Tree-shaped cathode vacuum arc plasma deposition and magnetic filtration device

A vacuum arc and magnetic filtration technology, applied in circuits, discharge tubes, electrical components, etc., can solve the problems of high cost, complex equipment, affecting the quality of the film layer, etc., to achieve uniform distribution of elements, stable performance, and good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

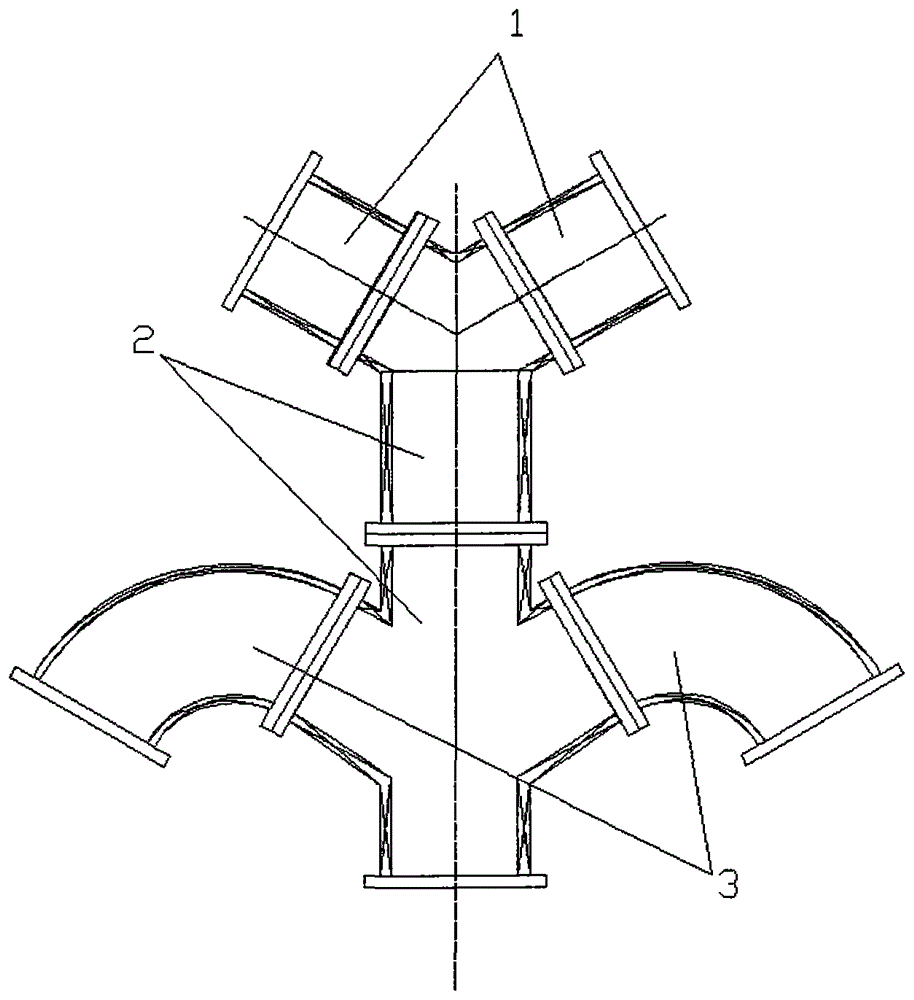

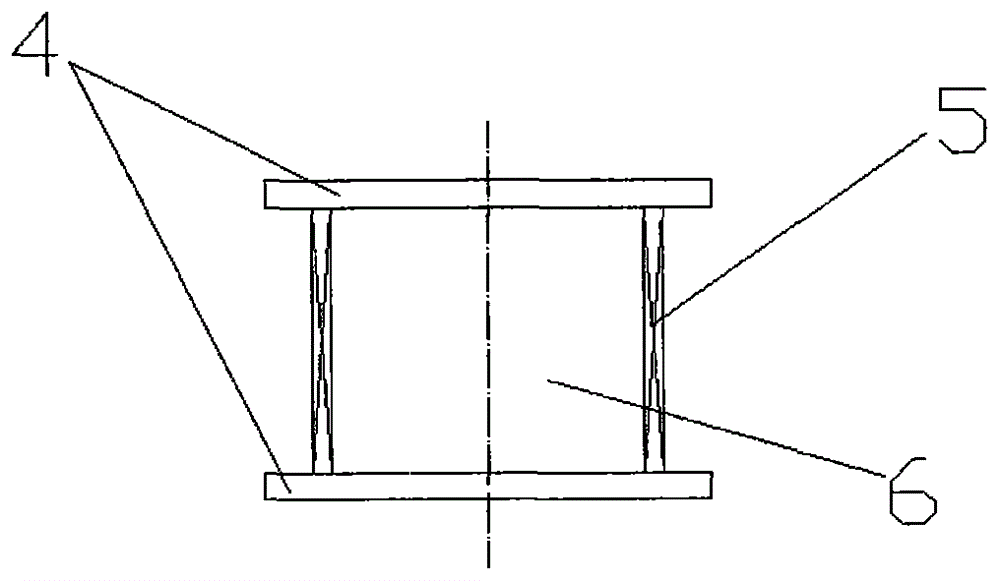

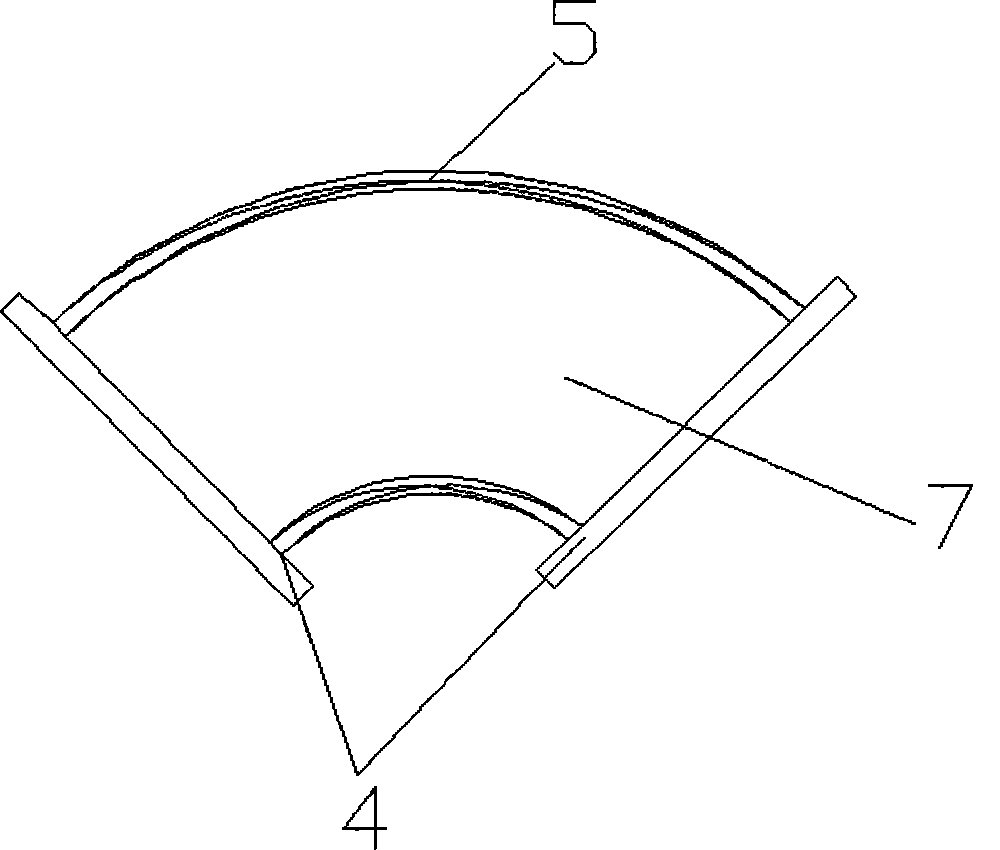

[0016] figure 1 The schematic diagram of the tree-shaped magnetic filter device shown is a schematic diagram of a feasible scheme of the present invention. The invention is composed of a plurality of magnetic filter branch pipes and a magnetic filter trunk pipe through reasonable matching and assembly. The magnetic filter branch line pipe and main line pipe can be straight pipe or bent pipe or a combination of various forms. The connection between the pipes can be a flange connection or a welded connection or other sealed connections. The length and angle of the pipeline should be selected to ensure that the outlet of the main pipe is outside the line of sight of the entrance of the branch pipe; the magnetic field direction of the magnetic filter branch pipe and the main pipe is along the pipeline axis, and the magnetic field strength is reasonably matched.

[0017] exist figure 1 Among them, the tree-shaped magnetic filter device is composed of a straight tube type magneti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com