Iron oxide red for lithium iron phosphate and preparation method and application thereof

A technology of iron oxide red and lithium iron phosphate, which is applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., can solve problems such as poor effect, and achieve the effect of low cost, high yield and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

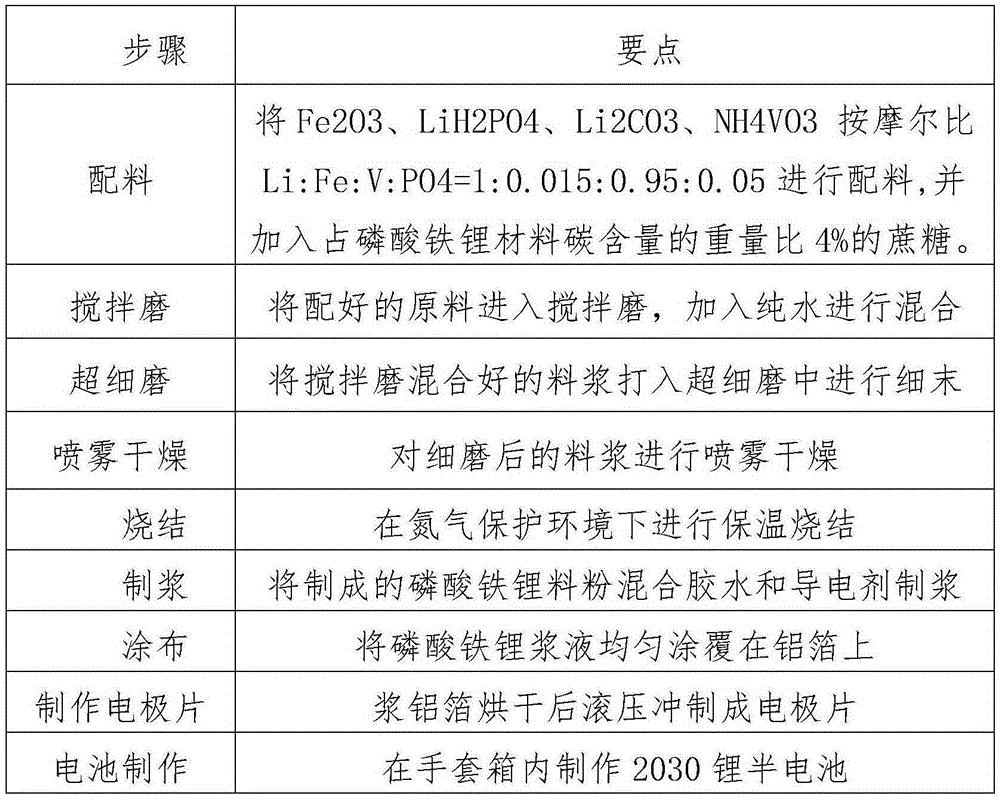

Method used

Image

Examples

Embodiment 1

[0028] The iron oxide red post-treatment of the steel mill of the present embodiment prepares the iron oxide red technology for lithium iron phosphate including the following steps:

[0029] 1) Turn on low-speed stirring, add electronic grade industrial ultra-pure water, and put in 1 ton of iron oxide red. The amount of water added is 1 times the amount of raw materials. After feeding, turn on the high-speed disperser and stir for 2 hours;

[0030] 2) select 40 mesh sieves for pre-screening;

[0031] 3) Put it into a horizontal sand mill, and control the grinding temperature to 60°C for grinding;

[0032] 4) Carry out magnetic filtration, control flow rate 1m 3 / H;

[0033] 5) Add 1L of Fe(OH) with a concentration of 10g / 100ml 2 ;

[0034] 6) Use a centrifuge to separate to obtain the lower iron oxide red slurry;

[0035] 7) Spray drying at 300°C;

[0036] 8) Add electronic grade industrial ultrapure water, control the water-to-material ratio to 7, and carry out circulat...

Embodiment 2

[0039] The iron oxide red post-treatment of the steel mill of the present embodiment prepares the iron oxide red technology for lithium iron phosphate including the following steps:

[0040] 1) Turn on low-speed stirring, add electronic grade industrial ultra-pure water, and put in 1 ton of iron oxide red at the same time. The amount of water added is 1.5 times the amount of raw materials. After feeding, turn on the high-speed disperser and stir for 1.5 hours;

[0041] 2) select 50 mesh sieves for pre-screening;

[0042] 3) Put it into a horizontal sand mill, and control the grinding temperature to 50°C for grinding;

[0043] 4) Carry out magnetic filtration, control flow rate 3m 3 / H;

[0044] 5) Add 2L of Fe(OH) with a concentration of 5g / 100ml 2 ;

[0045] 6) Use a centrifuge to separate to obtain the lower iron oxide red slurry;

[0046] 7) Spray drying at 250°C;

[0047] 8) Add electronic grade industrial ultrapure water, control the water-to-material ratio to 6, an...

Embodiment 3

[0050] The iron oxide red post-treatment of the steel mill of the present embodiment prepares the iron oxide red technology for lithium iron phosphate including the following steps:

[0051] 1) Turn on low-speed stirring, add electronic grade industrial ultrapure water, and put in 1 ton of iron oxide red at the same time, the amount of water added is twice the amount of raw materials, after feeding is completed, turn on the high-speed disperser and stir for 1 hour;

[0052] 2) select 60 mesh sieves for pre-screening;

[0053] 3) Put it into a horizontal sand mill, and control the grinding temperature to 40°C for grinding;

[0054] 4) Carry out magnetic filtration, control flow rate 5m 3 / H;

[0055] 5) Add 2L of Fe(OH) with a concentration of 10g / 100ml 2 ;

[0056] 6) Centrifuge separation to obtain the lower iron oxide red slurry;

[0057] 7) Spray drying at 200°C;

[0058] 8) Add electronic grade industrial ultrapure water, control the water-to-material ratio to 5, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com