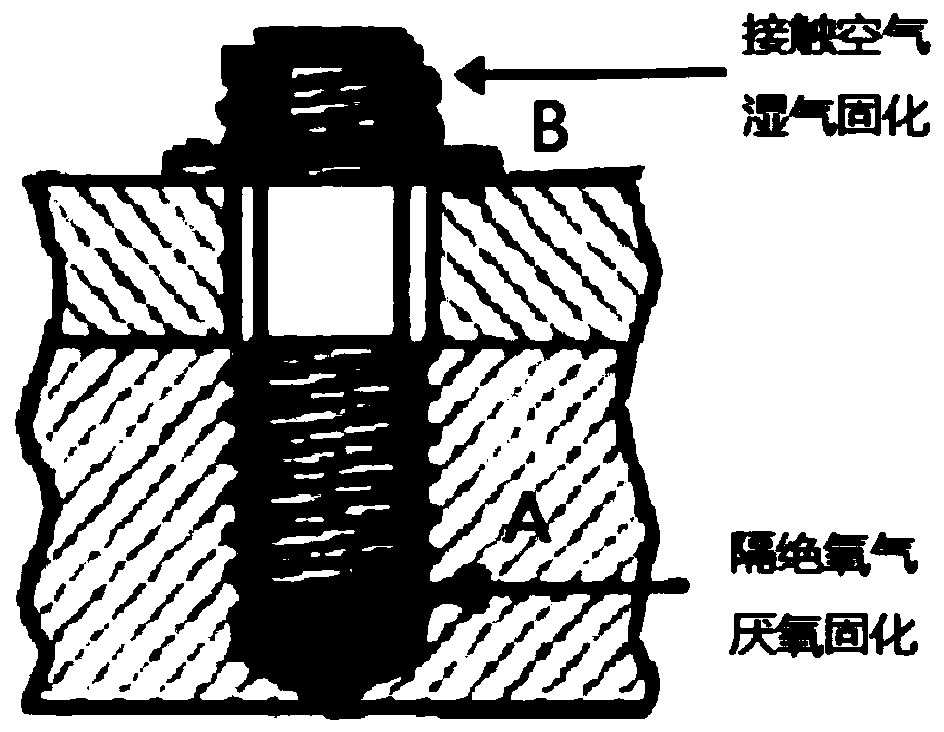

Moisture-curable anaerobic adhesive and preparation method thereof

An anaerobic adhesive, moisture curing technology, applied in the direction of adhesive, adhesive type, polyurea/polyurethane adhesive, etc., can solve the problem of large coating area of anaerobic adhesive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Example 1

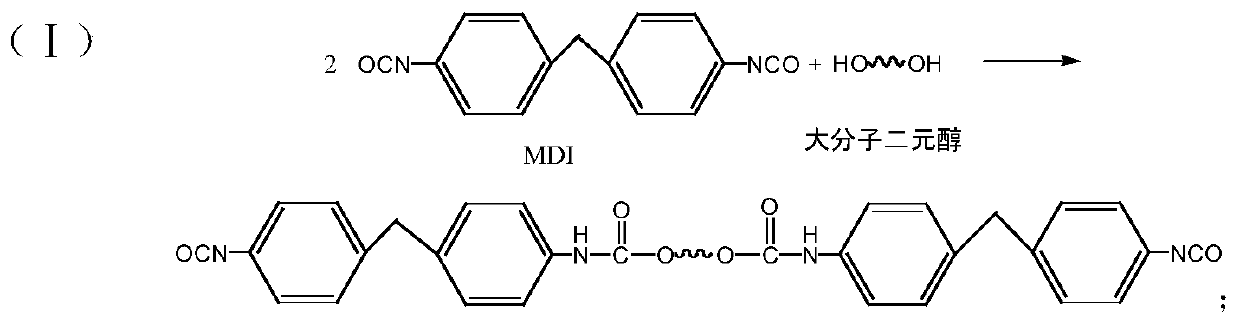

[0062] (1) Synthetic component a: prepolymer Y-1

[0063] ① Add 100g of macromolecular diol POL-3112T to a 500ml four-neck flask, stir at 200r / min, heat up to 100-110°C, vacuumize and dehydrate for 2 hours, and the vacuum degree is 0.07-0.1MPa;

[0064] ②Reduce the temperature in step ① to 50-60°C, add 86.7g of isocyanate monomer CDMDI-100L and 0.3g of catalyst dioctyltin dilaurate at one time, protect with nitrogen, and keep warm at 50-60°C for 2 hours;

[0065] ③Add 9g of small molecule polyol 1,4-butanediol to step ②, heat up to 70-80°C and keep warm for 3h; stop nitrogen, add 50g of reactive diluent isobornyl acrylate IBOA, stir at 200r / min for 10min, and discharge The obtained prepolymer Y-1 was sealed and kept until use.

[0066] The appearance of Y-1 is light yellow and transparent, the viscosity is 2060mPa·s.

[0067] Note: POL-3112T is polybutylene adipate, molecular weight 1000, and the manufacturer is Qingdao Xinyutian Chemical Co., Ltd.; CDMDI...

Embodiment 2

[0072] (1) Synthetic component a: prepolymer Y-1, same as Y-1 in Example 1.

[0073] (2) Preparation of moisture-curable anaerobic adhesive SYJ-2

[0074] In a 1L four-necked flask, one of the mouths of the flask was connected to the atmosphere, and 225g of polyurethane acrylic resin RS 1862, 200g of isobornyl acrylate IBOA, 0.3g of hydroquinone, and 0.6g of supernatant were added under the state of stirring at a rate of 300r / min. Dicumyl oxide, 0.6g N,N-diethyl-p-toluidine, 0.6g sodium saccharin, stir at 300r / min for 15min; add 75g of prepolymer Y-1, seal the flask, and stir at 300r / min for 5min. The appearance of SYJ-2 is slightly yellow and transparent, and the viscosity is 1254mPa·s.

Embodiment 3

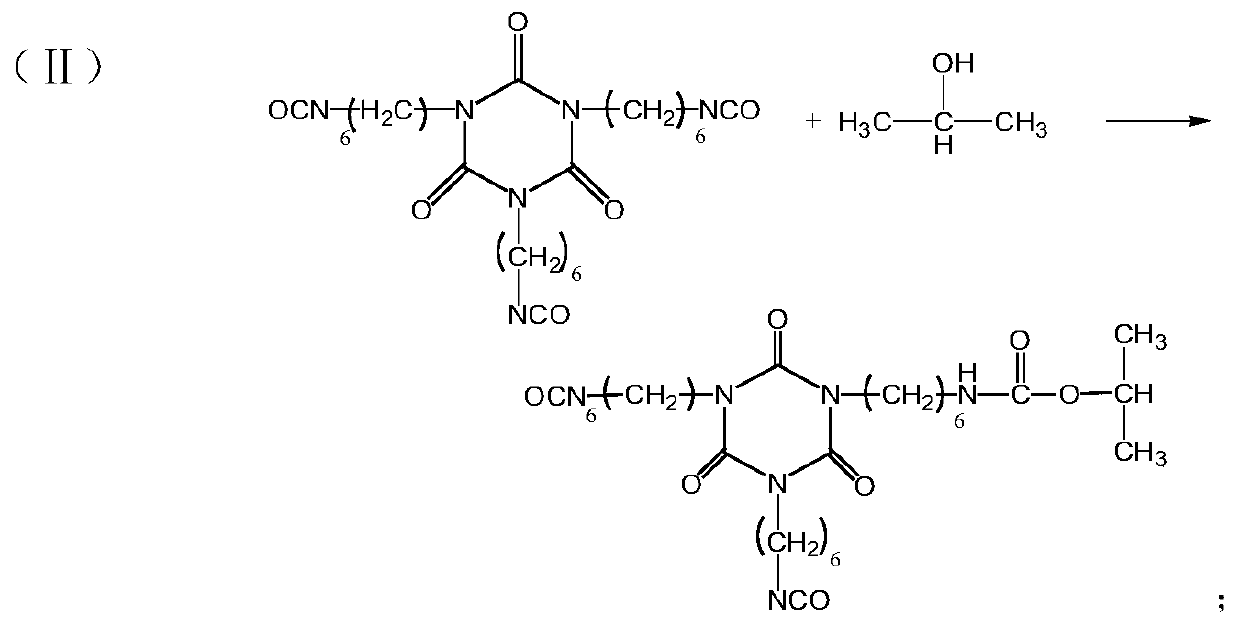

[0076] (1) Synthetic component a: prepolymer Y-2

[0077] ①In a 2000ml four-necked flask, add 572.7g of isocyanate monomer HT-100, 90g of small molecular unit alcohol n-butanol, stir at 200r / min, protect with nitrogen, heat up to 50-60°C for 2h;

[0078] ② Add 500g of vacuum dehydrated macromolecular polycarbonate diol PCDL T5651, 1.5g of catalyst dioctyltin dilaurate to step ① and heat it up to 70-80°C for 3 hours; stop nitrogen, add 200g of active diluent acrylic acid Stir at 200r / min for 10min after isobornyl IBOA, and discharge to obtain prepolymer Y-2, which is sealed and stored until use.

[0079] The appearance of Y-2 is clear and transparent, and its viscosity is 3170mPa·s.

[0080] Note: HT-100 is hexamethylene diisocyanate trimer, manufactured by Wanhua Chemical Group Co., Ltd.; PCDL T5651 is polycarbonate diol, molecular weight 1000, manufactured by Asahi Kasei Corporation.

[0081] (2) Preparation of moisture-curable anaerobic adhesive SYJ-3

[0082] In a 1L fou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com