Patents

Literature

164results about How to "Improve creep performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acrylic pressure-sensitive adhesive composition for polarizing film

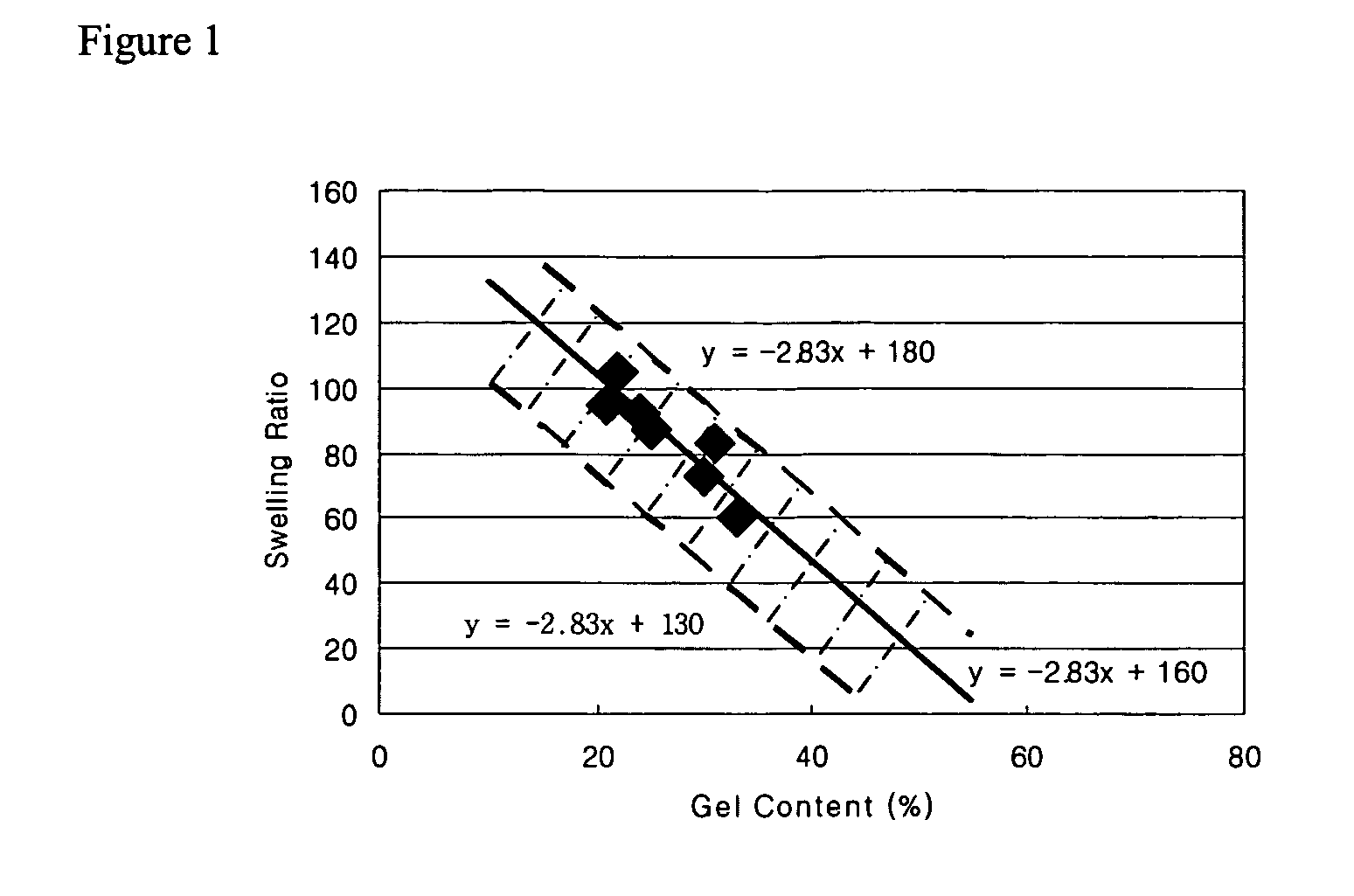

ActiveUS20070055006A1Improve light leakagePreventing operability decreaseEster polymer adhesivesEmulsion paintsPolymer scienceSwelling ratio

The present invention relates to an acrylic pressure sensitive adhesive composition comprising (meth)acrylic copolymers including alkyl(meth)acrylic acid ester monomer having 1˜12 carbon atoms of alkyl group, characterized in that the gel content is 10˜55%, the swelling ratio is 30˜110, the weight average molecular weight of sol eluted from the adhesive by ethyl acetate is at least 800,000, the molecular weight distribution is 2.0˜7.0; and a polarizer and a liquid crystal display comprising the above composition show excellent durability under a high temperature and humidity condition, and can improve the light leakage phenomenon and provide excellent operability at the time of manufacturing polarizer by effectively providing high modulus and stress release property.

Owner:SHANJIN OPTOELECTRONICS SUZHOU CO LTD

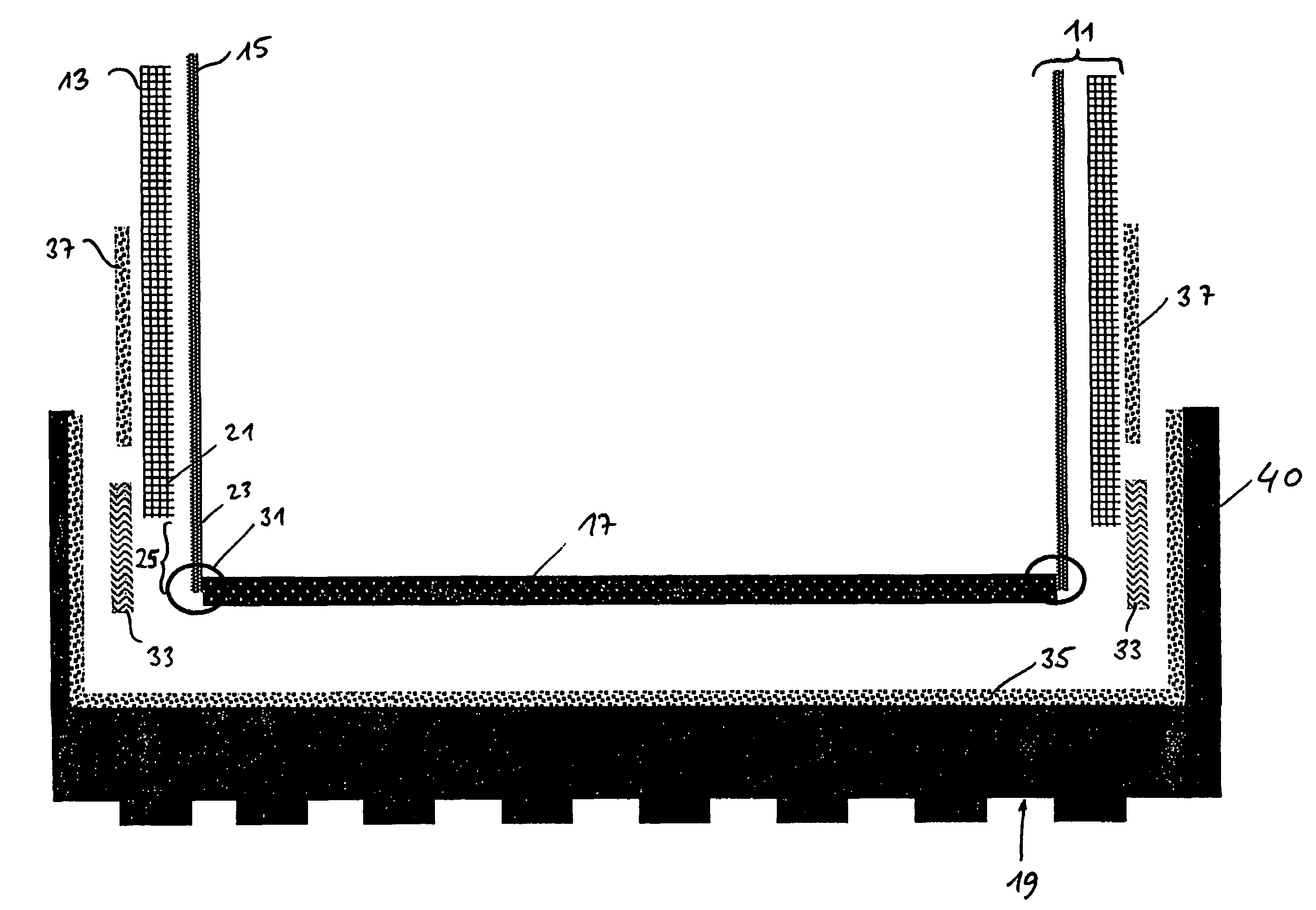

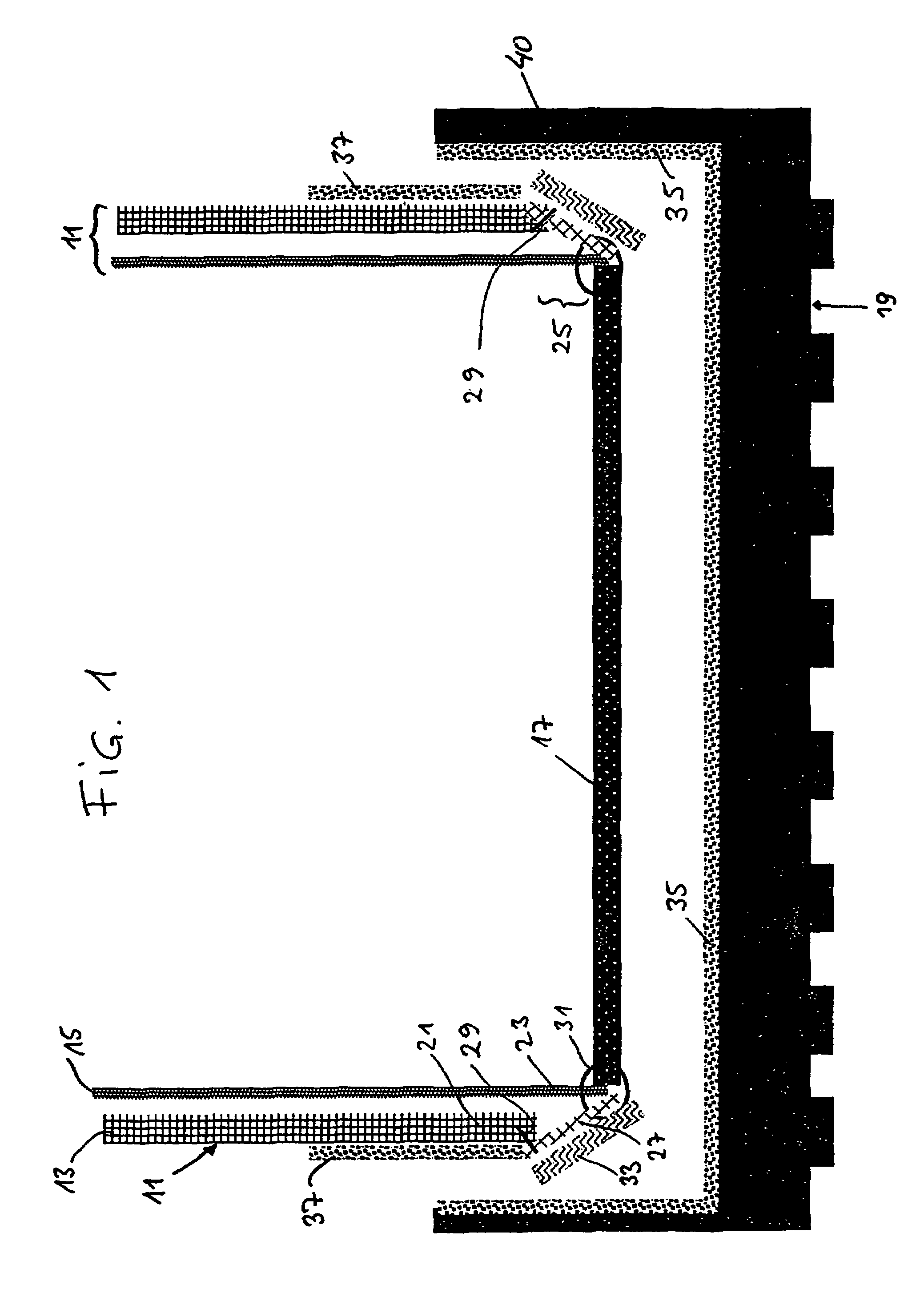

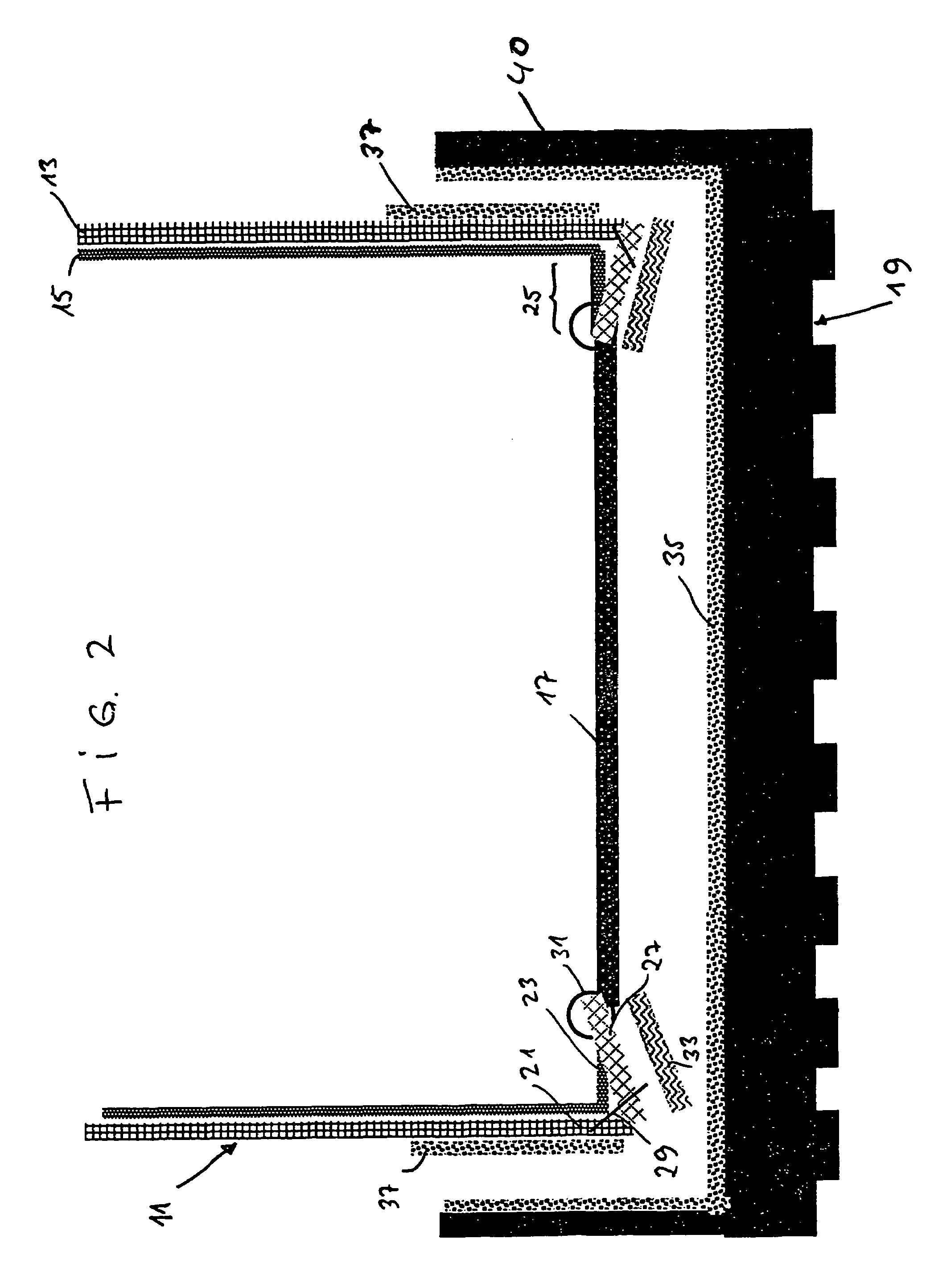

Containers and methods for containing pressurized fluids using reinforced fibers and methods for making such containers

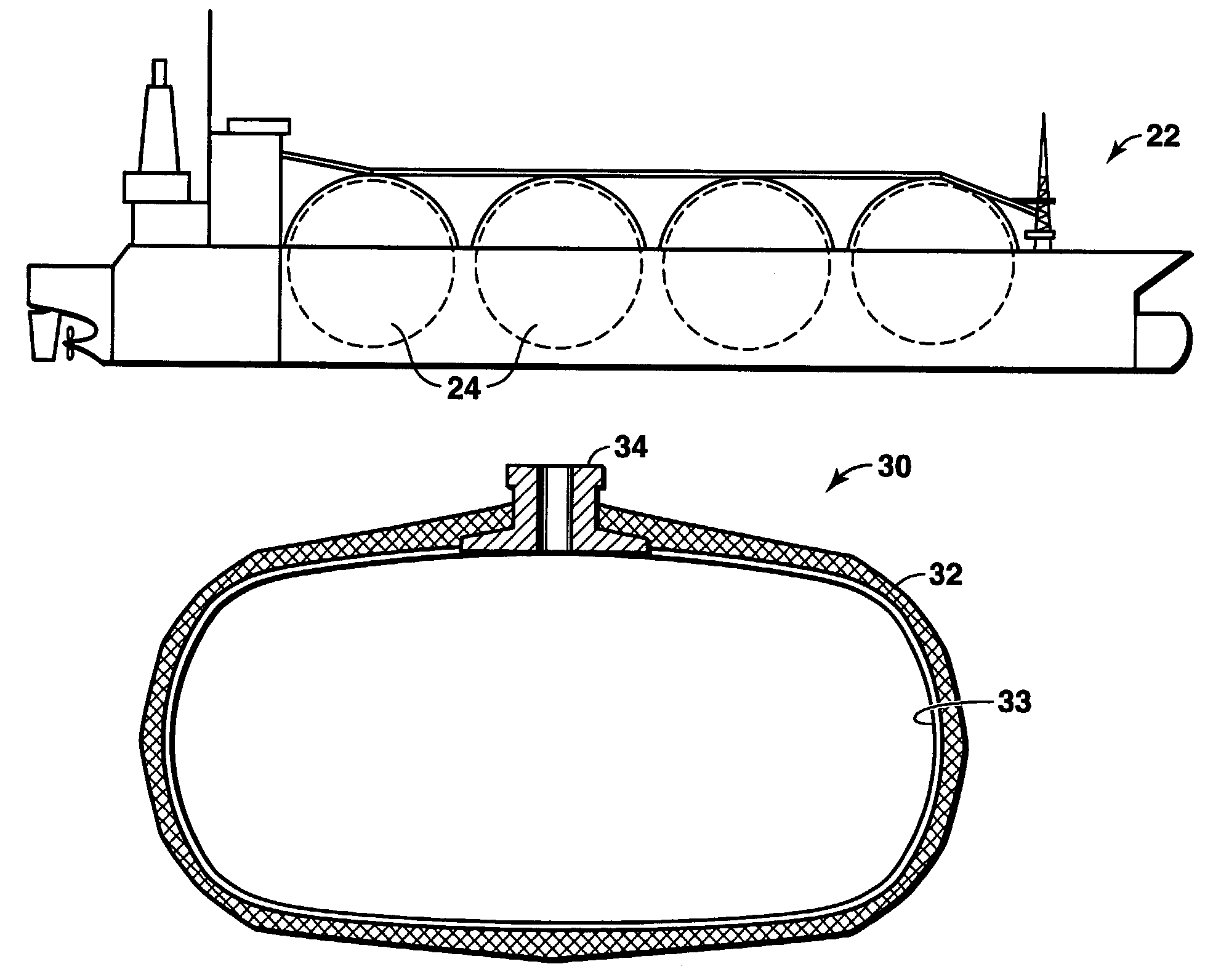

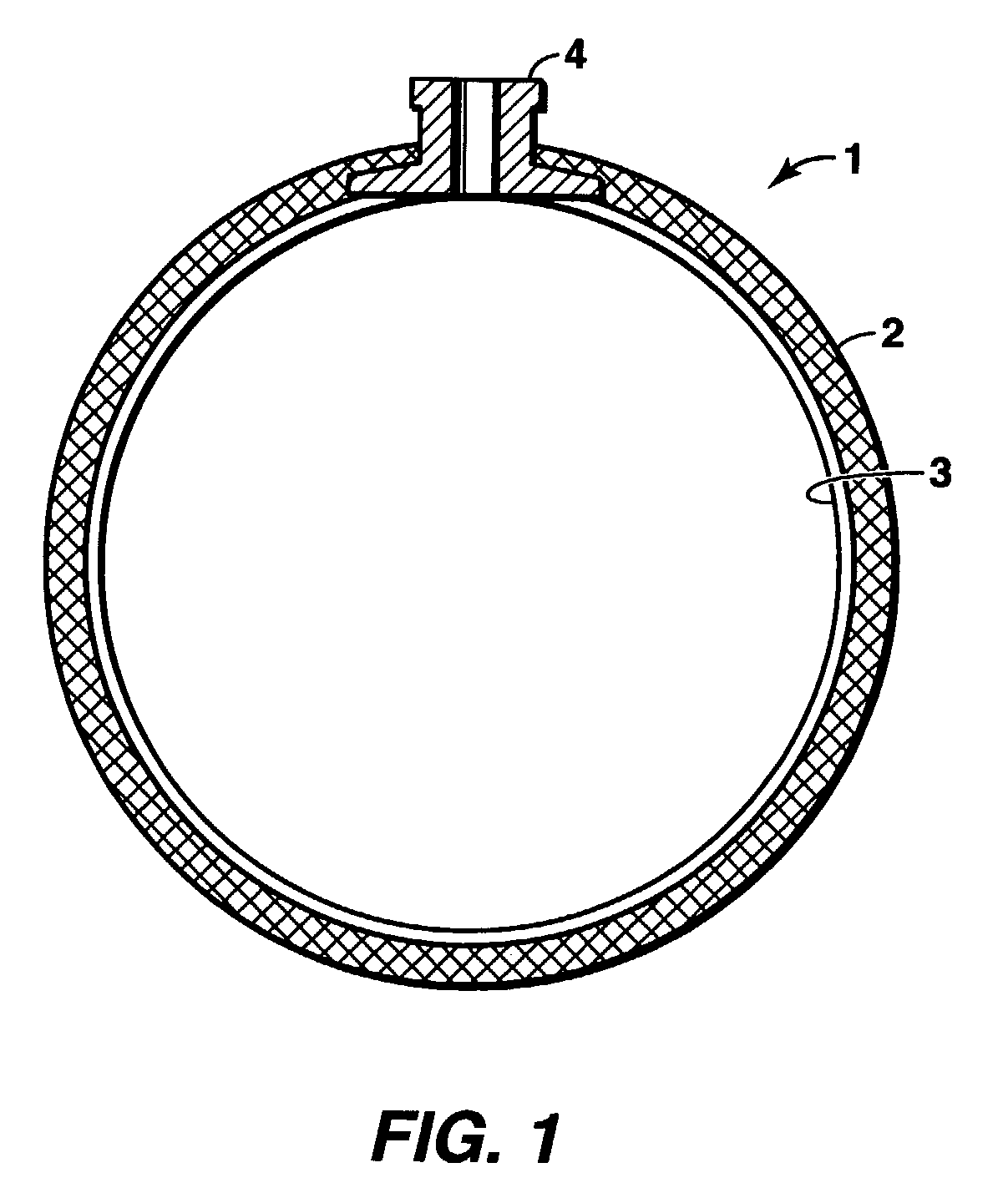

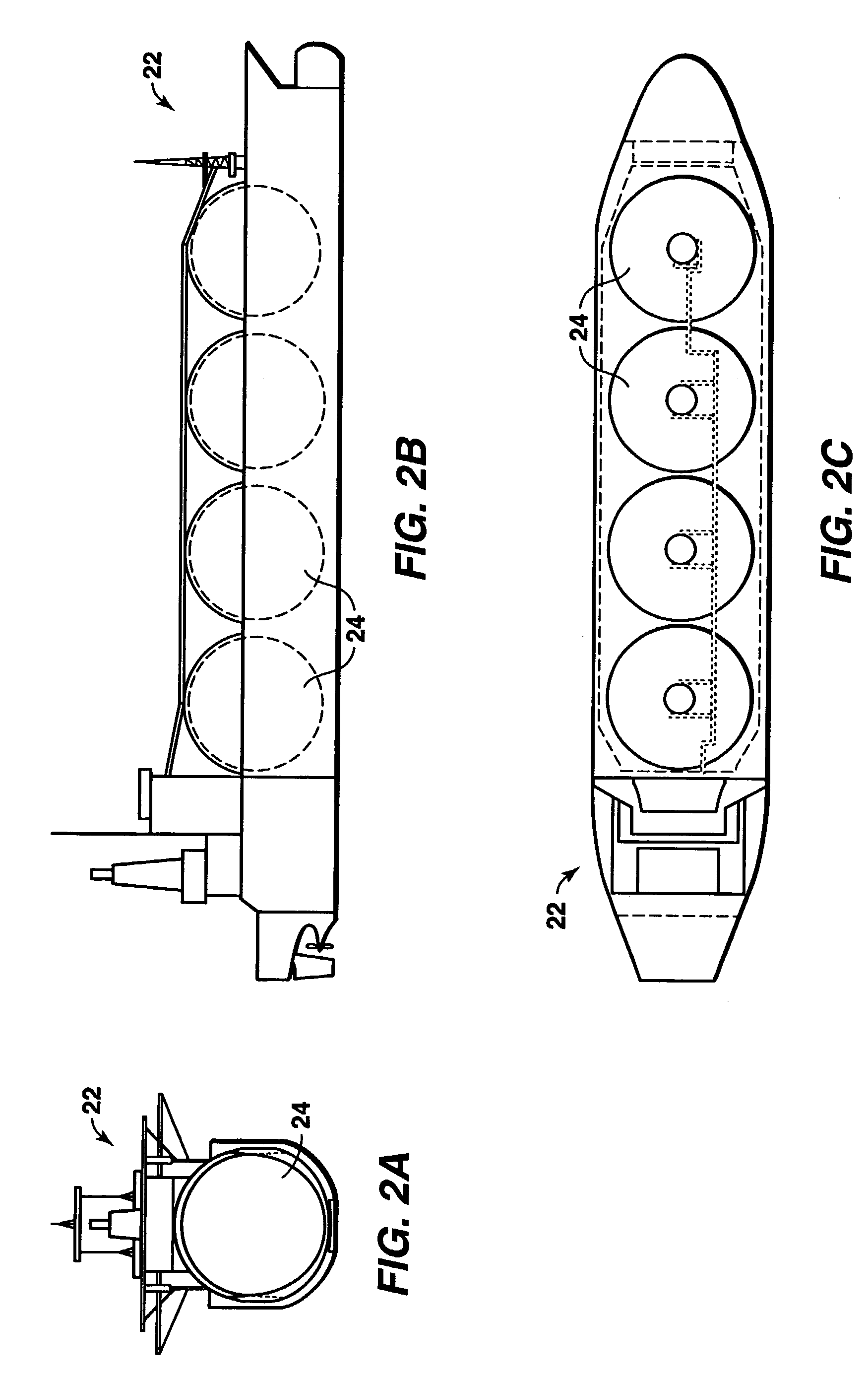

InactiveUS7147124B2Improve creep performanceImprove compactionVessel mounting detailsVessel manufacturingFiberPolymer science

Containers suitable for storing pressurized fluids at cryogenic temperatures of −62° C. (−80° F.) and colder are provided and comprise a self-supporting liner and load-bearing composite overwrap, whereby means are provided for substantially preventing failure of the container during temperature changes.

Owner:EXXONMOBIL UPSTREAM RES CO

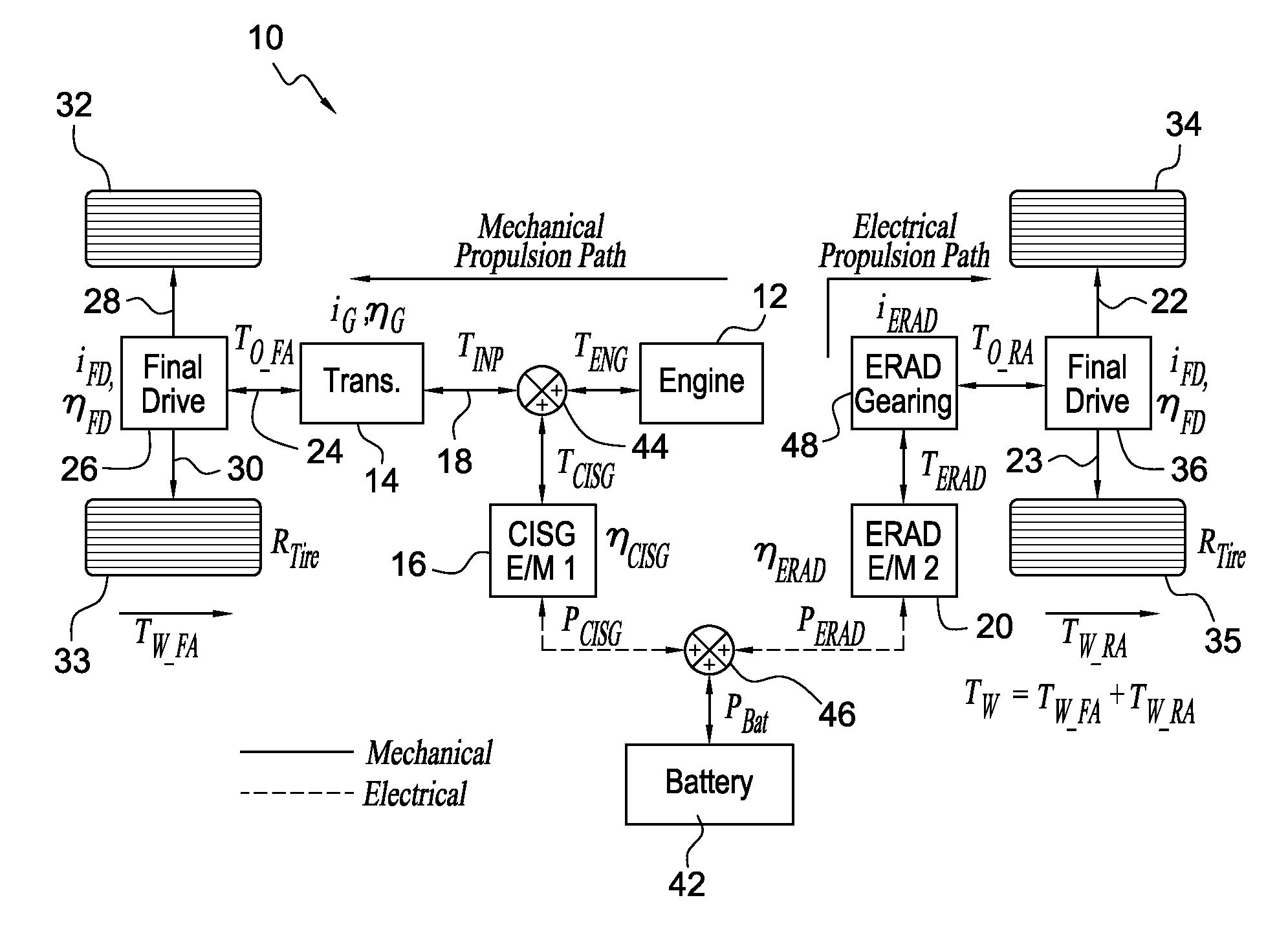

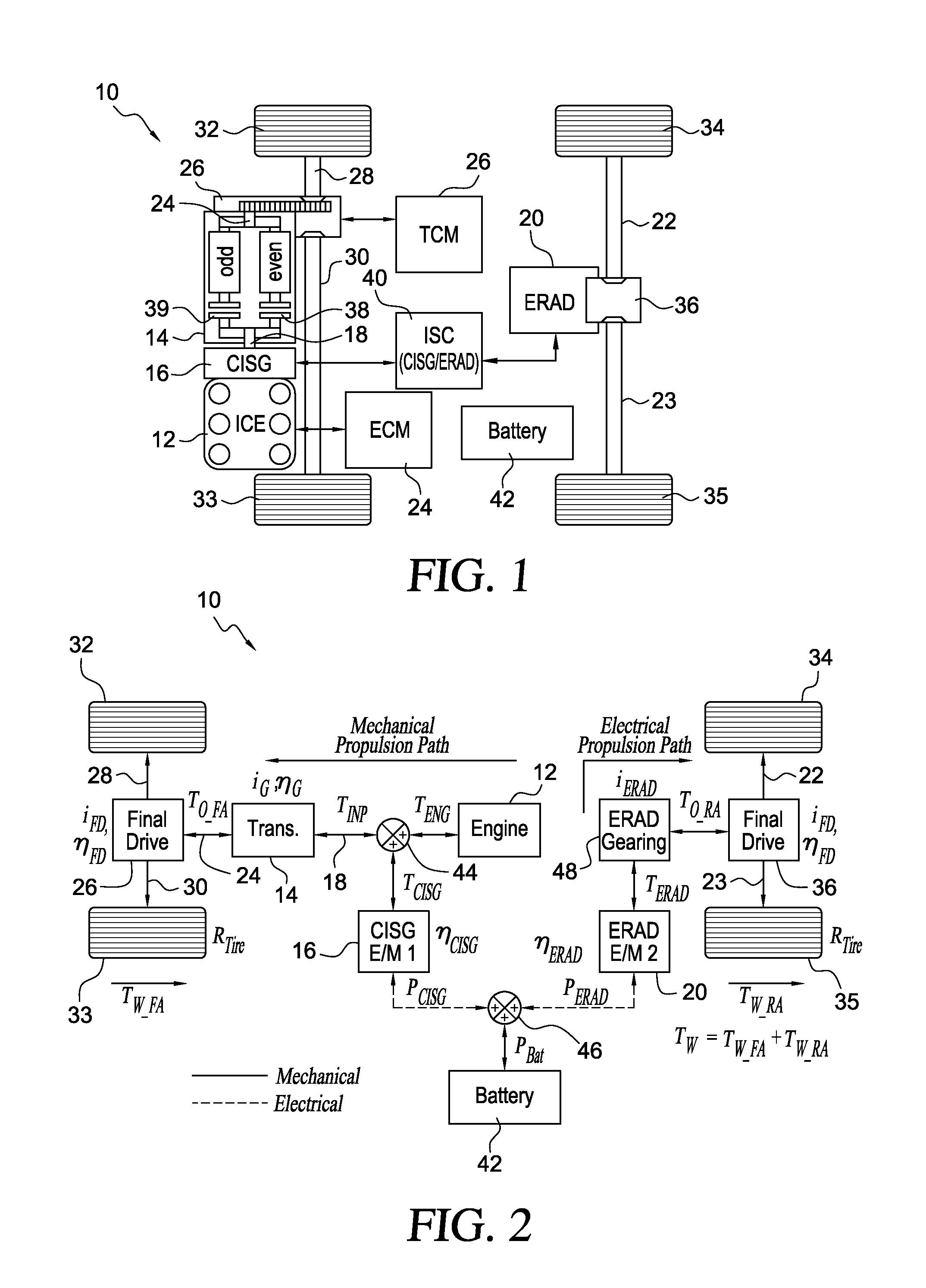

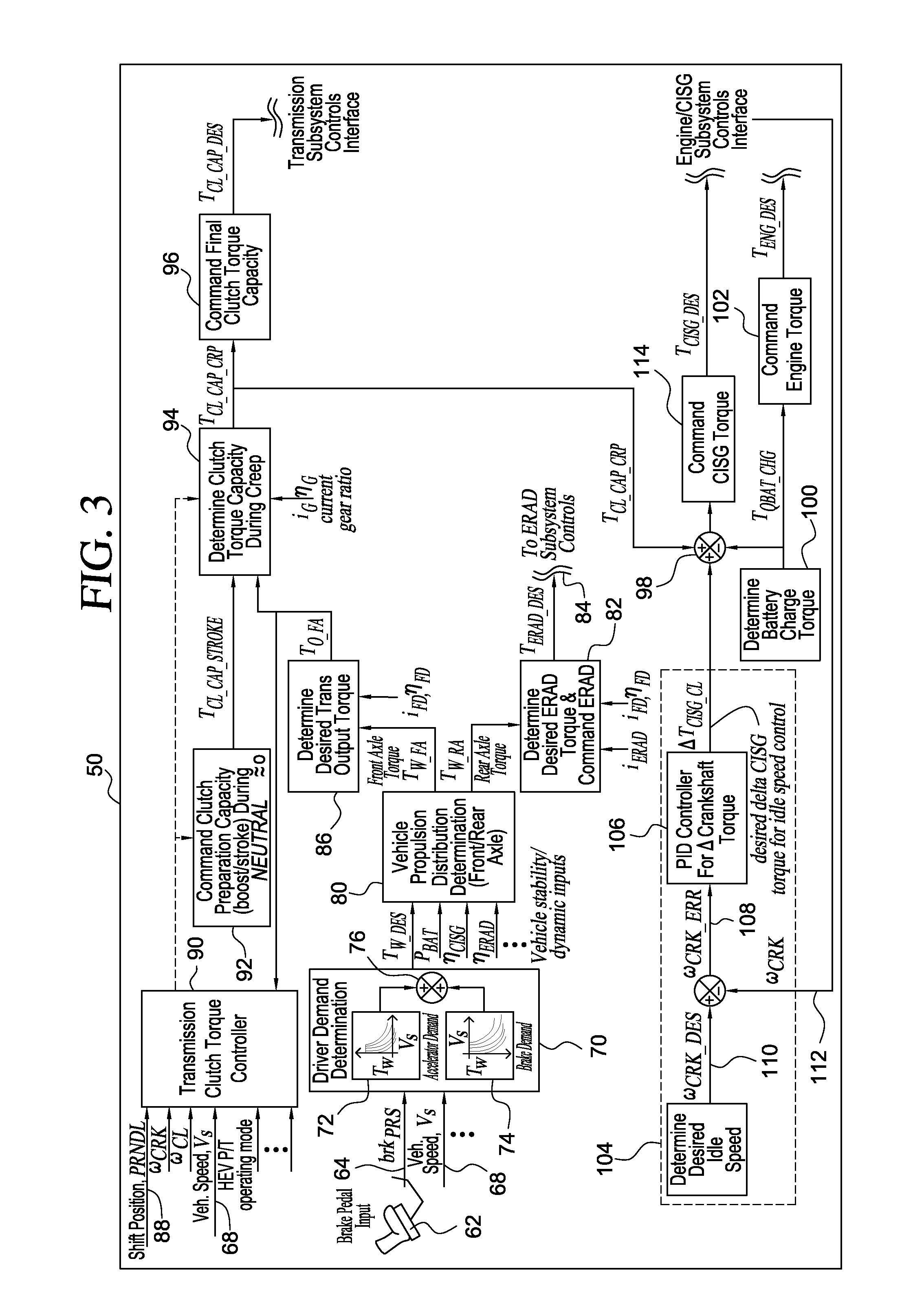

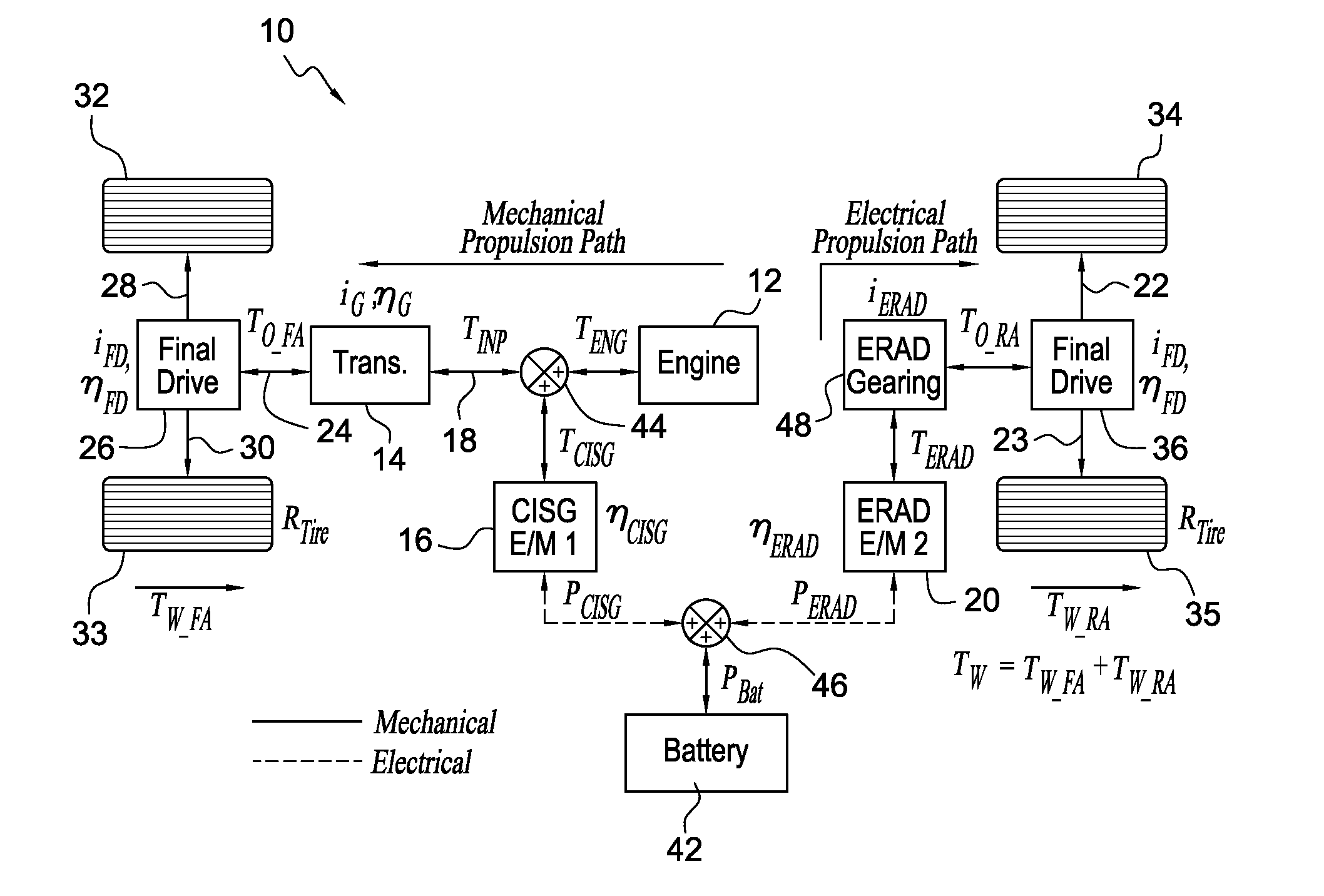

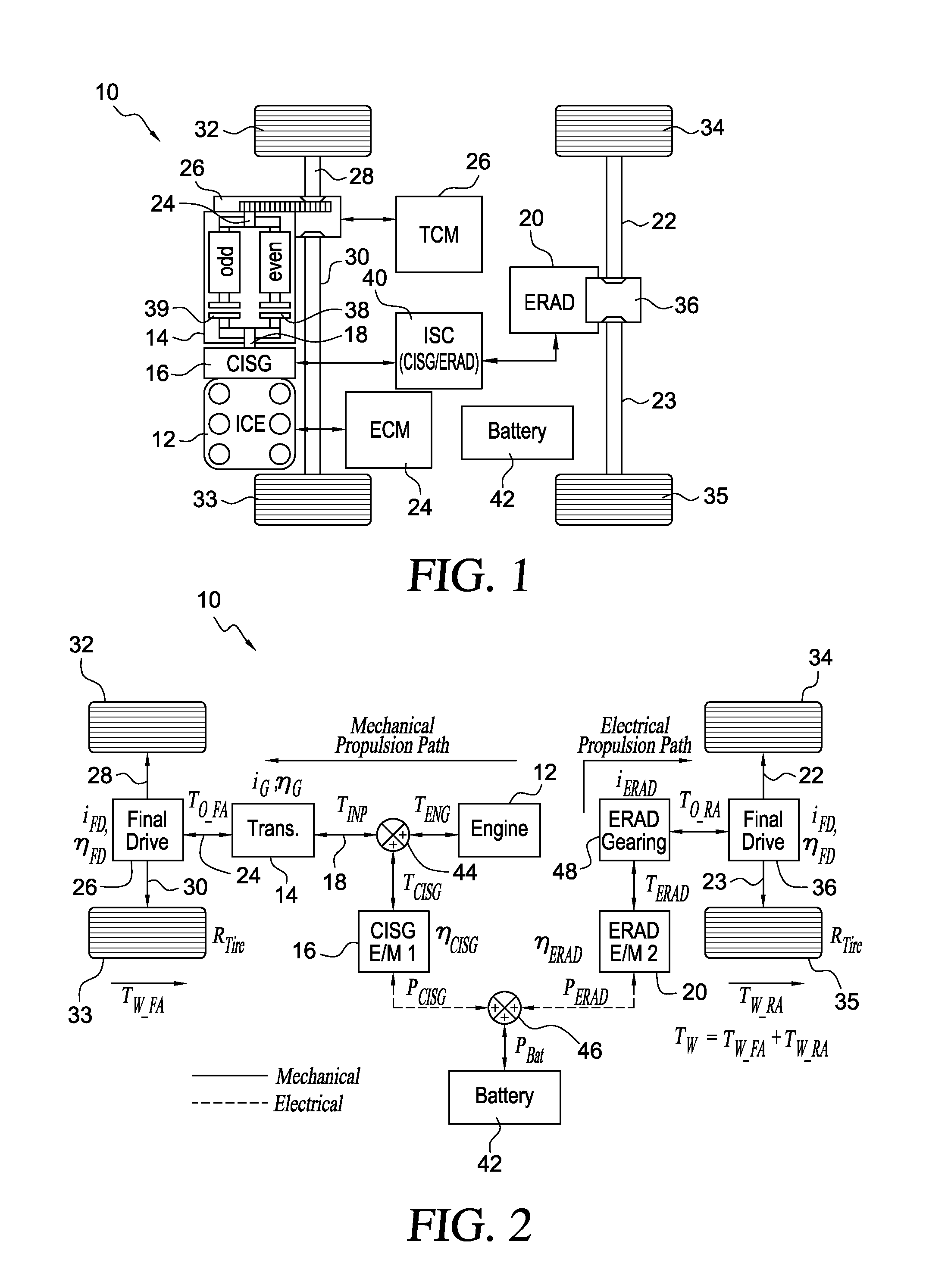

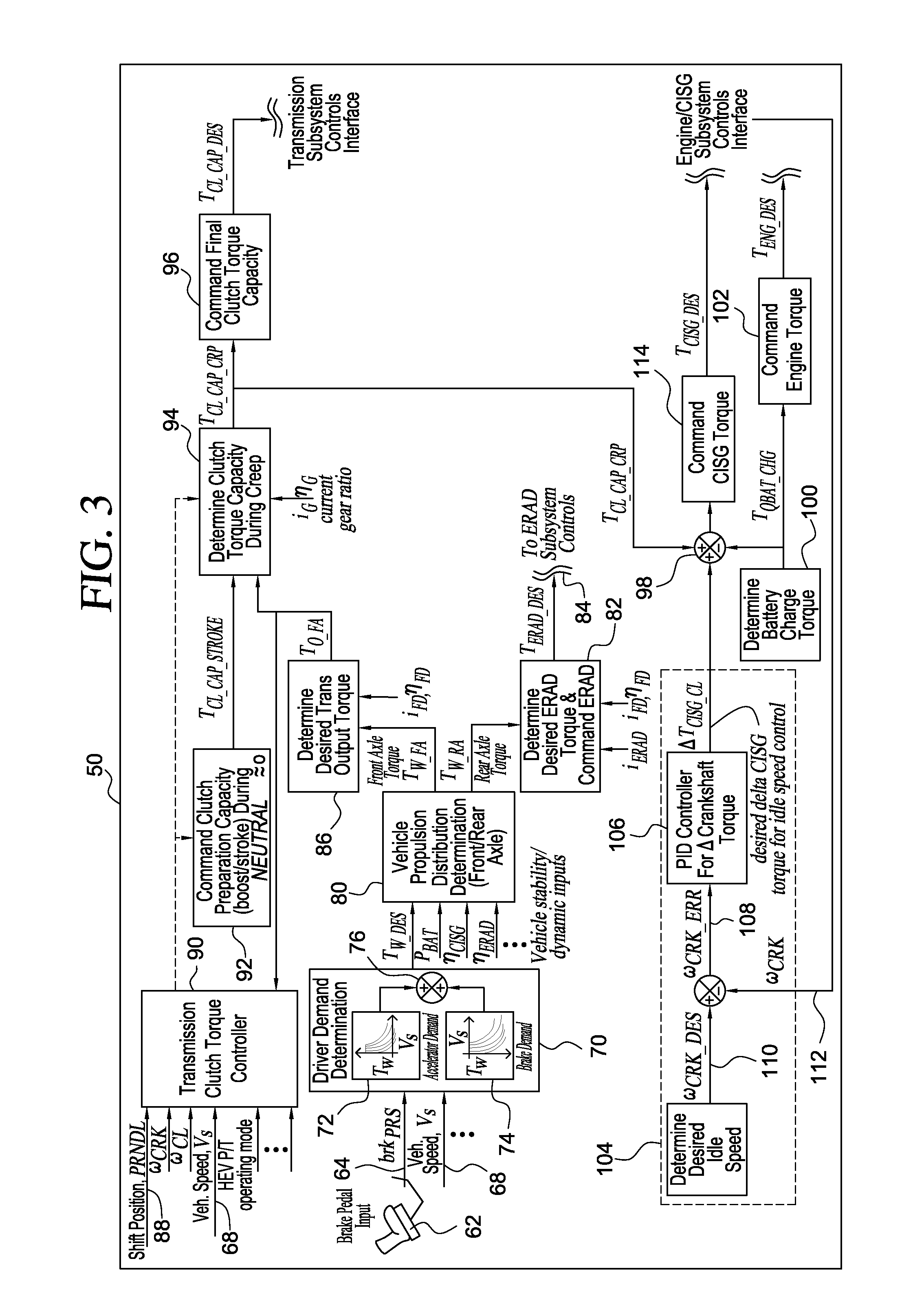

Vehicle Creep Control in a Hybrid Electric Vehicle

ActiveUS20090093336A1Improve vehicle creep performanceEnhances powershift transmission controlBatteries circuit arrangementsElectric propulsion mountingElectricityState of charge

In a powertrain that includes wheels for driving a vehicle, an engine including a crankshaft, a machine driveably connected to the crankshaft and able to operate alternately as an electric motor and electric generator, a transmission including an input clutch driveably connected to the crankshaft and an output driveably connected to at least two of the wheels, and an electric storage battery having a variable state of charge and electrically connected to the machine, a method for controlling vehicle creep including adjusting a torque capacity of the input clutch to a desired magnitude of input clutch torque transmitted to the wheels, determining a desired change in torque produced by the machine such that a speed of the crankshaft is controlled to a desired idle speed, using the magnitude of input clutch torque capacity and the desired change in torque produced by the machine to determine a desired magnitude machine torque, and using the machine to produce said desired magnitude of machine torque.

Owner:FORD GLOBAL TECH LLC

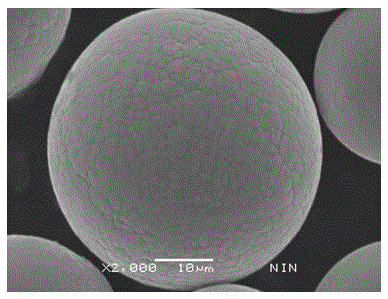

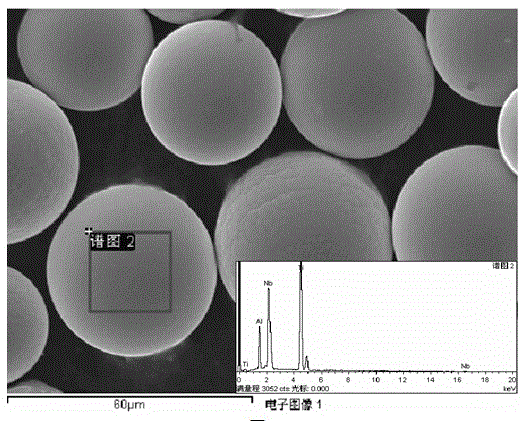

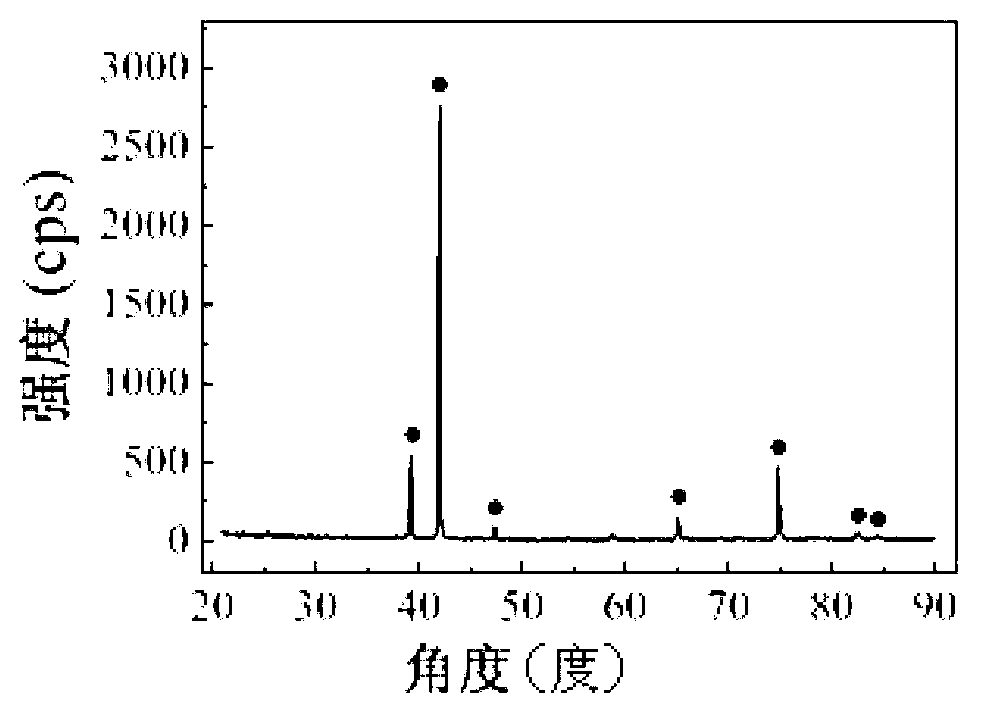

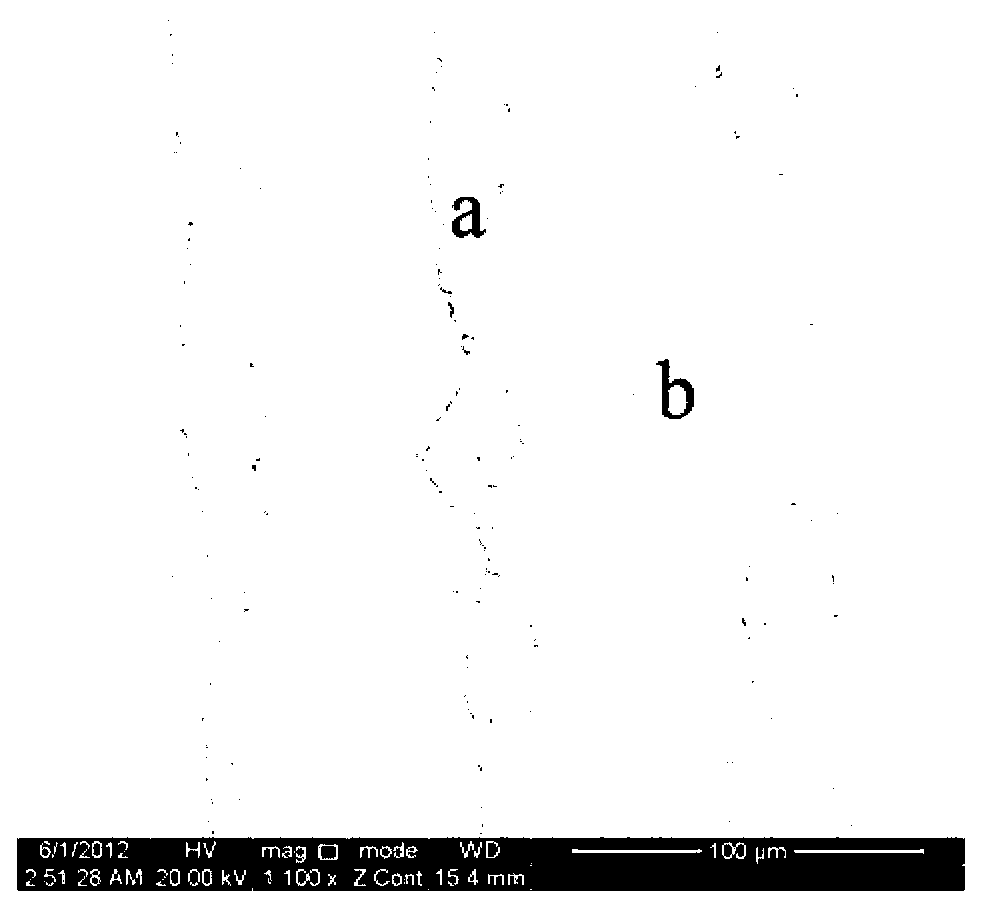

Preparing method for ultra-fine high-purity Ti2AlNb alloy powder

ActiveCN105537603AHigh purityHigh sphericityTransportation and packagingMetal-working apparatusAlloyUltra fine

The invention provides a preparing method for ultra-fine high-purity Ti2AlNb alloy powder. The preparing method comprises the following steps that 1, components of a Ti2AlNb base alloy are used as ingredients and smelted into a Ti2AlNb alloy bar; 2, finish turning is carried out on the smelted Ti2AlNb alloy bar, the diameter of a processed electrode bar ranges from 10 mm to 100 mm, and the length ranges from 100 mm to 1000 mm; 3, the electrode bar is loaded into a reaction chamber, the reaction chamber is vacuumized, and helium or argon or helium and argon mixed gas is introduced into the reaction chamber; 4, plasma gun powder of PREP powder manufacturing equipment ranges from 100 kW to 300 kW, a plasma torch comprises a tungsten cathode and a copper anode, the electrode bar is not used as an electrode, the end of the electrode bar is heated to be melted uniformly, atomized drops are tossed out from the end of the electrode bar, the drops are cooled fast in an inert gas environment to form spherical particles, and the spherical particles drop into a bottom collector of the reaction chamber; 5, prepared Ti2AlNb alloy powder is screened and packaged in the inert gas protection environment; 6, the Ti2AlNb alloy powder prepared through the method has the advantages of being ultra-fine, high in purity, high in spherical degree and low in oxygen content.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

Solid aluminum alloy conductor and preparation method thereof

ActiveCN103146960AUp to conductor cross sectionAchieve the required electricalCable/conductor manufactureRare-earth elementElectrical conductor

The invention provides a solid aluminum alloy conductor and a preparation method thereof. The solid aluminum alloy conductor contains by weigh 0.40-1.00% of iron, 0.05-0.20% of copper, 0.05-0.10% of silicon, 0.02-0.12% of zinc, 0.01-0.05% of magnesium, 0.02-0.12% of rare earth element and the balance of aluminum and unavoidable impurities. The method comprises steps of: completely melting an aluminum ingot; adding a magnesium ingot with a special tool; after melting, sequentially adding manganese aluminum alloy, zinc aluminum alloy, copper aluminum alloy, iron aluminum alloy, silicon aluminum alloy and rare earth aluminum alloy of different weights; fully mixing, refining and conducting ladle analysis; after qualification of all components, casting and rolling into a required aluminum alloy rod; conducting aging treatment; extruding the required solid core conductor according to the requirements; conducting special heat treatment to reach corresponding performance indicators, so as to meet the need to substitute a traditional copper core electrical wire of electrical wire materials.

Owner:ANHUI NANYANG NEW MATERIAL TECH CO LTD

Cellulosic inorganic-filled plastic composite

The present invention is a plastic composite reinforced by cellulosic material and talc. The composite preferably includes about 20% to 40% by weight of talc, about 10% to 60% by weight of a cellulosic material, and about 20% to 70% by weight of thermoplastic polymer, wherein the total amount of talc and cellulosic material comprise about 30% to 80% by weight of the composite. The present invention also includes articles made with composites of the present invention and methods for extruding such a composite.

Owner:IMERYS TALC AMERICA INC

Footwear with sealed sole construction and method for producing same

Footwear with an upper and a sole construction having an outsole, in which the upper is constructed with an outer material and with a waterproof functional layer at least partially lining the outer material on the inner side of the latter and having an upper end region on the sole side with an outer-material end region and a functional-layer end region, the outsole (19) is joined to the upper end region, the functional-layer end region has an overhang projecting beyond the outer-material end region and an adhesive zone which is closed in the direction of the sole periphery and comprises a reactive hot-melt adhesive which brings about waterproofness when in the fully reacted state is applied to the overhang.

Owner:HAIMERL FRANZ

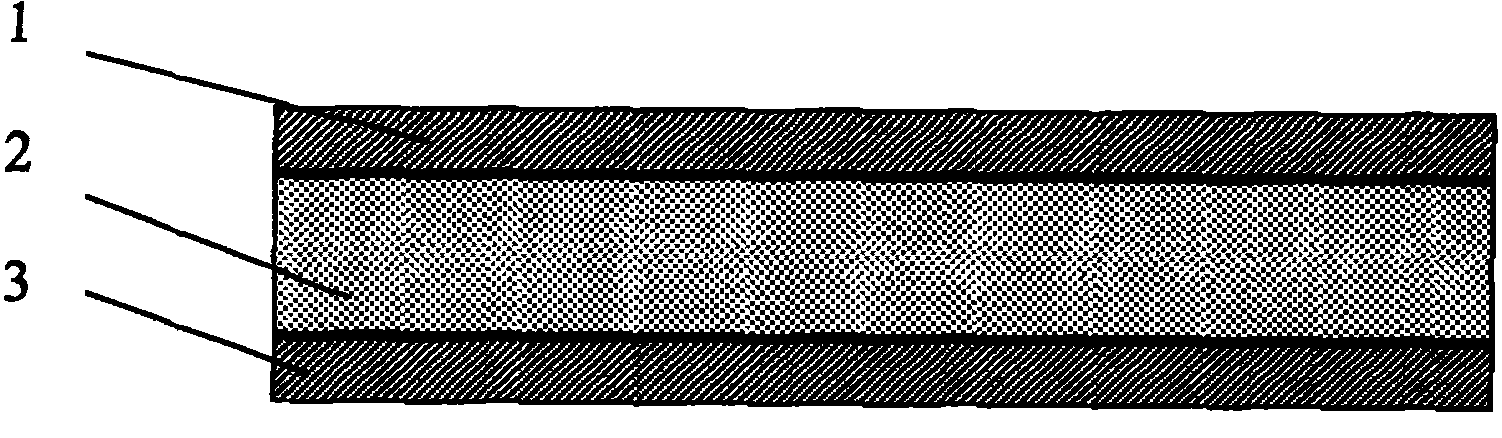

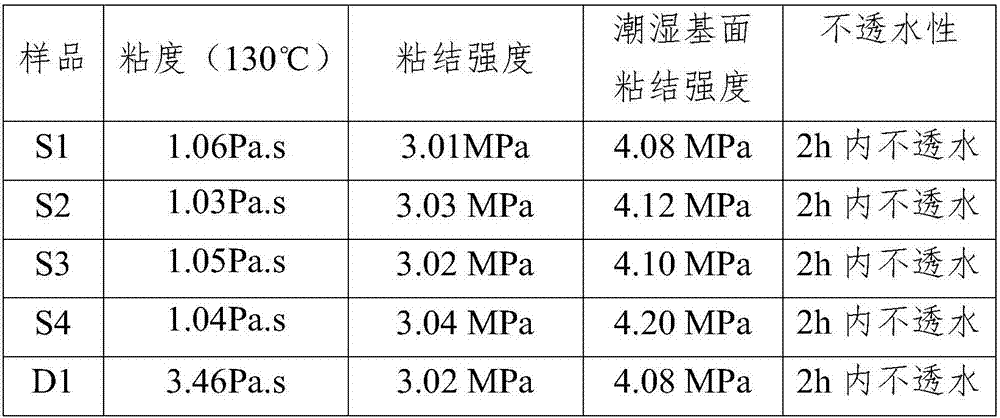

Reactive self-adhered ethylene-propylene-diene monomer waterproof roll

ActiveCN104017512ASelf-adhesiveSelf-healingNon-macromolecular adhesive additivesFilm/foil adhesivesPolyethylene terephthalate glycolWear resistant

The invention relates to a reactive self-adhered ethylene-propylene-diene monomer waterproof roll which consists of a surface waterproof layer, a middle self-adhering layer and a bottom isolating layer, wherein the surface waterproof layer is formed by co-mixing ethylene-propylene-diene monomer rubber, zinc oxide, sulfur, stearic acid, highly wear-resistant carbon black, processing oil and an accelerator DM, the middle self-adhering layer is an active self-adhered sizing material which is formed by co-mixing asphalt, a softener, a tackifier, butyl rubber IIR (Isobutylene-Isoprene Rubber), butadiene styrene rubber, an activator and filler, and the bottom isolating layer is a PET (Polyethylene Terephthalate) thin film. As the middle self-adhering layer which contains asphalt and active macromolecular active components and has the active reactive self-adhered sizing material is arranged in the upper layer on the inner surface of the surface waterproof layer which takes ethylene-propylene-diene monomer as a main material, so that edges of the roll and the roll and the base layer of concrete are directly adhered by the middle self-adhering layer without any adhesives in match. The generated waterproof layer has a service life effect which is equal to that of a main body material, so that the roll is an ideal upgrading product of existing single ethylene-propylene-diene monomer waterproof roll.

Owner:上海北新月皇新材料集团有限公司

RRP (polypropylene random) temperature-resistant water pipe

InactiveCN104059300AImprove creep performanceGood weather resistanceGeneral water supply conservationFlexible pipesLinear low-density polyethyleneWeather resistance

The invention relates to the technical field of plastic product processing, particularly a RRP (polypropylene random) temperature-resistant water pipe. The RRP temperature-resistant water pipe is prepared from the following raw materials in parts by weight: 60-80 parts of carrier resin, 10-30 parts of LLDPE (linear low-density polyethylene), 1-6 parts of butyl rubber and 3-8 parts of special coloring master batch for RRP pipes. The temperature-resistant pipe has the advantages of high toughness, favorable weather resistance, wide application range and high safety, and can be used as both a cold-water pipe and a hot-water pipe.

Owner:BLUESTAR CHENGDU NEW MATERIALS

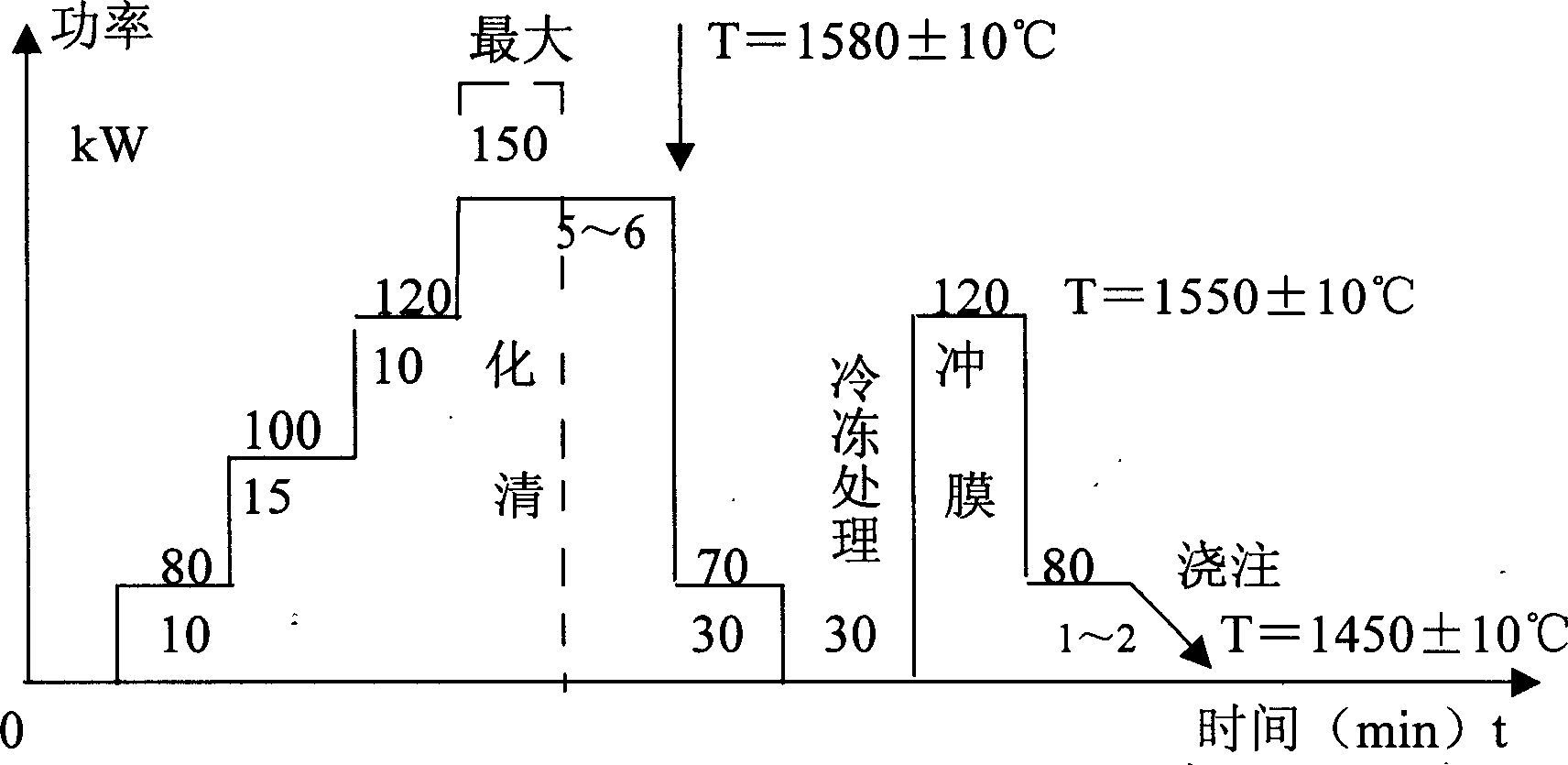

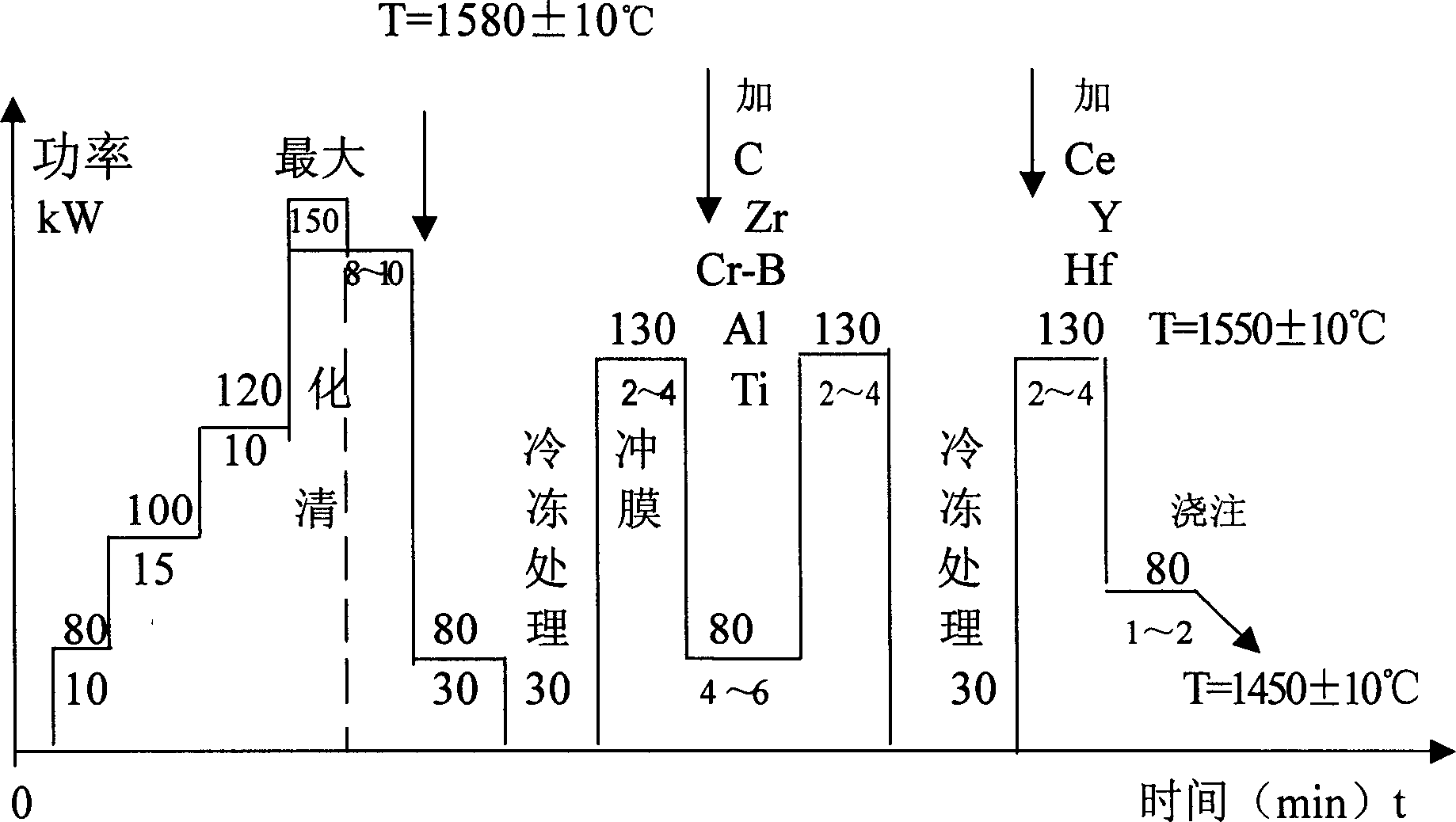

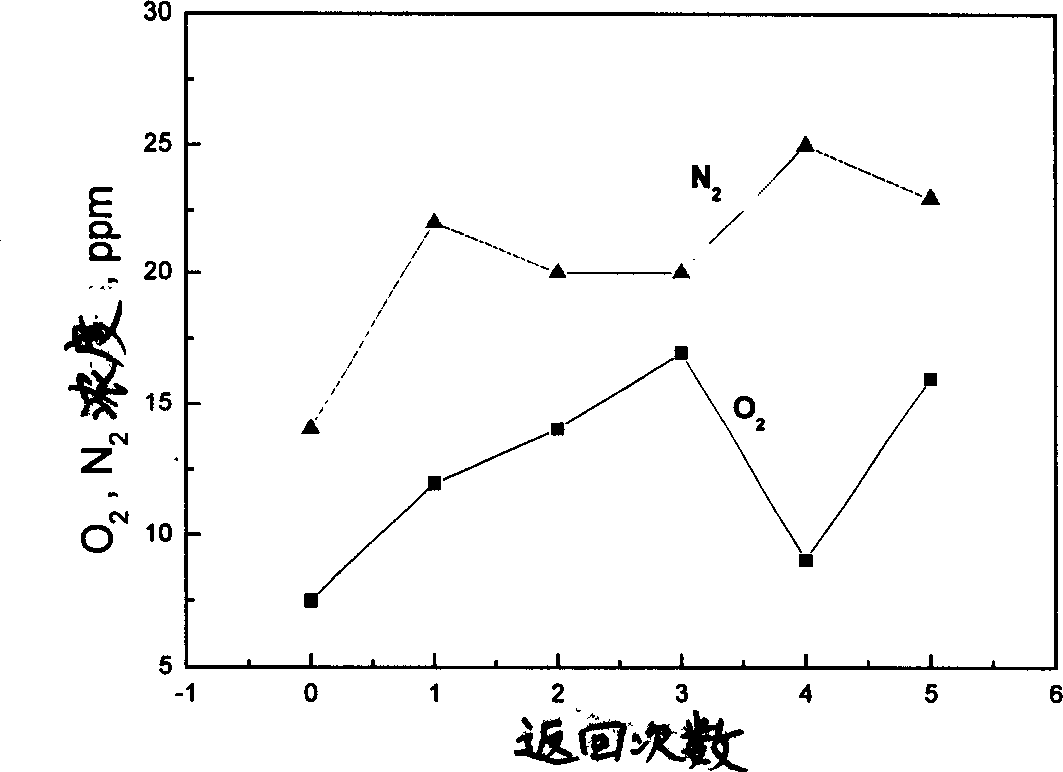

Vacuum smelting technology of hafnium containing nickel base casting high temperature alloy K488 reverse material alloy

InactiveCN1786228ADecreased tensile strength at room temperatureLower yield strengthRare-earth elementChemical composition

The invention relates to hafnium containing nickel base casting high temperature alloy K488 reverts alloy vacuum melting technique. It includes the following steps: melting reverts; pouring after melting, fining, cooling; using alumina ceramics filter screen to do the first filtration for alloy solution while pouring; adjusting the alloy solution component; mixing in proportion of 50% reverts and 50% fresh material; doing the first alloying treatment after melting, fining, cooling; adding dope material C, Cr-B inter-alloy, Al, Ti, Zr; doing the second alloying treatment after cooling; adding Ce, Y, Hf; and using alumina ceramics filter screen to do the second filtration for alloy solution while pouring to gain product. The technique adopts adding rare earth element method to purify reverting alloy. After many times returning melting, all of the alloy capability, chemical component, and impurity content can reach technical condition demand Q / 3B 1376-2005. The N content is far lower than 100ppm.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Alkaline-earth heat insulating magnesium alloy for vehicle use and producing method thereof

InactiveCN101067178AImprove performanceImprove flame retardant performanceRoom temperatureSolid solution

The heat resistant magnesium alloy for use in automobile has the components including Al 7-10 wt%, Zn 0.8-1.2 wt%, Mn 0.1-0.8 wt%, Ca 0.1-1.5 wt%, Sr 0.05-0.15 wt%, and Mg 88-91 wt%. During smelting, intermediate alloys Al-Ca and Al-Sr are added into magnesium alloy melt to increase Ca and Sr contents; and after smelting, the magnesium alloy is solid solution treated at 410 deg.c for 16-24 r and ageing treated at 180 deg.c for 16-40 hr to raise the strength. The heat resistant magnesium alloy is one kind of cast alloy with room temperature strength higher than that of AZ91 alloy, relatively high creep property at high temperature, high fire retarding performance, less interdendritic shrinkage and other casting faults and low cost, and is suitable for use in producing high temperature automobile parts.

Owner:HUNAN UNIV

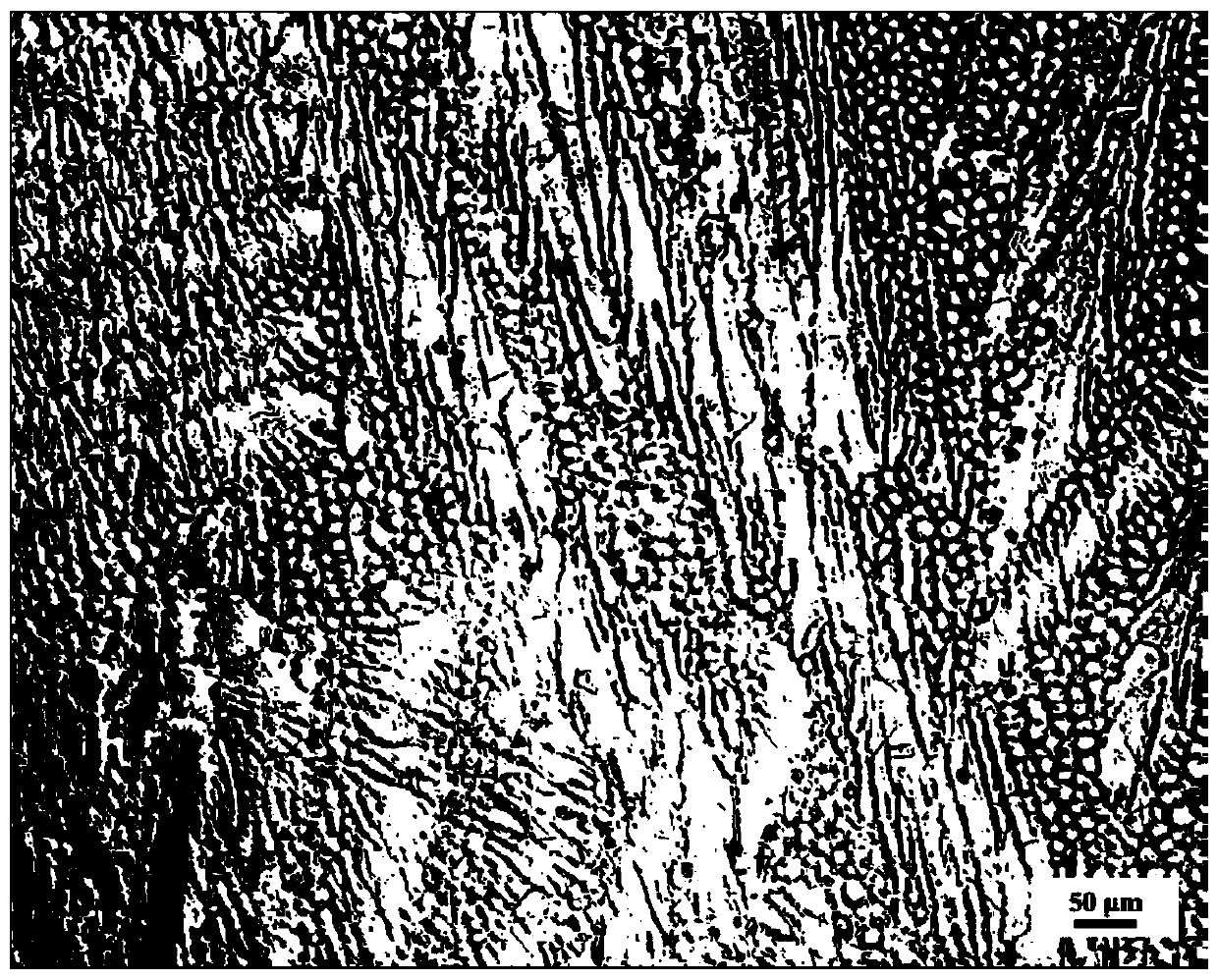

Titanium aluminum-ceramic layered material and preparation method thereof

InactiveCN103264542ASmall tissueHigh temperature strengthLaminationLamination apparatusTitaniumThermal treatment

The invention discloses a titanium aluminum-ceramic layered material and a preparation method thereof, which relate to a layered material and a preparation method thereof, and mainly solve the problem that aluminum fusion loss causes uncontrollable constituents when an element foil reaction annealing method is used for preparing a TiAl base plate material. The titanium aluminum-ceramic layered material is made by an in-situ synthesis technology and prepared from pure Ti foils and an Al base composite foils through alternating lamination, hot-pressing and reaction annealing. The method comprises the following steps of: firstly, preparing an Al base composite material; secondly, carrying out hot extrusion and rolling on the Al base composite material; thirdly, carrying out surface preparation on the rolled Al base composite material foils and the pure Ti foils; fourthly, carrying out alternating lamination and hot-pressing on the foils; fifthly, performing low temperature thermal treatment; sixthly, performing thermal treatment for densifying; and seventhly, performing heat preservation, thus obtaining the titanium aluminum-ceramic layered material. The preparation method provided by the invention is used for preparing the titanium aluminum-ceramic layered material.

Owner:HARBIN INST OF TECH

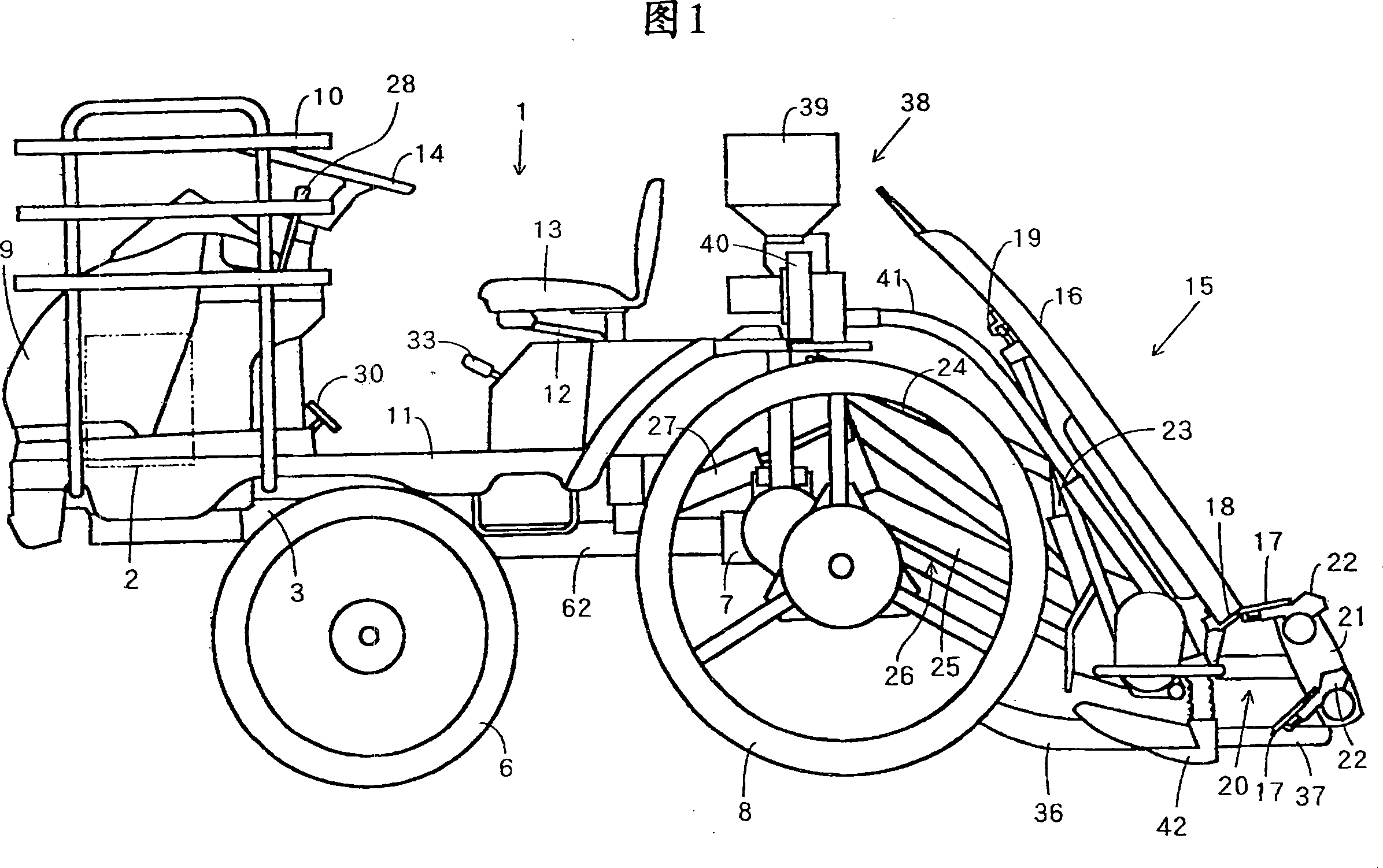

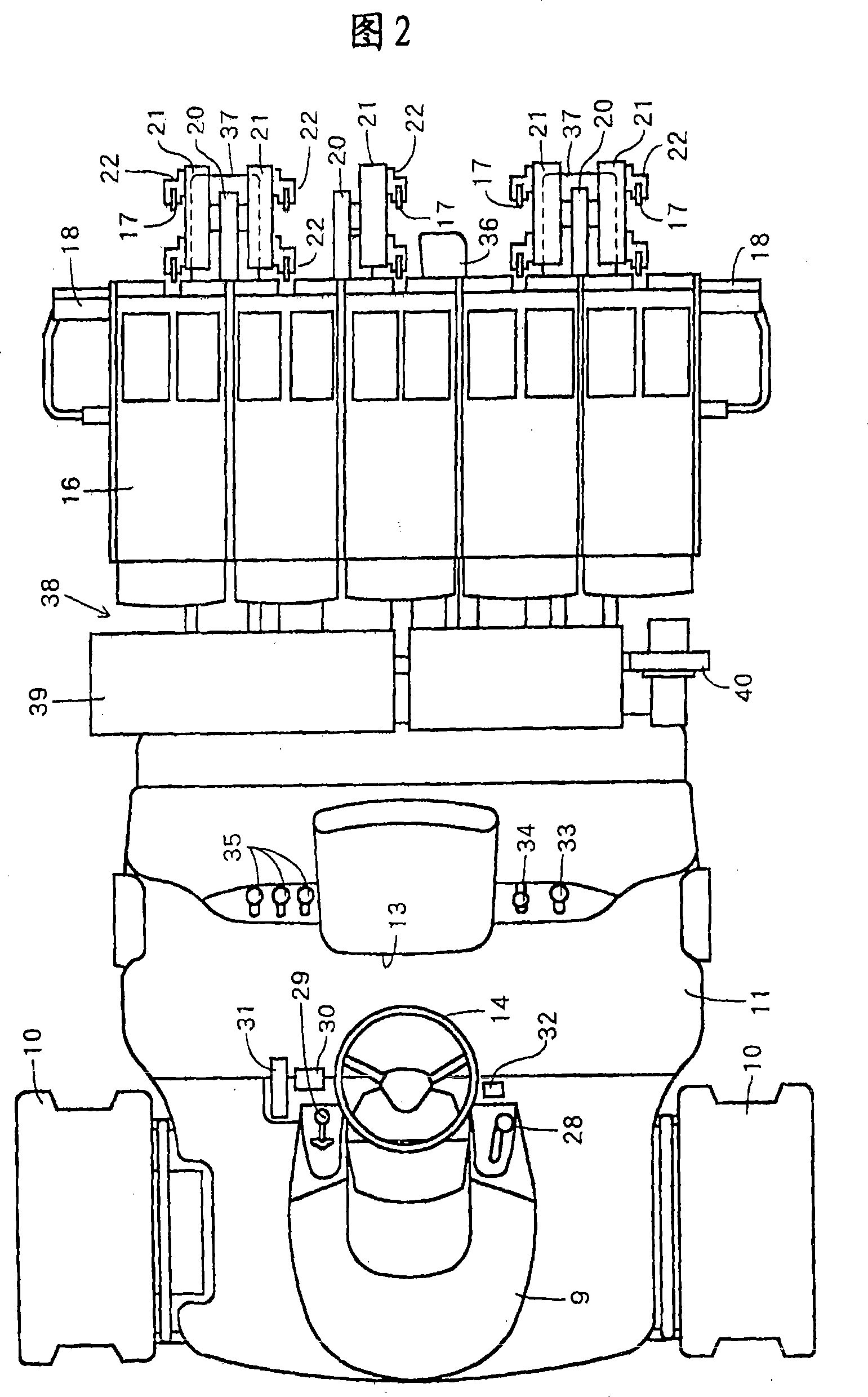

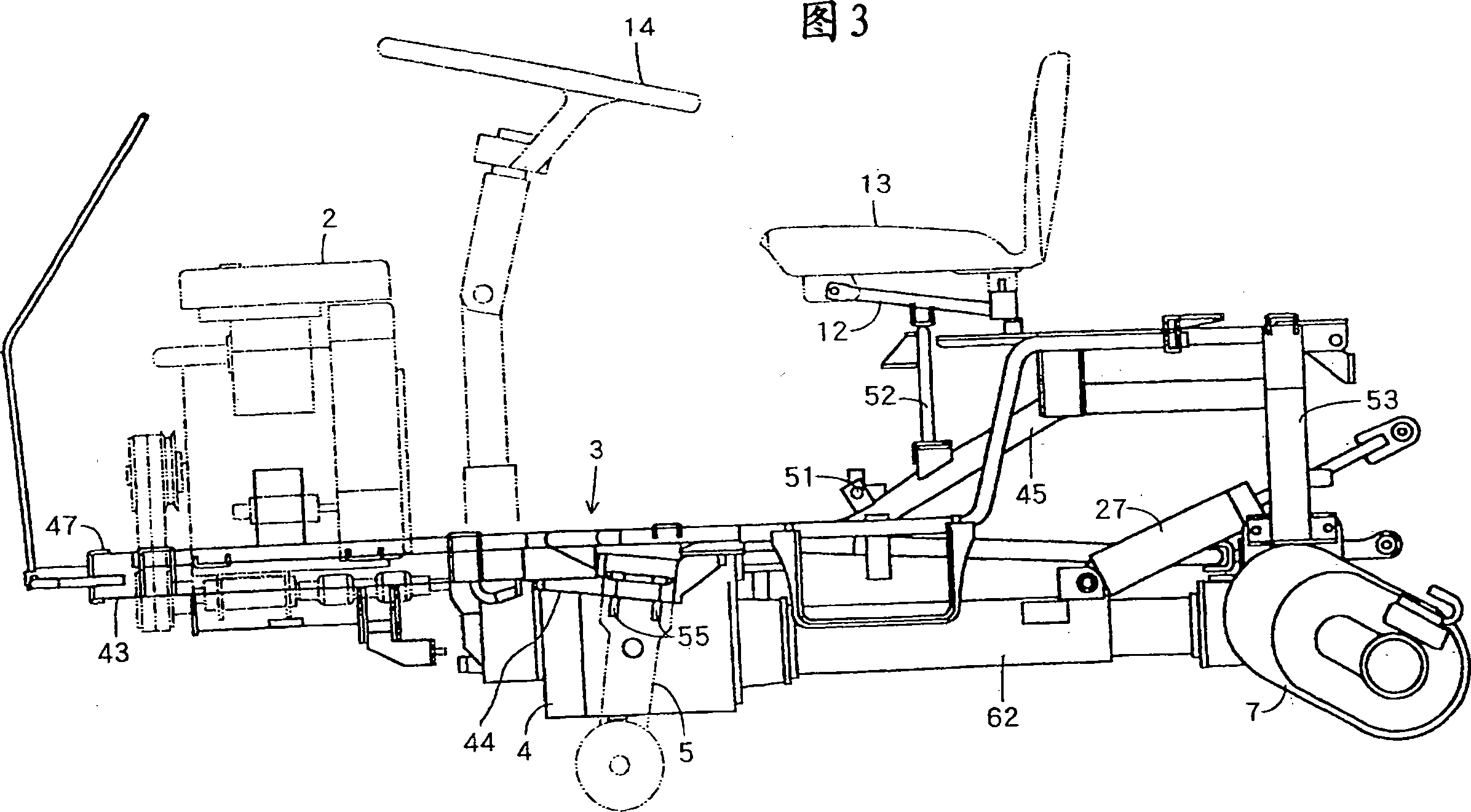

Working truck

InactiveCN101080972AEnsure output torqueImprove creep performanceToothed gearingsGearing controlGear wheelRoad surface

A hydraulic transmission mechanism (57) and a transmission gear (74) for transmitting the driving force of the engine (2) are provided, and the respective outputs of the hydraulic transmission mechanism (57) and the transmission gear (74) are synthesized to form a transmission output. (74), to obtain the output of high power transmission efficiency, use the above-mentioned hydraulic transmission mechanism (57), obtain the output of the stepless speed change that can advance zero position, with simple speed change operation, carry out speed adjustment according to the situation, seek the speed change function To improve and improve operability, etc., at the same time, through each output of forward rotation or reverse rotation of the hydraulic transmission mechanism (57), the composite output shaft (84) is rotated in one direction, and the composite output shaft (84) composite hydraulic transmission mechanism (57) and transmission gear (74) each output, carry out variable speed output, ensure the output torque when zero position advances easily, improve microspeed driving performance easily, and effectively utilize the high power of transmission gear (74) at working speed The output of transmission efficiency seeks to improve the working ability on dirt roads, etc.

Owner:YANMAR CO LTD

Polyurethane hard-foam composition and polyurethane hard-foam plastic prepared from same

The invention discloses a polyurethane hard-foam composition and a polyurethane hard-foam plastic prepared from the same. The polyurethane hard-foam composition comprises polyisocyanate, polyether glycol, polyester polyol I, additive flame retardant and foaming agent, wherein the polyester polyol I is flame-retardant polyester polyol. The flame-retardant polyester polyol is added in the polyurethane hard-foam composition, so that the consumption of the additive flame retardant can be reduced; and the plastification action of the additive flame retardant on the polyurethane hard-foam plastic can be reduced, the Van der Waals force among macromolecular chains of polyurethane can be increased, and the relative slippage among the macromolecular chains can be reduced, thereby reducing the sizes of foaming pores formed by the composition. Meanwhile, the Van der Waals force among the macromolecular chains is increased, so that the rigidity of the pore walls of the foaming pores in the polyurethane hard-foam plastic can be increased, thereby ensuring that the foaming pores are more regular in structure and the deformation degree of the foaming pores is weakened. The foaming pores are small in size and stable in structure, and can enhance the compression strength and creep property of the polyurethane hard-foam plastic.

Owner:北京碧海云智新材料技术有限公司

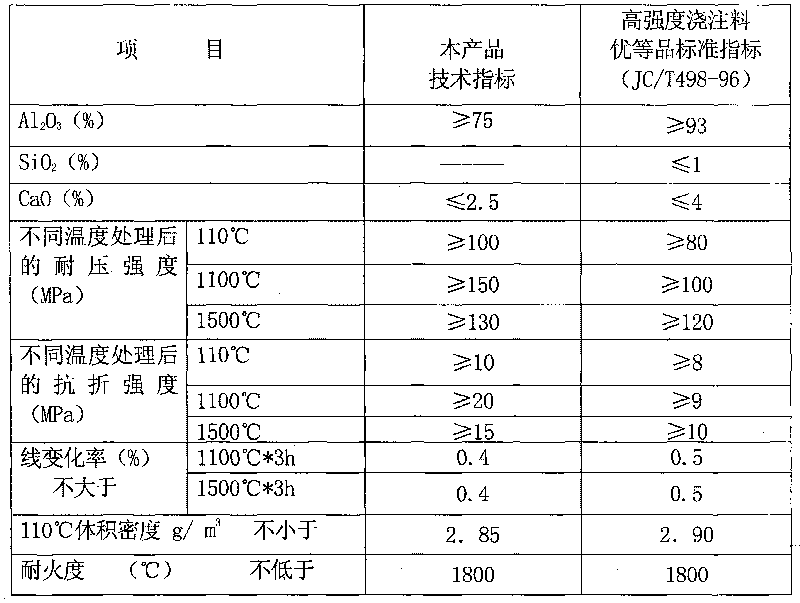

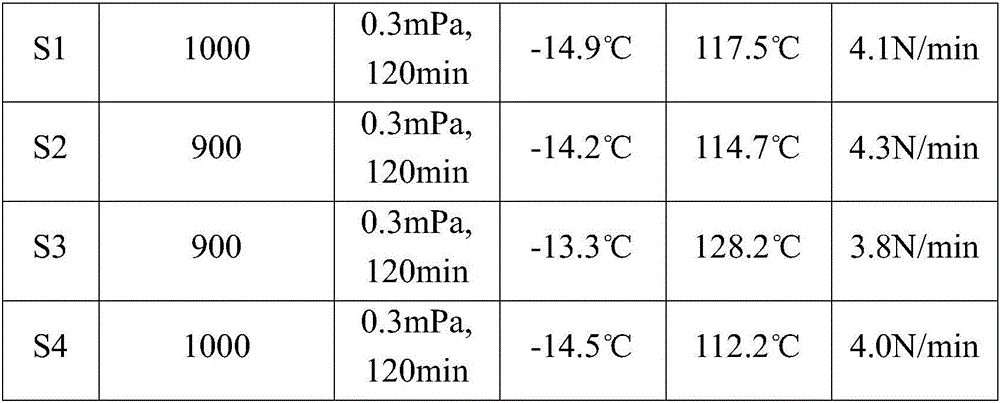

High-strength steel fibre castable

The invention discloses a high-strength steel fibre castable which is prepared by the following raw materials in parts by weight: 2.5 parts of bauxite material with the granularity of 8-5mm, 2.3 parts of bauxite material of which the granularity is more than 0.075mm and is less than 5mm, 2 parts of brown aluminium oxide particle material with the granularity of 3-1mm, 0.8 part of bauxite material of which the granularity is less than or equal to 0.075 mm, 0.4 part of alumina submicron powder of which the granularity is less than or equal to 0.025 mm, 0.6 part of carborundum powder of which the granularity is less than or equal to 0.075 mm, 0.3 part of silica micropowder of which the granularity is less than 0.019 mm, 0.6 part of CA-70 cement, 0.5 part of brown aluminium oxide powder of which the granularity is less than 0.053 mm, 0.2 part of No. 446 heat-resistant steel fiber, 0.02 part of anti-explosion steel fiber, sodium tripolyphosphate accounting for 0.1% of total material weight and sodium hexametaphosphate accounting for 0.08% of total material weight. The product has high compression strength, high breaking strength, high refractoriness under load and favorable thermal shock resistance stability, has the characteristic of microdilatancy at high temperature and has the advantages of favorable wear-resisting property and the like.

Owner:郑州真金耐火材料有限责任公司

Method for preparing Ti5Si3/TiAl composite material

The invention discloses a method for preparing a Ti5Si3 / TiAl composite material, relates to a method for preparing a composite material and aims to solve the problems of poor uniformity, relatively lower compactness and high cost of a TiAl composite material prepared by using the prior art. The method comprises the following steps of: stacking pure titanium particles into a steel mold to obtain a porous titanium prefabricated body; and linearly cutting an Al-Si alloy ingot into blocks, placing the blocks on the porous titanium prefabricated body for hot pressing and sintering under a vacuum condition, cooling the porous titanium prefabricated body to room temperature and demolding the porous titanium prefabricated body to obtain the Ti5Si3 / TiAl composite material. The method has the advantages of effectively improving material compactness (95 to 98 percent) and structural uniformity, improving high-temperature strength, creep property and oxidation resistance, meeting requirements on practicability, saving the process of ball milling and powder mixing in a powder metallurgical process, reducing the probability of the oxidation of Ti and Al and the blending of new impurities, and reducing the negative influence of the oxidation and the impurities on Ti Al-base alloy plates, and also has the advantages of simple process, easy operation, less equipment and low cost.

Owner:HARBIN INST OF TECH

Microporous oil-containing self-lubricating polytetrafluoroethylene (PTFE) material for sealing and preparation method and application thereof

ActiveCN102585406AImproved creep propertiesGood flexibilityOther chemical processesOil and greaseTetrafluoroethylene

The invention discloses a microporous oil-containing self-lubricating polytetrafluoroethylene (PTFE) material for sealing and a preparation method and application thereof. The PTFE material consists of the following components in percentage by mass: 50 to 98 percent of PTFE resin, 1 to 30 percent of naphthalene and 1 to 20 percent of oil. The method comprises the following steps of: mixing the PTFE resin and the naphthalene, performing die pressing, and sintering to prepare a porous PTFE semi-finished product; and soaking the porous PTFE semi-finished product in the oil, putting into a vacuum box, and keeping in vacuum for at least 2 hours to obtain the microporous oil-containing self-lubricating PTFE material for sealing. The microporous oil-containing self-lubricating PTFE material for sealing has high self-sealing property, lubricating property and elasticity, a good self-lubricating effect can be achieved even if the oil is not changed for a long time when the material is used as a sealing material, and a long-acting sealing effect is achieved; and if an anti-rusting agent permeates pores, machine equipment can be protected, and the service life of a machine is prolonged.

Owner:GUANGZHOU MECHANICAL ENG RES INST

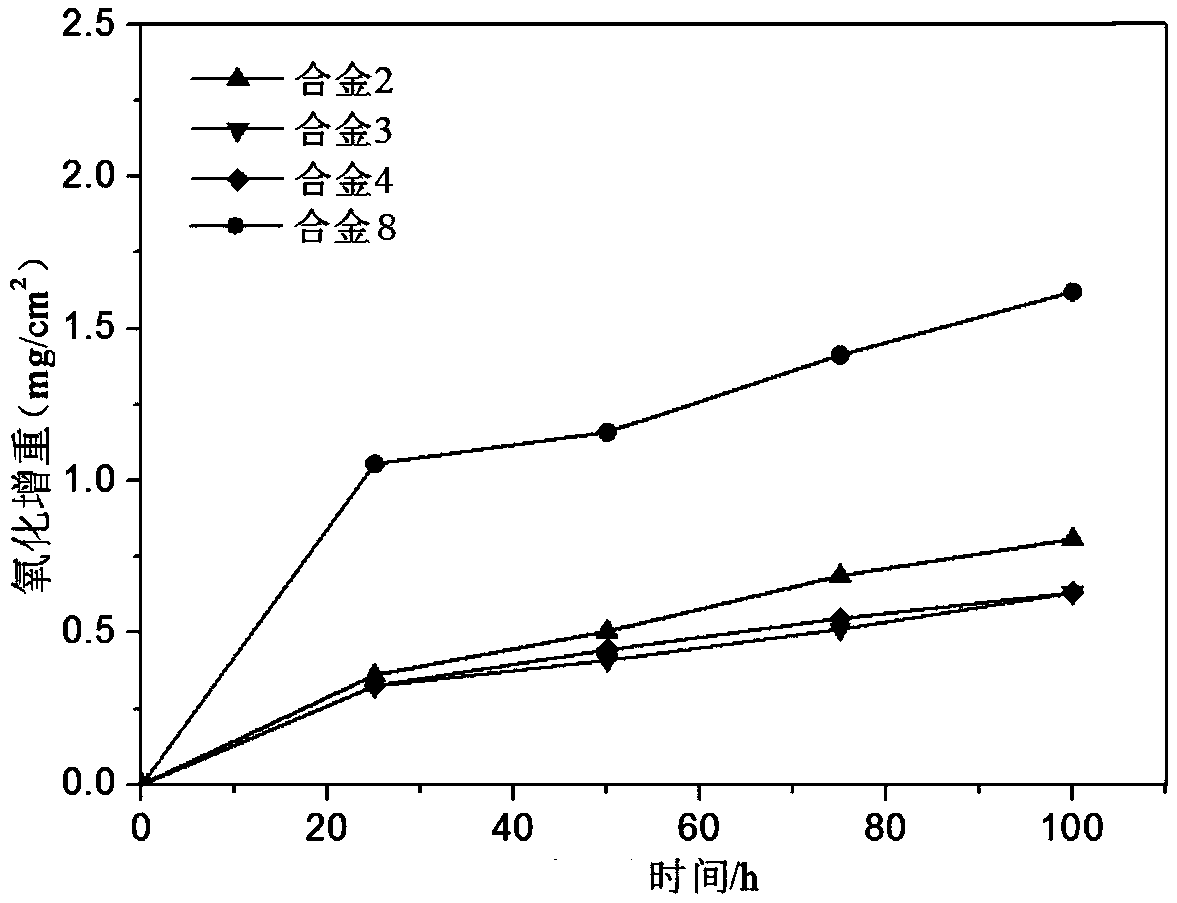

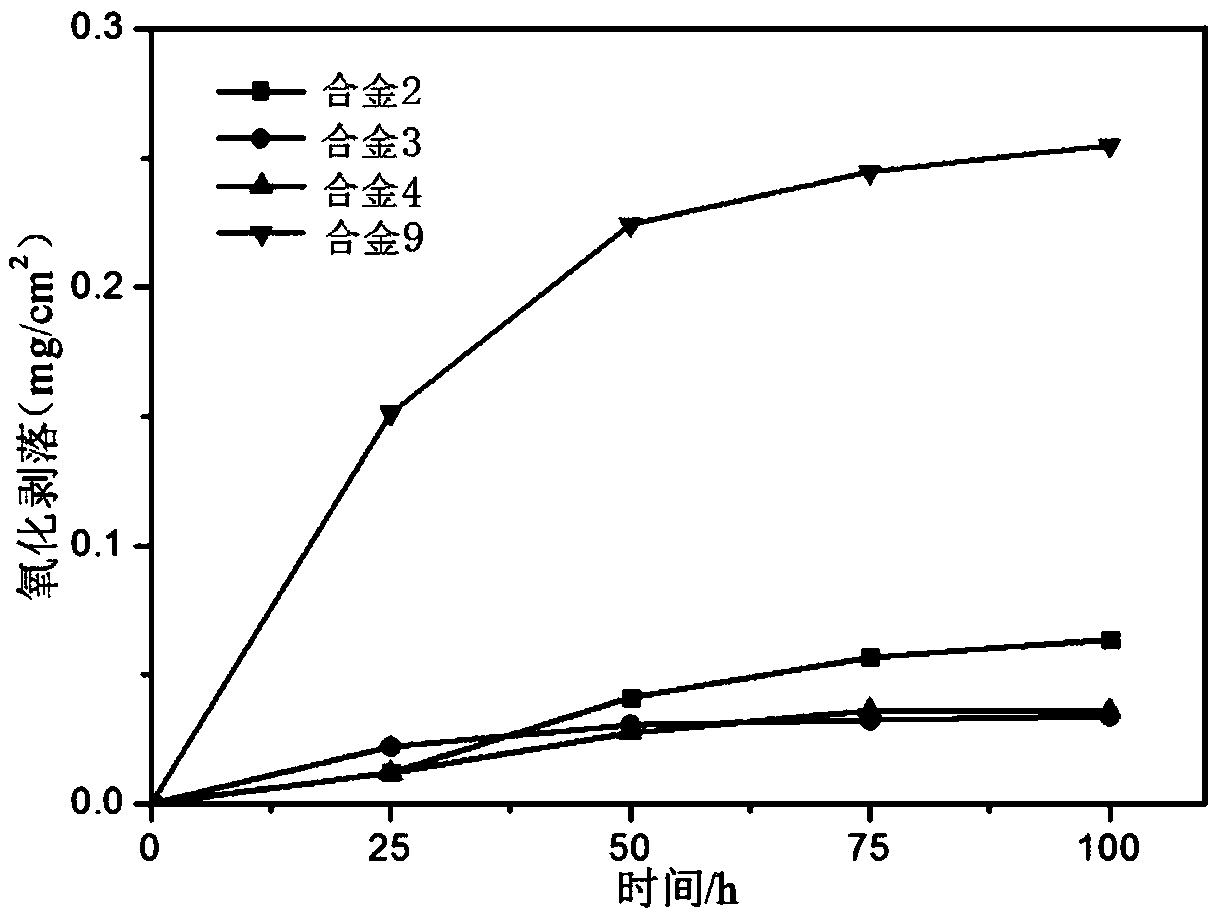

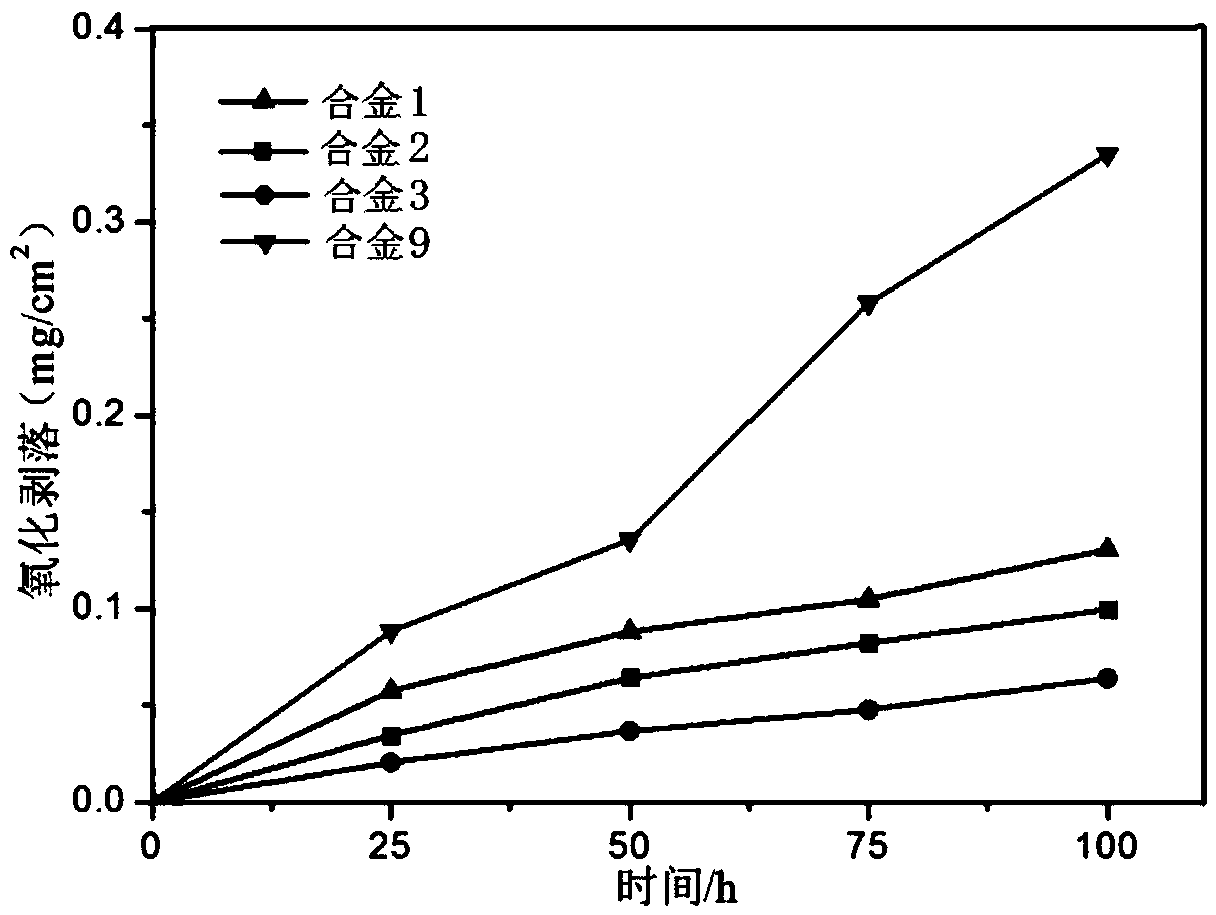

Antioxidant heat-resisting alloy and preparation method

ActiveCN109112327AImprove creep performanceImprove mechanical propertiesSolid state diffusion coatingMisch metalSlag

The invention relates to an antioxidant heat-resisting alloy and a preparation method and belongs to the technical field of alloys. The invention aims to solve the problems of high oxygen, sulfur andnitrogen contents, low proportion of Al2O3 film in the oxidation film on alloy surface, high aluminum content and low alloy toughness of the present alloy. The antioxidant heat-resisting alloy provided by the invention comprises the following components by weight percent: 2.5%-6% of Al, 24%-30% of Cr, 0.3%-0.55% of C, 30%-50% of Ni, 2%-8% of W, 0.01%-0.2% of Ti, 0.01%-0.2% of Zr, 0.01%-0.4% of Hf,0.01%-0.2% of Y, 0.01%-0.2% of V, less than 0.05% of N, less than 0.003% of O, less than 0.003% of S, less than 0.5% of Si and the balance of Fe and inevitable impurities, wherein only one of Ti andV exists. The preparation method for the antioxidant heat-resisting alloy comprises the following steps: smelting inactive element materials, refining, adding misch metal, adding slag and alloying theinactive elements. The full antioxidant temperature of the antioxidant heat-resisting alloy provided by the invention reaches up to 1200 DEG C and the alloy can long-term stably serve at 1200 DEG C or above.

Owner:QINGDAO NPA IND

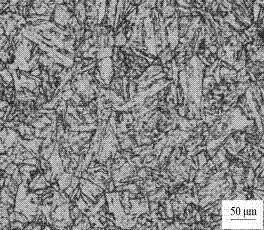

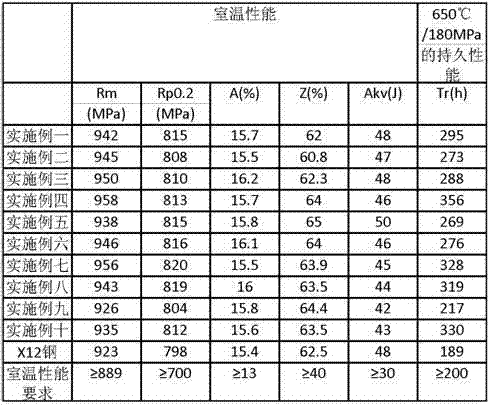

Heat-resistant steel for ultra-supercritical steam turbine rotor

The invention provides heat-resistant steel for an ultra-supercritical steam turbine rotor, which can solve the problem that an ultra-supercritical steam turbine rotor manufactured by adopting X12CrMoWVNbN10-1-1 ferrite heat-resistant steel can not satisfy the demand of an ultra-supercritical steam turbine unit with the temperature of 620 DEG C, and is characterized by comprising the following elements by mass percent: 0.1-0.15 percent of carbon (C), 0.15-0.25 percent of manganese (Mn), 10.00-11.00 percent of chromium (Cr), 2.0-4.0 percent of cobalt (Co), 0.6-1.1 percent of molybdenum (Mo), 1.0-3.0 percent of wolfram (W), 0.15-0.25 percent of nickel (Ni), 0.15-0.25 percent of vanadium (V), 0.07-0.09 percent of niobium (Nb), 0.02-0.04 percent of nitrogen (N), and the balance of Fe and impurity elements.

Owner:WUXI TURBINE BLADE

Resin composition and automobile under-hood parts thereof

ActiveUS20090105392A1Improve impact resistanceImprove creep performanceSpecial tyresGlass fiberHalogen

A resin composition including 30 to 90% by mass of polyamide (A), 70 to 10% by mass of glass fibers (B), a copper compound (C) and a halogenated compound (D), wherein polyamide (A) has a sum of a terminal carboxyl group concentration and a terminal amino group concentration of 100 milliequivalents / kg or more and 200 milliequivalents / kg or less, the terminal carboxyl group concentration being higher than the terminal amino group concentration; glass fibers (B) have a fiber diameter of 10 to 20 μm and a weight average fiber length of 5 to 30 mm; the content of copper based on polyamide (A) is 30 ppm or more and 200 ppm or less; and the molar ratio of halogen to copper (halogen / copper) is more than 5 and not more than 25.

Owner:ASAHI KASEI CHEM CORP

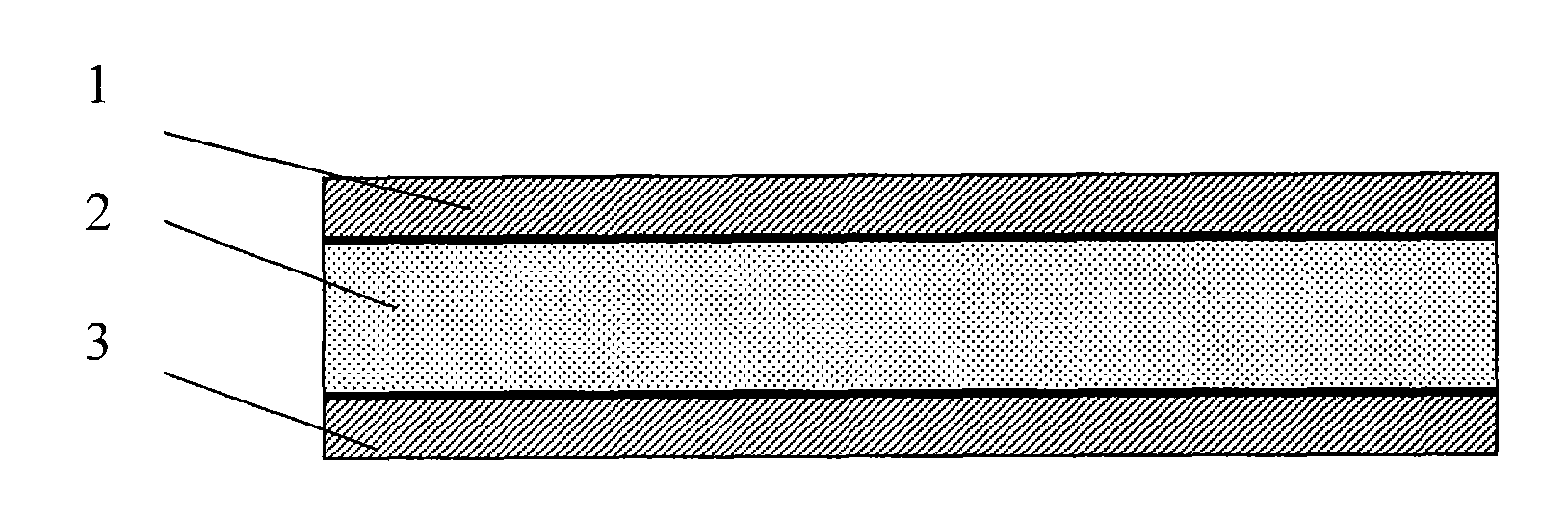

Composite buffer sheet

InactiveCN102114723AHigh modulus of elasticityImprove buffering effectFlexible coversWrappersLow-density polyethyleneHigh density

The invention discloses a composite buffer sheet which is composed of three elastic buffer layers, wherein the middle elastic buffer layer is composed of a low-density polyethylene foam board, and the other two elastic buffer layers are respectively composed of a high-density polyethylene foam board and respectively adhered to the upside and downside of the middle elastic buffer layer. The density of the middle elastic buffer layer is less than the densities of the other two elastic buffer layers. The composite buffer sheet disclosed by the invention has the advantages that through compositing the low-density and high-density materials, the buffering property, creep property, bearing capacity and puncture resistance of the composite buffer sheet are greatly enhanced; based on the enhancement of the properties, during the packing of products, less materials and smaller package size can be used so as to meet the requirements for product protection; because the package size is decreased, the volume of a packing case is correspondingly decreased, thereby greatly reducing the costs for storage and transportation; and because the application amount of materials is reduced, the resource degradation and the pollution to the environment are reduced, thereby reducing the overall packaging cost.

Owner:法科达拉泡沫材料(上海)有限公司

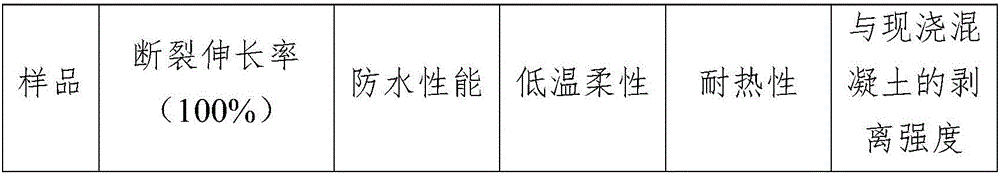

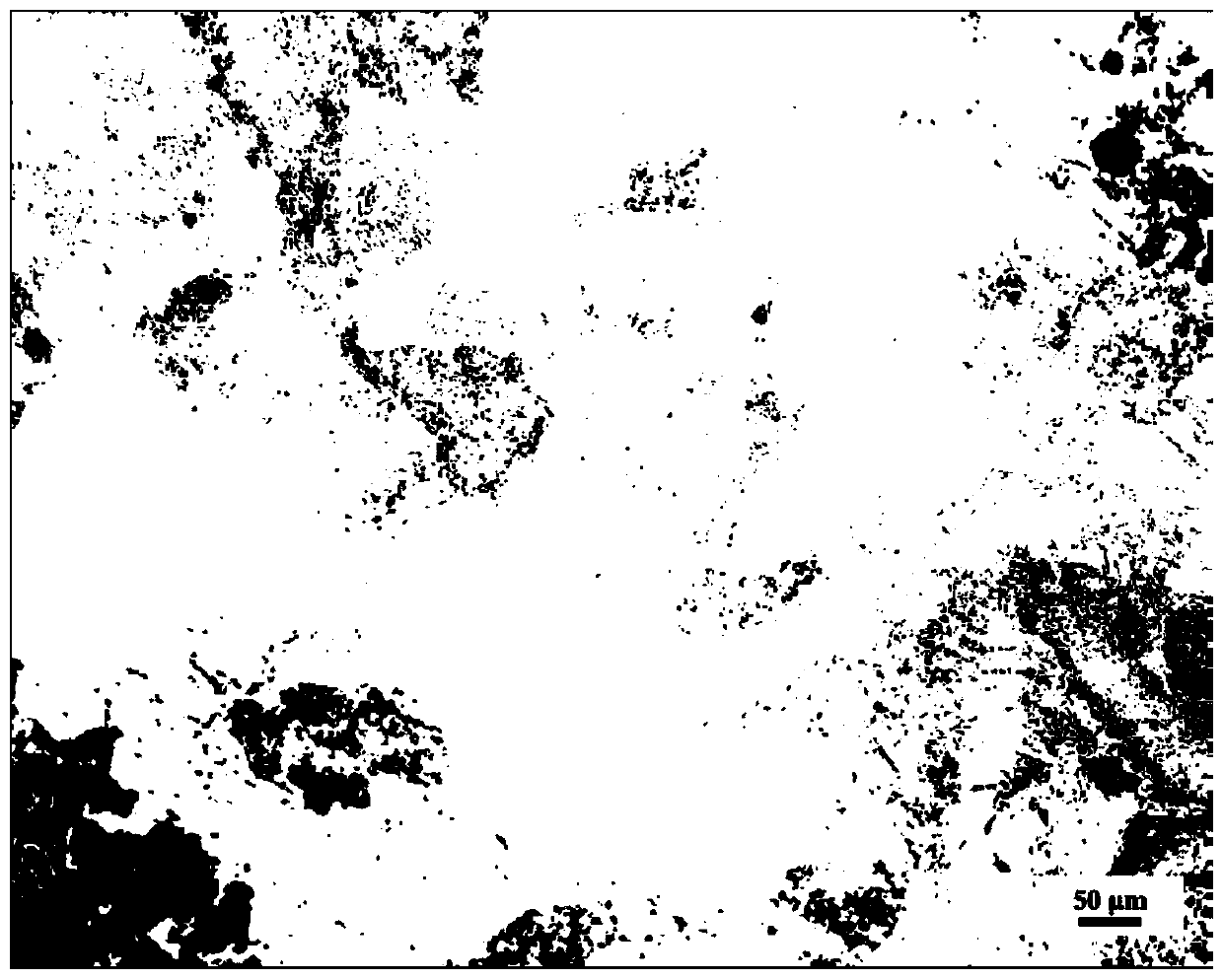

Creeping non-cured rubber asphalt waterproof roll material and preparation method thereof

ActiveCN106499067AImprove physical and chemical propertiesImprove creep performanceBuilding insulationsPolymer scienceBituminous waterproofing

The invention provides a creeping non-cured rubber asphalt waterproof roll material, aiming to solve the problems of poor water seepage resistance, poor tensile strength, poor weather resistance and poor basal plane binding capacity for cast-in-place concrete in the conventional self-adhered waterproof roll material. The creeping non-cured rubber asphalt waterproof roll material comprises a polyethylene membrane and an asphalt adhesive layer with which the polyethylene membrane is coated, wherein the asphalt adhesive layer is prepared from the following components of base asphalt, hot melt adhesive, rubber modifying agent, viscosity-enhancing rubber and modified padding; the modified padding is grafted fumed silica. Meanwhile, the invention further discloses a preparation method for the creeping non-cured rubber asphalt waterproof roll material. The creeping non-cured rubber asphalt waterproof roll material provided by the invention has high water seepage resistance, high tensile strength, high weather resistance and high basal plane binding capacity for the cast-in-place concrete.

Owner:中油佳汇(广东)防水股份有限公司

High-strength castable

The invention discloses a high-strength castable, which is prepared from the following raw materials in part by weight: 4.8 parts of bauxite aggregate, 2 parts of brown aluminium oxide granules, 0.8 part of bauxite powder, 0.4 part of alumina super-micro powder, 0.6 part of silicon carbide powder, 0.3 part of silicon micro powder, 0.6 part of CA-70 cement, 0.5 part of brown aluminium oxide powder, sodium tripolyphosphate accounting for 0.1 percent of weight of the total material, and sodium hexametaphosphate accounting for 0.08 percent of the weight of the total material. The castable has the advantages of high compression strength, high breaking strength, high load softening temperature, good thermal shock resistant stability, micro-expansion property at high temperature, good abrasion resistance and the like; the cost is reduced by about two fifth compared with that of the conventional high-strength castable; and the castable can be widely applied to kilns of cement kiln eyes, pre-heaters, grate coolers and the like with high strength requirement and severe using conditions, and is an ideal new product for replacing a high-strength corundum castable.

Owner:郑州真金耐火材料有限责任公司

Vehicle creep control in a hybrid electric vehicle

ActiveUS8043194B2Improve creep performanceEasy to controlBatteries circuit arrangementsElectric propulsion mountingEngineeringElectric vehicle

In a powertrain that includes wheels for driving a vehicle, an engine including a crankshaft, a machine driveably connected to the crankshaft and able to operate alternately as an electric motor and electric generator, a transmission including an input clutch driveably connected to the crankshaft and an output driveably connected to at least two of the wheels, and an electric storage battery having a variable state of charge and electrically connected to the machine, a method for controlling vehicle creep including adjusting a torque capacity of the input clutch to a desired magnitude of input clutch torque transmitted to the wheels, determining a desired change in torque produced by the machine such that a speed of the crankshaft is controlled to a desired idle speed, using the magnitude of input clutch torque capacity and the desired change in torque produced by the machine to determine a desired magnitude machine torque, and using the machine to produce said desired magnitude of machine torque.

Owner:FORD GLOBAL TECH LLC

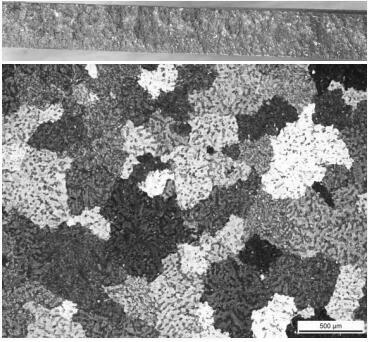

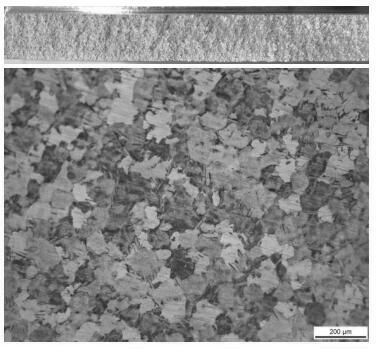

Titanium alloy surface processing process

The invention discloses a titanium alloy surface processing process which comprises steps of (1) sand blasting; (2), chemical processing; (3), rough polish; (4), burr removal; (5), fine polish; (6), finishing polish; (7), corona processing; (8), acid pickling processing; (9), drying by boiling and oil smearing. Titanium alloy processed through the process is smooth and bright in surface, uniform in color and free of color change, oxide skin and the like; and in addition, antioxygenation and creep performance of the titanium alloy processed through the process can also be greatly improved, and a surface microstructure is effectively refined.

Owner:当涂县宏宇金属炉料有限责任公司

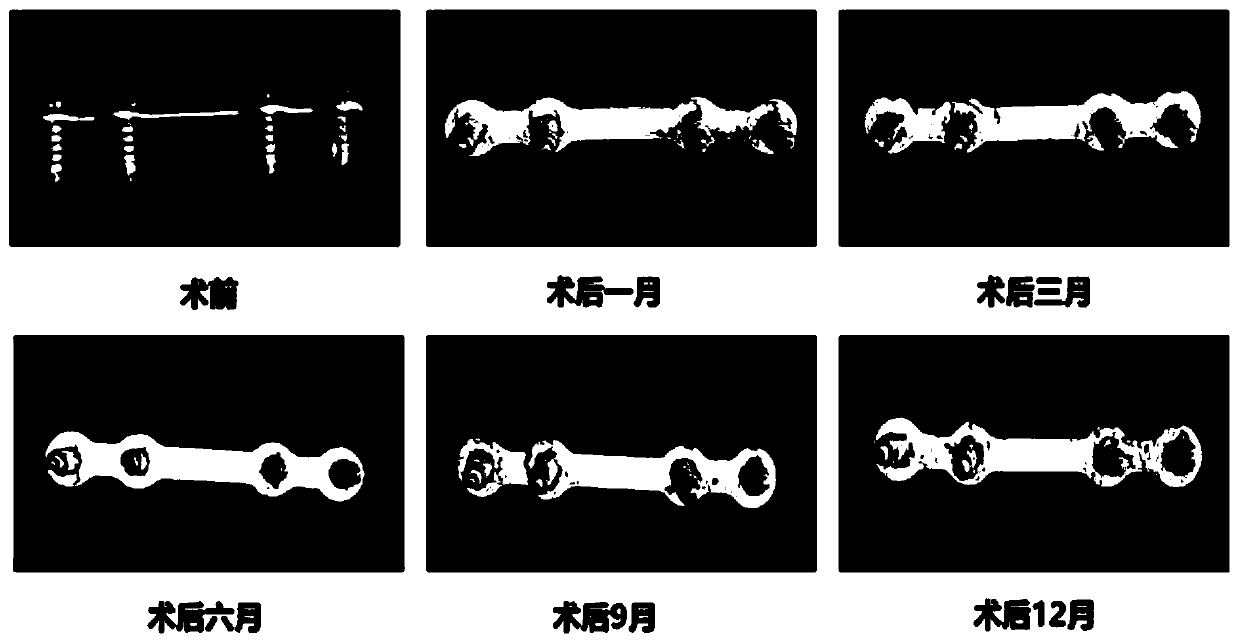

Degradable Zn-Ag series zinc alloy and preparing method and application thereof

InactiveCN110241330AReduce corrosion potentialImprove corrosion resistanceSurgeryTrace element compositionZinc alloys

The invention provides a degradable Zn-Ag series zinc alloy and a preparing method and application thereof. The zinc alloy is composed of Zn, Ag and a microelement. The mass percent of the Zn ranges from 89.85 to 99.4%, the mass percent of the Ag ranges from 0.01 to 10%, and microelement comprises one or multiple of Fe, Mg, Ca, Sr and Li. The mass percent of the microelement ranges from 0.01 to 0.55%. The method comprises the steps of heating metal zinc to be molten after burdening, adding metal silver, performing stirring until the metal silver is molten, adding the microelement, performing stirring, standing and pouring, and obtaining a zinc alloy cast ingot; and performing heat treatment and heat preservation on the zinc alloy cast ingot, and finally performing extrusion forming. The made zinc alloy has the higher strength and ultra-high plasticity, good anti-bacterium effect is achieved, and the alloy can serve as a degradable medical device implant to be applied into the human body to be subjected to non-toxic degradation.

Owner:湖南华耀百奥医疗科技有限公司

Ultralow temperature spraying non-curing rubber asphalt waterproof paint

ActiveCN107353828AImprove creep performanceImprove reaction binding abilityConjugated diene hydrocarbon coatingsBituminous coatingsBituminous waterproofingPolyamide

The invention provides an ultralow temperature spraying non-curing rubber asphalt waterproof paint, and aims to solve the problems caused by high temperature spraying of a conventional waterproof paint. The waterproof paint comprises asphalt, hot melt adhesive, tackifying rubber, modified filler, a polyamide epoxy curing agent, phosphatized nano silicon oxide, and dodecanol ester. The waterproof paint is modified by the polyamide epoxy curing agent, phosphatized nano silicon oxide, and dodecanol ester; the viscosity is reduced, the flowing performance is improved, the spraying can be carried out at a low temperature, and the high energy consumption and severe pollution of high temperature spraying are avoided. At the same time, the invention also discloses a preparation method of the ultralow temperature spraying non-curing rubber asphalt waterproof paint and a creep type non-curing rubber asphalt waterproof coiled material, which comprises an asphalt layer composed of the ultralow temperature spraying non-curing rubber asphalt waterproof paint.

Owner:中油佳汇(广东)防水股份有限公司

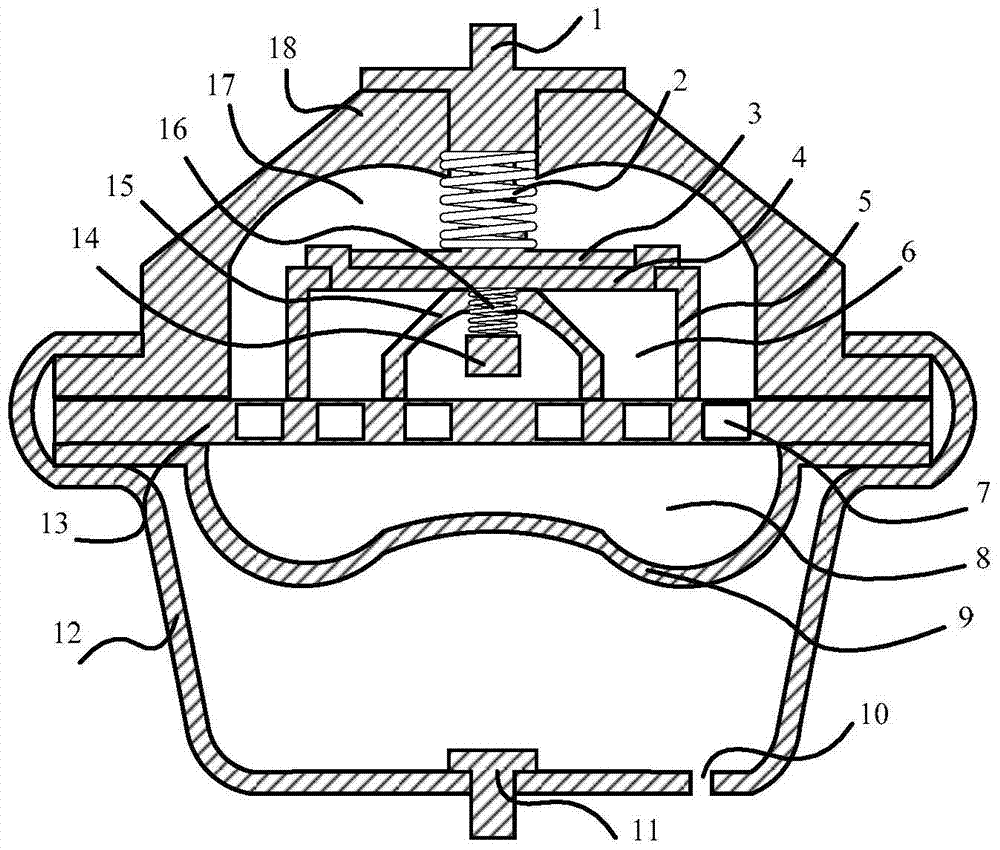

Passive fluidic resistor suspension with equivalent mechanical structure

InactiveCN103671686AReduce vibrationTo achieve the purpose of vibration reduction and sound insulationSpringsJet propulsion mountingDynamic stiffnessMainspring

The invention relates to a passive fluidic resistor suspension with an equivalent mechanical structure, and belongs to the technical field of engine supporting structures. The passive fluidic resistor suspension with the equivalent mechanical structure mainly comprises an external rubber mainspring, an upper connecting bolt connected with the external rubber mainspring, an external supporting spring, an upper fluid chamber, a lower fluid chamber, an inner gas chamber, an inner spring, a mass block and the like, wherein the inner spring and the mass block are arranged in the inner gas chamber. The upper fluid chamber which tightly abuts against the upper end face of a partition board between the upper fluid chamber and the lower fluid chamber, an external gas chamber and the inner gas chamber are arranged in sequence from outside to inside. The lower fluid chamber tightly abuts against the lower end face of the partition board between the upper fluid chamber and the lower fluid chamber. An inertia channel which enables the upper fluid chamber to be communicated with the lower fluid chamber is arranged in the partition board between the upper fluid chamber and the lower fluid chamber. According to the passive fluidic resistor suspension with the equivalent mechanical structure, the notch frequency of the fluidic resistor suspension is constant within a low frequency range, but the dynamic stiffness of the fluidic resistor suspension is reduced as far as possible within a notch frequency range; in addition, the dynamic stiffness of a corresponding peak frequency is reduced as far as possible, the noise lowering effect and the damping effect of the engine fluidic resistor suspension are improved within the low frequency range, and the fatigue performance and the creep property of the fluidic resistor suspension can also be improved.

Owner:SOUTH CHINA UNIV OF TECH

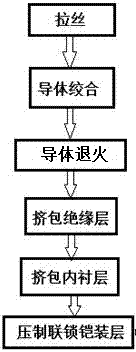

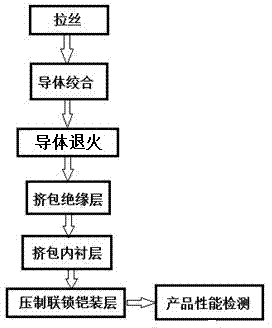

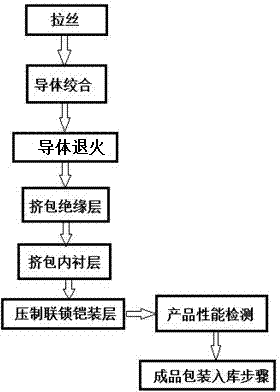

Manufacturing method for interlocked armored aluminum alloy flat cable

ActiveCN102969087APrevent disconnectionImprove conductivityFlat/ribbon cablesFlexible cablesElectrical conductorManufacturing technology

The invention discloses a manufacturing method for an interlocked armored aluminum alloy flat cable. According to the manufacturing technology, the manufacturing method comprises the following steps in sequence: drawing wires, stranding a conductor, annealing the conductor, extruding an insulating layer, extruding a lining layer, and pressing an interlocked armored layer, wherein the conductor annealing step comprises the steps: through boxcar type heating and annealing steps, heating the stranded conductor to 370-400 DEG C, lasting for 4-5 hours at the environment of 370-400 DEG C, and then naturally cooling to the room temperature; and the interlocked armored layer pressing step is that an aluminum alloy tape with the thickness of 0.5mm-0.6mm is arranged on the surface of the lining layer and pressed into a Z-shaped interlocked armored form with the arc-shaped height of 2mm-4mm according to pitches of 6mm-24mm. according to the manufacturing method, the conductivity property and creep property can be improved, the service life of the cable can be effectively prolonged, the system can have good radiating effect in short time under overload state, and can be ensured to run safely.

Owner:SICHUAN MINGXING CABLE

Flux-free vacuum-cast high-purity magnesium alloy and preparation method thereof

The invention provides a flux-free vacuum-cast high-purity magnesium alloy and a preparation method thereof. The method includes the following steps that (1) raw materials are preheated; (2) heating and smelting are performed as follows: after the inside of a furnace is pumped to be vacuum, the furnace is filled with inert gas to be under the pressure being 500-1,000 Pa, power-transmission heatingis started, and the three-stage type heating manner is adopted in the heating process; (3) gas introduction and refinement are performed as follows: gas introduction and refinement are performed in melt obtained in step (2), the inert gas is introduced, in the process of gas introduction and refinement, the temperature is increased to be 800-850 DEG C at the rate of 3-8 DEG C / min, then high-temperature standing is performed under the temperature condition that 800-850 DEG C is kept, and the standing time ranges from 15 min to 40 min; (4) filtering and casting are performed as follows: after high-temperature standing in step (3) ends, the temperature is reduced to be 760-820 DEG C, and casting is performed after filtering; (5) cooling is performed as follows: after casting in step (4), furnace cooling is started, or the inert gas is introduced for boosting cooling, and then a magnesium alloy cast ingot is obtained. The obtained magnesium alloy is uniform in structure, free of nonmetalslag inclusions (such as flux slag inclusions and oxidation slag inclusions), low in shrinkage porosity, few in cast ingot defect and obvious in effect on magnesium-rare earth alloys difficult in slagremoval.

Owner:郑州轻研合金科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com