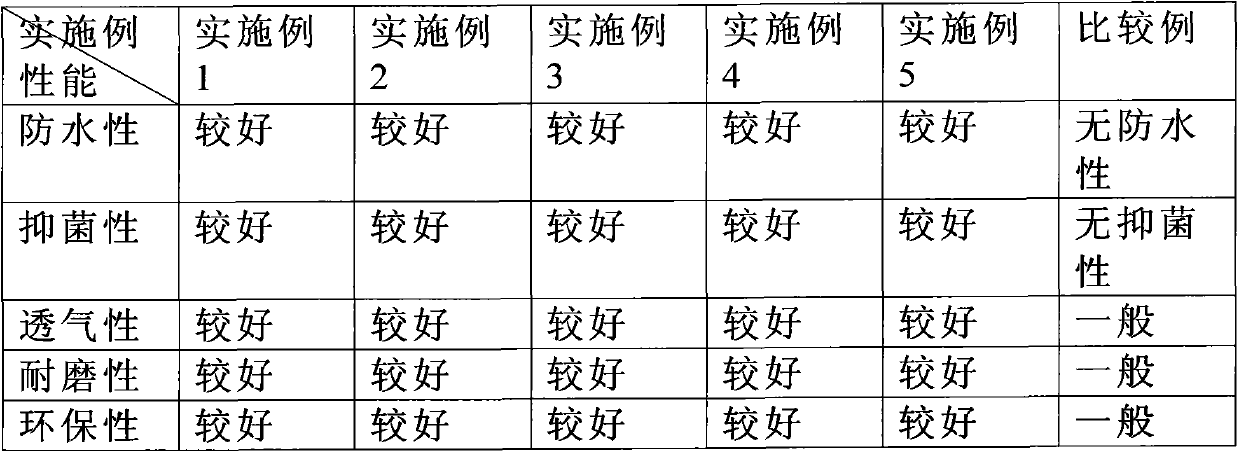

Patents

Literature

449results about How to "Good toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hard alloy sintered by high-entropy alloy binder and compound carbide and preparation method thereof

The invention relates the high entropy alloy binding agent and hard alloy sintered by multicarbide and preparing method, comprising the following steps: clinkering polyhydric high entropy alloy powder binding phase and multicarbide, the binding phase comprising 5-10 kinds metallic elements, every kind of whose content is between 5%-30%; the multicarbide hand base comprises 2-4 super hand carbides, every kind of whose content is between 5%-90%. The invention has the advantages of high hand, high tenacity and high fire-resisting property.

Owner:SHAOGUAN COLLEGE

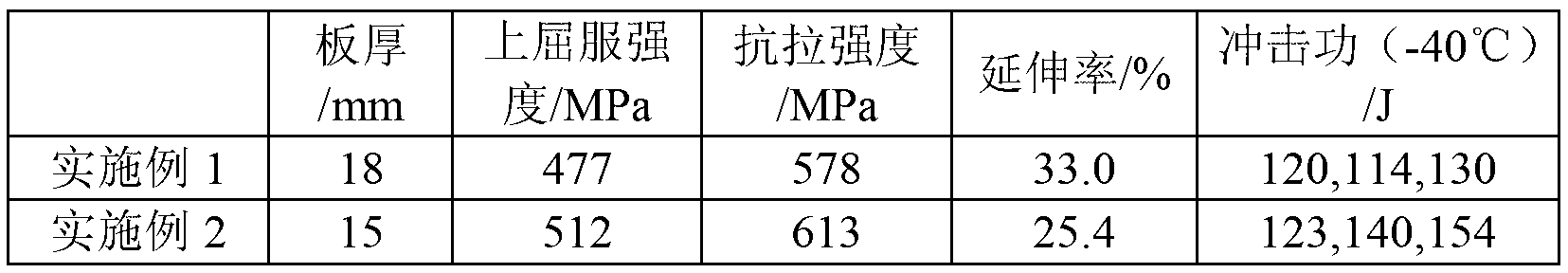

High-performance weather-proof building structural steel and manufacturing method thereof

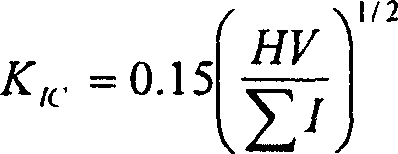

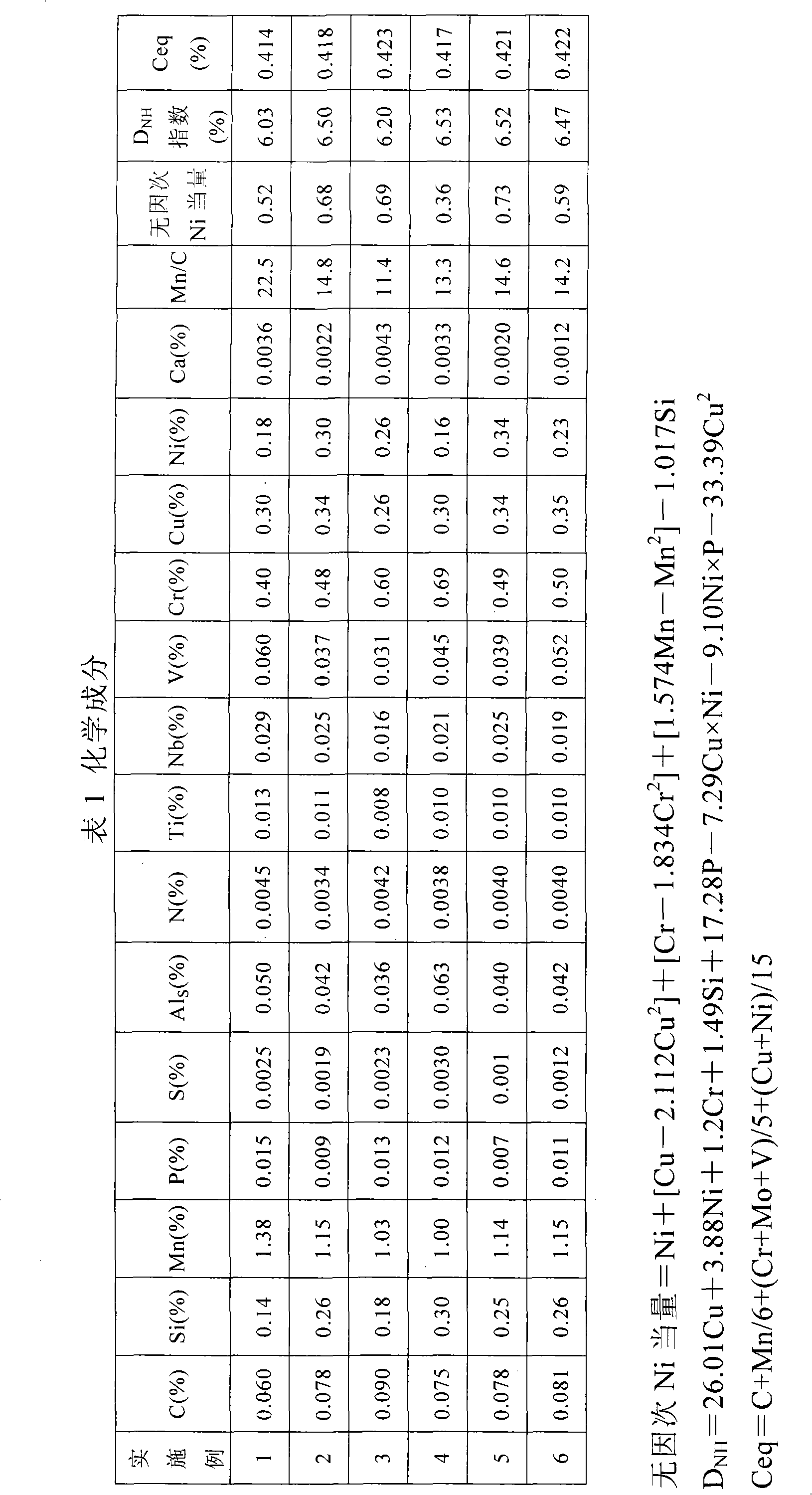

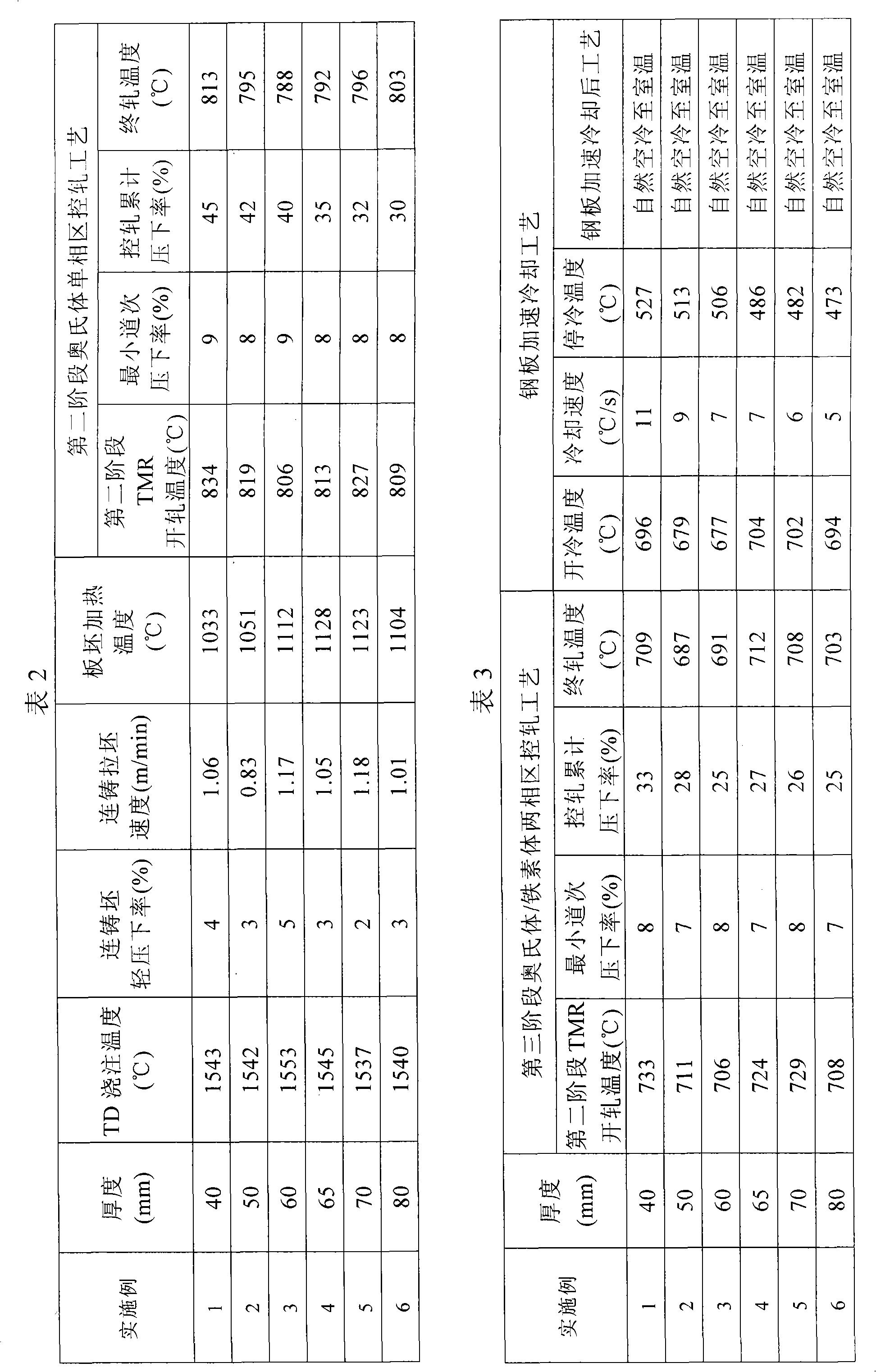

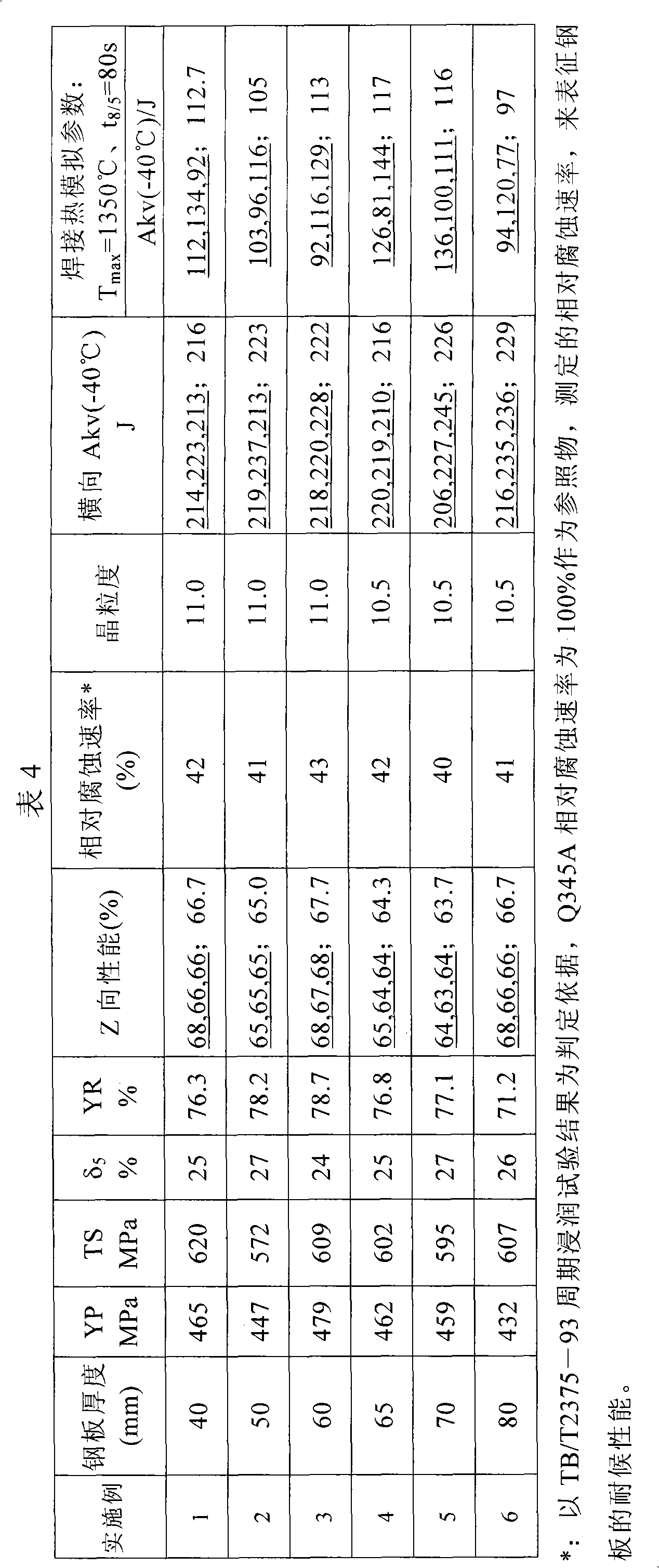

The invention relates to high-performance weather-proof building structural steel and a manufacturing method thereof. The composition system of low C-medium Mn-low N-micro Nb alloying-ultramicro Ti processing low content alloy weather-proof steel is taken as foundation, the acid solution Als content in the steel is increased properly, and the range of the acid solution Als content is controlled; the zero dimension Ni equivalent weight is controlled to be more than or equal to 0.35, the Ceq is less than or equal to 0.425%, and the Mn / C is more than or equal to 10; the weather-proof property index DNH is more than or equal to 6.0%; and the Ca is processed, the Ca / S is controlled within the range of 1.0-3.0, and Ca*S 0.28 is less than or equal to 1.0*10<-3>. By adopting a TMCP technique, a weather-proof steel plate with good toughness, strong plasticity matching, low yield ratio, atmosphere corrosion resistance, excellent weldability and anti-fatigue performance can be obtained, is especially suitable for non-coating high-rise building structure and bridge structure, and can realize stable batch industrialized production with low cost.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

Welding wire for modified 9Cr-1Mo steel, and submerged-arc welding material

InactiveUS20050257853A1Good toughnessImprove toughnessArc welding apparatusWelding/cutting media/materialsSubmerged arc weldingToughness

A welding wire for a modified 9Cr-1Mo steel is provided which comprises C: 0.070 to 0.150% by mass, Si: more than 0.15% by mass, but not more than 0.30% by mass, Mn: not less than 0.30% by mass, but less than 0.85% by mass, Ni: 0.30 to 1.20% by mass, Cr: 8.00 to 13.00% by mass, Mo: 0.30 to 1.40% by mass, V: 0.03 to 0.40% by mass, Nb: 0.01 to 0.15% by mass, N: 0.016 to 0.055% by mass, P: not more than 0.010% by mass, S: not more than 0.010% by mass, Cu: less than 0.50% by mass, Ti: not more than 0.010% by mass, Al: less than 0.10% by mass, B: less than 0.0010% by mass, W: less than 0.10% by mass, Co: less than 1.00% by mass, and O: not more than 0.03% by mass, wherein the total amount of Mn and Ni being not more than 1.50%. The welding wire provides good toughness without degradation of creep rupture strength even at the PWHT temperature of 760° C. or above.

Owner:KOBE STEEL LTD

Nano-silver-containing sodium alginate based antibacterial medical dressing and preparation method thereof

ActiveCN103446621AGood toughnessHemostasis Wound HealingAbsorbent padsBandagesChemistryInterpenetrating polymer network

The invention provides a preparation method of a nano-silver-containing sodium alginate based antibacterial medical dressing, and relates to an antibacterial medical dressing with sodium alginate as a main raw material, solving the problems that the air permeability is poor, the wettability is low, the antibacterial performance is not realized and the like in the existing dressing and a preparation method thereof. The medical dressing provided by the invention is composed of silver nanoparticles, sodium alginate and an interpenetrating polymer network film. The preparation method provided by the invention comprises the following steps: I, preparing nano-silver loaded sol; II, preparing a sodium alginate solution loaded with silver nanoparticles; III, preparing a crosslinked polymer solution; IV, preparing a mixing solution used for processing the dressing; V, preliminarily processing and forming the dressing; and VI, preparing the nano-silver-containing sodium alginate based antibacterial medical dressing. The dressing is able to quickly control major bleeding, has antibacterial performance, is outstanding in moisture absorption performance, high in moisture-vapor transmission and biocompatibility, and biodegradable, has the capacity of promoting wound healing and is low in price, simple and convenient to operate, and suitable for mass production.

Owner:哈尔滨生材新材料科技发展有限公司

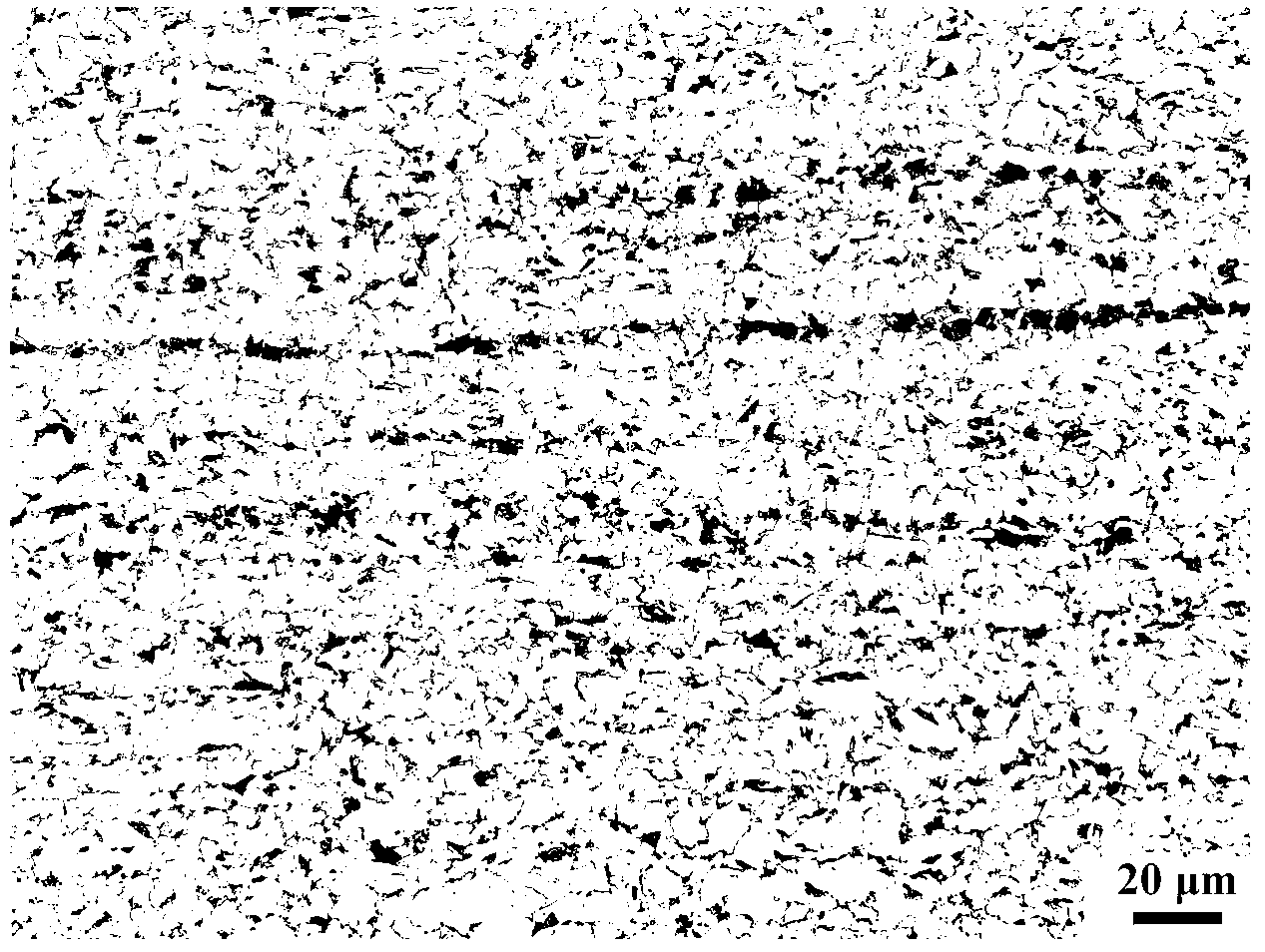

Normalizing vessel steel with 460MPa grade yield strength and manufacturing method thereof

The invention provides a normalizing vessel steel with a 460MPa grade yield strength. The steel comprises the following chemical components by weight: 0.10-0.20% of C, 0.30-0.40% of Si, 1.40-1.80% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.010-0.050% of Nb, 0.010-0.040% of Al, less than or equal to 0.10% and greater than or equal to 0.04% of Ti, and the balance Fe and inevitable impurities. The production process of the steel disclosed in the invention employs two-stage controlled rolling, controlled cooling and normalizing, and the manufactured steel plate has a microstructure composed of ferrites and pearlite, a yield strength of greater than or equal to 460MPa, a tensile strength of greater than or equal to 570MPa, and low temperature toughness of greater than or equal to 100J at -40DEG C. The steel provided in the invention has excellent obdurability and comprehensive performance, and can be used for manufacturing spherical gas storage tanks, liquefied gas tankers and the like.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

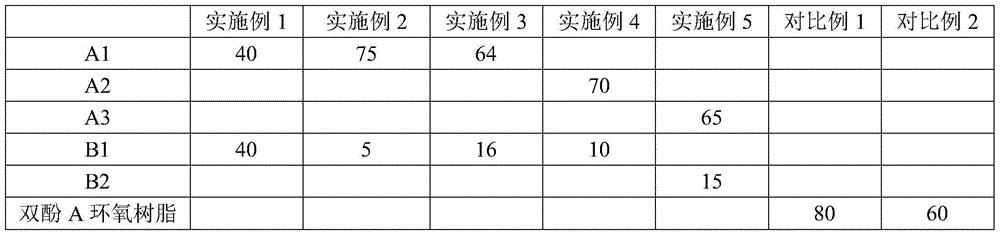

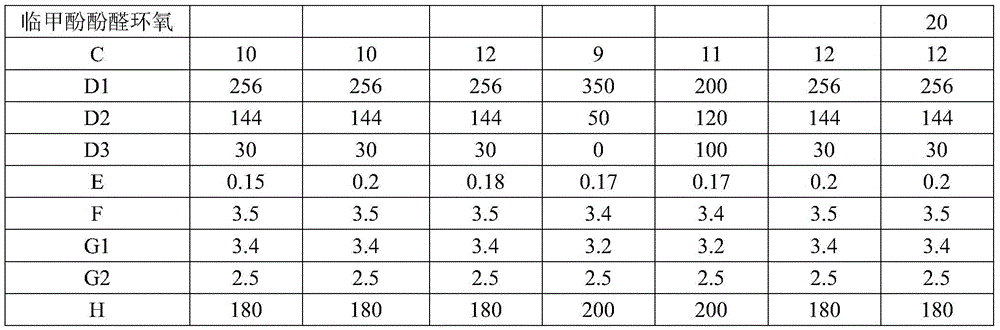

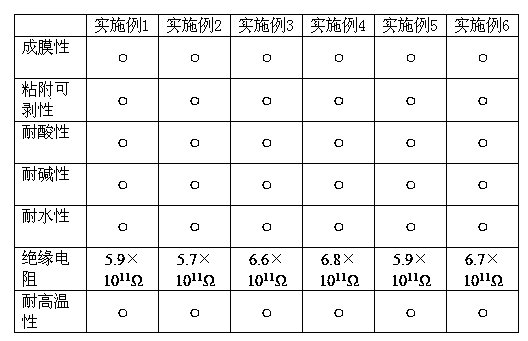

High-thermal conductivity resin composition and application thereof

The invention discloses a high-thermal conductivity resin composition. The high-thermal conductivity resin composition is prepared from the following components in parts by weight: 40 to 75 parts of BMI (Bismaleimides) modified epoxy resin, 5 to 40 parts of flexible modified epoxy resin, 360 to 480 parts of thermal conducting fillers, 8 to 30 parts of curing agent, 2 to 6 parts of coupling agent, 0.05 to 0.85 part of curing accelerator and 1 to 5 parts of additive. According to the high-thermal conductivity resin composition disclosed by the invention, by introducing the BMI modified epoxy resin in a system, the advantages of epoxy resin and BMI are integrated; meanwhile, the flexible modified epoxy resin and the thermal conducting fillers are added, so that a new resin composition has excellent toughness, excellent thermal conductivity and higher Tg (Glass Transition Temperature). A metal-based copper-clad plate prepared by adopting the high-thermal conductivity resin composition disclosed by the invention has the excellent comprehensive properties such as high thermal conductivity coefficient, high breakdown voltage, high peel strength, higher Tg and good flexibility.

Owner:SHAANXI SHENGYI TECH

Precision grinding wheel for high-efficiency aluminum oxide ceramic microcrystalline grinding materials

InactiveCN101797724AGood toughnessSmall grinding deformationAbrasion apparatusAlumina ceramicAluminium oxide

The invention relates to a precision grinding wheel for high-efficiency aluminum oxide ceramic microcrystalline grinding materials, comprising a grinding wheel basal body, grinding material particles distributed on the grinding wheel basal body and a bonding agent bonded and fixed on the grinding material particles, wherein the bonding agent comprises the following components in percentage by weight: 10-15 clay powder, 30-50 feldspar powder, 20-40 talcum powder and 10-20 high-boron glass powder. The grinding wheel has the functions of large cutting depth, high feeding strength, large load and high-efficiency grinding. According to tests, over 0.3 mm can be reached for one-way feeding and the metal removing rate is over 2 times higher than that of a common corundum grinding wheel. The grinding wheel ahs the advantages of high durability, long service life which is 5-10 times that of the common corundum grinding wheel, favorable self sharpening, no blockage and high capability of maintaining stable grinding performance.

Owner:SUZHOU FAR EAST ABRASIVES

Fe-Cr-B cast abrasion-resistant alloy and manufacturing method thereof

The invention discloses Fe-Cr-B cast abrasion-resistant alloy and a manufacturing method thereof, the alloy comprises the following chemical compositions by mass percent: 0.22-0.45% of C, 12.0-18.0% of Cr, 0-8-1.5% of Si, 0-6-1.5% of Mn, 0-9-1.2% of B, 0.30-0.45% of Ni, 0.02-0.04% of Mg, 0.03-0.05% of Ce, 0.04-0.08% of Ti, 0.008-0.015% of N, 0.06-0.09% of Zn, less than 0.04% of S, less than 0.04% of P and the balance of Fe. After melting, casting and hot-processing, the hardness and toughness of the Fe-Cr-B cast abrasion-resistant alloy can be adjusted in a wide range so as to meet the requirements of different abrasion working conditions. The invention uses low-cost chromium and boron as the main alloying elements, does not contain expensive alloying elements such as tungsten, molybdenum, vanadium, niobium and the like, has the characteristics of high hardness, good toughness and the like, and has low cost, and has good economic benefit when being popularized.

Owner:BEIJING UNIV OF TECH

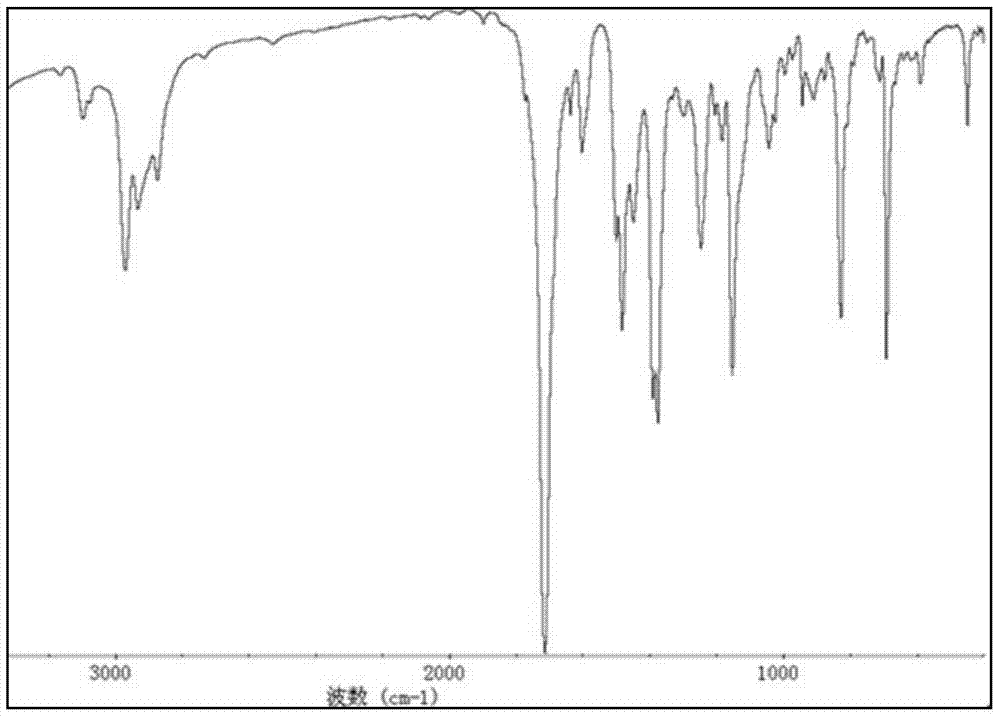

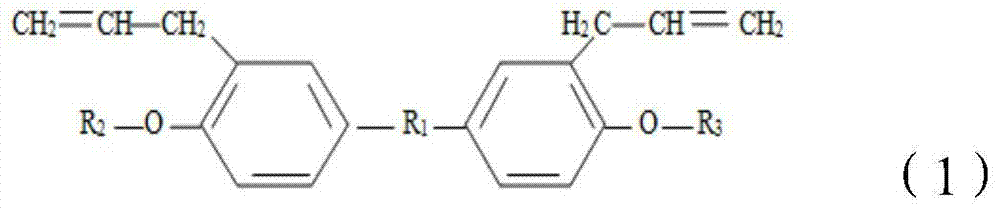

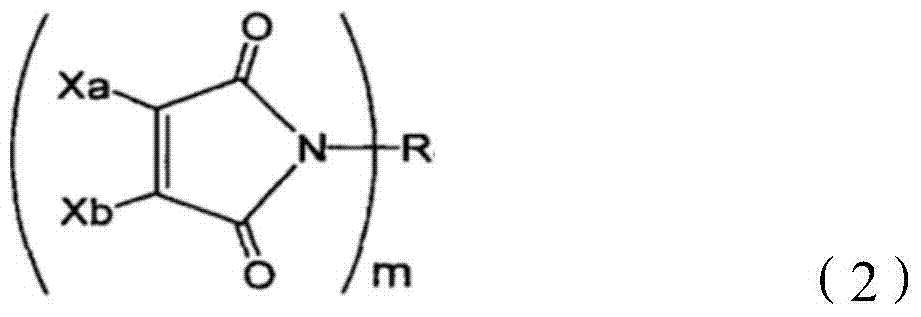

Thermosetting resin composition and applications thereof

ActiveCN103756315AGood thermal stability and heat and humidity resistanceGood toughnessSynthetic resin layered productsElectrical equipmentPrepolymerOxygen atom

The invention provides a thermosetting resin composition comprising a prepolymer of a diallyl compound and a maleimide compound, wherein the structural formula of the diallyl compound is shown as a formula (1) described in the specification; R1 is -C (CH3)2, -C (CF3)2, -SO2, -CH (CH3), -CH2 or an oxygen atom; R2 and R3 are same or different aliphatic hydrocarbon with the carbon number below 10 or aromatic hydrocarbon with the carbon number below 30; the R2 and the R3 contain no allyl group. The thermosetting resin composition has the advantages of good heat stability and heat and humidity resistance, low dielectric constant and dielectric loss angle tangent and excellent process machinability. The embodiment of the invention further provides applications of the thermosetting resin composition to resin sheets, resin composite metal foils, prepregs, laminated boards, metal foil clad laminates and printed circuit boards.

Owner:HONOR DEVICE CO LTD

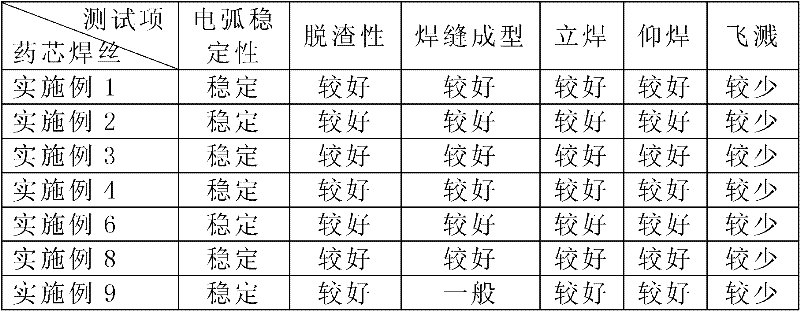

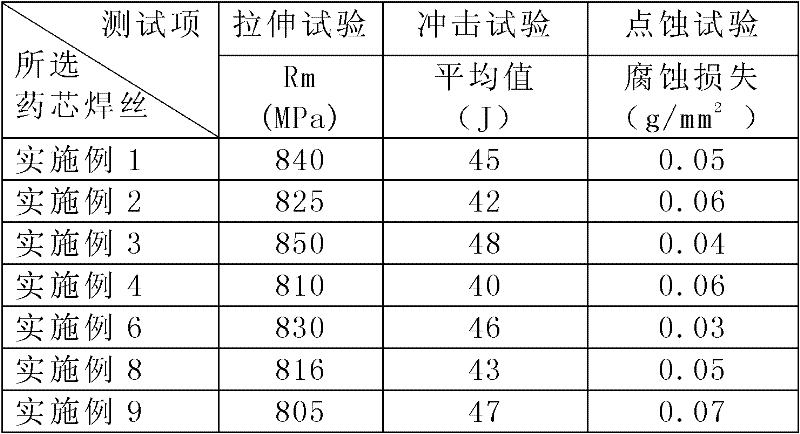

A metal powder type stainless steel flux cored welding wire

InactiveCN102267023ACompatibility is reasonableGood toughnessWelding/cutting media/materialsSoldering mediaCorrosionFilling rate

The invention relates to a metal-powder type stainless steel flux-cored wire and belongs to the technical field of welding materials. For the metal-powder type stainless steel flux-cored wire, a stainless steel belt serves as an outer skin, and a flux core is filled in the stainless steel belt at the filling rate of 30 to 40 percent to manufacture the flux-cored wire, wherein the flux core comprises chromium powder, nickel powder, molybdenum powder, manganese powder, an arc stabilizer, a deslagging agent and iron powder. The metal-powder type stainless steel flux-cored wire has the advantagesof reasonable compatibility, strong synergistic effect among components, good toughness, high metal strength and high corrosion resistance of a welded seam, stable combustion of the welding wire during welding, and low splattering; the welded seam is bright and elegant in molding; real production processes are simplified without subsequent acid-washing, grinding, polishing and the like; and industrialized production is more facilitated.

Owner:台州海翔焊接材料有限公司

Touch screen UV curing peelable blue gel and preparing method thereof

ActiveCN103421400AGood film formingGood toughnessInksPolyurea/polyurethane coatingsFirming agentBis epoxide

The invention relates to the technical field of touch screen peelable blue gel, in particular to touch screen UV curing peelable blue gel and a preparing method of the touch UV curing peelable blue gel. The touch screen UV curing peelable blue gel is composed of, by weight, 10-20% of organic fluorine silicone modified acrylic resin, 5-15% of phenolic epoxy acrylic resin, 5-15% of melamine acrylice resin, 5-15% of aliphatic polyurethane acrylic resin, 5-15% of acrylic monomers, 1-5% of light curing agents, 0.1-1% of silicon dioxide, 15-25% of nano barium sulfate, 10-20% of talcum powder and 0.1-1% of organic pigments, iron blue or ultramarine blue or cobalt blue or phthalocyanine blue. The four different kinds of resin are adopted to be cooperated and are mutually reinforced, the prepared peelable blue gel is good in film-forming property, and good toughness, good flexibility and good acid and alkali resistance are achieved after heat curing and film formation. After the conducting film protection process in the touch screen manufacturing process is completed, peeling is easy, and the situation that residues exist on the surface of materials, or the materials are contaminated is avoided.

Owner:DONGGUAN PINGBO ELECTRONICS

Solvent-free environment-friendly polyurethane automobile leather foamed layer resin, and preparation method and application thereof

ActiveCN104072715AGood toughnessGood water resistanceSynthetic resin layered productsTextiles and paperPolymer scienceAlcohol

The invention provides a solvent-free environment-friendly polyurethane automobile leather foamed layer resin which is formed by mixing a component A and a component B. The component A is composed of 50.0-85.0% of polyether dibasic alcohol, 10.0-37.5% of polyether tribasic alcohol, 1.5-5.5% of liquid chain extender, 0.5-2.0% of solid chain extender, 0.1-0.8% of deionized water, 0.8-1.2% of catalyst, 0.5-1.0% of light / heat stabilizer, 0.2-1.0% of foam stabilizer and 0.5-1.0% of solvent-free color paste. The component B is composed of 30.0-50.0% of polyether dibasic alcohol, 10.0-30.0% of polyether tribasic alcohol, 35.0-55.0% of aliphatic isocyanate, 0.05-0.1% of catalyst and 0.1-0.2% of H3PO4. The invention also provides a preparation method and application of the resin. The low-temperature bending strength of the resin can reach 0.1 million times at -25 DEG C.

Owner:XUCHUAN CHEM SUZHOU

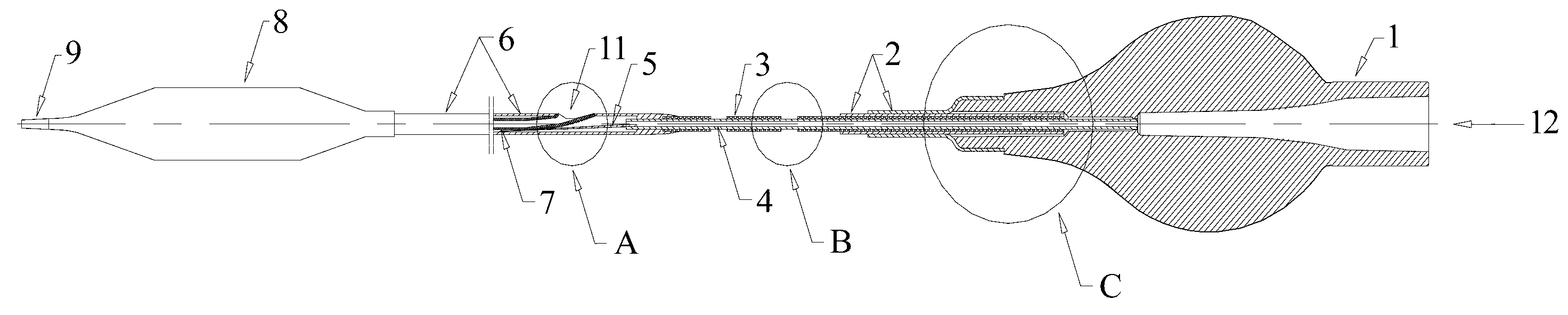

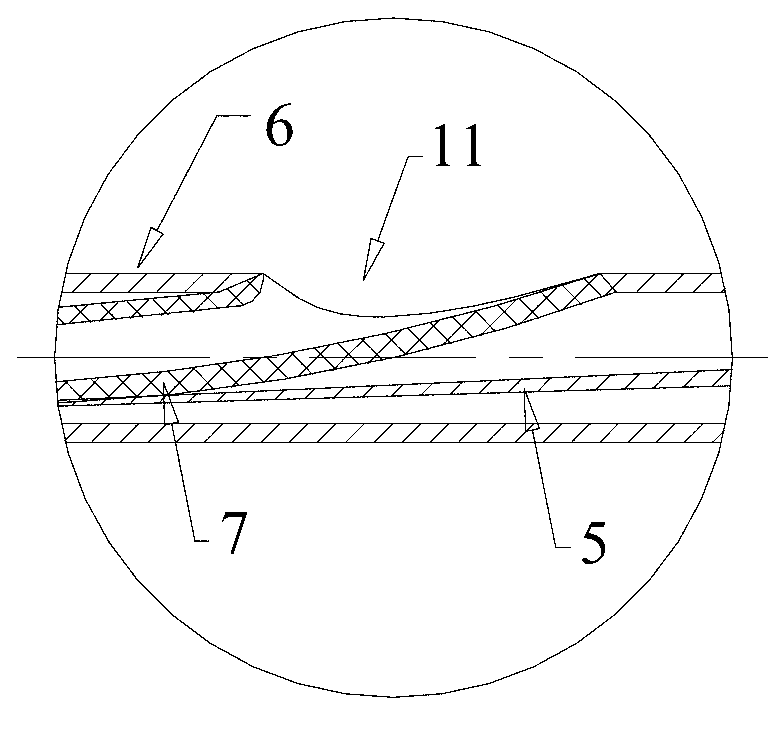

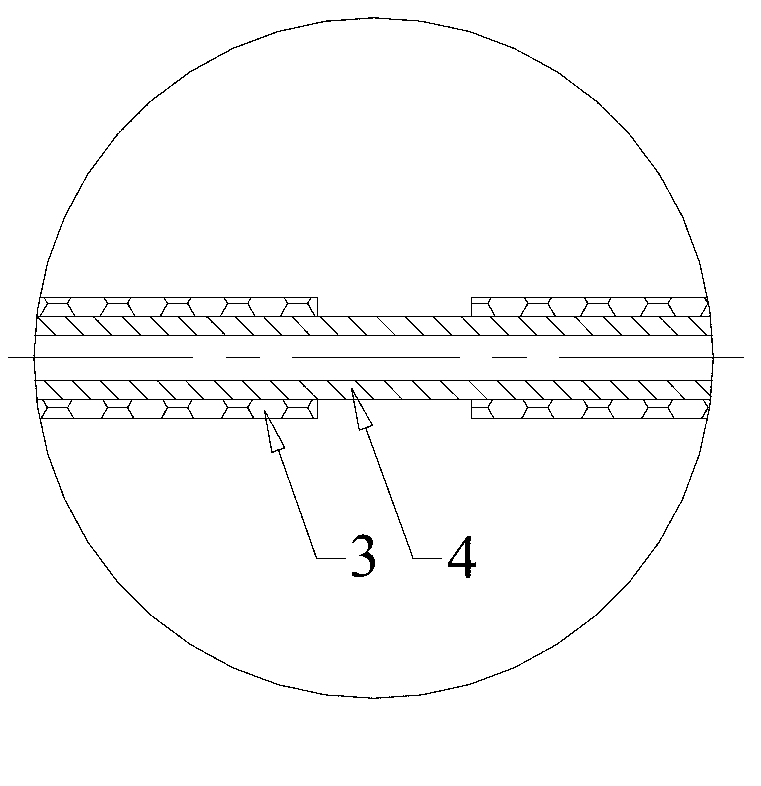

Balloon catheter and manufacturing method thereof

The invention discloses a balloon catheter and a manufacturing method thereof and aims to improve pushing capability and permeability of the balloon catheter, lower damage to blood vessels, and increase utilization rate of the balloon catheter. A balloon passes through a far-end outer catheter body and a near-end catheter body to a needle seat to form a pressure cavity. A far end of the balloon is connected with a catheter tip. The far-end outer catheter body is made of nylon or nylon elastomer. The near-end catheter body is made of stainless steel or nickel-titanium memory alloy. An inner catheter is arranged in the pressure cavity. A far end of the inner catheter is connected with the catheter tip. A near end of the inner catheter is a fast switching port for a guide wire. The manufacturing method includes obtaining parts and assembling. Compared with the prior art, by the catheter tip, the far end of the balloon catheter is good in tenacity and in good fit with the guide wire. During treating complex lesion such as curve blood vessels with lesion and chronic fully closed blood vessels with lesion, permeating capability of the balloon catheter through the blood vessels with lesion is high, the blood vessels with lesion can be expanded fully, blood vessel damage which can be caused easily can be reduced, and operation cost is lowered.

Owner:ORBUSNEICH MEDICAL SHENZHEN CO LTD

Preparation method of giant spiny frog feed

InactiveCN103461659AImprove disease resistanceLow costAnimal feeding stuffAnimal scienceAdditive ingredient

The invention discloses a preparation method of giant spiny frog feed. Premna herbs, pumpkins, chicory and soybeans are taken for use, sesame-seed cake dregs, sweet potato starch, blood meal, fish meal and the like are added as ingredients, and then the process including dosing, thickening, extrusion forming, drying and the like is performed, so that the nutrient health care daily feed taking the shape of an earthworm and used for giant spiny frogs can be prepared finally. In consideration of feeding habits of the giant spiny frogs, the finished feed comprises the tasty blood and fish meal with fishy smell as well as the sesame-seed cake dregs; the sweet potato starch, the premna herb leaves, the pumpkin pectin and the mucilage of soybean milk protein are contained in the feed, so that the surface of the matured feed is smooth, the density of the finished product is enhanced, the toughness is good, and the feed is still cohered when falling into water; the ingredients contain high content of nutrient health care components such as protein, amylopectin and various vitamins and microelements; as the daily feed for the giant spiny frogs, the feed is good in palatability, so that the appetite can be promoted, the daily gain is improved, and the disease resistance of the giant spiny frogs can be enhanced. The feed is low in cost, is adequate and balanced in various nutrient substances, is convenient to process, store and feed, and is high in input-output ratio.

Owner:珠海市德海生物科技有限公司

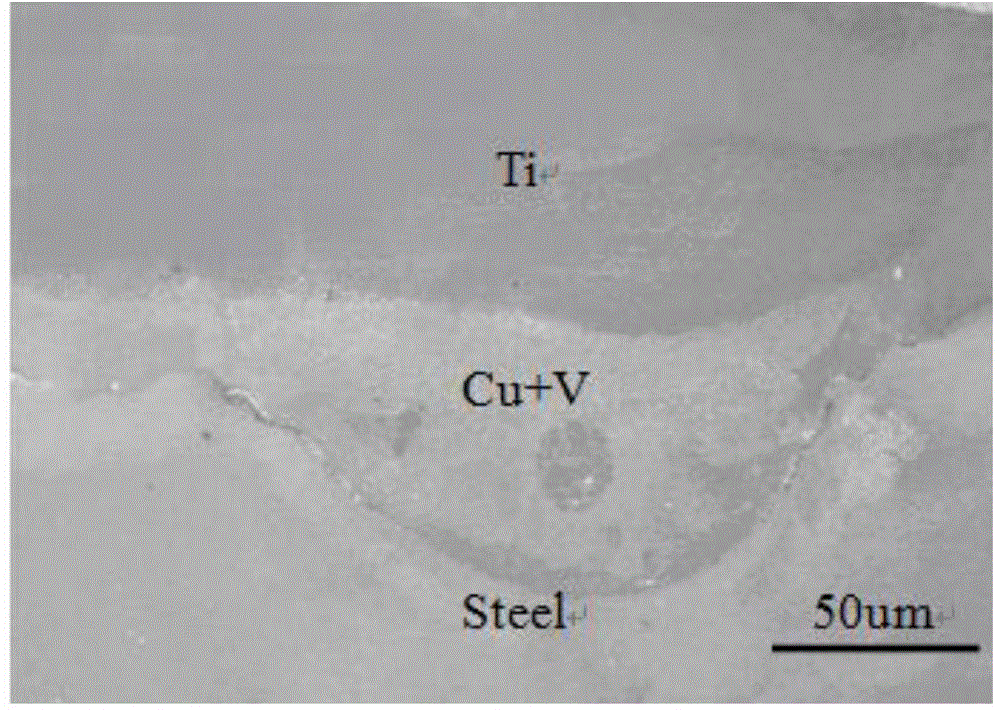

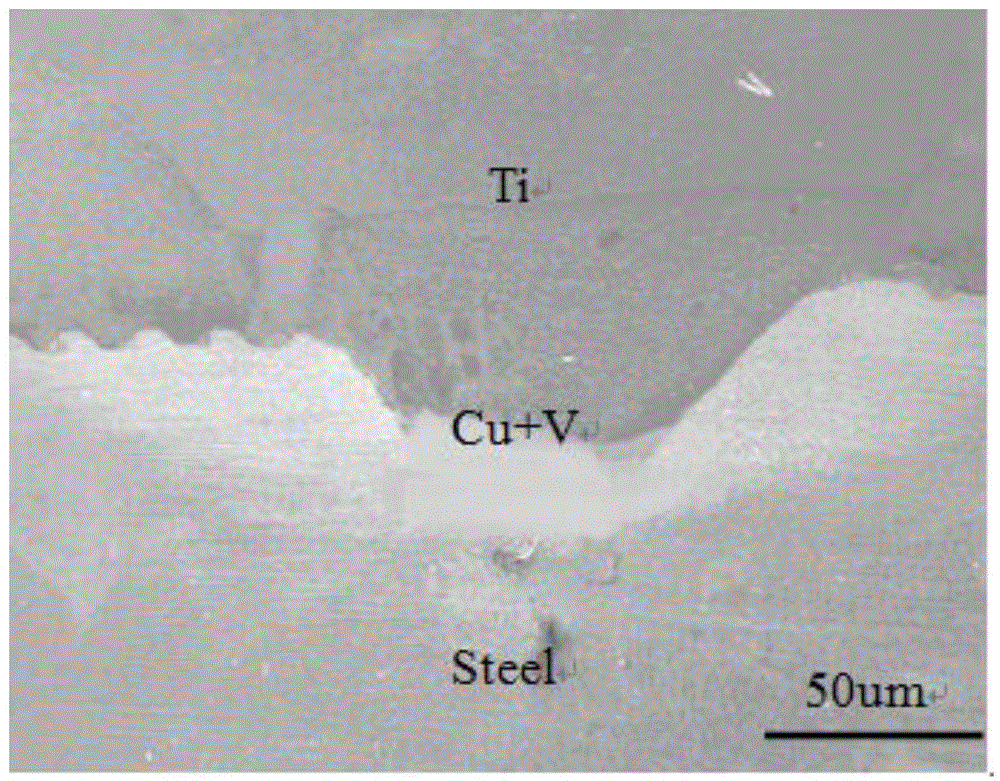

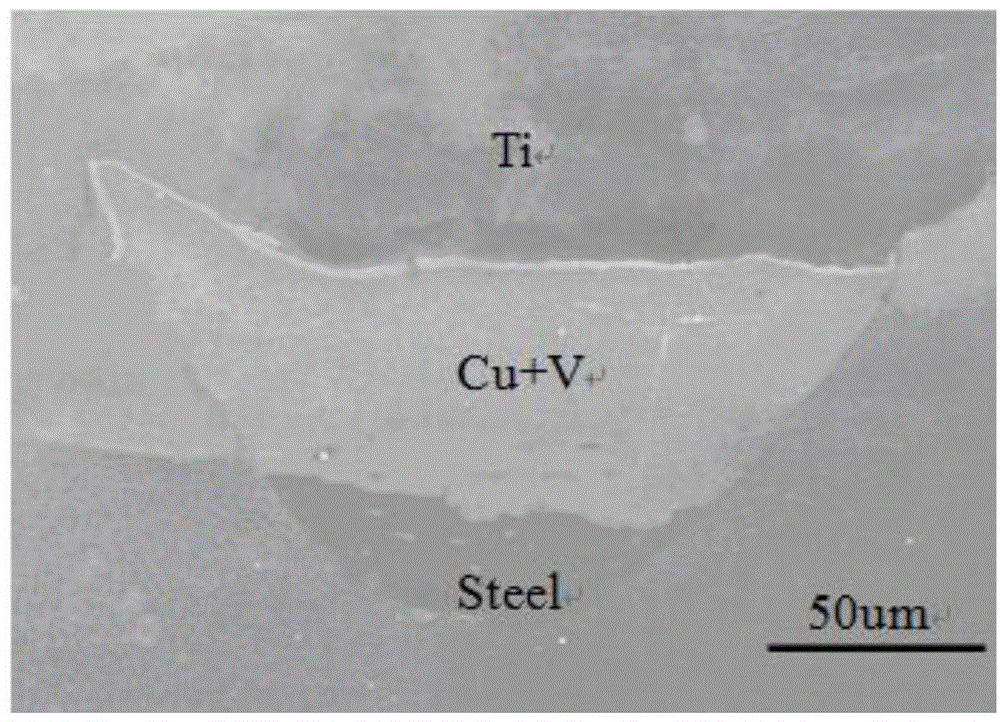

Flux-cored wire for titanium-steel composite board dissimilar joint transition layer and manufacturing method of flux-cored wire

InactiveCN104400249AGood toughnessEasy to control ingredientsArc welding apparatusWelding/cutting media/materialsTitaniumFusion welding

A flux-cored wire for a titanium-steel composite board dissimilar joint transition layer comprises a welding wire skin and a flux core; the skin is a copper strip with the purity of 99.99 percent; the flux core is made of vanadium powder; chemical components of the flux core comprise more than 99.9% of V, less than 0.05% of Fe, less than 0.05% of Si, less than 0.05% of Al, less than 0.04% of N, less than 0.05% of C, and less than 0.01% of H; and the sum of the mass percents of the chemical components is 100 percent. The invention further discloses a manufacturing method of the flux-cored wire. The method comprises the steps that the copper strip processed in the step 2 is rolled into a U shape through a forming machine, the vanadium powder dried in the step 1 is added into the copper strip and the filling rate of the vanadium powder is controlled in the range of 25 percent to 30 percent; then, six-level rough drawing is carried out on a welding wire until the diameter of the wire is 2.6 mm; and nine-level fine drawing is carried out on the welding wire until the diameter of the wire is 1.2 mm. The flux-cored wire can achieve fusion welding abut joint of a titanium-steel composite board; an obtained welding joint has the excellent toughness; the components can be easily controlled; a manufacturing technology is simple; and large-scale mass production can be conveniently carried out.

Owner:XIAN UNIV OF TECH

Multilayer film

ActiveUS20130167486A1Excellent processability and stiffnessGood toughnessPersonal careSynthetic resin layered productsPhysicsFood packaging

Multilayer film which comprises a core layer (C) and two outer layers (O—, O-2) sandwiching the core layer, wherein (i) the core layer (C) comprises a bimodal ethylene / 1-butene / C6-C12-alpha-olefin terpolymer, (ii) one outer layer (O-1) comprising (ii-1) a low density polyethylene or (ii-2) the bimodal terpolymer as defined for the core layer (C) or (ii-3) a metallocene produced linear low density polyethylene and optionally a low density polyethylene (iii) the other outer layer (O-2) comprising (iii-1) a metallocene produced linear low density polyethylene and optionally a low density polyethylene, and its use for packaging, especially for frozen food packaging.

Owner:BOREALIS AG

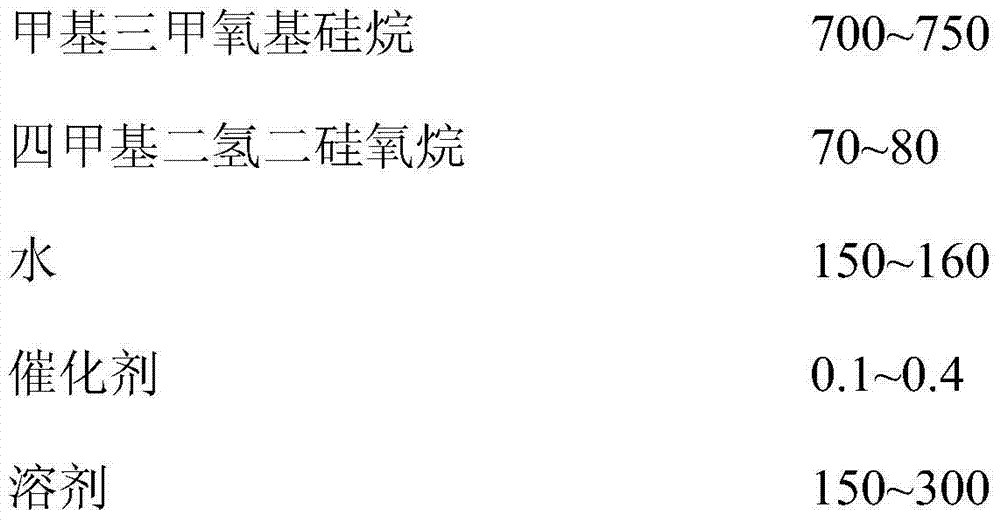

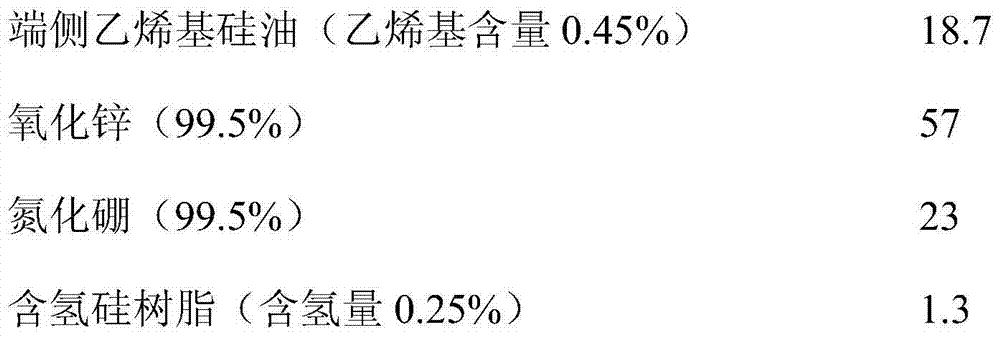

Bi-component heat conduction silica gel and application thereof

The invention relates to a bi-component heat conduction silica gel, which is composed of an A agent and a B agent. Specifically, the A agent includes end-side vinyl silicone oil, heat conduction filler and a platinum catalyst; and the B agent includes: 17.5-19.5wt% of the end-side vinyl silicone oil, 53-57wt% of zinc oxide, 23-27wt% of boron nitride, 1.3-1.6wt% of hydrogen-containing silicon resin, and 0.00015-0.00025wt% of a polymerization inhibitor. According to the invention, by introducing the end-side vinyl silicone oil with specific vinyl content and viscosity, and specific hydrogen-containing silicon resin to cooperate with the high heat conduction filler (especially alumina) vegetation, the heat conduction silica gel with heat conduction coefficient up to 3.5w / mk and elongation up to 500% can be obtained. And the heat conduction silica gel has very good toughness.

Owner:兆舜科技(广东)有限公司

Preparation method of reinforced carbon-based composite material of carbon foam preform

A preparation method of reinforced carbon-based composite material of carbon foam preform includes the following steps: (1) stirring phenolic resin, surfactant, foaming agent and curing agent according to the mixture rate, namely the mass percent of 100:5:5:25, then adding chopped carbon fiber accounting for 3-15wt.% of the total weight to be mixed with the materials, and after uniform dispersion,putting the mixture in a baking oven that is preheated to 80-100 DEG C to be heated, foamed and solidified, thus obtaining phenolic foam with reinforced carbon fiber; (2) putting the phenolic foam with reinforced carbon fiber obtained in step (1) in a vacuum carbonization furnace, heating the phenolic foam to the temperature of 900-1, 000 DEG C at the heating rate of 10-20 DEG C / h under 1-2Pa lowvacuum and preserving the heat for 2-3h to obtain the carbon foam preform with reinforced carbon fiber; (3) under the temperature of 1, 000-1050 DEG C and the deposition pressure of 0.5-5kPa, takingnatural gas as a carbon source and nitrogen as carrier gas and adopting CVI technology to conduct compaction for 400-600h; and (4) conducting heat treatment on the material at the high temperature of2, 000-2, 300 for 3-5h after compaction treatment. The material has the advantages of light weight, high strength, low cost, corrosion resistance, resistance to wear, low coefficient of thermal expansion, etc.

Owner:BEIHANG UNIV

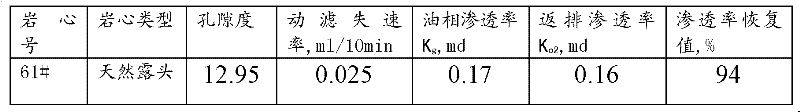

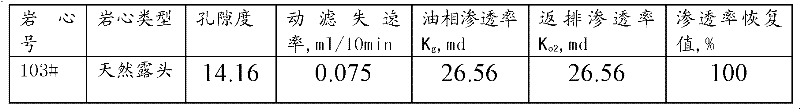

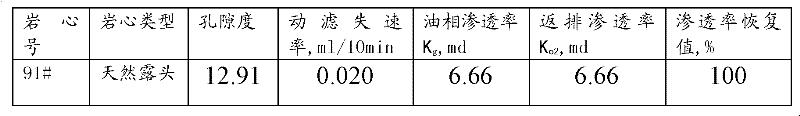

Plugging agent for drilling fluid and protecting low percolation reservoir

The invention discloses a plugging agent for a drilling fluid and protecting a low percolation reservoir, comprising the following components of: 10-40 parts of acid-soluble fiber, 5-10 parts of oil-soluble resin, 30-60 parts of acid-soluble deformed particles, 5-10 parts of high-temperature resistant natural small molecule materials and 10-15 parts of calcium carbonate. The basic component of the plugging agent is the acid-soluble fiber which is swelled and soft, has good tenacity and can expand by adsorbing partial moisture, and the like in the drilling fluid to form a meshy structure so as to form plugging on a hole throat under the action of flowing pressure. In addition, other components in the plugging agent, such as the deformed particles, the natural small molecule materials and the calcium carbonate can combine with the fiber to play a rapid plugging role, and therefore, the plugging agent has low damage depth on the reservoir. The plugging agent can be matched with the radius of the hole throat of the low percolation reservoir according to the regulation on the radius of the hole throat of a low percolation core. A drilling fluid system using the plugging agent as the main plugging material has the dynamic core filtration rate not more than 0.1ml / 10min at high temperature and high pressure.

Owner:CHINA NAT OFFSHORE OIL CORP +1

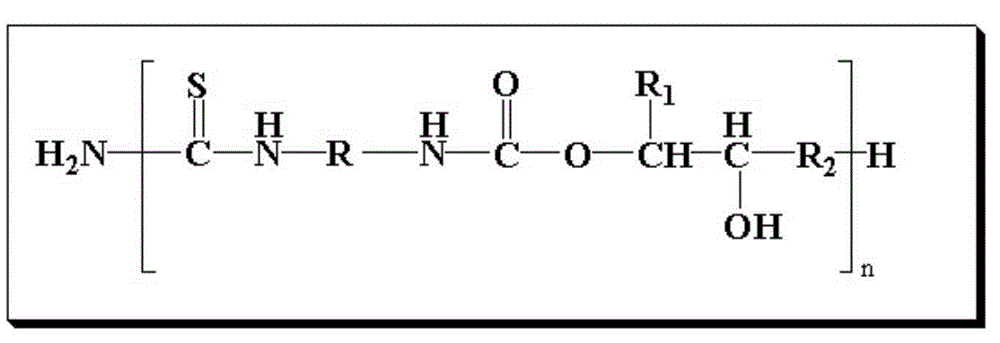

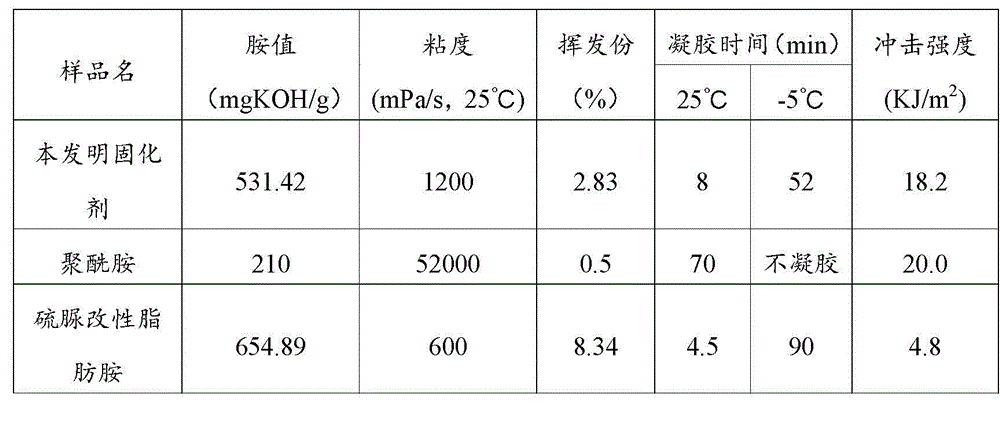

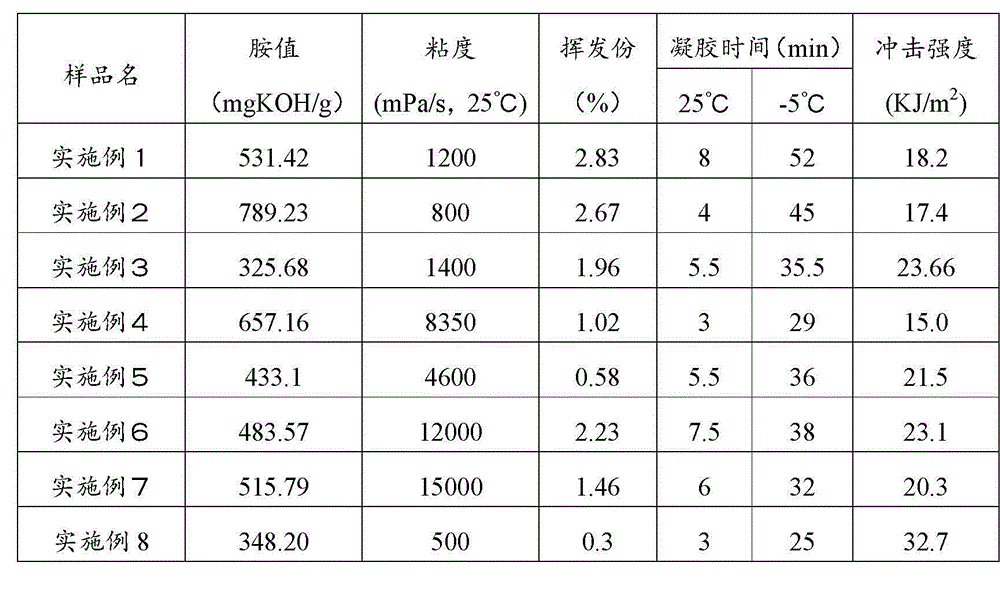

High-toughness high-activity epoxy resin curing agent and preparation method thereof

The invention discloses a high-toughness high-activity epoxy resin curing agent and a preparation method of the curing agent. The method comprises the following steps of: weighing cyclic carbonate and polyamine according to the condition that the molar ratio of the cyclic carbonate to the polyamine is (0.1-1):1, feeding the cyclic carbonate into a reactor filled with the polyamine in batches for reaction, weighing thiourea, the molar weight of which is 0.5-2.5 times that of the polyamine, feeding the thiourea into the reactor in batches, reducing the temperature of the system to 80 DEG C after the reaction is finished, adding an accelerant, the mass of which is 0.5-5% of the total mass of the products, into the products, uniformly mixing the accelerant and the products, discharging the mixture and storing the mixture. The curing agent prepared by using the preparation method disclosed by the invention is different from a traditional curing agent in that: the curing agent comprises a polyurethane flexible chain segment synthesized from nonisocyanate, and is excellent in toughness and good in impact resistance; a molecule of the curing agent comprises the polyamine of a thiourea link, which exists in a balanced state with a ketone form and an enol form; the enol compound can rapidly react with an epoxy group so that the epoxy resin can be completely cured in winter and a construction period is effectively shortened.

Owner:WUHAN KEDA MARBLE PROTECTIVE MATERIALS

Preparation method of iron, chromium and aluminum multielement electrothermal alloy with high resistance

The invention relates to a preparation method of an iron, chromium and aluminum multielement electrothermal alloy with high resistance and particularly relates to a preparation method of fusion and powder metallurgy combined for the iron, chromium and aluminum multielement electrothermal alloy with high resistance. The preparation method comprises the following steps: burdening; smelting; smashing; ball-milling; sintering by a discharge plasma; homogenizing annealing; isothermal forging; hot-rolling of a wire rod; stress relief annealing; and multi-pass drawing after rinsing and the like. The preparation method combining fusion and powder metallurgy can effectively avoid composition segregation in conventional smelting methods due to great difference on melting point, density and mass ratio of the components, so that the components are uniformly distributed. The microstructure of the alloy is effectively improved by combining subsequent processes such as homogenizing annealing, isothermal forging and wire rod hot-rolling, so that the toughness, the tensile strength and the inoxidizability of the alloy are improved.

Owner:YANCHENG XINYANG ELECTROTHERMAL MATERIAL CO LTD

Preparation method of microbial pre-fermentation coating multilayer microcapsule

ActiveCN103222539AGood toughnessHigh mechanical strengthAnimal feeding stuffSodium alginateFermentation

The present invention relates to a scale preparation method of microbial pre-fermentation coating multilayer microcapsule, and belongs to the fields of microbial technology and biotechnology. The method takes sodium alginate, calcium chloride and modified chitosan as the coated materials of microcapsule, wherein the deacetylation degree of the modified chitosan is more than 90% and molecular weight is about 40000; the method comprises the following steps of (1) preparing single-layer microcapsule and (2) preparing multilayer microcapsule. When performing second coating, a film of low concentration chitosan is formed, the amount of chitosan is little, and almost all of chitosan molecules can react with calcium alginate gel for polyelectrolyte complexation reaction, therefore, the compact film with good toughness can be easily formed; the film is thickened and the mechanical strength is increased along the increase of the chitosan concentration. Furthermore, the process is more convenient to reuse a buffer solution for dissolving chitosan, so as to reduce production costs.

Owner:TIANJIN BIOFEED TECH CO LTD

Processing technique and product of bamboo fiber imitated rattan mat

InactiveCN103417050AReduce deforestationGood toughnessCane mechanical workingReed/straw treatmentPaper sheetAntibacterial effect

The invention relates to a processing technique and a product of a bamboo fiber imitated rattan mat. The processing technique comprises the following steps of selecting vegetation waste, beating, producing semi-finished paper by a paper processing technique, carrying out waterproof treatment and slicing; coring cotton yarns with flaky paper and rolling to form weft yarns, taking bamboo fibers as warp yarns, and knitting the weft yarns and the warp yarns to form a bamboo fiber imitated rattan mat main body; carrying out calendering treatment and bonding the bottom surface of the bamboo fiber imitated rattan mat main body with a sandwich substrate by using environment-friendly adhesive to form a semi-finished product of the bamboo fiber imitated rattan mat, and carrying out tailoring, binding, compacting and flanging treatment to obtain the bamboo fiber imitated rattan mat. The bamboo fiber imitated rattan mat disclosed by the invention has the advantages of good waterproof performance, no damage after shot-time soaking in water, good antibacterial effect, good permeability, toughness, wear resistance, static resistance and other performances, firmness, good hand feeling and strong aesthetic feeling and grade feeling.

Owner:NINGBO YINZHOU LIMING ARTS & CRAFTS

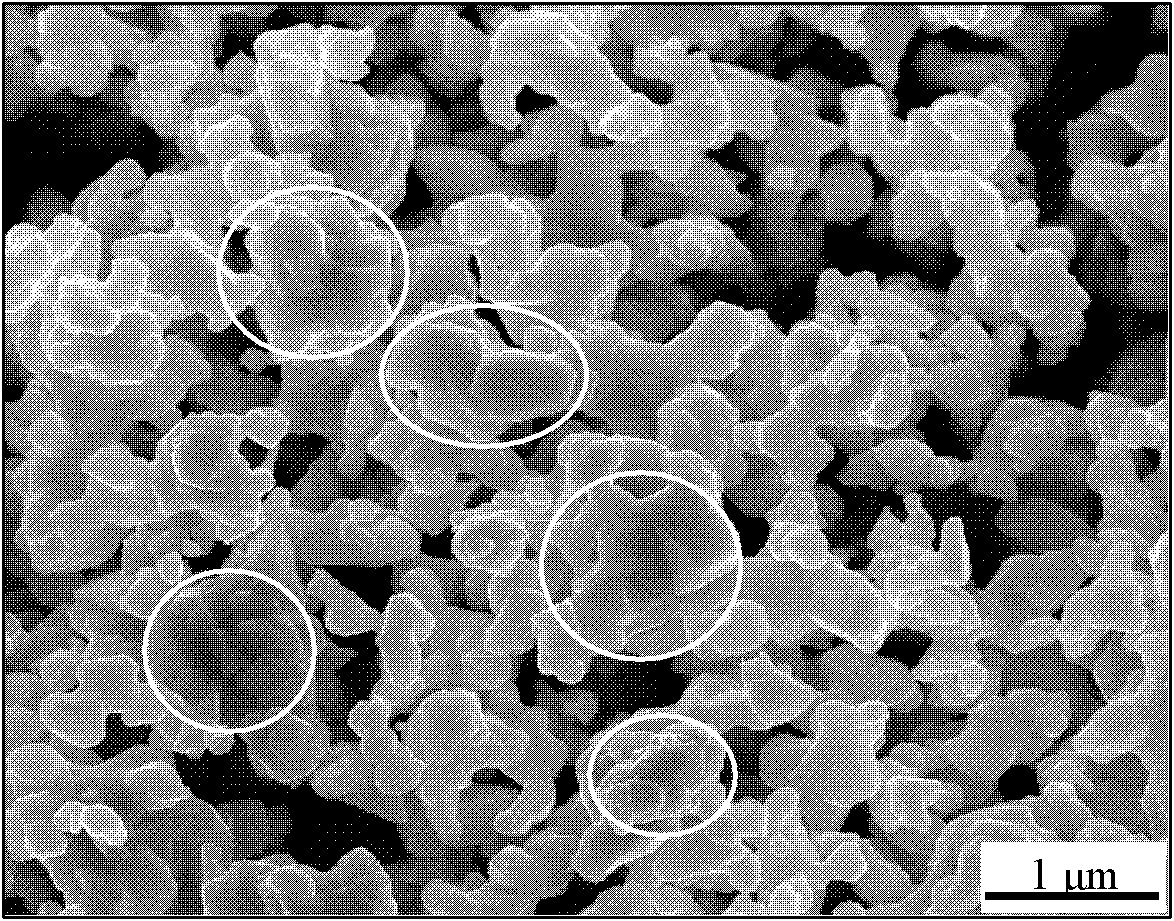

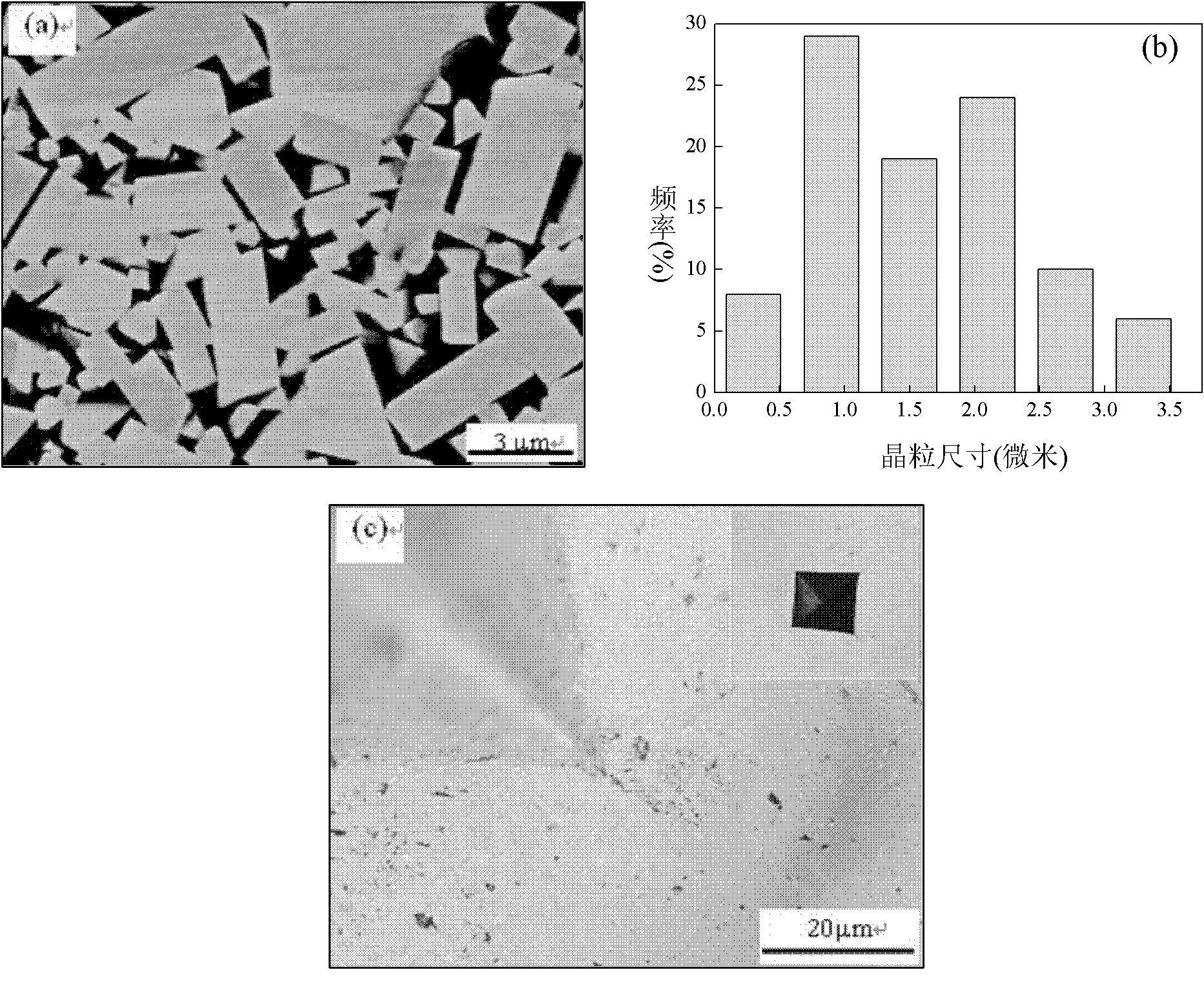

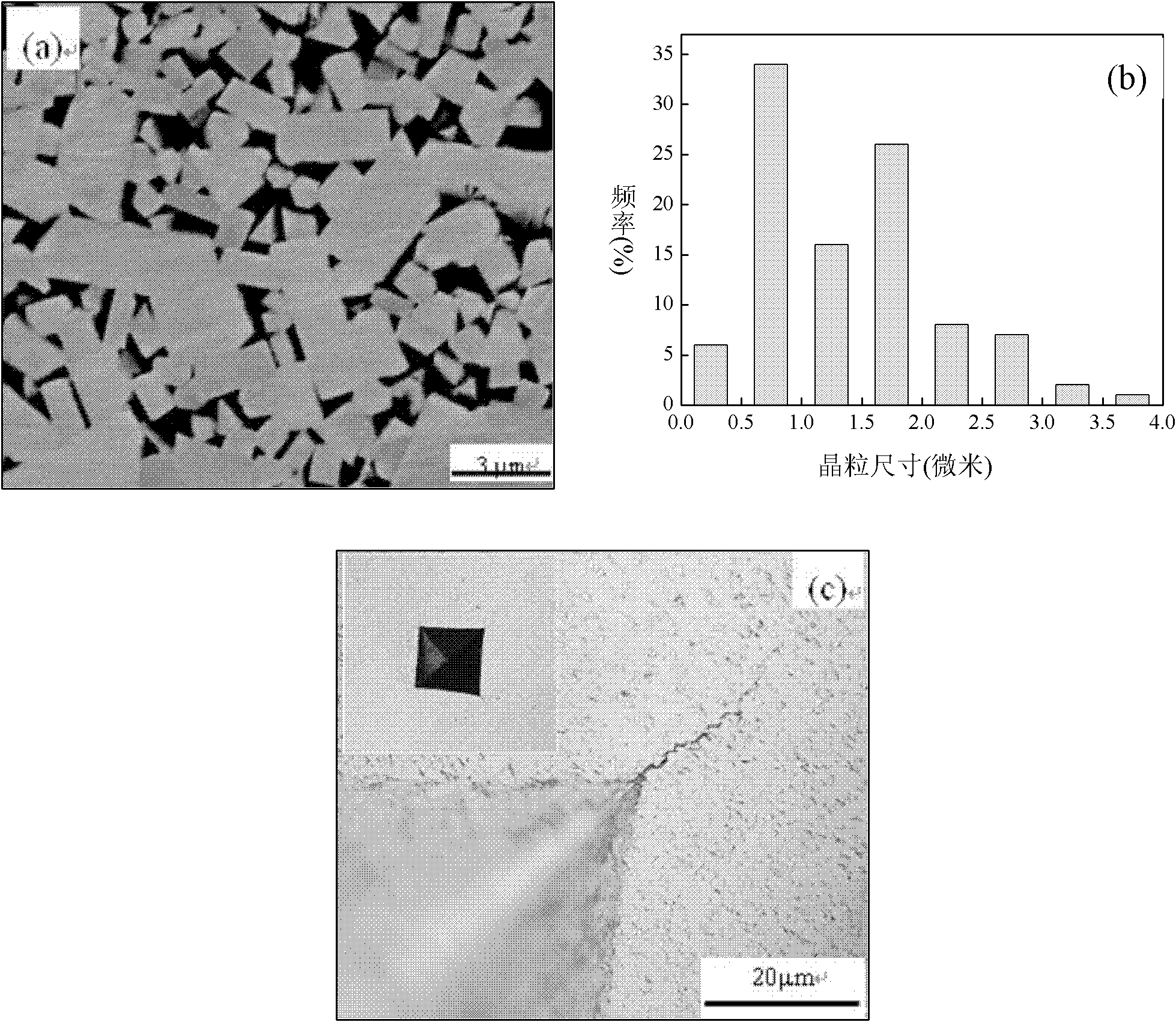

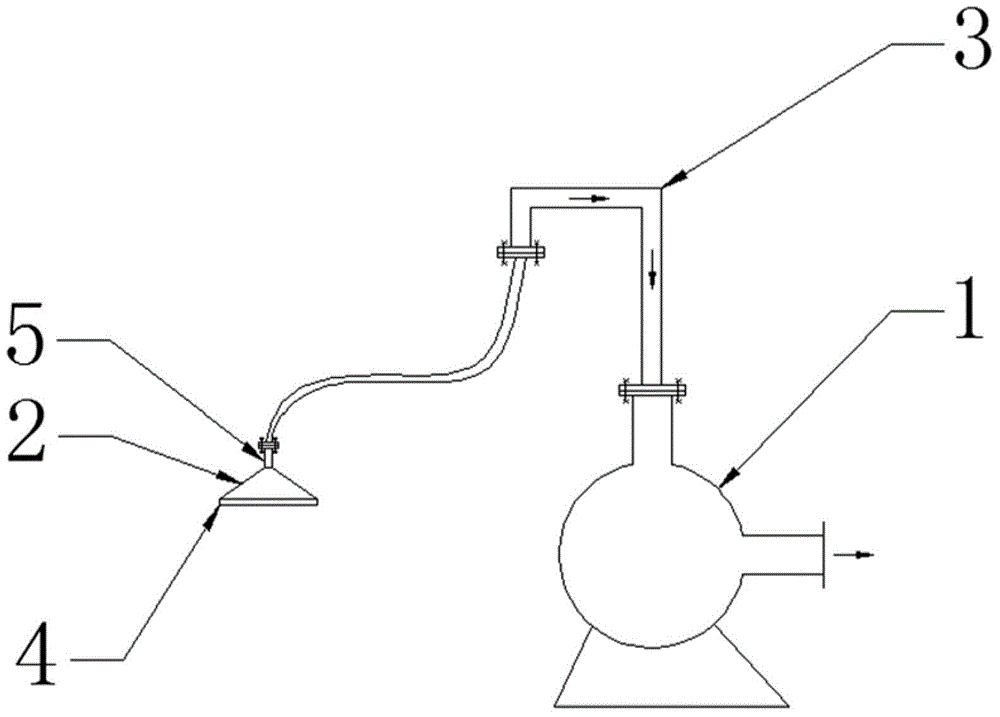

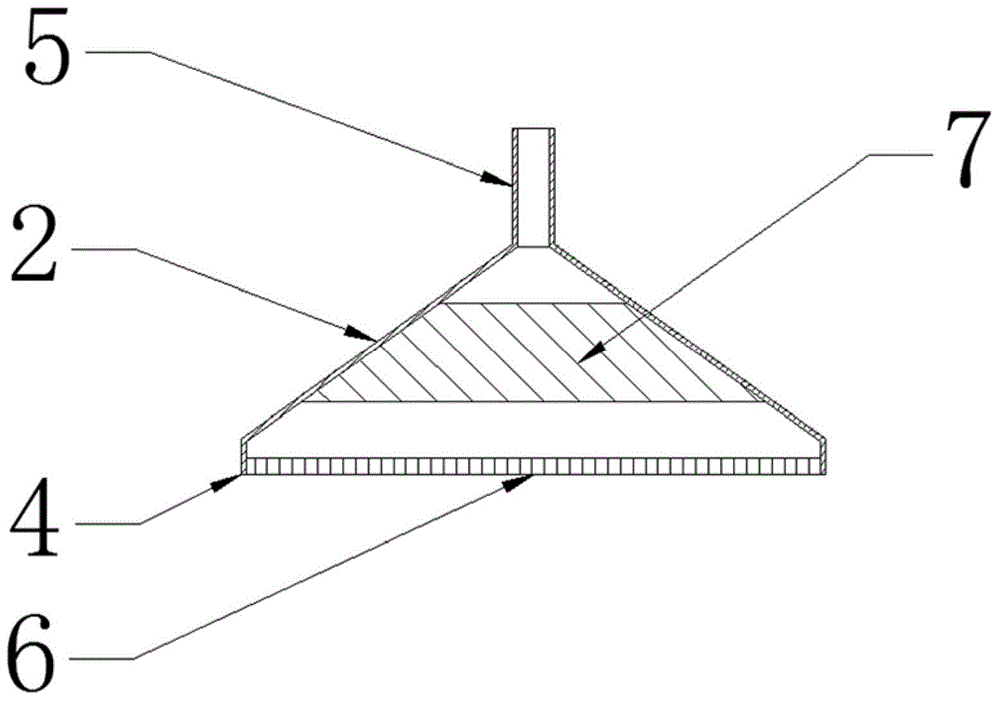

Method for industrially preparing dimorphic hard alloy with both high strength and high tenacity

The invention discloses a method for industrially preparing a dimorphic hard alloy with both high strength and high tenacity, belonging to the technical field of hard alloys. The method comprises the following steps of: according to the content of Co in the dimorphic hard alloy, ball-milling and mixing WO2.9, Co3O4 and carbon black; coldly pressing into a billet block; preparing WC-Co composite powder in a vacuum furnace; ball-milling by taking absolute ethyl alcohol or hexane as a medium; drying to obtain the WC-Co composite powder; under the protection of argon, performing powder aggregation pre-treatment; raising the temperature to 650-950 DEG C at a speed of 5-8 DEG C per minute; keeping the temperature for 30-60 min; adding 30-80 ml of polyethylene glycol forming agent to each kilogram of powder; moulding and forming; and sintering the moulded and formed powder billet in vacuum or at low pressure. The WC-Co dimorphic hard alloy prepared by the invention has both high strength andexcellent breakage tenacity. The method is an integral industrialization preparation technology route.

Owner:BEIJING UNIV OF TECH

Polygonal superhard abrasive compound and method for manufacturing abrasive tool with same

ActiveCN104440605AHigh hardnessGood toughnessOther chemical processesAbrasion apparatusHardnessHigh pressure

The invention discloses a polygonal superhard abrasive compound and a method for manufacturing an abrasive tool with the same. The polygonal superhard abrasive compound is synthesized through high temperature and high pressure after polygonal grooves of a graphite die are filled with abrasive powder and synthesis blocks are assembled. Due to the fact that the polygonal superhard abrasive compound is the abrasive material which is regular in shape and synthesized through high temperature and high pressure after the polygonal grooves of the graphite die are filled with the abrasive powder and the synthesis blocks are assembled, the hardness is high, and the toughness is good; the size dimension is controllable, the particle size is uniform, and good grinding performance is achieved; the shape is regular, the sharpness of the abrasive material is further improved, the abrasive tool with abrasive material cutting edges evenly distributed in a space can be obtained conveniently, the grinding quality and the grinding effect of the abrasive tool can be improved, and the polygonal superhard abrasive compound and the abrasive tool are suitable for application and popularization.

Owner:FUNIK ULTRAHARD MATERIAL

Prepn. process of intermingled chitin/cellulose material in sodium hydroxide/urea water solution system

The invention discloses a method of using the system of the sodium hydroxide / the carbamide to prepare the commixed materials of the crust element and the fibrin, and the method is as follows: using the water solution of the NaOH / the carbamide to be the solvent, commix the crust element and the fibrin according to different make-up proportion, then perform scraping film or spraying thread on the commixture, then make the film or the thread of the commixture solidify in the calcium chloride solution, and then make the crust element and the fibrin regenerate to get the above commixed materials. The method can prepare the film and thread by directly using the crust element to commix, the film and the thread have fine mechanical property, water resistance and anti-cruor capability, the have avirulence, innocuity, high security and biological degradability.

Owner:WUHAN UNIV

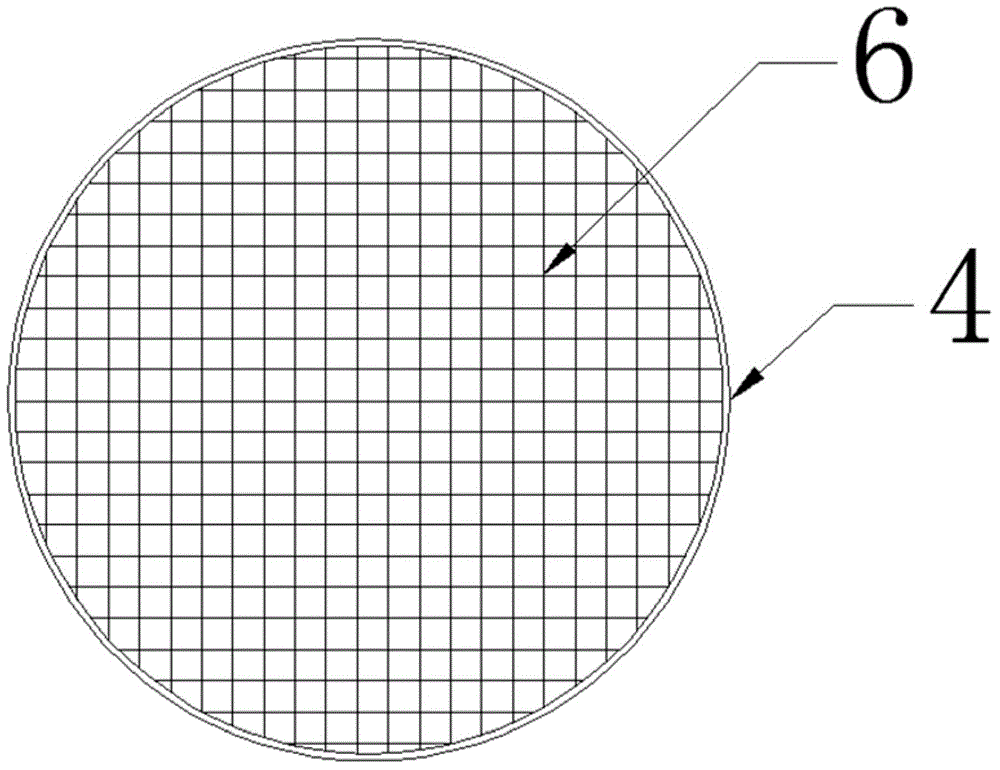

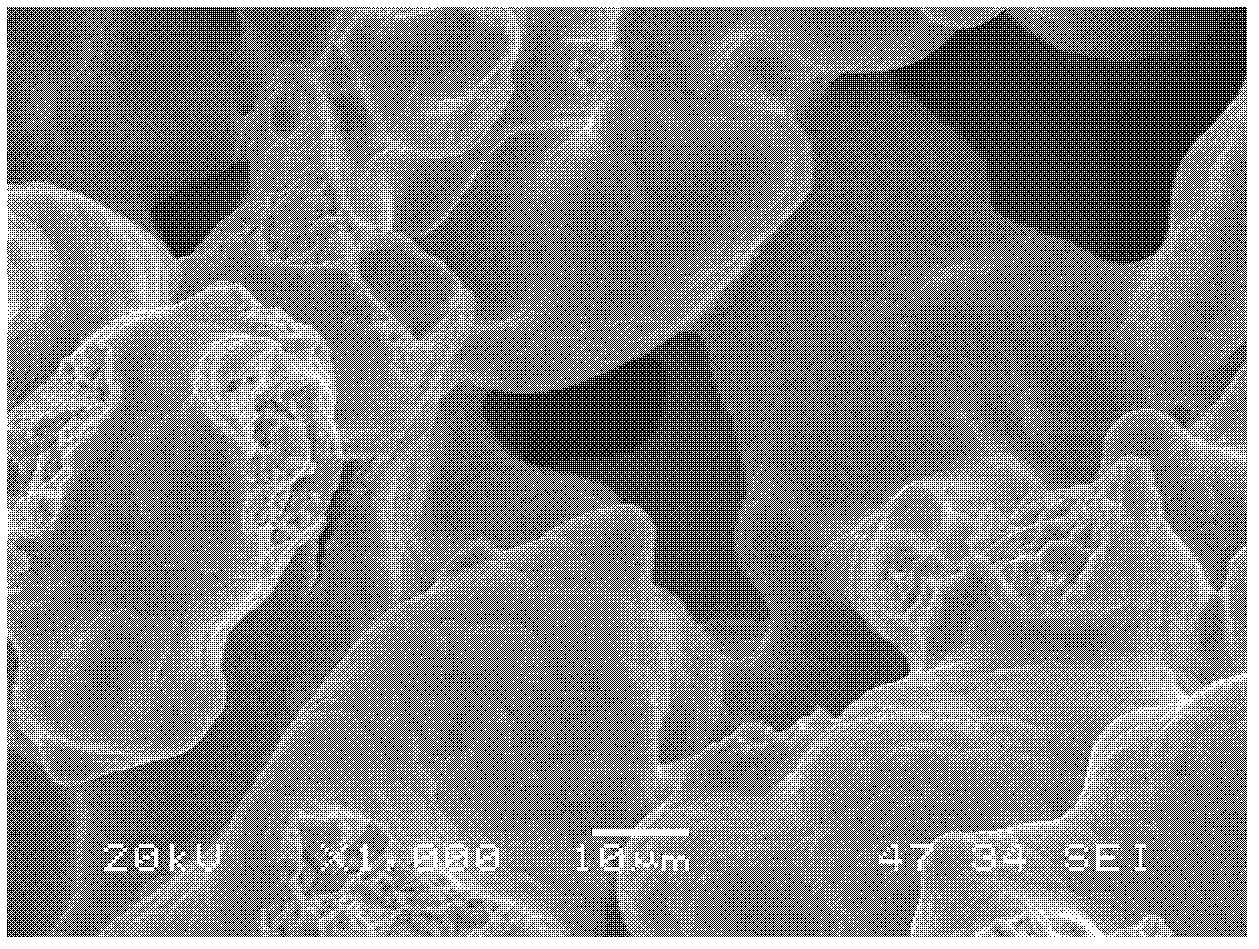

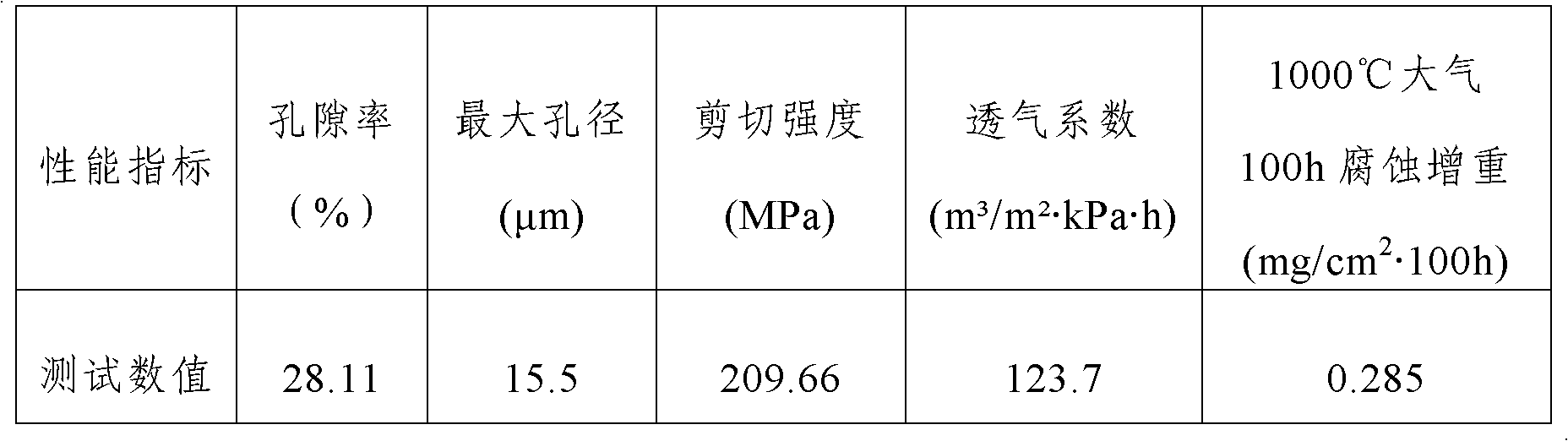

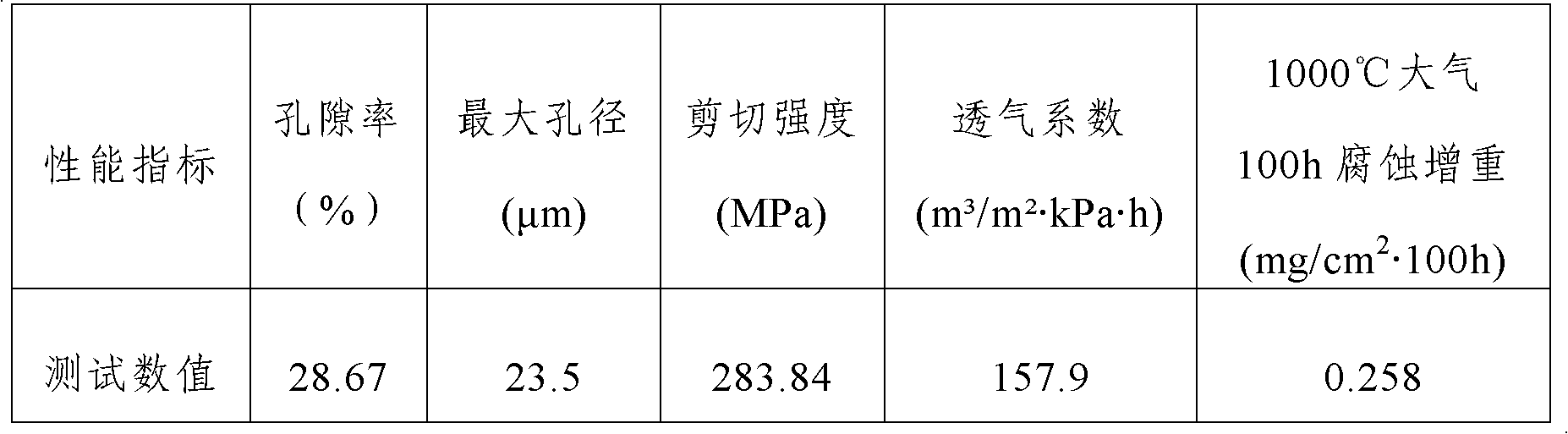

Porous material for purifying high-temperature gas and preparation method thereof

The invention discloses a porous material for purifying high-temperature gas, which is prepared from the following components in percentage by mass: 10-20% of Cr, 5-12% of Al, 1-3% of Fe, 0-0.1% of Y and the balance of Ni and inevitable impurities. The invention also discloses a preparation method of the porous material. Since the principal elements of the porous material are high-temperature alloy principal elements Ni and Cr, the porous material has the advantages of high strength, good toughness and good weldability in the high-temperature alloy, and the maximum application temperature is up to 800 DEG C; and since high-content Al is added, a compact and stable aluminum oxide film is formed on the surface of the pore walls of the porous material in the application process, thereby ensuring the excellent corrosion resistance under the conditions of high temperature and complex atmosphere. The powder classification and pressing technique ensures the uniformity of the porous material;and by adopting the vacuum sintering technique, the porous material has favorable comprehensive properties in the aspects of strength, toughness and filtering quality.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

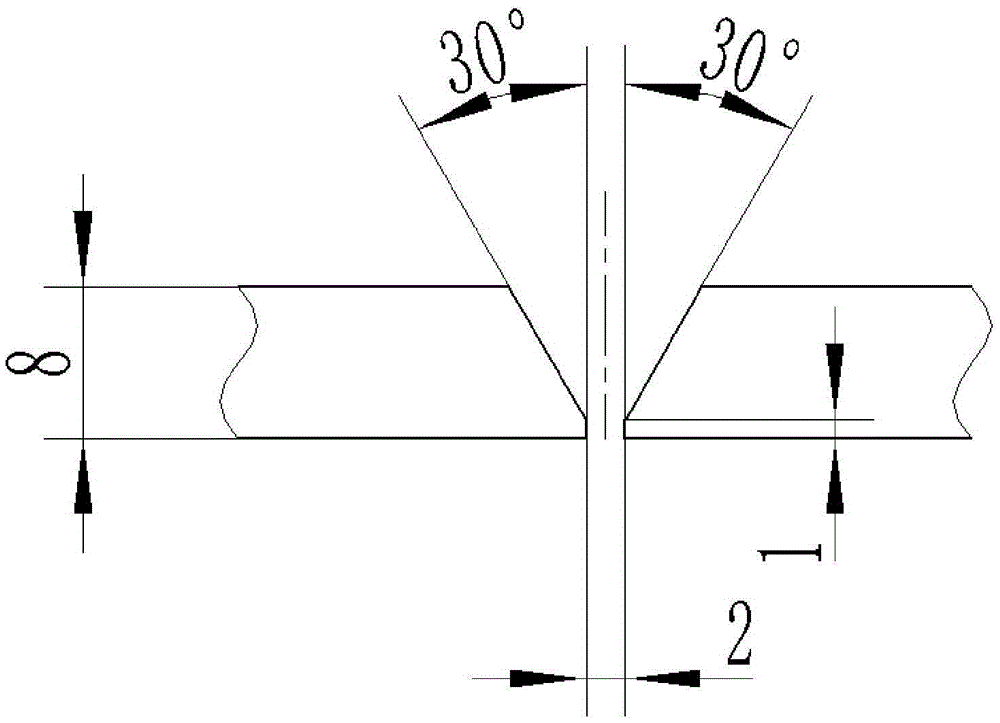

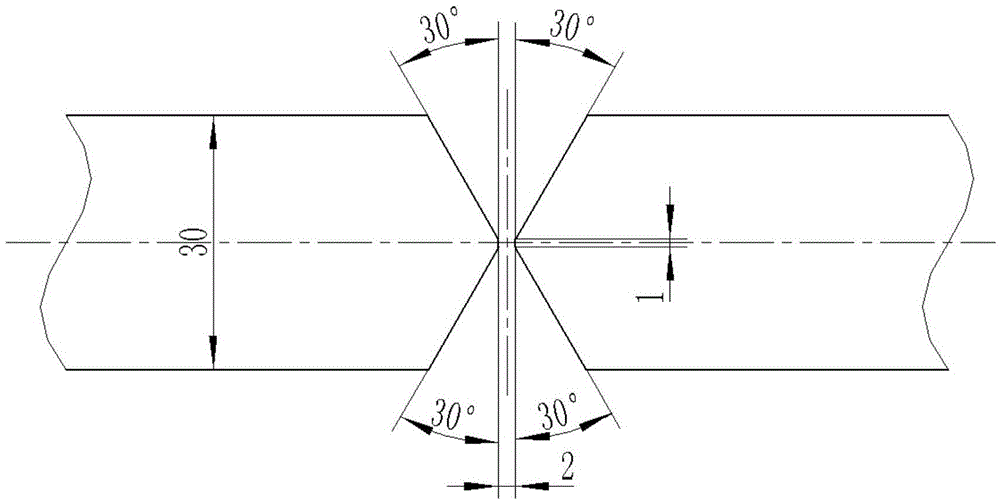

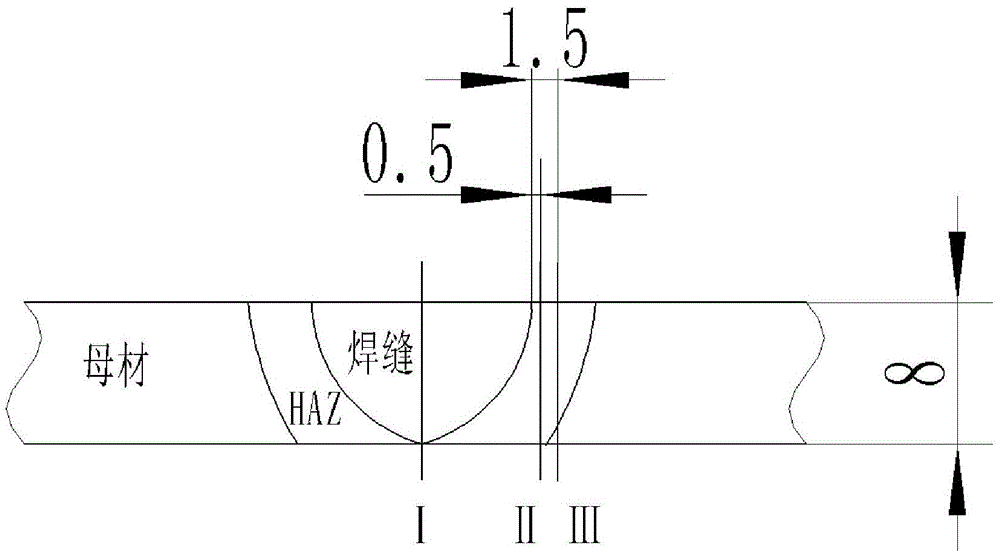

Welding method for low-alloy and ultrahigh-strength steel with yield strength being 1100 MPa

ActiveCN105522262AAvoid welding cold cracksGood toughnessArc welding apparatusWelding/soldering/cutting articlesCarbon dioxideWeld bead

Owner:NORTHEASTERN UNIV +1

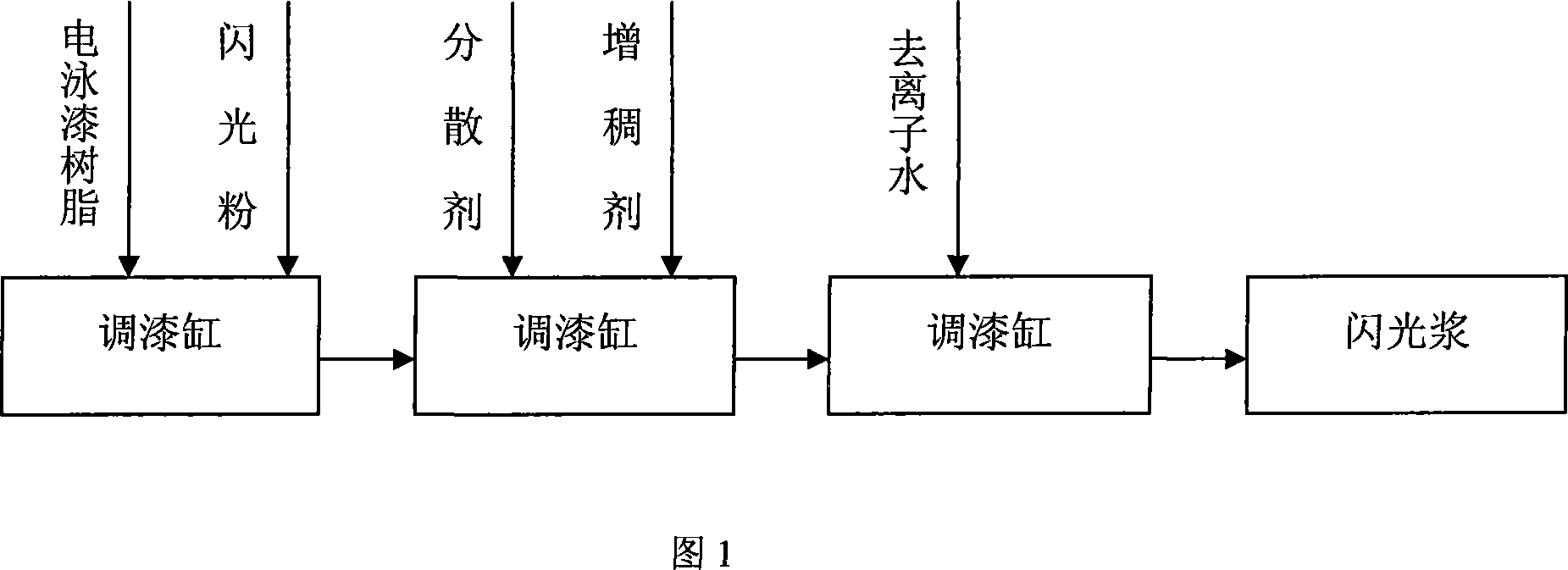

Flash electrophoretic paint and its prepn process

ActiveCN101089103AGood toughnessHigh hardnessPolyurea/polyurethane coatingsPaints for electrolytic applicationsSolventChemistry

The present invention discloses one kind of flash electrophoretic paint and its preparation process. The flash electrophoretic paint is compounded with the materials including resin as the base material 1000-1500 weight portions, flash powder 15-200 weight portions, dispersant 5-50 weight portions, thickener 5-100 weight portions, color paste 50-300 weight portions and deionized water 2000-4000 weight portions. The electrophoretic paint film formed with the flash electrophoretic paint and through an electrophoresis process has high toughness, high hardness, bright beautiful color, no discoloring and excellent corrosion resistance. The electrophoretic paint may be used to replace available paint combination of electrophoretic primer, color primer and coating varnish, and this results in short technological path and low cost. In addition, the water-thinned electrophoretic paint is environment friendly.

Owner:武汉双虎涂料股份有限公司

High-toughness, wear-resistant, self-lubricating polyamide material and preparation thereof

The invention discloses a polyamide material with high tenacity, wear-resisting capacity and self-lubricating property and a method for preparing the same. The compositions by weight percentage of the polyamide material are: 65 to 80 percent of polyhexamethylene adipamide, 15 to 23 percent of wear-resistant agent, 0 to 0.5 percent of lubricating agent, 0 to 3 percent of coupling agent, 0 to 0.5 percent of antioxidant, and 5 to 10 percent of toughener. The method improves wear-resisting property and self-lubricating property of the product mainly through auxiliary materials, thereby enlarging the application range of polyamide modified engineering plastics. The product of the invention has the advantages of good toughness, high impact strength, good surface glossiness, excellent chemical resistance and good dimension stability; a part of wear-resisting agent is added in the polyamide material, so the wear-resisting property of the material can be greatly improved; because the application range of the polyamide material is enlarged, wear-resisting requirements of partial transmission parts, shuttle wear parts and anti-sand-scraping parts can be met; and the polyamide material can be widely used for transmission components of an engine, an outer housing of a roller, an outer housing of an engine, a mechanical socket connector and transmission accessories, and can be used in positions which are often contacted and abraded in other transmission devices.

Owner:SHENZHEN KEJU NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com