Antioxidant heat-resisting alloy and preparation method

A heat-resistant alloy and anti-oxidation technology, which is applied in the field of alloys, can solve problems affecting the performance and quality stability of alloy furnace tubes, and achieve excellent oxidation resistance, good high-temperature strength, and excellent overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0075] The preparation method of the anti-oxidation and heat-resistant alloy of the present invention varies according to different uses. If it is used for high-temperature parts used in the aerospace field, vacuum induction melting and casting must be adopted, including the following steps:

[0076] 1. Ingredients. Electrolytic nickel, metal aluminum, metal chromium (or ferrochrome), pure iron, metal tungsten, graphite, sponge hafnium, sponge titanium, sponge zirconium, and metal yttrium are selected as raw materials, and the raw materials are weighed in proportion for use.

[0077] 2. Feeding. Electrolytic nickel, metal chromium (or ferrochromium), pure iron, and metal tungsten are placed in the crucible, and other elements are added from the hopper.

[0078] 3. Melting, melting is carried out in a medium frequency induction vacuum melting furnace.

[0079] Send electricity with low power for 10 minutes to remove hydrogen, then send electricity with high power to complete ...

Embodiment 1

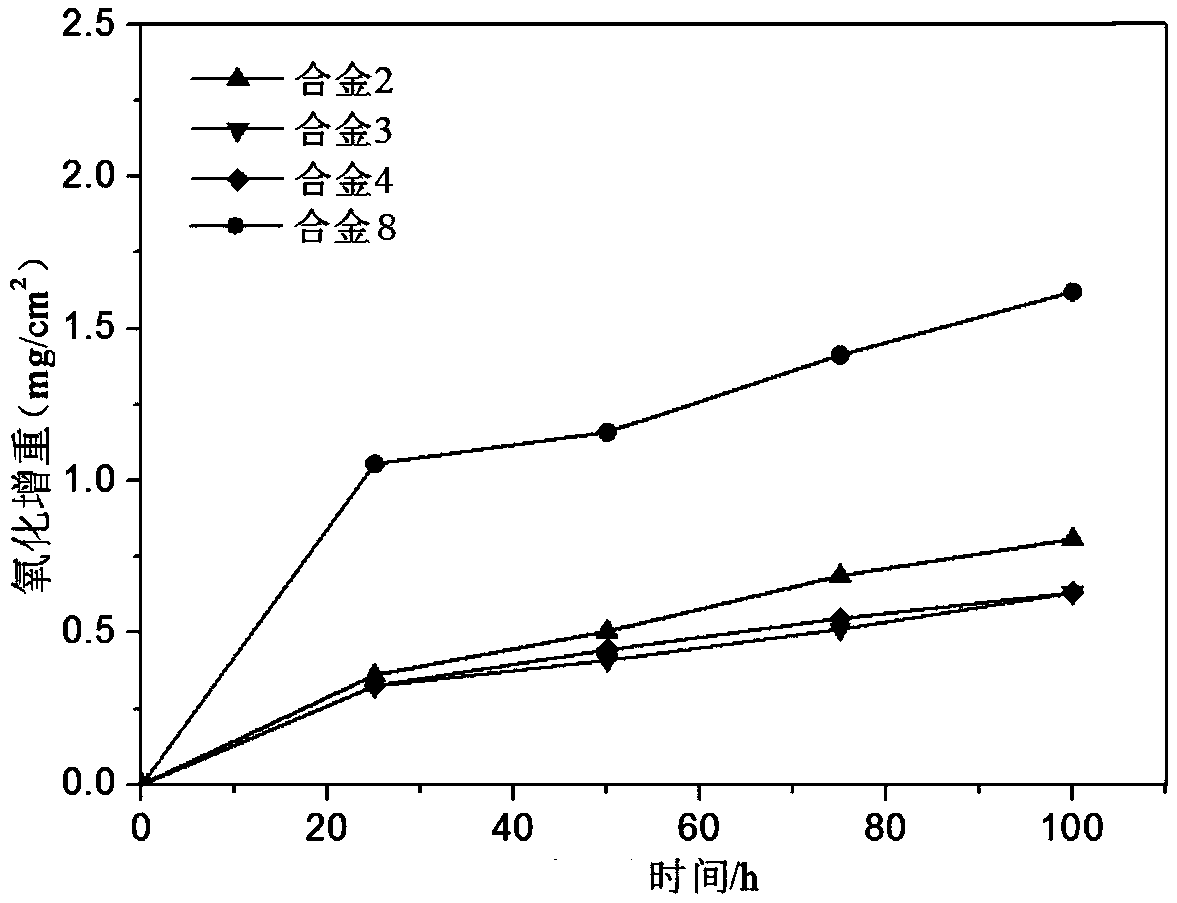

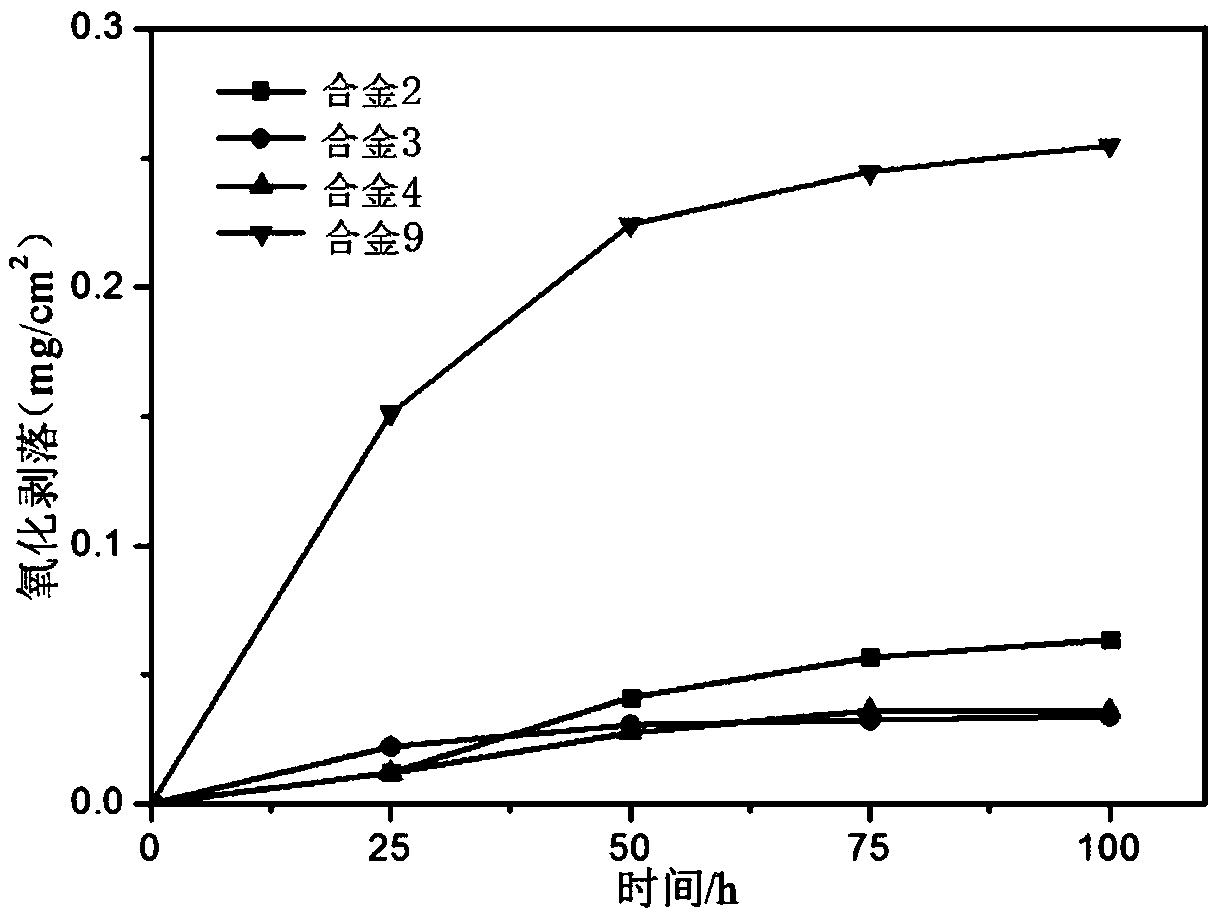

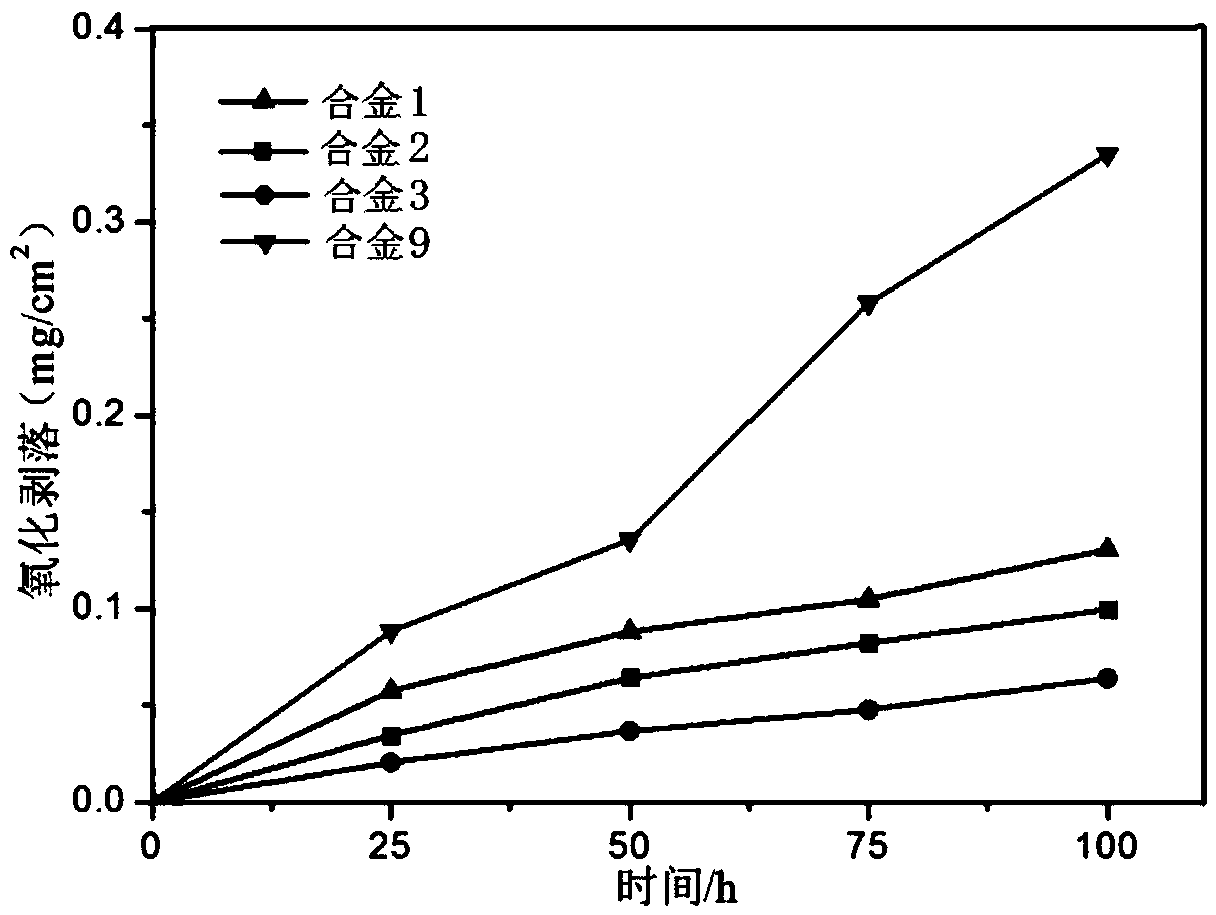

[0108] Example 1 corresponds to Alloy No. 1, Example 2 corresponds to Alloy No. 2, and so on. For convenience of comparison, Alloy No. 8 and Alloy No. 9 are the comparative materials of the prior art. Among them, No. 8 alloy is the weldable superalloy GH3230 with the highest service temperature, which is widely used in high-temperature parts of aerospace engine combustion chambers. No. 9 alloy is currently the best material HTE alloy for ethylene cracking furnace tubes in the petrochemical field.

[0109] The anti-oxidation heat-resistant alloy of embodiment 1-7 is prepared according to the following method:

[0110] Step 1: Weigh the raw materials for use;

[0111] Step 2: Put electrolytic nickel, pure iron and some graphite in the crucible of a non-vacuum intermediate frequency melting furnace with fixed-point casting function, and obtain molten steel after complete melting;

[0112] Step 3: The molten steel is heated up to the refining temperature and the remaining graphite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com