Environment-friendly biological plasticizer for biological specimen preservation

An environmentally friendly technology for biological specimens, applied to the preservation of plants, the preservation of human or animal bodies, and applications. It can solve problems such as damage to the health of operators, high production costs, and cumbersome production processes, and achieve cost reduction and improvement. Specimen stability and volatility are good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0024] The specific embodiment: the specific embodiment of the present invention is described in detail below:

[0025] Raw material preparation:

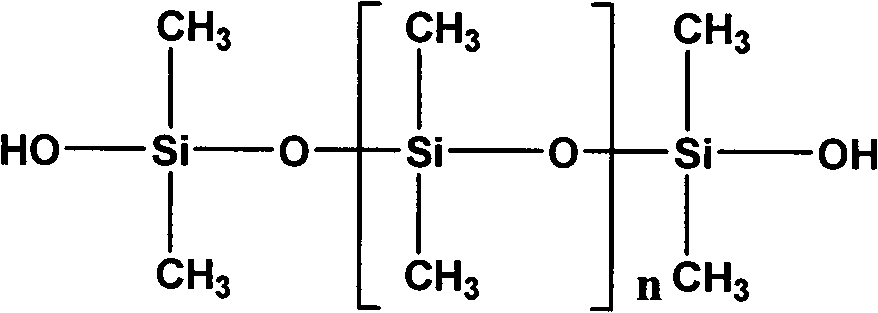

[0026] Silicone resin: using hydroxyl-terminated methyl silicone oil, its chemical structure is as follows:

[0027]

[0028] n=50~600, molecular weight is 5000~40000.

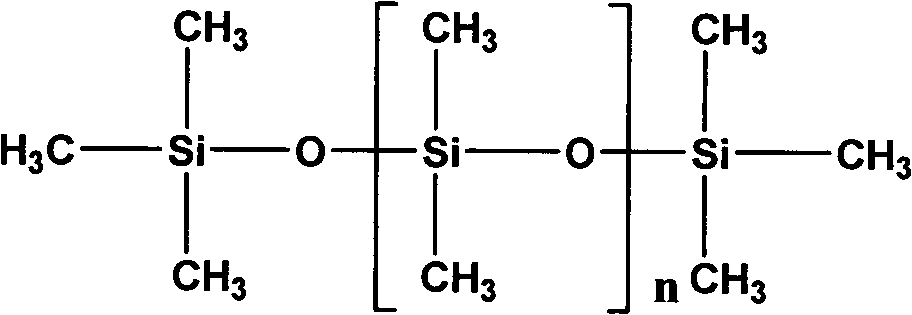

[0029] Plasticizer: using methyl-terminated methyl silicone oil, its chemical structure is as follows:

[0030]

[0031] n=5~600, molecular weight is 500~40000.

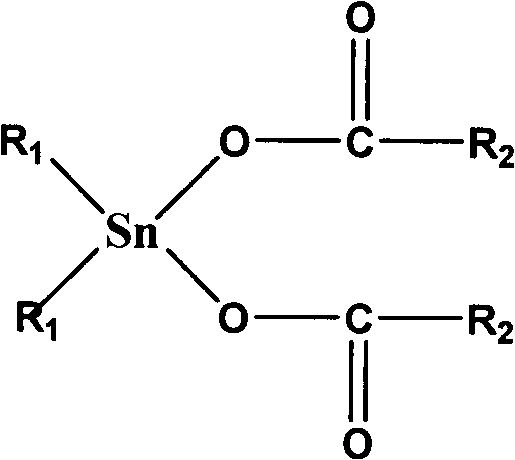

[0032] Catalyst: using organotin, its chemical structure is as follows:

[0033]

[0034] where R 1 for C 2 h 5 ~C 8 h 17 One of the R 2 for C 6 h 13 ~C 12 h 25 One of.

[0035] Cross-linking curing agent: organosiloxane is used, and its chemical structure is as follows:

[0036]

[0037] where R 3 for CH 3 ~C 2 h 5 One of the R 4 for CH 3 ~C 2 h 5 or NH 2 CH 2 CH 2 CH 2 One of.

Embodiment 1

[0038] Embodiment 1: Take 2 kg of hydroxyl-terminated methyl silicone oil (n=50~600 in this embodiment, molecular weight is 5000~40000), methyl-terminated methyl silicone oil (n=5~50 in this embodiment, molecular weight is 500 ~5000) 2 kilograms, organotin (this embodiment R 1 for C 2 h 5 ,R 2 for C 6 h 13 , which is 0.1 kg of tin diethyl dihexanoate) and 0.2 kg of organosiloxane (the present embodiment R 3 for CH 3 ,R 4 for CH 3 , which is tetramethoxysilane) to form a plasticizer.

Embodiment 2

[0039] Embodiment 2: Take 2 kg of hydroxyl-terminated methyl silicone oil (n=50-600 in this embodiment, molecular weight is 500-40000), methyl-terminated methyl silicone oil (n=5100 in this embodiment, molecular weight is 500-10000 ) 0.4 kg, organotin (the present embodiment R 1 for C 8 h 17 ,R 2 for C 12 h 25 , which is 0.01 kg of dioctyltin dilaurate) and 0.04 kg of organosiloxane (the present embodiment R 3 for C 2 h 5 ,R 4 for C 2 h 5 , which is tetraethoxysilane) to form a plasticizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com