Flash electrophoretic paint and its prepn process

An electrophoretic paint and glitter powder technology, applied in electrophoretic paints, coatings, epoxy resin coatings, etc., can solve the problems of large investment in production equipment, high technical personnel requirements, and high production costs, achieving low production costs and shortening the process route. , the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

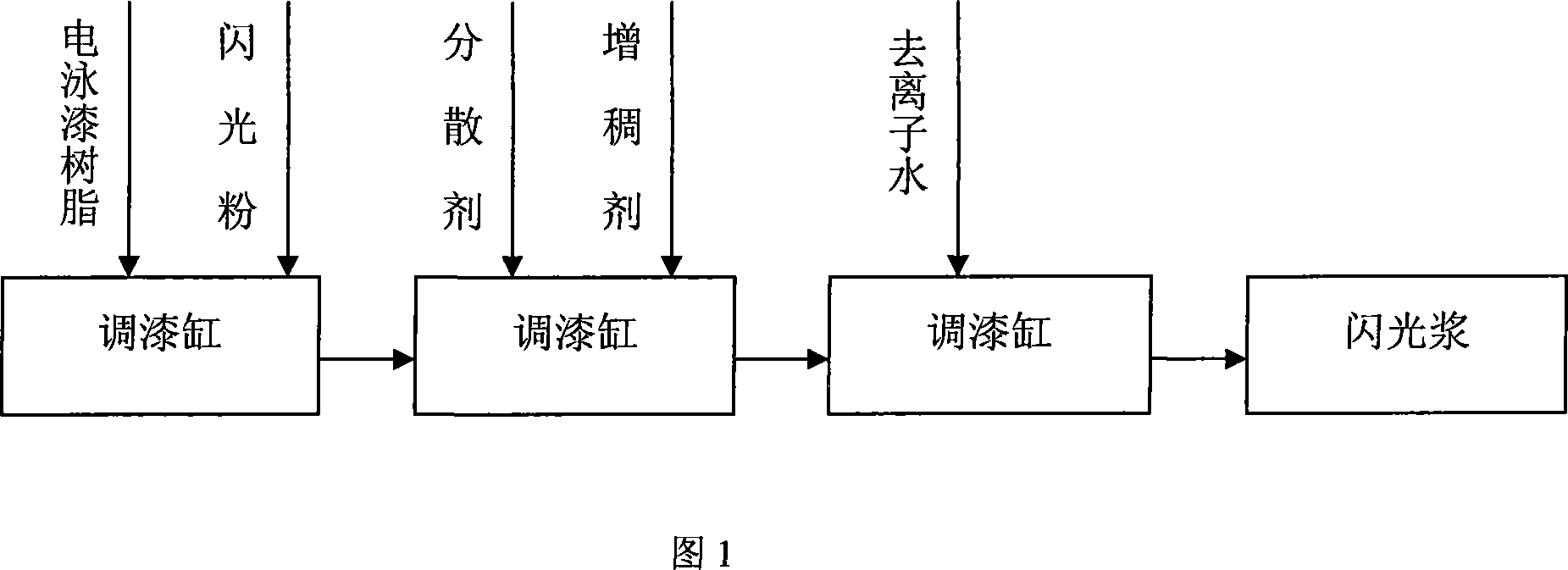

[0042] Referring to Figure 1, add 100g of aluminum silver powder into a reaction kettle equipped with 1000g of cationic acrylic resin, then add 20g of dispersant and 40g of thickener in sequence, control the stirring speed at 150 rpm, and control the temperature at 20°C for 3 hours. After the aluminum silver powder is fully wrapped by the resin, add 2000g of deionized water to emulsify, then add 80g of color paste to make a flash electrophoretic paint solution, and after aging for 2 hours, the present invention is obtained, and the flash electrophoretic paint can be obtained by carrying out electrophoretic construction of the present invention membrane.

Embodiment 2

[0044] Add 60g of pearlescent powder into a reaction kettle equipped with 1000g of cationic polyurethane resin, then add 10g of dispersant and 30g of thickener in turn, control the stirring speed at 1500 rpm, and control the temperature at 50°C for 0.5 hours, and the pearlescent powder passes through the resin After fully wrapping, add 2000g of deionized water for emulsification, then add 50g of color paste to make a flash electrophoretic paint solution, and after aging for 2 hours, the present invention is obtained, and the flash electrophoretic paint film can be obtained by carrying out electrophoretic construction of the present invention.

Embodiment 3

[0046] Add 100g of aluminum silver powder and 100g of pearl powder into a reaction kettle equipped with 1000g of cationic acrylic resin and 500g of cationic epoxy resin, then add 50g of dispersant and 40g of thickener in turn, control the stirring speed at 150 rpm, and control the temperature Stir at 25°C for 3 hours, after aluminum silver powder and pearl powder are fully wrapped by resin, add 4000g of deionized water for emulsification, then add 300g of color paste to make flash electrophoretic paint solution, and the present invention can be obtained after aging for 2 hours. The flash electrophoretic paint film can be obtained by electrophoretic construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com