Patents

Literature

445 results about "Liquid alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid Metal Alloys Liquidmetal alloys are a revolutionary class of metal materials that redefine performance, process, and design paradigms.

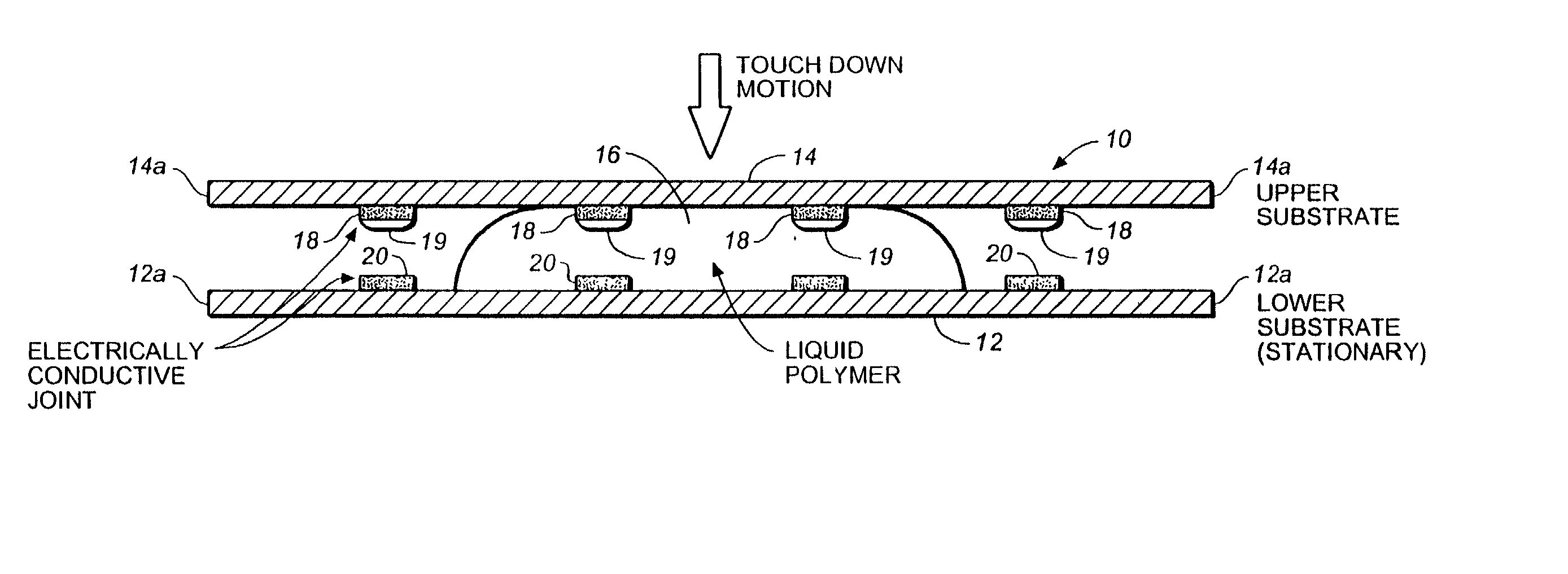

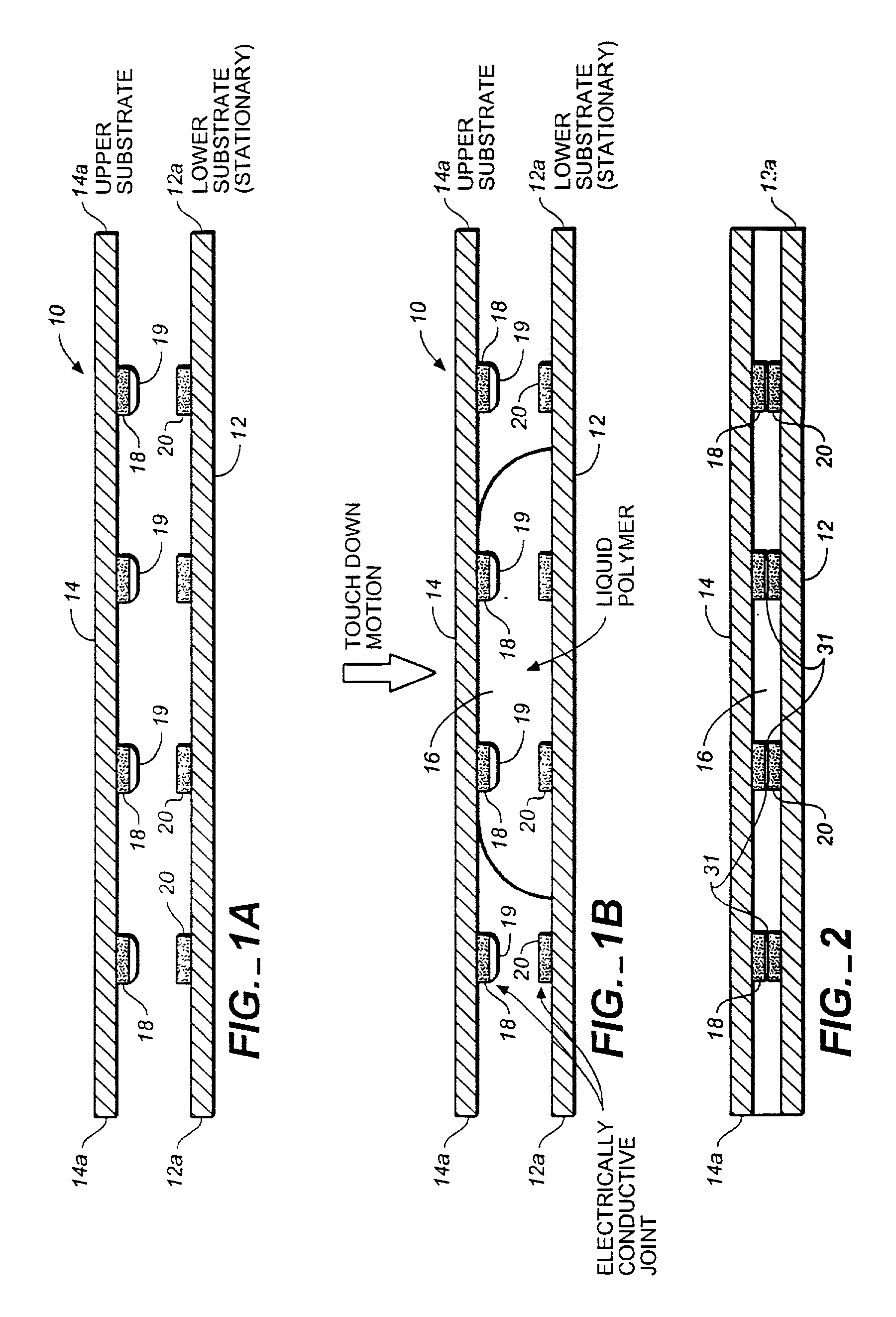

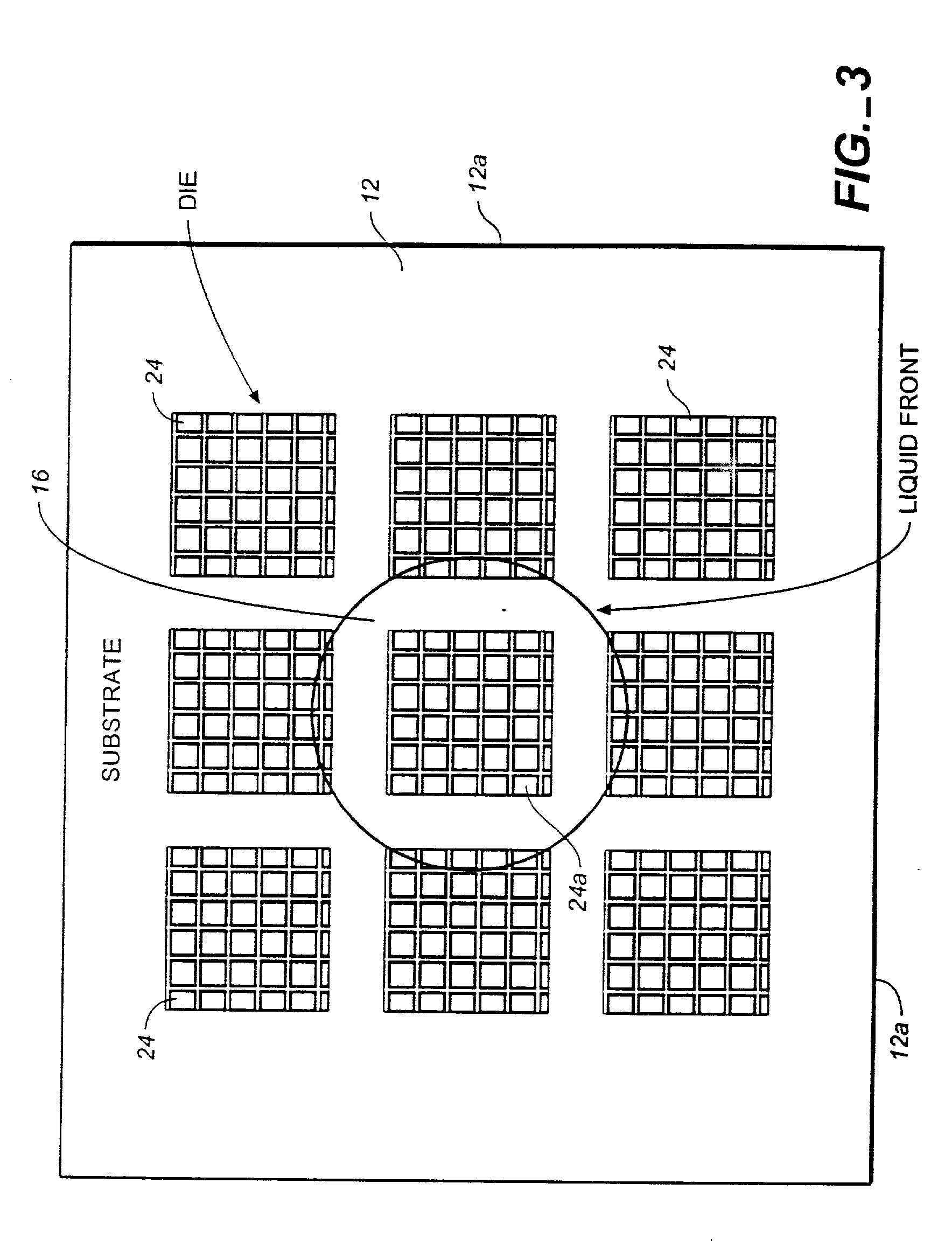

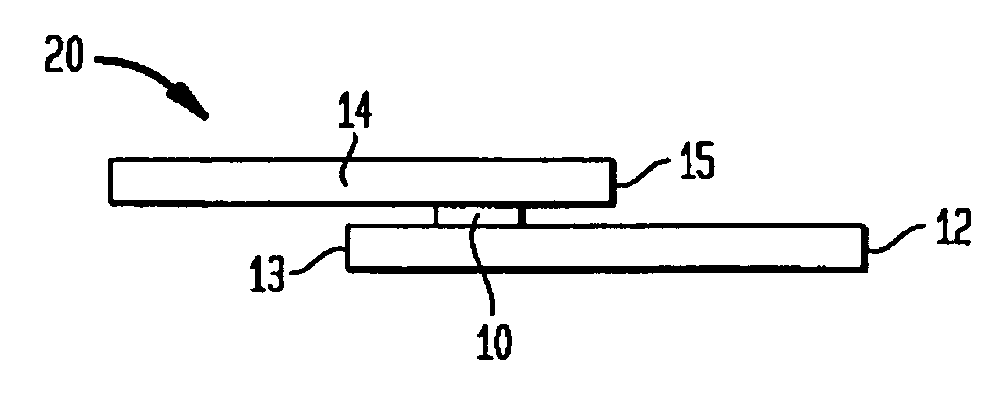

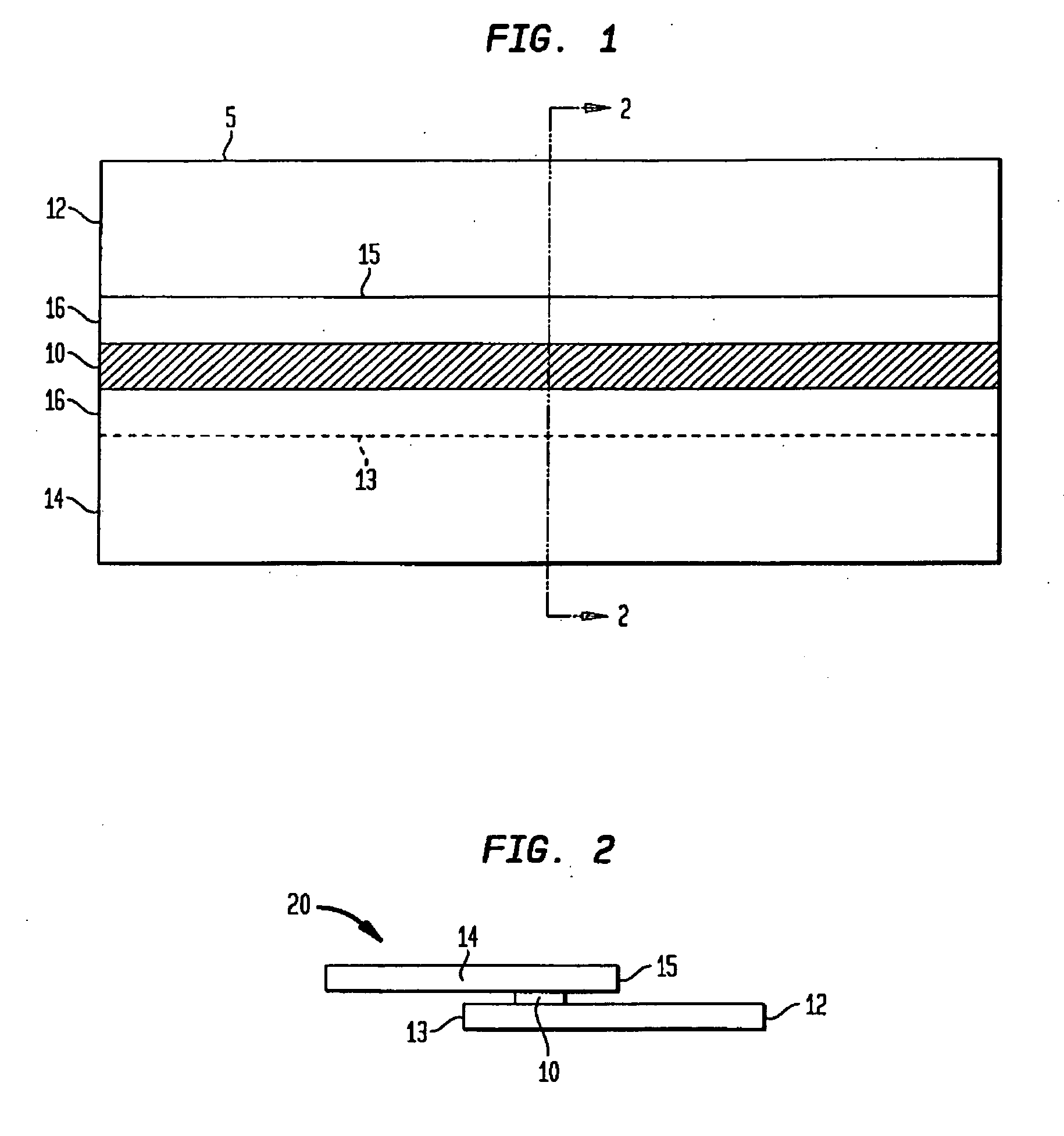

Method for joining and an ultra-high density interconnect

Embodiments of the invention are directed to a method comprising depositing a dielectric layer on a circuitized layer having a conductive region. The dielectric layer is preferably a bonding sheet. An aperture is formed in the dielectric layer over the conductive region. A conductive body, disposed on another circuitized substrate, is inserted into the aperture. The conductive body comprises a main region (e.g., a conductive post) and a depletion region (e.g., a thin layer of metal or transient liquid alloy bonding material). The depletion region contacts the conductive region on the circuitized layer, and the circuitized layers are laminated together. Heat and pressure can be applied to the combination in order to form an intermetallic region from the depletion region.

Owner:FUJITSU LTD

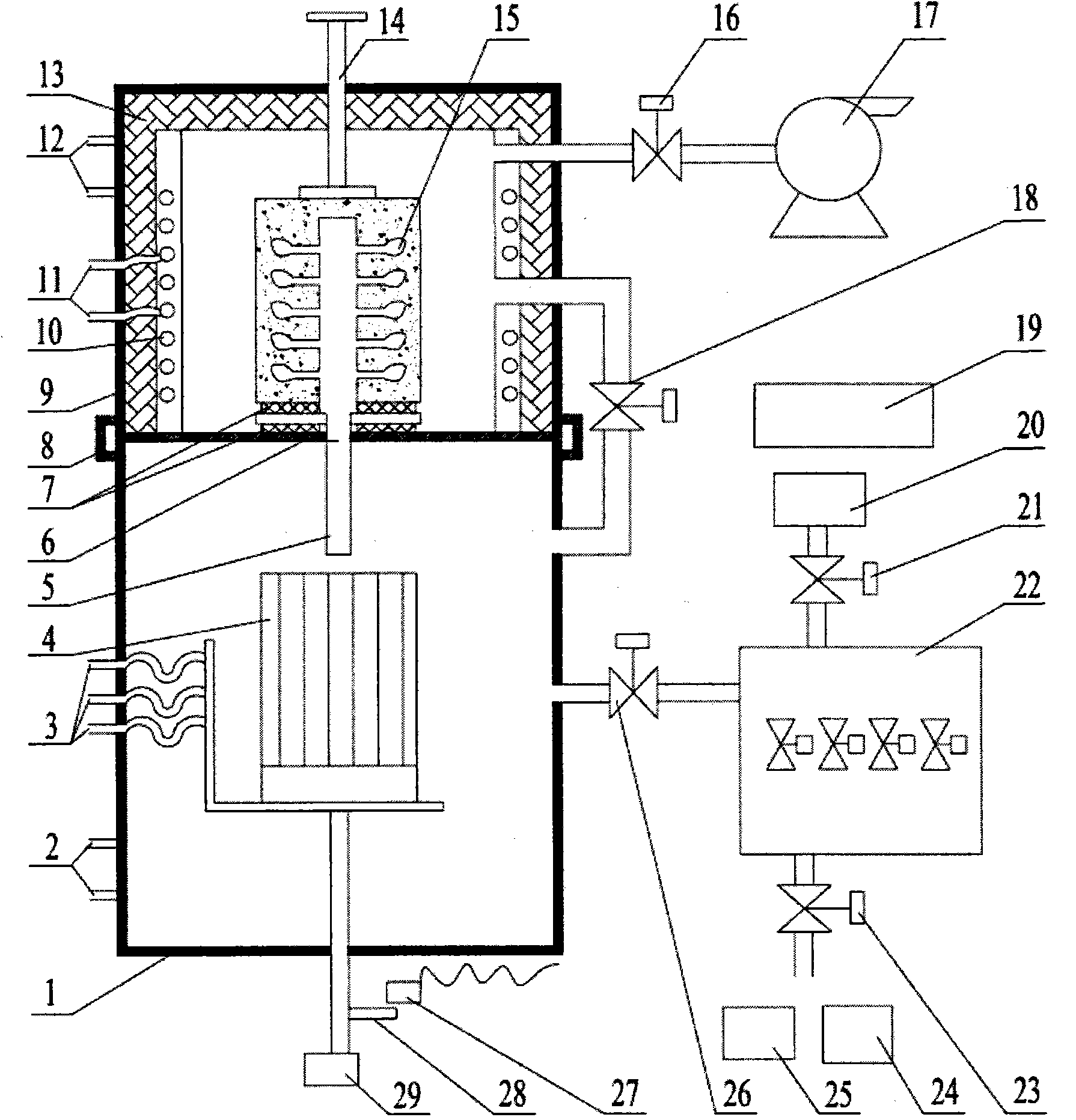

Antigravitational vacuum method and apparatus for asting Mg allor or Al alloy with lost mould

InactiveCN1382542ASuitable for mass productionImprove automationFoundry mouldsFoundry coresCrucibleShielding gas

An antigravitational casting technology includes putting a lost mould in a bottom running type sand box, adding sand, vibration compacting, loading molten MgAl alloy in filler while introducing protecting gas, introducing the pressure controllable inertial gas to the filler, and pouring the molten alloy into said sand box to gasify said list mould. Its apparatus is composed of filler, sand box, pouring pipe, crucible in the filler, and heating coil surrounding said pouring pipe. It is suitable for precision casting.

Owner:HUAZHONG UNIV OF SCI & TECH

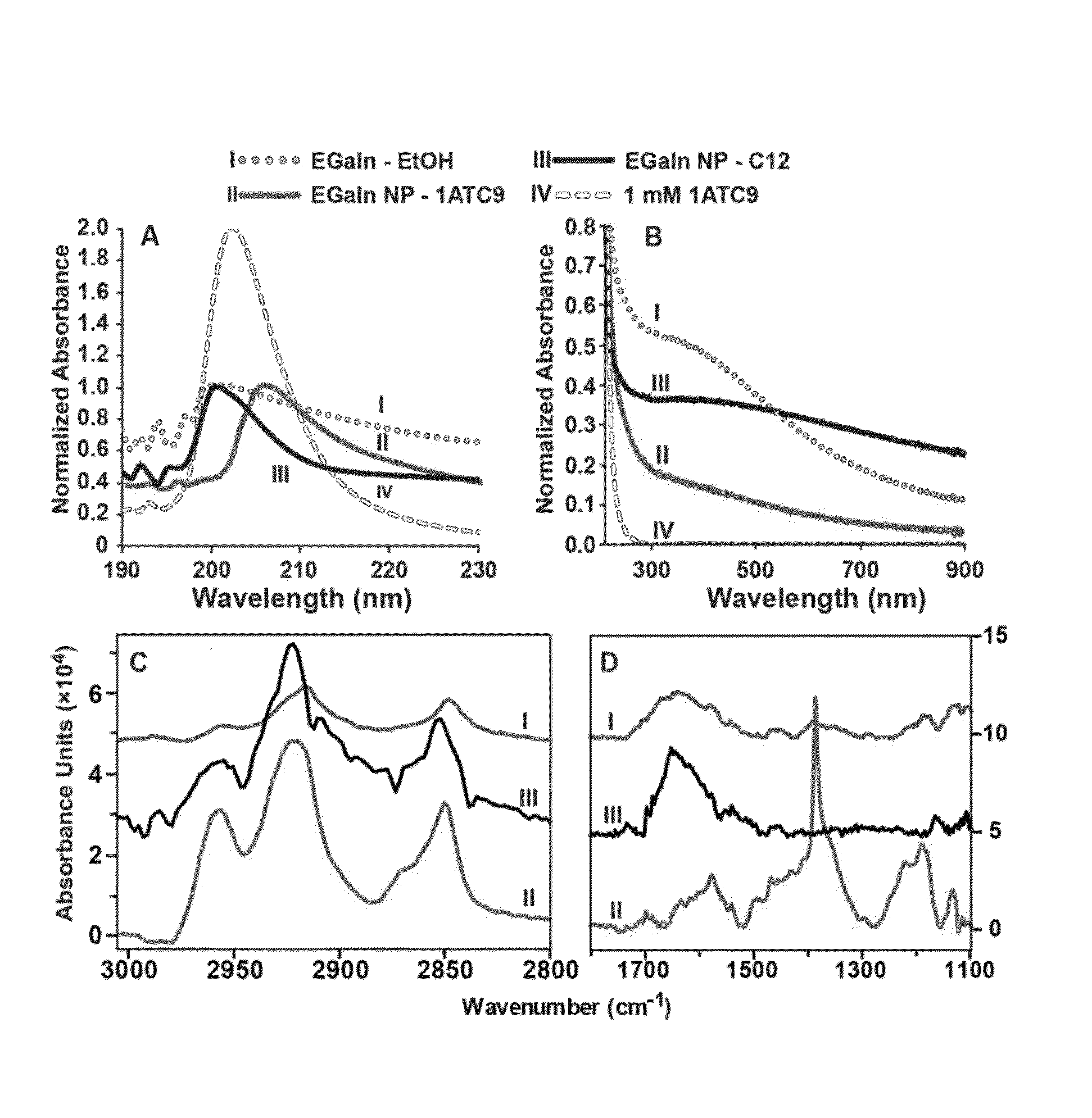

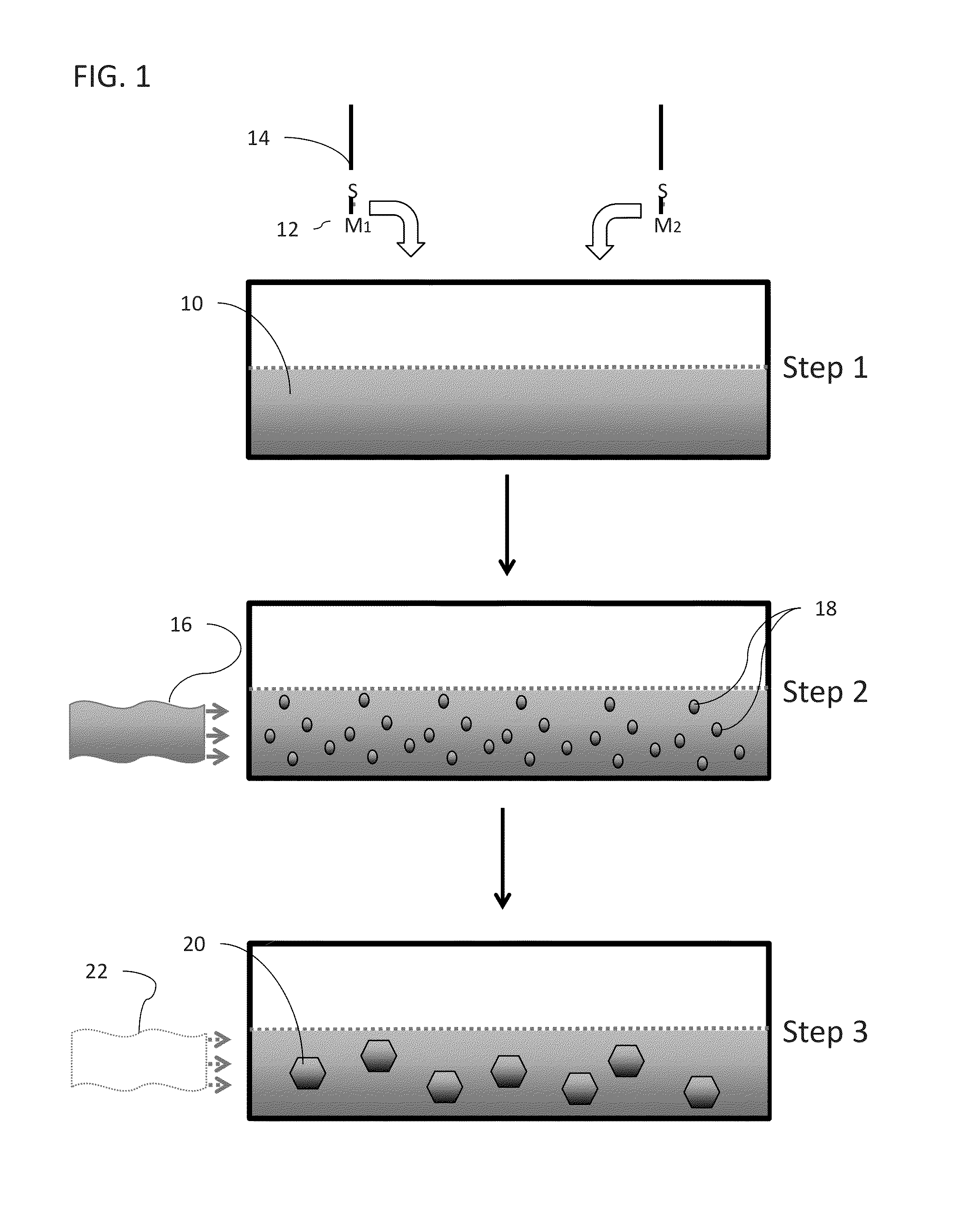

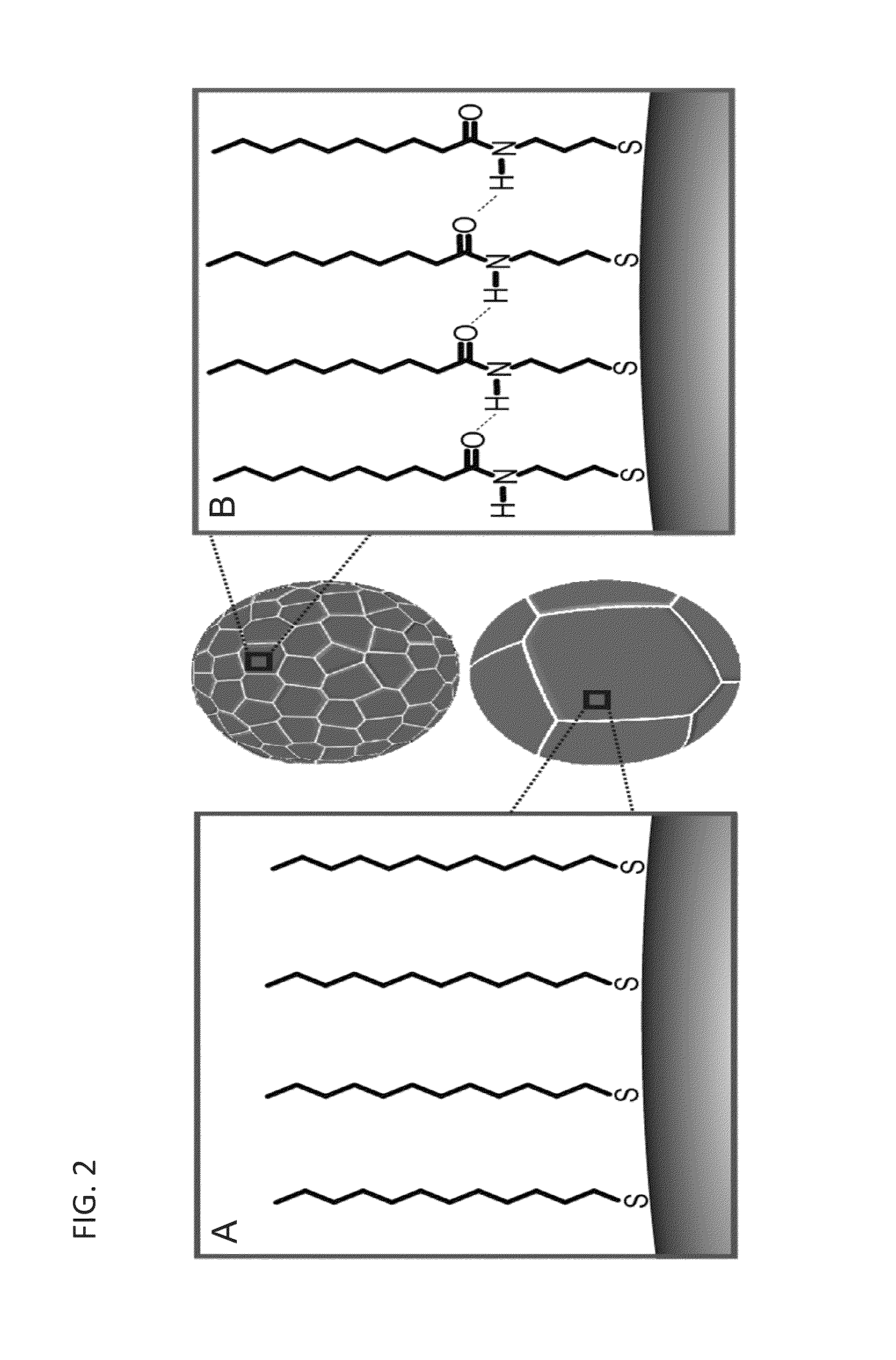

Metal alloy nanoparticle synthesis via self-assembled monolayer formation and ultrasound

ActiveUS20130244037A1Small sizeMaterial nanotechnologySynthetic resin layered productsIndiumSelf-assembled monolayer

Methods and assemblies for the construction of liquid-phase alloy nanoparticles are presented. Particle formation is directed by molecular self-assembly and assisted by sonication. In some embodiments, eutectic gallium-indium (EGaIn) nanoparticles are formed. In these embodiments, the bulk liquid alloy is ultrasonically dispersed, fast thiolate self-assembly at the EGaIn interface protects the material against oxidation. The assembly shell has been designed to include intermolecular hydrogen bonds, which induce surface strain, assisting in cleavage of the alloy particles to the nanoscale. X-ray diffraction and TEM analyses reveal that the nanoscale particles are in an amorphous or liquid phase, with no observed faceting.

Owner:RGT UNIV OF CALIFORNIA

High-strength, High-conductivity copper-base alloy material and preparing method thereof

The present invention relates to a high-strength high-conductivity copper base alloy material and its preparation method. Its composition comprises (wt%) 0.01-2.5% of Cr, 0.01-2.0 % of Zr, 0.01-2.0% of one or Y, La and Sm and the rest is Cu, and its preparation method includes the following steps: vacuum smelting the above-mentioned components to obtain the liquid alloy of the above-mentioned components, atomizing and quickly solidifying, making powder, pressing to make blank, sintering and extruding. Said alloy material has good electric conductivity, good heat conductivity, high high-temp. strength, high softening temp. and high conductivity.

Owner:KUNMING INST OF PRECIOUS METALS

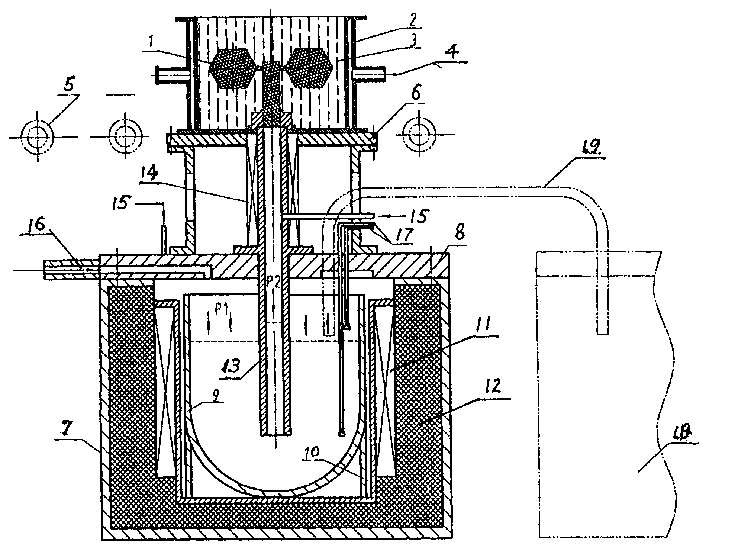

Vacuum low-pressure casting forming device for titanium alloy component

InactiveCN104028729AImprove feeding capacitySuppresses the tendency to segregate chemical componentsActuatorPressure difference

The invention provides a vacuum low-pressure casting forming device for a titanium alloy component. The vacuum low-pressure casting forming device for the titanium alloy component comprises a device body, a vacuum low-pressure casting pneumatic control system and an electronic control system. An upper chamber and lower chamber type structure is adopted by the device body, a water-cooled copper crucible is arranged in a lower chamber, a casting mold is arranged in an upper chamber, an intermediate separation plate is arranged between the upper chamber and the lower chamber, and a liquid lifting pipe is arranged on the intermediate separation plate. The vacuum low-pressure casting pneumatic control system is connected with the device body, a vacuum system and a protective gas source system, and digital combination valves are adopted as flow regulation actuators. The electronic control system is composed of an industrial control computer and a PLC. After the smelting process of titanium alloy is completed in a smelting chamber, the water-cooled copper crucible is lifted to a casting position through a lifting device, an upper chamber and lower chamber intercommunication valve is closed, the flow of protective gas fed into the lower chamber is controlled through the computer, the pressure difference between the upper chamber and the lower chamber is established, the liquid alloy is filled in the casting mold through the liquid lifting pipe under the action of the pressure difference, and the casting process is completed. Compared with traditional centrifugal casting and bottom leakage type suction casting, the mold-filling capacity and solidification feeding capacity of the titanium alloy can be improved, castings with better casting quality and thinner wall thicknesses can be obtained, and a new means is provided for batch production of minitype titanium alloy components.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

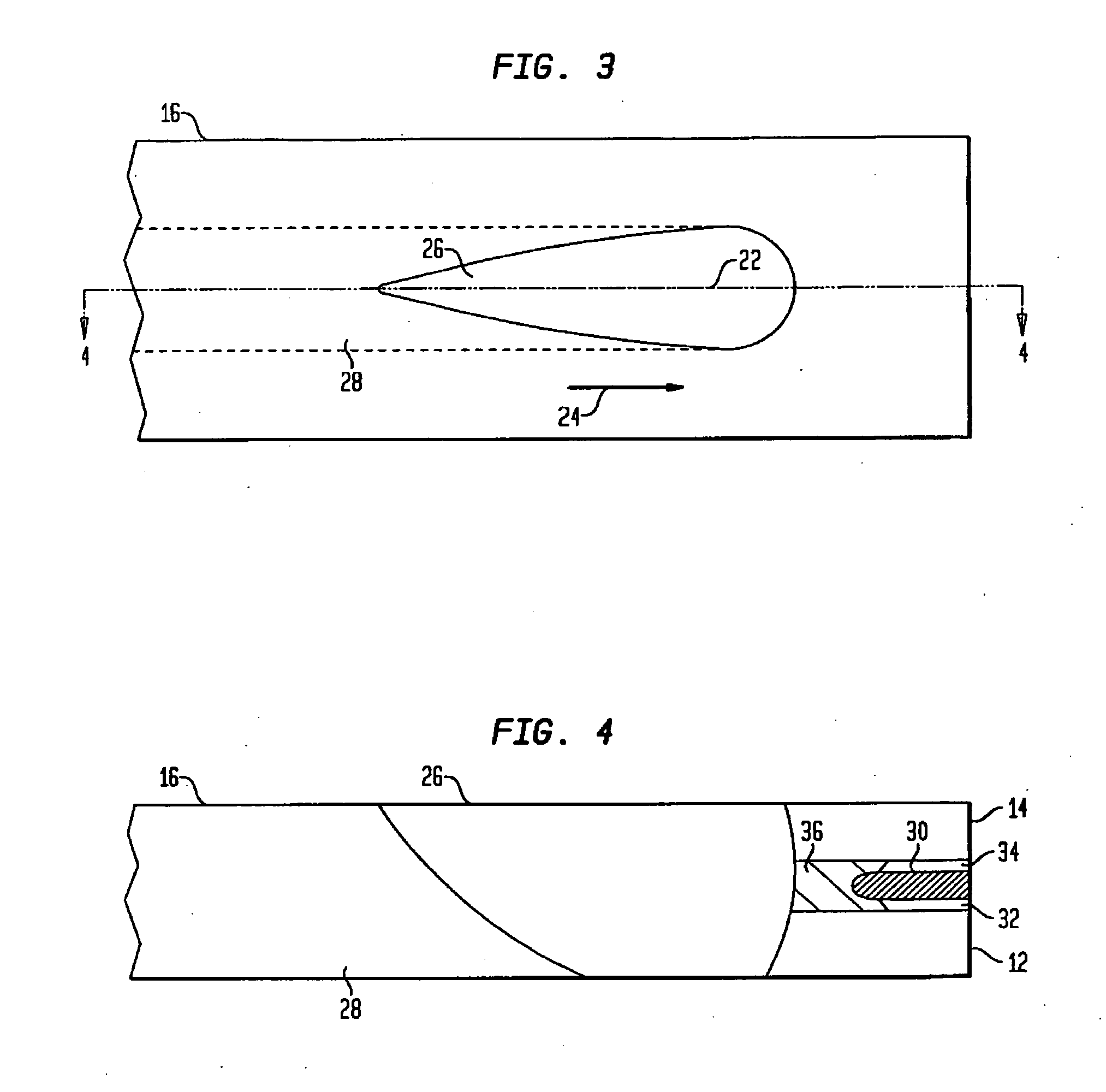

Lap welding of steel articles having a corrosion resisting metallic coating

Techniques are described for lap welding steel articles with a corrosion resistant coating. First and second steel members with a coating comprising zinc are welded together in a lap region. A metal selected to have a melting temperature below the boiling temperature of zinc, and to form a liquid alloy with the zinc, which alloy has a boiling temperature above the melting temperature of steel, is added to the lap region.

Owner:ZHOU Y NORMAN

Preparation method of low pressure guide connected hollow blade

The invention relates to the precision casting field, in particular to a preparation method of a low pressure guide connected hollow blade. The preparation method comprises the following steps: firstly quartz glass powder, mullite powder, a plasticizer and an additive are mixed to stir evenly, the mixture is filled in a core pressing device and prepared into a mother core; secondly quartz glass powder is filled in a charging bucket, the mother core is inserted in the powder, the quartz glass powder is filled in the entire charging bucket to sinter and prepare a core; the prepared core is placed in the corresponding place of a blade mould to fill wax, the mould is preheated to perform pressing, finally the obtained wax mould is dressed; then a pouring system shell is prepared; and the pouring system shell is preheated before pouring, a K417G alloy is used as the raw material, then the alloy raw material is refined at 1570+ / -10 DEG C for no less than 3 minutes, finally the liquid alloy steel is poured in the preheated pouring system shell, the pouring time is 3-5 seconds, and the finished product low pressure guide connected blade casting is formed.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

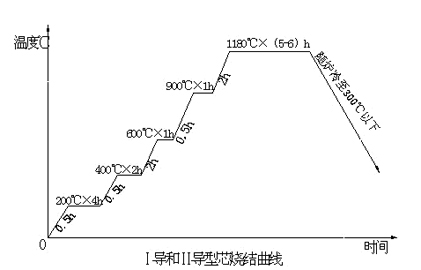

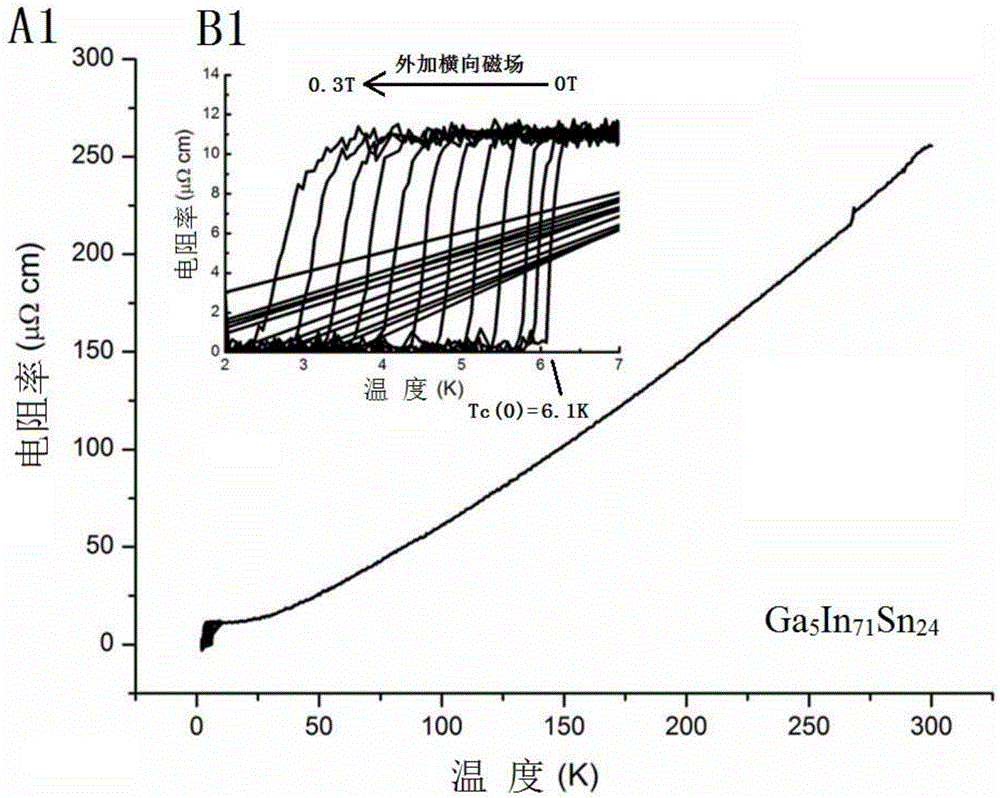

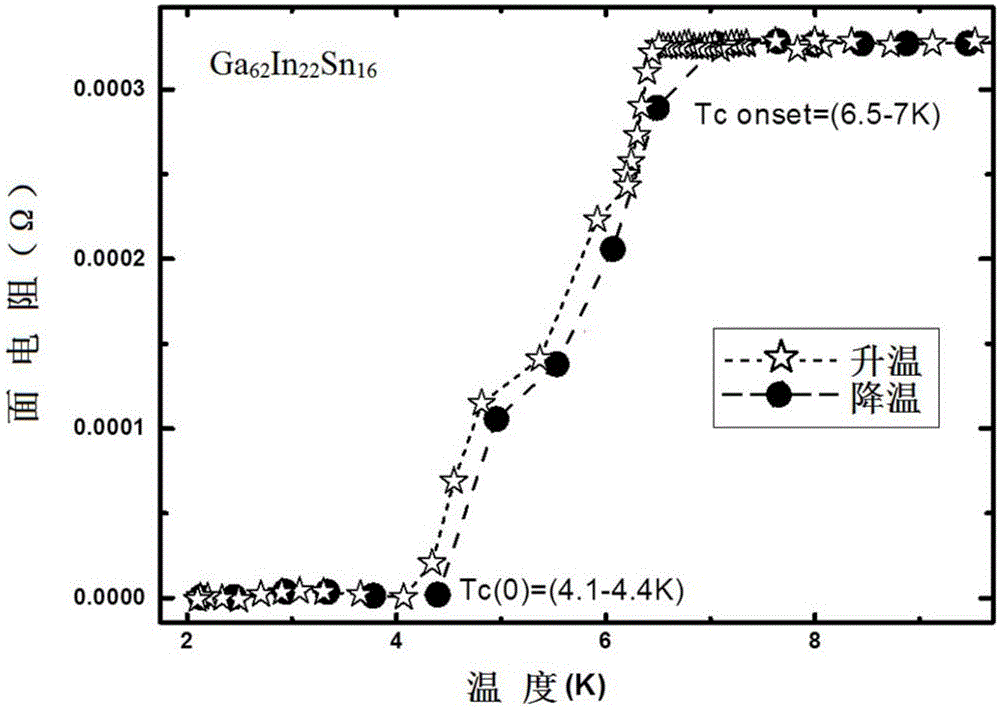

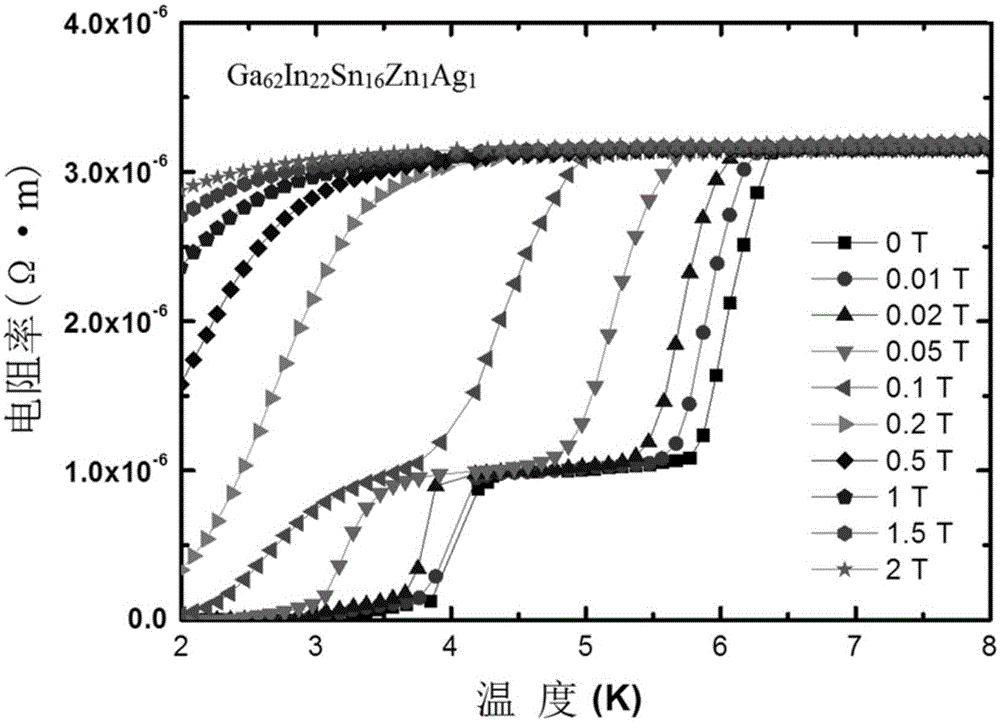

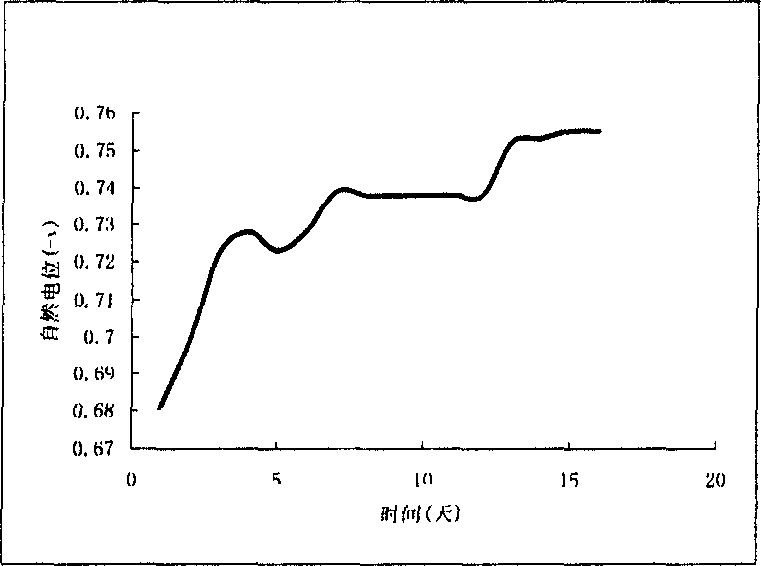

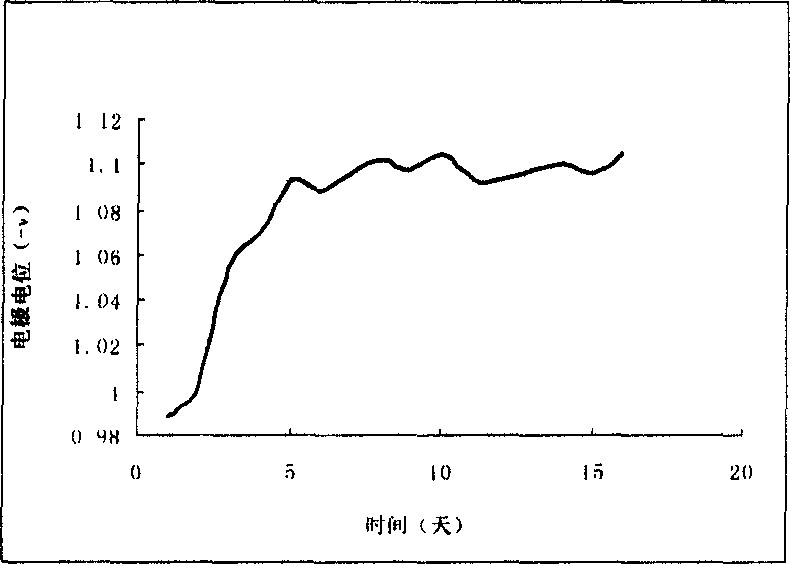

Liquid alloy, preparing method of liquid alloy and application of liquid alloy

ActiveCN105088043ALow toxicityImprove conductivitySuperconductors/hyperconductorsSuperconductor devicesElectrical conductorIndium

The invention relates to liquid alloy, a preparing method of the liquid alloy and application of the liquid alloy. The liquid alloy comprises the components, by weight part, of 1 part to 90 parts of gallium (Ga), 1 part to 75 parts of indium (In) and 1 part to 40 parts of tin (Sn). The liquid alloy has the superconductivity property in the critical temperature and belongs to nonideal type II superconductors. In addition, the liquid alloy has the excellent characteristics of being convenient to use, wide in application scope, low in cost, free of poison, good in mobility and excellent in electrical conductivity and heat conduction. The preparing method of the liquid alloy also is simple and high in efficiency, achieves environment friendliness and is economical. The liquid alloy can further by widely applied to electric connection of electronic components, electronic circuit boards and self-repairing conductors.

Owner:山西安耐哲新能源产业研究院有限公司

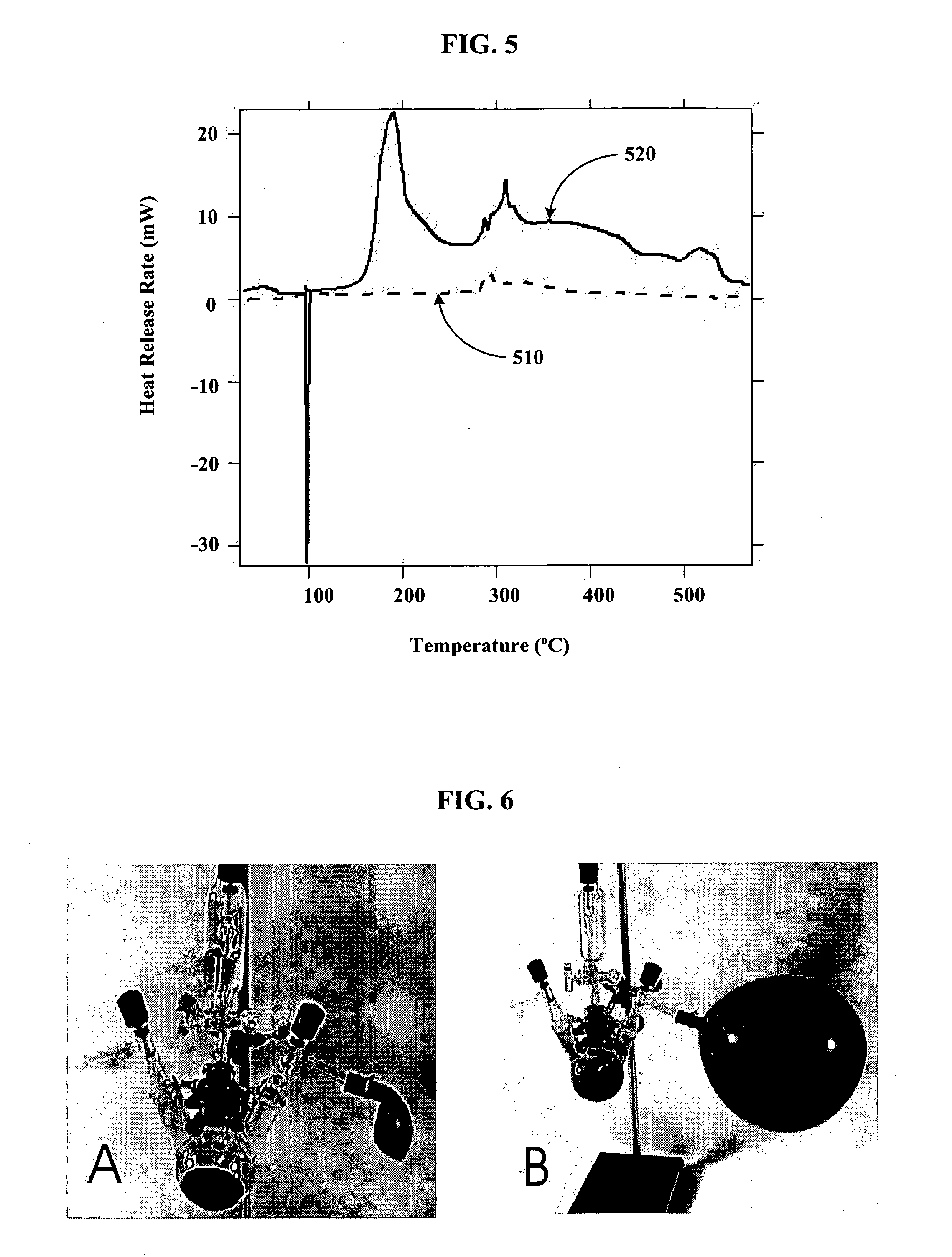

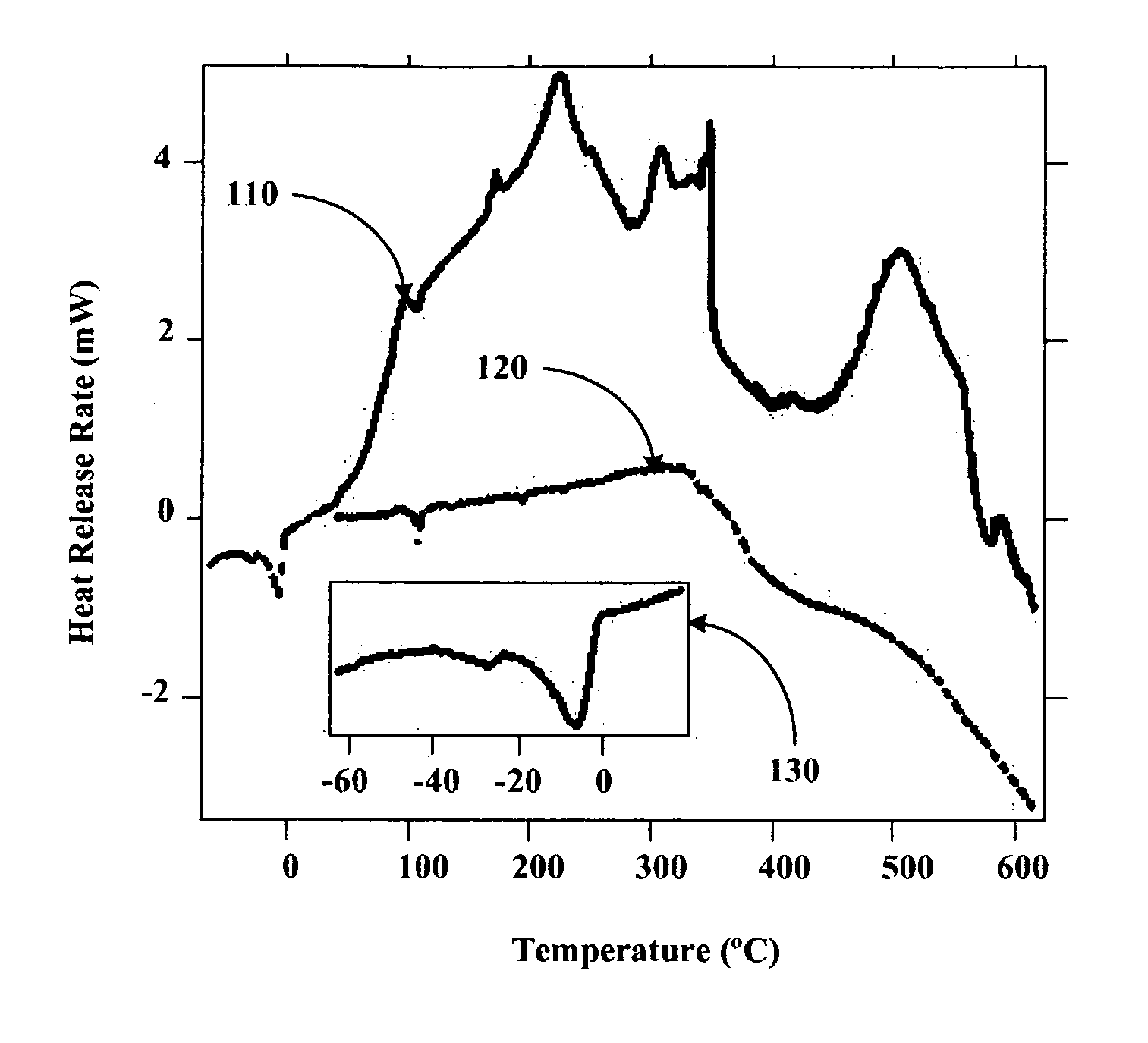

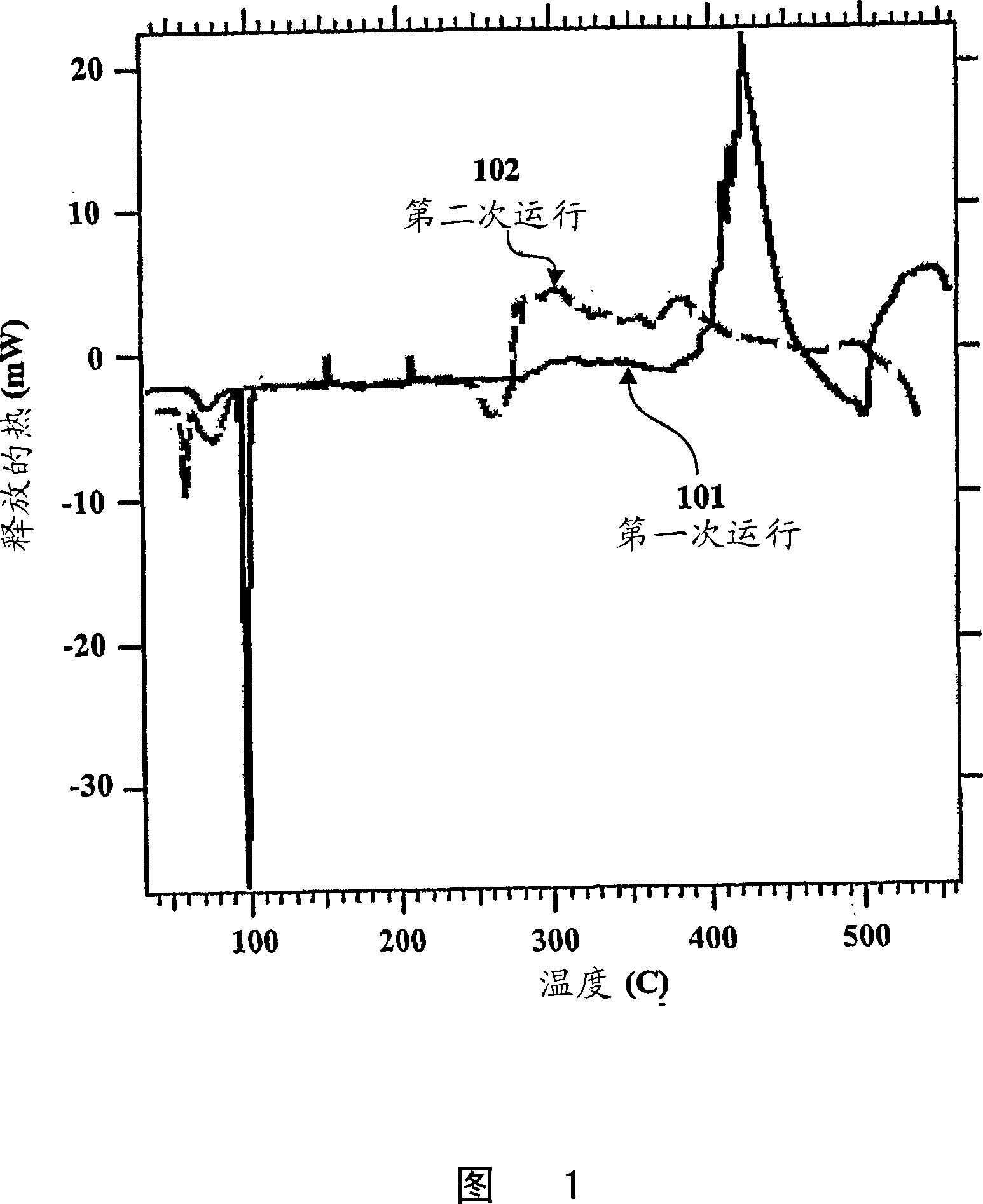

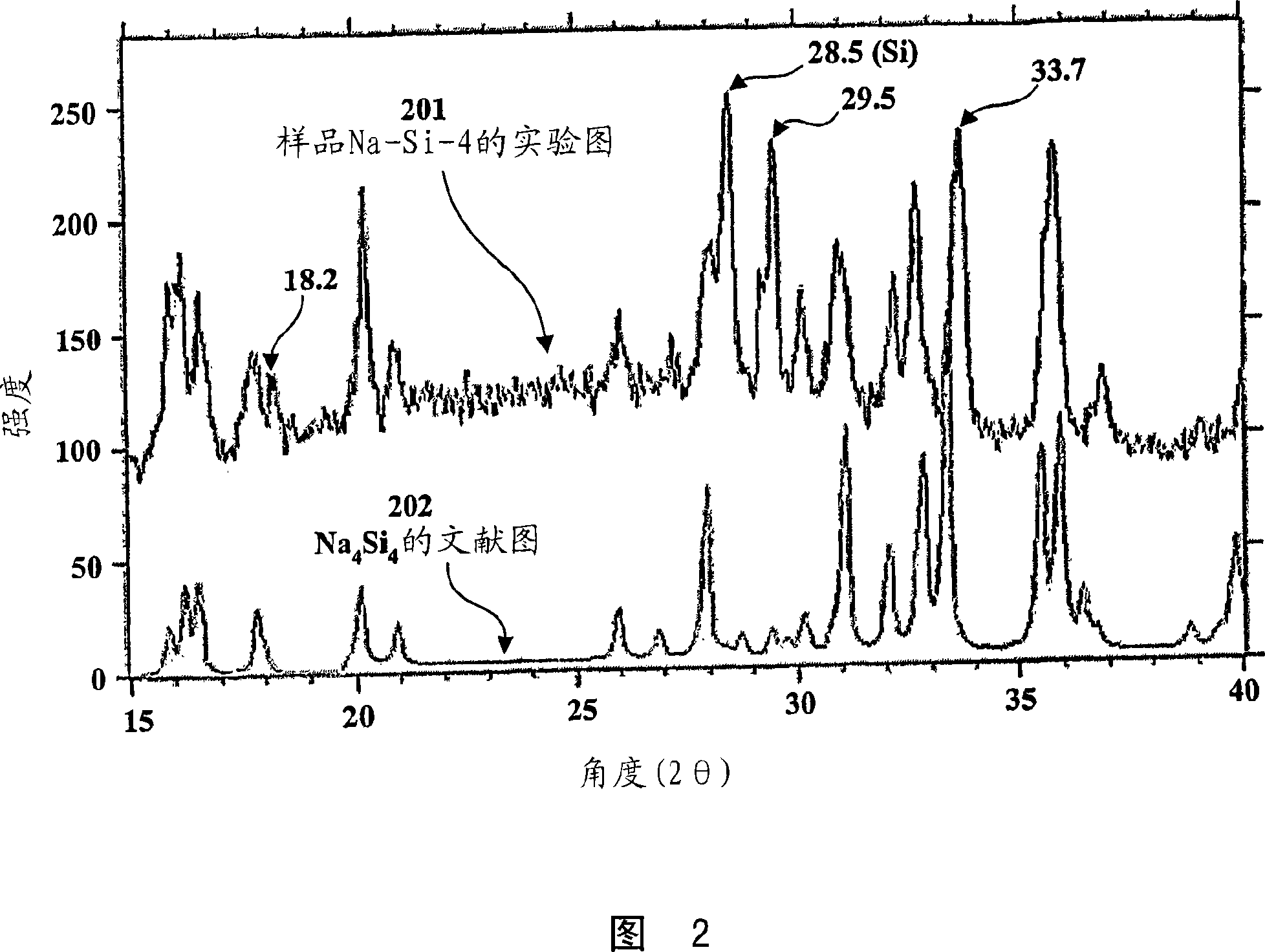

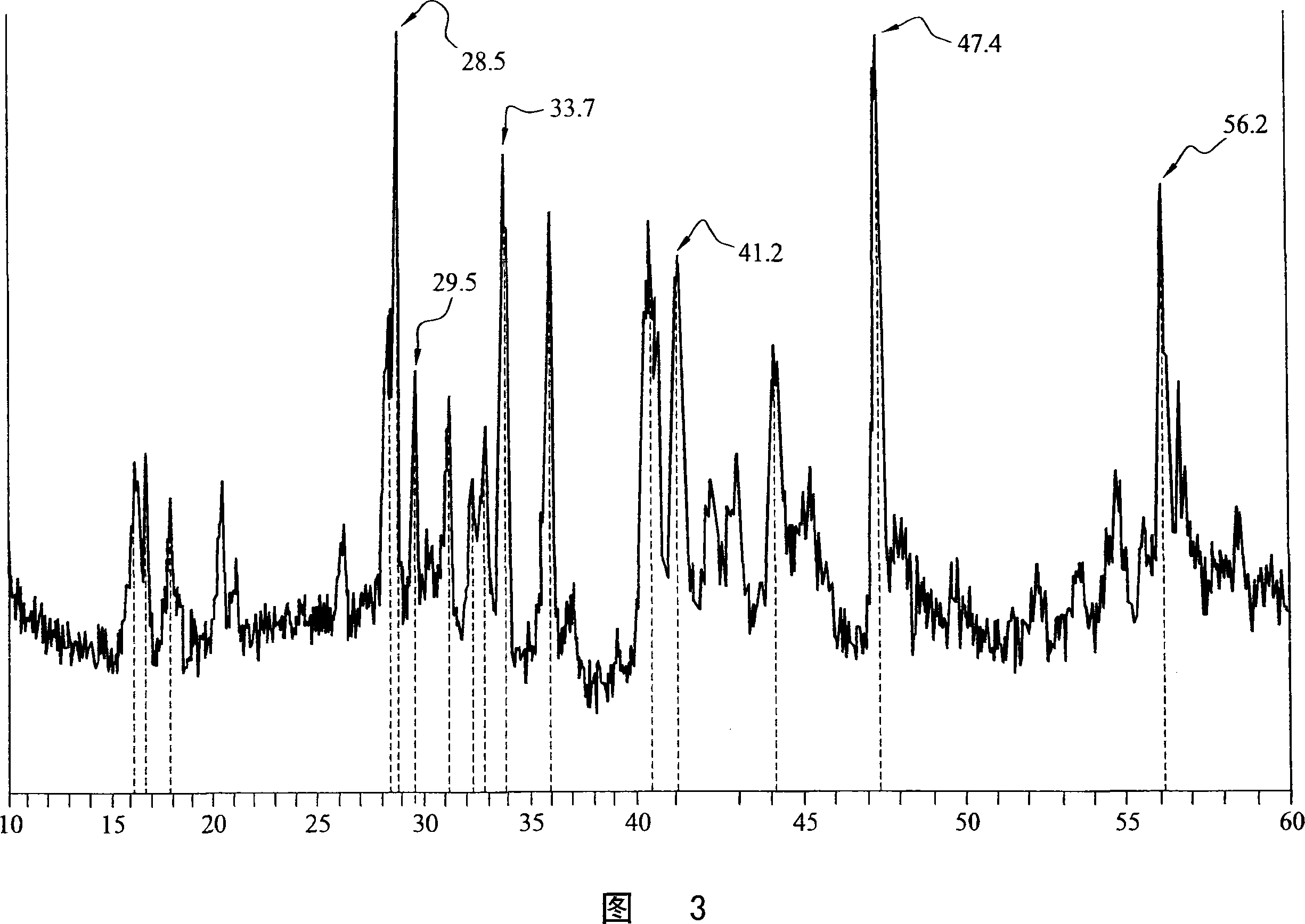

Silica gel compositions containing alkali metals and alkali metal alloy

ActiveUS20050151278A1Preparation by hydrogen halide split-offLithium organic compoundsChemical reactionRoom temperature

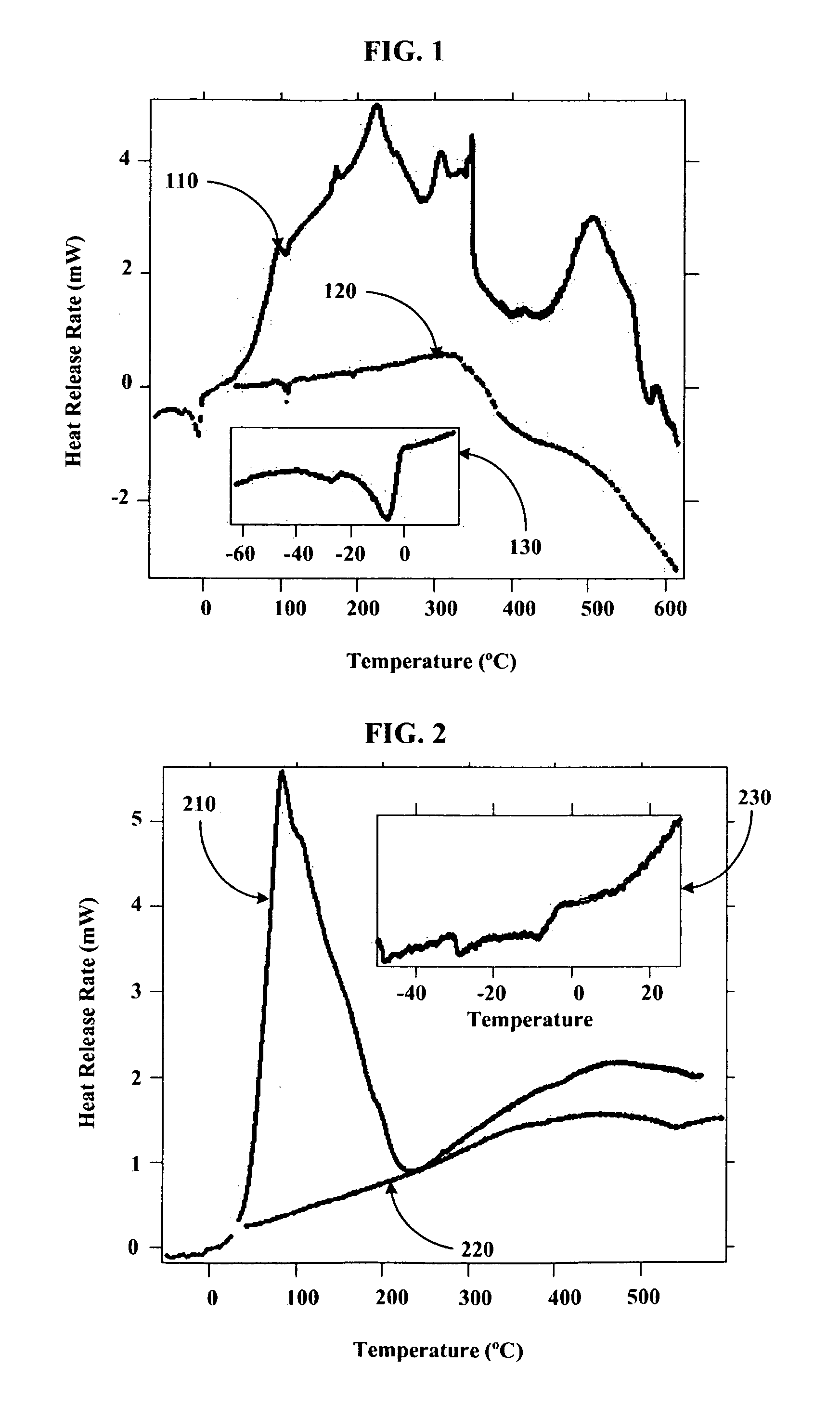

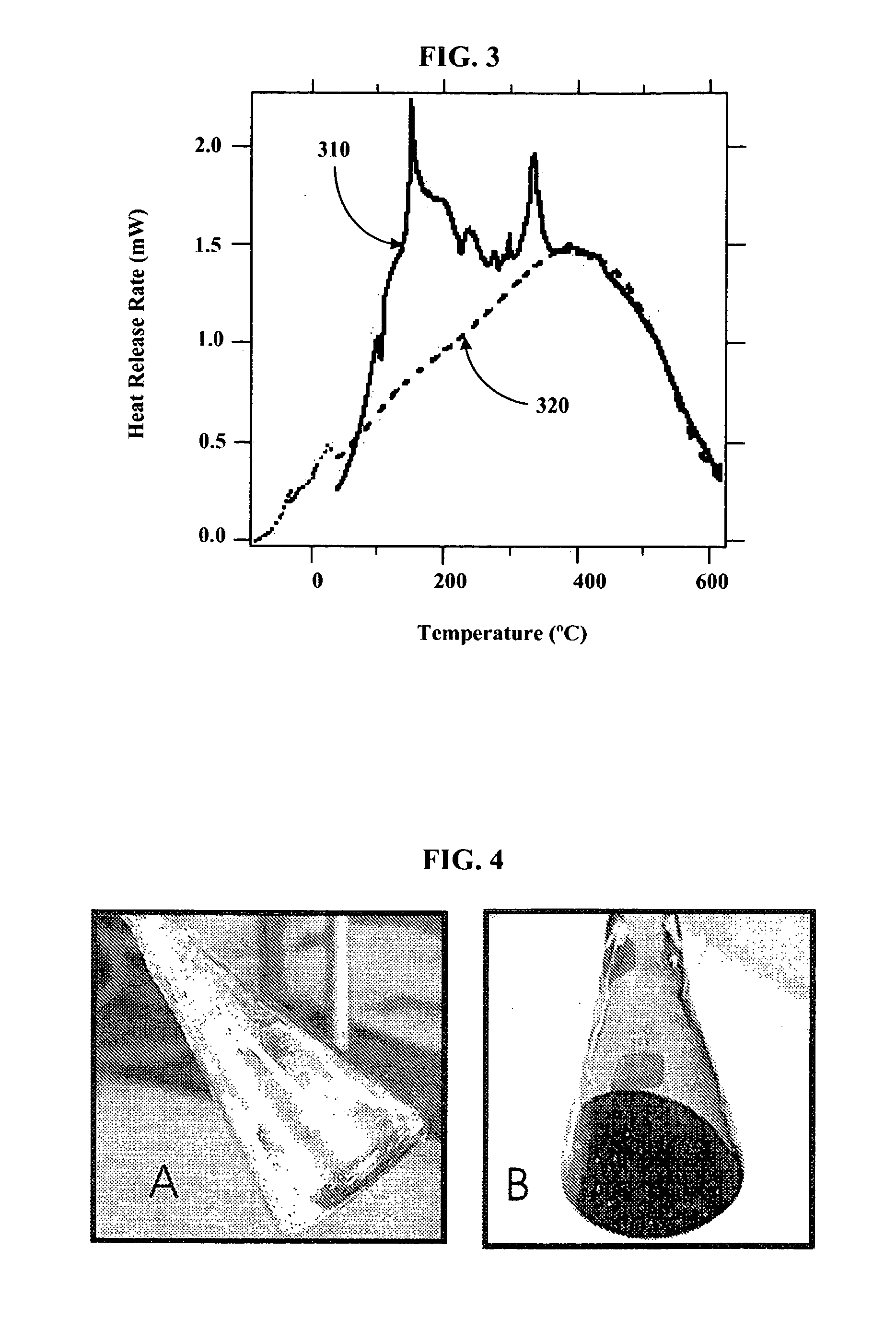

The invention relates to Group 1 metal / silica gel compositions comprising silica gel and an alkali metal or an alkali metal alloy. The compositions of the inventions are described as Stage 0, I, II, and III materials. These materials differ in their preparation and chemical reactivity. Each successive stage may be prepared directly using the methods described below or from an earlier stage material. Stage 0 materials may, for example, be prepared using liquid alloys of Na and K which are rapidly absorbed by silica gel (porous SiO2) under isothermal conditions, preferably at or just above room temperature, to form loose black powders that retain much of the reducing ability of the parent metals. When the low melting Group 1 metals are absorbed into the silica gel, a mild exothermic reaction produces Stage I material, loose black powders that are indefinitely stable in dry air. Subsequent heating to 400° C. produces Stage II materials, which are also loose black powders. Further heating above 400° C. forms Stage III material with release of some Group 1 metal. It is believed that Stage I, II and III materials represent reductions of the silica gel after absorption of the Group 1 metal. Preferred Group 1 metal / silica gel compositions of the invention are those containing sodium, potassium, or sodium-potassium alloys with sodium and sodium-potassium alloys being most preferred. Each stage of the Group 1 metal / silica gel composition of the invention may be used as a reducing agent reacting with a number of reducible organic materials in the same manner known for alkali metals and their alloys.

Owner:SIGNA CHEM INC +1

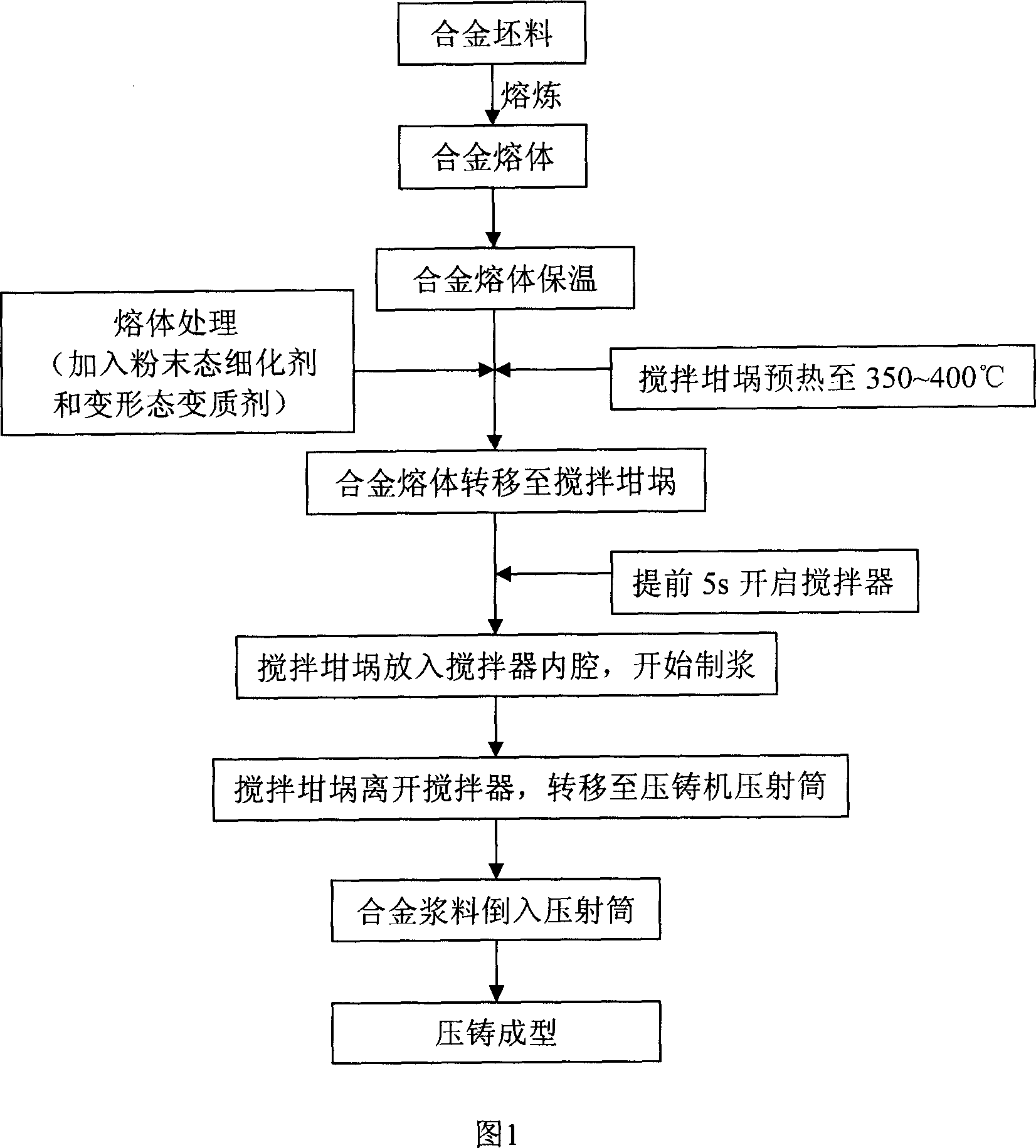

Slurrying-forming separated aluminium alloy rheological forming method

InactiveCN1994622AQuality improvementSolve the problem of complex structure and high cost of transformationCrucibleSemi solid

The invention relates to a pulping-shaping detachable aluminum alloy rheologic shaping method, wherein it also provides a quick prepare system of semi-solid alloy pulp. Said method comprises that: preparing heated liquid alloy; preheating mixing pot to 350-400Deg. C; filling heated flux into said semi-solid alloy pulp mixing pot; putting pot into electromagnetic mixer prepare room; starting the mixer to electromagnetically mix; when the mixing is end, taking out the pot, pouring the alloy pulp into the injection cylinder of casting machine; injecting and shaping at 220Deg. C of mould. In said invention, the mixer and shaping device are separated. And it has high efficiency.

Owner:TSINGHUA UNIV

Silica gel compositions containing alkali metals and alkali metal alloys

ActiveUS7211539B2Lithium organic compoundsPreparation by hydrogen halide split-offChemical reactionLiquid state

The invention relates to Group 1 metal / silica gel compositions comprising silica gel and an alkali metal or an alkali metal alloy. The compositions of the inventions are described as Stage 0, I, II, and III materials. These materials differ in their preparation and chemical reactivity. Each successive stage may be prepared directly using the methods described below or from an earlier stage material. Stage 0 materials may, for example, be prepared using liquid alloys of Na and K which are rapidly absorbed by silica gel (porous SiO2) under isothermal conditions, preferably at or just above room temperature, to form loose black powders that retain much of the reducing ability of the parent metals. When the low melting Group 1 metals are absorbed into the silica gel, a mild exothermic reaction produces Stage I material, loose black powders that are indefinitely stable in dry air. Subsequent heating to 400° C. produces Stage II materials, which are also loose black powders. Further heating above 400° C. forms Stage III material with release of some Group 1 metal. It is believed that Stage I, II and III materials represent reductions of the silica gel after absorption of the Group 1 metal. Preferred Group 1 metal / silica gel compositions of the invention are those containing sodium, potassium, or sodium-potassium alloys with sodium and sodium-potassium alloys being most preferred. Each stage of the Group 1 metal / silica gel composition of the invention may be used as a reducing agent reacting with a number of reducible organic materials in the same manner known for alkali metals and their alloys.

Owner:SIGNA CHEM INC +1

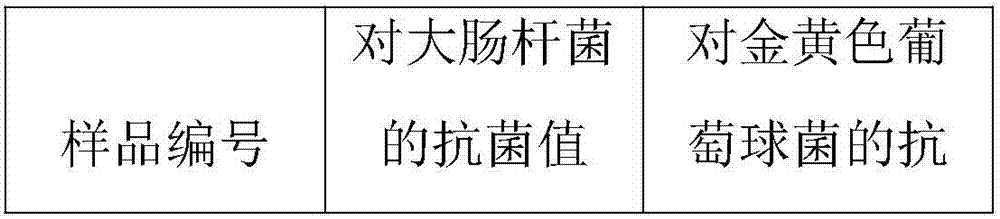

High-strength antibacterial aluminum alloy for aluminum alloy ladder and preparation method thereof

ActiveCN107201469AHigh hardnessImprove toughnessAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention relates to the technical field of aluminum alloy ladder preparation, and particularly relates to high-strength antibacterial aluminum alloy for an aluminum alloy ladder and a preparation method thereof. The aluminum alloy comprises a high-strength aluminum alloy matrix and a micro-arc oxidation film, wherein the micro-arc oxidation film is arranged on the surface of the aluminum alloy matrix, the weight of a hole sealing agent on the micro-arc oxidation film is 0.15 g / cm<2> to 0.90 g / cm<2>, and the hole sealing agent covers at least 92% of micropores in the micro-arc oxidation film. The preparation method comprises the steps of smelting metal, modifying, refining and degassing, pouring and forming and performing quenching treatment, aging treatment, micro-arc oxidation and hole sealing treatment, wherein in the step of modifying, nanometer modificators are uniformly dispersed into liquid alloy obtained by smelting; in the step of refining and degassing, 0.23% to 0.38% of hexachloroethane is added to the modified liquid alloy so as to refine and degas; and the aging treatment is divided into four-stage aging treatment. The aluminum alloy prepared by adopting the preparation method has the characteristics of high hardness, high strength, wear resistance, corrosion resistance, good anti-cracking performance, good antibacterial effect, difficulty in aging and deformation and long service life.

Owner:浙江洋铭实业有限公司

Conductivity liquid alloy and preparation method

This invention relates to electroconductive liquid alloy, the design and method for preparing the room temperature liquid and electroconductive alloy GalnSn and GalnSnAg. A metal with its purity being greater than 99.99% is selected and thein is smelted to produce the main alloy Galn. And then, Sn(or Sn and Ag) is (are) added into above mentioned Galn to produce GalnSn or GalnSnAg alloy. The product can be used in fields such as: oral surgery, electronics material and refrigeration system.

Owner:冯本政

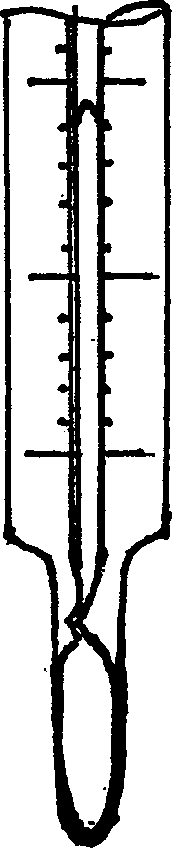

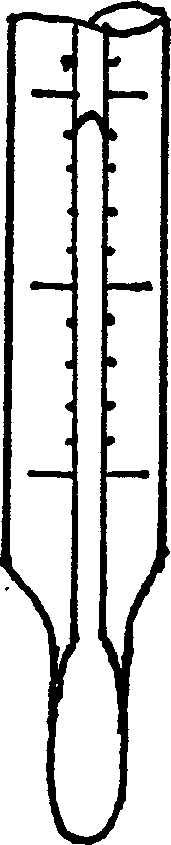

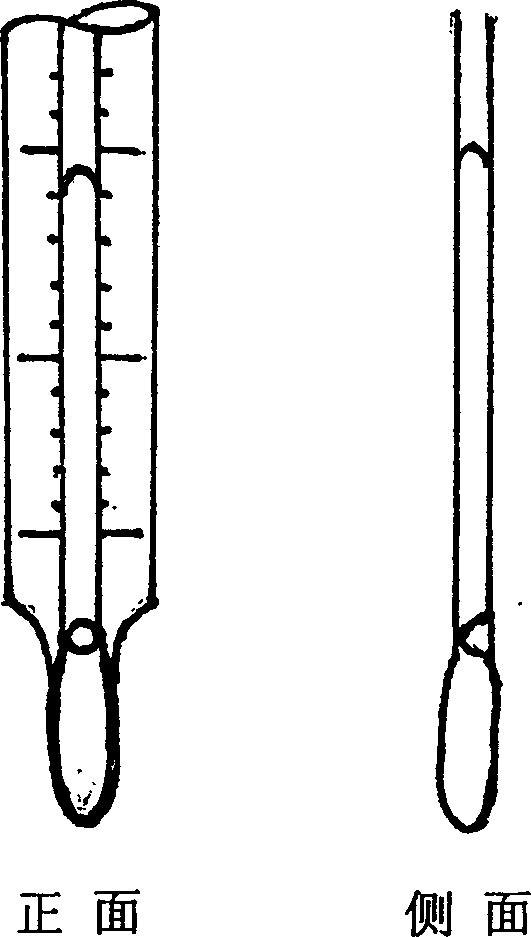

Production of non-mercury clinical thermometer and liquid alloy temperature carrier therefor

ActiveCN1818576ANo toxicityLow costThermometers using material expansion/contactionBody temperature measurementLiquid temperatureOxygen

A liquid-alloy temperature carrier used in thermometer of mercury free type is featured as applying low melting point of Ga-In-Sn-K-Na-Li alloy as stabilized liquid temperature carrier at temperature of 5-42DEG C; preparing said alloy by wt% as Ga of 65-80, In of 3-20,Sn of 1-15, Na and K of 0.001-5 and Li of 2.0; applying Na-K weight ratio as 21.6:78.4. The method for preparing said thermometer is also disclosed.

Owner:东阿阿华医疗科技有限公司

Thermal interface material for packaging and radiating chip and preparation method thereof

InactiveCN101864280AImprove cooling effectImprove stabilitySemiconductor/solid-state device detailsSolid-state devicesCarbon nanotubeLiquid metal

The invention discloses a thermal interface material for packaging and radiating a chip and a preparation method thereof. The thermal interface material comprises a carbon nano tube array on a substrate, and is characterized in that the thermal interface material contains liquid metal which is freely diffused and uniformly distributed in gaps of the carbon nano tube array. The invention uses the carbon nano tube having a high coefficient of heat conductivity to ensure that the thermal interface has a higher heat conductive property, uses the liquid alloy to promote the contact capability between the carbon nano tube and the heat sink and between the carbon nano tube and the chip so as to decrease the thermal resistance of the thermal interface and meet the radiating demand of high-performance chip. The preparation method thereof comprises the steps of: providing a carbon nano tube array vertically formed on the substrate, depositing a metal layer which is easily dissolved in liquid metal on the carbon nano tube, boosting to fully soak the carbon nano tube when the liquid metal is contacted with the carbon nano tube and filling the gaps of the carbon nano tube array.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

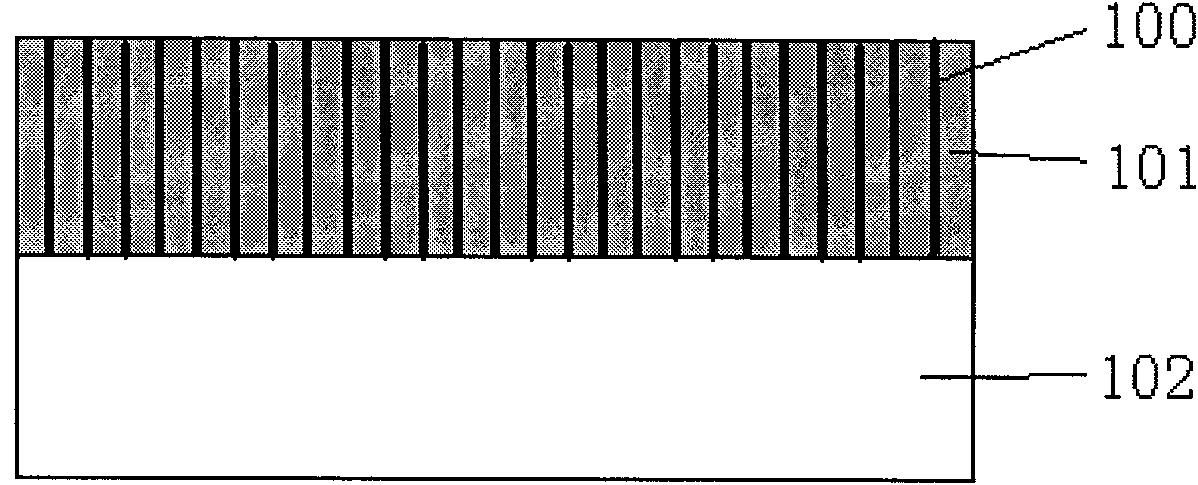

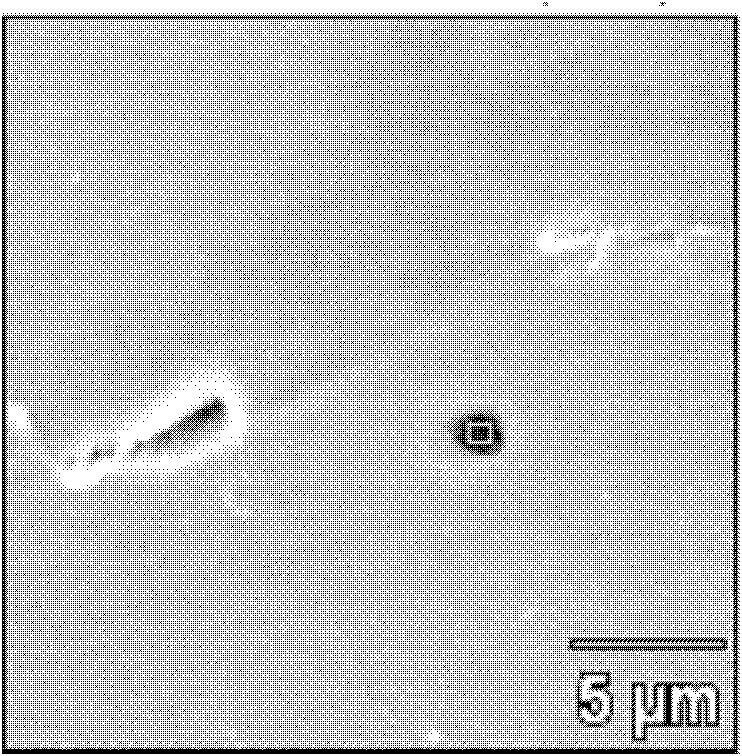

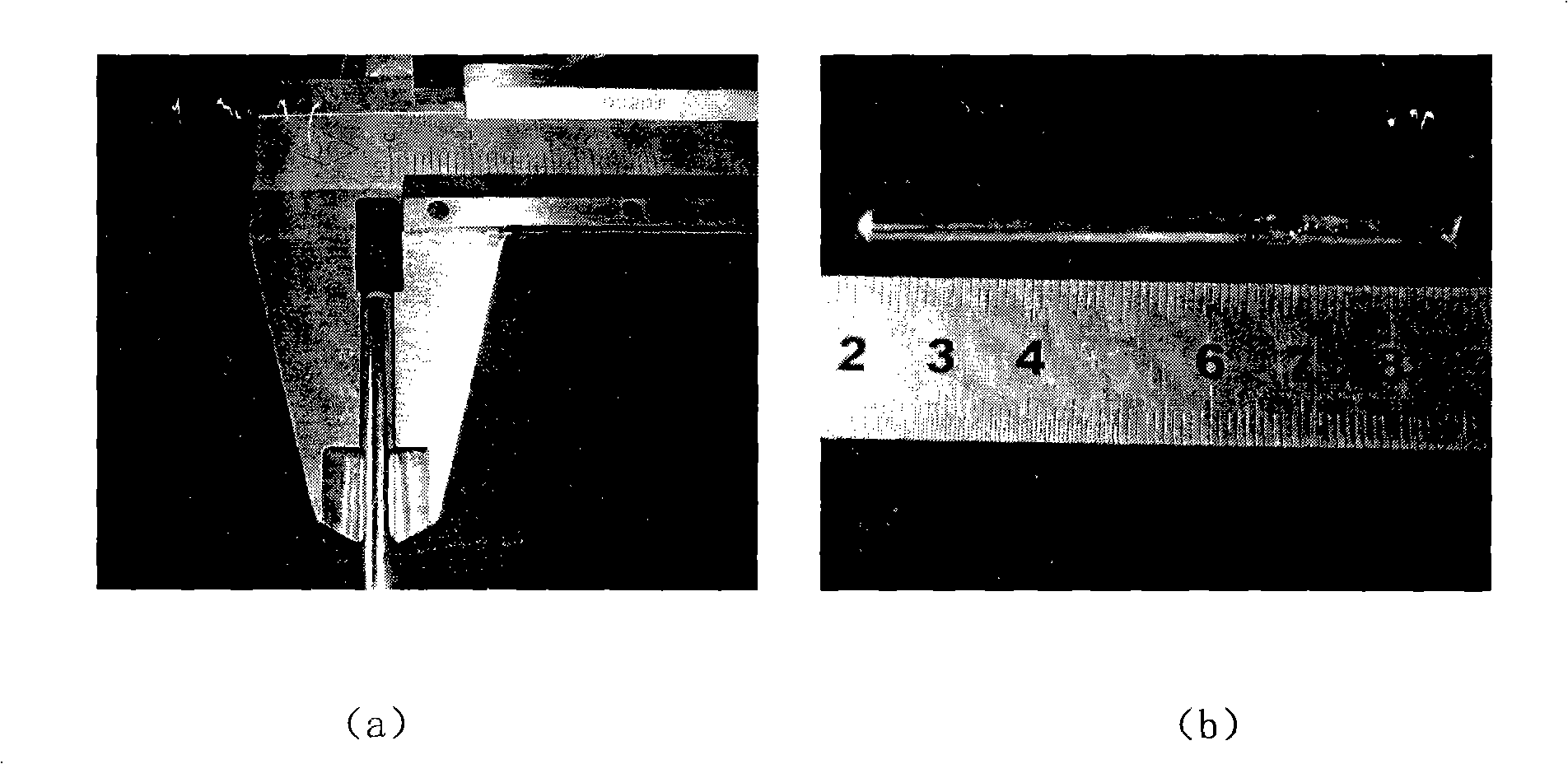

Active aluminum-rich alloy for preparing high purity hydrogen through hydrolysis and preparation method thereof

InactiveCN102560198AHigh hydrogen production rateEasy to prepareHydrogen productionVacuum induction furnaceLiquid alloy

The invention relates to an active aluminum-rich alloy for preparing high purity hydrogen through hydrolysis. The alloy is characterized in that the alloy which is composed of four elements of Al, Ga, In and Sn comprises the following two phases: an Al solid solution and GaIn3Sn. A preparation method of the alloy concretely comprises the following steps: 1, melting the alloy to form a molten alloy by adopting a vacuum induction furnace, wherein the vacuum degree of the vacuum induction furnace is 10<-2>-10<-3>Pa; and 2, stirring the molten alloy by adopting an electromagnetic stirring technology, casting the molten alloy to a water-cooled copper mold, and solidifying, wherein the cooling rate is 101-103DEG C / s. The alloy has the advantages of high hydrogen yield, no pollution, low cost, simple preparation method, convenient operation and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Mg Li Sr alloy and its electrlysis preparing method

InactiveCN101070576AWide variety of sourcesChange the problem of low mechanical propertiesMg alloysElectrolysis

One kind of Mg-Li-Sr alloy and its the electrolysis preparation method, which belongs to magnesium alloy material and it's the preparation technology area. The component and quality percentage of the alloy include: Lithium: 5-15%wt, strontium: 0.1-5%wt, aluminum:0.5-3%, zinc:0.5-3%, the remainder is magnesium, comparing with LA141Mg-Li alloy, the anticreep and corrosion resistance performance of the Mg-Li-Sr alloy are enhancement. This invention uses molten salt electrolysis method to prepare the Mg-Li-Sr alloy, its step is: melting magnesium alloy; configurating electrolyte; adding the electrolyte to magnesium melt body; The anode inducts in electrolyte, the negative pole inducts the Mg melt body; then made contact to electrolysis, lithium and strontium separate out and enter magnesium melt body, then obtain the liquid state Mg-Li-Sralloy, and get the Mg-Li-Sr alloy after condensation. Prepared the Mg-Li-Sr alloy with molten salt electrolysis has improved utilization rate of the material, and it is a new method to preparing Mg-Li-Sralloy.

Owner:CHONGQING UNIV

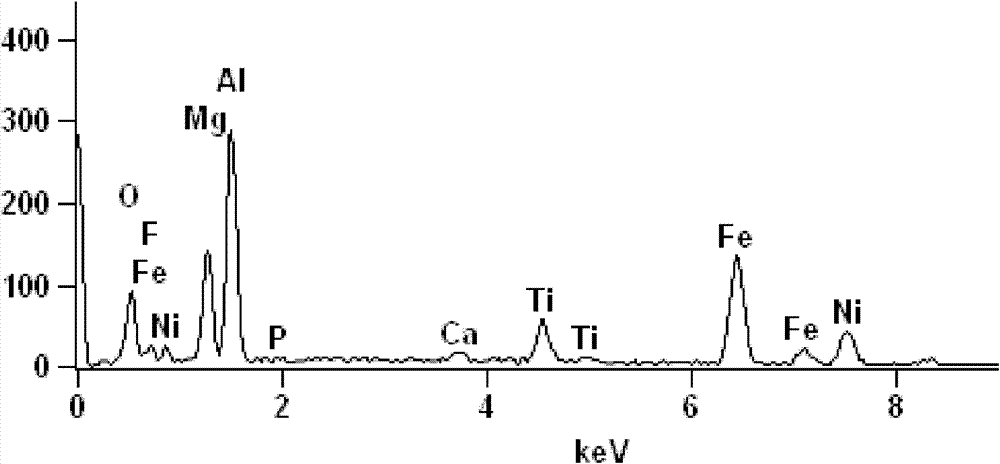

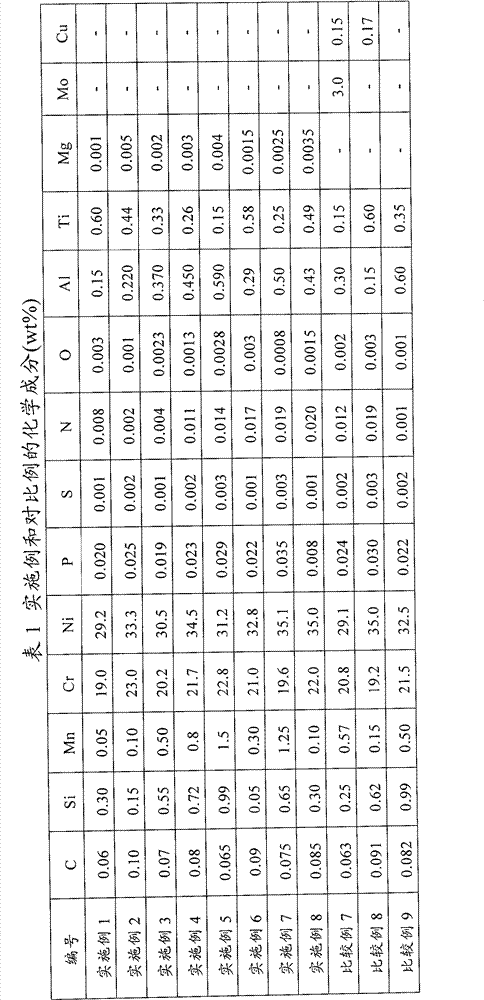

High strength nickel base corrosion resistance alloy and manufacturing method thereof

ActiveCN102899582AConducive to refining the initial solidification structure of continuous castingImprove mechanical propertiesTurbineMechanical property

Owner:BAOSHAN IRON & STEEL CO LTD

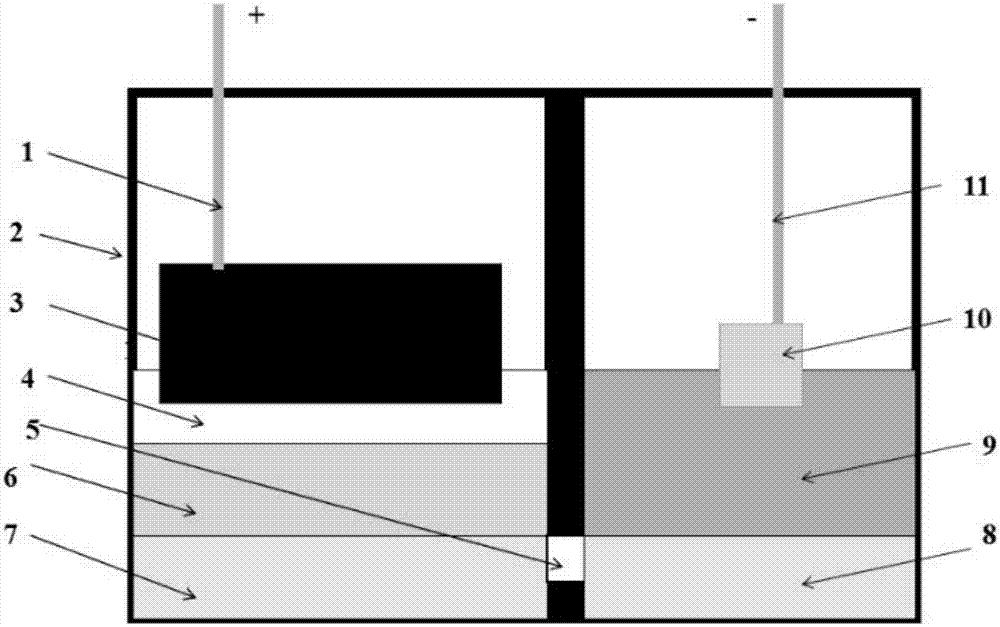

Room-temperature liquid metal battery

ActiveCN106025249ASmall electromotive forceLow densityCell electrodesSecondary cellsLiquid metalLiquid alloy

The invention provides a room-temperature liquid metal battery which comprises an anode, a cathode, an interlayer and a battery shell. The anode is made of a gallium-based or mercury-based liquid alloy, the cathode is made of an alkali metal liquid alloy, the interlayer is ionic liquid, and the anode, the interlayer and the cathode are arranged in the battery shell from bottom to top. The cathode is made of the alkali metal liquid alloy, the anode is made of the gallium-based or mercury-based liquid alloy, electrolyte is the ionic liquid, and the three materials are liquid at room temperature, so that heating and heat insulating devices are not needed, and the room-temperature liquid metal battery can be realized really.

Owner:YUNNAN KEWEI LIQUID METAL VALLEY R & D CO LTD

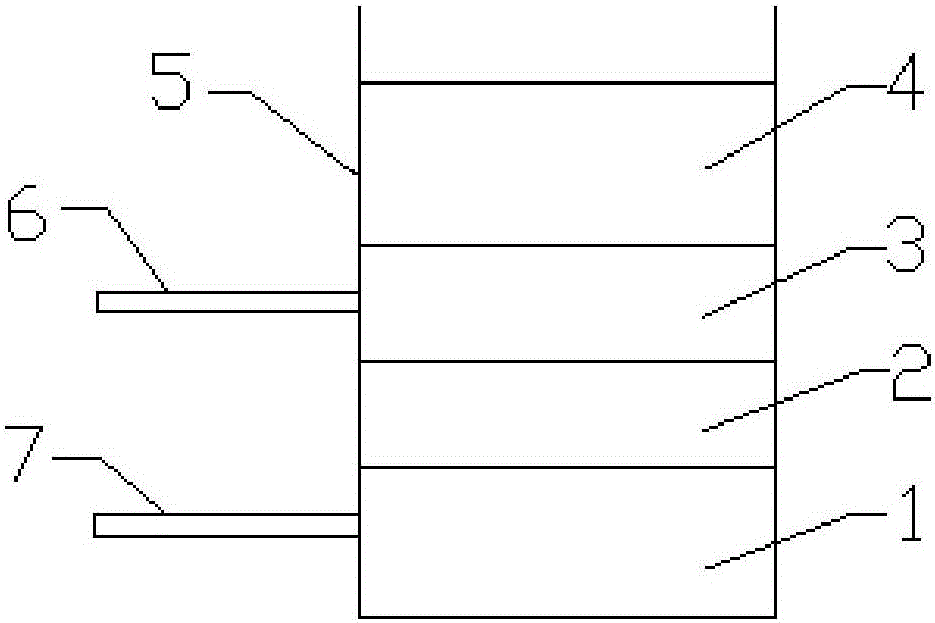

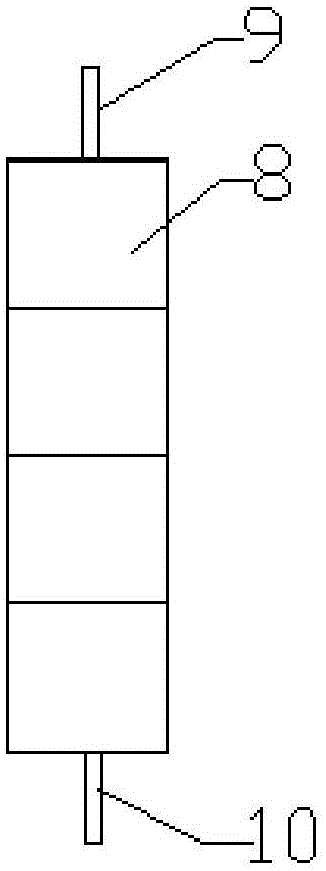

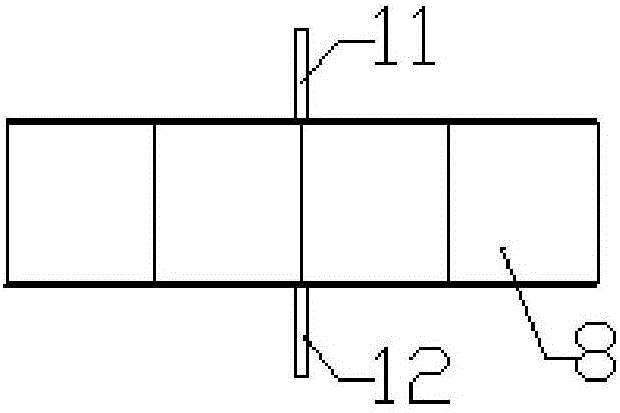

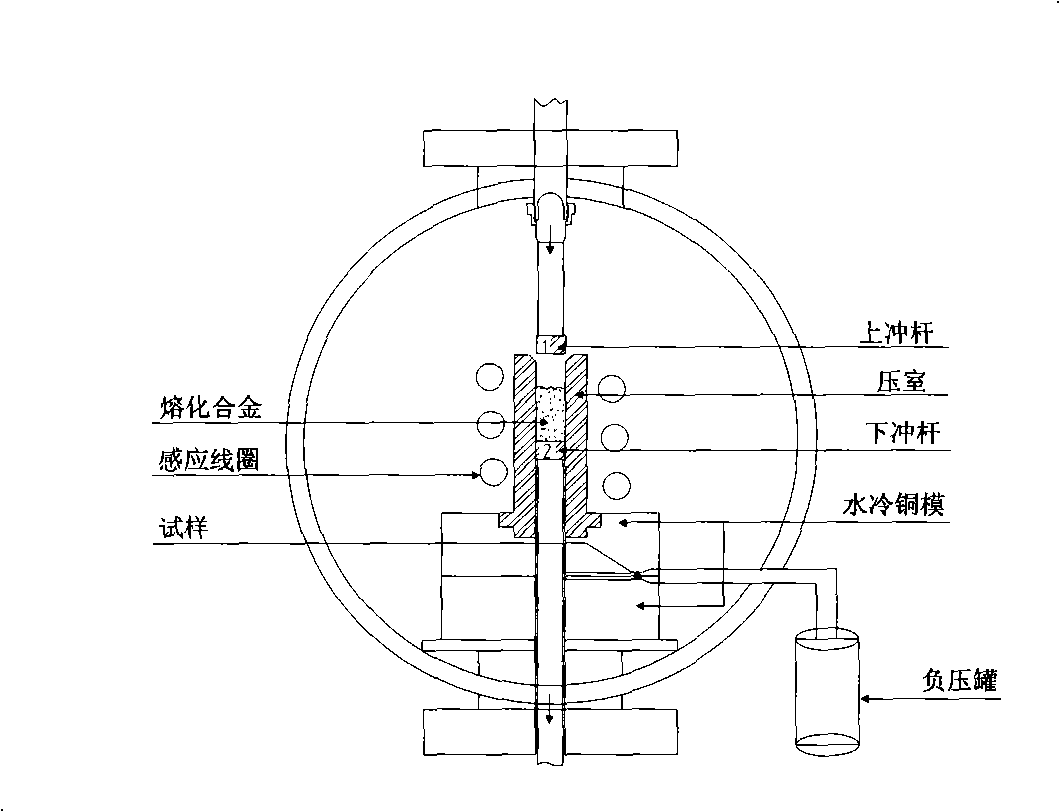

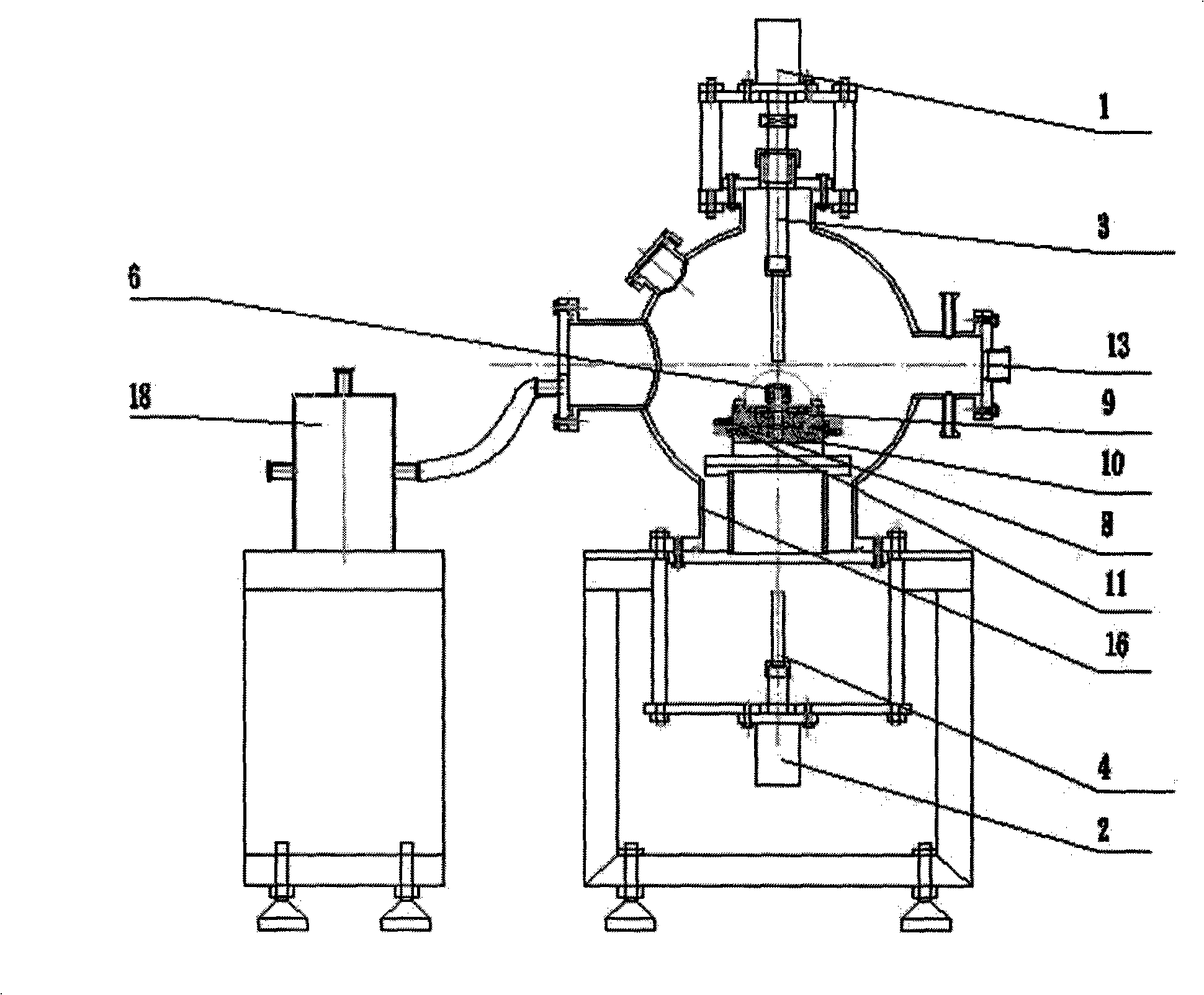

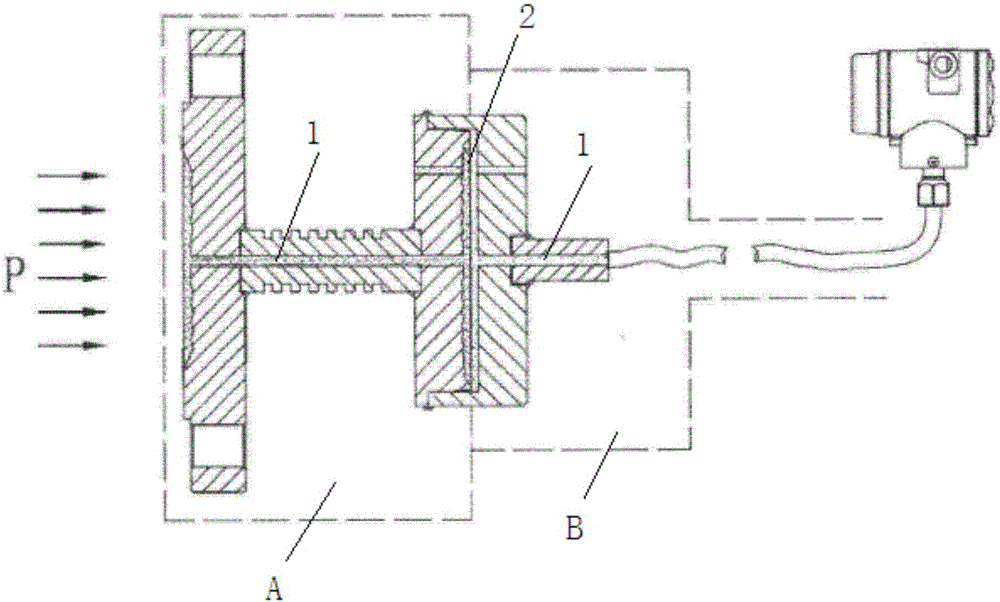

Pressure difference injection moulding method and equipment for amorphous magnesium alloy

The invention provides an amorphous magnesium alloy differential pressure injection molding method and equipment thereof and pertains to the technical field of alloy preparation engineering and equipment. A mould (10) is cooled; a mother alloy is added in from the upper end of a compression chamber (7); an upper compression bar (3) goes down to the place over the compression chamber (7); a working cavity (12) is vacuumized by a vacuum pump (16); the compression chamber (7) is heated by a heater coil (6) so as to cause the mother alloy to be melted; a quick-opening valve (19) is opened, the upper compression bar (3) and a lower compression bar (4) go down for carrying out the injection, and the liquid alloy is injected into a die cavity of a mould (10); the liquid ally is solidified and the amorphous magnesium alloy is obtained; the operation of injection is finished. The equipment includes the upper compression bar (3), the lower compression bar (4), the heater coil (6) and a working chamber (12), etc. The method and the equipment of the invention have high heating efficiency; the molten bath of magnesium alloy can be cooled quickly; the operation of differential pressure injection is simple, the applicability is better, the working is stable and reliable, and the process is easy to be controlled, thus being very suitable for preparing bulk amorphous magnesium alloy.

Owner:TSINGHUA UNIV

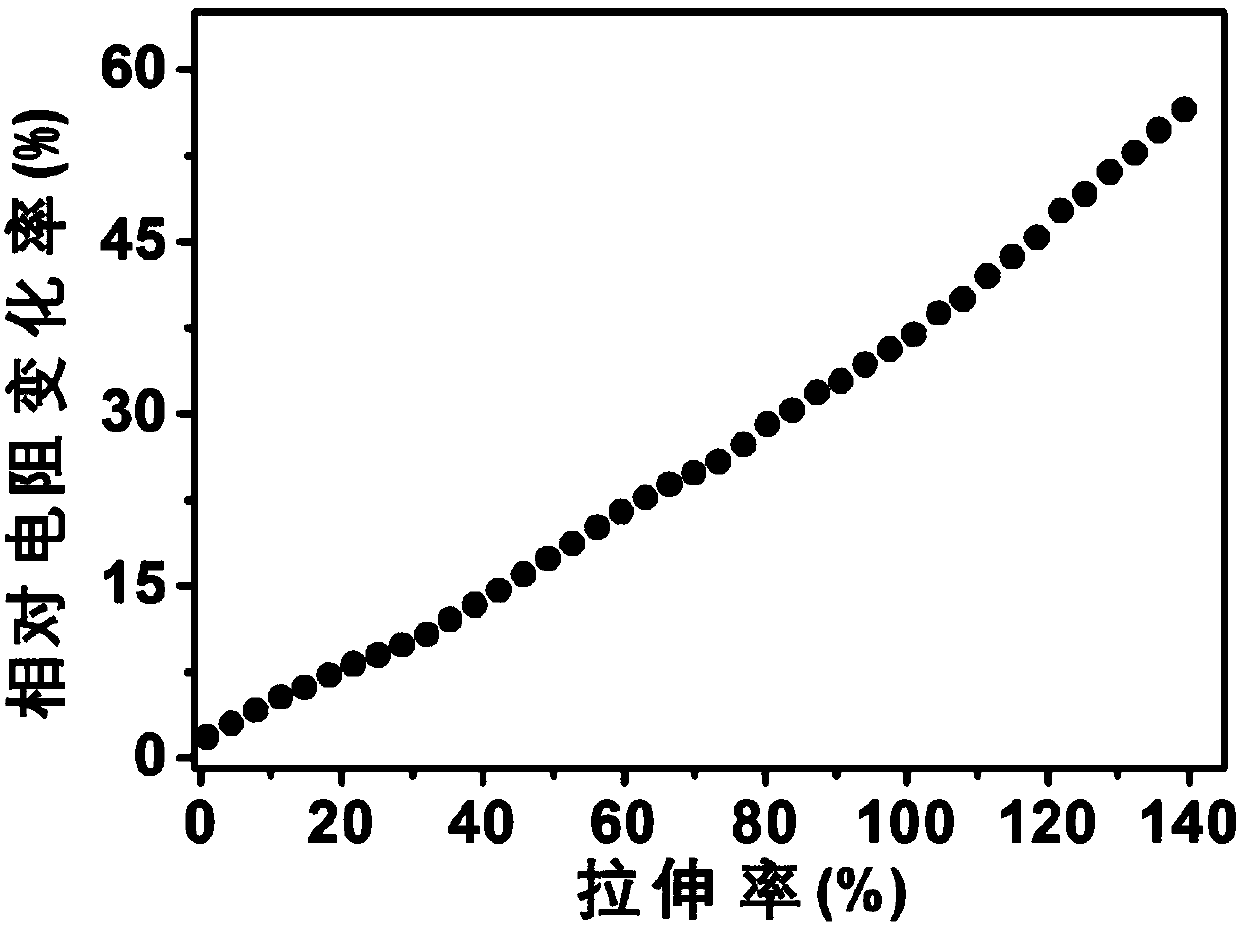

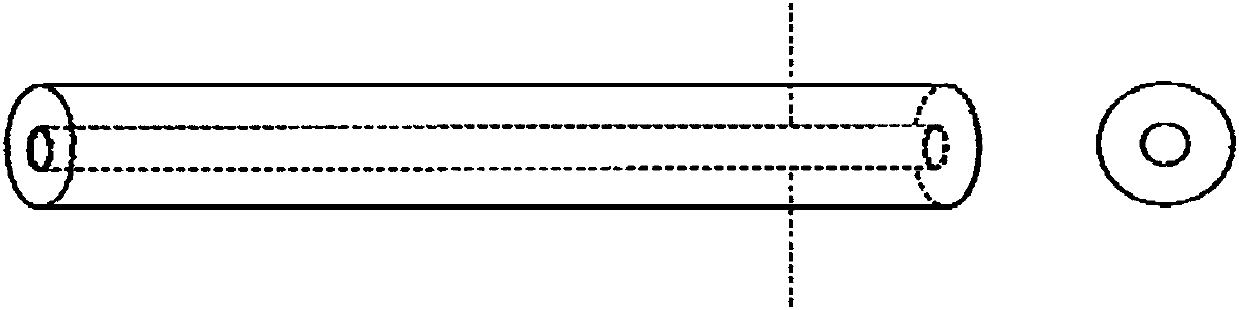

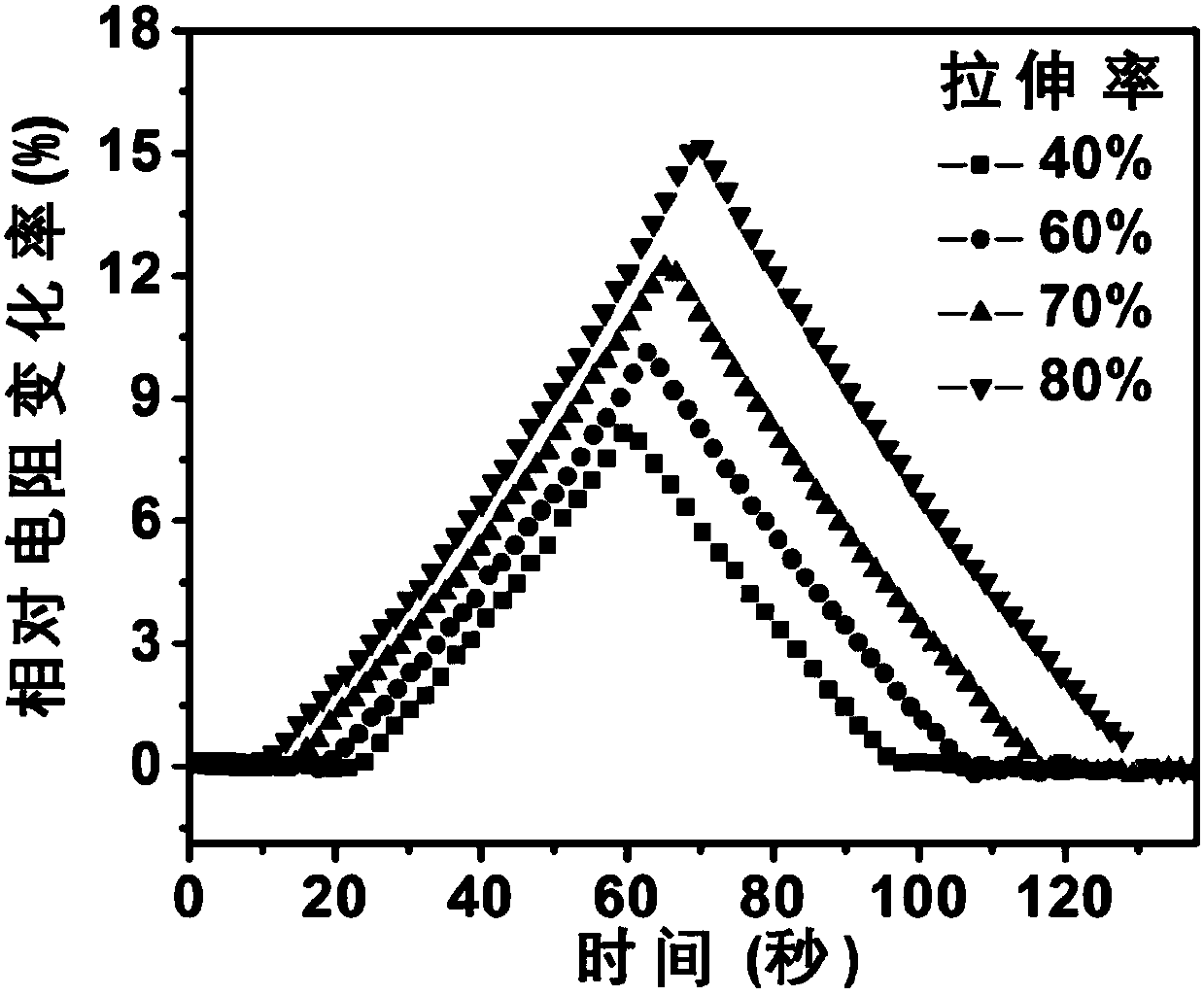

Stretchable flexible functional conductor

InactiveCN107833656AWith resistance-deformation response characteristicsAdapt to the needs of different application processesNon-insulated conductorsForce measurementFiberElectrical conductor

The invention discloses a stretchable flexible functional conductor. The stretchable flexible functional conductor comprises a hollow elastic fiber and a liquid metal. The hollow elastic fiber is an elastic fiber, acting as a conductor shell and having a hollow circular flow passage inside. The liquid metal is used as a conducting medium of the conductor, is encapsulated in the circular flow passage of the hollow elastic fiber, and is composed of a liquid metal tantalum and a liquid alloy of eutectic indium and tin thereof. The stretchable flexible functional conductor of the invention has a sensitive resistance-deformation response characteristic, the resistance change of the conductor at 0 to 140% tensile deformation can be clearly detected and the resistance response characteristic is exhibited at 0.1 V, so that the stretchable flexible functional conductor is allowed to have important application prospects in human limb movement detection.

Owner:SOUTH CHINA UNIV OF TECH

Gallium-based liquid alloy material and preparation method thereof

The invention discloses a gallium-based liquid alloy material and a preparation method thereof, the gallium-based liquid alloy material is composed of the following components: by mass, 70-85% of gallium, 10-15% of indium, 1-12% of tin, 2-6% of bismuth and 1-6% of zinc. In accordance with the ratio, the metal gallium is placed in a sealed flask, and then is placed in a water bath pot for heating to 50 DEG C, in a constant temperature state, the gallium in the flask is in a liquid state; then the indium, the tin, the bismuth and the zinc are put into the glass ware holding the liquid metal gallium; under argon protection, the indium, the tin, the bismuth and the zinc are stirred with a glass rod to completely melt into a liquid and evenly mix, and then the gallium-based liquid alloy material is obtained by thermal insulation for 10 minutes at 50 DEG C. The gallium-based liquid alloy material melting point is as low as about 1 DEG C. When in practical use, the radiator pipe cold end temperature can be as low as about-2 DEG C.

Owner:NINGBO SYRNMA METAL MATERIALS CO LTD

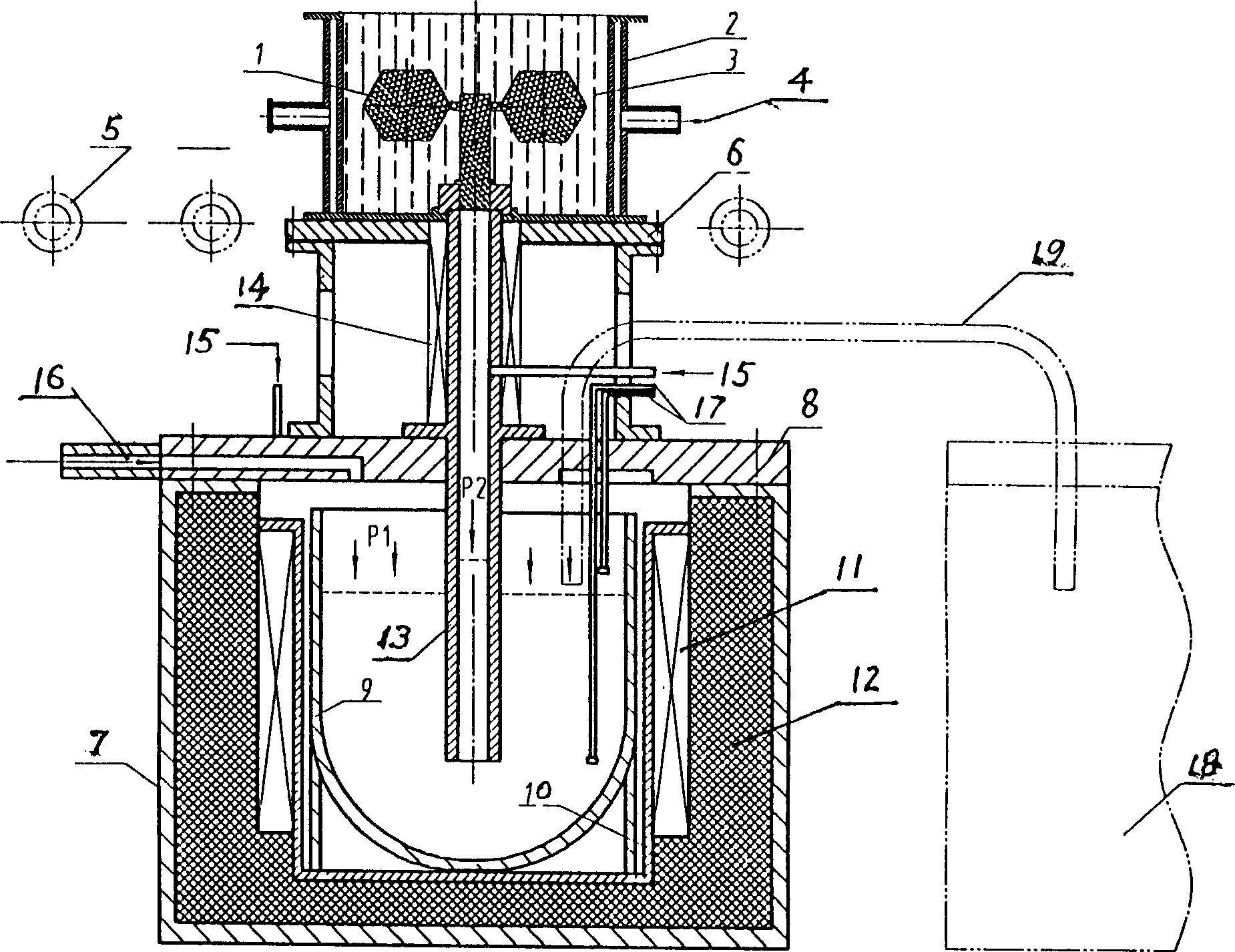

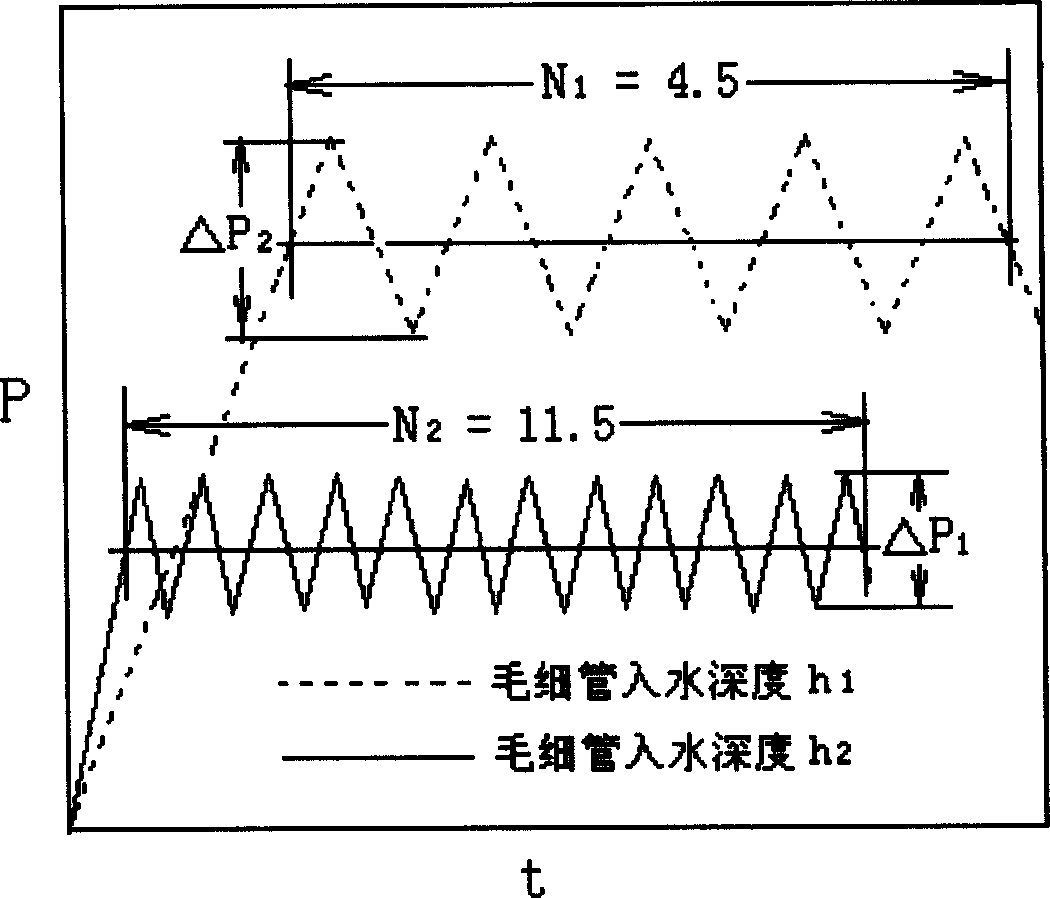

Quick determination device for surface tension of liquid metal and liquid alloy

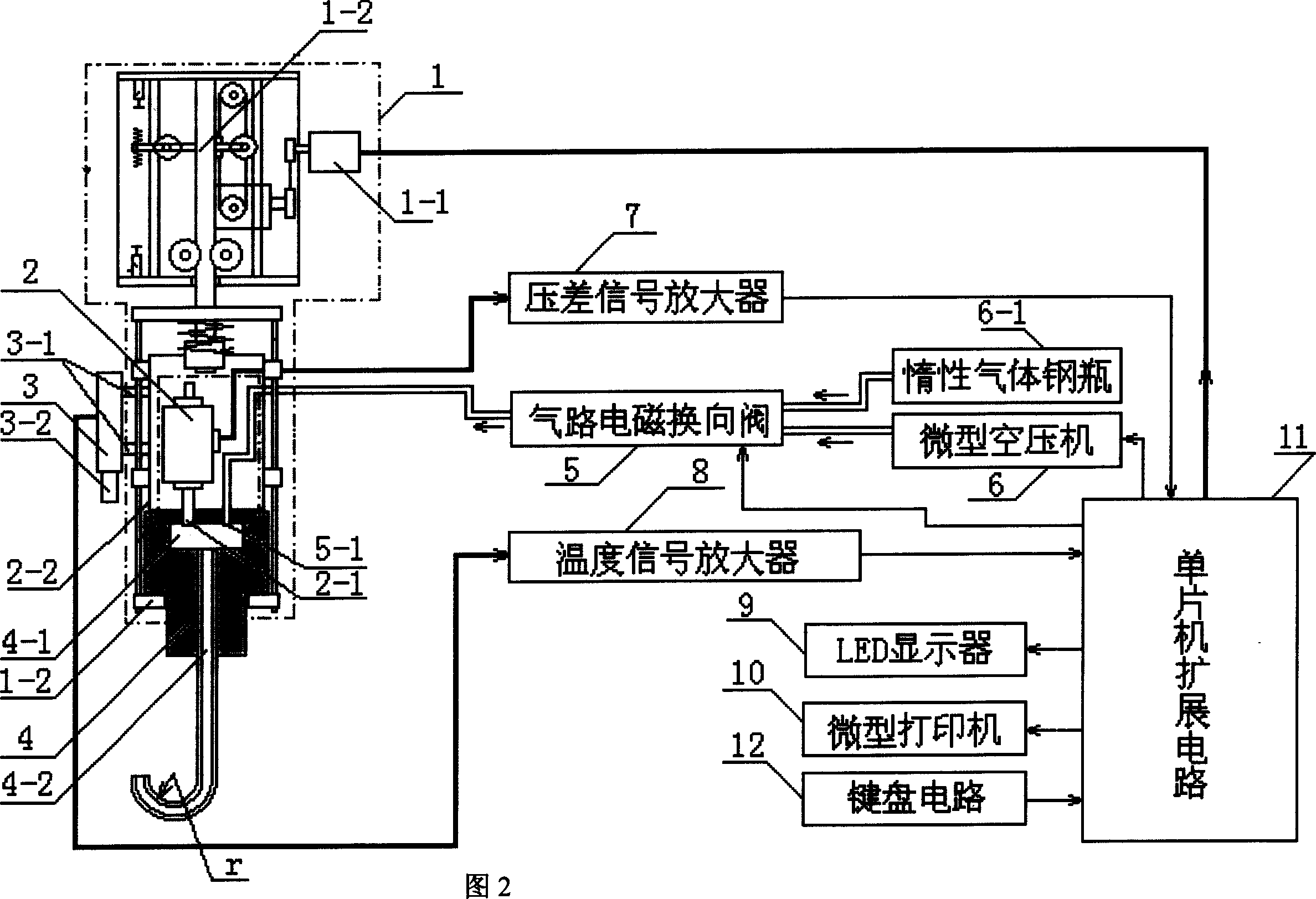

It is a rapid measurement apparatus for liquid metal and liquid alloy surface tension and it relates to metallurgy and foundry field. The power input end (1-1) is connected with output end of (11) power; the down end of (1-2) is connected with (4) and the upper end of (4-2) is connected with (4-1); the two gas-in end of (5) is separately connected with vent of (6)(6-1); the controlled end of (6) is connected with output end of (11); the controlled end of (5) is connected with output end of (11); the output end of (2) is connected with input end of (11) through (7); the output end of (3) is connected with input end of (11) through (11); the output end of (11)is connected with input end of (9); the output end of (12)is connected with input end of (11).

Owner:HARBIN UNIV OF SCI & TECH

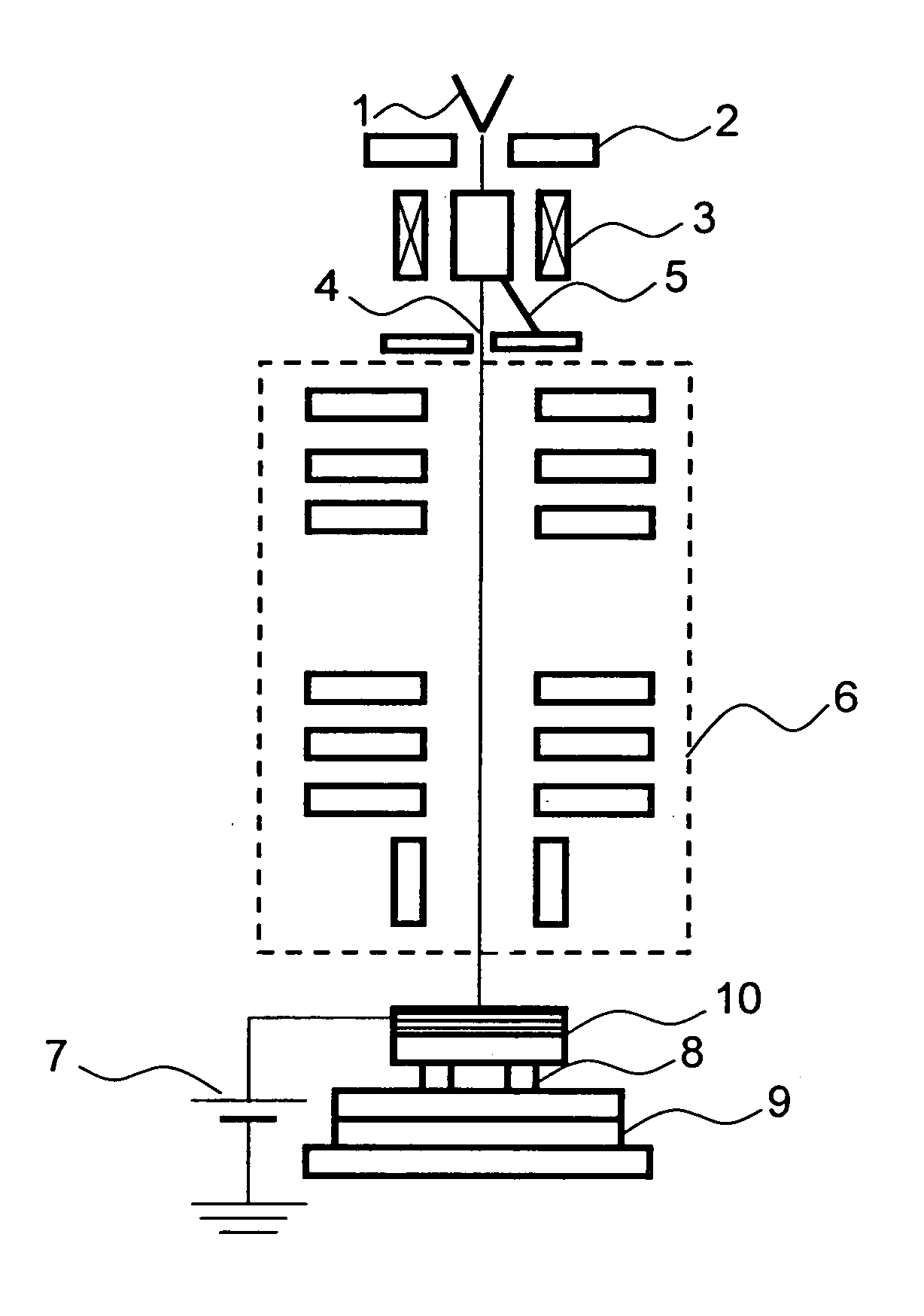

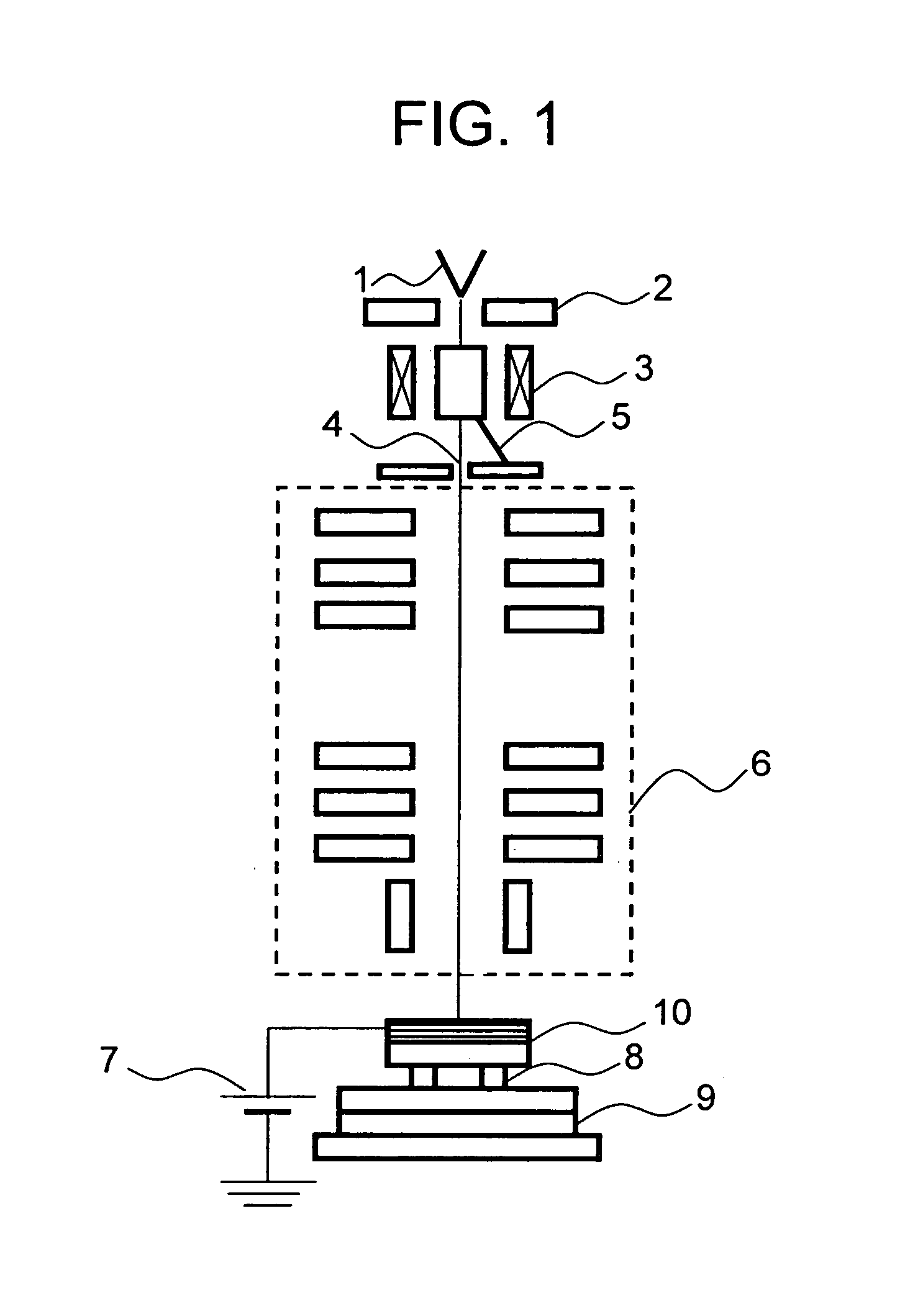

Device and method for preparing pure titanium with liquid alloys as electrodes

The invention provides a device and method for preparing pure titanium with liquid alloys as electrodes. The device comprises a first electrolysis cell, a second electrolysis cell and a bottom liquid alloy communicating hole; the first electrolysis cell comprises a CaCl2 transition anode, a Na2O-SiO2-TiO2 melt and a cathode Ti-Cu liquid alloy; the second electrolysis cell comprises an anode Ti-Cu alloy and a NaCl-KCl-TiClx melt; and the cathode Ti-Cu liquid alloy and the anode Ti-Cu alloy are connected through the bottom liquid alloy communicating hole. According to the device and method for preparing the pure titanium with the liquid alloys as the electrodes, oxygen and titanium elements in raw material TiO2 are separated, and after a titanium alloy is obtained, the titanium alloy can serve as an anode to perform electrolytic refining to obtain the pure titanium; and the process procedure is shortened, the energy consumption is reduced to the maximum extent, and it is achieved that the pure titanium is prepared in a molten salt electrolysis manner of industrialized and continuous production.

Owner:张龙

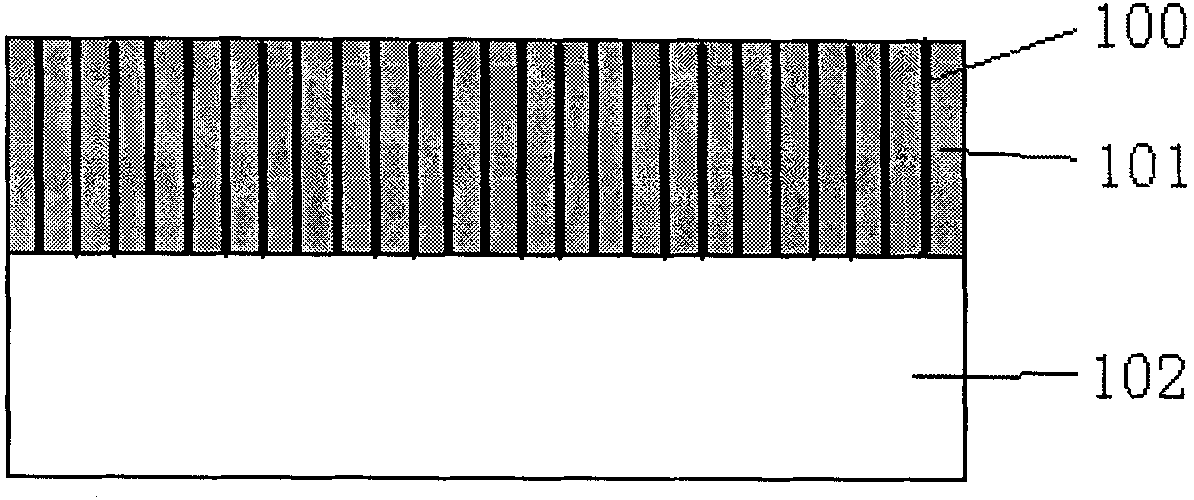

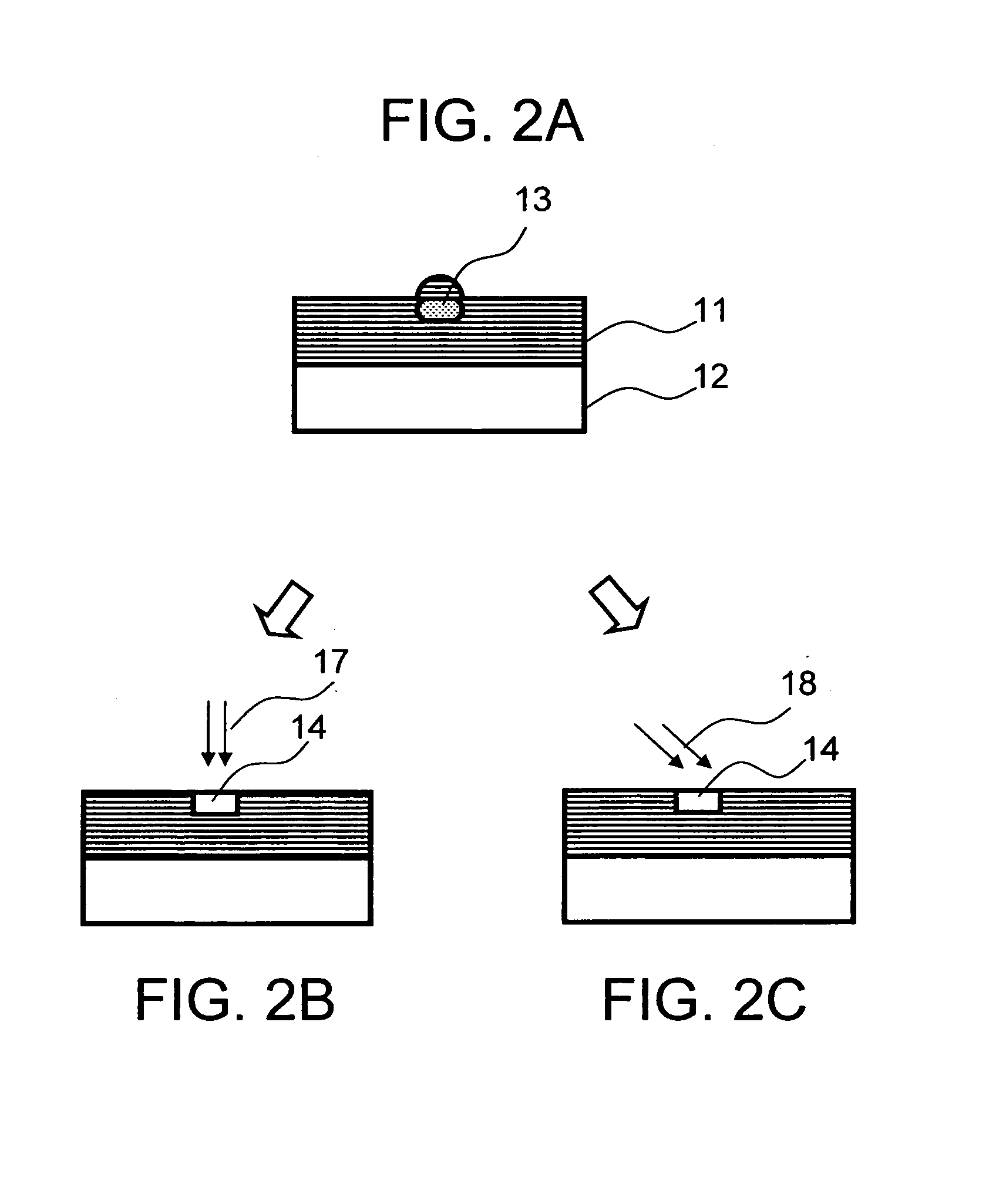

Method of correcting amplitude defect in multilayer film of EUVL mask

Owner:HITACHI HIGH TECH SCI CORP

Method for preparing molybdenum nickel alloy by directly reducing and smelting molybdenum nickel ore

The invention relates to a method for preparing molybdenum nickel alloy by directly reducing and smelting molybdenum nickel ore. The method comprises the following steps: grinding the molybdenum nickel ore into molybdenum nickel ore powder with the average particle size of less than or equal to 0.18 mm; adding a slag forming agent and a reducing agent with the average particle size of less than or equal to 0.18 mm into the molybdenum nickel ore powder to obtain furnace charge; mixing the furnace charge uniformly and pelletizing to obtain pellet; heating the pellet to 1,600 to 1,800 DEG C; smelting; and collecting liquid alloy, slag, smoke dust and furnace gas respectively, wherein the liquid alloy is crude molybdenum nickel alloy; the direct yield of the molybdenum and the nickel is 96 percent and 94 percent respectively; the molybdenum content of the smoke dust is less than 0.2 percent and the nickel content of the smoke dust is less than 0.2 percent; and the SO2 concentration of thefurnace gas is less than or equal to 400 mg / m<3>. The process method is simple and reasonable, and convenient to operate; the molybdenum nickel ore is not subjected to oxidizing roasting de-sulfuration; and the crude molybdenum nickel alloy is prepared by directly reducing and smelting the molybdenum nickel ore and by using the carbon of the molybdenum nickel ore as a reducing agent, so that indirect smelting is changed into direct smelting. The prepared molybdenum nickel alloy is low in sulfur content and phosphorus content, environment friendly and low in production cost; and the method is suitable for extraction of the molybdenum nickel ore.

Owner:CENT SOUTH UNIV +2

Silicide compositions containing alkali metals and methods of making the same

The invention relates to Group 1 metal / silica gel compositions comprising silica gel and an alkali metal or an alkali metal alloy. The compositions of the inventions are described as Stage 0, I, II, and III materials. These materials differ in their preparation and chemical reactivity. Each successive stage may be prepared directly using the methods described below or from an earlier stage material. Stage 0 materials may, for example, be prepared using liquid alloys of Na and K which are rapidly absorbed by silica gel (porous Si02) under isothermal conditions, preferably at or just above room temperature, to form loose black powders that retain much of the reducing ability of the parent metals. When the low melting Group 1 metals are absorbed into the silica gel, a mild exothermic reaction produces Stage I material, loose black powders that are indefinitely stable in dry air. Subsequent heating to 400 DEG C produces Stage II materials, which are also loose black powders. Further heating above 400 DEG C forms Stage III material with release of some Group 1 metal. It is believed that Stage I, II and III materials represent reductions of the silica gel after absorption of the Group 1 metal. Preferred Group 1 metal / silica gel compositions of the invention are those containing sodium, potassium, or sodium-potassium alloys with sodium and sodium- potassium alloys being most preferred. Each stage of the Group 1 metal / silica gel composition of the invention may be used as a reducing agent reacting with a number of reducible organic materials in the same manner known for alkali metals and their alloys.

Owner:SIGNA CHEM INC +1

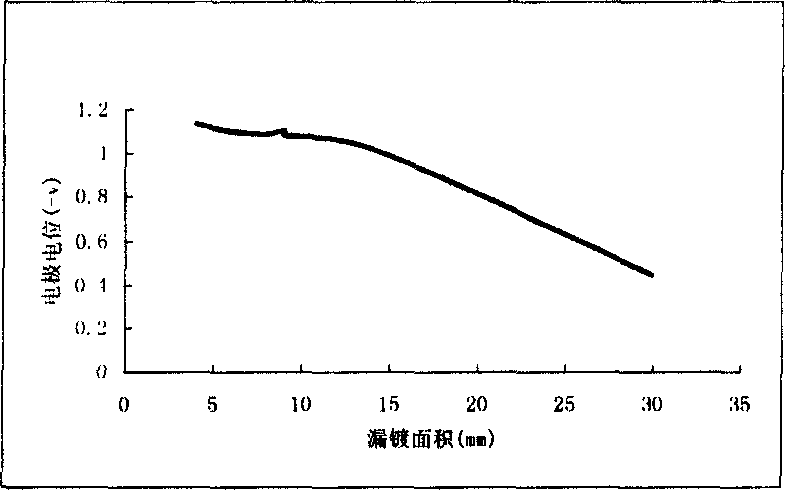

Gallium liquid metal material and application of gallium liquid metal material to teletransmission pressure and different pressure transmitter

ActiveCN105671394AStay sensitiveMaintain precisionFluid pressure measurementLiquid mediumMeasuring instrument

The invention discloses application of a gallium liquid metal material to a teletransmission pressure and different pressure transmitter. The pressure and different pressure transmitter is provided with a capillary tube filled with a liquid medium, and the whole or part of the capillary tube is filled with the gallium liquid metal material. According to parameter requirements of the gallium liquid metal material, the heat conductivity is larger than 10 W / m*k, the kinematic viscosity is (5*10-8-9*10-8) m<2> / s, the melting point is lower than 15 DEG C, and the boiling point is larger than 1000 DEG C. The gallium liquid metal material is gallium liquid metal or gallium-based liquid alloy metal. The application has the beneficial effects that the gallium liquid metal material with the very high nominal melting point is used on the pressure and different pressure transmitter, the gallium liquid metal material is not liable to be vaporized even the nominal high-temperature boundary point is approached, the gallium liquid metal material still has very good fluidity, the performance cannot be affected, and sensitivity and precision of a measuring instrument are maintained. The highest use temperature of the gallium liquid metal material can be 1200 DEG C or higher, and the gallium liquid metal material can also be used on high-temperature and negative-pressure occasions.

Owner:SHANGHAI ROCKSENSOR AUTOMATION

Preparation method of aluminum-titanium-boron wire grain refiner

The invention relates to a preparation method of an aluminum-titanium-boron wire grain refiner. The preparation method is implemented by continuous cast rolling after smelting and specifically comprises the following steps: (1) melting: adding a pure aluminum ingot into a crucible furnace, melting into liquid aluminum, and heating; (2) alloying: sequentially adding potassium chloride, potassium fluotitanate and potassium fluotitanate into the liquid aluminum in the liquid aluminum heating process in the step (1), and heating while stirring until the reaction is complete, thereby obtaining liquid alloy aluminum; (3) stirring, degassing and deslagging: transferring the liquid alloy aluminum prepared in the step (2) into an industrial-frequency core-free holding furnace, and stirring and degassing; and (4) continuous cast rolling: transferring the deslagged liquid aluminum into a mold, carrying out rubber filtration, crystallizing the wheel die cavity, carrying out continuous rolling by a continuous rolling machine, and taking up to obtain the aluminum-titanium-boron wire. The preparation method avoids the phenomenon of blistering or loosening since the liquid aluminum is oxidized or absorbs gas, and enhances the elongation percentage of the aluminum-titanium-boron wire.

Owner:NANTONG ANGSHEN METAL MATERIALS

Corrosion prevention technique of aluminum zinc rare earth alloying for oil pipe

InactiveCN1563471AHigh hardnessImprove corrosion resistanceHot-dipping/immersion processesCorrosion preventionRare earthZinc

This invention relates to ZnAl rare earth alloy antiseptic technology mainly solving the problem of poor antiseptic results of current or / tubs characterizing including the following steps: the inside and outside wall surfaces of the oil tube are de-fat, washed, washed with acid and processed with coating aid to be put into a Zn solution tank containing liquid ZnAl rare earth alloy under 430deg.C-440deg.C to be coated and taken out to be passivated with heavy sodium chromate and HNo3 and washed, said liquid alloy applies alloying method in smelting.

Owner:DAQING OILFIELD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com