Patents

Literature

211 results about "Magnetic filtration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-stage magnetic field straight pipe magnetic filtration and pulsed bias compounded electrical arc ion plating method

ActiveCN103276362ALow ionization rateLow pulse duty cycle to generate high ionization rateVacuum evaporation coatingSputtering coatingPlasmaMagnetic filtration

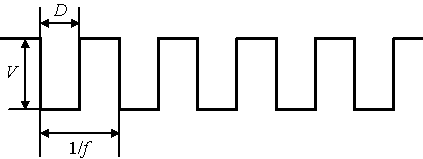

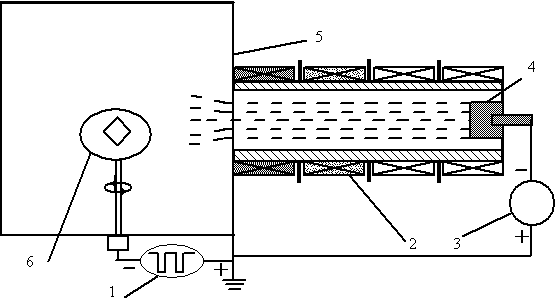

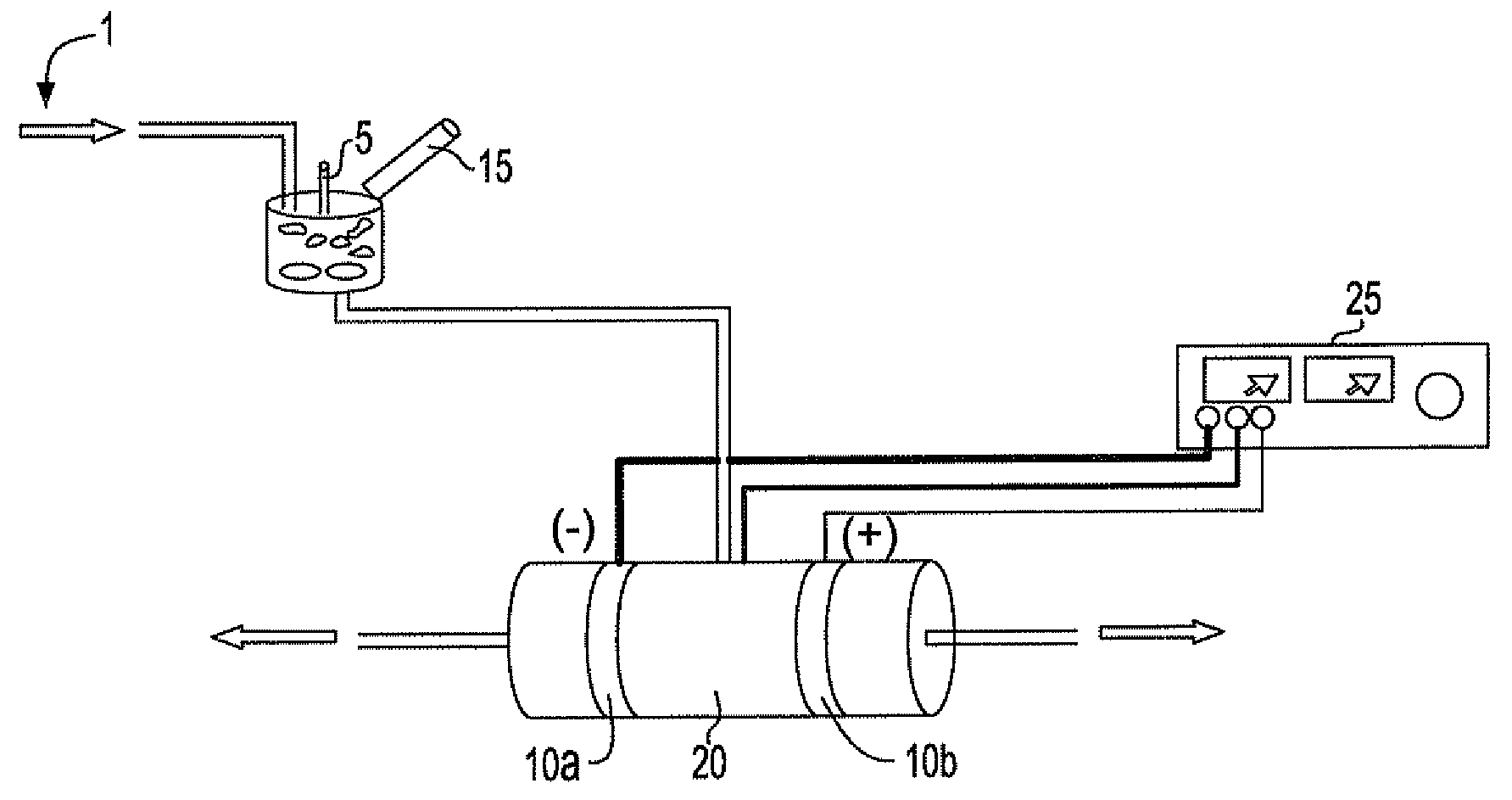

The invention relates to a multi-stage magnetic field straight pipe magnetic filtration and pulsed bias compounded electrical arc ion plating method, and belongs to the technical field of material surface treatments. In the prior art, plasma transmission efficiency is low and pulsed bias can not completely remove large particles due to applying of magnetic filtration on an arc source. A purpose of the present invention is to solve problems in the prior art. The method comprises: 1, connecting a workpiece to a pulsed bias power supply, connecting an electrical arc ion plating target source to a target power supply, and connecting a multi-stage magnetic field straight pipe magnetic filtration device in front of the target source; 2, carrying out thin film deposition, wherein work gas is introduced until achieving 0.01-10 Pa when a pressure in a vacuum chamber is less than 10<-2> Pa, the pulsed bias power supply is opened, a pulsed bias amplitude value, frequency and a duty ratio are adjusted, the target power supply is opened, plasma is generated, the multi-stage magnetic field straight pipe magnetic filtration device is opened, removal of large particles and efficient transmission of the plasma in the magnetic filtration device are achieved, process parameters are adjusted, and a thin film with no large particle defect is rapidly produced; and 3, adopting a single-stage magnetic field to combine direct current / pulsed bias to obtain a thin film with a certain thickness.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Magnetic particle-based therapy

InactiveUS20060025713A1Reduce and decrease deleterious activityReduced activityEnergy modified materialsMedical devicesDiseaseHazardous substance

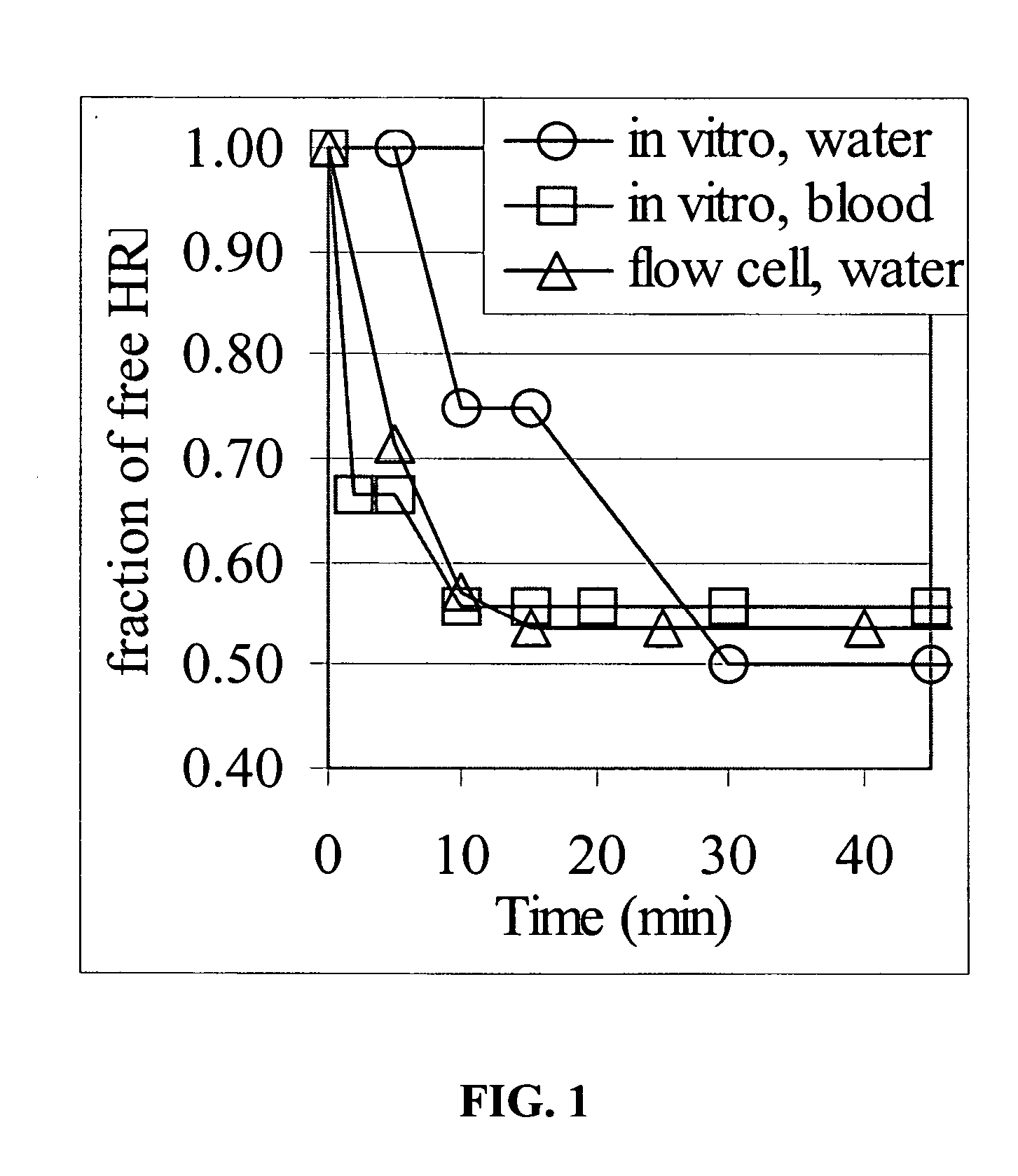

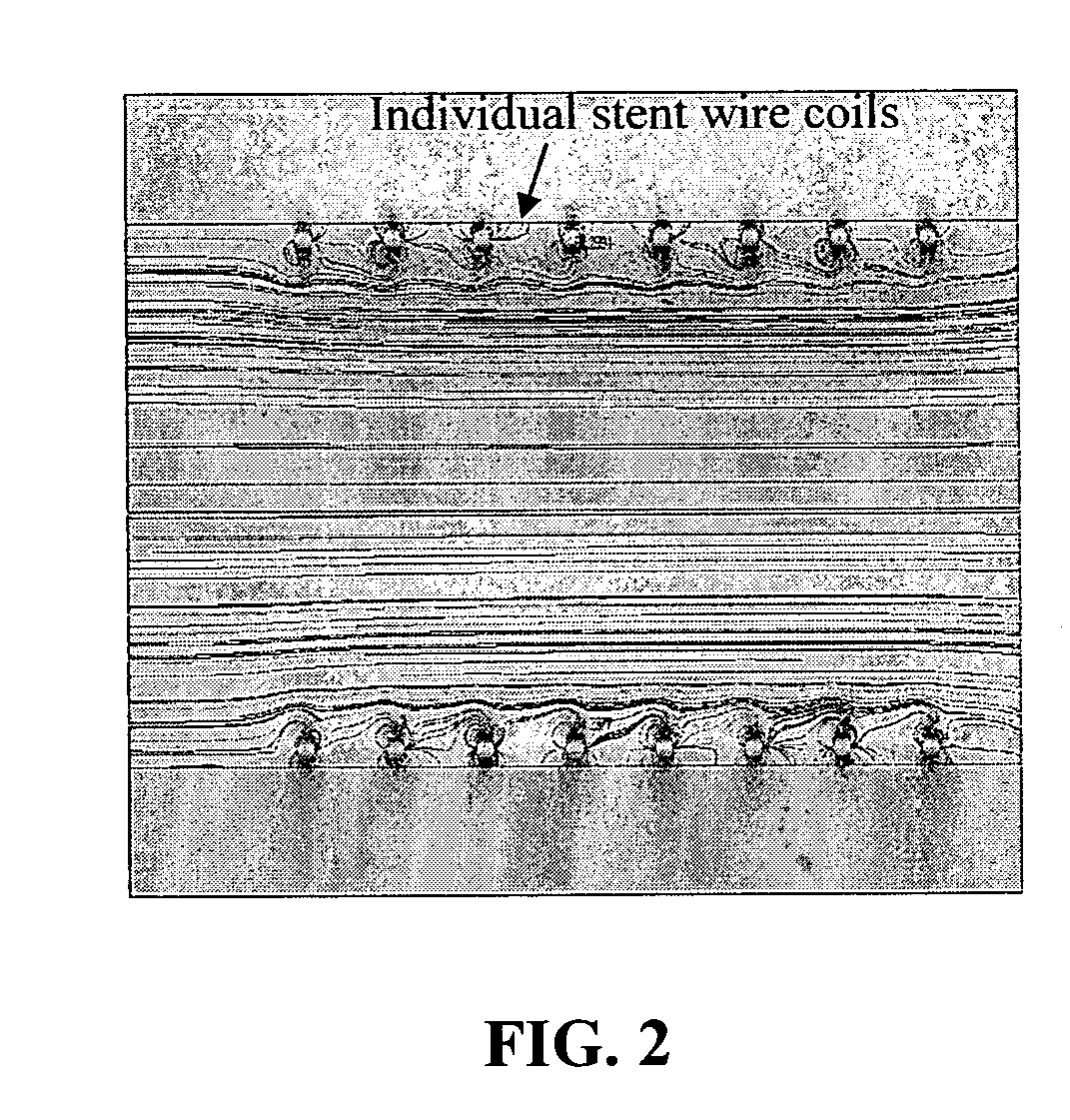

The invention provides materials and methods for the administration of an effectively magnetic medication or diagnostic reagent, or for the removal, sequestration, or effective conversion to a non-deleterious condition of a deleterious substance such as a toxin (e.g., biological, chemical, or radiological compound or composition) in vivo by administering a biocompatible magnetic particle to an organism in need, e.g., by delivery to the bloodstream, with the organism optionally having an internal magnetizable stent or magnetizable seed. The materials and methods are useful in the diagnosis and treatment of a variety of acute and chronic diseases, disorders and conditions afflicting man and other organisms, as well as for the removal of a variety of deleterious substances, including toxins, with the optional aid of an external magnetic generator and an optional magnetic filtration device.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

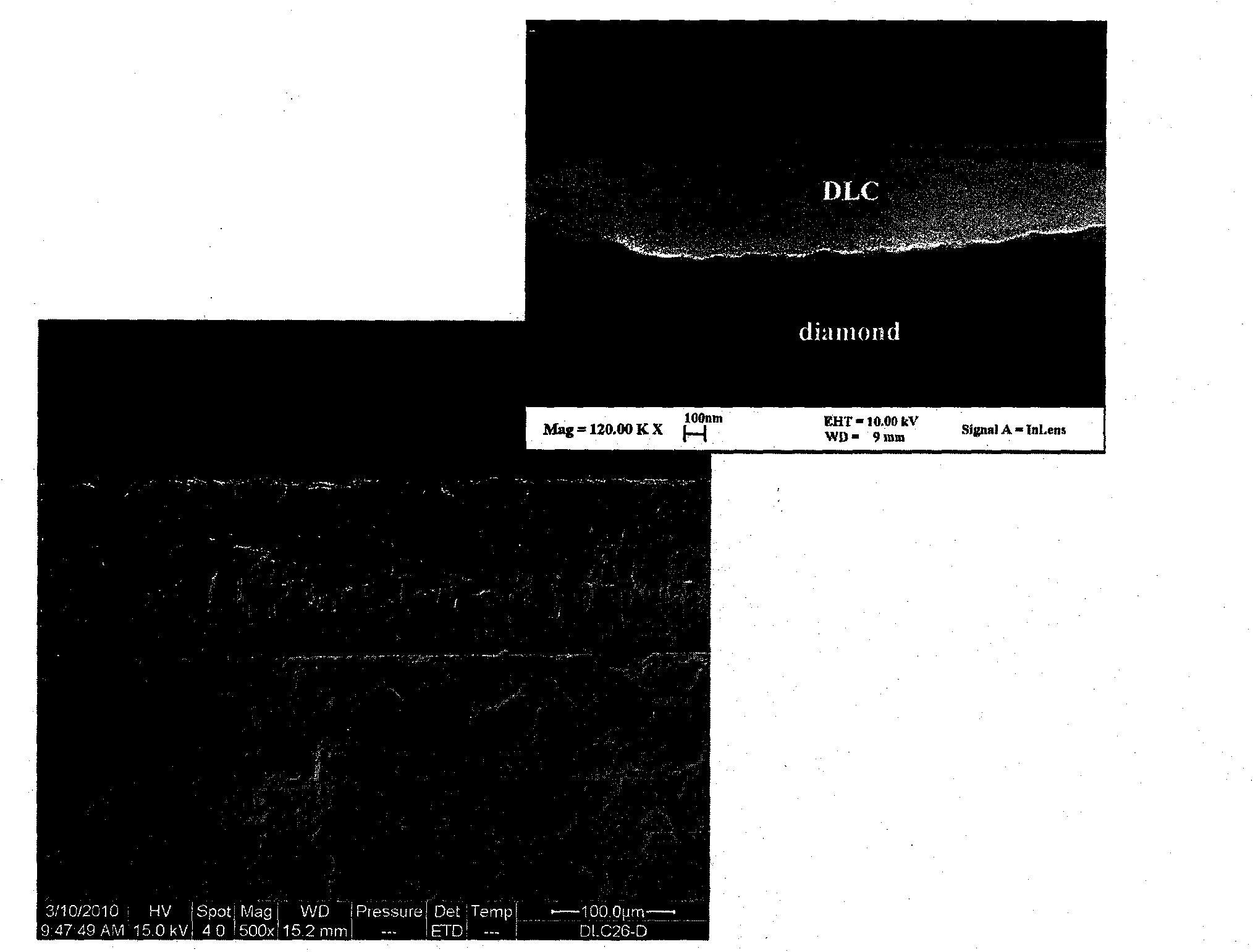

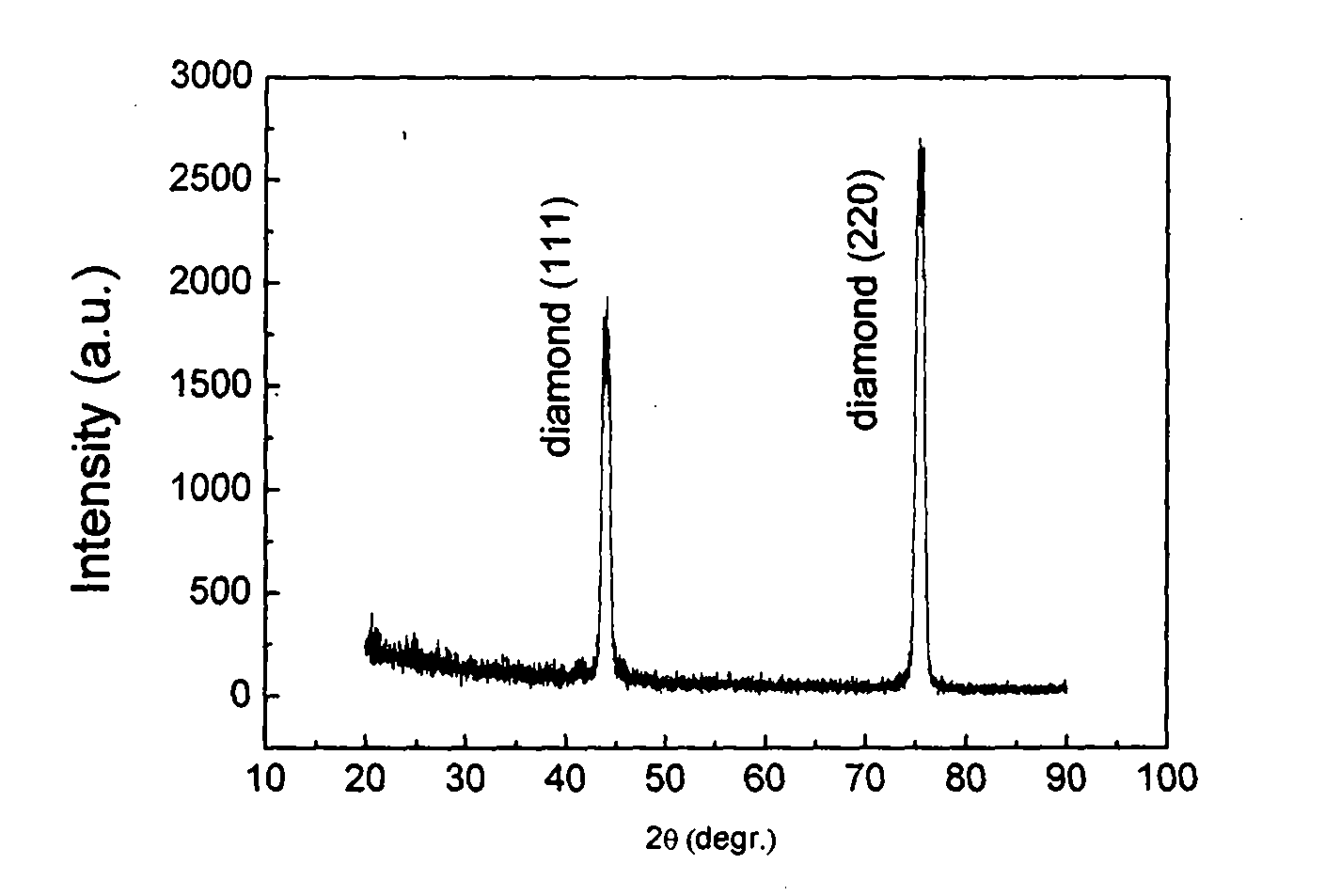

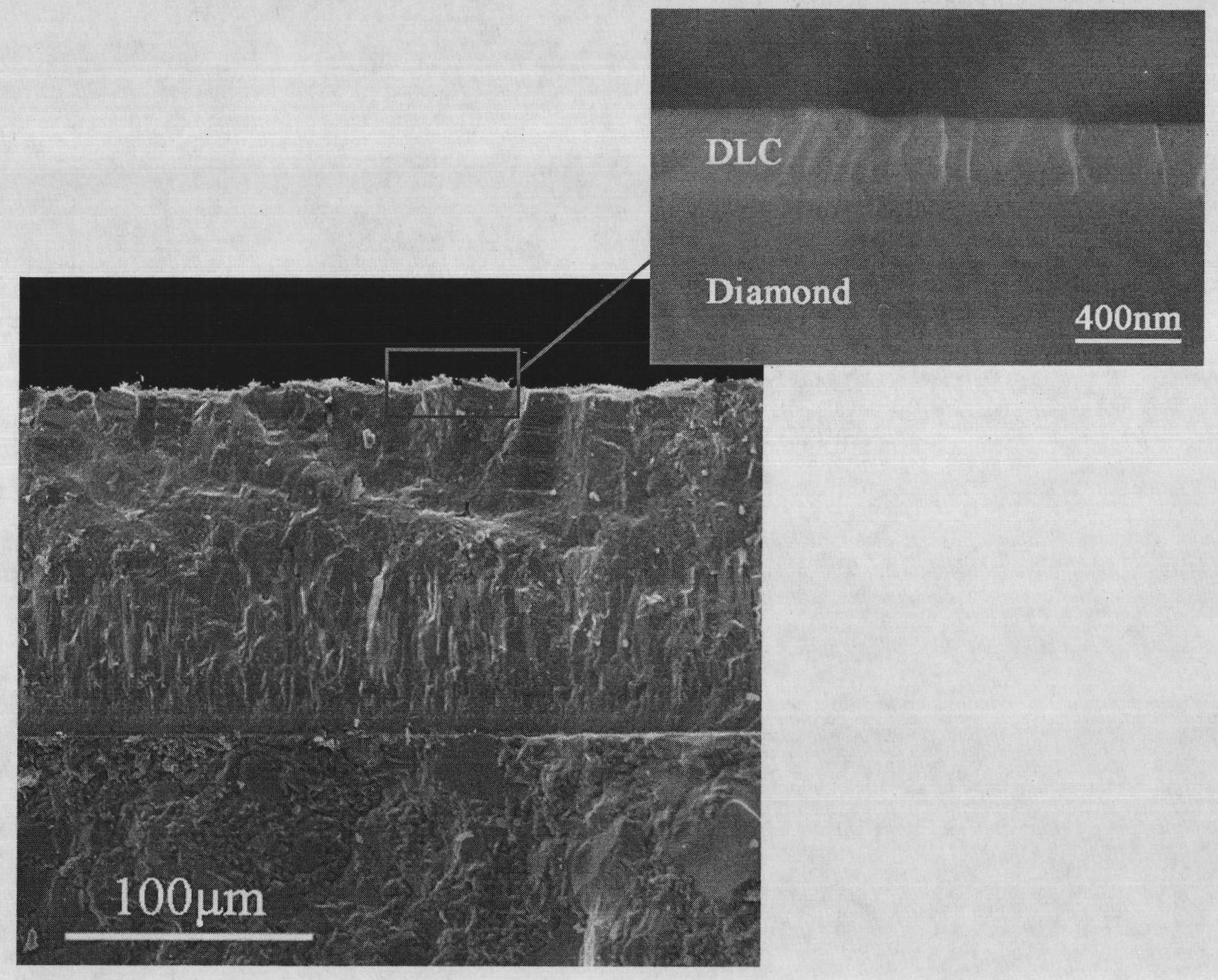

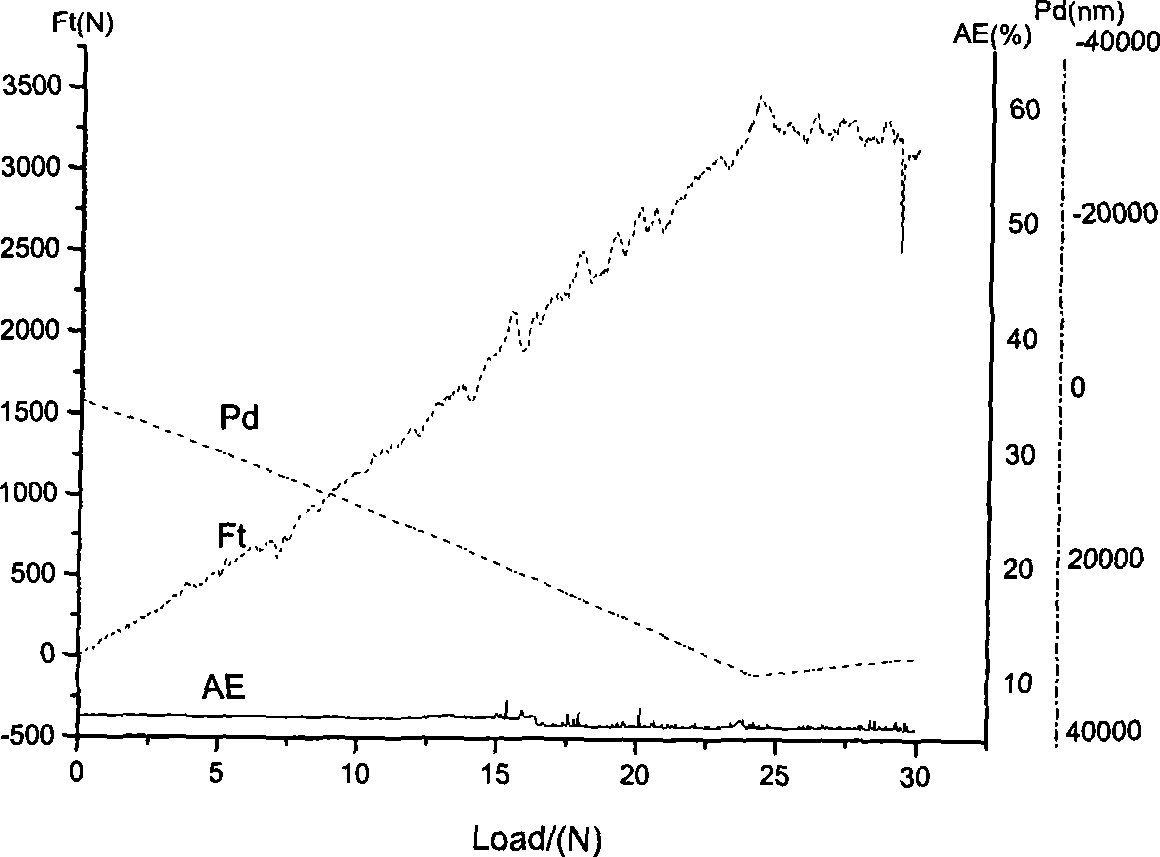

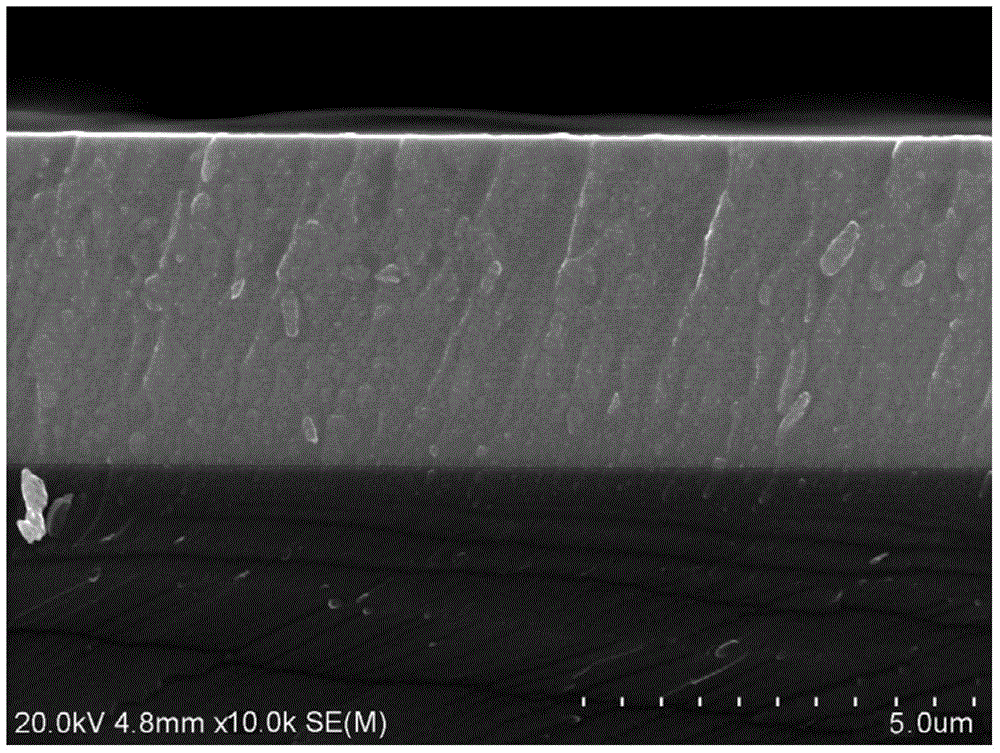

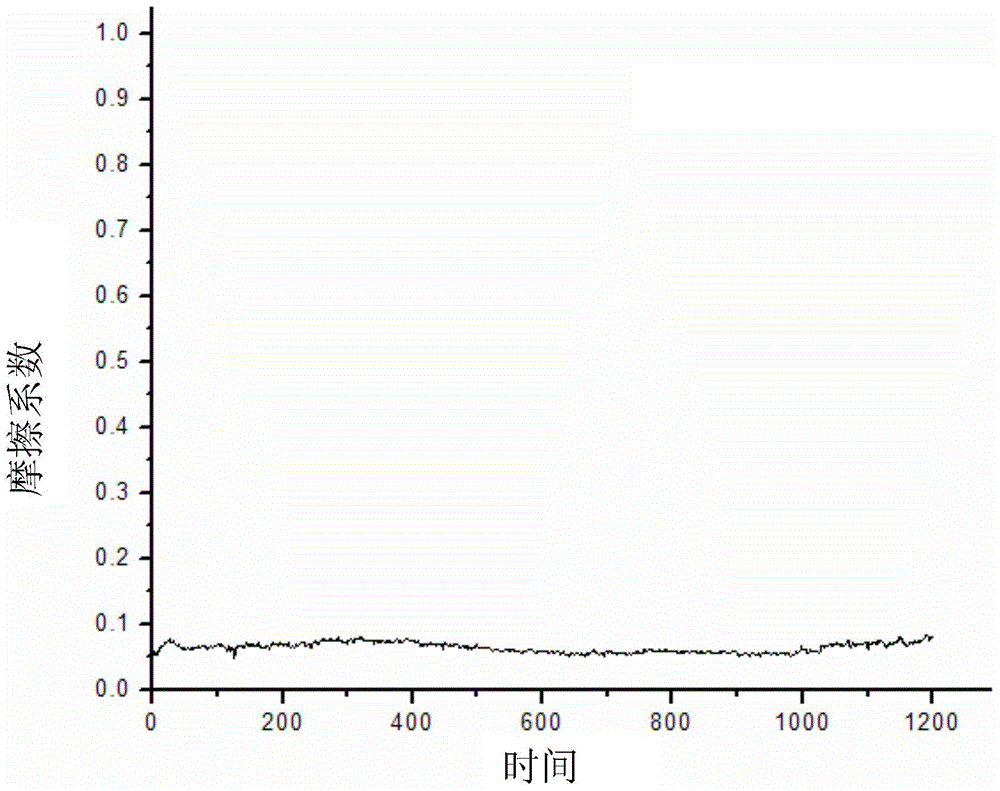

Super-hard self-lubricating diamond/diamond-like composite laminated coating material and preparation method thereof

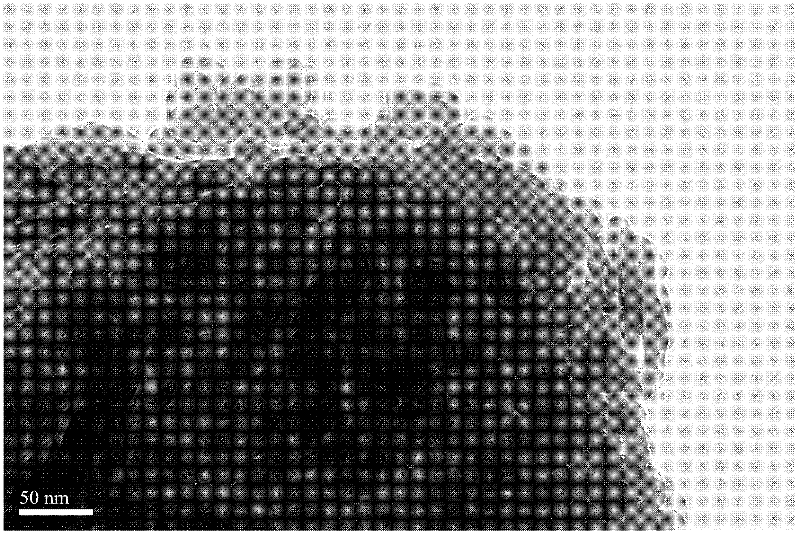

ActiveCN101818332AThe process steps are simplePrecise and controllable synthesis conditionsChemical vapor deposition coatingPolymer scienceMagnetic filtration

The invention relates to a tool coating material and a preparation method thereof, and belongs to the technical field of material preparation and application. The material is a diamond / diamond-like composite laminated coating material with super-hard self-lubricating property. The method for preparing the diamond / diamond-like composite laminated coating material is characterized by comprising the following steps of: firstly, pretreating a matrix by using mixed solution of acid and alkali respectively; secondly, synthesizing diamond with ultrahigh hardness and good crystalline form on the matrix, which serves as the main body of the composite coating, by adopting hot filament chemical vapor deposition; and finally, depositing a high-hardness diamond-like thin film on the main body of the diamond, which serves as a self-lubricating surface layer, by using magnetic filtration cathodic vacuum arc. In order to improve the binding force between the diamond thin film and the matrix and between the diamond-like thin film and the diamond thin film, a transition layer is coated between adjacent layers respectively. The method has the advantages of simple process, precise and controllable synthesis conditions, high film-forming quality, high product yield, low cost, and the like. The obtained diamond / diamond-like composite laminated coating material has ultrahigh hardness, extremely low friction factor and extremely low wear rate, shows excellent self-lubricating friction and wear resistance, and has significance for application of tools or molds under rigorous service conditions.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +2

Magnetic filtration process, magnetic filtering material, and methods of forming magnetic filtering material

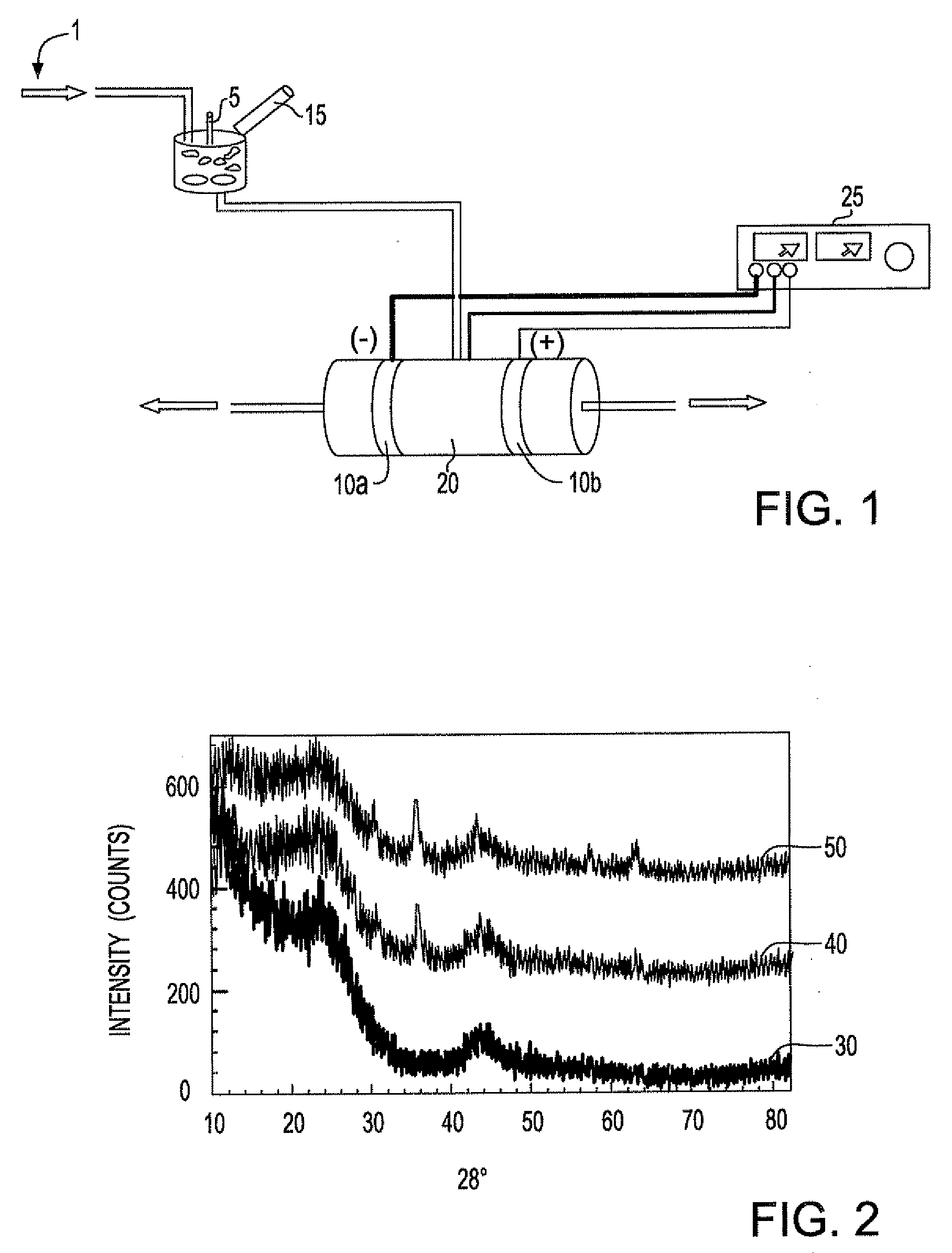

ActiveUS20100155335A1Increase valueIncreasing pH valueMaterial nanotechnologyTreatment involving filtrationWater useMagnetic susceptibility

The present invention provides magnetically responsive activated carbon, and a method of forming magnetically responsive activated carbon. The method of forming magnetically responsive activated carbon typically includes providing activated carbon in a solution containing ions of ferrite forming elements, wherein at least one of the ferrite forming elements has an oxidation state of +3 and at least a second of the ferrite forming elements has an oxidation state of +2, and increasing pH of the solution to precipitate particles of ferrite that bond to the activated carbon, wherein the activated carbon having the ferrite particles bonded thereto have a positive magnetic susceptibility. The present invention also provides a method of filtering waste water using magnetic activated carbon.

Owner:UT BATTELLE LLC

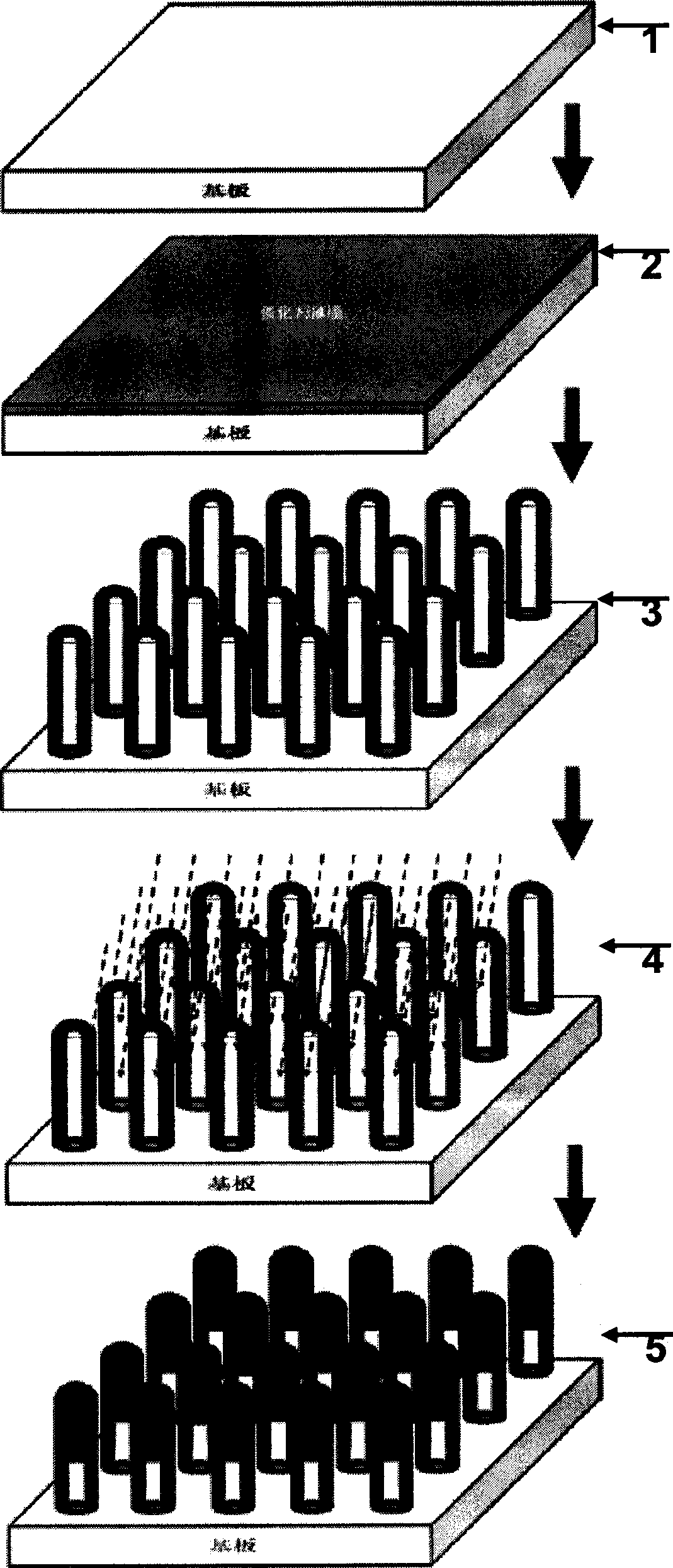

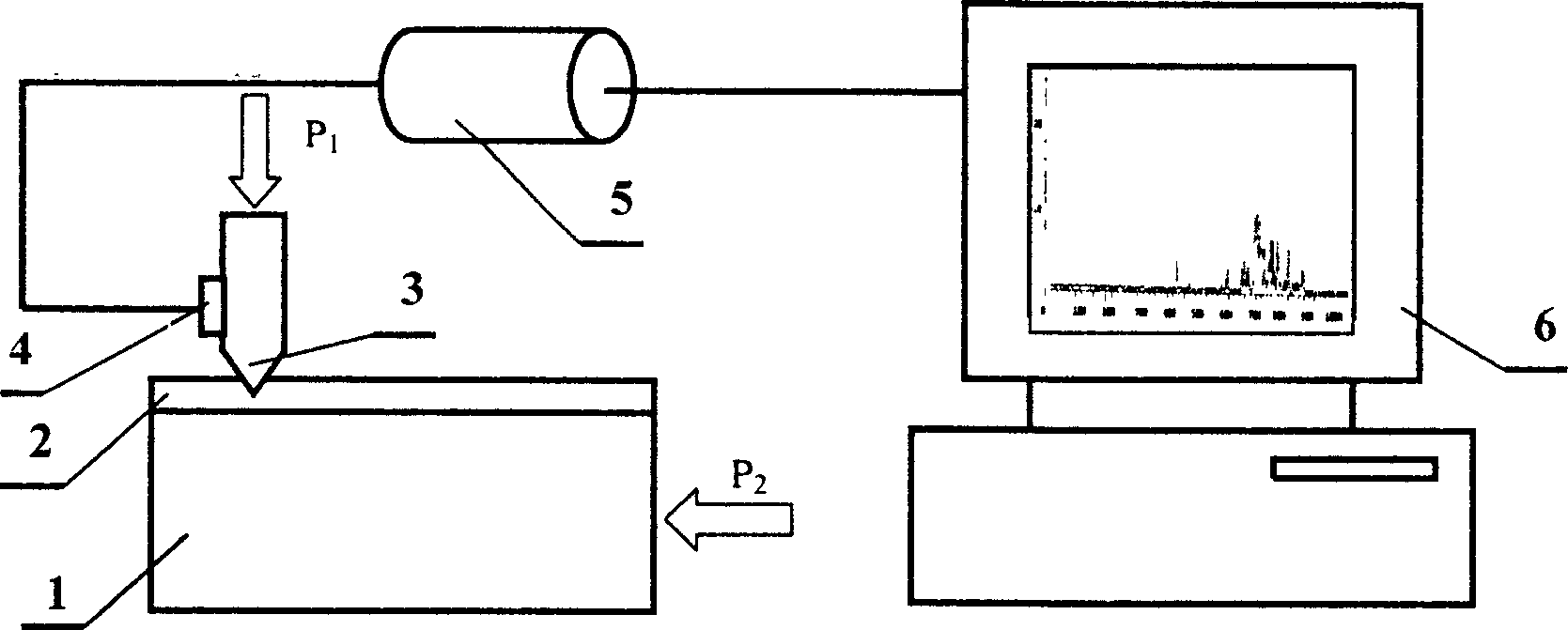

Carbon nano-fibre/carbon nano-tube heterogeneous nano-array for field electronic emitter and manufacturing technology thereof

InactiveCN101508421AEasy to operateImprove field emission performanceIndividual molecule manipulationImage/pattern display tubesFiberManufacturing technology

The invention discloses a carbon nano fiber / carbon nanotube heterogenous nano array capable of being used for a field electronic emitter and a preparation method thereof. The preparation method mainly comprises the following steps: (1) taking a silicon single-crystal chip or a glass sheet or a ceramic chip, and the like as a substrate; (2) utilizing magnetic filtration vacuum vapor arc plasma deposition technology or magnetron sputtering technology to deposit a catalyst film on the substrate; (3) performing high-temperature heat treatment on the catalyst film in an ammonia gas reaction chamber; (4) introducing working mixture taking hydrogen as carrier gas and acetylene as reaction gas at high temperature, and synthesizing a directional carbon nanotube array on the substrate subjected to heat treatment; (5) adopting an energy-carrying ion beam or a plasma to process the carbon nanotube, and forming the carbon nano fiber / carbon nanotube heterogenous nano array; and (6) using the carbon nano fiber / carbon nanotube heterogenous nano array to process the field electronic emitter.

Owner:BEIJING NORMAL UNIVERSITY

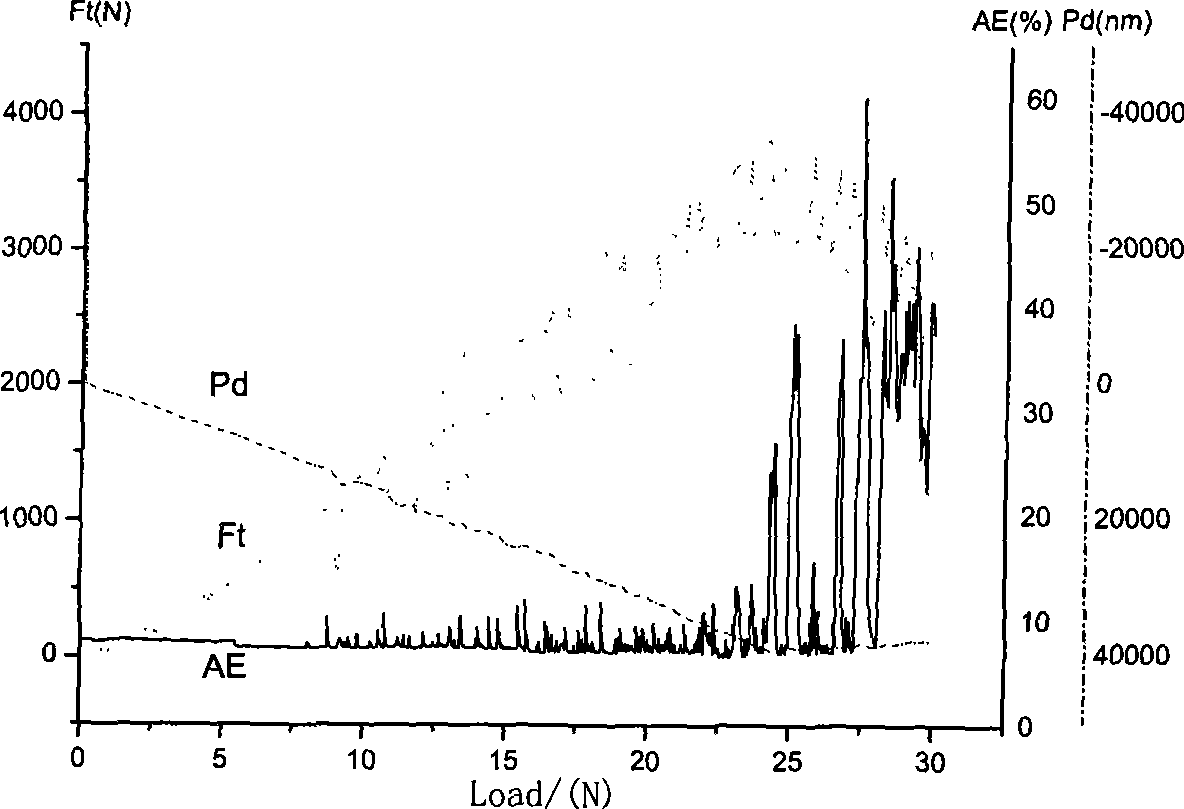

TiAlN/TiN for tool and mould material surface and preparation thereof

InactiveCN101435070AExtended service lifeImprove wear resistanceLayered productsVacuum evaporation coatingAutomatic controlWear resistance

The invention discloses a magnetic filtration TiAlN / TiN thin film on the surface of tool and die material and a preparation method thereof. A layer of magnetic filtration TiN thin film is firstly plated on the surface of the tool and die material by adopting a magnetic filter, then a layer of magnetic filtration TiAlN thin film is plated, and the total thickness of double layers of thin films is 1 to 4 Mu m. The magnetic filtration TiAlN / TiN thin film has short preparation time, low cost and good wear resistance, is beneficial to prolonging the service life of the tool and die; and the processing quality of the plated film is high, the preparation technique is simple, the operation is easy and the plating process adopts electrical and mechanical automatic control.

Owner:GUANGDONG ZHENGDE MATERIAL SURFACE TECH

Preparation method of spherical cobaltosic oxide with high battery security

ActiveCN101585559AHigh reactivityHigh densityElectrode manufacturing processesCobalt oxides/hydroxidesForeign matterCobalt(II,III) oxide

The invention relates to a preparation method of spherical cobaltosic oxide with high battery security. The point of the method lies in that the spherical cobaltosic oxide powder is obtained by direct oxidization. This powder uses a deironing device to reduce the content of the magnetic foreign substance. The specific steps are as follows: preparing the cobalt salt into the solution with concentration of 1 to 2 mol / L; then adding quantitative complexing agent A; the hydroxide solution being the first and second mixed solutions; simultaneously leading the first and second mixed solutions to a reaction container by means of parallel flow; making the first and second mixed solutions react with each other by strong stirring; strictly controlling pH value, flow, stirring speed and reaction temperature during the reaction process; continuously leading the oxidizing agent with certain flow to the reaction system during the reaction process; after the reaction is finished, aging for 3 to 24 hours in a constant temperature; filter pressing the material by a filter press and the washing the material; then washing the material by the washing kettle and filter pressing, washing it; drying it; filtering the powder by a ferromagnetic filtering device to reduce the content of the magnetic foreign substance; the spherical cobaltosic oxide with high battery security belongs to the battery anode material.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD +1

TiN two-layer film cladding for cutting tool material surface and its preparing method

InactiveCN1850402AImprove the interface binding forceLow costVacuum evaporation coatingSputtering coatingMicrometerTotal thickness

The present invention discloses a TiN double-layer film coat on the surface of cutting tool material and its preparation method. Its preparation method includes the following steps: firstly, adopting magnetic filter to electroplate a layer of nano-grade particle TiN film on the surface of cutting tool material, then adopting general multiple-arc electroplating process to electroplate a layer of micrometer-grade granule TiN film, in which nano-grade TiN particle size is 40-100 nm, film thickness if 50-300 nm, micrometer-grade TiN granule size is 0.5-1 micrometer, total thickness of double-layer film is 2-5 micrometers.

Owner:SOUTH CHINA UNIV OF TECH

Zinc oxide coating modified in vivo implanted artificial organ and preparation method thereof

InactiveCN101745147AGood blood compatibilityHigh puritySurgeryVacuum evaporation coatingRare-earth elementRadio frequency magnetron sputtering

The invention discloses an artificial organ used for in vivo implantation, which comprises an artificial organ matrix and an artificial organ surface modified layer, wherein the surface modified layer is a zinc oxide thin film the thickness of which is 10nm to 700nm, preferably a zinc oxide thin film the thickness of which is 200nm to 400nm. The zinc oxide thin film is doped preferably by light rare earth elements. The invention also discloses two methods for preparing the artificial organ the surface of which is modified by the zinc oxide coating, wherein in one method, a layer of pure or light rare earth-doped transparent zinc oxide thin film is prepared on the surface of the in vivo implanted artificial organ by adopting a radio frequency magnetic control sputtering technology to serve as a biological coating for improving an implant anticoagulant property; in the other method, the transparent zinc oxide thin film is deposited by adopting a method of magnetic filtration arc ion plating. The anticoagulant property and the mechanical property of the in vivo implanted artificial organ are improved.

Owner:SUN YAT SEN UNIV

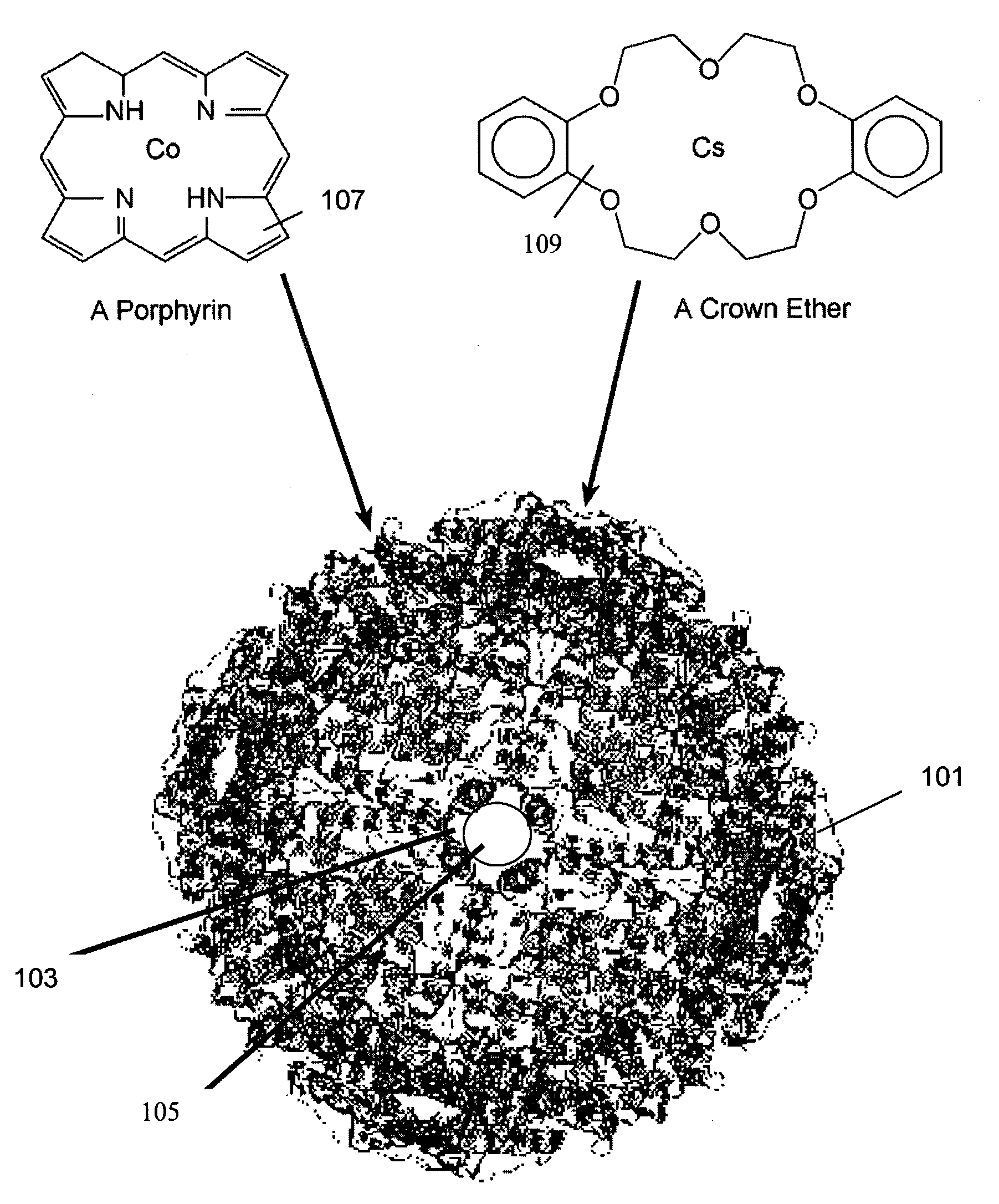

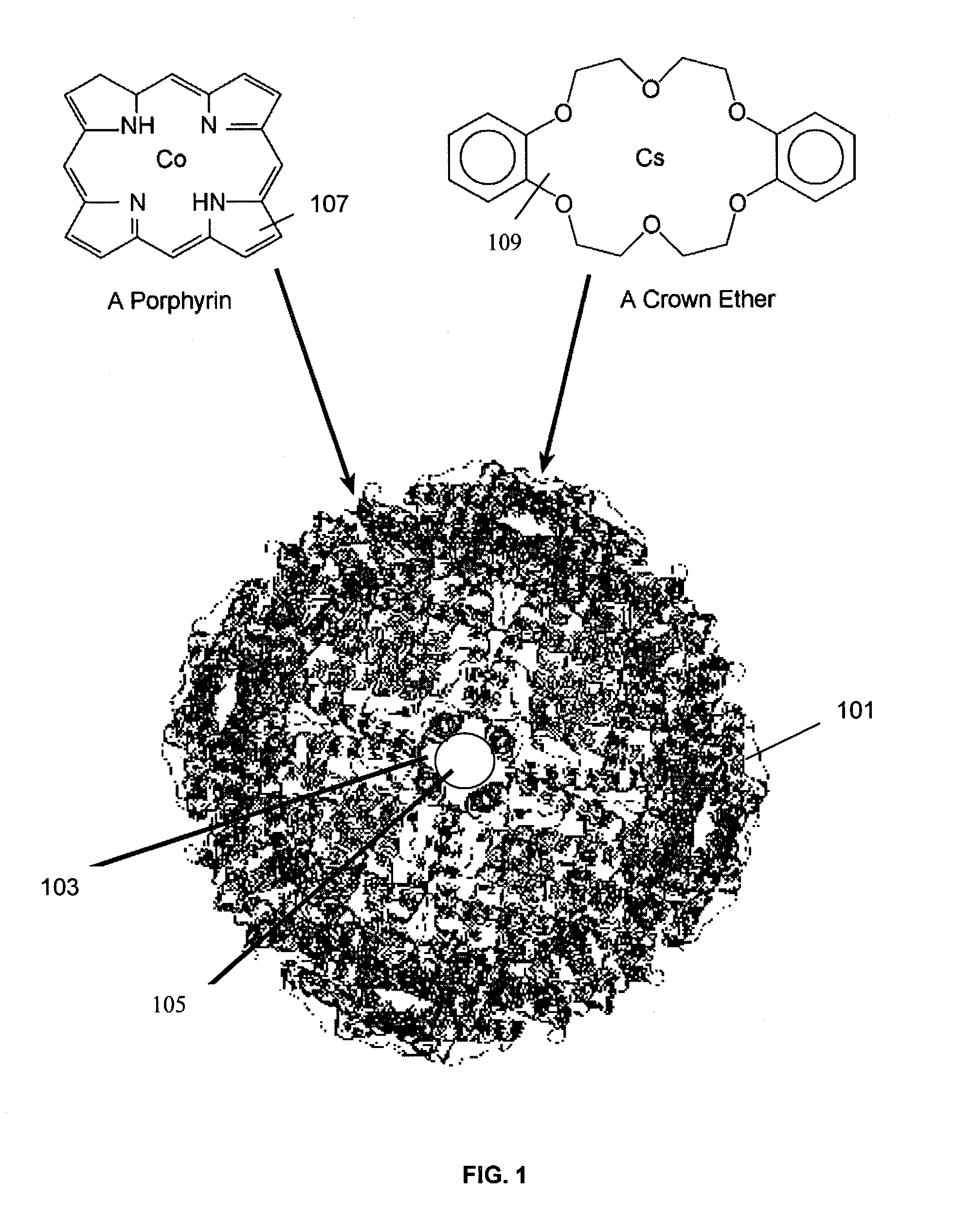

Magnetic molecules: a process utilizing functionalized magnetic ferritins for the selective removal of contaminants from solution by magnetic filtration

InactiveUS6972095B1Easily be flushed out of the filterTransuranic element compoundsIon-exchanger regenerationProtein structureIon exchange

A decontamination system uses magnetic molecules having ferritin cores to selectively remove target contaminant ions from a solution. The magnetic molecules are based upon a ferritin protein structure and have a very small magnetic ferritin core and a selective ion exchange function attached to its surface. Various types of ion exchange functions can be attached to the magnetic molecules, each of which is designed to remove a specific contaminant such as radioactive ions. The ion exchange functions allow the magnetic molecules to selectively absorb the contaminant ions from a solution while being inert to other non-target ions. The magnetic properties of the magnetic molecule allow the magnetic molecules and the absorbed contaminant ions to be removed from solution by magnetic filtration.

Owner:ELECTRIC POWER RES INST INC

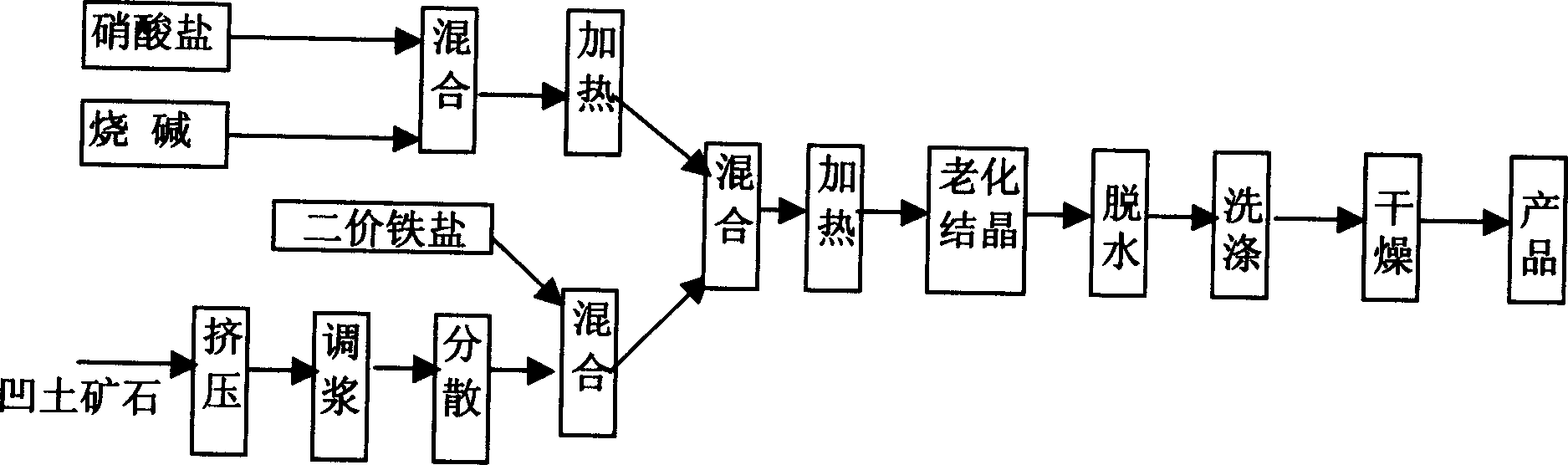

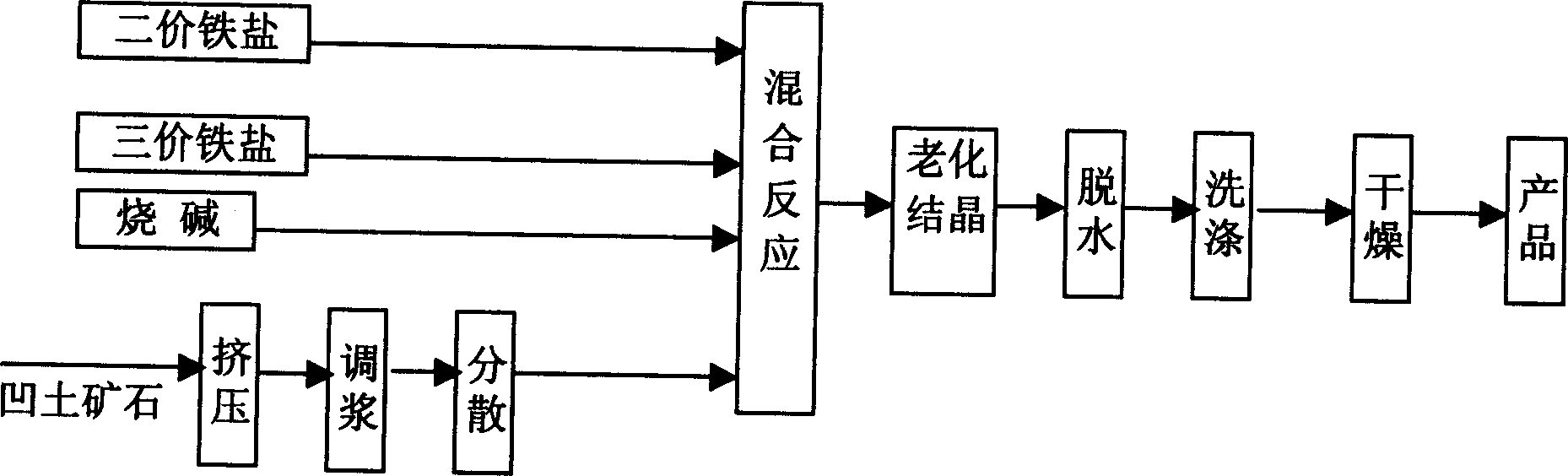

Method for preparing magnetic granule-attapulgite nano composite material

InactiveCN1850602AIncrease added valueImprove adsorption capacitySilicon compoundsIron saltsSuperparamagnetism

The invention is a method for preparing magnetic grain-attapulgite nano composite, characterized in using attapulgite clay and iron salt as raw materials, by nucleation of bivalent, or bivalent and trivalent iron ions on the attapulgite surface and their stable action on crystal nucleus, caused by the attapulgite clay, directly crystallizing nano magnetic grains in solution, and depositing on the surface of the attapulgite crystals, so as to compose the composite. And it has super paramagnetism and strong absorptivity, able to be controlled under the action of magnetic field to implement magnetic flocculation, magnetic recovery, magnetic filtration, and target control of attapulgite sorbent. And it can be widely applied to the fields of purification of industrial raw materials, deep filtration for air purification, nano film material, deep processing for water supply processing, etc.

Owner:HEFEI UNIV OF TECH

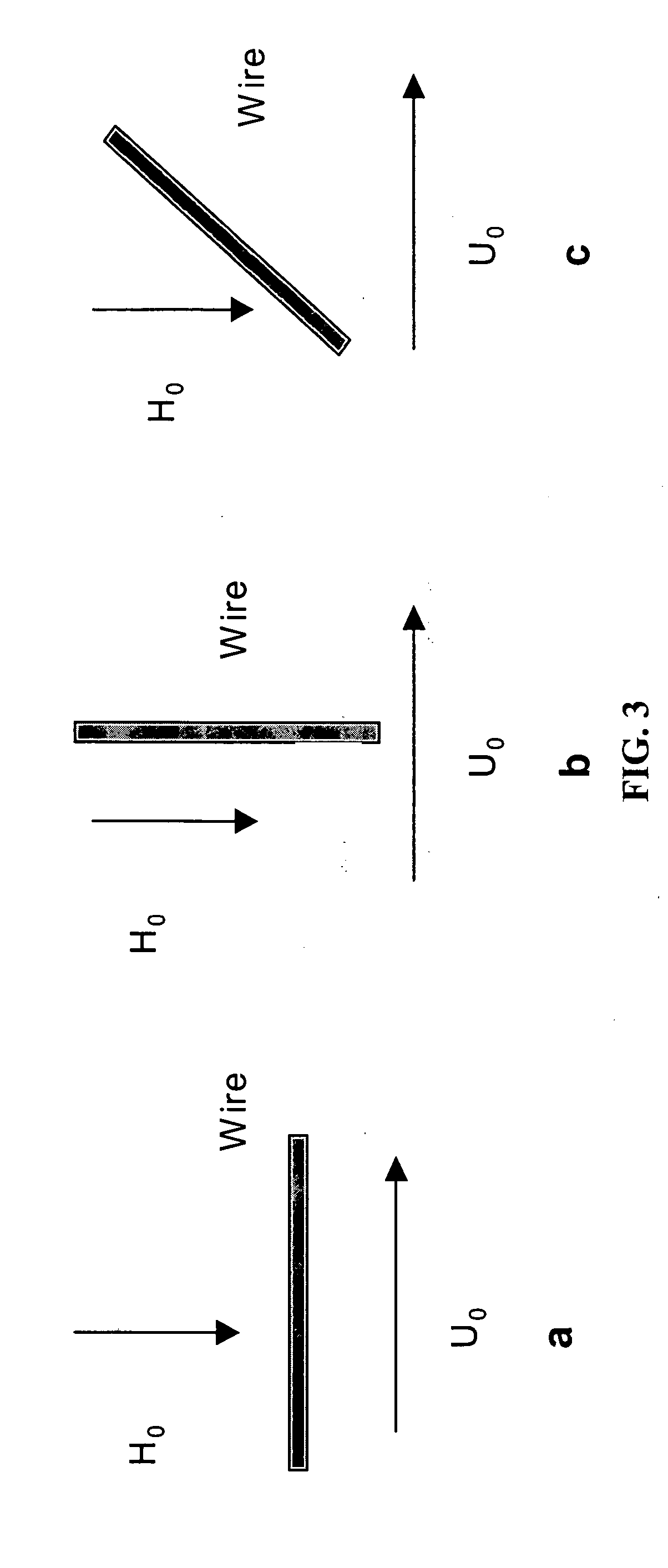

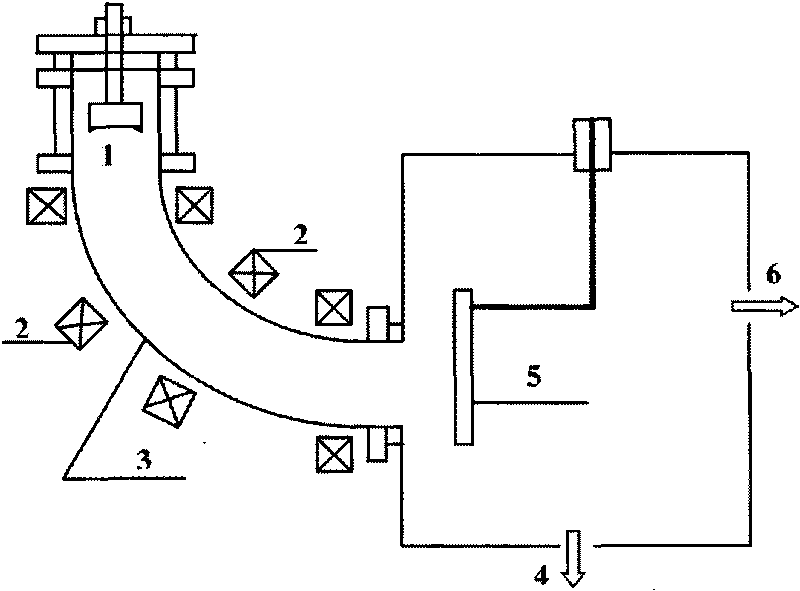

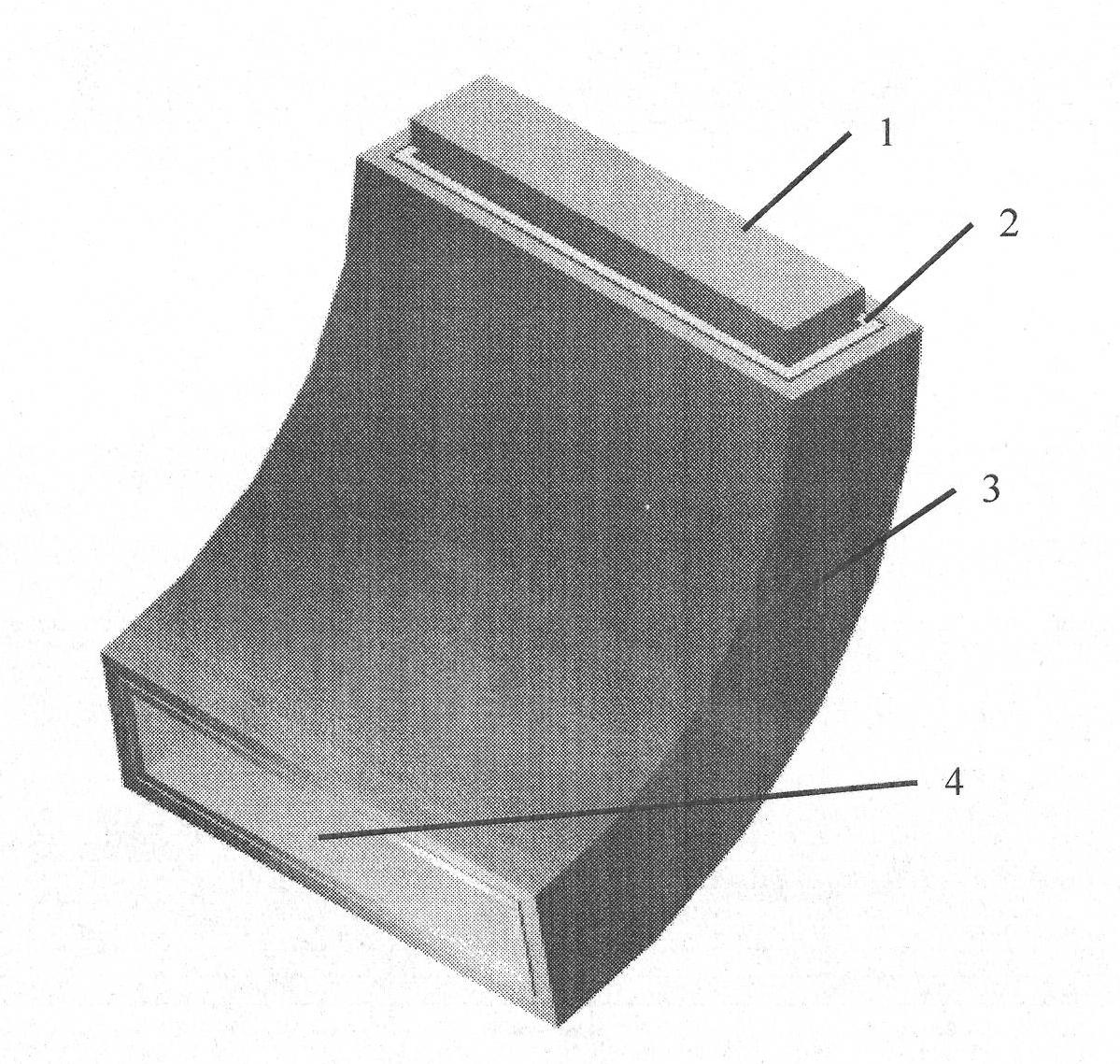

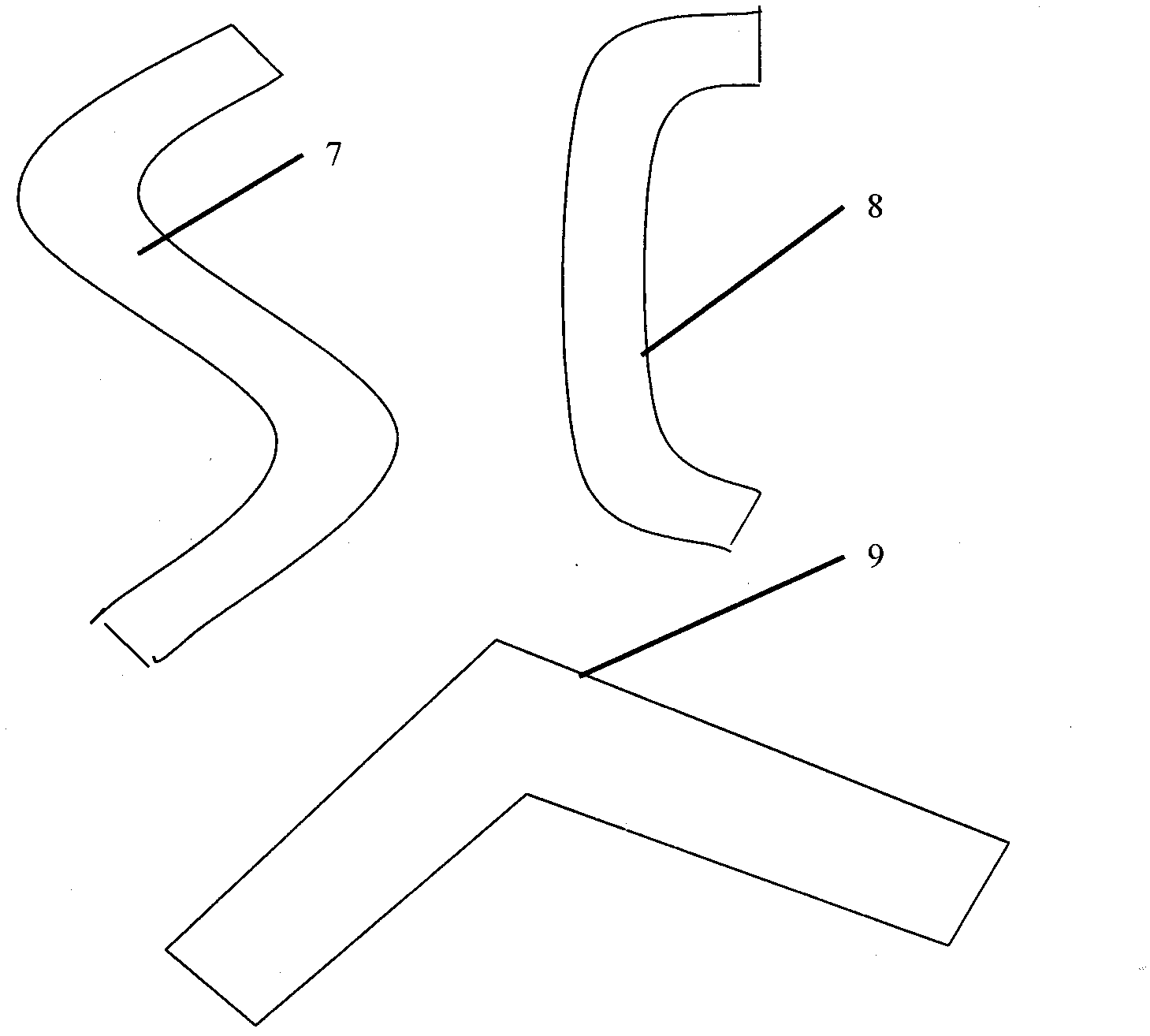

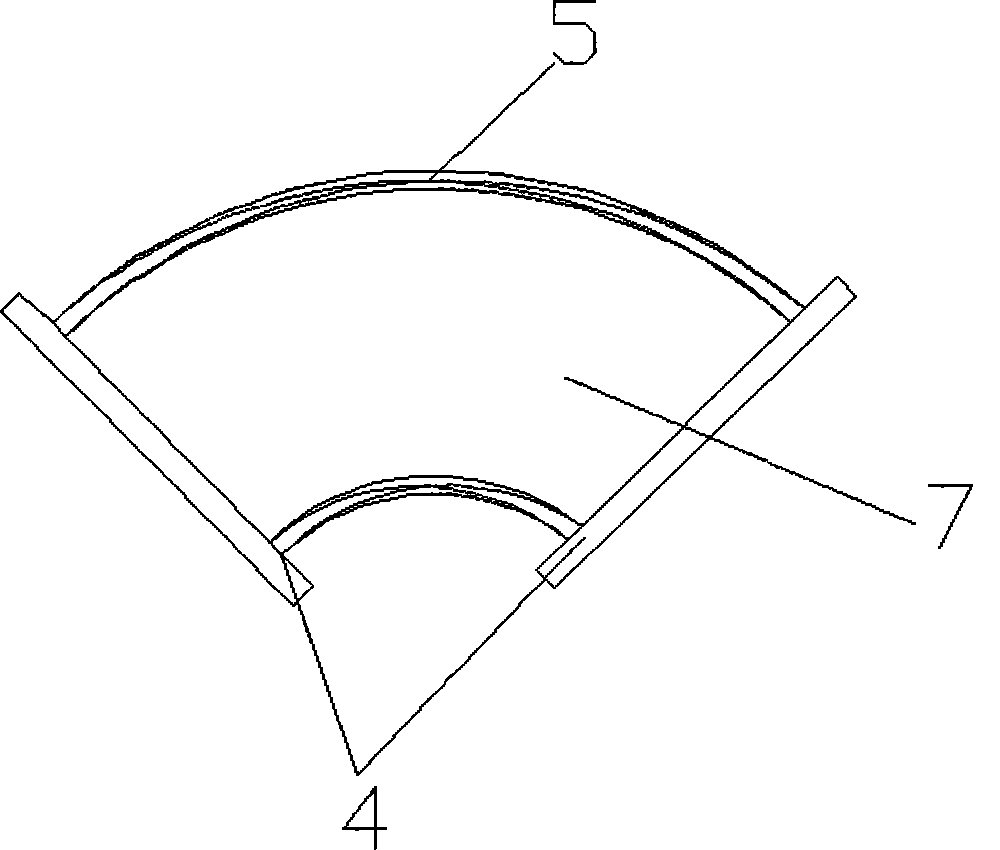

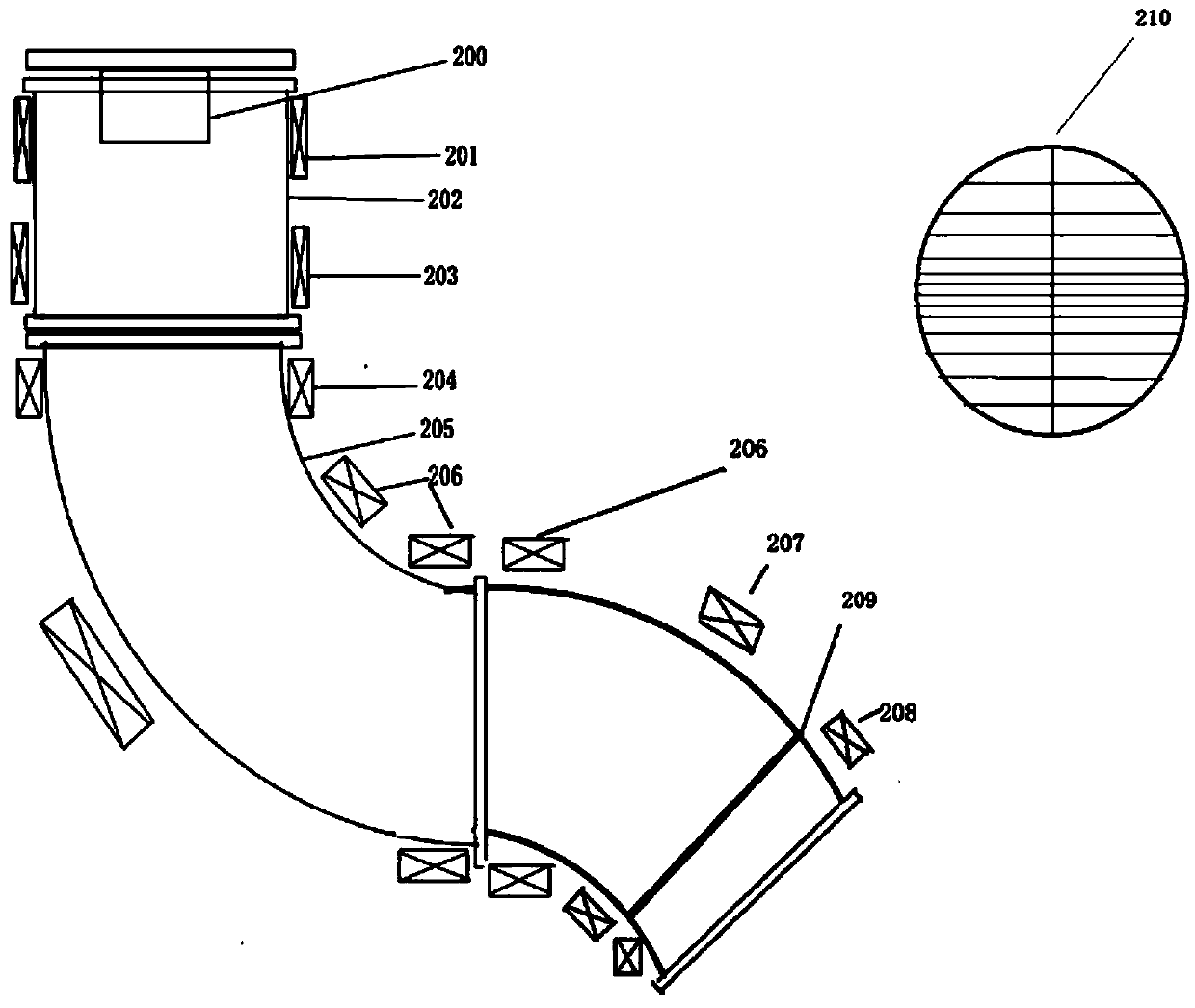

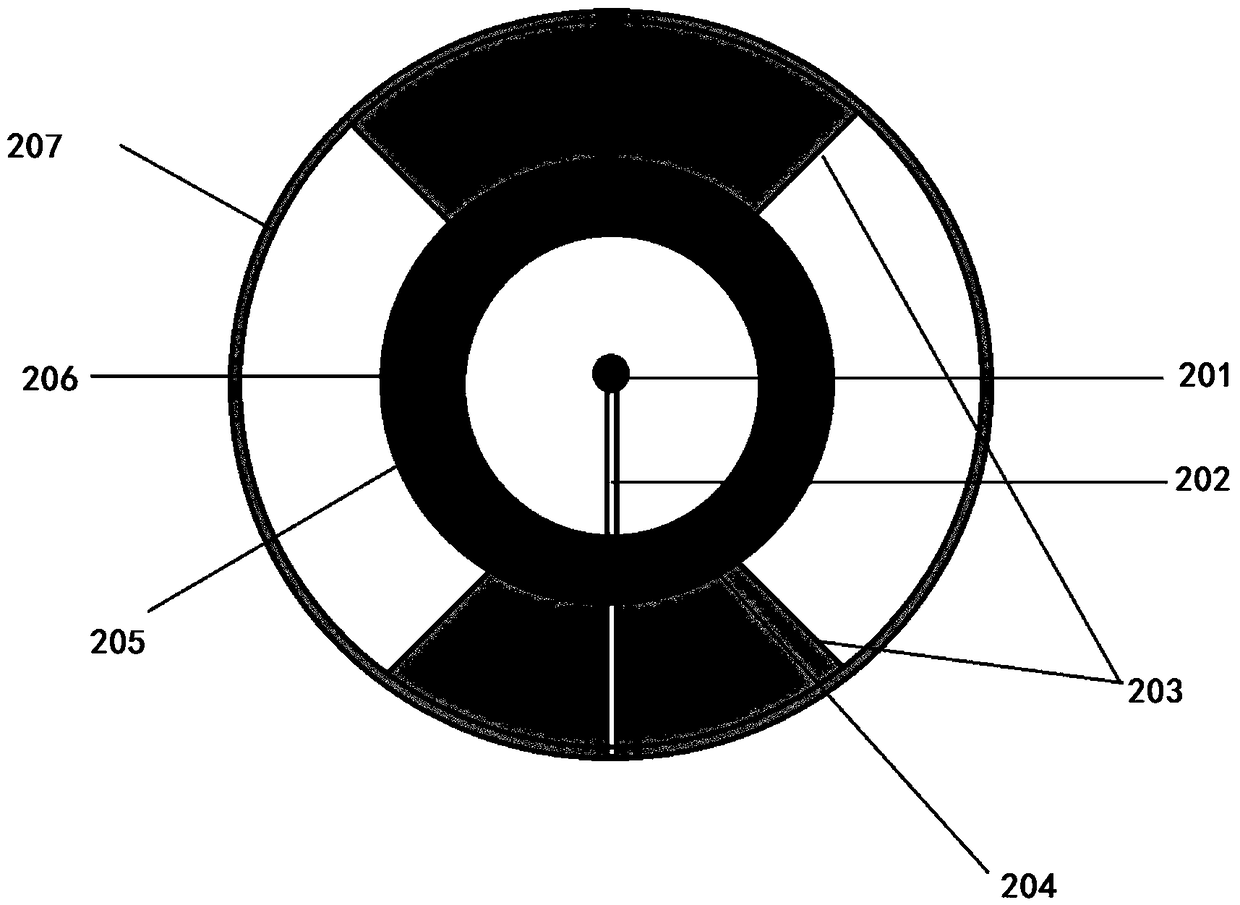

Method for magnetic filtration of strip-sectional vacuum cathodic arc plasma

InactiveCN102634761ASimple methodSuitable for high-volume industrial productionElectric discharge tubesVacuum evaporation coatingBand patternPlasma channel

The invention provides a method for removing electrically neutral drops and macroscopic particles in strip-sectional vacuum cathodic arc plasma, which belongs to the field of vacuum surface modification for materials, and particularly provides a method for magnetic filtration of electrically neutral drops and macroscopic particles by bending strip vacuum cathodic arc plasma by applying a magnetic field to a strip-sectional vacuum cathodic arc plasma channel. By the method, the defects that deposition area is small, deposition film is uneven, and scanning system equipment is complex and expensive and unsuitable for large-scale industrial coating application and the like in existing vacuum cathodic arc magnetic filtration methods for bends are overcome. By the method, coating plasma can be provided within a long strip range. By means of a rotating workpiece target table, application field of filtering arc can be widened greatly. Deposition efficiency is improved, large-space coating is achieved, coating efficiency is improved, and cost is reduced.

Owner:李刘合

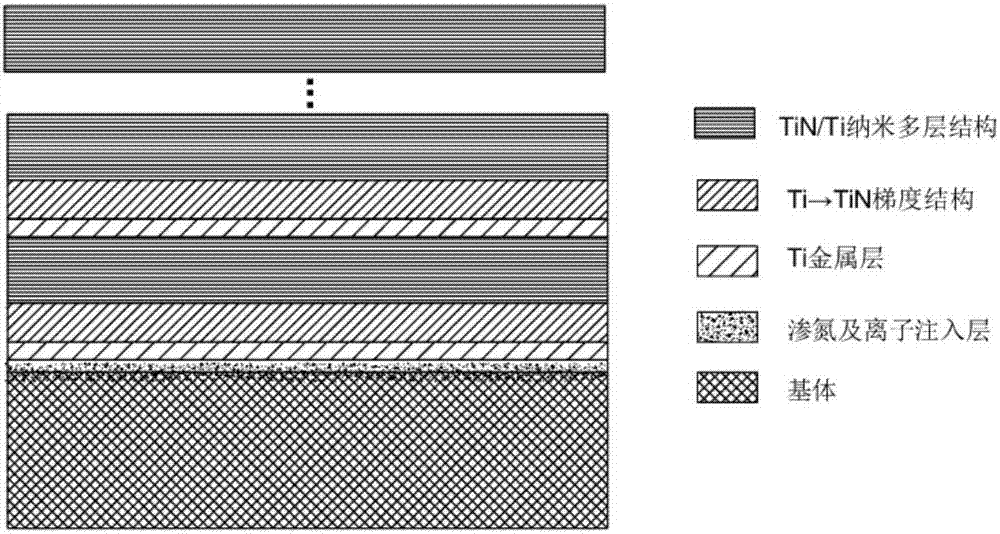

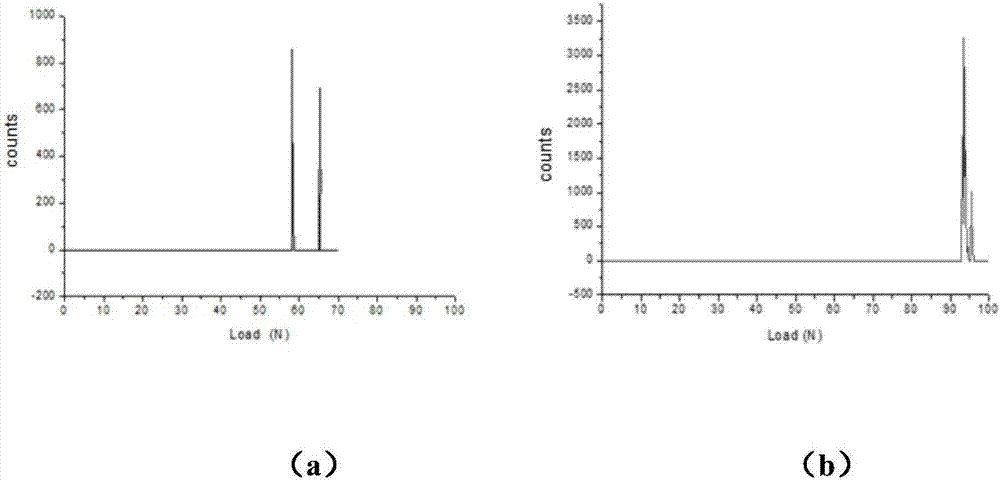

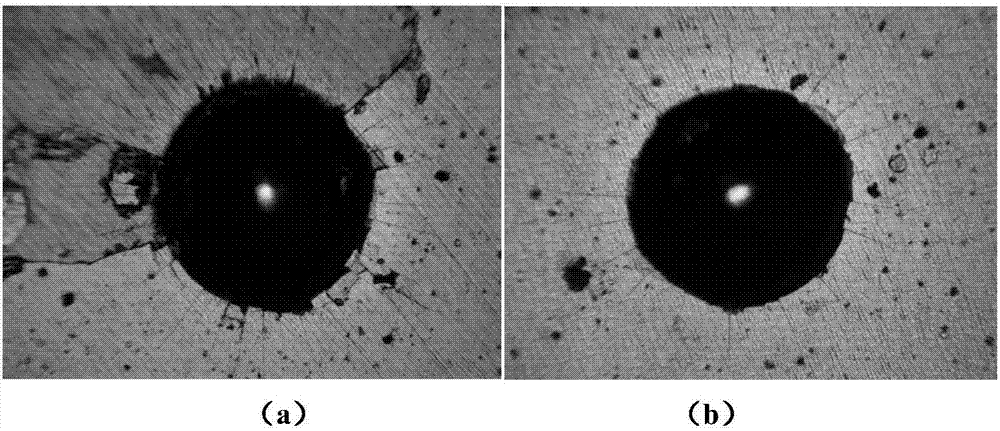

Nano multilayer gradient composite anti-erosion coating structure and preparation method thereof

ActiveCN107326360AReduce stress concentrationAvoid affecting performanceVacuum evaporation coatingSputtering coatingStress concentrationIon implantation

The invention discloses a nano multilayer gradient composite anti-erosion coating structure and additionally further discloses a preparation method of the coating strcuture. From a matrix to the surface of the coating surface, the coating structure sequentially comprises a nitriding layer, an embedded type combined layer and a structure body formed by circularly overlaying a Ti metal layer, a Ti-TiN gradient layer and a TiN / Ti nano multi-layer. The preparation method comprises the steps that through surface nitridation, the material property of the surface and subsurface of the matrix is similar to that of a coating material so as to relieve the stress concentration phenomenon of the film-matrix junction; by adoption of a metal vacuum steam ion source injection method, the nitrided matrix surface is subjected to ion injection to form the embedded type combined layer; and by adoption of a magnetic filtering vacuum cathode arc deposition method, by continuously controlling the flow of input N2, the periodically-circulated structure body which is sequentially composed of the Ti metal layer, the Ti-TiN gradient layer and the TiN / Ti nano multi-layer is deposited on the combined layer. The nano gradient multilayer composite coating structure simultaneously has high hardness, high toughness and excellent film-matrix combining force, so that the very good anti-erosion performance is achieved.

Owner:XI AN JIAOTONG UNIV

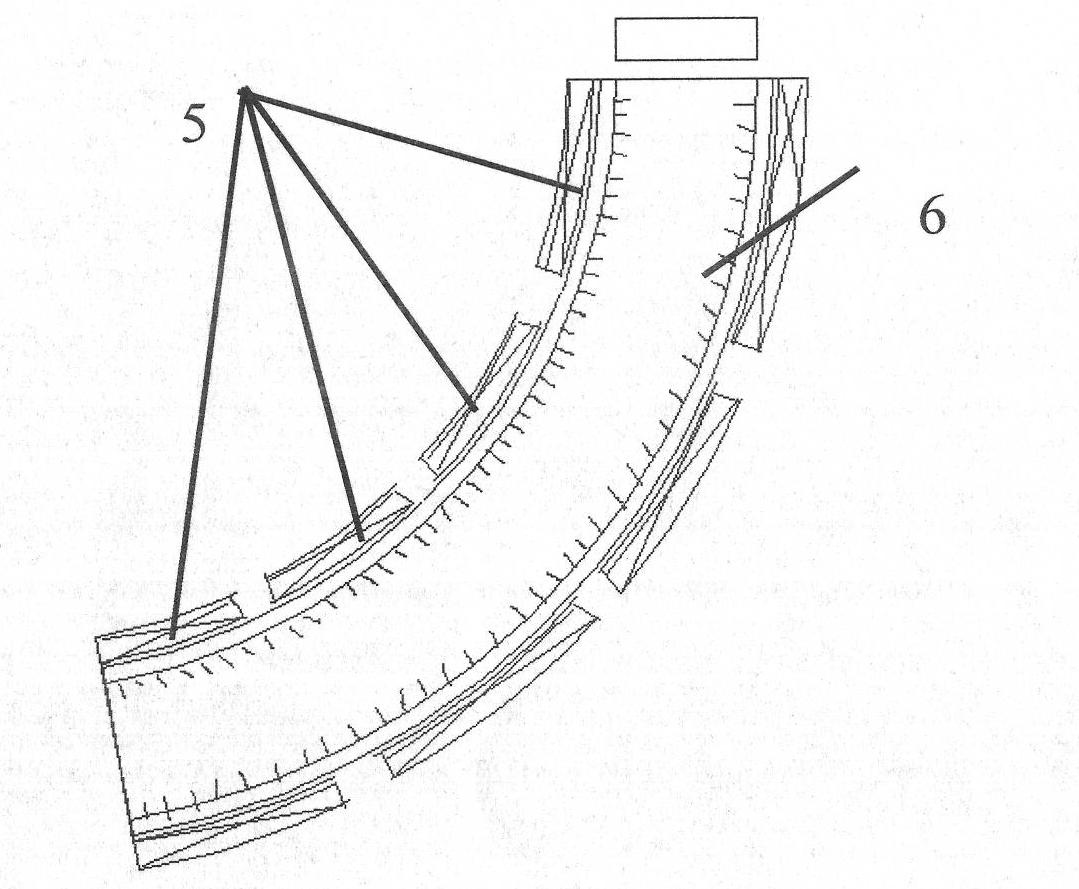

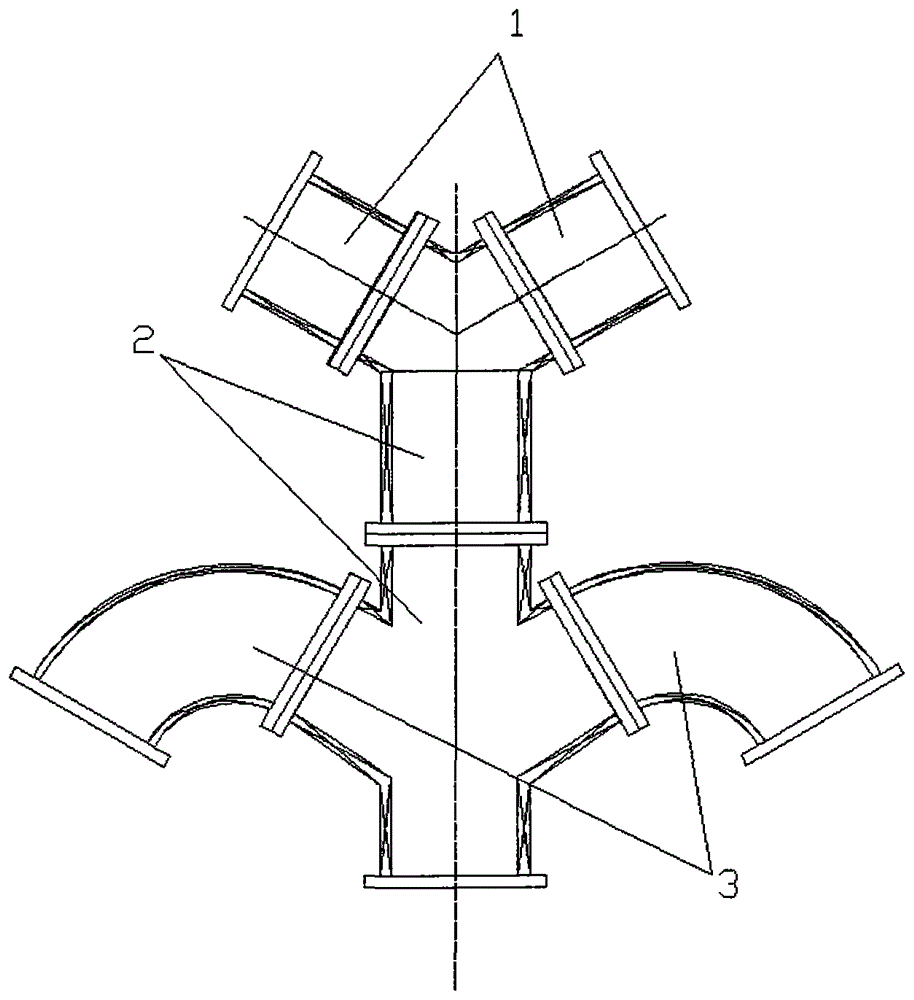

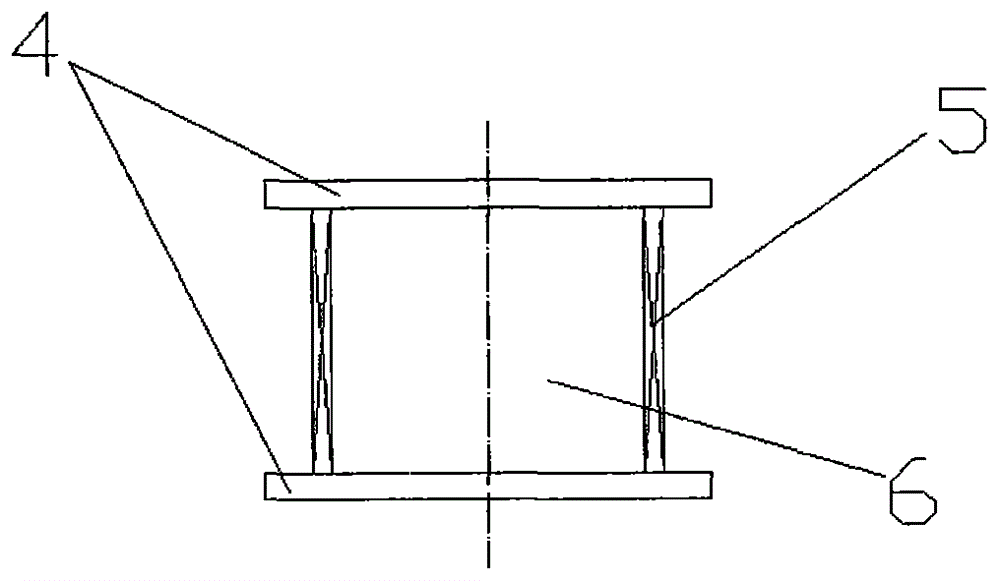

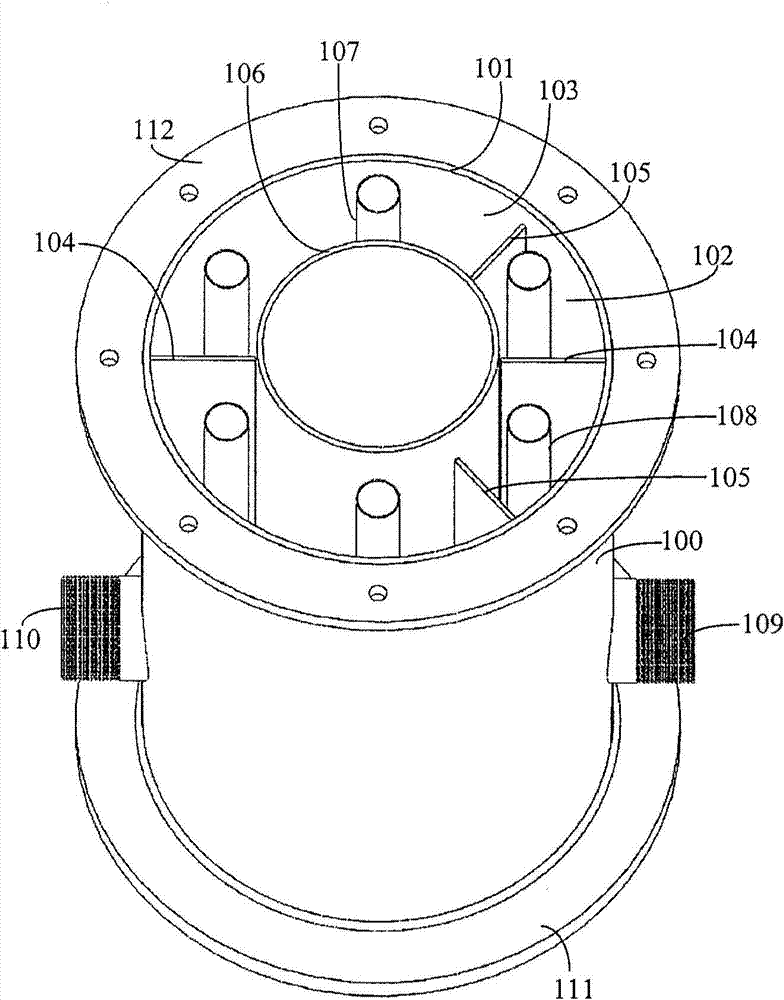

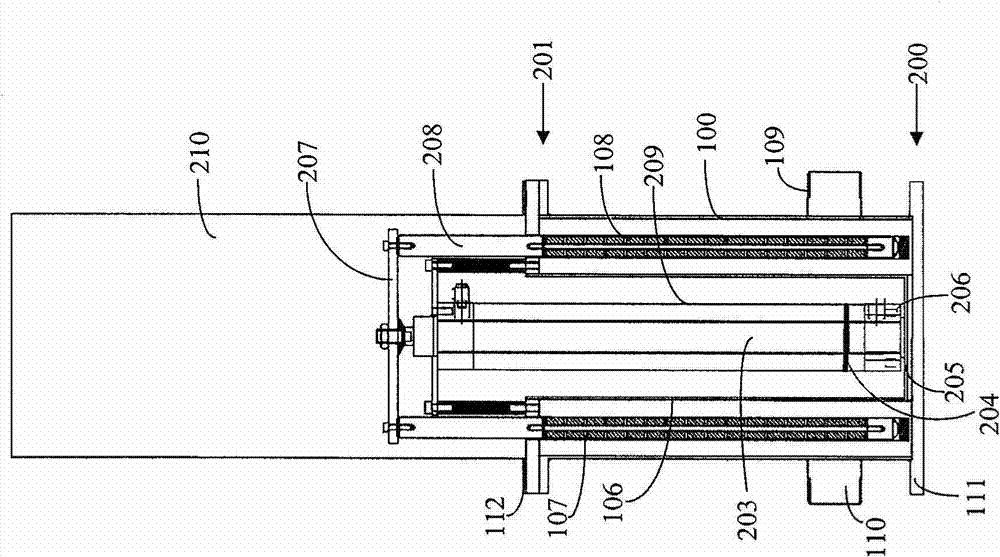

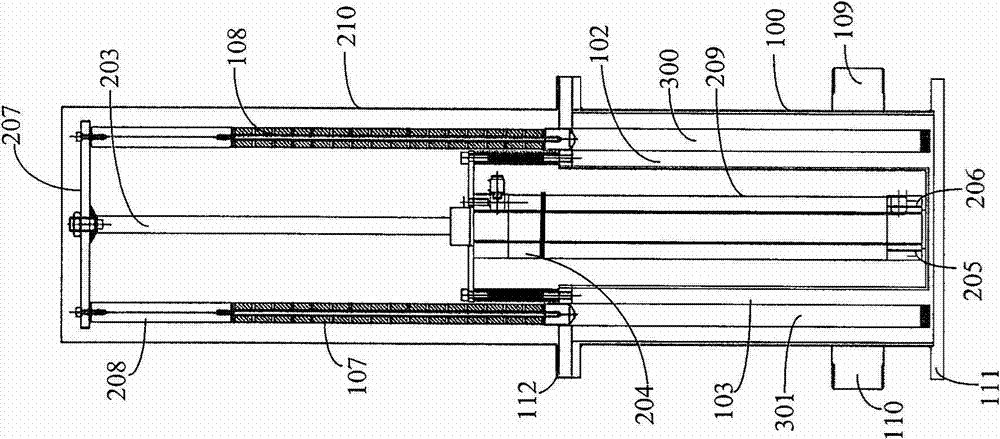

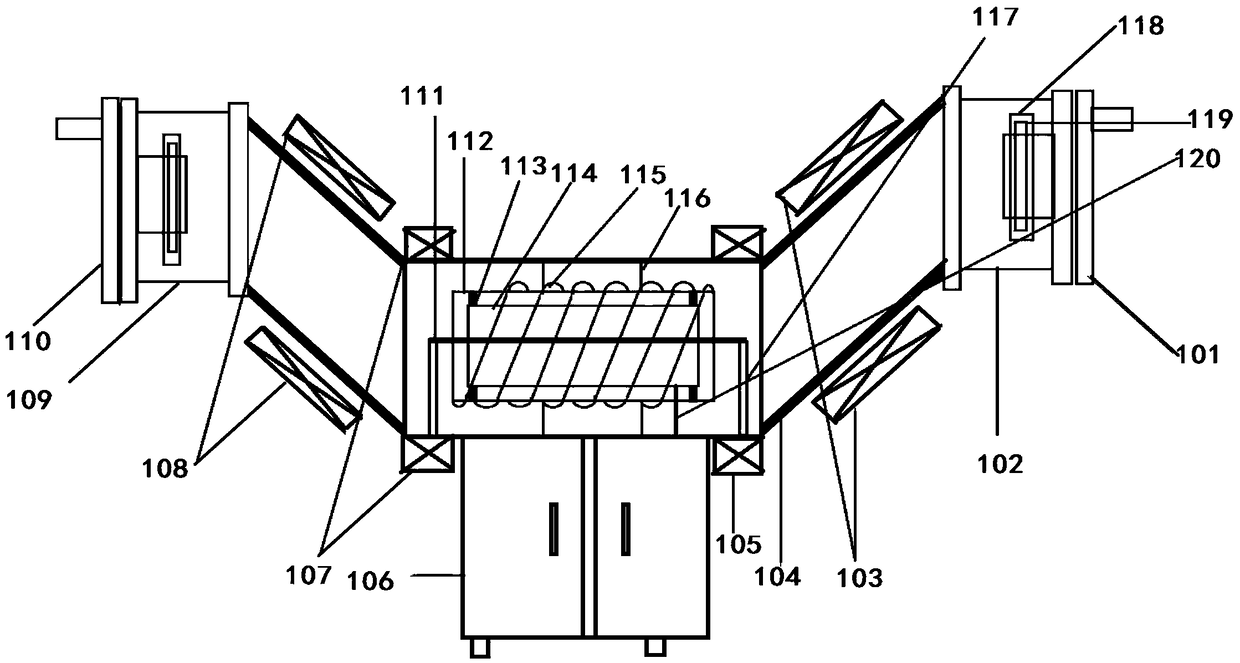

Tree-shaped cathode vacuum arc plasma deposition and magnetic filtration device

InactiveCN105296938AAchieve multiple depositionImprove performanceElectric discharge tubesVacuum evaporation coatingPlasma depositionEngineering

The invention provided with a tree-shaped cathode vacuum arc plasma deposition and magnetic filtration device which is formed by rationally combining and assembling two or more magnetic filtration branch pipes and a magnetic filtration main pipe, and then a tree-shaped structure is formed. In order to overcome the defects that the proportion of elementary components of a film layer of a multi-component laminated film prepared through an existing magnetic filtration cathode vacuum arc plasma deposition technology is hard to adjust and control and is not uniform along with changes of the position, the magnetic filtration device is provided; two or more arc sources can be assembled simultaneously, and therefore plasmas of two or more kinds of elements can be produced; the large particles of plasmas are filtered out through the magnetic filtration branch pipes and the plasmas are magnetized and guided into a vacuum target chamber through a magnetic field of the magnetic filtration main pipe, and then a multi-component deposition coating film is obtained. The tree-shaped cathode vacuum arc plasma deposition and magnetic filtration device can adjust and control components of the prepared film by adjusting the arc currents of different vacuum arc sources, the multi-component laminated film which is consistent in component proportion, compact in texture and smooth in surface is prepared.

Owner:BEIJING NORMAL UNIVERSITY

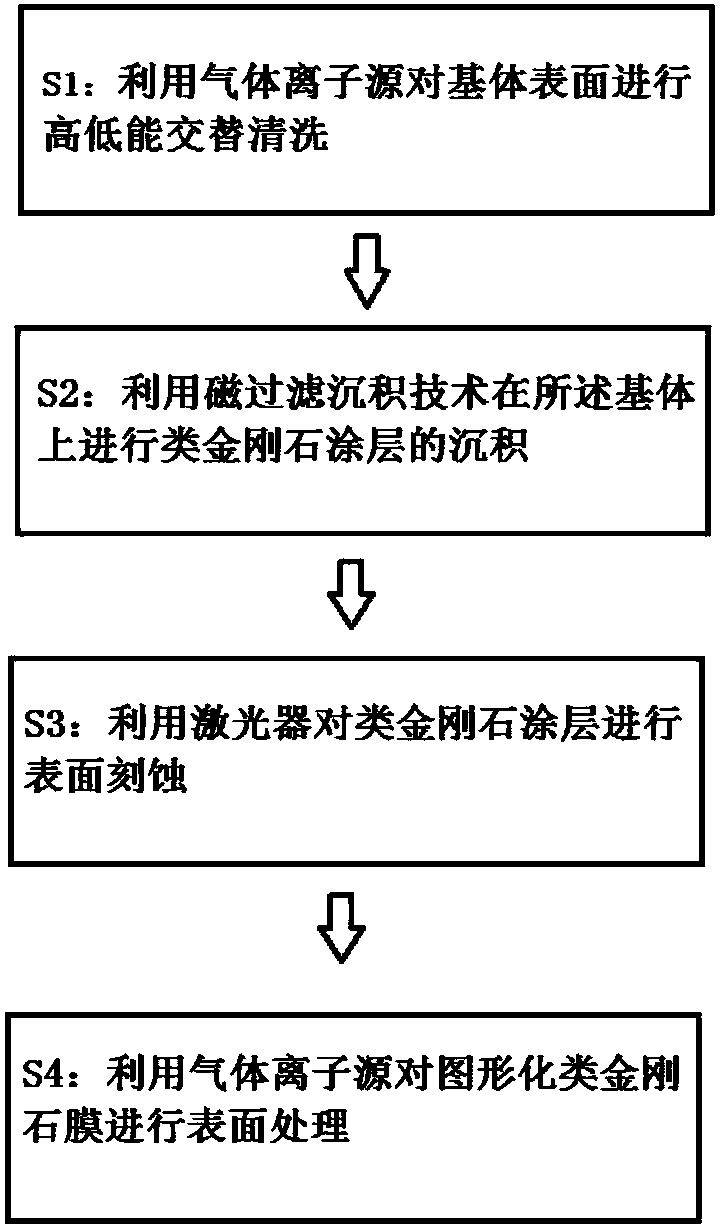

Preparation method of anti-abrasion diamond-like carbon coating layer

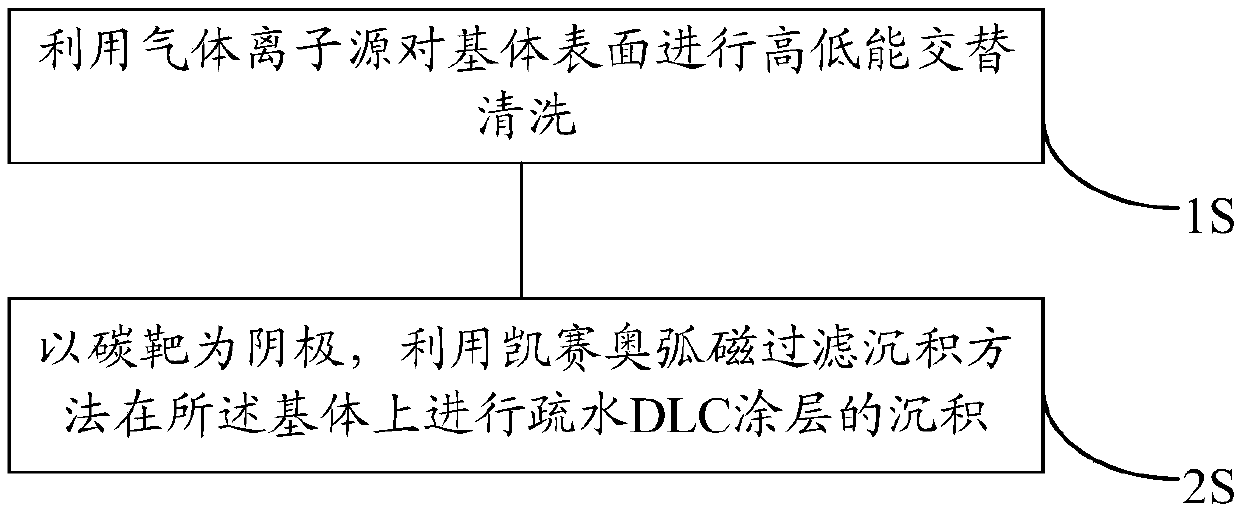

ActiveCN108359942AImprove compactnessExcellent friction and wear resistanceVacuum evaporation coatingSputtering coatingCarbon filmCarbon coating

The invention discloses a preparation method of an anti-abrasion diamond-like carbon coating layer. The preparation method comprises the following steps that S1, the surface of a substrate is subjected to high and low energy alternate cleaning through a gas ion source; S2, a diamond-like carbon coating layer is deposited on the substrate is through a magnetic filtering deposition technique with acarbon target as a cathode, wherein the method is high in deposition rate, low in cost and capable of achieving mass production; S3, the diamond-like carbon coating layer is subjected to surface etching through a laser device, and the etching interval is 2-10 [mu]m; and S4, a graphical diamond-like carbon film is subjected to surface treatment through the gas ion source. The coating layer preparedthrough the method is of a structure that the high-sp3 content and low-sp3 content of tetrahedron armorphous carbon are alternately changed; and the coating layer has the anti-abrasion performance and is higher in crack growing preventing capacity and friction and abrasion preventing performance compared with hydrogen containing diamond-like carbon, diamond-like carbon high in sp3 content and diamond-like carbon low in sp3 content.

Owner:BEIJING NORMAL UNIVERSITY

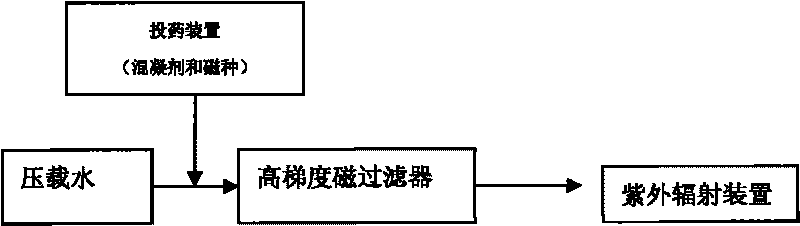

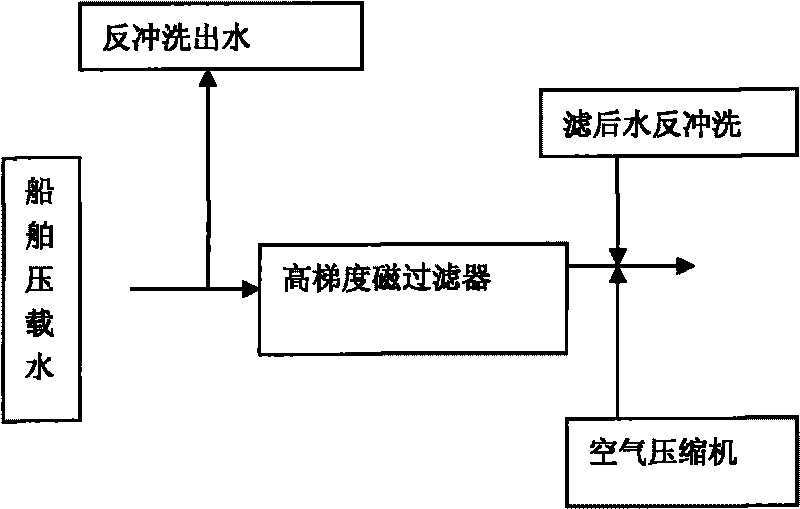

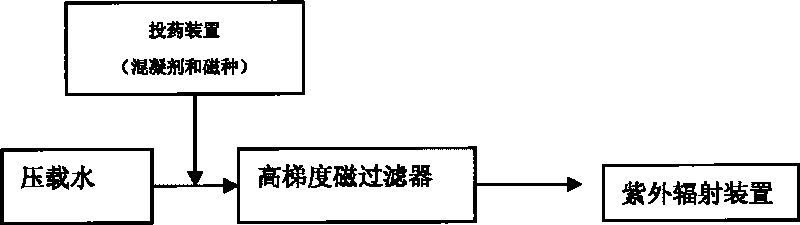

Combined treatment method for ship ballast water

InactiveCN101698548AMeet the protection requirementsMicrobial effect is obviousWater/sewage treatment by irradiationWater/sewage treatment by magnetic/electric fieldsSuspended particlesDisinfection by-product

The invention provides a combined treatment method for ship ballast water, which comprises two steps of high gradient magnetic filtration and ultraviolet radiation treatment, wherein the step of high gradient magnetic filtration is that a high gradient magnetic filter is connected in series with an output port where a ballast pump adds ballast water to a ship ballast tank and the high gradient magnetic filter is adopted to carry out high-efficiency filtration on the ship ballast water to remove planktons and suspended particles with the size more than 50 microns; and the step of ultraviolet radiation treatment is to adopt the ultraviolet radiation to treat the ship ballast water after the step of high gradient magnetic filtration. The combined treatment method has the advantages of easy realization of automation, reliable operating altitude, moderate maintenance, small occupation area, safety, reliability, no generation of deleterious disinfection by-products, obvious effect of killing or inactivating microorganisms in the ship ballast water, high water treatment capacity, high efficiency and speed, and also has the advantages of meeting environment protection requirements, not being affected by natural temperature and removing germs, virus, protozoans and the like in the ballast water in the process that a pipeline transports the ballast water.

Owner:HARBIN ENG UNIV

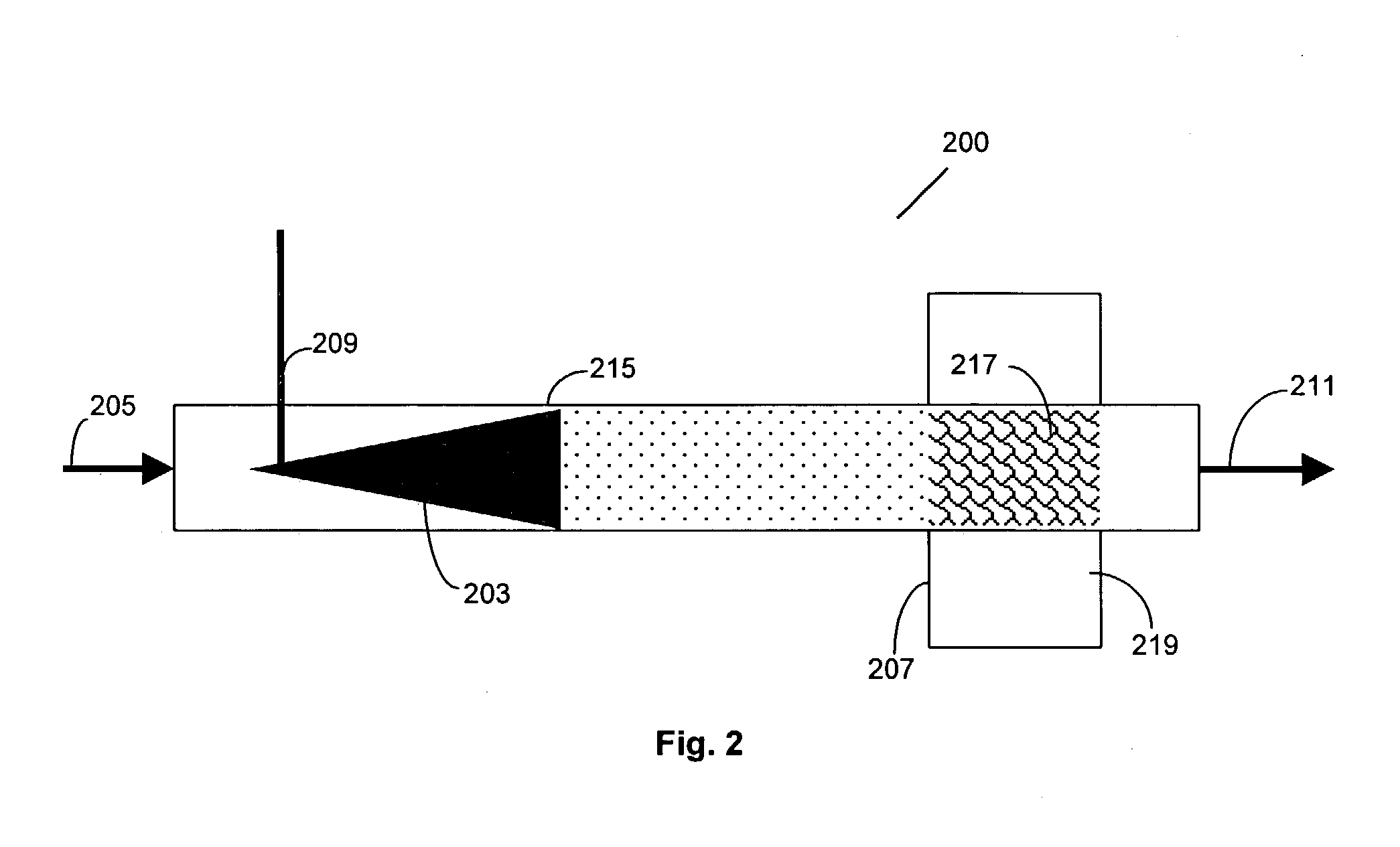

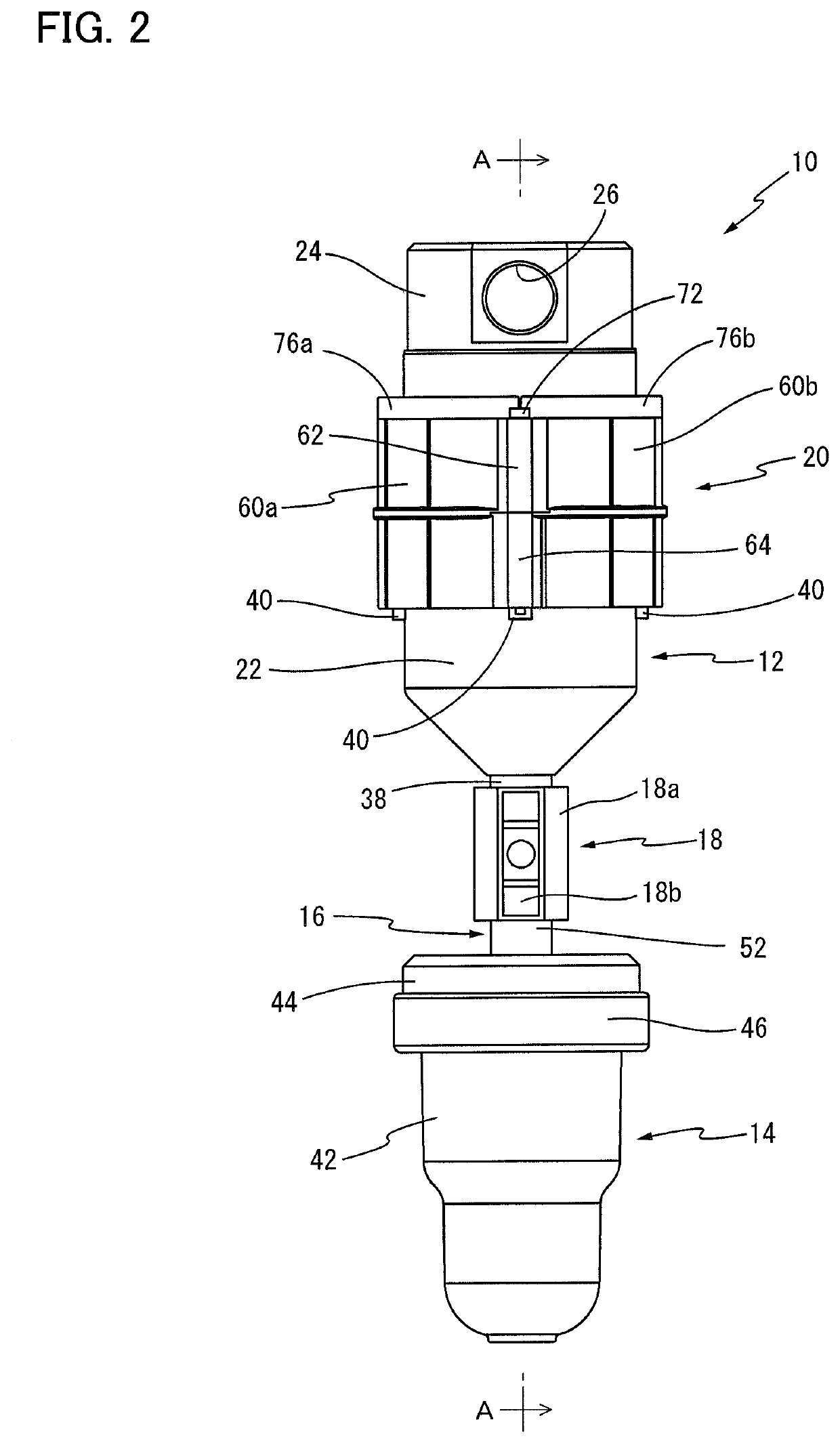

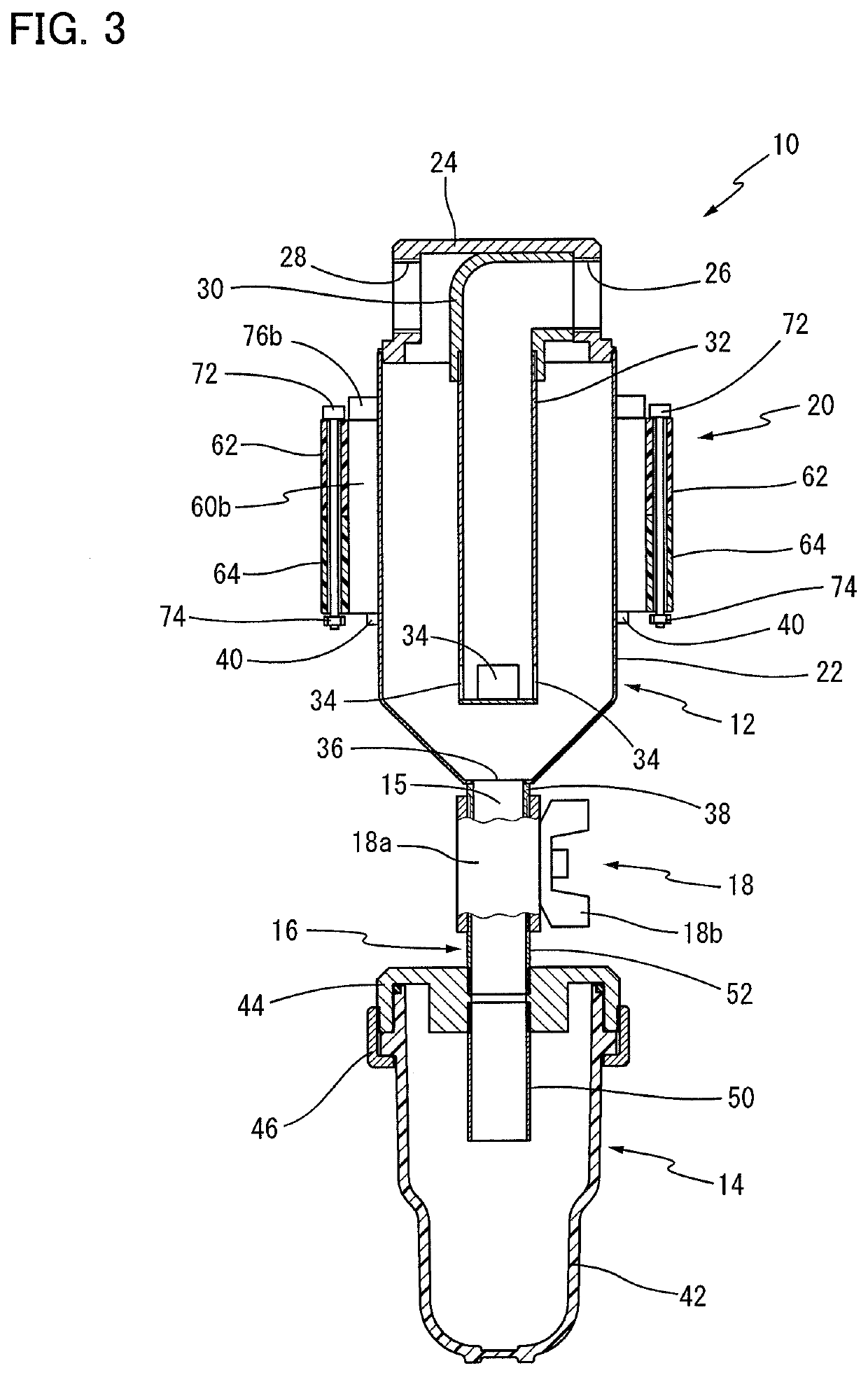

Magnetic filtration apparatus

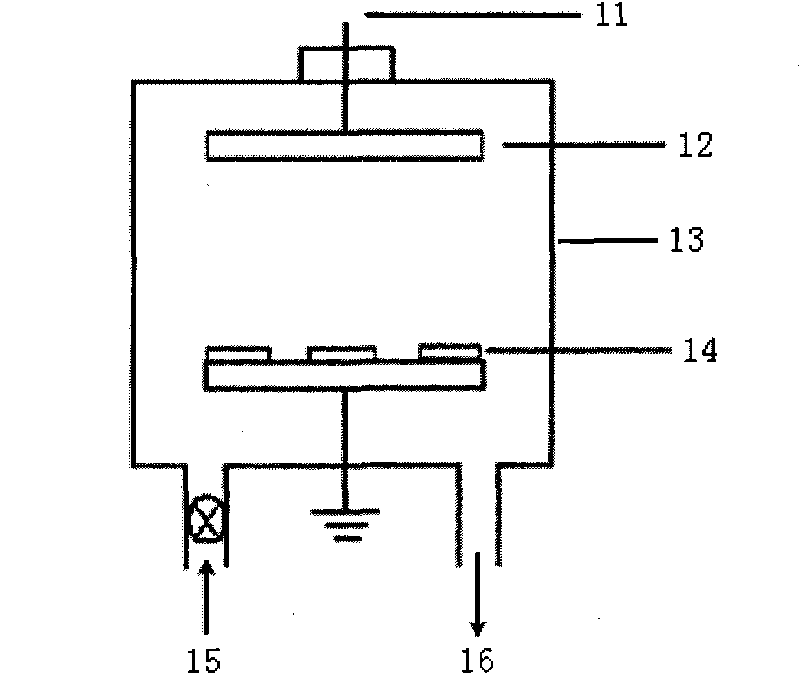

ActiveCN102740981ACompact structureElectrostatic separationHigh gradient magnetic separatorsWorking fluidEngineering

A magnetic filtration apparatus to separate ferrous contaminant material from a working fluid. The separation apparatus has a housing that is divided into a plurality of filtration chambers, each chamber having an elongate magnetic core to generate a magnetic field to entrap the contaminant material as it flows through the filter body. A fluid communication passageway is provided between the first and second chambers and is positioned such that the fluid exposure to the magnetic fields is maximized.

Owner:ECLIPSE MAGNETICS

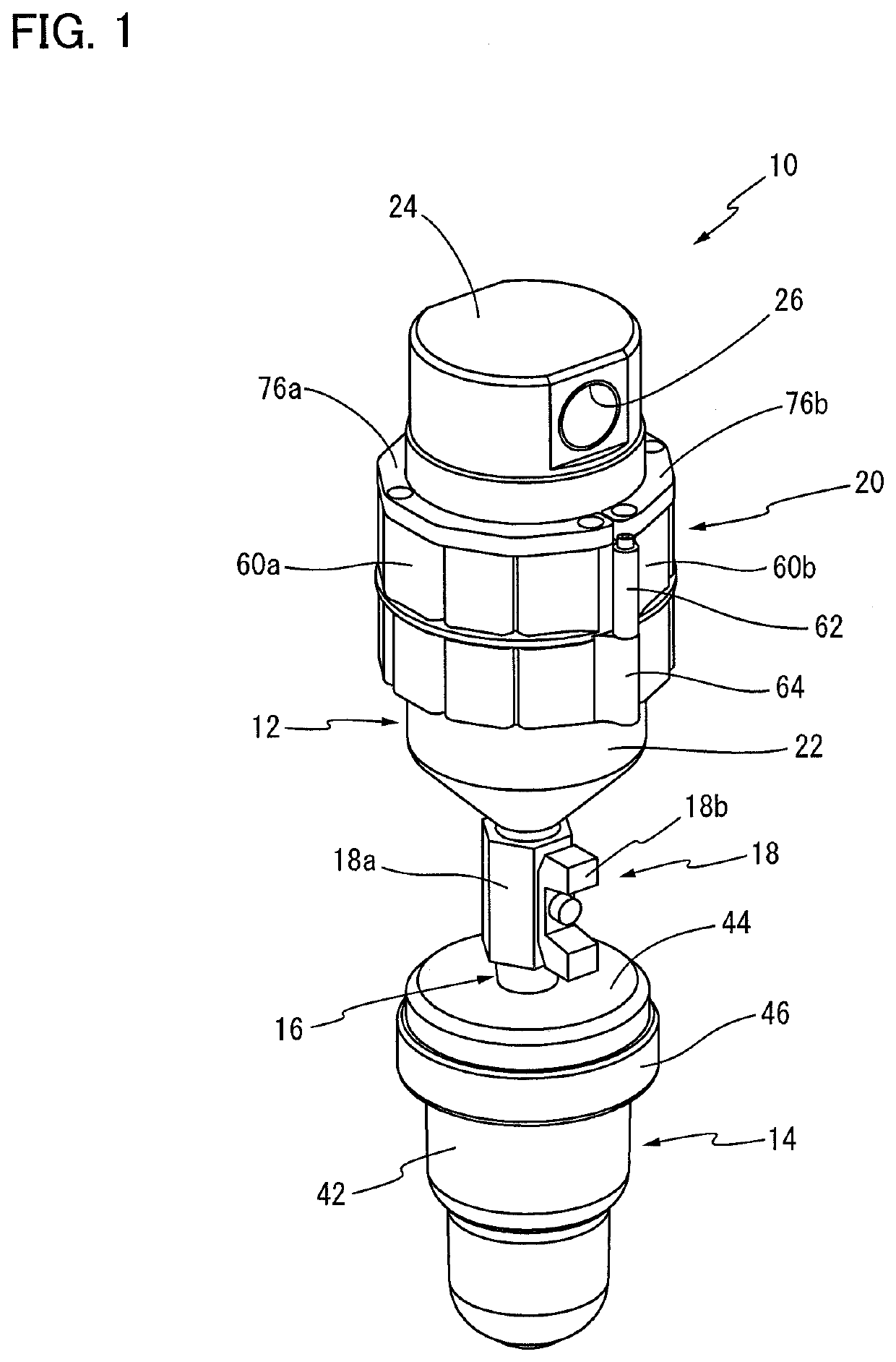

Magnetic filtration apparatus

ActiveUS20200155983A1Easy dischargeResolution problemElectrostatic separationLiquid displacementEngineeringMagnetic filtration

Provided is a magnetic filtration apparatus with a simple structure for permitting easy and effective discharge of magnetic substances from the inside of a flow passage to its outside, the magnetic substances being captured by attraction from a liquid to be treated by magnetic separation. The magnetic filtration apparatus includes a treatment container 12 having an inlet 26 and outlet 28 of the liquid, and a discharge port 36 of the separated magnetic substances. A magnetic apparatus 20 attached around the treatment container 12 attracts the separated magnetic substances to an inner wall of the treatment container 12, while cancellation of the effect of the magnetic field generated by the magnetic apparatus 20 allows the attracted magnetic apparatus to flow into a detachable collecting container 14 positioned below the treatment container 12, due to the gravity, through a communication passage 15.

Owner:MAEDA SHELL SERVICES CO LTD

Nanometer lithium iron phosphate power cell with super-high rate and super long cycle life and manufacturing method

ActiveCN102315486ALower internal resistanceGood low temperatureFinal product manufactureElectrolyte accumulators manufactureElectrical batteryInternal resistance

A nanometer lithium iron phosphate power cell with super-high rate and super long cycle life and a manufacturing method thereof. Based on weight percentage, the manufacturing method comprises the following steps of: 1) controlling environmental humidity; 2) preparing a LFP premixing liquid; 3) carrying out sand milling; 4) carrying out high magnetic filtering; 5) filtering by a filter; 6) preparing a glue solution; 7) preparing a slurry; 8) coating carbon aluminium foil and pole shoe coating; 9) processing the pole shoe by a hot roller; 10) baking in vacuum; 11) examining. The processed and manufactured nanometer lithium iron phosphate cell provided by the invention has much more excellent internal resistance, cycle performance, high rate discharge performance and low temperature performance than cells manufactured by common technologies; the self-discharge rate of the cell provided by the invention is much lower than that of the cells manufactured by common technologies; the cycle life of the cell provided by the invention at high rate is increased from 2000 times to over 8000 times; and the properties of the cell provided by the invention can all meet requirements of cells for electric vehicles and racing cars.

Owner:JIANGSU LENENG BATTERY INC

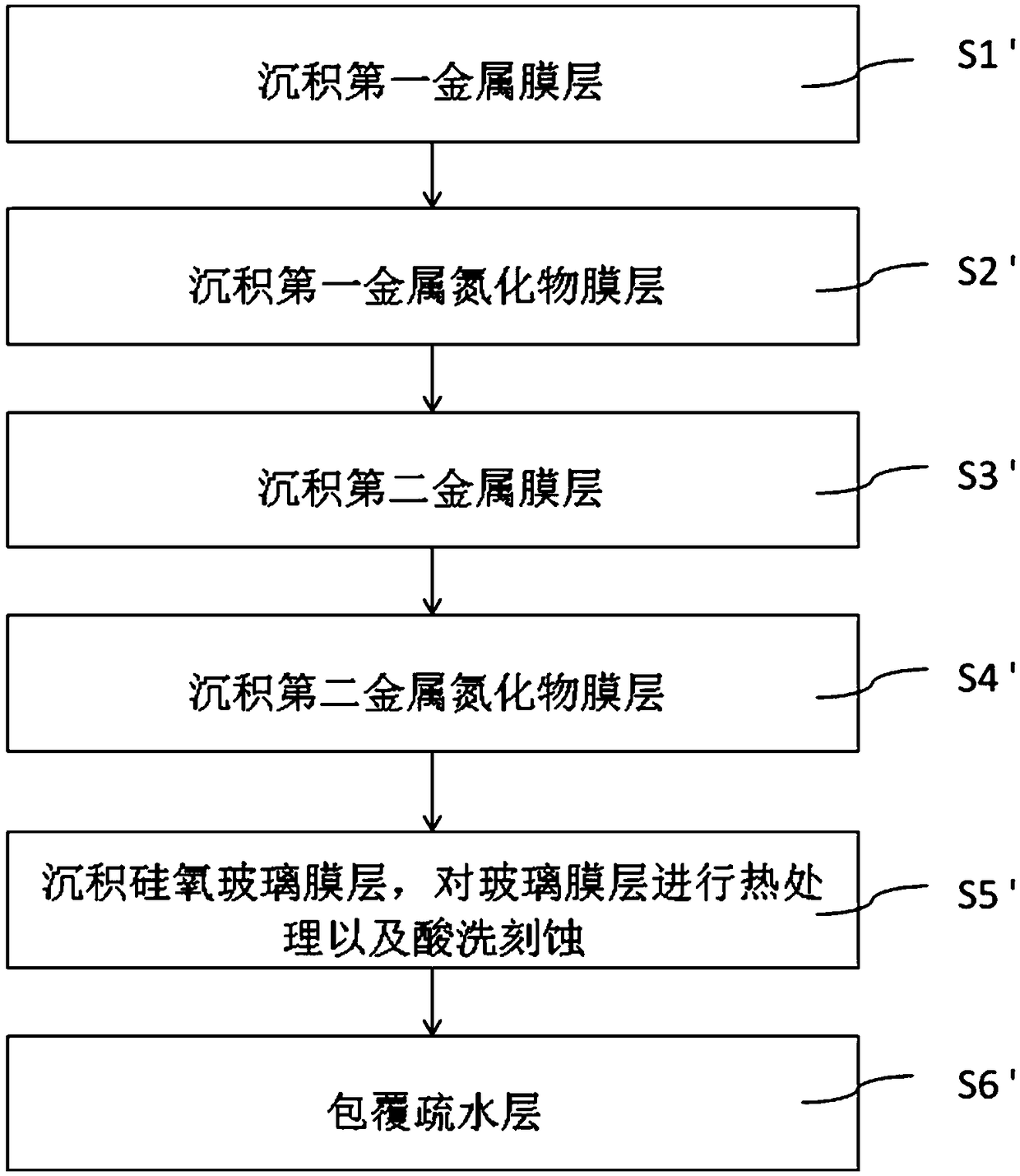

Method for producing hydrophobic DLC coating layer

ActiveCN108677142AEasy to achieve polishingEasy-to-implementer etchVacuum evaporation coatingSputtering coatingConvex structureDlc coating

Owner:BEIJING NORMAL UNIVERSITY

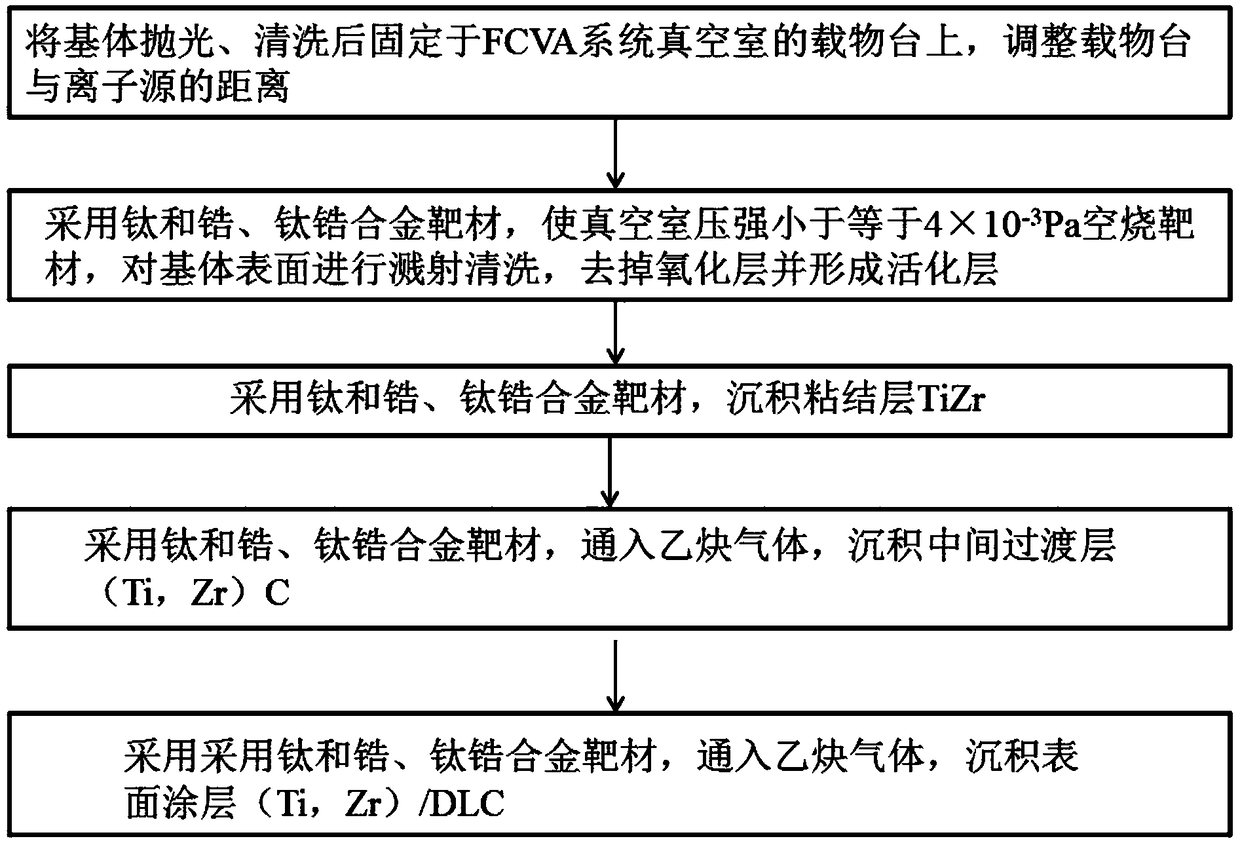

Multilayered high-temperature-resistant Ti/Zr codoped diamond-like coating and preparation method thereof

ActiveCN108728802AReduce internal stressImprove high temperature resistanceVacuum evaporation coatingSputtering coatingFilm baseMagnetic filtration

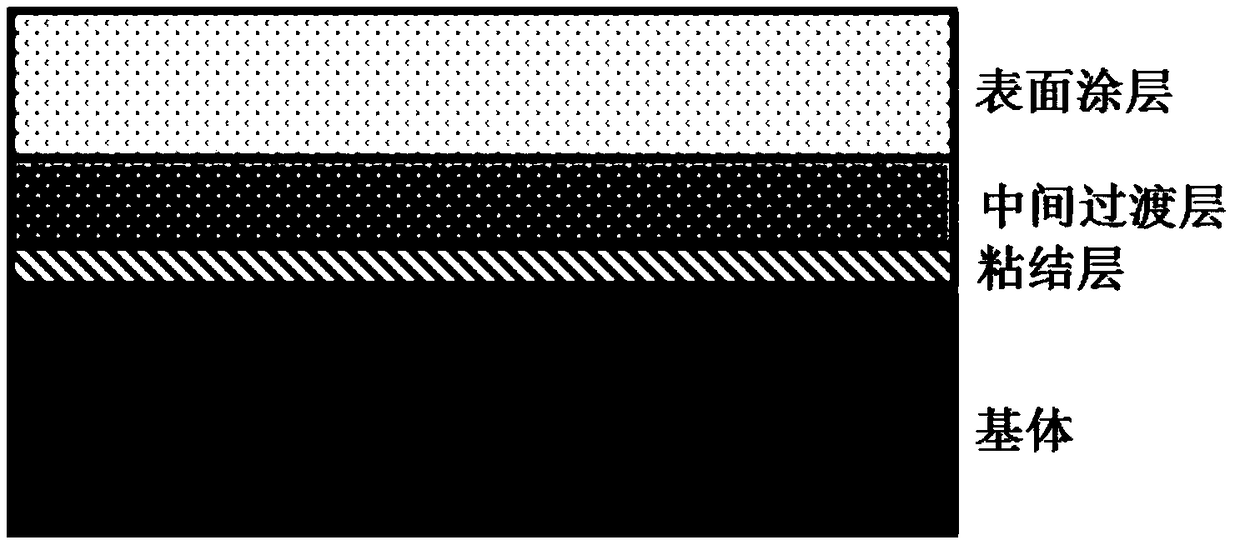

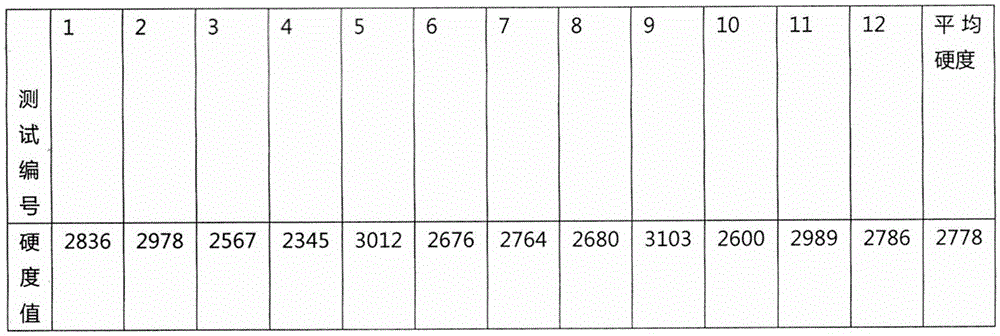

The invention relates to a multilayered high-temperature-resistant Ti / Zr codoped diamond-like coating and a preparation method thereof. The coating structurally comprises a bonding layer, an intermediate transition layer and a surface coating, wherein the bonding layer comprises metals TiZr, the intermediate transition layer comprises (Ti, Zr)C and the surface coating comprises (Ti, Zr) / DLC. The preparation method comprises the step of successively depositing the bonding layer, the intermediate transition layer in gradient change in component and the surface coating on the surface of a substrate after pre-treatment by adopting a magnetic filtration cathode vacuum arc deposition technology. The multilayered high-temperature-resistant Ti / Zr codoped diamond-like coating prepared by means of amulti-element codoping technology, a multi-layered coating technology and the magnetic filtration cathode vacuum arc deposition technology is low in internal stress, high in hardness, excellent in film base bonding strength, high-temperature resistant and friction resistant, the service life of the diamond-like coating is prolonged, and the application field of the coating is expanded.

Owner:XIANGTAN UNIV

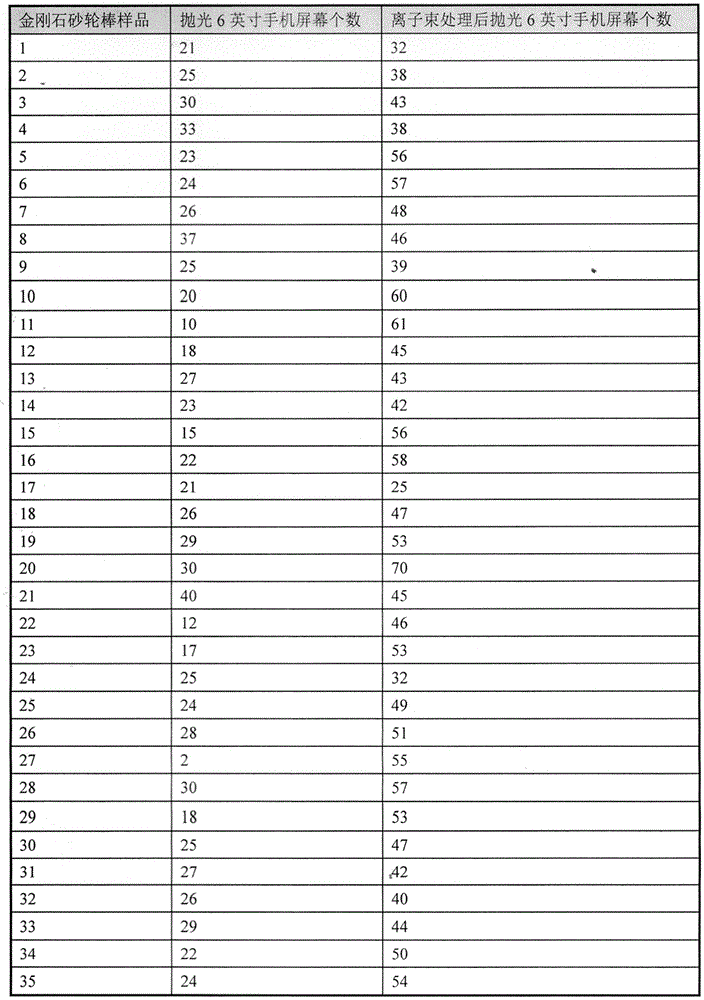

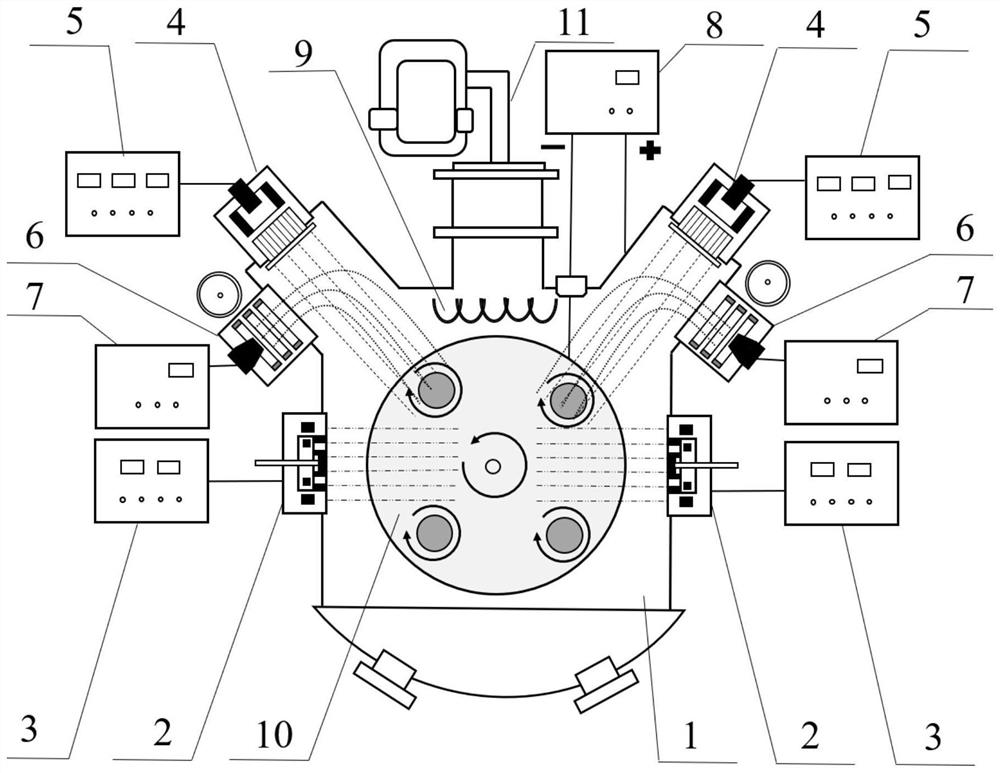

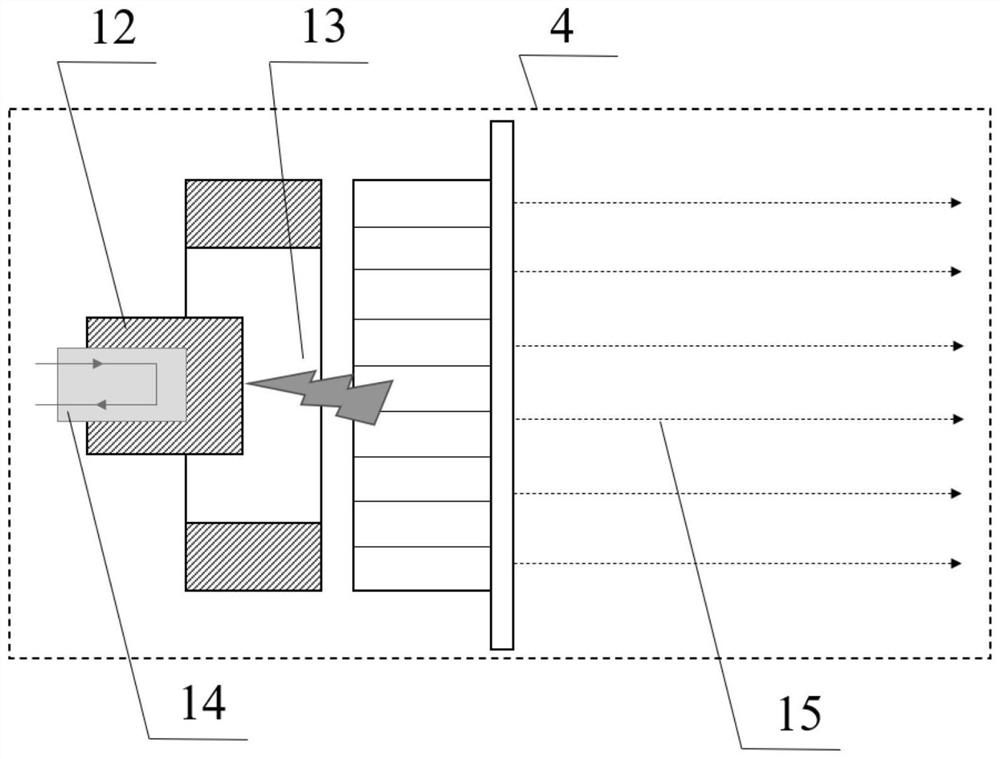

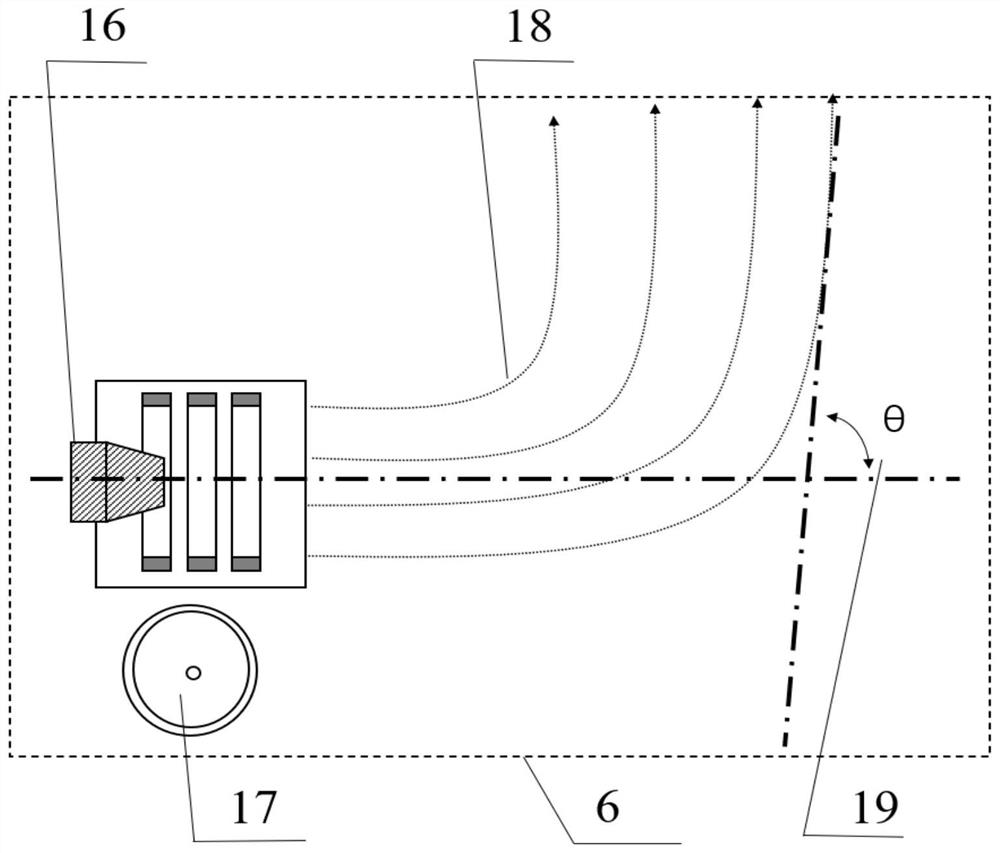

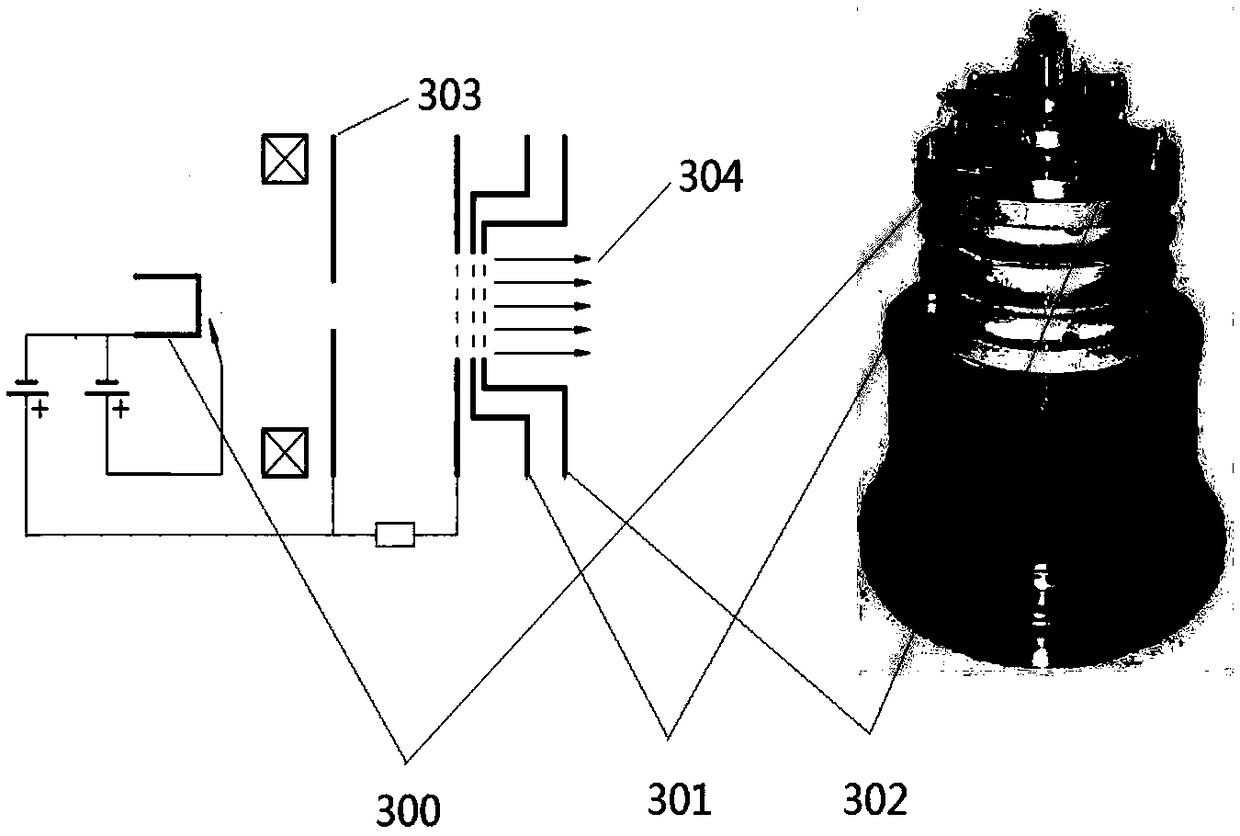

Method and device for prolonging service life of diamond grinding wheel rod of polished optical glass based on ion beam technology

InactiveCN105773462AImprove bindingHigh peel strengthVacuum evaporation coatingAbrasion apparatusComposite filmHigh energy

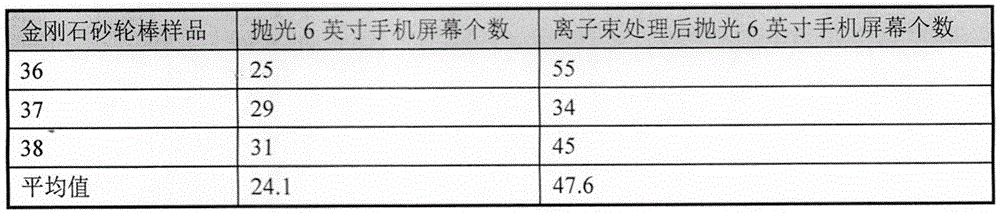

The invention discloses a method for prolonging the service life of a diamond grinding wheel rod of polished optical glass based on the ion beam technology. According to the method, an ultra-thick and ultra-hard (AlTi)1-xNx / AlTiCN / TiAl / (ZrAl)1-xNx composite film which is high in friction coefficient and good in toughness is deposited on the surface of silicon carbide through an ion implantation technique and a magnetic filtration deposition technique. A method for preparing the (AlTi)1-xNx / AlTiCN / TiAl / (ZrAl)1-xNx composite film comprises the steps that a metal cathode filtered cathodic vacuum arc (FCVA) system is adopted, and a workpiece is cleaned on the surface of the grinding wheel rod through high-energy large-beam metal ion beams; then a metal vacuum vapor ion source (MEVVA) method is adopted, and a metal "pinning layer" capable of improving the film-base combination force is injected into the surface of the workpiece; sine or cosine modulated deposition is conducted on the gas inlet amount on the metal"pinning layer" through a magnetic filtration filtered cathodic vacuum arc (FCVA) method, and the ultra-hard thick (AlTi)1-xNx / AlTiCN / TiAl / (ZrAl)1-xNx composite film which is good in toughness is obtained; and the modulation period is repeated till the total thickness of the (AlTi)1-xNx / AlTiCN / TiAl / (ZrAl)1-xNx composite film reaches 10-30 microns. By the adoption of the method, the (AlTi)1-xNx / AlTiCN / TiAl / (ZrAl)1-xNx composite film deposited on the workpiece is good in toughness and quite high in microhardness, and the service life of the grinding wheel rod can be prolonged by 2-5 times.

Owner:BEIJING NORMAL UNIVERSITY

Composite film plating device

PendingCN112522677AImprove general performanceEfficient preparationVacuum evaporation coatingSputtering coatingCarbon filmComposite film

The invention discloses a composite film plating device which comprises a vacuum chamber and a workpiece rotating frame located in the vacuum chamber. An ion beam source, a pulsed arc ion source and amagnetic filtering arc ion source are integrated in the vacuum chamber. The ion beam source is used for cleaning a workpiece or assisting deposition. The pulsed arc ion source is used for exciting agraphite target material to generate carbon ions and deposit a Ta-C carbon film. The magnetic filtering arc ion source is used for exciting the metal target material, generating metal ions and depositing a metal film, an alloy film or a compound film. According to the device, the ion beam technology, the magnetic filtering ion plating technology and the pulse ion plating technology are integratedin one vacuum chamber, multiple film plating modes are provided, multifunctional and structural advanced film preparation is achieved, and the device has the characteristics of being rich in functionand high in expansibility and is suitable for developing scientific research and diversified production in the industrial field. Particularly, the Ta-C carbon film which is low in stress, high in bonding strength and adjustable in structure and performance can be efficiently prepared by utilizing the device.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

Technology and equipment for coating film in deep hole

ActiveCN109295414AConvenient industrial application of internal platingImprove thickness uniformityVacuum evaporation coatingSputtering coatingMetallurgySurface cleaning

Owner:广东省广新离子束科技有限公司

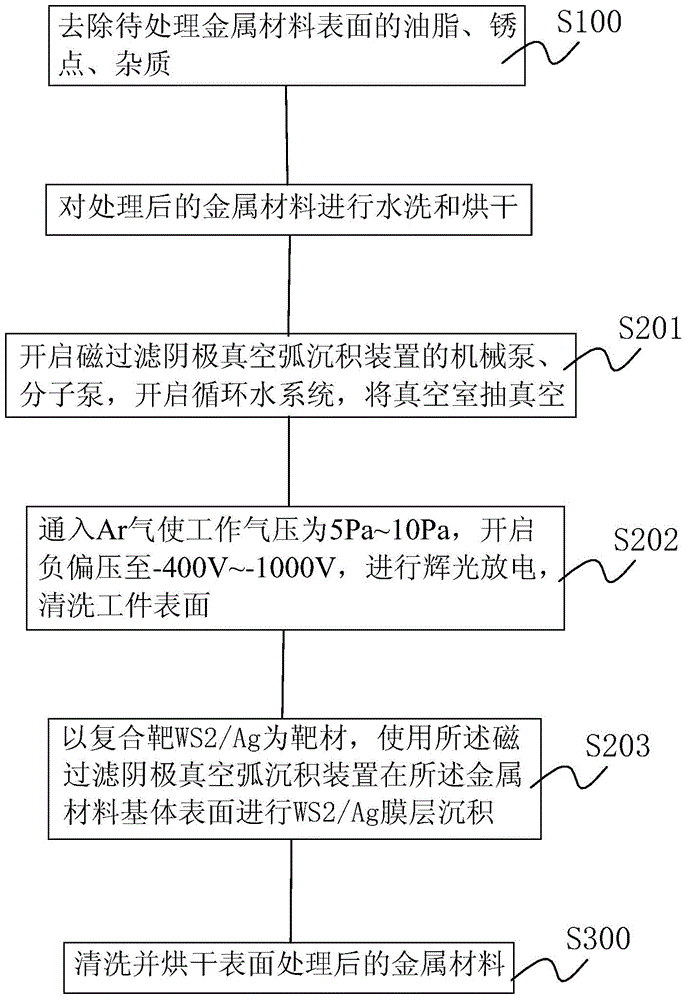

Method for manufacturing WS2 solid lubrication film

ActiveCN104928622AIncrease deposition rateShort preparation timeVacuum evaporation coatingSputtering coatingMetallic materialsLubrication

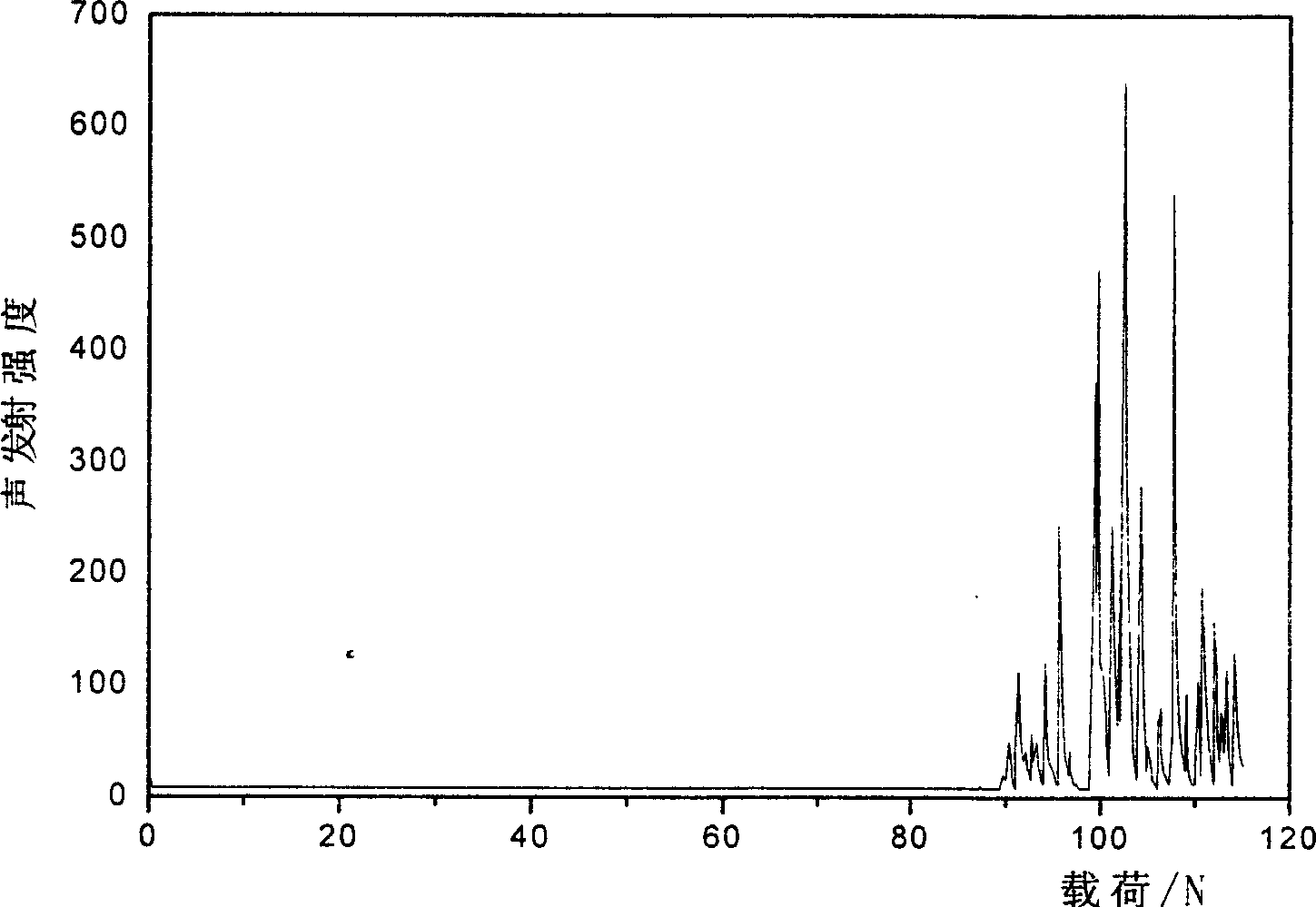

The invention provides a method for manufacturing a WS2 solid lubrication film. The WS2 solid lubrication film is formed by depositing a magnetic filter cathode vacuum arc on the surface of a metal material substrate. The method comprises the steps that the metal material substrate is preprocessed; the WS2 solid lubrication film is generated, and the metal material substrate is put into a vacuum chamber and is vacuumized; Ar gas is pumped in, the back bias voltage of a magnetic filter cathode vacuum arc deposition device is started to be -400 V to -1000 V, glow discharge is conducted, and the surface of the metal material substrate is washed; a WS2 / Ag composite target is used as a target material, the magnetic filter cathode vacuum arc deposition device is used for depositing a WS2 / Ag film layer on the surface of the metal material substrate, wherein the arc voltage of the magnetic filter cathode vacuum arc deposition device is 20 V to 36 V, the back bias voltage is -100 V to -800 V, the arc current is 90 A to 100 A, the duty ratio is 50%-90%, and the deposition time is 1 h; and the metal material substrate is sealed up for safekeeping.

Owner:BEIJING RES INST OF AUTOMATION FOR MACHINERY IND

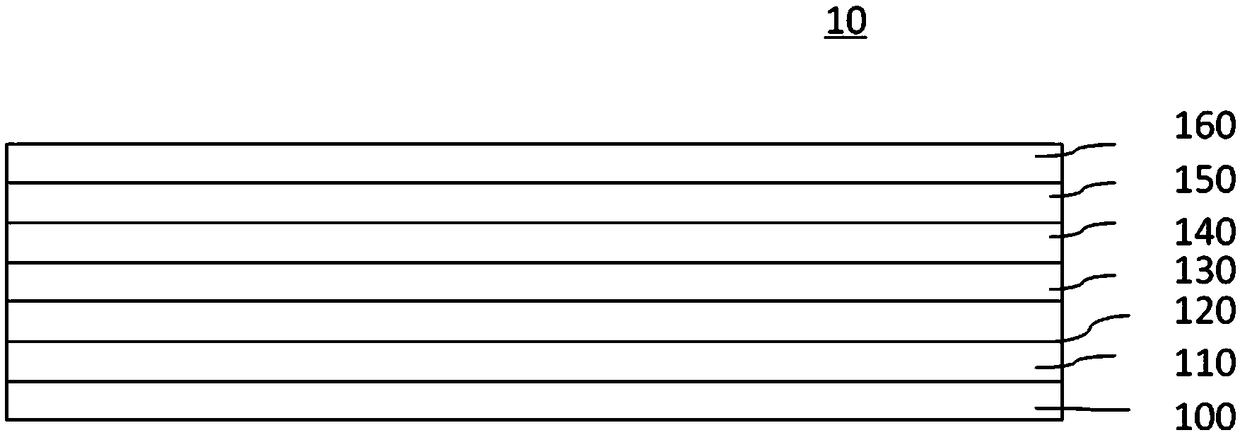

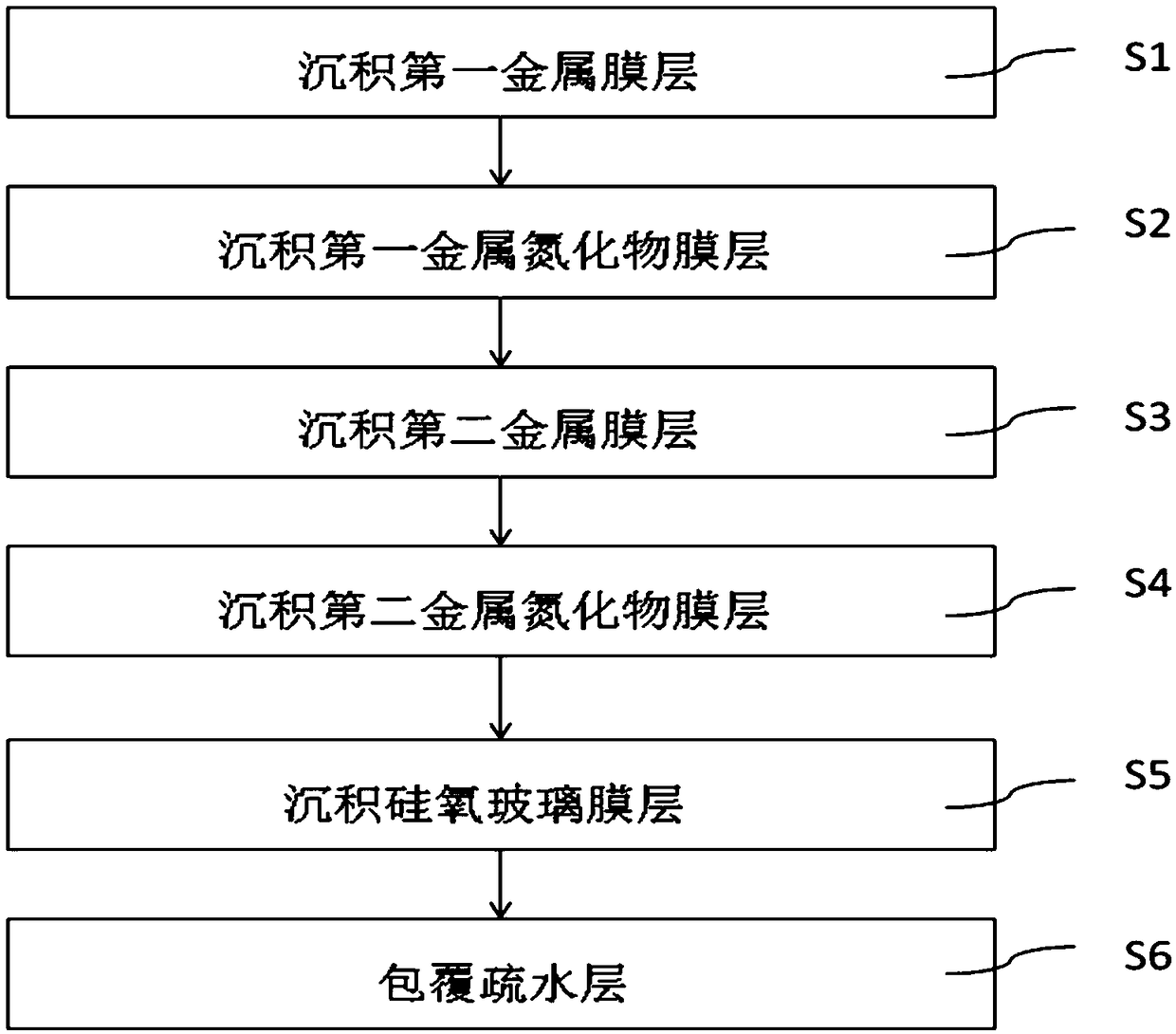

Super-hydrophobic composite coating and preparation method thereof as well as application

ActiveCN109295416AImprove surface hydrophobicityImprove high temperature oxidation resistanceVacuum evaporation coatingSputtering coatingDecompositionRadio frequency magnetron sputtering

The invention discloses a super-hydrophobic composite coating and a preparation method thereof as well as an application. The composite coating comprises a first metal film layer, a first metal nitride film layer, a second metal film layer, a second metal nitride film layer, a silicon oxygen glass film layer and a hydrophobic layer, wherein the first metal film layer is positioned on the surface of a base material, the first metal nitride film layer is located above the first metal film layer, the second metal film layer is located on the first metal nitride film layer, the second metal nitride film layer is positioned on the second metal film layer, the silicon oxygen glass film layer is provided with a porous structure, and is located on the second metal nitride film layer; and the hydrophobic layer is located on the silicon oxygen glass film layer. According to the coating, the method and the application, the super-hydrophobic composite coating is based on a multi-layer functional coating prepared by a magnetic filtration cathode vacuum arc discharge technology, a vacuum radio frequency magnetron sputtering technology and an amplitude modulation decomposition etching technology,has excellent super-hydrophobic performance and a contact angle is 150 degrees or above.

Owner:BEIJING RES INST OF AUTOMATION FOR MACHINERY IND

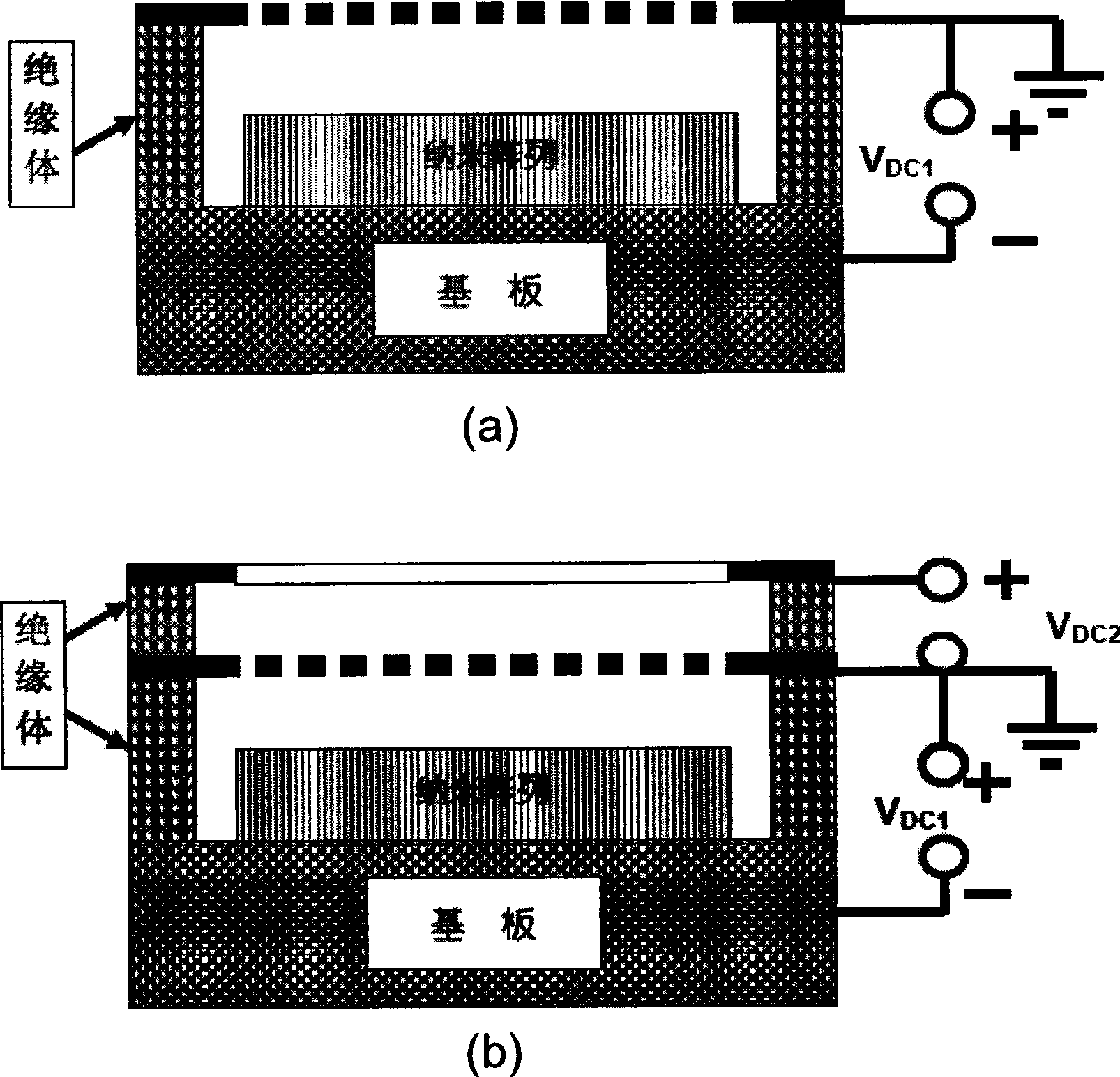

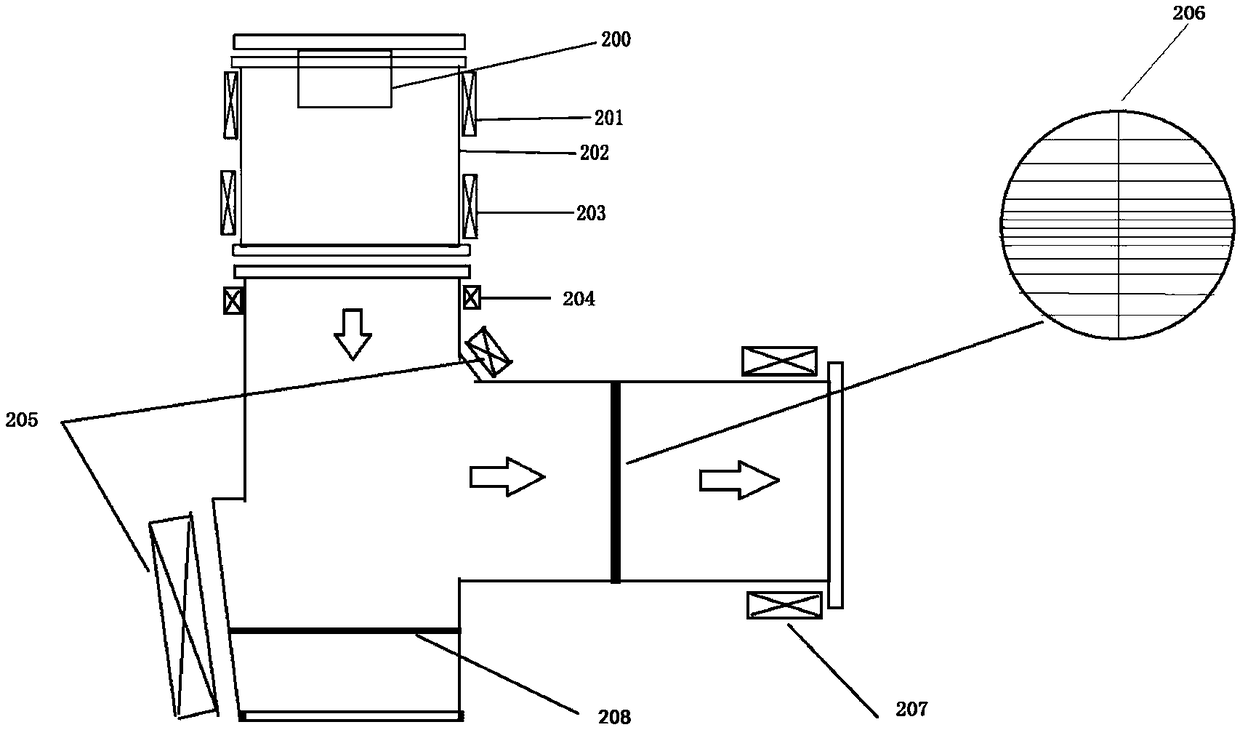

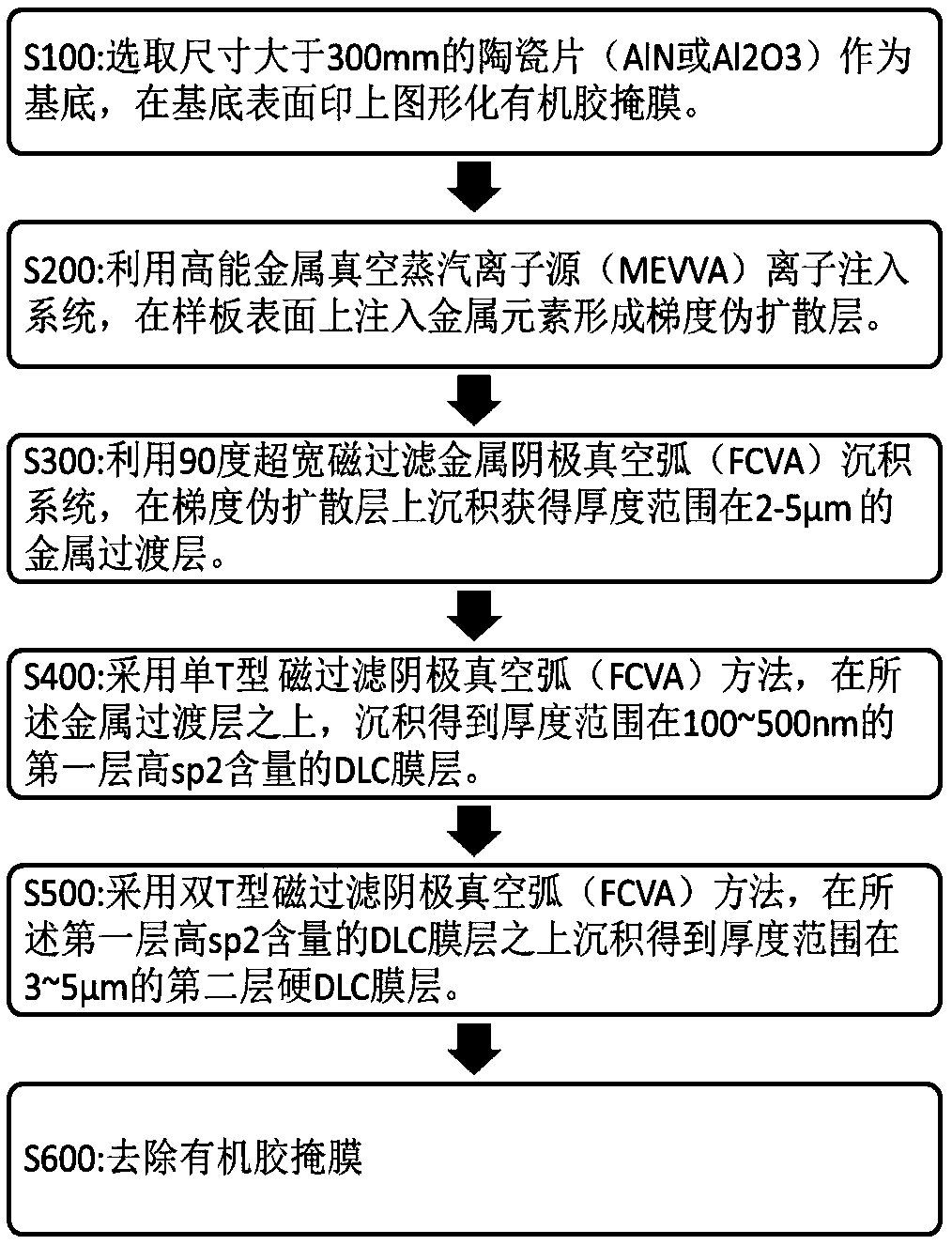

Preparation method and equipment of patterned electrostatic chuck

ActiveCN108842133AImprove bindingHigh peel strengthVacuum evaporation coatingSputtering coatingAdhesiveHigh energy

The invention discloses a preparation method and equipment of a patterned electrostatic chuck. The preparation method comprises the following steps that an ultra-large size (greater than 300 mm) ceramic sheet (AlN or Al2O3) is selected as a substrate, a patterned organic adhesive mask is printed on the substrate, and a high resistivity, high hardness, wear resistance and ion erosion resistance DLCfilm layer is deposited by utilizing an ion beam technology; a deposition method comprises the following steps that a high-energy metal vacuum vapor ion source (MEVVA ) is adopted, a metal element isinjected into the substrate to form a graded pseudo diffusion layer, and then a 90-degree ultra-wide magnetic filtration metal cathode vacuum arc (FCVA) technology is adopted, and a metal transitionlayer is deposited; a single T-shaped magnetic filtration cathode vacuum arc (FCVA) is adopted on the metal transition layer, and a DLC film layer with high sp2 content is obtained through the deposition; and a double-T-shaped magnetic filtration cathode vacuum arc (FCVA) is utilized on the DLC film layer with the high-sp2-content, and a super-hard DLC film layer is obtained through the deposition; and the resistance of the film layer can reach 10-50 megohm, and the hardness can reach 80 Gpa or above. According to the method and the equipment, the electrostatic chuck is enabled to have excellent wear resistance, and the service life is prolonged.

Owner:BEIJING NORMAL UNIVERSITY

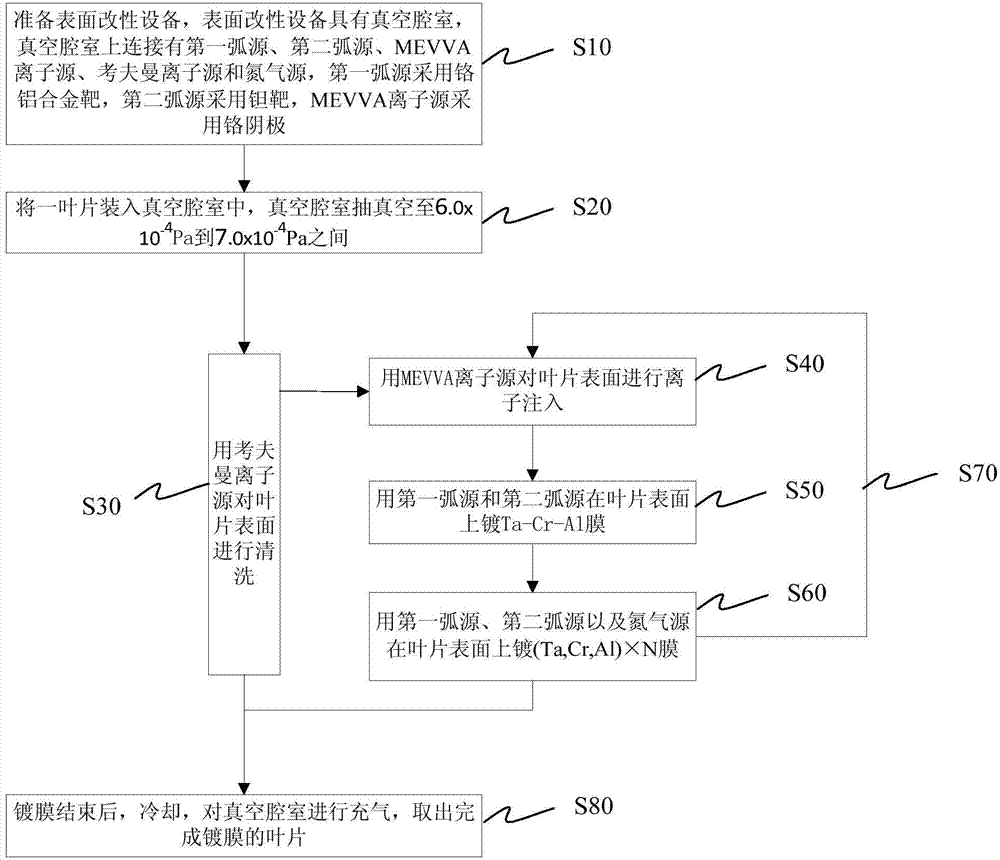

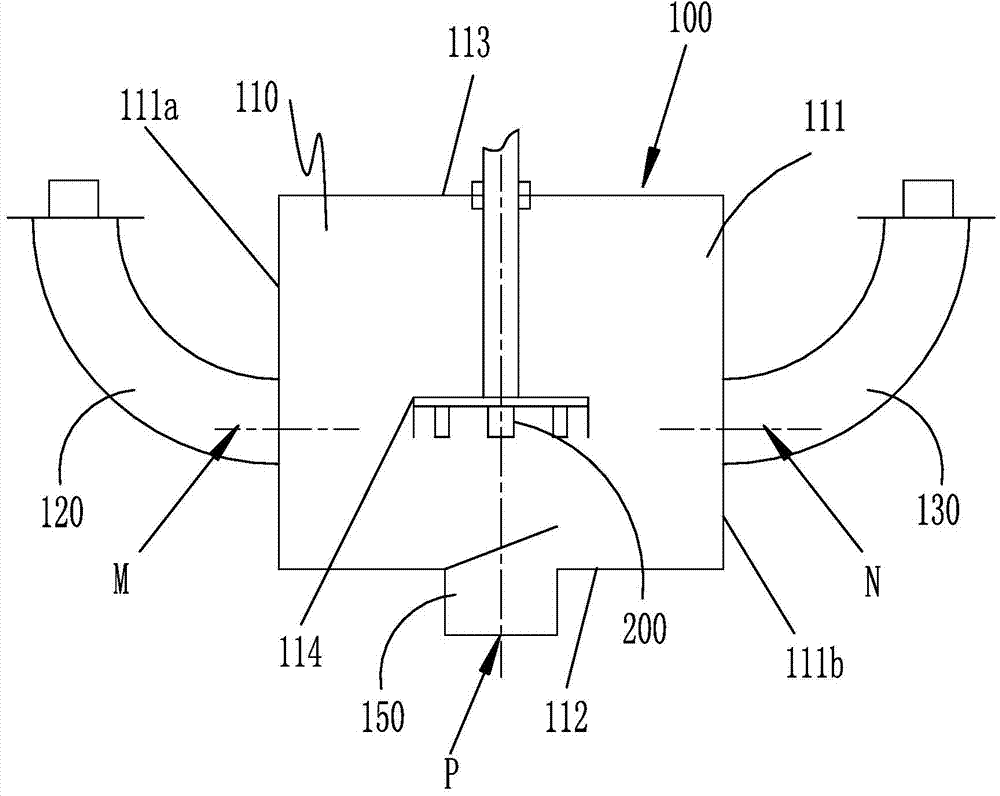

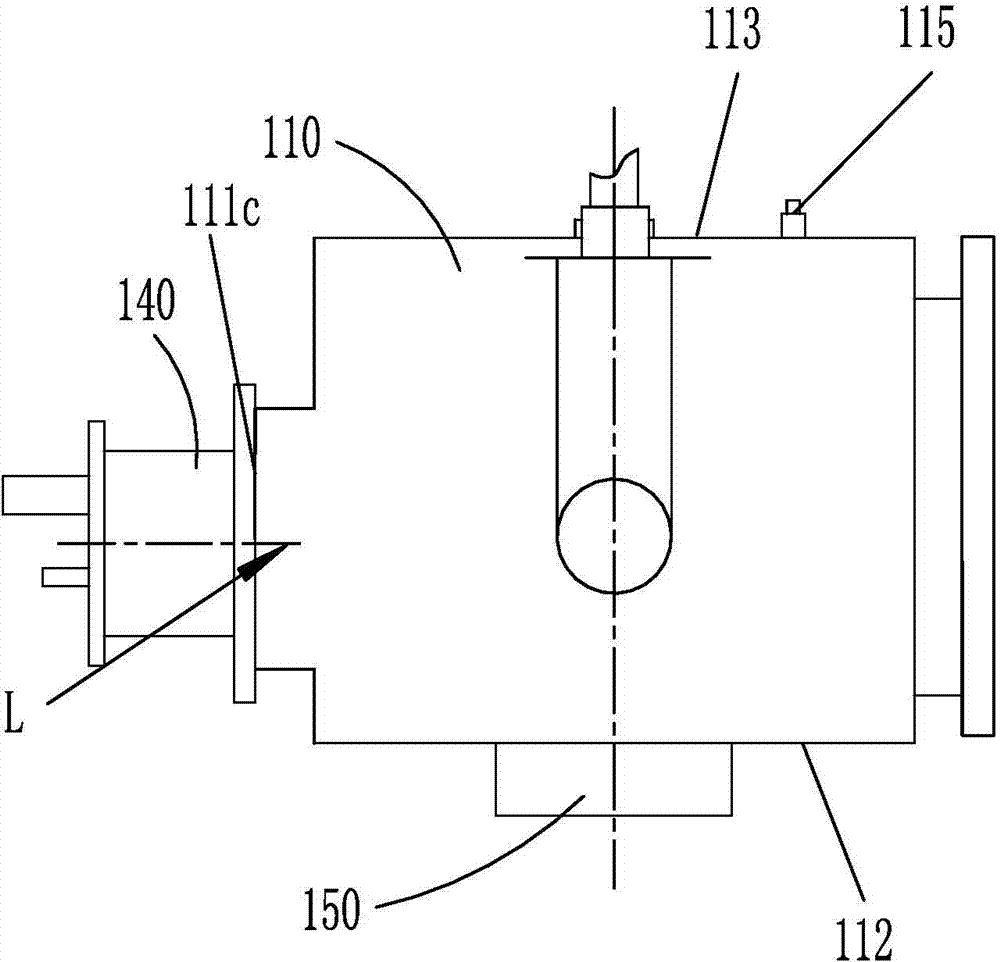

Preparation method of compressor blade coating and surface modifier

InactiveCN104328385AImprove the problem of poor deposition uniformityAccelerated corrosionVacuum evaporation coatingSputtering coatingEngineeringMagnetic filtration

The invention discloses a preparation method of a compressor blade coating and a surface modifier. The preparation method comprises the following steps: putting a blade into the vacuum chamber of the surface modifier and vacuuming, and connecting a first arc source, a second arc source, an MEVVA ion source, a kaufmann ion source and a nitrogen source to the vacuum chamber; cleaning the surface of the blade by use of the kaufmann ion source; performing ion injection on the surface of the blade by use of the MEVVA ion source; coating the surface of the blade with a Ta-Cr-Al film by use of the first arc source and the second arc source; depositing a (Ta, Cr, Al)*N film on the surface of the blade by use of the first arc source, the second arc source and the nitrogen source; and orderly and repeatedly completing coating. According to the preparation method of the compressor blade coating, the problem of poor deposition uniformity of the complex-structure film of the blade is improved by use of cathode magnetic filtration and plasma enhancement technologies; and meanwhile, the high temperature corrosion resistance and the erosion resisting capacity of the blade surface are improved by adopting a novel Al doped Ta-Cr-N nano multi-layer film.

Owner:BEIJING RES INST OF AUTOMATION FOR MACHINERY IND

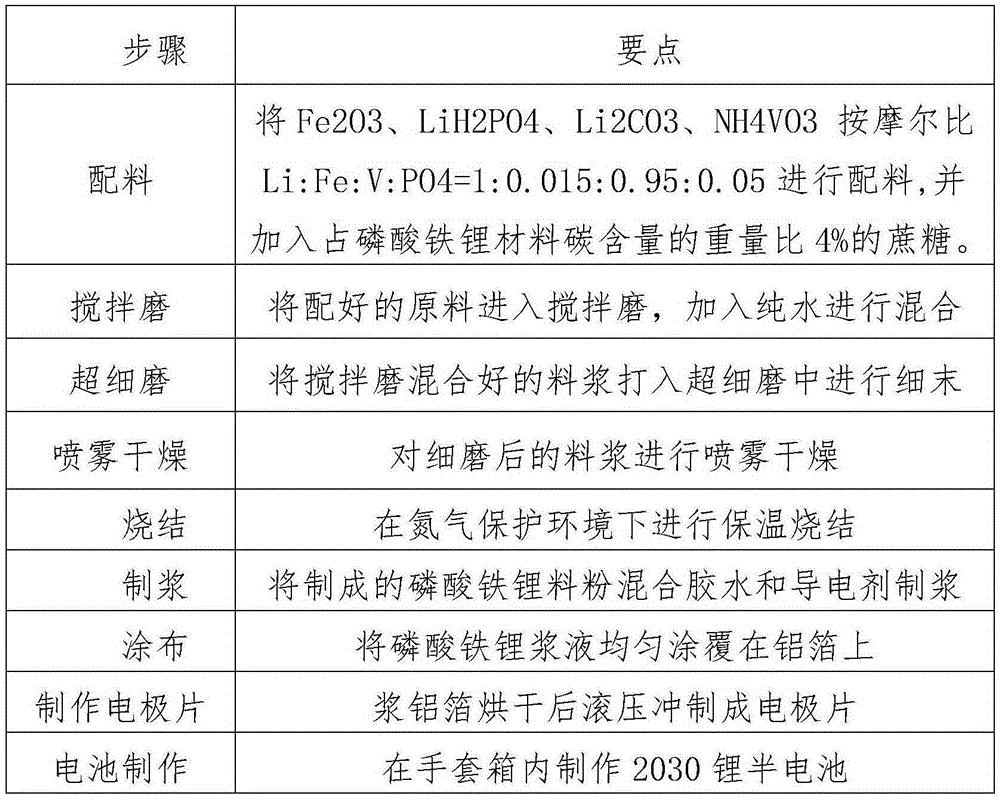

Iron oxide red for lithium iron phosphate and preparation method and application thereof

The invention belongs to the technical field of new energy powder, and in particular, relates to a preparation method of iron oxide red for lithium iron phosphate. The preparation method comprises the steps: dispersing electronic-grade industrial ultra-pure water and steel factory iron oxide red; sieving the iron oxide red suspension with a sieve, and sieving to remove large-particle matters; grinding the sieved iron oxide red suspension with a horizontal sand mill; carrying out magnetic filtration; adding an iron-based compound; treating the mixed solution with a material water separation device to obtain an iron oxide red slurry; carrying out spray drying; mixing and dispersing with electronic-grade industrial ultra-pure water, treating with the material water separation device, carrying out spray drying, and thus obtaining the iron oxide red for lithium iron phosphate. Compared with a process for preparing iron oxide red for lithium iron phosphate through a precipitation method, the preparation method has the advantages of low environmental effect, high material obtaining rate, good dispersion, narrower particle size distribution, and higher specific surface area; and compared with a conventional Ruthner method for iron oxide red for lithium iron phosphate, the method has the advantage that the performance has relatively large improvement.

Owner:SHANGHAI BAOSTEEL MAGNETICS

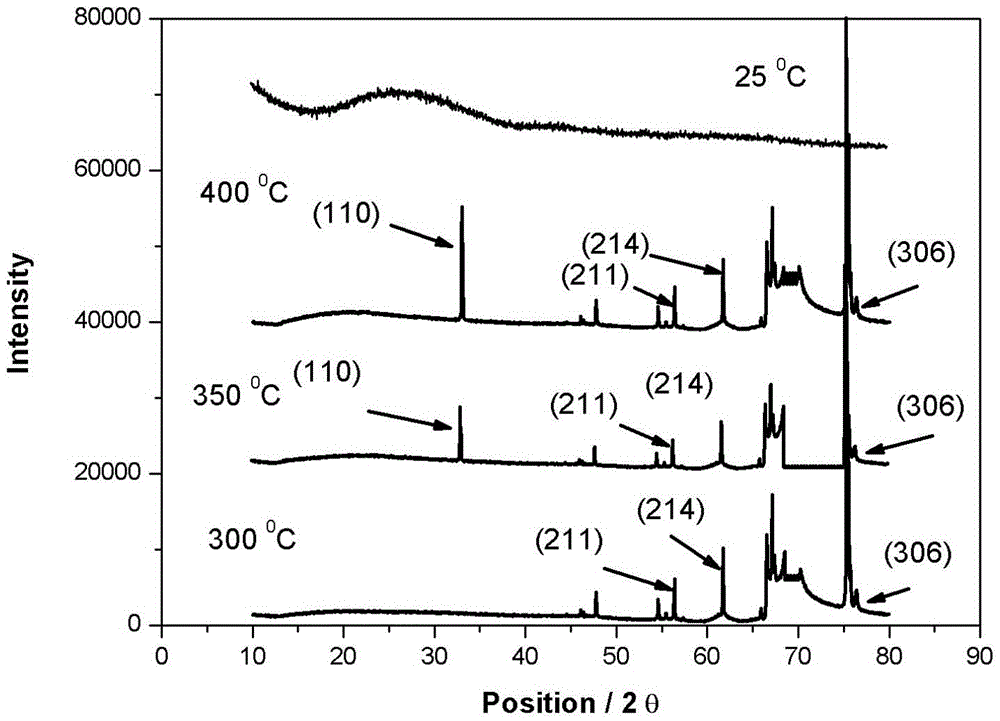

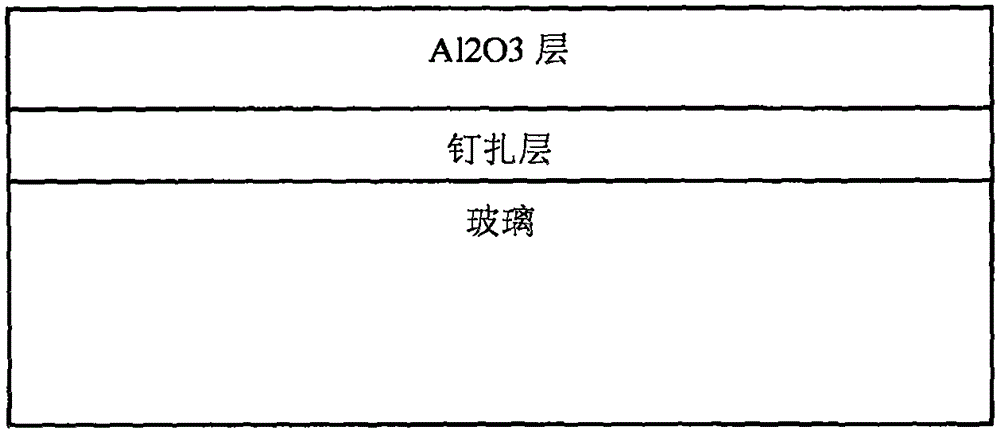

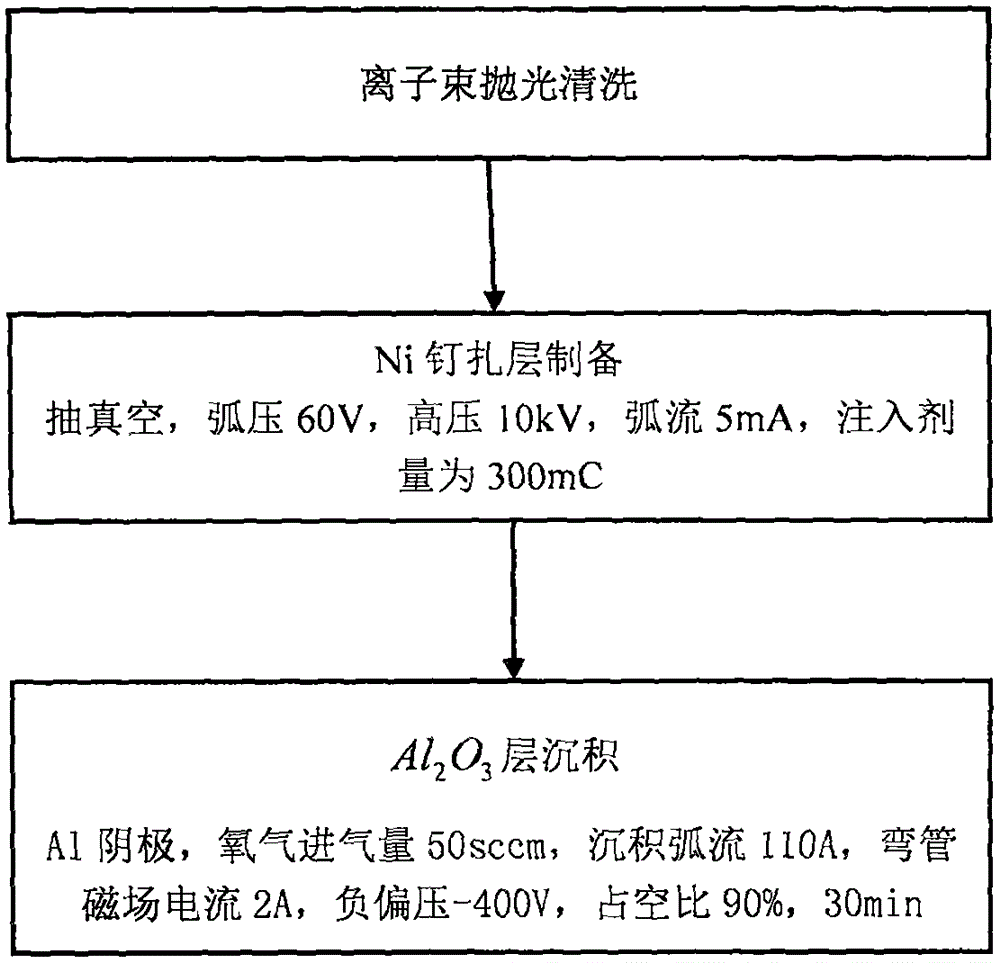

Method for preparing cellphone screen scratch-resistant aluminum oxide coating by ion beam dual-filtering deposition technique

ActiveCN105755429AEffective filteringHigh hardnessVacuum evaporation coatingSputtering coatingCathodic arc depositionPlasma deposition

The invention discloses a method for depositing Al2O3 film on glass and is applicable to cellphone screen surface coating, wherein a technique for preparing Al2O3 film by magnetically filtered plasma deposition is particularly related.The Al2O3 film structurally comprises an ion injection pinning layer and an Al2O3 film layer.The invention is intended to prepare high-cohesive Al2O3 film by combining ion injection technique, magnetic filtration technique and cathodic arc deposition technique and optimize the thickness, hardness, wear resistance, corrosion resistance and light transmittance of Al2O3 by controlling arc current intensity, bend magnetic field intensity and oxygen intake in the deposition process so as to prepare high-quality Al2O3 film, replacing a sapphire cellphone screen.Dual-magnetic filtering plasma deposition equipment is used herein, the equipment is simple to operate, and the method is mature, is available for batch production and is suitable for application in electronic product screen protection.

Owner:BEIJING NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com