Patents

Literature

40 results about "Flash powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flash powder is a pyrotechnic composition, a mixture of oxidizer and metallic fuel, which burns quickly and if confined produces a loud report. It is widely used in theatrical pyrotechnics and fireworks (namely salutes, e.g., cherry bombs, M-80s, firecrackers, and cap gun shots) and was once used for flashes in photography.

Process for dispersing hot-melt adhesive fillers

InactiveCN101289599AReduce joinImprove product added valueNon-macromolecular adhesive additivesGranulation by material expressionLight whiteTalc

The invention relates to a method for dispersing hot-melt adhesive filler. The method comprises the following steps that: filler and other components of hot-melt adhesive are evenly mixed by granulation equipment; or part of the filler and other components of the hot-melt adhesive are evenly mixed and granulated by granulation equipment, and then the left over filler is evenly mixed with the granulated mixture. Other components of the hot-melt adhesive comprise main body resin, tackifying resin and a diluent agent; the filler comprises toner, flash powder, calcium carbonate, micro silicon powder, talc powder, white carbon black, light white carbon black, metal nitride, metal oxide and metal nitride or metal oxide; moreover, extruding granulation adopts a single screw extruder or a double screw extruder. The method has the advantages that: the addition of a poisonous and harmful dispersing agent is reduced to protect the environment; the filler is evenly mixed through a physical method, and manufacturing technique is simplified to reduce cost; and because a granular material contains less air volatile matter, the product is not easy to generate air bubbles, thereby ensuring product quality.

Owner:金尔升

Environment protection type colourful flashing hot-melt adhesive

InactiveCN101289605AProportionally largeLow costPolyureas/polyurethane adhesivesRosin adhesivesPolymer scienceSolvent

The invention relates to environment-friendly colorized flash hot-melt adhesive, which comprises main body resin, tackifying resin, a diluent agent, flash powder, pigment and solvent, wherein the main body resin is selected from one sort or a plurality of sorts of ethylene-vinyl acetate copolymer EVA, ethylene-butyl acrylate copolymer EMA, ethylene-acrylic acid copolymer EAA, ethylene-ethyl acrylic acid copolymer EEA, styrene-isoprene copolymer SIS, styrene-butadiene copolymer SBS and amorphous alpha-olefin polymer APAO; and the tackifying resin is selected from one sort or a plurality of sorts of rosin, polymerized rosin, 145 resin, 138 resin, terpene resin, petroleum resin or hydrogenant petroleum resin. The environment-friendly colorized flash hot-melt adhesive adopts the nontoxic flash powder which has excellent suspension property and is cheap, environment-friendly, unprecipitated and easy to be dispersed evenly as filler; moreover, the usage amount of the tackifying resin is increased, thereby substantially reducing product cost and improving product bonding strength and performance.

Owner:金尔升

Flash powder paint

InactiveCN1740248AHigh transparencyStrong penetrating powerPowdery paintsEpoxy resin coatingsPigmentMaterials science

The flash powder paint consists of resin and curing leveling system 60-80 wt%, pigment 0-20 wt%, stuffing 0-30 wt%, deairing agent 0.2-0.4 wt%, flash pigment 0.1-5 wt%, directional assistant 0-0.2 wt%, and powder flowing promoter 0.1-0.2 wt%. It is prepared through the technological process including high speed mixing the first-mentioned four kinds of material, fusing and extruding, tabletting and crushing, grinding into powder and sieving, mixing the sieved powder with the last three kinds of material, and sieving.

Owner:XUZHOU ZENITH COATING

High decorative acrylic flashing paint and preparation method thereof

The invention discloses a high decorative acrylic flashing paint. The high decorative acrylic flashing paint comprises the following raw materials in parts by weight: 5.5-6.5 parts of flashing powder, 55-60 parts of acrylic resin, 1.5-2 parts of anti-settling agent, 0.08-0.12 part of promoter, 0.1 part of additive, 15-20 parts of colorant, 4-5 parts of 18% cellulose butyl acetate solution and 12-17 parts of solvent. The preparation method of the high decorative acrylic flashing paint comprises the following steps: soaking aluminum powder with the solvent, and stirring and mixing; then evenly stirring the acrylic resin, cellulose and solvent in a container, adding the anti-settling agent and promoter at rotation speed of 600-900rpm, stirring to ensure that the fineness is less than 15mu m, and adding the additive; and then adding the soaked aluminum powder in a container under stirring, then adding the colorant to stir evenly, and toning. Only a flashing paint layer is sprayed on the surface of a part, thus the flashing and beautiful effects of the metallic paint can be realized, the glossiness reaches above 80 and the flashing paint is first used for the part.

Owner:JIANGSU HAOYUE PAINT

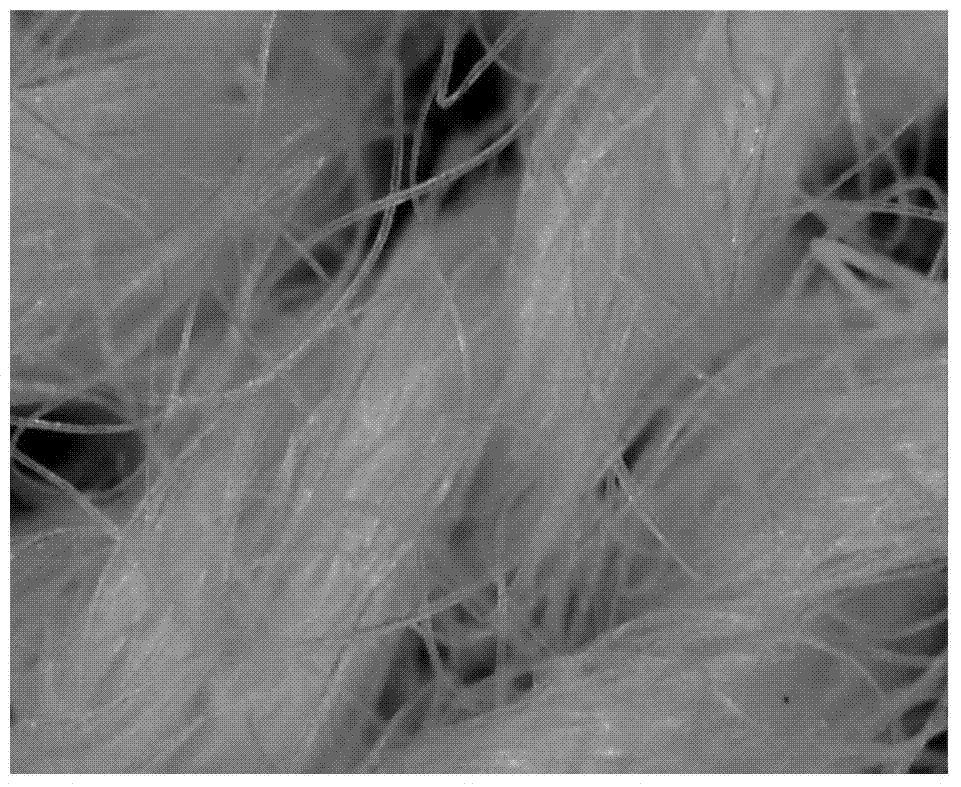

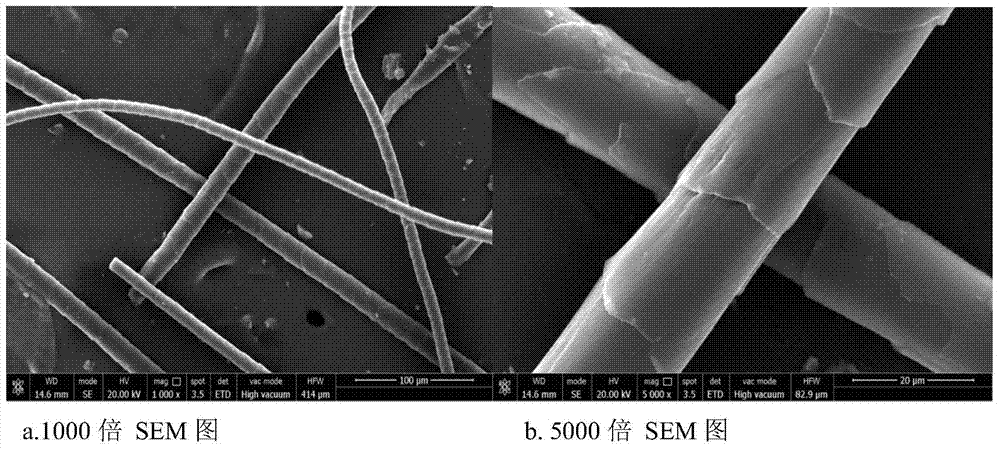

Elastic non-woven fabric

InactiveCN102444028AFunction increaseIncrease elasticityWoven fabricsTextile decorationElastomerPolymer science

The invention discloses an elastic non-woven fabric. The non-woven fabric is formed by mutually interweaving warps and wefts, wherein the warps and the wefts are made of 10 to 65 weight percent of jute fibers and 35 to 90 weight percent of blend fibers; 0.01 to 3 weight percent of polymer composition is coated on the surface of the non-woven fabric made of the warps and the wefts, the polymer composition comprises elastomer, and the elastomer is a block copolymer; and laser flash powder is adhered on the surface of the non-woven fabric coated with the polymer composition. Through the above mode, the non-woven fabric has flexibility and longitudinal and transverse strength; the surface of the non-woven fabric is provided with the polymer composition, so that the fold recovery function and the elasticity of the non-woven fabric are improved; and through the laser flash powder, the non-woven fabric is colorful and luxuriant and has wide application.

Owner:常熟市佳懿针纺织品有限公司

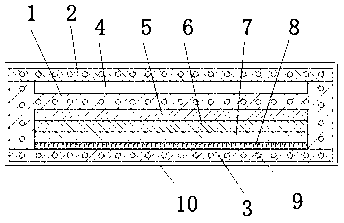

Flash scratchproof protection film and preparation method thereof

InactiveCN102390155ATransparent and brightStrong sense of fashionLiquid surface applicatorsSynthetic resin layered productsPolyethylene terephthalatePolyethylene terephthalate glycol

The invention discloses a flash scratchproof protection film, which comprises a scratchproof layer protection film PET (polyethylene terephthalate) substrate, a protection film glue layer, a scratchproof layer, a composite main film PET substrate, an installing glue layer and an installing flue protection film PET substrate, wherein at least one of scratchproof layer, the composite main film PET substrate and the installing glue layer contains flash powder, or a color transparent material or a mixture containing the flash powder and the color transparent material. According to the protection film, because at least one of the scratchproof layer, the composite main film PET substrate or the installing flue layer is the flash layer or the color transparent layer or the color flash layer, the whole protection film has the characteristics of multiple colors and flashing, transparent brightness, strong fashion sense and the like; the flash scratchproof protection film can be widely used for various liquid crystal displays or automobile protection films and satisfies fashion pursuing trends of young people; and a preparation method of the flash scratchproof protection film is simple and easy to operate and is suitable for industrial production.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

Method for producing and preparing artificial jade

The invention discloses a method for producing man-made jade, using polyester resin as main ingredient, hydrafil as filler and accelerator, using curing agent, flame retardant, coupling agent, defoamer, antioxidant, light stabilizer, color paste, noctilucence powder, flash powder as auxiliary material, wherein the materials can be used at one time and can choose several kinds to use, thereby having flexibility. Production steps are as follows: 1, coating demoulding wax on the surface of a mould, 2, painting a well-prepared gel coat resin with a brush on the surface of the mould, 3, stirring evenly the materials in proportion, 4, pouring the mixxed materials to the mould, 5, vacuumizing in a vacuum-pumping room, 6, solidifying, 7, demoulding, 8, polishing, 9, polishing and waxing, 10, making out the product. The product has the advantages of luxury style, realistic jade, rich color, high permeability, smooth surface, wearing resistance, hard, scale resistance, anti-ultraviolet, simple production, easy implementation.

Owner:金纪德

Preparation method of pure nosiheptide

InactiveCN105420319ASimple production processEasy to operatePeptide preparation methodsFermentationNosiheptideRotary evaporator

The invention relates to a preparation method of pure nosiheptide. The method comprises the steps that nosiheptide flashing powder is used as raw materials, a solvent is added for digestion, the temperature is controlled within 20-60 DEG C, and stirring is performed at the uniform rotating speed of 50-300 r / min for 1-3 h; a leaching solution obtained after the raw materials are processed is separated from solid mushroom dregs, the leaching solution is concentrated on a rotary evaporator at the temperature of 30-70 DEG C, and the organic solvent is recycled to obtain a concentrated solution; water and an elution agent are added into the concentrated solution, stirring is performed at the rotating speed of 100-400 r / min for 1-5 h, and then suction filtration is performed to obtain filter cakes; the filter cakes are placed into a vacuum drying oven, drying is performed at the temperature of 20-70 DEG C and the vacuum degree of minus 0.09 MPa for 6-16 h, and smashing is performed to obtain the pure nosiheptide. The method has the advantages that the production technology is simple, operation is convenient, the production efficiency is high, the product purity is high, and economy and environmental protection are achieved; the extracted nosiheptide can be prepared to obtain nosiheptide raw drugs or nosiheptide premixing agents of different specifications.

Owner:山东胜利生物工程有限公司

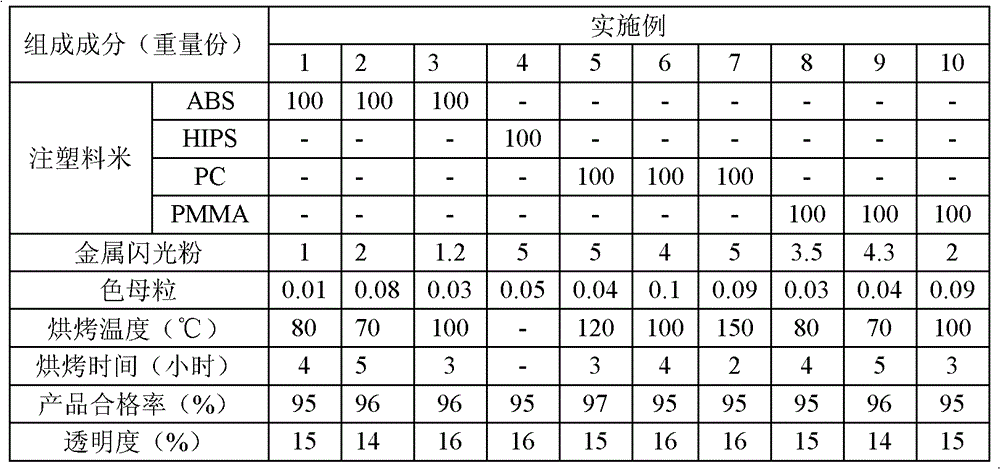

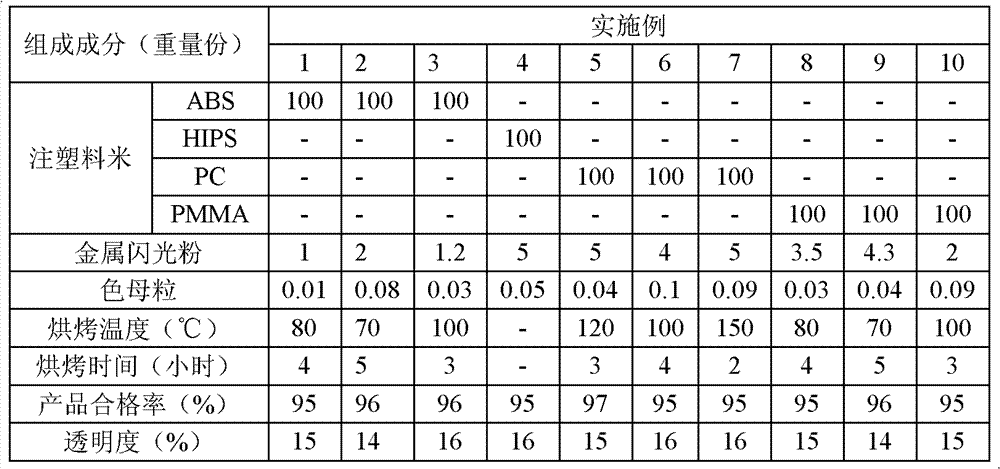

Injection molding material, preparation method thereof, and injection molding product thereby

The invention discloses an injection molding material, a preparation method thereof, and an injection molding product thereby. The injection material comprises metallic flashing powder and injection molding granules at the weight ratio of 1-5:100. With technical schemes of the invention and based on the prior injection molding technologies, the metallic flashing powder is added into the injection molding granules, so that the injection molding product prepared by the injection molding material has similar or even better effects of metallic flashing powder spraying. The product prepared by the injection molding material of the invention is finished by direct injection molding, so that compared with secondary processing of spraying, the product is prepared more efficiently and the qualified rate of the product is higher; and color and transparency are blended, so that the product prepared by the injection molding material achieves different light transmission effects.

Owner:GREE ELECTRIC APPLIANCES INC

Color-changing flashing interior wall decorative coating and preparation method thereof

InactiveCN108084815AIncrease variabilityGood dispersionLuminescent paintsMulticolor effect coatingsFluorescenceRare earth

The invention provides a color-changing flashing interior wall decorative coating. The decorative coating is prepared from, by mass, 30-50 parts of styrene-acrylic emulsion, 2-5 parts of film formingaid, 0.1-0.5 part of defoaming agent, 0.5-1 part of thickening agent, 5-8 parts of nano-titania, 3-5 parts of photochromic fluorescent pigment, 2-3 parts of flashing powder, 1-2 parts of dispersing agent, 1-2 parts of flatting agent, 1-2 parts of wetting agent, 5-8 parts of nano-sized tourmaline powder and 5-15 parts of water. The photochromic fluorescent pigment is obtained by roasting a mixtureof rare earth oxide, boric acid and lithium carbonate, and the particle size of the photochromic fluorescent pigment is 50-100 nm. By adding a nano-composite, color-changing filler and flashing fillerto the coating, a coating layer is environmentally friendly and capable of displaying different colors under different illumination conditions.

Owner:宁波爱克创威新材料科技有限公司

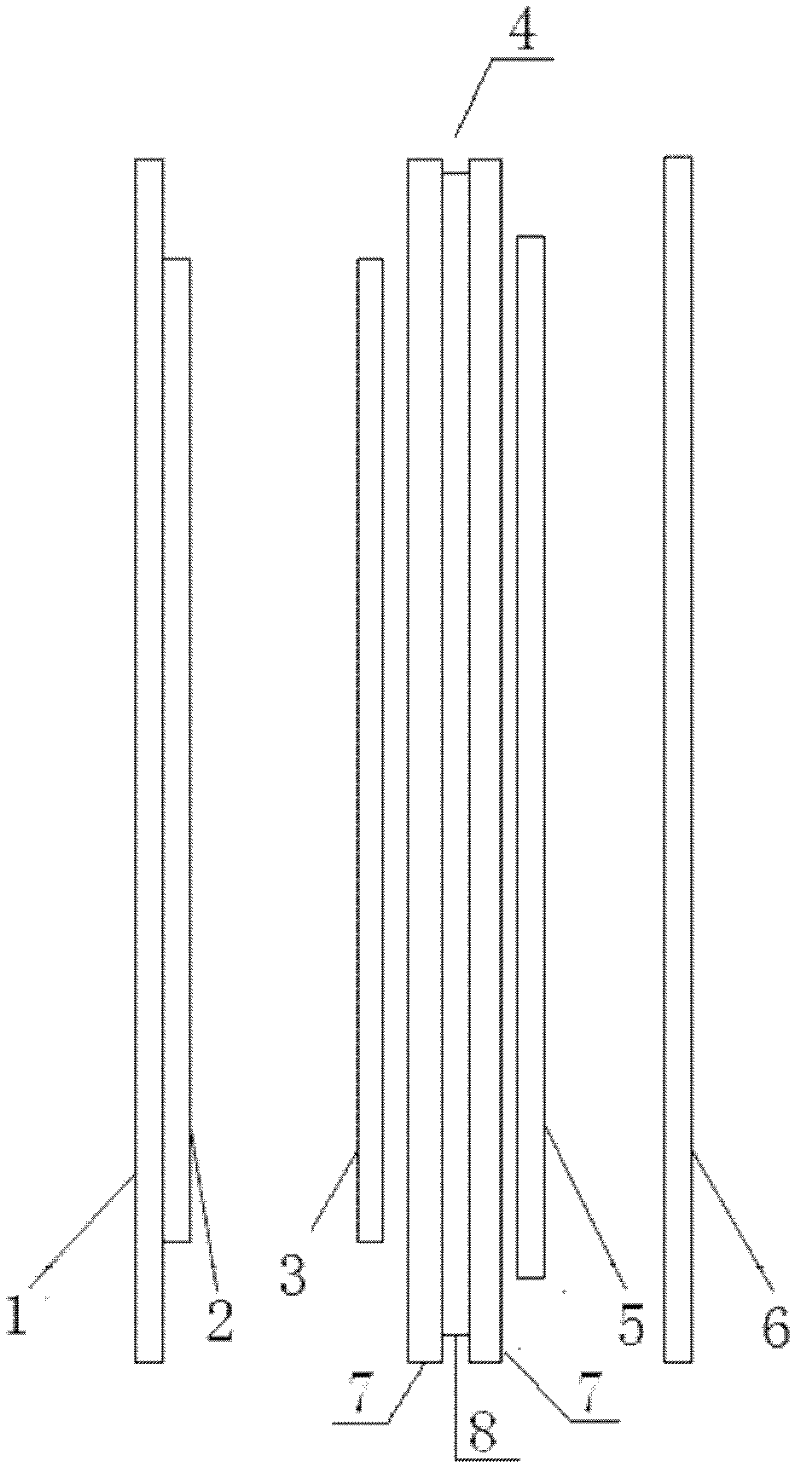

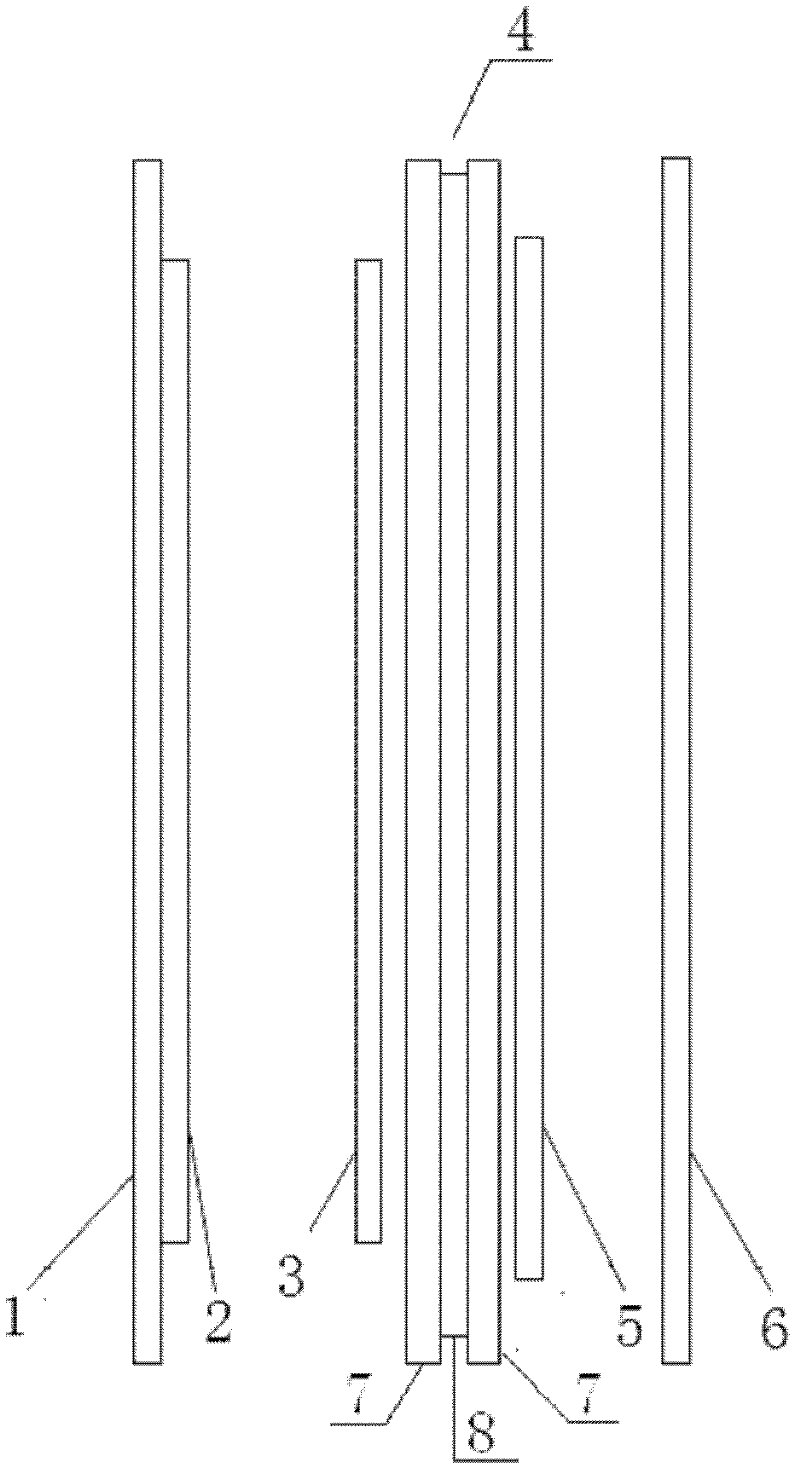

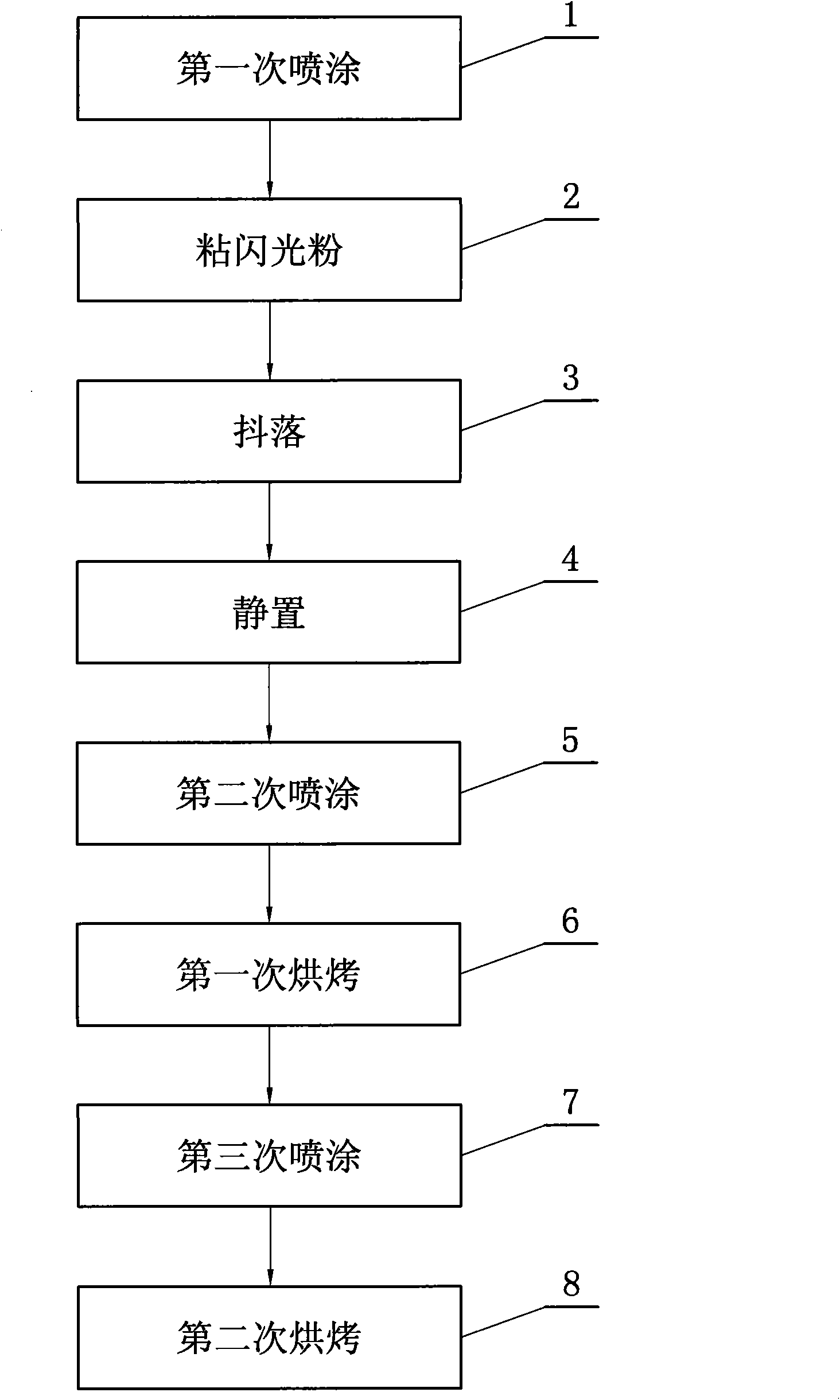

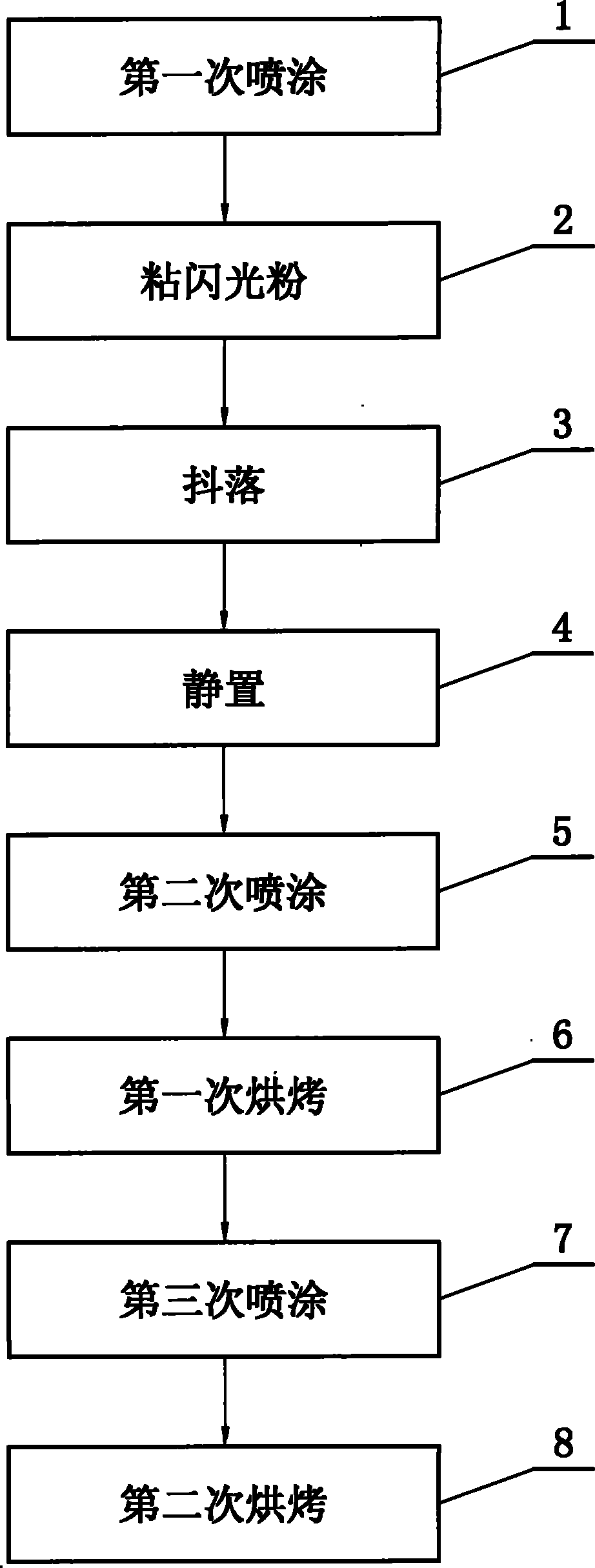

Spraying process of flash powder

InactiveCN101869883AReduce dosageNot easy to fall offPretreated surfacesCoatingsMaterials scienceFlash powder

The invention discloses a spraying process of flash powder, which sequentially comprises the following steps: A, carrying out primary spraying; B, sticking the flash powder; C, shaking off; D, keeping standing; E, carrying out secondary spraying; F, carrying out primary baking; G, carrying out tertiary spraying; and H, carrying out secondary baking. The spraying process of the invention has the advantages of effectively improving the adhesion efficiency of the flash powder, improving the surface uniformity of the product, saving the dosage of the flash powder, achieving no waste and effectively saving cost, thus the flash layer on the surface of the product is firm and not easy to drop off; and the flash powder does not need to be sprayed on the surface of the product through a spray gun, thus avoiding clogging a nozzle.

Owner:平湖市东洋塑胶真空涂膜厂

Fluorescent adhesive for COB encapsulation of LED

InactiveCN104576897AGood spatial chromaticity uniformityHigh color renderingSemiconductor devicesFluorescenceAdhesive

The invention discloses a fluorescent adhesive for COB encapsulation of an LED. The fluorescent adhesive is formed by mixing the following components in parts: 80-100 parts of allochroic silicagel, 50-60 parts of waterproof silicagel, 3-5 parts of rare earth long-acting noctilucent powder, 2-3 parts of reflecting powder, 2-3 parts of colorful flash powder, 1-3 parts of aluminium paste, 3-5 parts of resin diamond, 10-15 parts of blue fluorescent powder and 10-12 parts of yellow fluorescent powder. As the materials, such as the noctilucent powder and the reflecting powder, are added into the fluorescent adhesive for COB encapsulation of the LED, the spatial chroma uniformity of the LED is great, and the color rendering of the LED is effectively improved. The fluorescent adhesive is particularly suitable for vehicle lamps and can reduce the difference between the scene seen by a driver and the actual object state, so that the driving safety is improved.

Owner:广东赛铭照明科技有限公司

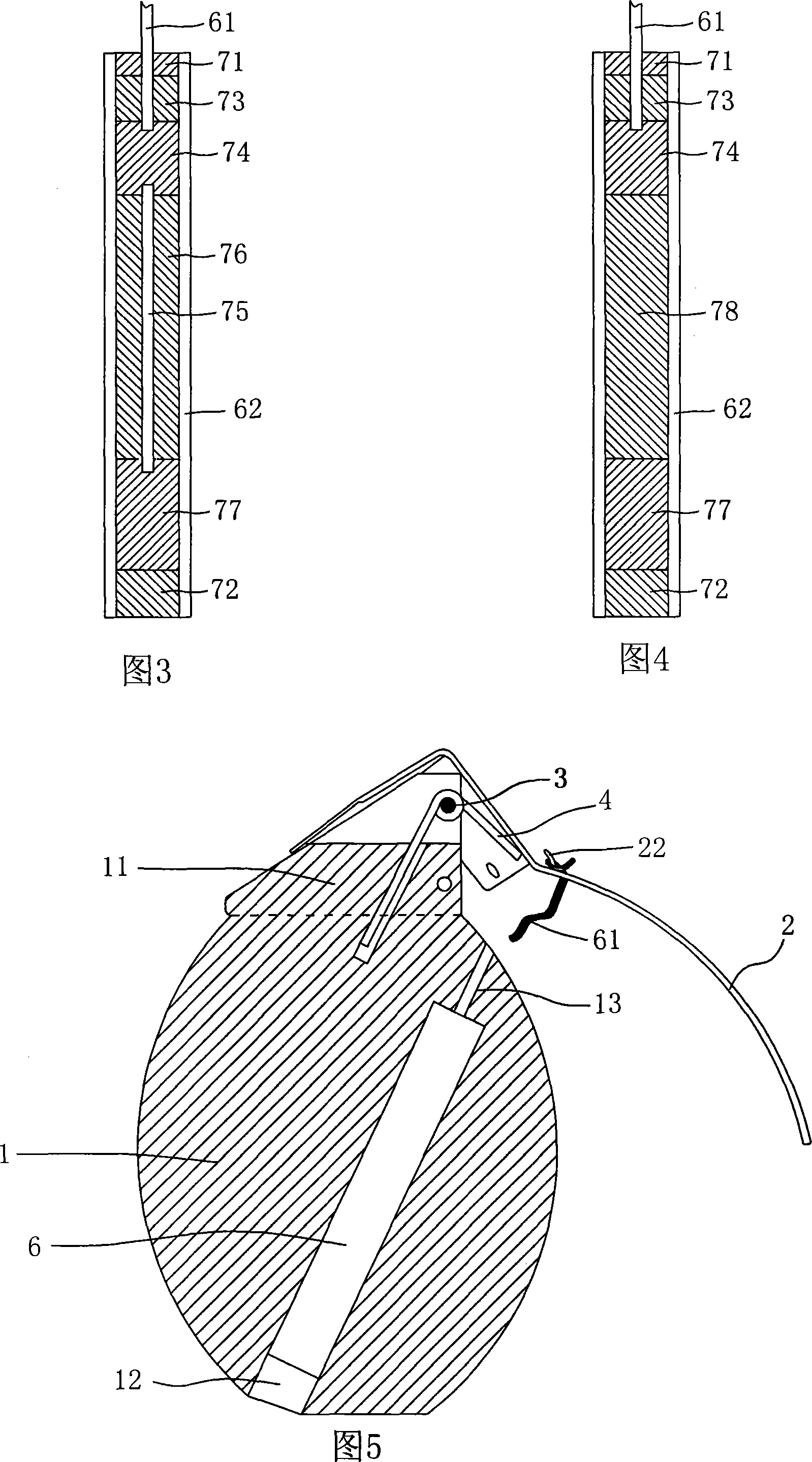

Smokeless flash powder

InactiveUS20110168307A1Effective lightingHeavy smokeExplosivesPyrophoric compositionsZirconium hydrideFlash powder

A flash powder formulation for use in flash grenades that produces reduced smoke containing from about 10 percent by weight to about 60 percent by weight of zirconium hydride, from about 40 percent by weight to about 90 percent by weight CAN, and from zero percent by weight to about 5 percent by weight of a binder material.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Purifying method of enramycin

ActiveCN105037497AOvercome the shortcomings of the purification methodEfficient removalPeptide preparation methodsButyl acetateEnramycin

The invention provides a purifying method of enramycin. The purifying method comprises the steps of regulating the pH value of a flash powder mixture of methanol and enramycin by using hydrochloric acid to be acidic to obtain an enramycin extracting solution; then, regulating the pH value of the enramycin extracting solution to be neutral, and sequentially eluting by taking column-layer chromatographic silica gel as a separating medium and taking petroleum ether, ethyl acetate, butyl acetate and methanol as eluants to remove impurities; next, eluting enramycin by using a methanol solution of hydrochloric acid to obtain an eluant containing enramycin; and carrying out rotary evaporation and drying after regulating the pH value of the eluant containing enramycin to be neutral to obtain enramycin. By using the method provided by the invention, the impurities can be effectively removed, and defects in the existing purifying method of enramycin can be overcome; experiments prove that the content of enramycin can be up to more than 98% if enramycin is prepared by using the method provided by the invention.

Owner:CHINA ANIMAL HUSBANDRY IND

High-glossiness paint

The invention discloses a high-glossiness paint. The high-glossiness paint is characterized by comprising the following raw materials in parts by mass: 40-47 parts of solvent, 17-22 parts of epoxy resin, 12-16 parts of alumina, 3-5 parts of glass fibers, 3-7 parts of flash powder, 4-6 parts of paraffin, 2-5 parts of zinc sulfate, 2.5-4 parts of thickening agent, 1.5-2.5 parts of brightening agent,2-3 parts of paraffin, and 3-5 parts of anti-precipitating agent. The high-glossiness paint is simple in formula, high in glossiness, high in hardness, quick to dry, free from irritating odor, free from influence on human body, high in safety, high in adhesion, and high in resistance to acid, alkali and water, and meets demands of people.

Owner:常盛杰

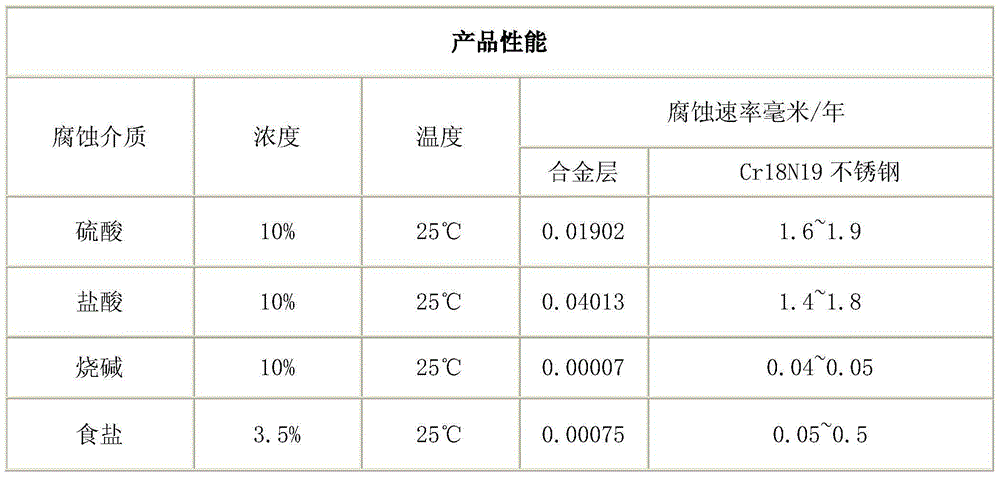

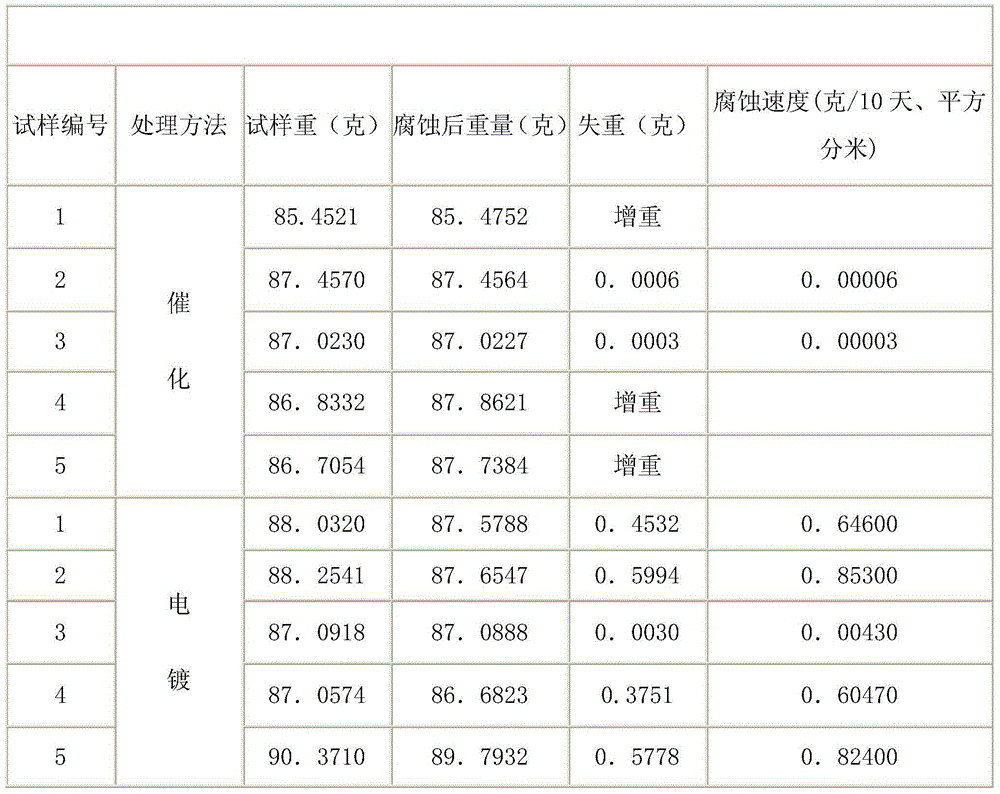

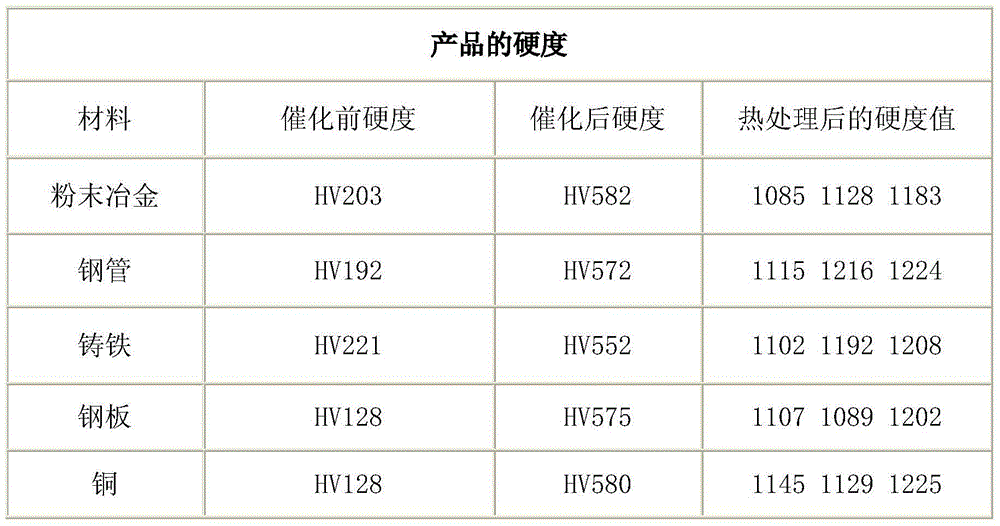

Novel environment-friendly alloy catalytic liquid and preparation method thereof

The invention discloses a novel environment-friendly alloy catalytic liquid and a preparation method thereof and belongs to the technical field of alloy catalytic liquid. The catalytic liquid is mainly prepared from the following raw materials in percentage by weight: 1 to 8 percent of nickel sulfate, 1 to 8 percent of sodium hypophosphite, 0.2 to 2 percent of sodium citrate, 0.2 to 2 percent of 2-hydracrylic acid, 0.5 to 3 percent of acetic acid, 0.5 to 5 percent of sodium acetate, 0.06 to 0.5 percent of hydrazine sulfate, 0.0001 to 0.0005 percent of sulfur flash powder, 2 to 12 percent of ammonia water, 0.5 to 3 percent of sulfuric acid and 55 to 90 percent of water. The method comprises the following steps: (1) weighing all raw materials; (2) sequentially and uniformly stirring all raw materials at normal temperature to obtain a semi-finished product of mixed liquid; (3) regulating the PH value to be 4.5-5.2 and uniformly stirring to obtain the catalytic liquid. The invention aims to provide the novel environment-friendly alloy catalytic liquid which is reasonable in formula, high in catalyzing speed, stable in quality and high in cyclic utilization rate; the novel environment-friendly alloy catalytic liquid is used for replacing electroplating.

Owner:梅州市星泰环保科技有限公司

Method for making high-brightness color light-accumulation luminescent powder

The present invention relates to the preparation process of one kind of high brightness color light accumulating phosphor. The high brightness color light accumulating phosphor consists of phosphor and light accumulating and emitting powder. The preparation process includes preparing fluorescent solvent, adding the light accumulating and emitting powder, drying in air, grinding and other steps. The high brightness color light accumulating phosphor has light color depending on the phosphor, and may have one, two and three kinds of color. During the preparation, flash powder and transparent color slurry may be added. The solvent thinner is used to make the preparation process simple and practical, and make the phosphor and the light accumulating and emitting powder well combined, raise the color of the material and raise the combination of the material with silica gel, organic glass or plastic.

Owner:SICHUAN SUNFOR LIGHT

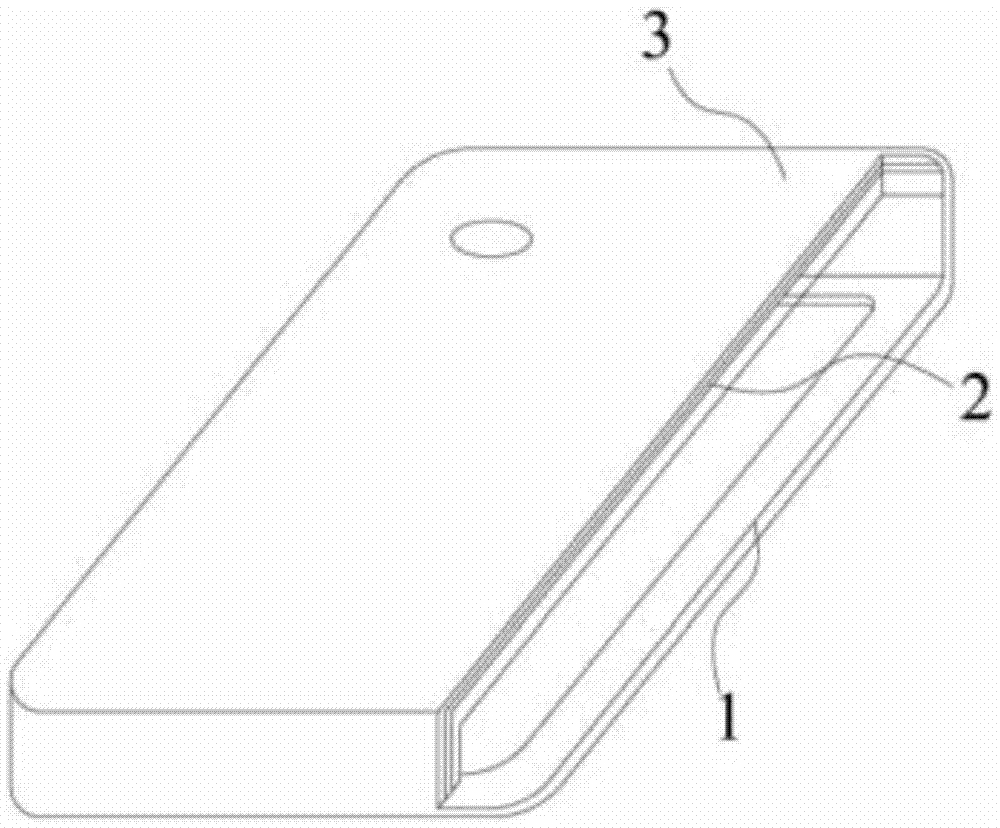

Color changing noctilucent mobile phone protection sleeve and processing process thereof

InactiveCN106913038ARealize the color changing functionRealize night light functionOther accessoriesSpecial surfacesPhosphorProtection KIT

The invention relates to a mobile phone fitting part and a processing process thereof, particularly to a color changing noctilucent mobile phone protection sleeve and a processing process thereof. The color changing noctilucent mobile phone protection sleeve comprises a silica gel mobile phone sleeve body provided with a mobile phone accommodation cavity, wherein the surface of the silica gel mobile phone sleeve body is sprayed with a mixed color changing layer, the mixed color changing layer is sprayed with a flash powder layer, the surface of the flash powder layer is sprayed with an UV curable varnish layer, the mixed color changing layer is formed by mixing 20-40% by mass of phosphor, 10-20% by mass of color changing powder and 40-60% by mass of UV curable varnish, and the flash powder layer is a 80-160 mesh pearl powder layer. According to the present invention, the color changing noctilucent mobile phone protection sleeve can simultaneously achieve the functions of color chaging and noctilucence, can be changed into different colors in the case of illumination and temperature changing, and can emit light in the dark, such that the visual effect requirement of people can be met, and the user can conveniently find the mobile phone in the dark.

Owner:宁波福天新材料科技有限公司

Flashing powder coating containing pigment scarlet

InactiveCN107118667AImprove the decorative effectImprove durabilityPowdery paintsEpoxy resin coatingsPolyester resinStearic acid

The invention discloses a flashing powder coating containing a pigment scarlet. The flashing powder coating is characterized by comprising the following components in parts by weight: 28-30 parts of bisphenol-A epoxy resin, 28-30 parts of saturated polyester resin, 25-28 parts of precipitated barium sulphate, 1-1.2 parts of a leveling defoamer, 0.5-1 part of stearic acid, 7-9 parts of titanium dioxide, 0.5-1 part of carbon black and 3-4 parts of pigment scarlet; and the flashing powder coating is prepared through mixing various components, carrying out melting, extruding and cold pressing to form sheets, crushing and grinding the sheets into powder, sieving the powder and then mixing with aluminite powder of which the particle sizes are 30-50mm. The flashing powder coating prepared by adopting the formula and the process has the characteristic of being stable and persistent in flashing effect.

Owner:东莞市联盈粉末制品有限公司

Acrylic board

InactiveCN109808246AWith heat-resistant functionRich varietySynthetic resin layered productsGlass/slag layered productsGlass fiberHeat resistance

The invention discloses an acrylic board, which comprises an acrylic base plate, an acrylic upper cover plate and an acrylic lower bottom plate. The acrylic base plate is of an H-shaped structure, anda decorative cavity is formed between the acrylic base plate and the acrylic upper cover plate; a gypsum board layer, a deadening felt layer, a sound-absorbing sponge layer and a glass fiber layer are sequentially arranged between the acrylic base plate and the acrylic lower bottom plate from top to bottom; heat dissipating holes are formed in the acrylic base plate, the acrylic upper cover plateand the acrylic lower bottom plate correspondingly; a heat-resisting layer is arranged on the outer side face of a cuboid defined by the acrylic base plate, the acrylic upper cover plate and the acrylic lower bottom plate; and an image-text layer is arranged in the decorative cavity, flashing powder is arranged in the decorative cavity, and the heat-resisting layer is formed through spraying. Thestructure is compact, the design is reasonable, the functions of deadening and heat resistance are further achieved, and practicability is high.

Owner:安徽迈明亚克力科技有限公司

Smokeless flash powder

A flash powder formulation for use in flash grenades that produces reduced smoke containing from about 10 percent by weight to about 60 percent by weight of zirconium hydride, from about 40 percent by weight to about 90 percent by weight CAN, and from zero percent by weight to about 5 percent by weight of a binder material.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Ceramic flash powder glaze and preparation method thereof

The invention discloses ceramic flash powder glaze and a preparation method thereof. The glaze used by the ceramic flash powder glaze contains the following components in parts by mass: 59.8 parts ofwater-based acrylic resin, 0.2 part of water-based curing agent, 30 parts of colored flash powder and 10 parts of purified water. By using the glaze disclosed by the invention, the ceramic has a highflash property, the visual effect of a ceramic product is enhanced, and the ceramic product has a three-dimensional effect.

Owner:HUNAN YINHE CERAMICS IND

A kind of purification method of enramycin

ActiveCN105037497BOvercome the shortcomings of the purification methodEfficient removalPeptide preparation methodsButyl acetateEnramycin

The invention provides a purifying method of enramycin. The purifying method comprises the steps of regulating the pH value of a flash powder mixture of methanol and enramycin by using hydrochloric acid to be acidic to obtain an enramycin extracting solution; then, regulating the pH value of the enramycin extracting solution to be neutral, and sequentially eluting by taking column-layer chromatographic silica gel as a separating medium and taking petroleum ether, ethyl acetate, butyl acetate and methanol as eluants to remove impurities; next, eluting enramycin by using a methanol solution of hydrochloric acid to obtain an eluant containing enramycin; and carrying out rotary evaporation and drying after regulating the pH value of the eluant containing enramycin to be neutral to obtain enramycin. By using the method provided by the invention, the impurities can be effectively removed, and defects in the existing purifying method of enramycin can be overcome; experiments prove that the content of enramycin can be up to more than 98% if enramycin is prepared by using the method provided by the invention.

Owner:CHINA ANIMAL HUSBANDRY IND

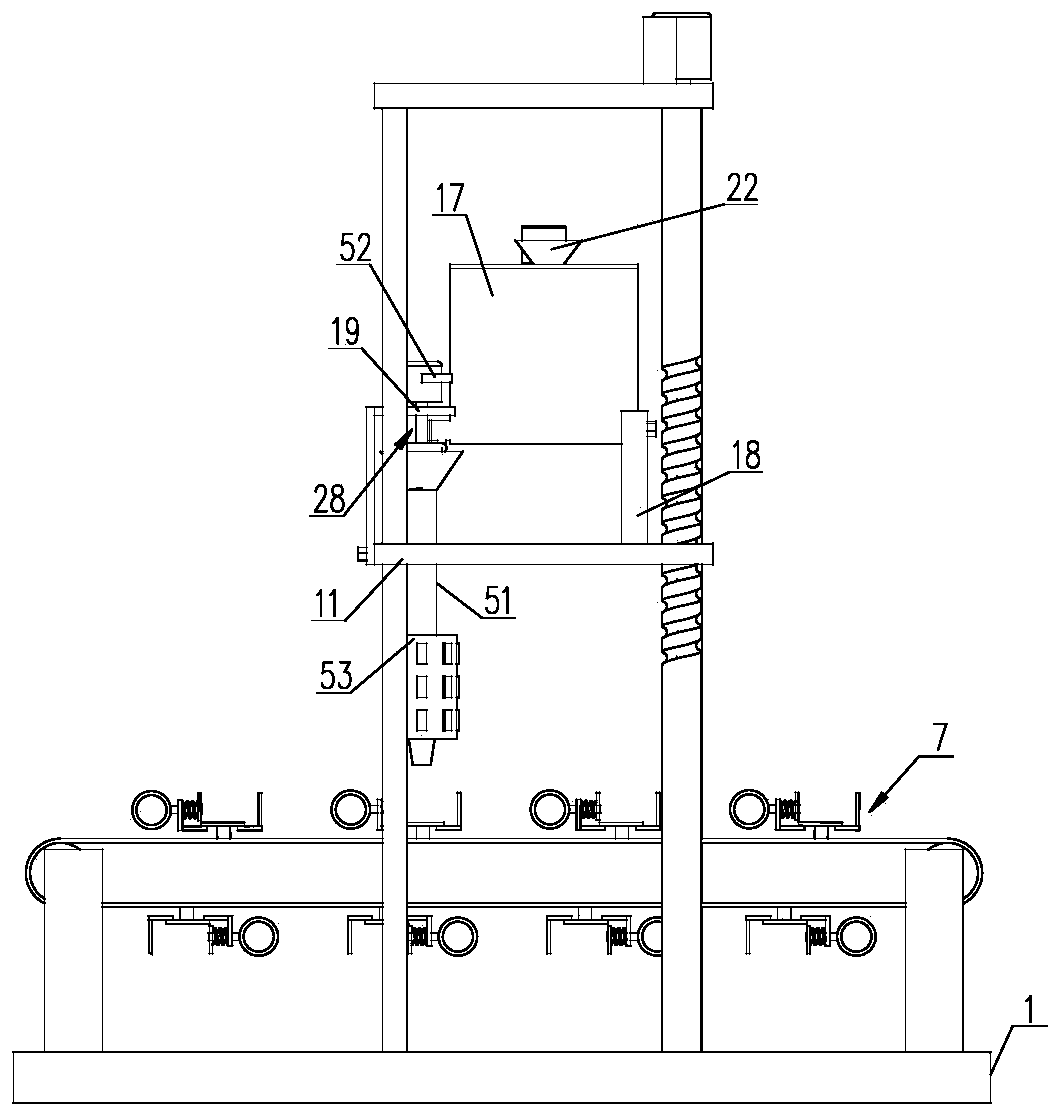

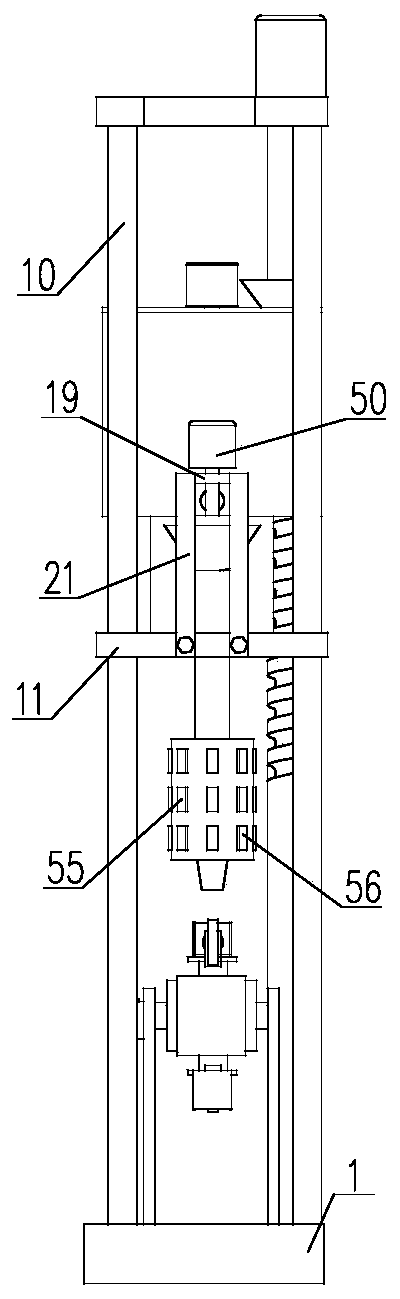

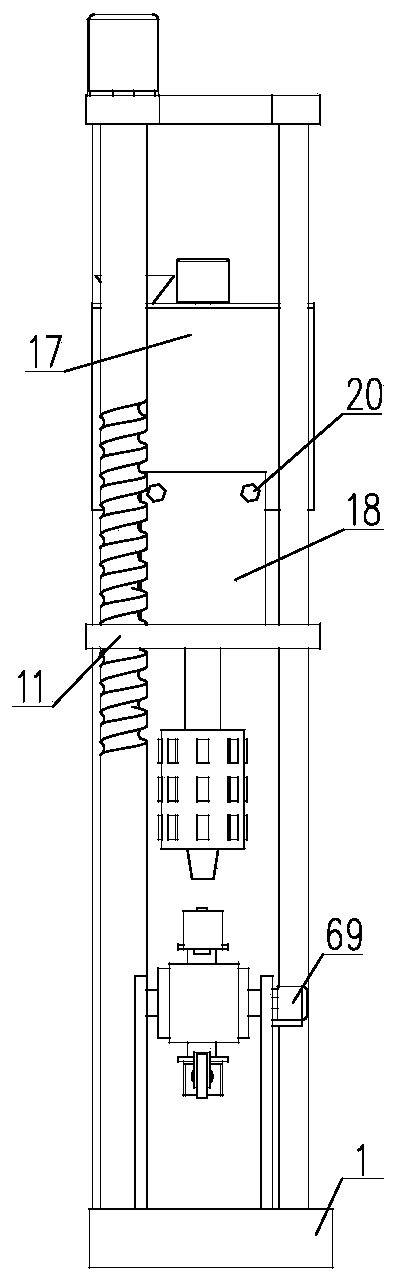

Glitter powder with color changed with angle and processing equipment of glitter powder

PendingCN110591440AImprove efficiencyGood effectLiquid surface applicatorsCoatingsEpoxyColor changes

The invention discloses glitter powder with a color changed with an angle. The glitter powder includes the following components in parts by weight: 2 to 3 parts of epoxy resin A glue, 2 to 3 parts ofepoxy resin B glue, 12 to 16 parts of color changing powder, 4 to 6 parts of an organic oligomer, 11 to 17 parts of tetraethoxysilane, 2 to 5 parts of ethylene glycol ethyl ether, 16 to 24 parts of polycarbosilane, 8 to 12 parts of a nano oxide filler, 1 to 3 parts of silicon dioxide, 13 to 15 parts of flashing powder, 9 to 10 parts of a levelling agent, 15 to 18 parts of tetrahydrofuran, 10 to 12parts of xylene, 0.5 to 0.7 part of sodium hexametaphosphate, 0.8 to 1 part of phthalocyanine blue and 3 to 6 parts of n-butanol. The coating efficiency and effect are improved by the preparation provided by the invention, and the color changing and flashing effects of the glitter powder produced by the method can be improved; and equipment has the beneficial effects of a simple structure, low preparation costs and convenient use.

Owner:广东冠虹金葱科技有限公司

A kind of luminous glue and preparation method thereof

InactiveCN103265904BEasy to identifyEasy to prepareN-vinyl-pyrrolidone polymer adhesivesUnsaturated alcohol polymer adhesivesPolymer sciencePolymer resin

The invention discloses a luminescence gel, which is characterized by comprising the following raw materials, by weight: 5-20% of a polymer resin, 0.1-15% of flash powder, 1-15% of an excipient, 3-40% of luminescence powder, and 20-85% of water. The preparation method comprises the following steps: (1) adding a polymer resin and water to a reaction kettle, heating to a temperature of 60-95 DEG C, and stirring for 30-90 min; (2) adding an excipient to the reaction kettle, carrying out thermal insulation stirring for 10-40 min at a temperature of 60-95 DEG C, and stopping heating, such that the material is naturally cooled along with stirring; (3) adding luminescence powder and flash powder to the reaction kettle, and stirring for 10-40 min to obtain a mixture; and (4) carrying out filling packaging on the obtained mixture to obtain the finished product. According to the present invention, the long time luminescence function under a dark state of the luminescence gel can be achieved through absorbing natural light or artificial light.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Breakfast powder nourishing and protecting the stomach

InactiveCN107549797AReasonable ratioNutritional balanceMilk preparationFood scienceLycium barbarum fruitRhizome

Breakfast powder nourishing and protecting the stomach is disclosed. The breakfast powder includes 10-20 parts of millet powder, 5-15 parts of coix seed powder, 4-8 parts of oat powder, 1-2 parts of freshwater clam flash powder, 1-2 parts of chicken powder, 6-10 parts of peanut powder, 2-4 parts of walnut powder, 3-5 parts of common yam rhizome, 3-5 parts of milk powder, 3-5 parts of spinach powder, 2-4 parts of tremella fuciformis powder and 2-4 parts of barbary wolfberry fruit powder. The breakfast powder is reasonable in ratio, balanced in nutrition, convenient and rapid, has effects of nourishing yin, improving eyesight, and warming and nourishing the stomach, and can adjust stomach and intestine functions and increase motive power of the stomach after long-term application.

Owner:刘连锋

Injection molding material, preparation method thereof, and injection molding product thereby

ActiveCN102746604BImprove pass rateEfficient secondary processingInjection molding machinePowder Spray

The invention discloses an injection molding material, a preparation method thereof, and an injection molding product thereby. The injection material comprises metallic flashing powder and injection molding granules at the weight ratio of 1-5:100. With technical schemes of the invention and based on the prior injection molding technologies, the metallic flashing powder is added into the injection molding granules, so that the injection molding product prepared by the injection molding material has similar or even better effects of metallic flashing powder spraying. The product prepared by the injection molding material of the invention is finished by direct injection molding, so that compared with secondary processing of spraying, the product is prepared more efficiently and the qualified rate of the product is higher; and color and transparency are blended, so that the product prepared by the injection molding material achieves different light transmission effects.

Owner:GREE ELECTRIC APPLIANCES INC

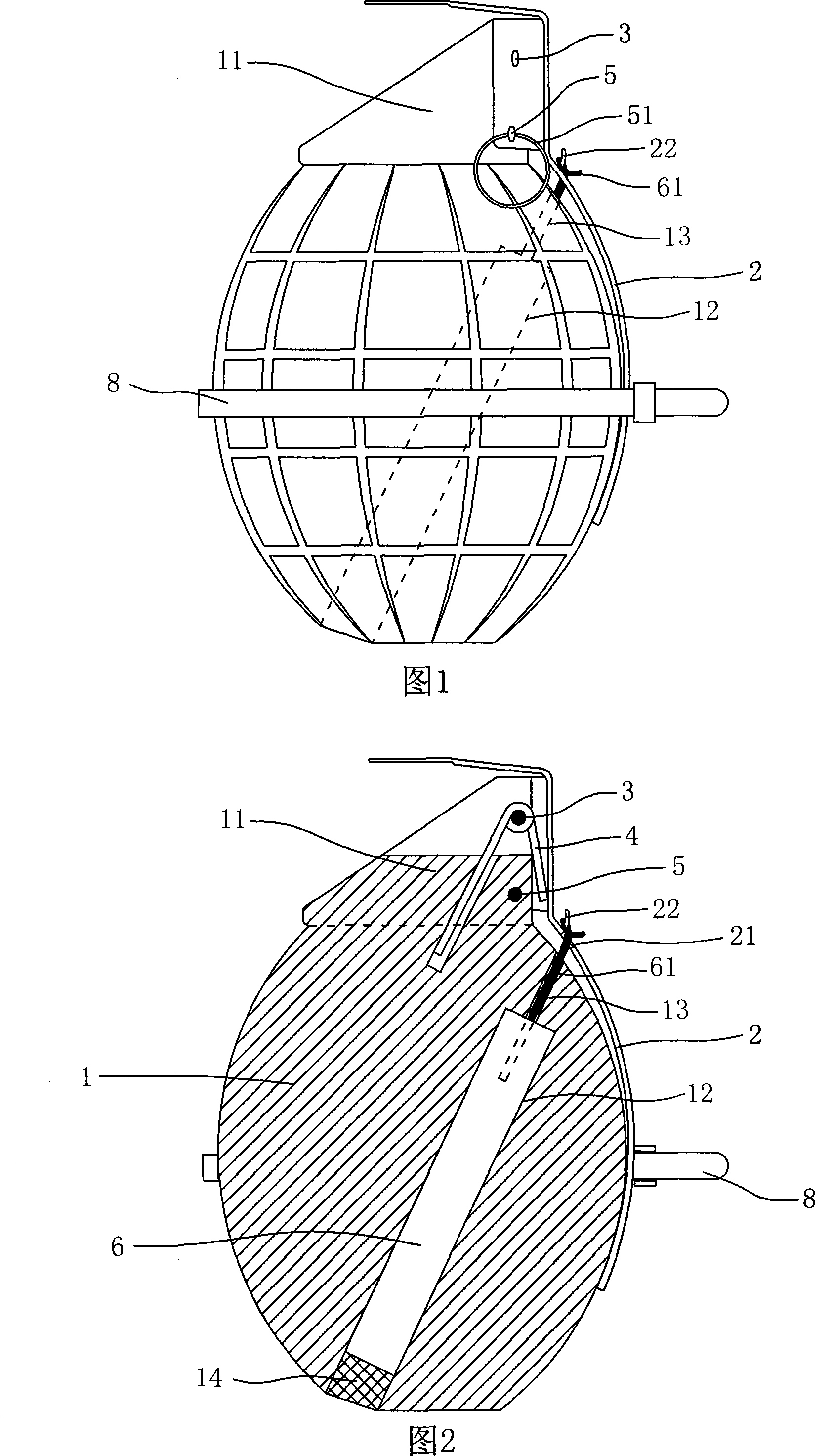

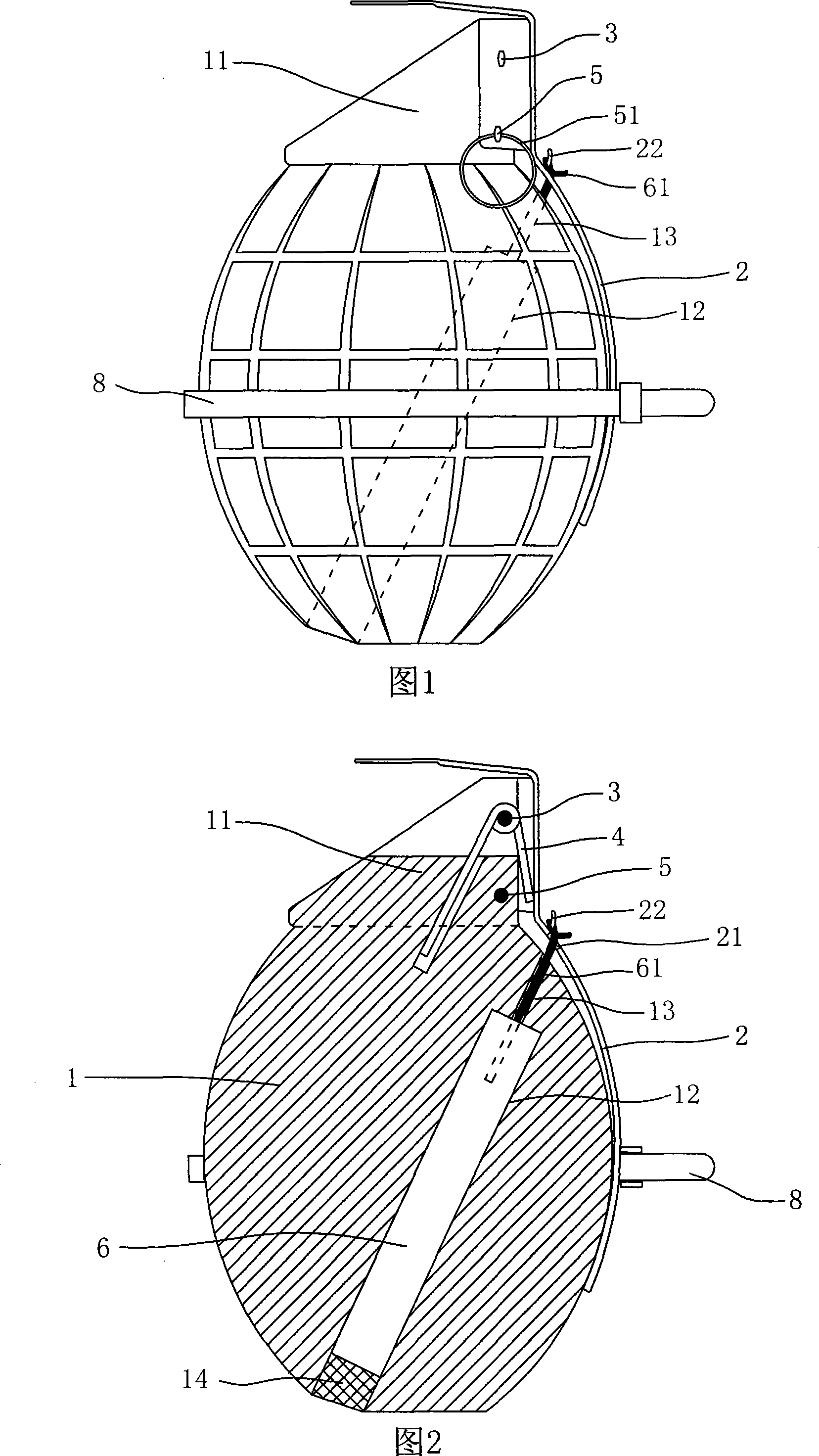

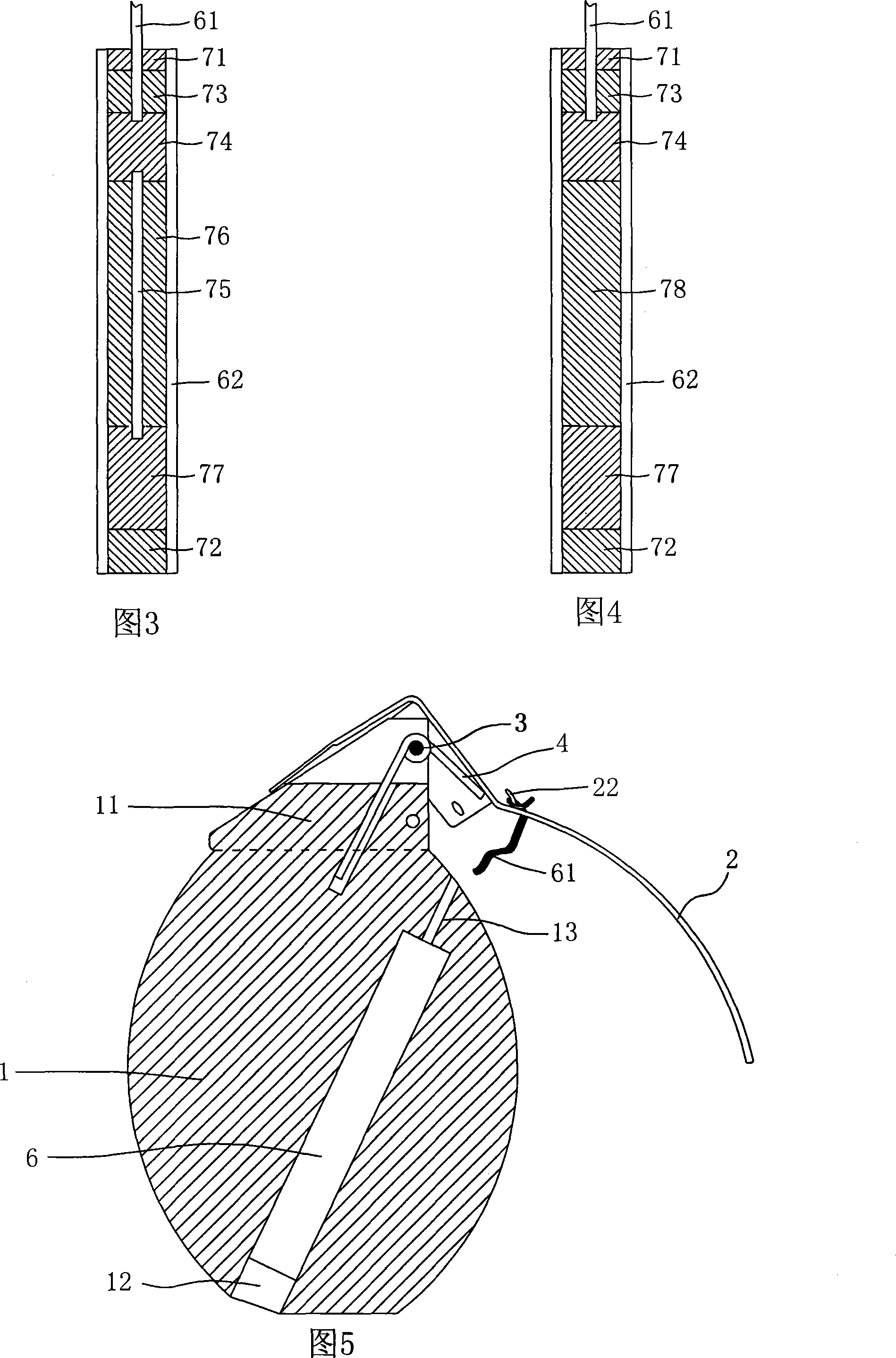

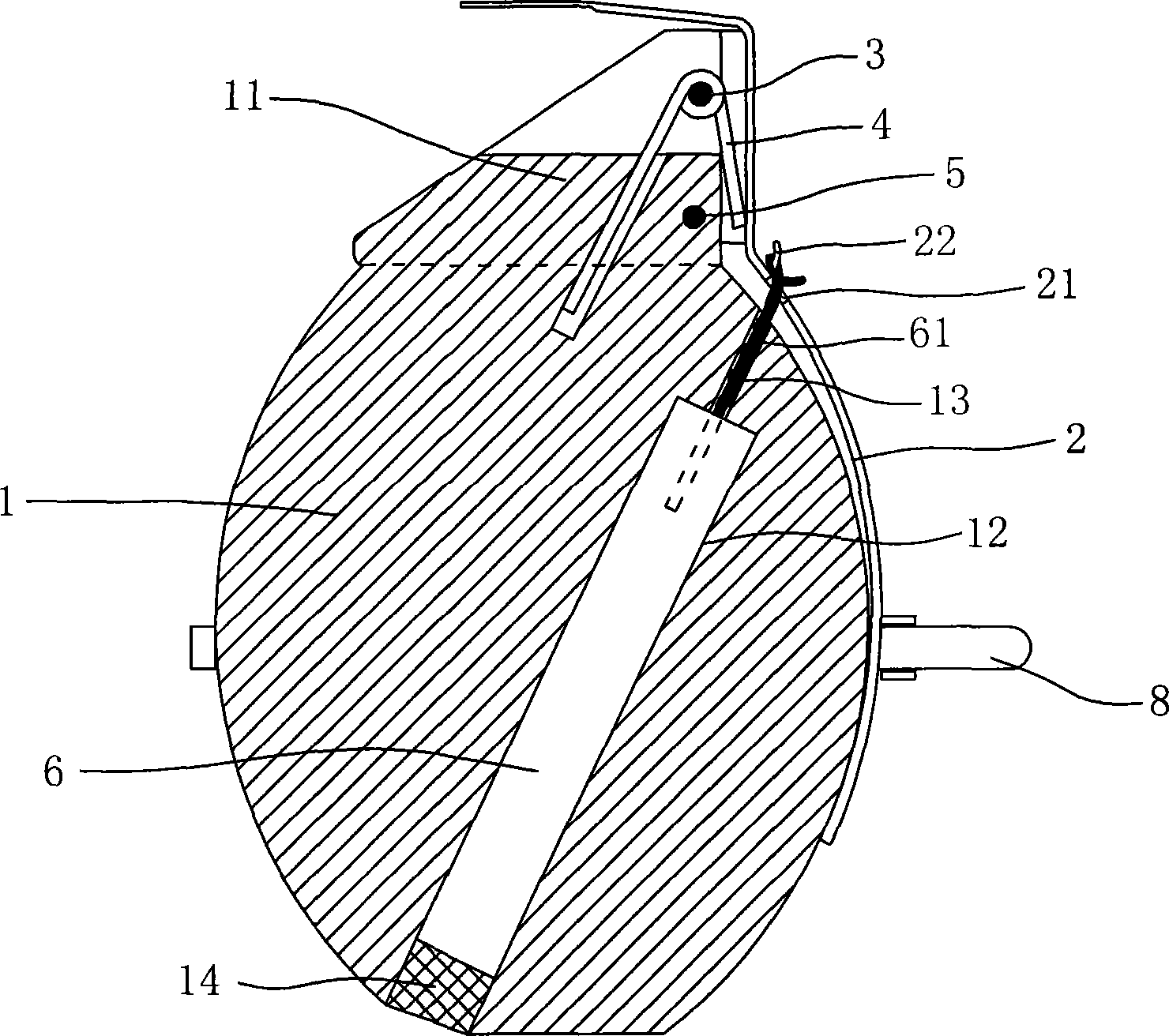

Steel ball free simulated antitank grenade for training

InactiveCN101126617AFully simplify the structureFully simplify materialsTraining ammunitionDetonatorEngineering

The utility model relates to a simulated grenade without steel ball used for training, comprising a rubber or plastic simulated grenade case, a safety plate and a safety pin with pulling ring, an accommodation hole arranged on the middle of the grenade case for penetrating bottom surface, an explosive device with a firing lanyard arranged in the accommodation hole. The explosive device comprises an outer cartridge without explosive powder bottom plates at the upper and lower ends, a plurality of flash powder, igniting powder, deferring detonator and explosive powder with safety dose arranged in the space between the upper and lower bottom plates. The flash powder is connected with one end of the firing lanyard coated with friction composition, and the safety plate is connected with the other end passing through the upper end and the grenade case. The sealing glue is arranged on the bottom port of the accommodation hole of the grenade case. The utility model has the advantages that the appearance of the simulated grenade is similar to the actual grenade, the actuating mechanism and explosive device can realize the simulated smog and sound, the explosive device is safety without lethality, the verisimilar training can be guaranteed; the simulated grenade is safe with simple structure, can avoid casualty accident, reach the training effectiveness of live ammunition, decrease the consumption material and reduce the training costs.

Owner:李增加

Steel ball free simulated antitank grenade for training

InactiveCN101126617BSimple and safe operationRealistic operationTraining ammunitionDetonatorEngineering

The utility model relates to a simulated grenade without steel ball used for training, comprising a rubber or plastic simulated grenade case, a safety plate and a safety pin with pulling ring, an accommodation hole arranged on the middle of the grenade case for penetrating bottom surface, an explosive device with a firing lanyard arranged in the accommodation hole. The explosive device comprises an outer cartridge without explosive powder bottom plates at the upper and lower ends, a plurality of flash powder, igniting powder, deferring detonator and explosive powder with safety dose arranged in the space between the upper and lower bottom plates. The flash powder is connected with one end of the firing lanyard coated with friction composition, and the safety plate is connected with the other end passing through the upper end and the grenade case. The sealing glue is arranged on the bottom port of the accommodation hole of the grenade case. The utility model has the advantages that theappearance of the simulated grenade is similar to the actual grenade, the actuating mechanism and explosive device can realize the simulated smog and sound, the explosive device is safety without lethality, the verisimilar training can be guaranteed; the simulated grenade is safe with simple structure, can avoid casualty accident, reach the training effectiveness of live ammunition, decrease the consumption material and reduce the training costs.

Owner:李增加

Pigment printing method for cashmere sweater

The invention relates to a common paint printing method for cashmere sweaters and a gold and silver powder paint printing method, specifically comprising the following steps: slurry preparation, printing, drying, baking, and post-press softening treatment. The general paint printing of the invention has clear outlines without bleeding, strong layering, and a hand feeling close to that of dye printing; the gold and silver powder paint printing has high shininess and does not drop powder.

Owner:内蒙古新力纺织科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com