Patents

Literature

109results about How to "Play a plasticizing role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

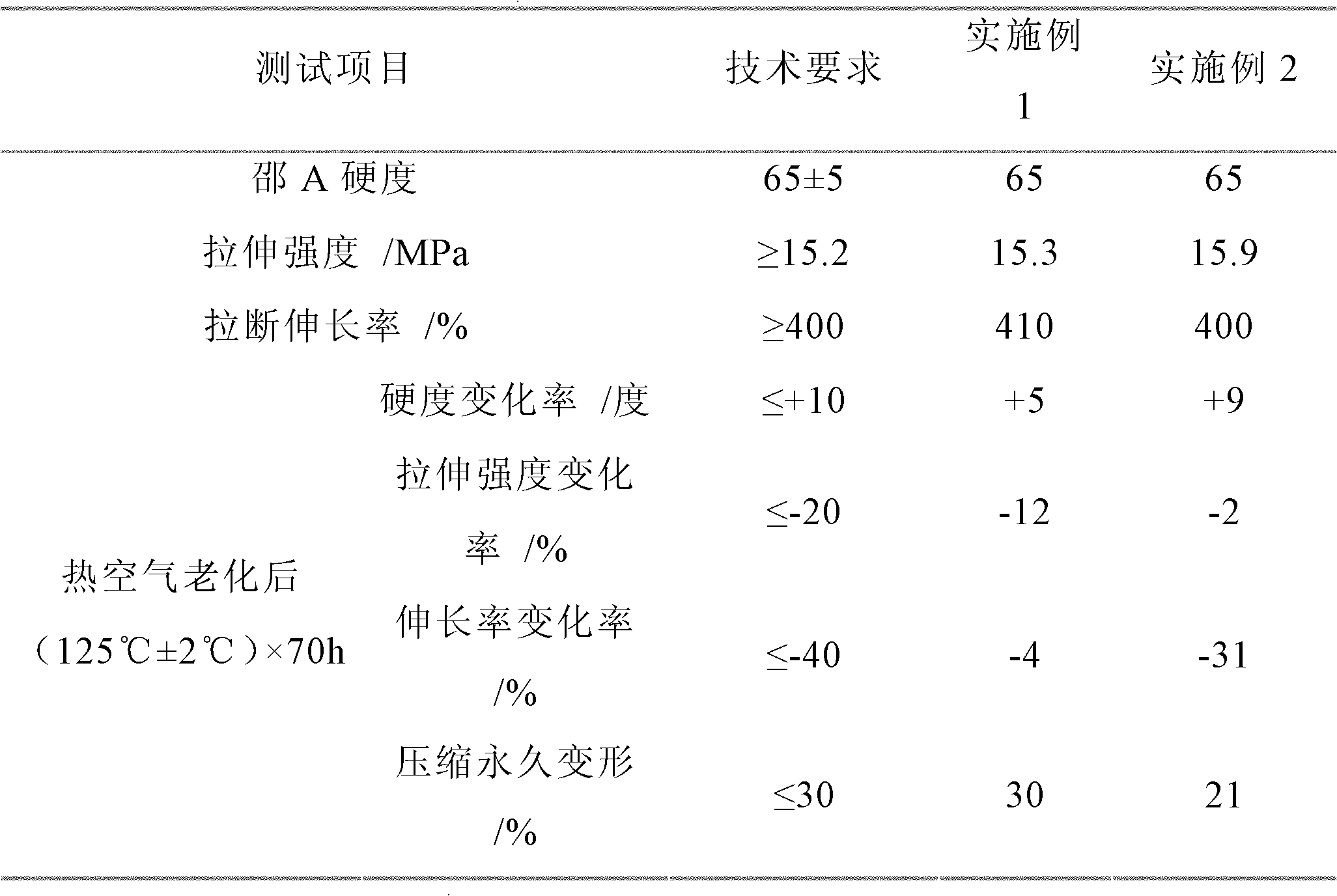

Ethylene propylene diene rubber composition and preparation method

The invention discloses an ethylene propylene diene rubber composition and a preparation method. The preparation method comprises the following steps of: firstly, performing after plastication on ethylene propylene diene rubber; then, adding zinc oxide, stearic acid, anti-aging agent, carbon black, plasticizers, accelerant, vulcanizer and the like in sequence; evenly mixing and then extruding a sheet; and preparing the sheet into the ethylene propylene diene rubber / carbon black nanometer composite material by adopting the after vulcanization process. Through adding various plasticizers and adopting special process treatment, the tensile strength of the ethylene propylene diene rubber composition disclosed by the invention is at least 15.2MPa, the elongation at break is at least 400 percent, and the compression set is lower than 30 percent under the condition of 125 DEG C*70h. The composite material can be used as a sealing article of rubber, especially a rubber sealing washer applied to a groove-type pipeline joint part of an automatic water spray fire extinguishing system, and thereby, a long-term sealing effect is ensured.

Owner:BEIJING RES & DESIGN INST OF RUBBER IND

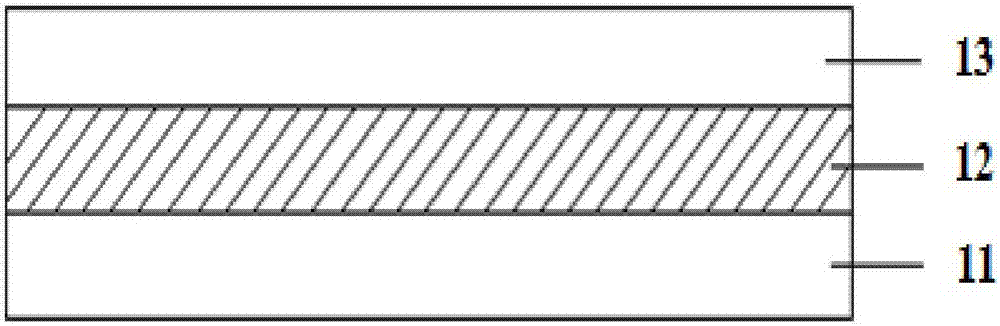

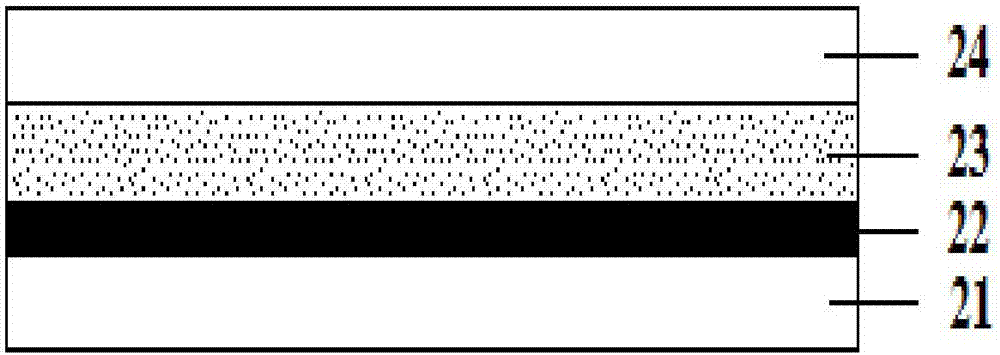

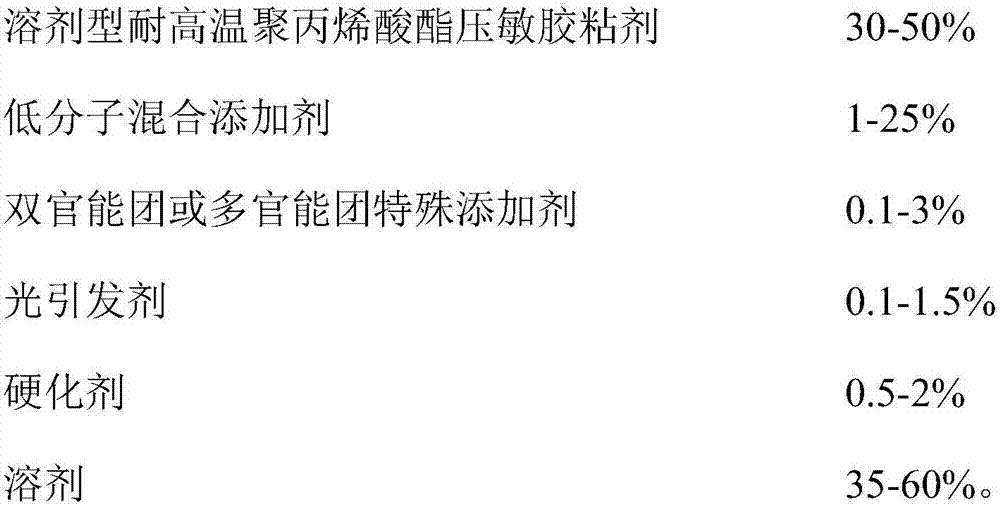

Heat-resistant UV viscosity breaking film and preparation method thereof

ActiveCN106995665AImprove peel forceImprove adhesionMacromolecular adhesive additivesOrganic non-macromolecular adhesiveTemperature resistancePressure sensitive

The invention provides a heat-resistant UV viscosity breaking film. The heat-resistant UV viscosity breaking film comprises a substrate layer, a UV photosensitive adhesive layer and a release film layer sequentially. The invention further provides a preparation method of the UV photosensitive adhesive layer. The UV photosensitive adhesive layer comprises the ingredients in percentage by weight: 30% to 50% of solvent type high-temperature resistant polyacrylate pressure-sensitive adhesive, 1% to 25% of micromolecular mixed additives, 0.1% to 3% of difunctional or polyfunctional special additive, 0.1% to 1.5% of photoinitiator, 0.5% to 2% of curing agent and 35% to 60% of solvent. The invention further provides a preparation method of the heat-resistant UV viscosity breaking film. According to the heat-resistant UV viscosity breaking film and the preparation method thereof, the sealing performance and high-temperature resistance of a UV photosensitive adhesive to corona PET substrates are improved, base coat treatment technologies are reduced, and the product structure is optimized.

Owner:新纶电子材料(常州)有限公司

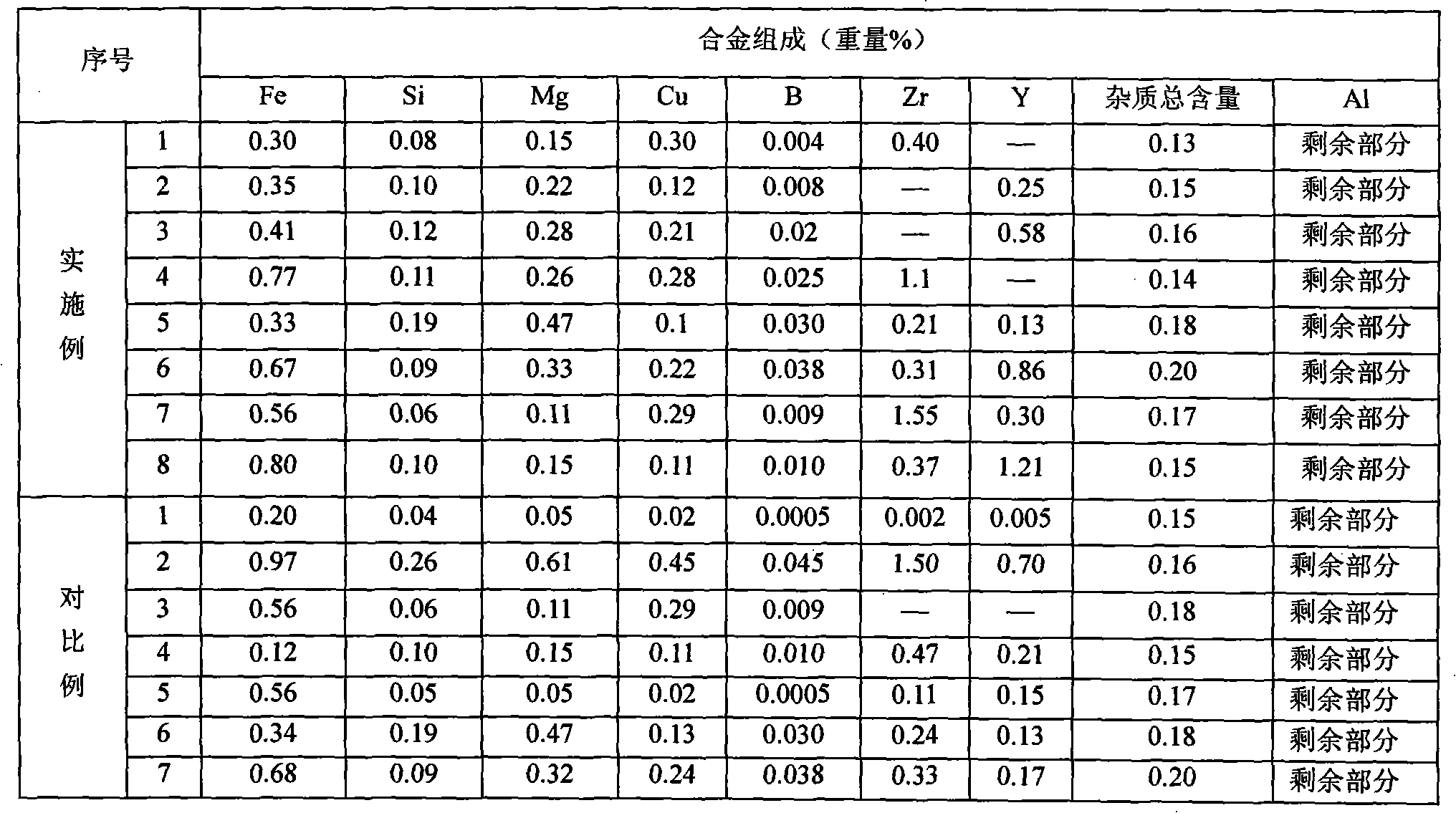

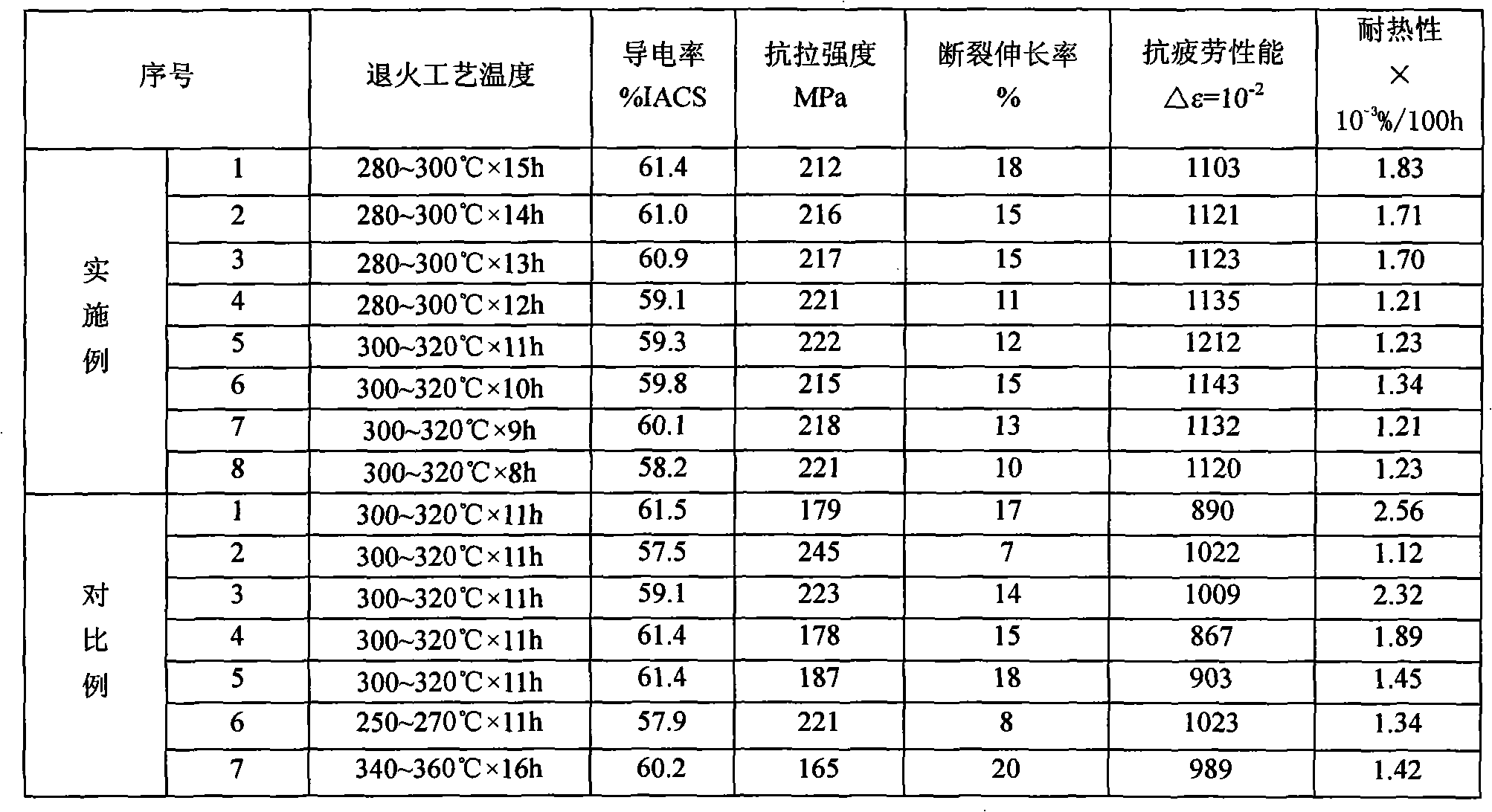

Aluminium alloy conductor for automotive wires and manufacturing method thereof

ActiveCN101923908AHigh tensile strengthImprove corrosion resistanceInsulated cablesMetal/alloy conductorsYttriumMagnesium

The invention discloses an aluminium alloy conductor for automotive wires, which has the advantages of high heat resistance, conductivity, tensile strength, extensibility and fatigue resistance, and a manufacturing method thereof. The alloy contains 0.3 to 0.8 weight percent of iron, 0.05 to 0.20 percent of silicon, 0.1 to 0.5 weight percent of magnesium, 0.1 to 0.3 weight percent of copper, 0.001 to 0.04 weight percent of boron, 0.001 to 0.04 weight percent of zirconium, 0.001 to 0.04 weight percent of yttrium, and the balance of aluminium and inevitable impurities, wherein one or two elements, except the aluminium and the inevitable impurities, account for 0.1 to 2.0 weight percent. The manufacturing method comprises the following steps of: adding the iron, silicon, magnesium, copper, boron, zirconium, yttrium and aluminium into a smelting furnace; smelting, and casting and rolling; performing intermediate annealing treatment; drawing into aluminium alloy filaments with the diameterof 0.5mm; and stranding into wire cores, and performing annealing treatment. The conductor prepared by the method has the tensile strength of 210MPa and above, the elongation at break of over 10 percent, the conductivity of over 58 percent, and excellent heat resistance and flexibility.

Owner:安徽中青欣意铝合金电缆有限公司

Reactive monomer modified nano calcium carbonate/polypropylene master batch and its preparing method

The present invention relates to a reactive monomer modified nano calcium carbonate / polypropylene mother material and its production method. Said mother material is formed from polypropylene base body, nano calcium carbonate filling material, reactive monomer (including maleic anhydride, acrylic acid and its esters and styrene) and universal stabilizing agent D of PP material. Its preparation method includes the steps of uniformly mixing by using high-speed mixing machine and extruding by means of twin screw extruder machine. Said invention can raise the mechanical property of nano calcium carbonate filled polypropylene material.

Owner:SUN YAT SEN UNIV

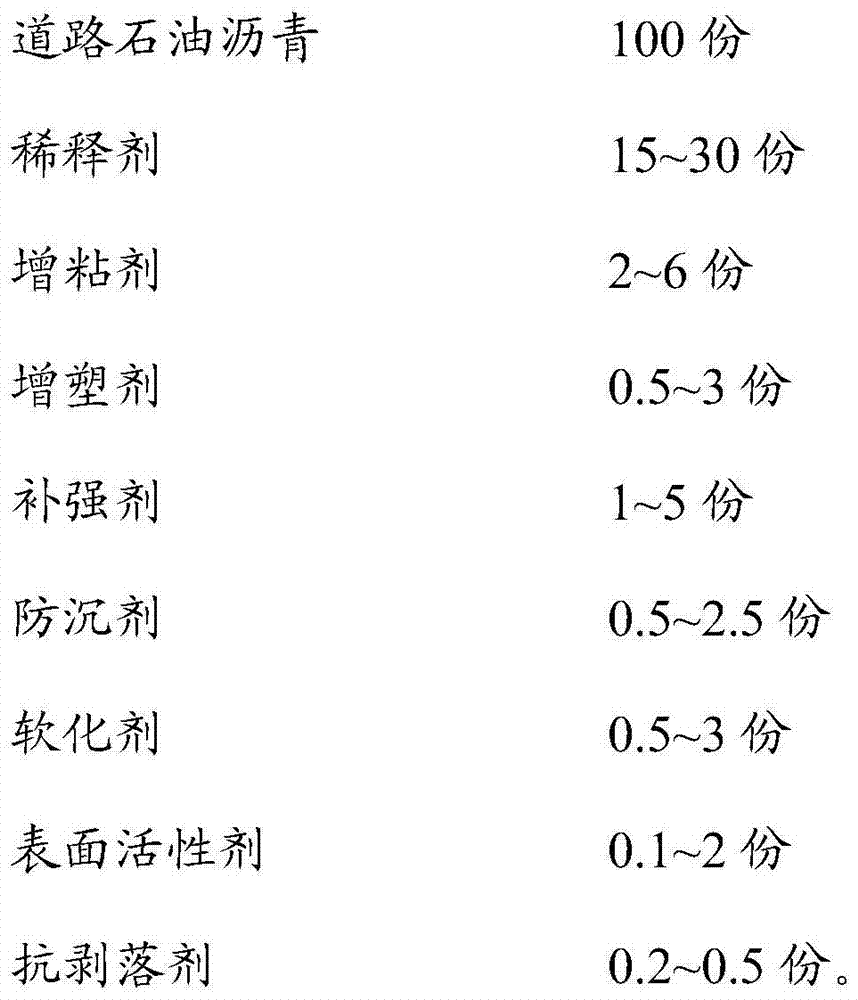

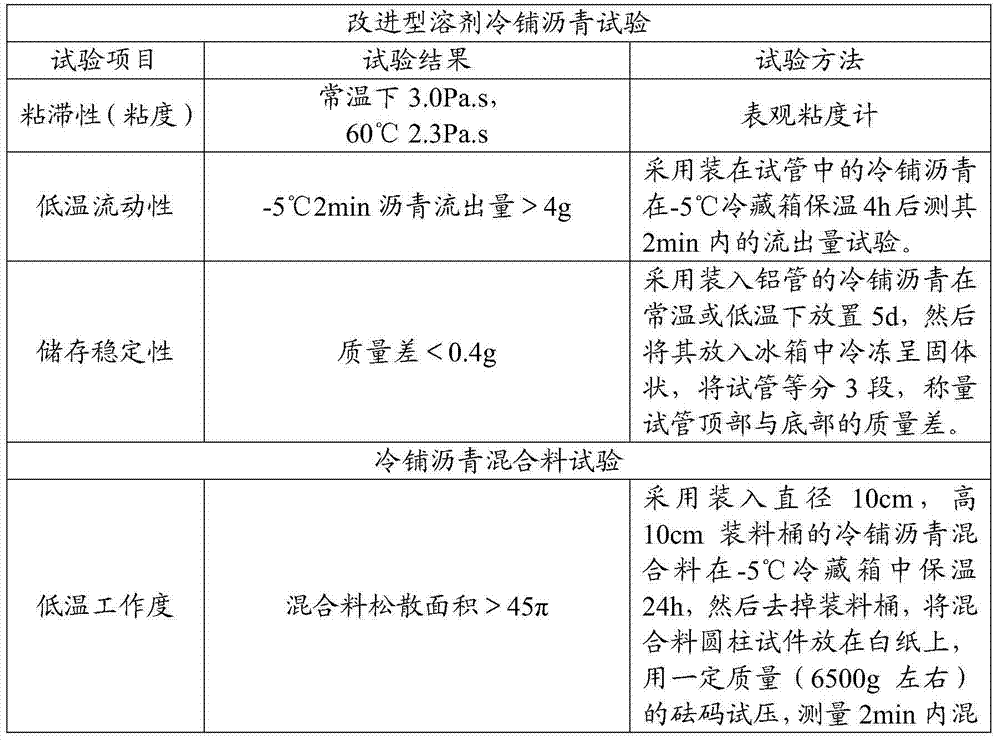

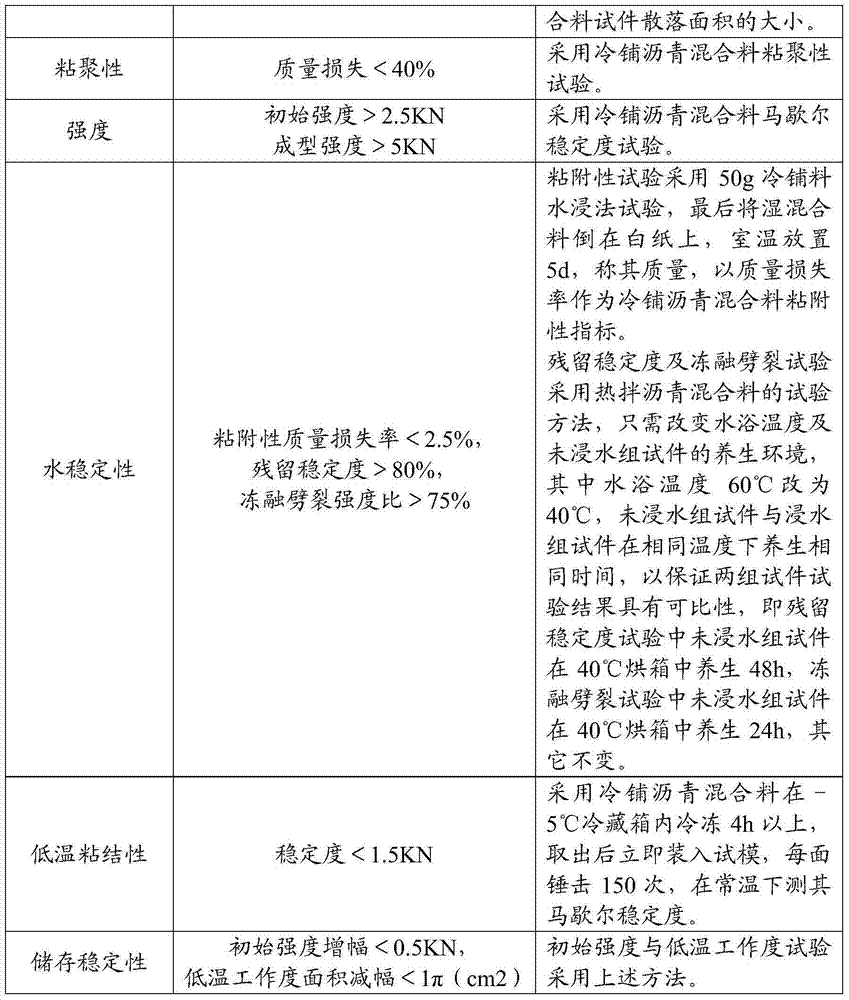

Improved solvent cold laid asphalt as well as preparation process and using method thereof

InactiveCN103923475AImprove adhesionImprove liquidityIn situ pavingsBuilding insulationsLiquid stateEngineering

The invention discloses an improved solvent cold laid asphalt as well as a preparation process and using method thereof. The improved solvent cold laid asphalt is at a liquid state under normal temperature or low temperature; cold oil and cold materials can be directly blended for construction on the spot without heating, and the construction can be carried out at high / low temperature seasons and rain / snow weather, and a large number of machinery and labor are not required in the construction process, the construction is simple and convenient and the repair effect is good; traffic can be immediately opened after repair without affecting the travel of people; the improved solvent cold laid asphalt is usually used for daily maintenance, such as pot slot repair and emergency repair; meanwhile, the improved solvent cold laid asphalt has the advantages of no deterioration, no layering and the like after being stored for a long time.

Owner:CHANGAN UNIV

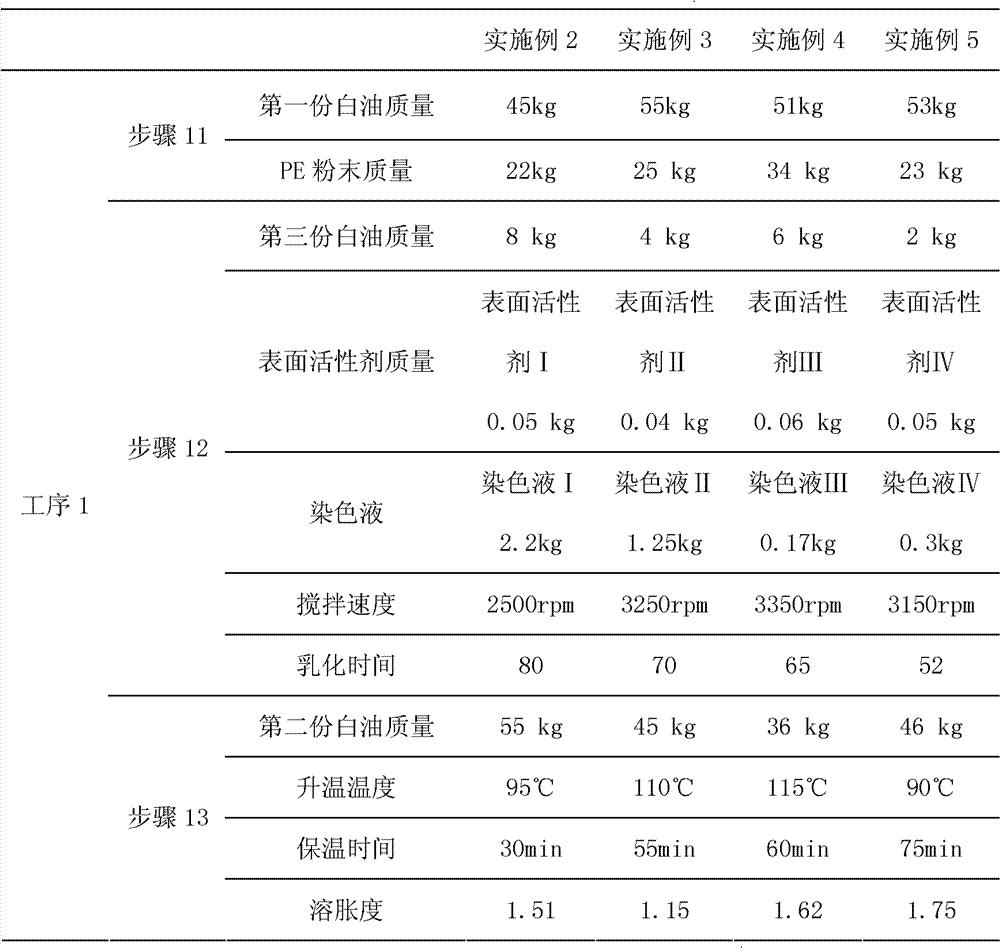

Spinning swelling solution used for preparation of ultra-high molecular weight colored polyethylene fiber and spinning stock solution

ActiveCN102776596AImprove mechanical propertiesEvenly dispersedMonocomponent polyolefin artificial filamentPigment addition to spinning solutionFiberStaining

The invention discloses a spinning swelling solution used for preparation of an ultra-high molecular weight colored polyethylene fiber. The spinning swelling solution comprises, by weight: 10-50% of ultra-high molecular weight polyethylene; a staining solution accounting for 0.01-10% of the weight of the ultra-high molecular weight polyethylene; and spinning solvents. In the invention, first, the staining solution is prepared into a swelling solution, in which the staining solution can be uniformly dispersed. Preparation of the staining solution into a spinning stock solution can be beneficial to uniform dispersion of the staining solution in the spinning stock solution. When using the spinning stock solution for gel spinning, after the spinning stock solution undergoes melting, dispersion, uniform mixing and unwrapping in a twin-screw extruder, the pigment particles in the staining solution can induce crystallization as a nucleating agent and form microcrystals. Extrusion molding of a crystal nucleus-containing spinning melt is in favor of obtaining nascent filaments characterized by low crystallinity and uniform crystal nucleus distribution. Thus, mechanical properties of the ultra-high molecular weight polyethylene fiber can be improved finally.

Owner:BEIJING TONGYIZHONG NEW MATERIAL TECH CORP

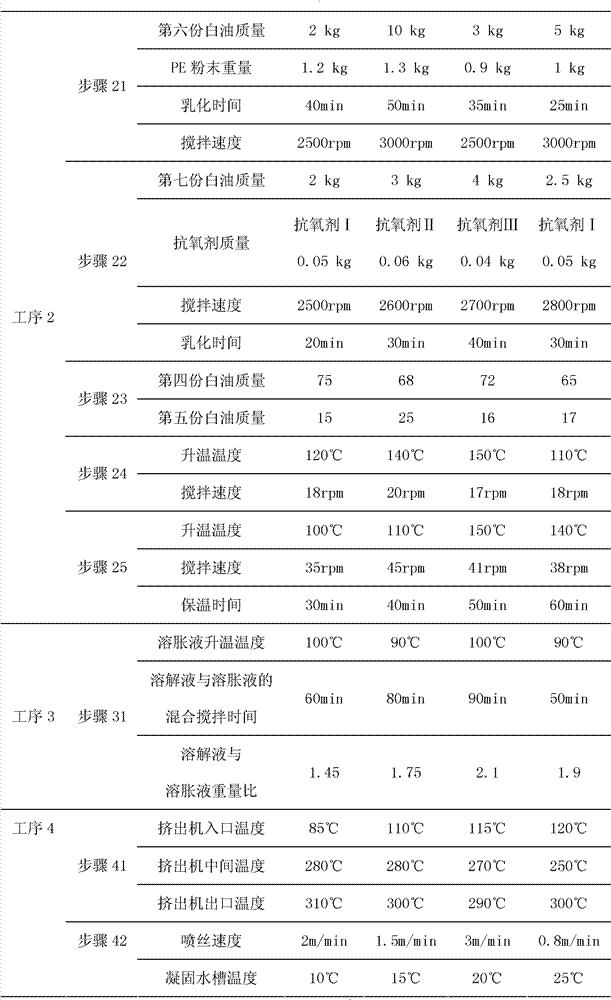

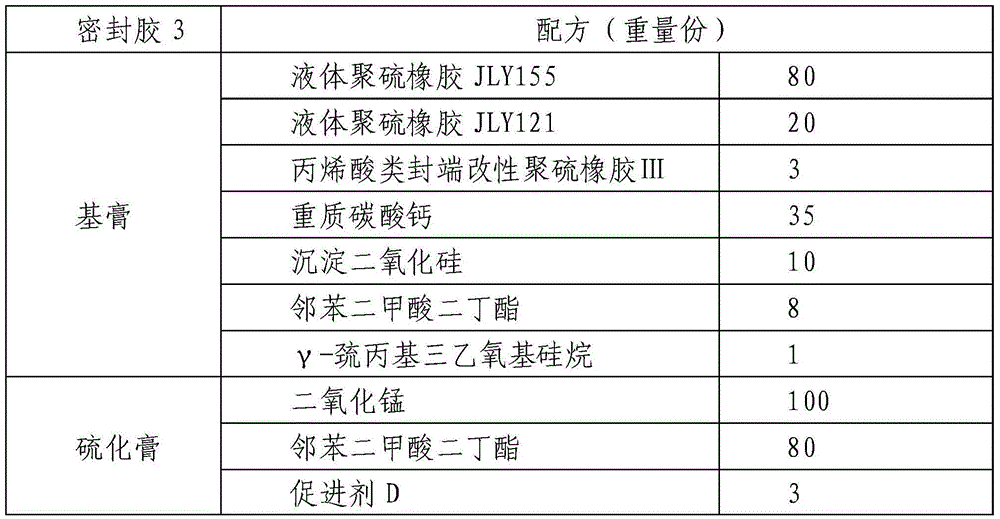

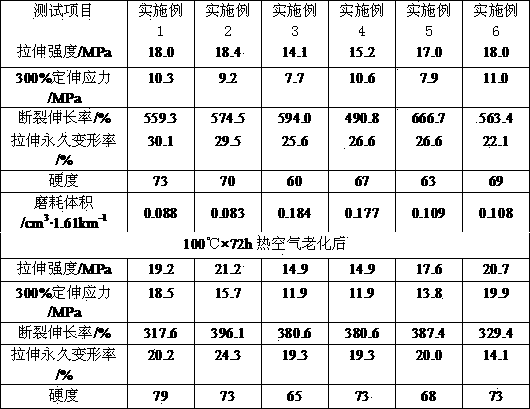

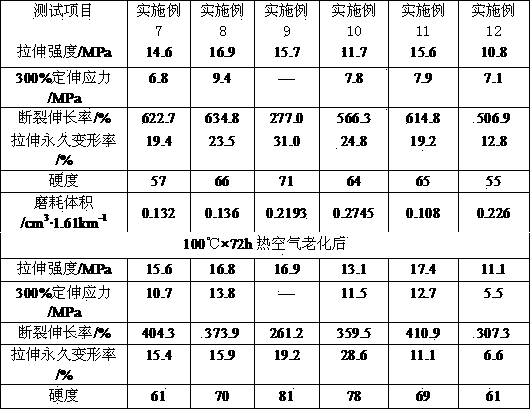

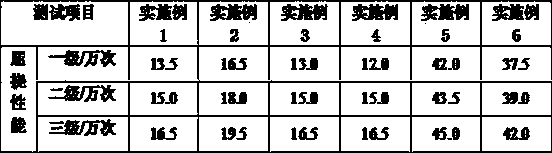

High peeling strength polysulfide sealant and sealing method

ActiveCN103555264AGood adhesionAdhesion does not increaseNon-macromolecular adhesive additivesOther chemical processesPolysulfide rubberPolymer science

The invention belongs to the technical field of polymer sealants, and relates to a high peeling strength polysulfide sealant and a method for sealing by using the sealant. The sealant is composed of a component A-based paste and a component B sulfur paste, wherein the component A is composed of a filler, a plasticizer, a crylic acid-terminated modified polysulfide rubber, a coupling agent and a liquid polysulfide rubber; and the component B is composed of manganese dioxide, dibutyl phthalate and an accelerator D. The invention provides the high peeling strength polysulfide sealant and a sealing method thereof. The adhesive property of the sealant is increased without increasing the viscosity of the sealant.

Owner:BAIMTEC MATERIAL CO LTD

NBR/PVC elastomer by taking LNBR as plasticizer and preparation method of elastomer

The invention discloses an NBR / PVC elastomer by taking LNBR as a plasticizer and a preparation method of the elastomer and relates to a rubber blended elastic material and a preparation method thereof. The elastomer consists of the following components in parts by mass: 70 parts of butadiene-acrylonitrile rubber, 30 parts of polyvinyl chloride (PVC), 10-50 parts of reinforcing agent, 10-30 parts of plasticizer, 2.5-3.5 parts of anti-aging agent, 1.0-2.0 parts of vulcanizing agent, 5.0-7.0 parts of vulcanizing activator, 1.0-2.0 parts of vulcanization accelerator and 1.5-2.0 parts of stabilizer. According to the preparation method of the elastomer, the used vulcanizing temperature is 165 DEG C, so that the elastomer has excellent performances such as hot air aging resistance, wear resistance, fatigue resistance and solvent extraction resistance. The elastomer can be widely applied to the industries such as printing rubber rolls, fuel oil rubber tubes and accumulator capsules.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

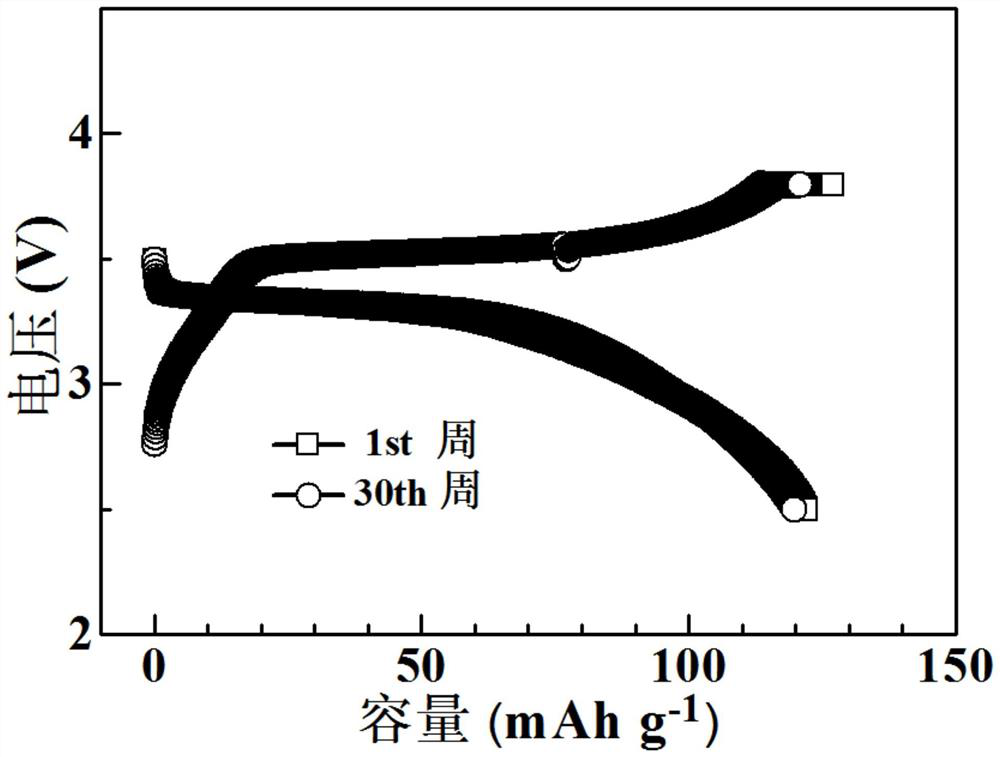

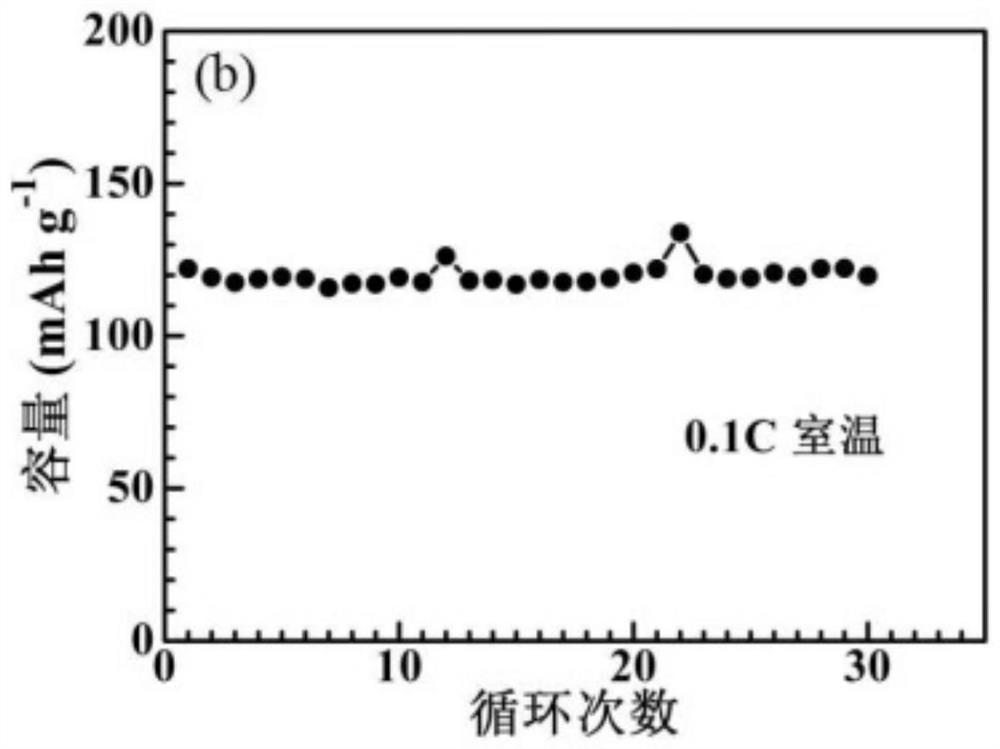

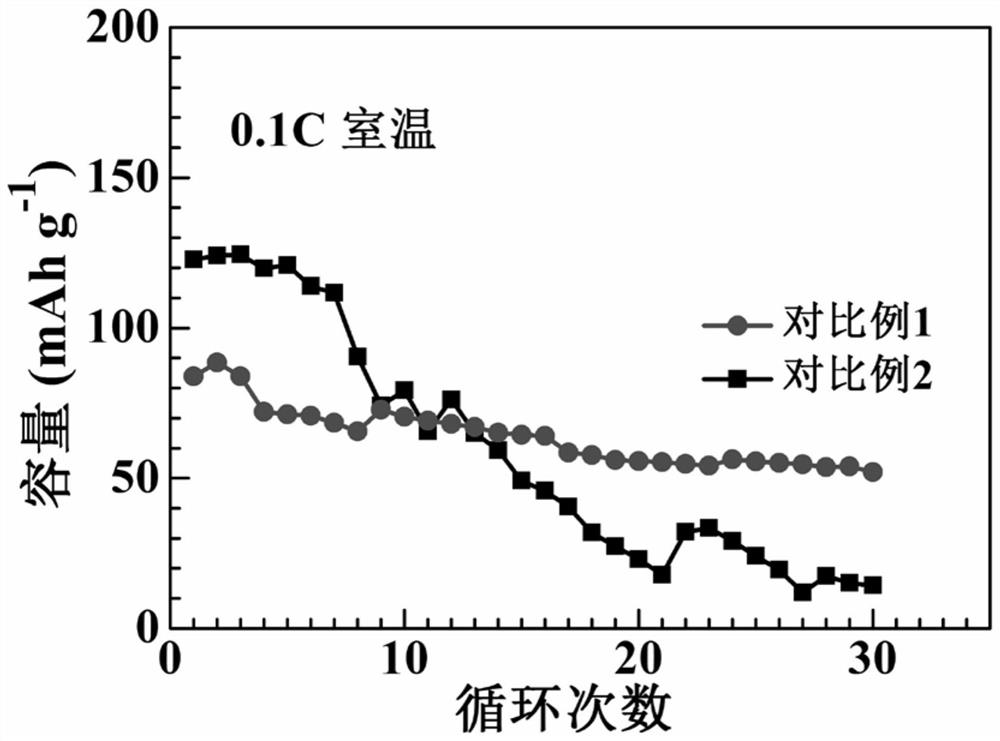

Composite solid electrolyte prepared based on in-situ thermal polymerization method and preparation method and application thereof

InactiveCN112018430AIncreased degree of amorphousnessMove quicklyFinal product manufactureElectrolyte accumulators manufactureVinylene carbonateIn situ polymerization

The invention discloses a composite solid electrolyte, an in-situ preparation method thereof and an application of the composite solid electrolyte in a solid lithium ion battery. The composite electrolyte is composed of an inorganic solid electrolyte, polyvinyl carbonate, a lithium salt, a small molecular organic solvent and an initiator. Vinylene carbonate is subjected to in-situ polymerization through temperature adjustment, and an electrolyte is fully infiltrated with positive and negative electrode materials, so that the interface compatibility of the electrolyte and an electrode is improved, and the interface impedance is reduced; the inorganic solid electrolyte and the small molecular organic solvent are added as plasticizers, so that the ionic conductivity of the electrolyte can beimproved, an additional lithium conduction channel is provided, and the performance of the solid lithium ion battery is improved.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +1

Acrylic acid grafted polypropylene modified aluminium hydroxide/polypropylene flameretardant material and preparing process thereof

A modified flame-retarding aluminium hydroxide / polypropylene material is prepared from polypropylene as basic material, aluminium hydroxide as flame-retarding agent, acrylic acid grafted polypropylene as modifier and universal stabilizer for PP materials through high-speed mixing and extrudnig out in dual-screw extruder. Its advantages are high fusion index, flame retarding performance and bend strength, and improved flowability.

Owner:SUN YAT SEN UNIV

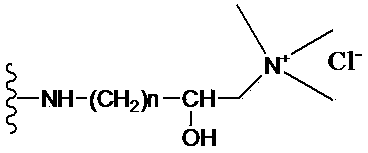

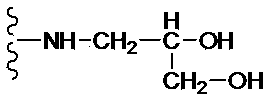

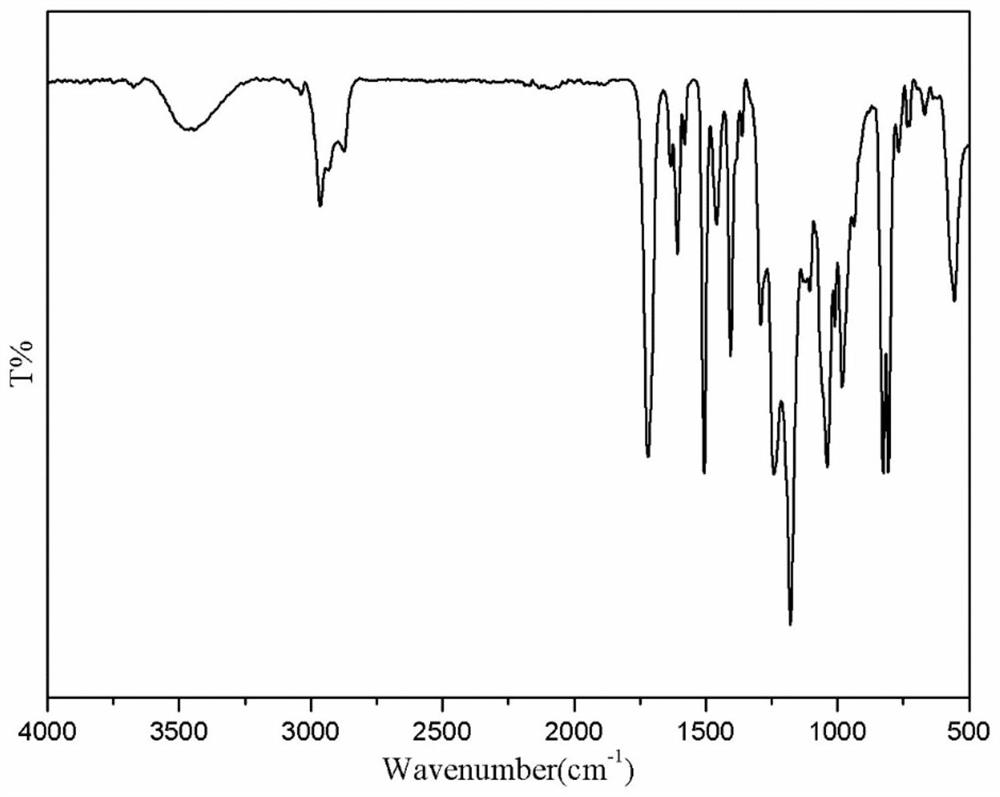

Polysiloxane, glycidol and quaternary ammonium salt-containing multifunctional gelatin leather finishing agent and preparation method

ActiveCN103436167AImprove anti-corrosion and anti-bacterial abilitySpecific performanceAntifouling/underwater paintsFibre treatmentActive agentPolytetrafluoroethylene

The invention relates to a polysiloxane, glycidol and quaternary ammonium salt-containing multifunctional gelatin leather finishing agent and a preparation method. The preparation method comprises the following steps: dissolving gelatin in water to prepare aqueous solution with mass concentration of 2-20 percent; adding epoxy quaternary ammonium salt into a first reaction flask under the conditions of temperature of 40-70 DEG C and pH of 6-12 to obtain solution 1; adding glycidol into a second reaction flask to obtain solution 2; adding a surfactant into a third reaction flask, and meanwhile adding Si-O-Si repetitive unit-containing epoxypolysiloxane in batches or continuously to obtain solution 3; mixing the solution 1, the solution 2 and the solution 3 in different proportions, weighing 15-20 g of the mixed solution to be placed in a mold of polytetrafluoroethylene, adding 5-10 mL of one or three or four of ethanol, tetrahydrofuran, acetone and methanol and drying in a normal pressure drying oven at the temperature of 40-80 DEG C to obtain the multifunctional gelatin leather finishing agent. The finishing agent has the characteristics of strong hydrophobicity, flexible film, antibacterial property, high heat stability, organic solvent resistance, wet scrubbing resistance and the like.

Owner:山东山科美谷科技发展有限公司

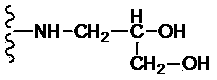

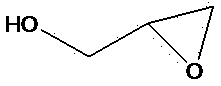

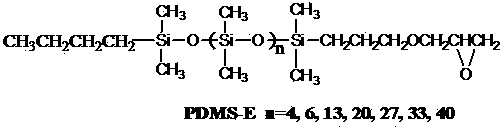

Polysiloxane and glycidol-containing strong-hydrophobicity gelatin leather finishing agent and preparation method

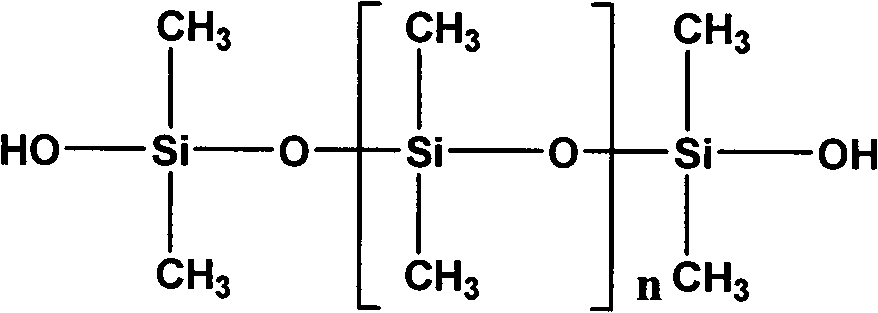

ActiveCN103436168APlay a plasticizing roleImprove performanceFibre treatmentProtein coatingsActive agentPolytetrafluoroethylene

The invention relates to a polysiloxane and glycidol-containing strong-hydrophobicity gelatin leather finishing agent and a preparation method. The preparation method comprises the following steps: dissolving gelatin in water to prepare aqueous solution with mass concentration of 2-20 percent; adding glycidol into a first reaction flask under the conditions of temperature of 40-70 DEG C and pH of 6-12 to obtain solution 1; adding a surfactant into a second reaction flask, continuously stirring, and meanwhile adding Si-O-Si repetitive unit-containing epoxypolysiloxane in batches or continuously to obtain solution 2, wherein the using amount of the surfactant is 0.5-20 percent of the mass of the gelatin; mixing the solution 1 and the solution 2 in different proportions, weighing 15-20 g of the mixed solution to be placed in a mold of polytetrafluoroethylene, adding 5-10 mL of one or two or three of ethanol, tetrahydrofuran and methanol and drying in a normal pressure drying oven at the temperature of 40-80 DEG C to obtain the gelatin leather finishing agent with a superior function. The finishing agent has the characteristics of strong hydrophobicity, super extensibility, heat resistance, oxidation resistance, wet scrubbing resistance and the like.

Owner:QILU UNIV OF TECH

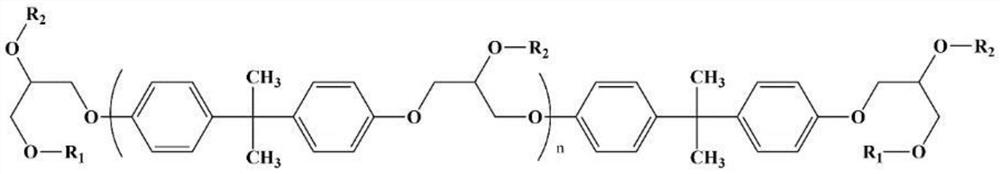

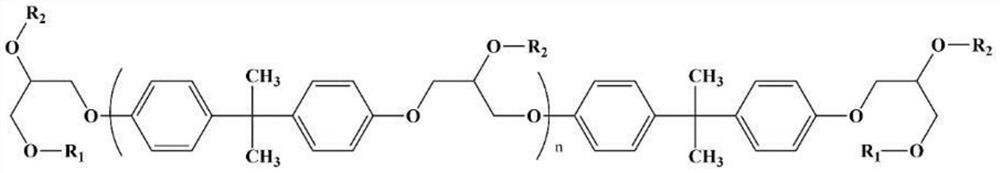

Reinforcing yarn size for glass fibers and preparation method thereof

The invention relates to a reinforcing yarn size for glass fibers and a preparation method thereof, and belongs to the technical field of sizes for glass fibers. The size comprises 4.0-5.5% of a filmogen emulsion, 1.7-4% of a lubricating agent, 0.5-1.5% of a water soluble epoxy resin binder, 0.2-1.0% of an inorganic antistatic agent, 0.5-1.5% of an aminosilane coupling agent and the balance softened water. The filmogen emulsion comprises polyethylene glycol-4000 (PEG-4000), boron trifluoride diethyl etherate, epoxy resin E-44, epoxy resin E-20 and water with a ratio of (1-2): (0.005-0.01): (1-1.5): (0.8-1.2): (8-10). Glass fibers drawn through the size can bear repeatedly bending deformation and have a good textile performance, and woven glass fiber cloth can be applied to production of composite materials without heat treatment and is quick in soakage and high in binding force when compounded with matrix resin.

Owner:SICHUAN FIBERGLASS GRP

Vegetable oil acid modified epoxy acrylate light-cured resin and preparation method thereof

InactiveCN111777742ALow viscosityImprove brittlenessEpoxy resin coatingsPolymer scienceGlycidyl methacrylate

The invention discloses a vegetable oil acid modified epoxy acrylate light-cured resin and a preparation method thereof. Vegetable oil fatty acids containing unsaturated double bonds are used for a ring-opening reaction of glycidyl ether type epoxy resin to prepare epoxy oleoresin, and meanwhile hydroxyl is formed in the molecular structure. Generated hydroxyl reacts with maleic anhydride to prepare carboxyl-containing half ester, and carboxyl-containing half ester reacts with glycidyl methacrylate to prepare the vegetable oil acid modified epoxy acrylate resin with light-cured activity. The resin contains a long-chain grease structure, and has good wettability to a coated base material and added pigments and fillers. After the common bisphenol A epoxy resin and carboxyl are subjected to ring opening, the hydroxyl number in the molecular structure is generally greater than 2, so that the functionality of the prepared vegetable oil acid modified epoxy acrylate resin can be greater than2. Unsaturated fatty acid with a molecular structure can be catalytically oxidized, cured and cross-linked, so that a dual-curing cross-linked network can be formed, and the performance of the coatingis further improved.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

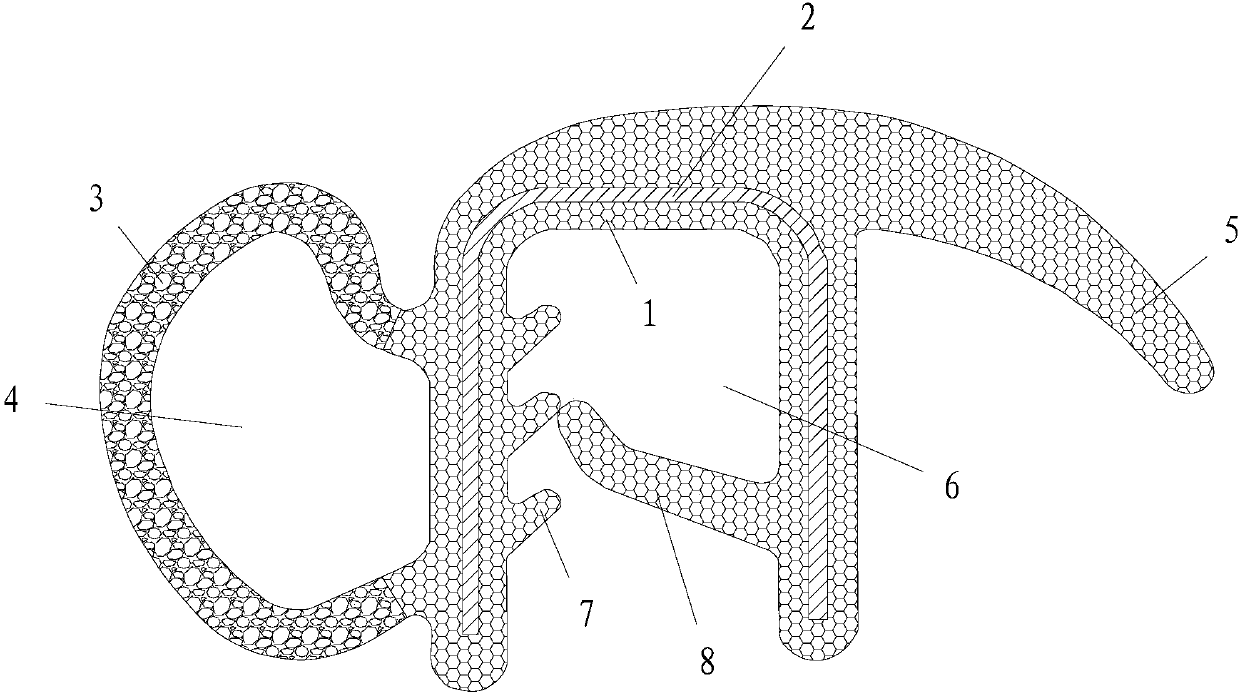

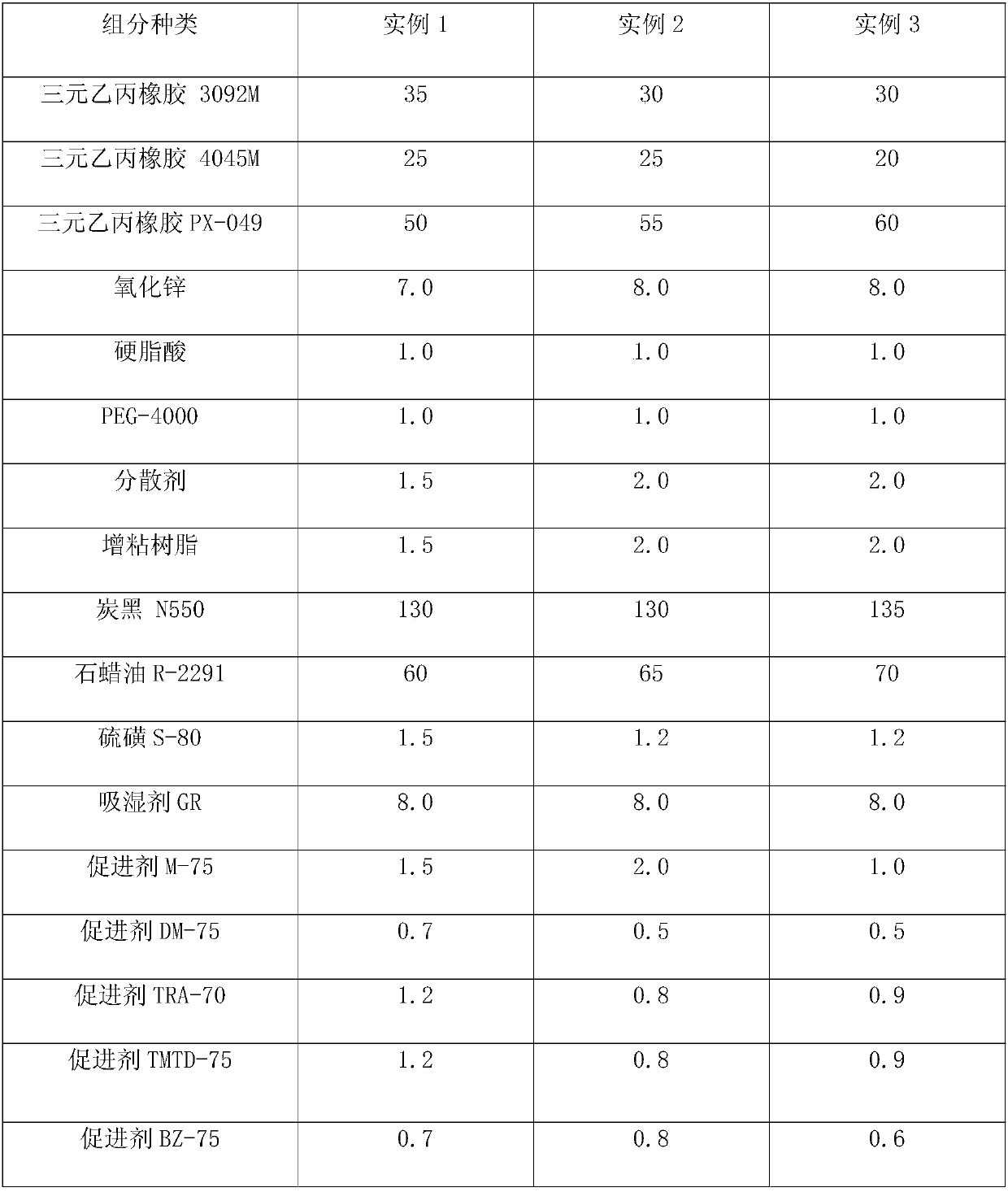

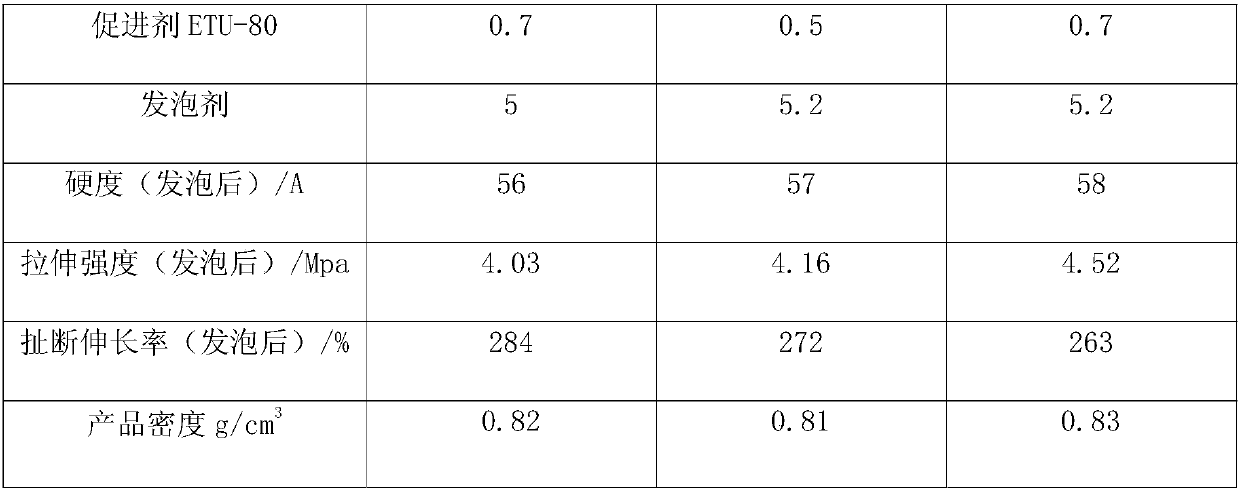

Sealing strip cladding sizing material and preparation method thereof as well as car door sealing strip and preparation method thereof

The invention provides a sealing strip cladding sizing material and a preparation method thereof as well as a car door sealing strip and a preparation method thereof. The sealing strip cladding sizingmaterial of the invention is prepared from the following components: EPDM (Ethylene-Propylene-Diene Monomer) 3092M, EPDM 4045M, EPDM PX-049, zinc oxide, stearic acid, PEG-4000, a dispersing agent, tackifying resin, paraffin oil R-2291, carbon black N550, sulfur S-80, a moisture absorbent GR, an accelerant M-75, an accelerant DM-75, an accelerant TRA-70, an accelerant TMTD-75, an accelerant BZ-75,an accelerant ETU-80, and a microsphere foaming agent EWE-60GE. The sealing strip cladding sizing material of the invention can implement the light-weight design of a sealing strip product, also hasrelatively good physical properties such as processability and surface quality, and can improve the quality of a sealing strip utilizing the sealing strip cladding sizing material.

Owner:NUOBO RUBBER PRODION

High temperature-resistant polyphenylene sulfide hollow fiber membrane and preparation method thereof

InactiveCN107224881AImprove breathabilityImprove filtration efficiencyMembranesSemi-permeable membranesOrganic solventHigh intensity

The invention discloses a high temperature-resistant polyphenylene sulfide hollow fiber membrane and a preparation method thereof. The preparation method comprises the following steps: step 1, preparing polyphenylene sulfide and a composite pore-forming agent with a mass part ratio being (50 to 90) : (10 to 50); step 2, mixing the ready materials until the materials are uniform; step 3, sending the uniformly mixed ready material in an extruder; and step 4, melting and blending the uniformly mixed ready material and supercritical carbon dioxide in the extruder, hollowly extruding a mixture after melting and blending, and carrying out drawing traction, cooling and forming on an extrusion to obtain the high temperature-resistant polyphenylene sulfide hollow fiber membrane. The preparation method has the advantages that the hollow fiber membrane obtained by preparation is large in flux and high in strength; the processing temperature of the polyphenylene sulfide with the temperature being 20-60 DEG C can be lowered, an organic solvent is not used in a preparation process, and the preparation method is low-cost, is easy for processing, and is environmentally friendly.

Owner:DYNABAT NEW ENERGY SCI & TECH CO CLD FUJIAN

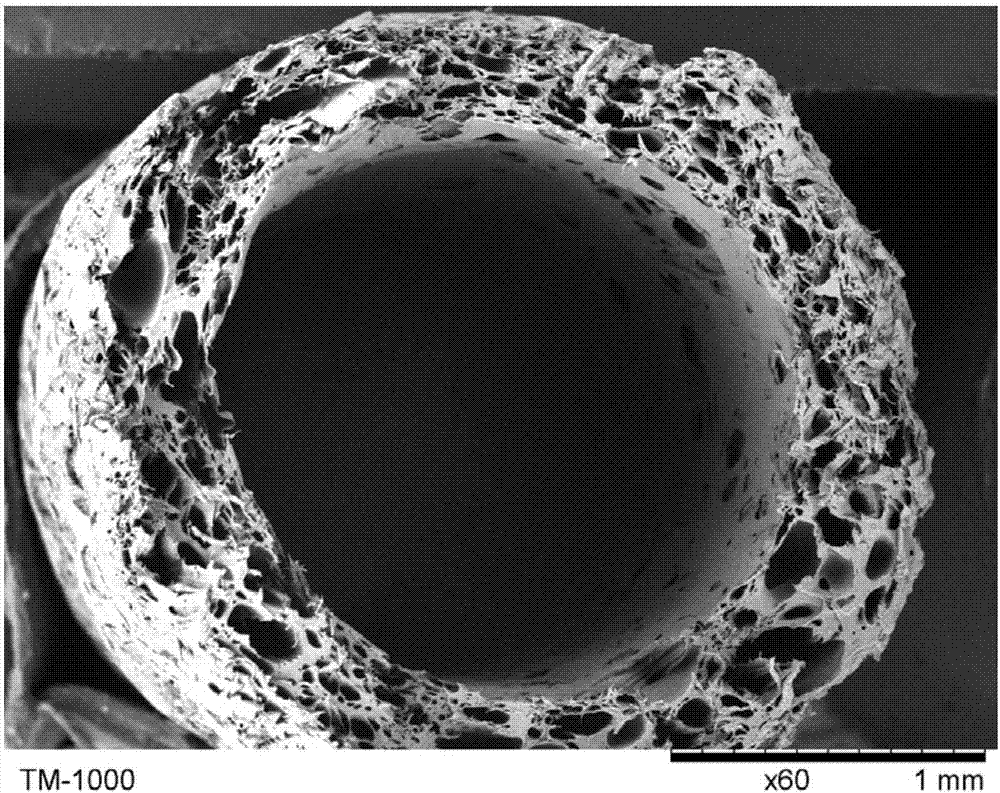

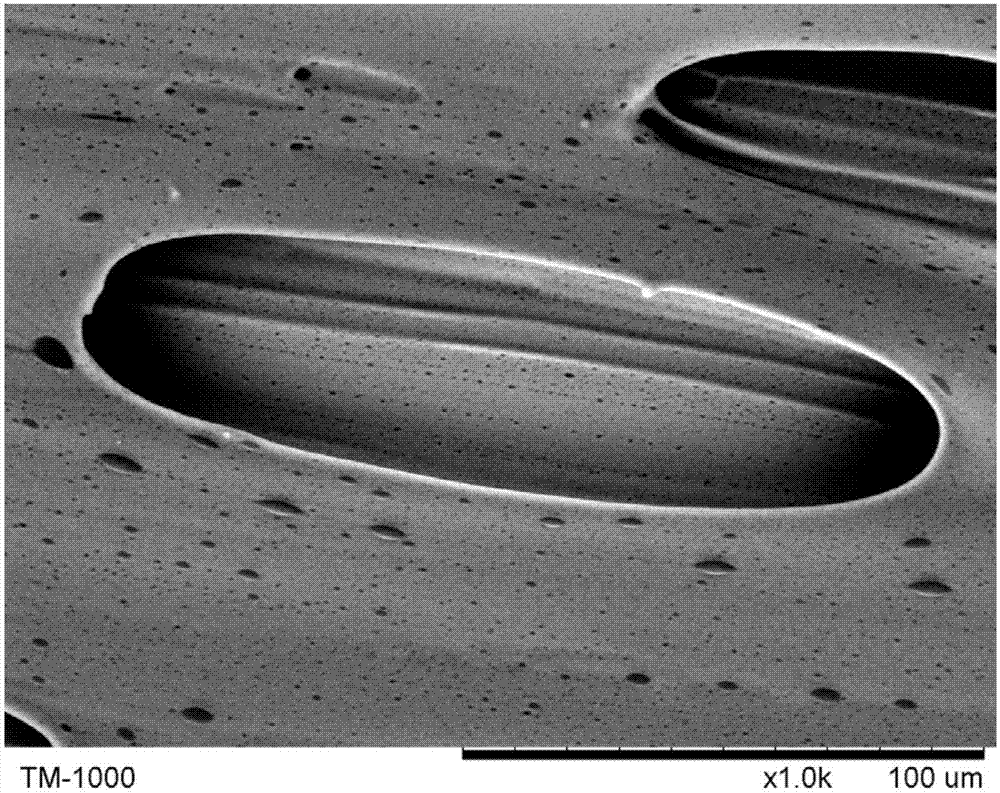

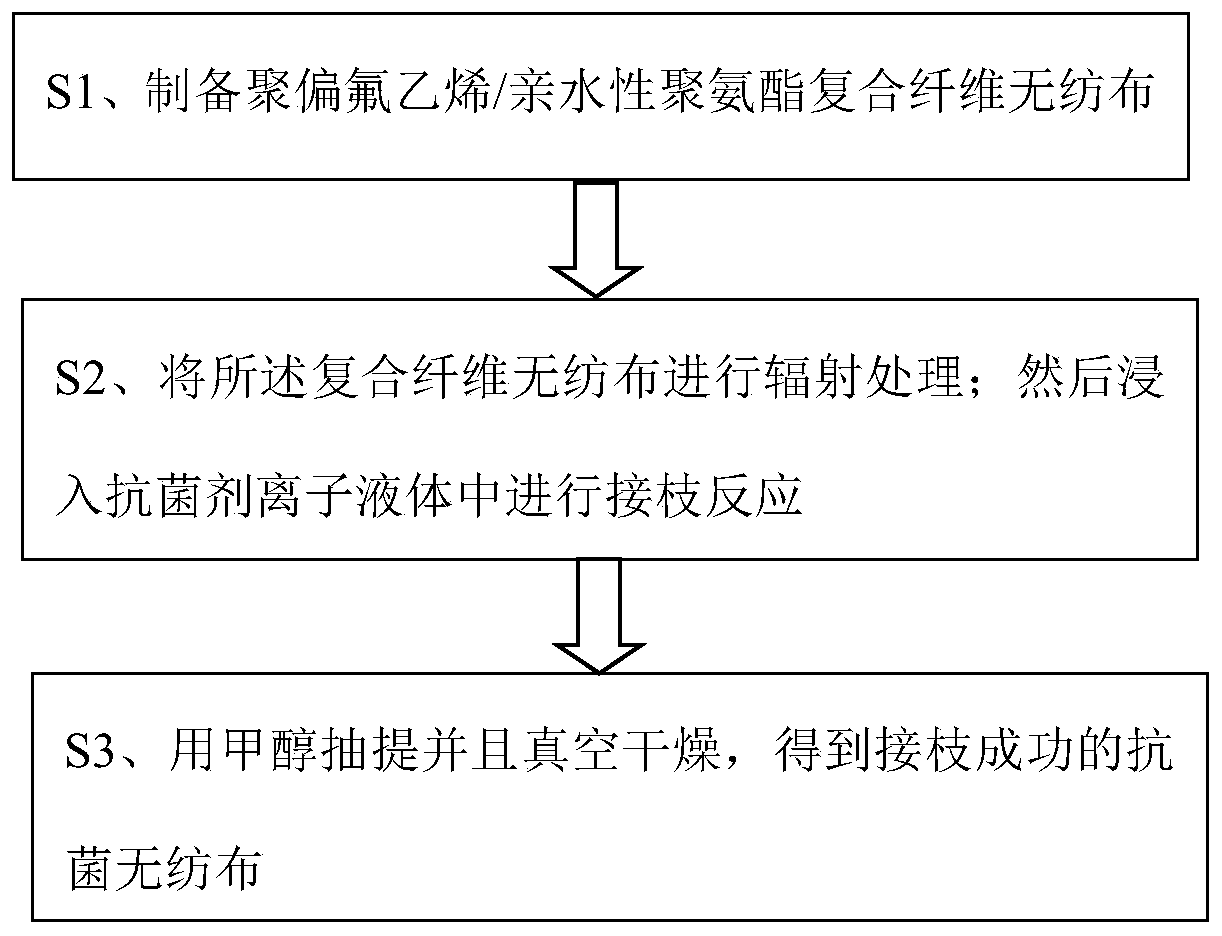

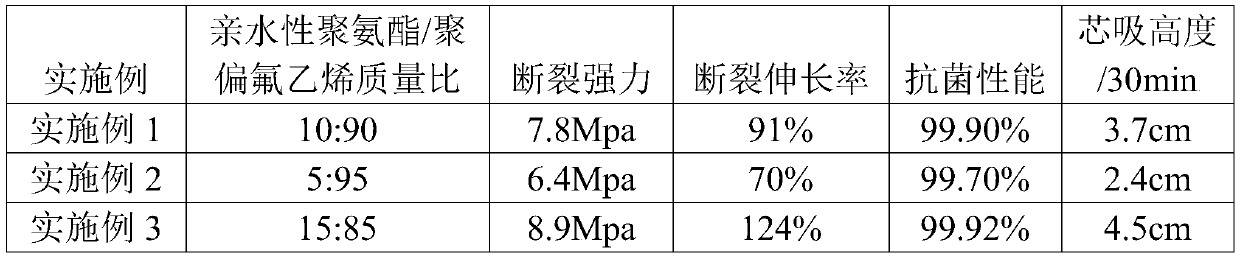

Antibacterial non-woven fabric and preparation method thereof

ActiveCN110938992AExcellent antibacterial properties and chemical stabilityGood broad-spectrum antibacterial propertiesPhysical treatmentBiochemical fibre treatmentPolyvinylidene fluorideWoven fabric

The invention provides an antibacterial non-woven fabric and a preparation method thereof. The preparation method comprises the following steps of firstly, preparing a polyvinylidene fluoride / hydrophilic polyurethane composite fiber non-woven fabric, and then performing electron beam radiation treatment on the composite fiber non-woven fabric; then immersing the composite fiber non-woven fabric into an antibacterial agent ionic liquid for grafting reaction; and finally, performing extracting with methanol and performing vacuum drying to obtain the successfully grafted antibacterial non-woven fabric. According to the preparation method, a polyvinylidene fluoride polymer is taken as a fiber main body, and hydrophilic polyurethane is introduced for composite spinning, so that the mechanical property and the hydrophilic property of the prepared antibacterial non-woven fabric are remarkably improved. By utilizing the grafting reaction of the polyvinylidene fluoride polymer and the antibacterial agent ionic liquid, the prepared antibacterial non-woven fabric is excellent in broad-spectrum antibacterial property, and the sterilizing rate of staphylococcus aureus reaches 99 percent or above.

Owner:金华市华尔汽车饰件有限公司

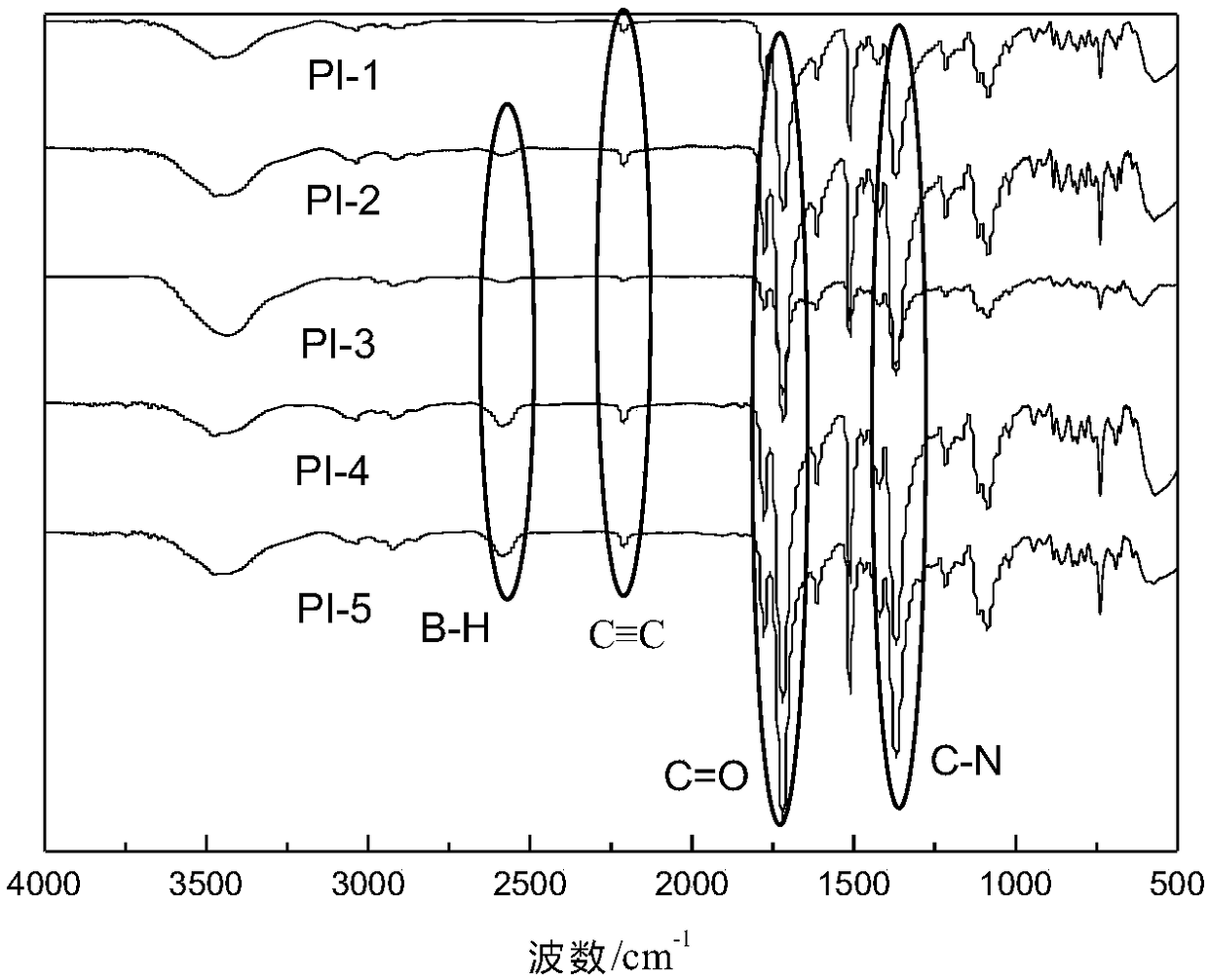

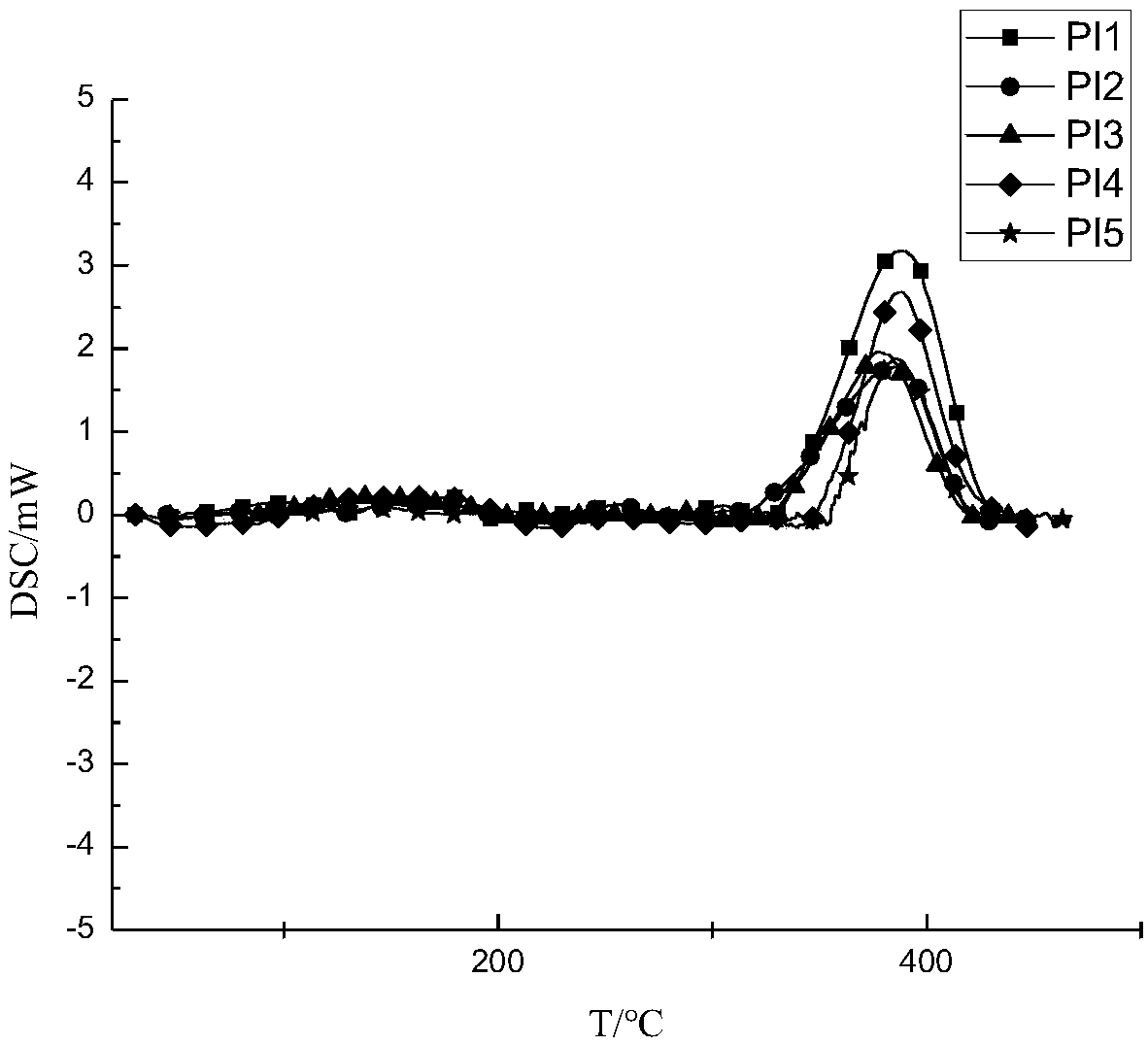

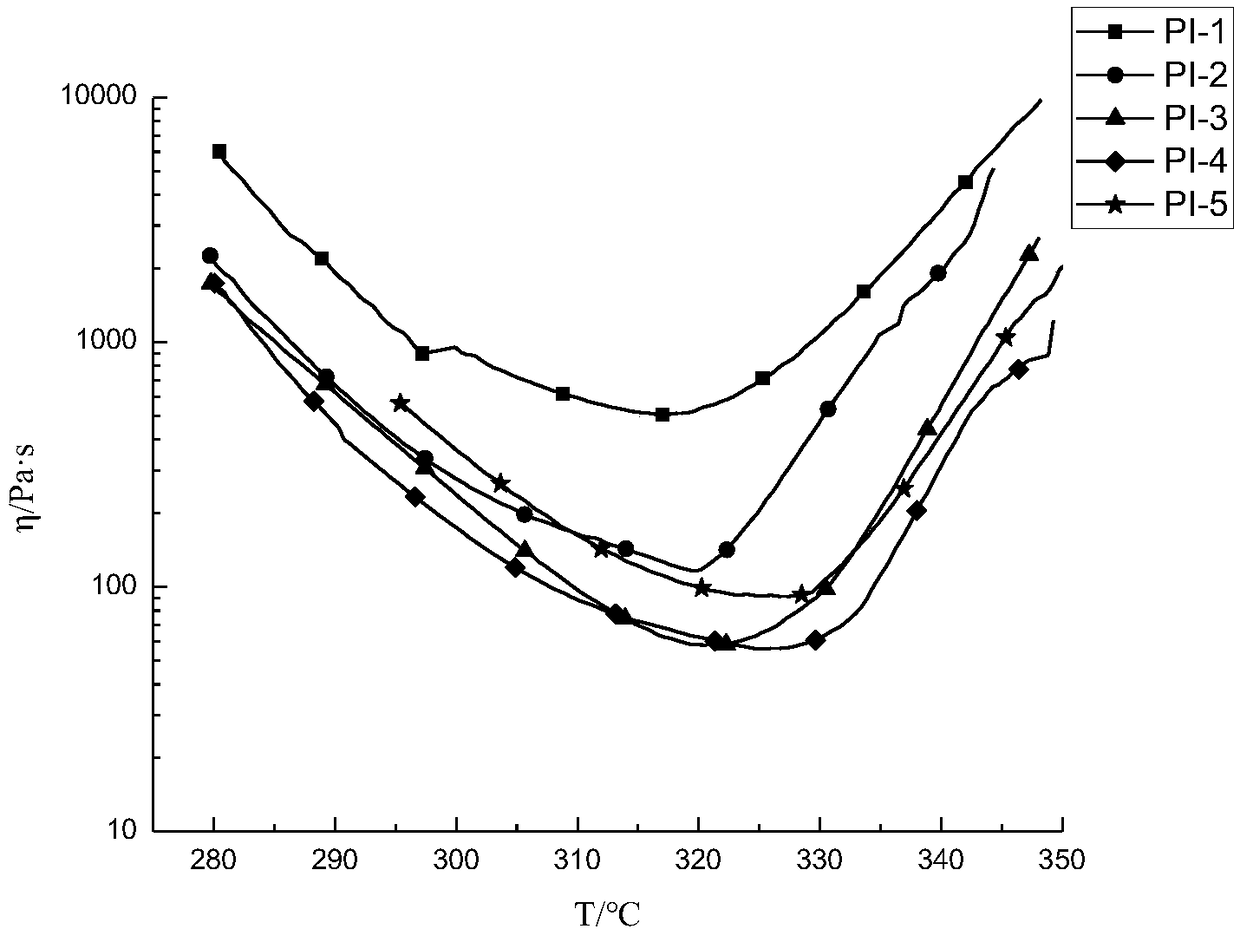

Low viscosity polyimide copolymerized thermosetting resin and preparation method and application thereof

The invention relates to the technical field of high molecular materials, and particularly relates to copolymerized polyimide thermosetting resin comprising a carborane structure and a preparation method and an application thereof. The copolymerized polyimide resin is prepared by thermally cross-linking and solidifying polyimide oligomers represented by a formula I as a raw material. The oligomersintroduce the carborane of a certain composition into a conventional thermosetting polyimide resin system by means of a copolymerization method, so that the conventional thermosetting polyimide resinhas relatively low hot melt viscosity and a higher glass-transition temperature (higher than 500 DEG C) and also has more excellent thermal oxidation resistance and heat stability resistance. Therefore, the thermosetting resin has the extremely low hot melt viscosity. The resin is more easily prepared into a composite material part of a complex structure through a conventional processing technology, can improve the thermal oxidation resistance of the material to a great extent, and has very high application value and innovation to prepare a light high strength high-temperature-resistant easily processed polyimide composite material for a structural material in the aerospace field.

Owner:BEIHANG UNIV

Polyurethane sealant and preparation method and application thereof

ActiveCN105331323ALow modulusPlay a plasticizing roleNon-macromolecular adhesive additivesOther chemical processesSelf-healingPolyol

The invention provides a polyurethane sealant and a preparation method and application of the polyurethane sealant. The polyurethane sealant is prepared from a component A and a component B, wherein a polyurethane prepolymer is formed by polyether polyol and methylbenzene-2,4-diisocyanate in the component A; polyurethane molecular chain segments are provided with branch chains after the polyurethane prepolymer is cured by a curing agent, a plasticizing effect is obtained, the modulus of the material is reduced, and the modulus is below 0.2MPa under an environment that the temperature is 20 DEG C below zero. Because the polyurethane molecular chain segments are provided with the branch chains, and the branch chains have plasticizing performance, the polyurethane sealant can still have lower modulus even though a plasticizer migrates after long-time curing of the polyurethane sealant, and the service life of the polyurethane sealant is prolonged; the polyurethane sealant has self-healing performance, so that self healing can be obtained when the polyurethane sealant is damaged by an external force; the polyurethane sealant has repetitive adhesion performance; in addition, the requirements on the temperature and the humidity of an external environment are not high, and low-temperature construction can be carried out; the polyurethane sealant is suitable for all kinds of fields and is specifically suitable for caulking of buildings, road bridges and ballastless tracks of high-speed railway.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Method for preparing stretchable bending-resistant PVC hose

InactiveCN109251442AImprove low temperature tensile propertiesImprove low temperature flexibilityDecompositionPlasticizer

The invention discloses a method for preparing a stretchable bending-resistant PVC hose, which belongs to the technical field of preparation of a PVC material. The main raw material of the PVC hose ofthe invention is polyvinyl chloride, and the polyvinyl chloride is mechanically modified by EPDM raw rubber, and the ethylene content of the used EPDM raw rubber is 50-55%, the EPDM can effectively improve the low temperature tensile properties and low temperature flexibility of polyvinyl chloride, and can effectively solve the problem of large changes in the low temperature tensile properties ofthe finished products caused by the use of a plasticizer, the EPDM easily absorbs the accumulated and modified zeolite powder surface, oriented and orderly arranged crystallization can be differentlygenerated, hydrogen chloride due to heat and photodegradation can be rapidly absorbed, so that the continuous decomposition of polyvinyl chloride can be blocked, the aging resistance performance of polyvinyl chloride is increased and is stable, and the method has wide application prospect.

Owner:FOSHAN CHANCHENG DISTRICT NUOGAO ENVIRONMENTAL PROTECTION TECH CO LTD

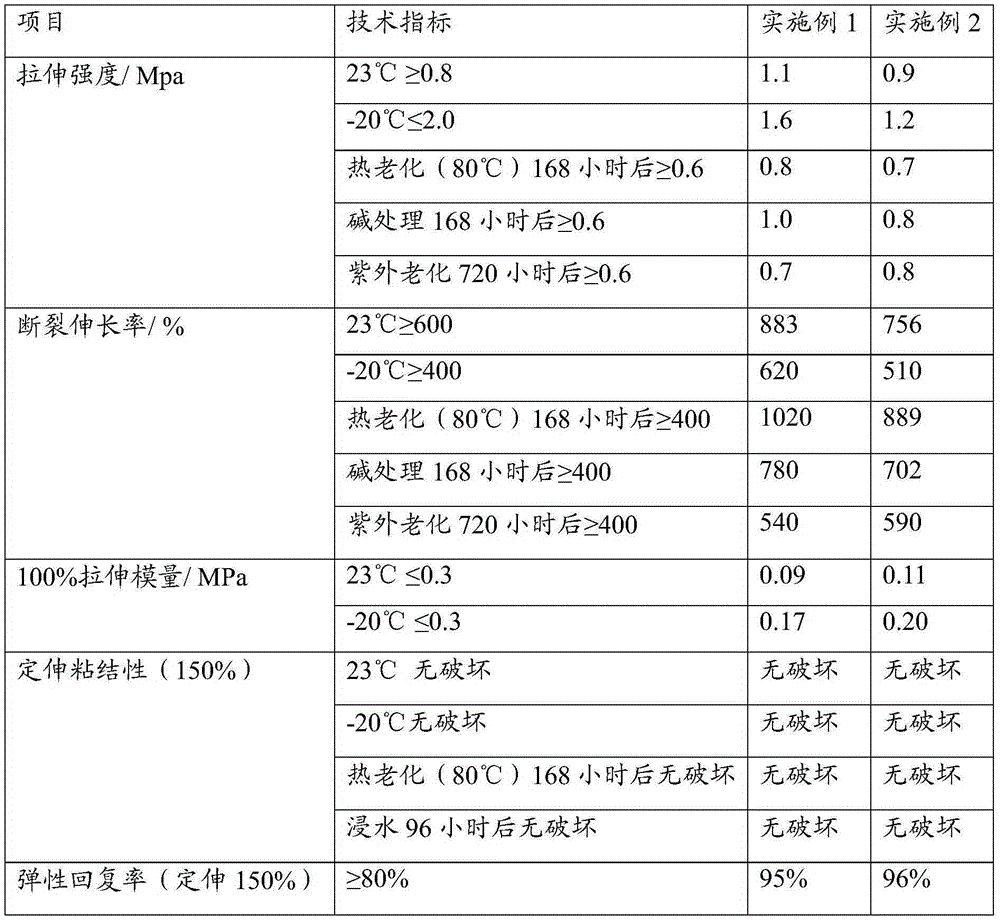

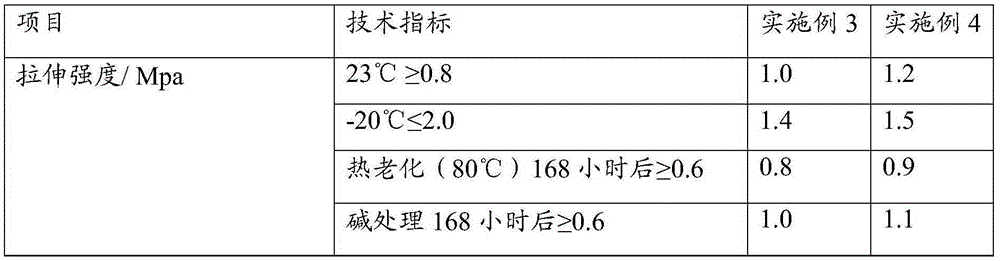

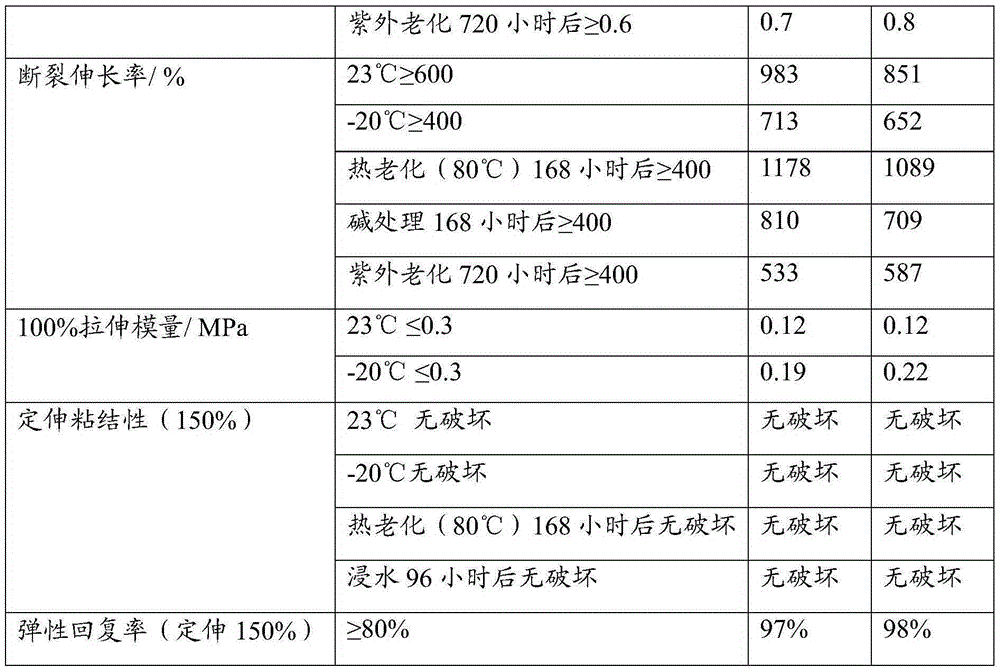

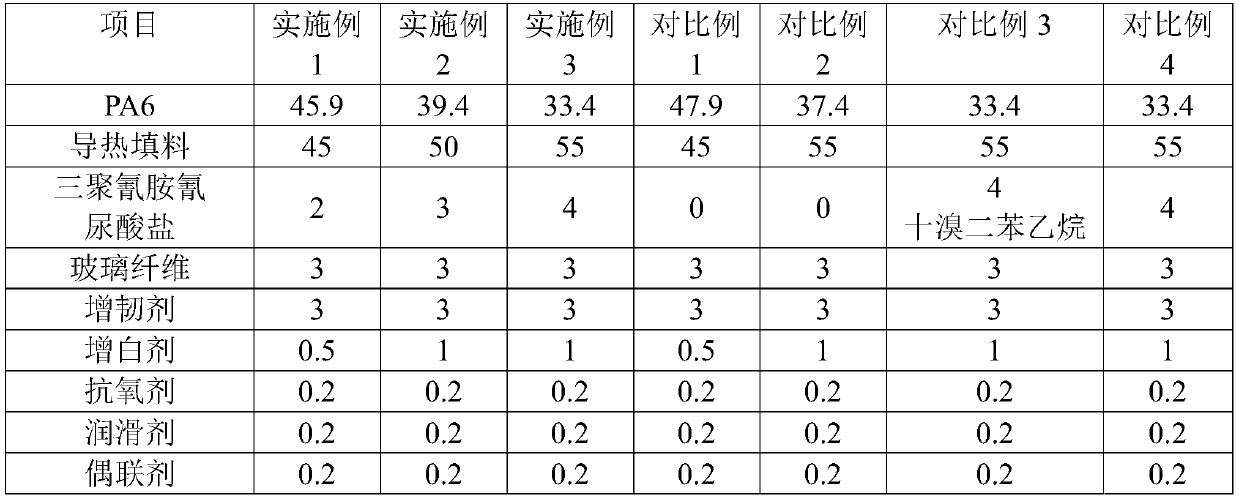

High-flow heat-conducting nylon composite material, preparation method and application thereof

InactiveCN110218442AImprove liquiditySignificant technical and market valueHeat-exchange elementsThermal conductivityThin walled

The invention belongs to the composite material field and discloses a high-flow heat-conducting nylon composite material, a preparation method and an application thereof. The high-flow heat-conductingnylon composite material comprises nylon resin, heat conductive filler, melamine cyanurate and optionally glass fiber, toughening agent, whitening agent, antioxidant, lubricant and coupling agent, The heat conductive filler is hydroxide, and the weight ratio of the heat conductive filler, the melamine cyanurate and the nylon resin is (0.5-2):(0.04-0.13): 1. The nylon composite material provided by the invention has the advantages of high fluidity and high thermal conductivity, and can be well applied in the fields of home appliances, lighting and the like, especially in some thin-wall products, and has remarkable technical and market value.

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD

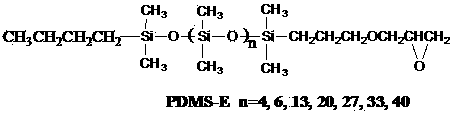

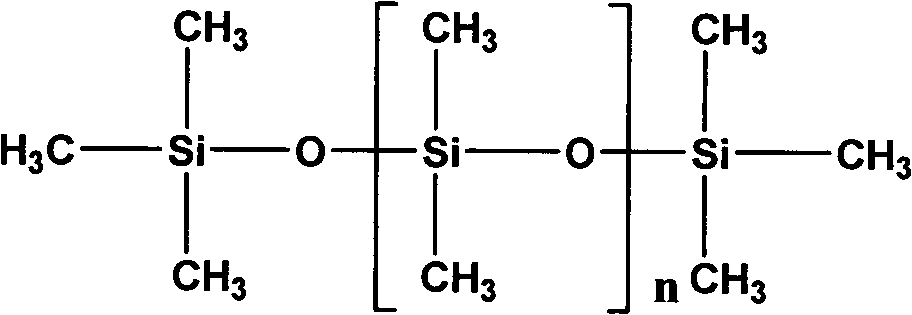

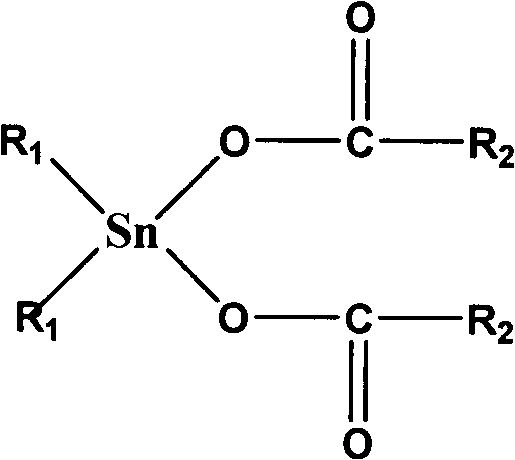

Environment-friendly biological plasticizer for biological specimen preservation

ActiveCN102134398APlay a plasticizing roleImprove stabilityDead plant preservationDead animal preservationPlasticizerBio-Specimen

The invention discloses an environment-friendly biological plasticizer for biological specimen preservation, which is prepared from the following components in parts by weight: 100 parts of silicone resin, 20-100 parts of plasticizer, 0.5-5 parts of catalyst and 2-10 parts of crosslinking and curing agent, wherein the silicone resin is hydroxyl-terminated methyl silicone oil, the plasticizer is methyl-terminated methyl silicone oil, the catalyst is organotin, and the crosslinking and curing agent is organosiloxane. The invention has the advantages of no toxicity, no harm, no smell and no pollution, and is transparent; the specimen plasticized by the plasticizer has the advantages of strong authenticity, good hand feeling and high vividness, and can be stored for a long time; the environment-friendly biological plasticizer for biological specimen preservation can ensure the manufacture of biological specimens to be carried out at ordinary temperature, and avoids using chloro-platinic acid and other noble and highly-corrosive reagents, thereby greatly lowering the cost and reducing the harm to operating personnel; and the invention avoids using a diluter, and simplifies the operation steps.

Owner:山东聚众数字医学科技开发有限公司

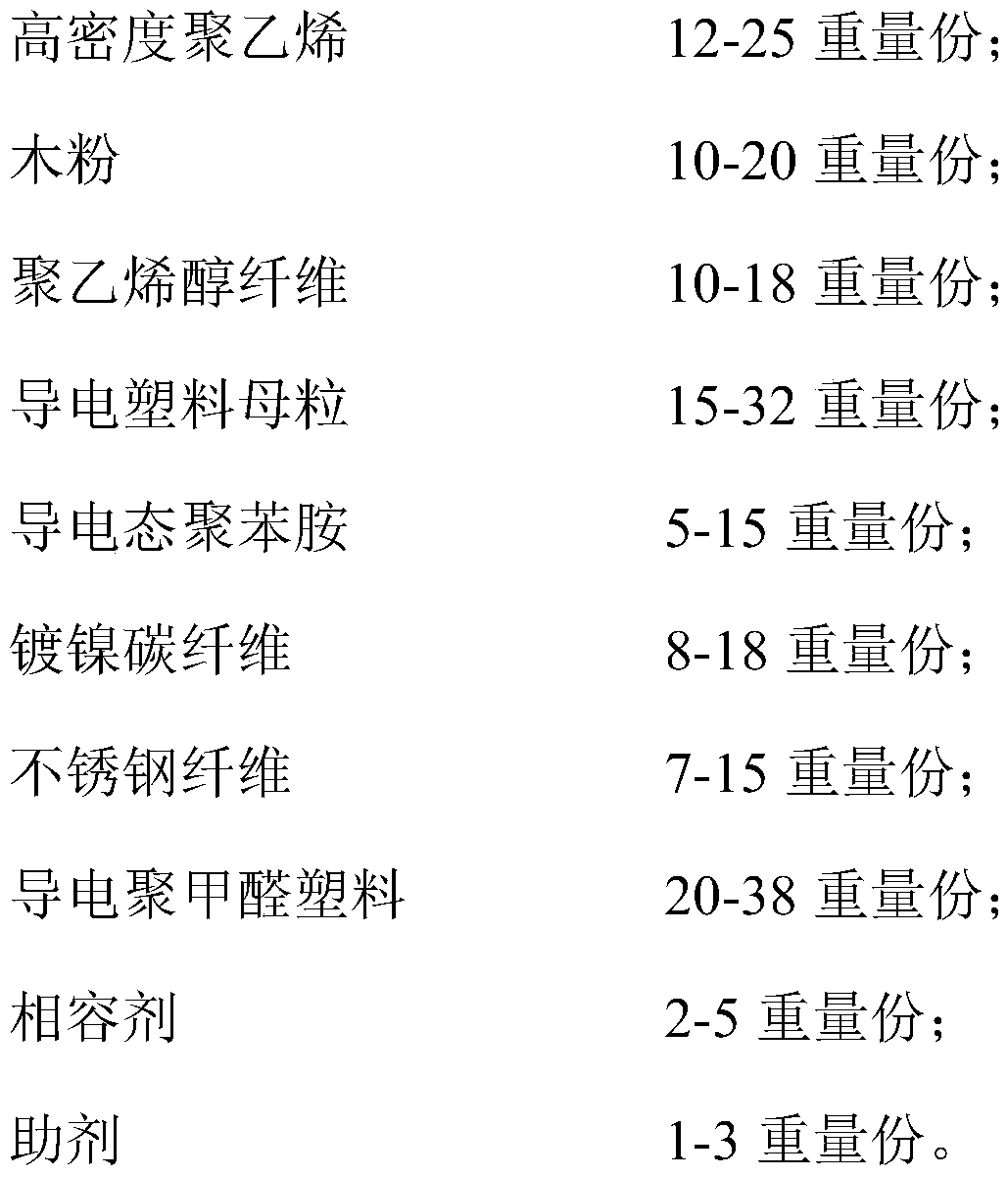

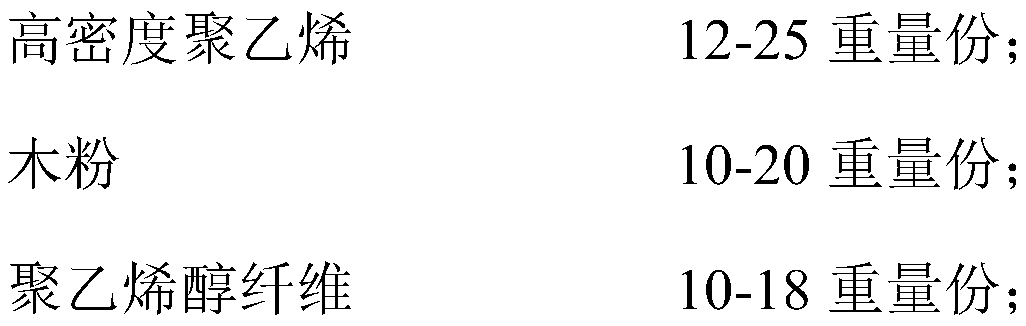

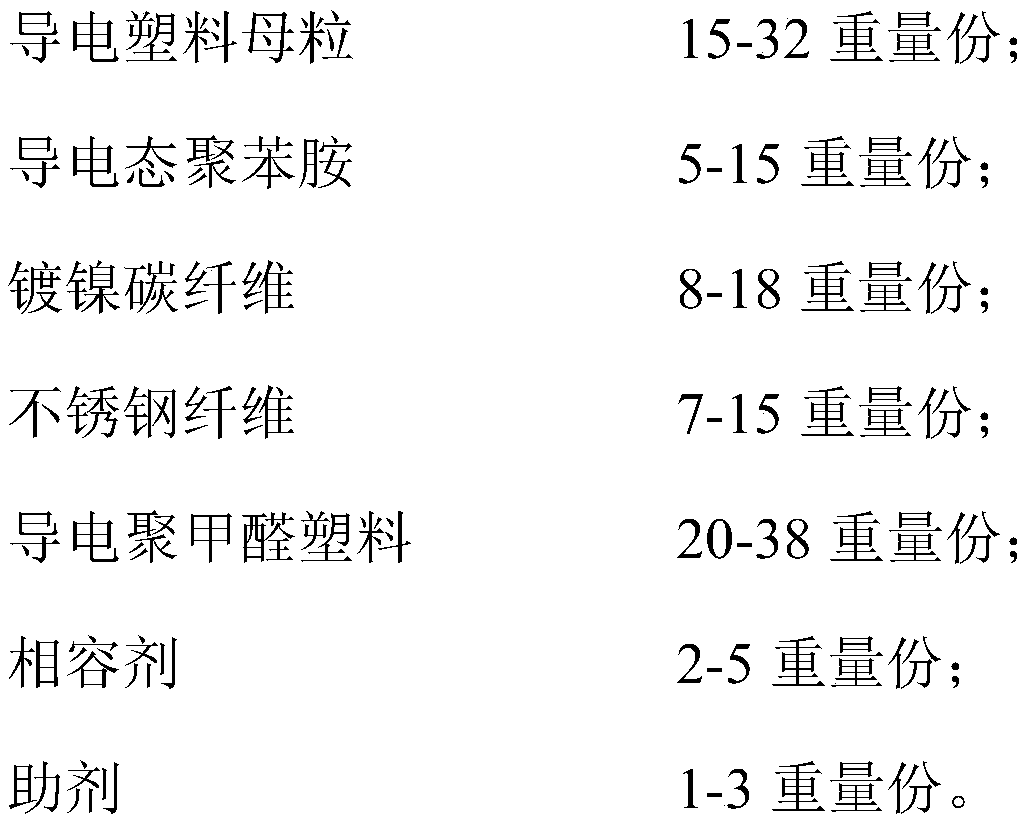

Anti-bending, anti-slip and anti-static type plastic-wood composite material and preparation method thereof

InactiveCN110283420AHigh mechanical strengthImprove antistatic performanceCarbon fibersPolyvinyl alcohol

The invention belongs to the technical field of functional plastic-wood materials, specifically relates to an anti-bending, anti-slip and anti-static type plastic-wood composite material, and further discloses a preparation method thereof. According to the anti-bending, anti-slip and anti-static type plastic-wood composite material disclosed by the invention, high-density polyethylene, wood powder, high-strength and high-modulus polyvinyl alcohol fibers, conductive plastic masterbatches, conductive-state polyaniline, nickel coated carbon fibers, 304 stainless steel fibers, conductive polyformaldehyde plastic, a compatibilizer, and auxiliaries such as a coupling agent, a lubricant, and an ultraviolet absorbent are taken as raw materials, and a product is obtained through extrusion pelleting, molding, and surface brush grinding and coarsen treatment through a wire brush. The plastic-wood composite material provided by the invention integrates outstanding anti-bending, surface anti-slip and anti-static properties, and has significant application value.

Owner:HUANGSHAN HUASU NEW MATERIAL SCI & TECH CO LTD

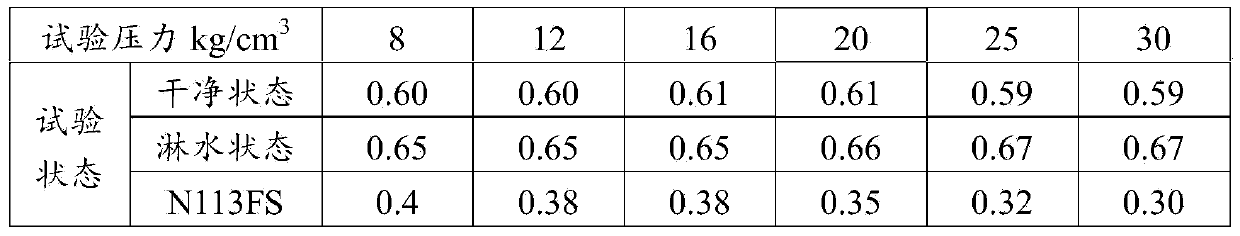

Fraction lining for mine hoist and preparation method of fraction lining

The invention relates to a fraction lining for a mine hoist and a preparation method of the fraction lining. Base materials comprise powdered butadiene-acrylonitrile rubber and phenolic resin; a vulcanization system comprises sulfur, magnesium oxide, zinc oxide, iron oxide yellow, an accelerant M and an accelerant DM; a reinforcing material is nano white carbon black; an anti-ageing system comprises an anti-ageing agent RD and an anti-ageing agent D; and a plasticizing system comprises DOP and stearic acid. The preparation method comprises the following steps: proportioning the raw materials in parts by mass, and pressing and molding the raw materials in a mould after mixing according to a certain sequence, thus obtaining the fraction lining. The prepared fraction lining is high in friction coefficient which is not lower than 0.3 under various working conditions, has high abrasive resistance, high-temperature fusion resistance, tearing resistance, chemical corrosion resistance and the like, further has good mechanical performance and processing performance, does not contain substances which damage a steel wire rope, is long in service life and is capable of satisfying using requirements of various types of friction equipment.

Owner:洛阳百克特科技发展股份有限公司

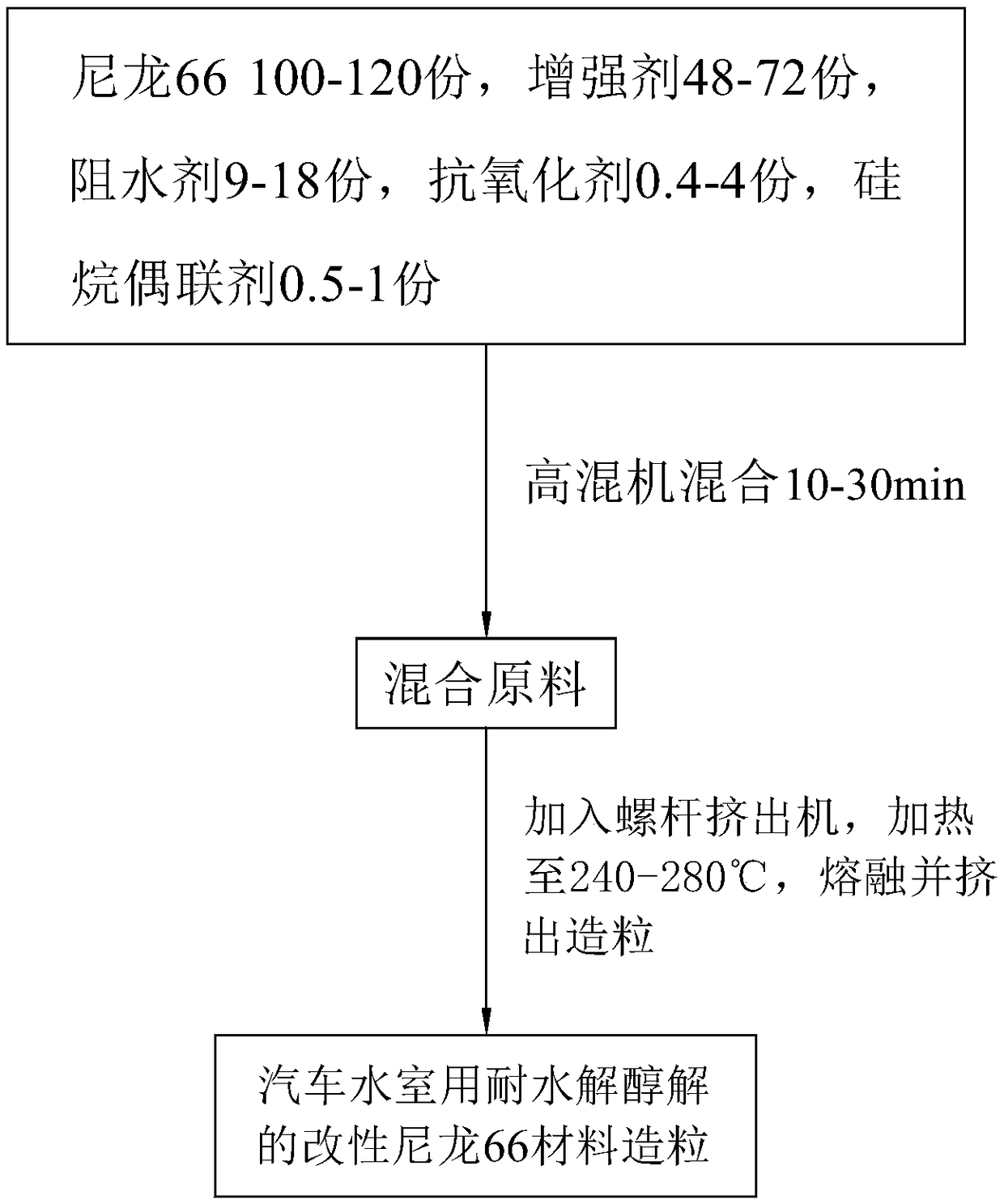

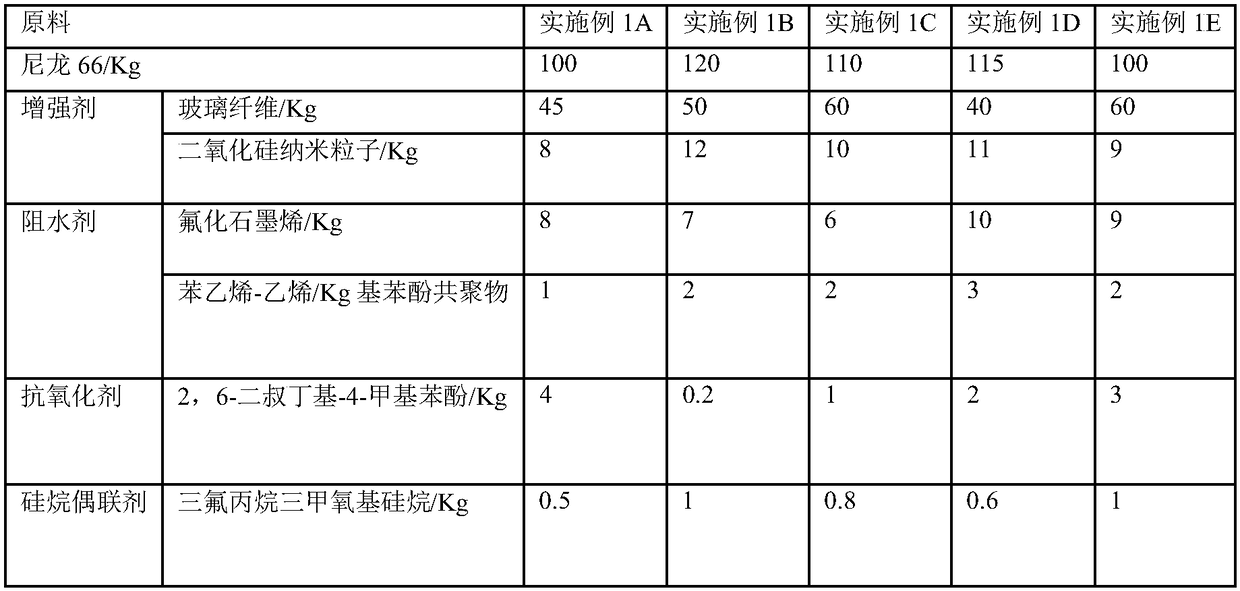

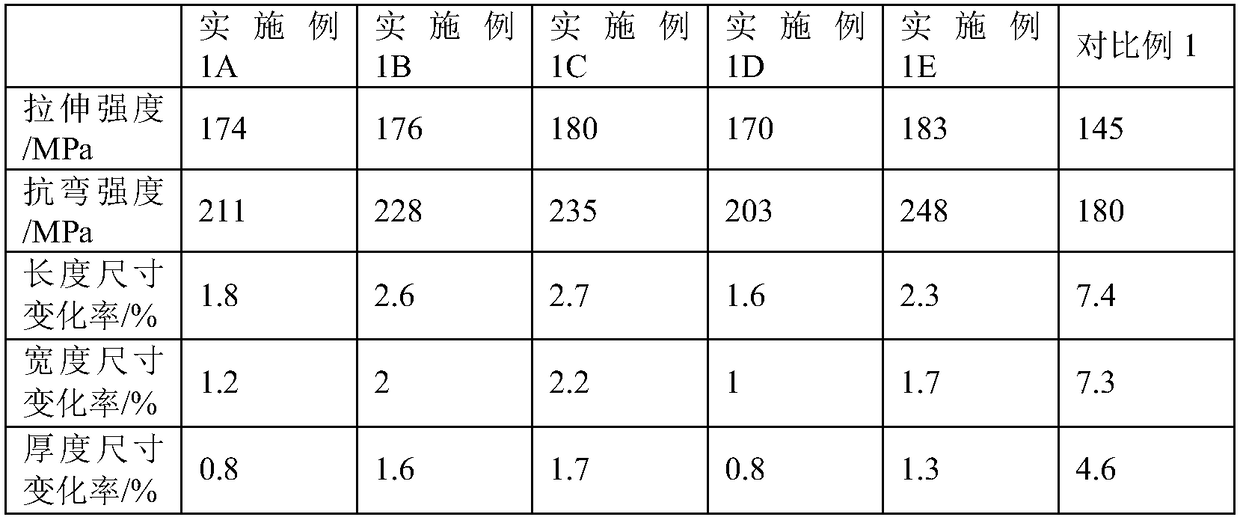

Hydrolysis and alcoholysis resistant modified nylon 66 material for automotive water chamber and preparation method of modified nylon 66 material

The invention relates to modified nylon materials and discloses a hydrolysis and alcoholysis resistant modified nylon 66 material for an automotive water chamber and a preparation method of the modified nylon 66 material. The modified nylon 66 material comprises the following raw materials: 100-120 parts of nylon 66, 48-72 parts of an enhancer, 9-18 parts of a water resistance agent, 0.4-4 parts of an antioxidant and 0.5-1 part of a silane coupling agent, wherein the enhancer comprises 40-60 parts of glass fibers; and the water resistance agent comprises 6-10 parts of fluorinated graphene and3-8 parts of a styrene-vinyl phenol copolymer. The preparation method comprises the following steps: weighing the raw materials in parts by mass, mixing after drying, adding the mixture into a screw extruder, heating and melting, and performing extrusion pelletizing, thereby obtaining the modified nylon 66 material. The tensile property and bending performance of the modified nylon 66 material areimproved, and the nylon material has hydrolysis and alcoholysis resistance and excellent dimensional stability, difficultly causes size distortion at a high temperature and meets the service conditions and environment of the automotive water chamber.

Owner:NINGBO EAGLE NEW MATERIAL

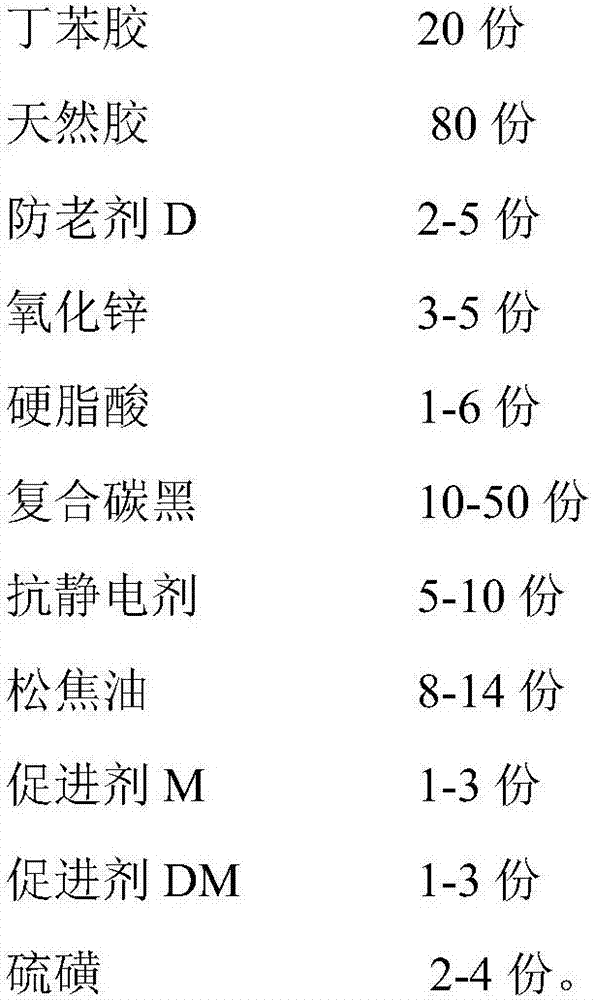

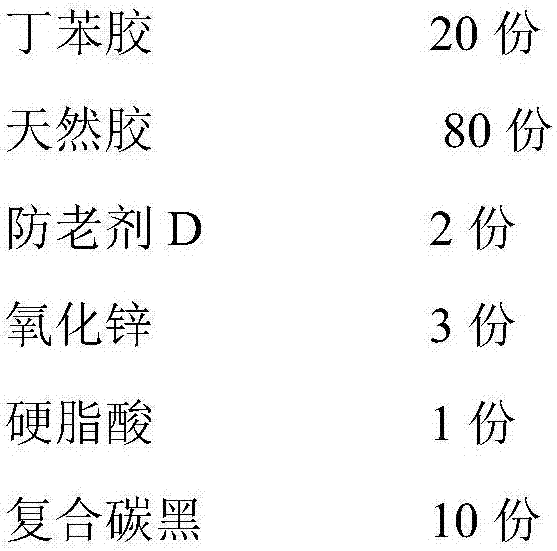

Anti-static rubber and preparation method thereof

InactiveCN107417991AEasy to processImprove wear resistanceBuilding insulationsAntistatic agentHardness

The invention discloses an anti-static rubber and a preparation method thereof and belongs to the field of rubber manufacturing. The anti-static rubber and the preparation method thereof aim at solving the problems of anti-static deficiency, poor physical performance and low heat generation rate in the prior art. The anti-static rubber is a compound conductive carbon black composition combined with anti-static agent, thereby effectively guaranteeing anti-static effects, improving wear resistance; compounded carbon black is low in heat value during operation and can ensure hardness and ductility of the anti-static rubber. By means of a two-section plastifying manner and through synergistic effects of the compounded carbon black and the anti-static agent, the anti-static rubber achieves good anti-static effects, excellent physical performance, good hardness and tensile strength, low heat value and simple production processes.

Owner:MAANSHAN TIANXIN ROLL IND

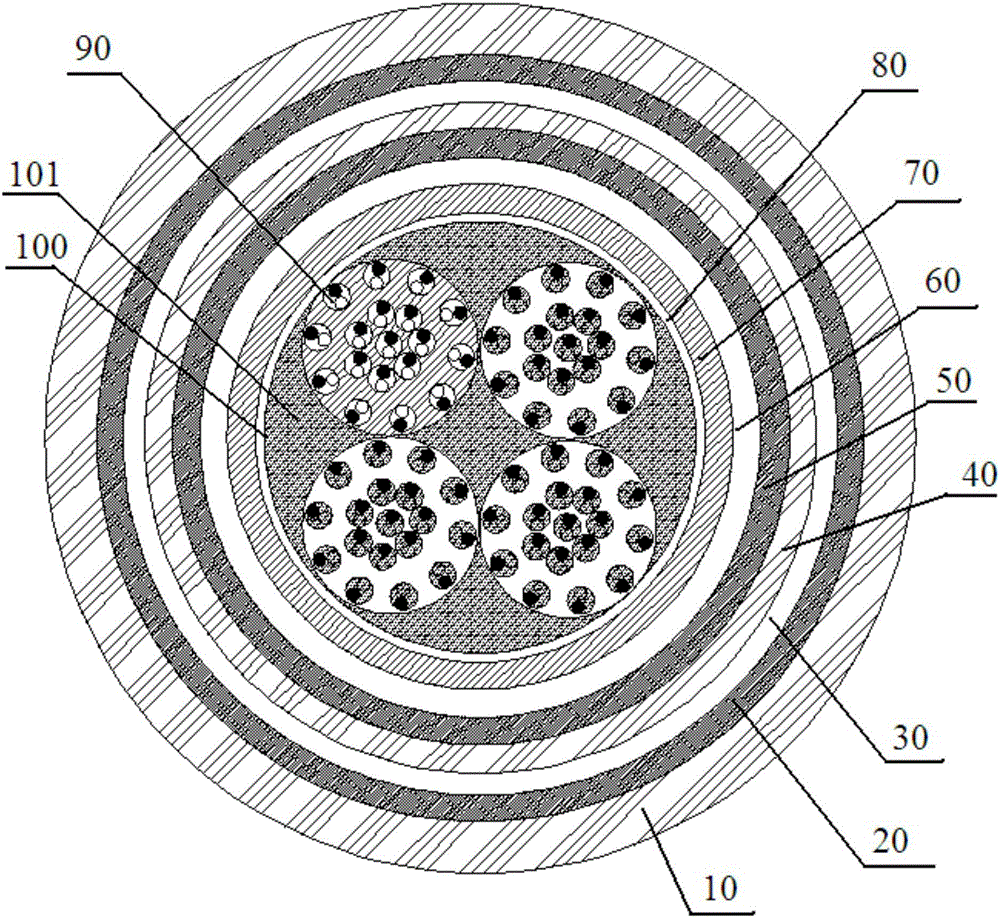

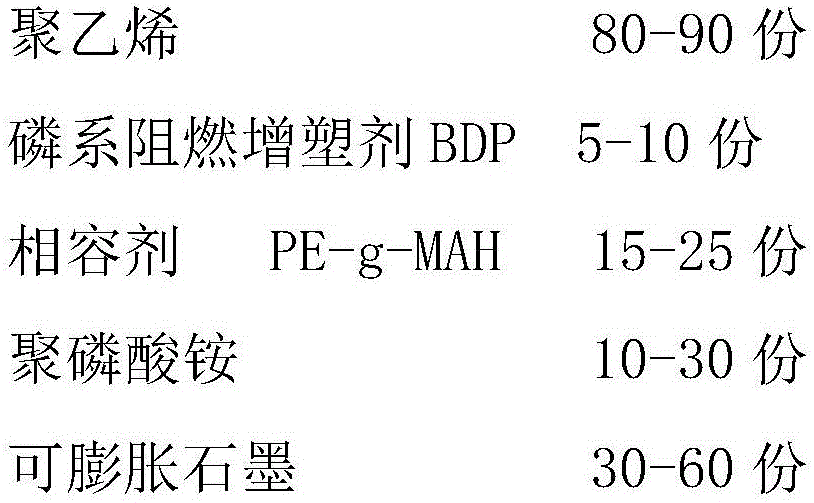

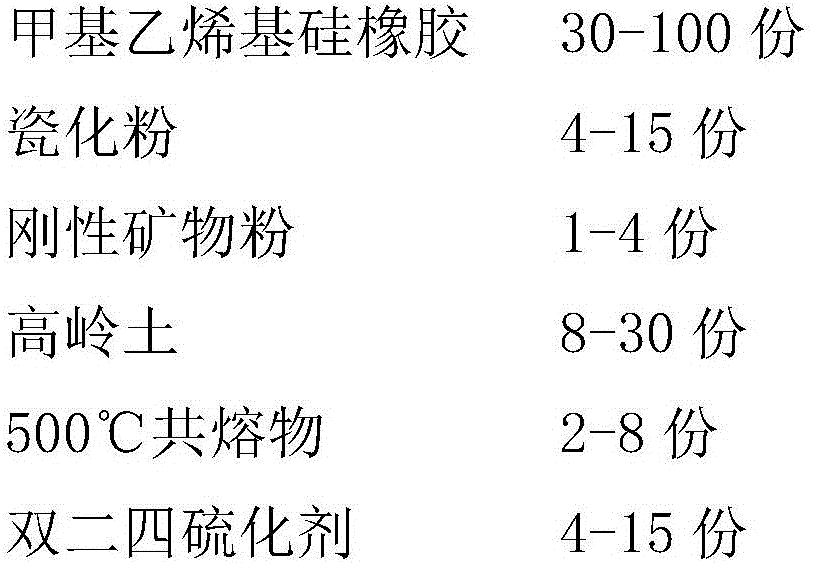

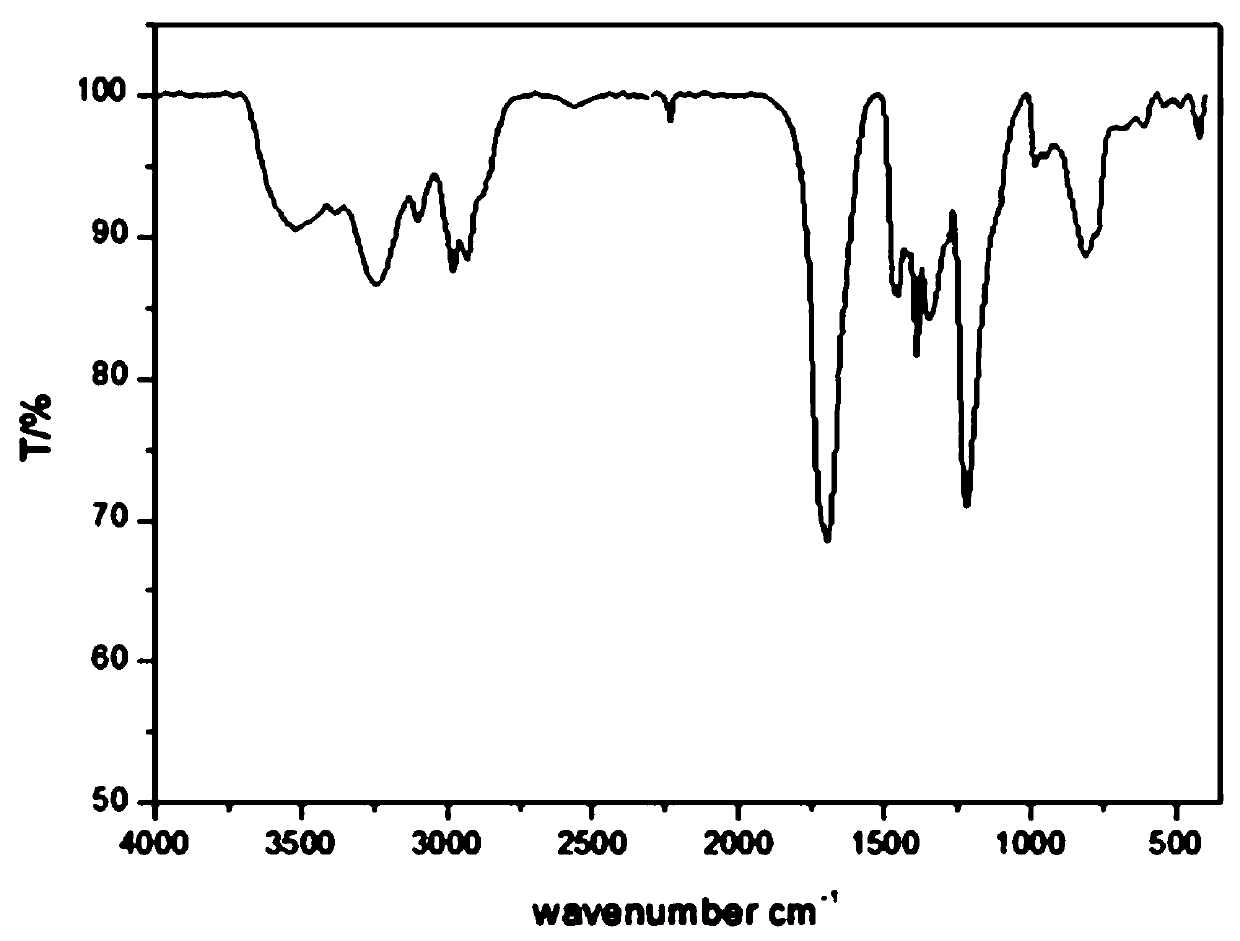

Fireproof flame-retardant rail transit communication cable

ActiveCN106084427AReduce heat exposureKeep the lightingCommunication cablesInsulated cablesEngineeringRail transit

The invention discloses a fireproof flame-retardant rail transit communication cable. The fireproof flame-retardant rail transit communication cable comprises a low-smoke zero-halogen outer sheath, a first fireproof layer, a high-magnetic-conductive steel tape armoring layer, a low-smoke zero-halogen inner sheath, a second fireproof layer, an aluminum sheath, a PE heat insulating layer, a waterproof layer and multiple strands of stranded insulating core wires. A low-smoke zero-halogen polyethylene material is prepared from 80-90 parts of polyethylene, 5-10 parts of phosphorus flame-retardant plasticizer BDP, 15-25 parts of PE-g-MAH, 10-30 parts of ammonium polyphosphate and 30-60 parts of expansible graphite. The second fireproof layer is made of a fireproof silicone rubber material. The fireproof silicone rubber material is prepared from 30-100 parts of methyl vinyl silicone rubber, 4-15 parts of vitrified powder, 1-4 parts of rigid mineral powder, 8-30 parts of kaolin, 2-8 parts of 500DEG C eutectic and 4-15 parts of DCBP. All the layers are retardant to flames, most of heat can be absorbed, and optical fibers can keep optical connectivity for a long time.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Preparation method of microporous polymethacrylimide foaming agent

The invention relates to the field of preparation of new materials, and discloses a preparation method of a microporous polymethacrylimide foaming agent. By using the novel microporous foaming agent,a series of problems are solved that the compatibility of a blended compound foaming agent, an inorganic foaming agent and the like used at present with PMI resin is poor, the foaming agent is easy tomigrate, the foaming pore size is not uniform and the foaming temperature is unstable. The foaming agent has good compatibility with the PMI resin in the using process, and has a stable foaming effect. The prepared polymethacrylimide foam has small and uniform foaming pore size, so that the toughness and elongation at break of the material are improved.

Owner:CASHEM ADVANCED MATERIALS HI TECH CO LTD ZHEJIANG

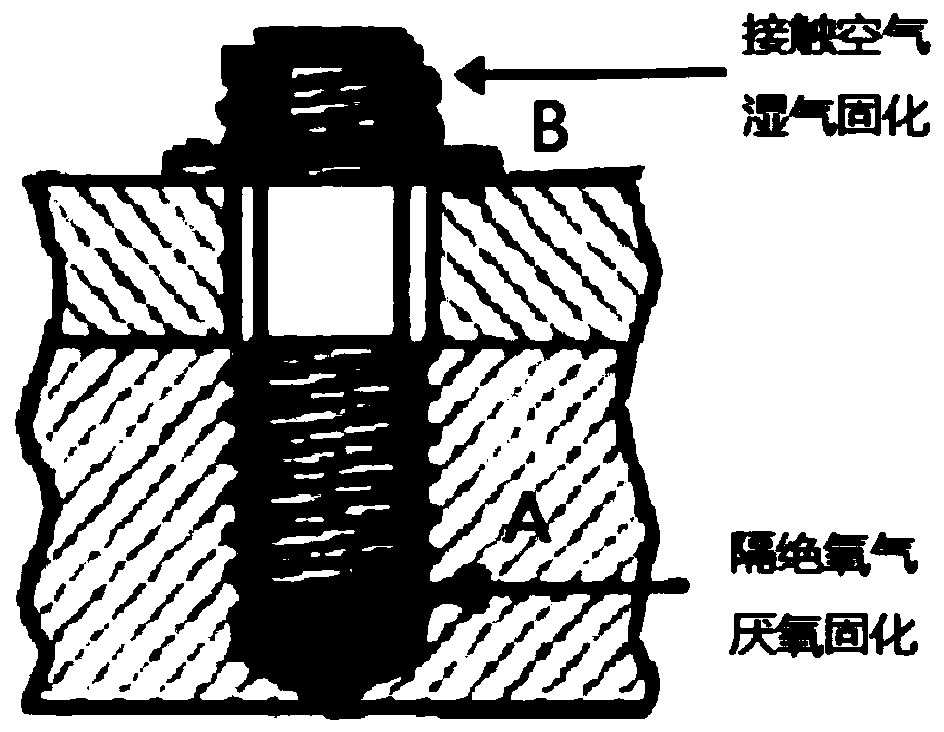

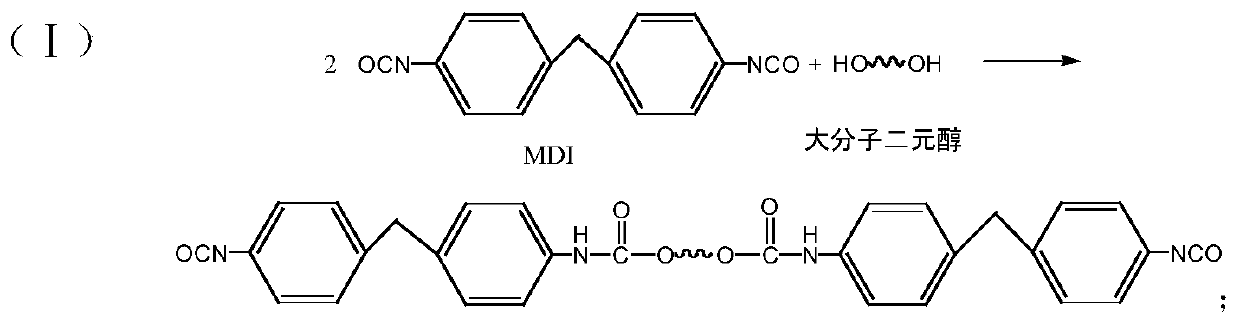

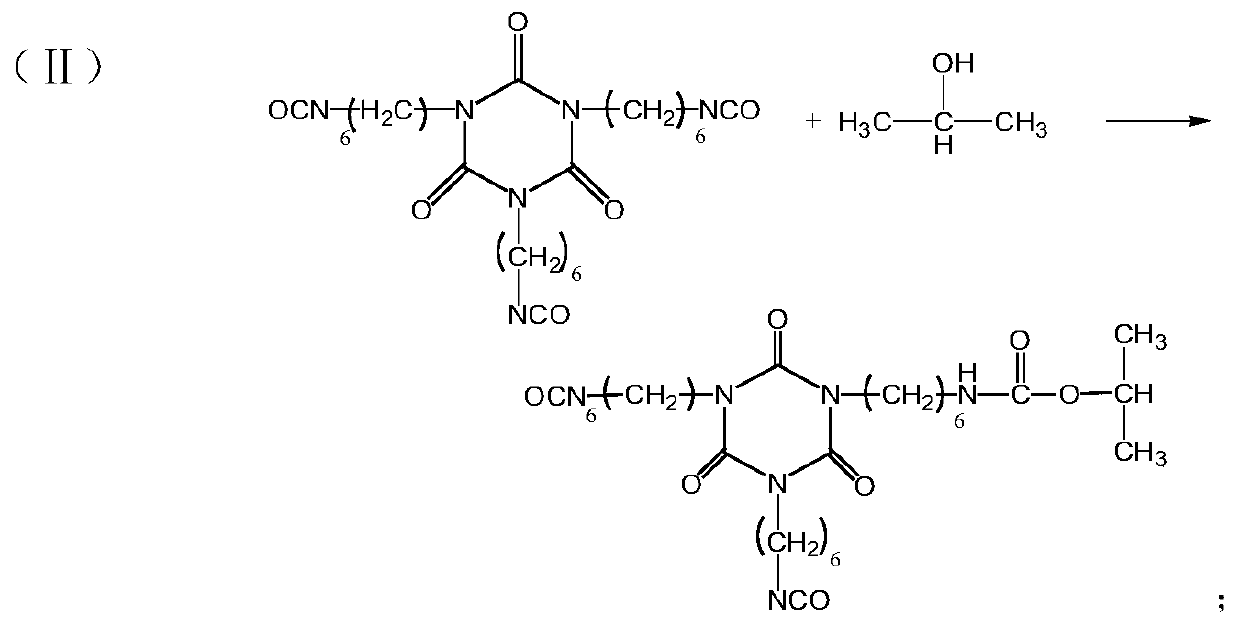

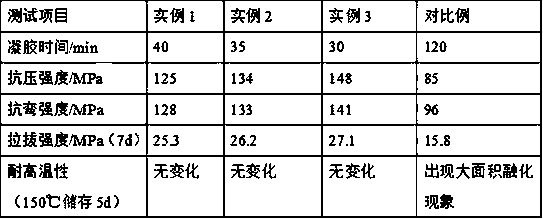

Moisture-curable anaerobic adhesive and preparation method thereof

PendingCN110128994AImprove initial tackReduce bond strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesChemical reactionAdhesive

The invention relates to a moisture-curable anaerobic adhesive and a preparation method thereof. According to the present invention, when a metal material is adhered, the closed anoxic environment ofthe adhered surface can cause a chemical reaction between the isocyanate group-containing monomer pr prepolymer in an anaerobic adhesive and the polar group on the surface of the metal substrate to generate bridging effect so as to improve the initial adhesion of the anaerobic adhesive to the metal substrate, and the(meth)acryloyloxy group contained in the anaerobic adhesive is subjected to rapidradical polymerization, and the monomer or prepolymer containing more than or equal to 2 isocyanate groups in the system can provide plasticizing effect to maintain the adhesion of the system at a high level so as to achieve the effects of curing and firm adhesion, such that the bonding strength of the anaerobic adhesive is greatly improved; and a small amount of the isocyanate group contained inthe moisture-curable anaerobic adhesive overflowing from the seam of the adhered surface chemically reacts with the water in the air to dry the surface, such that the defect of the contamination on the metal material is avoided while the excess curing glue can be conveniently cut off by using a cutter blade.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Preparation method of high-temperature-resistant anchoring glue

InactiveCN108587540AGood heat resistance and mechanical propertiesImprove mechanical propertiesNon-macromolecular adhesive additivesEpoxy resin adhesivesChemistryBENZYL ALCOHOL/WATER

The invention relates to the technical field of preparation of reinforcing materials for building structures, particularly to a preparation method of a high-temperature-resistant anchoring glue. According to the present invention, a modified epoxy resin is used as a matrix, modified diatomaceous earth powder and modified carbon fiber are used as filler reinforcing agents, cyclohexanone peroxide isused as an initiator, ethylenediamine is used as a curing agent, and benzyl triethyl ammonium chloride, benzyl alcohol and salicylic acid are mixed to form a curing accelerator, such that the anchoring glue with high mechanical property and high-temperature resistance is prepared; the epoxy resin is modified with a bismaleimide resin and a cyanate resin so as to improve the mechanical property ofthe epoxy resin and enhance the high-temperature resistance of the epoxy resin; the diatomaceous earth powder is modified with a silane coupling agent; and the carbon fiber is modified through nitricacid-ultrasonic synergistic treatment so as to improve the mechanical property of the anchoring glue, such that the mechanical strength and the high-temperature resistance of the anchoring glue are further improved, and the application prospects are broad.

Owner:陈合华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com