Hot melt adhesive for waterproof roll and preparation method of hot melt adhesive

A technology of waterproof membrane and hot melt adhesive, which is applied in the direction of adhesive, adhesive type, mineral oil hydrocarbon copolymer adhesive, etc. The strength and volatility cannot meet the higher requirements for use, so as to achieve the effect of improving the anti-aging ability, improving the service life and reducing the volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

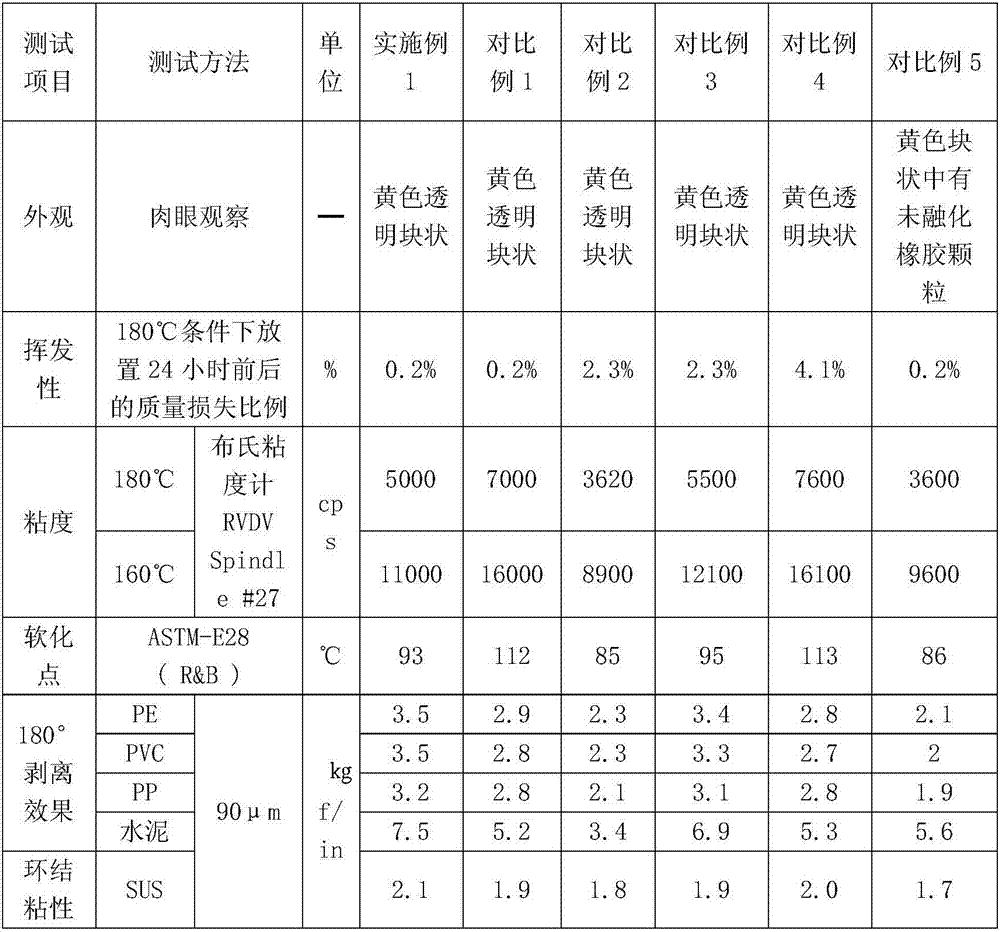

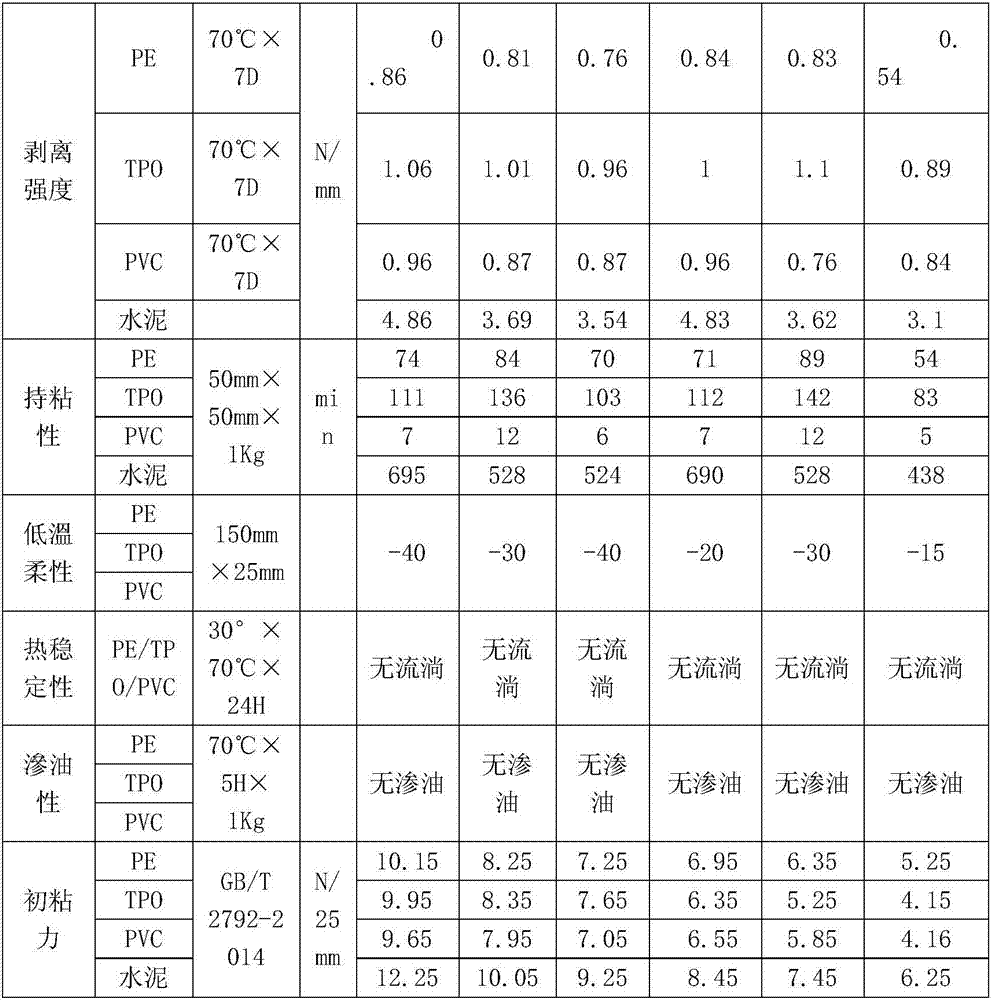

Examples

Embodiment 1

[0029] A hot-melt adhesive for waterproof membranes, prepared from the following components in parts by weight: 100 parts of styrene-butadiene rubber, 250 parts of SIS rubber, 250 parts of Kristalex5140, tetrakis[β-(3,5-di-tert-butyl 5 parts of -4-hydroxyphenyl) propionate] pentaerythritol ester, 5 parts of n-octadecyl β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate, 5 parts of 2-(2-hydroxy -10 parts of 5'-methylphenyl)benzotriazole, 100 parts of Karamay 4010, 100 parts of Ssangyong 250N, and 100 parts of polyisobutylene PB1300.

[0030] The preparation method of the above-mentioned waterproof coiled material hot melt adhesive comprises the following steps:

[0031] 1) Take part of Karamay 4010 and South Korea Ssangyong 250N into the reactor, heat to 150°C, add styrene-butadiene rubber, turn on the vacuum device to make the vacuum in the reactor reach 0.08 atmospheres, continue heating to 150-165°C, butadiene After the styrene rubber is completely melted, add the remaining K...

Embodiment 2

[0034] A hot-melt adhesive for waterproof membranes, prepared from the following components in parts by weight: 50 parts of styrene-butadiene rubber, 200 parts of SEPS rubber, 200 parts of Kristalex3085, tetrakis[β-(3,5-di-tert-butyl 2 parts of -4-hydroxyphenyl) propionate] pentaerythritol ester, 3 parts of n-octadecyl β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate, 2-(2-hydroxy -5'-methylphenyl)benzotriazole 5 parts, Karamay 4010 200 parts, polyisobutylene PB1300 100 parts

[0035] The preparation method of the above-mentioned waterproof coiled material hot melt adhesive comprises the following steps:

[0036] 1) Take part of Karamay 4010 and add it to the reactor, heat it to 150°C and add styrene-butadiene rubber, turn on the vacuum device to make the vacuum in the reactor reach 0.08 atmospheres, continue heating to 150-165°C, and the styrene-butadiene rubber is completely melted Finally, add the remaining Karamay 4010, all SEPS rubber and 160 parts of Kristalex3085, and ...

Embodiment 3

[0039] A hot-melt adhesive for waterproof coils, prepared from the following components in parts by weight: 50 parts of styrene-butadiene rubber, 300 parts of SIS rubber, 300 parts of C9 petroleum resin, tetrakis [β-(3,5-ditert 10 parts of butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 10 parts of n-octadecyl propionate of β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate, 2-(2 -Hydroxy-5'-methylphenyl)benzotriazole 10 parts, 2-(2-hydroxy-3-tert-butyl-5-methylphenyl)-5-chlorobenzotriazole 10 parts, South Korea Ssangyong 250N 200 parts, polyisobutylene PB1300

[0040] The preparation method of the above-mentioned waterproof coiled material hot melt adhesive comprises the following steps:

[0041]1) Take part of Ssangyong 250N of South Korea and add it to the reactor, heat it to 150°C and add styrene-butadiene rubber, turn on the vacuum device to make the vacuum in the reactor reach 0.08 atmospheres, continue heating to 150-165°C, the styrene-butadiene rubber is compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com