High-performance recovered PET/ABS alloy

A high-performance, alloy technology, applied in the field of polymer materials, can solve problems such as the narrow controllable temperature range of alloy processing, the decrease of PET molecular weight, and the difficulty of guaranteeing product quality, etc., to achieve good fluidity, improved impact strength, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]Weigh and dry recycled PET flakes 80.0%, ABS resin 10.1%, AS resin 1.0%, AS-g-MAH 3.0%, polybutadiene rubber 5.0%, ethylene glycol 0.5%, antioxidant Tetrakis(β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate) pentaerythritol ester (antioxidant 1010) 0.4%. The mixed material is fed into a twin-screw extruder, melted and blended, extruded and granulated into an alloy material. Among them, the processing temperature is 190~235℃, the residence time is 2~3min, and the melt pressure is above 12MPa.

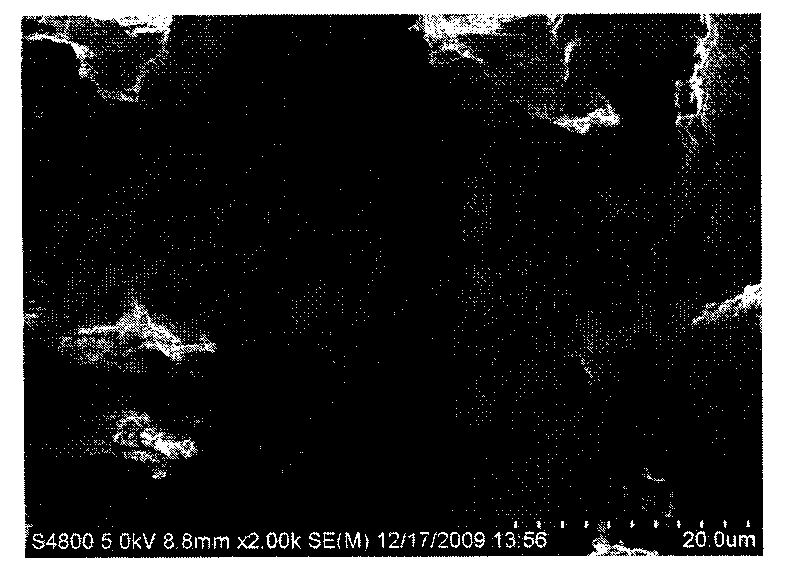

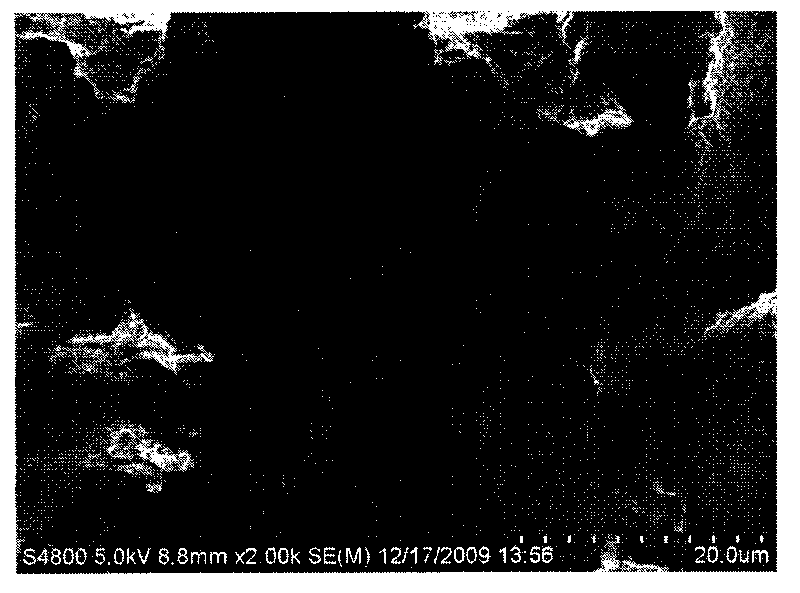

[0039] figure 2 It is the electron micrograph of embodiment 1 high performance recycling PET / ABS alloy impact section

[0040] From figure 2 It can be seen that the section of the high-performance recovered PET / ABS alloy provided by the present invention exhibits large undulations, is an obvious ductile fracture morphology, and has continuous alloy morphology without obvious macroscopic phase separation; and figure 1 The cross-section of the alloy shown is smooth, with obvious...

Embodiment 2

[0042] Weigh and dry recycled PET flakes 69.8%, ABS resin 10.8%, polymethyl methacrylate 5.8%, PS-g-PMMA 5.1%, methyl methacrylate-butadiene-styrene Terpolymer 4.5%, 1,10-decanediol 3.0%, antioxidant 1010 1.0%. The mixed material is fed into a twin-screw extruder, melted and blended, extruded and granulated into an alloy material. Among them, the processing temperature is 190~235℃, the residence time is 2~3min, and the melt pressure is above 12MPa.

Embodiment 3

[0044] Weigh and dry recycled PET flakes 60.3%, ABS resin 16.2%, glass fiber 3.6%, SEBS-g-MAH 12.1%, chlorinated polyethylene 4.3%, polyethylene glycol 2.7%, antioxidant 10100.8%. The mixed material is fed into a twin-screw extruder, melted and blended, extruded and granulated into an alloy material. Among them, the processing temperature is 190~235℃, the residence time is 2~3min, and the melt pressure is above 12MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com