Patents

Literature

6055results about "Looms" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

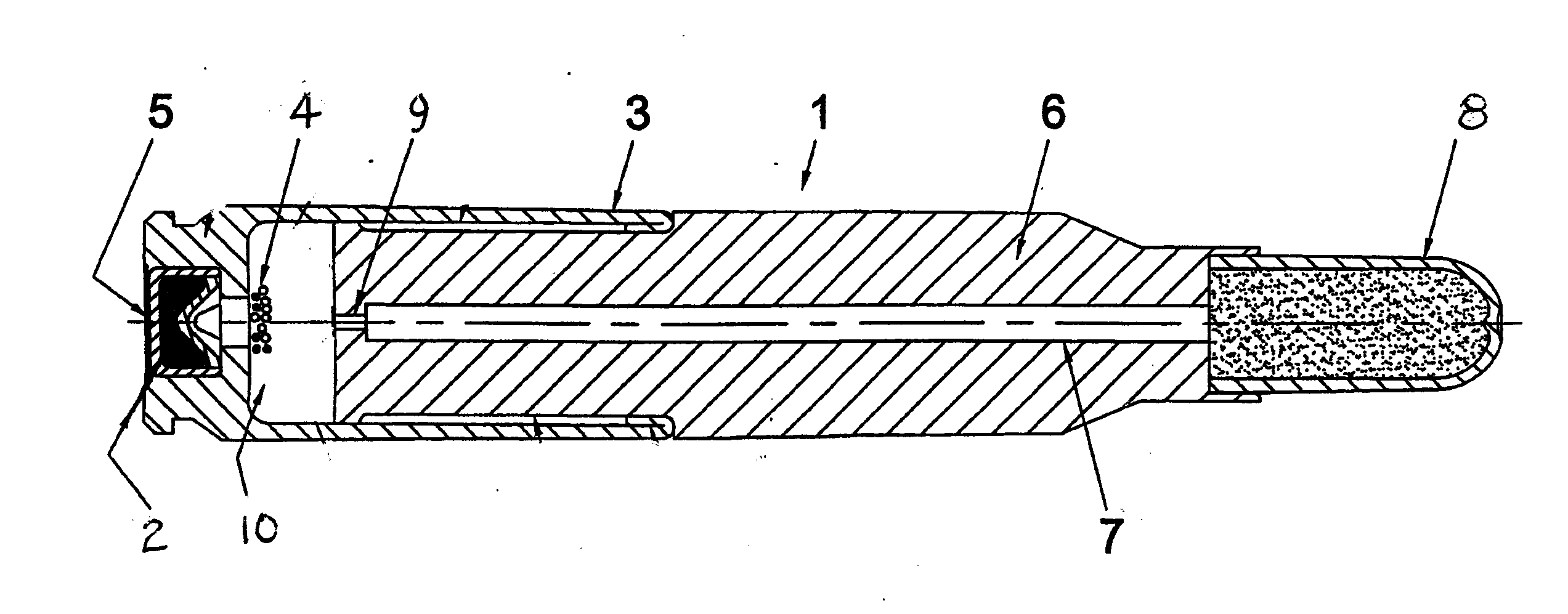

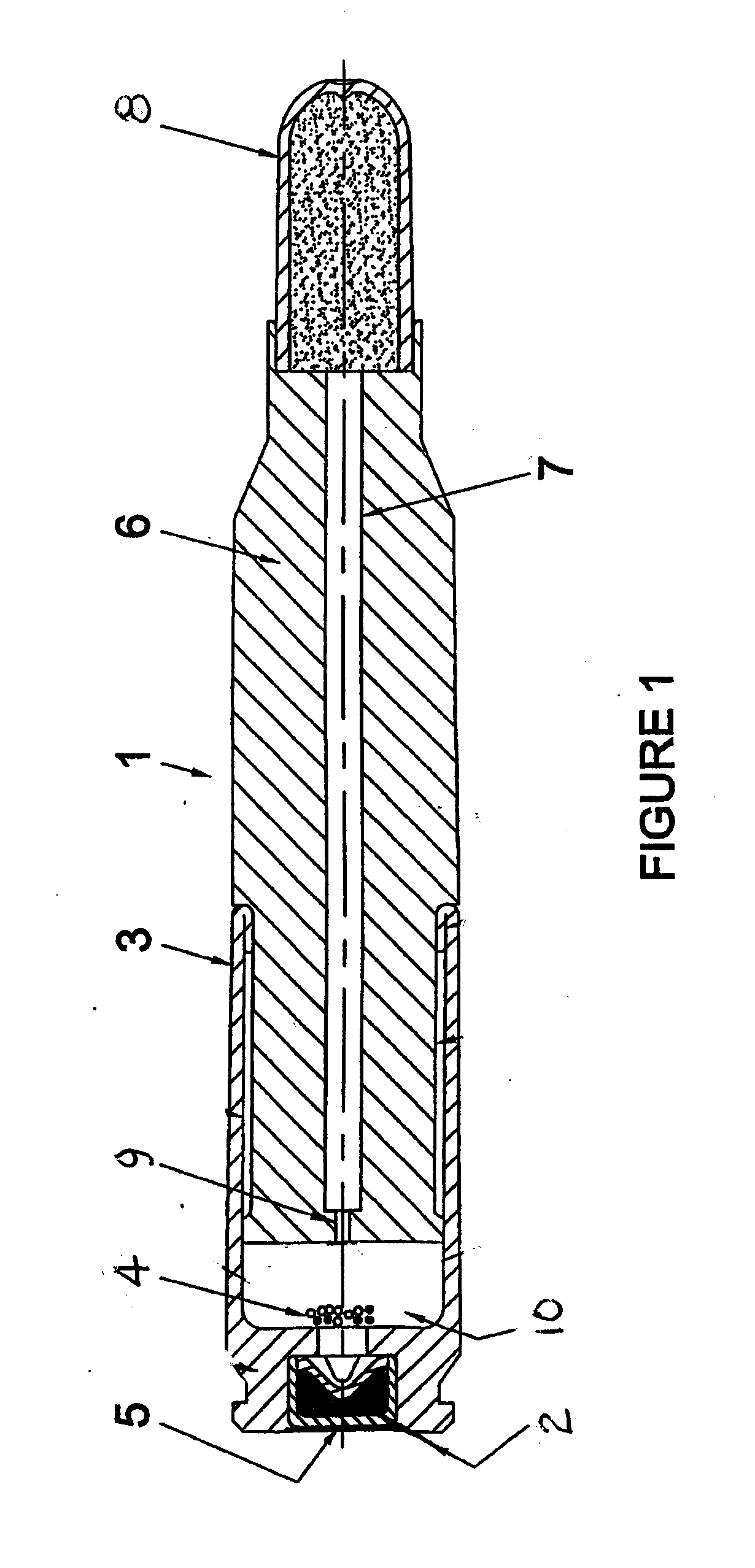

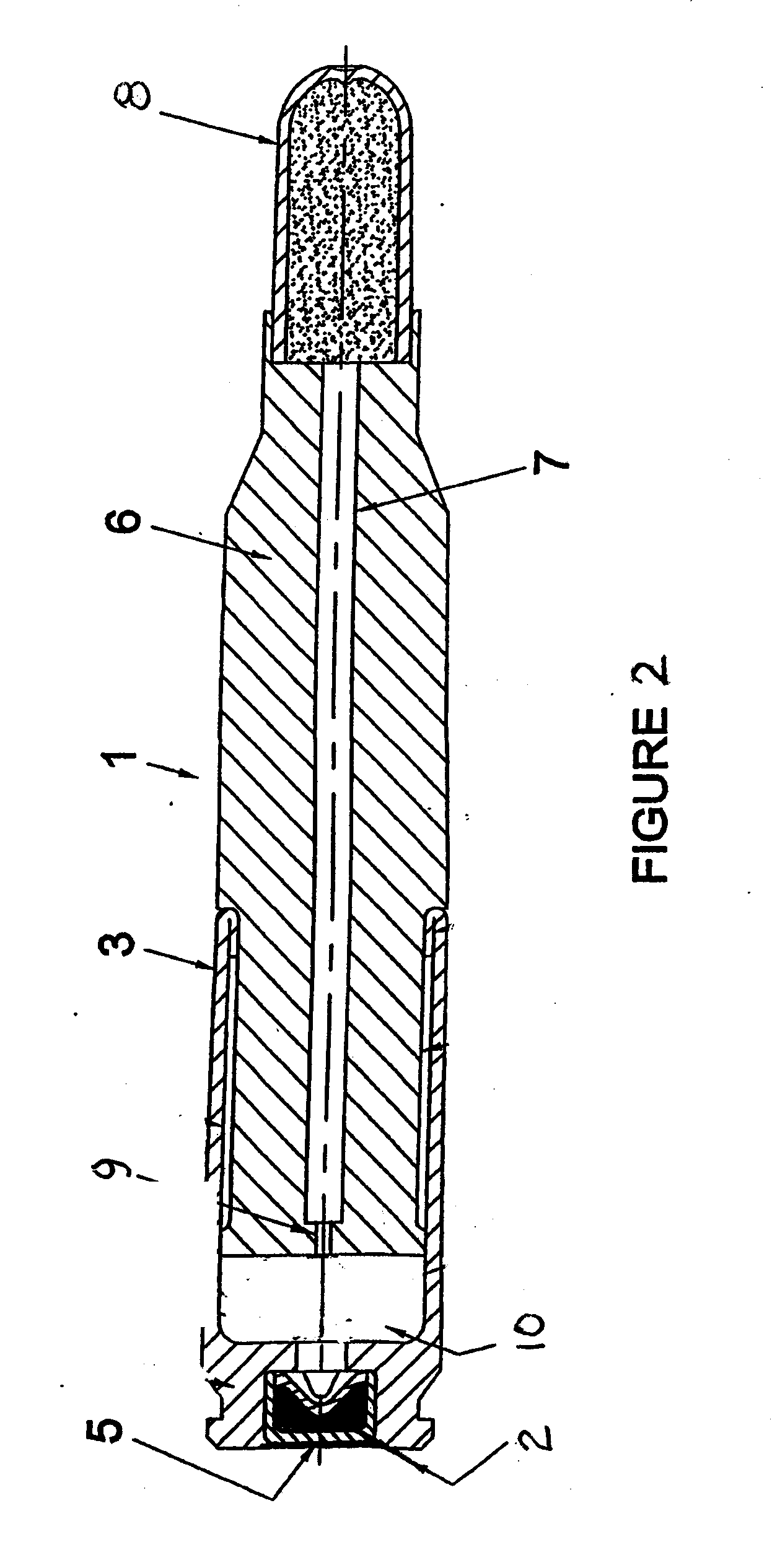

Non-toxic, heavy-metal free sensitized explosive percussion primers and methods of preparing the same

ActiveUS8206522B2Metal azide explosive compositionsMetal fulminate explosive compositionsEngineeringOxidizing agent

A non-toxic, non-hydroscopic percussion primer composition and methods of preparing the same, including at least one explosive component that has been traditionally considered a moderately insensitive explosive or secondary explosive, and at least fuel particle component having a particle size of about 1.5 microns to about 12 microns, which allows the use of moderately active metal oxidizers. The sensitivity of the primer composition is created by the interaction between the moderately insensitive explosive and the fuel agent such that traditional primary explosives such as lead styphnate or DDNP are not needed. The primer composition also eliminates the risks and dangers associated with traditional nano-sized fuel particles.

Owner:FEDERAL CARTRIDGE

Nontoxic, noncorrosive phosphorus-based primer compositions and an ordnance element including the same

A primer composition that includes red phosphorus having an acid scavenger and a polymer thereon. The primer composition includes at least one other component that is substantially free of lead. The other component is at least one oxidizer, or at least one oxidizer and at least one of at least one secondary explosive composition and at least one energetic binder. The primer composition optionally includes at least one element having an ionic charge to ionic radius ratio of 4 or of 8, such as magnesium, zirconium, aluminum, silicon, titanium, tungsten, alloys thereof, and combinations thereof. The red phosphorus and the at least one oxidizer are present in the primer composition at approximately stoichiometric amounts. An ordnance element including the primer composition is also disclosed.

Owner:NORTHROP GRUMMAN SYST CORP

Propellant compositions including stabilized red phosphorus, a method of forming same, and an ordnance element including the same

Propellant compositions include an energetic binder, such as nitrocellulose, and a stabilized, encapsulated red phosphorous as a ballistic modifier. The propellant composition may additionally include an energetic plasticizer, such as nitroglycerine. For example, the propellant composition may be formed by mixing a double or multi base propellant that includes nitrocellulose plasticized with nitroglycerine with the stabilized, encapsulated red phosphorus. The propellant compositions may be substantially lead-free and may exhibit improved ballistic properties. Methods of forming such propellant compositions and an ordnance device including such propellant compositions are also disclosed.

Owner:NORTHROP GRUMMAN SYST CORP

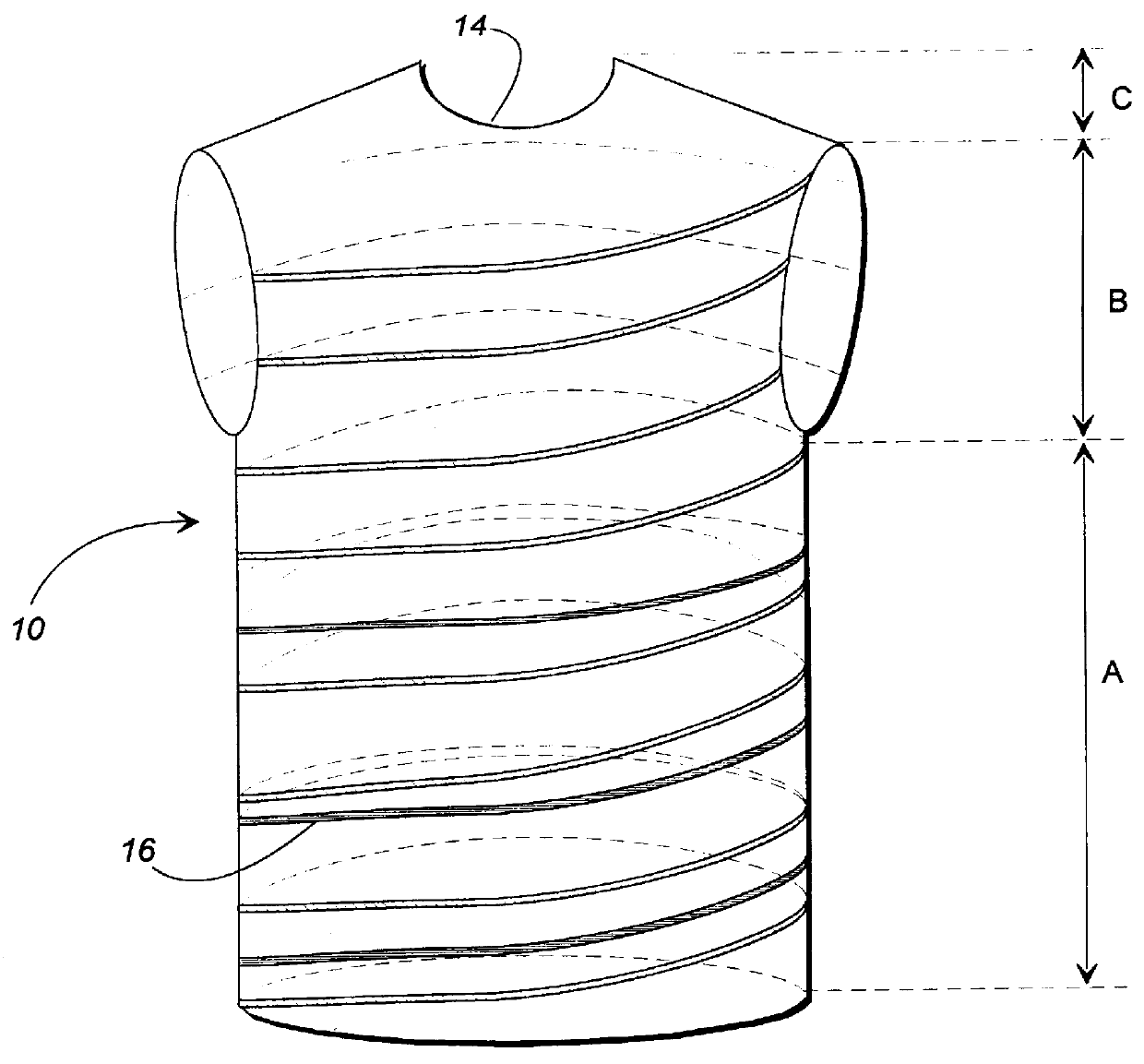

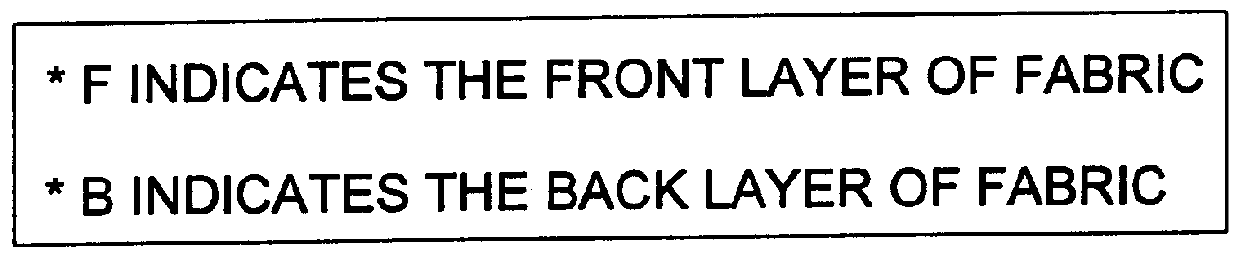

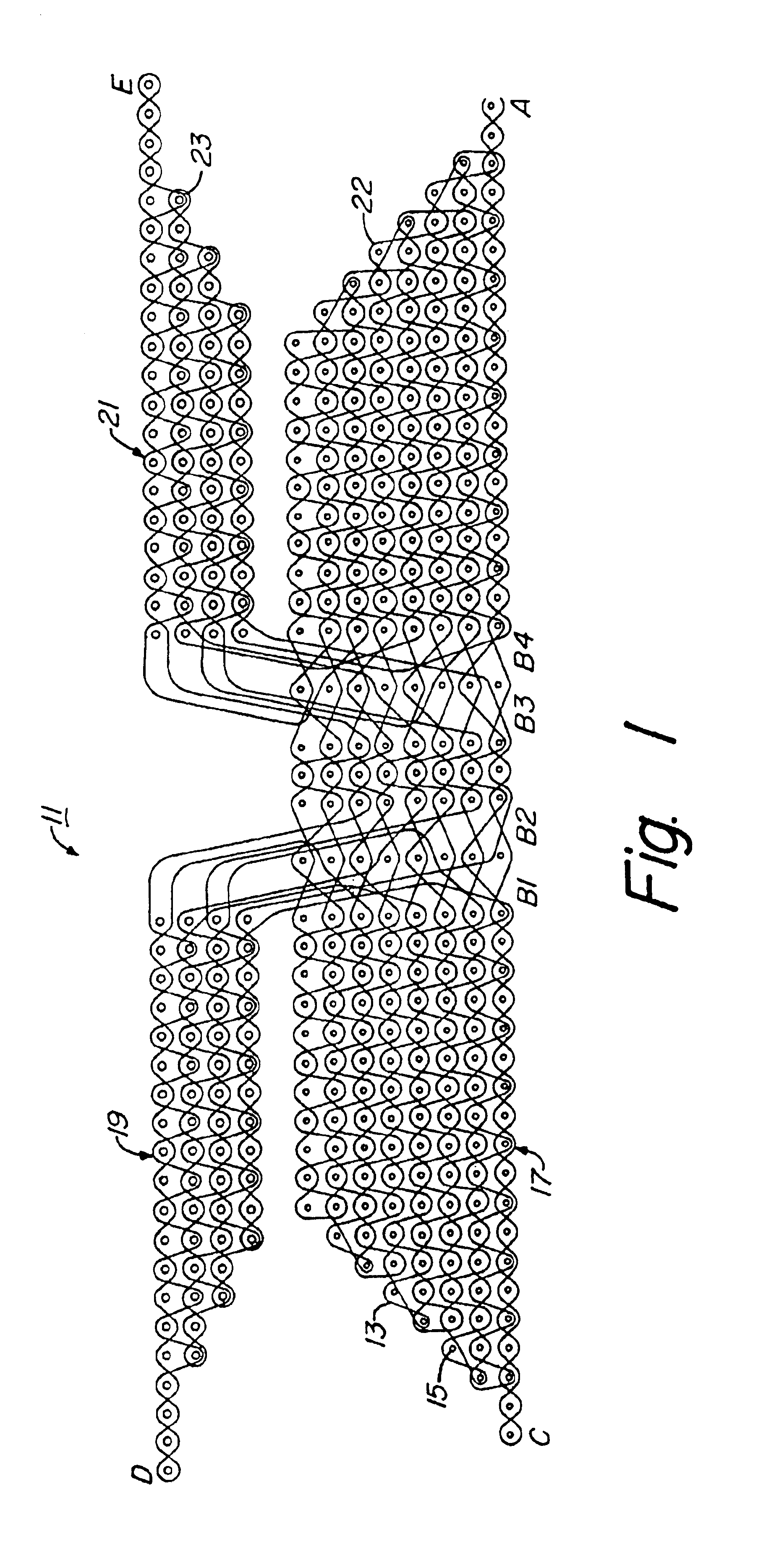

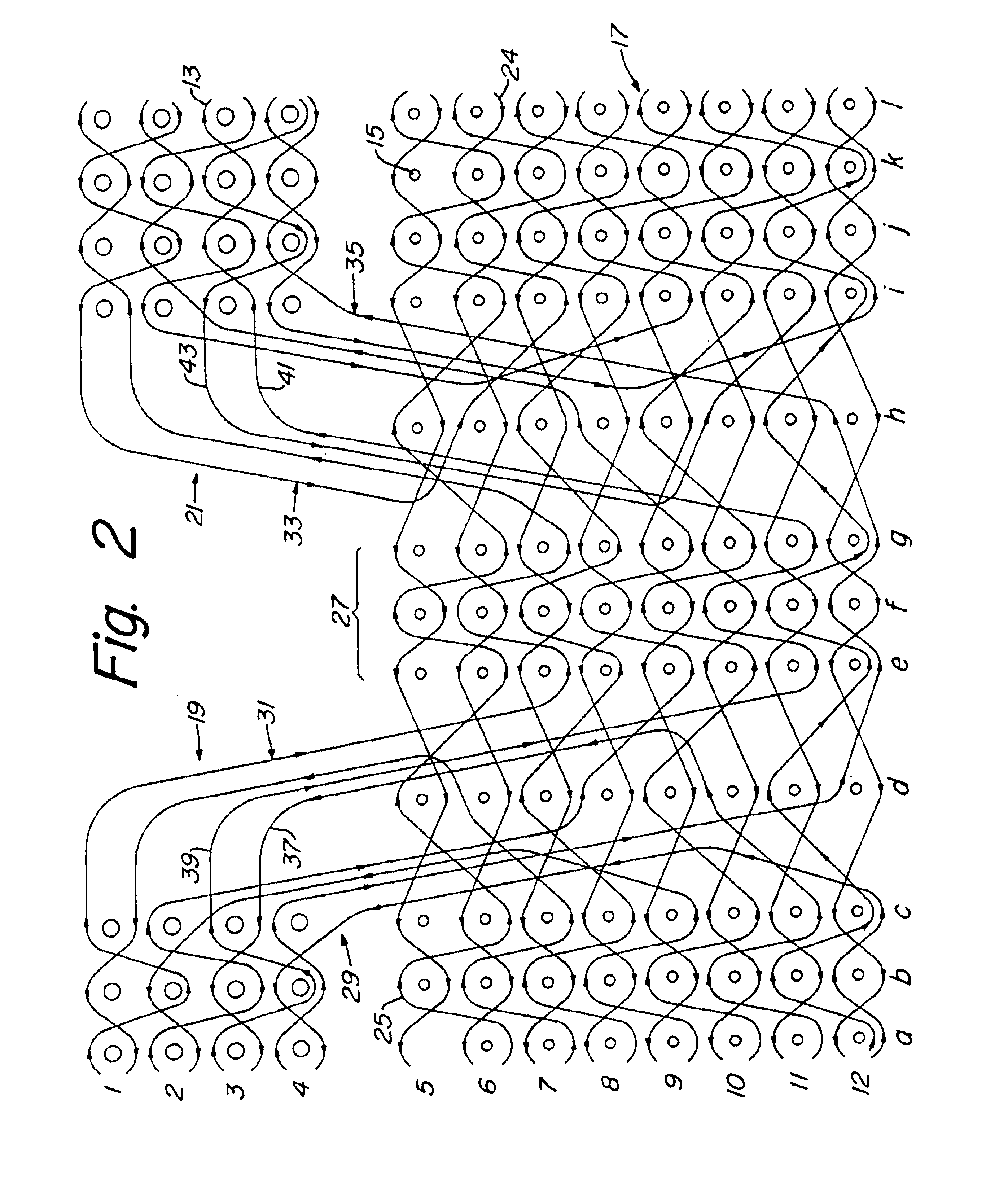

Full-fashioned weaving process for production of a woven garment with intelligence capability

A full-fashioned weaving process for the production of a woven garment which can accommodate and include holes, such as armholes. The garment is made of only one single integrated fabric and has no discontinuities or seams. Additionally, the garment can include intelligence capability, such as the ability to monitor one or more body vital signs, or garment penetration, or both, by including a selected sensing component or components in the weave of the garment.

Owner:GEORGIA TECH RES CORP

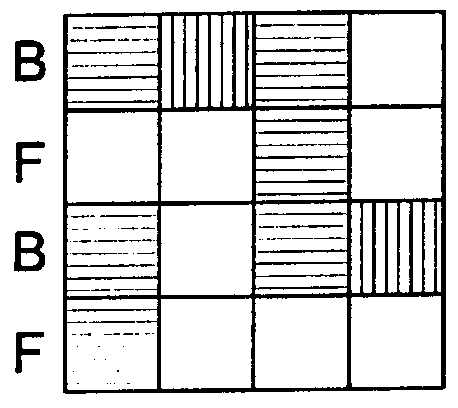

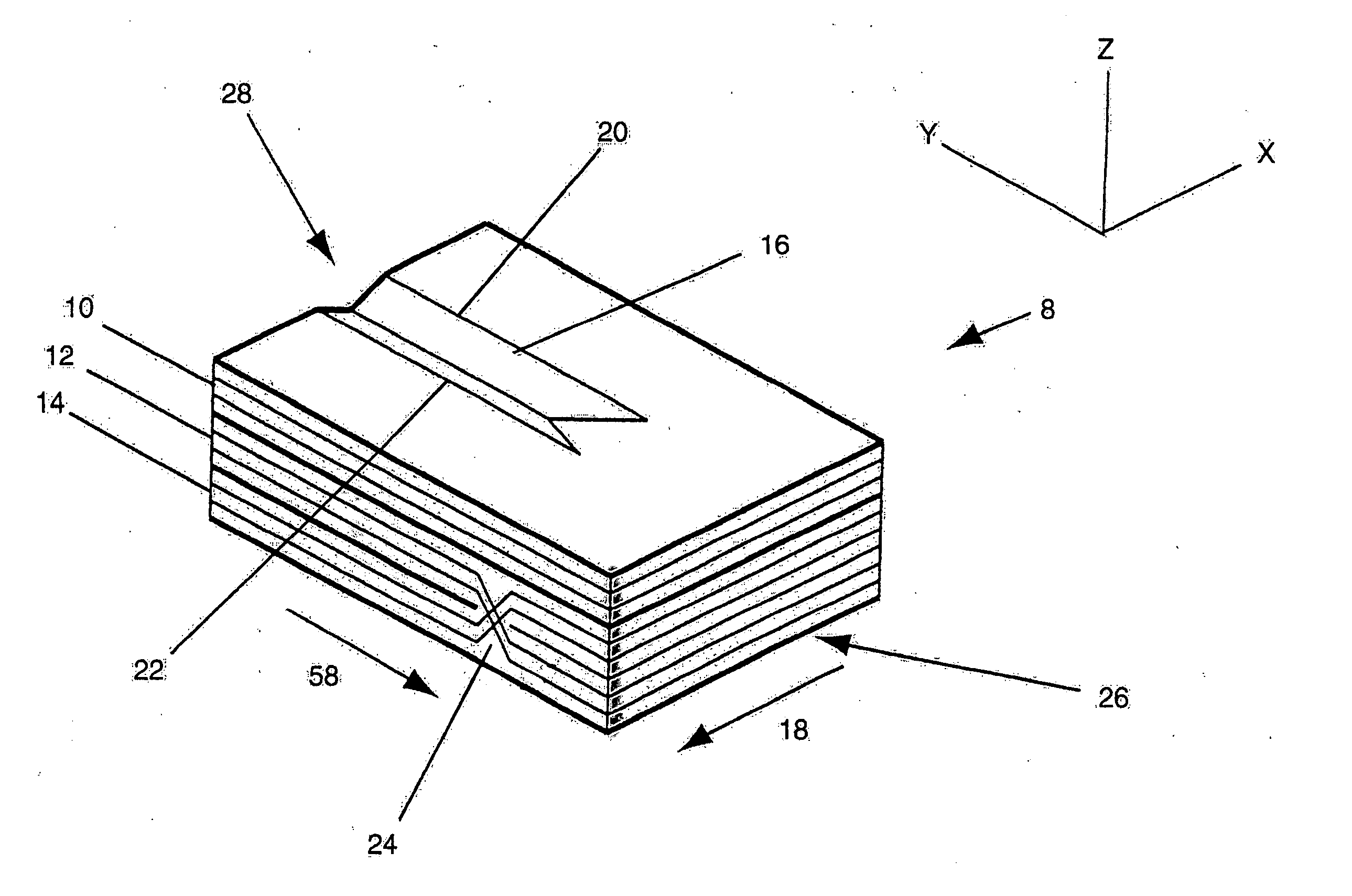

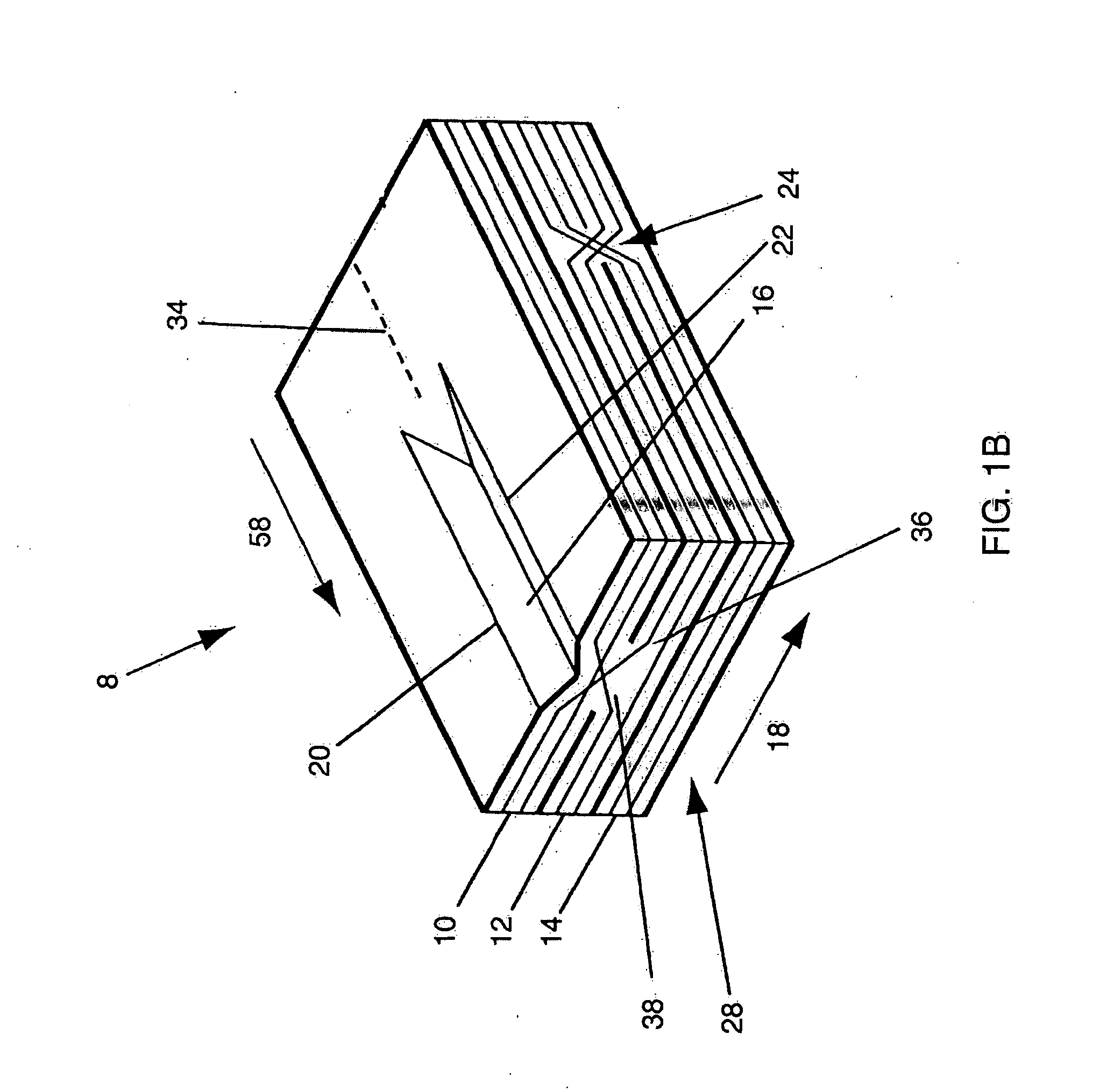

Woven preform for structural joints

A preform for structural joints has a three-dimensional weave architecture with fill fibers woven to provide layer-to-layer interlocking of layers of warp fiber as well as interlocking of fibers within each layer. At least two legs extend from a base, the base and legs each having at least two layers of warp fibers. The legs are connected at a symmetrical, distributed-column intersection, with an odd number of columns of warp fibers being located being the legs. The outer ends of the base and legs preferably have tapers formed from terminating layers of warp fibers in a stepped pattern. Tracer fibers that include a colored strand and an x-ray opaque strand are woven into the preform at selected locations as a warp fiber. The tracer fibers allow for identification of a selected location or a selected portion of the preform through visual inspection or by x-ray image.

Owner:LOCKHEED MARTIN CORP

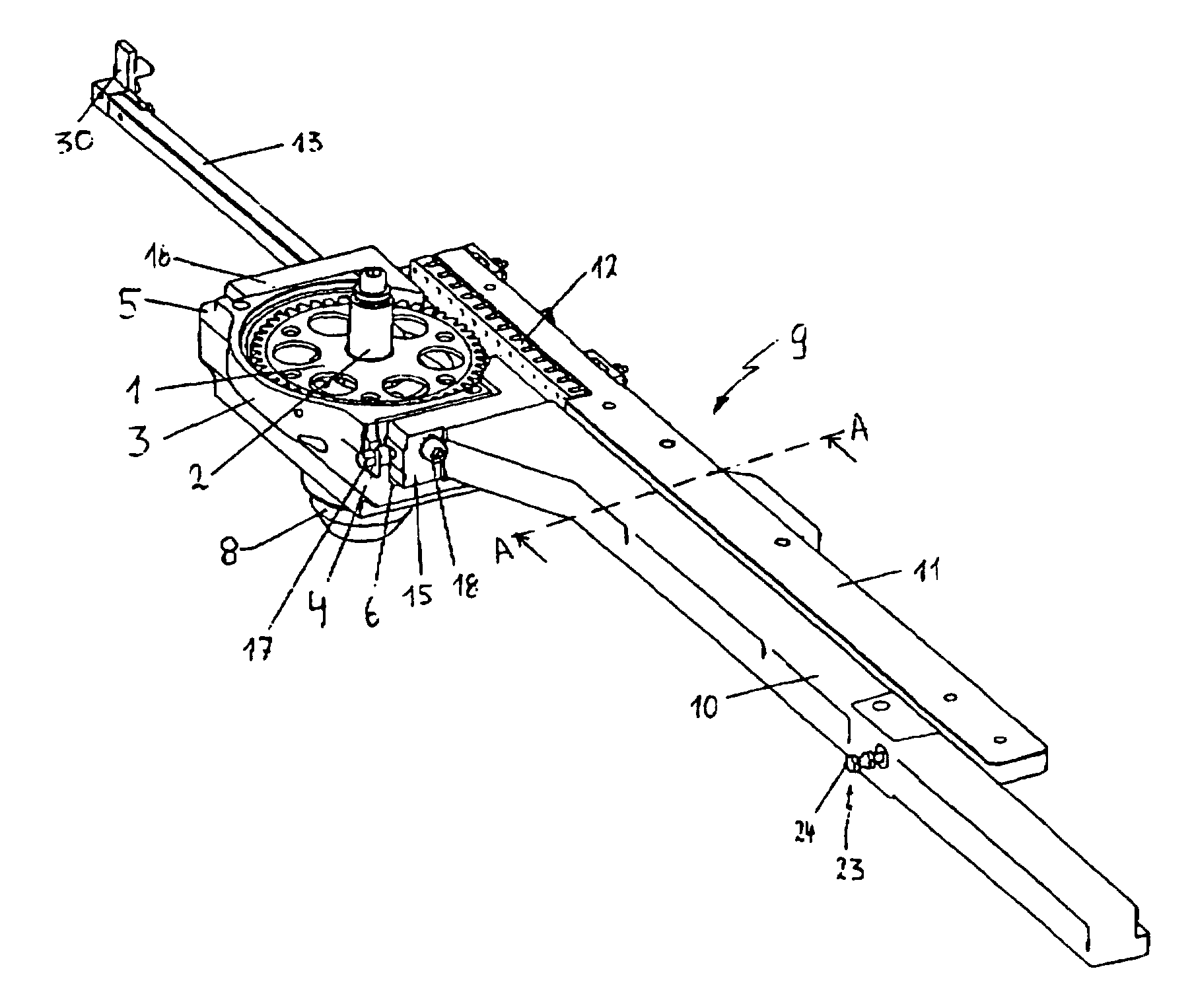

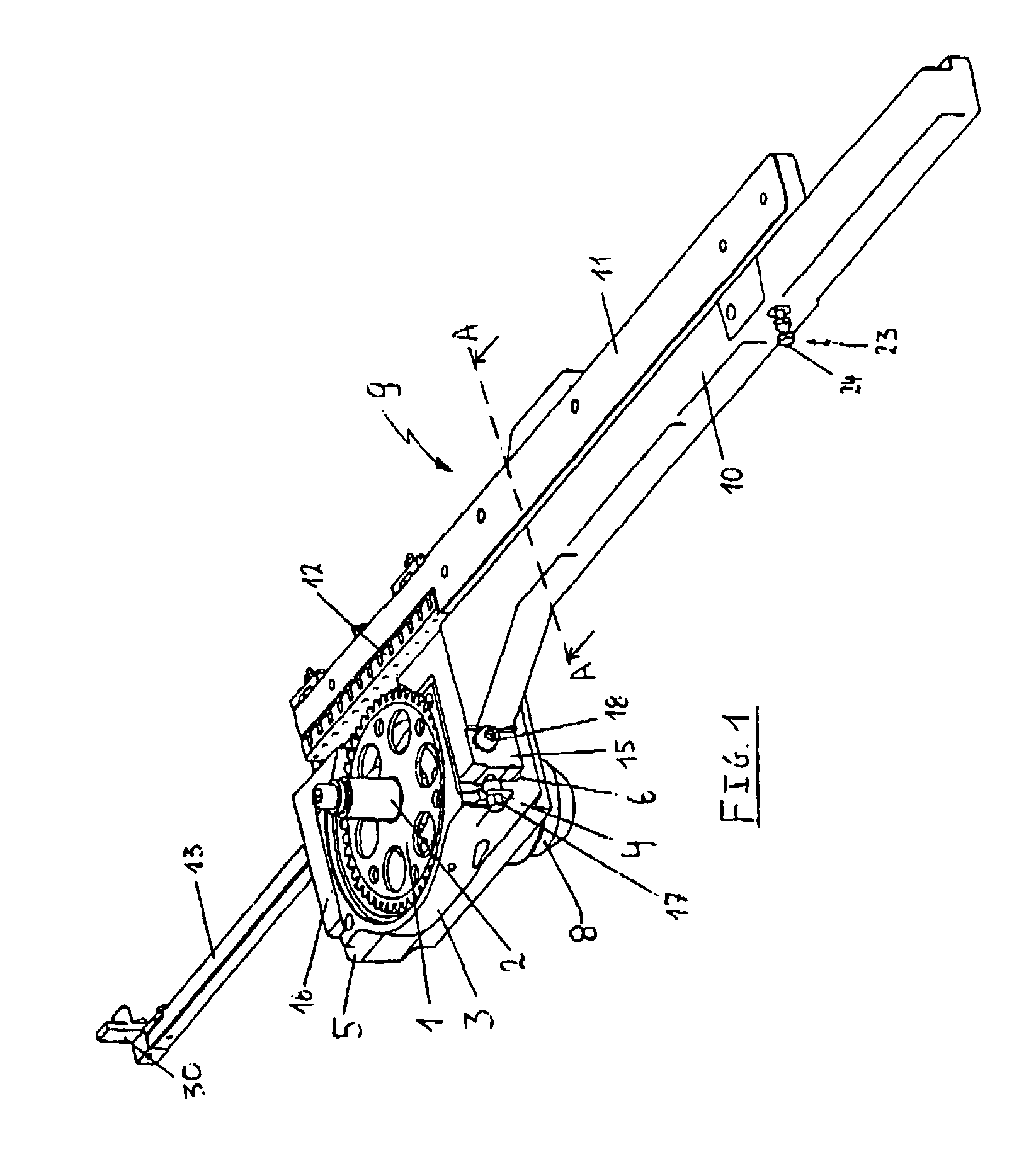

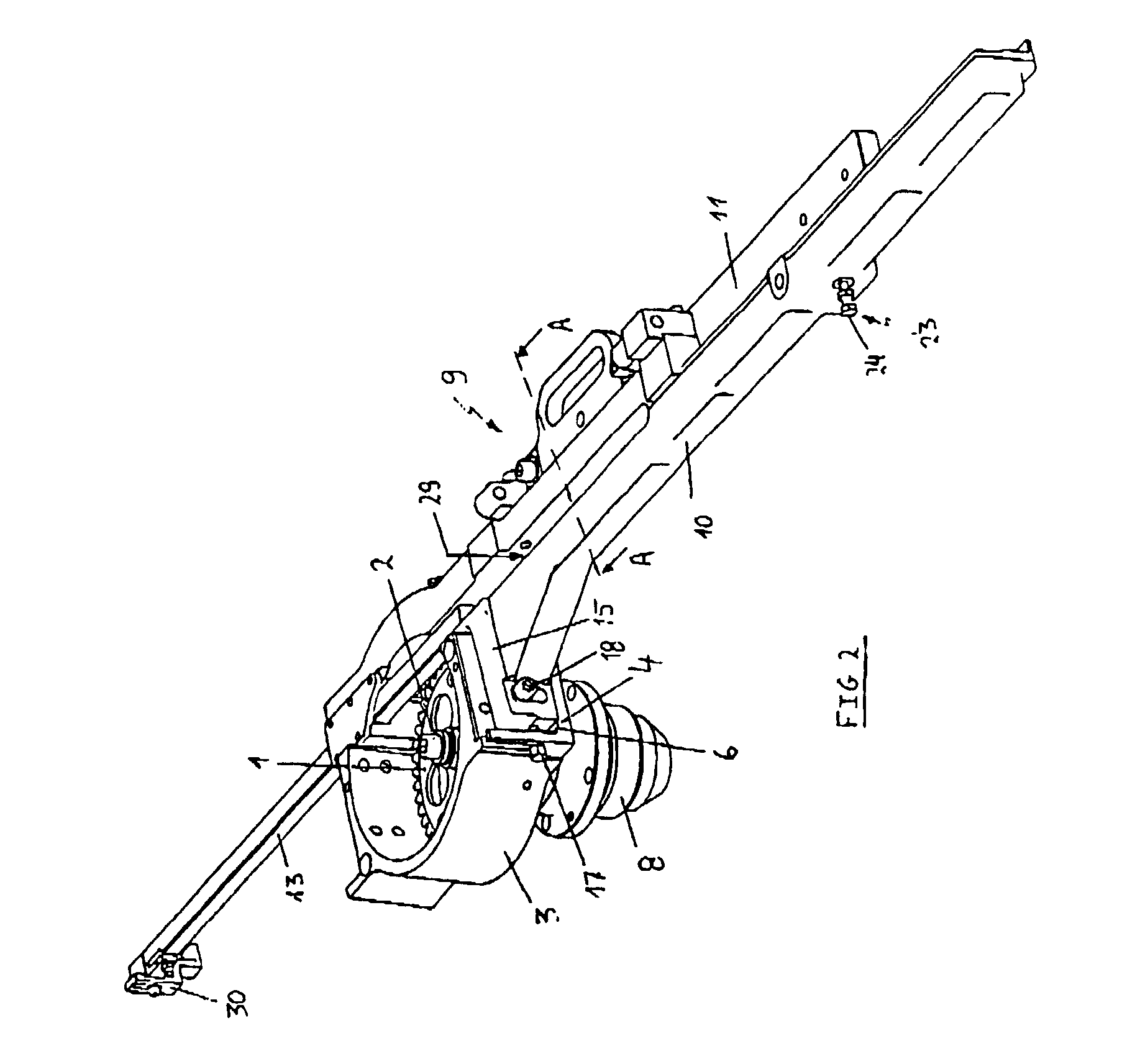

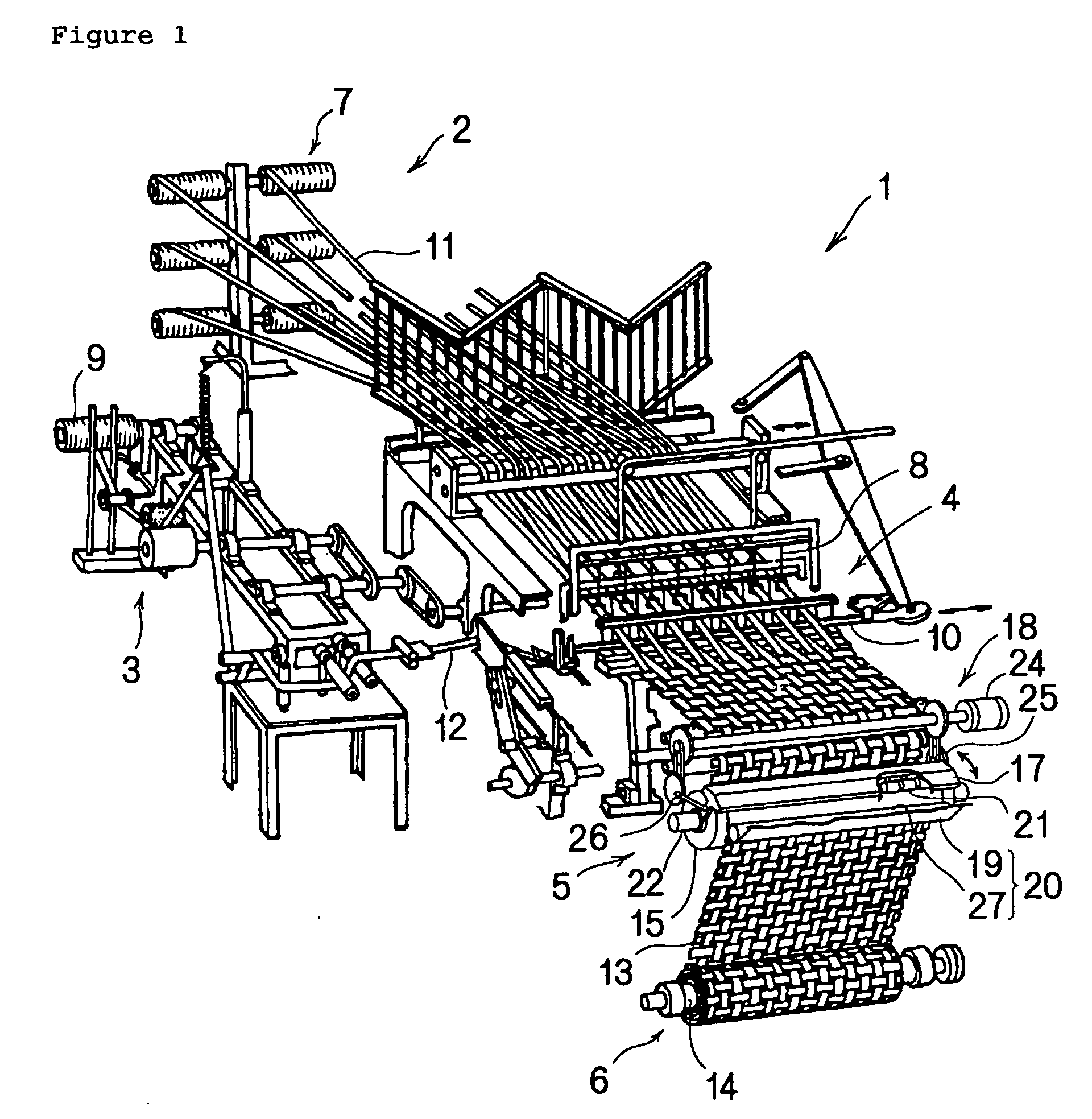

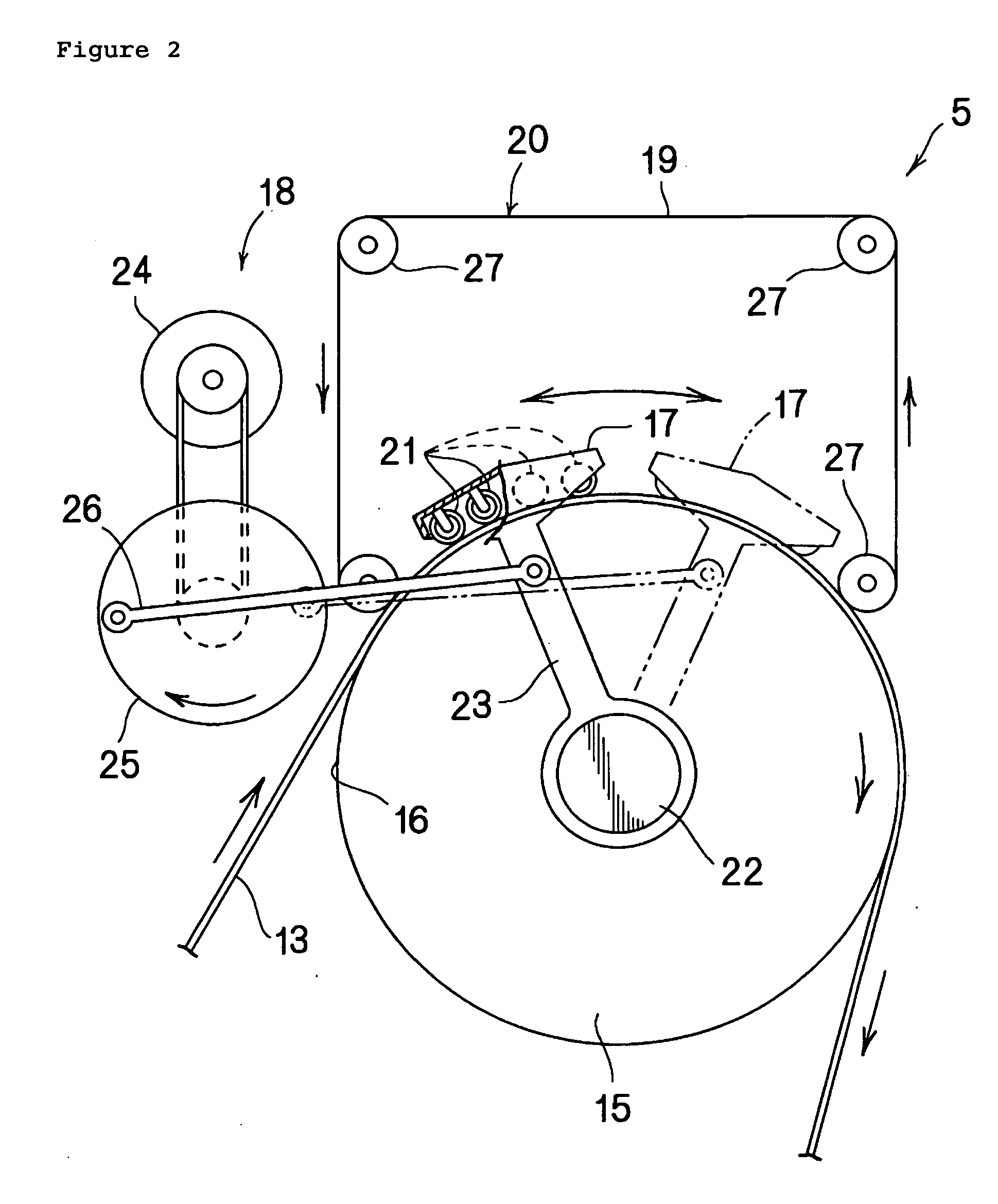

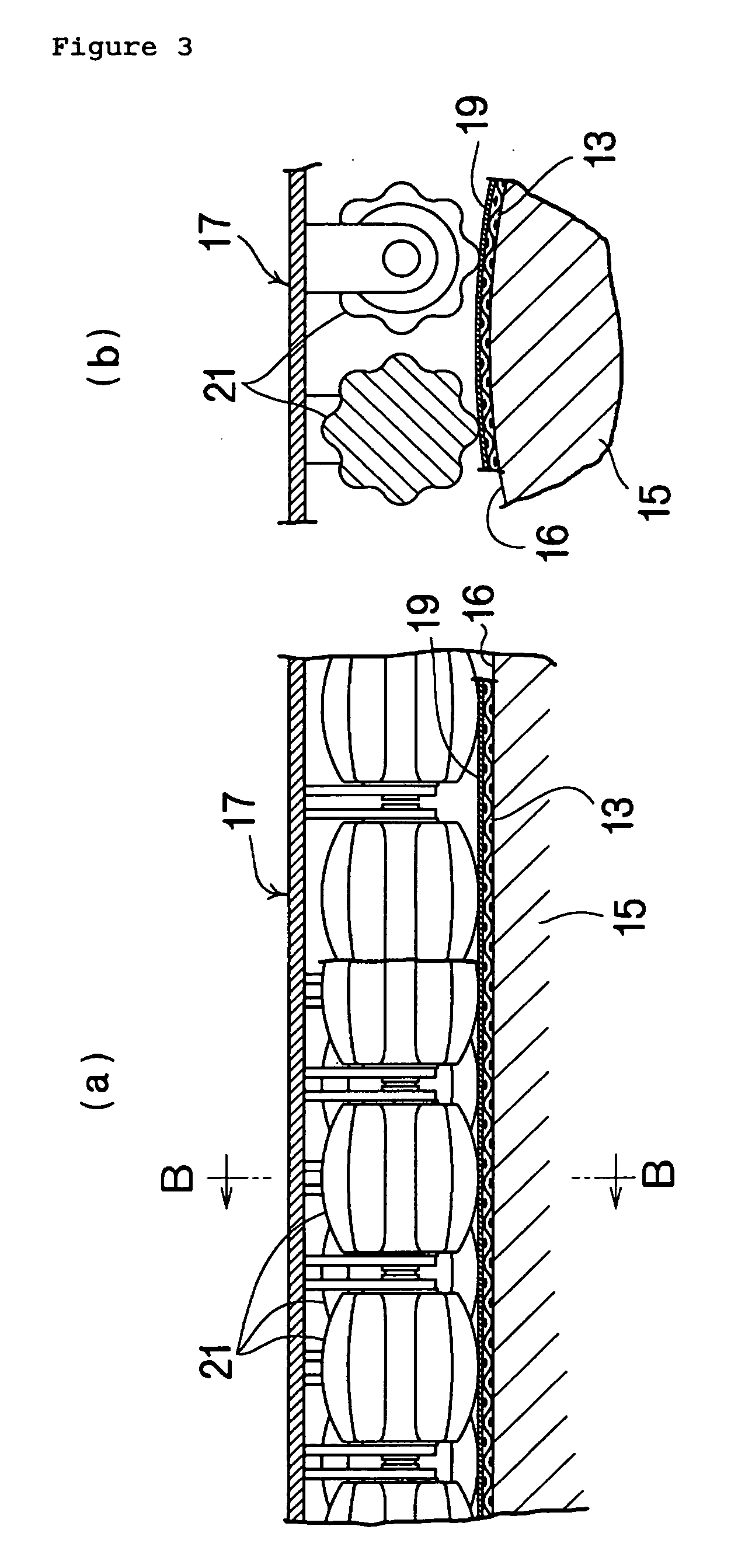

Device for driving and guiding a rapier of a weaving machine

A device for driving and guiding a rapier of a weaving machine, comprises a rotatable drive wheel (1) provided for driving a rapier rod (14) in a back and forth movement and a guide channel formed by adjustable guide bodies (10), (11) in order to guide the said rapier rod (14) according to a guide path in co-operation with the drive wheel (1). The guide bodies (10), (11) are part of a guide unit (9) which, as a whole, is adjustable in order to modify the distance between the guide path and the rotation shaft (2) of the drive wheel (1), and where the drive wheel (1) is continuously adjustable in the longitudinal direction of its shaft (2). With this device the clearances of the rapier rod with respect to the drive wheel can be performed easily, rapidly and with great precision, so that this device is able to work with a minimum development of heat and wear.

Owner:N V MICHEL VAN DE WIELE

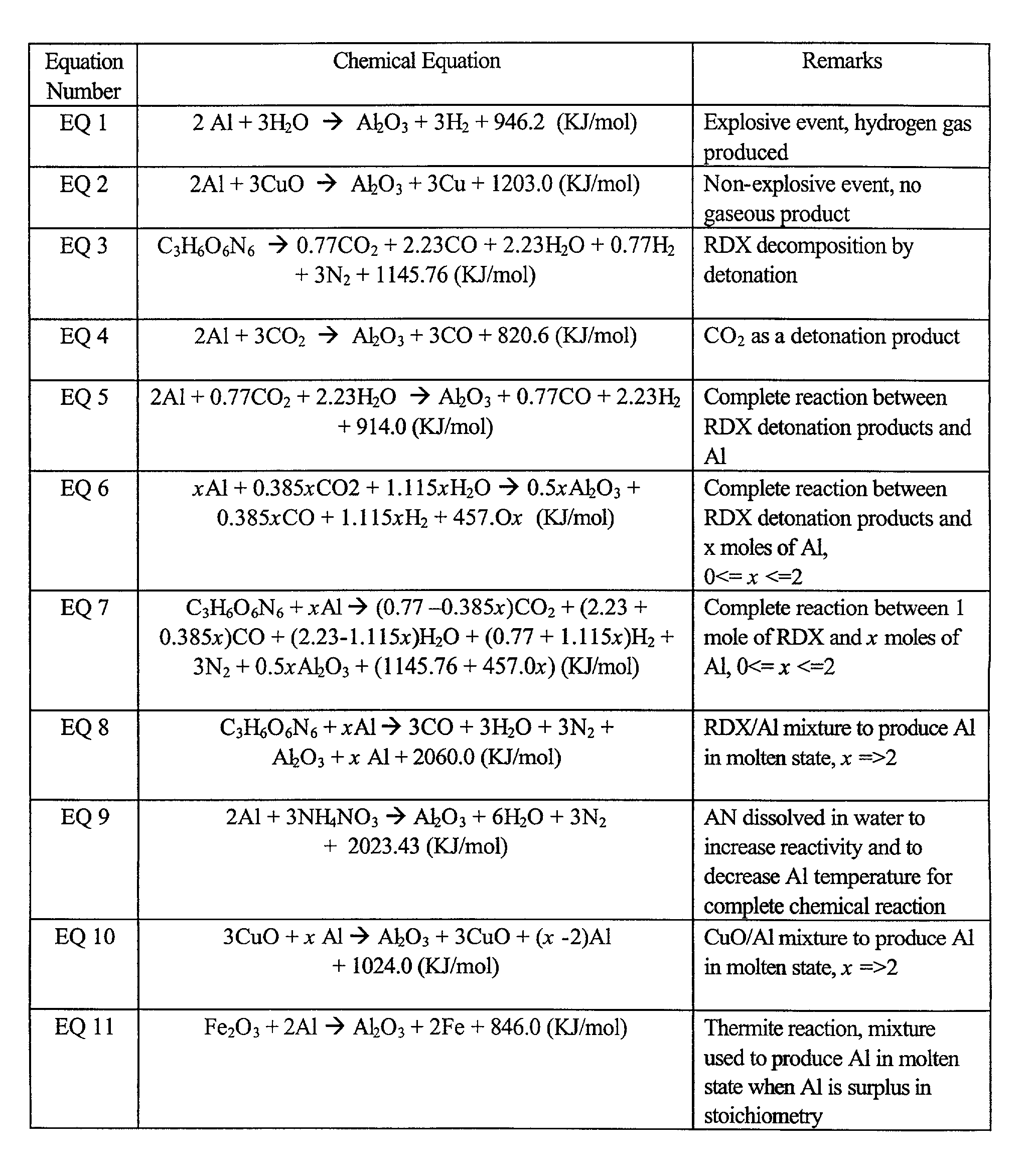

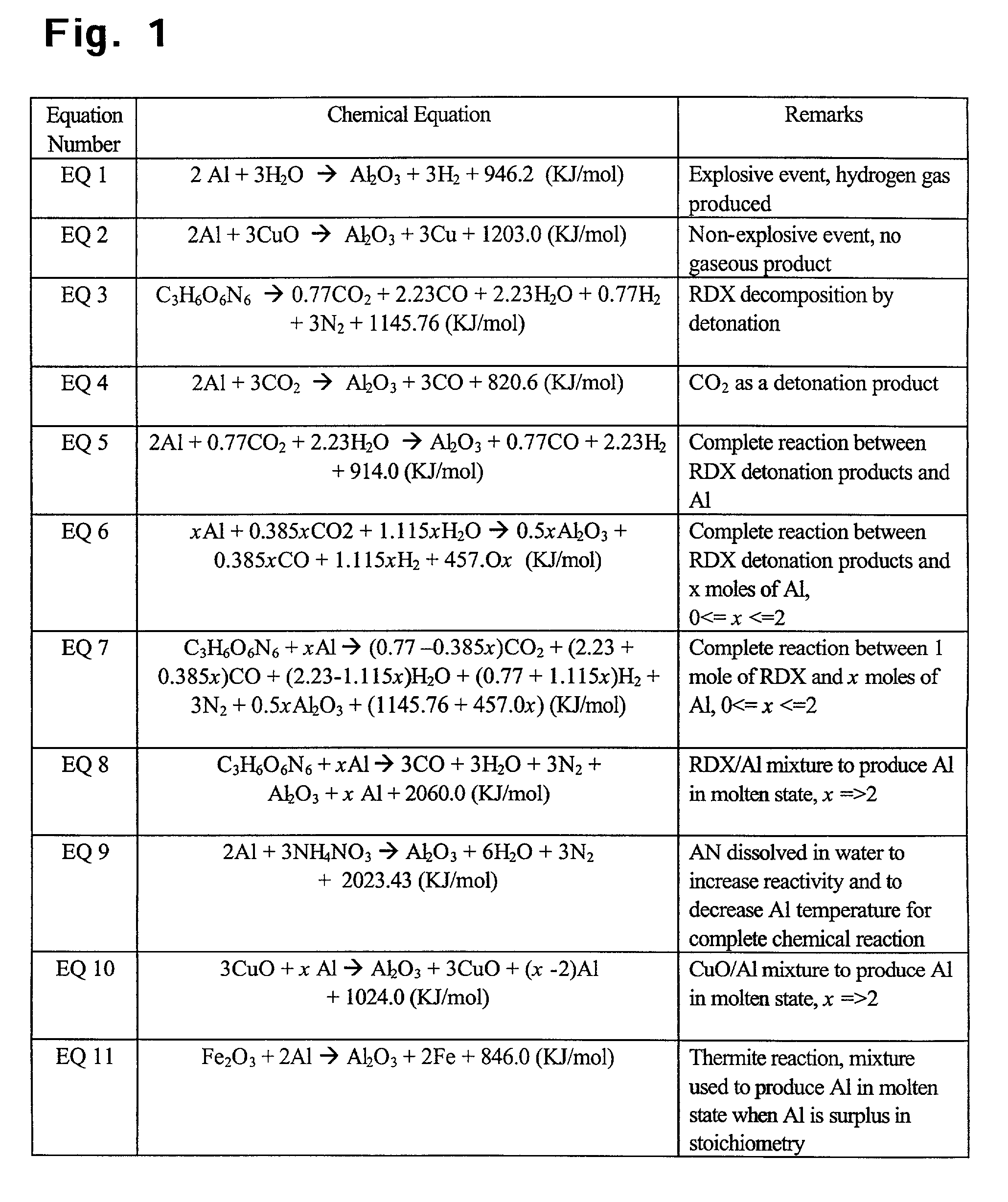

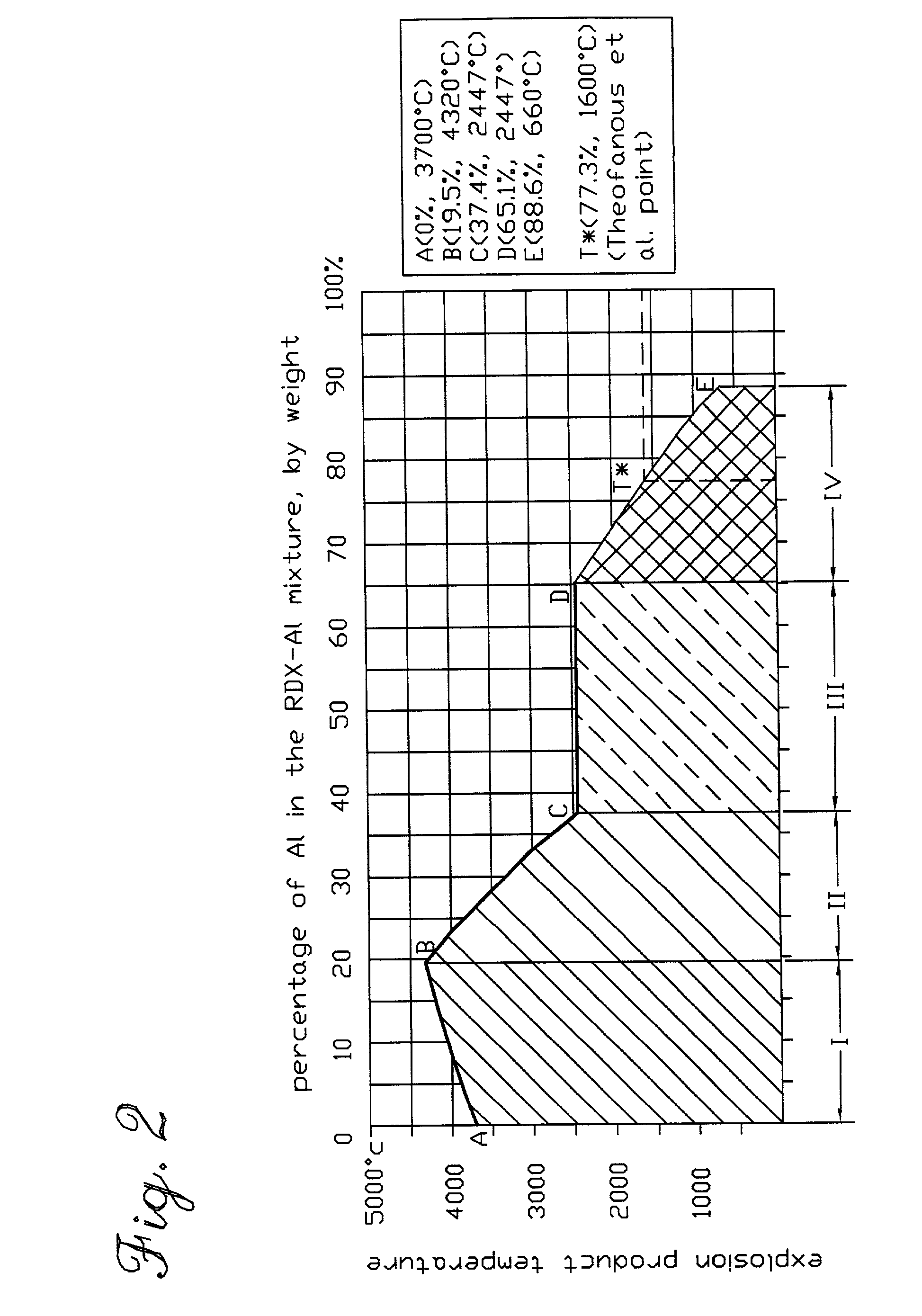

Use of aluminum in perforating and stimulating a subterranean formation and other engineering applications

InactiveUS7393423B2More energy outputImprove mechanical propertiesExplosive chargesBlasting cartridgesMolten stateThermal energy

A chemical reaction between molten aluminum and an oxygen carrier such as water to do useful work is disclosed, and in particular two chemical methods to obtain aluminum in its molten state. One is to detonate a HE / Al mixture with surplus Al in stoichiometry, and the other is to use an oxidizer / Al mixture with surplus Al in stoichiometry. Additionally, there is a physical method of shocking and heating Al using high temperature reaction products. The produced Al in its liquid form is forced to react with an oxygen carrying liquid (e.g. water), giving off heat and releasing hydrogen gas or other gaseous material. A water solution of some oxygen-rich chemicals (e.g. ammonium nitrate) can be advantageously used in place of water. A shaped charge is also disclosed having a liner that contains aluminum, propelled by a high explosive such as RDX or its mixture with aluminum powder. Some aluminum in its molten state is projected into the perforation and forced to react with water that also enters the perforation, creating another explosion, fracturing the crushed zone of the perforation and initializing cracks. Another shaped charge is shown having a liner of energetic material such as a mixture of aluminum powder and a metal oxide. Upon detonation, the collapsed liner carries kinetic and thermal energy. Also shown are methods to build and to detonate or fire explosive devices in an oxygen carrying liquid (e.g. water) to perforate and stimulate a hydrocarbon-bearing formation.

Owner:GEODYNAMICS

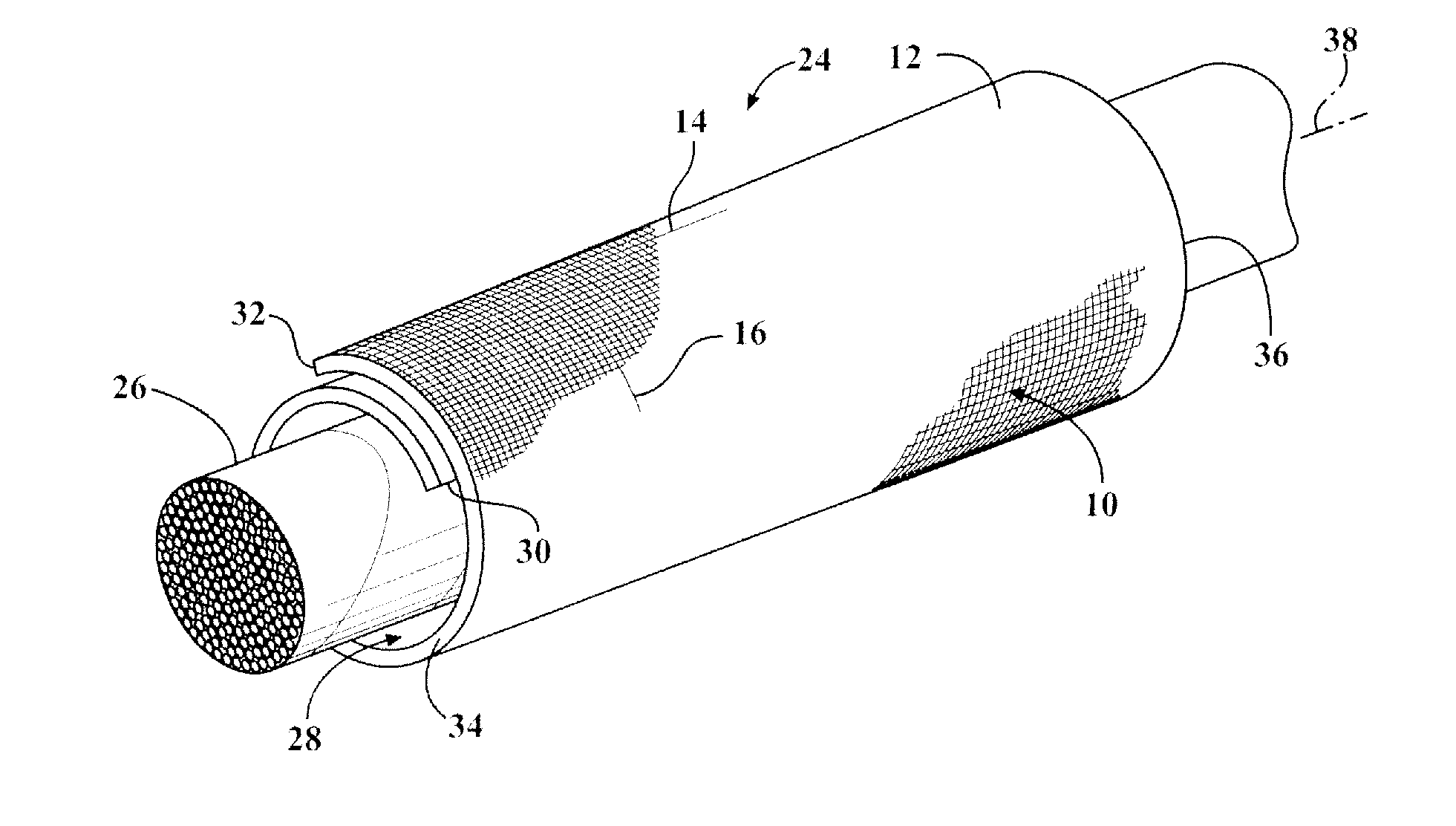

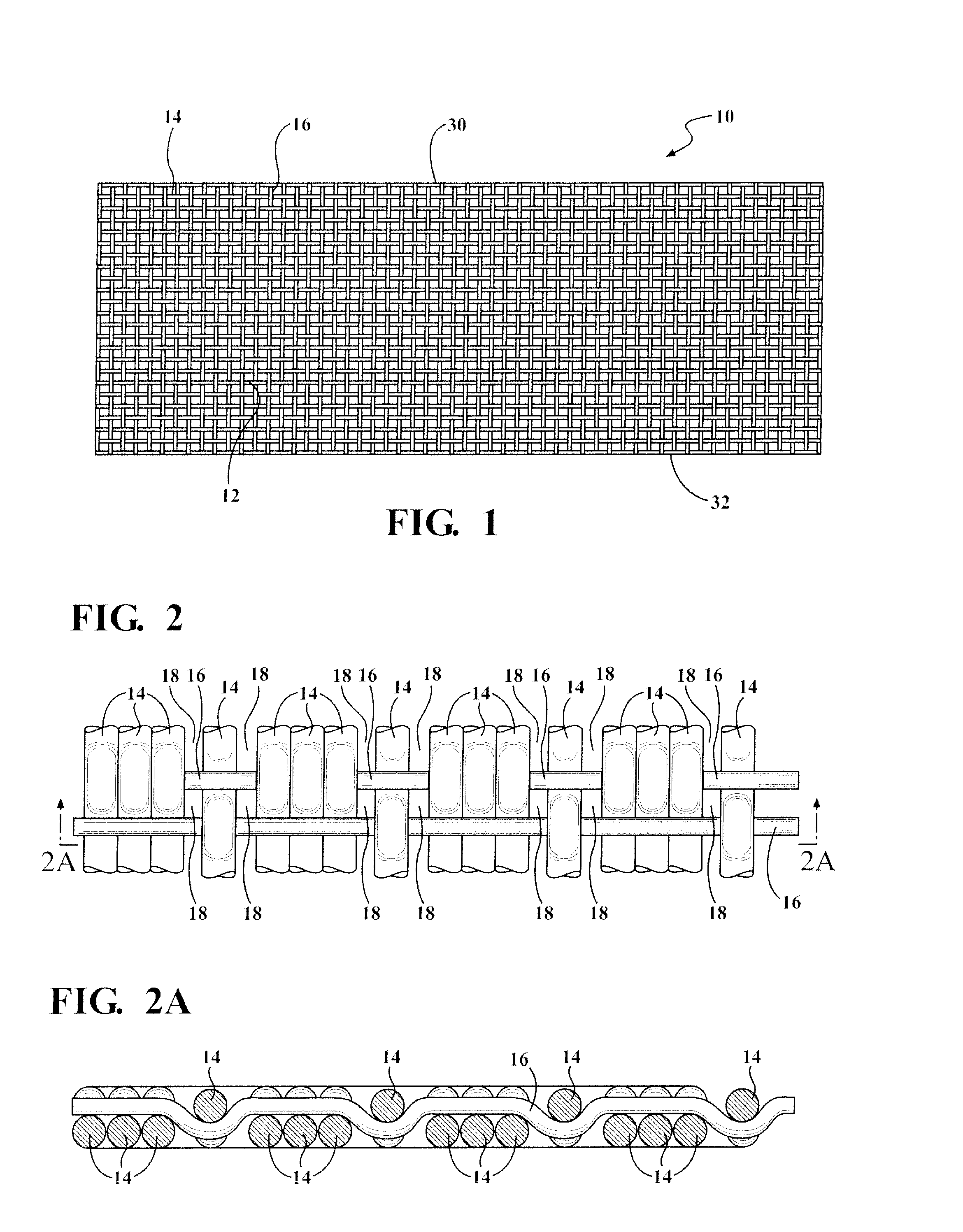

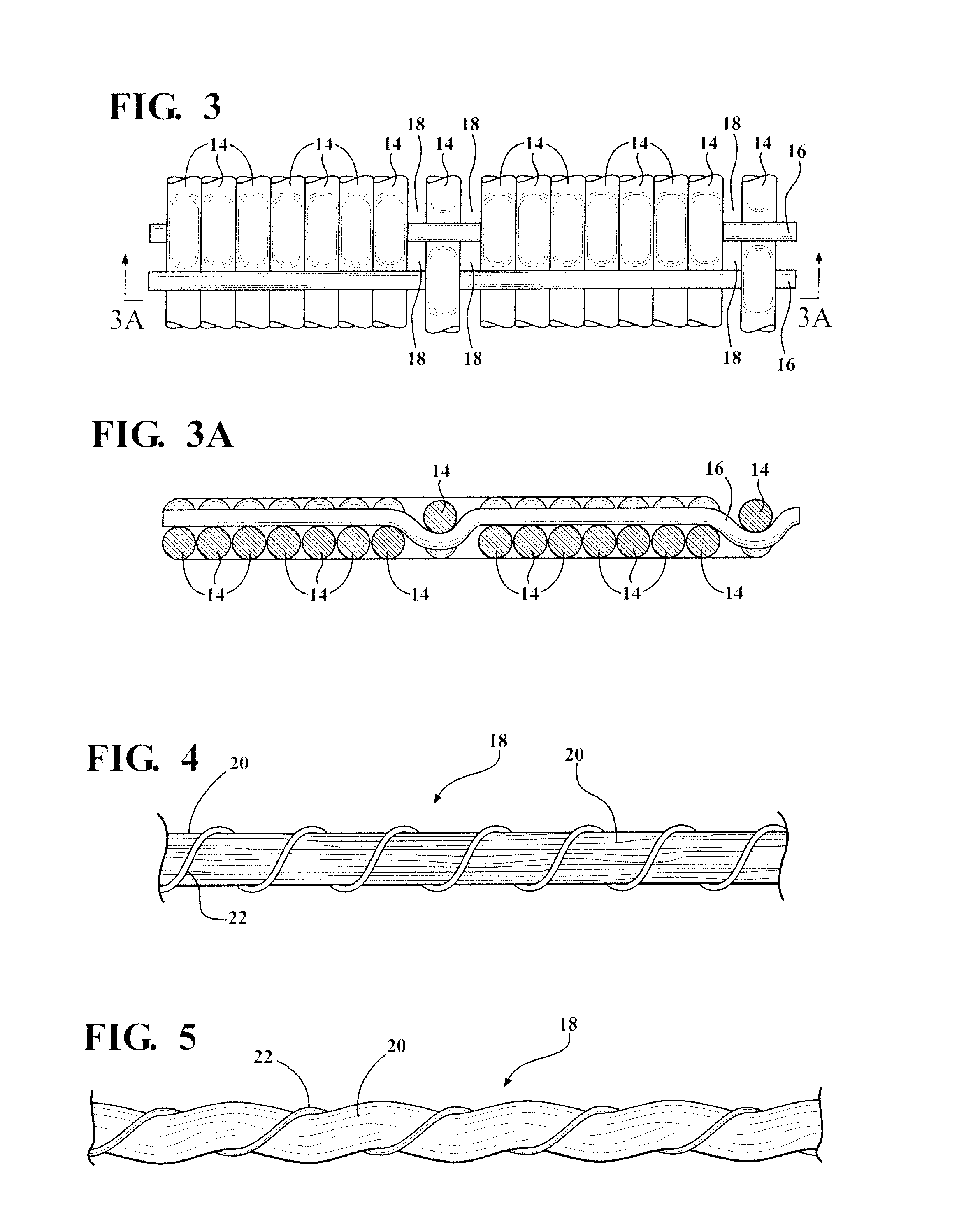

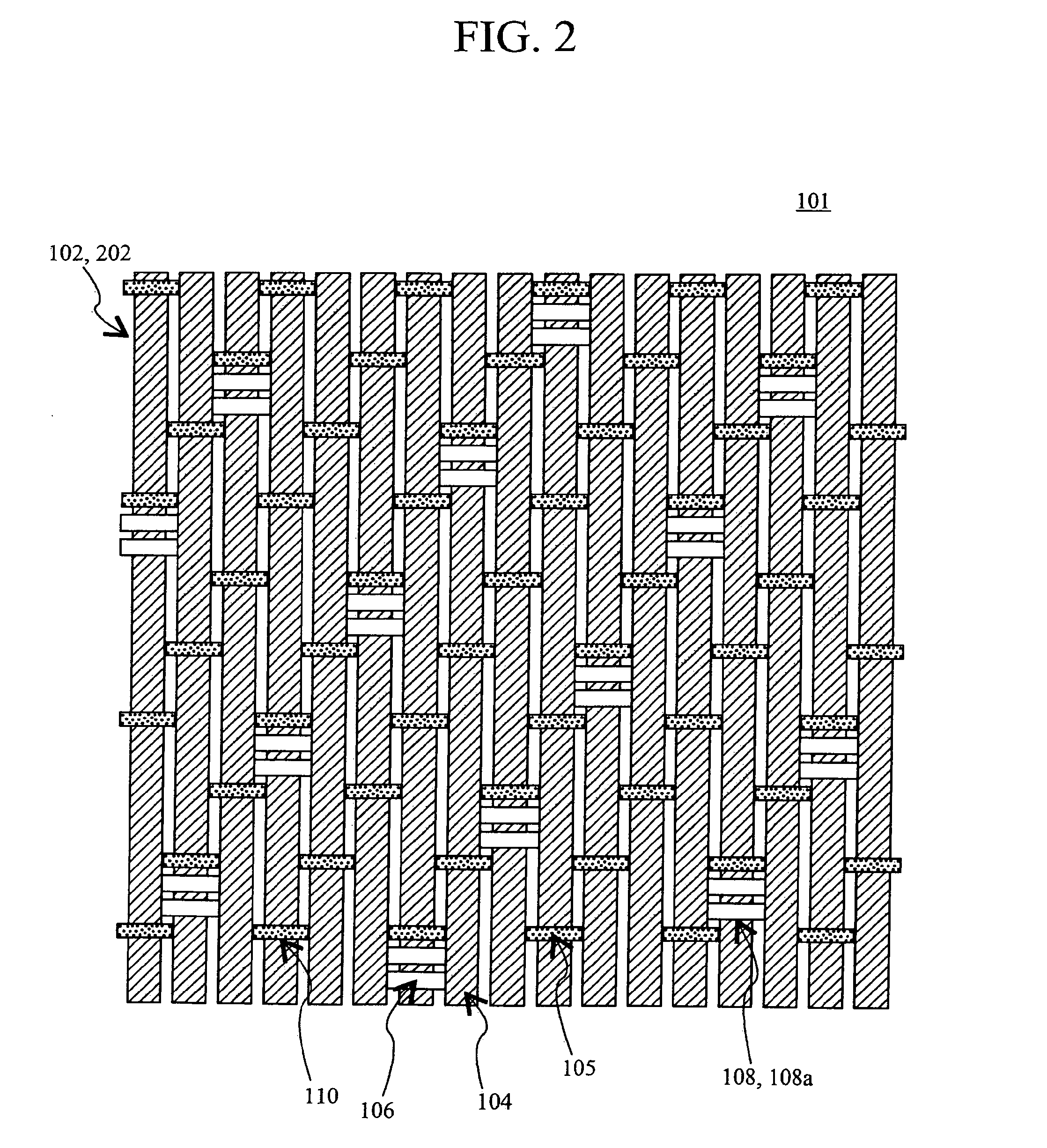

EMI Shielding Textile Fabric, Wrappable Sleeve Constructed Therefrom and Method of Construction Thereof

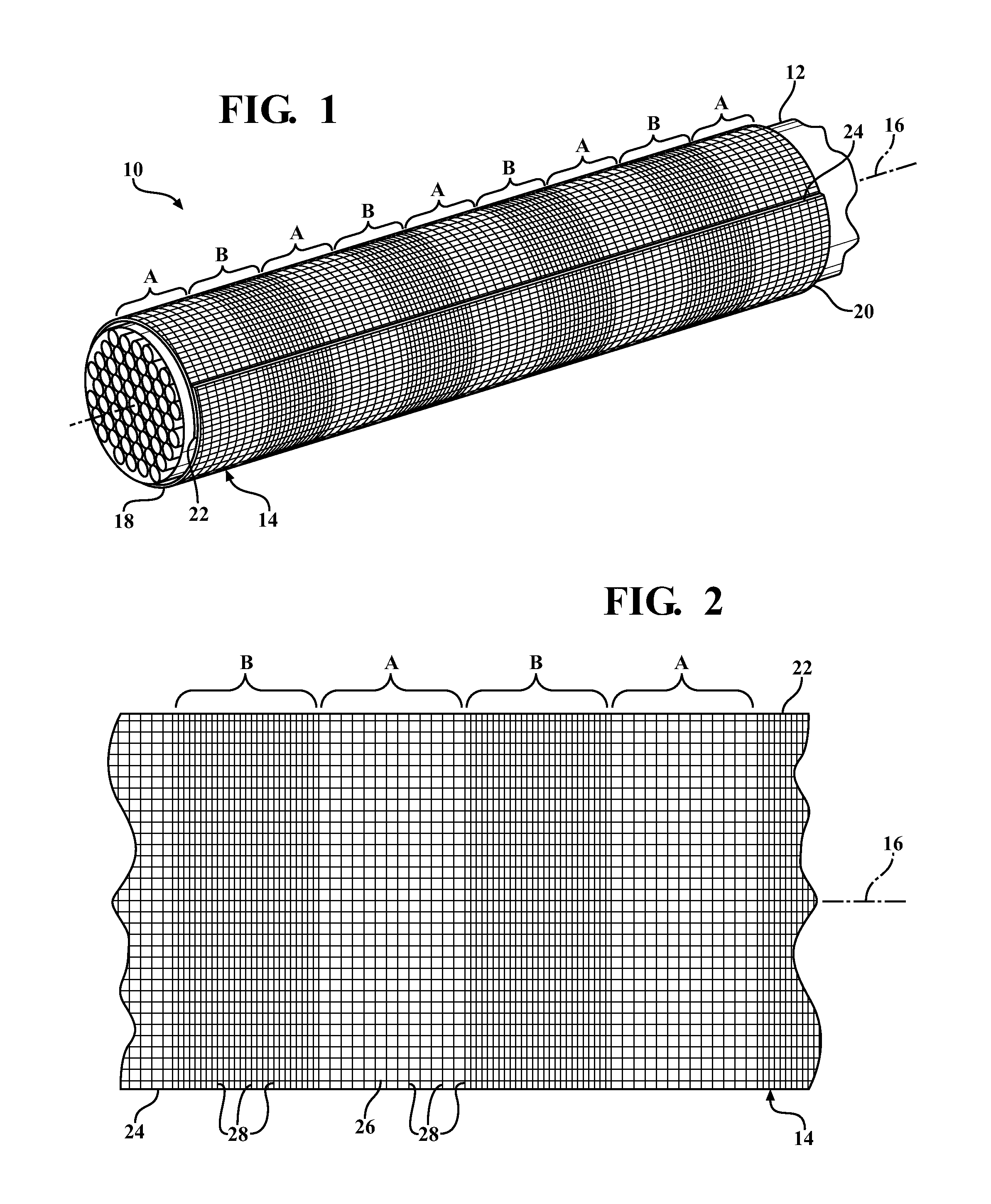

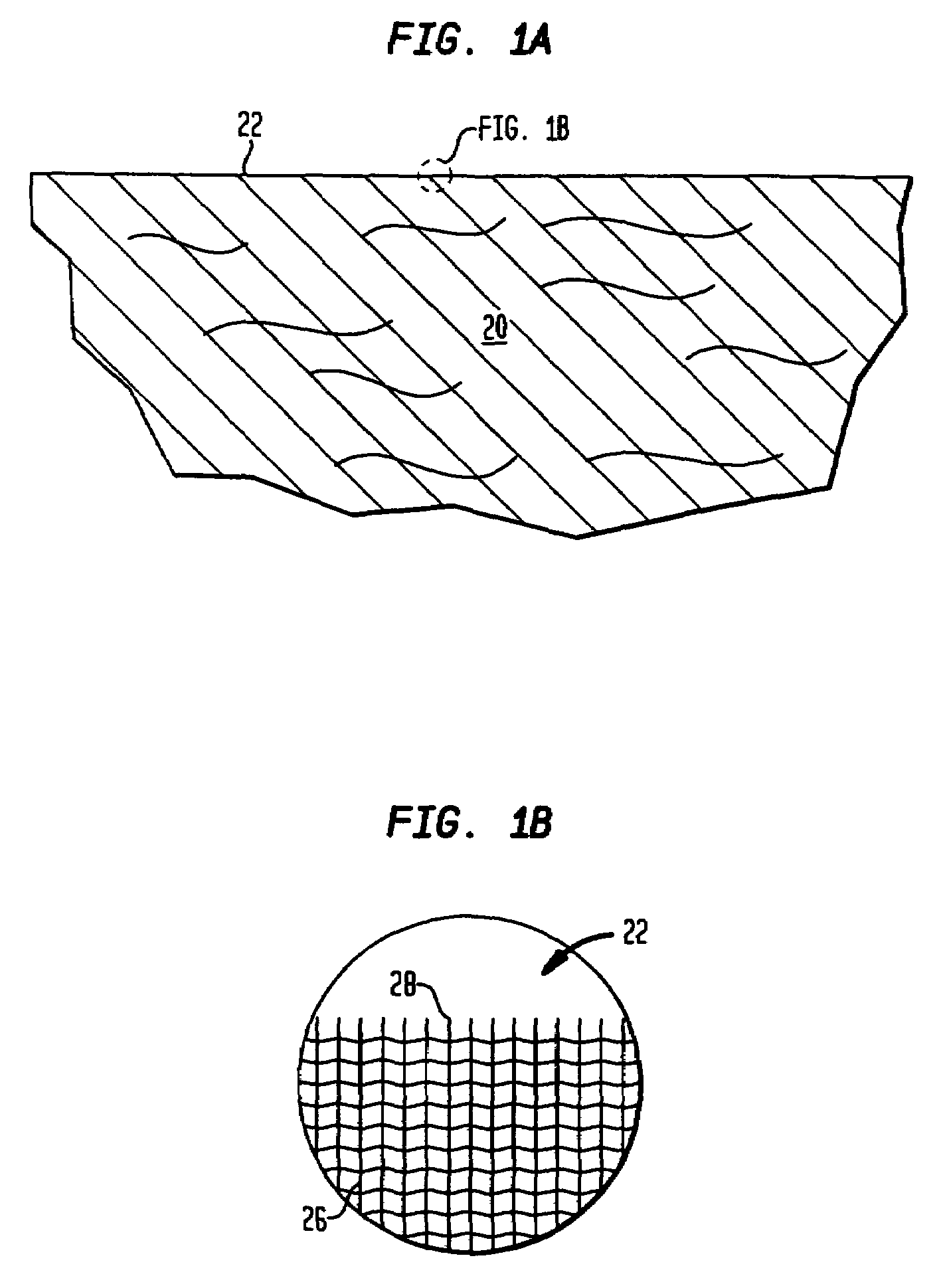

ActiveUS20140262478A1Improve abilitiesClose proximityShielding materialsLoomsArchitectural engineeringWeft yarn

A textile fabric, sleeve formed therefrom, and methods of construction thereof are provided. The fabric forms an elongate wall constructed from lengthwise extending warp yarns woven with widthwise extending weft yarns. At least some of the warp yarns are electrically conductive and have a first diameter. The weft yarns have a second diameter that is at least 25 percent less than the first diameter of the warp yarns. As such, the conductive warp yarns are brought into closer proximity with one another than if the weft yarns were the same diameter as the warp yarns. Accordingly, the ability of the fabric and sleeve formed therewith to provide shielding protection against EMI is enhanced.

Owner:FEDERAL MOGUL POWERTAIN LLC

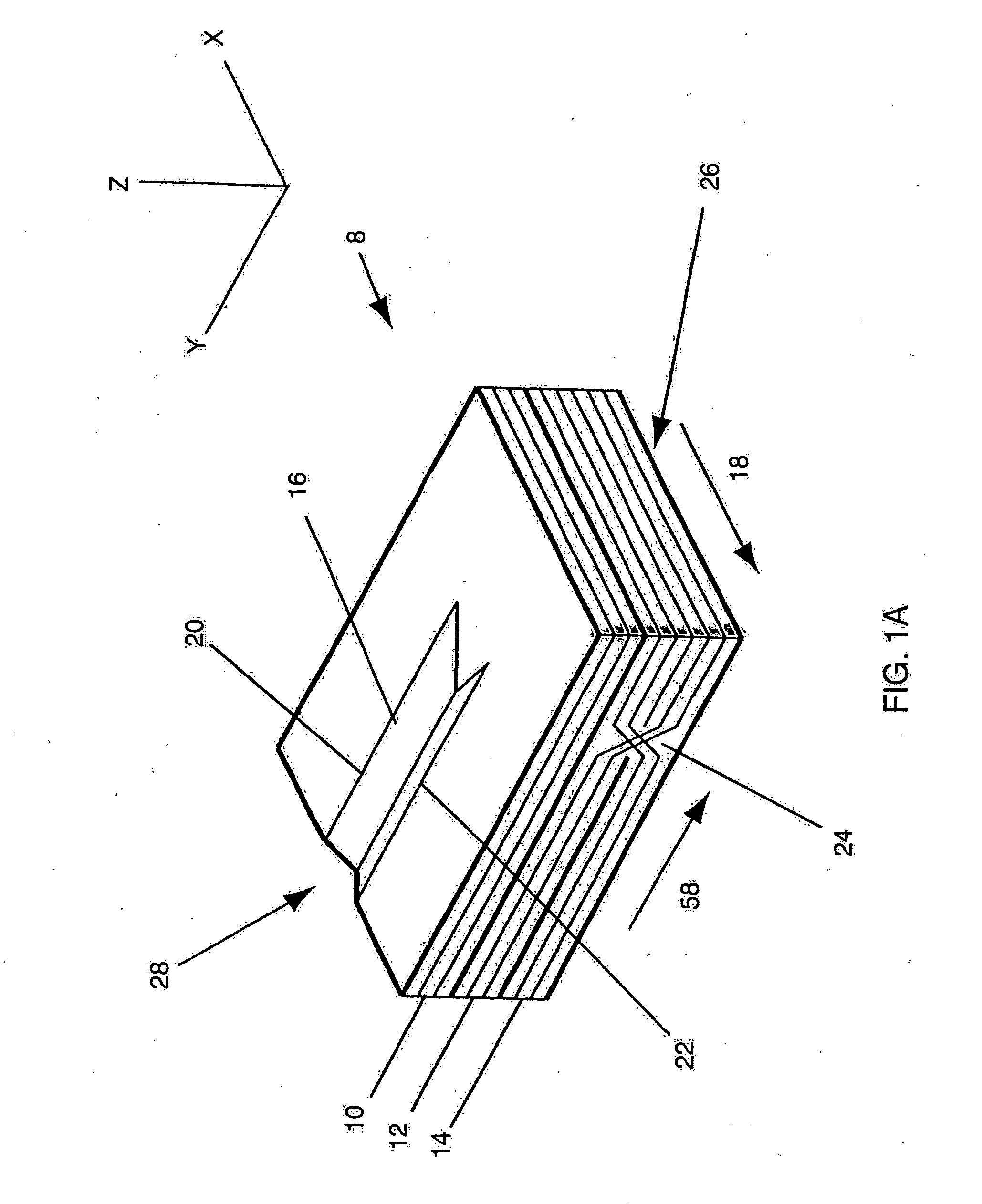

Three-dimensional woven integrally stiffened panel

Owner:ALBANY ENGINEERED COMPOSITES

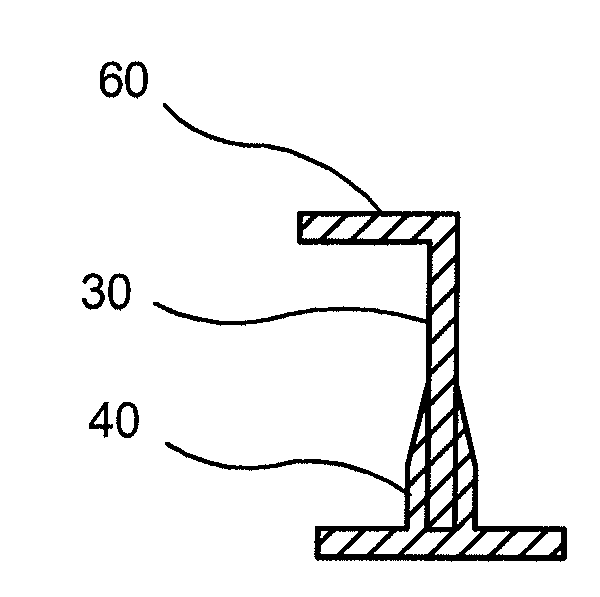

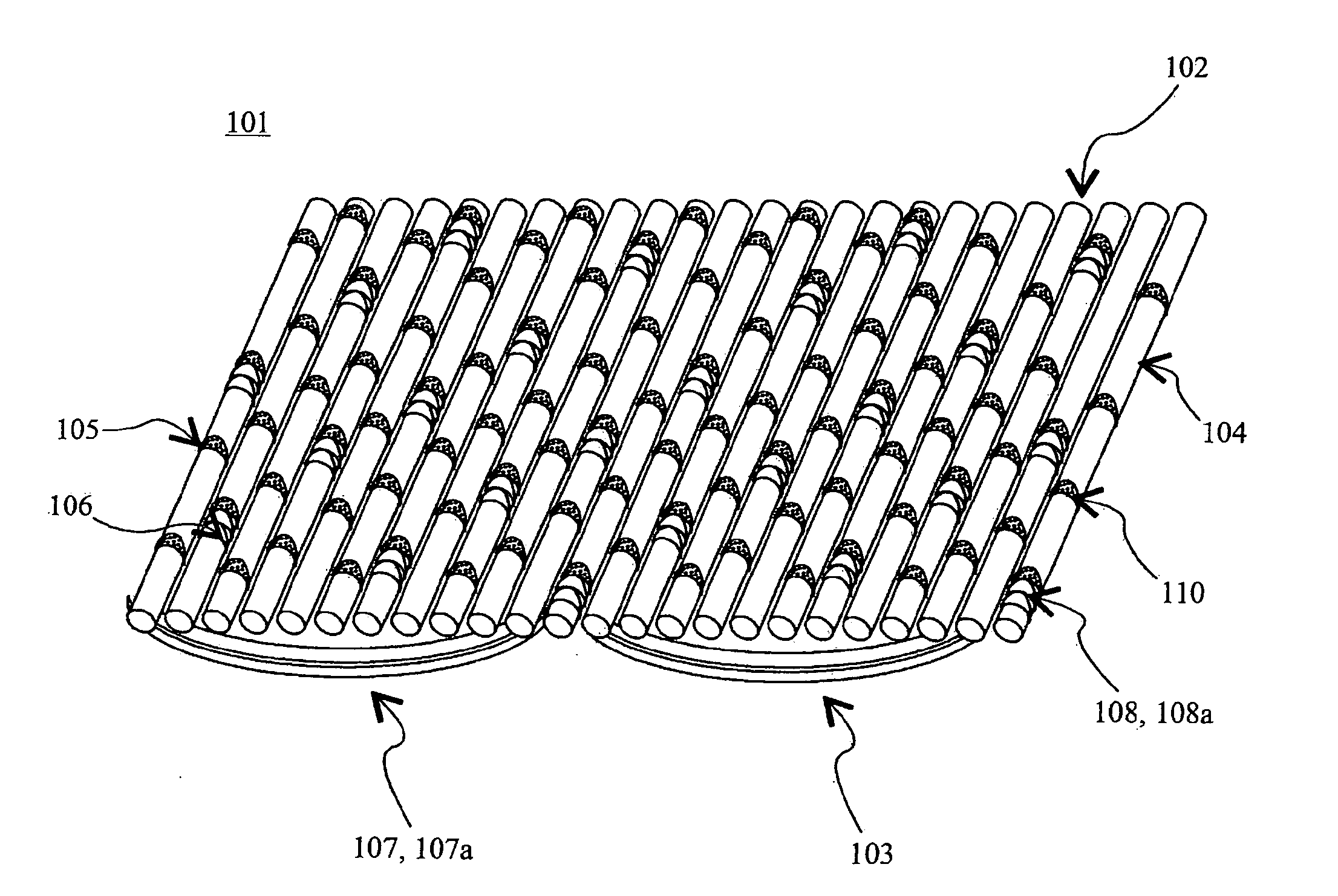

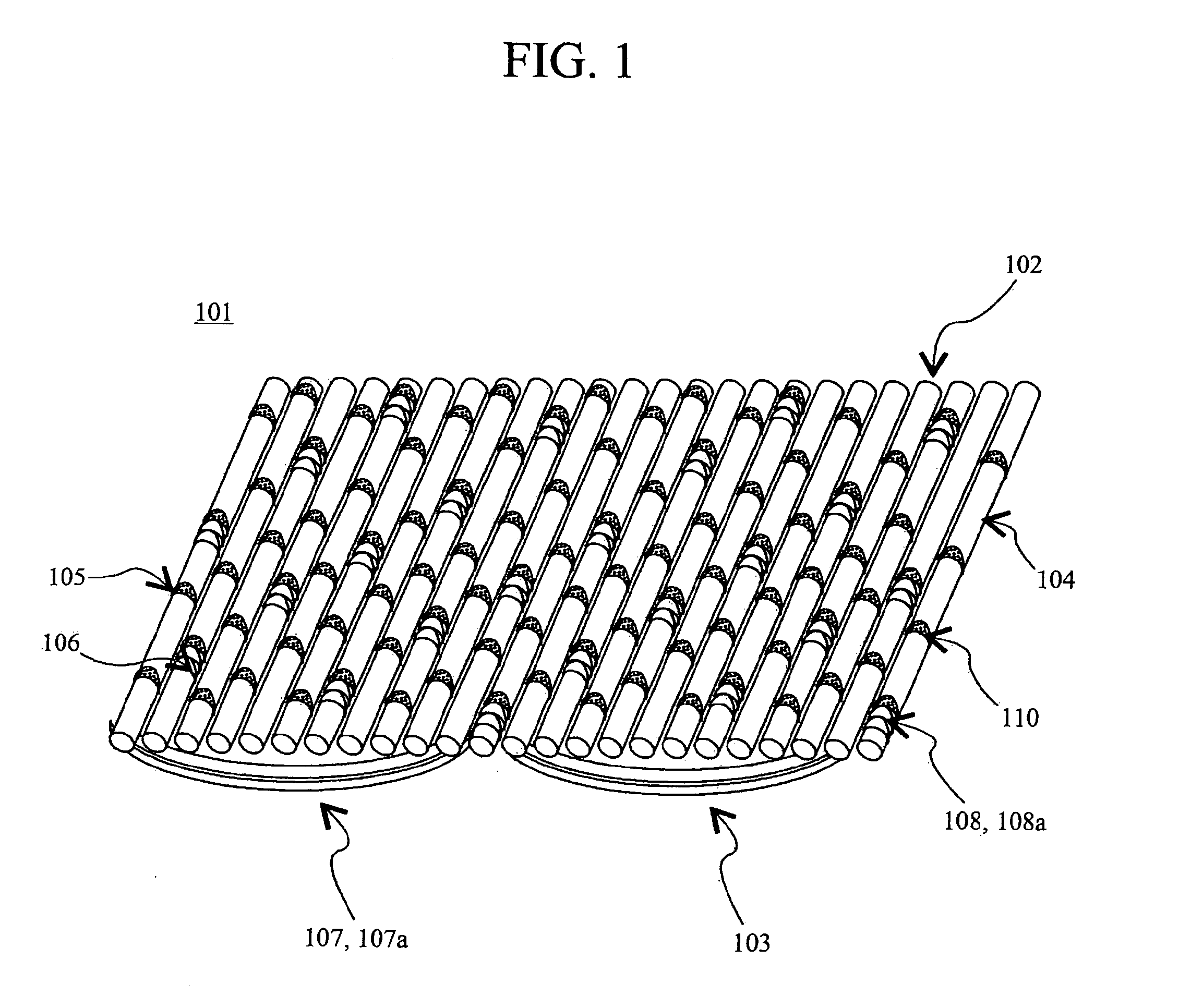

Multidirectionally Reinforced Shape Woven Preforms for Composite Structures

ActiveUS20090202763A1High strengthReadily conformsLoomsPedestrian/occupant safety arrangementFiberNacelle

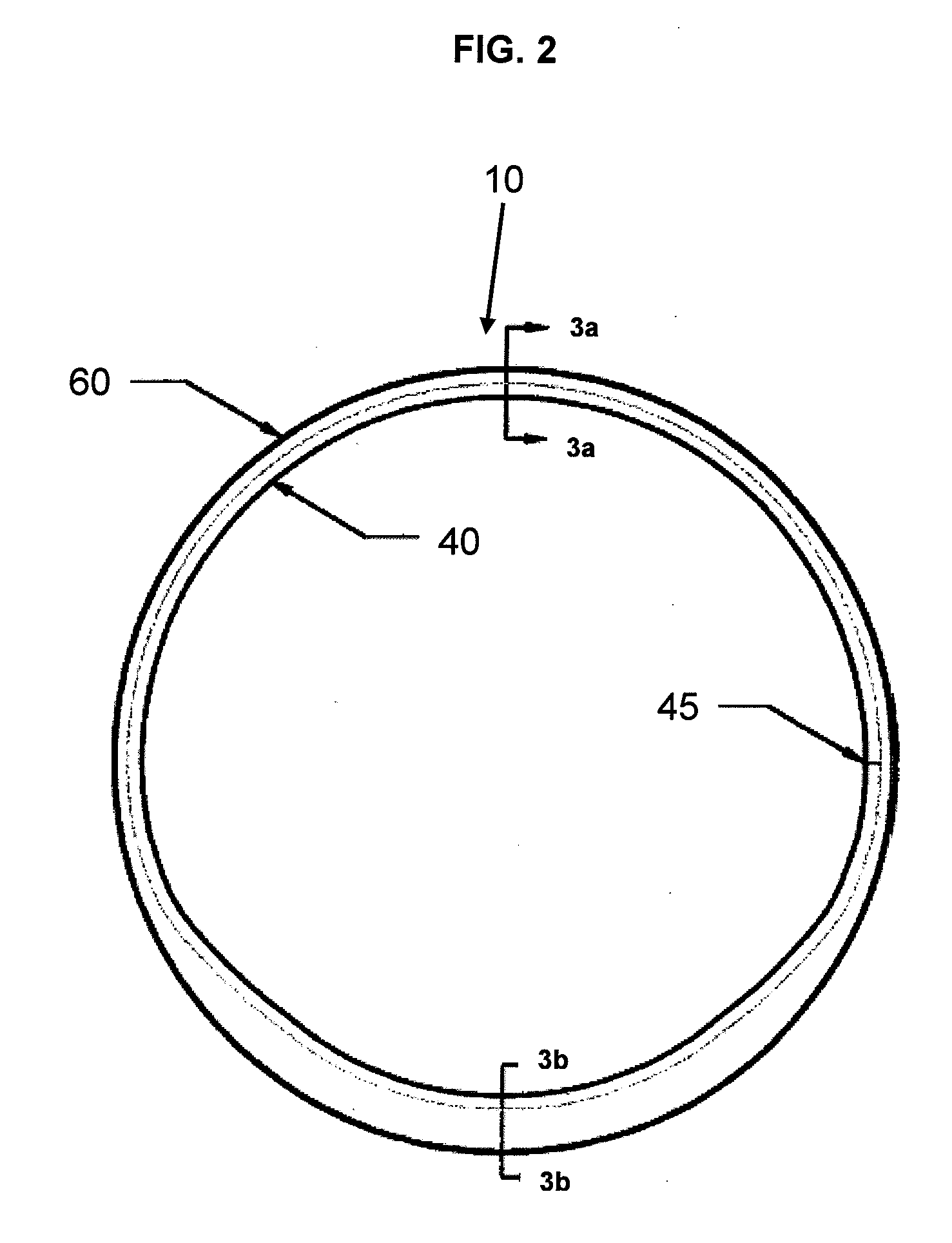

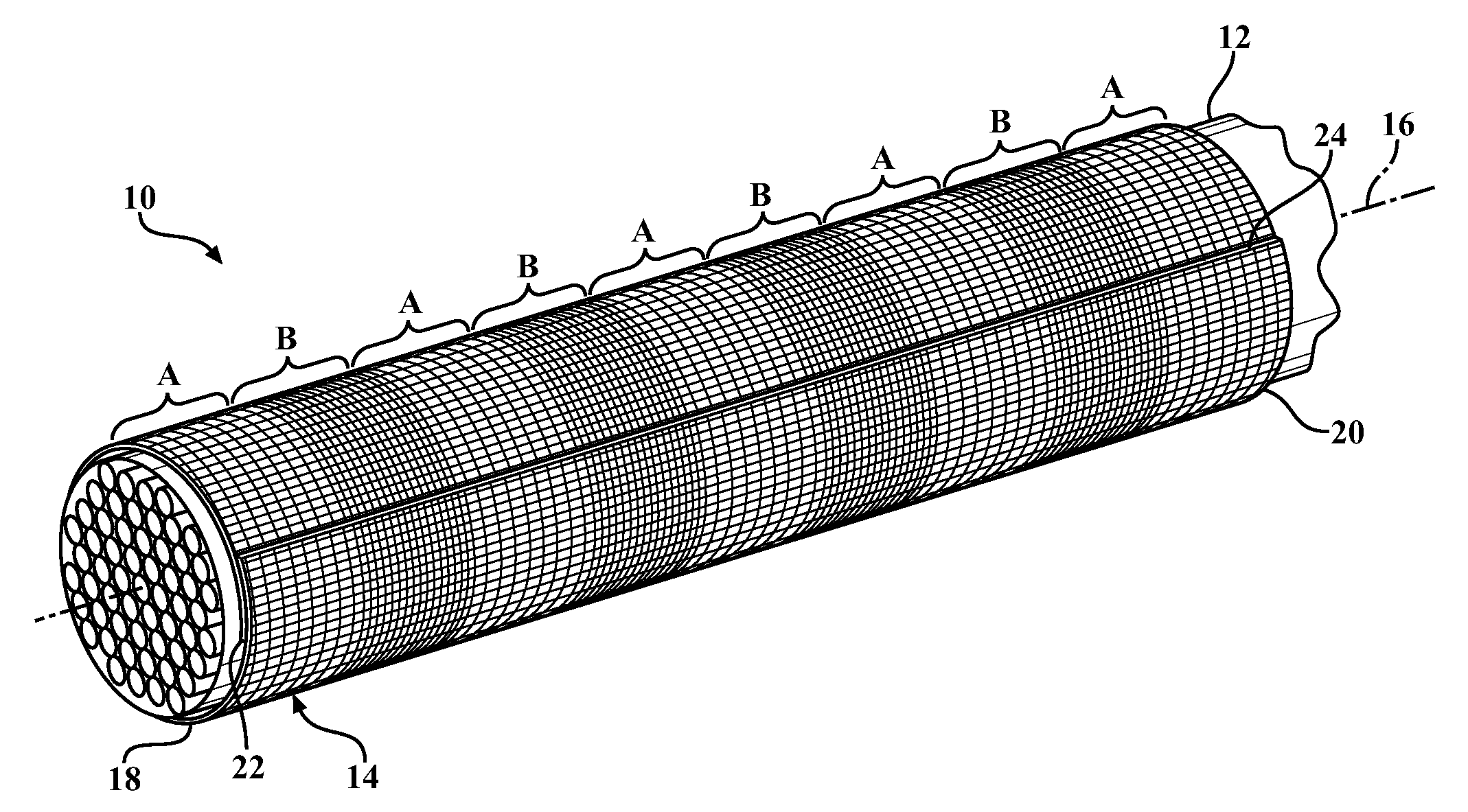

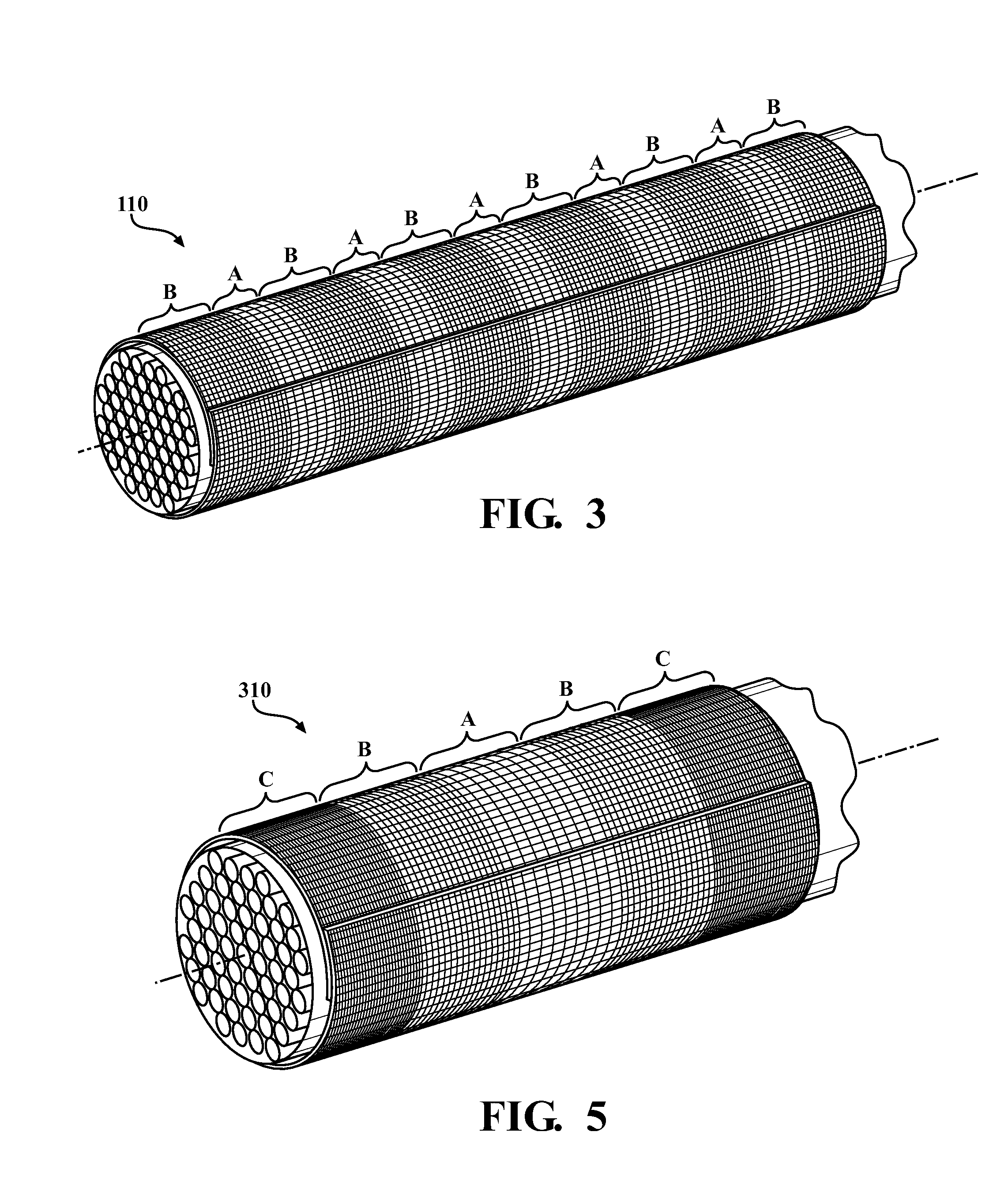

The present invention relates to multidirectionally reinforced fiber preforms that conform easily to complex curvatures, such as, composite turbine fan cases, jet engine containment rings, aircraft fuselage frames, aircraft window frames, and flanged rings for attaching nacelles to aircraft engines. The present invention provides multidirectionally reinforced shape woven preforms with improved strength for composite structures that are axisymmetric as well as non-axisymmetric in nature. The invention is a preform used to reinforce a composite structure which includes a contour woven fabric portion, bi-axially braided, tri-axially braided or bias fabric portion, and / or a polar woven fabric portion, and a method of making thereof. The preform may optionally include a three-dimensionally woven portion. The combination of different forms of fabrics allows the preform to be produced without cutting and darting of the individual plies. Eliminating these cuts and darts improves the strength and performance of the resulting structure.

Owner:ALBANY ENGINEERED COMPOSITES

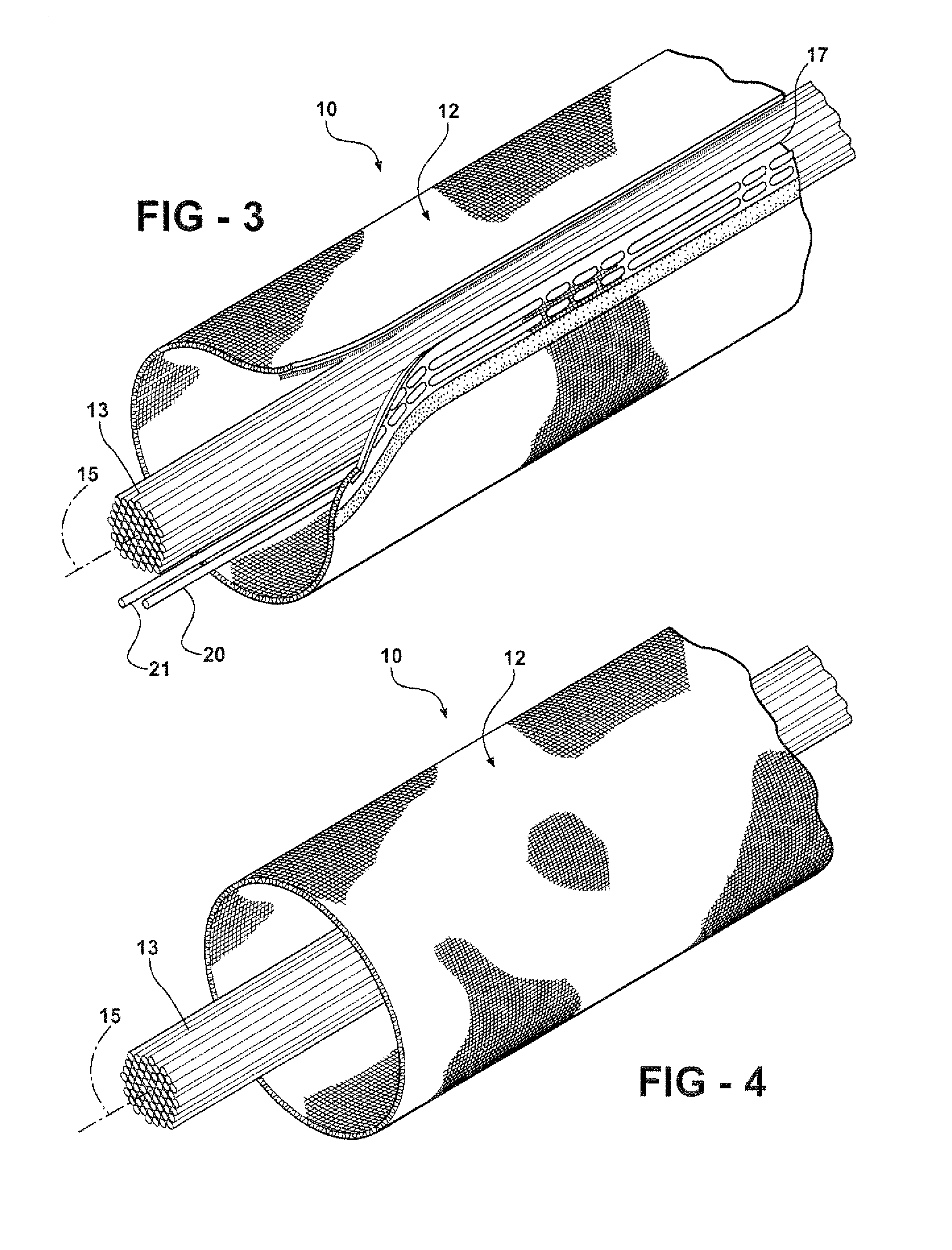

Non-kinking self-wrapping woven sleeve and method of construction thereof

ActiveUS20120037263A1Increase flexibilityRaise countElectrical apparatusLoomsUltimate tensile strengthWeft yarn

A wrappable textile sleeve and method of construction thereof is provided. The textile sleeve includes an elongate wall extending along a longitudinal axis between opposite ends with lengthwise extending edges extending along the longitudinal axis between the opposite ends. The wall is woven from lengthwise extending warp yarns and circumferentially extending weft yarns with at least some of the weft yarns being heat-set to impart a self curling bias on the wall to bring the edges into overlapping relation with one another. Further, the weft yarns form a plurality of discrete annular bands that extend circumferentially about the longitudinal axis with adjacent bands having different picks-per-inch from one another to provide the sleeve with enhance regions of flexibility, self-curling bias and hoop strength.

Owner:FEDERAL MOGUL POWERTAIN LLC

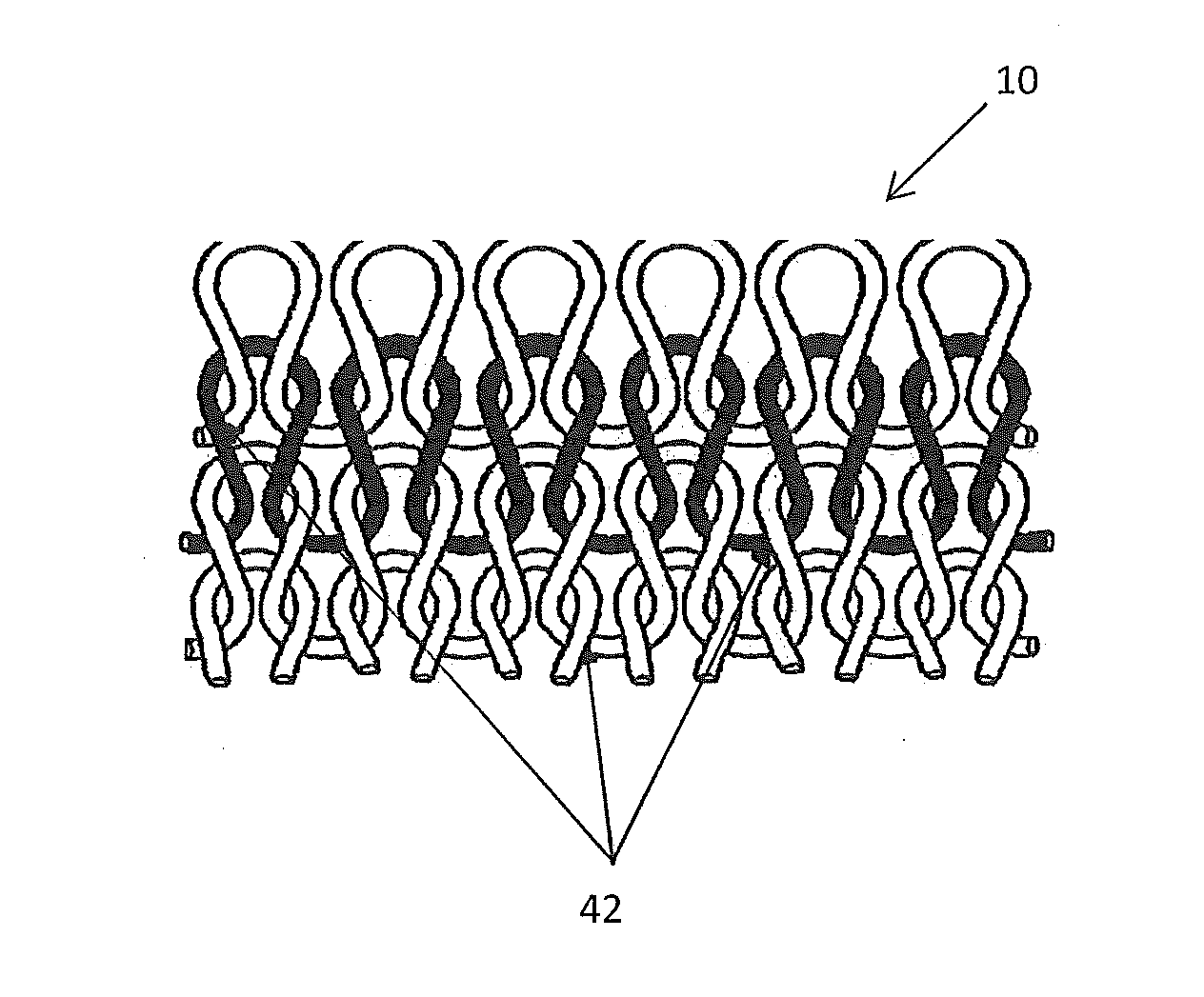

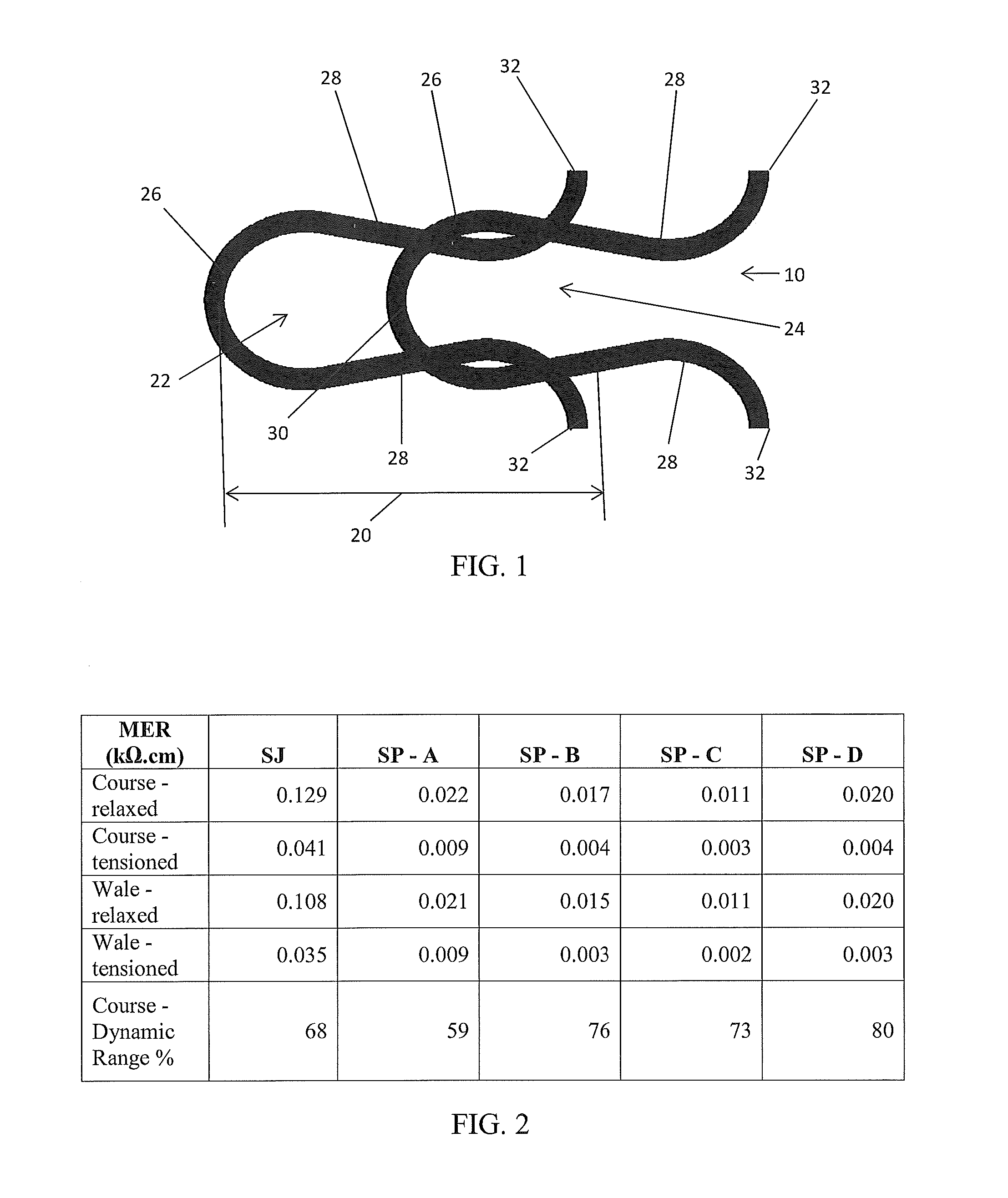

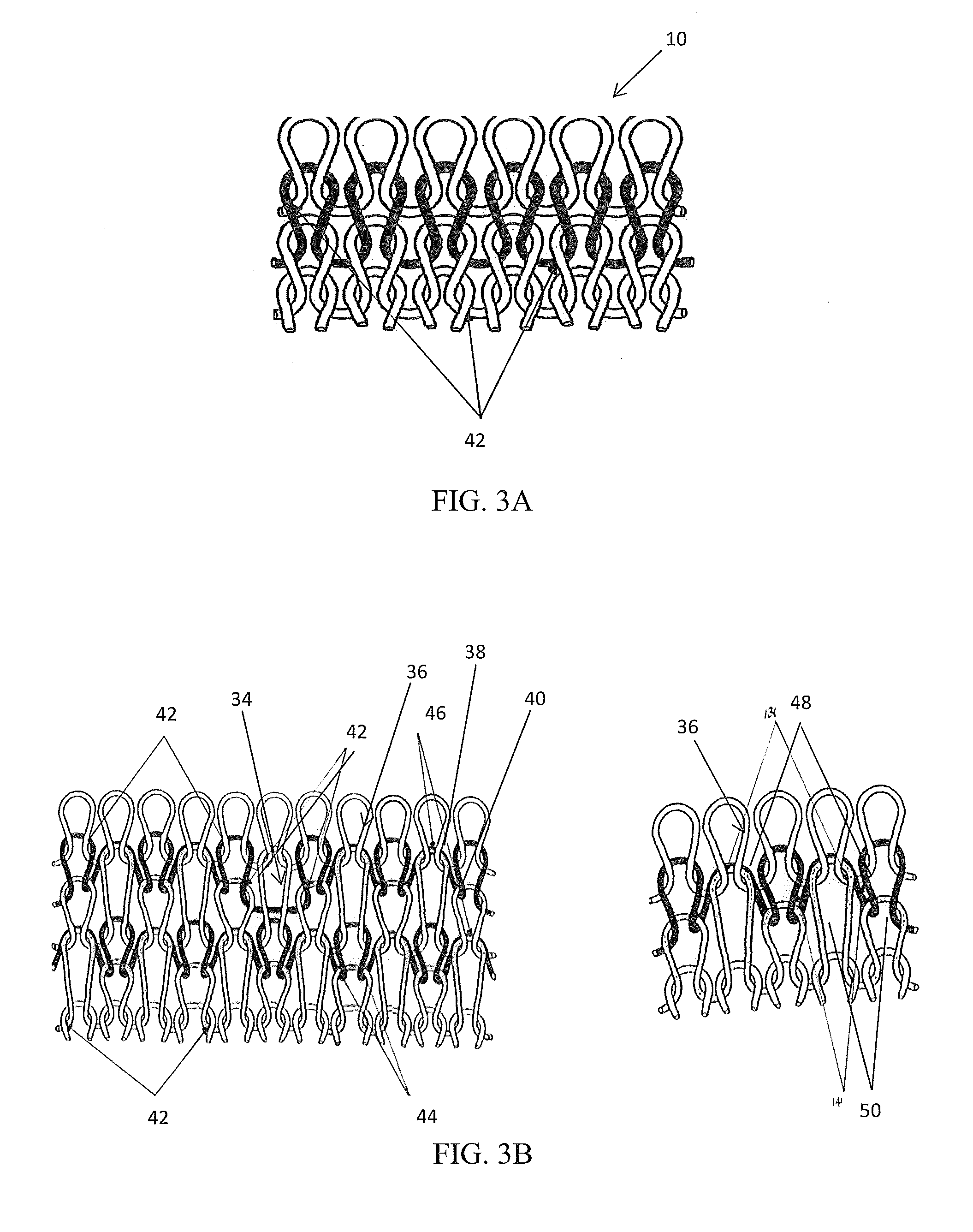

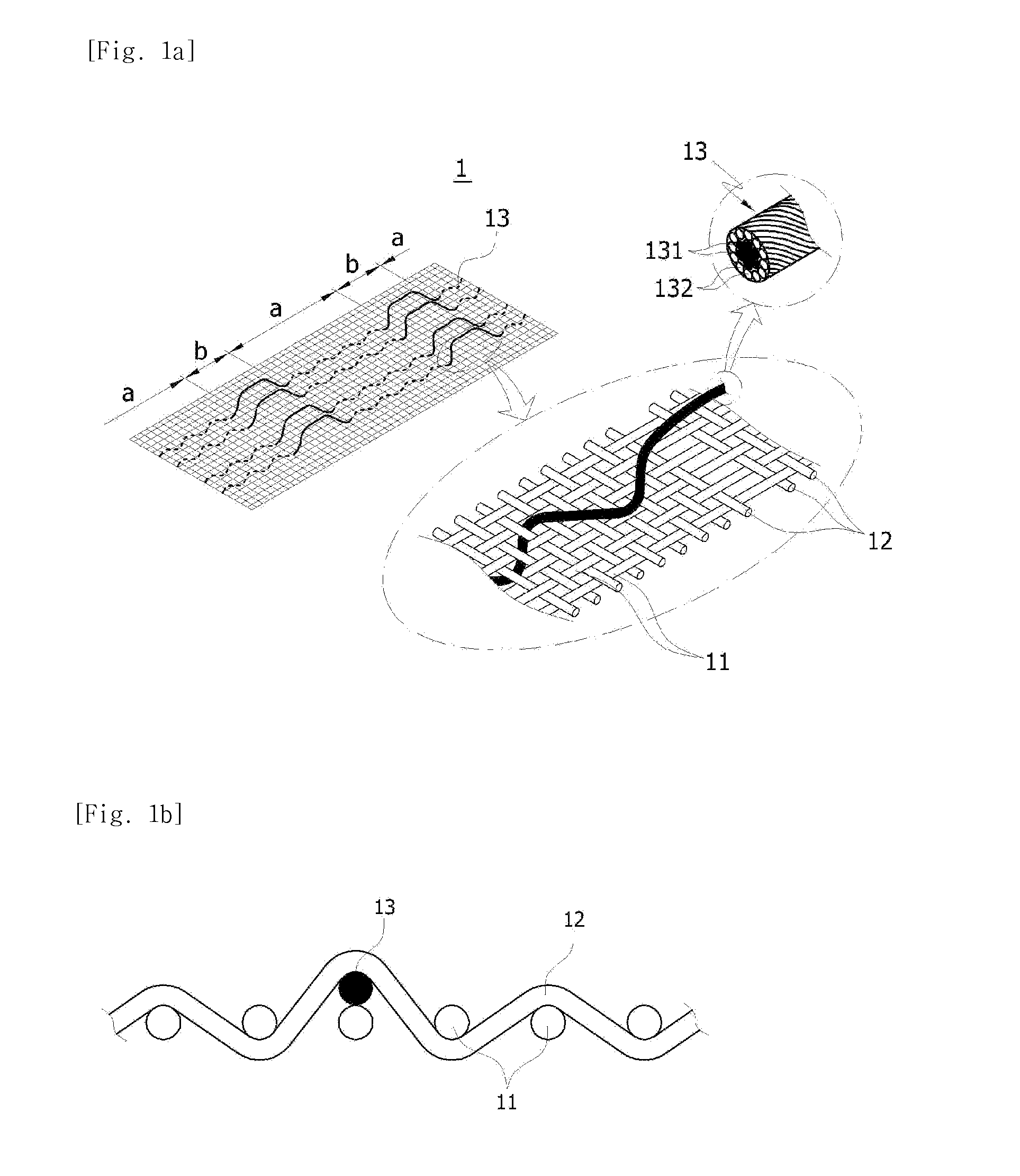

Method for making electrically conductive textiles and textile sensor

ActiveUS20160186366A1Automatically calibratingIncrease contact resistanceCrochetingOrnamental textile articlesYarnElectrical resistance and conductance

A method for making a textile sensor and a textile sensor can include selecting a combination of variables from the group consisting of yarn variables, stitch variables, and textile variables; and knitting an electrically conductive yarn in the textile sensor in accordance with the selected combination of variables, wherein the combination of variables is selected so as to provide a controlled amount of contact resistance in the textile sensor. The method and textile can further include a capacitive textile-sensor having at least two integrally knit capacitor plate elements and having a configuration adapted for a sensing activity. Resistance in the textile sensor can automatically calibrate to a stable baseline level after the textile sensor is applied to a body.

Owner:FOOTFALLS & HEARTBEATS (UK) LTD

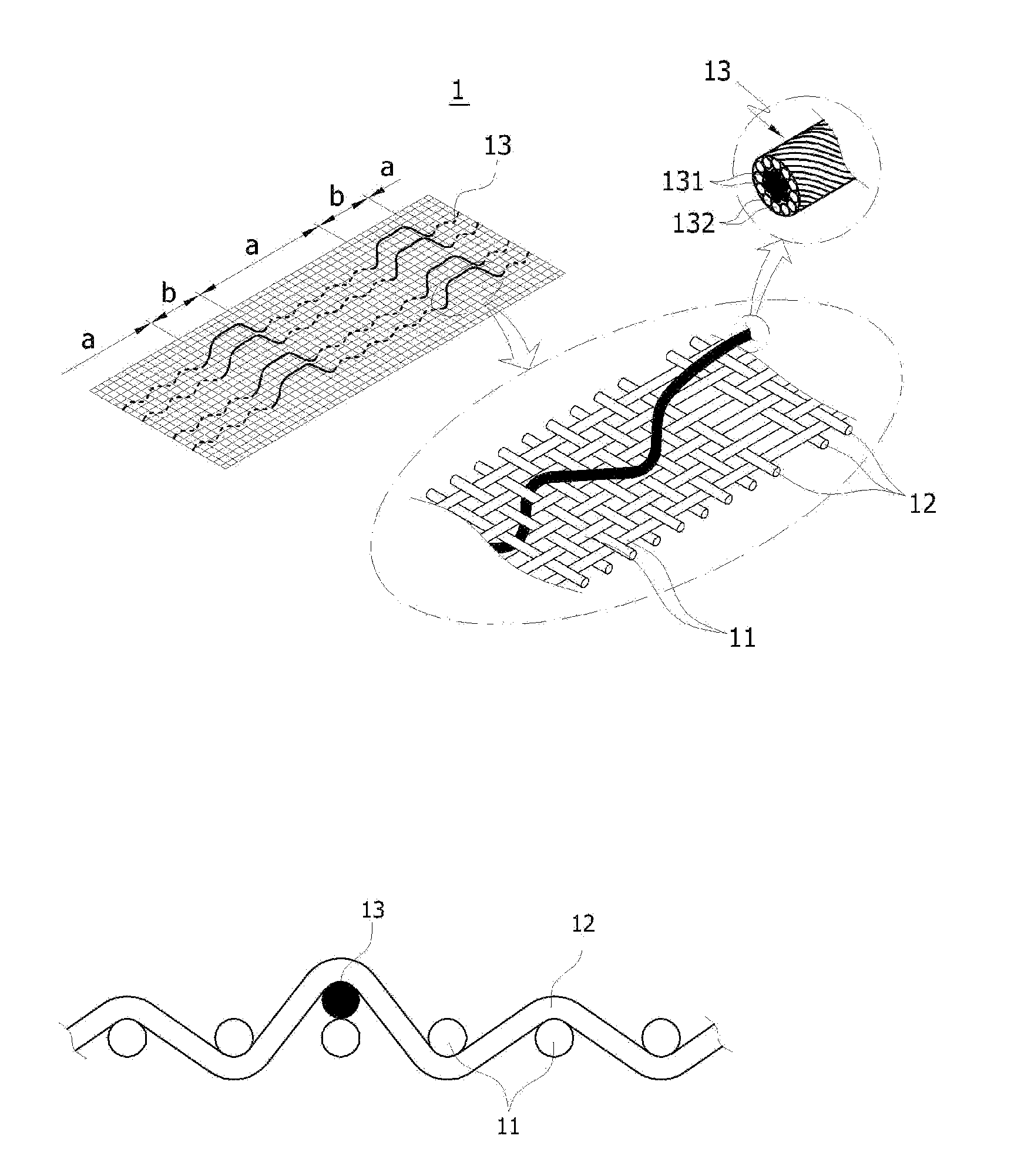

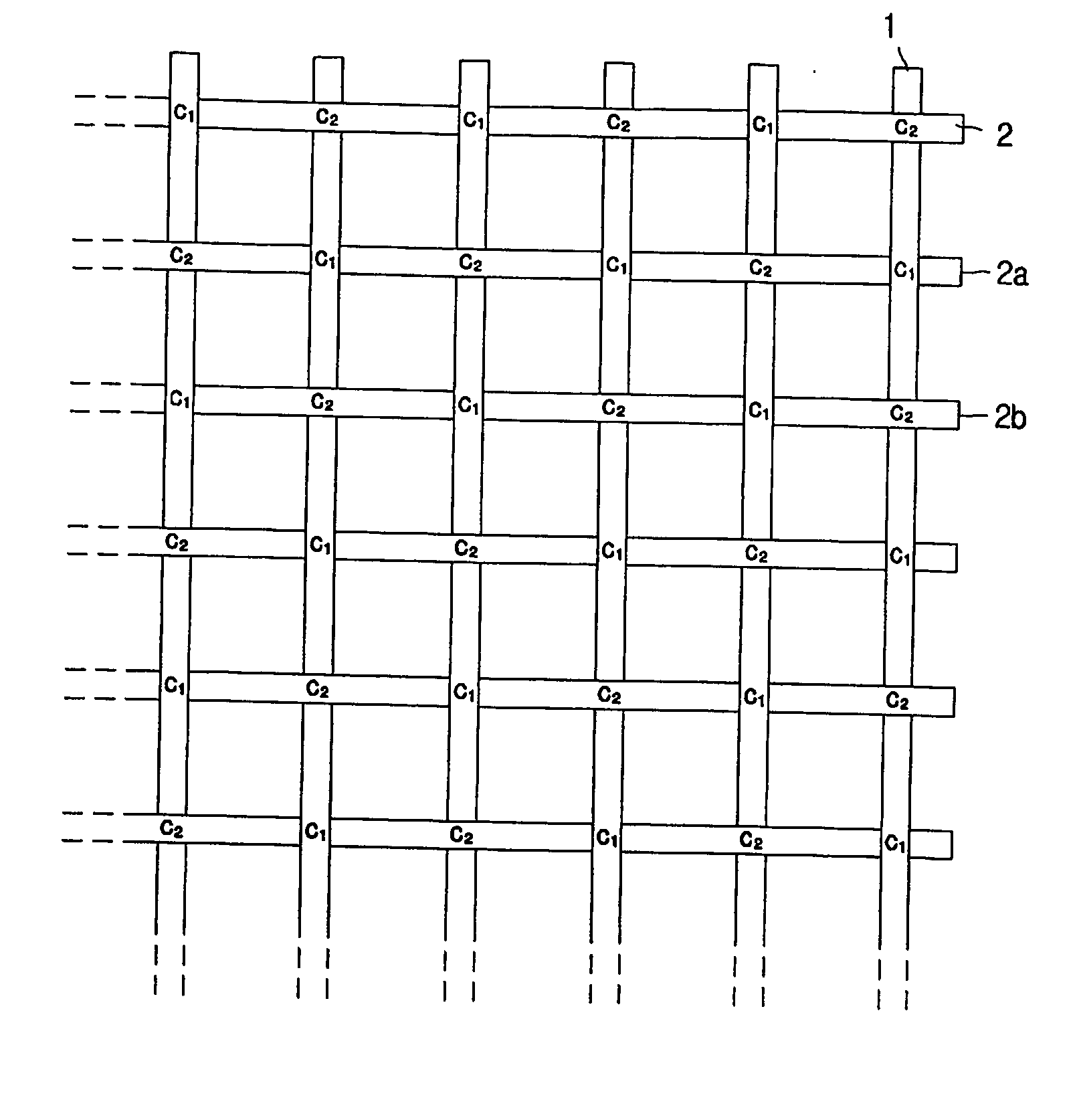

Electrically conductive fabric and manufacturing method and apparatus thereof

InactiveUS20130102217A1Improve workabilityIncrease productivityLoomsWarp knittingComputer moduleEngineering

The present invention discloses to relates to an electrically conductive fabric, and a manufacturing method and an apparatus thereof, and more specifically to an electrically conductive fabric, and a manufacturing method and an apparatus thereof, wherein part of electrically conductive wire woven together into fabric is selectively exposed to the outside of the fabric to perform the tying of electrically conductive wires and the connection of various elements and modules quickly and conveniently, so that workability and productivity can be improved.

Owner:SILVERAY CO LTD

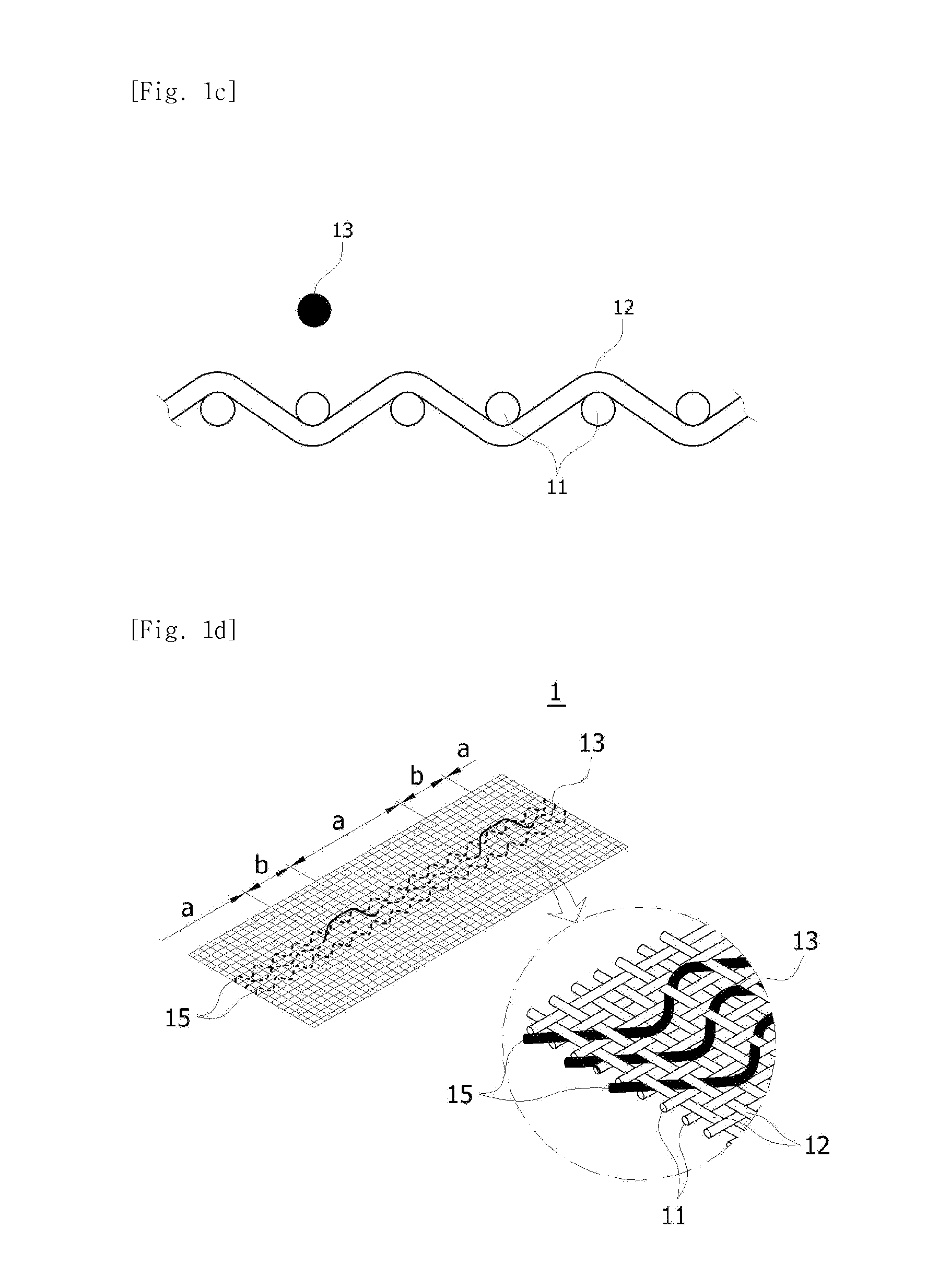

Protective sleeve fabricated with hybrid yard, hybrid yarn, and methods of construction thereof

ActiveUS20100084179A1Improve conductivityNon-insulated conductorsMagnetic/electric field screeningYarnArchitectural engineering

A hybrid yarn filament and sleeve constructed therefrom for protecting elongate members against at least one of EMI, RFI or ESD is provided, along with methods of constructing the hybrid yarn filament and sleeves. The hybrid yarn filament has a nonconductive filament and at least one conductive wire filament overlying an outer surface of the nonconductive filament. The hybrid yarn filament is arranged in electrical communication with itself or other hybrid yarn filaments during construction of the sleeve to provide uniform shielding against EMI, RFI, and and / or ESD.

Owner:FEDERAL MOGUL POWERTAIN LLC

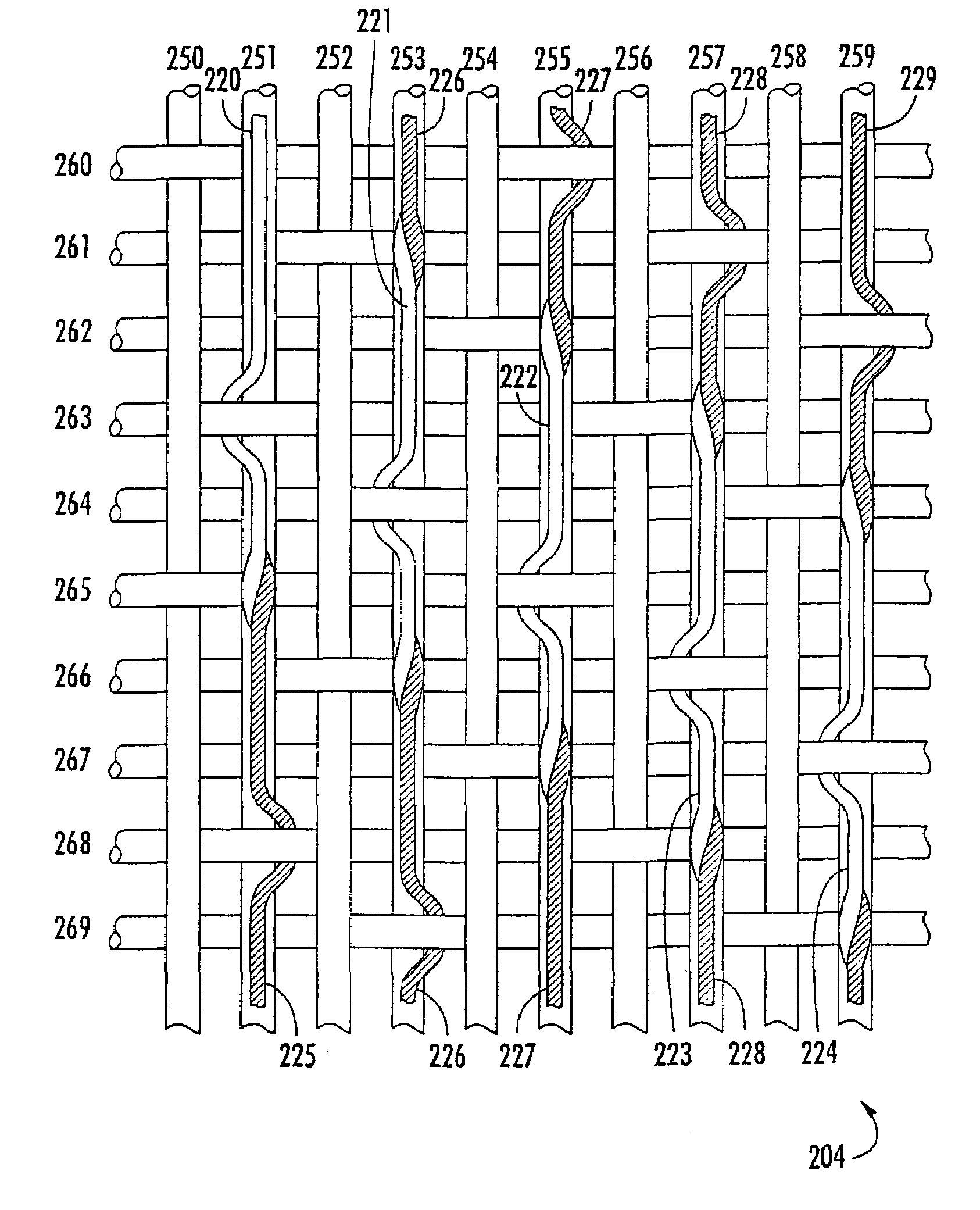

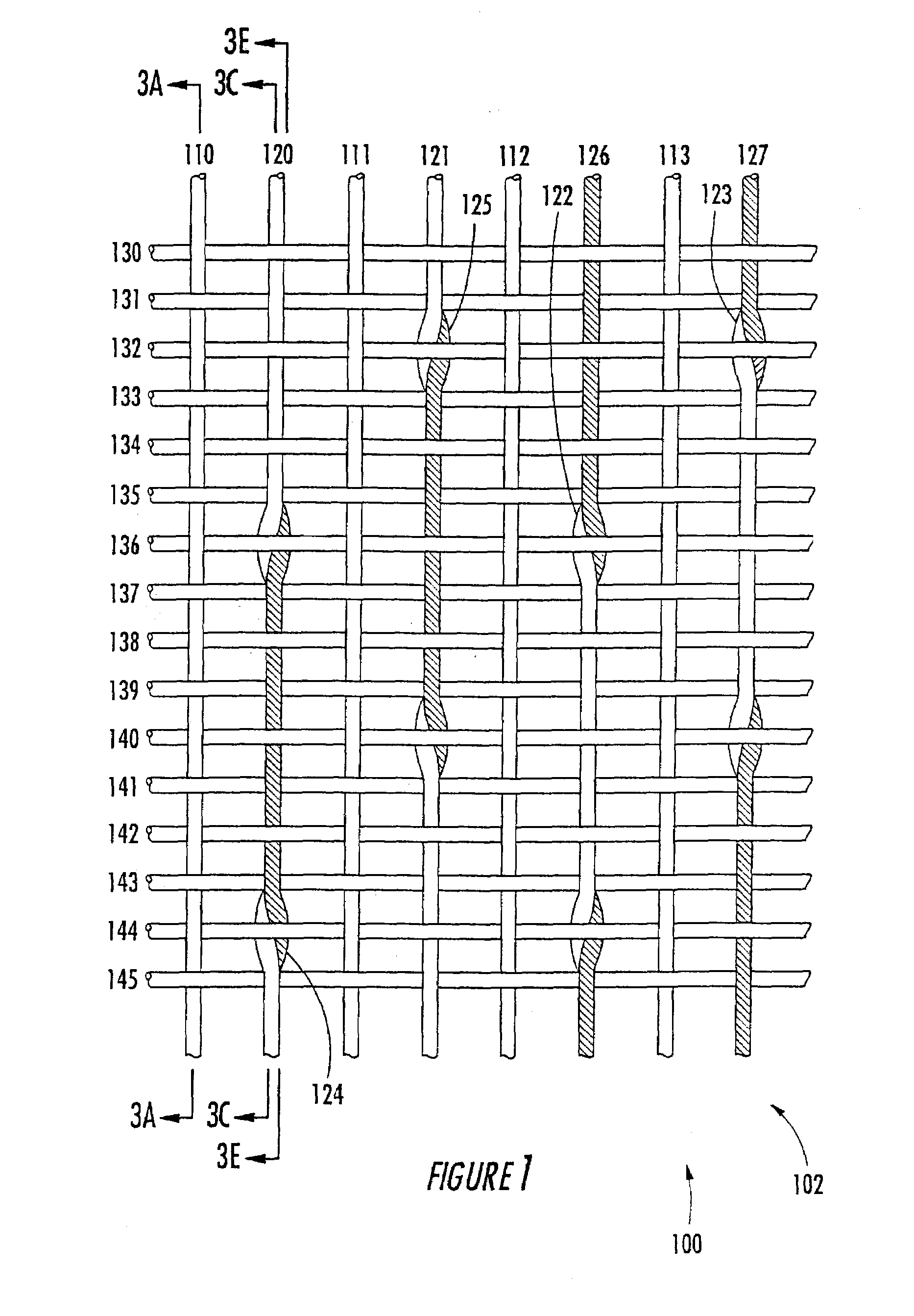

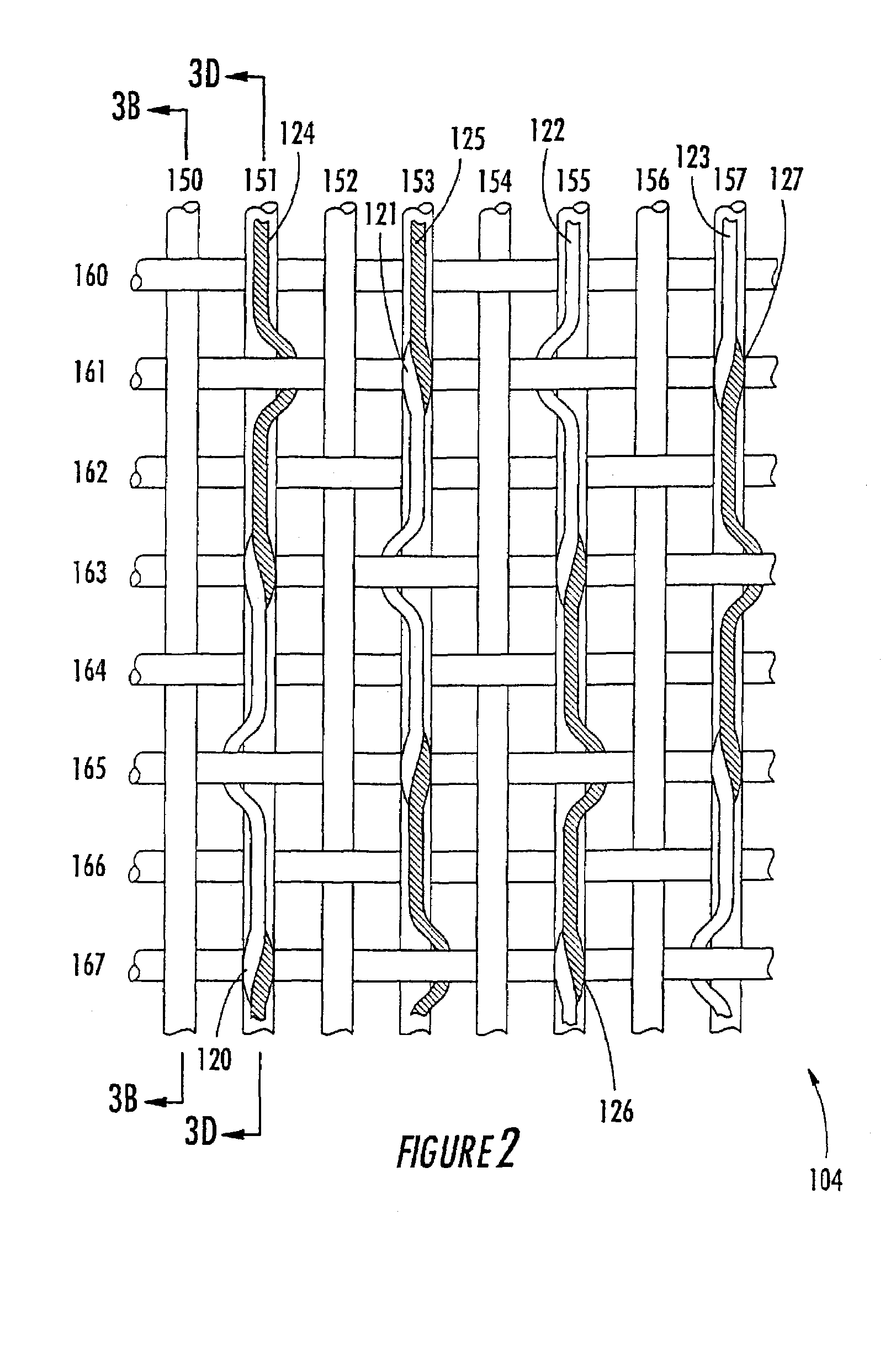

Warp-stitched multilayer papermaker's fabrics

InactiveUS7059357B2Easy to drainImprove joint strengthCellulosic pulp after-treatmentNon-fibrous pulp additionWeft yarnWarp knitting

A warp-stitched multilayer papermaker's fabric has a set of bottom warp yarns, a set of bottom weft yarns, a set of top weft yarns and a set of warp stitching yarn pairs. The bottom warp yarns are interwoven with the bottom weft yarns. The stitching warp yarns interweave with both the bottom weft yarns and the top weft yarns, and are woven such that at locations where the first of the stitching warp yarns in a pair weaves in the top fabric layer, the second stitching warp yarn in the pair drops below the top fabric layer to interweave with one or more bottom weft yarns to bind the top fabric layer and the bottom fabric layer together. The first stitching warp yarn of the stitching warp yarn pair may weave on a first side of one of the bottom warp yarns while the second stitching warp yarn of each stitching yarn pair may weave on the other side of that bottom warp yarn. Each stitching yarn pair may be substantially stacked above a bottom warp yarn. The fabric may further include a set of top warp yarns that interweave with the top weft yarns in the top fabric layer. The set of top warp yarns may be woven from a first warp beam, the set of bottom warp yarns may be woven from a second warp beam and the set of stitching warp yarns may be woven from a third warp beam.

Owner:WEAVEXX

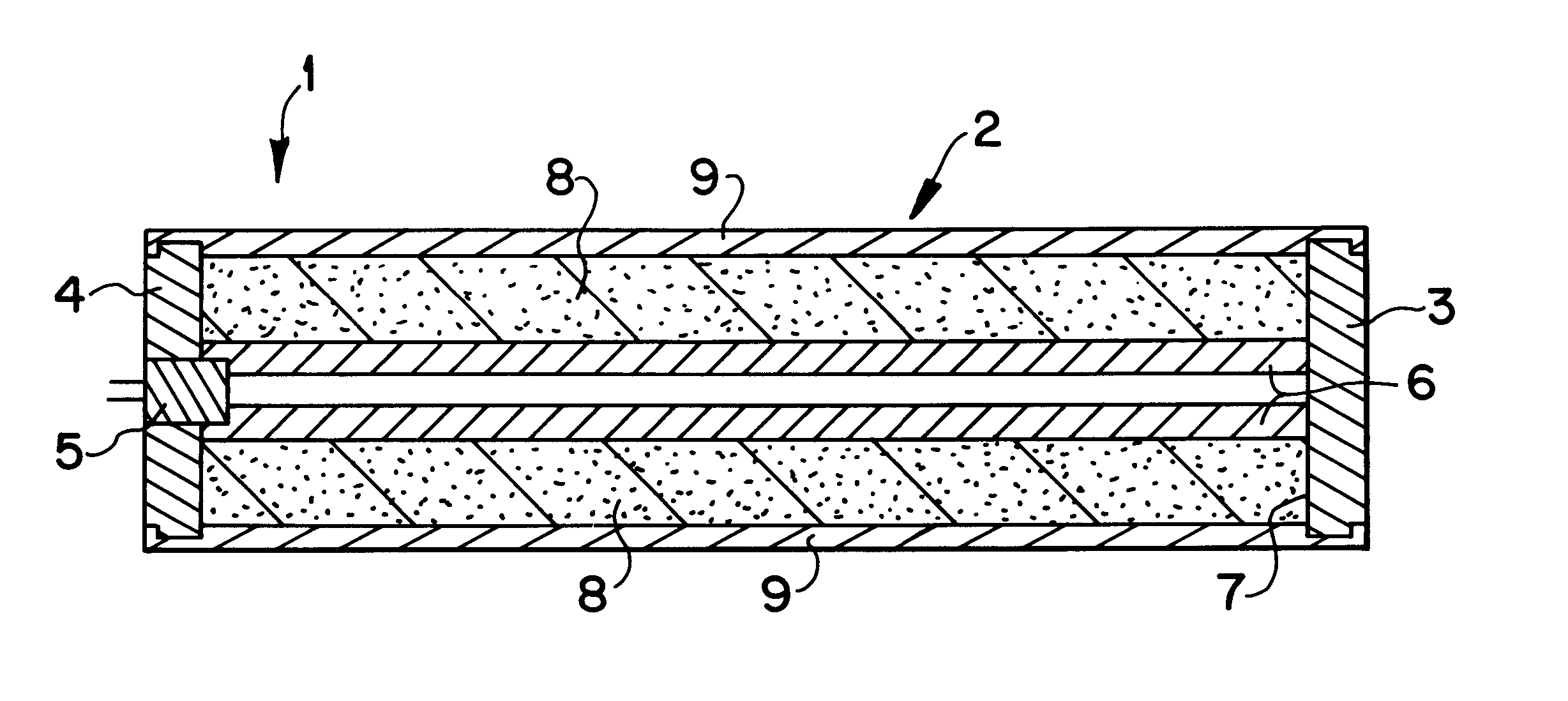

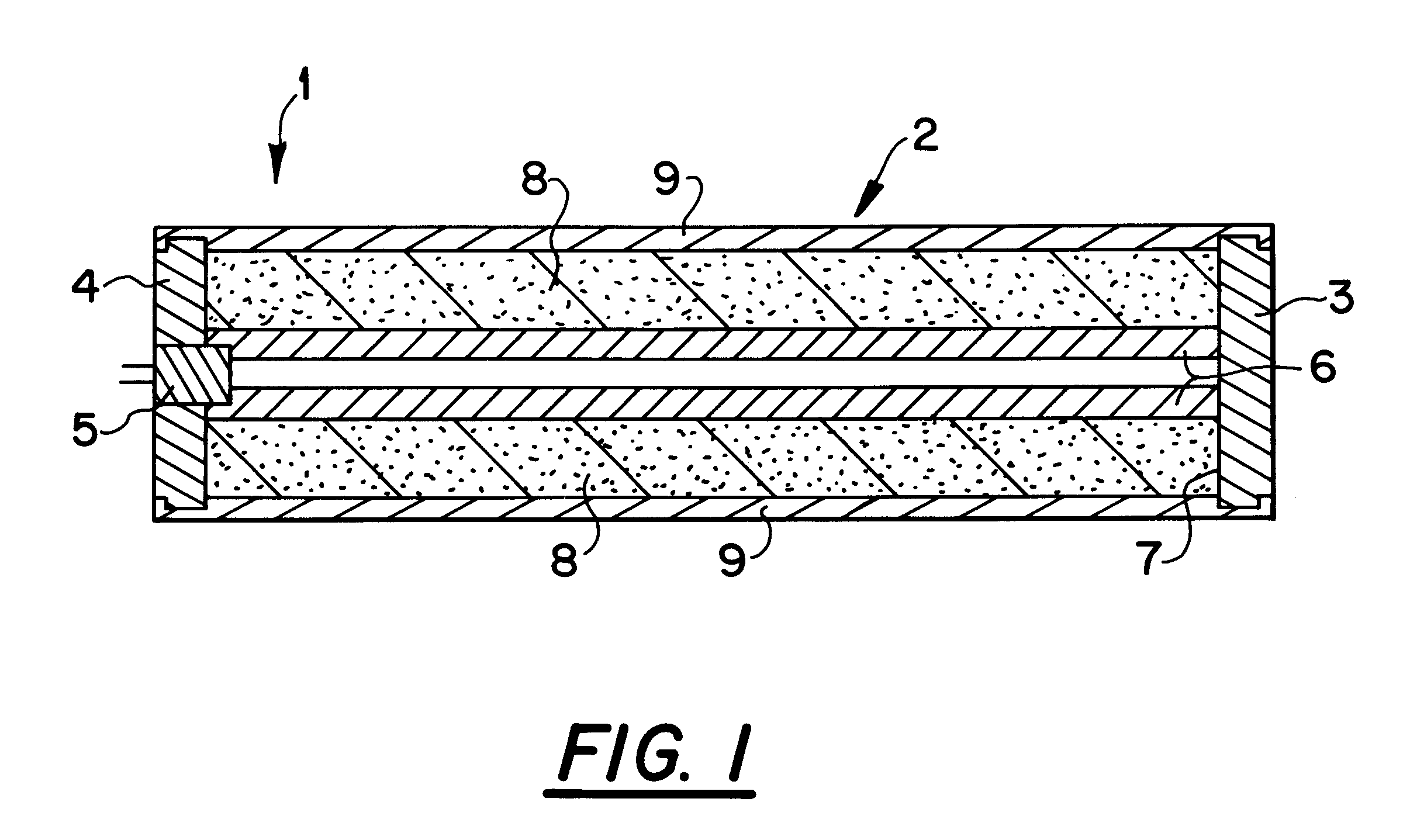

Supplemental-restraint-system gas generating device with water-soluble polymeric binder

InactiveUS6224099B1Easy to manufactureSelectable characteristicLoomsPedestrian/occupant safety arrangementSystems designIn vehicle

Owner:NORTHROP GRUMMAN INNOVATION SYST INC

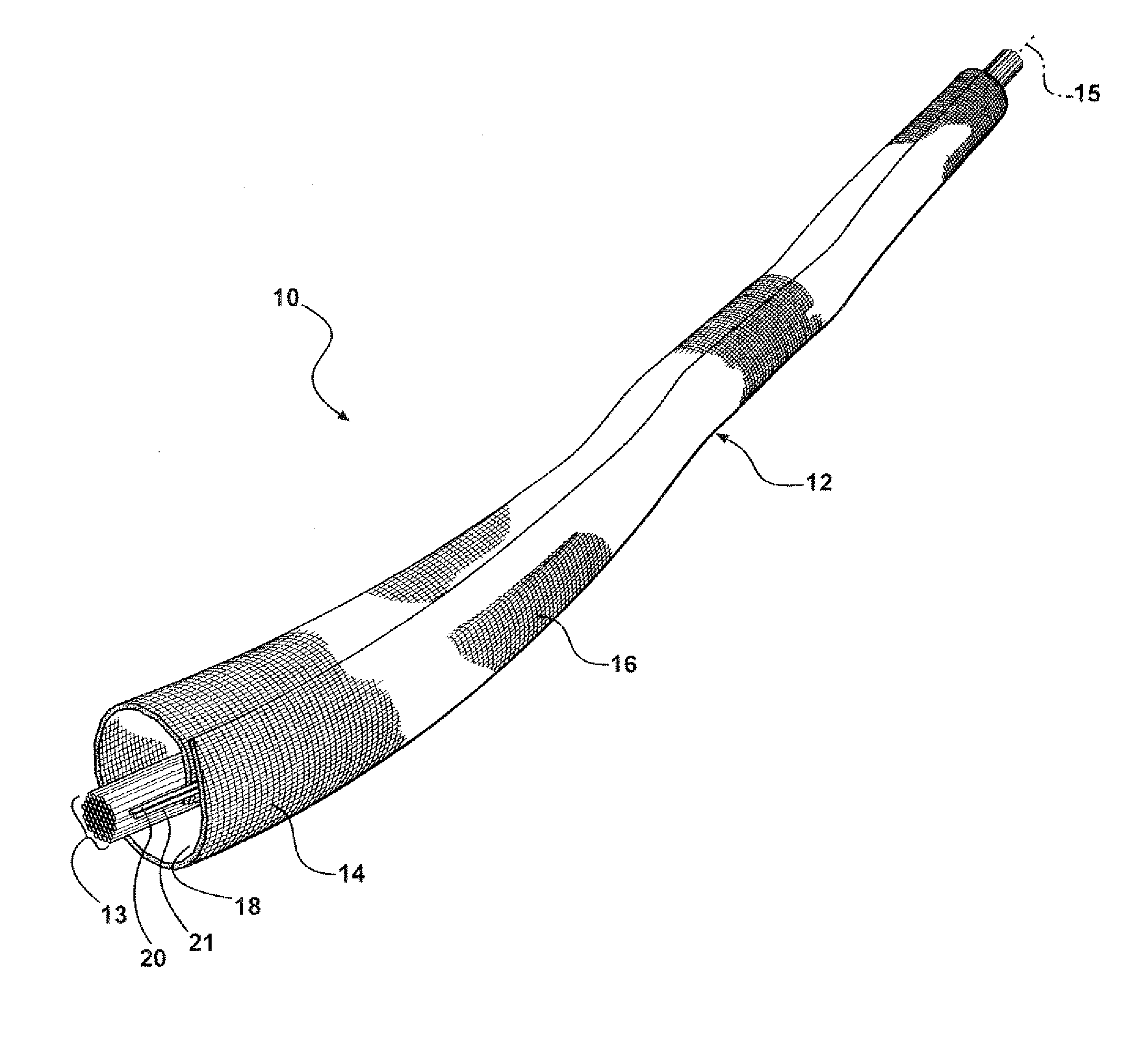

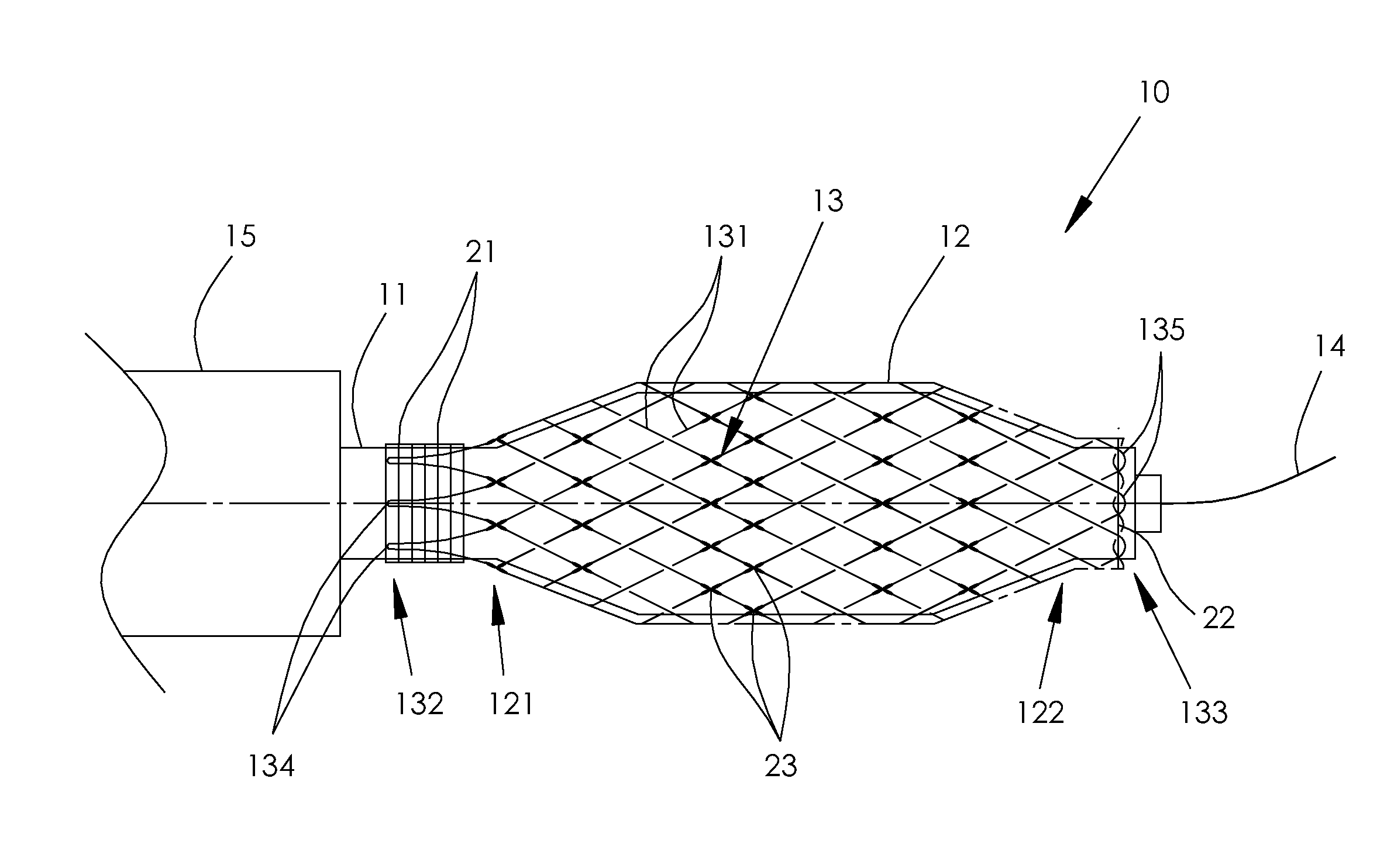

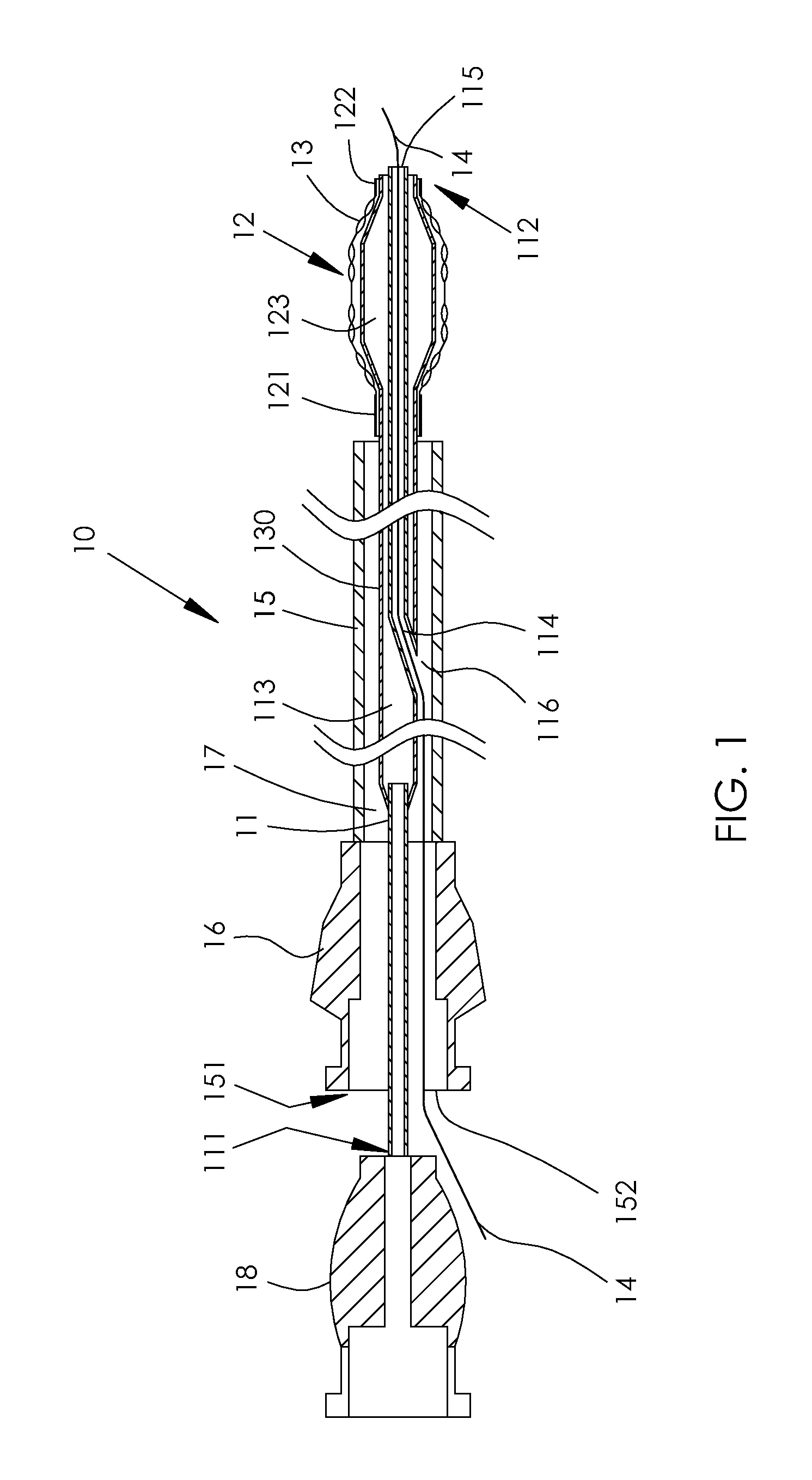

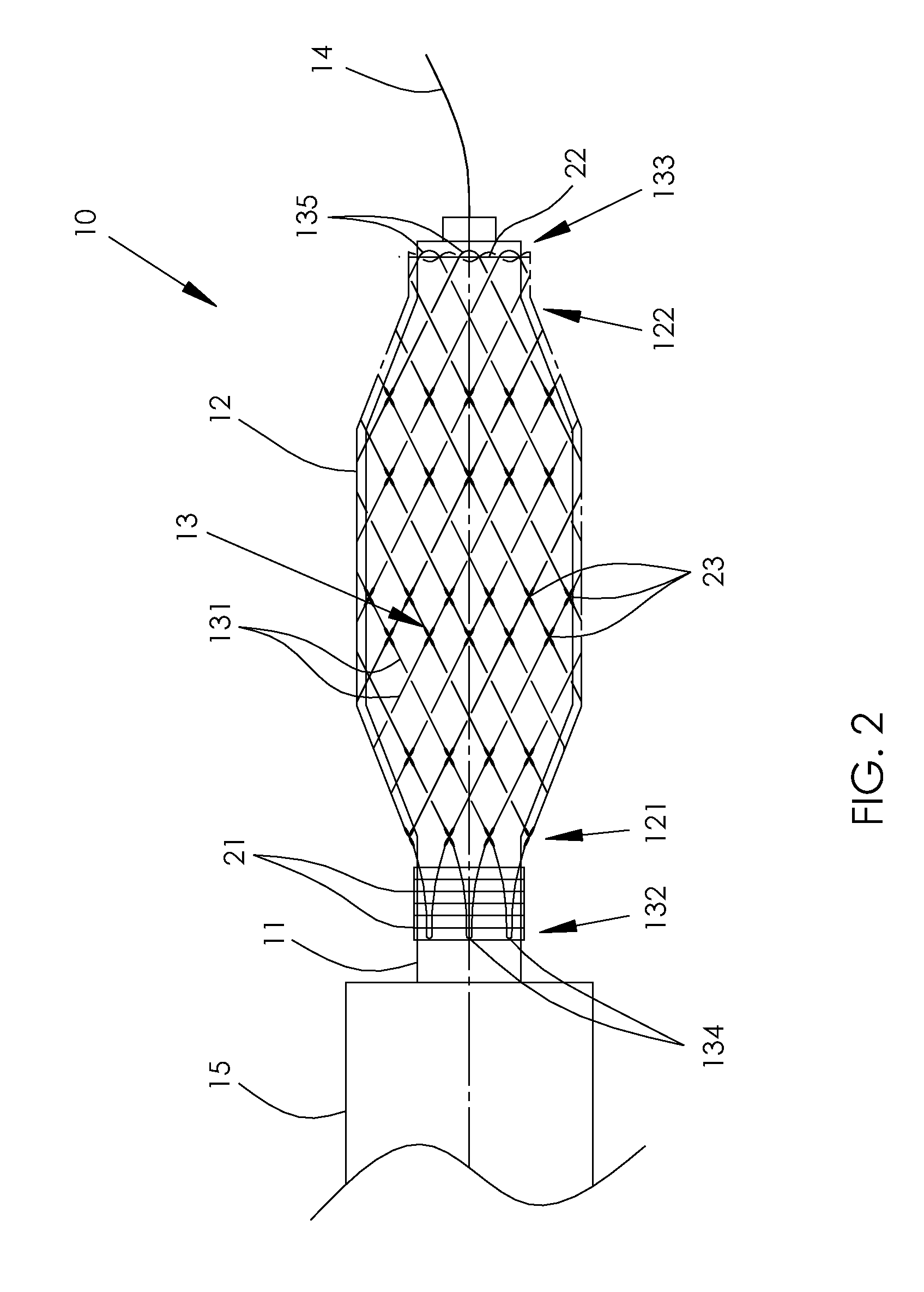

Cutting balloon assembly and method of manufacturing thereof

InactiveUS20110082483A1Improved dilatationImprove treatmentStentsBalloon catheterGeneral surgeryCatheter device

A cutting balloon assembly and a method for fabrication of the assembly is described. The cutting balloon assembly comprises a delivery catheter, an expandable balloon mounted on the catheter distal end, and a scoring mesh disposed around the expandable balloon. The scoring mesh comprises interlacing filaments that extend from a mesh proximal end towards a mesh distal end, form distal filament loops at said mesh distal end, and then return to the mesh proximal end. At least a part of the interlacing filaments forms one or more permanent links with neighboring filaments between the mesh proximal end and the mesh distal end.

Owner:NORDSON CORP

Protection product

A protection product made of (i) a woven fabric woven with a high-performance fiber, in which the opening rate of thread-opening treatment is 0 to 5%, and the width of a thread constituting the woven fabric is 10-fold or more relative to the thread thickness, (ii) a woven fabric in which the cross-sectional shape of a thread constituting the woven fabric is thinner on an edge side of both ends as compared with an intermediate part in the width direction, or (iii) a woven fabric woven with a twistless high-performance fiber having a fineness of 200 to 15,000 dtex, in which the ratio of the thread width to the thread thickness of at least one of a warp and a weft is 10 to 100, and the opening rate is 0 to 5%.

Owner:SOWA TEXTILE +2

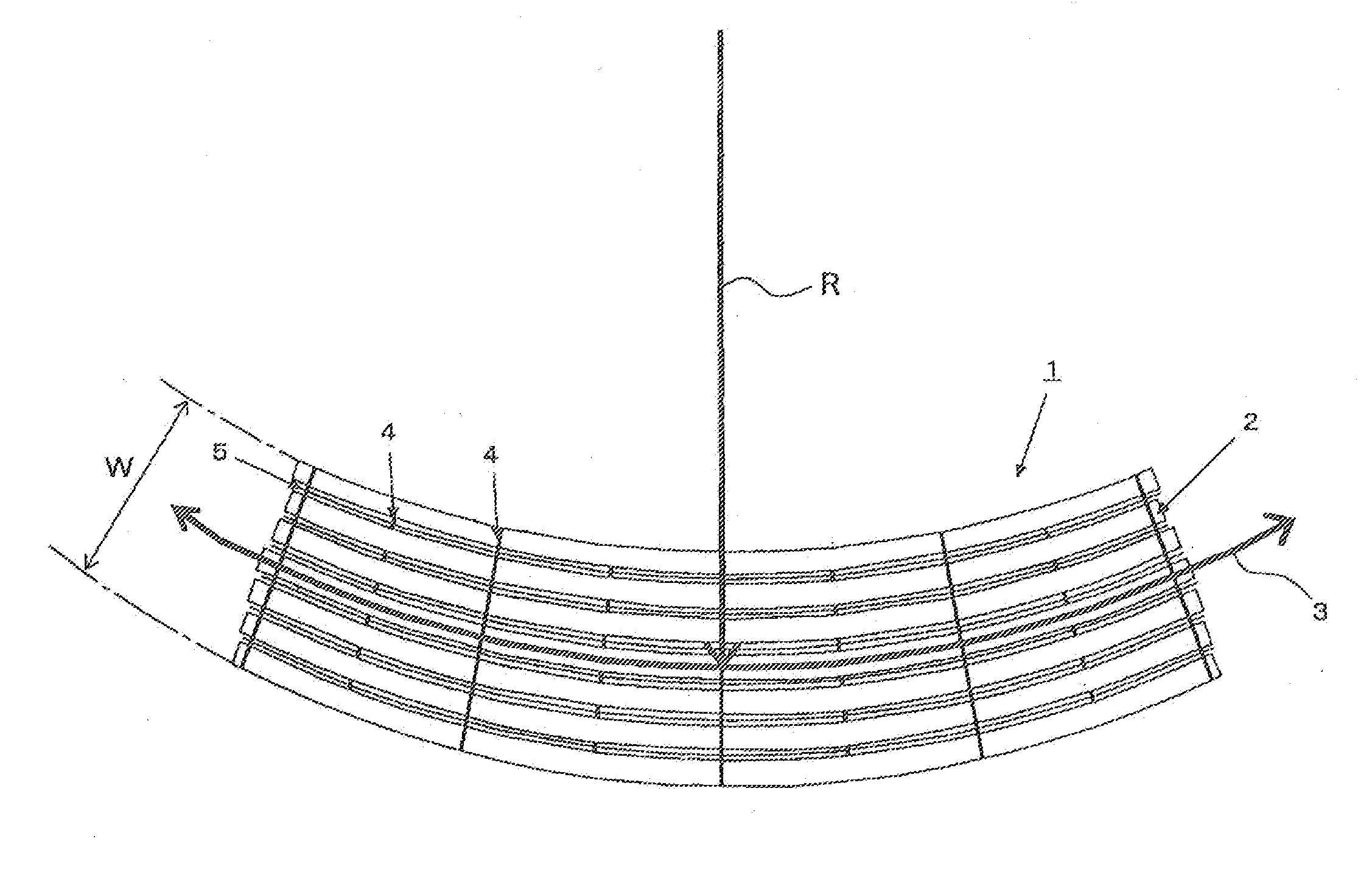

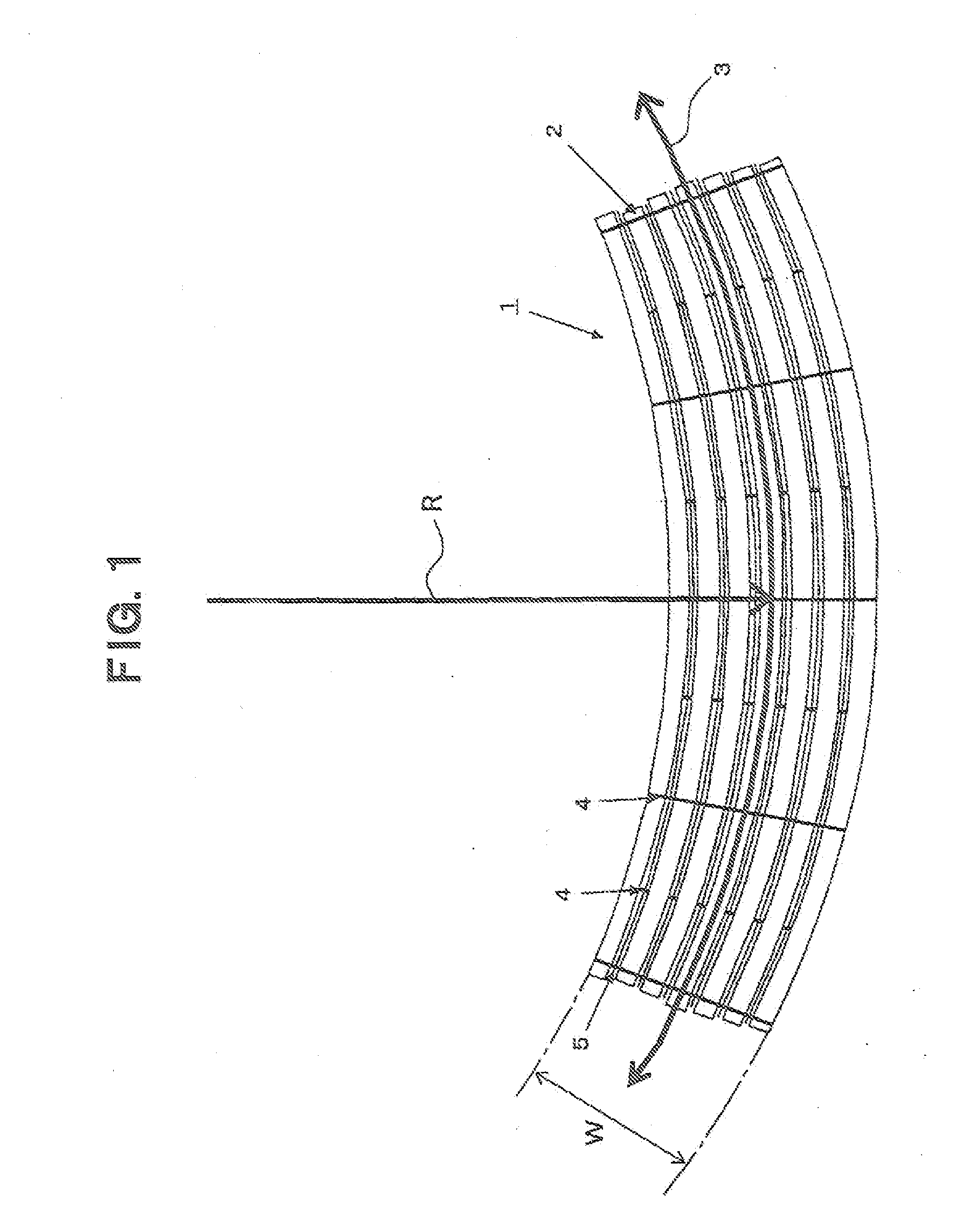

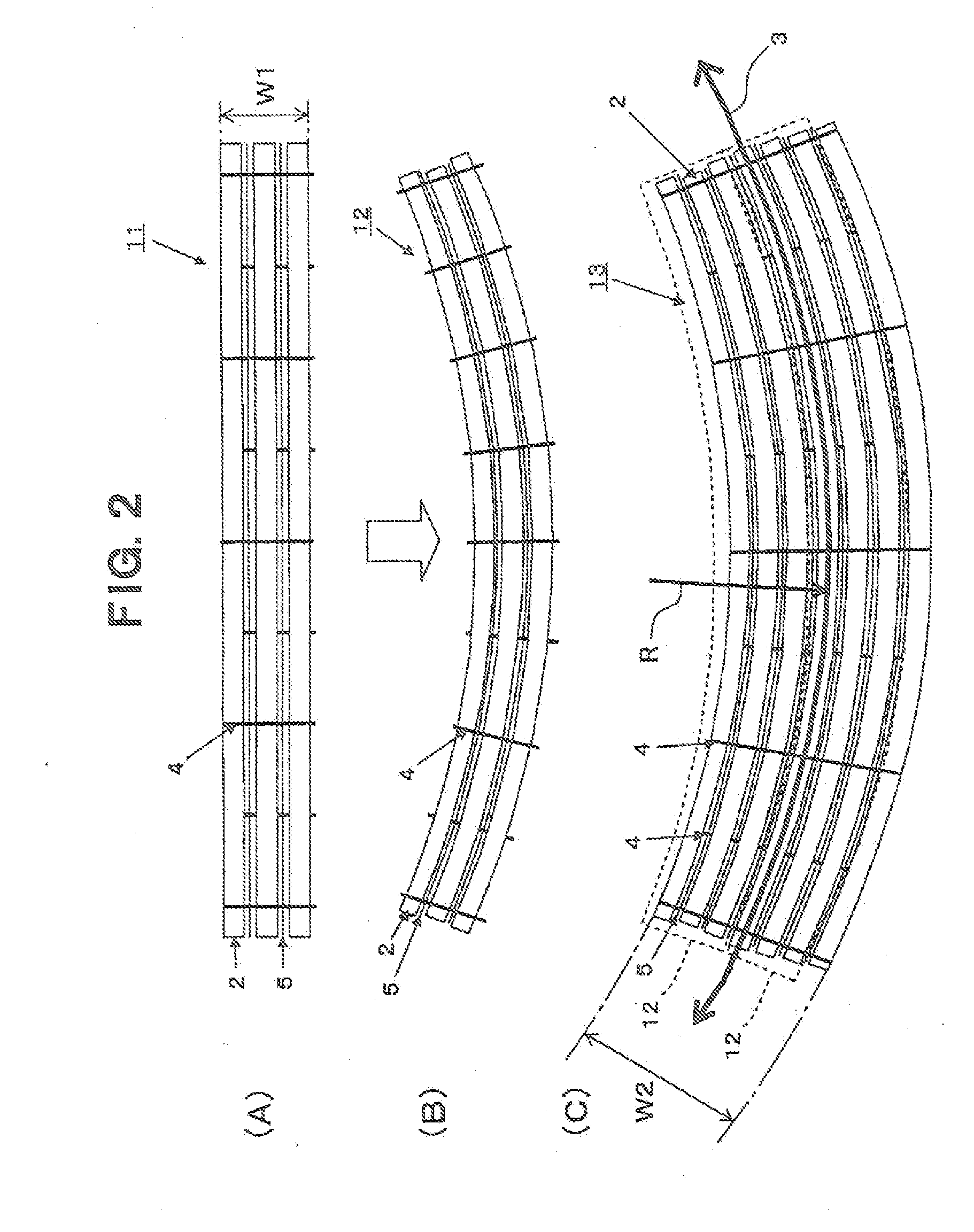

Reinforcing fiber substrate of curved shape, layered product using the same, preform, fiber-reinforced resin composite material, and processes for producing those

InactiveUS20100285265A1Efficient formationSimple structureLoomsSynthetic resin layered productsYarnCurve shape

A curved reinforcing fiber substrate having a curved planar shape comprising a plurality of reinforcing fiber yarns arranged parallel to a direction along a circumferential direction of the curved shape, and auxiliary weft yarns arranged in directions crossing the plurality of reinforcing fiber yarns each arranged in one direction of the circumferential direction.

Owner:TORAY IND INC

Low toxicity primer compositions for reduced energy ammunition

InactiveUS20100300319A1Increased heat generationHigh sensitivityAmmunition projectilesShotgun ammunitionToxic materialOxidizing agent

A primer composition with reduced toxicity suited for reduced-energy ammunition comprises bismuth (III) oxide as the principal oxidizer and contains a portion of propellant composition mixed therein. This composition may also be used in a cartridge which is otherwise substantially free of any other propellant compound and preferably produces a residue which is substantially free of toxic substances.

Owner:GENERAL DYNAMICS ORDNANCE & TACTICAL SYST CANADA VALLEYFIELD INC

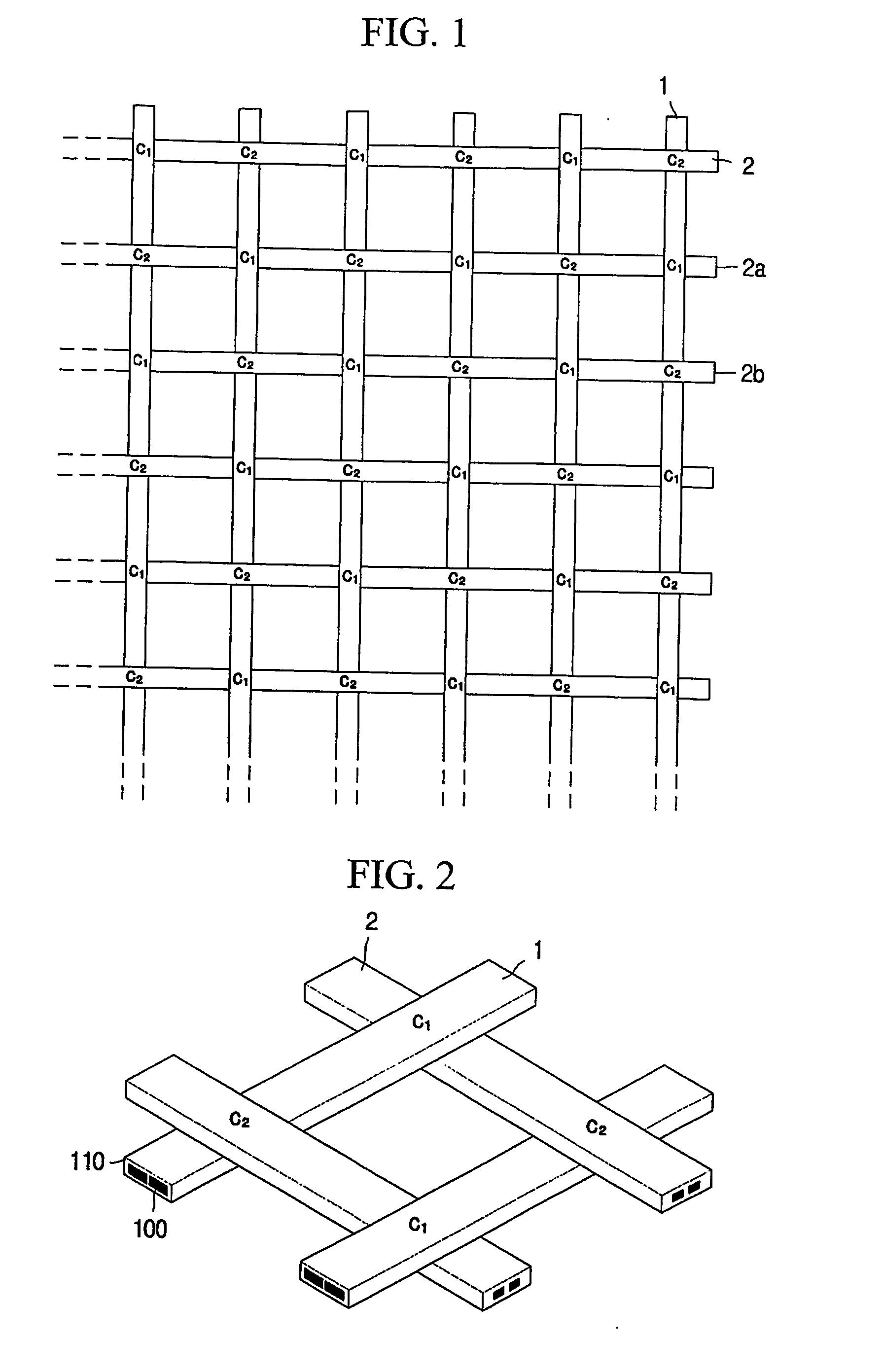

Geogrid composed of fiber-reinforced polymeric strip and method for producing the same

InactiveUS20060116040A1Increase resistance against vertical loadIncrease friction forceWarp knittingWelding/cutting auxillary devicesTensile strainGeogrid

A geogrid using fiber-reinforced polymeric strips and its producing method are disclosed. The geogrid of a lattice shape includes plural longitudinal fiber-reinforced polymeric strips longitudinally arranged in parallel at regular intervals and formed by reinforcing fiber in a thermoplastic polymer resin, and plural lateral fiber-reinforced polymer strip laterally arranged in parallel at regular intervals and formed by reinforcing fiber in a thermoplastic polymer resin. Each longitudinal fiber-reinforced polymer strip has at lease one first contact point crossed with the lateral fiber-reinforced polymer strip on the upper surface and at least one second contact point crossed with the lateral fiber-reinforced polymer strips on the lower surface. The contact points are fixed by welding the longitudinal and lateral fiber-reinforced polymer strips. The geogrid is excellent in installation capacity, frictional feature and shape stabilisation and shows high tensile strength and low tensile strain and low creep deformation.

Owner:SAMSANG CORP

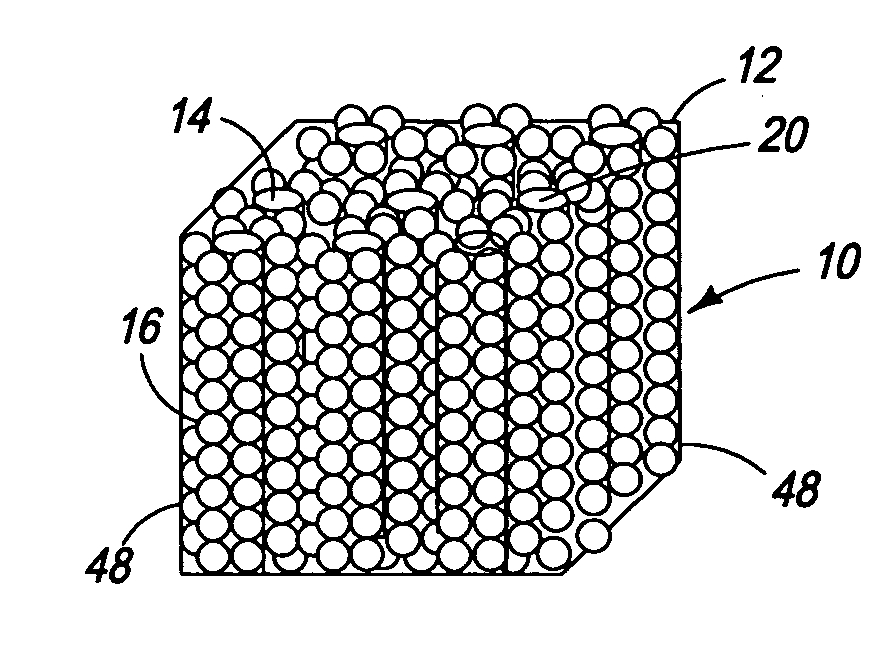

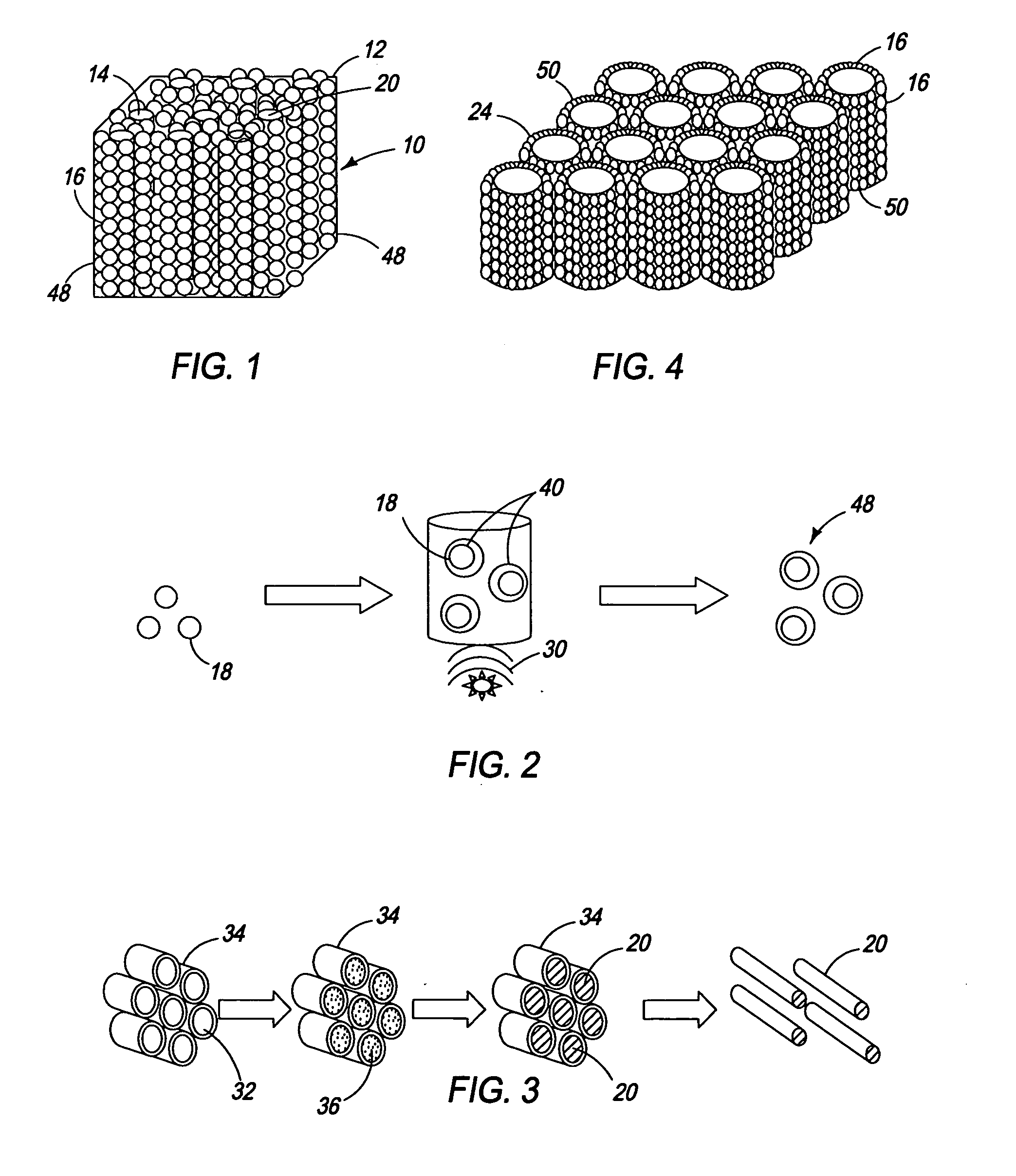

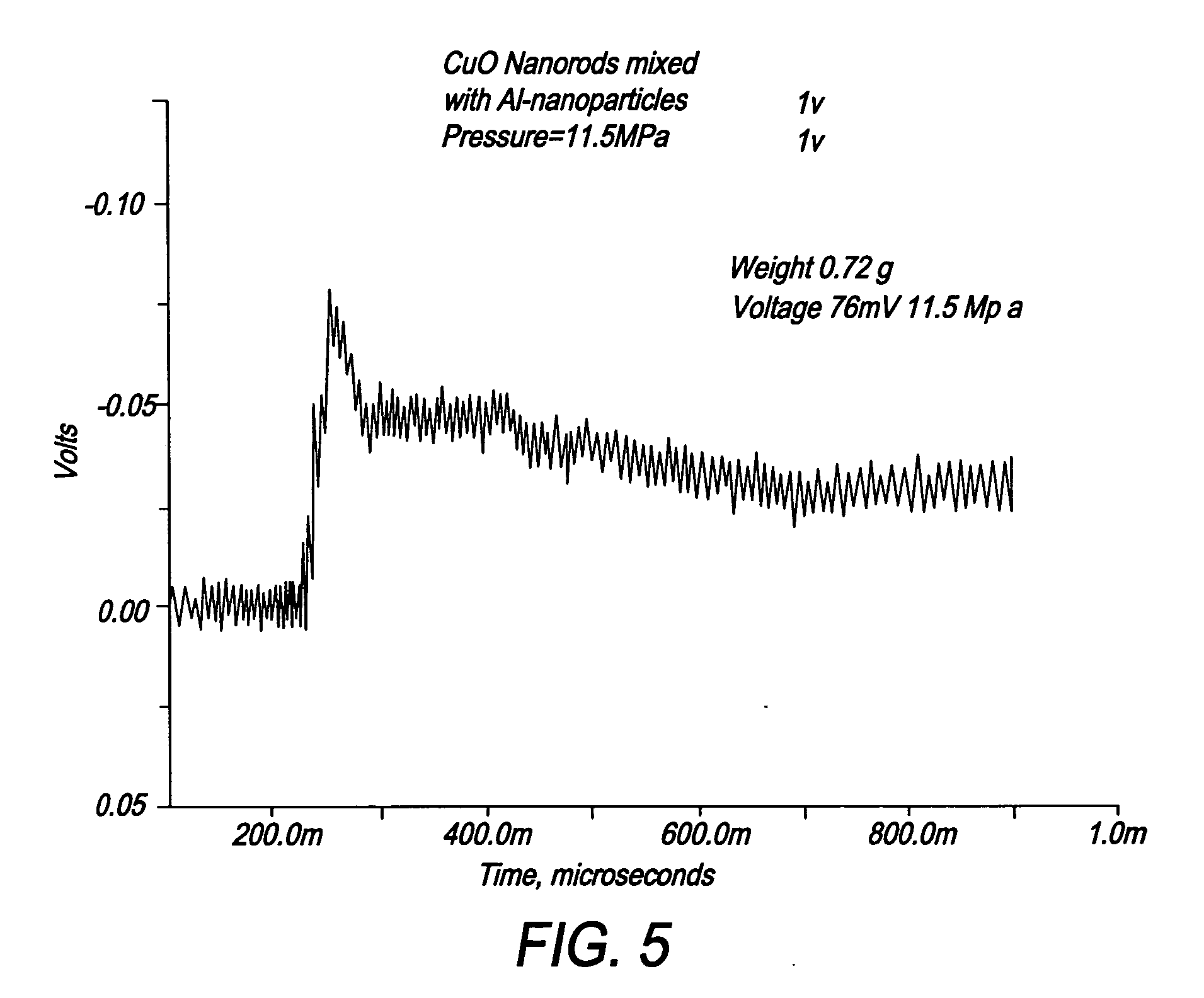

Ordered nanoenergetic composites and synthesis method

A structured, self-assembled nanoenergetic material is disclosed that includes a nanostructure comprising at least one of the group consisting of a fuel and an oxidizer and a plurality of substantially spherical nanoparticles comprising at least the other of the group consisting of a fuel and an oxidizer. The spherical particles are arranged around the exterior surface area of said nanorod. This structured particle assures that the oxidizer and the fuel have a high interfacial surface area between them. Preferably, the nanostructure is at least one of a nanorod, nanowire and a nanowell, and the second shaped nanoparticle is a nanosphere.

Owner:UNIVERSITY OF MISSOURI

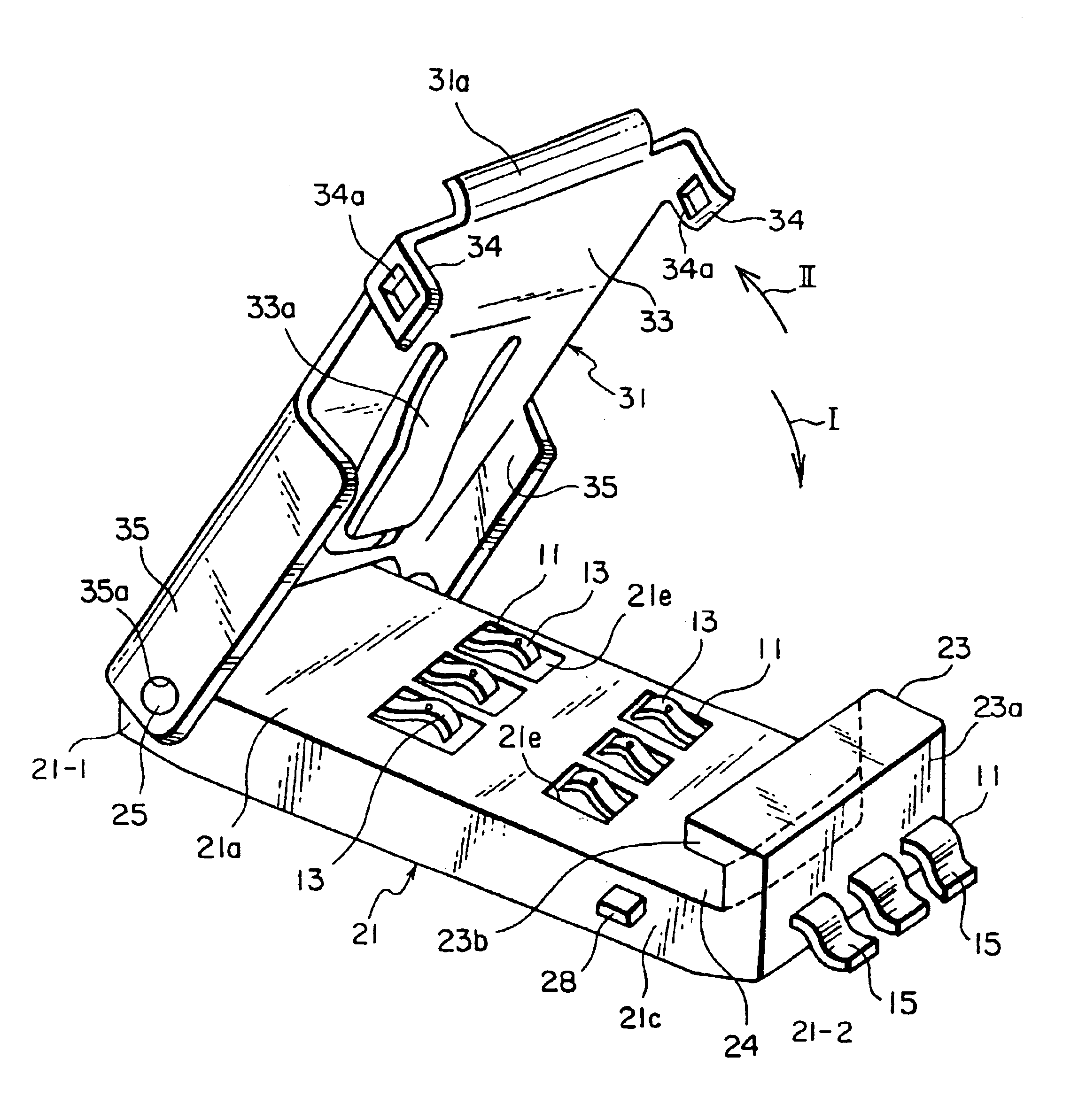

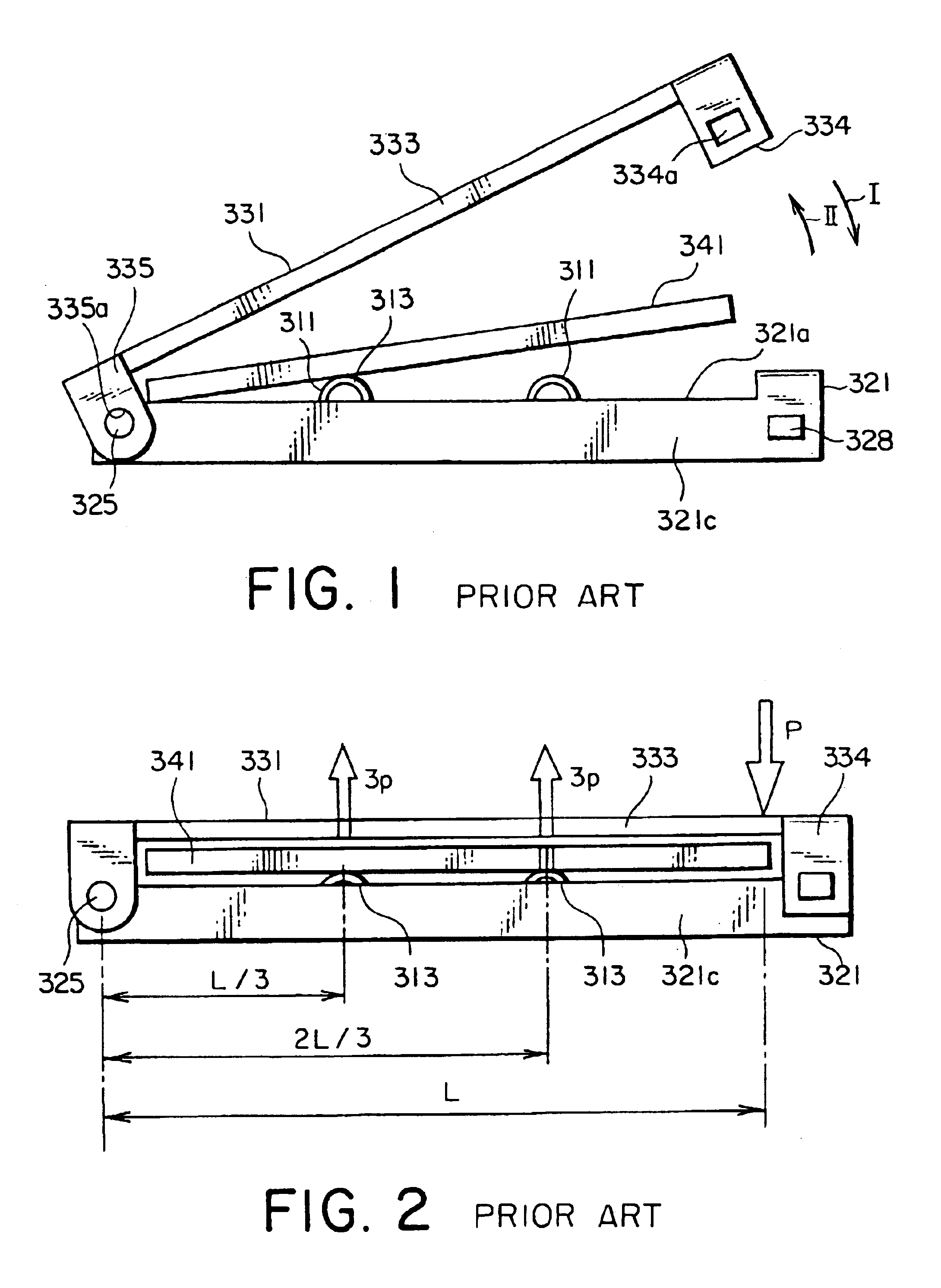

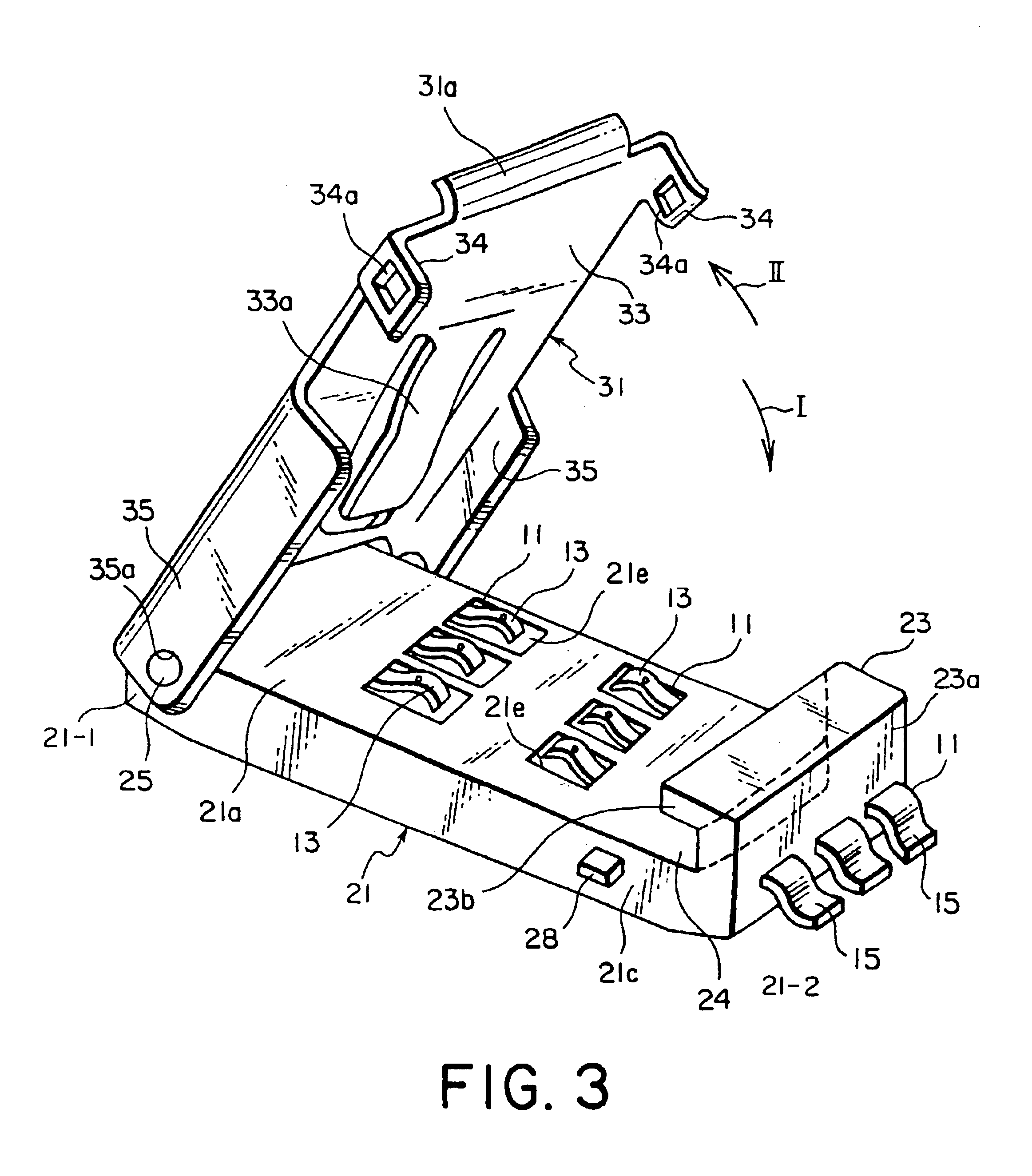

Card connector reduced in operating force

InactiveUS6890203B2Reduce operating forceReduce forceEngagement/disengagement of coupling partsConveying record carriersEngineeringMechanical engineering

Owner:JAPAN AVIATION ELECTRONICS IND LTD

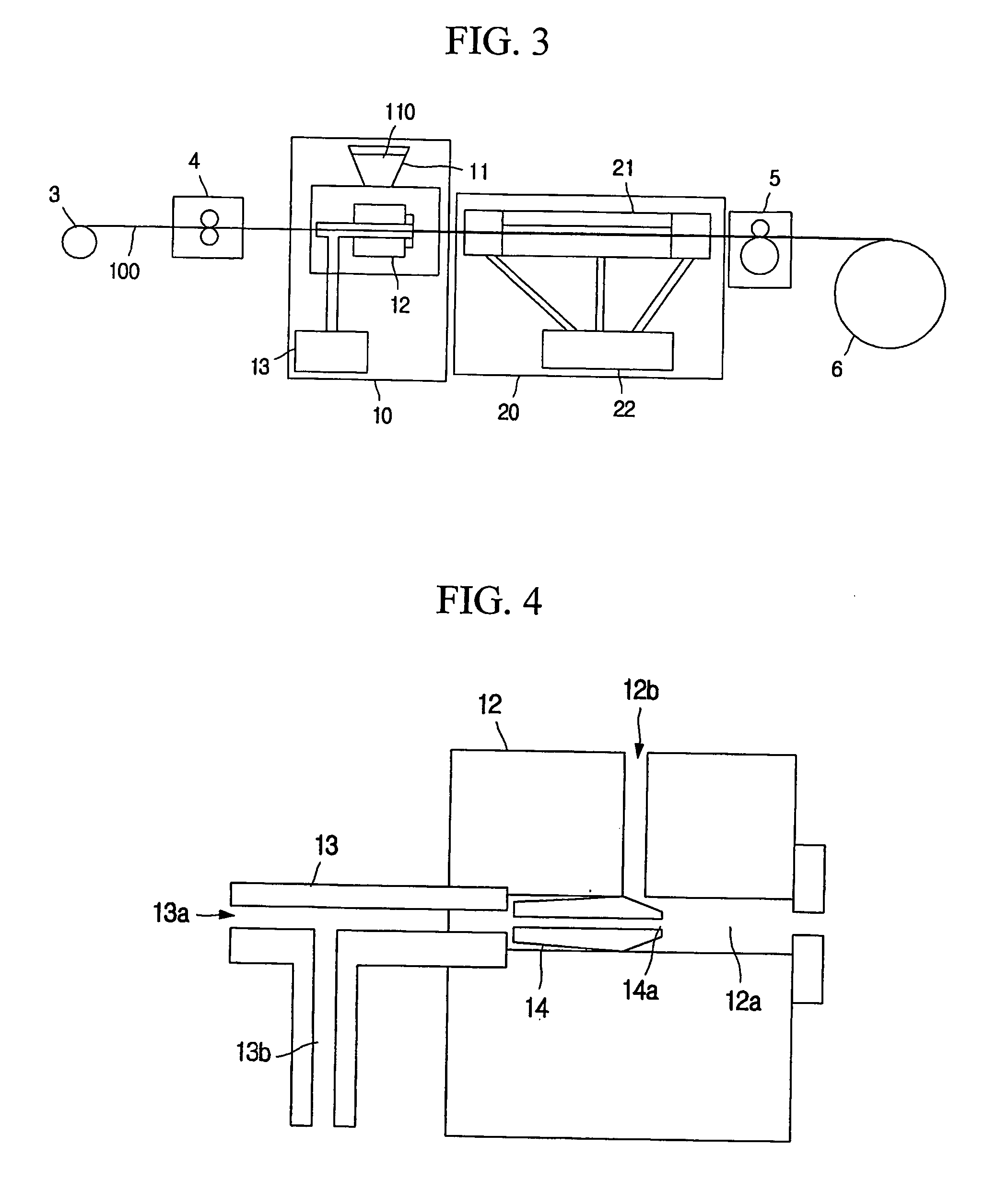

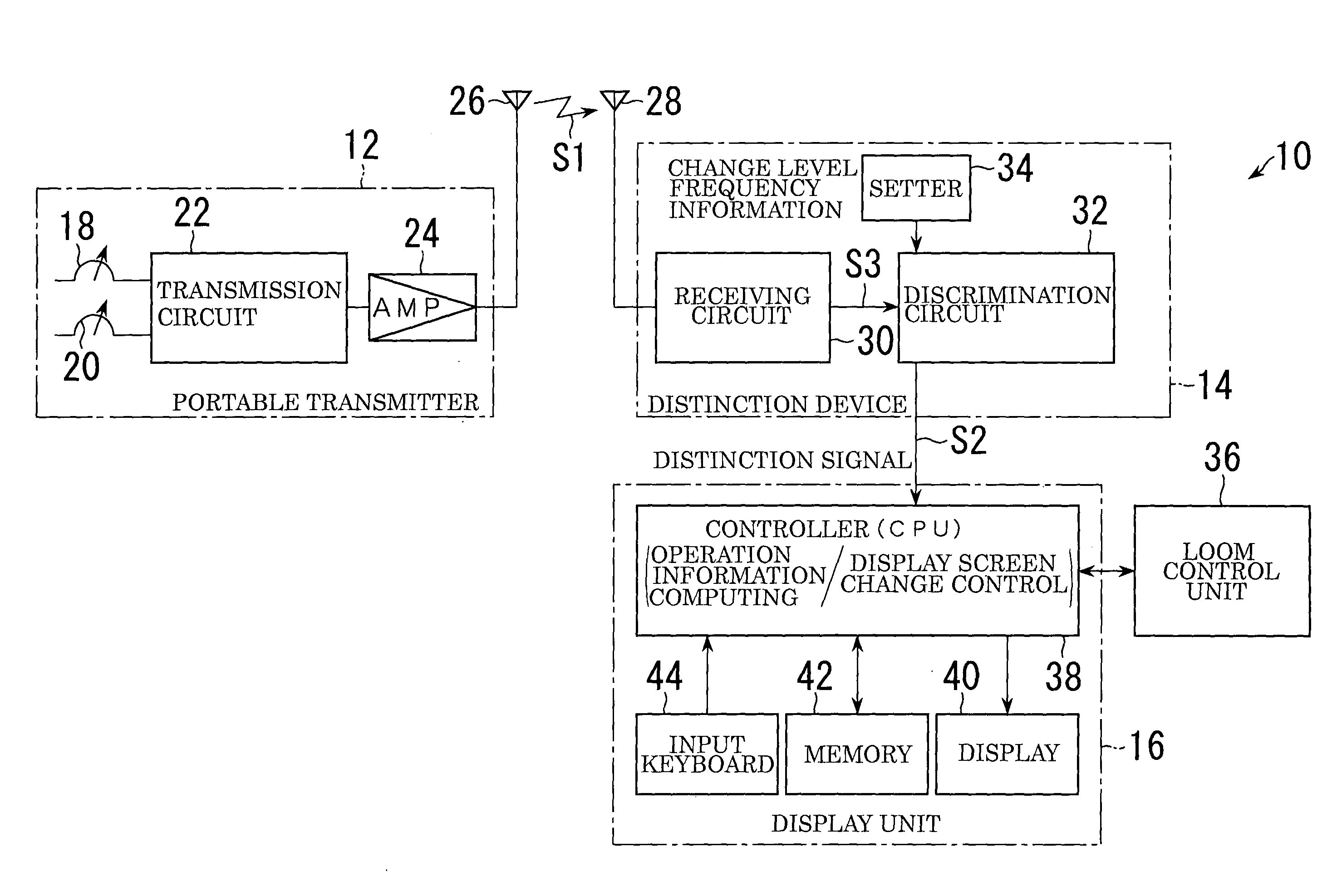

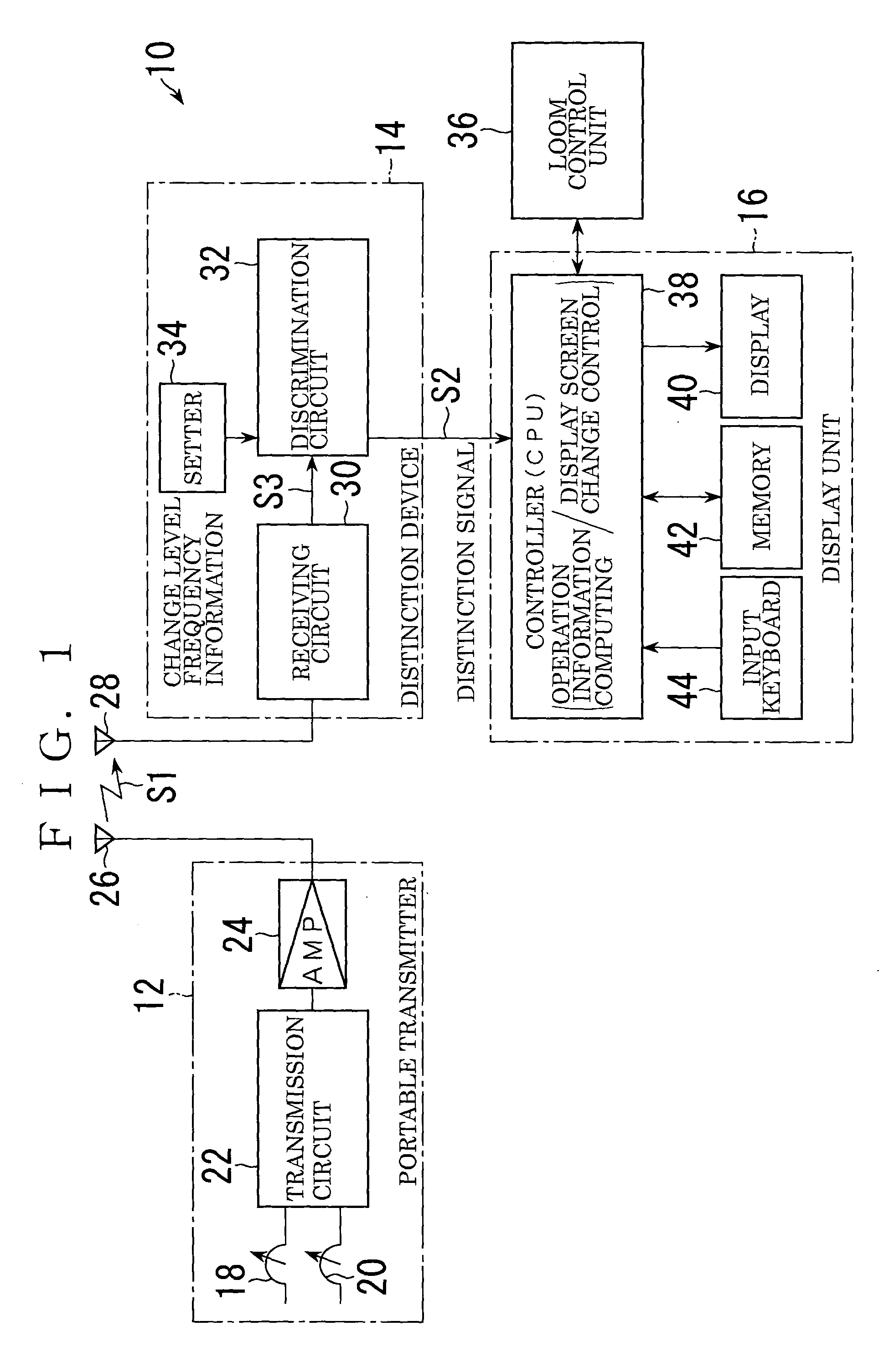

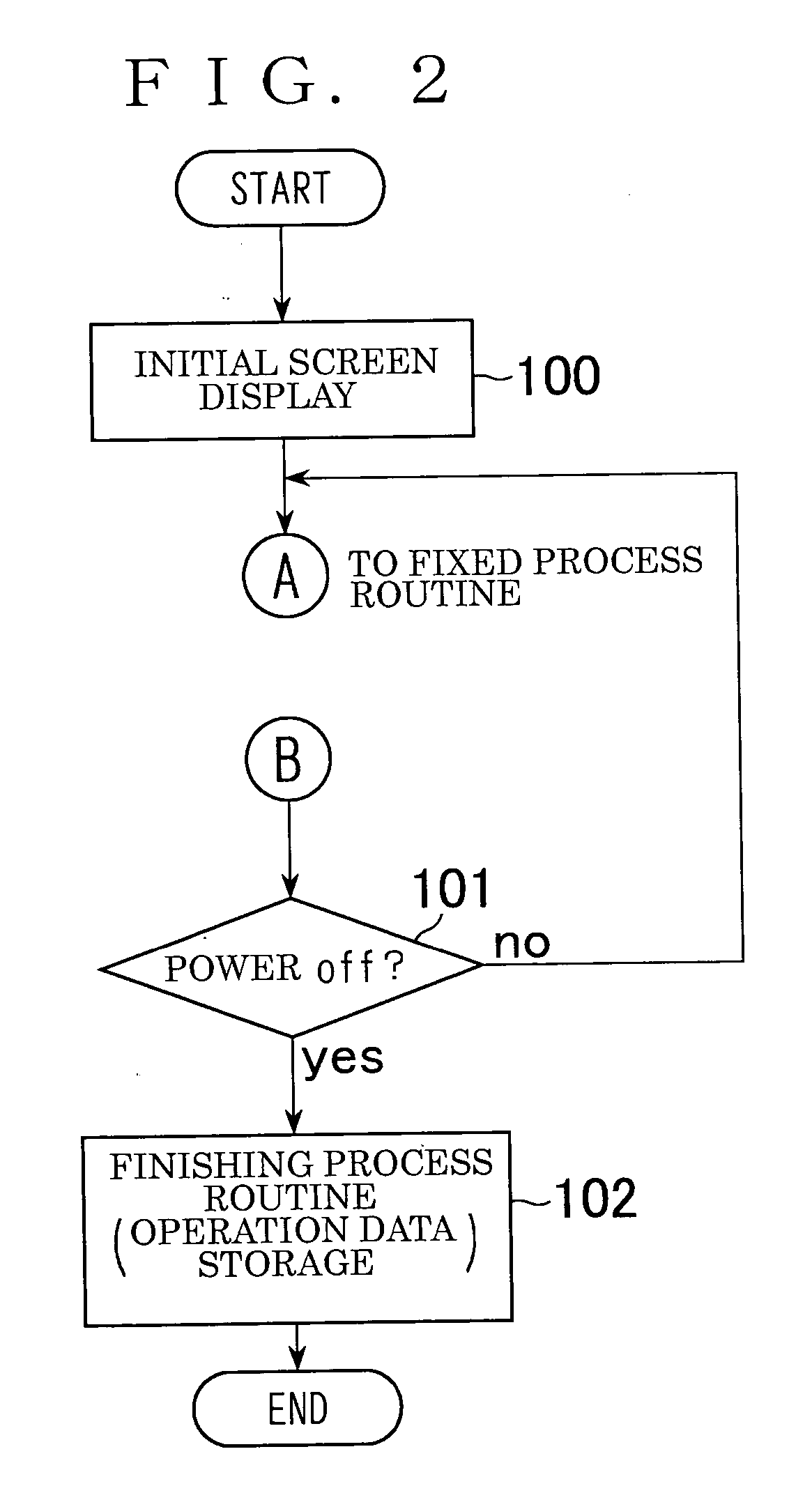

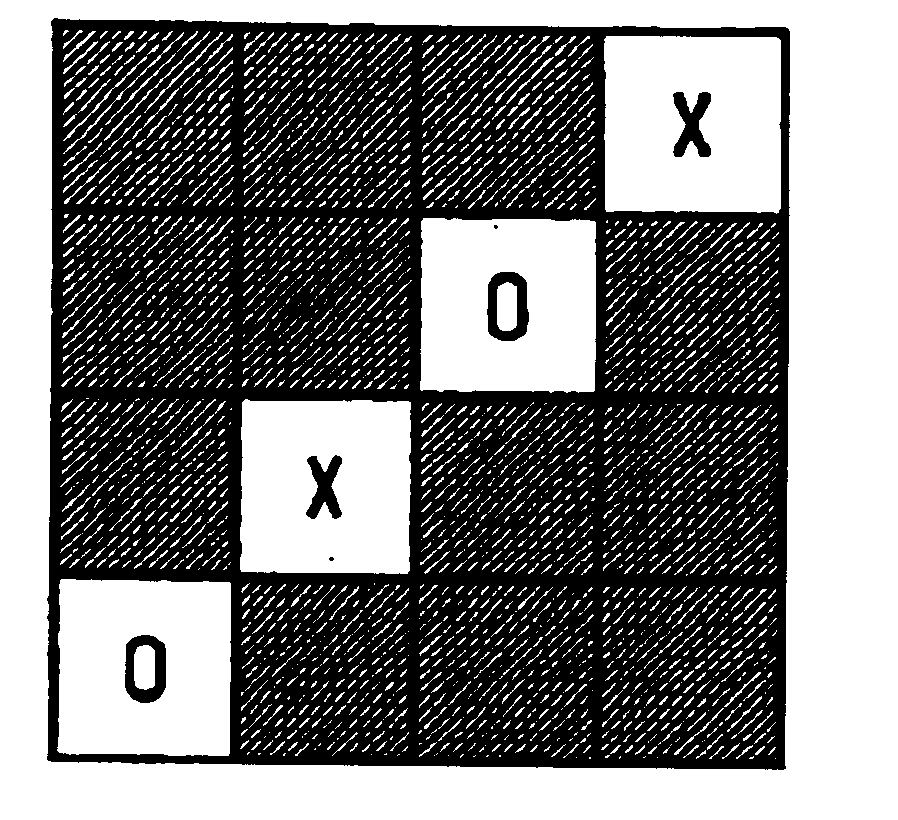

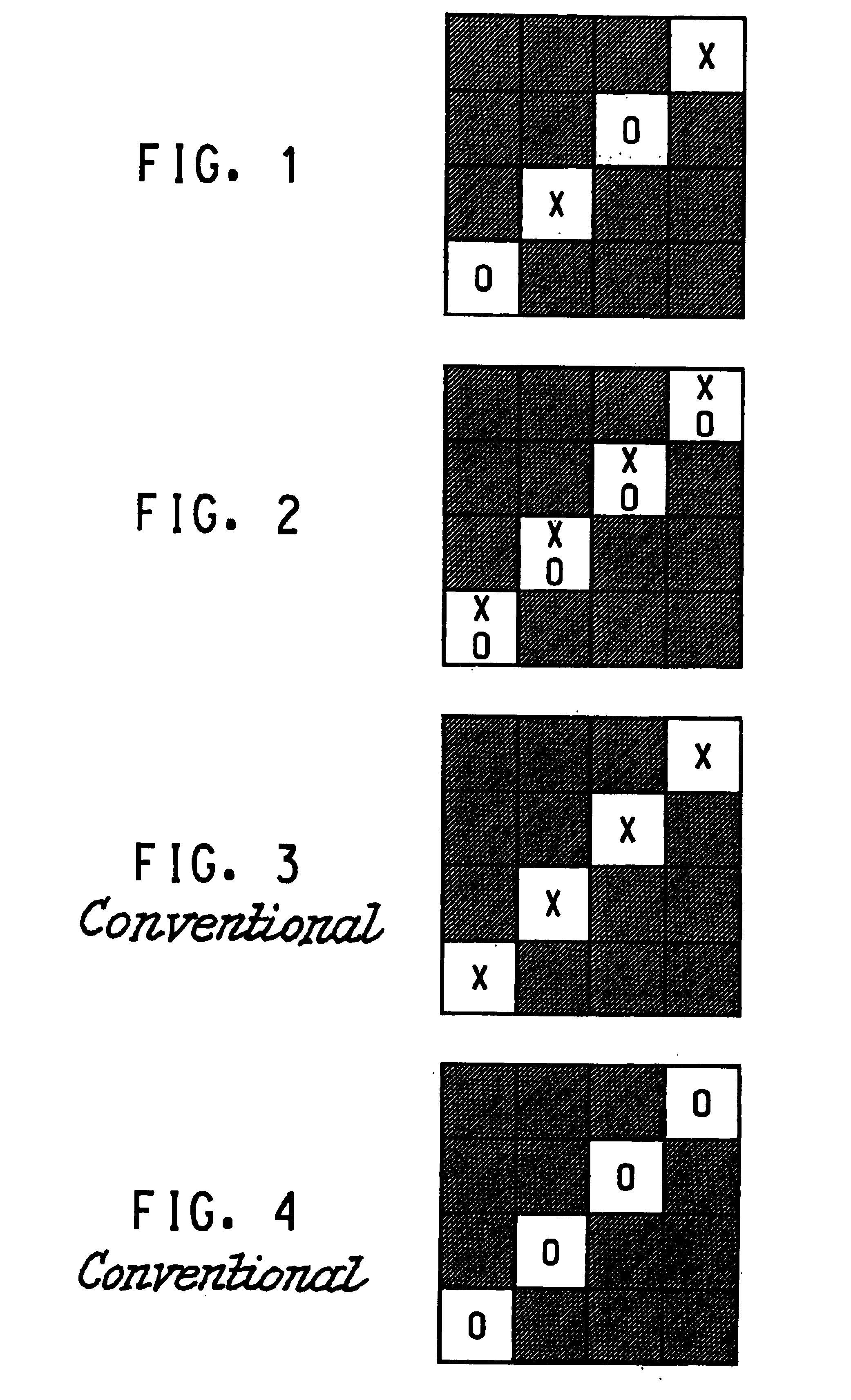

Information display apparatus of a loom

The information display apparatus is characterized by storing at least plural pieces of loom information, by comprising: data control means capable of outputting the stored loom information; display means for displaying in a screen the loom information outputted from data control means; and distinction means for distinguishing a kind of a person engaged in weaving and outputting a distinction result in the data control means, and by presetting in the data control means the item for display corresponding to the distinction result, thereby outputting the loom information relative to the item for display corresponding to the distinction result from the data control means to the display means.

Owner:TSUDAKOMA KOGYO KK

Weft-stretch woven fabric with high recovery

A woven fabric comprising warp fibers and a weft is provided. The weft may be of pick-and-pick or co-insertion constructions. The weft includes a spun staple yarn and a polyester bicomponent filament. The polyester bicomponent filament includes poly(ethylene terephthalate) and poly(trimethylene terephthalate), and has an after heat-set crimp contraction value of from about 10% to about 80%. A process for making such a fabric is also provided.

Owner:THE LYCRA CO LLC

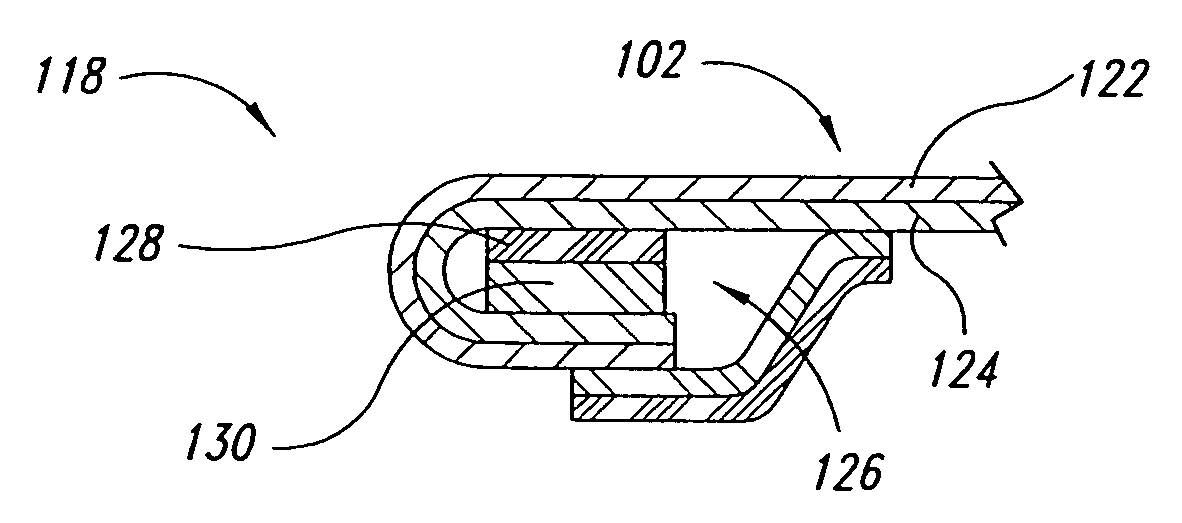

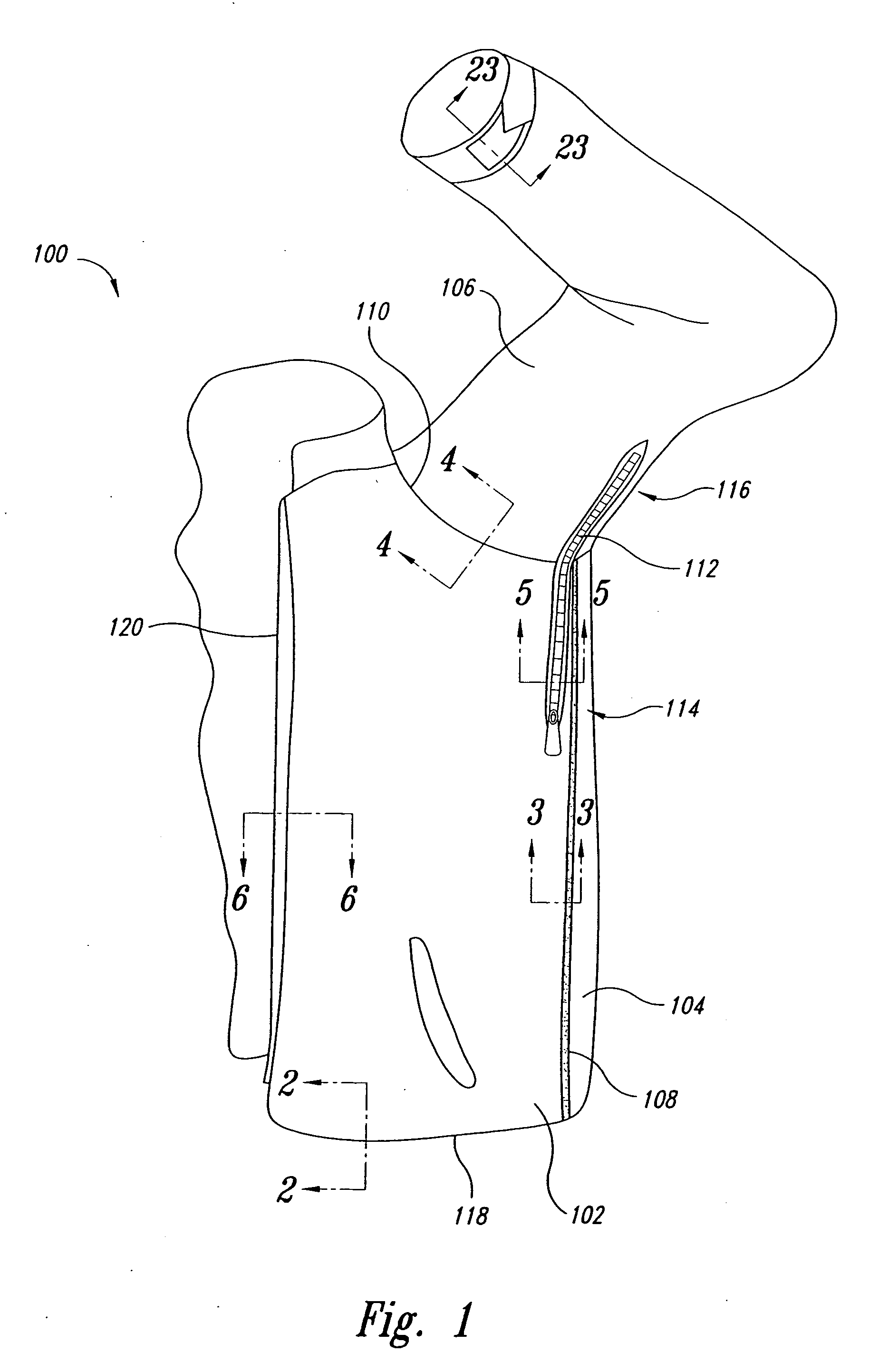

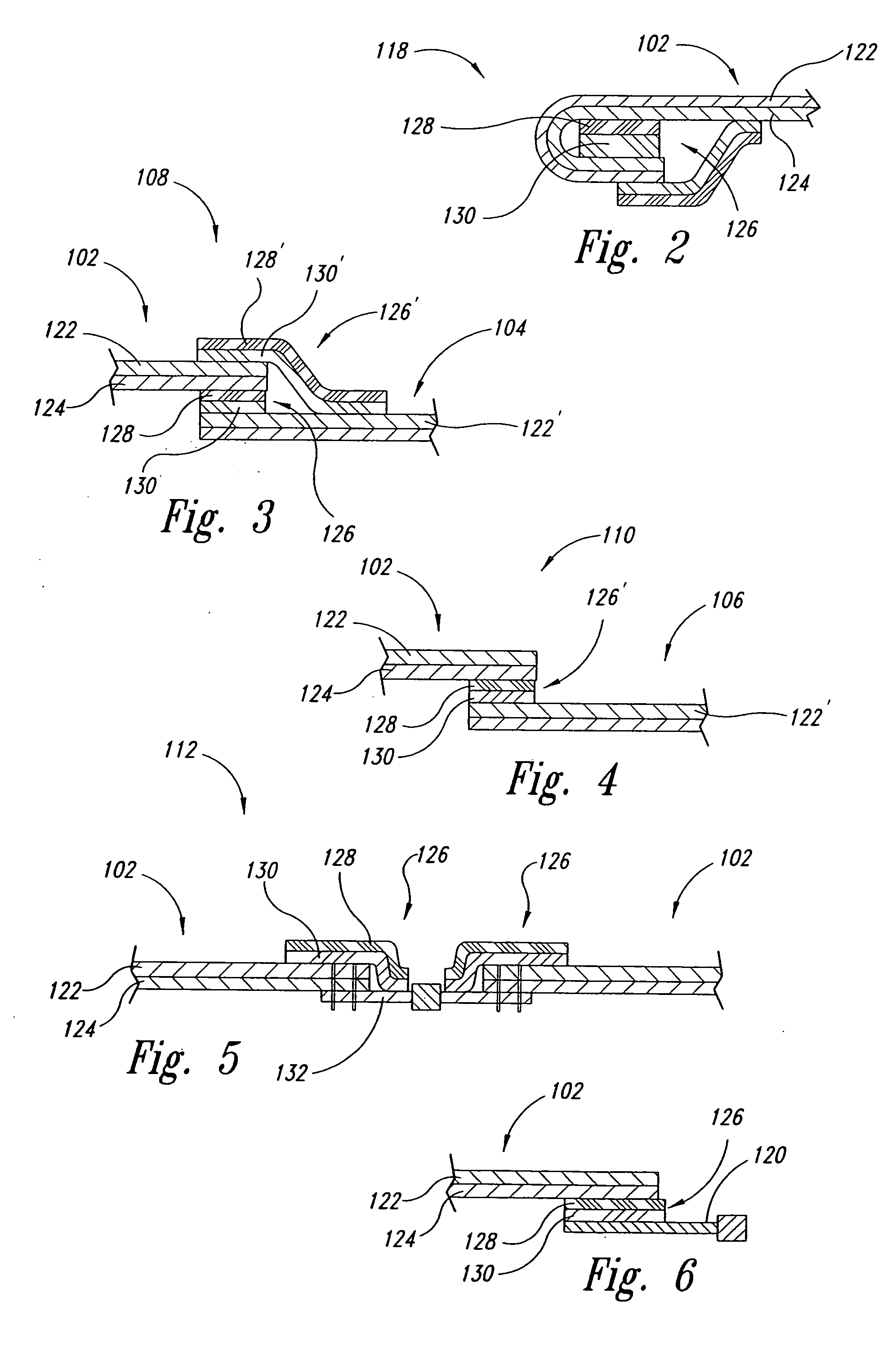

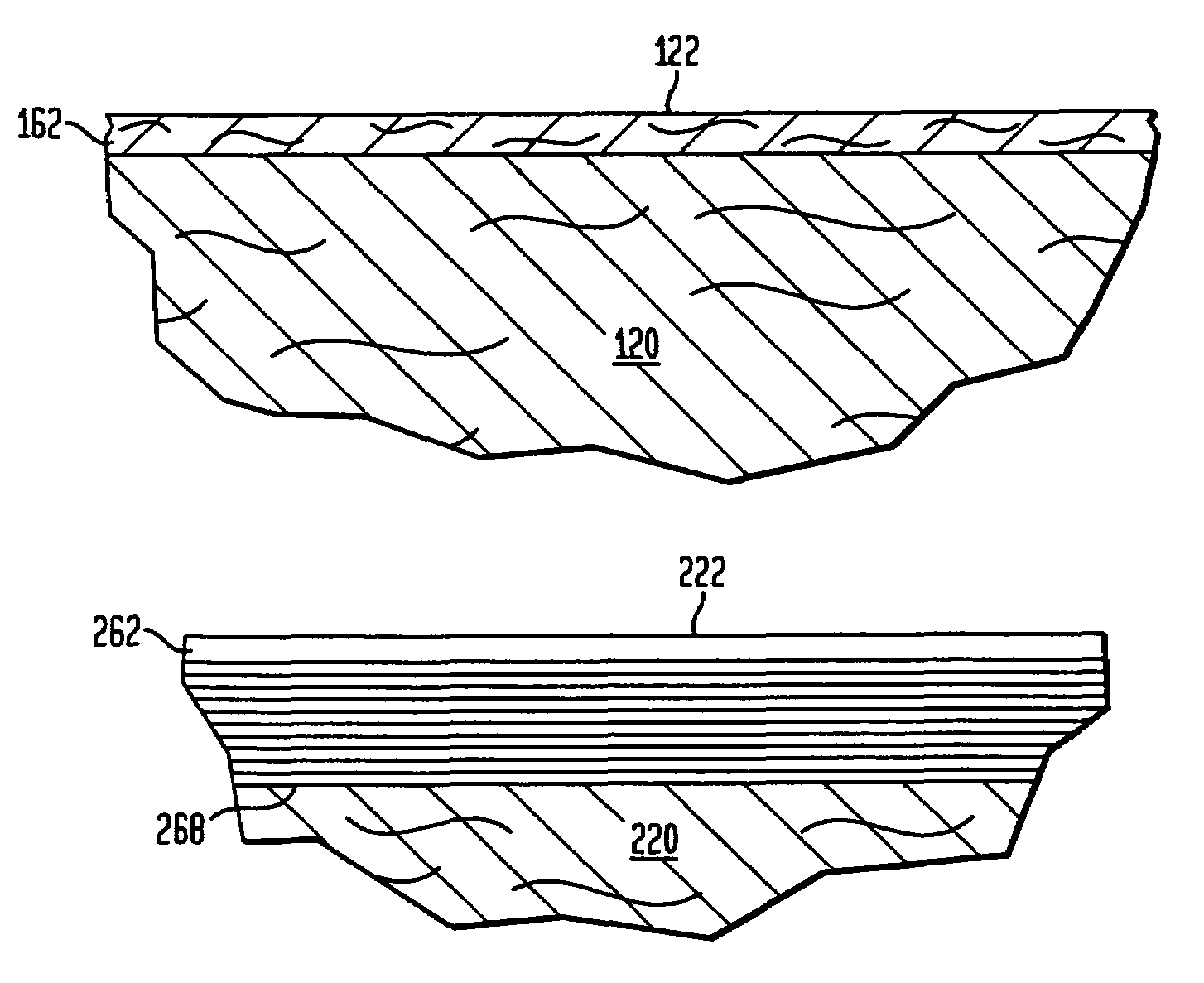

Hems, edges, patches and seams for durable, water repellant woven fabric, and methods for making the same

Edges, hems, patches and seams for woven fabric that has been treated for water repellency, and methods for making the same, are shown and described. In one particular embodiment of the invention, for example, a lapped seam between two pieces of water repellent fabric has an outer material at least partially overlapping an inner material, and a laminate strip positioned between the overlapping portions of the materials. The outer and inner materials, which are both oriented in the same direction, have an exterior layer of woven fabric that has been treated with water repellent and / or stain repellent chemicals, and an inner layer comprising a polymer membrane, such as polyurethane. The laminate strip has a bottom portion in contact with the outer layer of the inner material. The bottom portion has a low melt point, high flow rate adhesive system of one or more layers that penetrates and surrounds the fibers in the woven fiber of the outer layer of the inner piece of material. The laminate strip also has a top layer in contact with the inner layer of the outer piece of material. The top layer of the laminate is a thin, elastic, highly abrasion resistant material with a strong bonding affinity for polyurethane. The layers of the laminate strip bond to the adjacent layers of the overlapped material to create a strong lap seam.

Owner:FOWLER

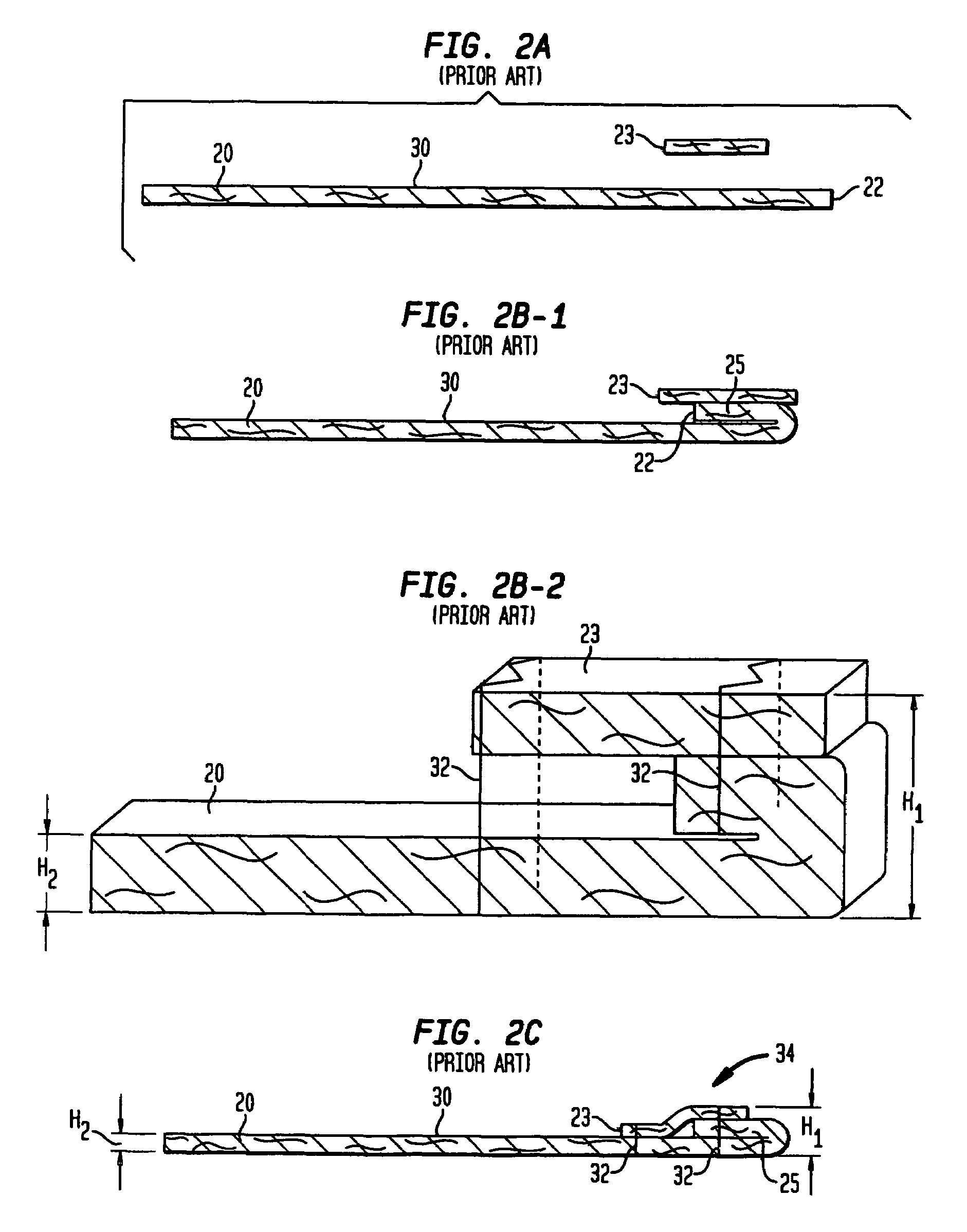

Undergarments having finished edges and methods therefor

ActiveUS7228809B2Improve material yieldDirect contact guaranteeLeather sewingWork-feeding meansFiberEngineering

A method of making a fabric having a finished edge includes providing a fabric having a plurality of fibers with free ends of the fibers at an edge of the fabric, disposing a curable polymer such as silicone over the edge of the fabric so that the curable polymer engages the free ends of the fibers at the edge of the fabric, and, after the disposing step, curing the polymer for finishing the edge of the fabric. The polymer binds the free ends of the fibers to prevent fraying of the fabric. The fabric is cut into a pattern piece for a garment before the step of disposing the curable polymer on the edge of the fabric.

Owner:CUPID FOUND

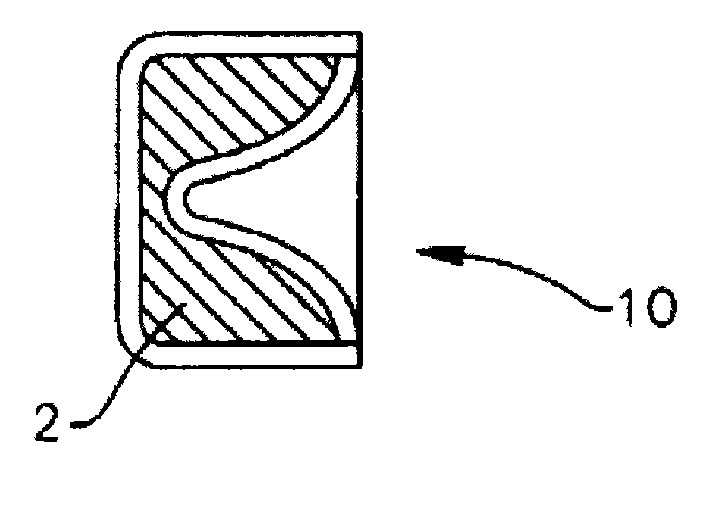

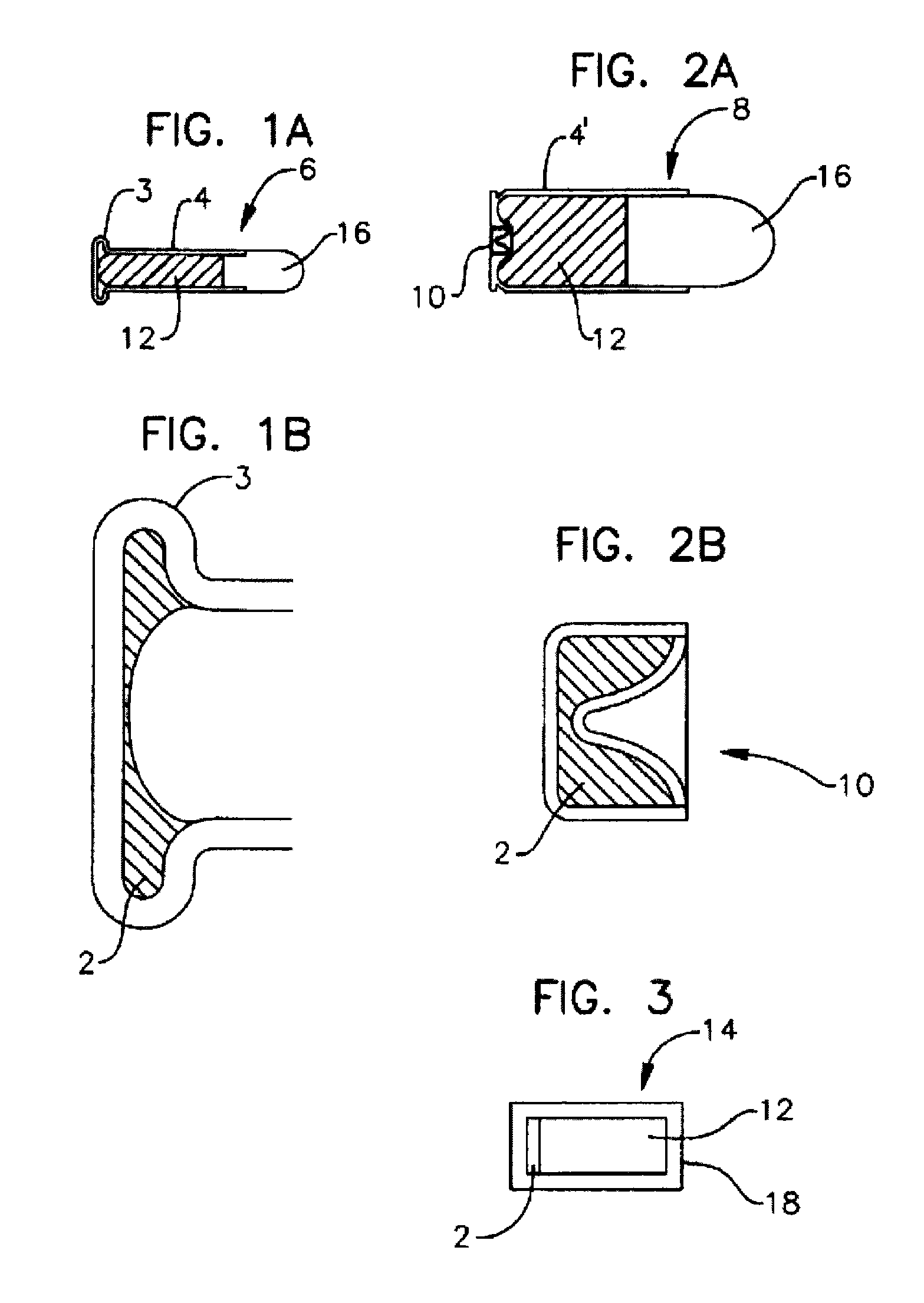

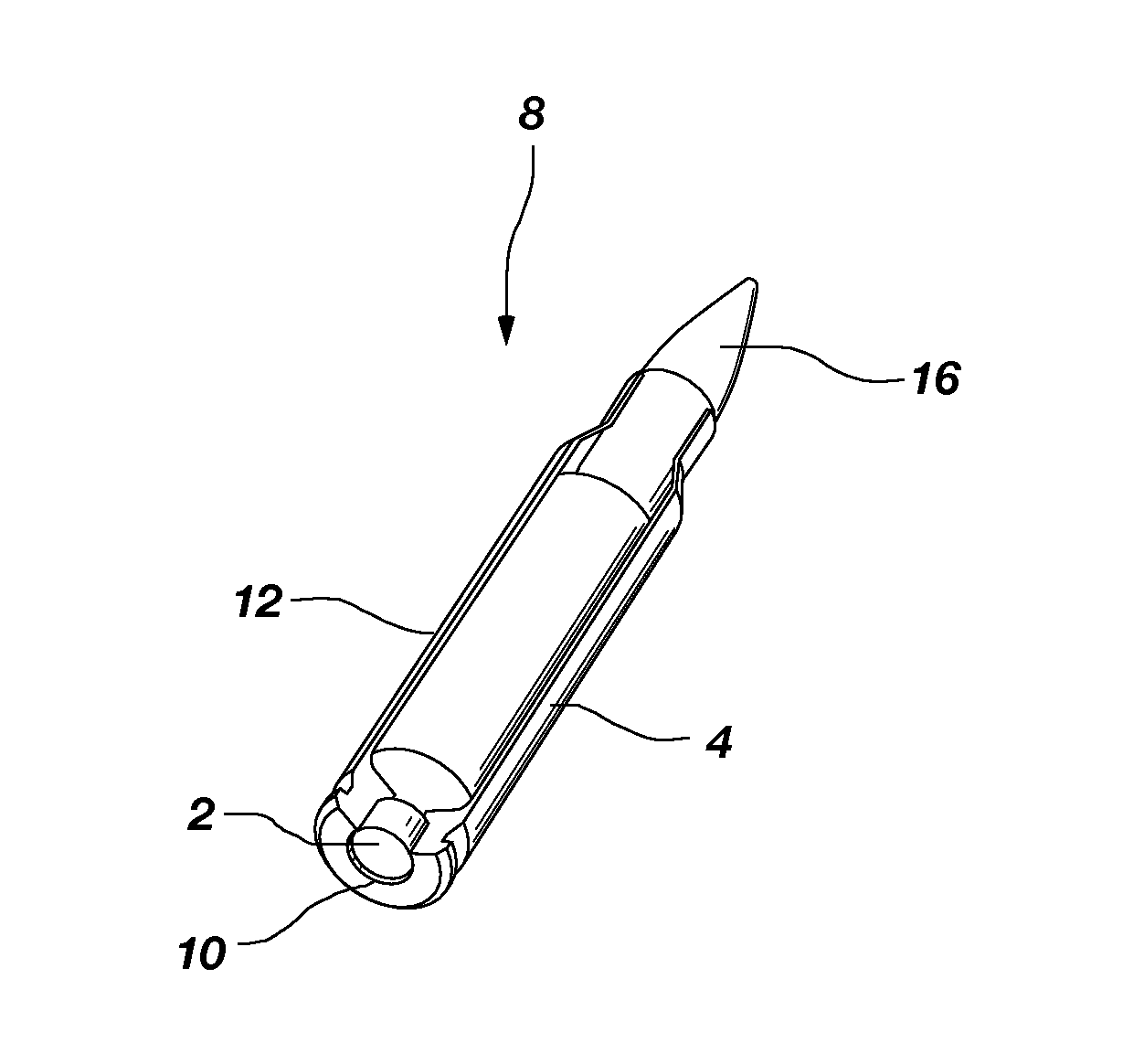

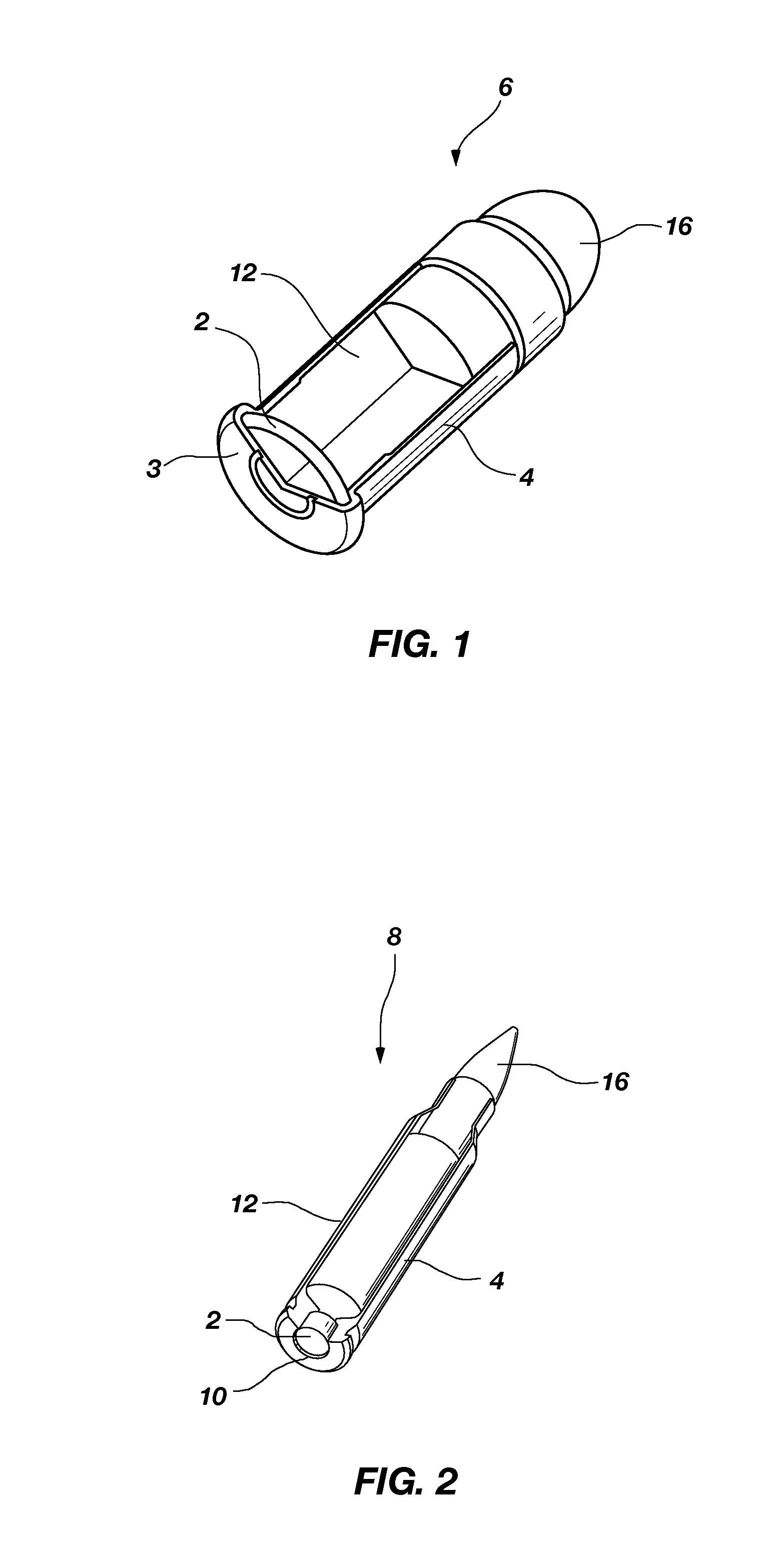

Wet processing and loading of percussion primers based on metastable nanoenergetic composites

InactiveUS20060113014A1Reduce degradationExtended shelf lifeLoomsWoven fabricsLiquid waterCompound (substance)

A method is disclosed for preparing metastable nanoenergetic composites (MNC) and for wet loading those MNCs into percussion primer cups. The method involves dispersing nanosize reactants in an inert liquid or, alternatively, making a nanosize reactant surface modification for improvement of reactant's chemical inertness towards water, followed by application of additives supporting a solid reactant particle dispersion in water or water solution prior to mixing. After mixing of the reactants, one maintains the presence of liquid water together within an energetic material in order to enhance safety during pre-loading of the primer mixture into the primer cups and during the final drying.

Owner:INNOVATIVE MATERIALS & PROCESSES LLC +1

Pyrotechnical, aerosol-forming composition for extinguishing fires and process for its preparation

The invention relates to fire-extinguishing technology, in particular a process for producing aerosol-forming pyrotechnical compositions for extinguishing fires. The process includes the steps of mixing powdery combustible binder, oxidizing agent and dicyandiamide. The combustible binder is a polycondensate of formaldehyde and a organic compound, of a fraction from 70 to 120 mum. The oxidizing agent is an alkali nitrate of a fraction from 15 to 25 mum. The dicyandiamide is a fraction from 40 to 80 mum. Subsequently, there is added to the above, respective fractions of the combustible binder of 10 to 25 mum of the oxidizing agent of 1 to 7 mum and of the dicyandiamide of 7 to 15 mum. The weight ratios of the fractions of combustible binder, oxidizing agent and dicyandiamide are 70:30, 25:75 and 80:20. The resulting mixture is molded while the content of the components is 9 to 20 weight percent dicyandiamide, 6 to 14 weight percent combustible binder, and the balance weight percent oxidizing agent.

Owner:R AMTECH INT

Woven fabric that looks and performs like a knitted fabric and method of making thereof

A fabric with wefts that include hard yarns and elastomeric yarns in a predetermined arrangement such that at least one hard yarn is alternately arranged with at least one elastomeric yarn, the elastomeric yarns having a greater shrinkage ratio than that of the hard yarns; the hard yarns form under portions and over portions with respect to warps, said under portions being formed when said hard yarns pass along the back side of the warps and defining loop portions, and said over portions being formed when the hard yarns pass along the front side of the warps and define connection portions, wherein for each hard yarn, the number of warps passed by the loop portion is at least 6, and the elastomeric yarns form under portions and over portions with respect to said warps in a weave that is tighter than the weave of the hard yarns.

Owner:SANKO TEKSTIL ISLETMELERI SANAYI & TICARET A S

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com