Stripper for amorphous strip production

A technology of amorphous strips and strippers, applied in the field of iron-based amorphous spray strips, can solve problems such as easy to be moved, accumulated, unfavorable production experience, etc., to ensure verticality, improve material yield, improve production efficiency and The effect of production stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

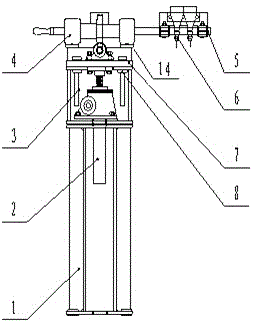

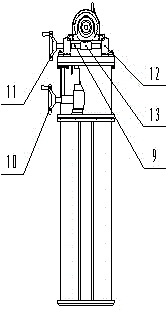

[0023] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0024] The technical solution of this embodiment is: a stripper for amorphous strip production, comprising a frame at the lower part and a main body part at the upper part, the main part includes a gas nozzle, a lifting mechanism and a rotating mechanism; the lifting mechanism It is used to adjust the height of the gas nozzle, and the rotating mechanism is used to adjust the angle of the gas nozzle.

[0025] Wherein, the main body part also includes a first axle seat, a first flat plate and an air nozzle shaft; the first flat plate is arranged on the upper part of the main body part, and the first axle seat is installed on the first flat plate; one end of the air nozzle shaft passes through the first The shaft seat, the gas nozzle is arranged at the other end of the gas nozzle shaft.

[0026] Wherein, the lifting mechanism includes a lifting wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com