MEMS device and method of forming MEMS device

A dielectric layer and backplane technology, applied in the field of micro-electromechanical, can solve the problems of poor tensile properties of the backplane, the sensitivity and accuracy of the interference pull-in voltage test, etc., to ensure the tensile performance, facilitate the high sensitivity requirements, and improve the overall effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

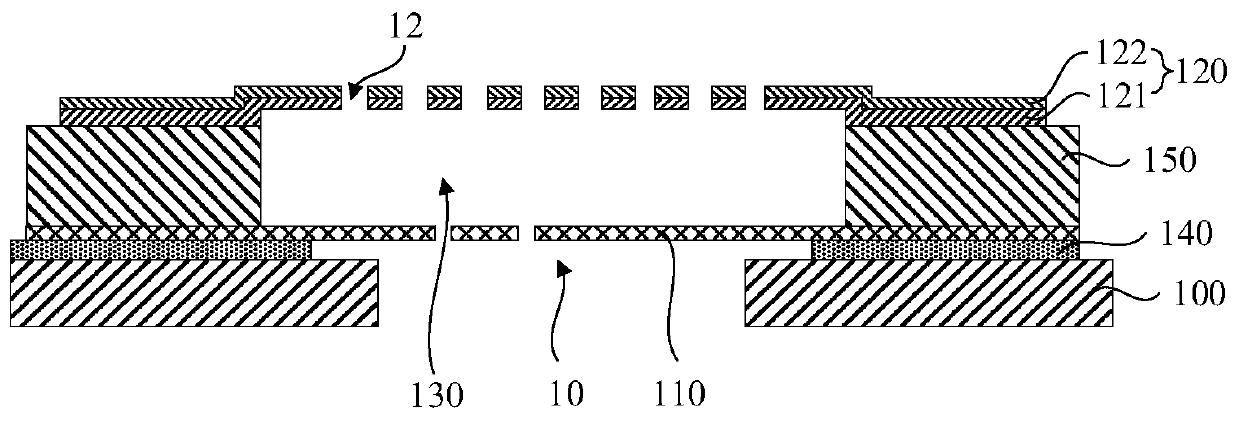

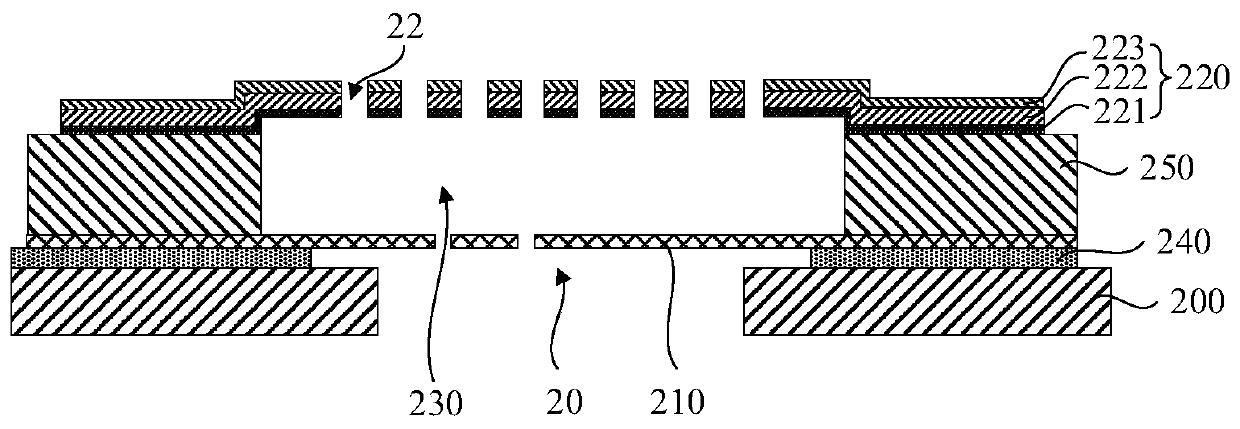

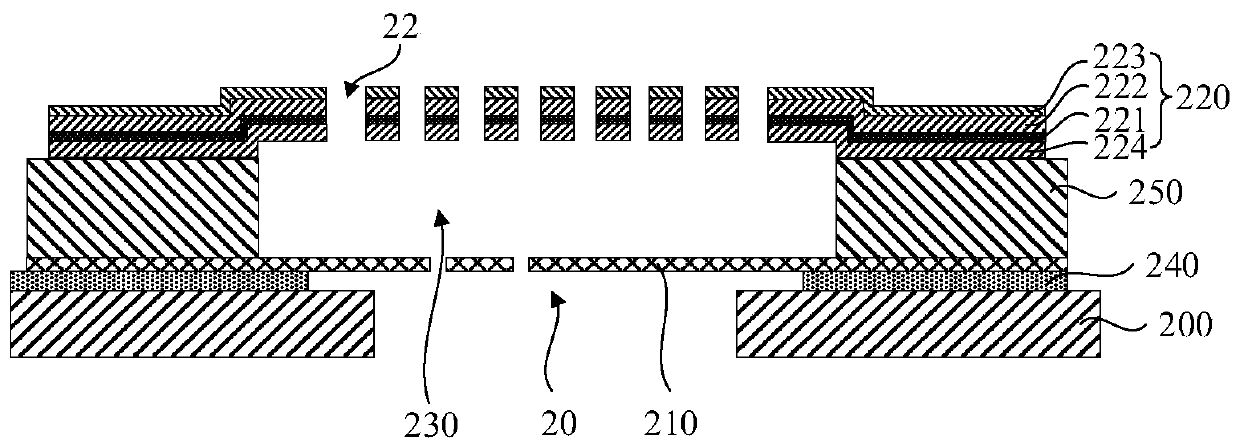

[0030] The MEMS device and the method for forming the MEMS device of the present invention will be further described in detail below with reference to the drawings and specific embodiments. The advantages and features of the present invention will become clearer from the following description. It should be noted that in the following description, many specific details and numerical values are given in order to provide a more thorough understanding of the present invention. However, it is obvious to those skilled in the art that the present invention may not require one or more In other instances, some technical features known in the art are not described in order to avoid obscuring the present invention. It should be understood that the drawings in the description are all in very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0031] For the convenience of de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Internal stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com