Patents

Literature

57 results about "Elementary component" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crystallizer casting powder for high-aluminum steel continuous casting

The invention relates to a crystallizer casting powder for high-aluminum steel continuous casting. The casting powder comprises the following elementary components in percentage by weight: not less than15% but not more than 40% of CaO, not less than 3% but not more than 15% of SiO2, not less than 10% but not more than 20% of Al2O3, not more than 3% of MgO, not more than 3% of Fe2O3, not less than6% but not more than 15% of F, not more than 1.5% of Na2O, not less than 3% but not more than 10% of Li2O, not less than 5% but not more than 20% of BaO, not more than 5% of SrO, not more than 5% o B2O3, not less than 2% but not more than 15% of C, and the balance of impurities. The preparation method of the casting powder comprises the following steps of: calculating and weighing the required raw materials according to ratio ranges of the elementary components, mixing and uniformly smelting the mixture in an ore heating furnace, cooling, crushing, adding required carbon materials, carrying out fine grinding, and finally drying and granulating in a spray granule drying tower. The casting powder has the capability of reducing the reactivity of slag steel so that the performance deterioration of the casting powder caused by the reaction of the slag steel can be slowed, the interfacial tension of the slag steel is improved so as to prevent slag entrainment, excellent casting blank lubricating and heat-transfer controlling characters are ensured, the capability of absorbing Al2O3 inclusions is improved, and a high-aluminum steel casting blank which has excellent surface quality and high quality can be cast.

Owner:CHONGQING UNIV

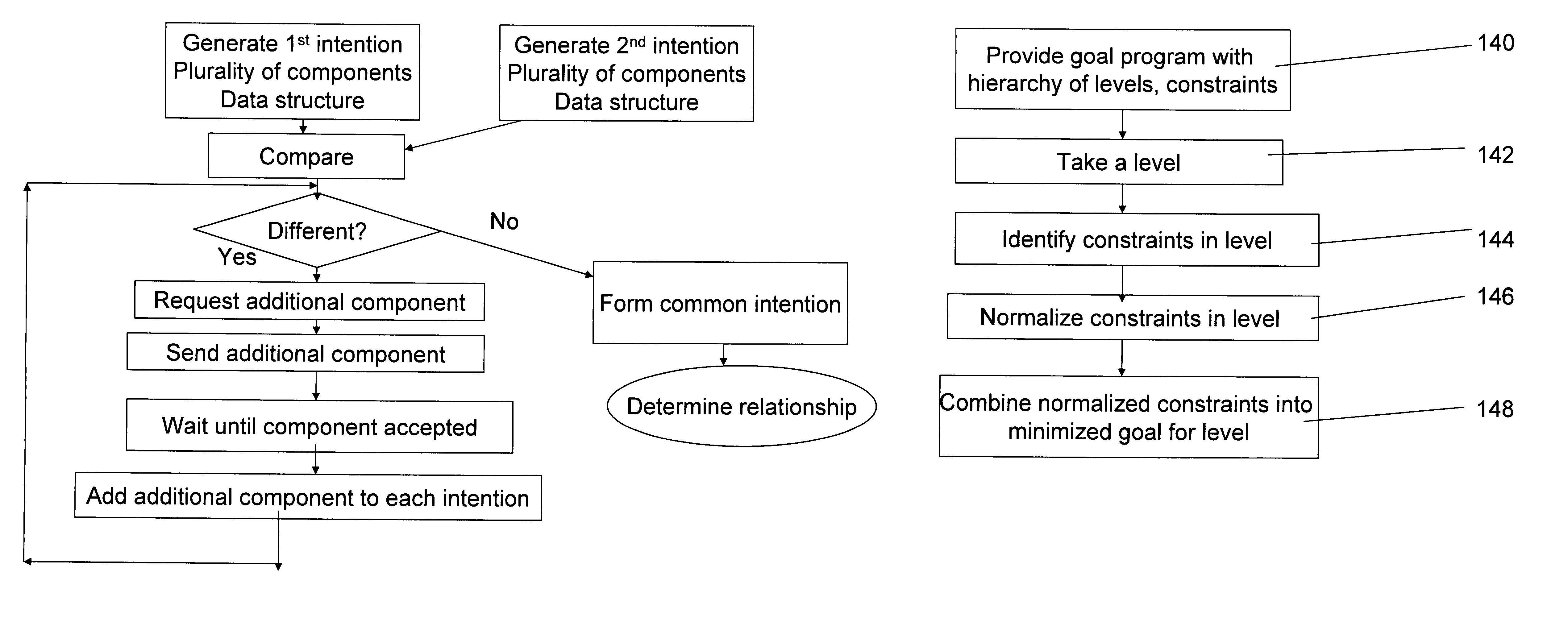

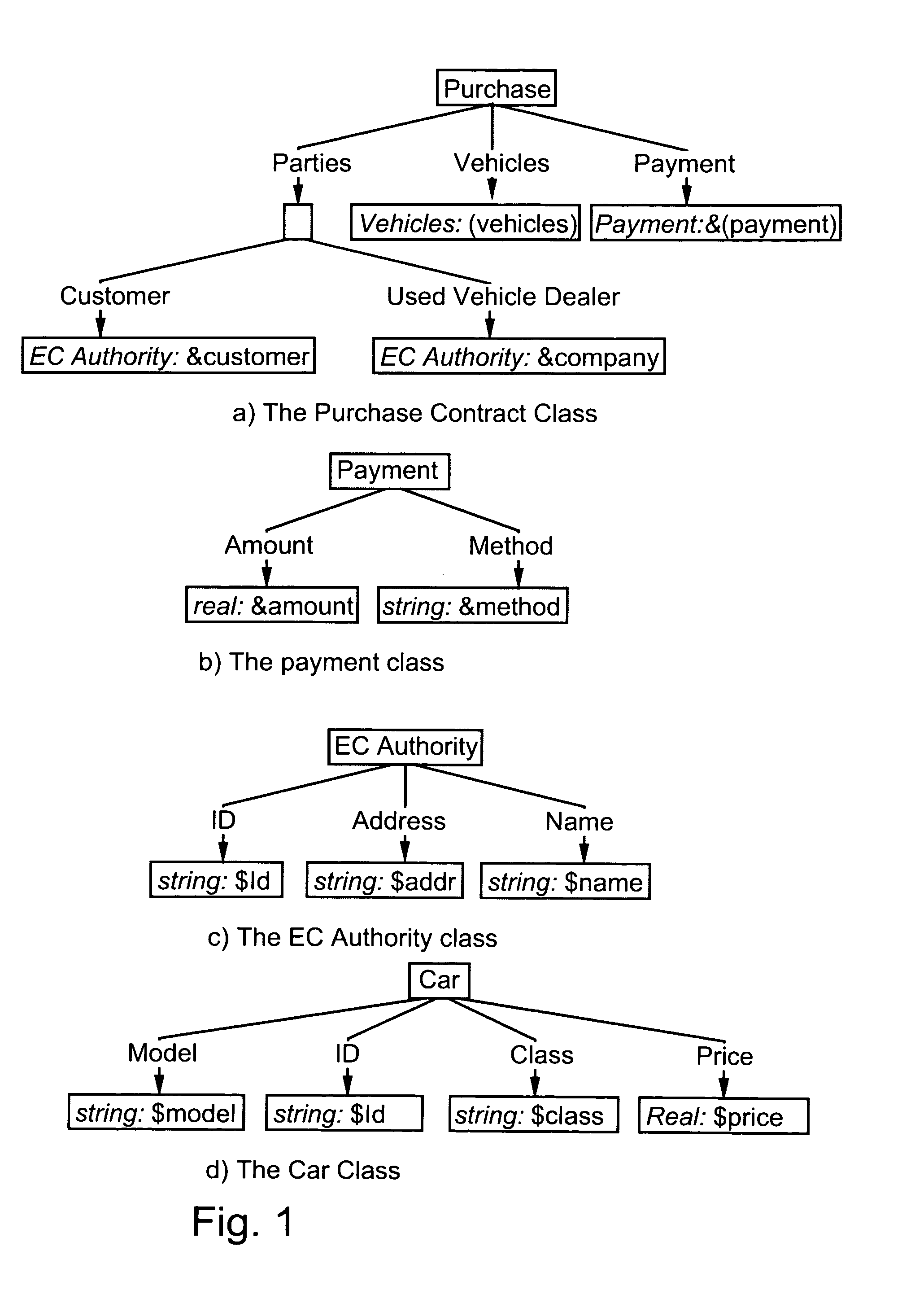

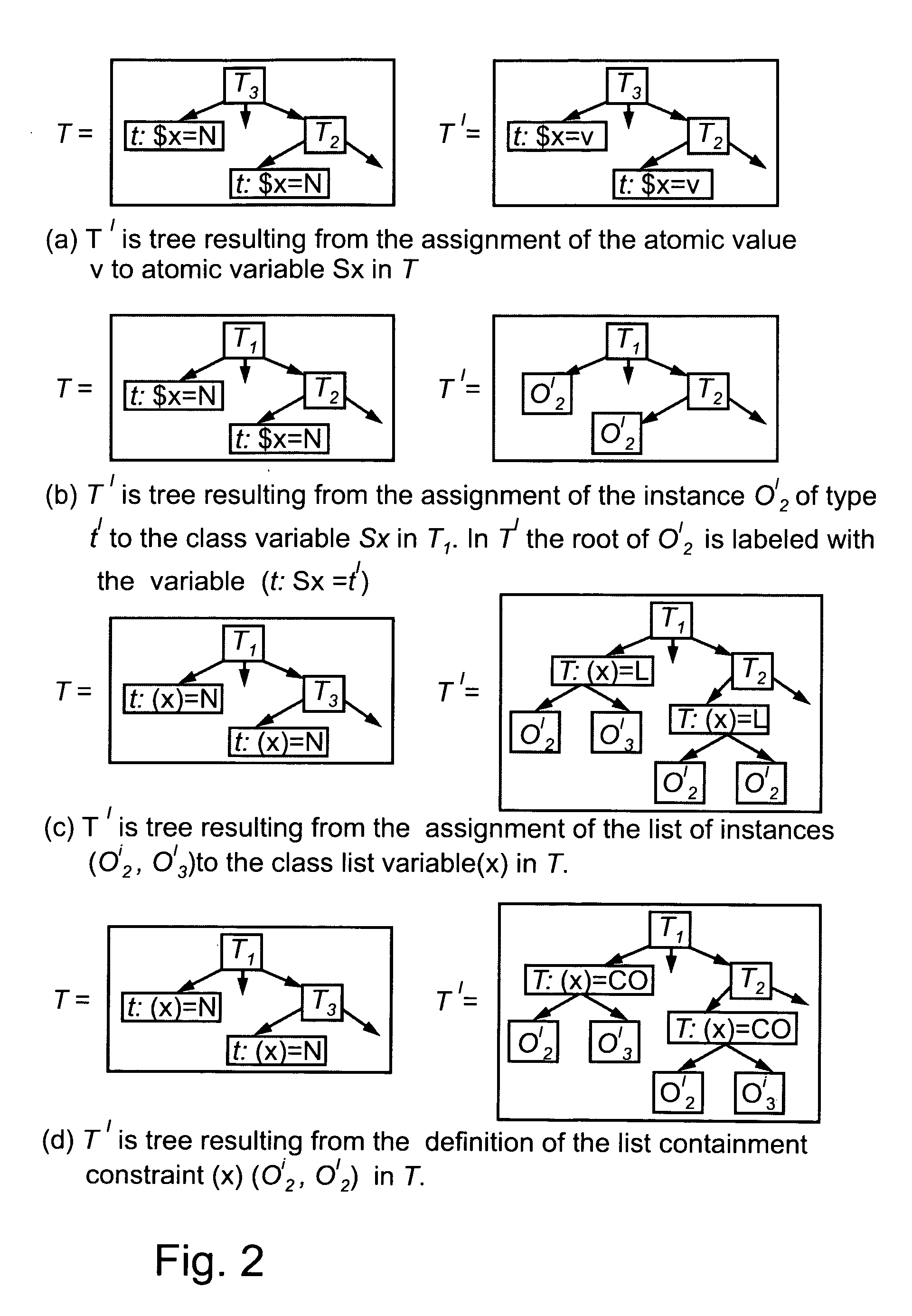

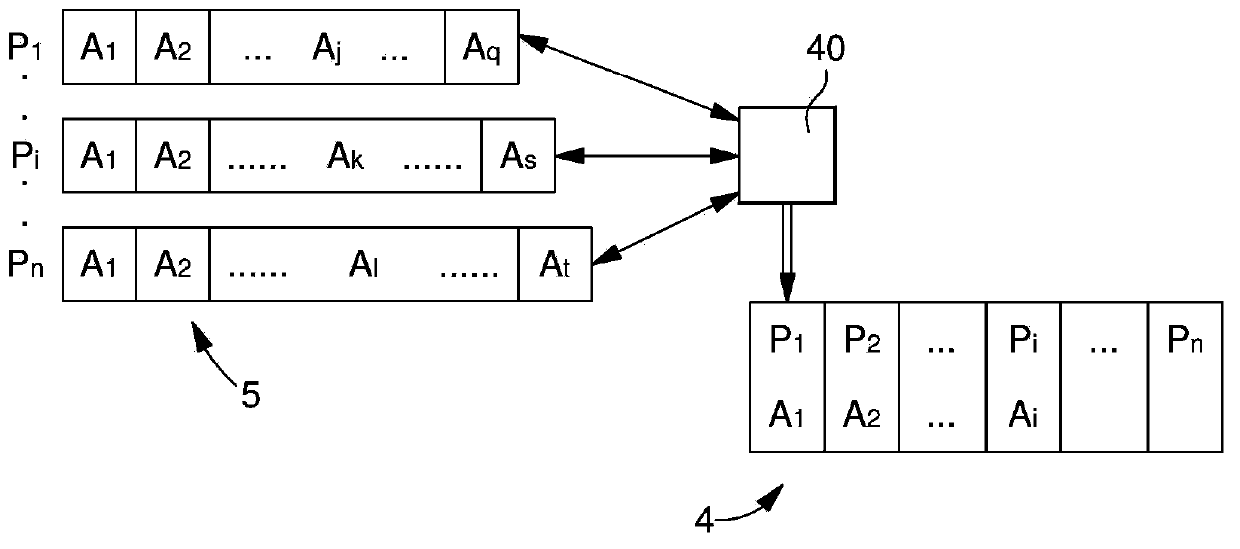

System and method for automated contract formation

A system, method and device for (semi-)automated e-commerce on the Internet, the WWW and other networks. Trading parties present intentions, made of more elementary components, which are used to express their willingness to engage in deals subject to constraints. Parts of intentions may be variable components. Some variable components may be associated with computational devices that transform them, optionally communicating via messages, into more specified components. This mechanism encodes business rules. By fitting intentions, contracts are formed. While fitting intentions, negotiations are carried out via the exchange of messages. Negotiations are automated by encoding users wishes as mathematical programs. Following the deal formation an optional deal improvement phase, in one-to-one mode or one-to-many mode, is carried out to improve the deal. The improvement phase may be based on a trading mechanselected from an available collection of such mechanisms including such mechanisms as constructed by users of the system.

Owner:DEALIGENCE

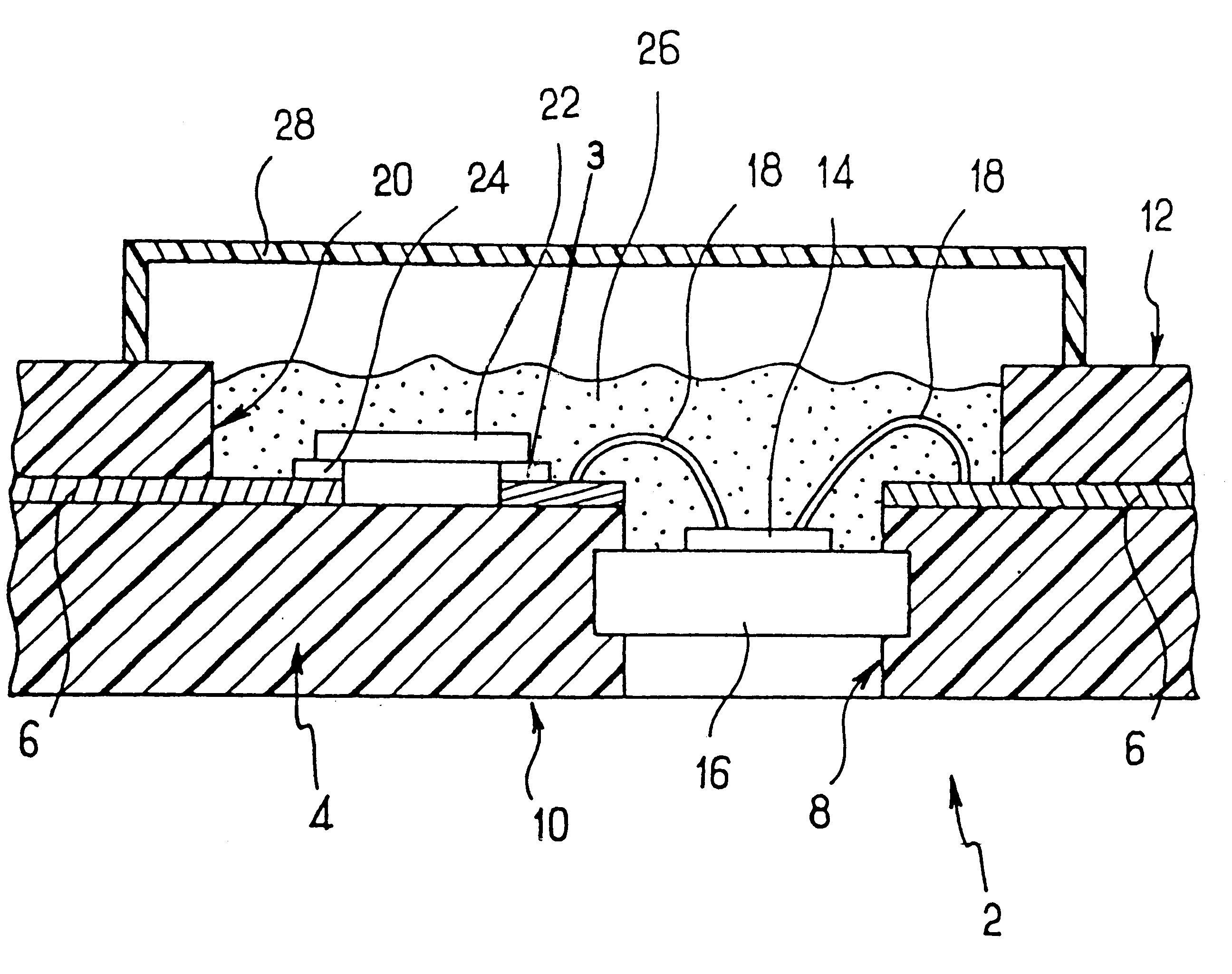

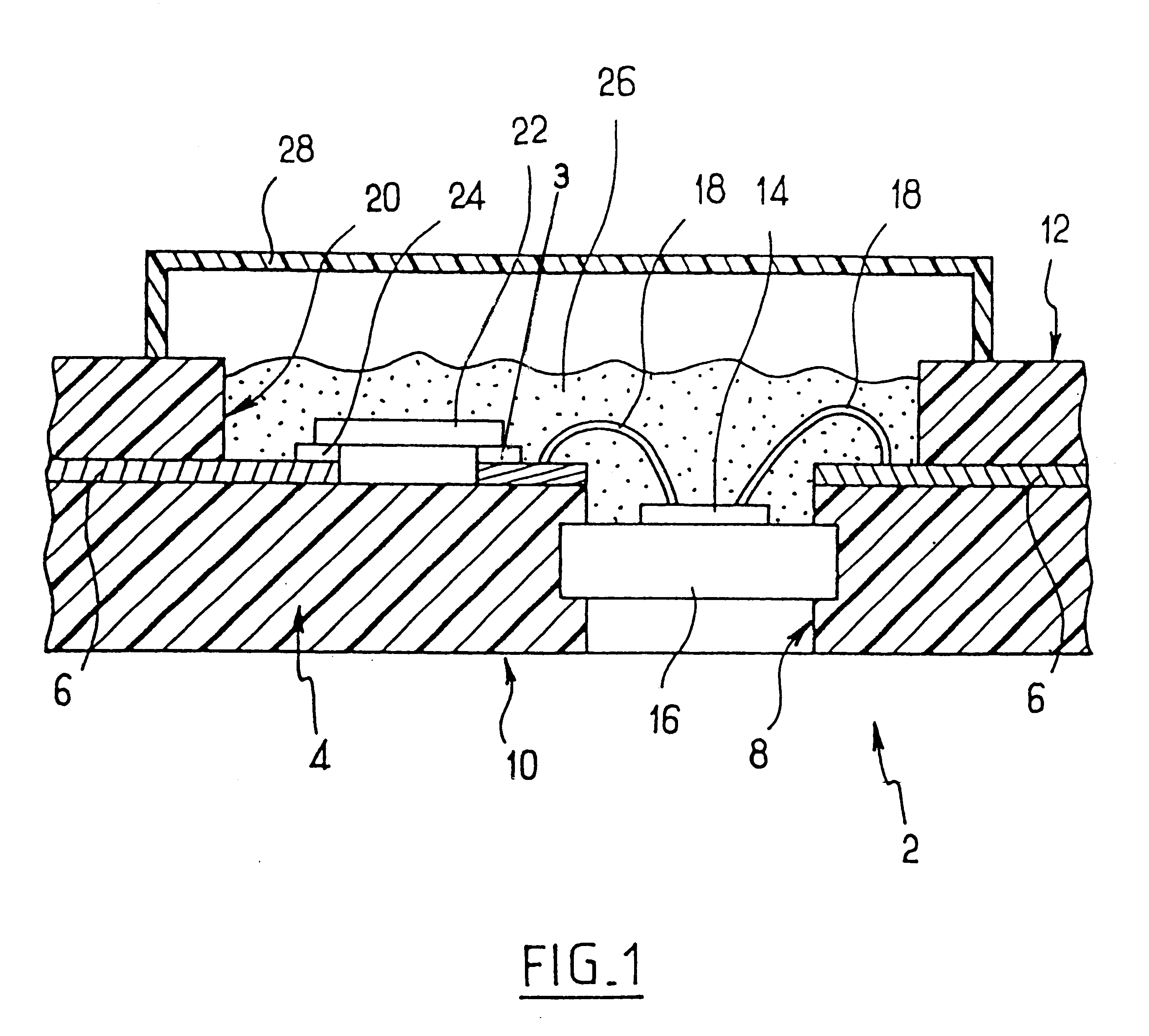

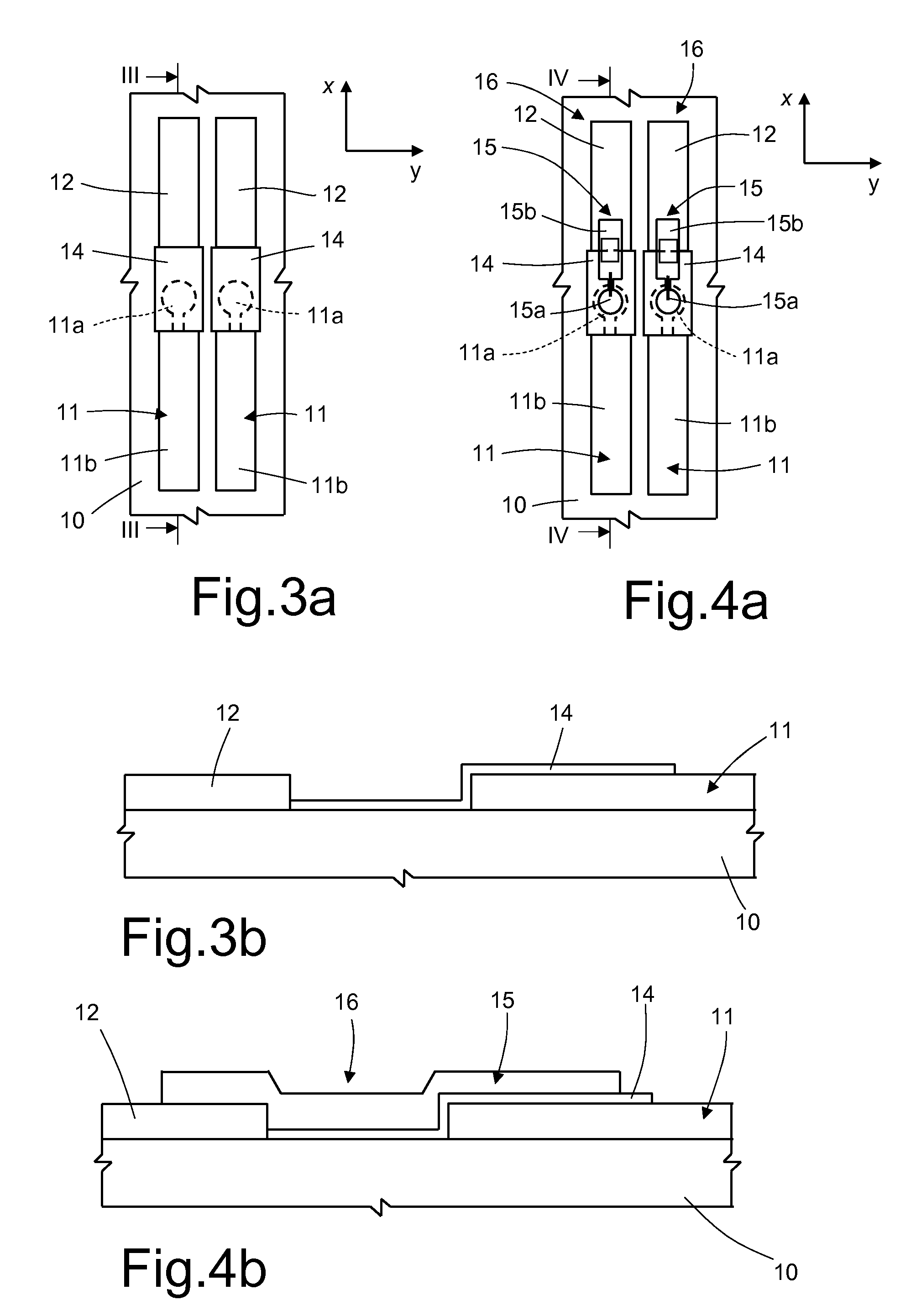

Sub-assemblies with electronic components, for motor vehicle alternators

InactiveUS6271607B1Quicker and cheapMake fastSynchronous generatorsSolid-state devicesAlternatorSurface mounting

A regulator sub-assembly for an alternator comprises a substrate having a through aperture, with an integrated circuit component mounted within this aperture, while an elementary electronic component other than an integrated circuit (and being for example a capacitor) is also fixed to the substrate. The elementary component is surface mounted on the substrate.

Owner:VALEO EQUIP ELECTRIC MOTEUR

Method for producing perovskite-type composite oxide

InactiveUS7381394B2Highly hygienicImprove securityInternal combustion piston enginesMercury oxidesCITRATE ESTERComposite oxide

Methods of producing a safe and hygienic method for industrially and efficiently producing a perovskite-type composite oxide are provided that can maintain the catalytic activity of a noble metal at a high level. Methods include preparing a precursor of the perovskite-type composite oxide by mixing organometal salts of elementary components of the perovskite-type composite oxide and heat treating the precursor. The precursor may be prepared by mixing all elementary components constituting the perovskite-type composite oxide, or by mixing one or more organometal salts of part of the elementary components with the other elementary components prepared as alkoxides, a coprecipitate of salts, or a citrate complex of the respective elements.

Owner:DAIHATSU MOTOR CO LTD +1

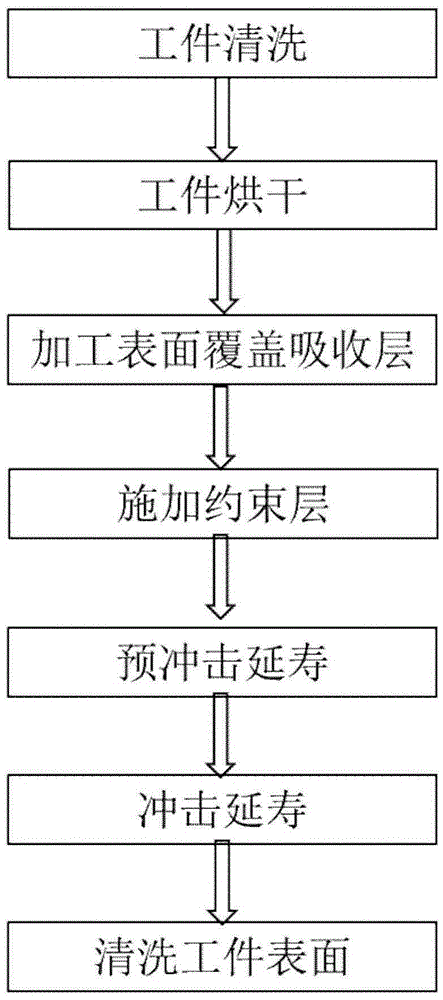

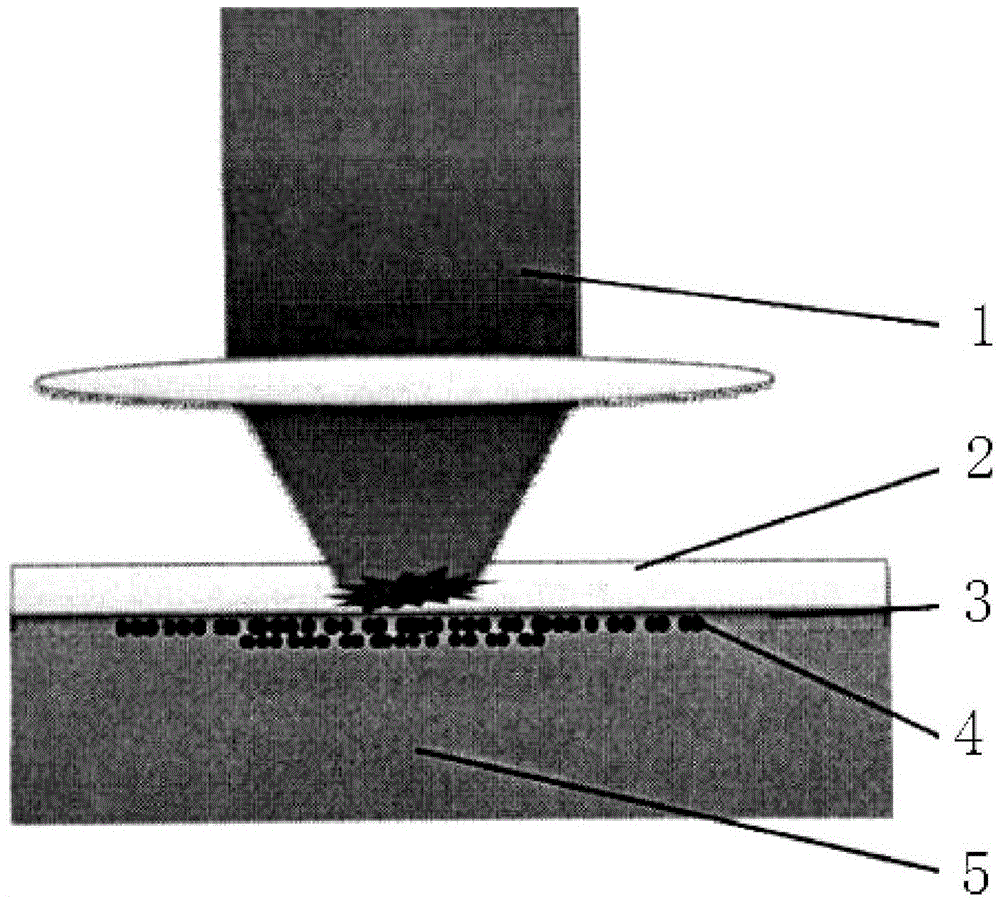

Metal surface nanometer powder permeating method based on laser induction shock waves

The invention relates to a metal surface nanometer powder permeating method based on laser induction shock waves. The method comprises the following steps that base materials are pretreated; a machining surface is covered with an absorbing layer; a base metal surface is covered with the absorbing layer; a restraining layer is exerted on the base metal surface; pre-impact life-extension treatment is carried out on the base metal surface on which the restraining layer is exerted; impact life extension is carried out on the base metal surface subjected to the impact life extension treatment; and base metal materials are subjected to aftertreatment. In the process of covering the machining surface with the absorbing layer, in a clean room, a thin plate is taken, and an opening with the needed size and shape is shorn out in the middle; the thin plate is attached to the surface of the absorbing layer, and the middle of the thin plate is evenly coated with nanometer particles; and the rest is removed thoroughly, and a particle coating layer with the thickness equal to that of the thin plate is formed on the surface of the absorbing layer. According to the metal surface nanometer powder permeating method, a crystal structure, orientation distribution and metal surface elementary components on the base metal surface are obviously changed, the hardness, the fatigue life, the abrasion resistance and the corrosion resistance of the metal surface are effectively improved, operation is simple, and cost is low.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

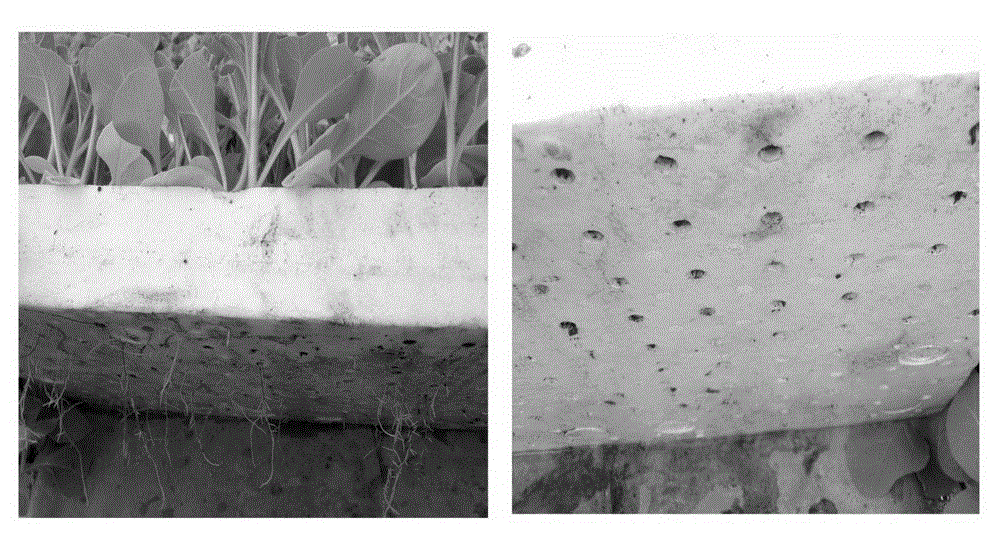

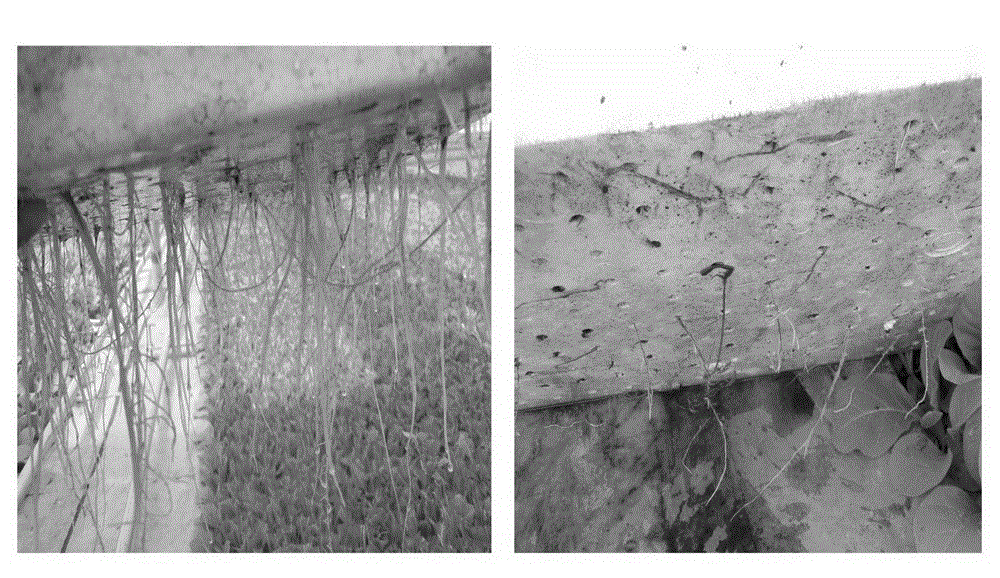

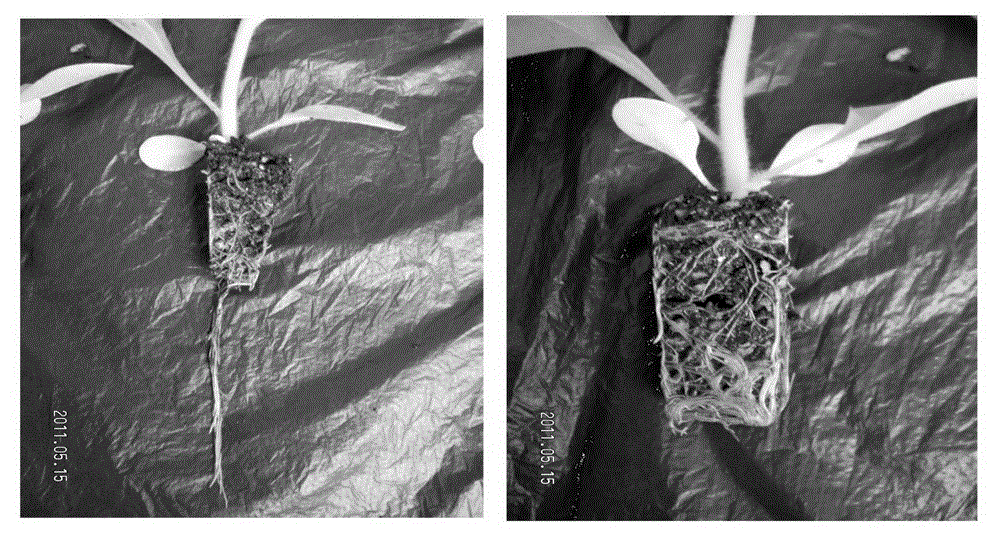

Special fertilizer for float seedling raising of tobacco

InactiveCN102746050APromote growth and developmentPromote absorptionFertilising methodsFertilizer mixturesNicotiana tabacumPhosphate

The invention relates to the field of a fertilizer, and specifically relates to a special fertilizer for float seedling raising of tobacco, which comprises the main components: 15-20% of potassium dihydrogen phosphate, 18-22% of potassium nitrate, 6-10% of potassium sulfate, 40-45% of ammonium nitrate, 6-10% of copper sulfate, 0.1-0.3% of zinc sulfate, 0.1-0.3% of borax, 0.1-0.3% of ammonium molybdate and 0.1-0.3% of iron chelate. According to the invention, the ratio of the nutrient components conforms with the fertilizer requiring rule of tobacco seedlings, and the elementary components are coordinated with each other, so that the absorption and conversion of various nutritive elements are facilitated and the growth and development of the tobacco seedling root system are obviously promoted; and under the same conditions, compared with other fertilizer, the fertilizer has the advantages that the early growth is rapid, the root system is stronger, the absorption and utilization of various nutritive element by the tobacco seedlings are facilitated, the sound seedling rate is obviously improved, the spiral roots and water roots are significantly reduced, and algae in a seedling raising tank is significantly reduced.

Owner:HENAN AGRICULTURAL UNIVERSITY

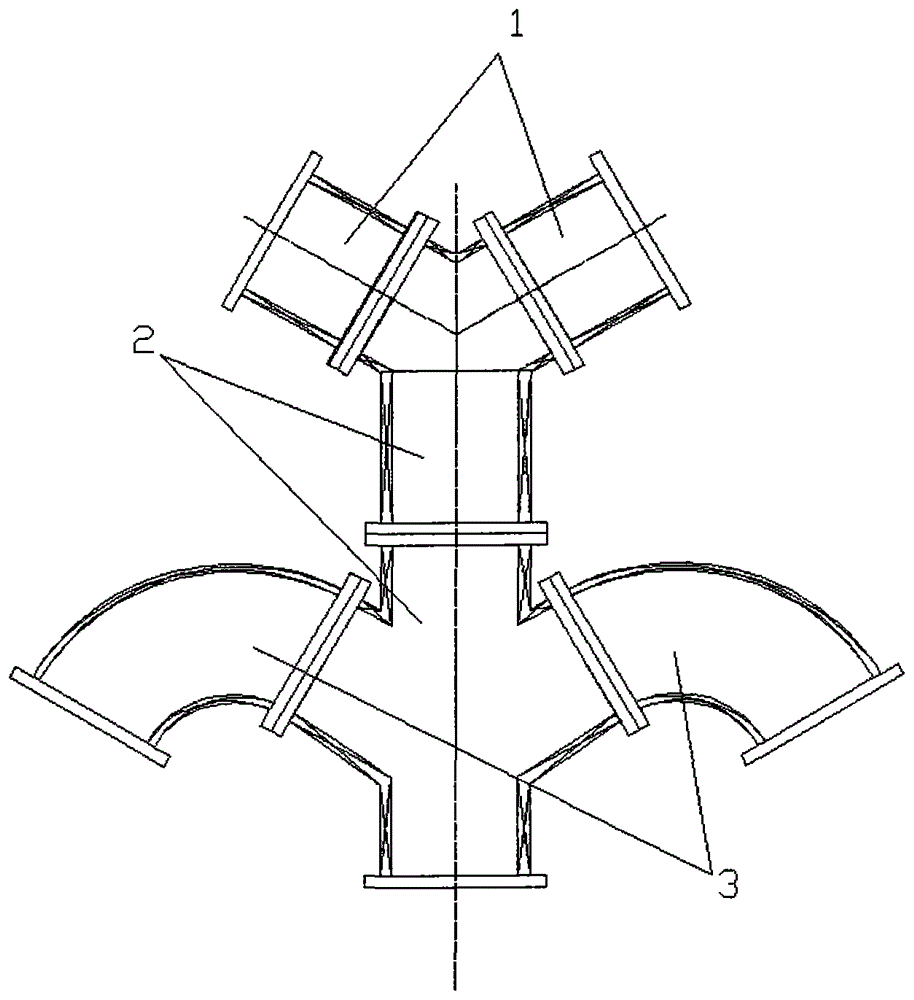

Tree-shaped cathode vacuum arc plasma deposition and magnetic filtration device

InactiveCN105296938AAchieve multiple depositionImprove performanceElectric discharge tubesVacuum evaporation coatingPlasma depositionEngineering

The invention provided with a tree-shaped cathode vacuum arc plasma deposition and magnetic filtration device which is formed by rationally combining and assembling two or more magnetic filtration branch pipes and a magnetic filtration main pipe, and then a tree-shaped structure is formed. In order to overcome the defects that the proportion of elementary components of a film layer of a multi-component laminated film prepared through an existing magnetic filtration cathode vacuum arc plasma deposition technology is hard to adjust and control and is not uniform along with changes of the position, the magnetic filtration device is provided; two or more arc sources can be assembled simultaneously, and therefore plasmas of two or more kinds of elements can be produced; the large particles of plasmas are filtered out through the magnetic filtration branch pipes and the plasmas are magnetized and guided into a vacuum target chamber through a magnetic field of the magnetic filtration main pipe, and then a multi-component deposition coating film is obtained. The tree-shaped cathode vacuum arc plasma deposition and magnetic filtration device can adjust and control components of the prepared film by adjusting the arc currents of different vacuum arc sources, the multi-component laminated film which is consistent in component proportion, compact in texture and smooth in surface is prepared.

Owner:BEIJING NORMAL UNIVERSITY

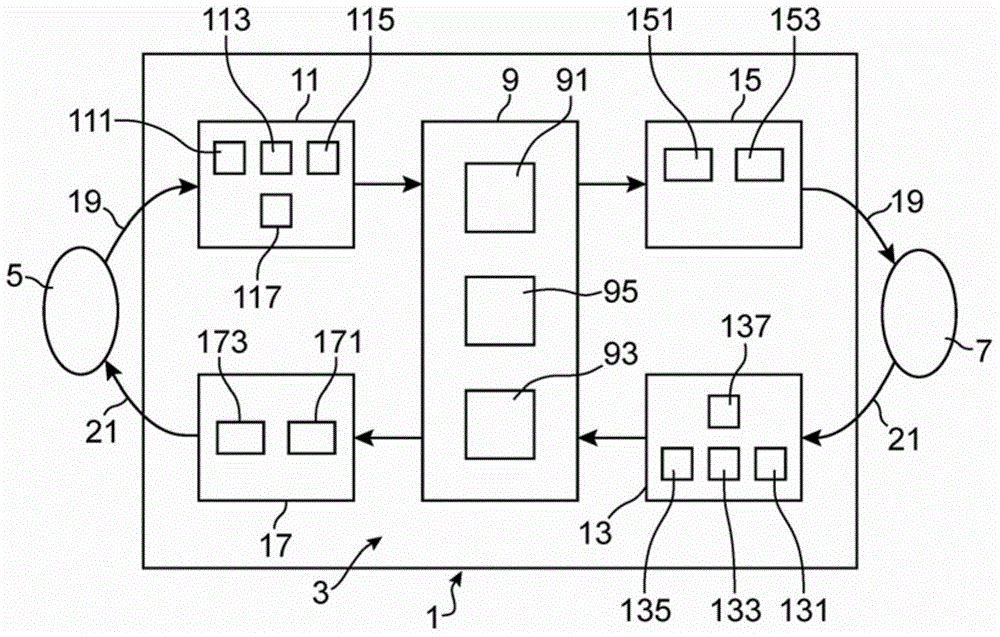

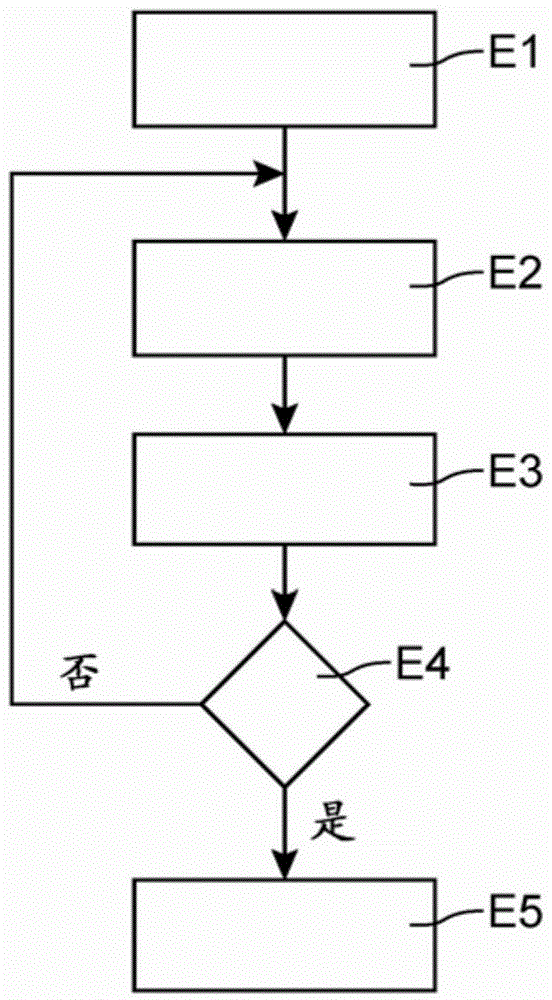

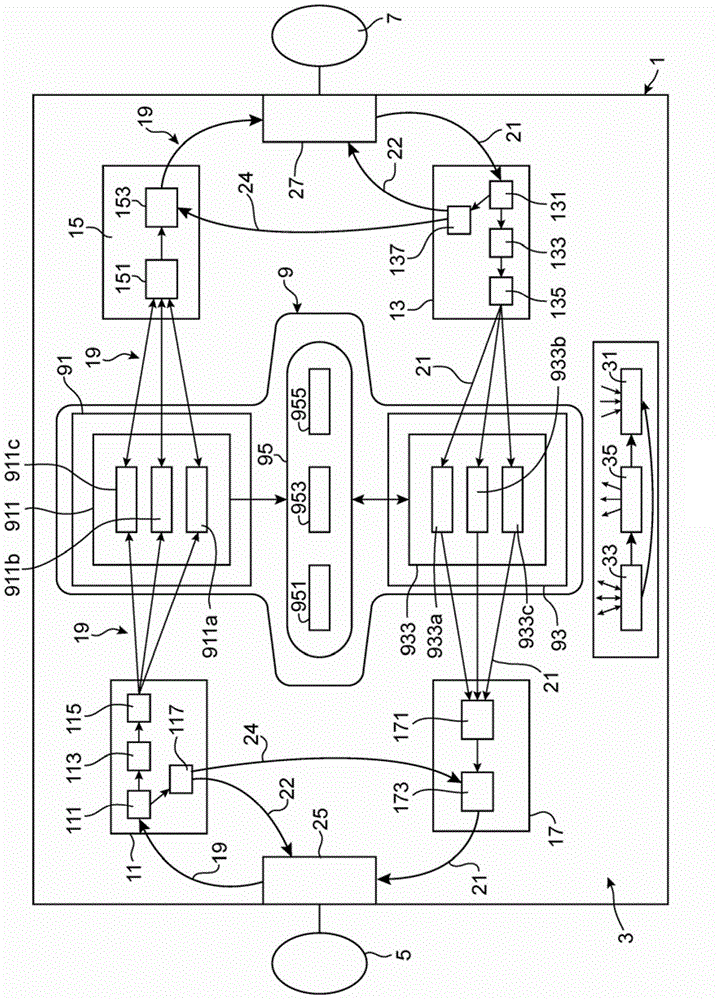

High assurance security gateway interconnecting different domains

The present invention proposes a gateway having an architecture which authorises a bidirectional communication between applications located in different domains and presents a high assurance level of protection. The gateway uses a virtualisation platform and comprises a set of functional blocs (9, 11, 13, 15, 17) configured to authorise secure bidirectional flow of data along two different paths (19, 21) between first and second domains (5, 7), said set of functional blocs being decomposed into a plurality of elementary evaluable components each one of which having a specified function and being adapted to communicate with other predefined elementary components.

Owner:AIRBUS OPERATIONS (SAS) +1

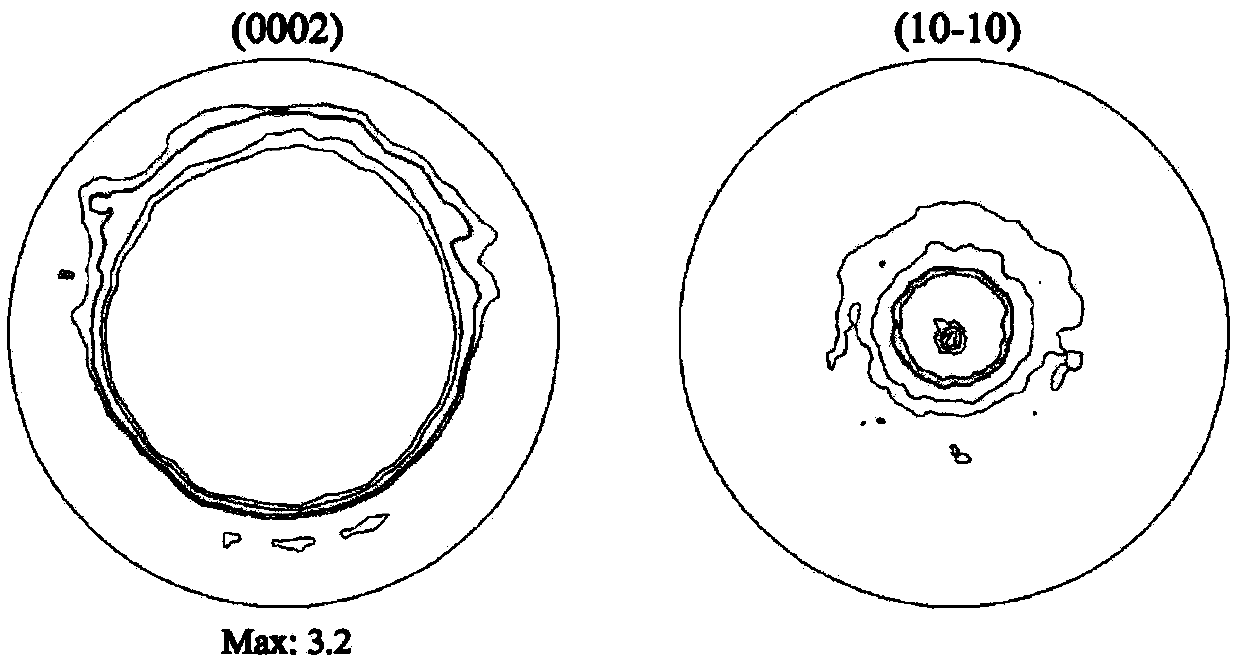

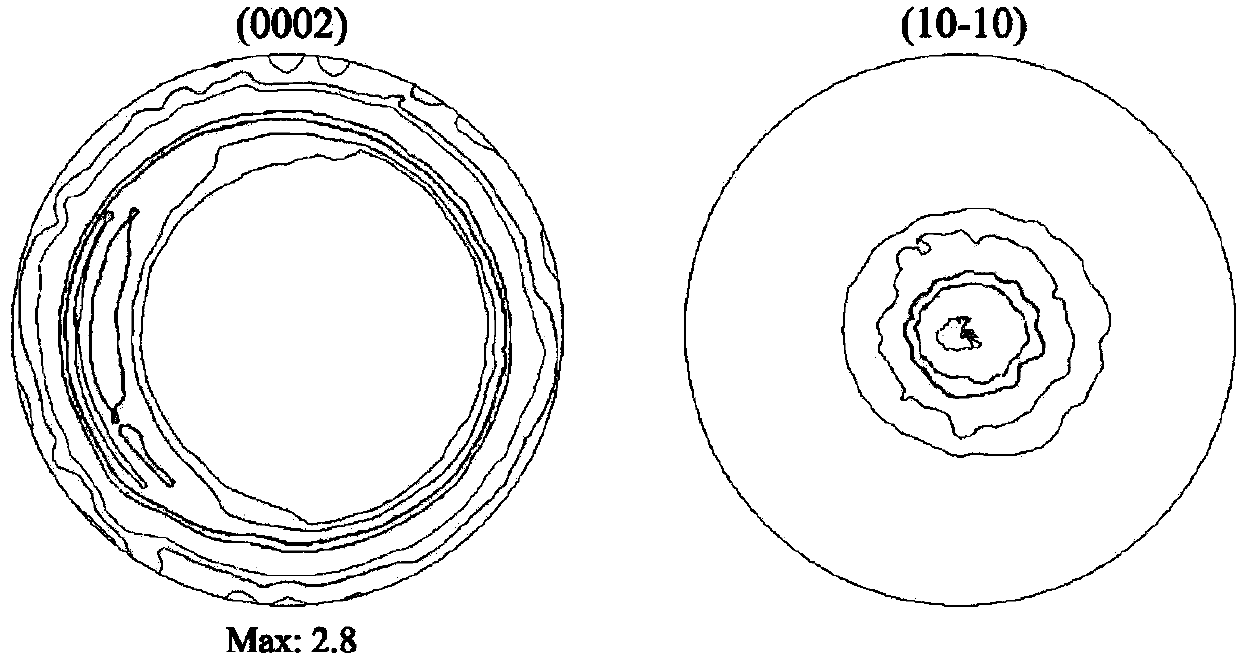

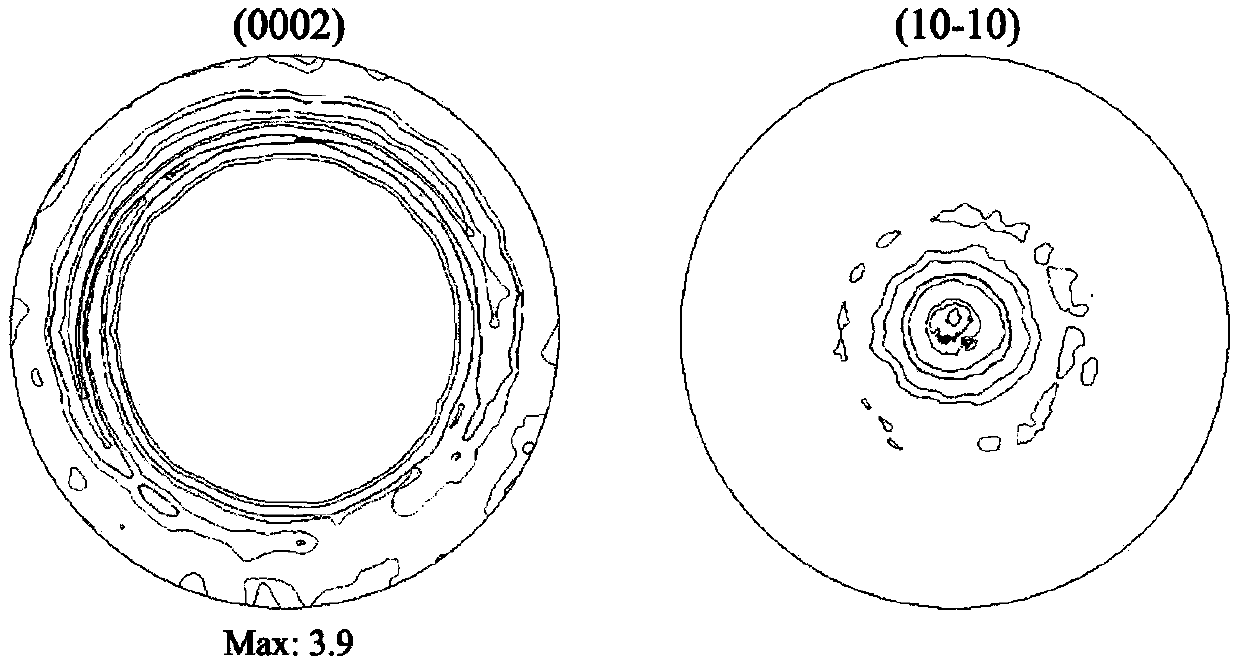

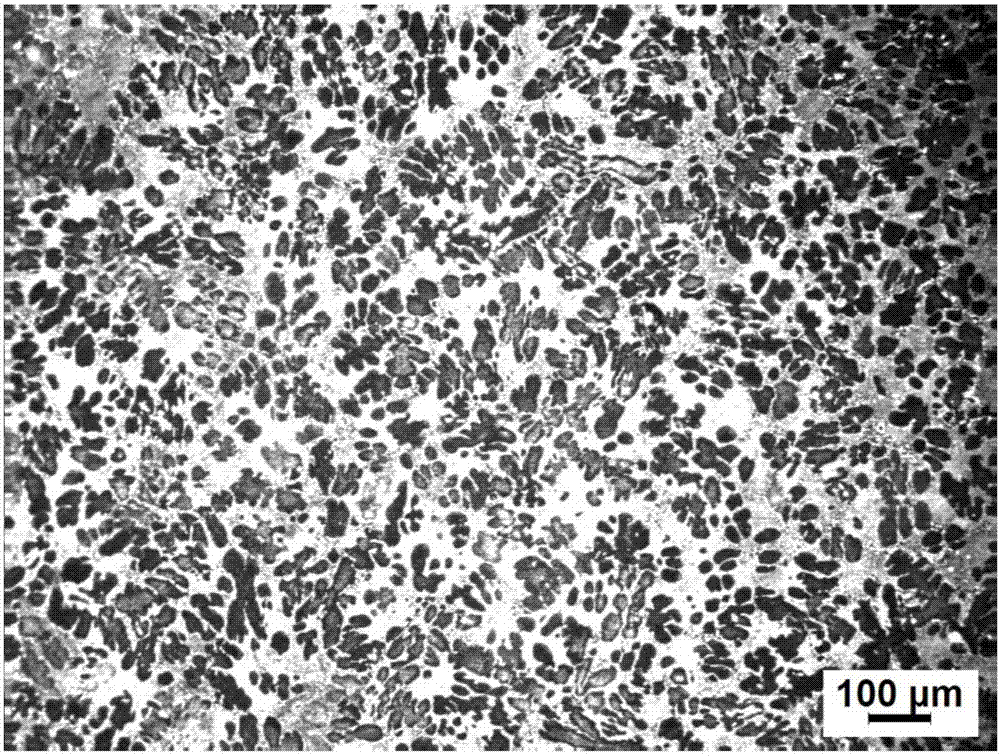

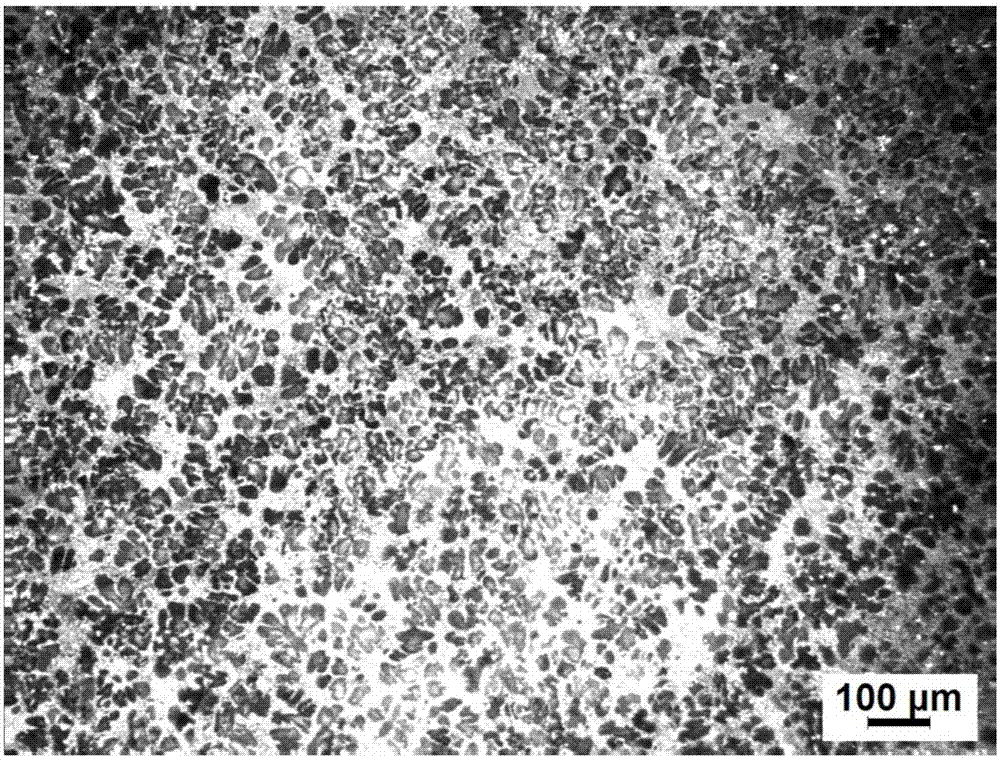

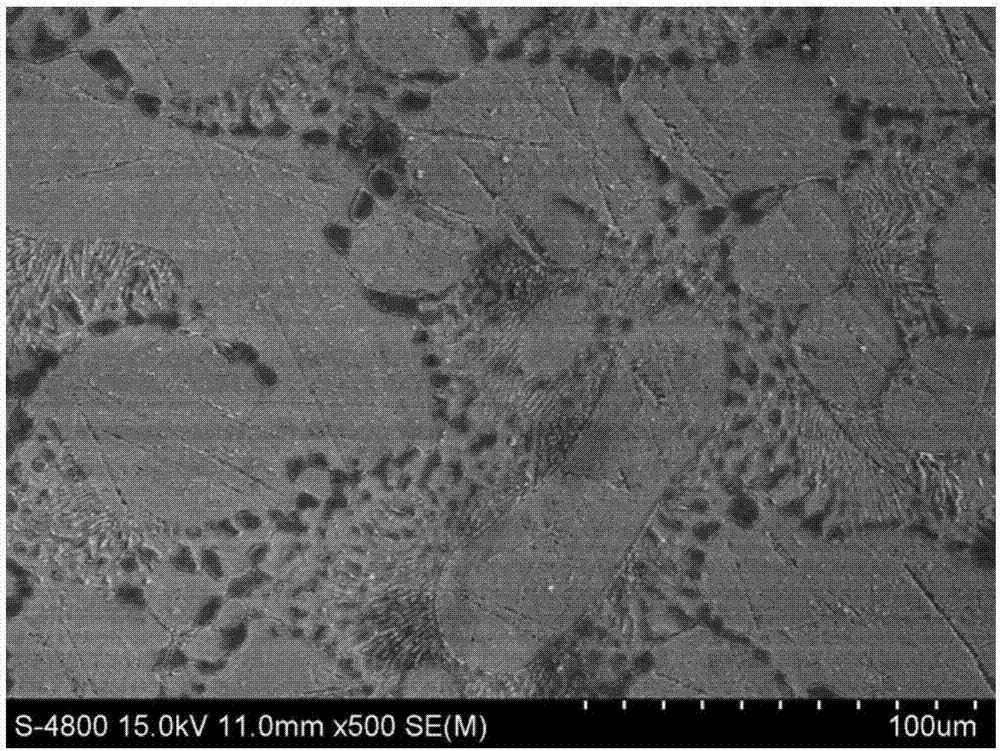

Multi-element compound reinforced weak-texture wrought magnesium alloy and preparing method thereof

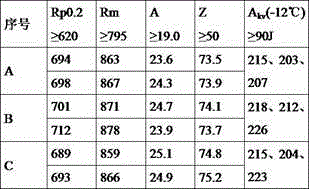

The invention relates to a multi-element compound reinforced weak-texture wrought magnesium alloy and a preparing method thereof. The wrought magnesium alloy comprises the following elementary components in content: 5.5%-6.5% of Zn, 1.0%-6.5% of Al, 0.1%-0.4% of Mn, 0.1%-0.4% of Sn, 0.1%-0.4% of Ca, 0.1%-0.4% of Cu, smaller than or equal to 0.15% of unavoidable impurities and the balance of Mg. Compared with the existing non-rare-earth wrought magnesium alloy, the material of the invention has the following advantages that the alloy has high strength and great elongation after conventional extrusion treatment; the alloy has weak macro-texture and great dynamic isotropy; the alloy preparing cost is low, and the preparing technology is simple; and the application range of the wrought magnesium alloy is further increased.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing aluminum alloy by virtue of molten salt electrodeoxidation-ingot metallurgy

InactiveCN104451215AEvenly distributed ingredientsSimple preparation processCompression moldingElectrolysis

The invention discloses a method for preparing an aluminum alloy by virtue of molten salt electrodeoxidation-ingot metallurgy, and belongs to the technical field of electrolytic metallurgy. The method comprises the following steps: (1) uniformly mixing metal powder with oxide powder, and performing compression molding; (2) putting graphite serving as an anode and a mixed pressed sheet serving as a cathode into a molten salt electrolyte to perform electrolytic reduction by using a molten salt electrodeoxidation method; (3) heating the molten salt electrolyte to a smelting temperature, and adding an electrolysis product for smelting; and (4) analyzing elementary components of an intermediate alloy, preparing metals required to be added, mixing and heating to melt, refining by adding a refining agent under a vacuum condition, standing, and then casting into the aluminum alloy. The method disclosed by the invention is simple in preparation process, the prepared aluminum alloy is uniform in component distribution, various properties meet requirements, and element segregation is obviously reduced compared with that of a conventional direct reaction method.

Owner:NORTHEASTERN UNIV

Nodular iron casting for heavy axle main speed reducer shell and preparation process of nodular iron casting

The invention relates to a nodular iron casting for a heavy axle main speed reducer shell. The nodular iron casting is prepared from following elementary components in percent by mass: 3.40-4.0% of C,1.90-2.30% of Si, 0.30-0.50% of Mn, 0.30-0.40% of Cu, 0.20-0.36% of Mo, 0.02-0.04% of Sn, 0.01-0.020% of Sb, smaller than or equal to 0.04% of P, smaller than or equal to 0.035% of S, 0.038-0.06% ofMg, 0.02-0.04% of RE and the balance Fe and inevitable impurities. The nodular iron casting for the heavy axle main speed reducer shell and a preparation method of the nodular iron casting are provided aiming at the problems that a speed reducer shell of a heavy axle is large in force bearing, complex in force bearing and high in required strength. The nodular iron casting for the heavy axle mainspeed reducer shell is low in alloy, high in strength and low in cost. According to the method, mainly, furnace charges of waste steel, nodular cast iron slag and carburant are matched, a small amountof copper, molybdenum, tin and antimony alloy is added, the interval degree of a thermal treatment casting is controlled, and in cooperation with thermal treatment processes of spraying and air-cooling, a metallographic structure is obtained, wherein the metallographic structure comprises larger than or equal to 95% of carbide-free pearlite and granular ferrite. The casting has the beneficial effects of being high in tensile strength, not high in hardness, high in toughness, good in machinability and the like, and the excellent mechanical performance and the low production cost of the nodulariron casting for the axle main speed reducer shell are achieved.

Owner:HEBEI XINGSHENG MACHINERY

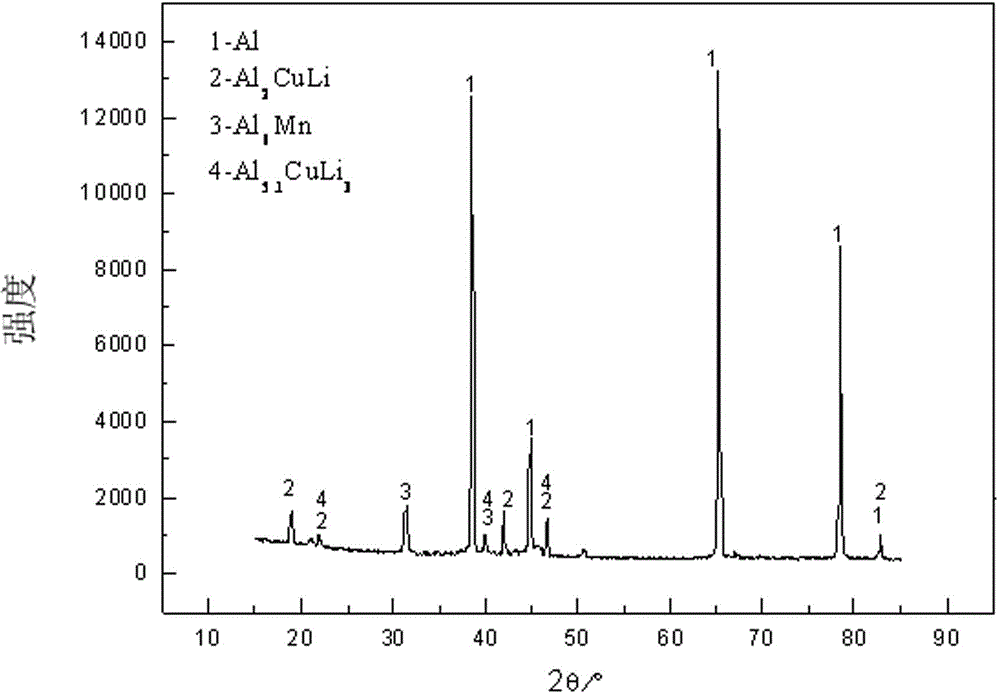

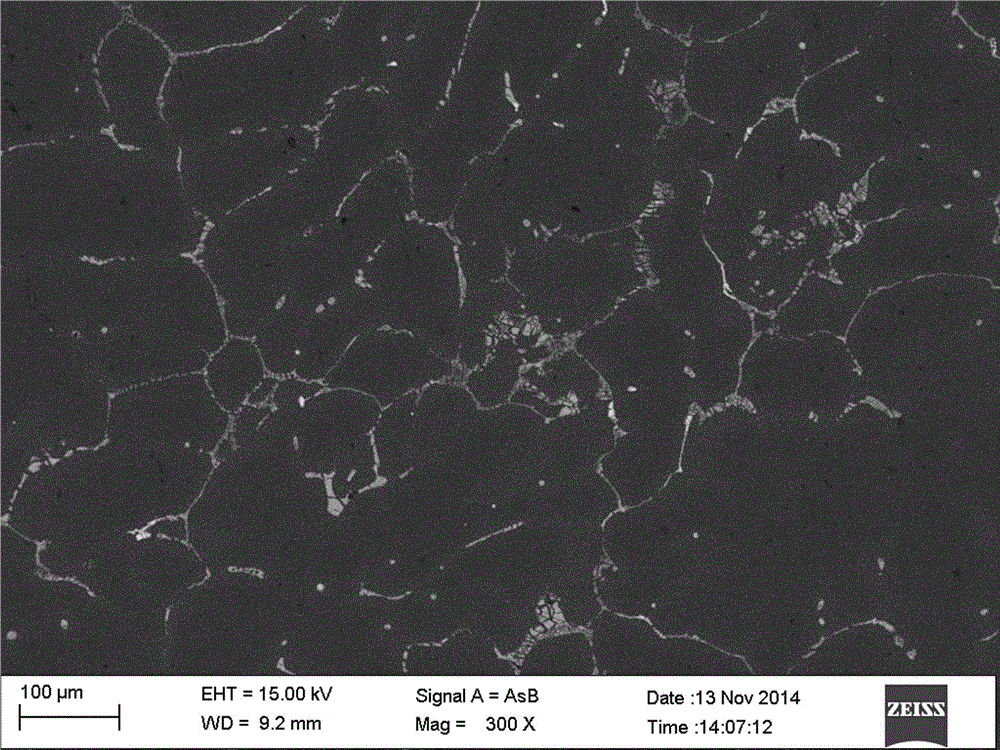

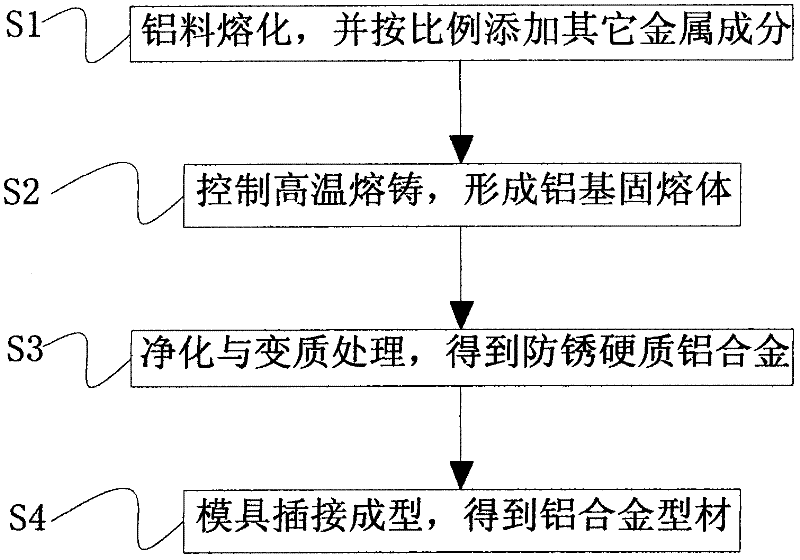

Aluminium alloy section and manufacture method thereof

InactiveCN102127667AGood corrosion resistanceHigh mechanical strengthAnodisation5005 aluminium alloy5052 aluminium alloy

The invention discloses an aluminium alloy section and a manufacture method thereof. The aluminium alloy section comprises the following elementary components of 87.5 percent of Al, 0.4 percent of Si, 1.1 percent of Fe, 0.75 percent of Mn, 0.8 percent of Mg, 2.1 percent of Zn, 4.4 percent of Cu, 0.1 percent of Ni and 0.1 percent of Ti. The manufacture method of the aluminium alloy section comprises the following process steps of: (1) melting an aluminium material, and adding metal components including the Si, the Fe, the Cu, the Mn, the Mg, the Zn, the Ni and the Ti; (2) controlling high temperature for casting to form an aluminium-based solid solution; (3) carrying out purification treatment and modification to enable grains to be refined and reduced to 1 / 20 before treatment and enable the total content to be reduced by 30 percent to obtain antirust hard aluminium alloy; and (4) splicing and molding by adopting a mould to obtain the aluminium alloy section. The aluminium alloy section provided by the invention has favorable corrosion resistance and excellent mechanical strength and is superior to a general section for a common laboratory.

Owner:湖南朗圣实验室技术股份有限公司

Preparing method for rare earth enhanced titanium alloy material

InactiveCN105463251AHigh tensile strengthHigh elongationAdditive manufacturing apparatusIncreasing energy efficiencyGranularityRare earth

The invention provides a preparing method for a rare earth enhanced titanium alloy material. The preparing method comprises the steps of powder preparing, laser 3D printing, vacuum annealing and electrochemical polishing. By means of selection of elementary components of titanium alloy powder raw materials, the tensile strength, the ductility and the reduction of area of titanium alloy are obviously improved. 3D printing raw materials even in component and good in granularity are obtained in the manner of ball milling, sintering and re-ball-grinding. The 3D printing technology and vacuum annealing are combined, and the performance of printed titanium alloy is improved. The problem that 3D printing finished products are high in roughness is solved through electrochemical polishing.

Owner:毛培

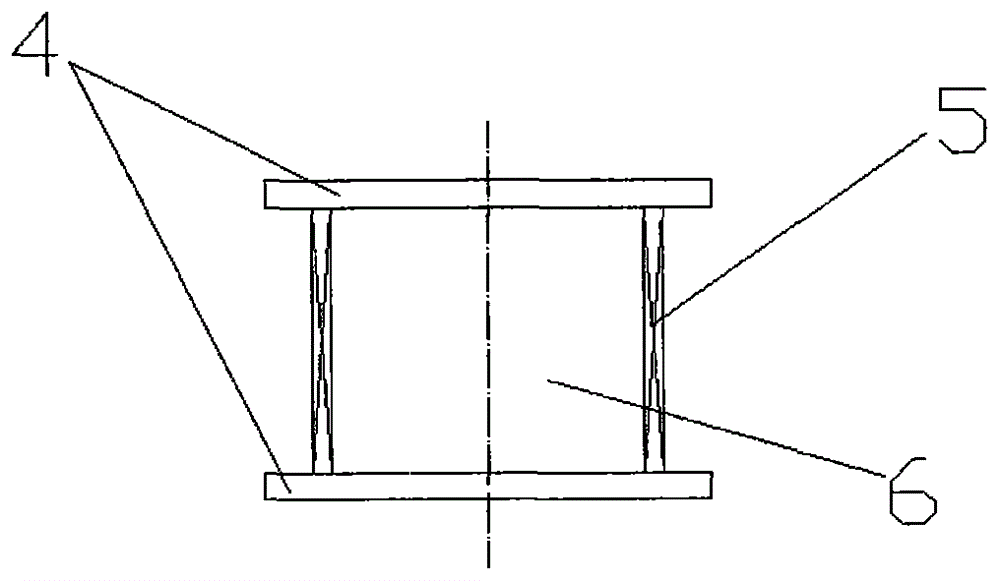

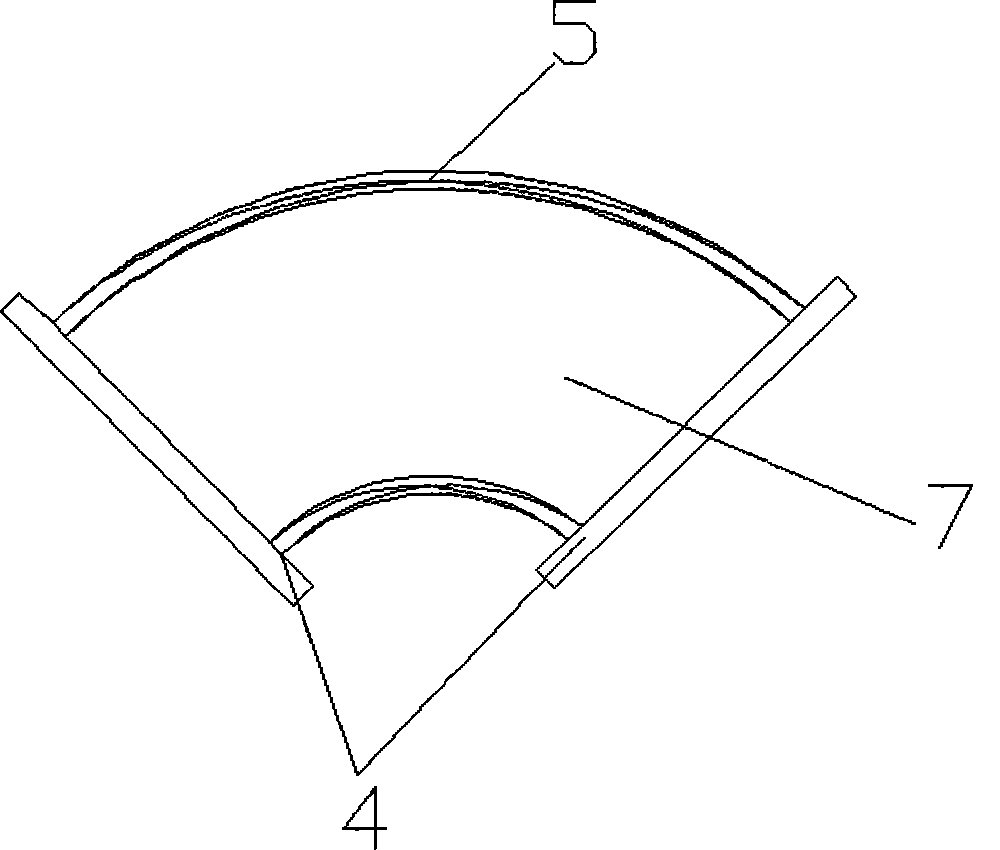

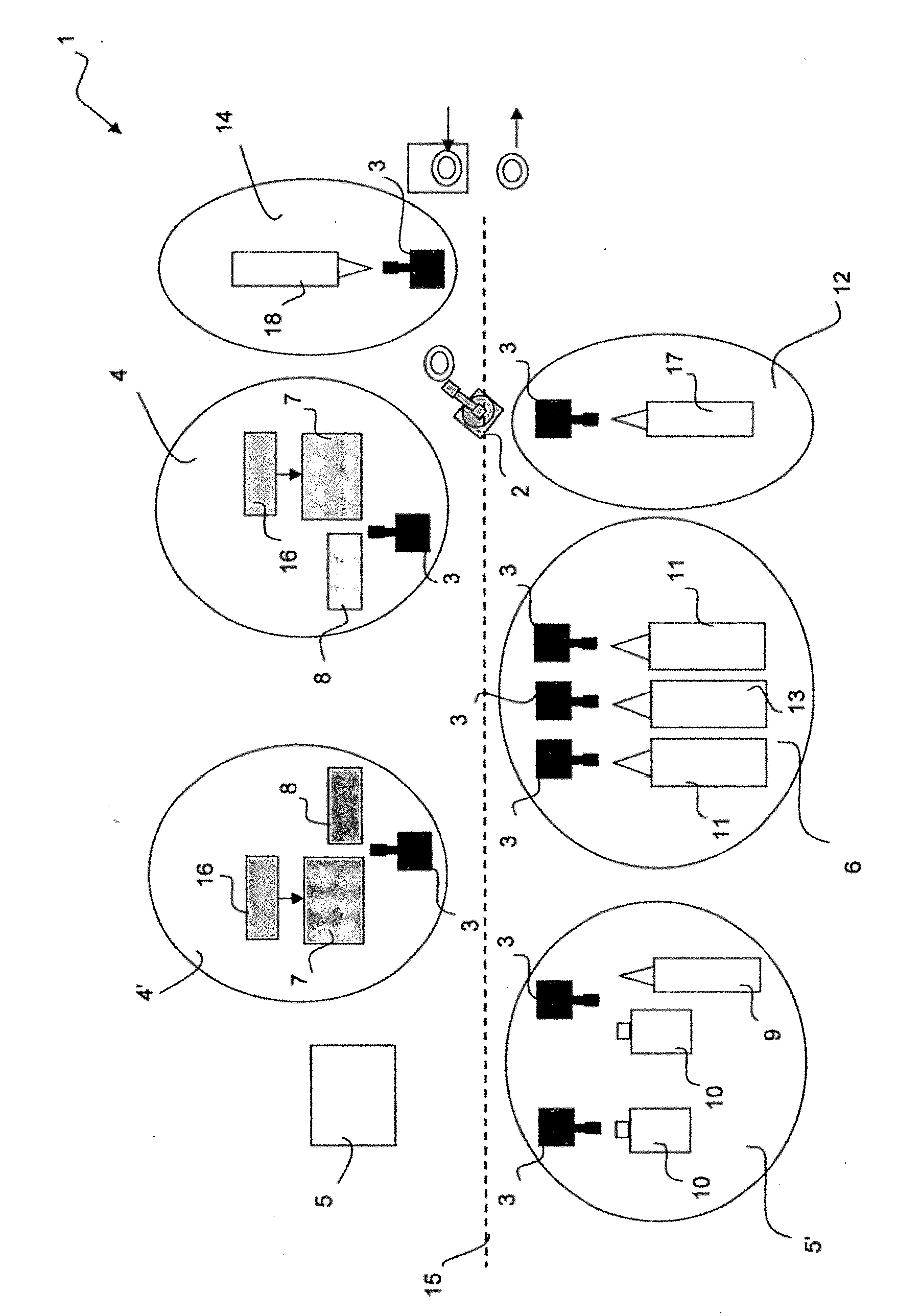

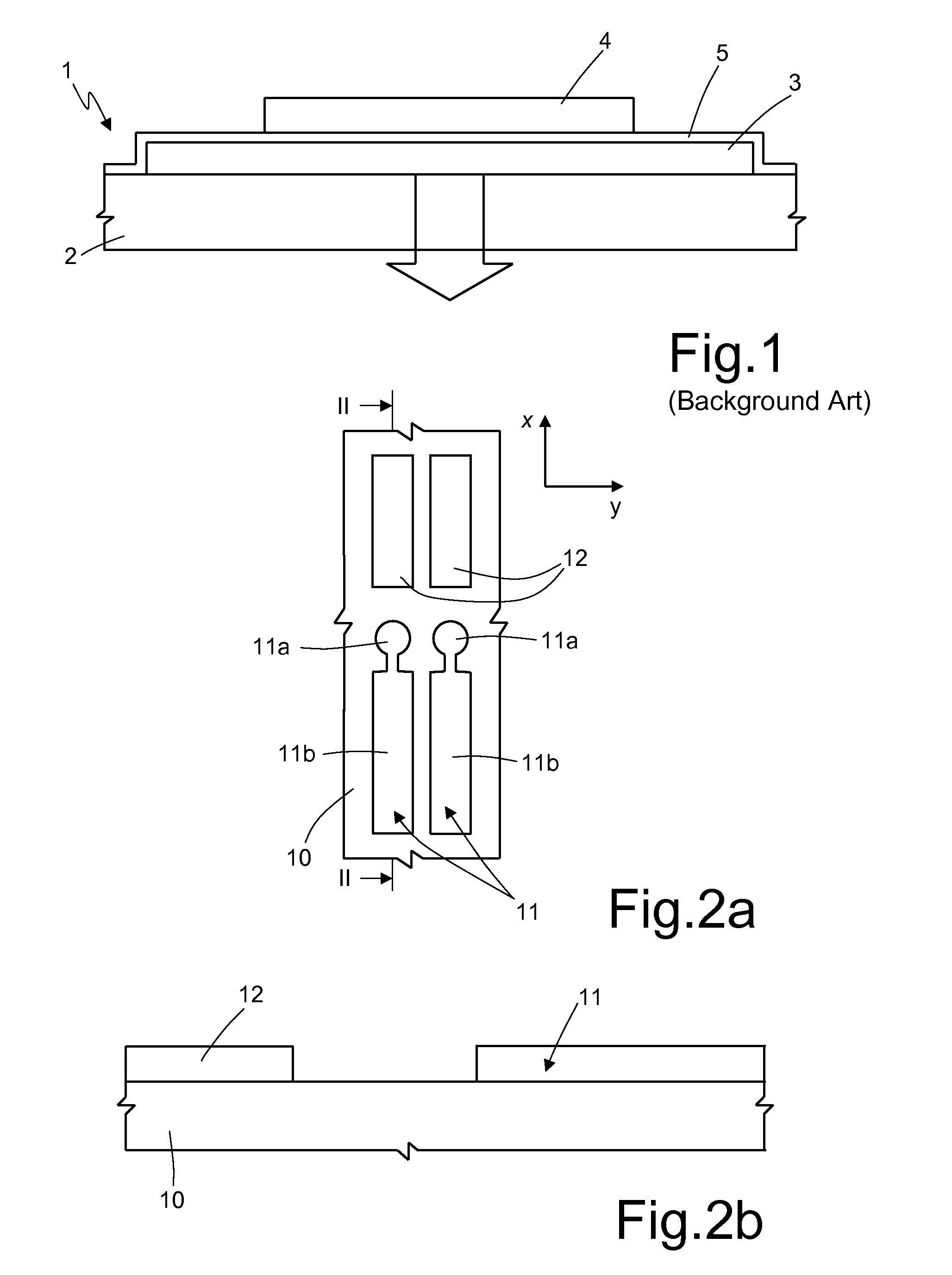

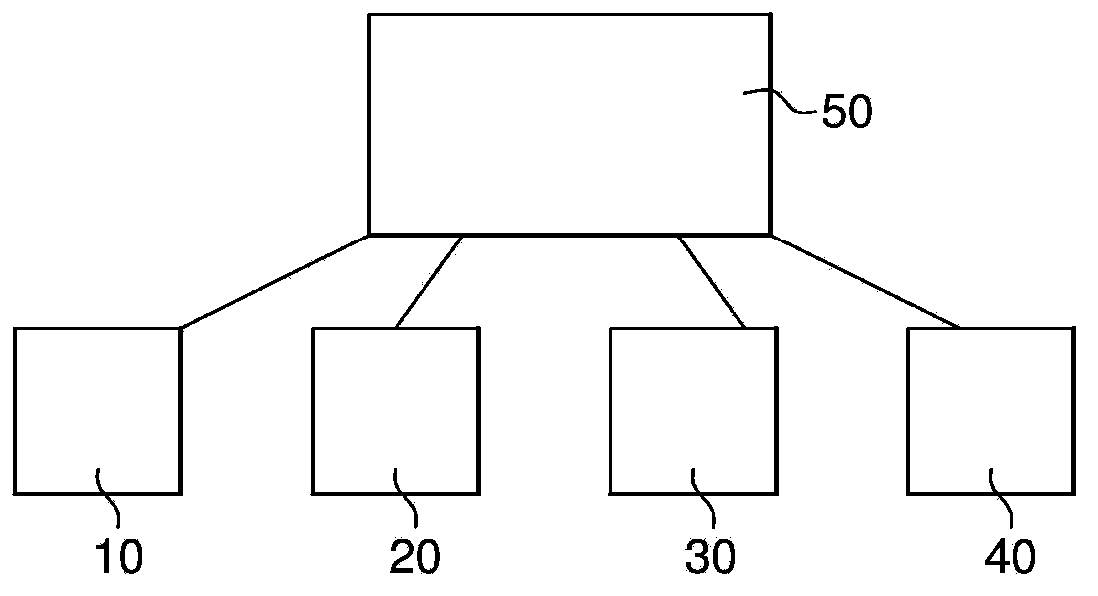

Process and plant for building tyres for vehicle wheels

There is described a plant for building tyres for vehicle wheels, said tyres being of at least two different models, comprising at least a tyre building line (1) which in turn comprises: - a plurality of work stations (4, 4', 5, 5', 6, 12, 14) arranged according to a sequential series, each work station (4, 4', 5, 5', 6, 12, 14) being adapted for building at least one structural component of each tyre, assembling at least one elementary component; - at least one handling device (3) for the tyres being processed on the respective forming supports associated to each work station (4, 4', 5, 5', 6, 12, 14); and - at least one transfer device (2) adapted for transferring the tyre being processed on its forming support from any first work station (4, 4', 5, 5', 6, 12, 14) of said sequential series to any other second work station (4, 4', 5, 5', 6, 12, 14) not adjacent thereto of said sequential series, so that the tyre being processed on its forming support only passes in said first and second work station (4, 4', 5, 5', 6, 12, 14). There are also described a process for manufacturing tyres for vehicle wheels and a method for selecting work stations (4, 4', 5, 5', 6, 12, 14) of a tyre building plant.

Owner:PIRELLI TYRE SPA

High-strength spring steel and preparation method thereof

The invention discloses high-strength spring steel containing the following chemical elementary components in percentage by mass: 1.0-1.3% of C, 0.6-0.9% of Si, 0.4-0.5% of Cu, 14.0-14.5% of Ni, 1.7-2.1% of Mn, 0.03-0.05% of Ce, 0.006-0.008% of Ti, 0.02-0.05% of Zn, 0.004-0.005% of Sn, 1.0-1.3% of Cr, less than or equal to 0.030% of P, less than or equal to 0.030 of S and the balance of Fe. The alloy material prepared from various raw materials such as Ni, Si, Mn and the like through setting a reasonable ratio and production process and reasonably setting the adding order has excellent comprehensive mechanical properties, particularly has ultrahigh strength, hardness, toughness, plasticity and fatigue resistance and also has corrosion resistance; part of waste iron is used as a raw material, so that the quality stability and uniformity of the alloy are improved; the high-strength spring steel is suitable for elastic parts.

Owner:TONGLING ANDONG CAST STEEL

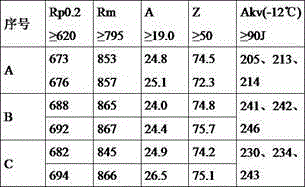

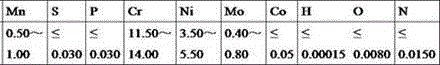

Method for smelting return scrap of martensitic stainless steel used for impeller

ActiveCN104404356AImprove purityImprove performance indicatorsIncreasing energy efficiencyManganeseMartensitic stainless steel

The invention relates to a method for smelting return scrap of martensitic stainless steel used for an impeller. The method comprises the following steps that the return scrap and / or waste forged pieces are put into a vacuum induction furnace to be refined, and are cooled and poured to form a primary ingot; after the primary ingot is subjected to chemical component analysis, nickel, manganese, chromium, molybdenum and aluminum intermediate alloys and / or carbon serve as materials for adjustment of elementary components, and the alloy components are adjusted. The primary ingot and nickel, chromium, molybdenum and / or silicon in the materials for adjustment of the elementary components are refined for the second time, heating and pouring are conducted after film forming, alternatively, liquid alloy where a film is formed after secondary refinement is added, the carbon and / or the manganese intermediate alloy are alloyed, and heating and pouring are conducted after film forming, so an electrode cast ingot used for a protective atmosphere electroslag furnace is formed. Electroslag remelting is conducted, and a steel ingot for production of impeller products is prepared. The alloy ingot of the recycle scrap can completely meet the requirement of production of qualified impeller products, the production cost is greatly reduced, requirements of projects are met and economic benefits are created.

Owner:沈阳科金特种材料有限公司

Preparing method for La and Nd doping titanium alloy materials

InactiveCN105463252AHigh tensile strengthHigh elongationAdditive manufacturing apparatusIncreasing energy efficiencyGranularityElectrochemistry

The invention provides a preparing method for La and Nd doping titanium alloy materials. The preparing method comprises the steps of powder preparing, laser 3D printing, vacuum annealing and electrochemical polishing. By means of selection of elementary components of titanium alloy powder raw materials, the tensile strength, the ductility and the reduction of area of titanium alloy are obviously improved. 3D printing raw materials even in component and good in granularity are obtained in the manner of ball milling, sintering and re-ball-grinding. The 3D printing technology and vacuum annealing are combined, and the performance of printed titanium alloy is improved. The problem that 3D printing finished products are high in roughness is solved through electrochemical polishing.

Owner:毛培

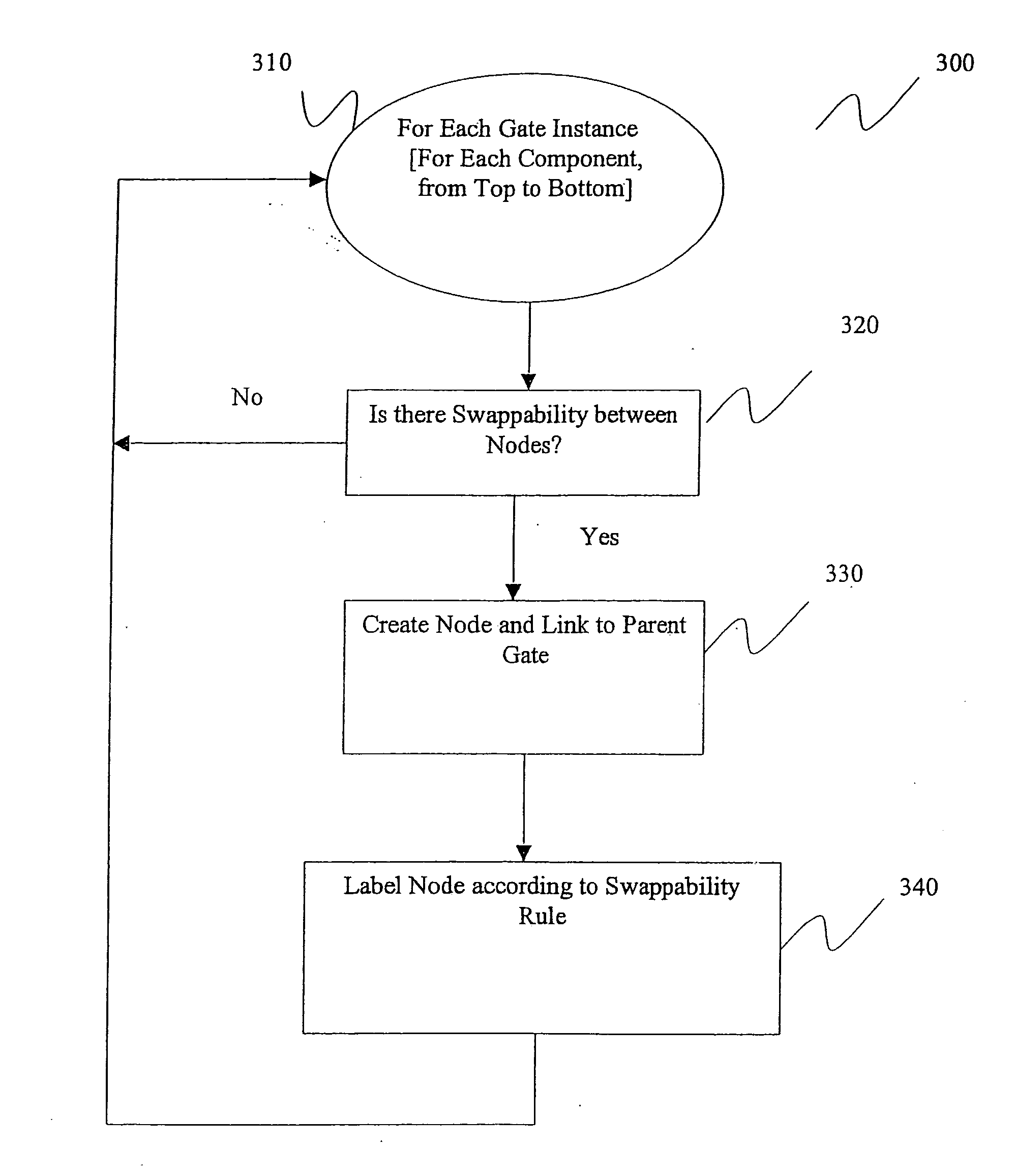

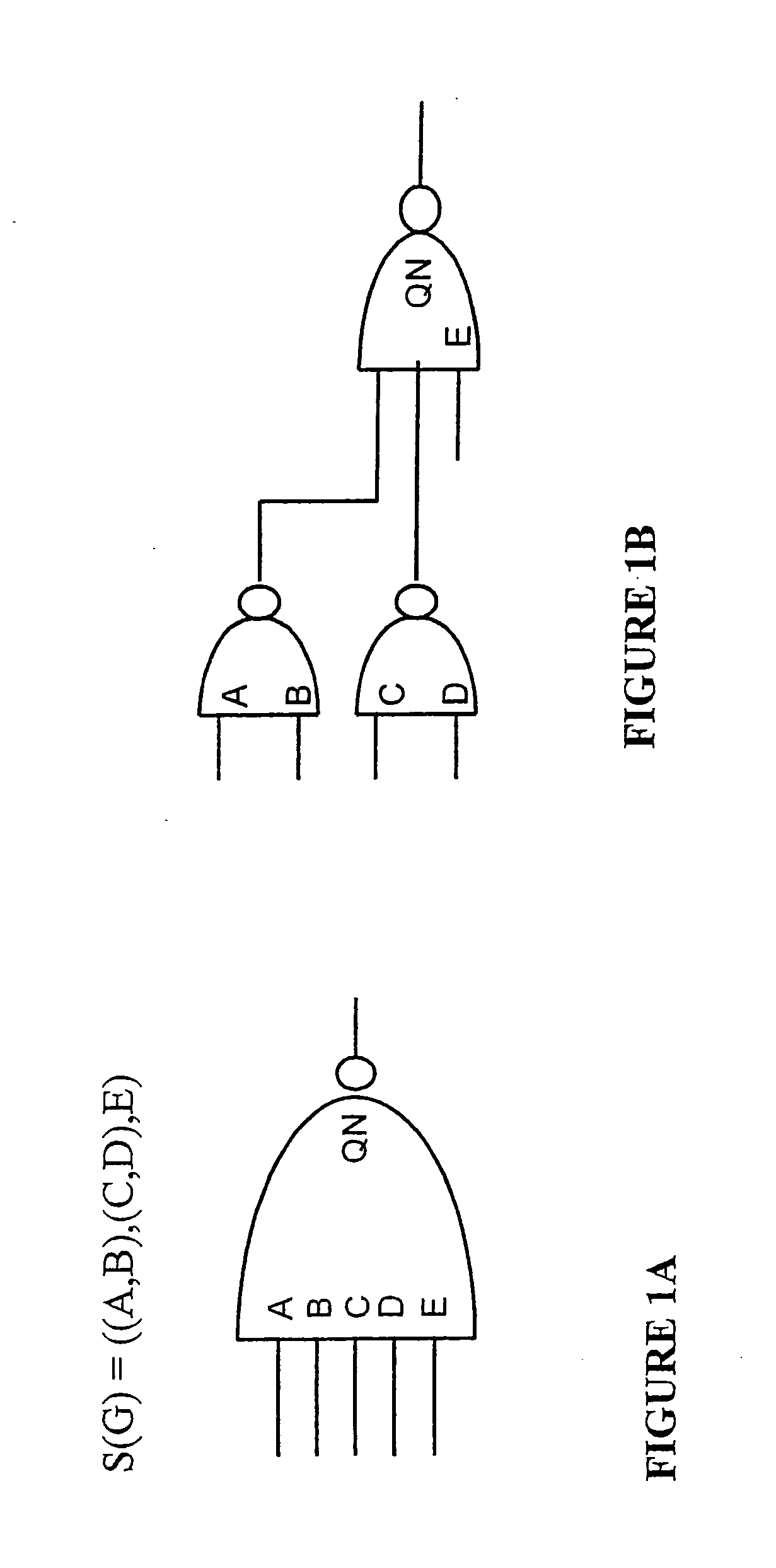

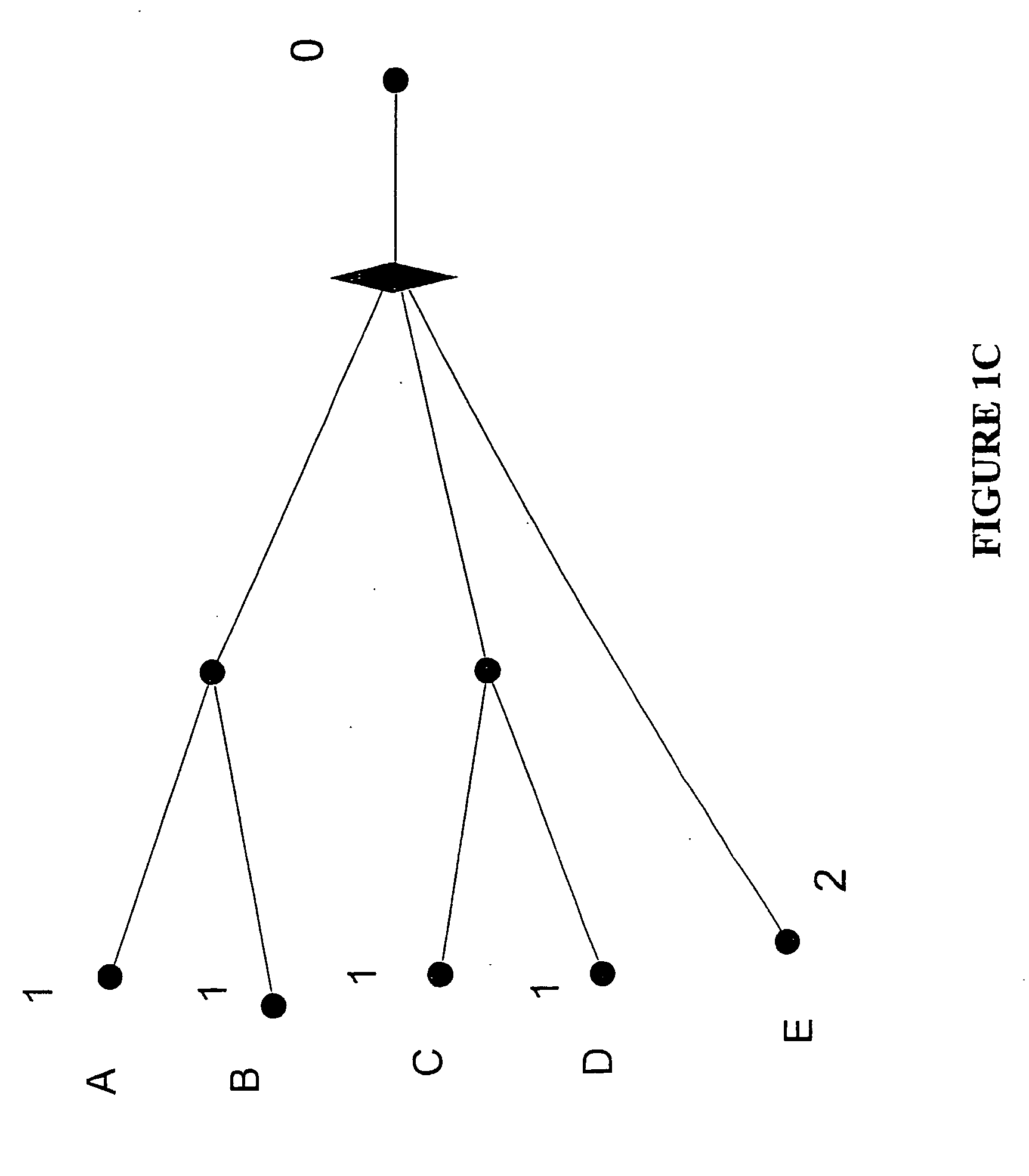

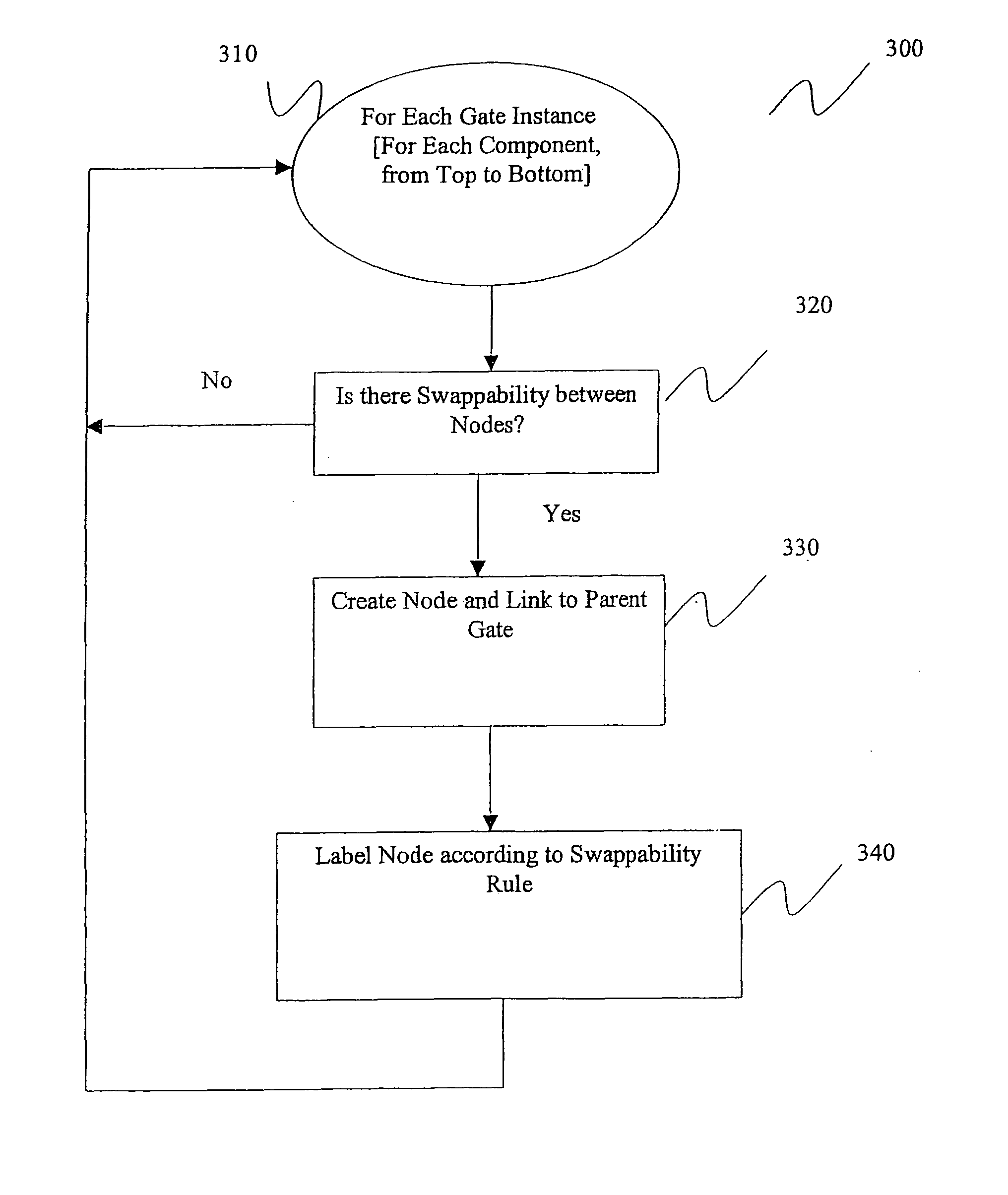

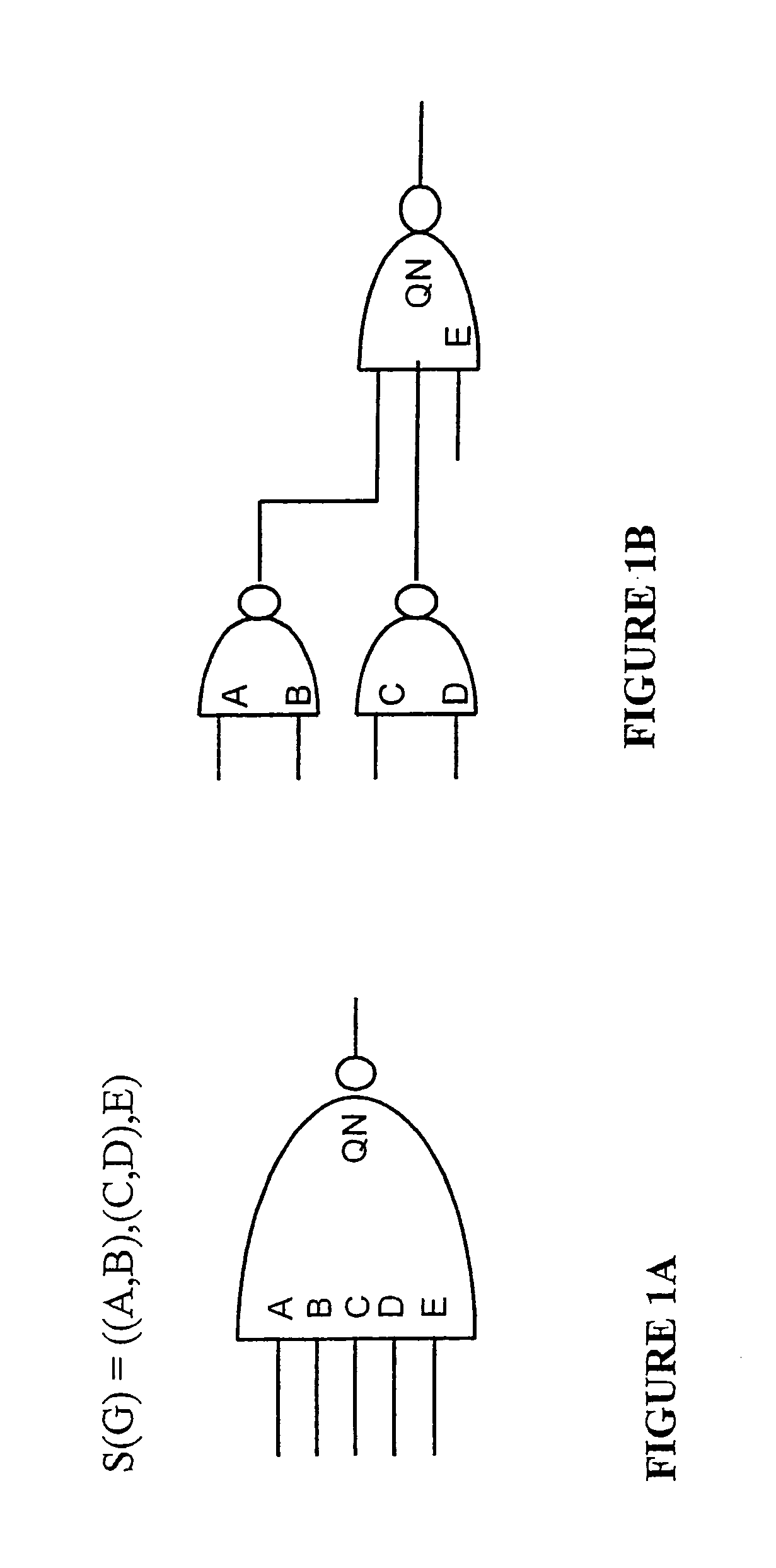

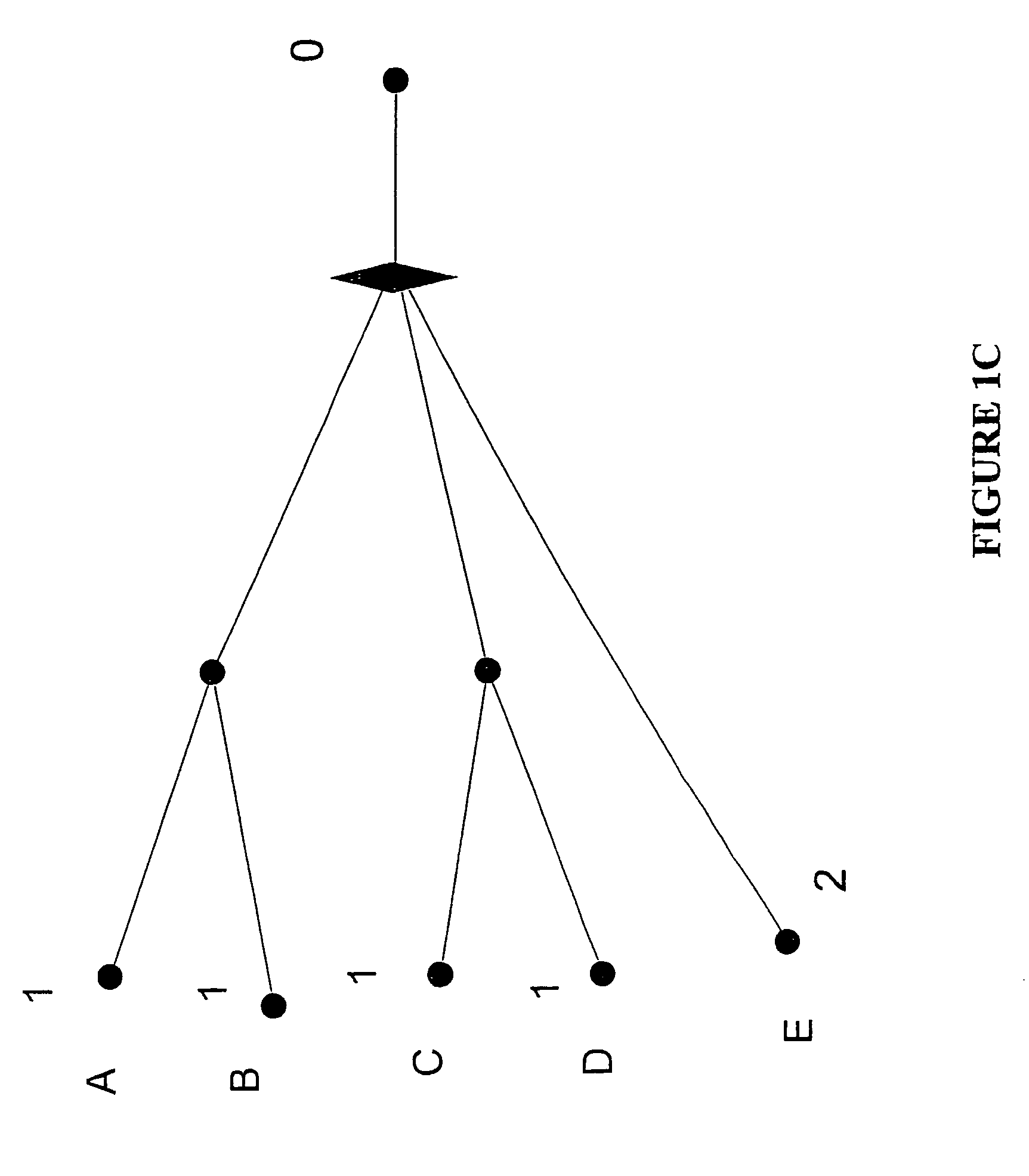

Method of labelling swappable pins for integrated circuit pattern matching

ActiveUS20090119623A1High computational complexityDetecting faulty computer hardwareCAD circuit designPattern matchingTheoretical computer science

The present invention seeks to provide a simple, but novel regime, for re-labelling swappable pins that permits swappability information to be maintained without significantly increasing computational complexity and is conducive to inexact pattern matching for the purposes of developing more complex logical processing blocks from elementary components in design analysis. The method comprises a recursive application of a simple labelling procedure. This method is repeated recursively until all gate instances in the circuit fragment have been assigned a swappability number.

Owner:TECHINSIGHTS

Zinc base alloy and preparation method thereof

The invention discloses a zinc base alloy and a preparation method thereof, and relates to a zinc base alloy taking aluminum as a secondary principal component. The zinc base alloy is a Zn-Al-Cu-Ba-Mg-La-Ce zinc base alloy which comprises the elementary components, by mass percent, 5.5-7.5% of Al, 2.5-4.5% of Cu, 3.5-5.5% of Ba, 0.011-0.016% of Mg, 0.13-0.17% of La, 0.22-0.29% of Ce, and the balance Zn. Ba is added to Zn-Al-Cu-Mg molten metal, then LaBr3 and CeBr3 are added for modification treatment, and then AlCl3 is used for refining treatment, thus the high-intensity wear-proof Zn-Al-Cu-Ba-Mg-La-Ce zinc base alloy is obtained. The defects that the prepared zinc base alloy is thick and big in grain structure, the impurity content is high, the mechanical property is poor, and environmental pollution and potential safety hazards are caused in the preparation process in the prior art are overcome.

Owner:HEBEI UNIV OF TECH +1

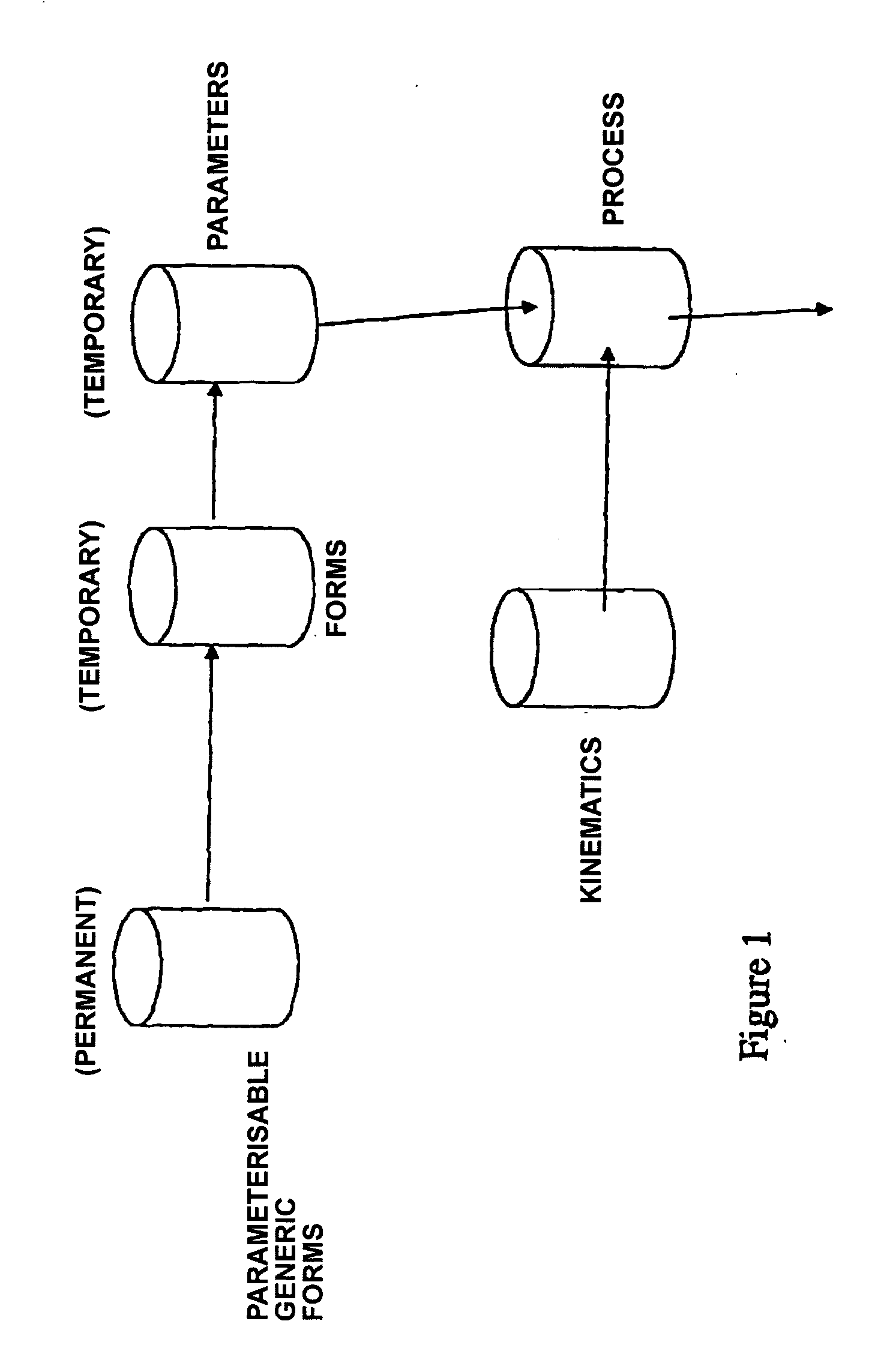

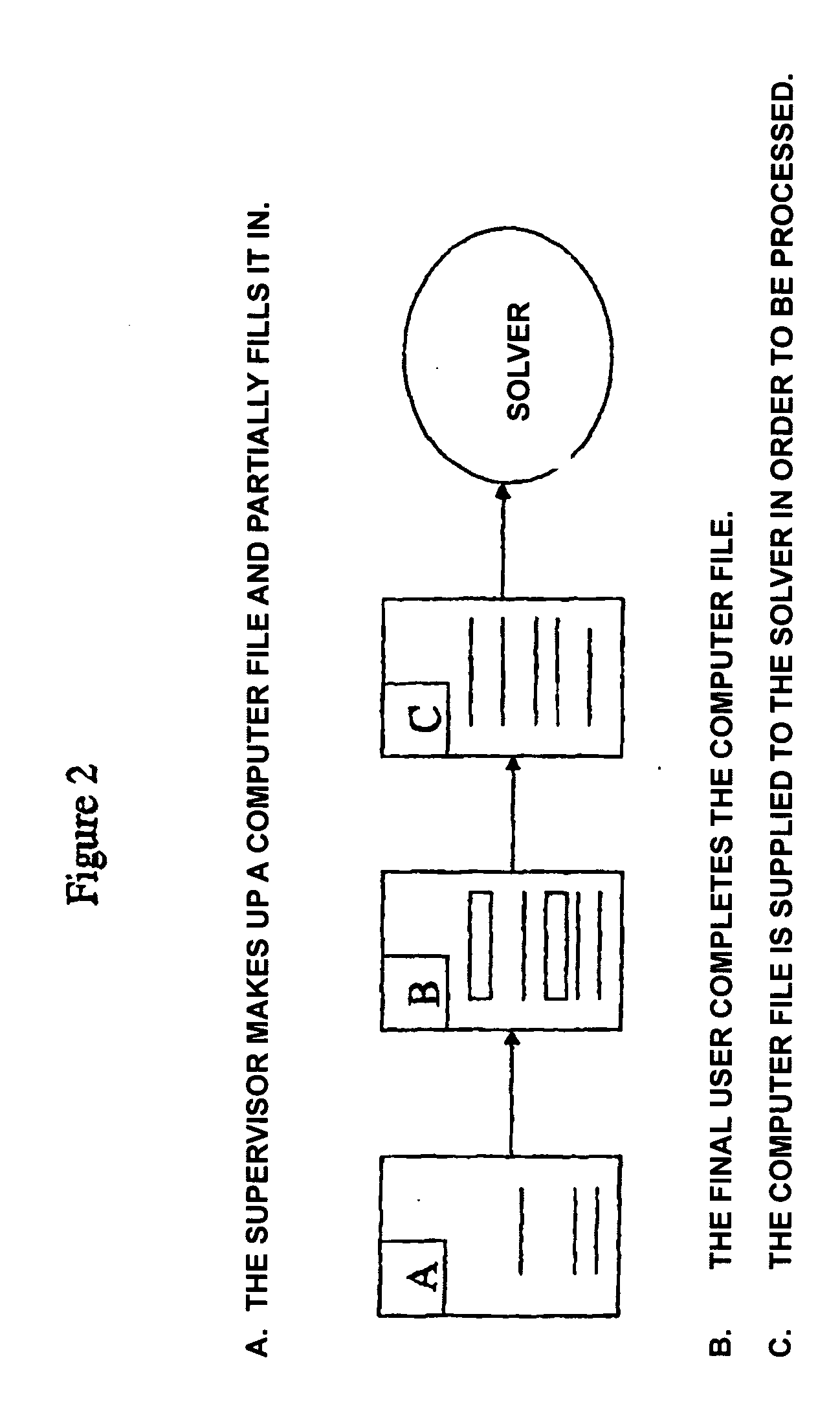

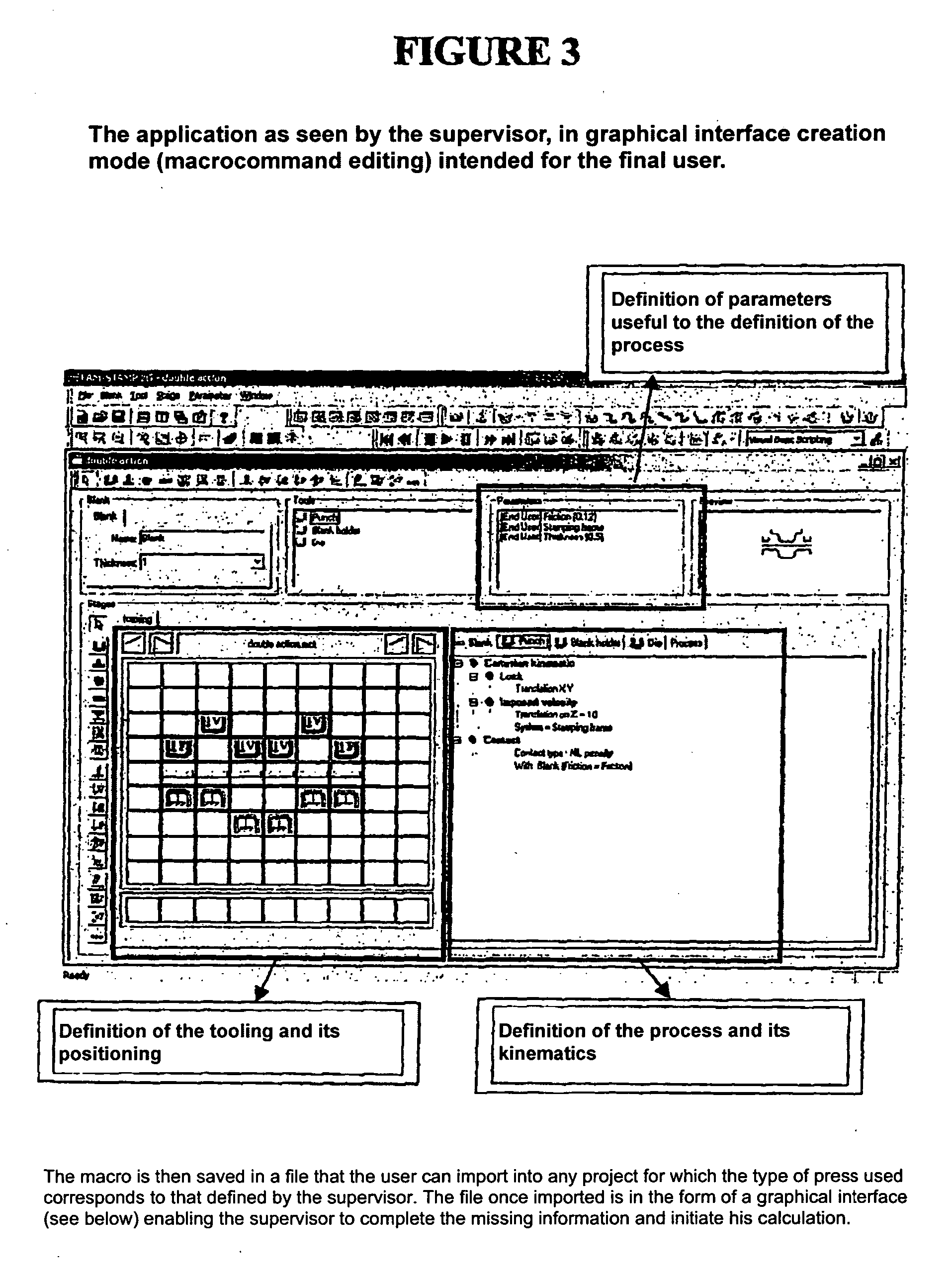

Software for die-stamping modelling

InactiveUS20060149523A1Performance advantageAnalogue computers for chemical processesDesign optimisation/simulationDigital dataSoftware engineering

The invention concerns a method for digital simulation of a die-stamping process comprising the following steps: recording at least one metamodel consisting of a permanent collection of the digital representations of elementary components of die-stamping tools, each of the elementary components being defined in the form of finished elements, and comprising digital static attributes; recording a digital model for deforming a blank used in the process to be simulated; selecting a subassembly of the permanent collection, by temporarily recording the elementary components representing a particular die-stamping tool corresponding to the simulation concerned, the subassembly constituting a specific collection in the form of digitized finished elements of the specific collection, parameterizing said digitized finished elements of the specific collection, and the corresponding attributes based on the characteristics of the process to be simulated; recording the digital data representing the relative movements of the components of the specific collection, based on operating cycles of the die-stamping process to be simulated; recalculating the digital models for deforming the blank based on the recorded digitized data in the parameterized specific collection, of the digital model of the blank, and of the specific displacements; generating a digital or visual representation of deformations of the blank by applying the recalculated digital model.

Owner:ESI GROUP

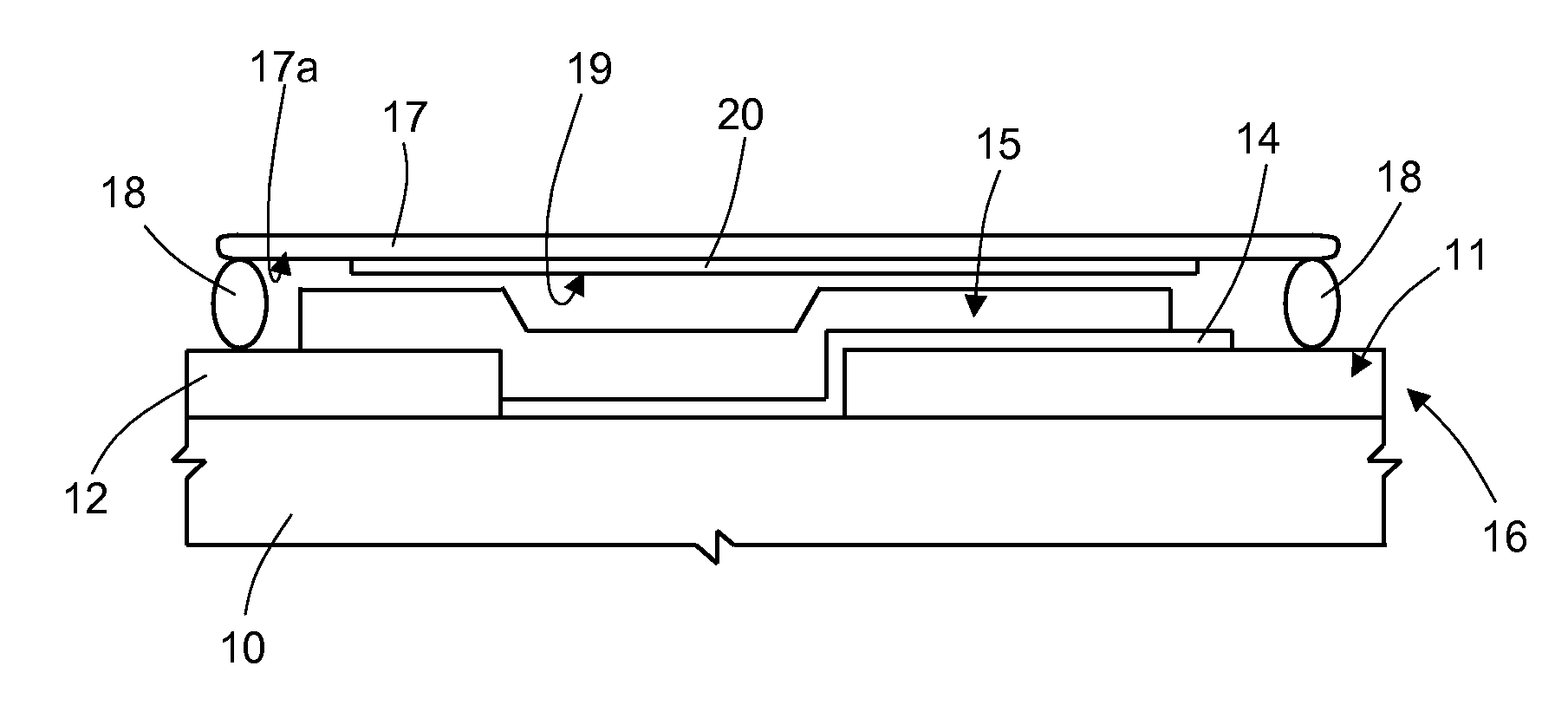

Encapsulated Organic Electronic Device With Improved Resistance To Degradation

InactiveUS20090066244A1High strengthImprove stabilityDischarge tube luminescnet screensLamp detailsElementary componentPhysics

An encapsulated organic electronic device is provided with: a substrate; at least one first elementary component and one second elementary component set above the substrate, each of said first and second elementary components being provided with a respective first electrode set above the substrate, a respective region of organic material set above the first electrode, and a respective second electrode set above the region of organic material at least partially in an area corresponding to the first electrode; and an encapsulation structure, defining an encapsulation space isolated from an external environment and designed to protect the first and second elementary components from the external environment. In particular, the regions of organic material of the first and second elementary components are separated and distinct from one another and are set entirely within the encapsulation space.

Owner:STMICROELECTRONICS SRL

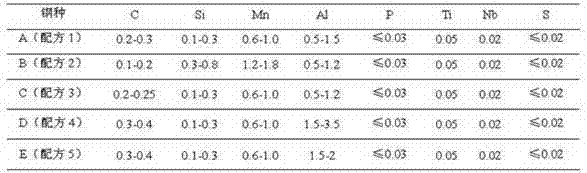

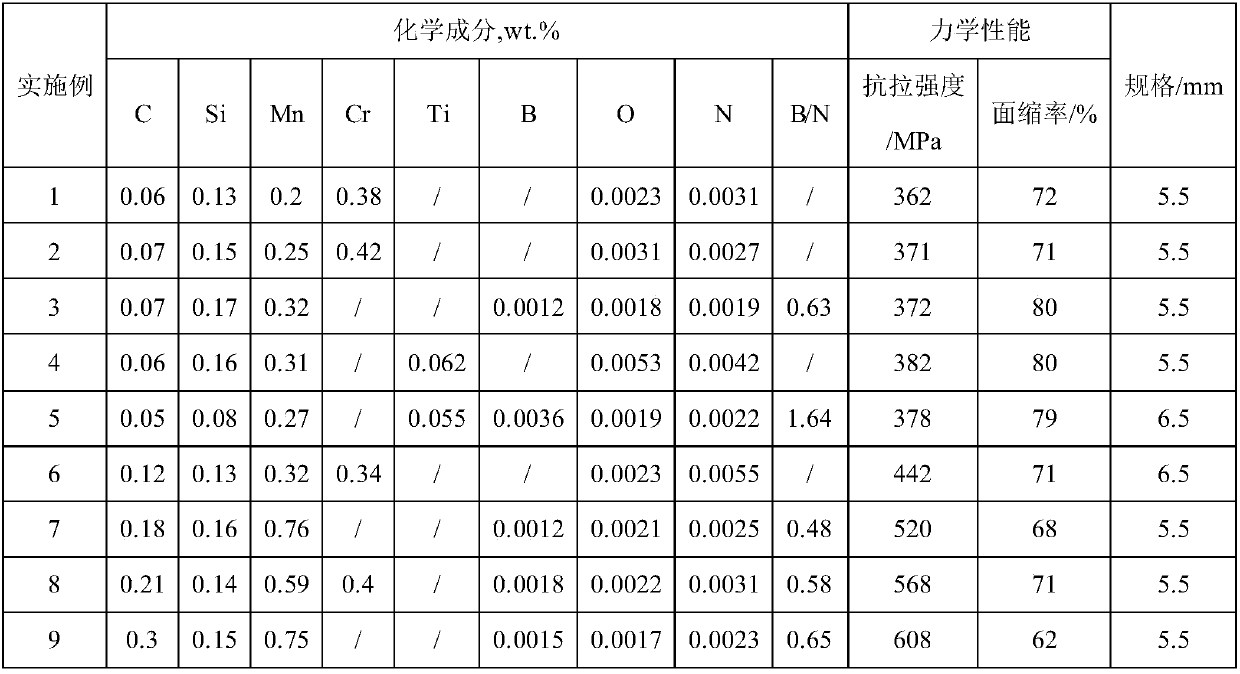

Low-carbon steel wire rod and manufacturing method thereof

The invention discloses a low-carbon steel wire rod and a manufacturing method thereof. Key points of chemical components and rolling processes of the low-carbon steel wire rod are designed, by optimizing the chemical components of the wire rod, calculation is carried out in percentage by weight, elementary components are controlled that 0.06-0.30% of C, less than or equal to 0.18% of Si, 0.15-0.80% of Mn, less than or equal to 0.007% of N, and less than or equal to 0.004% of O, arbitrary one or two of Cr, Ti and B are added at the same time, when the single element Cr is added or the added two elements comprise Cr and when the single element Ti or B is added or Ti and B are added at the same time, manganese content is adjusted and controlled according to carbon content, when B is added, contents of B and N are required to be controlled, when the C content is 0.06-0.12%, B / N is ensured to be 0.4-1.8; when the C content is 0.12-0.30%, B / N is ensured to be 0.4-0.9. When rolling is carried out, the initial rolling temperature is controlled to be 900-930 DEG C, the spinning temperature is 900-920 DEG C, the roller bed speed is controlled to be 0.2-0.6m / s, front 0-6 draught fans are started, the aperture of an optitflex is adjusted to 40%, and heat preservation covers are all started.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

Method of labelling swappable pins for integrated circuit pattern matching

ActiveUS8051395B2High computational complexityDetecting faulty computer hardwareCAD circuit designPattern matchingTheoretical computer science

The present invention seeks to provide a simple, but novel regime, for re-labelling swappable pins that permits swappability information to be maintained without significantly increasing computational complexity and is conducive to inexact pattern matching for the purposes of developing more complex logical processing blocks from elementary components in design analysis. The method comprises a recursive application of a simple labelling procedure. This method is repeated recursively until all gate instances in the circuit fragment have been assigned a swappability number.

Owner:TECHINSIGHTS

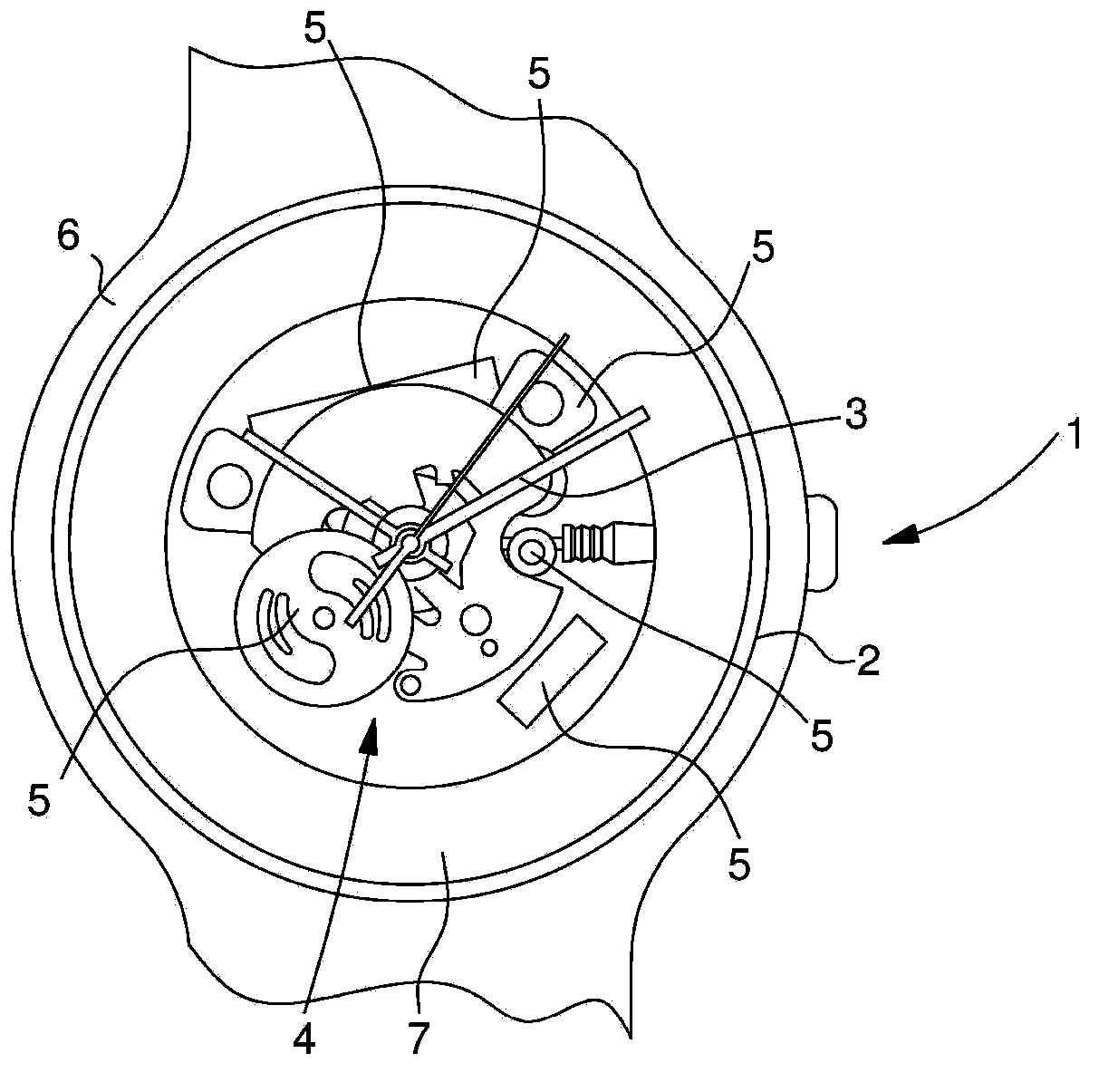

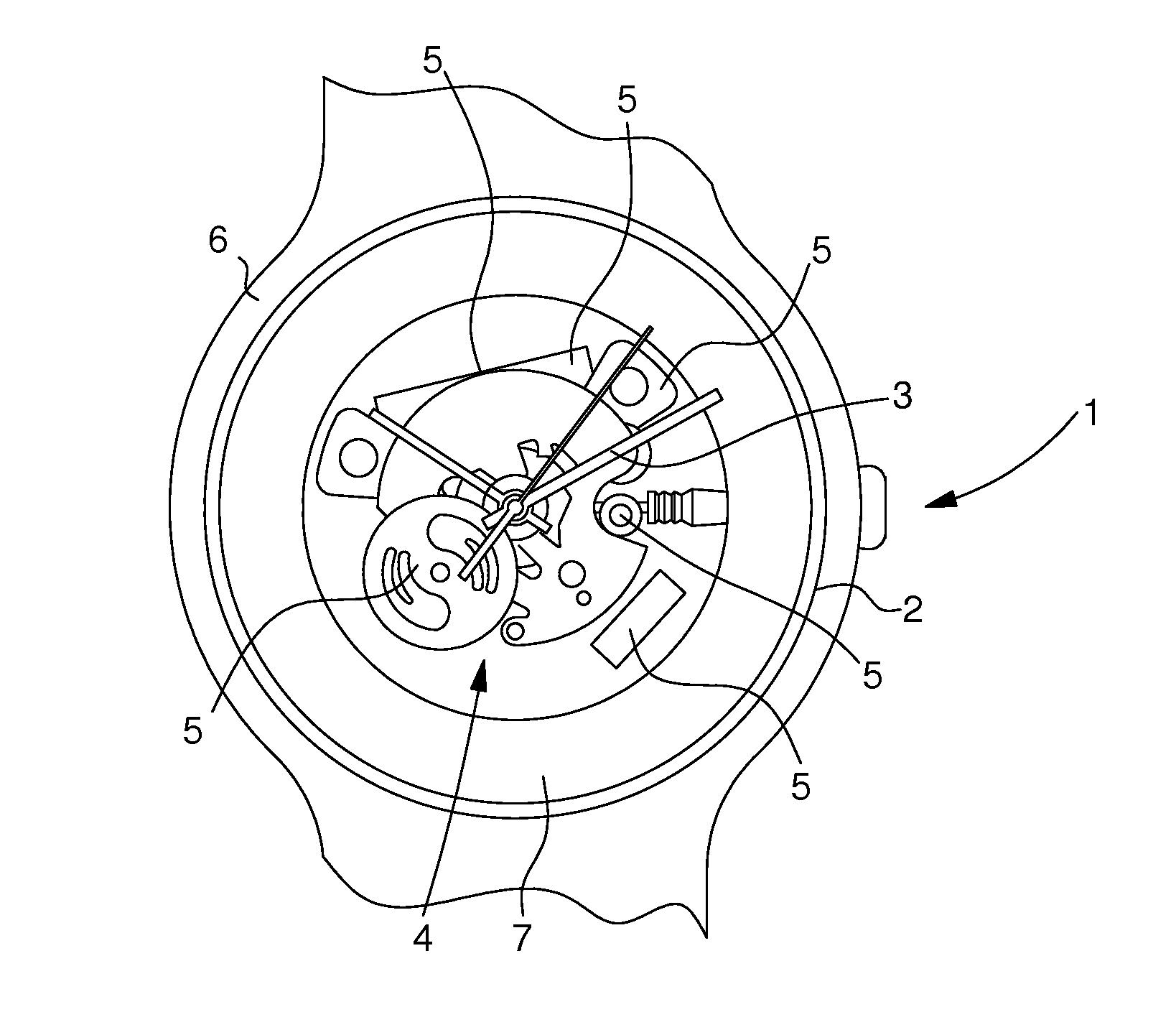

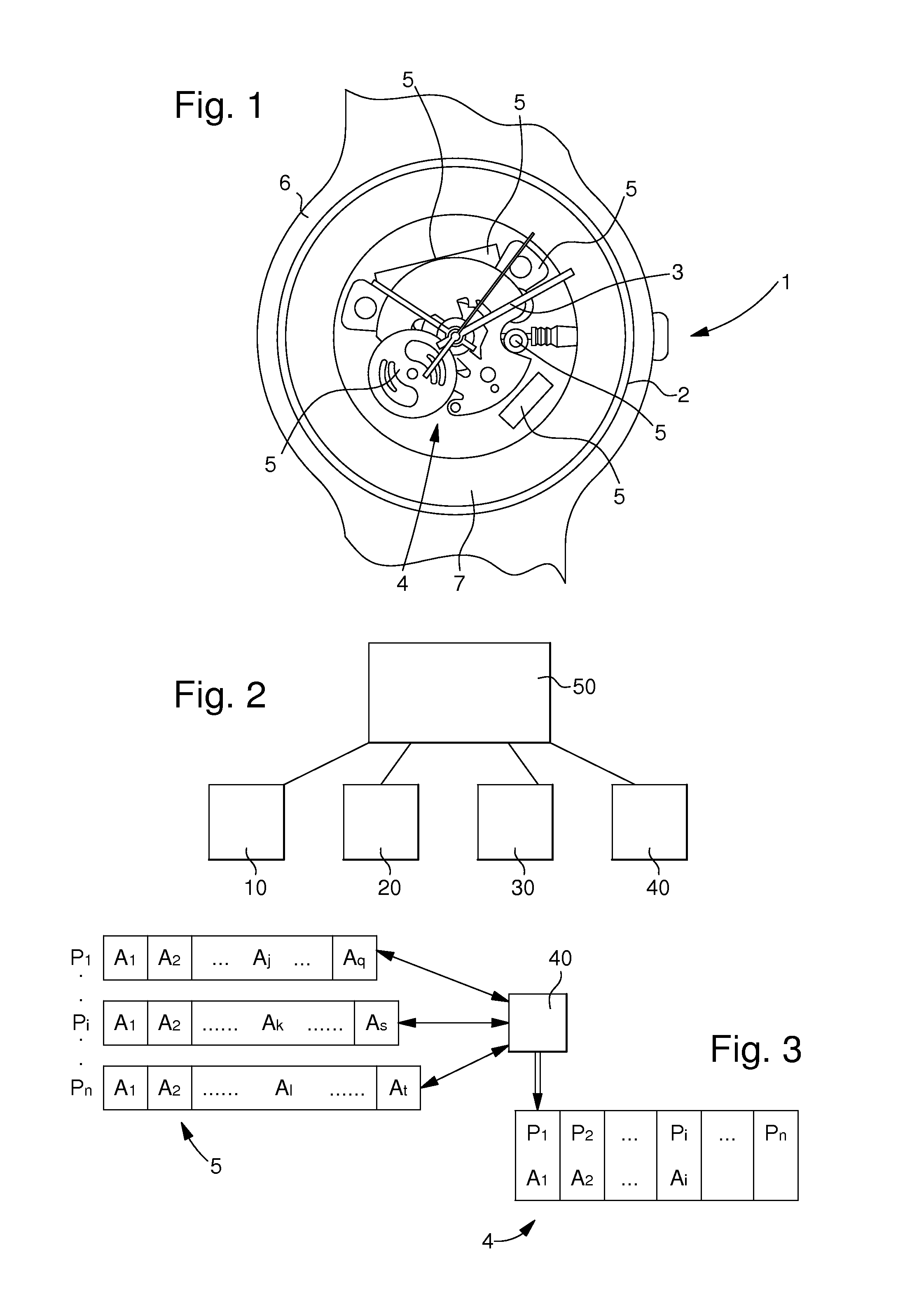

Watch with multicolored components

Owner:ETA SA MFG HORLOGERE SUISSE

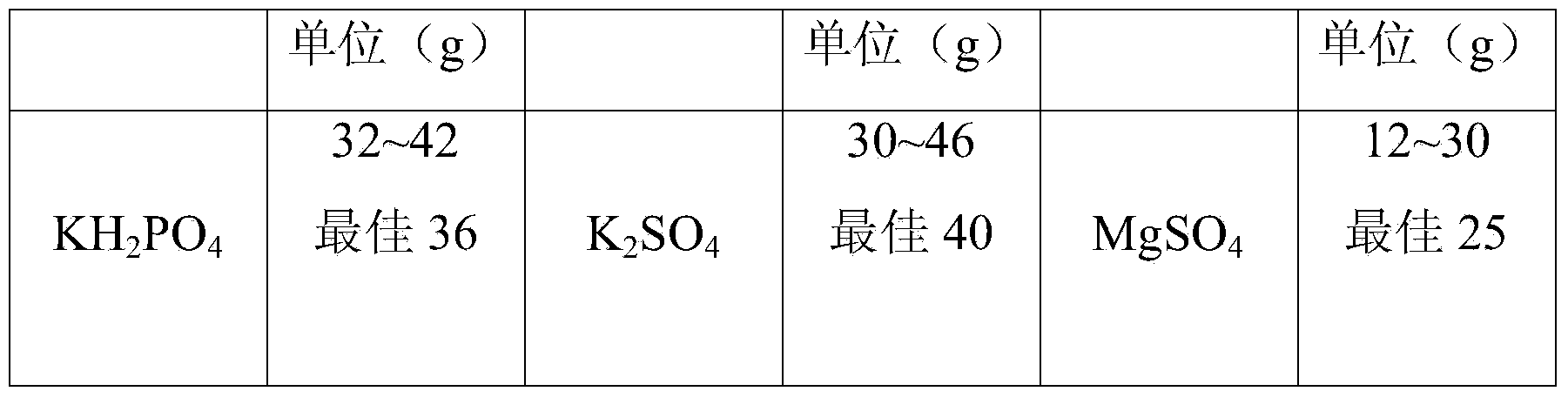

Musaica cultivation nutrient solution and fertilizing method thereof

InactiveCN103664290AStrong disease resistanceNo disease infestationFertilising methodsFertilizer mixturesDiseasePotting soil

The invention belongs to the field of plant cultivation nutrient solutions, in particular to a musaica cultivation nutrition solution and a fertilizing method thereof. The musaica cultivation nutrition solution is composed of a liquid A and a component B. The liquid A uses Huaduoduo TM20-10-20 and mainly comprises the following elementary components: N 20%, P 10%, K 20%, Mg 0.1%, S 0.1%, Fe 0.1%, Mn 0.06%, Mo 0.006% and Zn 0.015%; the component B comprises 32 to 42 g of KH2PO4, 30 to 46 g of K2SO4 and 12 to 30 g of MgSO4; the w / w ratio of the liquid A to the component B is 62: 80-118; and the pH value of the musaica cultivation nutrition solution is 5.0 to 6.0. When the EC value of pot soil is higher than 0.3 ms / cm, the nutrient solution is poured; when the EC value of pot soil is lower than 0.3 ms / cm, clear water is poured; and the pH values of both clear water and the nutrient solution are in a range of 5.0 to 6.0; fertilization and watering are carried out synchronously, irrigation is carried out three times each month, and the nutrient solution or clear water is poured into a leaf cup each time. With the nutrient solution provided by the invention, the survival rate and the abloom rate of musaica are 95% and 93%, respectively, plant drug resistance is strong, and no disease and infection occur.

Owner:DASHUN INT FLOWER

Medium carbon steel material for pump bearing and preparation method of medium carbon steel material

The invention discloses a medium carbon steel material for a pump bearing. The medium carbon steel material contains the following chemical elementary components in percentage by mass: 0.4-0.6% of C, 0.4-0.6% of Si, 1.1-1.3% of Mn, 0.7-0.9% of Cr, 0.03-0.05% of Ni, 0.12-0.15% of Mo, 0.6-0.8% of Co, 0.02-0.04% of V, 0.5-0.7% of W, 0.2-0.4% of Ti, 0.01-0.02% of Yb, 0.03-0.04% of Lu, less than or equal to 0.04% of S, less than or equal to 0.04% of P and the balance of Fe. The alloy steel prepared by adding various elements such as rear earth elements, tungsten, molybdenum and the like is high in hardness, good in wear resistance, favorable in toughness of medium carbon, strong in impact resistance, suitable for key parts such as the pump bearing and the like, long in service life and not easy to damage; a refining agent is used for casting production, so that the porosity in a casting is reduced by 1-2, and oxide inclusions are kept at about level 2.

Owner:江苏星爵实业有限公司

Neutron protective body plug and material thereof

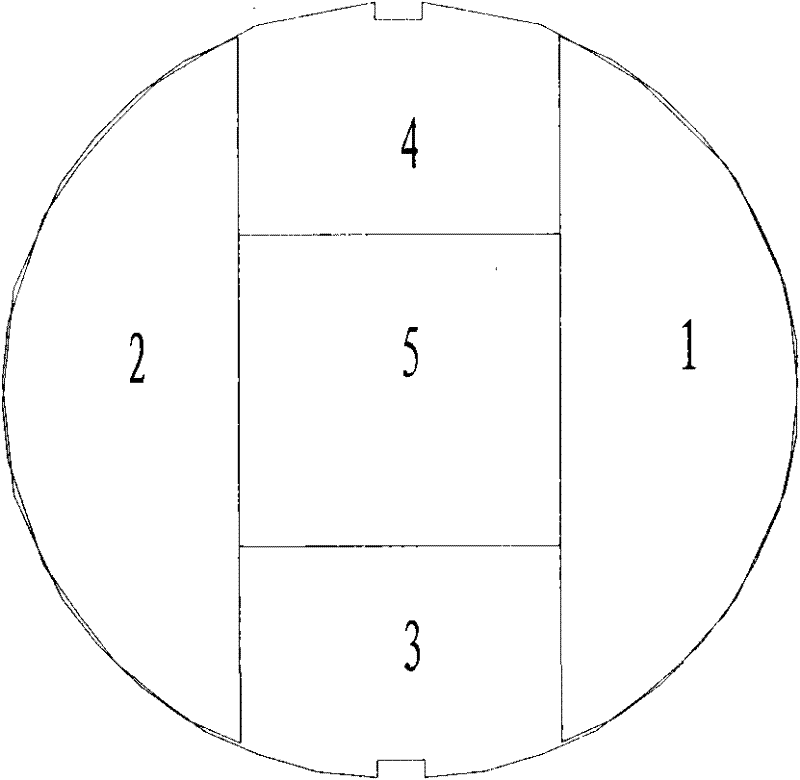

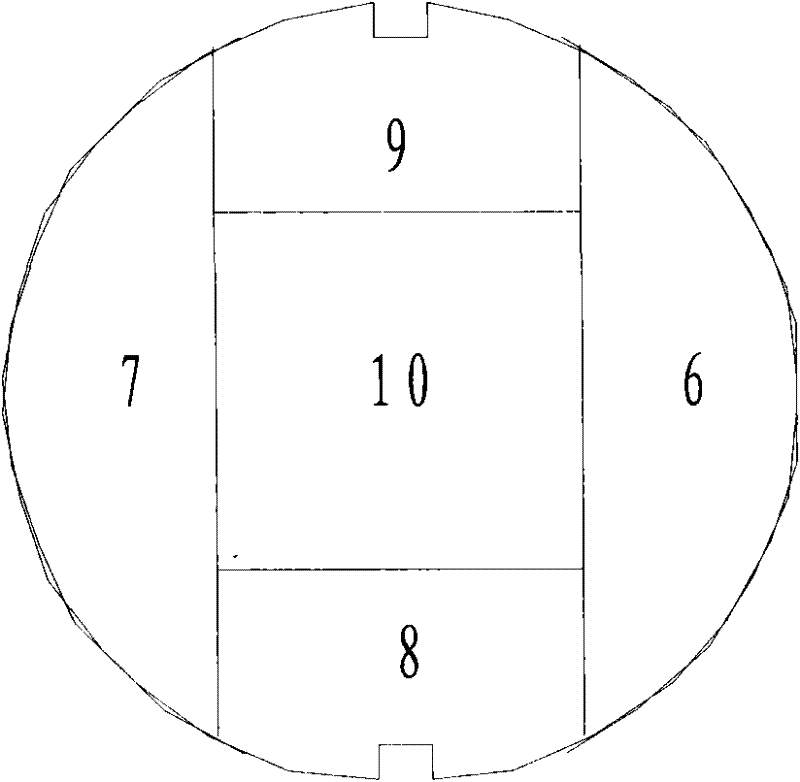

ActiveCN102176328AImprove flame retardant performanceMaintain stabilityNuclear energy generationShieldingColemanitePolyvinyl alcohol

The invention discloses a neutron protective body plug and a material thereof, and the plug is composed of front and rear blocks (3,4,8,9), left and right blocks (1,2,6,7) and middle blocks (5,10), wherein the front and the rear blocks (3,4,8,9), the left and the right blocks (1,2,6,7) and the middle blocks (5,10) are arranged on an upper layer and a lower layer and are symmetrical in shape respectively, the external circles of the front and the rear blocks and the left and the right blocks of the upper layer and the lower layer are all arc curved surfaces, and the middle blocks are of a quadrangular-prism shape; and a cylindrical structure is formed after the blocks are combined, and grooves with same widths but different depths are respectively processed on the arc curved surfaces of the front and the rear blocks of the upper layer and the lower layer so as to ensure that the grooves are rightly engaged after the upper layer and the lower layer are combined. The material of the neutron protective body plug comprises the following components: 30-40% of polyethylene, 10-20% of chlorinated polyethylene, 6-14% of polyvinyl alcohol, 25-35% of aluminium hydroxide and 5-10% of colemanite; and the neutron protective body plug comprises the elementary components with the contents as follows: not less than 9.0% of aluminium, not less than 0.85% of boron, not less than 1.10% of calcium, not less than 40% of carbon, not less than 3.5% of chlorine, not less than 7.5% of hydrogen, not less than 25% of oxygen and not less than 1.0% of impurity. The neutron protective body plug can effectively absorb and shield radiation generated by a neutron-ray, and has stability and fine mechanical strength under thermal neutron radiation.

Owner:HENAN SHUANGFU TECH CO LTD

Multi-element rare earth magnesium alloy powder of cored wire

The invention relates to alloy powder of a cored wire and discloses multi-element rare earth magnesium alloy powder of a cored wire. The alloy powder comprises the following elementary components in percentage by mass: 10-20% of Mg, 0.5-2.5% of Ca, 1.0-2.5% of Al, 25-35% of Si, 1-2.5% of Ti, 0.5-3.5% of Ba, 2.5-5.0% of Mn, 0.5-1.0% of Nb, 0.5-1.0% of V, 1.0-5.0% of rare earth elements, less than or equal to 0.1% of P, less than or equal to 0.1% of S and the balance Fe. The alloy powder is added into microalloyed steel by using a cored wire method, so that the magnesium treatment process is smooth, the relatively high absorption rate can be obtained, and the problems existed at present are better solved.

Owner:浙江宝信炉料股份有限公司

Watch with multi-coloured components

Method for forming an assembly of elementary timepiece components, each available in different coloured variants, wherein at least some of said different elementary components are the same colour as each other, characterized in that a random selection of each said elementary component is made until said complete assembly is obtained, so that at least two elementary components are of different colours.

Owner:ETA SA MFG HORLOGERE SUISSE

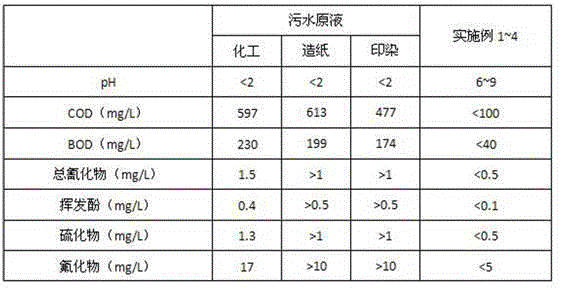

Sewage treatment agent and application thereof

ActiveCN105129938ASignificant flocculation purification effectSimple ingredientsWater/sewage treatment by flocculation/precipitationChemical industryTreated water

The invention relates to the sewage treatment field, and specifically relates to a sewage treatment agent and an application thereof. The sewage treatment agent is prepared through the following steps: adding 10-20 parts by weight of aluminum into 20-30 parts by weight of fuming hydrochloric acid, stirring for 2-10 hours, then adding 100-1000 parts by weight of carbonate, and stirring for 12-36 hours; adding 100-200 parts by weight of polymeric chloride into 300-600 parts by weight of water, and fully stirring until being completely dissolved; mixing the substances obtained in the step 1 and the step 2, carrying out a stirring reaction for at least one hour, and thus obtaining the sewage treatment agent. The sewage treatment agent has concise composition, has simple preparation method, and cannot cause secondary pollution on water bodies due to introduction of a variety of elementary components; treated water bodies are transparent and pure, and conform to national A-level discharge requirements. The sewage treatment agent is particularly suitable for sewage treatment of leather, coking, medicines, electroplating, printing and dyeing, chemical industry, papermaking industries and domestic wastewater with complex pollutants and high degree of pollution.

Owner:孙锡增

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com