Patents

Literature

142results about How to "Improve material yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

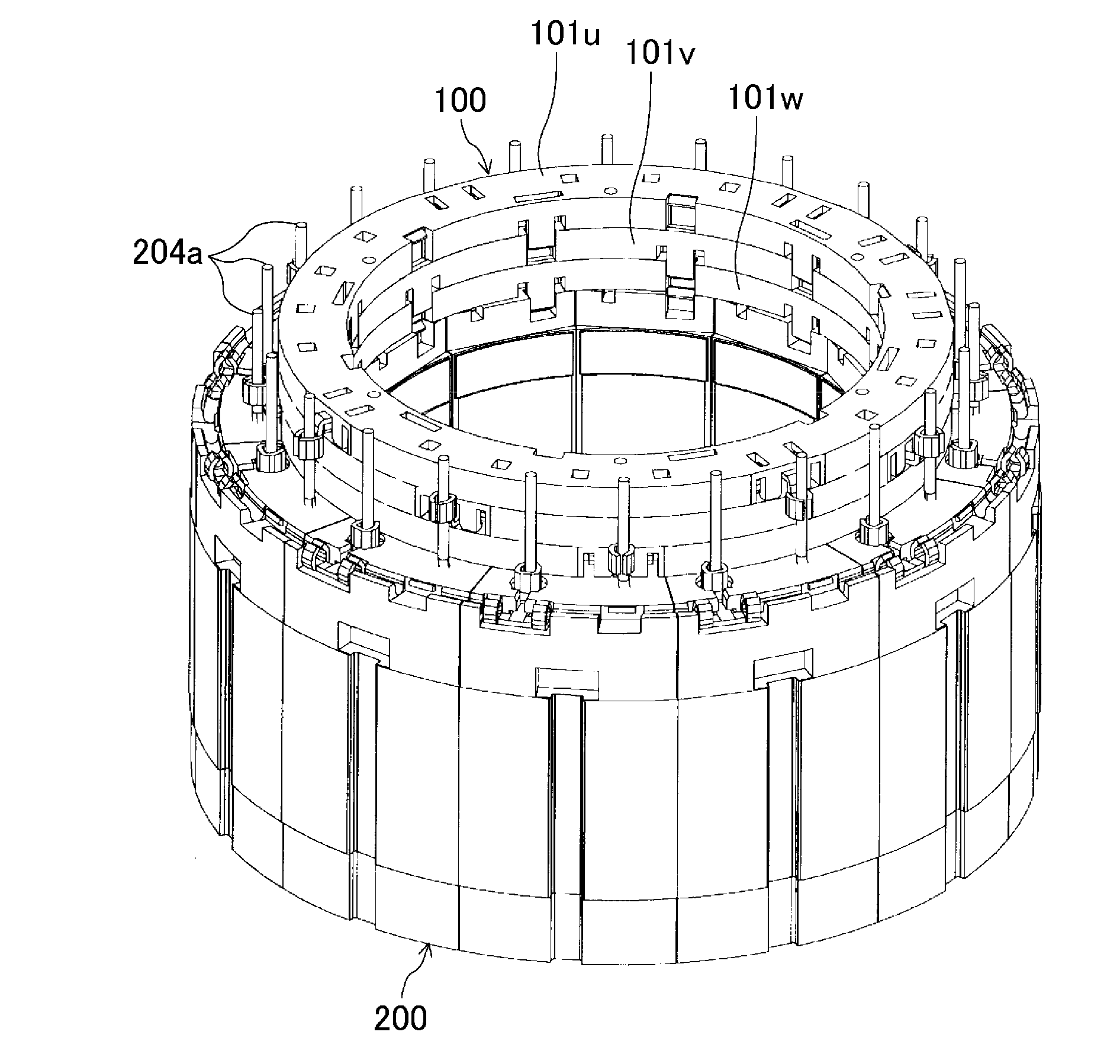

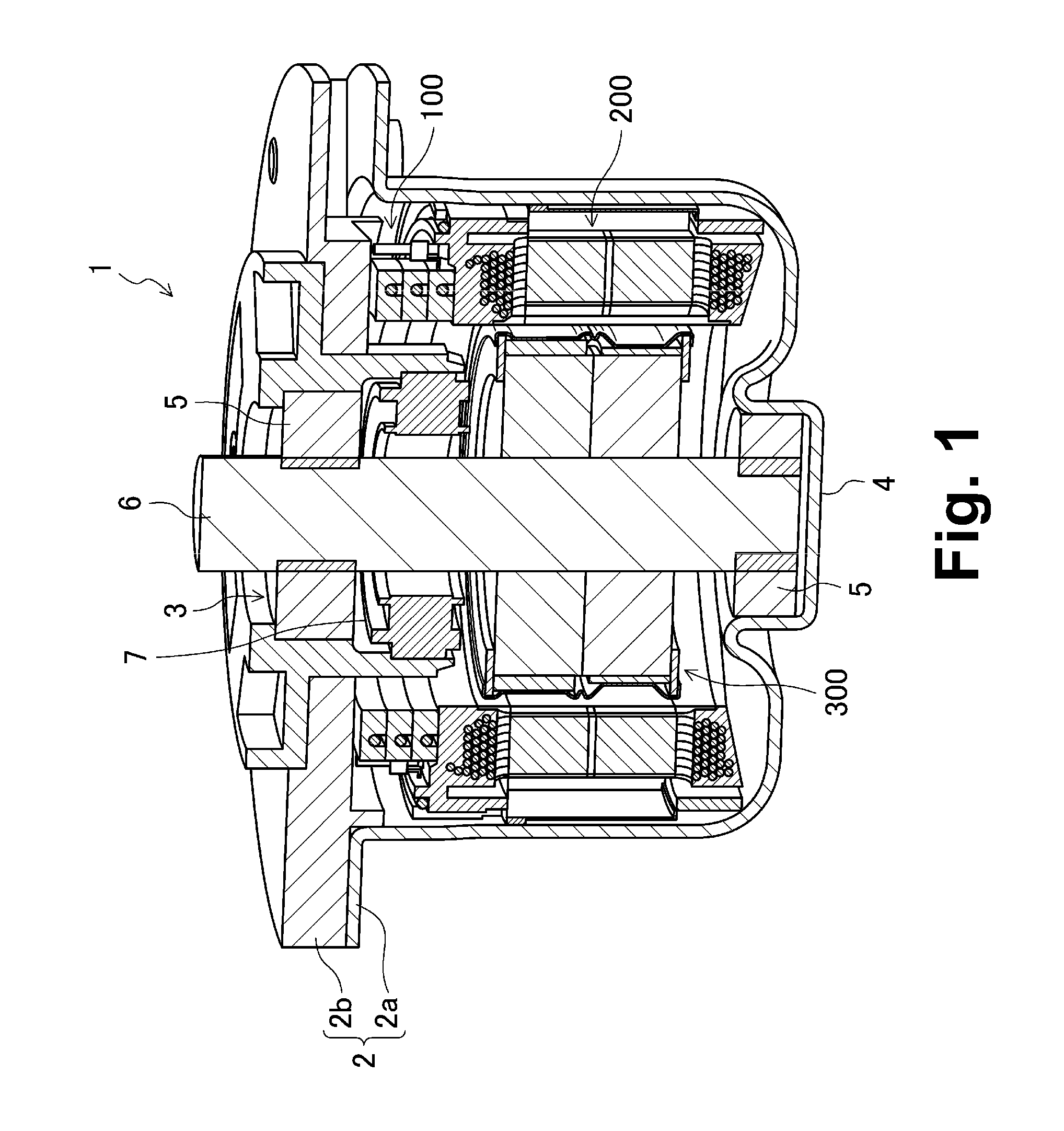

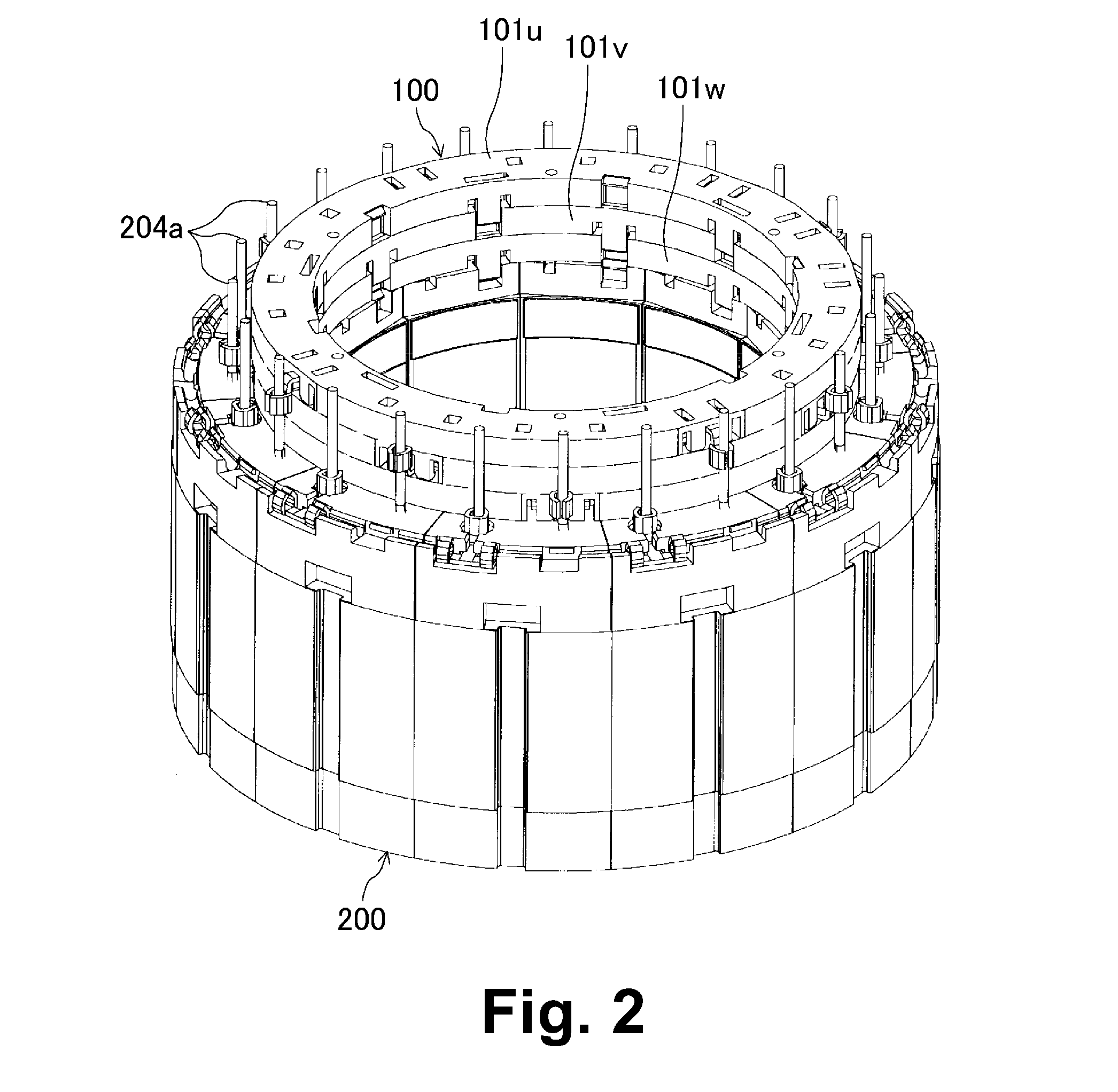

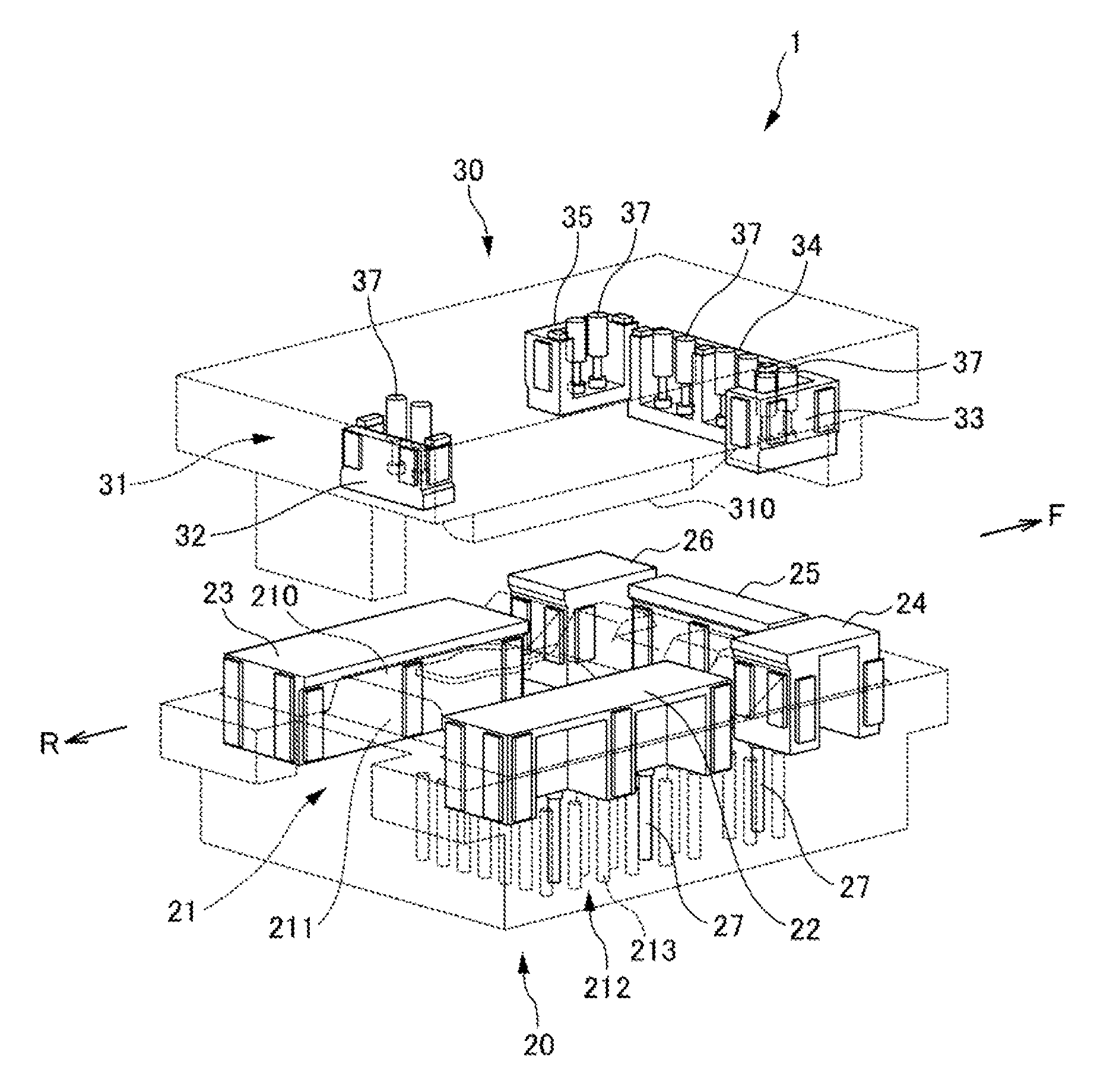

Busbar unit and motor

ActiveUS20120319512A1Improve material yieldImprove workabilityMagnetic circuitManufacturing dynamo-electric machinesBusbarElectric machine

A busbar unit is arranged on an axial end portion of a stator and electrically connected with a plurality of coil wire terminals arranged to project in an axial direction above the axial end portion of the stator. The busbar unit includes a plurality of busbars each including a body portion defined by an electrically conductive wire having an annular or “C” shape, the body portion being arranged around an axis of the stator; a holder member arranged on the axial end portion of the stator to hold the busbars; and a plurality of terminal members each including a busbar connection portion connected with the body portion of one of the busbars, and a coil connection portion connected with one of the coil wire terminals.

Owner:NIDEC CORP

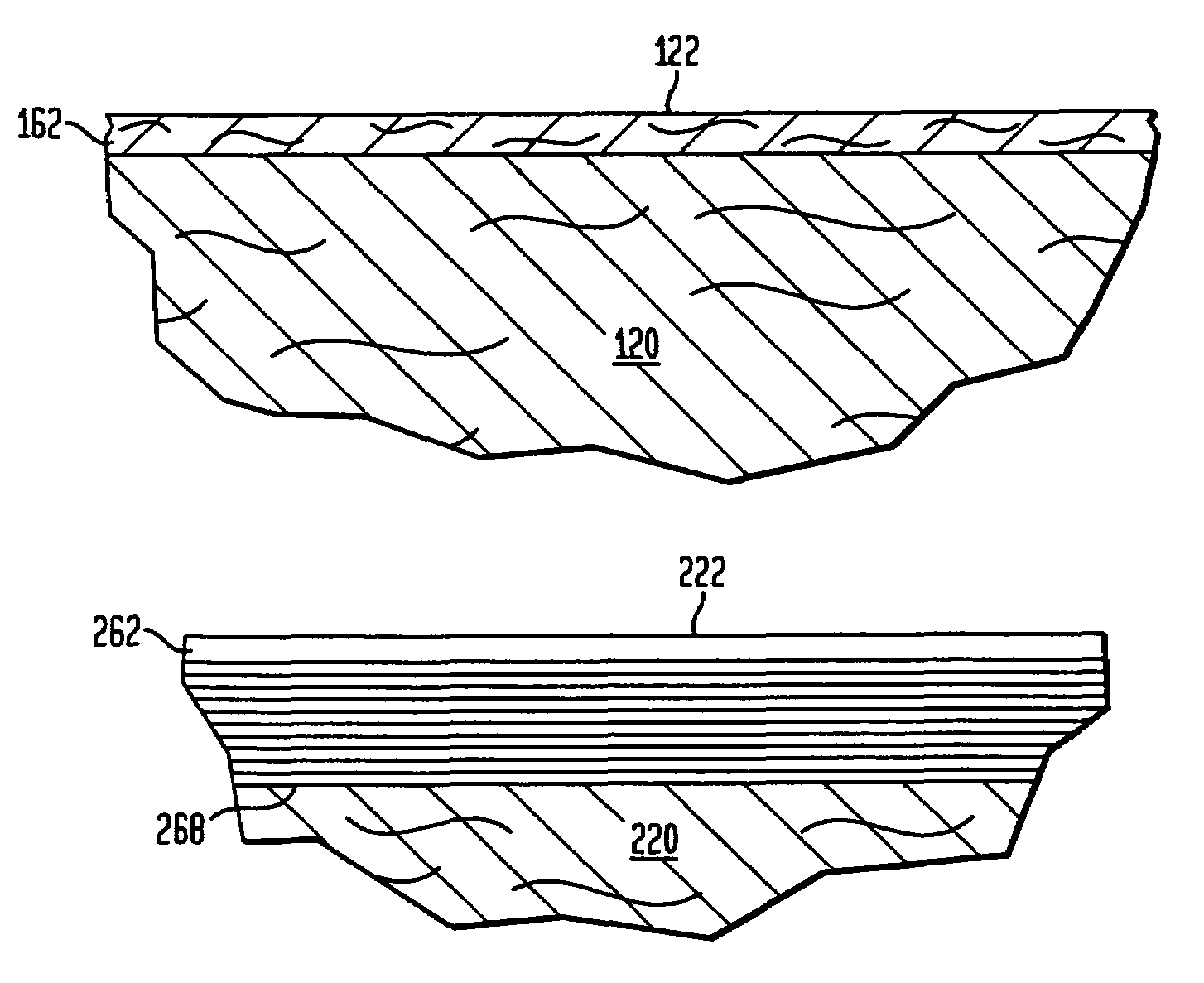

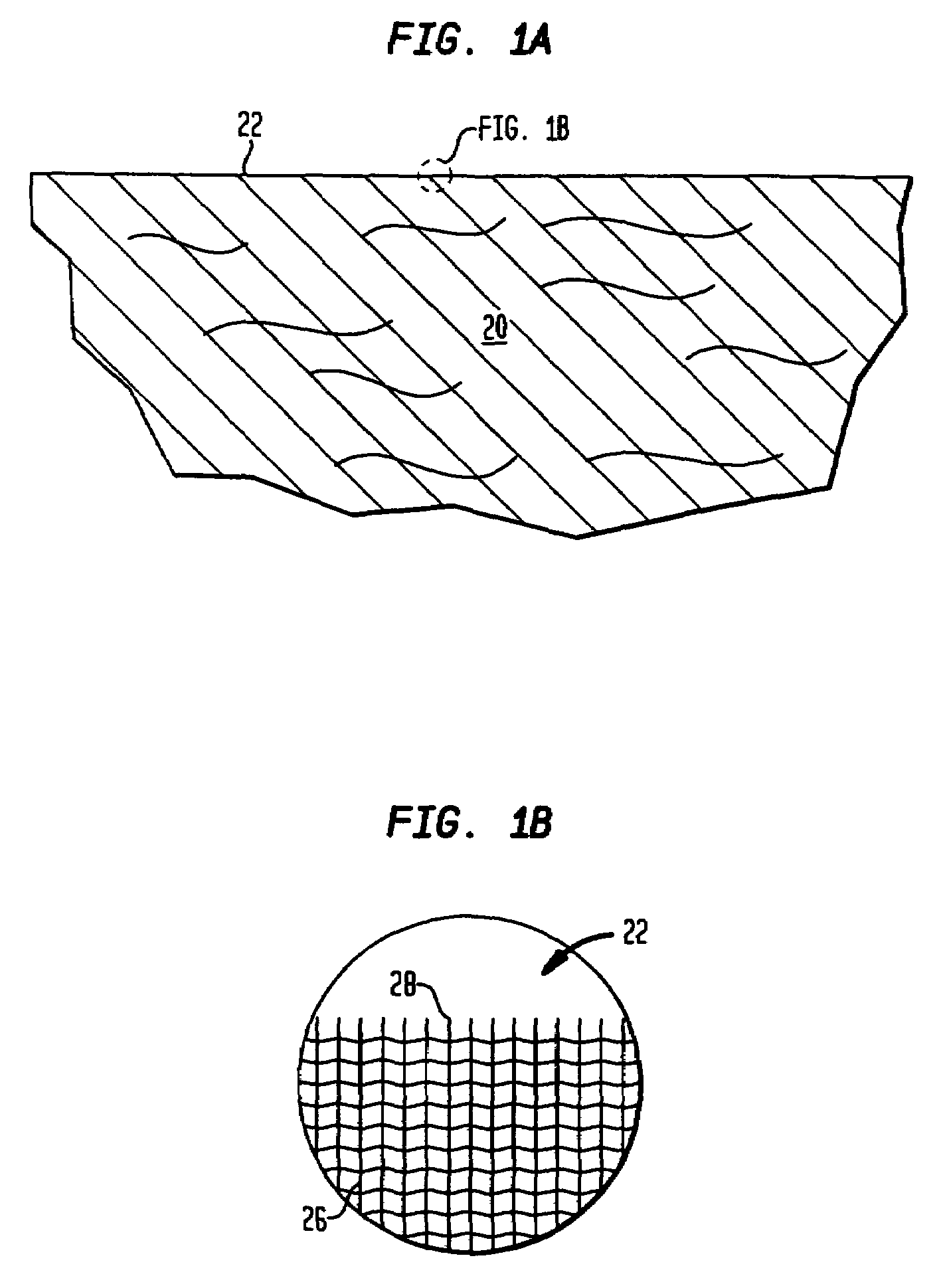

Undergarments having finished edges and methods therefor

ActiveUS7228809B2Improve material yieldDirect contact guaranteeLeather sewingWork-feeding meansFiberEngineering

A method of making a fabric having a finished edge includes providing a fabric having a plurality of fibers with free ends of the fibers at an edge of the fabric, disposing a curable polymer such as silicone over the edge of the fabric so that the curable polymer engages the free ends of the fibers at the edge of the fabric, and, after the disposing step, curing the polymer for finishing the edge of the fabric. The polymer binds the free ends of the fibers to prevent fraying of the fabric. The fabric is cut into a pattern piece for a garment before the step of disposing the curable polymer on the edge of the fabric.

Owner:CUPID FOUND

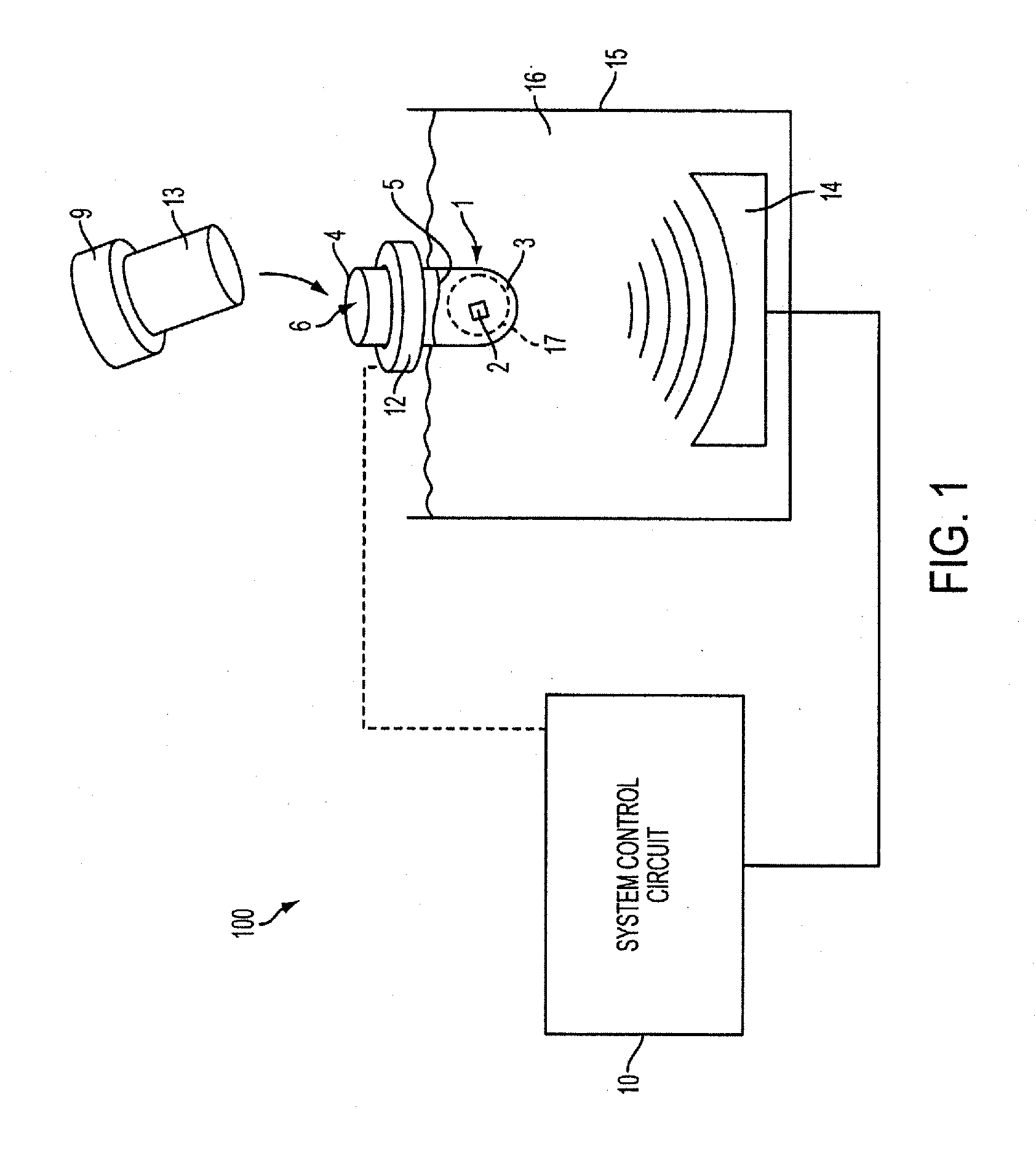

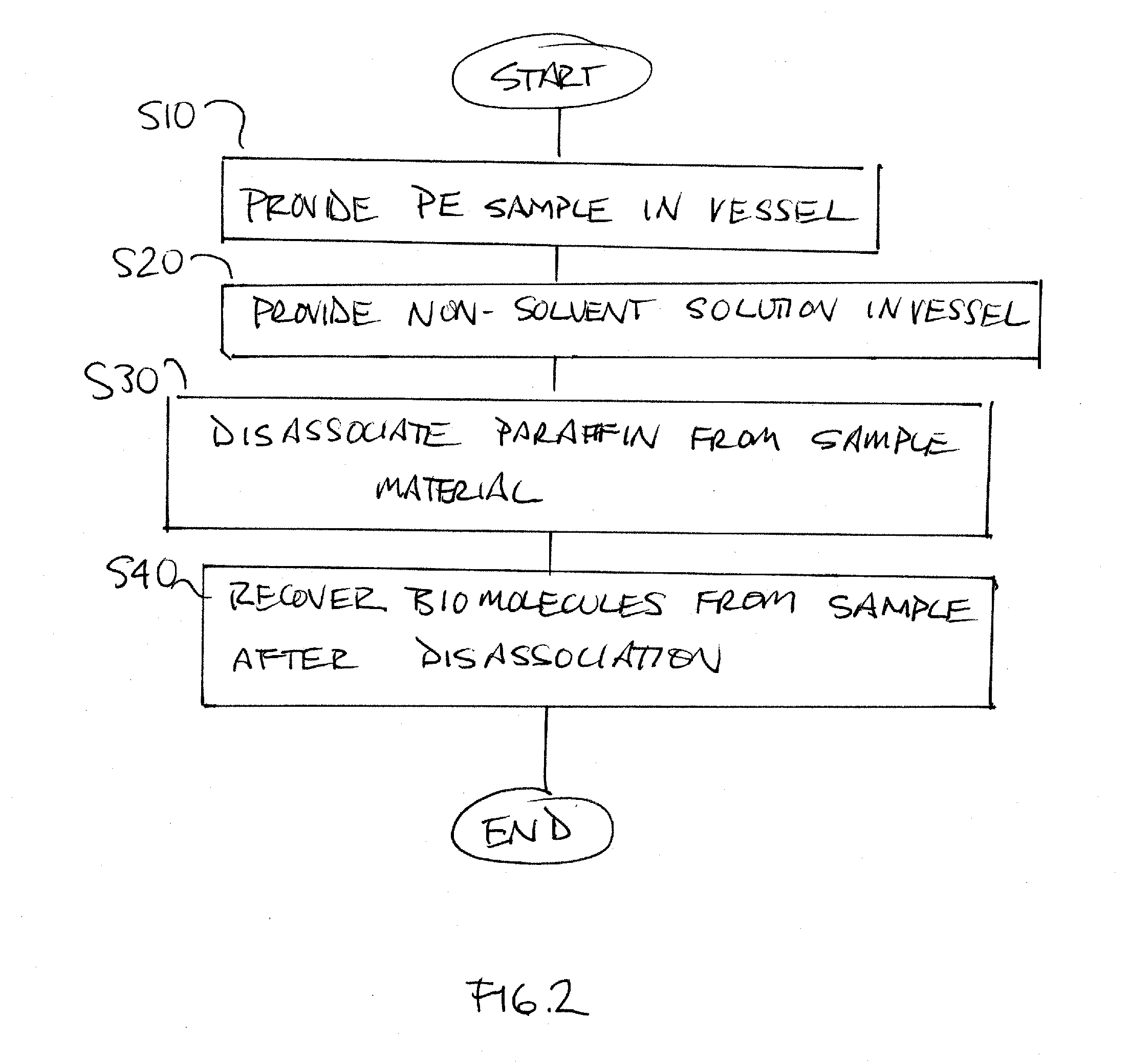

System and method for processing paraffin embedded samples

ActiveUS20140141413A1Reduce yieldIncrease nucleic acid material yieldMicrobiological testing/measurementSurgeryNon solventAcoustic energy

Method and apparatus for processing paraffin embedded samples, e.g., to disassociate paraffin from tissue components and / or other biomolecules from the paraffin. The sample may be exposed to focused acoustic energy while held in a vessel containing a non-solvent, aqueous solution. Disassociated paraffin may be emulsified into the liquid or otherwise separated from the sample.

Owner:COVARIS INC

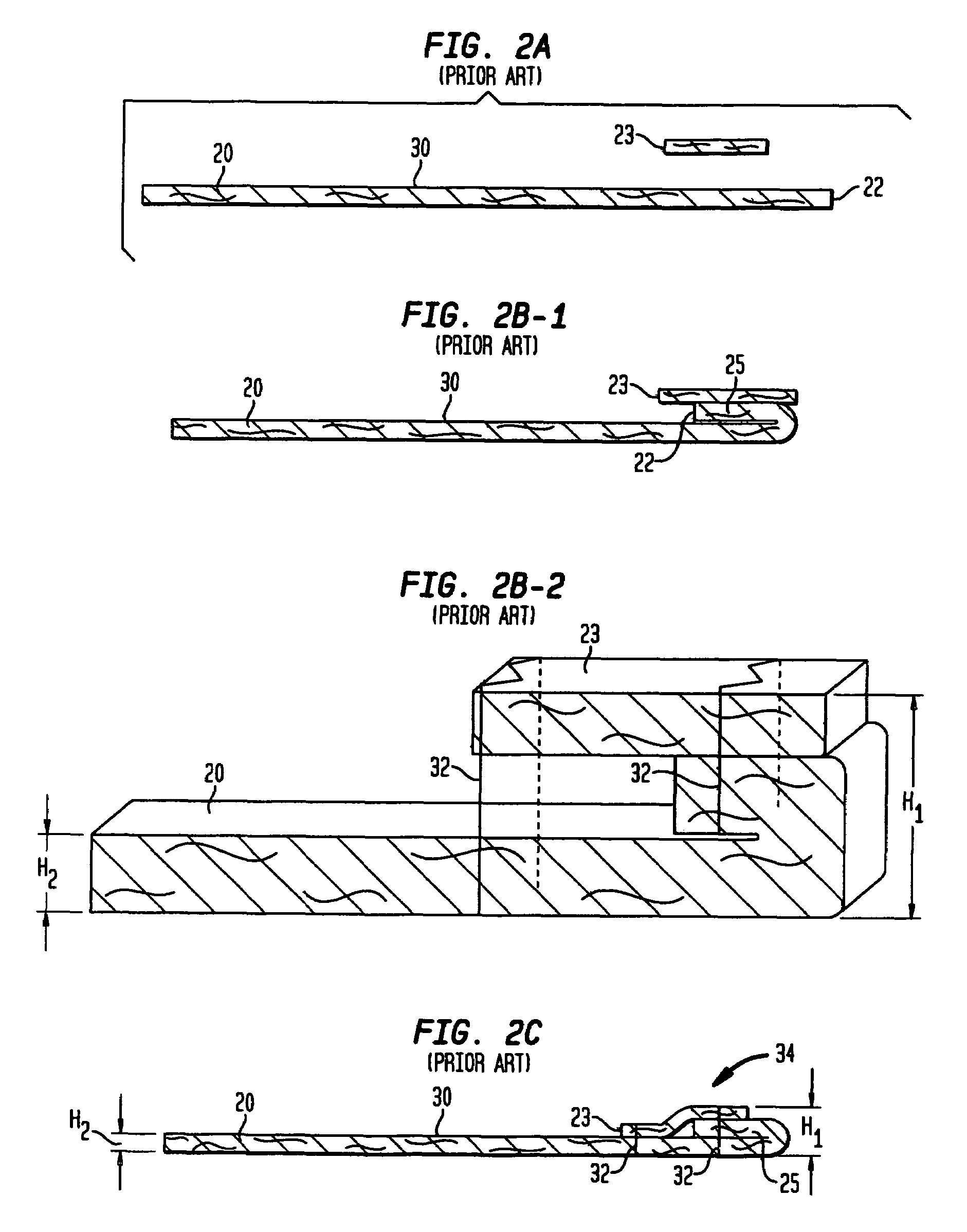

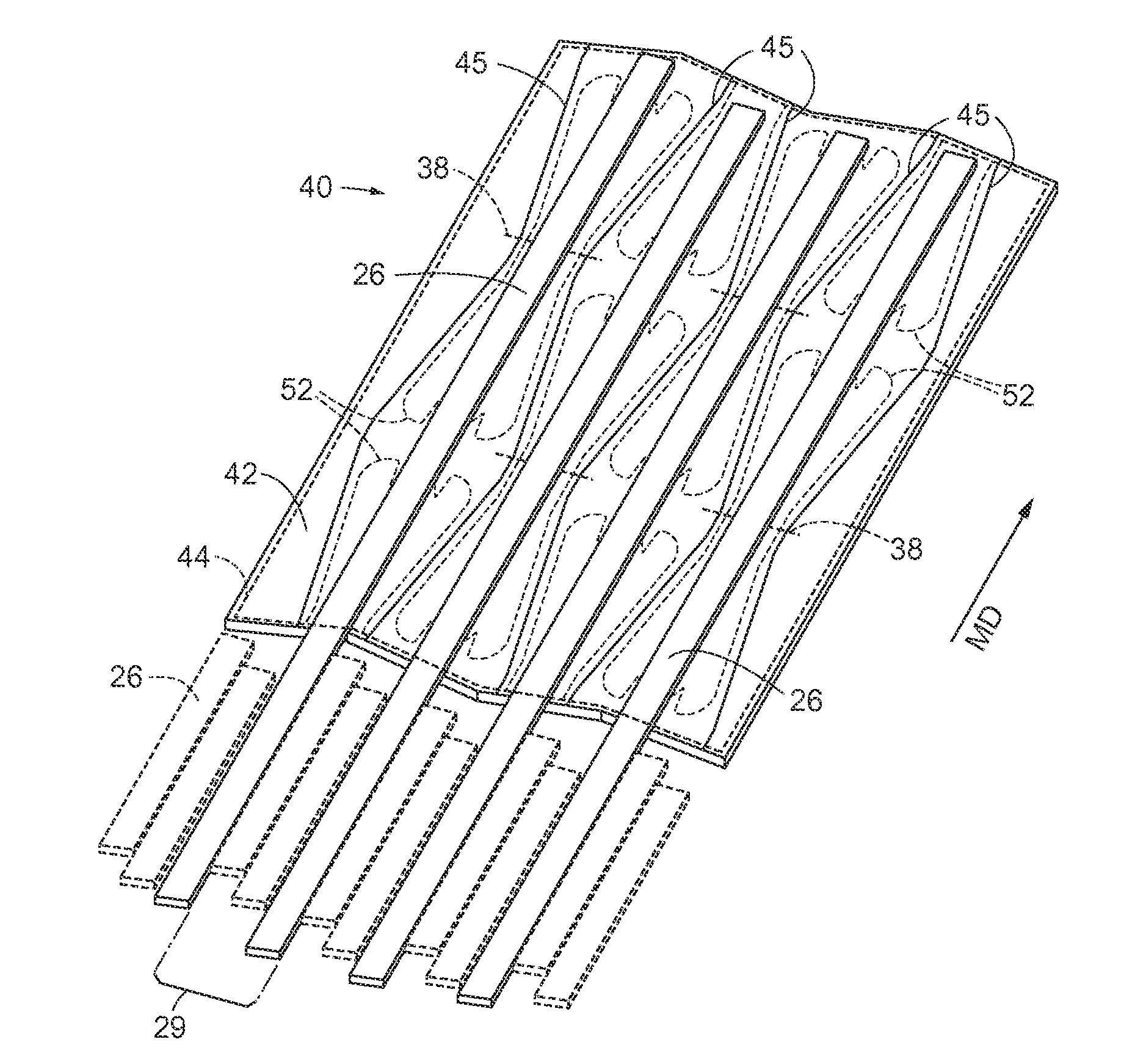

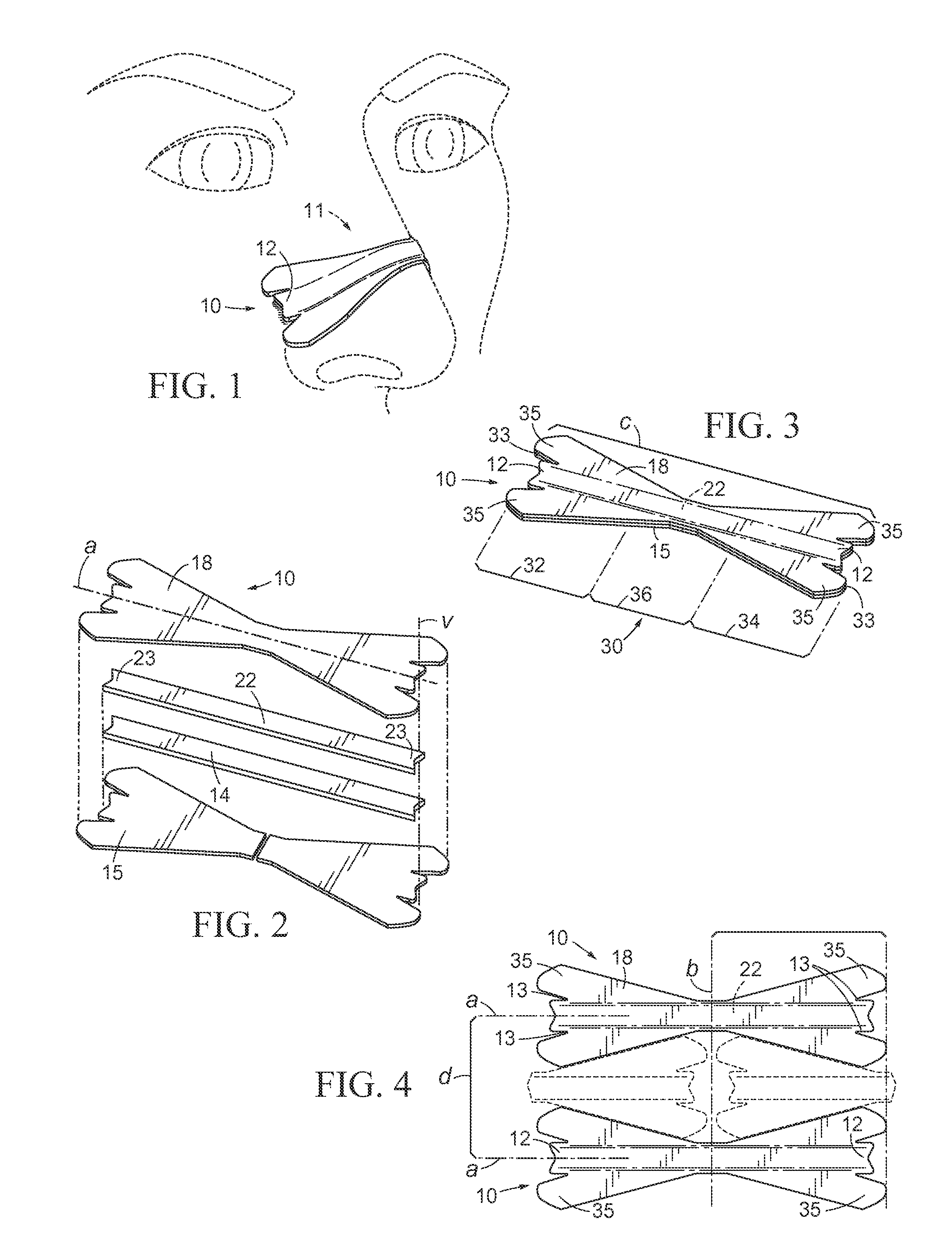

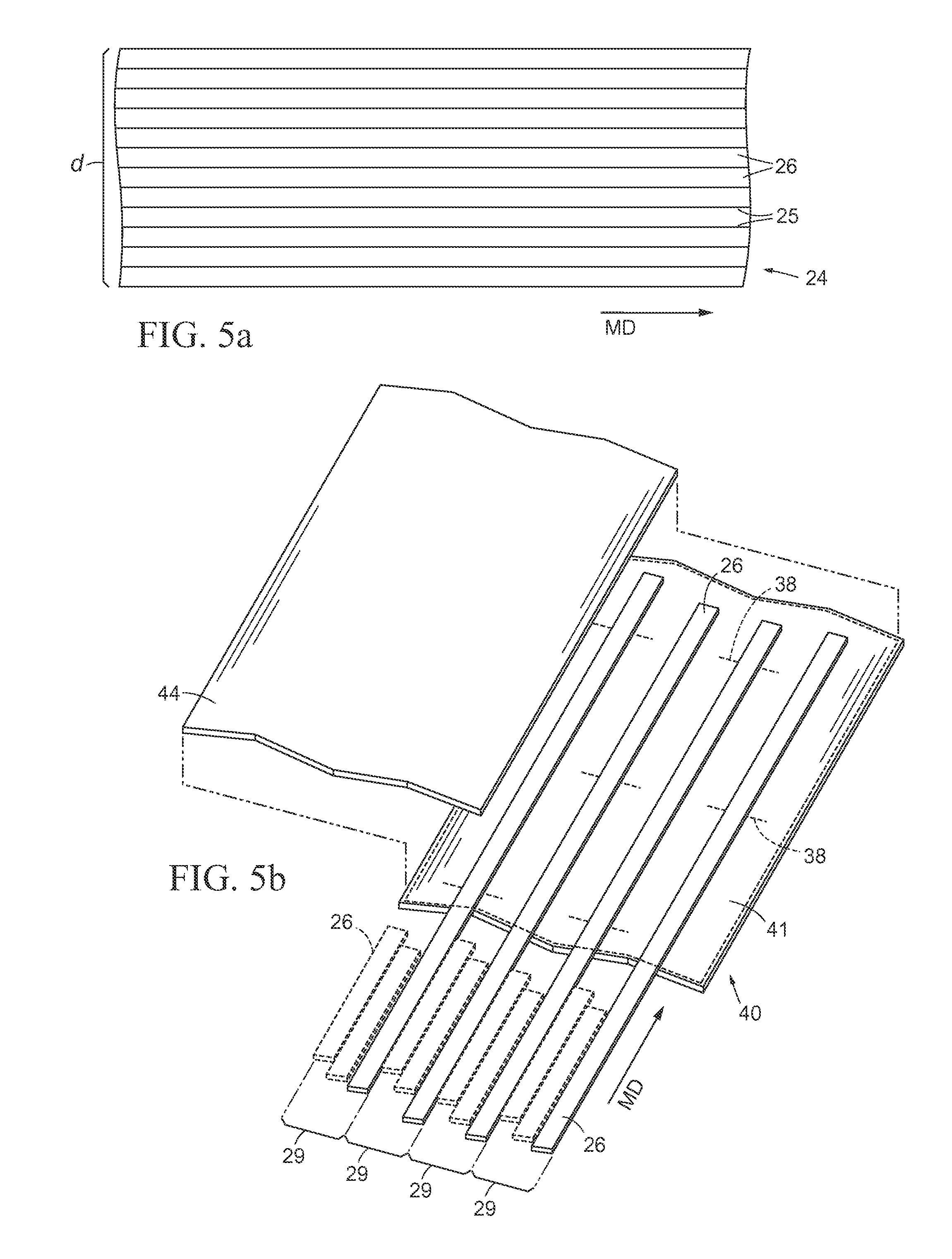

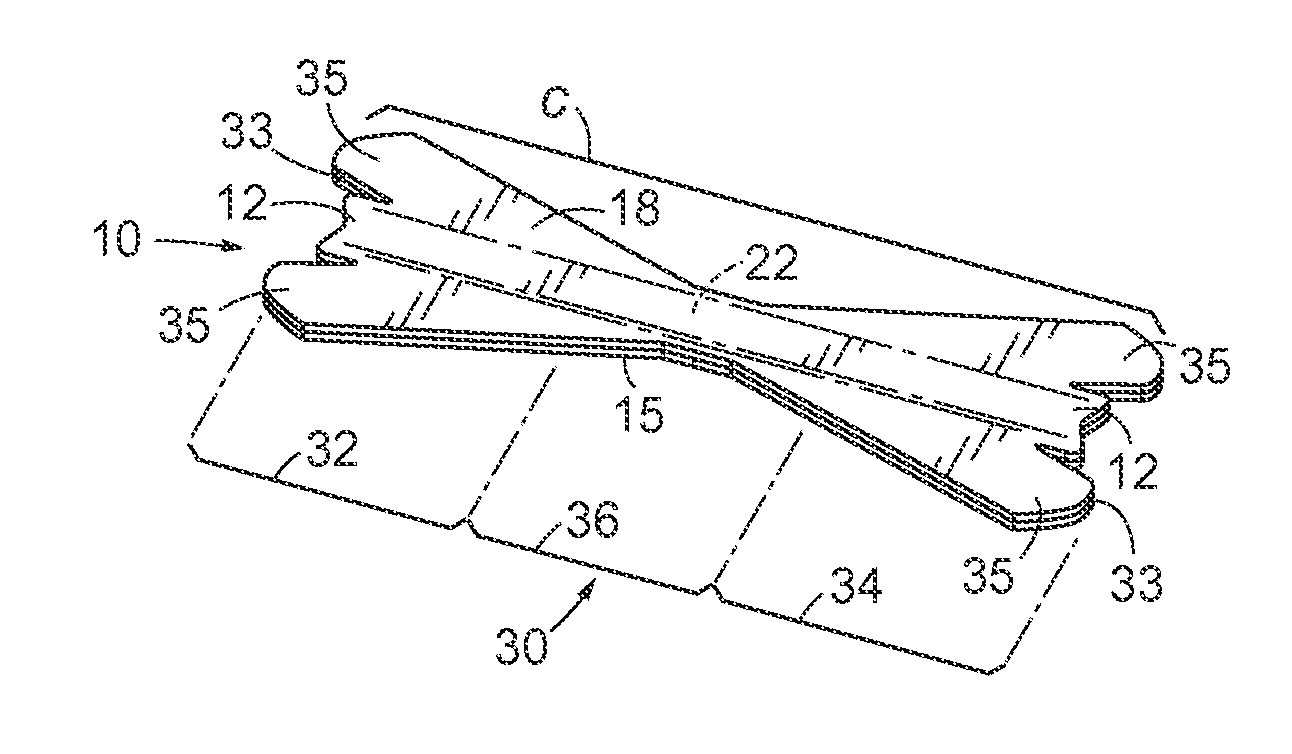

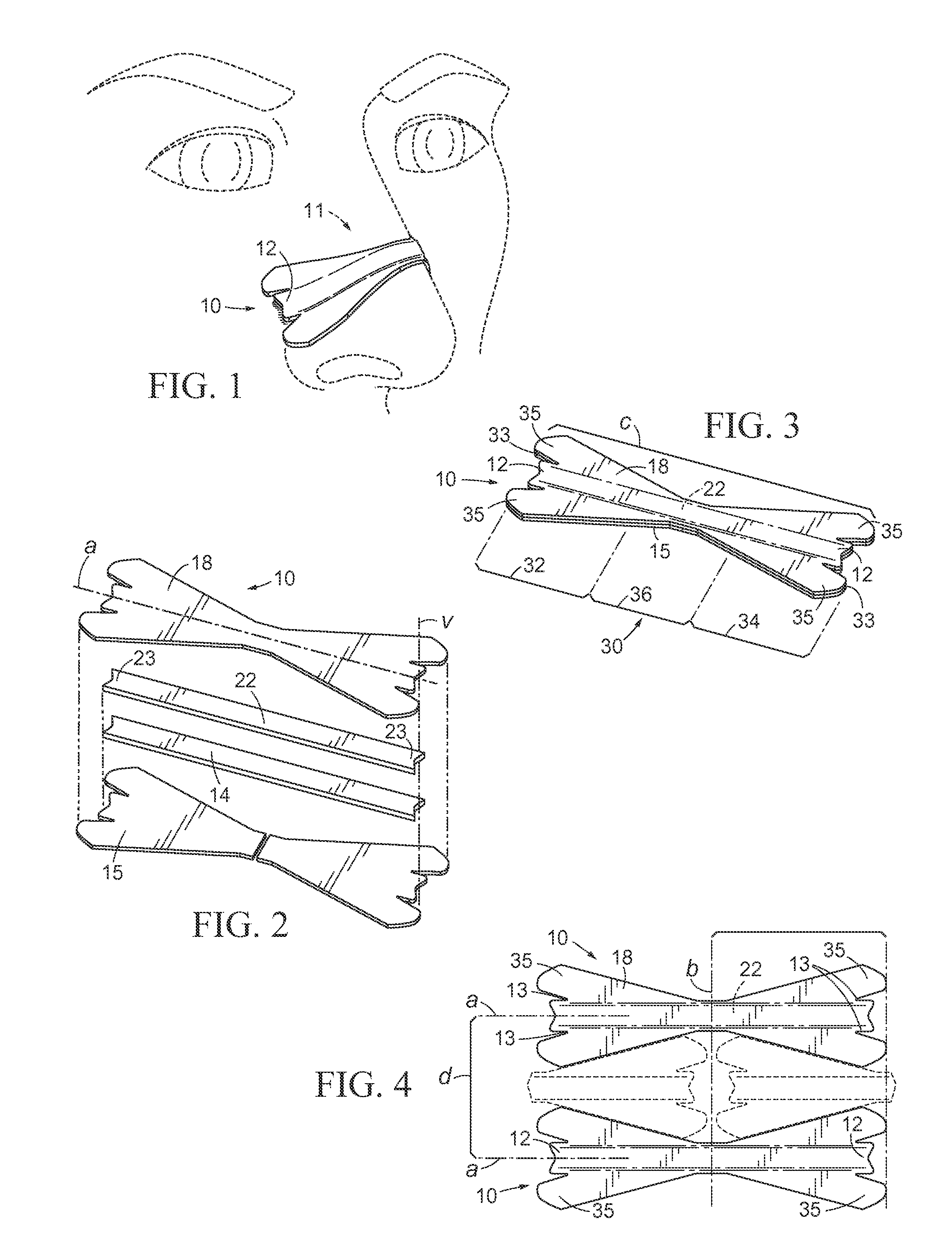

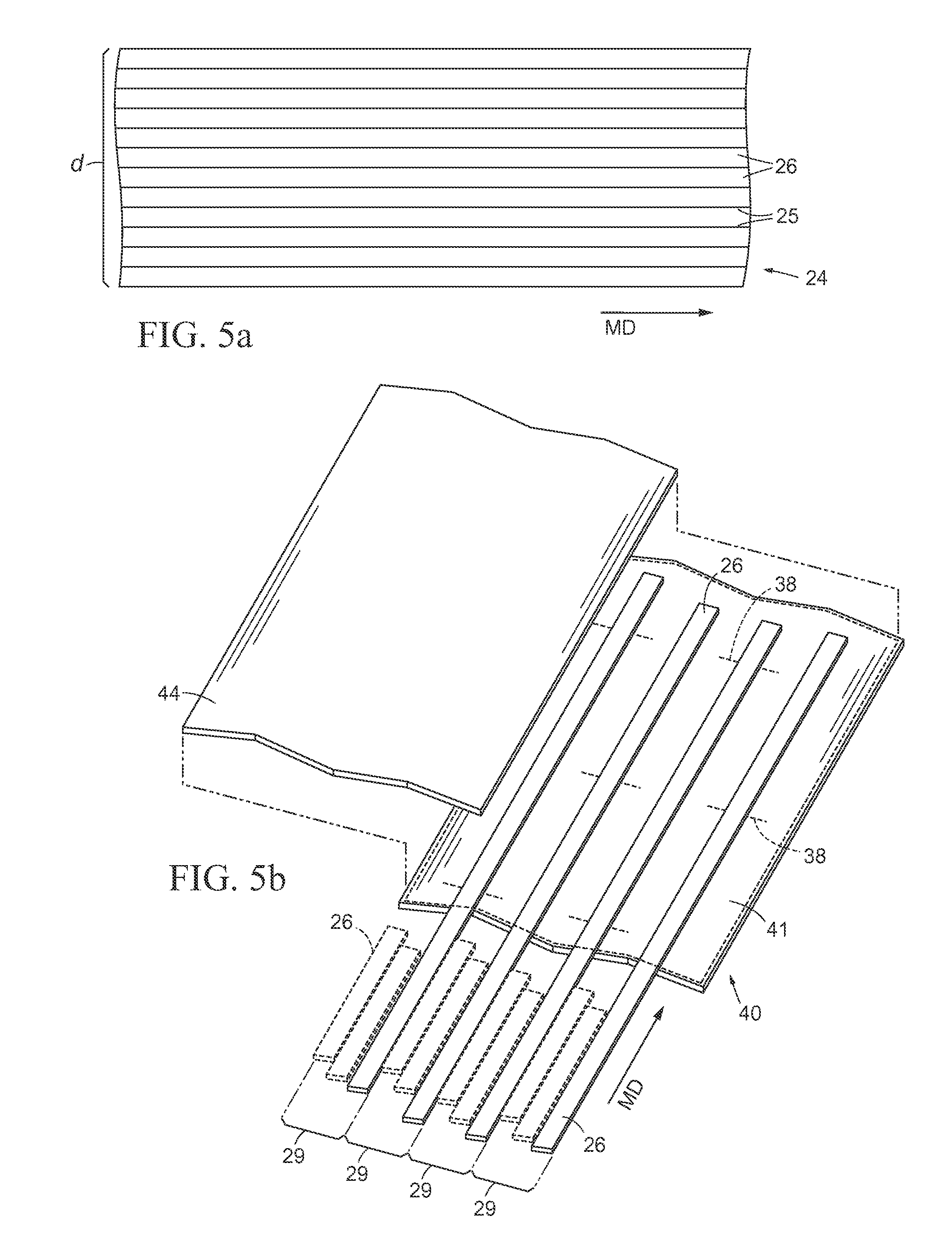

Nasal dilator and methods of fabricating medical devices

ActiveUS8641852B2Increase conversion timeEliminate material wasteLamination ancillary operationsMedical devicesNasal passagesMedical device

Owner:HORIZON IP TECH LLC

Nasal Dilator and Methods of Fabricating Medical Devices

ActiveUS20110093004A1Easy to disassembleNo pressureLamination ancillary operationsMedical devicesNasal passageNasal passages

Methods are disclosed for converting on a mass scale elongated material webs into finished parts or devices. Slits form strands in a web, the strands comprising interconnected objects which correspond to parts of finished devices. Strands are combined with additional webs to form a material laminate from which finished devices are die cut. The methods are suitable for a range of converting applications including medical devices, particularly the external nasal dilator. Complex dilator devices produced from the methods are formed as a single body truss having horizontal regions adapted to engage outer wall tissues of first and second nasal passages of a nose. When in use the dilator stabilizes or expands nasal outer wall tissues and prevents the outer wall tissues from drawing inward during breathing. Methods of manufacture comprise separate steps for fabricating and assembling the elements and layers of finished dilator devices and for packaging finished devices individually or in groups. Waste material is incorporated into subsequent fabrication processes to produce the same or complementary devices.

Owner:HORIZON IP TECH LLC

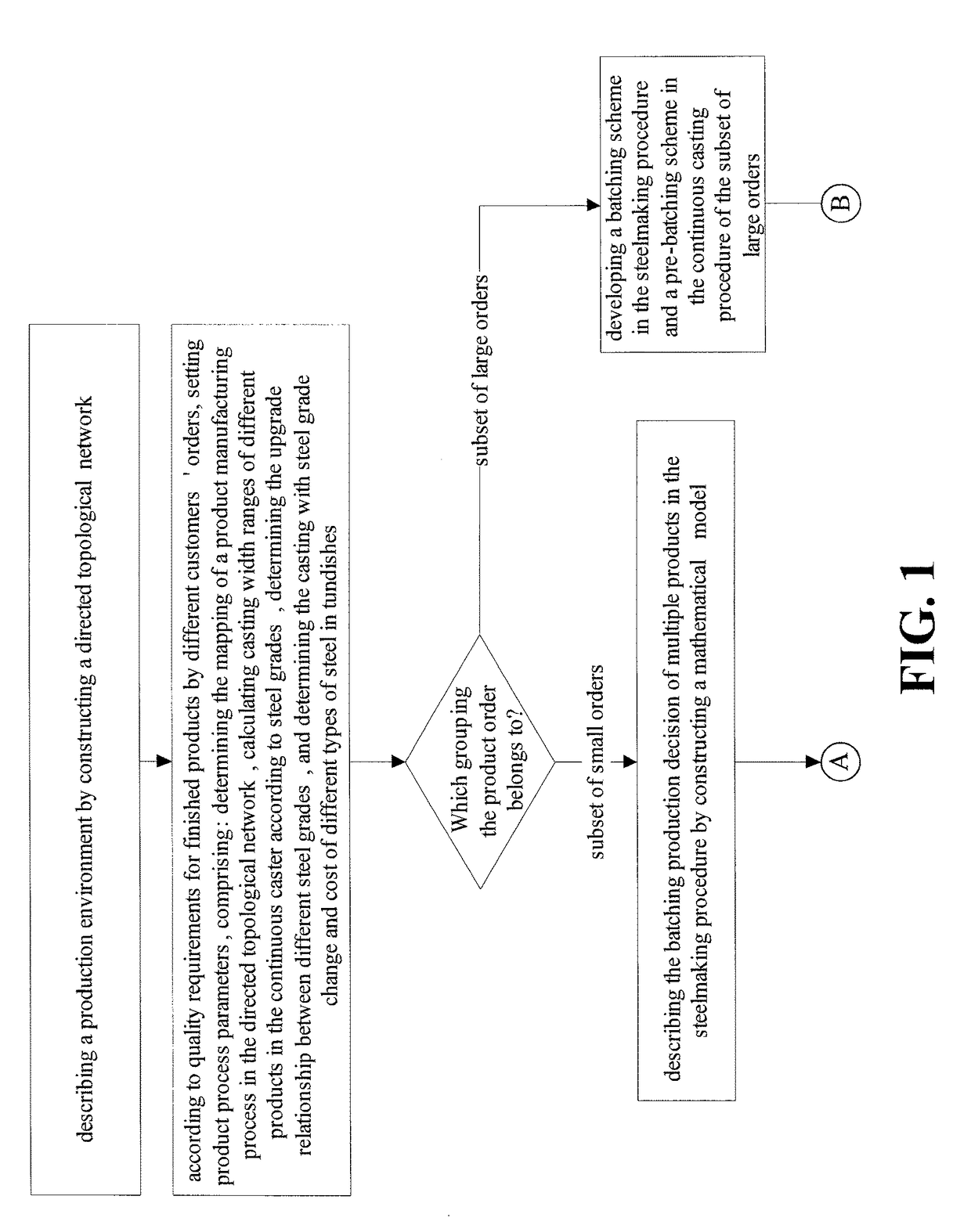

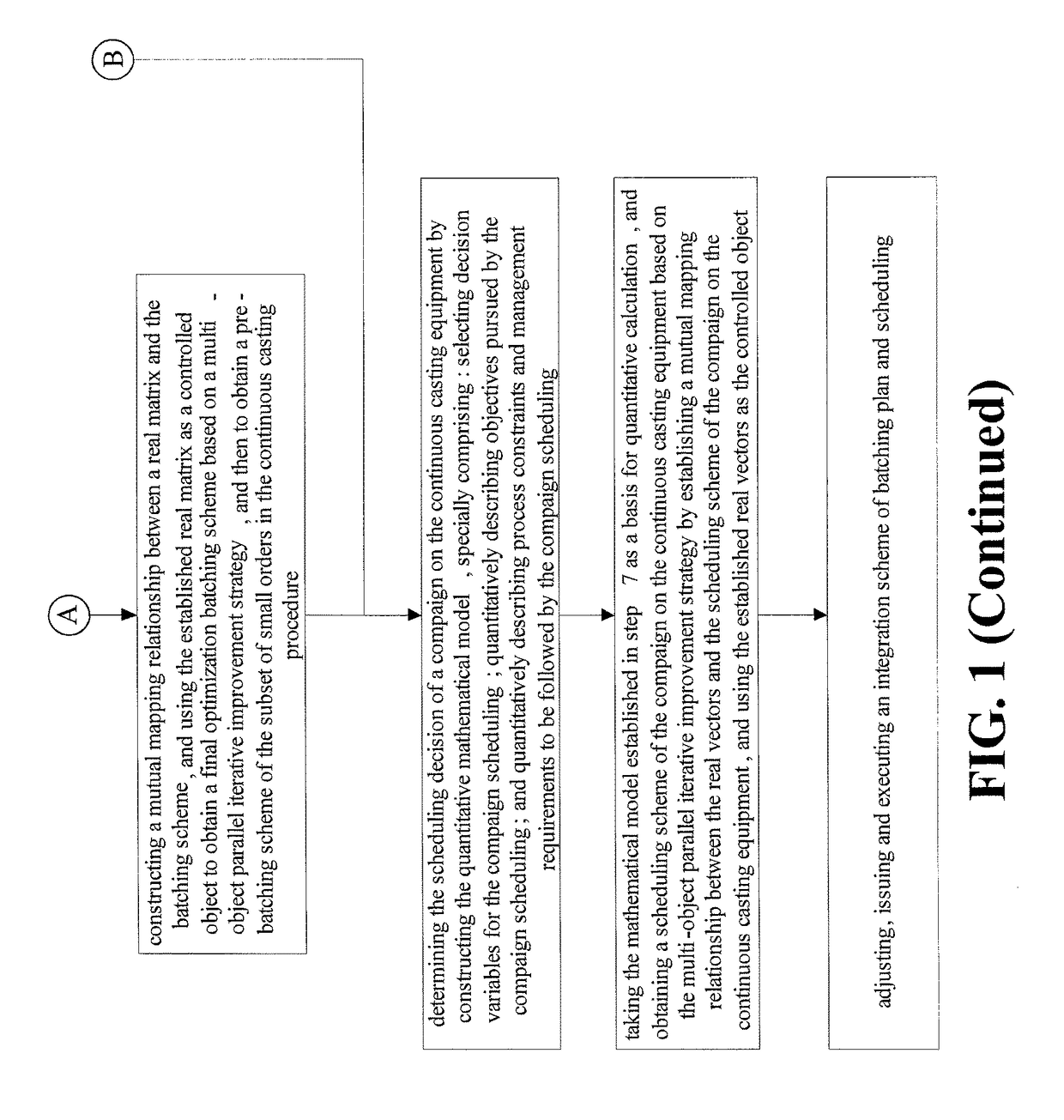

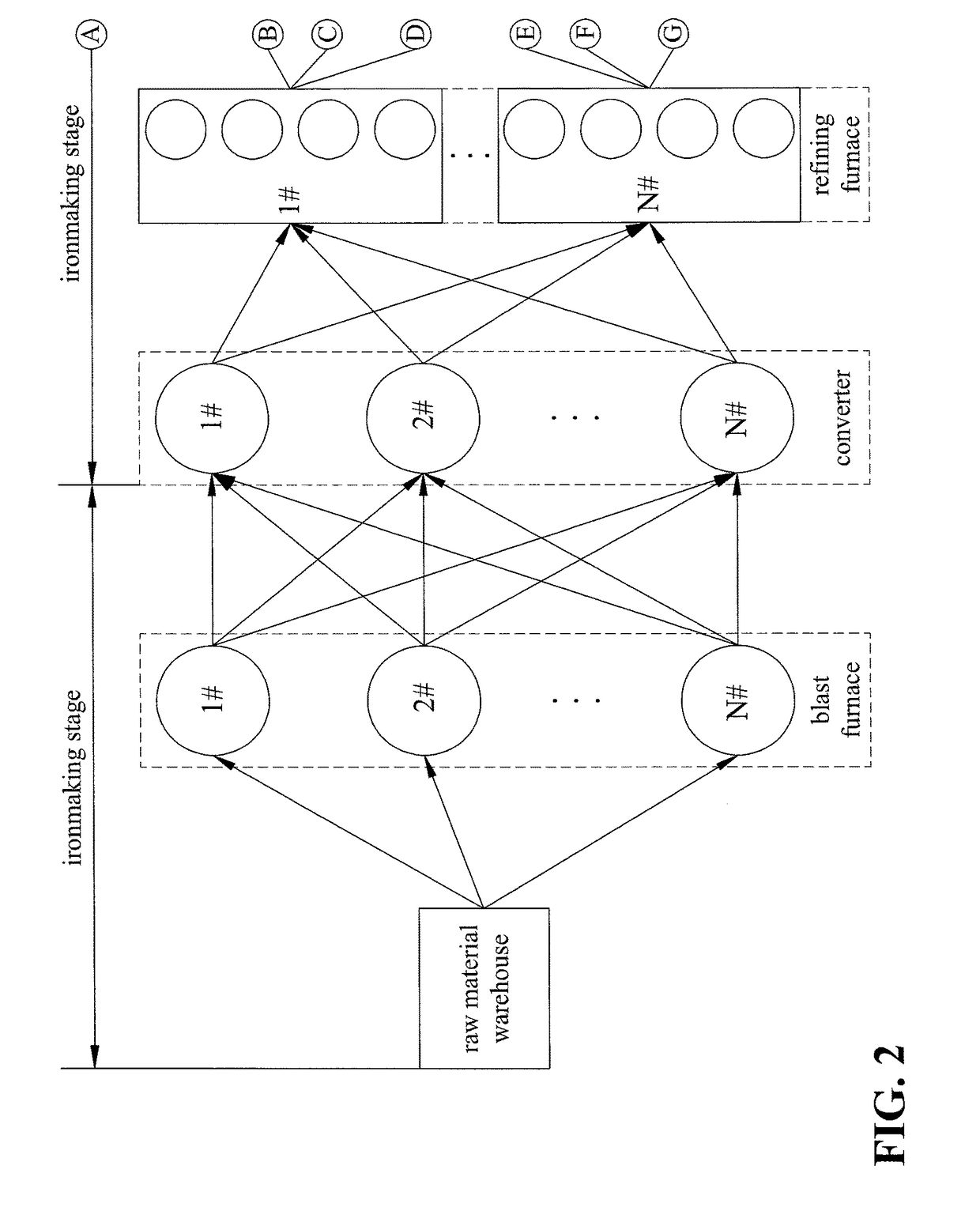

Method of batching and scheduling for steelmaking production with plant-wide process consideration

ActiveUS20170316131A1Improve product qualityImprove material yieldHot-dipping/immersion processesData processing applicationsSteelmakingLogistics management

Provided is a method of batching and scheduling for steelmaking production with plant-wide process consideration, including the steps of: establishing a mathematical model for quantitatively describing the decision problem of batching on steelmaking and continuous casting procedures; starting from the production capacity balance between parallel equipment of the same procedure, and material flow convergence between upstream and downstream procedures, establishing a model for the assignment and sequencing of batches on continuous casting equipment and the time dimension; integrating the batching plan and the production scheduling scheme, issuing the batching plan and the production scheduling scheme integrated to all production and manufacturing units at the steelmaking stage. The present invention improves product quality, increases the material yield, resource utilization rate and equipment operation efficiency, realizes load balance on parallel equipment and smooth material linkage between serial equipment, and reduces the material flow transportation jam, downstream equipment waiting time and inventory.

Owner:NORTHEASTERN UNIV

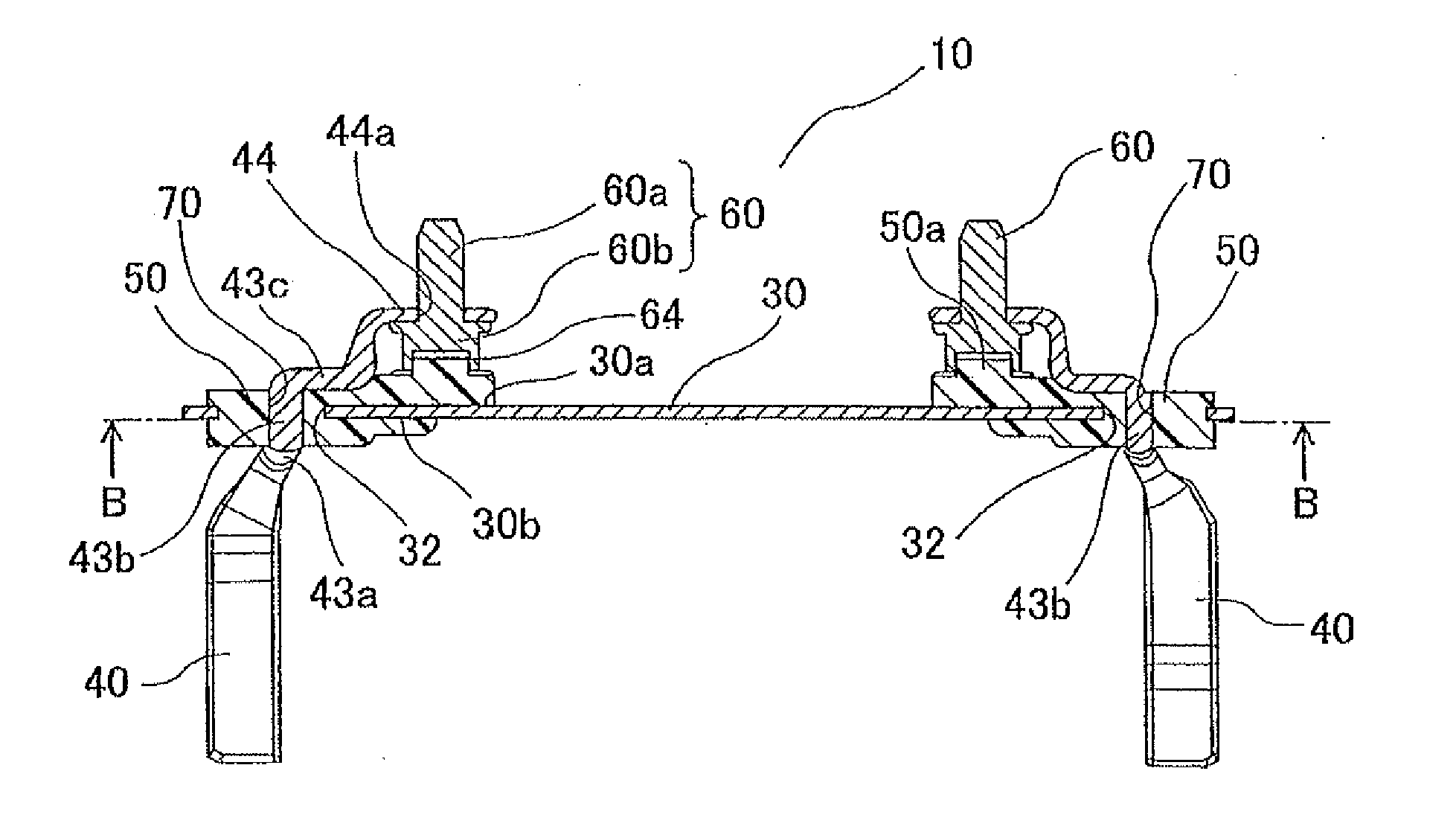

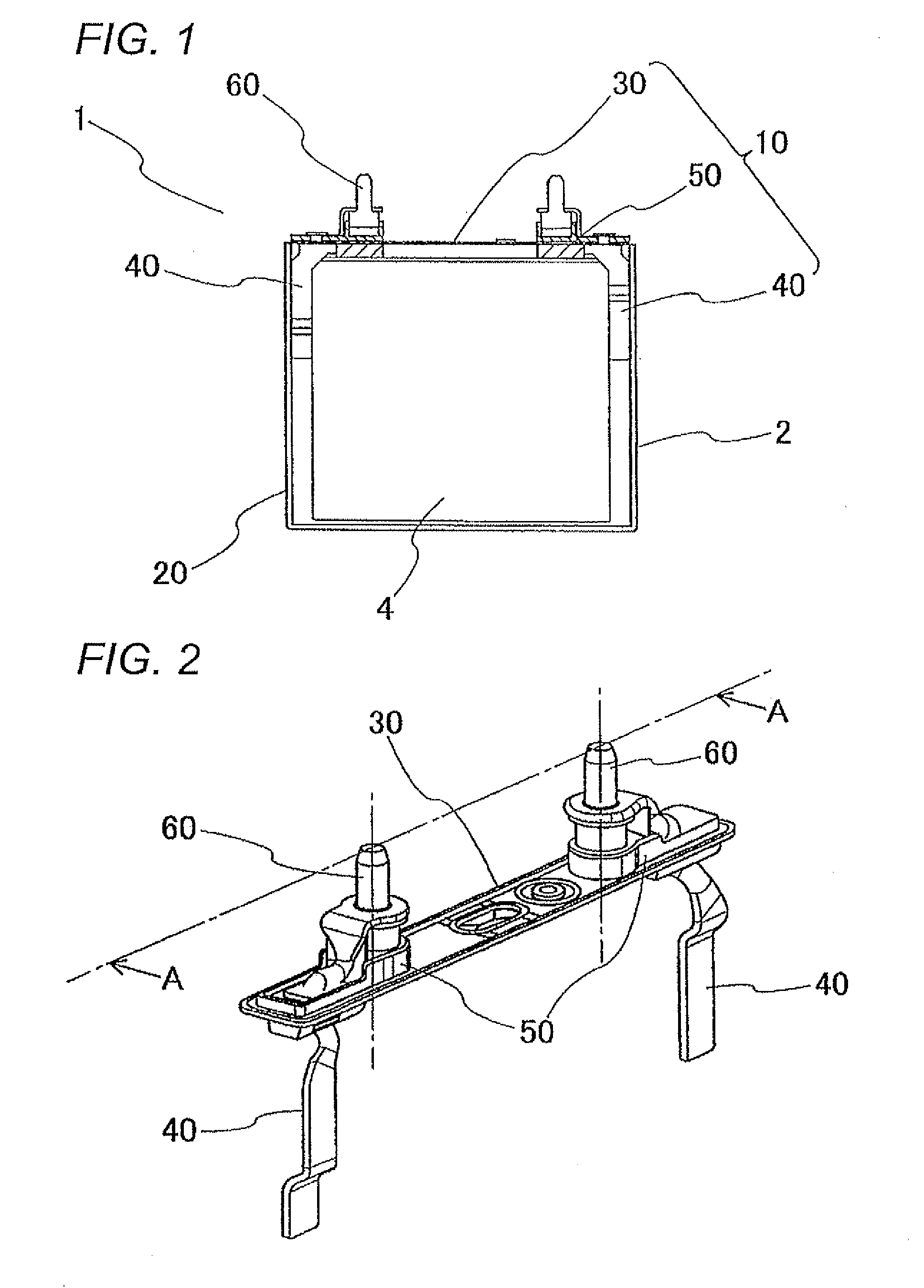

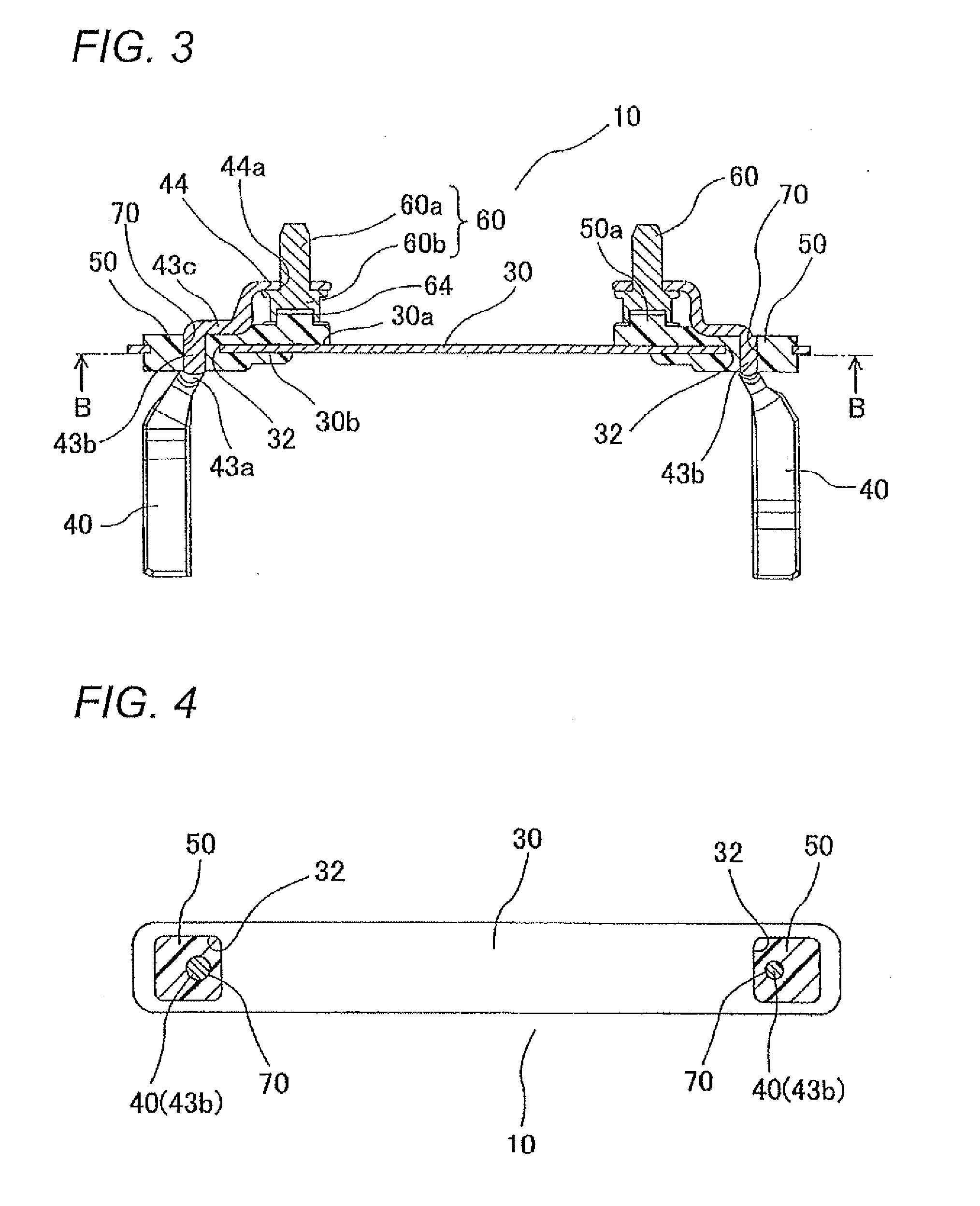

Battery cover member

InactiveUS20110076553A1Improve sealing propertiesUniform surface treatmentSmall-sized cells cases/jacketsSecondary cellsMetallic electrodeEngineering

A battery cover member (10) of the present invention includes a metallic electrode terminal (40), a metallic cover member (30) having through holes (32), and an insulating resin member (50), in which the electrode terminals inserted into the through hole and the cover member are integrally bonded together by the insulating member, wherein at least a sealing area (70) of the electrode terminal that adheres to the insulating member is formed as a columnar shape or an elliptically columnar shape.

Owner:TOYODA GOSEI CO LTD

Manufacture method of sputtering targets

InactiveCN101224496ALowering Amount and DepthImprove material yieldVacuum evaporation coatingSputtering coatingVolumetric Mass DensityRaw material

The invention provides a manufacture method of a sputtering target, which is characterized in that a target raw material powder is arranged in a die and sintered in a hot pressing type with lower temperature and lower pressure; after that, the initial blank is uniformly heated; the hot pressing type with low temperature and low pressure is adopted to lead the target blank not to have open pores; furthermore, the density of the target can be increased by more than 96% by the uniform heating type; therefore, a tank sealing process with high cost is not required, and the hot pressing preparation under low temperature and low pressure is easy to be executed; therefore, the targets with good performance can be obtained by the process with low cost.

Owner:SOLAR APPLIED MATERIALS TECHNOLOGY CORPORATION

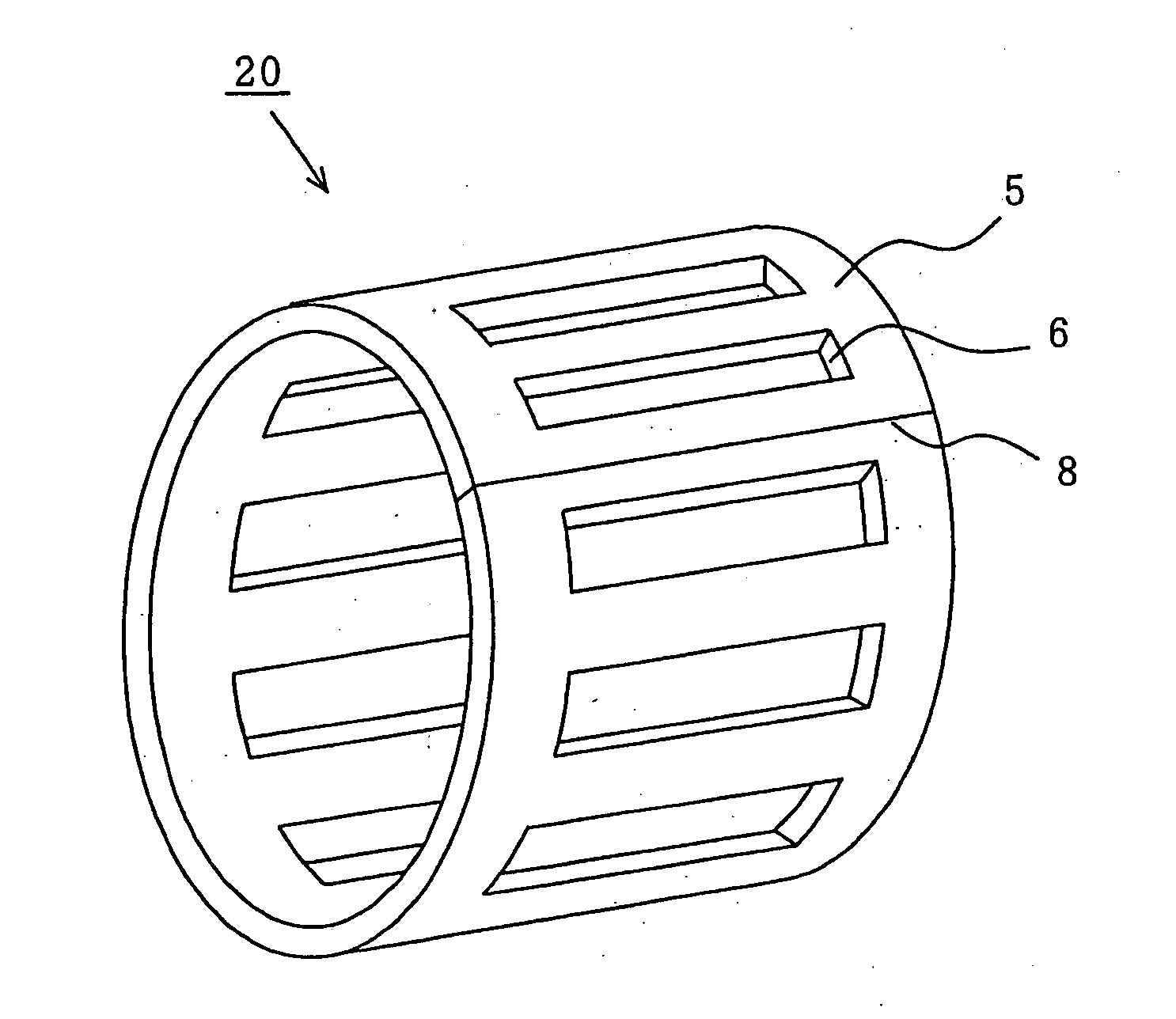

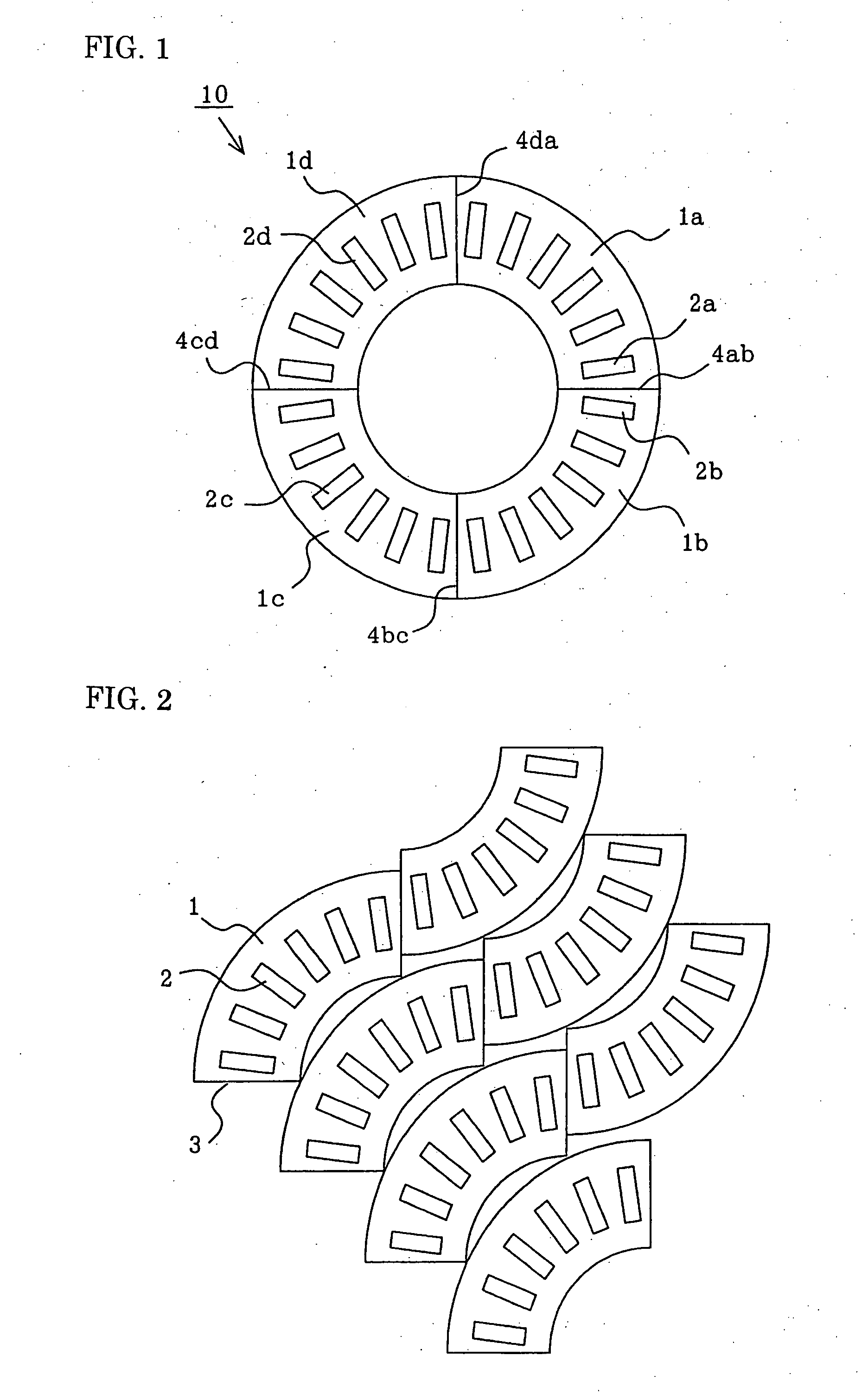

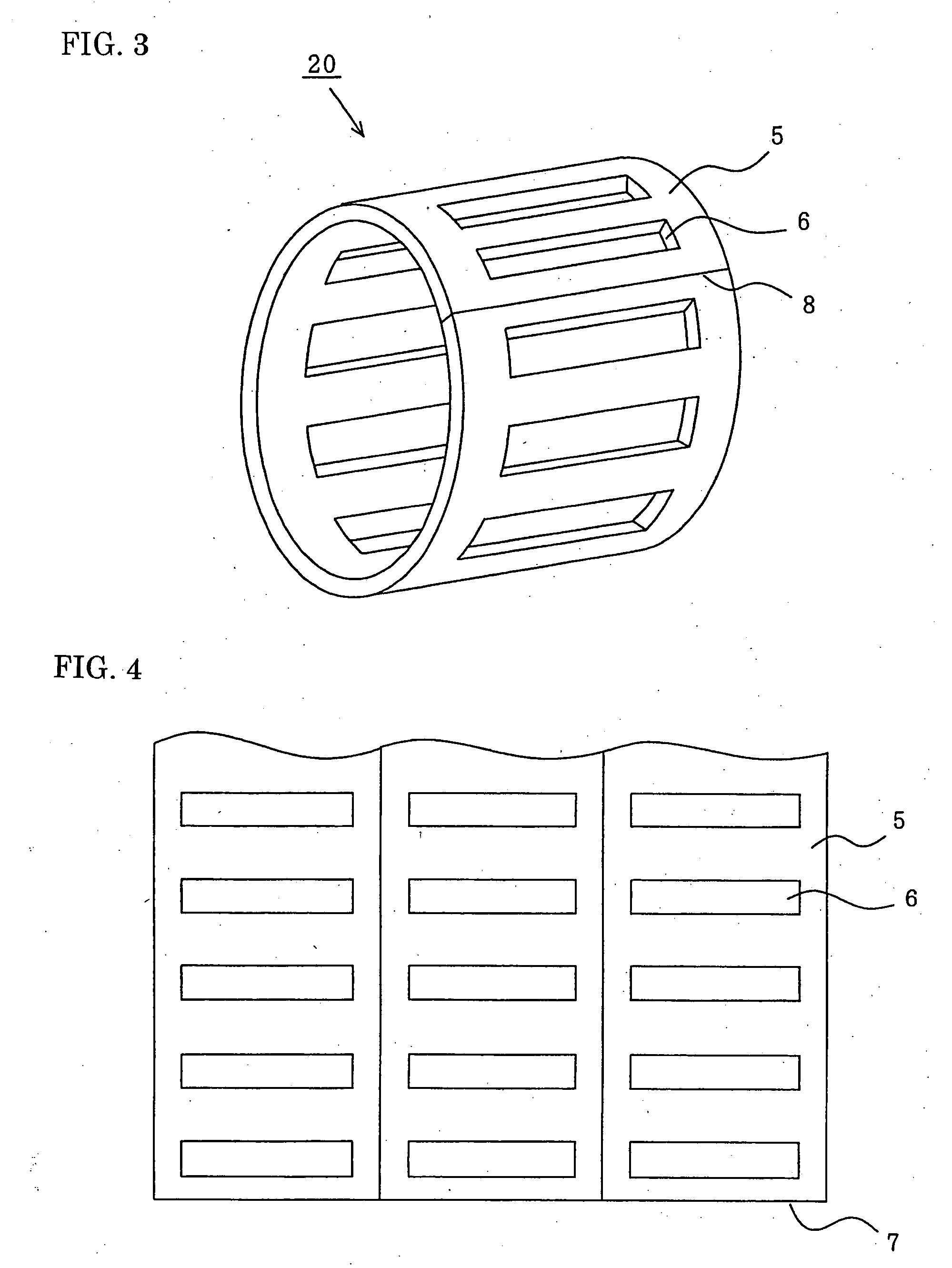

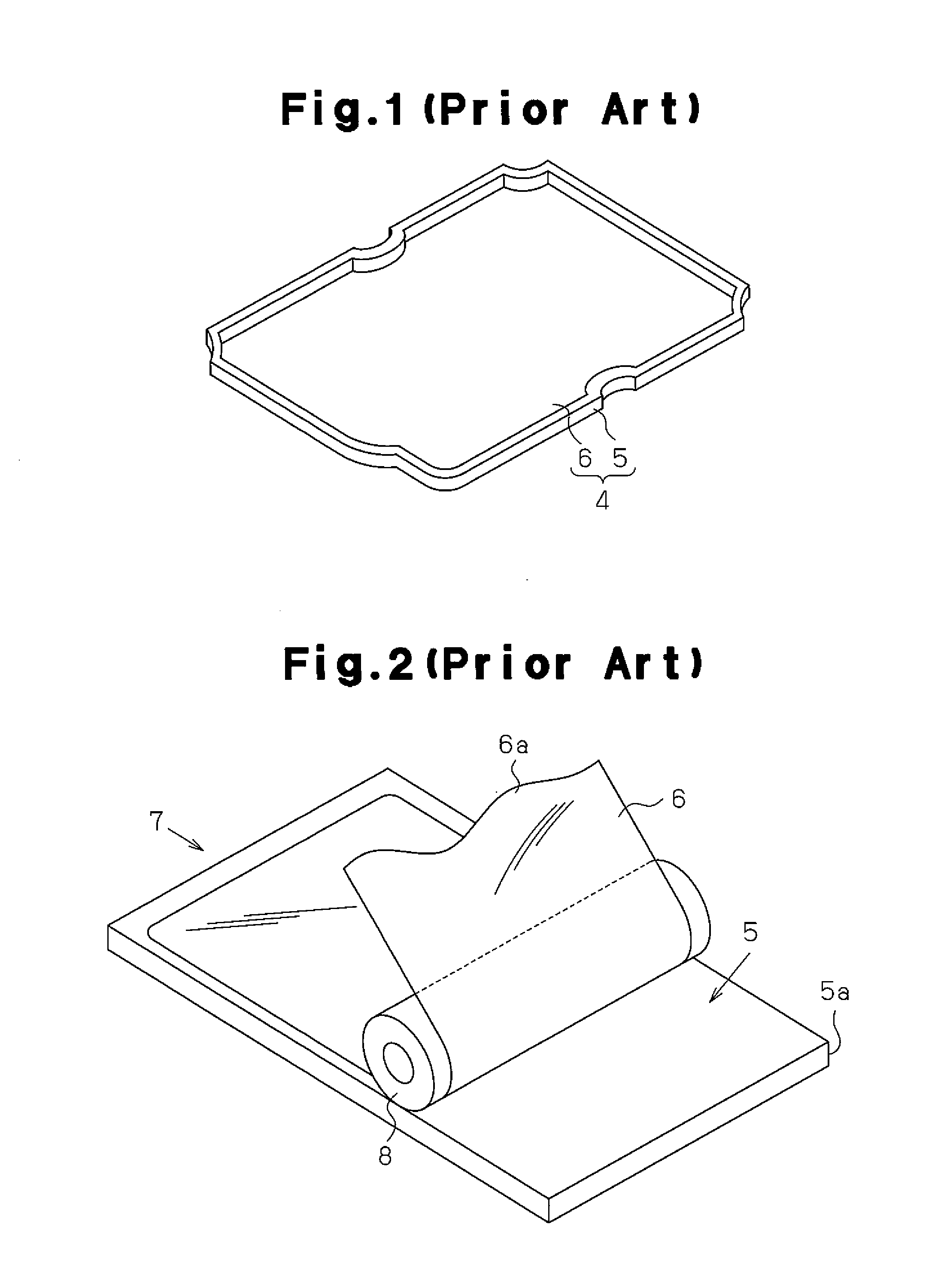

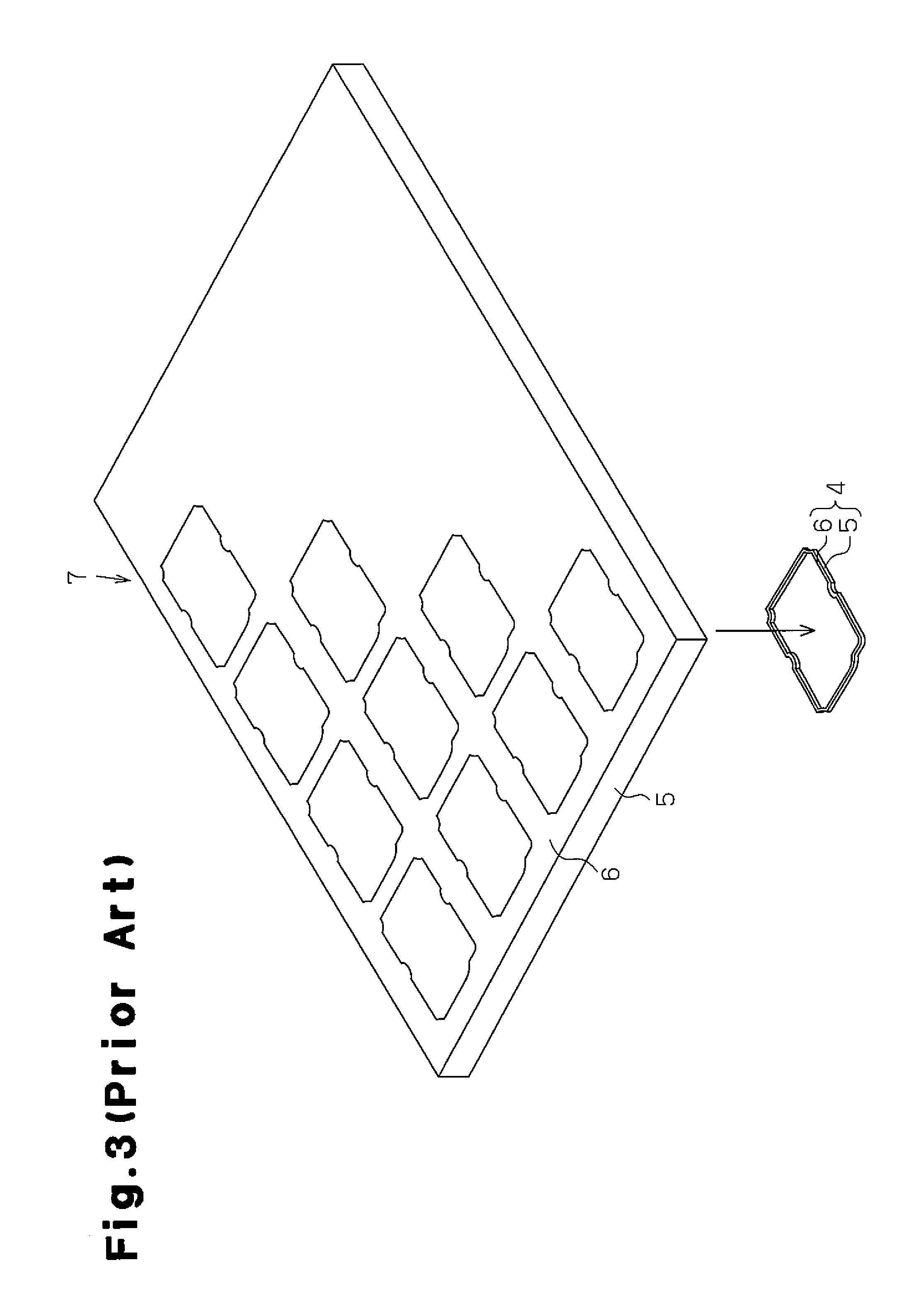

Roller bearing cage, roller bearing, and method of producing roller bearing race and roller bearing outer ring

InactiveUS20070248298A1High strengthImprove material yieldRoller bearingsBearing assemblyEngineeringUltimate tensile strength

The present invention provides a roller bearing cage and a roller bearing, in which predetermined strength can be obtained without decreasing the number of rollers being able to be arranged while a yield of a material dividing scheme is improved. A thrust roller bearing cage 10 is a plate-shape circular ring in which four arcuate pieces 1a, 1b, . . . are laser welded on laser welding lines 4ab, 4bc, . . . respectively. In the thrust roller bearing cage 10, plural rectangular pockets 2a, 2b, . . . are formed at regular intervals, even at the intervals including the laser welding lines 4ab, 4bc, . . . . Each of the laser welding lines 4ab, 4bc, . . . lies across a total length from an inner periphery to an outer periphery of the circular ring, so that the laser welding line can have sufficient length and bonding strength.

Owner:JTEKT CORP

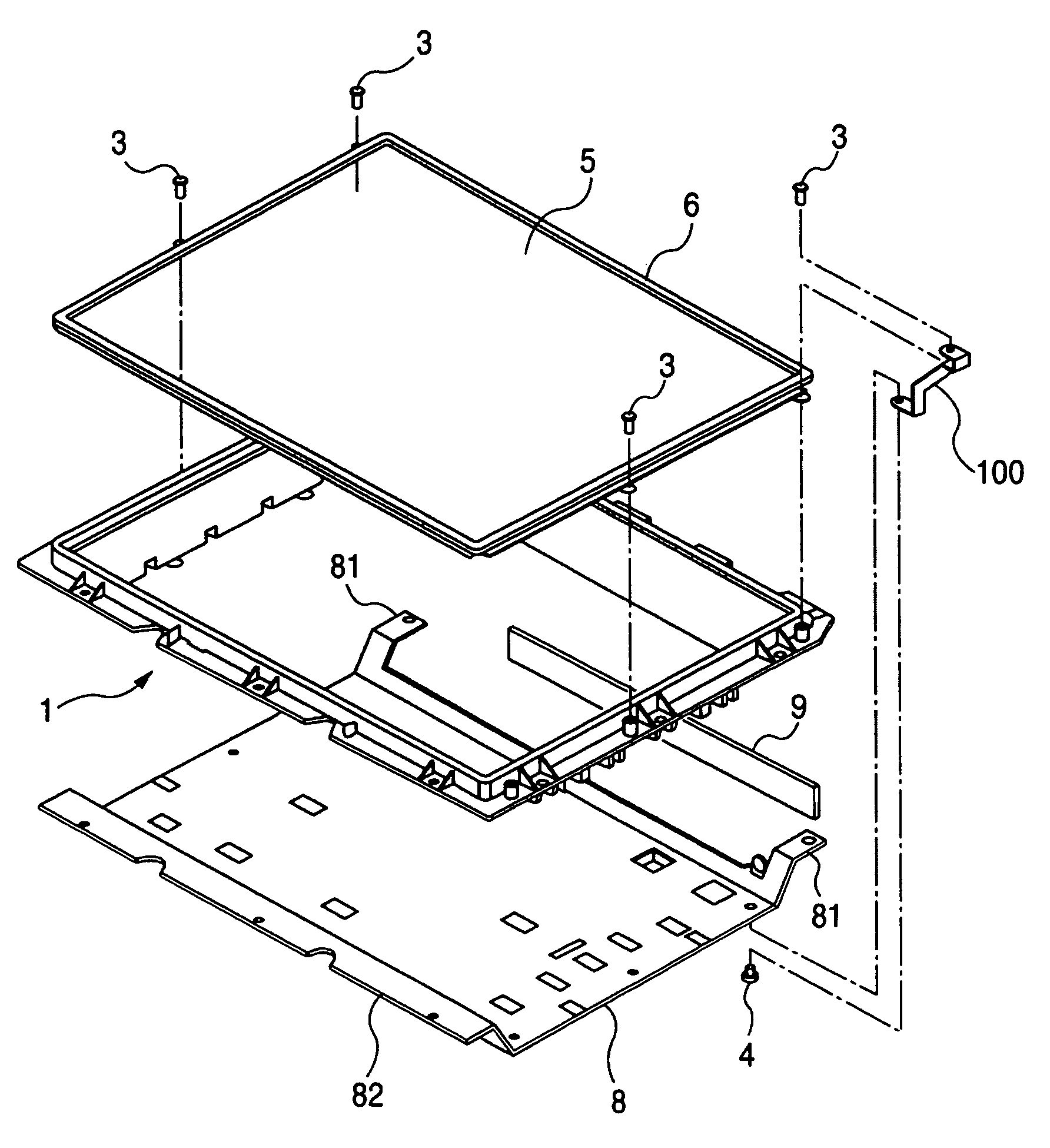

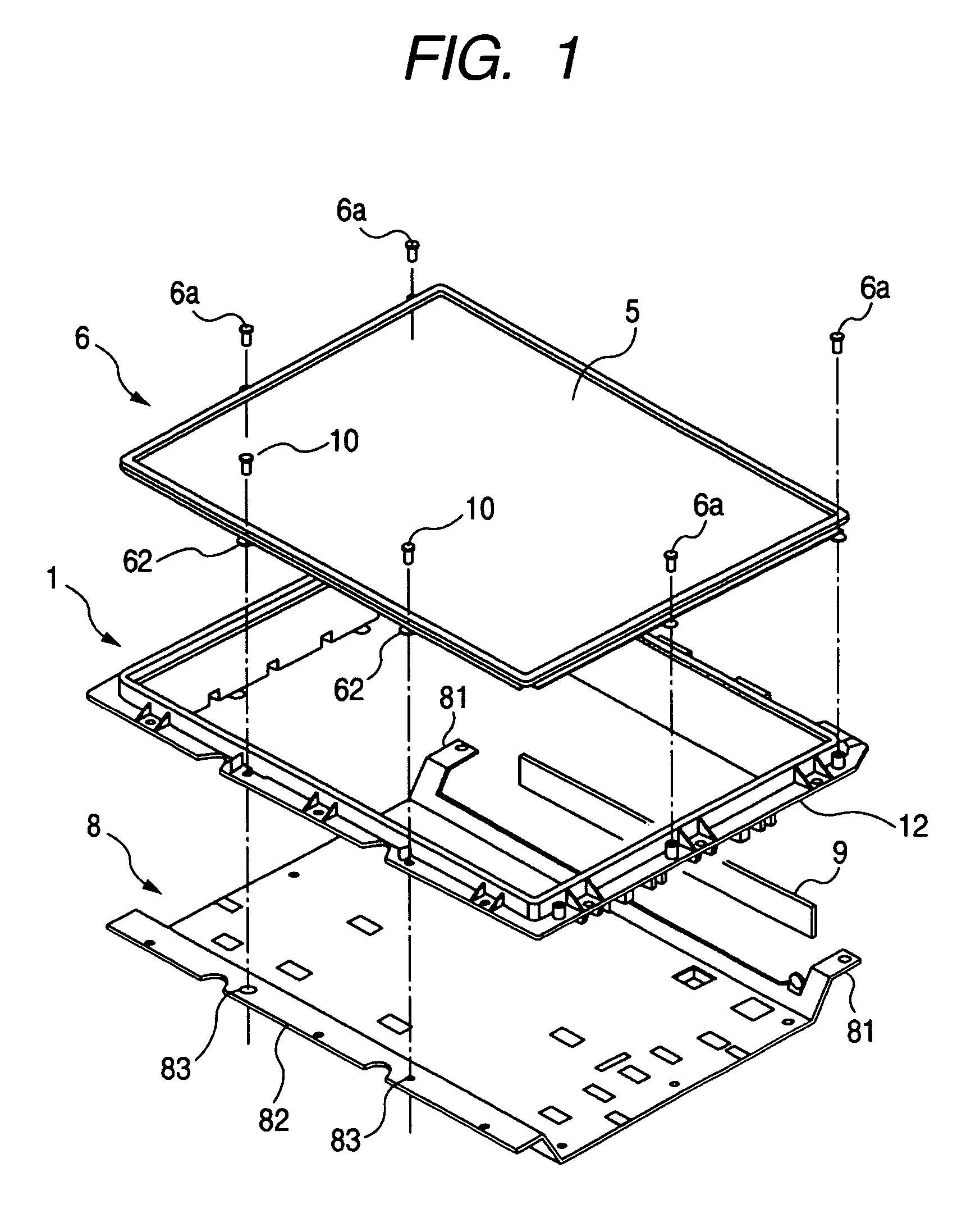

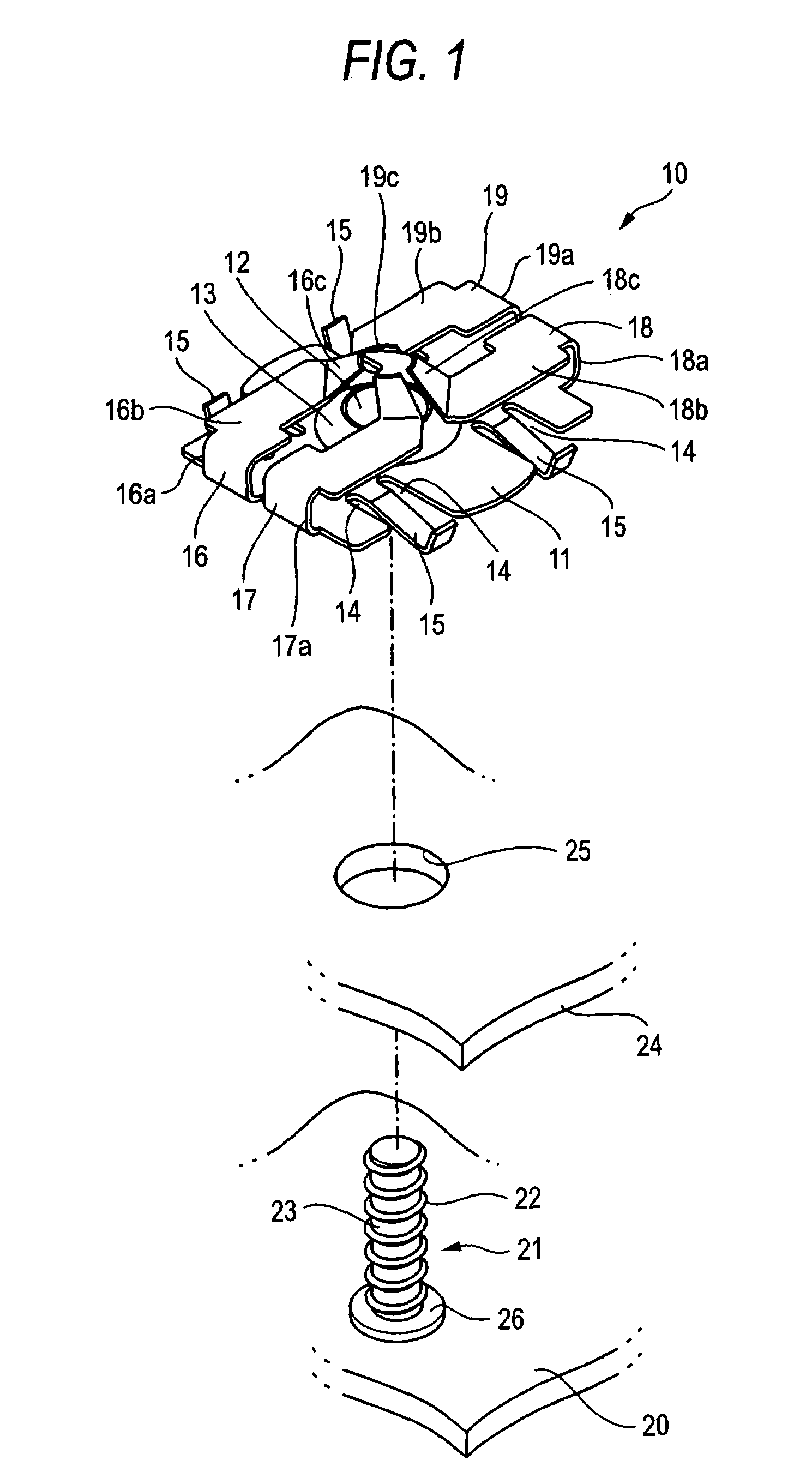

Liquid crystal display apparatus

InactiveUS7728855B2Improve material yieldLow costTelevision system detailsStatic indicating devicesLiquid-crystal displayEngineering

Owner:FUNAI ELECTRIC CO LTD

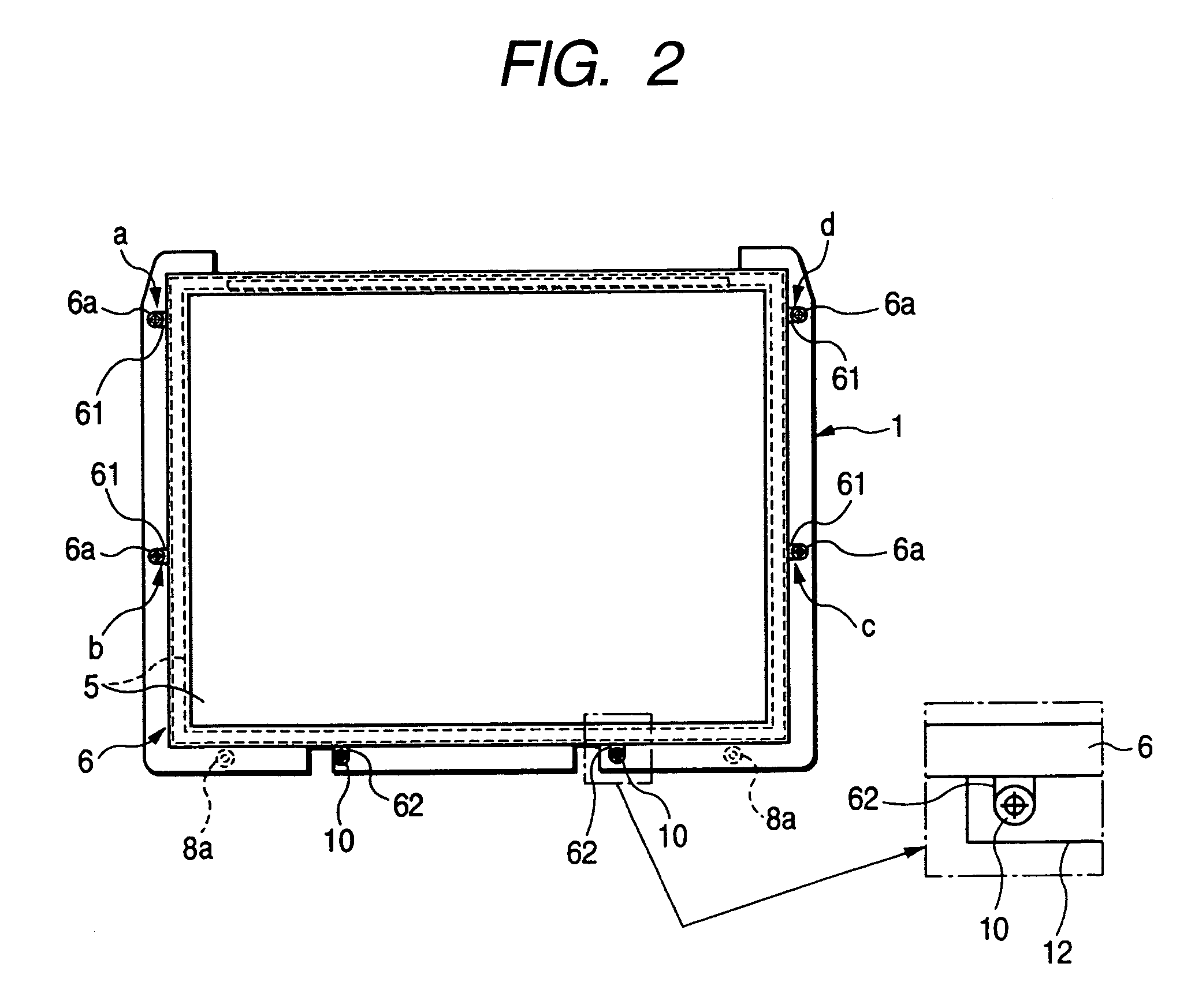

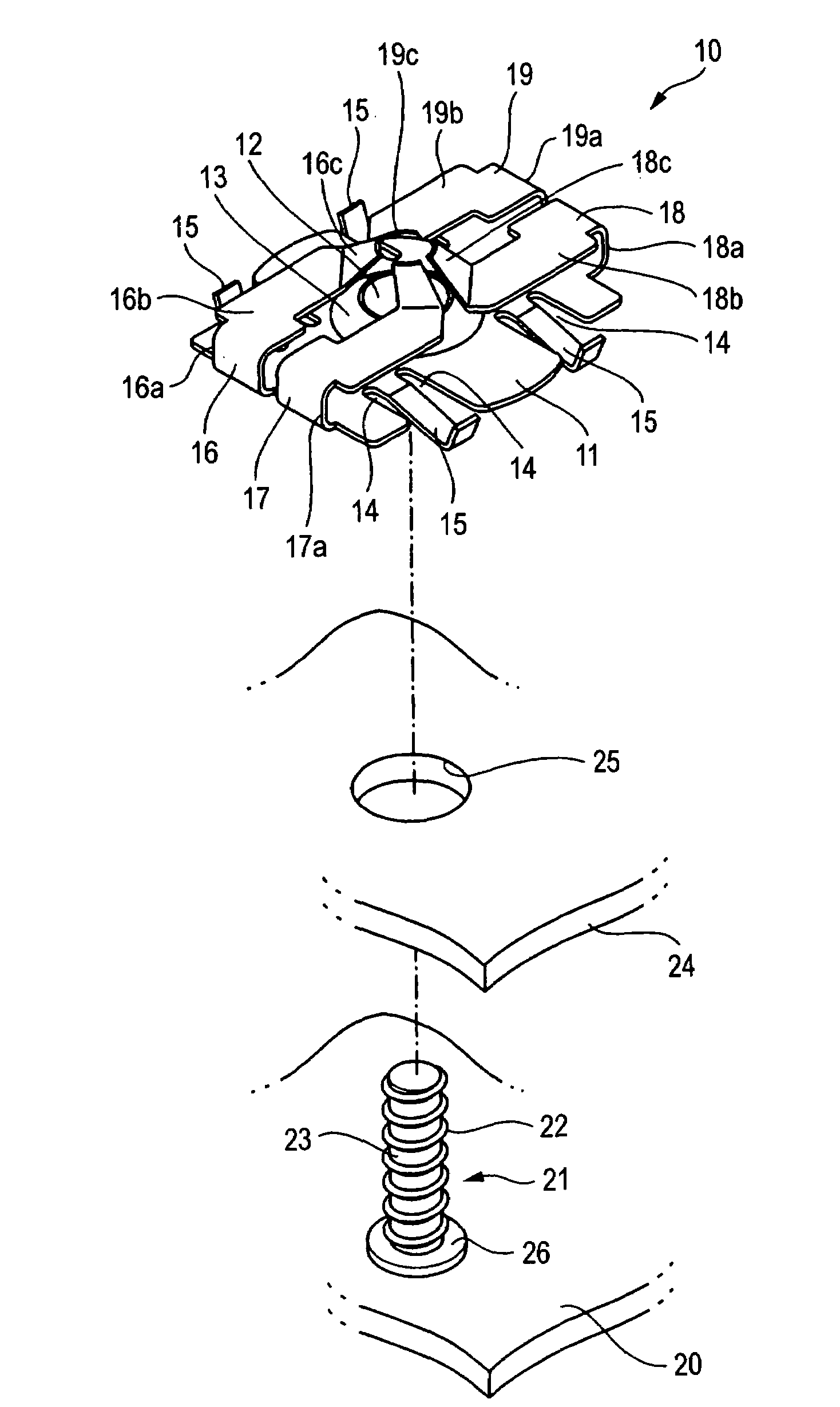

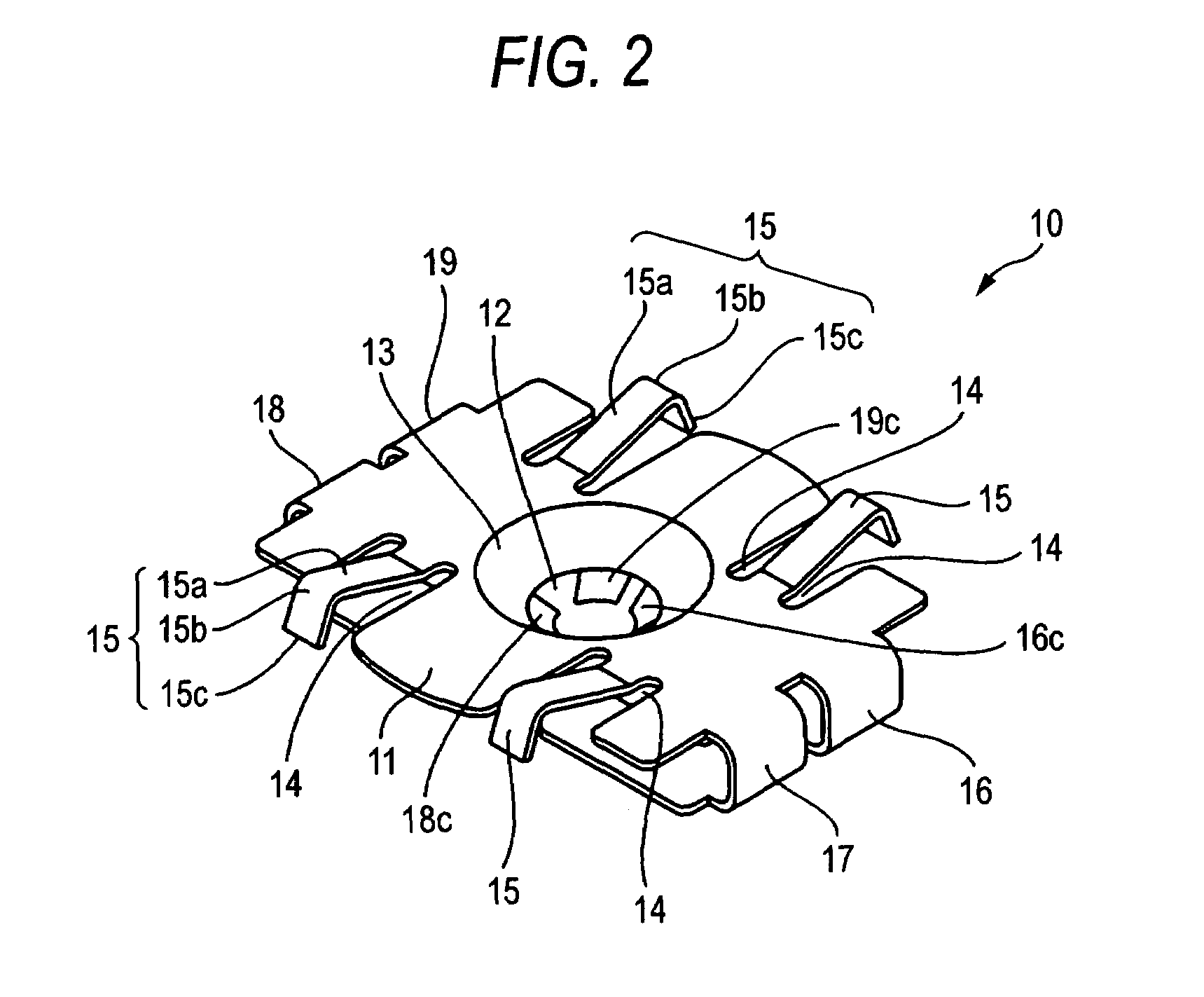

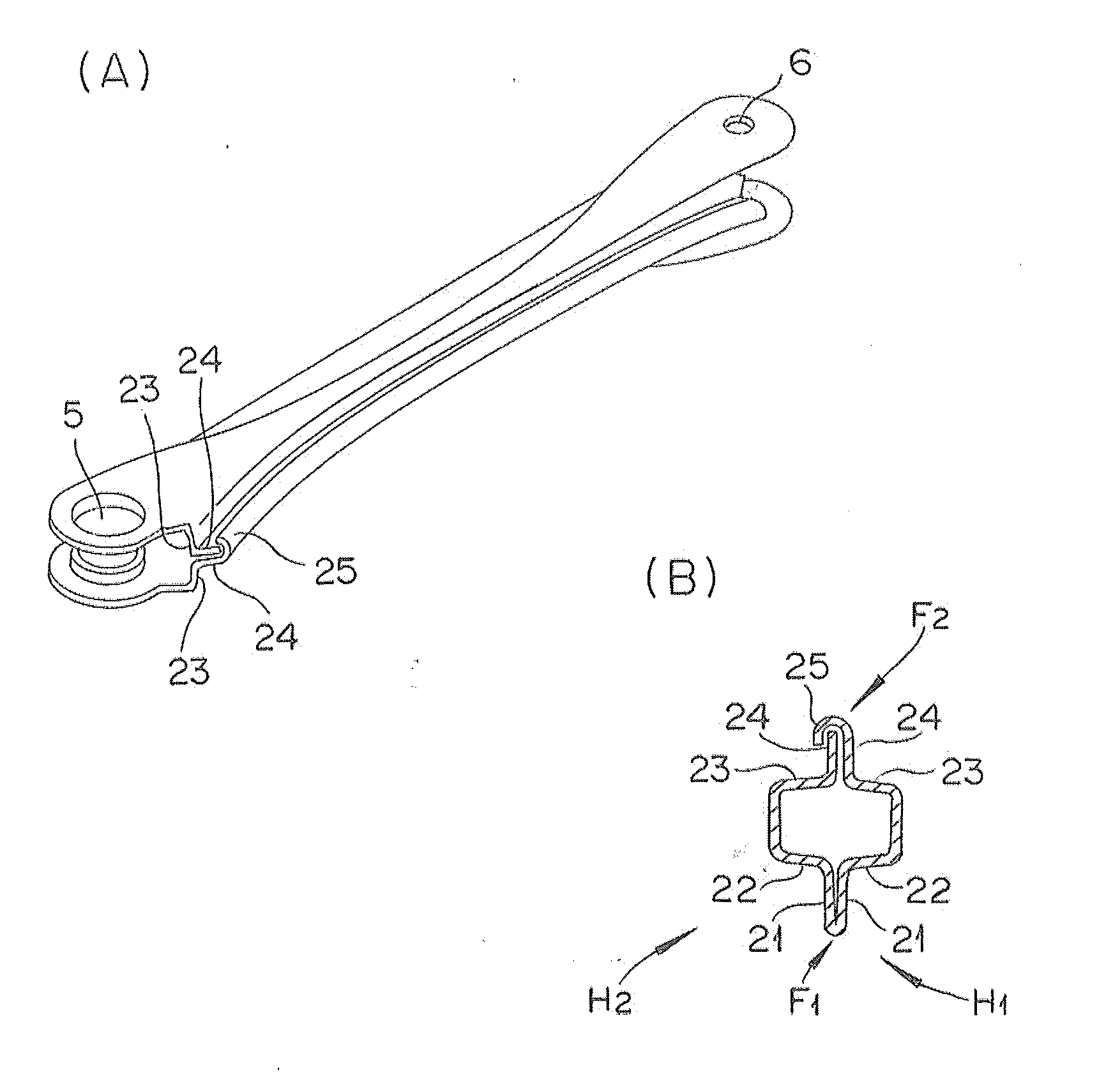

Push nut

A push nut including a base plate formed with a bolt passing hole at a center of the base plate and four engaging pieces. Pairs of engaging pieces extend respectively from a pair of opposing sides of the base plate, base portions of the four engaging pieces are folded back to have a U-shape, and tip end portions of the engaging pieces extend to a surrounding of the bolt passing hole. The tip end portions of the four engaging pieces surround a periphery of the bolt passing hole. The four engaging pieces incline toward an insertion direction of a bolt and elastically abut against an outer circumference of the bolt, which is inserted into the bolt passing hole.

Owner:PIOLAX CO LTD

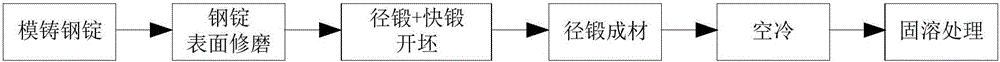

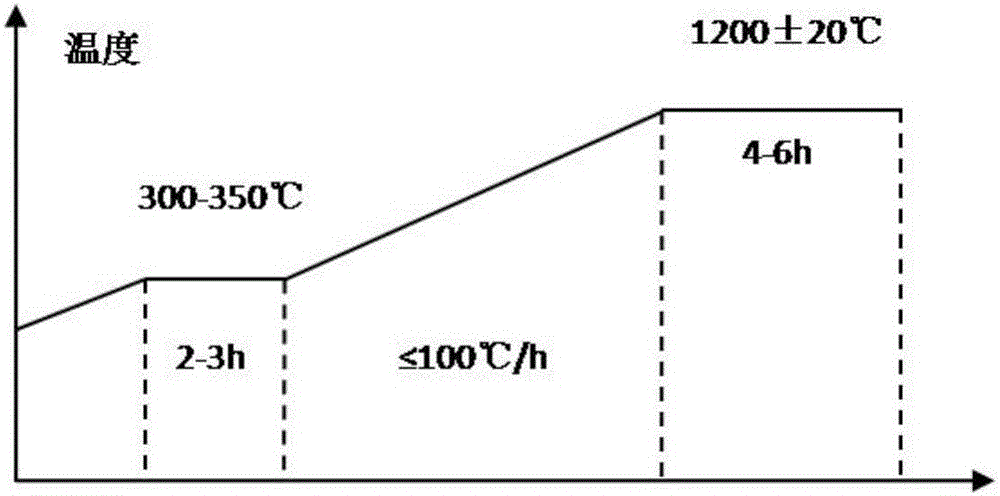

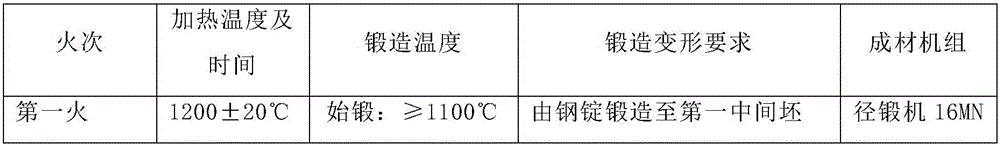

Special forging method suitable for super duplex stainless steel bars

ActiveCN105689613AImprove material yieldIncrease productivityHeating/cooling devicesSolution treatmentManufacturing technology

The invention belongs to the technical field of pressure machining and manufacturing and relates to a special forging method suitable for super duplex stainless steel bars. The novel special forging method suitable for the super duplex stainless steel bars is innovatively created with the advantages and disadvantages of radial forging machines and rapid forging presses fully considered and the characteristics of super duplex stainless steel considered. With steel ingots as raw materials, the method sequentially comprises the processes of radial forging and rapid forging combined blooming, radial forging finishing, air cooling and solution treatment. The yield of finished products of the super duplex stainless steel bars forged through the technology is high and is increased by more than 5% than the yield of original methods, the production efficiency is high, and the energy consumption is low. According to the method, the square or polygonal steel ingots with the section being 200-700*200-700 can be forged into the bars with Phi ranging from 60 mm to 400 mm.

Owner:DAYE SPECIAL STEEL CO LTD

Arm component for vehicles and its manufacturing method

InactiveUS20140008886A1Quickly and simply formedGood lookingConnecting rodsMetal-working apparatusEngineeringFlange

Disclosed herein is a suspension arm component for vehicles with sufficient strength or rigidity to withstand repetitive compressive and tensile forces, and a method for manufacturing such a component by pressing or hemming process alone, without recourse to any welding process, forming quickly and simply, a process with advantages in terms of material yield and cost. The suspension arm component for vehicles includes first flange pieces as well as second flange pieces, and a pair of half members, each having a hat-like shaped cross-section perpendicular to its axis, are joined together to protrude the first flange part and the second flange part from an expanded part, where both the first flange part and the second flange part extend linearly along the axis of the main body part. The main body part presents a rectangular shape in its side view.

Owner:YOROZU

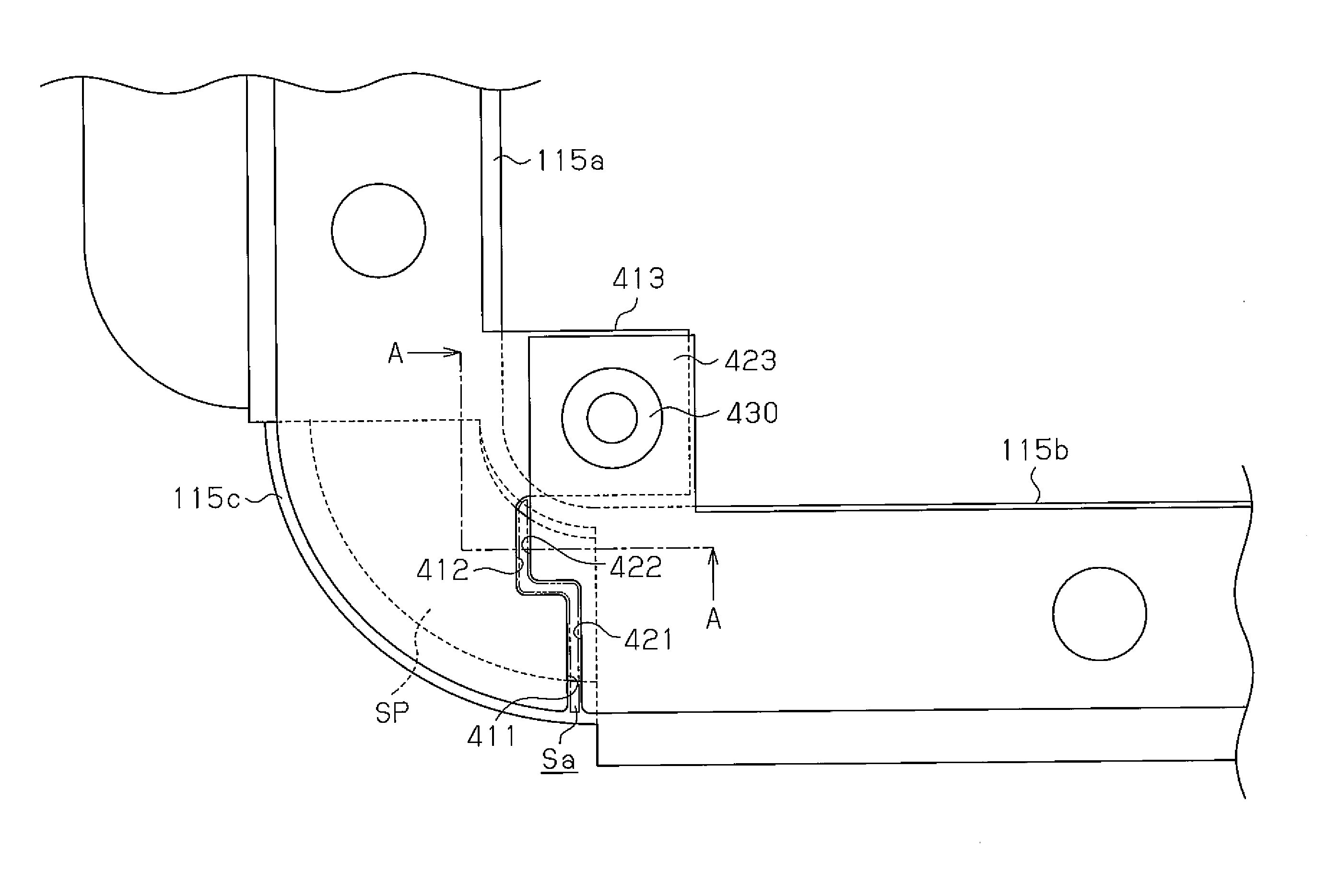

Seal structure using gasket

A gasket arranged between two sealed subject surfaces includes a plurality of segments. A recess is arranged in one of the two sealed subject surfaces at a portion corresponding to a clearance between adjacent segments. A seal is filled in the recess and deformed in accordance with the shape of the clearance between the segments.

Owner:PANASONIC EV ENERGY CO LTD

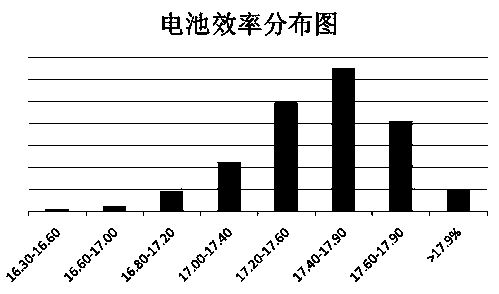

Polycrystalline silicon and preparation method thereof

InactiveCN103422165AImprove material yieldLow costPolycrystalline material growthSingle crystal growth detailsSilicon chipCrystal growth

The invention discloses a preparation method of polycrystalline silicon. According to the method, the twin crystal growth control technology is adopted, the ordinary polycrystalline process is optimized, a heat insulation cage is quickly opened, and the opening of the heat insulation cage is adjusted to be 6-8cm; at the initial stage of growth of the crystal, the temperature of a heater is adjusted to be 1425-1440 DEG C, the heat insulation cage is slowly lifted, a layer of uniform dendritic crystal grows vertically on a nucleation source layer along the bottom of a crucible, then dendritic crystal is taken as the seed crystal, and vertically upward directionally grows to form the polycrystalline silicon. The polycrystalline silicon prepared by the invention contains a great quantity of twin crystals, as the twin crystals have the advantages that the interfacial energy of the twin crystals is low, the twin crystals are relatively more stable, and the like, and the polycrystalline silicon prepared by the method has the advantage of few dislocation defects, the battery efficiency of the polycrystalline silicon is higher than that of the ordinary polycrystalline silicon for 0.2-0.4%, the average battery efficiency of a whole silicon wafer reaches 17.5%, and the highest efficiency reaches 18.0%.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

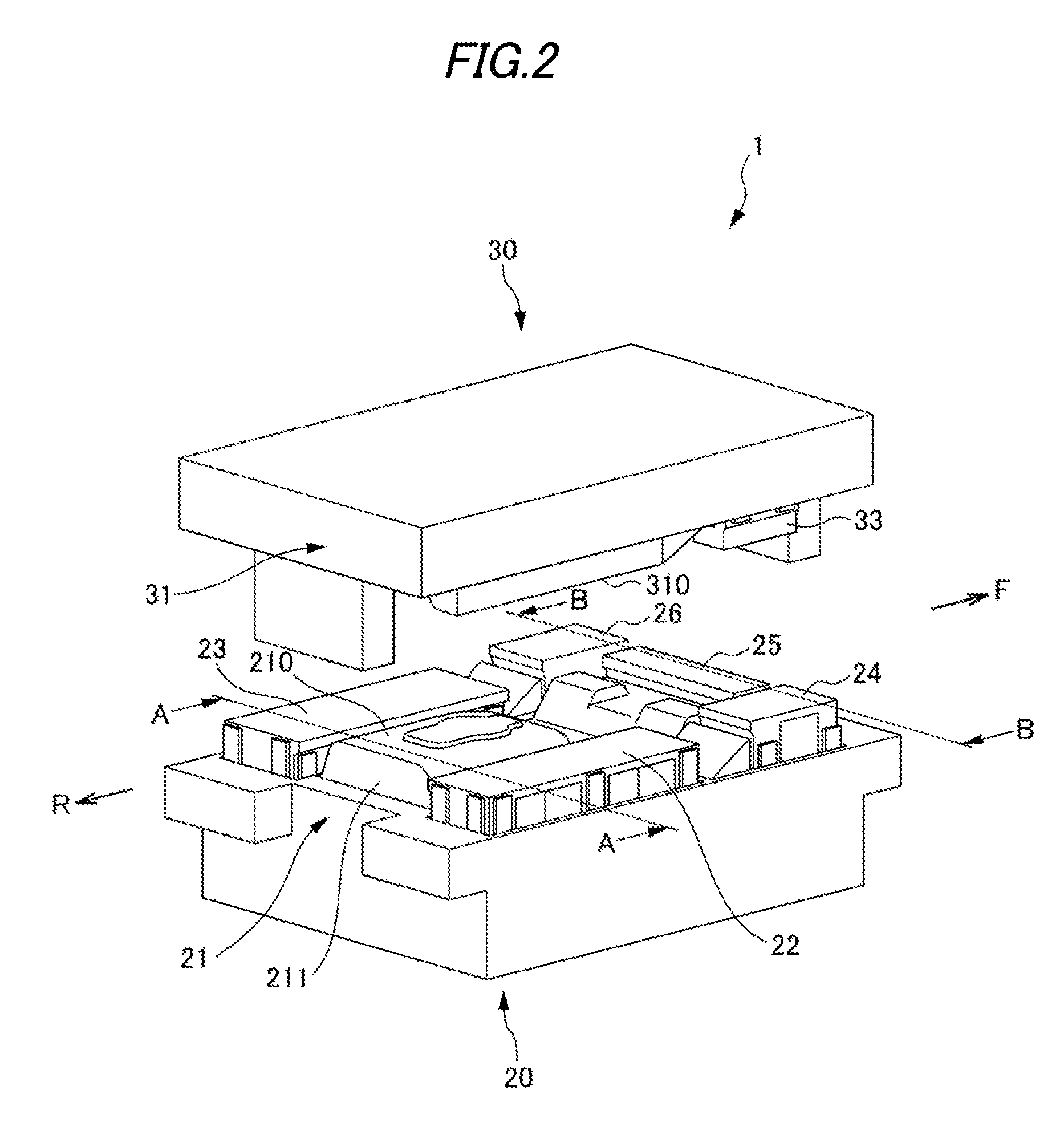

Press-forming method and press-forming apparatus

ActiveUS20120324974A1Avoiding increase of sizeImprove material yieldEngineeringMechanical engineering

A workpiece is press-formed into a press-formed product in a single stroke using a punch and a die by grasping a first portion of the workpiece by a blank holder at a first timing in the single stroke, and grasping a second portion of the workpiece which is different form the first portion by the blank holder at a second timing in the single stroke which is different from the first timing.

Owner:HONDA MOTOR CO LTD

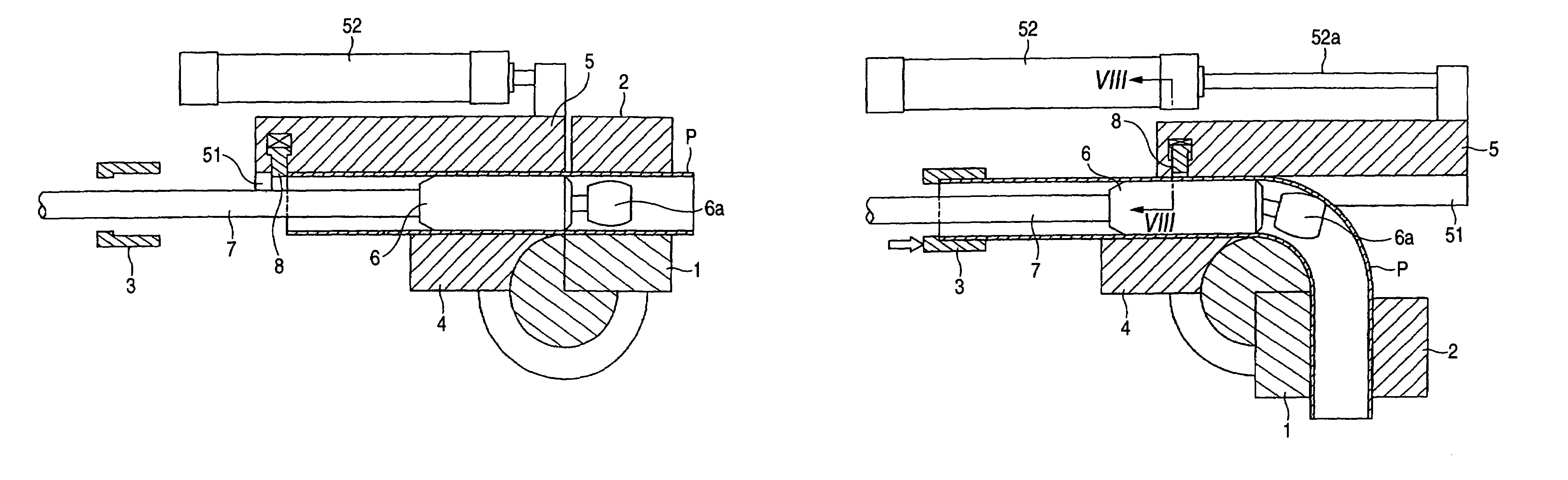

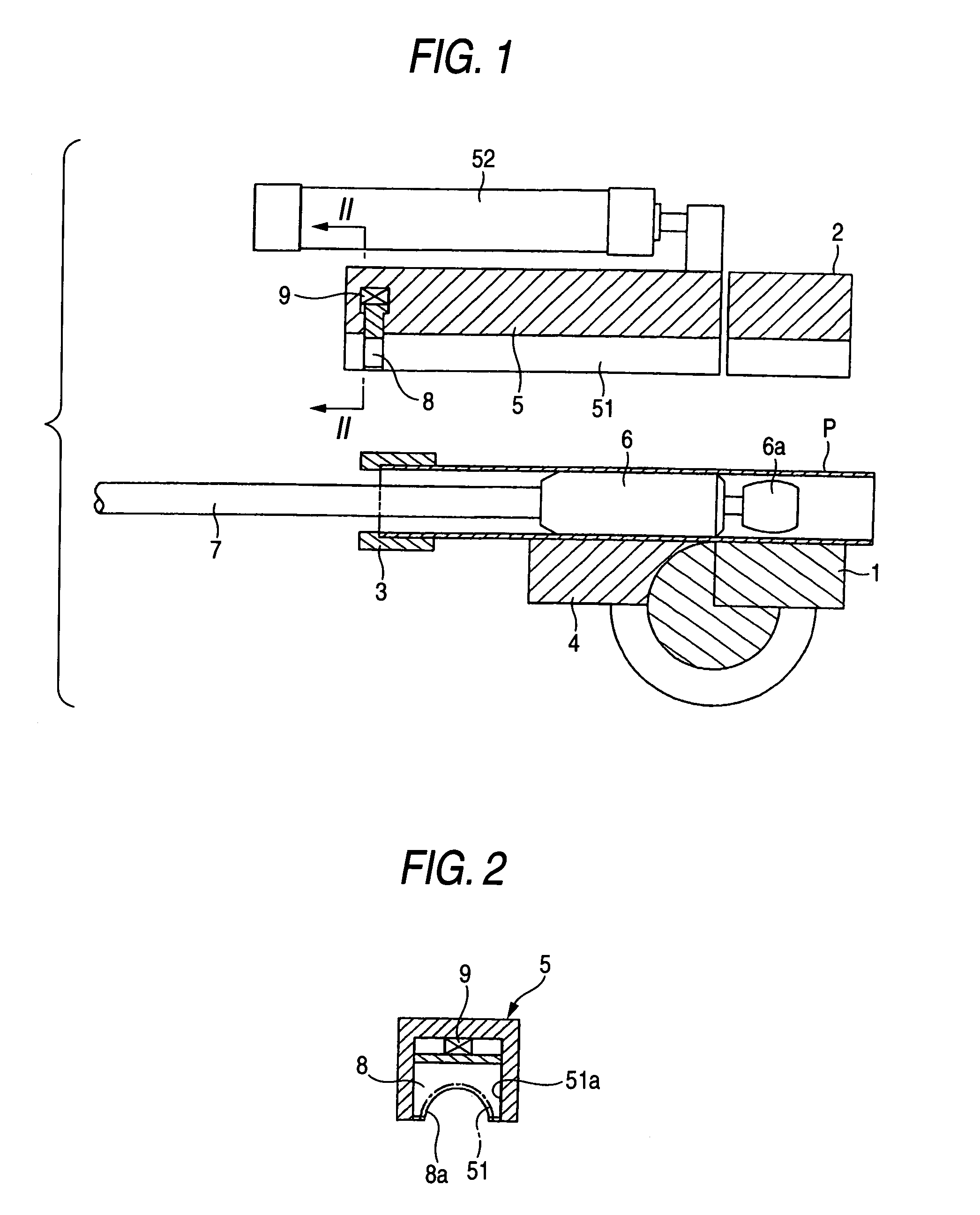

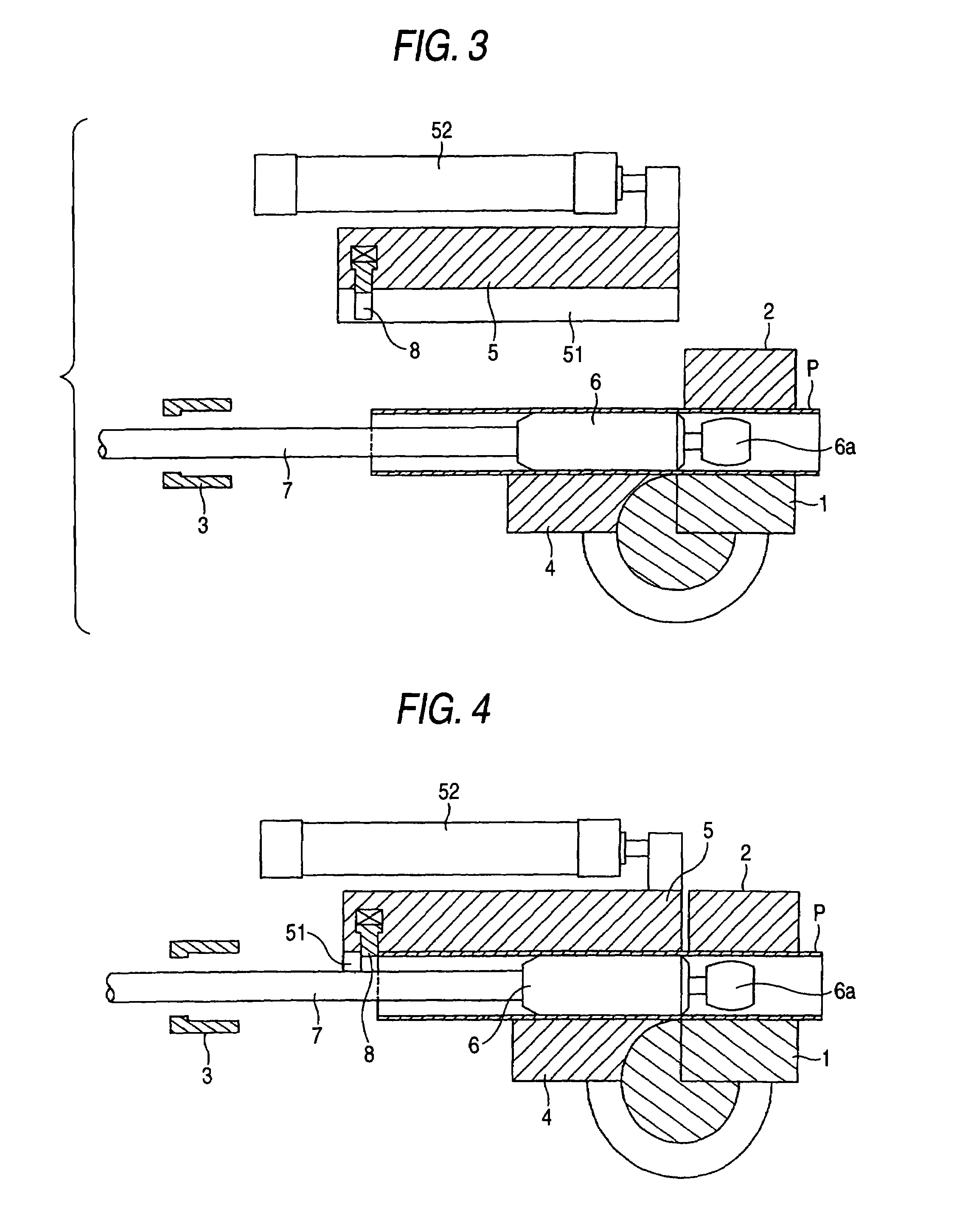

Pipe bending processing apparatus and pipe bending processing method

A pipe bending processing apparatus includes a drawing and bending section for pressingly contacting a drawing and bending mold, a clamp mold with one end of a pipe P and performing drawing and bending processing, compression bending section for pressingly contacting a chuck with the other end of the pipe and performing compression bending processing, side bending section for pressingly contacting a wiper, and a side bending mold with the side of the pipe and performing side bending processing. The side bending mold provides a stopper 8 which advances and retracts from a pipe pressingly contact surface and engages with the other end of the pipe.

Owner:CALSONIC KANSEI CORP

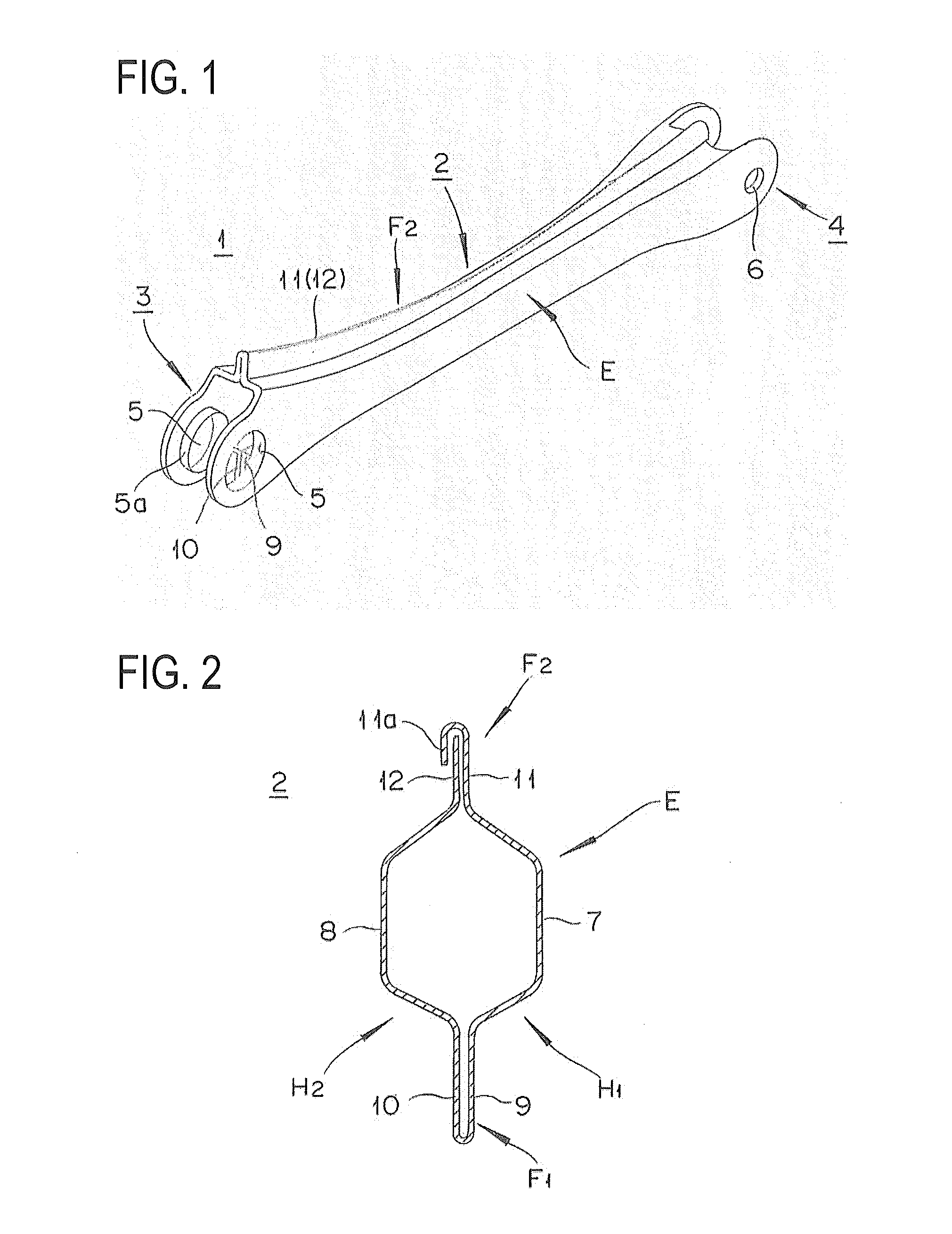

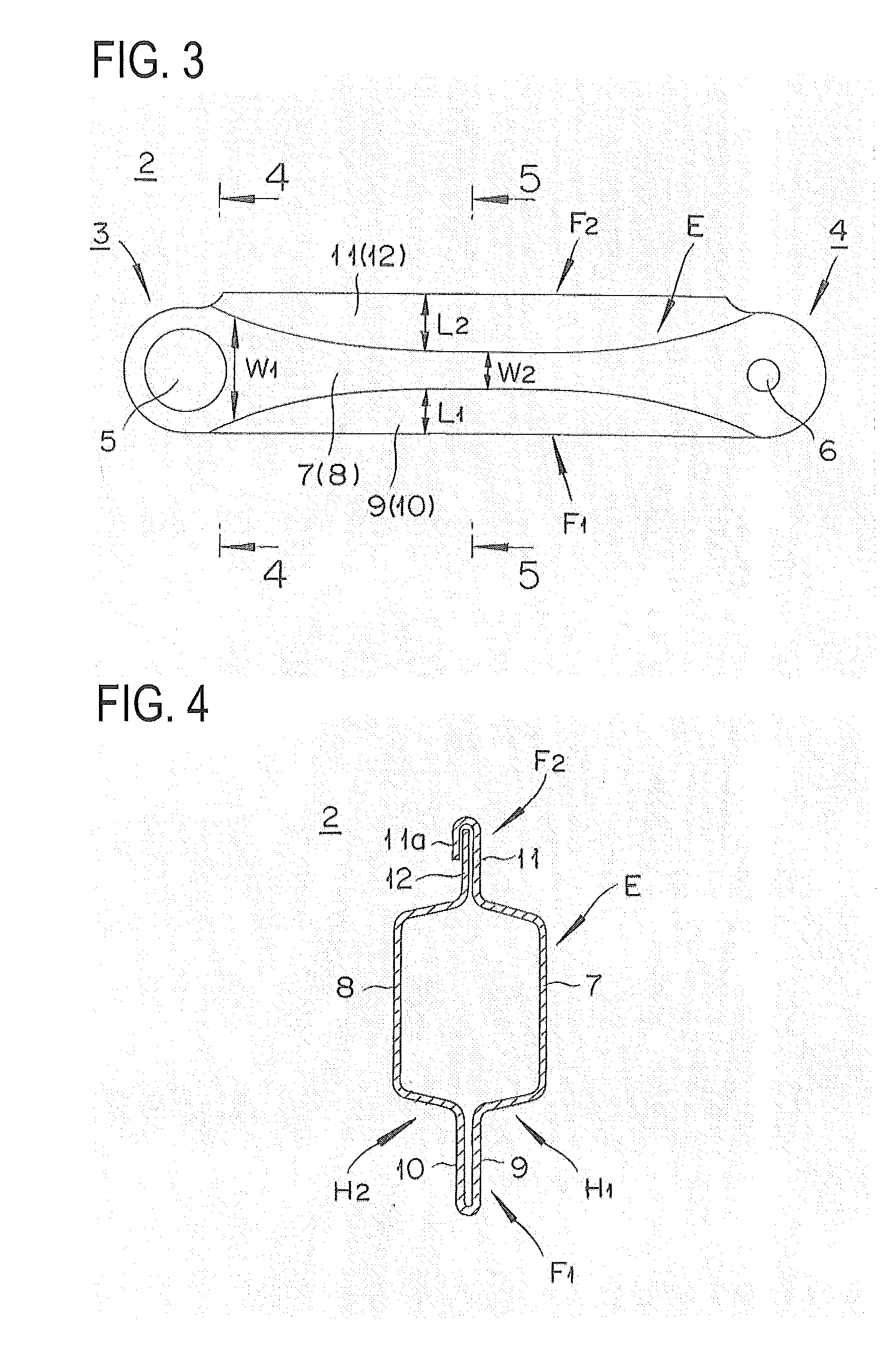

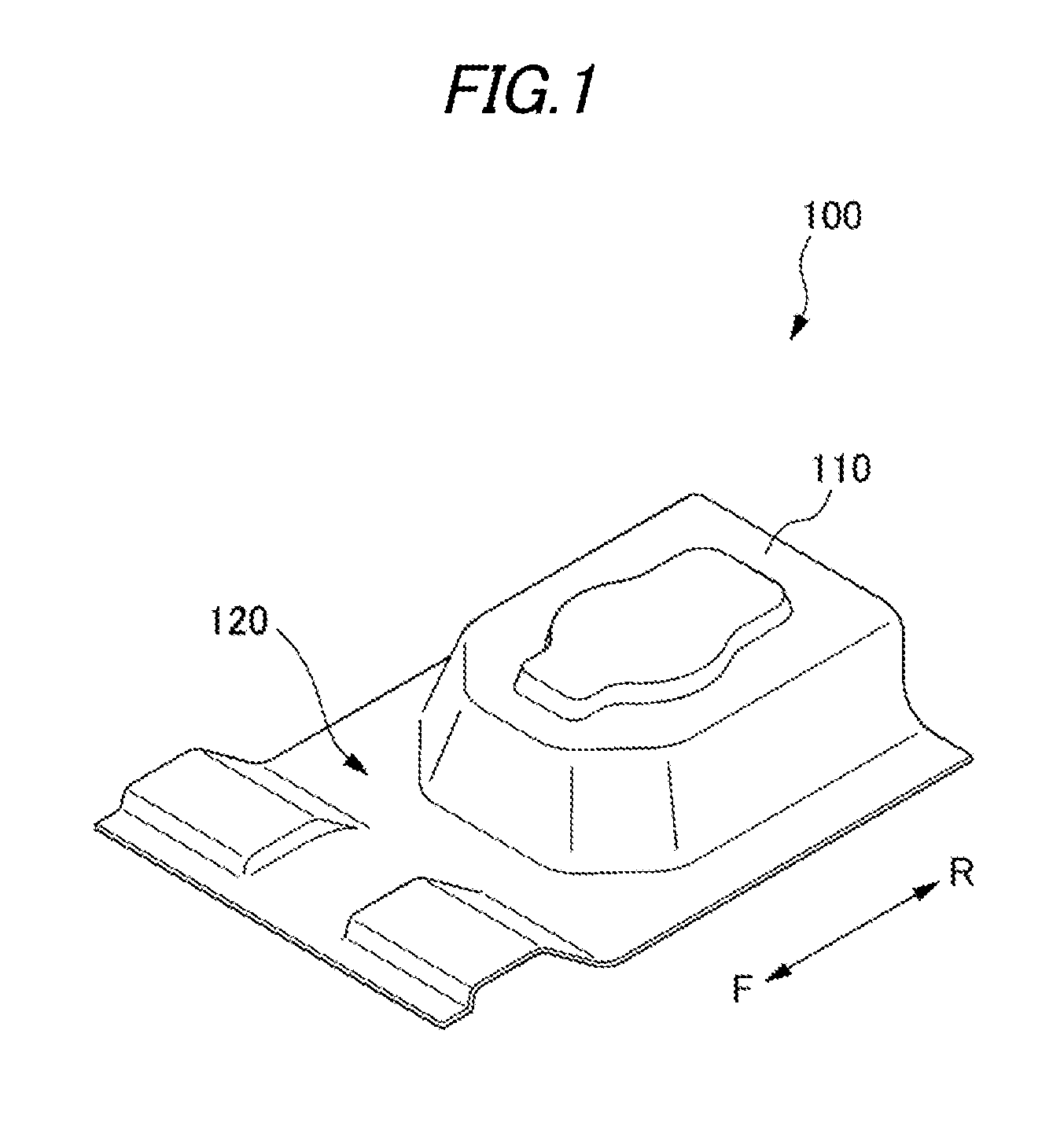

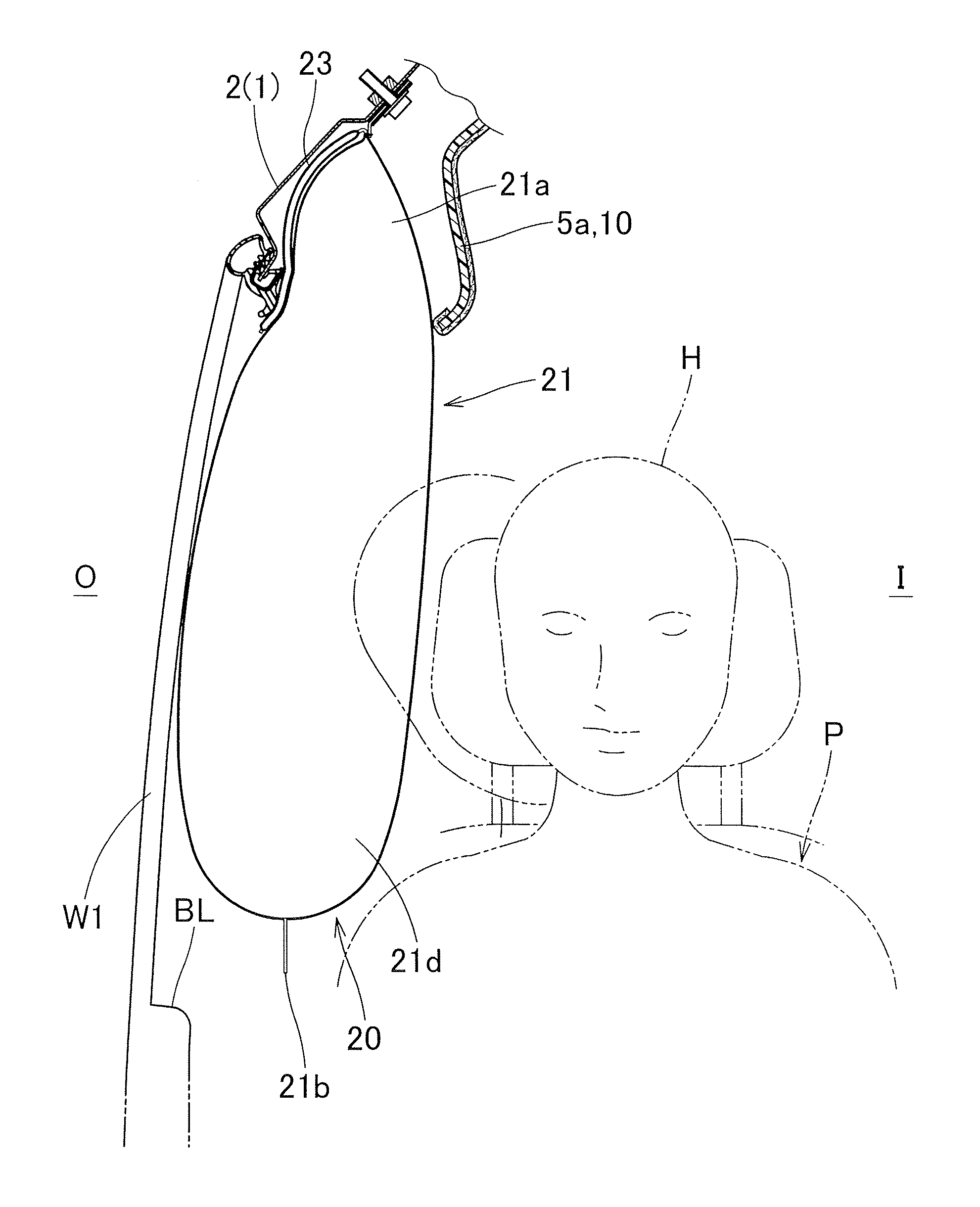

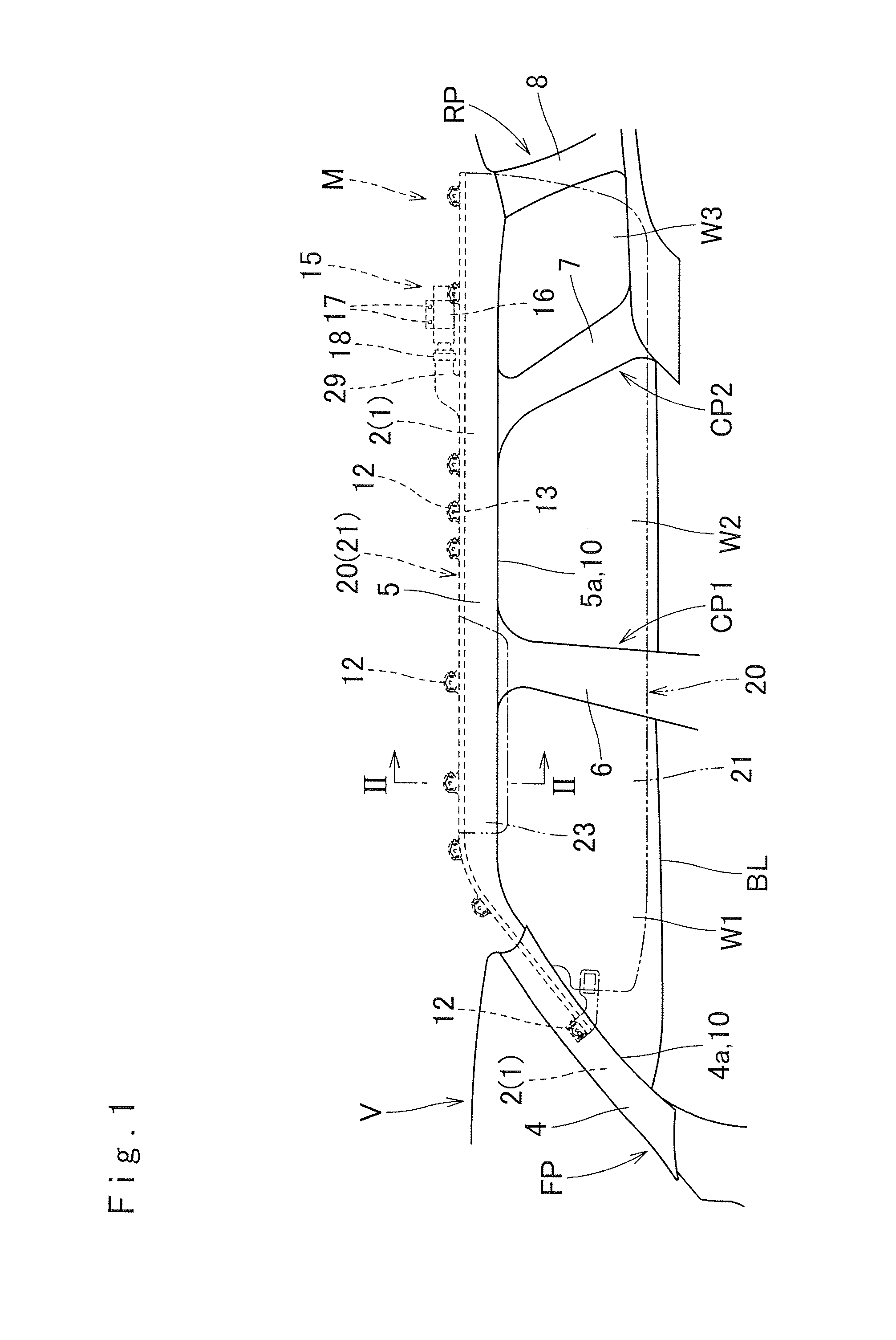

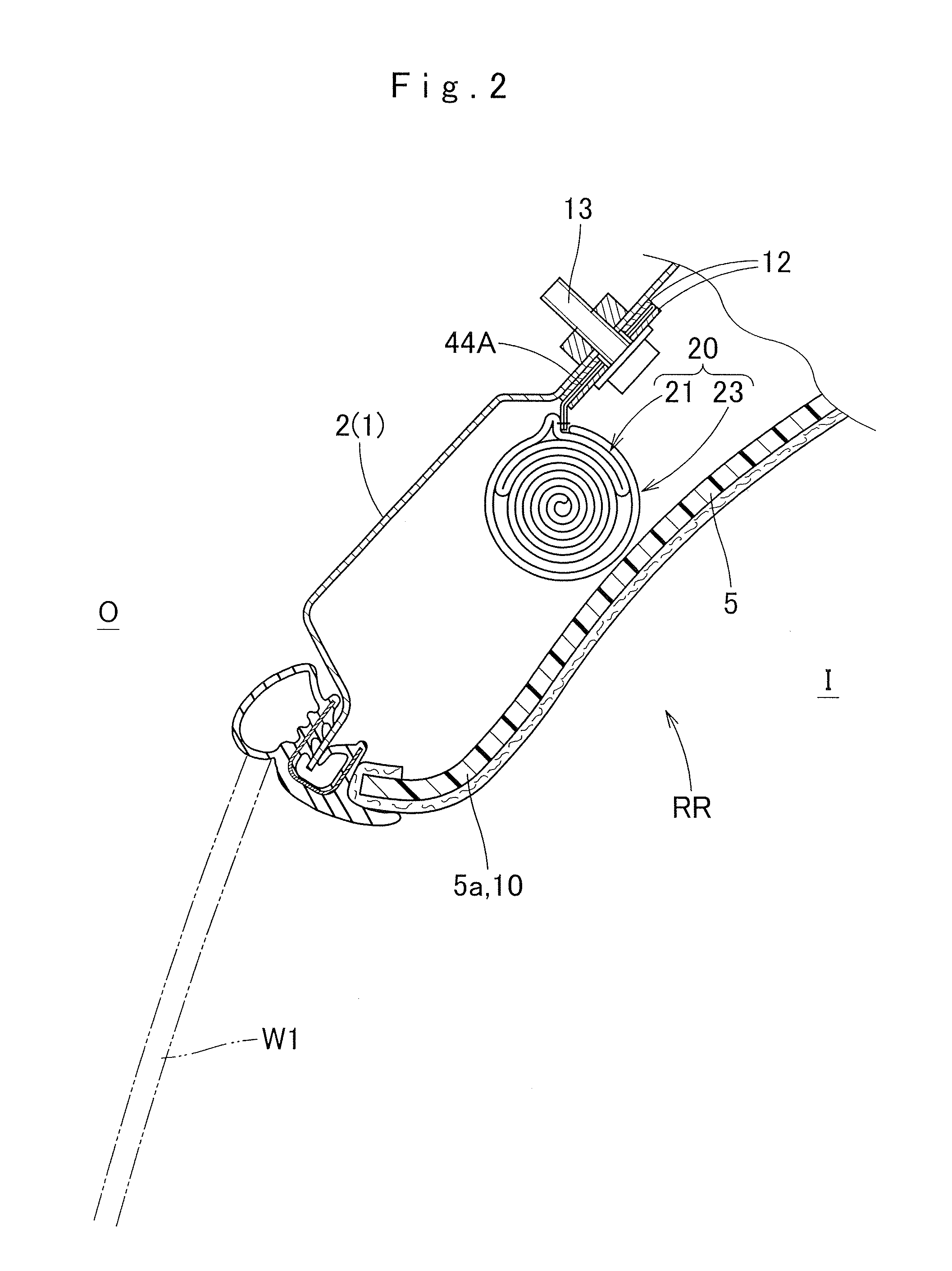

Head-protecting airbag apparatus

ActiveUS20120032426A1Improve material yieldLower the volumePedestrian/occupant safety arrangementAirbagAerospace engineering

A head-protecting airbag apparatus mountable on a vehicle having a window is disclosed. The airbag apparatus includes an airbag adapted to be secured to a member of a vehicle body structure by an upper edge thereof in an upper edge of the window and housed in the upper edge of the window in a folded-up configuration. The airbag includes an inflatable shielding section that covers an inboard side of the window at full airbag deployment, a supporting inflatable region that is in gas communication with the shielding section and deployable between an outboard side of a vicinity of an upper end of the shielding section and the member of the vehicle body structure in an upper area of the window, and delaying means that delays inflation of the supporting inflatable region relative to the shielding section. The supporting inflatable region inflates after the shielding section does between the shielding section and the member of the vehicle body structure, and supports the outboard side of the vicinity of the upper end of the shielding section.

Owner:TOYODA GOSEI CO LTD

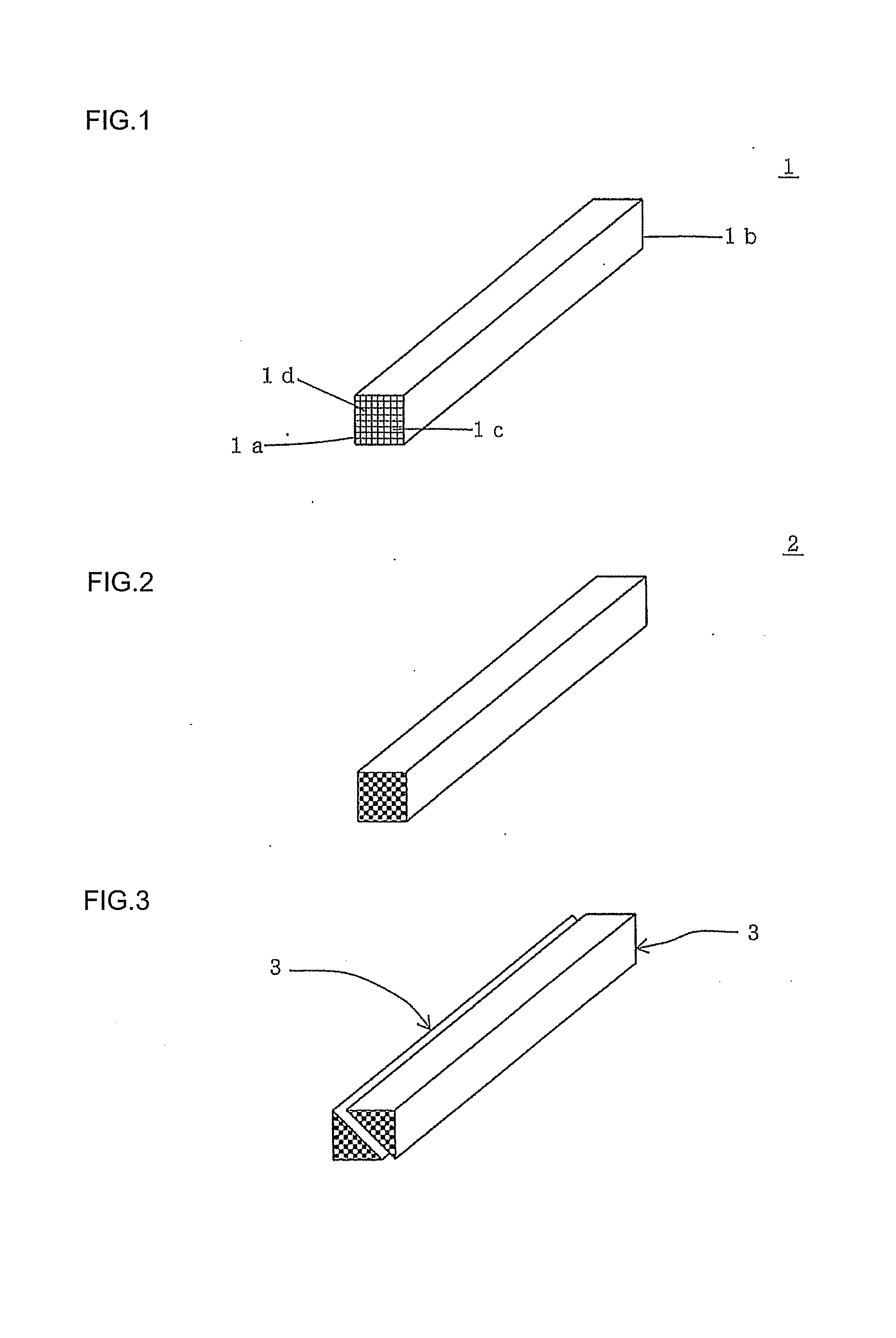

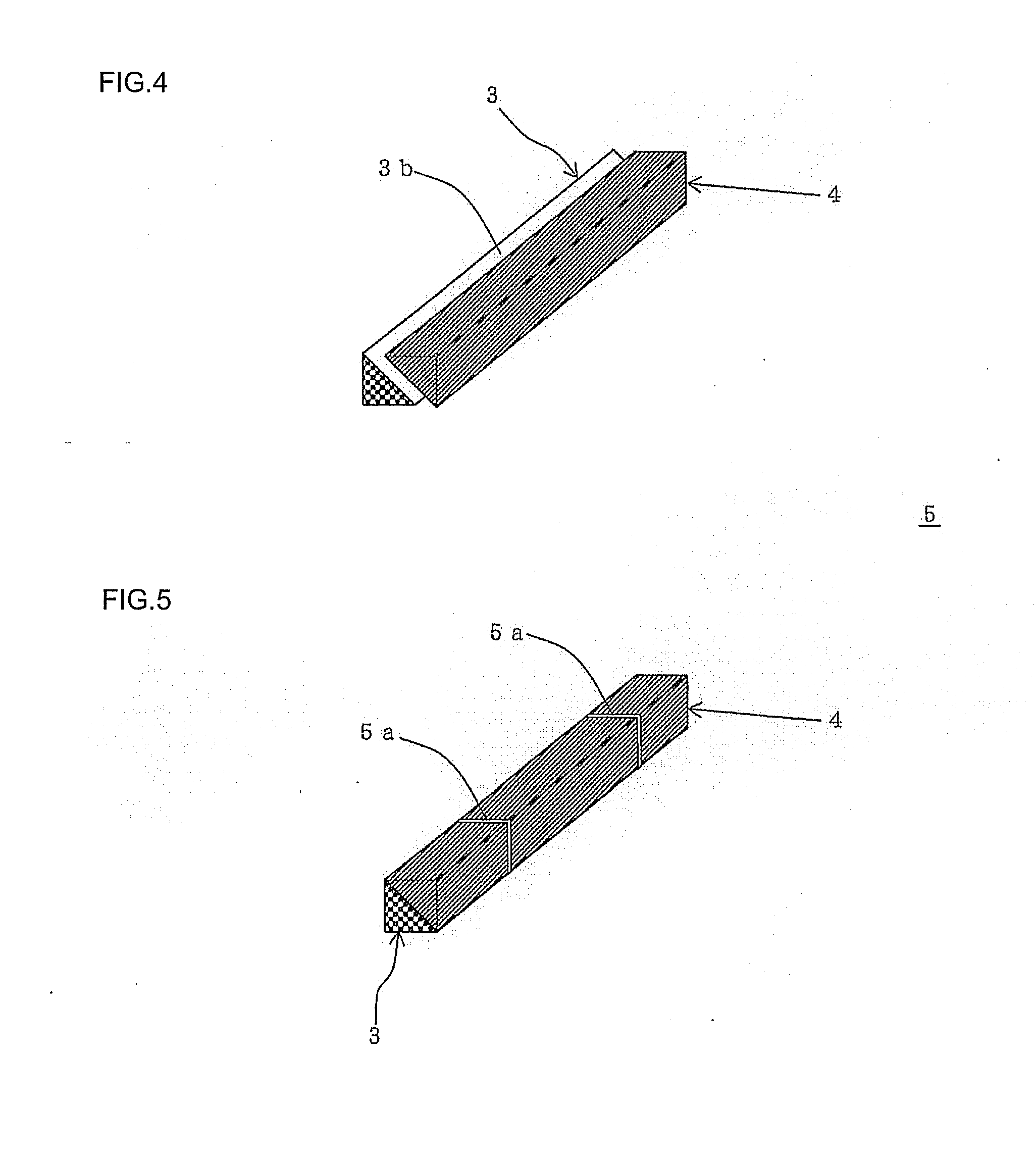

Method for manufacturing honeycomb structure

ActiveUS20110240205A1Material yield be improveHigh strengthPhysical/chemical process catalystsDispersed particle filtrationHoneycomb structurePrism

A method for manufacturing a honeycomb structure includes the steps of: producing triangular segments as cut quadrangular prism honeycomb fired bodies in double by cutting half, forming a pseudo quadrangular segment by fitting a hollow auxiliary member whose outer peripheral shape is triangular on a cut triangular segment, disposing the honeycomb fired bodies and the pseudo quadrangular segments to form an assembly, bonding the assembly by applying a bonding material, and then applying pressure to thus bonded assembly to obtain a honeycomb block body with the hallow auxiliary members, drying the applied bonding material and then detaching the hollow auxiliary members to obtain a honeycomb block body, and grinding an outer peripheral portion of a resultant honeycomb block body to obtain a honeycomb structure.

Owner:NGK INSULATORS LTD

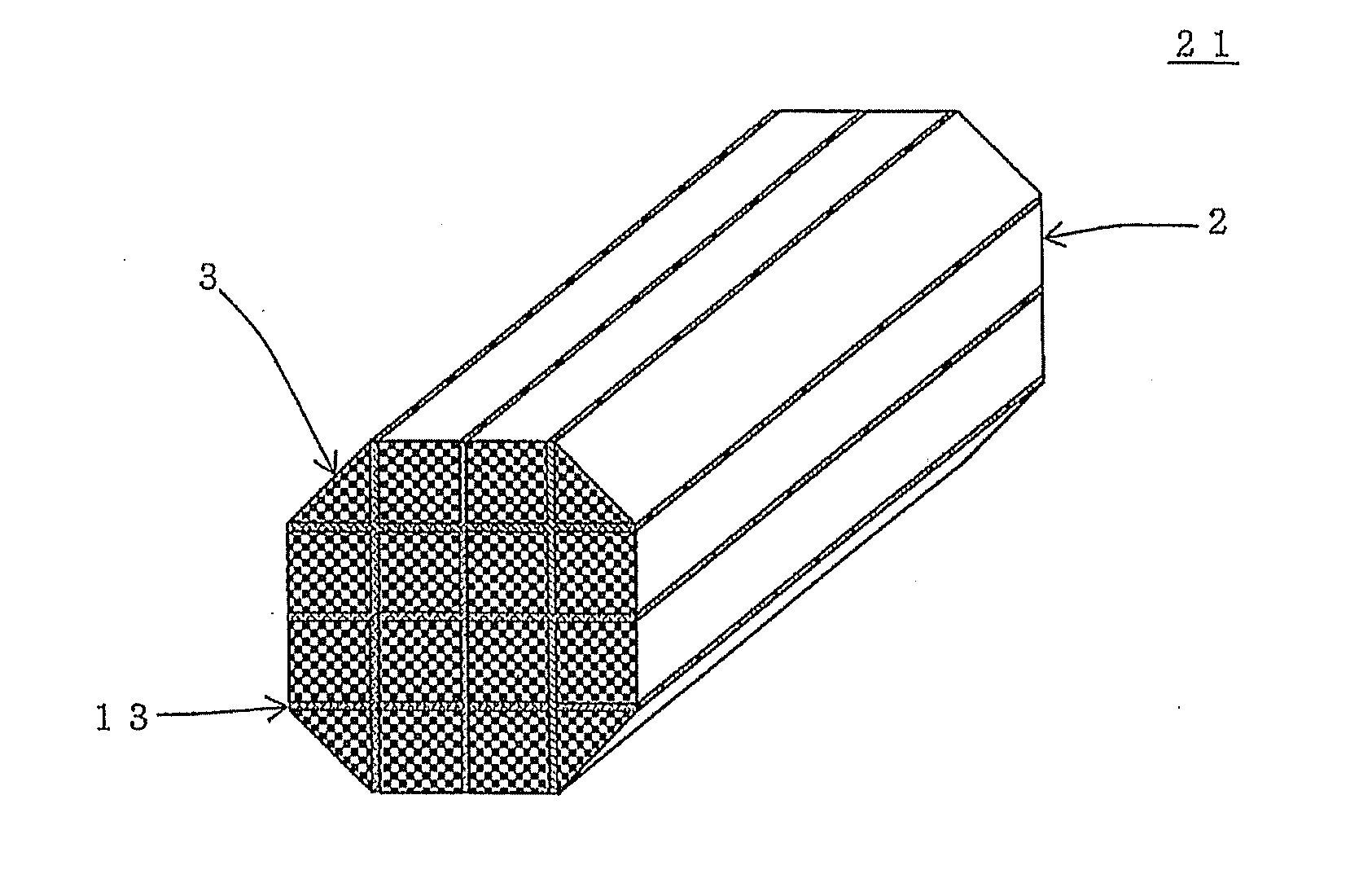

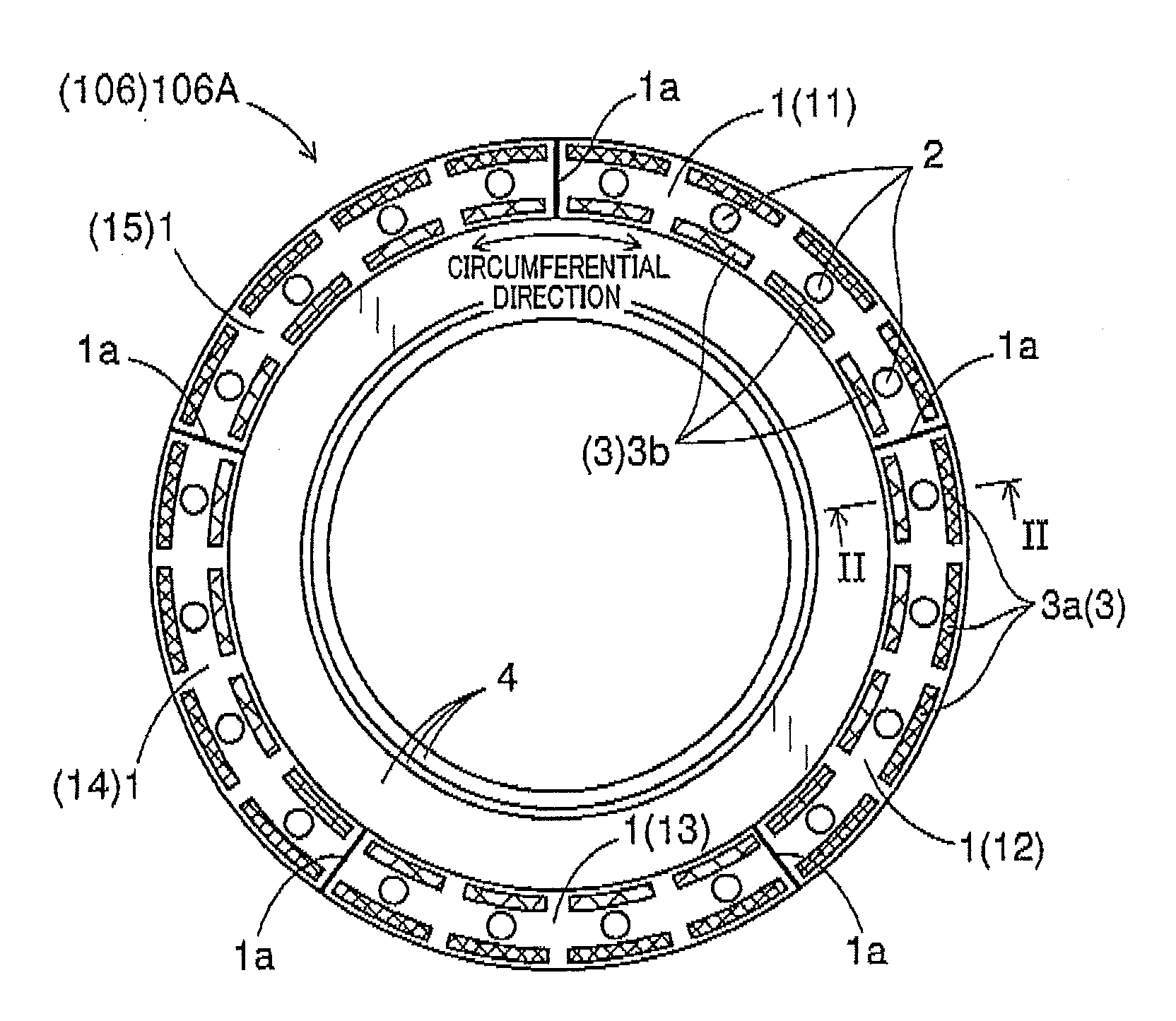

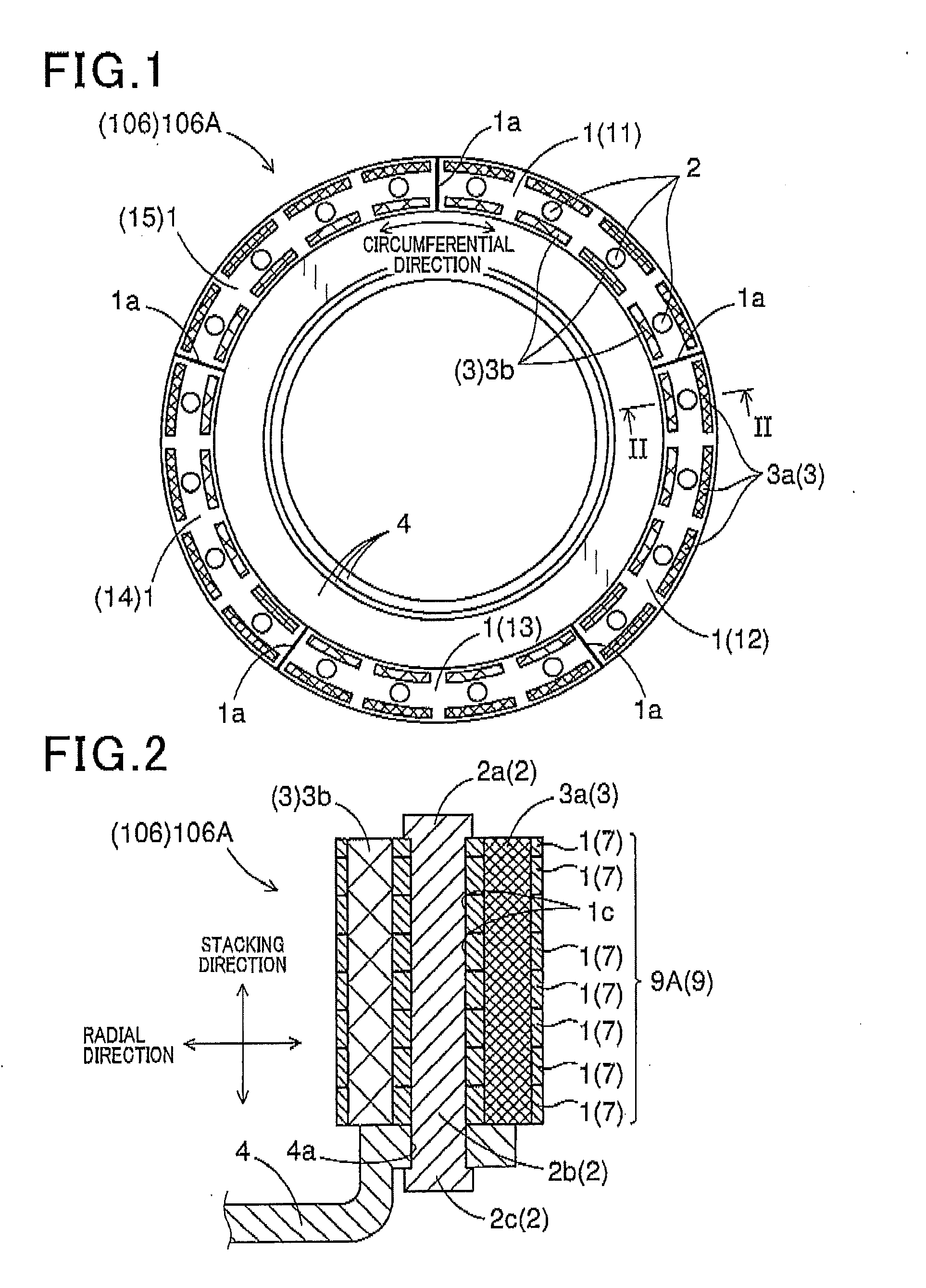

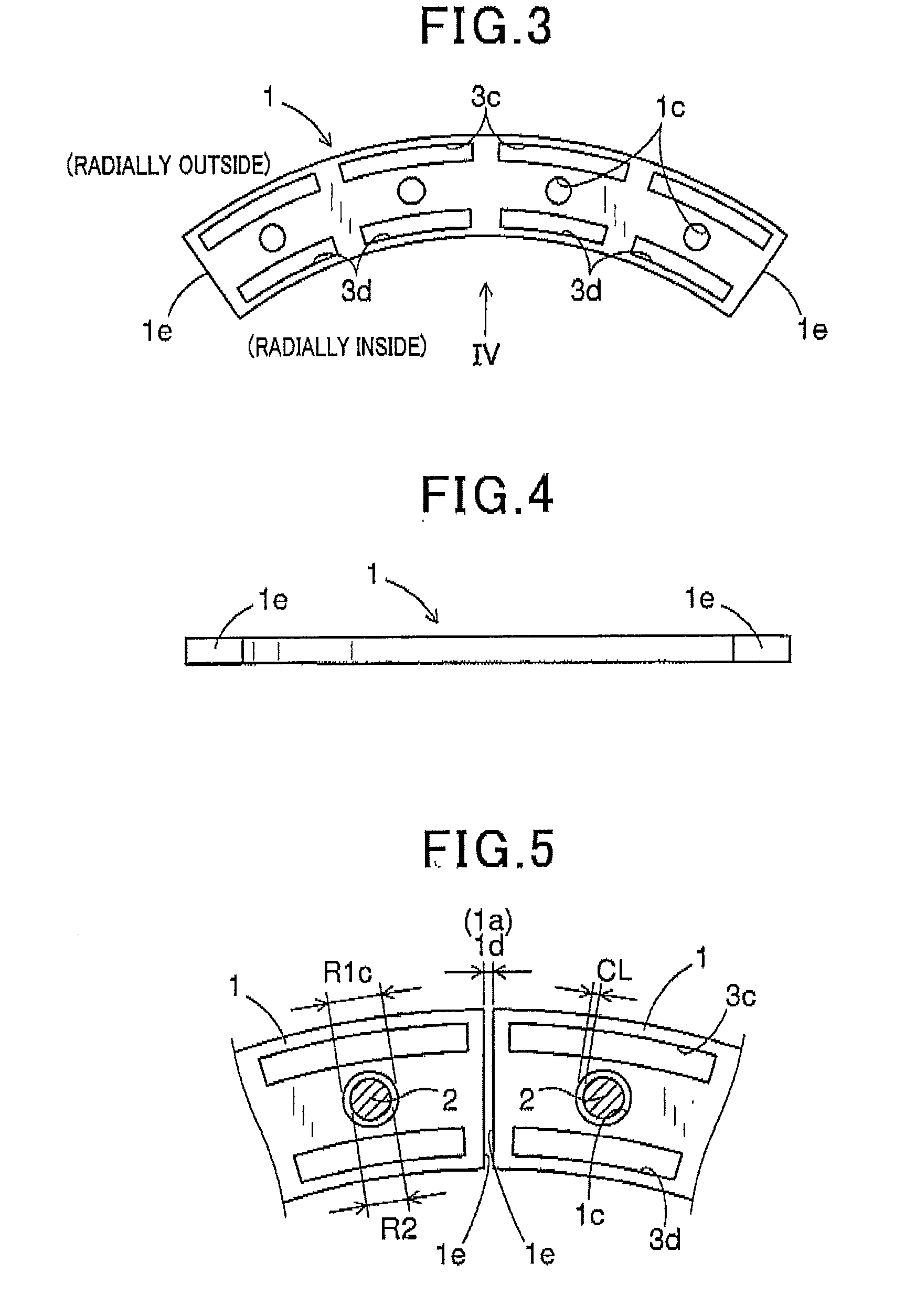

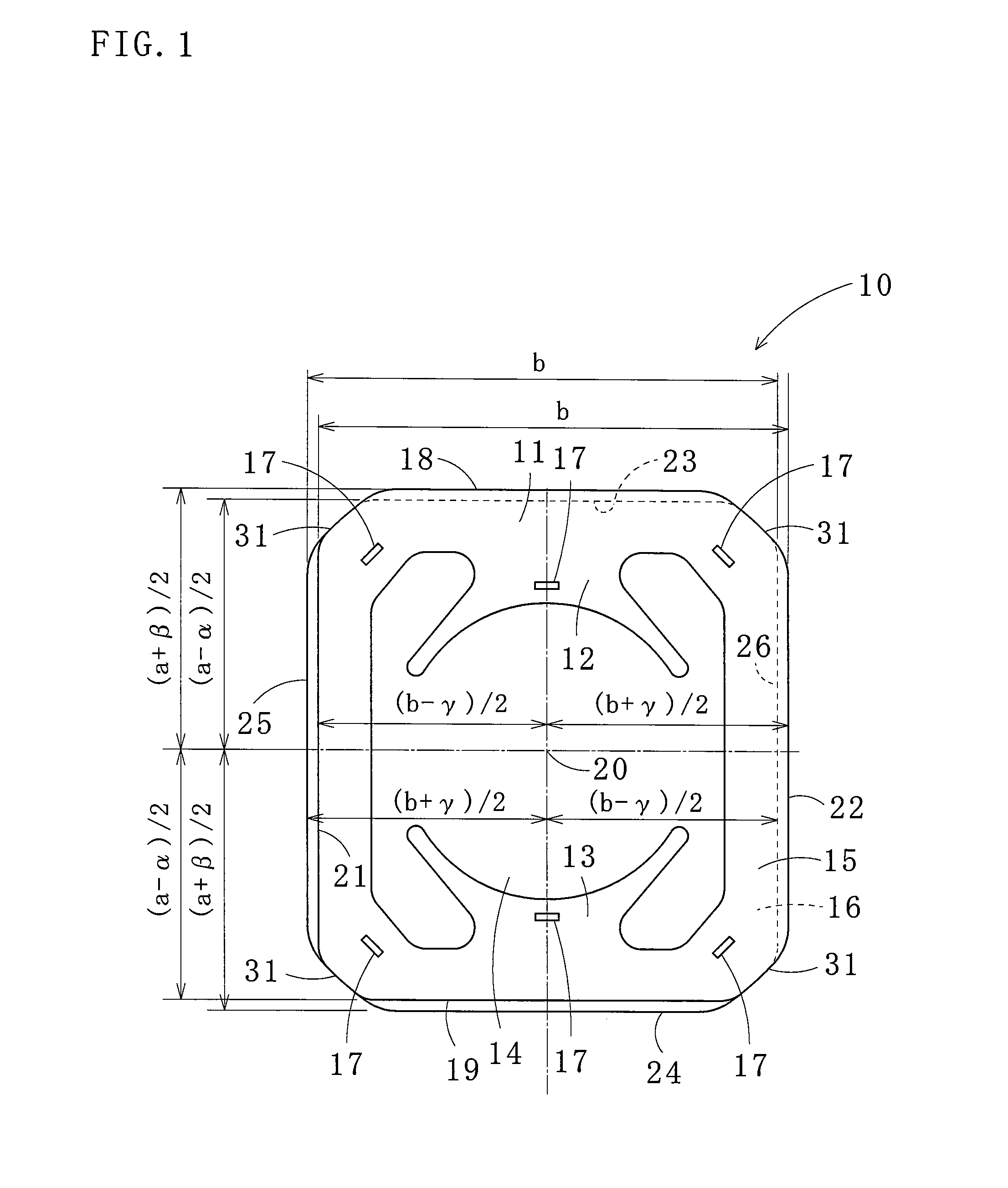

Laminated core

InactiveUS8466596B2Avoid stress concentrationAvoid large gapsMagnetic circuit stationary partsManufacturing dynamo-electric machinesElectrical and Electronics engineeringAdjacent segment

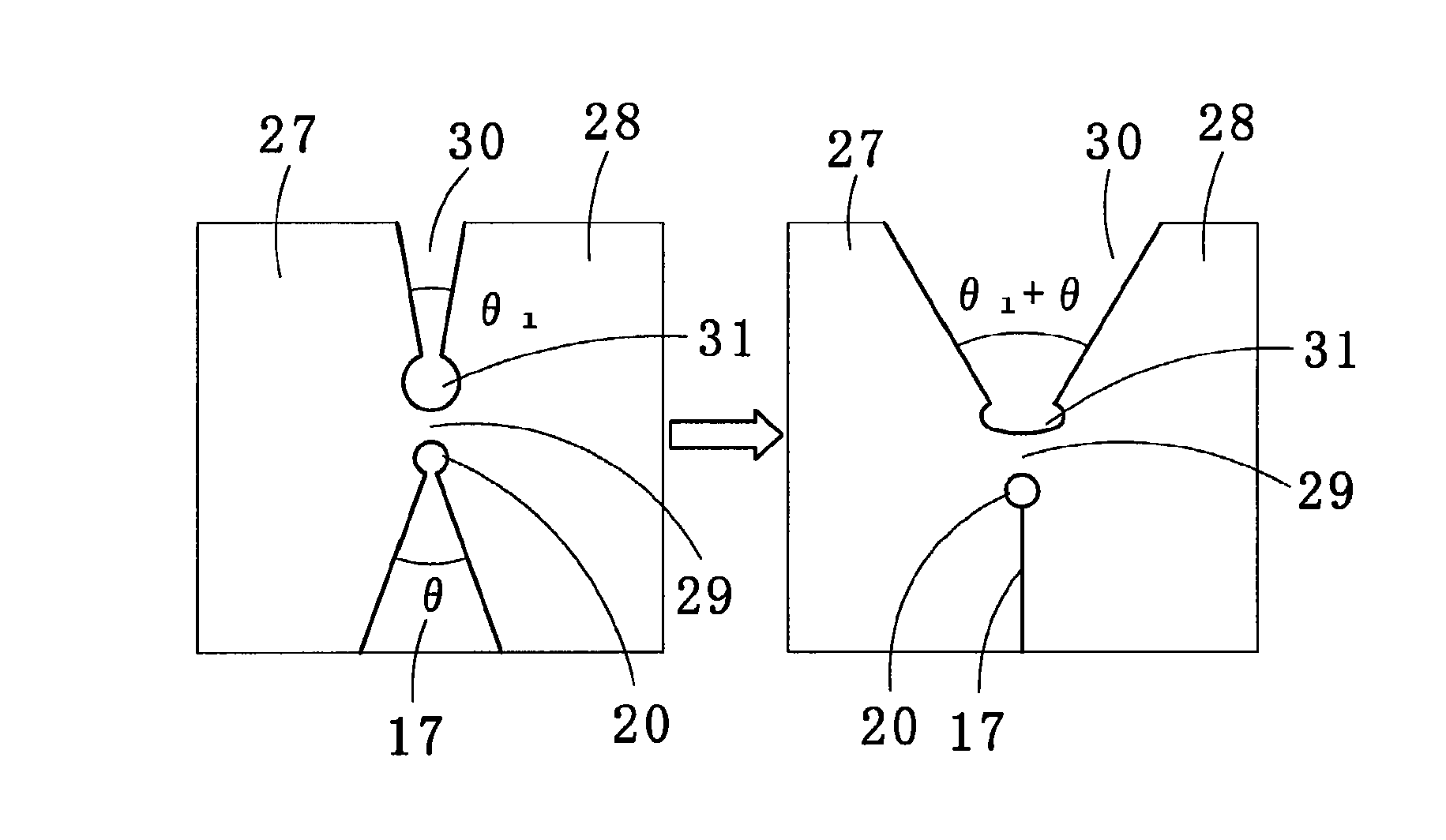

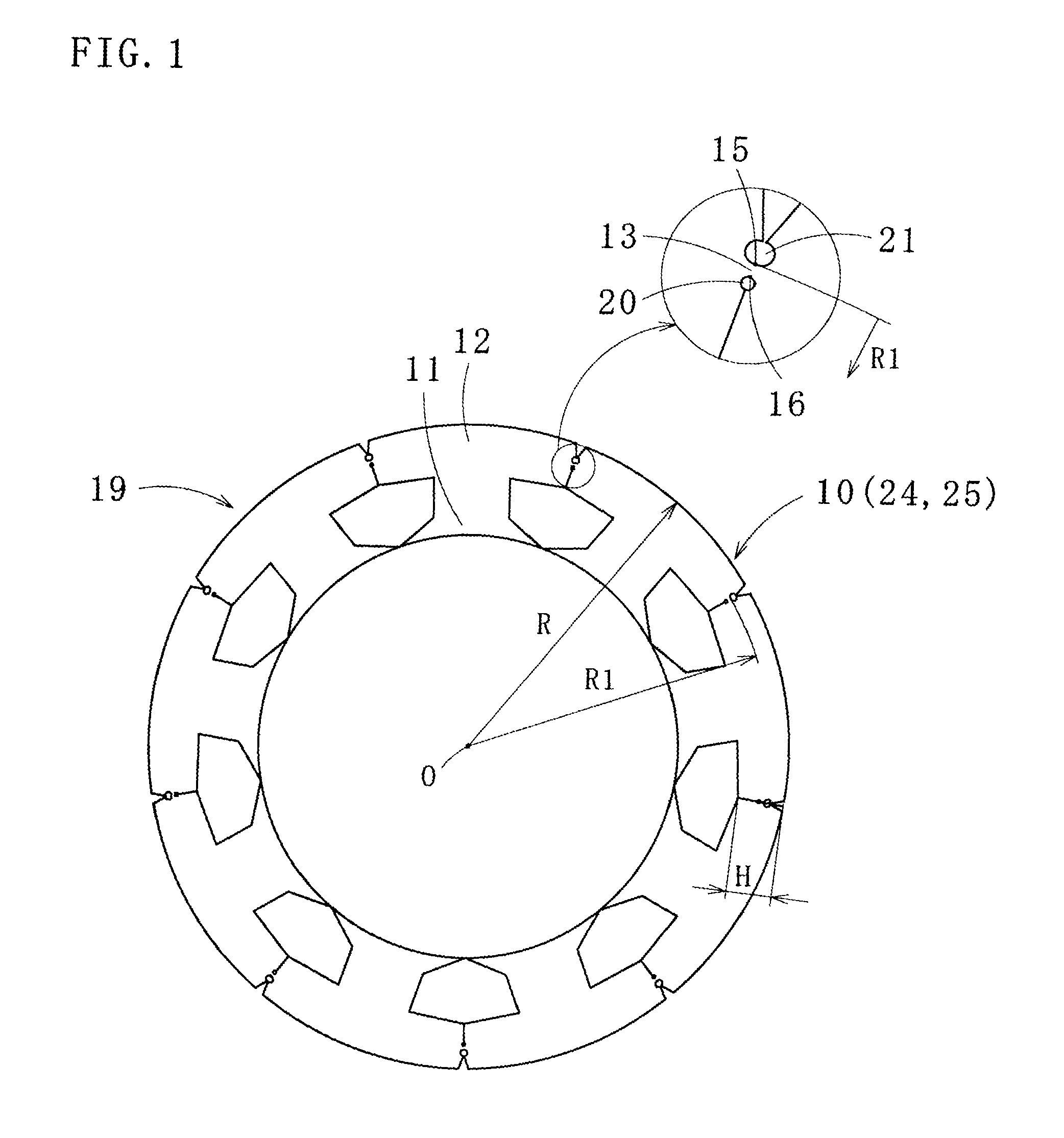

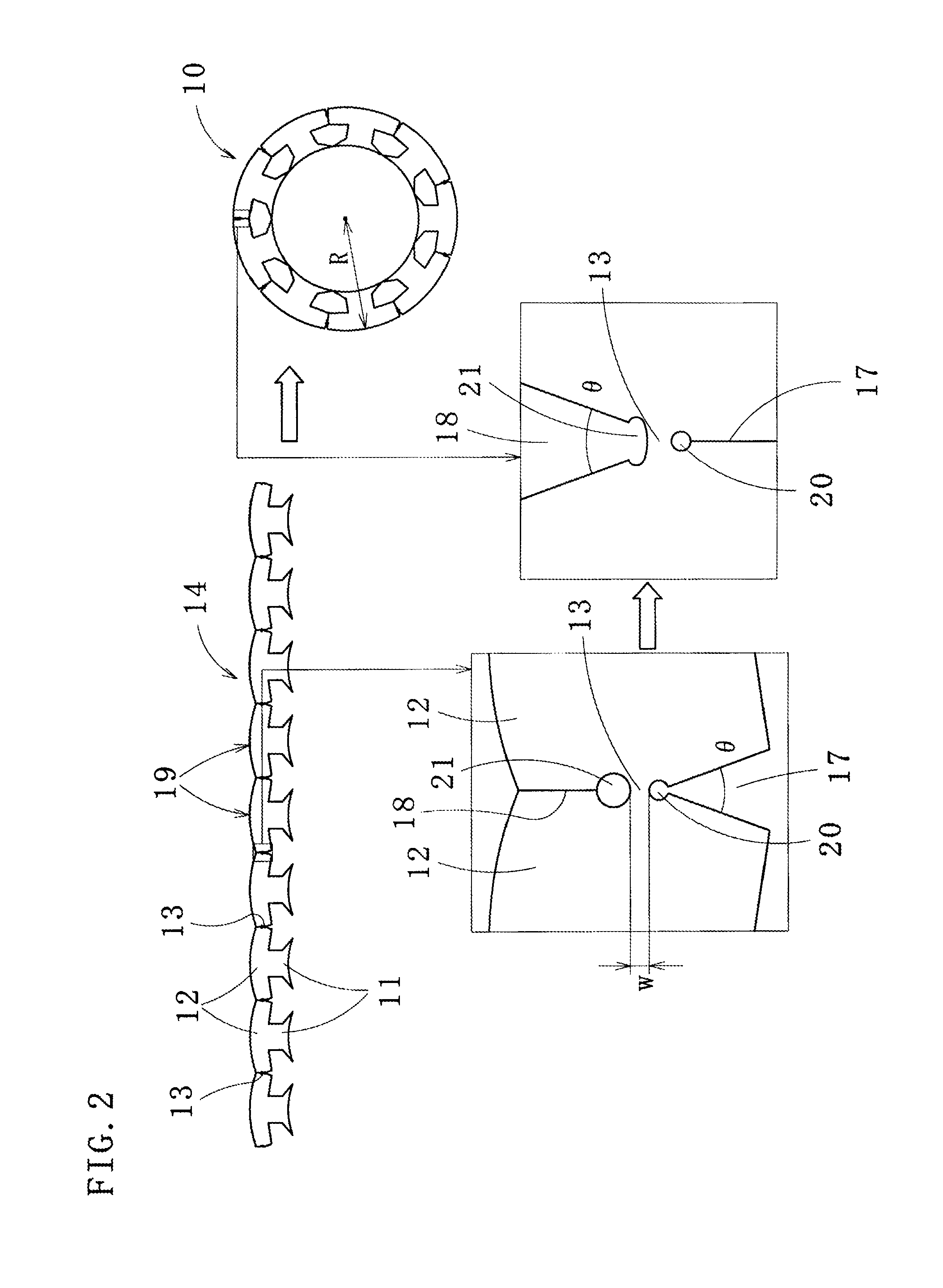

A laminated core 10 improves material yield and prevents cracks or breakages of core pieces by relaxing stress on connecting portions 13. A connected core segment 14 to be the laminated core 10 includes: a V-shaped cutout 17 located radially inward from the connecting portion 13, the cutout 17 opening in a radially inward direction with an opening angle of 360° / n given that n is a number of core segments 19; a slit 18 located radially outward from the connecting portion 13, the slit 18 dividing adjacent segment yokes 12 located radially outward from the connecting portion; a first through-hole 20 having a circular arc formed in a radially outward end of the cutout 17 in contact with the connecting portion 13; and a second through-hole 21 having a circular arc formed in a radially inward end of the slit 18 in contact with the connecting portion 13.

Owner:MITSUI HIGH TEC INC

Stripper for amorphous strip production

ActiveCN104399925ASolve the adjustment problem of stripping air nozzleImprove material yieldEngineeringIron based

The invention belongs to the technical field of iron-base amorphous jet strips and particularly relates to a stripper for amorphous strip production. The stripper comprises a rack on the lower portion and a body portion which is disposed on the upper portion. The body portion comprises air nozzles, a lifting mechanism and a rotation mechanism. The lifting mechanism is used for adjusting the height of the air nozzles, and the rotation mechanism is used for adjusting the air nozzle angle. By means of the stripper, the air nozzles are fixed so firmly that the air nozzles cannot move easily during the production, online stripping nozzle height and angle mechanical operations can be achieved, production experience accumulation is facilitated, the problem of stripping air nozzle adjusting when production conditions are changed can be solved thoroughly, amorphous strips can be stripped from the cooling roller surface completely, and the production efficiency and the production stability are improved.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

Rotor and rotating electric machine

ActiveUS20160094098A1Easy to assembleShorten the timeMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsElectric machineMagnetic poles

A rotor includes a rotor core and permanent magnets. The rotor core includes annular bodies that are stacked in a stacking direction and each formed of core segments arranged along a circumferential direction. The number of the core segments in each of the annular bodies is set based on k, where k is the number of magnetic poles formed by the permanent magnets. The rotor core has n through-holes, where n≧k. The rotor further includes n fixing members each of which extends in the stacking direction through one corresponding through-hole of the rotor core. Between each circumferentially adjacent pair of the core segments, there is formed a gap that is greater than a clearance provided between the through-holes of the rotor core and the fixing members. At least one of the annular bodies is circumferentially offset from another annular body by an integer multiple of one magnetic pole.

Owner:DENSO CORP

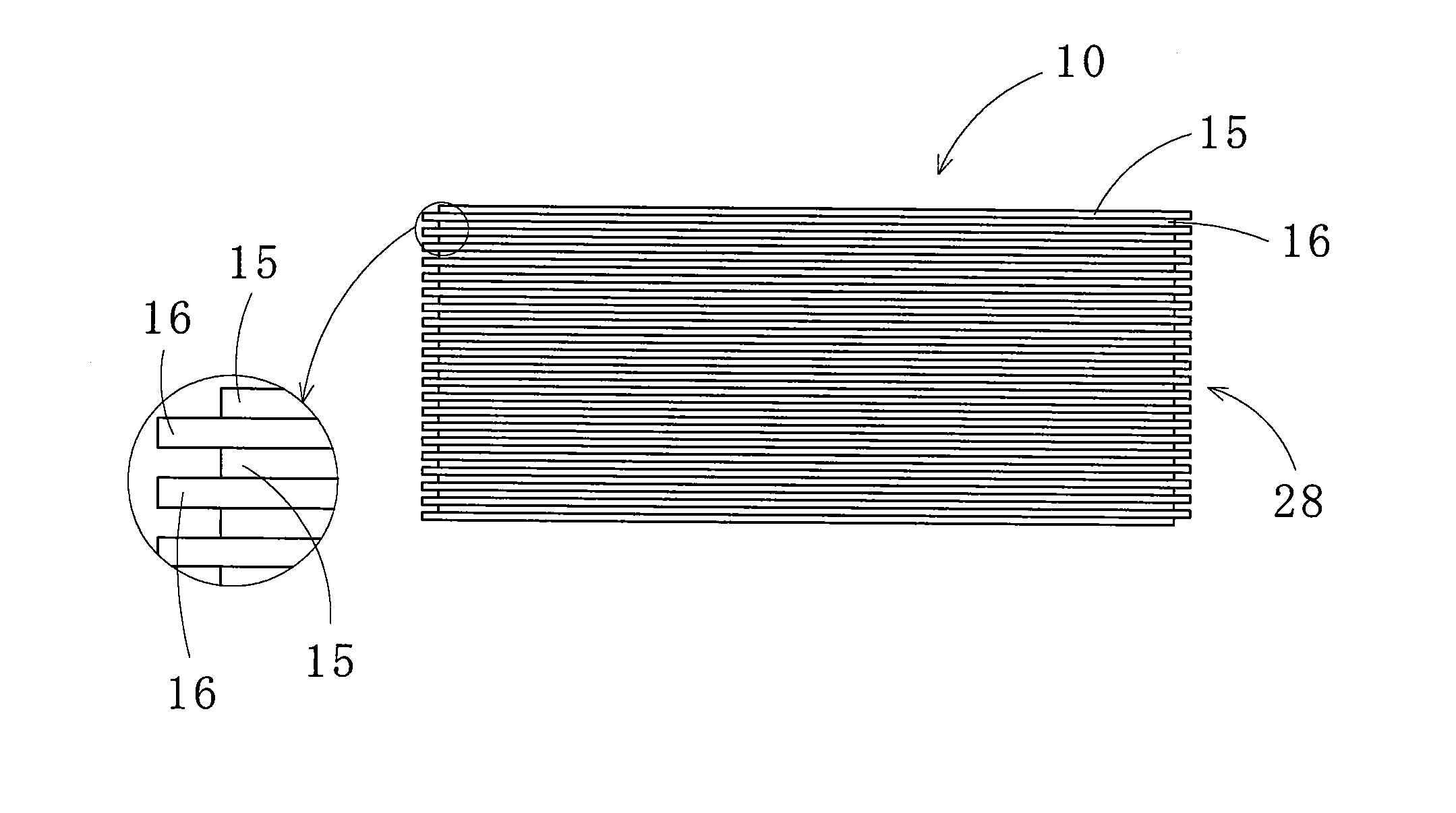

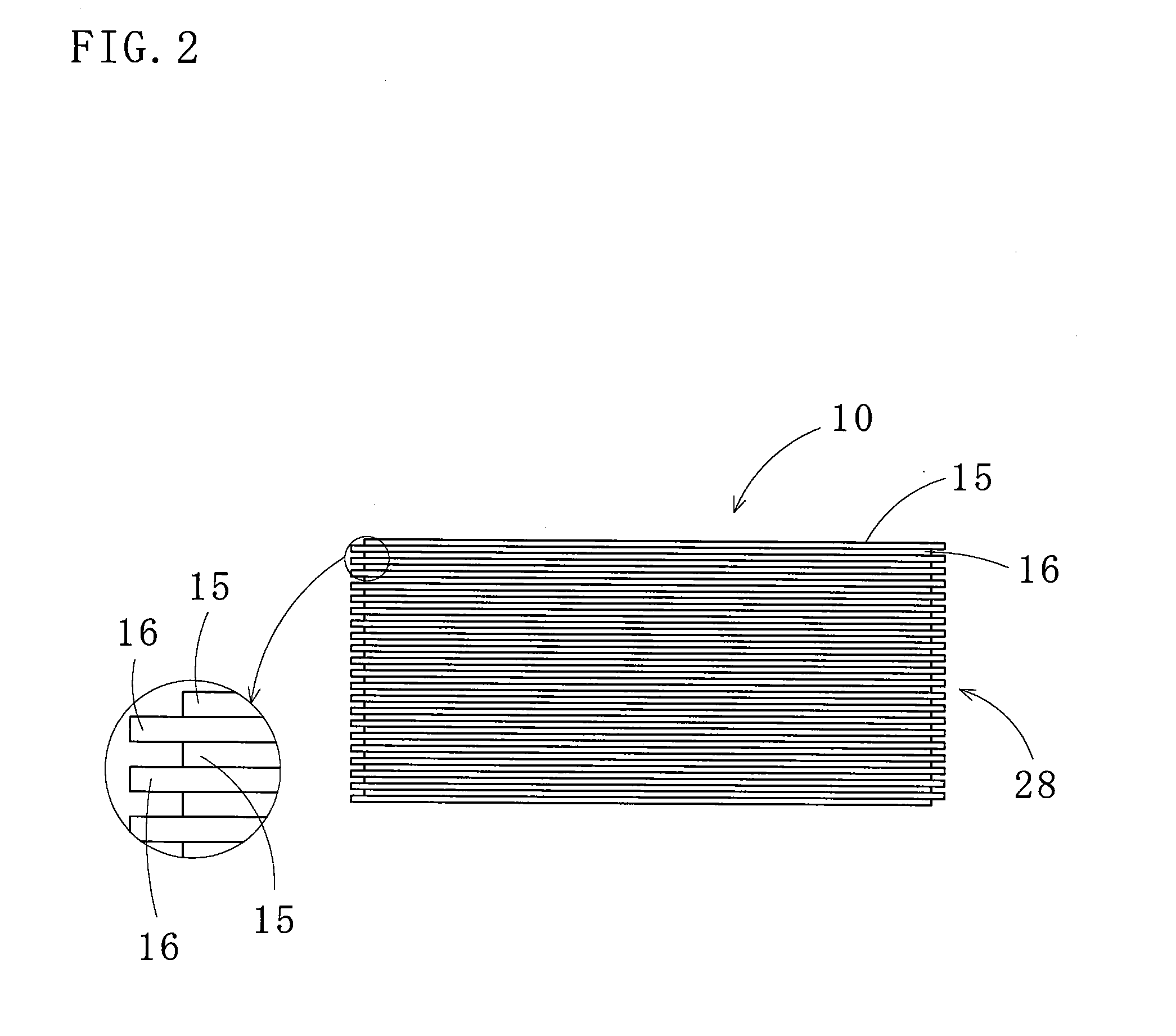

Laminated stator core and method for manufacturing the same

InactiveUS20100327690A1Simplified suppressionImprove material yieldMetal-working feeding devicesMagnetic circuit stationary partsStatorMechanical engineering

A laminated stator core 10 and a manufacturing method thereof, the method including producing a plurality of core sheets 15 and 16 from a strip 33, ends 34 of the strip 33 being a part of a product without being cut twice, and rotating and laminating the core sheets. A laminated stator core formed by core sheets blanked from a magnetic strip, both ends of the magnetic strip being one of the sides of the core sheets, wherein the identically shaped core sheets each have a rotor space in the center thereof, each rotor space having a center located off-center in one direction with respect to each center of the core sheets, and the core sheets are rotated by a predetermined angle before being laminated with the rotor spaces vertically aligned.

Owner:MITSUI HIGH TEC INC

Technique for improving surface quality of cold-rolled titanium strip coil

ActiveCN108262359AImprove surface qualityAvoid stickingWork treatment devicesMetal rolling arrangementsWork in processTitanium

The invention provides a technique for improving the surface quality of a cold-rolled titanium strip coil. The technique for improving the surface quality of the cold-rolled titanium strip coil comprises the step of annealing, shot-blasting and pickling, the step of coping of a hot-rolled titanium coil, the step of cold rolling, the step of degreasing, the step of coping of a semi-finished product, and the step of shot-blasting and pickling. According to the technique for improving the surface quality of the cold-rolled titanium strip coil, through reasonable process circuit arrangement and adefect coping and removal method, defects, such as peeling, indentations, oxide residues and scratches, on the surface of the titanium strip coil can be eliminated to the maximum extent, and thus, thesurface quality of the cold-rolled titanium strip coil is remarkably improved. The technique is simple in operation, good in stability and reliability and suitable for mass industrial production, andcan obtain the cold-rolled titanium strip coil with excellent surface quality.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

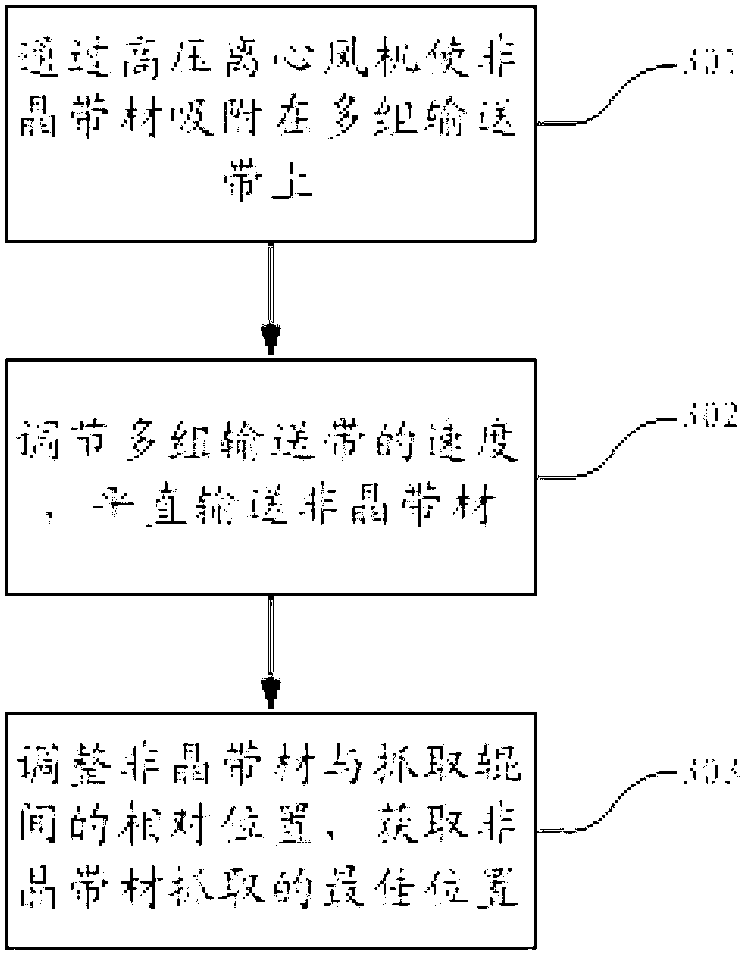

Online amorphous ribbon conveying equipment and realization method thereof

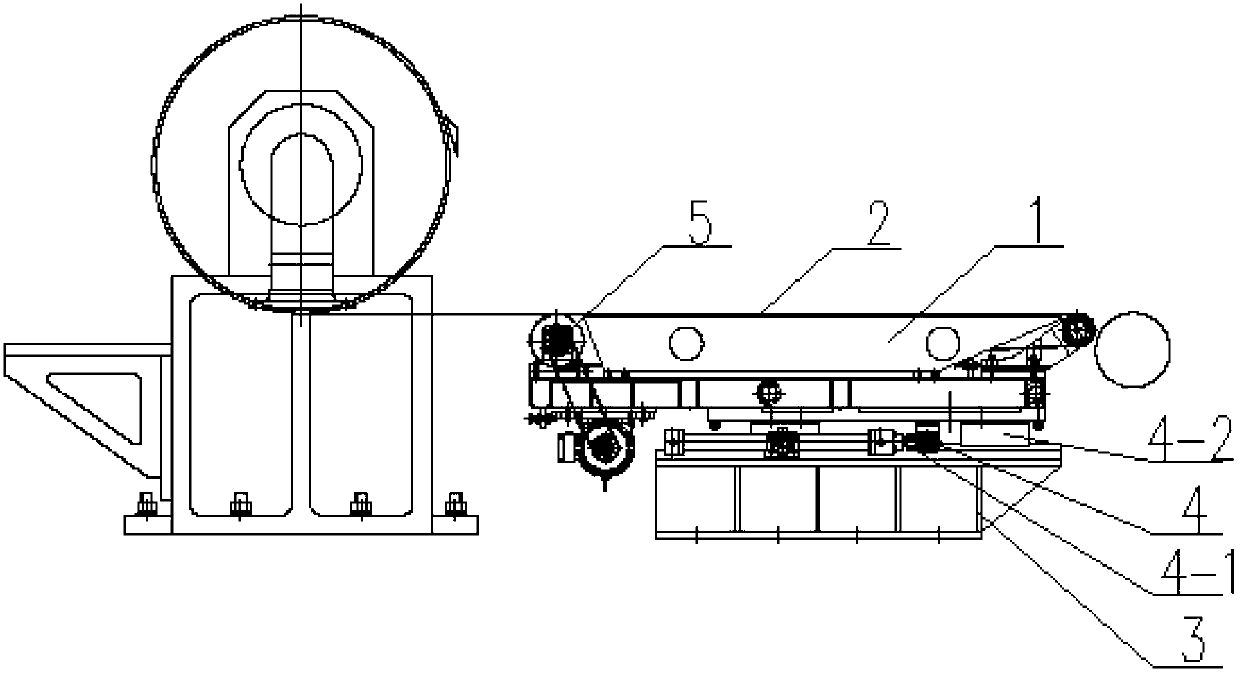

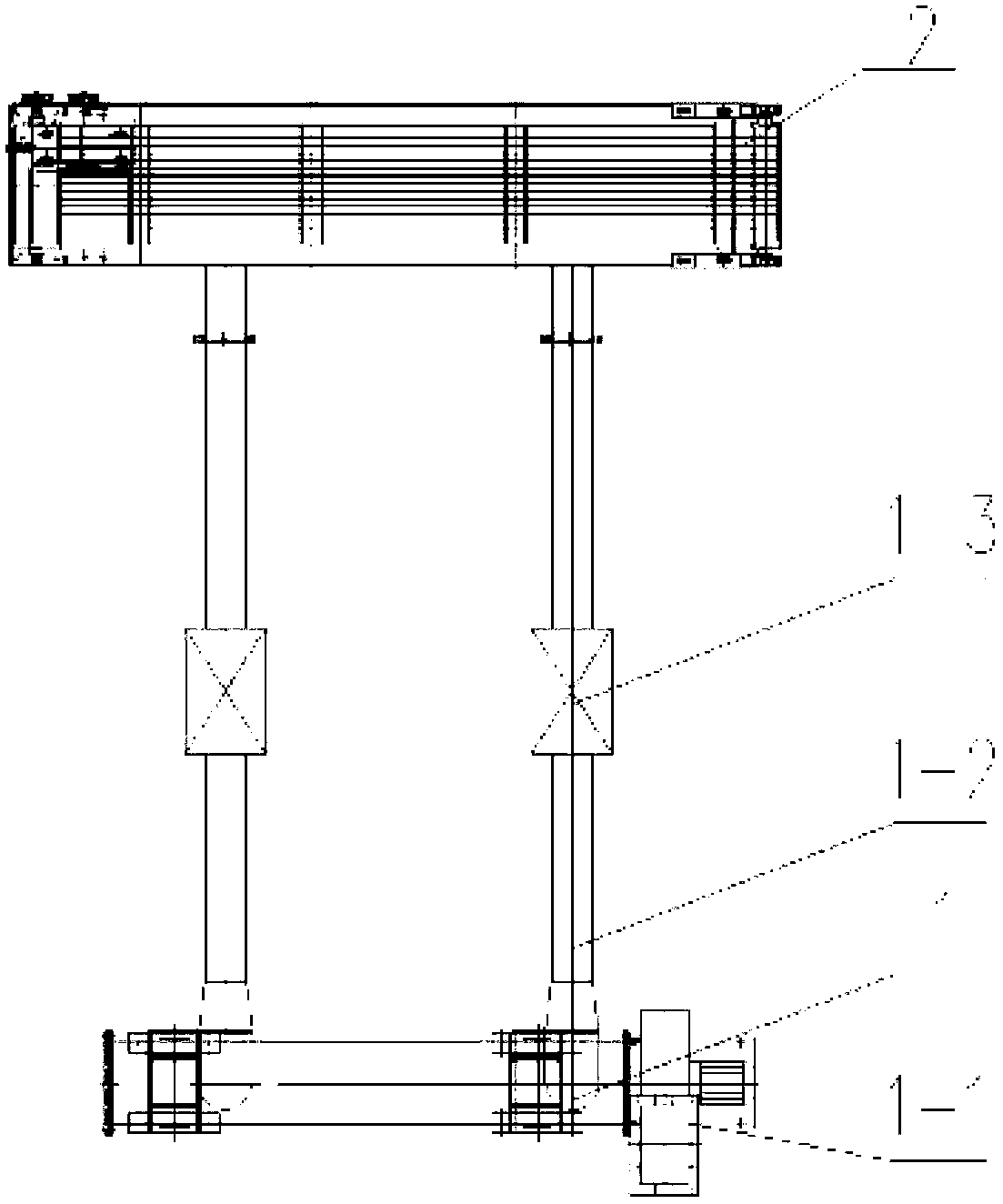

ActiveCN102992070ARealize long-distance grabbingImprove material yieldWebs handlingSuction forceStructural engineering

The invention relates to online amorphous ribbon conveying equipment and a realization method thereof. The realization method comprises the following steps of: causing amorphous ribbons breaking away from ribbon manufacturing rollers to be adsorbed on multiple groups of conveying belts through suction generated by a high-pressure centrifugal blower; adjusting the speed of the multiple groups of conveying belts so that the amorphous ribbons have tensile force in the conveying process and are straightly conveyed to grabbing rollers; and grabbing the amorphous ribbons after adjusting the relative positions between the amorphous ribbons and the grabbing rollers to the best grabbing positions according to the relative positions between the amorphous ribbons conveyed by the multiple groups of conveying belts and the grabbing rollers. According to the realization method, the amorphous ribbons are prevented from having head upwarping or breaking away from the conveying belts through the multiple-group combination manner of the multiple groups of conveying belts. The yield of the amorphous ribbons is increased by using a distance fine adjusting system for adjusting the best positions for grapping; and a reeling technology is optimized so that the safety is greatly increased, and the problems of low yield, poor reliability and difficulty in treatment of waste ribbons in the ribbon coiling process are avoided.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

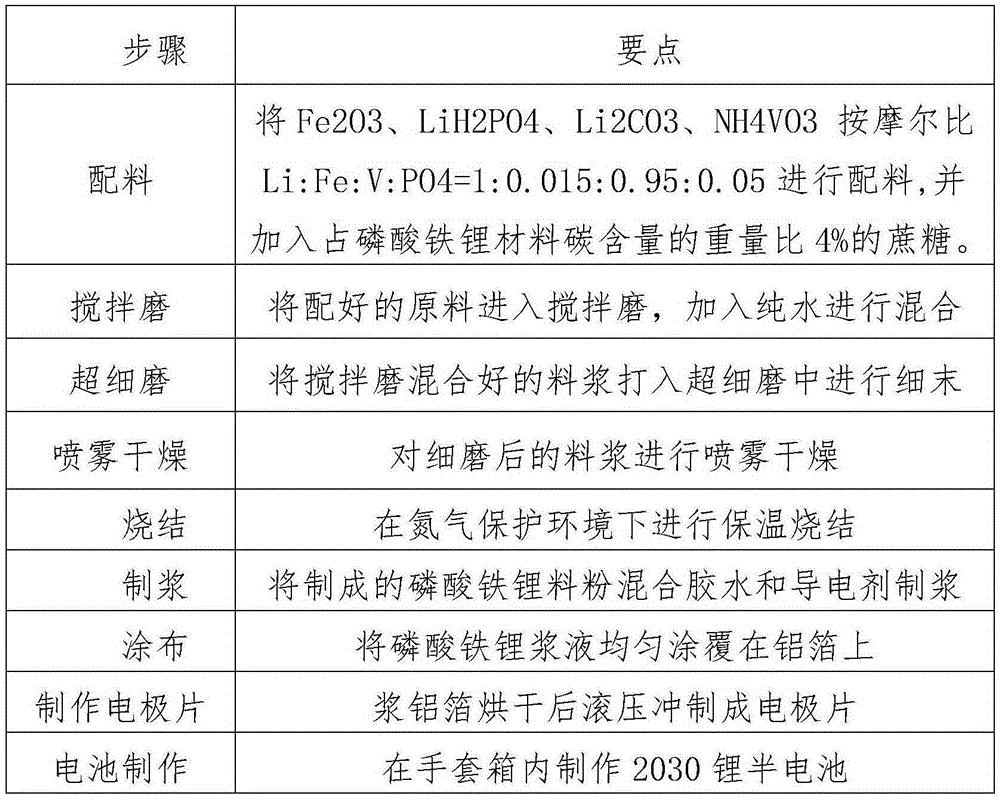

Iron oxide red for lithium iron phosphate and preparation method and application thereof

The invention belongs to the technical field of new energy powder, and in particular, relates to a preparation method of iron oxide red for lithium iron phosphate. The preparation method comprises the steps: dispersing electronic-grade industrial ultra-pure water and steel factory iron oxide red; sieving the iron oxide red suspension with a sieve, and sieving to remove large-particle matters; grinding the sieved iron oxide red suspension with a horizontal sand mill; carrying out magnetic filtration; adding an iron-based compound; treating the mixed solution with a material water separation device to obtain an iron oxide red slurry; carrying out spray drying; mixing and dispersing with electronic-grade industrial ultra-pure water, treating with the material water separation device, carrying out spray drying, and thus obtaining the iron oxide red for lithium iron phosphate. Compared with a process for preparing iron oxide red for lithium iron phosphate through a precipitation method, the preparation method has the advantages of low environmental effect, high material obtaining rate, good dispersion, narrower particle size distribution, and higher specific surface area; and compared with a conventional Ruthner method for iron oxide red for lithium iron phosphate, the method has the advantage that the performance has relatively large improvement.

Owner:SHANGHAI BAOSTEEL MAGNETICS

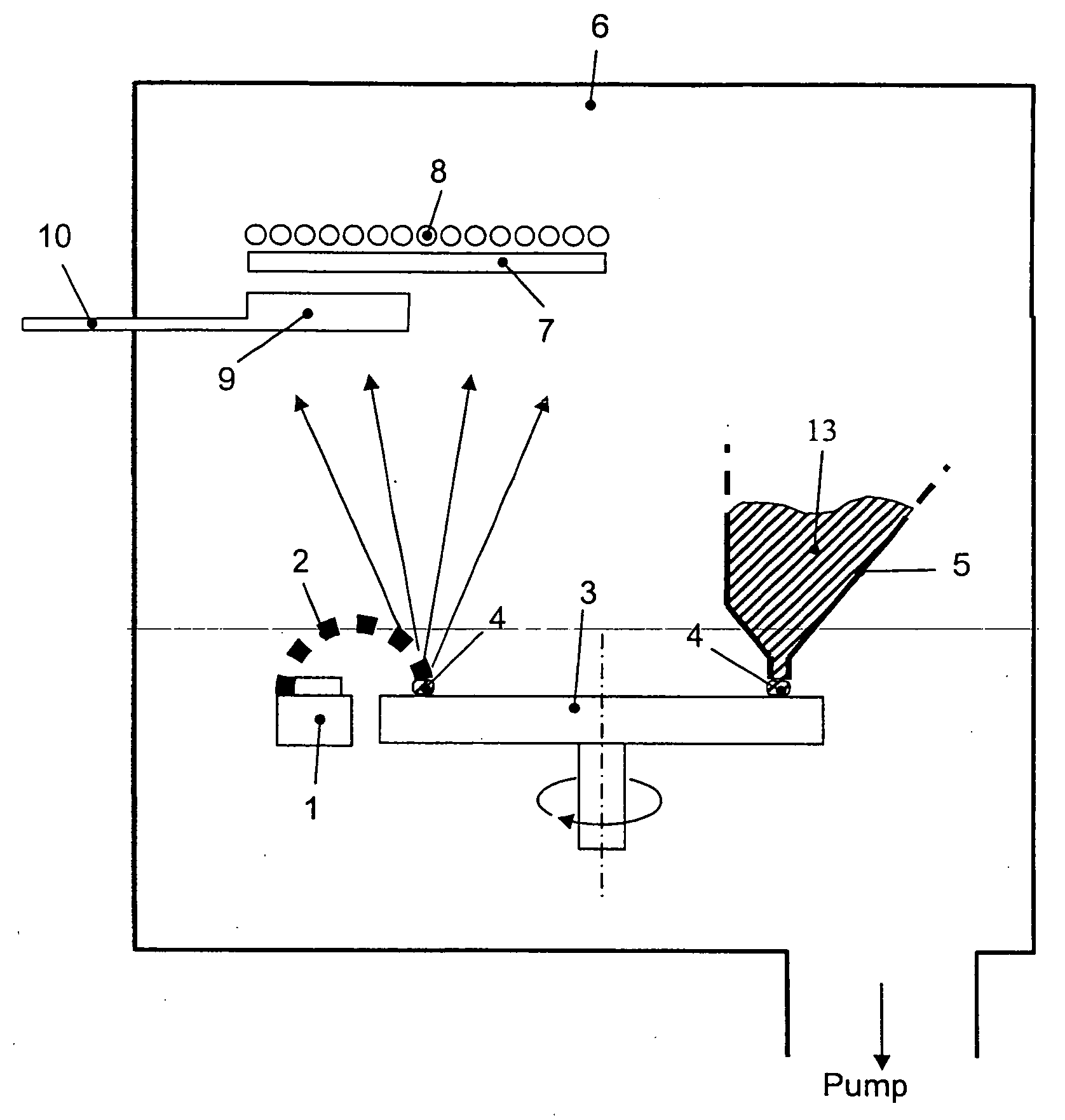

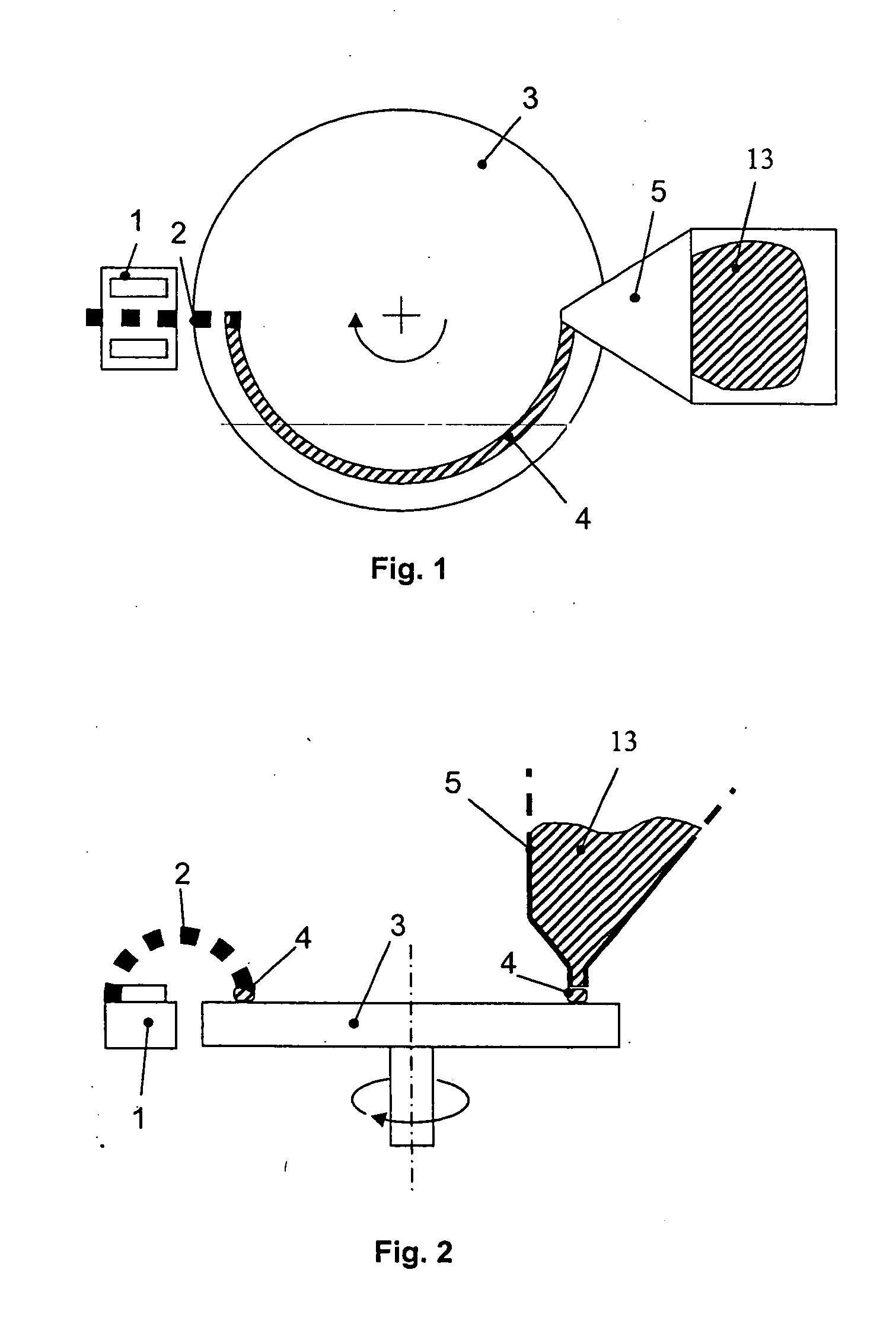

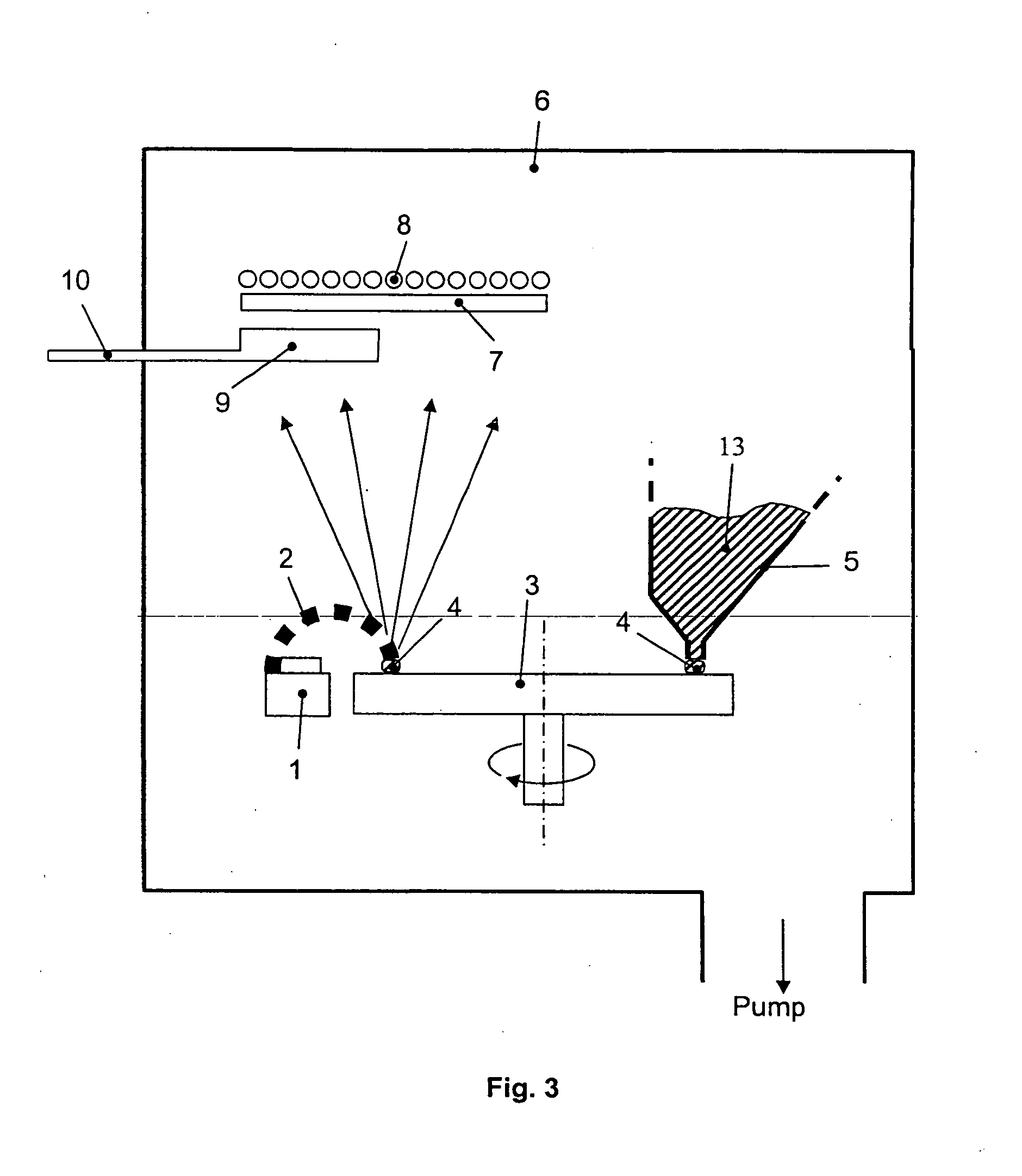

Device and method for the evaporative deposition of a coating material

ActiveUS20060051495A1Improve material yieldEasy to adjustVacuum evaporation coatingSemiconductor/solid-state device manufacturingEnergy transferElectrical conductor

According to a first aspect, the present invention relates to a device for depositing a high temperature superconductor onto a substrate in vacuum comprising a refilling device for containing a stock of high temperature superconductor material, an evaporation device, that evaporates the high temperature superconductor material within an evaporation zone by means of an energy transferring medium, and a conveyor that transports the high temperature superconductor material continuously from the refilling device to the evaporation zone in such a way that the high temperature superconductor material delivered into the evaporation zone is evaporated essentially without residues. According to a further aspect, the present invention relates to a method to evaporate a high temperature superconductor coating onto a substrate in vacuum, comprising the steps of continuous delivery of granular high temperature superconductor material into an evaporation zone and the operation of a beam of an energy transferring medium, so that the delivered granulate is evaporated in the evaporation zone essentially without residues.

Owner:THEVA DUENNSCHICHTTECHN

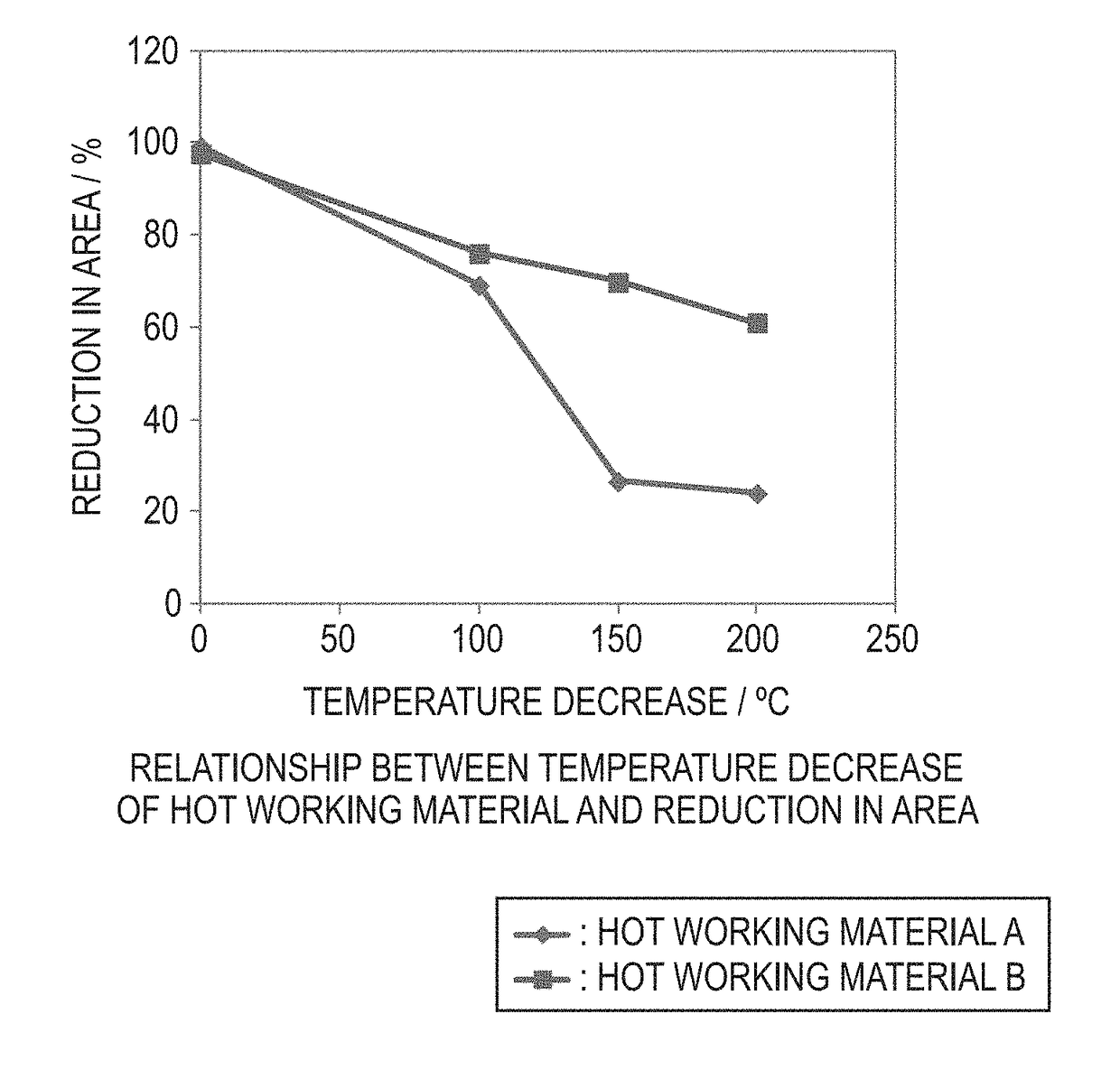

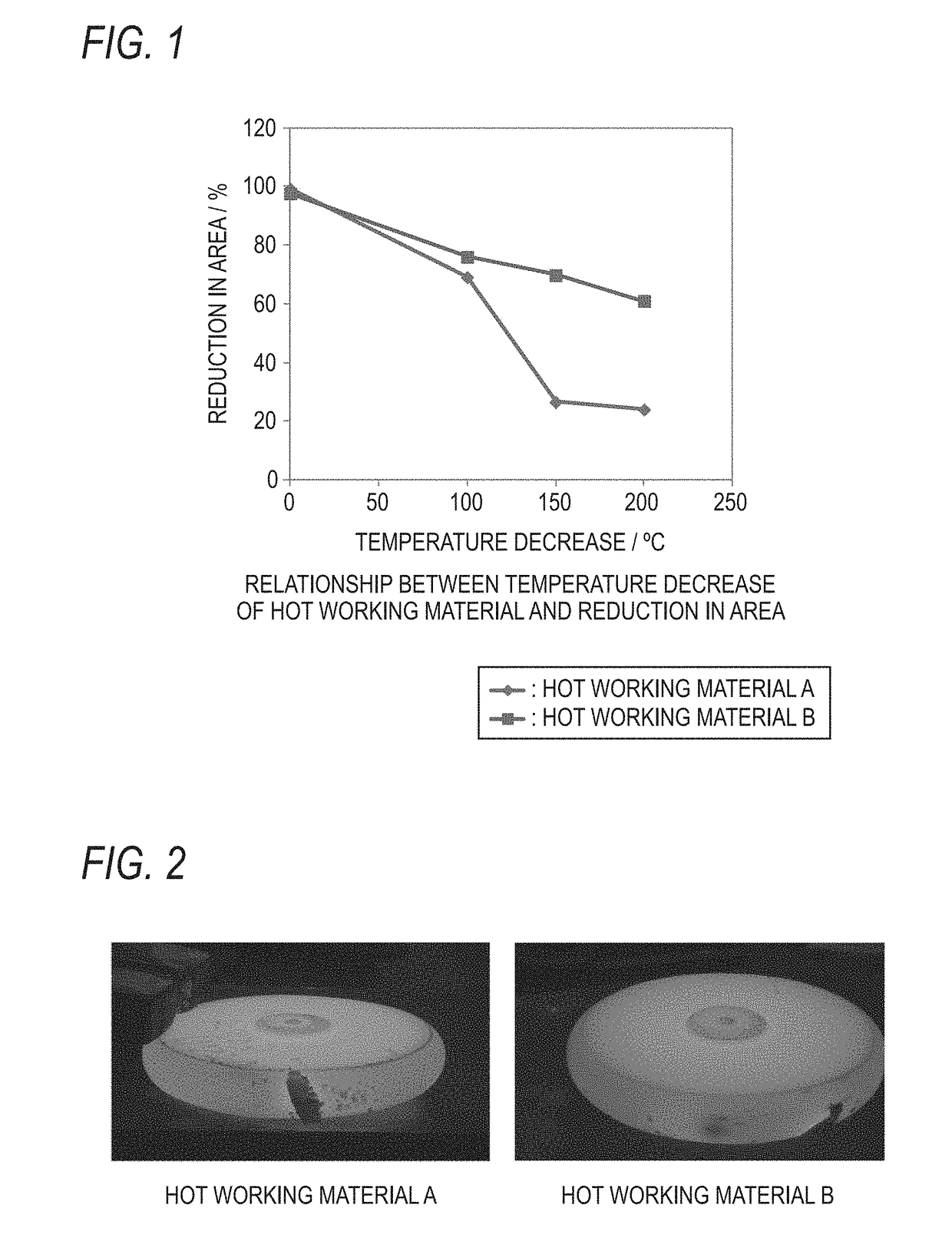

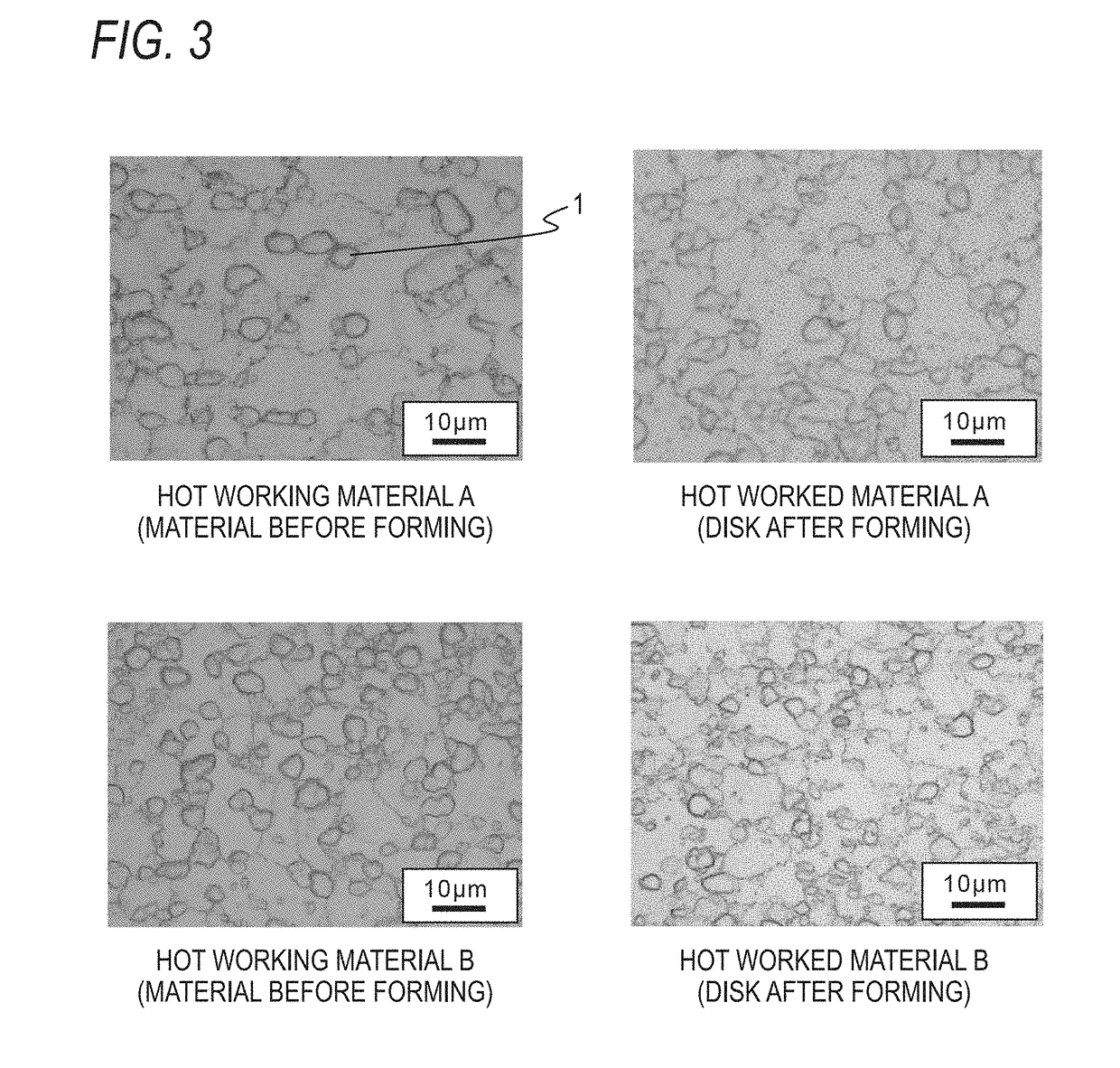

METHOD OF PRODUCING Ni-BASED SUPERALLOY

ActiveUS20180057921A1High strengthImprove material yieldForging/hammering/pressing machinesSuperalloyHot working

A method of producing a Ni-based super heat-resistant alloy in which a hot working material is subjected to hot working with a mold is provided. The hot working material consists of, in mass %, 0.001 to 0.050% of C, 1.0% to 4.0% of Al, 3.0% to 7.0% of Ti, 12% to 18% of Cr, 12% to 30% of Co, 1.5% to 5.5% of Mo, 0.5% to 2.5% of W, 0.001% to 0.050% of B, 0.001% to 0.100% of Zr, 0% to 0.01% of Mg, 0% to 5% of Fe, 0% to 3% of Ta, 0% to 3% of Nb, and the remainder of Ni and impurities. The method includes: heating and holding the hot working material in a temperature range of 950° C. to 1150° C. for 1 hour or longer; and performing hot working on the material with the mold that is heated to a temperature range of 800° C. to 1150° C.

Owner:HITACHI METALS LTD

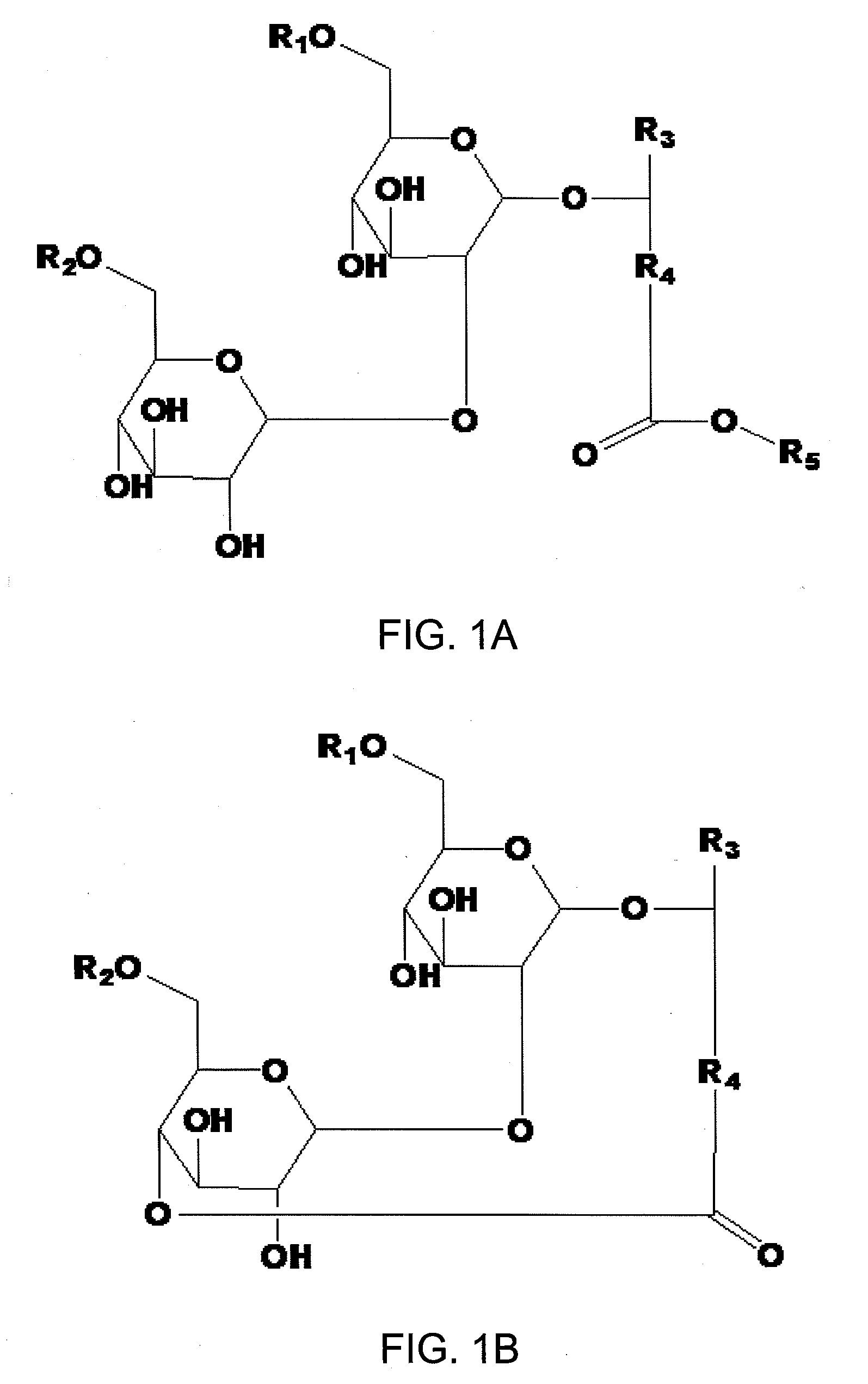

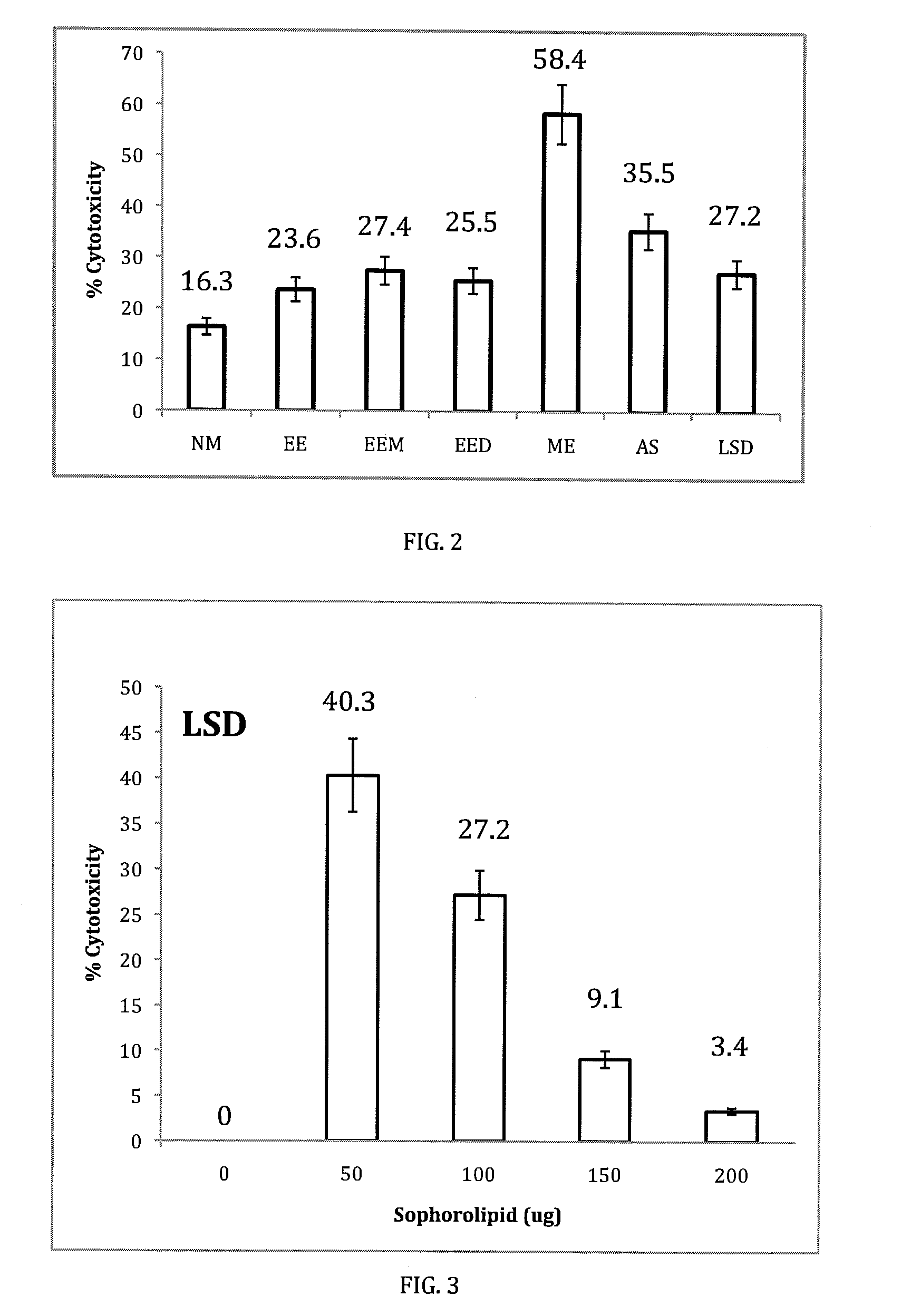

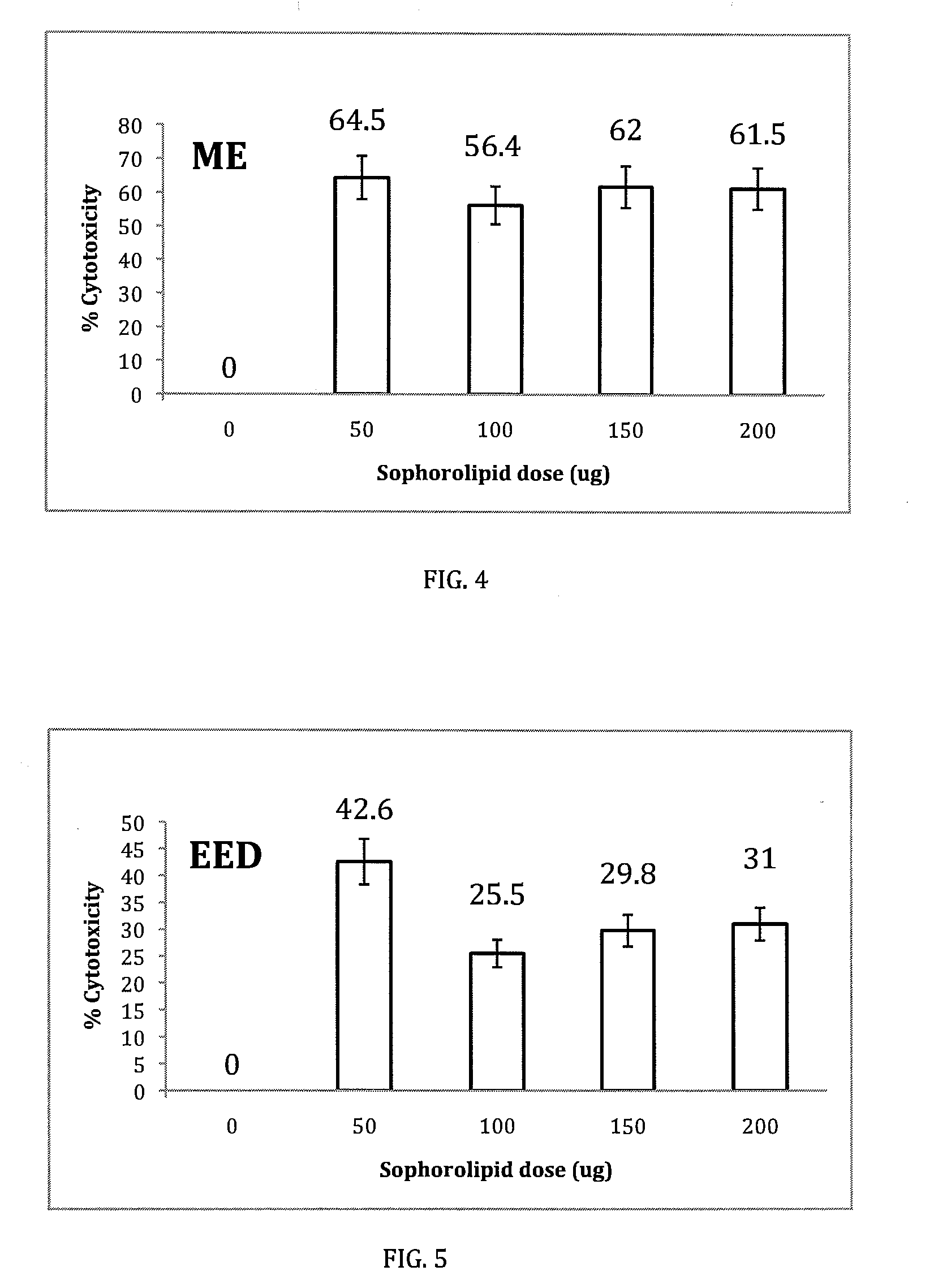

Treatment and prophylaxis of cancer

InactiveUS20090186835A1Improve material yieldMinimize side effectsBiocideCarbohydrate active ingredientsCancer preventionUrology

A method and composition for the prophylaxis or treatment of humans or animals for cancer using a mixture of sophorolipids.

Owner:SYNTHEZYME +1

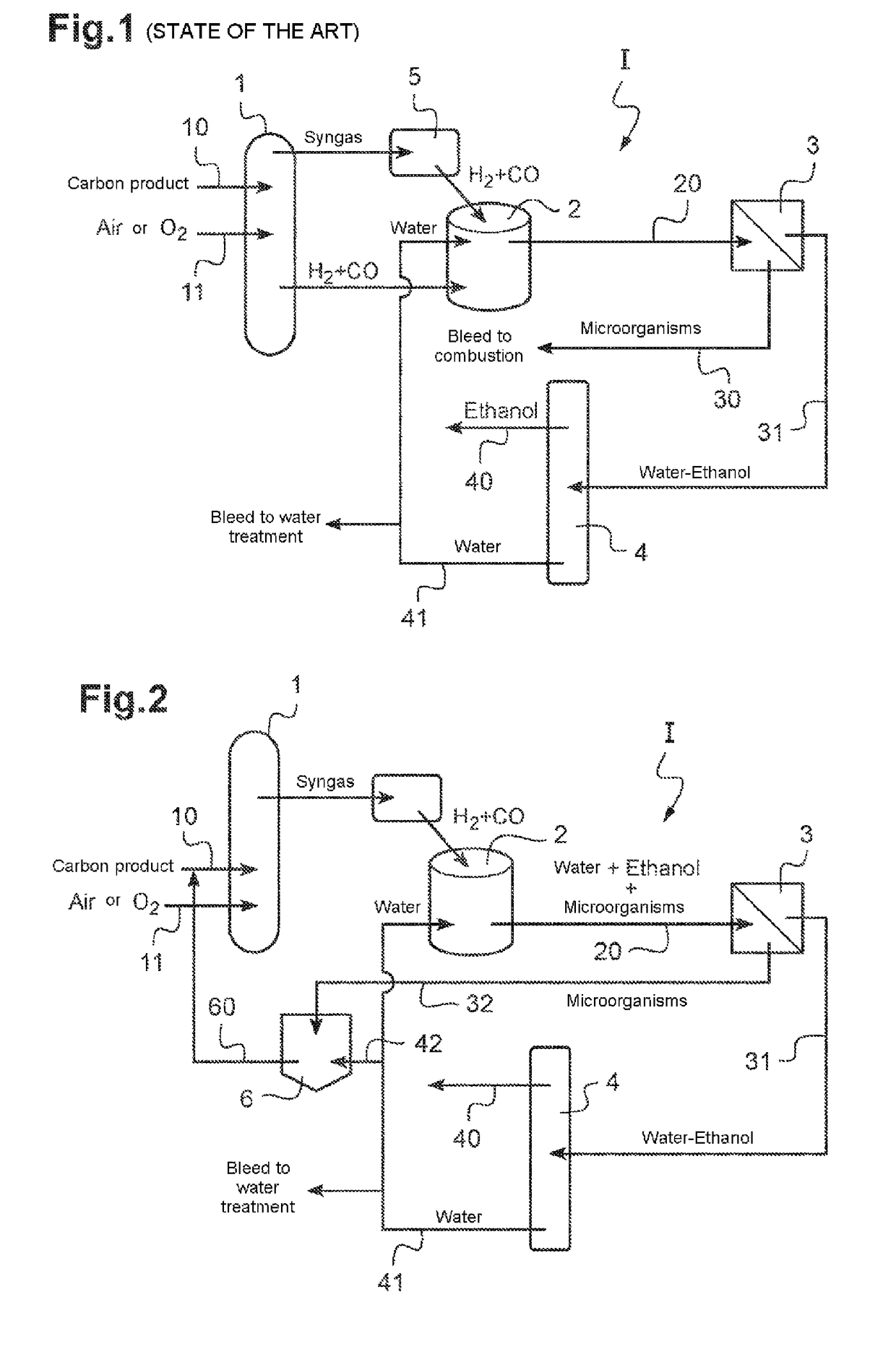

Process for producing an organic product from a carbon-based matter feedstock using gasification followed by fermentation of the synthesis gas

InactiveUS10066247B2Improve material yieldBioreactor/fermenter combinationsBiological substance pretreatmentsSyngasLiquid fuel

The invention relates to a process for producing a fuel, in particular a liquid fuel, or another organic product, from a carbon-based matter feedstock, comprising the following steps: a / gasification of the carbon-based matter feedstock in a first reactor, termed gasifier (1), b / downstream of the gasification, fermentation of the synthesis gas produced according to step a / , by means of microorganisms, water and nutrients in a second reactor, termed fermenter (2), c / recovery, downstream of the fermenter, of the microorganisms and of the water, d / injection of at least a part of the recovered microorganisms and, where appropriate, of at least a part of the recovered water at the inlet (10) of the gasifier.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com