Heat treatment method for improving mechanical property of GH738 bolt type products

A technology of GH738 and heat treatment method, which is applied in the field of heat treatment to improve the mechanical properties of GH738 bolt products, and can solve the problems that the mechanical properties of GH738 bolt products cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

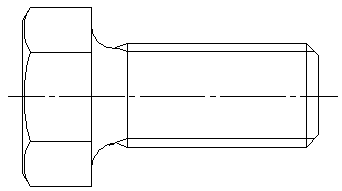

[0023] This embodiment is a processing technology for GH738 bolt products used on a kind of aero-engine. When processing the existing GH738 bolts, solid solution materials are selected to carry out head forming and heading, such as figure 1 As shown, then carry out stabilization treatment, then through machining, thread rolling, rolling R, and finally aging treatment after being processed into a product. Using the existing processing method, its tensile strength and high temperature durability are not ideal.

[0024] In order to improve the mechanical properties of GH738 bolt products, after the stabilization treatment, an aging treatment is carried out, and then the second aging treatment is added. The specific processing steps are: select solid solution materials and perform head forming and heading, Such as figure 1As shown, and then carry out stabilization treatment, the process parameters of the stabilization treatment are as follows: put into the furnace at room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com