Patents

Literature

65results about How to "Increased stress levels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

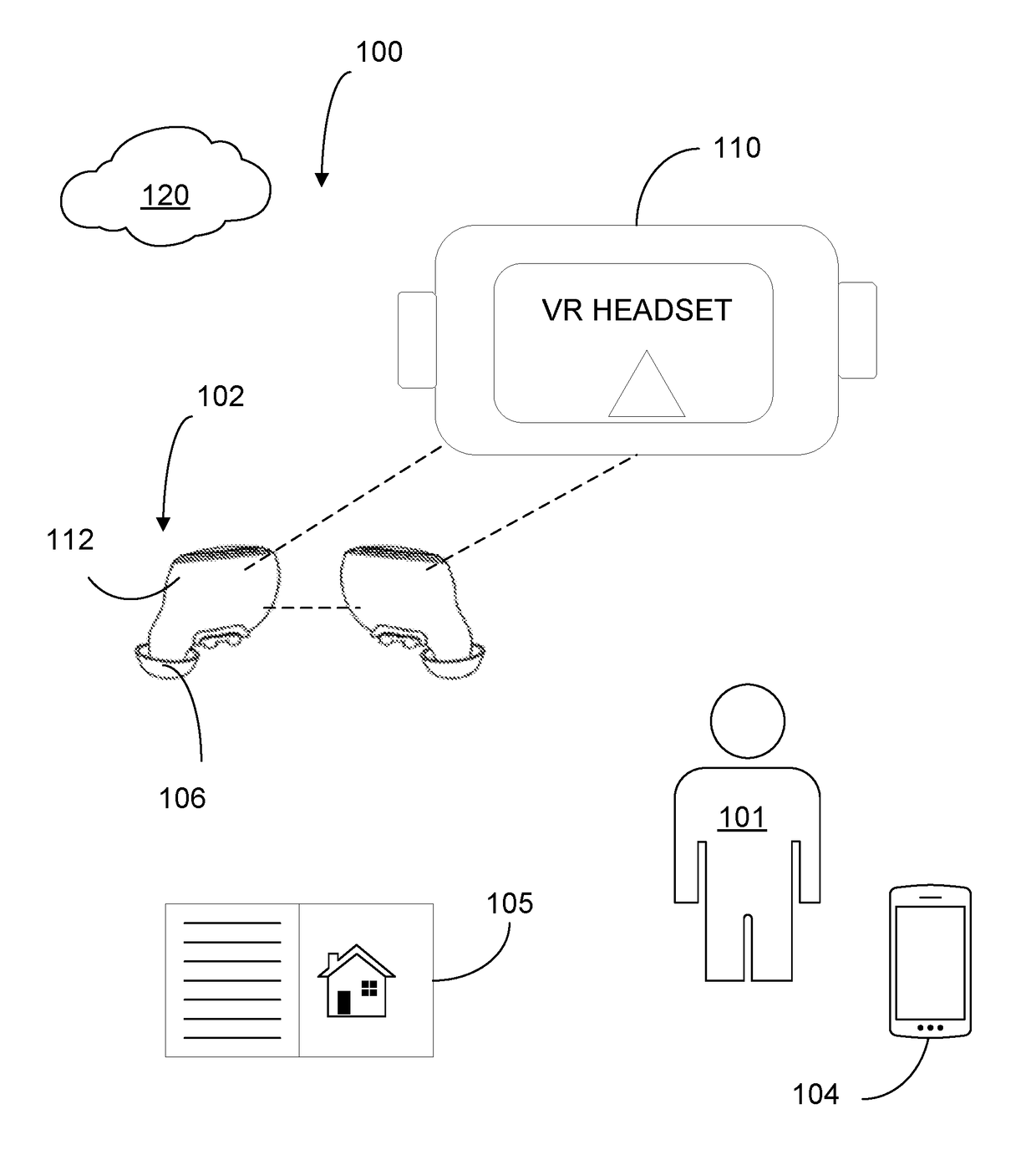

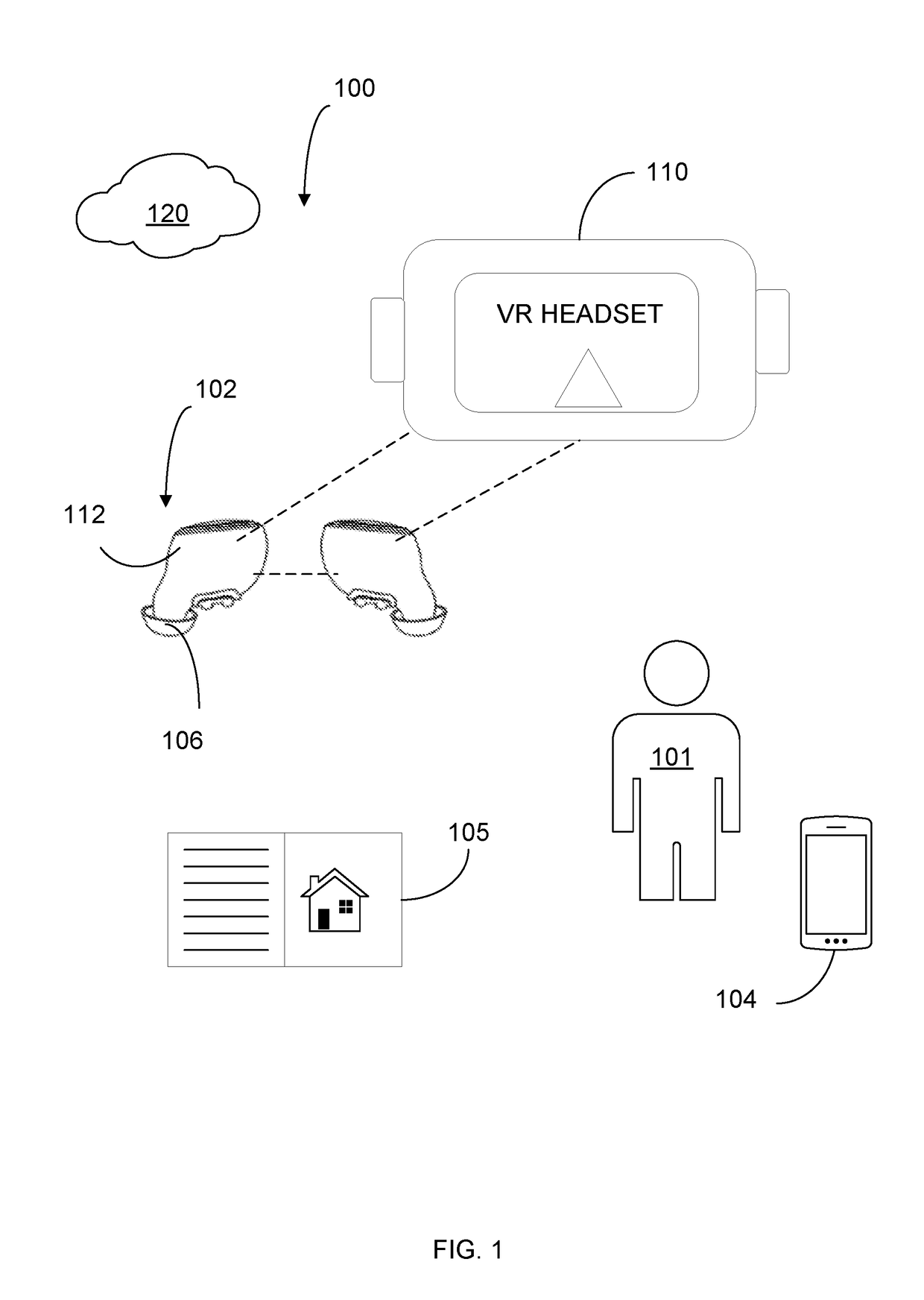

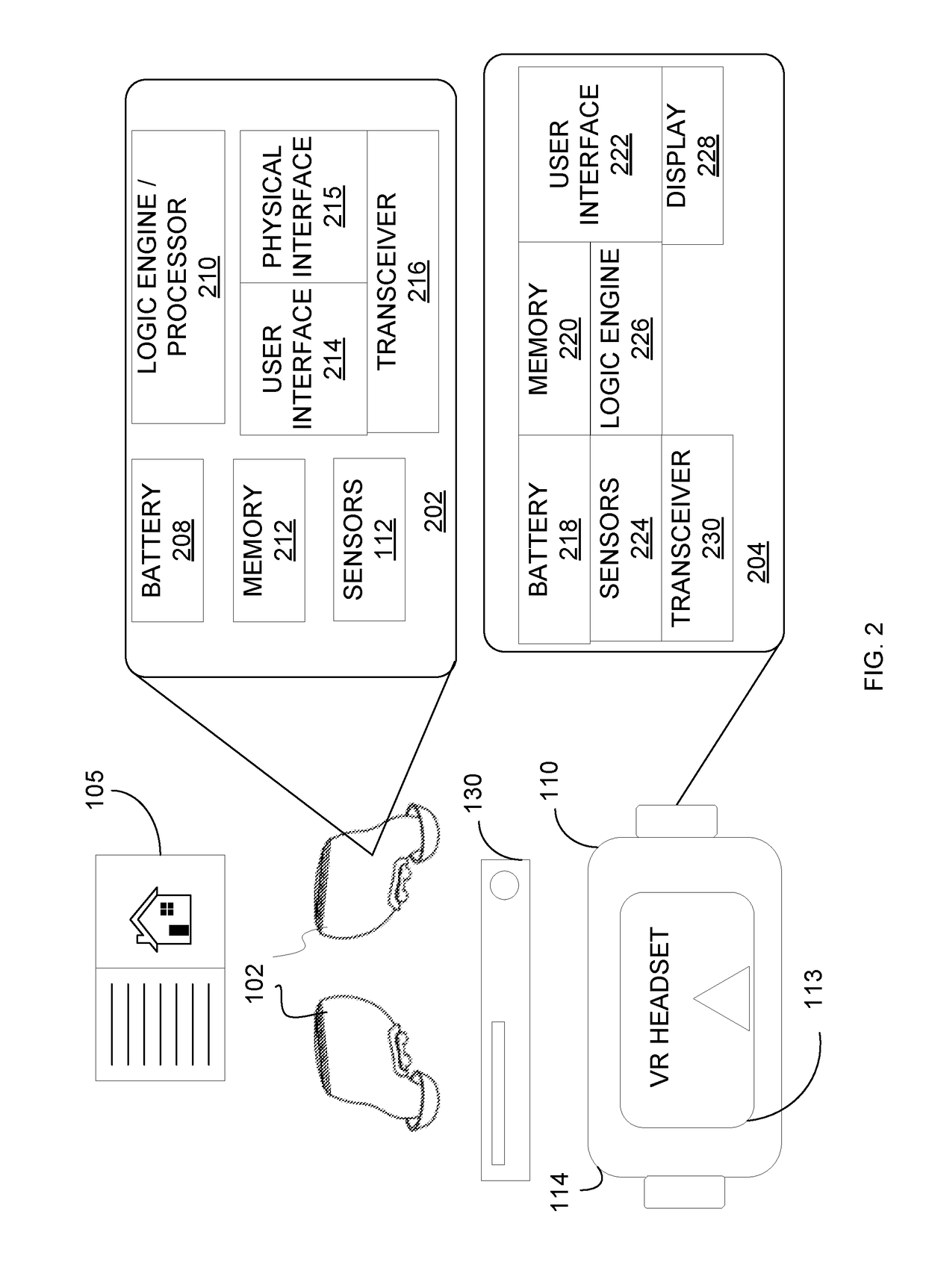

Variable computing engine for interactive media based upon user biometrics

ActiveUS20180011682A1Reduce intensityImprove actionInput/output for user-computer interactionPosition data use in hearing devicesBiometricsInteractive media

A system and method for implementing interactive media content is provided. Interactive media content is received for communication to a user through at least wireless earpieces. User biometrics are measured utilizing the wireless earpieces. A user condition associated with the user biometrics is determined. Branching patterns of the interactive media content are modified in response to the user condition. The interactive content may be a game or story.

Owner:BRAGI

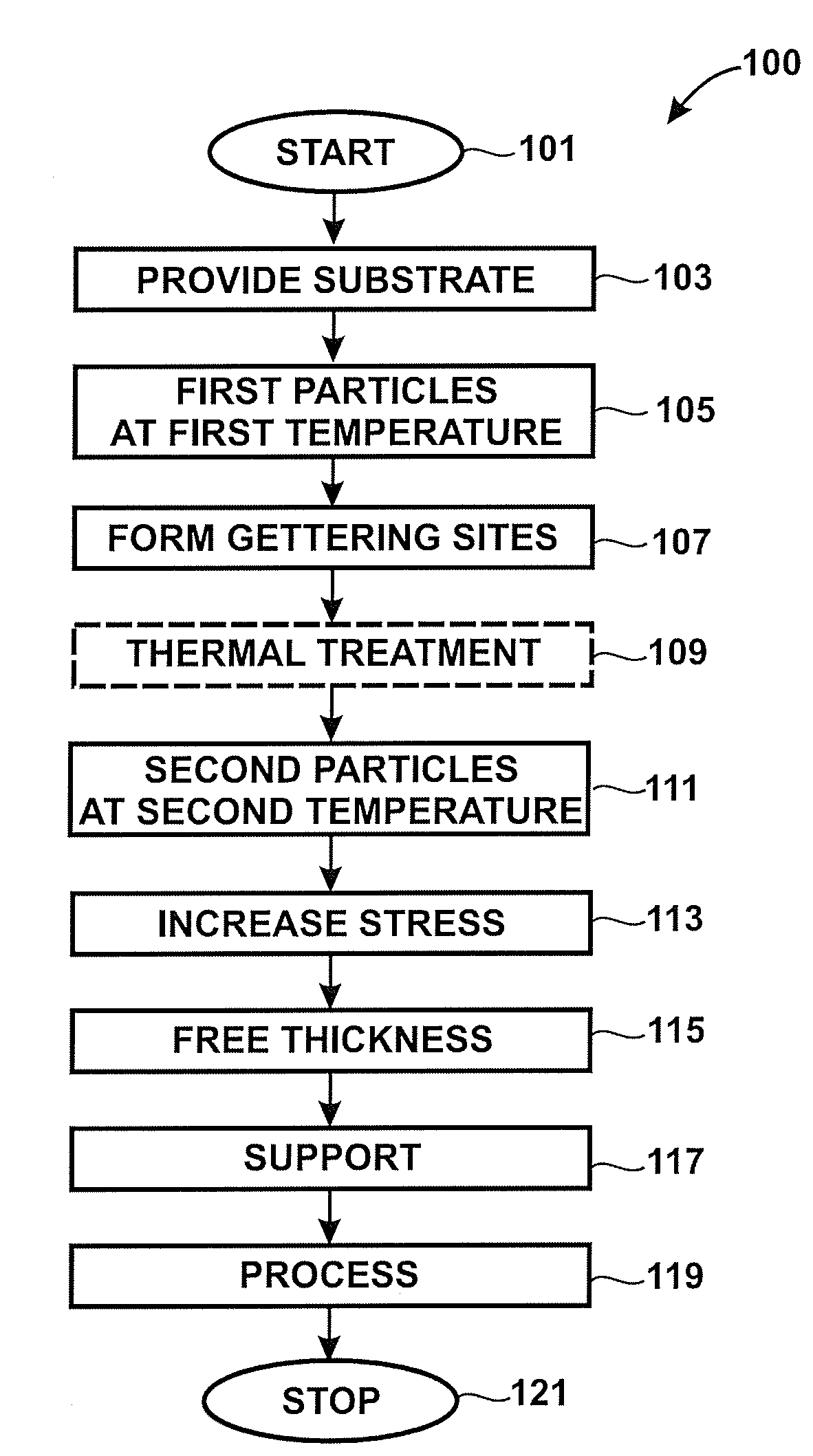

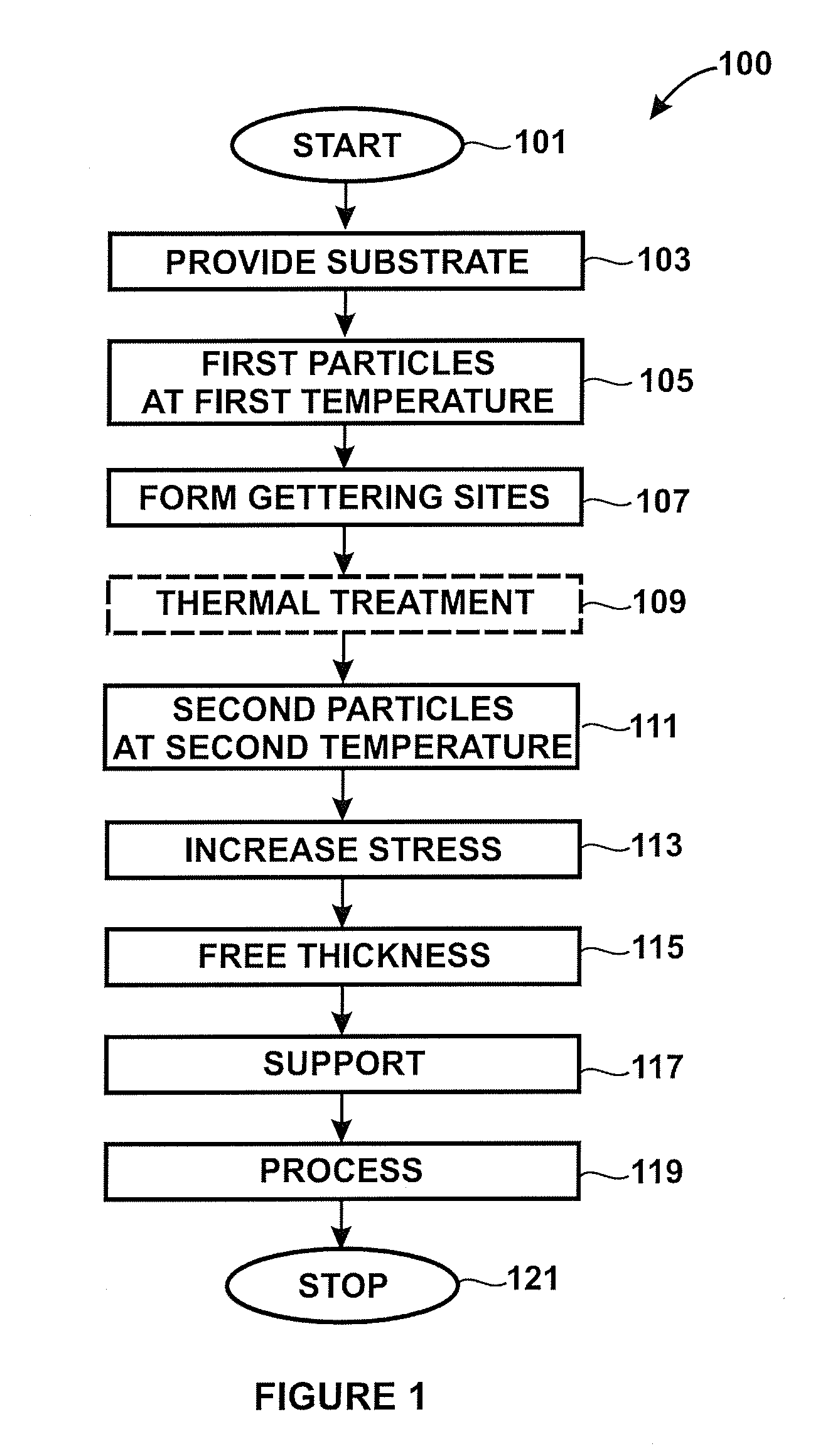

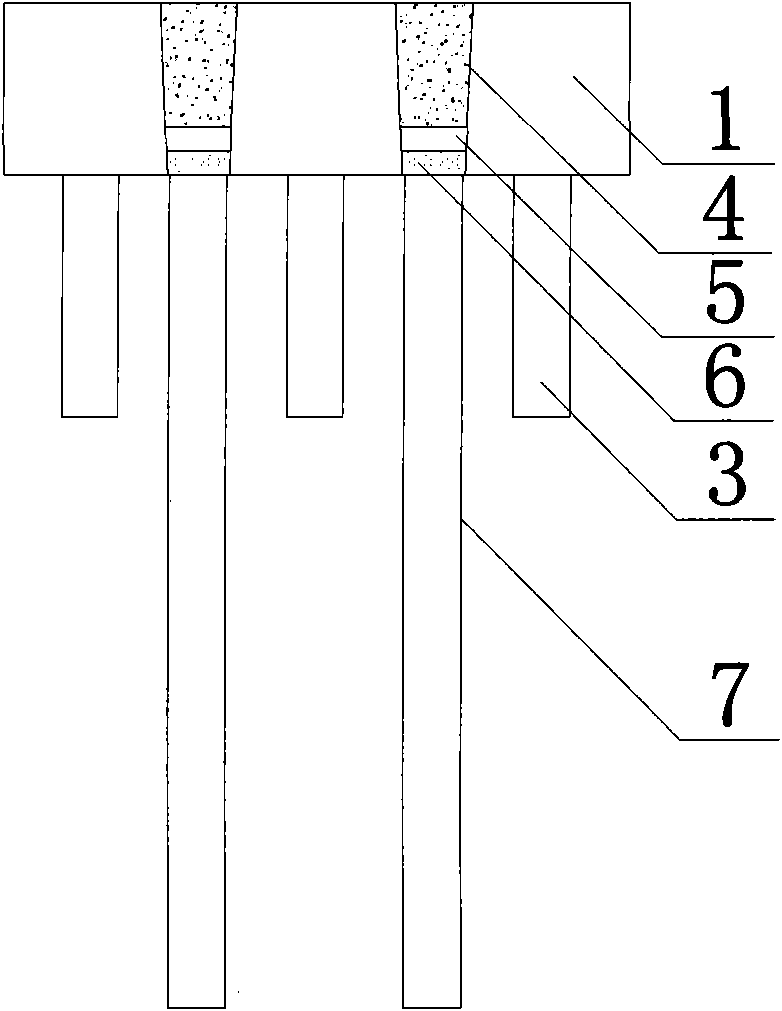

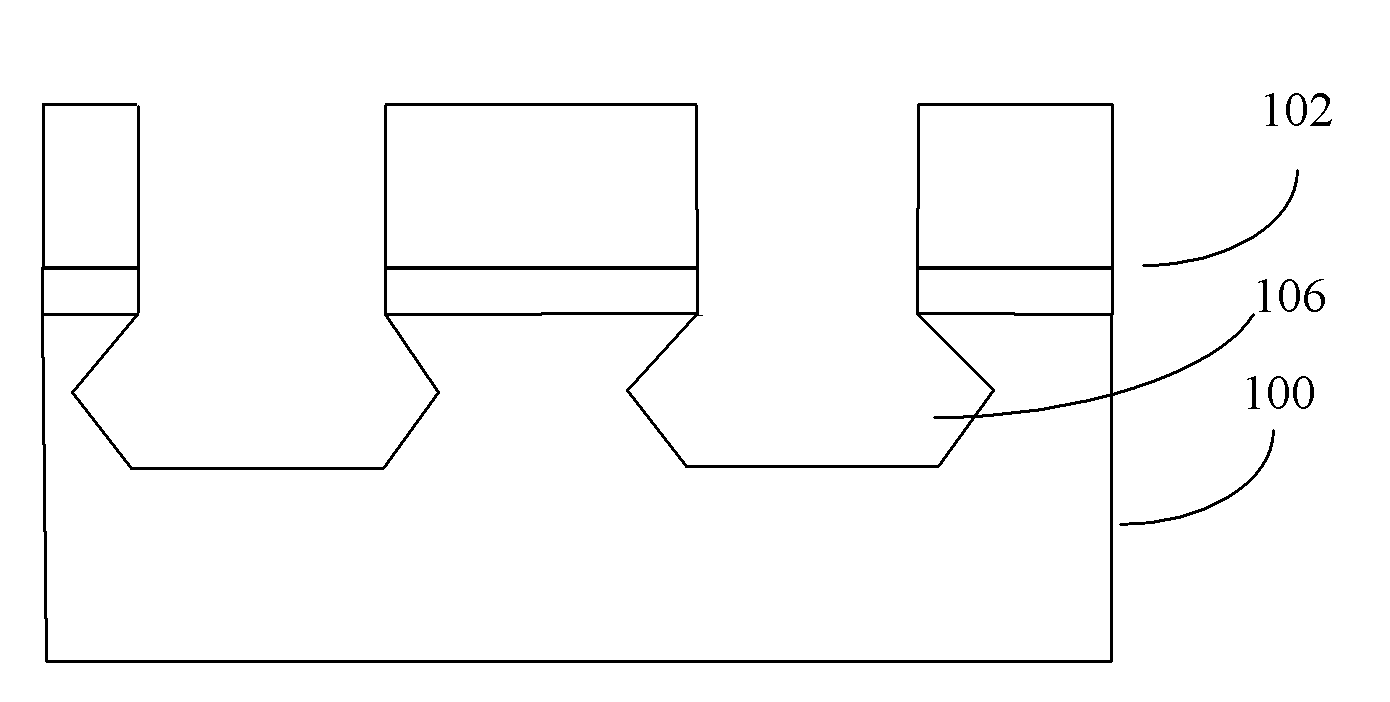

Method and structure using selected implant angles using a linear accelerator process for manufacture of free standing films of materials

InactiveUS20090042369A1Increased stress levelsImprove the level ofSemiconductor/solid-state device manufacturingPresent methodStress level

A method for fabricating free standing thickness of materials using one or more semiconductor substrates, e.g., single crystal silicon, polysilicon, silicon germanium, germanium, group III / IV materials, and others. In a specific embodiment, the present method includes providing a semiconductor substrate having a surface region and a thickness. The method includes subjecting the surface region of the semiconductor substrate to a first plurality of high energy particles provided at a first implant angle generated using a linear accelerator to form a region of a plurality of gettering sites within a cleave region, the cleave region being provided beneath the surface region to defined a thickness of material to be detached, the semiconductor substrate being maintained at a first temperature. In a specific embodiment, the method includes subjecting the surface region of the semiconductor substrate to a second plurality of high energy particles at a second implant angle generated using the linear accelerator, the second plurality of high energy particles being provided to increase a stress level of the cleave region from a first stress level to a second stress level. In a preferred embodiment, the semiconductor substrate is maintained at a second temperature, which is higher than the first temperature. The method frees the thickness of detachable material using a cleaving process, e.g., controlled cleaving process.

Owner:SILICON GENERAL CORPORATION

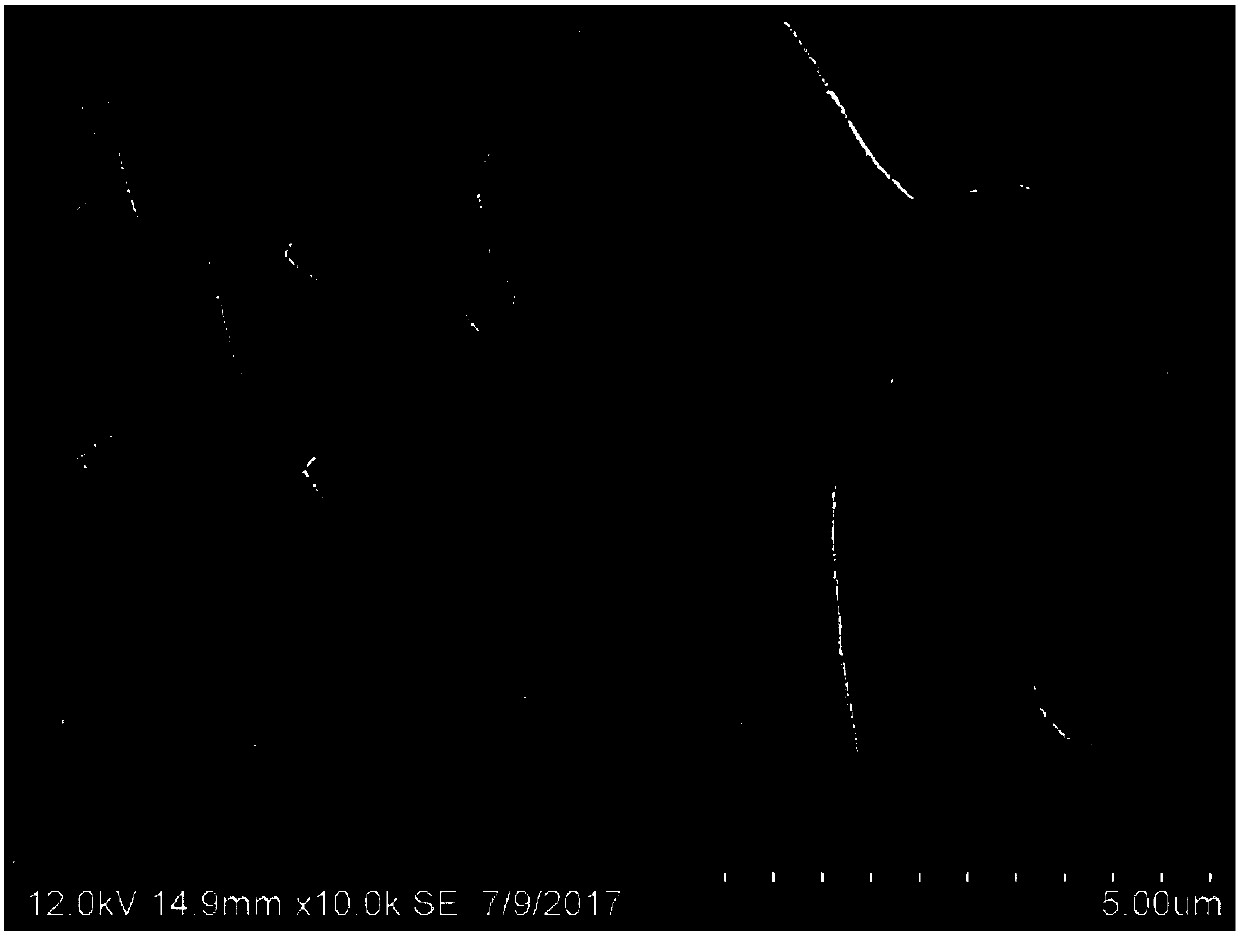

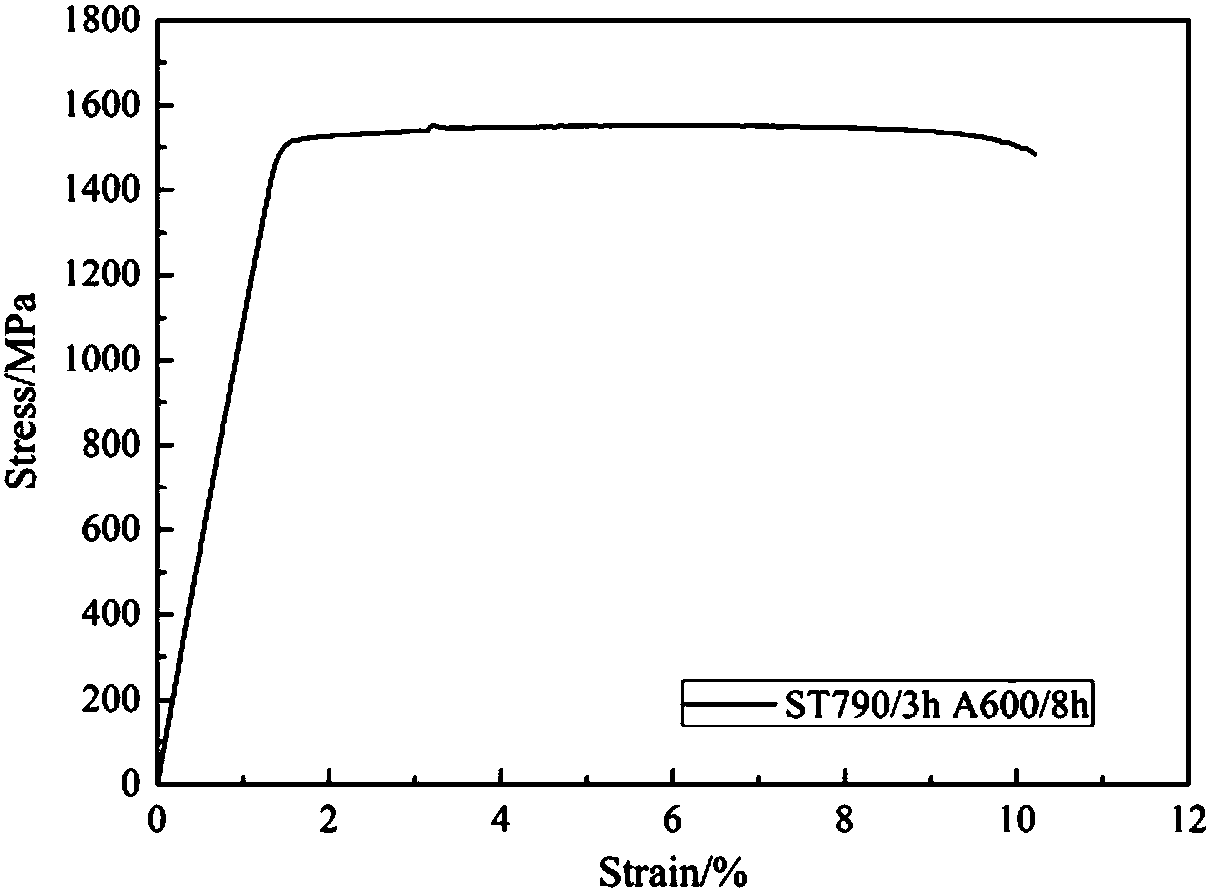

Ultrahigh-strength Ti-Al-Zr-Mo-Cr-series beta titanium alloy and thermal treatment process thereof

Ultrahigh-strength Ti-Al-Zr-Mo-Cr-series beta titanium alloy and a thermal treatment process thereof. The thermal treatment includes steps of performing solution treatment to Ti-Al-Zr-Mo-Cr-series beta titanium alloy and then performing aging treatment. The Ti-Al-Zr-Mo-Cr-series beta titanium alloy includes, by weight, 4.5-5.5% of Al, 3.5-4.5% of Zr, 9.5-10.5% of Mo, and 2.5-3.5% of Cr, the balanced being Ti. The alloy, after smelting, forging and toughening thermal treatment, has ultrahigh strength and plasticity. The alloy includes aluminum and also a certain amount of a neutral element, zirconium, so that alpha-phase is further reinforced; by adding the molybdenum at high mass percentage, a beta-matrix is reinforced; in addition, due to the low diffusion rate of molybdenum, temperaturesensitivity of the alloy in a two-phase zone during forging is reduced, thus enlarging processing window of the alloy.

Owner:XI AN JIAOTONG UNIV

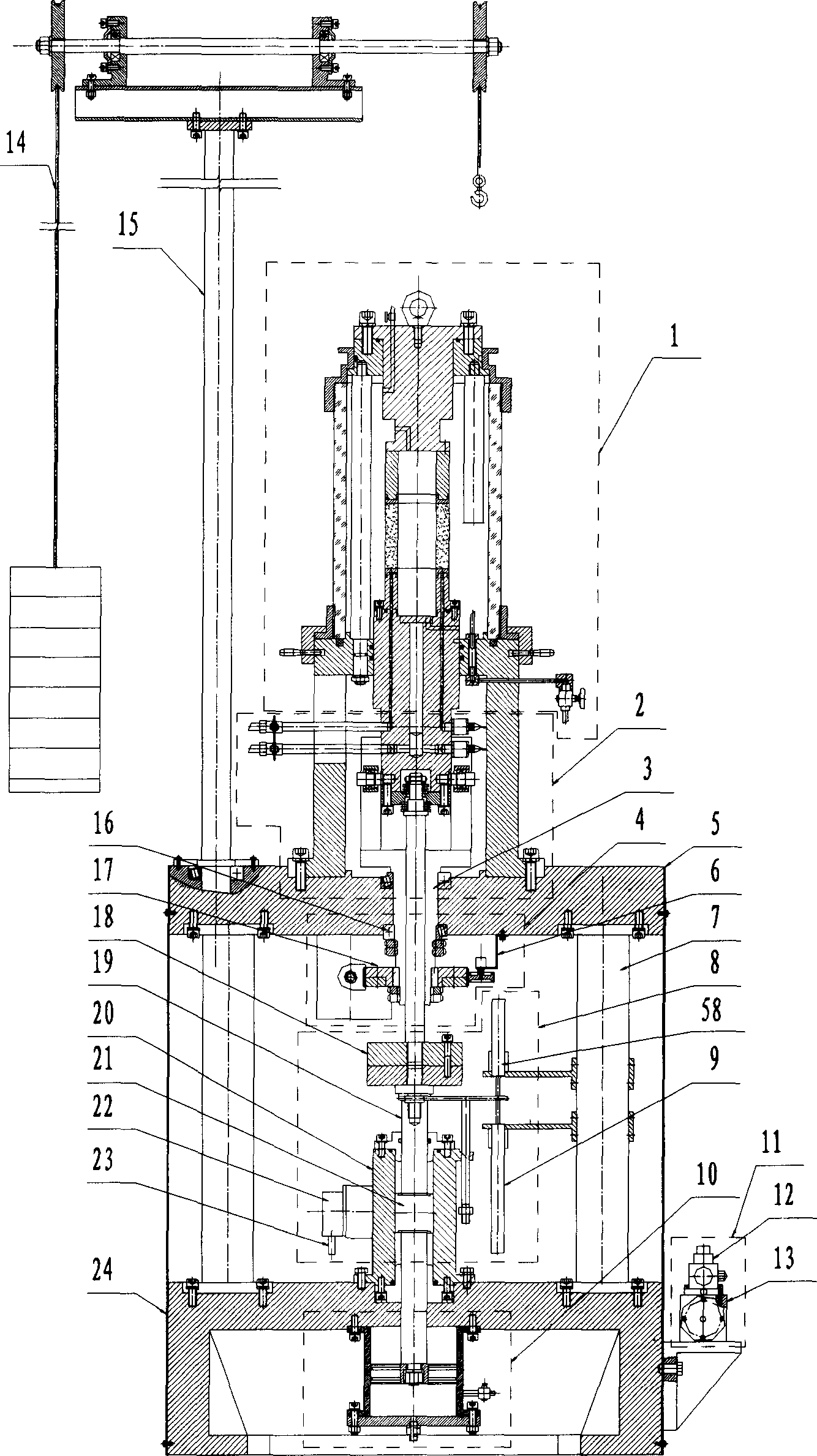

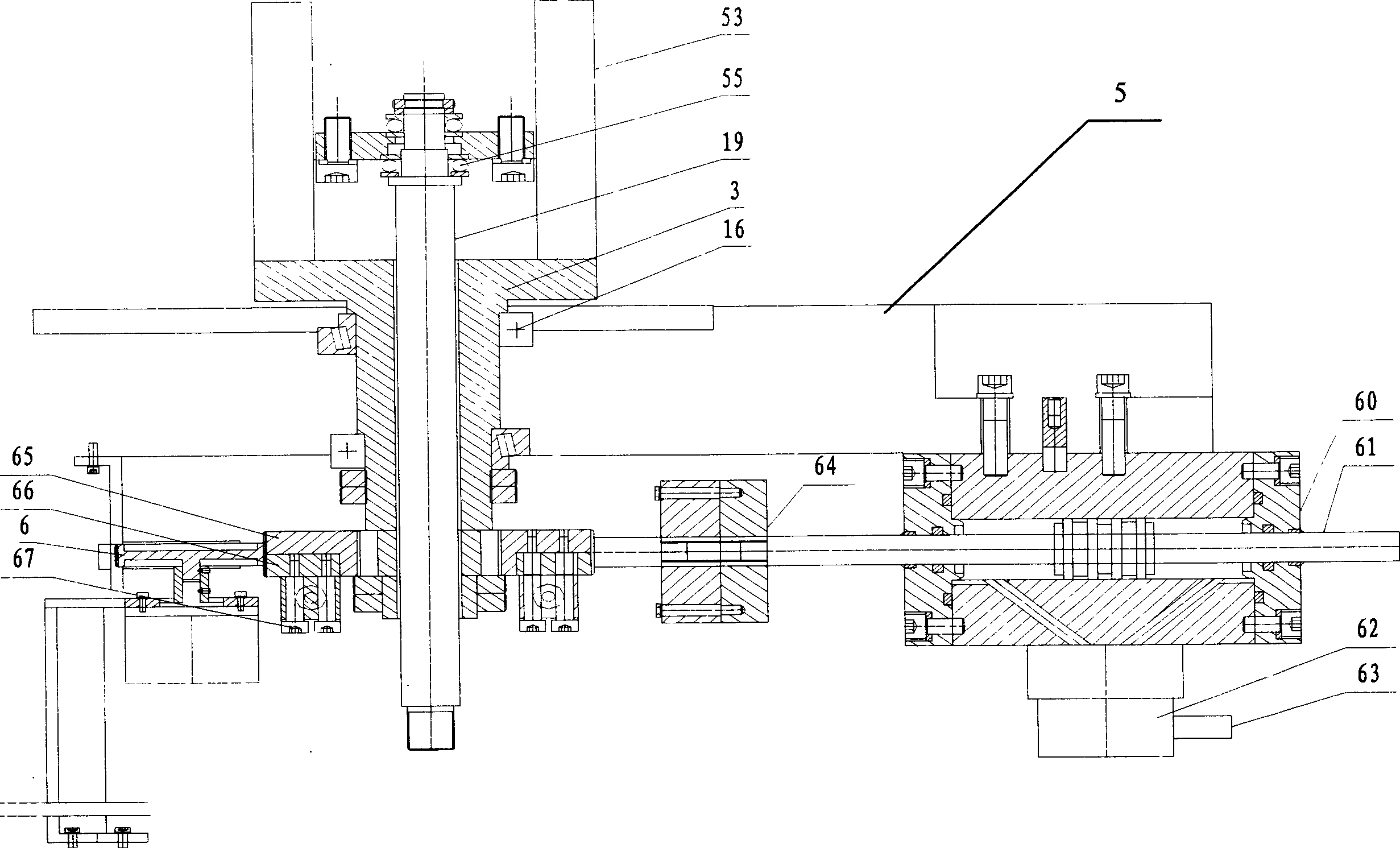

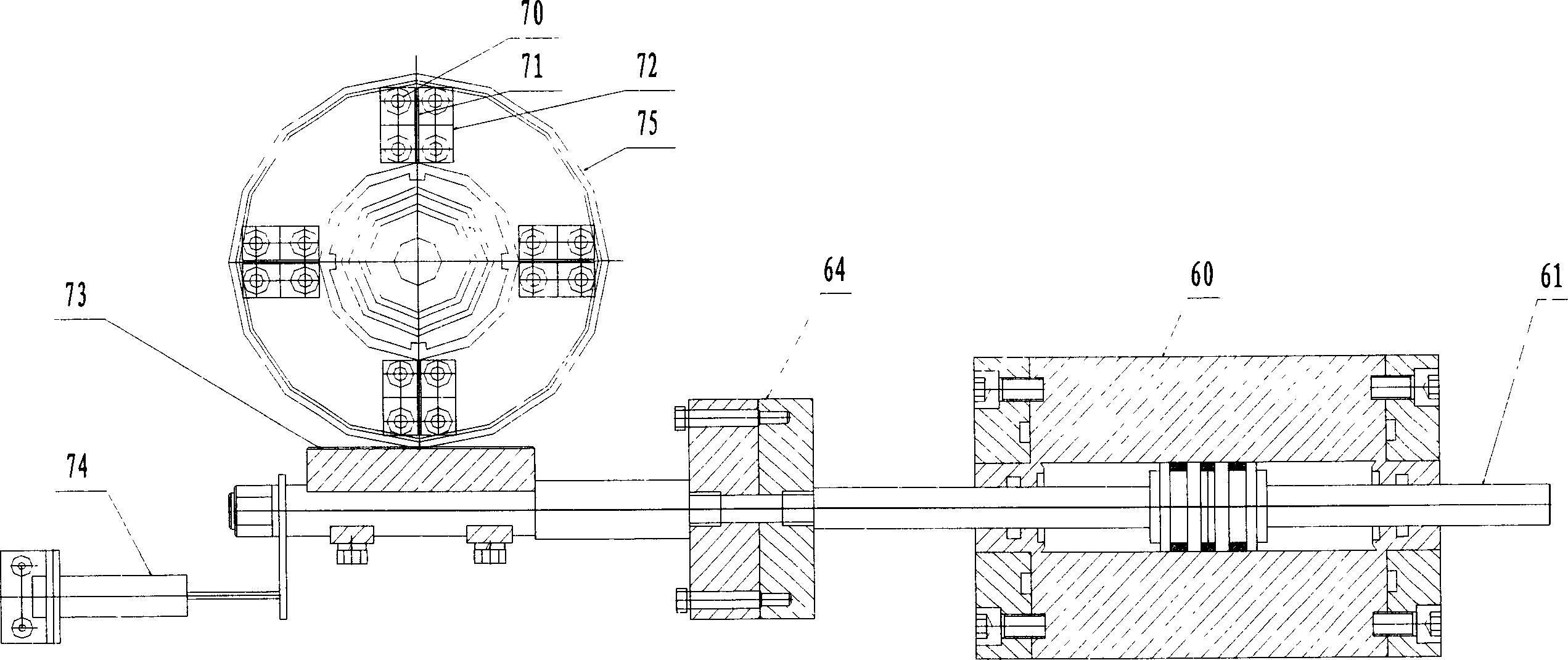

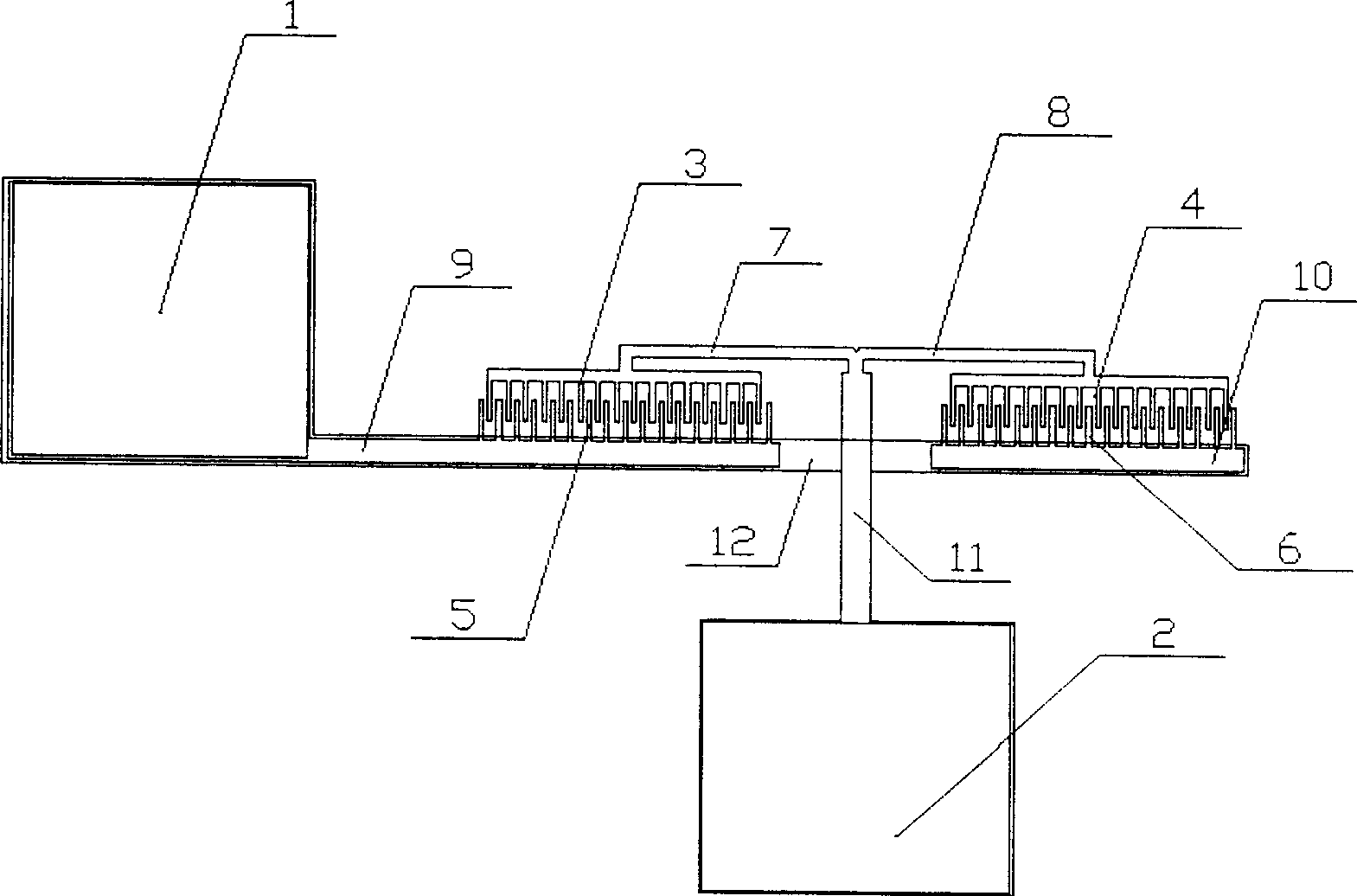

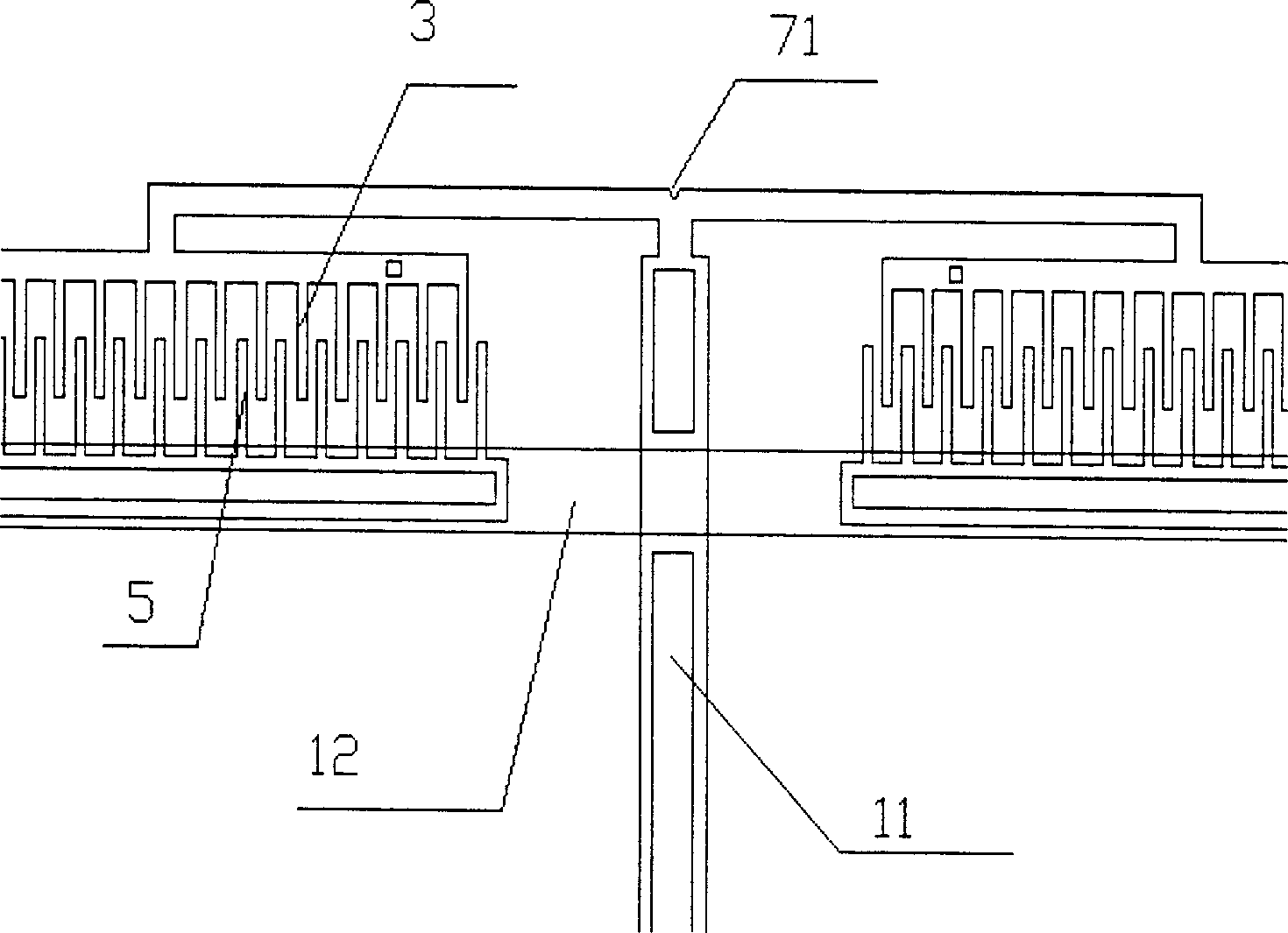

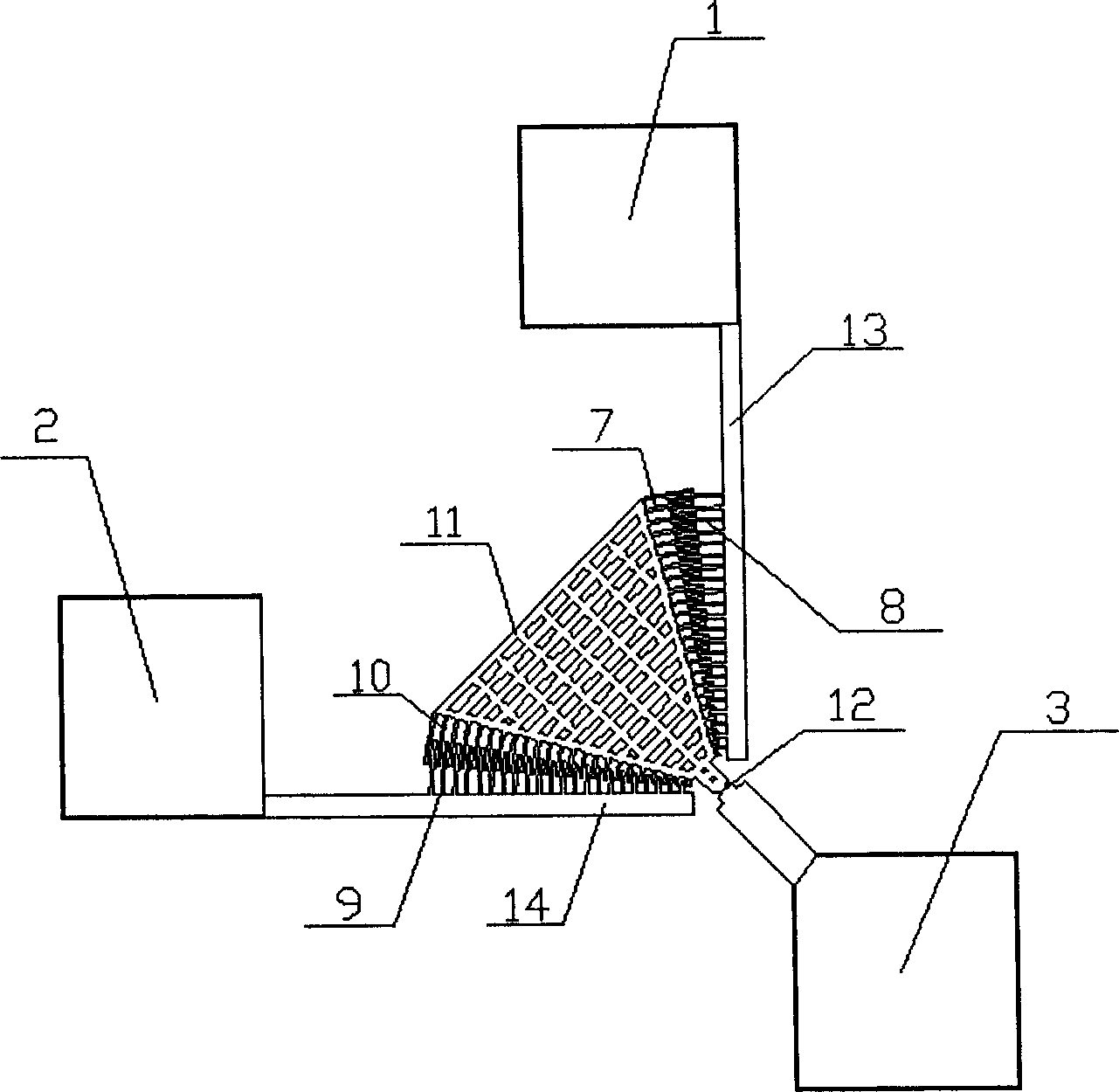

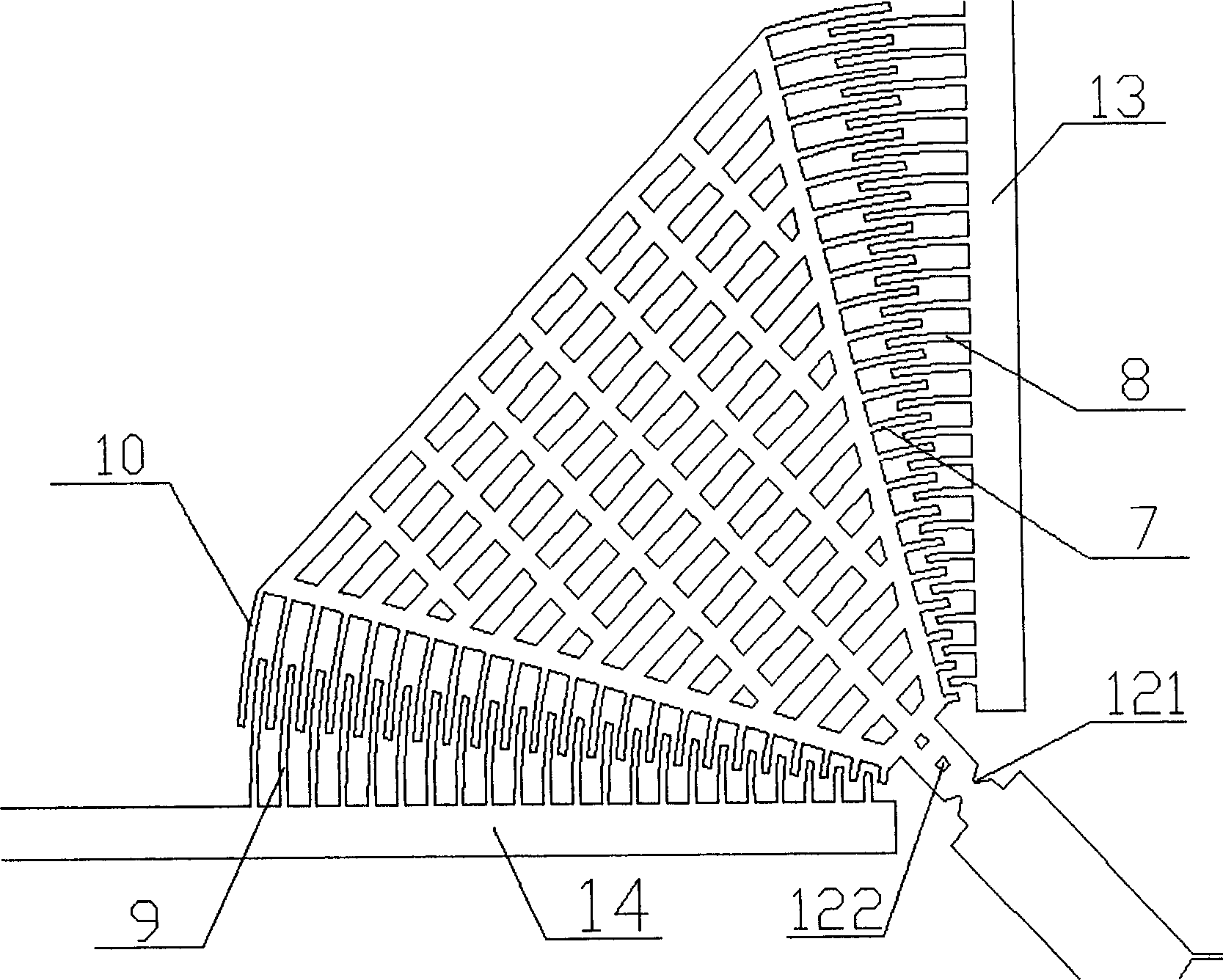

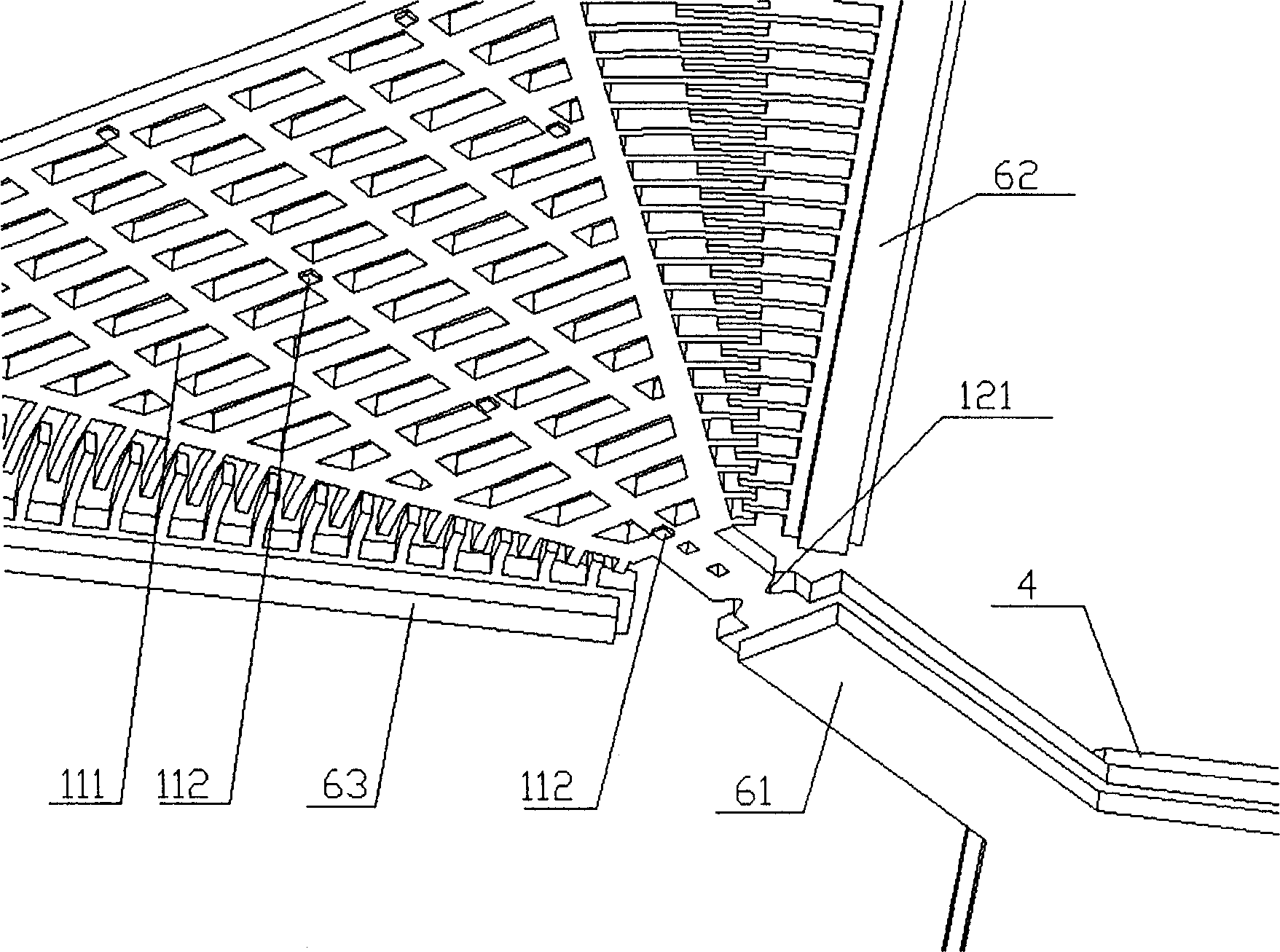

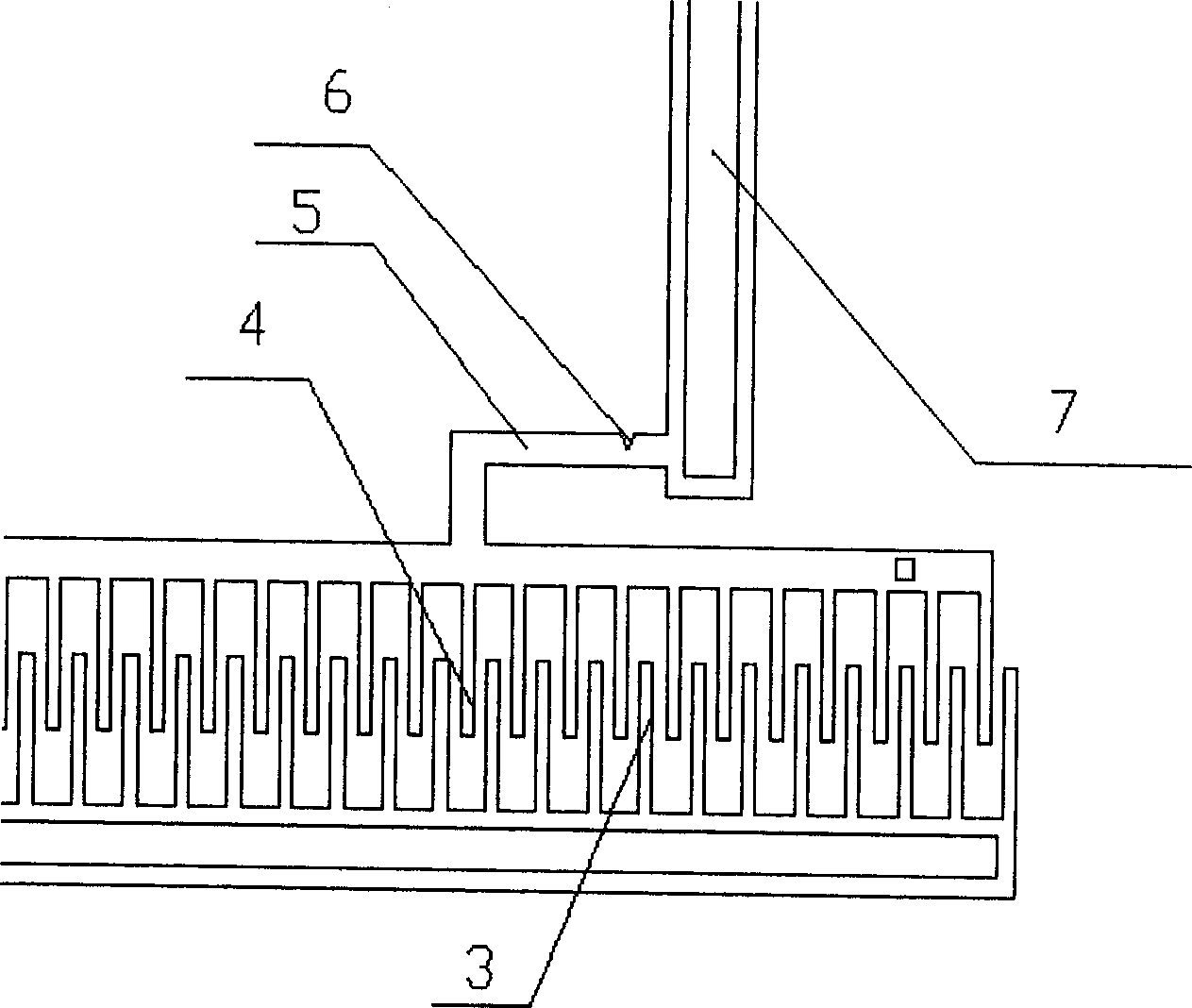

Electrohydraulic servo pressure-torque coupling three-way vibration loading tree-axis instrument

InactiveCN1776402AImprove mutual interferenceIncrease smoothnessUsing mechanical meansStrength propertiesAutomatic controlControl system

The triaxial apparatus includes three portions: host; hydraulic power source connected to servo valve for loading electrohydraulic in three directions in host through pipe; automatic control system connected to the input signal measured by sensor as well as connected to electrical signal output from servo valve. The host includes pressure chamber, axle load mechanism, twist mechanism connected to the axle load mechanism in coaxial coupling, pressing-twisting mechanism between the pressure chamber and twist mechanism, balance-cylinder and side pressure mechanism. The balance-cylinder, side pressure mechanism and pressure chamber are connected through pipe so as to constitute self-balanced mechanism of hydraulic pressure. The invention overcomes interactional movement between axle load mechanism and twist mechanism of current triaxial apparatus of vibration and torison shear as well as overcomes disadvantages of side pressure mechanism. Features are: smooth waveform of load, and low cost.

Owner:XIAN UNIV OF TECH

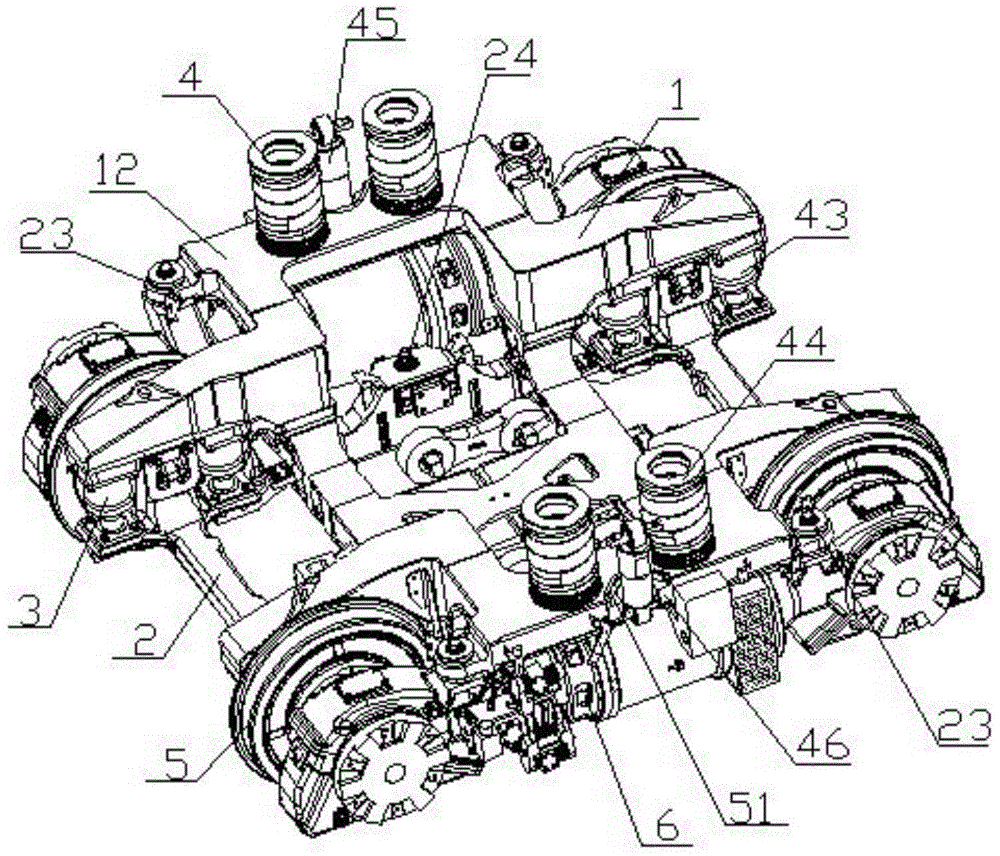

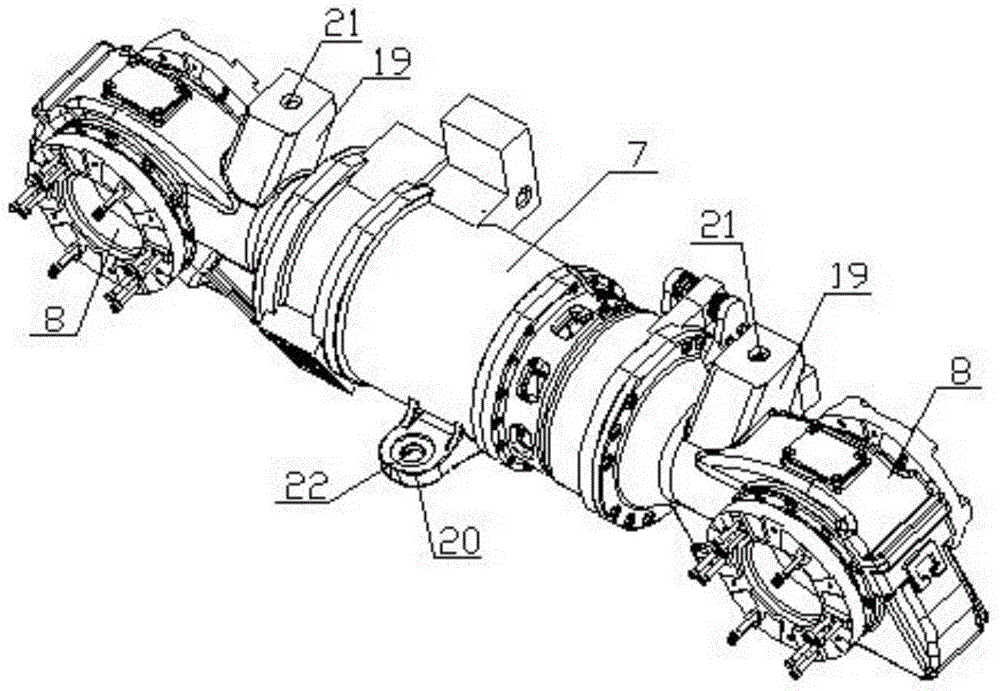

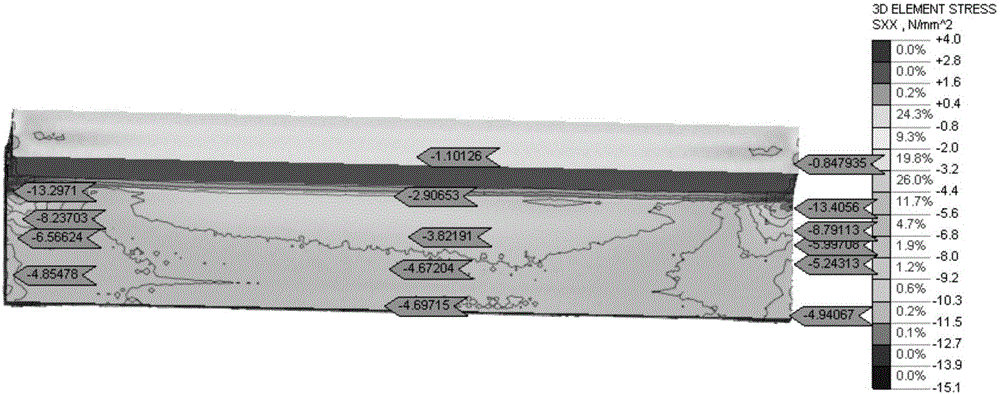

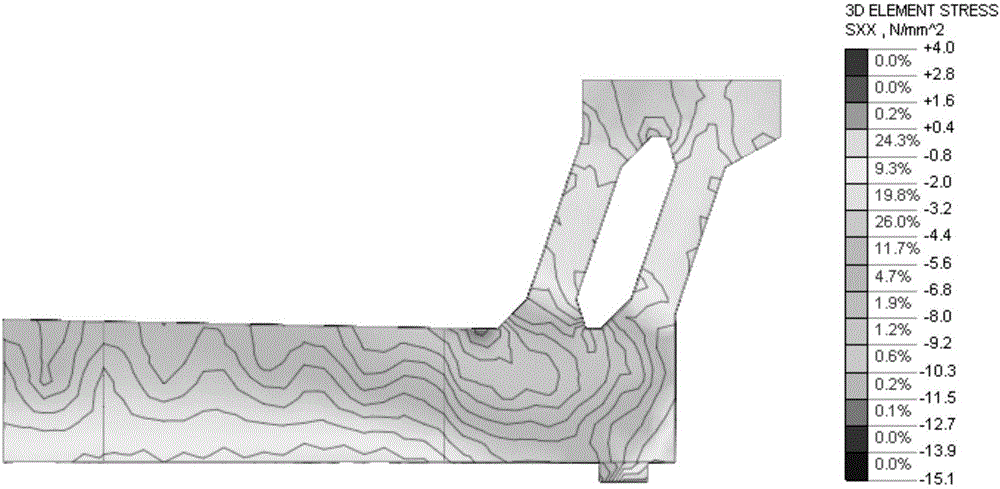

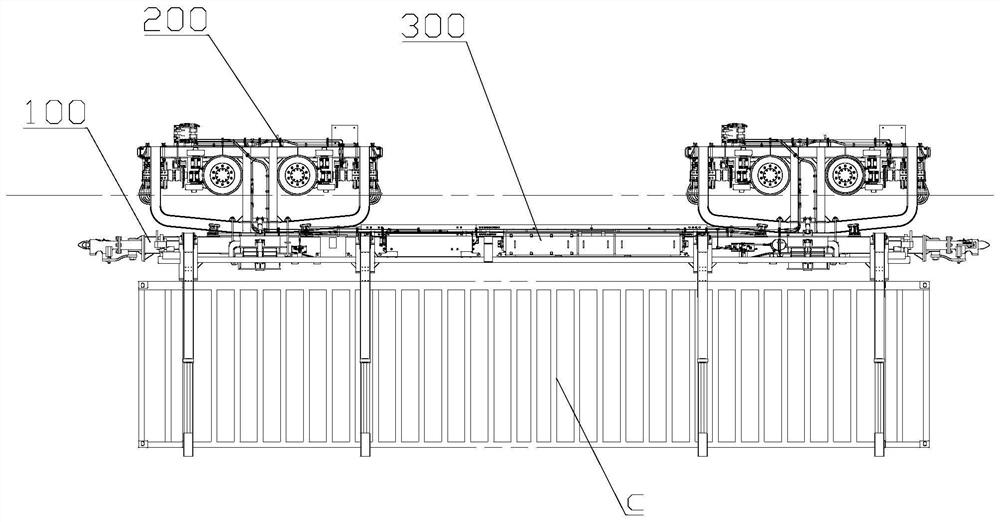

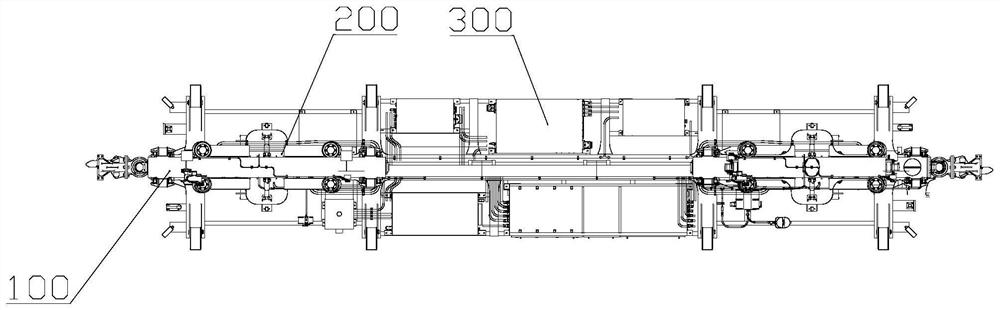

Low-floor railway vehicle bogie

ActiveCN104608788AReduce stressImprove stress levelsBogiesBogie-underframe connectionsEngineeringCantilevered beam

The invention relates to a low-floor railway vehicle bogie which comprises a framework, axles, a primary suspension, a secondary suspension, wheels and motor gear cases. The framework comprises side beams, cross beams and girders. Each cantilever beam protrudes outwards from the center of the corresponding side beam. The motor gear cases are hung on the outer sides of the side beams. The two sides of each cantilever beam are provided with upper hanging seats. The girder located on the same side of the corresponding cantilever beam is provided with a lower hanging seat. An upper part composed of the motor gear cases is provided with two upper installation seats relative to the two upper hanging seats. A side part composed of the motor gear cases is provided with a lower installation seat relative to the lower hanging seat. The upper installation seats and the upper hanging seats are fixedly connected through first connecting structures. The lower installation seat and the lower hanging seat are fixedly connected through a second connecting structure. A three-point hanging mode is adopted in the bogie, stress of the cantilever beams can be effectively reduced, the overall bearing state of the framework is improved, and the use space of a passenger chamber in a vehicle can be effectively increased.

Owner:CRRC QINGDAO SIFANG CO LTD

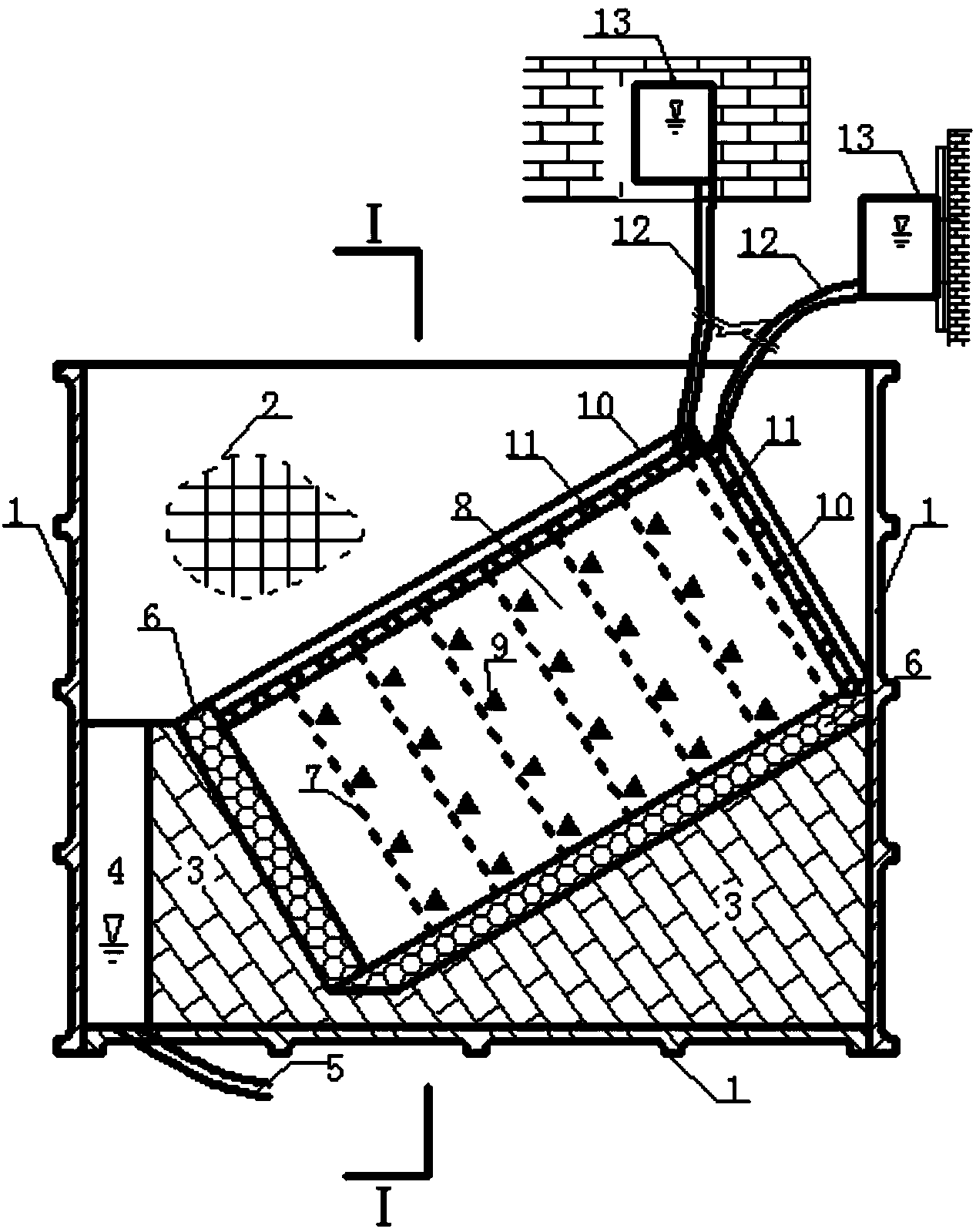

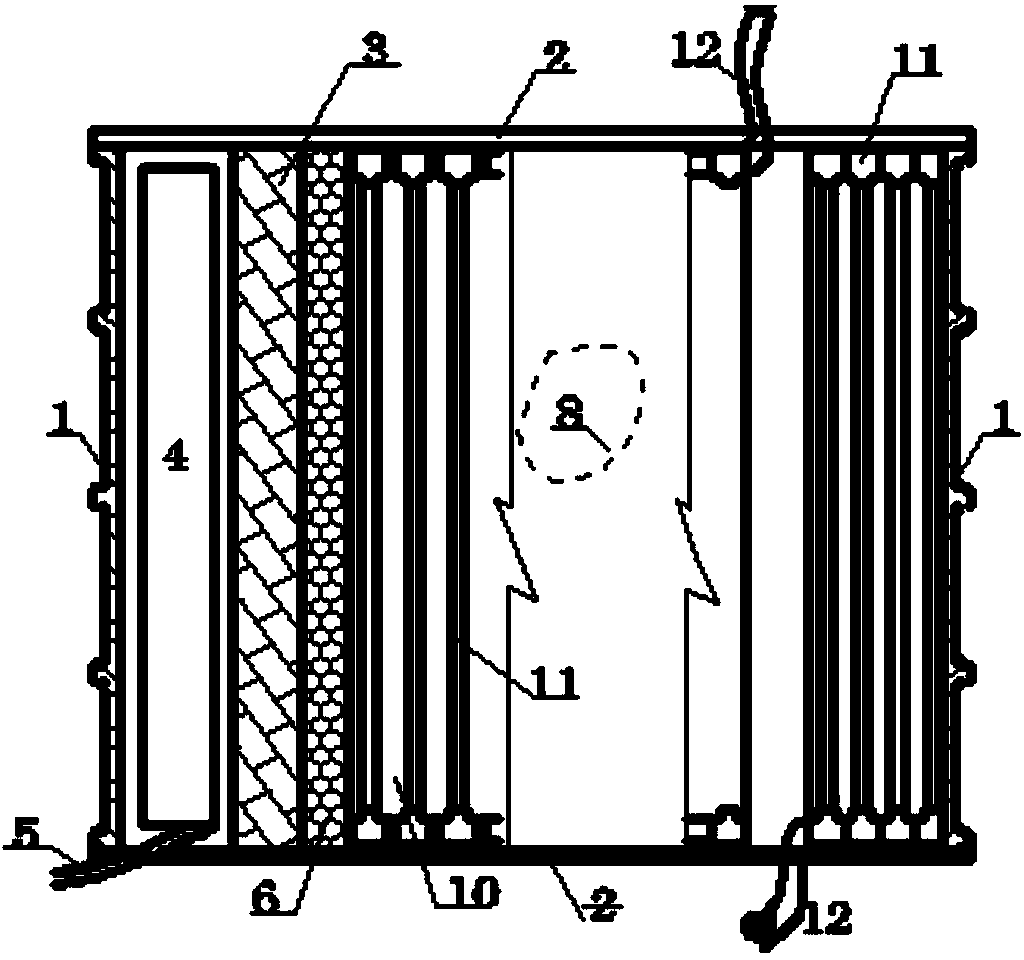

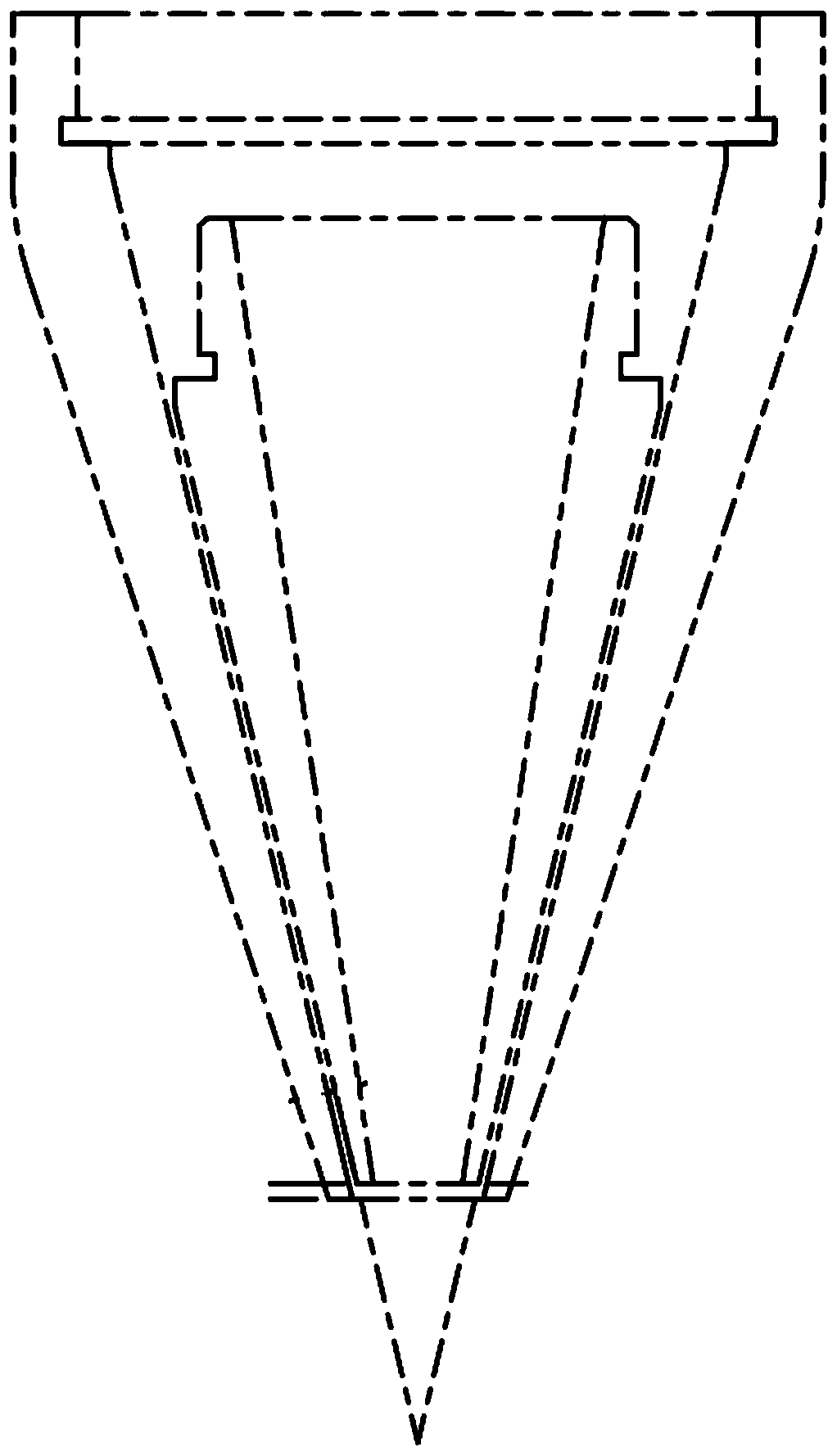

Bidirectional penetration model testing device suitable for soil-rock slopes

InactiveCN103760318ADischarge in timeOvercome the disadvantages of not being able to reflect the stress level of the soilEarth material testingWater sourceSeepage force

The invention discloses a bidirectional penetration model testing device suitable for soil-rock slopes. The bidirectional penetration model testing device comprises a slope deposit, water penetration pipes, cover plates, a water source, a deformable water permeable bearing pad body, a water permeable support body, pore pressure gauges and inclinometer tubes, wherein the slope deposit is obliquely arranged and has two upper oblique side surfaces of water penetration surfaces; the water penetration pipes are positioned above the water penetration surfaces of the slope deposit; the cover plates are positioned above the water penetration pipes, made of transparent materials and used for sealing penetration water; the water source is connected with the water penetration pipes the deformable water permeable bearing pad body is opposite to the water penetration surfaces of the slope deposit and positioned below the slope deposit; the water permeable support body is positioned below a deformable water permeable layer and used for supporting the slope deposit; the pore pressure gauges are buried in the slope deposit; the inclinometer tubes are used for enabling a probe of an inclinometer to get in and out. The long slope surface in the slope deposit forms an angle of 20-45 degrees with the ground, and the water penetration pipes which are horizontally arranged are respectively designed with a plurality of water penetration holes. The bidirectional penetration model testing device can truly simulate the effective stress and the water pressure in a slope body of a soil-rock slope under the synergy of penetration along the slope direction and the penetration which is vertical to the slope surface according to an amplification ratio, and solve the difficult that a general geotechnical model is difficult to simultaneously meet geometric similarity and physical similarity.

Owner:SICHUAN UNIV +2

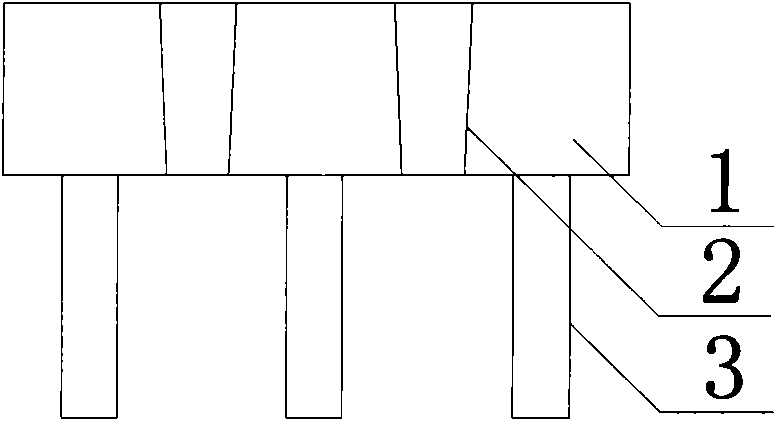

Long-short pile composite foundation top-down construction method

InactiveCN101538867AIncrease the load sharing ratioImprove carrying capacityFoundation engineeringStress levelJoint working

The invention discloses a long-short pile composite foundation top-down construction method, comprising: a) carrying out construction for a short pile according to the design requirement; b) casting foundation bottom plate and obligating a long-pile hole site during construction; c) constructing an upper structure; d) constructing a long pile; and e) closing a long-pile hole. In the invention, the short pile and soil form composite foundation to be loaded firstly, thereby improving the stress level of the short pile and the soil in early stage of loading and increasing the load sharing ratio of the short pile and the soil; afterwards, the long pile participates in the load, which is favorable for the short pile, soil and long pile to work together; besides, the vertical pressure of soil between piles is increased so that the lateral additional stress in the foundation is enhanced correspondingly, the frictional resistance around piles of the long pile and the short pile is improved, edge load effect is generated at the end of long pile, and the load ability of the long pile is enhanced; the design should consider the foundation bearing ability and settlement situation under two different foundation states which is similar to check calculation of composite beam during structural engineering; the long pile in the topdown construction is a soil extruding pile generally, and informatization feedback should be strengthened and parameters such as speed of pile construction should be strictly controlled, thereby preventing the quality of the short pile body from being affected. The invention is beneficial to improving the coaction level of piles in the long-short pile composite foundation, improves the safety and reliability of the composite foundation and shortens the construction period.

Owner:叶长青 +1

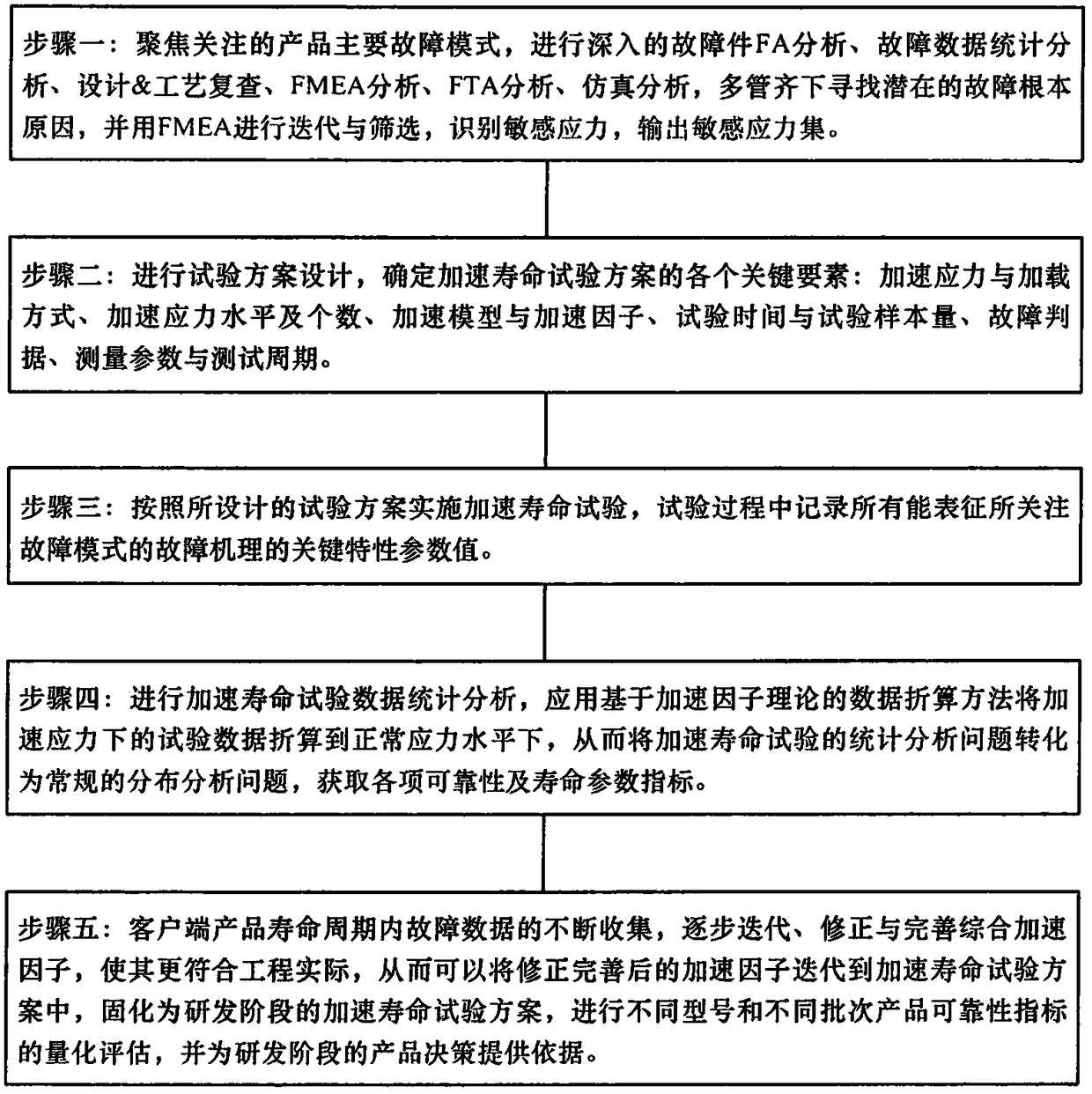

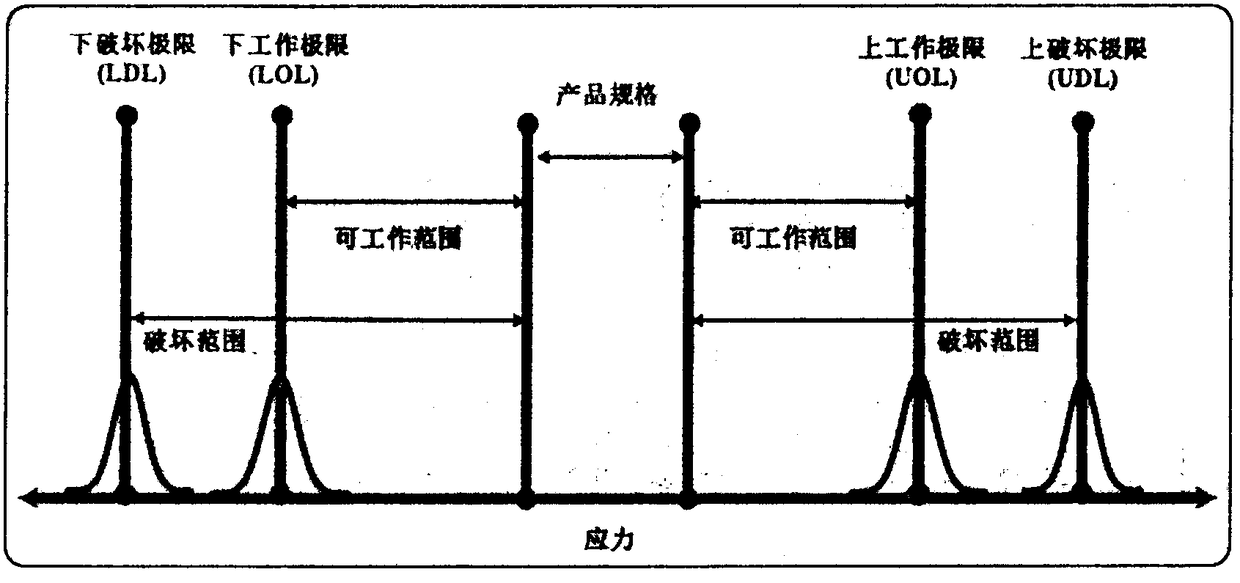

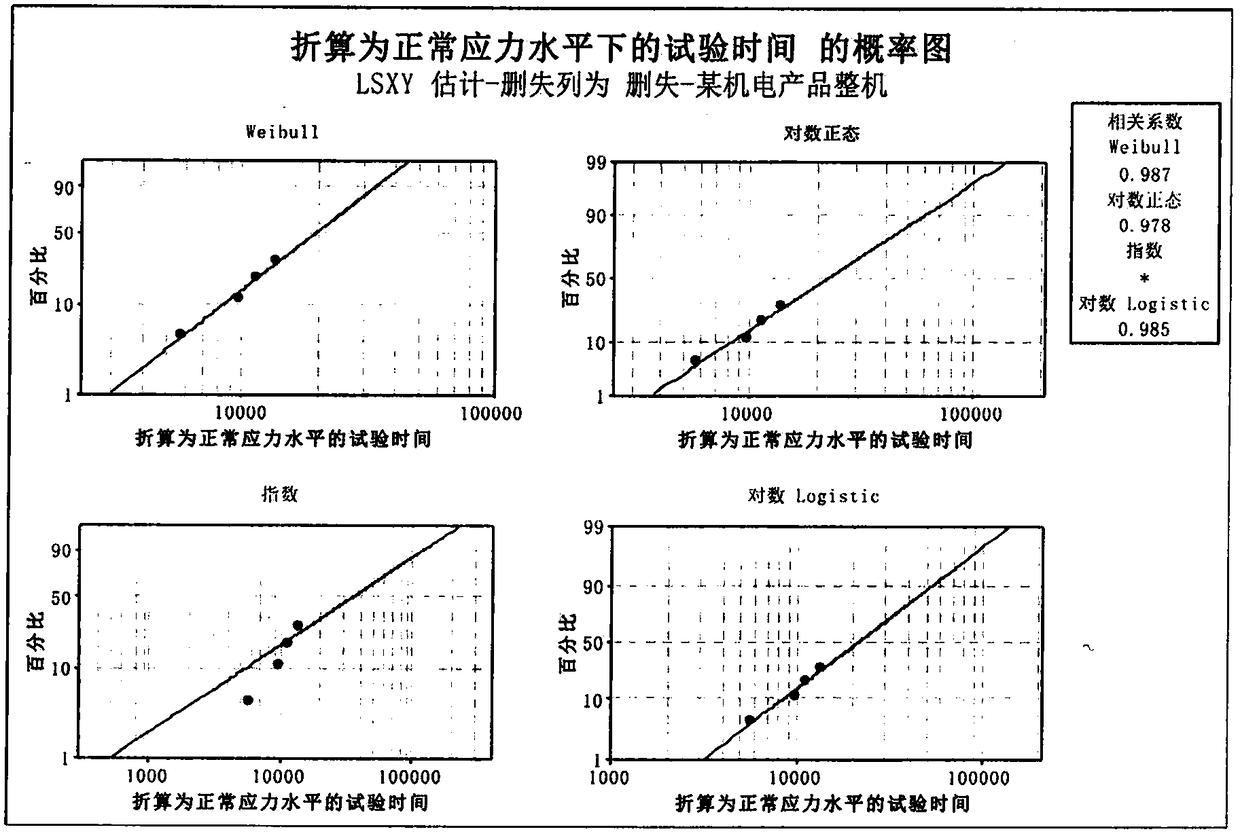

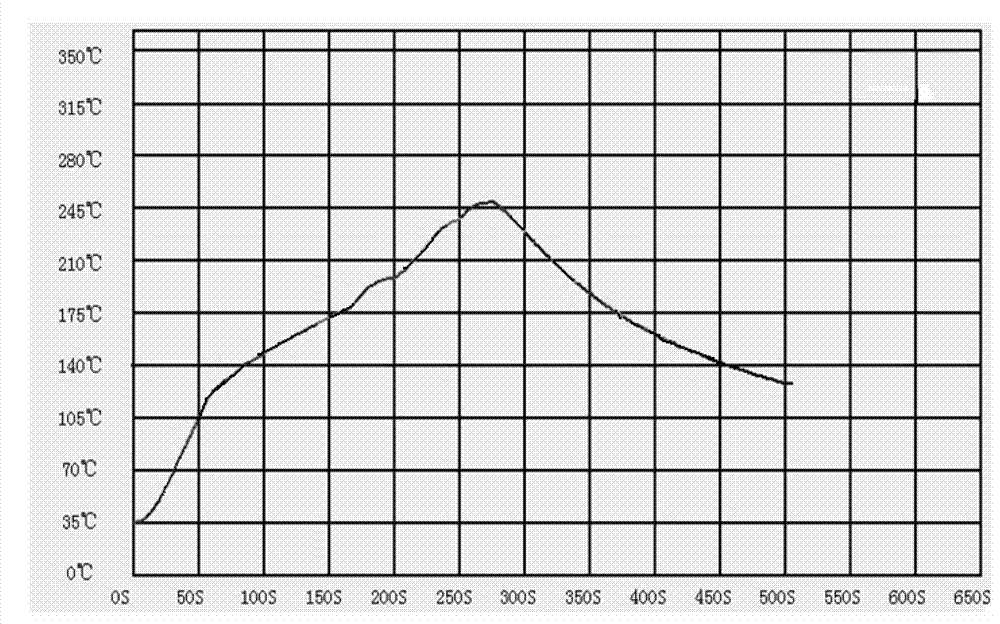

Integrated acceleration factor based electromechanical product reliability index evaluation method

InactiveCN108510133AShorten test timeAdapt to the requirements of R&D progressResourcesAcceleration factorTest efficiency

The invention discloses an integrated acceleration factor based electromechanical product reliability index evaluation method. The method is characterized by comprising the steps that a basic reason for a fault is searched for from many aspects with the focus on a main fault mode, and a sensitive stress set is determined; a test scheme is designed, and key factors of the acceleration life test scheme are determined; acceleration life test is carried out; test data is analyzed statistically; and fault data of full life periods of client products are collected continuously, and an integrated acceleration factor is corrected iteratively and improved gradually so that the factor satisfies the engineering practicality more. The problems that an electromechanical product is not sensitive to theacceleration stress, the product is single in the acceleration stress and low in the test efficiency, and error of the acceleration factor is large are solved, the feasibility of engineering practiceis taken into full consideration, and the method is more suitable for evaluation of the reliability index of the high-reliability long-life product.

Owner:SUNLIGHT TECH BEIJING

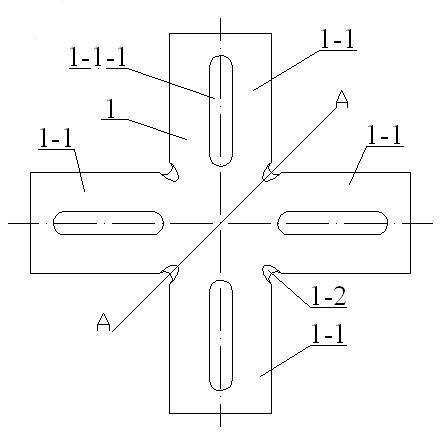

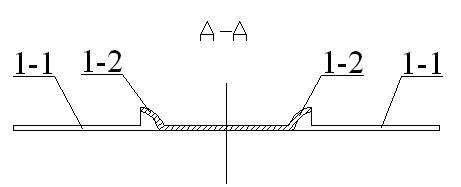

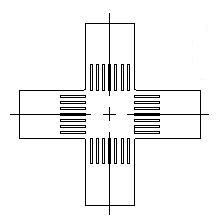

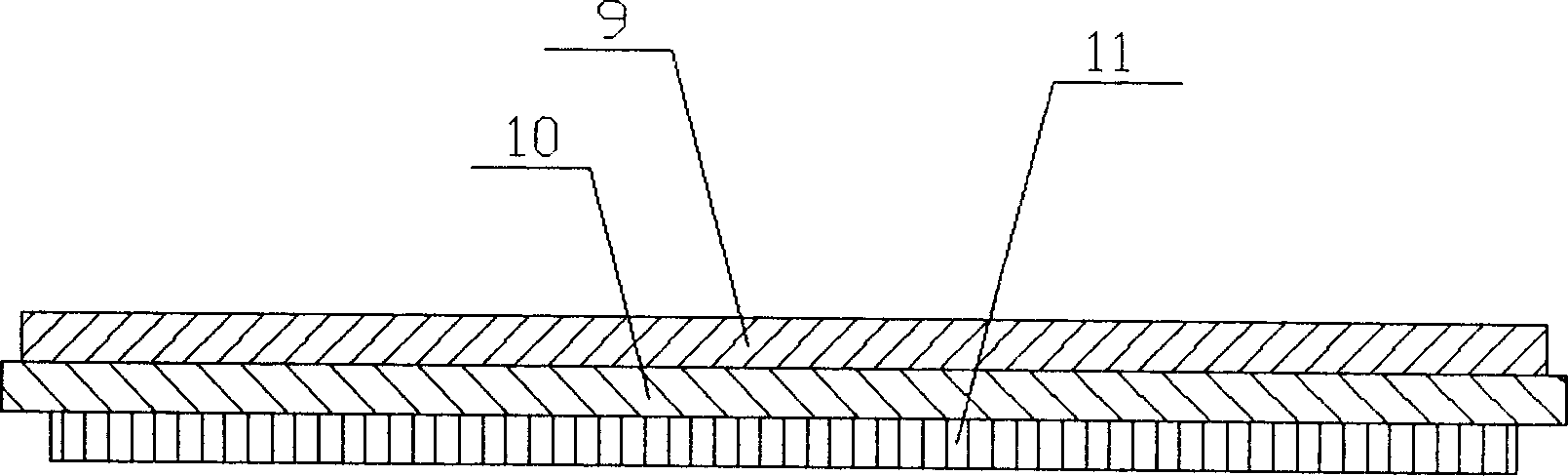

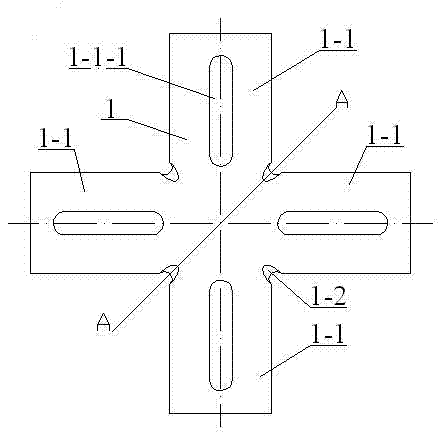

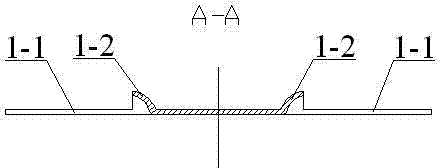

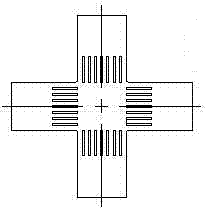

Three-dimensional cross-shaped biaxial tension test piece

InactiveCN101893532AReduce the impactSolve the force problemStrength propertiesEngineeringLarge deformation

The invention provides a three-dimensional cross-shaped biaxial tension test piece. The invention relates to a biaxial tension test piece. The invention solves the problems that stress at the center of the existing cross-shaped test piece is nonuniform and large deformation can not be achieved. The invention is composed of one cross-shaped tension piece (1), the end face at the junction of each two adjacent arms of the four arms (1-1) on the cross-shaped tension piece (1) is provided with a pit (1-2), and the four pits (1-2) are arranged on the same side of the cross-shaped tension piece (1). The invention is used for providing a biaxial tension test piece, so as to test the biaxial tension property of plate and obtain accurate material model.

Owner:HARBIN INST OF TECH

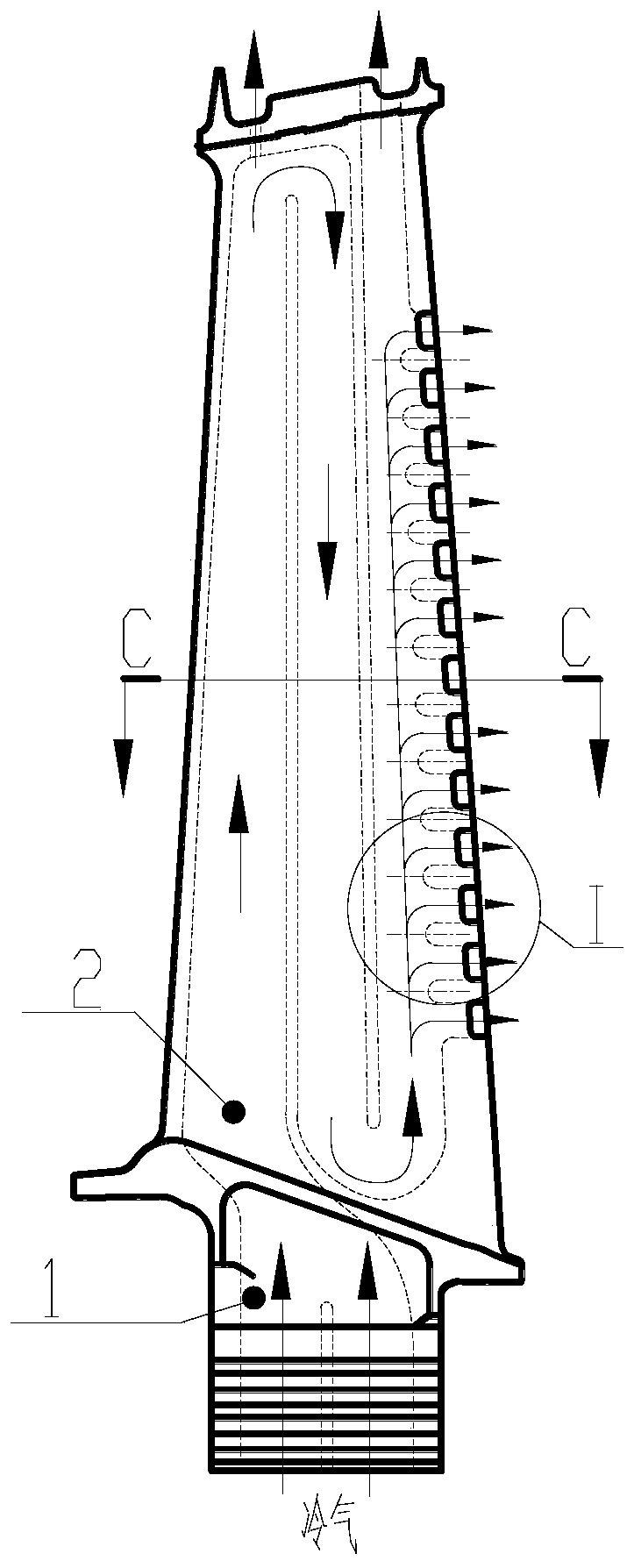

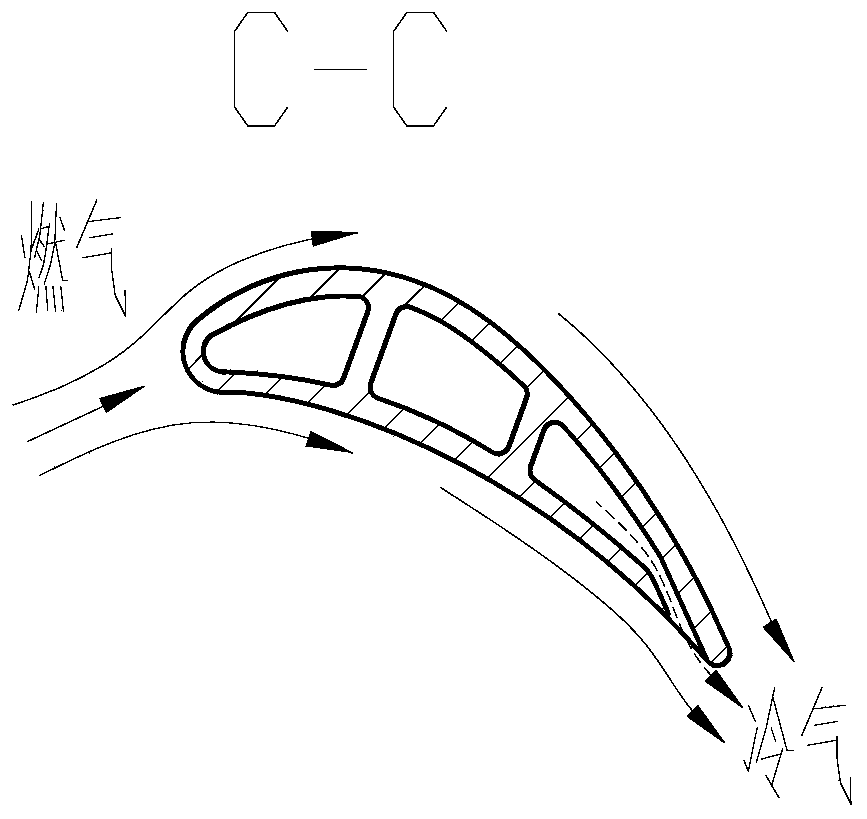

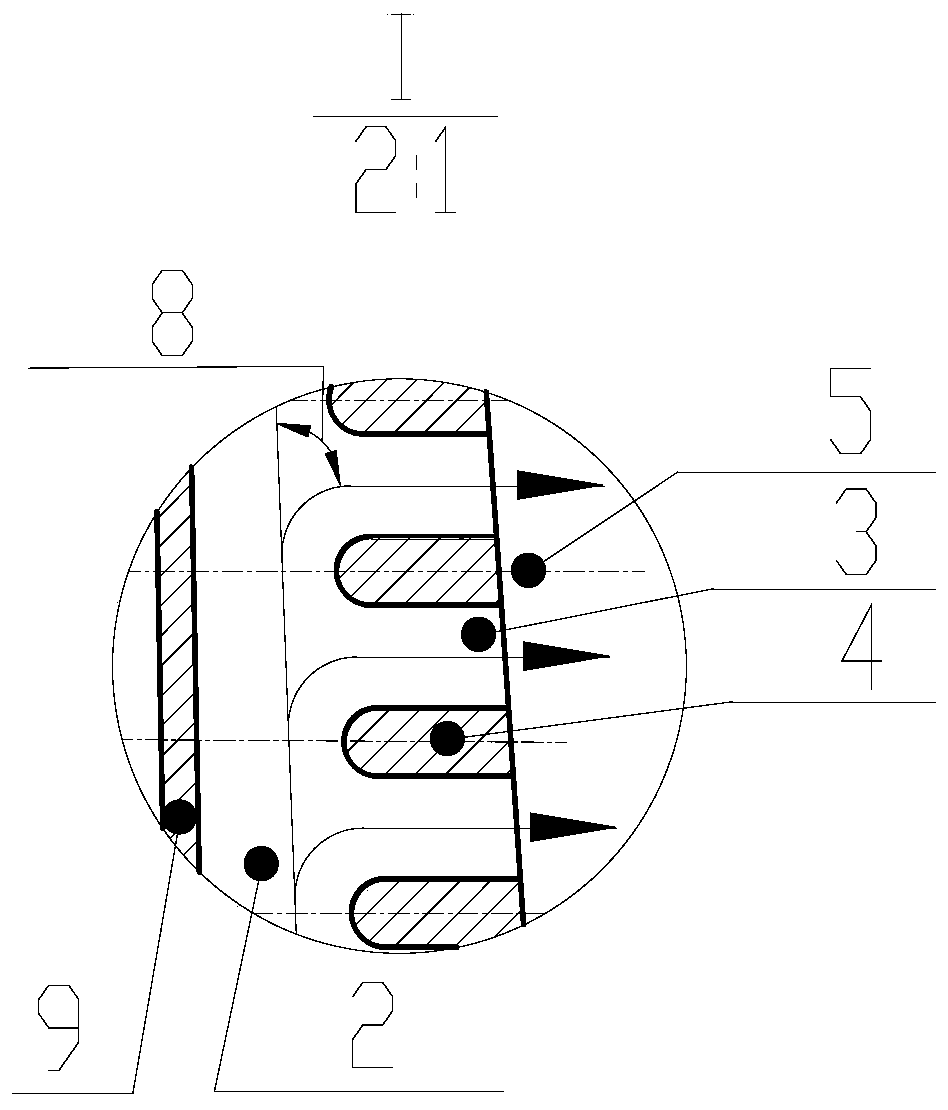

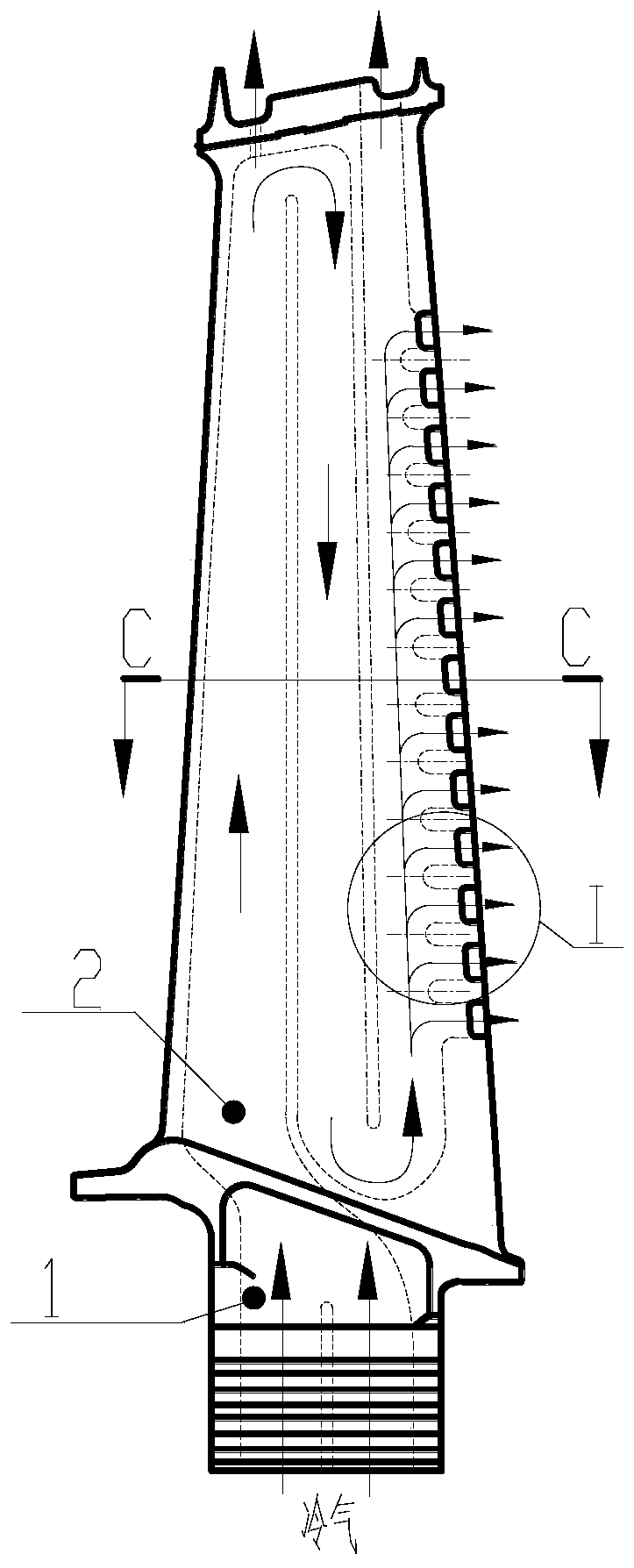

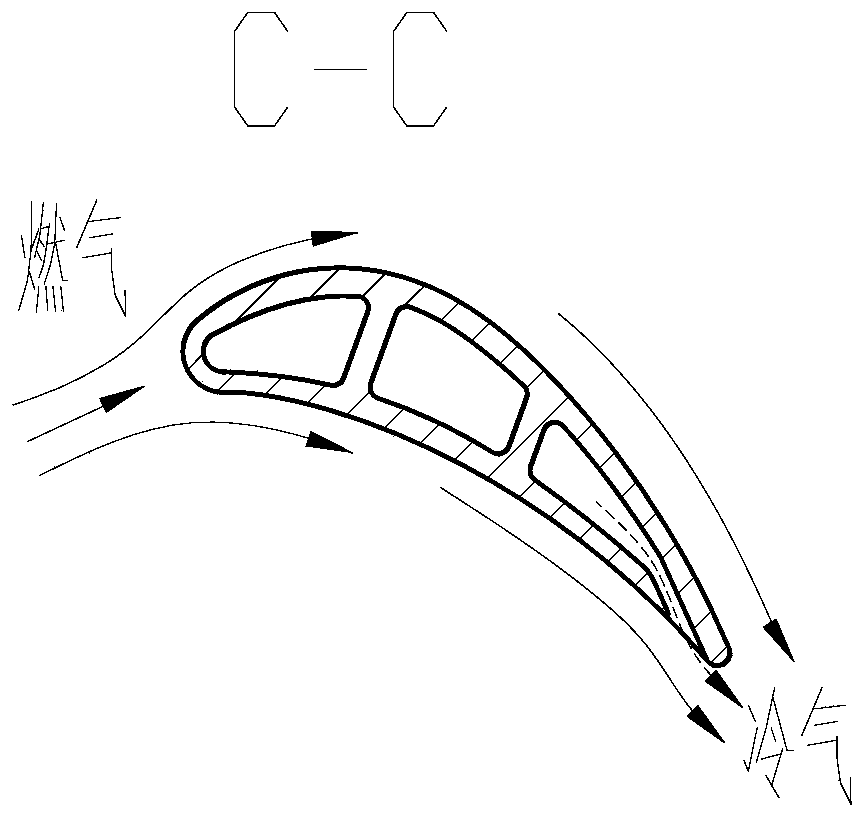

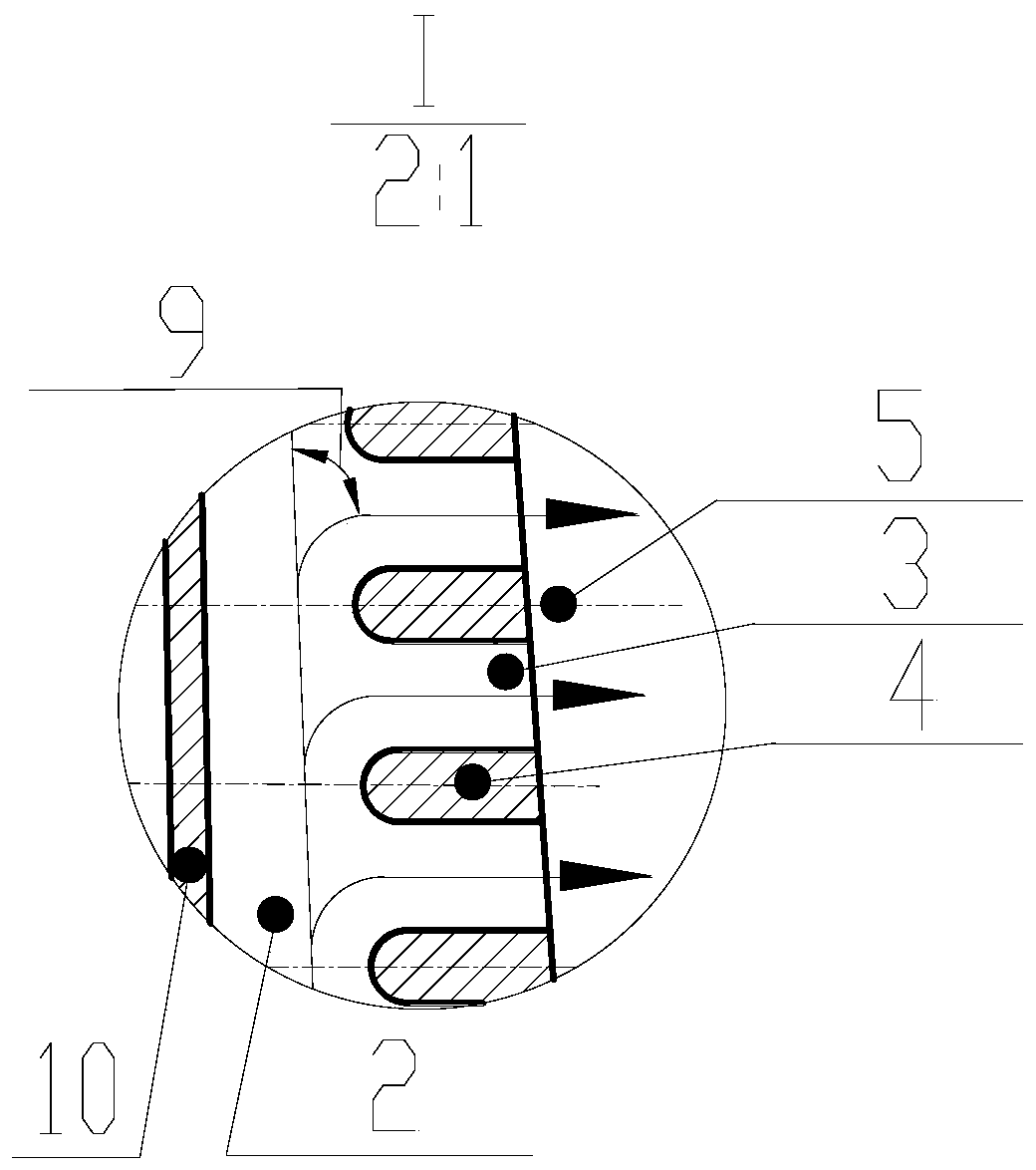

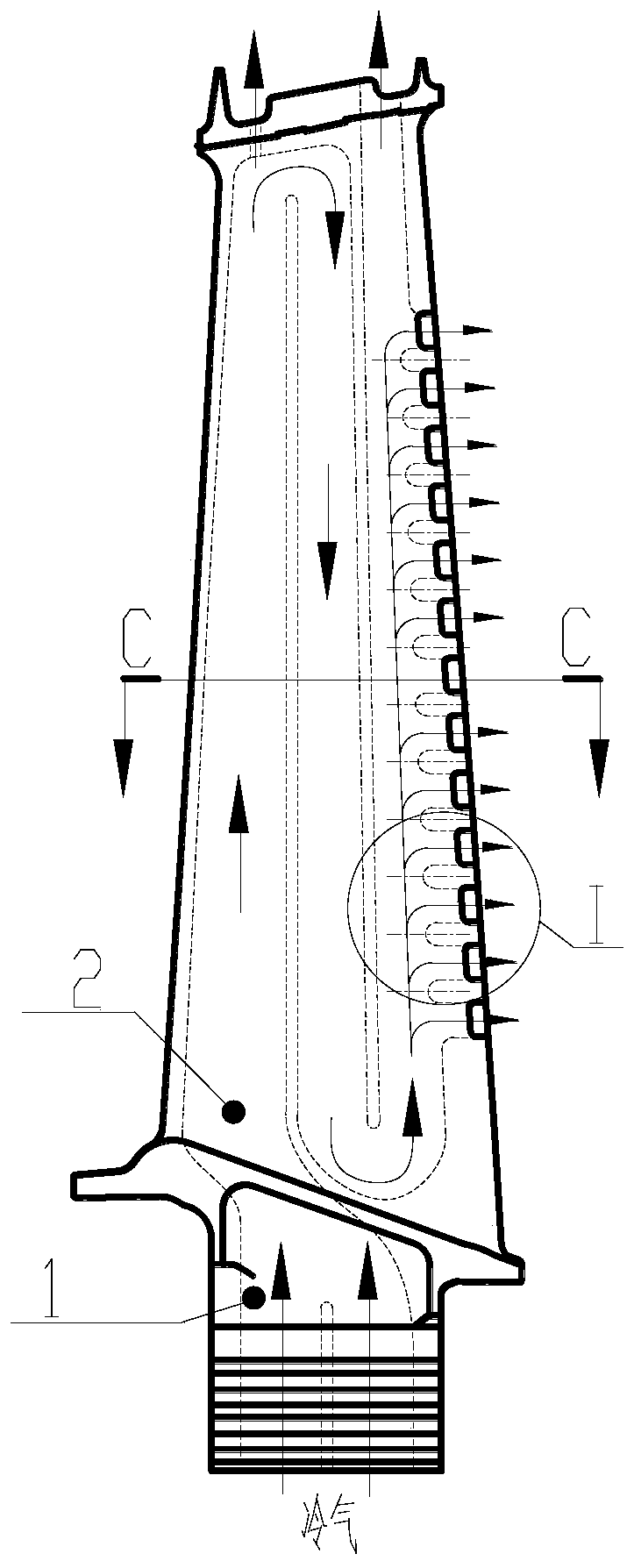

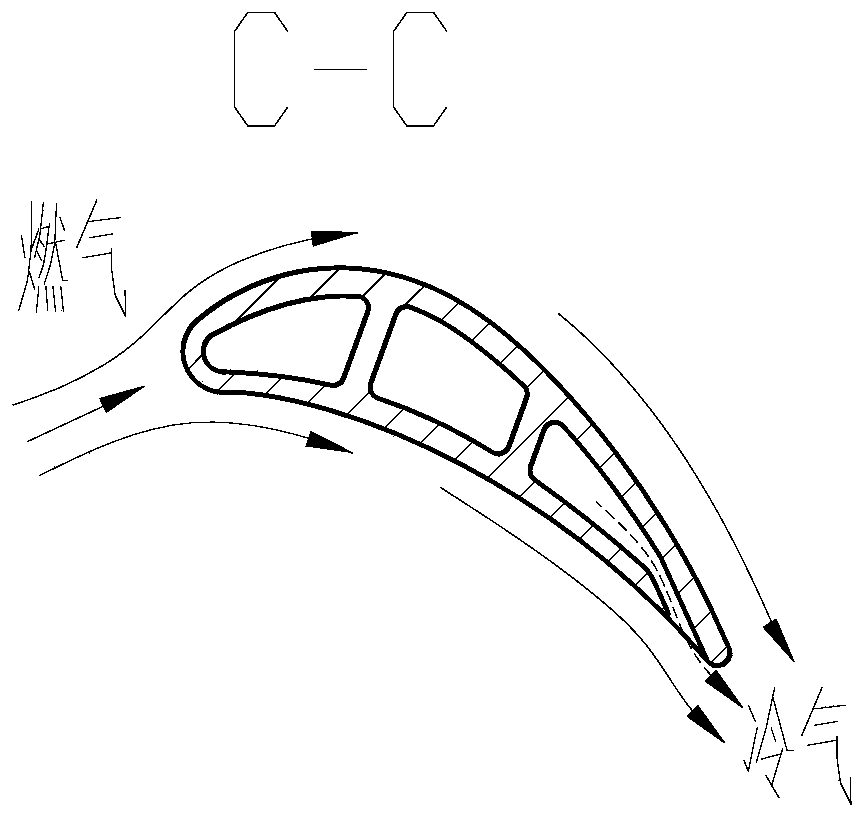

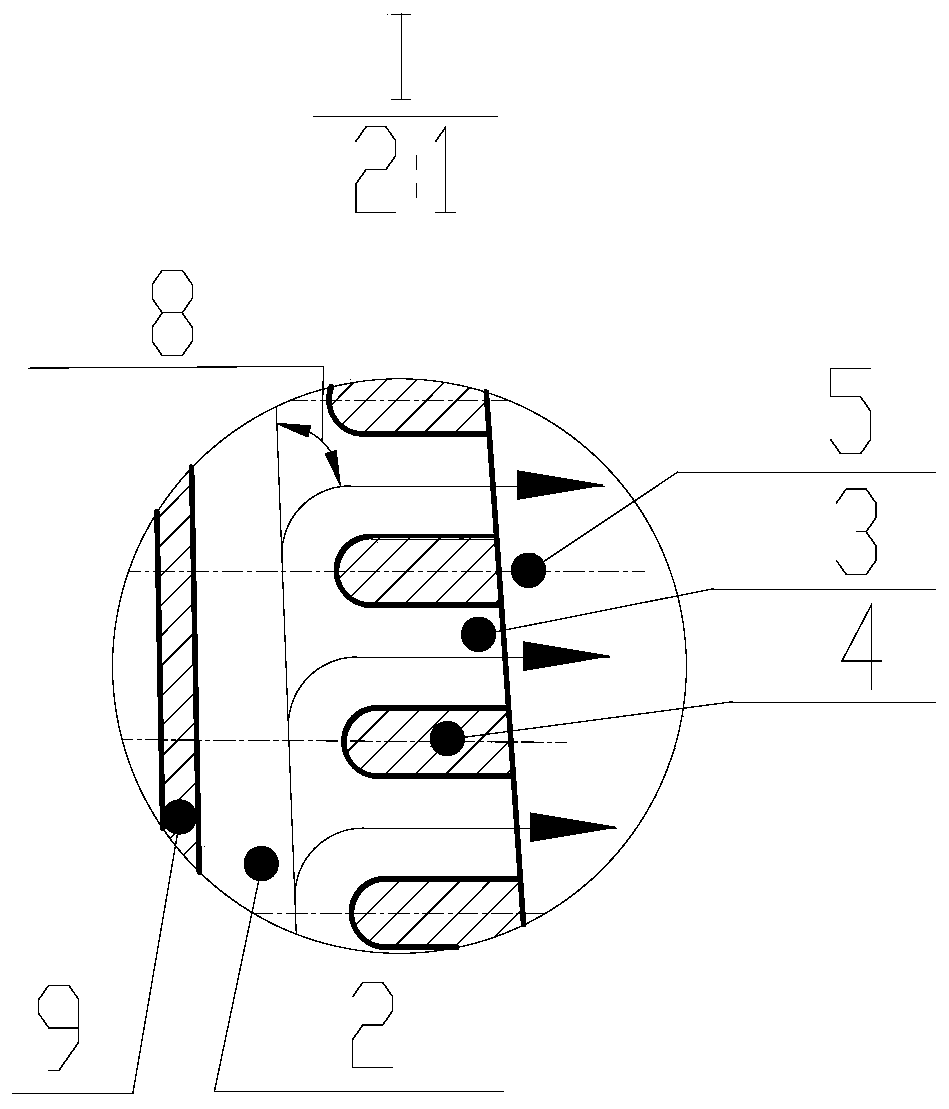

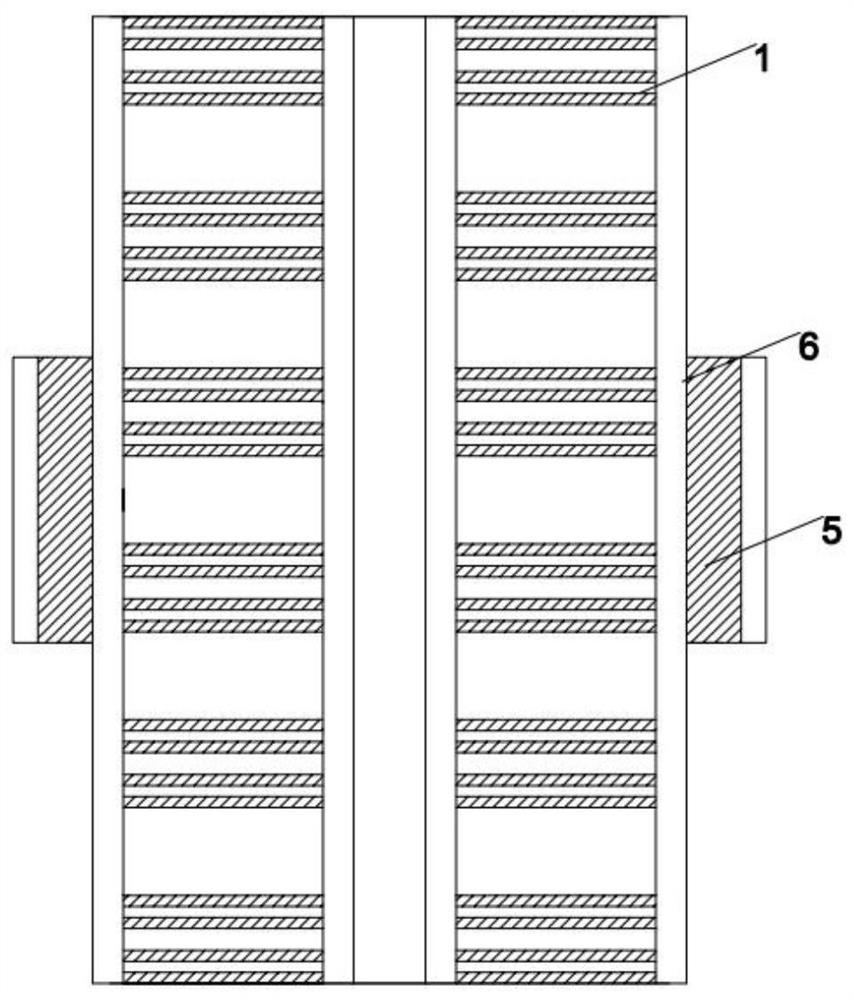

Tapered inclined exhaust splitting seam structure for turbine blade trailing edge

InactiveCN110925027AIncrease flow rateReduce blending lossBlade accessoriesMachines/enginesTurbine bladeCooling effect

The invention belongs to the technical field of aero-engine turbine cooling, and relates to a tapered inclined exhaust splitting seam structure for a turbine blade trailing edge. The inclined exhaustsplitting seam structure comprises a hollow turbine blade, an inner cavity cool air channel, a trailing edge exhaust splitting channel and trailing edge splitting seam partition ribs, wherein the inner cavity cool air channel is formed inside the hollow turbine blade, the trailing edge of the hollow turbine blade is provided with the trailing edge splitting seam partition ribs arranged side by side, and the trailing edge exhaust splitting seam channel is formed between the trailing edge splitting seam partition ribs arranged side by side for allowing cooling air to be discharged out of the blade and meanwhile carrying out air film coverage cooling on the blade trailing edge. According to tapered inclined exhaust splitting seam structure for the turbine blade trailing edge, the cool air canflow much smoothly, so that flow resistance and loss of the cool air in an cavity of the blade is reduced, and the flow resistance can be reduced by about 16%; and through designing an inclined exhaust trailing edge splitting seam into a tapered structure, the outflow speed of the cool air can be improved, internal convection heat exchange is strengthened, an air film coverage dead zone is reduced, in this way, comprehensive cooling effects of the blade trailing edge is further improved while blending loss is reduced, and heat exchange can be enhanced by about 8%.

Owner:DALIAN UNIV OF TECH

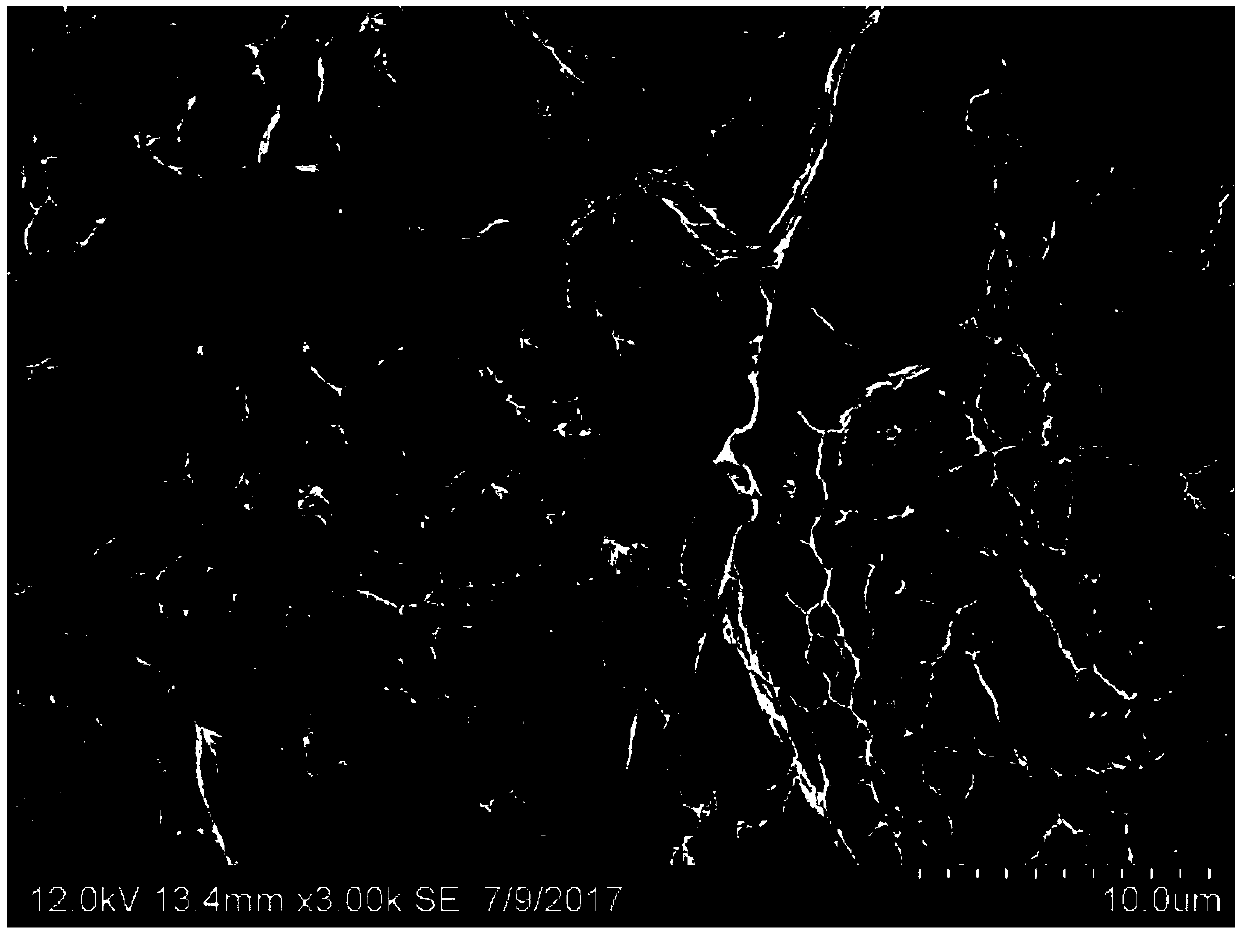

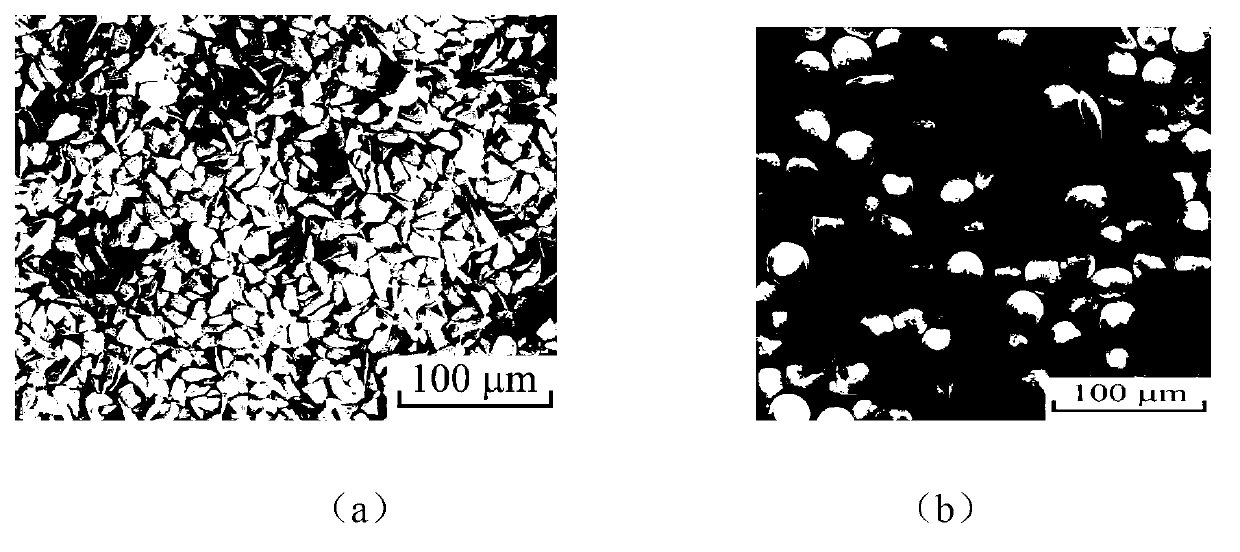

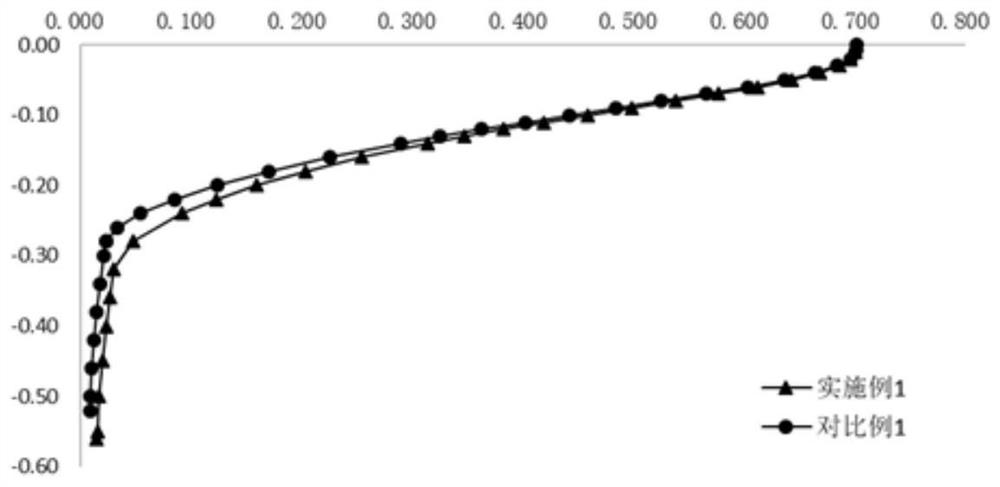

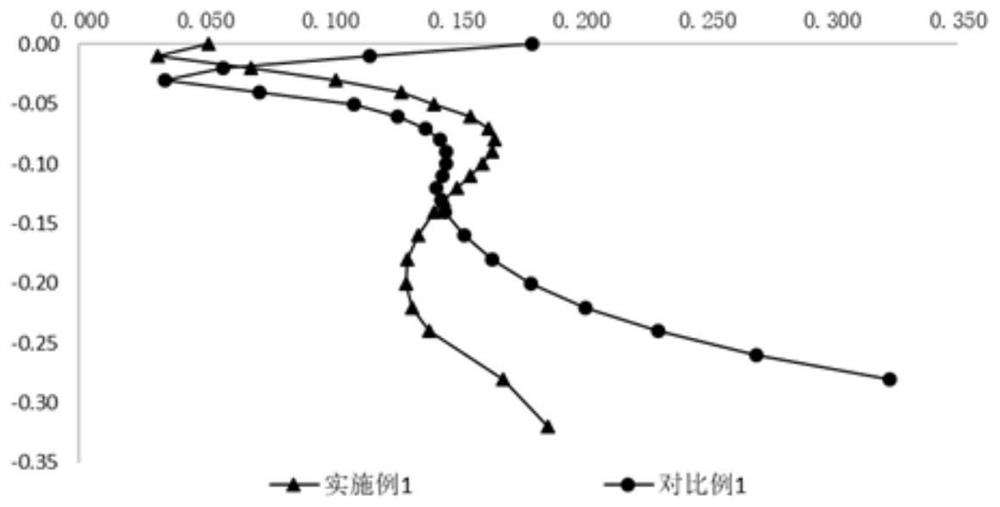

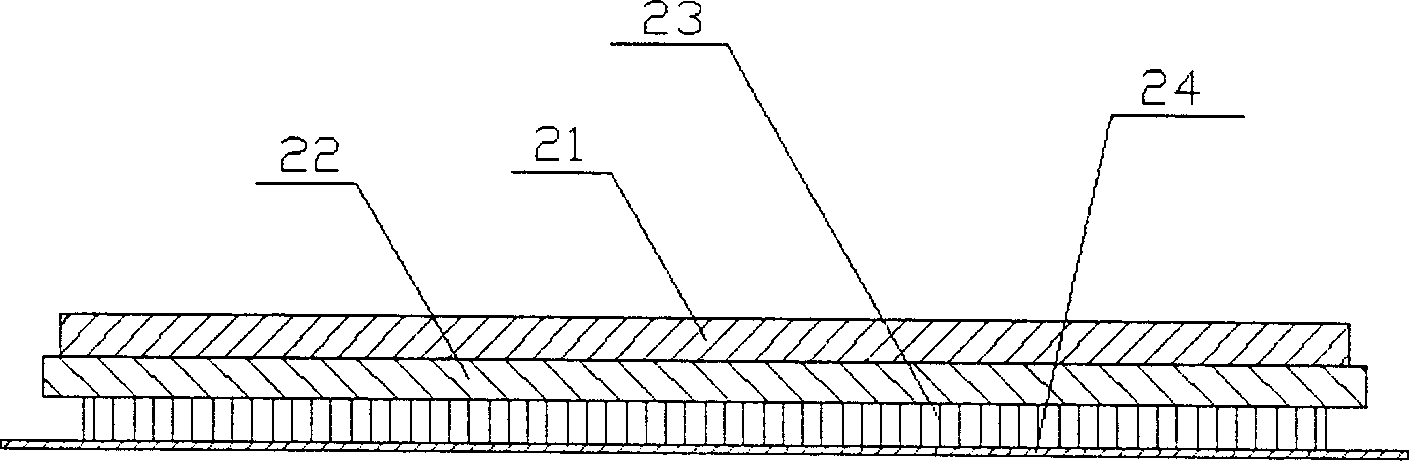

Method for preparing erosion resistive and high-temperature abradable seal coating based on hot spraying

InactiveCN103103473AReduced erosion resistanceIncreased stress levelsMolten spray coatingThermal sprayingLiquid state

The invention discloses a method for preparing an erosion resistive and high-temperature abradable seal coating based on hot spraying. The method comprises the following steps: liquid-solid two-phase particles with molten surfaces are collided and deposited on the surface of a substrate; the temperature of the surface of the substrate is controlled in order to form a phase structure with high hot stability when the liquid states of the liquid-solid two-phase particles are partially condensed; the surface of the substrate is effectively combined with the solid-phase particle in the liquid-solid two-phase particles; the follow-up liquid-solid two-phase particles are deposited on the surfaces of the deposited particles and gradually accumulated to form a depositional layer with a pore structure; and the filling powder with the particle size less than that of the pore structure of the depositional layer or the precursor of the filling powder is filled into communication pores in the depositional layer in form of solid phase or suspension liquid, thus obtaining the erosion resistive and high-temperature abradable seal coating. The seal coating prepared by the method disclosed by the invention is wide in selective scope, holes are uniformly distributed in a coating, the cost is lower, and the method is simple and convenient.

Owner:XI AN JIAOTONG UNIV

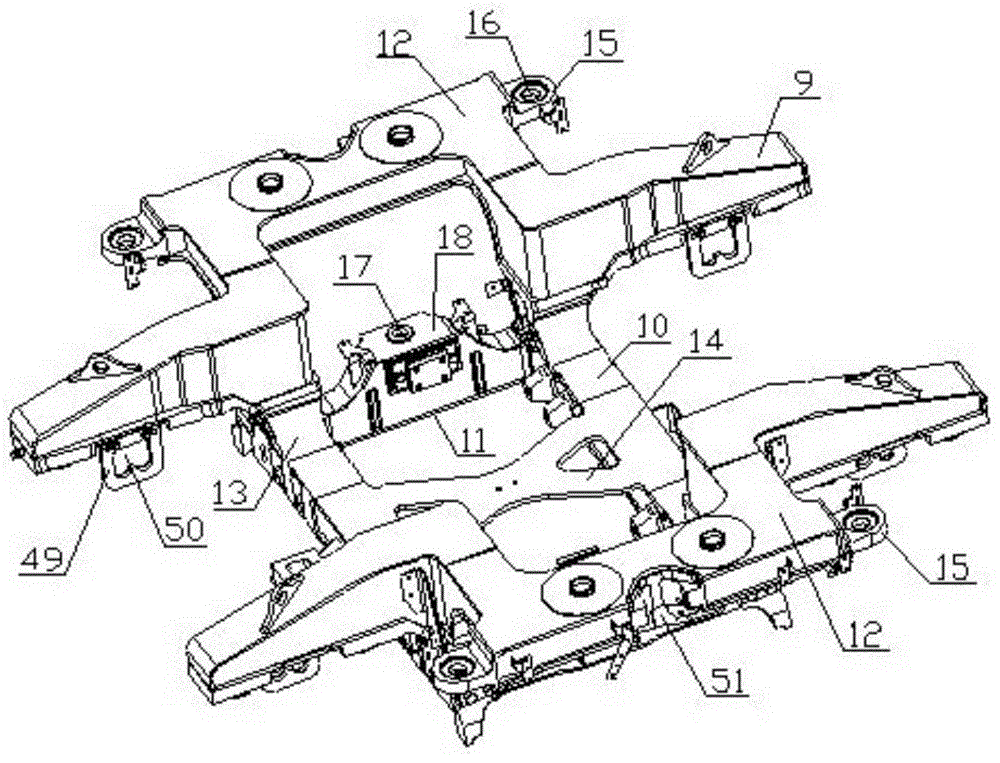

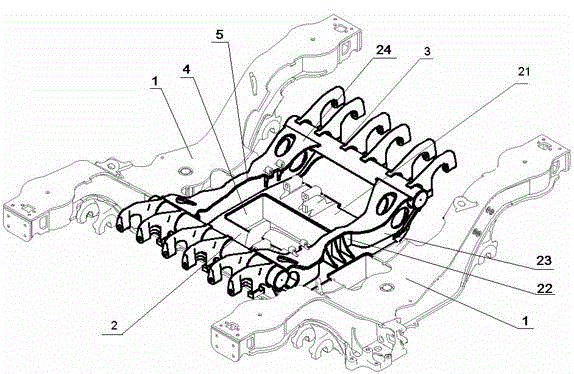

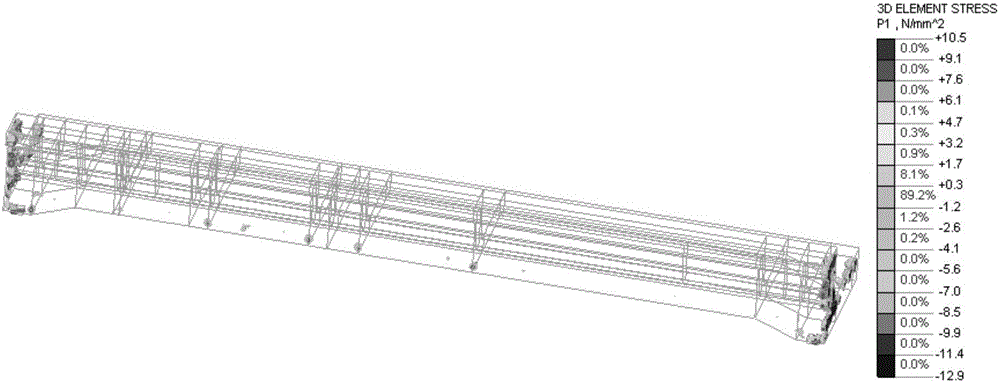

Trailer bogie framework for standard EMU (Electric Multiple Units)

The invention discloses a trailer bogie framework for a standard EMU (Electric Multiple Units). The trailer bogie framework is characterized in that a main body is composed of two side beams and a transverse beam; the body of each of the side beams and the transverse beam is of a box-type welding structure; the side beams and the transverse beam are respectively welded with various types of installation seats; a longitudinal beam is designed at the transverse beam position; braking beams are connected with the transverse beam in a box-type transition manner; meanwhile the box-type structures of the braking beams are also longitudinally connected, so that a dual-longitudinal-beam structure is formed in the transverse beam position. According to the trailer bogie framework for the standard EMU, the box-type structure of a connection region is formed by an upper cover plate of the transverse beam, inner vertical plates of the braking beams, outer vertical plates of the braking beams and upper cover plates of the braking beams, so that the transition connection between the transverse beam and the braking beams is realized, therefore the loaded cross section of the connection region is increased, the stress level of the connection region is improved, and the reliability of the region is improved. Meanwhile, the inner vertical plate of each braking beam is designed to be of an integral structure, and is longitudinally connected with the corresponding braking beam at the rear side, so that an upper longitudinal beam is formed, and torsional moment formed by braking forces of a front shaft and a rear shaft can be absorbed in the upper longitudinal beam, therefore the torsional working condition of the body of the transverse beam is reduced, and the stress state of the connection region between the transverse beam and transverse side beams is also improved. Meanwhile, the geometric cross section of the transverse beam is increased through the formed dual-longitudinal-beam structure, so that the whole strength of the transverse beam is improved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

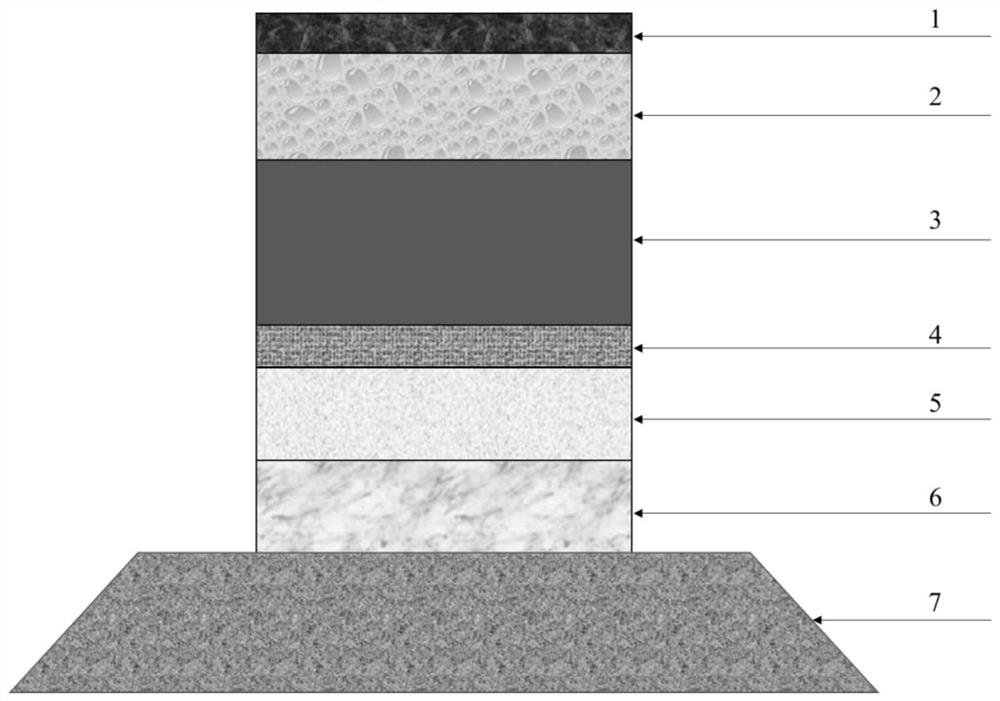

Long-service-life flexible base asphalt pavement structure

ActiveCN112376349AGuaranteed service lifeImproves rutting resistanceIn situ pavingsCrushed stoneStructural engineering

The invention discloses a long-service-life flexible base asphalt pavement structure, and belongs to the technical field of pavement structures. The pavement structure sequentially comprises, from topto bottom: an asphalt concrete upper surface layer with a thickness of 3-6 cm; a high-modulus anti-rutting asphalt concrete middle surface layer with a thickness of 6-12 cm; a high-modulus asphalt concrete lower surface layer with a thickness of 8-16 cm; an anti-fatigue asphalt concrete layer with a thickness of 4-6 cm; a graded broken stone base layer with a thickness of 10-16 cm; a reinforced graded broken stone subbase layer with a thickness of 12-18 cm; a roadbed improvement soil layer. According to the long-service-life flexible base asphalt pavement structure, the defect of inherent reflection cracks existing all the time is overcome, the consumption of non-renewable resource gravel aggregate is reduced from the perspectives of environment and resources, and the problem that the service life design and the service state evaluation of an asphalt pavement are not clear is solved.

Owner:SOUTHEAST UNIV

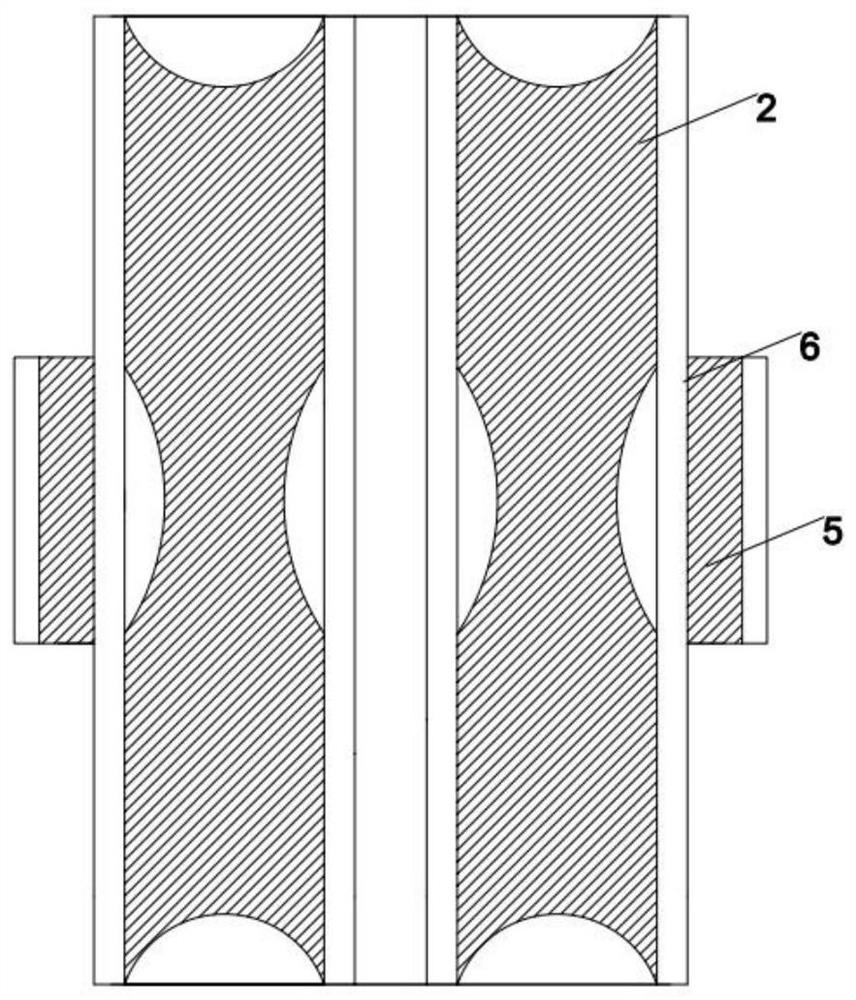

Turbine blade tailing edge curved type exhaust crack structure

ActiveCN111022127ALow flow resistanceReduce flow lossBlade accessoriesMachines/enginesCold airTurbine blade

The invention belongs to the technical field of cooling of aero-engine turbines, and relates to a turbine blade tailing edge curved type exhaust crack structure. The curved type exhaust crack structure comprises hollow turbine blades, inner cavity cold air channels, tailing edge exhaust crack channels and tailing edge crack partition ribs. The inner cavity cold air channels are formed in the hollow turbine blades so that low-temperature cooling air can flow in the blades and cool the blades. The tailing edge crack partition ribs arrayed side by side are arranged on the tailing edges of the hollow turbine blades. The tailing edge exhaust crack channels are formed between the tailing edge crack partition ribs arrayed side by side so that cooling air can be discharged out of the blades. Bladetailing edge cracks are designed to have an inclined curved type exhausting function, the turning angle of the cooling air in the cracks is reduced, the turning process is continuous and gentle, andtherefore the flowing resistance and loss of the cooling air in inner cavities of the blades are reduced, and the flowing resistance can be reduced by about 20%.

Owner:DALIAN UNIV OF TECH

Lead-free solder for electronic packaging

InactiveCN102962599AHigh melting pointImprove wettabilityWelding/cutting media/materialsSoldering mediaElectronic packagingMechanical property

The invention relates to a lead-free solder for electronic packaging. The invention solves the technical problems that: the cost of the conventional high-silver solder is higher, and the mechanical property of the conventional low-silver solder is poor. According to percentage by weightmass, the lead-free solder for electronic packaging is composed of Ag, Cu, Ni, Bi, Sb, Ti and the balance of Sn. By designing and optimizing the solder ingredients, the lead-free solder for electronic packaging, which has excellent properties and is low in cost, is obtained. The addition of a variety of elements takes the complementation between the elements into consideration, consequently, while the properties of a certain element are improved, the other adverse affection is reduced, and thereby therefore the comprehensive properties of the solder are effectively enhanced.

Owner:HARBIN UNIV OF SCI & TECH

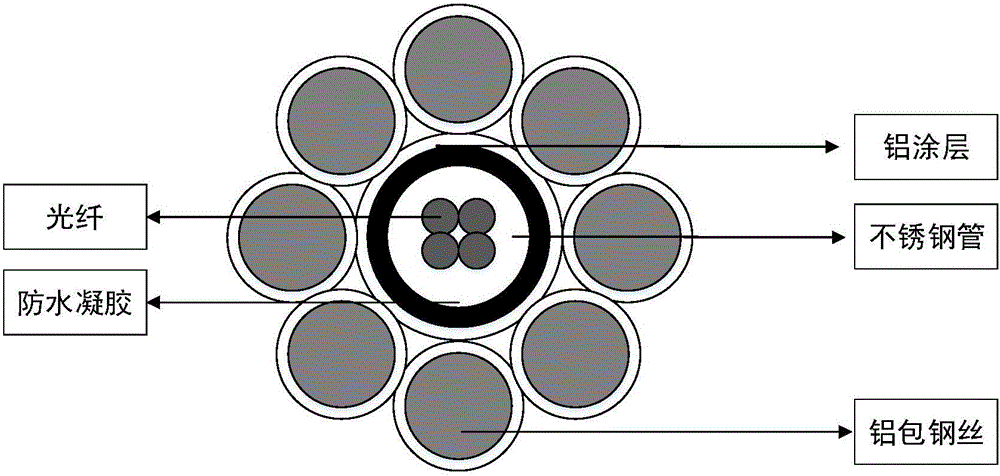

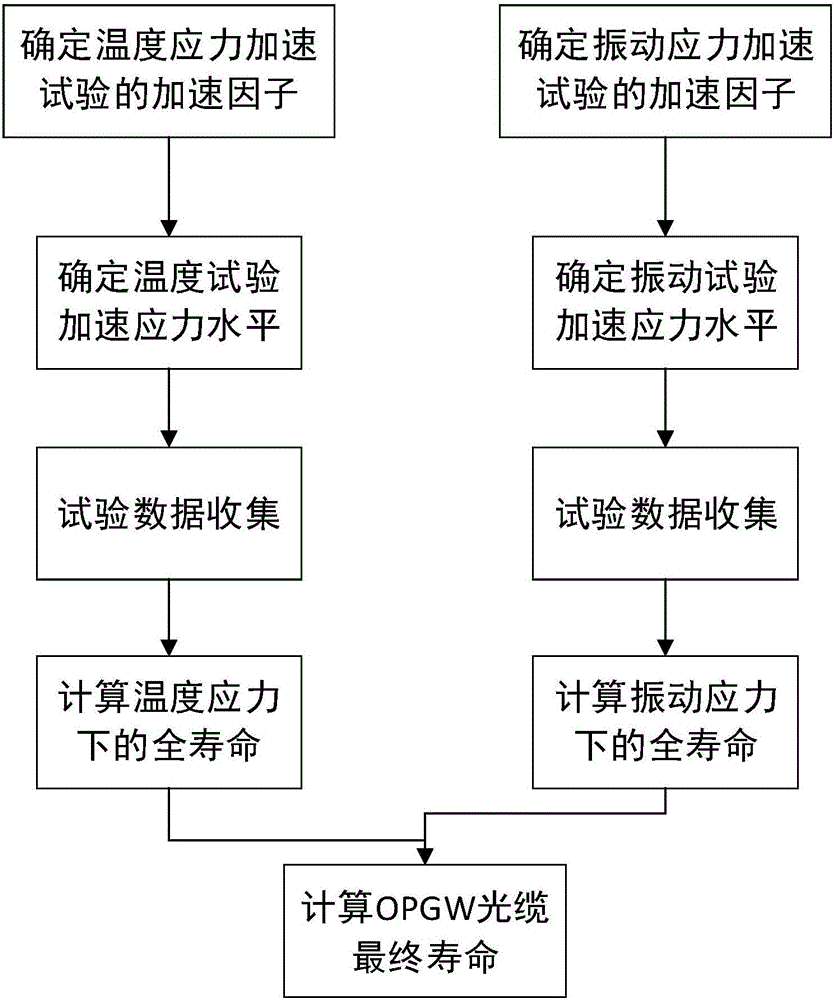

OPGW optical fiber dual-stress accelerated life comprehensive evaluation method

InactiveCN106096213AIncreased stress levelsSpeed up the failure processComputer aided designSpecial data processing applicationsTemperature stressStress level

The invention discloses an OPGW optical fiber dual-stress accelerated life comprehensive evaluation method which comprises the following steps: (I) evaluating the accelerated life based on temperature stress; (II) determining 48 hours as the time of a cycle test of an accelerated life test based on temperature stress, and distributing the test time on different temperature stress levels in a cycle according to the year-round actual use condition of the OPGW optical cable; (III) determining the conversion coefficient K(temperature) value; and in combination with the test time, obtaining the whole-life T(temperature) of the OPGW optical cable; (IV) evaluating the accelerated life based on vibration stress; (V) determining 48 hours as the time of a cycle test of an accelerated life test based on vibration stress and W(de) as the stress level; (VI) determining the conversion coefficient K(vibration) value; and in combination with the test time, obtaining the whole-life T(vibration) of the OPGW optical cable; and (VII) obtaining the whole-life value T=min{T(temperature), T(vibration)} of the OPGW optical cable according to the whole-life T(temperature) of the OPGW optical fiber under temperature stress obtained in the step (III) and the whole-life T(vibration) of the OPGW optical fiber under vibration stress obtained in the step (VI).

Owner:BEIHANG UNIV +2

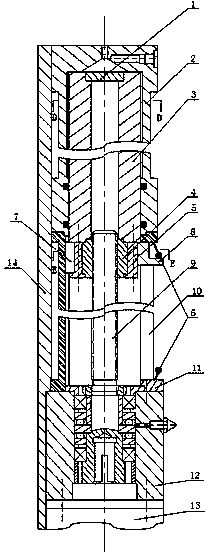

Electrostatic force driven apparatus for testing resonant two-side flexural-tensile fatigue of microstructure

InactiveCN1800815AAvoid clamping and centeringIncreased stress levelsMaterial strength using repeated/pulsating forcesMicrostructureTensile fatigue

The invention discloses a microstructure resonance dual-side bending fatigue experiment device driven on electrostatic force, which comprises: an electrode connected to ac and fixed lifetime with two side arms by the bottom electrode layer, another electrode grounding, a structure layer crossed opposite to said fixed comb and connected to a suspension comb with side arms, a horizontal side arm between two fixed combs connected to the ac electrode, a T-shaped side arm between two suspension combs and with horizontal side arm connected to suspension combs and vertical side arm connected to the grounding electrode by suspension beam as the fatigue test piece. This invention improves greatly the strain level of test piece.

Owner:BEIJING UNIV OF TECH

Turbine blade trailing edge fold line type exhaust split seam structure

ActiveCN110748384AIncrease widthLower temperature levelBlade accessoriesMachines/enginesCold airTurbine blade

The invention belongs to the technical field of aero-engine turbine cooling, and relates to a turbine blade trailing edge fold line type exhaust split seam structure. The turbine blade trailing edge fold line type exhaust split seam structure comprises a hollow turbine blade, an inner cavity cold air channel, a trailing edge exhaust split seam channel and trailing edge split seam partition ribs, wherein the inner cavity cold air channel is formed in the hollow turbine blade, and low-temperature cooling gas flows in the blade to cool the blade; the trailing edge split seam partition ribs arranged side by side are arranged on the trailing edge of the hollow turbine blade; and the trailing edge exhaust split seam channel is formed between the trailing edge split seam partition ribs arranged side by side. According to the turbine blade trailing edge fold line type exhaust split seam structure, a trailing edge exhaust split seam is designed into an inclined fold line type exhaust mode, theturning angle of the cooling gas in the split seam is reduced, and cold air is turned twice or multiple times instead of being turned once, so that the flow resistance and loss of the cold air in an inner cavity of the blade are reduced, and the flow resistance can be reduced by about 19%.

Owner:DALIAN UNIV OF TECH

Titanium-alloy-containing cast steel roller and production process thereof

InactiveCN110952027AImprove wear resistanceImprove hardenabilityFoundry mouldsFurnace typesAustenite grainTitanium

The invention discloses a titanium-alloy-containing cast steel roller and a production process thereof. The titanium-alloy-containing cast steel roller comprises the following chemical components of,in percentage by mass, 0.6%-1.2% of C, 0.2%-1.0% of Si, 0.5%-1.2% of Mn, 0%-0.03% of P, 0%-0.03% of S, 0.6%-2.0% of Cr, 0.60%-1.0% of Ni, 0.2%-0.6% of Mo, 0.2%-0.5% of Ti, and the balance Fe and inevitable impurities. According to the titanium-alloy-containing cast steel roller and the production process thereof, elements such as the Cr, the Ni, the Mo and the Ti can improve toughness, abrasion resistance and hardenability, and the Ti plays a role in refining grains and reducing enrichment of harmful aluminum oxide; TiN particles separated out of steel can remove the influence of nitrogen on the steel and preventing excessive growth of austenite grains in the roller heat treatment process, and early perfect recrystallization is ensured, so that the austenite structure is refined, and the performance of the roller is enhanced; TiC separated out of the steel has high microhardness, and wear-resistant particles are formed in a material, so that the wear resistance of the roller is furtherimproved; and meanwhile, the added content is proper, and the production cost is reduced while the performance of the roller is ensured.

Owner:江苏凯达重工股份有限公司

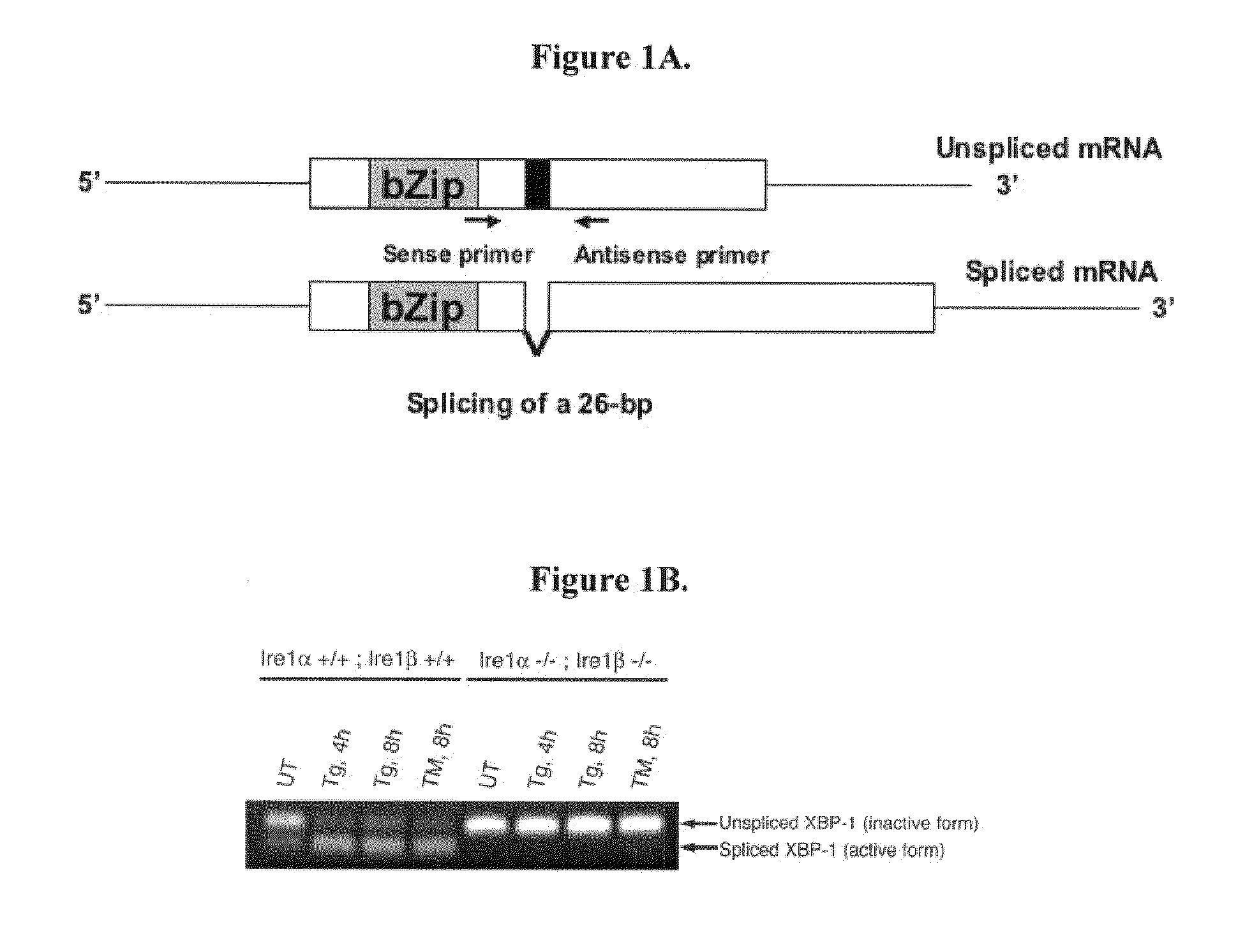

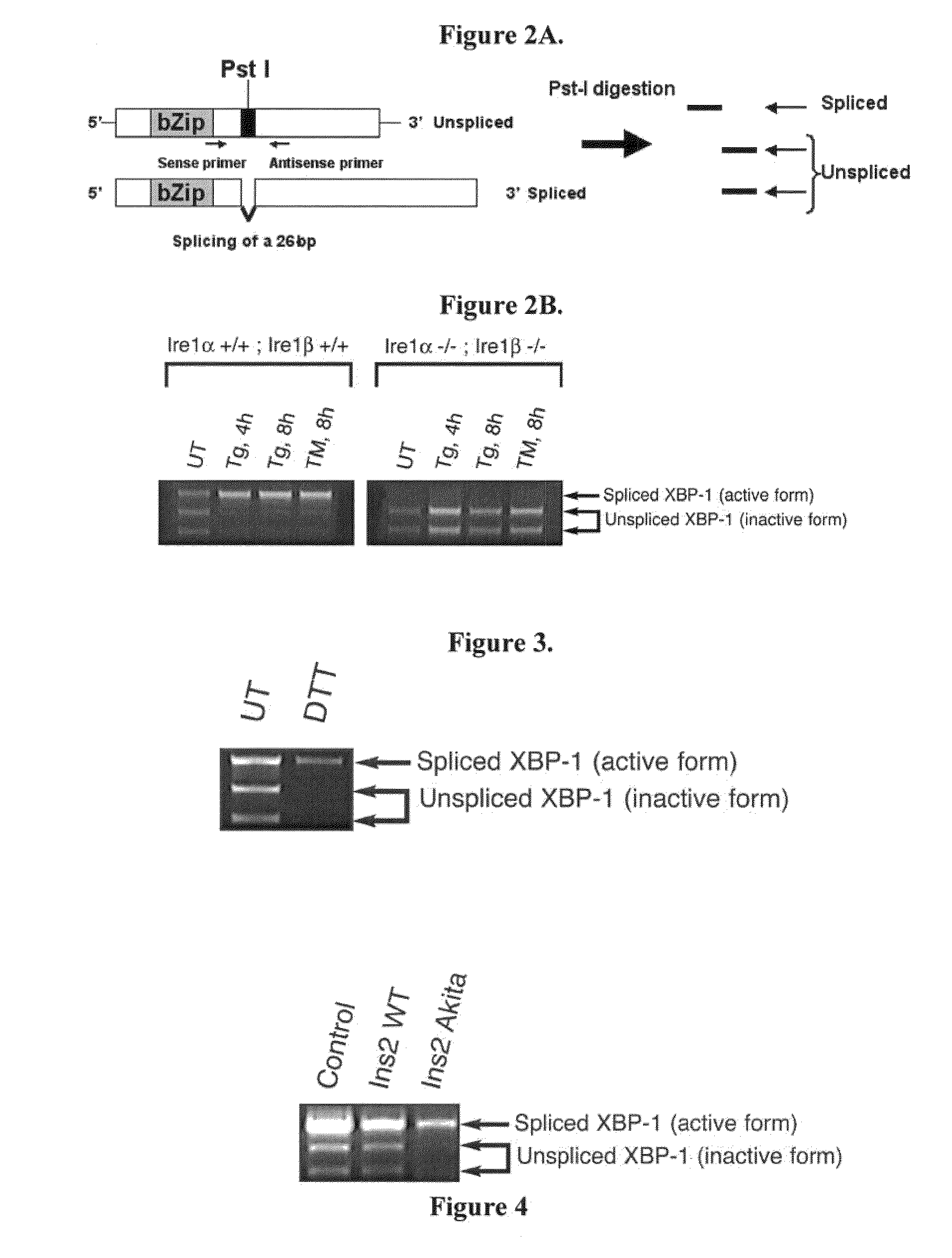

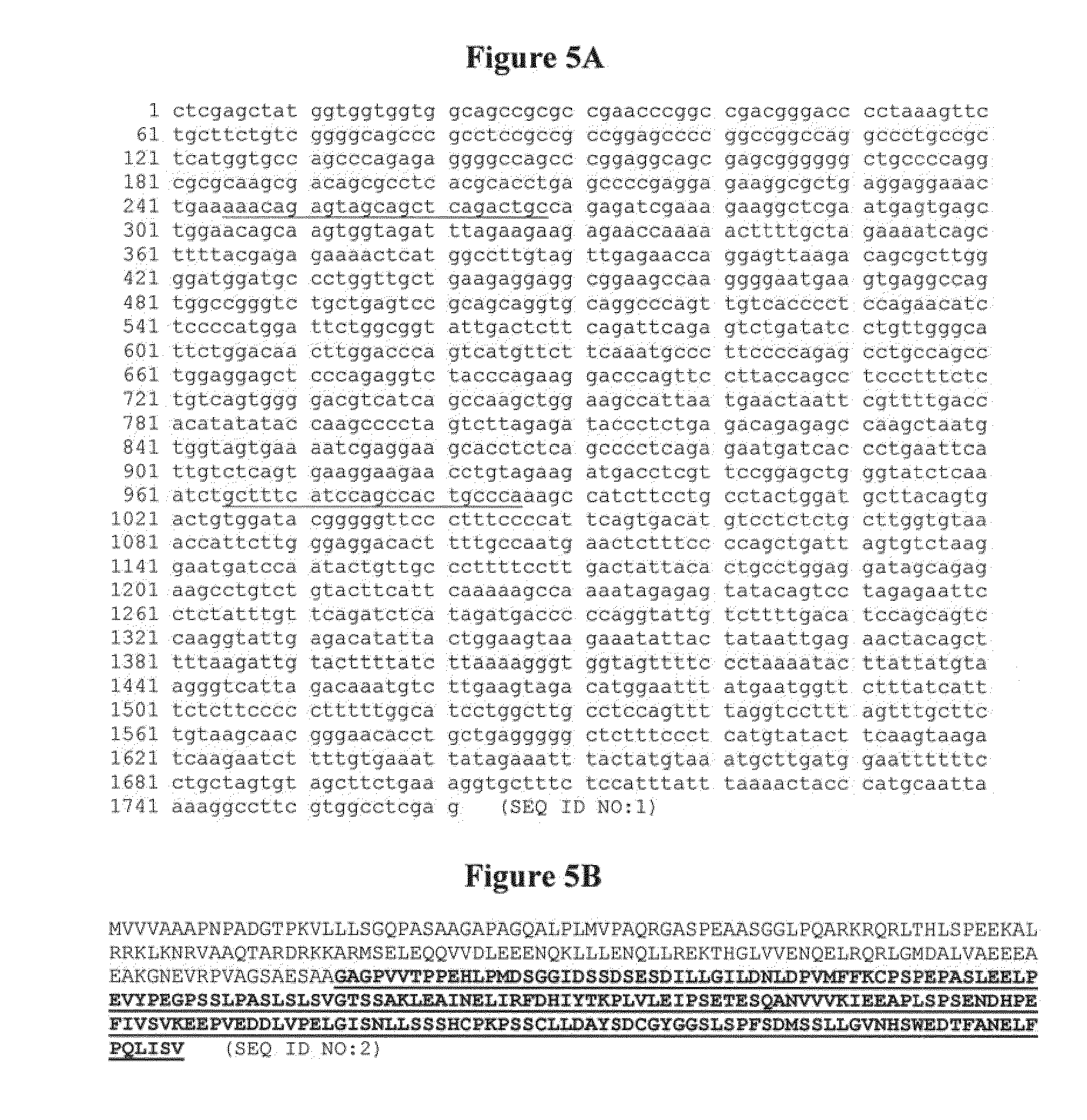

Methods for Diagnosing and Treating Endoplasmic Reticulum (ER) Stress Diseases

InactiveUS20100221743A1Increased stress levelsBiocidePeptide/protein ingredientsDiabetes mellitusDisease

The present invention provides methods and reagents to quantify endoplasmic reticulum stress (ER stress) levels, and methods and compounds for treating ER stress disorders such as diabetes. Methods for quantifying ER stress in mammalian cells are exemplified.

Owner:UNIV OF MASSACHUSETTS

Microstructure resonance single direction bending pulling multiaxle fatigue experimental device

InactiveCN1793827AAvoid clamping and centeringIncreased stress levelsMaterial strength using repeated/pulsating forcesMicrostructureTest sample

A resonant one¿Cway bending and multiaxial fatigue test device of microstructure is prepared as fixing the driving electrode on outer side wall of silicon substrate through anchored layer then connecting it to driving broach pair; fixing the detecting electrode on outer side wall of silicon substrate through anchored layer then connecting it to detecting broach pair; connecting end portion of suspension vibrating block between driving broach and detecting broach to one end of test sample generating alternative stress; connecting another end of test sample to earthing electrode and forming test sample, driving unit and detecting unit to be an integral structure.

Owner:BEIJING UNIV OF TECH

Box type web simply supported U-shaped girder of double-track railway

InactiveCN105696455AStrong torsion resistanceImprove torsional load capacityBridge structural detailsStress levelPre stress

The invention discloses a box type web simply supported U-shaped girder of a double-track railway. The box type web simply supported U-shaped girder comprises a roadbed slab; a set of edge box girders is symmetrically arranged at two side end parts of the width direction of the roadbed slab; end cross beams are arranged at two end bottoms of the length direction of the roadbed slab; the roadbed slab is provided with multiple weep holes at intervals in the length direction; the edge box girders extend out from two sides of the roadbed slab, and are hollow cavity structures; multiple first longitudinal prestressed tendons parallel to the length direction of the roadbed slab and multiple transverse prestressed tendons parallel to the width direction of the roadbed slab are arranged in the roadbed slab and a baseplate; multiple second longitudinal prestressed tendons parallel to the length direction of the roadbed slab are arranged in the side walls of the hollow cavities; and multiple vertical prestressed tendons are arranged in the side walls of the hollow cavities at intervals. The box type web simply supported U-shaped girder is higher in torsion resistance and horizontal resistance, is excellent in all beam stress level, has no web splitting problem, needs no additional powerful web stiffening ribs, is simple in structure, and can reach maximum horizontal width.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Electrostatic force driven apparatus for testing resonant one-way flexural-tensile fatigue of microstructure

InactiveCN1789959AAvoid interferenceIncrease vibration amplitudeMaterial strength using repeated/pulsating forcesVibration amplitudeResonance

The invention discloses a unidirectional bending fatigue test device of microstructure resonance based on driving electrostatic force, which is characterized by the following: the lateral wall of fixing comb connects the AC electrode; the hung comb connects the ground electrode through the connection bridge and fixing block on the base, which interlaces the fixing comb; one end of connection bridge is the middle point of connection arm of hung comb; the other end is fixed on the lateral arm of base through anchor layer; the connection bridge is the fatigue sample. The invention contains broader comb without relative rotation between hung and fixing comb, which avoids the interference of two combs to generate more vibration amplitude.

Owner:BEIJING UNIV OF TECH

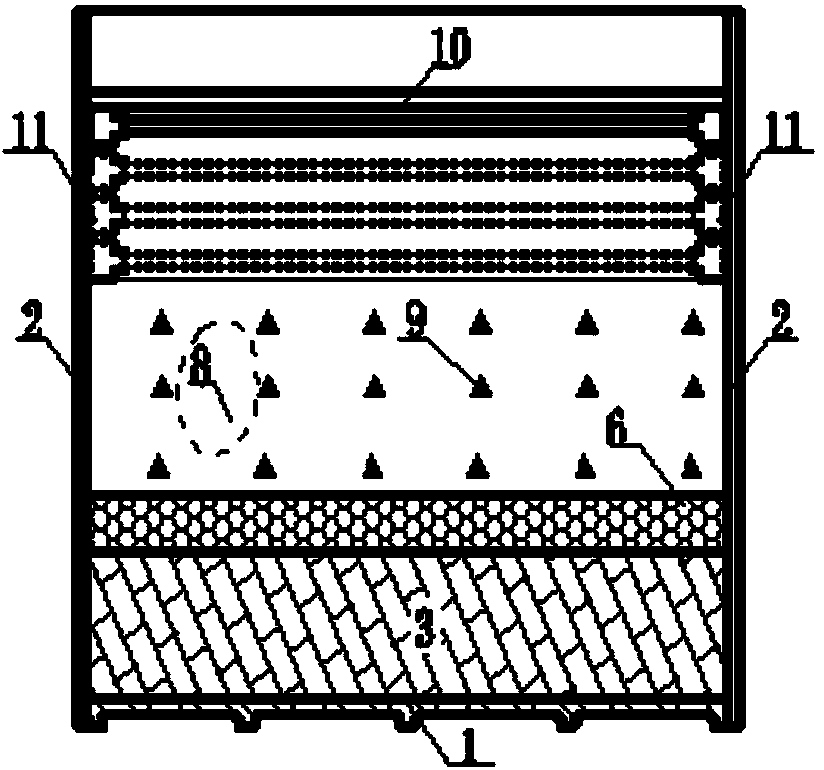

Unsaturated soil water-gas motion combined determination triaxial apparatus

ActiveCN111413263AReal-time monitoring of changesInvestigate humidification deformation characteristicsPermeability/surface area analysisSuction stressAxial pressure

The invention discloses an unsaturated soil water-gas motion combined determination triaxial apparatus. The triaxial apparatus comprises an actuating system, a seepage pressure chamber and a control system for controlling the actuating system and the seepage pressure chamber, wherein the seepage pressure chamber comprises a frame formed by combining a base, a stand column and a cross beam; a hydraulic mechanism is mounted in the center of the base; the top of the hydraulic mechanism abuts against the bottom of the test piece seat; a confining pressure cylinder which is used for containing a test piece and is provided with a confining pressure air inlet pipe is arranged on the test piece seat; an upper pressure head and a sample holder are respectively arranged at the upper part and the lower part of the confining pressure cylinder; a pressure rod is immovable when axial pressure is applied, an upper pressure head is ejected, argil plates and waterproof breathable films are arranged onthe lower surface of the upper pressure head and the upper surface of the sample holder in a crossed manner, and the argil plates and the waterproof breathable films are respectively connected with water-phase and gas-phase volume and pressure controllers through pressure sensors. The water-gas two-phase permeability coefficient of the soil sample can be measured under the condition of controllingthe matrix suction of the soil sample, and the change characteristics of the matrix suction along the height direction of the soil sample can be quantitatively described.

Owner:XIAN UNIV OF TECH

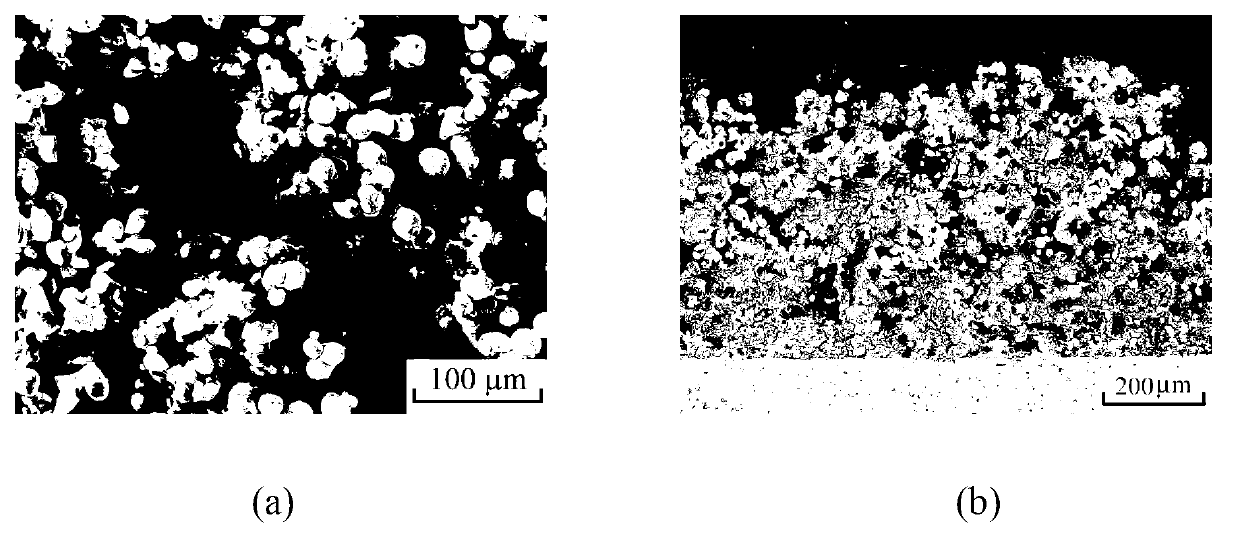

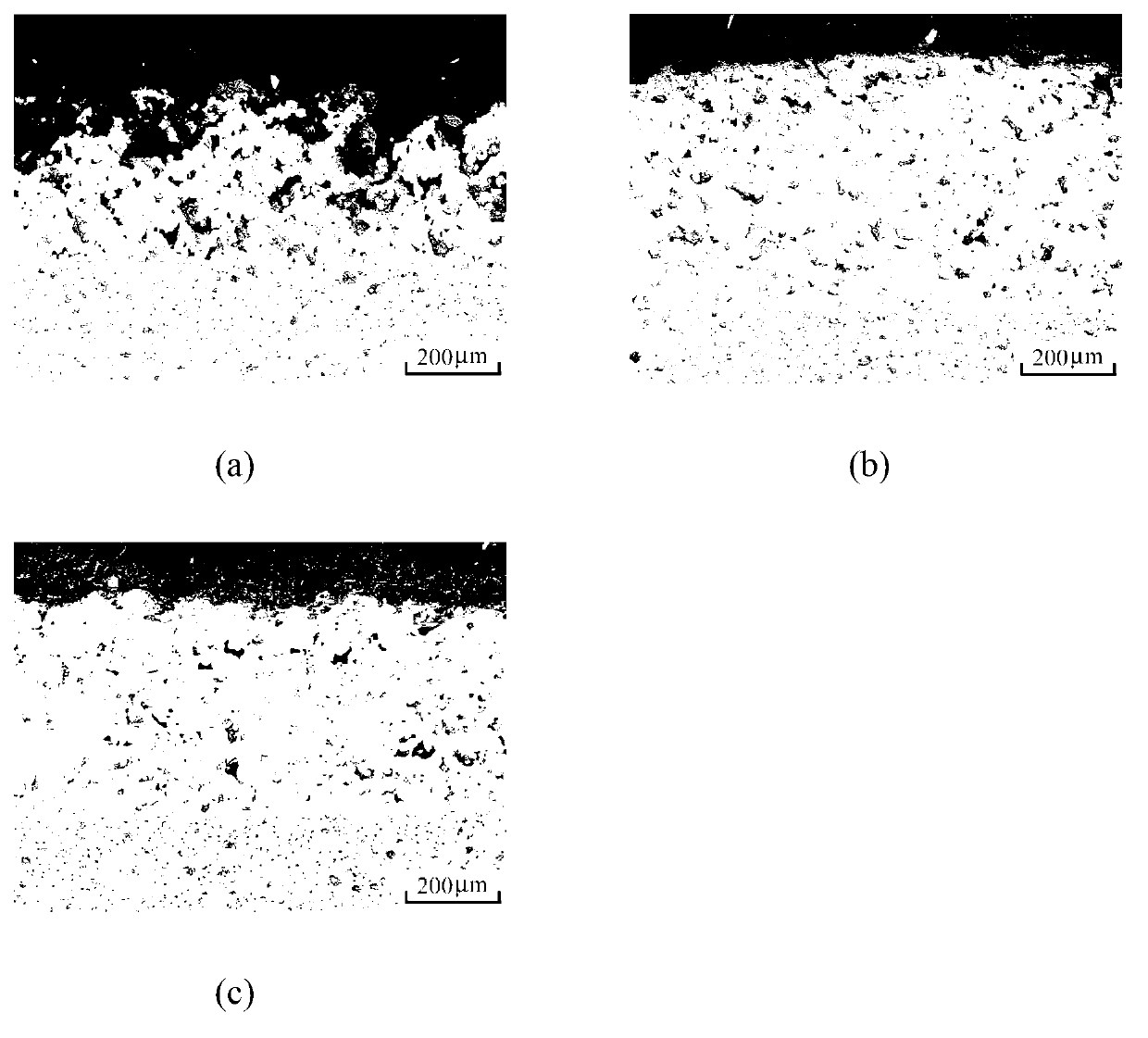

Titanium-nickel alloy anti-cavitation thermal spraying powder and method for preparing thermal spraying coating

ActiveCN111270187AHigh bonding strengthImprove cavitation resistanceMolten spray coatingTransportation and packagingSurface engineeringNiti alloy

The invention discloses titanium-nickel alloy anti-cavitation thermal spraying powder and a method for preparing a thermal spraying coating and belongs to the technical field of surface engineering. The titanium-nickel alloy anti-cavitation thermal spraying powder working layer is prepared by adopting 58% of nickel-titanium alloy powder and 42% of titanium-coated nickel powder, and a titanium-coated nickel powder transition layer with the thickness of 10 micrometers-2 millimeters is arranged between the working layer and a base body; the bonding strength between the working layer and the basebody is enhanced, a beta-phase structure in the nickel-titanium alloy powder is of a body-centered cubic structure, and particle structures of the nickel-titanium alloy powder and the titanium-coatednickel powder each are of a spherical structure. By using the NiTi alloy beta-phase structure of the body-centered cubic structure, the slippage system in the crystal is reduced, the stress level of the slippage is increased, the surface of the alloy has good wear resistance, and the formed coating has high cavitation resistance, high erosion resistance and high bonding strength and is suitable for large-area use of water conservancy machines.

Owner:XIAN YUFENG SPRAYING TECH CO LTD

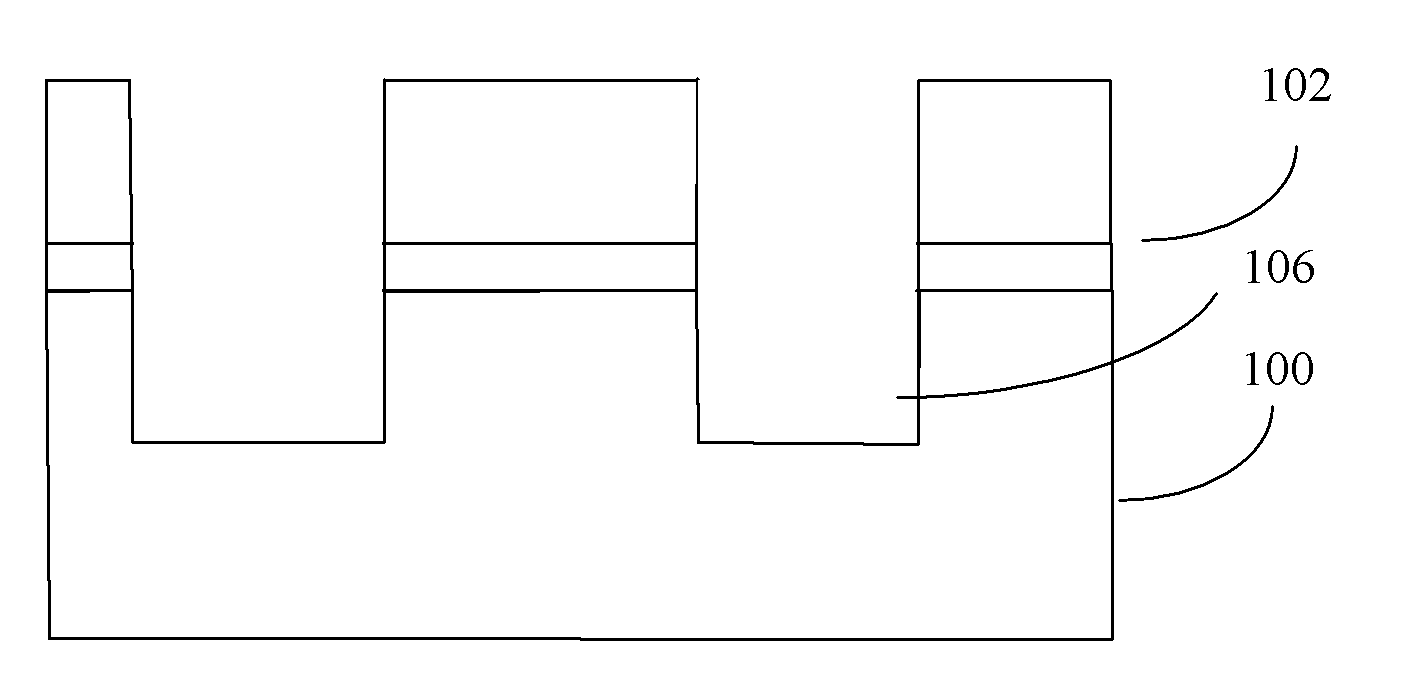

Shallow groove isolation structure and manufacturing method thereof

ActiveCN103681446AEliminate chargeImprove performanceTransistorSemiconductor/solid-state device manufacturingDielectricSemiconductor

The invention relates to a shallow groove isolation structure and a manufacturing method thereof. The method comprises the following steps: providing a semiconductor substrate; forming at least one groove in the semiconductor substrate; filling the grooves with stressed metal or submetallic oxide thereof; converting the metal or submetallic oxide into a metal oxide dielectric medium. According to the method, the crystal metal oxide dielectric medium, instead of an amorphous dielectric medium, is adopted to serve as an isolating material of the shallow groove isolation structure, so that the device performance is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Three-dimensional cross-shaped biaxial tension test piece

Owner:HARBIN INST OF TECH

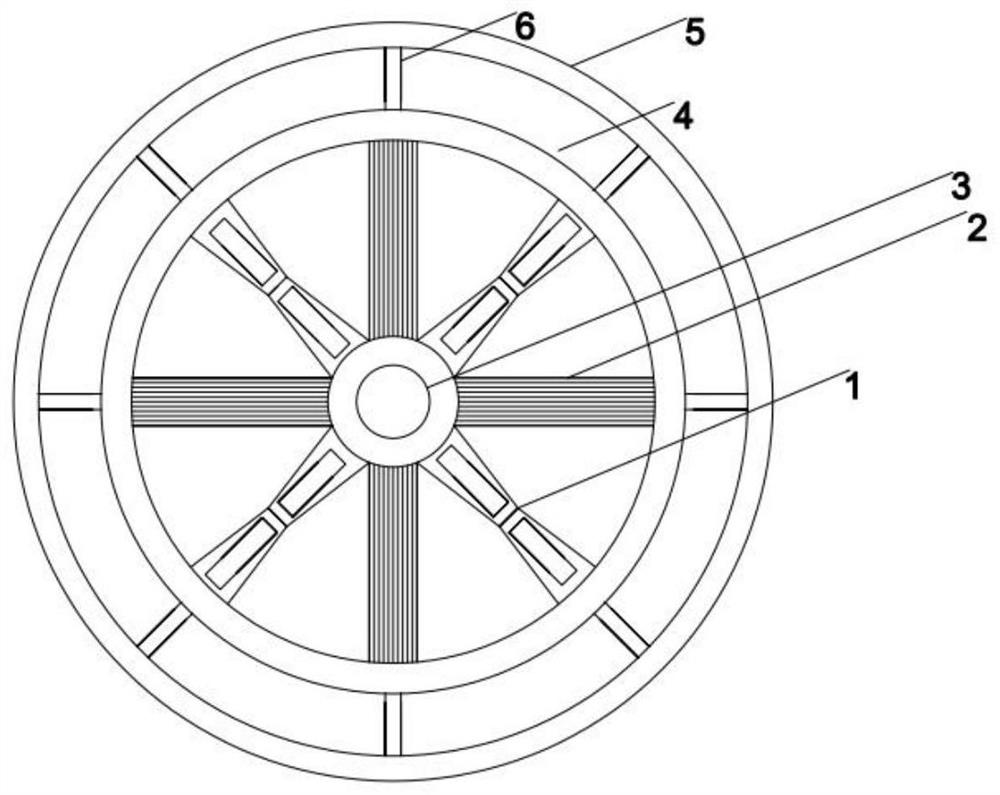

Composite low-yield-point metal damper with multi-dimensional energy dissipation function

ActiveCN113323178AAchieve full cross-sectionImprove performanceProtective buildings/sheltersShock proofingShock absorberSteel cylinder

The invention discloses a composite low-yield-point metal damper with a multi-dimensional energy dissipation function. The composite low-yield-point metal damper is arranged in an interlayer support, aims to play a role in energy dissipation and shock absorption in any direction in a plane, and simultaneously has vibration damping and resetting functions in the vertical direction and the torsion direction. The damper consists of a bending energy-dissipation damper, a shearing energy-dissipation damper, an inner steel cylinder, an outer steel cylinder, an outer steel ring and a steel plate, and is characterized in that the inner steel cylinder, the outer steel cylinder and the outer steel ring are coaxial, the bending energy-dissipation damper and the shearing energy-dissipation damper are horizontally and symmetrically arranged along the radial direction of the circumference of the steel cylinder, two ends of the bending energy-dissipation damper and the shearing energy-dissipation damper are respectively fixed on the inner steel cylinder and the outer steel cylinder, one side of the outer steel cylinder is welded, one side of the inner steel cylinder is welded, the outer steel cylinder and the outer steel ring are coaxial, the steel plates are horizontally and symmetrically arranged in the radial direction of the circumference and fixed in a welding mode, and the two ends of each steel plate are fixed to the outer steel cylinder and the outer steel ring respectively. According to the composite low-yield-point metal damper, deformation, energy dissipation and shock absorption can be carried out in any direction in a plane, in the vertical direction and in the torsion direction, the yield strength is low, and the energy dissipation efficiency is high.

Owner:BEIJING UNIV OF TECH

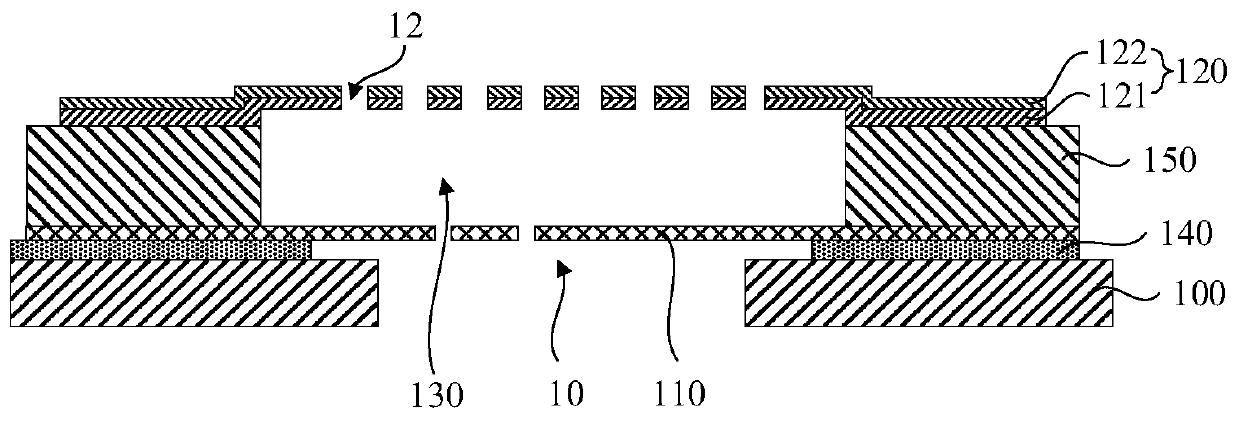

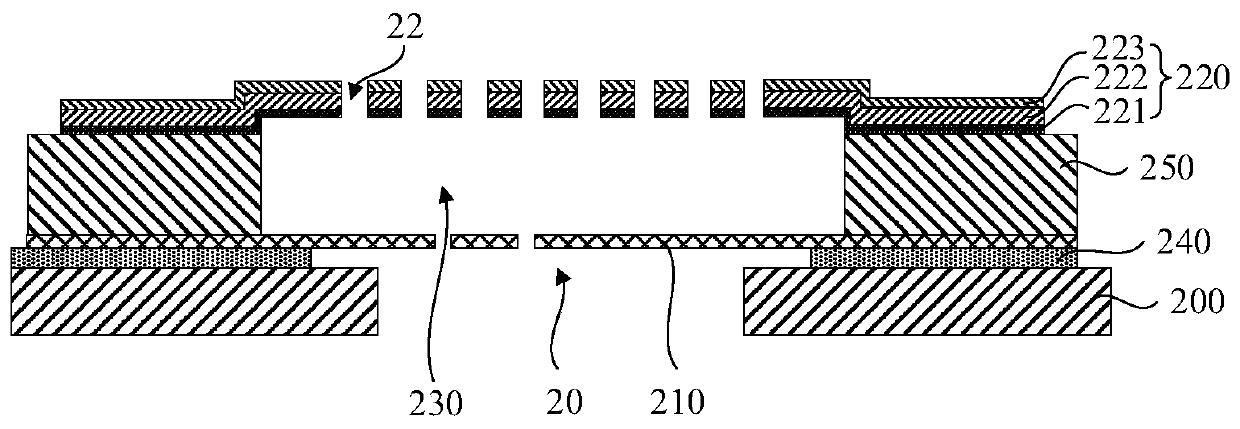

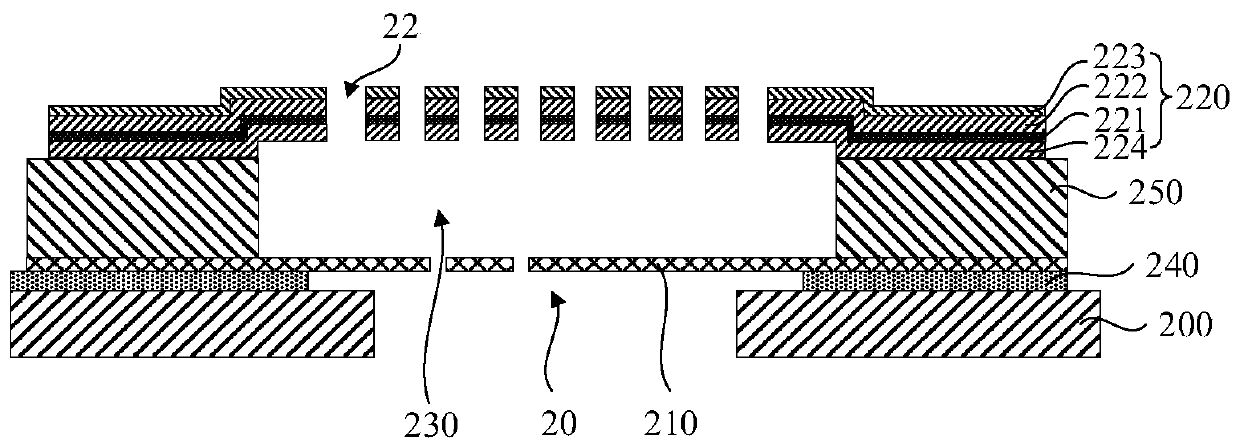

MEMS device and method of forming MEMS device

ActiveCN111246355AIncrease overall stressImprove sensitivity and accuracySemiconductor electrostatic transducersPhysicsElectrically conductive

The invention relates to a MEMS device and a method of forming an MEMS device. In the MEMS device, a back plate comprises a first dielectric layer, a second dielectric layer and a conductive layer which are sequentially stacked. The stress level of the first dielectric layer is higher than that of the second dielectric layer, the overall stress and rigidity of the back plate can be improved by utilizing the first dielectric layer, the improvement of the sensitivity and accuracy of the test is facilitated when the pull-in voltage test is carried out, and the tensile property of the back plate is ensured while the larger size of the back plate is realized. In addition, since the conductive layer is still in contact with the second dielectric layer, the influence of the first dielectric layeron the contact performance of the conductive layer is small. In the MEMS device, a third dielectric layer can be arranged on the side, far away from the second dielectric layer, of the first dielectric layer so as to protect the first dielectric layer from being corroded. The method of forming an MEMS device can be used for forming the MEMS device.

Owner:SEMICON MFG ELECTRONICS (SHAOXING) CORP +1

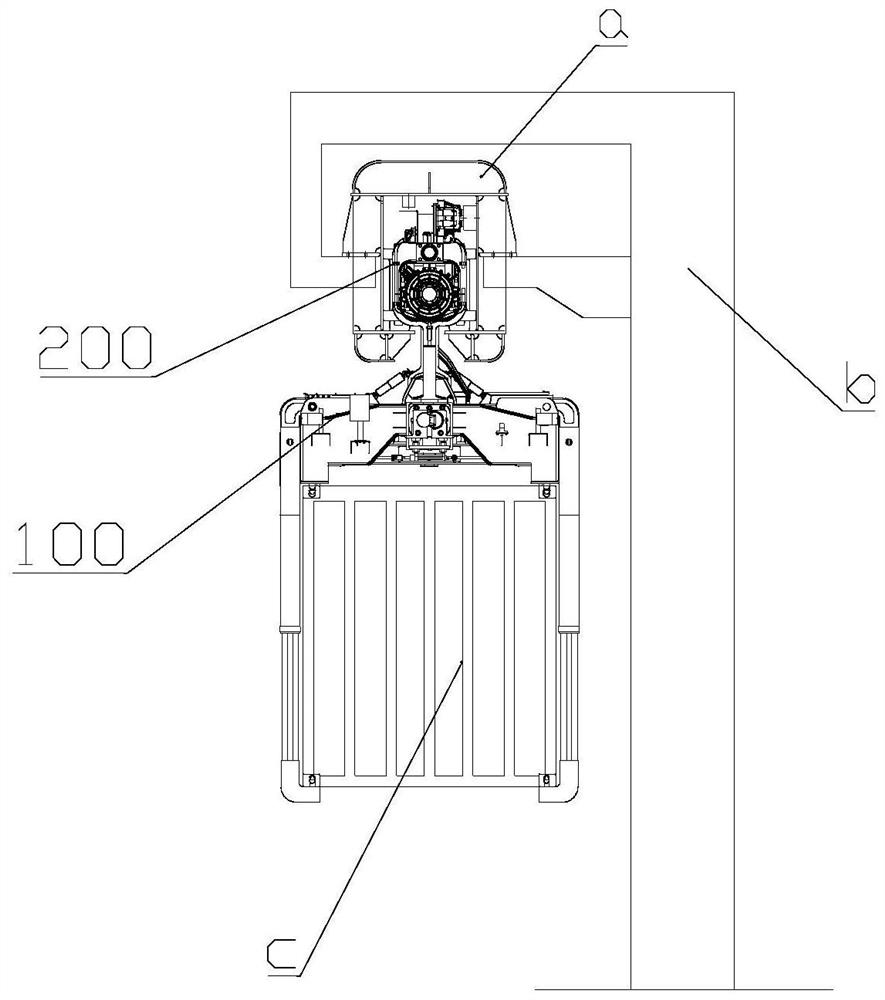

Vehicle frame

PendingCN112277969AIncreased stress levelsImprove fatigue lifeRope railwaysElevated railway with suspended vehicleVehicle frameEngineering

The invention belongs to the technical field of rail transit, and particularly relates to a vehicle frame. The vehicle frame comprises a basic frame, the basic frame comprises a main longitudinal beam, a plurality of center pin holes are formed in the main longitudinal beam at intervals, the center pin holes and center pins are arranged in a one-to-one correspondence mode, the lower ends of the center pins movably penetrate through the corresponding center pin holes, the lower ends of the center pins are connected with a swing bolster, and the swing bolster is located below the basic frame. And a plurality of elastic pieces are arranged between the swing bolster and the main longitudinal beam. The stress level of the frame can be improved, and the fatigue life of the frame is prolonged.

Owner:CRRC YANGTZE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com