Medical-packaging use paper-plastic lamination adhesive based on waterborne epoxy resin type and preparation method thereof

A water-based epoxy resin, paper-plastic composite technology, applied in the direction of epoxy resin glue, adhesive, wax adhesive, etc., can solve the problems of low peel strength, poor water resistance, high temperature resistance, etc., and achieve smooth hand feeling and water resistance Increased, high-adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

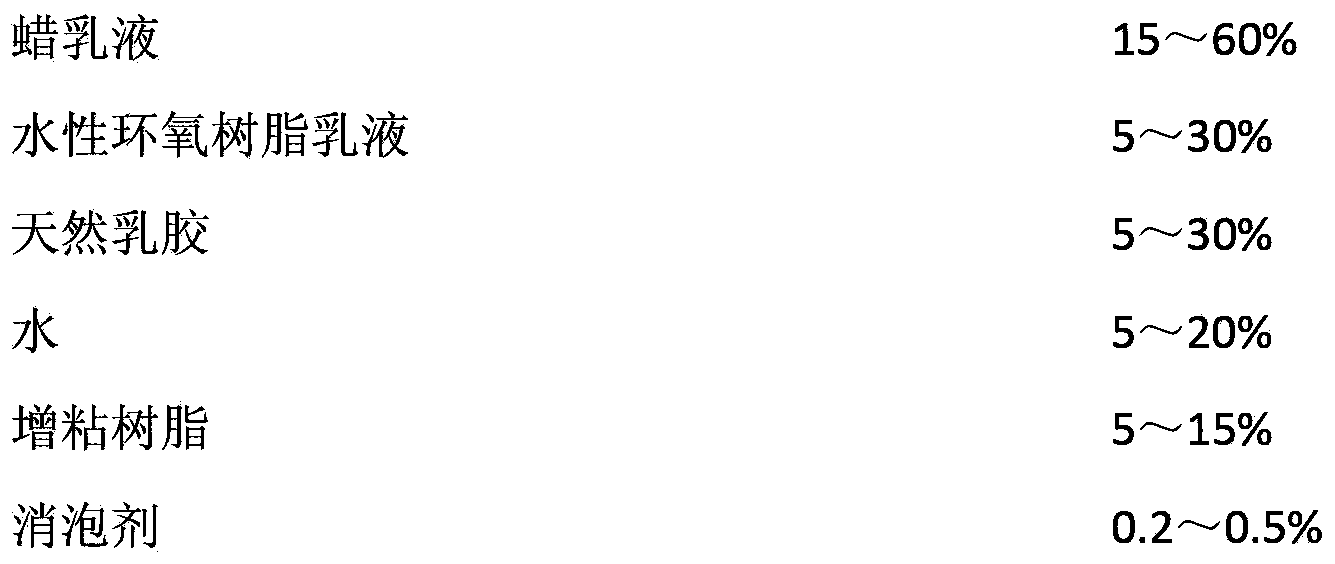

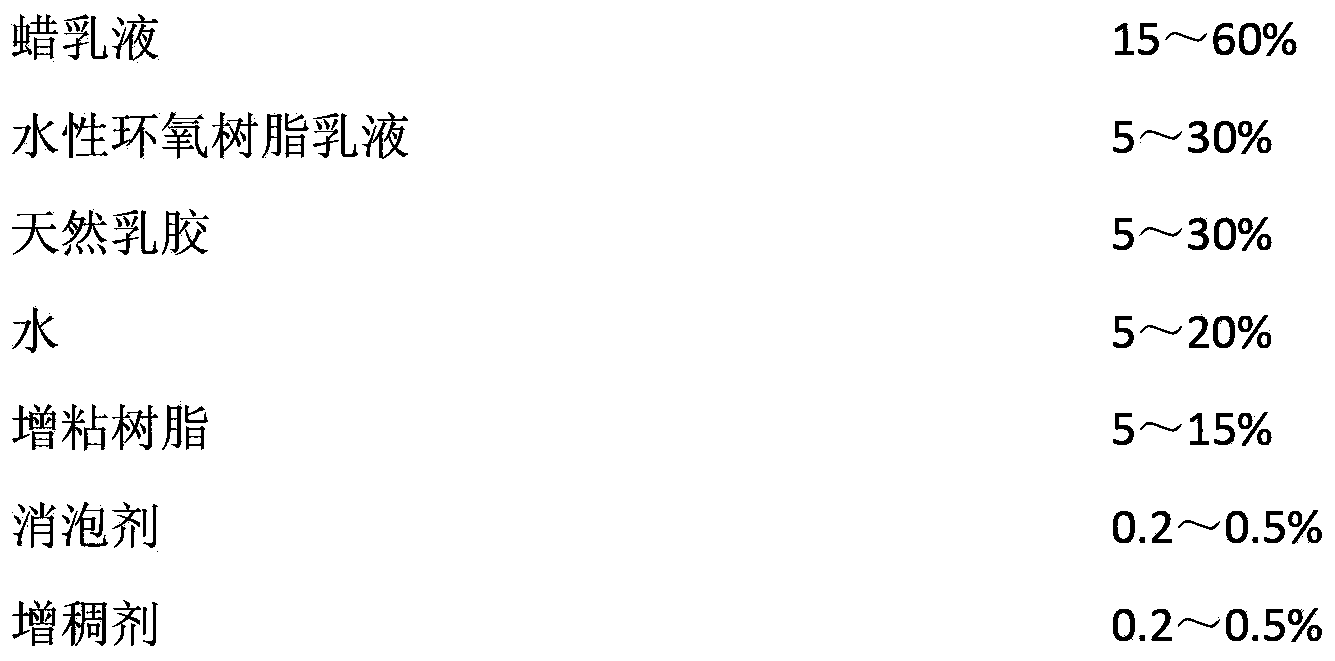

Method used

Image

Examples

Embodiment 1

[0057] (1) Take 4g of carnauba wax, 3g of South African Sasol wax, and 3g of ozokerite wax and put them into the reactor, dissolve all the mixed wax at 120°C and a stirring speed of 300rpm, and add 2g of triethanolamine; another 2g of OP ‐10, 2g fatty alcohol polyoxyethylene ether (AEO), 1g fatty alcohol polyoxyethylene ether sulfate (AES) and 2g sodium dodecyl sulfate (SDS), dissolved together in 40g deionized water, sheared at 2000rpm Slowly add it to the mixed wax while dispersing, and after dispersing for 50 minutes, a wax emulsion is obtained.

[0058] (2) Mix the wax emulsion obtained in step (1) with 8g of water-based epoxy resin emulsion 3522 (Guangzhou Libaoshi Trade Development Co., Ltd.) and place it in a dispersion kettle. Add 0.3g of it at room temperature at a stirring speed of 600rpm SPA‐202, disperse for 10 minutes.

[0059] (3) After adjusting the stirring speed in step (2) to 200rpm, add 10g of natural latex and disperse for 90min.

[0060] (4) Keep the sti...

Embodiment 2

[0073] (1) Put 10g of beeswax, 5g of liquid paraffin, and 5g of microcrystalline wax into the reactor, dissolve the mixed wax at 60°C and a stirring speed of 400rpm, and add 3g of triethanolamine; Oxyethylene ether (AEO), 2g sodium dodecylbenzenesulfonate (SDBS), 2g sodium dodecyl sulfate (SDS), 1g alkylphenol polyoxyethylene (10) ether (OP‐10) and dissolve together In 60g of deionized water, slowly add to the mixed wax under 3000rpm shear dispersion, and after dispersing for 30min, a wax emulsion is obtained.

[0074] (2) Mix the wax emulsion obtained in step (1) with 15g of water-based epoxy resin emulsion 3520‐WY‐55A (Guangzhou Libaoshi Trade Development Co., Ltd.) Add 0.1g BKY‐045, 0.2g DEUCHEM090, and disperse for 60min.

[0075] (3) After adjusting the stirring speed in step (2) to 300rpm, add 20g of natural latex and disperse for 80min.

[0076] (4) Keep the stirring speed in step (3) constant, add 3g of terpene resin emulsion, 3g of water-based rosin glyceride emulsi...

Embodiment 3

[0089] (1) Put 30g of modified montan wax (Beijing Kangli, model s) into the reactor, melt the epoxy resin and wax at 100°C and a stirring speed of 500rpm, and add 5g of triethanolamine; another 2g of Tween-20 , 2g Span‐20, 1g fatty alcohol polyoxyethylene ether sulfate (AES), 1g sodium dodecyl sulfate (SDS) were dissolved in 50g deionized water together, and slowly added to the mixed emulsion under the shear dispersion of 2500rpm , after dispersing for 30min, a wax emulsion was obtained.

[0090] (2) Mix the wax emulsion obtained in step (1) with 12g of water-based epoxy resin emulsion 3540‐WY‐55A (Guangzhou Libaoshi Trade Development Co., Ltd.) Add 0.4g DEUCHEM091 at room temperature and disperse for 15min.

[0091] (3) After adjusting the stirring speed in step (2) to 300rpm, add 20g of natural latex and disperse for 80min.

[0092] (4) Keep the stirring speed in step (3) constant, add 10g of water-based rosin glyceride emulsion to disperse for 15min.

[0093] (5) Keep t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com