Patents

Literature

137results about How to "Guaranteed tensile properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

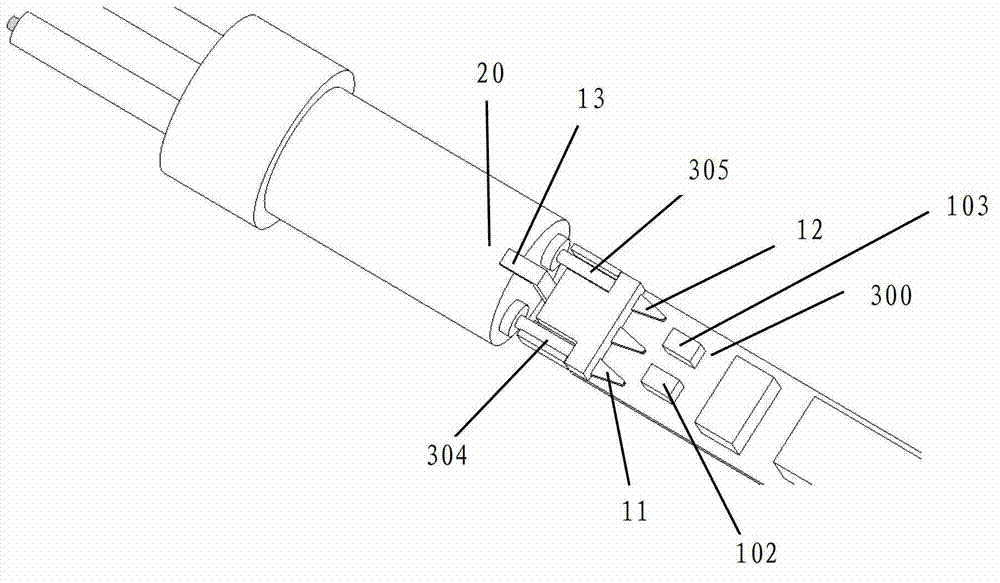

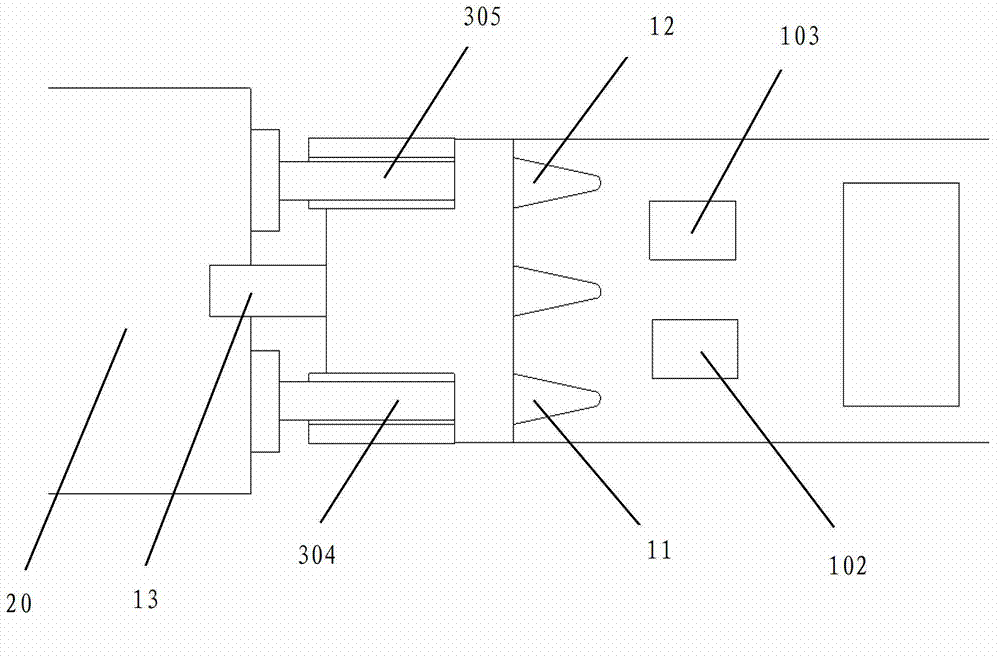

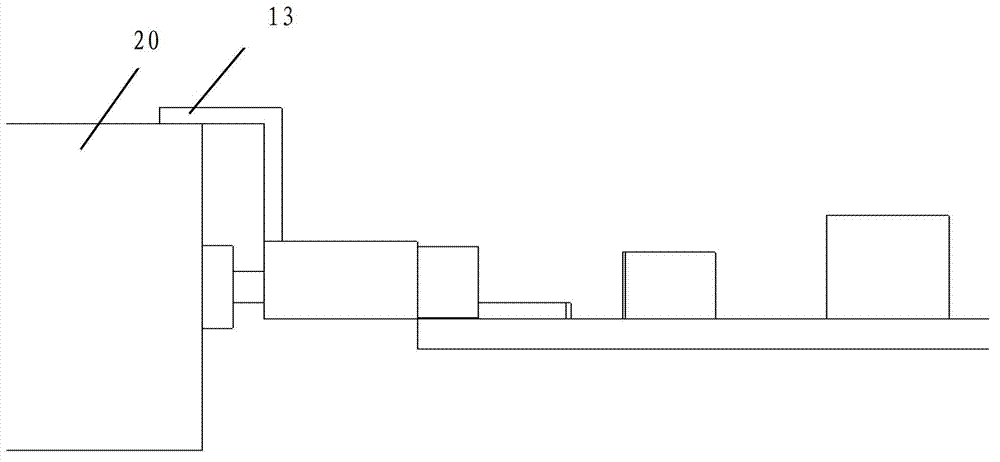

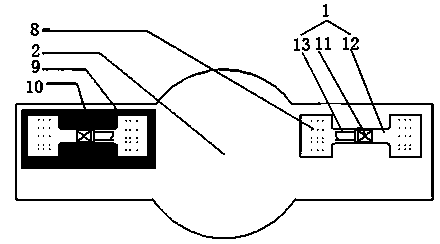

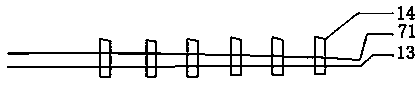

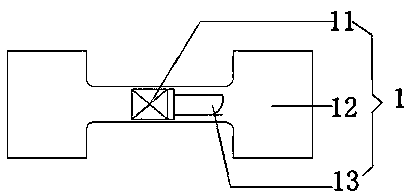

Anti-static structure of electronic detonator

ActiveCN103033100AAvoid damagePrevent accidental explosionAmmunition fuzesDetonatorElectrical resistance and conductance

The invention provides an anti-static structure of an electronic detonator, wherein two leg wires of the electronic detonator are electrically connected with a control circuit of a control circuit board. The anti-static structure of the electronic detonator is characterized by further comprising a discharge metal connecting piece; one end of the discharge metal connecting piece is electrically connected with a metal casing of the electronic detonator; two anti-static electronic devices are connected between the other end of the discharge metal connecting piece and one leg wire, as well as between the other end of the discharge metal connecting piece and the other leg wire respectively; and the anti-static electronic devices are transient suppression diodes, discharge tubes or voltage dependent resistors. By additionally arranging the anti-static structure on the electronic detonator, electricity can be preferentially discharged through the anti-static devices when the electronic detonator carries out electrostatic discharge, so that an error explosion can be prevented in the production and use processes; and moreover, one leg wire of the electronic detonator is connected with a first metal connecting piece and a second metal connecting piece in a manner of metal compression joint, the connecting operation is simple, tensile resistance is strong, and the electronic detonator can be prevented from being damaged by an external force in the production and use processes.

Owner:BEIJING QAML OF SCI & TECH CO LTD

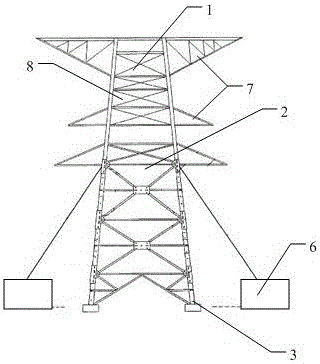

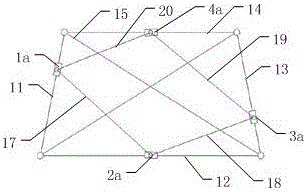

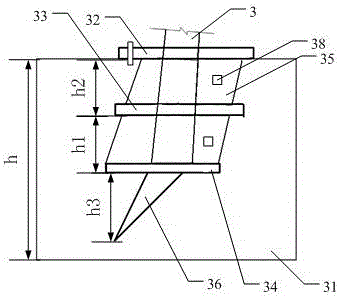

Anticorrosion assemblage supporting mechanism system used for power supply system and having tilting early warning function

ActiveCN105927023ALarge swingGuaranteed anti-overturn performanceProgramme controlComputer controlTransverse forceWireless transmission

The invention discloses an anticorrosion assemblage supporting mechanism system used for a power supply system and having a tilting early warning function. The system comprises a tower head, a tower body and tower feet, and further comprises a wireless tilt angle sensor, a temperature sensor, a video detector, a solar assembly, a power supply battery, a power supply battery voltage transformation module, a data processor, a date counter, a wireless transmission module, a wind force sensor and settlement monitors, wherein the wireless tilt angle sensor, the temperature sensor, the video detector, the solar assembly, the power supply battery, the power supply battery voltage transformation module, the data processor and the date counter are arranged on the tower body; the wireless transmission module is used for being in communication connection with a monitoring center; the wind force sensor is arranged on the tower head; and the settlement monitors are arranged on the parts, extending into a tower foundation, of the tower feet. Transverse force can be released through reinforcing ribs, and the strength of a supporting mechanism in the longitudinal direction is reinforced. The reinforcing ribs form included angles with the horizontal plane and can supply part of transverse supporting force and ensure longitudinal rigidity. In addition, in the swing process of the supporting mechanism, the reinforcing ribs arranged in a rhombus shape has certain resilience force, and the supporting mechanism can be kept in a fixed gesture and is prevented from swinging in large amplitude.

Owner:国网山东省电力公司泗水县供电公司 +1

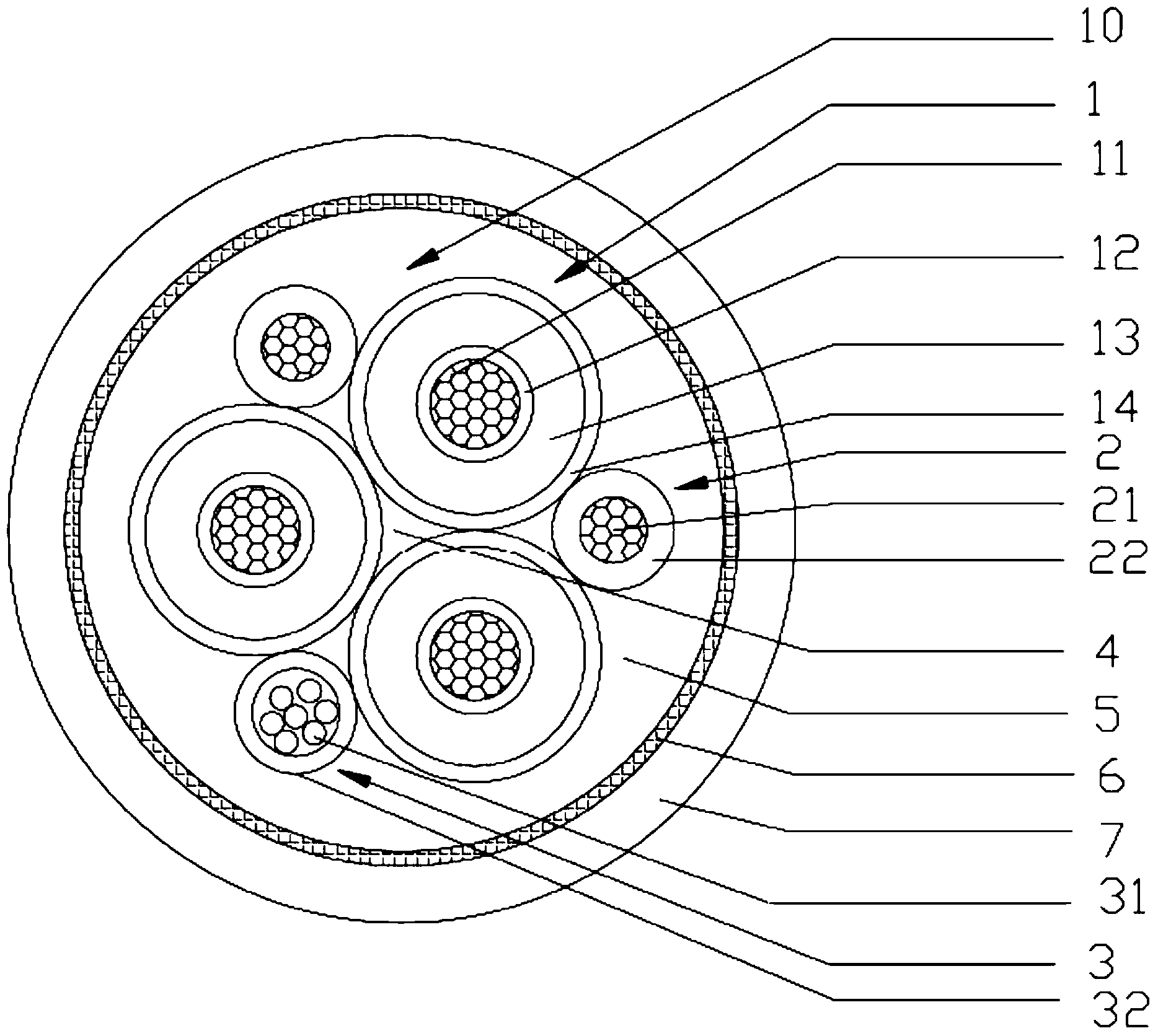

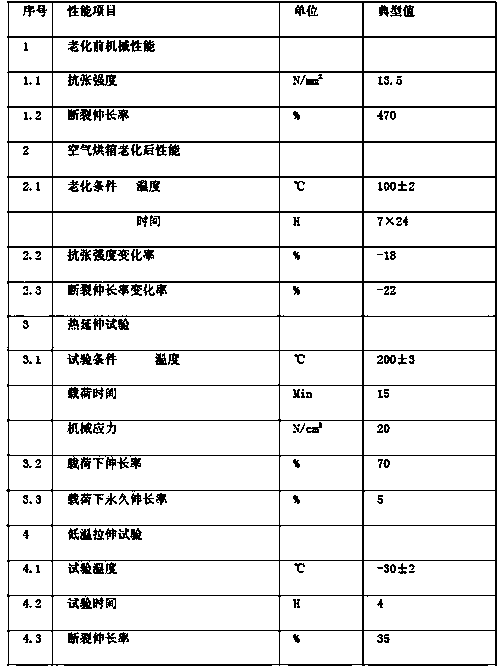

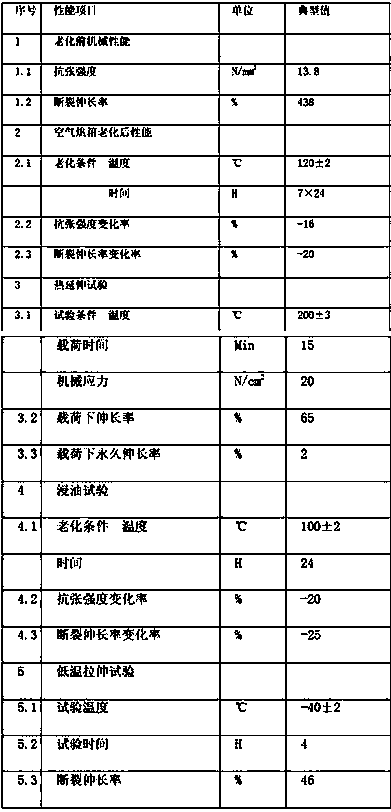

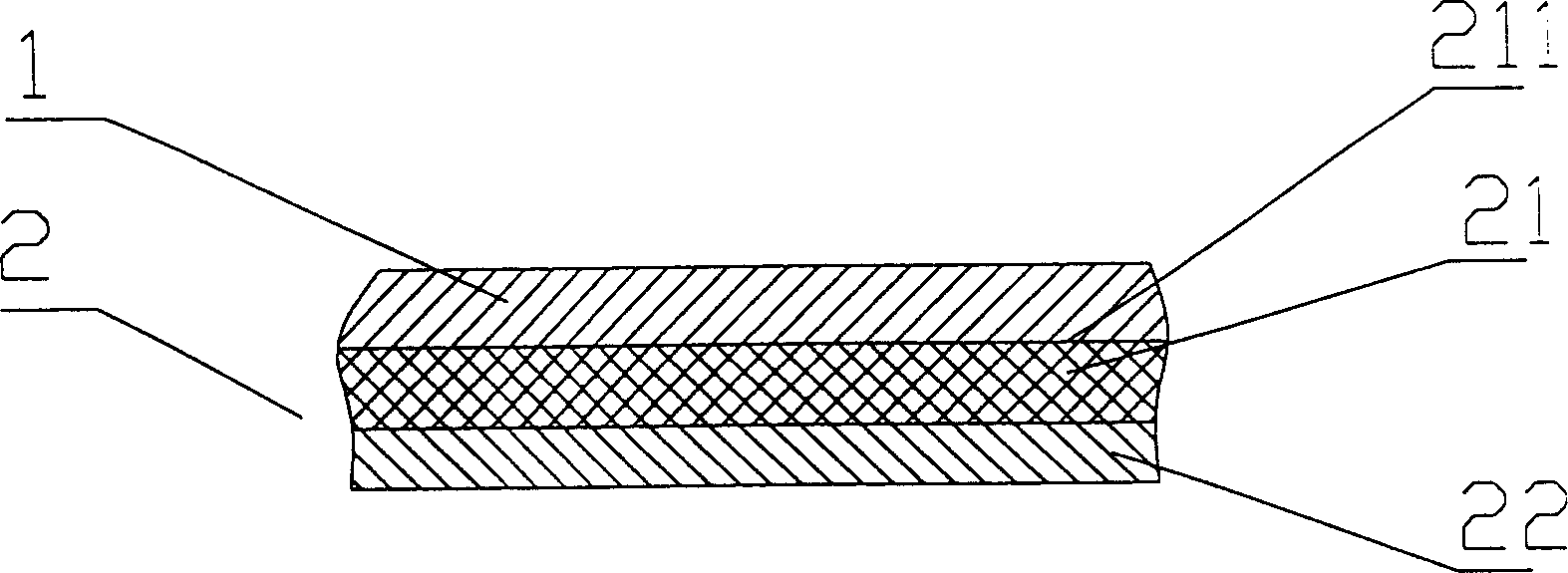

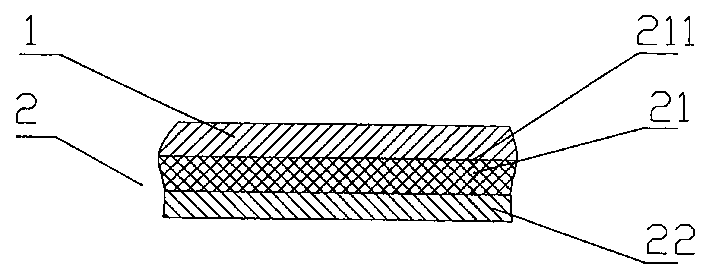

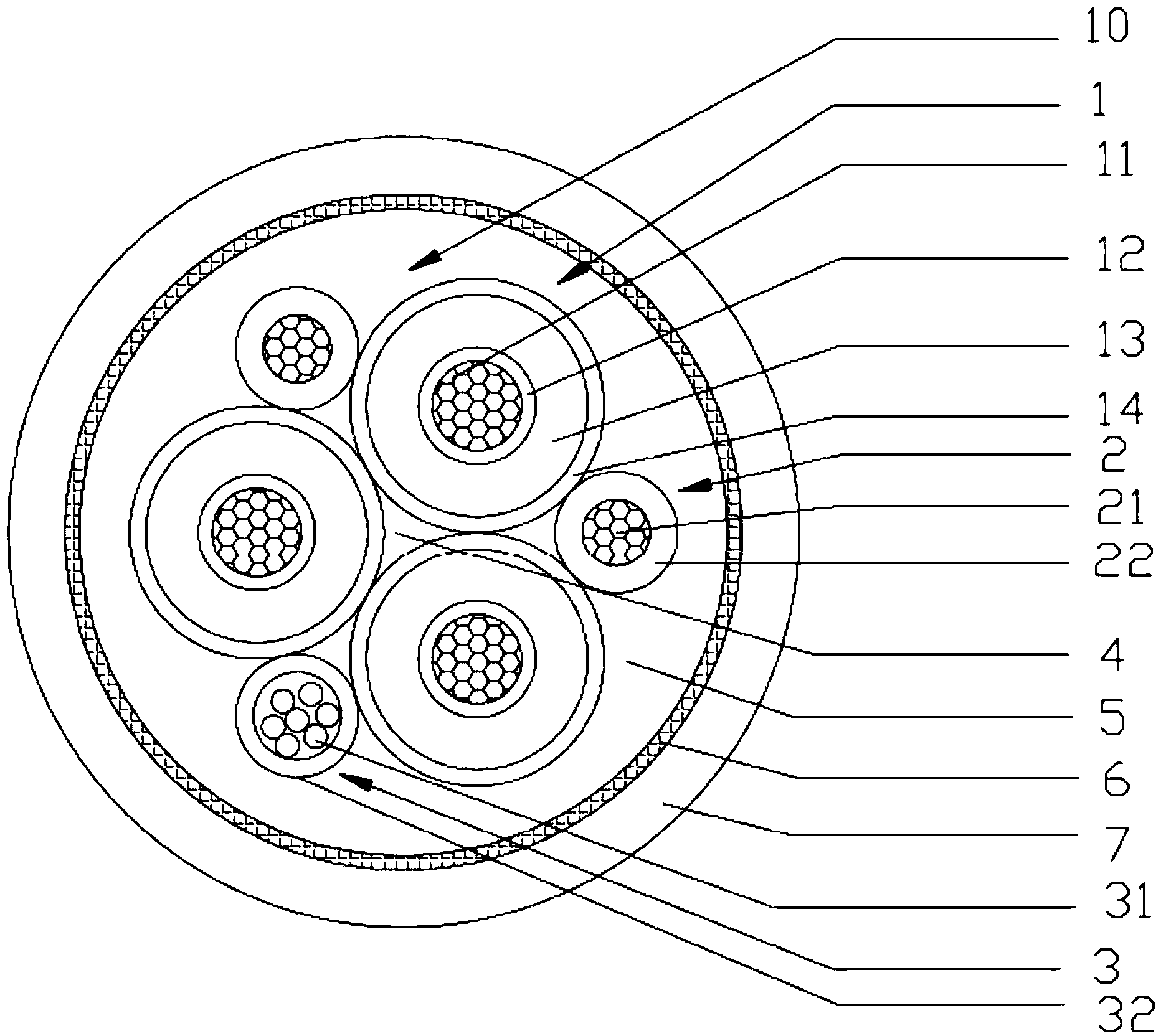

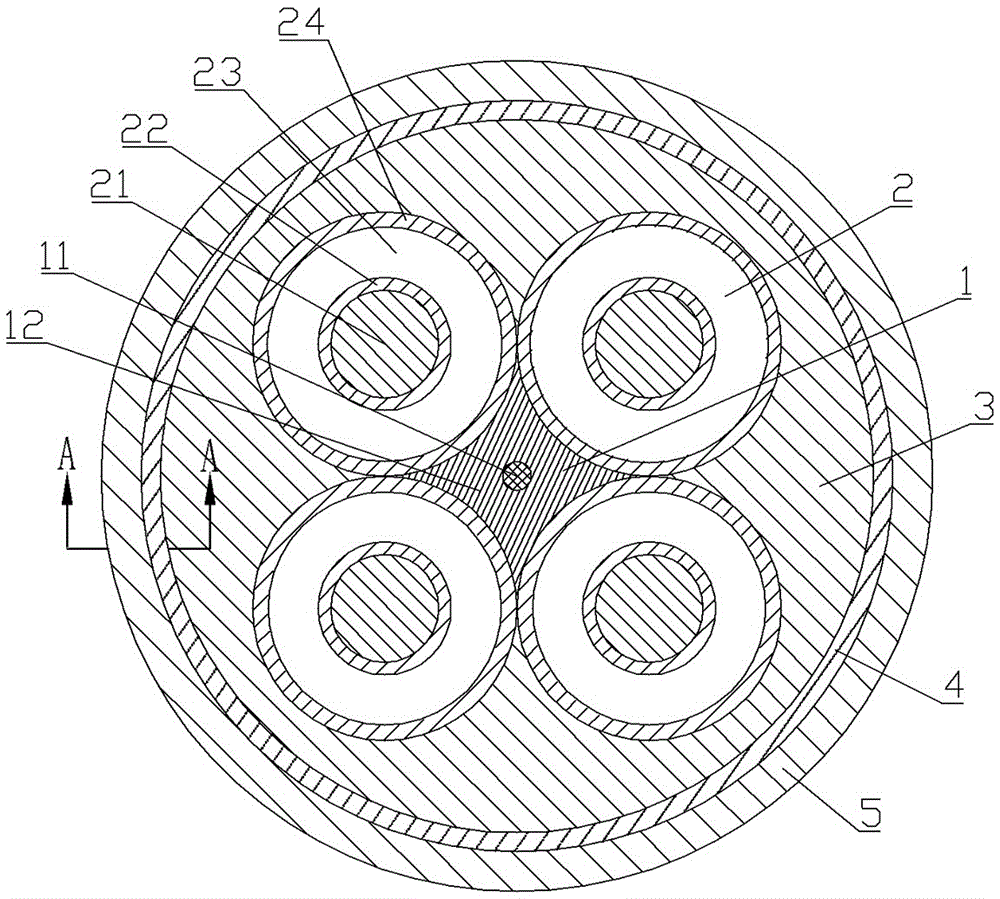

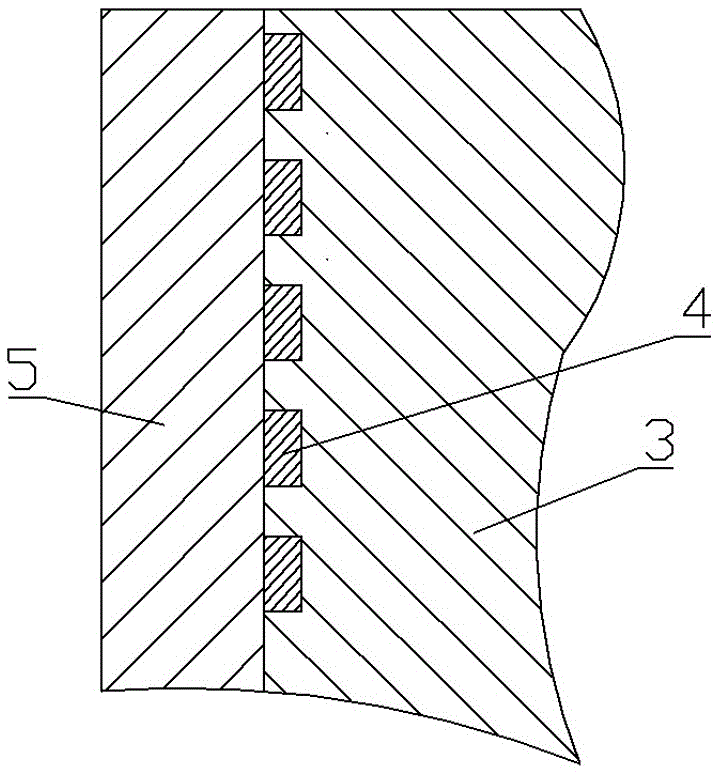

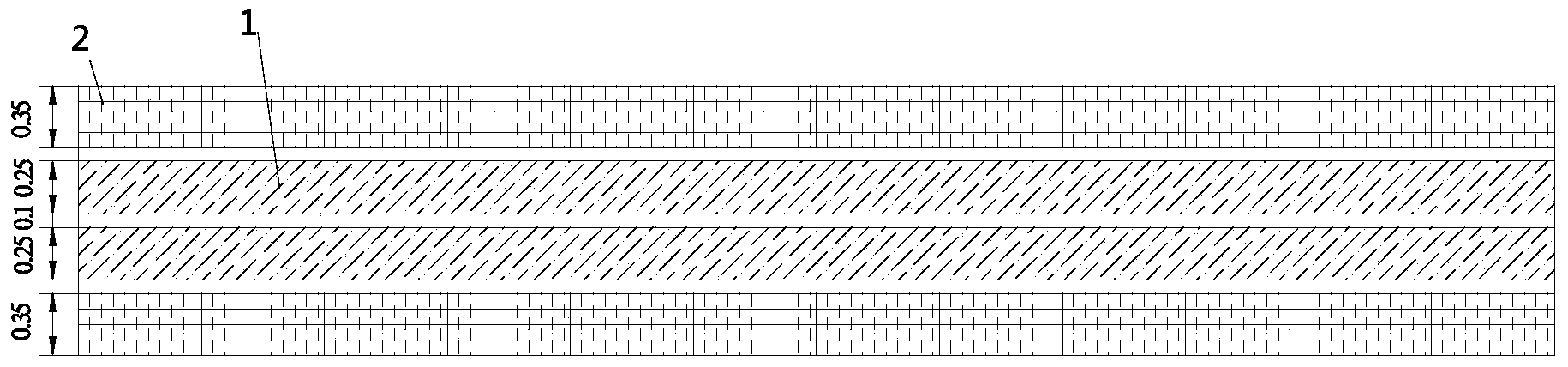

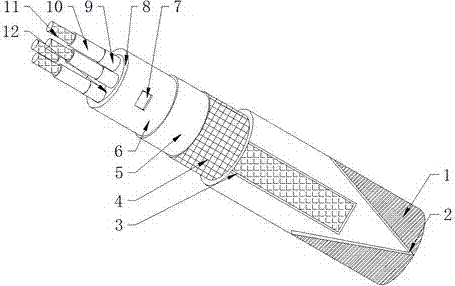

Torsion resistant photoelectric composite medium-voltage drum cable

ActiveCN104036859AExtended service lifeExtend your lifePower cables with screens/conductive layersInsulated cablesYarnPolytetramethylene terephthalate

The invention discloses a torsion resistant photoelectric composite medium-voltage drum cable. The torsion resistant photoelectric composite medium-voltage drum cable comprises a plurality of power line cores and a plurality of ground line cores which are twisted together to form a cable core, as well as at least one optical unit, a special chloroprene rubber inner sheath wrapping the cable core, a reinforcing layer which is woven at the exterior of the special chloroprene rubber inner sheath and is embedded in the special chloroprene rubber inner sheath, and a special chloroprene rubber outer sheath wrapping the reinforcing layer; in power line core conductors and ground line core conductors, the stranding directions of two adjacent layers are opposite, and the stranding direction of each layer is opposite to the stranding direction of strand lines in a corresponding layer; the reinforcing layer is a terylene wire-woven reinforcing layer; insulating layers in the power line cores are ethylene propylene rubber layers; loose bushings are made of polybutylene terephthalate plastics; water-resisting yarns are made of water-resisting aramid fibers; thixotropic composites are made of factice; and nonmetallic reinforcing members are made of aramid fibers. With the torsion resistant photoelectric composite medium-voltage drum cable of the invention adopted, the special chloroprene rubber sheaths are adopted as the inner sheath and the outer sheath of the cable, and therefore, the torsion resistant photoelectric composite medium-voltage drum cable has excellent low temperature resistance, wear resistance, oil resistance and other properties, and the service life of the cable can be prolonged.

Owner:JIANGSU HENGTONG POWER CABLE

Composite packaging bag

InactiveCN1428276ANot corrodedGuaranteed tensile propertiesFlexible coversWrappersHeat resistanceEngineering

The present invention relates to the field of package bag technology, in particular, it is a composite package bag with excellent tensility. It is made up by adopting PE.PP or other plastic material, and includes internal and external two layers which are press-combined and bound together, its internal layer is made up by using PE material, and its external layer is made up by adopting PP material which is not undergone the process of two-way stretching treatment, said external layer is divided into two layers, including stretch-resisting layer and heat-resisting layer, said heat-resisting layer is made up by adopting PP material which is not completely stretched, and the inside surface of the stretch-resisting layer is used for printing surface, so that the pattern can be printed on the inside surface of stretch-resisting layer, and can obtain effective protection.

Owner:党令军 +1

Method for manufacturing photoelectric composite medium-voltage drum cable

ActiveCN104036885AImprove performanceExtended service lifeCable/conductor manufactureRubber materialQuinoline

The invention discloses a method for manufacturing a photoelectric composite medium-voltage drum cable. The photoelectric composite medium-voltage drum cable comprises power line cores, ground line cores, at least one optical element, a special neoprene inner sheath wrapping a cable core, a reinforcing layer which is woven at the exterior of the special neoprene inner sheath and embedded in the special neoprene inner sheath and a special neoprene outer sheath wrapping the reinforcing layer; chlorinated polyethylene rubber materials include the following components of: a chlorinated polyethylene raw rubber, magnesium oxide, dibasic lead sulfate, lead sulfate tribasic, paraffin, chlorinated paraffin, antioxidant, namely, poly(1,2-dihydro-2,2,4-trimethyl-quinoline), a reinforcing agent (carbon black), flame retardant (antimony oxide), a filler (talcum powder), a filler (calcium carbonate), a reinforcing and filling agent (white carbon black), a vulcanizing promoter (triallyl isocyanurate), and a vulcanizing agent (dicumyl peroxide). With the method for manufacturing the photoelectric composite medium-voltage drum cable of the invention adopted, the cable can still keep excellent insulation performance under high temperature burning and humid conditions, and it can be ensured the cable can work normally for a long time under burning, mechanical percussion and water spraying situations.

Owner:JIANGSU HENGTONG POWER CABLE

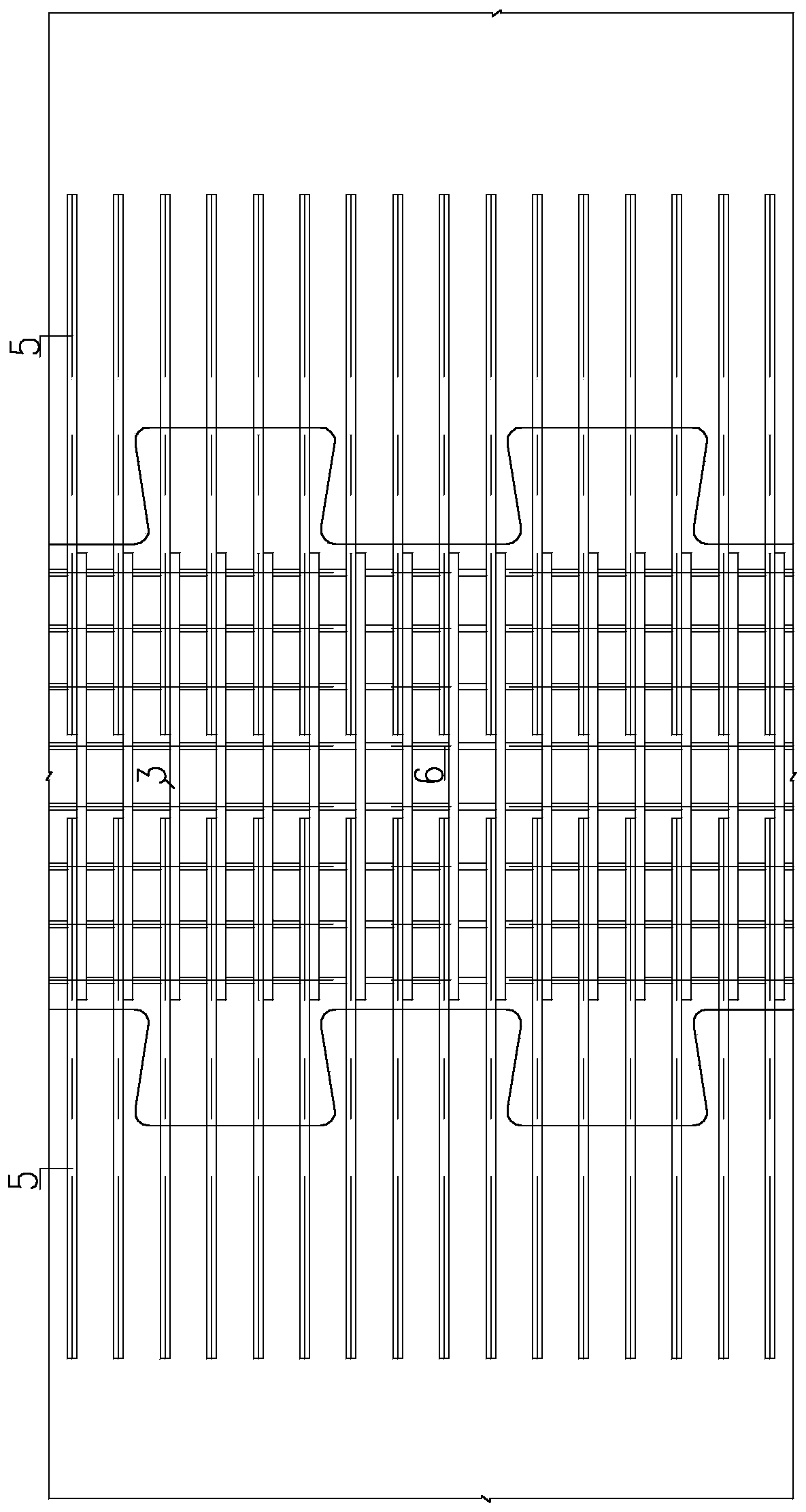

Ultra-high performance concrete composite beam bridge deck slab wet joint continuous structure with template

InactiveCN110952446AHigh tensile strengthHigh compressive strengthBridge structural detailsButt weldingArchitectural engineering

The invention discloses an ultra-high performance concrete composite beam bridge deck slab wet joint continuous structure with a template, which comprises a prefabricated section, a wet joint sectionand a steel bottom template; the prefabricated section bridge deck slab is made of an ultra-high performance concrete material; the steel bottom template is an extension section of the prefabricated section bridge deck slab bottom template, butt welding is conducted in the middle of the wet joint, and the steel bottom template serves as a bottom template of the wet joint section; the wet joint section is supported on the steel bottom template and connected with the steel bottom template and the prefabricated section in a pouring mode, the wet joint section is laid continuously, the thickness of the wet joint section is equal to that of the bridge deck slab, and the wet joint section is made of ultra-high performance concrete materials the same as those of the bridge deck slab. The wet joint is provided with the template, is high in tensile strength and compressive strength and good in durability, can effectively guarantee the performance continuity of the ultra-high performance concrete at the wet joint interface, has the advantages of being effective in steel bar connection, convenient to construct and easy to maintain, and can solve the problem of the connection quality of the ultra-high performance concrete wet joint.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

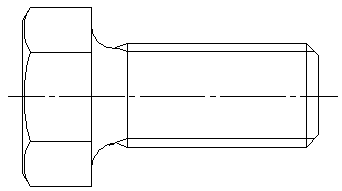

Heat treatment method for improving mechanical property of GH738 bolt type products

InactiveCN109306399AImprove mechanical propertiesGuaranteed tensile propertiesFurnace typesHeat treatment furnacesHigh densityCarbide

The invention discloses a heat treatment method for improving mechanical property of GH738 bolt type products. The GH738 bolt type products are subjected to head molding and heading through a solid solution state material, then stabilizing treatment is conducted, then primary aging treatment is conducted, then secondary aging treatment is conducted, and thus heat treatment of the GH738 bolt type products is finished. During secondary aging treatment, much more high-density gamma' strengthening phases are separated out, so that much more gamma' strengthening phases with smaller size and large degree of dispersion and much more carbide are obtained, the alloy is strengthen sufficiently, and accordingly the mechanical property of the GH738 bolt type products is improved. By the adoption of the heat treatment method, the technical problem that the mechanical property usually cannot meet the requirements in ordinary heat treatment production is solved, and the prepared GH738 bolt type products can be applied and popularized in the field of aero-engines.

Owner:GUIZHOU AEROSPACE PRECISION PRODS

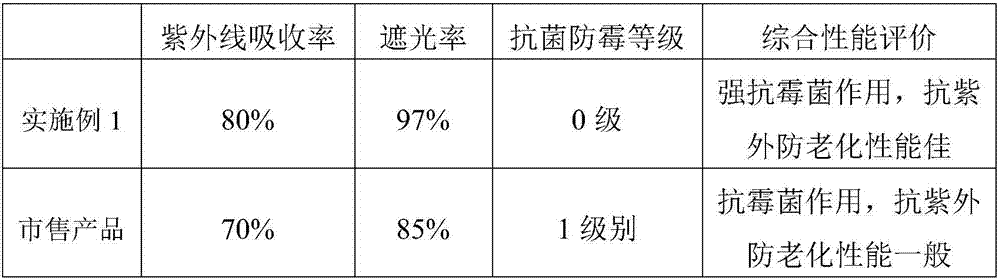

Preparation method of shading screen cloth with antibacterial and antiageing performances

InactiveCN107160786AGuaranteed tensile propertiesAnti-Aging GuaranteeAgricultural articlesSynthetic resin layered productsFiberAdhesive

The invention discloses a preparation method of shading screen cloth with antibacterial and antiageing performances. The prepared shading screen cloth is of a double-layered composite structure. The preparation method comprises the following steps: firstly, separately synthesizing outer screen cloth of an anti-ultraviolet layer and inner screen cloth of an antibacterial layer; then preheating and melting the two screen cloth through adjustment variation of the temperature of a heating roller, and assisted by an adhesive, pressing a rubber roller with an iron roller, and forming cooling forming to boating the shading screen cloth. The shading screen cloth of the double-layered composite structure is directly prepared from functional composite high molecular fibers separately without adding an anti-ultraviolet agent and an antibacterial agent. A finished product not only has an excellent anti-ultraviolet function, but also has a strong antibacterial and anti-mold property, is stable in chemical property, and also avoids use of external additives. Various stretch resisting, anti-ageing, corrosion-resisting, radiation-resisting and light characteristics of the screen cloth are guaranteed to the maximum.

Owner:JIANGSU HUACHANG YARNS & FABRICS CO LTD

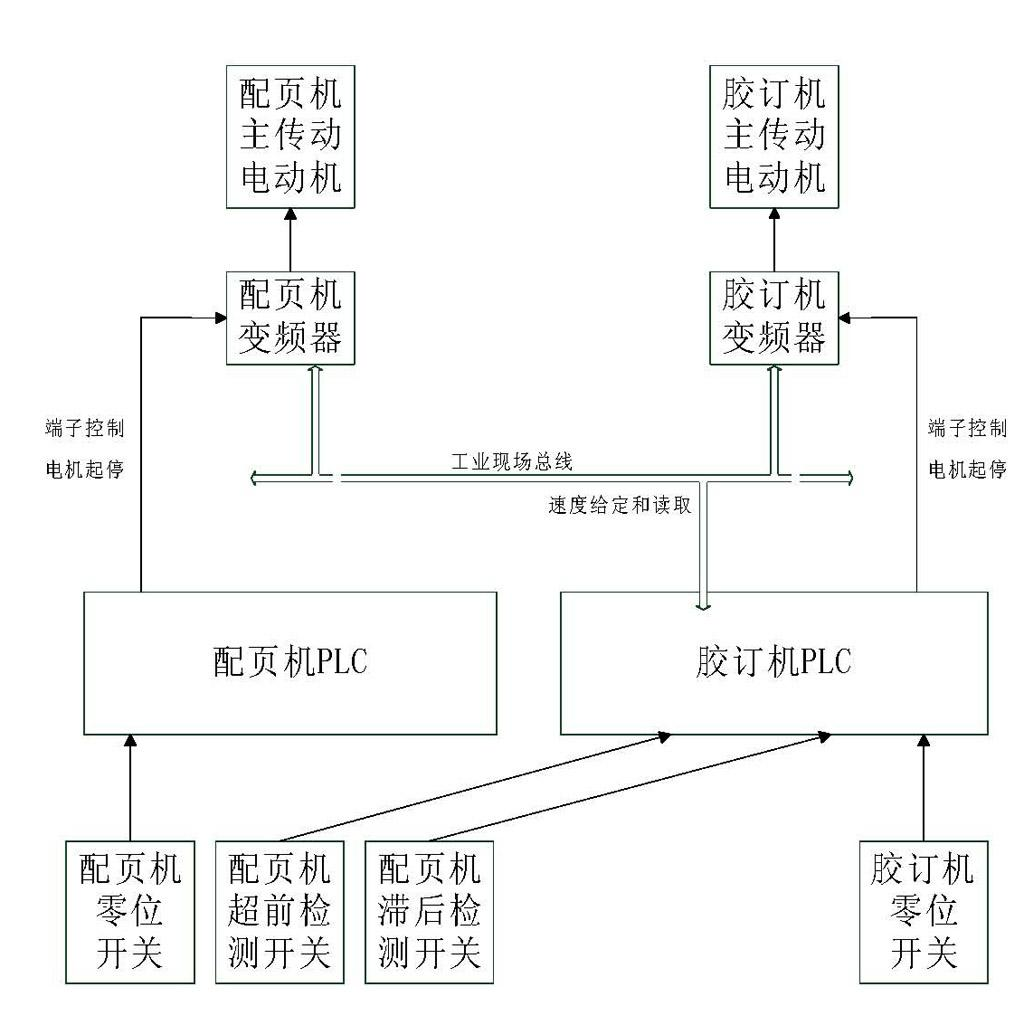

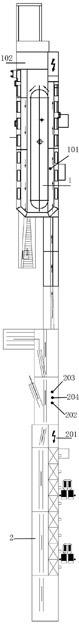

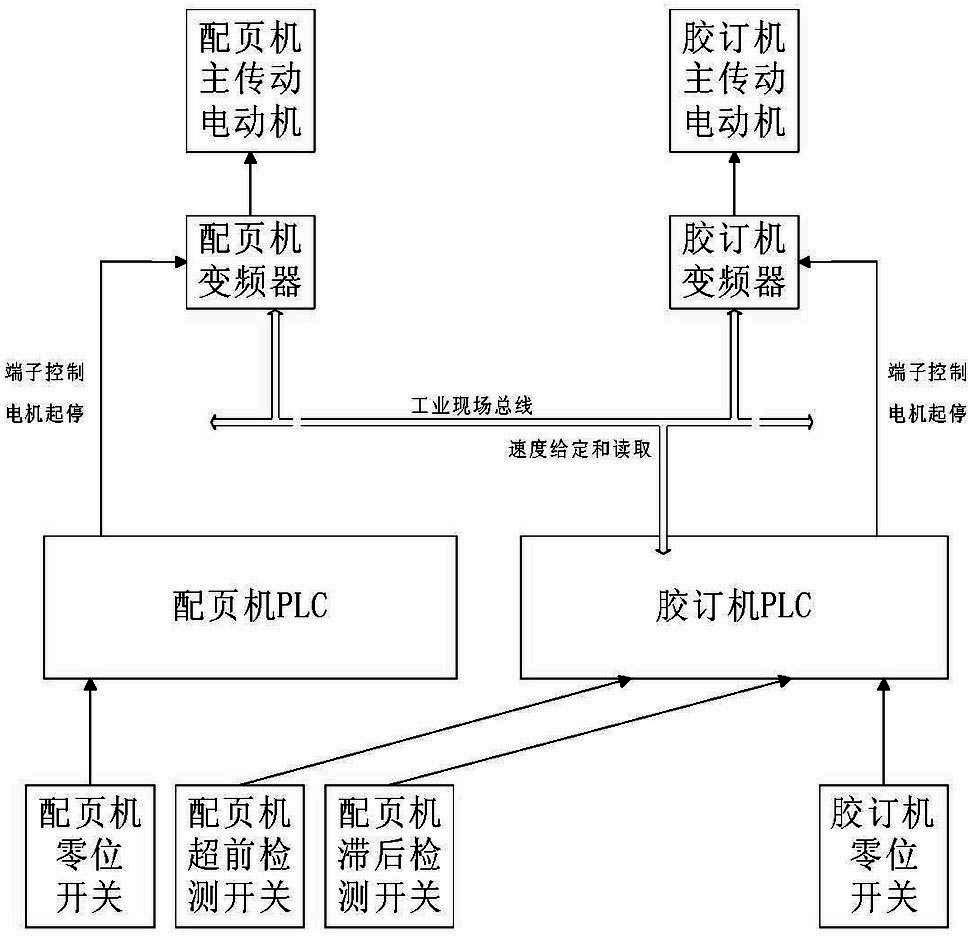

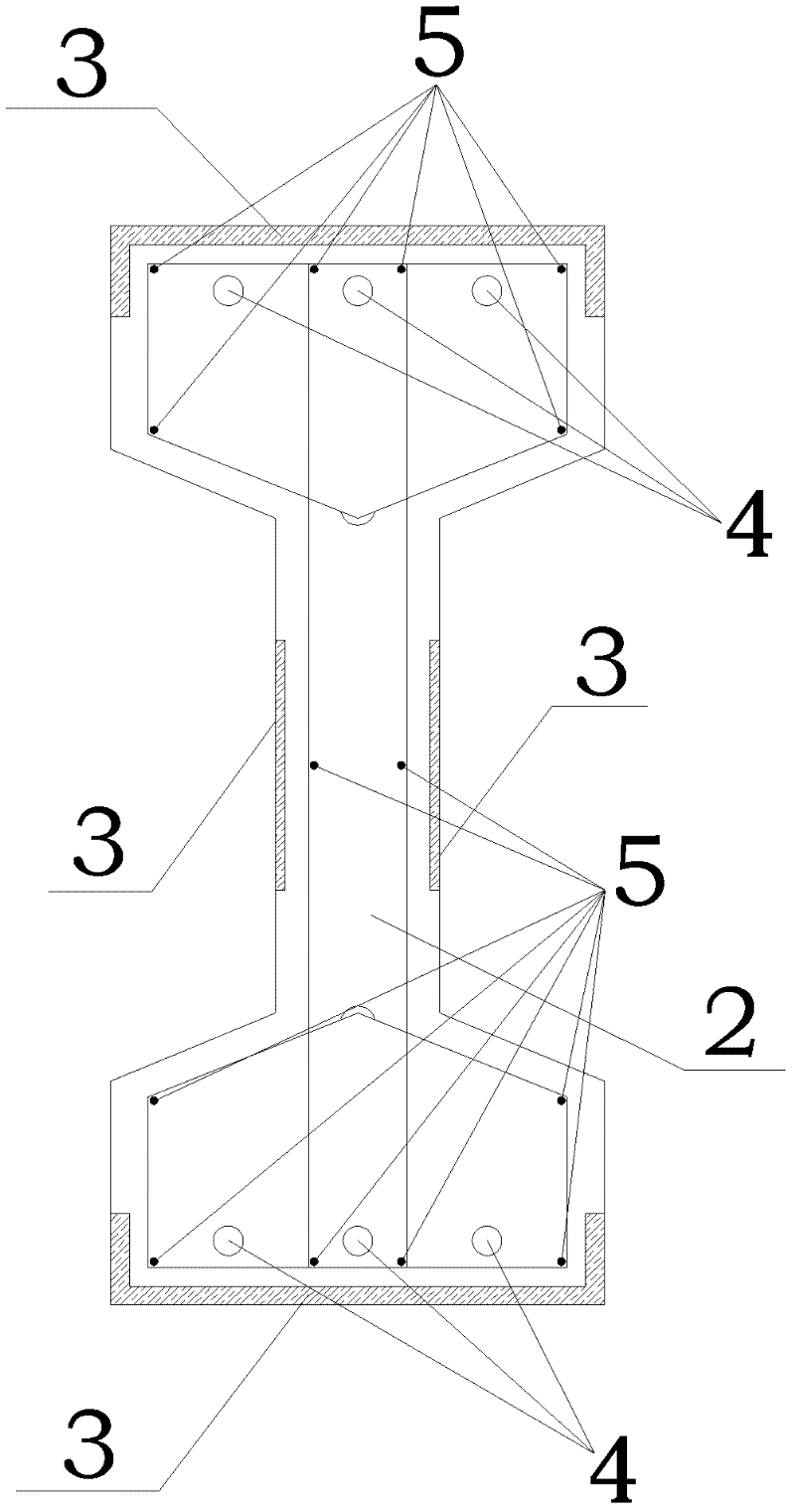

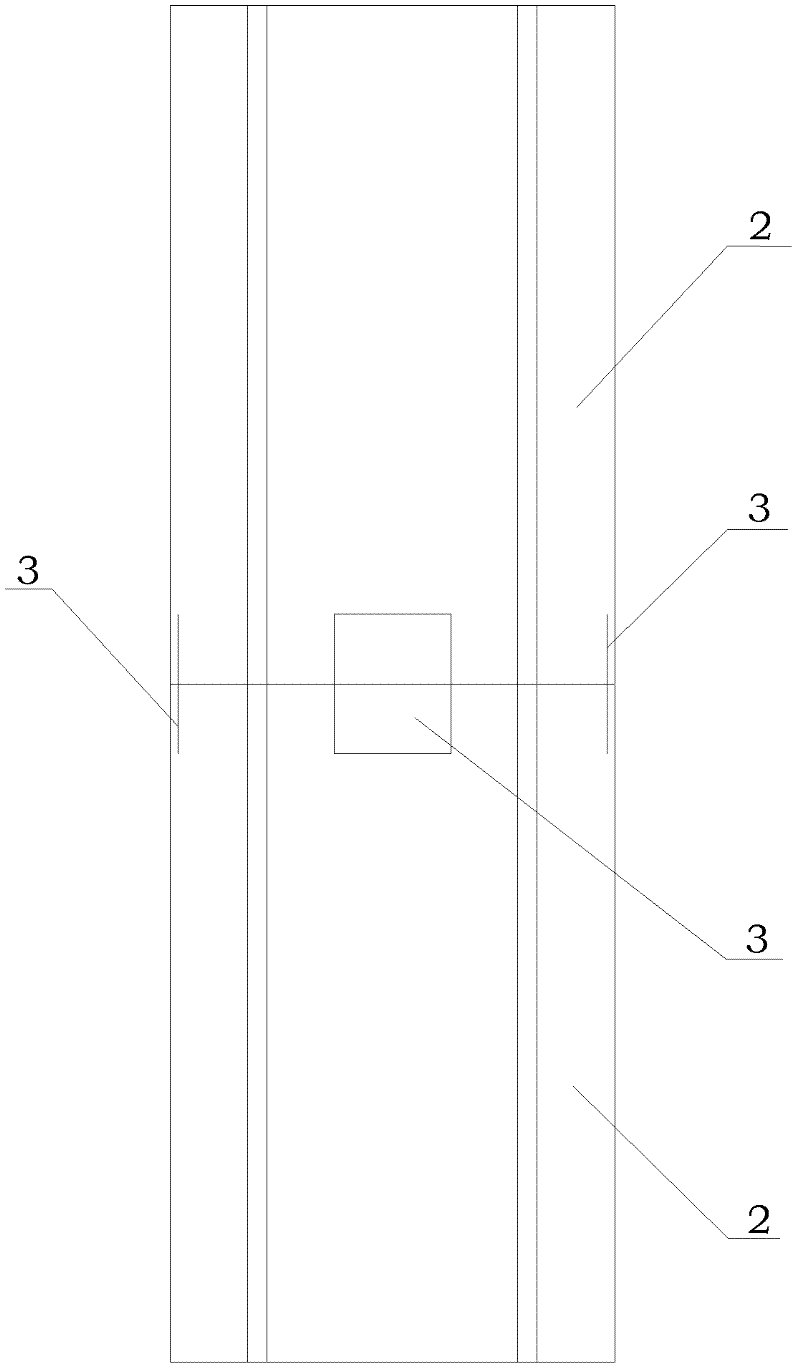

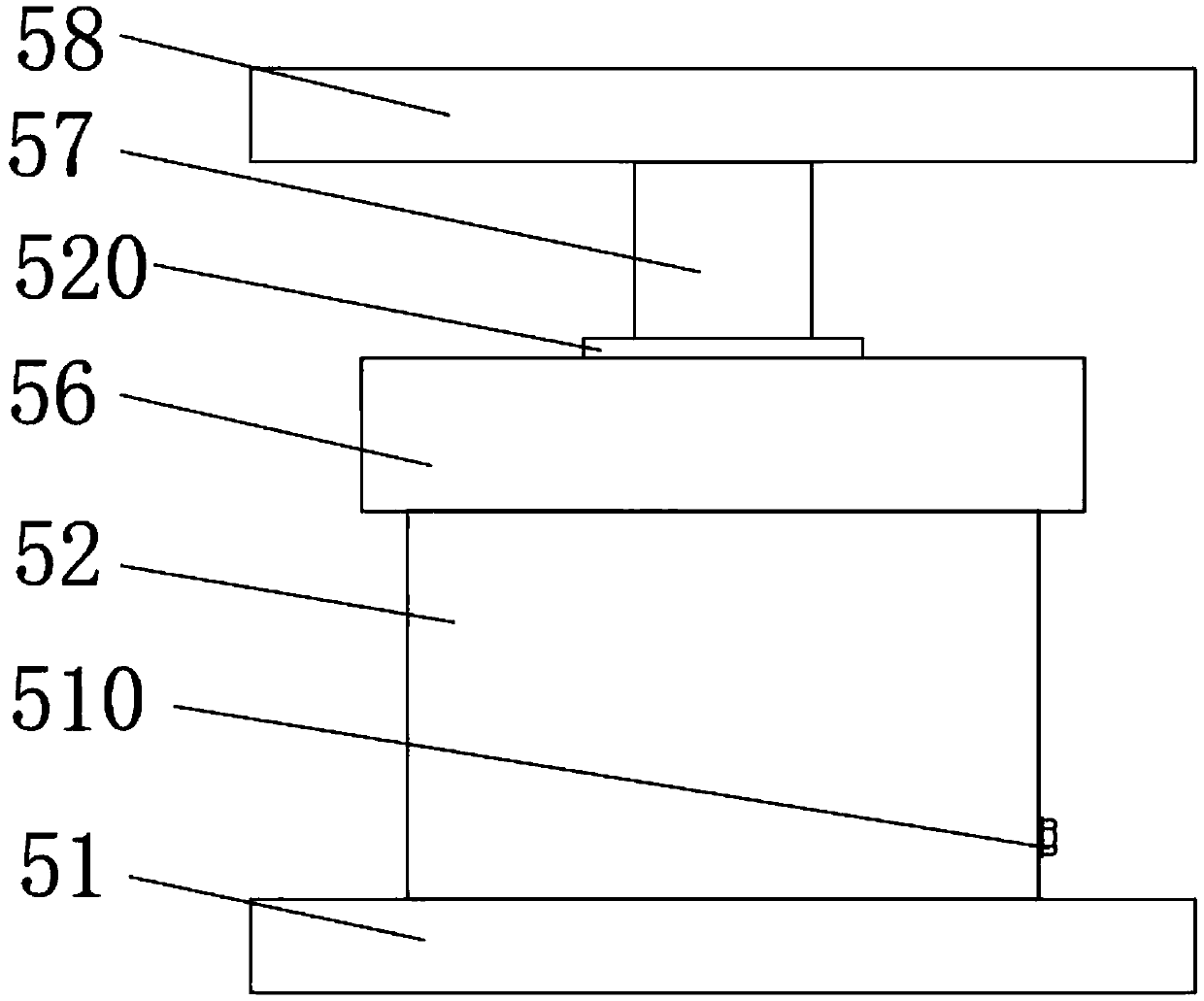

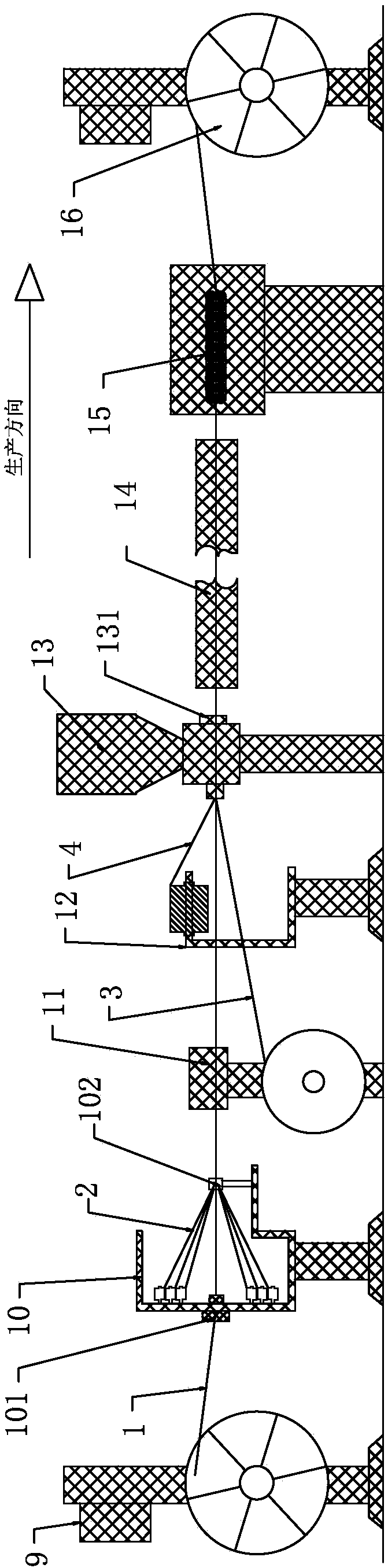

New process and equipment for manufacturing book block of hardcover book

InactiveCN102152687AStrong pullGood temperature adaptabilityBook making processesSheet bindingAdhesiveEngineering

The invention provides a new process for manufacturing the book block of a hardcover book, and the new process comprises the following steps: printing paper, folding, collating, milling the back of the book block, coating a PUR (Poly Urethane Resin) primer, coating an EVA (Ethylene Vinyl Acetate) side adhesive, placing gauze, playing and molding the book block, transporting the book block, solidifying an adhesive layer, cutting the book block and the like; and the step of wire locking which has the disadvantages of time consumption and long labor hours in the traditional process is omitted. In order to enable the book block to reach the service standards, the PUR primer is adopted; compared with the traditional EVA hot-melting primer, the PUR primer has a series of advantages of greater tension, better temperature adaptability, stronger strength and the like; the tension resistance of the book is ensured under the condition that the wire locking is not carried out on the book block; and simultaneously, the book is beautiful and is easy to store. Furthermore, the new equipment suitable for the new process for manufacturing the book block of the hardcover book provide by the invention comprises an adhesive binding machine and a collating machine, can carry out the revision and collation on the book block without the operation of wire locking and has the advantages of labor hour saving and cost reduction.

Owner:深圳市精密达机械有限公司 +1

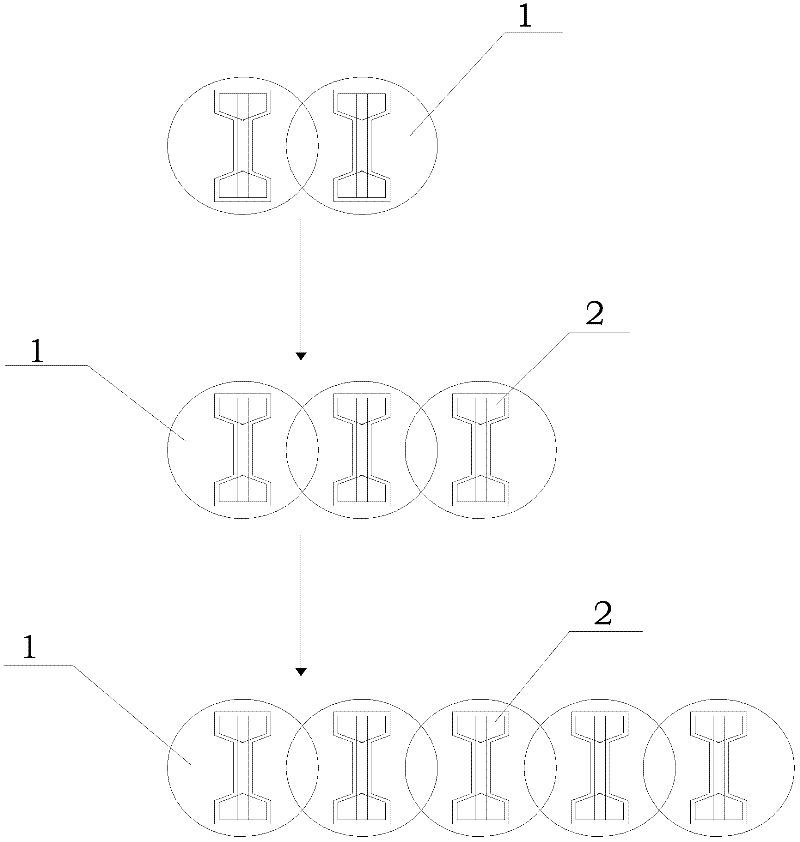

Prestressed reinforcement and non-prestressed reinforcement combined H-shaped reinforced concrete sheet pile and manufacture method thereof

InactiveCN102518120AIncrease stiffnessIncreased durabilityCeramic shaping apparatusBulkheads/pilesEnvironmental resistanceReinforced concrete

The invention relates to a prestressed reinforcement and non-prestressed reinforcement combined H-shaped reinforced concrete sheet pile and a manufacture method thereof. The H-shaped reinforced concrete sheet pile adopts an I-shaped structure; and prestressed reinforcement and non-prestressed reinforcement are arranged in the H-shaped reinforced concrete sheet pile at the same time. Compared with the prior art, the H-shaped reinforced concrete sheet pile has the advantages of good bending resistance and shearing resistance, low cost, high efficiency, zero contamination, environmental protection and the like.

Owner:SHANGHAI CHENGDI CONSTR

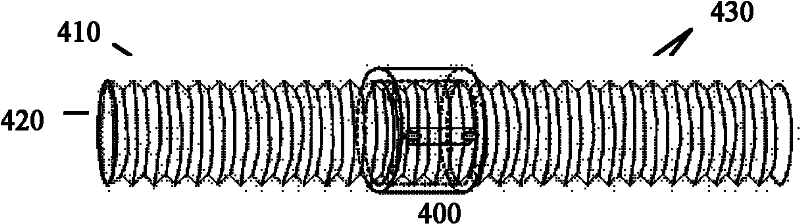

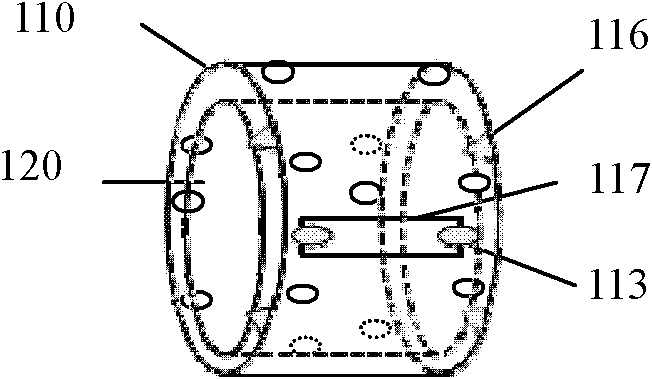

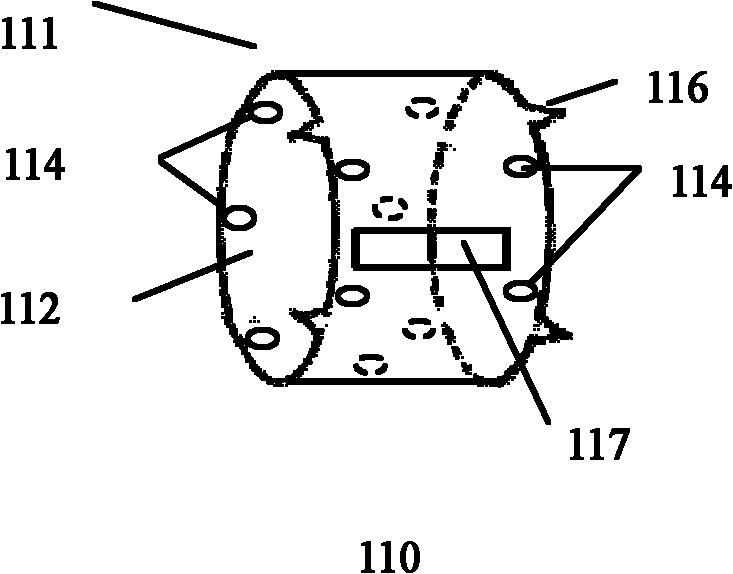

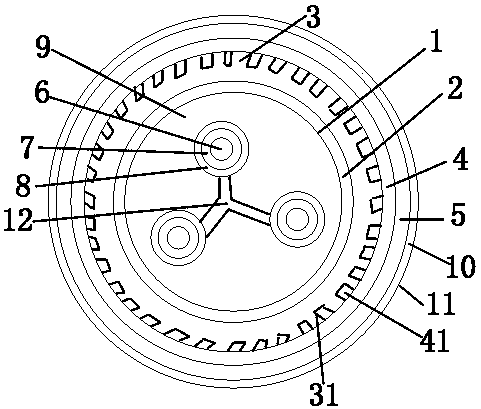

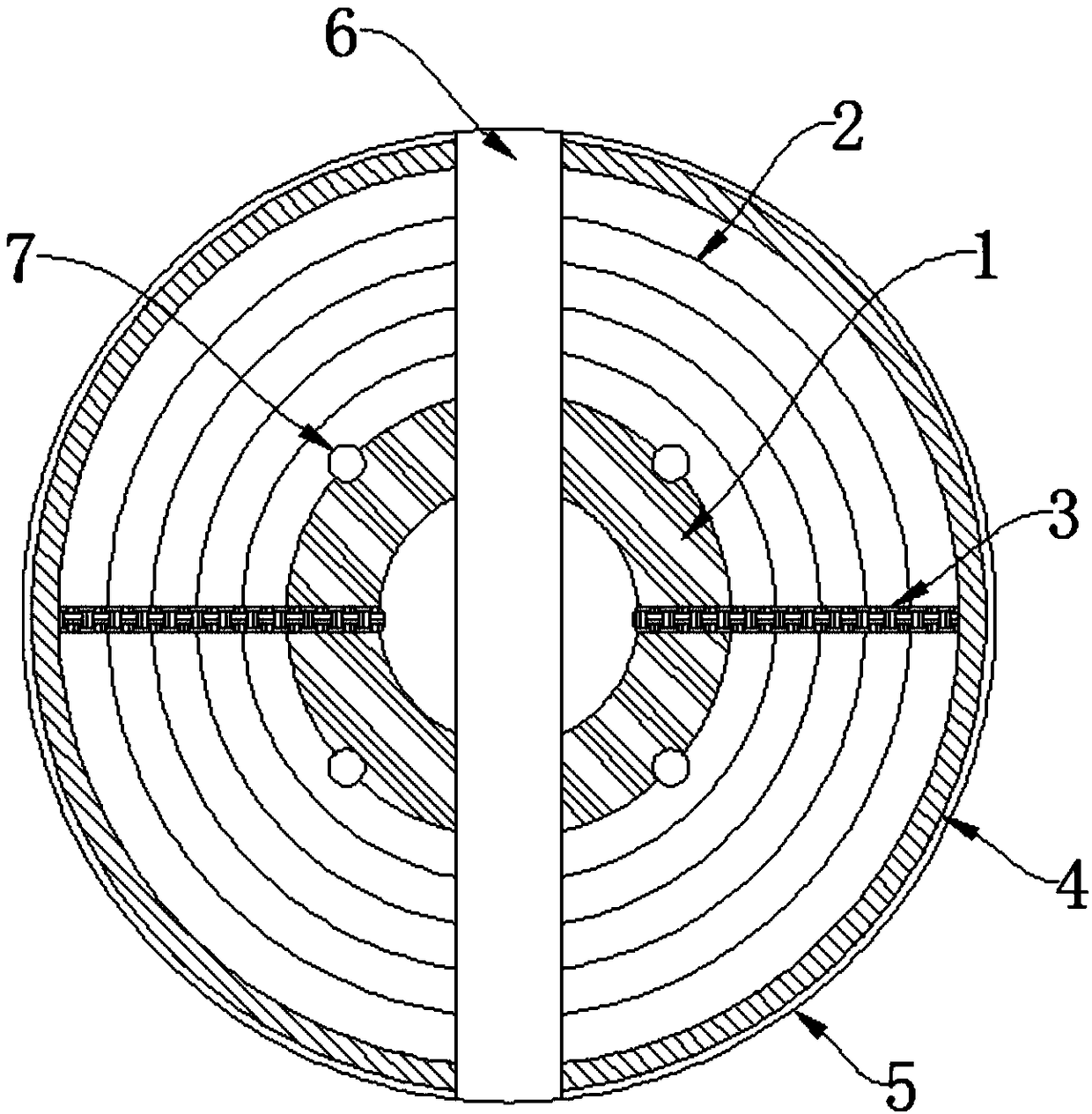

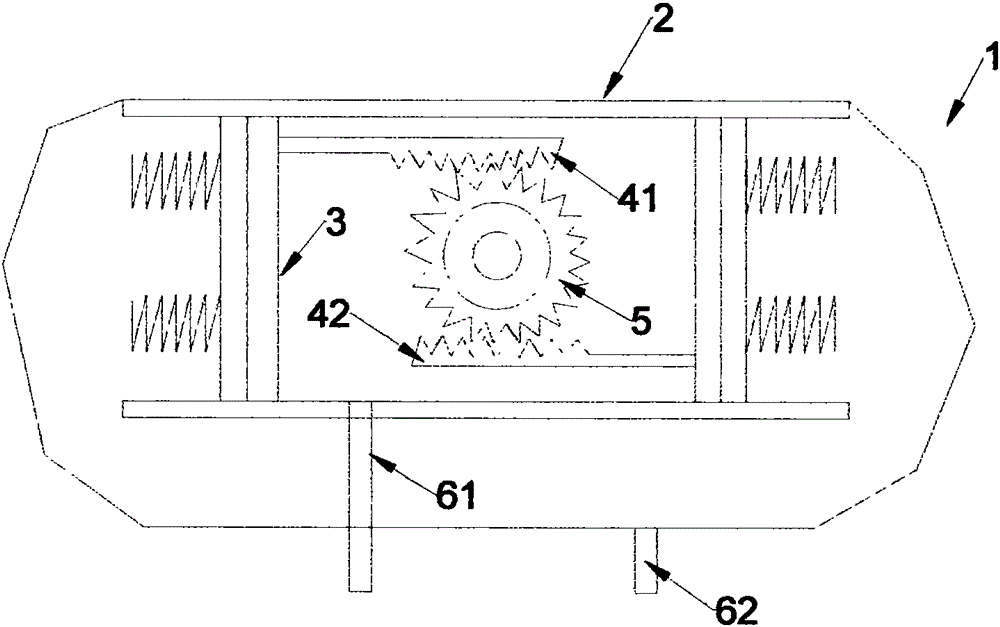

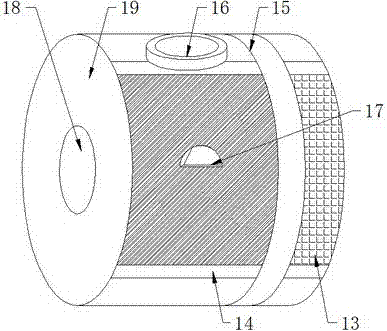

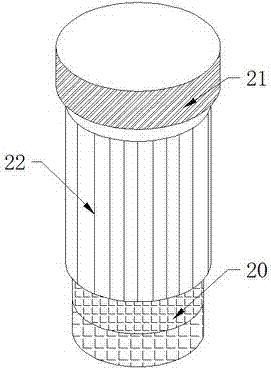

Small and medium diameter artificial blood vessel with adjustable pressure and flow

The invention discloses a small and medium diameter artificial blood vessel with adjustable pressure and flow. The artificial blood vessel comprises a blood vessel wall, a blood vessel cavity is in the blood vessel wall, and a pressure and flow controller capable of adjusting the diameter of the artificial blood vessel is arranged outside the artificial blood vessel. Concave and convex grains are arranged on the blood vessel wall. The pressure and flow controller comprises a fixed shell and a control spring, wherein the fixed shell takes the shape of a cylindrical structure, and the control spring is configured to be a cylindrical structure, the control spring is arranged in the fixed shell and sleeved outside of the blood vessel wall of the artificial blood vessel, the control spring is provided with a limit spring handle for adjusting the diameter of the blood vessel, and the spring handle passes through a control frame. The fixed shell is provided with position fixing holes, and the control spring is provided with position fixing holes. The fixed shell is provided with a fastener. The pressure and flow controller comprises a mechanical pressure and flow controller, an in-vitro remote control pressure and flow controller and an in-vivo induction pressure and flow controller. The blood vessel is applicable to controlling the size of fractional flow according to an induced pressure of a hepatic portal vein after a portosystemic blood vessel is anastomosed and shunted so as to ensure the hepatic portal vein perfusion pressure required by individuals.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

Starch-based adhesive with high binding power and good heat conductivity for paperboard

ActiveCN106047233ALow costHigh bonding strengthNon-macromolecular adhesive additivesProtein adhesivesAluminium hydroxideAdhesive

The invention discloses a starch-based adhesive with high binding power and good heat conductivity for a paperboard. The starch-based adhesive with high binding power and good heat conductivity for a paperboard comprises the following raw materials in parts by weight: 40-80 parts of an acrylate adhesive, 20-40 parts of modified plant protein, 5-15 parts of lotus root starch, 1-3 parts of diphenylmethane diisocyanate, 1-2 parts of sodium hypochlorite, 1-2 parts of hydrogen peroxide, 1-3 parts of borax, 2-6 parts of a silane coupling agent KH-570, 2-6 parts of vinyl acetate, 1-2 parts of calcium carbonate, 2-10 parts of urea resin, 1-4 parts of sodium hydroxide, 2-10 parts of silicon dioxide, 1-6 parts of aluminium hydroxide, 1-4 parts of aluminium oxide, 1-5 parts of magnesium oxide, 0.1-0.8 part of ammonium persulfate, 1-5 parts of croscarmellose sodium, 1-3 parts of a stabilizer, 1-2 parts of a defoamer, and 10-30 parts of water. The starch-based adhesive is good in heat conductivity, high in binding power and excellent in waterproofing, toughness and stability.

Owner:太湖县市场监督检验所(太湖县功能膜检测研究院)

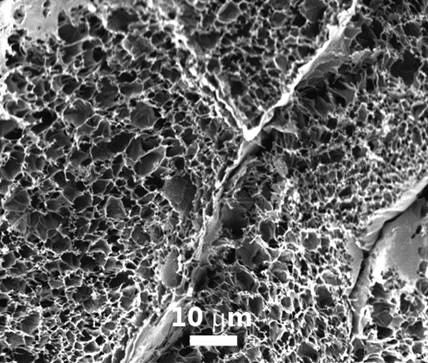

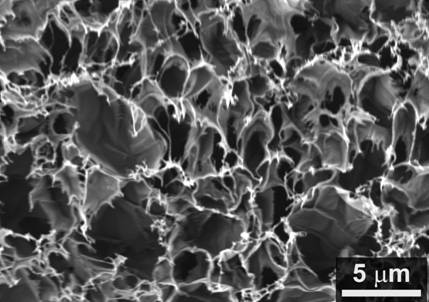

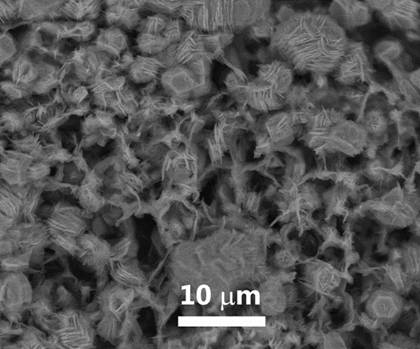

Preparation method of halloysite-based soft magnetic ferrite wave absorbing material

ActiveCN107418510AImprove absorbing performanceLow densityOther chemical processesHalloysiteVolumetric Mass Density

The invention discloses a preparation method of a halloysite-based soft magnetic ferrite wave absorbing material. The preparation method comprises the following steps: S1, after using ferrous chloride, nickel chloride, aluminum chloride and magnesium chloride as main materials, adding hydrochloric acid, and dissolving the main materials, then adding barium oxide, cerium oxide, titanium oxide and vanadium oxide, and stirring until completely dissolving, thus obtaining a material 1; S2, adding halloysite into an ionic solution, carrying out ultrasonic dispersion, adding the material 1, and uniformly mixing, thus obtaining a material 2; S3, uniformly mixing ammonium hydroxide, 1,3-propane diamine and triethanolamine according to a volume ratio that ammonium hydroxide to 1,3-propane diamine to triethanolamine is (3 to 5) to (1 to 2) to (2 to 3), thus obtaining a mixed alkaline solution; S4, dropwise adding the mixed alkaline solution into the material 2, continuously stirring during a dropwise adding process, rising the temperature to 50 to 70 DEG C after completely finishing dropwise adding, standing and keeping warm, filtering after cooling, and drying, thus obtaining a material 3; S5, carrying out microwave sintering on the material 3 in nitrogen gas, and cooling, wherein nitrogen gas partial pressure and the sintering temperature meet a following relation expression: 1gPnitrogen gas equals to k-1454 / (T+273). According to the preparation method disclosed by the invention, the wave absorbing performance of a ferrite material is increased, the density is small, the weight is light, and actual using requirements are met.

Owner:ZHONGDE ELECTRONICS

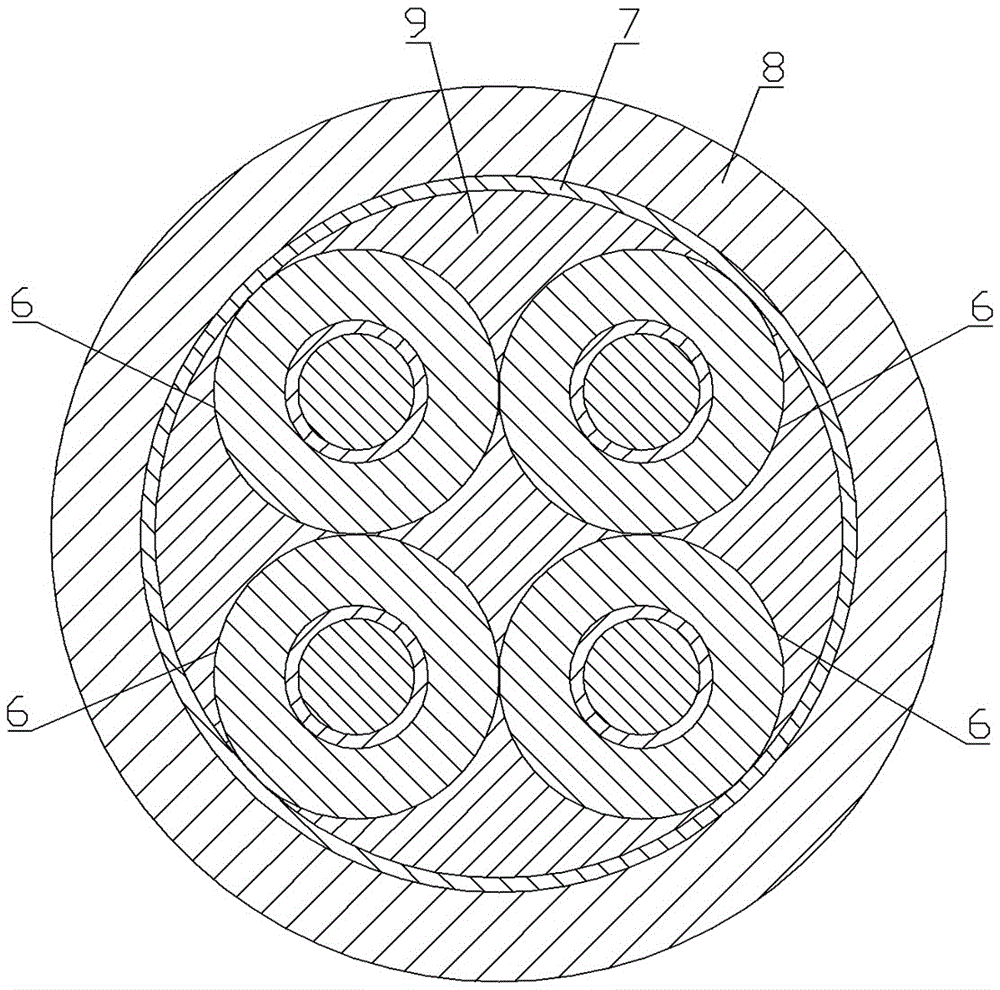

Deep submersion pressure-resistant waterproof cable and preparation method thereof

PendingCN105575511APitch stabilityGuaranteed against torsionSubmarine cablesCable/conductor manufactureSeawaterPull force

The invention provides a deep submersion pressure-resistant waterproof cable comprising a flexible cable core, insulting wire cores, an internal sheath layer, a braided reinforcing layer and an external sheath layer. There are at least four insulating wire cores which are evenly distributed around the flexible cable core so as to form a strand through twisting to enclose the flexible cable core. The internal sheath layer fills and adheres the external part of the insulating wire cores. The braided reinforcing layer open wraps the external part of the internal sheath layer. The external sheath layer wraps the external part of the braided reinforcing layer. The advantages of the deep submersion pressure-resistant waterproof cable are that the cable is compact in integral structure and stable in performance. The integral structure of the cable is formed, and force can be evenly dispersed when the cable bears deep seawater pressure, pull force of the cable and external pull force so that damage to the external sheath layer caused by force bearing can be effectively reduced, and the phenomenon of "snakeskin" of the sheath layer can be effectively prevented.

Owner:长沙恒飞电缆有限公司

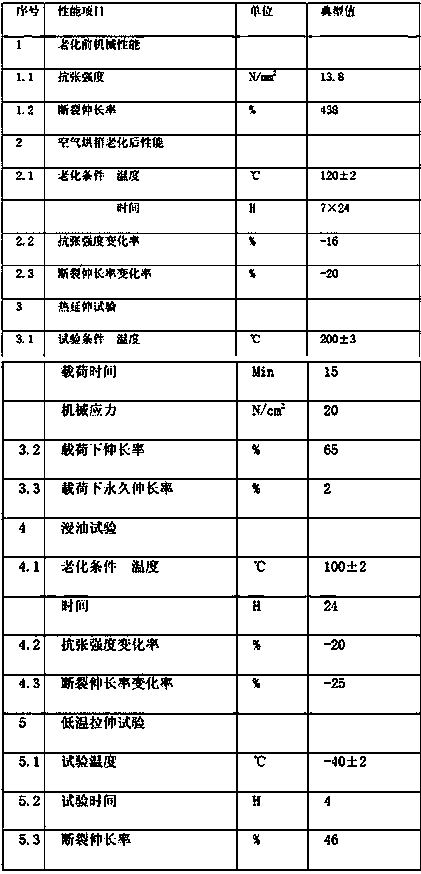

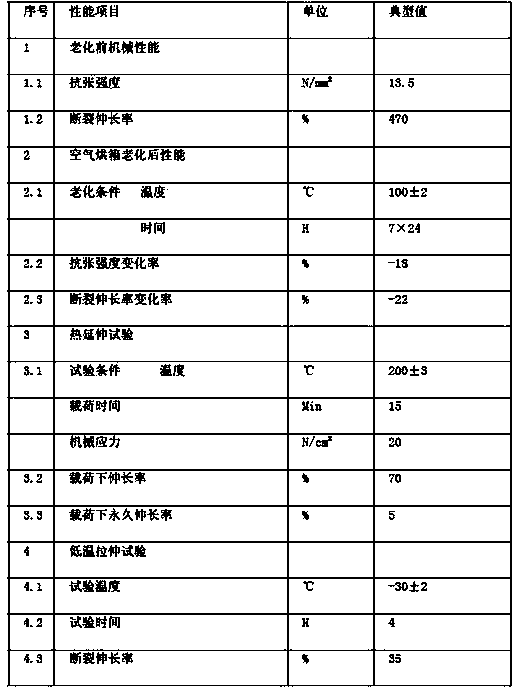

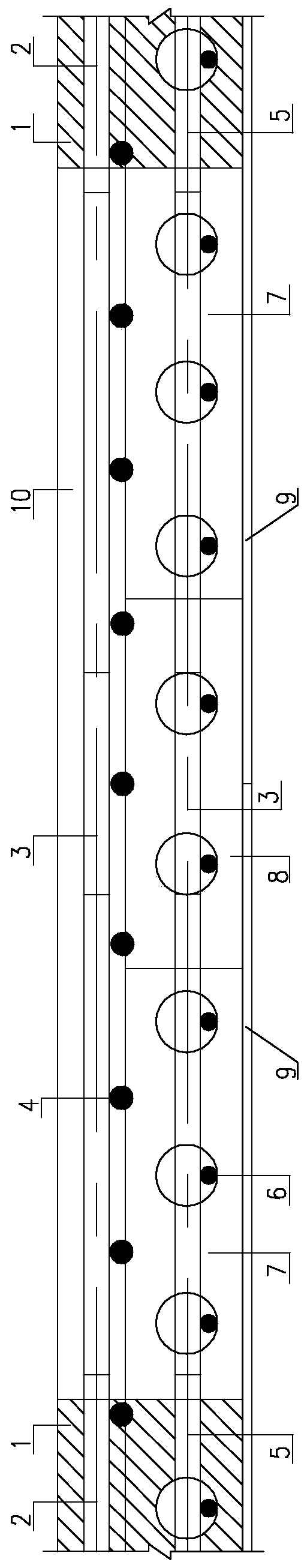

High pressure flexible rubber hose and manufacturing process thereof

InactiveCN106838491AGuaranteed tensile propertiesProtect the safety of useFlexible pipesTubular articlesPolymer scienceManufacturing technology

A high-pressure flexible rubber hose and a manufacturing process thereof relate to the technical field of rubber products, in particular to a high-pressure flexible rubber hose and a manufacturing process thereof. The object of the present invention is to provide a high-pressure flexible rubber hose with tight connection between layers and strong pressure resistance. A high-pressure flexible rubber hose is characterized in that: it includes an inner rubber layer, and a high elastic rubber layer is arranged outside the inner rubber layer, and a non-woven fabric winding layer is arranged outside the high elastic rubber layer; In the rubber layer, the steel wire mesh is staggered in the middle rubber layer; the polyethylene film is arranged outside the middle rubber layer, and the protective armor is arranged on the outside of the polyethylene film.

Owner:SHENYANG SAIYA RUBBER PRODS

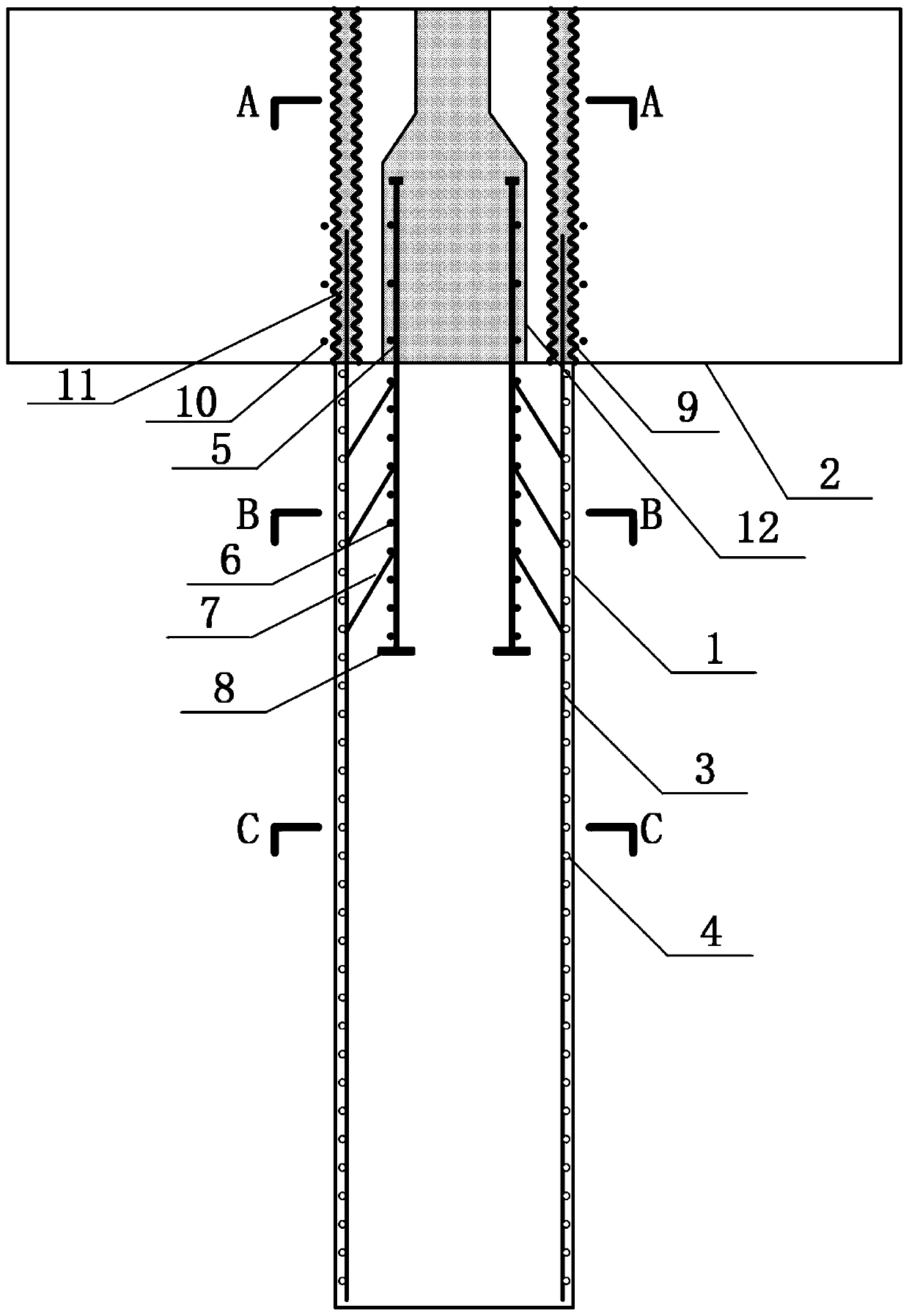

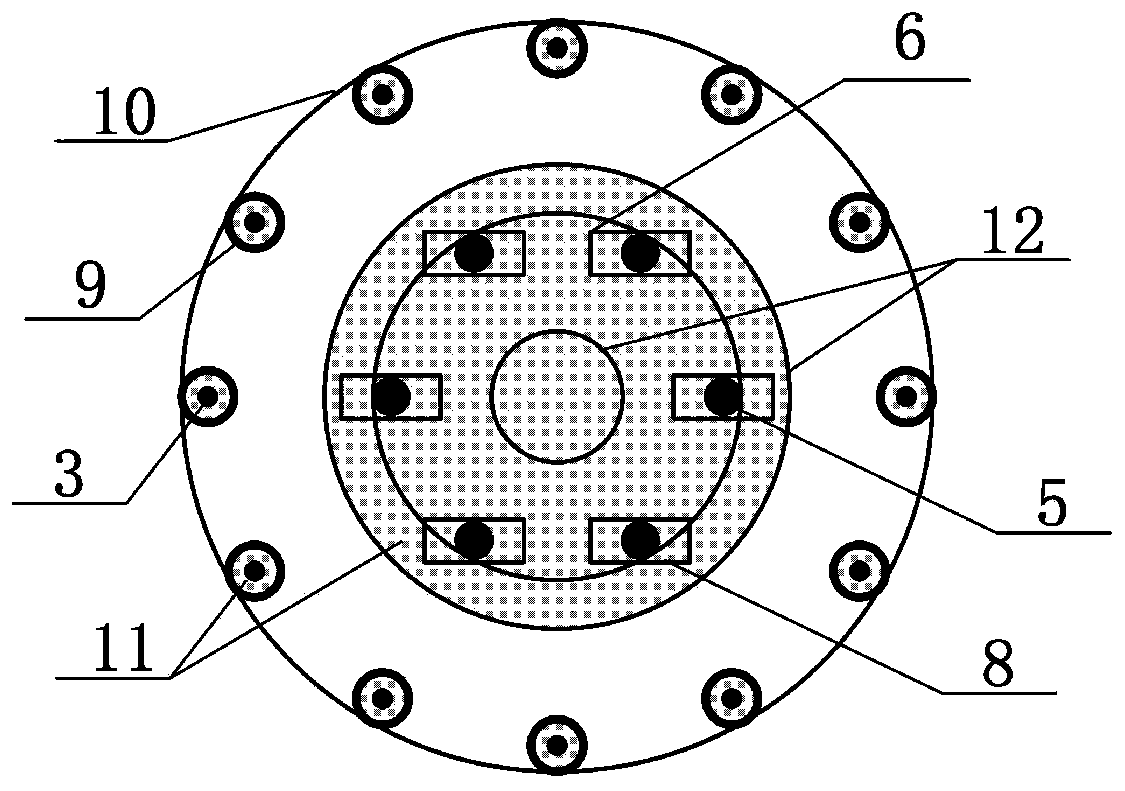

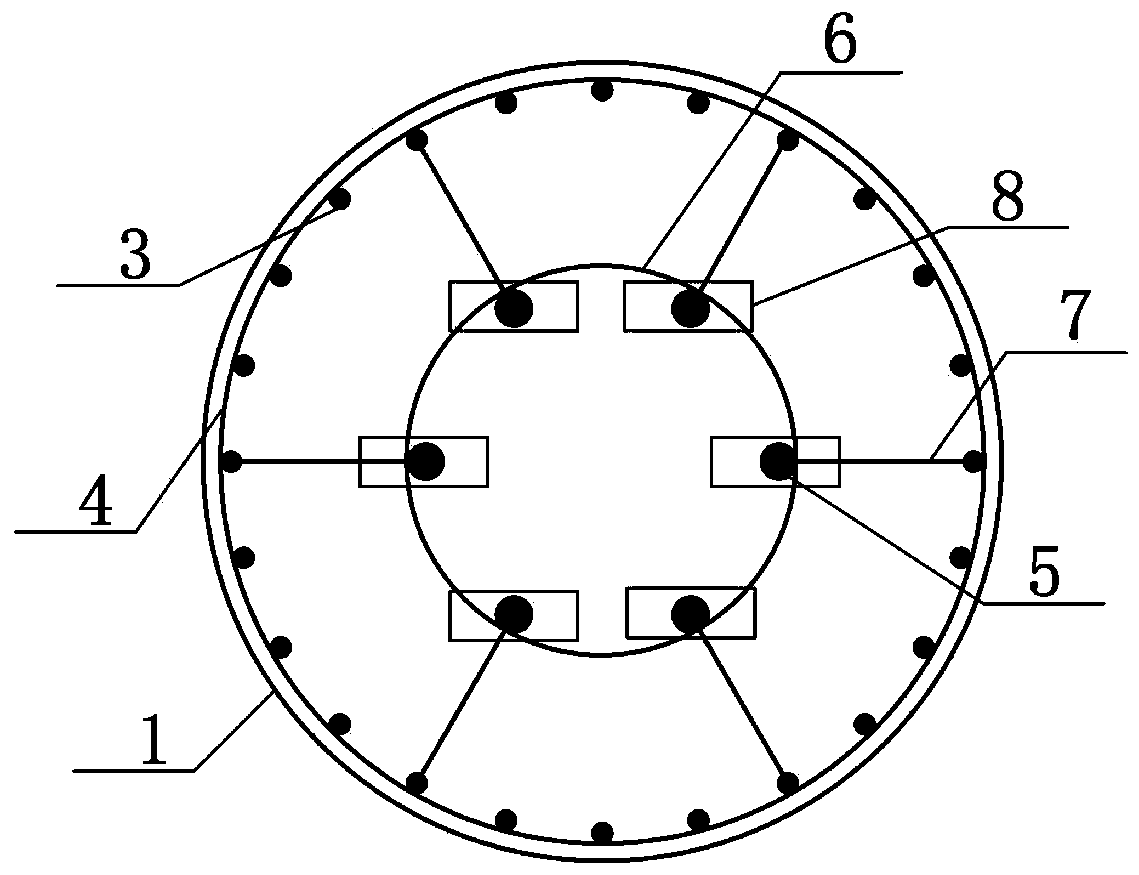

Supporting and protecting composite anti-slide pile suitable for high-attitude and high-intensity regions

InactiveCN103967004AGood tensile performanceSlow to overcome hardeningExcavationsBulkheads/pilesPre stressHigh intensity

A supporting and protecting composite anti-slide pile suitable for high-attitude and high-intensity regions is composed of a pile core and a pile cylinder, wherein the pile cylinder is tightly pasted on the outer side of the pile core. The pile core is composed of a prefabricated prestressed pile, grouting pipes and a center grouting pipe, wherein the cross section of the prefabricated prestressed pile is orthohexagonal. Each side face of the prefabricated prestressed pile is provided with a groove in the axis direction. The grouting pipes are arranged in the grooves. A center grouting hole is formed in the prefabricated prestressed pile in the central axis direction. The center grouting pipe is arranged in the center grouting hole. The pile cylinder is composed of multiple layers of reinforcing steel bar cages and a grouting body. The reinforcing steel bar cage on the innermost layer tightly wraps the pile core, the reinforcing steel bar cage on the outermost layer is tightly attached to the hole wall, and the rest layers of reinforcing steel bar cages are evenly distributed. The reinforcing steel bar cages are wrapped in the grouting body. The concrete strength of the pile core reaches more than 80 MPa, and therefore the defects that the cast-in-place concrete hardening speed is low at a low temperature, and the quality is difficult to ensure are overcome; the tension resistance of the pile is greatly improved due to the prestress of the pile core and the reinforcing steel bar cages of the pile cylinder, and therefore the horizontal bearing capacity is improved, and larger anti-slide force can be provided by the supporting and protecting composite anti-slide pile.

Owner:BEIJING UNIV OF TECH

Tensile anti-rat and anti-termite water-blocking low voltage cable

PendingCN107731356AImprove stabilityEasy to useInsulated cablesInsulated conductorsLow voltageEngineering

The invention discloses a tensile anti-rat and anti-termite water-blocking low voltage cable, which comprises a cable core, wherein the cable core is formed by twisting three insulated wire cores; cable core filling for filling a gap of the cable core is arranged in the cable core; the cable core is sequentially coated with a shielding layer, an insulating layer and an outer sheath layer from inside to outside; a bonding layer is also arranged between the insulating layer and the outer sheath layer; a plurality of uniformly arranged grooves are formed in the contact surface of the insulating layer and the bonding layer; convex blocks matched with the grooves are arranged on the bonding layer and are clamped into the grooves; the outer surface of the outer sheath layer is firstly plated with a water-blocking film and then coated with an anti-rat and anti-termite coating layer; and a plastic reinforcing rib for connecting and fixing the three insulated wire cores is arranged among the three insulated wire cores. The tensile anti-rat and anti-termite water-blocking low voltage cable has the characteristics of tensile property, shielding property and rat and termite bite resistance.

Owner:WUXI GREAT WALL ELECTRIC WIRE & CABLE

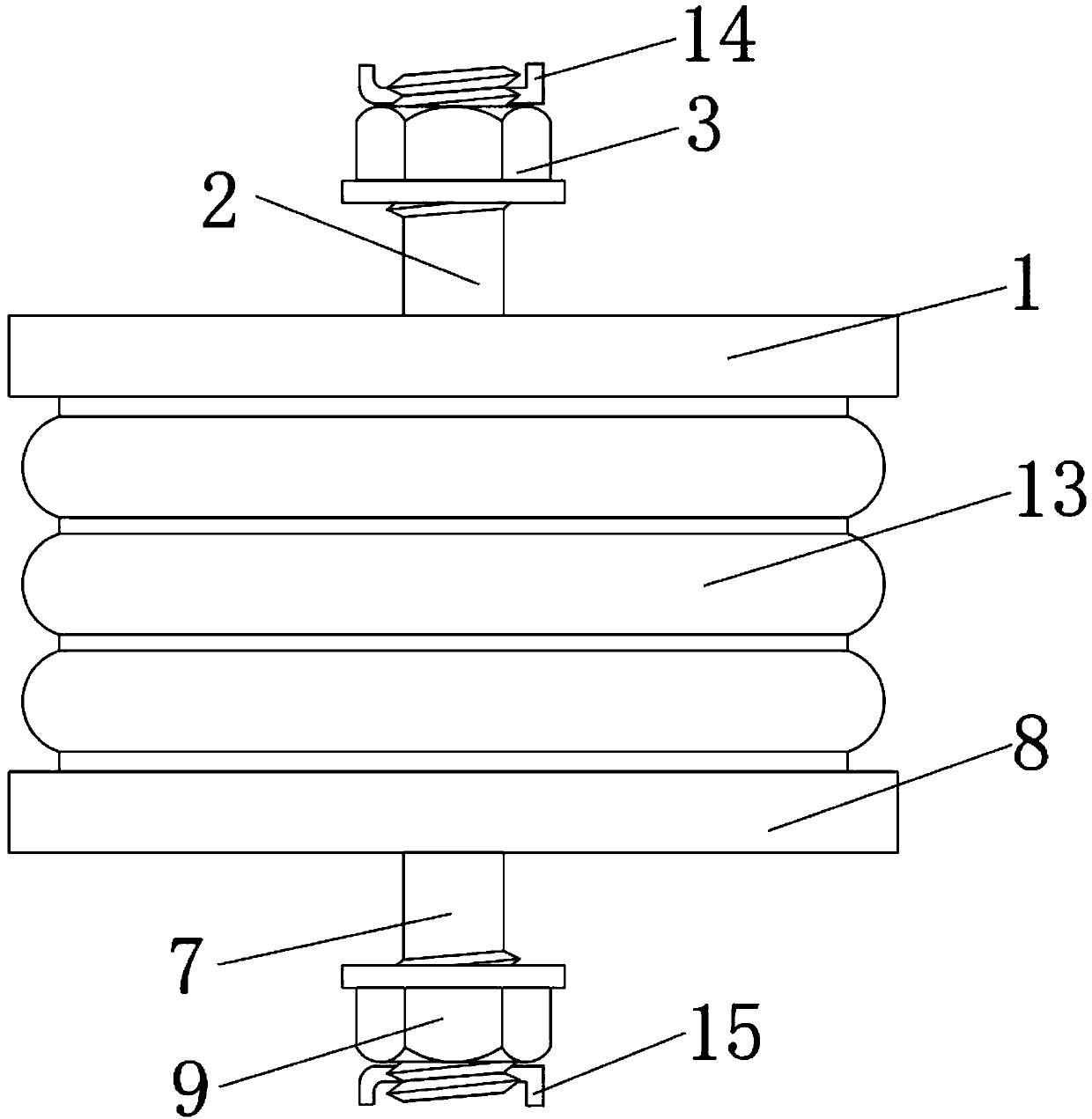

An aging resistant rubber bushing for automobile chassis

ActiveCN109094659AExtended service lifeAvoid lowering the amount of vibrationNon-rotating vibration suppressionVehicle body-frame connectionsAgricultural engineeringShock absorber

The invention discloses an aging-resistant rubber bushing for automobile chassis, include a glue pad, a first fixing block is fixedly connected to the inside of the upper rubber cushion, one side surface of the first fixing block is threaded with a first fixing nut, one side of the first fixing block is fixedly connected with a first bearing plate, one side of the first bearing plate is fixedly connected with a shock absorbing device, a second bearing plate is fixedly connected to one side of the shock absorber, one side of the second bearing plate is fixedly connected with a second fixing block, The surface of the second fixing block is fixedly connected with a lower rubber cushion, the surface of the second fixing block is threadably connected with a second fixing nut, and a shock absorbing spring is fixedly connected between two opposite sides of the first load bearing plate and the second load bearing plate and on the surface of the shock absorbing device. The invention relates tothe technical field of automobile parts. The anti-aging rubber bushing for automobile chassis solves the problem that the rubber bushing will be aged, cannot play the role of shock absorption, affectsthe driving comfort, and seriously affects the driving safety.

Owner:ANHUI AOFENG AUTOMOBILE FITTINGS

Highly seismic region prefabricated assembled bridge central pier stud-cover beam node pouring connection mode and construction

PendingCN110804944ABuild fastImprove construction fault toleranceBridge structural detailsBridge erection/assemblyArchitectural engineeringRebar

The invention discloses a highly seismic region prefabricated assembled bridge central pier stud-cover beam node pouring connection mode and construction and belongs to the field of bridge engineering. The construction comprises a prefabricated pier stud and a prefabricated cover beam. The prefabricated pier stud and the prefabricated cover beam are connected into a bridge pier system through pouring of high-performance materials and splicing. The prefabricated pier stud is composed of a pier stud longitudinal bar, a pier stud stirrup, an overlap-joint large-diameter longitudinal bar, an overlap-joint stirrup and an inclined rebar jointly. The prefabricated cover beam comprises a grouting pipeline, a cover beam construction stirrup and a pouring inserting groove. The splicing quantity of the pier stud longitudinal bar is only a half or much less of the total quantity of longitudinal stressed rebars, and high-performance materials are adopted for pouring splicing. Small damage to a post-earthquake pier stud plastic hinge region is ensured while a large-diameter overlap joint longitudinal bar meets the bridge anti-seismic requirement in a highly seismic region. The bridge building speed can be increased greatly and construction convenience is improved greatly while the bridge anti-seismic requirement in the highly seismic region is met and construction quality is ensured, and a completely novel technical solution can be provided for prefabricated assembled bridge engineering application in the highly seismic region.

Owner:BEIJING UNIV OF TECH

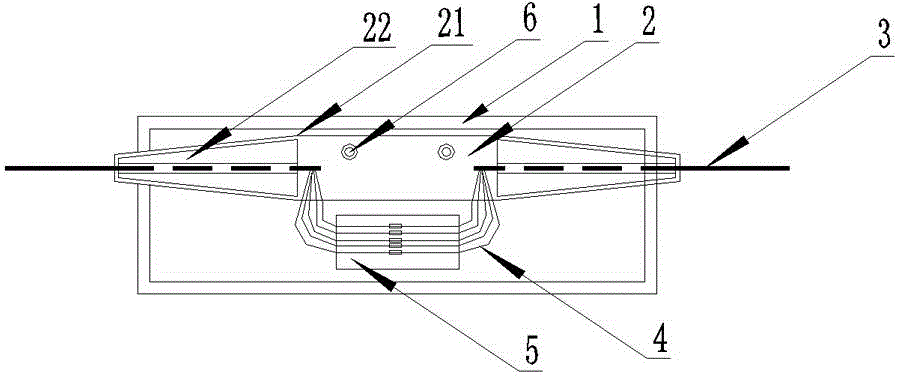

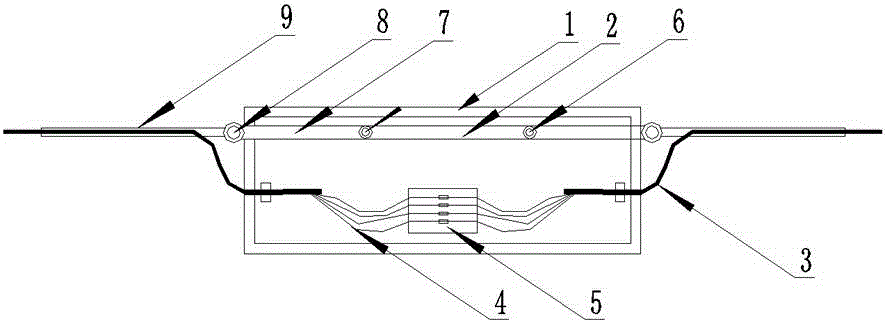

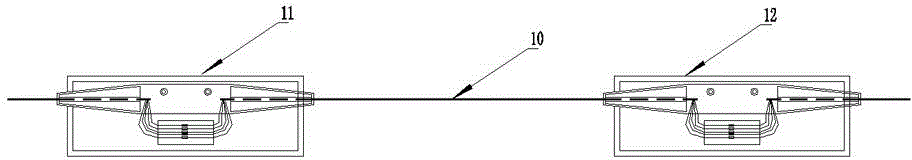

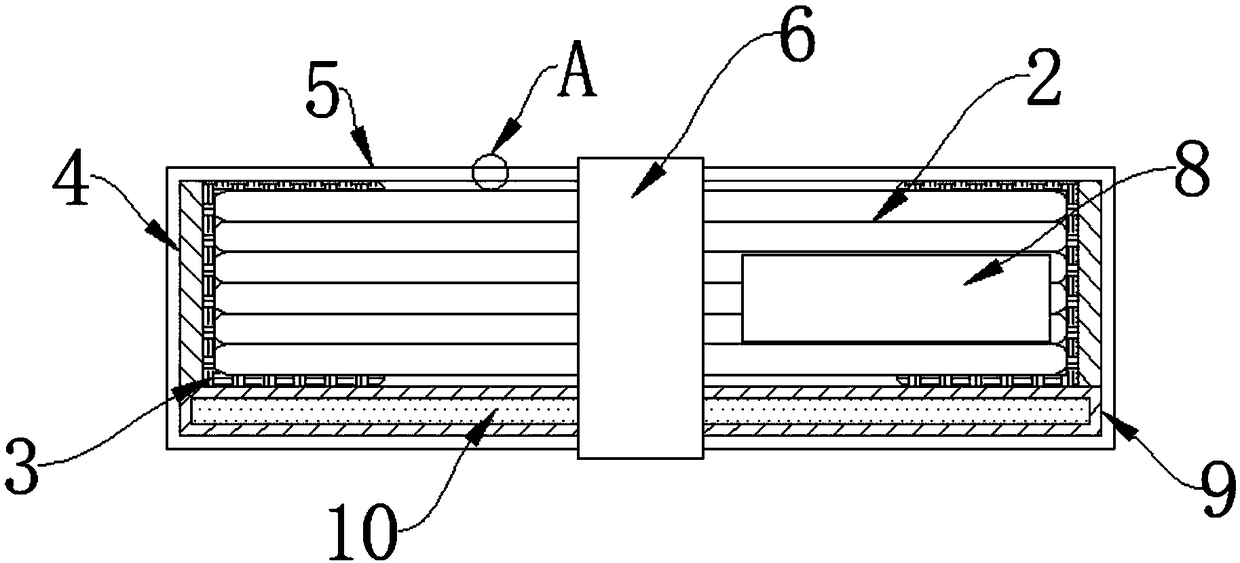

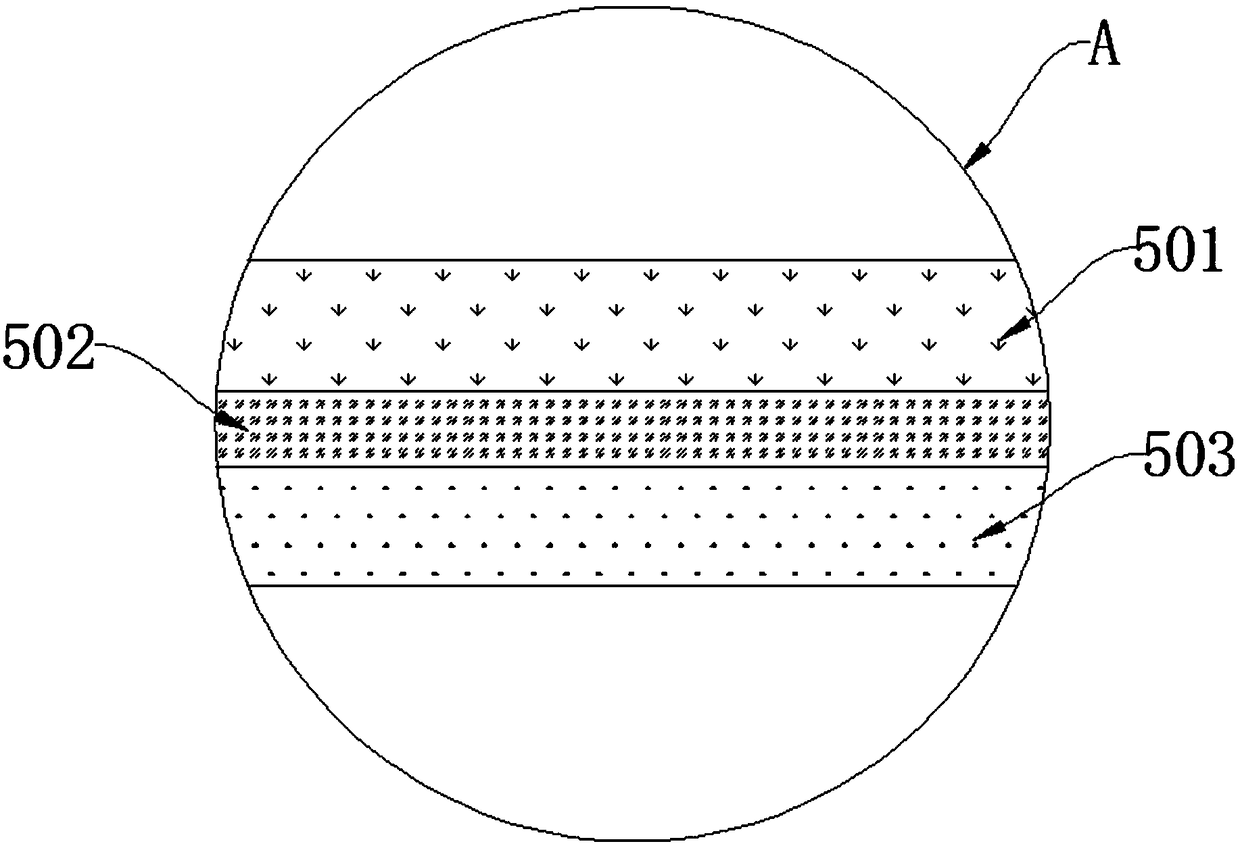

ADSS optical cable air-connection box

InactiveCN104536106ARealize dockingGuaranteed tensile propertiesFibre mechanical structuresFiberEngineering

The invention relates to an ADSS optical cable air-connection box, belongs to the technical field of ADSS optical cable installation, and aims at providing the ADSS optical cable air-connection box that can used for ADSS cable air connection. An original stretching resistance of a cable can be maintained in the connection point after connection, the diameter of a cable channel is variable, the ADSS optical cable air-connection box can be adapted to cables of different external diameters, and two optical cables which cannot realize butt joint due to the lengths can be connected via a double-box structure. The ADSS optical cable air-connection box comprises a box body, a bearing body and a fiber fusion disk, wherein the box includes a hollow casing, the bearing body and the fiber fusion disk are fixed in the box, the cables are tightened by the bearing body, fibers of two optical cables are welded via the fiber fusion disk and the bearing body is fixed in the box via fasteners. The air-connection box can be widely applied to the technical field of ADSS optical cable installation.

Owner:STATE GRID CORP OF CHINA +1

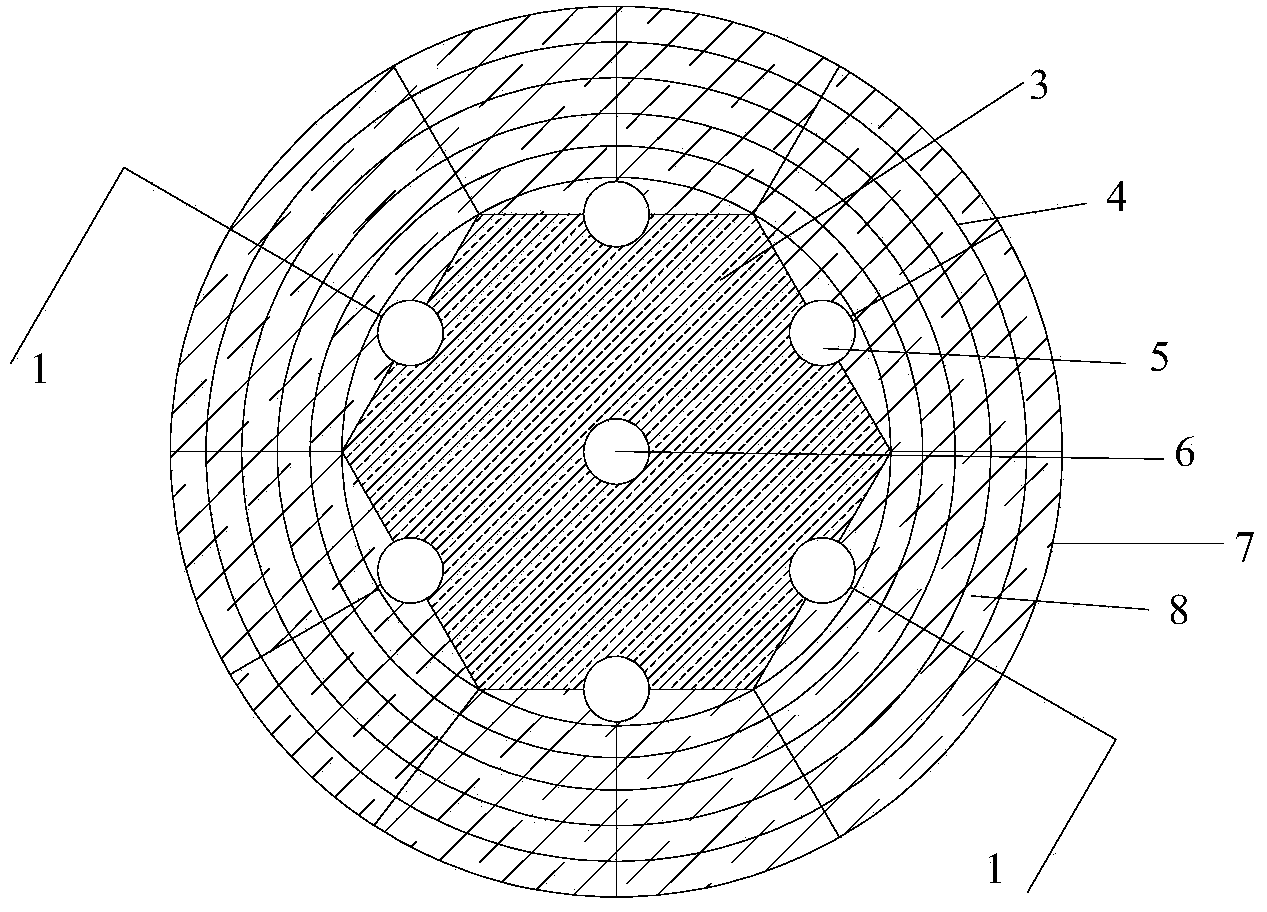

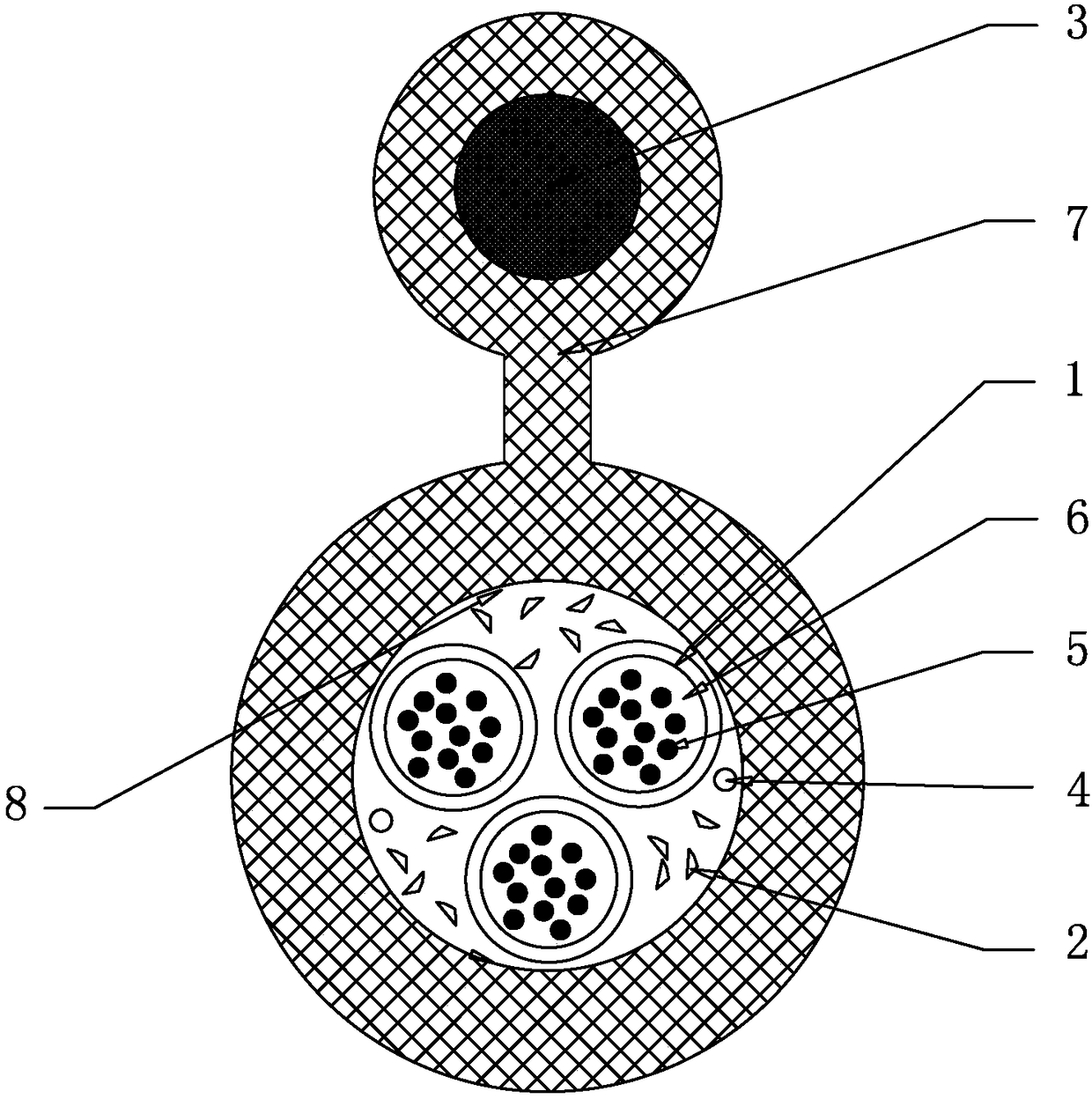

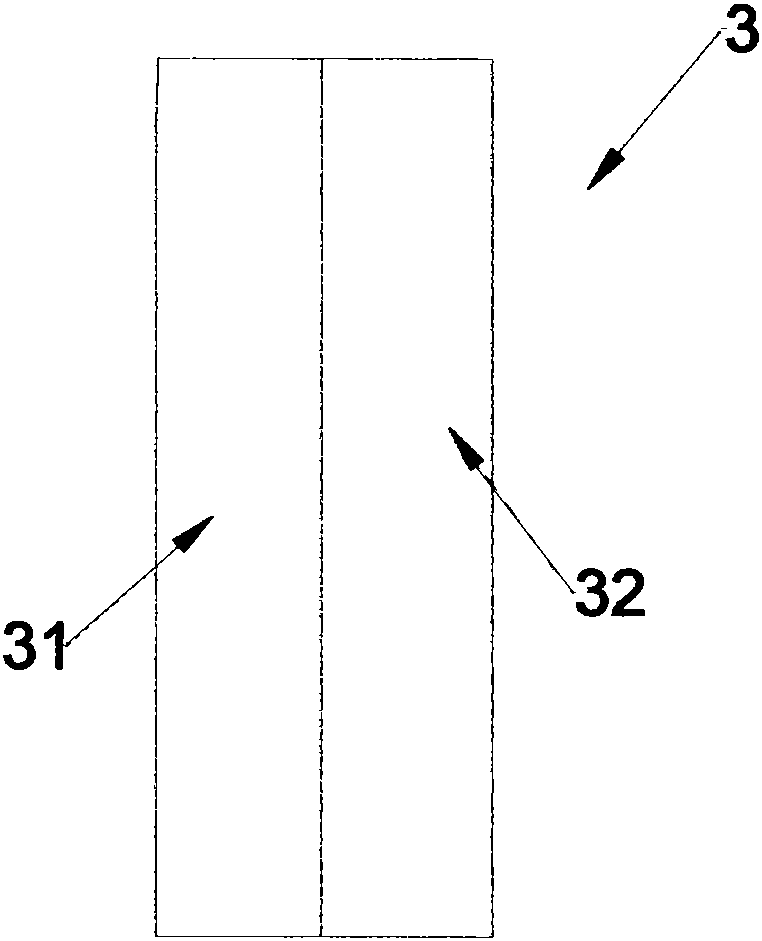

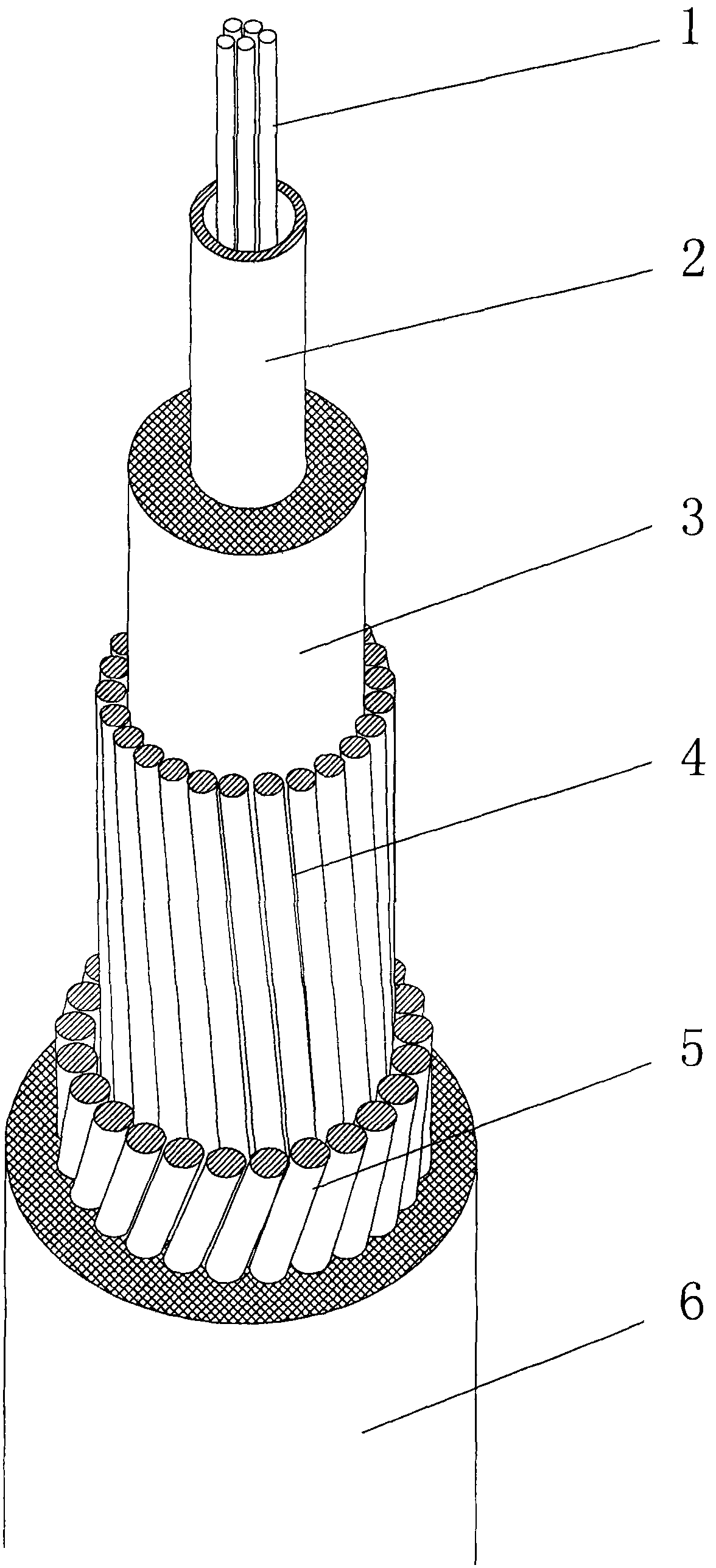

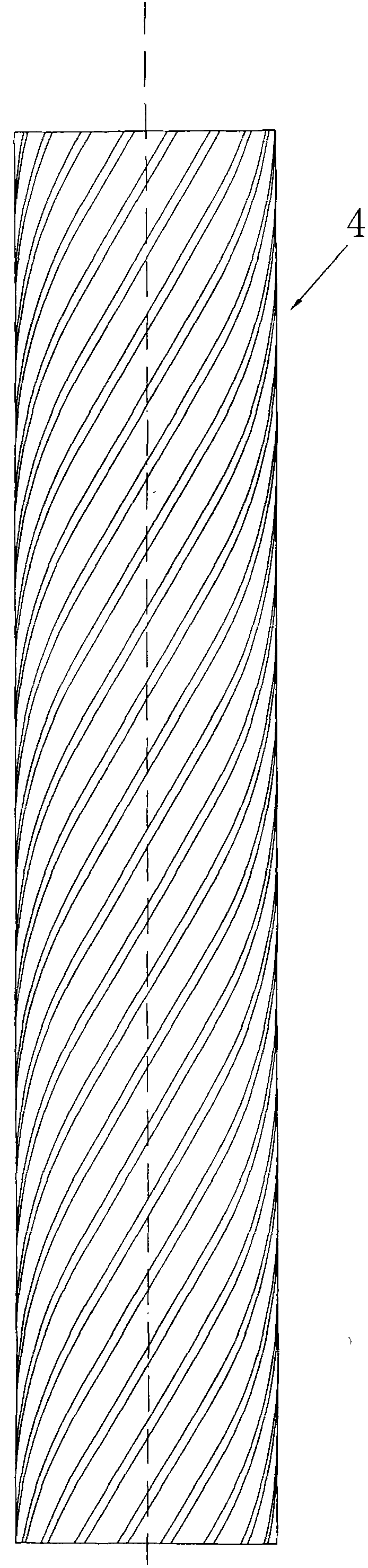

Multicore bundling self-supporting optical fiber cable and manufacturing method thereof

PendingCN108152902AGuaranteed tensile propertiesImprove bending performanceFibre mechanical structuresLow smoke zero halogenEngineering

The invention discloses a multicore bundling self-supporting optical fiber cable and a manufacturing method thereof, the multicore bundling self-supporting optical fiber cable structurally comprises asuspension wire part and an optical fiber cable part which are connected through a sling; the optical fiber cable part is formed through extruding and wrapping of a low smoke zero halogen flame-retardant jacket by a cable core and two tearing ropes. According to the optical fiber cable, a plurality of loose tubes are used for accommodating a plurality of optical fibers respectively, the loose tubes perform parallel wiring directly in the jacket process, the cabling process is saved, the production work flow is simplified, the production efficiency is improved, and the plurality of core loosetubes can be laid in a branching manner simultaneously.

Owner:SHANDONG PACIF OPTICS FIBER & CABLE CO LTD

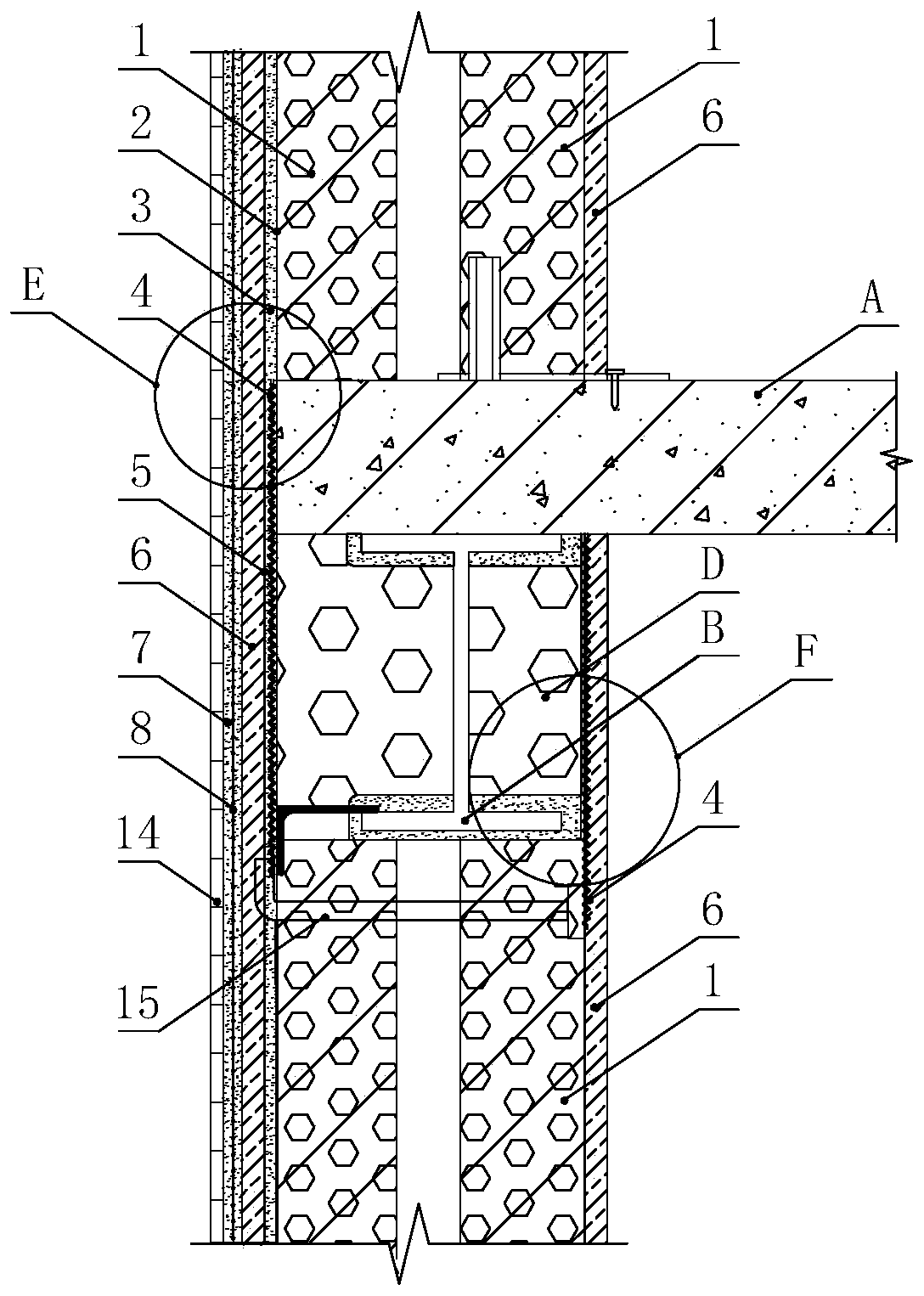

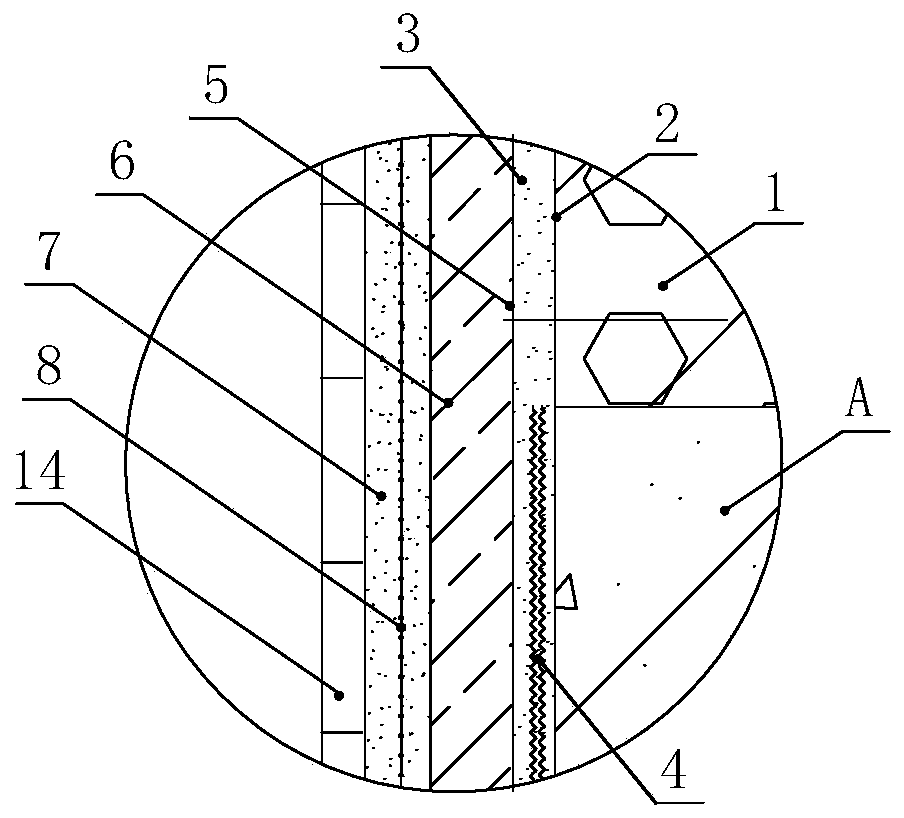

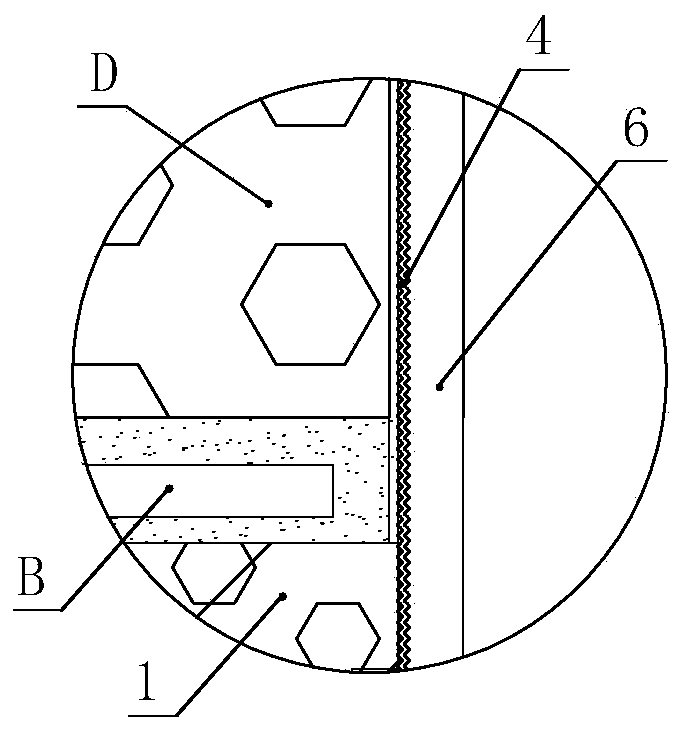

Embedded type light wallboard steel structure building structure and construction method

PendingCN110273490AStrong enough to resist crackingReliable waterproof and anti-seepage structureCovering/liningsWallsGlass fiberStructure building

The invention provides an embedded type light wallboard steel structure building structure. The embedded type light wallboard steel structure building structure comprises an inner wall wallboard structure, a steel beam joint structure, a corner column joint structure, a flat column joint structure and a wallboard splicing seam structure. Glass fiber gridding cloth is laid on the surfaces of an inner wall steel beam groove filling wall of the inner wall wallboard structure and an outer wall steel beam groove filling wall of the steel beam joint structure, joints of a steel structure corner column, a steel structure flat column and light wallboards and joints between the light wallboards, the outer wall faces of the light wallboards are sequentially coated with third waterproofing layers, special interface agents, wall face leveling layers, second waterproofing layers, steel wire nets and first waterproofing layers from inside to outside, the steel wire nets are laid in the second waterproofing layers and combined with the second waterproofing layers to form an outer wall waterproofing and anti-cracking layer, and the glass fiber gridding cloth and the third waterproofing layers are combined to form a waterproofing and anti-cracking layer of the inner wall steel beam groove filling wall. The building structure has good anti-cracking, water-proofing and seepage-proofing performance, scientific in design and simple, a construction method is simple, the operation is easy, materials are easy to purchase, and application and popularization are facilitated.

Owner:广西建工第五建筑工程集团有限公司

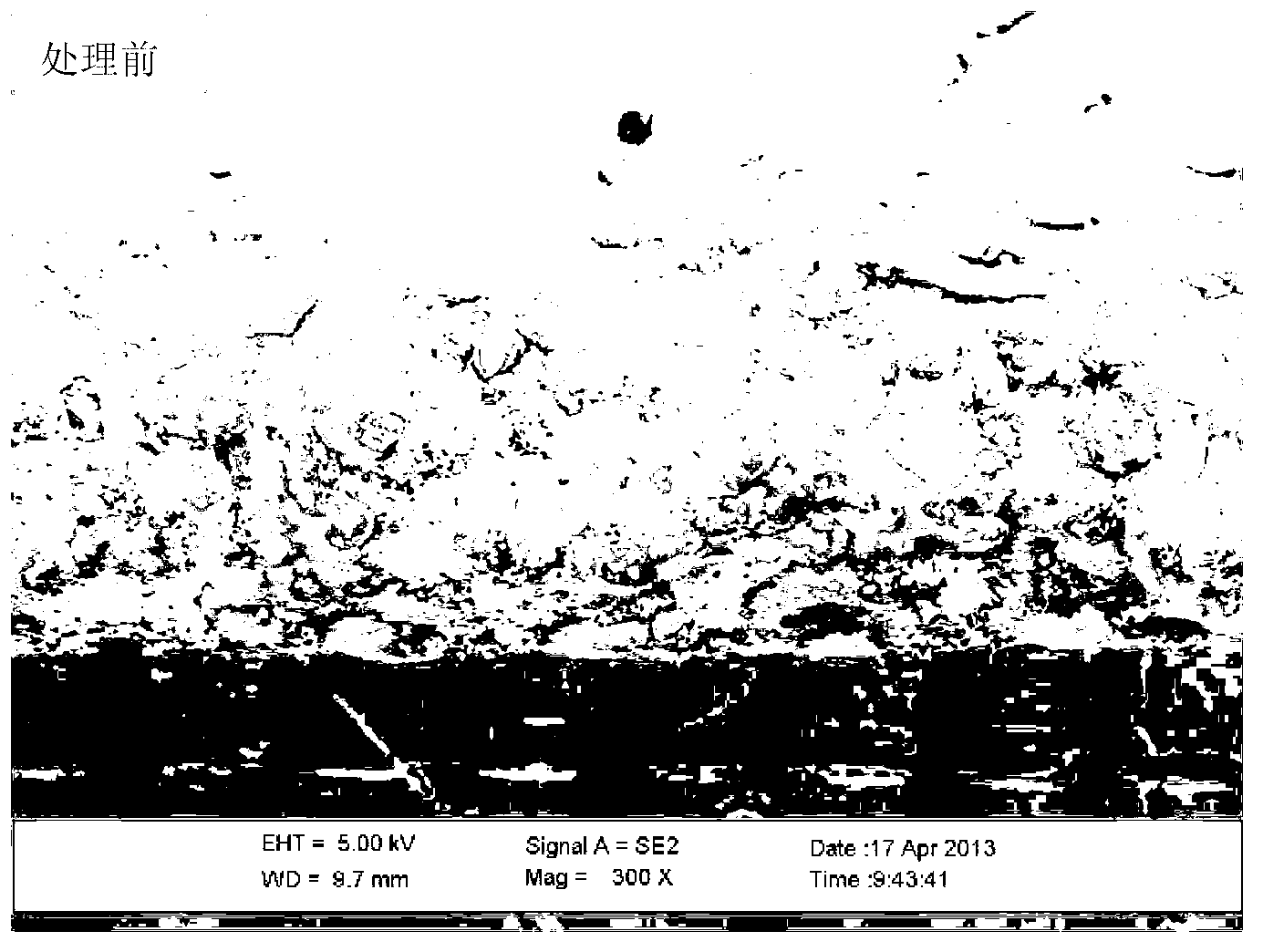

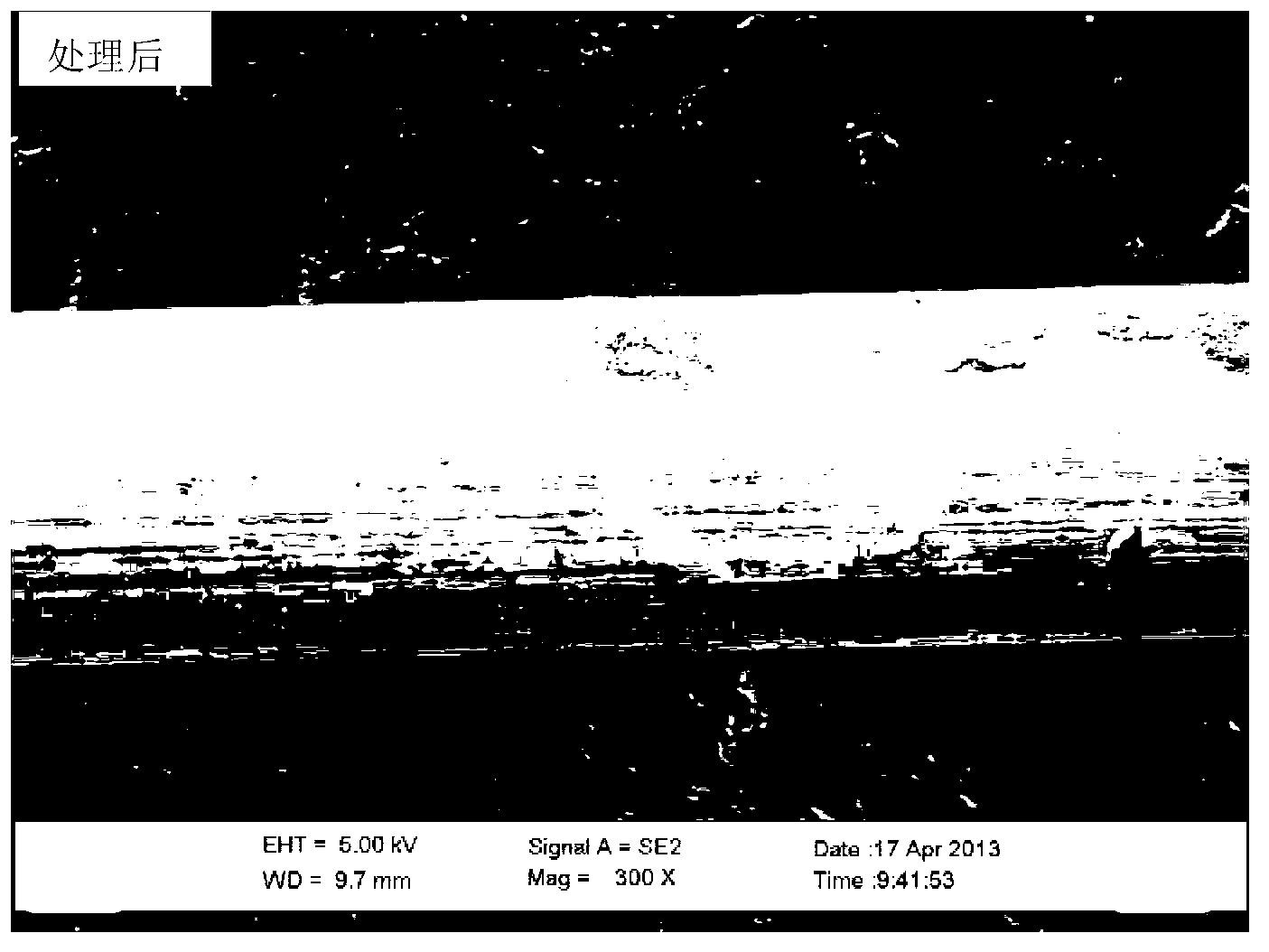

Resin dissolved solution of resin diamond wire and broken-wire connecting method of resin diamond wire

InactiveCN103289837AGuaranteed tensile propertiesMeet cutting needsSawing tools dressing arrangementsNon-surface-active detergent solventsDiamond wire sawSolvent

The invention provides a resin dissolved solution of a resin diamond wire. The resin dissolved solution of the resin diamond wire comprises the following components in percentage by weight: 20%-80% of dissolving agent, 2%-40% of washing agent, 0.2%-5% of solubilizer and 10%-80% of pure water. The resin dissolved solution can be used in a resin diamond wire saw broken-wire connecting method. The method comprises the following steps of: cleaning broken heads of two resin diamond wire saw broken wires and immersing the broken heads into the resin dissolved solution for dissolving; cleaning and drying the broken heads of the dissolved resin diamond wire saw broken wires and welding the broken heads of the two resin diamond wire saw broken wires together. According to the resin dissolved solution of the resin diamond wire and the broken-wire connecting method of the resin diamond wire disclosed by the invention, the resin dissolved solution is used for dissolving and corroding a redundant resin layer on the end head of the resin diamond wire to weld after removing the redundant resin layer. In a wire welding process, the core wire inside the resin diamond wire can be completely fused, so that the tensile strength after the wire welding can satisfy the cutting needs, and therefore, the processing cost is reduced.

Owner:GCL POLY ENERGY HLDG +1

Electric wire and cable packaging part

InactiveCN109436566AStable structureIncrease shock resistance and drop resistanceContainers to prevent mechanical damageRigid containersCardboardPolyethylene

Owner:邓翠玲

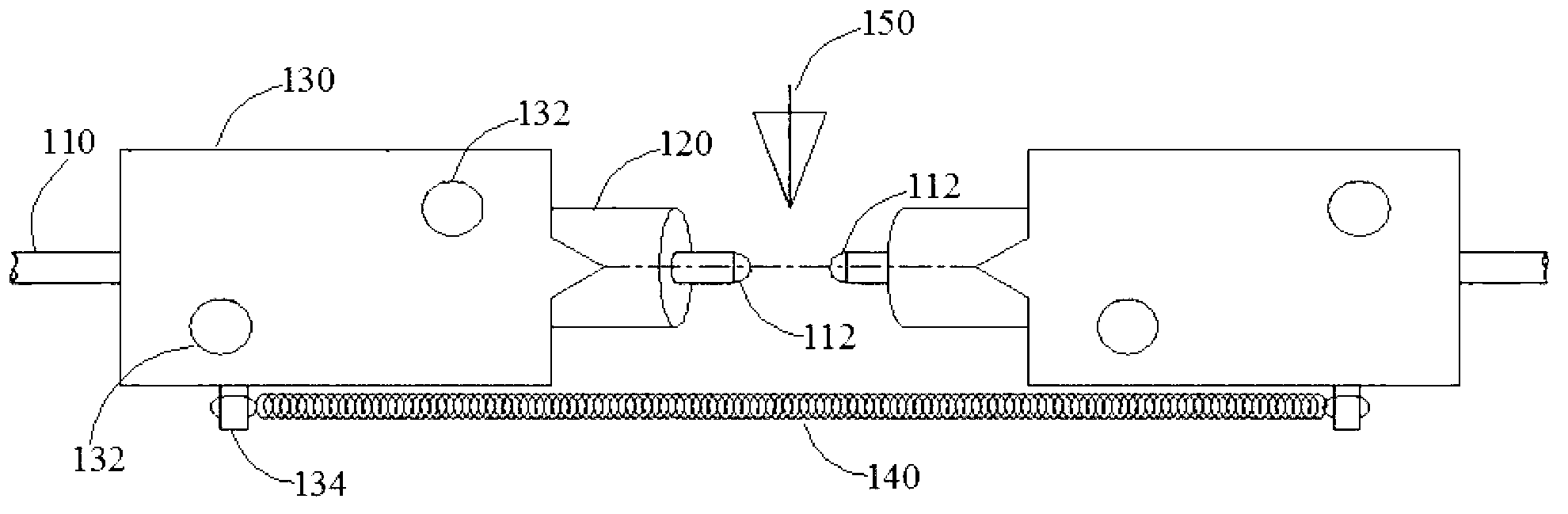

Detective vehicle-mounted weighing system and installing technology thereof based on I-shaped weighing sensor

InactiveCN104764512ANo change in structureSimple structureTransmission systemsWeighing apparatus detailsWeather resistanceThe Internet

The invention discloses a detective vehicle-mounted weighing system and an installing technology thereof based on an I-shaped weighing sensor. The I-shaped weighing sensor is connected with an integrated data processing terminal. The integrated data processing terminal is in a wireless connection with a Beidou or GPS remote terminal through Beidou or GPS, and the Beidou or GPS remote terminal is connected with a monitoring platform. The installing technology includes the steps that 1 the I-shaped weighing sensor is manufactured; 2 polishing is conducted; 3 spot welding is conducted; 4 sealing gluing is conducted; 5 connecting is conducted; 6 fixing is conducted; 7 accomplishment is conducted. The system has the advantages that a vehicle structure is not changed, traffic safety is not affected, and the structure is simple and practical. Fusion of an internet of things and an internet of vehicles is achieved through the Beidou or GPS. The installing method has the advantages that batch of vehicle loading is easy to control, the bonding durability and weather resistance are good, and the problem of installing and signal line transmission signal reliability of the vehicle-mounted weighing system based on the I-shaped weighing sensor is solved.

Owner:HUNAN SANDOU SCI & TECH CO LTD

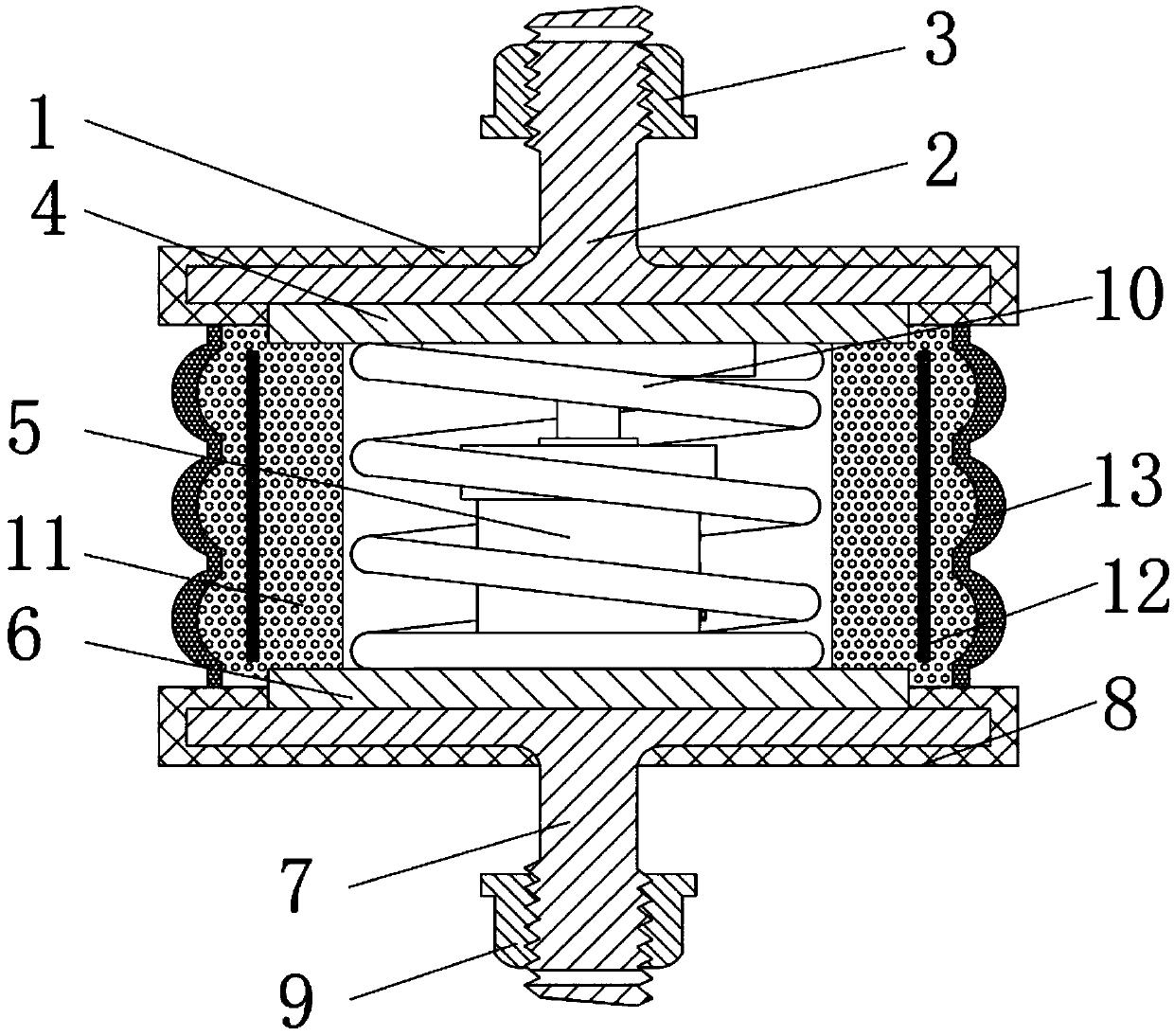

Pneumatic actuator

InactiveCN105889605AExtended service lifeGuaranteed tensile propertiesOperating means/releasing devices for valvesPistonInterior space

The invention discloses a pneumatic actuator. The pneumatic actuator comprises a cylinder, wherein a pair of pistons are arranged in the cylinder; the sides, positioned outside the cylinder, of the pistons, are connected with springs; a first rack and a second rack are respectively arranged on the sides, positioned inside the cylinder, of the pistons; an output shaft is arranged between the pistons inside the cylinder; the first rack and the second rack drive the output shaft to rotate; a first air hole and a second air hole are further formed in the pneumatic actuator; the first air hole communicates with the internal space between the pistons; the second air hole communicates with the external space of the cylinder; and the pistons are double-layer structures comprising metal layers and ceramic layers. According to the pneumatic actuator, the pistons in a cylinder body are arranged as structures with double layers, one layer is the metal layer, the other layer is the ceramic layer, the two layers are in tight press fit, the metal layer guarantees the tensile strength of the pistons, the ceramic layer guarantees the abrasion resistance of the pistons, and the pistons are firmer and more abrasion-resistant when the two layers are combined for utilization, so that the service life of the pneumatic actuator is greatly prolonged.

Owner:JIANGSU TONGDA MARINE TYPE VALVE & PUMP

Zinc/graphene three-dimensional composite structure negative electrode for zinc battery and preparation method thereof

InactiveCN113328101ALow costFast and time-saving processingElectrode manufacturing processesFinal product manufactureFiberPolyimide membrane

The invention discloses a zinc / graphene three-dimensional composite structure negative electrode for a zinc battery and a preparation method thereof. The preparation method comprises the following steps of: taking polyimide fiber paper or a polyimide film as a carbon source, taking CO2 laser as a heat source, and preparing a three-dimensional graphene layer by using a laser irradiation induction method to obtain laser-induced graphene; and taking the laser-induced graphene of a three-dimensional structure as a working electrode, taking a zinc sheet as a reference electrode and a counter electrode, immersing the working electrode and the zinc sheet into an electrolyte solution, and electroplating under constant voltage to obtain the zinc / graphene three-dimensional composite structure negative electrode. The zinc / graphene negative electrode of the three-dimensional structure has the advantages of bendable material, light weight and high cycling stability, can improve the rate and power performance of a battery, and can prolong the charge-discharge cycle life of a device.

Owner:CAPITAL NORMAL UNIVERSITY

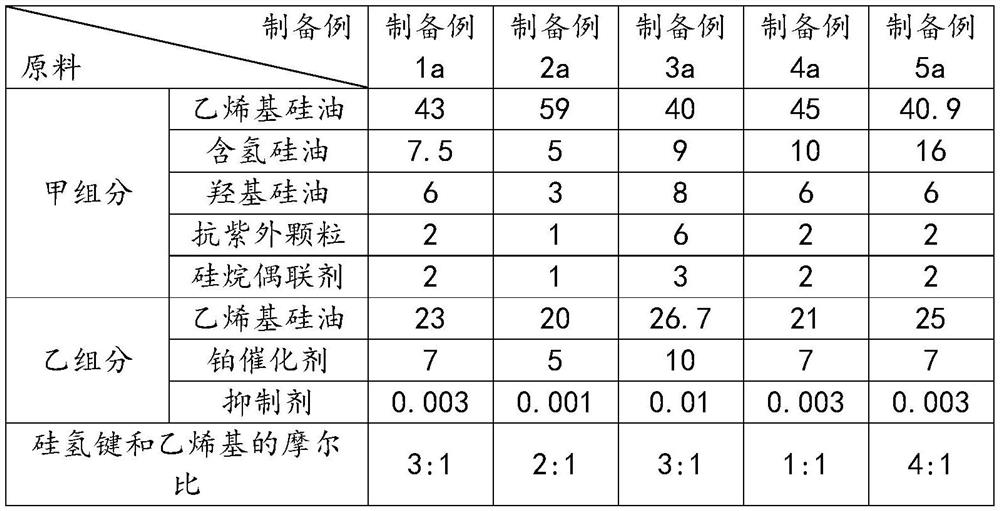

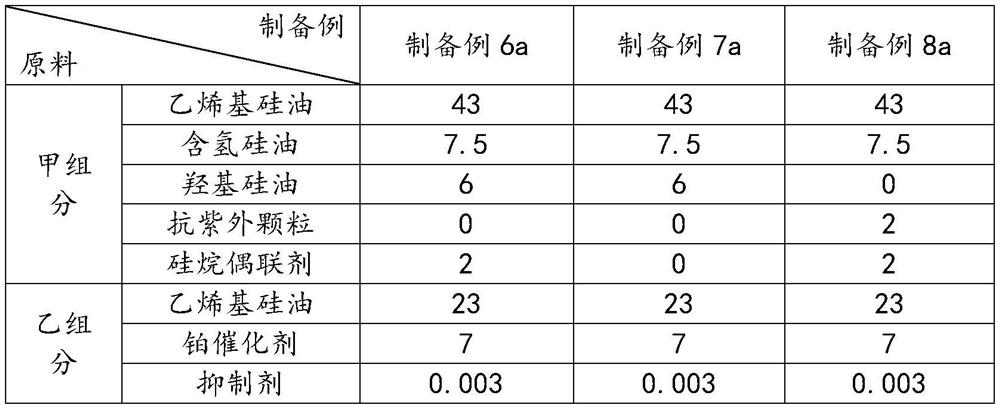

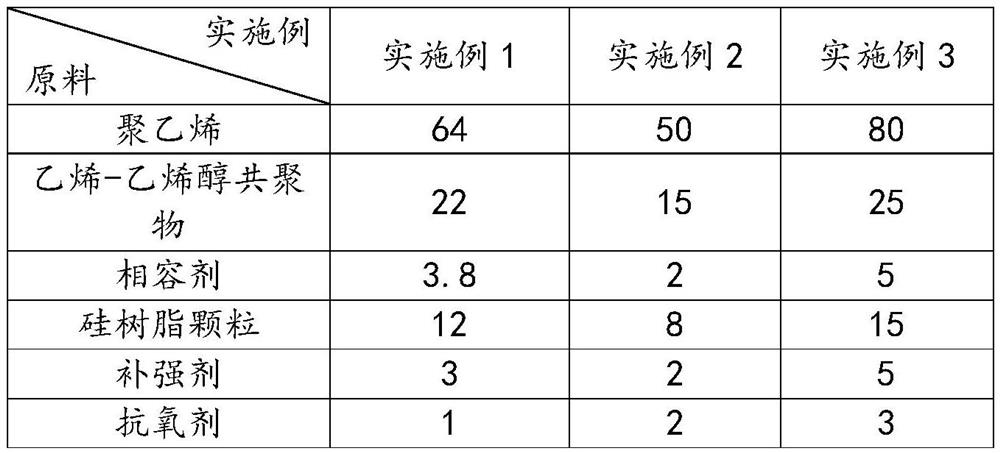

Pesticide bottle capable of resisting oil agent permeation and preparation method of pesticide bottle

The invention discloses an oil agent permeation resistant pesticide bottle and a preparation method thereof. The oil agent permeation resistant pesticide bottle is prepared from the following raw materials in parts by weight: 50-80 parts of polyethylene; 15 to 25 parts of an ethylene-vinyl alcohol copolymer; 2-5 parts of a compatilizer; 5 to 15 parts of silicon resin particles; 3-6 parts of a reinforcing agent; 1 to 3 parts of an antioxidant; the silicon resin particles are obtained by mixing and reacting a component A and a component B in a mass ratio of 1: 1 and then carrying out ball milling; the component A comprises the following raw materials in parts by weight: 30-60 parts of vinyl silicone oil; 5 to 20 parts of hydrogen-containing silicone oil; the component B comprises the following raw materials in parts by weight: 20-30 parts of vinyl silicone oil; 5-10 parts of a platinum catalyst; 0.001 to 0.01 part of an inhibitor; in a mixed system of the component A and the component B, the molar ratio of silicon-hydrogen bonds to vinyl is (2-3): 1. The pesticide bottle prepared by the invention has relatively good strength performance and oil penetration resistance.

Owner:杭州恒峰塑料制品有限公司

Wear-resistant and corrosion-resistant cable for electricity

InactiveCN107221384AWear and corrosion resistance guaranteeImprove wear resistance and corrosion resistanceInsulated cablesPower cablesEpoxyElectricity

The invention discloses a wear-resistant and corrosion-resistant cable for electric power, comprising a cable body, a plastic polyurethane layer is installed on the side of the cable body, and the plastic polyurethane layer and the cable body are bonded by super glue. The top of the plastic polyurethane layer is provided with a corrosive electrostatic net, and the corrosive electrostatic net and the plastic polyurethane layer are movably connected through the cable body. One side of the corrosive electrostatic net is installed with a hot-dip silver-plated layer. The anti-corrosion buffer zone is installed on the side of the anti-corrosion buffer zone, and the anti-corrosion buffer zone is embedded in the hot-dip silver layer, the top of the anti-corrosion buffer zone is installed with a steel strand, and one end of the steel strand is installed with an insulating sleeve , and the other end is provided with an insulated wire core. By being provided with a plastic polyurethane layer and an epoxy resin coating, the rapid aging of the cable can be prevented, the mechanical and electrical properties of the power cable can be maintained, the service life of the power cable can be maintained, and the cable can be guaranteed. electrical properties.

Owner:熊琪辉

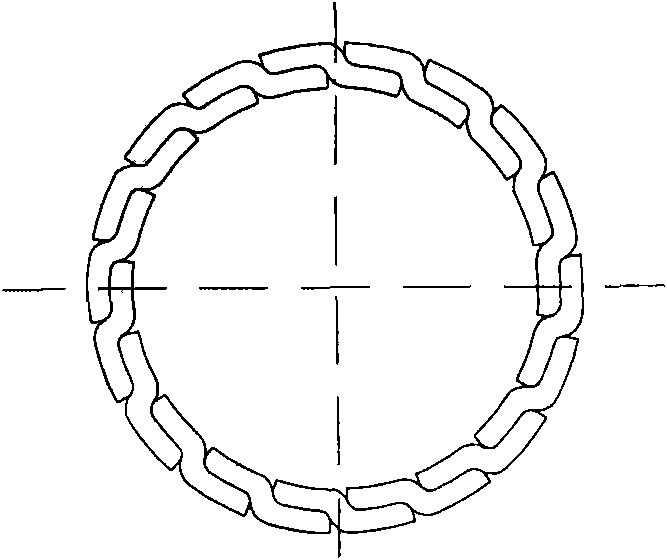

High-strength metal sleeve for optical cables

The invention relates to photo-communication transmission equipment, in particular to a high-strength metal sleeve for optical cables. In the sleeve, a plurality of bar-shaped metal sheets are overlapped transversely to form a circular tube, and each metal sheet is arranged in a spiral form and is made of stainless steel, the section of each metal sheet is pressed into a Z shape basically, and the height of the formed step is matched with the height of the metal sheet. Compared with a sleeve formed by arranging steel wires into a circle, under the condition that the weights of used materials are same, the sleeve has obviously reduced thickness, thus the overall diameter of a cable is reduced, and the manufacture, transportation, construction and maintenance costs of the product are lowered. Since inner and outer cambered surfaces formed by the sleeve of such a structure are a full circle, forces acting on the cable are uniform, and the cable can be better protected; in addition, the metal sheets are overlapped transversely, compression resistance is improved greatly while tensile strength is ensured.

Owner:张建军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com