Patents

Literature

280results about How to "Change mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

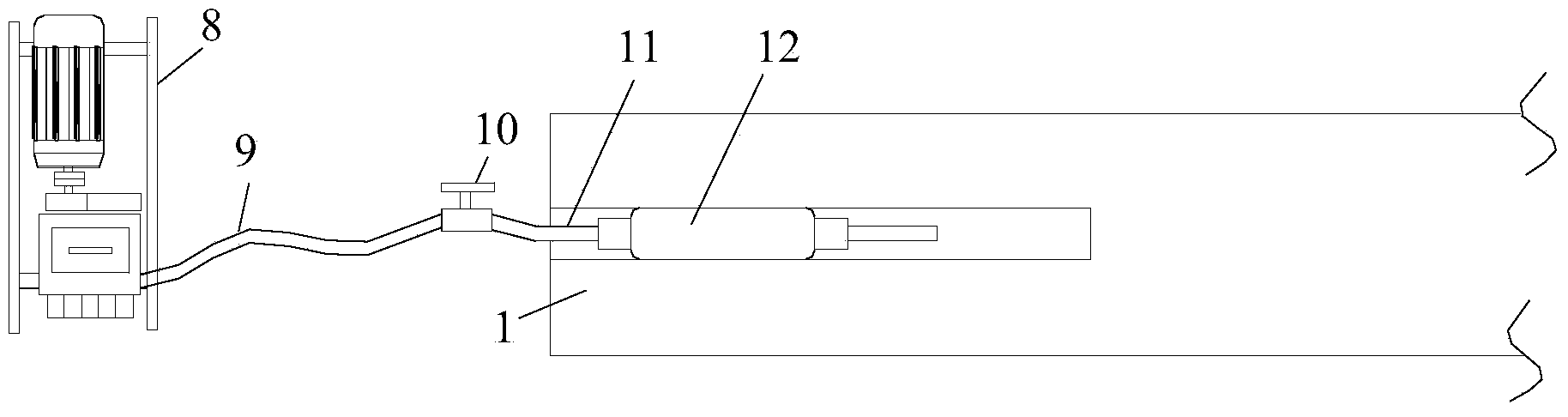

Method for extracting gas in low air permeability coal layer by pulse fracture anti-reflection

ActiveCN102155254AChange mechanical propertiesImprove breathabilityFluid removalGas removalPulse pressureDischarge rate

The invention relates to a method for extracting gas in low air permeability coal layer by pulse fracture anti-reflection, comprising the following steps: firstly using the blast-proof pulse-type coal layer high pressure water injector with adjustable frequency and pressure from the coal layer, high tunnel or low tunnel; using the pulse water effect generated by the periodical change of high pressure pulse water inside the drill hole of coal body, wherein the maximum pulse pressure is 35 MPa, the flow is about 300 L / min, and the pulse frequency is 0-1460 times / min; forcing the macroscopic fracture in the coal layer to be expanded and communicated; promoting the micro-pore fracture to be formed and extended; forming a new regeneration fracture net; providing a permeable channel of water inthe coal layer so as to achieve the effects of improving the mechanical property of the coal body, reducing the stress of the coal body in front of the working face and improving the discharge rate of the gas. Through the method, the pressure releasing range of the coal layer is enlarged, the whole pressure is adequately released, the radius of influence range of fracture can reach 10-40 m, and the air permeability of the coal body can be improved by 100-1000 times; and the method is simple, easy to operate and good in effect.

Owner:CHINA UNIV OF MINING & TECH

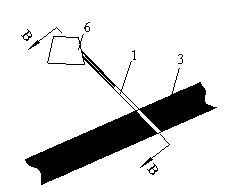

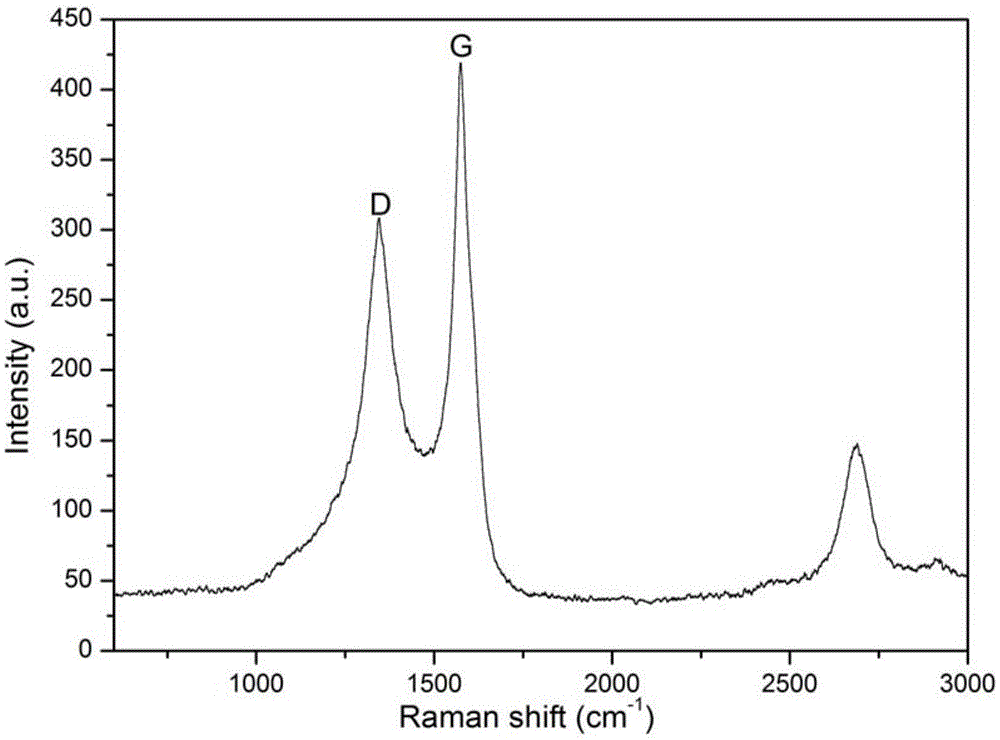

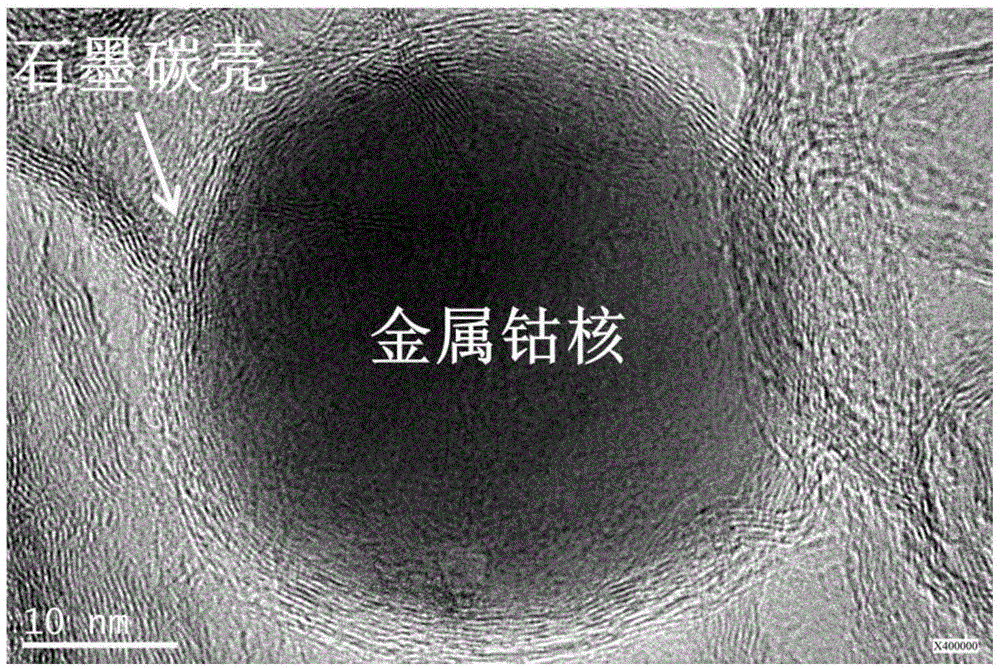

Method for preparing non-metallic element doped carbon coated metal nanoparticle magnetic composite

ActiveCN105478755AGood dispersionHigh purityTransportation and packagingMetal-working apparatusDispersityCyanamide compound

The invention discloses a method for preparing a non-metallic element doped carbon coated metal nanoparticle magnetic composite. The method comprises the steps that water-soluble metal divalent salt, a cyanamide compound and a nitrogen or boron or sulfur containing non-metallic compound are added into a methanol solution to be mixed, dissolved, dried and ground, and obtained homogeneous-phase powder is subjected to roasting pyrolysis under the protection of inert gas; and a pyrolysis product is subjected to acid pickling, washing, drying and grinding, and a target product is obtained. According to the whole preparing process of the method, metal ion reduction, metal nanoparticle coating and doping of nitrogen / boron / sulfur and other non-metallic elements are achieved in one step. The composite prepared through the method is high in degree of graphitization, good in dispersity between particles and high in purity, and the preparing method has the advantages that the cost is low, the process is simple, and large-quantity synthesis can be easily achieved.

Owner:合肥庐阳科技创新集团有限公司

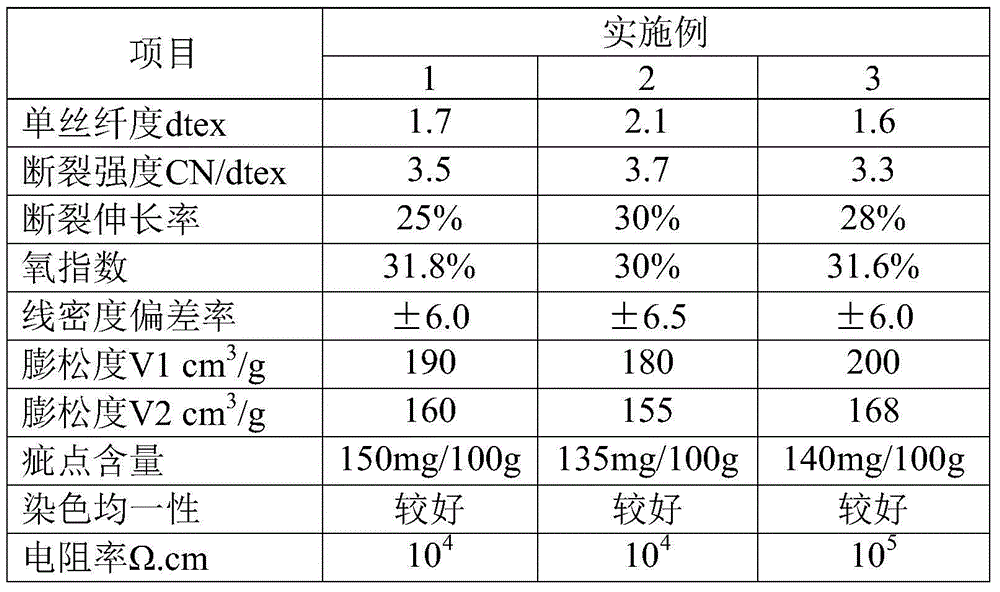

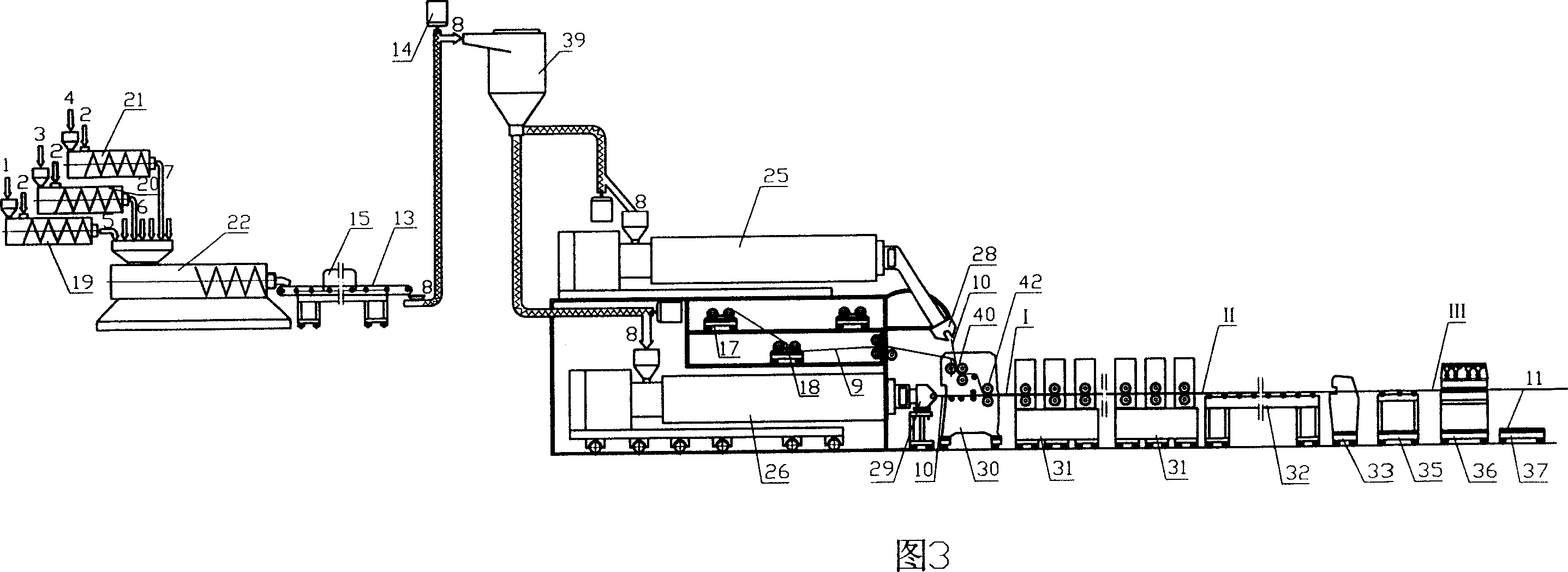

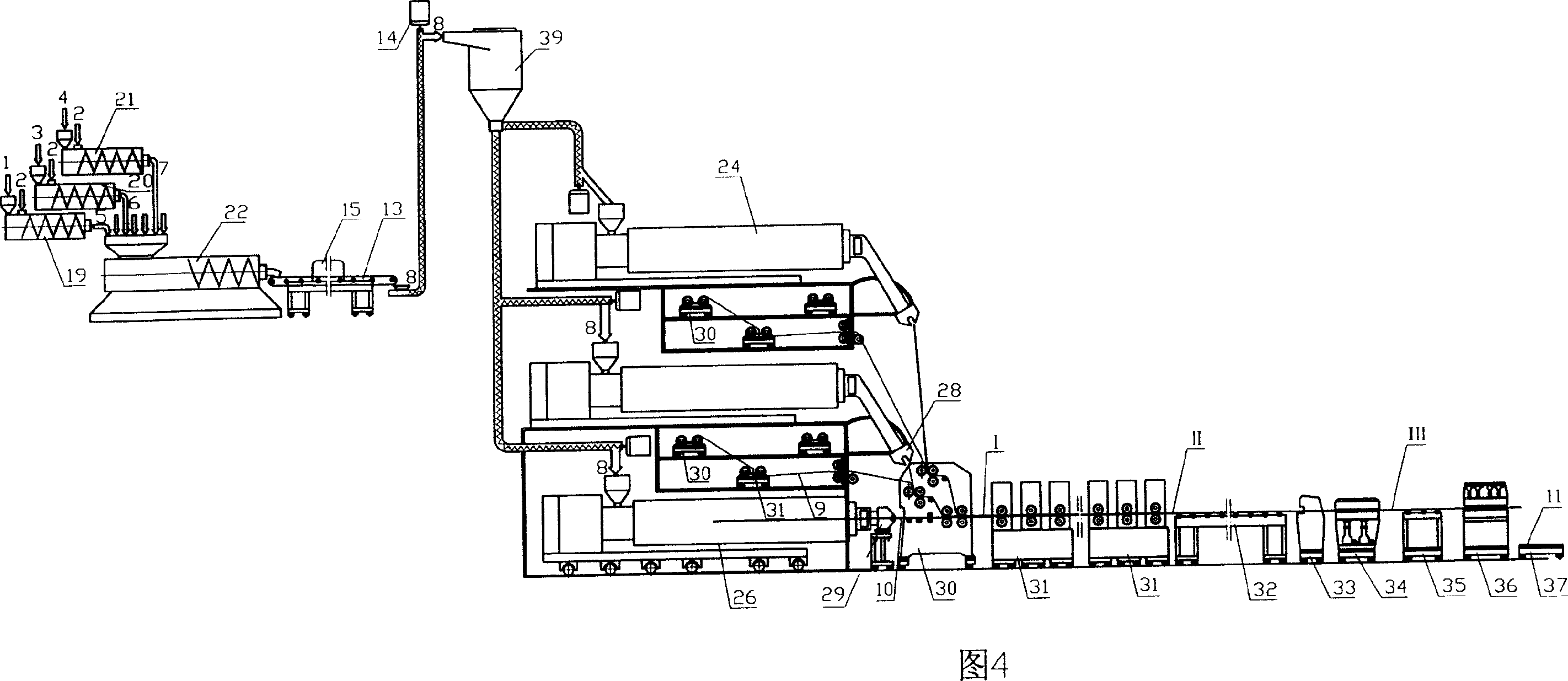

Preparation method of graphene based reinforced and flame-retarded recycled polyester staple fiber

ActiveCN104630928ASpin wellImprove qualityMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The invention provides a preparation method of a graphene based reinforced and flame-retarded recycled polyester staple fiber. The method comprises the following steps: preparing graphene master batch; preparing phosphate based halogen-free flame retardant master batch; weighing the graphene master batch and the phosphate based halogen-free flame retardant master batch, mixing with a recycled polyester raw material, drying, feeding molten dried raw materials into an impurity removal stirrer under the action of a screw extruder by a melt pump for carrying out homogenization impurity-removal treatment, feeding a homogenized and impurity-removal polyester melt into a secondary filter by the melt pump, enabling a filtered melt to pass through a mixed melt on a pipeline to enter a spinning manifold, carrying out drafting processing on a spun fiber to obtain the reinforced and flame-retarded recycled polyester fiber, cutting off bundles and packaging. The reinforced and flame-retarded recycled polyester chip has the good spinning forming property, the fiber quality is high, the using amount of a fire retardant can be effectively reduced under the synergistic effect of grapheme and the phosphate based flame retardant, the cost is reduced, the reinforcement effect can be achieved and the mechanical property of the fiber is effectively improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

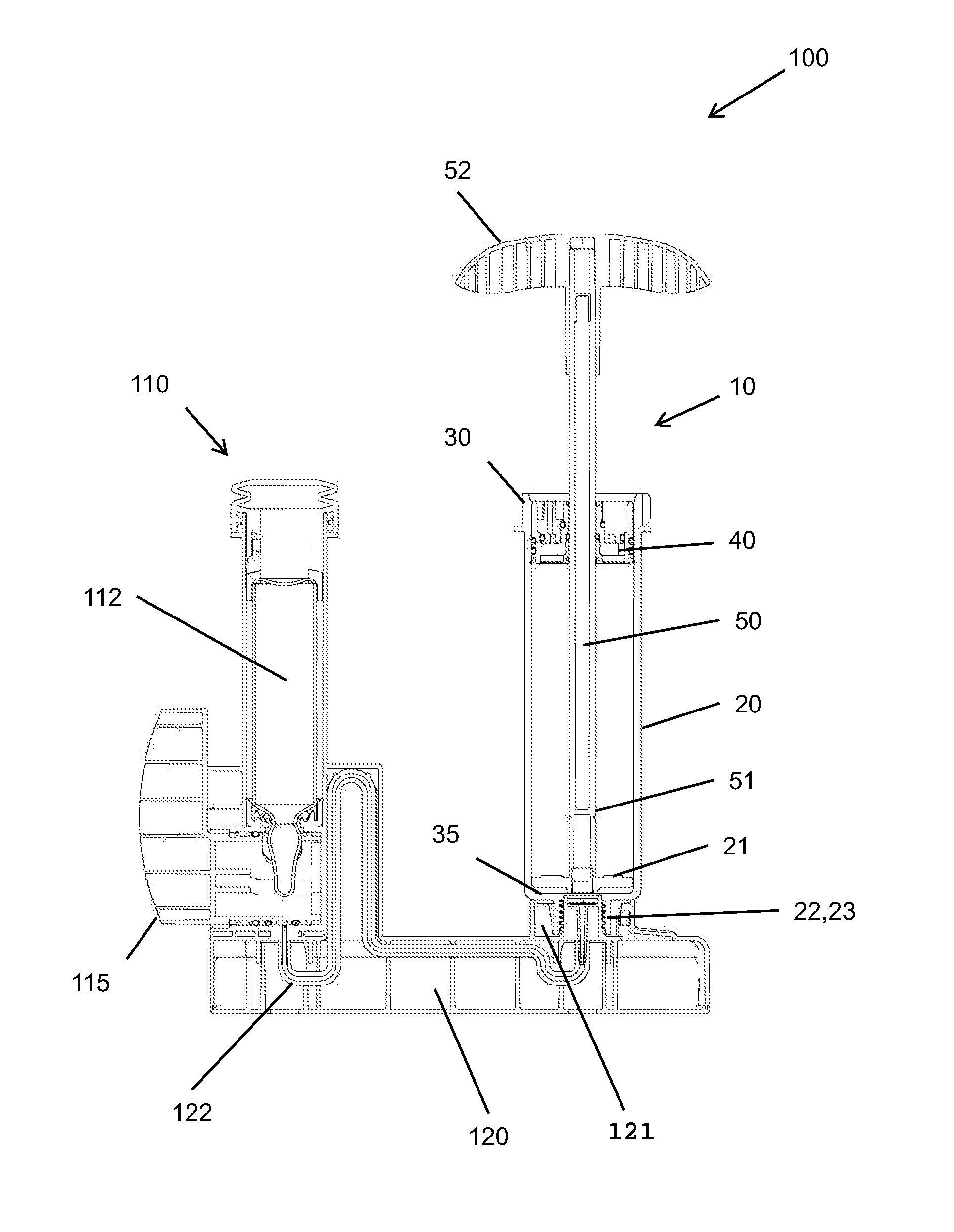

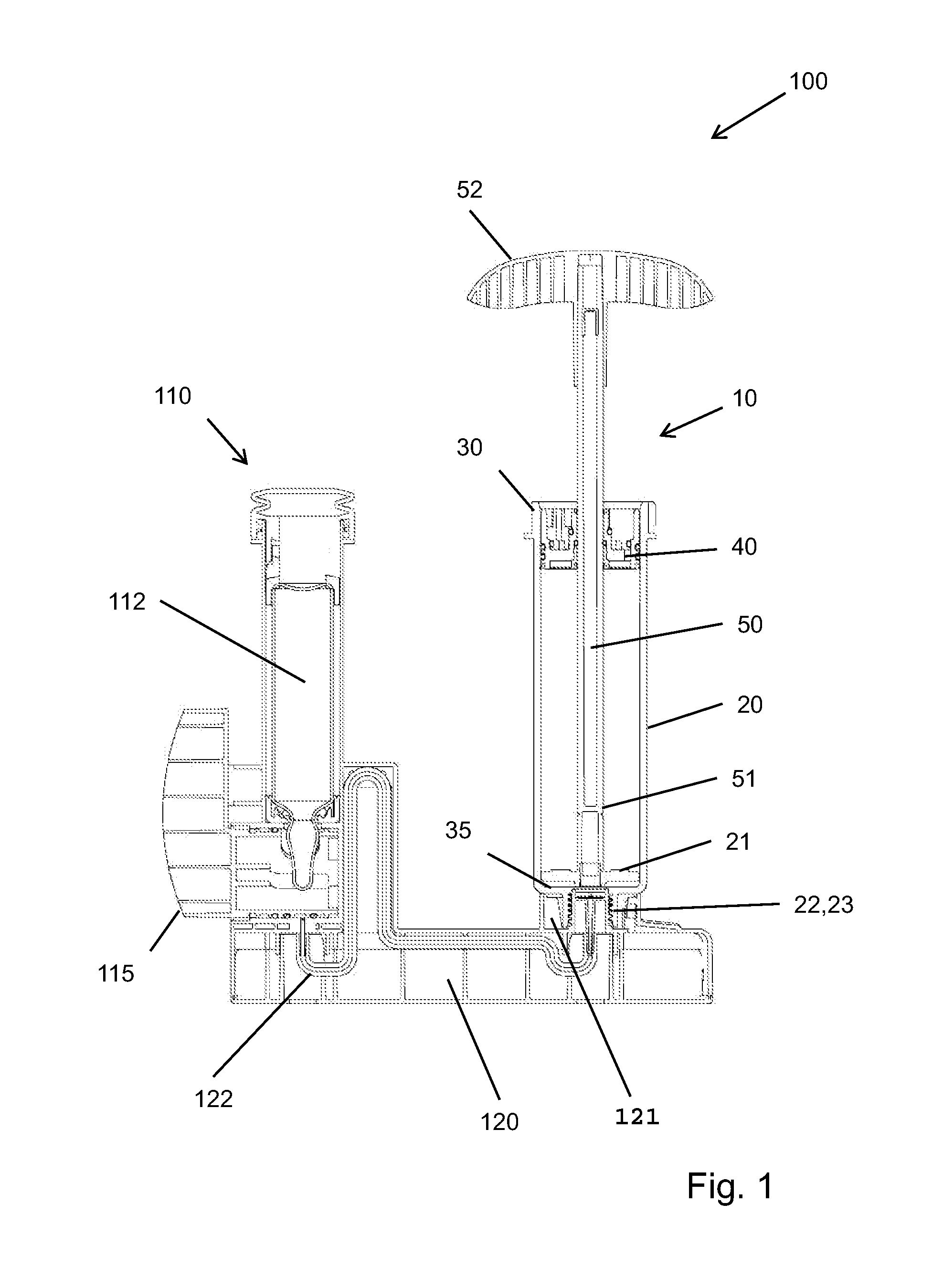

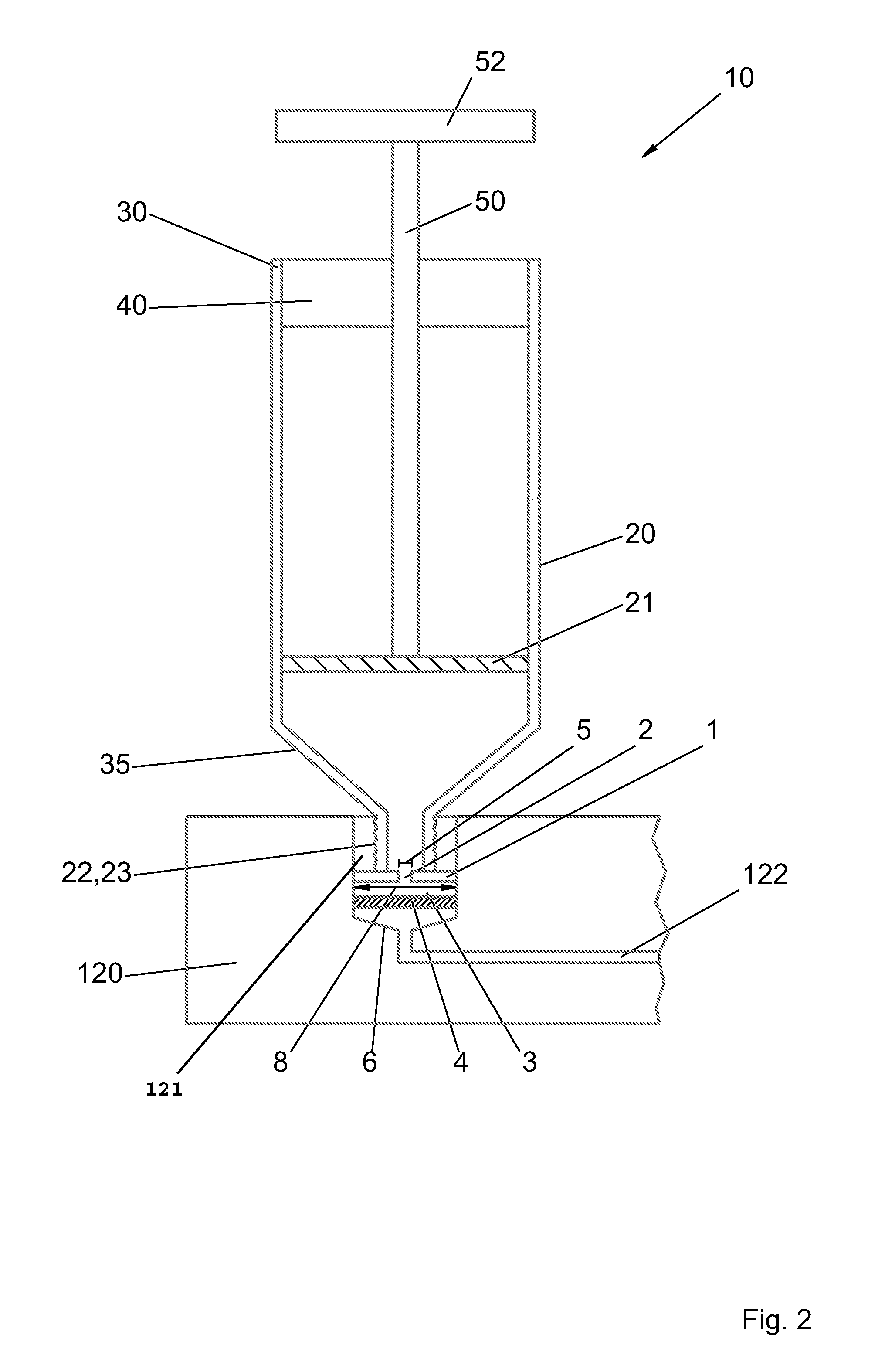

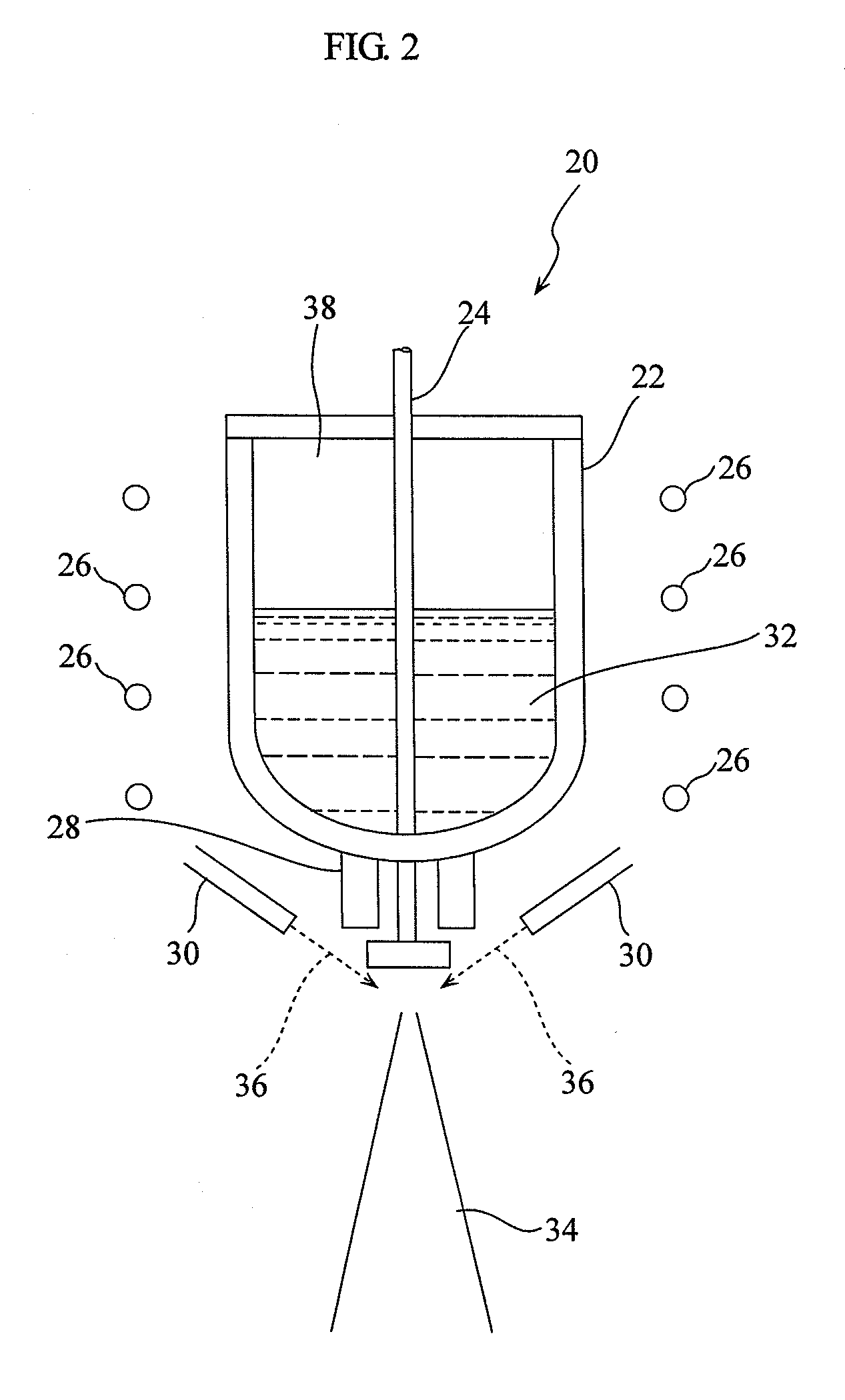

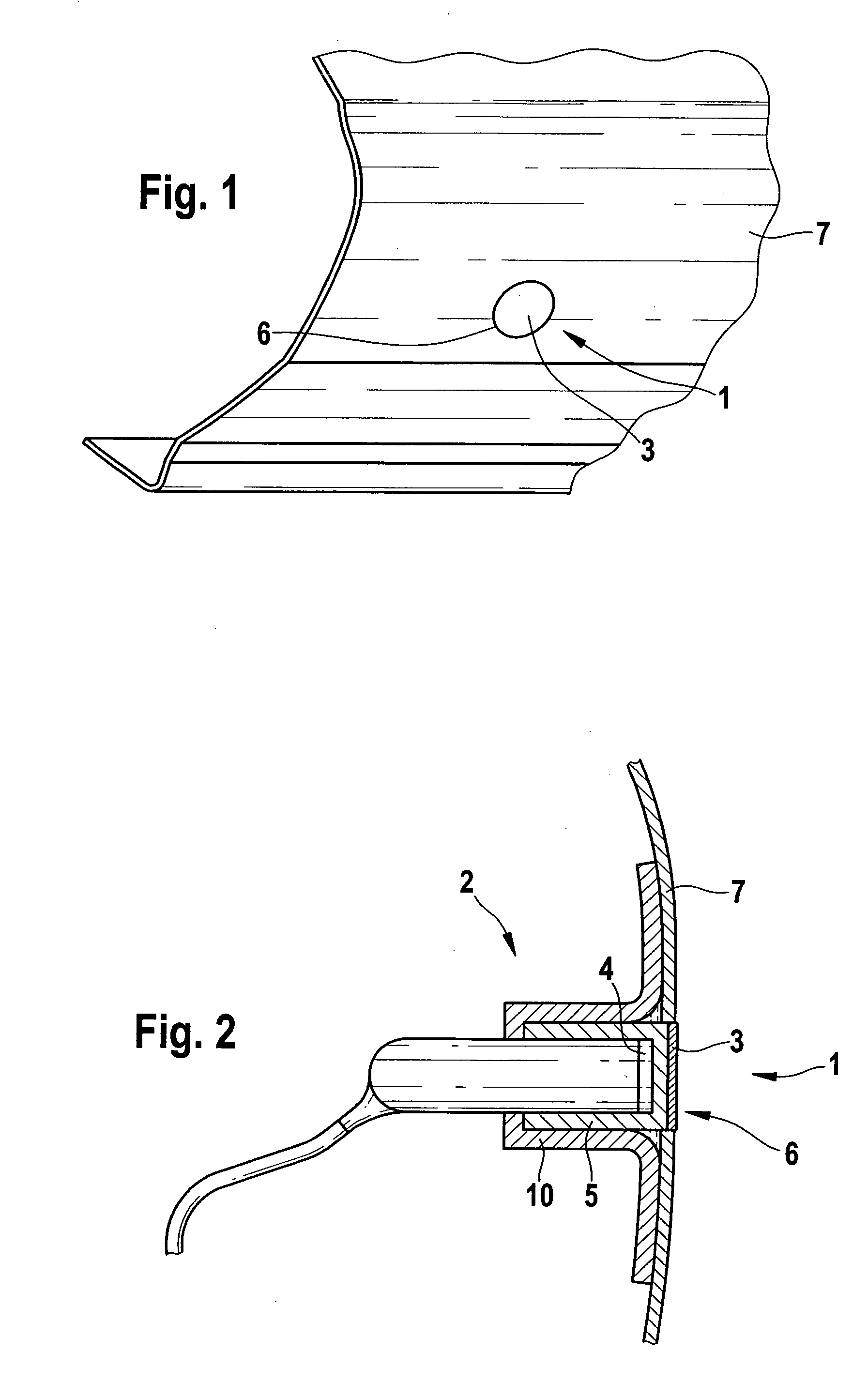

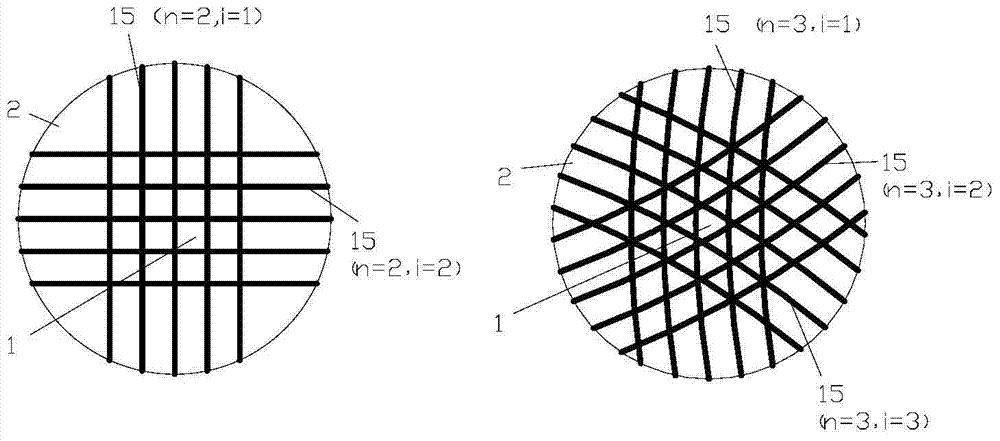

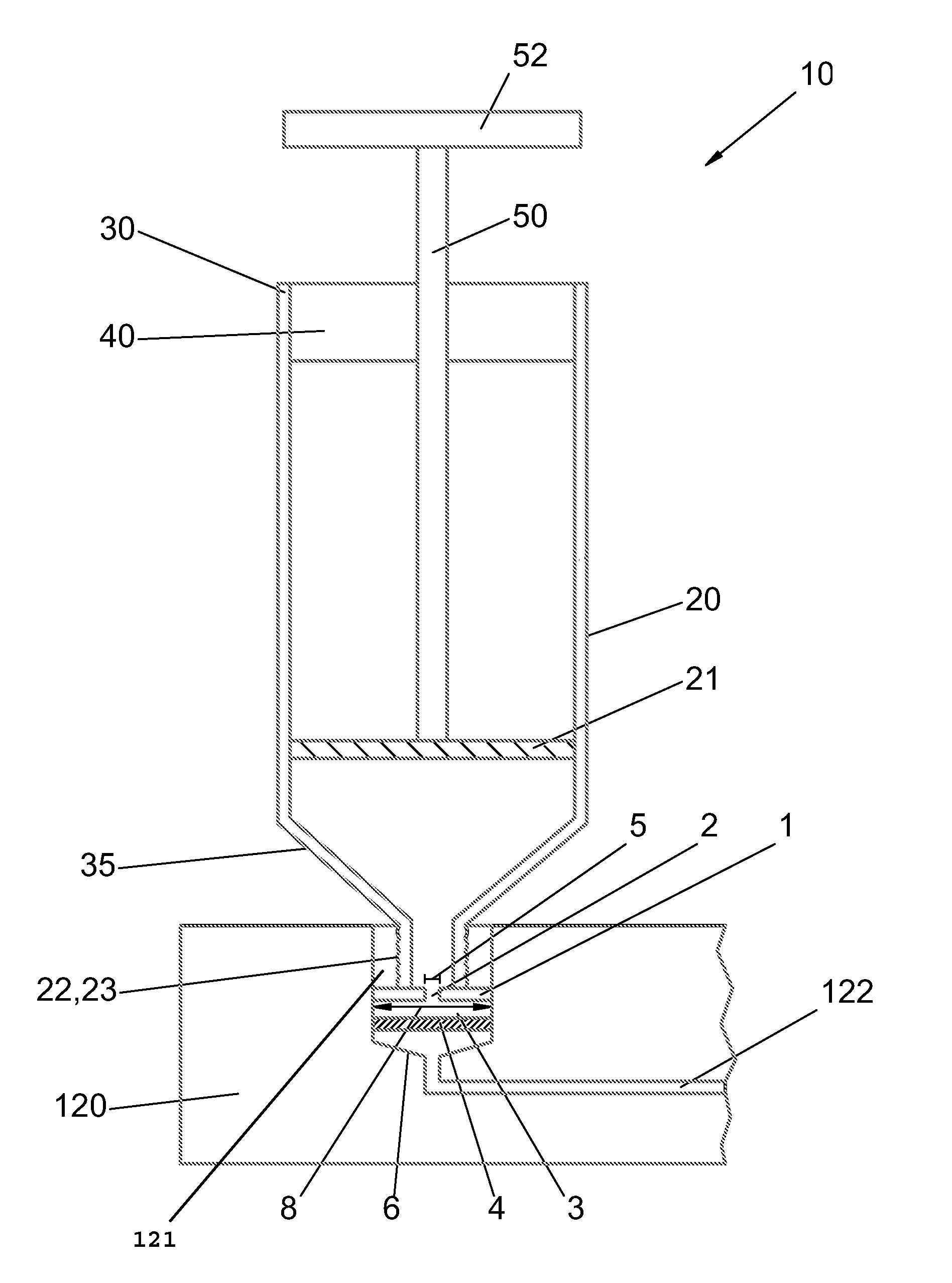

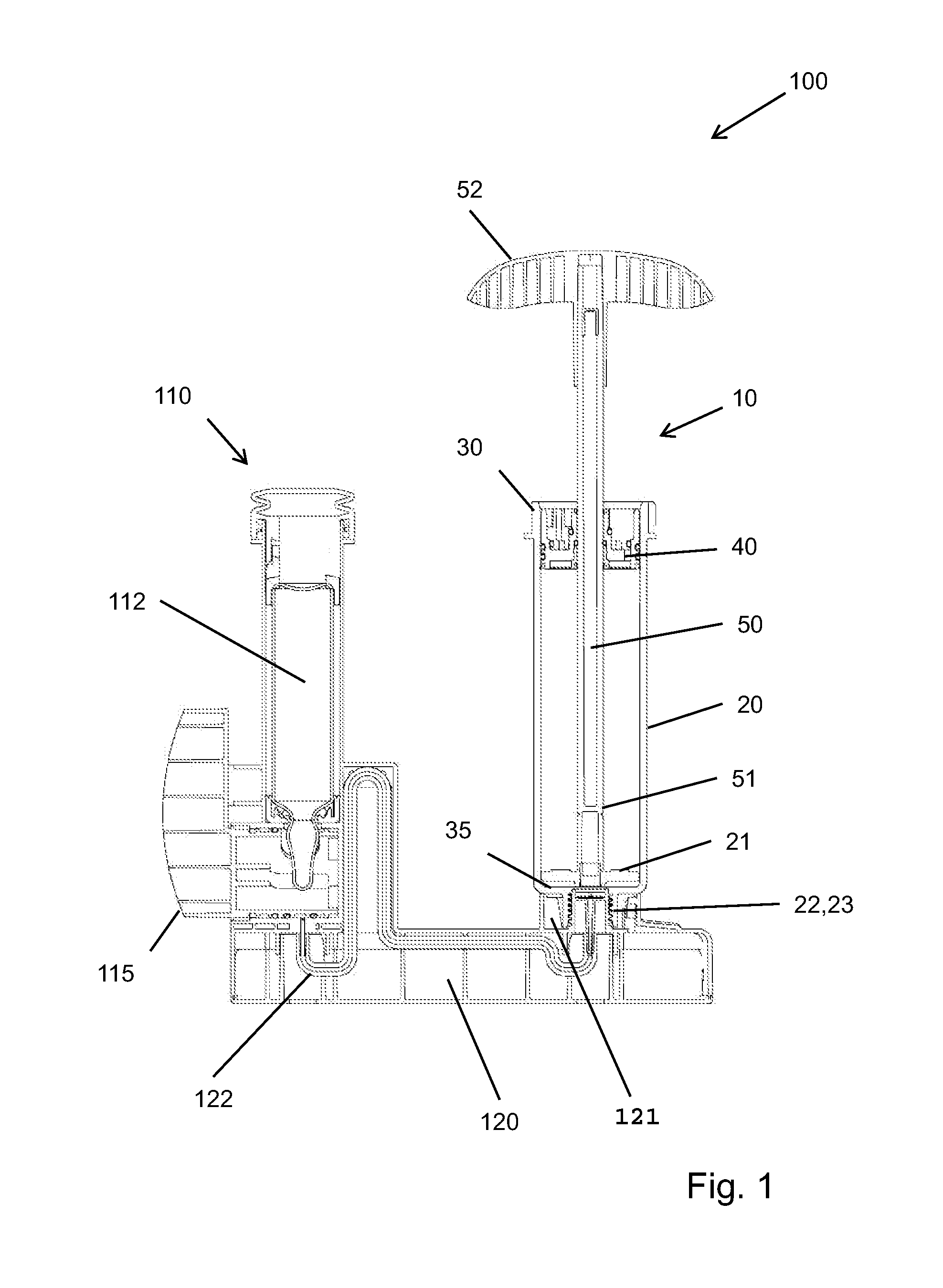

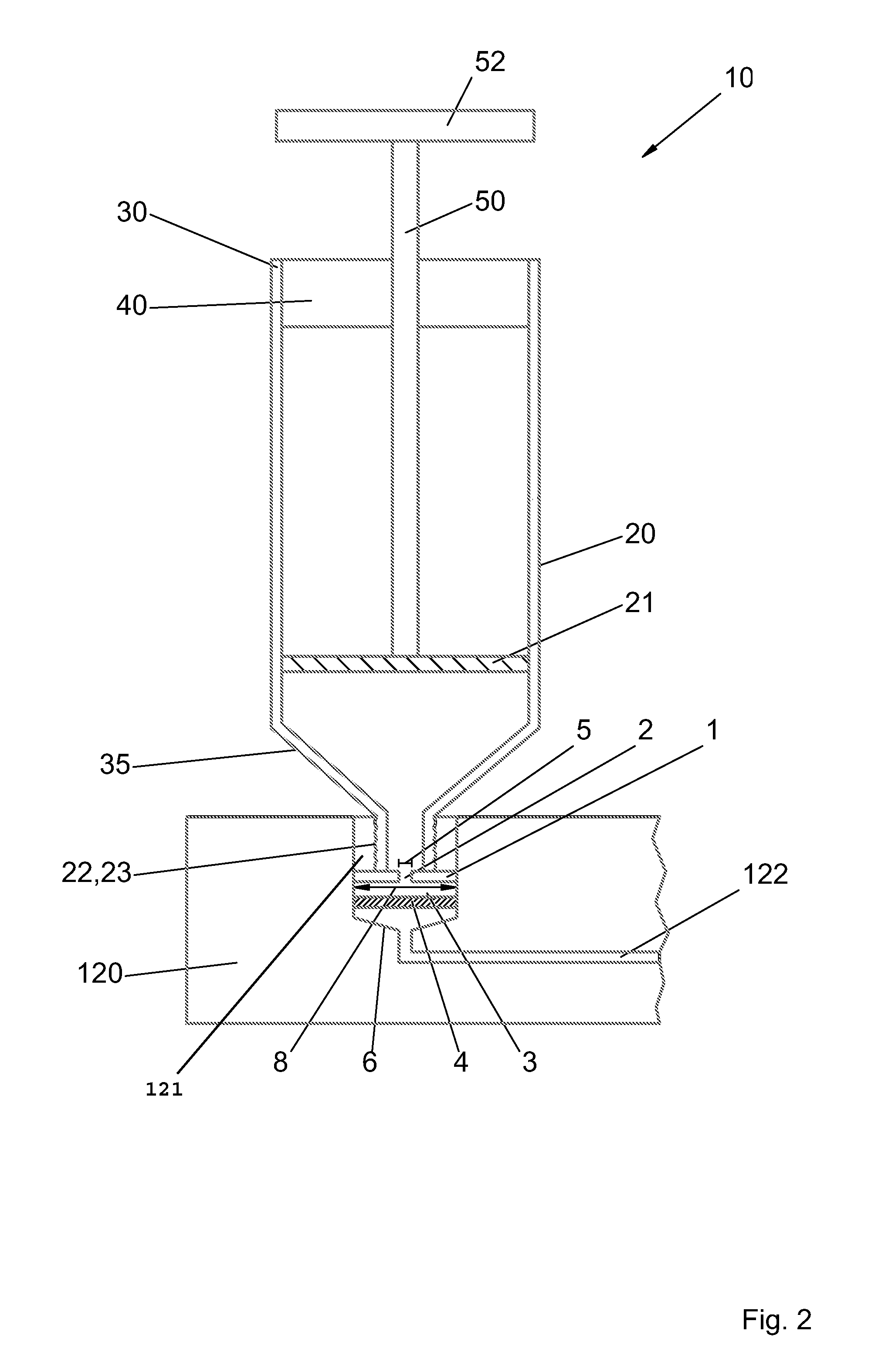

Bone cement system

ActiveUS8662736B2Avoid stickinessMore viscousFlow mixersTransportation and packagingBone cementBiomedical engineering

A bone cement system (100) is provided having a mixing facility (10) for mixing and dispensing of bone cement, a reservoir container (112) for a monomer, and a conveyor (122). The mixing facility (10) has a mixing cylinder (20), which stores a bone cement powder. The monomer can be conveyed from the reservoir container (112) into the mixing cylinder (20) by the conveyor (122). A sieve element is (4) is arranged between the reservoir container (112) and the mixing facility (10), in order to prevent ingress of the bone cement powder from the mixing cylinder (20) into the conveyor (122). The mixing device (10) included a dispensing opening (23) for dispensing a bone cement mixed from the bone cement powder and the monomer. The dispensing opening (23) includes a shield (1) having at least one through-opening (2). The ratio of the area of the through-opening (2) to the area of the sieve element (4) is at least 1 to 3, and the distance between the shield (1) and the sieve element (4) is at least 1 mm.

Owner:HERAEUS MEDICAL

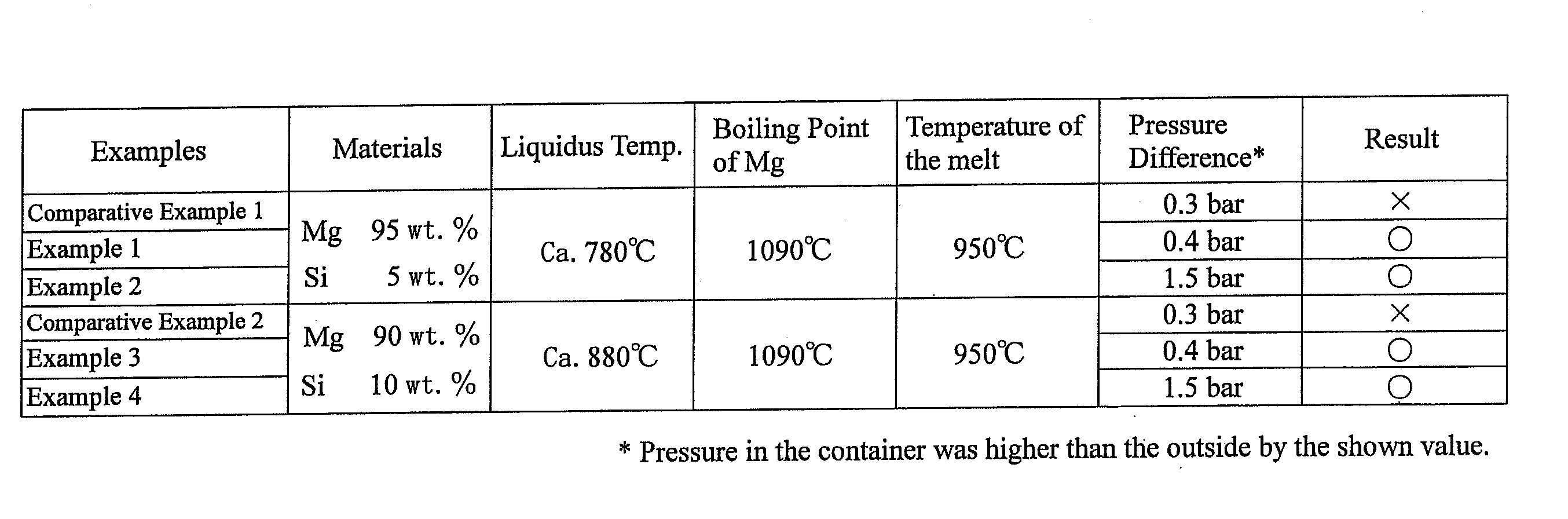

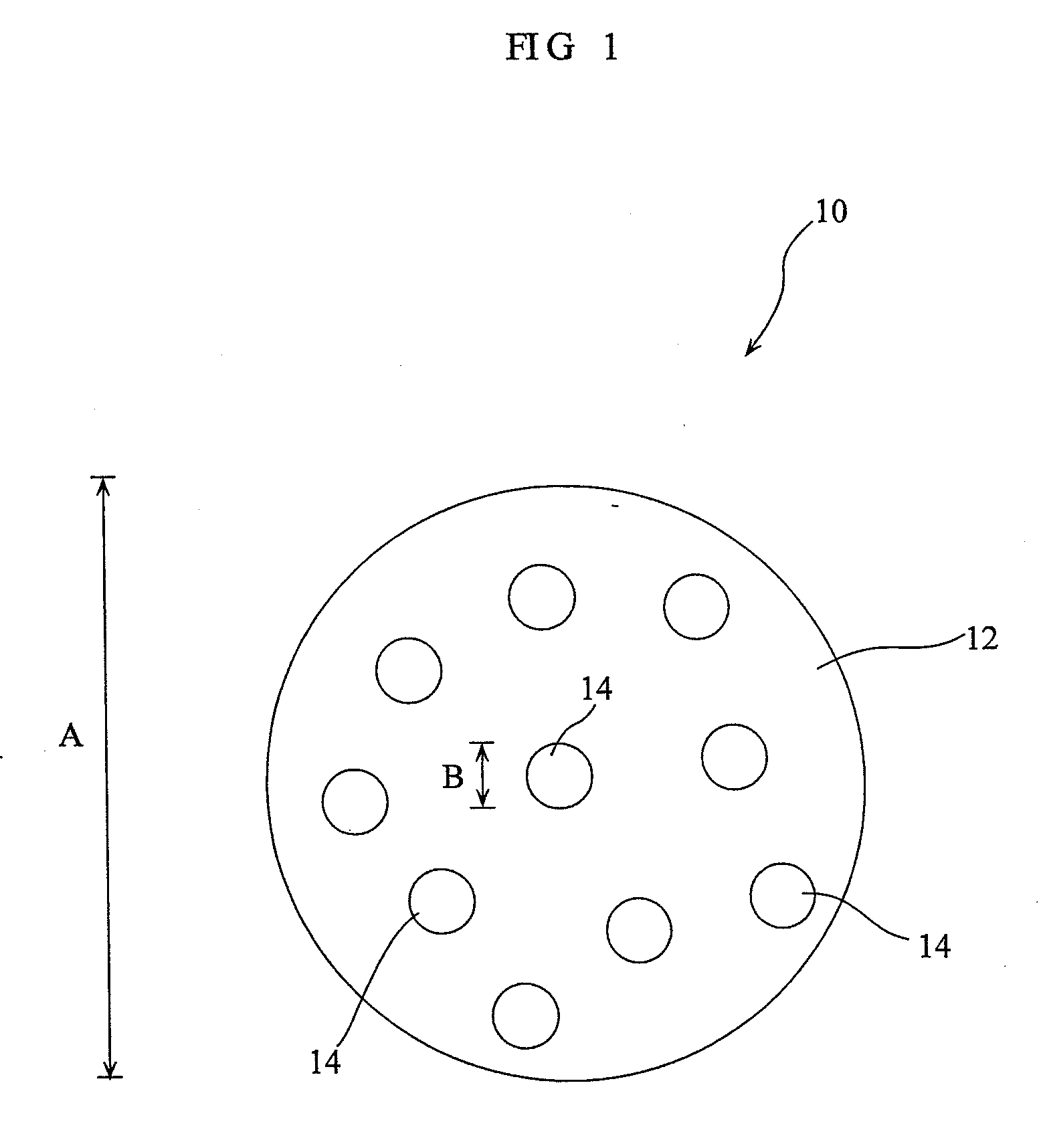

Metal particles, process for manufacturing the same, and process for manufacturing vehicle components therefrom

InactiveUS20070048167A1Light weightGood mechanical propertiesTransportation and packagingMetal-working apparatusMagnesium silicideMetal particle

Owner:FUJI JUKOGYO KK

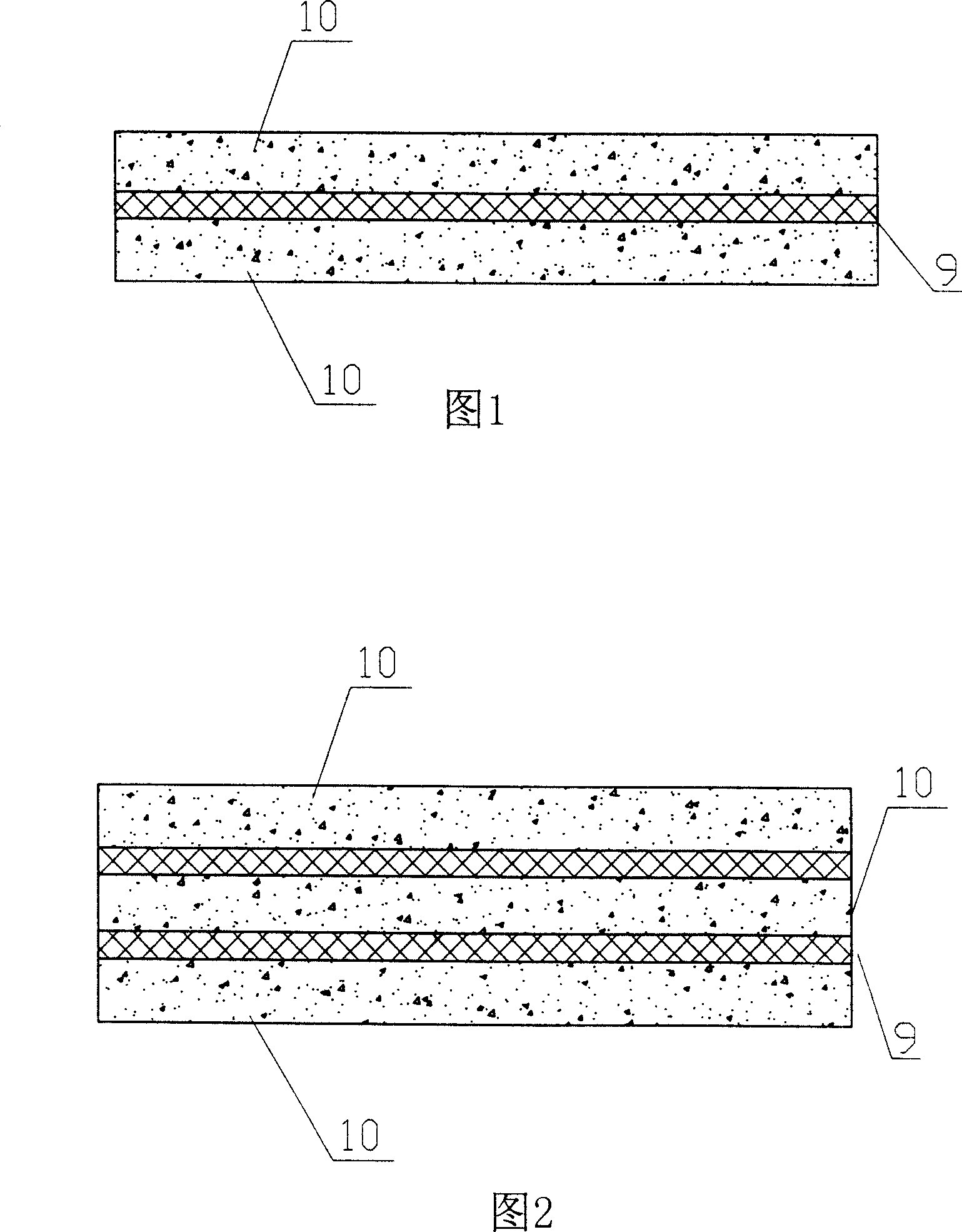

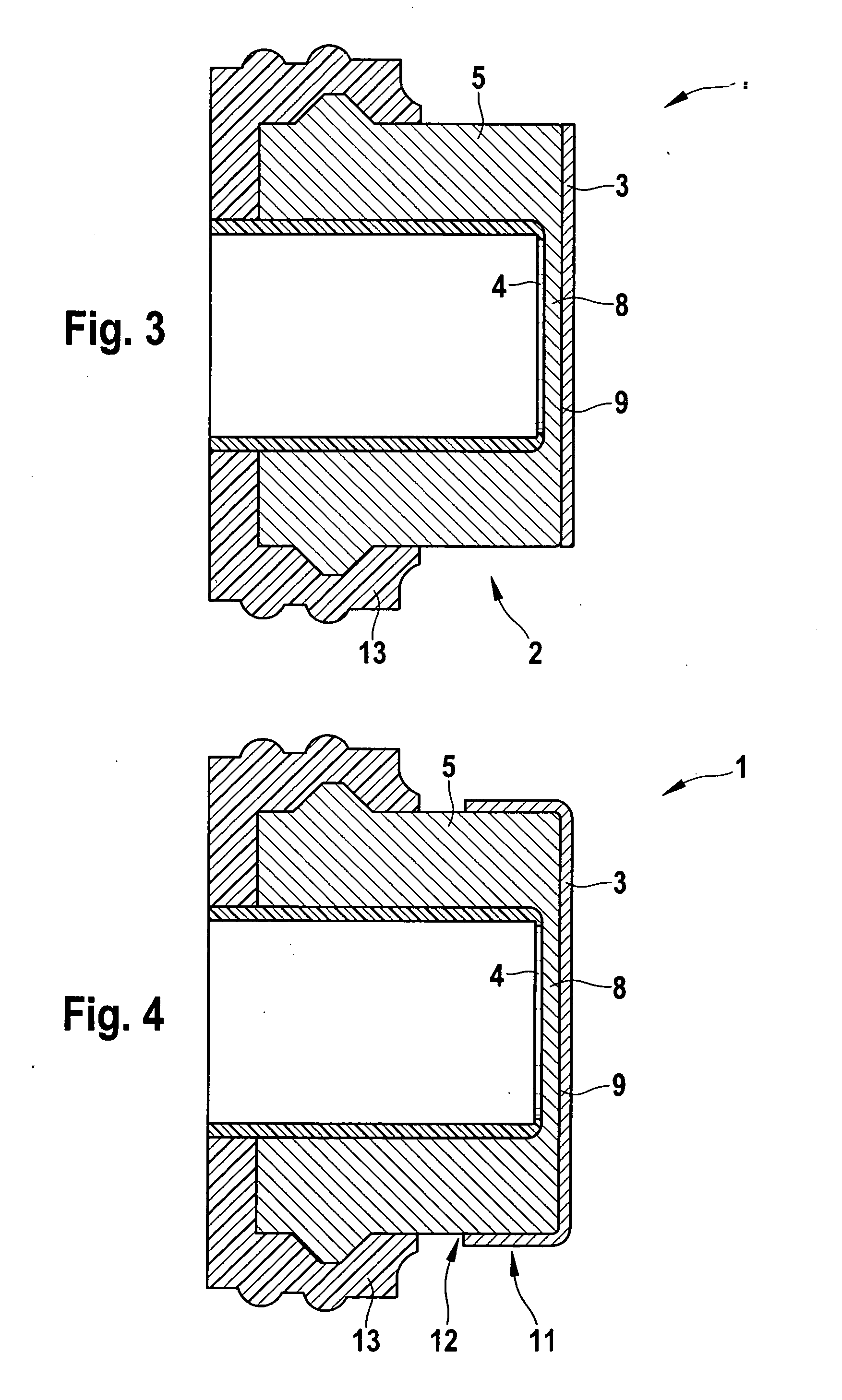

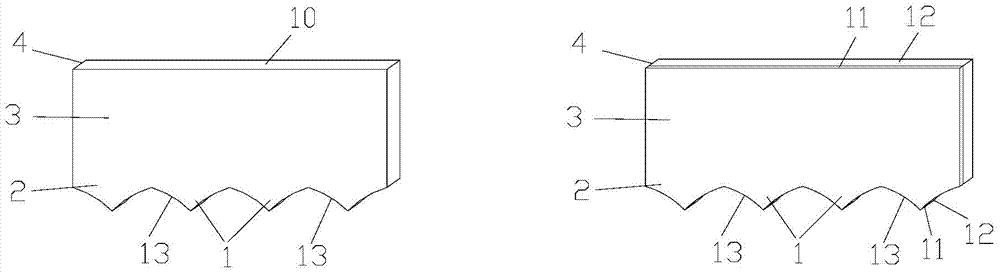

Wood-plastic formwork for construction engineering

InactiveCN1987018AExcellent mechanical propertiesFlat and smooth appearanceSolid waste managementLaminationFiberGlass fiber

A wood-plastics shuttering board for building engineering is composed of at least two basic wood-plastic ply layers made of the filler (vegetative fibers, glass fibers and plastics) and assistant (calcium carbonate, modifier, coupling agent and lubricant), and at least one lattice material layer between two basic wood-plastic ply layers and with two adhesive layers coated on its both surfaces. Its manufacture technology is also disclosed.

Owner:徐肖虎

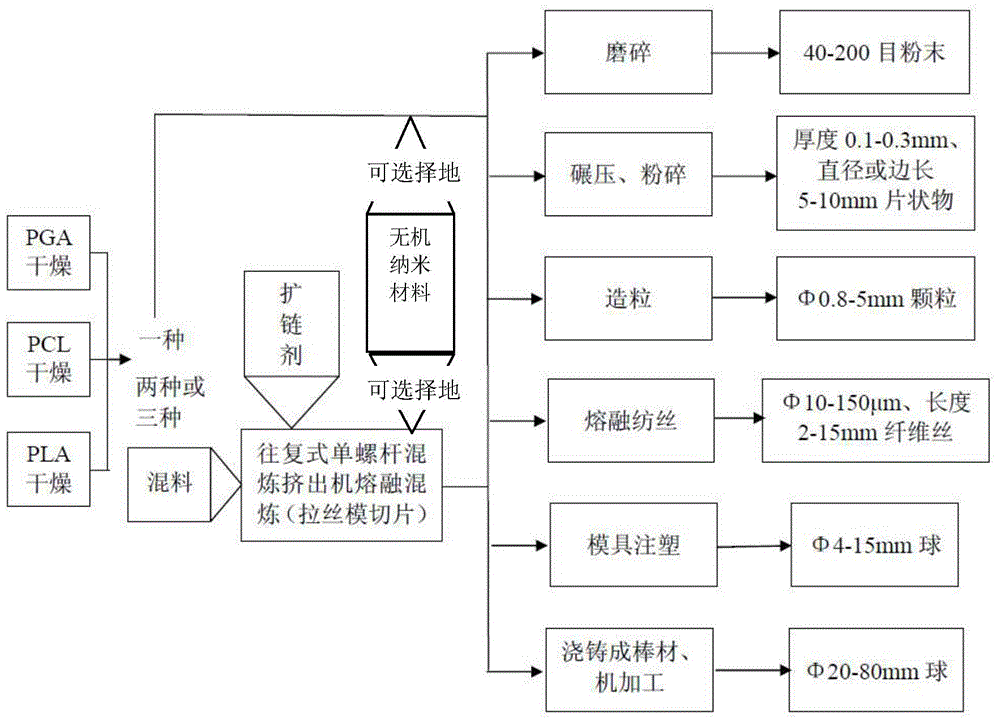

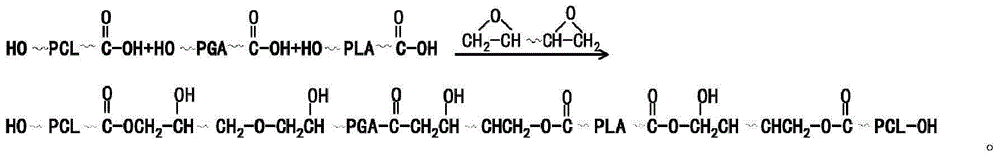

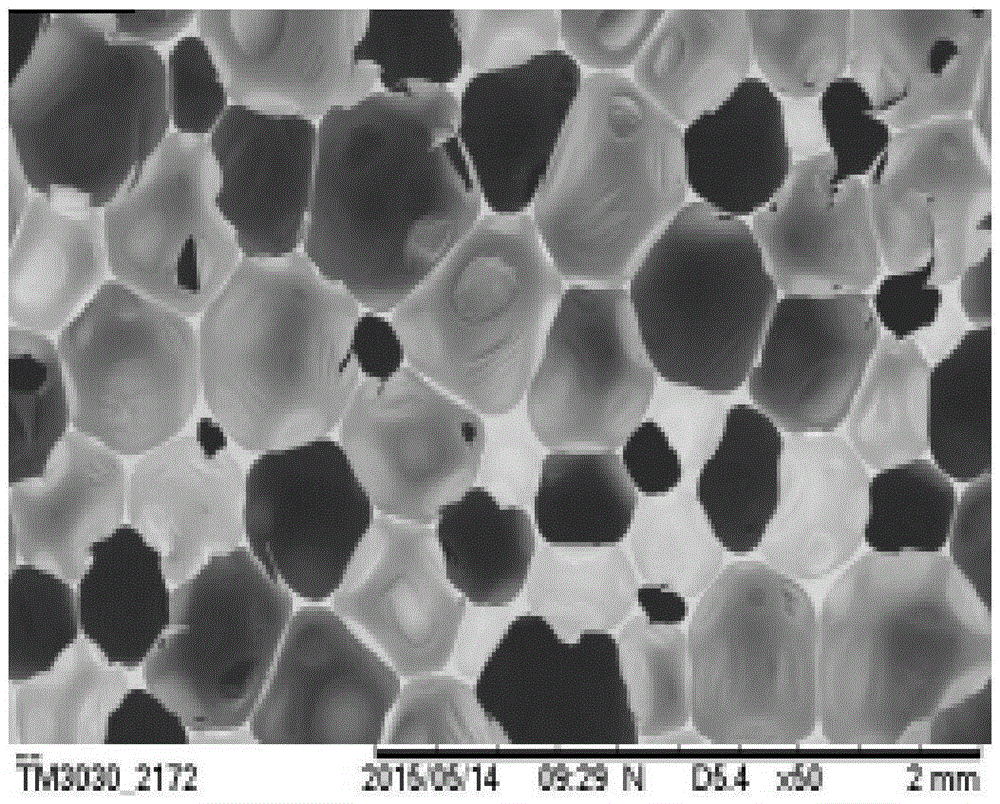

Biodegradable resin material applied to oil and gas fields and preparation method for biodegradable resin material

InactiveCN104987682ANew mechanical propertiesChange mechanical propertiesDrilling compositionWell drillingAlloy

The invention provides a biodegradable resin material applied to oil and gas fields and a preparation method for the biodegradable resin material. According to the preparation method for the biodegradable resin material applied to the oil and gas fields, two or three polymers of polyglycolic-colactic acid, polycaprolactone and polylactic acid and a chain extender are subject to melt mixing reaction to obtain a resin alloy, namely the biodegradable resin material applied to the oil and gas fields. The biodegradable resin material applied to the oil and gas fields is prepared from the method, can be prepared into the shapes of sheets, powder, granules, spheres and the like, or can be prepared into the shapes of the sheets, the powder, the granules, the spheres and the like by one of the polyglycolic-colactic acid, the polycaprolactone and the polylactic acid, is used for temporarily blocking filtrate to protect a reservoir, temporarily blocking a blast hole, a constructed layer section and the like in various construction (well drilling, well completing, well repairing, and acidizing and fracturing) operations of the oil and gas fields, and has the advantages of complete degradation and zero damage to stratum.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

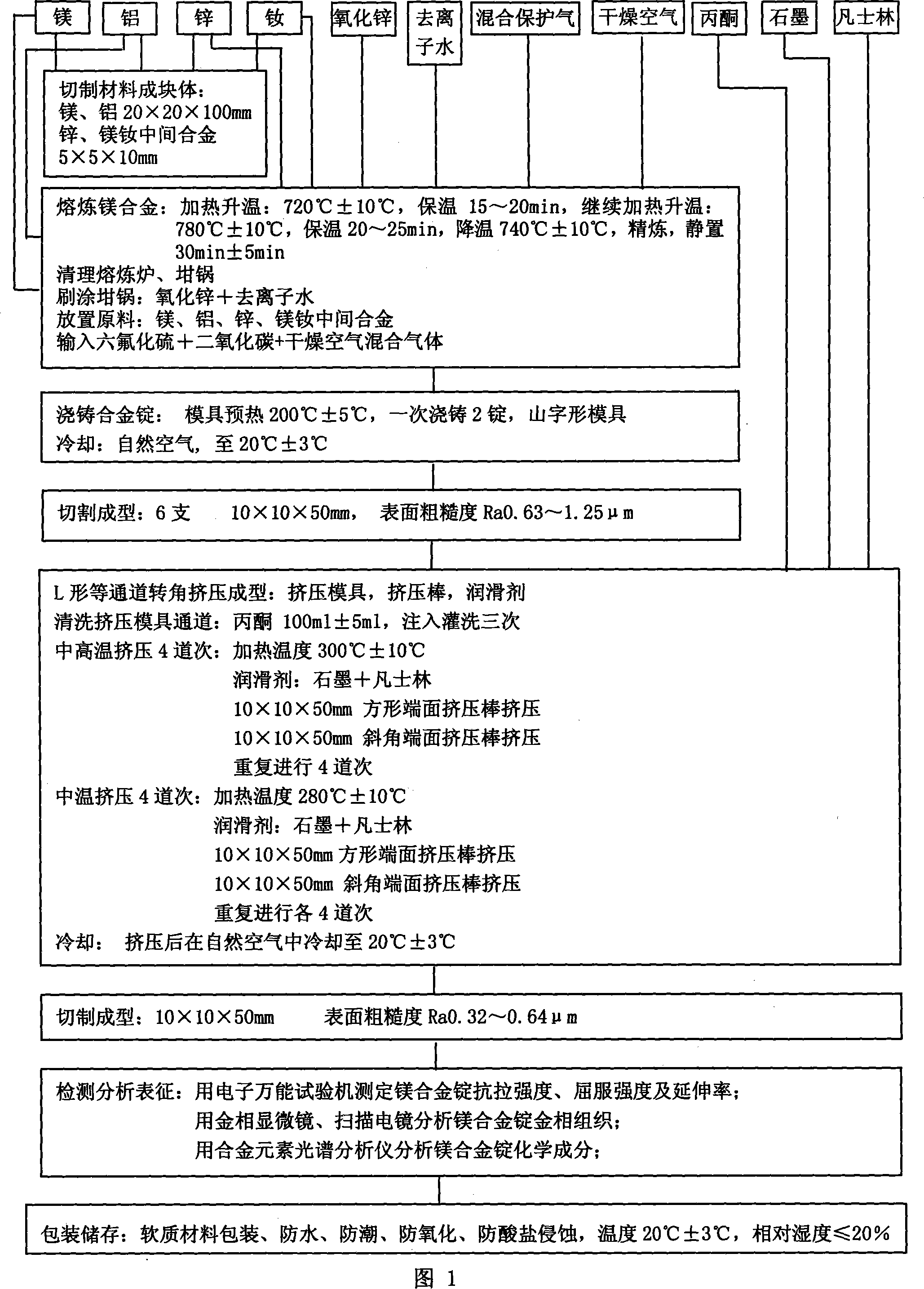

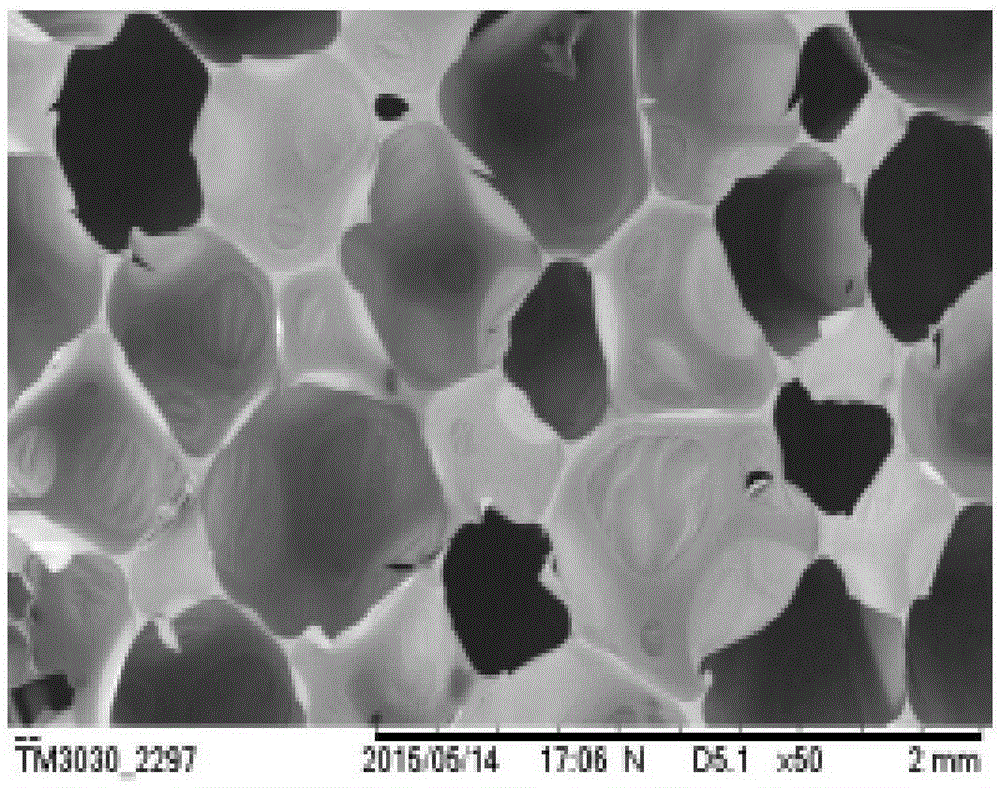

High-strength magnesium alloy and preparation method thereof

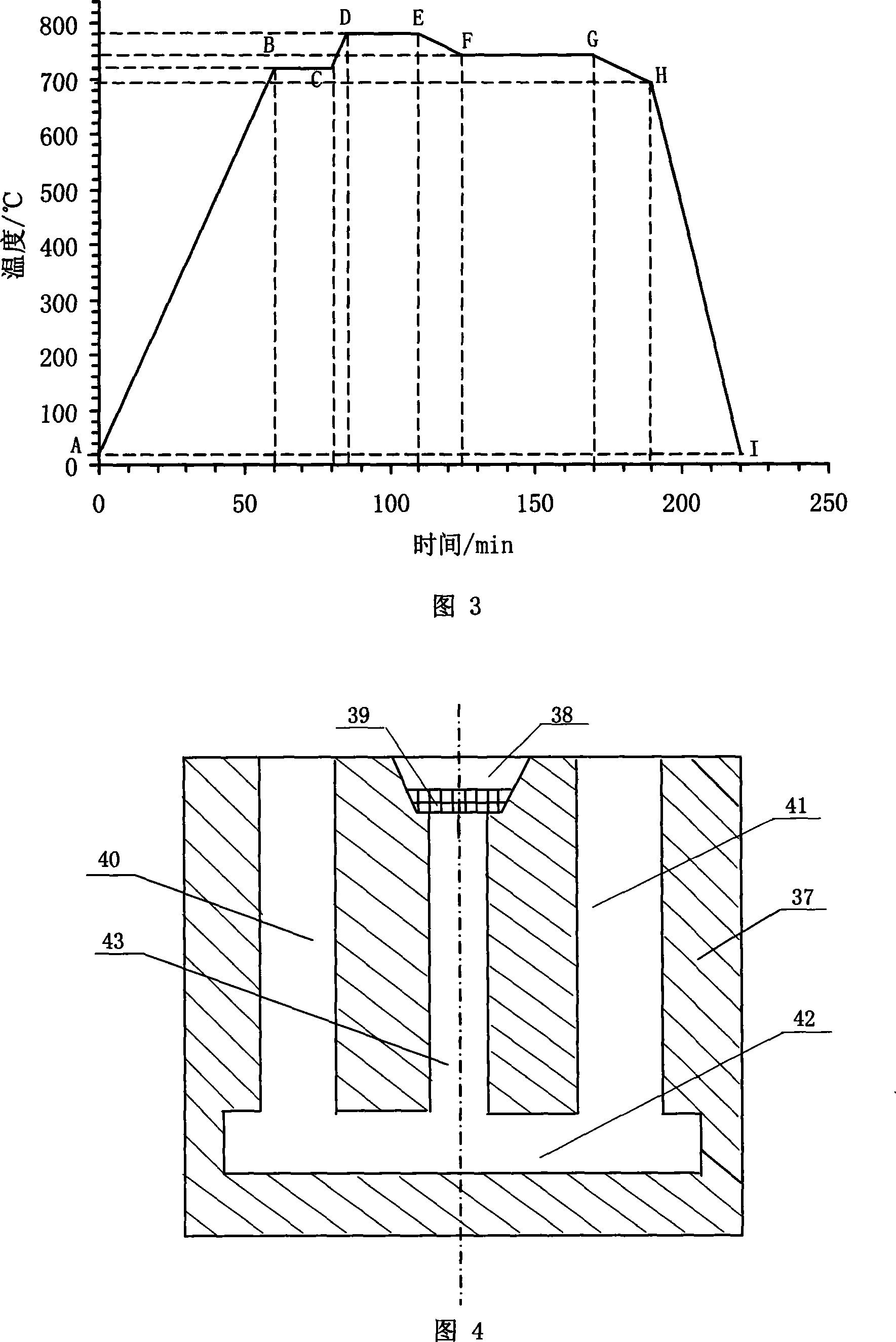

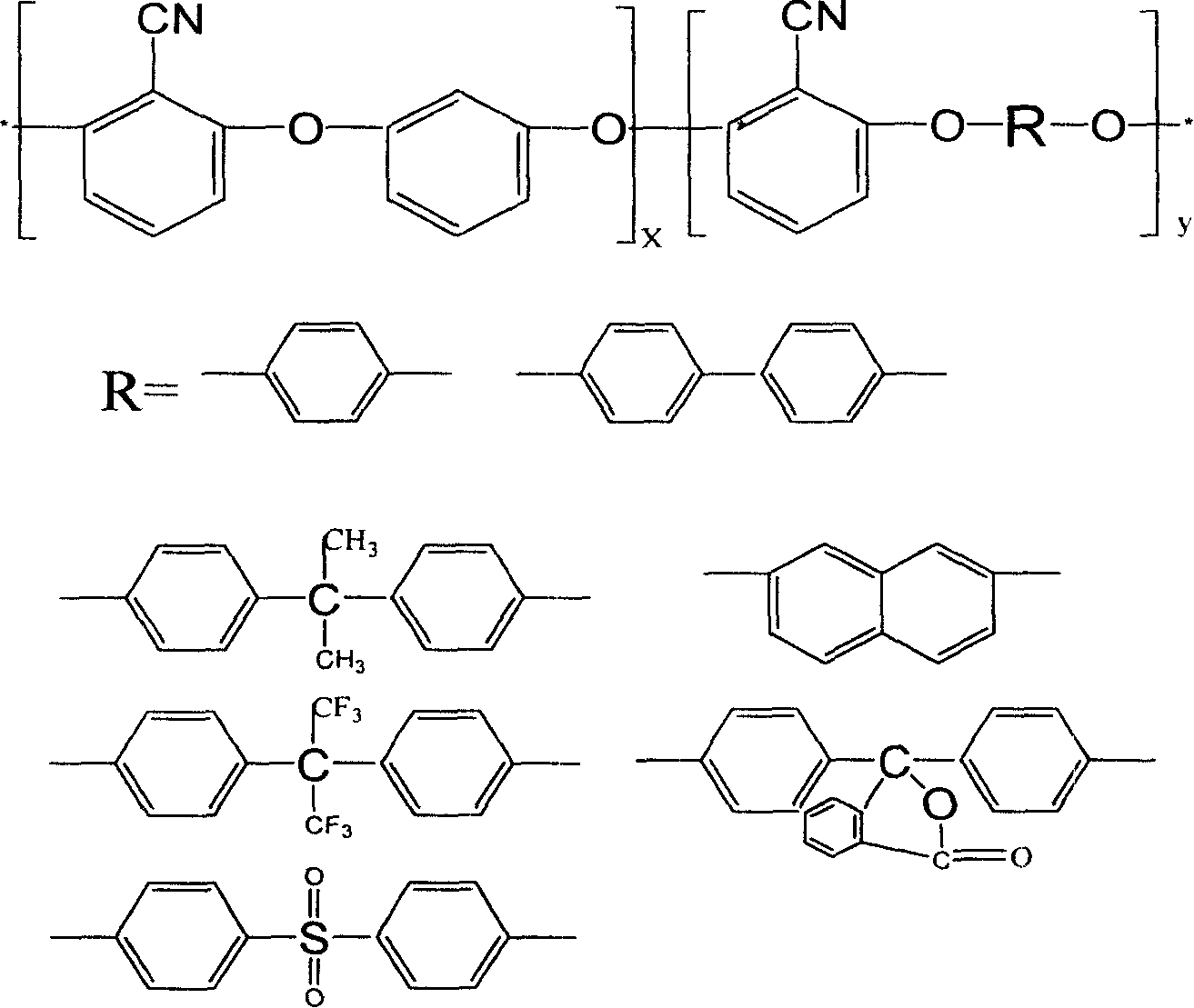

The present invention relates to a high intensity magnesium alloy and the preparation method. Magnesium, aluminum, zinc and neodymium are adopted as raw materials, which are melted in a melting furnace, under the protection of the mixed gases, and are melted down at the temperature of 720 plus or minus 10 degrees Celsius system, magnesium- neodymium alloy is added at the temperature of 780 plus or minus 10 degrees Celsius system, refined and the heat is preserved at the temperature of 740 plus or minus 10 degrees Celsius system and then the magnesium-aluminum-zinc-neodymium melt is obtained. When the temperature is lowered to 680-700 degrees Celsius system, the magnesium-aluminum-zinc-neodymium melt is discharged and cut into shapes after being moulded and cooled and then made into high intensity aluminum-magnesium alloy ingots after an 8-channel equal channel rotor angle pinch. The raw material mixture ratio of magnesium, aluminum, zinc and neodymium is 82 to 15 to 2 to 1 and aluminum makes up 15 percent. The aluminum material is abundant in resource, low in price and more economical and the lanthanon neodymium can change the metallurgical structure and mechanical property. The method has a short process flow and a slight pollution to the environment. The tensile strength, yield strength and elongation of the magnesium alloy ingots can be increased by 147.4 percent, 210.6 percent and 448.3 percent respectively. The metallurgical structure is compact and even and the average crystal grain size is less than or equal to 2 micrometers.

Owner:TAIYUAN UNIV OF TECH

Anionic abrasive particles treated with positively charged polyelectrolytes for cmp

InactiveCN1630697AIncrease speedIdeal planarization efficiencyOther chemical processesSemiconductor/solid-state device manufacturingPolyelectrolytePolymer science

The invention provides chemical-mechanical polishing systems, and methods of polishing a substrate using the polishing systems, comprising (a) an abrasive, (b) a liquid carrier, and (c) a positively charged polyelectrolyte with a molecular weight of about 15,000 or more, wherein the abrasive comprises particles that are electrostatically associated with the positively charged polyelectrolyte.

Owner:CMC MATERIALS INC

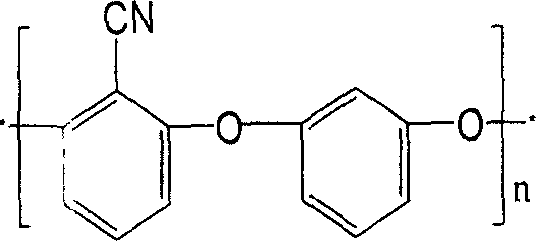

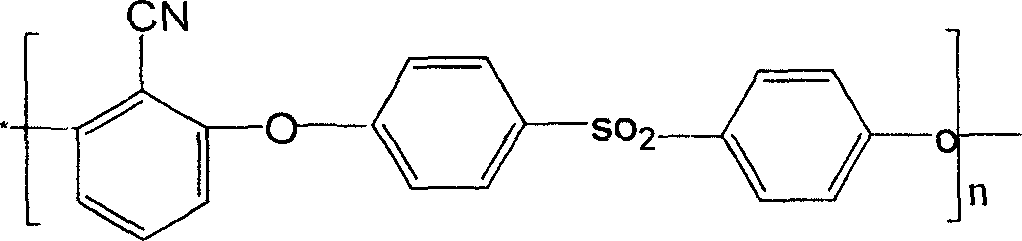

Copolymer of polyarylether nitrile containing chian element of iso-benzene and preparation method

This invention relates to arylether-nitrile copolymer with isobenyl units. This invention can facilitate easy breakage of structural symmetry, easy control over the synthesis process, and easy increase of the product molecular weight by copolymerization reaction. This invention can control the structure and properties of the product by adjusting the ratio of resocin to the other dihydric phenol as well as its variety. This method can change the mechanical and thermal properties of the copolymer by changing the variety of the dihydric phenol, and improve the mechanical and thermal properties by increasing the amount of the dihydric phenol. This invention has such advantages as low raw material cost, abundant raw materials, low product price, high cost performance, and wide applications.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

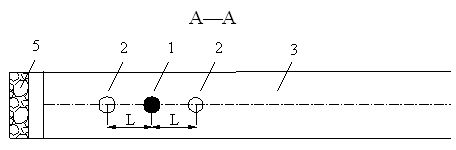

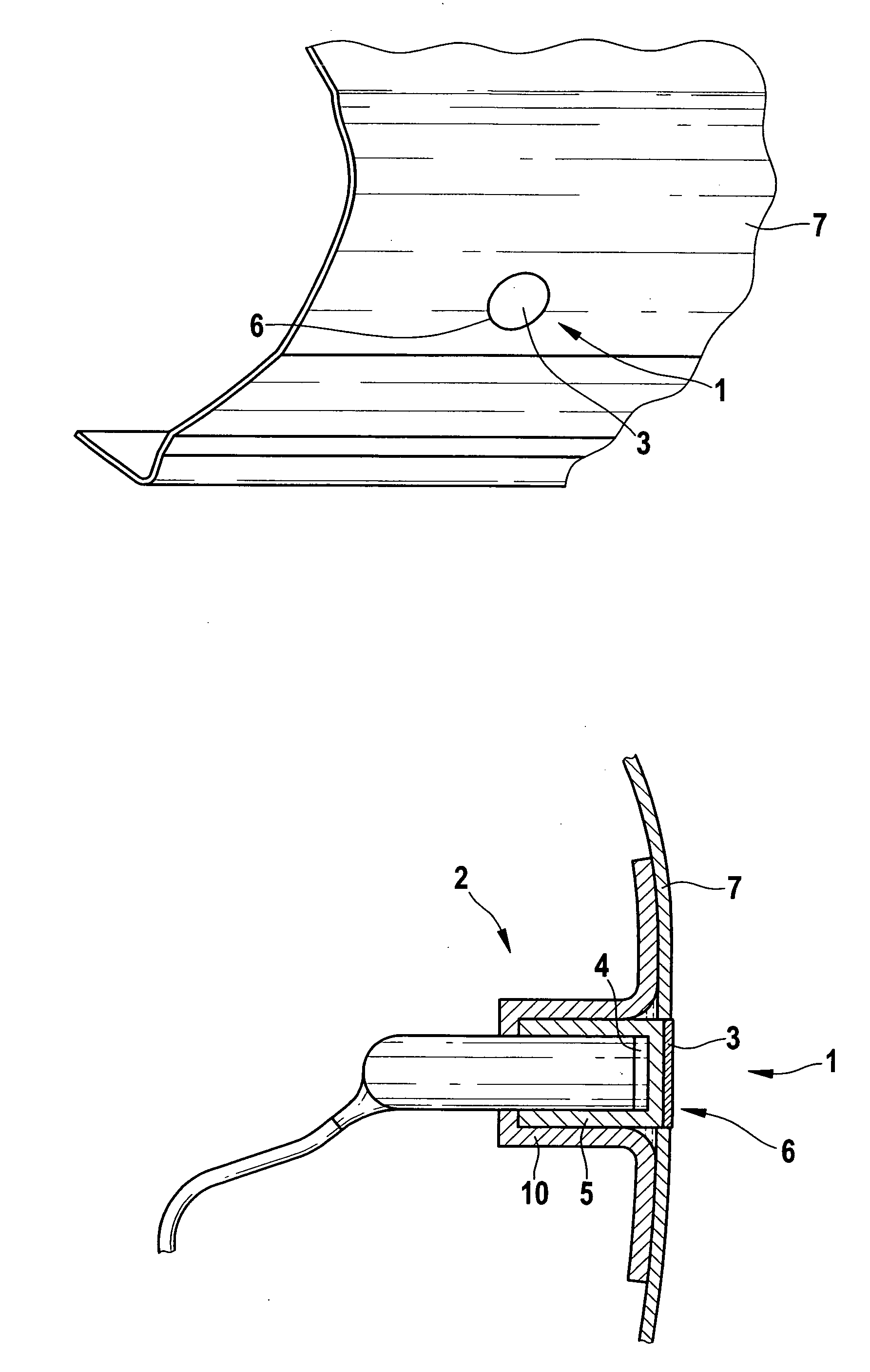

Sensor device for vehicles

ActiveUS20070194892A1Excellent visual adaptationMinimal detuningVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic sensorEngineering

A sensor device includes an ultrasonic sensor and a sensor cover in the form of a foil, the ultrasonic sensor having an oscillatory sensor element, which is affixed inside a housing, having an end face, of the ultrasonic sensor, the ultrasonic sensor being able to be accommodated in a recess or bore hole of an external vehicle component, and the sensor element and the housing being able to be covered by the sensor cover on the outside, the sensor cover being mountable directly on the ultrasonic sensor and forming an at least essentially planar surface whose outline is adapted to the outline of the end face of the housing and coincides in an essentially flush manner with the end face of the housing of the ultrasonic sensor, and the sensor cover reflecting light having a color spectrum in the range of chrome color and a reflection capacity in the range of polished chrome.

Owner:ROBERT BOSCH GMBH

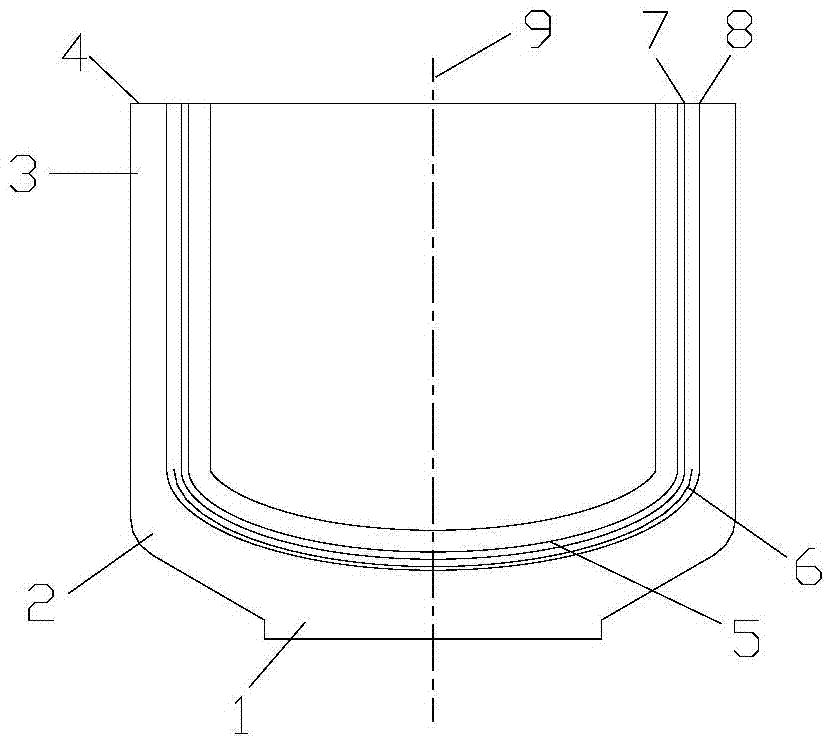

Continuous carbon fiber reinforced crucible preform and preparation method thereof

ActiveCN103482995AIncrease contentAvoid crackingAfter-treatment apparatusCarbon fibersStress conditions

The invention discloses a continuous carbon fiber reinforced crucible preform and a preparation method thereof. The preform is molded from basic unit layers and continuous fiber reinforced layers through needle punching; the bottom of a crucible and a connection area of the side and the bottom of the crucible are respectively reinforced by using the continuous fiber winding and laying technology, so the content of continuous fibers connected in an integral structure is effectively increased, strength needed during high load and high swelling stress conditions is guaranteed, cracking of the crucible or disconnection of the connection area of the side and the bottom of the crucible is prevented, and excellent shape stability can be maintained. Thus, the preform has excellent mechanical properties and a stable structure; after carbon / carbon composition, the crucible has good resistance to expansion, good structural stability, high thermal conduction efficiency and a long service life under a high load condition and can meet usage requirements of large-size crystalline silicon furnace crucibles.

Owner:JIANGSU TIANNIAO HIGH TECH

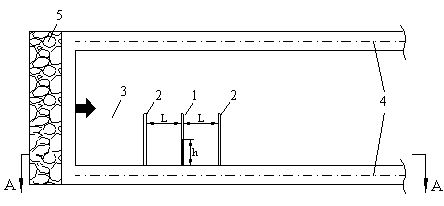

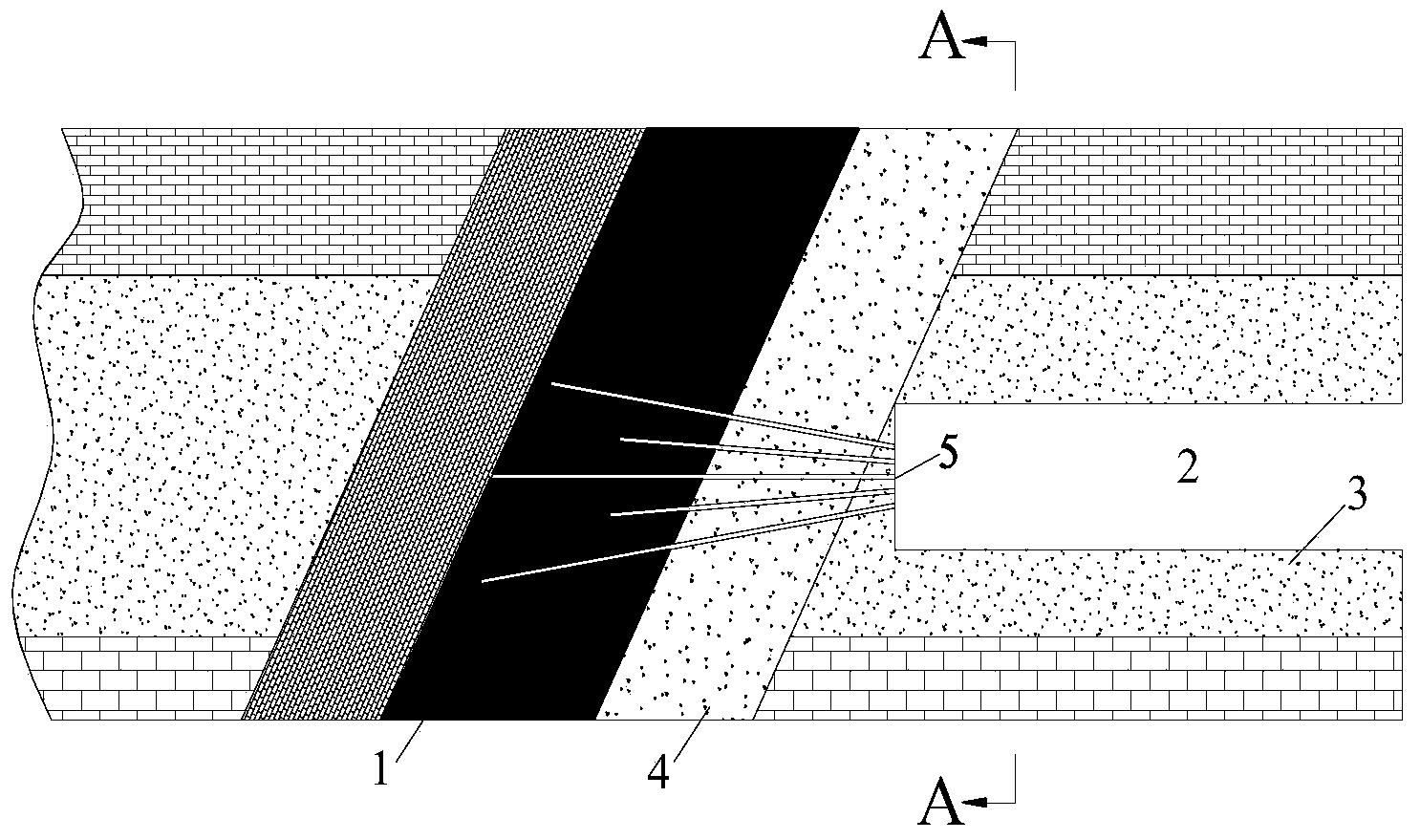

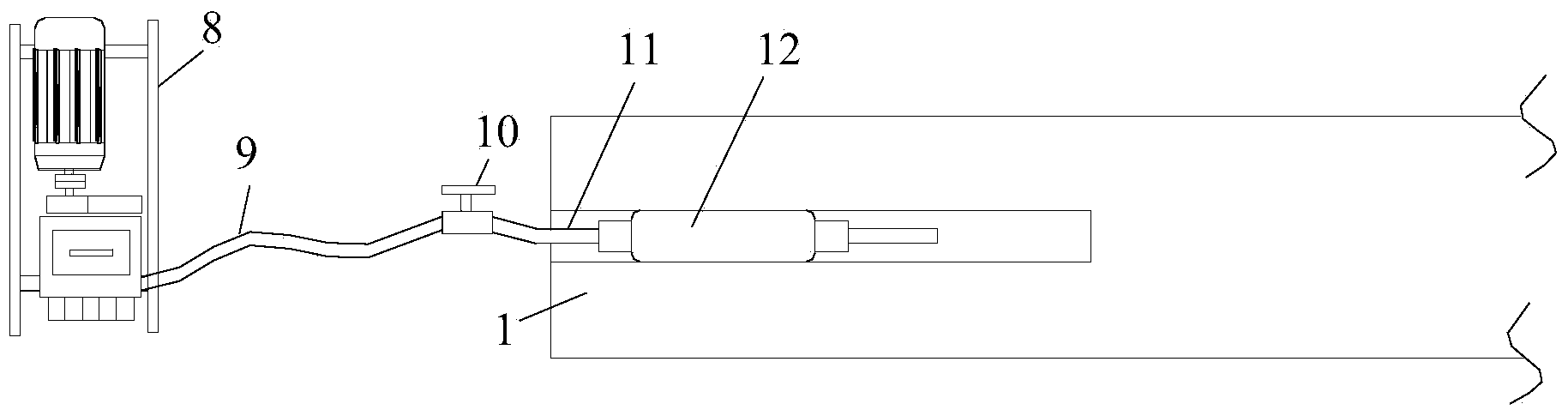

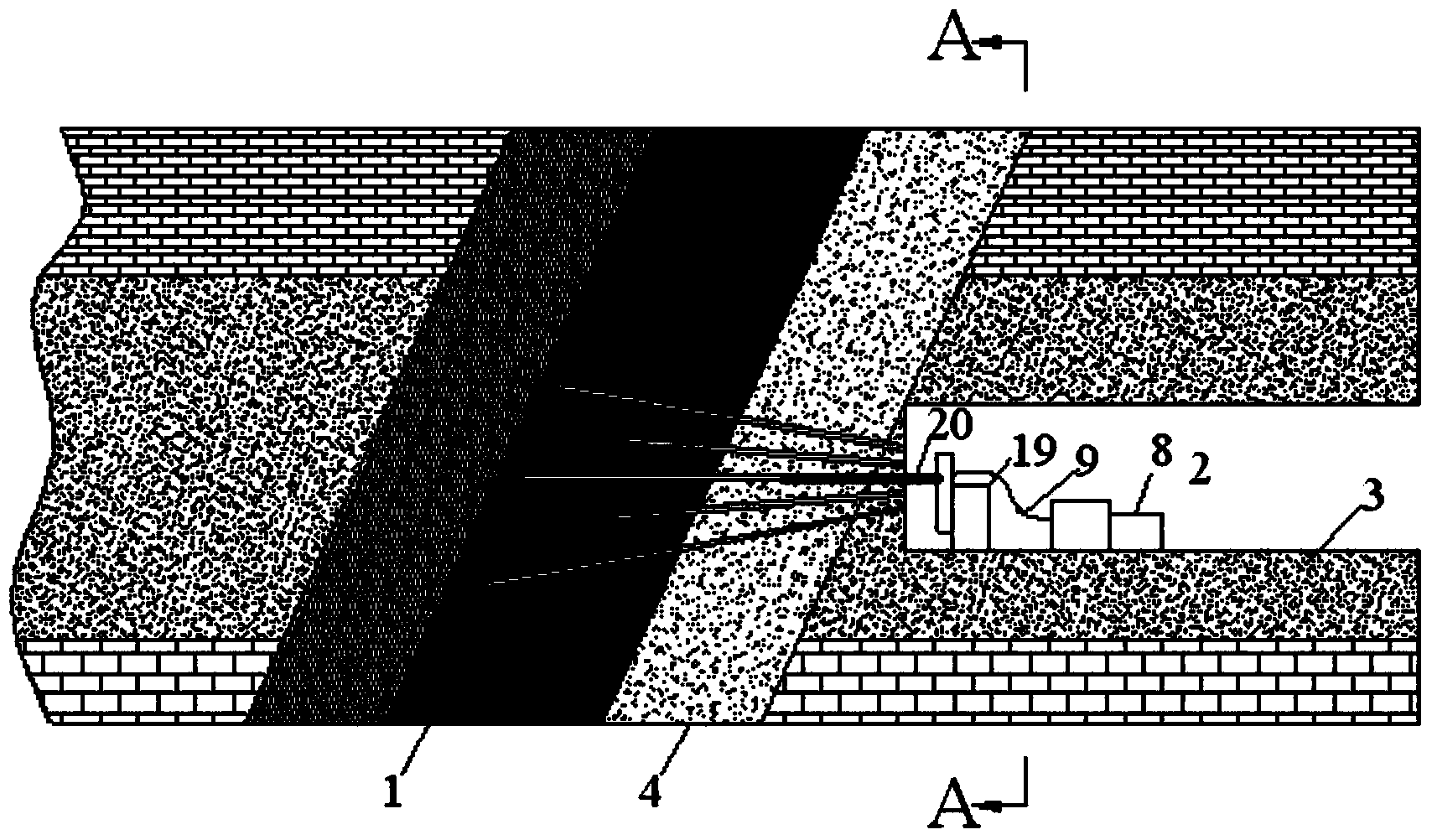

Outburst coal bed hydraulic phase change cracking cross-cut coal uncovering method

ActiveCN104213932AChange mechanical propertiesImprove breathabilityUnderground miningSurface miningLiquid stateFreezing thawing

The invention provides an outburst coal bed hydraulic phase change cracking cross-cut coal uncovering method, which is applicable to high-gas-outburst coal bed cross-cut coal uncovering operation. The minimum normal distance from the cross-cut coal uncovering working face to the coal bed is greater than or equal to 7m position, a plurality of holes are respectively drilled in the coal uncovering region, a conventional capsule hole sealing coal bed water injection technology is adopted for injecting water into the coal bed through the drilled holes, after the water injection completion, a conventional refrigeration freezing technology is adopted for freezing the coal bed around the water injection hole, in the freezing process, free water in the coal bed is gradually converted from the liquid state into the solid state, and the volume of the water expands for 9.1 percent in the phase change process; after the freezing completion, the freezing coal bed absorbs the underground environment head and gradually thaws. After the freezing thawing completion, the water injection hole and a gas extraction pipeline are connected for gas extraction, or the gas extraction drilling is implemented on the coal bed in the phase change cracking region for gas extraction. When the coal bed gas content is less than 8m<3> / t, the gas extraction is stopped, the water is injected into the water injection hole again, the secondary freezing of the coal bed is completed, and then, the coal bed is uncovered according to a conventional coal uncovering method.

Owner:CHINA UNIV OF MINING & TECH

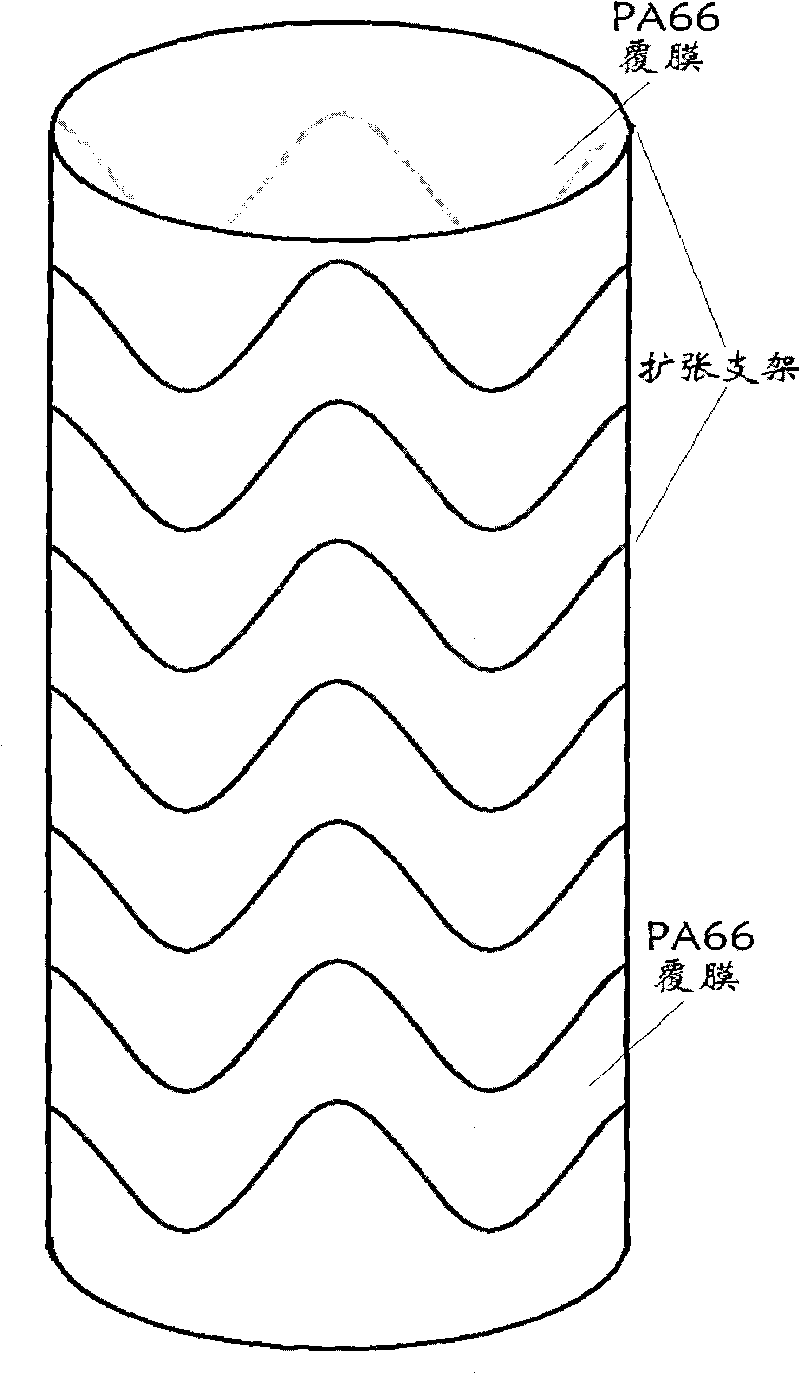

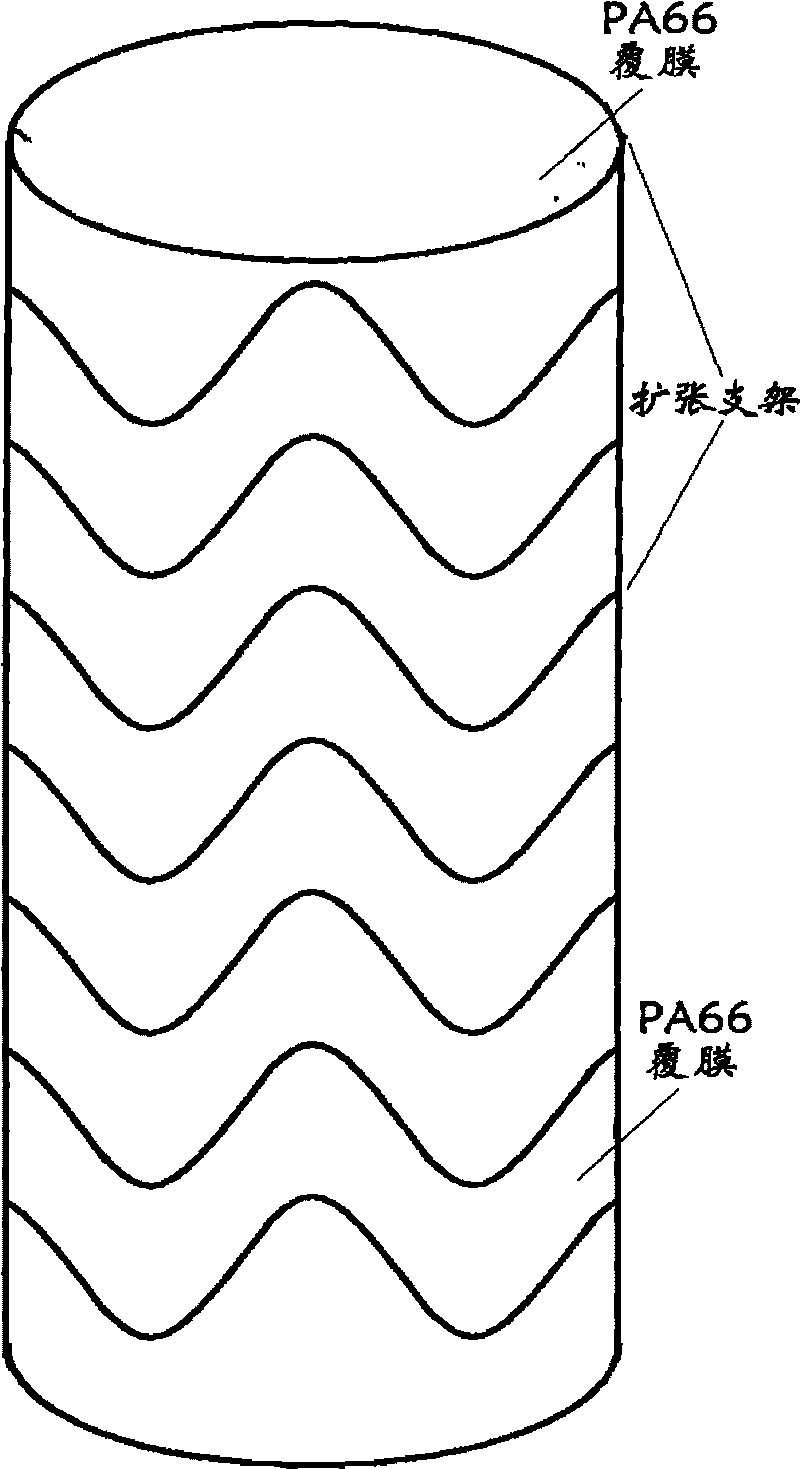

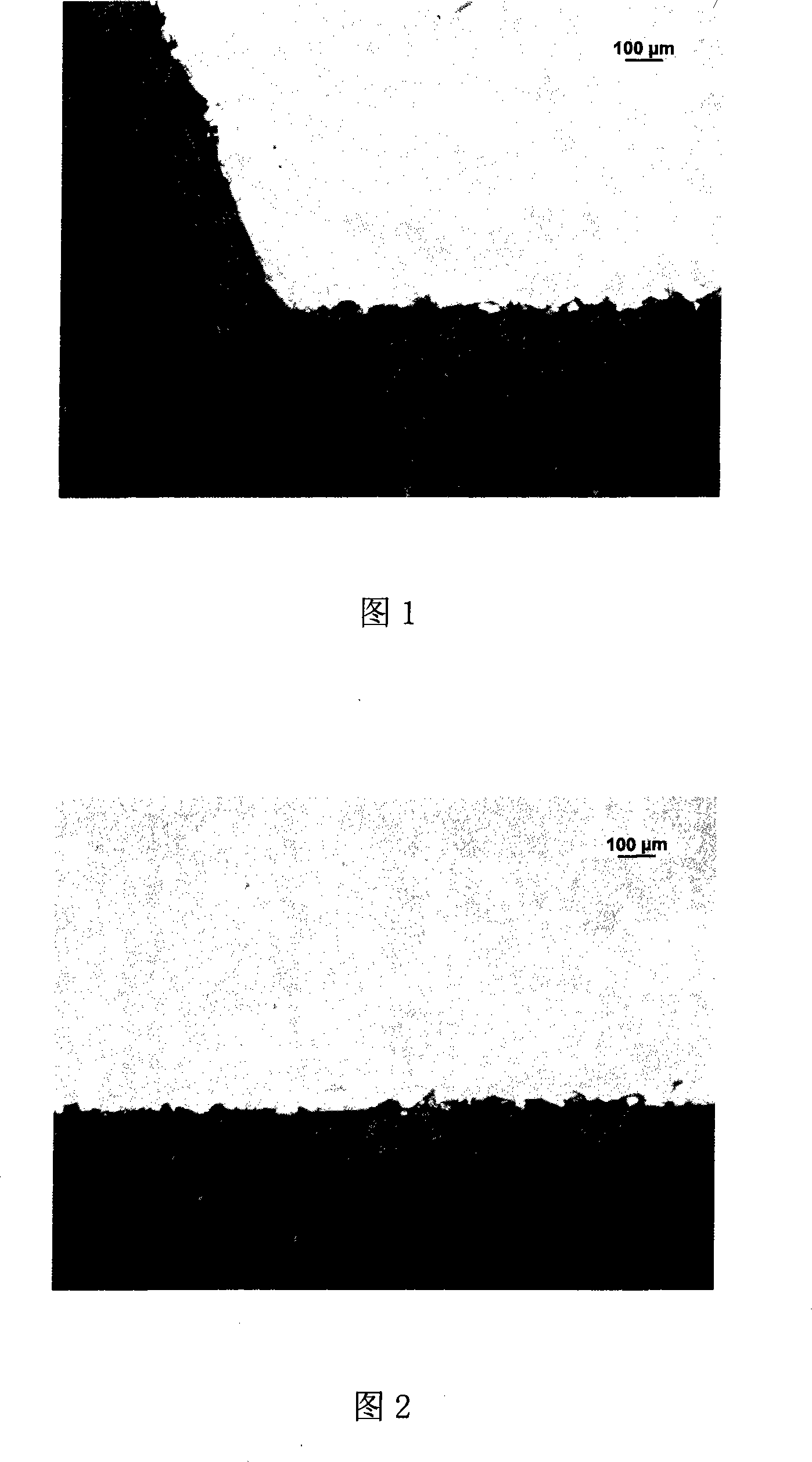

Polyamide 66 membrane covered nickel-titanium alloy intravascular scaffold and preparation method thereof

InactiveCN101703812AImprove impact toughnessExcellent formabilityLiquid surface applicatorsSurgeryNitinol stentPolyamide

The invention relates to a polyamide 66 membrane covered nickel-titanium alloy intravascular scaffold and a preparation method thereof. The intravascular scaffold comprises a nickel-titanium alloy scaffold and a polyamide 66 membrane, and is provided with a tubular blood vessel shaped structure or a cylindrical blood vessel shaped structure, wherein the surfaces of an inner wall and an outer wallof the scaffold are covered by thin membranes with the thickness between 0.2 and 5 millimeters. The preparation method comprises the following steps of: preparing 1 to 20 percent of polyamide 66 solution by using formic acid as a solvent; coating a layer of the polyamide 66 solution on a glass rod and volatizing the solvent; sleeving a nickel-titanium shape memory alloy expanding scaffold on the glass rod; coating another layer of the polyamide 66 solution on the glass rod and volatizing the solvent; and peeling off the polyamide 66 membrane and the nickel-titanium alloy intravascular scaffold from the glass rod, and performing vacuum drying to obtain the polyamide 66 membrane covered intravascular scaffold. The intravascular scaffold prepared by the method has a stable structure, good mechanical property, transportability and anti-seepage property, overcomes the performance defects of a single material, and has a simple preparation process.

Owner:DONGHUA UNIV

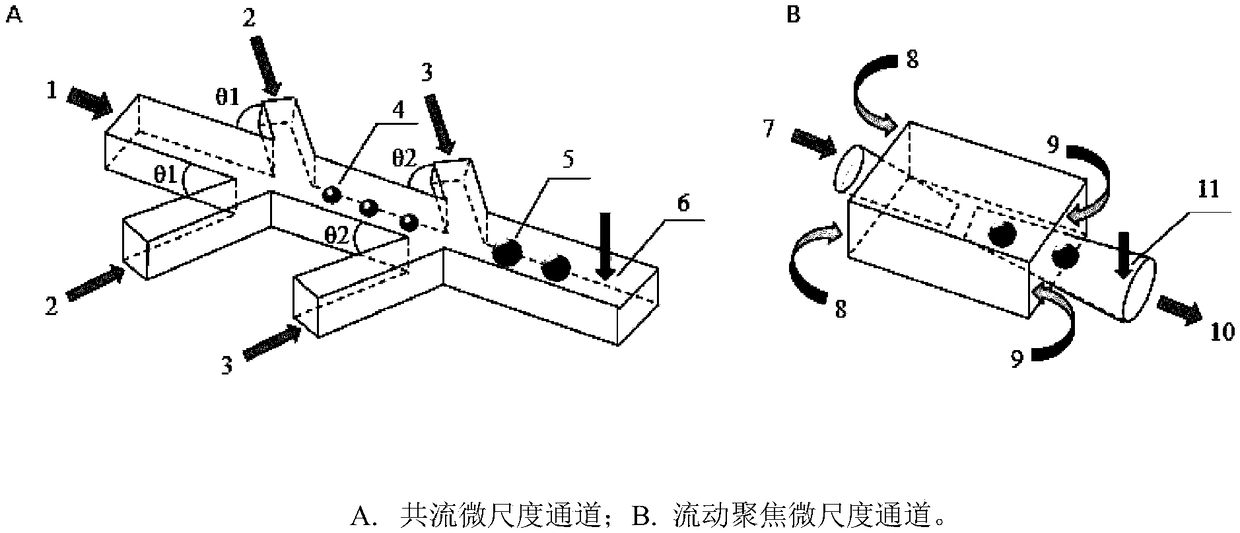

Core-shell type pre-charged chemotherapy medicine embolization microsphere and preparation method thereof

InactiveCN108721684ATargetedWith controlled releaseSurgical adhesivesTissue regenerationEmulsionArterial Embolization

The invention provides a core-shell type pre-charged chemotherapy medicine embolization microsphere and a preparation method thereof. The method comprises the following steps of using water / oil / water(W / O / W) complex emulsion type or oil / water / oil (O / W / O) complex emulsion type emulsified micro liquid drips as templates; coating tiny liquid drips containing medicine into outer layer liquid drips; high molecular polymers in the inner and outer layer liquid drips are converted through measures such as physical measures and chemical measures to form an inner layer core and an outer layer shell. Theformed core-shell structure medicine microsphere is formed by polymers of two-layer structures; the inner core contains medicine; the outer shell is favorable for maintaining the activity of the inner core medicine; the stable medicine release is realized; the sudden release is prevented; the safety is enhanced. The medicine carried microsphere prepared by the method has the advantages that the particle diameter range is 10 to 1000 micrometers; the sphere degree is good; the particle diameter is uniform; (the dimension deviation is 5 percent); the medicine encapsulation rate is high; the structure / carried medicine is controllable; meanwhile, the preparation method of the pre-charged chemotherapy medicine embolization microsphere can provide a novel idea for the clinic application study ofthe transcatheter arterial embolization.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

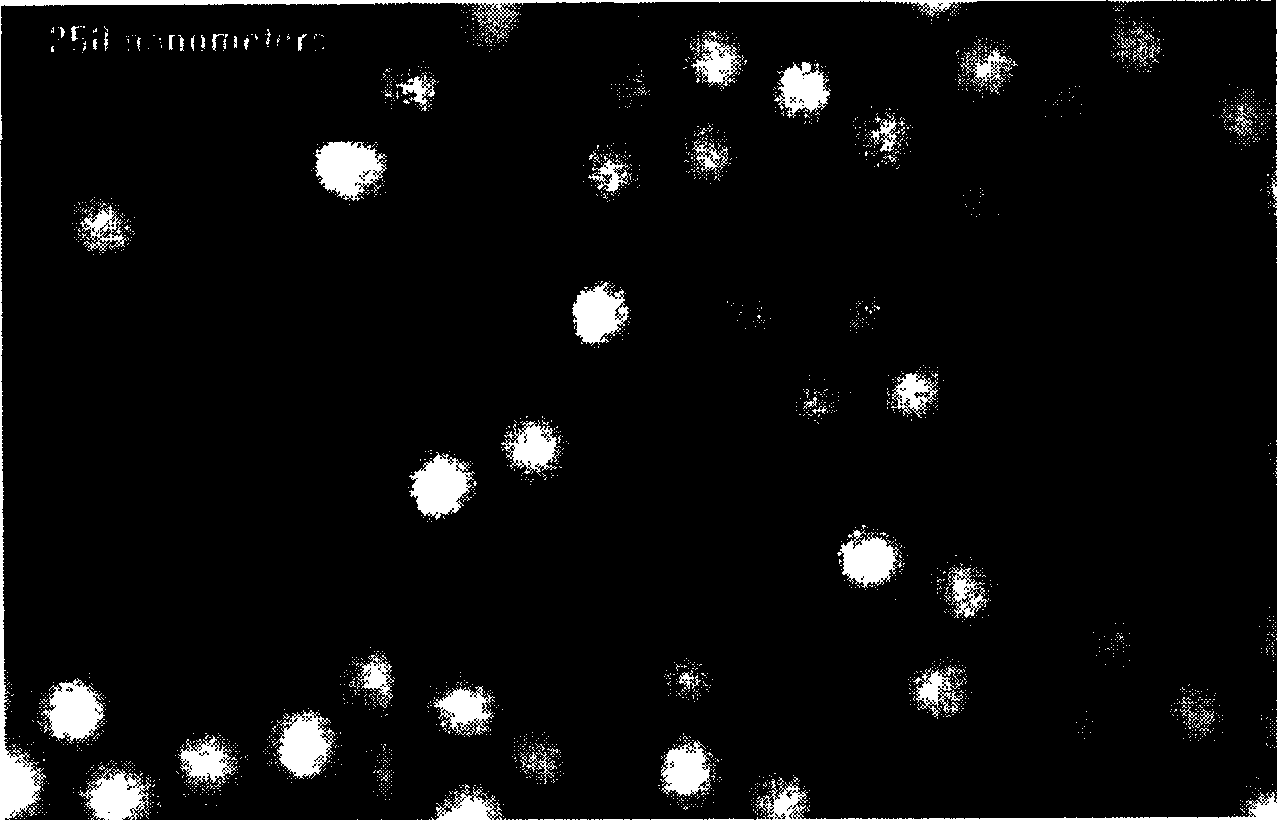

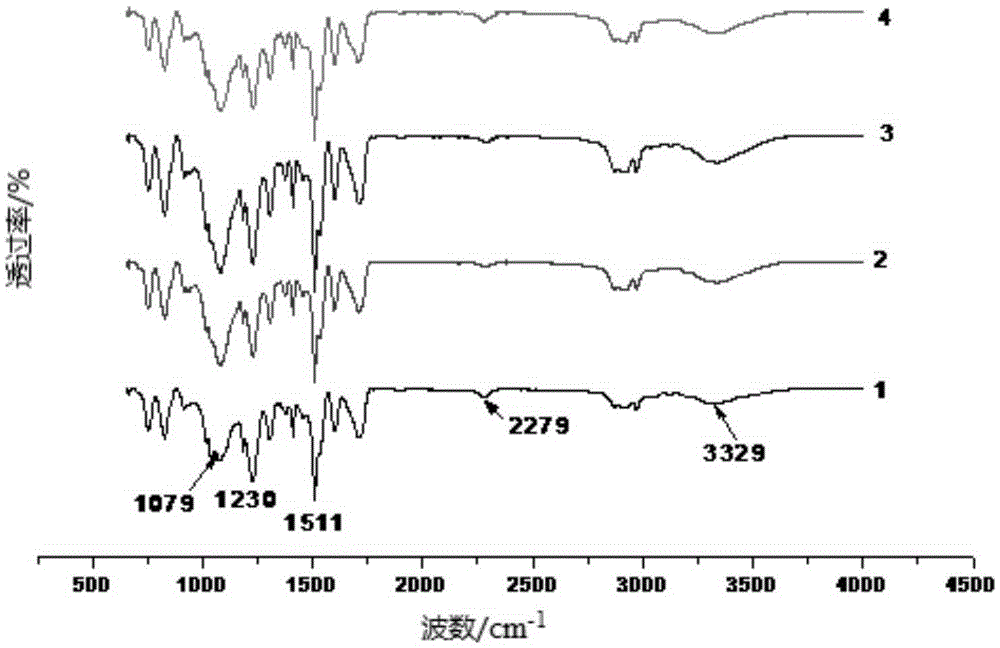

Chemically mechanical polishing solution

InactiveCN1621469ANarrow particle size distributionLess polishing damagePolishing compositions with abrasivesNanometreSurface finishing

The present invention belongs to the field of chemical and mechanical polishing technology in microelectronic processing, and is especially chemical and mechanical polishing fluid for multilayer insulating film in superlarge scale integrated circuit manufacture. The polishing fluid has nanometer spherical mesoporous powder as grinding material and contains nanometer spherical mesoporous powder as grinding material, stabilizer, surfactant, pH regulator to regulate pH to 8.5-12.5, and high purity deionized water. The present invention utilizes the grinding material with rich surface hydroxy groups and excellent dispersivity in water in polishing interlayer medium of integrated circuit, and has no submicron scratches, high levelness, easy cleaning and high polishing rate.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for processing fast powder sherardizing surface coat

InactiveCN101122005AFast heatingImprove efficiencySolid state diffusion coatingHeating timeMicrowave

The invention relates to a method of processing a fast powder sherardizing surface coating. A metal component is embedded in a metal powder sherardizing agent ceramic sherardizing can containing zinc powder or zinc / aluminum composite powder, put into a microwave heating furnace for microwave heat treatment when slowing rolling, cooled after temperature preserving, and taken out for post treatment. In the zinc / aluminum composite metal powder, the volume fraction of the aluminum powder is less than or equal to 40percent, and the rest is zinc powder. Composition of the metal powder sherardizing agent: the volume percent of the zinc powder or zinc / aluminum composite powder is 10 to 40percent; the volume percent of activating agent is 0 to 3percent; and the rest is SiO2 or AL2O3 filling agent. The filled ceramic sherardizing can is put into the microwave heating furnace for heat treatment. The invention uses microwave to obviously shortens the heating time, which is only 1 / 5 to 1 / 8 of that of traditional sherardizing technologies, saves more than 50 percent energy, greatly improves the production efficiency of the powder sherardizing processing, and reduces the manufacturing cost.

Owner:TIANJIN UNIV

Cellulose-reinforced polyurethane/epoxy resin interpenetrating polymer network hard composite foam material and preparation method thereof

InactiveCN105348473AHigh compressive strengthGood sound absorptionInterpenetrating polymer networkIsocyanate compound

The invention discloses a cellulose-reinforced polyurethane / epoxy resin interpenetrating polymer network hard composite foam material and a preparation method thereof, relates to a foam material and a preparation method thereof and aims at solving the problems that existing polymer formed through mutual interpenetrating of two types of polymer, namely polyurethane and epoxy resin, is poor in sound absorption property and low in mechanical property. The sound absorption property of the composite foam material ranges from 80% to 92%, and the composite foam material is prepared from polyether polyol, isocyanate, water, a foaming agent, foam stabilizer, initiator, hydrosol of nano-crystalline cellulose with the mass percentage being 1%, chain extender, a cross-linking agent and epoxy resin. The preparation method comprises the steps of firstly, mixing the polyether polyol, the foam stabilizer, the initiator, the foaming agent, the chain extender and the water with cellulose obtained after pretreatment, then adding the epoxy resin and the cross-linking agent, and obtaining a mixture; then mixing the isocyanate with the mixture, conducting stirring till bubbles are generated, leaving the mixture standing still, obtaining a foamed mixture, finally, conducting curing on the foamed mixture at the room temperature, and then conducting curing at the high temperature.

Owner:NORTHEAST FORESTRY UNIVERSITY

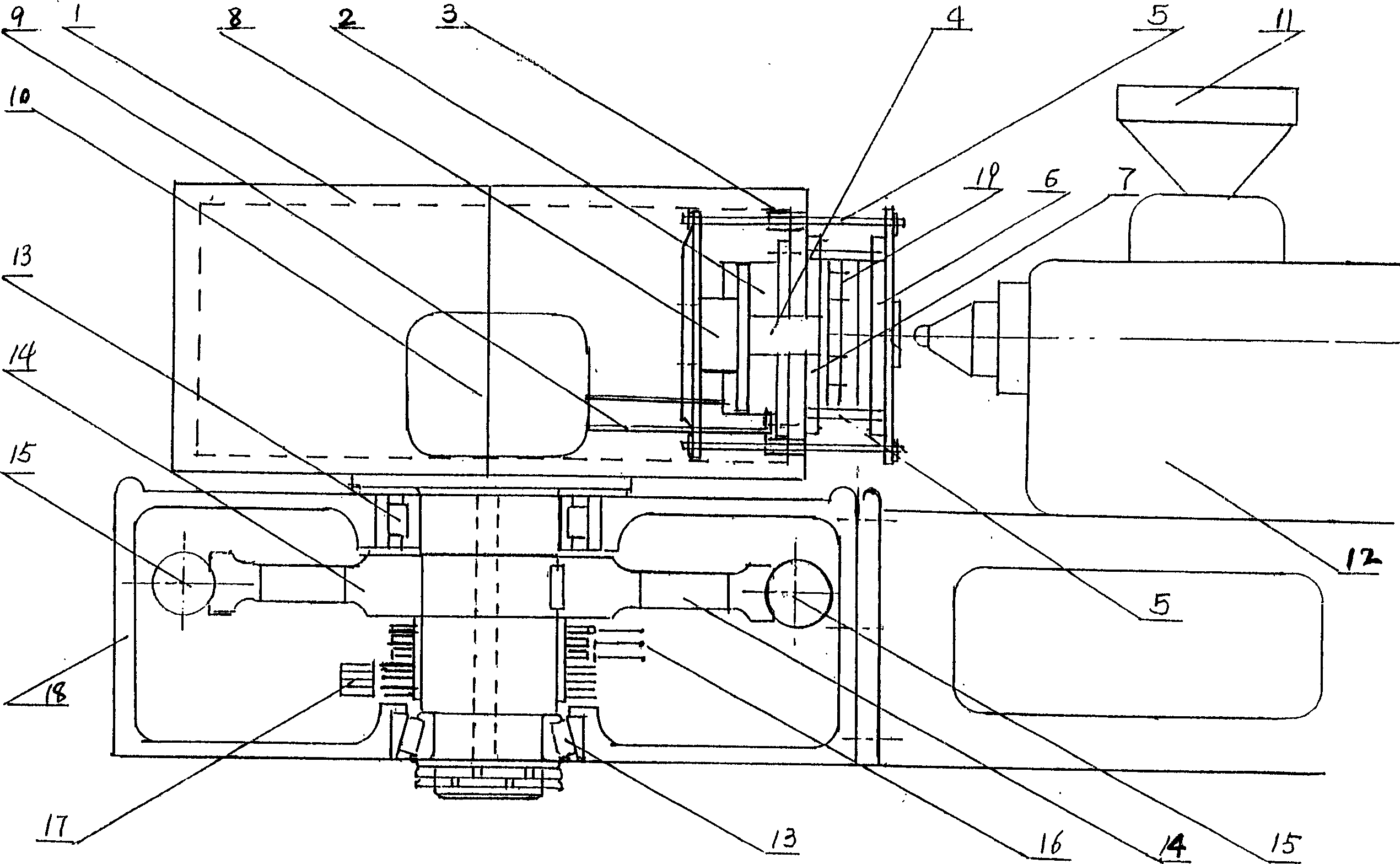

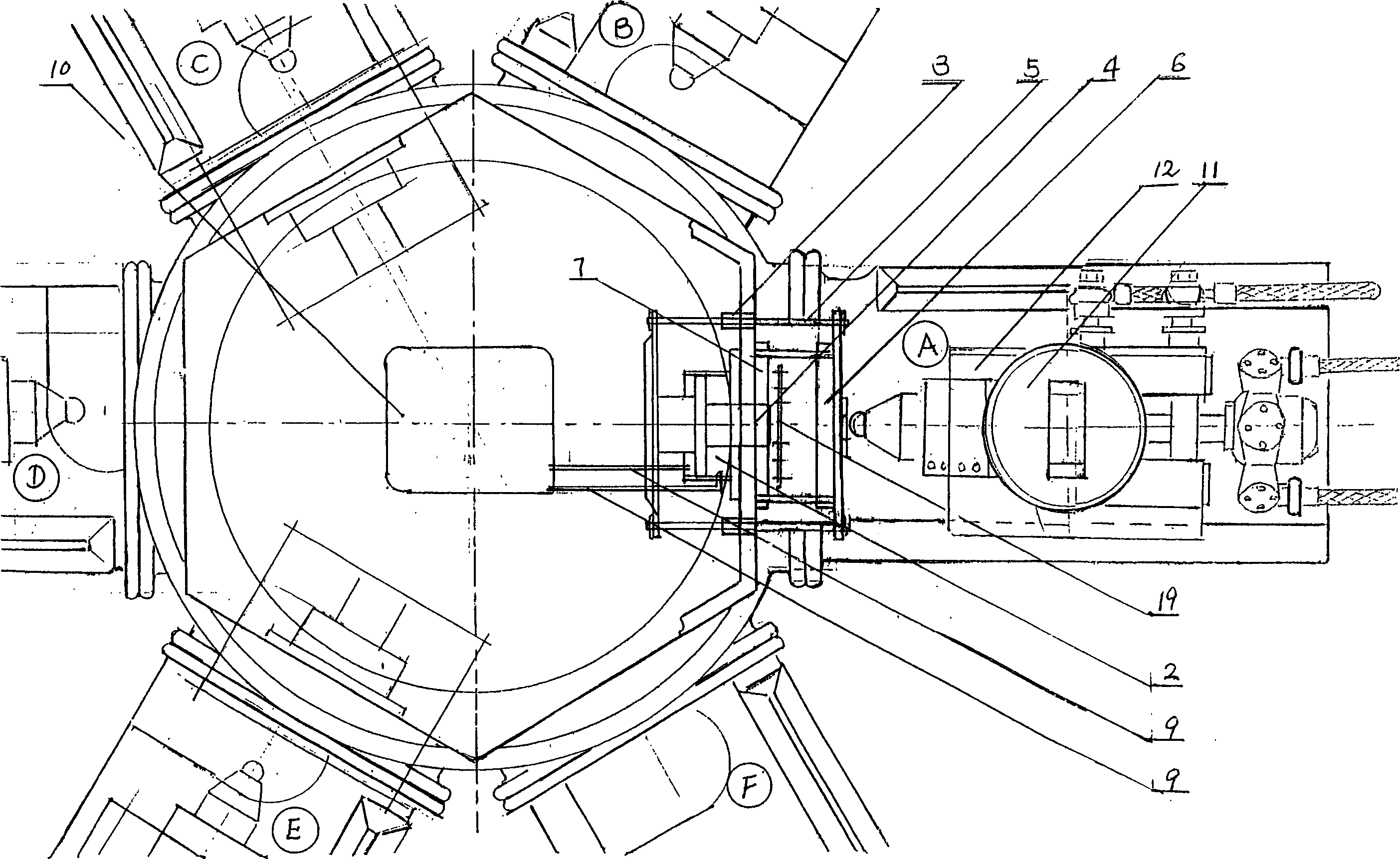

Multifunctional plastic jetting-molding machine

A multifunctional injection moulding machine is composed of a rotary bench with multiple work positions for moulds consisting upper and lower die plates and driven by motor via drive mechanism, and injection moulding unit, a mould closing unit, which is a pressure-holding high-pressure mould locking structure consisting of guide sleeve, beating rod, guide rod and upper and lower die plates, and a hydraulic system consisting of high-pressure cylinder and the booster installed in the center of said rotary bench.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

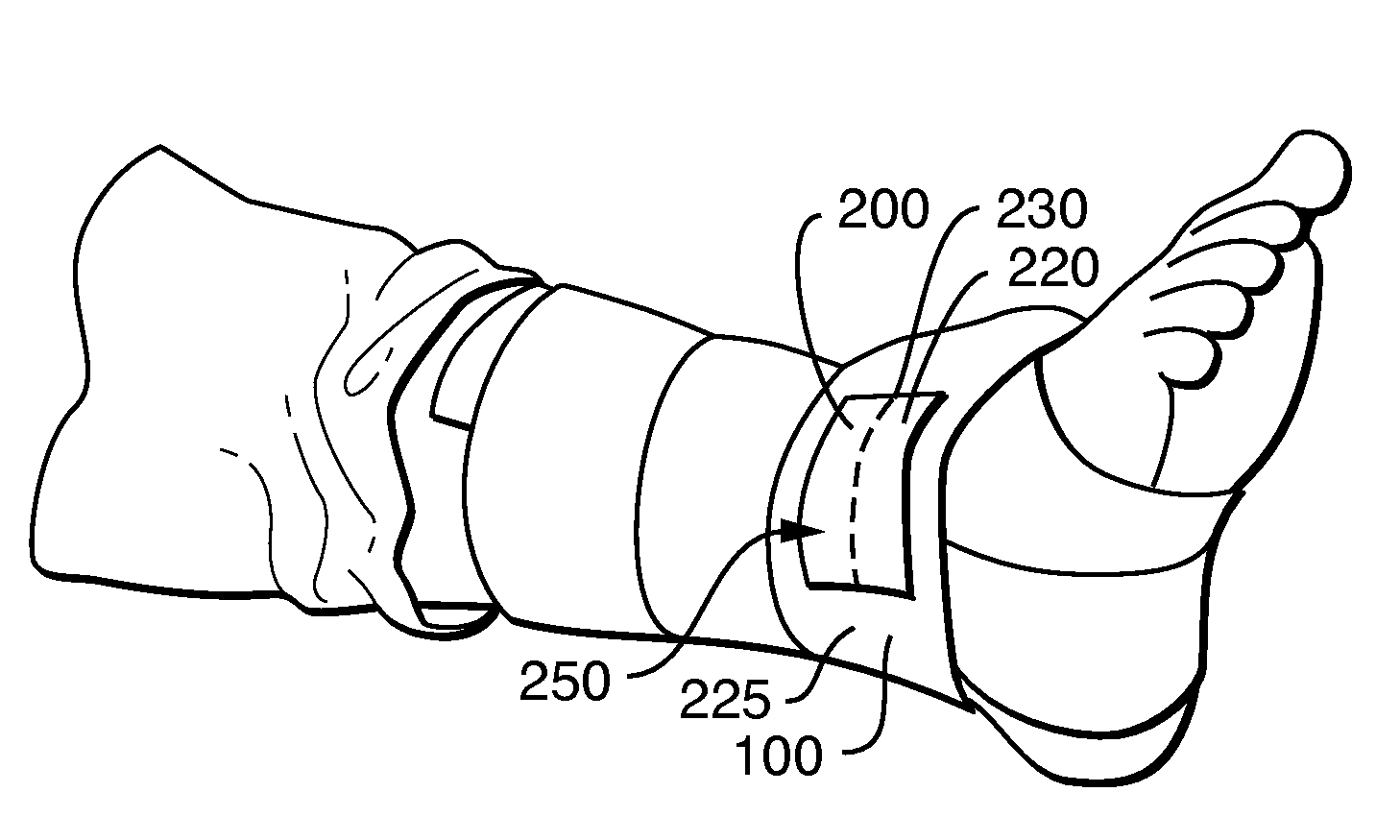

Wearable Article That Stiffens Upon Sudden Force

InactiveUS20110155141A1Change mechanical propertiesReduce riskRestraining devicesFibre treatmentPolymer scienceSilanes

A wearable article made from a nonwoven fabric that includes a plurality of coated fibers. The coated fibers have an exterior surface and a coating composition on at least a portion of the exterior surface. The coating composition includes an aminofunctionalized silane and a dialdehyde, where the weight percent of the dialdehyde in the coating composition is greater than the weight percent of the silane in the coating composition. The wearable article can be a wrap, brace, support, compression hosiery, bandage or compress. When worn, the wearable article is initially flexible but becomes rigid and stiff when the coated fibers experience a sudden force or impact. The wearable article does not include a fluid.

Owner:KIMBERLY-CLARK WORLDWIDE INC

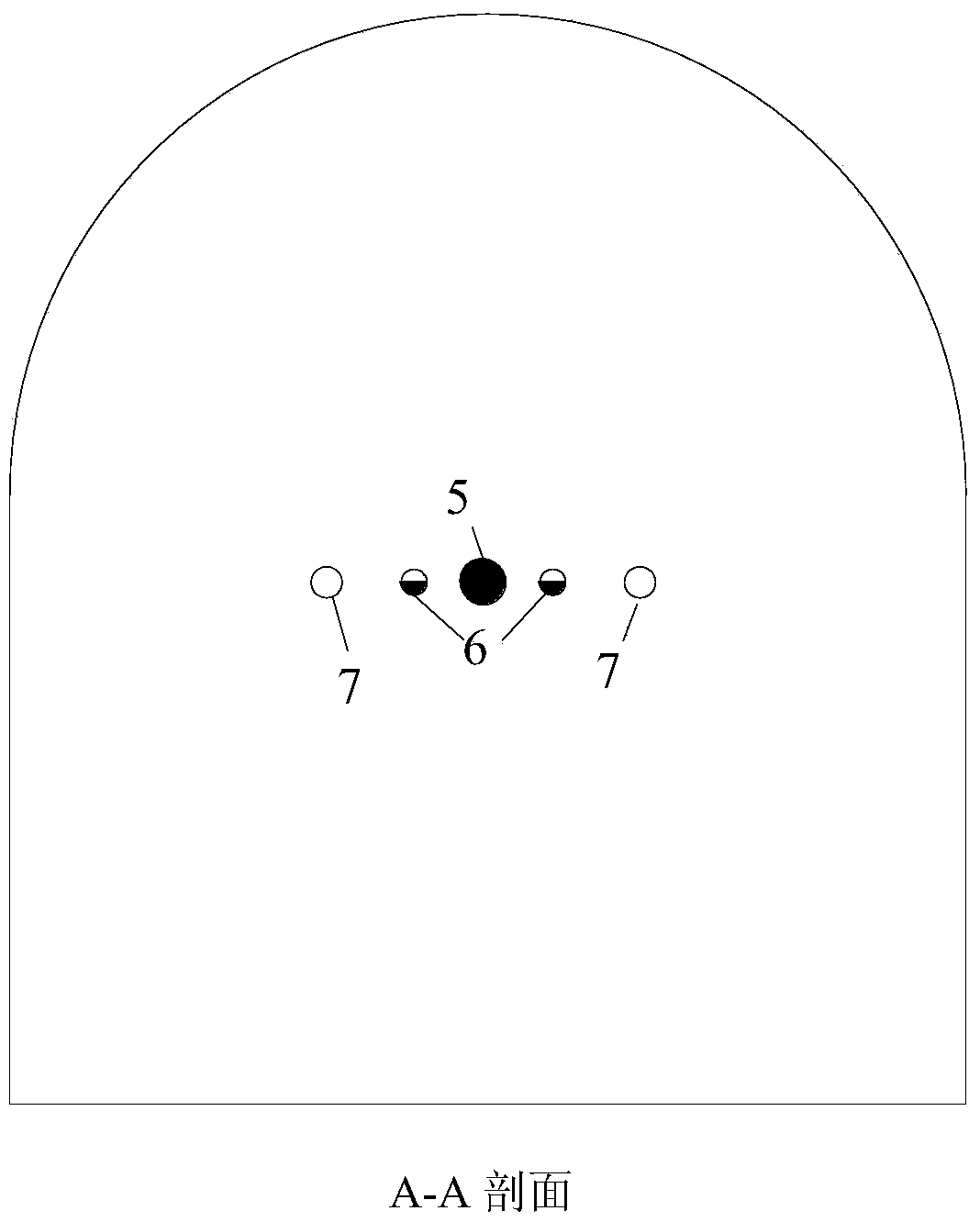

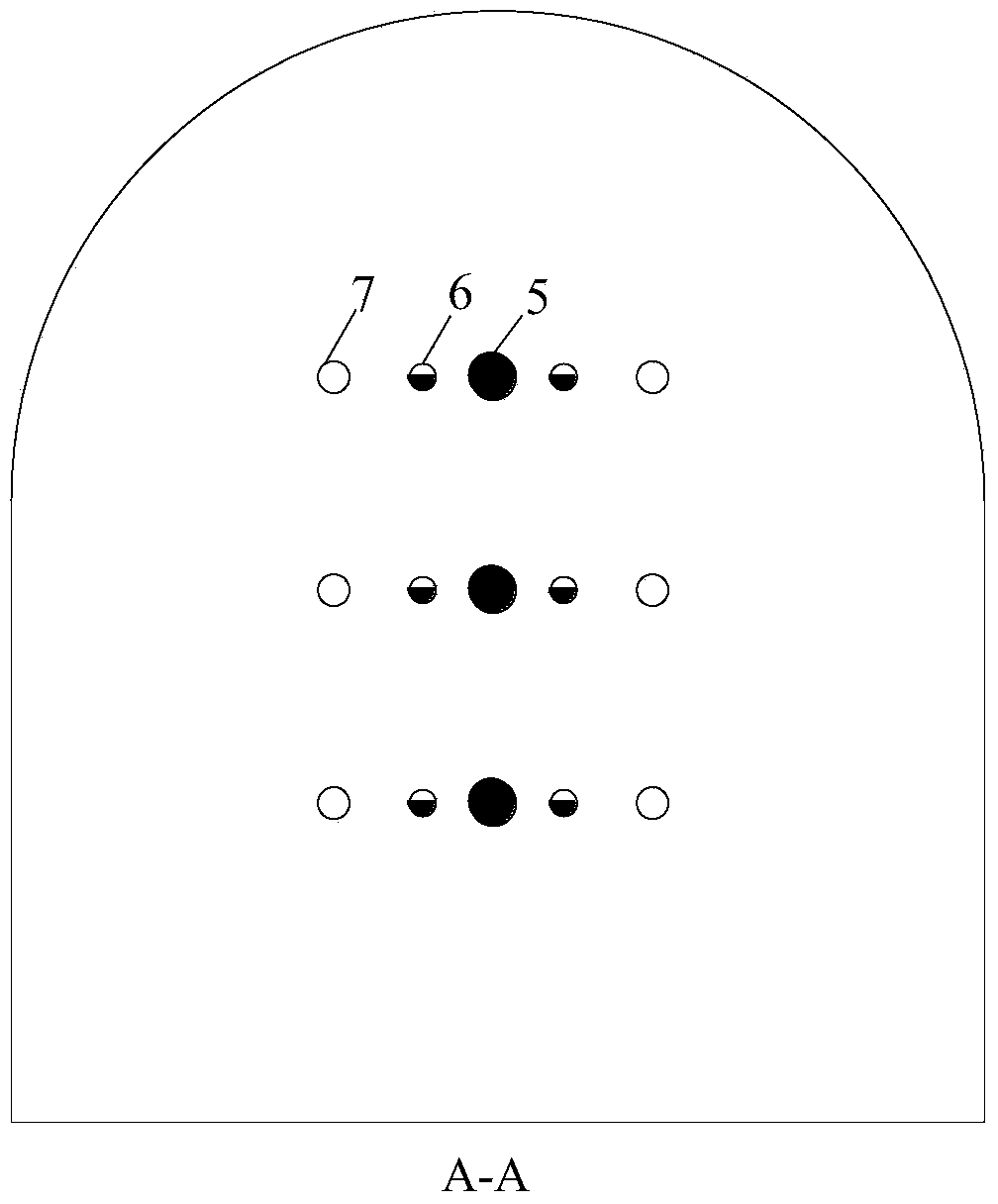

Freezing-type stone door cross-measure coal uncovering method based on hydraulic seam cutting

ActiveCN104213921AImprove flow statusImprove breathabilityUnderground miningSurface miningUltimate tensile strengthCoal

A freezing-type rock cross-measure coal uncovering method based on hydraulic seam cutting is suitable for a rock cross-measure coal uncovering operation in a high-gas outburst coal seam. The method includes following steps: (1) constructing a plurality of water injection holes into a coal uncovering operation surface at a position of the coal uncovering operation surface, wherein a minimum normal distance from the coal seam to the position is not less than 7 m; (2) performing hydraulic seam cutting to the water injection holes through a conventional hydraulic seam cutting technology; (3) when the hydraulic seam cutting is finished, connecting the water injection holes to a gas extraction pipe network to perform gas extraction; (4) when the content of gas in the coal seam is less than 8 m<3> / t, stopping the gas extraction; (5) constructing a freezing holes and a temperature measuring hole respectively at the two sides of the water injection holes; (6) sealing the holes through a capsule hole-sealing device; (7) injecting water into the coal seam through the water injection holes and closing valves when the water injection process is finished to enable the water injected into the coal seam to gradually seep into micro cracks in coal; (8) freezing the coal seam around the water injection holes through a conventional freezing technology to enable free water in the micro cracks in the coal seams to gradually convert from liquid phase into solid phase during the freezing process, so that a strength and an anti-impact performance of the coal are increased and an effect of solidification of the coal seam is achieved; and (9) uncovering the coal seam through a conventional coal uncovering method.

Owner:CHINA UNIV OF MINING & TECH

High-temperature high-power rare earth resistance paste and preparation method thereof

InactiveCN106131982ACompatibility improvements improvedGood compatibilityNon-conductive material with dispersed conductive materialHeating element materialsMicrometerRare earth

The invention discloses a high-temperature high-power rare earth resistance paste and a preparation method thereof. The high-temperature high-power rare earth resistance paste comprises a functional phase, an inorganic adhesive phase, a burning promoter and an organic carrier, wherein the functional phase is composite powder consisting of micrometer silver powder and bismuth ruthenate powder; the inorganic adhesive phase is lead-free pyroceram powder consisting of SiO2, MgO, B2O3, ZnO, Bi2O3, rare earth oxides and a nucleation agent; and the organic carrier is a mixture consisting of a solvent, resin, a dispersing agent, a deforming agent and a thixotropic agent. The resistance paste has the advantages that firstly, the damages of lead on the environment and human bodies can be avoided; secondly, the resistance paste is high in compatibility, wettability, thermal performance, electrical performance, manufacturability and adaptability; thirdly, the resistance paste is high in binding performance with ceramic and stainless steel substrates; and fourthly, the resistance paste is high in printing performance, burning performance and compatibility. The preparation method comprises preparation of the inorganic adhesive phase, preparation of the functional phase, preparation of the organic carrier and preparation of the resistance paste in sequence, and the resistance paste can be produced and prepared effectively.

Owner:DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

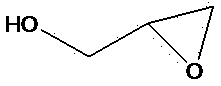

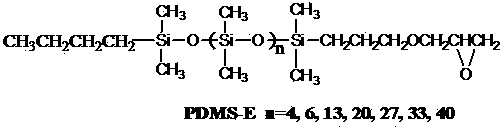

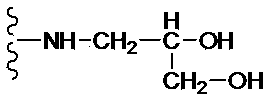

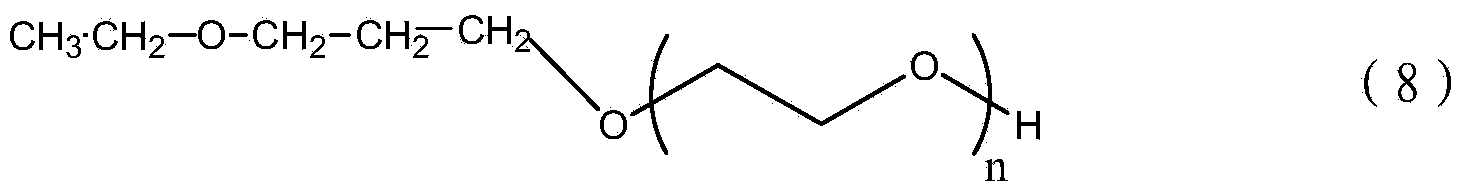

Polysiloxane and glycidol-containing strong-hydrophobicity gelatin leather finishing agent and preparation method

ActiveCN103436168APlay a plasticizing roleImprove performanceFibre treatmentProtein coatingsActive agentPolytetrafluoroethylene

The invention relates to a polysiloxane and glycidol-containing strong-hydrophobicity gelatin leather finishing agent and a preparation method. The preparation method comprises the following steps: dissolving gelatin in water to prepare aqueous solution with mass concentration of 2-20 percent; adding glycidol into a first reaction flask under the conditions of temperature of 40-70 DEG C and pH of 6-12 to obtain solution 1; adding a surfactant into a second reaction flask, continuously stirring, and meanwhile adding Si-O-Si repetitive unit-containing epoxypolysiloxane in batches or continuously to obtain solution 2, wherein the using amount of the surfactant is 0.5-20 percent of the mass of the gelatin; mixing the solution 1 and the solution 2 in different proportions, weighing 15-20 g of the mixed solution to be placed in a mold of polytetrafluoroethylene, adding 5-10 mL of one or two or three of ethanol, tetrahydrofuran and methanol and drying in a normal pressure drying oven at the temperature of 40-80 DEG C to obtain the gelatin leather finishing agent with a superior function. The finishing agent has the characteristics of strong hydrophobicity, super extensibility, heat resistance, oxidation resistance, wet scrubbing resistance and the like.

Owner:QILU UNIV OF TECH

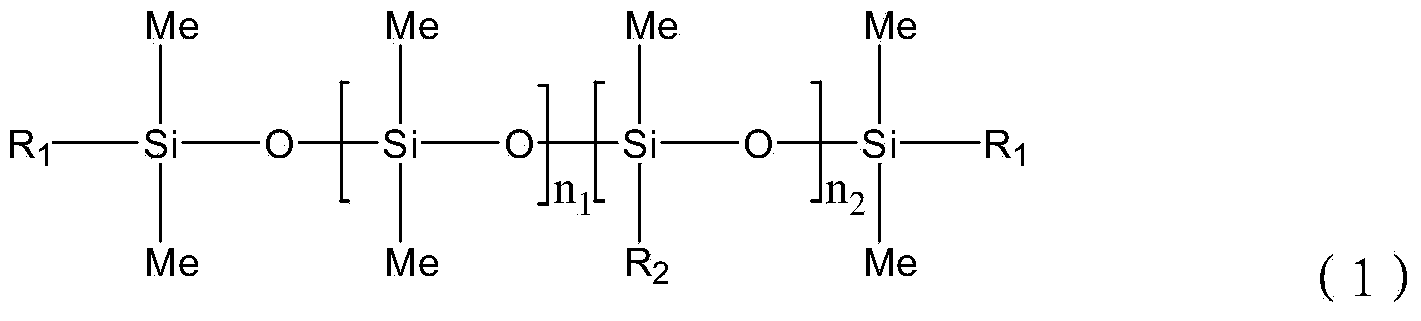

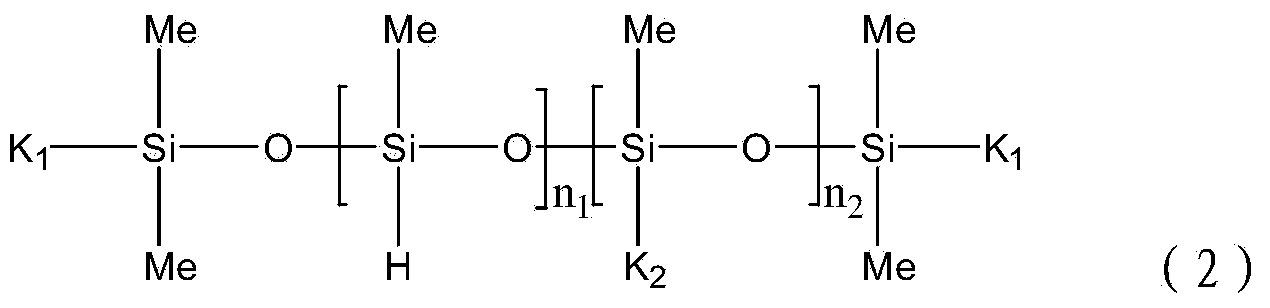

Antistatic organosilicon gel used for heat-conducting gasket and preparation method of the organosilicon gel

The invention relates to antistatic organosilicon gel used for a heat-conducting gasket and a preparation method of the organosilicon gel. The organosilicon gel comprises an A component and a B component in a weight ratio of 1:1. The A component comprises following raw materials by weight: 95-99.84 parts of a basic material, 0.1-1 part of a catalyst, 0.05-2 parts of an adhesive and 0.01-2 parts of an antistatic agent. The B component comprises following raw materials by weight: 84-94.9 parts of the basic material, 5-15 parts of a cross-linking agent and 0.1-1 part of an inhibitor. The organosilicon gel prepared by the invention has good fluidity. After sulfuration, the organosilicon gel has excellent adhesive property, holding power and antistatic property.

Owner:YANTAI DARBOND TECH

Bone cement system

ActiveUS20120026825A1Avoid stickinessMore viscousFlow mixersTransportation and packagingBone cementBiomedical engineering

A bone cement system (100) is provided having a mixing facility (10) for mixing and dispensing of bone cement, a reservoir container (112) for a monomer, and a conveyor (122). The mixing facility (10) has a mixing cylinder (20), which stores a bone cement powder. The monomer can be conveyed from the reservoir container (112) into the mixing cylinder (20) by the conveyor (122). A sieve element is (4) is arranged between the reservoir container (112) and the mixing facility (10), in order to preventingress of the bone cement powder from the mixing cylinder (20) into the conveyor (122). The mixing device (10) included a dispensing opening (23) for dispensing a bone cement mixed from the bone cement powder and the monomer. The dispensing opening (23) includes a shield (1) having at least one through-opening (2). The ratio of the area of the through-opening (2) to the area of the sieve element (4) is at least 1 to 3, and the distance between the shield (1) and the sieve element (4) is at least 1 mm.

Owner:HERAEUS MEDICAL

Method for producing multi-metal wear-resistant steel pipe

The invention discloses a method for producing a multi-metal wear-resistant steel pipe, and the method belongs to the technical field of production of tubes and pipes. The mixing of materials is firstly carried out: the following components by weight content are taken and evenly mixed: 58-61 percent of copper chrome alloy power, 16-18 percent of iron oxide powder, 22-24 percent of aluminium powder and 0.001-0.005 percent of nano-silicon carbide powder; then a seamless steel pipe or a straight seam steel pipe with the wall thickness of 3-5mm is further taken and cut into the appropriate length; then the steel pipe is fixed on a pipe molding machine to lead the steel pipe to rotate at the speed of 1000-1400rpm; the composition is further sent into an inner cavity for centrifugal casting, thereby leading the thickness of a multi-metal layer which is evenly distributed on the pipe wall to be 3-15mm; the rotation state of the steel pipe is continuously kept, and the steep pipe is removed after the curing of the inner wall of the steel pipe or the direct cooling to the room temperature. The method can line the thicker multi-metal layer in the thin-walled steel pipe, and the produced steel pipe has the advantages of great strength, good toughness and wear resistance.

Owner:YANGZHOU JUYE WEAR-RESISTANT COMPOSITE MATERIAL CO LTD

Method for improving dispersibility of single-walled carbon nanotube in aqueous solution

InactiveCN101941690AChange electrical propertiesChange mechanical propertiesNanostructure manufactureSolubilityCarbon nanotube

The invention belongs to the field of materials chemistry and in particular relates to a method for improving the dispersibility of a single-walled carbon nanotube in aqueous solution. The method comprises the following detailed steps of: dispersing a single-walled carbon nanotube purification sample in the aqueous solution of ethanol, and performing ultrasonic dispersion on the sample to uniformly suspense the sample in the solution; quickly cooling the obtained solution by using liquid nitrogen as a cooling medium and continuously supplying the cooling medium to guarantee that the cooling temperature of the sample reaches -50 to -190 DEG C; at normal temperature and under normal pressure, placing the solid sample in a closed device in which a high-speed blade rotates, wherein the rotation speed is 22,500rpm, the rotation time is 1 minute and the crushing process is repeated for 1 to 7 times; and filtering and drying the obtained sample to obtain the single-walled carbon nanotube aqueous solution with relatively good water solubility finally. In the invention, a physical method is adopted at normal temperature and under normal pressure, so that the structure of the single-walled carbon nanotube in aqueous solution is not damaged in a treatment process; the ethanol serving as a raw material is simple and available and causes no pollution to environment; and the method has the advantages of simple process and easy processing, so that the method is suitable for commercial production.

Owner:TONGJI UNIV

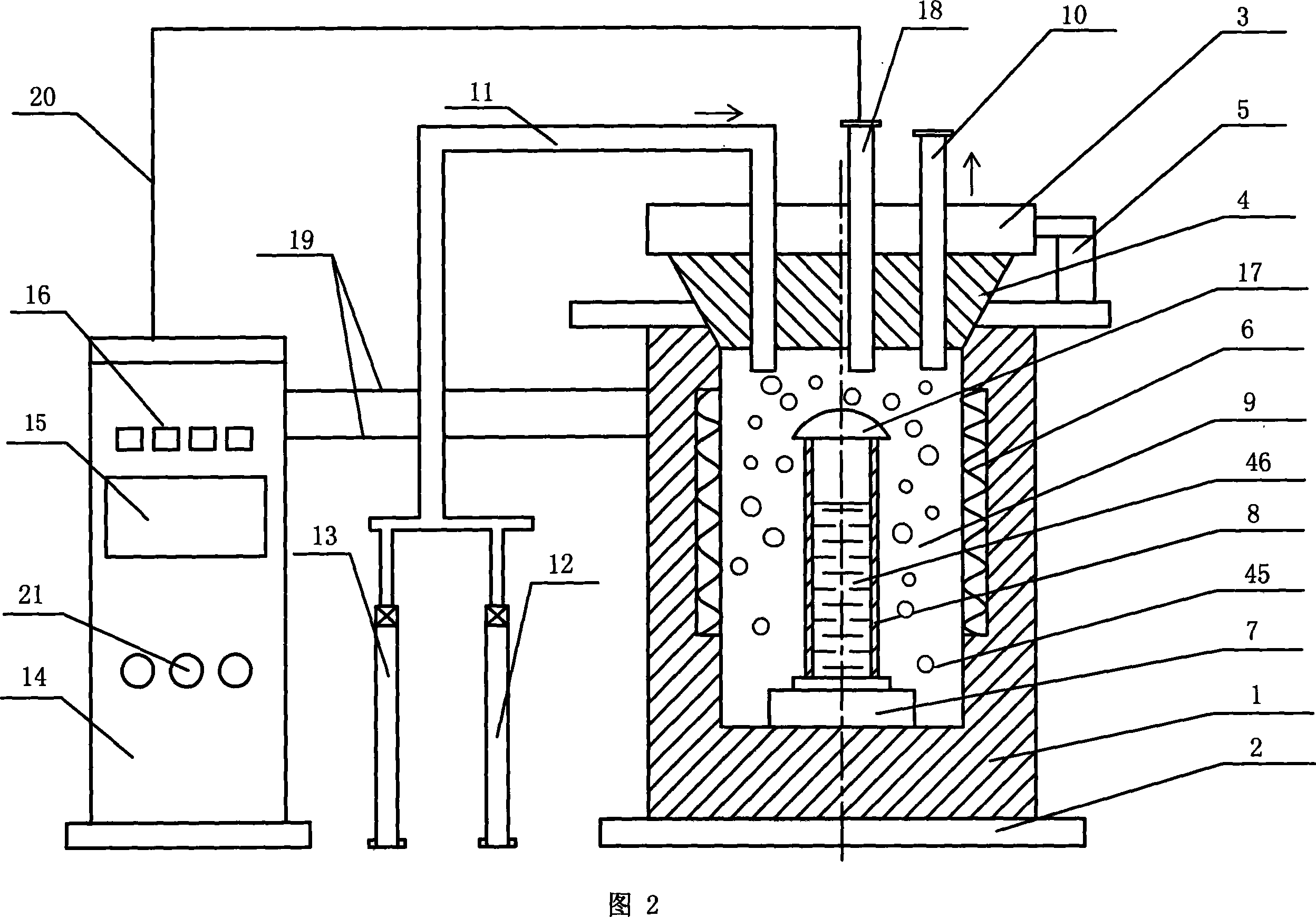

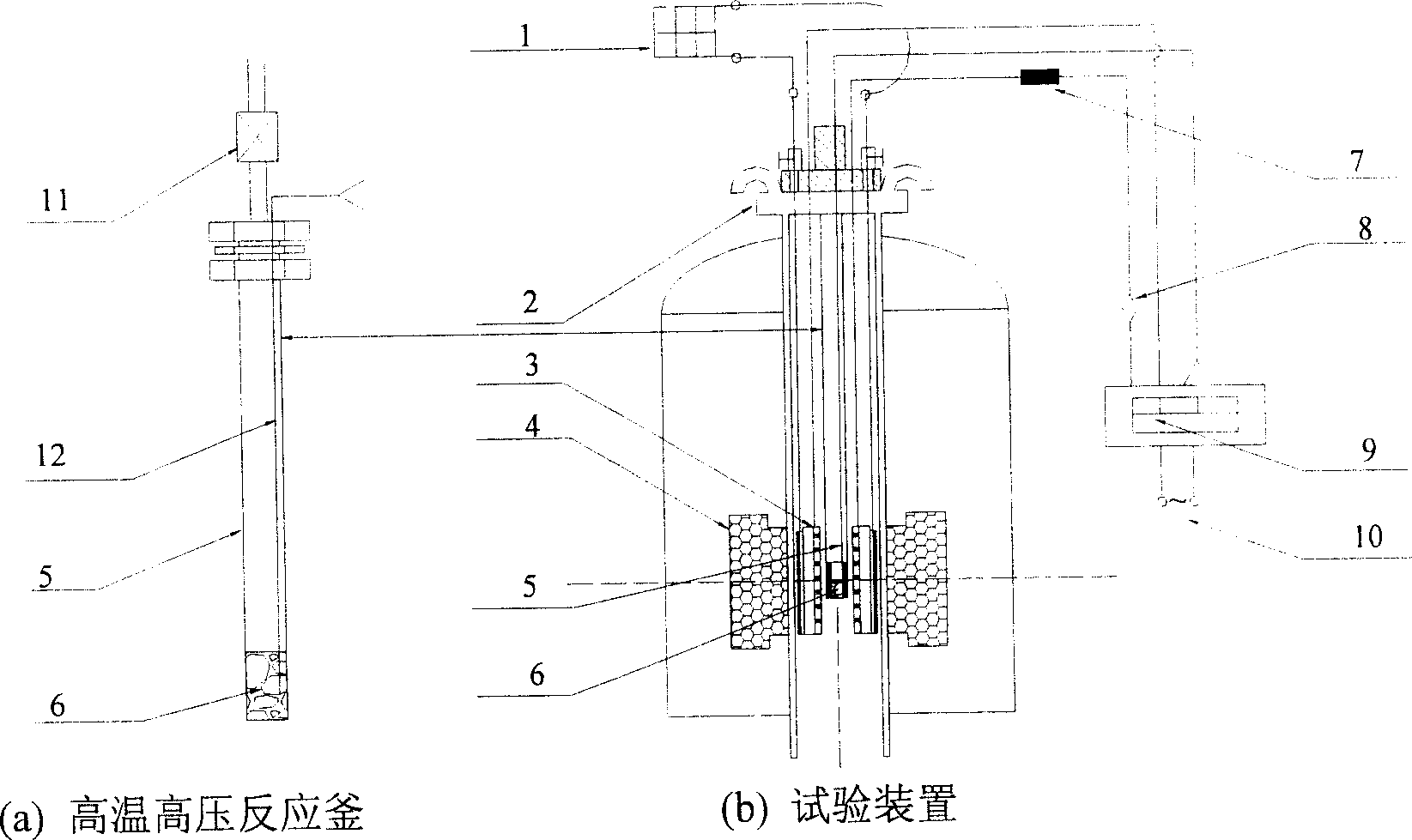

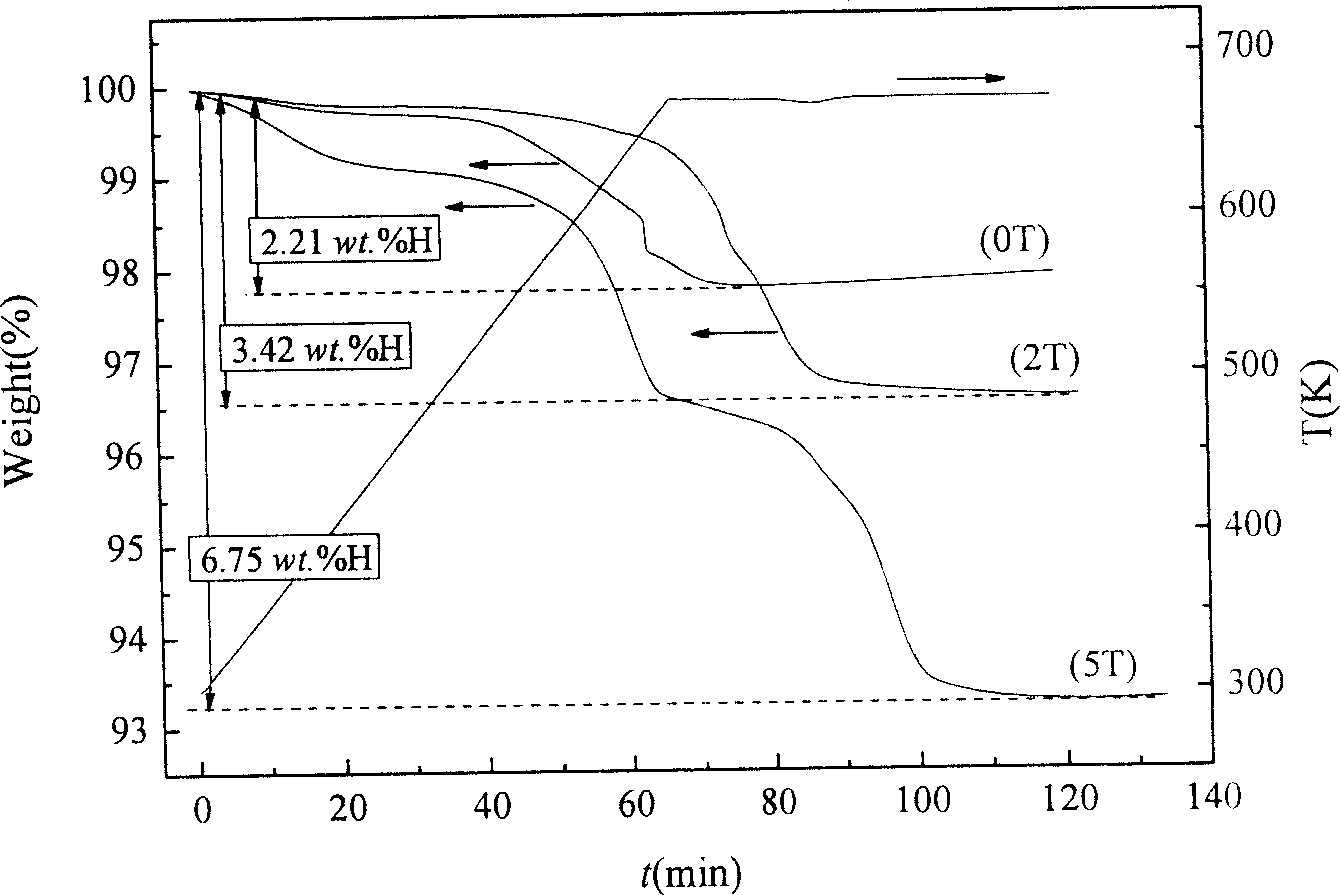

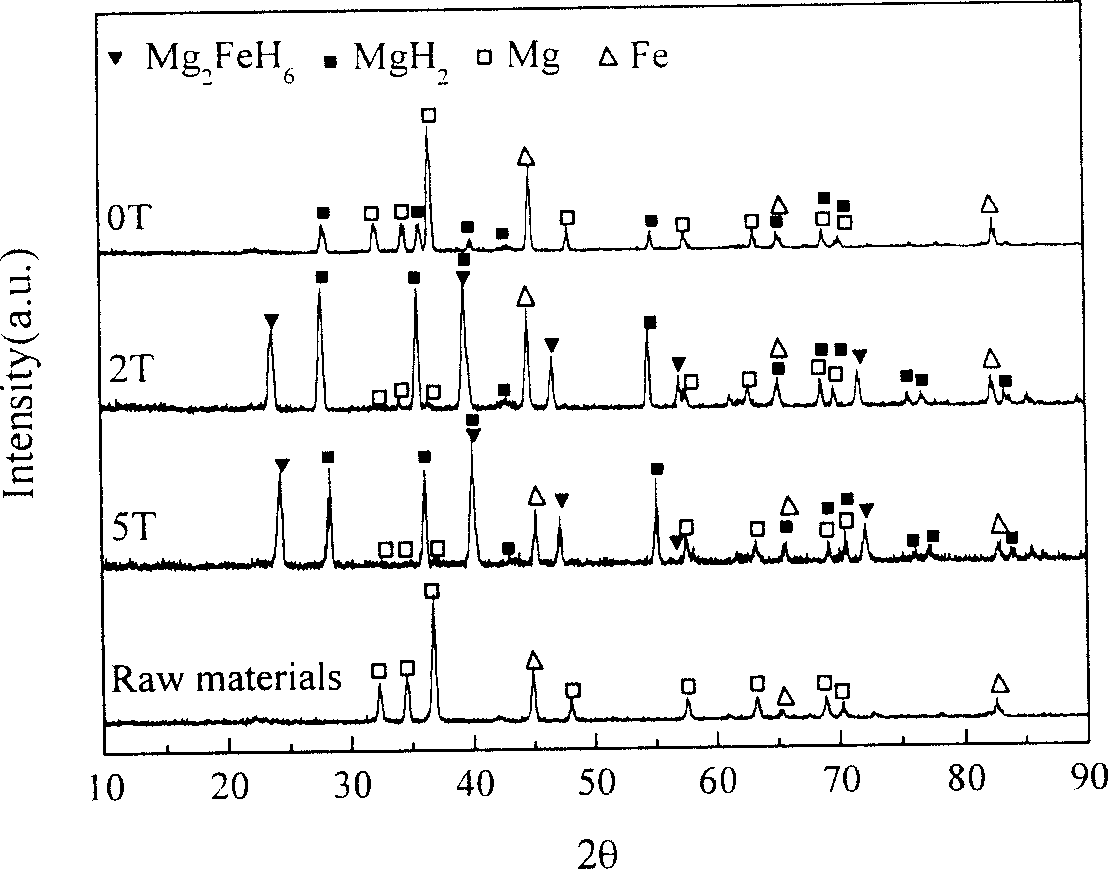

Production of magnesium-based hydrogen-storage material under equalized strong magnetic field and its producer

InactiveCN1896289AChange mechanical propertiesChange dynamic conditionsOther chemical processesChemical compositionUltrasonic dispersion

The present invention relates to the preparation process and device of Mg-based hydrogen storage materials in homogeneous high magnetic field. In this process metal powder is mixed as the designed chemical composition, dispersed by ultrasonic, dried, compacted and fragmented; then it is placed in the reaction kettle that is vacuumized and charged with hydrogen; then in homogeneous high magnetic field of 1-14T it is heated to 400-750DEG C slowly and the temperature is preserved, the hydrogen storage alloy is obtained after cooling. The special device in the present invention features that it includes generating system of homogeneous high magnetic field and reaction kettle for high temperature and pressure. This invention decreases the dehydriding temperature of the Mg-based hydrogen storage material while increases its absorbing and releasing rates of hydrogen.

Owner:SHANGHAI UNIV

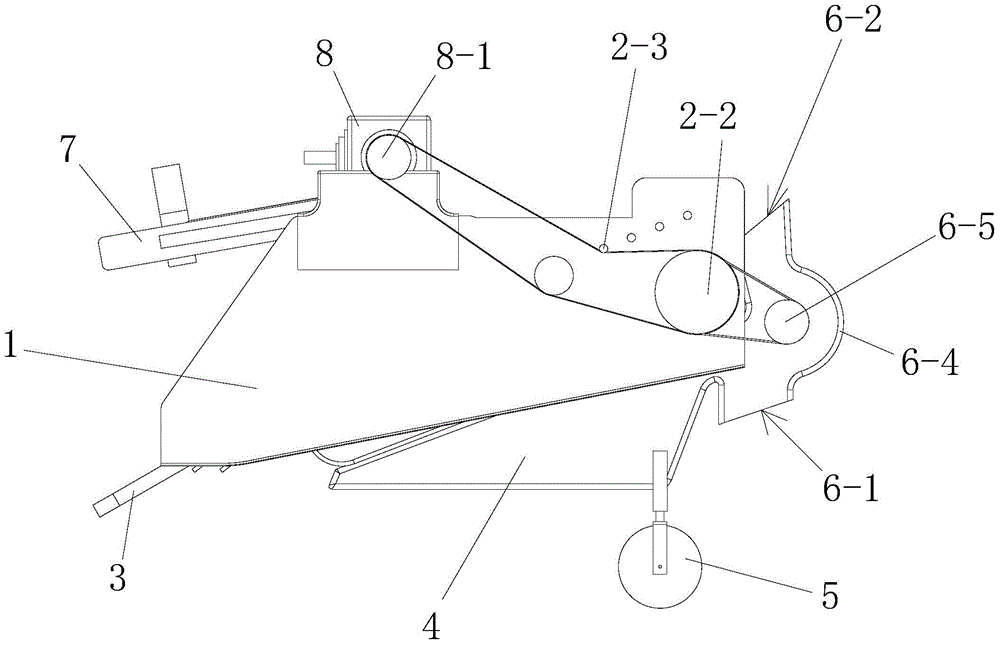

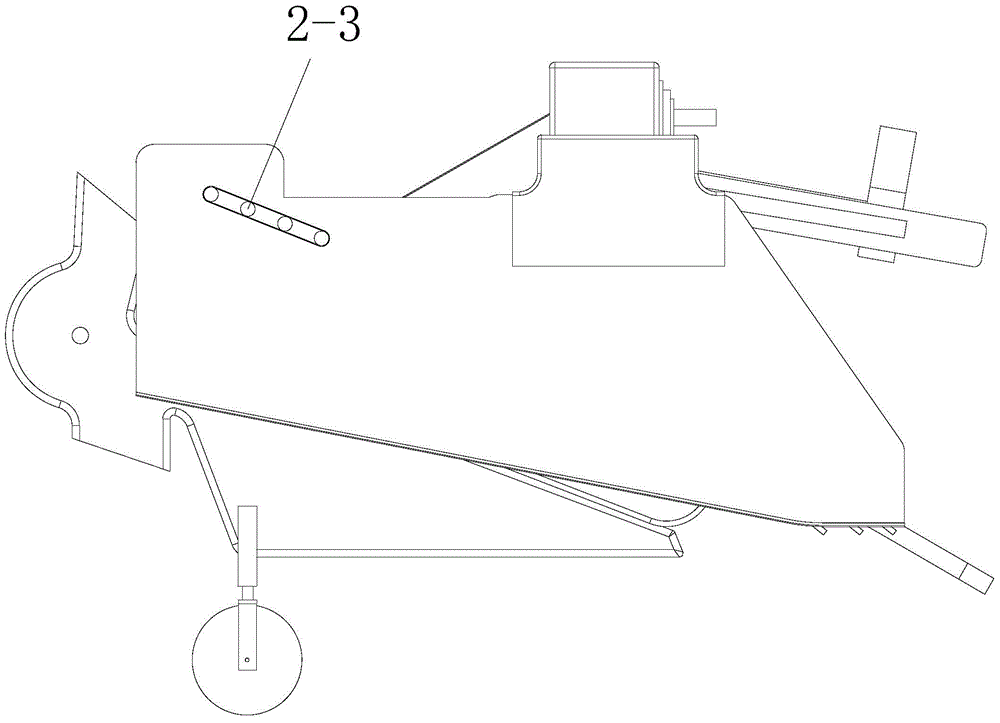

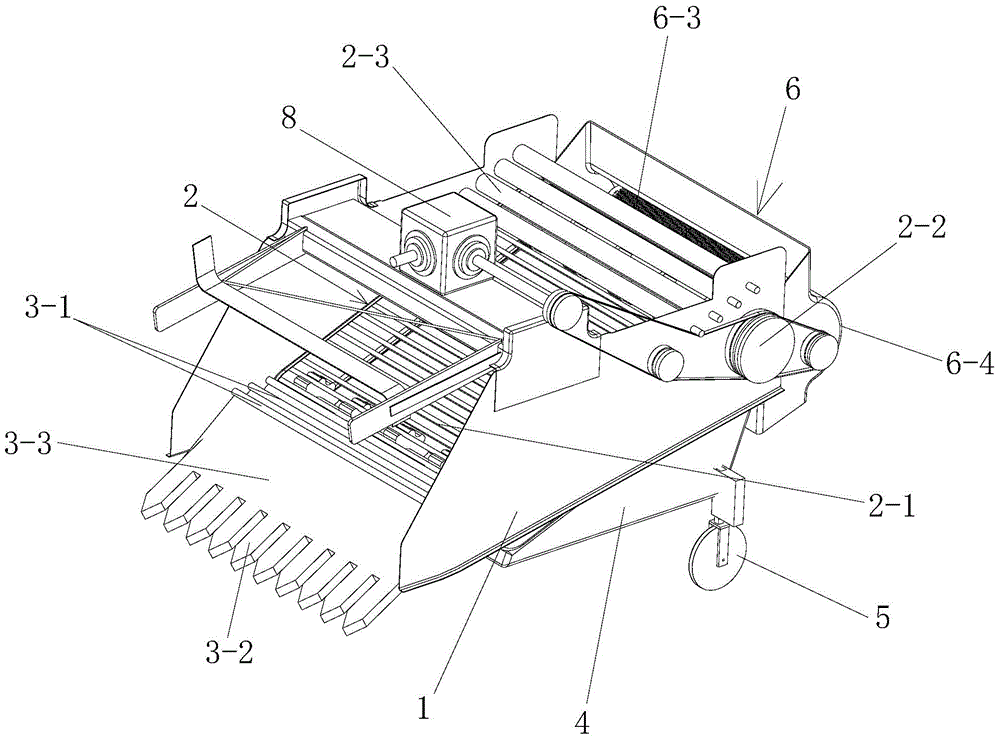

Sweet potato collecting equipment

The invention discloses sweet potato collecting equipment. The sweet potato collecting equipment comprises an equipment body, rollers, a tractor connection arm, a digging shovel, a soil sieving mechanism, a conveying mechanism and a sweet potato collecting box, wherein the rollers are rotationally arranged on the lower part of the equipment body; one end of the tractor connection arm is hinged to the equipment body; the digging shovel is arranged below the front part of the equipment body, and is used for digging out planted sweet potatoes; the soil sieving mechanism is arranged on the back part of the equipment body, and is used for sieving soil from the dug sweet potatoes; the sweet potato collecting box is used for collecting sweet potatoes from which soil is sieved by the soil sieving mechanism. Through adoption of the sweet potato collecting equipment, the current situation that mechanical digging and manual collection are adopted at present can be improved, and the aims of digging, soil sieving and collecting of the sweet potatoes from a growing underground environment are fulfilled at a time.

Owner:YANCHENG INST OF TECH

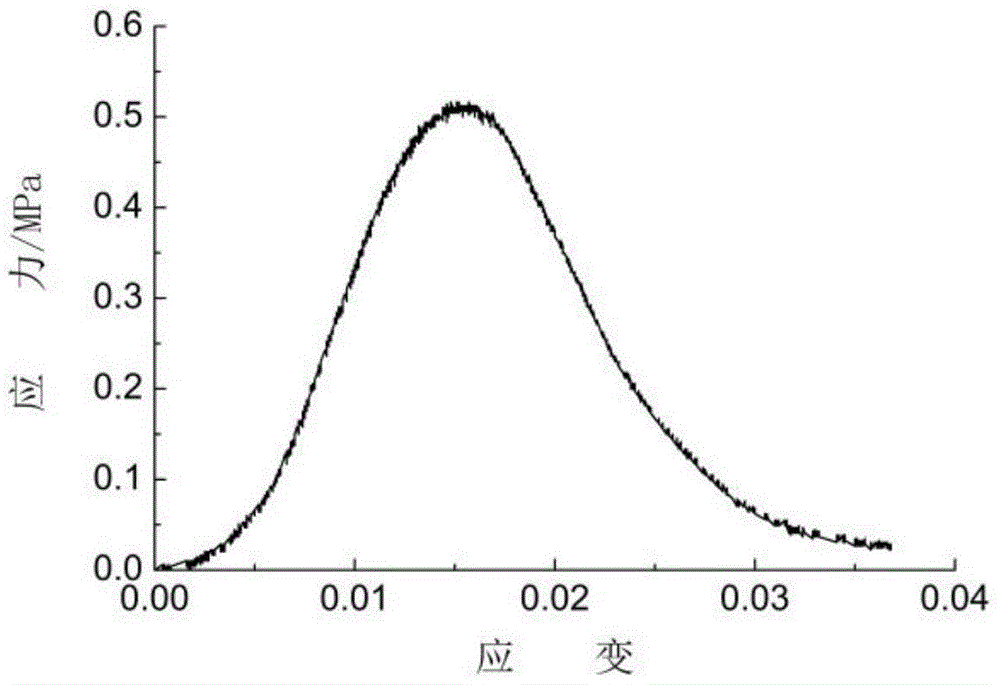

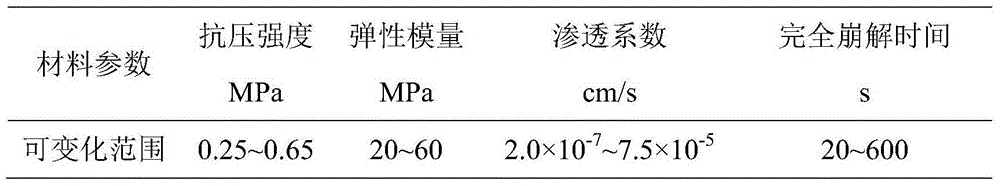

Similar material for fault mud burst model test and preparing method thereof

ActiveCN104891928AExperimental research results are accurateSolve the difficult problem of simulating similar materials of water-weakened disintegrating faultsCeramic shaping apparatusParaffin waxSodium Bentonite

The invention relates to a similar material for a fault mud burst model test and a preparing method thereof; the similar material comprises the components by weight: 1 part of a talcum powder, 2-7 parts of sand, 0.8-1.6 parts of gypsum, 0.2-0.6 part of bentonite, 0.01-0.4 part of liquid paraffin, and 0.2-0.7 part of mixing water. The preparing method comprises the steps: according to the proportion, weighing the talcum powder, sand, gypsum, bentonite and liquid paraffin; mixing evenly the talcum powder, sand, gypsum and bentonite in a stirrer; adding the mixing water, and fully stirring; adding the liquid paraffin and stirring; putting the mixed material into a molding die, and carrying out compaction molding; placing the molded material in a ventilated dry place for 24-36 h, and thus obtaining the similar material for the fault mud burst model test. The similar material can be slowly weakened and disintegrated under a water action, the disintegration performance can be changed through changing the composition, and a possibility is provided for fault mud burst in a process of real simulation of tunnel excavation.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com