High strength nickel base corrosion resistance alloy and manufacturing method thereof

A technology of corrosion-resistant alloy and manufacturing method, which is applied in the field of nickel-based corrosion-resistant alloy to achieve the effects of easy control of process parameters, simple process flow and improved mechanical properties

Active Publication Date: 2013-01-30

BAOSHAN IRON & STEEL CO LTD

View PDF1 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0009] It can be seen that some nickel-based corrosion-resistant alloys in the prior art cannot fully meet the current use and manufacturing require

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

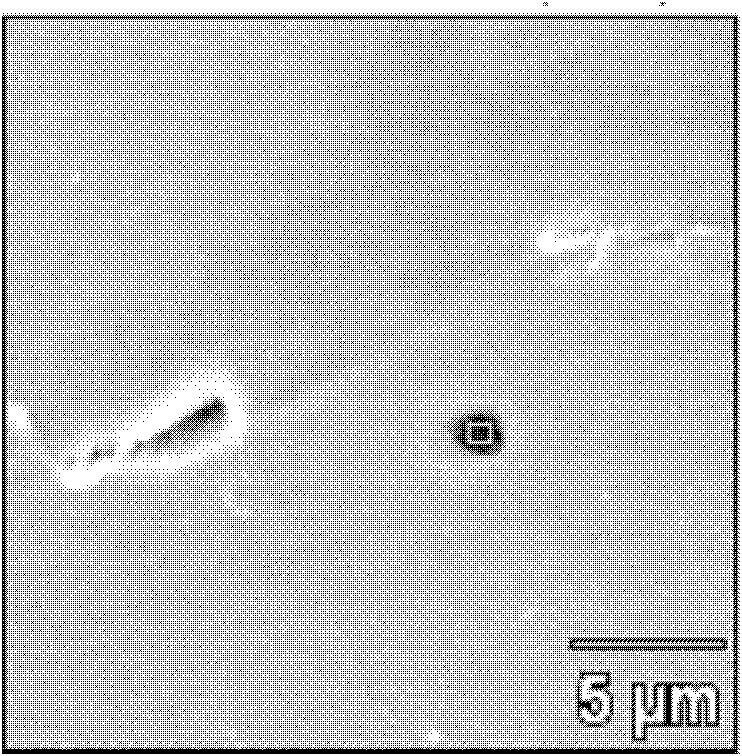

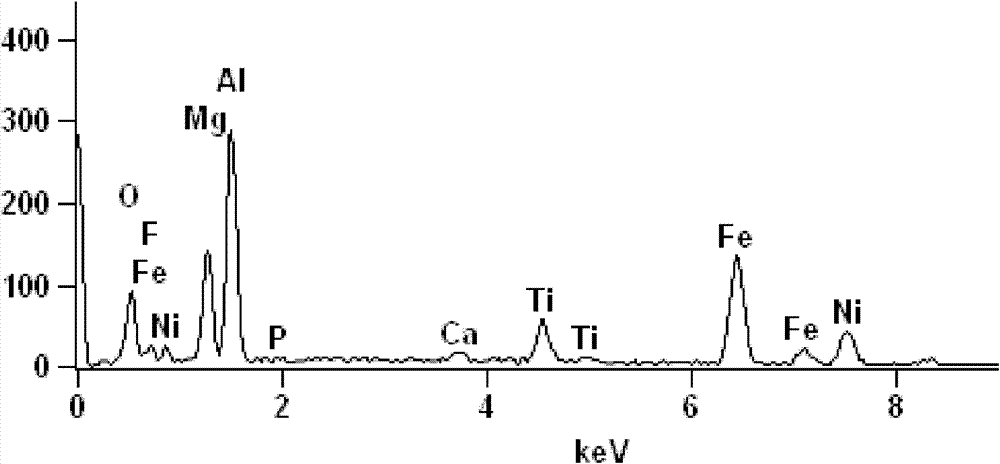

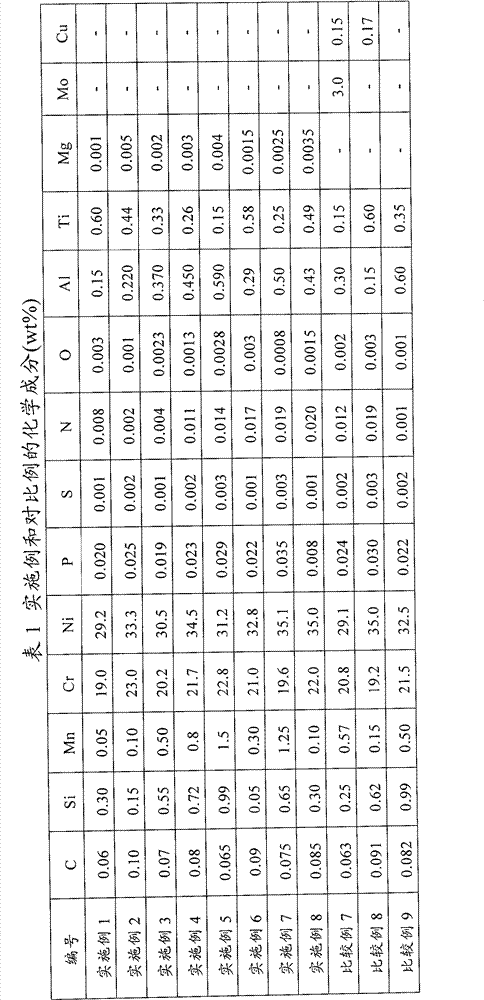

The present invention relates to a high strength nickel base corrosion resistance alloy, which has the following components, by mass, 0.06-0.10% of C, less than or equal to 1.0% of Si, less than or equal to 1.50% of Mn, 19.0-23.0% of Cr, less than or equal to 0.035% of P, less than or equal to 0.001% of S, less than or equal to 0.020% of N, 29.0-35.0% of Ni, 0.15-0.6% of Ti, 0.15-0.6% of Al, 0.001-0.005% of Mg, less than or equal to 0.5% of Cu+O, and the balance of Fe and unavoidable impurities. The nickel base corrosion resistance alloy has a fully austenite structure, and forms MgO and/or MgO.Al2O3 particles with a diameter of about 10 nm-1 mum and a number of 30-50/mm<2> in a liquid alloy so as to refine the diameter of the initial solidified grains of the alloy continuous casting billet to about 0.5-1.0 mm. In addition, a vertical continuous casting process is adopted to produce, such that surface cracks of the continuous casting billet are avoided; and the grain size of the final product is controlled to the 3.5-4 level, such that the product has characteristics of excellent mechanical property, excellent high temperature creep resistance, and the like, and is suitable for manufacture of parts of furnace devices, heat exchangers, steam-powered turbines, and the like.

Description

technical field [0001] The invention belongs to the field of nickel-based corrosion-resistant alloys, and mainly relates to the smelting and vertical continuous casting of a nickel-based corrosion-resistant alloy with complete austenitic structure, in particular to a high-strength austenitic nickel-based corrosion-resistant alloy Alloys and methods of making them. Background technique [0002] The 800 series of nickel-based corrosion-resistant alloys entered the market in the 1950s, with the purpose of meeting the needs of heat resistance and corrosion resistance at a relatively low Ni content. Over the past 50 years, these nickel-based corrosion-resistant alloys have been widely used for their high-temperature strength, oxidation resistance, and other high-temperature corrosion resistance properties. Applications include furnace units, oil lines, sumps, heat exchangers, steam power turbines and more. The performance and operational reliability of these devices will direct...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/50C22C30/00C22C30/02B22D11/111B22D11/041C21D8/02

Inventor 郑宏光李元马天军杨健朱信国刘旭峰范正洁沈建国

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com