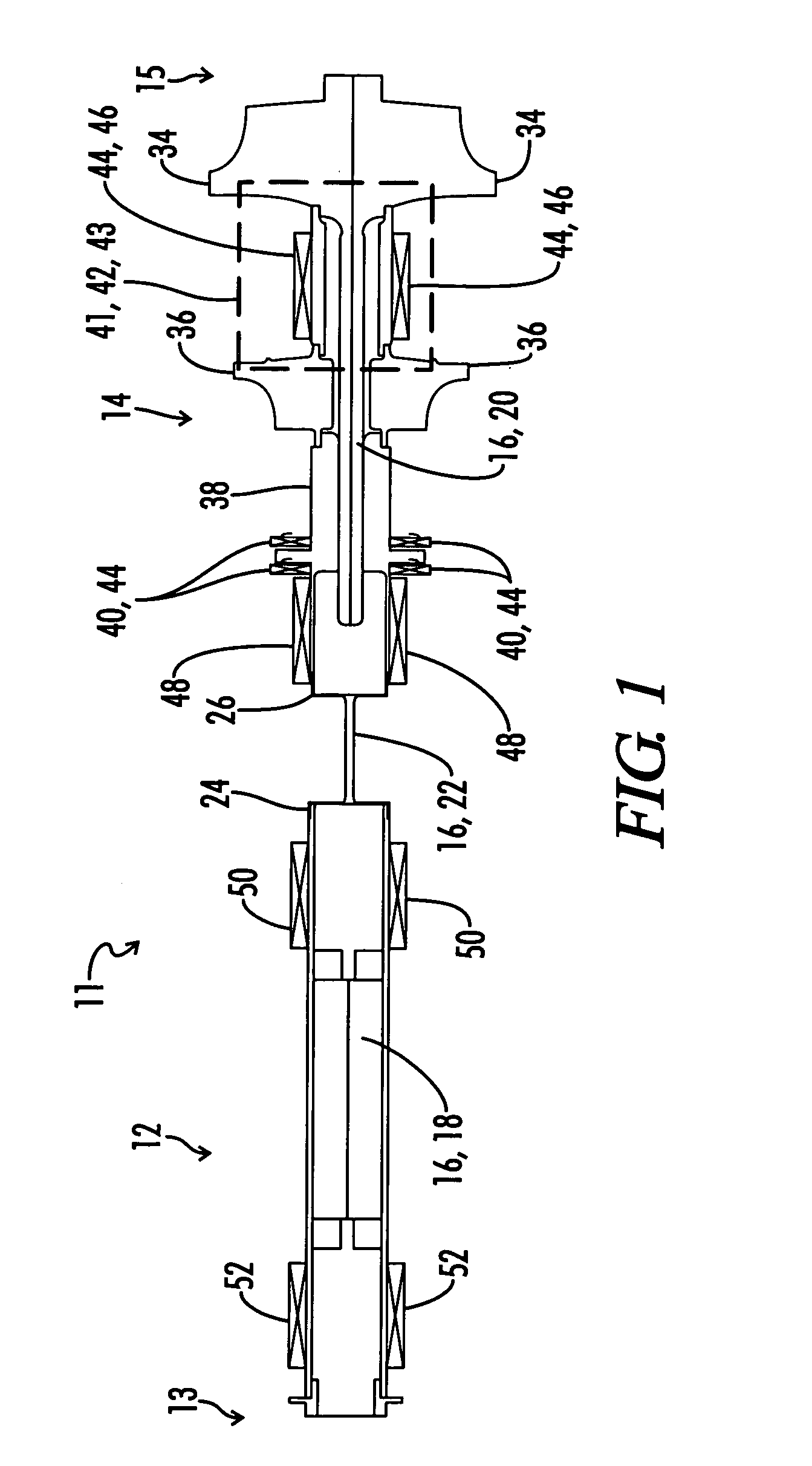

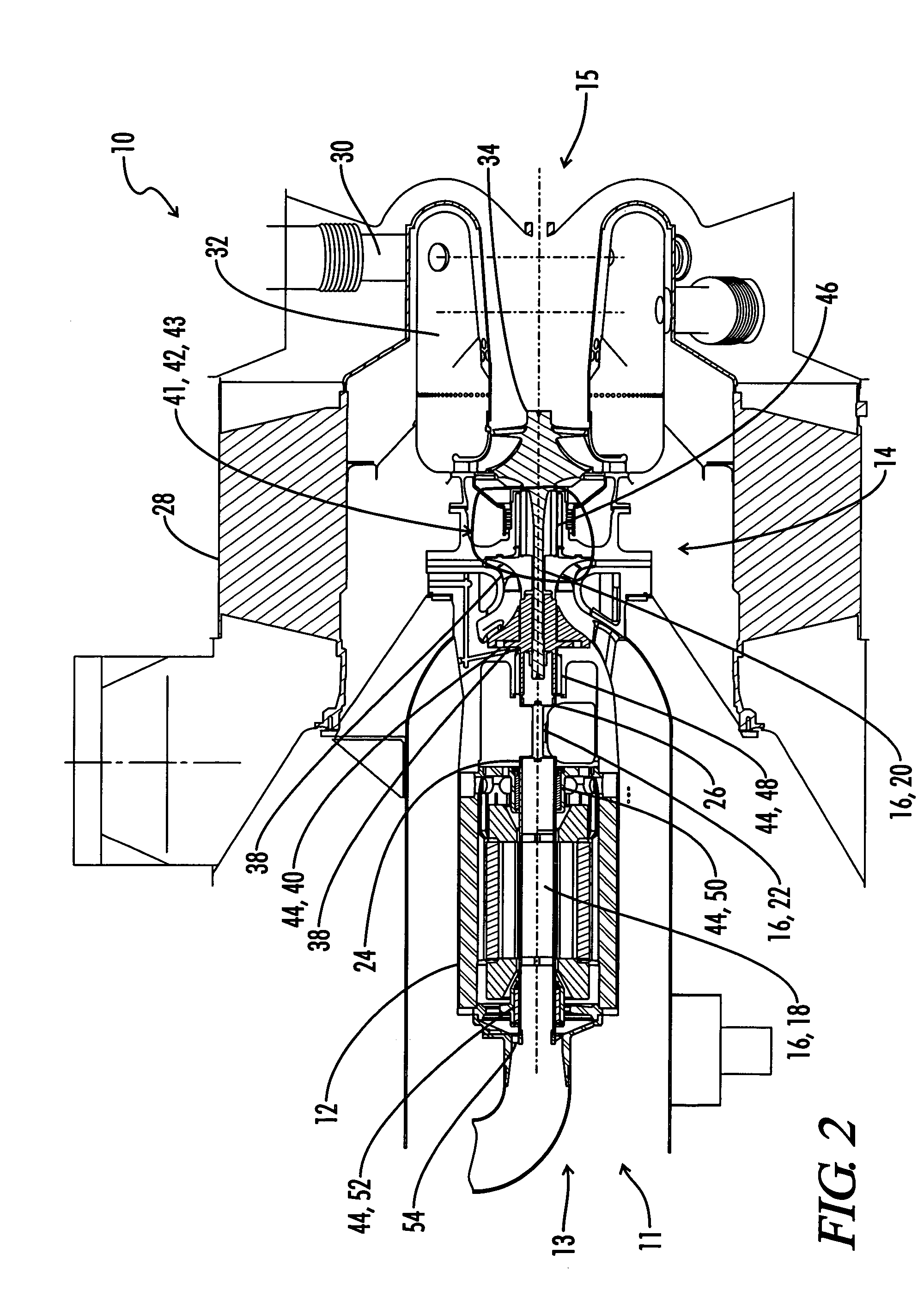

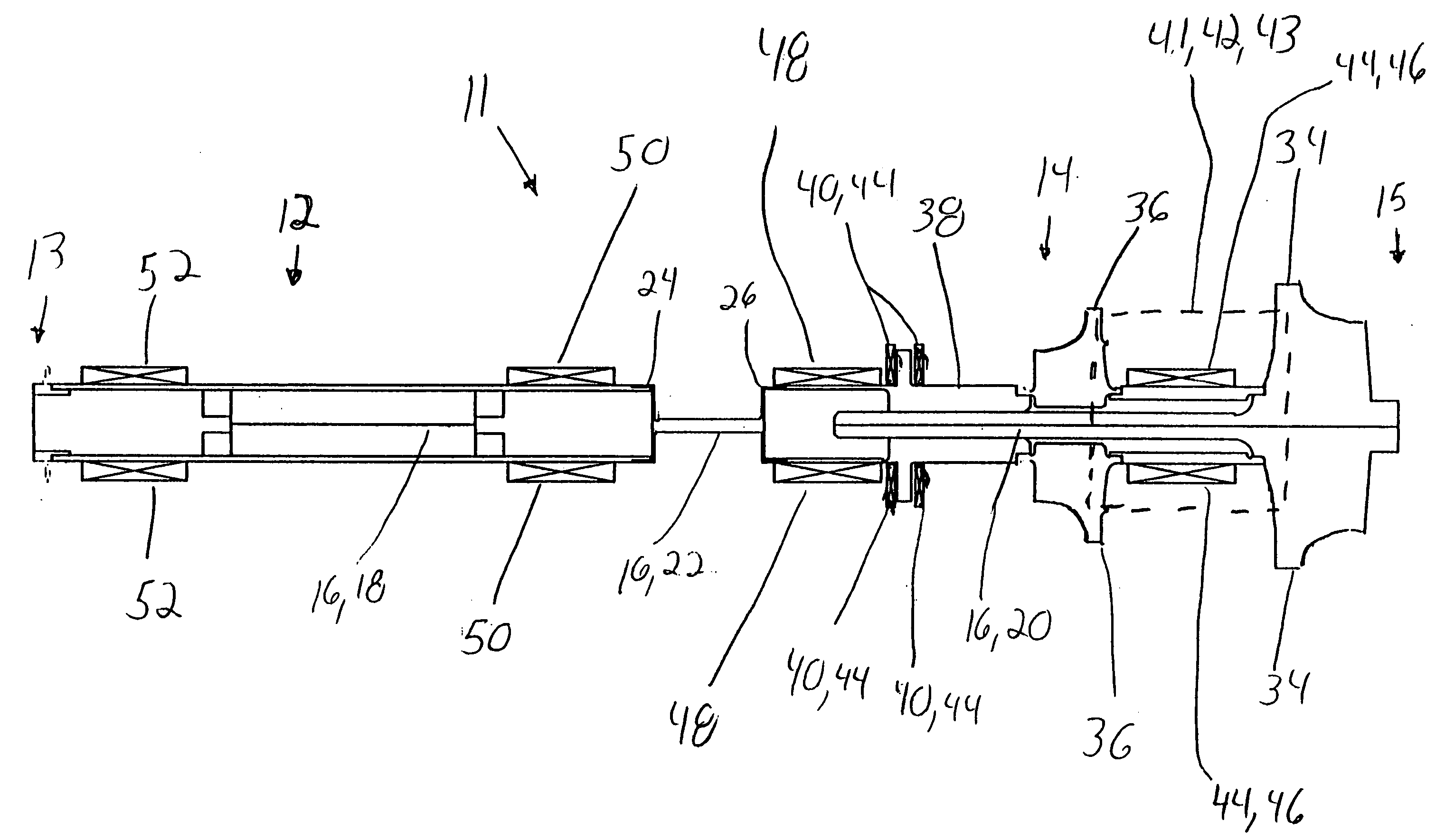

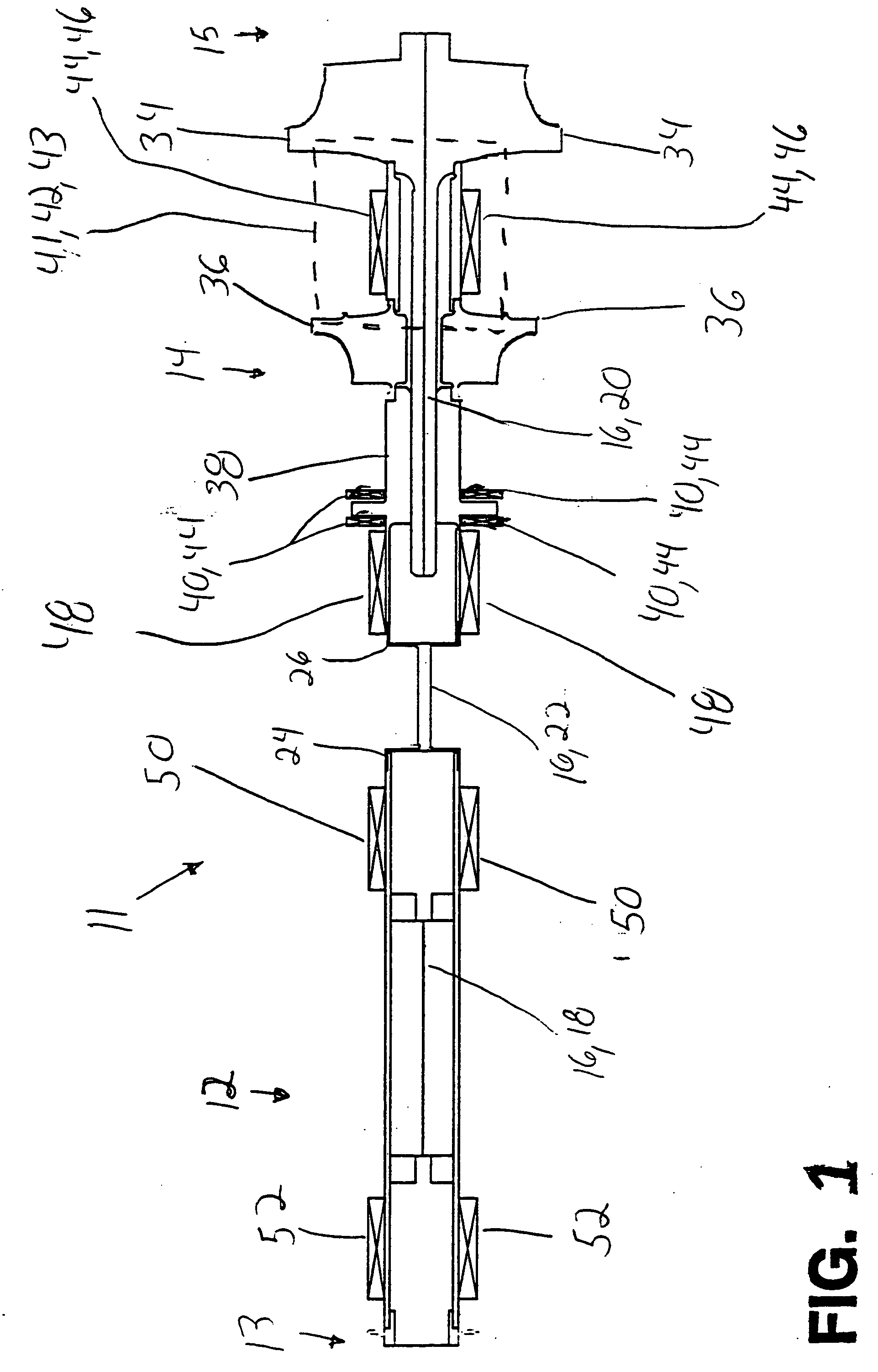

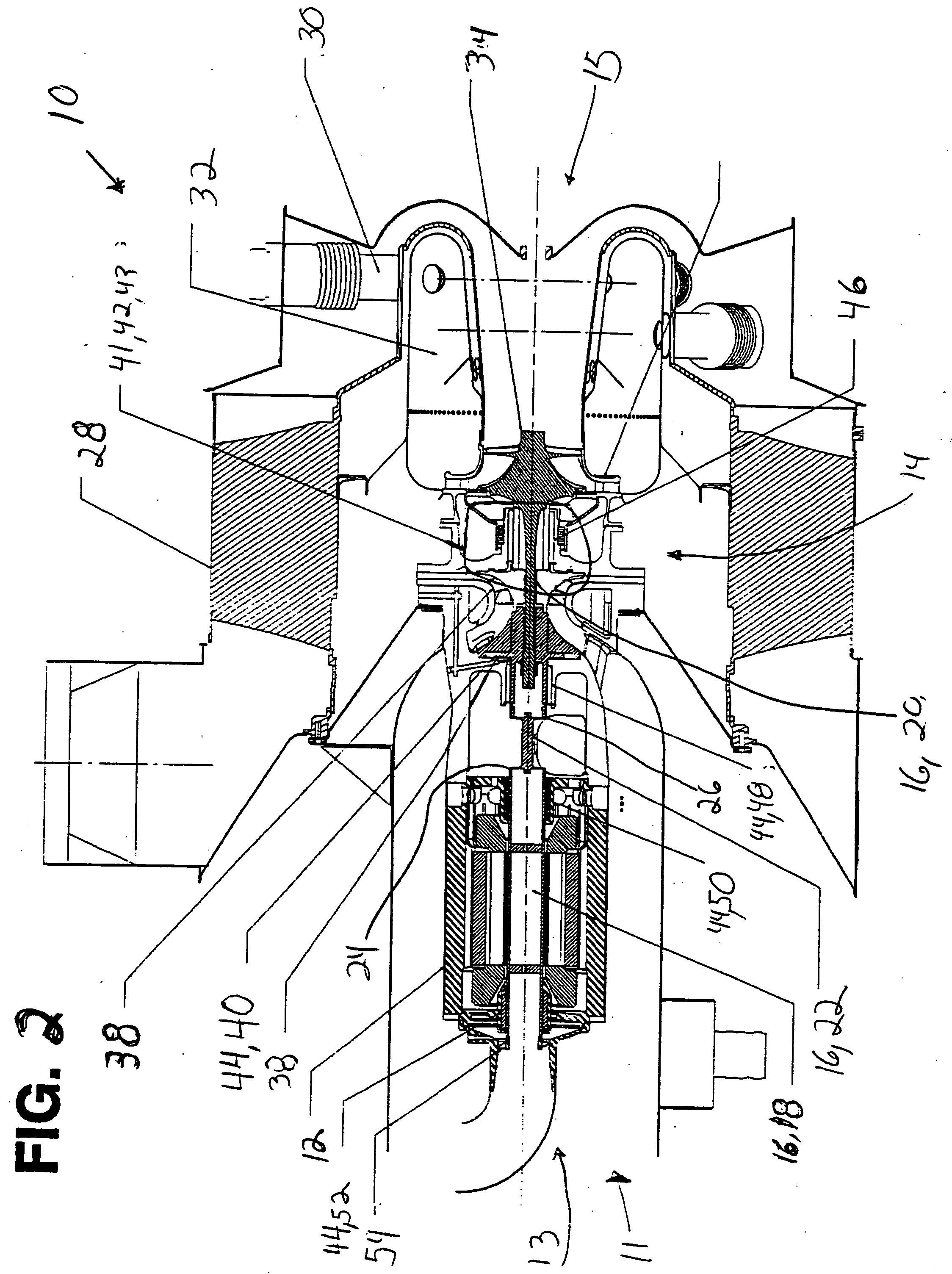

Rotor and bearing system for a turbomachine

ActiveUS7112036B2Reduce wear and temperatureHeavy loadPump componentsPiston pumpsImpellerDrive shaft

A rotor and bearing system for a turbomachine. The turbomachine includes a drive shaft, an impeller positioned on the drive shaft, and a turbine positioned on the drive shaft proximate to the impeller. The bearing system comprises one gas journal bearing supporting the drive shaft between the impeller and the turbine. The area between the impeller and the turbine is an area of increased heat along the drive shaft in comparison to other locations along the drive shaft. The section of the drive shaft positioned between impeller and the turbine is also a section of the drive shaft that experiences increased stressed and load in the turbomachine. The inventive bearing machine system positions only one radial bearing in this area of increased stress and load.

Owner:CAPSTONE GREEN ENERGY CORP

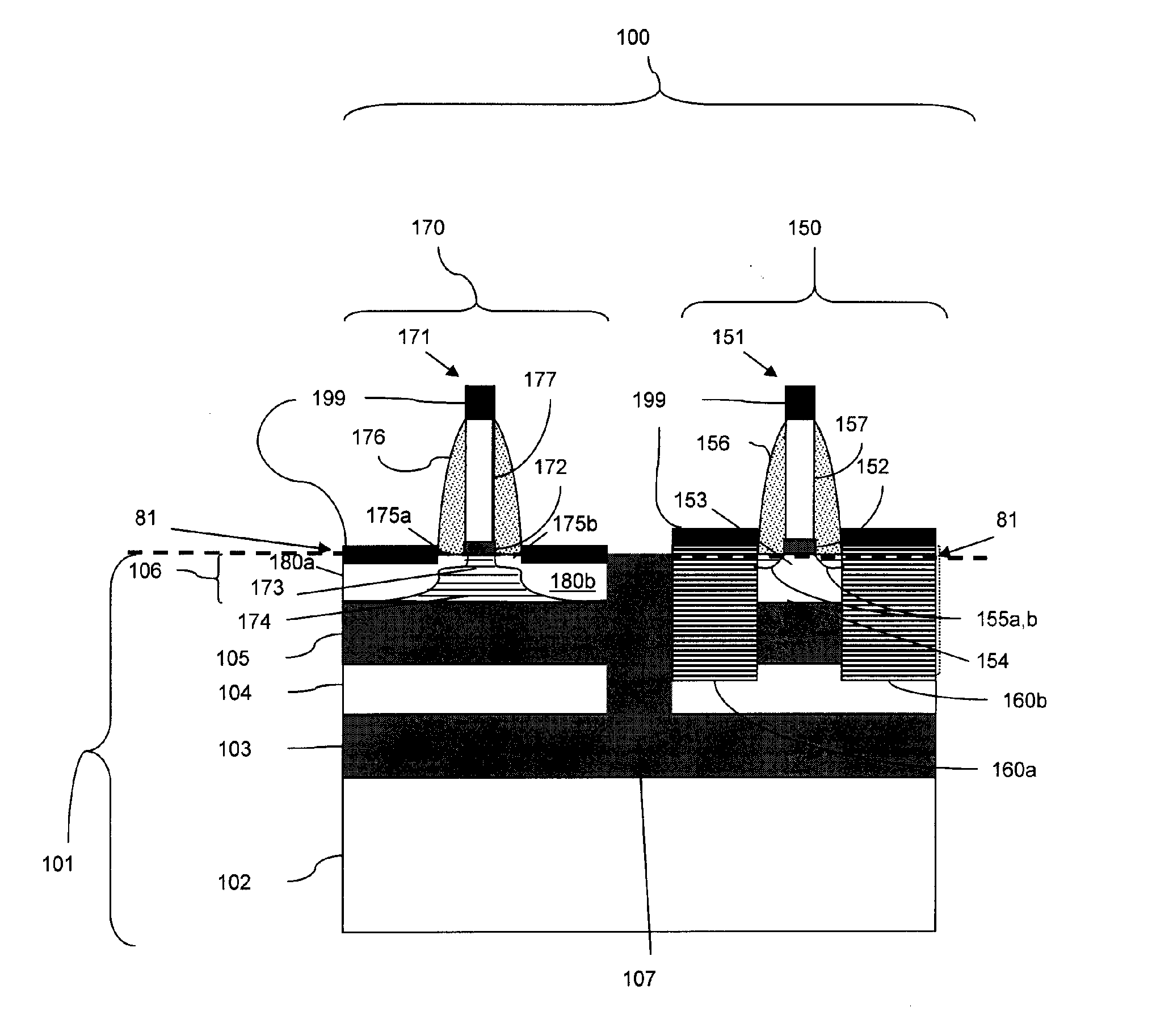

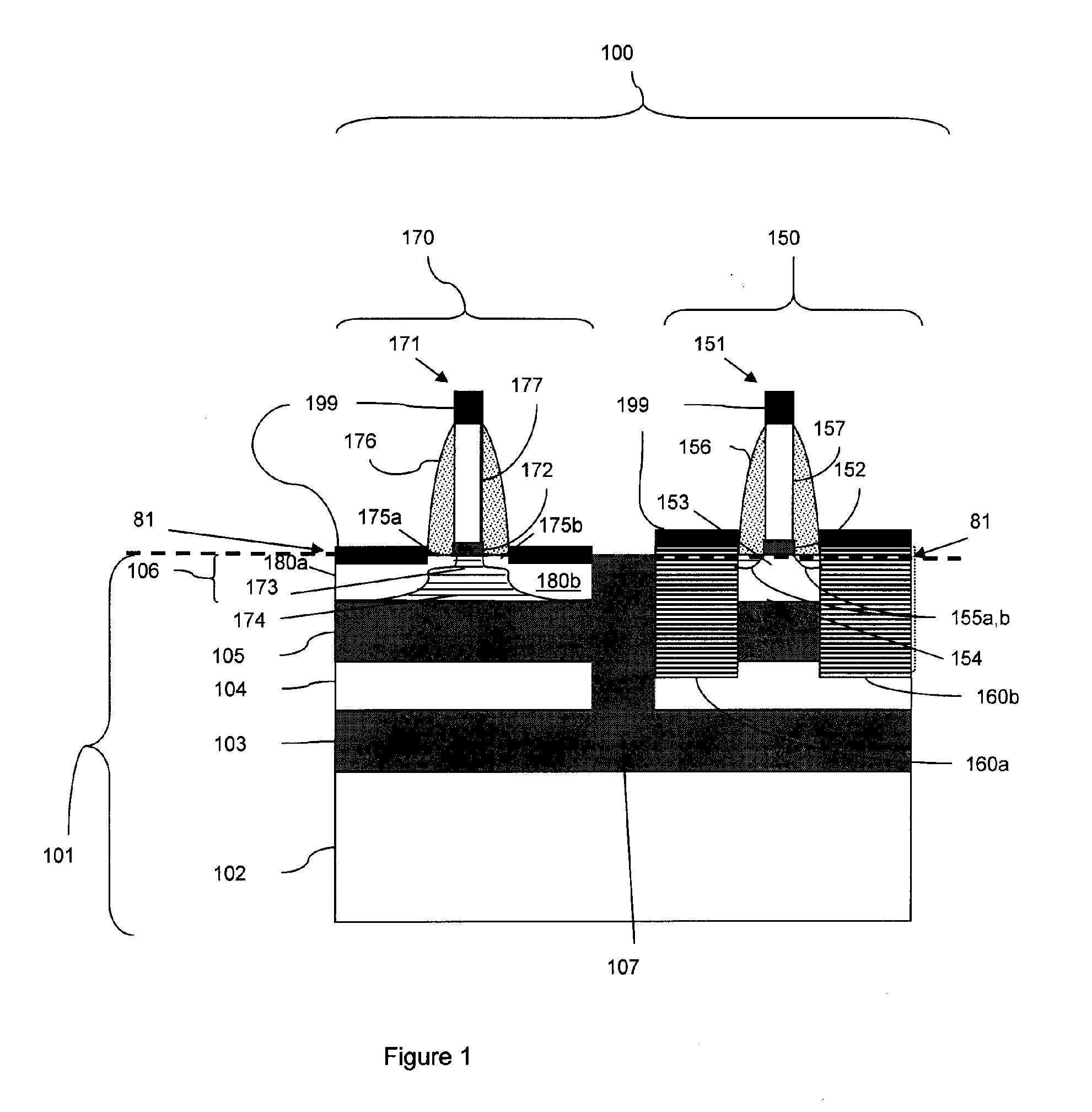

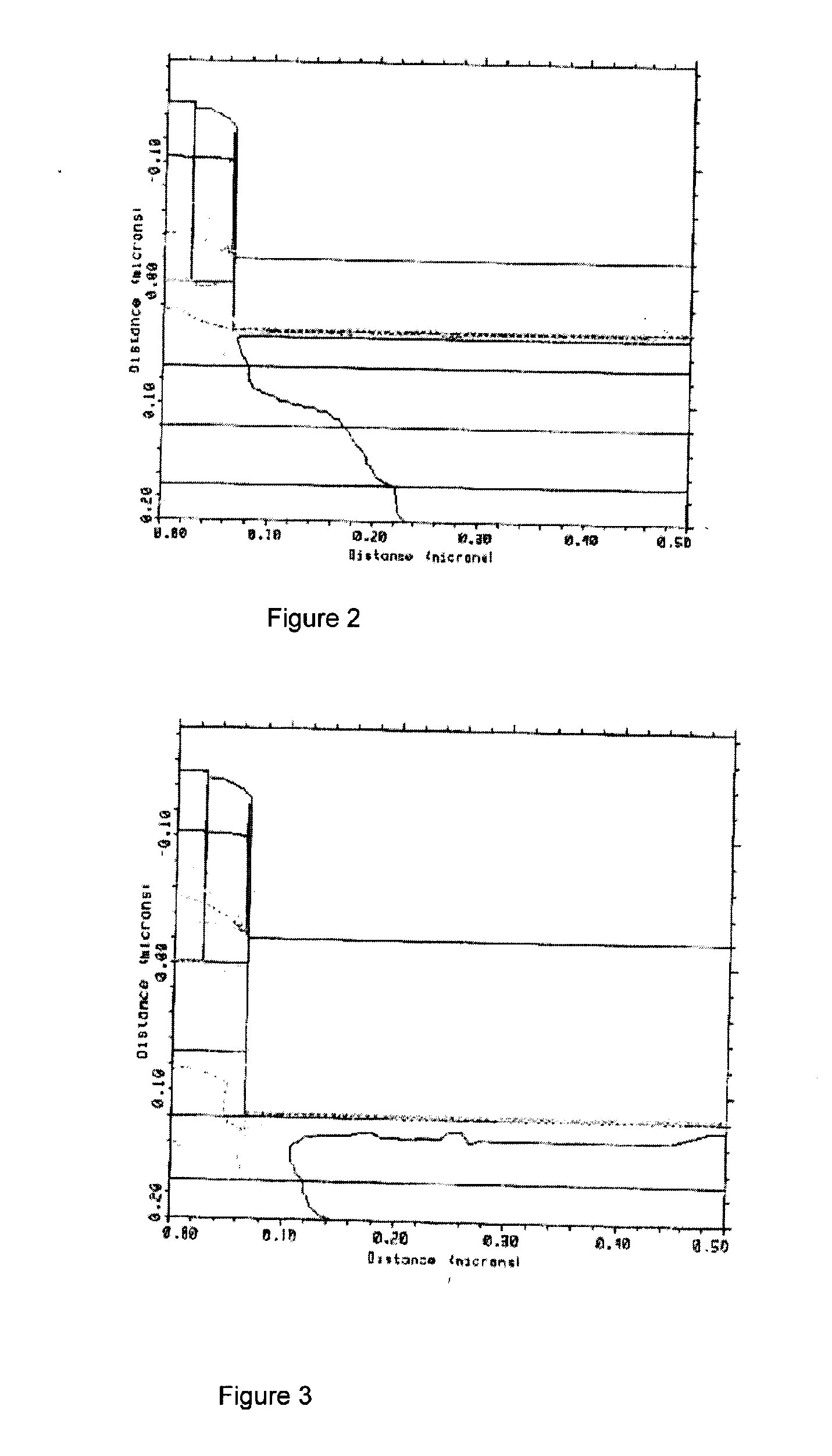

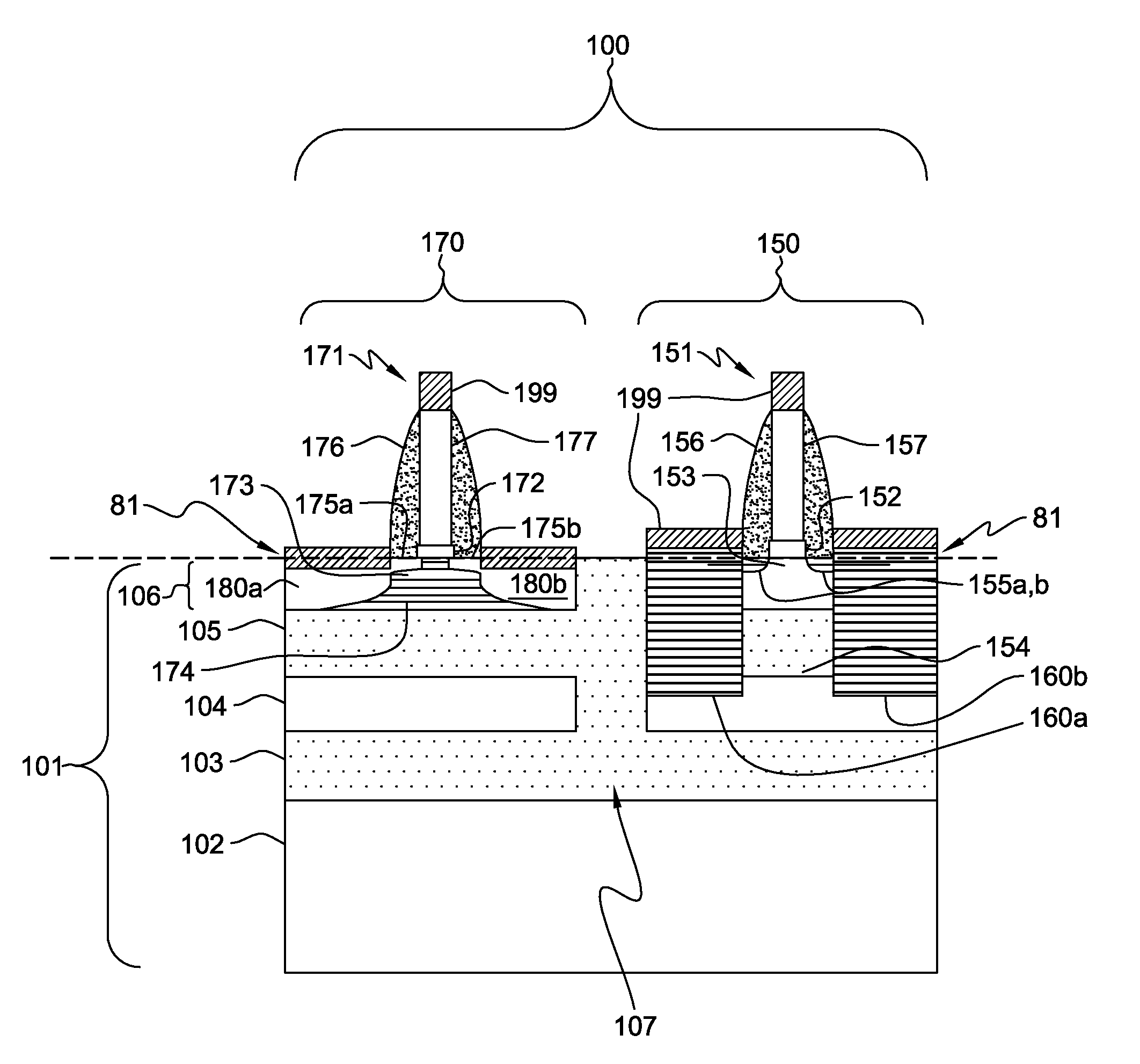

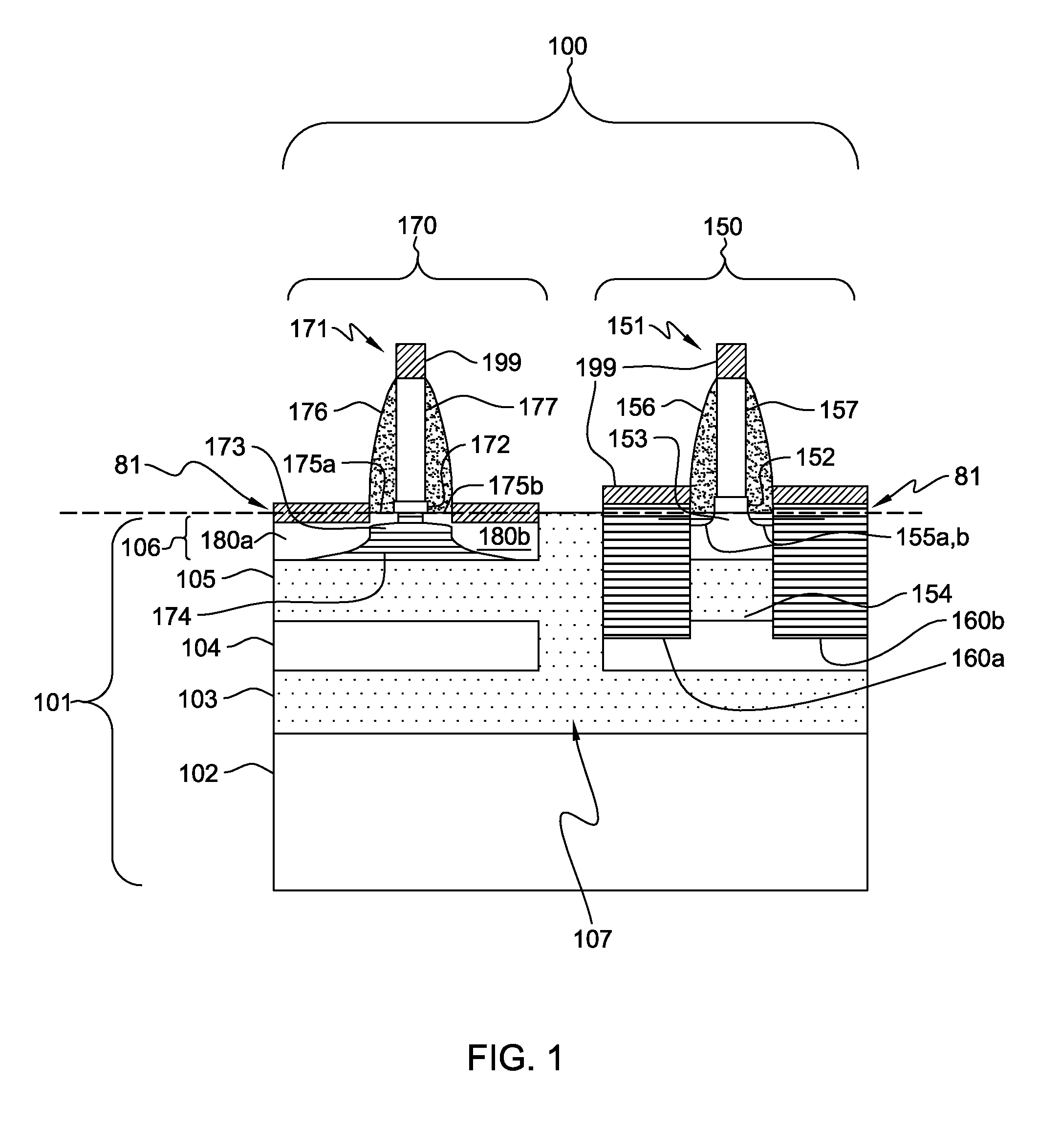

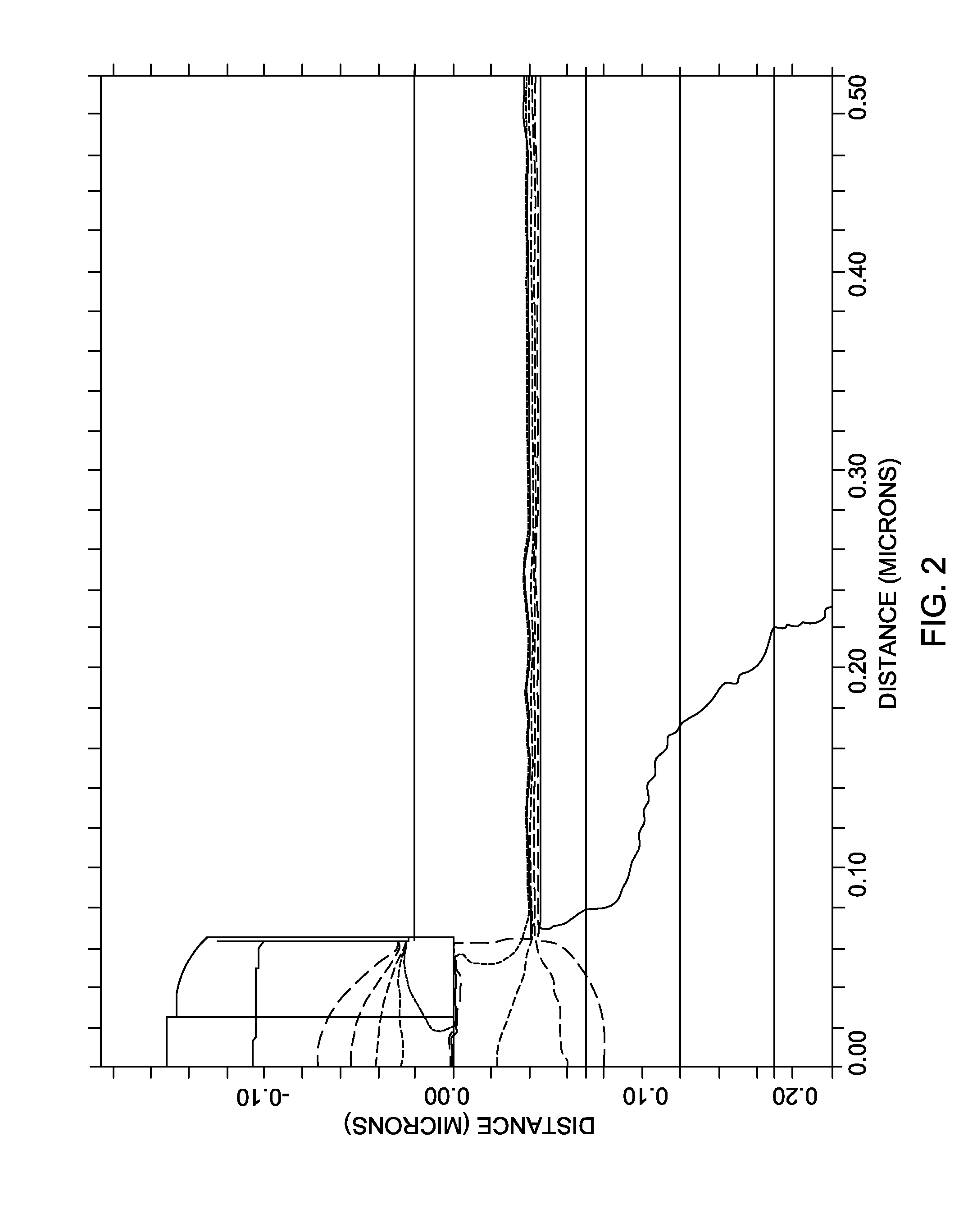

Embedded silicon germanium using a double buried oxide silicon-on-insulator wafer

ActiveUS20060255330A1Increase longitudinal stressImprove stress conditionTransistorSolid-state devicesField-effect transistorP channel

Disclosed is a p-type field effect transistor (pFET) structure and method of forming the pFET. The pFET comprises embedded silicon germanium in the source / drain regions to increase longitudinal stress on the p-channel and, thereby, enhance transistor performance. Increased stress is achieved by increasing the depth of the source / drain regions and, thereby, the volume of the embedded silicon germanium. The greater depth (e.g., up to 100 nm) of the stressed silicon germanium source / drain regions is achieved by using a double BOX SOI wafer. Trenches are etched through a first silicon layer and first buried oxide layer and then the stressed silicon germanium is epitaxially grown from a second silicon layer. A second buried oxide layer isolates the pFET.

Owner:GLOBALFOUNDRIES US INC

Fiber optic articles, assemblies, and cables having optical waveguides

ActiveUS7050688B2Optical fibre with multilayer core/claddingFibre mechanical structuresFiberUltrasound attenuation

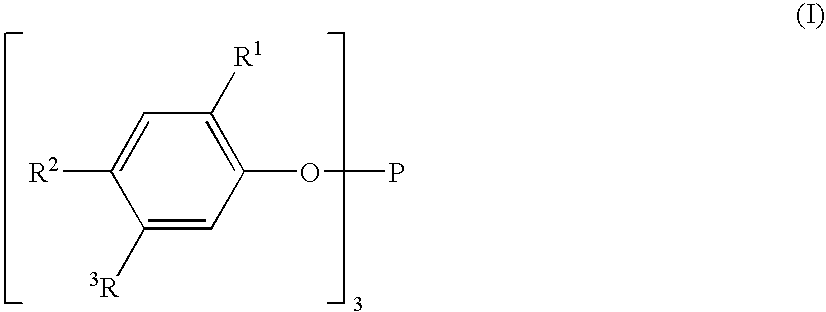

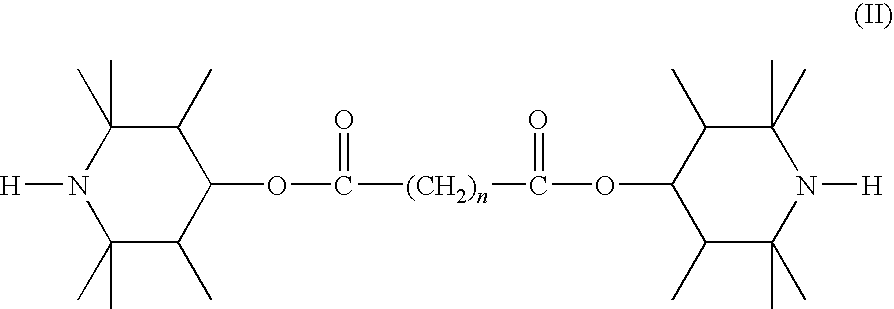

Fiber optic articles, assemblies, and cables preserve optical performance by using optical waveguides having a core, a cladding, and a coating system according to the present invention. Moreover, the optical articles, assemblies, and cables of the present invention may achieve performance levels that were previously unattainable, for instance, the present invention contemplates acceptable optical performance for wavelengths such as 1625 nm and higher. Additionally, articles, assemblies, and / or cables of the present invention advantageously preserve optical performance, i.e., have relatively low delta attenuation, when subjected to manufacturing processes and / or environmental conditions such as temperature cycling. In other words, the articles, assemblies, and cables can withstand increased stress / strain before having significant attenuation.

Owner:CORNING OPTICAL COMM LLC

Rotor and bearing system for a turbomachine

ActiveUS20050089392A1Increase temperatureIncrease pressurePump componentsPiston pumpsImpellerDrive shaft

A rotor and bearing system for a turbomachine. The turbomachine includes a drive shaft, an impeller positioned on the drive shaft, and a turbine positioned on the drive shaft proximate to the impeller. The bearing system comprises one gas journal bearing supporting the drive shaft between the impeller and the turbine. The area between the impeller and the turbine is an area of increased heat along the drive shaft in comparison to other locations along the drive shaft. The section of the drive shaft positioned between impeller and the turbine is also a section of the drive shaft that experiences increased stressed and load in the turbomachine. The inventive bearing machine system positions only one radial bearing in this area of increased stress and load.

Owner:CAPSTONE TURBINE

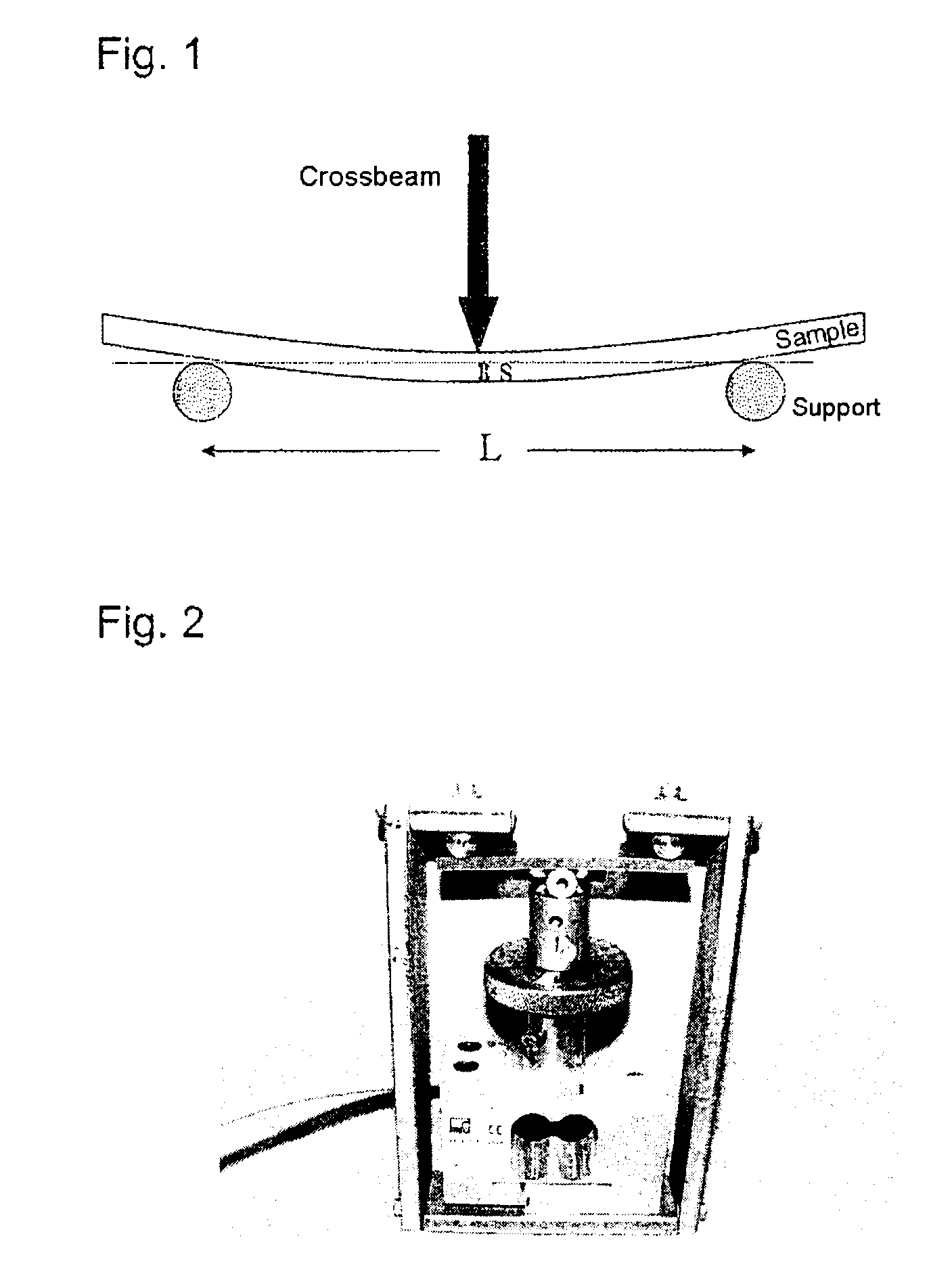

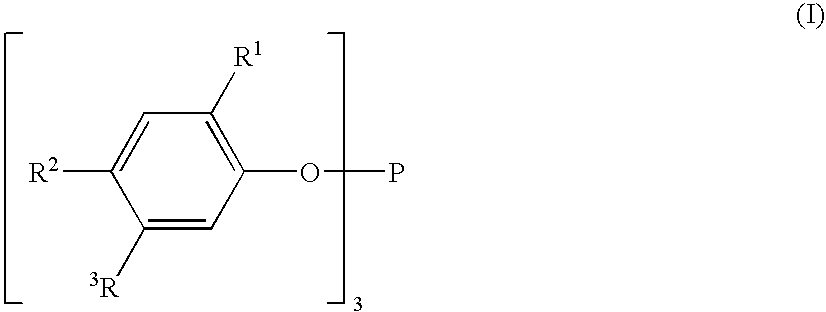

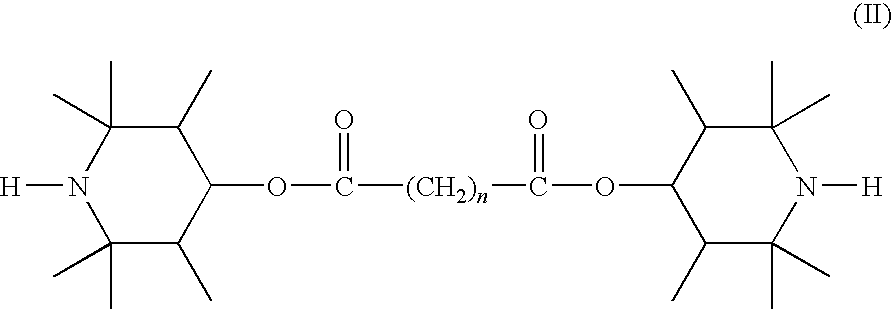

Composition with increased stress cracking resistance

InactiveUS20100174022A1Improved stress crack resistanceImprove heat deformation resistanceInksOrganic dyesMeth-Crack resistance

Composition containing, based in each case on its total weight,A) 50.0% by weight to 99.5% by weight of at least one (meth)acrylate (co)polymer andB) 0.5% by weight to 50.0% by weight of at least one copolymer obtainable by polymerisation of a monomer mixture comprisingi. 70% by weight to 92% by weight of a vinylaromatic monomer andii. 8% by weight to 30% by weight of acrylonitrile or methacrylonitrile or mixtures thereof andiii. 0% by weight to 22% by weight of at least one further monomer, the composition having a haze according to ASTM D1003 of less than 2.0% at 23° C. and a haze according to ASTM D1003 of less than 4.0% at 40° C. and the composition containing at least one (meth)acrylate (co)polymer a) having a solution viscosity in chloroform at 25° C. (ISO 1628—part 6) of greater than 55 ml / g.The mouldings obtainable from the composition are distinguished in particular by improved stress cracking resistance and are suitable in particular for coverings, finishes or films.

Owner:EVONIK ROEHM GMBH

Coloured composition with increased stress cracking resistance

InactiveUS20100148401A1Improved stress crack resistanceImprove heat deformation resistanceOrganic dyesCeramic shaping apparatusCrack resistanceMeth-

The invention relates to a composition containing, in relation to the total weight of said composition, A) between 50.0% by weight and 99.5% by weight of at least one (meth)acrylate (co)polymer and B) between 0.5% by weight and 50.0% by weight of at least one copolymer, obtained by the polymerisation of a monomer mixture consisting of i. between 70% by weight and 92% by weight of a vinyl aromatic monomer and ii. between 8% by weight and 30% by weight of acryl nitrile or methacryl nitrile or mixtures thereof iii. between 0% by weight and 22% by weight of at least one other monomer, the composition having at 50° C. a ΔE of less than 0.15, ΔE being defined according to the relationship (1): (1) in which ΔL*: the modification of the colour co-ordinates L* compared with the colour co-ordinates L* at 23° C., Δa*: the modification of the colour co-ordinates a* compared with the colour co-ordinates a* at 23° C., Δb*: the modification of the colour co-ordinates b* compared to the colour co-ordinates b* at 23° C., and the composition contains at least one (meth)acrylate (co)polymer a) with a solution viscosity in chloroform at 25° C. (ISO 1628 part 6) greater than 55 ml / g. The moulded bodies that can be obtained from the composition are characterised in particular by improved stress cracking resistance and are suitable in particular for use in coatings, paints or films.

Owner:EVONIK ROEHM GMBH

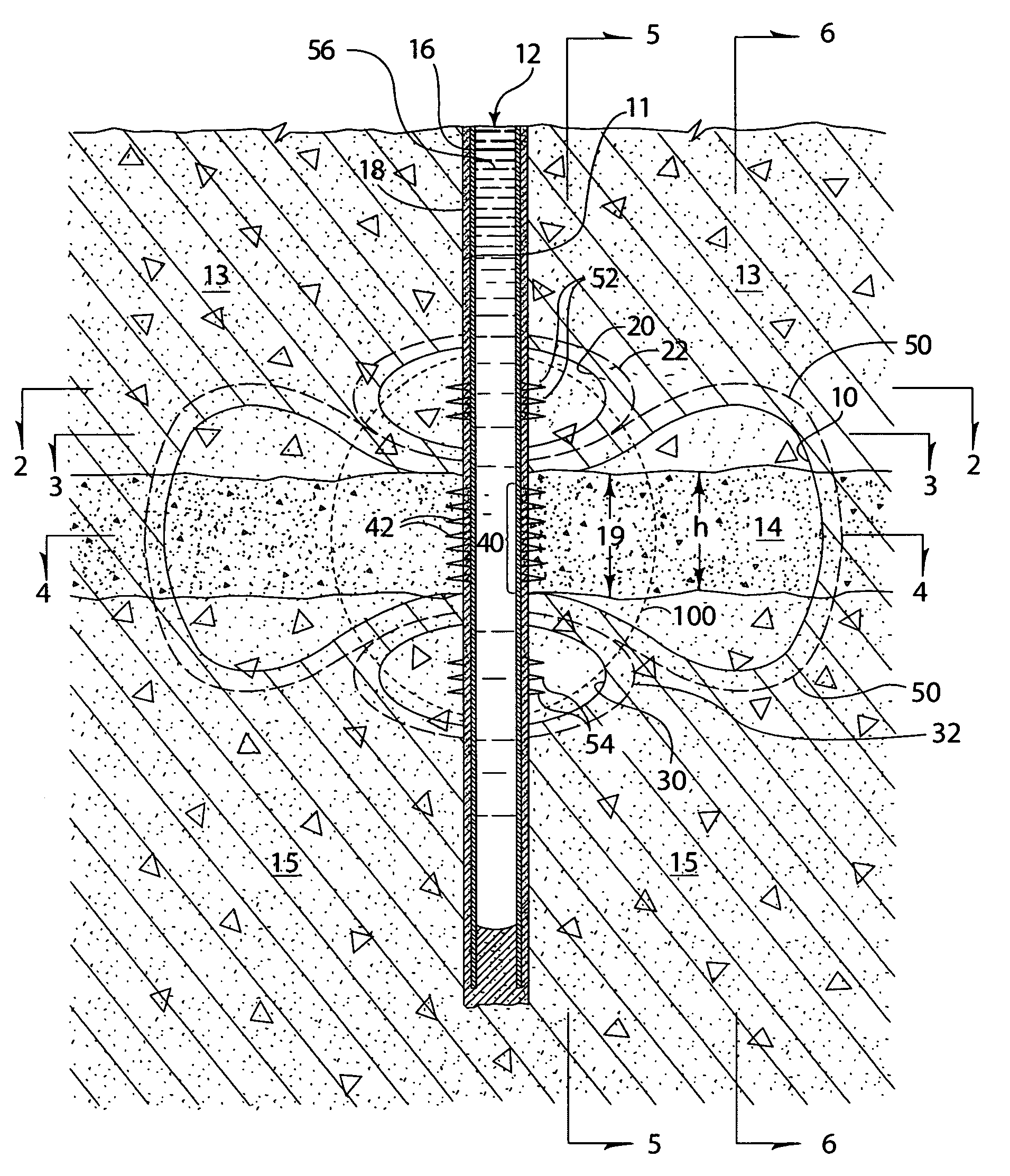

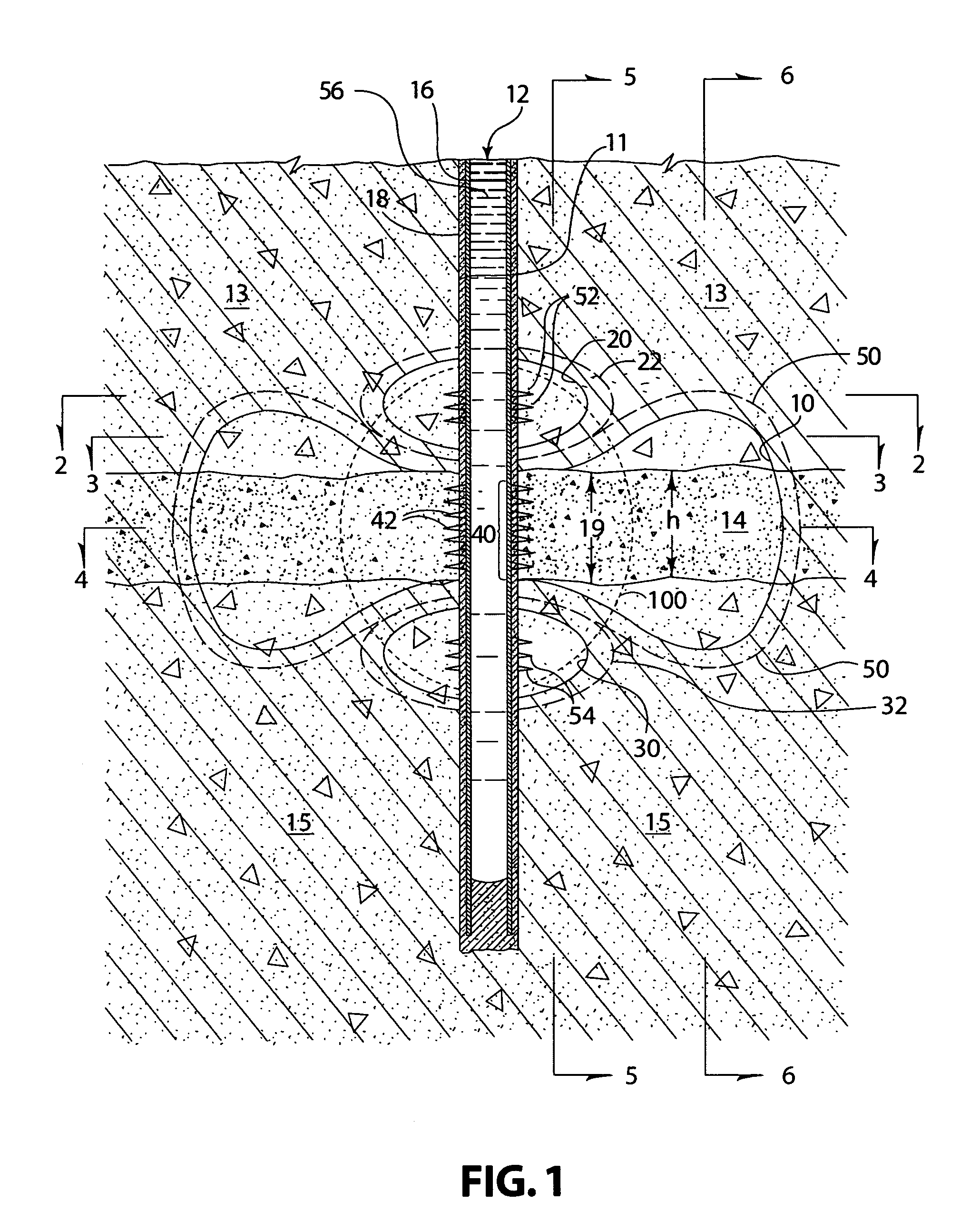

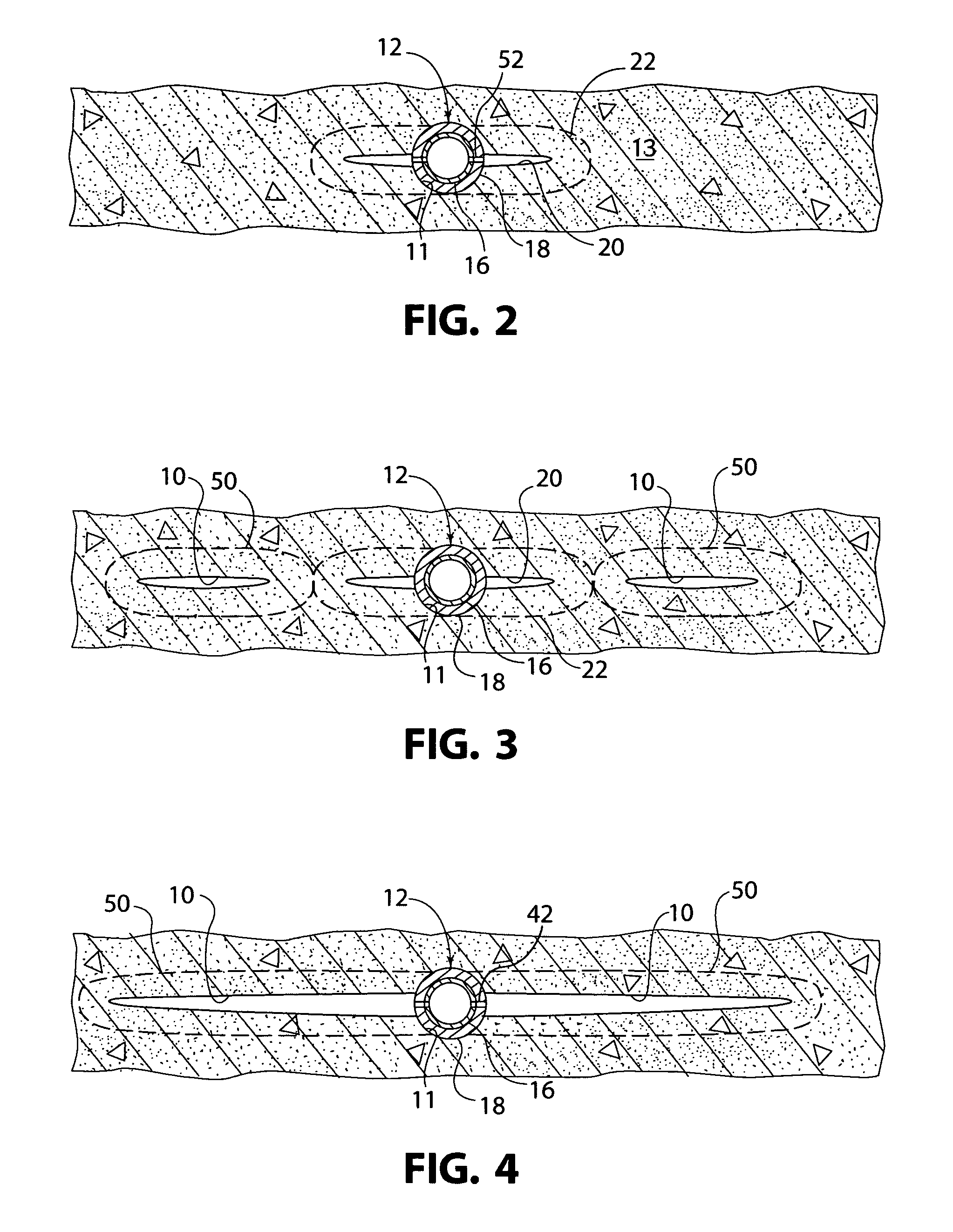

Method for increasing fracture penetration into target formation

InactiveUS7032671B2Reliable and goodReliable methodSurveyFluid removalFracturing fluidVertical growth

A method of propagating a fracture farther from a well-bore into an oil and / or gas-bearing zone of a target formation while inhibiting growth of the fracture into an adjacent water-bearing zone under or over the oil and / or gas-bearing zone, comprises creating a zone of increased in-situ stress a vertical distance adjacent a target interval and then creating a main fracture in the target interval by, for example, fracturing the target interval with enough fracture fluid and pressure to propagate the main fracture, inter alia, vertically to the zone of increased in-situ stress. When vertical growth of the main fracture reaches the limit set by the zone of increased stress, additional fracture fluid pumped into the target interval tends not to propagate the main fracture vertically beyond that limit and, instead, tends to propagate the main fracture more laterally and farther from the well. Such zone(s) of increased in-situ stress can be created above, below, or both above and below the target interval.

Owner:NEW IPT INC

Embedded silicon germanium using a double buried oxide silicon-on-insulator wafer

InactiveUS20080265281A1Improve stress conditionSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsField-effect transistor

Disclosed is a p-type field effect transistor (pFET) structure and method of forming the pFET. The pFET comprises embedded silicon germanium in the source / drain regions to increase longitudinal stress on the p-channel and, thereby, enhance transistor performance. Increased stress is achieved by increasing the depth of the source / drain regions and, thereby, the volume of the embedded silicon germanium. The greater depth (e.g., up to 100 nm) of the stressed silicon germanium source / drain regions is achieved by using a double BOX SOI wafer. Trenches are etched through a first silicon layer and first buried oxide layer and then the stressed silicon germanium is epitaxially grown from a second silicon layer. A second buried oxide layer isolates the pFET.

Owner:GLOBALFOUNDRIES US INC

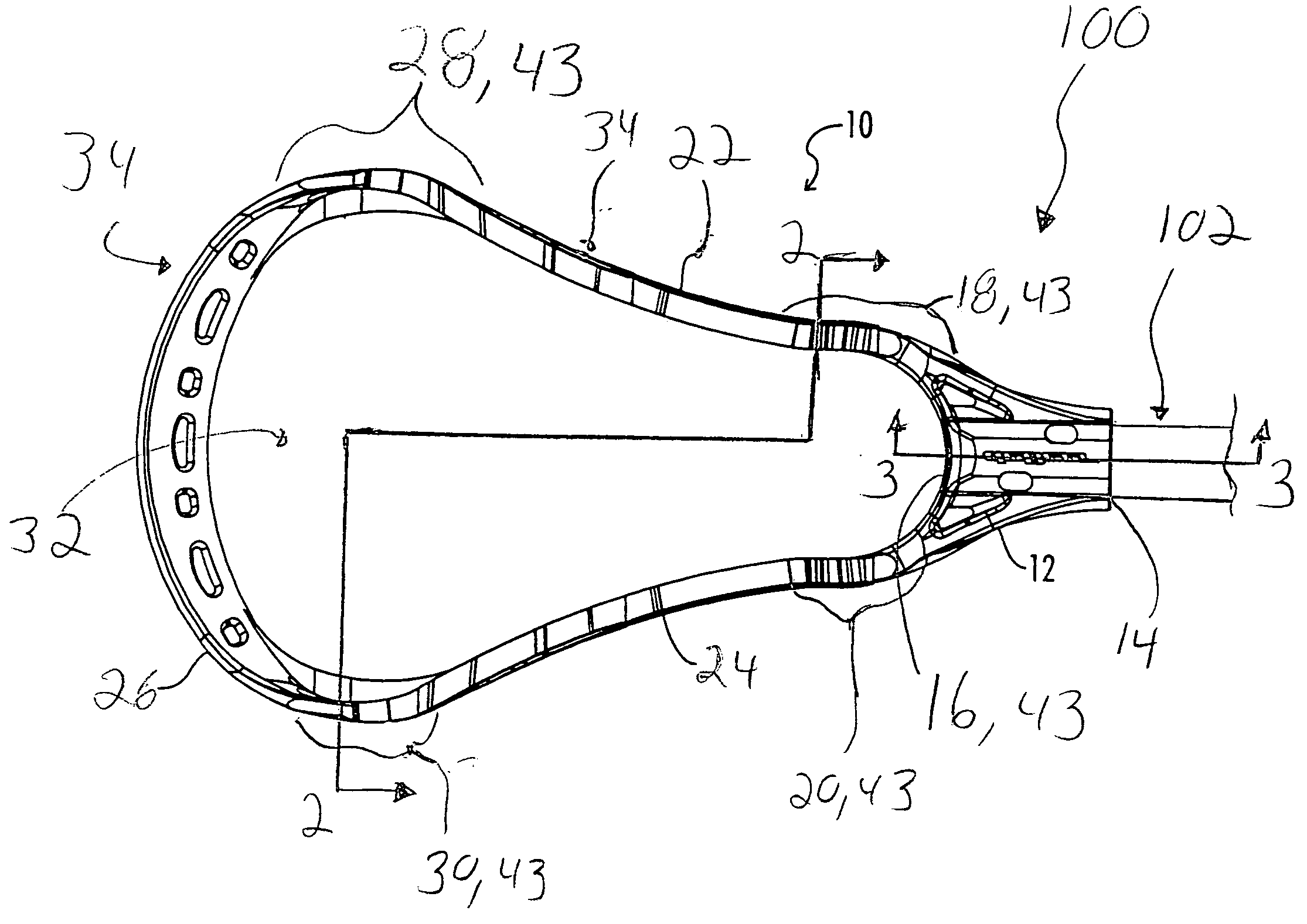

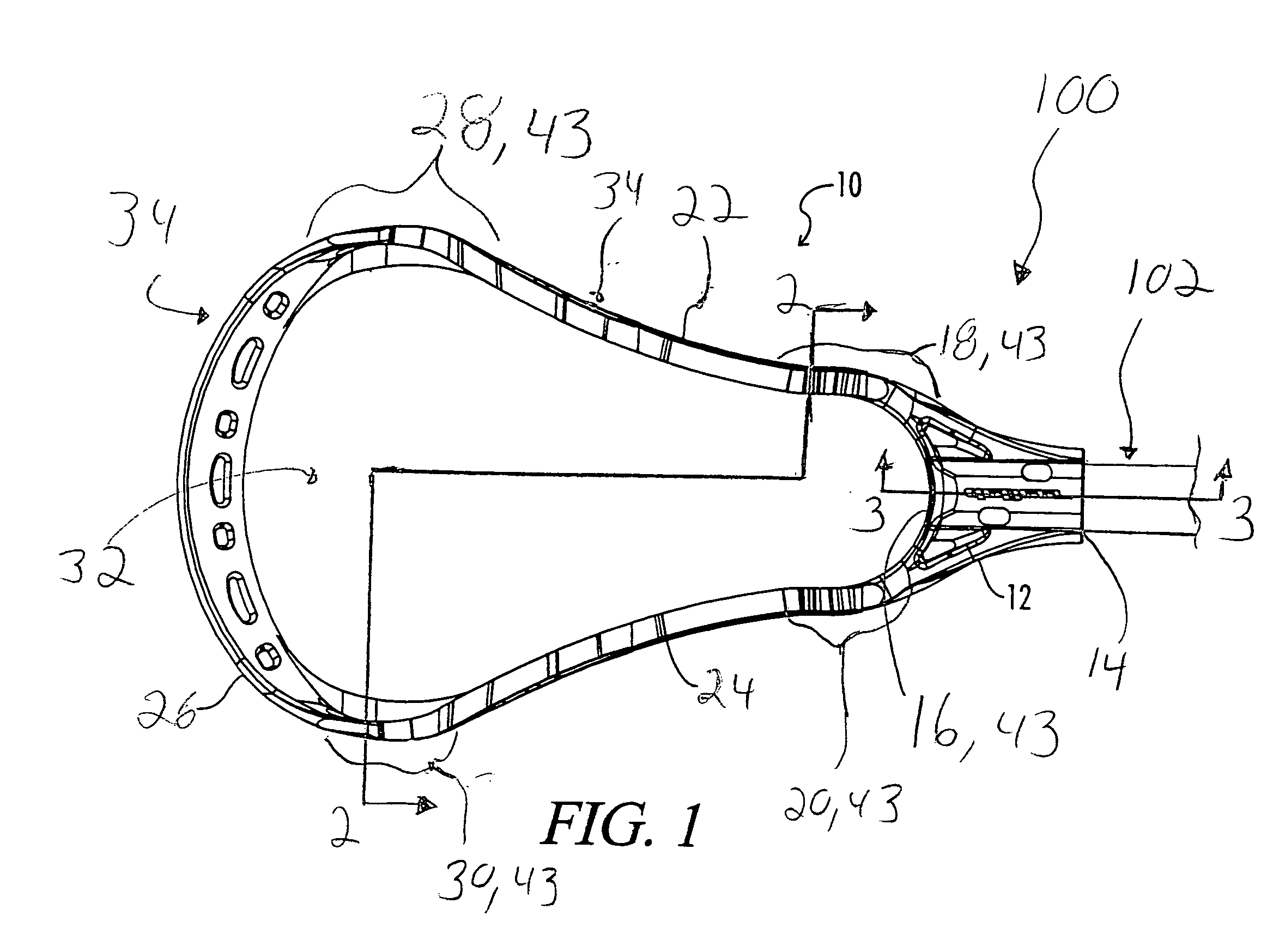

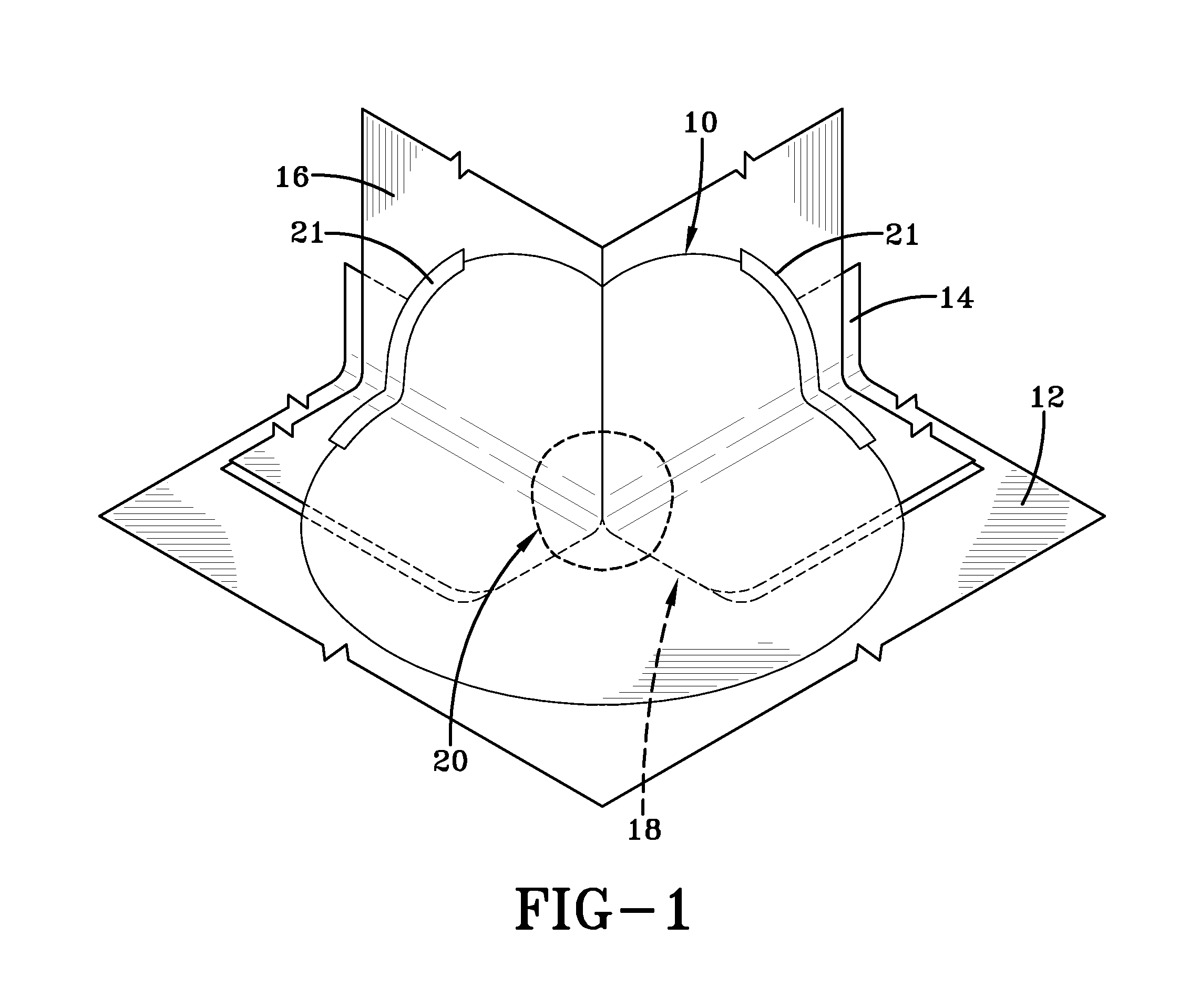

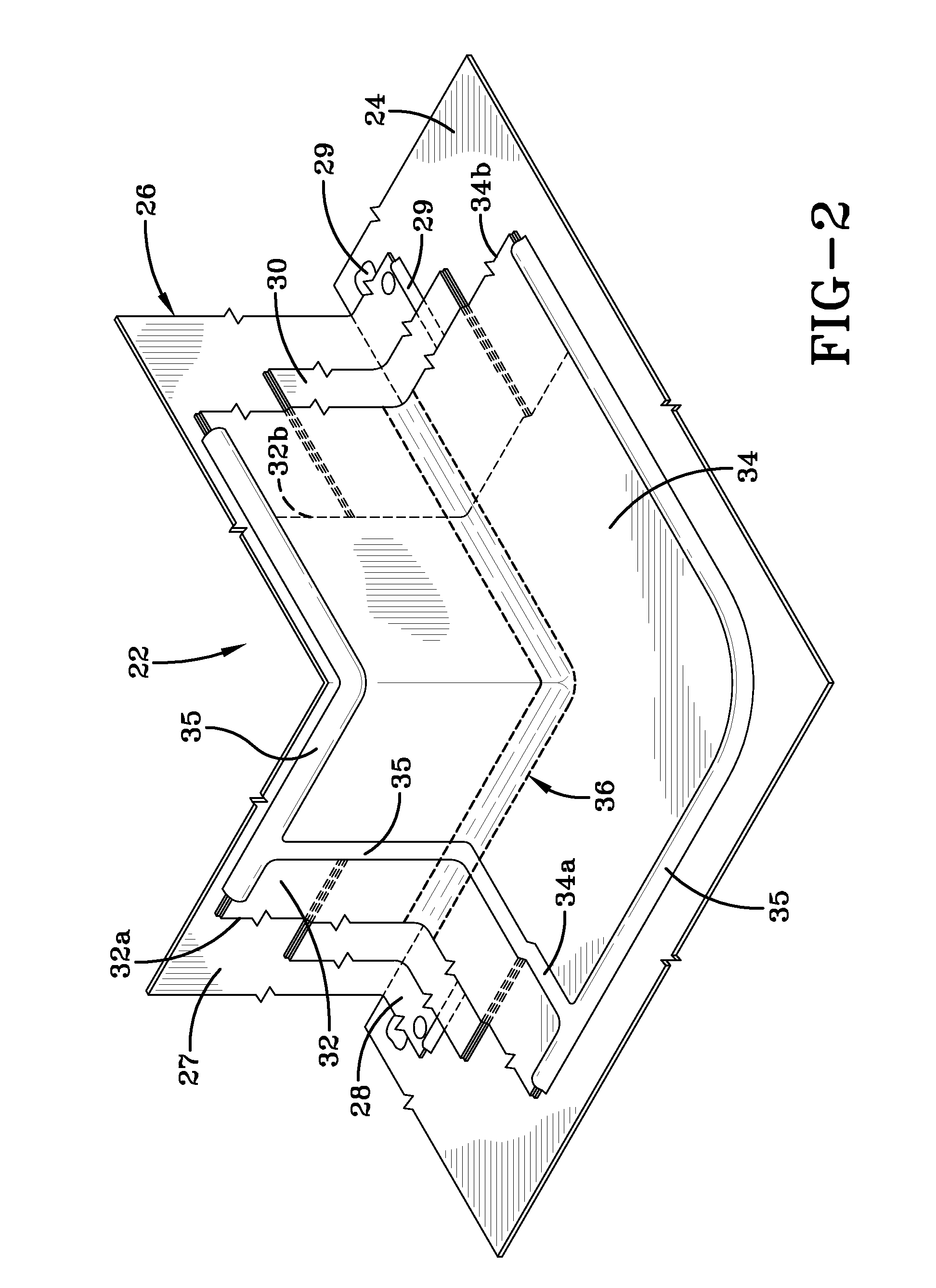

Lacrosse head with metal frame

InactiveUS20050215359A1Easy to collectIncrease pressureBall sportsThrow gamesMetal frameworkEngineering

The present invention discloses a lacrosse head having internal metal supports within a plastic casing. The internal metal supports can comprise an entire metal frame running throughout the lacrosse head or can be positioned as sections supporting areas of increased stress within the lacrosse head. Preferably the metal supports include a textured surface to increase the strength and bonding characteristics of the elements of the lacrosse head.

Owner:J DEBEER & SON

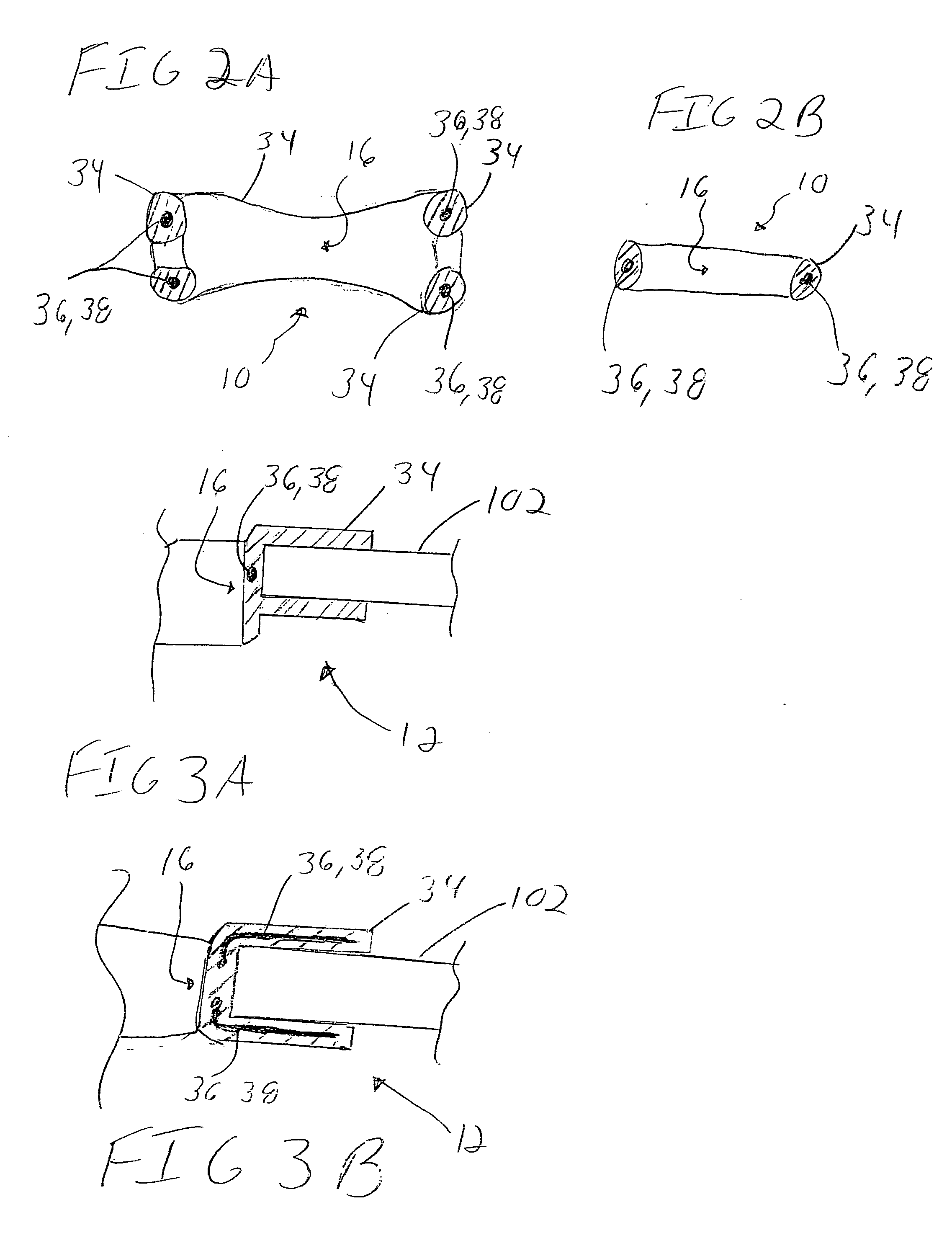

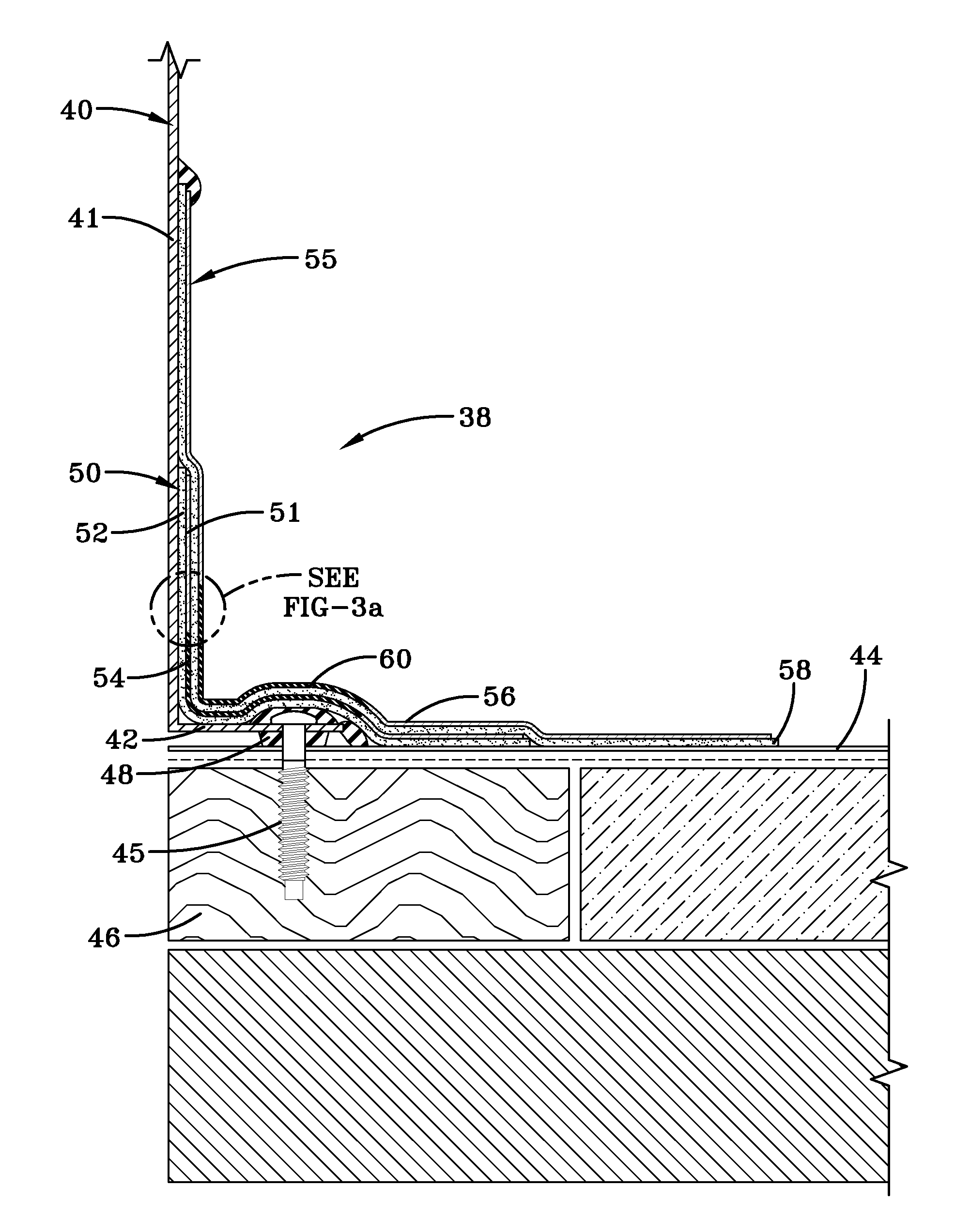

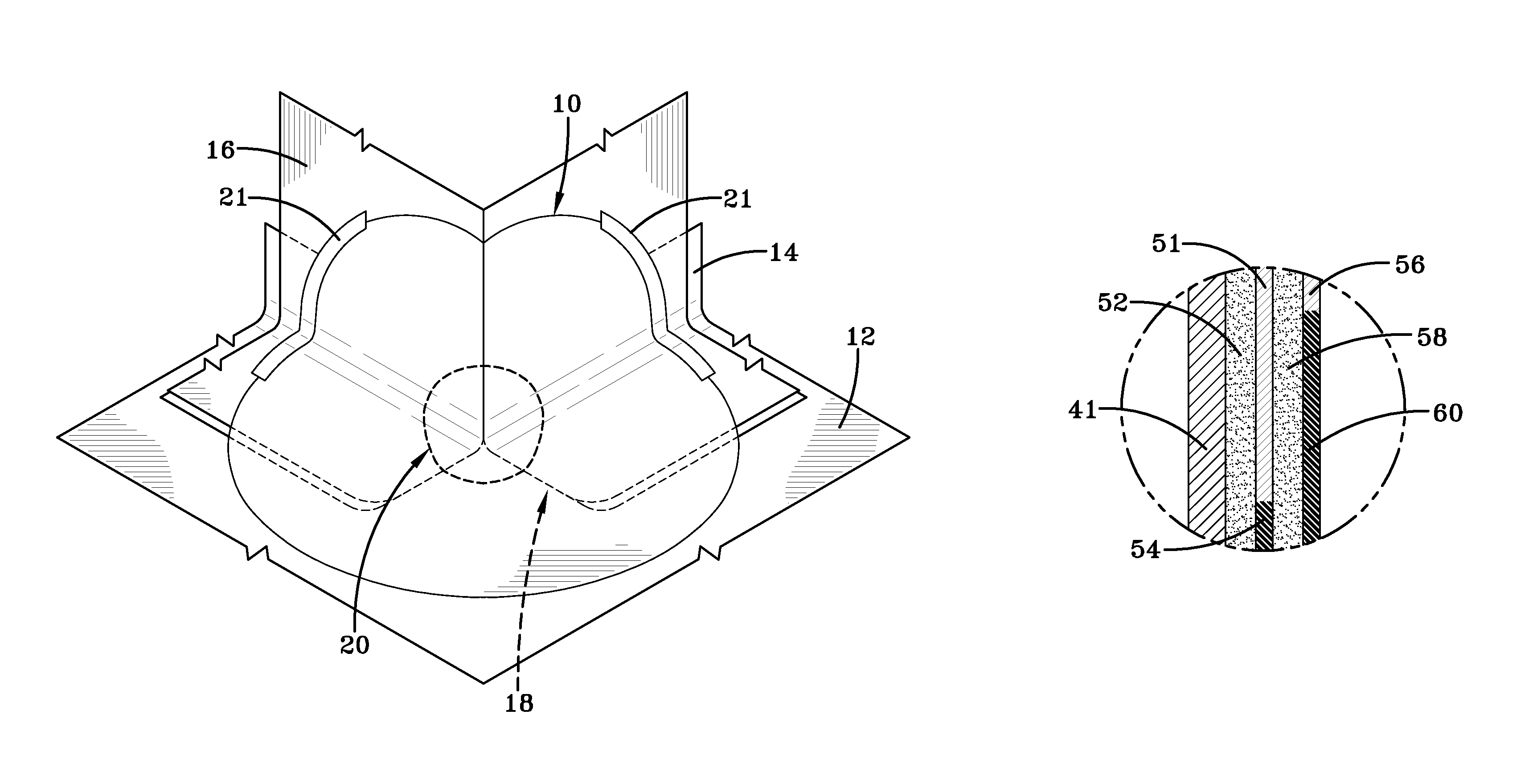

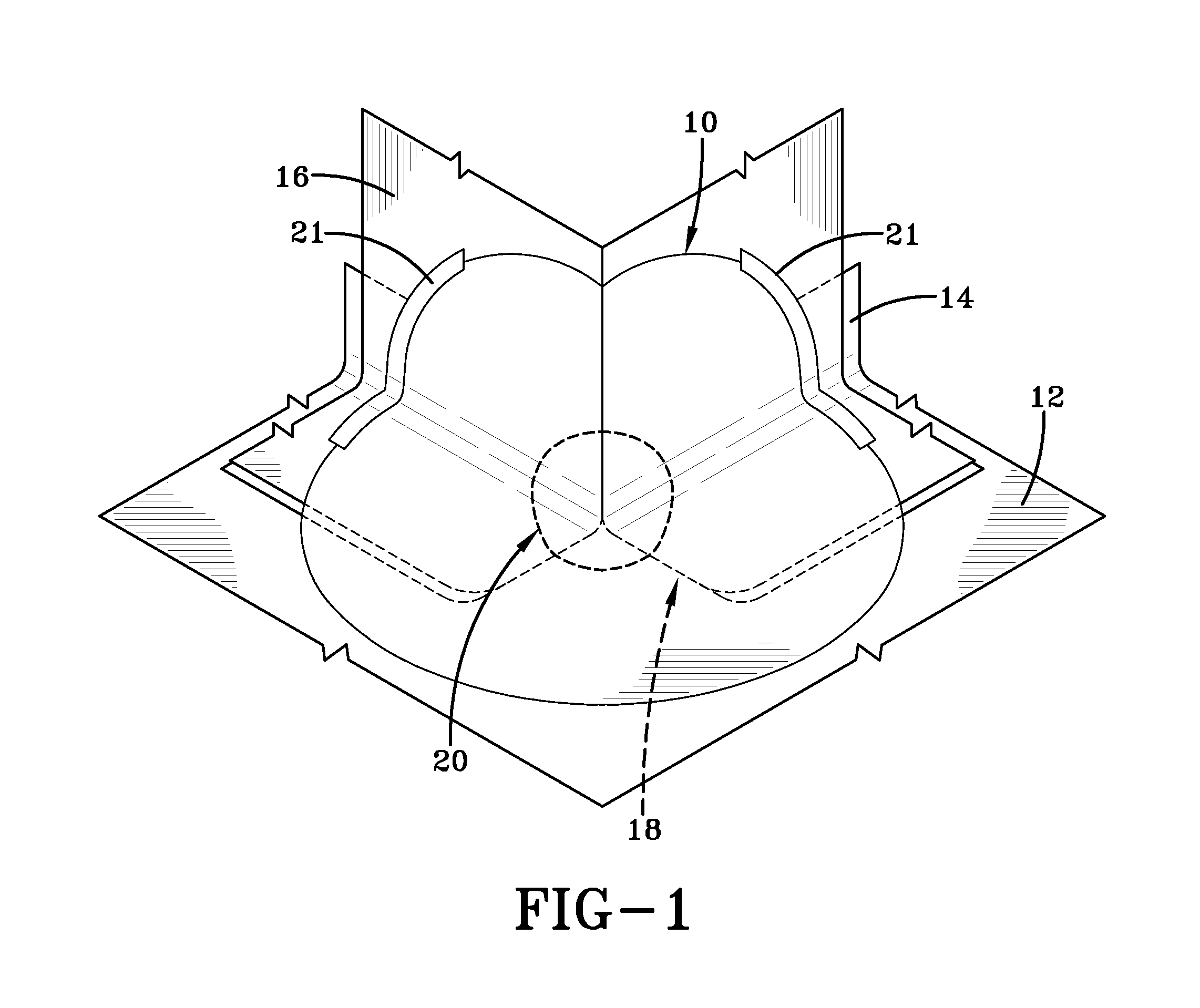

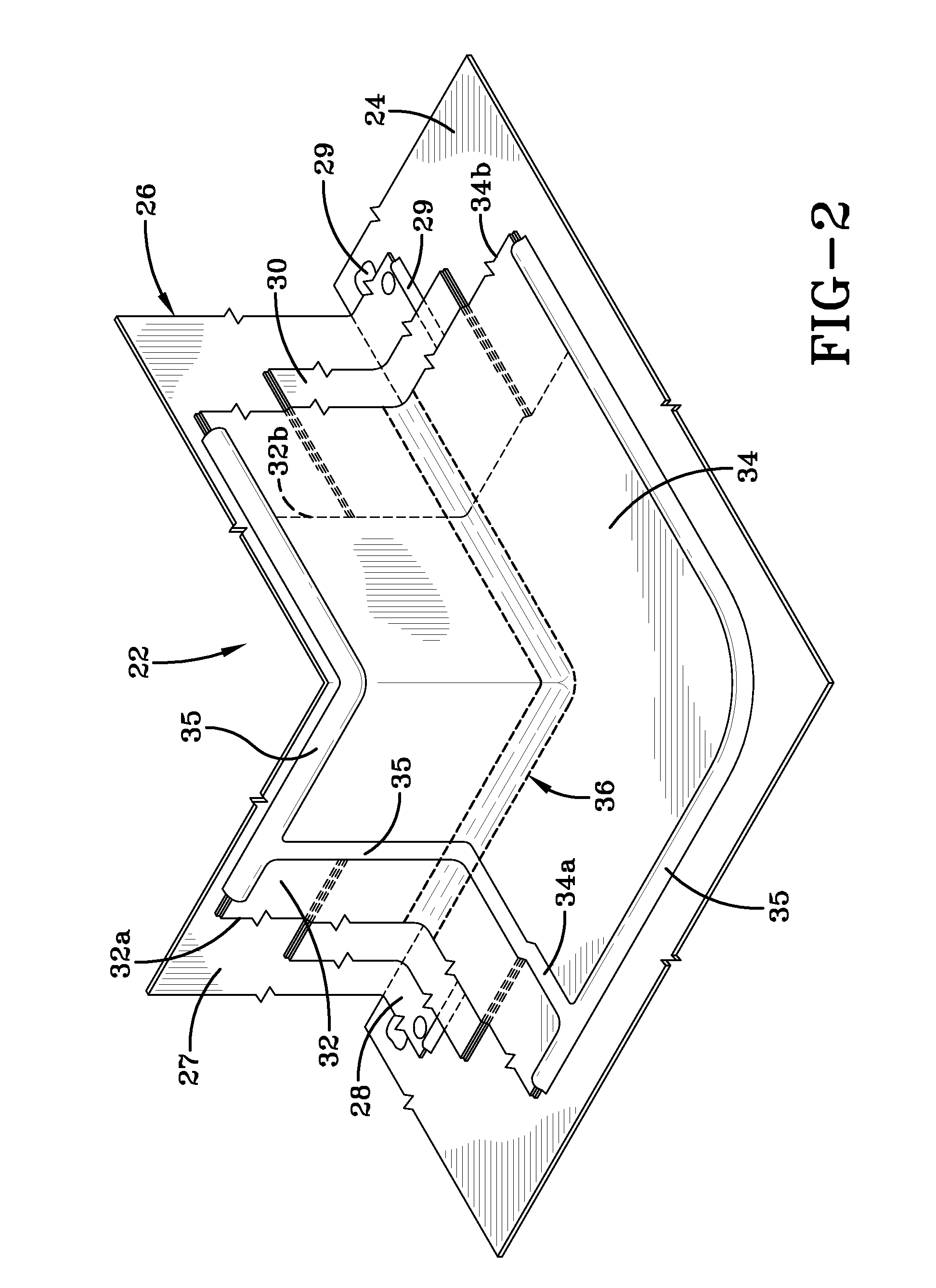

Fortified flashing laminate

ActiveUS20120204508A1Reduce risk of damageRoof coveringConstruction materialEngineeringMechanical engineering

A fortified flashing laminate including a polymeric layer having an uncured portion and a cured portion forming a fortified area. The fortified area strengthens the flashing laminate at an area of known vulnerability or increased stress to prevent damage to the flashing laminate during installation and prior to curing of the remainder of the polymeric layer. The fortified flashing laminate may also include a layer of adhesive tape covering at least a portion of the bottom surface of the polymeric layer.

Owner:HOLCIM

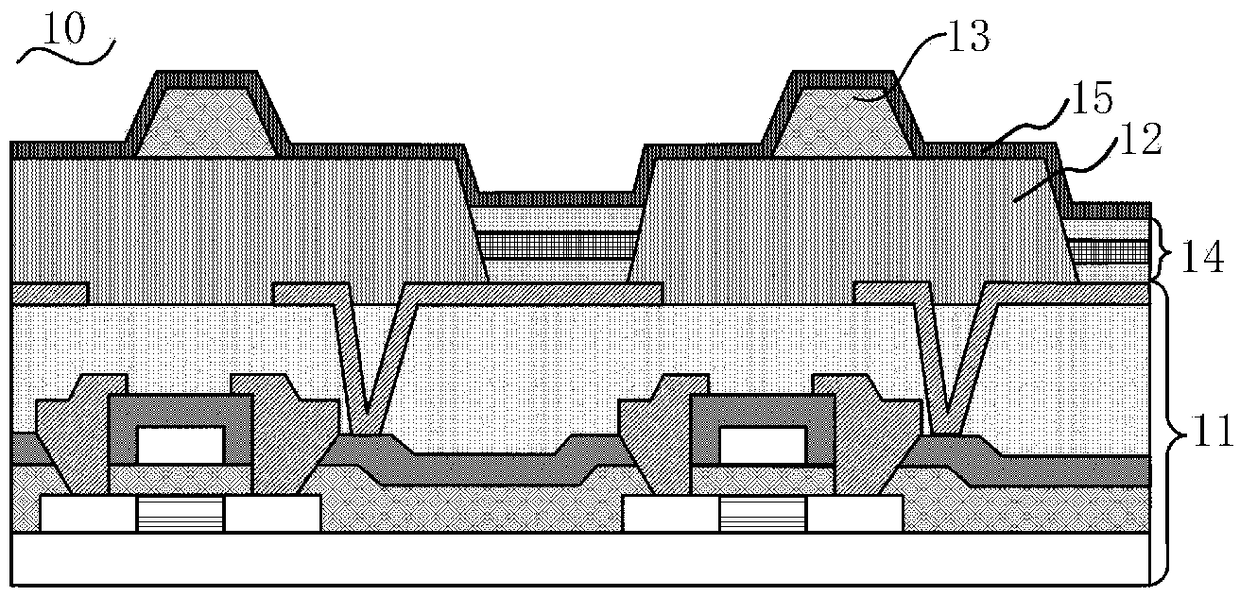

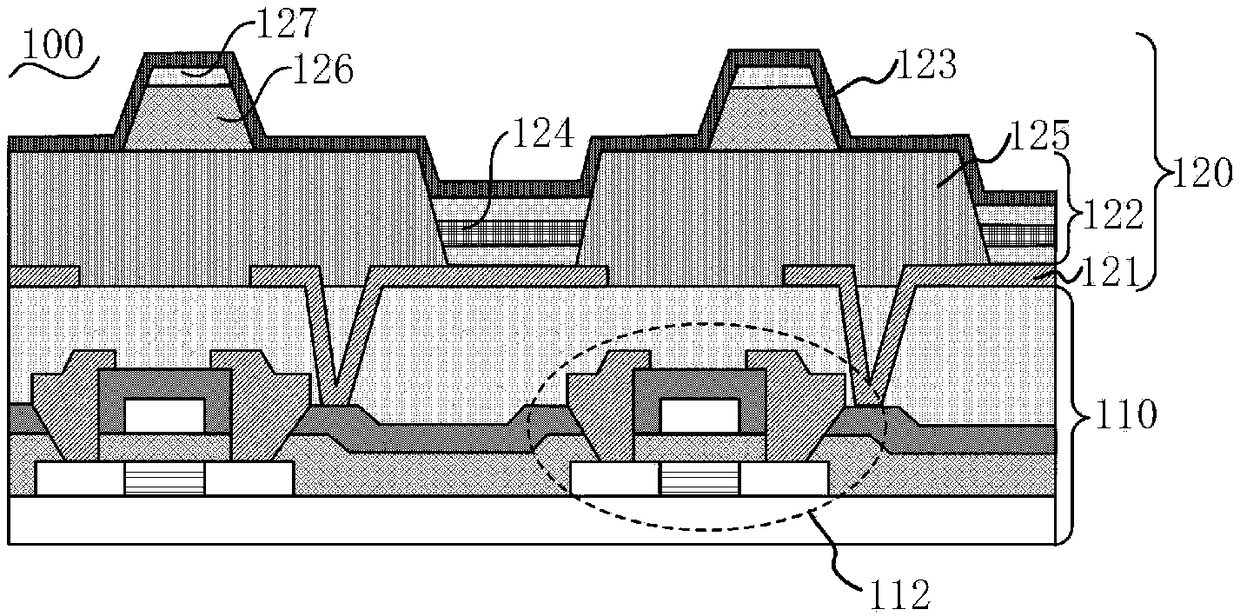

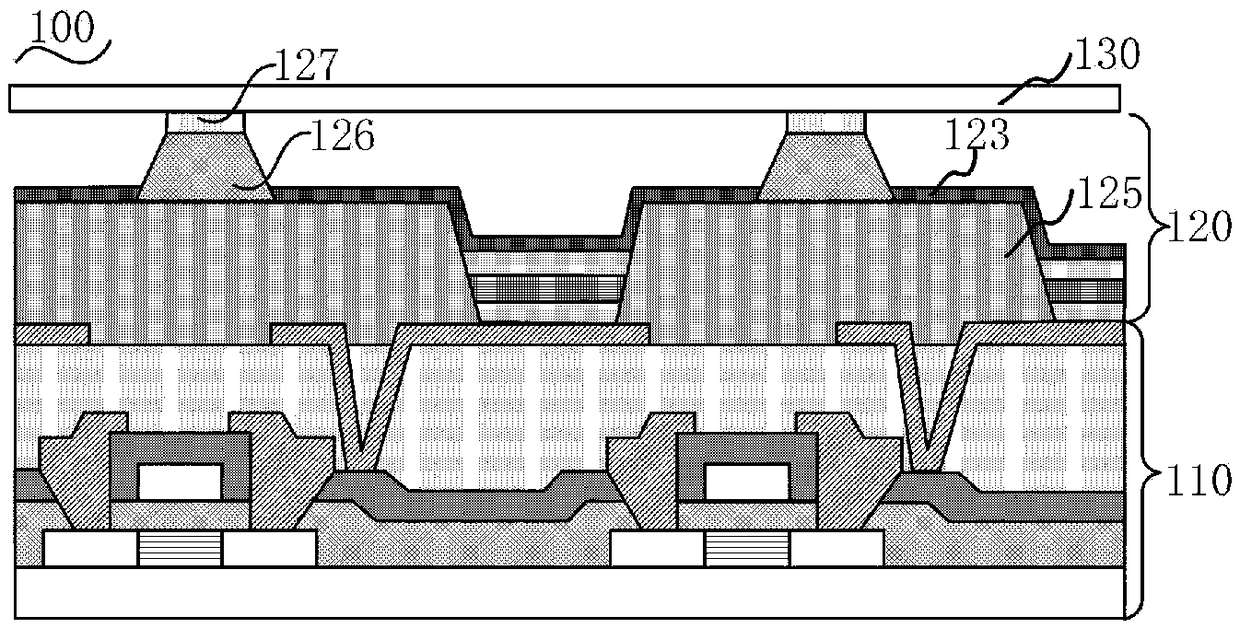

Display panel and display device

InactiveCN109103225AImprove impact resistanceIncrease stressSolid-state devicesSemiconductor devicesDisplay deviceOptoelectronics

The invention relates to a display panel and a display device. The display panel includes an array substrate and a light emitting structure arranged on the array substrate. The light emitting structure includes a first electrode, an organic light emitting layer formed on the first electrode, and a second electrode. The organic light emitting layer includes pixels and a pixel defining layer arranged between adjacent pixels. The light emitting structure further comprises a plurality of support columns and a plurality of buffer structures. Each support column is independently disposed on a surface of the pixel defining layer facing the second electrode, and each buffer structure is correspondingly disposed on a surface of the support column remote from the pixel defining layer. The display panel and the display device can effectively reduce the damage to the luminescent structure layer on the supporting pillar when the display panel is subjected to external impact, can effectively disperse and absorb the instantaneous increased stress on the display panel, increase the impact resistance of the screen, achieve the purpose of protecting the film layer structure under the impact of external force and improve the stress diffusion ability.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

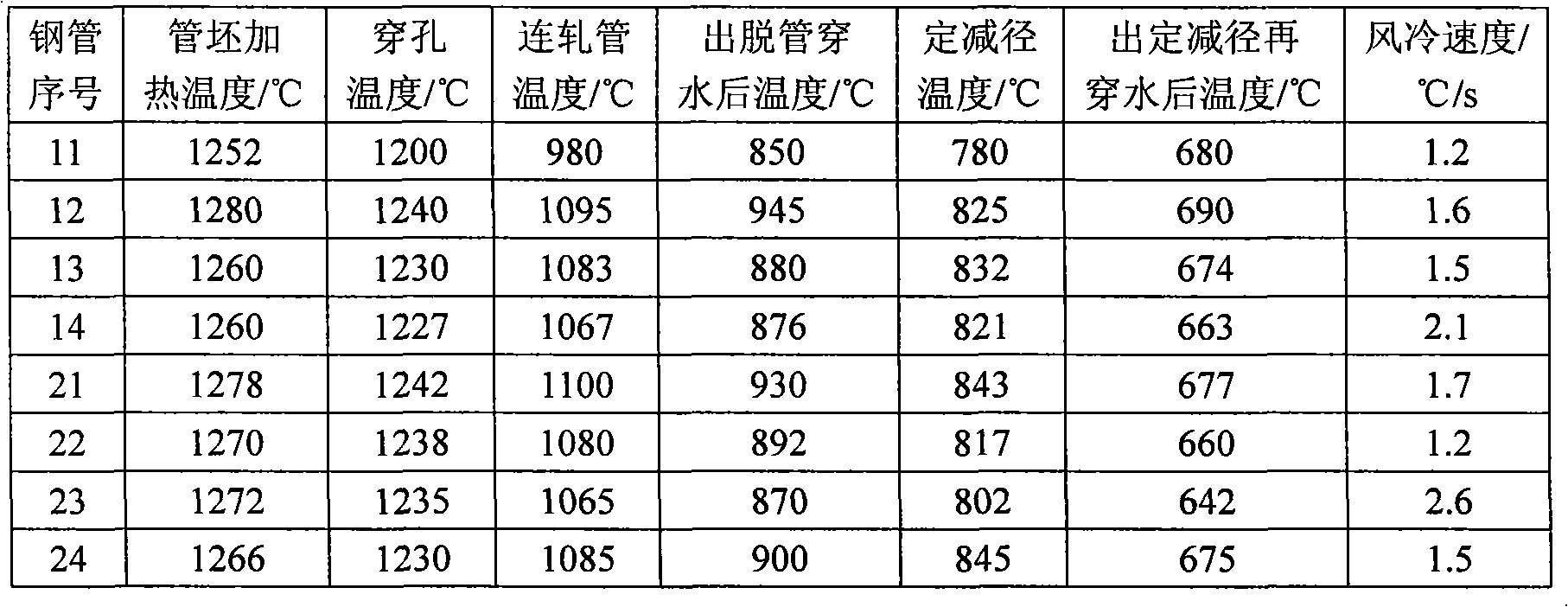

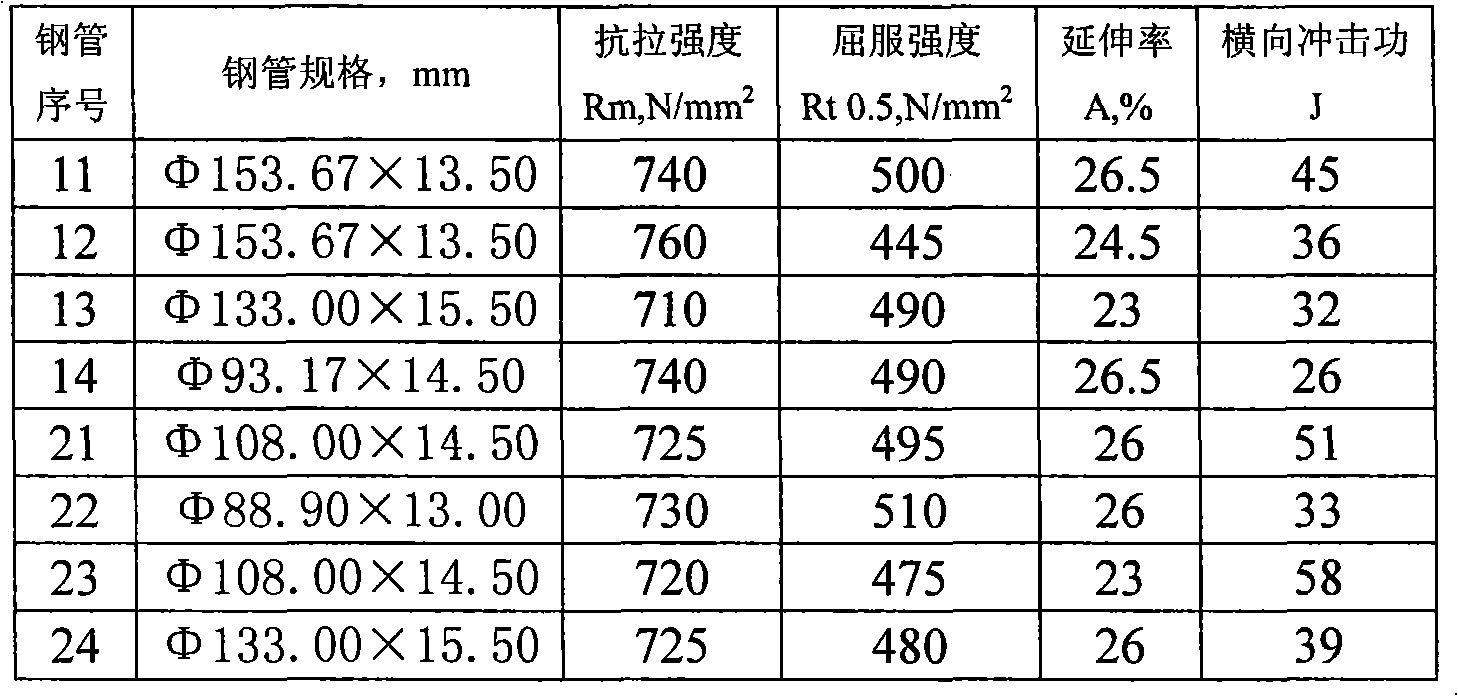

Production method for producing shock toughness of pipe coupling material of hot rolled oil well

ActiveCN101829679AIncrease subcoolingGood mechanical propertiesMetal rolling arrangementsSizingSteel tube

The invention discloses a production method for producing shock toughness of pipe coupling material of a hot rolled oil well. The method comprises the steps of: heating pipe blanks at the temperature of 1250-1280 DEG C, punching at the temperature of 1200-1250 DEG C, and continuously rolling at the temperature of 980-1100 DEG C; quickly cooling to 850-950 DEG C with water after rolling; and then carrying out temperature equilibrium on steel pipes; pressing the steel pipes subject to temperature equalization in a sizing and reducing rolling mill at the temperature of 40-140 DEG C above Ar3; quickly cooling the steel pipes subjected to sizing to the temperature of Ar1 to 70 DEG C above Ar1; and finally, moving the steel pipes to a cooling bed for air cooling. After being continuously rolledand deformed, the steel pipes are quickly cooled with water to an austenite area with lower temperature to inhibit the growth of the crystallized austenite grains; in addition, the two-stage type cooling is carried out after sizing, the increased stress even deformation in the steel pipes caused by the one-stage type forced cooling of the final rolling can be avoided, the recrystallized austenite, the final ferrite and pearlite are fined, the toughness and strength of the steel pipes are both enhanced and the quality rate of the product is enhanced from 43.6% to more than 99%.

Owner:ANGANG STEEL CO LTD

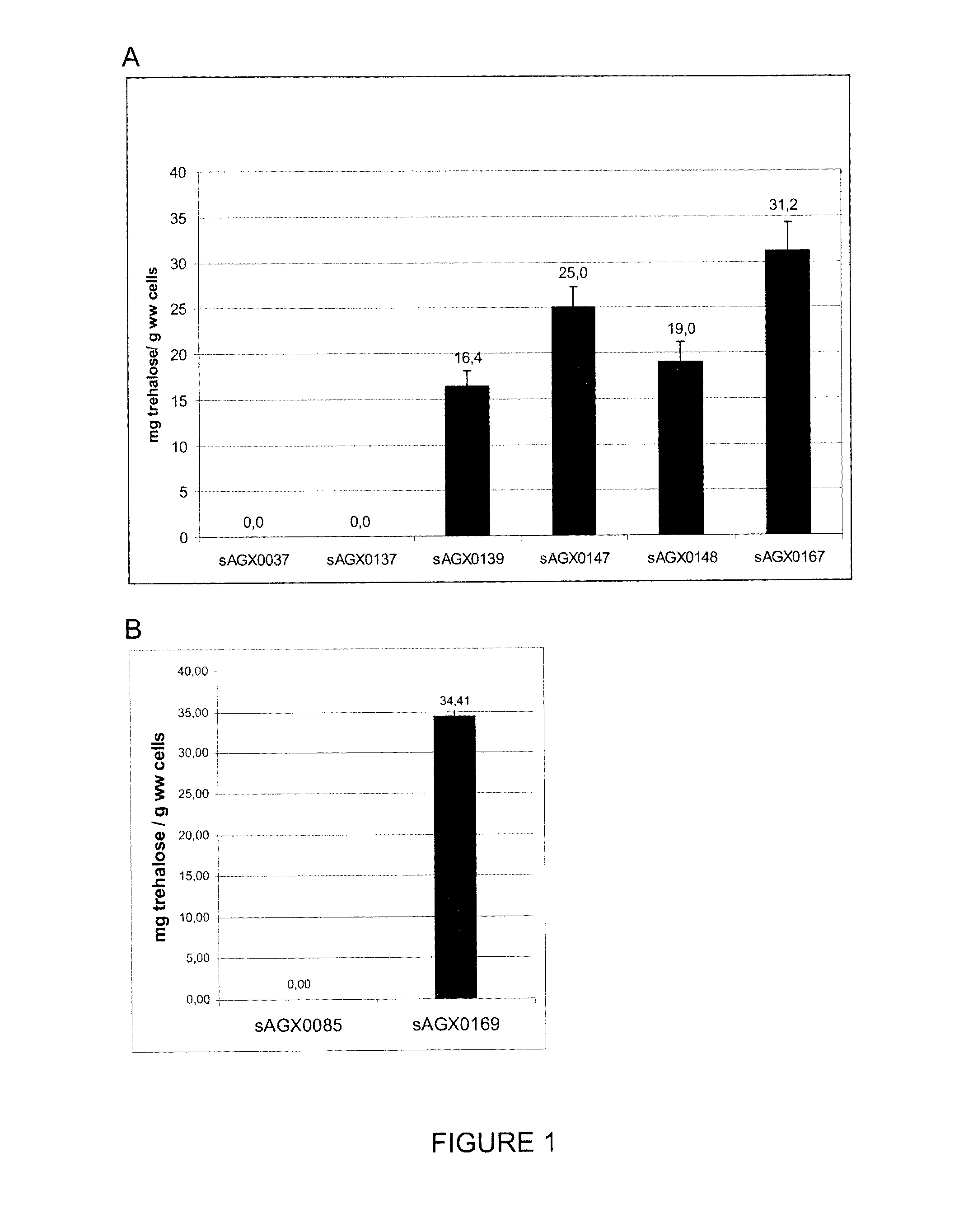

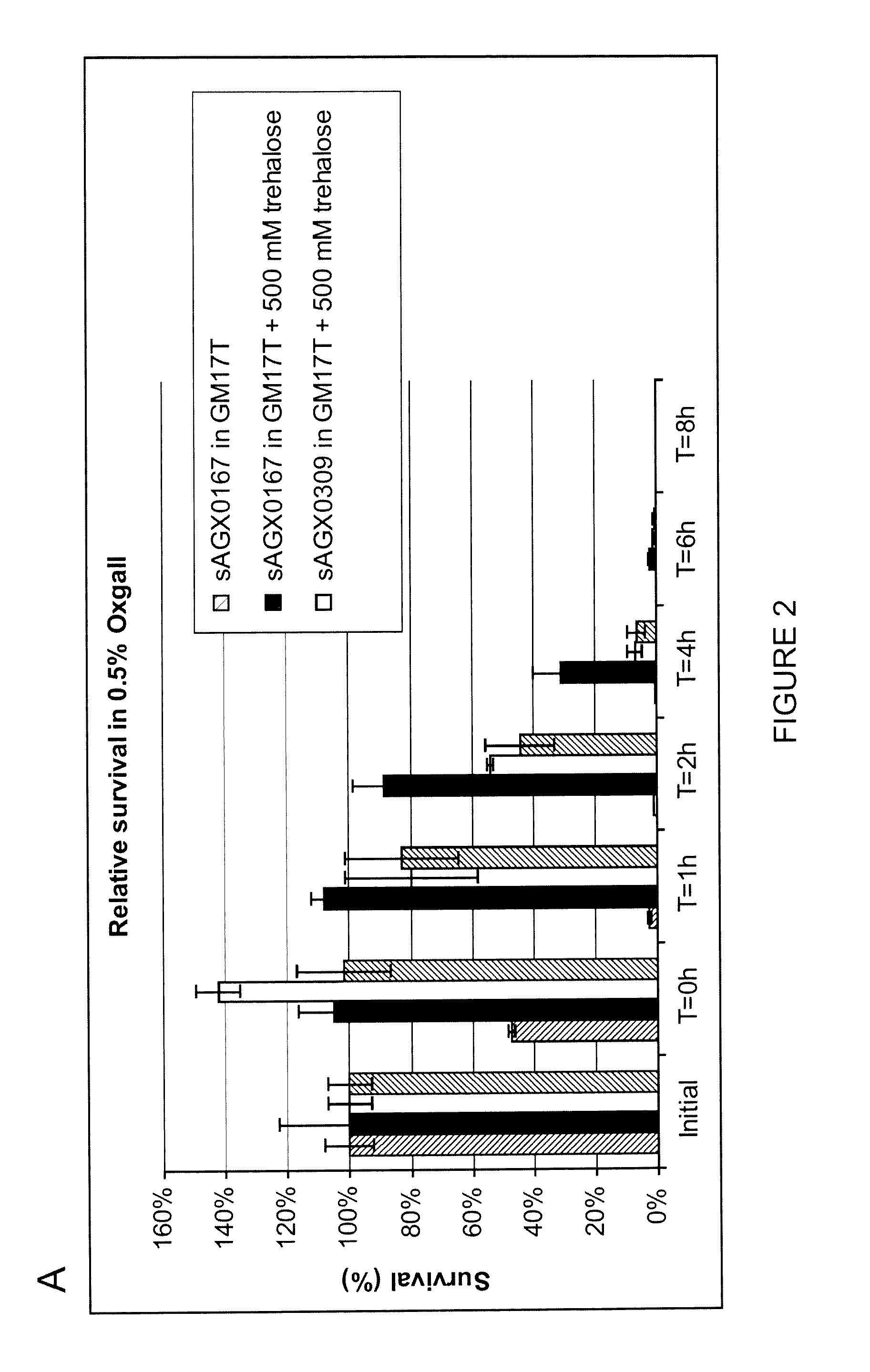

Modified gram positive bacteria and uses thereof

ActiveUS20140234371A1Improve the immunityImprove survivalBiocideBacteriaBifidobacteriumLactic acid bacterium

The present invention relates to a gram positive bacterium, preferably a lactic acid bacterium (LAB) or Bifidobacterium, with increased stress resistance and / or improved manufacturing, processing and / or storage characteristics. In particular, the invention relates to a gram positive bacterium which accumulate intracellular trehalose. The gram positive bacterium according to the invention lack trehalose 6-phosphate phosphorylase (TrePP) activity. The gram positive bacterium may further lack cellobiose-specific PTS system IIC component (ptcC) activity. The gram positive bacterium may further overexpress trehalose transporters. The invention further relates to compositions comprising such gram positive bacterium as well as methods and uses thereof.

Owner:INTREXON ACTOBIOTICS NV

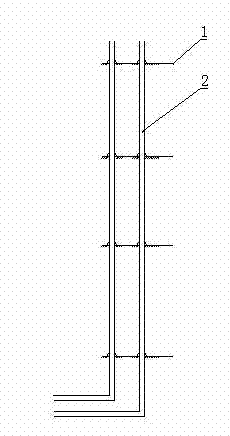

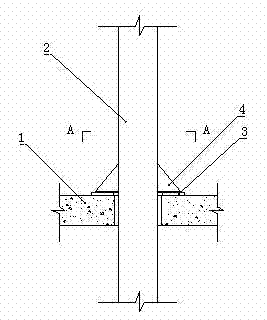

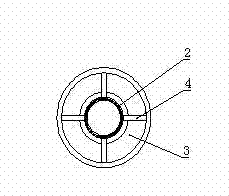

Slideable annular tray bracket mounting structure of large-diameter stand pipe

The invention relates to a slideable annular tray bracket mounting structure of a large-diameter stand pipe. The structure comprises a metal pipeline vertically penetrating through each floor of a high-rise building, and is characterized by also comprising multiple annular trays vertically arranged on the floorslab of each floor at intervals; the metal pipeline passes through the centers of the annular trays; multiple triangular support steel plates in radial distribution are uniformly distributed on the upper end surfaces of the annular trays; and the support steel plates are fixedly welded with the side wall of the metal pipeline. The annular trays are placed on the floorslab of each floor, the metal pipe is firmly welded with the triangular support steel plates, and the weight of the metal pipeline is transferred to the concrete floorslab through a tray bracket. Thus, the increased stress is not directly transferred to a basement horizontal U-steel bracket to cause damage. Since the trays are not fixed with the floor, the pipeline can freely extend upward for sure, and particularly after use, the metal pipeline with relatively great extension amount for storing and transporting cold / hot medium can be fixed in the floor.

Owner:JIANGSU JIANGZHONG GROUP

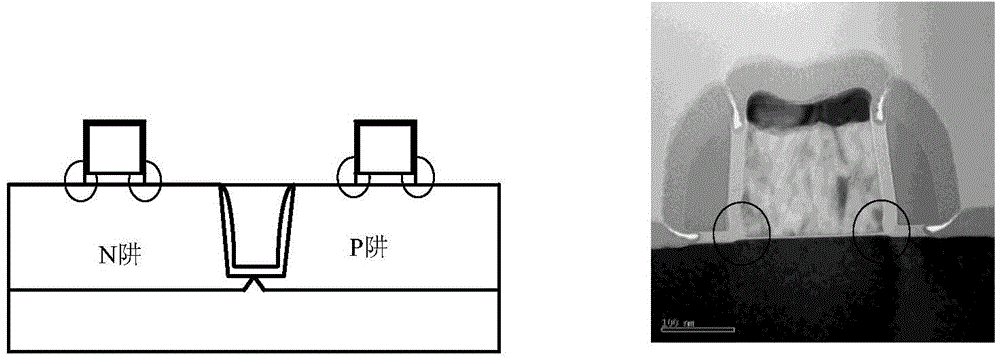

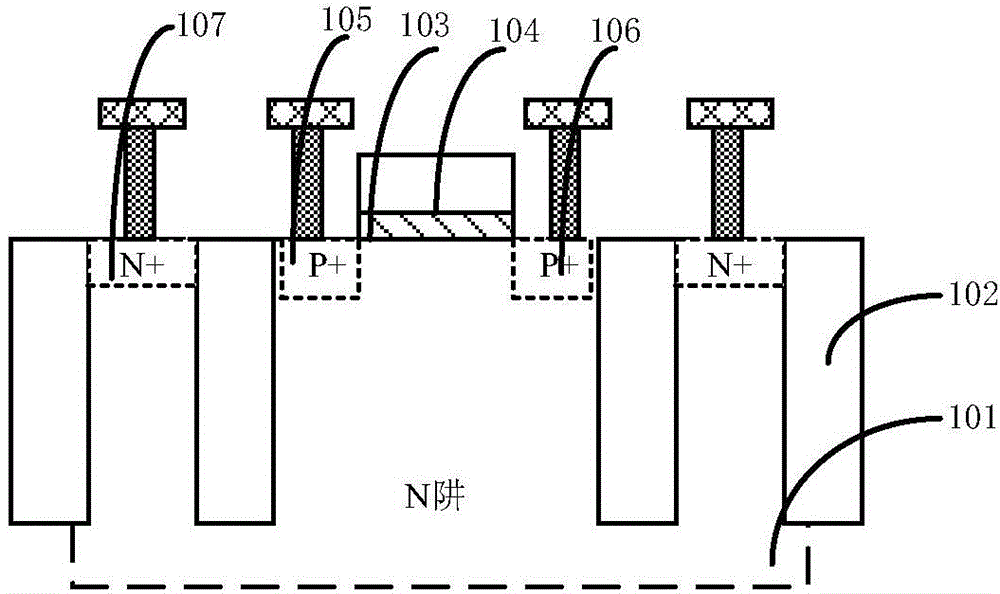

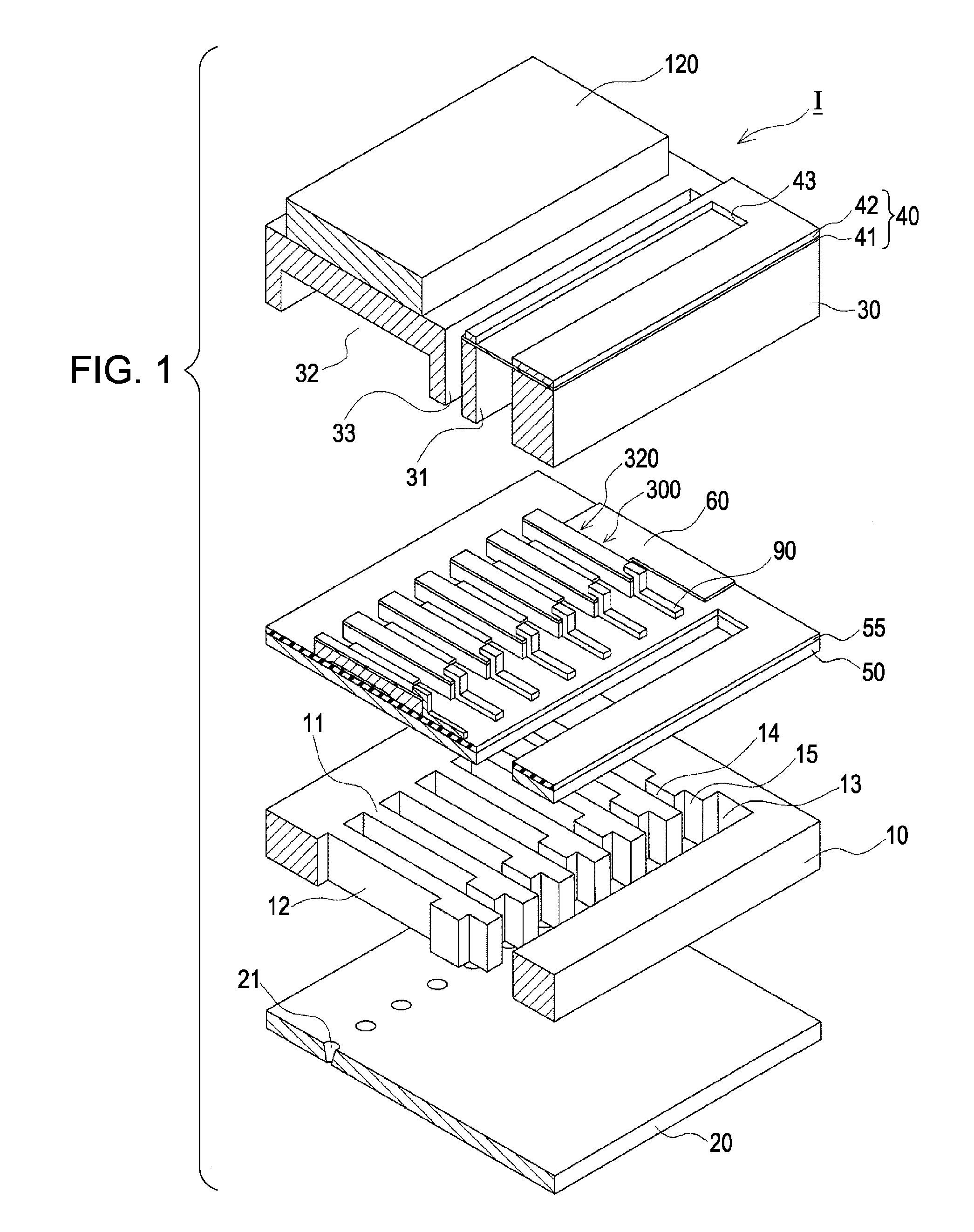

Test structure and test method for gate oxide integrity

ActiveCN105097782AReduce layout areaEvaluate Damage EfficientlySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsGate oxideSemiconductor

The invention relates to a test structure and a test method for gate oxide integrity. The test structure comprises the components of a semiconductor substrate on which an N well and a P well are separately formed; a gate electrode structure which comprises a gate oxide and a gate electrode, wherein the gate structure is partially arranged above the N well and is partially arranged above the P well; and a source region and a drain region which are respectively arranged in the N well and the P well at two sides of the gate electrode structure, wherein a gradually increased stress voltage is applied on the gate electrode structure. The test structure can effectively evaluate device damage of the gate electrode in a patterning process. Not only is detecting efficiency improved, but also the area of the test structure can be further reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP

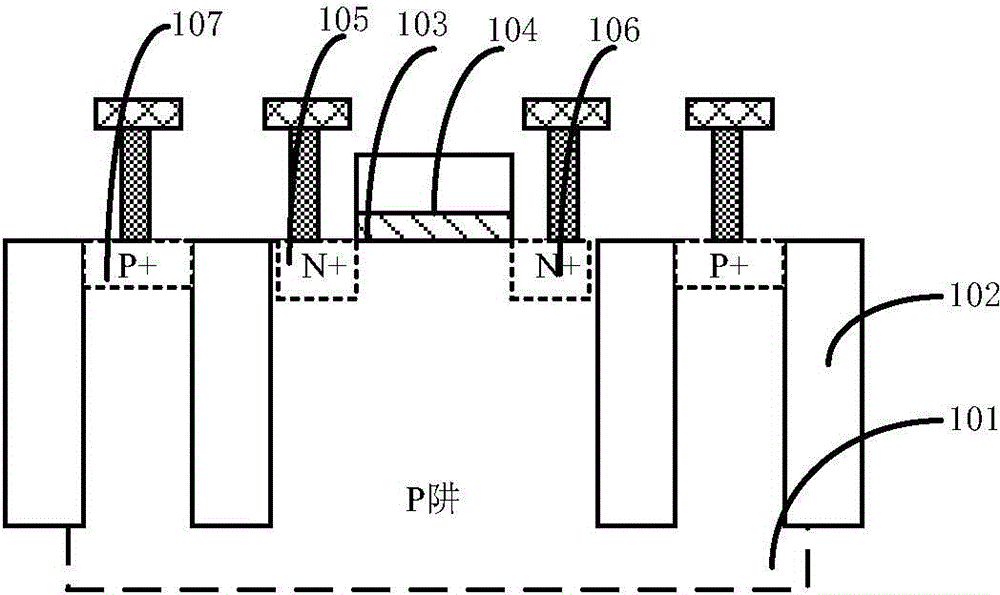

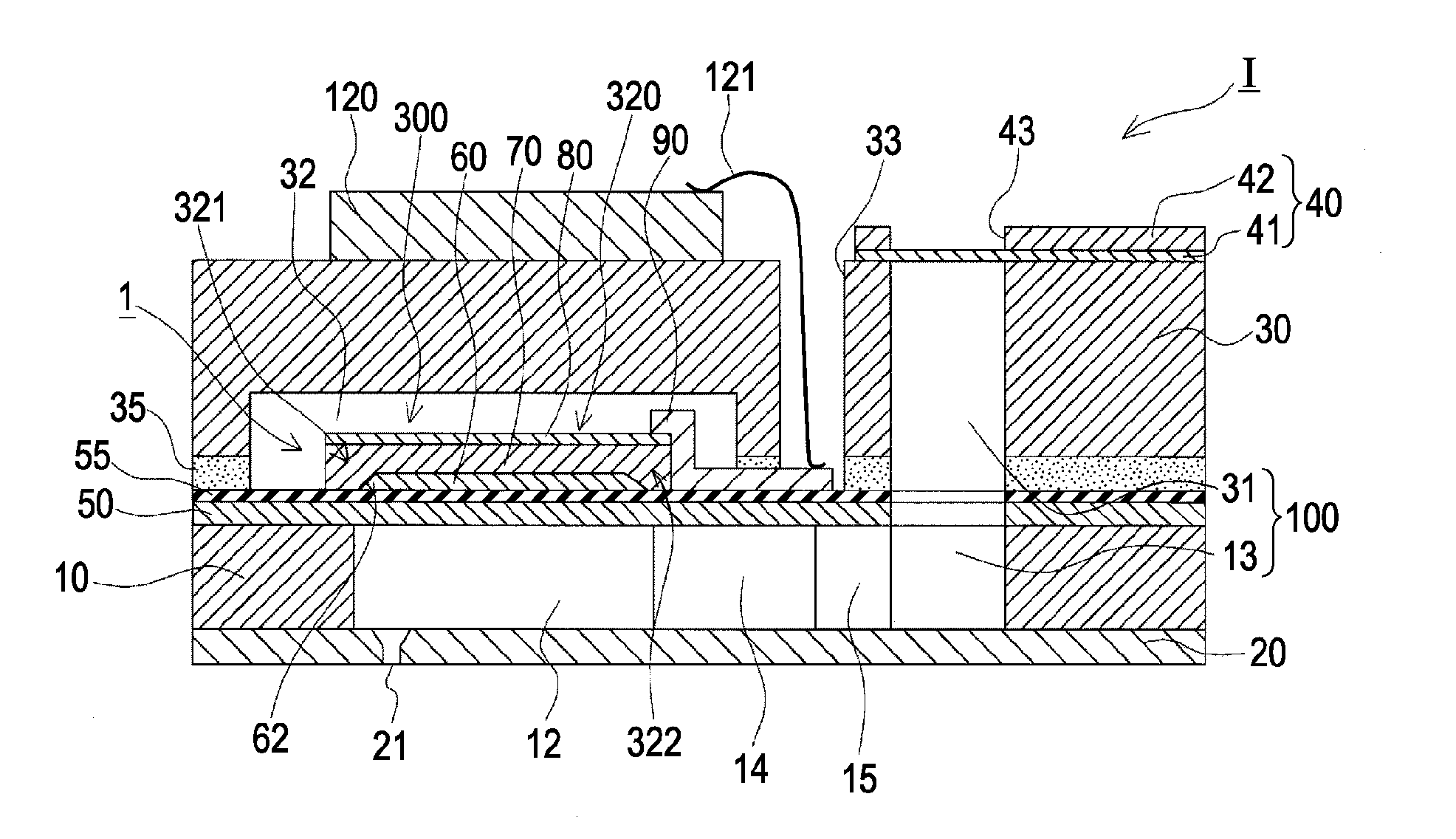

Actuator device and liquid ejecting head including the same

ActiveUS20080170107A1Improve stress resistanceHigh strengthInking apparatusPiezoelectric/electrostriction/magnetostriction machinesEngineeringActuator

An actuator device includes a piezoelectric element including a lower electrode, a piezoelectric layer, and an upper electrode that are displaceably provided in sequence on a substrate. The lower electrode includes a flat center portion and an inclined end portion that descends toward the substrate. The piezoelectric layer is disposed above the lower electrode and the substrate, and includes a first, second, and third piezoelectric layer portion constituted by a plurality of columnar crystals. The columnar crystals of the first and second piezoelectric layer portions are orthogonal to the flat portion of the lower electrode and surface of the substrate, while the columnar crystals of the third piezoelectric layer portion extend orthogonally from a surface of the inclined portion and bend to be orthogonal to the surface of the upper electrode, giving the grains of the columnar crystals of the third piezoelectric layer portion larger widths and increased stress resistance.

Owner:SEIKO EPSON CORP

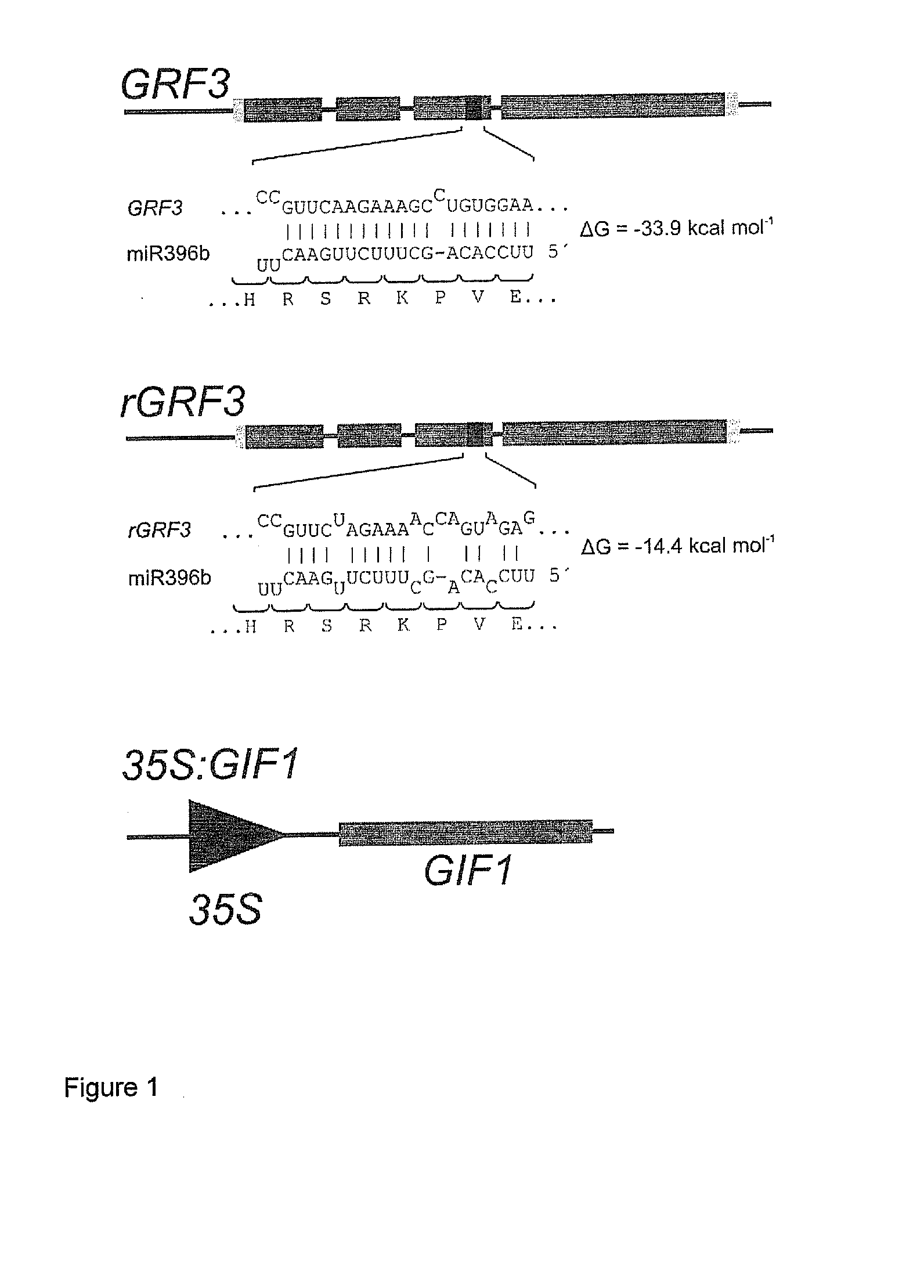

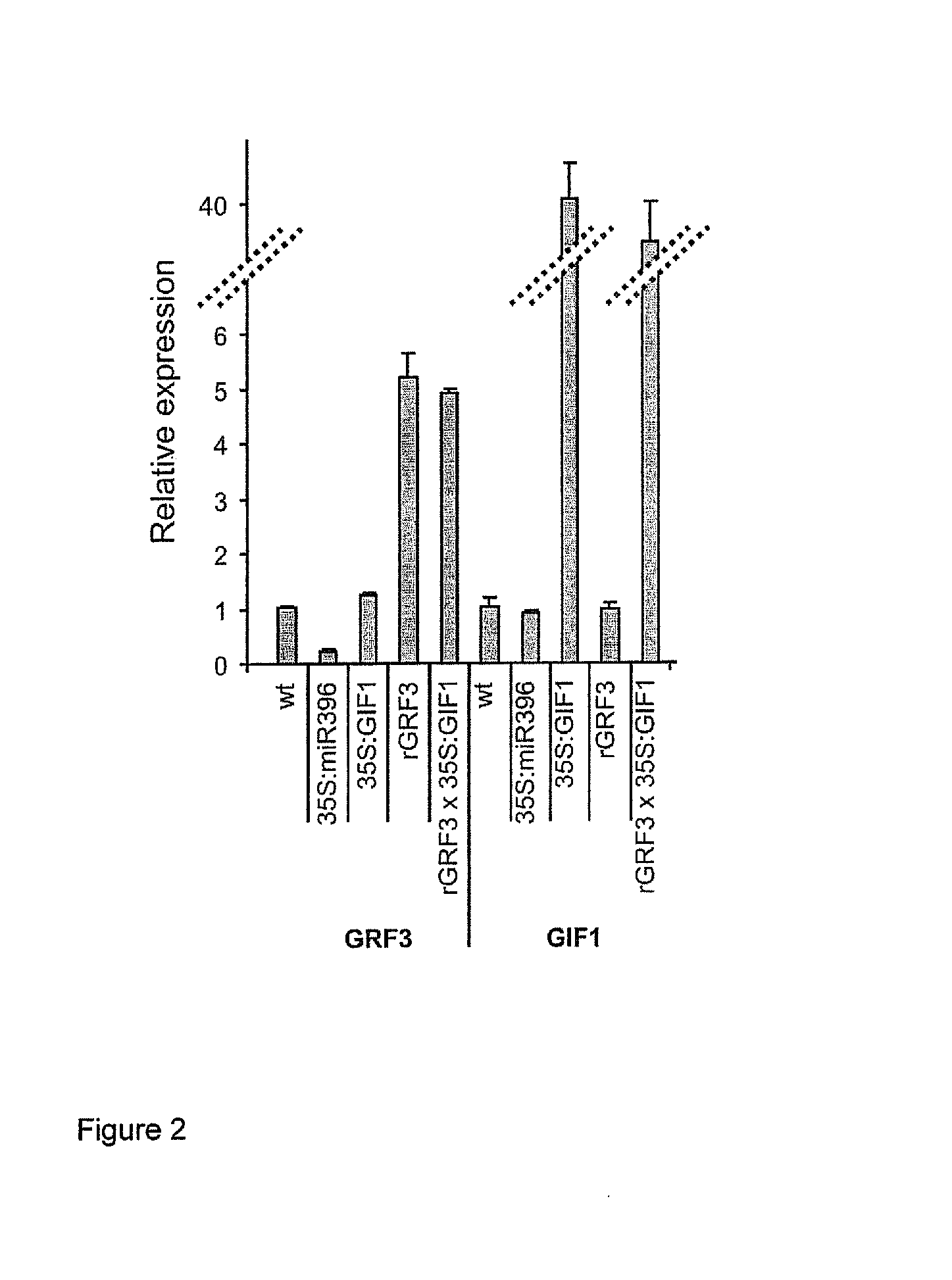

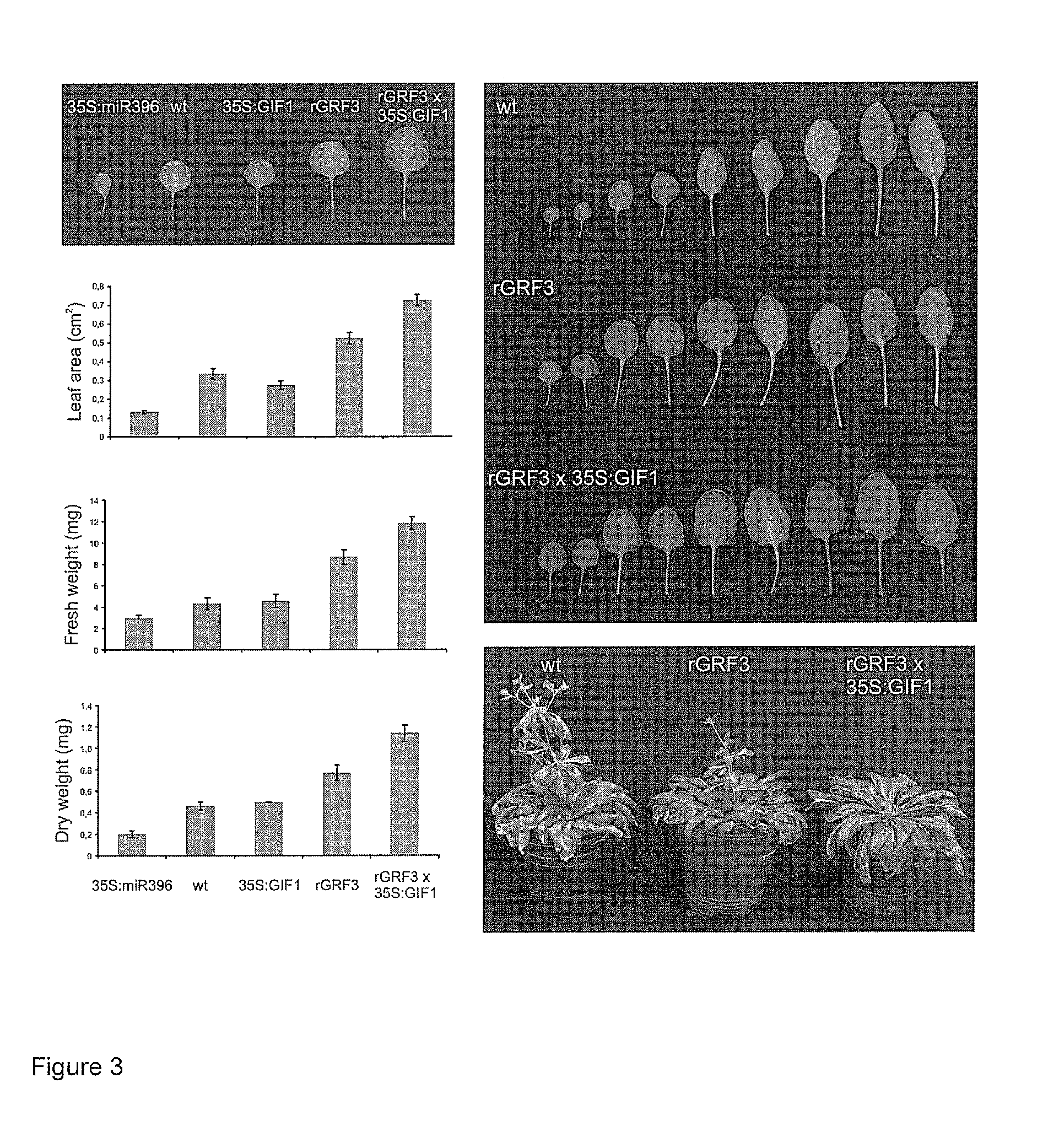

GRF3 Mutants, Methods and Plants

ActiveUS20150033413A1Increase productivityHigh yieldSugar derivativesClimate change adaptationRoot growthMutant

The present disclosure provides a novel modified gene, rGRF3, or an orthologue thereof, which is shown to be decoupled from control by miR396, particularly in the presence of over-expression of at least one GIF gene, such as GIF1, AtGIF 2, AtGIF 3, Os11g40100, Os12g31350, Os03g52320 or combinations thereof. When present in a plant, the rGRF3 results in a phenotype of increased productivity (e.g. increased yield, increased biomass, increased stress resistance, increased seed production, increased seed yield, increased root growth, increased root elongation speed, delayed leaf senescence or increased drought tolerance and combinations thereof).

Owner:UNIV NACIONAL DE ROSARIO +1

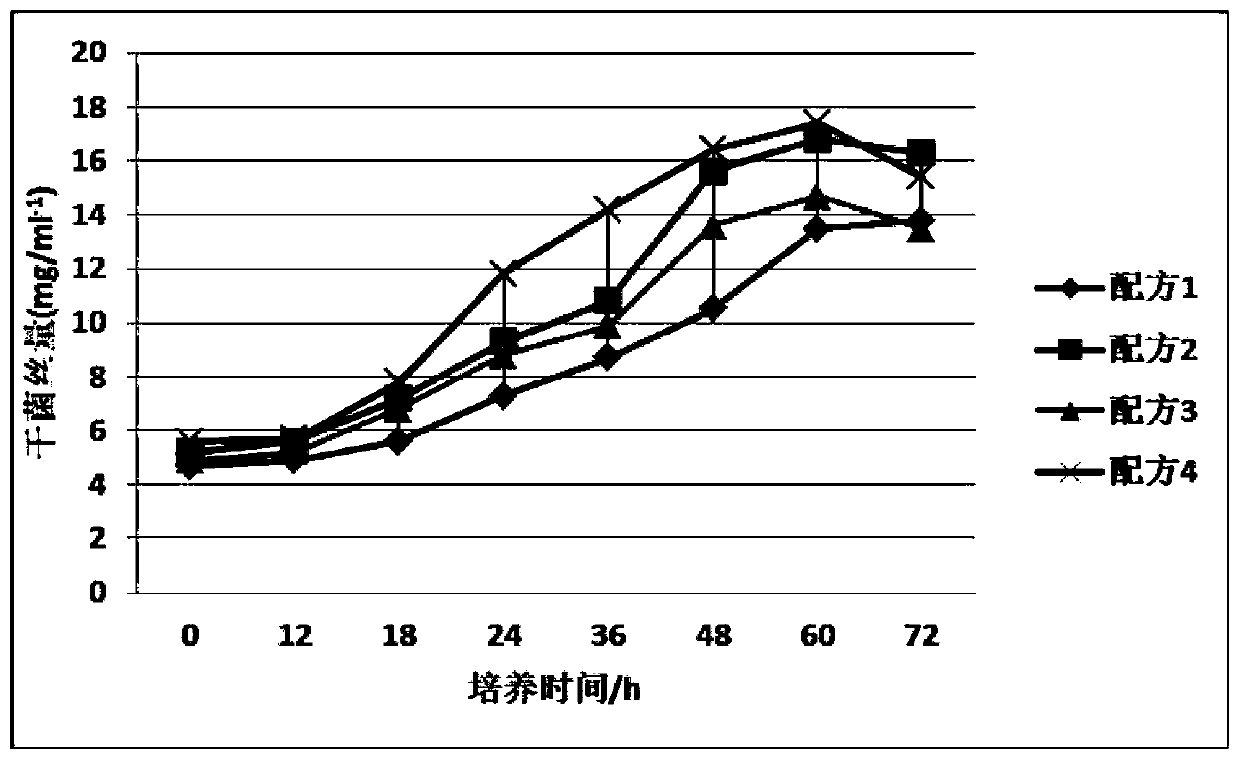

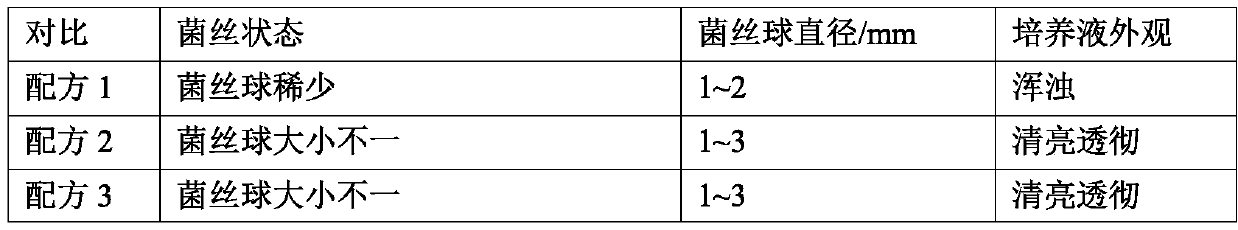

Straw mushroom culture method

ActiveCN110214626AIncrease productionIncrease fruiting rateCultivating equipmentsMushroom cultivationBiotechnologyMushroom

The invention discloses a straw mushroom culture method, which respectively improves a fermentation culture medium and a cultivation culture material of the straw mushroom, reduces the shrinkage rateof the straw mushroom and the death rate of young mushrooms through combination of a plurality of ways, and finally cultivates the straw mushroom with high protein content, increased yield, high fruiting rate, increased stress resistance, less contamination of miscellaneous bacteria and accelerated growth speed.

Owner:灌南县人民政府蔬菜办公室 +1

Composition with increased stress cracking resistance

InactiveUS8227549B2Improved stress crack resistanceImprove heat deformation resistanceInksOrganic dyesCrack resistanceMeth-

Owner:EVONIK ROEHM GMBH

Fortified flashing laminate

ActiveUS8567143B2Roof coveringSynthetic resin layered productsMechanical engineeringIncreased stress

A fortified flashing laminate including a polymeric layer having an uncured portion and a cured portion forming a fortified area. The fortified area strengthens the flashing laminate at an area of known vulnerability or increased stress to prevent damage to the flashing laminate during installation and prior to curing of the remainder of the polymeric layer. The fortified flashing laminate may also include a layer of adhesive tape covering at least a portion of the bottom surface of the polymeric layer.

Owner:HOLCIM TECHNOLOGY LTD

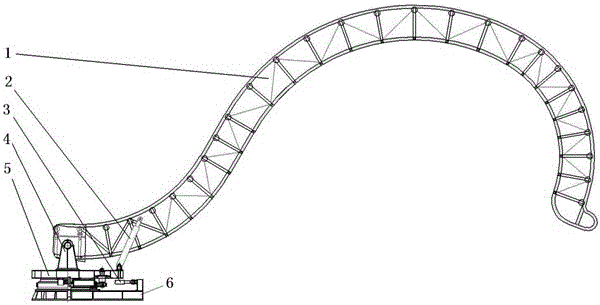

Hydraulic submarine cable cable-passing bridge frame

The invention relates to a hydraulic submarine cable cable-passing bridge frame which is composed of a bridge frame body, an amplitude-changing oil cylinder, a rotation oil cylinder, a cable-passing bridge frame hinged seat and a self-rotating type pedestal. The bridge frame body is connected with the self-rotating type pedestal via the cable-passing bridge frame hinged seat, and the bridge frame body and the cable-passing bridge frame hinged seat are connected in a rotating way along a vertical direction of a bridge frame axis. The amplitude-changing oil cylinder is connected between the bridge frame body and the self-rotating type pedestal. The rotation oil cylinder is connected between the self-rotating type pedestal 5 and a pedestal. With combination of a self-rotating type cable-bearing disc, stress of a submarine cable can be released via movement of the cable-passing bridge frame during the laying process of the submarine cable, and damage generated by suddenly increased stress on the submarine cable during the construction process is ensured to be avoided.

Owner:SHANGHAI FOUND ENG GRP

Method of producing a dental restoration

InactiveUS20150230896A1Increased Design FreedomSmall diameterProgramme controlWorkpiecesMachine partsEngineering

The present invention relates to a method of producing a dental restoration from a partially-sintered or non-sintered blank using a three-dimensional dental restoration model, comprising the steps of: generating at least one or more first milling path for rough and / or fine milling; determining areas or zones of increased stress in the three-dimensional dental restoration model and generating at least one modified milling path; machining the blank by milling utilising one or more first milling paths; selectively machining parts of the blank utilising at least one modified milling path; and sintering the machined blank.

Owner:3M INNOVATIVE PROPERTIES CO

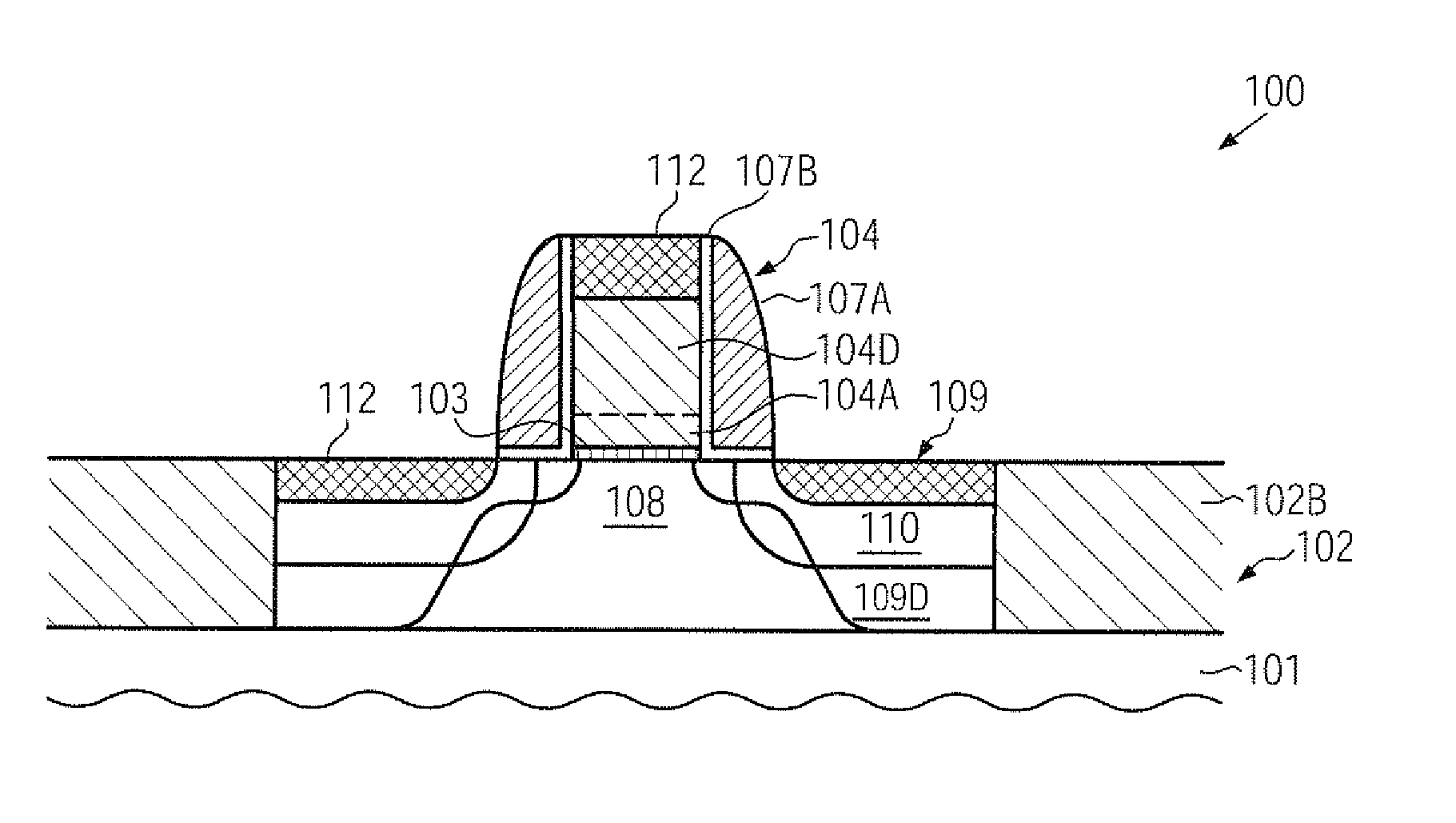

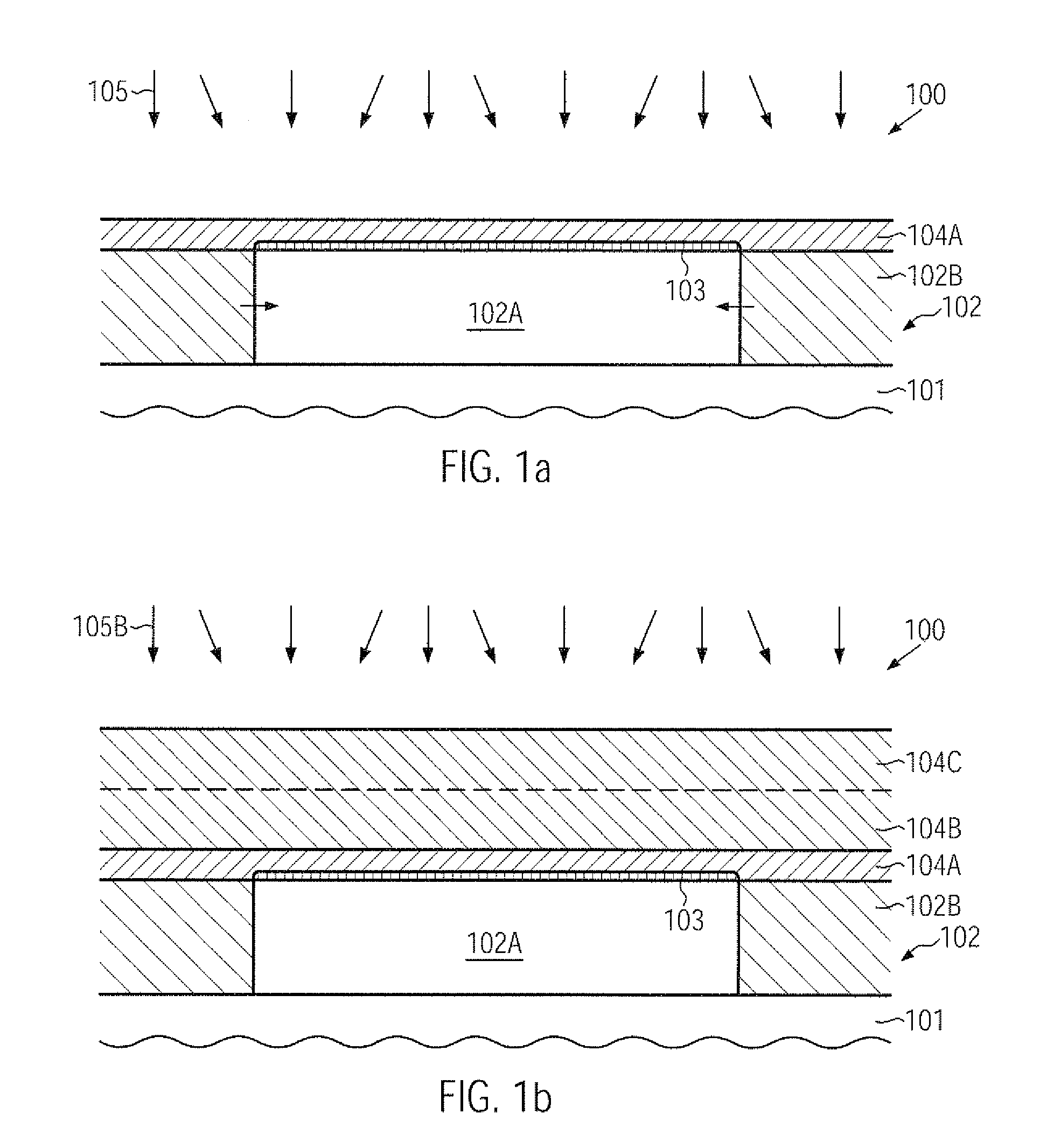

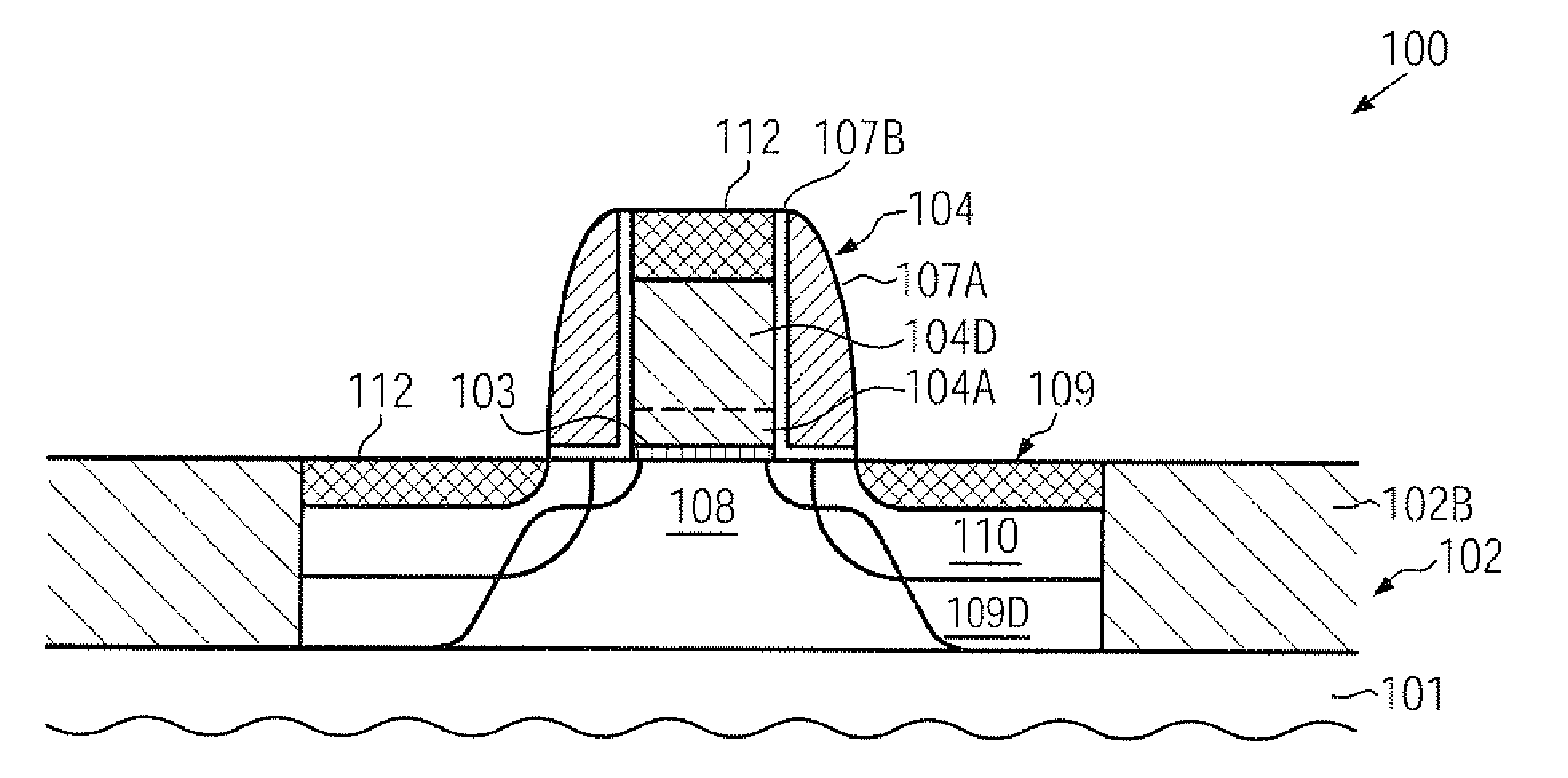

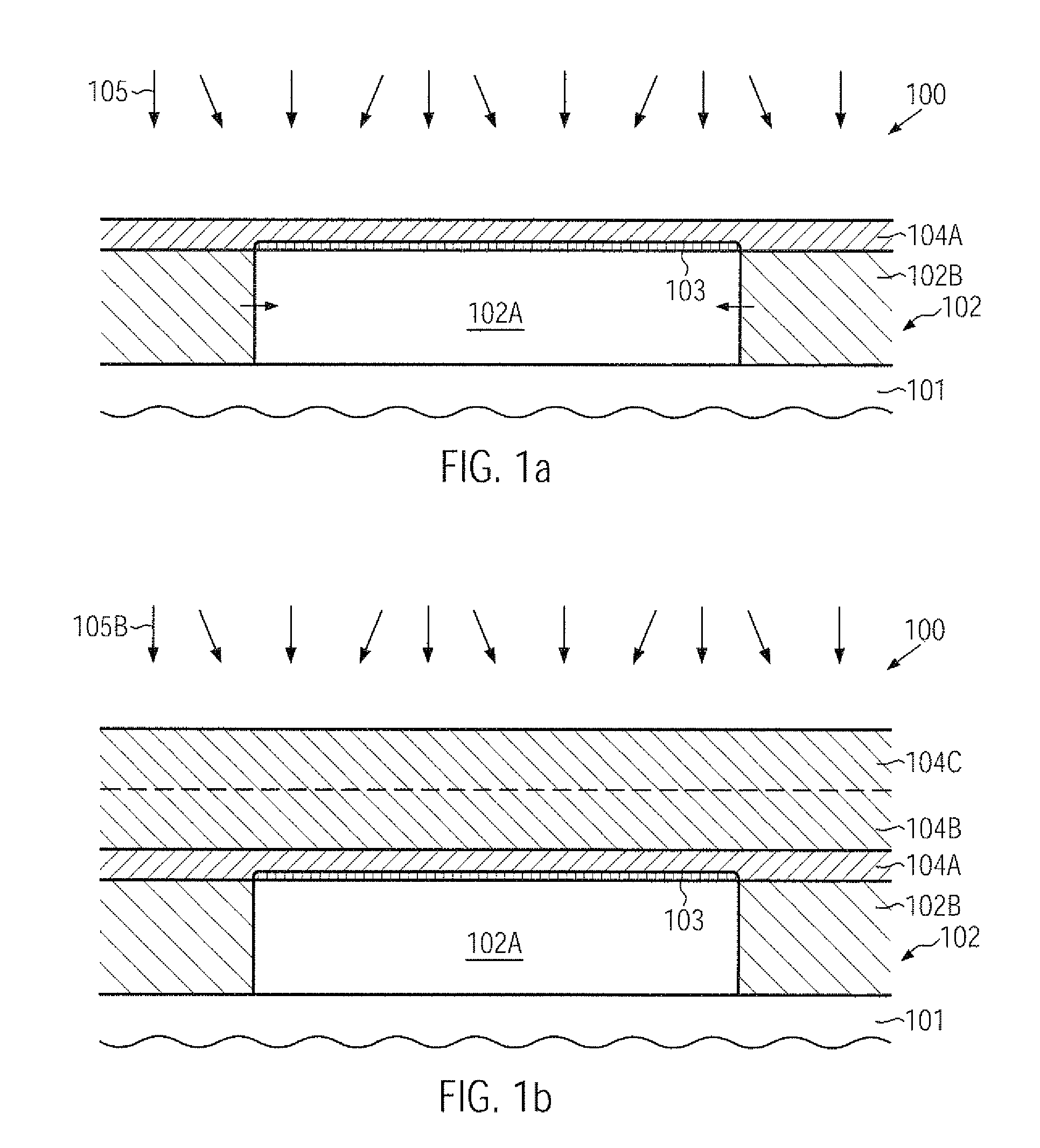

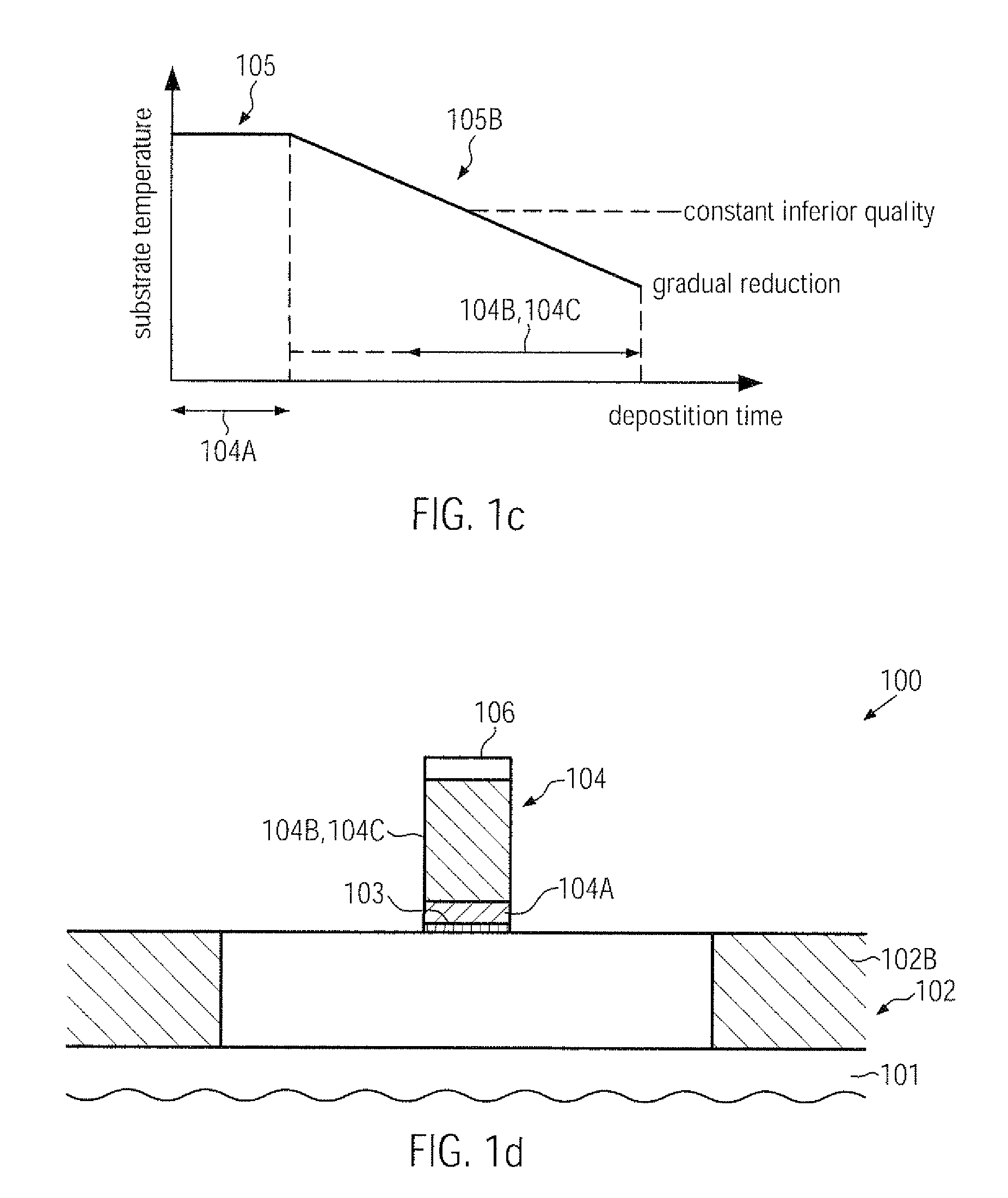

Stress transfer enhancement in transistors by a late gate re-crystallization

InactiveUS20100109012A1Enhanced transistor performanceEfficient stress transferTransistorSemiconductor/solid-state device manufacturingGate dielectricEngineering

A gate electrode structure of a transistor may be formed so as to exhibit a high crystalline quality at the interface formed with a gate dielectric material, while upper portions of the gate electrode may have an inferior crystalline quality. In a later manufacturing stage after implementing one or more strain-inducing mechanisms, the gate electrode may be re-crystallized, thereby providing increased stress transfer efficiency, which in turn results in an enhanced transistor performance.

Owner:GLOBALFOUNDRIES INC

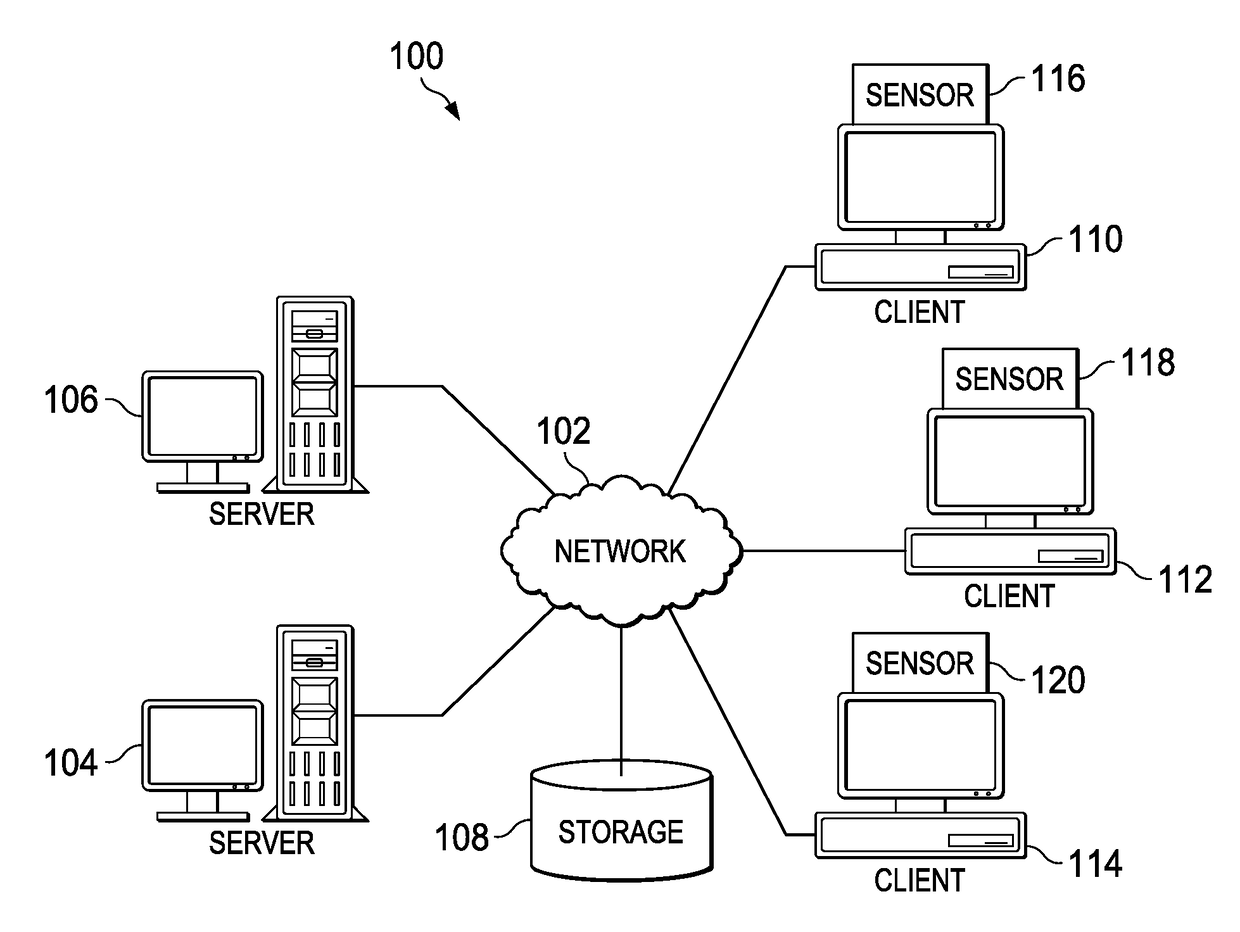

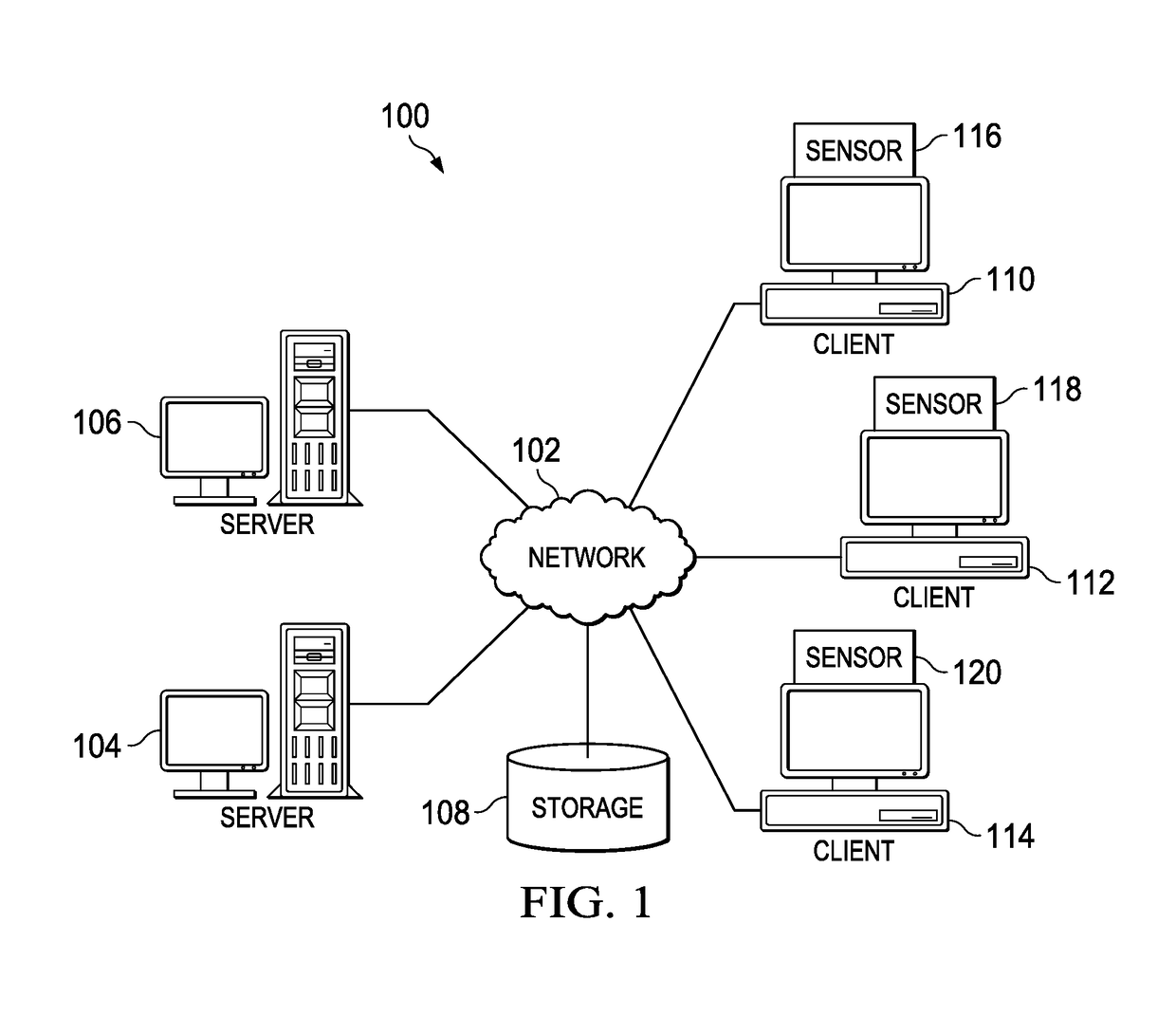

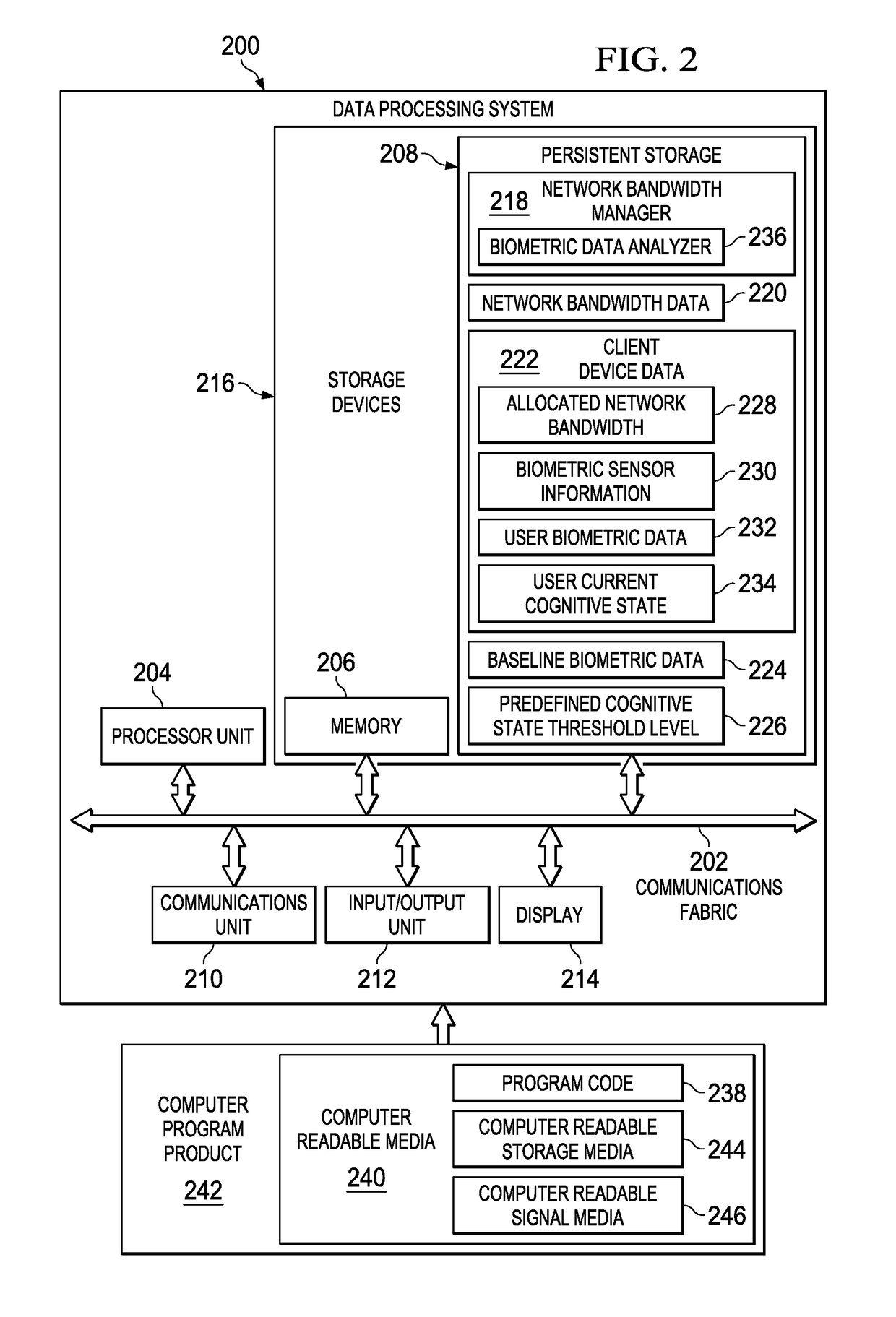

Adjusting Network Bandwidth Based on an Analysis of a User's Cognitive State

ActiveUS20180041448A1Increased stress levelsImprove the level ofParticular environment based servicesWireless commuication servicesStress levelCognitive status

Adjusting network bandwidth is provided. An indication that a client device corresponding to a user is using a level of bandwidth of a network that the computer and client device are connected to is received. An indication via a set of biometric sensors communicatively coupled to the client device that the user is experiencing an increased stress level also is received. The level of bandwidth allocated to the client device of the user is increased based on the received indication that the user is experiencing the increased stress level.

Owner:KYNDRYL INC

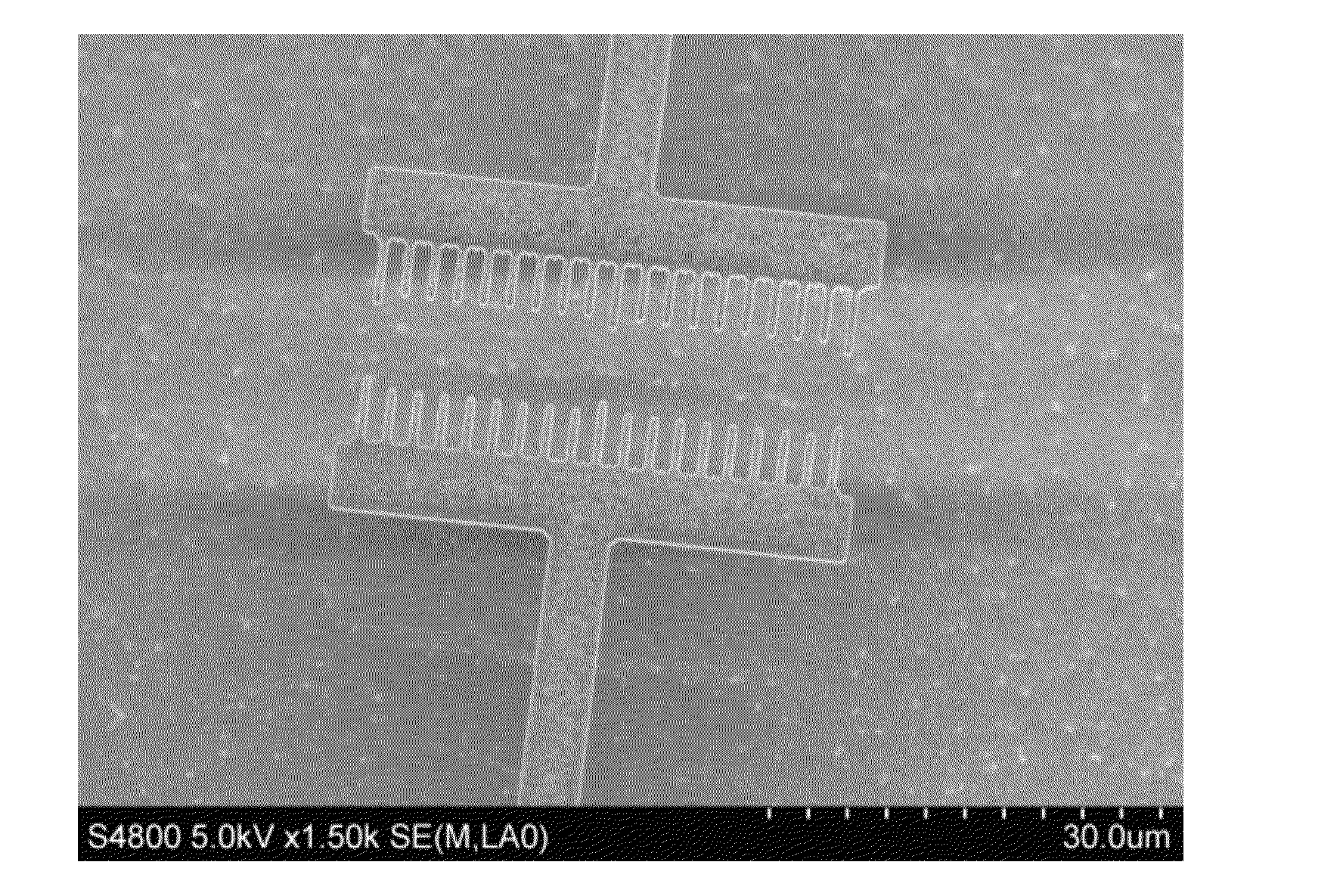

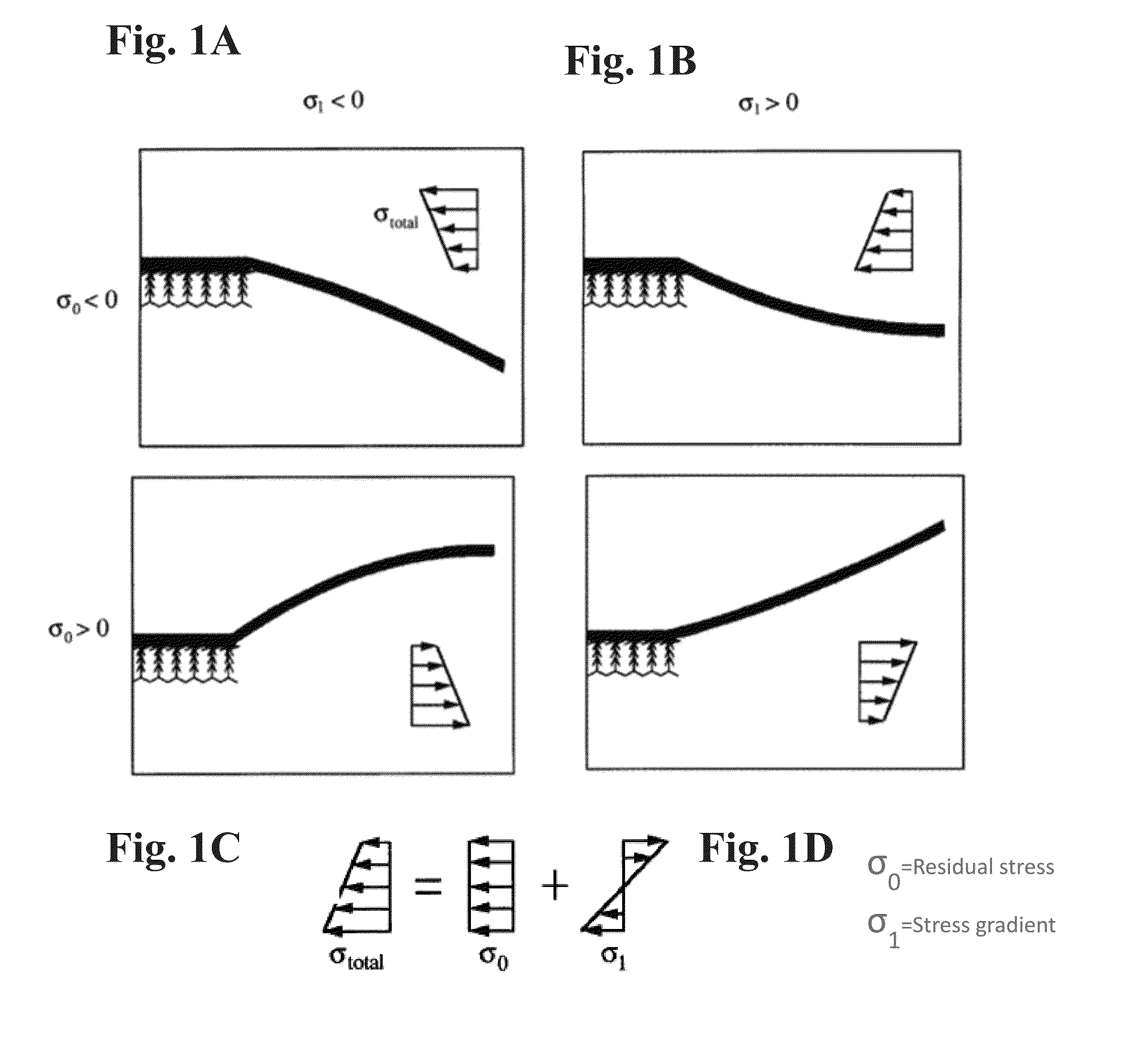

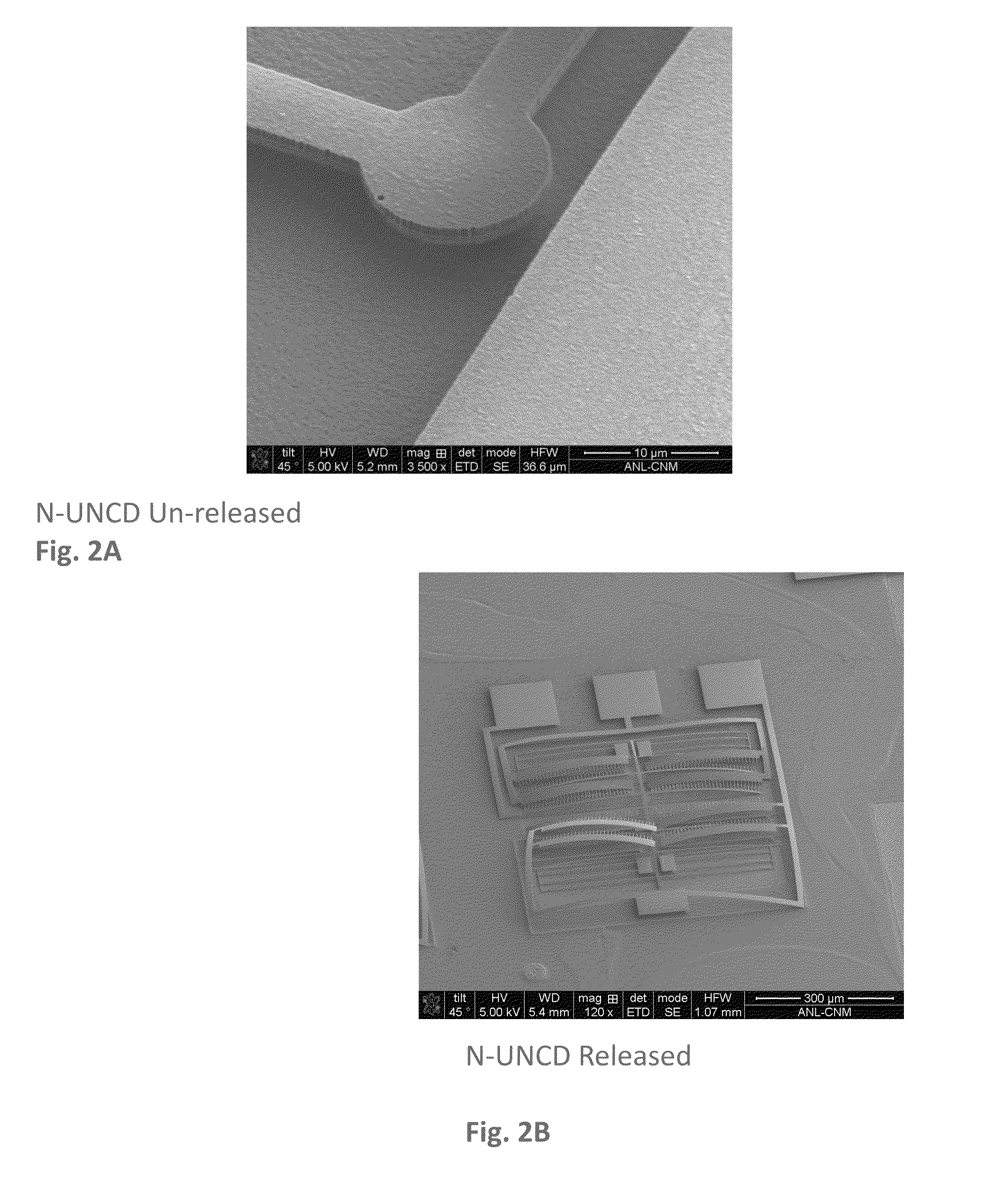

Low-stress doped ultrananocrystalline diamond

Nanocrystalline diamond coatings exhibit stress in nano / micro-electro mechanical systems (MEMS). Doped nanocrstalline diamond coatings exhibit increased stress. A carbide forming metal coating reduces the in-plane stress. In addition, without any metal coating, simply growing UNCD or NCD with thickness in the range of 3-4 micron also reduces in-plane stress significantly. Such coatings can be used in MEMS applications.

Owner:UCHICAGO ARGONNE LLC

Coloured composition with increased stress cracking resistance

InactiveUS8178624B2Improved stress crack resistanceImprove heat deformation resistanceOrganic dyesCeramic shaping apparatusCrack resistanceMeth-

Owner:EVONIK ROEHM GMBH

Stress transfer enhancement in transistors by a late gate re-crystallization

InactiveUS8198633B2Low efficiencyEfficient transferTransistorSemiconductor/solid-state device manufacturingGate dielectricEngineering

A gate electrode structure of a transistor may be formed so as to exhibit a high crystalline quality at the interface formed with a gate dielectric material, while upper portions of the gate electrode may have an inferior crystalline quality. In a later manufacturing stage after implementing one or more strain-inducing mechanisms, the gate electrode may be re-crystallized, thereby providing increased stress transfer efficiency, which in turn results in an enhanced transistor performance.

Owner:GLOBALFOUNDRIES INC

Chick feed

InactiveCN107751555AImprove stress resistanceEnhance the immune function of the bodyAnimal feeding stuffAccessory food factorsAnimal scienceWheat flour

The invention discloses a chick feed, which is made of the following materials: corn flour, wheat flour, bone meal, fish meal, stone powder, sorghum, sweet potato leaves, cabbage leaves, peanut powder, and traditional Chinese medicine powder; the feed of the invention does not contain any Chemical additives, rich in vitamins, iron, zinc, calcium, various trace elements and amino acids, can significantly improve the anti-stress ability and body immunity of chicks, reduce the disease rate of chicks, increase the survival rate of chicks, and promote the growth and development of chicks. The chick grows rapidly, and the digestive system of the chick is not perfect enough. The traditional Chinese medicine powder contained in the invention is beneficial to the development of the gastrointestinal tract of the chick and improves the digestibility.

Owner:韦直磊

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com