Bi-component heat conduction silica gel and application thereof

A heat-conducting silicon, two-component technology, applied in the field of two-component heat-conducting silicone gel, can solve the problems of low production efficiency, insufficient elongation, insufficient material toughness, etc., to facilitate foam removal and operation, improve production efficiency, The effect of short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A two-component thermally conductive silicone gel, which is obtained by mixing and preparing the following raw materials according to the ratio:

[0041] Raw material mass ratio:

[0042] Agent A includes:

[0043] End-side vinyl silicone oil (vinyl content 0.45wt%) 22g

[0044] Alumina (spherical, particle size 15um) 78g

[0045] Platinum catalyst (5000ppm) 0.001g

[0046] Agent B includes:

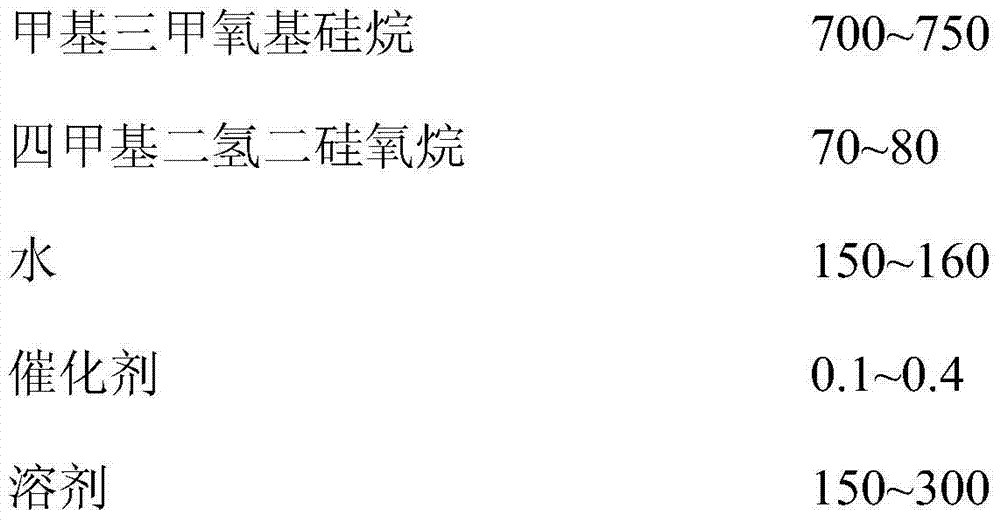

[0047]

[0048]

[0049] Wherein, the hydrogen-containing silicone resin is prepared by the following method:

[0050] (1) Put 155 parts by mass of water and 0.30 parts by mass of hydrochloric acid into the reactor, add 70 parts by mass of tetramethyldihydrodisiloxane, stir and reflux at a stirring speed of 250 to 300 rpm;

[0051] (2) Open the condensed water to reflux, when the temperature of the reaction solution is raised to 30°C, 720 parts by mass of methyltrimethoxysilane is added dropwise, and the temperature is continued to rise to 50°C.

[0052] (3) When the t...

Embodiment 2

[0055] A two-component thermally conductive silicone gel, which is obtained by mixing and preparing the following raw materials according to the ratio:

[0056] Raw material mass fraction ratio:

[0057] Agent A includes:

[0058] End-side vinyl silicone oil (vinyl content 0.45wt%) 20g

[0059] Alumina (spherical, particle size 15um) 80g

[0060] Platinum catalyst (5000ppm) 0.001g

[0061] Agent B includes:

[0062]

[0063]

[0064] Wherein, the hydrogen-containing silicone resin is prepared by the following method:

[0065] (1) Put 150 parts by mass of water and 0.4 parts by mass of hydrochloric acid into the reactor, add 70 parts by mass of tetramethyldihydrodisiloxane, stir and reflux at a stirring speed of 250 to 300 rpm;

[0066] (2) Open the condensed water to reflux, when the temperature of the reaction solution is raised to 30°C, 700 parts by mass of methyltrimethoxysilane is added dropwise, and the temperature is continued to rise to 50°C.

[0067] (3) Wh...

Embodiment 3

[0070] A two-component thermally conductive silicone gel, which is obtained by mixing and preparing the following raw materials according to the ratio:

[0071] Raw material mass fraction ratio:

[0072] Agent A includes:

[0073] End-side vinyl silicone oil (vinyl content 0.45wt%) 18g

[0074] Alumina (spherical, particle size 15um) 82g

[0075] Platinum catalyst (5000ppm) 0.001g

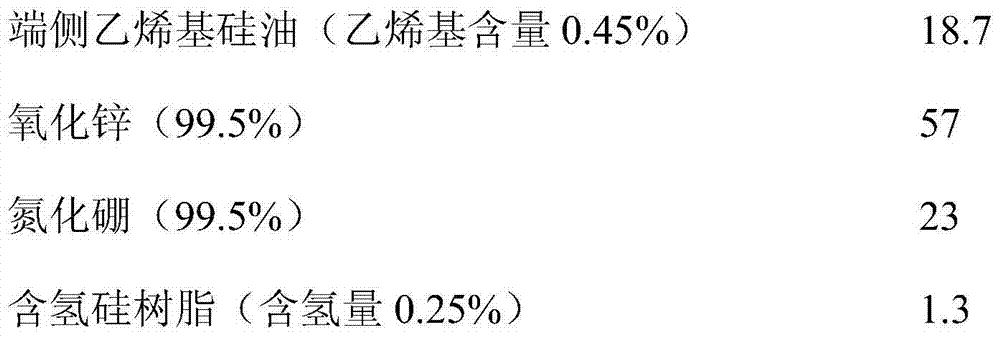

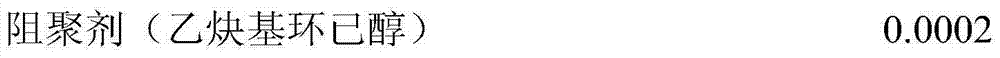

[0076] Agent B includes:

[0077]

[0078]

[0079] Wherein, the hydrogen-containing silicone resin is prepared by the following method:

[0080] (1) Put 160 parts by mass of water and 0.1 parts by mass of hydrochloric acid into the reactor, add 80 parts by mass of tetramethyldihydrodisiloxane, stir and reflux, and the stirring speed is 250-300 rpm;

[0081] (2) Open the condensed water to reflux, when the temperature of the reaction solution is raised to 30°C, 750 parts by mass of methyltrimethoxysilane is added dropwise, and the temperature is continued to rise to 50°C.

[0082] (3) W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com